Patents

Literature

142 results about "Diesel injector" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

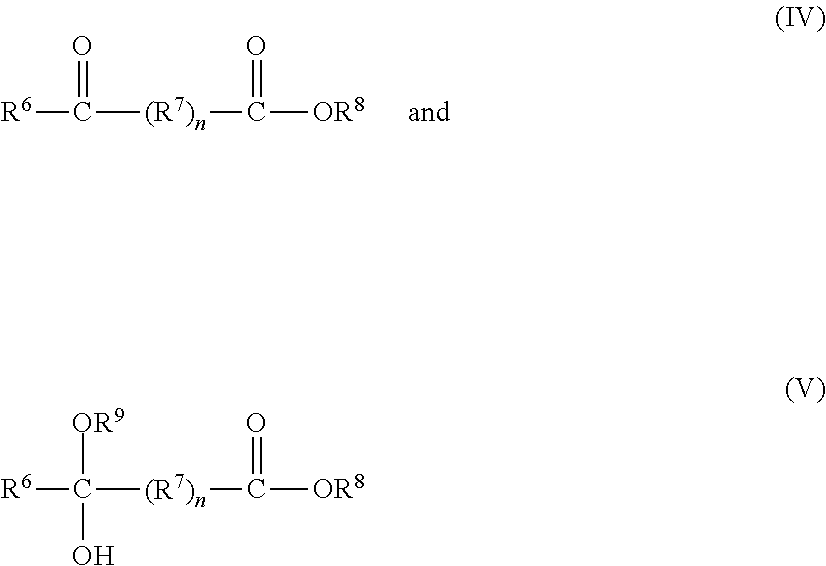

Acid-free quaternized nitrogen compounds and use thereof as additives in fuels and lubricants

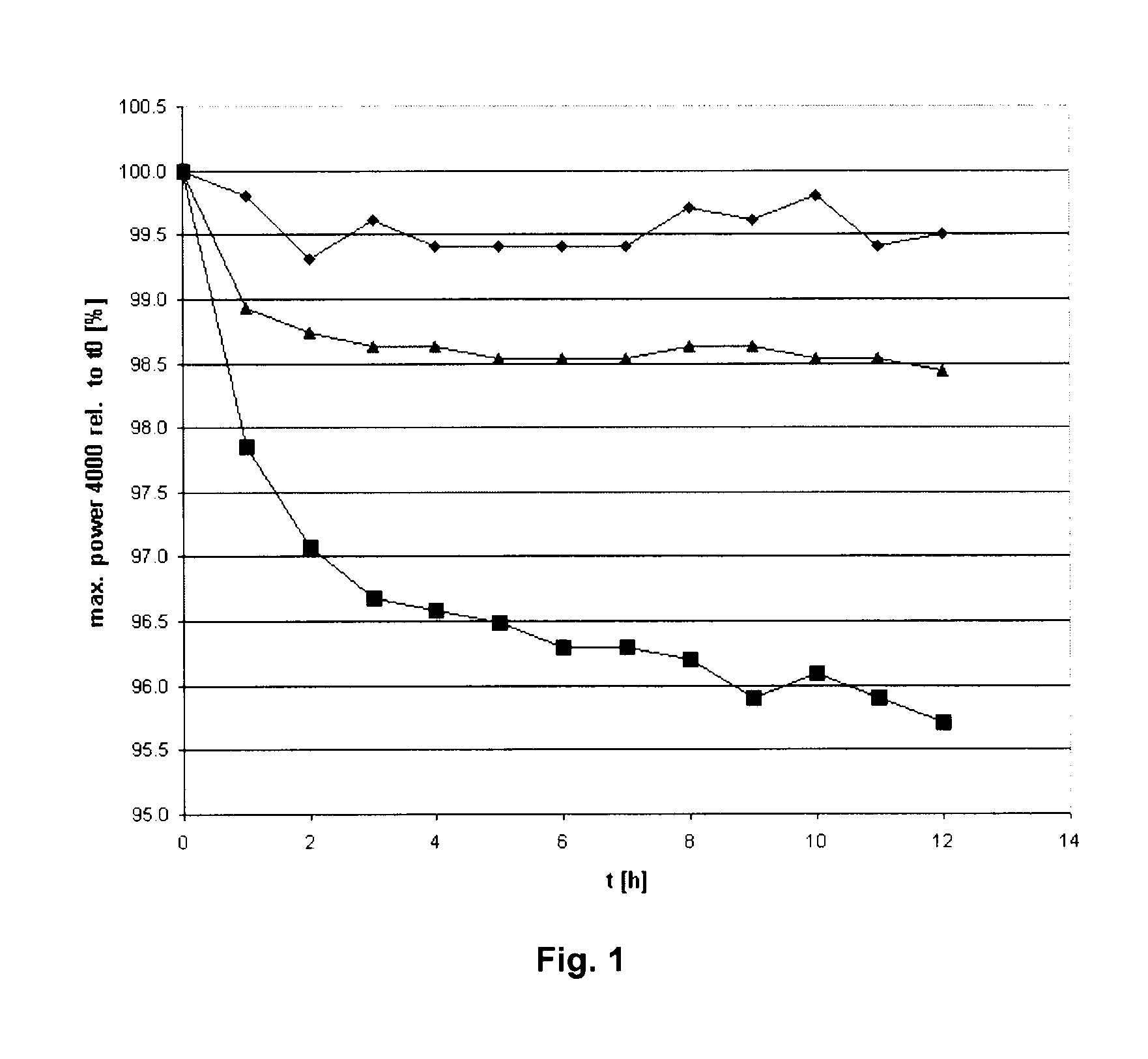

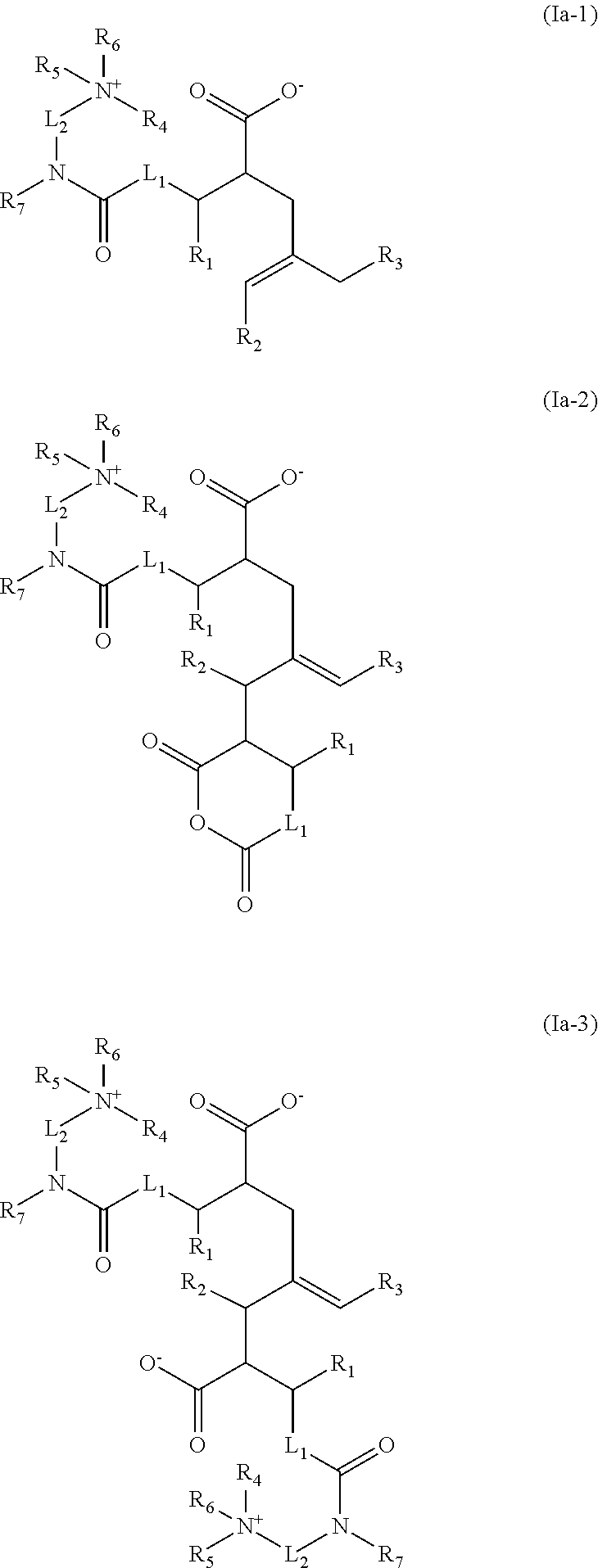

The present invention relates to novel acid-free quaternized nitrogen compounds, to the preparation thereof and to the use thereof as a fuel and lubricant additive, more particularly as a detergent additive, as a wax antisettling additive (WASA) or as an additive for reducing internal diesel injector deposits (IDID); to additive packages which comprise these compounds; and to fuels and lubricants thus additized. The present invention further relates to the use of these acid-free quaternized nitrogen compounds as a fuel additive for reducing or preventing deposits in the injection systems of direct-injection diesel engines, especially in common-rail injection systems, for reducing the fuel consumption of direct-injection diesel engines, especially of diesel engines with common-rail injection systems, and for minimizing power loss in direct-injection diesel engines, especially in diesel engines with common-rail injection systems.

Owner:BASF AG

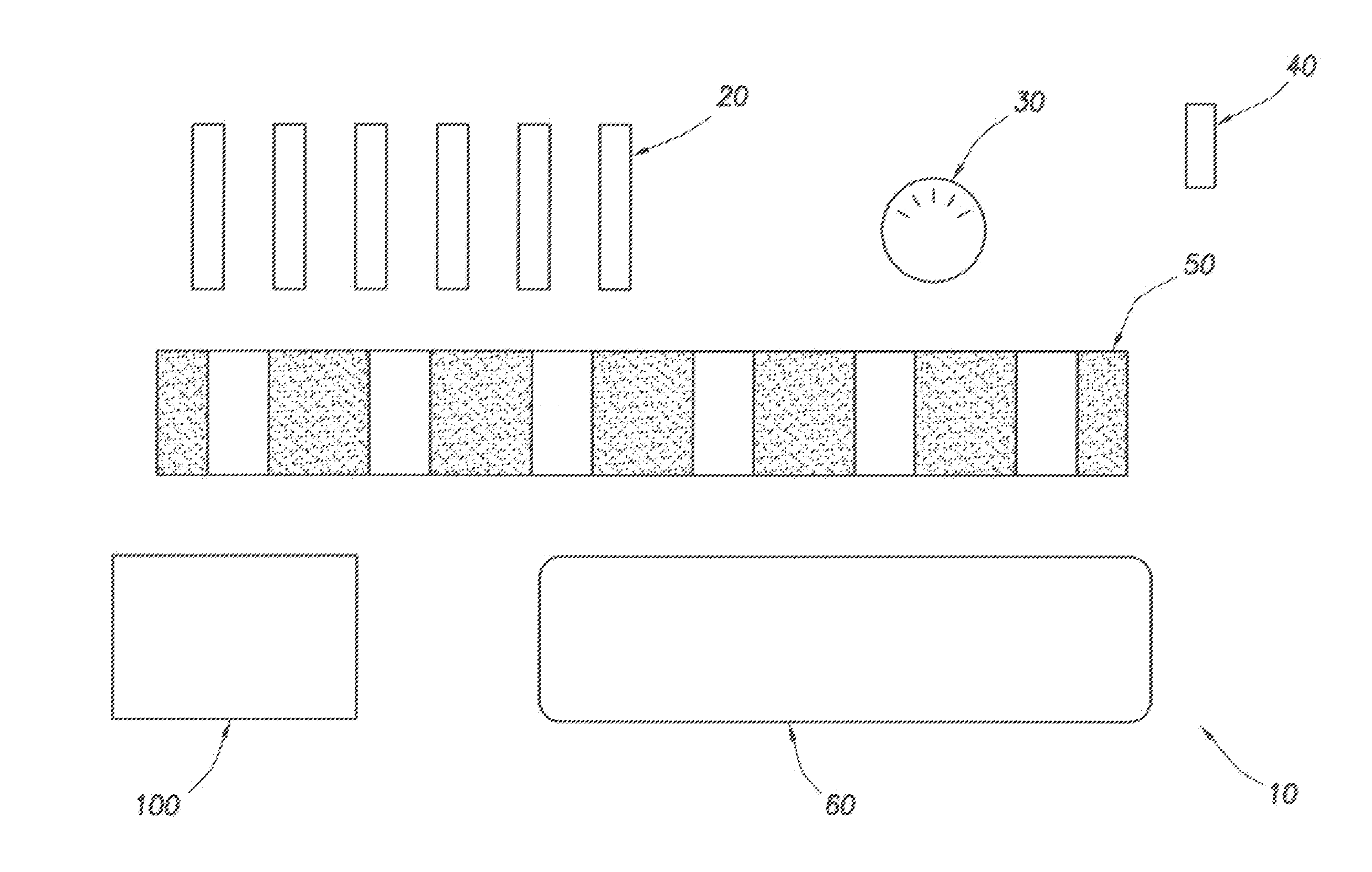

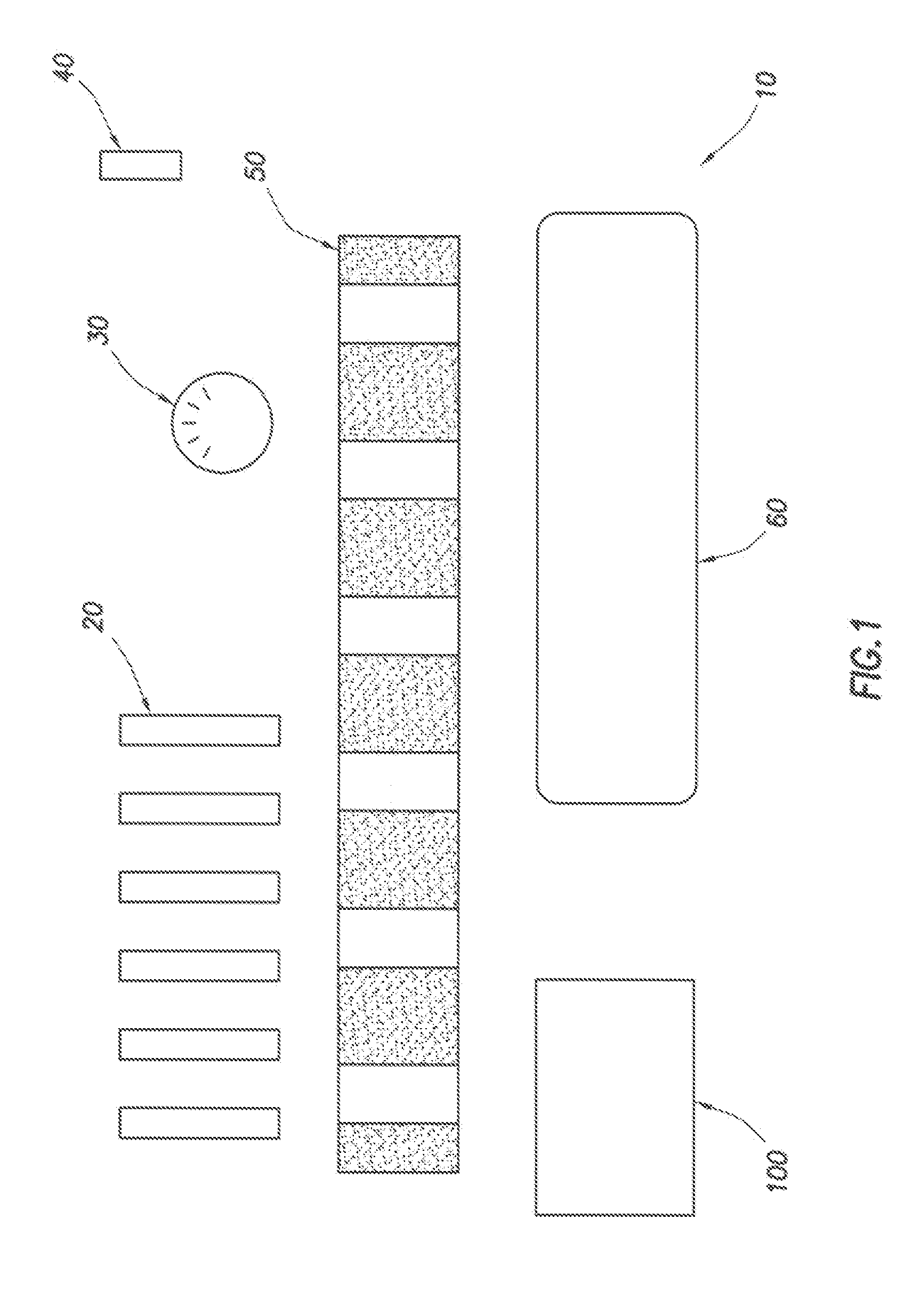

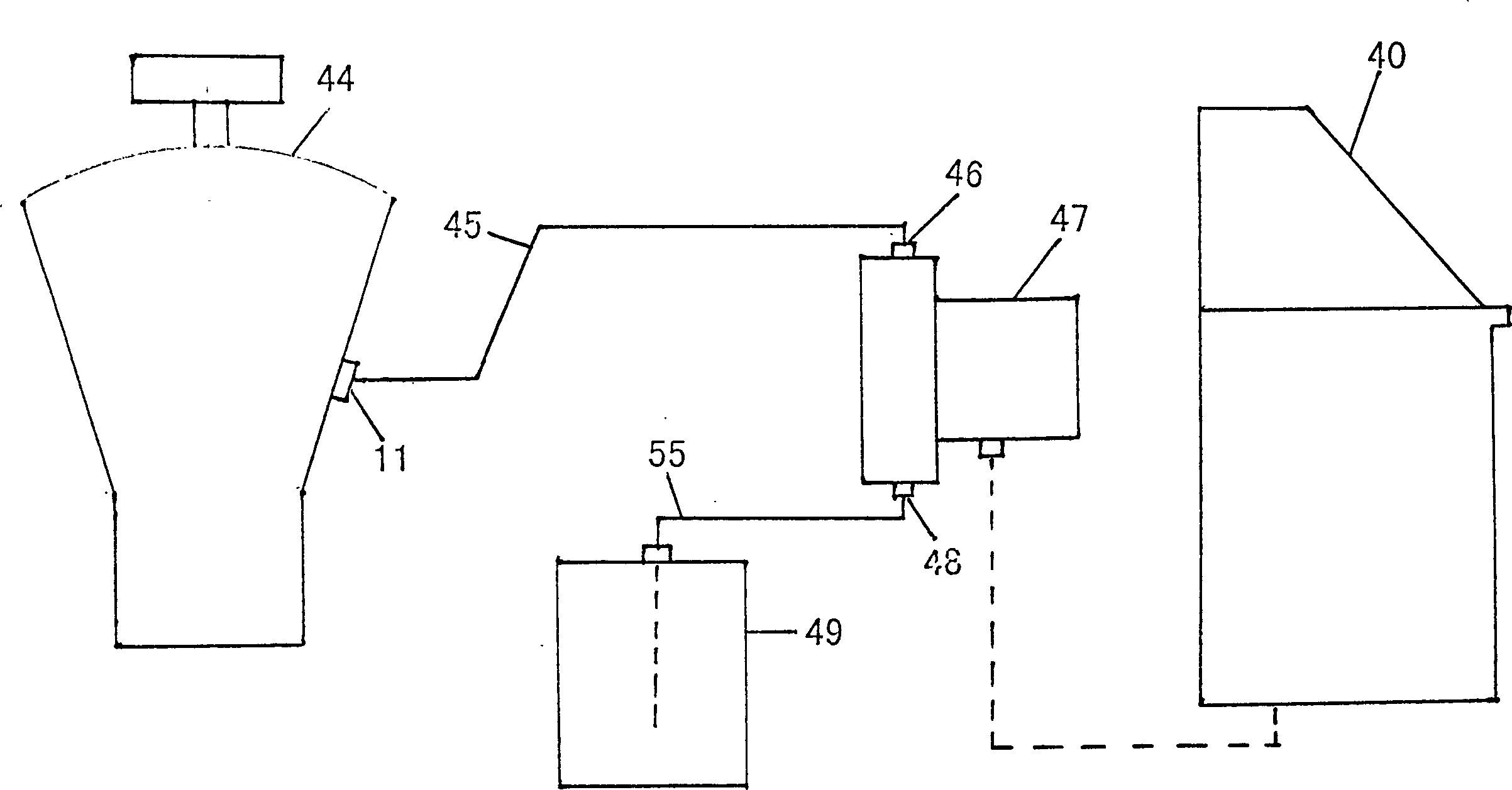

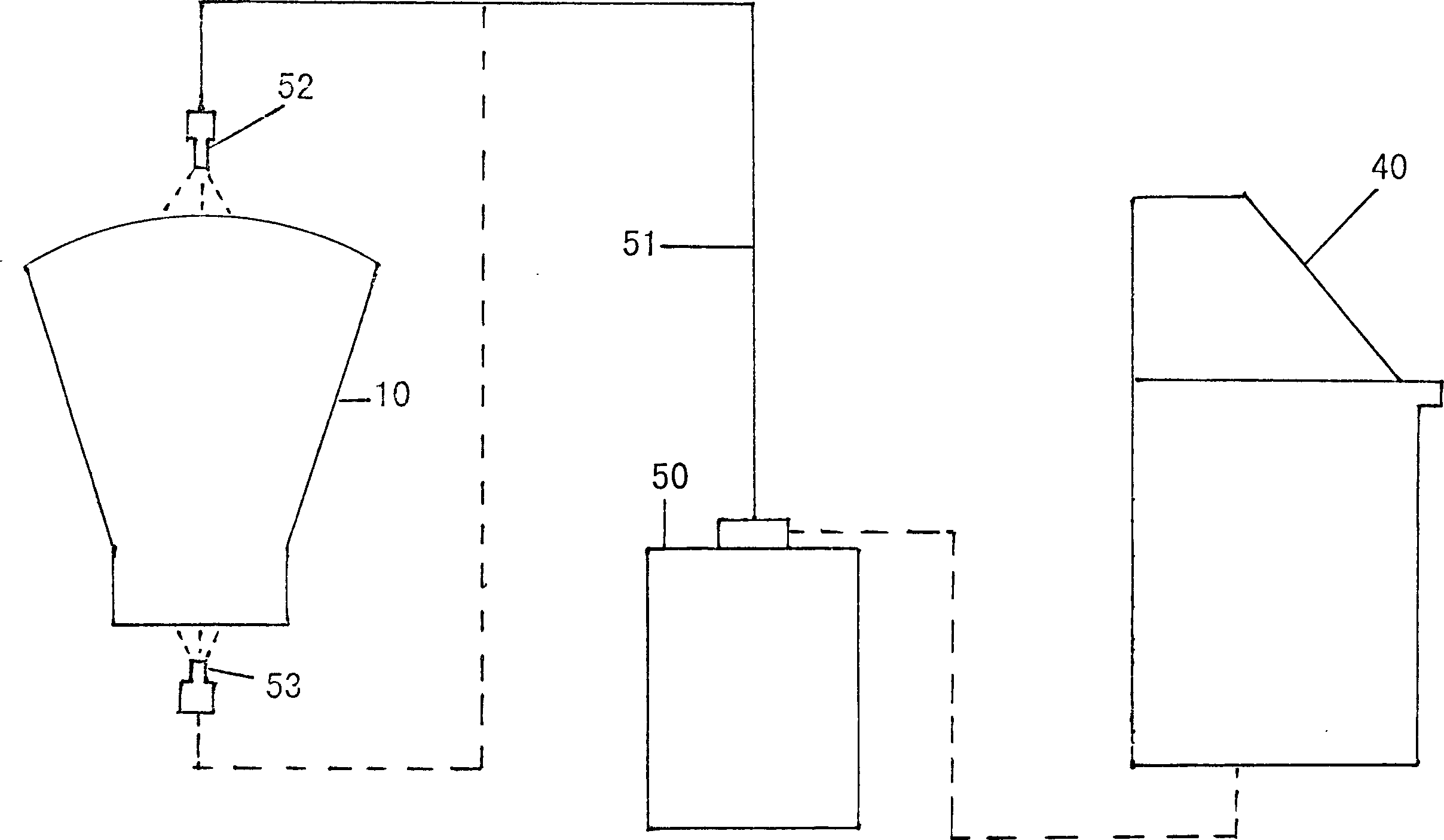

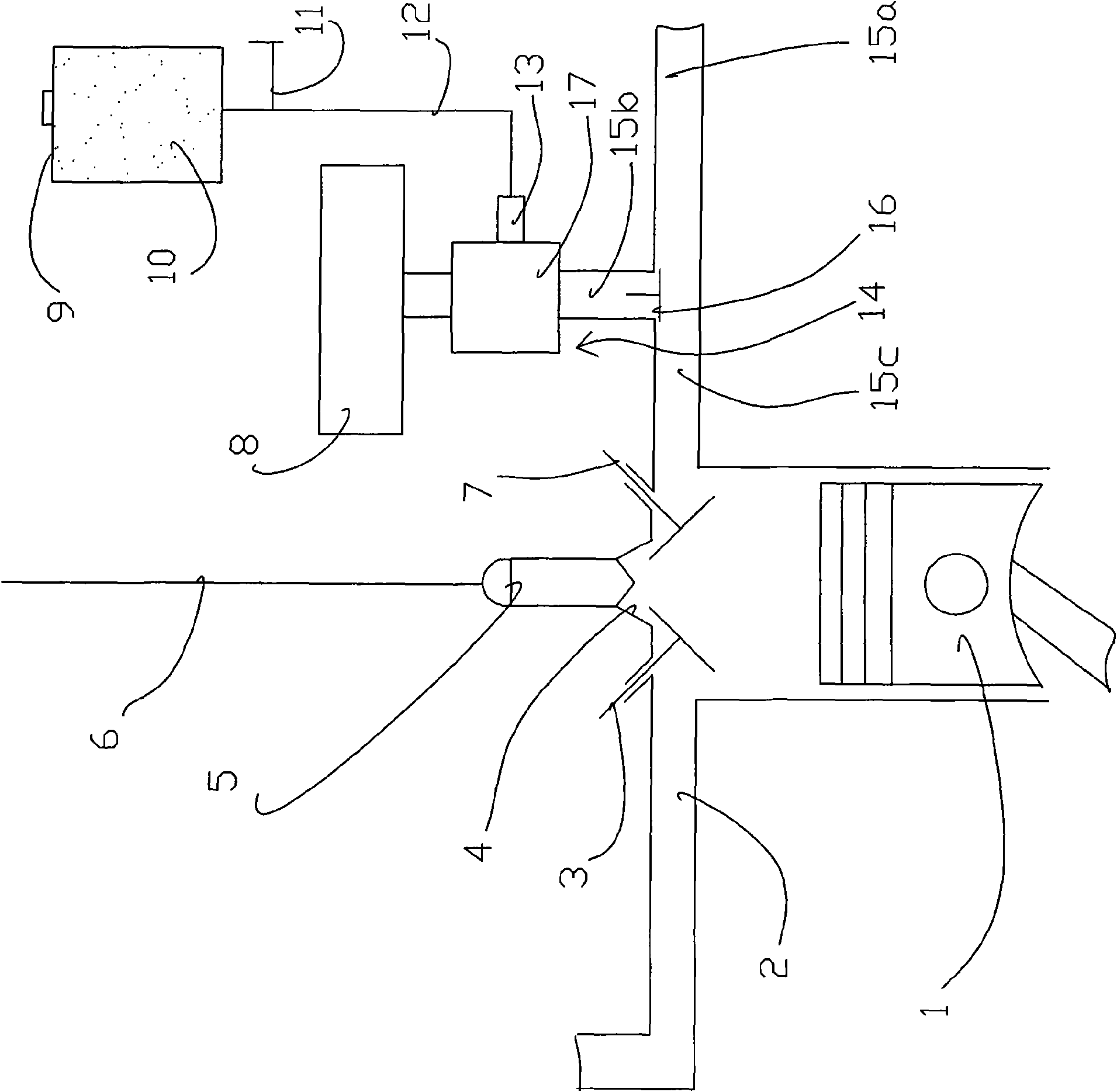

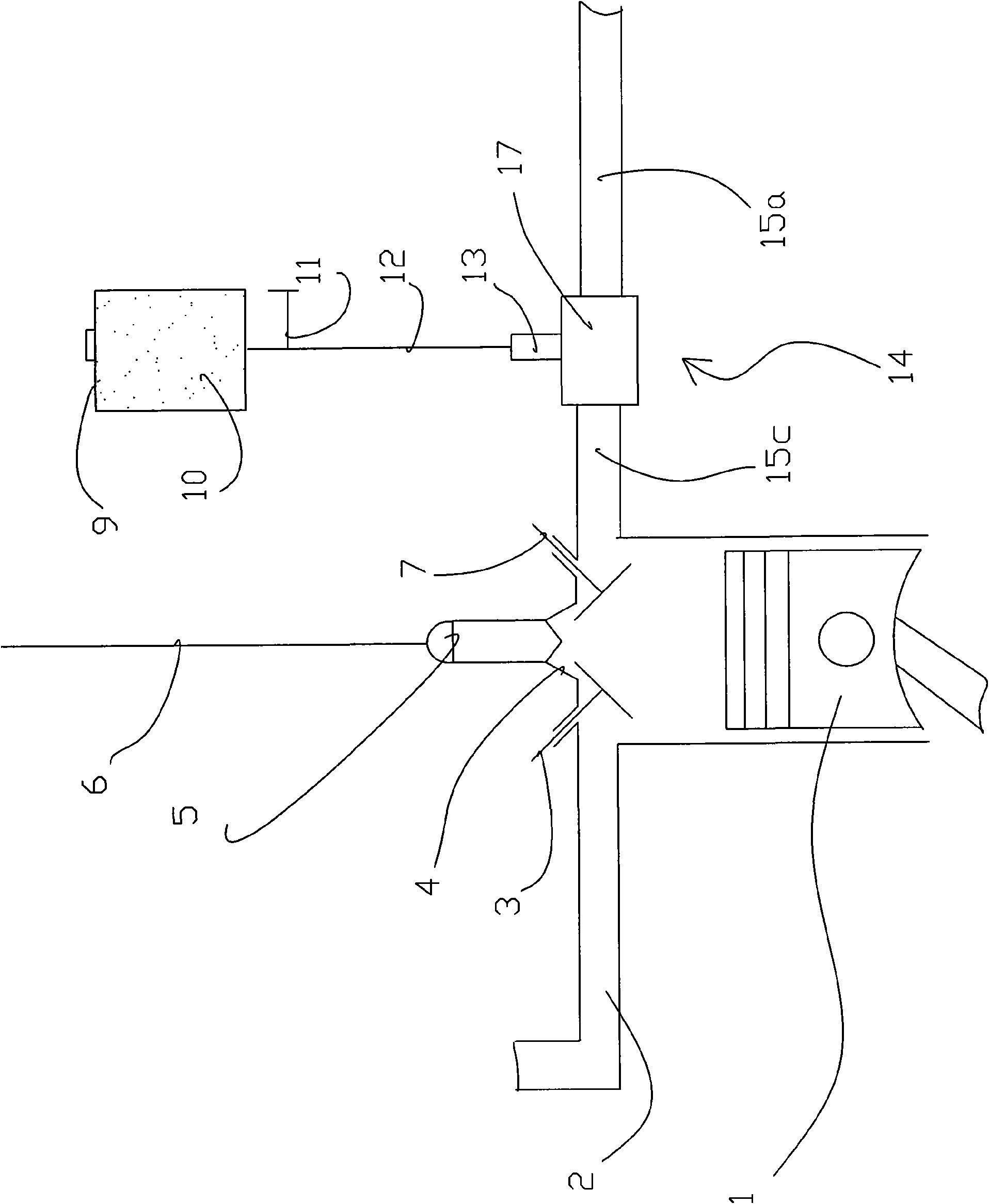

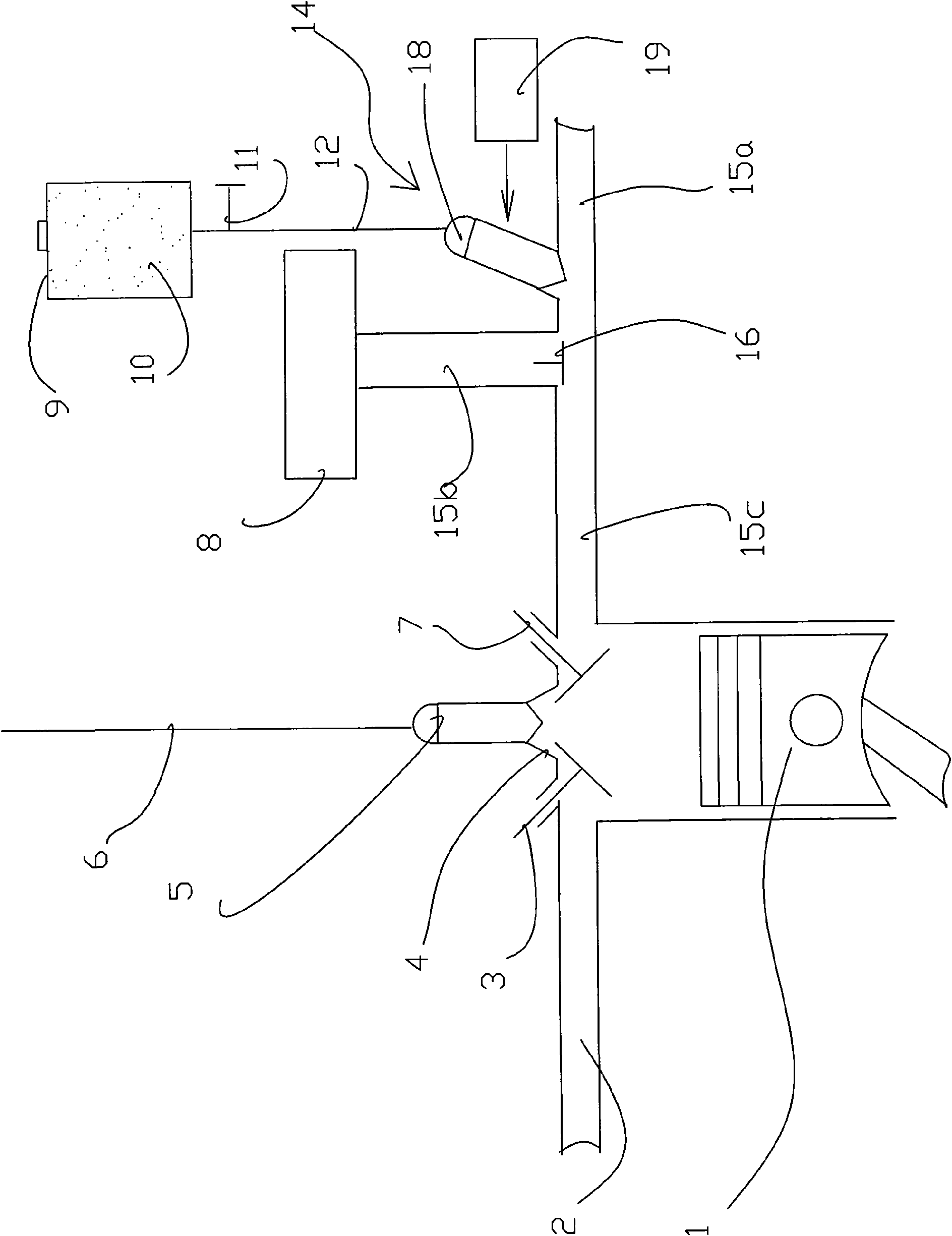

Dual fuel engine

InactiveUS20050205021A1Preventing operation of engineEasy to adaptElectrical controlInternal combustion piston enginesDiesel injectorPiston

