Patents

Literature

2769results about How to "Improve deformation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polydopamine-based biofunction modification method

InactiveCN102000658AImprove deformation resistanceImprove stabilityPretreated surfacesCoatingsAir atmosphereMetallic materials

The invention discloses a polydopamine-based biofunction modification method. The method comprises the following steps of: soaking clean inorganic / metal materials in dopamine alkaline aqueous solution with a pH value of 7.2 to 10, introducing oxygen to fully oxidize the clean inorganic / metal materials to obtain a monolayer polydopamine modification layer, drying, placing the material in the air atmosphere at 50 to 200 DEG C, performing thermal oxidation to obtain a multi-layer firmly-combined high-reactivity polydopamine layer, and soaking the treated material into the amino-containing and sulfydryl-containing biofunctional molecular solution to obtain a firmly combined biofunction simulate modification layer on the surface of the materials. The polydopamine modification layer obtained bythe method has excellent anti-deformation performance, stability and reactivity, can directly react with amino or the sulfydryl in the biomolecule to immobilize the bioactive molecule on the surface by covalent bonds; moreover, the process is simple, the condition is mild, and the method is easy to implement.

Owner:CO WITH LTD LIABILITY OF MEDICAL SCI +1

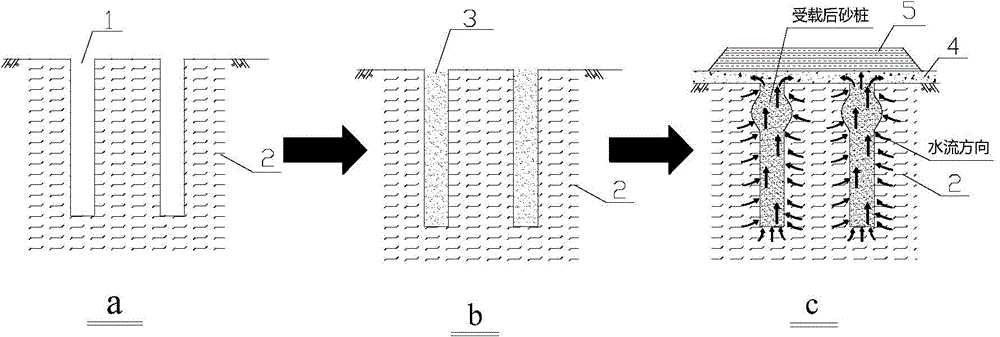

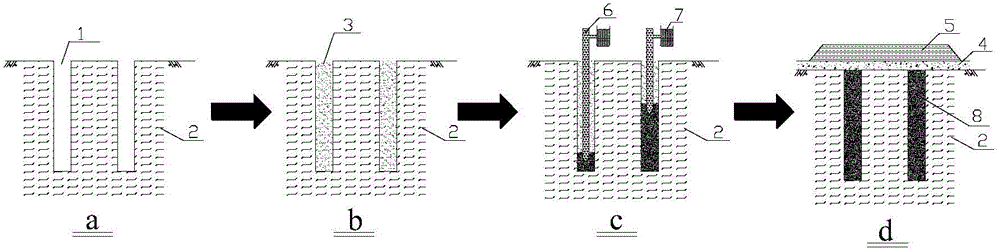

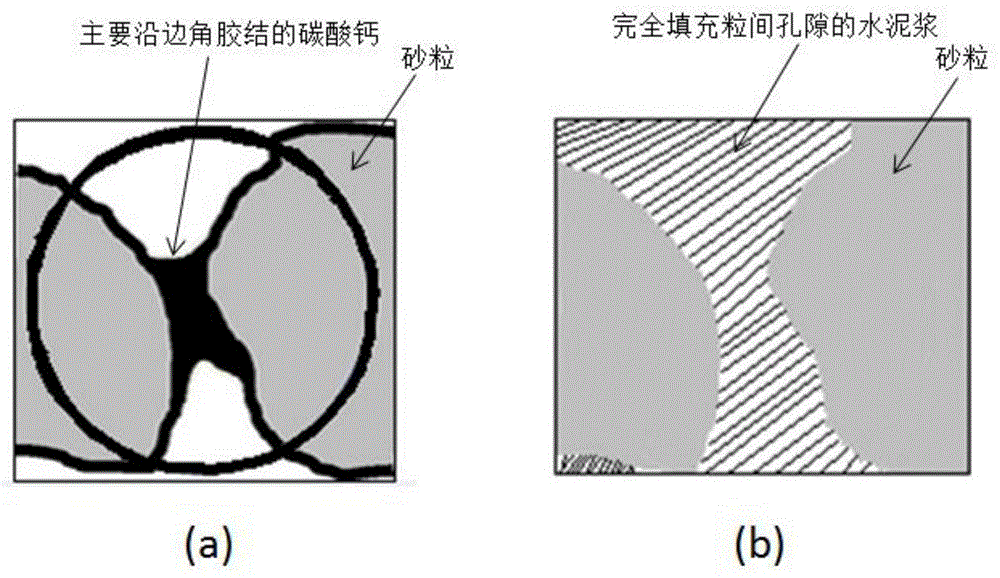

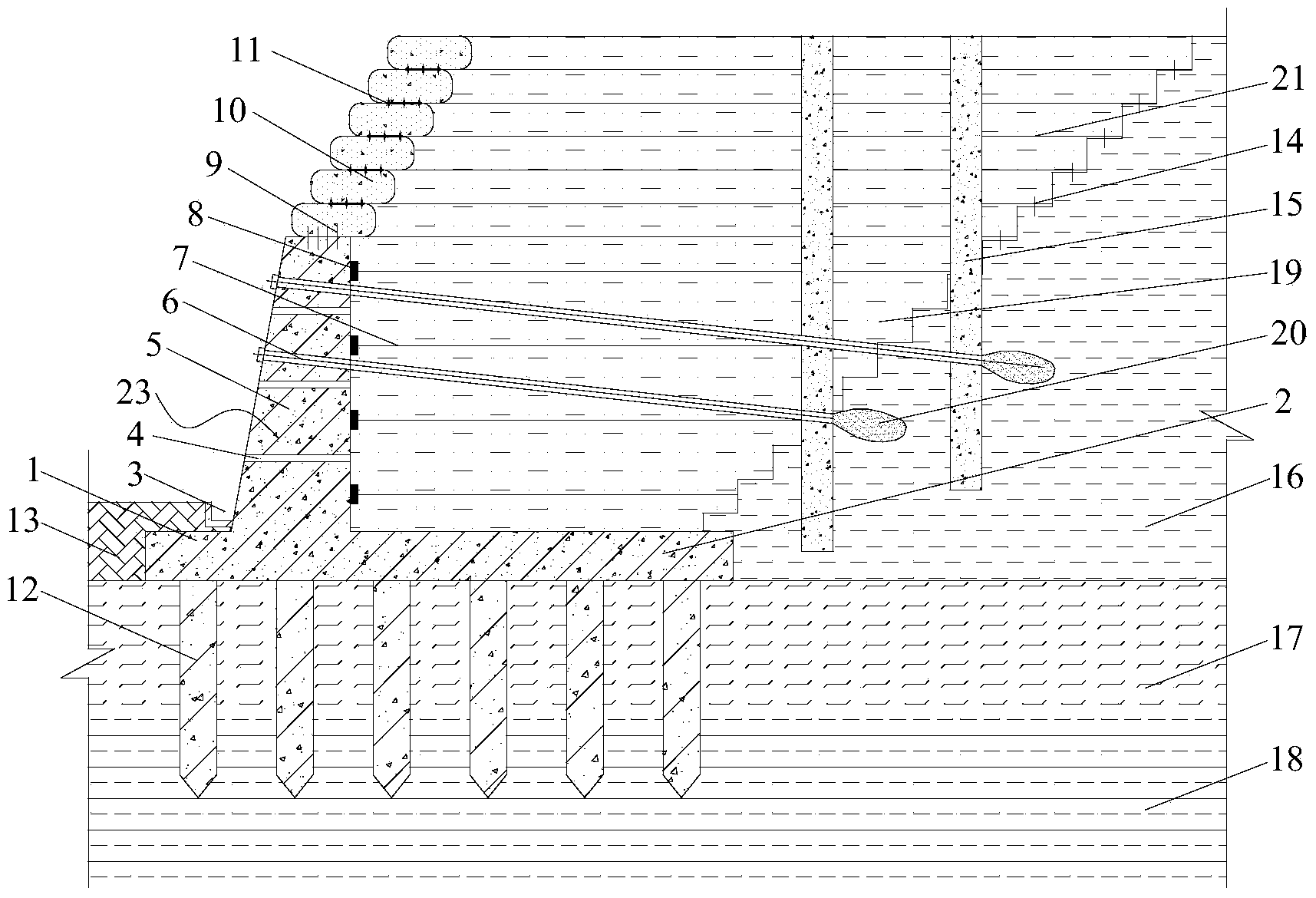

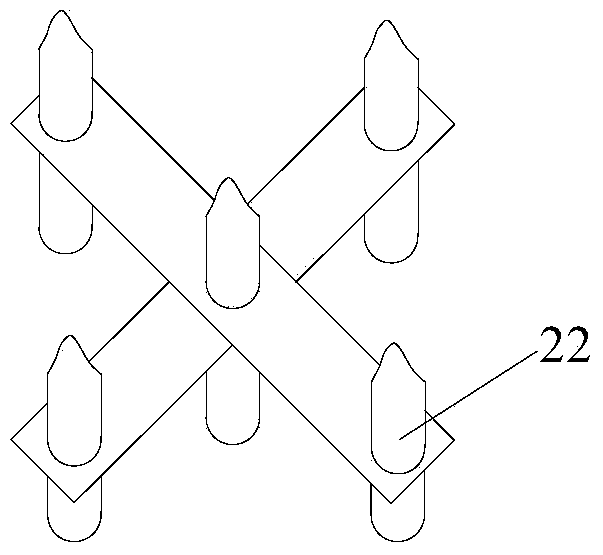

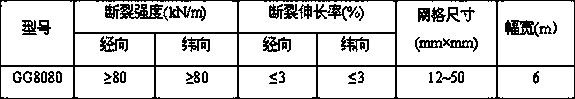

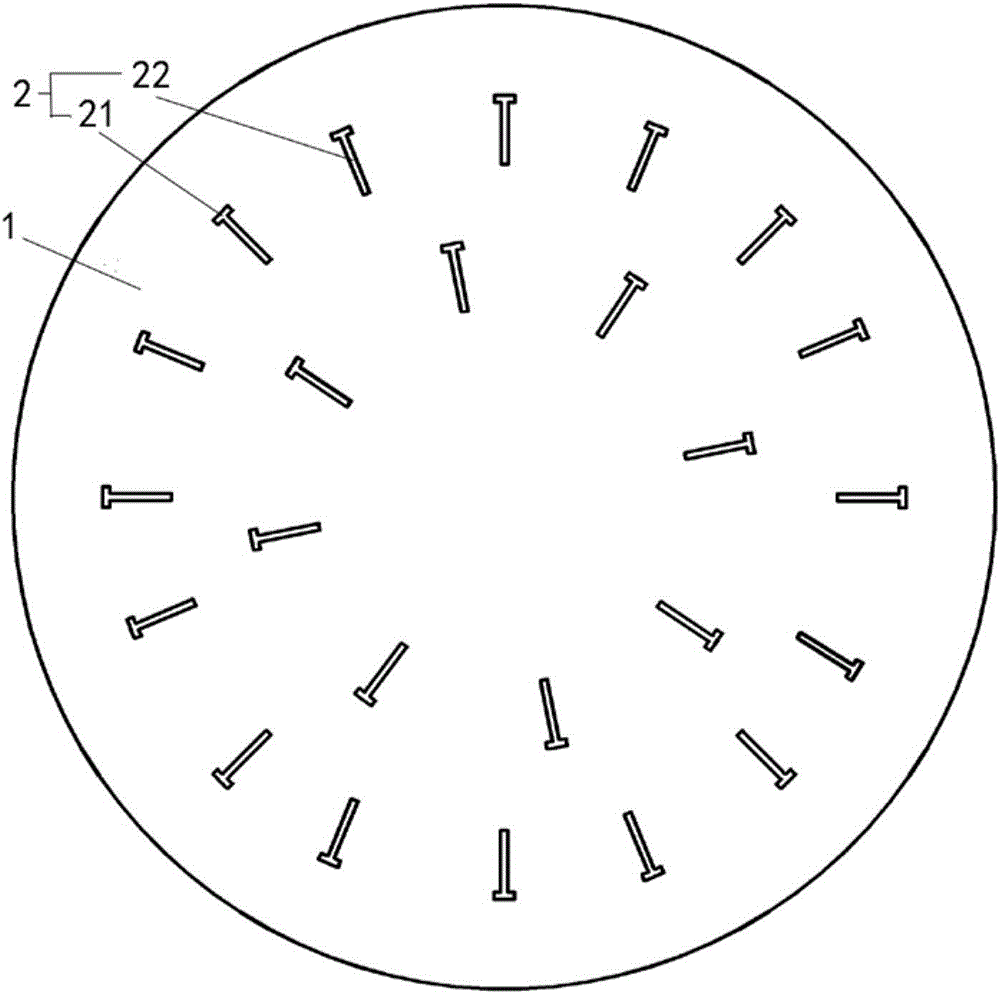

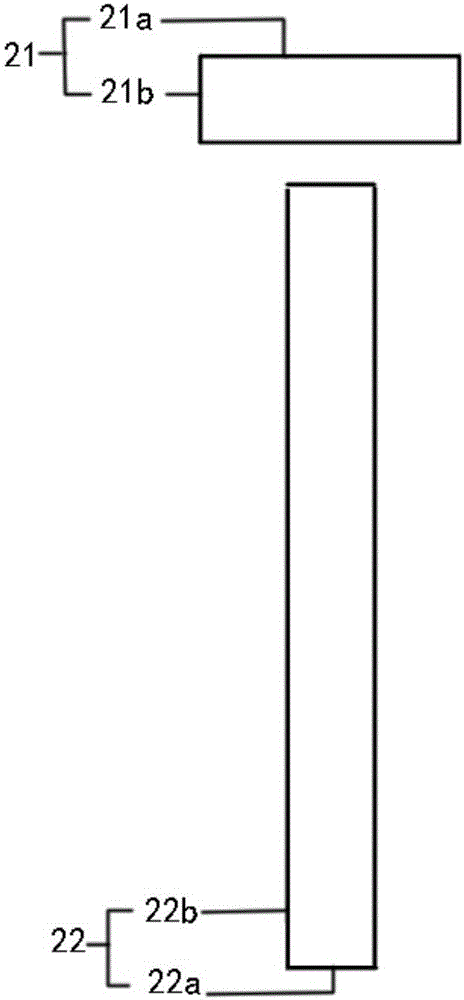

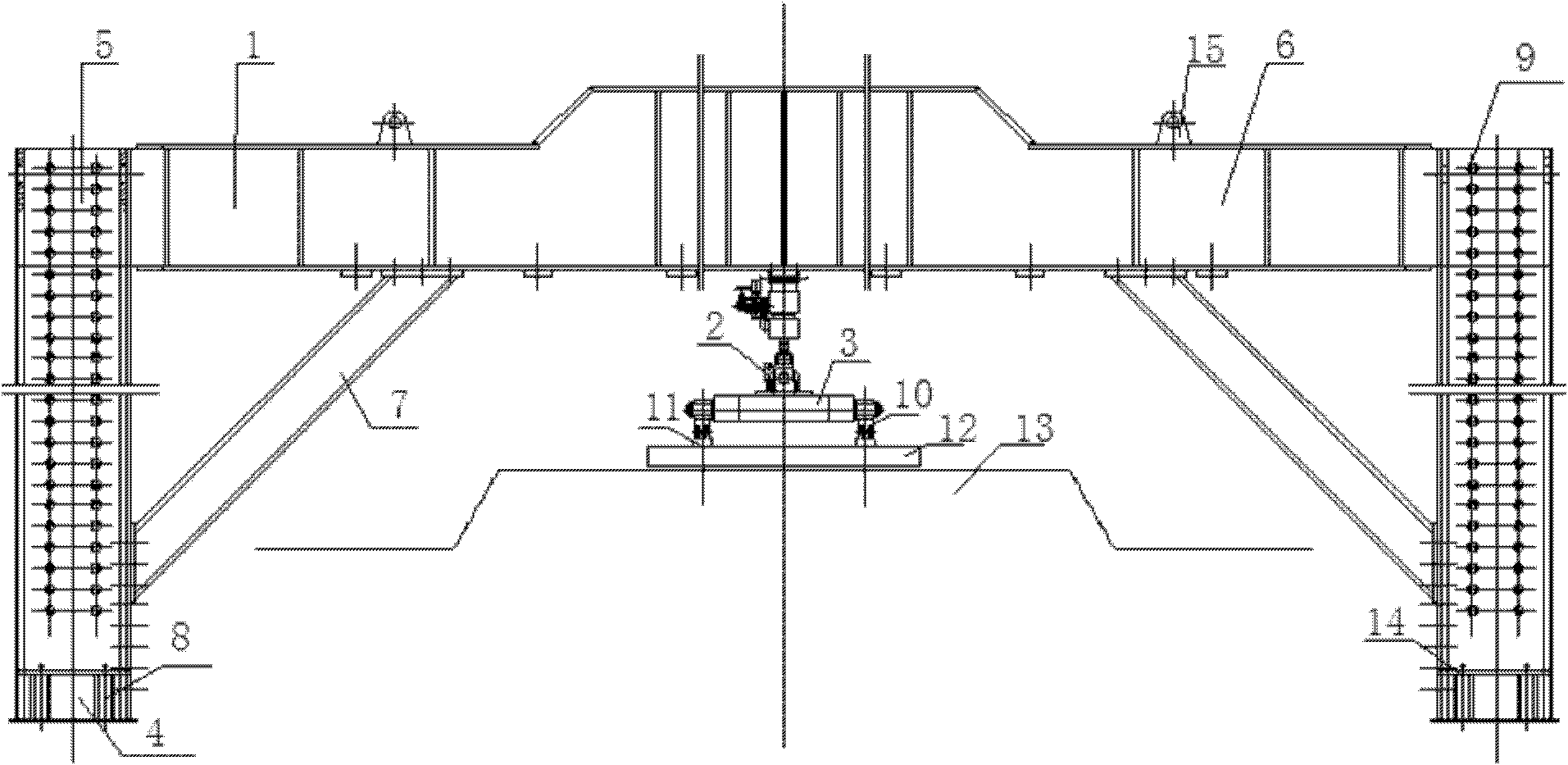

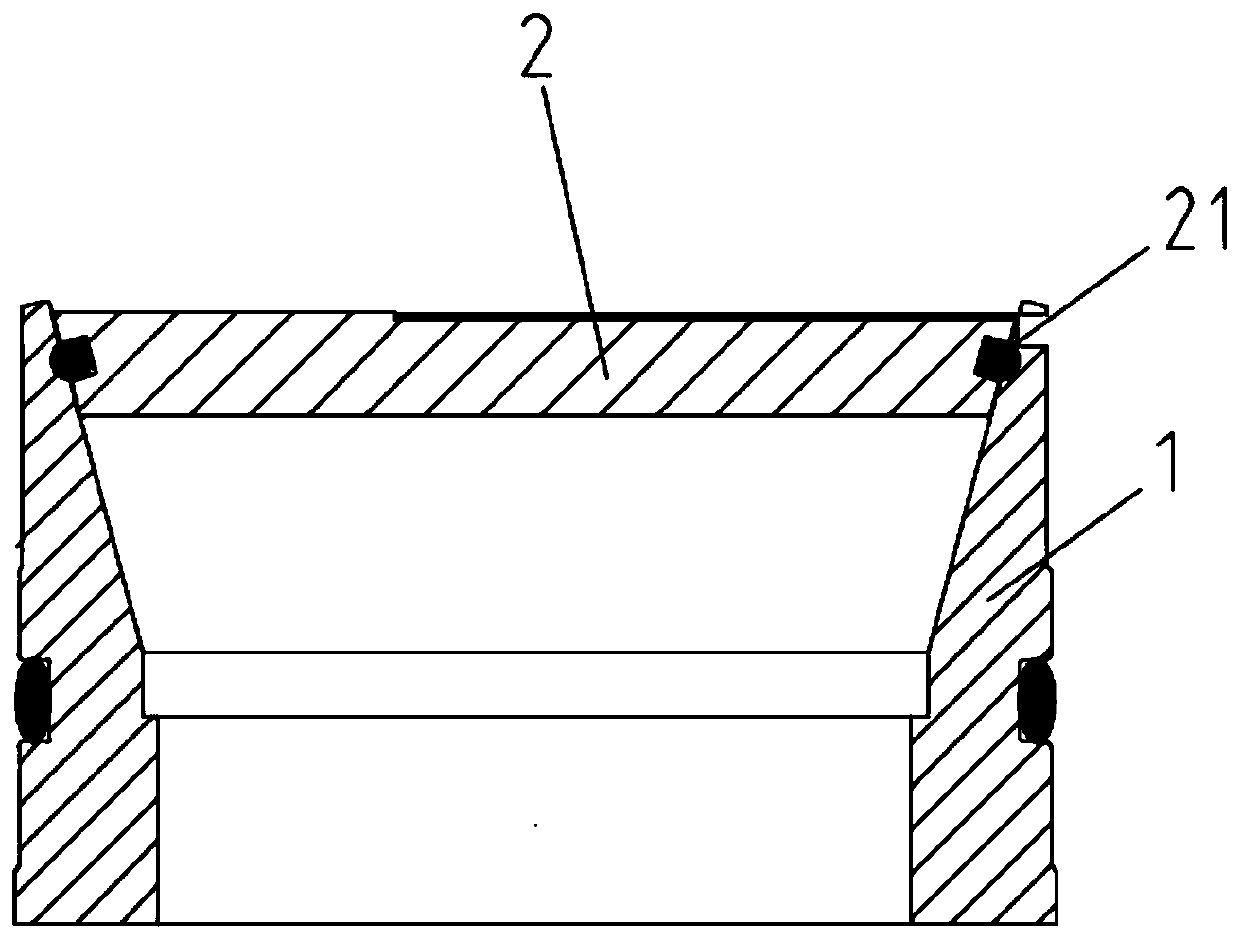

