Patents

Literature

3429results about How to "Improve high temperature performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

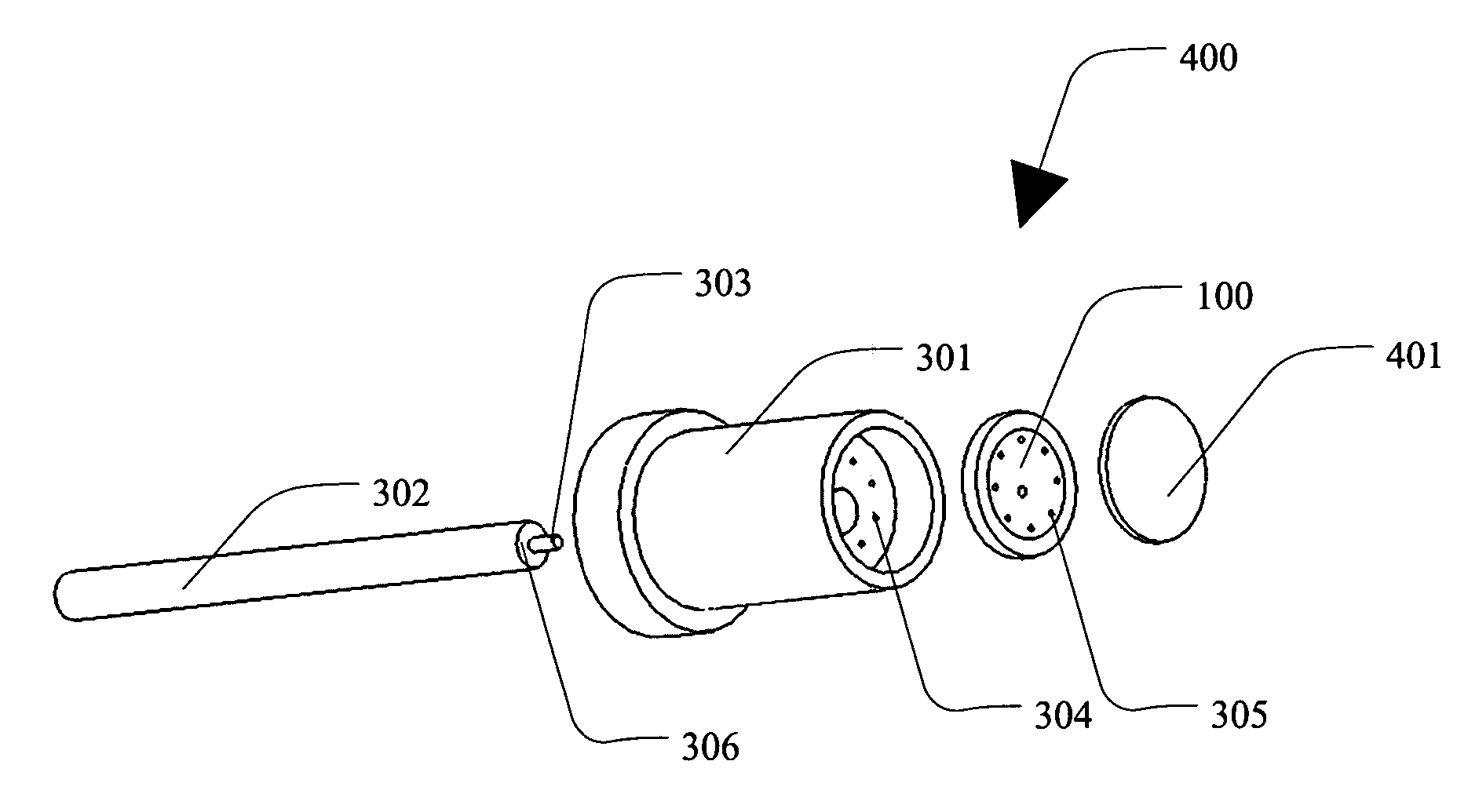

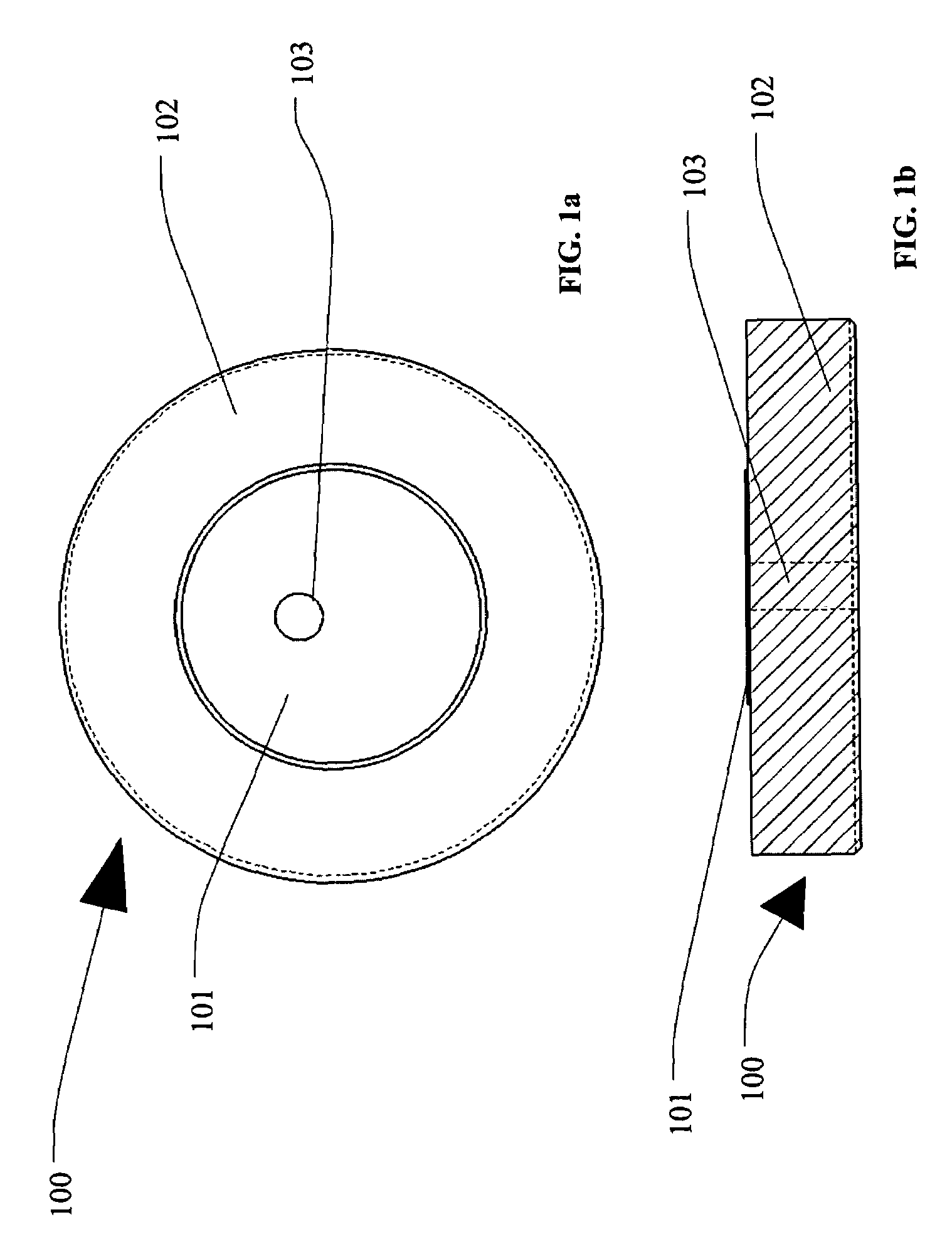

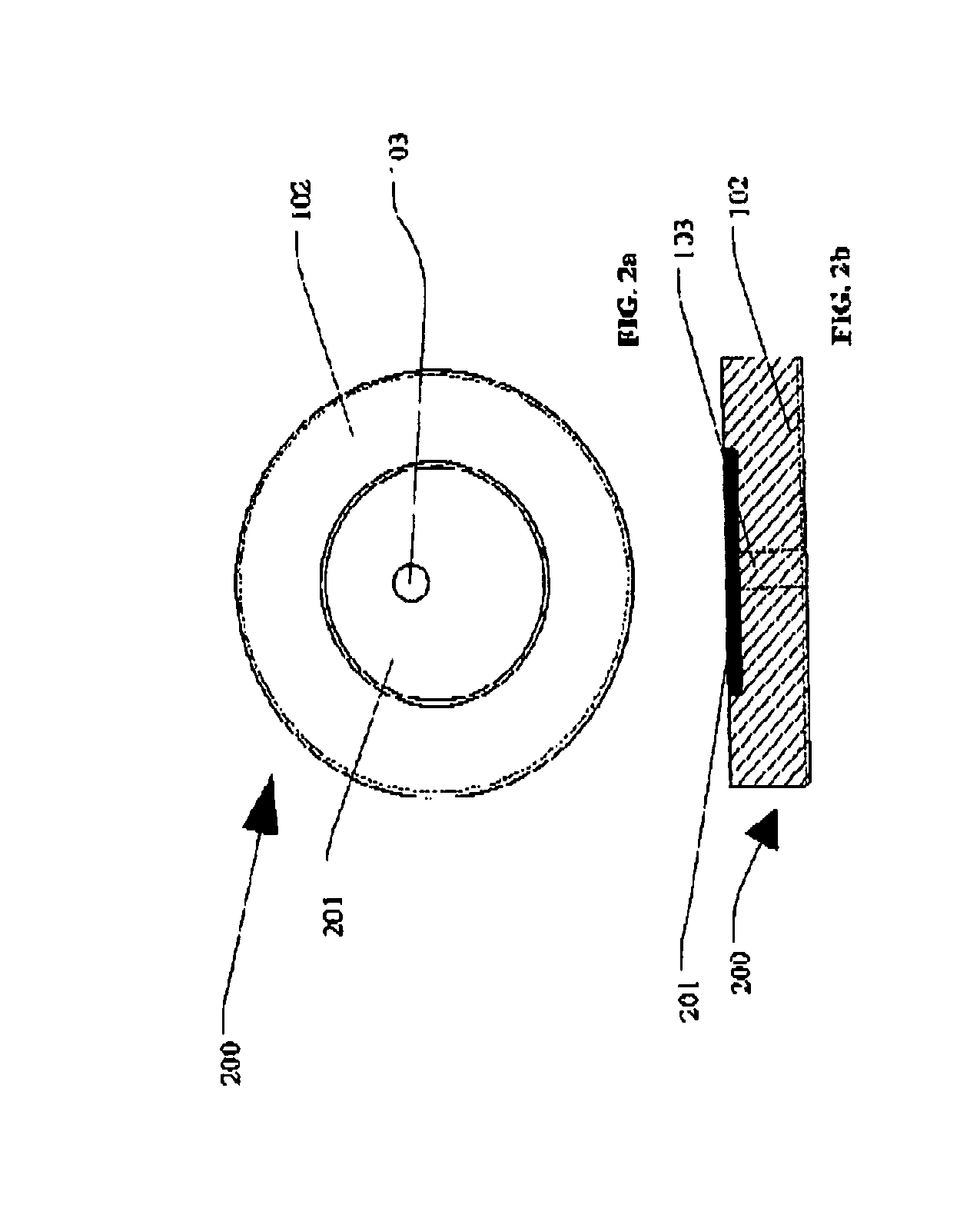

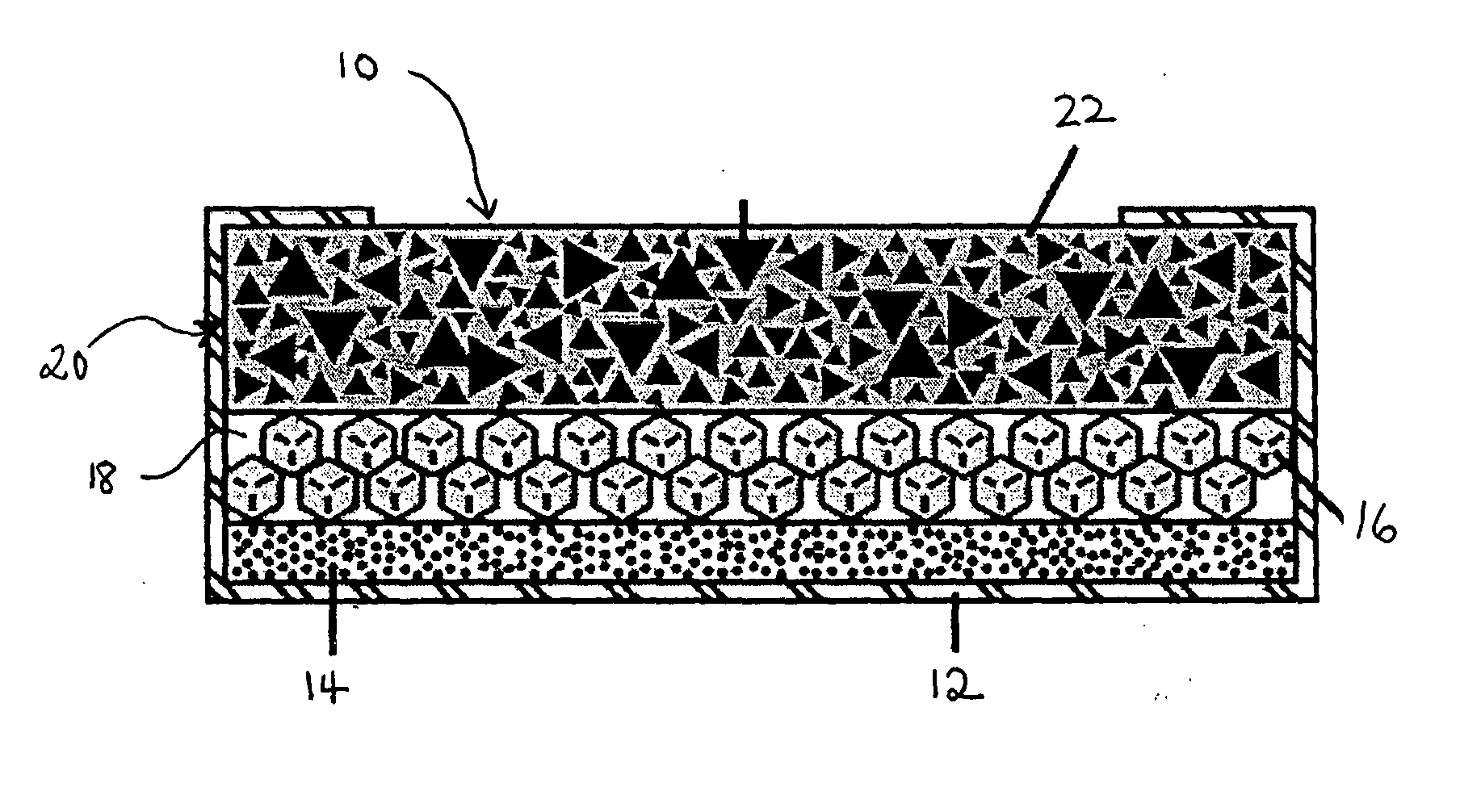

Microstrip patch antenna for high temperature environments

ActiveUS7283096B2Improve performanceImprove reliabilitySimultaneous aerial operationsAntenna adaptation in movable bodiesMicrostrip patch antennaSpray coating

A patch antenna for operation within a high temperature environment. The patent antenna typically includes an antenna radiating element, a housing and a microwave transmission medium, such as a high temperature microwave cable. The antenna radiating element typically comprises a metallization (or solid metal) element in contact with a dielectric element. The antenna radiating element can include a dielectric window comprising a flame spray coating or a solid dielectric material placed in front of the radiating element. The antenna element is typically inserted into a housing that mechanically captures the antenna and provides a ground plane for the antenna. Orifices or passages can be added to the housing to improve high temperature performance and may direct cooling air for cooling the antenna. The high temperature microwave cable is typically inserted into the housing and attached to the antenna radiator to support the communication of electromagnetic signals between the radiator element and a receiver or transmitter device.

Owner:MEGGITT SA

Nanodiamond PCD and methods of forming

InactiveUS20050019114A1Improve high temperature performanceReduce manufacturing costMaterial nanotechnologyPigmenting treatmentDiamond crystalPolycrystalline diamond

A nanodiamond tool, including a mass of sintered nanodiamond particles can be produced having improved mechanical, thermal, and electrical properties. The sintered mass can contain greater than about 95% by volume nanodiamond and greater than about 98% by volume carbon. Such nanodiamond tools can be formed by assembling a mass of nanodiamond particles and sintering the mass of nanodiamond particles to form a sintered mass. Prior to sintering, the mass of nanodiamond particles can be substantially free of non-carbon materials such as metal binders, sintering aids or the like. Upon sintering, the nanodiamond particles sinter together at high pressures and lower temperatures than those typically required in producing polycrystalline diamond compacts with diamond crystals of a larger size. The absence of non-carbon materials improves the high temperature performance and reliability of the nanodiamond tools of the present invention.

Owner:SUNG CHIEN MIN

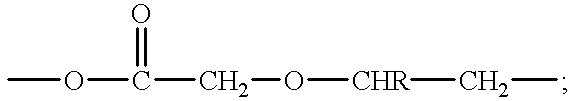

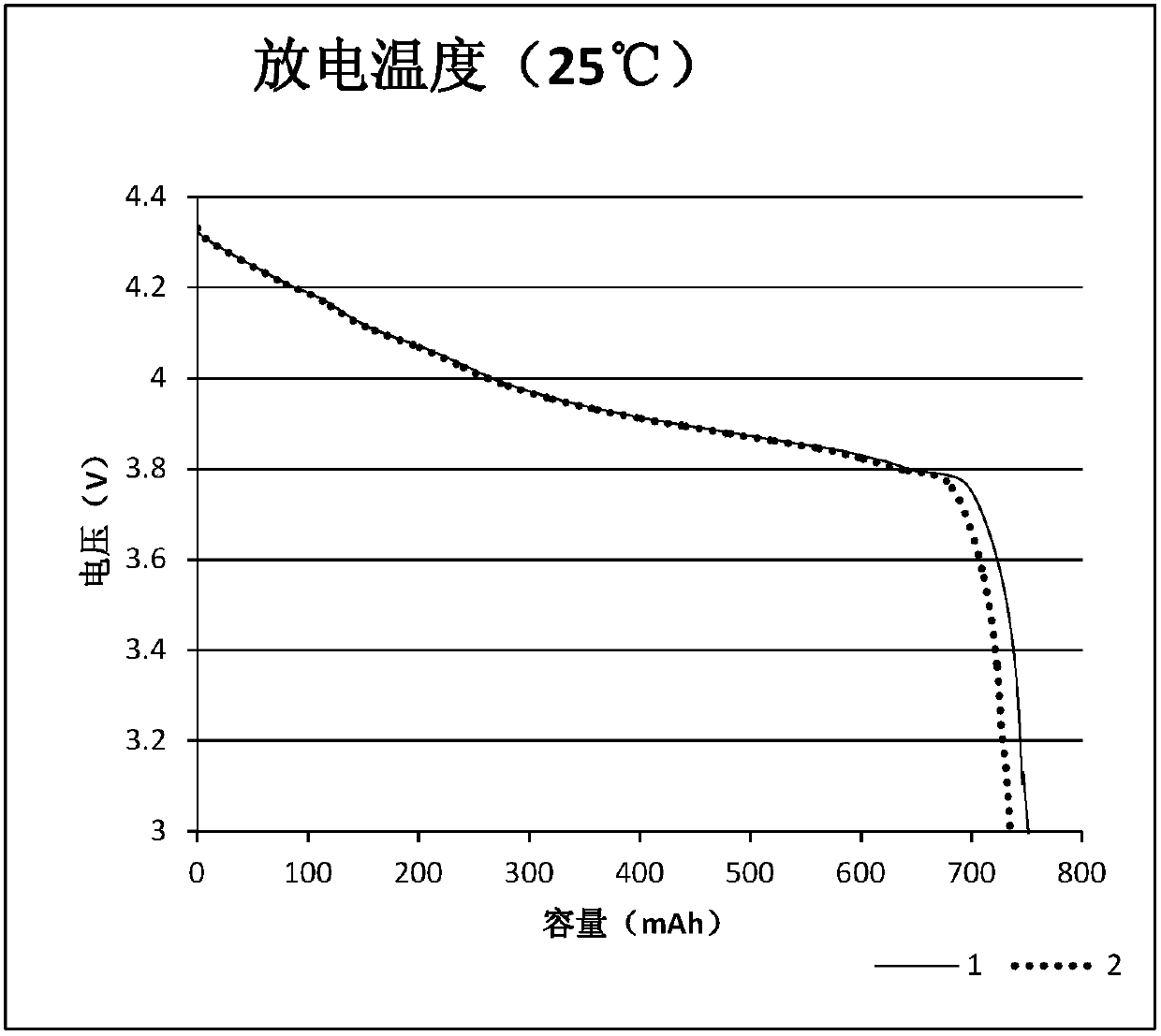

High-capacity lithium-ion electrolyte, battery and preparation method of battery

ActiveCN101771167AIncrease capacityLow costFinal product manufactureCell electrodesElectrolytic agentPhysical chemistry

The invention relates to a high-capacity lithium-ion electrolyte, a battery and a preparation method of a battery, in particular to the high-capacity lithium-ion electrolyte and the battery using the high-capacity lithium-ion electrolyte and the preparation method of the battery. The electrolyte disclosed by the invention comprises lithium salt and non-aqueous organic solvent, and also consists of the following components in weight percent in terms of the total weight of the electrolyte: 0.5-7% of film-forming additive, 0-15% of flame-retardant additive, 2-10% of antiovefill additive, 0.01-2% of stabilizer and 0.01-1% of wetting agent; the electrolyte can enable the anode with high Ni content to work stably, and reduce the battery cost; the high-capacity lithium-ion battery can perform high ratio capacity and excellent safety and high temperature property and cyclic life fully due to the addition and synergetic functions of various functional additives.

