Patents

Literature

112 results about "Diesel injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid-free quaternized nitrogen compounds and use thereof as additives in fuels and lubricants

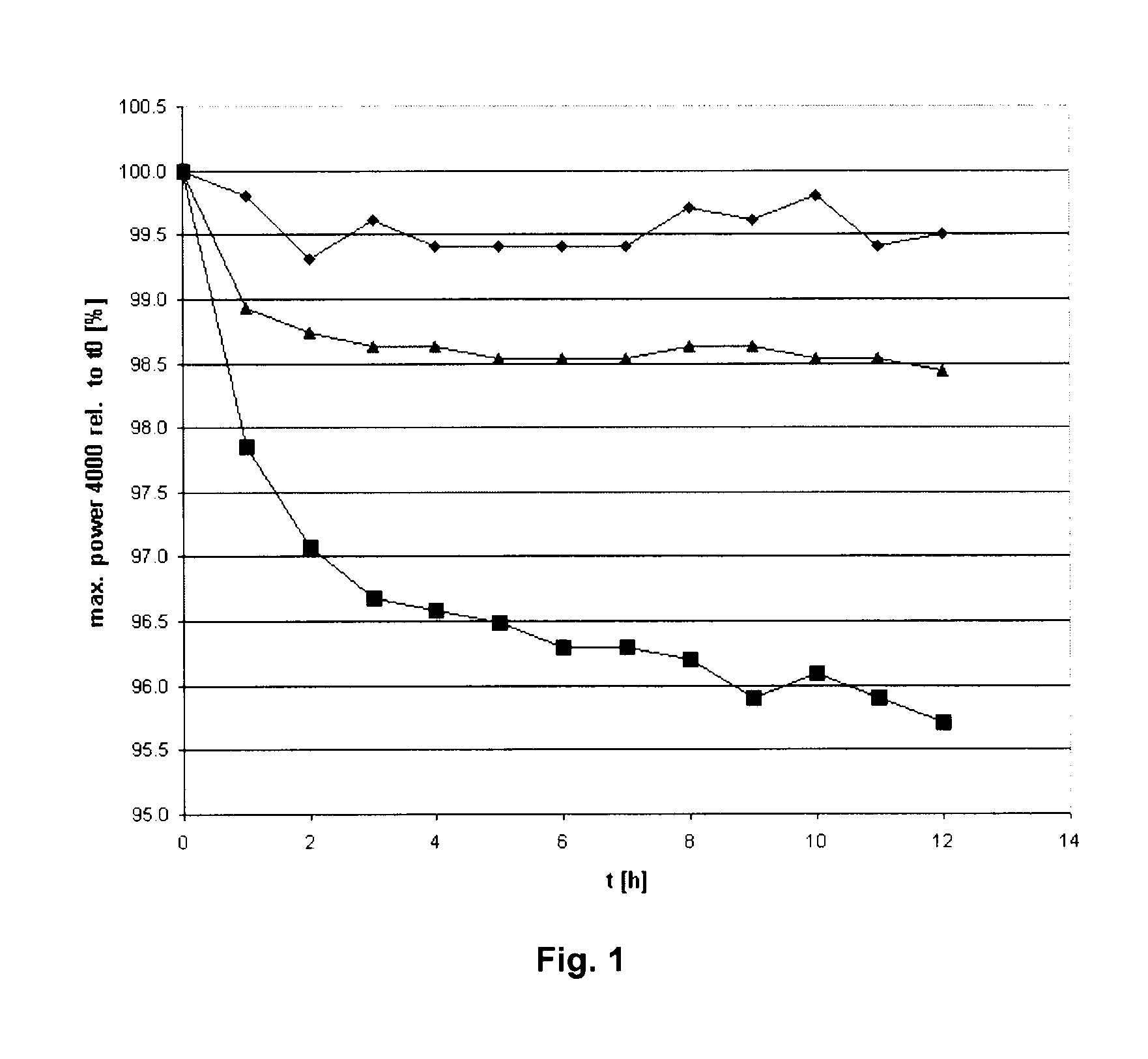

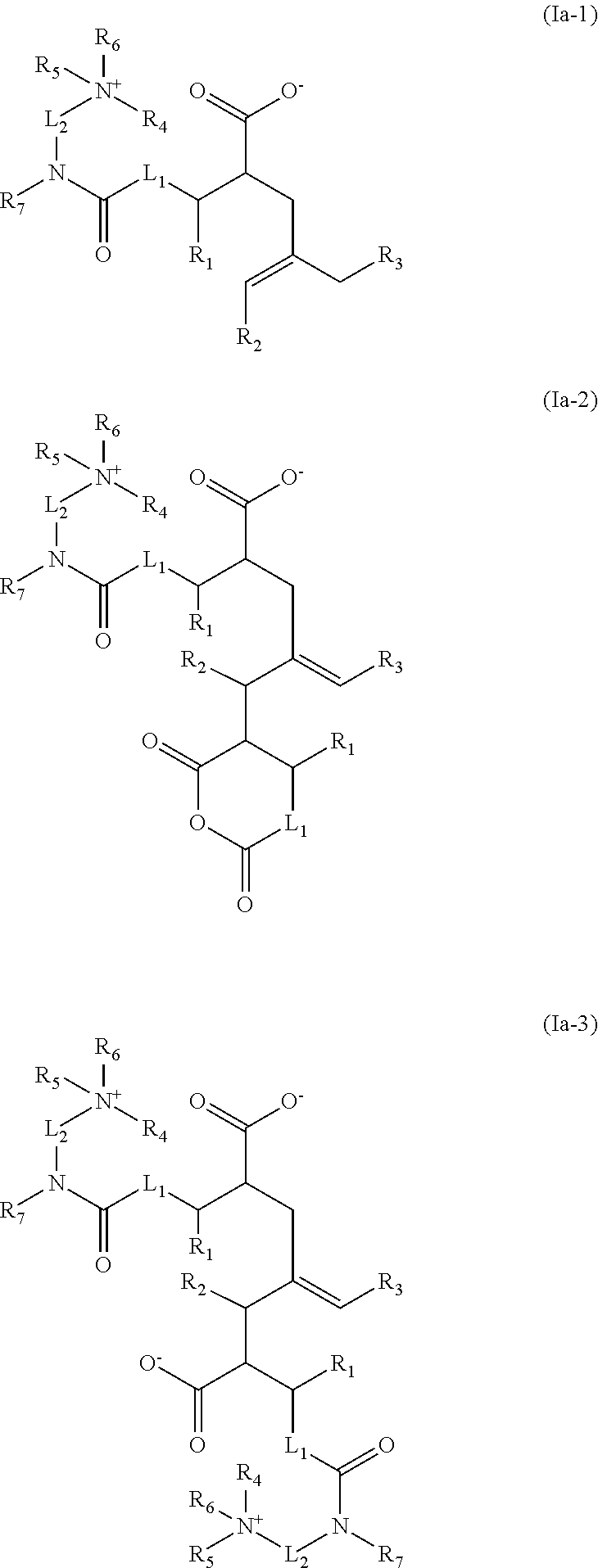

The present invention relates to novel acid-free quaternized nitrogen compounds, to the preparation thereof and to the use thereof as a fuel and lubricant additive, more particularly as a detergent additive, as a wax antisettling additive (WASA) or as an additive for reducing internal diesel injector deposits (IDID); to additive packages which comprise these compounds; and to fuels and lubricants thus additized. The present invention further relates to the use of these acid-free quaternized nitrogen compounds as a fuel additive for reducing or preventing deposits in the injection systems of direct-injection diesel engines, especially in common-rail injection systems, for reducing the fuel consumption of direct-injection diesel engines, especially of diesel engines with common-rail injection systems, and for minimizing power loss in direct-injection diesel engines, especially in diesel engines with common-rail injection systems.

