Patents

Literature

13736results about "Additives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

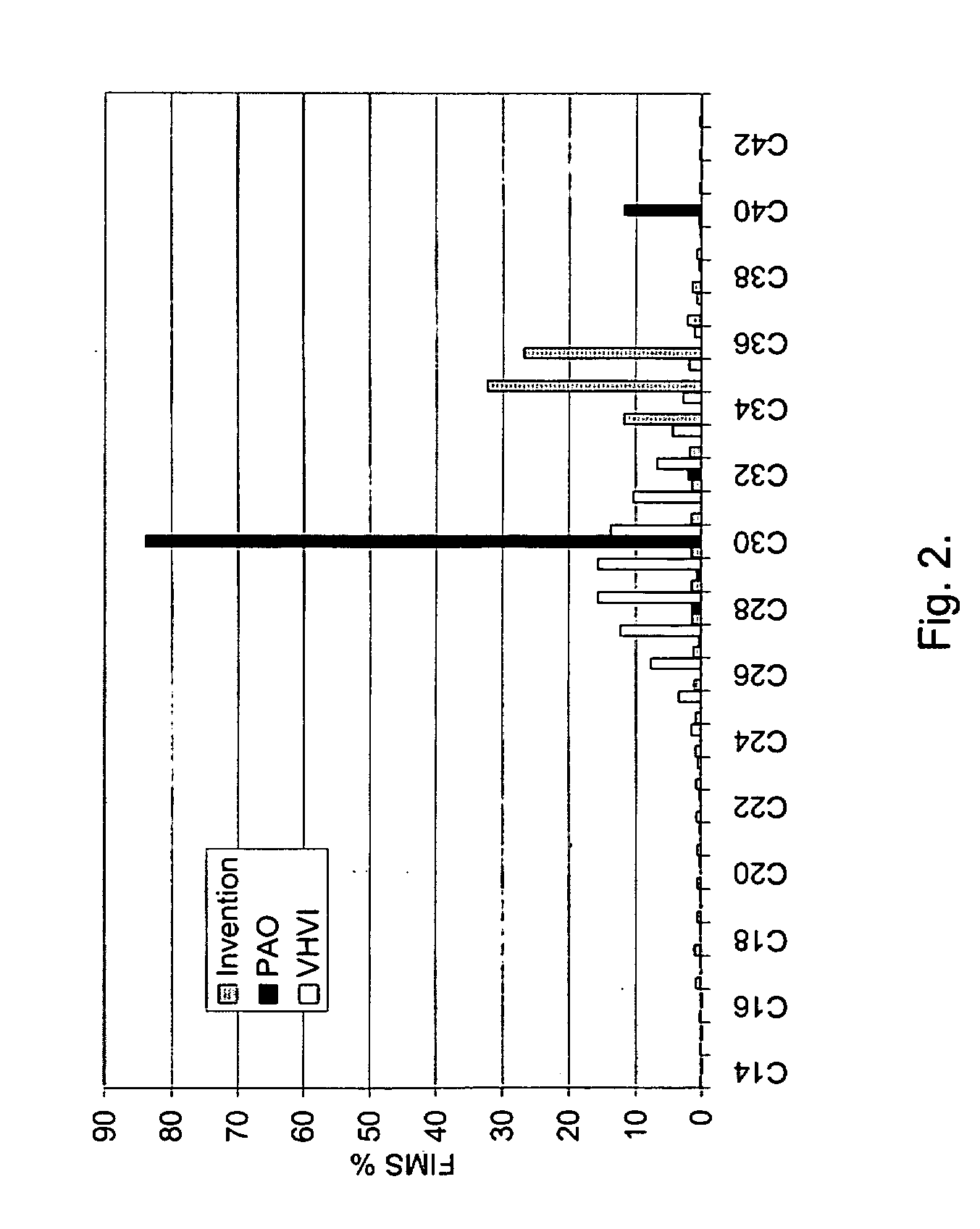

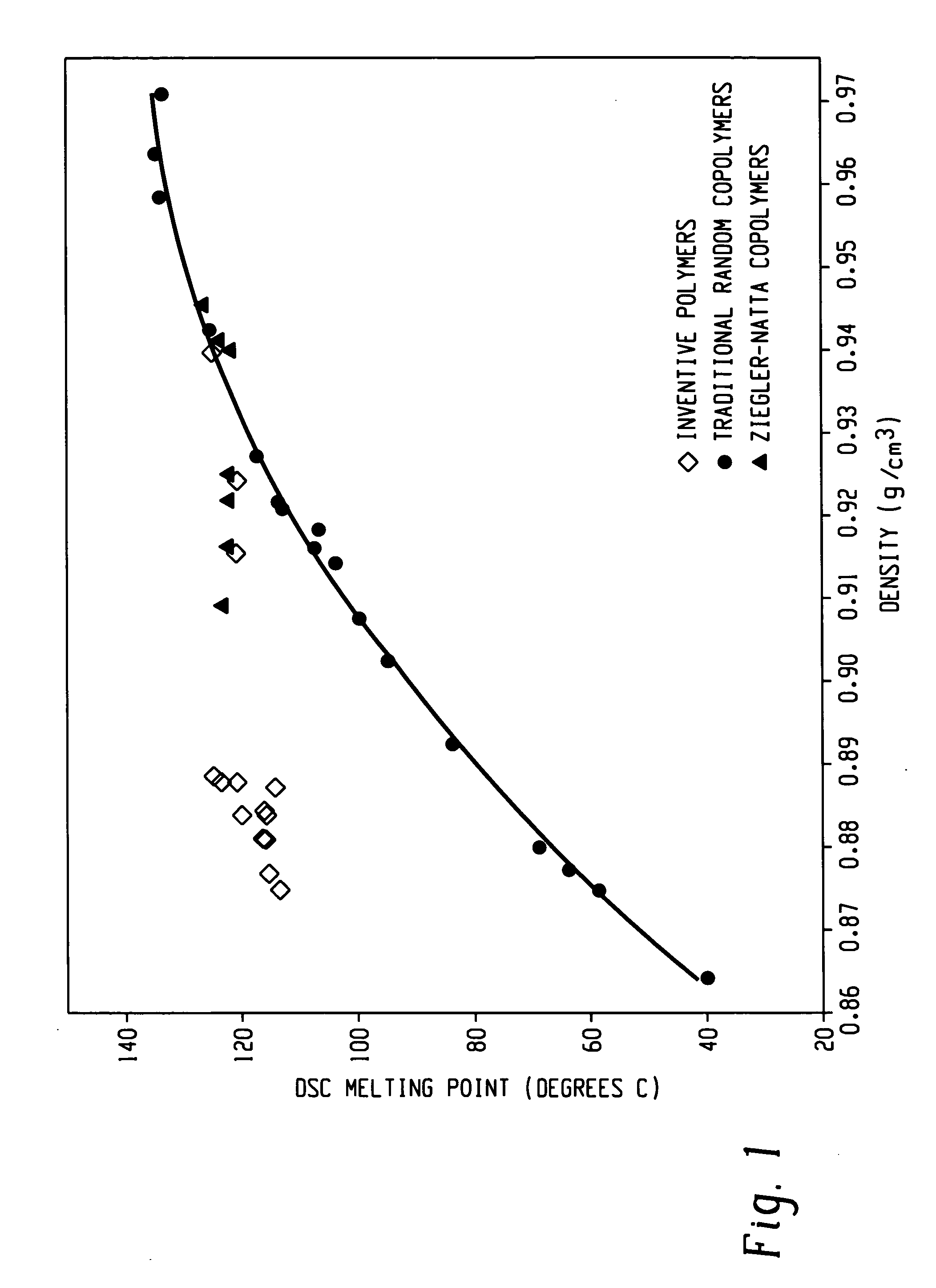

Premium synthetic lubricant base stock having at least 95% non-cyclic isoparaffins

InactiveUS6080301ARefining to change hydrocarbon structural skeletonHydrocarbon purification/separationParaffin waxAlkane

A premium synthetic lubricating oil base stock having a high VI and low pour point is made by hydroisomerizing a Fischer-Tropsch synthesized waxy, paraffinic feed wax and then dewaxing the hydroisomerate to form a 650-750 DEG F.+ dewaxate. The waxy feed has an initial boiling point in the range of about 650-750 DEG F., from which it continuously boils up to at least 1050 DEG F. and has a T90-T10 temperature difference of at least 350 DEG F. The feed is preferably hydroisomerized without any pretreatment, other than optional fractionation. The 650-750 DEG F.+ dewaxate is fractionated into two or more base stocks of different viscosity.

Owner:EXXON RES & ENG CO

Premium wear resistant lubricant

A premium synthetic lubricant having antiwear properties comprises a synthetic isoparaffinic hydrocarbon base stock and an effective amount of at least one antiwear additive. The antiwear additive is preferably at least one of a metal phosphate, a metal dialkyldithiophosphate, a metal dithiophosphate a metal thiocarbamate, a metal dithiocarbamate, an ethoxylated amine dialkyldithiophosphate and an ethoxylated amine dithiobenzoate. Metal dialkyldithiophosphates are preferred, particularly zincdialkyldithiophosphate (ZDDP). The base stock is derived from a waxy, Fischer-Tropsch synthesized hydrocarbon feed fraction comprising hydrocarbons having an initial boiling point in the range of about 650-750 DEG F., by a process which comprises hydroisomerizing the feed and dewaxing the isomerate. The lubricant may also contain hydrocarbonaceous and synthetic base stock material in admxture with the Fischer-Tropsch derived base stock.

Owner:EXXON RES & ENG CO

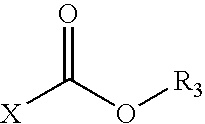

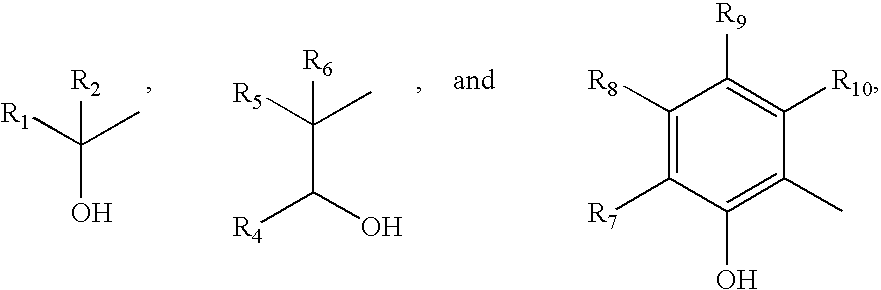

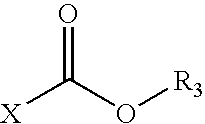

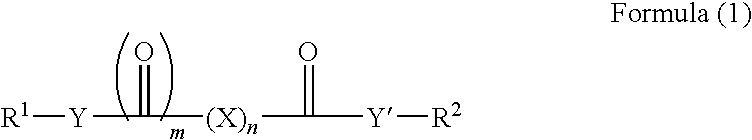

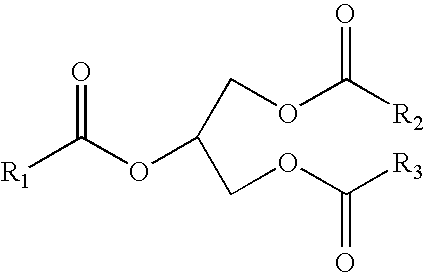

Lubricant and fuel compositions containing hydroxy carboxylic acid and hydroxy polycarboxylic acid esters

InactiveUS20050198894A1Reduce the amount requiredWithout diminishing anti-wear performanceOrganic chemistryLiquid carbonaceous fuelsCarboxylic acidMedicinal chemistry

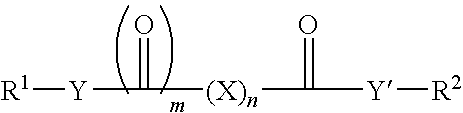

Disclosed herein is a composition comprising: (A) a lubricant or a hydrocarbon fuel; (B) at least one hydroxy carboxylic acid ester or hydroxy polycarboxylic acid ester having the generic formula defined herein; and (C) at least one phosphorus-containing additive.

Owner:CHEMTURA CORP

Lubricating Composition Containing Ashfree Antiwear Agent Based on Hydroxypolycarboxylic Acid Derivative and a Molybdenum Compound

InactiveUS20100197536A1Reducing and preventing emissionImprove fuel economyAdditivesMolybdenum sulfidesAntioxidantAcid derivative

The invention provides a lubricating composition containing an oil of lubricating viscosity, an oil soluble molybdenum compound, and an ashless antiwear agent. The invention further provides for a new antioxidant. The lubricating composition is suitable for lubricating an internal combustion engine.

