Preparation method of manganese Li-NiCoMn ternary material for lithium ion battery

A technology of nickel-cobalt lithium manganese oxide and lithium-ion batteries, which is applied in the field of new energy material preparation, can solve the problems of difficulty in obtaining materials without impurities, reduction of comprehensive electrical properties, difficulty in drying and water removal, etc., and achieve high-temperature cycle performance Bad, improved high temperature performance, excellent basic indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

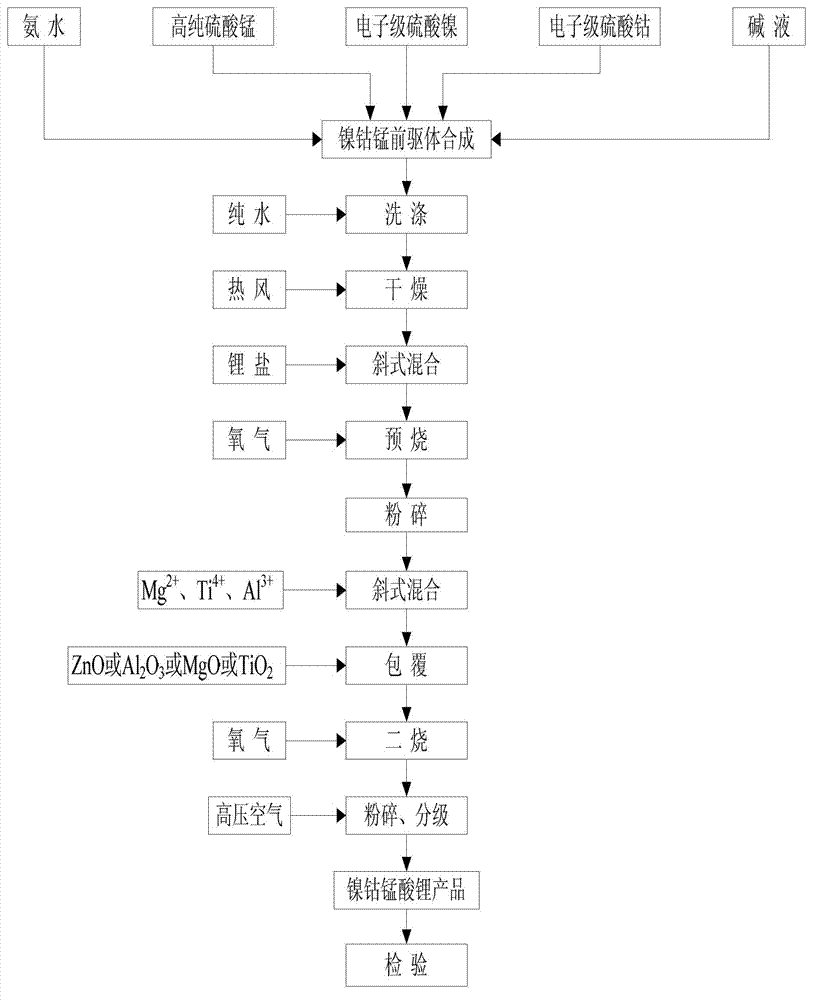

Method used

Image

Examples

Embodiment 1

[0035]According to the molar ratio Ni:Mn:Co=1:1:1, prepare a mixed aqueous solution of cobalt sulfate, nickel sulfate, and manganese sulfate with a total metal concentration of 1mol / L; place it in a reaction kettle with a draft tube. Prepare a caustic soda solution with a concentration of 10mol / L; prepare NH with a concentration of 10mol / L 4 + solution.

[0036] The above caustic soda solution and NH 4 + The solution is evenly added to the reaction kettle to control the content of NH 4 + The amount of compound added is the molar ratio NH 4 + / (Ni+Mn+Co)=4:1; add caustic soda solution to control the pH value of the reaction to 12.5; the reaction temperature is room temperature (30°C), react for 8 hours and then age for 8 hours, pay attention to the control of the aging process The pH value is consistent with the pH value of the reaction process. Filter, wash, and dry to obtain the nickel-cobalt-manganese ternary precursor. The average particle size of the ternary precur...

Embodiment 2

[0041] According to the molar ratio Ni:Mn:Co=4:4:2, prepare a mixed aqueous solution of cobalt chloride, nickel chloride, and manganese chloride with a total metal concentration of 1mol / L; place it in a reaction kettle with a draft tube. Prepare a caustic soda solution with a concentration of 5mol / L; prepare NH with a concentration of 5mol / L 4 + solution.

[0042] The above caustic soda solution and NH 4 + The solution is evenly added to the reaction kettle to control the content of NH 4 + The amount of compound added is the molar ratio NH 4 + / (Ni+Mn+Co)=2:1; add caustic soda solution to control the pH value of the reaction to 10.0; the reaction temperature is room temperature (25°C), react for 10 hours and then age for 8 hours, pay attention to the control of the aging process The pH value is consistent with the pH value of the reaction process. Filter, wash, and dry to obtain the nickel-cobalt-manganese ternary precursor. The average particle size of the ternary pre...

Embodiment 3

[0047] Prepare a mixed aqueous solution of cobalt nitrate, nickel nitrate and manganese nitrate with a total metal concentration of 1.5 mol / L according to the molar ratio Ni:Mn:Co=5:3:2; place it in a reaction kettle with a draft tube. Prepare a caustic soda solution with a concentration of 8mol / L; prepare NH with a concentration of 5mol / L 4 + solution.

[0048] The above caustic soda solution and NH 4 + The solution is evenly added to the reaction kettle to control the content of NH 4 + The amount of compound added is the molar ratio NH 4 + / (Ni+Mn+Co)=3:1; add caustic soda solution to control the pH value of the reaction to 12.0; the reaction temperature is room temperature (15°C), react for 12 hours and then age for 8 hours, pay attention to the control of the aging process The pH value is consistent with the pH value of the reaction process. Filter, wash, and dry to obtain the nickel-cobalt-manganese ternary precursor. The average particle size of the ternary precu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com