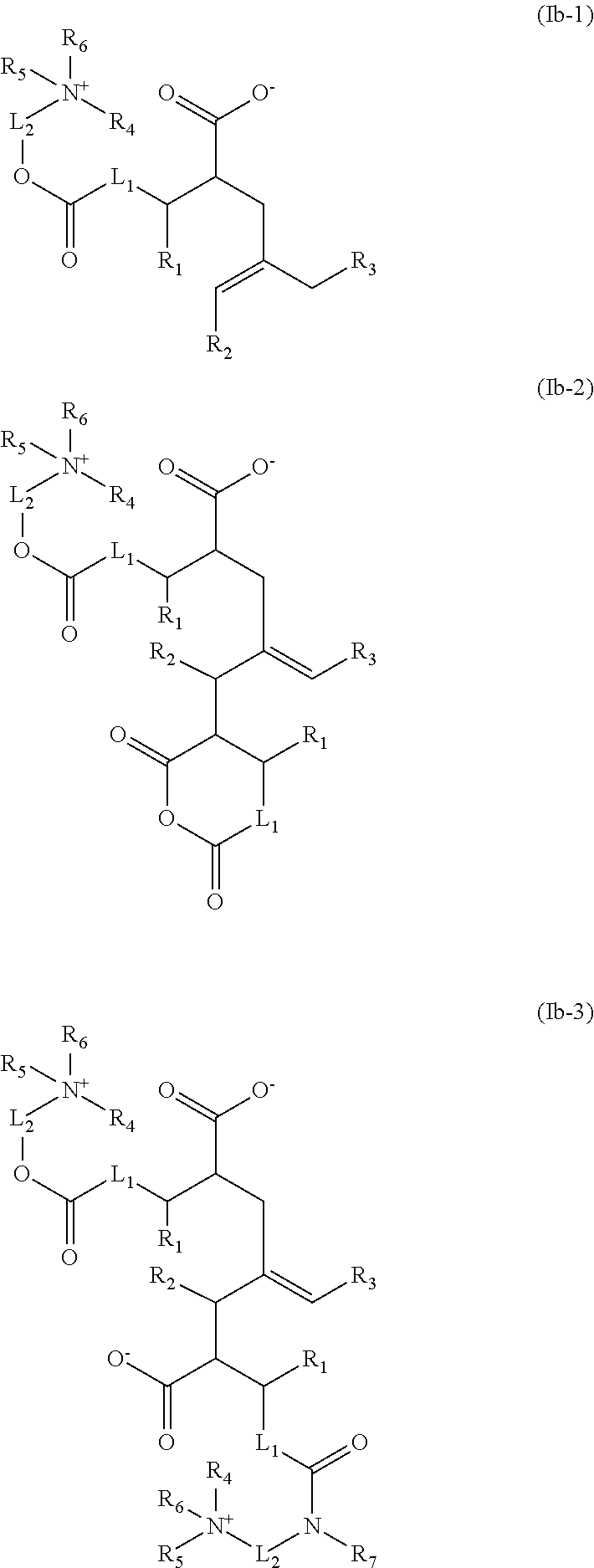

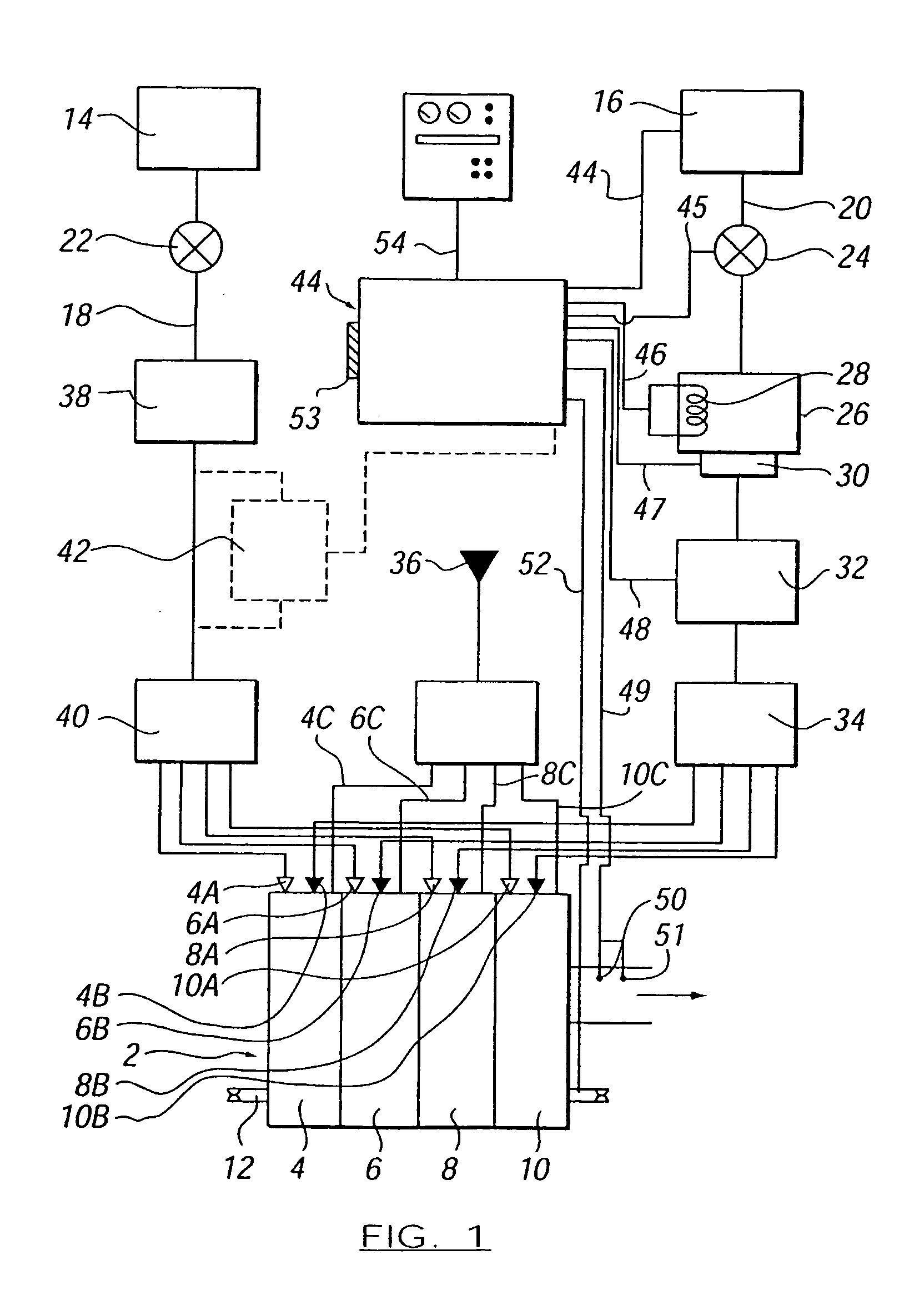

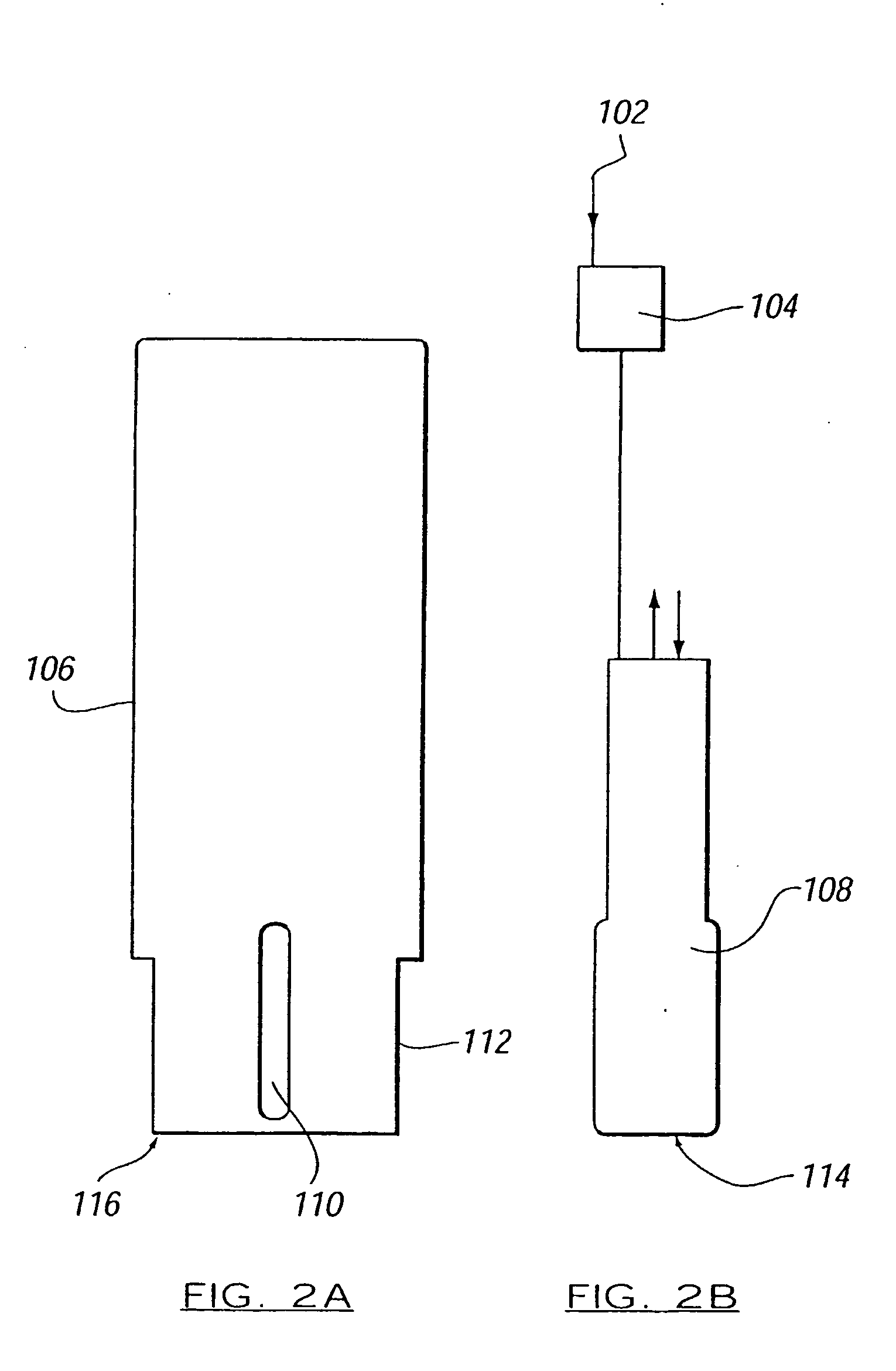

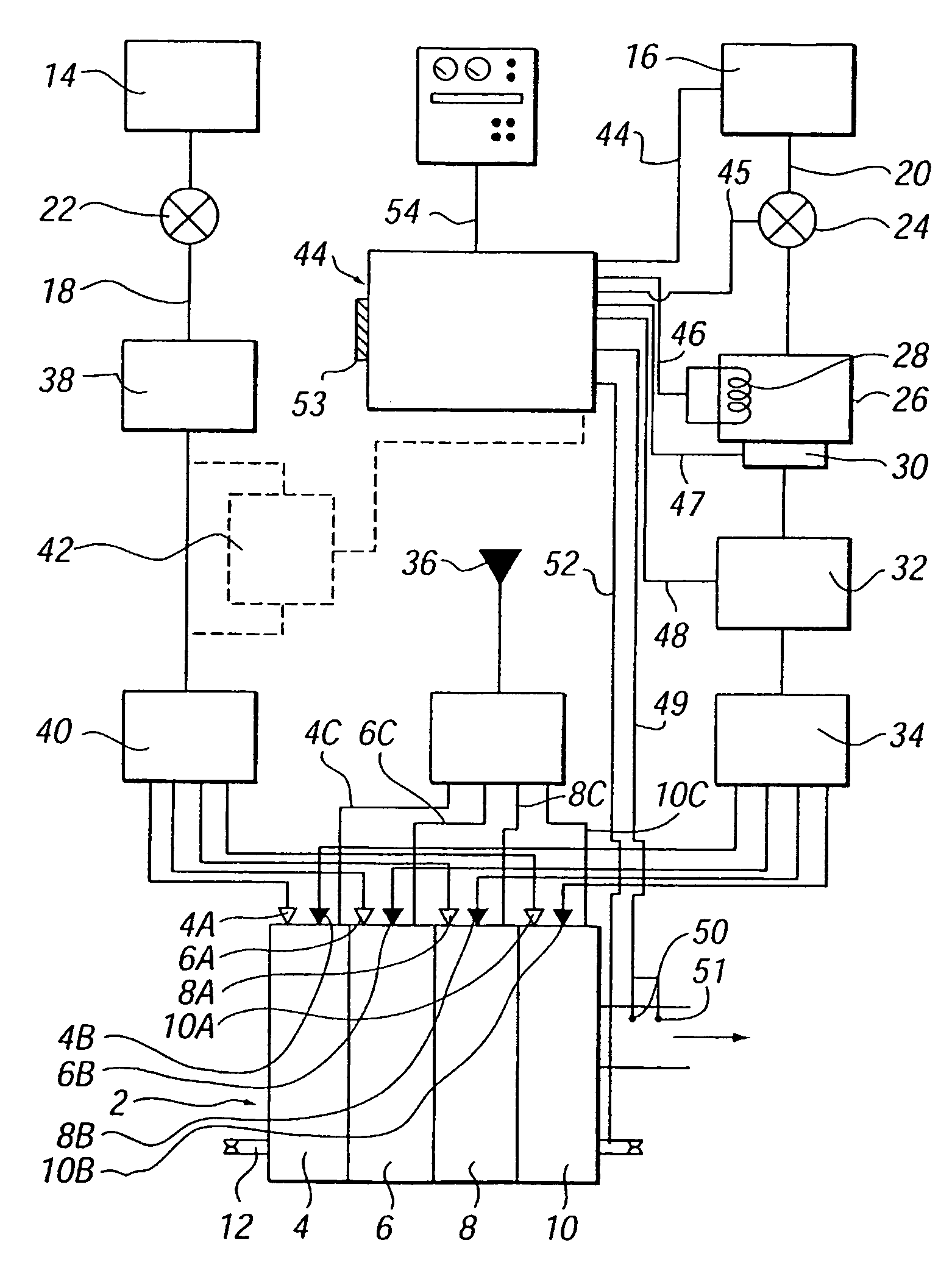

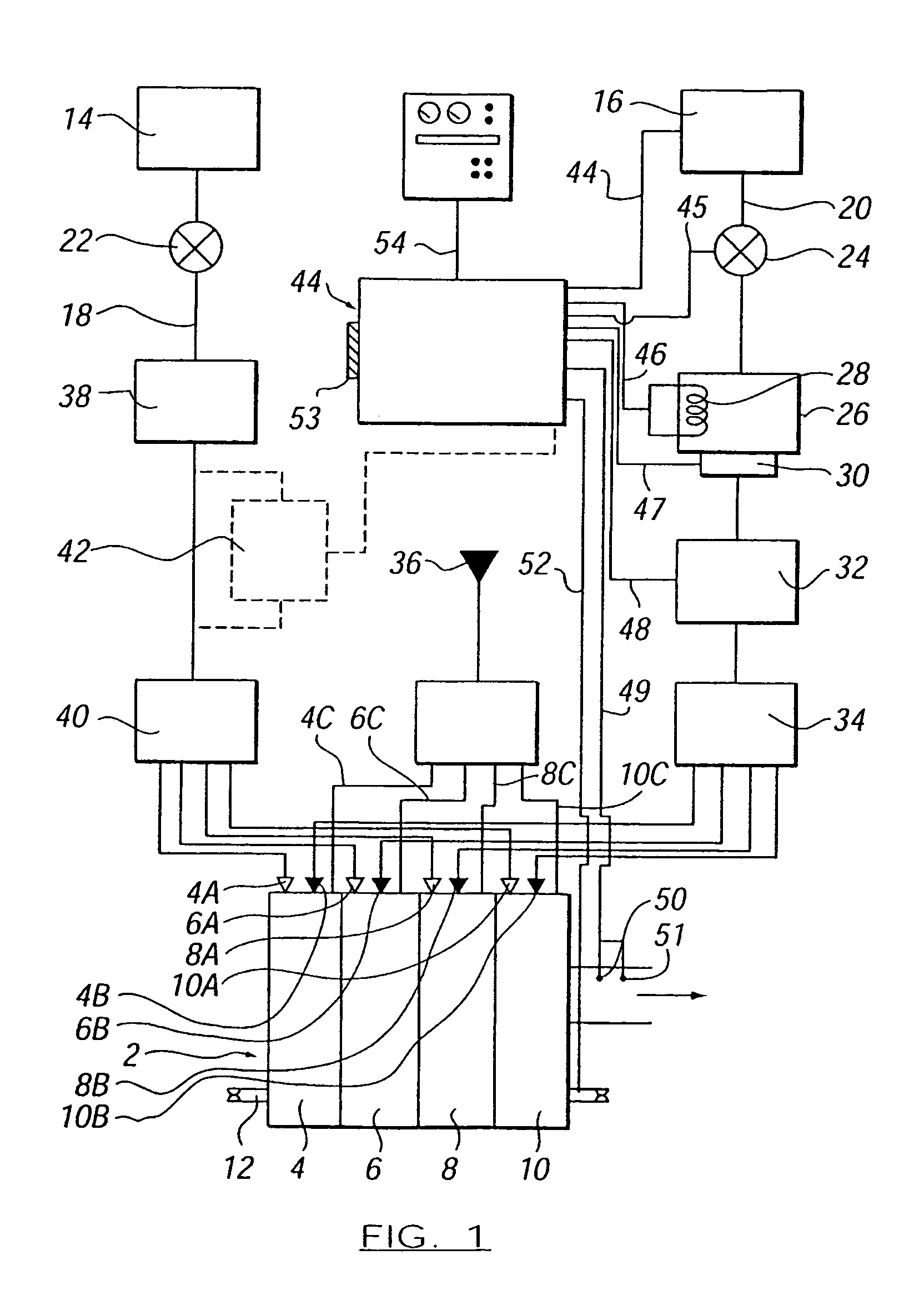

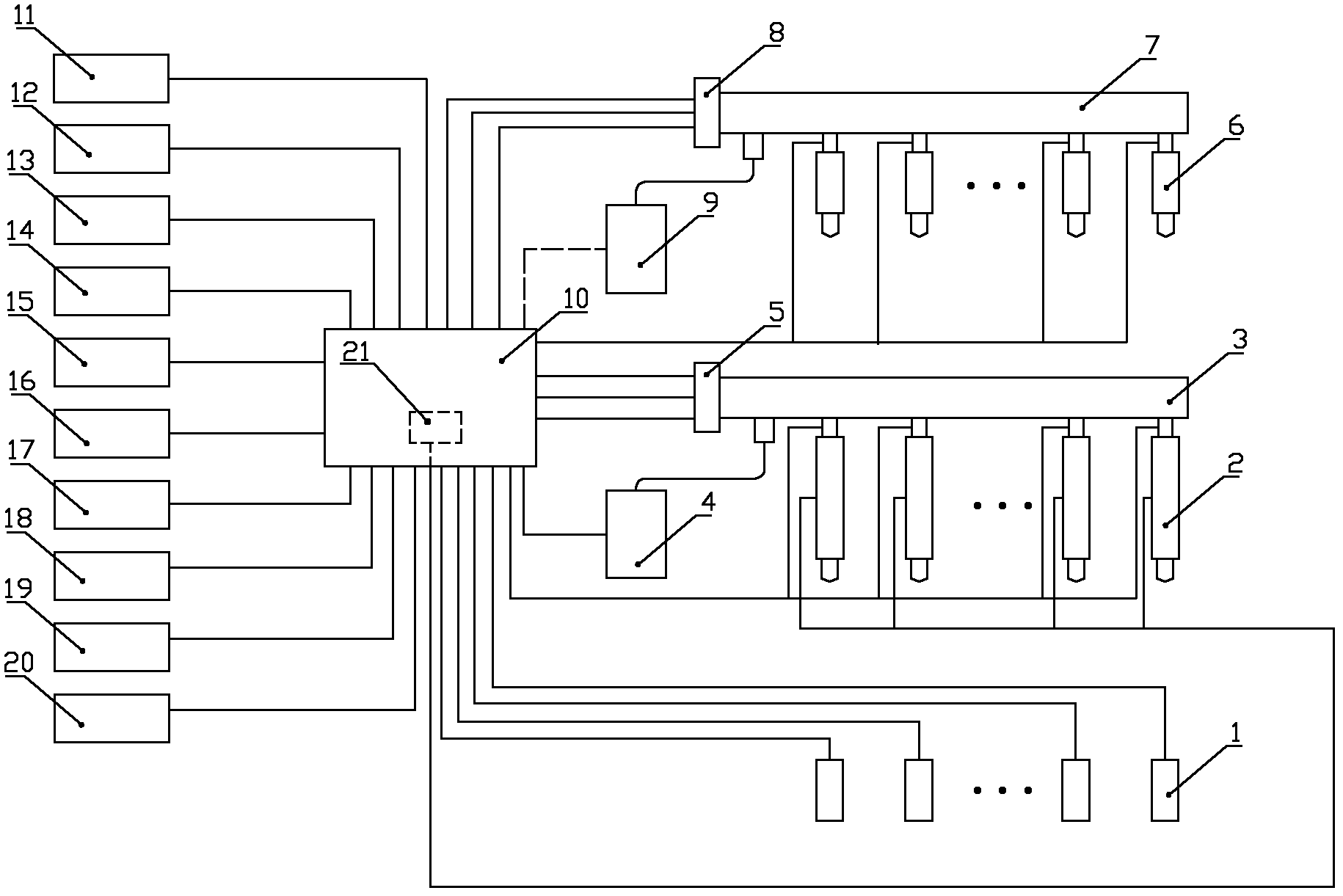

A dual fuel engine (2) is provided which is supplied with diesel fuel and at least one secondary fuel, such as LPG. The engine (2) has a plurality of cylinders (4, 6, 8, 10) in which pistons reciprocate. Each cylinder has diesel injectors (4A, 6A, 8A, 10A) for injecting the diesel fuel into the cylinder during an appropriate stroke of the piston and an air inlet valve (4C, 6C, 8C, 10C) which opens during the appropriate stroke of the piston to permit air flow therethrough. Each cylinder is further provided with LPG injectors (4B, 6B, 8B, 10B) for injecting the secondary fuel into the cylinders. The LPG injectors are independent to and separate from the diesel fuel injectors. The LPG and diesel fuel injectors are also independently controlled.

Owner:INTELLIGENT DIESEL SYST

Dual fuel engine

InactiveUS7444986B2Reduce stepsEasy to adaptElectrical controlInternal combustion piston enginesDiesel injectorPiston

A dual fuel engine (2) is provided which is supplied with diesel fuel and at least one secondary fuel, such as LPG. The engine (2) has a plurality of cylinders (4, 6, 8, 10) in which pistons reciprocate. Each cylinder has diesel injectors (4A, 6A, 8A, 10A) for injecting the diesel fuel into the cylinder during an appropriate stroke of the piston and an air inlet valve (4C, 6C, 8C, 10C) which opens during the appropriate stroke of the piston to permit air flow therethrough. Each cylinder is further provided with LPG injectors (4B, 6B, 8B, 10B) for injecting the secondary fuel into the cylinders. The LPG injectors are independent to and separate from the diesel fuel injectors. The LPG and diesel fuel injectors are also independently controlled.

Owner:INTELLIGENT DIESEL SYST

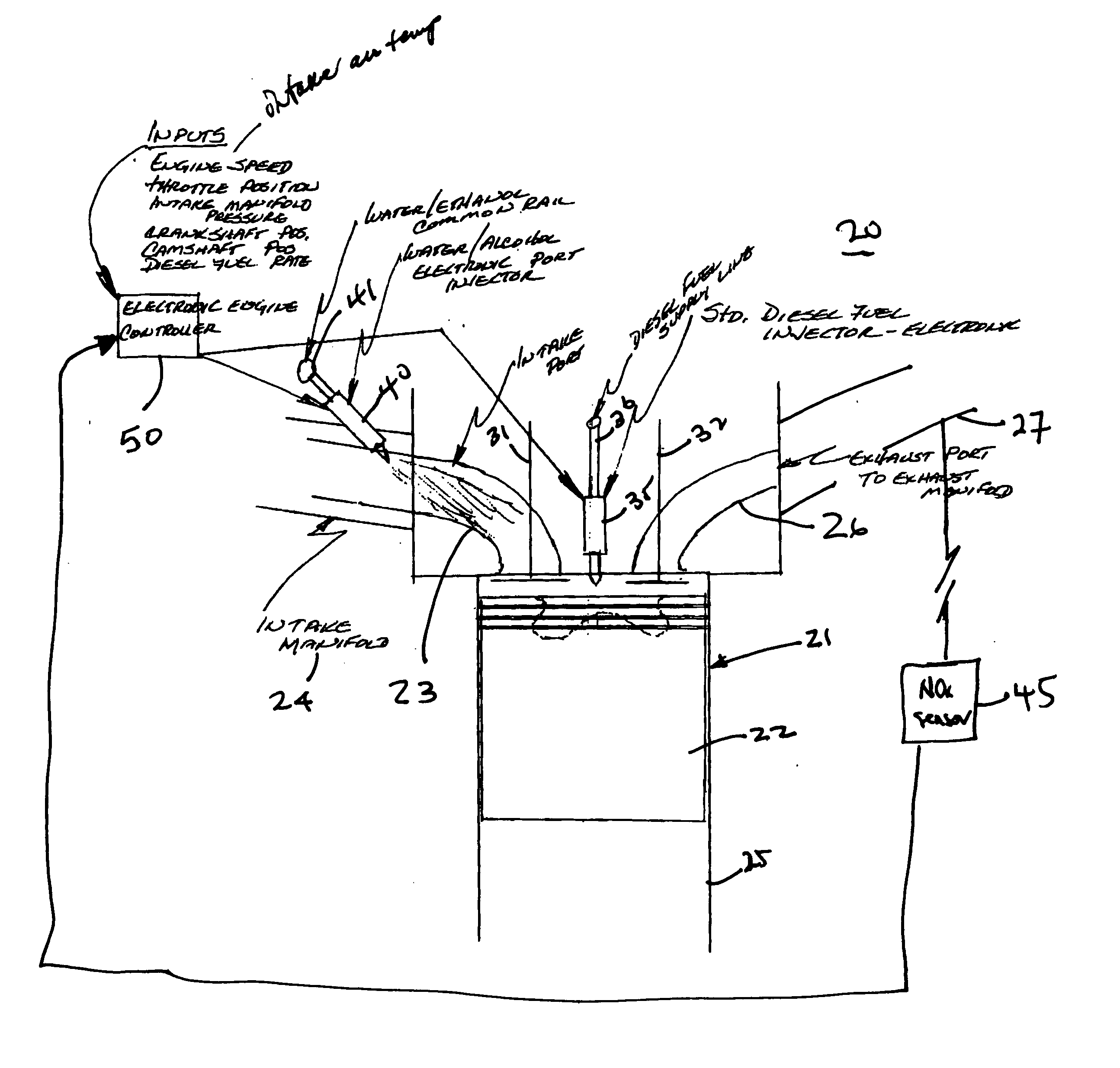

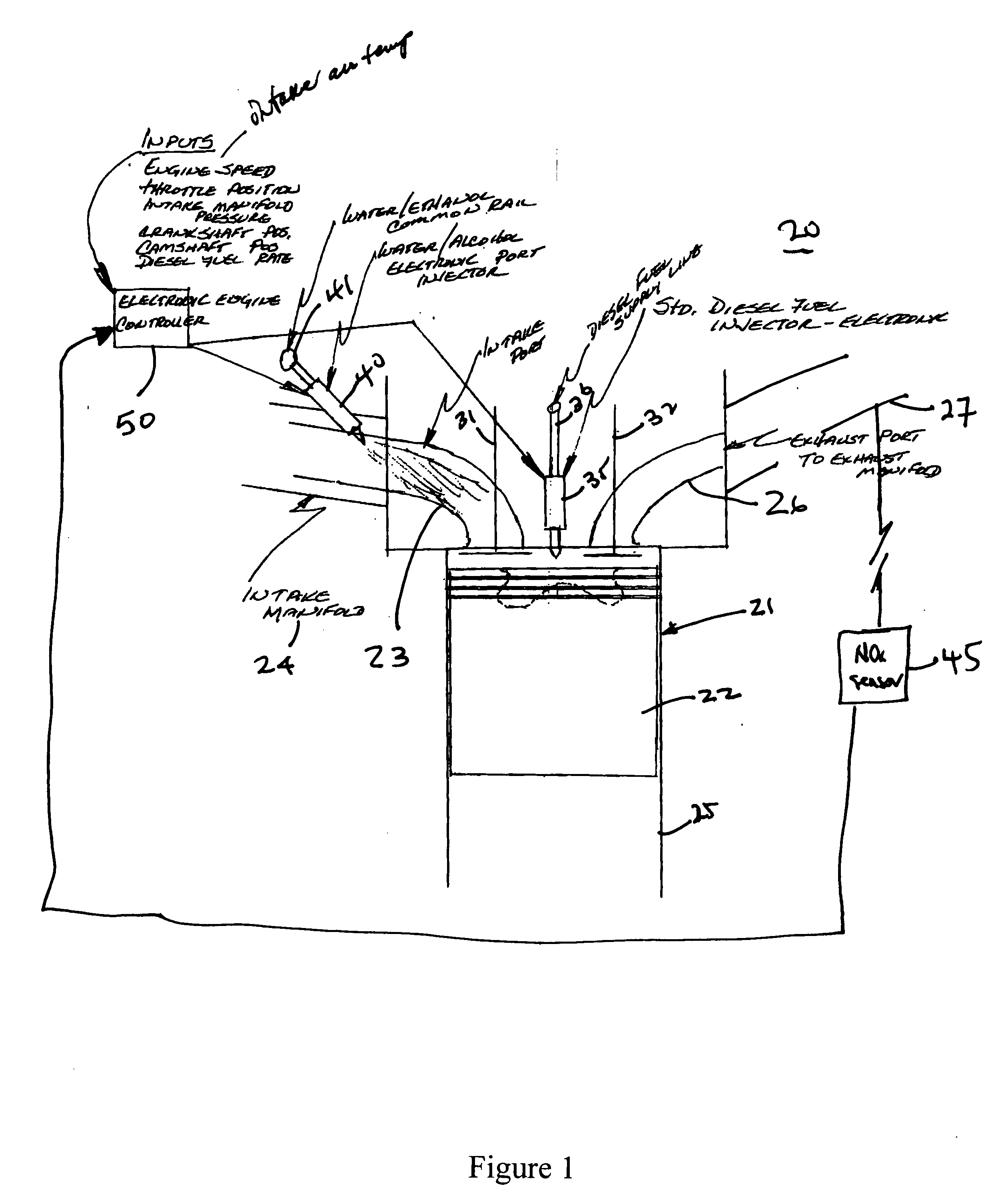

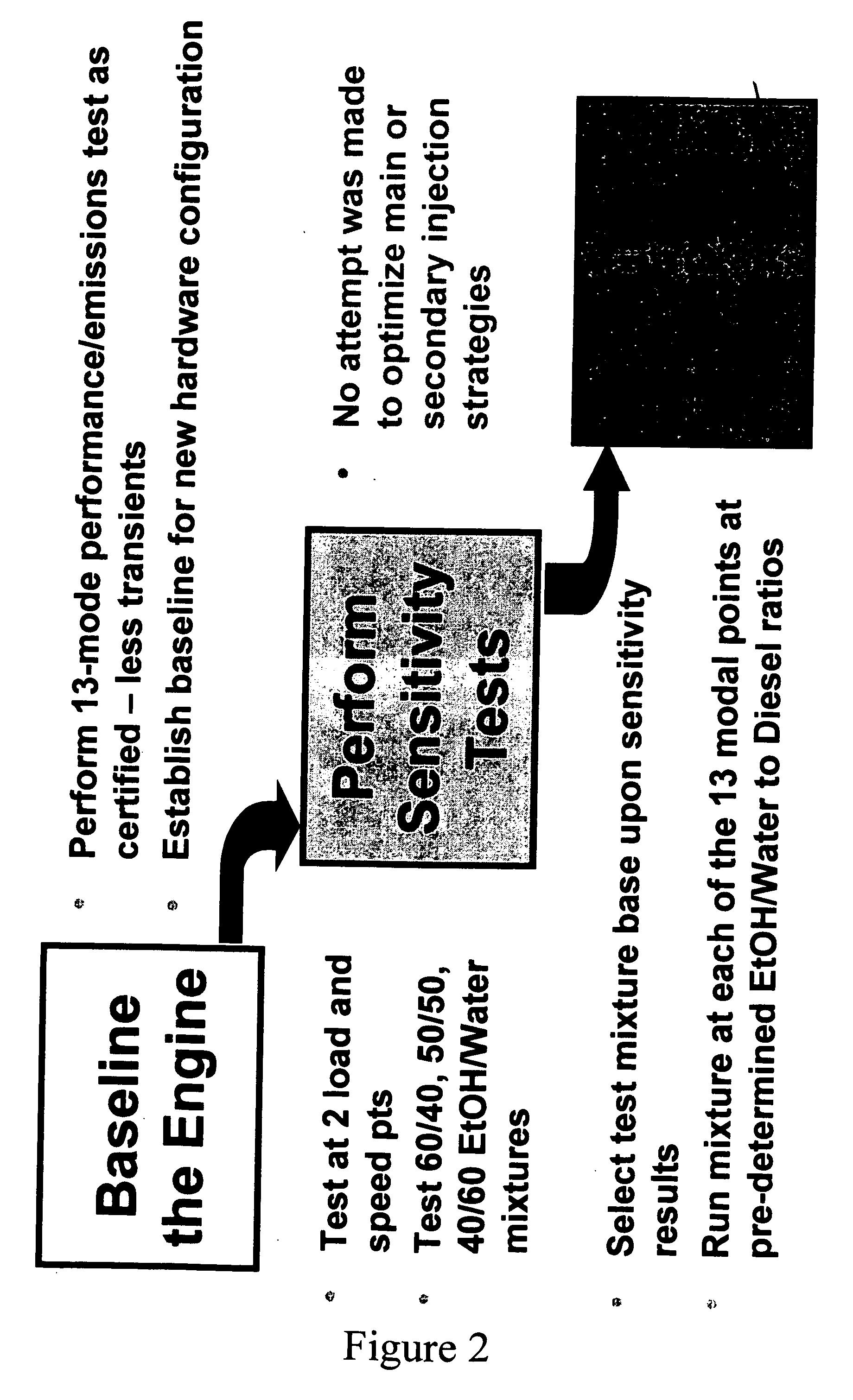

Water and/or alcohol water secondary injection system for diesel engines

InactiveUS20070131180A1Emission reductionImprove fuel efficiencyInternal combustion piston enginesNon-fuel substance addition to fuelCombustion chamberFuel efficiency

A system for reducing the emissions of the oxides of nitrogen(NOx) and improving the fuel efficiency of a diesel engine having at least one combustion chamber and a camshaft and a crankshaft and an intake port and an operator controlled throttle with at least one electronically actuated diesel fuel injector; a diesel fuel supply reservoir communicatively connected with the diesel fuel injector and including diesel fuel pumping means for maintaining diesel fuel pressure at the inlet of the diesel fuel injector; at least one electronically actuated water and / or alcohol injector; a water and / or alcohol supply reservoir communicatively connected with the water and / or alcohol injector and including water and / or alcohol pumping means for maintaining liquid pressure at the inlet of the water and / or alcohol injector; and an electronic regulating means for controlling the rate at which atomized diesel fuel and water and / or alcohol are independently injected respectively into the combustion chamber and intake port. The electronic regulating means is being operatively connected to the injectors and is responsive to one or more of air temperature in the air intake manifold, the position of the throttle, the intake manifold pressure, the camshaft position, the crankshaft position, the engine rotational speed wherein the amount of water and / or alcohol injected into the intake port is controlled as a function of both the amount of diesel fuel and alcohol injected and the ratio of diesel fuel and alcohol to air in the combustion fuel mixture to reduce NOx emissions and improve fuel efficiency over the operating range of the diesel engine.

