Polyurethane/nano-composite modified asphalt and preparation method thereof

A nano-composite and modified asphalt technology, applied in building components, building thermal insulation materials, buildings, etc., can solve the problems of not obvious improvement effect and limited improvement range of asphalt performance in an all-round way, so as to improve the anti-rutting ability and improve the high temperature performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the above-mentioned polyurethane / nano composite modified asphalt is specifically implemented according to the following steps:

[0023] Step 1, respectively weighing 2% to 15% of polyurethane, 0.1% to 5% of graphene oxide and 80% to 97.9% of matrix pitch according to mass percentage, and the sum of the mass percentages of the above components is 100%;

[0024] Step 2, heat the base asphalt to melt, keep the temperature at 150-200°C, add polyurethane and graphene oxide, manually stir for 20-40 minutes, then stir with shears for 80-100 minutes, cool down to 100-150°C, and place for 20-20 minutes 50min to make it fully swell;

[0025] In step 3, the asphalt mixture obtained in step 2 is sheared again on a shearing machine for 80 to 100 minutes, until the polyurethane and graphene oxide are uniformly dispersed in the asphalt, and the polyurethane / nano composite modified asphalt is obtained.

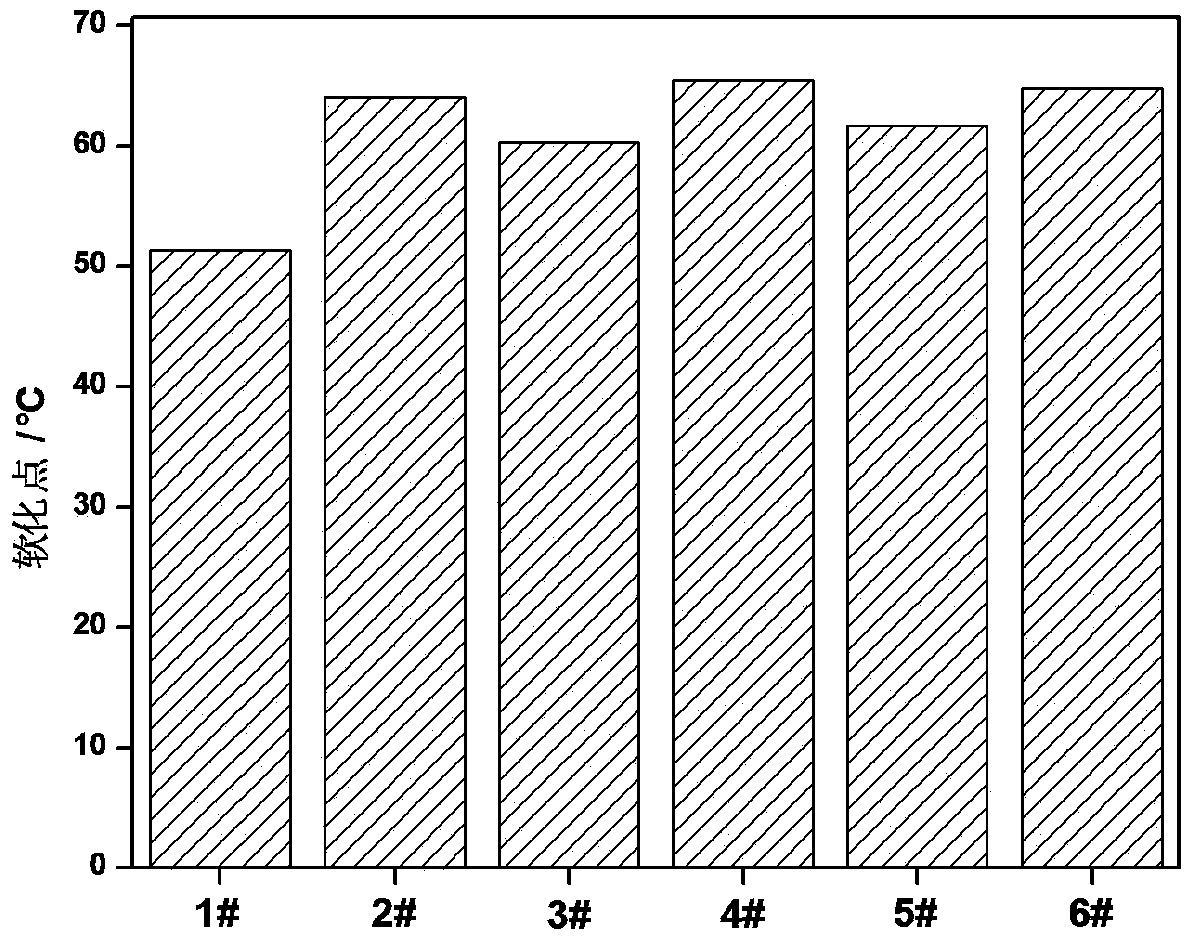

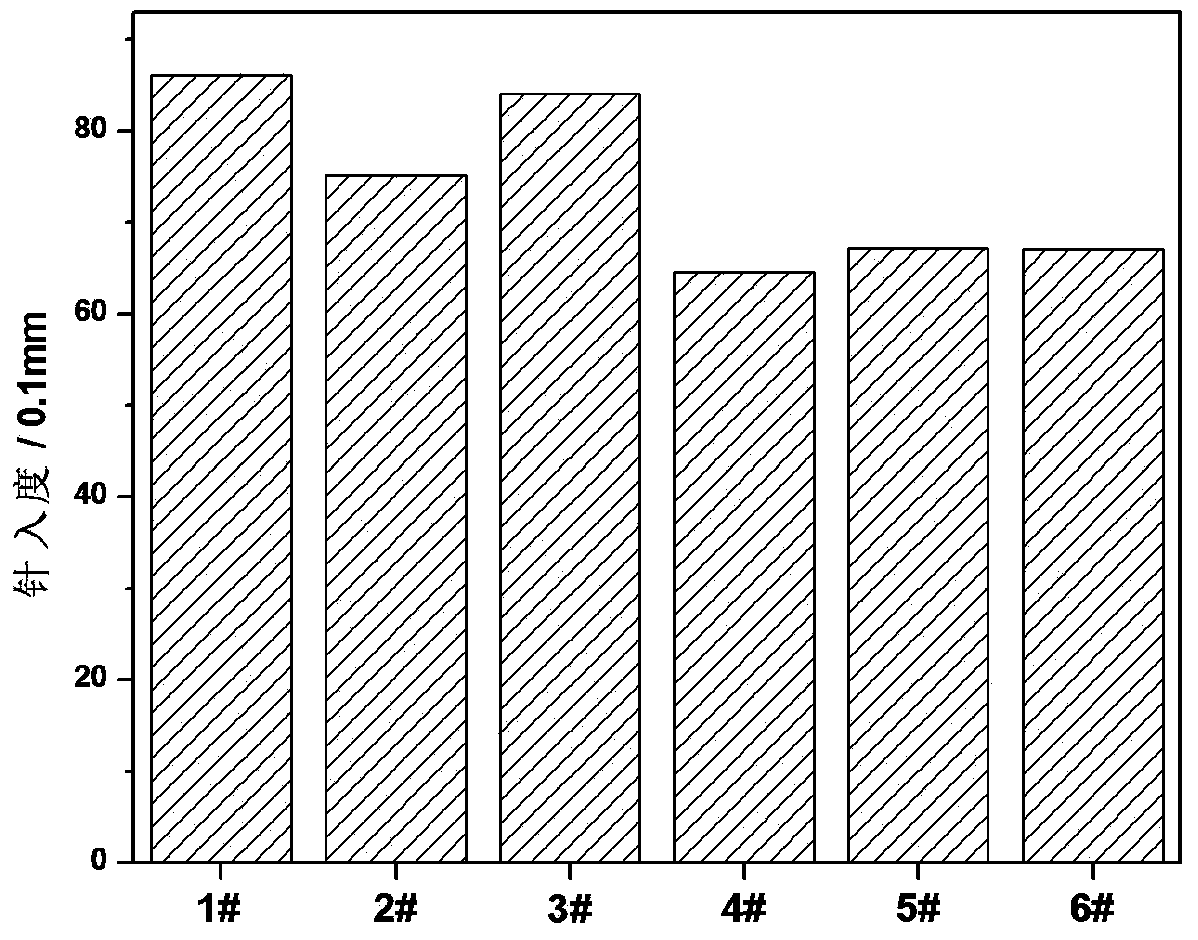

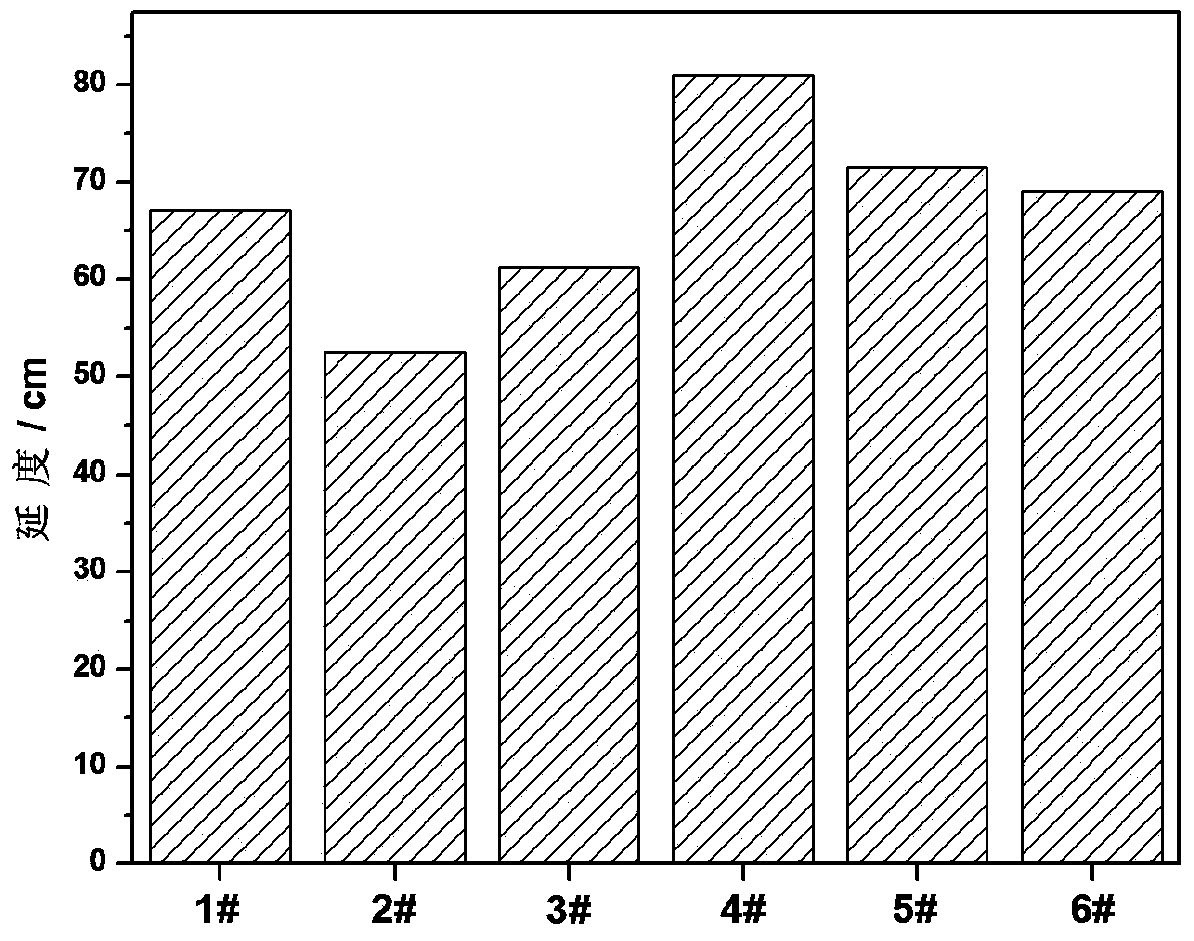

Embodiment 1

[0038] Take 80% of the base asphalt by mass and heat it to melt, keep the temperature at 180°C, add 15% of polyurethane and 5% of graphene oxide according to the mass percentage, manually stir for 20 minutes, stir with shears for 100 minutes, cool down to 100°C, and place for 20 minutes , to make it fully swell; shear the mixture again on a shearing machine for 100 minutes until the polyurethane and graphene oxide are uniformly dispersed in the asphalt.

[0039] The softening point of the polyurethane / nanocomposite modified asphalt obtained in Example 1 was measured to be 67.3° C., the penetration was 69.3 (0.1 mm), and the ductility was 69 cm.

Embodiment 2

[0041]Take 97.9% of the base asphalt by mass and heat it to melt, keep the temperature at 150°C, add 2% polyurethane and 0.1% graphene oxide according to the mass percentage, stir manually for 40 minutes, stir with shears for 80 minutes, cool down to 150°C, and place for 50 minutes , to make it fully swell; shear the mixture again on a shearing machine for 80 minutes until the polyurethane and graphene oxide are uniformly dispersed in the asphalt.

[0042] The softening point of the polyurethane / nanocomposite modified asphalt obtained in Example 2 was measured to be 63.2° C., the penetration was 68.7 (0.1 mm), and the ductility was 73 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com