Owner:JIUJIANG TINCI ADVANCED MATERIALS CO LTD

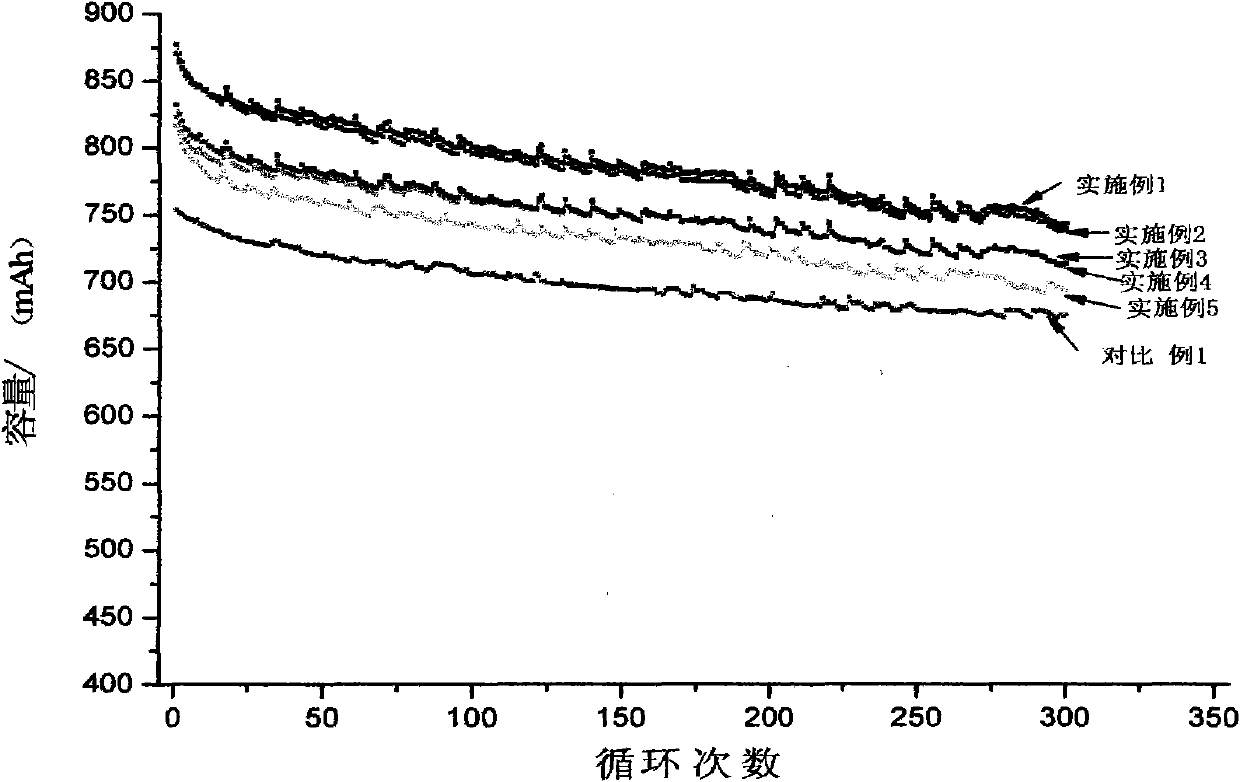

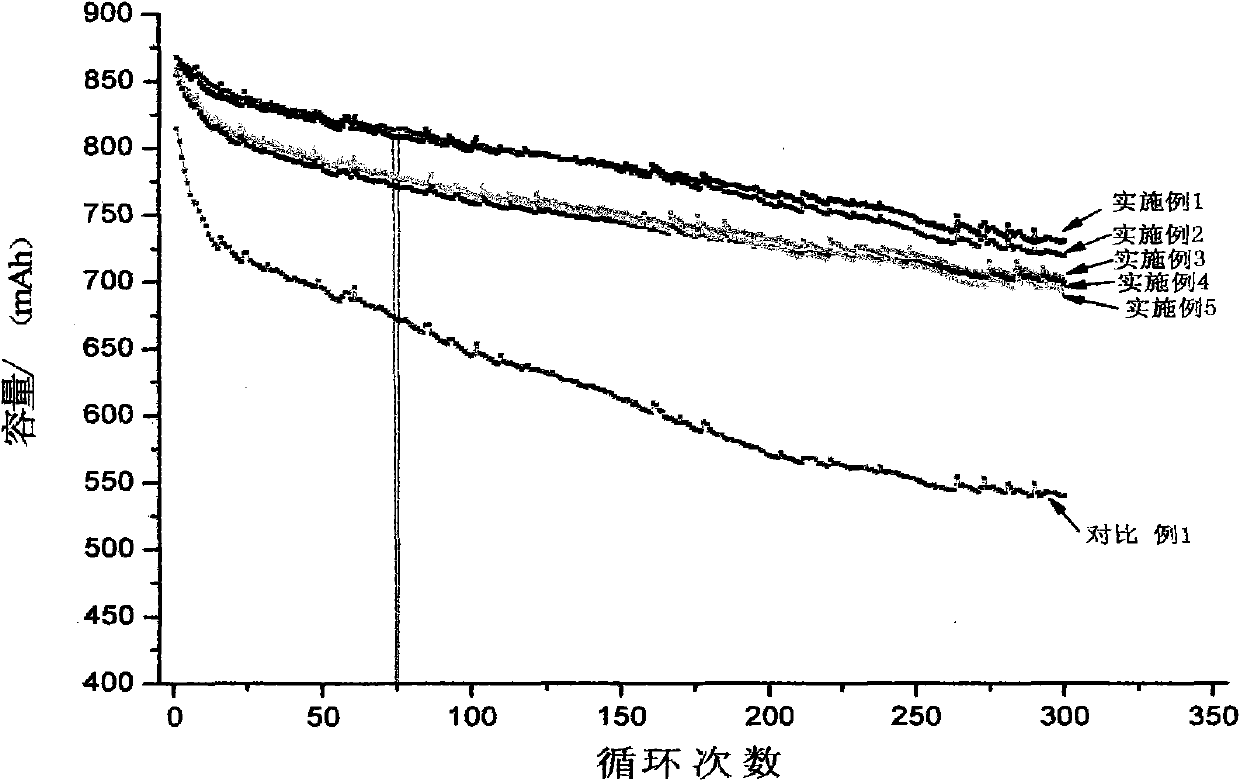

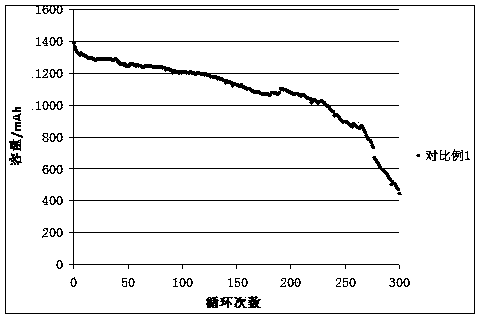

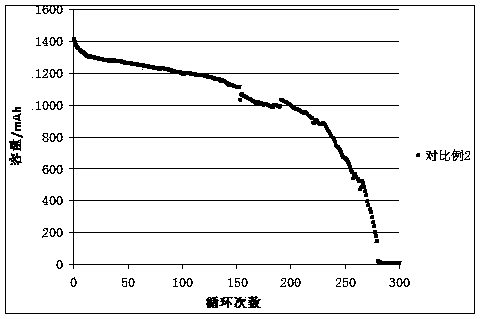

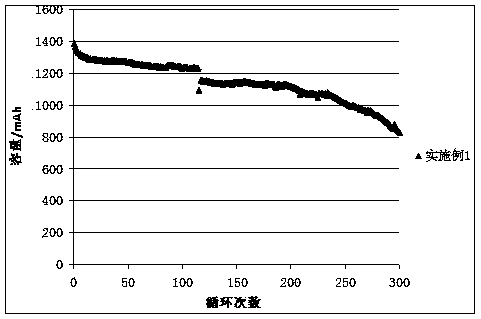

Anode and cathode conductive additive for secondary lithium battery, method for preparing conductive additive, and method for preparing secondary lithium battery

ActiveCN102544502AImprove conductivityQuick migrationFinal product manufactureCell electrodesHigh rateOrganic solvent

The invention discloses an anode and cathode conductive additive for a secondary lithium battery, a method for preparing the conductive additive, and a method for preparing the secondary lithium battery. The conductive additive is graphene or a mixture of the graphene and other conductive materials, is graphene powder or mixture powder of graphene and other conductive materials, and also can be graphene or mixture conductive agent slurry of the graphene and other conductive materials, which is uniformly dispersed in water or an organic solvent or in water or an organic solvent which contains a dispersing agent. The graphene conductive additive is suitable for preparing the anode and cathode of the secondary lithium battery, and has the obvious advantage of improving the high-rate performance and cycle stability of the secondary lithium battery compared with other conductive additives at present.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Amphiphilic polymer micelles and use thereof

InactiveUS20080160305A1Improve high temperature performanceImprove propertiesMaterial nanotechnologySynthetic resin layered productsElastomerThermoplastic

A nano-particle composition including a polar core and a hydrophobic surface layer is provided. The nano-particles have a mean average diameter less than about 100 nm. Methods are disclosed for making and using the nano-particles. The nano-particles can be modified via, for example, hydrogenation or functionalization. The nano-particles can advantageously be incorporated into rubbers, elastomers, and thermoplastics.

Owner:BRIDGESTONE CORP

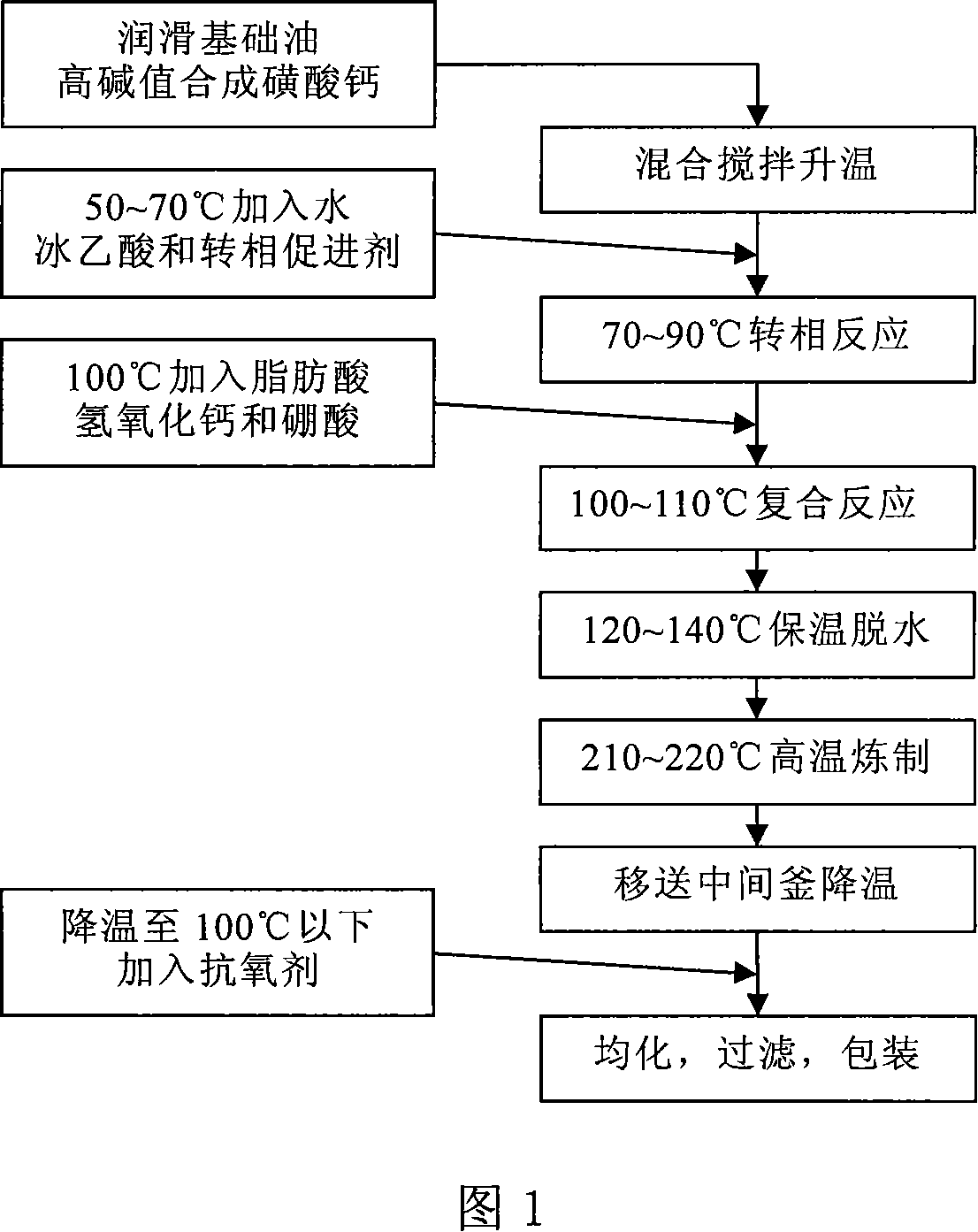

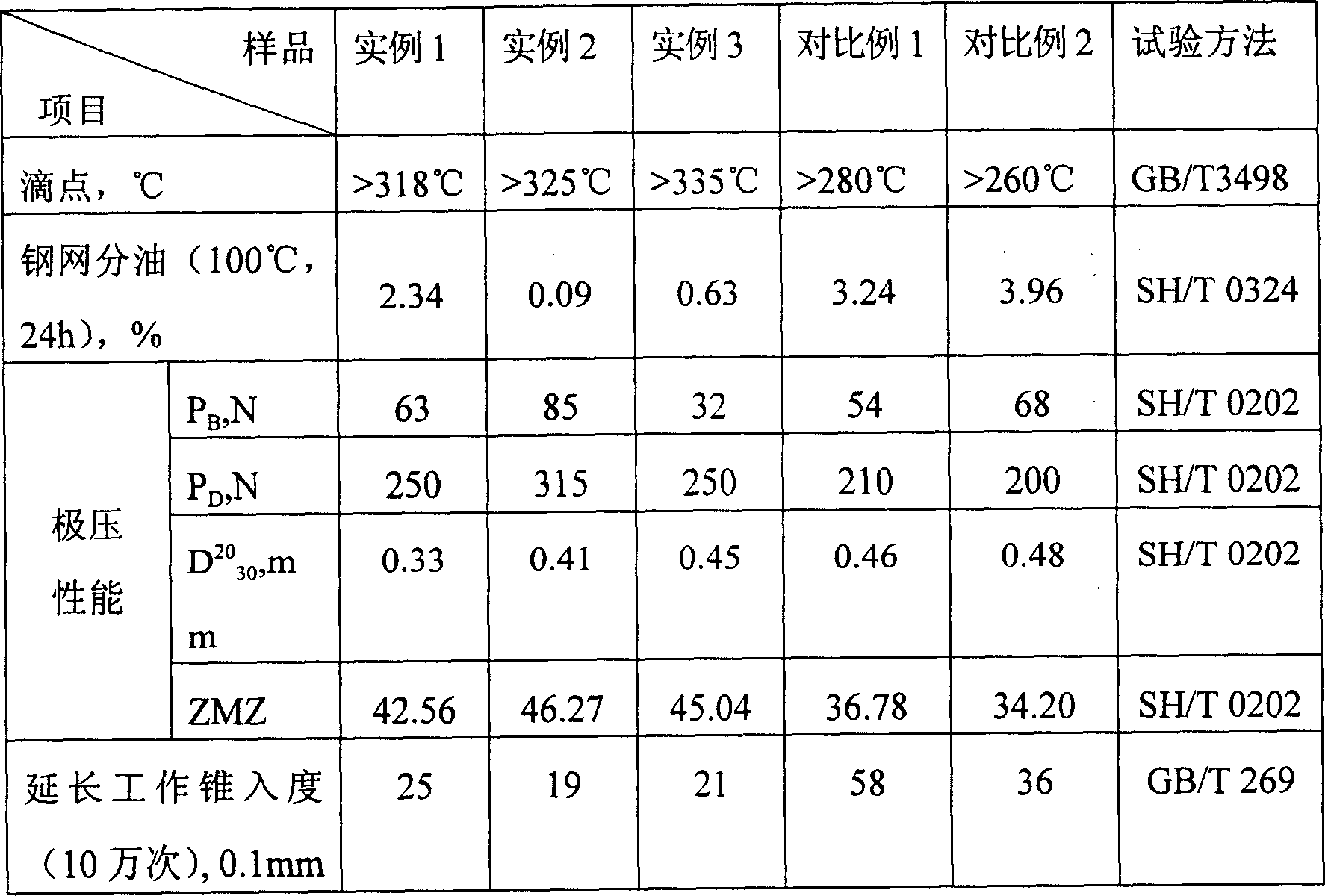

Compound sulphonic acid albany grease and method for producing the same

ActiveCN101153239AImprove performanceImprove water resistanceLubricant compositionAntioxidantManufacturing enterprises

The invention relates to calcium sulfonate complex grease and a manufacture method thereof, in particular to grease producing the thickening agent by synthetic reaction with super-high base value. At first, the lubricating base oil and the calcium sulfonate are added into an opening reaction kettle to be stirred, the phase inversion promoter, the glacial acetic acid and the water are added into the kettle to boost the temperature to make the insulating reaction until the materials are thickened, then the calcium hydroxide, the aliphatic acid and the boric acid are added into make an insulating reaction, a temperature rise, an insulating dehydration and a refining in turn, then the materials are moved into an intermediate kettle, the antioxidant is added to disperse and homogenize, and the finished product is produced after the filtering. The invention has excellent anti-spray performance, excellent high temperature performance, good extreme pressure anti-abrasion performance, prominent anti-shear performance, good pumping performance, anti-rust performance and water adding shear stability; has apparent phase inversion effect and good product performance, decreases the grease exchange times under the same working condition and increases the service life of the equipment, which is proved by the trial applications of a plurality of appliance manufacture enterprises, steel works, paper mills and so on.