Owner:THE LUBRIZOL CORP

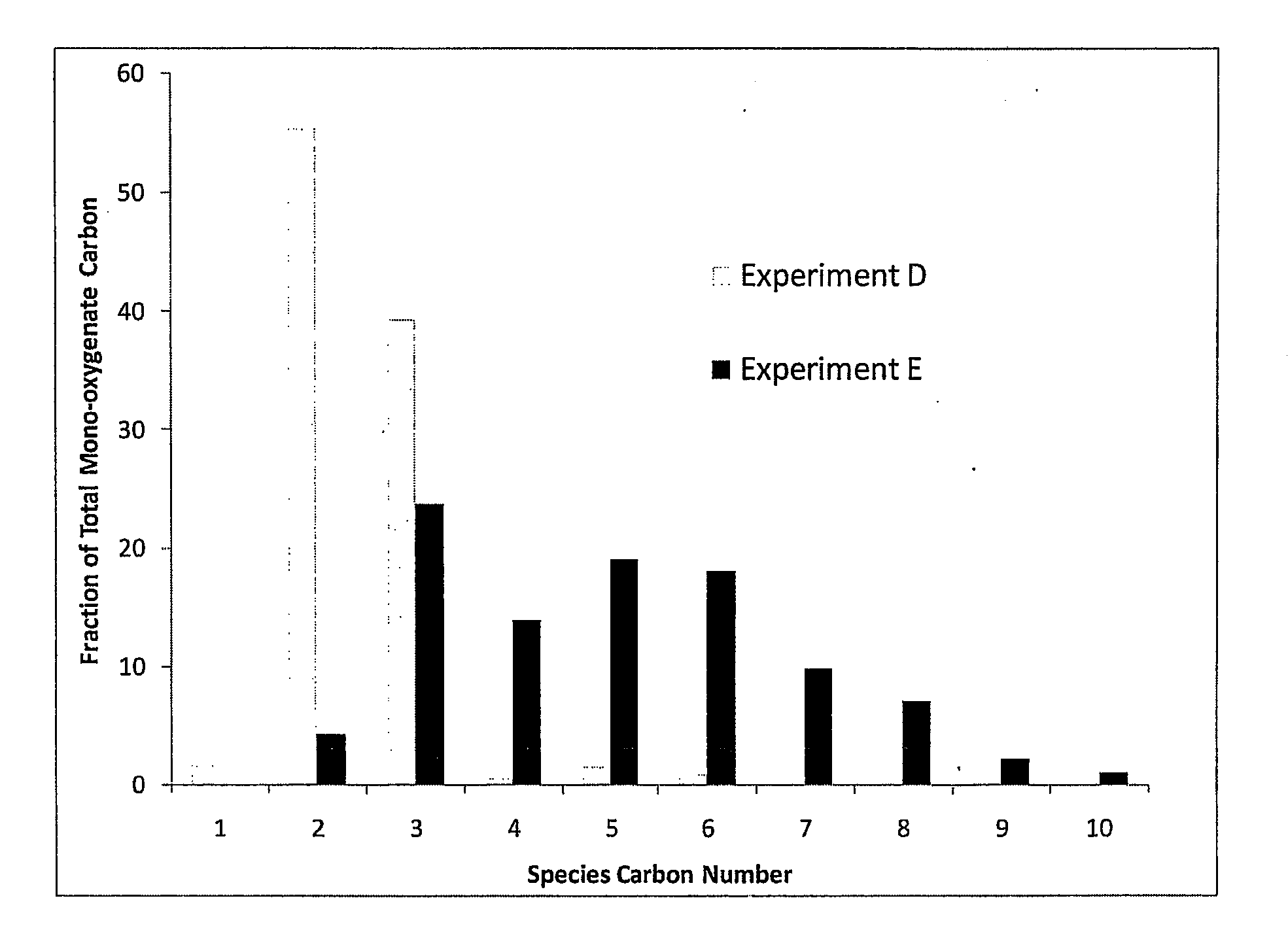

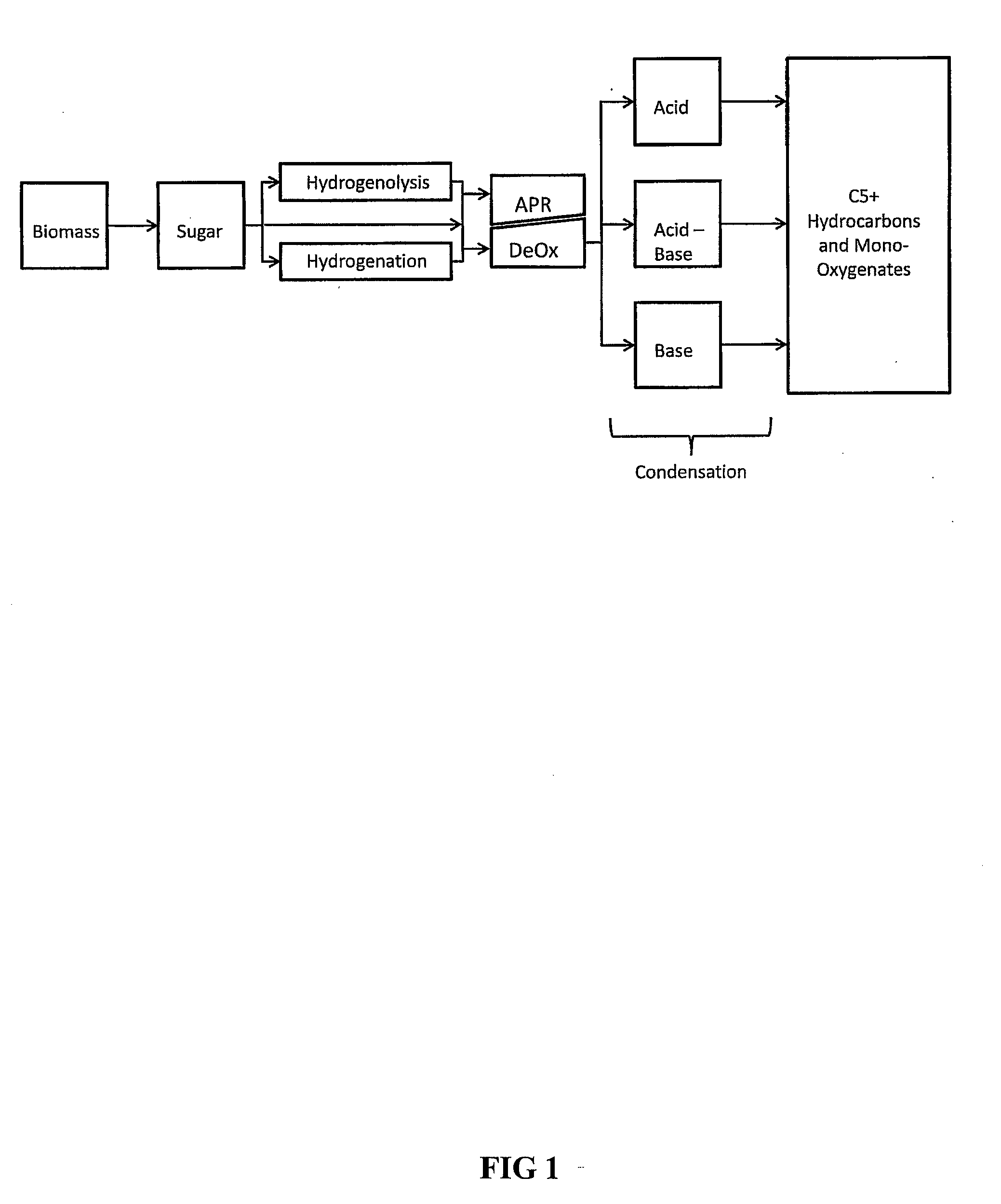

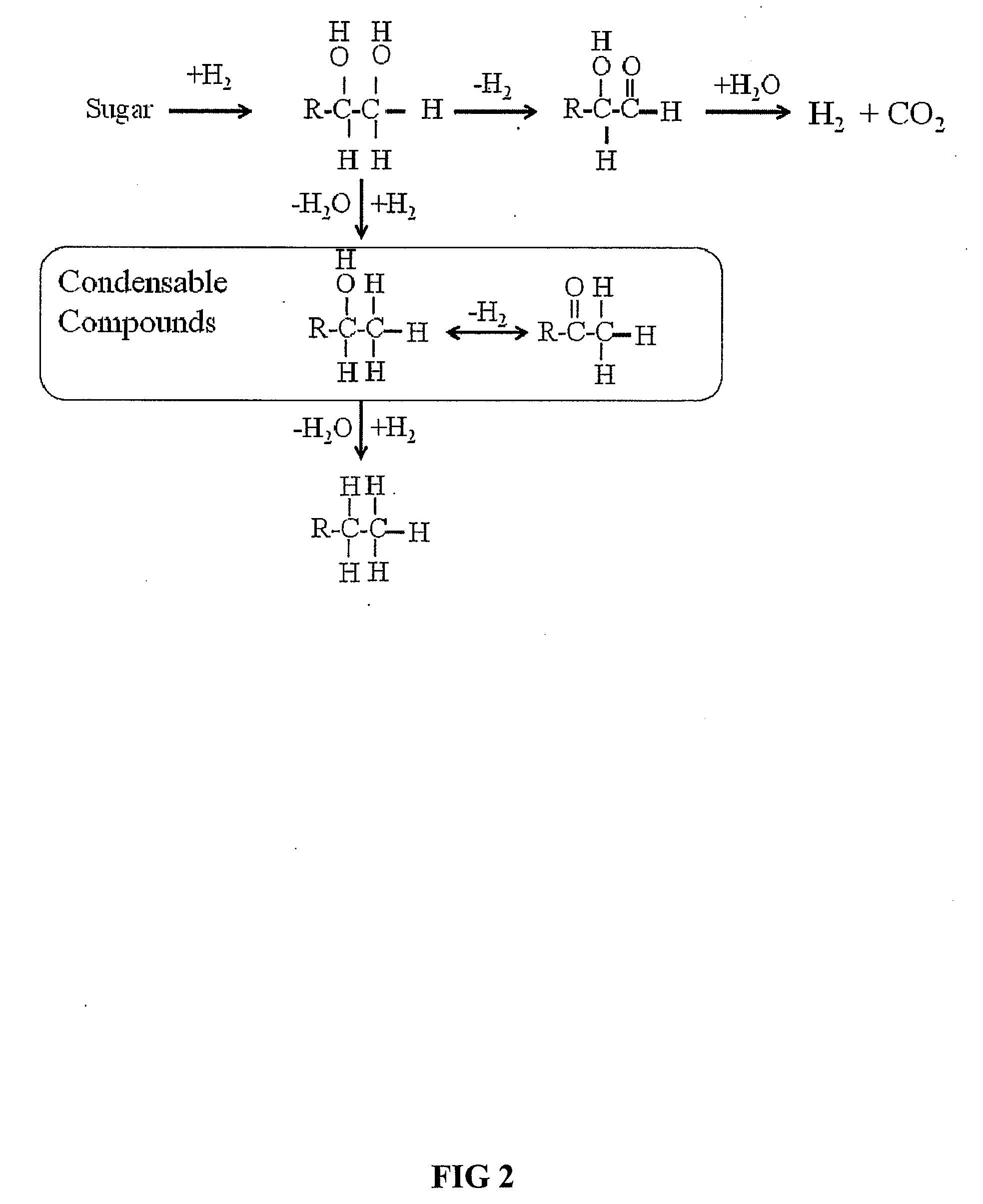

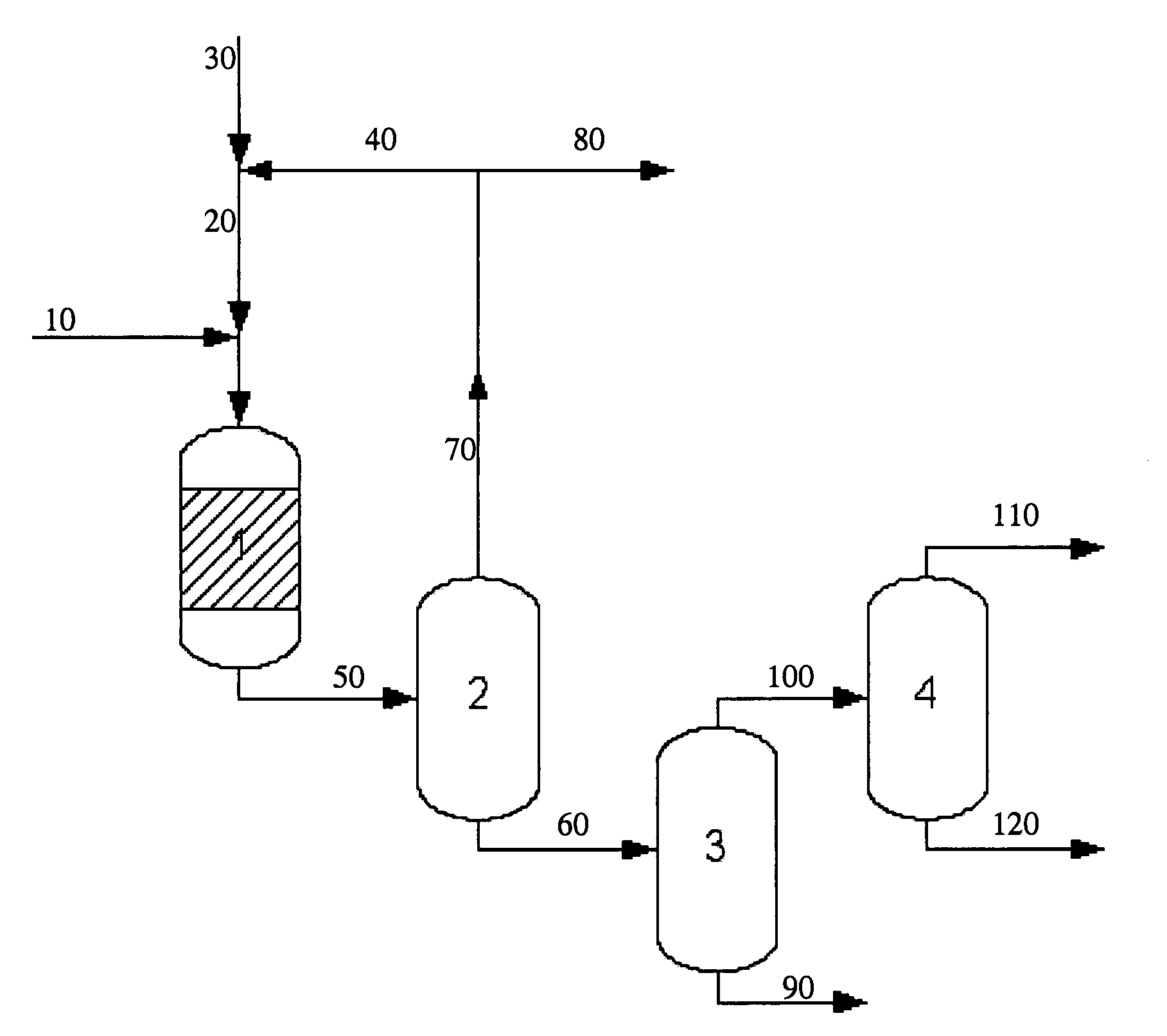

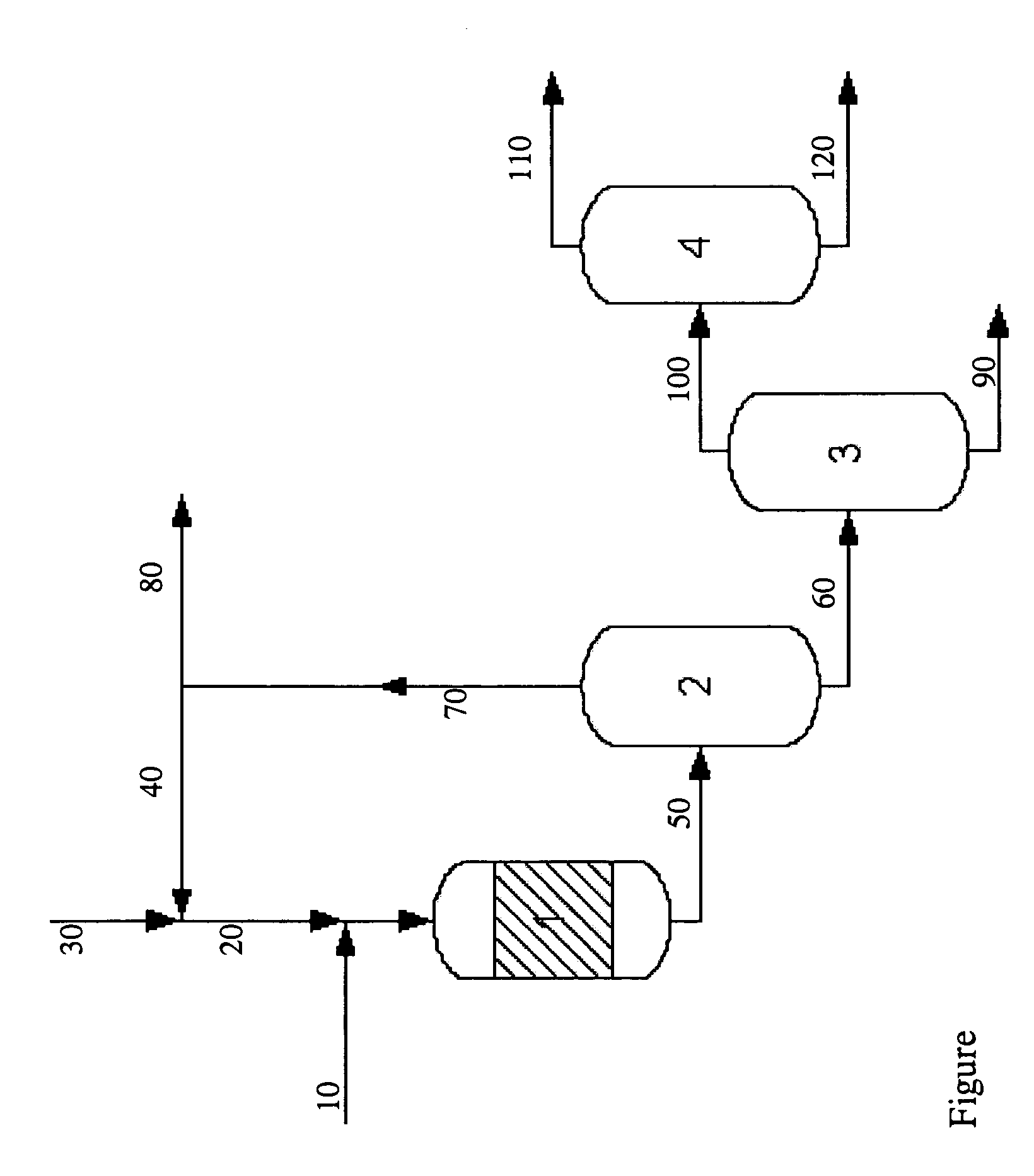

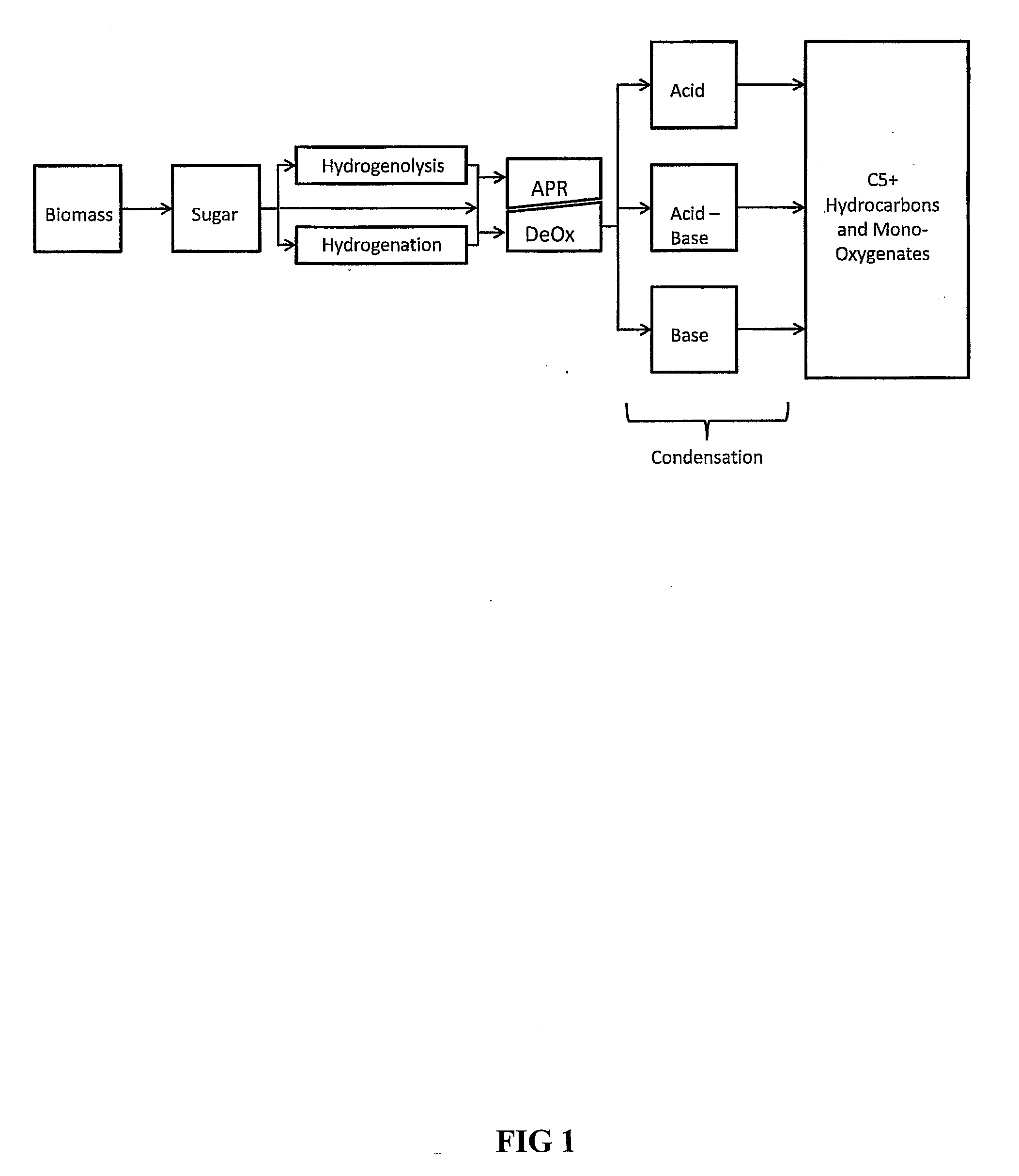

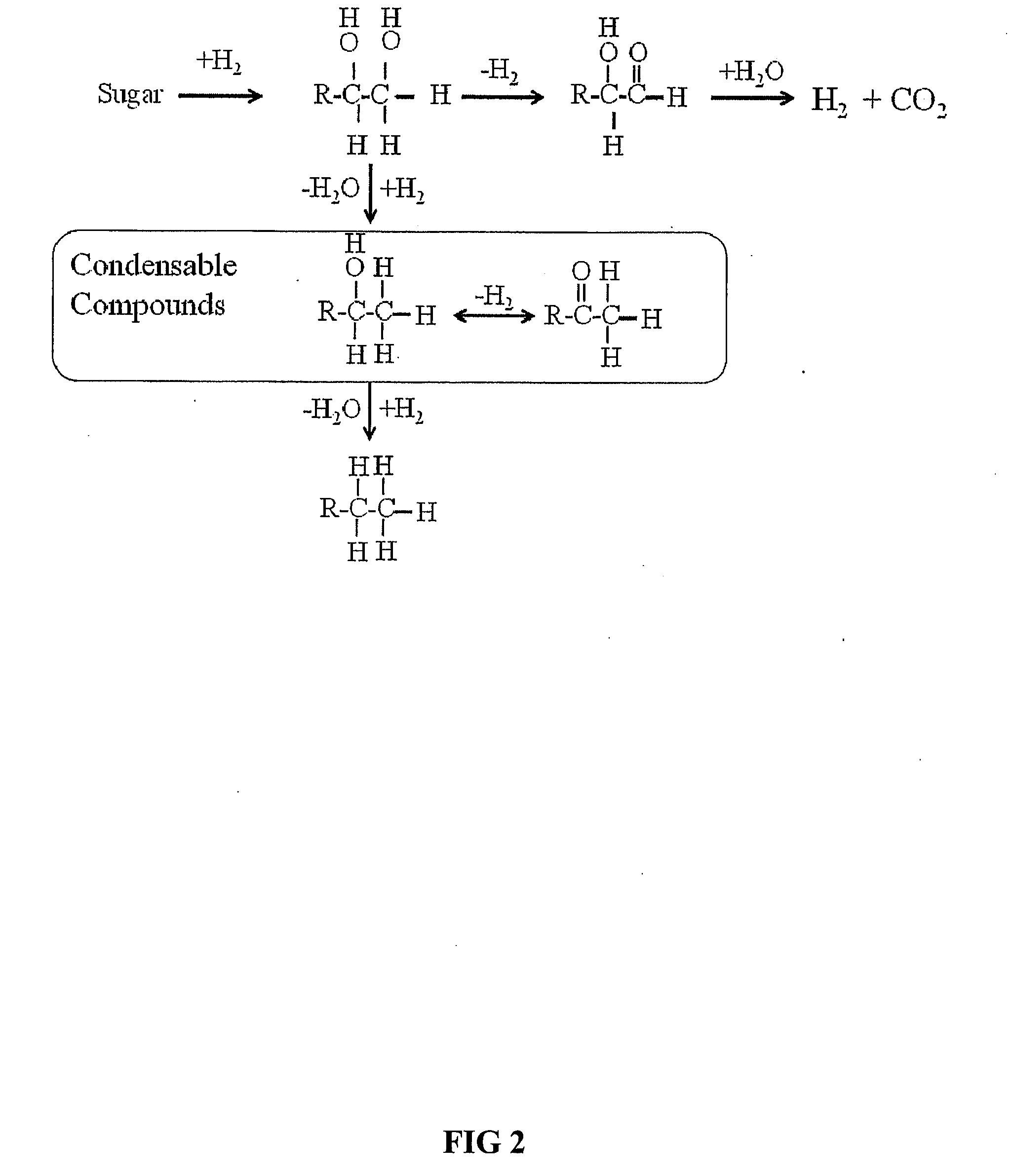

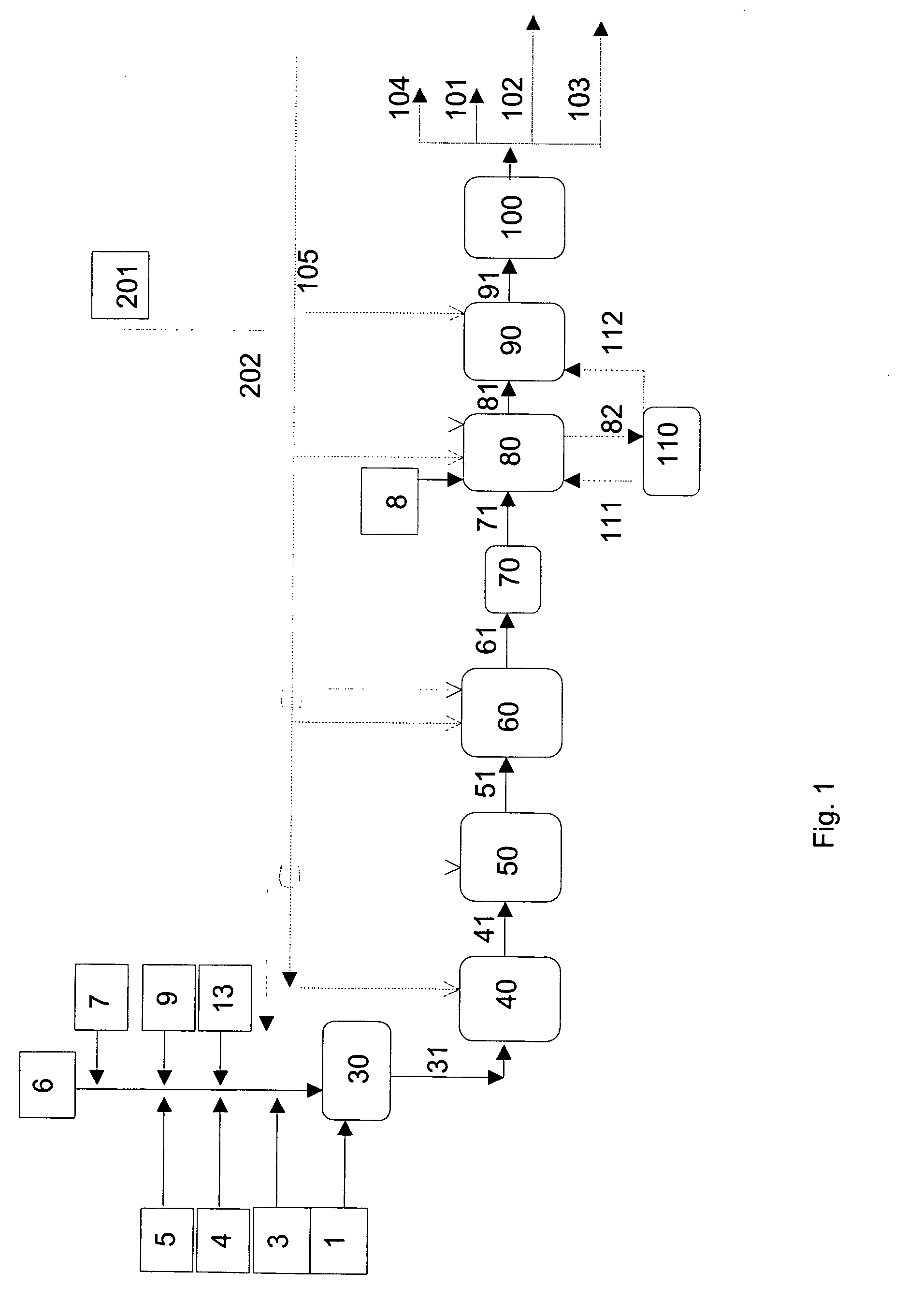

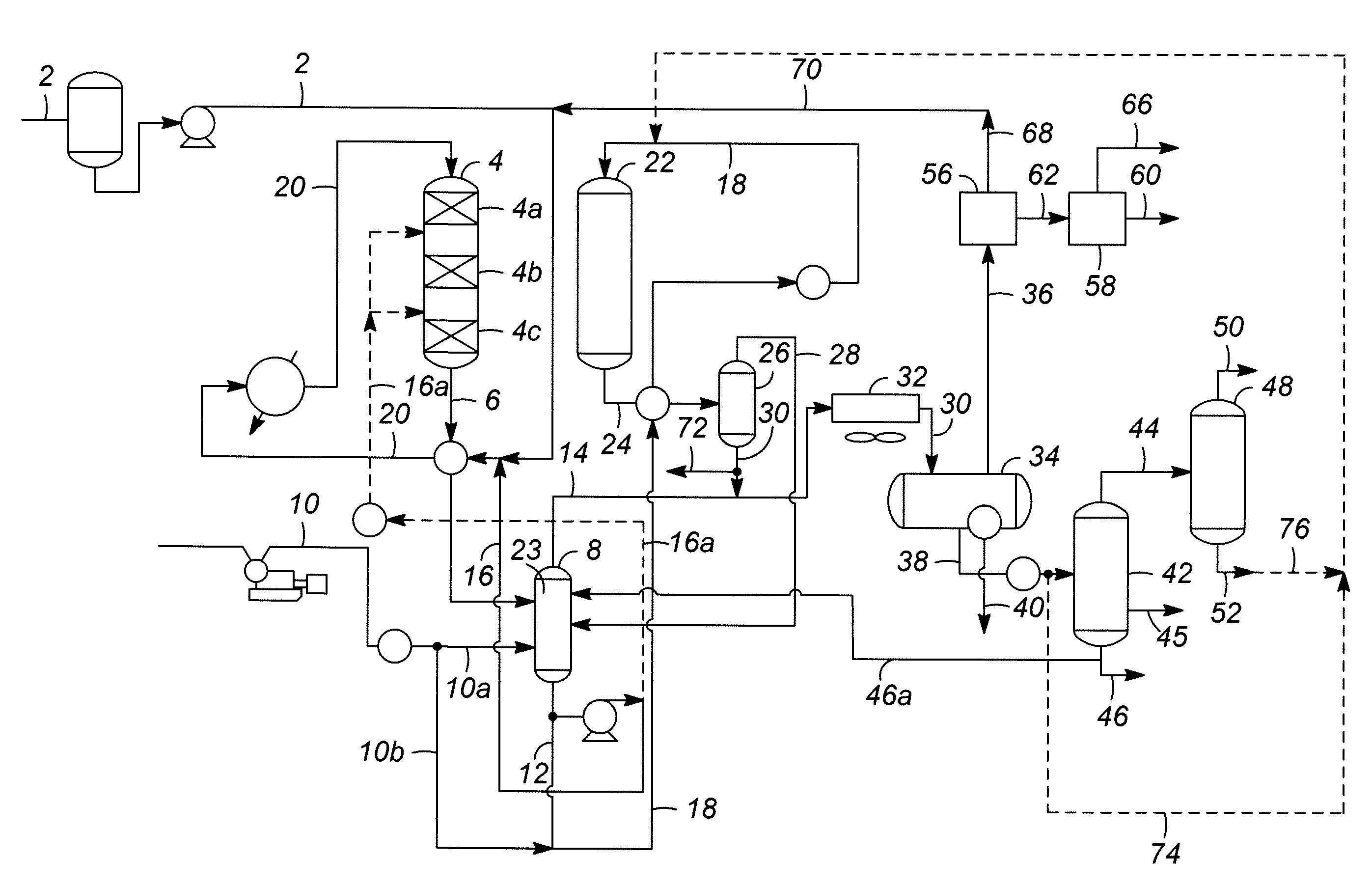

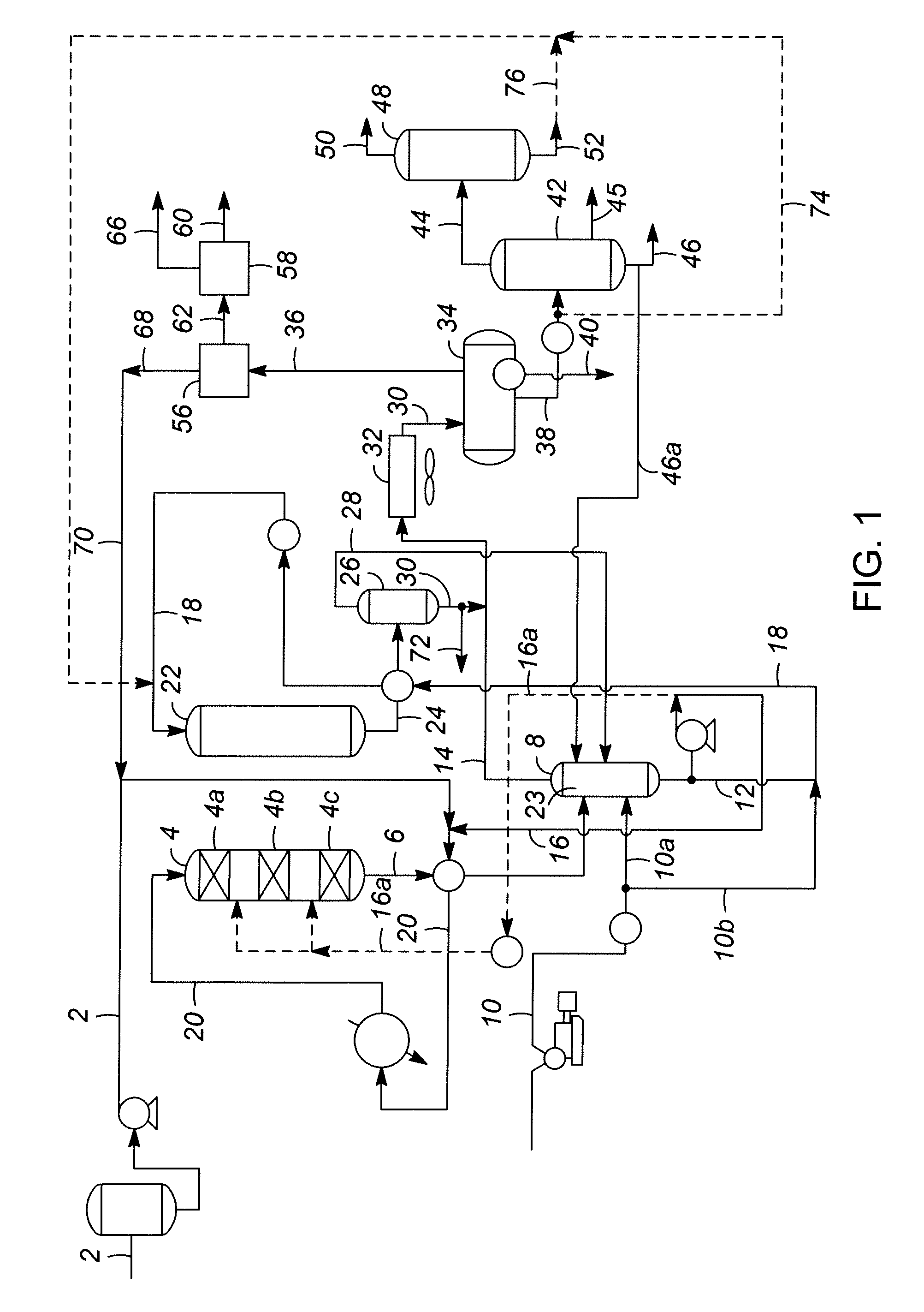

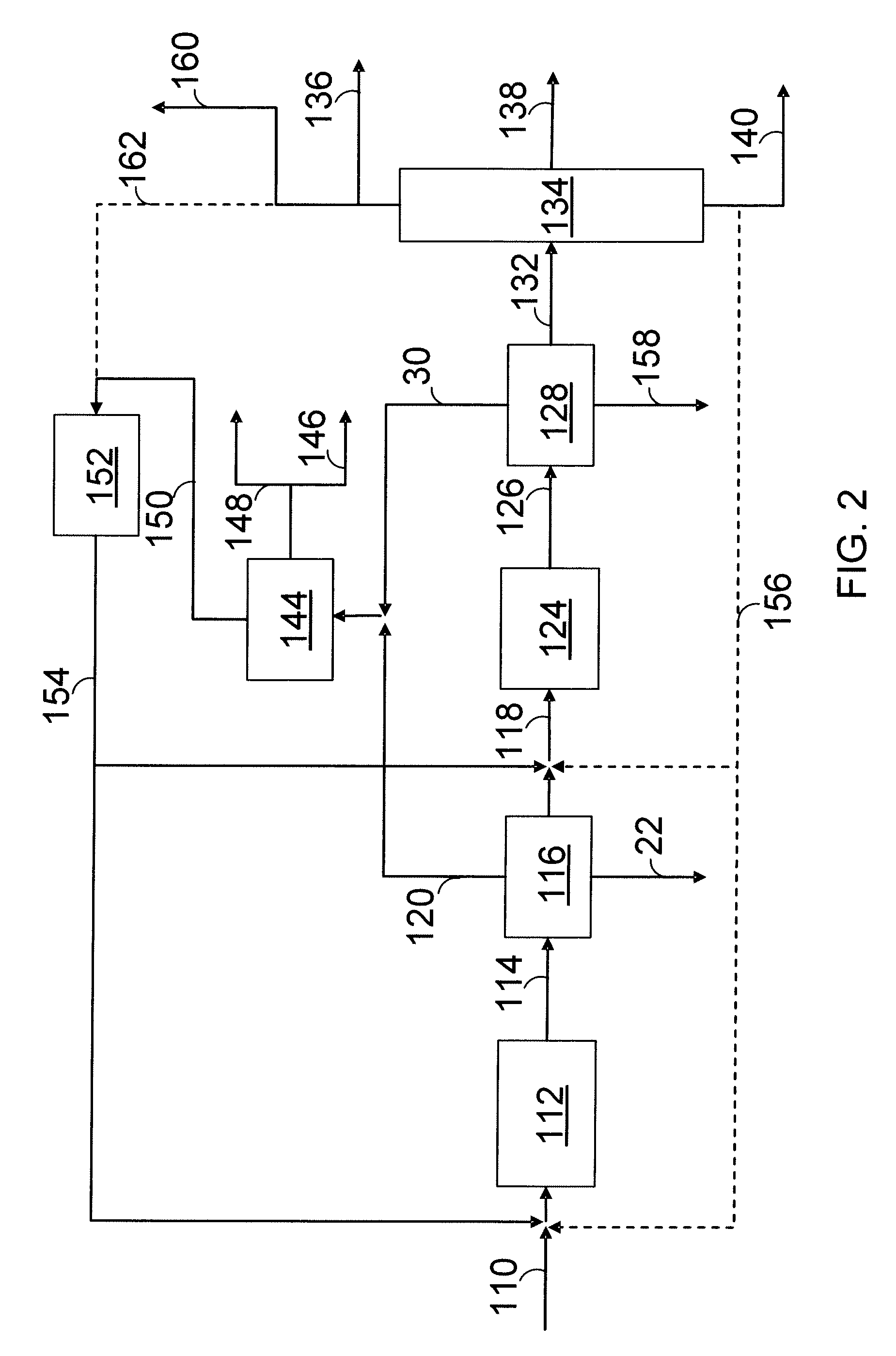

Synthesis of liquid fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080300435A1Oxygen-containing compound preparationLiquid hydrocarbon mixture productionFuranLiquid fuel

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

Production of diesel fuel from vegetable and animal oils

A process for producing a fuel composition from vegetable and / or animal oil comprises hydrodeoxygenating and hydroisomerizing the oil in a single step. The fuel composition has acceptable lubricity and comprises a mixture of C14 to C18 paraffins having a ratio of iso to normal paraffins of 2 to 8 and less than 5 ppm sulfur.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

Titanium compounds and complexes as additives in lubricants

A lubricating composition comprising an oil of lubricating viscosity, 1 to 1000 parts per million by weight of titanium in the form of an oil-soluble titanium-containing material, and at least one additional lubricant additive provides beneficial effects on properties such as deposit control, oxidation, and filterability in engine oils.