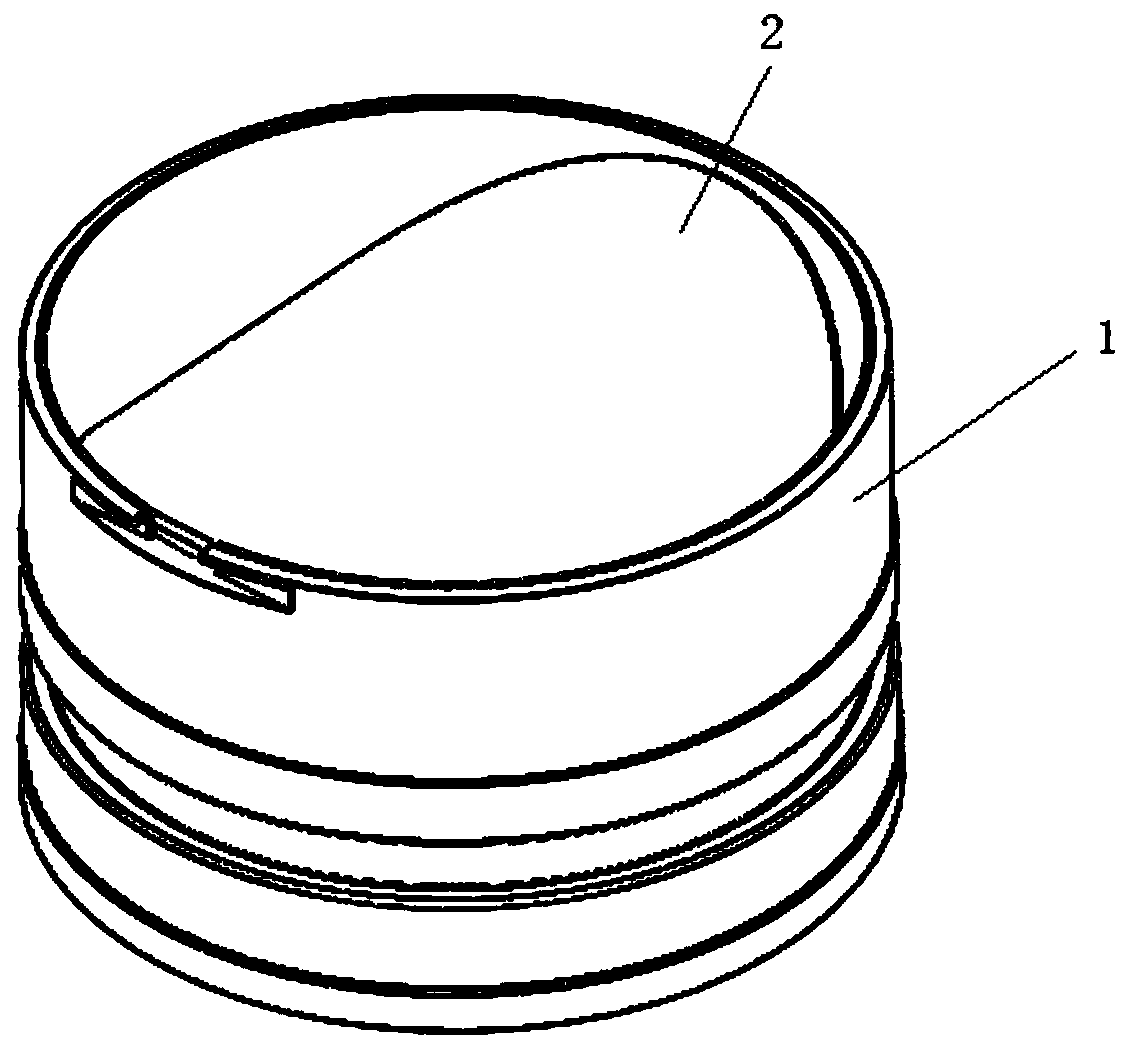

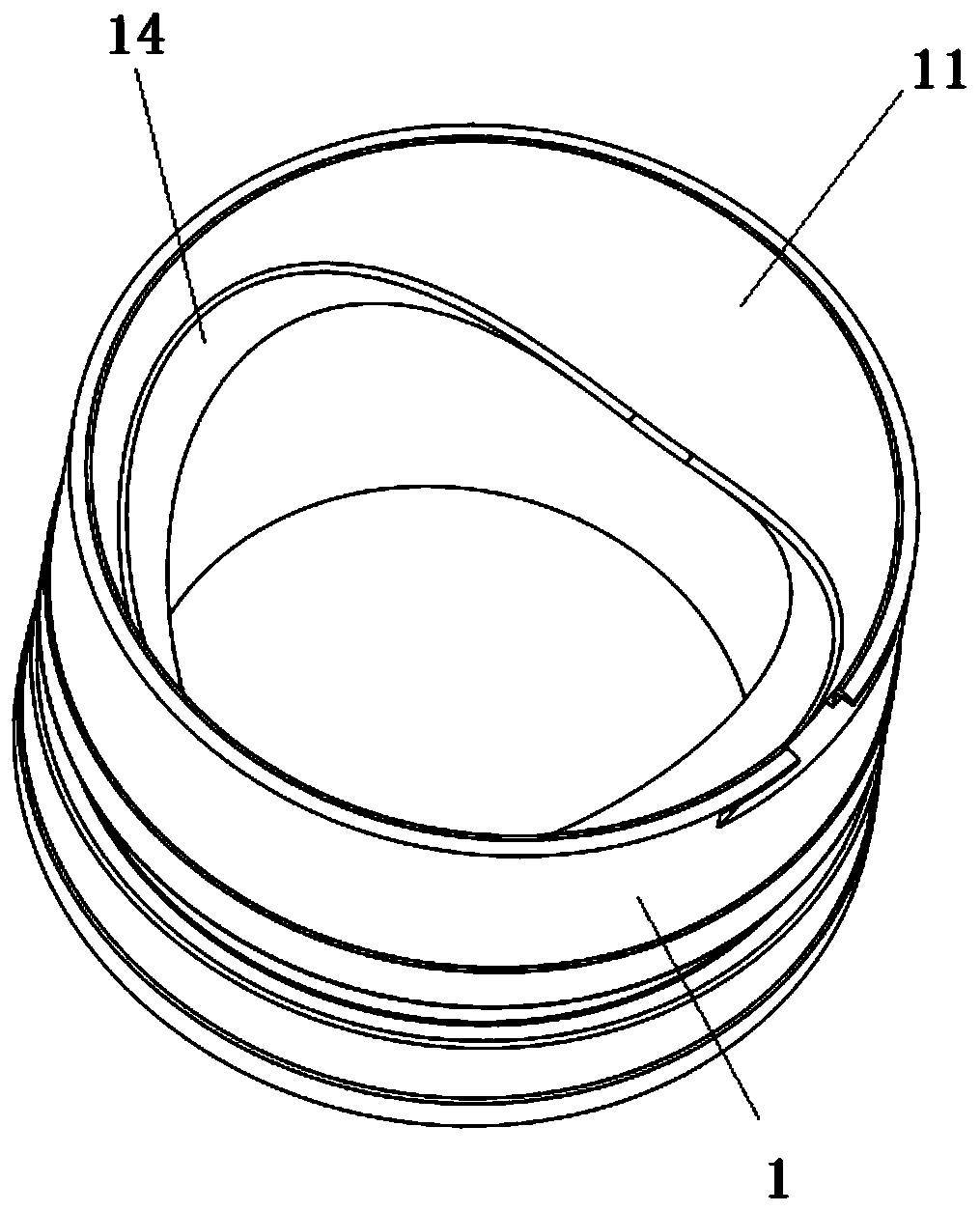

Method for soft soil foundation treatment through microorganism grouting sand drain

InactiveCN104631430AImprove vertical load carrying capacityPermeability changeOrganic fertilisersSoil conditioning compositionsSoil scienceSalt solution

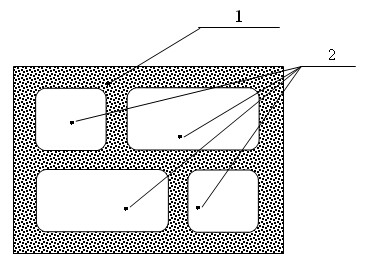

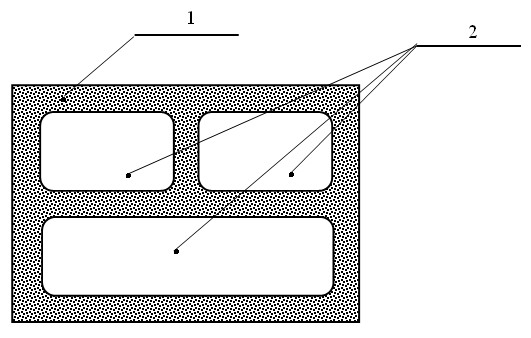

Disclosed is a method for soft soil foundation treatment through microorganism grouting sand drain. The method comprises the steps that a, a pile hole 1 is formed in a soft soil foundation to be treated, and sand is poured into the pile hole 1 to form a sand pile; b, a urease-producing microorganism solution 9 and a nutritive salt solution 10 are sequentially and evenly injected into the sand pile through a grouting tube 6, sand cementation is achieved through the microorganism induction calcium carbonate crystal technology, the concentration of the urease-producing microorganism solution 9 and the concentration of the nutritive salt solution 10 are controlled, sand in the pile body forms a specific cementation mode, and the good water permeable characteristic is ensured; c, after the microorganism grouting solidification sand pile is formed, a flexible water permeable sand cushion 4 is laid on the top of the foundation jointly formed by the sand oil and pile space soil 2, prepressing loads 5 are exerted on the top of the flexible water permeable sand cushion 4, pore water in the pile space soil 2 is made to be drained along a drainage channel formed by the sand pile and the sand cushion, the pile space soil is solidified, and the composite foundation with the high bearing capacity is formed jointly through the soft soil obtained after drainage and solidification are carried out on the microorganism grouting sand pile and the flexible water permeable sand cushion covering the soft soil.