Owner:UCHICAGO ARGONNE LLC

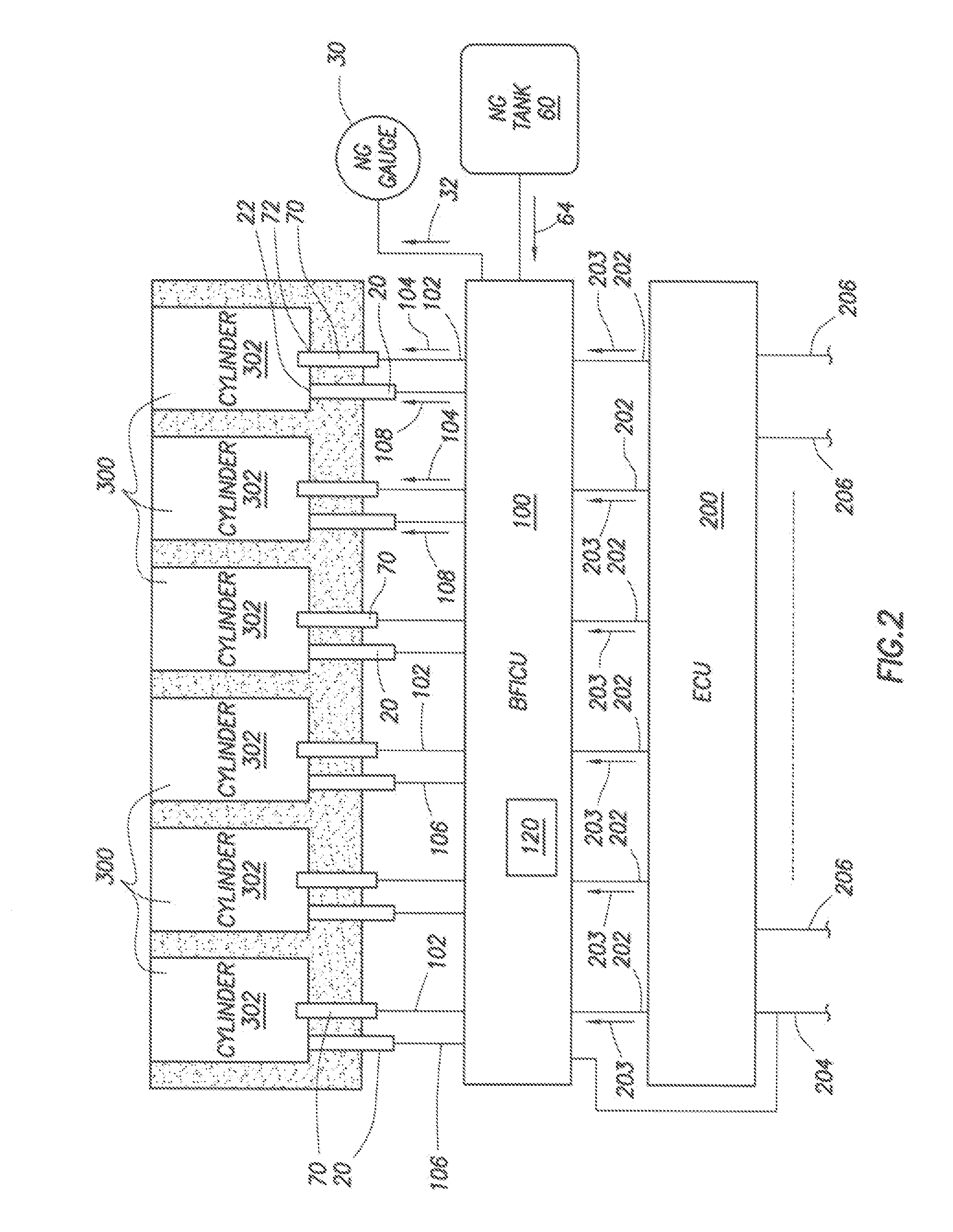

Method and apparatus for converting diesel engines to blended gaseous and diesel fuel engines

InactiveUS20120085326A1Electrical controlInternal combustion piston enginesControl signalDiesel injector

The invention presents a method of converting a diesel fueled engine to a blended-fuel engine capable of operating on blended gaseous fuel and diesel fuel, where the diesel fueled engine has a plurality of cylinders, a plurality of diesel fuel injectors for injecting diesel fuel into the cylinders, and an Engine Control Unit (ECU) for controlling at least the operation of the diesel injectors by sending diesel fuel injector control signals to the diesel fuel injectors.

Owner:BEX AMERICA

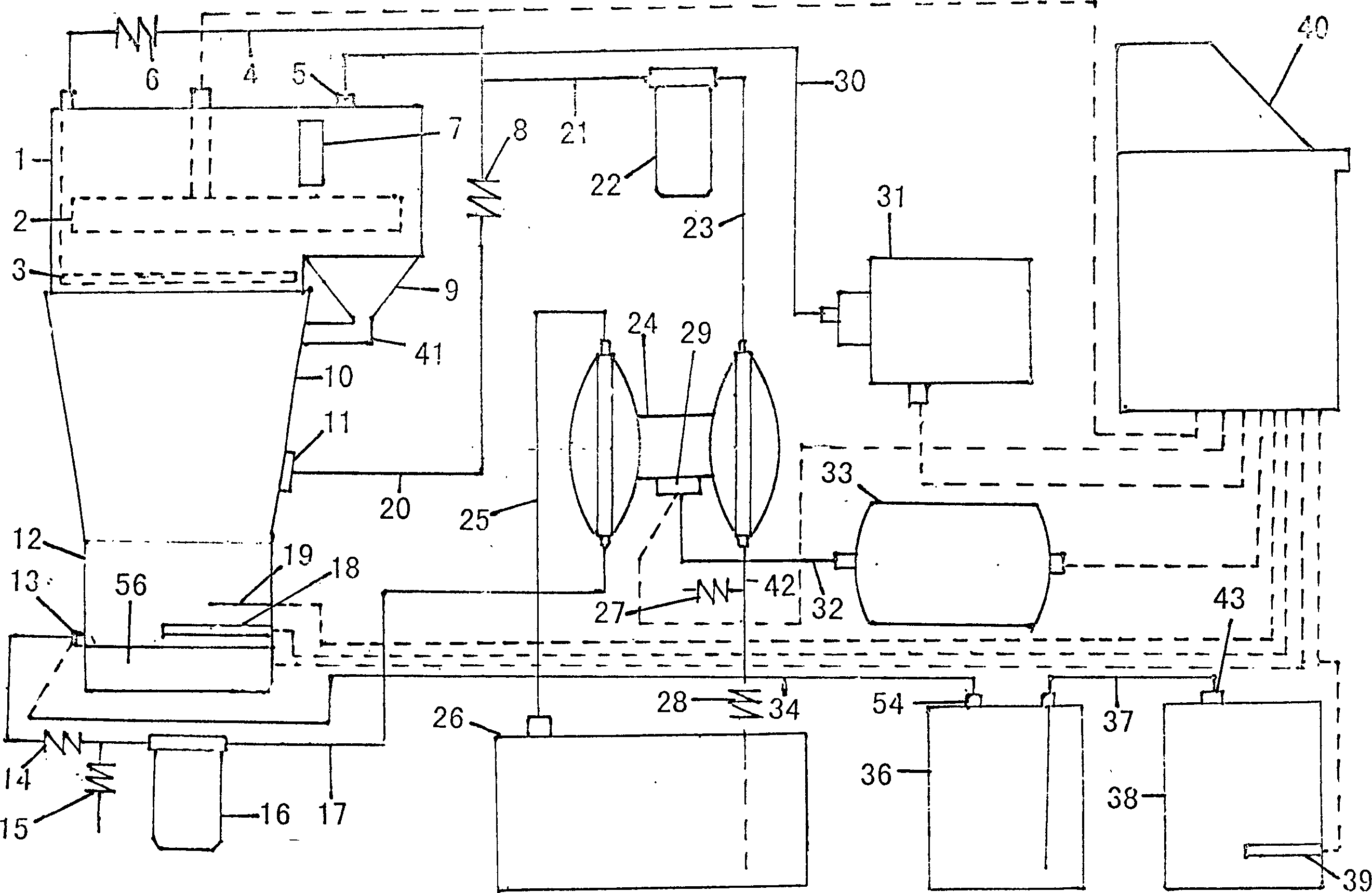

Dismounting free series cleaning method and apparatus for engine

InactiveCN1546854AThe performance of the original assembly has not been changedRapid recovery of mechanical propertiesMachines/enginesEngine componentsCombustion chamberDiesel injector

The present invention relates to dismounting free series cleaning method and apparatus of carbon dioxide ice, pulse circulation, vacuum ultrasonics and vapour, for engines. Said apparatus comprises an upper ultrasonic cleaning box connected with a spiracular atrium and a burning compartment of the engine, a lower ultrasonic cleaning crankcase oil tray connected with a crankshaft case, and a washer consisting of a carbon dioxide ice injection pump, a pulse diaphragm pump, a vacuum pump, a lotion vapour canister, a cog-wheel pump and a body case. The process for the apparatus is as follows: dismounting the valve bonnet, the carburettor or the electrical fuel oil injector, the sparking plug or the diesel oil injector; injecting, brushing and cleaning the machine members by using the carbon dioxide ice injection pump; connecting the ultrasonic cleaning box to the engine spiracular atrium, connecting the ultrasonic cleaning crankcase oil tray to the crankshaft case, and vacuum pumping the cleaning box, then executing the liquid-inletting pulse circulation cleaning under the function of the pumps; ultrasonic cleaning inside of the cylinder by ultrasonic cleaning the plates in the cleaning box and the cleaning crankcase oil tray; pumping back the cleaning agent; at the liquid-outlet, exchanging the cleaning agent and vapor tubes which are then dry-cleaned; reverting all the machine members; injecting new lubricant oil into the engine by using the cog-wheel pump.