Owner:BASF AG

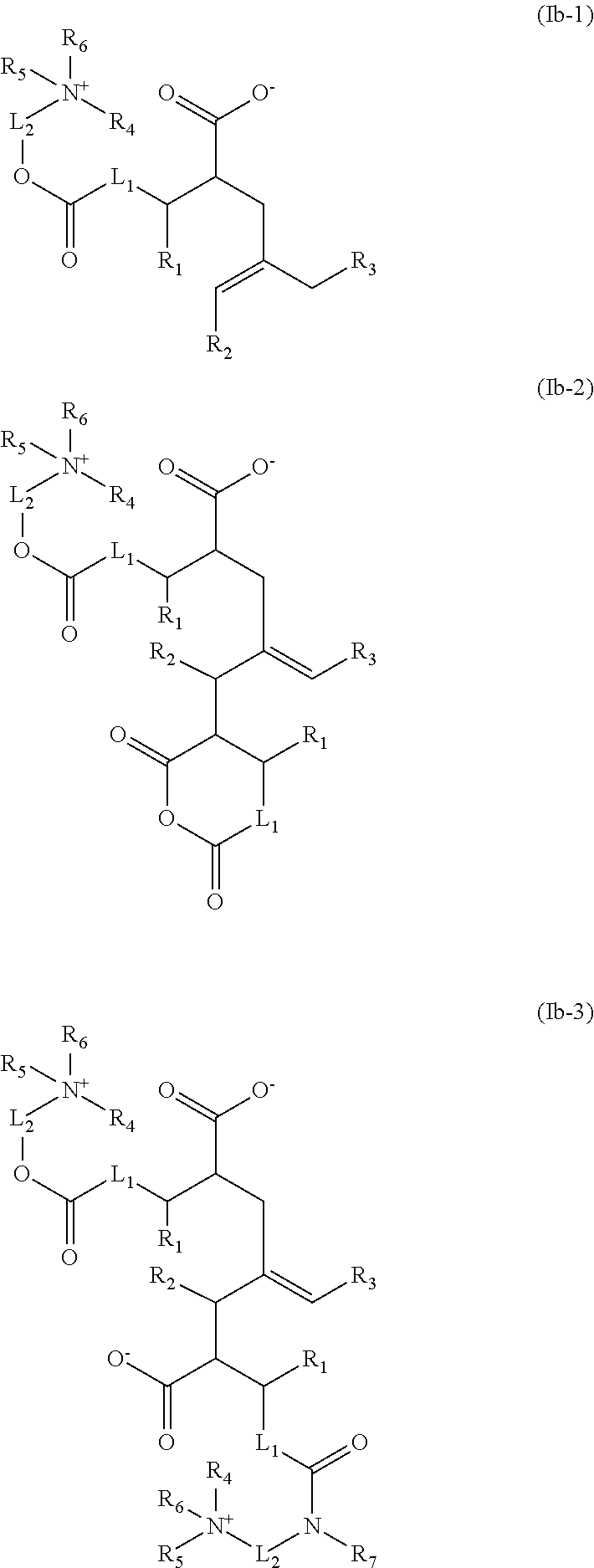

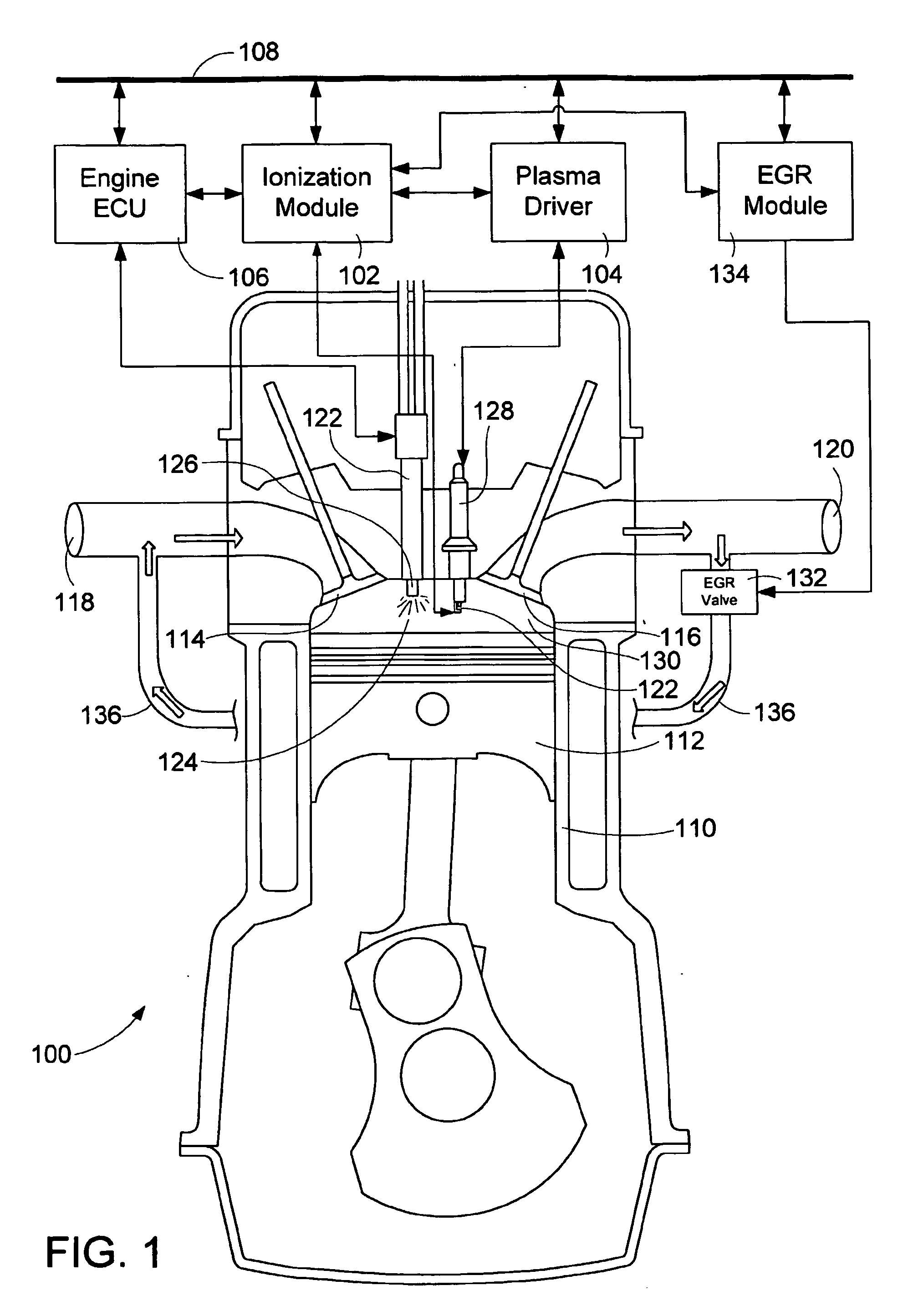

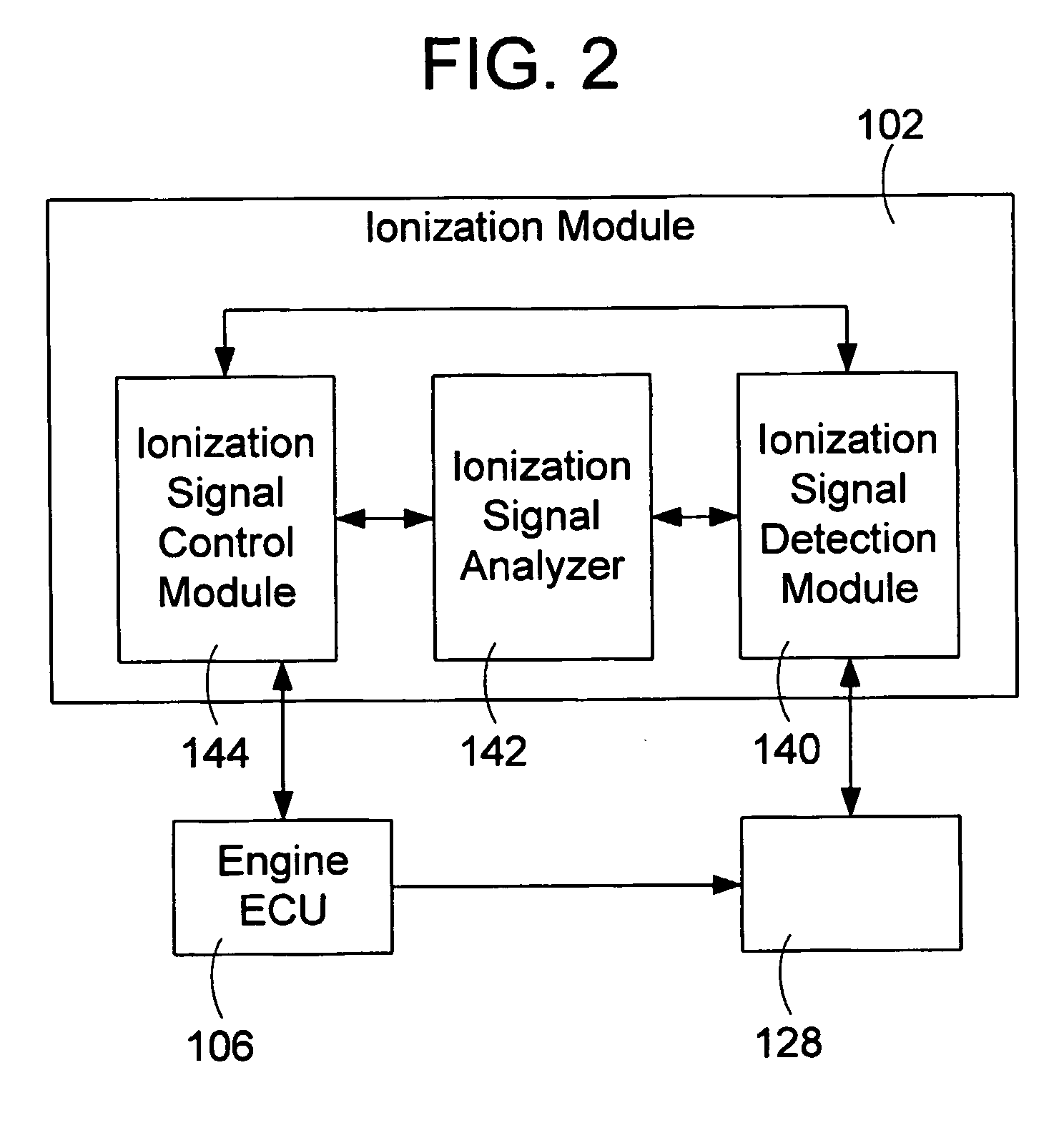

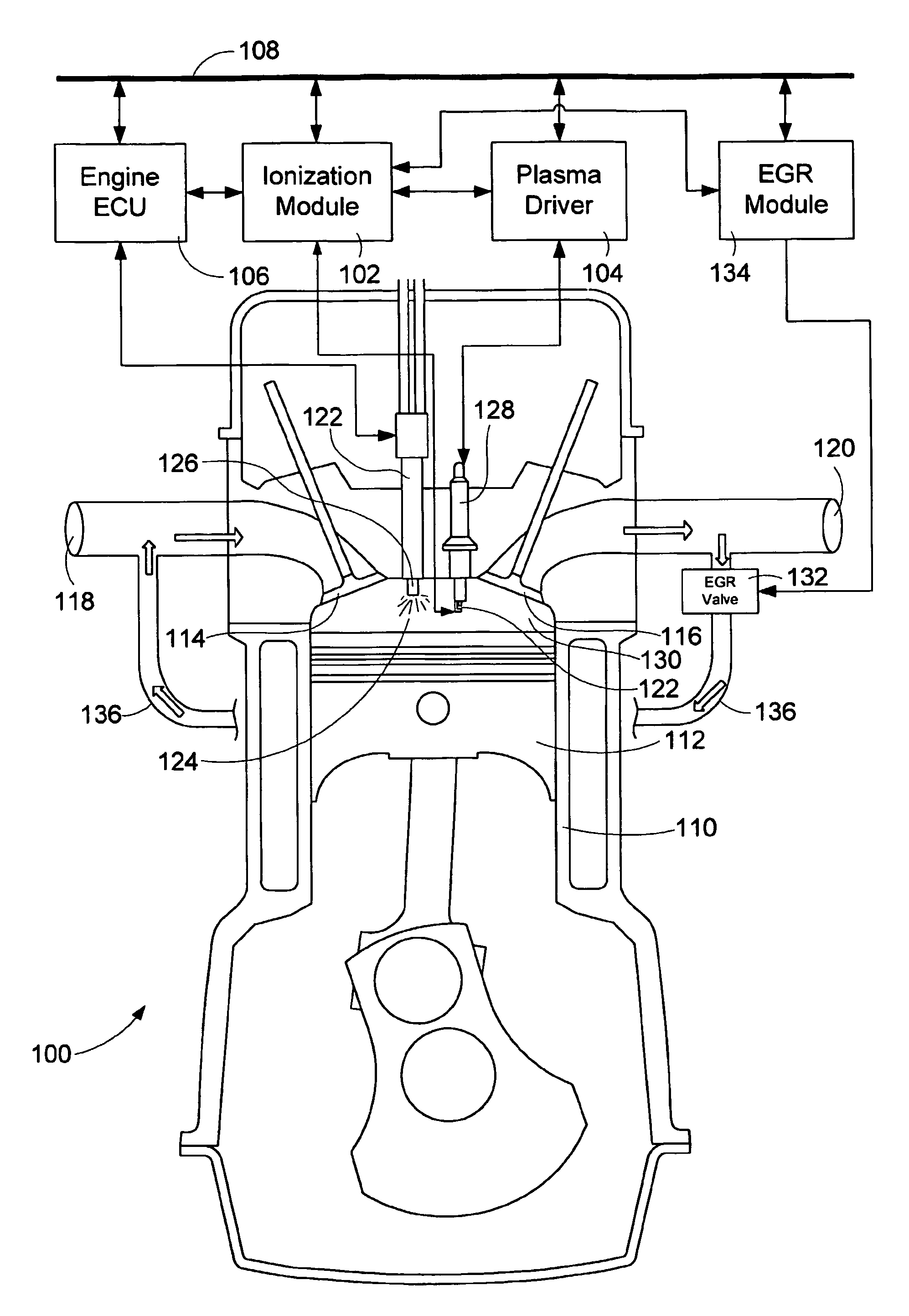

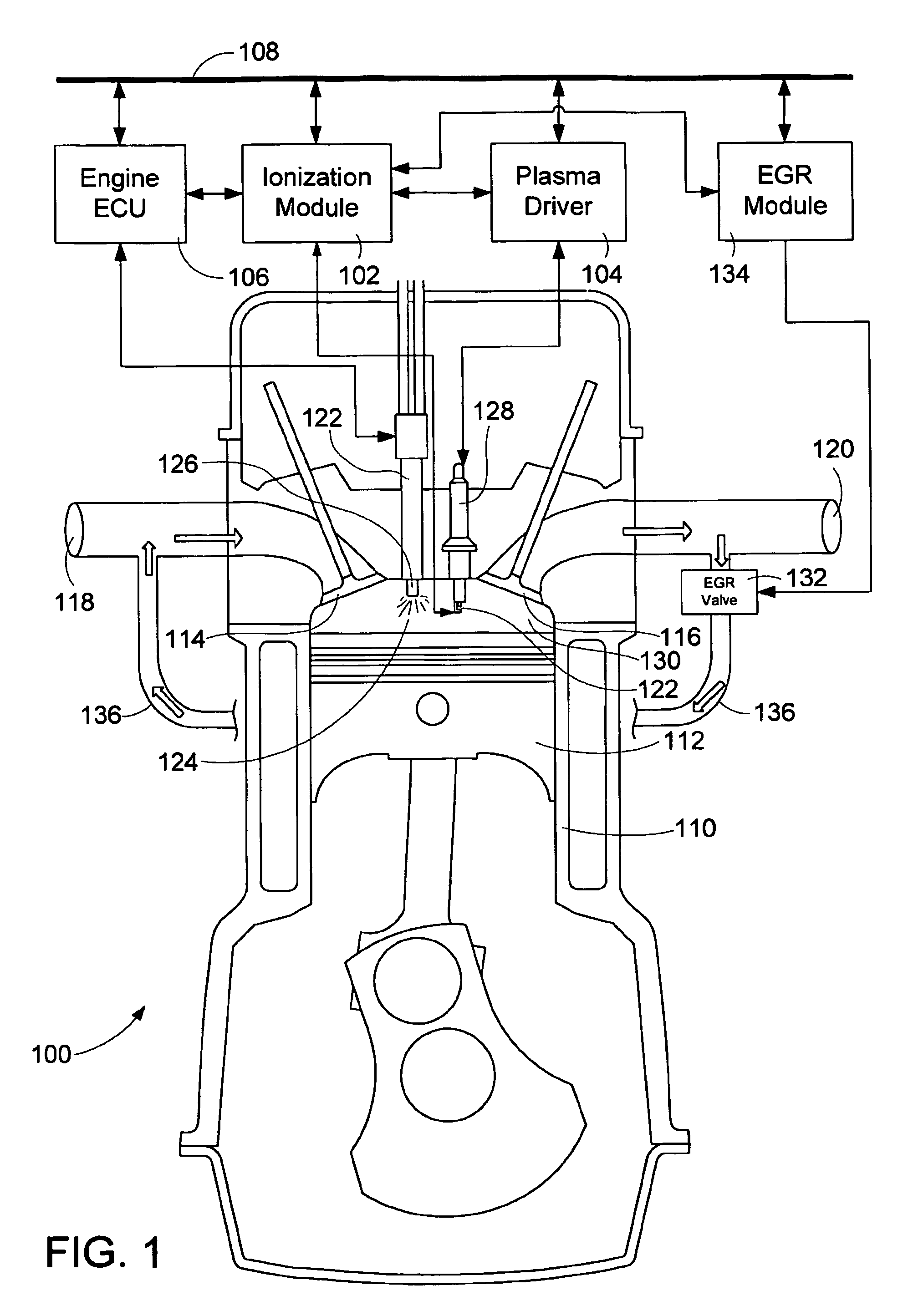

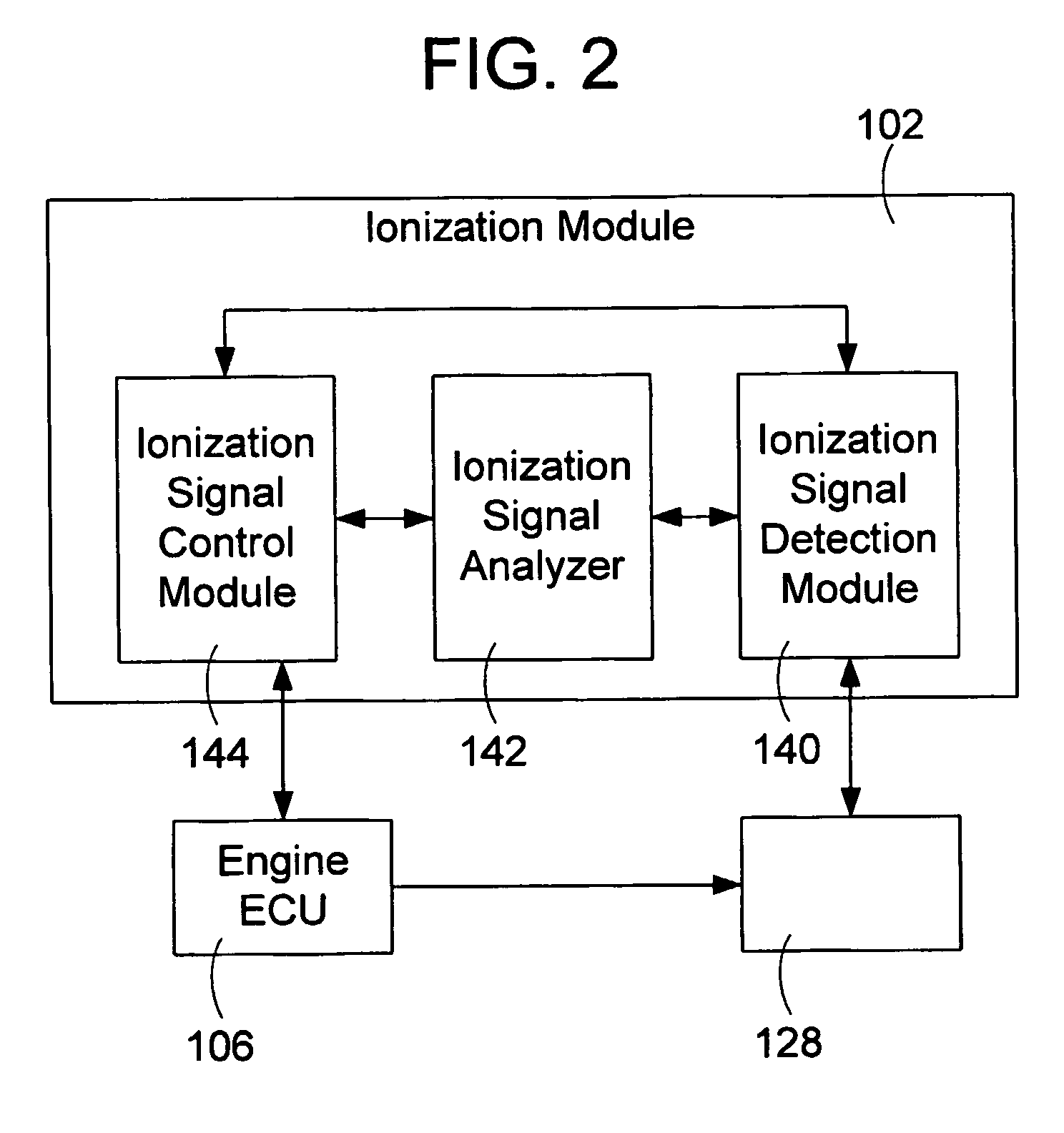

Method and apparatus for controlling exhaust gas recirculation and start of combustion in reciprocating compression ignition engines with an ignition system with ionization measurement

ActiveUS20070079817A1Reliable detectionElectrical controlInternal combustion piston enginesEngineeringExhaust gas recirculation

An apparatus and method to detect combustion conditions using ion signals for use in a feedback control of a reciprocation engine is presented. The ion signals are used as a feedback signal to control EGR and diesel injection timing. The apparatus is an ignition system with a spark plug type of sensor. The ignition system is used to provide a cold start mechanism for diesel engines and start of combustion for spark ignition engines. The ignition is combined with ion sensing feedback that can control the engine.

Owner:WOODWARD GOVERNOR CO

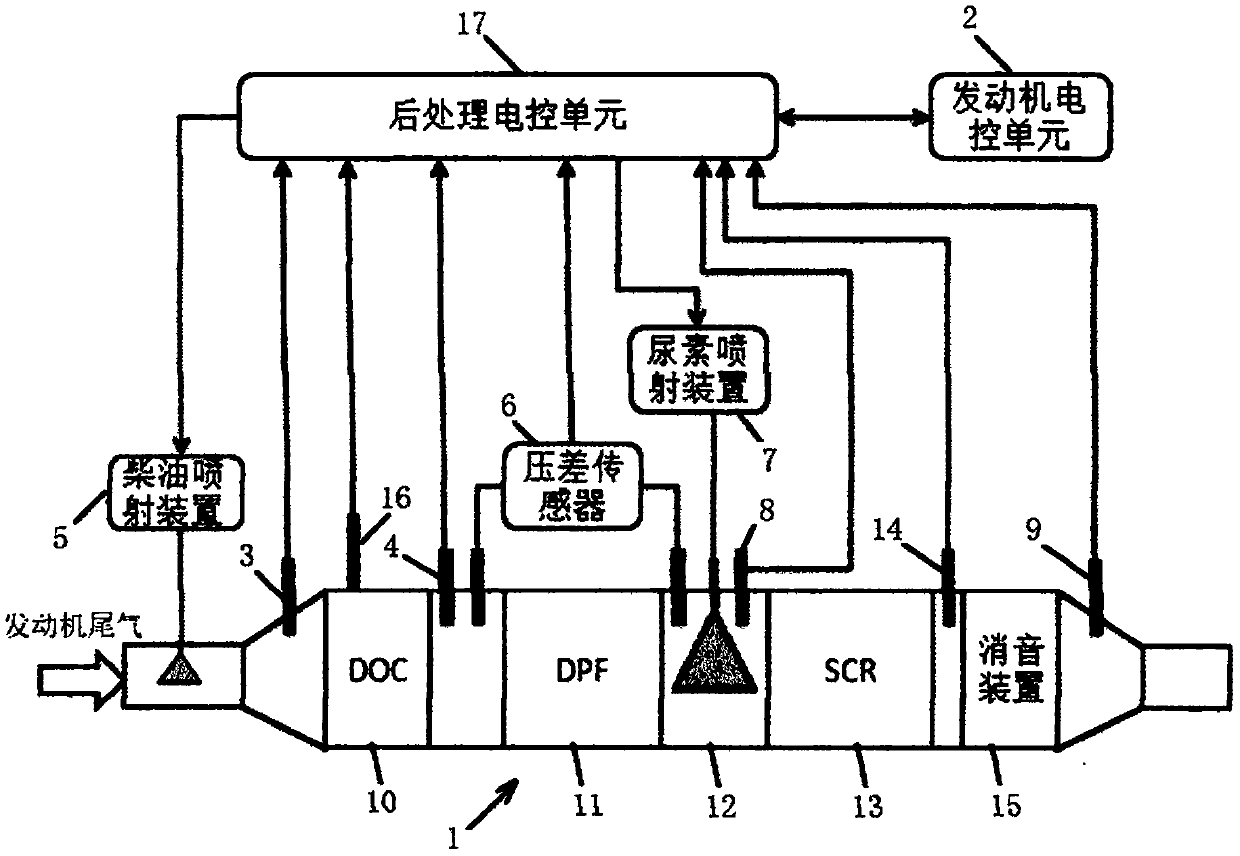

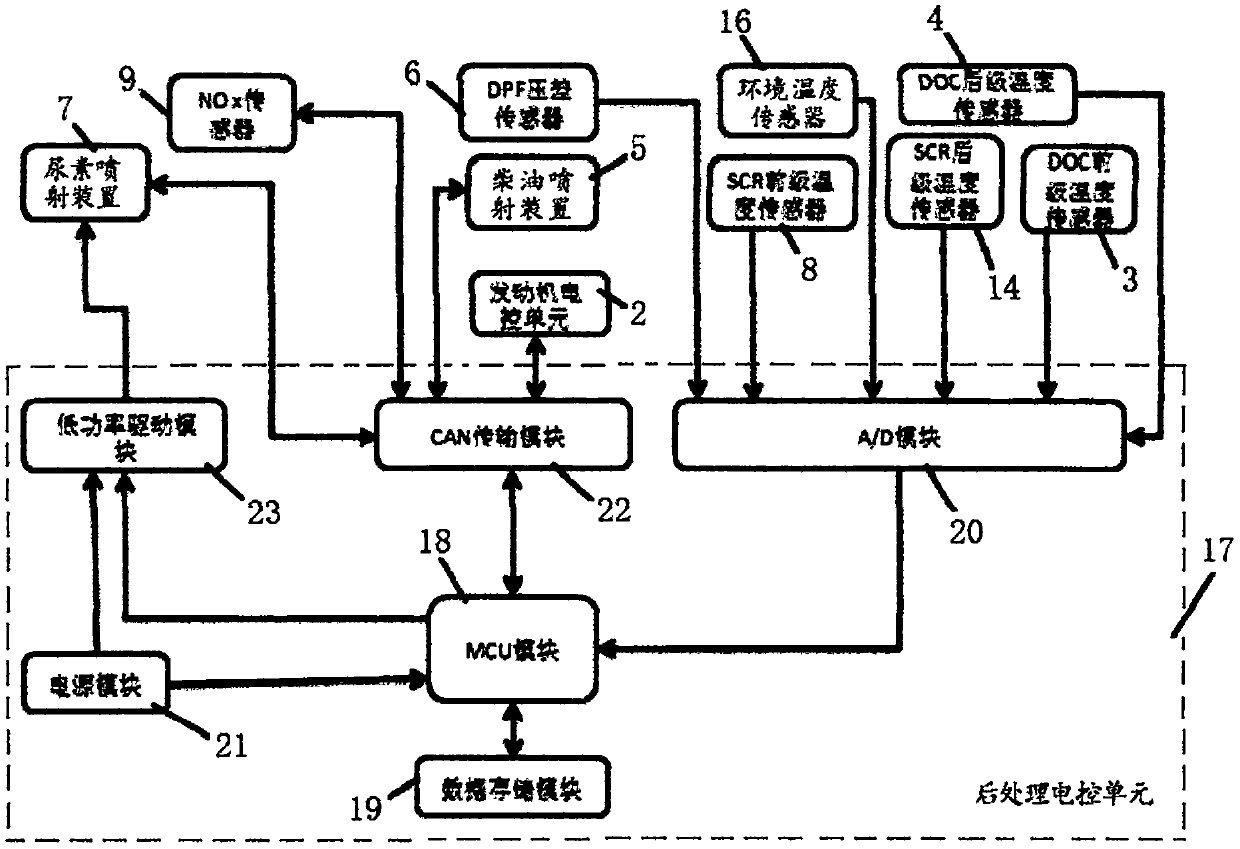

Engine tail gas after-treatment control system and control method

InactiveCN110206623AMeet emission standardsFix stability issuesInternal combustion piston enginesExhaust apparatusSoftware systemDifferential pressure

The invention provides an engine tail gas after-treatment control system and control method. The engine tail gas after-treatment control system and control method are applied to after-treatment of tail gas. The control system comprises a tail gas post-processor, an engine electric control unit, a diesel injection device, a urea spraying device and a post-treatment electric control single element.The control method is based on the measured values of different sensors and the working condition parameters of an engine, and is based on a pre-calibrated data model to complete the four functions ofDPF active regeneration controlling, DPF accumulated dust cleaning, SCR urea injection controlling and system fault diagnosing. The system is composed of a software system and a hardware system, wherein a transient segmented linear interpolation algorithm is adopted for MAP data, and the calculation precision and the execution efficiency are improved to a great extent. A DPF differential pressuresensor adopts a differential pressure dynamic integral and time-sharing comparison method, so that the condition that the differential pressure value is unstable and the fluctuation is large due to the fact that the differential pressure sensor is influenced by various factors is solved, the robustness of a control strategy of the tail gas after-treatment system is enhanced, and the misjudgment of regeneration is reduced to a great extent, so that the improper active regeneration operation is reduced, and the oil consumption is reduced.