Owner:NANJING FORESTRY UNIV

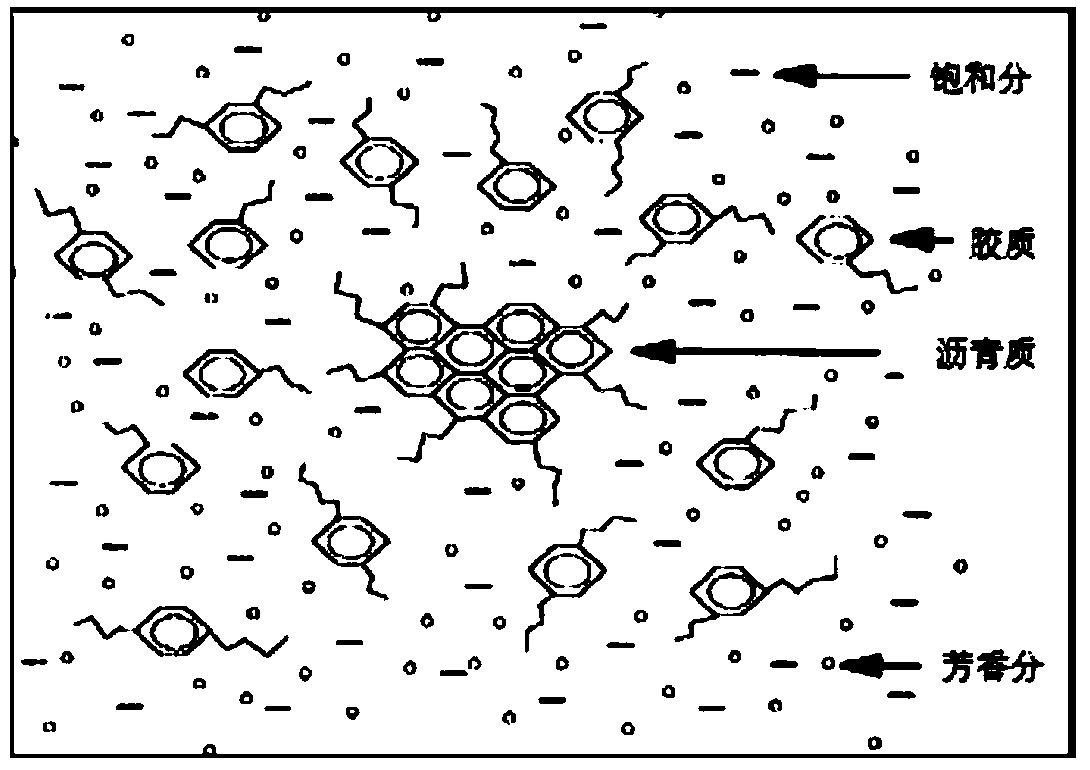

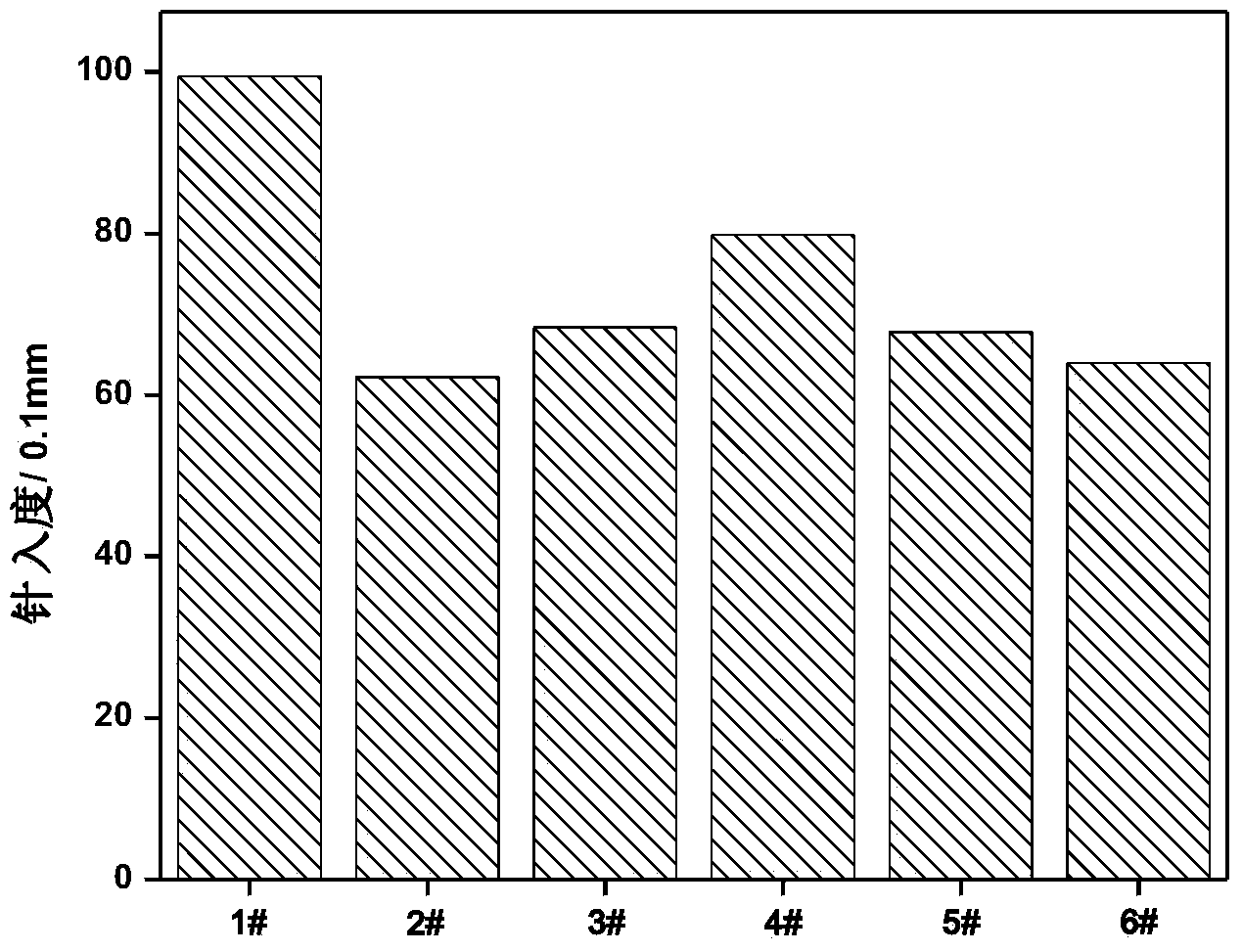

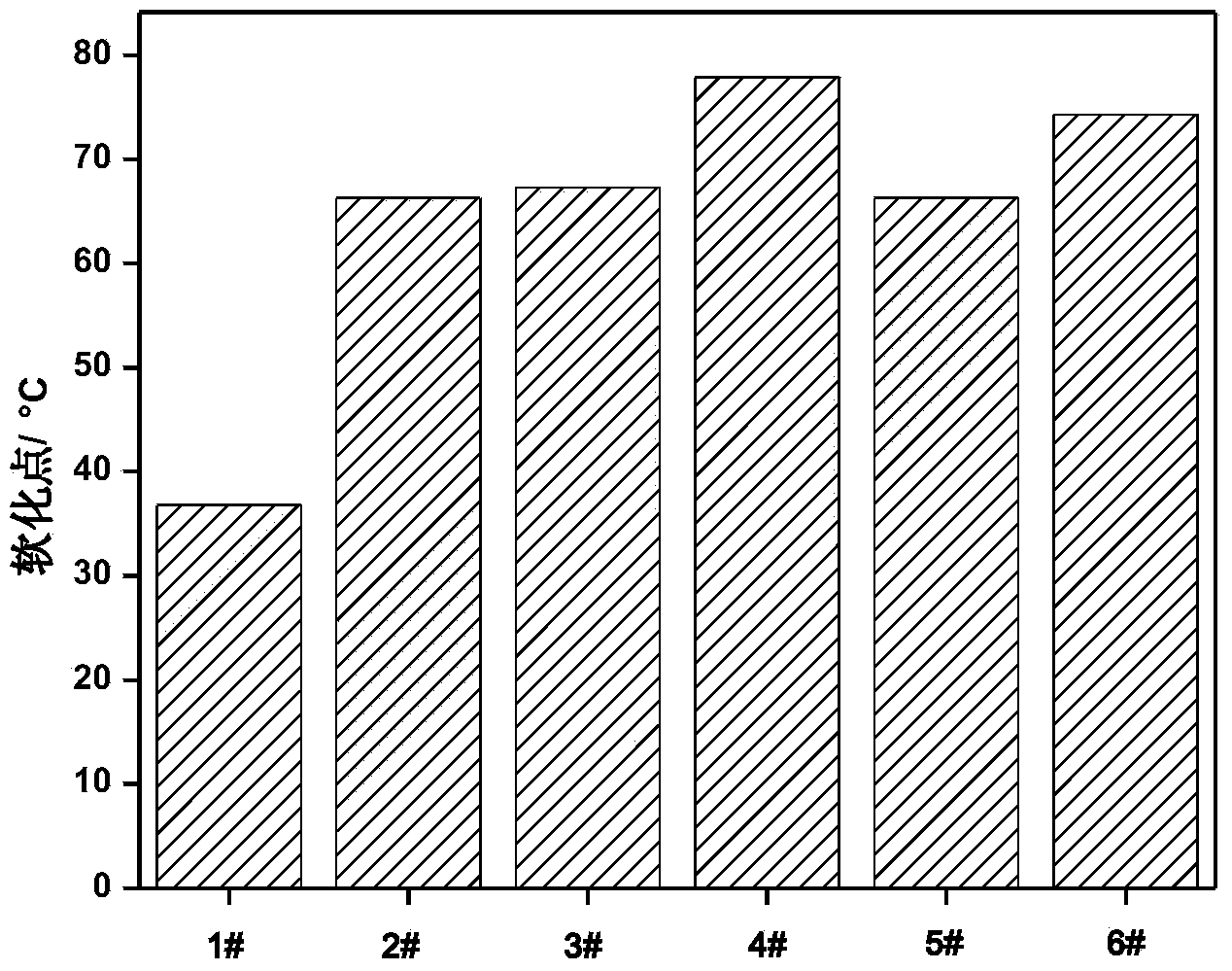

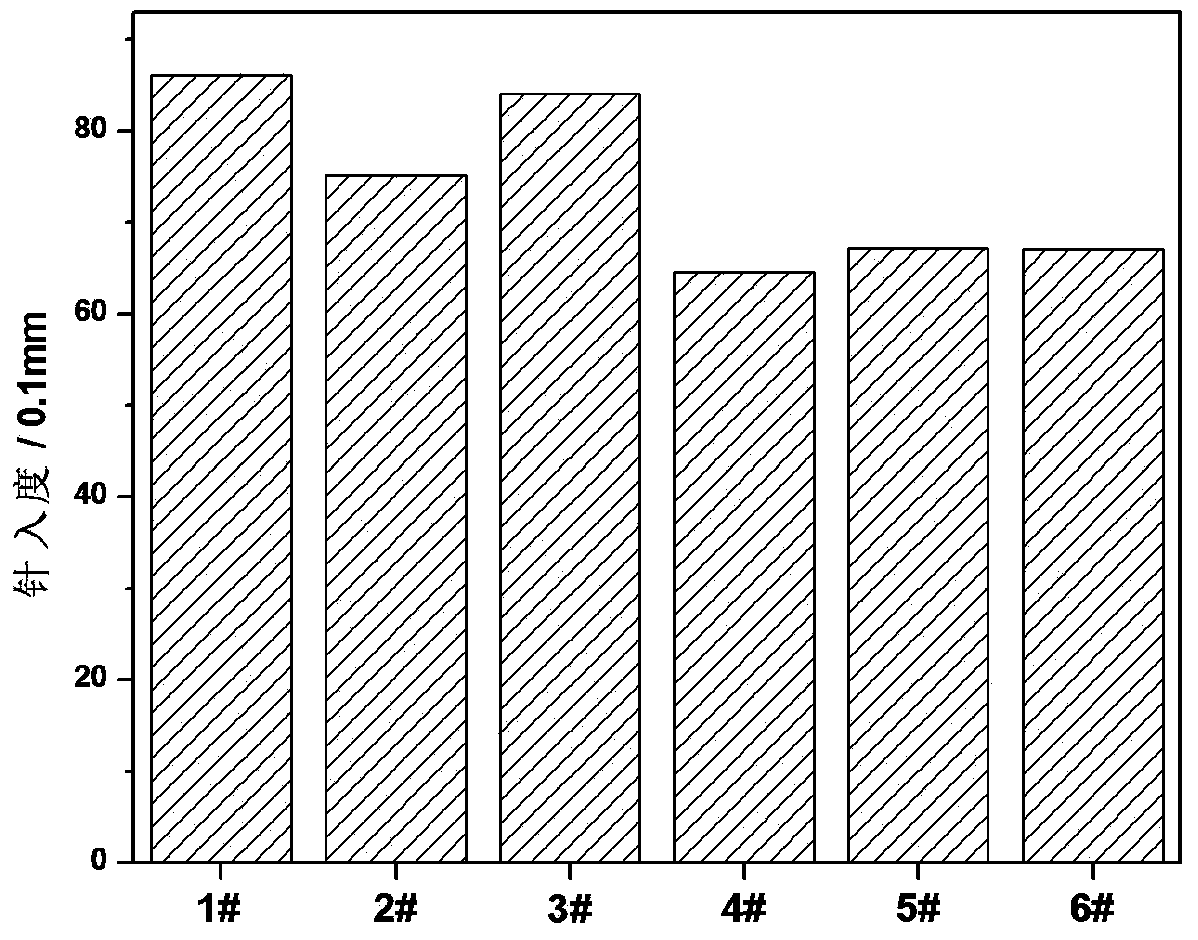

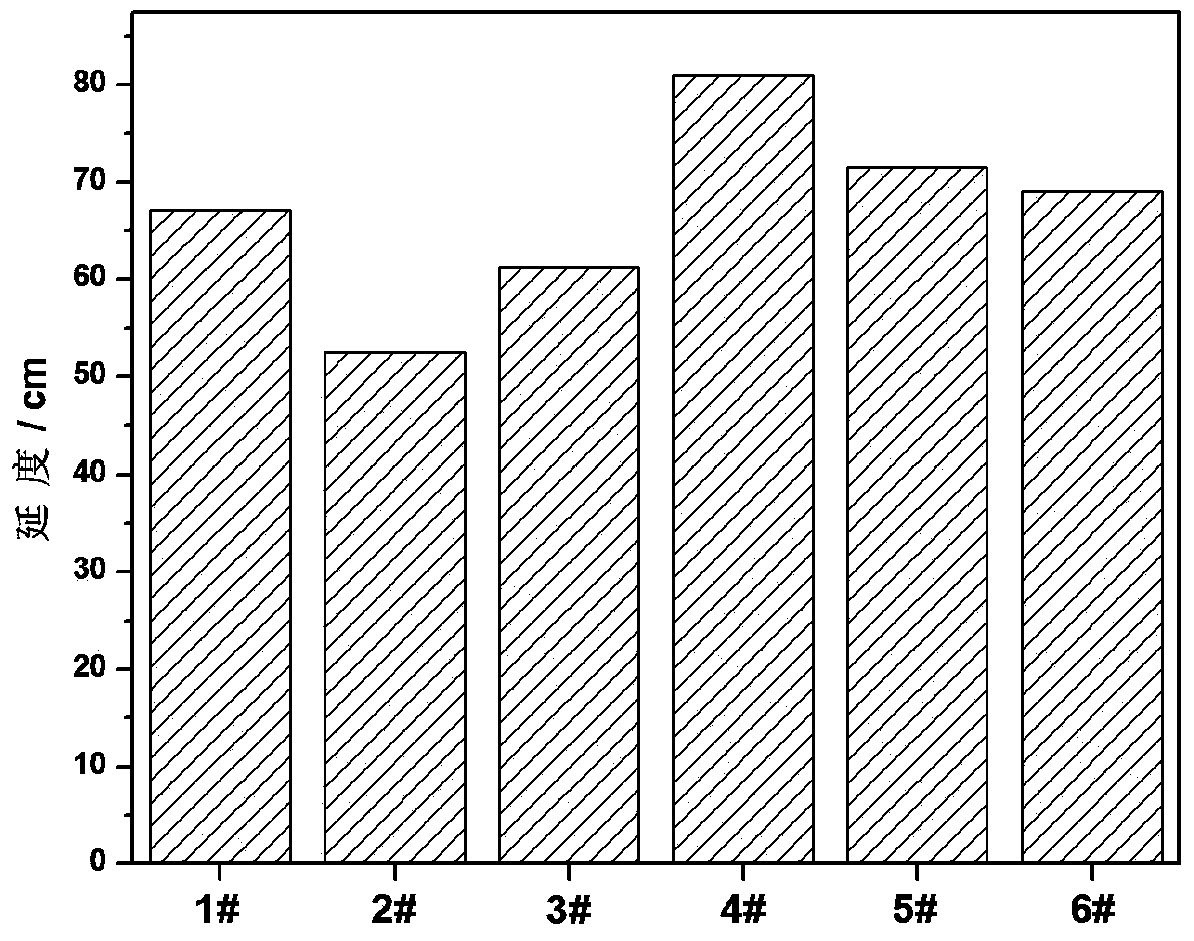

Graphene oxide modified asphalt and preparation method thereof

ActiveCN103819915AImprove high temperature performanceImproves rutting resistanceBuilding insulationsGraphite oxidePitch blende

The invention provides graphene oxide modified asphalt, comprising, by mass, 0.5 to 15% of graphene oxide and 85 to 99.5% of matrix asphalt, wherein the above mentioned mass percent sums to 100%. A preparation method for the graphene oxide modified asphalt comprises the following steps: heating and fusing matrix asphalt, maintaining a temperature to be 120 to 200 DEG C, adding graphene oxide, carrying out artificial stirring for 20 to 40 min, then carrying out stirring with a shearing machine for 20 to 120 min, cooling an obtained mixture to 100 to 150 DEG C and standing the mixture for 20 to 50 min so as to allow the mixture to be fully swollen; and subjecting the asphalt mixture to shearing on the shearing machine again for 80 to 100 min until graphene oxide is uniformly dispersed in asphalt. The graphene oxide modified asphalt provided by the invention uses graphene oxide as a modifier for modification of asphalt, can substantially improve high temperature performance and anti-deformation capability of matrix asphalt and greatly improves anti-tracking capability of a bituminous pavement.

Owner:浙江威克新材料科技发展有限公司

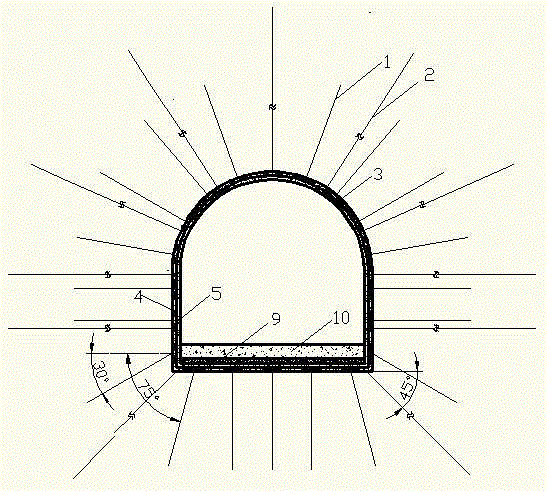

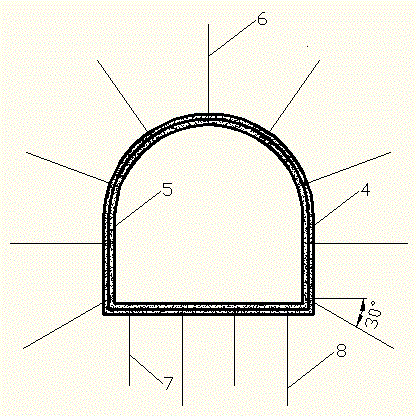

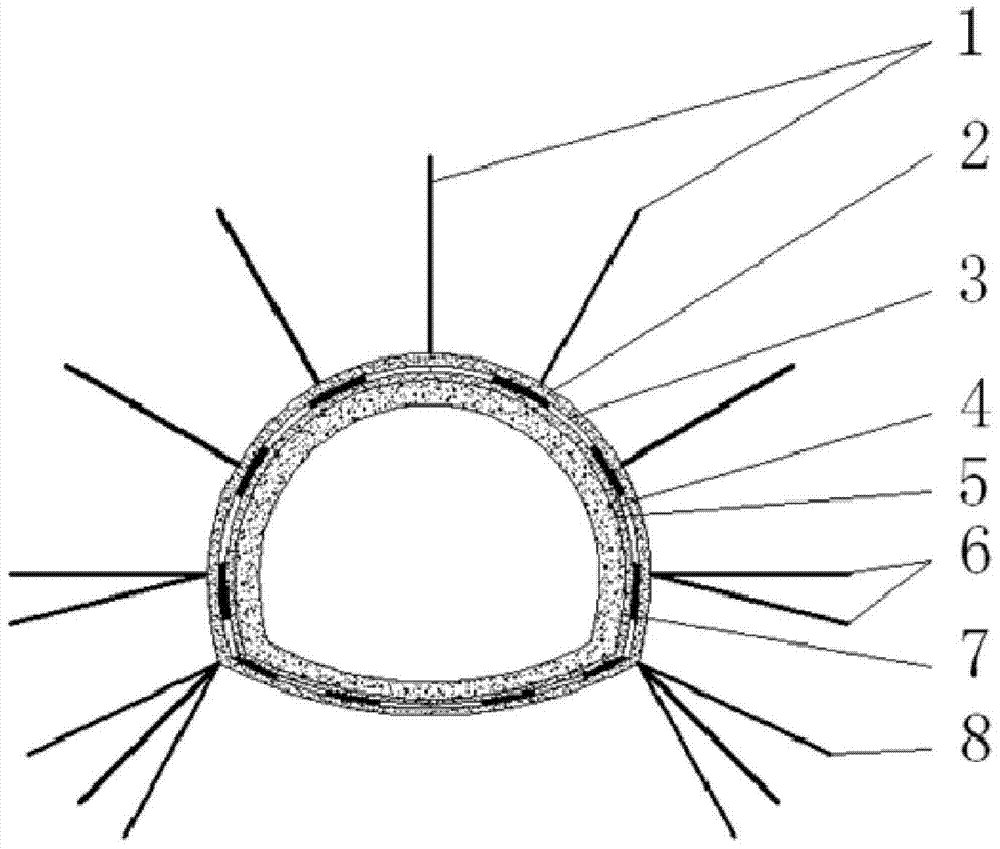

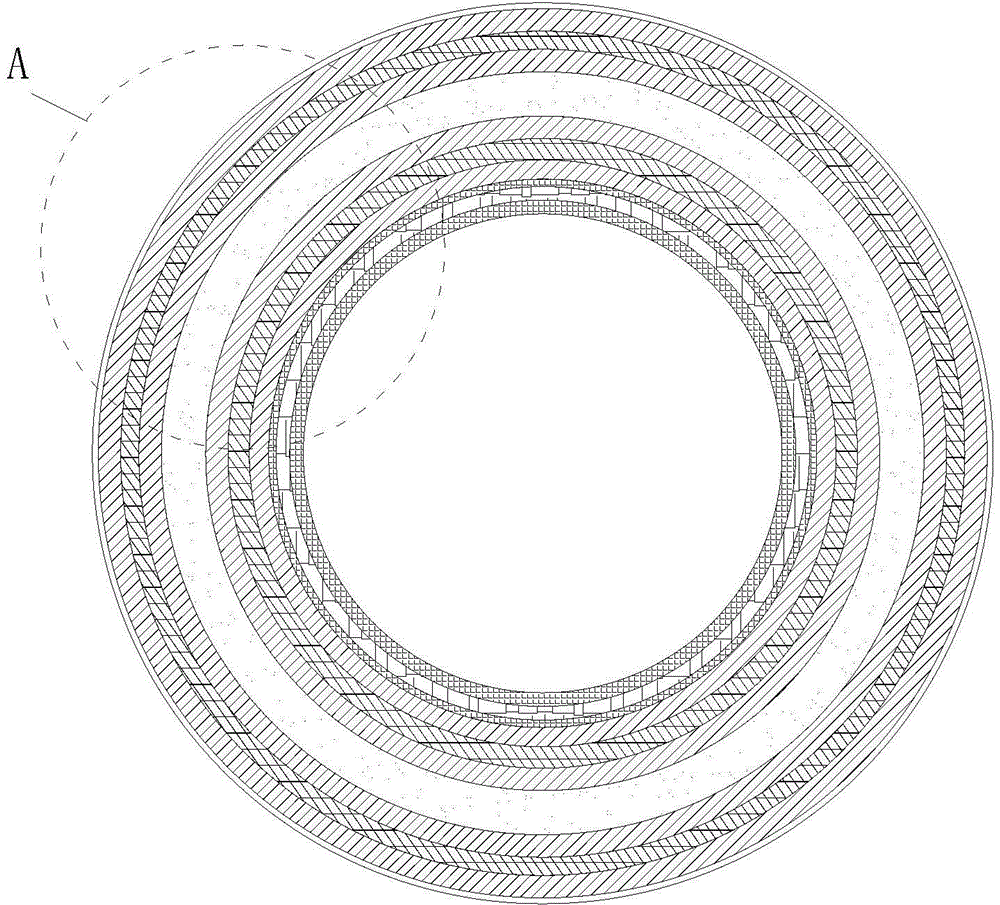

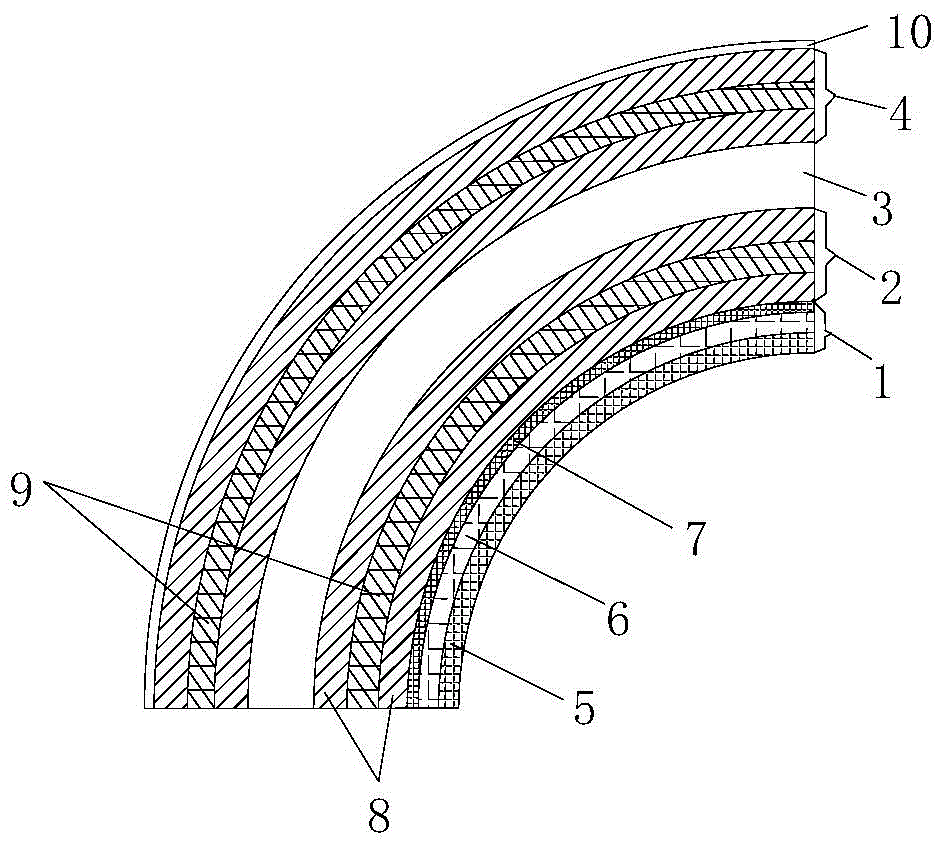

Total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method for incompact and fractured soft-rock roadway

InactiveCN105178981AImprove support strengthWatch protection effect is goodUnderground chambersTunnel liningCouplingStructure of the Earth

The invention relates to a total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method for an incompact and fractured soft-rock roadway. On the basis of a multilayered cooperative supporting principle, a spraying net combined isolating arch, an anchor rod extruding reinforcing arch, a total-section closed type grouting reinforcing ring and a deep slurry diffusion reinforcing arch are respectively formed on surrounding rock of the roadway from shallow to deep finally, and are combined to form a multilayered effective combined arch by a suspension effect of a high-strength grouting anchor cable, advantages of yielding supporting, bolting-grouting supporting and deep-shallow coupling supporting are combined organically, bearing range, integrity and bearing capability of a supporting structure are improved obviously, a control effect on deformation characteristics of large deformation, high speed, long duration, wide destroying range, peripheral pressing, obvious floor heaves and the like of the surrounding rock of the incompact and fractured soft-rock roadway is excellent, and various deformations of the surrounding rock of the incompact and fractured soft-rock roadway are controlled effectively. The total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method is particularly suitable for a large-section incompact and fractured soft-rock roadway of a deep well, is simple in work procedures and low in cost, and has high field promotion and application value; and parallel operation can be realized.