Owner:无锡中石油润滑脂有限责任公司

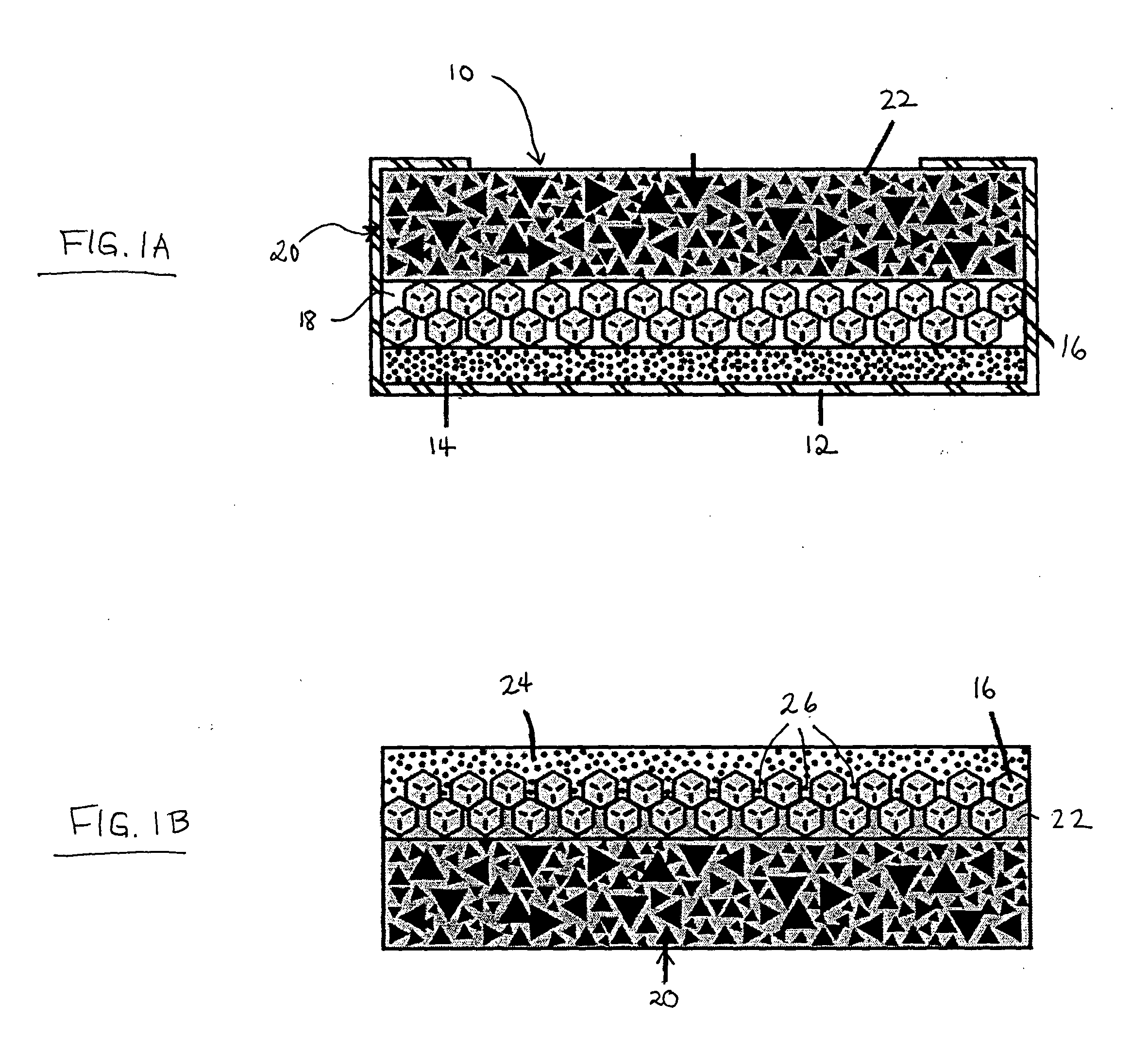

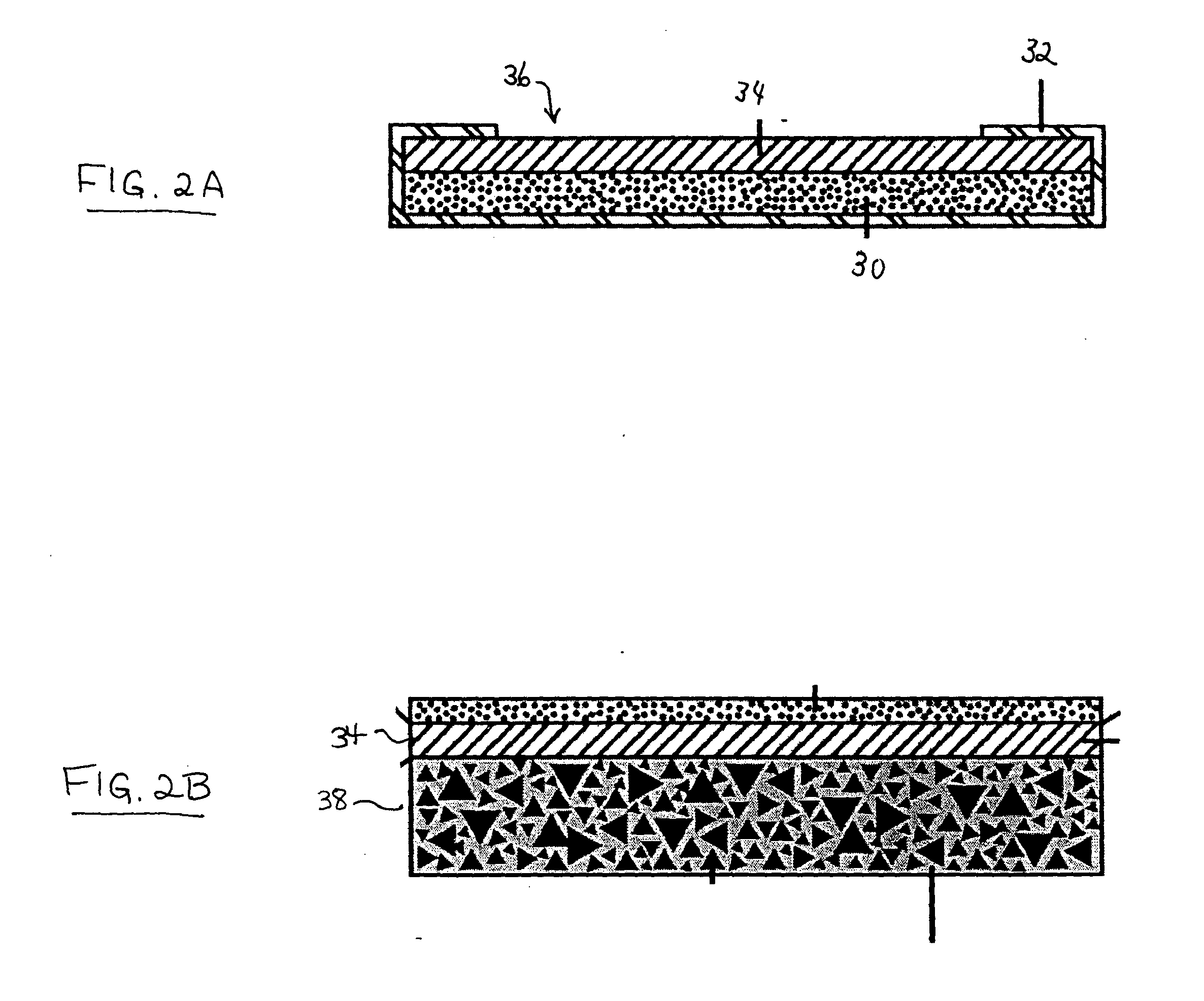

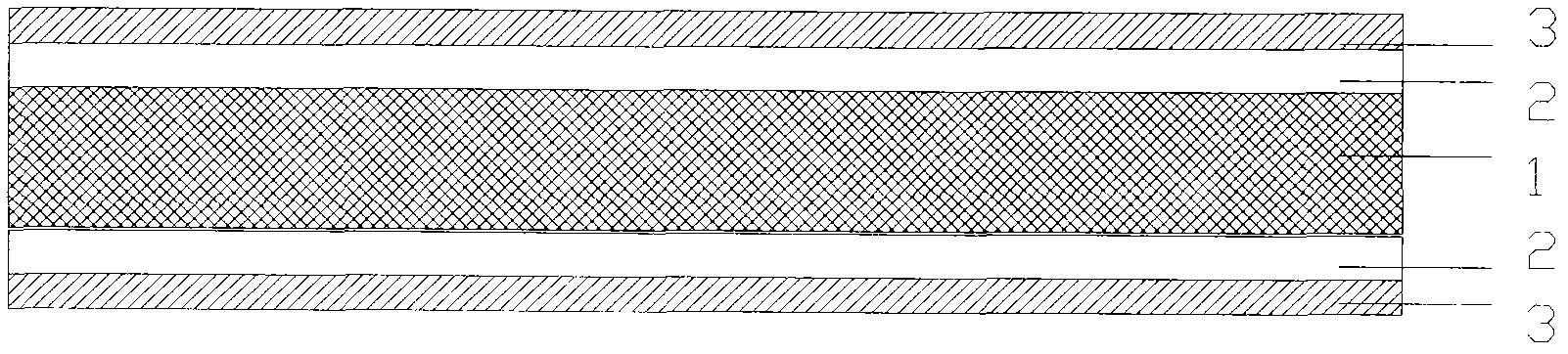

Lithium ion battery and membrane thereof

InactiveCN102569701AImprove securityImprove mechanical propertiesSecondary cellsCeramic layered productsElectrical batteryLithium-ion battery

The invention belongs to the technical field of lithium ion batteries and particularly relates to a membrane for a lithium ion battery, which is good in safety performance and mechanical performance. The membrane for the lithium ion battery comprises a porous membrane substrate, a ceramic material layer coated on the surface of the porous membrane substrate, and a polymer sticking layer which is coated on the ceramic material layer and is located on the surface layer. Compared with the prior art, the ceramic material layer can form a microcosmic physical separation on the surface of the membrane so as to reduce the piercing effect of a lithium pine-tree crystal on the membrane; the ceramic material layer coated on the porous membrane substrate can improve the heat resistance of the membrane; the polymer sticking layer which is coated on the ceramic material layer and has a sticking effect can be used for preventing an inner short circuit caused by staggering of the membrane and an electrode, so that the safety performance of the battery is enhanced. In addition, the membrane, an anode sheet and a cathode sheet are joined together through the effect of the polymer sticking layer, so that the mechanical performance of the battery can be enhanced. Furthermore, the invention further discloses the lithium ion battery containing the membrane.

Owner:NINGDE AMPEREX TECH

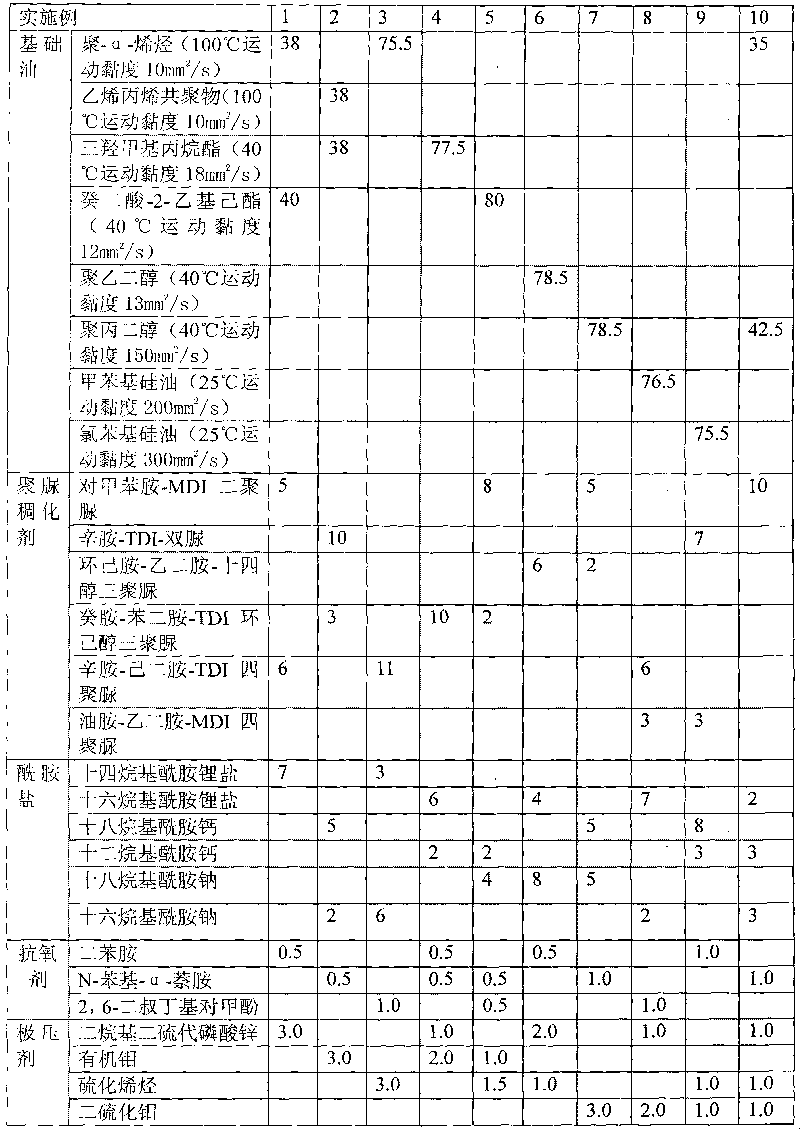

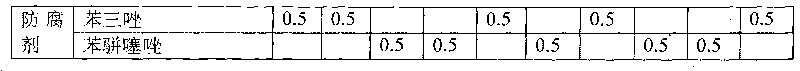

Synthetic high-temperature lubricating grease and production method thereof

InactiveCN101693851AGood colloidal stabilityGood shear stabilityThickenersAdditivesAntioxidantColloid

The invention discloses a synthetic high-temperature lubricating grease and a production method thereof. The synthetic high-temperature lubricating grease is produced by taking synthetic oil as base oil and mixing the base oil with thickening agents, an extreme-pressure additive, an antioxidant and an anticorrosive agent, wherein the weight ratios of all ingredients are as follows: 47-94% of base oil, 2-20% of polyurea thickening agent, 2-20% of acylamide thickening agent, 0.5-5.0% of antioxidant, 1.0-5.0% of extreme-pressure additive and 0.5-3.0% of anticorrosive agent. In the invention, the synthetic base oil, the polyurea thickening agent and the acylamide thickening agent all have excellent high-temperature performance, and the organic combination thereof leads the lubricating grease to obtain excellent high-temperature performance; the polyurea thickening agent endows the lubricating grease with good colloid stability, and the acylamide thickening agent endows the lubricating grease with excellent anti-shear stability, therefore, the organic combination of colloid stability and anti-shear stability leads the lubricating grease to have excellent high-temperature performance and good losing resistance, does not change to thin and avoids losing at high temperature. The extreme-pressure anti-wear additive endows the lubricating grease with excellent extreme-pressure anti-wear performance, and the bearing capacity is high.

Owner:CHINA PETROLEUM & CHEM CORP

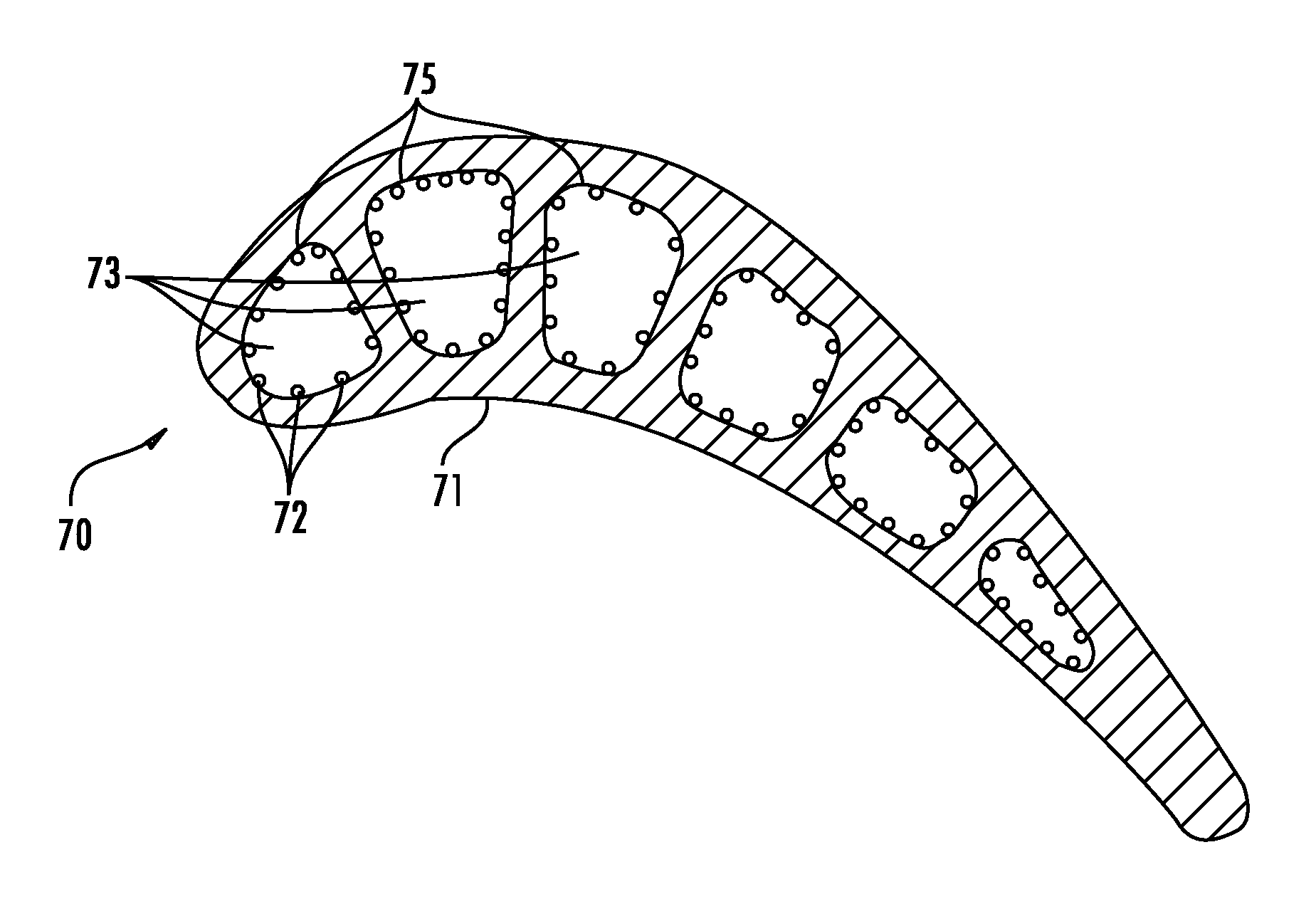

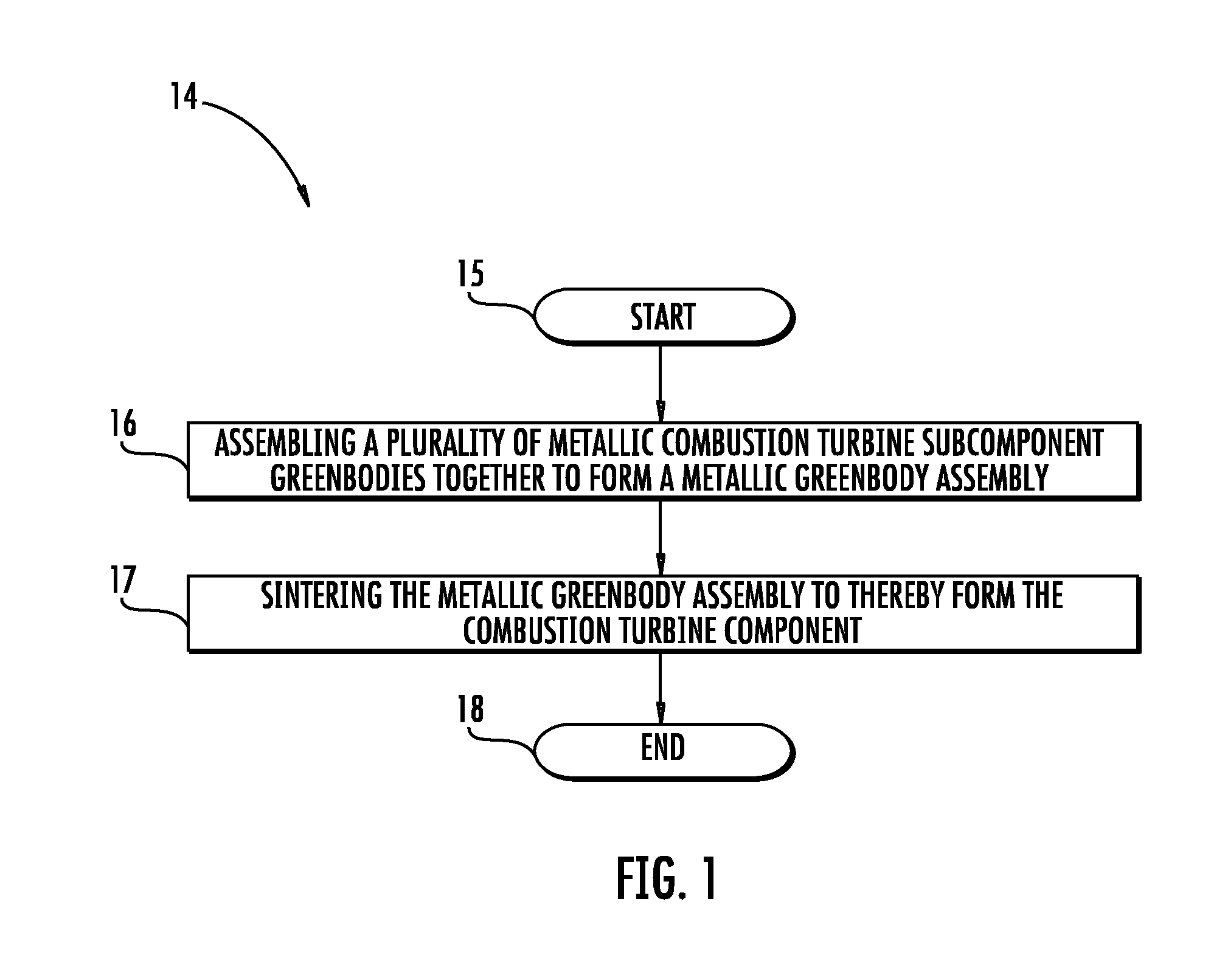

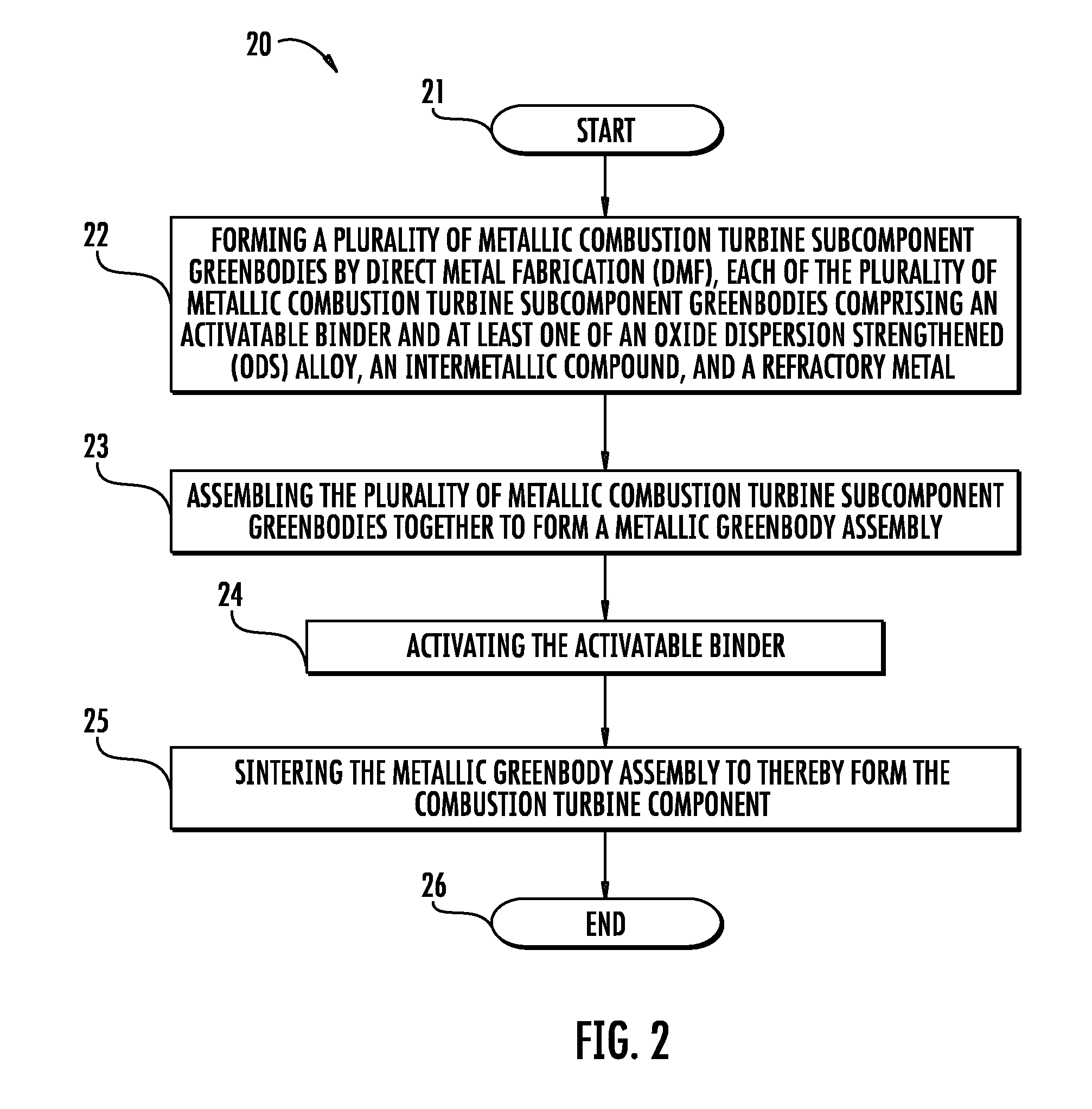

Method of Making a Combustion Turbine Component Having a Plurality of Surface Cooling Features and Associated Components

InactiveUS20110016717A1Increase surface areaHigh temperature performance be improveTurbinesMetal-working apparatusSurface coolingGas turbines

A method of making a combustion turbine component includes forming a metallic body by direct metal fabrication (DMF) to have at least one surface portion defining a first plurality of surface cooling features each having a first dimension and at least one second surface cooling feature on at least one of the first plurality of surface cooling features and having a second dimension less than said first dimension and less than 200 μm. Forming the metallic body by DMF may include forming a plurality of metallic combustion turbine subcomponent greenbodies by DMF and assembling the plurality of metallic combustion turbine subcomponent greenbodies together to form a metallic greenbody assembly. The metallic greenbody assembly may be sintered to thereby form the metallic body.