Owner:戴中平

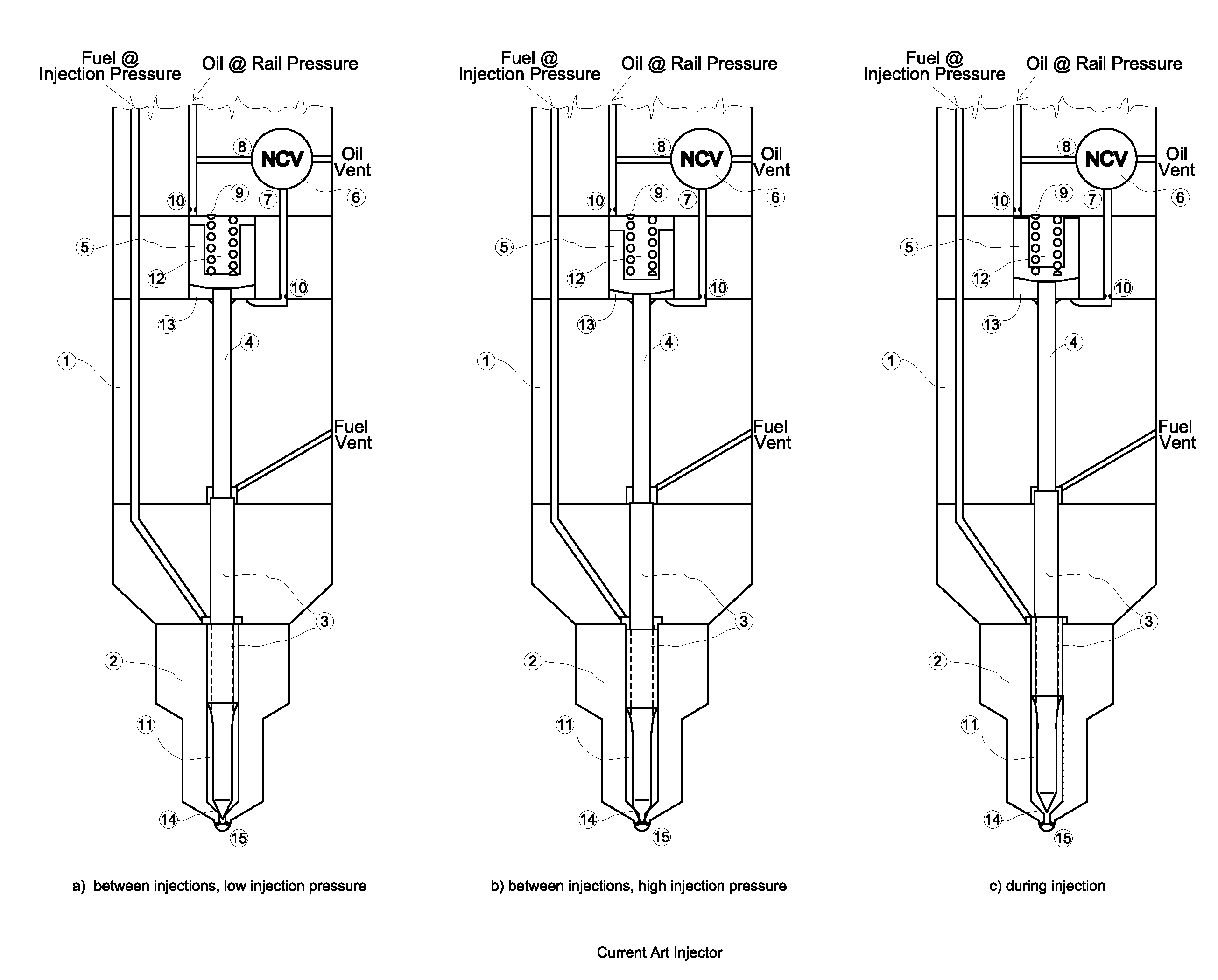

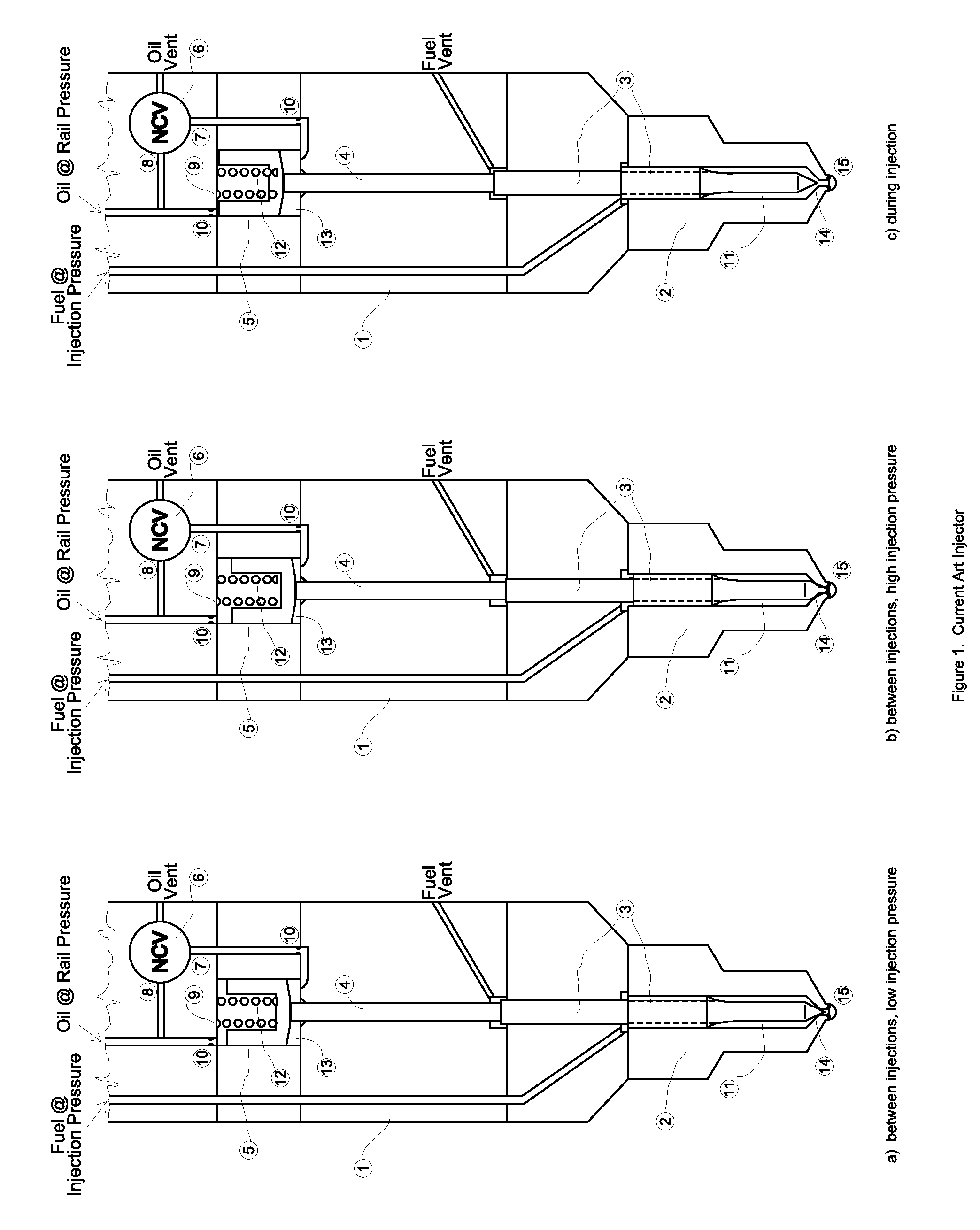

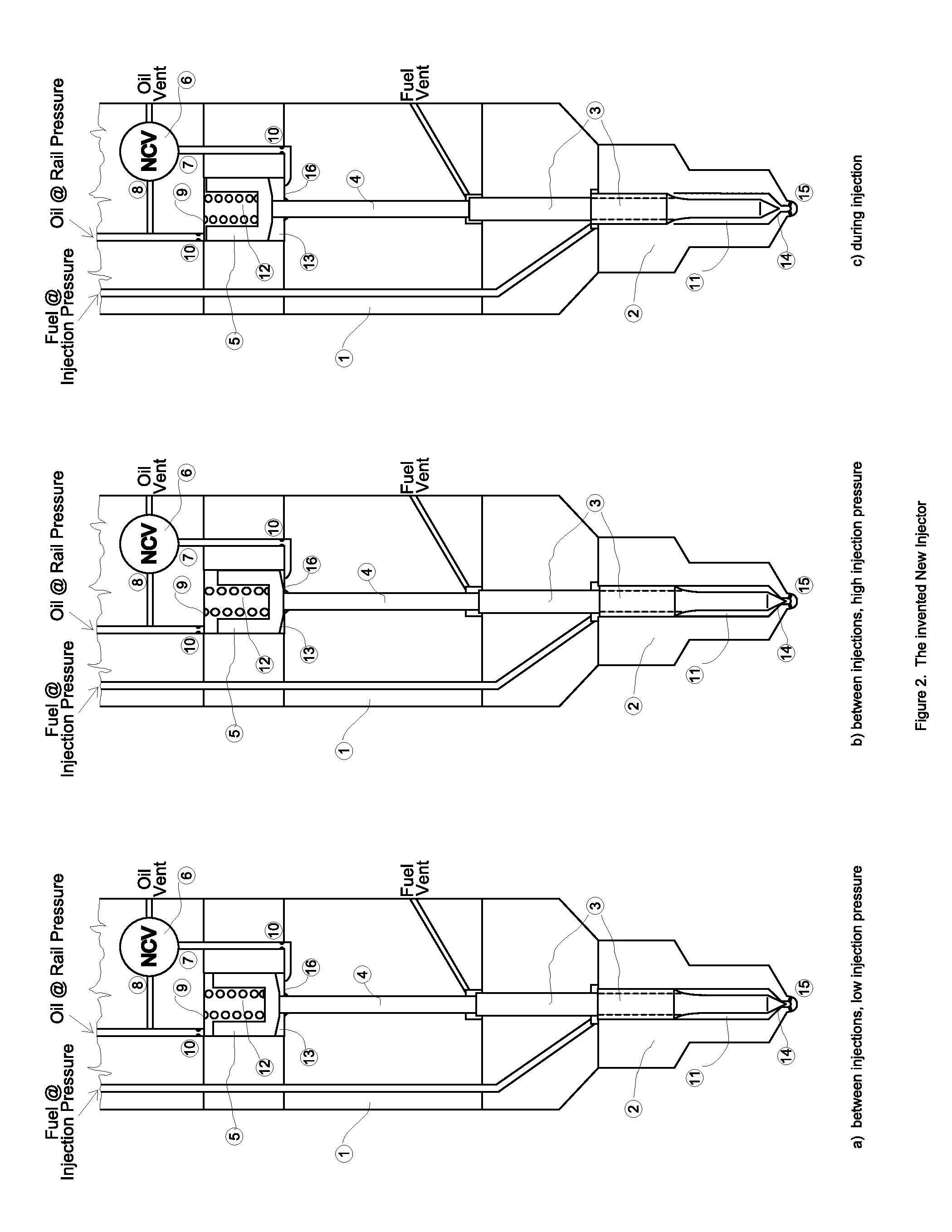

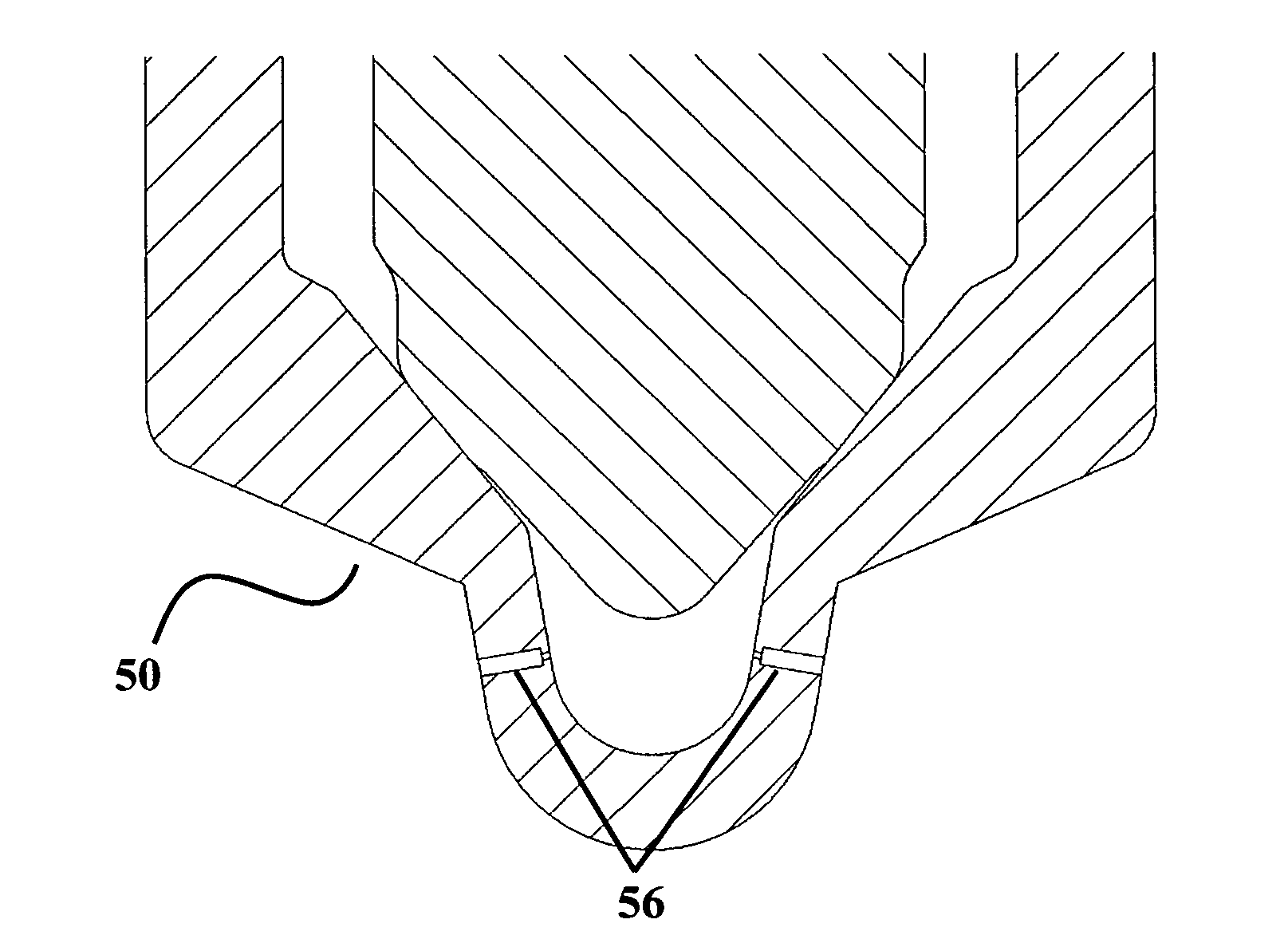

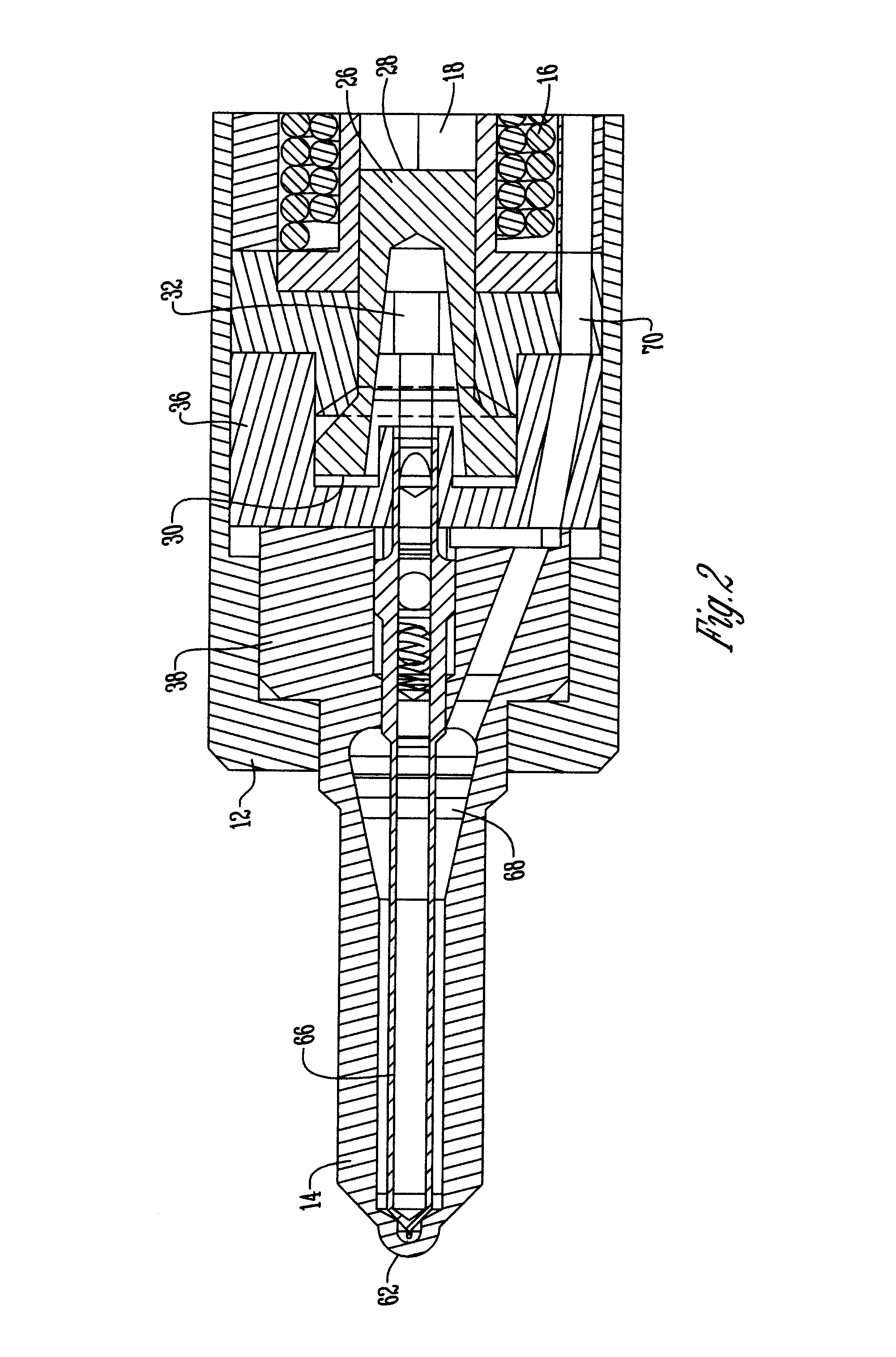

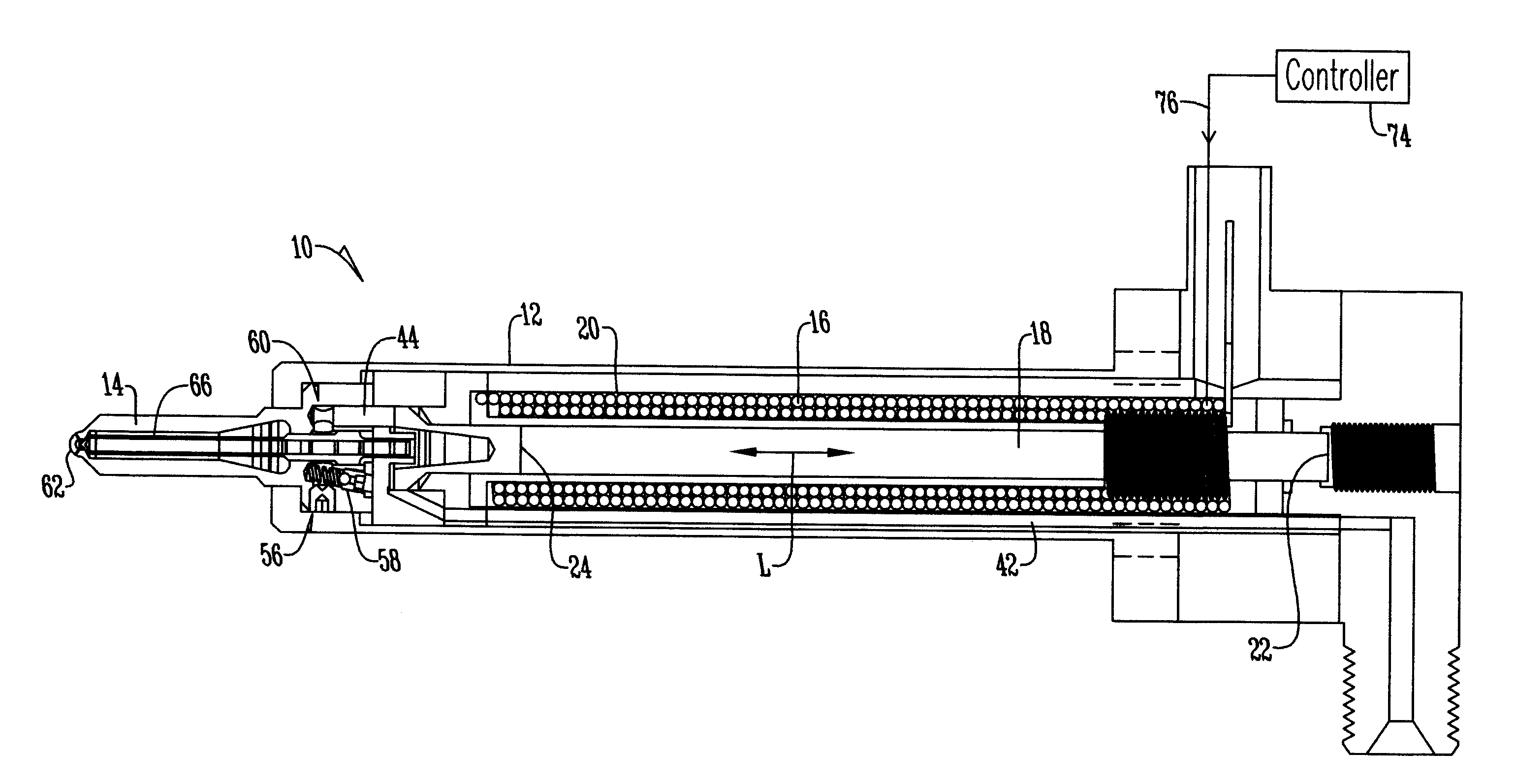

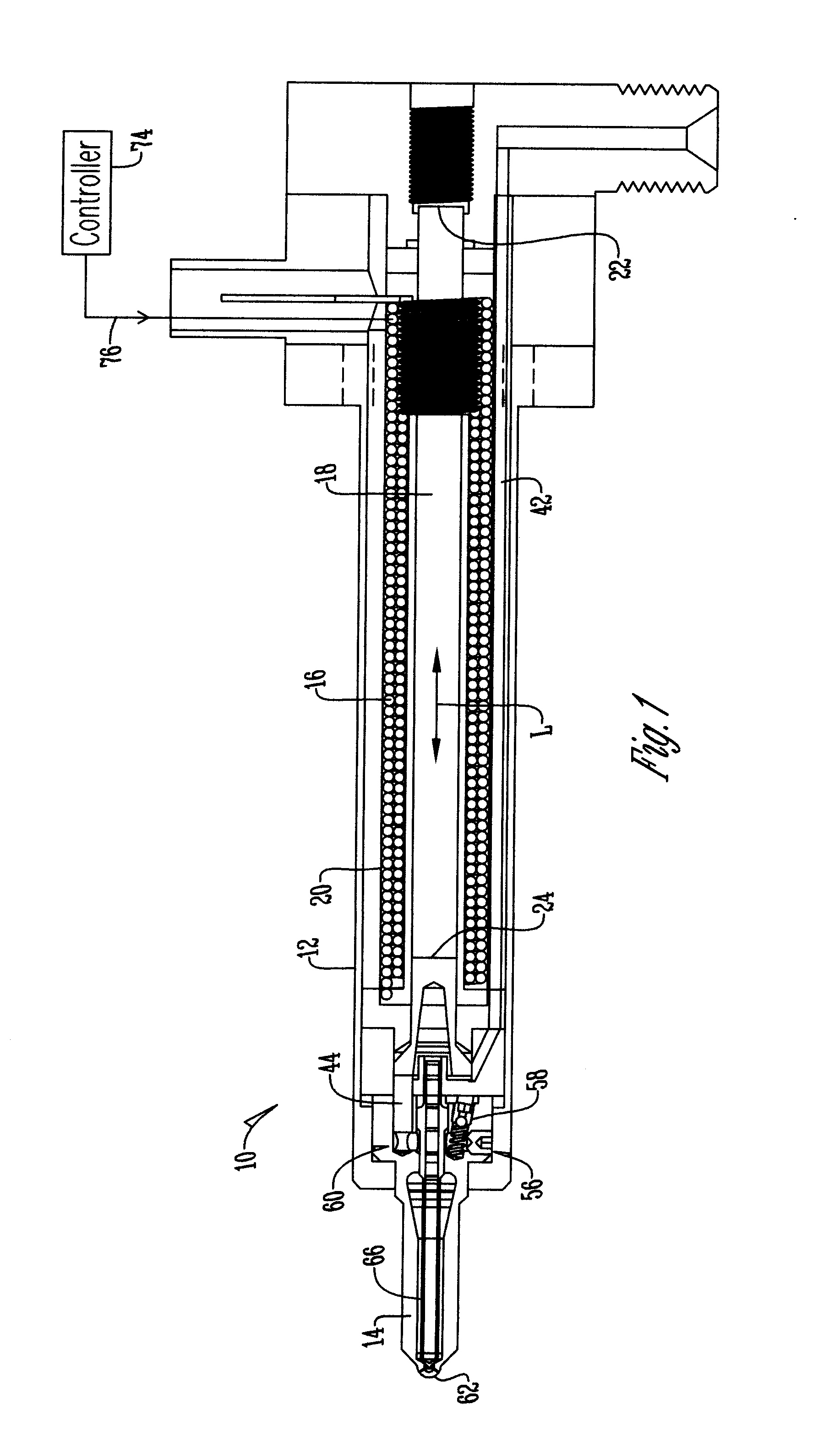

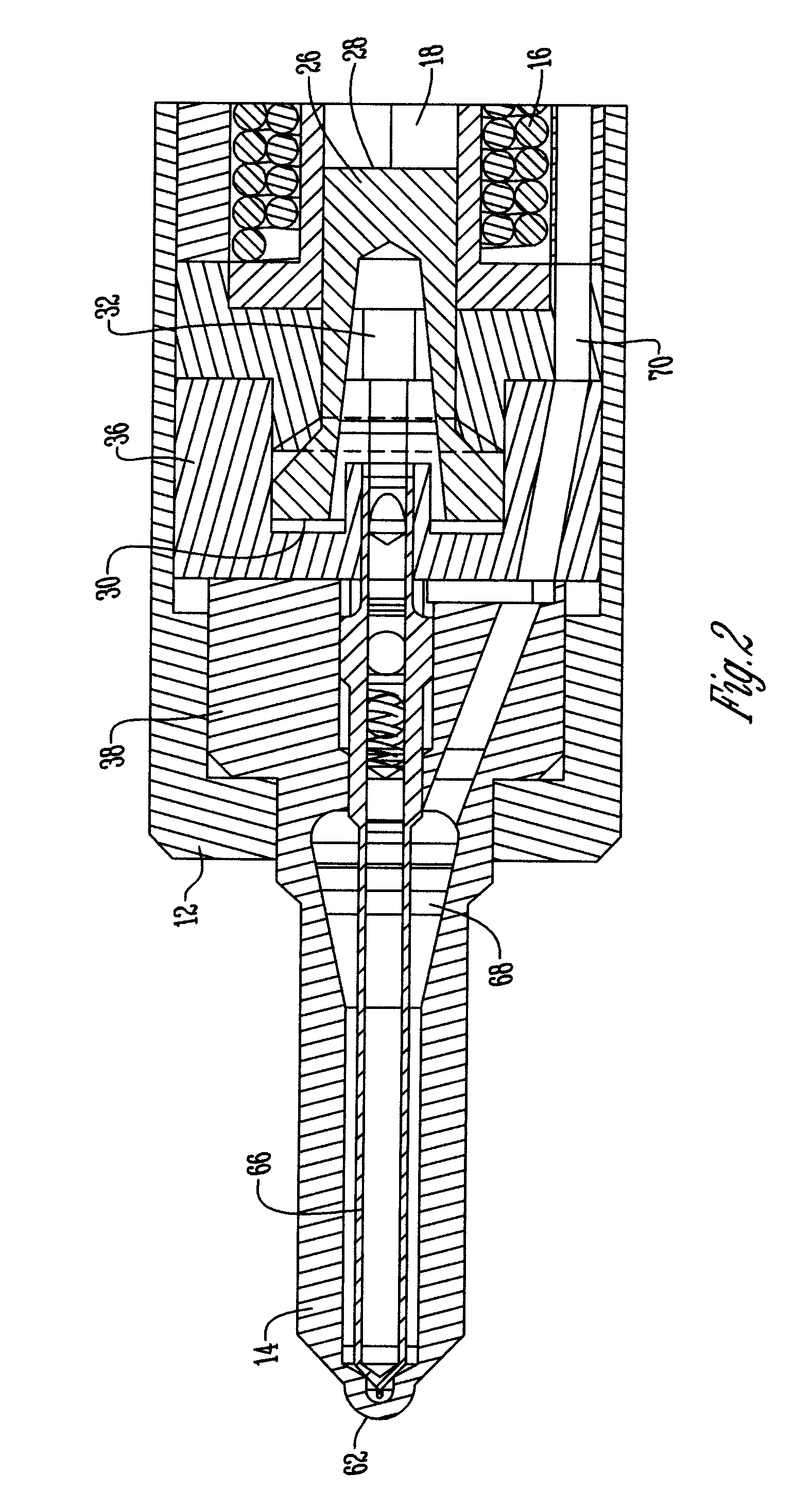

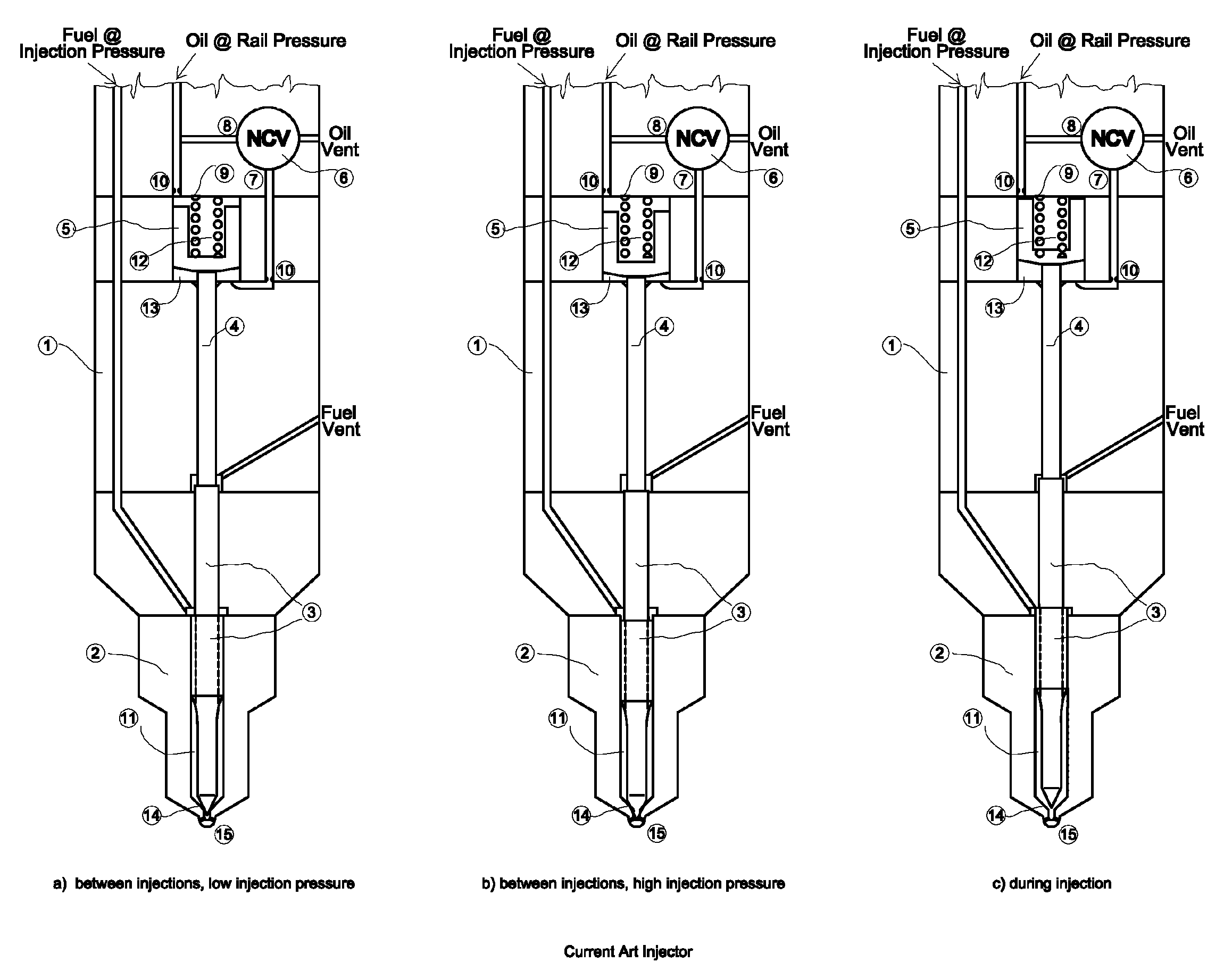

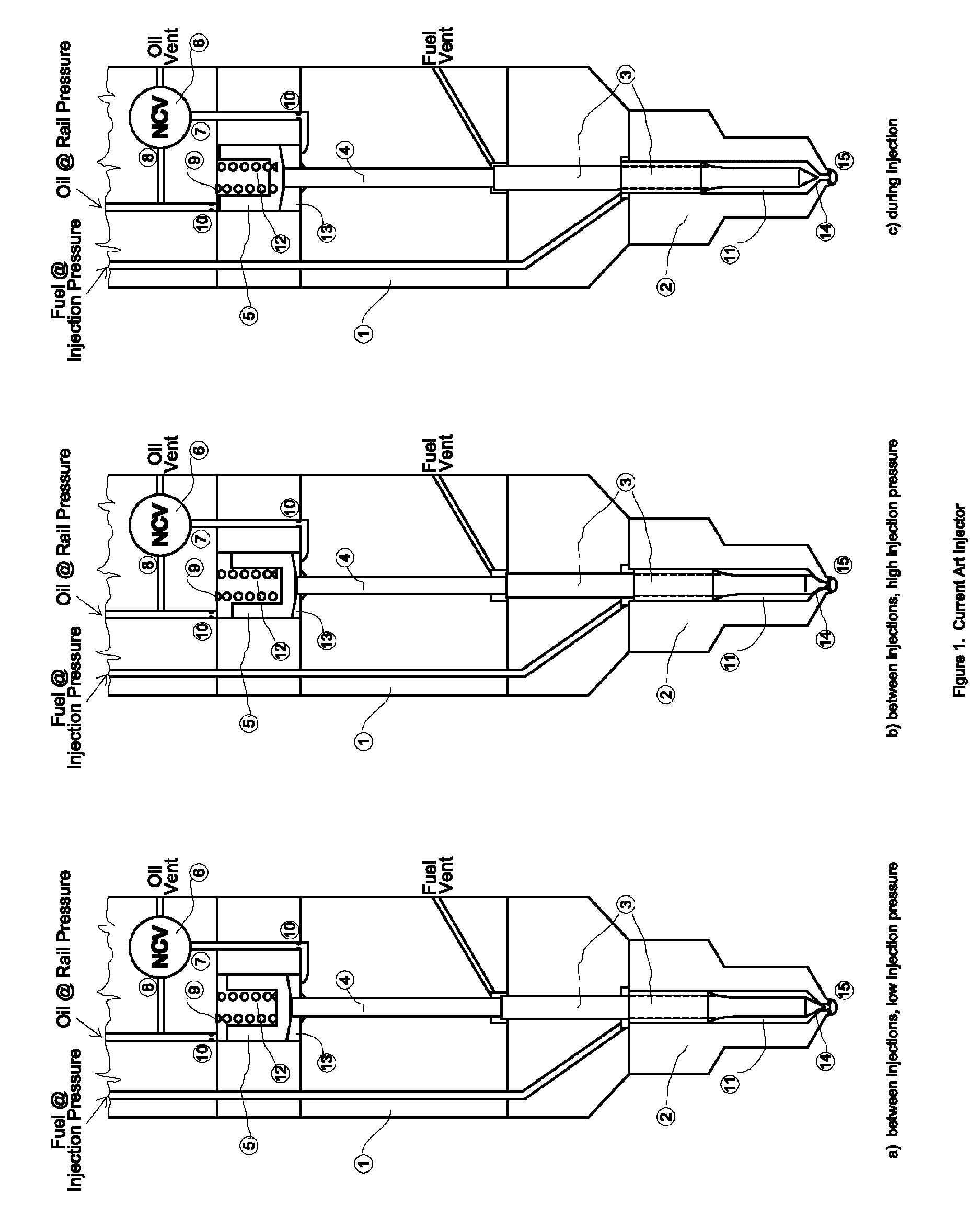

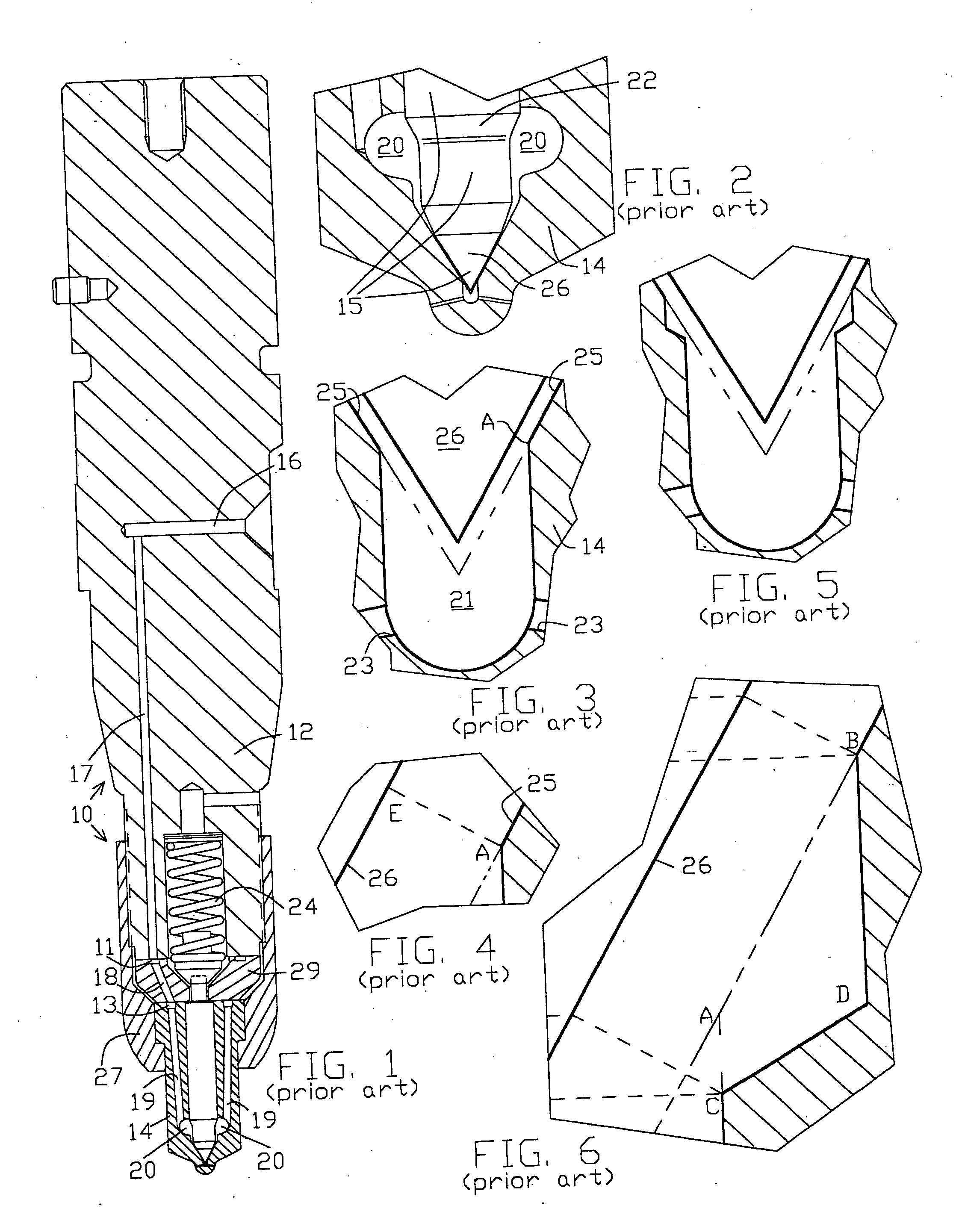

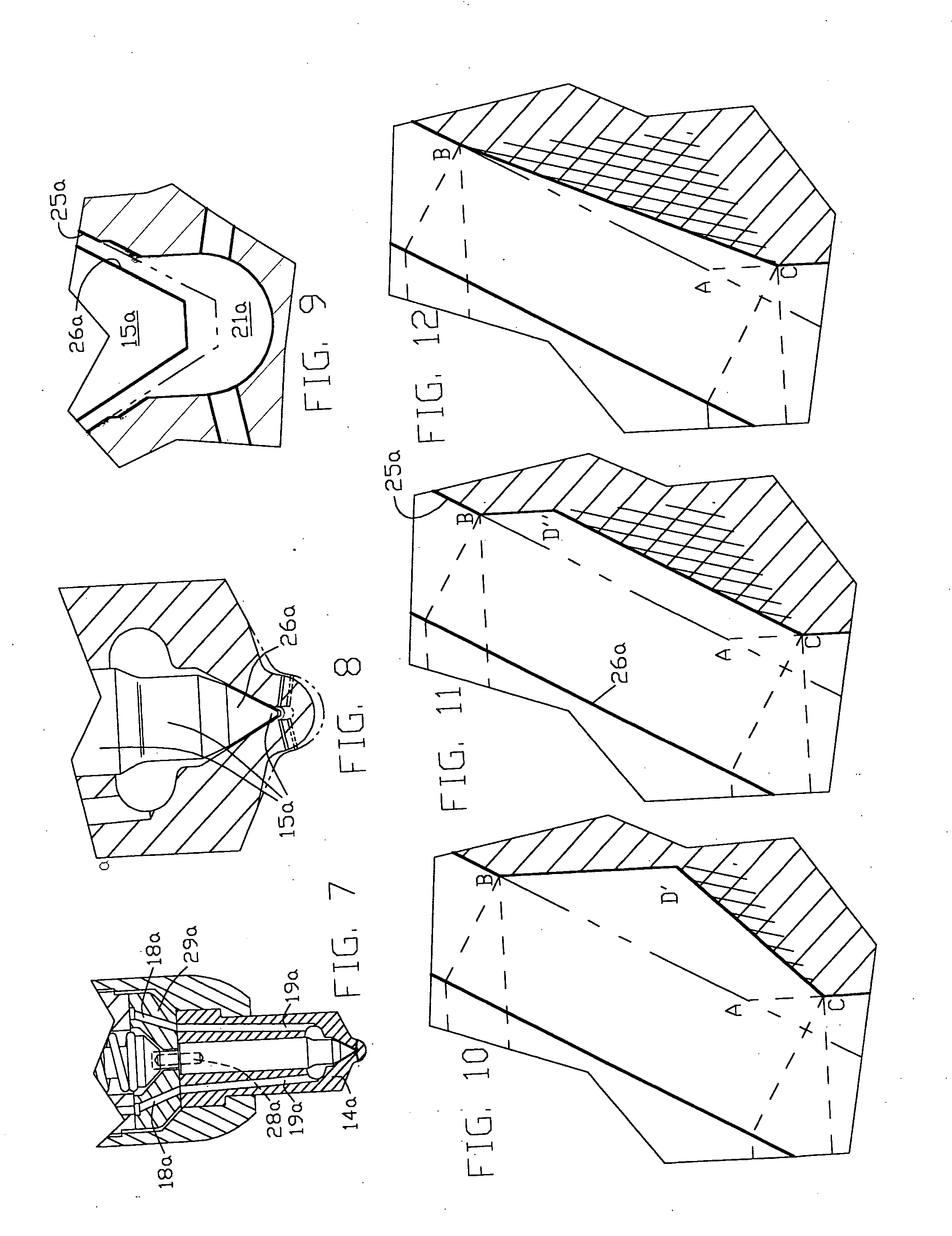

Method and Apparatus for Controlling Needle Seat Load in Very High Pressure Diesel Injectors

Method and apparatus for controlling needle seat load in very high pressure diesel injectors. In accordance with the method, a needle control piston responsive to hydraulic forces for controllably forcing the injector needle against the needle seat is provided, as is a stop for the needle control piston to limit the needle control piston movement toward the needle seat. This provides a stop for the needle control piston, so that the compressive deflection between the needle control piston and the needle seat limits the force of the injector needle on the needle seat against increasing hydraulic forces on the needle control piston once the needle control piston reaches the needle control piston seat.

Owner:STURMAN INDS

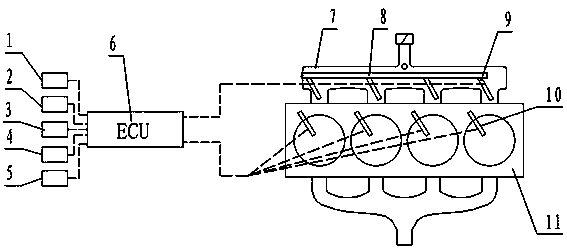

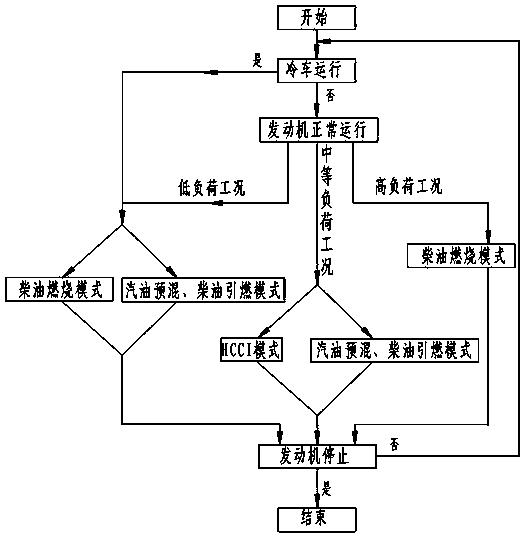

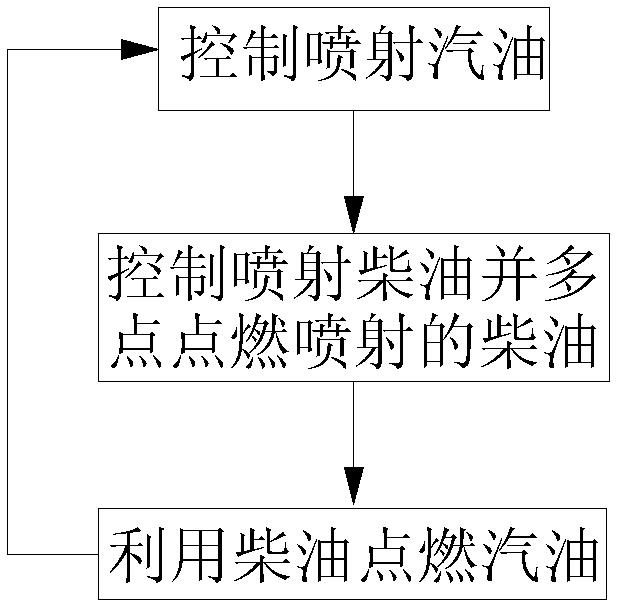

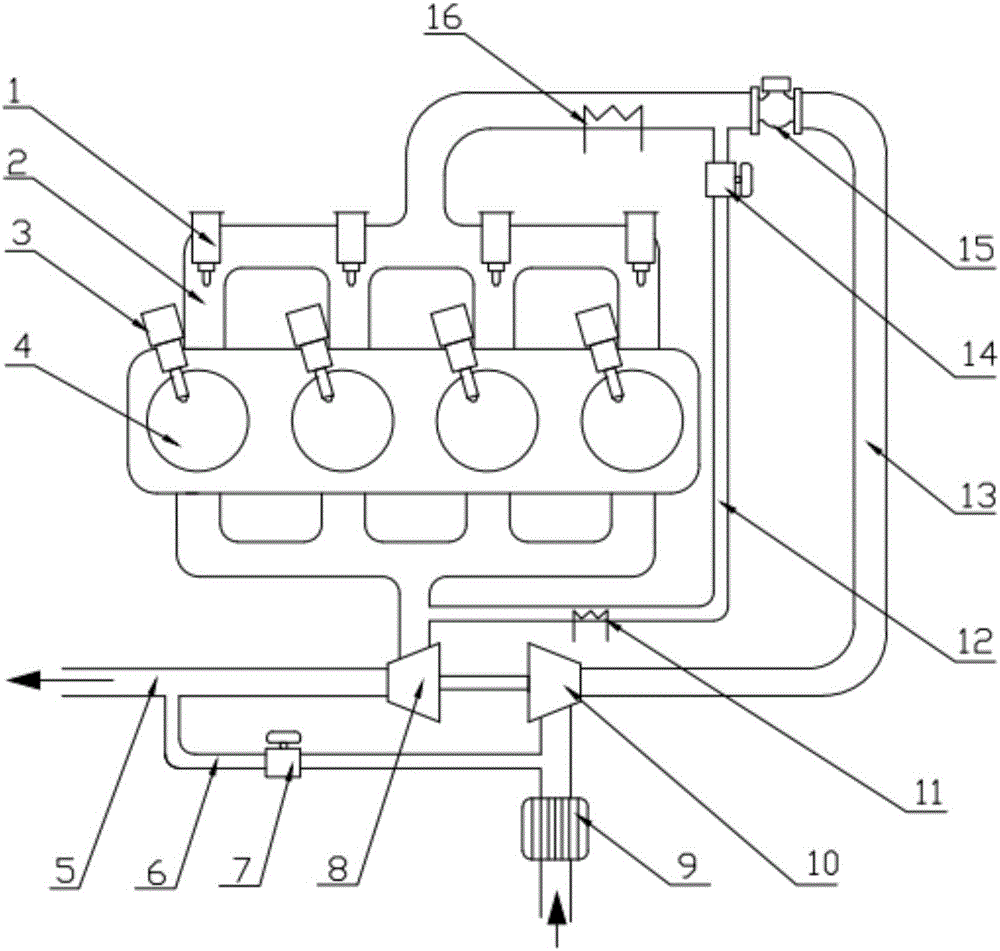

Combustion mode control system of gasoline premixing and diesel igniting engine and control policy thereof

ActiveCN104265471AImprove powerImprove economyElectrical controlMachines/enginesCombustionMode control

The invention discloses a combustion mode control system of a gasoline premixing and diesel igniting engine and a control policy thereof. After an electronic control unit acquires the cooling water temperature, the air inlet temperature, the air flow, the engine crankshaft rotating speed and the accelerator pedal position information to judge the operating conditions of the engine, action commands are sent to a gasoline injector and a diesel injector to control the combustion mode of the engine; the operation steps are as follows: (a) the automobile operation state is judged; and the corresponding engine combustion mode is selected; (b) the engine load state is judged, and the corresponding engine combustion mode is selected; and (c) when the engine is positioned in the working condition of medium load, the engine combustion mode is selected. The dynamic performance and the economic performance of automobiles are guaranteed; and the nitric oxide and PM discharge indexes are reduced.