Owner:CHINA UNIV OF MINING & TECH

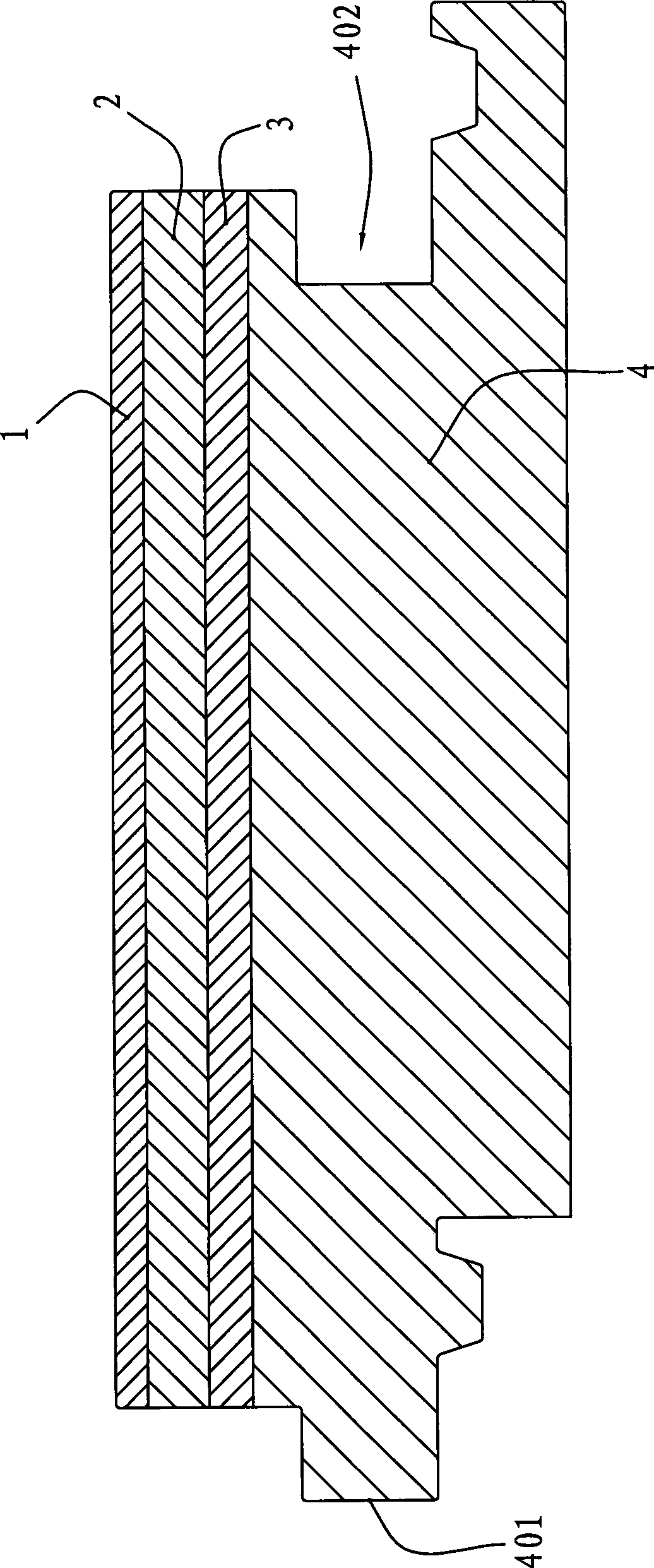

Composite floor board and method for producing the same

ActiveCN101487336AWith natural textureWith comfortWood working apparatusFlooringThermoplasticSolid wood

The invention relates to a composite floor and a preparation method thereof. Thermoplastic plastics and wood powder are mixed and extruded to obtain a mixed layer, and then the mixed layer is mixed with thermofusible resin and extruded to obtain a profile which is taken as basic material of the floor, a decorating layer and an exterior wear-resisting layer are laid on the surface of the basic material of floor in sequence to obtain a floor blank, finally, after processes like conventional gouging and the like, an end product of composite floor is obtained. The obtained composite floor has the natural grain and the amenity of the solid wood floor, and overcomes the shortcomings of non-watertight, being easy to rot, easy to be deformed and low wear resistance of the conventional wood floor. The preparation method of the composite floor is simple and feasible and has low cost.

Owner:来安县扬子地板有限公司

Three-dimensional reinforced rigid-soft composite ecological retaining wall and construction method

ActiveCN103410167AHigh strengthAchieve reorganizationArtificial islandsUnderwater structuresFilling materialsEngineering

The invention relates to a three-dimensional reinforced rigid-soft composite ecological retaining wall and a construction method. The retaining wall is characterized by comprising an upper portion soft ecological retaining wall body and a lower rigid retaining wall body, wherein the upper portion soft ecological retaining wall body and the lower rigid retaining wall body are connected through anchor bars. All layers of filling materials of the upper portion soft ecological retaining wall body are connected through connecting buckle parts, and water draining pipes, the connecting and fixing ends of horizontal ribbing bodies and inclined tie bars are evenly arranged on the lower rigid retaining wall body. A wall heel of a foundation of the retaining wall extends backwards to the edge of a stable soil body, vertical reinforcing piles are arranged at the bottom of the retaining wall, the horizontal ribbing bodies are laid in the filling materials behind the retaining wall, the wall toe of the retaining wall is filled back with a wall foot pressing soil body, and vertical ribbing bodies are vertically arranged at the connection position between the filling materials behind the retaining wall and an original soil body. The retaining wall structurally combines the advantages of a rigid retaining wall and the advantages of a soft retaining wall, achieves ecological slope protection, reduces pressure of soil behind the retaining wall, enhances structural integrity and has good technical and economical benefits.

Owner:SHENZHEN FUTIAN JIANAN CONSTR GRP

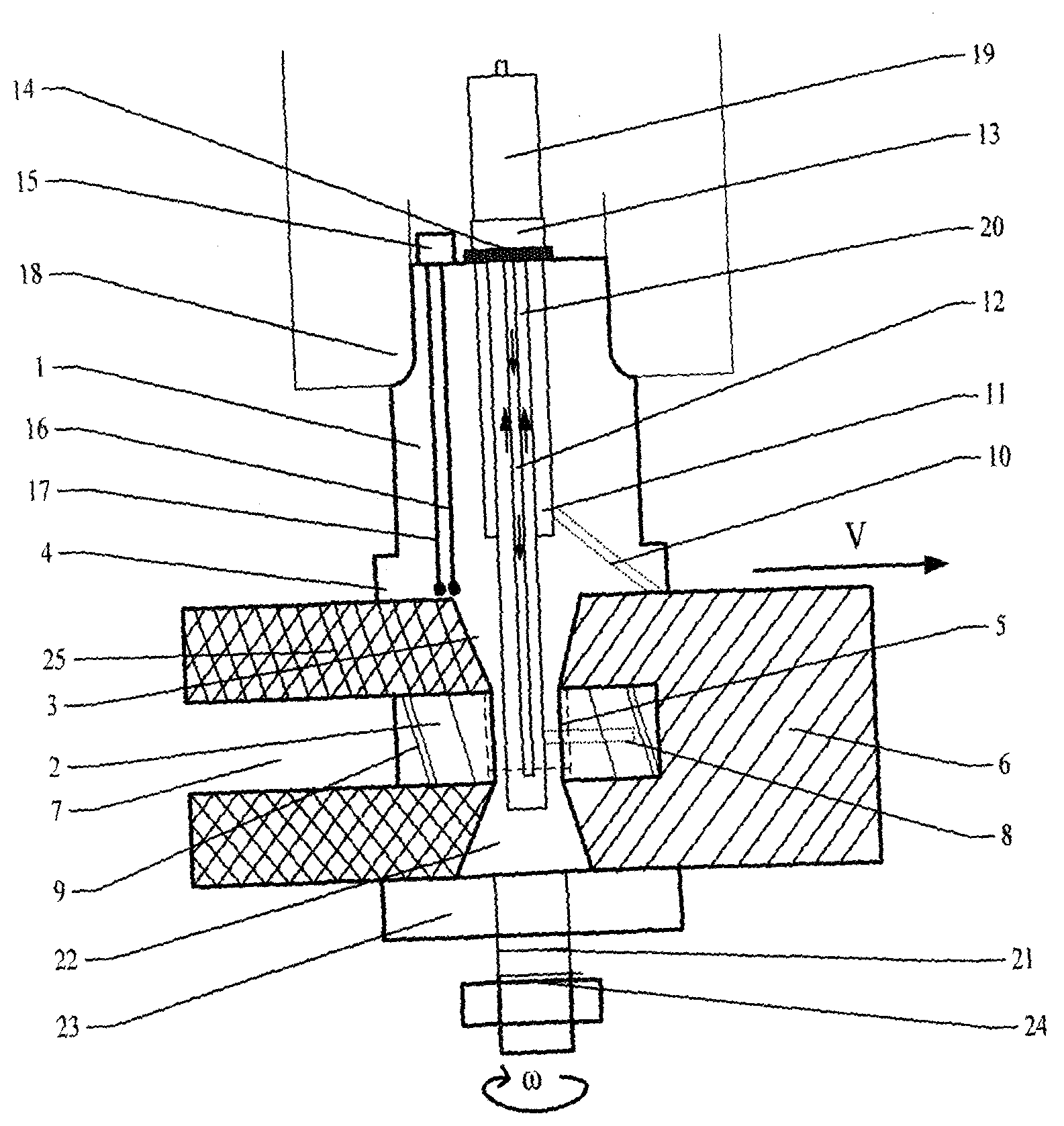

Cutting-stirring friction welding composite processing device for floating double-shaft-shoulder double-stirring needle and manufacture method thereof

InactiveCN102490018AEfficient coolingAvoid glitchesOther manufacturing equipments/toolsNon-electric welding apparatusInduction systemTemperature sensing

The invention discloses a cutting-stirring friction welding composite processing device for a floating double-shaft-shoulder double-stirring needle and a manufacture method thereof, and particularly relates to a combined or composite processing device capable of simultaneously carrying out milling or cutting processing and stirring friction welding processing and a method thereof. The cutting-stirring friction welding composite processing device for the floating double-shaft-shoulder double-stirring needle integrates a cutting system or a milling system, a stirring friction welding system, a forced cooling system, a gas protection system, a temperature sensing system, a pressure induction system, a milling liquid supply system and a sensing-free system. The cutting-stirring friction welding composite processing device has functions of temperature control, gas protection, pressure detection, cooling liquid protection, milling head replacing and floating double-shaft-shoulder self-supporting stirring friction welding. The method for carrying out cutting-stirring friction welding composite processing on workpieces can meet strength requirements of mechanical processing of ferrous light metal materials, carbon steel materials and alloy steel materials. The cutting-stirring friction welding composite processing device for a floating double-shaft-shoulder double-stirring needle and the manufacture method of the cutting-stirring friction welding composite processing device reduce manufacture procedures, save processing cost, have the advantages of being high in efficiency, excellent in quality, high in stability and saving in energy, break through limitation of conventional machining technology, form a new method and a new thought for machinery processing, and have wide application prospects in industries of heating, air conditioners, ice manufacture, freshness keeping, medicine preparation, construction, aquatic products and foods.