Owner:三河市科达科技有限公司

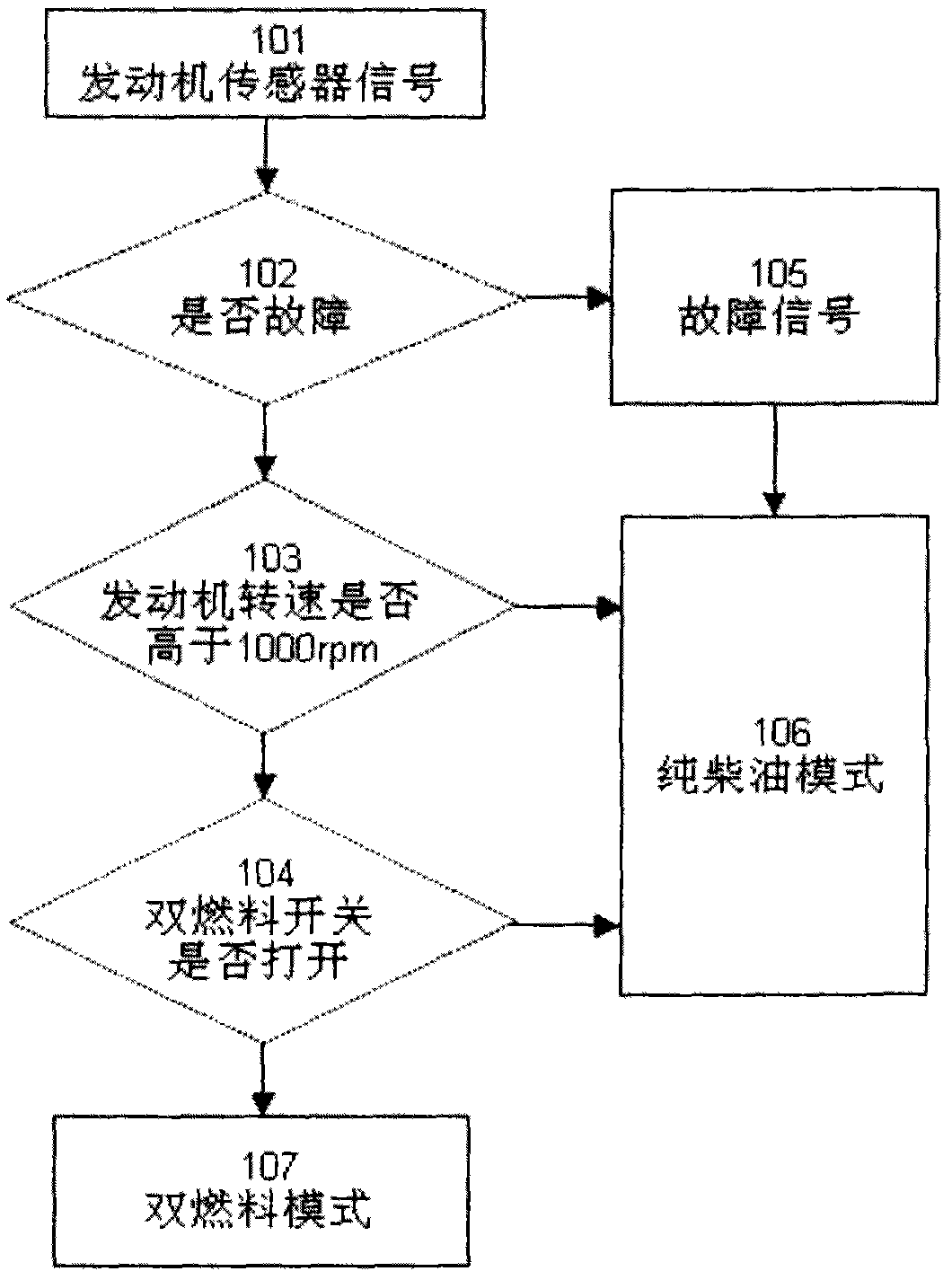

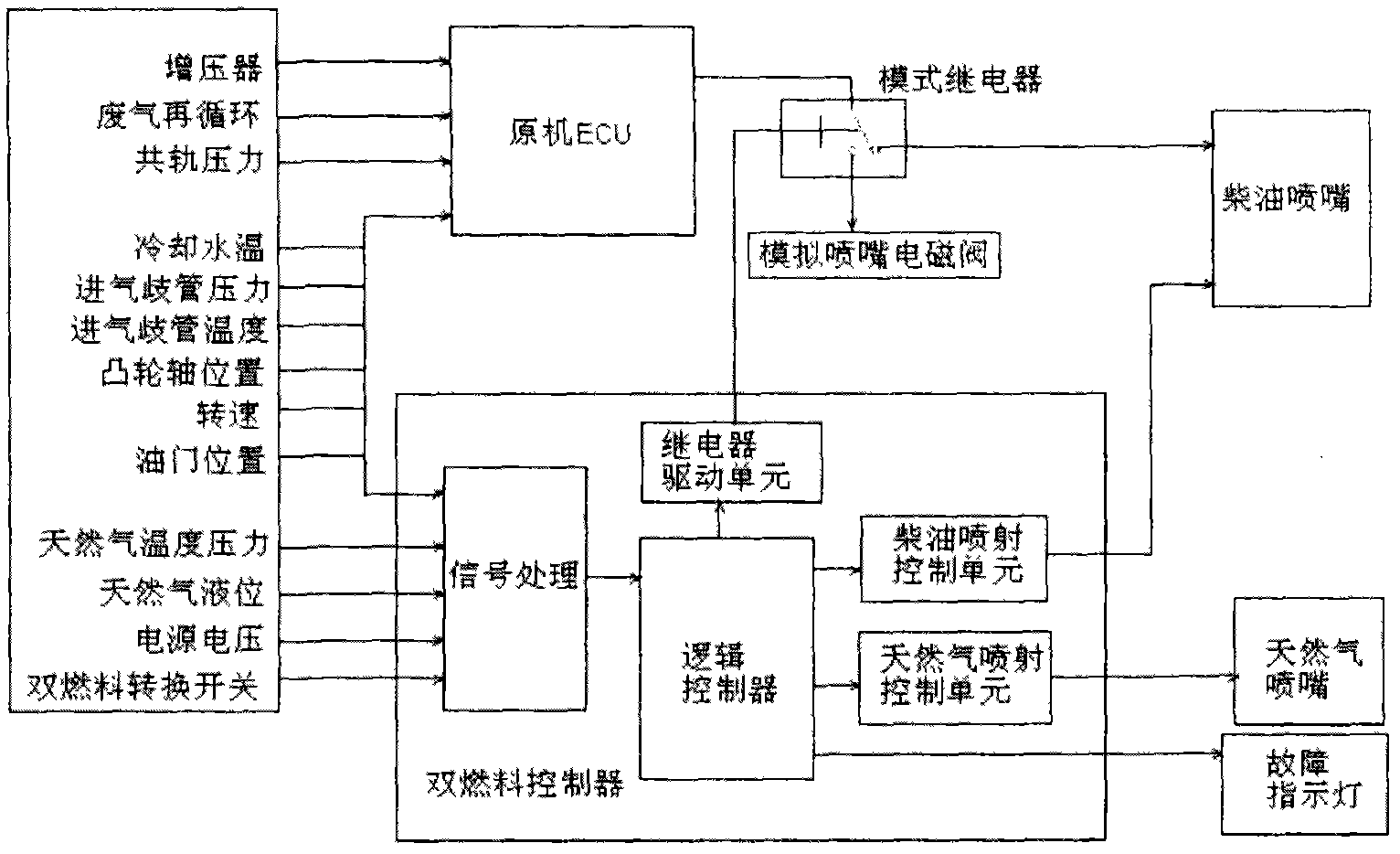

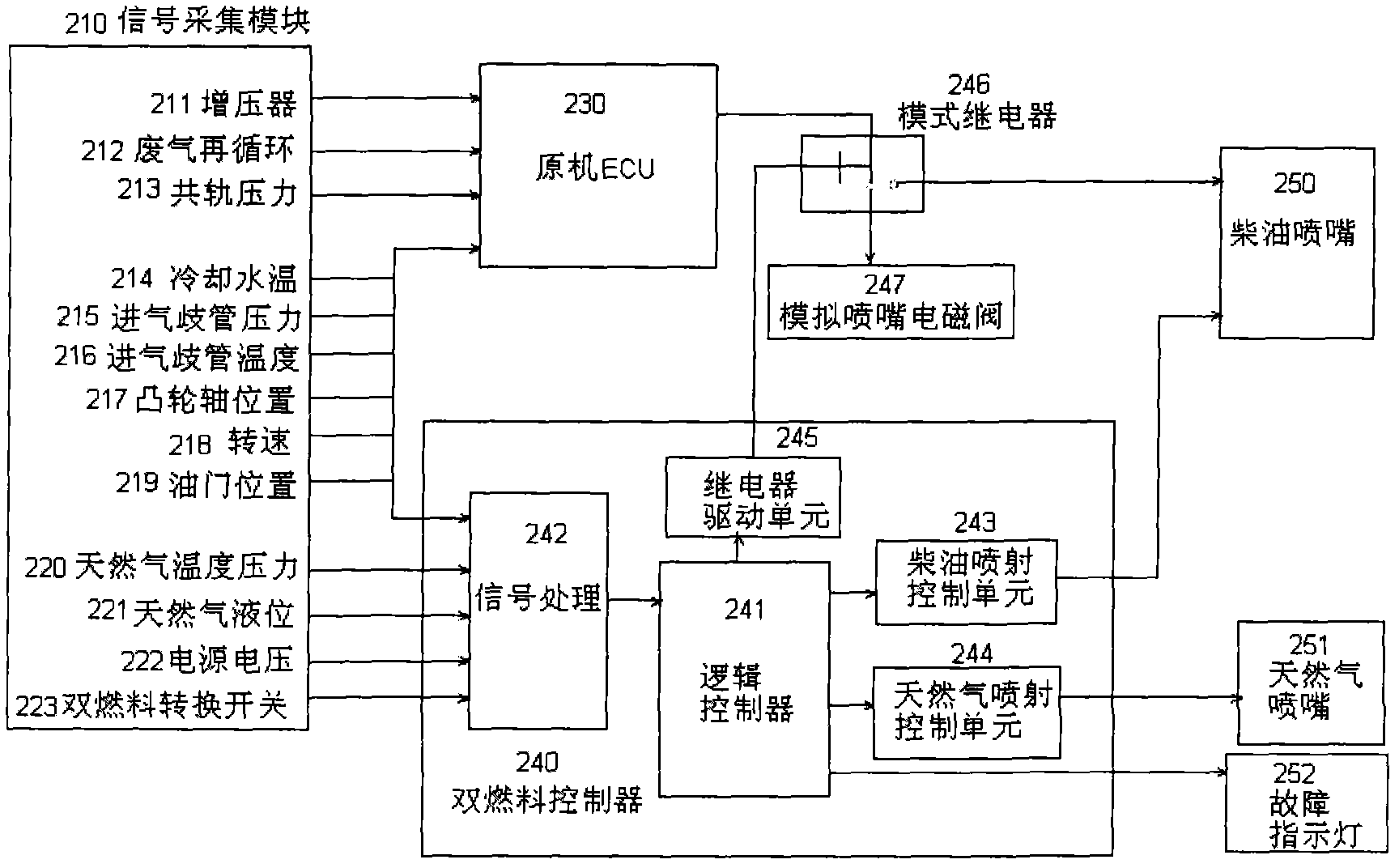

Diesel engine/natural gas dual-fuel engine electric control system

InactiveCN103016168AGuaranteed to workElectrical controlInternal combustion piston enginesFuel control unitControl system

The invention discloses a control method and a control device of a diesel / natural gas dual-fuel engine. The method is characterized in that that on the basis of maintaining an original engine control system, a diesel and gas control unit is added. Signals of all sensors of the original machine are shared by the dual-fuel control system and an electric control system of the original machine. The added dual-fuel control unit can control the injection of the diesel and an additionally-installed gas injection system (including a gas nozzle electromagnetic control, a gas switch valve control, gas liquid level or pressure monitoring and the like), and the added dual-fuel control unit can also process signals which are associated to the gas system. The injection volume and the oil injection moment of the diesel can be precisely controlled according to different working states of a diesel engine, and the injection time and the injection duration of the natural gas can also be controlled. The duel-fuel engine can be enabled to run safely and stably, the fuel consumption can be reduced, and the emission of tail gas can be reduced.

Owner:BEIJING YIKONG LINGBO AUTOMOBILE ELECTRONICS TECH

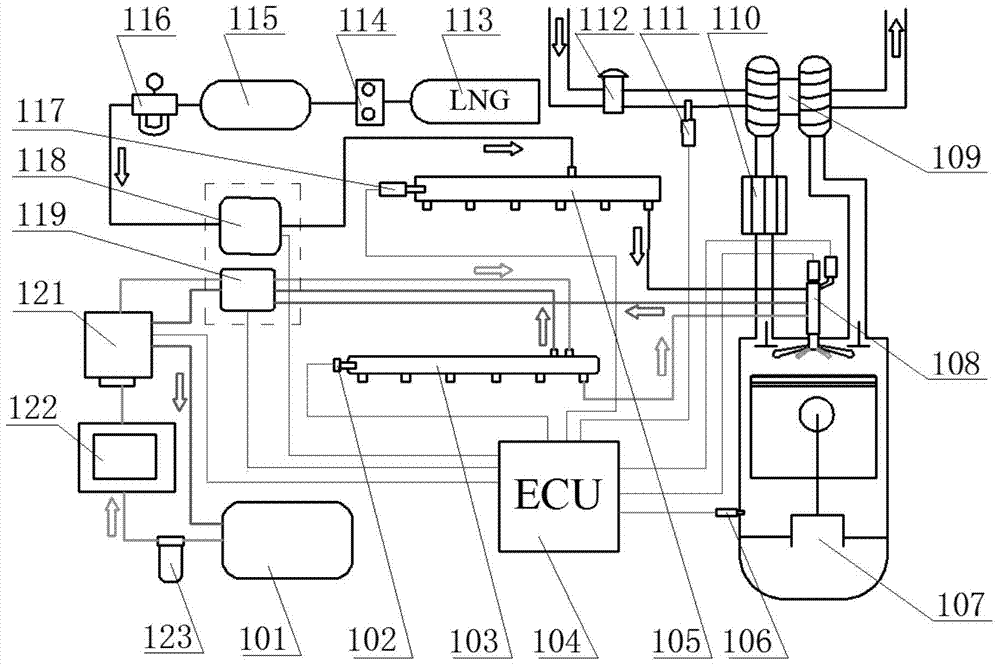

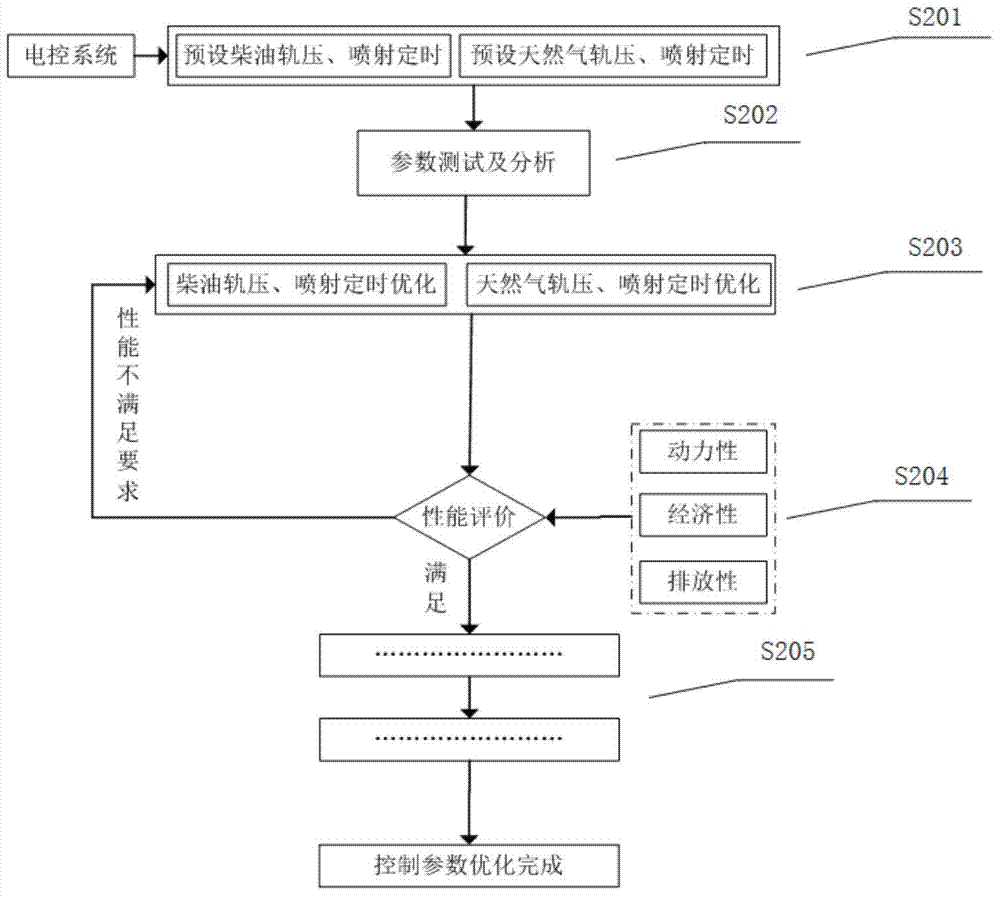

Fuel feeding system of micro diesel oil ignition direct-injection natural gas engine and control method thereof

ActiveCN104121102AEfficient combustionElectrical controlInternal combustion piston enginesElectronic control systemCommon rail

The invention discloses a fuel feeding system of a micro diesel oil ignition direct-injection natural gas engine and a control method of the fuel feeding system. The fuel feeding system comprises an electronic control common rail ignition diesel oil feeding device and an electronic control common rail high-pressure direct-injection natural gas feeding device, wherein the electronic control common rail ignition diesel oil feeding device and the electronic control common rail high-pressure direct-injection natural gas feeding device are independently controlled through an electronic control system,the electronic control system supplies ignition diesel oil with certain pressure to the natural gas engine in an adjusting mode by having control over a diesel oil pressure adjusting module of the electronic control common rail ignition diesel oil feeding device according to the working condition of the natural gas engine, and the electronic control system supplies main jet natural gas with certain pressure to the natural gas engine in an adjusting mode by having control over a natural gas pressure adjusting module of the electronic control common rail high-pressure direct-injection natural gas feeding device according to the working condition of the natural gas engine.Injection pressure of the ignition diesel oil and jet pressure of the main jet natural gas are controlled through the electronic control system, and the purpose of quick low-emission efficient combustion of the engine is achieved.

Owner:SHANDONG UNIV

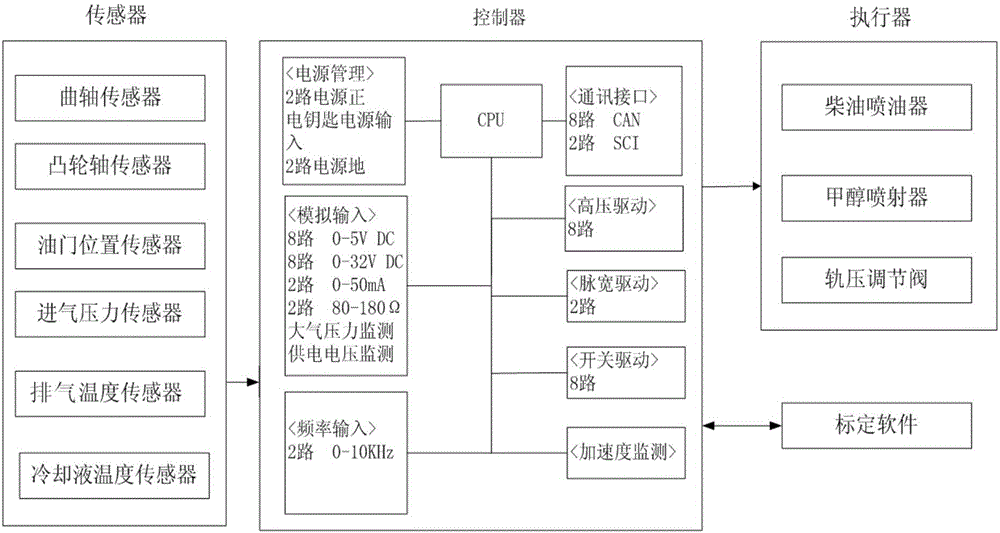

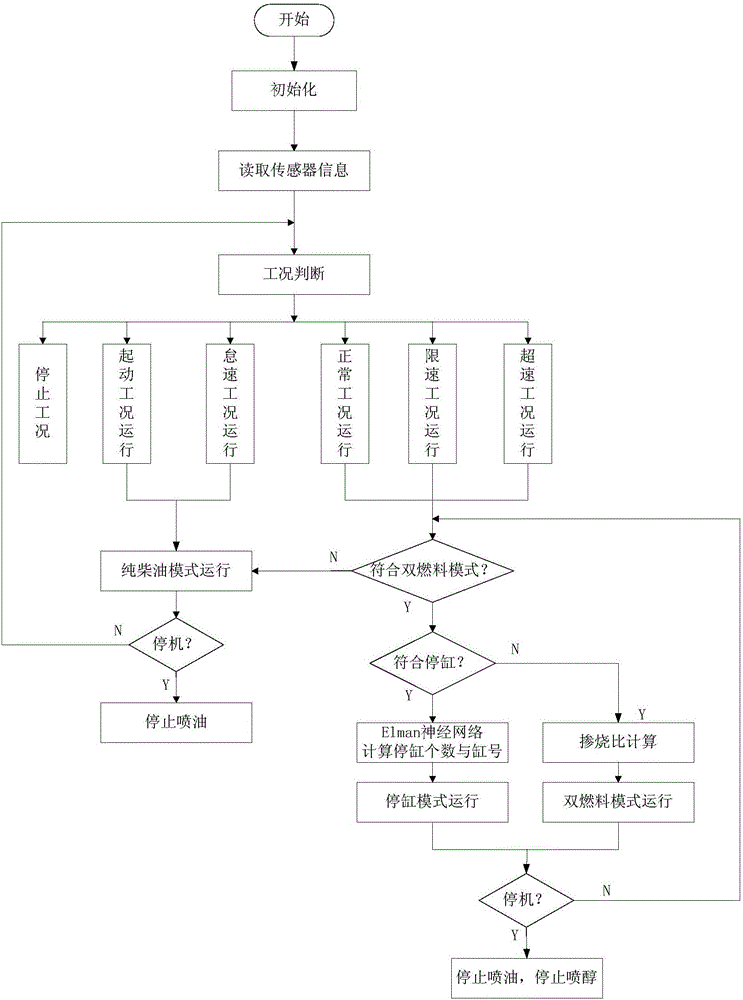

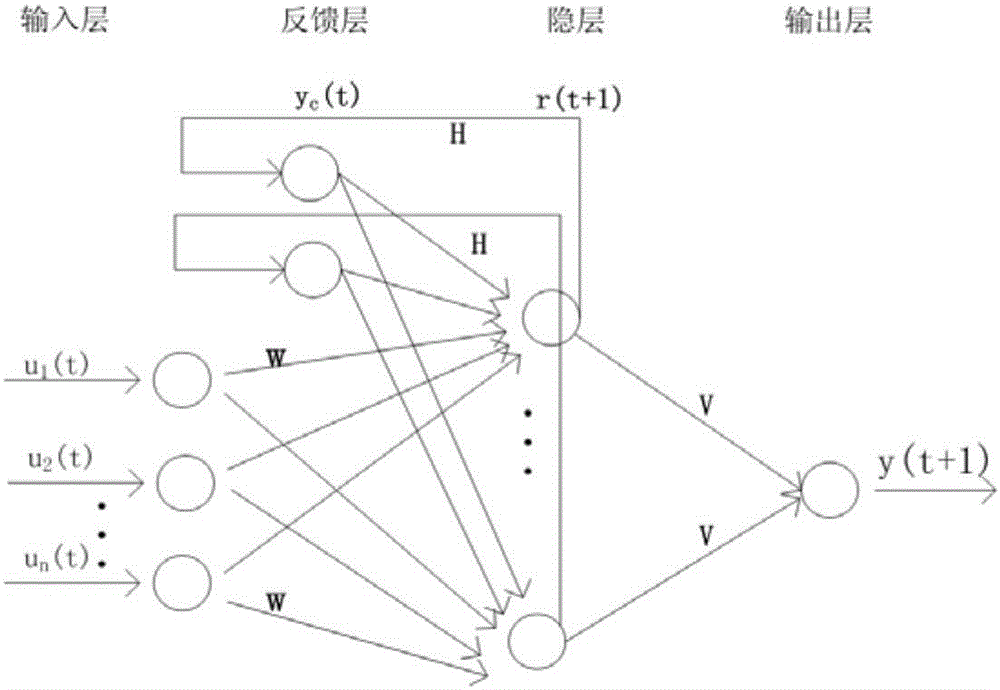

Methanol-diesel dual-fuel engine control system and method

InactiveCN106704012AImprove economyImprove emission effectElectrical controlInternal combustion piston enginesControl systemCrankshaft

The invention discloses a methanol-diesel dual-fuel engine control system and method. precise control over methanol and diesel injection can be completed at the same time through an ECU, an Elman neural network is adopted to predicate a crank signal pulse width in an online manner, according to the predicated pulse width and the output torque, the number of stopped cylinders and the corresponding cylinder numbers controlled by methanol injection cylinder stopping are determined under the dual-fuel mode, and random cylinder stopping of methanol injection in the dual-fuel running mode can be achieved. In the dual-fuel mode, according to the real-time work state of an engine, the mixed burning ratio is dynamically calculated, the methanol injection strategy is selected, multi-point injection of methanol and diesel can be achieved, and stable efficient running of the dual-fuel engine is ensured.