Owner:SIEMENS ENERGY INC +1

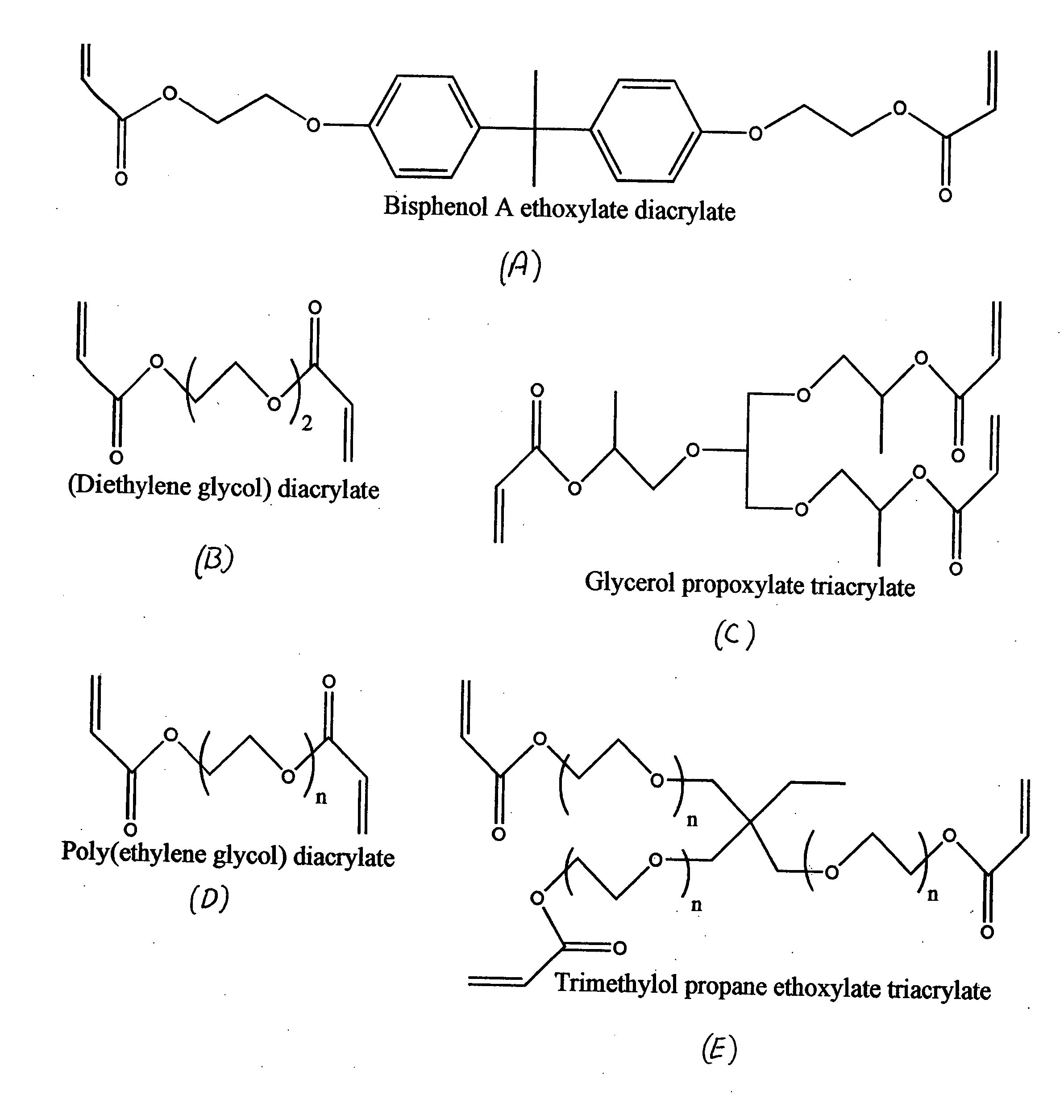

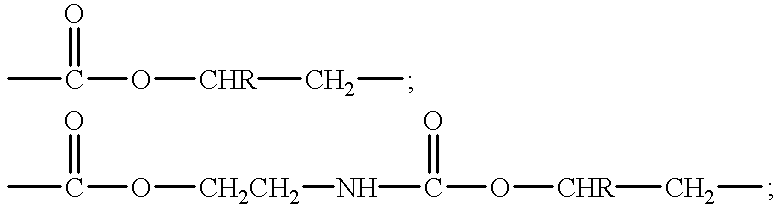

Transdermal pressure sensitive adhesive drug delivery system

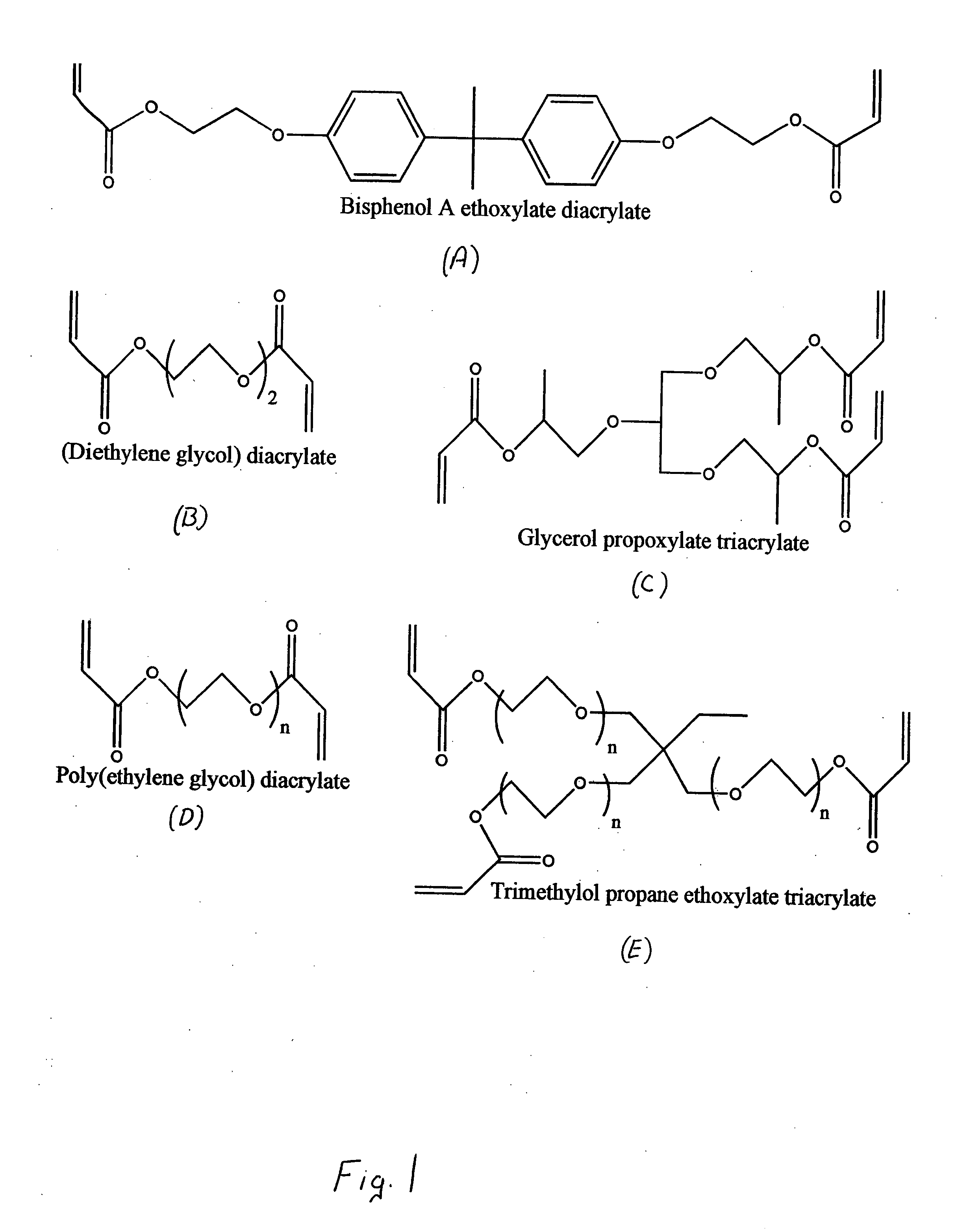

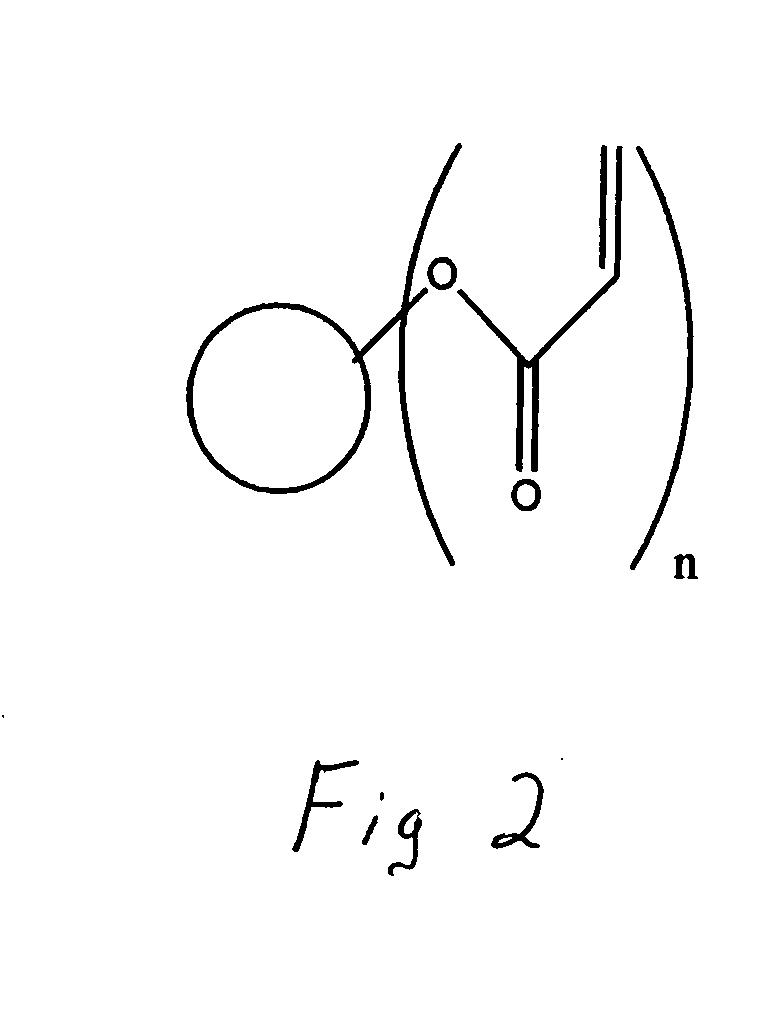

InactiveUS6174546B1Maintenance characteristicTrend downAdhesive dressingsAbsorbent padsMeth-Macromonomer

A transdermal drug delivery system is provided which includes an optionally crosslinked macromer-reinforced (meth)acrylic ester base copolymer pressure sensitive adhesive wherein the macromer includes repeat hydrophilic units.

Owner:ADHESIVES RES

Anode material of lithium ion cell and preparation method

InactiveCN1627550AGood cycle performanceGood high temperature performanceElectrode thermal treatmentActive material electrodesAnodeMetallurgy

The anode material is prepared from oxidation material layer of covering surface of at least one anode active material among LiCoO2, LiNi1-xCOxO2, LiNi1 / 3Mn1 / 3O2 and LiMn2O4. Weight of non-oxygen element in oxidation material layer can be 0.01-10 weight% of anode active material. Advantages of the anode material are: good cycle performance, favorable high temp property and high power discharge property, and anti over change property as well as simple technique and easy of production.