Owner:THE LUBRIZOL CORP

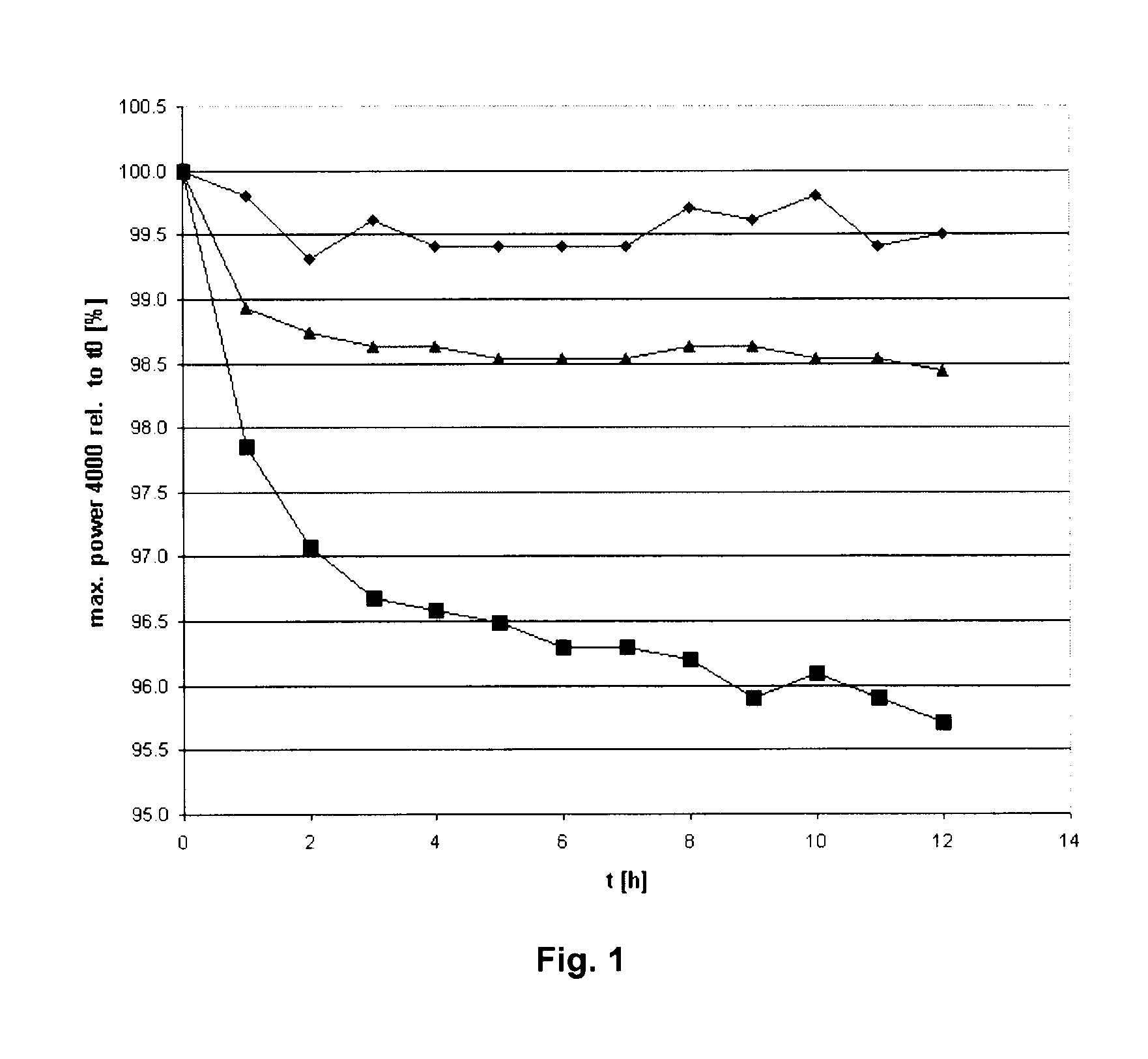

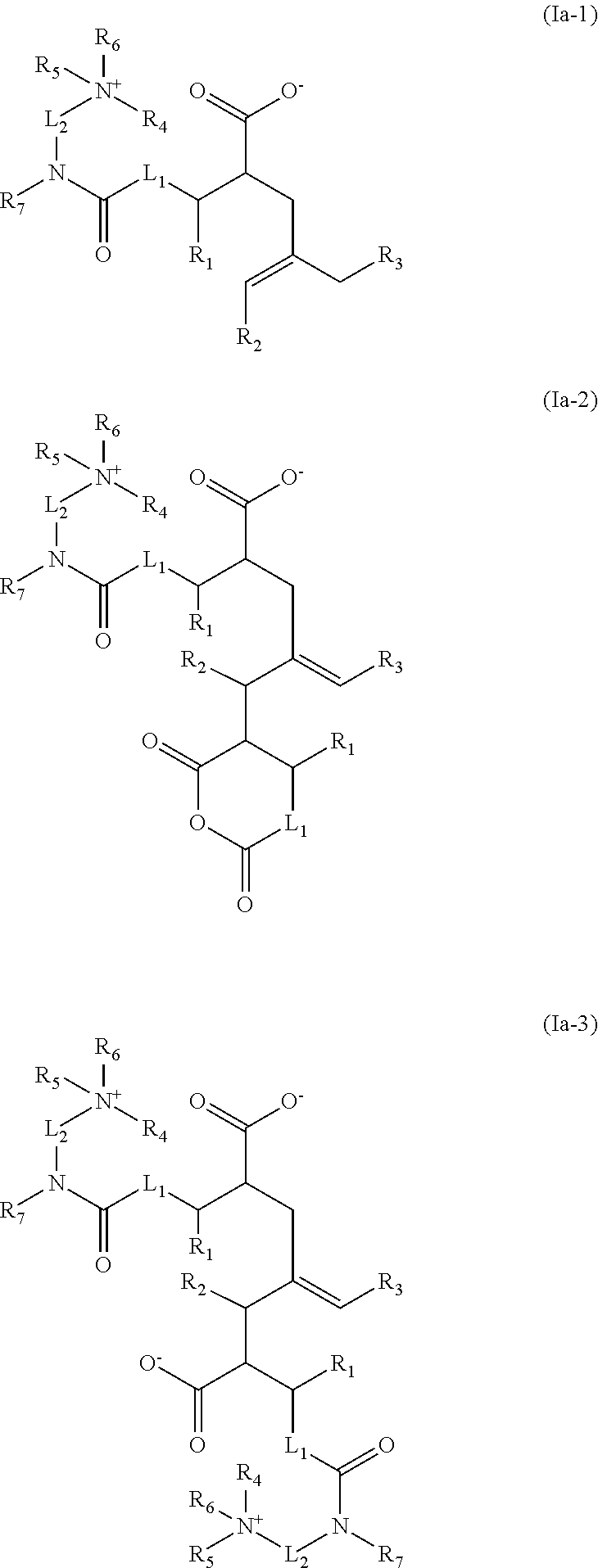

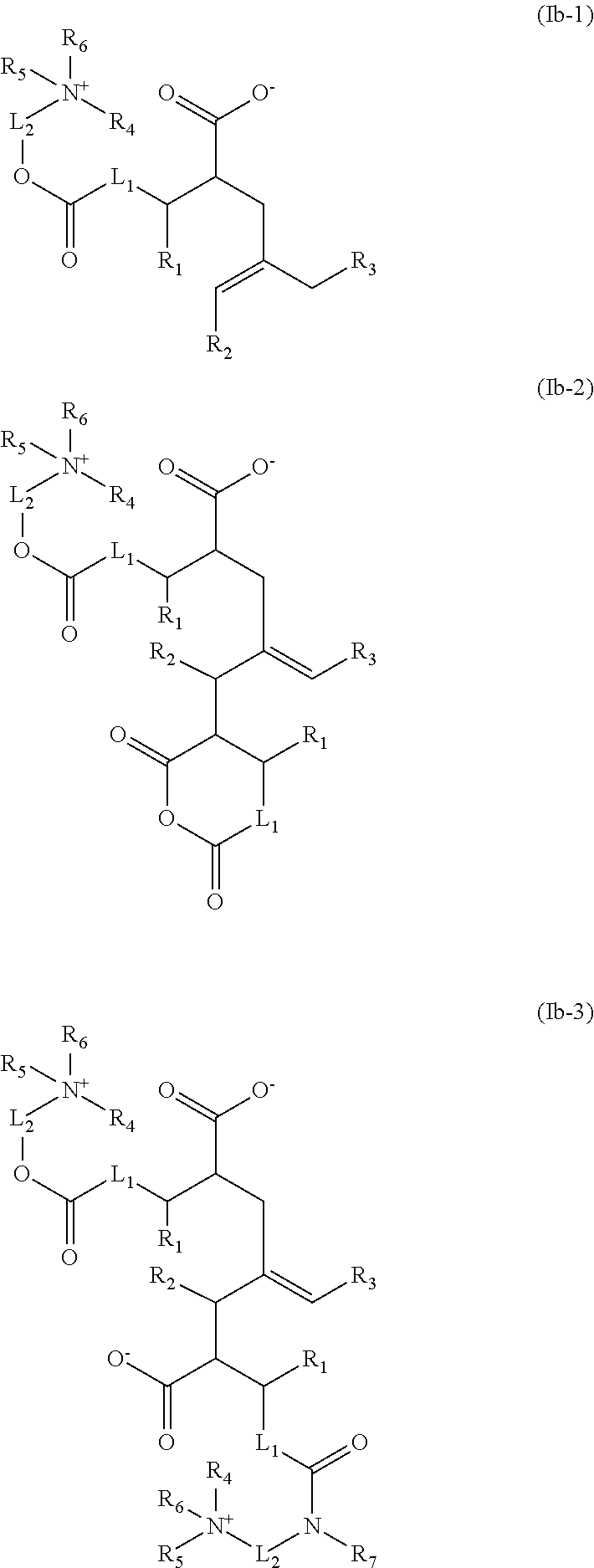

Acid-free quaternized nitrogen compounds and use thereof as additives in fuels and lubricants

The present invention relates to novel acid-free quaternized nitrogen compounds, to the preparation thereof and to the use thereof as a fuel and lubricant additive, more particularly as a detergent additive, as a wax antisettling additive (WASA) or as an additive for reducing internal diesel injector deposits (IDID); to additive packages which comprise these compounds; and to fuels and lubricants thus additized. The present invention further relates to the use of these acid-free quaternized nitrogen compounds as a fuel additive for reducing or preventing deposits in the injection systems of direct-injection diesel engines, especially in common-rail injection systems, for reducing the fuel consumption of direct-injection diesel engines, especially of diesel engines with common-rail injection systems, and for minimizing power loss in direct-injection diesel engines, especially in diesel engines with common-rail injection systems.

Owner:BASF AG

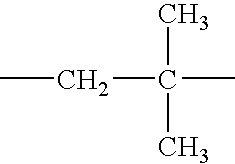

Quaternary Ammonium Salt of a Polyalkene-Substituted Amine Compound