Owner:CHANGAN UNIV

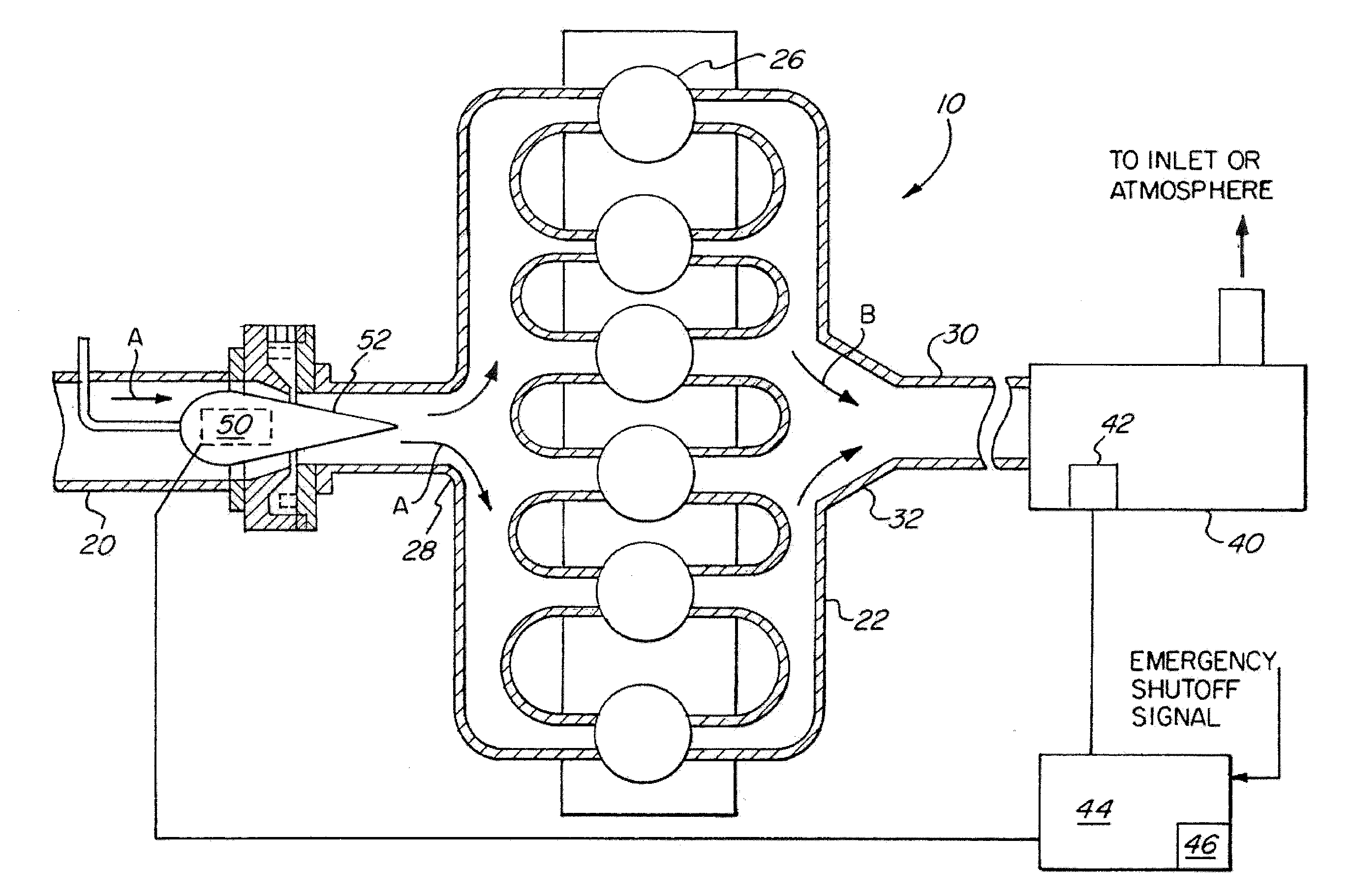

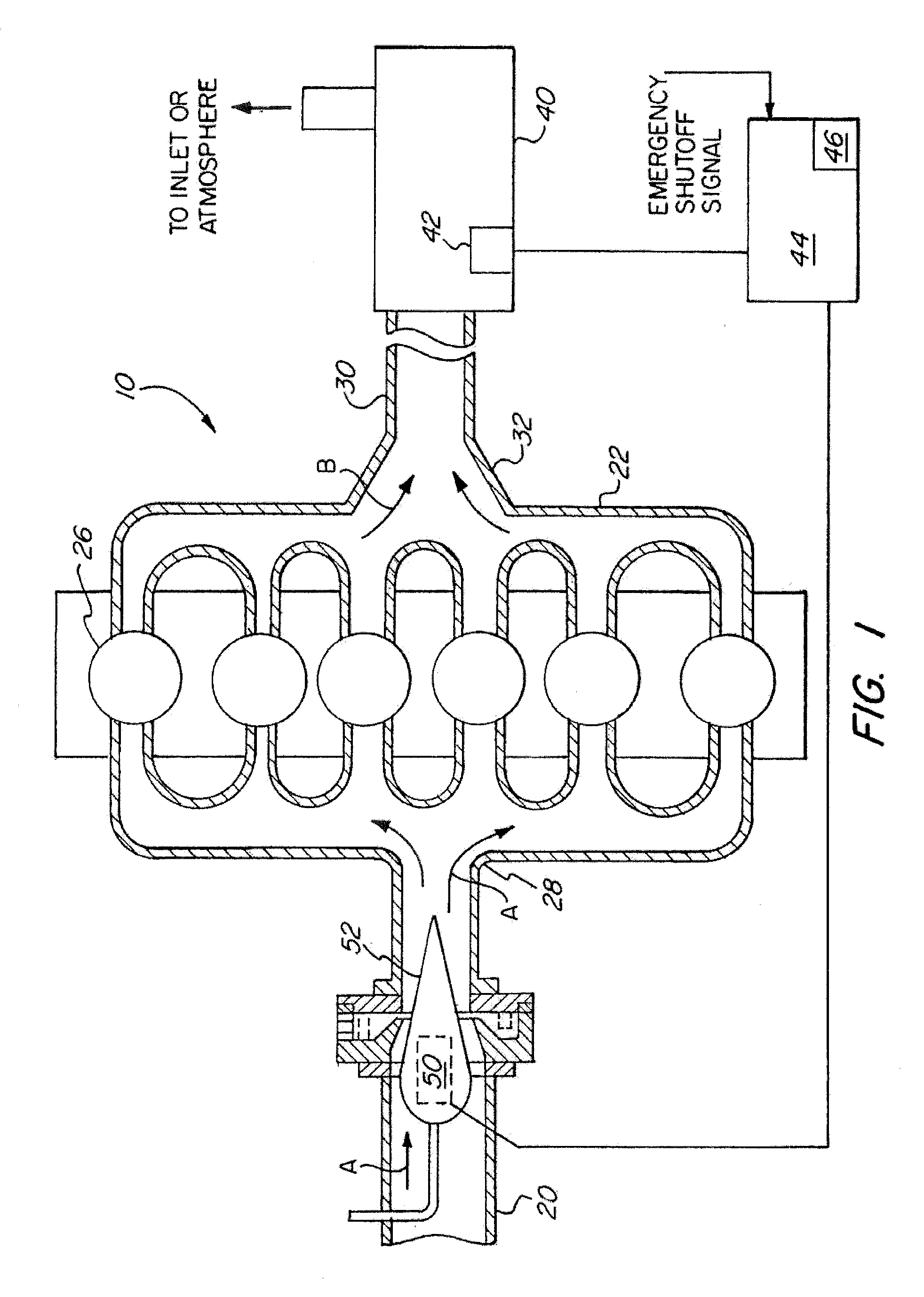

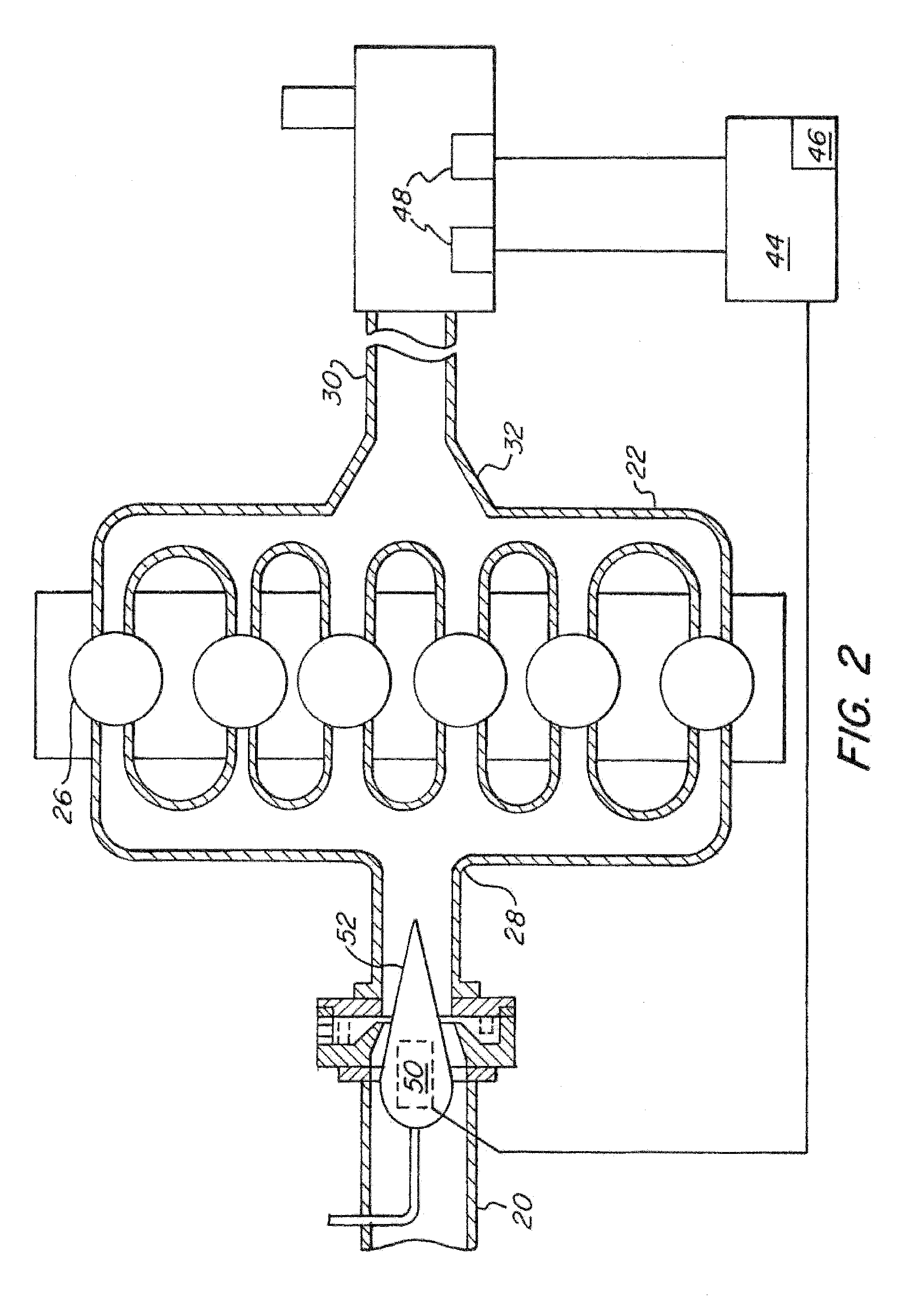

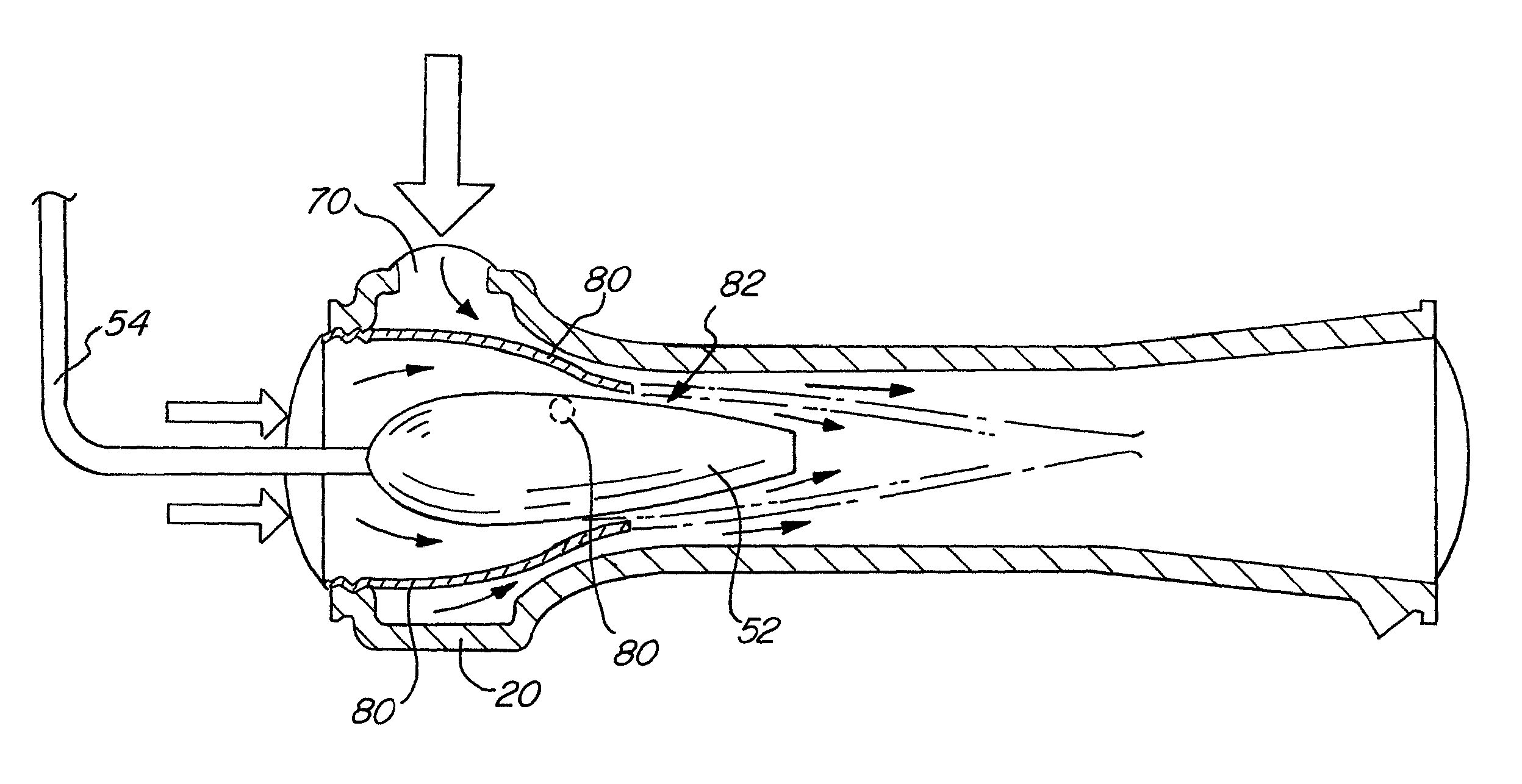

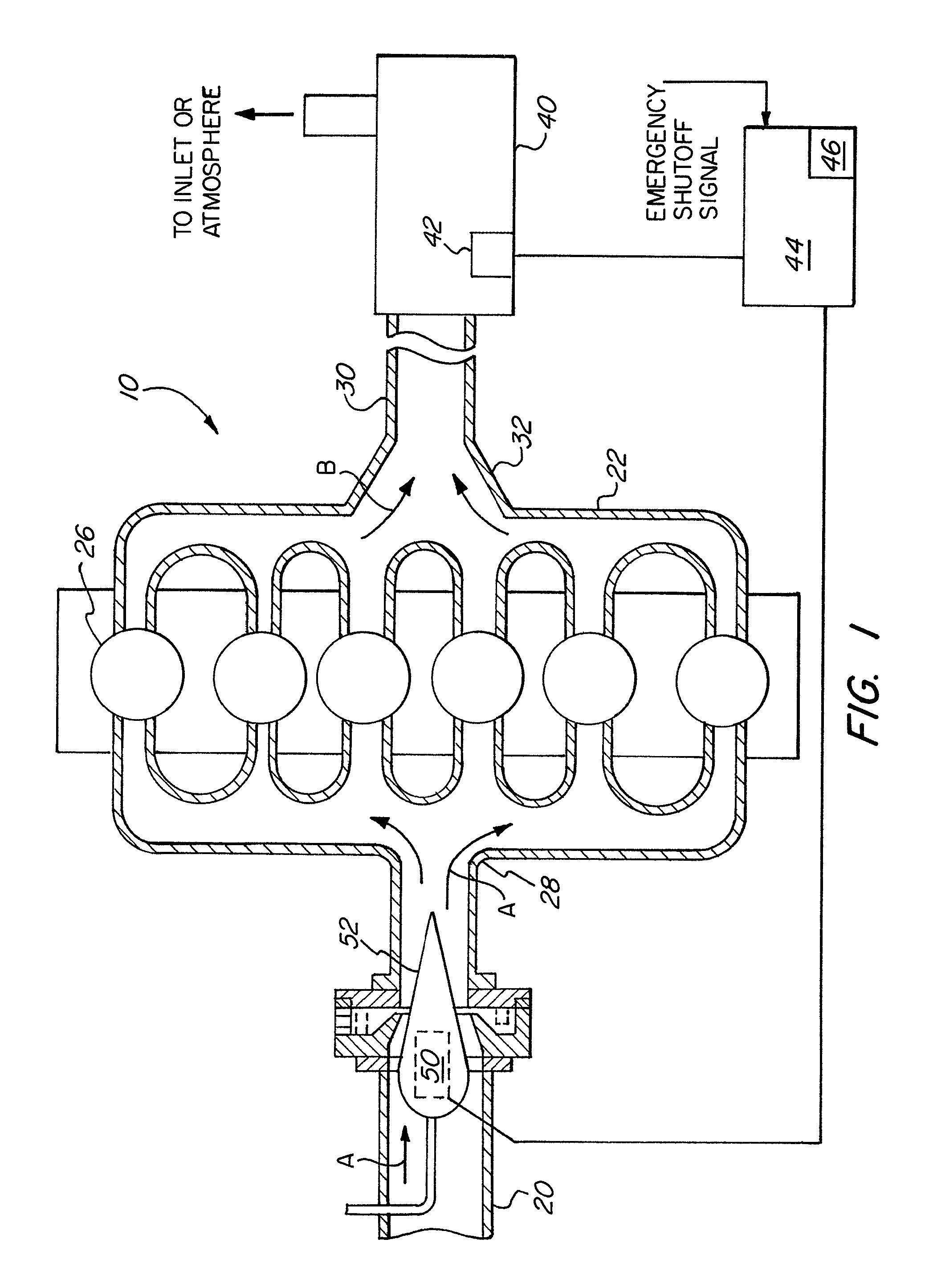

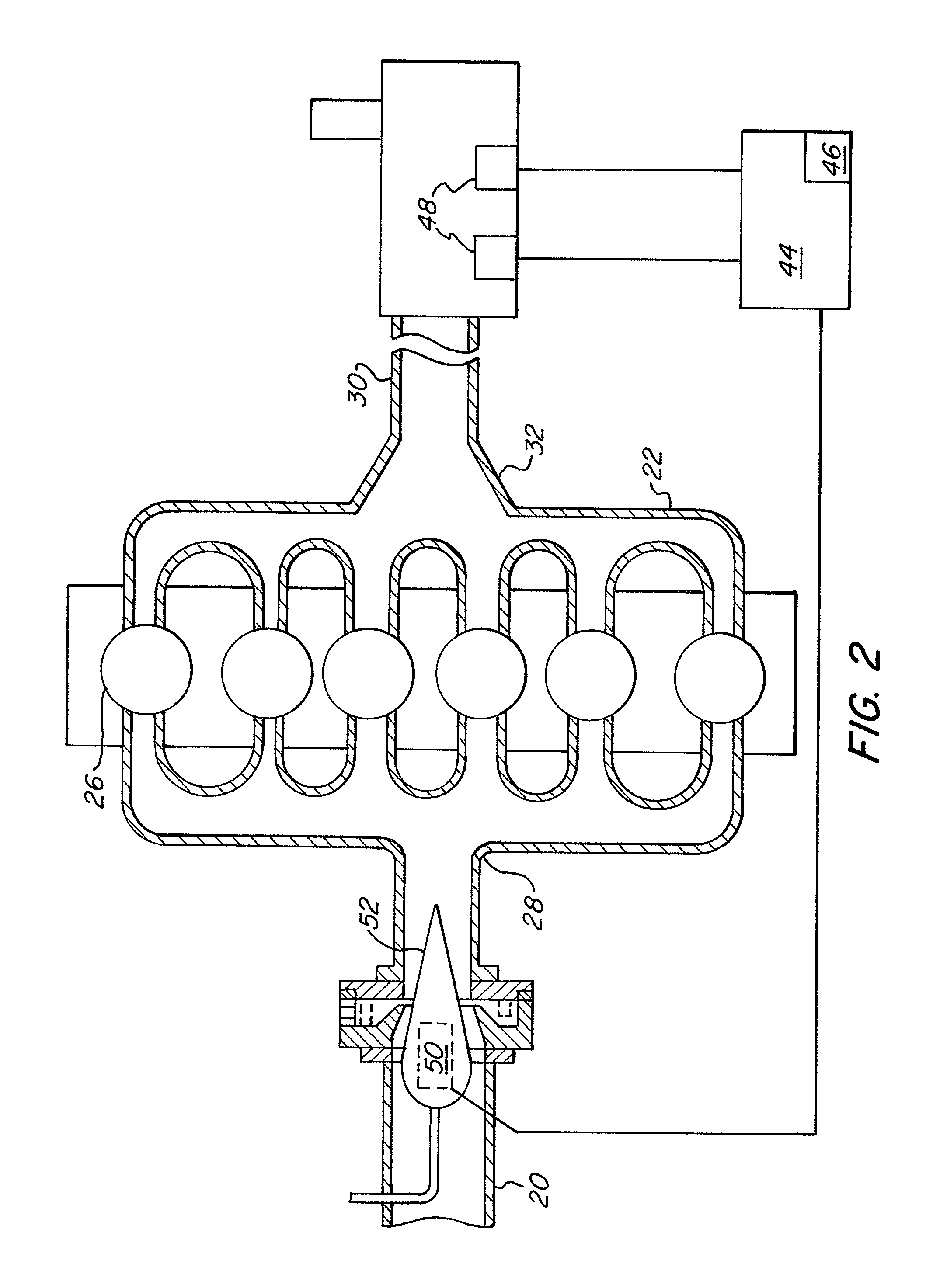

EGR Venturi Diesel Injection

InactiveUS20130047959A1Cutting portionNon-fuel substance addition to fuelInternal combustion piston enginesMixed flowEngineering

An arrangement for mixing a first and a second gas flow, for example, an inlet flow with an exhaust gas return flow in a diesel engine. An air conduit has an inlet for the first flow and an inlet for the second flow, in order to achieve the mixing. A valve body is arranged to be displaced in the longitudinal direction of the air conduit at the inlet for the second flow in order to achieve a variable venturi effect and in this way a variable suction effect and mixture of the mixed flow. One or more fuel injectors inject fuel into the air conduit to pre-mix fuel with the first and second gas flows before reaching the engine cylinders for combustion.

