Graphene oxide modified asphalt and preparation method thereof

A graphene modification and graphene technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of limited improvement range and ineffective overall improvement of asphalt performance, so as to improve rutting resistance and high temperature performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of above-mentioned graphene oxide modified asphalt specifically implements according to the following steps:

[0032] Step 1, weighing 0.5% to 15% of graphene oxide and 85% to 99.5% of matrix pitch respectively by mass percentage, the sum of the mass percentages of the above components is 100%;

[0033] Step 2: Heat the base asphalt to melt, keep the temperature at 120-200°C, add graphene oxide, stir manually for 20-40 minutes, stir with shears for 20-120 minutes, cool down to 100-150°C, and place for 20-50 minutes. make it fully swell;

[0034] In step 3, the asphalt mixture obtained in step 2 is sheared again on a shearing machine for 80 to 100 minutes until the graphene oxide is uniformly dispersed in the asphalt, and the graphene oxide modified asphalt is obtained.

[0035] Take base asphalt that is pure, free from weathering, free from harmful impurities, and has a good chip shape. In this experiment, Zhonghai 36-190# base asphalt was selec...

Embodiment 1

[0047] Take 94% of the base asphalt by mass and heat it to melt, keep the temperature at 180°C, add 5% graphene oxide according to the mass percentage, stir manually for 20 minutes, stir with a shear for 80 minutes, cool down to 150°C, and place it for 50 minutes to fully swell ; The mixture is sheared again on a shearing machine for 80 minutes until the graphene oxide is evenly dispersed in the asphalt.