InactiveUS20080113890A1Organic compound preparationTransportation and packagingCompound aQuaternary ammonium cation

A quaternary ammonium salt detergent made from the reaction product of the reaction of: (a) polyalkene-substituted amine having at least one tertiary amino group; and (b) a quaternizing agent suitable for converting the tertiary amino group to a quaternary nitrogen and the use of such quaternary ammonium salt detergents in a fuel composition to reduce intake valve deposits.

Owner:THE LUBRIZOL CORP

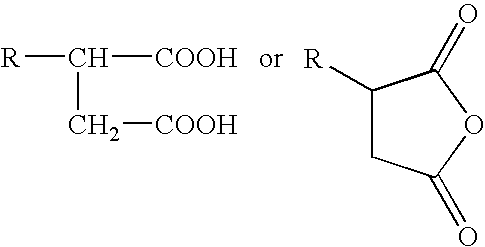

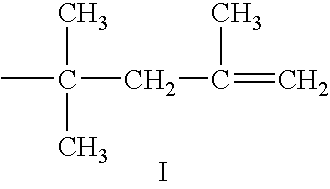

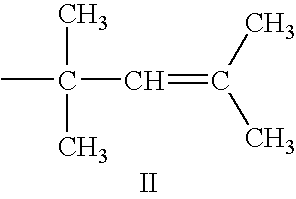

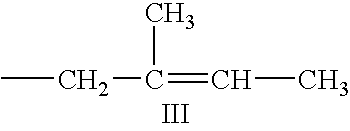

Process for the preparation of polyalkenyl succinic anhydrides

A polyalkenyl succinic anhydride is prepared with low amounts of resinous or chlorinated byproducts in a two-step process whereby a polyalkene is first reacted with an unsaturated organic acid in a thermal ene reaction, followed with exposure to a gaseous halogen in presence of an additional amount of the unsaturated organic acidic reagent. The foregoing process produces a polyisobutenyl succinic anhydride having a high ratio of succinic anhydride functional groups to polyisobutenyl backbone groups. Such a polyisobutenyl succinic anhydride is particular suitable for the production of oil-soluble hydrocarbyl succinimides that have good dispersant properties when added to lubricating oil compositions.