Owner:CHONGQING UNIV

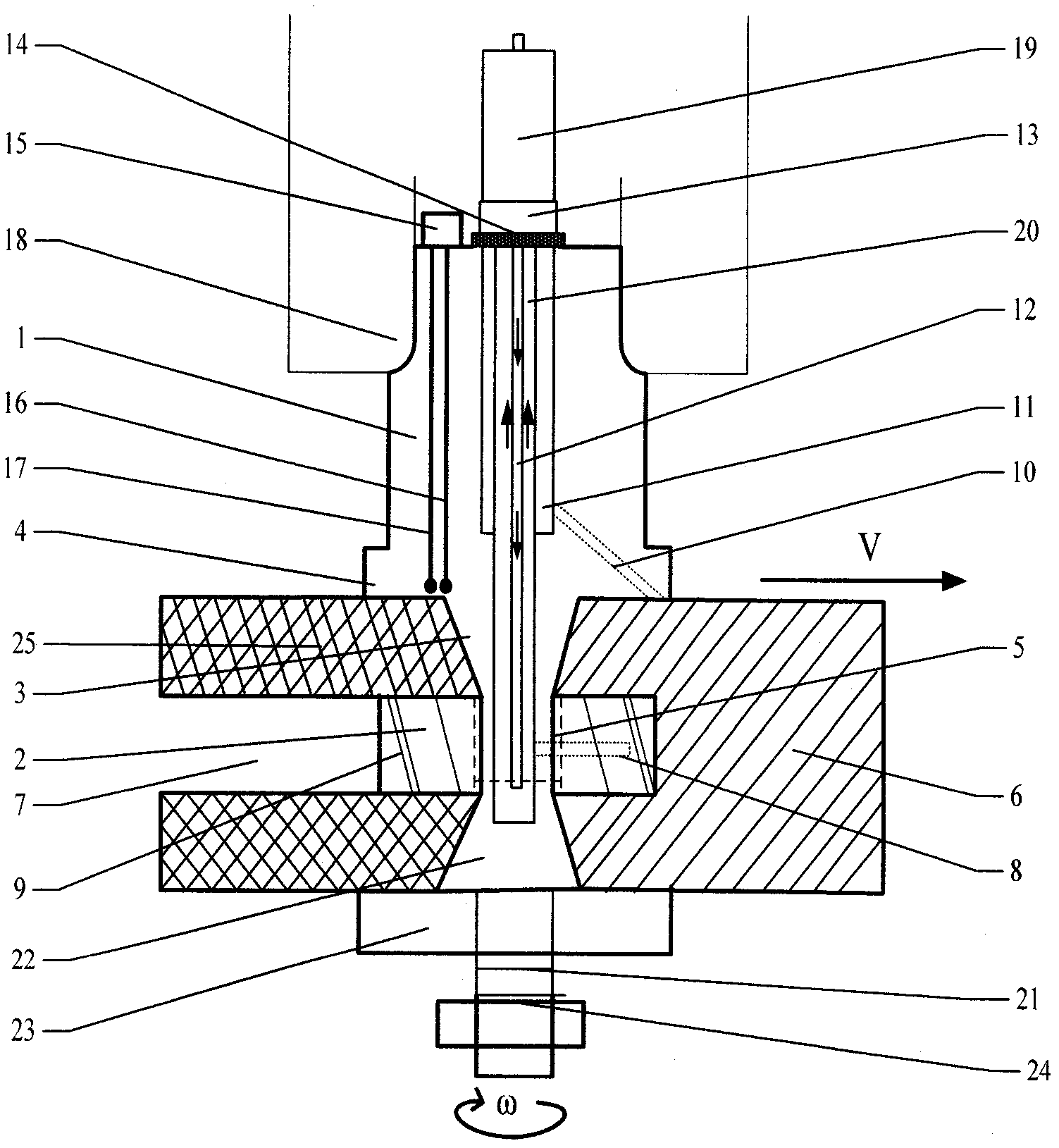

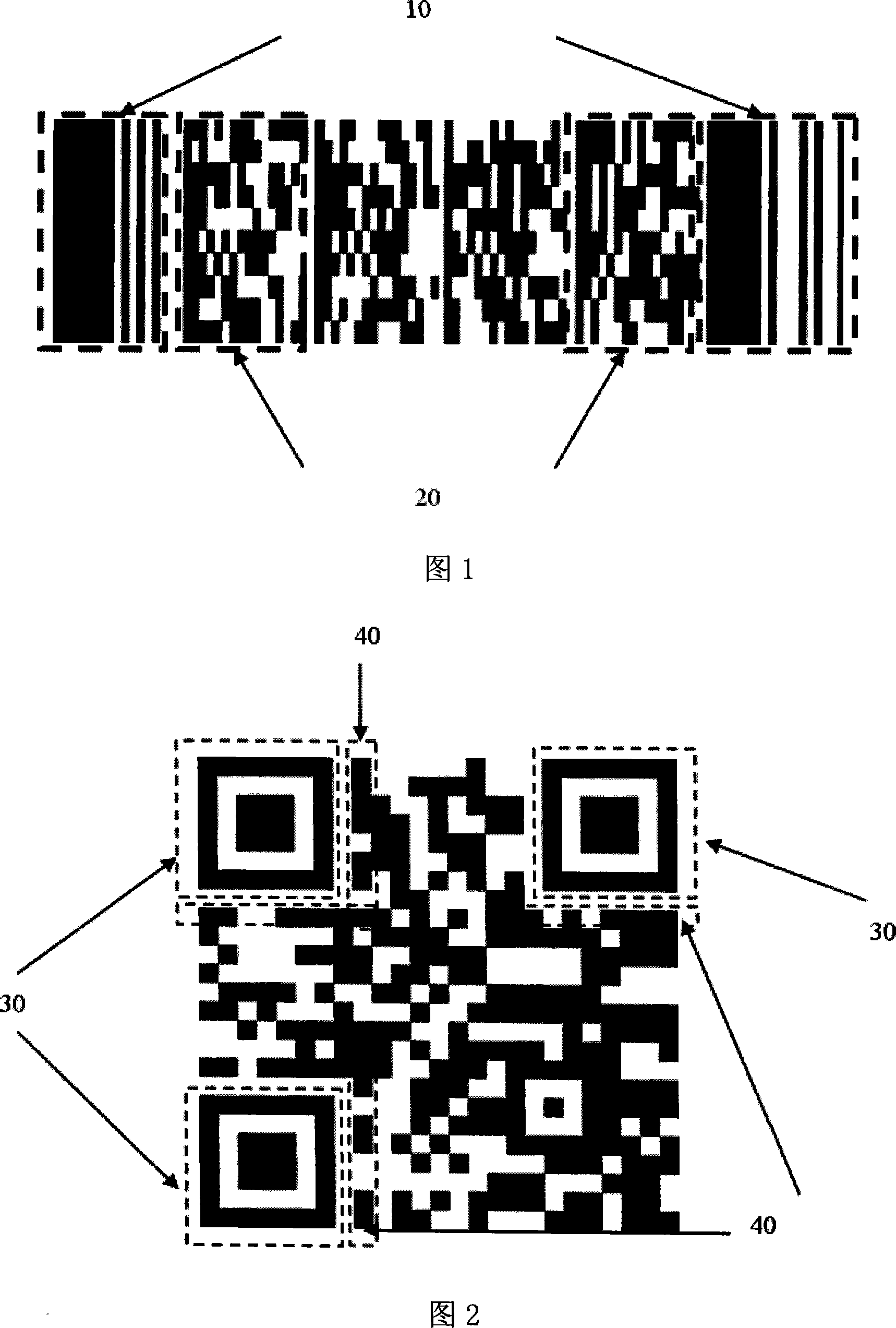

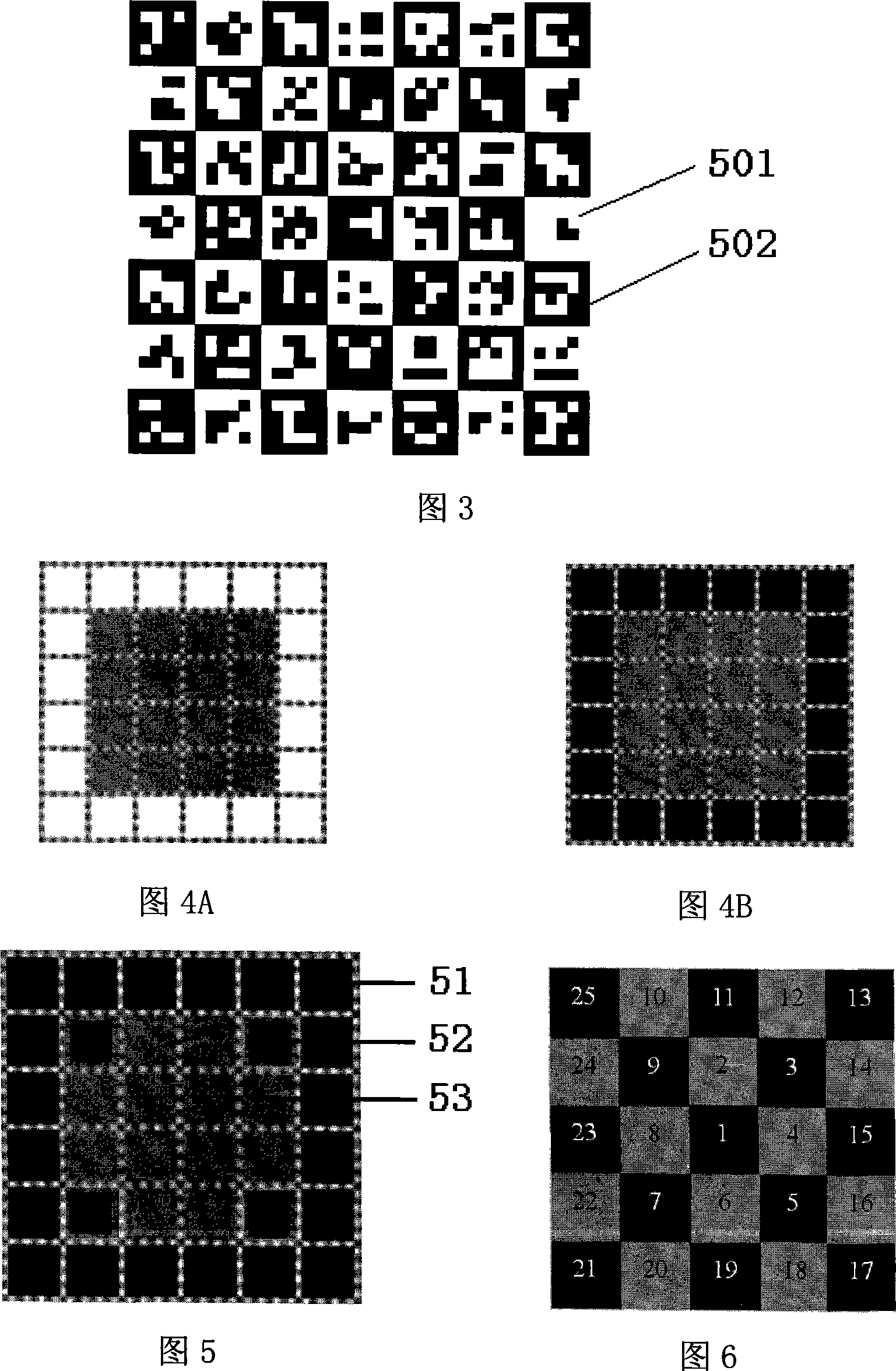

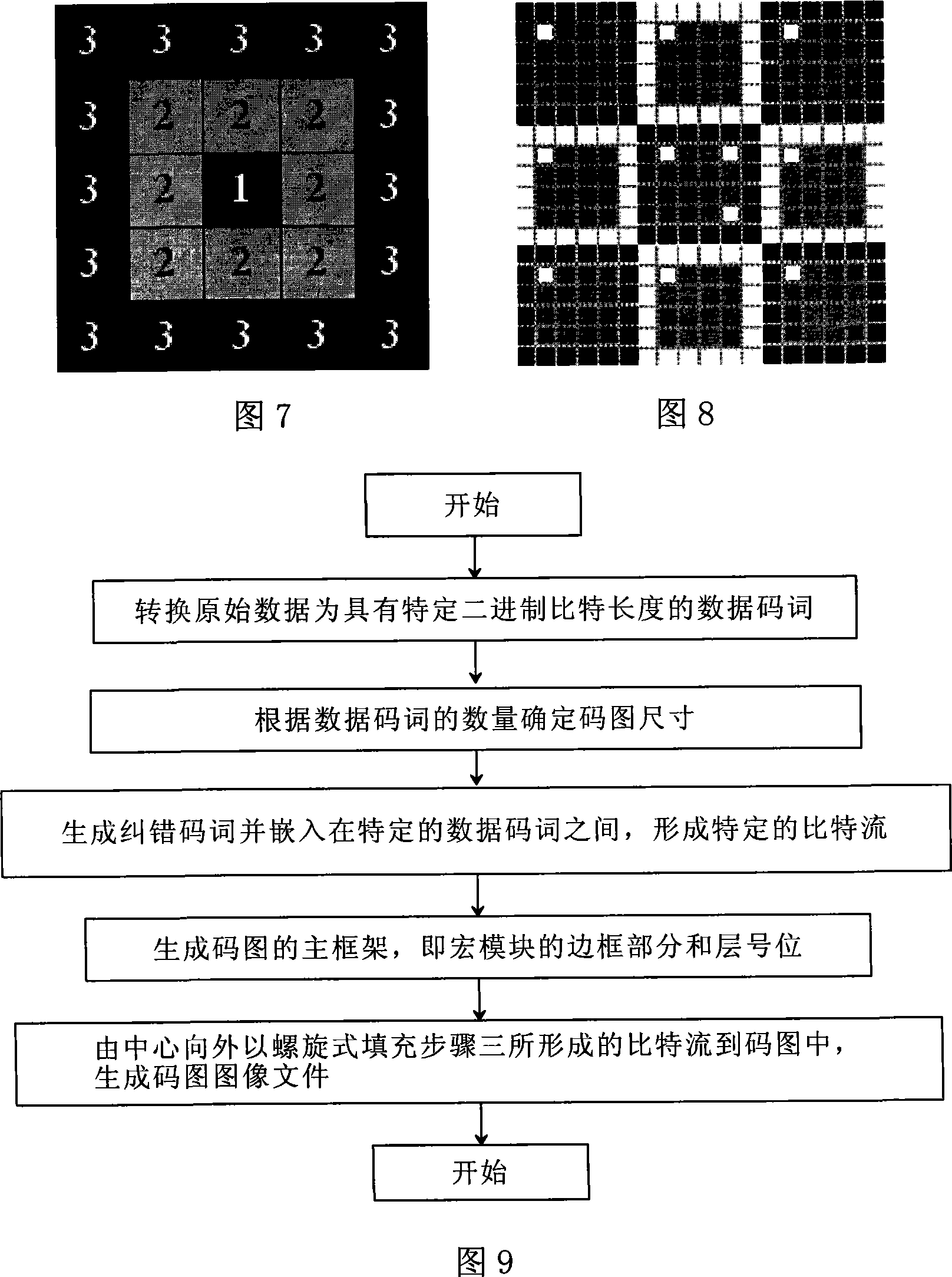

Two-dimension bar code and its coding and decoding method

InactiveCN101197004ADirection is easy to determineSmooth decodingRecord carriers used with machinesSensing by electromagnetic radiationProgramming languageError correcting

The present invention discloses a method for coding and decoding two-dimensional bar codes. The coding method comprises a data code word generating step, an error-correcting code word generating step, a main code pattern frame generating step and a code pattern image forming step through code word filling. The decoding method is that: a gray scale image of a code pattern is acquired through a digital photography mode; the gray value distribution of different pixels in the gray scale image is counted; a threshold value is determined; the gray scale image is converted into a binary image and an edge image is acquired; the four-corner coordinate of each macro block in the code pattern and the center coordinate of each unit module inside the macro blocks are calculated; the bit value stored by each unit module is determined so as to acquire a data code word matrix corresponding to the decoded code pattern; the data code word is read according to a correct center macro block and the code pattern direction; RS error-correcting algorithm is used to correct the errors in the code word according to a preset error-correcting grade; the data code word is output and recovered as a binary number.

Owner:SHENZHEN SYSCAN TECHC CO LTD

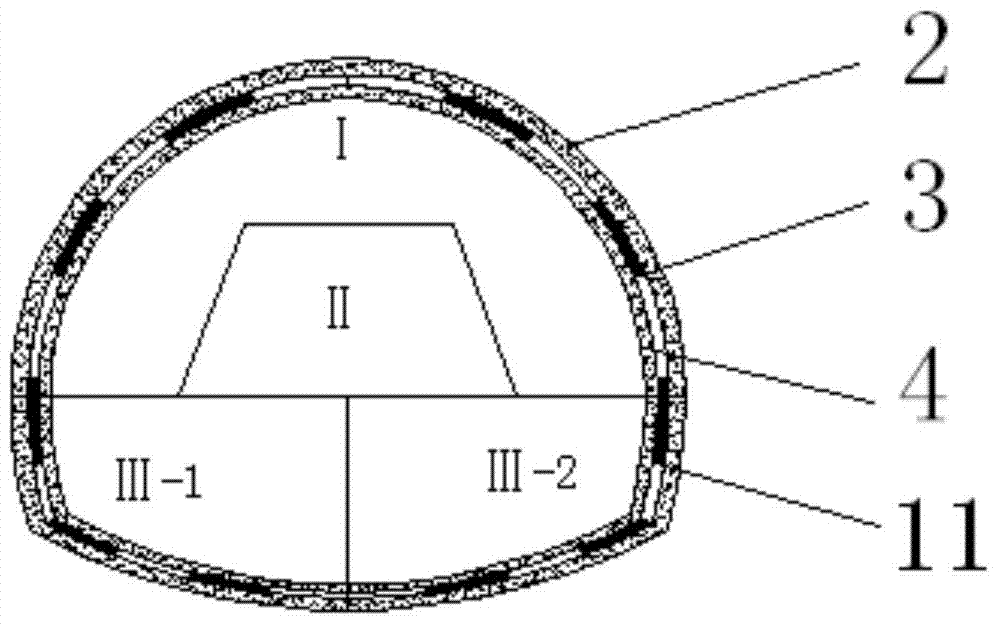

Soft rock large-deformation tunnel supporting system and construction method thereof

InactiveCN104847374AEnsure safetySmall overall deformationUnderground chambersTunnel liningSupporting systemLarge deformation

The invention discloses a soft rock large-deformation tunnel supporting system and a construction method thereof. The system comprises a forepoling, a preliminary bracing, a waterproof layer, a secondary lining and other main structures, wherein the structures are constructed in sequence according to construction procedures. Surrounding rock is reinforced through advanced small pipe grouting by means of the forepoling, the preliminary bracing comprises lengthened anchor rods, a primary spraying layer, steel arches and a re-jetting layer, feet-lock bolts are further arranged at the positions of an upper bench and arch feet to be welded to the steel arches, the adjacent steel arches are connected through longitudinal connecting ribs, and the secondary lining is constructed at last to form the supporting system. The steps are simple and linked with one another, supporting lag caused by idling of labor force is avoided, and large-deformation of tunnels is well controlled.

Owner:CHANGAN UNIV

Steel for enamel and production method thereof

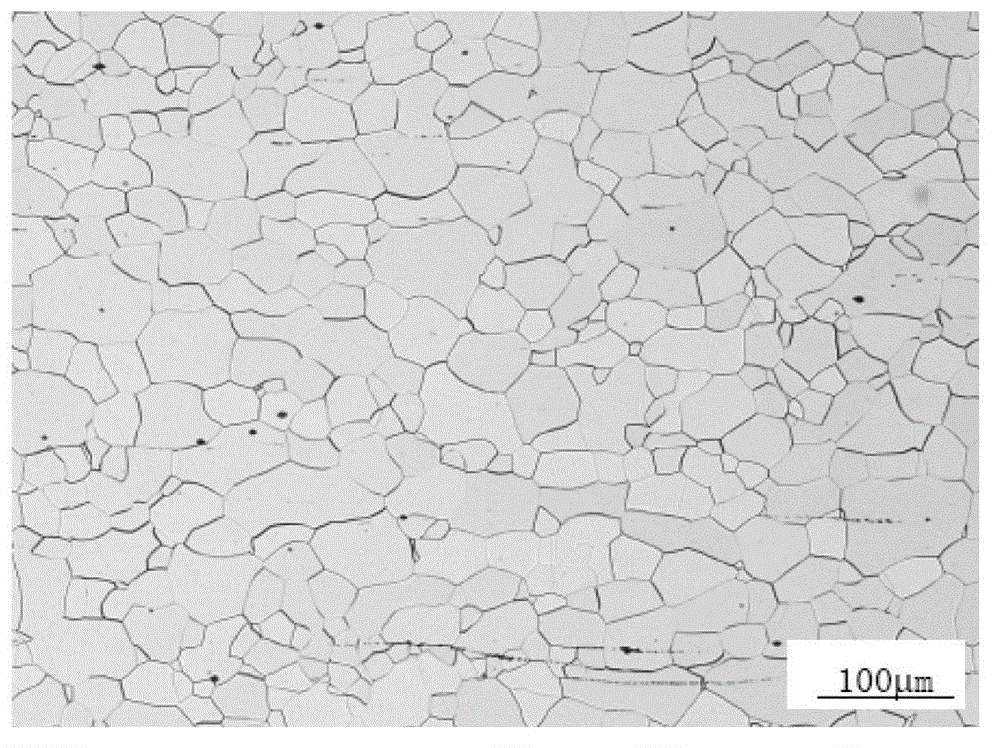

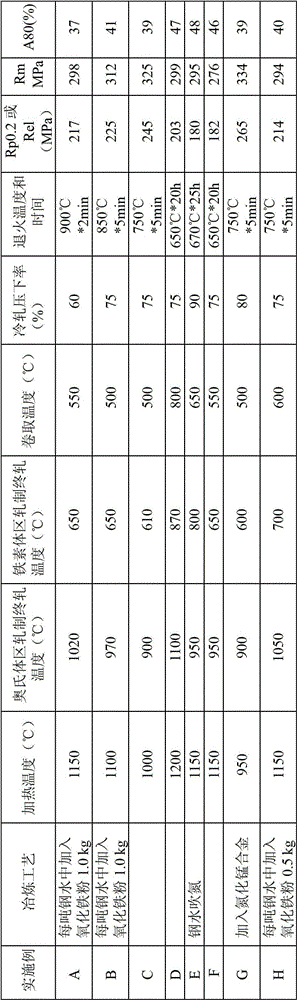

The invention discloses a steel for enamel, and is characterized by comprising the following chemical elements by mass: not more than 0.020% of C, not more than 0.05% of Si, 0.10-0.50% of Mn, not more than 0.03% of P, 0.003-0.050% of S, 0.001-0.03% of Al, 0.001-0.015% of N, 0.005-0.050% of O, not more than 0.005% of Ca, not more than 0.005% of Mg, not more than 0.10% of Cu, not more than 0.10% of Cr, not more than 0.10% of Ni, not more than 0.10% of Mo, at least one of 0.0005-0.003% of B, not more than 0.01% of Nb, not more than 0.02% of V, and 0.001-0.05% of Ti, and the balance of Fe and other inevitable impurities, wherein N(%)*Ti(%) is not more than 3*10<-4>. Correspondingly, the invention further discloses a production method of the steel for enamel. The steel for enamel has excellent comprehensive performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preparing super-hydrophobic fabric through polyphenol modification

ActiveCN106087404AIncrease productivityGood soaping resistanceFibre treatmentTextile technologyIron(III) chloride

The invention discloses a method for preparing super-hydrophobic fabric through polyphenol modification, and belongs to the technical field of weaving. The method comprises dipping fabric successively in a ferric chloride solution and a polyphenol compound solution, so as to obtain fabric of which the surface is modified by a metal-polyphenol layer; then dipping the fabric of which the surface is modified by the metal-polyphenol layer into an ethanol-water mixed solution containing a low-surface-energy substance, reacting for 6-24 h, washing successively by deionized water and absolute ethyl alcohol, and drying the fabric at 40 DEG C in vacuum for 5-10 h, so as to obtain phenol-modified super-hydrophobic fabric. The super-hydrophobic fabric possesses extremely good soaping resistance and efficient endurable hydrophobicity, the static contact angle is still larger than 150 DEG after the fabric is washing for 20 times, the fabric variety is diversified, application is wide, and the preparation technology is simple, green, friendly to environment, low in cost and suitable for large-scale production.

Owner:DONGGUAN YIMAO FILTER MEDIA

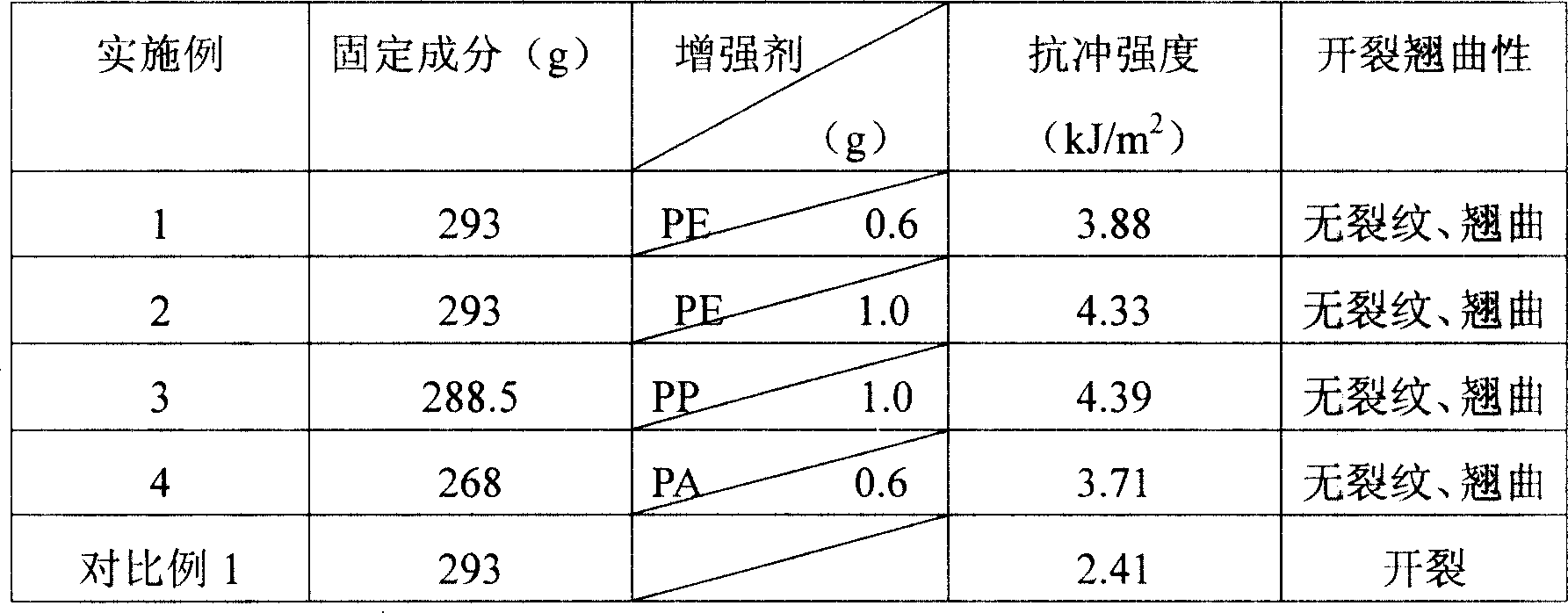

Artwork with modified urea-formaldehyde resin as adhesive and preparing method thereof

InactiveCN101012360AHigh impact strengthImprove cracking performanceDecorative surface effectsOrnamental structuresAqueous solutionPoly methacrylate

The invention discloses a binder and making method of modified urea-formaldehyde resin, which comprises the following steps: adopting urea-formaldehyde resin, fill, reinforcer, deoxidation agent, formaldehyde catching agent, anti-aging agent, anti-shrinking agent, hardener and auxiliary reinforcer; adopting modified copolymer of acrylic acid, sodium acrylate, N, N-dimethylamino propyl methyl acrylamide as anti-shrinking agent; making polyacrylamide solution reacted by acrylamide and ammonium persulphate as formaldehyde catching agent; allocating each component according to proportion; blending evenly; casting; extracting into vacuum; stripping; stewing; drying naturally; coating a layer of polymethacrylate paint on the surface of product; proceeding colorful paint; obtaining the product.