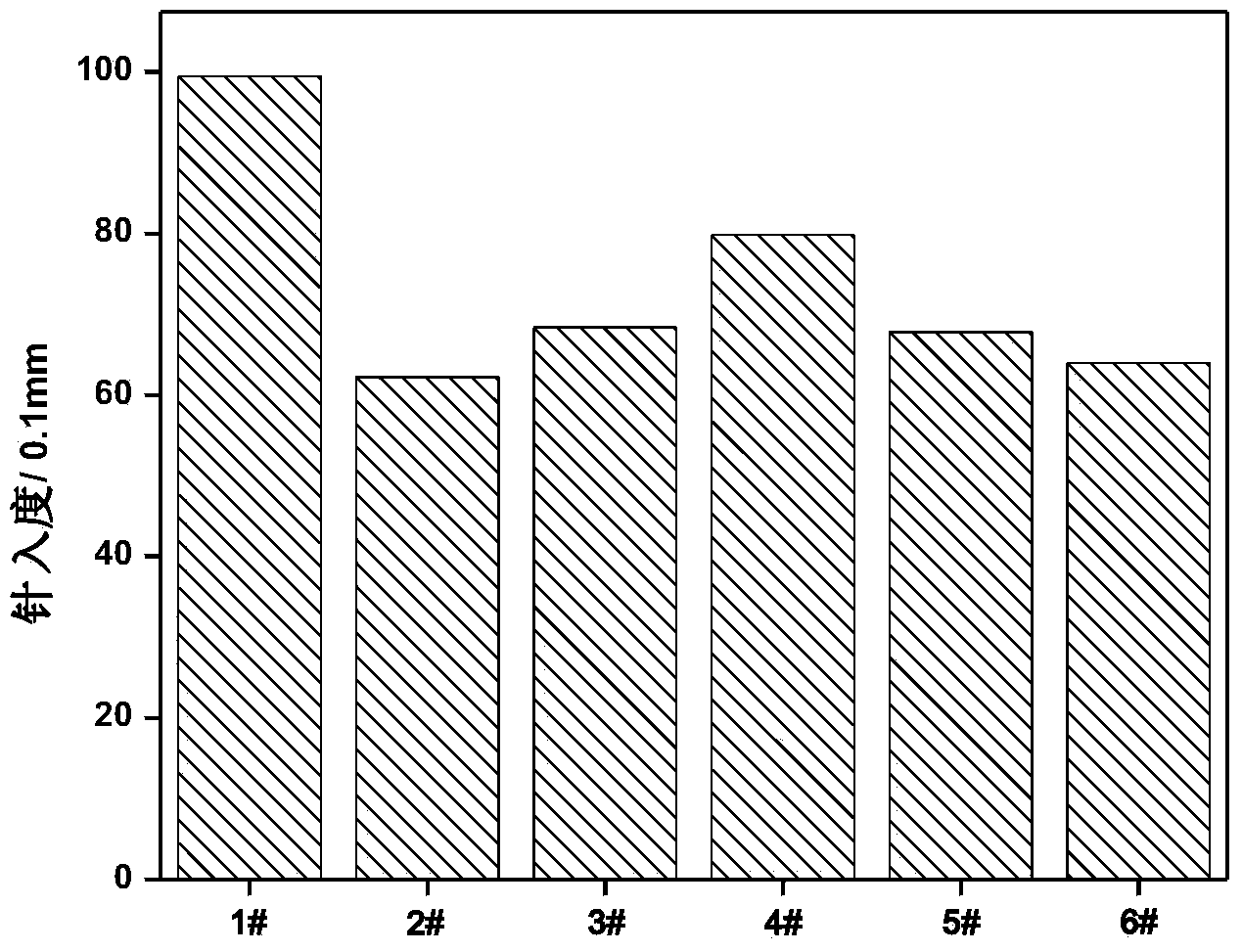

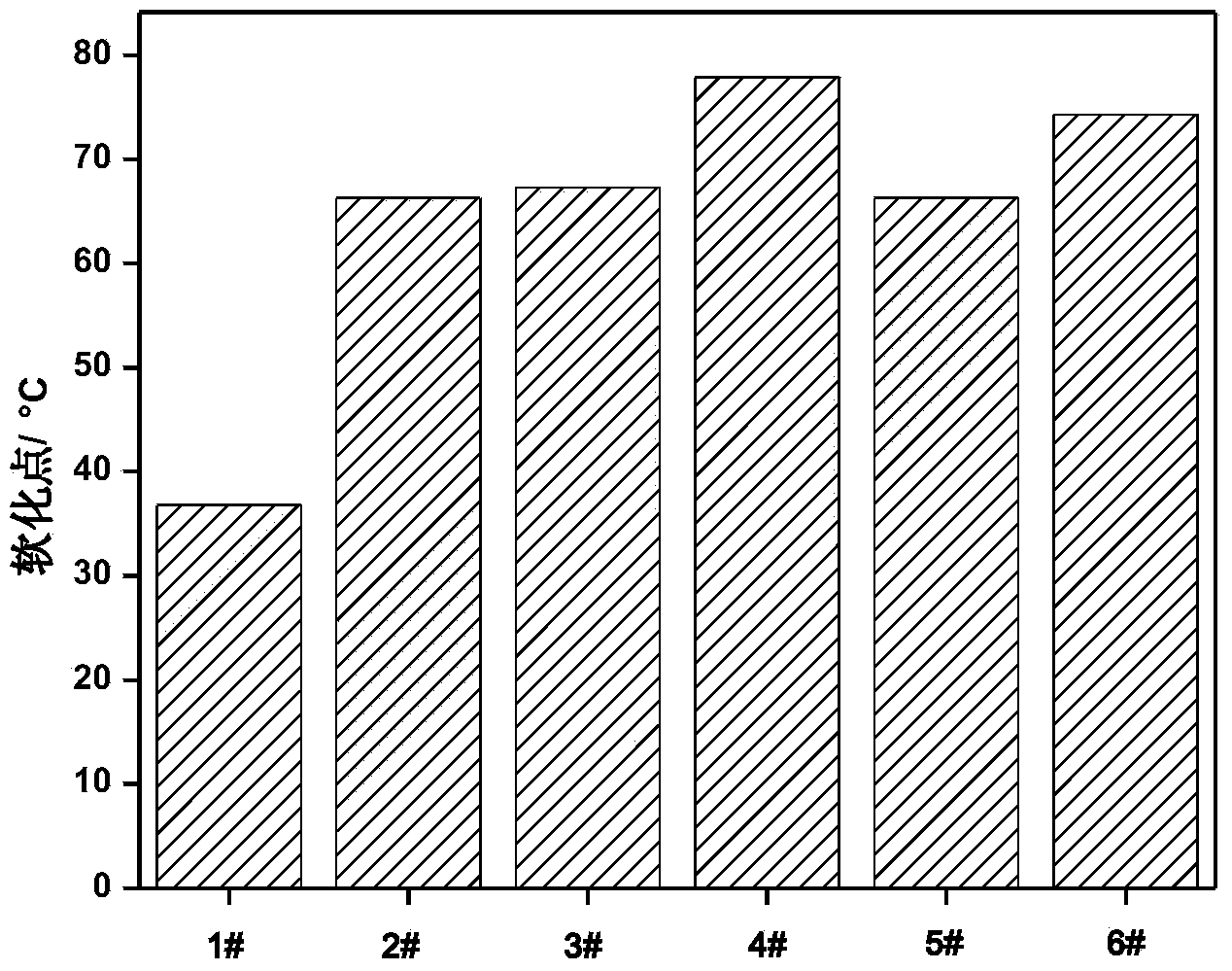

[0048] The softening point test result of the graphene oxide modified pitch prepared in Example 1 was 73.4°C, and the penetration was 63.4 (0.1 mm).

Embodiment 2

[0050] Take 96% of the base asphalt and heat it to melt, keep the temperature at 180°C, add 4% graphene oxide according to the mass percentage, manually stir for 20 minutes, stir with shears for 80 minutes, cool down to 150°C, and let it stand for 50 minutes to fully swell ; The mixture is sheared again on a shearing machine for 80 minutes until the graphene oxide is evenly dispersed in the asphalt.

[0051] The softening point of the graphene oxide-modified asphalt prepared in Example 2 was tested to be 66.3°C, and the penetration was 76.8 (0.1 mm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com