Owner:AFTON CHEMICAL

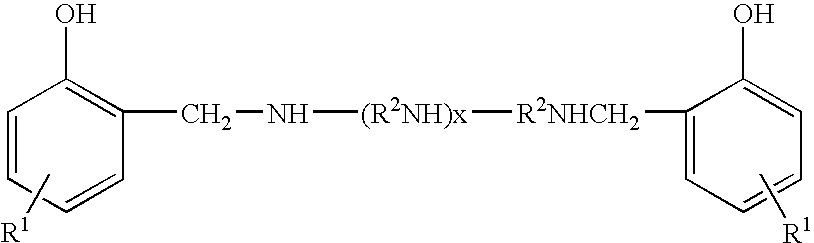

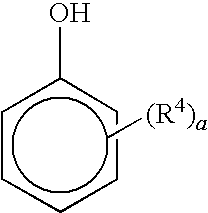

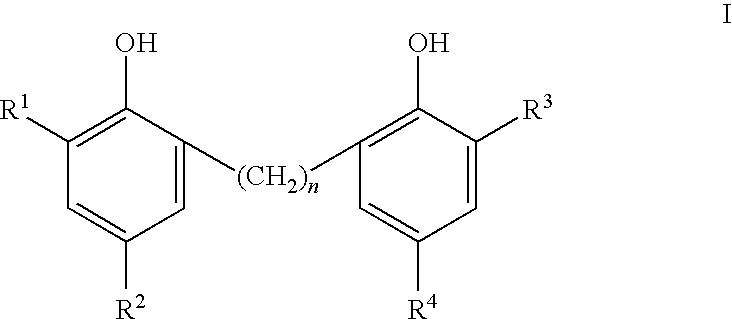

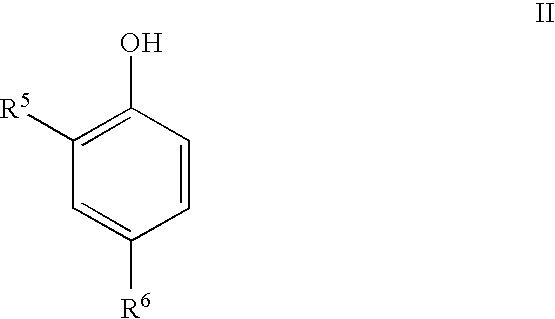

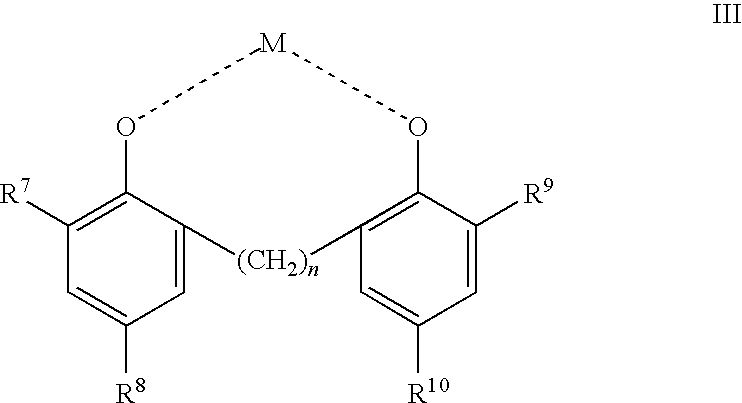

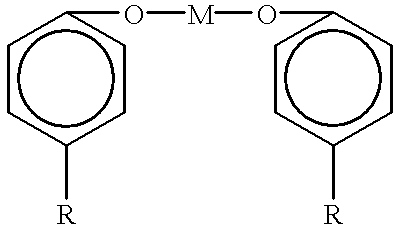

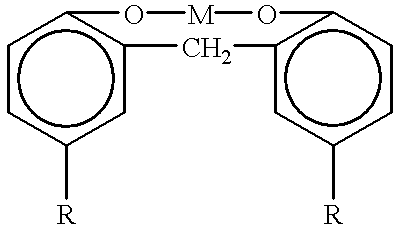

Phenolic dimers, the process of preparing same and the use thereof

Owner:AFTON CHEMICAL

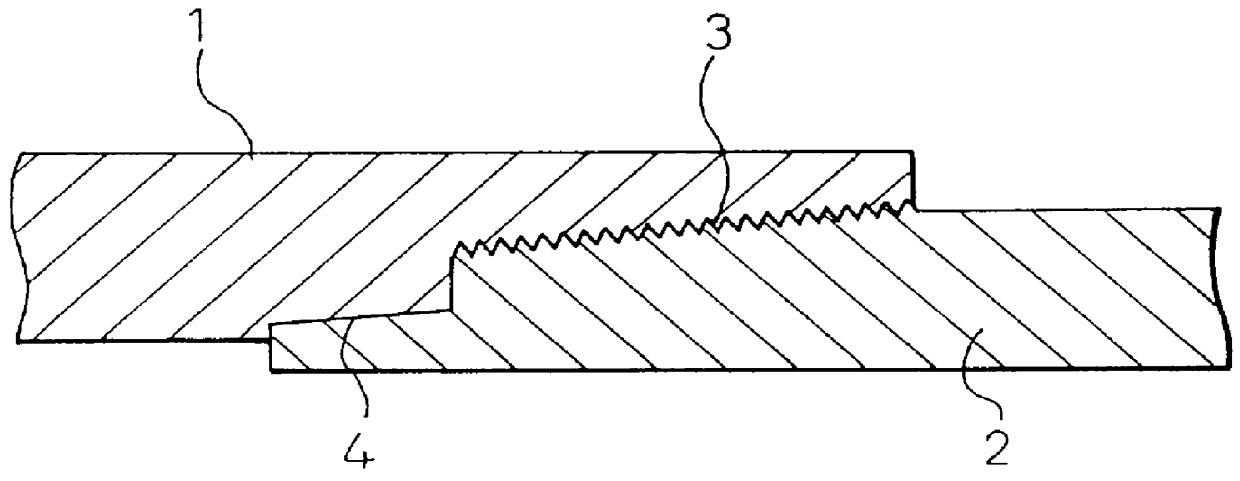

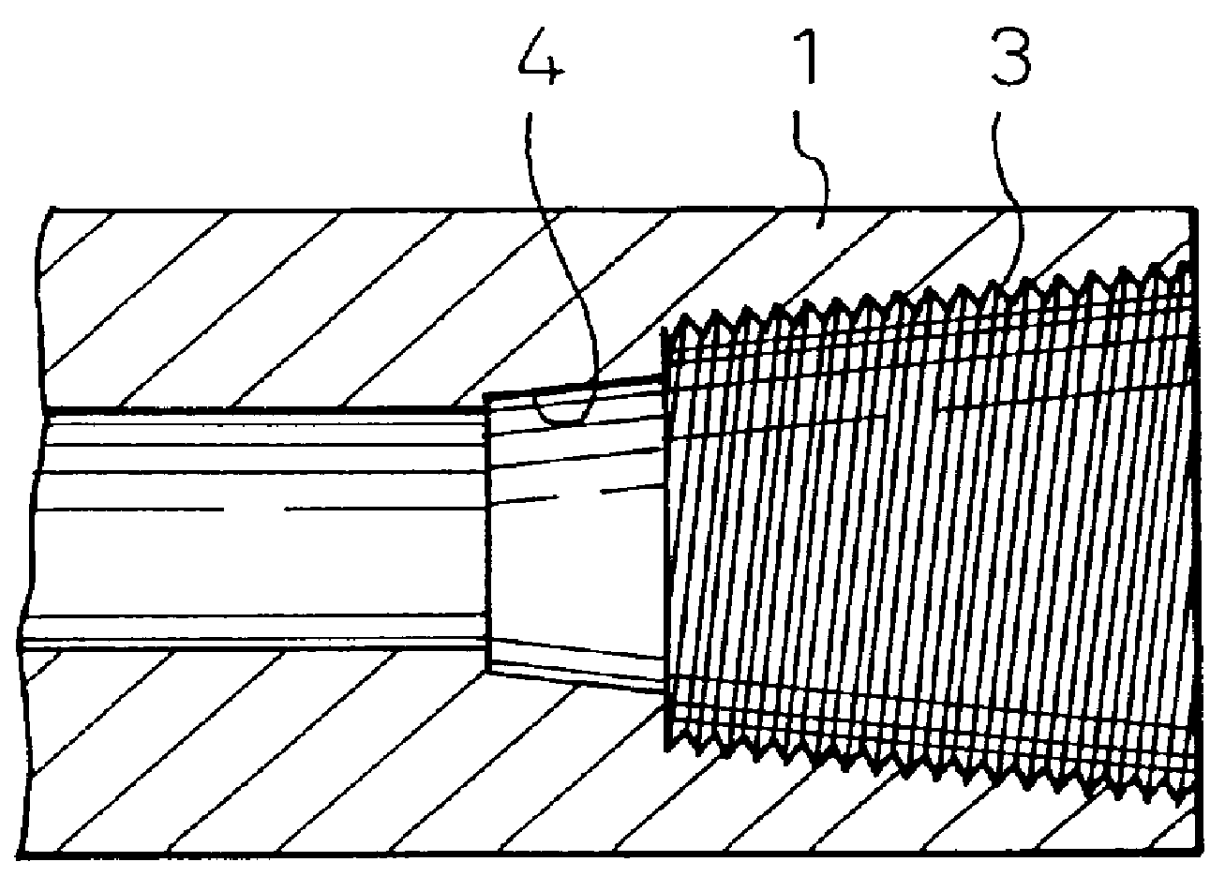

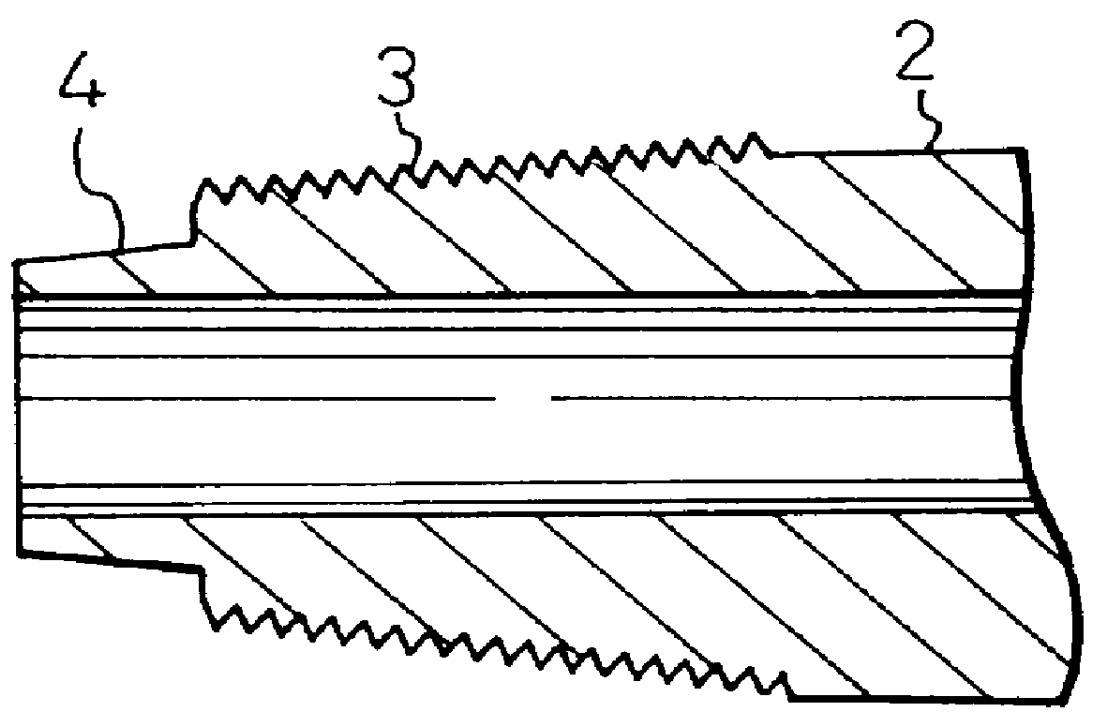

Joint for steel pipe having high galling resistance and surface treatment method thereof

InactiveUS6027145AShorten heating timeImprove the lubrication effectDrilling rodsPretreated surfacesEpoxyPolyamide

PCT No. PCT / JP95 / 02034 Sec. 371 Date May 23, 1997 Sec. 102(e) Date May 23, 1997 PCT Filed Oct. 4, 1995 PCT Pub. No. WO96 / 10710 PCT Pub. Date Apr. 11, 1996An object of the present invention is to provide galling resistance to a threaded joint used for an oil well pipe. On a thread portion and a metallic sealing portion of the joint, there is provided a manganese phosphate chemical formation coating layer, or alternatively there are provided a nitriding layer of 1 to 20 mu m thickness and a manganese phosphate chemical formation coating layer of 5 to 30 mu m thickness, and also there is coated a solid lubricant which contains powder of molybdenum disulfide or tungsten disulfide and also contains one of epoxy resin, furan resin and polyamide resin as an essential component, and a ratio of composition is maintained at a specific value, so that a solid lubricant coating layer of 10 to 45 mu m thickness can be formed by heating. Due to the above surface treatment, even when the frequency of repetition of fastening and unfastening of the joint is increased, the occurrence of galling can be prevented over a long period of time.

Owner:NSCT PREMIUM TUBULARS

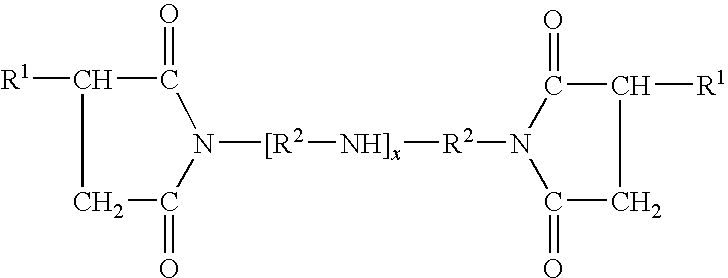

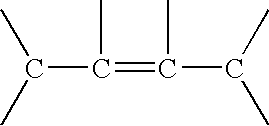

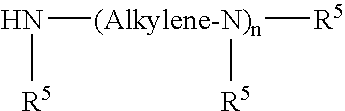

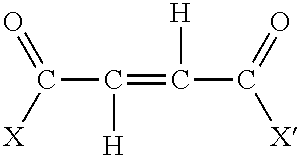

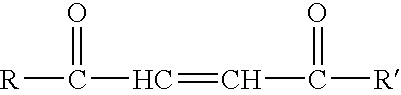

Low-chlorine, polyolefin-substituted, with amine reacted, alpha-beta unsaturated carboxylic compounds

A composition of matter comprising an amine acylated with a hydrocarbyl group substituted carboxylic acylating agent containing an average of from 1.3 to 1.6 groups derived from α,β-unsaturated carboxylic compounds per Mn of the hydrocarbyl group, wherein the hydrocarbyl group has Mn determined by GPC ranging from 1500 to 3000, the amine comprises polyamine bottoms and said acylated amine has total base number (TBN) ranging from 17 to 35. A method for preparing the composition, lubricating oils containing the composition and, in another embodiment, lubricating oil compositions of this invention further comprising a metal overbased sulfonate detergent.

Owner:THE LUBRIZOL CORP

Mixed dispersants for lubricants

A dispersant composition comprising the product of an amine, an alcohol, or an amino alcohol, with a hydrocarbyl-substituted succinic anhydride component exhibits improved viscosity stability and reduced chlorine content, when the hydrocarbyl-substituted succinic anhydride component comprises: (a) 10 to 95 weight percent of a component prepared by reacting a polyisobutylene with maleic anhydride in the presence of chlorine; and (b) 5 to 90 weight percent of a component prepared by reacting a polyisobutylene with maleic anhydride in the substantial absence of chlorine.