Owner:BYD CO LTD

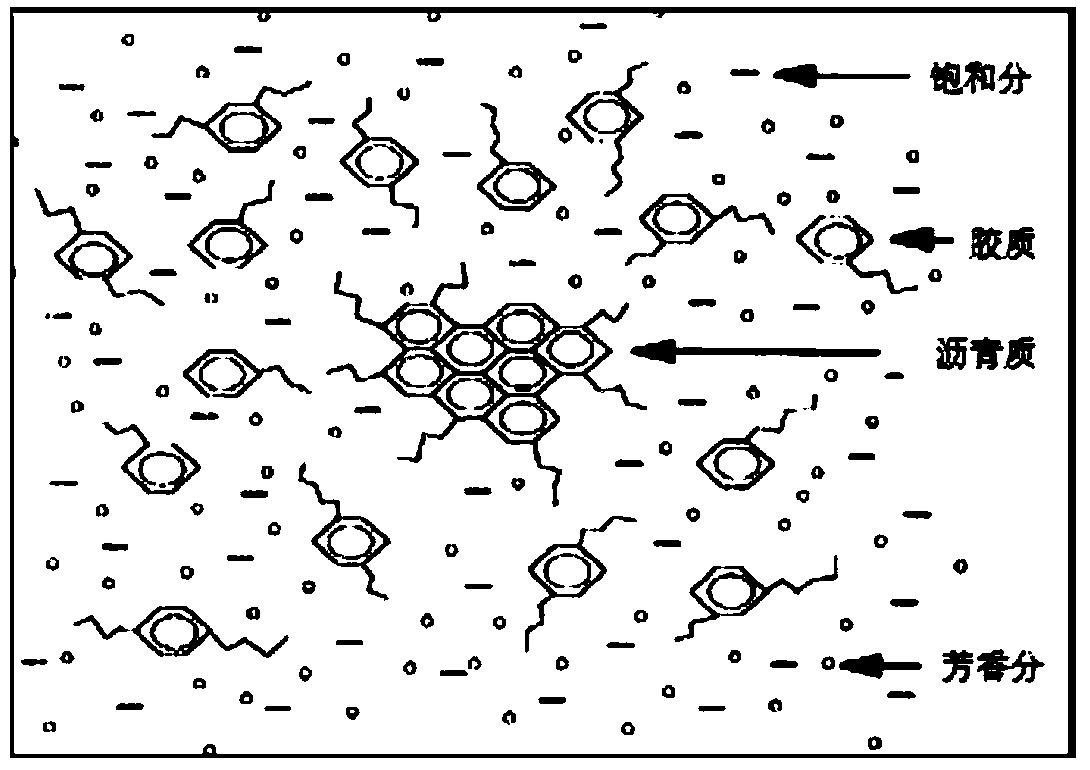

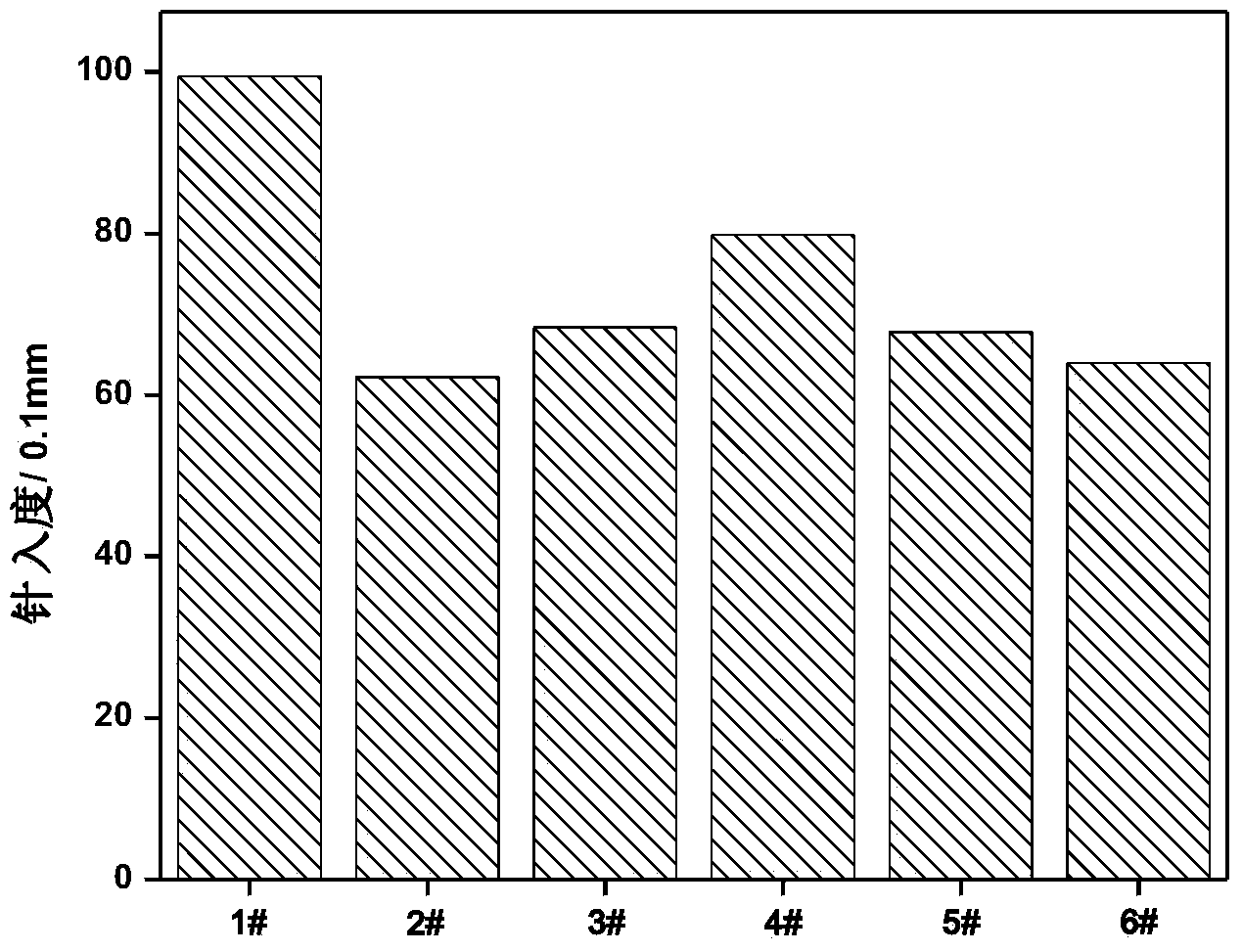

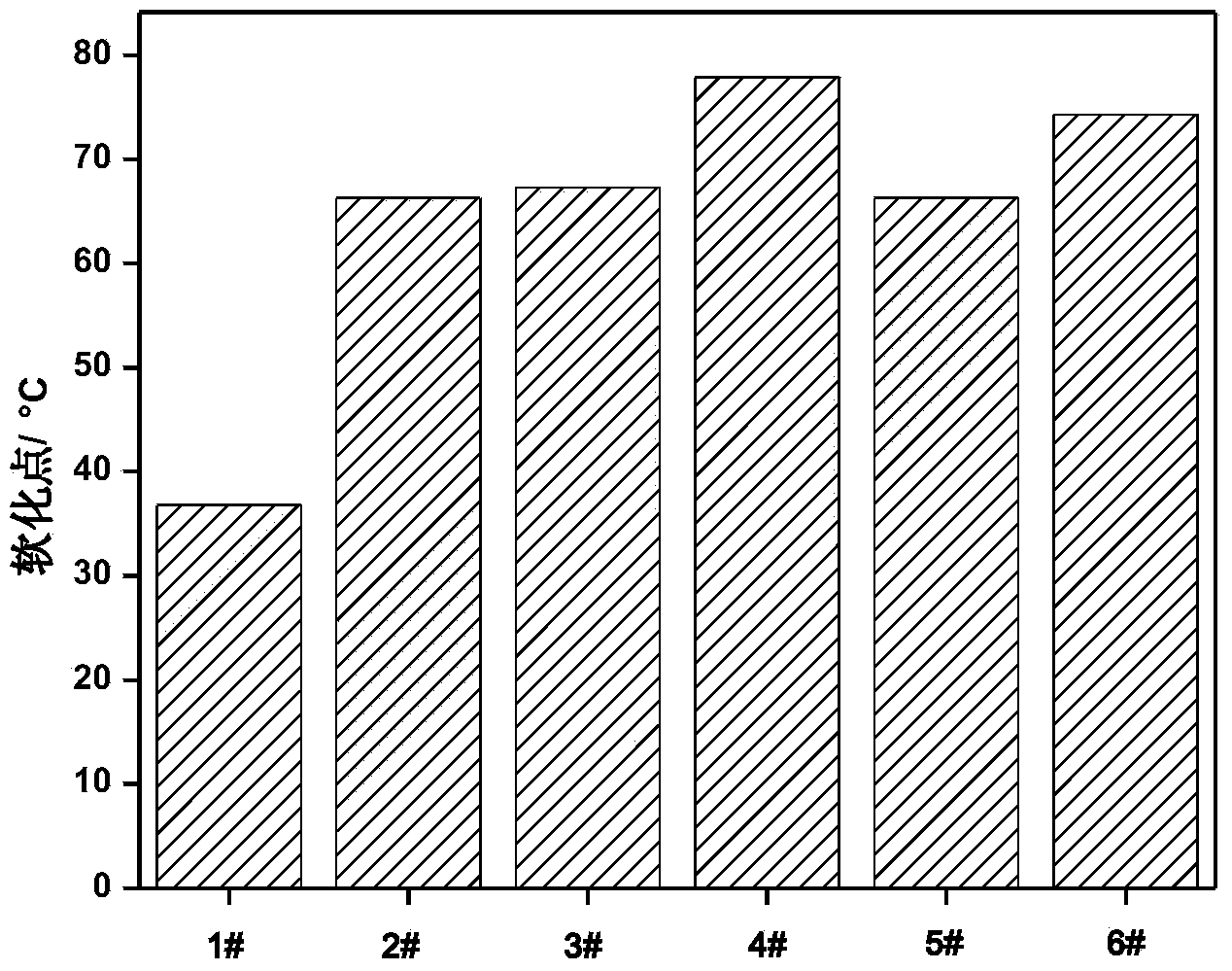

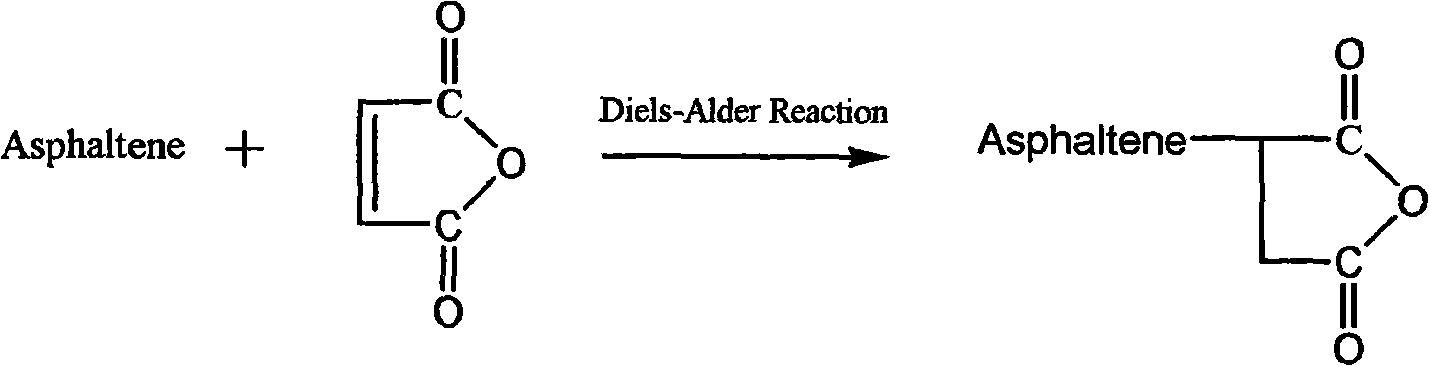

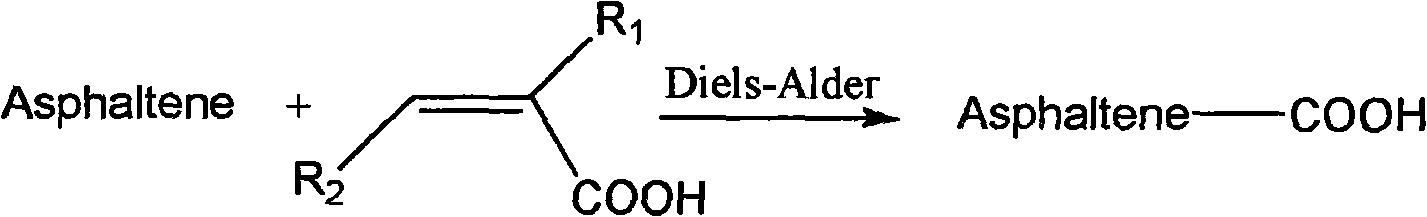

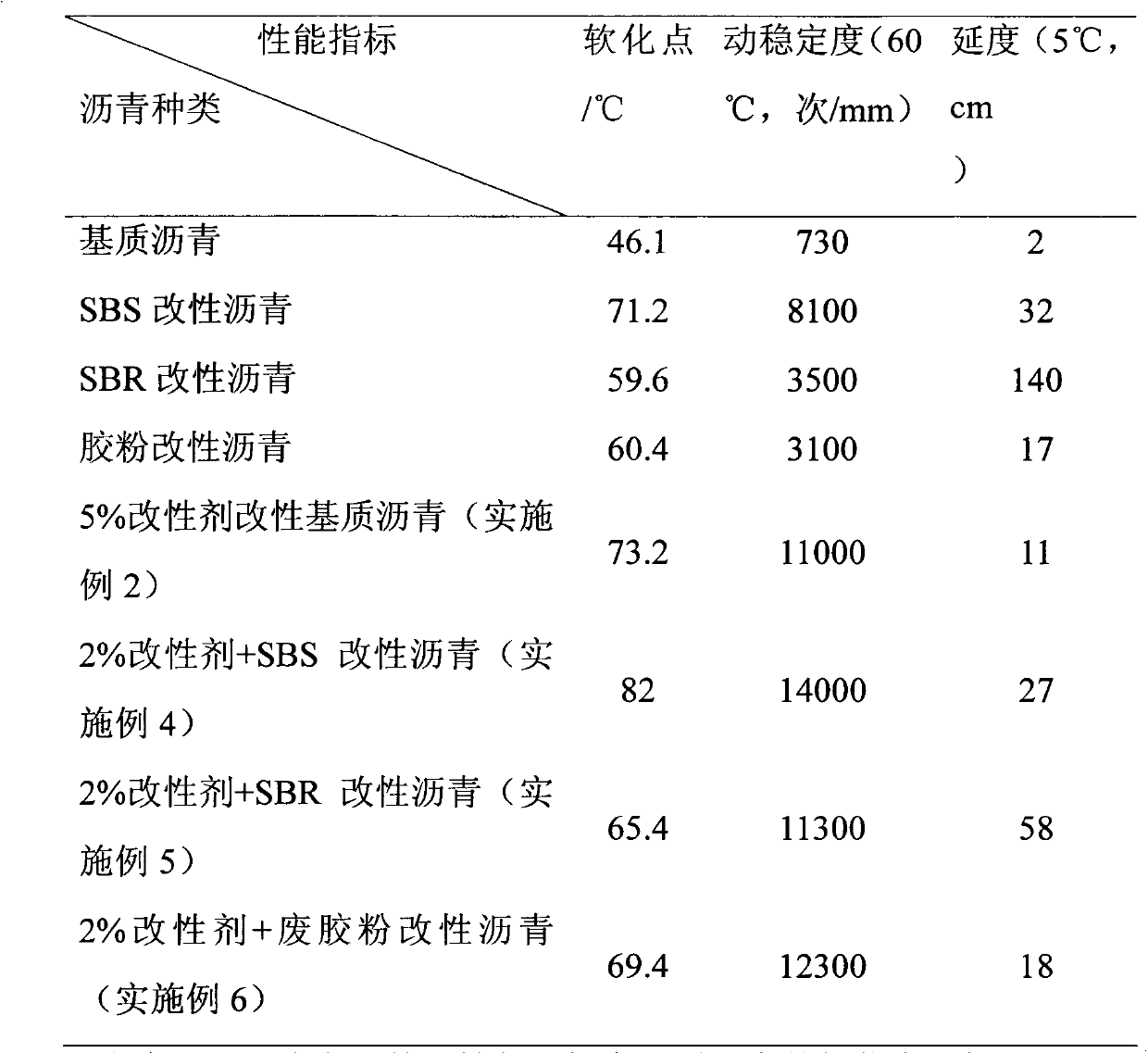

Graphene oxide modified asphalt and preparation method thereof

ActiveCN103819915AImprove high temperature performanceImproves rutting resistanceBuilding insulationsGraphite oxidePitch blende

The invention provides graphene oxide modified asphalt, comprising, by mass, 0.5 to 15% of graphene oxide and 85 to 99.5% of matrix asphalt, wherein the above mentioned mass percent sums to 100%. A preparation method for the graphene oxide modified asphalt comprises the following steps: heating and fusing matrix asphalt, maintaining a temperature to be 120 to 200 DEG C, adding graphene oxide, carrying out artificial stirring for 20 to 40 min, then carrying out stirring with a shearing machine for 20 to 120 min, cooling an obtained mixture to 100 to 150 DEG C and standing the mixture for 20 to 50 min so as to allow the mixture to be fully swollen; and subjecting the asphalt mixture to shearing on the shearing machine again for 80 to 100 min until graphene oxide is uniformly dispersed in asphalt. The graphene oxide modified asphalt provided by the invention uses graphene oxide as a modifier for modification of asphalt, can substantially improve high temperature performance and anti-deformation capability of matrix asphalt and greatly improves anti-tracking capability of a bituminous pavement.

Owner:浙江威克新材料科技发展有限公司

Preparation method of polyurea-composite calcium lubricating grease

InactiveCN1493673APrevent volatilizationImprove high temperature performanceAdditivesCalcium hydroxideOrganic acid

A lubricating polyureas-composite calcium grease is prepared through proportionally mixing basic oil, calcium hydroxide (oxide), water and C1-C20 organic acid together, heating to 30-100 deg.C, adding diisocyanate and organic amine, draining water, saponifying, heating to 210-230 deg.C, cooling and homogenizing. Its advantages are high refractory performance, stability and extreme-pressure antiwear nature.

Owner:CHINA PETROLEUM & CHEM CORP +1

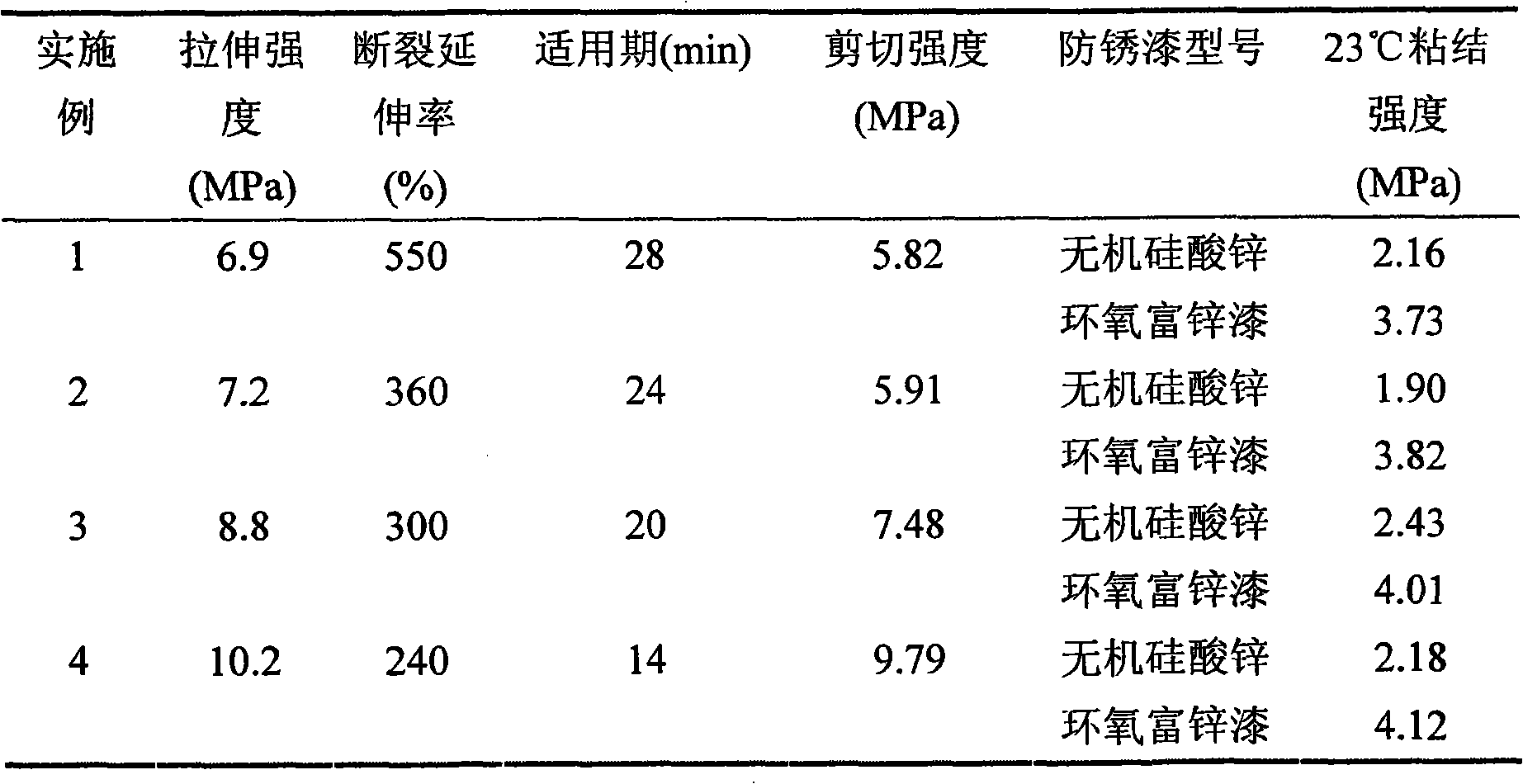

Epoxy asphalt material for road-bridge and environment-friendly preparation method thereof

The invention provides an epoxy asphalt material for bridge and green preparation method, comprising A part and B part, wherein the weight constitute of the A part is: modified asphaltum with carboxyl or anhydride group 60-76 parts, monohydric alcohol or polyhydric alcohol 2-20 parts, aliphatic diprotic acid, dimer acid or alkyd resin 11-25 parts, fatty acid anhydride 10-25 parts, solidified promoter 0.05-0.65 parts; and the constitute of the B part is epoxy resin. The mass ratio of A and B part is 2.2:1-10:1. The epoxy resin modified asphalt material has excellent property with high intensity and good flexibility; provides corresponding operation time according to different requirement and adjust the operation time to satisfy the different performance requirement at will with good storage stability. The corresponding epoxy asphalt concrete has excellent high, low temperature performance and fatigue endurance, and the environment is friendly, suitable for occasion with higher requirement such as autoroute and bridge, and arterial street, bus stop and airfield path. The invention also provides a preparation method thereof.

Owner:SOUTHEAST UNIV

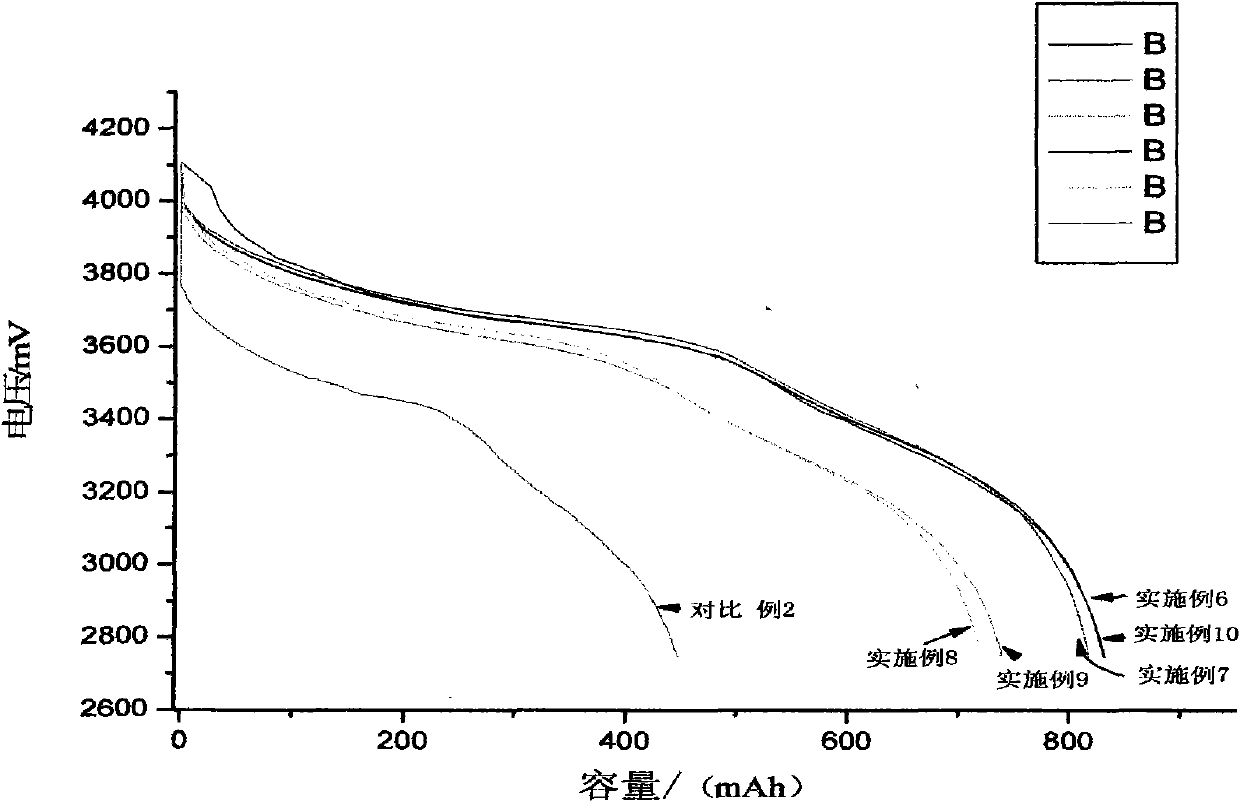

Preparation method of lamellar lithium manganese battery

ActiveCN101964428ALow costGood high temperature performanceFinal product manufactureCell electrodesLithium electrodeCooking & baking

Owner:BTR NEW MATERIAL GRP CO LTD

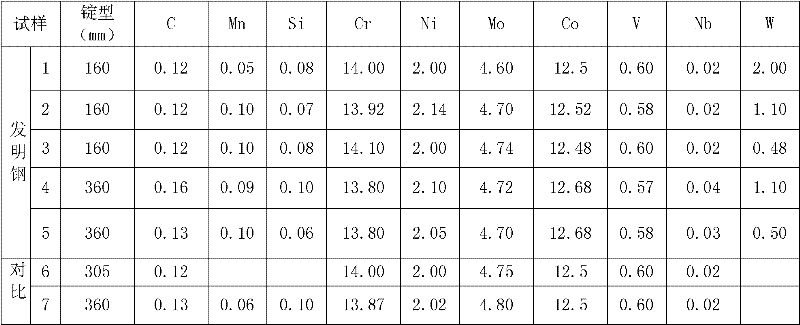

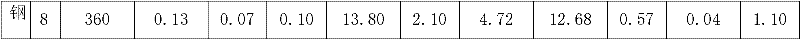

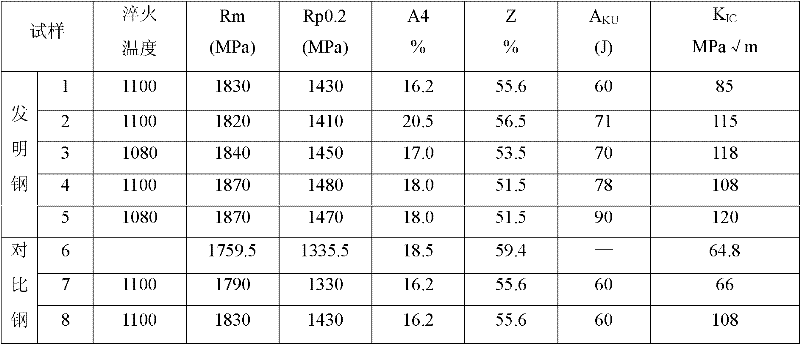

High-strength high-toughness anticorrosion high-temperature bearing/pinion steel and preparation method thereof

The invention relates to a high-strength high-toughness anticorrosion high-temperature bearing / pinion steel and a preparation method thereof, belonging to the technical field of bearing / pinion steel. The bearing / pinion steel comprises the following chemical elements in percentage by weight: 0.10-0.22% of C, at most 0.5% of Mn, at most 0.5% of Si, 12.0-15.0% of Cr, 1.50-3.00% of Ni, 4.00-6.00% of Mo, 0.50-0.90% of V, 12.0-15.0% of Co, 0.30-2.00% of W, 0.02-0.08% of Nb and the balance of Fe and inevitable impurities, wherein the V / Nb ratio is 25-35, the Mo / W ratio is 6-12, the Co / Mo ratio is 2-3, Cr+6Si+4Mo+1.5W+11V+5Nb<=52%, 40C+2Mn+4Ni+30N+2Co>=42%, and [O]+[N]+[H]<=0.0040%. The preparation method comprises the following steps: proportioning and controlling the components; carrying out vacuum smelting; carrying out hot working on a steel ingot to obtain a steel product; carrying out surface carburized hardening treatment on the steel product; and carrying out heat treatment on the steel product. The invention can satisfy the requirements of new-generation bearing / pinion steel for bearing the actions of high temperature and corrosive environment in the service process, and implements good cooperation of high strength, high hardness, high toughness, high temperature properties and anticorrosion property.