Owner:CONCENTRIC SKANES FAGERHULT

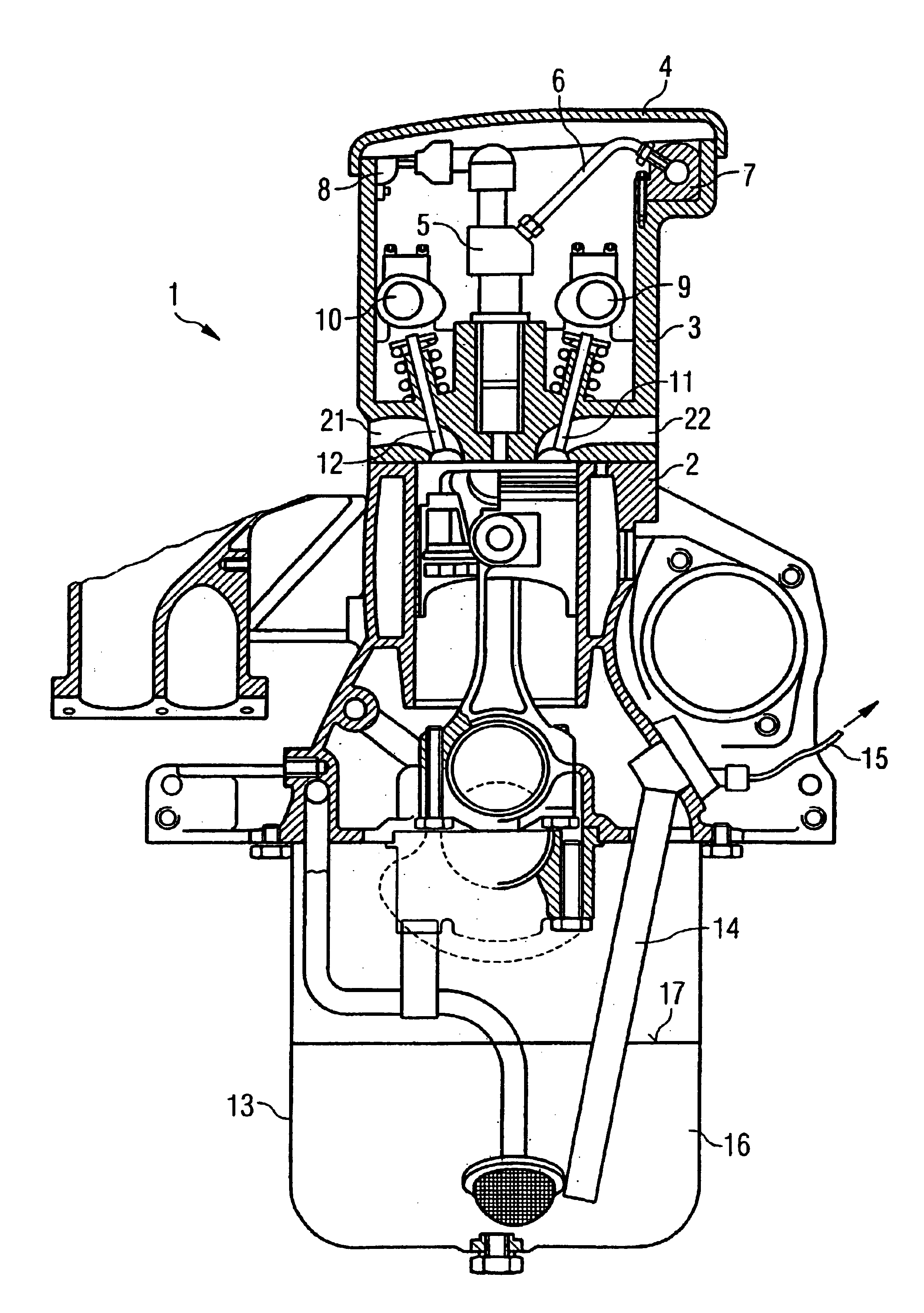

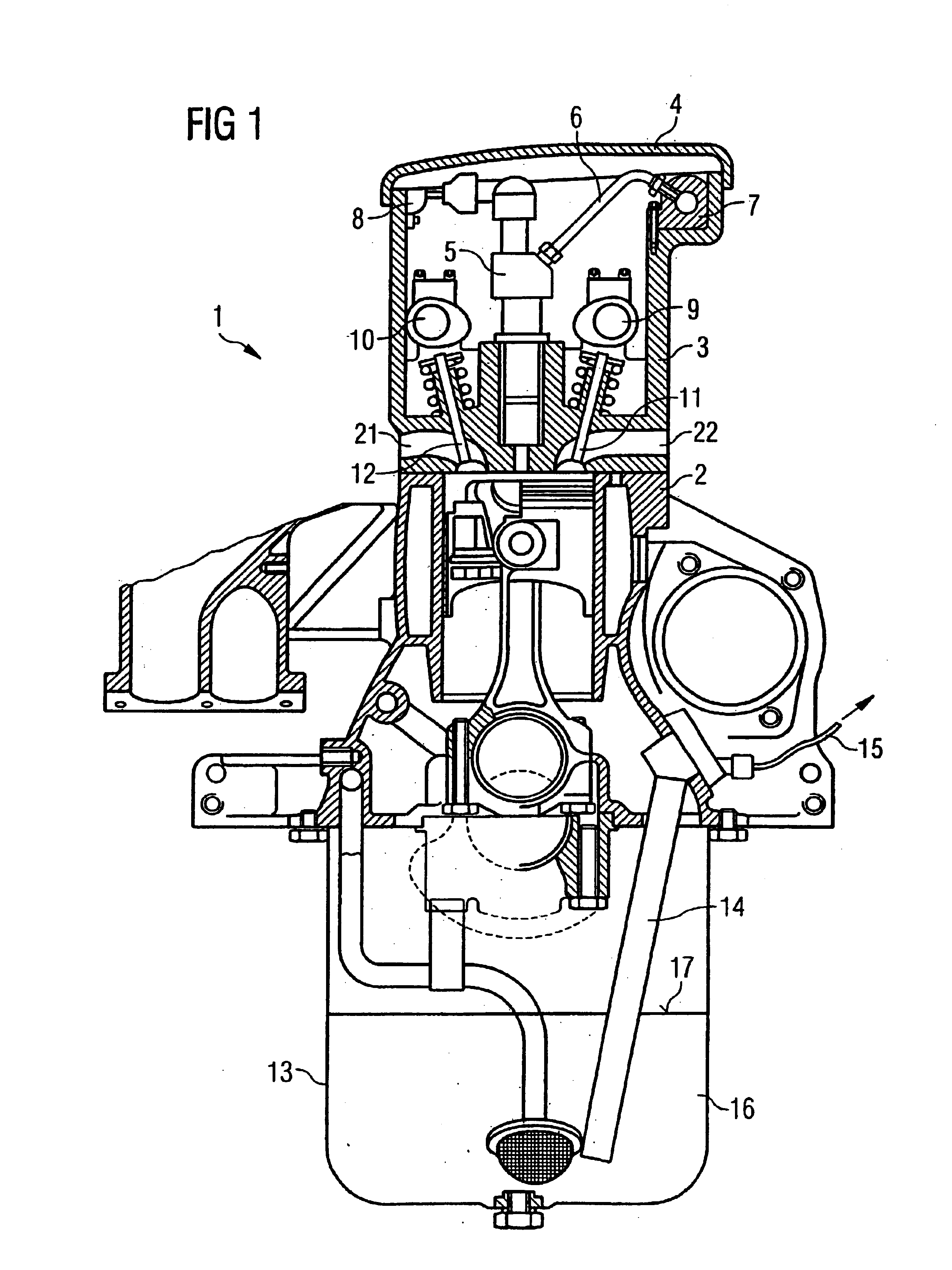

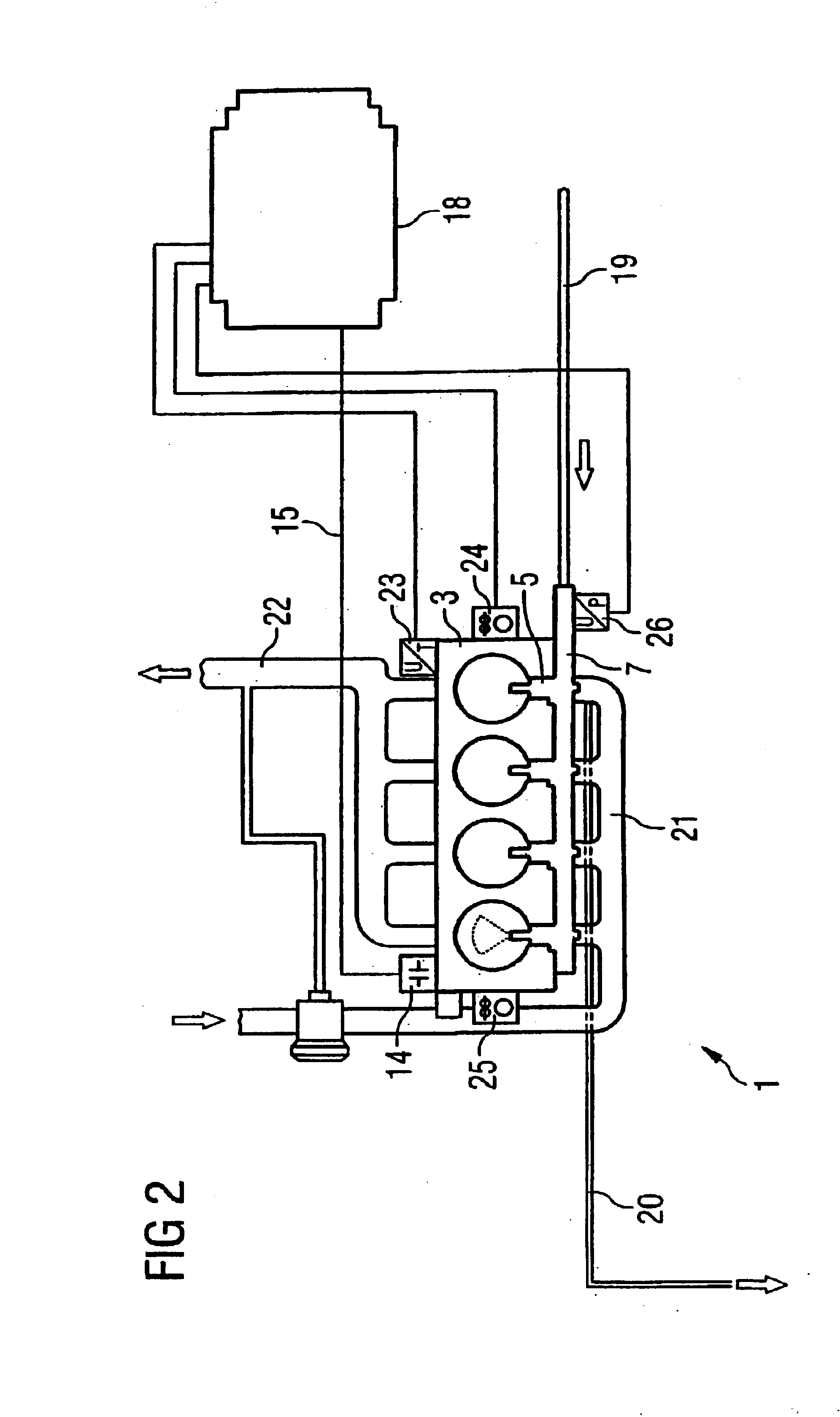

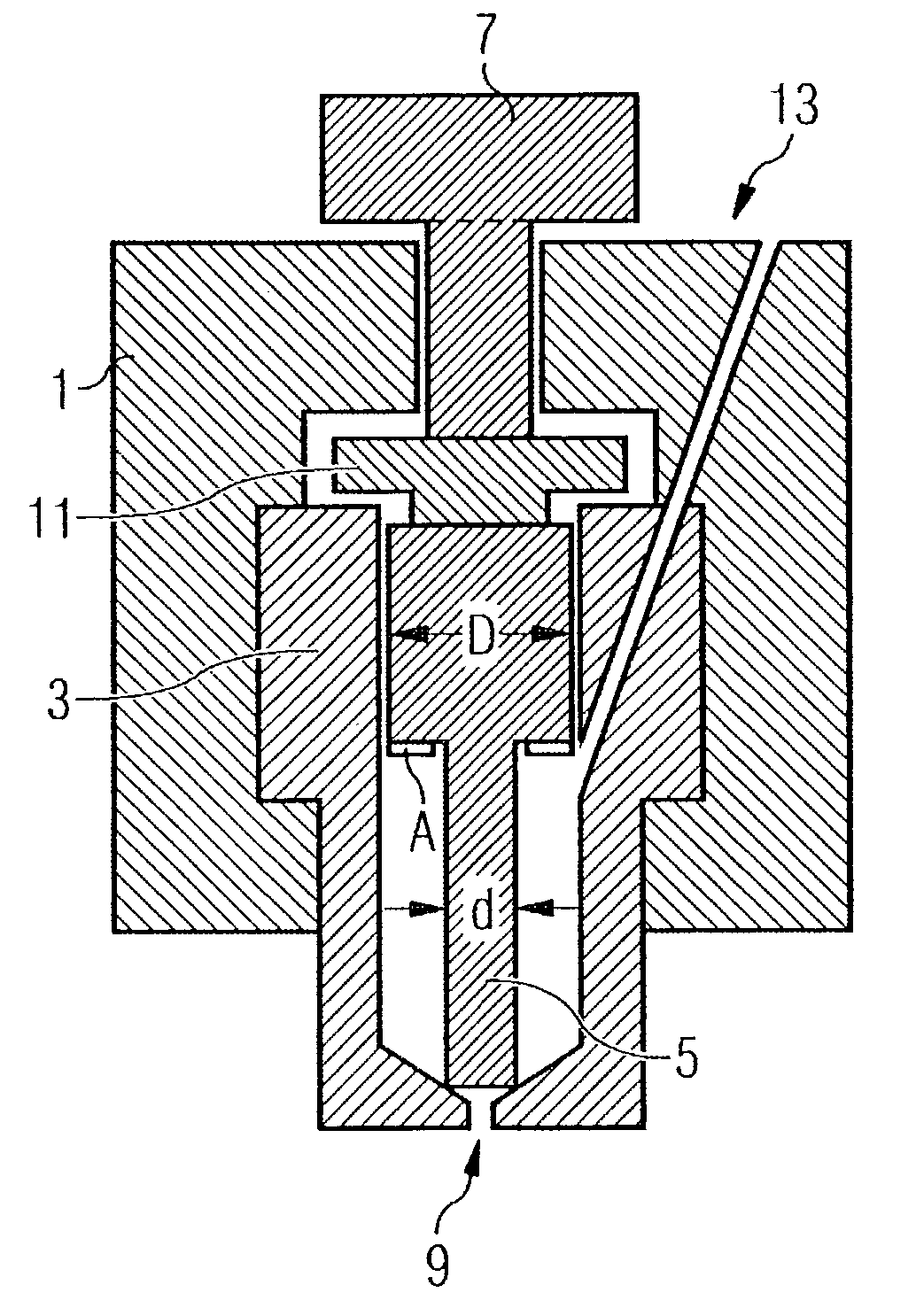

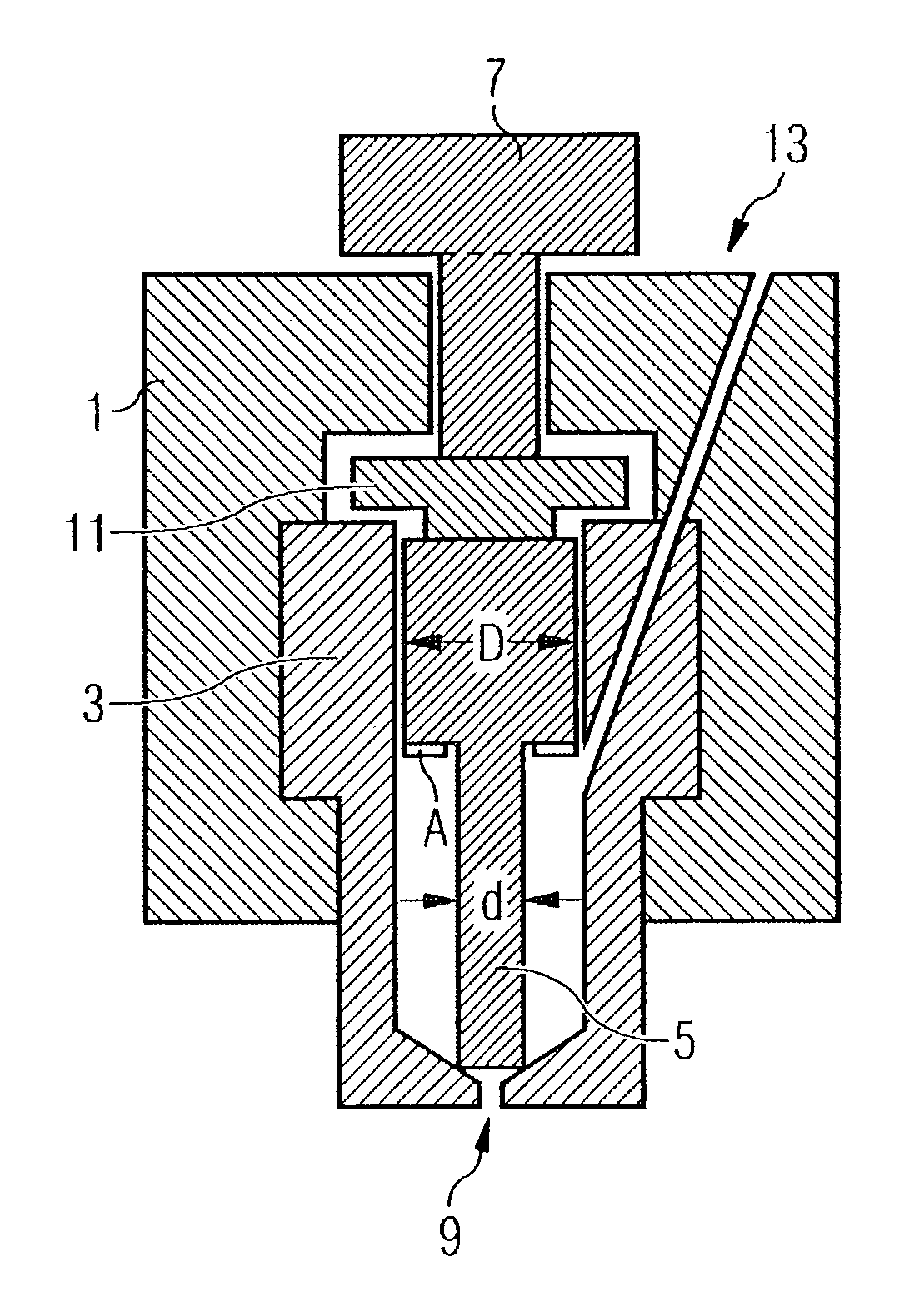

Cylinder-head-integrated diesel injection system with oil sensor

InactiveUS6880528B2Reduce noiseCompact designElectrical controlInternal combustion piston enginesCombustion chamberCylinder head

The present invention relates to an accumulator-type injection system for injecting fuel from an accumulator into a combustion chamber of an internal combustion engine by means of injectors, the injectors being arranged completely within the cylinder head of the internal combustion engine.