Owner:THE LUBRIZOL CORP

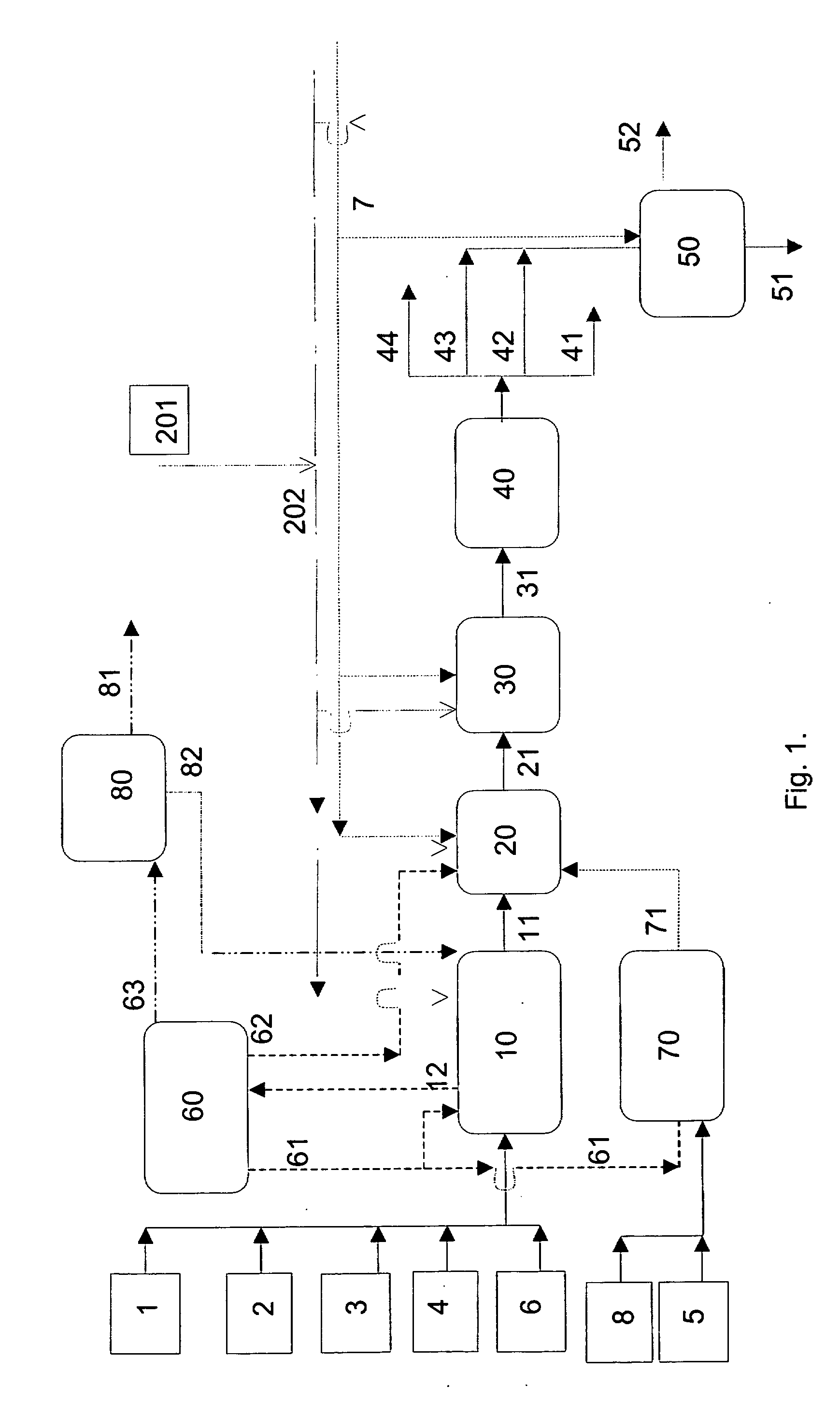

Process for producing a saturated hydrocarbon component

ActiveUS20070131579A1Reduce carbon dioxide emissionsIncrease carbon dioxide loadProductsReagentsCarboxylic acidBase oil

The invention relates to a process for producing high-quality saturated base oil or a base oil component based on hydrocarbons. The process of the invention comprises two main steps, the oligomerization and deoxygenation. A biological starting material containing unsaturated carboxylic acids and / or esters of carboxylic acids is preferably used as the feedstock.

Owner:NESTE OIL OY

Viscosity index improver for lubricant compositions

Owner:DOW GLOBAL TECH LLC

Additive formulation for lubricating oils

InactiveUS7285516B2Reduce the amount requiredOrganic chemistryOrganic compound preparationSulfurPhosphorus

Lubricating oils containing an additive formulation including at least one sulphonate, saligenin and salixarate detergent provide improved wear performance and decreased sulphur and phosphorus emissions.

Owner:THE LUBRIZOL CORP

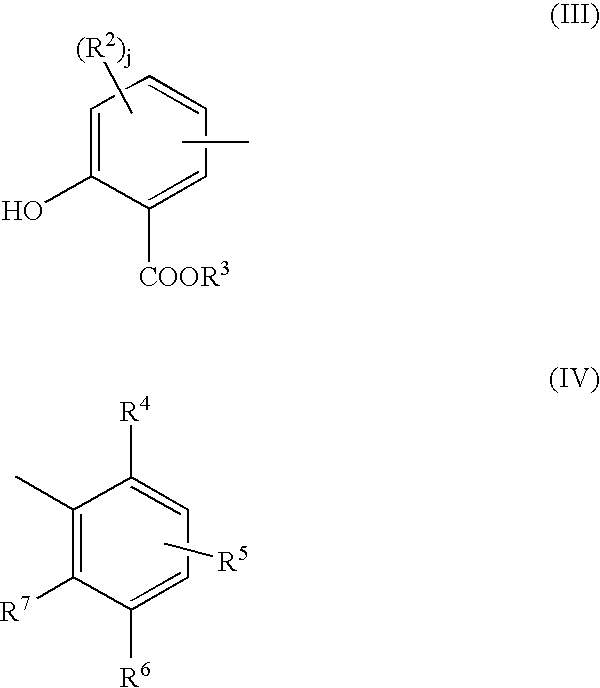

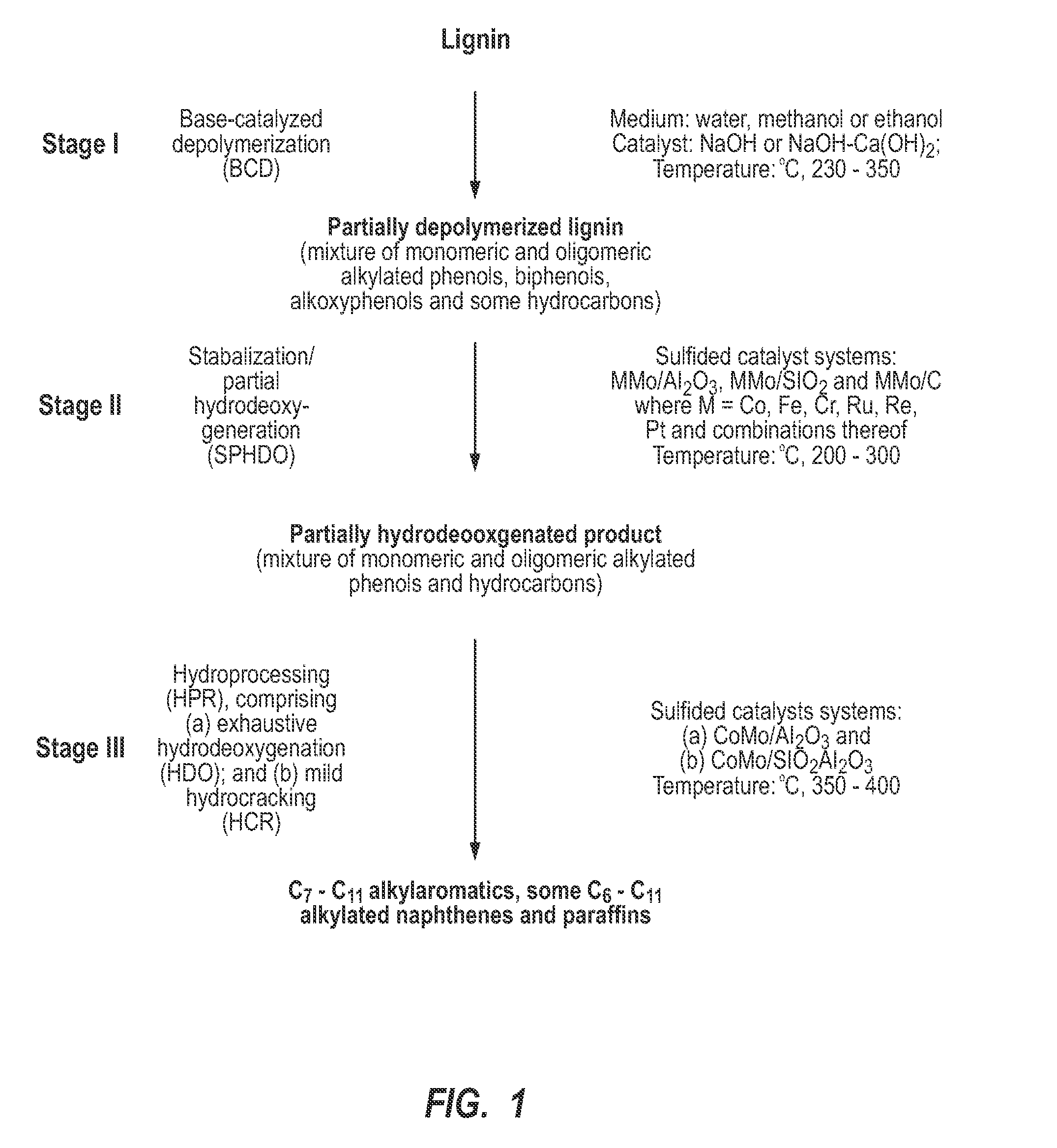

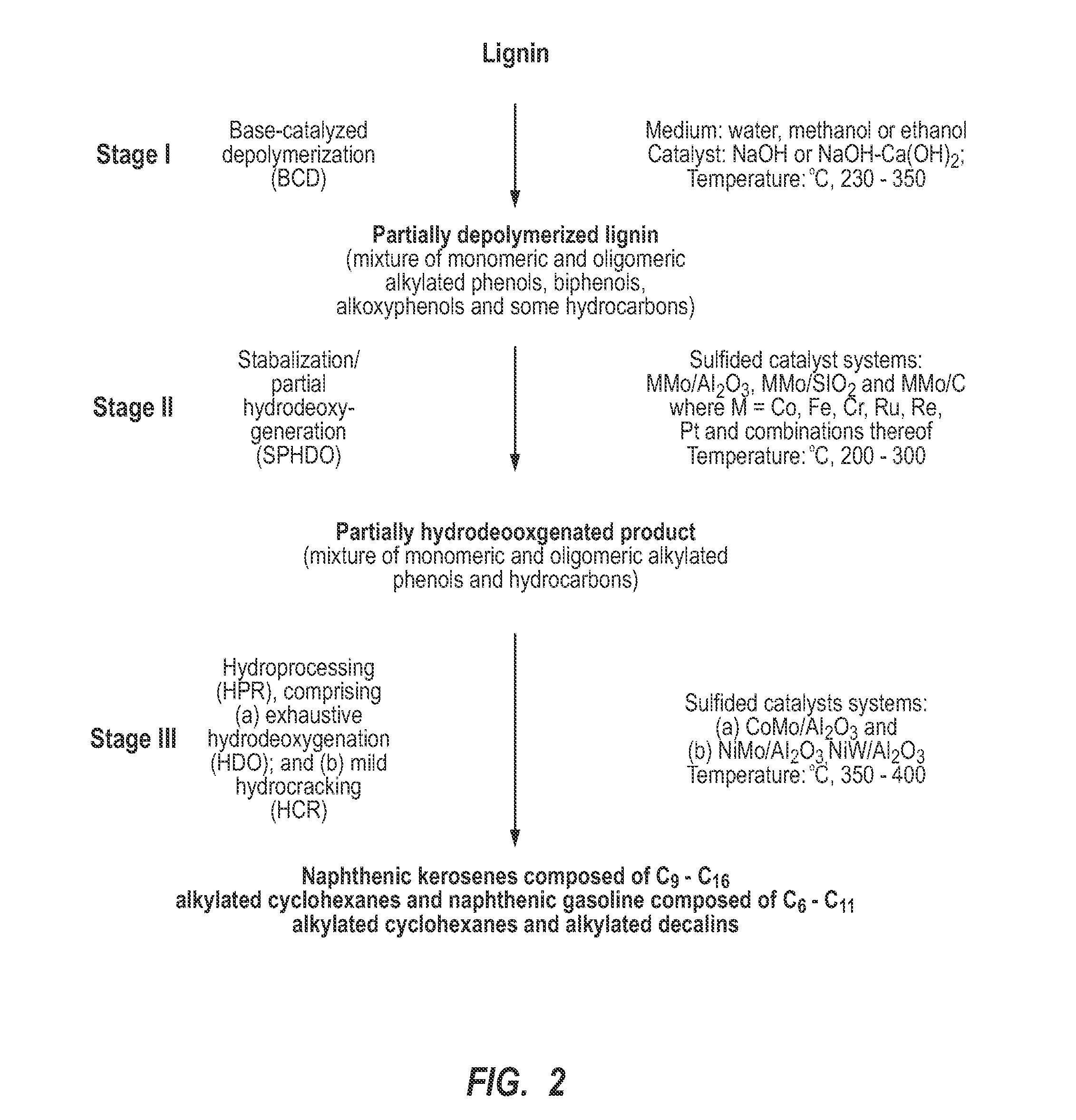

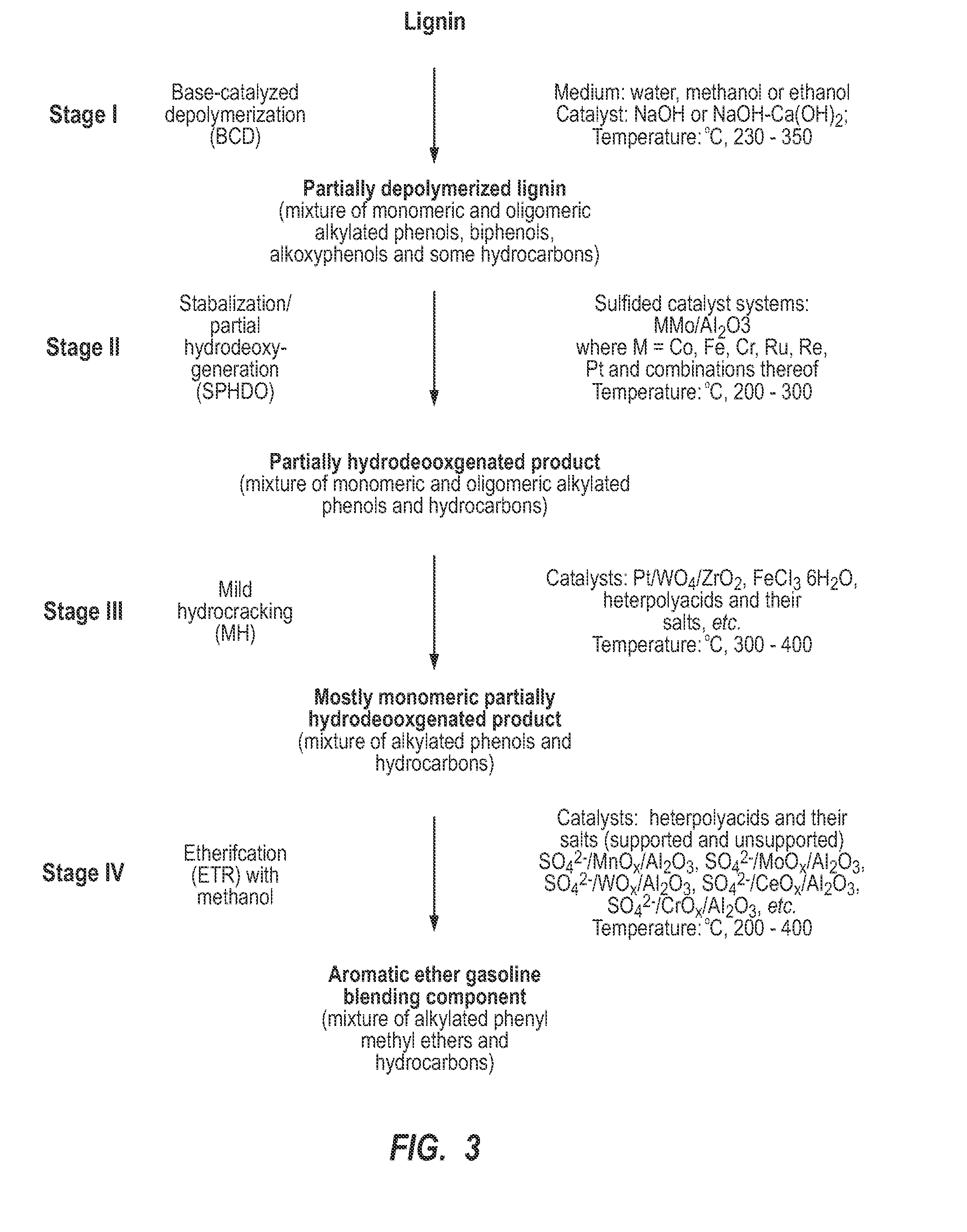

Processes for catalytic conversion of lignin to liquid bio-fuels and novel bio-fuels

InactiveUS20080050792A1Increase productionAcceptable processing conditionBiofuelsSolid fuelsLiquid productLignin degradation

Processes for conversion of lignin to liquid products such as bio-fuels and fuel additives are disclosed and described. A process for conversion of a lignin material to bio-fuels can include subjecting the lignin material to a base catalyzed depolymerization reaction to produce a partially depolymerized lignin. The partially depolymerized lignin can then be subjected to a stabilization / partial hydrodeoxygenation reaction to form a partially hydrodeoxygenated product. Following partial hydrodeoxygenation, the partially hydrodeoxygenated product can be reacted in a hydroprocessing step to form a bio-fuel. Each of these reaction steps can be performed in single or multiple steps, depending on the design of the process. The production of an intermediate partially hydrodeoxygenation product and subsequent reaction thereof can significantly reduce or eliminate reactor plugging and catalyst coking. A variety of useful bio-fuels such as fuels, fuel additives, and the like, including gasoline and jet or rocket fuels are describe which can be readily produced from renewable lignin materials in an improved conversion process.