Owner:XIAMEN UNIV

High-strength glass fiber-reinforced plastic pipeline and production method thereof

The invention discloses a high-strength glass fiber reinforced plastic pipeline and a production method thereof, and belongs to the technical field of glass fiber reinforced plastic pipelines and production methods thereof. The high-strength glass fiber reinforced plastic pipeline is a circular pipeline, and is characterized by comprising a lining layer, an inner structural layer, a middle sand inclusion layer and an outer structural layer, wherein the lining layer is formed by soaking and bonding a glass fiber surface felt layer, a glass fiber knitted felt layer and a grid cloth layer in sequence through lining resin from inside to outside; the inner structural layer and the outer structural layer are constructed by one or more glass fiber yarn annular winding layers and one or more glass fiber yarn crossed winding layers; the annular winding layers and the crossed winding layers are formed at intervals; the middle sand inclusion layer consists of upper layer sand inclusion cloth, lower layer sand inclusion cloth and a sand material compressed and clamped between the upper layer sand inclusion cloth and the lower layer sand inclusion cloth; the sand material is formed by mixing quartz sand and sand adhesion resin. The pipeline has the advantages of high compressive strength, high axial tensile strength, large pipe diameter span, light weight, high hydraulic performance, freeness from scaling, insulation, flame retardance and corrosion resistance.

Owner:HUNAN XIAOXIANGYUAN TECH DEV

Preparation method of lodging-resistant multi-difference polyester low-elastic filament

ActiveCN106400179AImprove heat resistanceEasy to processMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyethylene glycol

The invention relates to a preparation method of a lodging-resistant multi-difference polyester low elastic filament. The preparation method comprises the following steps: firstly, mixing nano sepiolite fibers, organic magnesium hydroxide whisker, organic barium sulfate nano powder, ethylene glycol, propylene glycol, p-hydroxybenzoic acid and sodium germanate to obtain a high-modulus composite alcohol solution; secondly, mixing organic wollastonite nano needle-like fibers, mica powder, polyethylene glycol, the propylene glycol, an antioxidant 1010, ethylene glycol antimony and protonated agent phosphoric acid to obtain a high-modulus composite promoter; thirdly, co-polycondensing the high-modulus composite multifunctional alcohol solution and the high-modulus composite promoter with purified terephthalic acid and the ethylene glycol to obtain high-modulus modified polyester; a melt of the high-modulus modified polyester is sprayed from a T-shaped spinneret orifice in a spinneret plate; the lodging-resistant multi-difference polyester low elastic filament is prepared by a special cooling mode and a low-temperature texturing process. The fiber prepared by the preparation method has multiple different properties of different crystallization, different orientation and different shrinkage; after different shrinkage, the appearance is good, and a brushed fabric prepared from the lodging-resistant multi-difference polyester low elastic filament is not easy to lodge.

Owner:荣翔化纤有限公司

Disk shearing blade and method for manufacturing the same

ActiveCN101177765AImprove wear resistanceHigh strengthShearing machinesFurnace typesHigh intensityWear resistance

A disc scissors blade and its manufacturing method, the composition weight percentage of the material of the disc scissors blade is: C: 0.40-0.70%, Si: 0.50-1.2%, Mn: 0.20-0.50%, Ni: 1.00-1.50% %, Cr: 4.00-6.00%, Mo: 0.50-2.00%, V: 0.30-1.50%, Nb: 0.10-0.80%, P≤0.02%, S≤0.02%. The method introduces an electroslag remelting process into a common manufacturing method of disc shears, and increases the temperature of quenching and tempering heat treatment and final heat treatment. The disc scissors have good wear resistance and deformation resistance, and are suitable for slitting or trimming hot-rolled high-strength thick steel plates. In addition, the disc shear blade of the present invention also has a good use effect on disc shears in other similar working conditions, and can also be applied to disc shears for stripping or edge trimming of cold-rolled strip steel, and also has a promotional effect on non-ferrous metal disc shears. value and application prospects.

Owner:BAOSHAN IRON & STEEL CO LTD +1

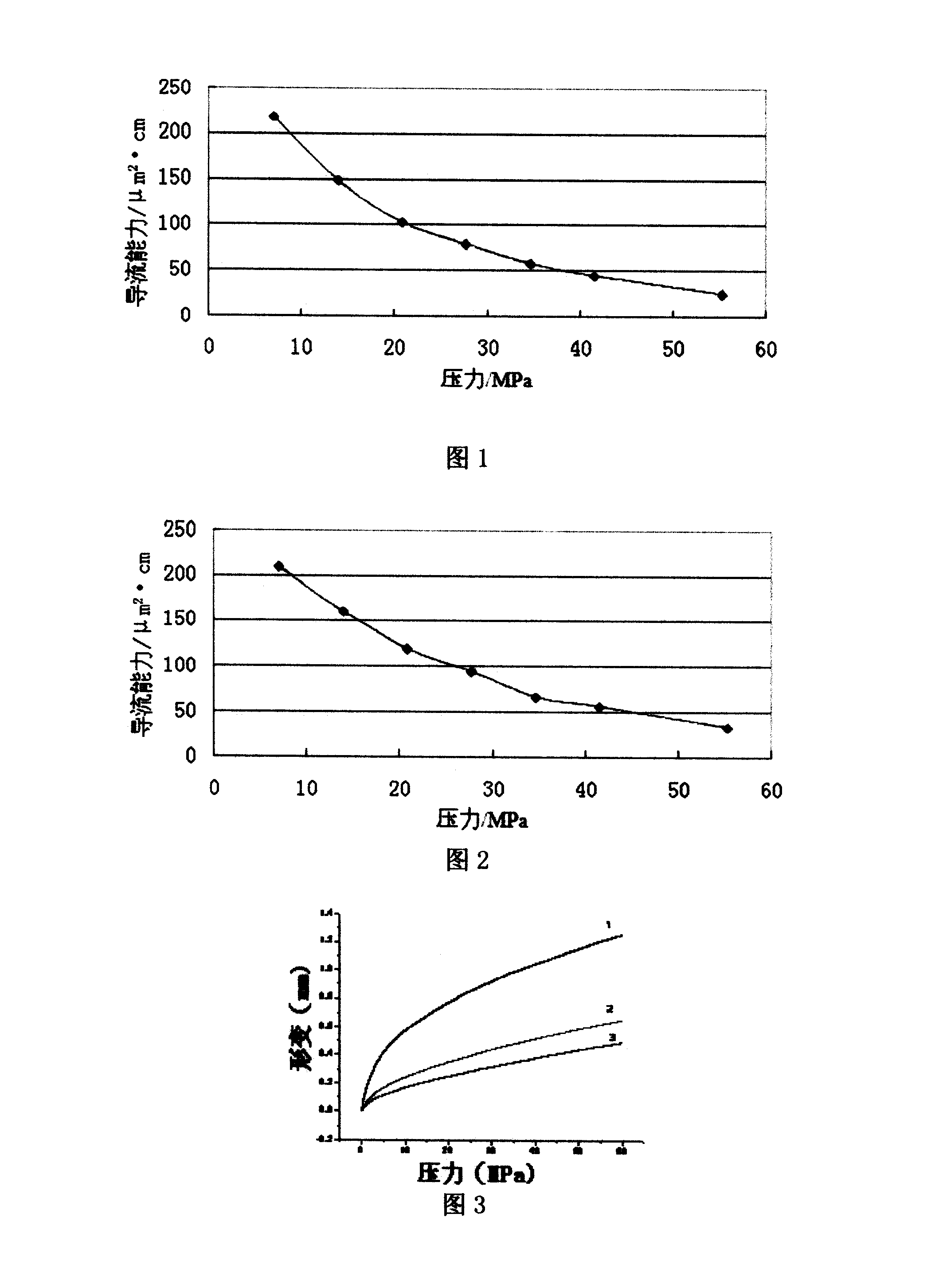

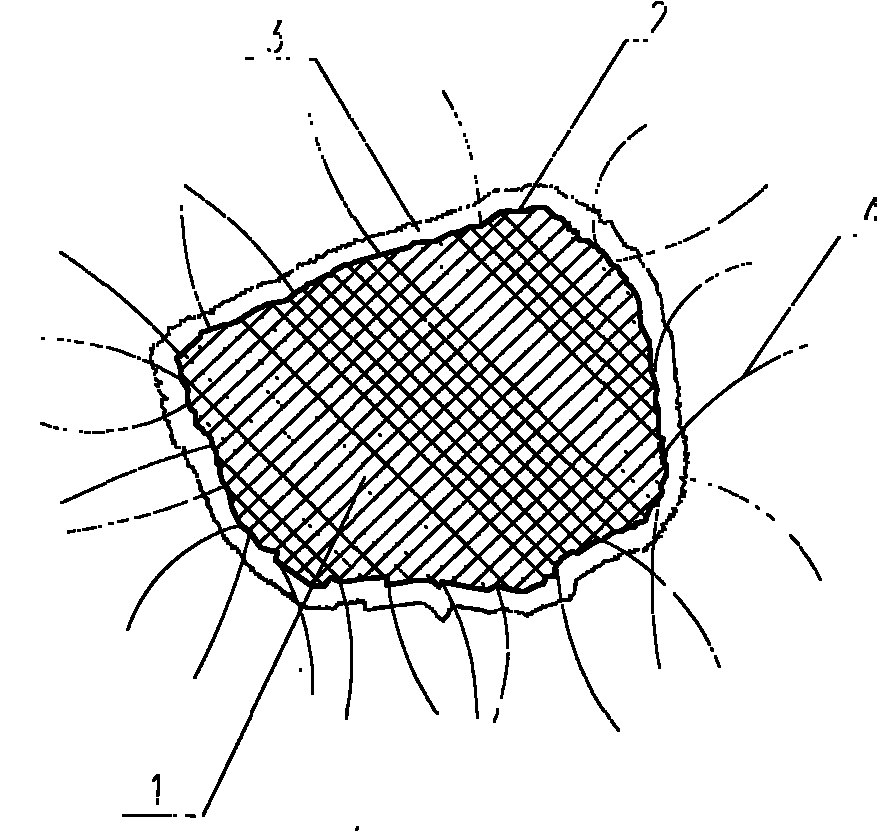

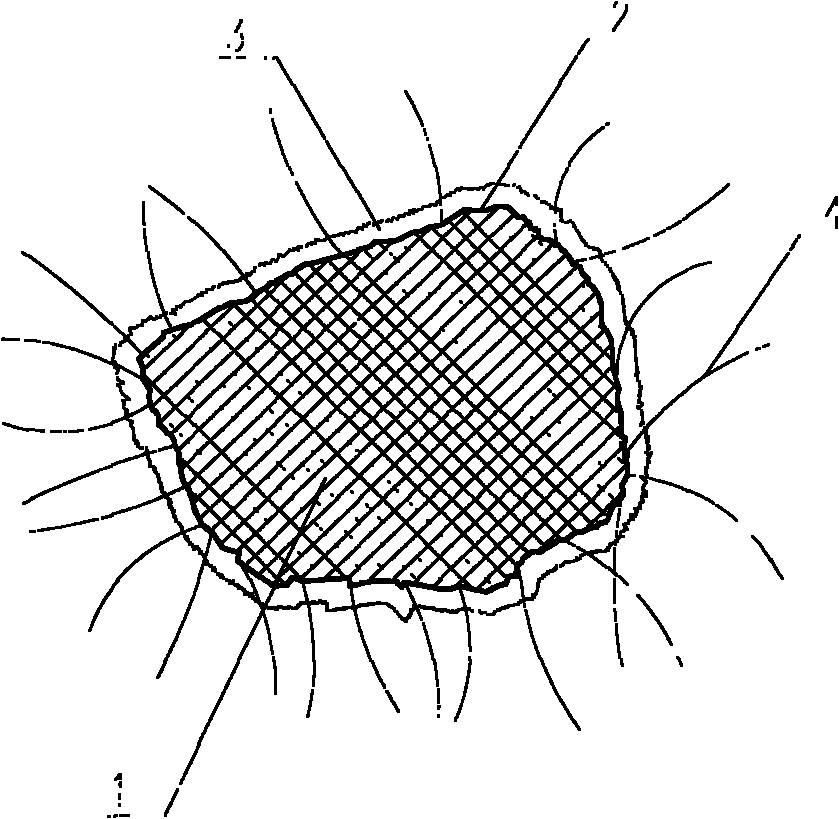

Method and technique for preparing low-density propping agent

InactiveCN101200632AImprove deformation resistanceReduced resistance to deformationFluid removalDrilling compositionPlant fibreHydraulic fracturing

The present invention relates to propping agent which is widely applied to the oil and gas well hydraulic fracturing technology, and the present invention especially relates to a manufacturing method and a preparation technology of low-consistency propping agent and is characterized in that firstly, plant fibre material is used as the raw material and is crushed and grinded as plant fibre granules; secondly, modifying agent solution dips and solidifies the plant fibre granules; thirdly, macromolecular resin is used to covering the granules which are crushed and filtered again to form the propping agent. The propping agent prepared by the technology and method can conquers that the prior propping agent has large energy consumption and high expense of the whole construction, or the propping agent of the present invention does not easily cause the phenomena of propping agent disgorging or crack emptying.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Stone aggregate wrapped by microfine fibre polymer mortar thin layer and preparation method thereof

InactiveCN101863631AHigh compressive strengthStrong resistance to deformationSilica fumeVolcanic ash

The invention discloses a stone aggregate wrapped by a microfine fibre polymer mortar thin layer and a preparation method thereof; the stone aggregate is formed by stone aggregate inner cores, an adhesive inner wrapping layer, a polymer cement mortar outer wrapping layer and an adhesive microfine fibre hair layer, wherein the adhesive inner wrapping layer and the stone aggregate are adhered firmly; microfine fibre filaments are anchored and rooted on the adhesive inner wrapping layer; and the polymer cement mortar outer wrapping layer and the adhesive inner wrapping layer are soluble mutually and can effectively form a whole body. Active powder in the polymer cement mortar outer wrapping layer contains silica fume, zeolite powder, finely-ground mineral slag, pulverized coal ash and the like, and can generate volcanic ash reaction with Ca(OH)2 crystal at the interface position of the set cement so as to generate gelled materials, and further carry out improved treatment on the weakest interfaces of set cement and the stone aggregate in concrete. The modified stone aggregate of the invention has good affinity with the set cement, and has higher binding power with the set cement.

Owner:NANTONG ZHONGRUN CONCRETE +1

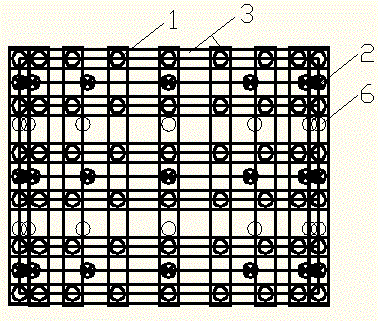

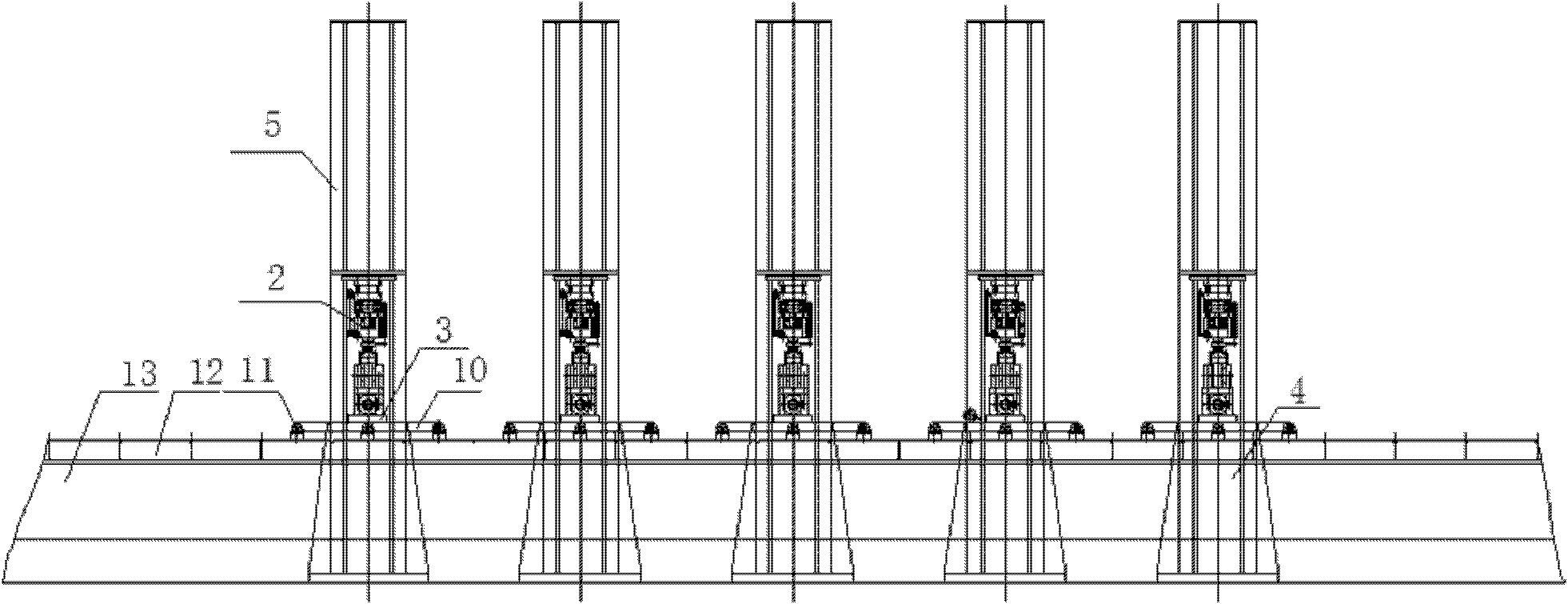

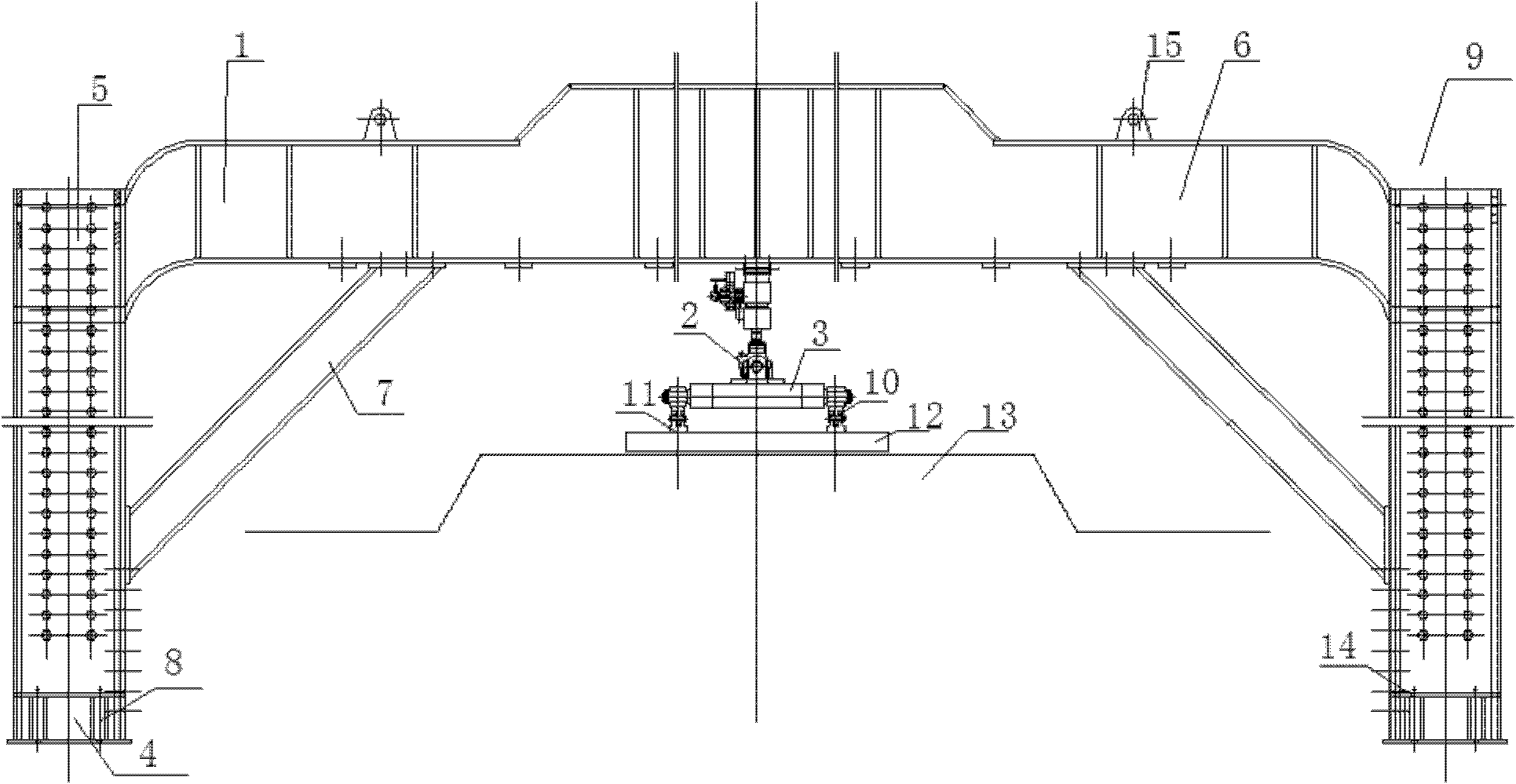

Dynamic load simulation device for high-speed railway

InactiveCN102650574ASolve delivery problemsRealize the implementation of dynamic loadingMaterial strength using tensile/compressive forcesStructural/machines measurementFrame basedActuator