Owner:SIEMENS AG

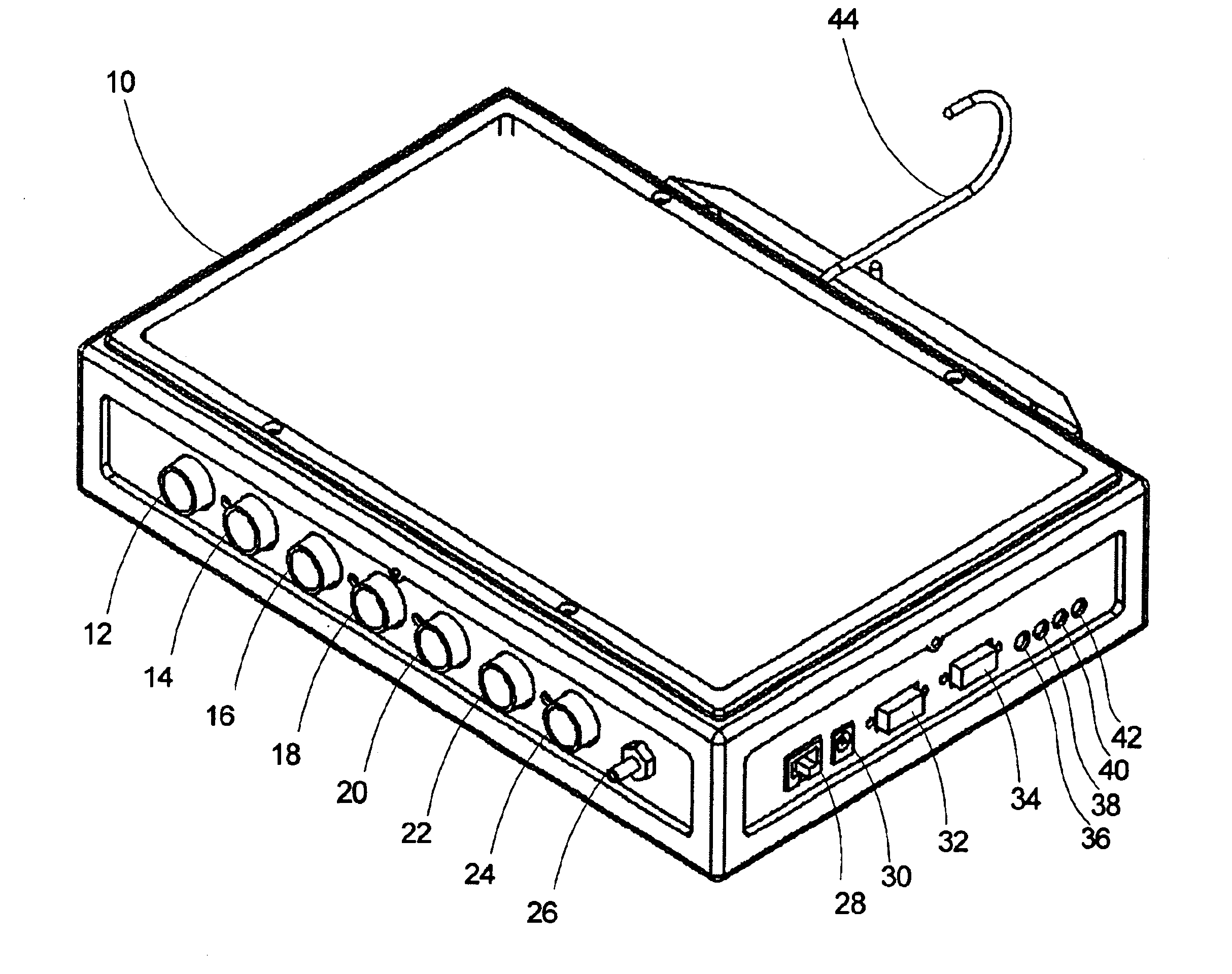

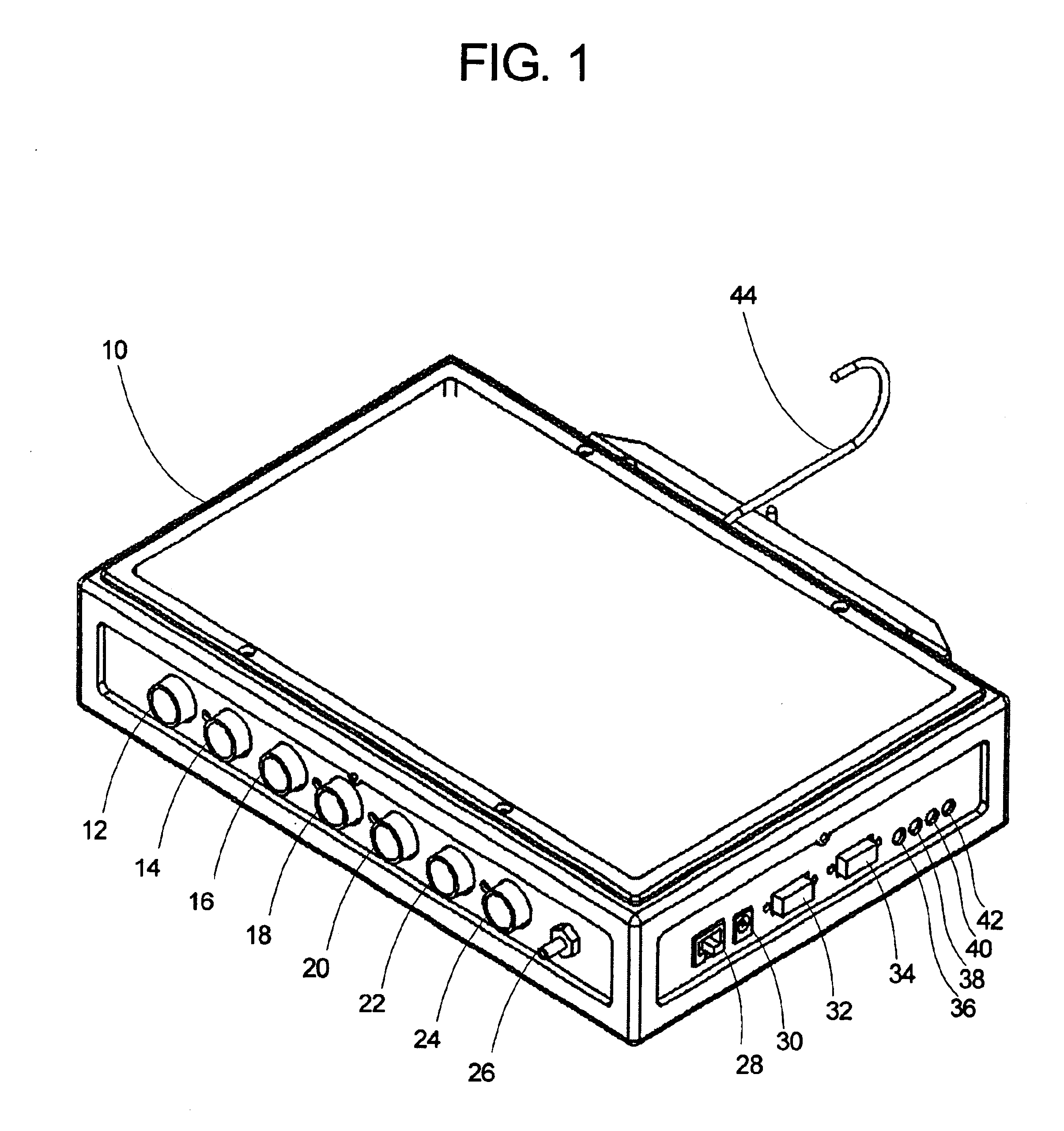

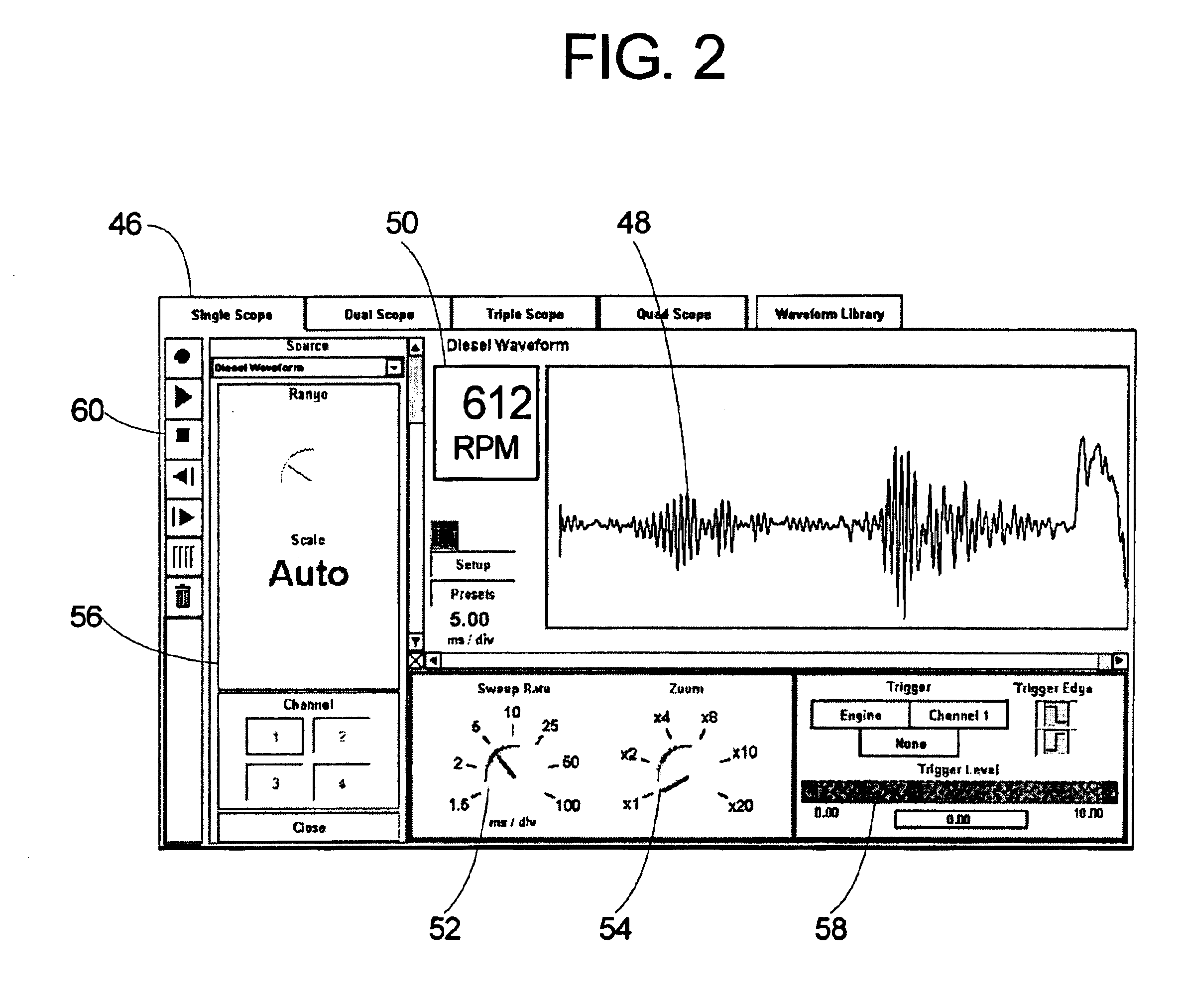

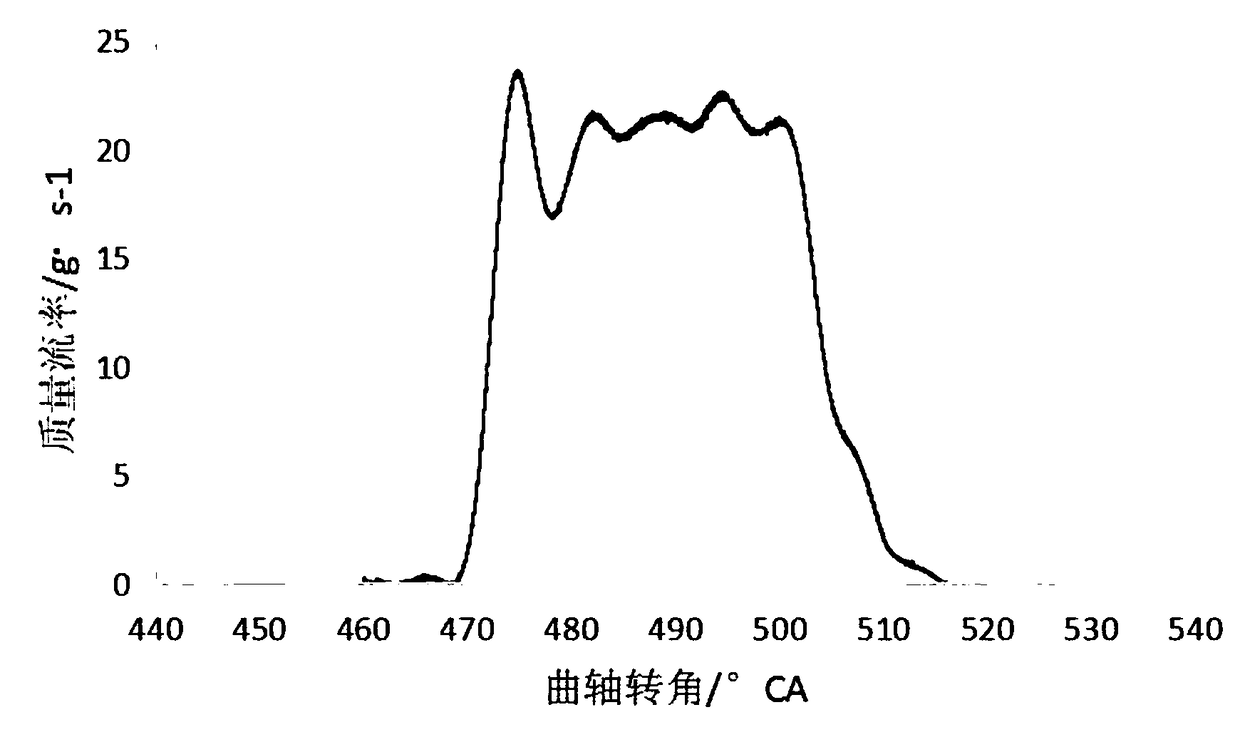

Method and apparatus for processing and display of diesel injection waveform

A signal processing apparatus for detecting and displaying the properties of diesel fuel powered compression-ignition engines senses strain pulses in the fuel injection rail structure to perform a variety of testing functions. Among other capabilities, the apparatus permits the user to establish stroboscope timing, to measure engine RPM, to view the relationship between crankshaft position and injection time, and to examine the time-dependent properties of strain pulses on individual fuel injectors in order to evaluate the condition of the diesel engine.

Owner:SPX CORP

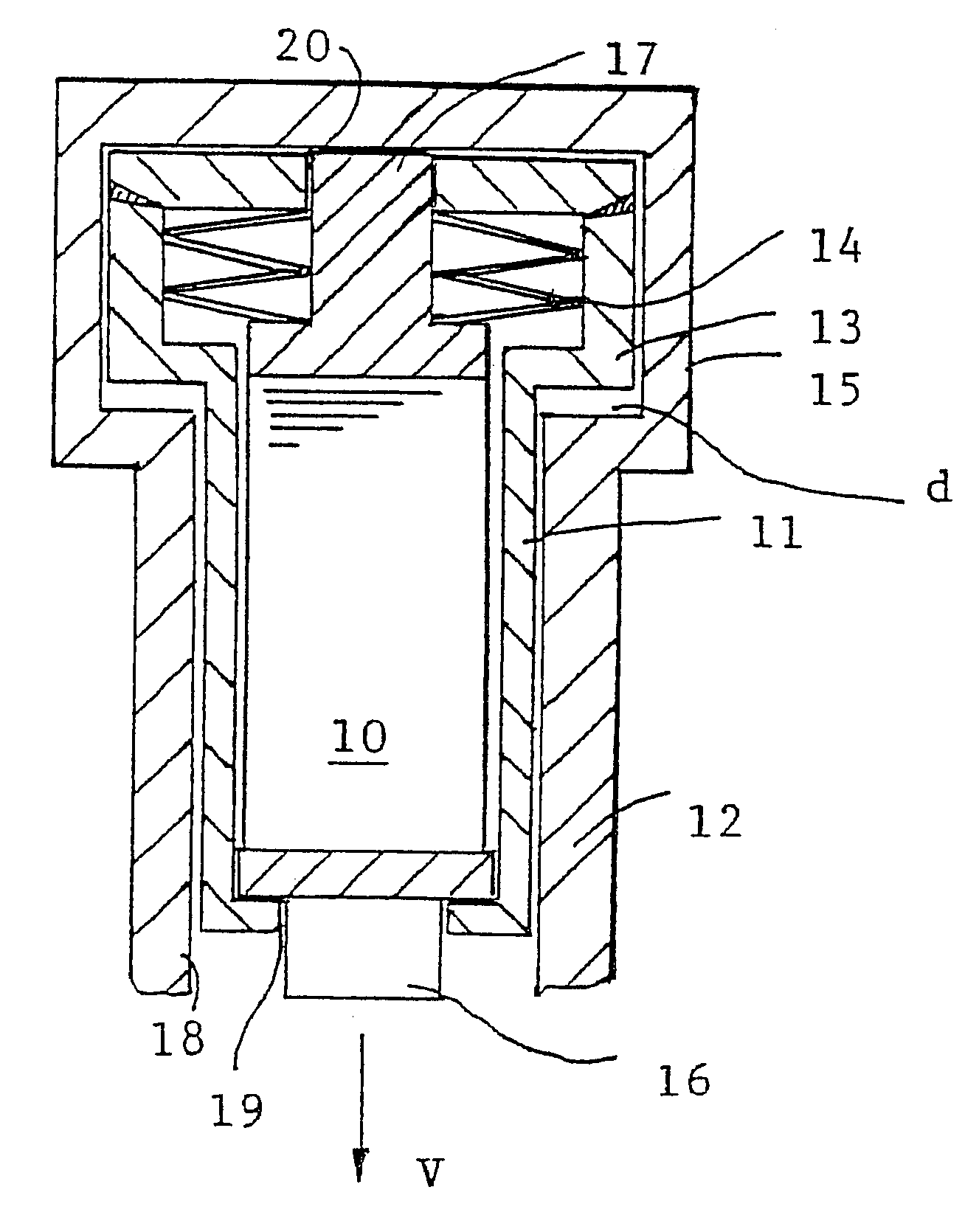

Injector with a multilayer piezoelectric actuator

InactiveUS6371085B1Operating means/releasing devices for valvesSpray nozzlesPiezoelectric actuatorsCommon rail

An injector for common rail Diesel injection systems of motor vehicles, having a multilayer piezoelectric actuator which has a multilayer actuator body. The actuator body is prestressed on a face end by a prestressing device and is seated inside a center longitudinal bore of an injector housing. The injector is characterized in that the prestressing device have at least one cup spring, which in a prestressing movement engages the face end of the actuator body opposite an injector valve (V), as well as a force transmission member seated in the injector housing and axially movable therein, the transmission member transmits the spring force of the at least one cup spring to the face end, toward the valve, of the actuator body.

