Wire heat-peeling forceps

A wire and stripping pliers technology, applied in circuit/collector parts, electrical components, equipment for dismantling/armored cables, etc. The effect of high capacity, improved high temperature performance and work flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

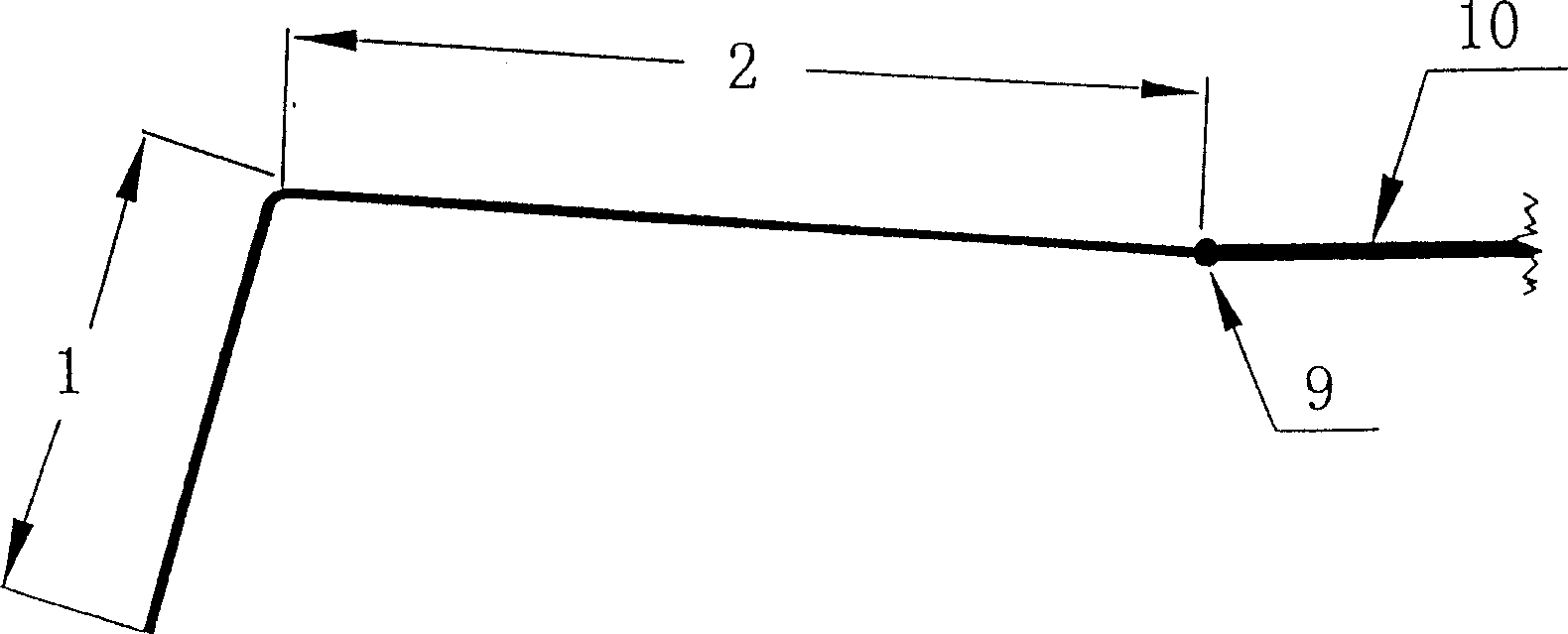

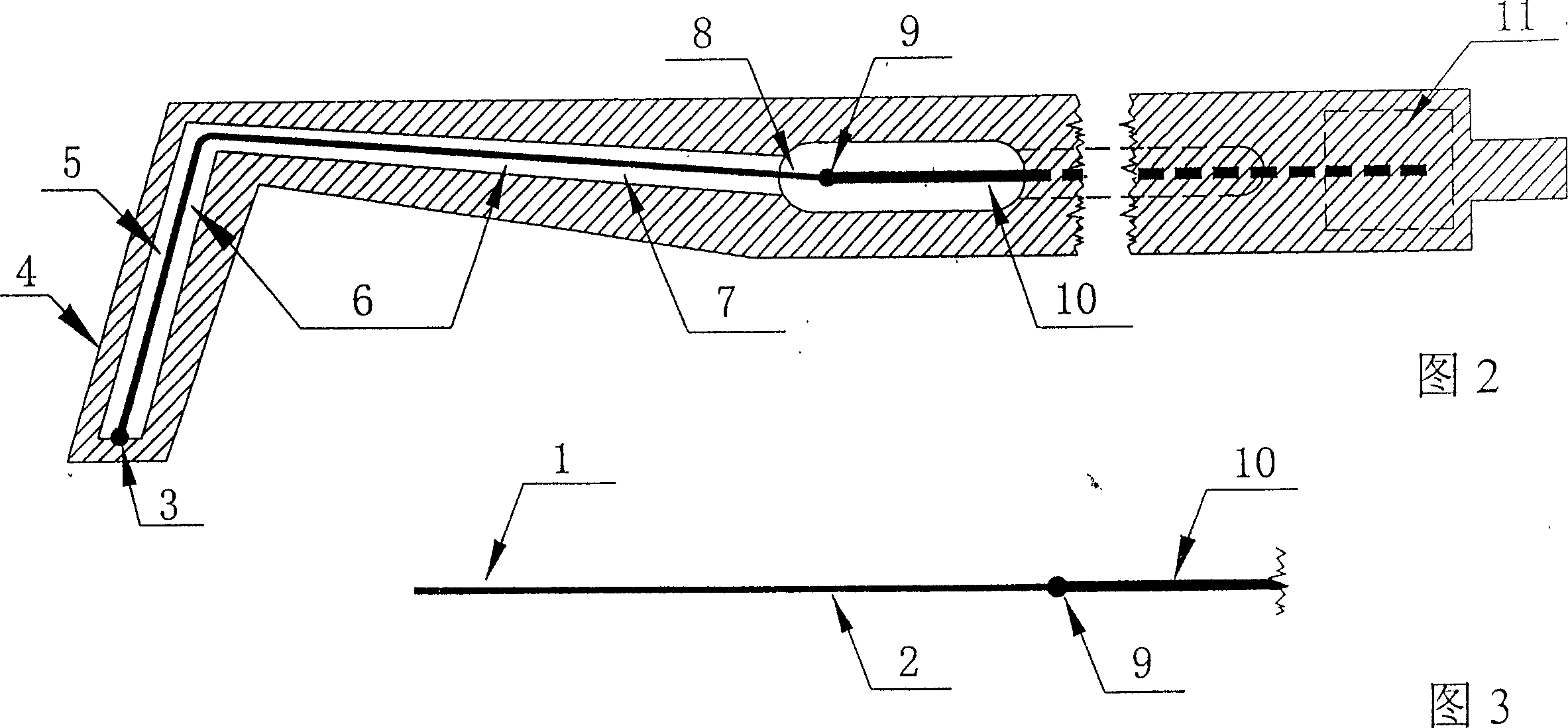

[0020] The method that the present invention implements: see Fig. 5.

[0021] For the first defect, the groove width of 0.5mm where the resistance wire is installed at the blade has no possibility of expansion, but the original groove depth of 0.8mm still has room for expansion, so it is decided to deepen the groove depth to 1.2mm, and change the