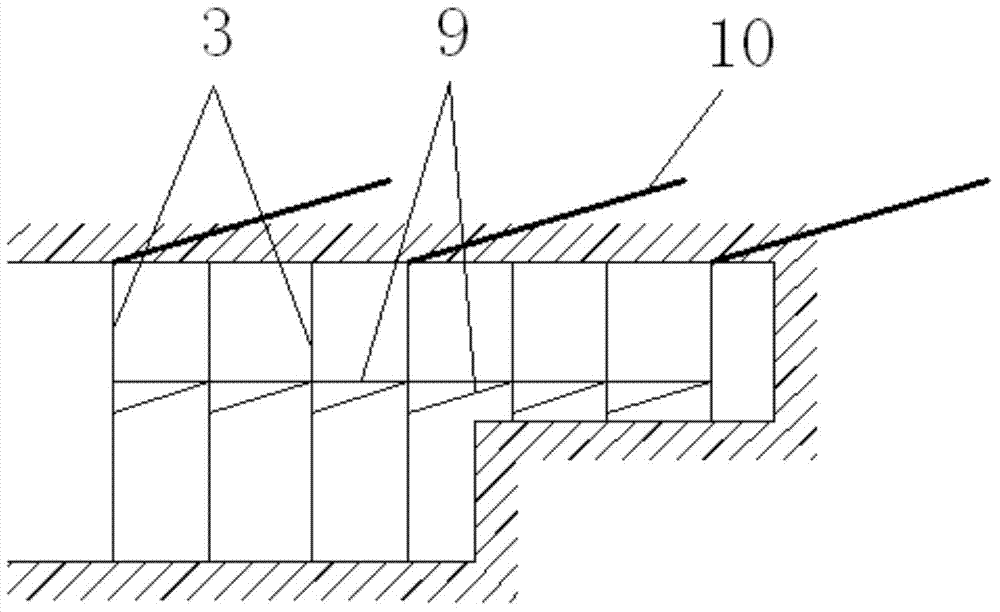

The invention relates to a dynamic load simulation device for a high-speed railway, which comprises a reaction frame (1), an actuator (2) and a rigid distribution beam (3). The reaction frame (1) comprises a reaction frame base (4), a reaction frame column (5), a reaction frame crossbeam (6) and a reaction frame bracing rod (7). The dynamic load simulation device is characterized in that the reaction frame column (5) is connected with the reaction frame base (4) through an anchor bolt (8) of the column, the reaction frame crossbeam (6) is connected with the reaction frame column (5) through a hexagonal bolt (9) of the column, the two ends of the reaction frame bracing rod (7) are respectively butt-welded with the reaction frame crossbeam (6) and the reaction frame column (5) through steel plates, the upper part of the actuator (2) is connected with the reaction frame crossbeam (6) through bolts, the lower part of the actuator (2) is connected with the rigid distribution beam (3) through bolts, the rigid distribution beam (3) is arranged vertically and symmetrically on two rows of short steel rails (10), the short steel rails (10) are buckled on buckle points (11), and the buckle points (11) are buried in a track slab (12) laid on a roadbed (13). The dynamic load simulation device has a reasonable structure and can be operated conveniently, and the dynamic load of trains of different speeds and different axle loads on the track slab can be simulated.

Owner:NAT ENG LAB FOR HIGH SPEED RAILWAY CONSTR

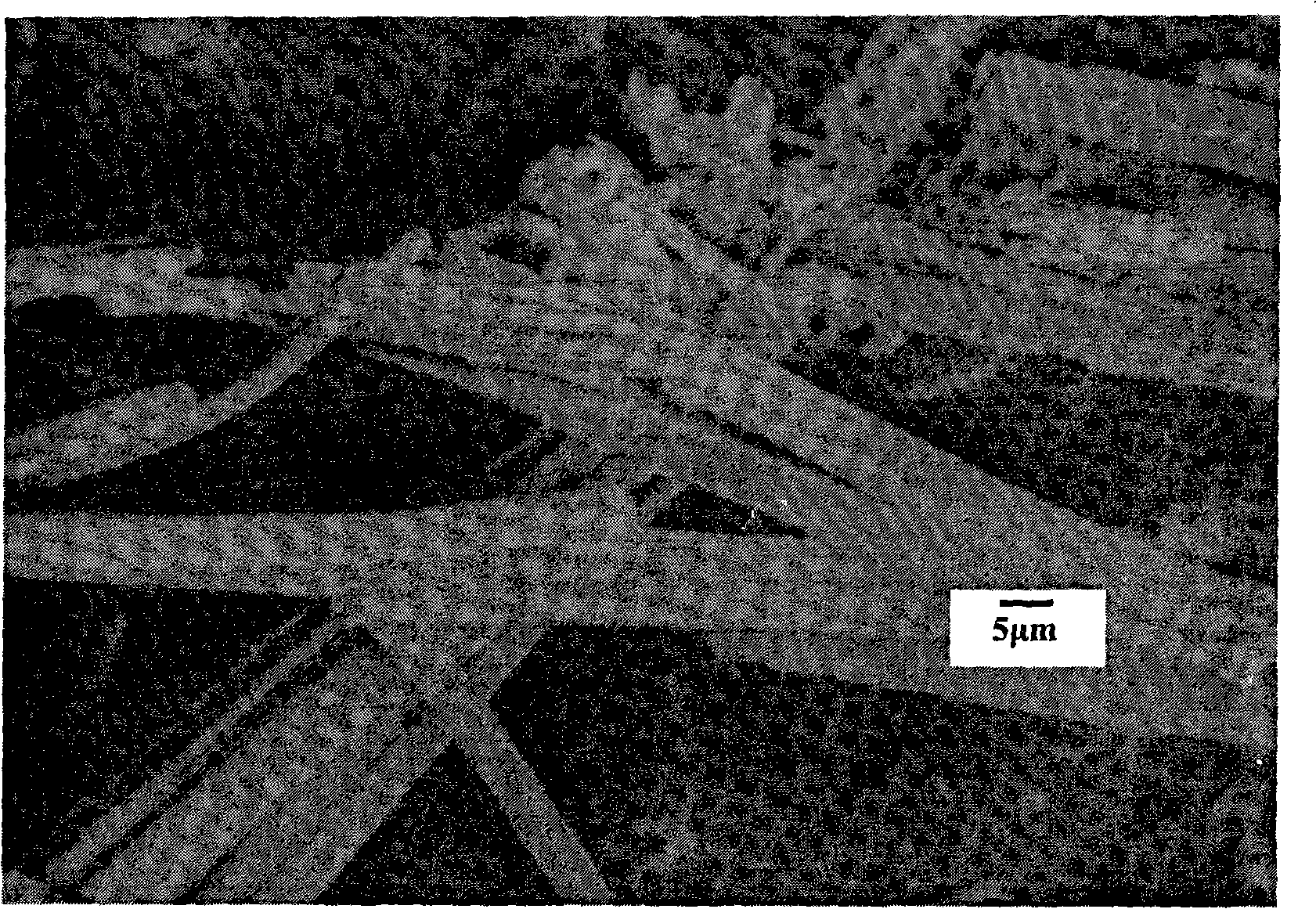

Carbon nano-tube fiber cement-based material and preparation thereof

The invention relates to a cement-based material of carbon nano tube fiber and a preparation method thereof, in particular to a toughened cement-based material and a preparation method thereof. The invention solves the problems of relatively low anti-bending and anti-breaking intensity and toughness of the existing fiber toughened cement-based material. The material is produced by a fiber dispersant, an organic solvent, carbon fibers, carbon nano tubes, deionized water, a superplasticizer, a polymer emulsion, mineral admixture and cement. The preparation method of the invention is as follows: the fiber dispersant is added into mixed slurry of the cement and stirred; the primarily mixed slurry is fed into a high shearing colloid mill for shearing at high speed for 5 to 30min; the evenly stirred slurry is poured into a test mould which is moved to a vacuum drying case for pressure reducing and bubble-removing and heated for evaporation of the solvent for 0.5 to 3 hours; after 24 hours, and the material is obtained after tearing the mould and maintained in water at room temperature. The fracture energy GF and the fracture toughness of the material obtained by using the method of the invention respectively are 106.3N question mark m and 0.998Mpa / m<-1 / 2>, which are respectively 112.6 percent and 33.1 percent higher than the fracture energy and the fracture toughness of the existing fiber toughened cement-based material.

Owner:HARBIN INST OF TECH

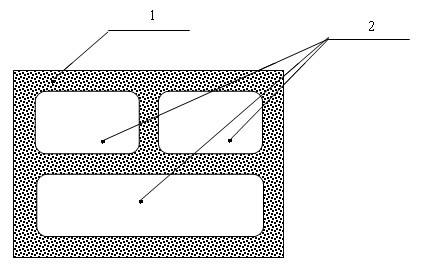

Method for preparing self-thermal-insulation concrete building block

InactiveCN102490247AAdaptableEliminate thermal bridgesCeramic shaping apparatusCeramicwareThermal insulationBuilding material

The invention provides a method for preparing a self-thermal-insulation concrete building block, and belongs to the technical field of preparation of building materials. The main body of the self-thermal-insulation concrete building block is a thermal insulation concrete structural frame; a plurality of sandwich cavities are enclosed on the outer wall and the inner wall of the frame; and organic light materials, inorganic light materials or organic-inorganic composite light materials are packed or filled in the cavities to form a thermal insulation core layer. The self-thermal-insulation concrete building block prepared by the method has high self-thermal-insulation performance, high shock resistance and high tenacity, is a structural material and a thermal insulation material and has remarkable effects of energy conservation, environment friendliness and reduction in building cost after being used.

Owner:徐州东兴能源有限公司

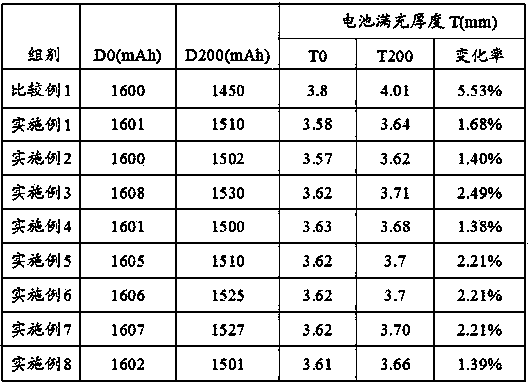

Gel polymer lithium ion battery

ActiveCN103474697AHigh mechanical strengthImprove deformation resistanceSolid electrolytesCell electrodesCross-linkPolymer science

The invention belongs to the technical field of lithium ion batteries, in particular relates to a gel polymer lithium ion battery which comprises a gel polymer electrolyte, a cathode, an anode and a diaphragm between the cathode and the anode, wherein the gel polymer electrolyte comprises a lithium salt, a non-aqueous solvent and a polymer monomer; the polymer monomer contains at least one epoxy monomer containing epoxy groups and double bonds and at least one acrylic ester monomer; an anode adhesive comprises a polymer of which the main chain or side chain contains amino groups or imino groups. Compared with the prior art, by introducing the epoxy compound as a monomer and adopting a polymer containing amino groups or imino groups as an anode adhesive (epoxy groups react with the amino groups or imino groups to form a cross-linked network), the gel polymer electrotype can be tightly connected with the anode, thus improving the mechanical strength and deformability resistance of the battery, greatly reducing interface impedance of the battery and enhancing the cycle performance and the dynamic performance of the battery.

Owner:DONGGUAN AMPEREX TECH

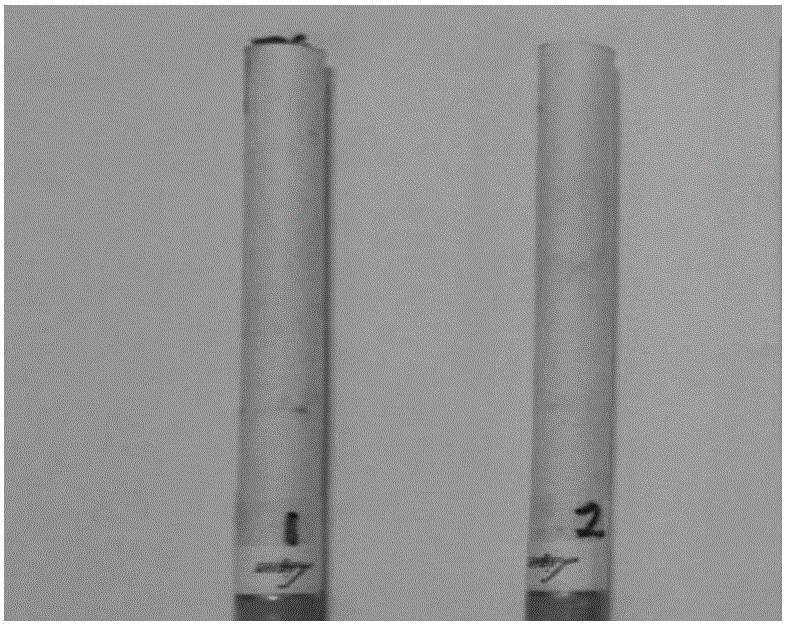

Heating non-combustible cigarette paper and preparation method thereof

ActiveCN106368069ANo tar spotsDoes not start carbonationInorganic fibres/flakesSpecial paperFiberBurn cigarette

The invention discloses heating non-combustible cigarette paper and a preparation method thereof. The preparation method of the heating non-burning cigarette paper comprises the following steps: 1) pulping the plant fiber with the length of 0.5 to 4mm, or adding the appropriate proportion of inorganic fiber; 2) adding the inorganic filler in the process of dilution of the pulp, wherein the addition ratio of the inorganic filler is 5 to 50% of the mass of the pulp; 3) sizing the paper to improve water and oil resistance, and cigarette paper is quantified at 50 to 120 g / m<2>. Compared with the existing heated non-combustible cigarette paper that is heated at 350 DEG C, the non-combustible cigarette paper of the present invention has very few yellow stitches, and no tar spots and carbonization, while the entire surface of the existing non-combustible cigarette paper turns yellow, with large tar penetrating and carbonized. In addition, the non-combustible cigarette paper of the present invention is rarely present broken in actual production, and there is almost no deformation and wrinkling after being sucked as the heated cigarette paper.

Owner:中烟摩迪(江门)纸业有限公司

Waterproof and anti-corrosion repair mortar for polymer cement-based concrete structure

The invention relates to a waterproof and anti-corrosion repair mortar for a polymer cement-based concrete structure, in particular to a cement concrete repair material for a cement concrete structure, which is used for carrying out bonding reinforcement and repair on defects of municipal roads, municipal services, bridges and water conservancy projects (dams and gates). The waterproof and anti-corrosion repair mortar is prepared by mixed materials and water, and the mixed materials comprise the following components in parts by weight: 20-30 parts of portland cement, 0.01-0.05 part of high-performance water-reducing agent, 1-5 parts of high-aluminum cement, 15-30 parts of quartz sand, 25-60 parts of gravel and 1-3 parts of acrylic adhesive powder, 1-3 parts of fiber material, while the using amount of water accounts for 5-14% of the total parts of the mixed materials. Due to the adoption of the technical scheme, the waterproof and anti-corrosion repair mortar has the characteristics of good pressure resistance, high flexural strength, high bonding strength, good durability, convenient and fast construction, fast setting and early strength shrinkage control, and can greatly shorten the repair time and quickly resume the traffic in particular to roads.

Owner:卢建华

780MPa-level ultrahigh-strength Fe-Mn-Al-C lightweight cast steel and preparation method thereof

The invention provides 780MPa-level ultrahigh-strength Fe-Mn-Al-C lightweight cast steel and a preparation method thereof. The low-density cast steel comprises, by mass, 0.80-1.30% of C, 15.00-20.00%of Mn, 3.50-8.00% of Al, 0.05-0.25% of Si, 0.5-1.5% of Cr, 0.01-0.06% of Cu, 0.30-0.80% of Mo, 0.05-0.20% of V, 0.01-0.10% of Nb, 0.005-0.025% of Ce, less than or equal to 0.01% of P, less than or equal to 0.01% of S, less than or equal to 0.01% of N, and the balance Fe and unavoidable impurities. Meanwhile, the weight percentage ratio of Mn to Al is no less than 2.5% and no more than 3.0%, and the sum of the weight percentages of Nb and V is no less than 0.10% and no more than 0.20%. The preparation process is simple and free of rolling, and the method can be used for manufacturing automobilestructure castings with complex shapes.

Owner:HEBEI UNIV OF TECH

Composite porous isolating film and electrochemical device

ActiveCN103904276AImprove puncture strengthImprove thermal stabilitySecondary cellsCell component detailsPorous substratePorous coating

The invention provides a composite porous isolating film and an electrochemical device. The composite porous isolating film comprises a composite porous base material and a composite porous coating which is coated on at least one surface of the composite porous base material. The composite porous base material comprises filler A and a polymer substrate, and the filler A is selected from at least one of inorganic particles and organic particles; the composite porous coating comprises filler B and an adhesive, and the filler B is selected from at least one of inorganic particles and organic particles. The electrochemical device has a composite porous isolating film. By adopting the composite porous isolating film, the heat stability of the composite porous isolating film is improved, the deformation resistance and the capacity maintaining rate of the electrochemical device can be improved, and the cycling performance and low-temperature kinetic performance of the electrochemical device can be improved.