Owner:ROBERT BOSCH GMBH

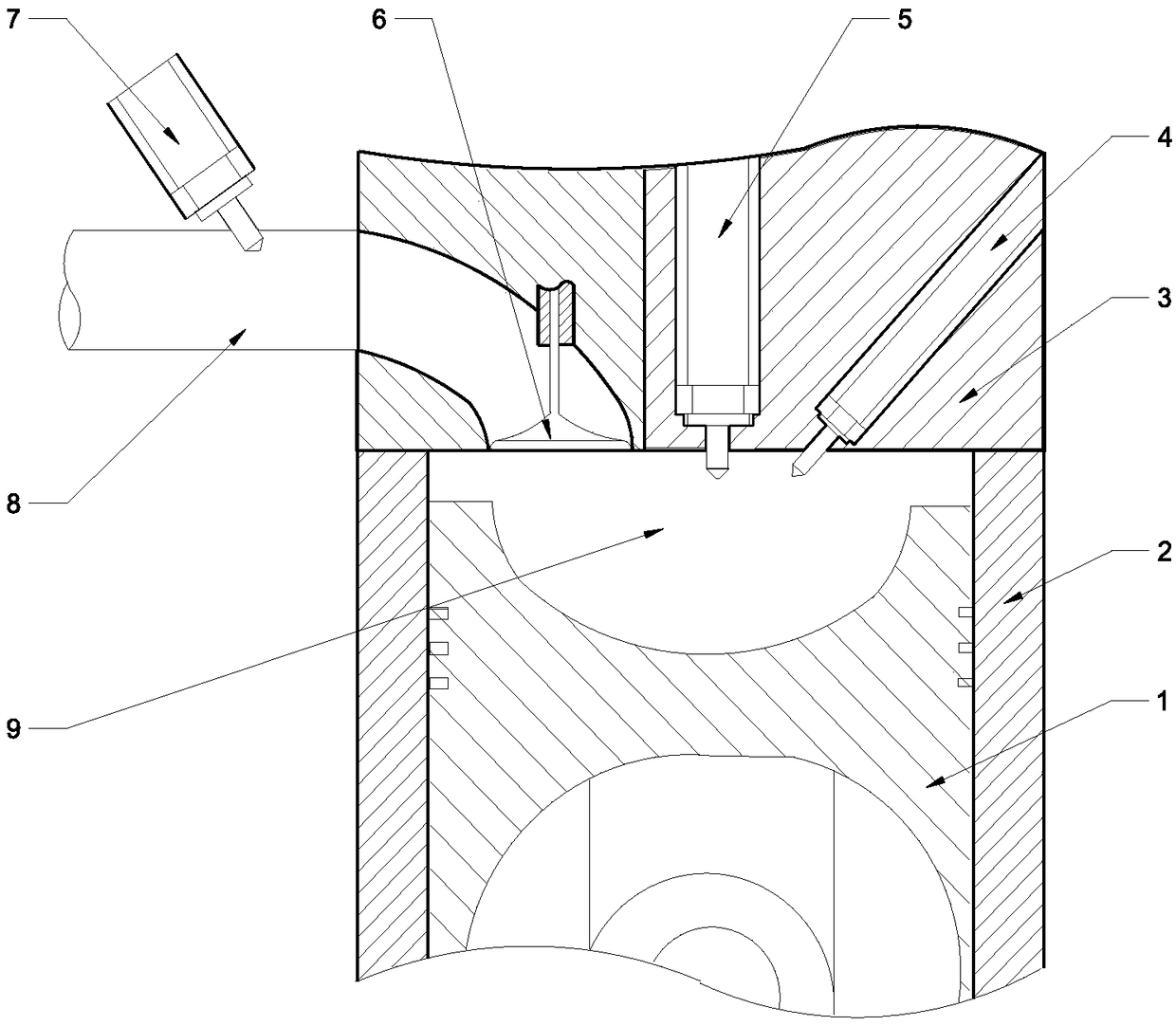

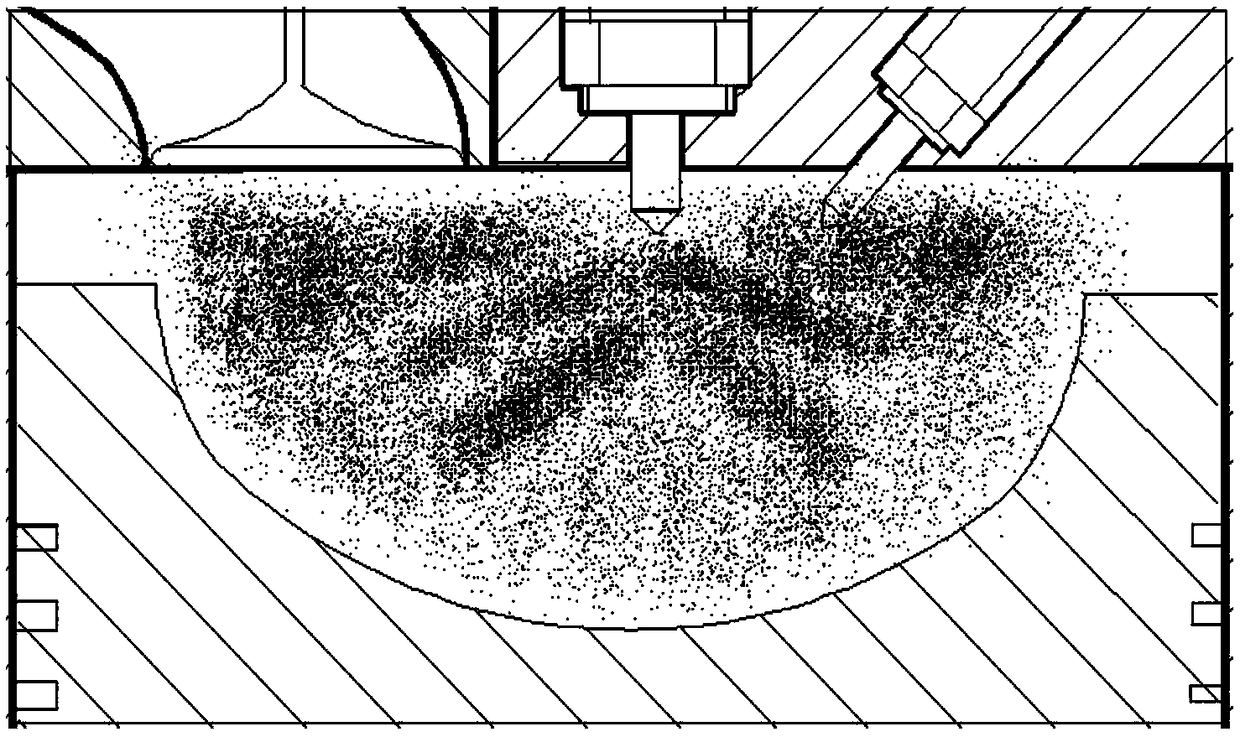

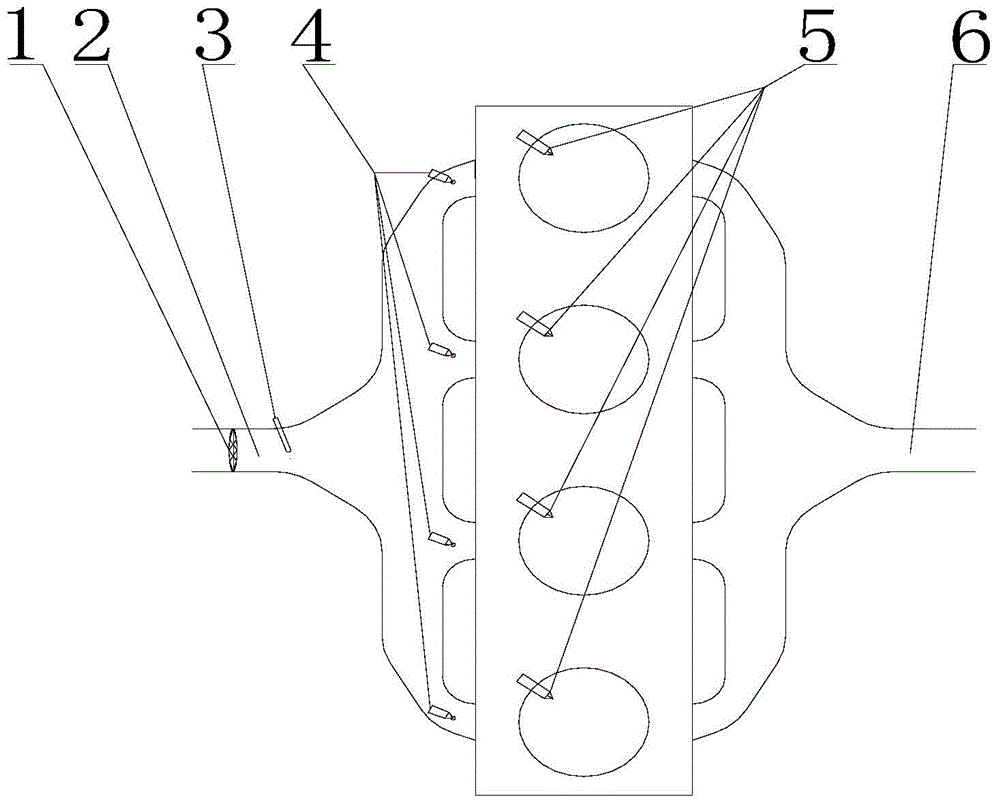

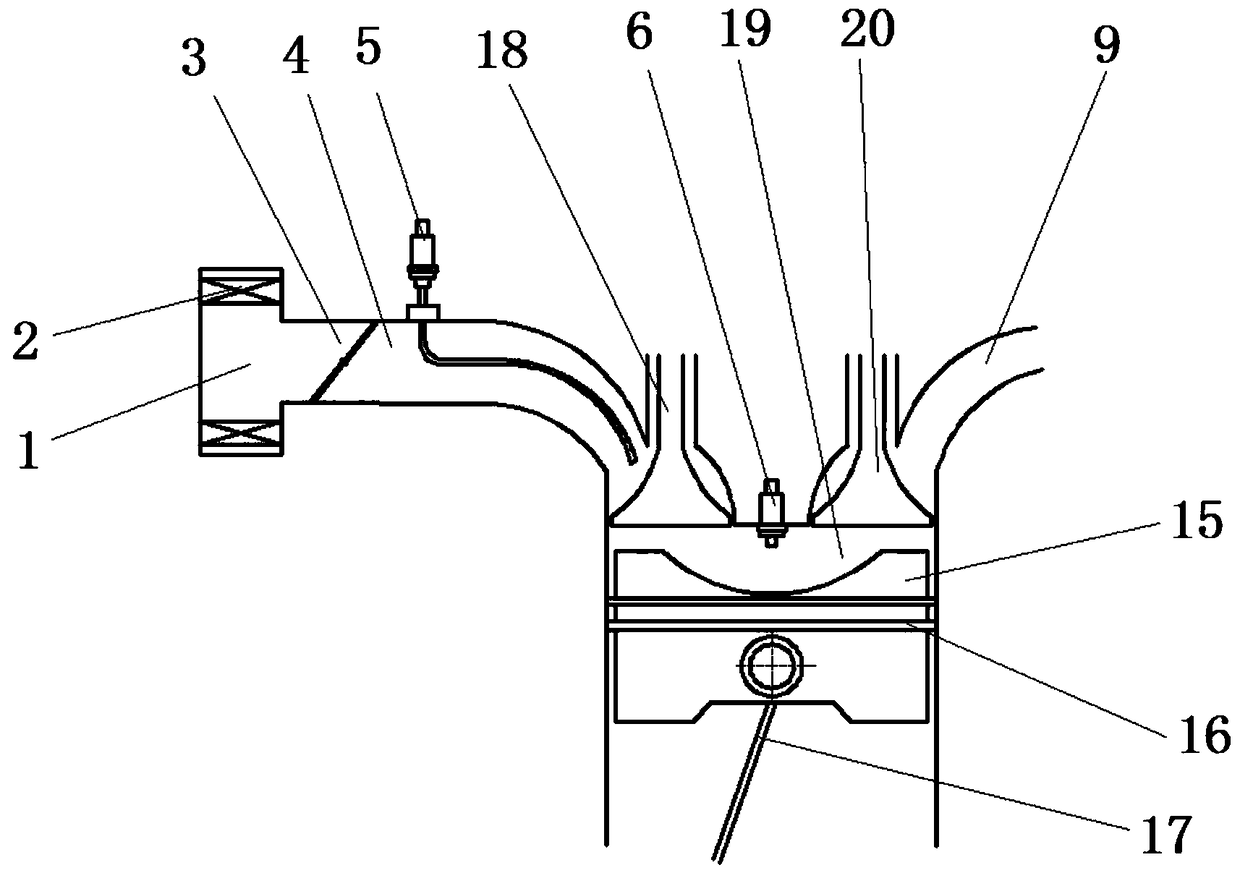

Dual-fuel engine adopting main and auxiliary oil injectors and manifolds for multiple times of spraying, and combustion organization method of dual-fuel engine

ActiveCN109441626AImprove performanceGuaranteed ignition stabilityElectrical controlInternal combustion piston enginesBurning tissueTop dead center

The invention belongs to the technical field of combustion of internal combustion engines, and particularly relates to a dual-fuel engine adopting main and auxiliary oil injectors and manifolds for multiple times of spraying, and a combustion organization method of the dual-fuel engine. The dual-fuel engine comprises a piston, an air cylinder sleeve, an air cylinder cover, the main oil injector, the auxiliary oil injector, a manifold low-pressure gas jetting device and the like; the main oil injector is mounted at the center of the air cylinder cover, and the diesel injection ratio during thelow load can be controlled by changing the oil spraying pulse width of the main oil injector; the auxiliary oil injector is obliquely mounted on the air cylinder cover, diesel micro-jet is conducted during the middle and high load, and natural gas is ignited after diesel nearby a top dead center is self-ignited; and a manifold low-pressure gas jetting valve is mounted on the gas inlet manifold ofeach cylinder, during the middle and high load, the number of times of jetting and the timing of the low-pressure gas jetting valves are controlled, and thus reasonable mixed gas concentration distribution is formed in the cylinders. According to the dual-fuel engine, ignition stability under different working conditions is ensured through diesel ignition, and different oil and gas jetting strategies are adopted under the different working conditions, so that reasonable oil and gas distribution is achieved in the cylinders to achieve the good combustion effect, and thus the economical efficiency and emission performance of the engine are improved.

Owner:HARBIN ENG UNIV

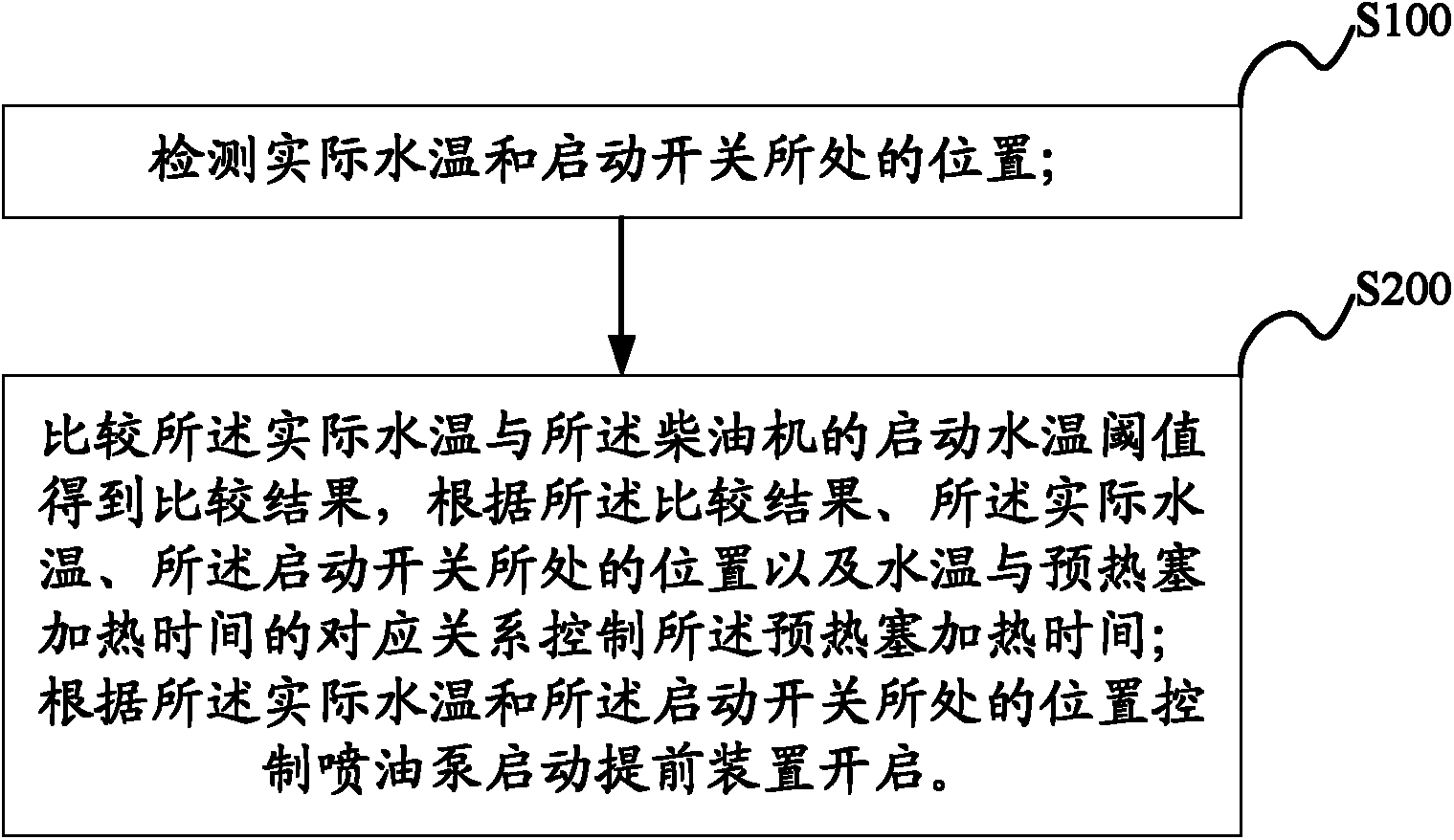

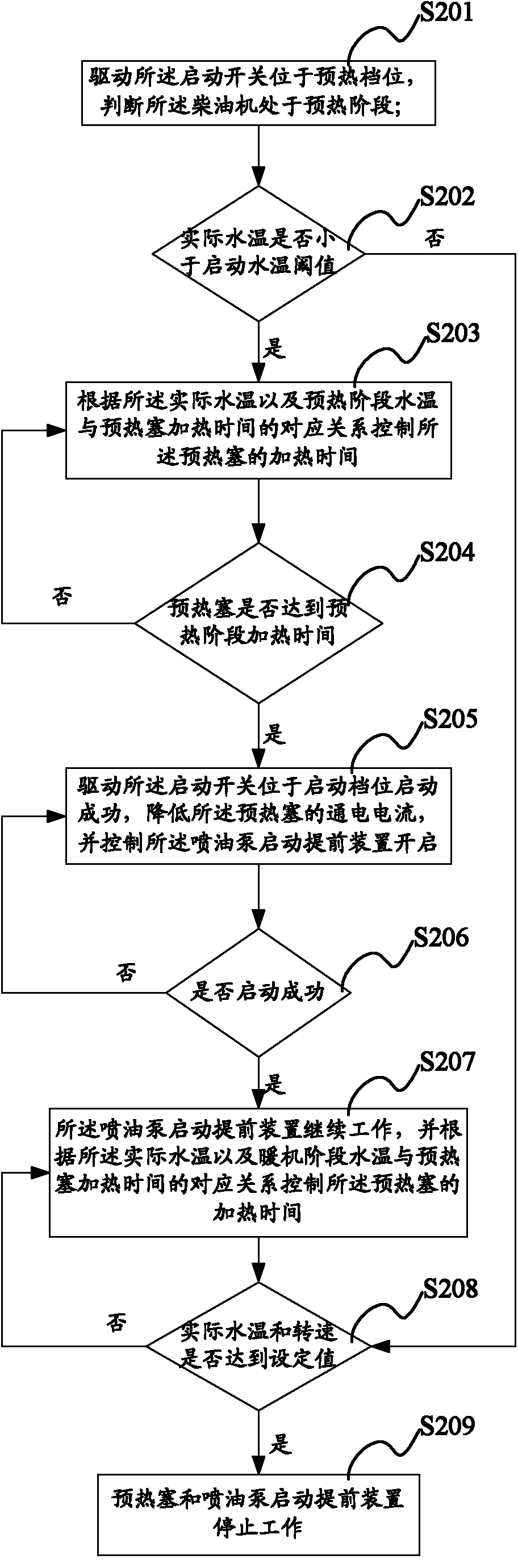

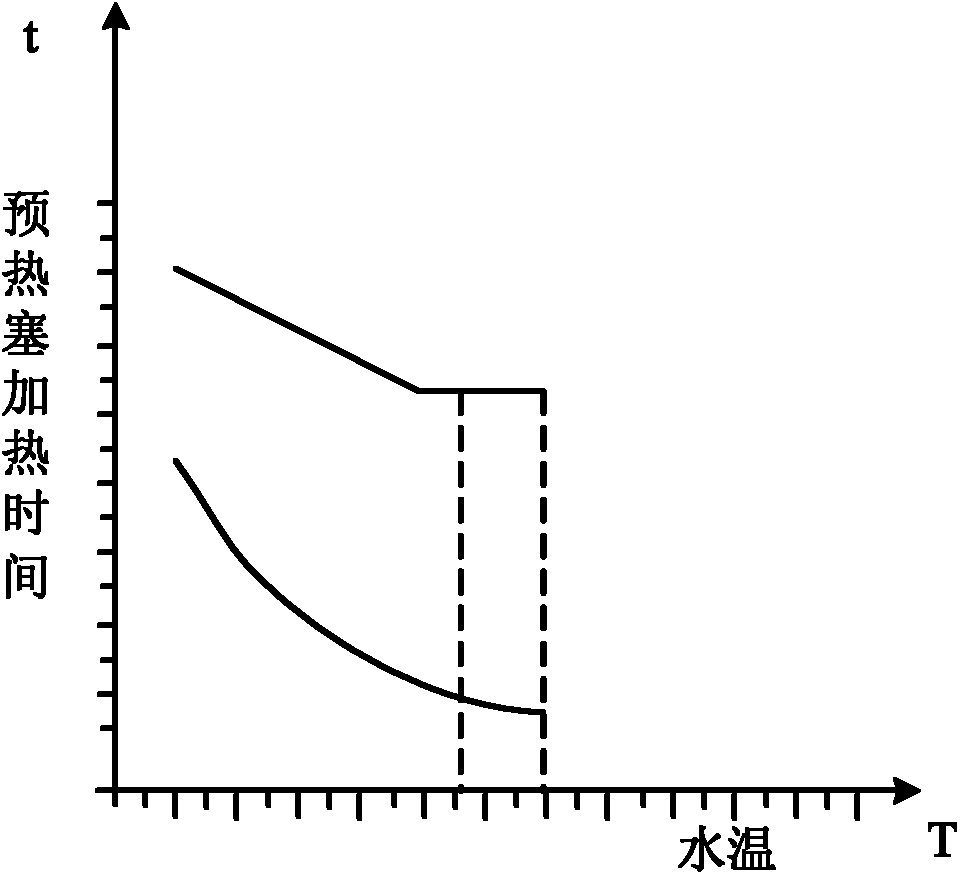

Cold-booting auxiliary device for diesel engine and control method

InactiveCN102493905AImprove cold start performanceIncrease temperatureFuel-injection pumpsMachines/enginesHeating timeGlowplug

An embodiment of this invention discloses a cold-booting auxiliary device for a diesel engine and a control method; because the cold-booting auxiliary method disclosed by this invention adjusts a heating time of a preheating plug according to an actual water temperature, the method disclosed by this invention realizes to adjust the heating time of the preheating plug according to change of an environment temperature and develops heating action at a stating stage and an idling warming-up stage, the temperature of a combustion chamber of an engine is increased, and combustion and tail gas emission of the engine can be improved obviously; simultaneously, an actual temperature and a position of a booting switch are detected so as to control a booting time and a diesel injection quantity of a diesel injection pump advancer, thus, a diesel supply advancing angle of the diesel engine is changed; when a water temperature is low, diesel injection of the diesel engine can be assisted so as to further improve cold-booting performance of the diesel engine; based on an above-mentioned method, the cold-booting auxiliary device disclosed by this invention improves the cold-booting performance of the diesel engine.

Owner:WEICHAI POWER CO LTD

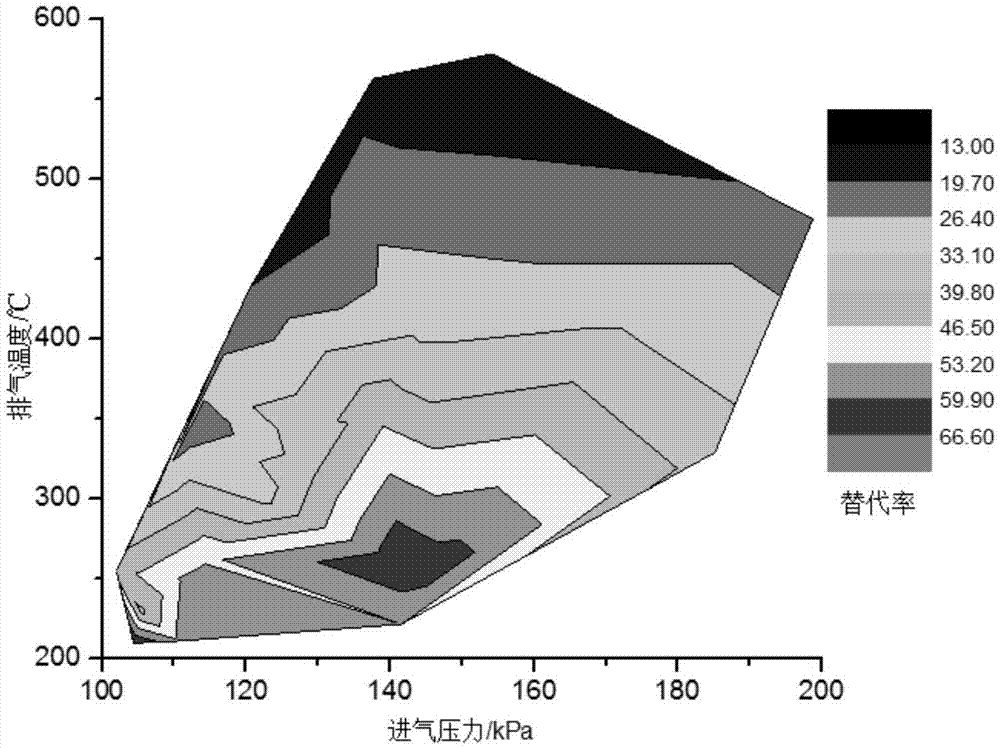

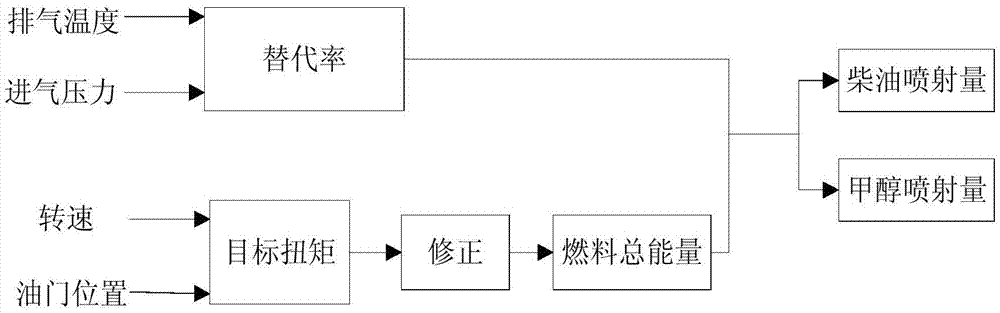

Fuel supply control method of electric control methanol-diesel dual-fuel engine for vehicle

InactiveCN105443251AIncrease usageLow running costElectrical controlMachines/enginesElectric controlIntake pressure

The invention discloses a fuel supply control method of an electric control methanol-diesel dual-fuel engine for a vehicle. The methanol-diesel substitution rate is dynamically determined according to the exhaust temperature and intake pressure of the engine, and therefore different methanol-diesel injection amount proportions can be determined according to different conditions of the engine. By means of the fuel supply control method, the knocking phenomenon can be avoided as far as possible on the premise of guaranteeing the maximum substitution rate, and the effects of increasing the use economy of the methanol-diesel dual-fuel engine and prolonging the service life of the methanol-diesel dual-fuel engine can be achieved.