Owner:GREAT WALL MOTOR CO LTD

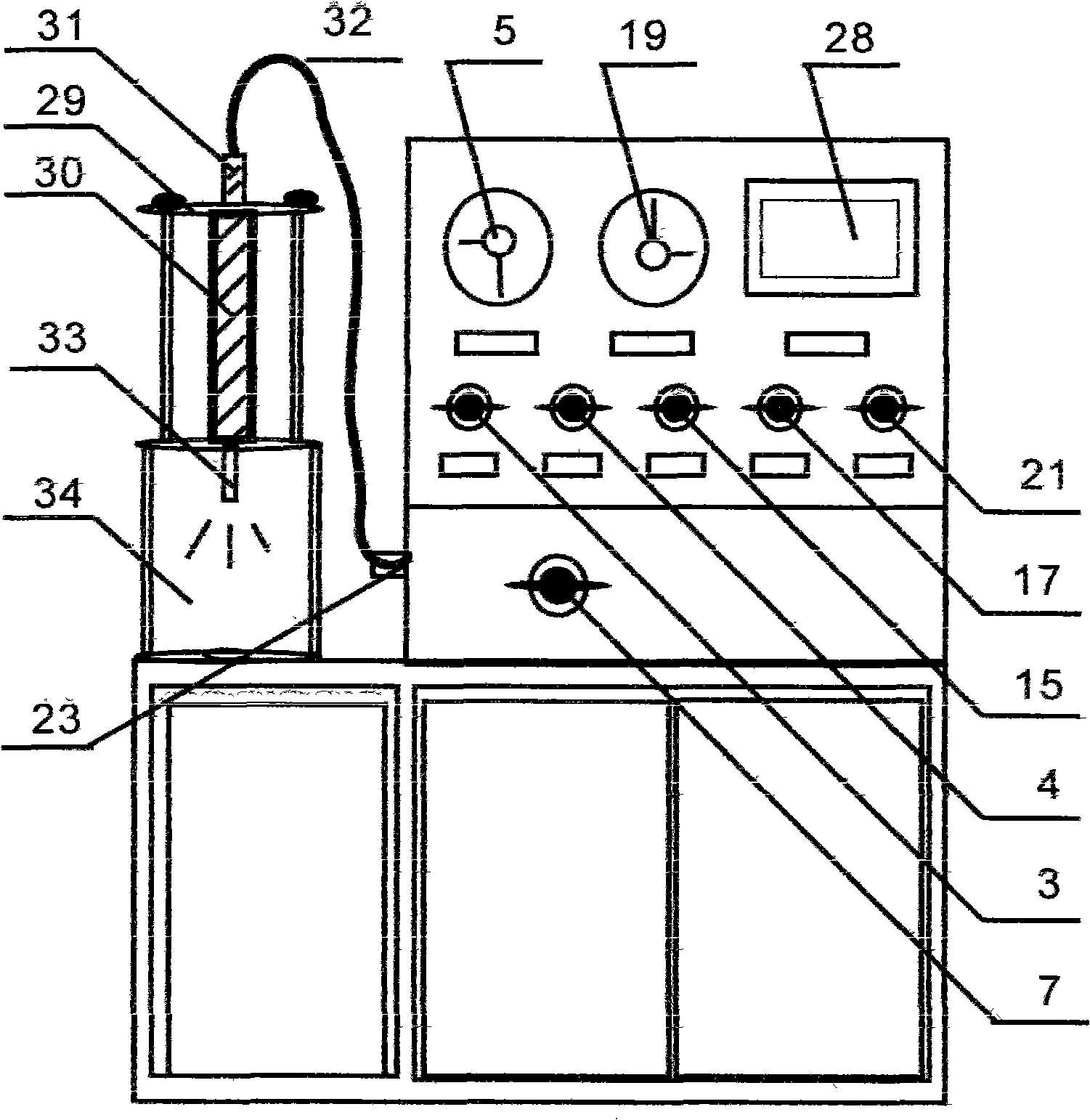

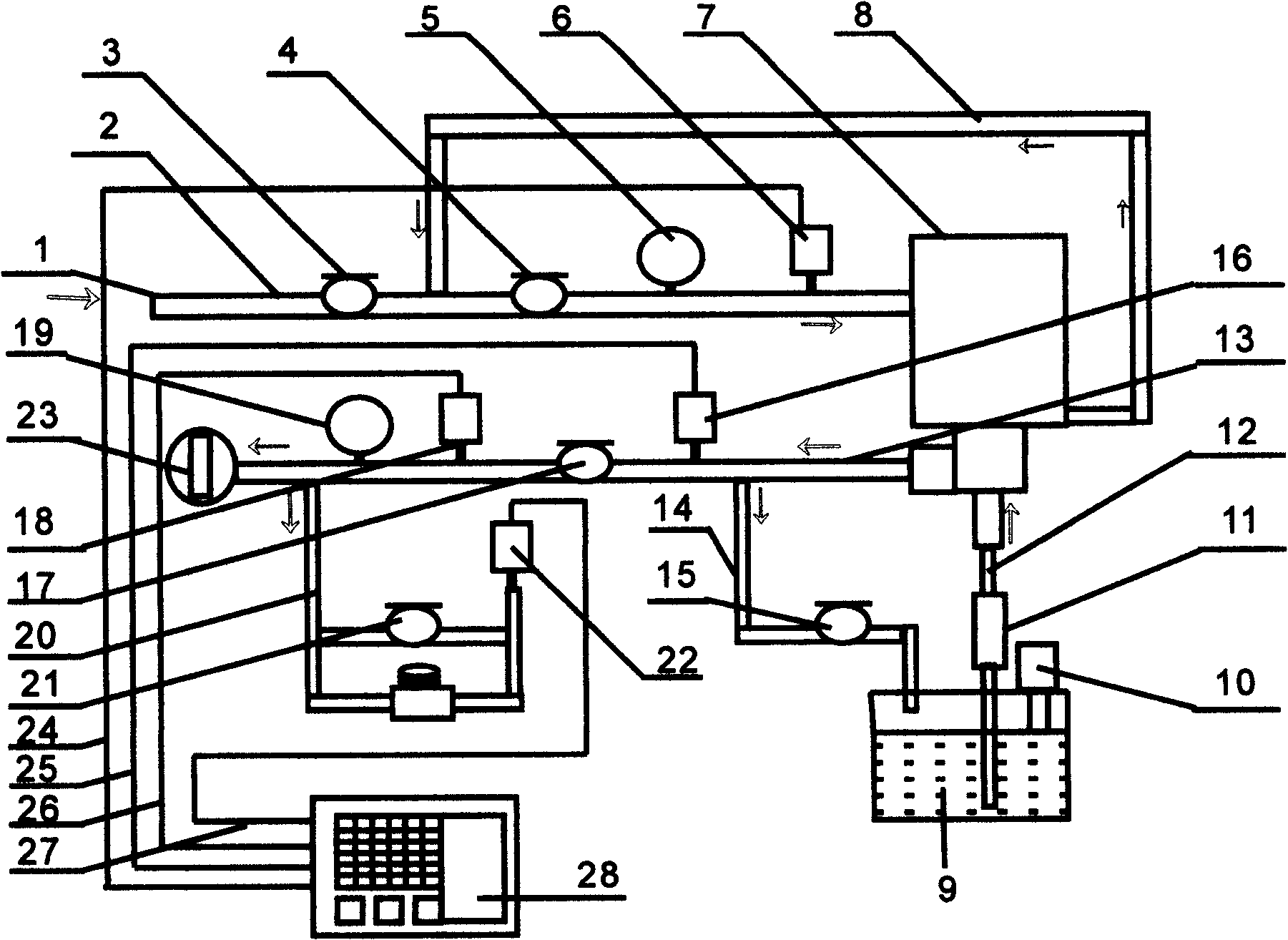

Test table for oil injector of marine diesel and fuel injector test methods

InactiveCN101275529AAccurate detection of quality effectsHigh-precision detection quality effectEngine testingFuel injection apparatusDiesel injectorHydraulic pump

The invention relates to a test stand for a marine diesel injector and a testing method for the injector, characterized in that the test stand for the marine diesel injector integrates a mechanical manometer display system and an electronic liquid crystal tester display system, mainly composed of a pneumatic hydraulic pump system, a system connecting the injector and fuel equipments and an electronic sensor system, capable of performing leakage test and calibration test on the injector, testing the release pressure of the slide valve in the nozzle component of the injector and the sealing property of a valve line, testing the open pressure of the injector, checking the atomization quality, and testing the seal of the sealing ring of the nozzle. Because of the two set of tester display systems of the testing stand, a tested injector has high precise and accurate testing quality; when the testing method is performed standardly, unsafe factors can be reduced and avoided.

Owner:宋玉堂

Diesel detergent without a low molecular weight penalty

The composition of the present invention related to a quaternary ammonium salt detergent and the use of such quaternary ammonium salt detergents in a fuel composition to reduce diesel injector deposits and remove or clean up existing deposits on the diesel injectors.

Owner:THE LUBRIZOL CORP

Gasoline burning device for diesel engine

InactiveCN101598069AImprove qualityReduce consumptionElectrical controlInternal combustion piston enginesCyclic processDiesel injector

The invention discloses a gasoline burning device for a diesel engine, which comprises a diesel component provided with at least one set of gasoline combustion component. The gasoline combustion component comprises a gasoline tank, combustion gasoline, a gasoline pipe and a gasoline combustion mechanism, wherein the gasoline combustion mechanism is mechanical or electric and forms a uniform fuel management system with a diesel injector; the fuel management system respectively manages and controls in mechanical mode or electric mode; and the gasoline combustion mechanism cooperates with the diesel injector to supply the needed combustion gasoline at proper time to improve the quality of diesel. On the premise of guaranteeing the performance of the diesel engine, the gasoline combustion device for the diesel engine uses the combustion gasoline to improve the quality of diesel, has favorable effect on the whole cycle process including formation of a gas mixture, ignition, combustion and discharge, and can achieve the multiple aims of reducing diesel consumption, improving fuel oil structure and meeting discharge requirements. The gasoline combustion device for the diesel engine can comprehensively improve the performance of the diesel engine and meet the demand for the future development of internal-combustion engines.

Owner:赵志贤

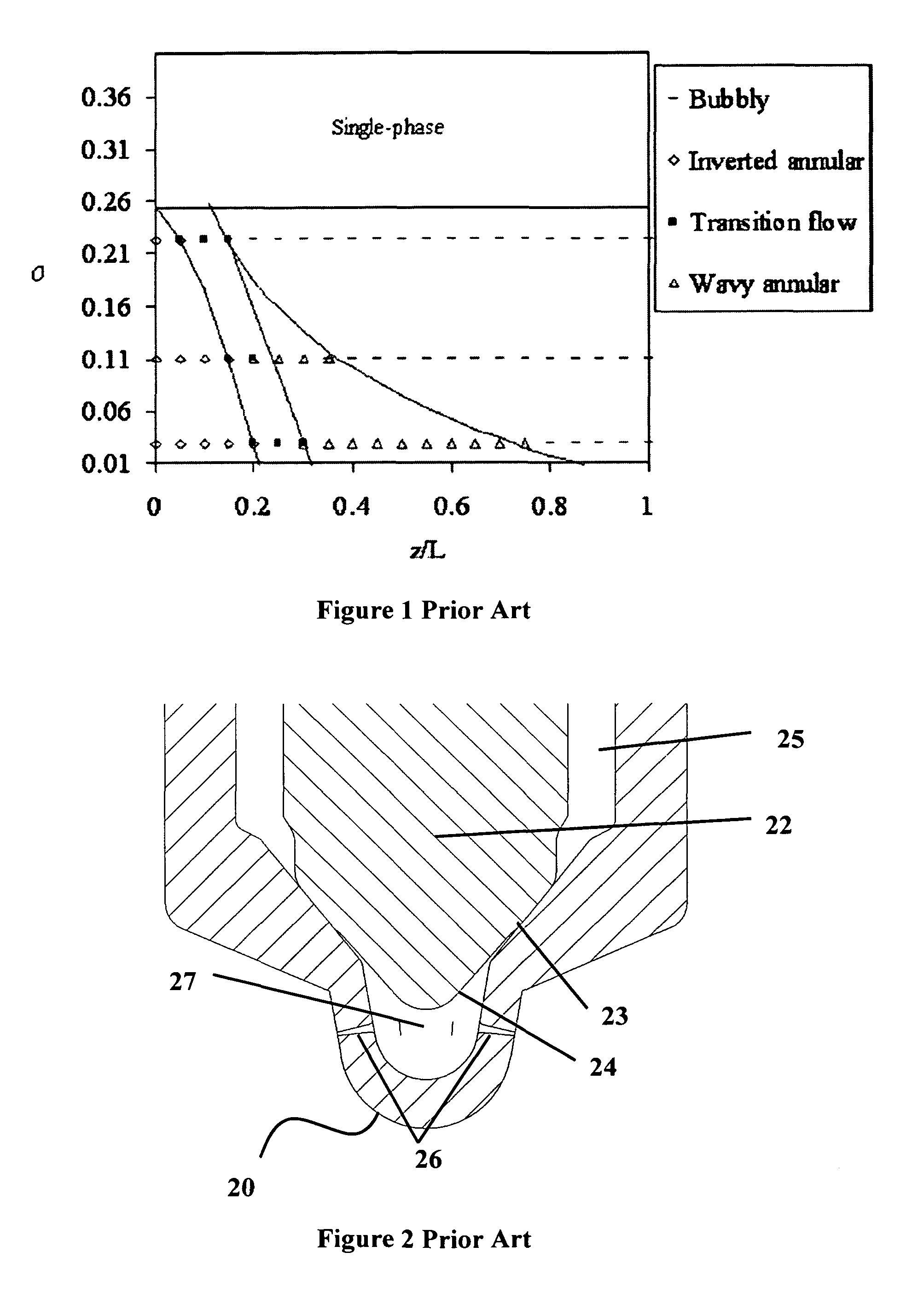

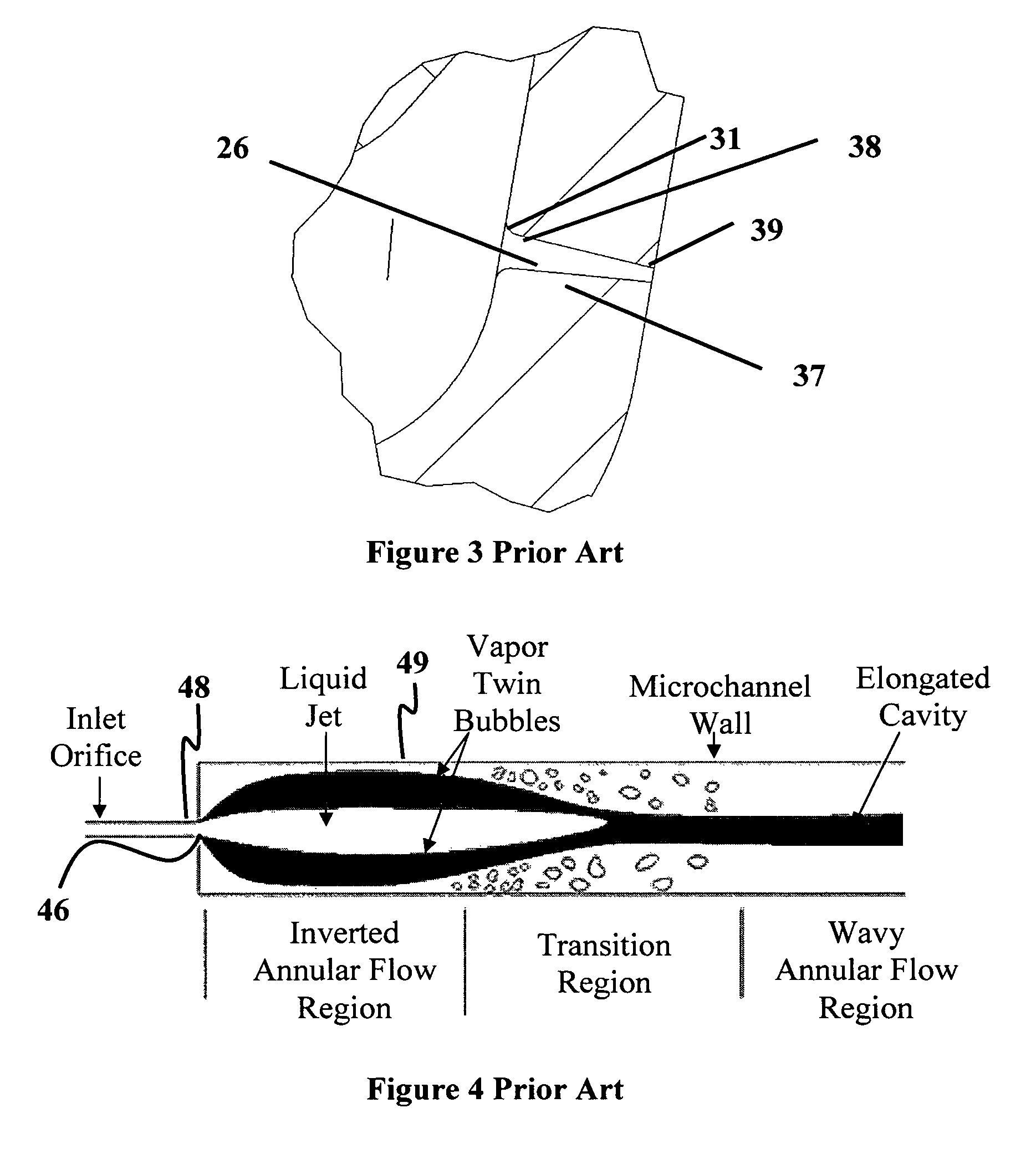

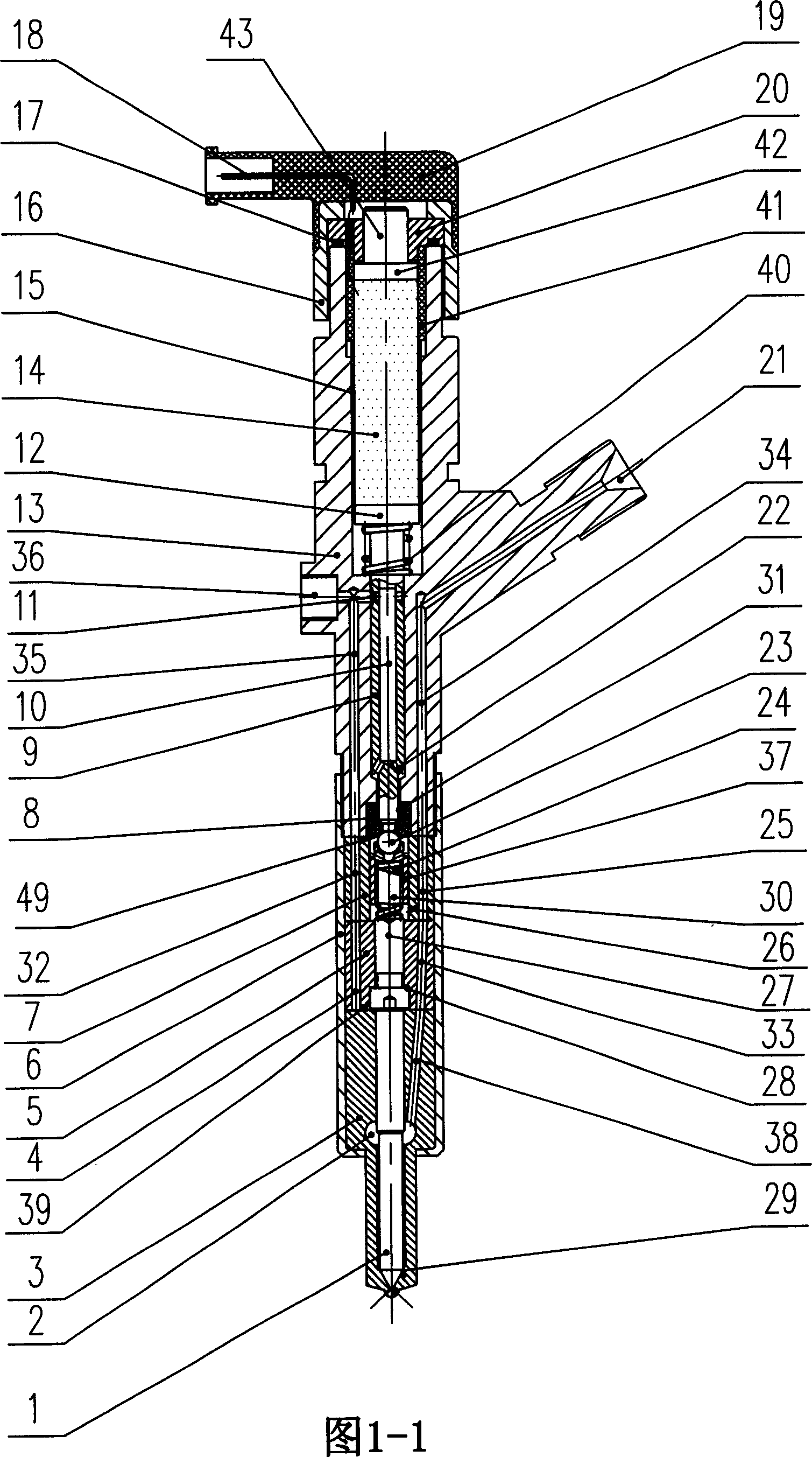

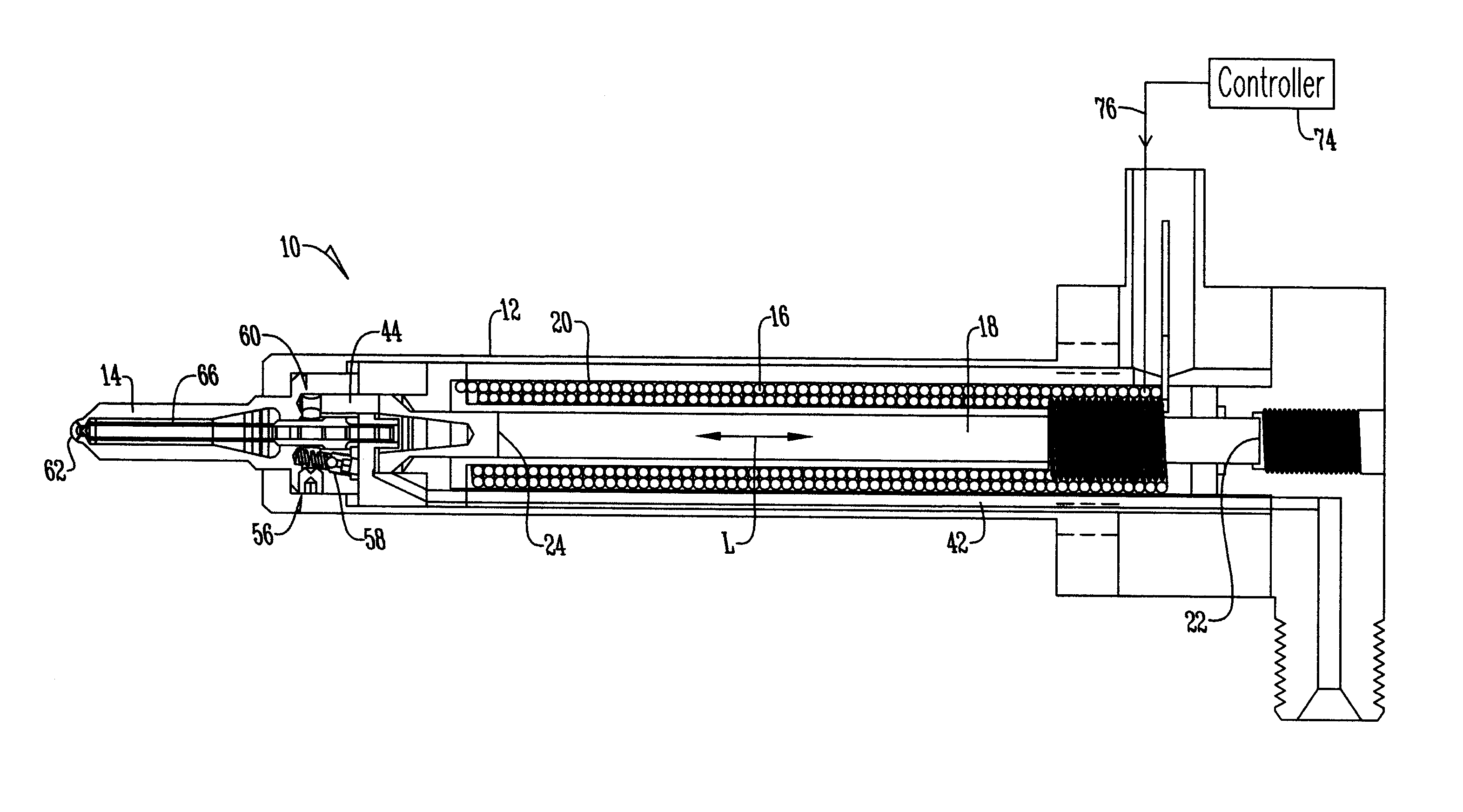

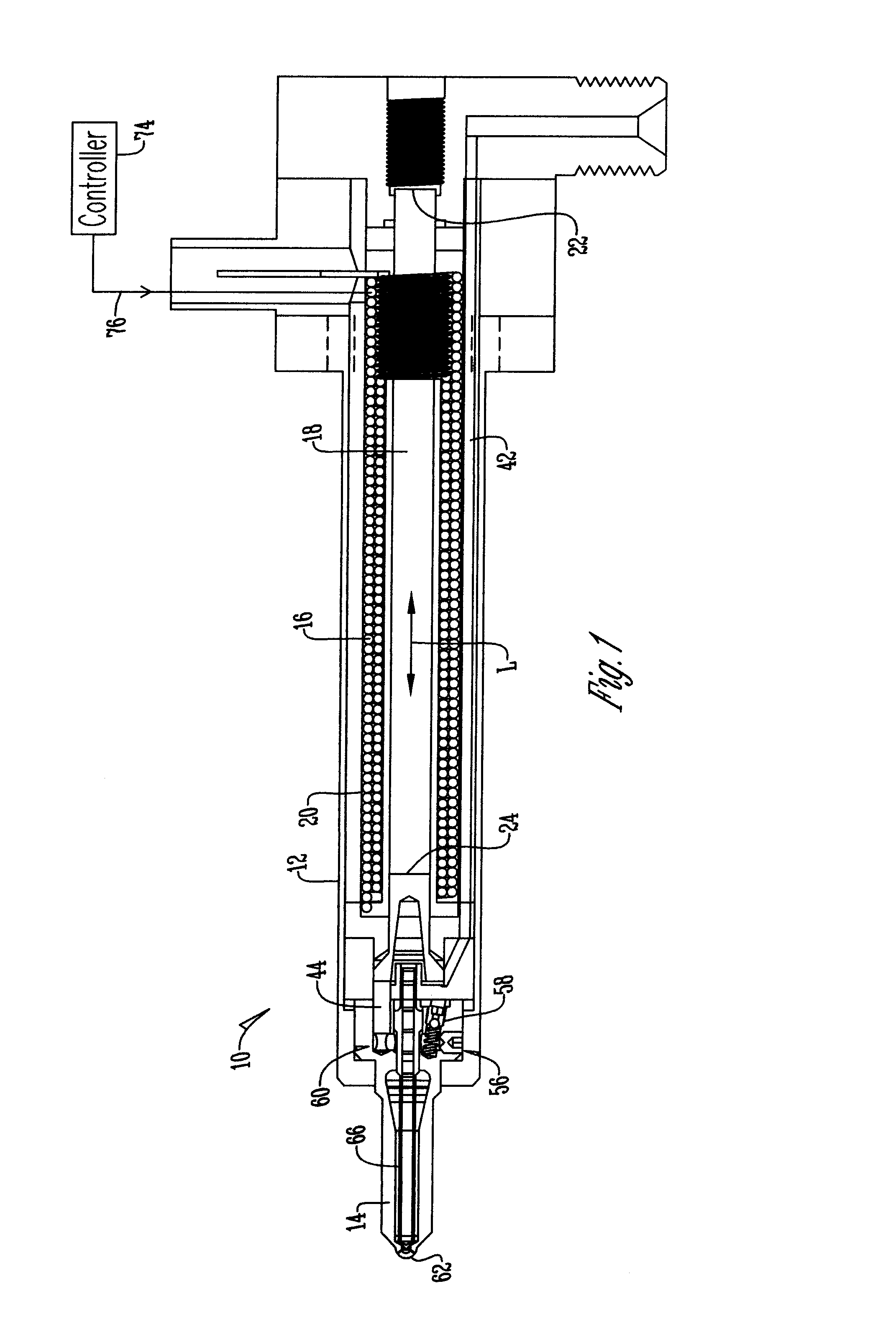

Diesel injector and method utilizing focused supercavitation to reduce spray penetration length

ActiveUS8905333B1Avoid excessive momentum fluxQuick fuel deliveryFuel-injection pumpsSpray nozzlesDiesel injectorHigh pressure

A method and apparatus are disclosed for inducing a supercavitating flow inside a fuel injection nozzle orifice to reduce the penetration length of the fuel spray, maintain high levels of fuel atomization, and improve uniformity of the fuel spray exiting the nozzle such that high-pressure injectors can be used on small engines. This reduction in penetration length is accomplished without any reduction in upstream fuel pressure.

Owner:MAINSTREAM ENG

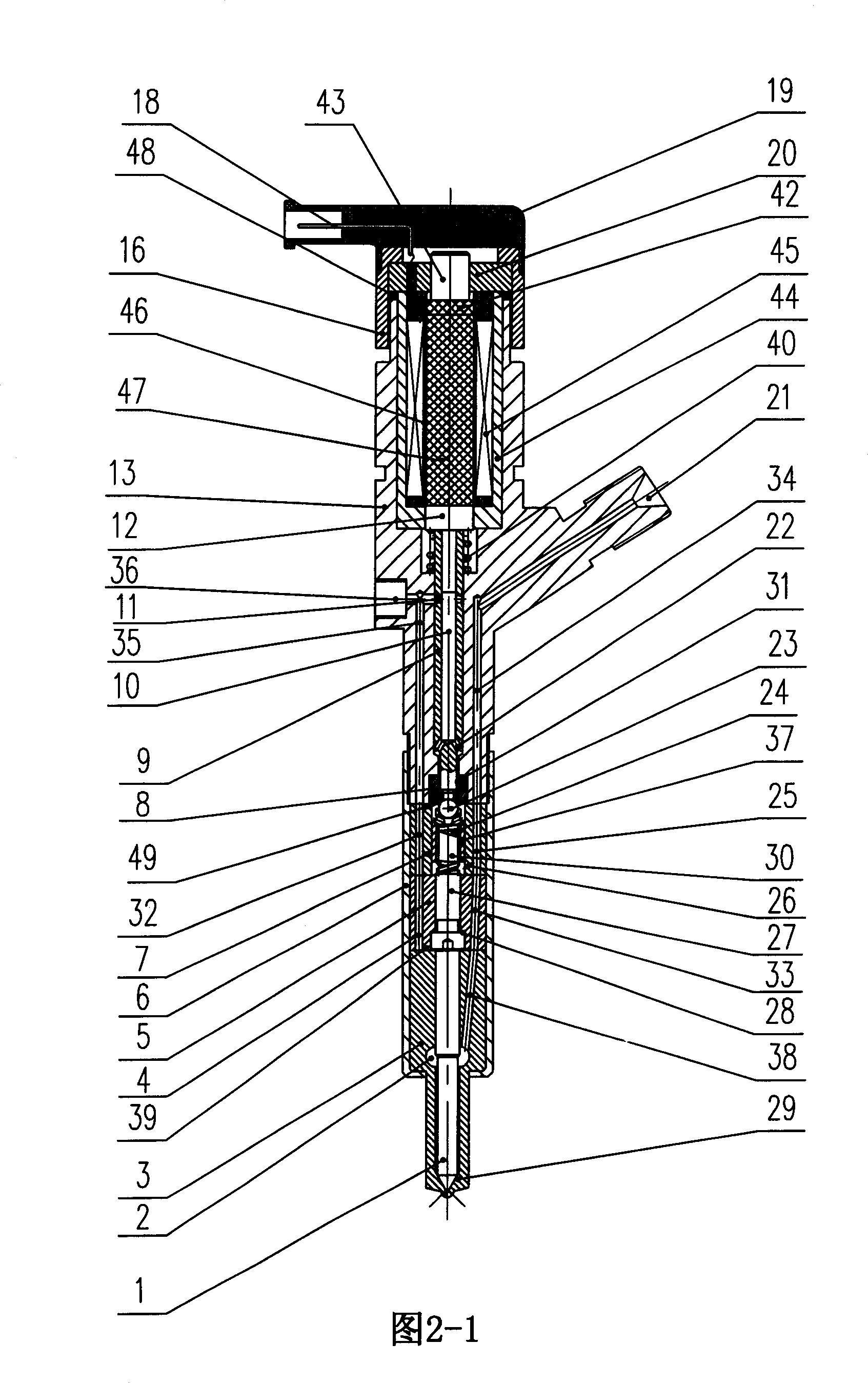

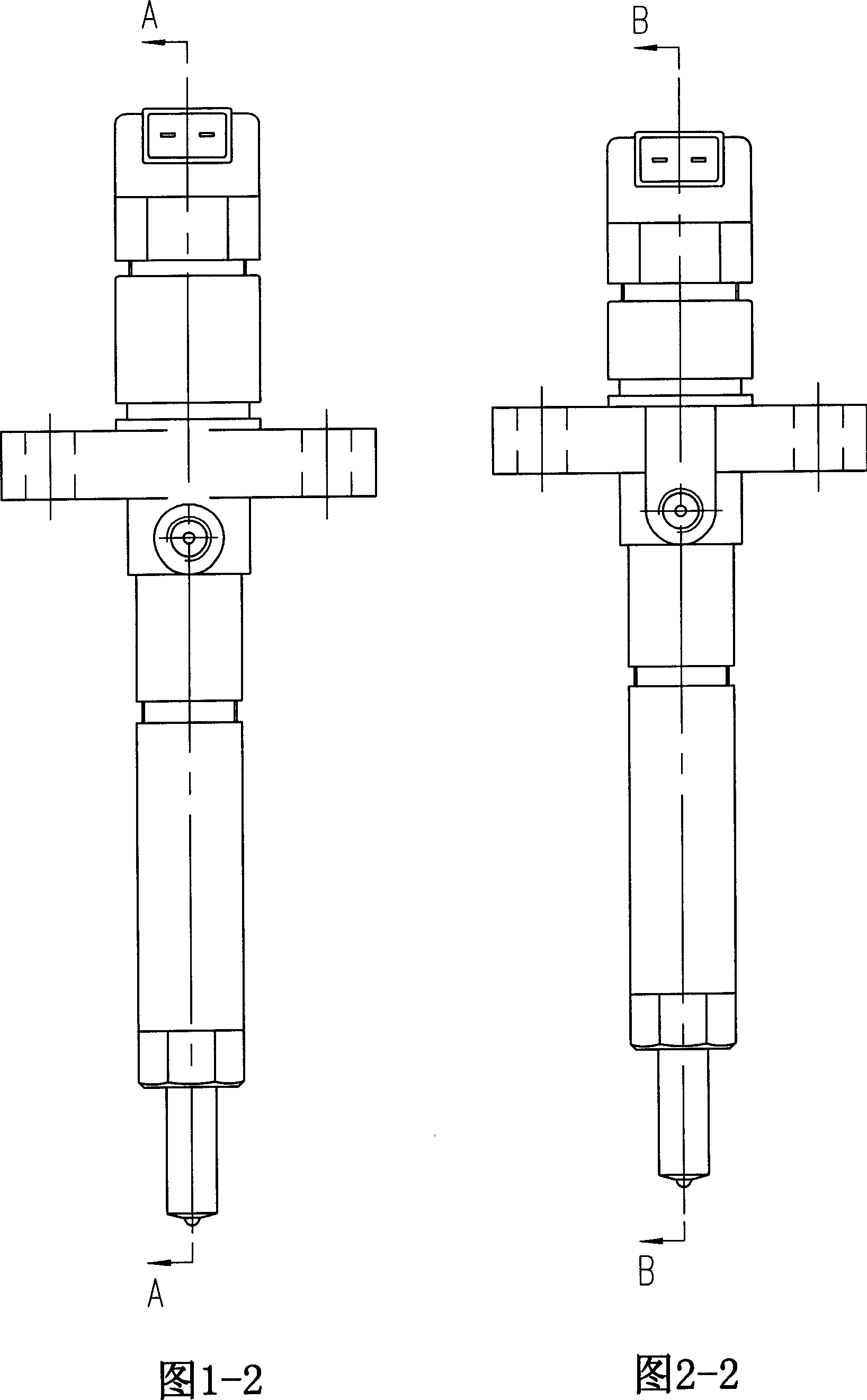

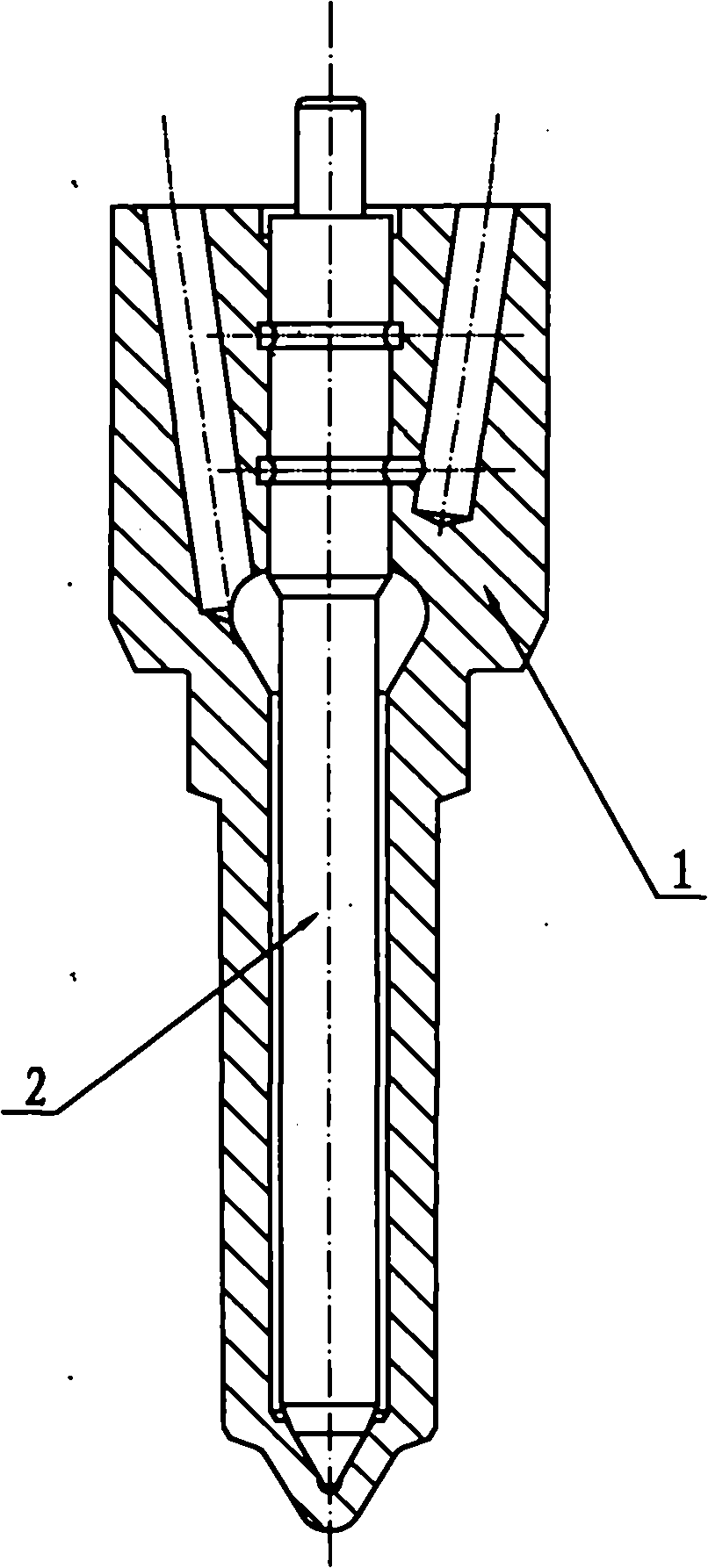

Electric-controlled diesel oil fuel oil injector driven by telescoping element

InactiveCN101096938APrecision injectionJet easyFuel injection apparatusMachines/enginesElectricityDiesel injector