original Φ0.24mm resistance wire to Fold in double strands into a U shape, and keep a necessary gap in the middle of the U shape to ensure that they will not touch each other and short circuit. The solder joint with the site (thermal stripper shell) is moved from the front to the rear, thus doubling the total length of the resistance wire on the blade. This means that the power distribution in the blade part has doubled to 2 / 3 of the total power.

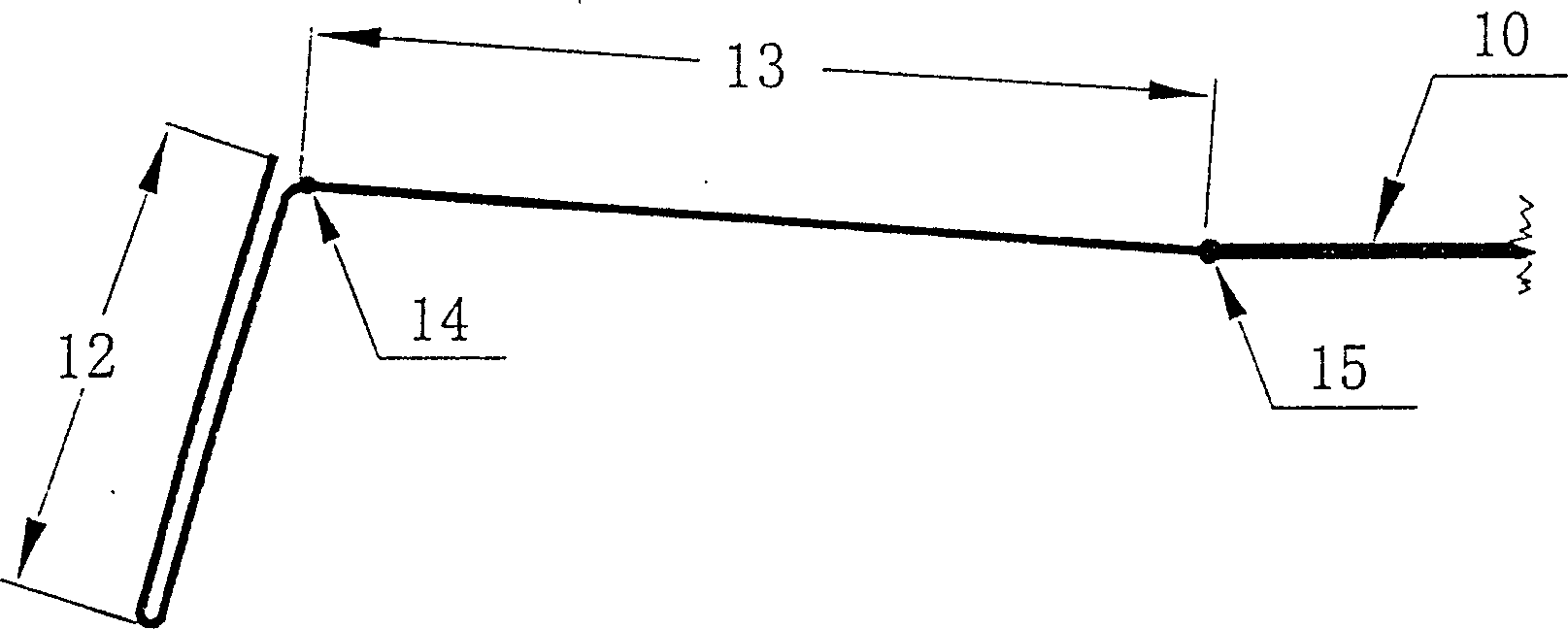

[0022] For the second kind of defect, the present invention can meet the requirements of transformation due to the 0.6mm groove width and 1mm groove depth at the support, so the groove siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com