Owner:DONGGUAN AMPEREX TECH

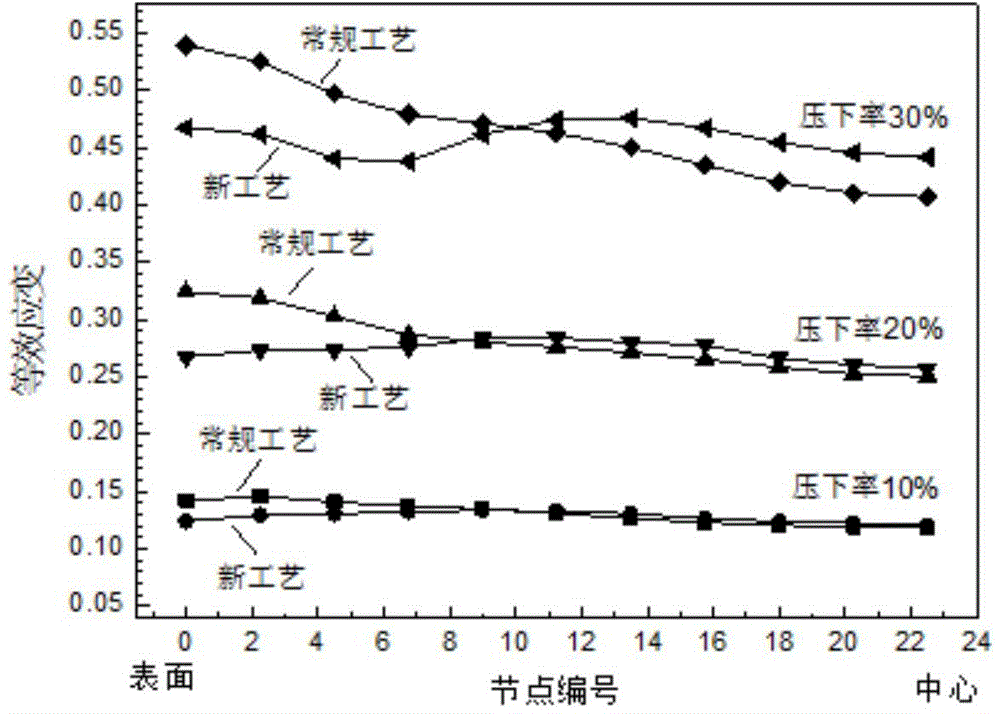

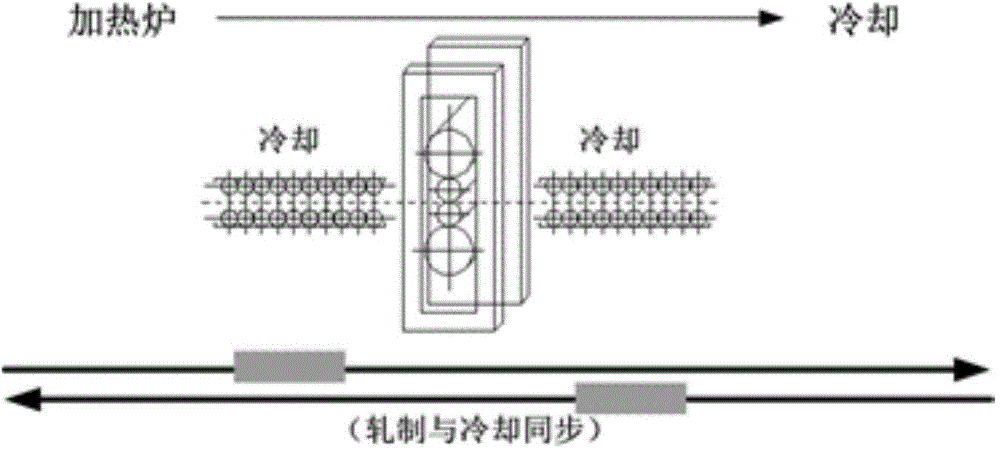

Method for improving deformation and permeability in high-thickness standard steel plate hot rolling process

ActiveCN104525588AEvenly distributedIncreased deformation resistanceWork treatment devicesMetal rolling arrangementsCryogenic hardeningSteel ball

A method for improving deformation and permeability in the high-thickness standard steel plate hot rolling process is characterized in that a uniform fast cooling device is arranged at a position close to the opening of a heavy and medium plate mill or hot strip roughing mill with the length being 5 to 15 meters and the cooling total water being 3,000 to 6,000 cubic meters per hour respectively; before rolling, the cooling device conducts asymmetrical uniform fast cooling to the upper and lower surfaces of a plate blank, a low-temperature hardened layer is formed on the surface of the plate blank, the temperature gradient of a core reaches 2 to 3 DEG C per millimeter, before the cooling returns red, the cooling device can quickly enter the mill to conduct differential temperature rolling, and plate blank core deformation is improved; the cooling device is further combined with asymmetrical rolling, while deepening the plate blank core deformation, the cooling device solves the warping problem caused by the asymmetrical rolling through the asymmetrical cooling of the upper and lower surfaces of the plate blank before rolling. For a steel ball needing two-stage control, the uniform fast cooling device can replace a middle cooling device, shortens or even eliminates the temperature waiting time of swinging steel, and improves the production efficiency.

Owner:NORTHEASTERN UNIV

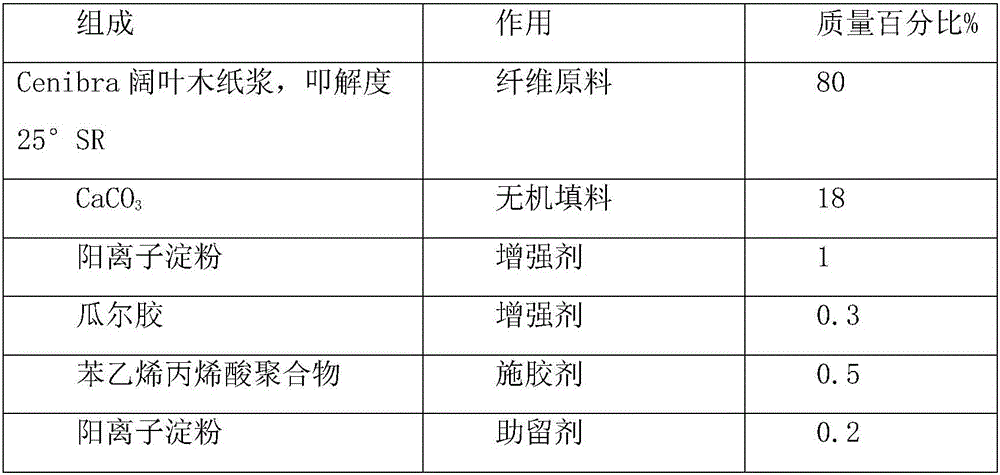

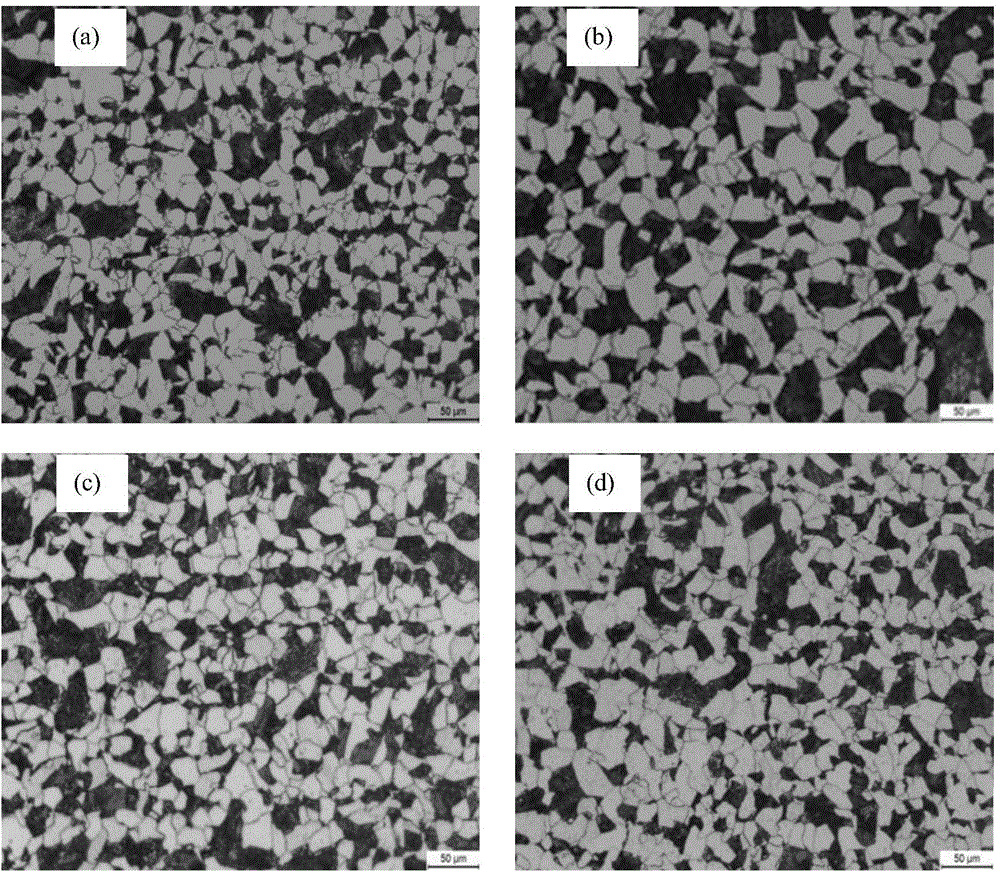

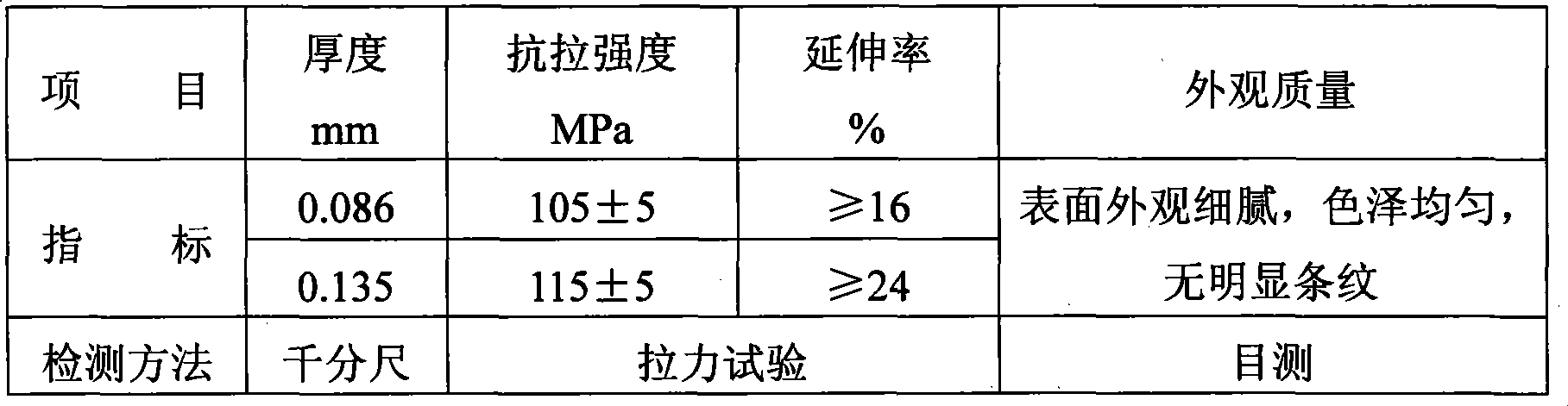

Aluminium alloy foil material for container and method for producing the same

ActiveCN101397622AReduce the influence of plasticityHigh elongationRoll mill control devicesMetal rolling arrangementsManganeseTitanium

The invention discloses an aluminum alloy foil used for containers, which is characterized in that: the components and the weight ratios are: 0.42 to 0.52 percent of iron, 0.05 to 0.20 percent of silicon, 0.04 to 0.13 percent of copper, 1.10 to 1.30 percent of manganese, 0.020-0.040 percent of titanium and the residual quantity of aluminum. The manufacturing method of the aluminum alloy foil used for containers comprises slab casting and rolling, pre-annealing, plank cold rolling, intermediate annealing, cold rolling, finished product annealing, greasing and cutting. Compared with the prior art, the aluminum alloy foil has the remarkable advantages: higher tensile strength and elongation; good deep-drawing performance, formability and stiff and smooth degree, beautiful appearance, uniform color and luster without defect, thus meeting the requirement of the users.

Owner:JIANGSU ALCHA ALUMINUM CO LTD

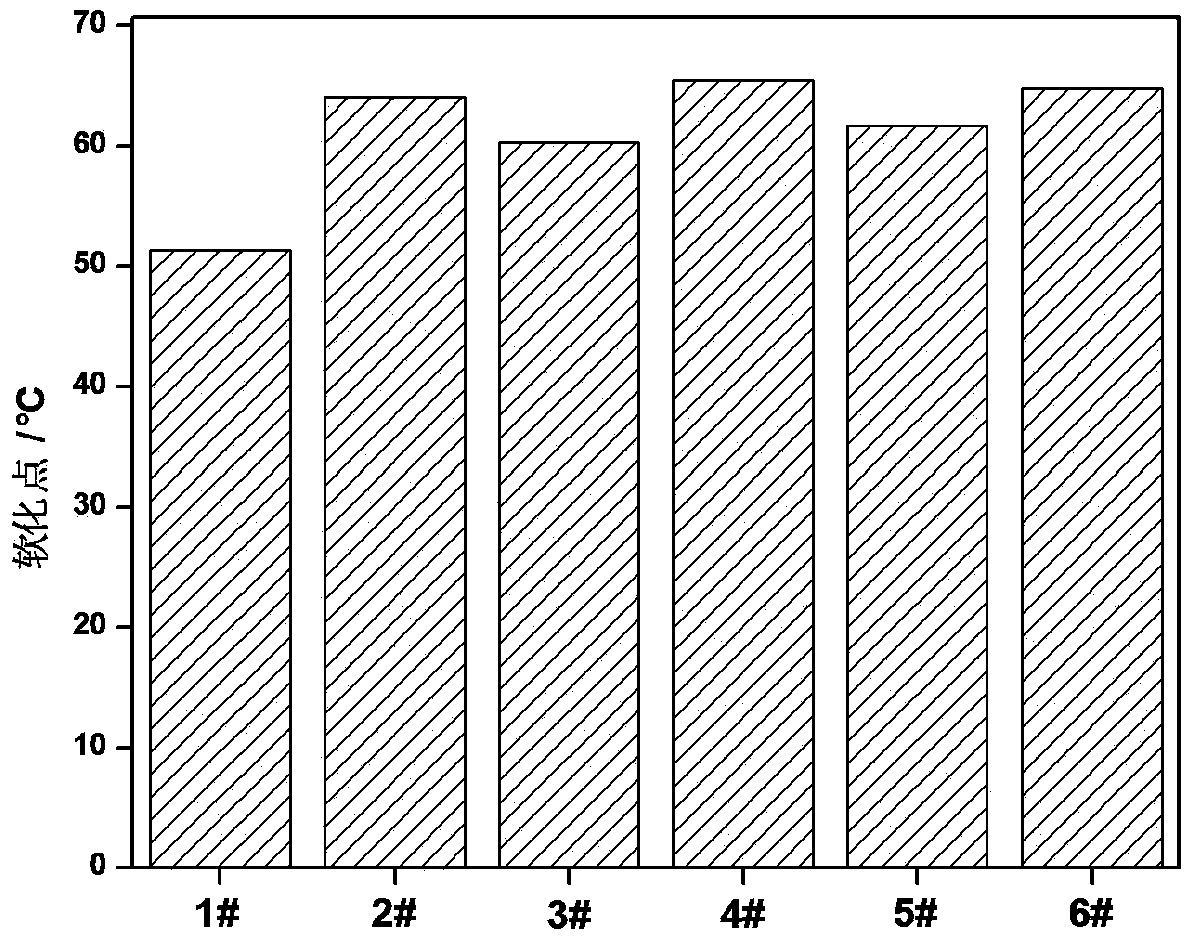

Polyurethane/nano-composite modified asphalt and preparation method thereof

ActiveCN103834185AImprove high temperature performanceImprove deformation resistanceBuilding insulationsRoad surfaceTwo step

The invention provides polyurethane / nano-composite modified asphalt. The polyurethane / nano-composite modified asphalt comprises the following components in percentage by mass: 2%-15% of polyurethane, 0.1%-5% of graphene oxide and 80%-97.9% of matrix asphalt, wherein the sum of the mass percentage of the components is 100%. A preparation method of the polyurethane / nano-composite modified asphalt comprises the following steps: heating and melting the matrix asphalt, maintaining temperature at 150-200 DEG C, adding the polyurethane and the graphene oxide, manually mixing for 20-40 minutes, then stirring for 80-100 minutes by using a shearing machine, cooling to 100-150 DEG C, standing for 20-50 minutes, and shearing an asphalt mixture by using the shearing machine again for 80-100 minutes till the polyurethane and the graphene oxide are uniformly dispersed in the asphalt, thus obtaining the polyurethane / nano-composite modified asphalt. The preparation method has the advantages that the polyurethane and the graphene oxide are used as modifying agents, a two-step method modification technology is adopted so as to give full play to good performances of the polymer and nanometer materials, and the high-temperature performance and anti-modification capacity of the matrix asphalt and the anti-rutting capacity of asphalt pavements are obviously improved.

Owner:XIAN UNIV OF TECH

Flap valve structure of pressure-maintaining coring device

PendingCN110847856AImprove deformation resistanceGood pressure holding effectWell/borehole valve arrangementsSealing/packingEngineeringFlap valve

The invention relates to a flap valve structure of a pressure-maintaining coring device. The flap valve structure comprises a valve seat and a valve flap, one end of the valve flap is movably connected with the upper end of the valve seat, the top of the valve seat is provided with a valve port sealing surface matched with the valve flap, the valve port sealing surface is a conical surface, the valve flap is provided with a valve flap sealing surface matched with the valve port sealing surface, and the taper of the valve flap sealing surface is the same as the taper of the valve port sealing surface; the valve port sealing surface is provided with a bearing surface for supporting the valve flap; and when the valve flap is closed, the bottom of the valve flap abuts against the bearing surface of the valve seat. According to the flap valve structure of the pressure-maintaining coring device, when the valve flap is closed, displacement constraint is applied to the bottom surface and the side surface of the valve flap, the anti-deformation capability of the sealing surface can be effectively improved, the valve can bear higher pressure, and the pressure maintaining capability of the valve is improved; and the valve seat has magnetism, and the valve flap can be attracted to be closed.

Owner:SICHUAN UNIV

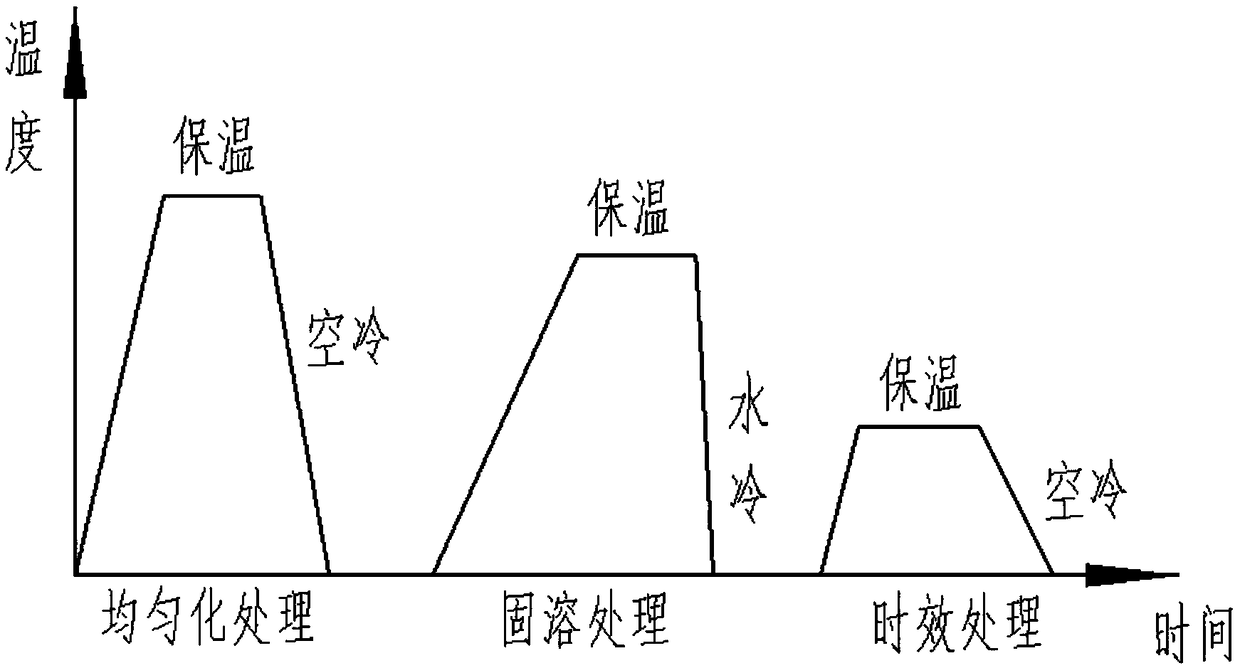

Aluminum alloy and casting method thereof, and method for extruding profile

The invention belongs to the technical field of aluminum alloys, and particularly relates to an aluminum alloy, a method for casting a cast ingot from the aluminum alloy, and a method for extruding a profile from the cast ingot. The invention aims to provide an aluminum alloy which has high strength and favorable processability. The high-strength aluminum alloy provided by the invention comprises the following components in percentage by weight: 0.5-1.5% of Mg, 0.25-1.2% of Si, 0.6-1.2% of Cu, 0.1-0.8% of Mn, 0.01-0.2% of Cr, 0.01-0.15% of Ti and the balance of Al. The yield strength of the hollow profile of the alloy in the T6 state (after completing aging treatment) is up to 350 MPa, the tensile strength is up to 400 MPa, and the plasticity is higher than 10%; and the hollow profile has favorable welding performance and fatigue resistance.

Owner:SNTO TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com