Owner:CENT IRON & STEEL RES INST

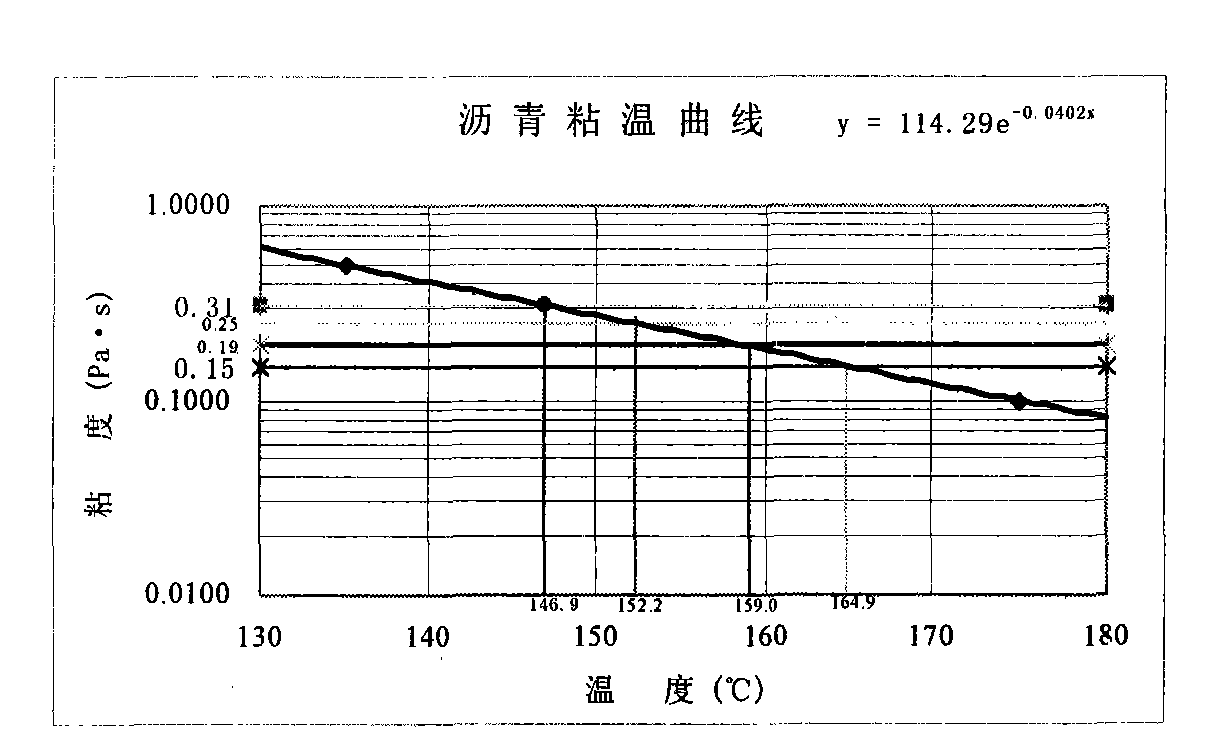

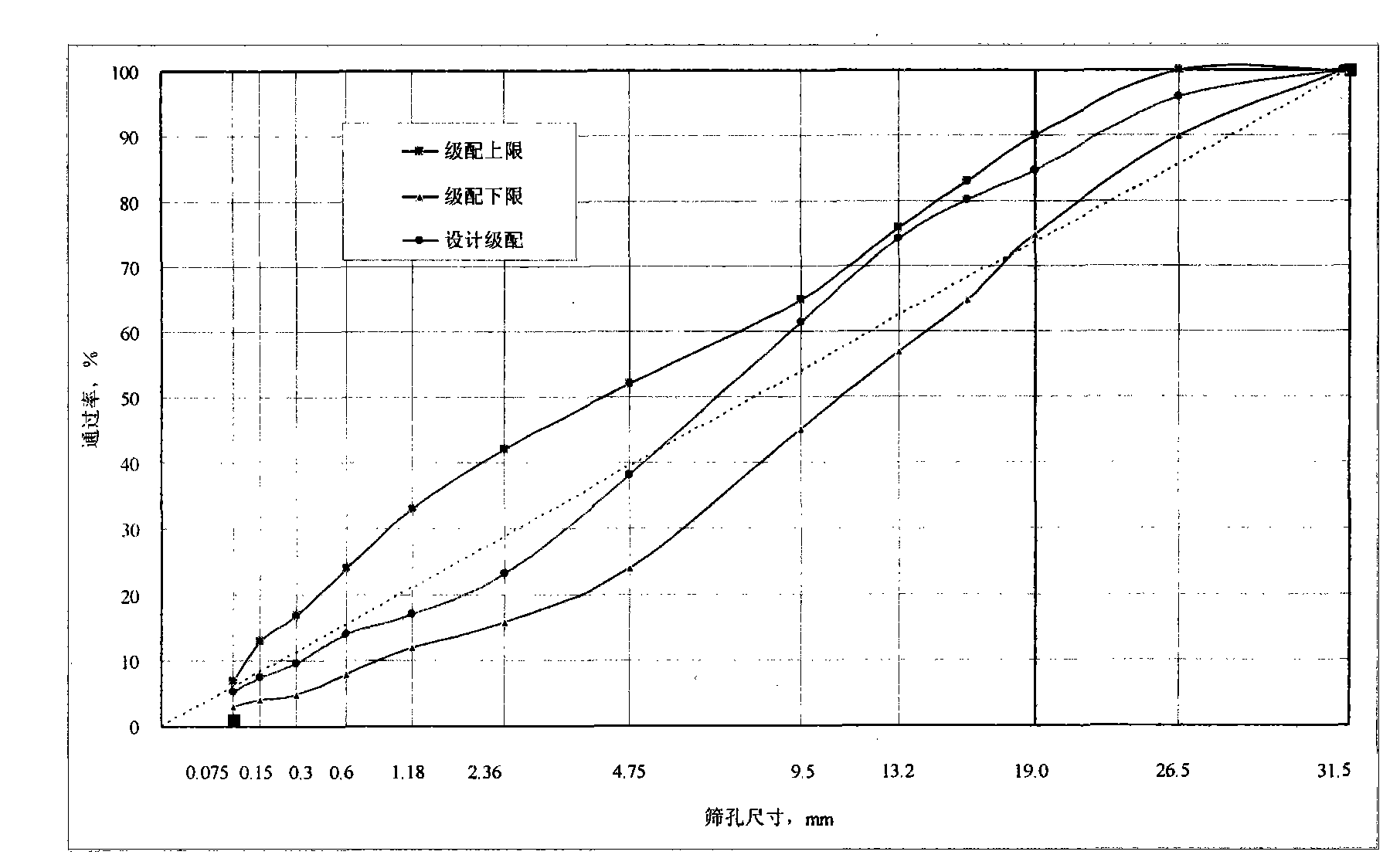

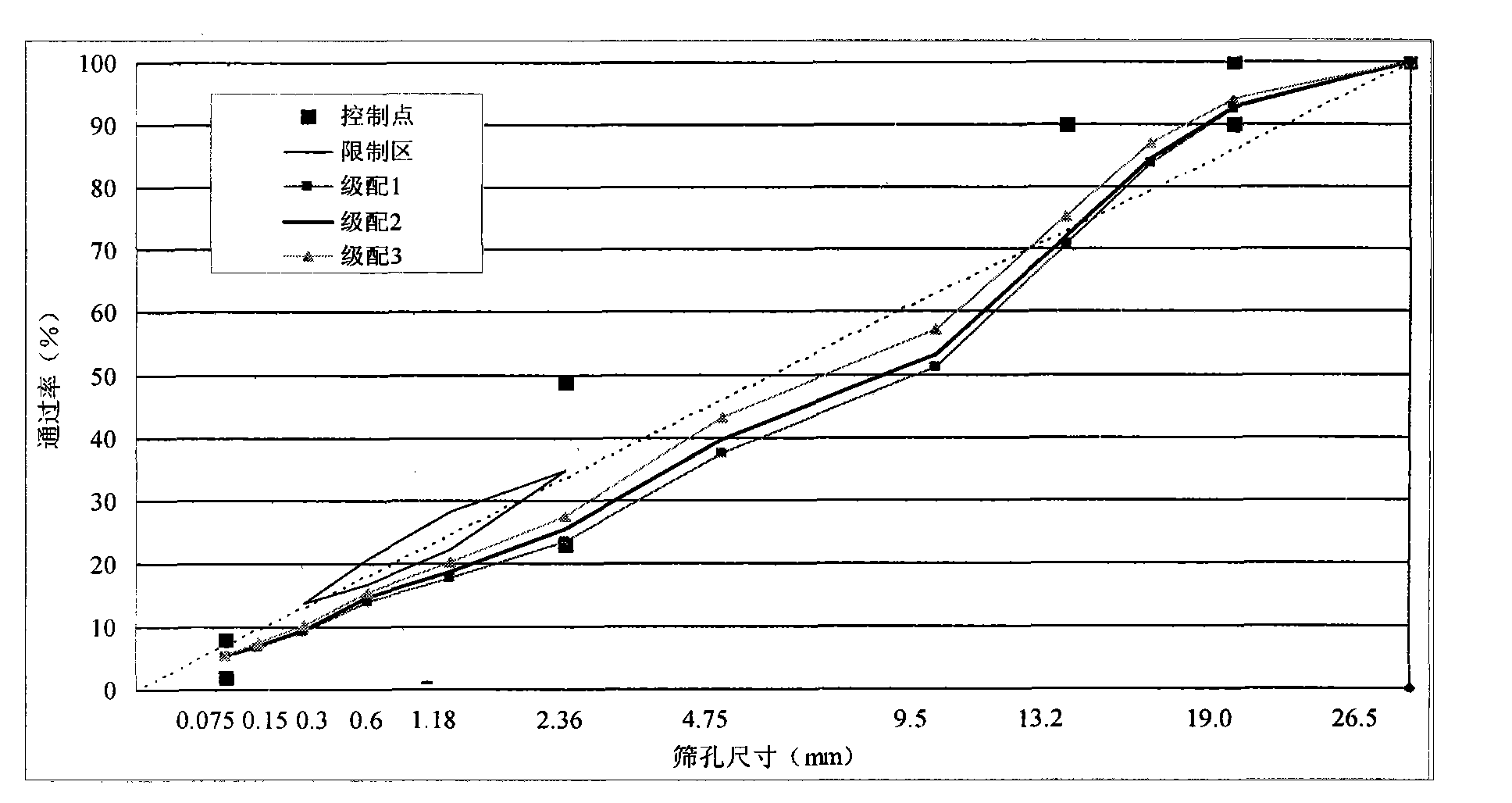

Hot in-plant reclaimed asphalt mixture

ActiveCN101654347AIncrease dosageImprove high temperature performanceSolid waste managementEconomic benefitsRoad surface

The invention relates to a hot in-plant reclaimed asphalt mixture. The mixture includes the following components by mass percent: 30 to 50 percent of milling materials, 44 to 67 percent of newly collected materials, 1.5 to 4 percent of mineral powder, 1.5 to 4 percent of new asphalt, and ARA regenerant which is 0 to 10 percent of the mass of the recycled asphalt contained in the milling materials.The processing method includes the following steps: (1) extraction and analysis of the milling materials; (2) asphalt performance test; (3) regenerant addition; (4) formation of mixture of the recycled asphalt; (5) Marshall test or rotary compacting test; and (6) mixture performance test. The proportion of milling material RAP reaches as high as 50 percent in the engineering application of the hot recycled asphalt mixture, the milling material RAP can be applied to a middle layer, and the proportion is higher than the proportions of other hot recycled mixtures by more than 20 percent. The mixture can be applied to various grades, such as the AC type, SUPERPAVE, and the like, and the RAP proportion can respectively reach 30 percent or even more than 50 percent. When the mixture is used forpaving a road surface, the road performance can respectively meet the requirements on performance of a newly proportioned asphalt mixture, and the high temperature performance is even superior to thenewly proportioned asphalt mixture. Therefore, the invention has obvious economic benefit.

Owner:JIANGSU HUAIAN TRAFFIC SURVEY & DESIGN INST

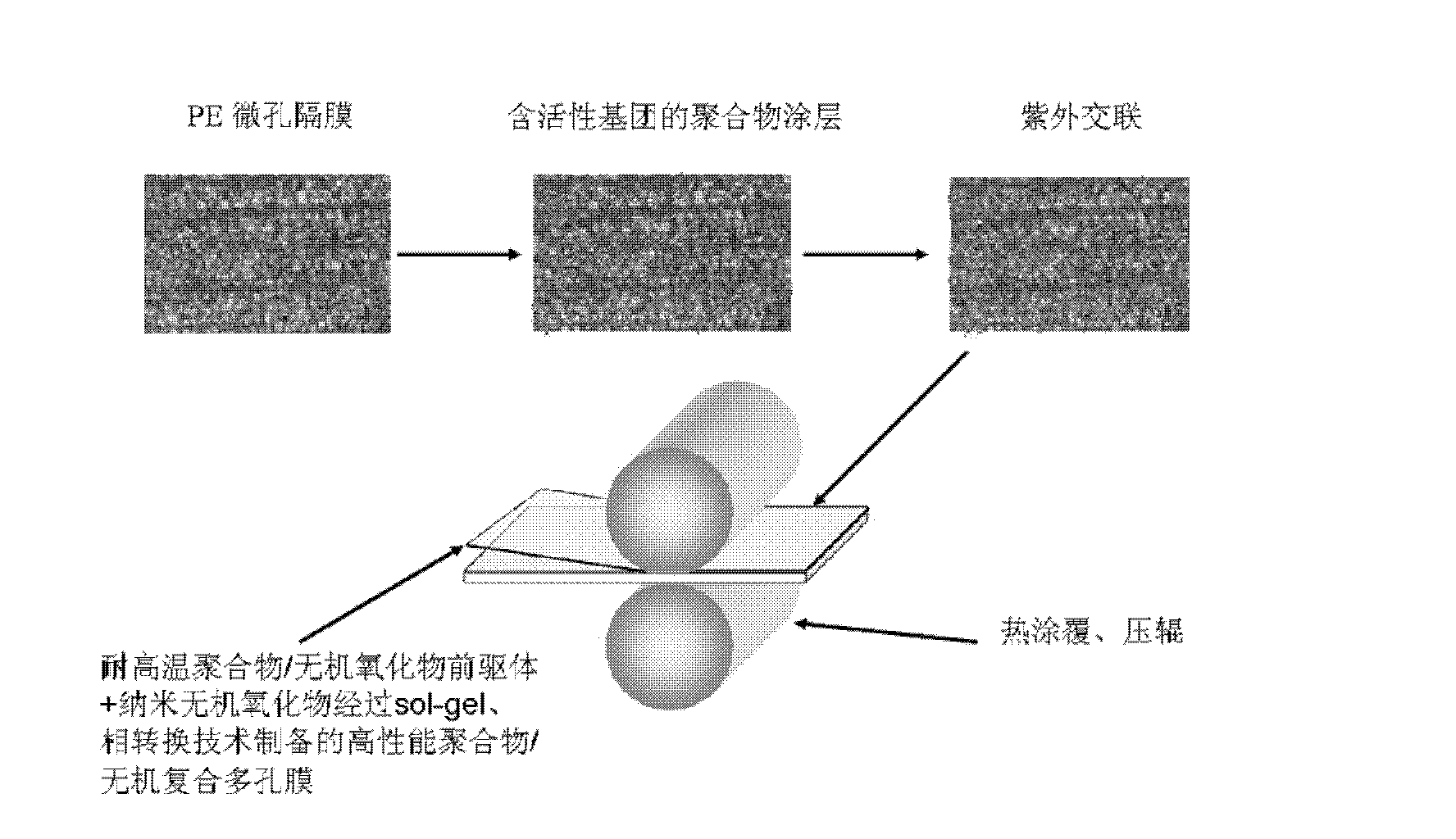

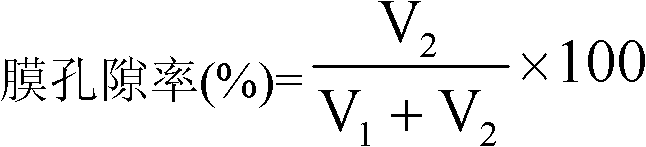

Composite microporous membrane used as lithium ion battery diaphragm as well as preparation method and application thereof

ActiveCN102122704AImprove bonding strengthEasy to prepareCell component detailsPolyolefinHigh performance polymer

The invention discloses a composite microporous membrane used as a lithium ion battery diaphragm as well as a preparation method and application thereof. The composite microporous membrane is prepared by the following steps of: steeping a polyolefin porous framework membrane in a modified liquid a and carrying out radiation crosslinking to obtain a modified framework membrane; preparing a modified liquid b, steeping the modified framework membrane in the modified liquid b and adding a sol-gel reaction catalytic agent to carry out a sol-gel condensation reaction; and immersing the modified membrane in a phase transforming agent solution, carrying out phase conversion to form a membrane and then drying to obtain a high-performance polymer / inorganic composite microporous membrane. In the invention, the preparation process is simple and the industrialization is easy to realize; the obtained composite microporous membrane has high air permeability, good electrolyte-favoring performance andhigh temperature resistance, a composite layer and the framework polyolefin membrane have good adhesion strength and cannot be separated when being placed in a lithium ion electrolyte solution with very good adhesion and without power-dropping and shedding. By means of the product of the invention, a series of defects in the prior art can be overcome.

Owner:河南惠强新能源材料科技股份有限公司

High temperature biobased lubricant compositions from boron nitride

InactiveUS20100105583A1Improve the lubrication effectEnhanced anti-wearBase-materialsBoron nitrideAlpha-olefin

This present invention discloses a method for the preparation of an improved high temperature engine lubricant composition comprising the steps of: 1) providing at least one biobased natural oil or biobased synthetic oil selected from the group consisting of natural or synthetic vegetable oil, natural or synthetic animal oil, genetically modified vegetable oil, genetically modified synthetic vegetable oil, natural or synthetic tree oil, and mixtures thereof; 2) providing at least one boron nitride; and 3) optionally, providing at least one base oil selected from the group consisting of a synthetic ester, solvent refined petroleum oil, a hydrocracked petroleum white oil, an all hydroprocessed synthetic oil, Fischer Tropsch oil, petroleum oil group I, group II, group III, a polyalphaolefin (PAO), and mixtures thereof; 4) optionally, providing at least one additive or combination of additives selected from the group consisting of anti-oxidant(s), corrosion inhibitor(s), metal deactivator(s), viscosity modifier(s), anti-wear inhibitor(s), friction modifier(s), and extreme pressure agent(s); 5) blending 1), 2), 3), and 4) in any sequence to form said composition.