The invention discloses an electric control diesel injector of adjustable element drive, which is characterized by the following: comprising belt entering, injector casing of back oil passage and nut cover; assembling push bar spring, push bar, push bar seat, adjustable element component, pad, upper end lid and axial locating axle in the casing along axially; arranging ball valve seat on the lower end of the casing; assembling fuel spray nozzle double element, dictating trunk piston, steel ball seat, dictating trunk piston valve body, dictating oil cavity valve body, spring and steel ball; loading element to back injector casing; screwing up with the nut cover; connecting each element end face tightly; constructing the device. This invention can decrease cost of diesel machine electric control injector and preparing hardness.

Owner:柳州华威电控技术有限公司

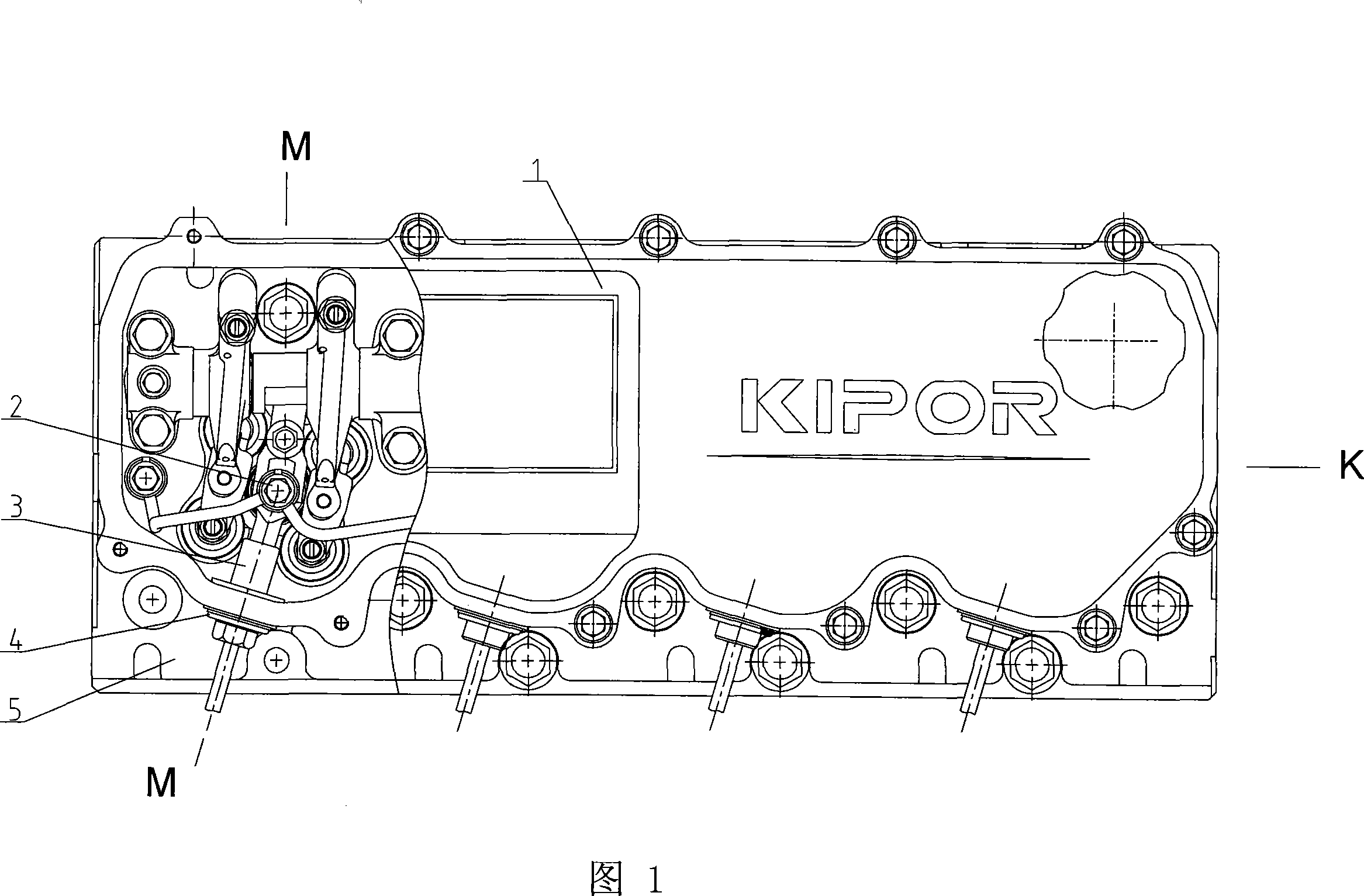

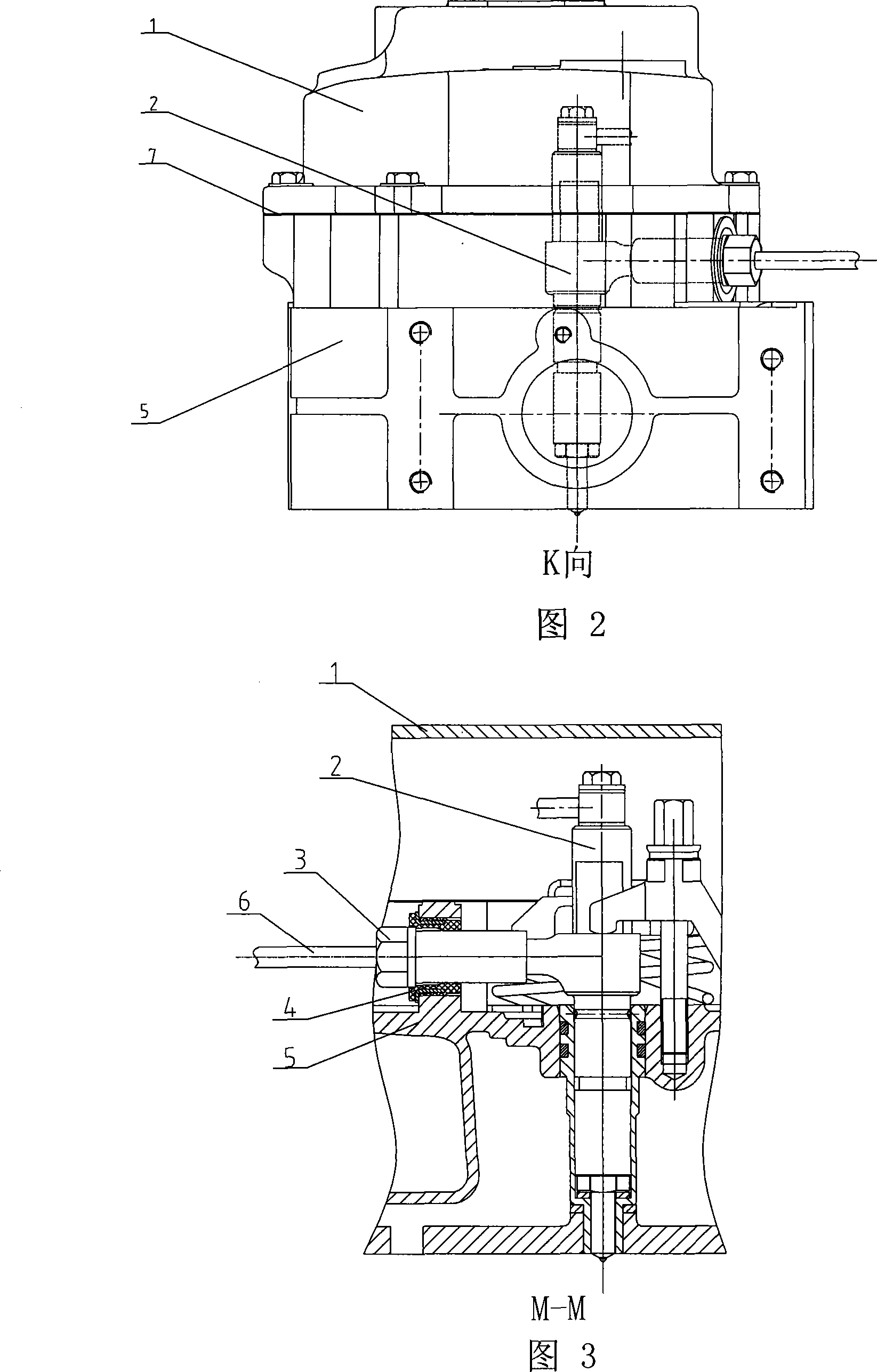

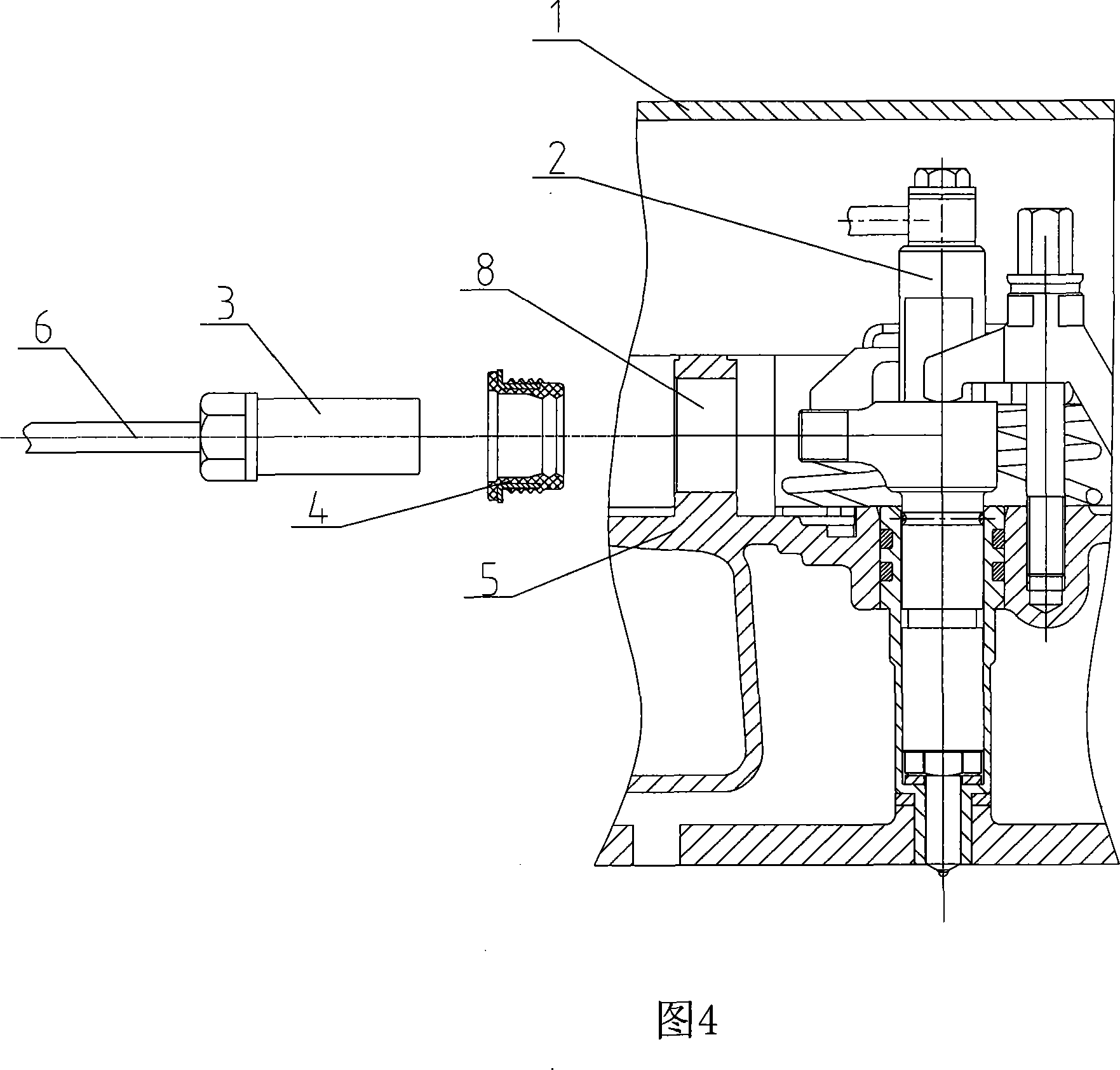

Diesel engine fuel injector mounting structure

InactiveCN101216007ASimple structureCompact structureFuel injection apparatusMachines/enginesLow speedCylinder head

The invention relates to an installation structure for a diesel injector, in particular belongs to the technical field of a power plant. An oil atomizer is arranged in a sealed valve control cabin consisting of a cylinder head, a seal ring and a cylinder cover hood, and is fixed on the cylinder head. The invention is characterized in that: the cylinder head is provided with a high pressure pipe hole; a high pressure pipe joint is connected with the oil atomizer fixed on the cylinder head through the high pressure pipe hole; a sealing element is arranged between the high pressure pipe joint and the high pressure pipe hole. The structure of the invention is simple, compact and rational; the cost of manufacture is reduced; the invention is overhauled conveniently; just the cylinder cover hood is needed to be removed without needing to remove the fuel injection pipe components when the internal components of the cylinder cover hood are maintained; when the invention runs at a low speed, the cylinder cover hood is not required to be covered, and whether the fuel injection pipe joint leaks oil can be observed directly.

Owner:WUXI KIPOR POWER CO LTD

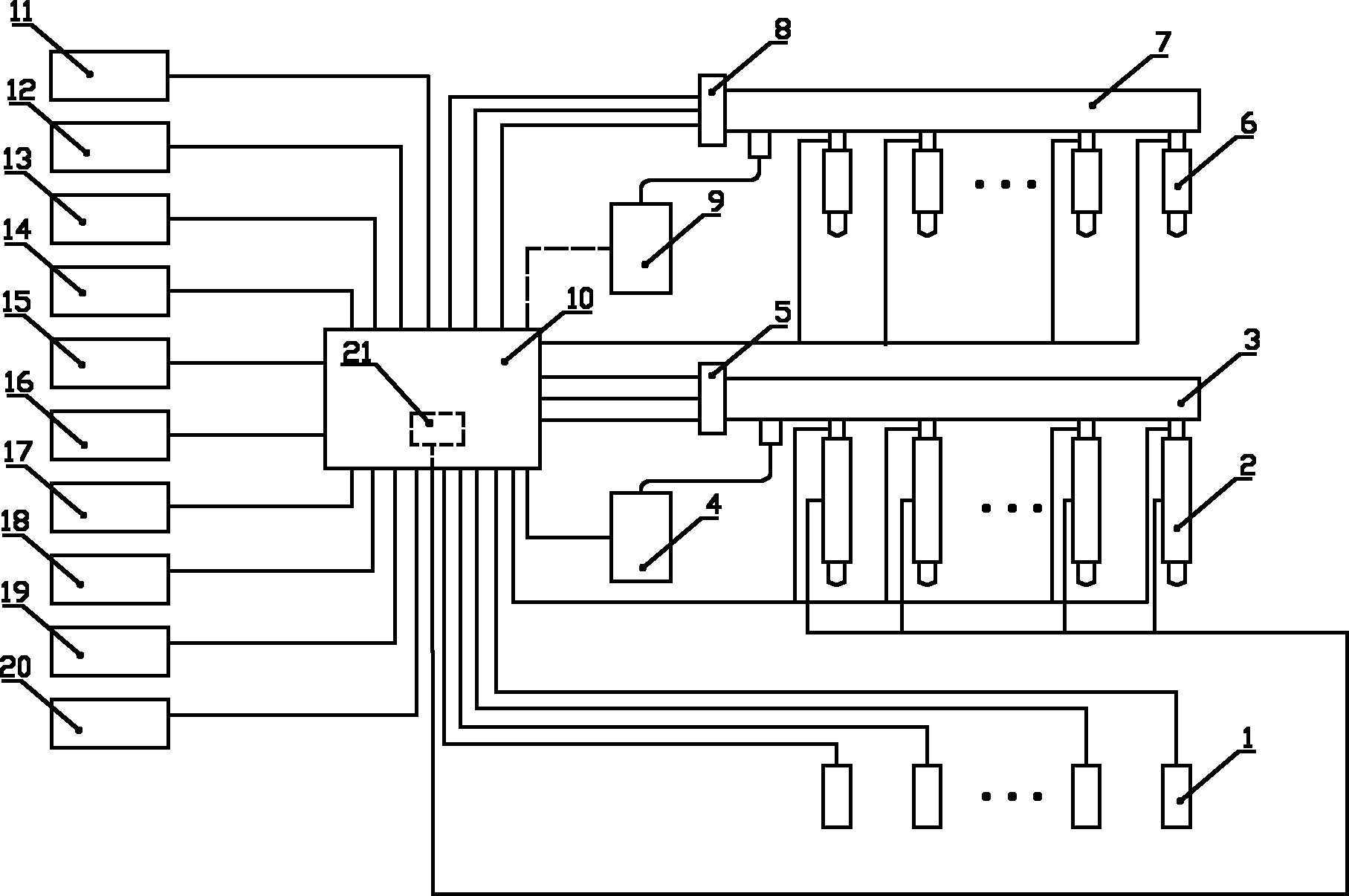

Control system of automotive diesel and gasoline dual-fuel engine and control method thereof

ActiveCN102661205AImprove fuel efficiencyReduce pollutantsElectrical controlMachines/enginesControl signalControl system

The invention discloses a control system of a diesel and gasoline dual-fuel engine and a control method thereof. The control system comprises an engine control unit, a signal collection unit, a high pressure diesel supply pump and a gasoline supply pump, wherein the engine control unit collects signals from the signal collection unit, sends control signals to the high pressure diesel supply pump and the gasoline supply pump and simultaneously sends the control signals to an electronic control diesel injector and an electronic control gasoline injector. The control method of the control system comprises the step that gasoline in a cylinder is ignited at multiple points through compression ignition and the injection of diesel at multiple points. According to the control method, the gasoline is ignited at multiple points through the compression ignition of the diesel, so not only can the effective heat efficiency of the gasoline be improved, but also the emission of pollutants can be reduced. The control system and the control method are suitable for various vehicles utilizing the diesel to ignite the gasoline.

Owner:GREAT WALL MOTOR CO LTD

Programmable diesel fuel injector

An apparatus for injecting fuel into a combustion chamber of an internal combustion engine. The apparatus includes a solid magnetostrictive material with a favored direction of magnetostrictive response formed into a shape with ends that are substantially parallel to each other and substantially perpendicular to the favored direction of magnetostrictive response. A fuel control valve element is located coaxial to the favored direction of magnetoelastic response of the magnetostrictive material, the element opening inwardly. A solenoid coil is located concentric with the magnetostrictive material and coaxial to the favored direction of magnetoelastic response, the solenoid coil adapted to excite the magnetostrictive material into mechanical motion. An excitation signal is provided within the solenoid coil consisting of a main current signal with a superposed alternating signal approximately the width of a hysteresis loop of the solid magnetostrictive material. Finally, a magnetic return path circuit in magnetic communication with the solid magnetostrictive material is provided.

Owner:QUANTUM CONTROL WORKS L C

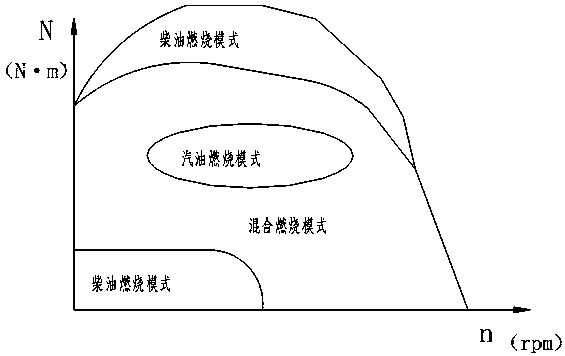

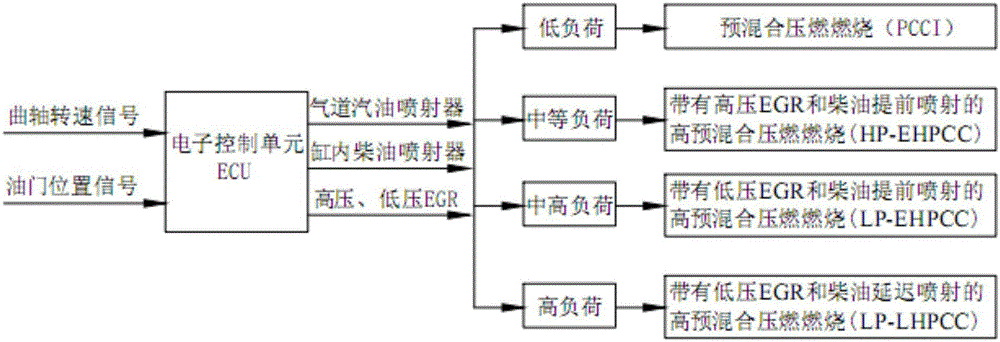

Method for flexibly controlling engine combustion mode

ActiveCN106762294AImprove consumption rateEnsure normal dischargeFuel injection apparatusMachines/enginesCombustionLow load

The invention discloses a method for flexibly controlling an engine combustion mode. Engine speed signals and throttle position signals are read by an electronic control unit to judge the engine operation load according to the read signals; if under the low load condition, an diesel injector is controlled for early injection to form PCCI combustion mode in a cylinder; if under the moderate load condition, the diesel injector is controlled for injection in advance twice, and high-pressure EGR is performed to form HP-EHPCC combustion mode; if under the medium-to-high load condition, the diesel injector is controlled for injection in advance twice, and low-pressure EGR is performed to form LP-EHPCC combustion mode; if under the high load condition, the diesel injector is controlled for delayed injection once, and the low-pressure EGR is performed to form LP-LHPCC combustion mode. High-efficiency clean combustion within a wide load range is implemented through combination of different combustion modes under different working conditions.

Owner:TIANJIN UNIV

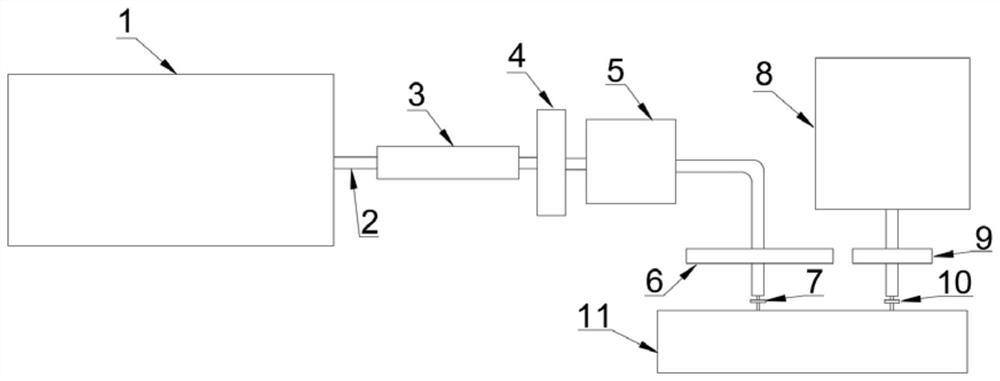

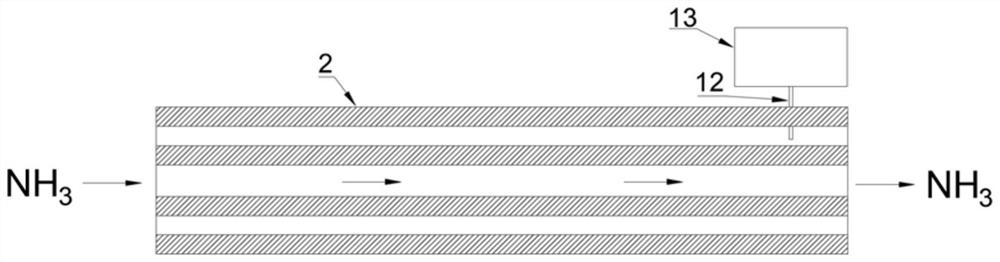

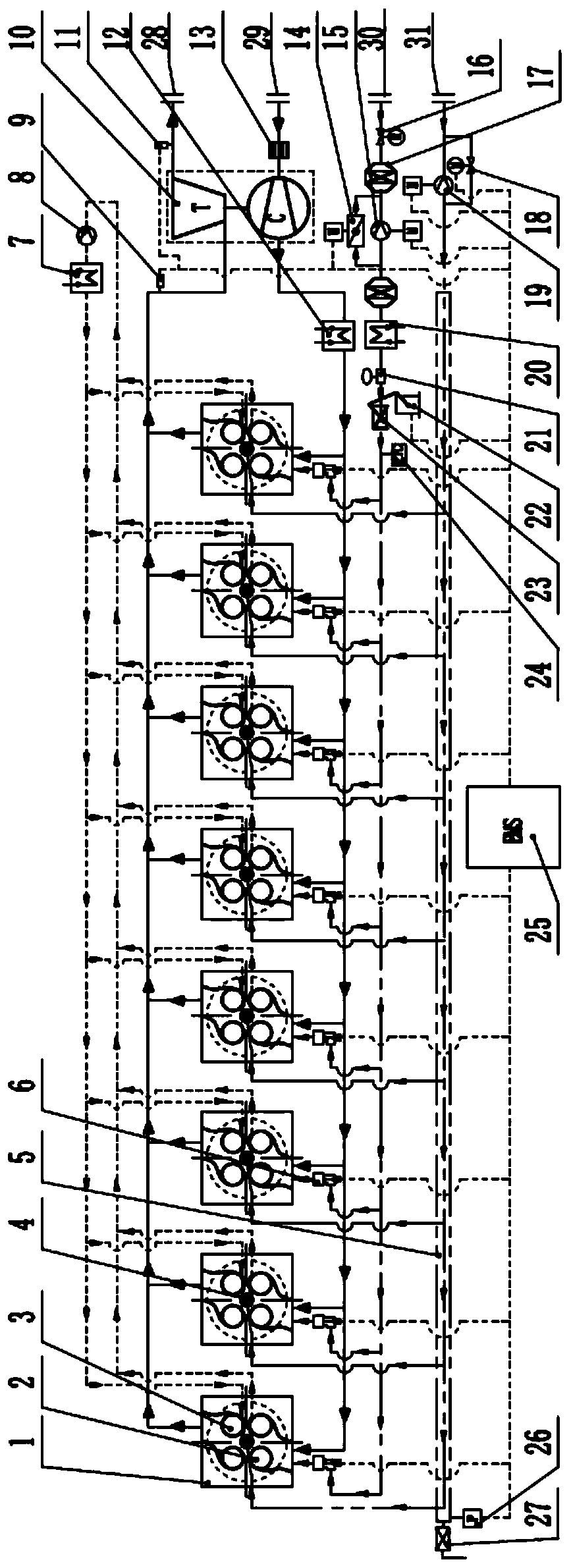

Marine diesel engine ammonia fuel supply system

InactiveCN112628030AEnsure safetyIncrease energy densityInternal combustion piston enginesFuel supply apparatusAmmonia storageCommon rail

The invention aims to provide a marine diesel engine ammonia fuel supply system. The marine diesel engine ammonia fuel supply system comprises a diesel engine, an ammonia storage tank and an oil tank, wherein the ammonia storage tank is sequentially connected to a vaporization tank, a filter cavity, a pressurizing tank and an ammonia high-pressure common rail pipeline through an ammonia transmission pipeline, the ammonia high-pressure common rail pipeline is connected to the diesel engine through an ammonia injection valve, the oil tank is connected to a diesel oil high-pressure common rail pipe, and the diesel high-pressure common-rail pipe is connected to a diesel engine through a diesel atomizer. According to the marine diesel engine ammonia fuel supply system, ammonia can be used as fuel for the engine to burn, environmental problems such as emission pollution and the like are reduced, the ammonia is coupled with high-activity fuel for blending combustion, so that the combustion characteristic of the ammonia can be effectively improved, the external output power is increased, in addition, vaporization heat absorption of the ammonia can be applied to a refrigerating system of a steamship, and the utilization efficiency of energy on the steamship is improved.

Owner:HARBIN ENG UNIV

Programmable diesel fuel injector

An apparatus for injecting fuel into a combustion chamber of an internal combustion engine. The apparatus includes a solid magnetostrictive material with a favored direction of magnetostrictive response formed into a shape with ends that are substantially parallel to each other and substantially perpendicular to the favored direction of magnetostrictive response. A fuel control valve element is located coaxial to the favored direction of magnetoelastic response of the magnetostrictive material, the element opening inwardly. A solenoid coil is located concentric with the magnetostrictive material and coaxial to the favored direction of magnetoelastic response, the solenoid coil adapted to excite the magnetostrictive material into mechanical motion. An excitation signal is provided within the solenoid coil consisting of a signal, before a main current signal, sufficient to cause magnetic domain alignment but not rotation, and finally a magnetic return path circuit is provided in magnetic communication with the solid magnetostrictive material.