Owner:UNIV OF UTAH RES FOUND

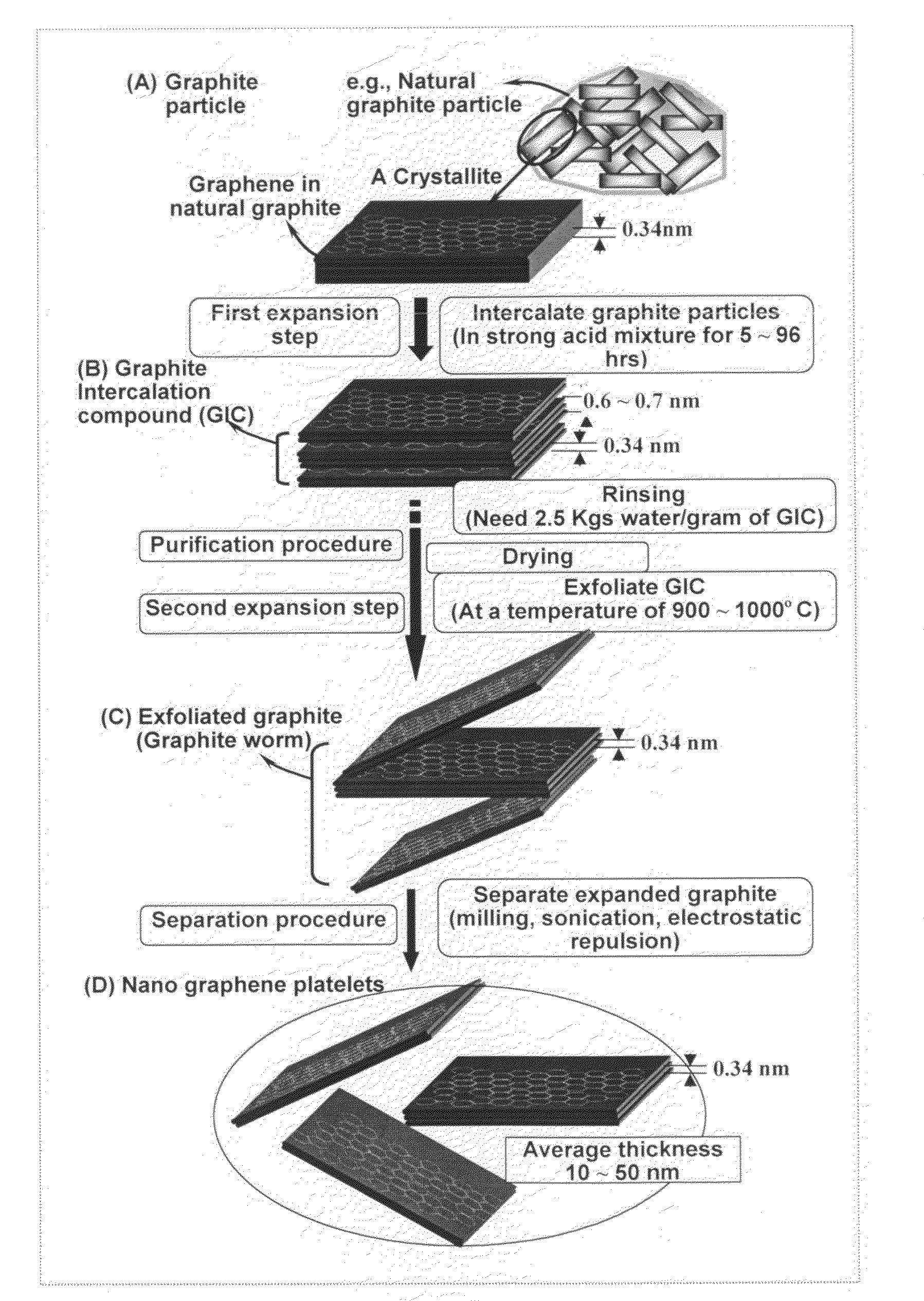

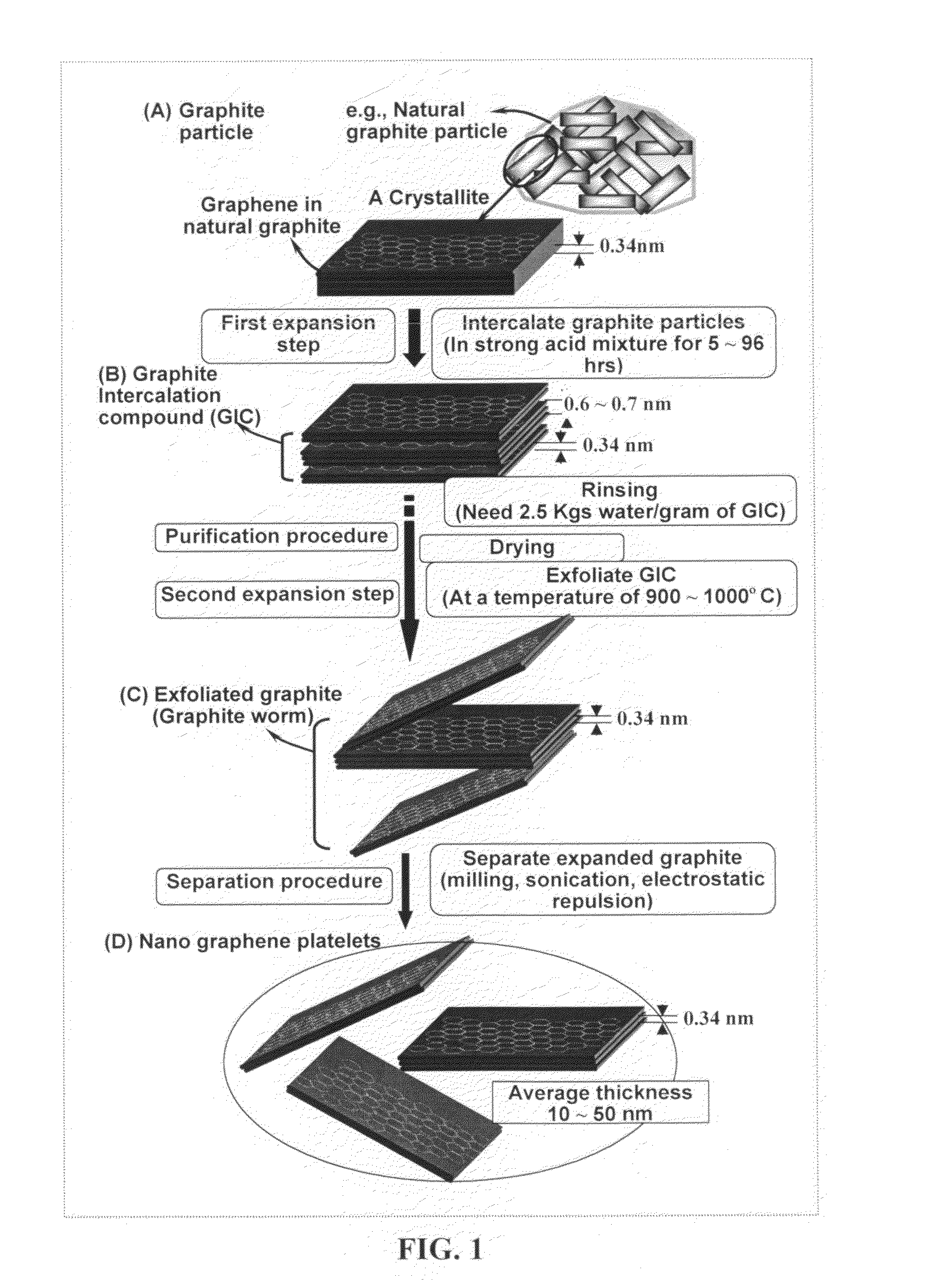

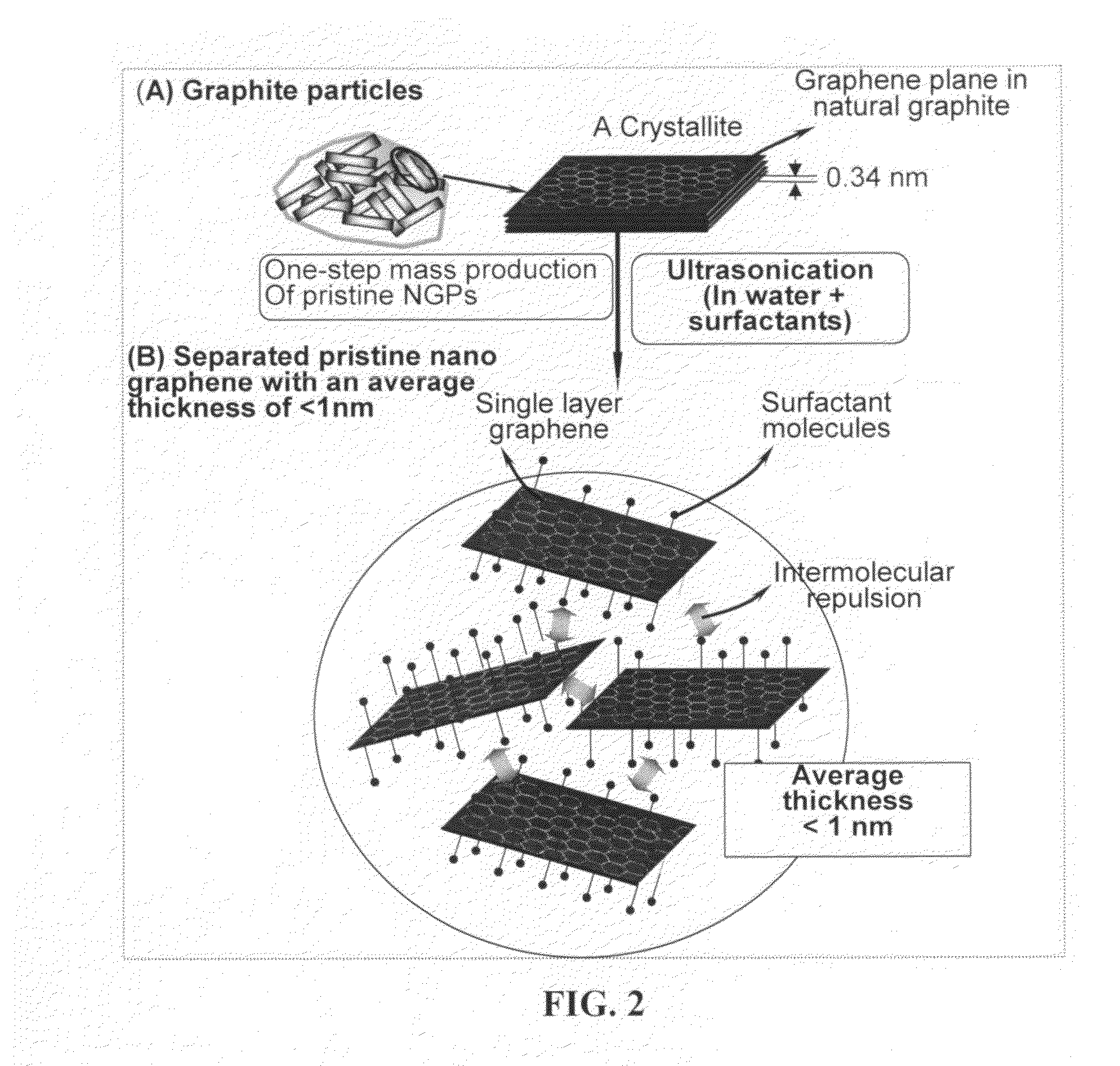

Nano graphene-modified lubricant

ActiveUS20110046027A1Modulate viscosityImprove the lubrication effectAdditivesBase-materialsCarbon nanotubeSingle layer graphene

A lubricant composition having improved lubricant properties, comprising:(a) a lubricating fluid; and (b) nano graphene platelets (NGPs) dispersed in the fluid, wherein nano graphene platelets have a proportion of 0.001% to 60% by weight based on the total weight of the fluid and the graphene platelets combined. Preferably, the composition comprises at least a single-layer graphene sheet. Preferably, the lubricating fluid contains a petroleum oil or synthetic oil and a dispersant or surfactant. With the addition of a thickener or a desired amount of NGPs, the lubricant becomes a grease composition. Compared with graphite nano particle- or carbon nanotube-modified lubricants, NGP-modified lubricants have much better thermal conductivity, friction-reducing capability, anti-wear performance, and viscosity stability.

Owner:GLOBAL GRAPHENE GRP INC

Lubricant additive

ActiveUS20120101017A1Good viscosity performanceIncrease VISolid-state devicesLiquid carbonaceous fuelsBase oilButadiene-styrene rubber

A hydrogenated styrene butadiene star copolymer is incorporated in a lubricant additive package. The star copolymer can include about 3 to 25% and about 97 to 75% butadiene. The star copolymer may further be incorporated in a lubricant additive in the amount of about 12 wt % of the star copolymer as compared to the base oil.

Owner:AFTON CHEMICAL

Micro-emulsion type metal cutting liquor composition

InactiveCN101240217AEasy to handleImprove the lubrication effectAdditivesBase-materialsMaterials scienceCutting fluid

Disclosed is a microemulsifying metal-cutting-fluid composition, comprising base oil or oily agent, mixed alcohol-amine, boric acid, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative, deionized water and the like. The invention has the advantages of excellent lubricity, cooling ability, cleaning ability and a long lifetime of metal cutting fluid, being suited to various metal processing technologies such as cutting, reaming, boring, grinding. Also, the wastewater is easy to treat.

Owner:益田润石(北京)化工有限公司

Process for manufacturing lubricating base oil with high monocycloparaffins and low multicycloparaffins

InactiveUS20050133409A1Improve Oxidation StabilityHigh viscosity indexTreatment with hydrotreatment processesAdditivesSyngasMolecular sieve

A process for manufacturing a lubricating base oil by: a) performing Fischer-Tropsch synthesis on syngas to provide a product stream; b) isolating from said product stream a substantially paraffinic wax feed having less than about 30 ppm total nitrogen and sulfur, and less than about 1 wt % oxygen; c) dewaxing said feed by hydroisomerization dewaxing using a shape selective intermediate pore size molecular sieve comprising a noble metal hydrogenation component, wherein the hydroisomerization temperature is between about 600° F. (315° C.) and about 750° F. (399° C.), to produce an is dimerized oil; and d) hydrofinishing said isomerized oil to produce a lubricating base oil having specific desired properties.

Owner:CHEVROU USA INC

Synthesis of liqiud fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080300434A1Oxygen-containing compound preparationHydrocarbon purification/separationFuranCarboxylic acid