Owner:RENEWABLE LUBRICANTS INC

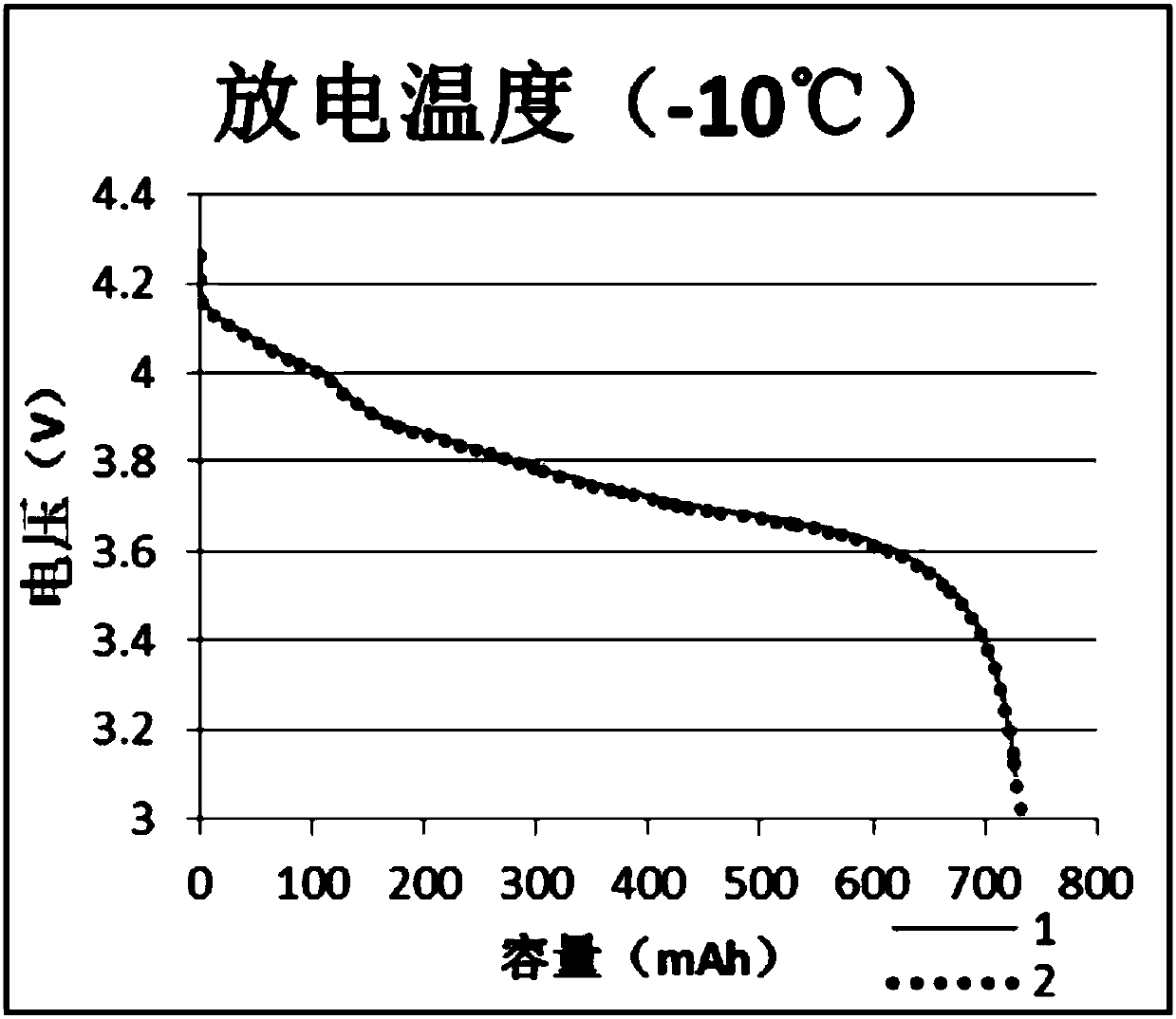

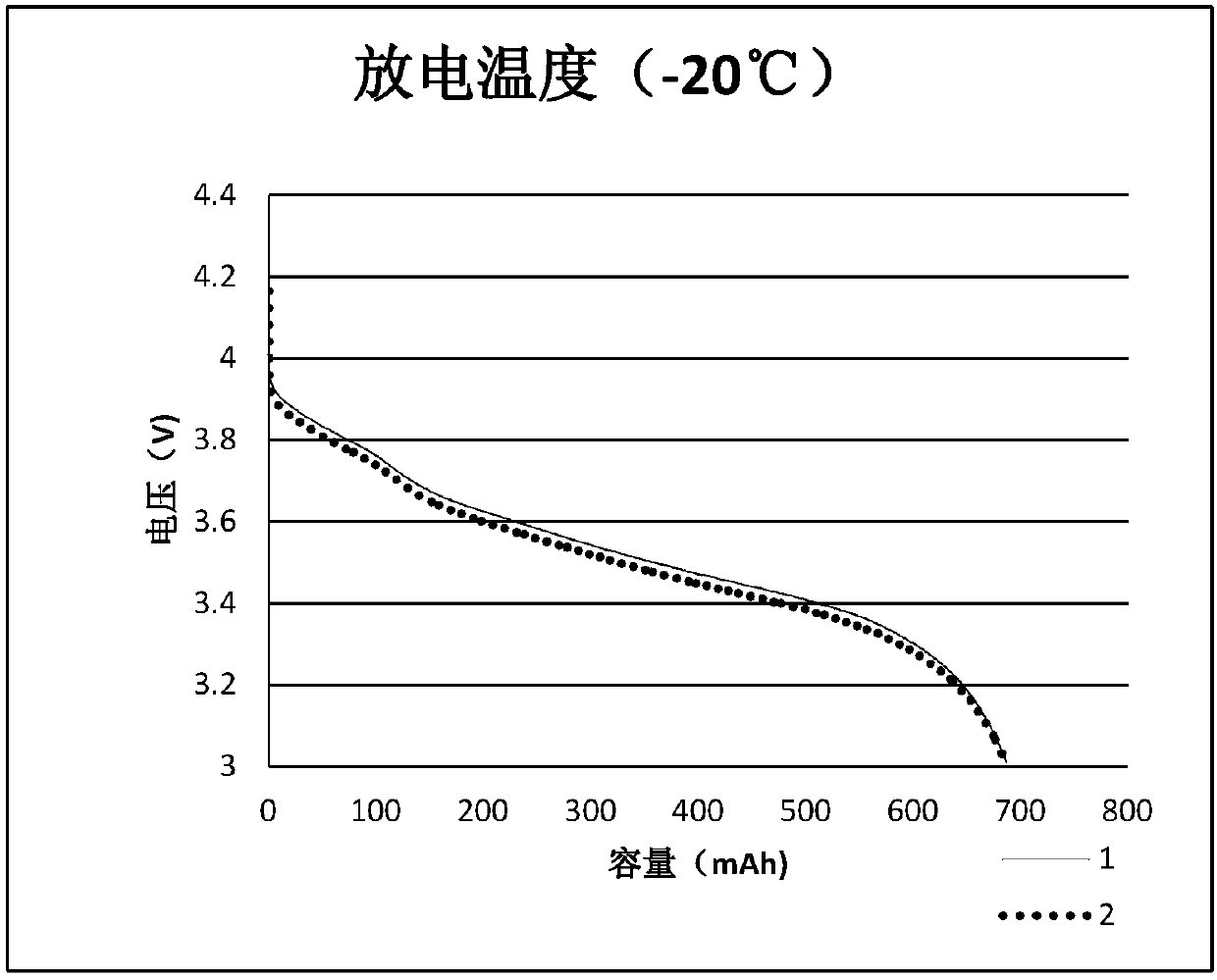

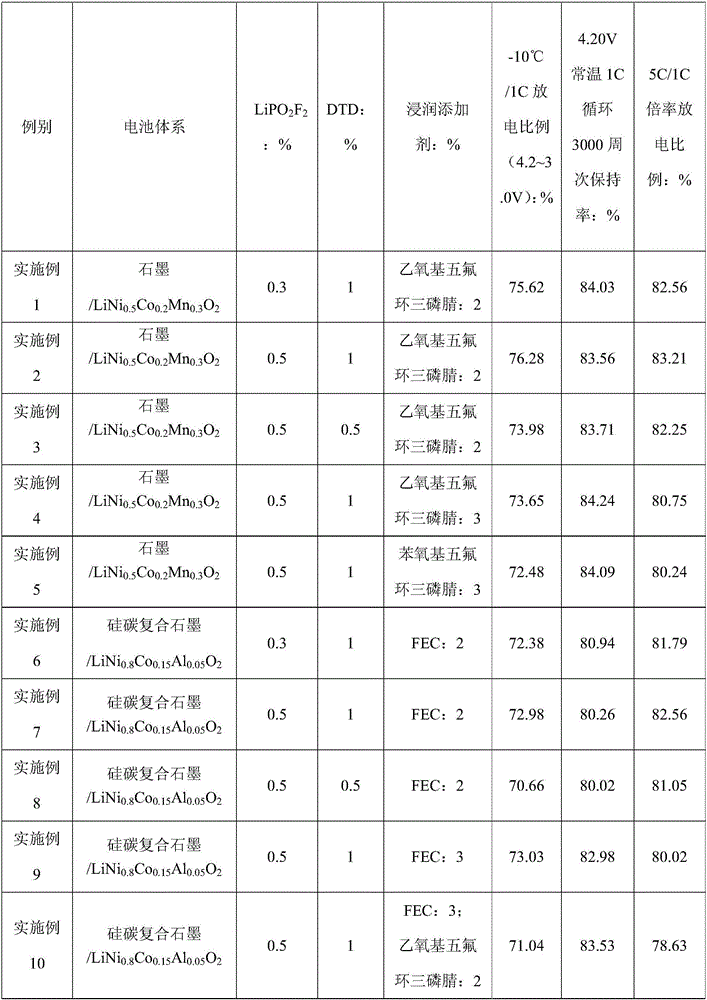

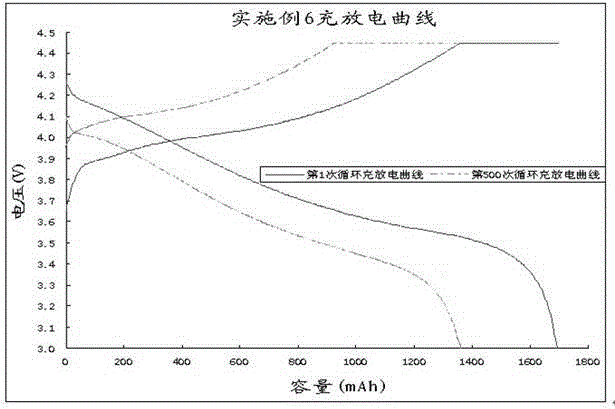

High-voltage rate electrolyte with high-and-low temperature performance and lithium ion battery using electrolyte

PendingCN107706455AAvoid decompositionImprove high temperature storage performanceSecondary cellsOrganic electrolytesHigh temperature storageLithium-ion battery

The invention discloses a high-voltage rate electrolyte with high-and-low temperature performance and a lithium ion battery using the electrolyte. The electrolyte comprises a non-aqueous solvent, a lithium salt dissolved in the non-aqueous solvent and additives, wherein the non-aqueous solvent comprises propylene carbonate (PC) and linear carboxylic ester; and the additives comprise citraconic anhydride, lithium difluorophosphate (LiPO<2>F<2>), fluoroethylene carbonate, ethylene sulfate and 1, 2-di(2-cyanoethoxyl)ethane. By applying the synergistic effect generated by the solvent system and the additive optimization combination to the lithium ion battery, excellent cycle life, low-temperature discharge characteristic and high-temperature storage characteristic of the battery still can be maintained at high-voltage rate.

Owner:EVE ENERGY CO LTD

High-strength cast Mg alloy containing rare-earth and preparing process thereof

A high-strength cast RE-contained Mg-alloy contains Nd (2.5-3.6 Wt%), Zr (0.35-0.8), Zn (0-0.4), Ca (0-0.5), impurities (0-0.02) and Mg (rest). It is prepared through smelting Mg, adding Nd, Zr and Ca in Mg-Nd, Mg-Zr and Mg-Ca alloy mode, adding Zn, solution treating at 525-540 deg.C for 4-12 hr, quenching in water and ageing at 200 deg.C for 12-20 hr. It has high strength, hardness and high-temp creep performance.

Owner:SHANGHAI JIAO TONG UNIV

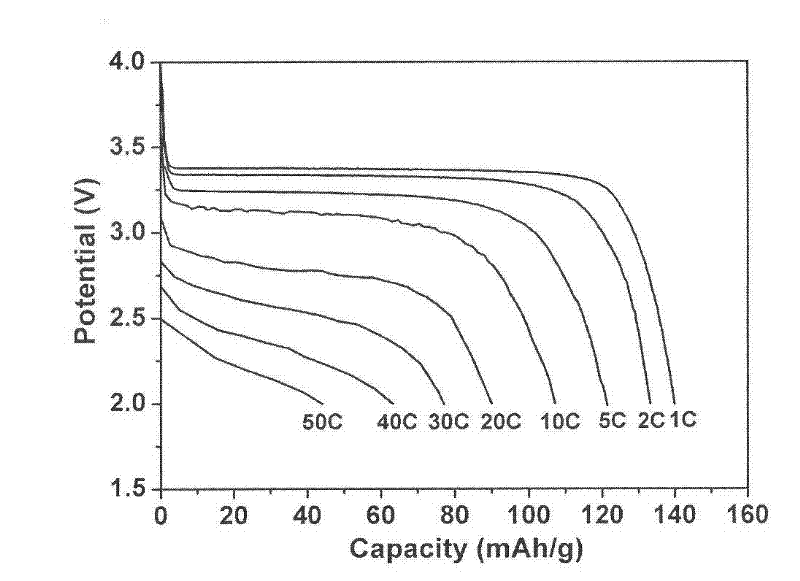

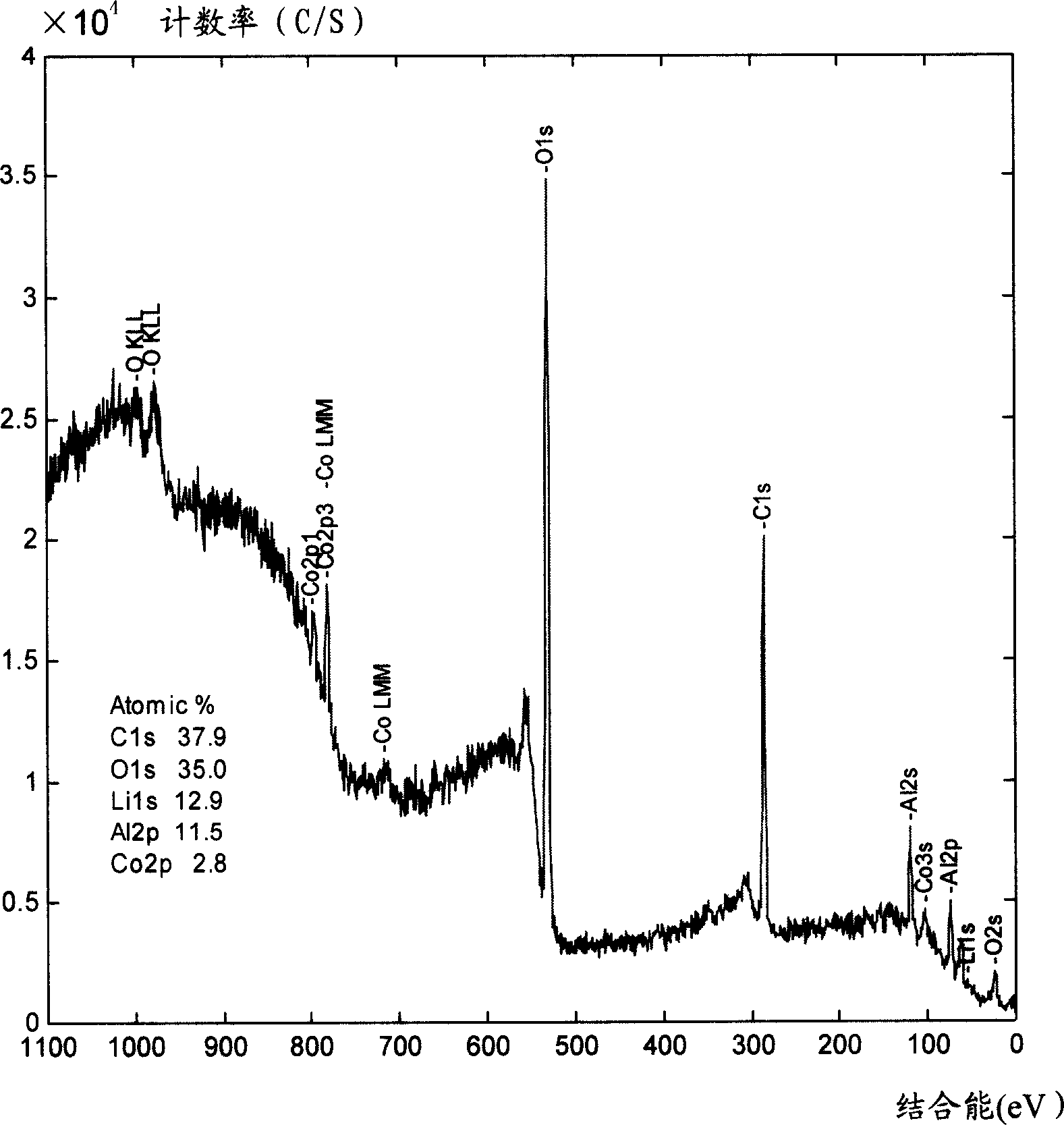

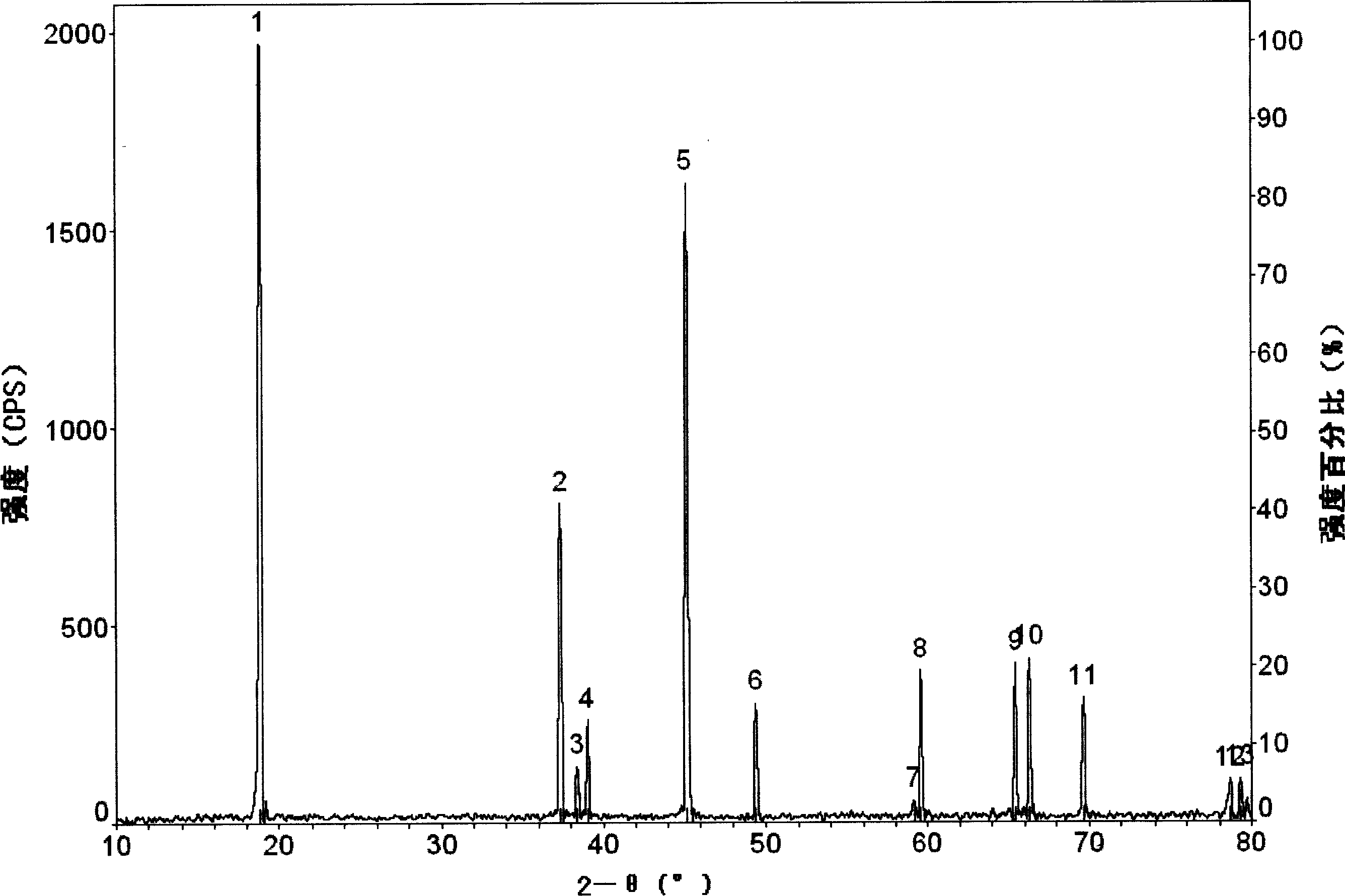

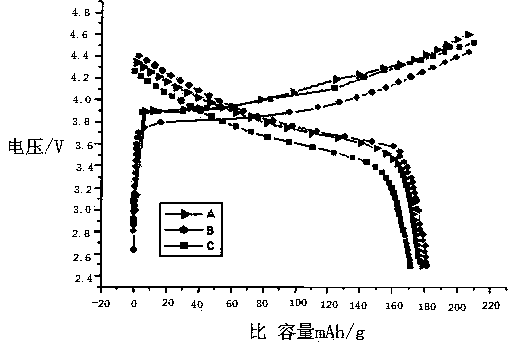

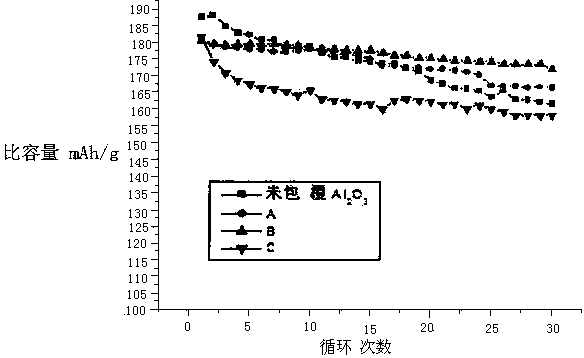

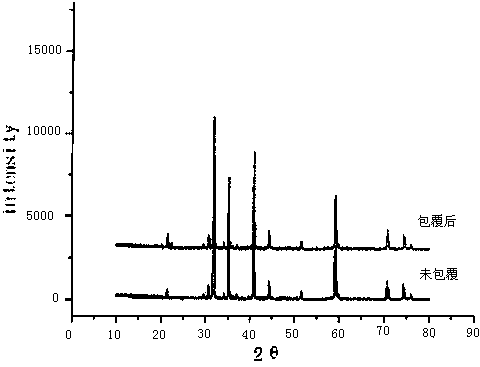

Preparation method of alumina composite nickel-cobalt lithium manganate ternary material

ActiveCN103618064AImproved magnification performanceImprove high temperature performanceCell electrodesSecondary cellsElectrochemical responseAlumina composite

The invention provides a preparation method of an alumina composite nickel-cobalt lithium manganate ternary material. The preparation method comprises the following steps: (1), preparing liquor A; (2), preparing liquor B; (3), installing and configuring a reaction flask; (4), adding the liquor A and the liquor B into the reaction flask to participate in hybrid reaction; (5), preparing liquor C, and adding into the flask for reaction; (6), obtaining a precursor by suction-filtering, washing and drying; and (7), mixing and roasting the precursor with a lithium source to prepare the alumina composite nickel-cobalt lithium manganate ternary material. The preparation method disclosed by the invention has the beneficial effects that firstly, liquid-phase coating is adopted, production preparation period is short, efficiency is high, and coating and dispersing are uniform; secondly, the coating layer alumina on the surface of the ternary material is a film with an amorphous structure, so that charging and discharging voltage difference is reduced, multiplying power performance and high-performance performance of the material are improved; and thirdly, characteristics of a solid-liquid phase interface among an anode material, electrolyte and a diaphragm are improved by alumina film-coating, so that velocity and efficiency of electrochemical reaction are improved.