Owner:QUANTUM CONTROL WORKS L C

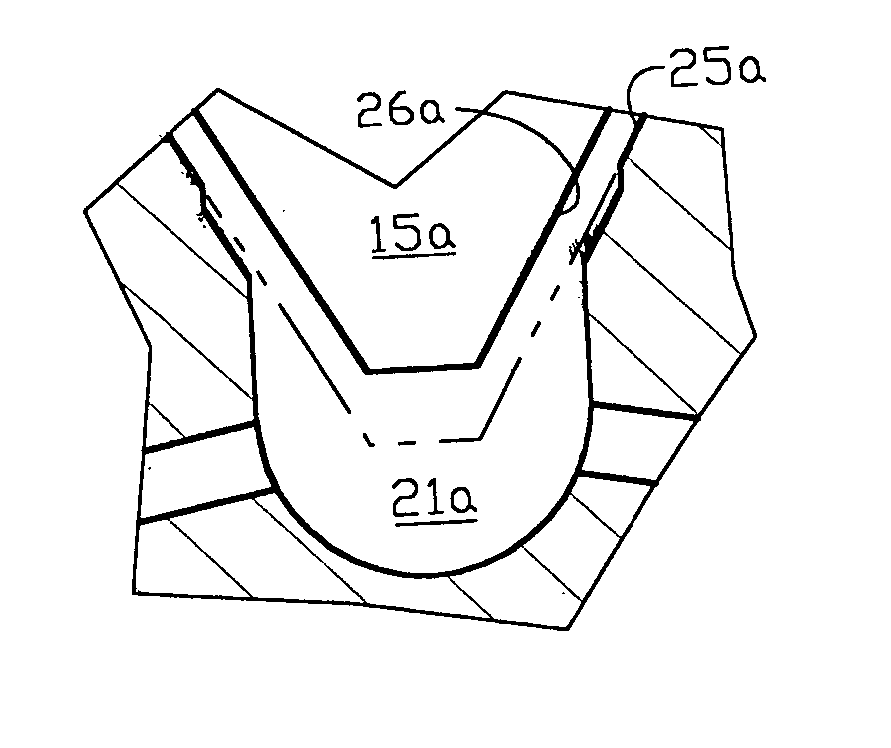

Method and apparatus for controlling needle seat load in very high pressure diesel injectors

Method and apparatus for controlling needle seat load in very high pressure diesel injectors. In accordance with the method, a needle control piston responsive to hydraulic forces for controllably forcing the injector needle against the needle seat is provided, as is a stop for the needle control piston to limit the needle control piston movement toward the needle seat. This provides a stop for the needle control piston, so that the compressive deflection between the needle control piston and the needle seat limits the force of the injector needle on the needle seat against increasing hydraulic forces on the needle control piston once the needle control piston reaches the needle control piston seat.

Owner:STURMAN INDS

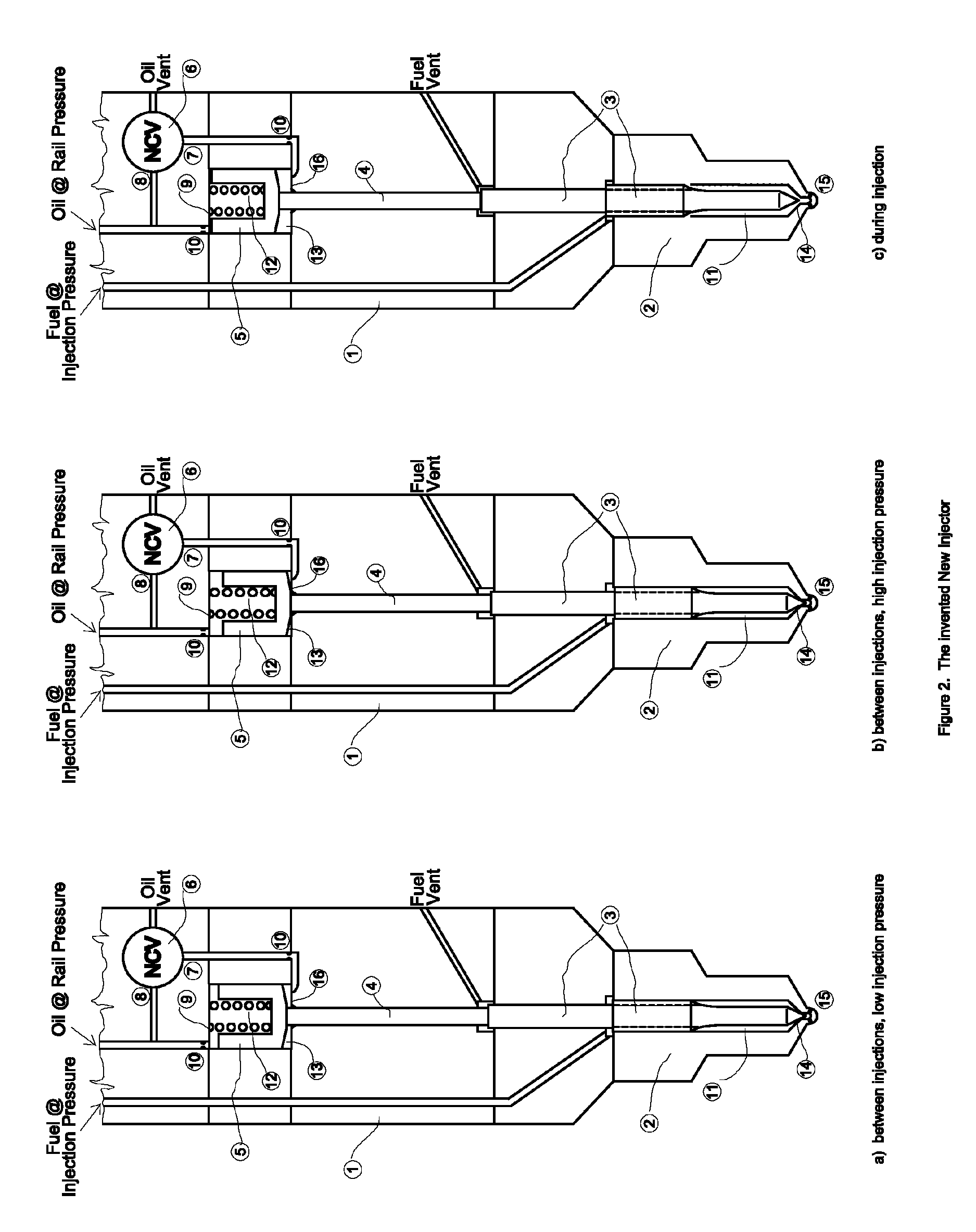

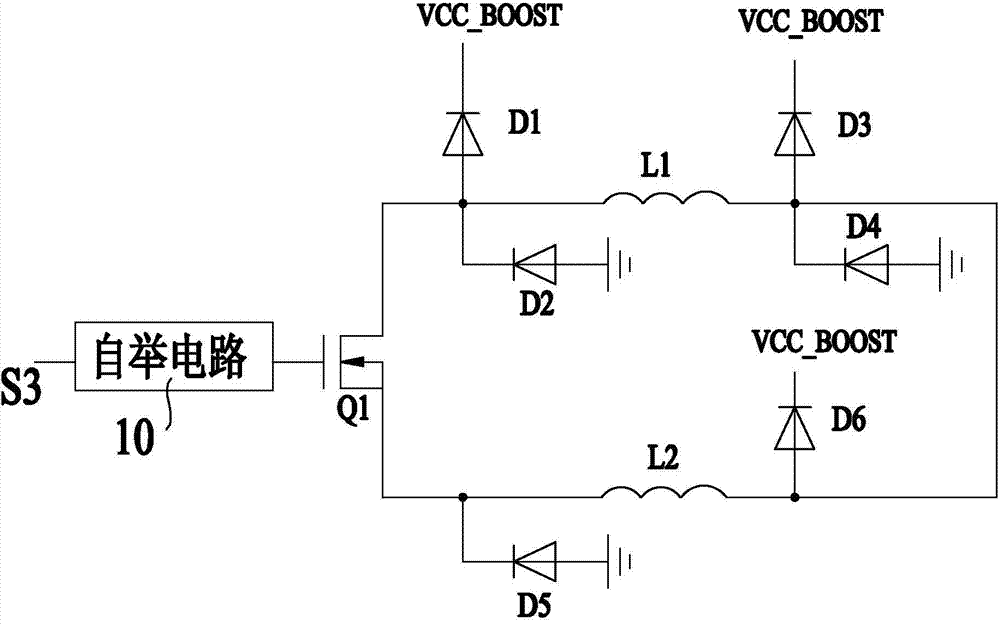

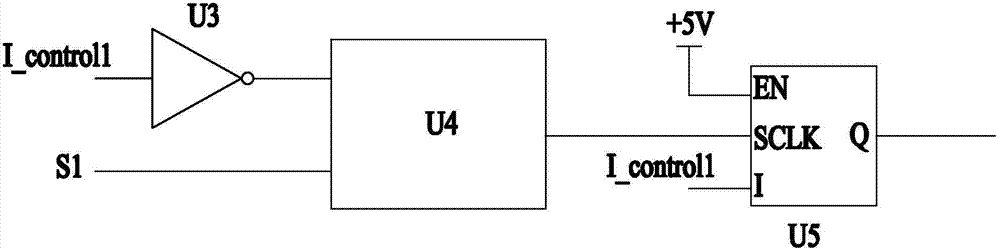

Driving current control circuit of piezoelectric ceramic diesel injector

ActiveCN104500298AImprove reliabilityEasy to controlFuel injection apparatusMachines/enginesLow voltageDiesel injector

The invention relates to a driving current control circuit of a piezoelectric ceramic diesel injector. The driving current control circuit of the piezoelectric ceramic diesel injector comprises a first processor and a piezoelectric ceramic executor, wherein the high-voltage end of the piezoelectric ceramic executor is connected with the source electrode end of a high-voltage charging switch tube T1 and is connected with the drain electrode end of a discharge switch tube T2; the source electrode end of the discharge switch tube T2 is grounded; the low-voltage end of the piezoelectric ceramic executor is connected with a sampling threshold value processing circuit for sampling working current of the piezoelectric ceramic executor; the sampling threshold value processing circuit is connected with a current control circuit; the current control circuit is connected with the grid electrode end of the high-voltage charging switch tube T1 and the grid electrode end of the discharge switch tube T2 through a driving logic circuit respectively. The driving current control circuit of the piezoelectric ceramic diesel injector is compact in structure, and can accurately control driving current so as to ensure the consistency of the driving current, reduce the switching loss and improve the reliability of an electric control system.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

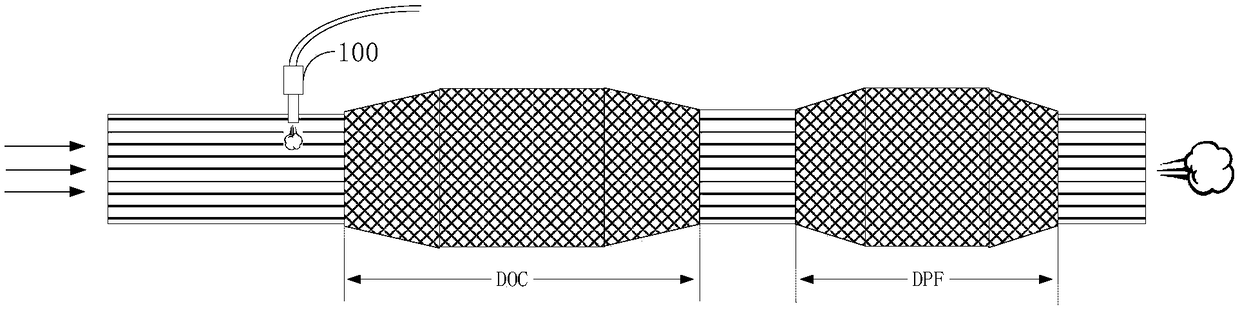

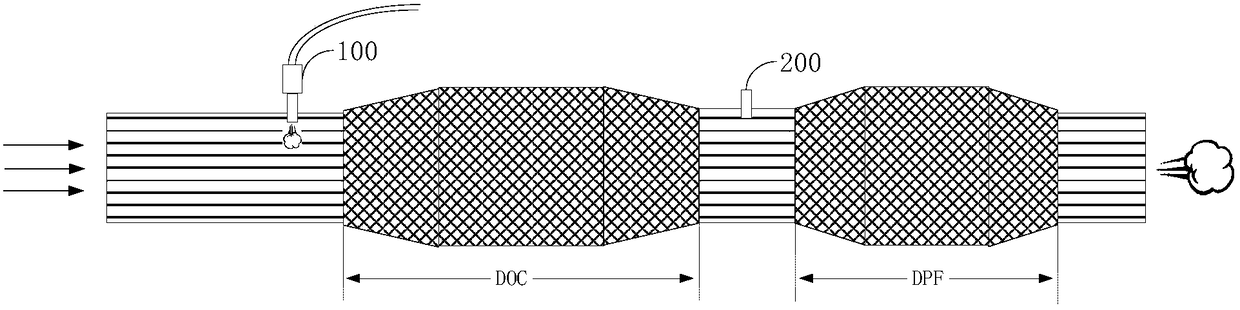

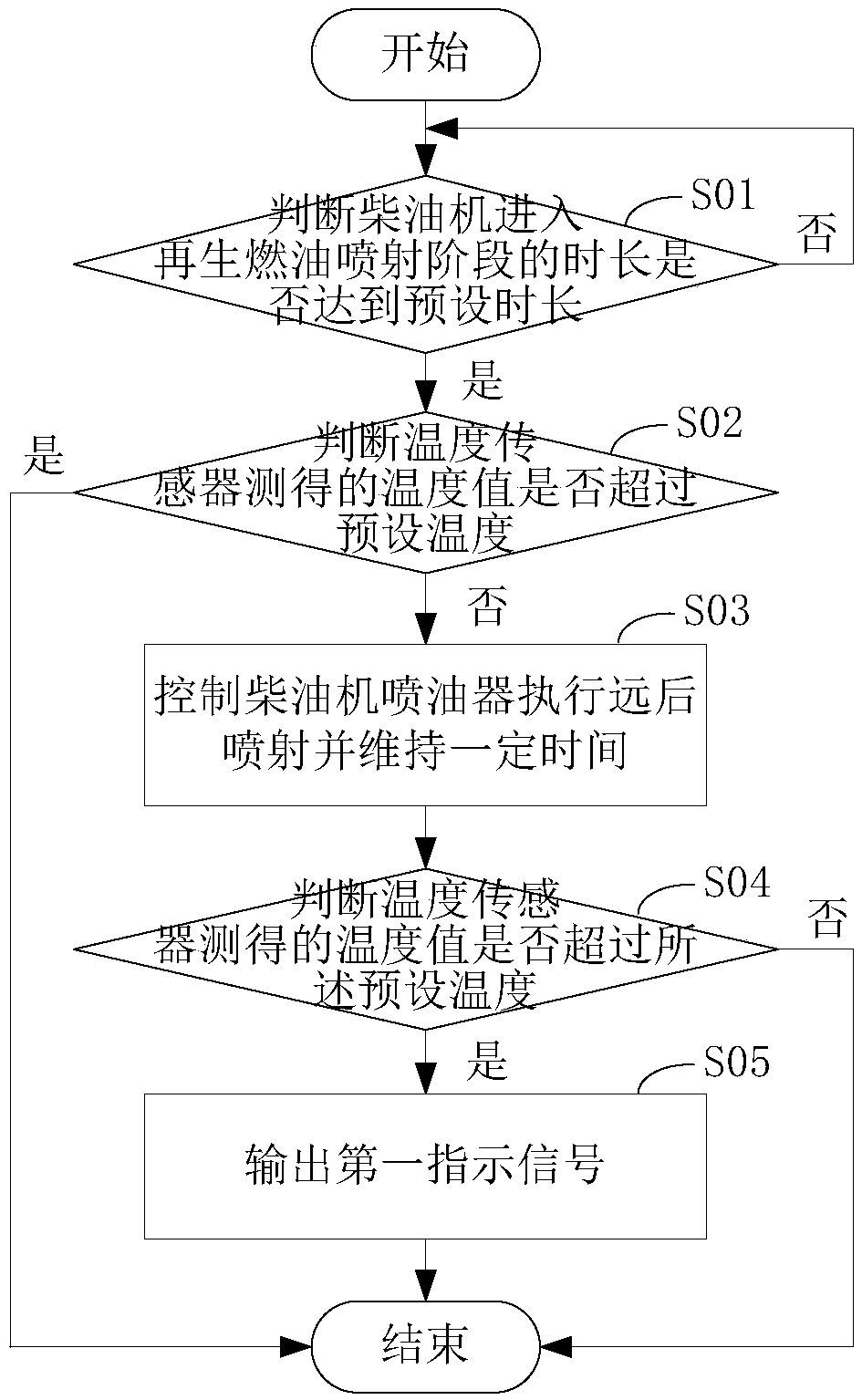

Method and device for detecting faults of gas exhaust pipeline of diesel engine

ActiveCN109252928ATimely detection of blockageInternal combustion piston enginesExhaust treatment electric controlDiesel injectorDiesel particulate filter

the invention discloses a method and a device for detecting faults of a gas exhaust pipeline of a diesel engine. The method and the device are used for detecting whether the gas injection valve is blocked or not in time. A temperature sensor is mounted on the gas exhaust pipeline of the diesel engine and is positioned downstream from a DOC (diesel oxidation catalyst) and upstream from a DPF (diesel particulate filter). The method for detecting the faults includes: judging whether the time for the diesel engine to enter a recycled diesel oil injection stage reaches to preset time or not; if yes, judging whether a temperature value sensed by the temperature sensor exceeds a preset temperature or not; if not, controlling a diesel injector to inject diesel oil in a distance backwards for a certain time, and judging whether the temperature value sensed by the temperature sensor exceeds the preset temperature or not again, and if yes, outputting a first indication signal which indicates thatthe DOC is normal but the diesel oil injection valve is blocked.

Owner:WEICHAI POWER CO LTD

Ultralow-concentration gas machine combustion system and control method thereof

PendingCN111237092AIncrease intake pressureImprove inflation efficiencyElectrical controlInternal combustion piston enginesCombustion systemCommon rail

The invention provides an ultralow-concentration gas machine combustion system and a control method thereof. The ultralow-concentration gas machine combustion system comprises an air exhaust turbocharging device, an ultralow-concentration gas pressurizing inlet device, a diesel common-rail micro-jet ignition device, a diesel injector cooling circulation device, an EMS control unit and a pluralityof cylinders, wherein the air exhaust turbocharging device can improve the air inlet pressure and efficiency, the ultralow-concentration gas pressurizing inlet device can improve the gas inlet densityto meet the requirements of different loads for a high-pressure gas flow rate, and the diesel injector cooling circulation device decreases the combustion temperature of an injector under a high loadand greatly lowers the probability that the ejector burns down or gets stuck. Under the combined action of all the devices, normal ignition and normal combustion based on the ultralow-concentration gas machine combustion system are realized, and normal starting and operating of a gas machine are ensured.

Owner:中科环能(天津)动力科技有限公司

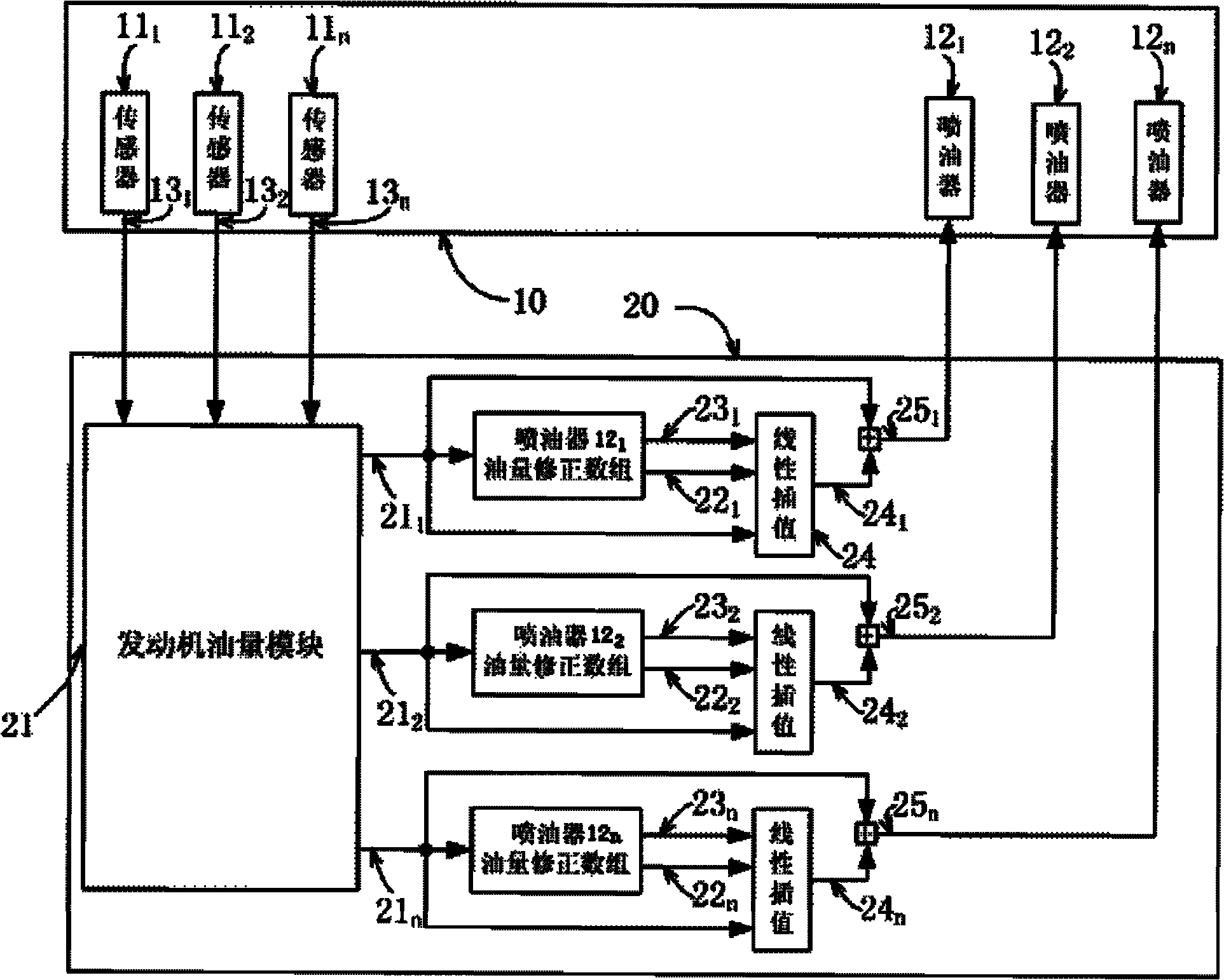

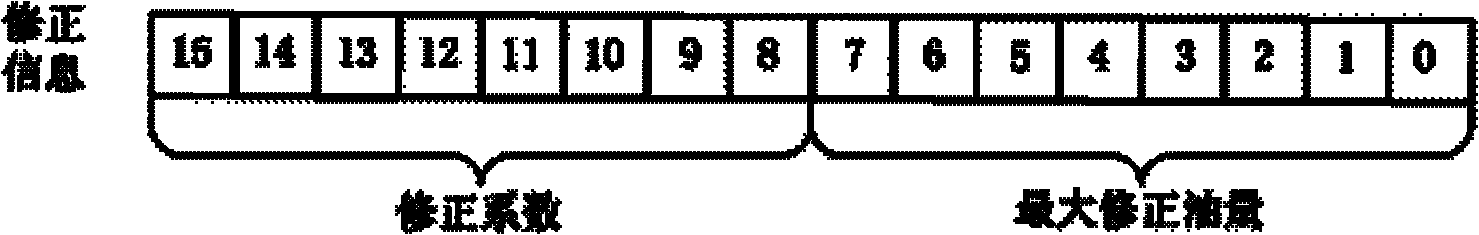

Correcting method for electromagnetic valve of common-rail diesel injector

ActiveCN102192034AImprove the correction effectTakes up little storage spaceElectrical controlMachines/enginesArray data structureCommon rail

The invention discloses a correcting method for an electromagnetic valve of a common-rail diesel injector. The correcting method comprises the following steps: (1) a sensor of a diesel engine, injectors and a management module are installed, wherein the management module is internally provided with an oil mass module and an oil mass correcting array, the oil mass correcting array comprises two lines of data, wherein the first line of data is the oil mass of a fixed point, and the second line of data is correcting information corresponding to the oil mass of the fixed point and is the 16-bit data; (2) the oil mass module obtains the oil mass of each injector before correction through computation; (3) the management module obtains the oil mass of the fixed point and the corrected oil mass which are closest to the input oil mass from the corresponding oil mass correcting array by using the oil mass before correction as the input; (4) the linear interpolation computation is carried out so as to obtain the corrected oil mass which corresponds to the input mass by using the obtained oil mass before correction as the input and the oil mass of the corresponding fixed point and the corrected oil mass as known quantities; and (5) the corrected oil mass and the oil mass before correction are added so as to obtain the ultimate corrected oil mass. The corrected oil mass is determined by using the oil mass as the input, and therefore the correcting method disclosed by the invention is more suitable for the common-rail system with injection oil mass being irrelevant to the rotating speed and has better correcting effect.

Owner:TSINGHUA UNIV +1

Diesel injection nozzle

An annular notch is provided in the body seat associated with the nozzle valve of an ALCO-type diesel injector. The notch extends from (i) an upper edge that is on the seat and is above the imaginary edge that would have been the sac inlet edge had the notch not been provided to (ii) a lower edge below such imaginary edge. The notch has a lowest wall that, at least at the portion of its length where such lowest wall approaches such lower edge, has a given angle-to-vertical of less than 60°.

Owner:BUESCHER DEV

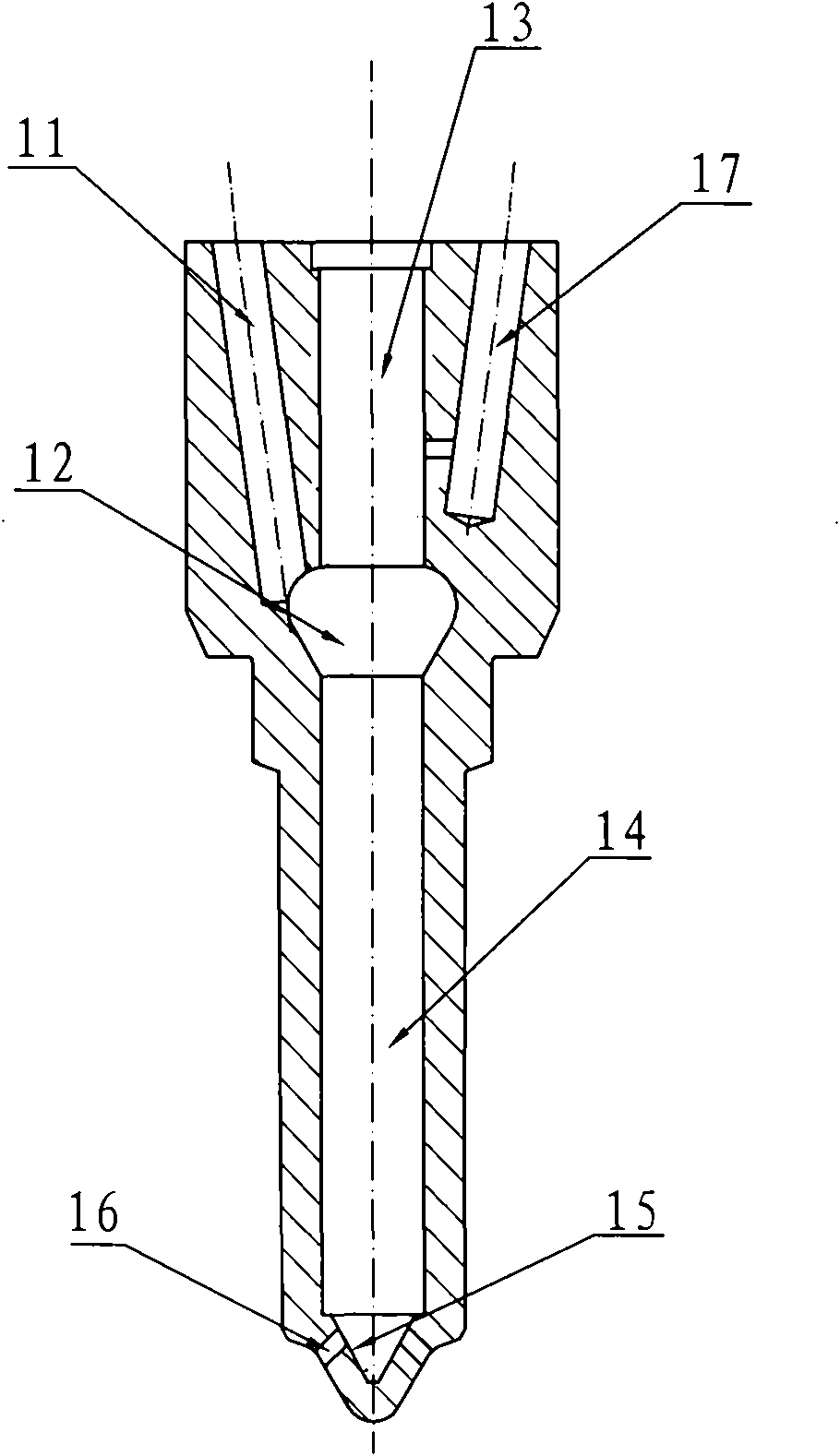

Diesel injector coupler applied to multiple fuels

InactiveCN101985912AIncrease axial lengthMake sure to formLubrication of auxillariesFuel injection apparatusDiesel injectorProcessing cost

The invention discloses a diesel injector coupler applied to multiple fuels. A needle valve body is provided with a fuel passage, a fuel accommodating cavity, a needle valve guide hole, a needle bar hole, a sealed inner conical surface, an oil jet hole and a lubricating oil passage, wherein the oil jet hole is formed on the sealed inner conical surface; the fuel passage is communicated with the fuel accommodating cavity; the lubricating oil passage is communicated with the needle valve guide hole; a guide section is sleeved in the needle valve guide hole on the needle valve body; a conical surface sealing bar is positioned in the needle bar hole; the sealed outer conical surface of a needle valve is matched with the sealed inner conical surface of the needle valve body; the guide section of the needle valve is provided with a lubrication groove; and when the needle valve is positioned at a limit position, the lubrication groove is communicated with the lubricating oil passage. The lubrication groove is formed on the guide section of the needle valve so as to increase the axial length of the lubrication groove between the needle valve and the needle valve body, reduce the processing cost and prevent the needle valve and the needle valve body from being blocked due to lubrication lack; and an abrasion-resistant coating is arranged on the sealed outer conical surface of the needle valve so as to prolong the sealing life between the needle valve and the needle valve body and prevent the fuel liquid from leaking.

Owner:CHANGZHOU YITONG FUEL EJECTOR MFG

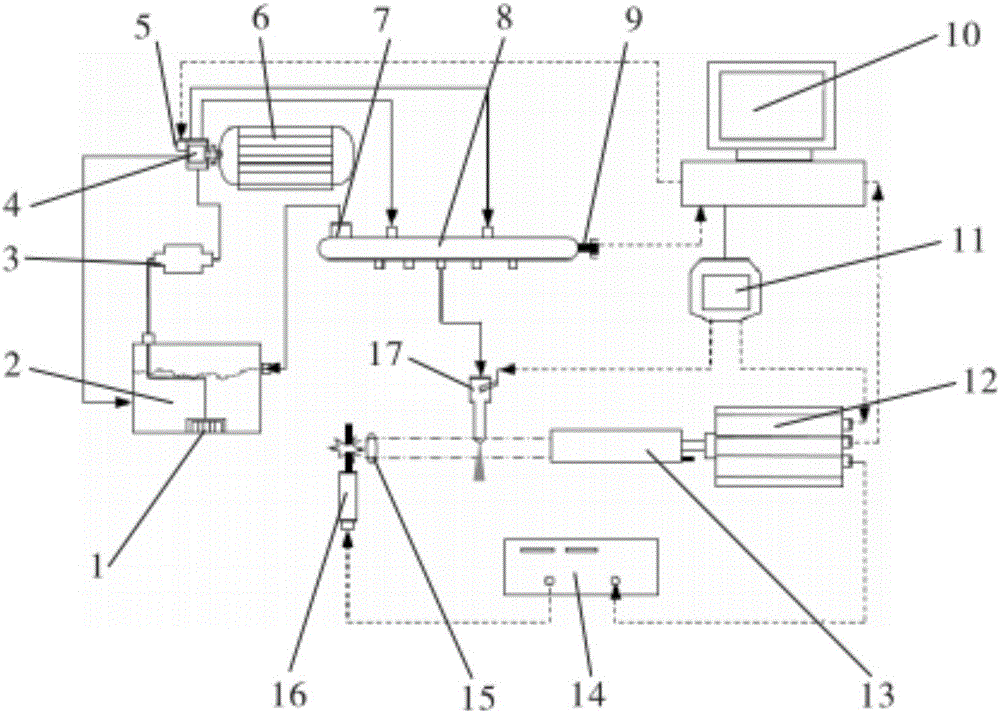

Method and device for measuring diesel injector needle valve movement rule of diesel engine based on visualization method

ActiveCN105927446APrecise measurement of movementMotion measurementEngine testingFuel injection apparatusCommon railData acquisition

The invention discloses a method and a device for measuring a diesel injector needle valve movement rule of a diesel engine based on a visualization method. A high-pressure common rail injecting system comprises a diesel filter oil tank, an oil tank, a low-pressure oil pump, a high-pressure oil pump, a fuel metering valve, a variable frequency motor, a pressure release valve, a common rail pipe, a common rail pressure sensor, a control computer, and an electric control oil injector with a transparent head part; and a data acquiring system includes a synchronous delay controller, a high-speed camera, a microscope lens, a nanosecond flashlight controller, a convex lens and a nanosecond flashlight. The lower end of a diesel engine nozzle is changed to a transparent material for directly observing the movement of a needle valve; and the high-speed camera captures the transient movement rule of the needle valve at higher shooting speed. The device not only can precisely measure the movement of the needle valve in the vertical direction, but also can measure the eccentric movement of the needle valve.