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

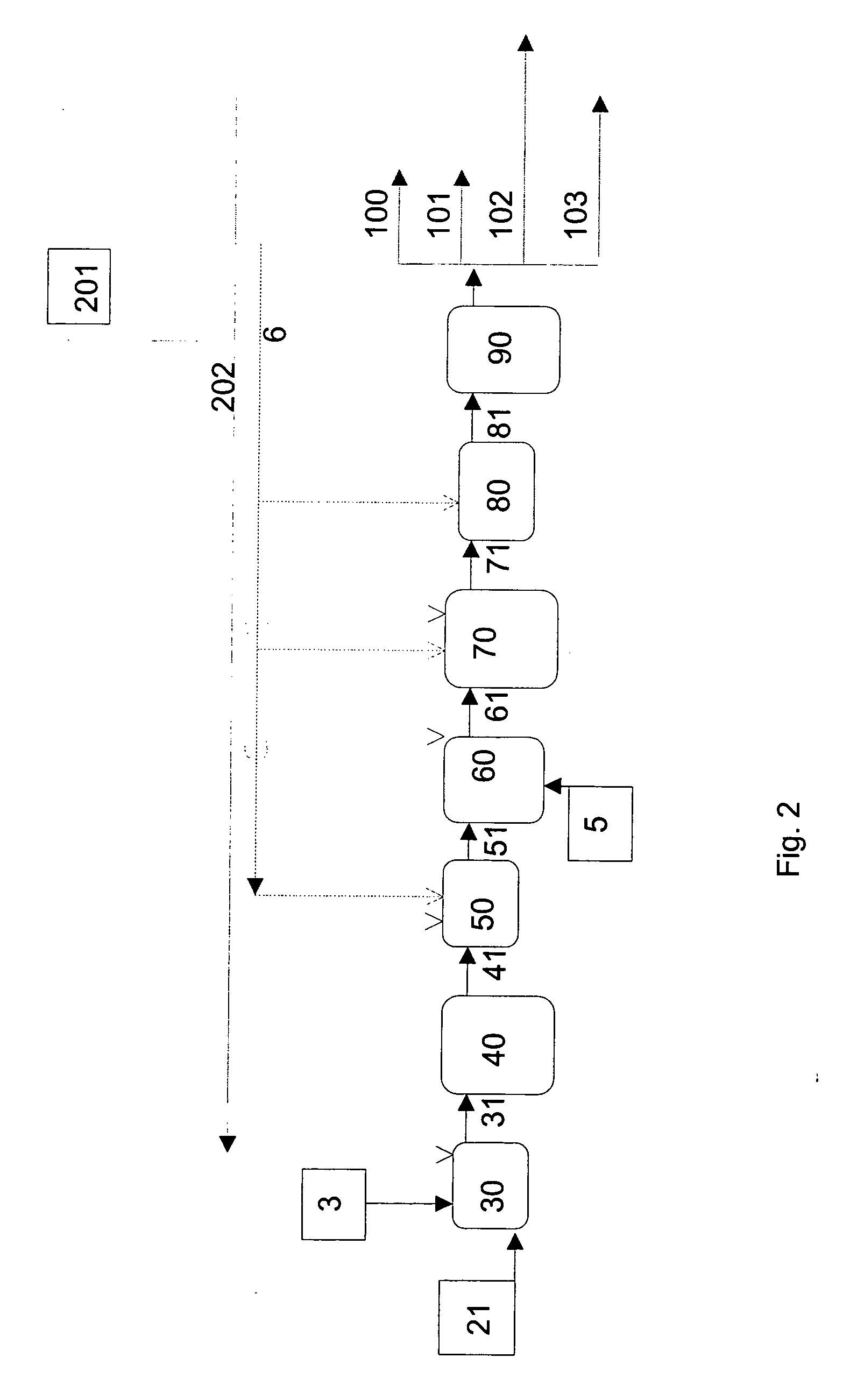

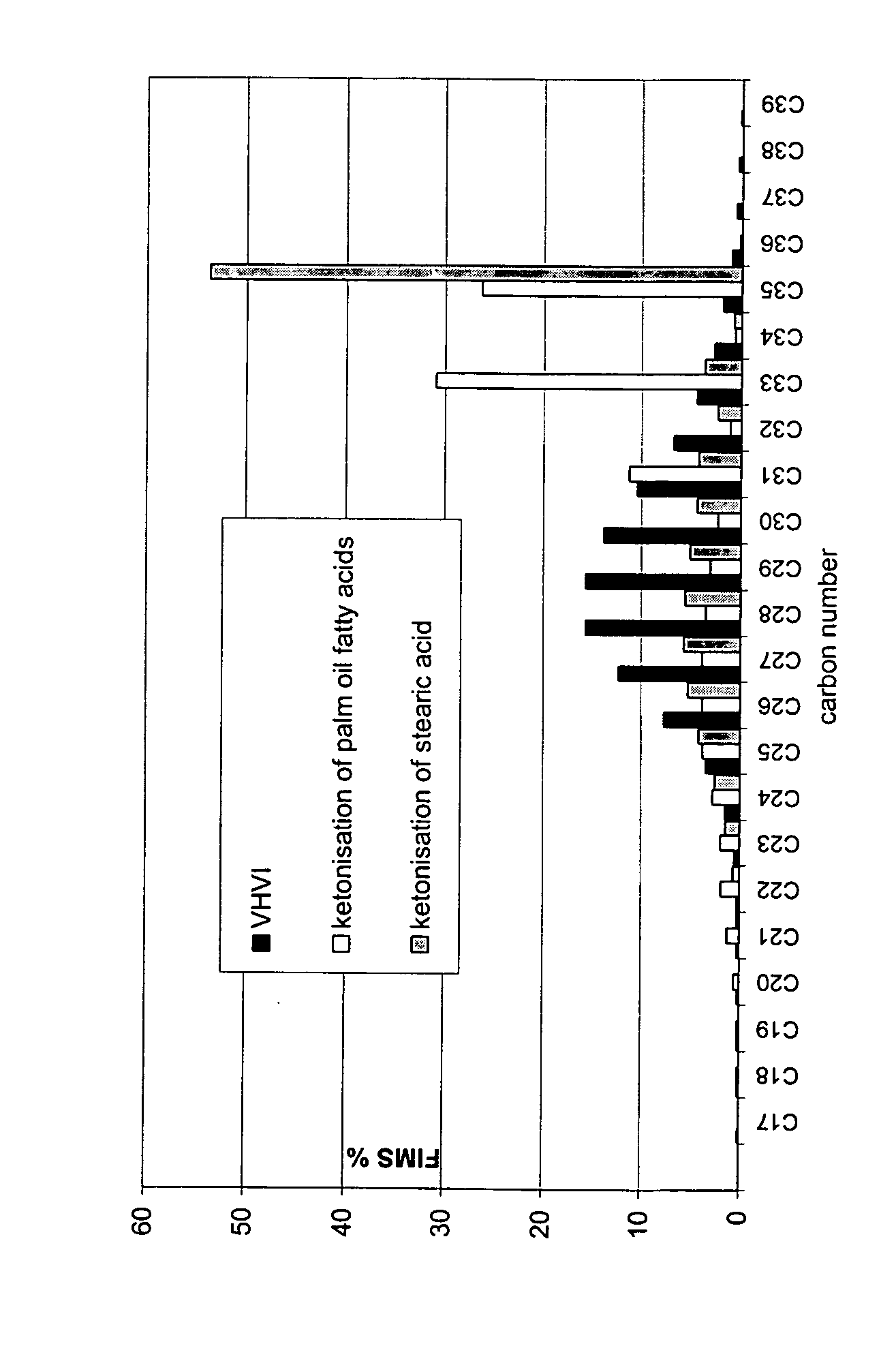

Process for producing a hydrocarbon component

ActiveUS20070161832A1Reduce carbon dioxide emissionsImprove low temperature performanceFatty oils/acids recovery from wasteFatty acid hydrogenationIsomerizationHydrodeoxygenation

The invention relates to a process for producing a new type of high-quality hydrocarbon base oil of biological origin. The process of the invention comprises ketonisation, hydrodeoxygenation, and isomerization steps. Fatty acids and / or fatty acid esters based on a biological raw material are preferably used as the feedstock.

Owner:NESTE OIL OY

Production of Blended Fuel from Renewable Feedstocks

A process for producing a blended fuel from a paraffin rich component and a cyclic rich component, where each of the components are generated from a renewable feedstock, is presented. The paraffin rich component is generated from a first renewable feedstock comprising at least one component selected from the group consisting of glycerides, free fatty acids, biomass, lignocellulose, free sugars, and combinations thereof. The cyclic rich component is generated from a second renewable feedstock comprising at least one component selected from the group consisting of glycerides, free fatty acids, free fatty alkyl esters, biomass, lignocellulose, free sugars, and combinations thereof. The blended fuel may a gasoline boiling point range blended fuel, a diesel boiling point range blended fuel, an aviation boiling point range blended fuel, any combination thereof, or any mixture thereof.

Owner:UOP LLC

Lubricants containing molybdenum compounds, phenates and diarylamines

There is disclosed a lubricating oil composition which contains from about 50 to 1000, preferably 50 to 500 parts per million of molybdenum from a molybdenum compound which is oil-soluble and substantially free of reactive sulfur, about 1,000 to 20,000, preferably 1,000 to 10,000 parts per million of a diarylamine and about 2,000 to 40,000 parts per million of a phenate. This combination of ingredients provides improved oxidation control and improved deposit control to the lubricating oil. The composition is particularly suited for use as a crankcase lubricant.

Owner:AFTON CHEM INTANGIBLES

Finished lubricating comprising lubricating base oil with high monocycloparaffins and low multicycloparaffins

ActiveUS20050133407A1Improve Oxidation StabilityReduce wearRefining to change hydrocarbon structural skeletonLiquid hydrocarbon mixture productionMolecular sieveWax

A process for manufacturing a finished lubricant by: a) performing Fischer-Tropsch synthesis on syngas to provide a product stream; b) isolating from said product stream a substantially paraffinic wax feed having less than about 30 ppm total nitrogen and sulfur, and less than about 1 wt % oxygen; c) dewaxing said feed by hydroisomerization dewaxing using a shape selective intermediate pore size molecular sieve comprising a noble metal hydrogenation component, wherein the hydroisomerization temperature is between about 600° F. (315° C.) and about 750° F. (399° C.), to produce an isomerized oil; and d) hydrofinishing said isomerized oil, whereby a lubricating base oil is produced having specific desired properties; and e) blending the lubricating base oil with at least one lubricant additive.

Owner:CHEVROU USA INC

Pentafluoropropene-based compositions

ActiveUS6858571B2Reduce flammabilityMaximize effectivenessBiocideOrganic chemistry1,1-Difluoroethane1,3,3,3-Tetrafluoropropene

Provided are azeotrope-like compositions comprising pentafluoropropene (HFO-1225) and a fluid selected from the group consisting of 3,3,3-trifluoropropene (“HFO-1243zf”), 1,1-difluoroethane (“HFC-152a”), trans-1,3,3,3-tetrafluoropropene (“HFO-1234ze”), and combinations of two or more thereof. Also provided are uses thereof including as refrigerants, blowing agents, sprayable compositions, flame suppressant, and the like.

Owner:HONEYWELL INT INC

Lubricating oil formulations

Lubricating oil compositions having excellent thermal and oxidative stability, wear control, copper corrosion control and compatibility with seal materials comprising a mineral oil having a) a Viscosity Index of greater than 110 and an aniline point of greater than 110 DEG C. and / or b) a linear+single ring paraffin content of greater than 68 wt %, and at least one polymer selected from olefin (co) polymer(s), polyalkyl (meth) acrylate(s) and mixtures thereof. The lubricating oil compositions are particularly useful as manual transmission and axle lubricants.

Owner:AFTON CHEM INTANGIBLES

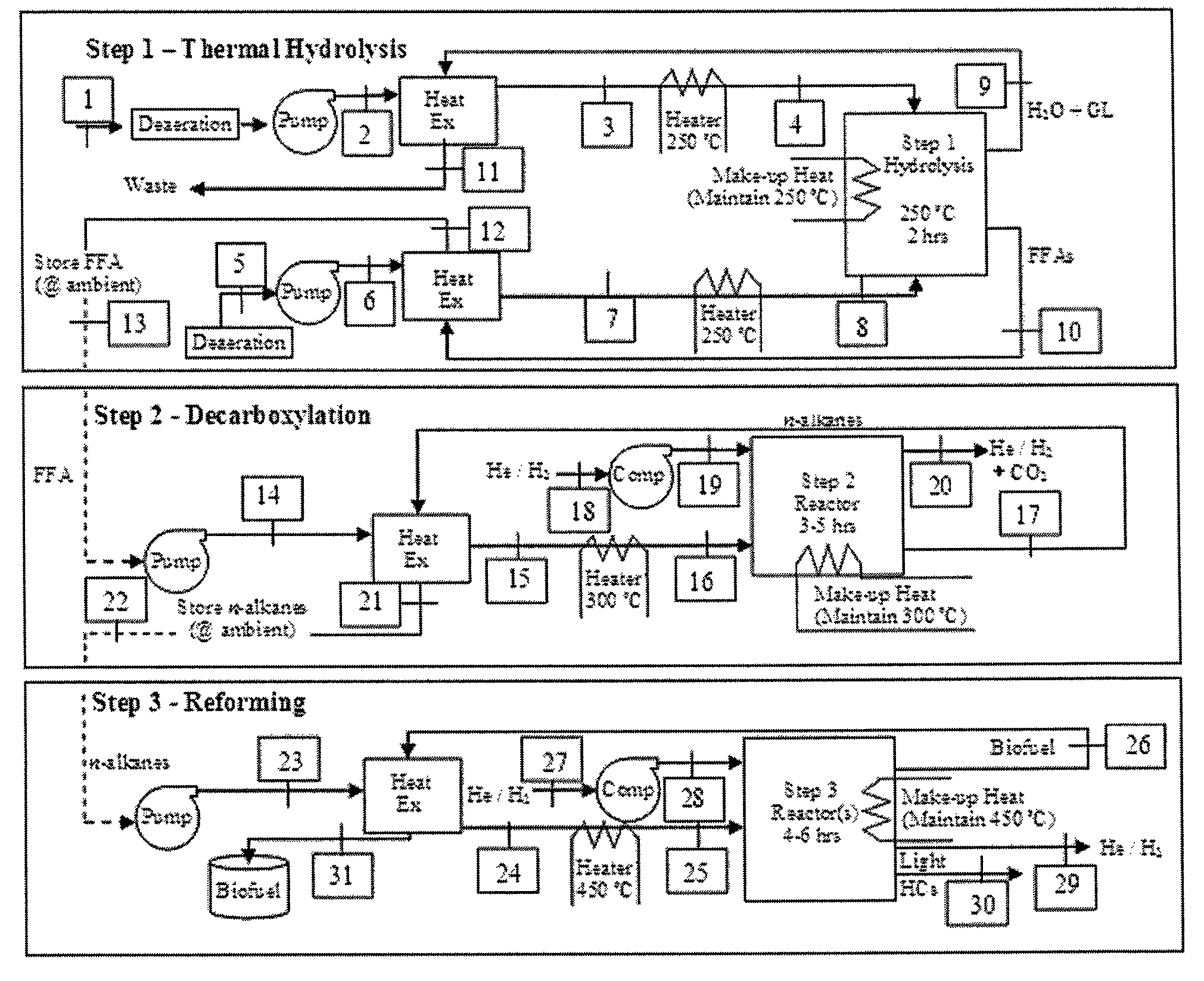

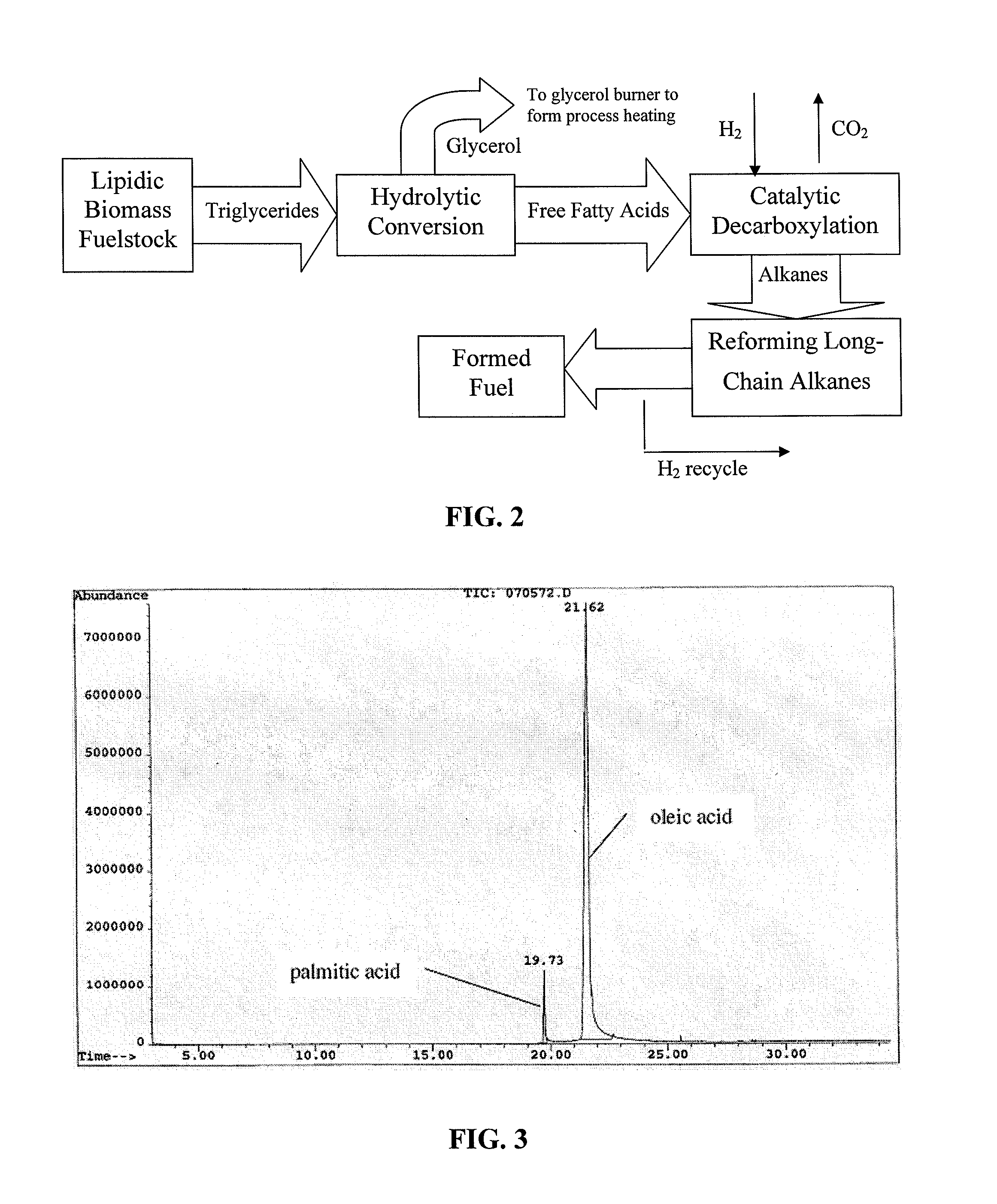

Process for conversion of biomass to fuel

ActiveUS7816570B2Meet growth needsEasy to processFatty acid esterificationRefining to change hydrocarbon structural skeletonAlkaneChain length

Owner:NORTH CAROLINA STATE UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com