Owner:博尔特新材料(银川)有限公司

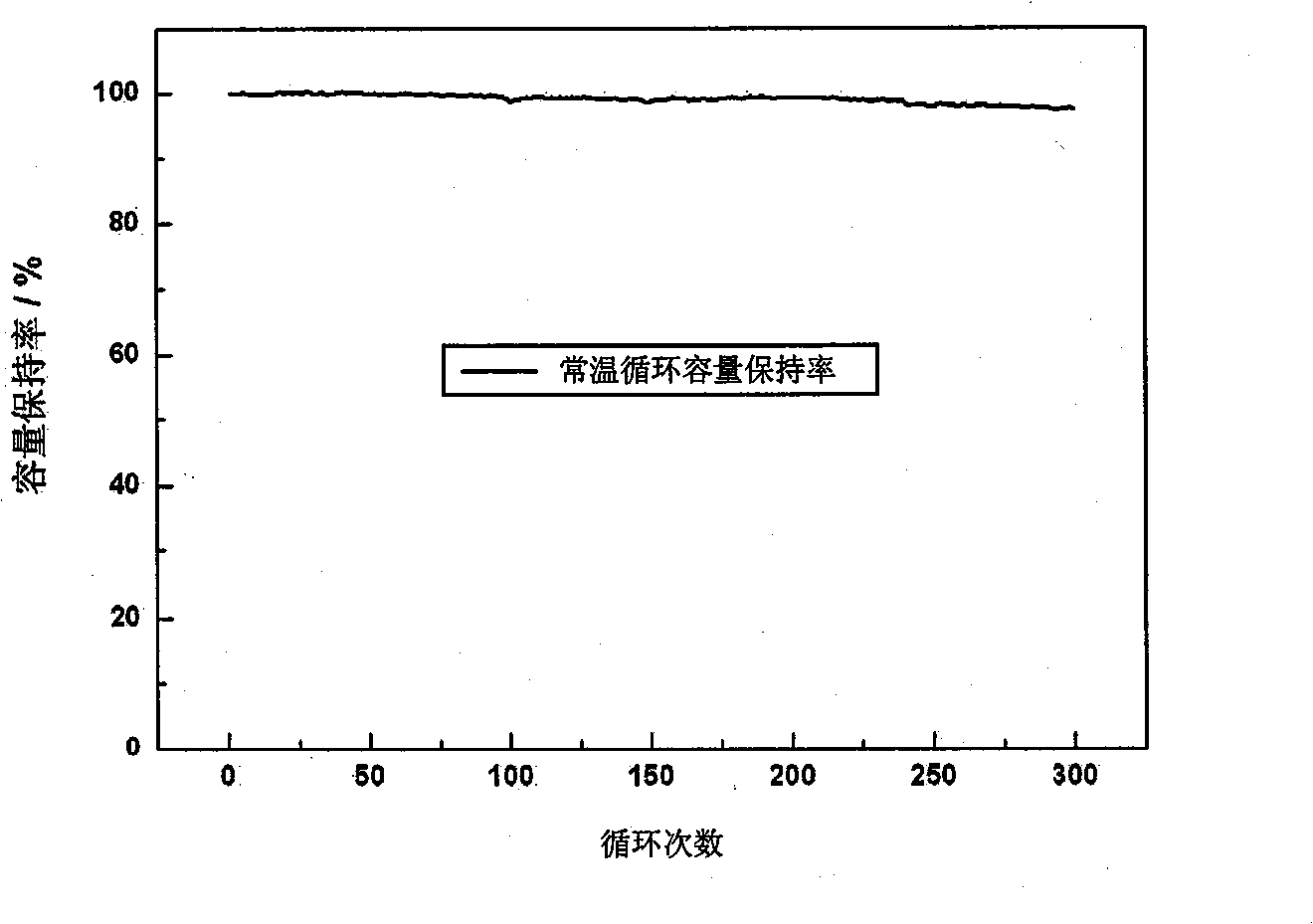

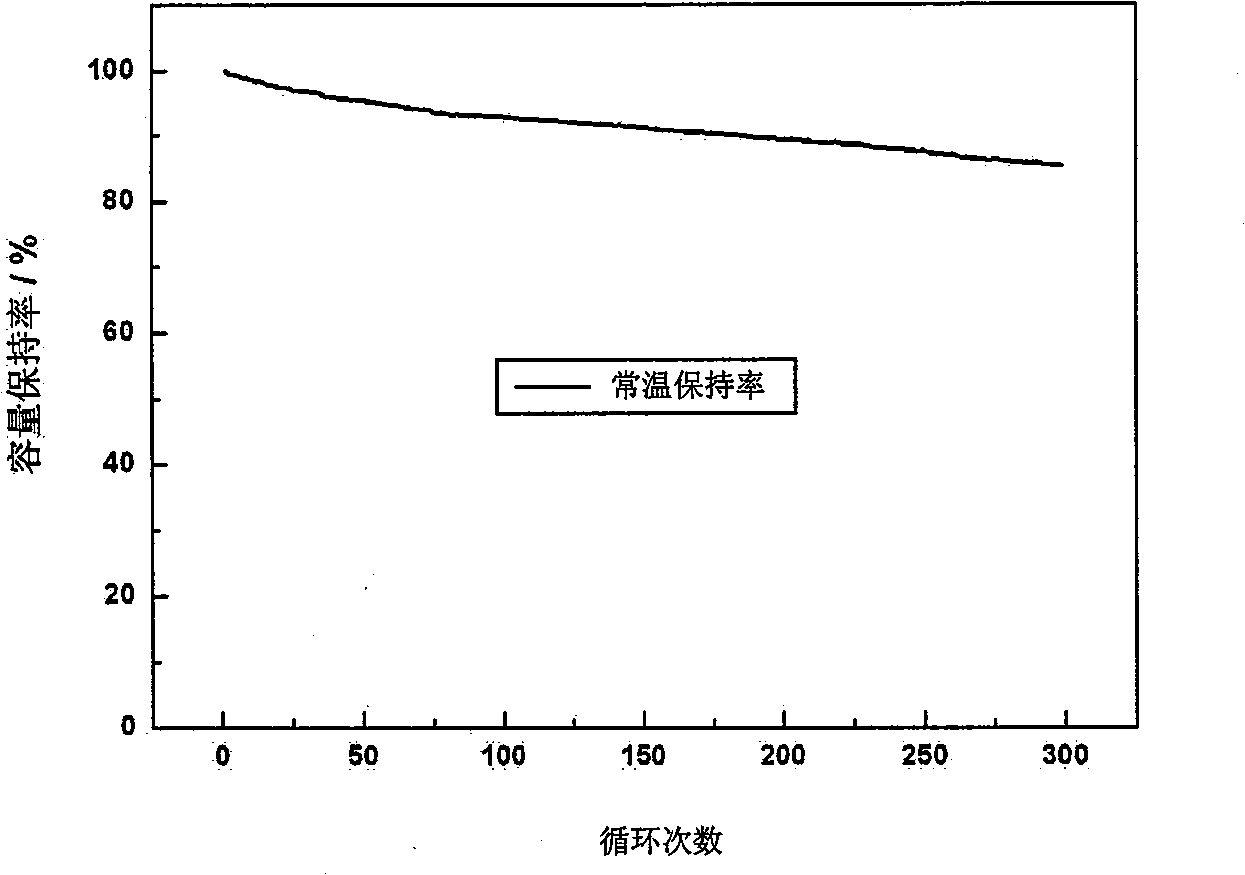

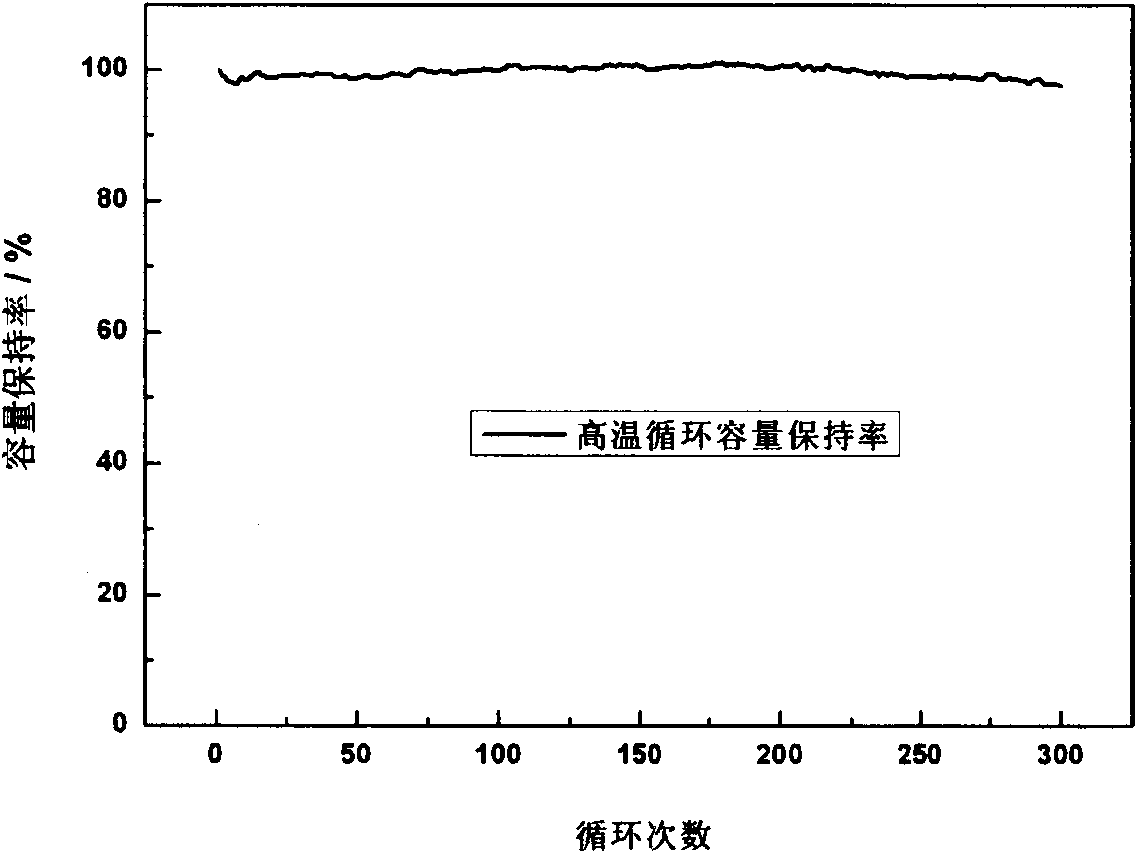

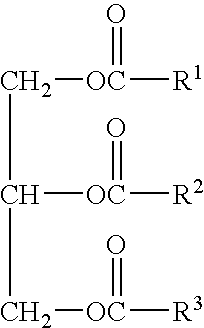

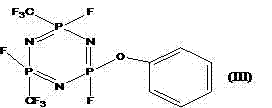

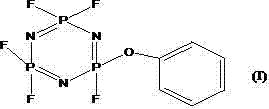

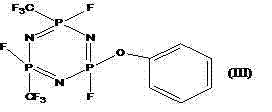

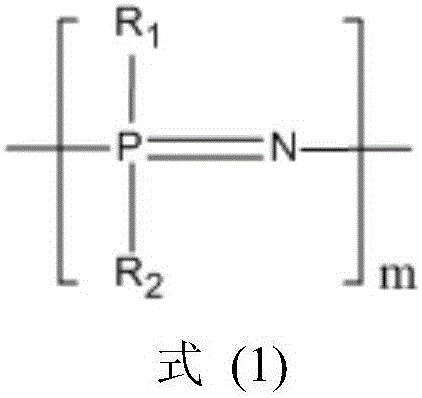

Lithium ion battery with nickel-based cathode, and electrolyte therefor

ActiveCN103208653AGood high temperature performanceGood low temperatureSecondary cellsElectrolytic agentOrganic solvent

The invention belongs to the technical field of lithium ion batteries and particularly relates to electrolyte for a lithium ion battery with a nickel-based cathode. The electrolyte comprises non-aqueous organic solvent, lithium salt, boron-containing lithium salt additive, cyclic ether compound and cyclic phosphonitrile compound. The cyclic phosphonitrile compound is hexaphenoxycyclotriphosphazene or cyclic phosphonitrile derivative. Compared with the prior art, the electrolyte is provided with the boron-containing lithium salt additive capable of improving high temperature performance of the lithium ion secondary battery with nickel-based cathode material, the cyclic phosphonitrile compound, and the cyclic ether compound, and the addition of the cyclic phosphonitrile compound and the cyclic ether compound enables the battery to be fine in high temperature performance, low temperature performance and cycle performance. In addition, the invention discloses the lithium ion battery comprising the electrolyte.

Owner:DONGGUAN AMPEREX TECH

High-voltage lithium ion battery electrolyte

ActiveCN103401020AIncrease oxidation potentialSolve severe flatulenceSecondary cellsElectrolytic agentInternal resistance

The invention specifically relates to a high-voltage lithium ion battery electrolyte, which belongs to the technical field of lithium ion battery electrolytes. The high-voltage lithium ion battery electrolyte provided by the invention comprises a non-aqueous solvent, a lithium salt and an additive, wherein the additive comprises a mixture of a fluoro-ether additive and an alkyl dinitrile additive. A lithium ion battery using the high-voltage lithium ion battery electrolyte has stable cycle performance at normal temperature, no gas generation at a high temperature condition and small changes of internal resistance. A preparation process for the high-voltage lithium ion battery electrolyte is simple and easy to implement and has good market prospects.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

Magnesia-calcia dry type working liner for tundish and preparation thereof

The invention relates to a magesia-calcia tundish dry working lining refractory and a method for preparing the same. The technical scheme comprises mixing 55-65wt% of particle material with a grain size of 3-0mm, 22-35wt% of powder with a grain size less than 0.088mm, 0 or 0.5-8wt% of additives and 6-12wt% of binding agent according to a theoretical content of MgO 55-85wt% and CaO 10-40wt%, baking at 200-350 DEG C after stirring and vibration molding, getting the tundish dry working lining after demoulding, wherein the particle material is one or a mixture more than one selected from the magnesia, magnesite, limestone and dolomite; the powder is one or a mixture more than one selected from the magnesia, hydrated lime, limestone, dolomite and magnestie. The invention has advantages of simple technology, convenient construction, low cost, environment friendly and saving energy, and the magesia-calcia tundish dry working lining has a good metallurgical effect and the feature of easy disintegration after use.

Owner:WUHAN UNIV OF SCI & TECH

Polyurethane high-temperature-resistant anti-rutting modifier for road asphalt

ActiveCN103102706AGood anti-rutting performanceExcellent high temperature resistance and anti-rutting performanceBuilding insulationsPolymer sciencePolyol

The invention discloses a polyurethane high-temperature-resistant anti-rutting modifier for road asphalt. The modifier comprises the following components in parts by the total weight of the modifier: 25-65 parts of one or two or more of diisocyanate, polyaryl polymethylene isocyanate and diisocyanate derivatives, 15-60 parts of one or two or more of polymer polyol and polymer polyamine, 2-15 parts of one or two or more of micromolecular polyol chain extender, micromolecular polyamine chain extender and micromolecular polyatomic acid chain extender, 0.01-3 parts of organic polyurethane catalyst, and 0-45 parts of poly-alkadiene polymer compound with a number-average molecular weight of 500-50000. The modifier can greatly improve the high-temperature resistance and anti-rutting properties of matrix asphalt and modified asphalt; and prepared modified asphalt is balanced in high and low-temperature performances, good in compatibility with matrix asphalt, and stored stably.

Owner:WANHUA CHEM GRP CO LTD +1

Novel synthetic fire-resistant hydraulic oil composition

The invention relates to a novel synthetic fire-resistant hydraulic oil composition. The composition is characterized in that the fire-resistant hydraulic oil composition is prepared by using low-viscosity ester oil as basic oil, little synthetic hydrocarbon component as a solubilizer and high-viscosity ester oil as a tackifier, and adding proper functional additives. The composition has lower volatility, excellent lubricating property, high and low temperature stability, wider using temperature range, excellent flame resistance, biodegradability, long service life and other excellent performance. The composition comprises the following components in percentage by weight: 40 to 70 percent of the low-viscosity ester oil, 10 to 20 percent of the synthetic hydrocarbon component, 0 to 10 percent of the high-viscosity ester oil, 2 to 10 percent of composite additive, and 10 to 200ppm of anti-foaming agent. The composition is mainly applied to steel continuous casting production line systems and hydraulic systems of blast furnaces, hot rolling, casting, power stations, coal mines and the like which require flame resistance and safe equipment.

Owner:益田润石(北京)化工有限公司

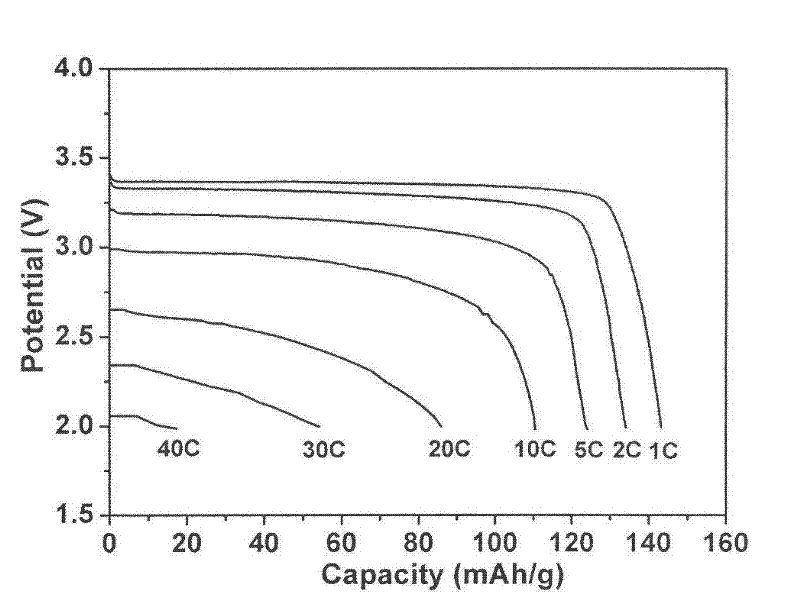

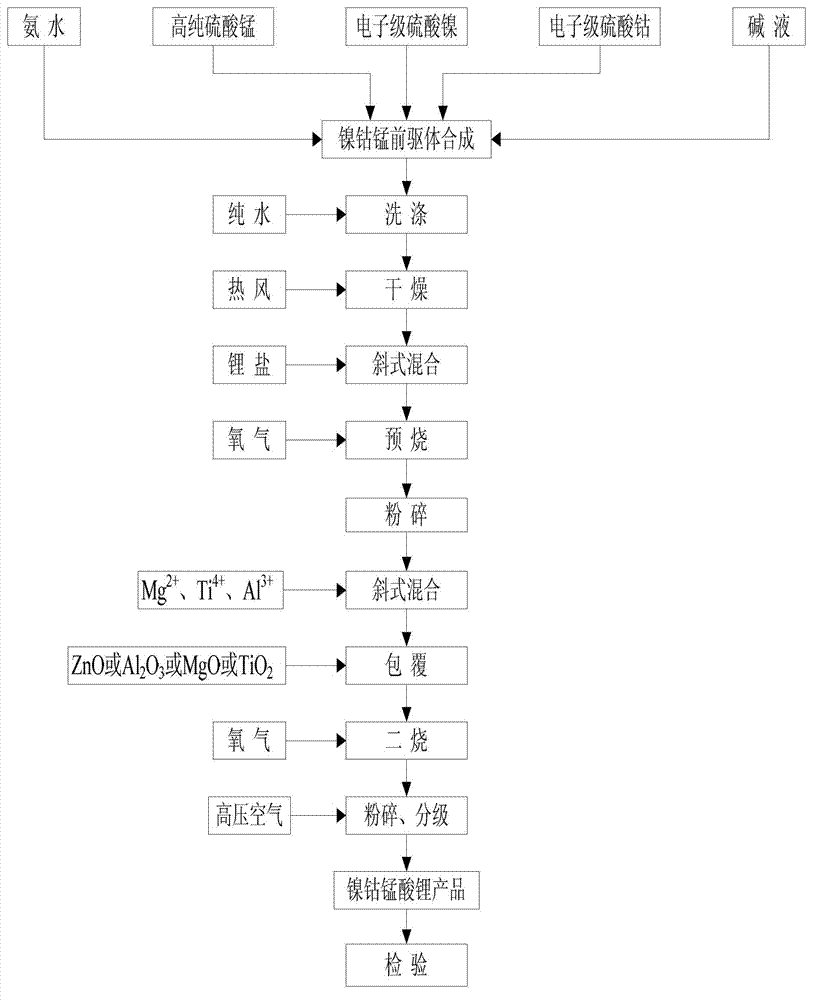

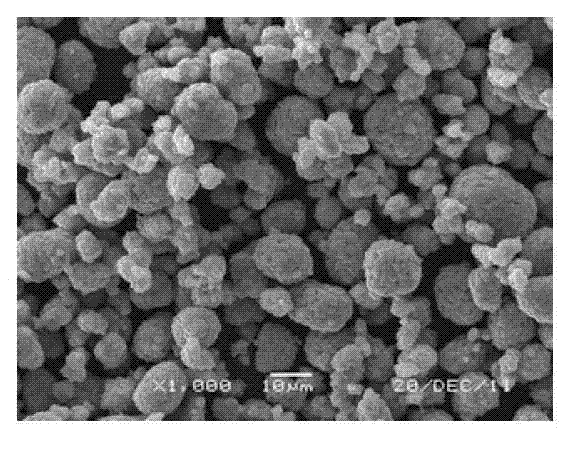

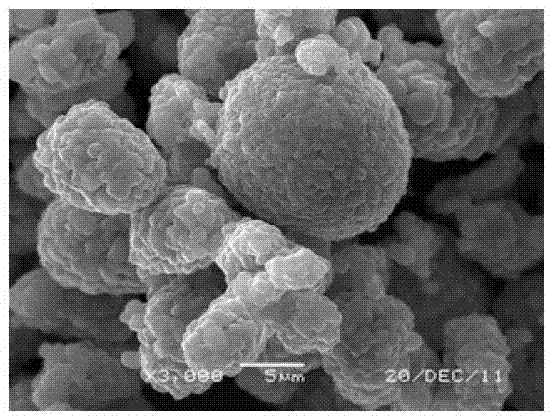

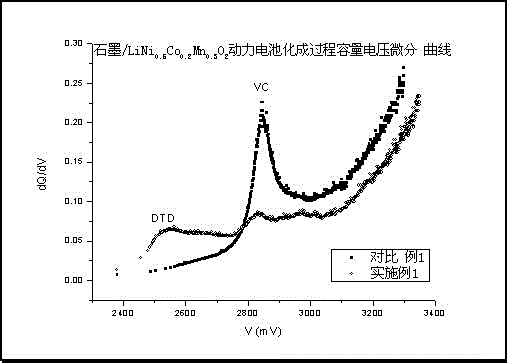

Preparation method of manganese Li-NiCoMn ternary material for lithium ion battery

InactiveCN103117380AImprove high temperature performanceHigh densityCell electrodesPhysical chemistryManganese

The invention relates to a preparation method of a manganese Li-NiCoMn ternary material for a lithium ion battery. The chemical formula of the manganese Li-NiCoMn ternary material is LiNixMnyCo(1-x-y)O2, wherein x is equal to 0.1 to 0.5, y is equal to 0.1 to 0.6, and 1-x-y is more than or equal to 0. According to the manganese Li-NiCoMn ternary material for the lithium ion battery, prepared by the method, the volume ratio capacity of a final product is increased by improving the density of a NiCoMn ternary precursor material, the high-temperature performance of the Li-NiCoMn is improved through composite cladding, and the problems that the Li-NiCoMn is poor in high-temperature cycle performance and poor in storage performance can be solved. Advantages such as high compaction density, large specific volume, good cycle performance, stability in quality, low cost, simplicity in preparation process and easiness for realizing industrialization can be realized.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

High-nickel ternary lithium ion power battery electrolyte and high-nickel ternary lithium ion power battery

InactiveCN106058316AImprove transmission characteristicsImprove dynamic propertiesSecondary cellsBatteriesDifluorophosphatePower battery

The invention discloses a high-nickel ternary lithium ion power battery electrolyte and a high-nickel ternary lithium ion power battery. The electrolyte includes a non-aqueous organic solvent, a lithium salt, a conductive additive, a film forming additive and an infiltration additive, wherein the conductive additive is lithium difluorophosphate, the film forming additive is ethylene sulfate, and the infiltration additive is at least one of fluorophosphazene and fluoroethylene carbonate; and synergism and mutual promotion of the three additives makes an excellent SEI film be formed on the surface of an electrode and effectively promotes all dynamic processes in the lithium ion battery. The power battery electrolyte has the advantages of good lithium ion transmission characteristic, good oxidation resistance, guaranteeing of high power characteristic and good cycle performances of the power battery, and high safety.

Owner:GUANGZHOU TINCI MATERIALS TECH

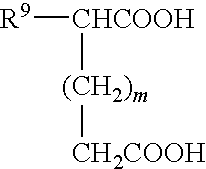

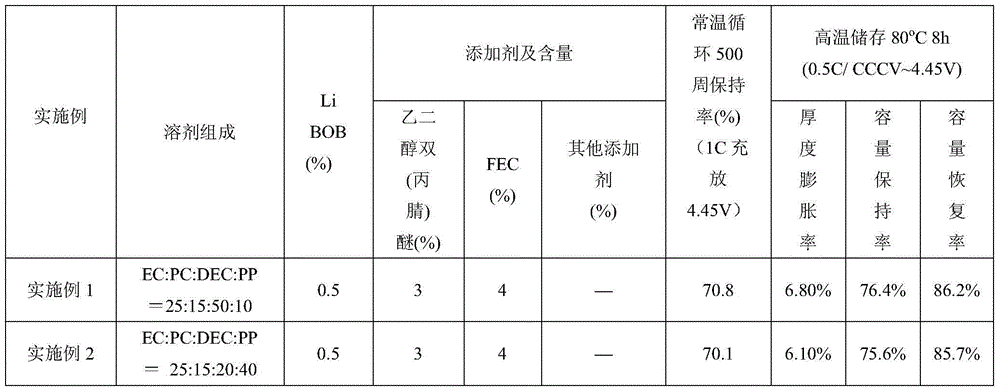

High-voltage electrolyte and lithium ion battery using electrolyte

InactiveCN104979589APromote circulationHigh decomposition voltageSecondary cellsHigh temperature storageEthylene glycol bis

The invention discloses high-voltage electrolyte and a lithium ion battery using the electrolyte. The invention is realized by the following technical scheme: the high-voltage electrolyte comprises a non-aqueous solvent, lithium salt and an additive, wherein the non-aqueous solvent is a carboxylic ester compound which accounts for 1-40% by mass of the high-voltage electrolyte; the additive is any one or more of lithium bis(oxalate)borate (Li BOB), fluoroethylene carbonate (FEC) and ethylene glycol bis(propionitrile) ether. The high-voltage electrolyte contains carboxylic ester solvents capable of improving an electrode / electrolyte interface, and through optimized combination of the carboxylic ester solvents, Li BOB, FEC, ethylene glycol bis(propionitrile) ether and other various additives, the good cycle performance of a high-voltage battery can be ensured, meanwhile, the high-temperature storage performance of the high-voltage battery can be effectively improved, and gas generation of the battery under high-voltage high-temperature storage condition can be obviously inhibited.

Owner:DONGUAN KAIXIN BATTERY MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com