Owner:JIANGSU UNIV

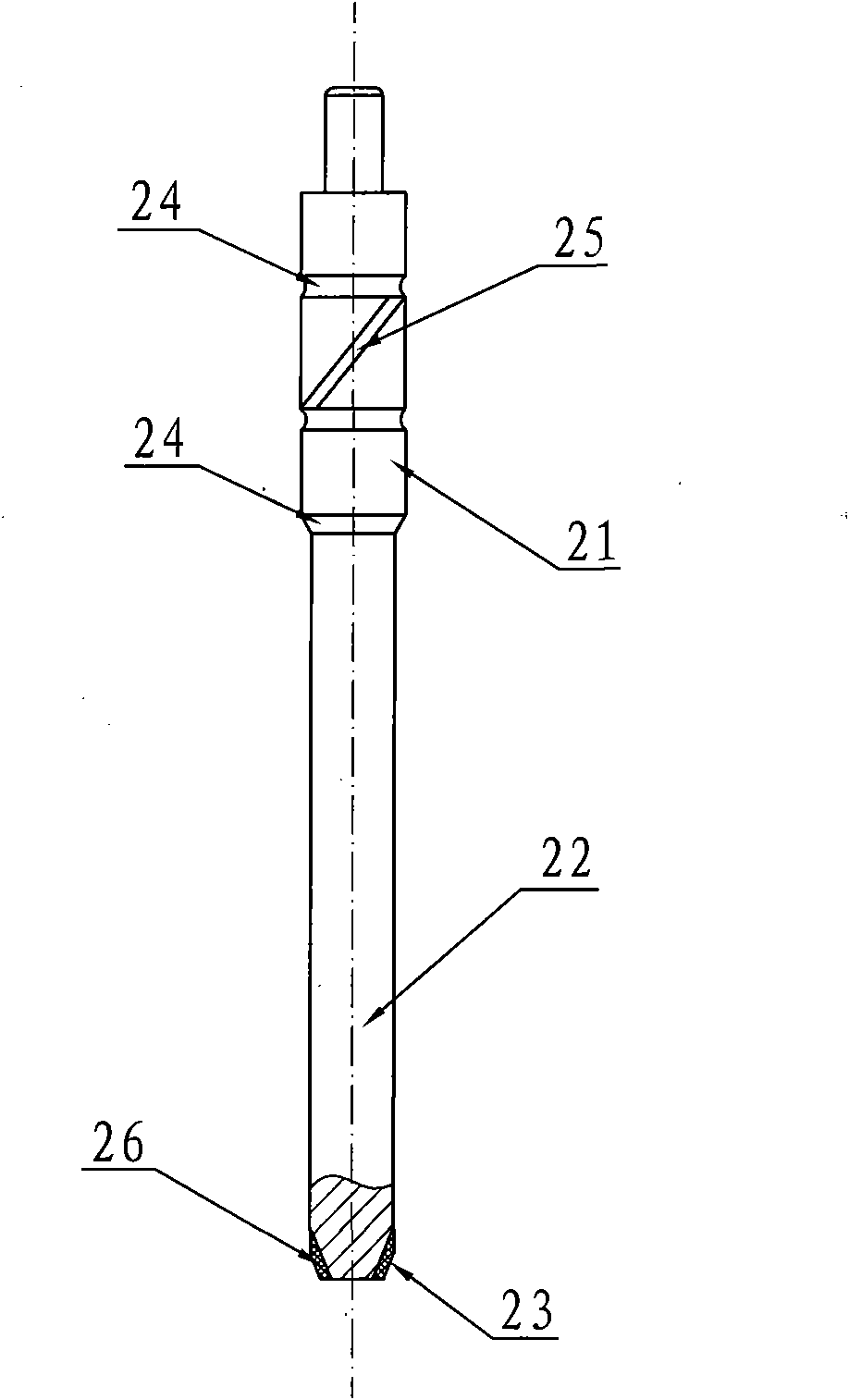

Diesel injector capable of successively injecting oil

InactiveCN103615344AImprove atomization effectImprove uniformityFuel injection apparatusMachines/enginesLow loadDiesel injector

The invention aims to provide a diesel injector capable of successively injecting oil. The diesel injector comprises an outer shell and a needle valve body. The needle valve body is located in the outer shell. The outer shell is provided with an oil inlet groove and a needle valve cavity. The oil inlet groove is communicated with the needle valve cavity. The needle valve body comprises a sealing piston and a needle valve conical surface, wherein the sealing piston is arranged on the end portion of the needle valve body, and the needle valve conical surface is located above the sealing piston. The inner wall of the outer shell is provided with a needle valve sealing surface which is located below the needle valve cavity. An oil injection cavity is formed between the sealing piston and the bottom end of the inner wall of the outer shell. The needle valve cavity is communicated with the oil injection cavity through passages. The upper ends of the passages are located in the needle valve sealing surface. When the needle valve body drops in place, the needle valve conical surface is matched with the needle valve sealing surface to enable the passages to be disconnected with the needle valve cavity. A first layer of spray orifices and a second layer of spray orifices are formed in the bottom end of the outer shell respectively. The first layer of spray orifices is located below the second layer of spray orifices. Through the diesel injector capable of successively injecting the oil, the fuel oil atomization performance at low load, the fuel oil wall-wetting phenomenon at high load and fuel oil distribution uniformity in the air are improved, so efficiency is improved, and soot emission and HC emission are reduced.

Owner:HARBIN ENG UNIV

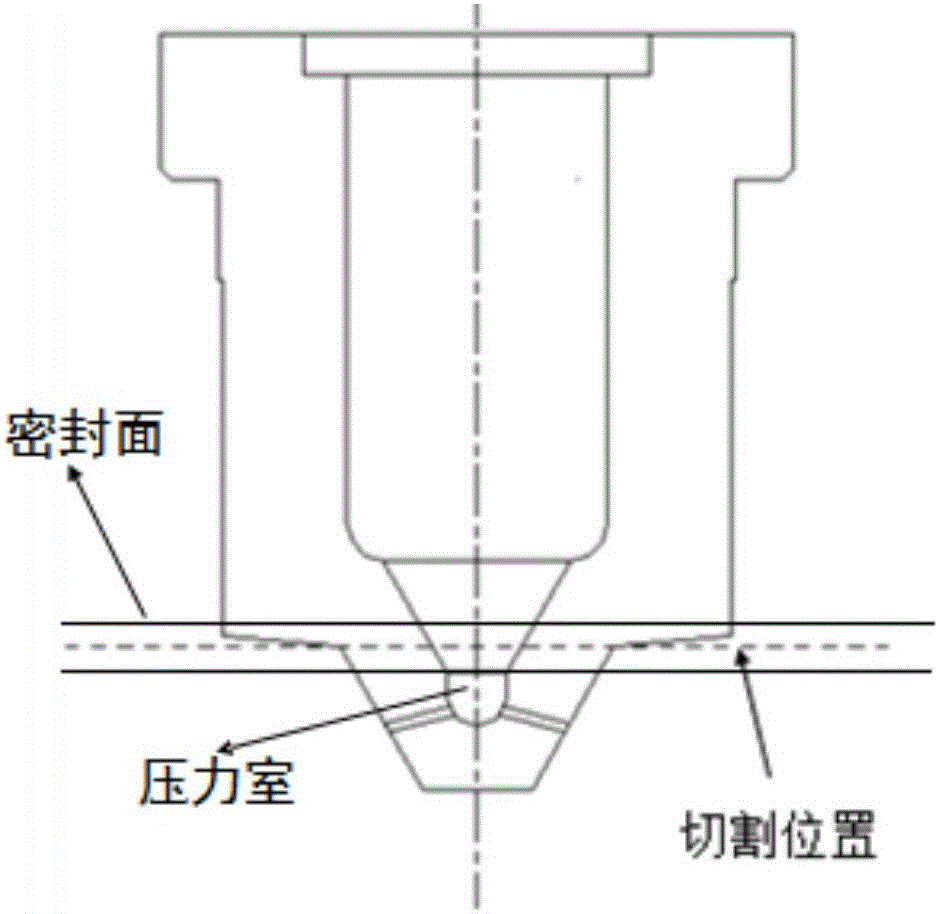

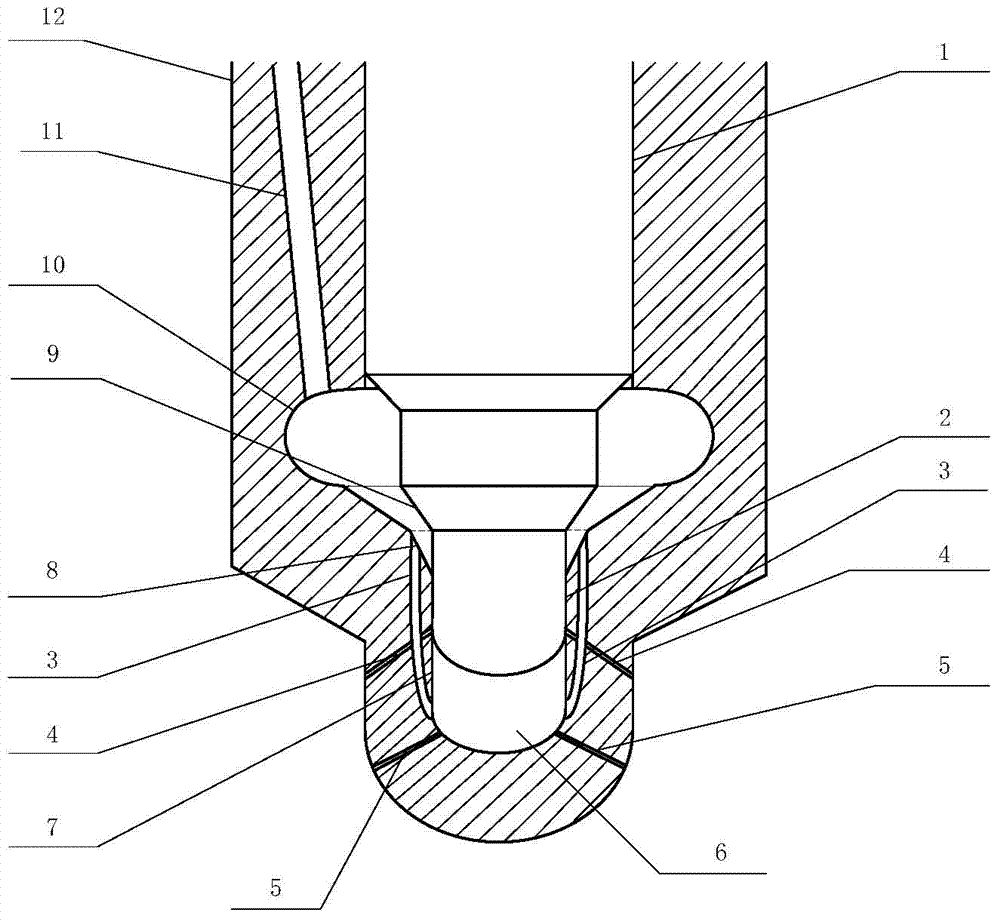

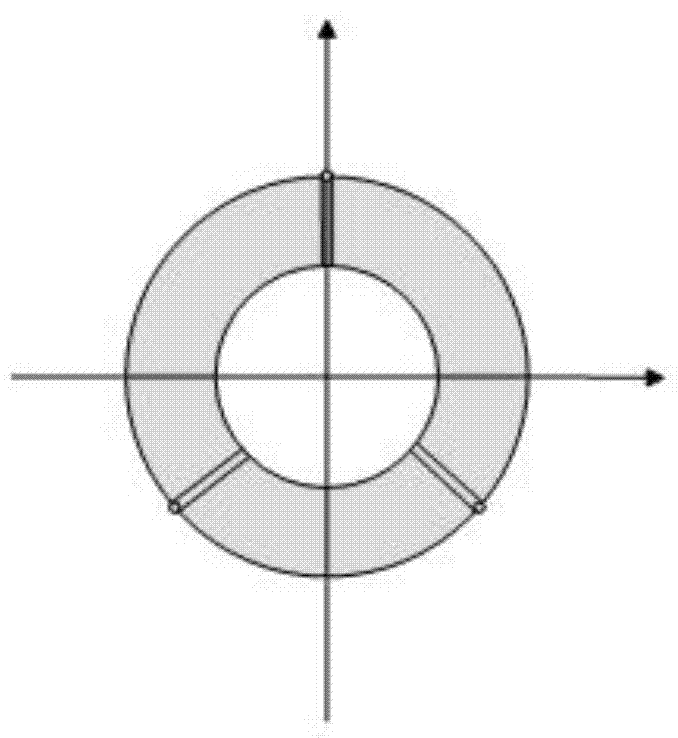

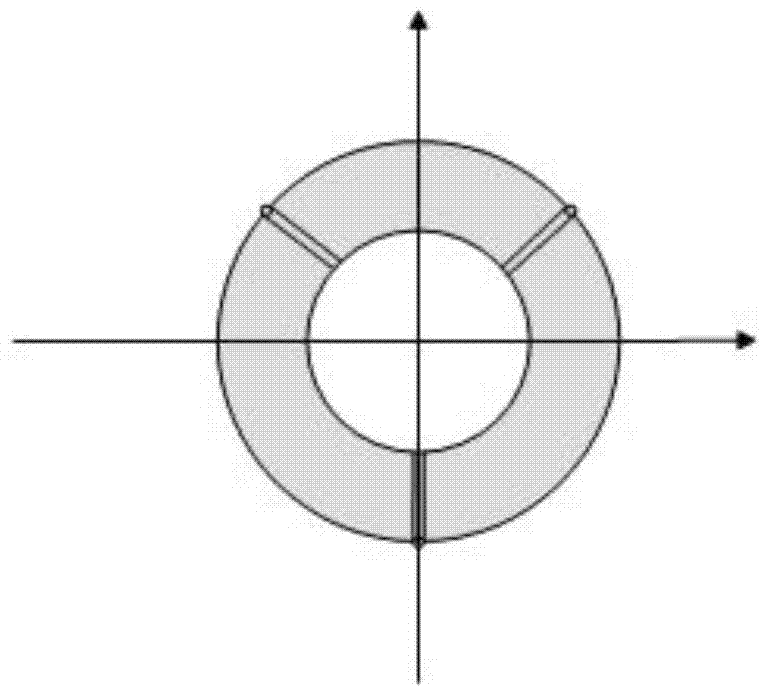

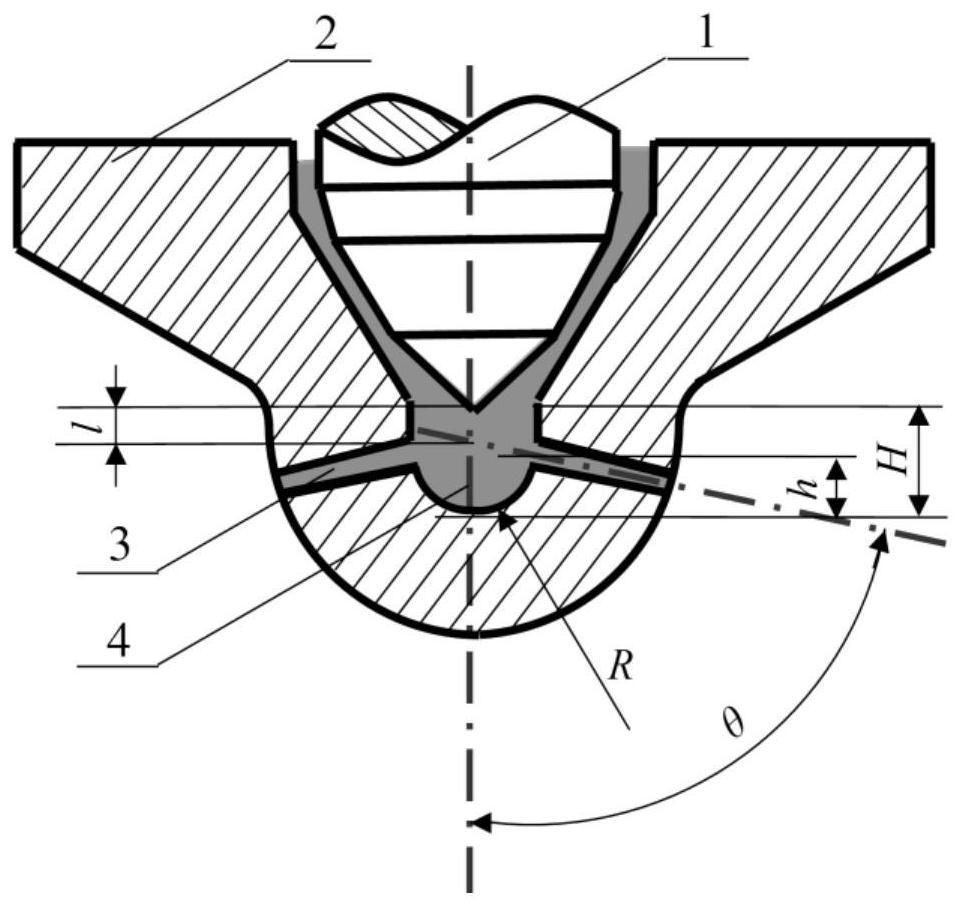

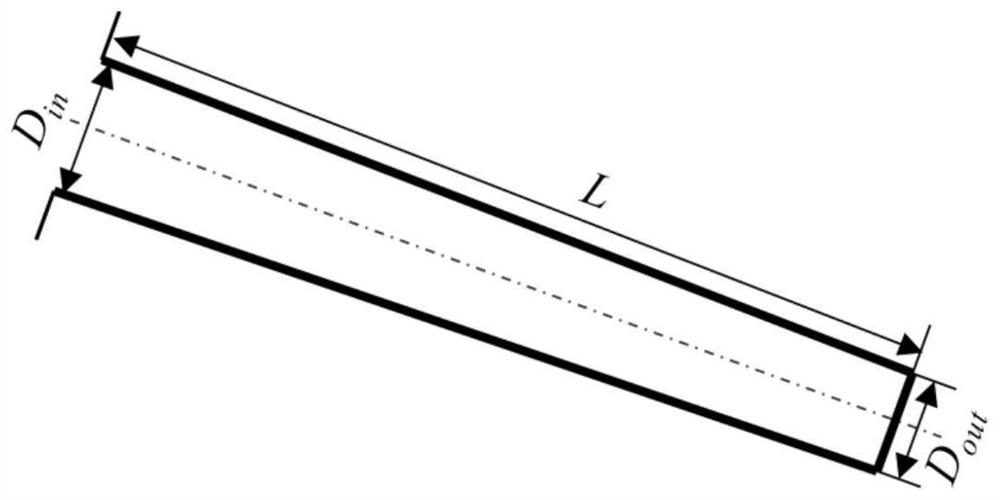

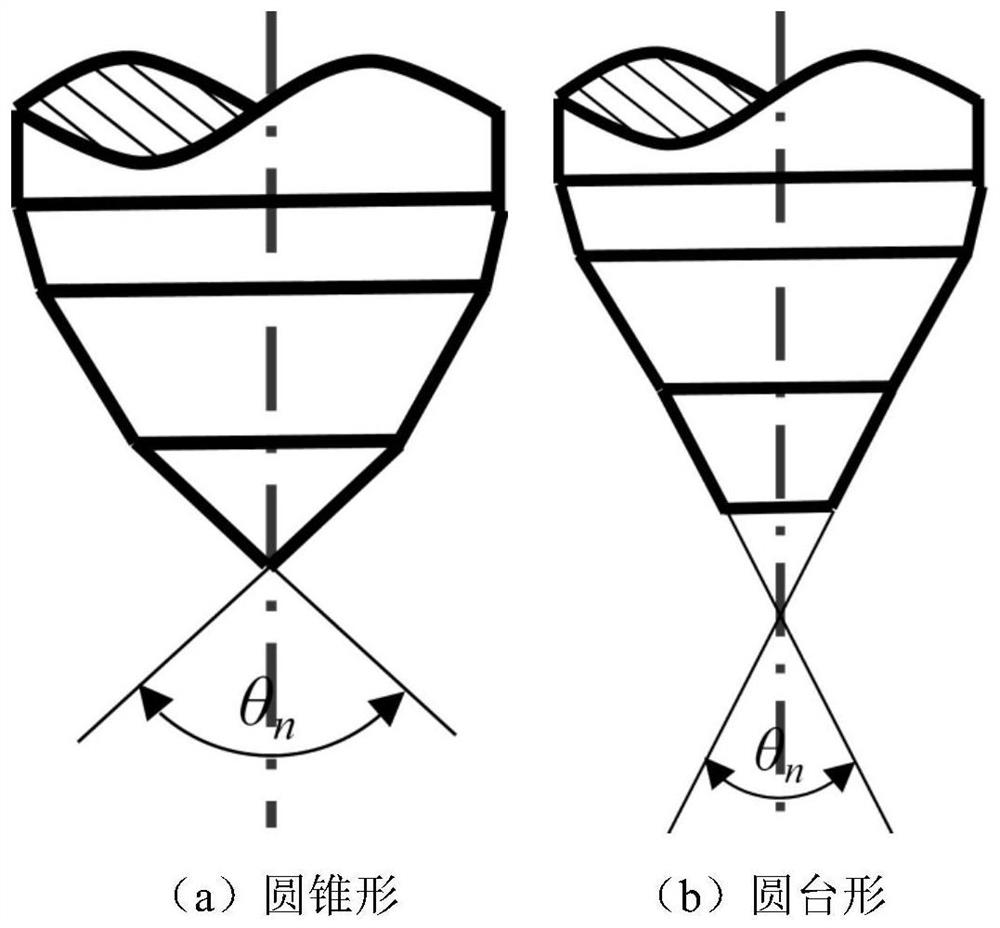

Diesel injector based on nozzle inner vortex cavitation induced hollow spraying structure

ActiveCN112228262AEnhancing and stabilizing the cavitation phenomenon of inner vortex linesEnhance and stabilize cavitationInternal combustion piston enginesFuel injection apparatusDiesel injectorDieseling

The invention discloses a diesel injector based on a nozzle inner vortex cavitation induced hollow spraying structure. The diesel injector comprises a needle valve, a needle valve body, spraying holesand a pressure chamber; the axis of the needle valve of the injector coincides with the axis of the needle valve body; the multiple identical reduced conical spraying holes are evenly distributed inthe head of the needle valve body; and the outlet ends of all the spraying holes communicate with the pressure chamber. The pressure chamber of the injector is composed of the hemisphere and the cylinder which are equal in diameter, the geometrical structure of the injector is optimized, the vortex cavitation phenomenon in the diesel injector under different loads is strengthened, and the fuel atomization quality of the injector is effectively improved.

Owner:JIANGSU UNIV

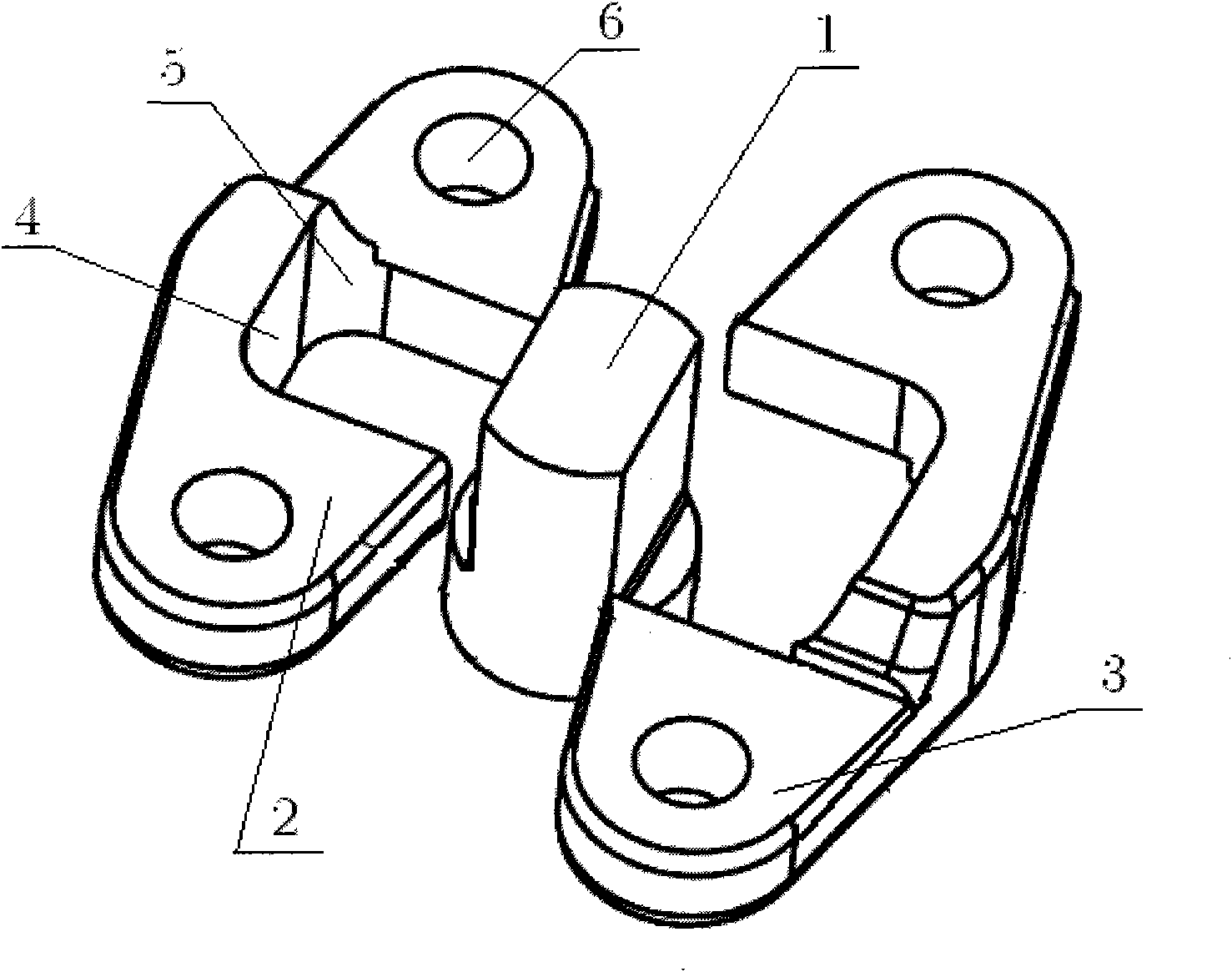

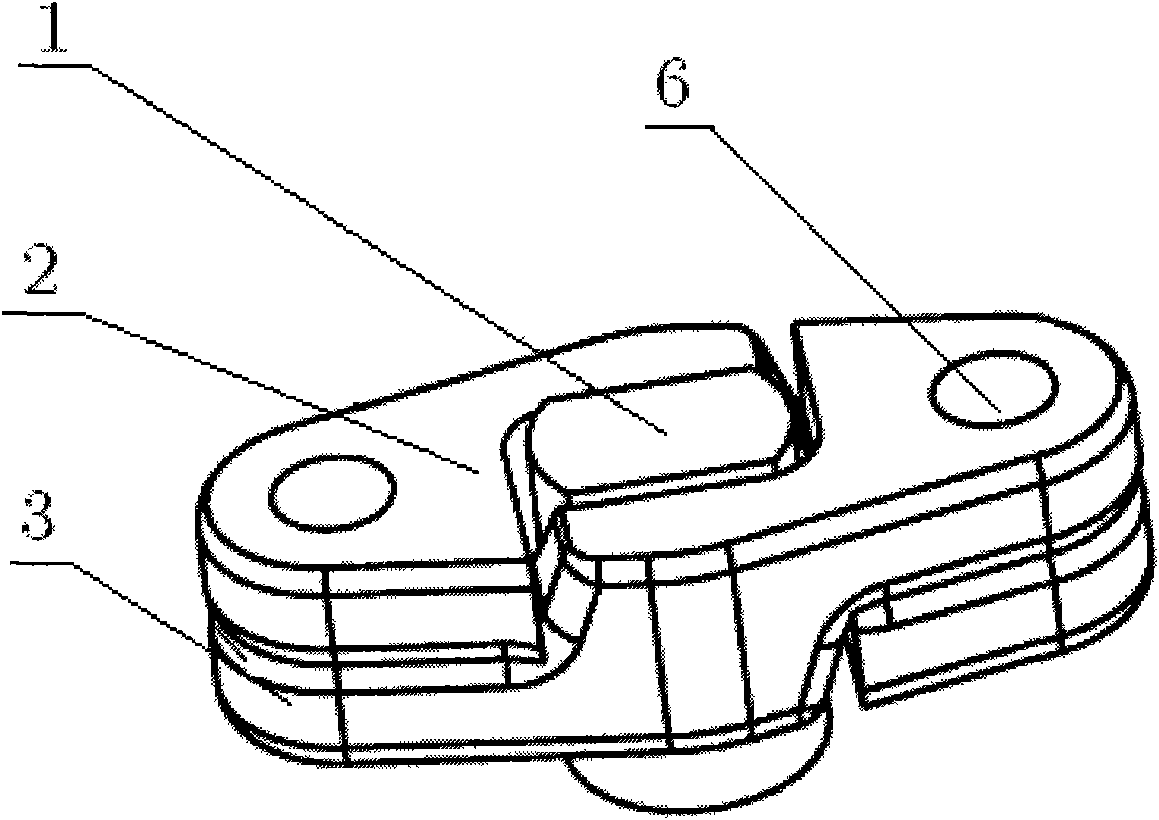

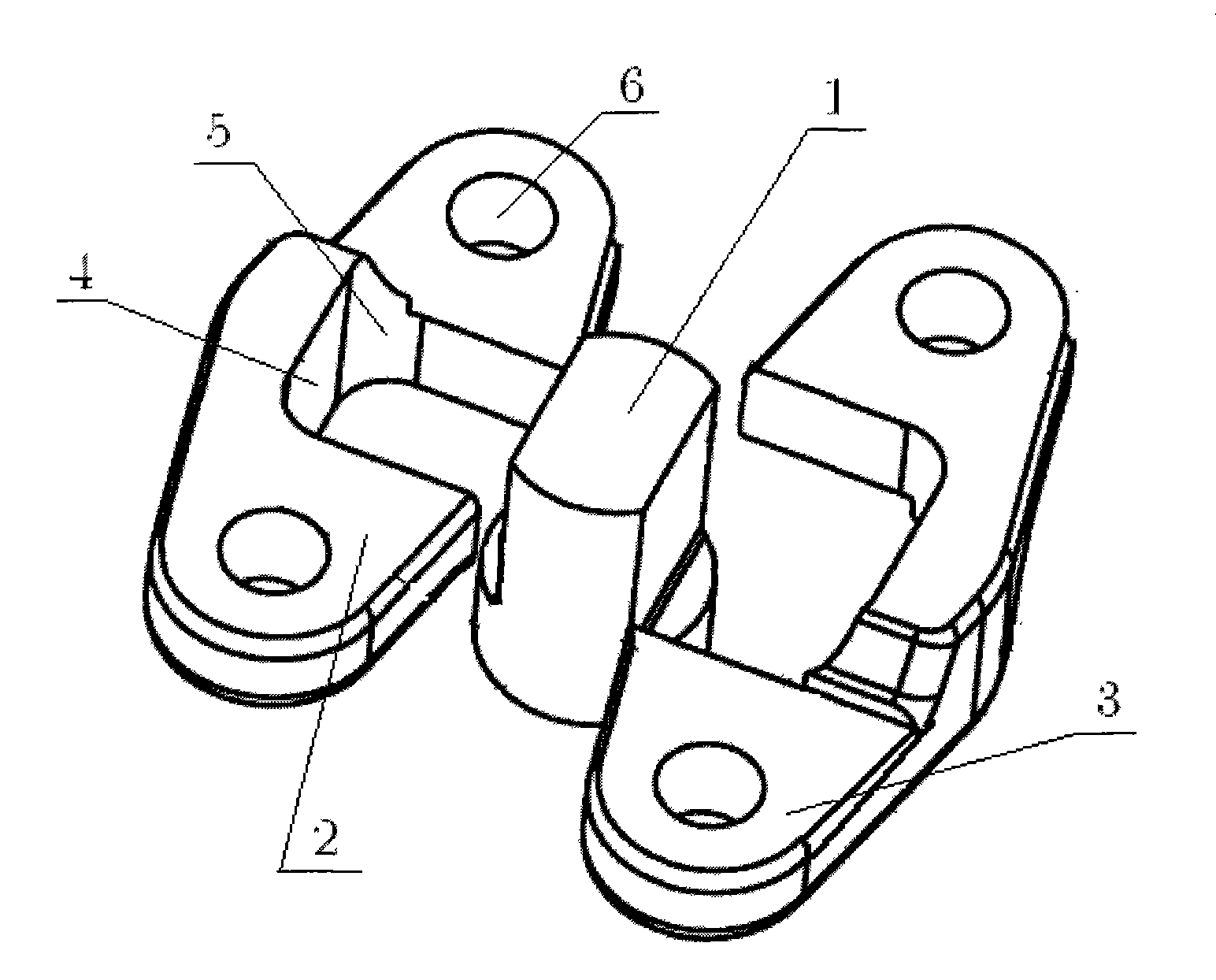

Coupling type injector pressing device

InactiveCN101865063AReasonable structureEasy to disassembleFuel injection apparatusMachines/enginesDiesel injectorEngineering

The invention discloses a diesel injector pressing device which comprises pressing plates and an injector, wherein the cylindrical injector is provided with two parallel vertical surfaces, the cylindrical injector is coupled, installed and fixed by a sub-pressing plate and a mother pressing plate, and the structures and the sizes of the two pressing plates are fully symmetrical; the height of the two parallel vertical surfaces of the cylindrical injector is equal to that of a vertical surface pressing surface on the sub pressing plate and the mother pressing plate; the processing radius of a cambered surface pressing surface on the sub pressing plate and the mother pressing plate is equal to that of a cylinder of the cylindrical injector; fastening bolt holes are arranged at two ends of the two pressing plates; and the thickness of the vertical surface pressing surface and the cambered surface pressing surface of the pressing plates is twice as much as that of each of the bolt holes at two ends of the pressing plates. The invention has the advantages that the two pressing plates are coupled and assembled to solve the problems of difficult assembly and uneven stress for an integrated pressing plate, the sub-pressing plate and the mother pressing plate can together bear the pre-tightening force of bolts and the pulse impact force from the inner part of the cylinder, and the device of the invention can be widely applied to fix and assemble injectors on various kinds of diesel cylinder covers.

Owner:DONGFENG CHAOYANG DIESEL ENGINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com