Owner:CHANGAN UNIV

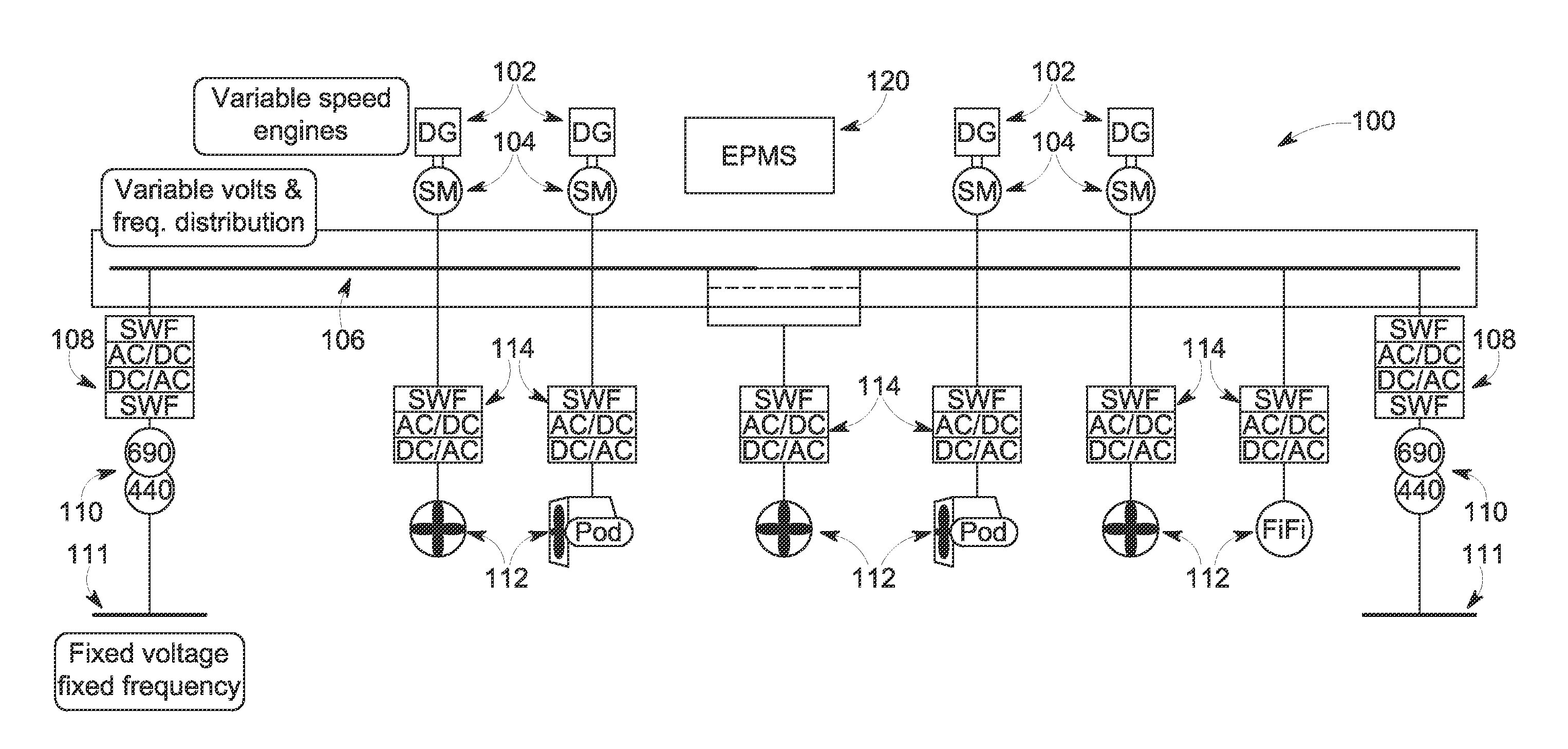

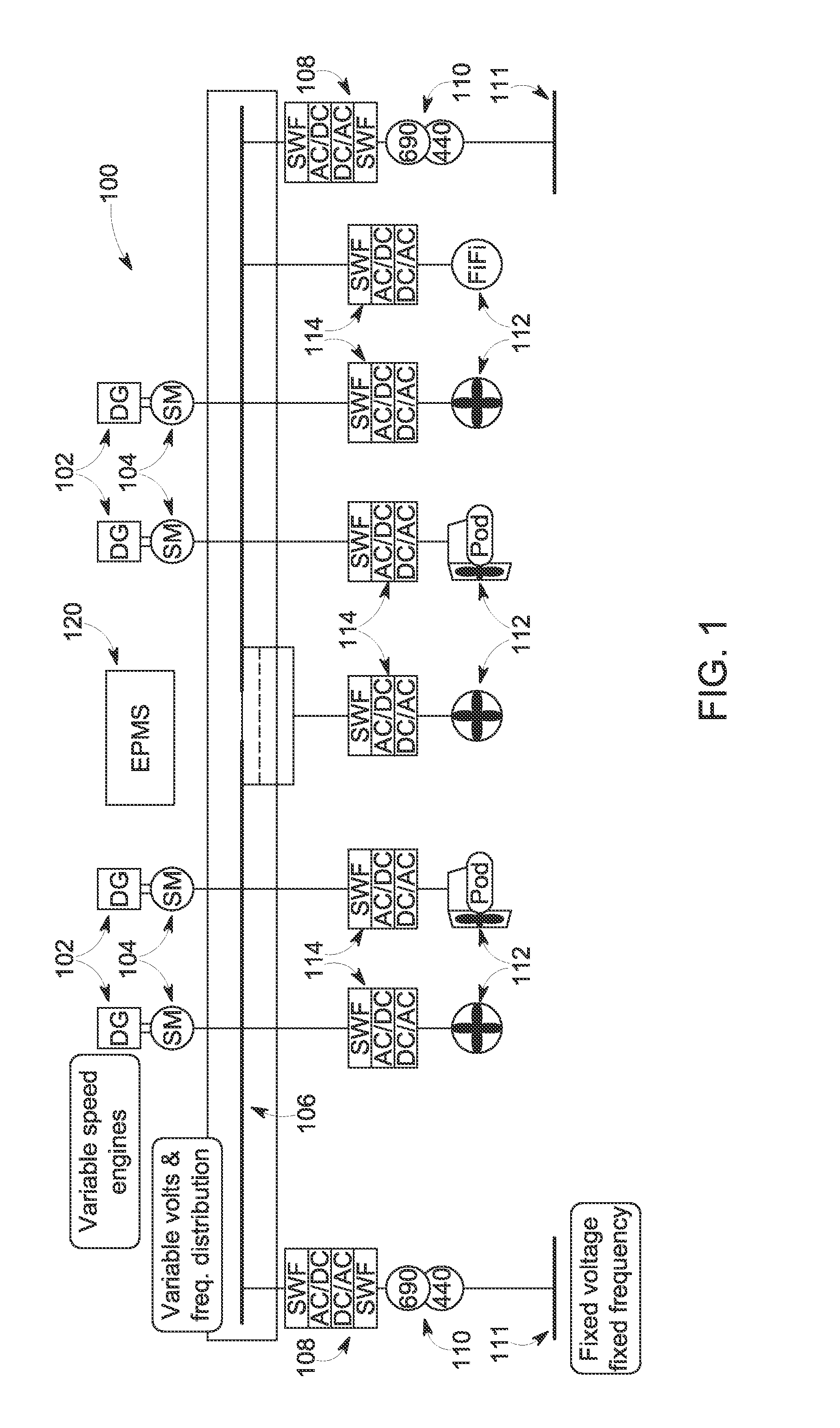

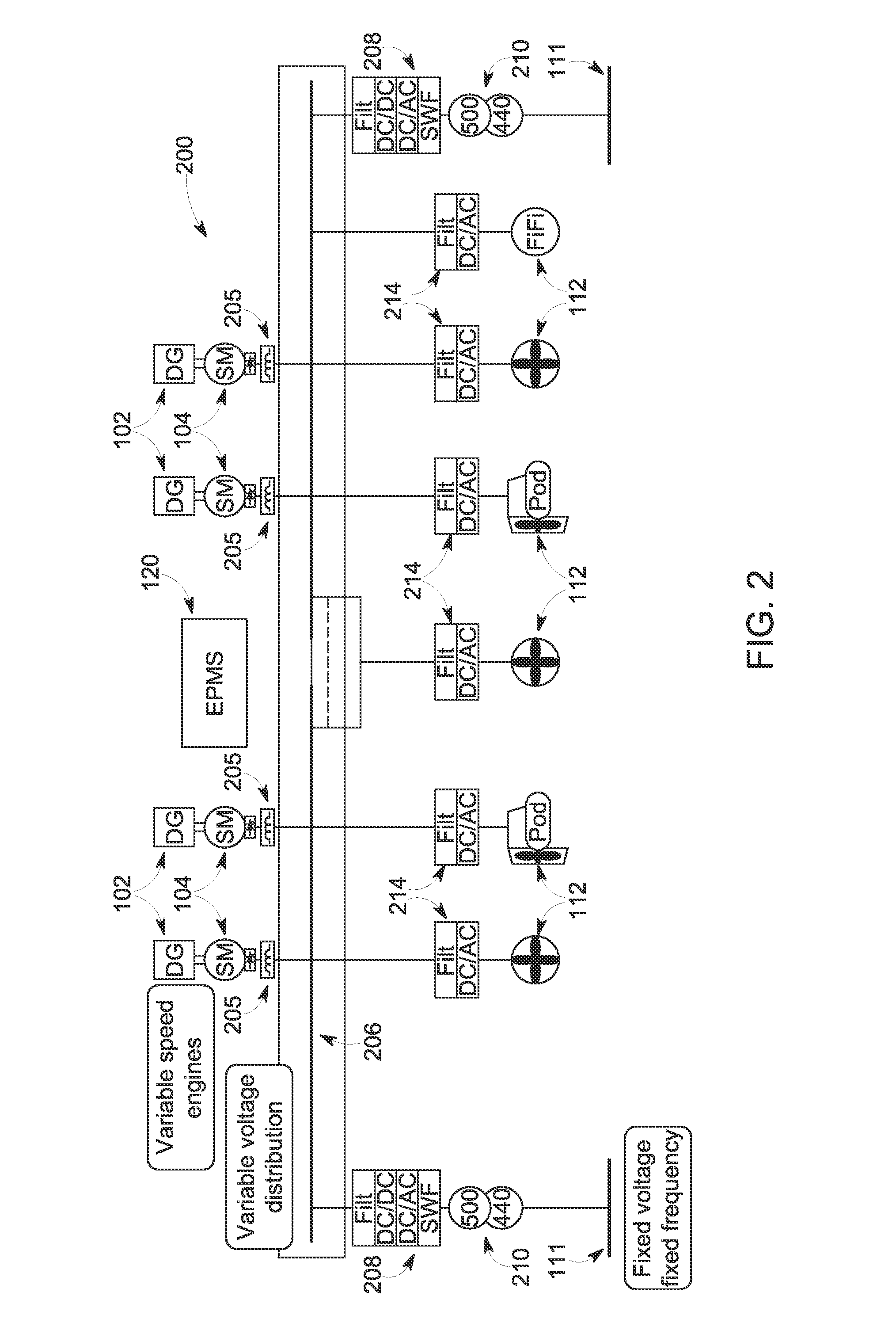

Variable speed dual fueled engine and electrical power management apparatus and methods

InactiveUS20140182560A1Increase engine speedElectrical controlInternal combustion piston enginesEngineeringElectric power

A fuel system is provided for use with a variable speed dual fuel engine. The fuel system comprises a first fuel injector configured for supplying diesel fuel to the engine, a second fuel injector configured for supplying natural gas to the engine, and a fuel controller configured to implement a diesel injection schedule and a natural gas injection schedule based on at least a fuel map, an optimal engine speed and a current engine speed.

Owner:GENERAL ELECTRIC CO

Method and apparatus for controlling exhaust gas recirculation and start of combustion in reciprocating compression ignition engines with an ignition system with ionization measurement

ActiveUS7707992B2Reliable detectionElectrical controlInternal combustion piston enginesExhaust gas recirculationFeedback control

An apparatus and method to detect combustion conditions using ion signals for use in a feedback control of a reciprocation engine is presented. The ion signals are used as a feedback signal to control EGR and diesel injection timing. The apparatus is an ignition system with a spark plug type of sensor. The ignition system is used to provide a cold start mechanism for diesel engines and start of combustion for spark ignition engines. The ignition is combined with ion sensing feedback that can control the engine.

Owner:WOODWARD GOVERNOR CO

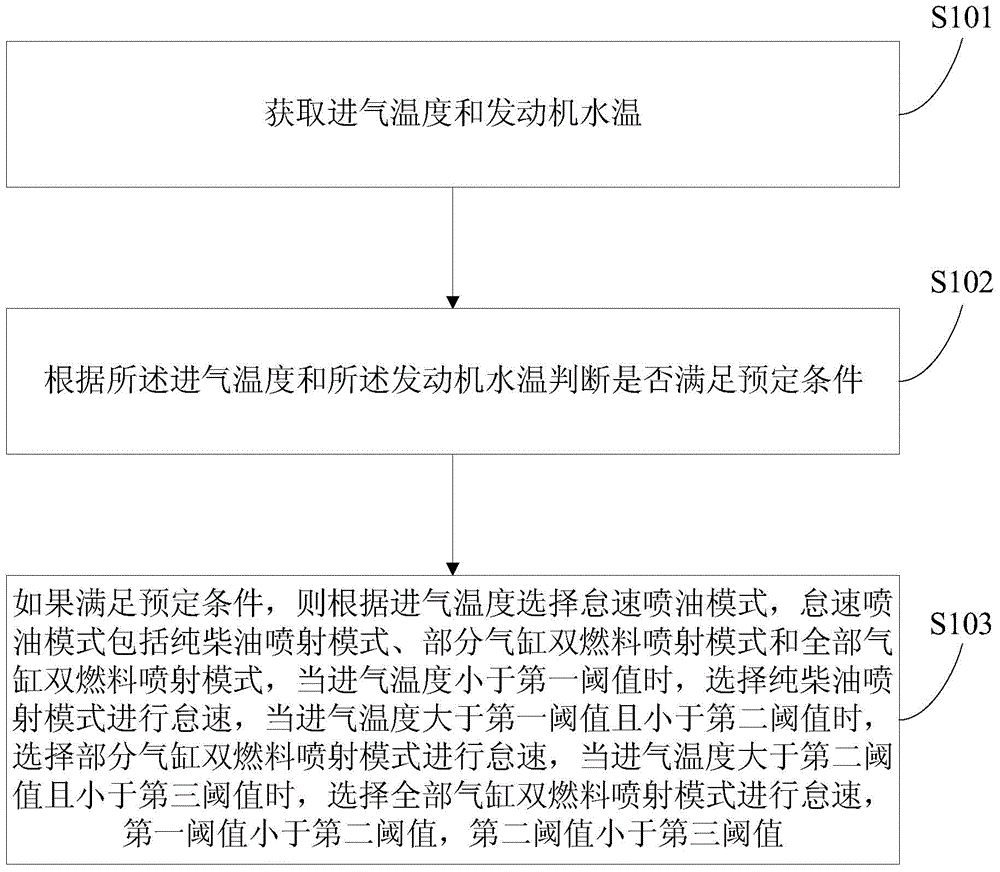

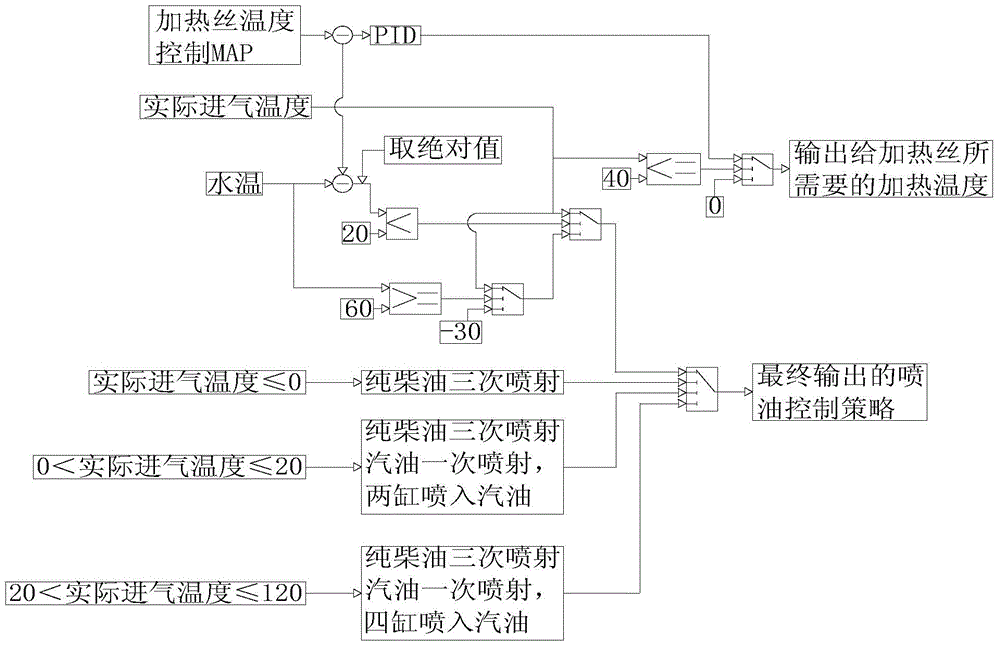

Idling control method and system for dual-fuel engine, and vehicle

ActiveCN106150709AAdvantages of idle speed control methodSolve the problem of injection combustion instabilityElectrical controlMachines/enginesControl systemEngineering

The invention provides an idling control method and an idling control system for a dual-fuel engine, and a vehicle. The method comprises the following steps: acquiring intake air temperature and engine coolant temperature; judging whether a preset condition is met according to the intake air temperature and engine coolant temperature; and if the preset condition is met, selecting an idling fuel injection mode according to the intake air temperature, wherein the idling fuel injection mode comprises a pure diesel injection mode, a partial-cylinder dual-fuel injection mode and a full-cylinder dual-fuel injection mode: when the intake air temperature is less than a first threshold value, selecting the pure diesel injection mode for idling; when the intake air temperature is greater than the first threshold value and less than a second threshold value, selecting the partial-cylinder dual-fuel injection mode for idling; when the intake air temperature is greater than the second threshold value and less than a third threshold value, selecting the full-cylinder dual-fuel injection mode for idling, wherein the first threshold value is less than the second threshold value, and the second threshold value is less than the third threshold value. The method disclosed by the invention has the advantage of effectively reducing the emission of exhaust gas pollutants during idling.

Owner:GREAT WALL MOTOR CO LTD

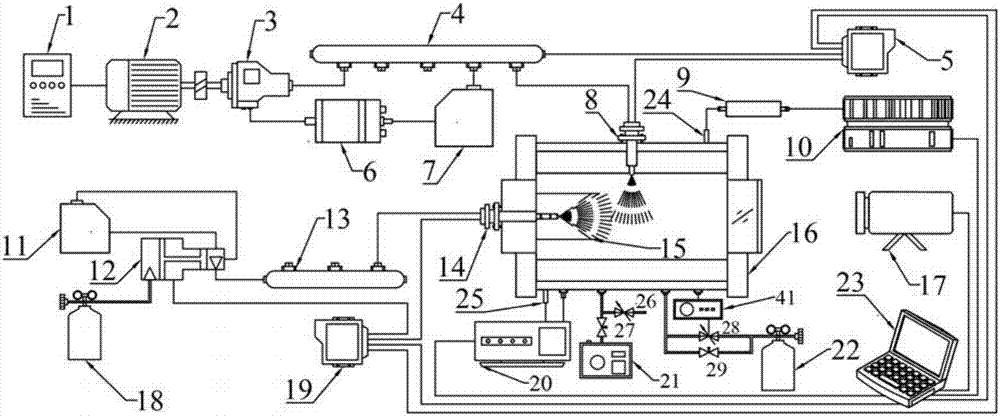

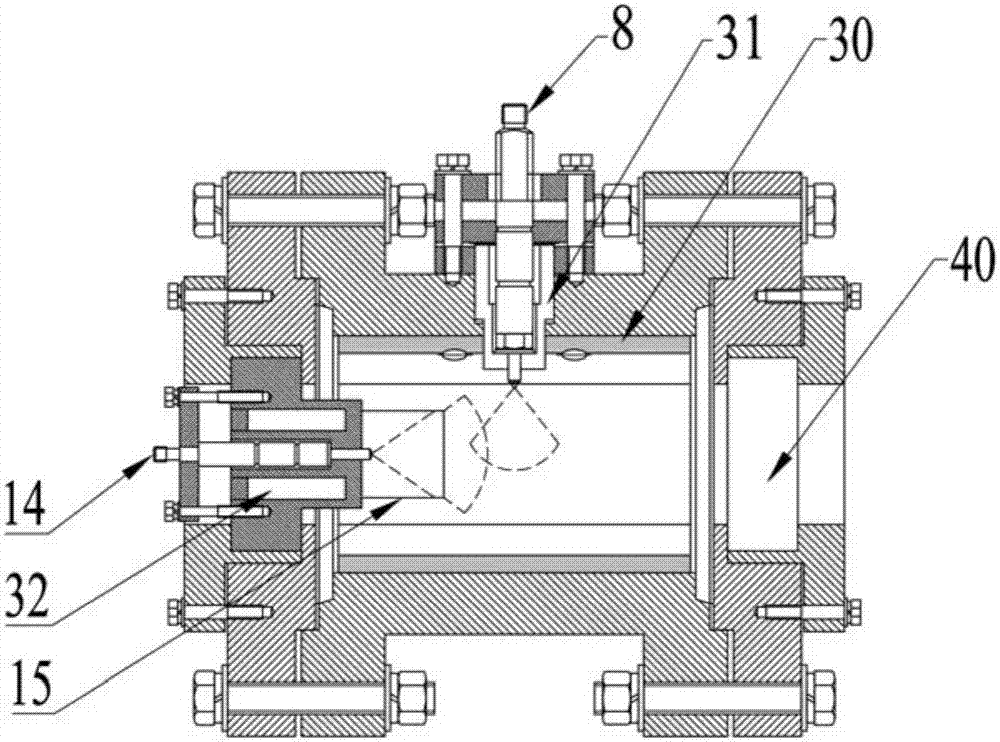

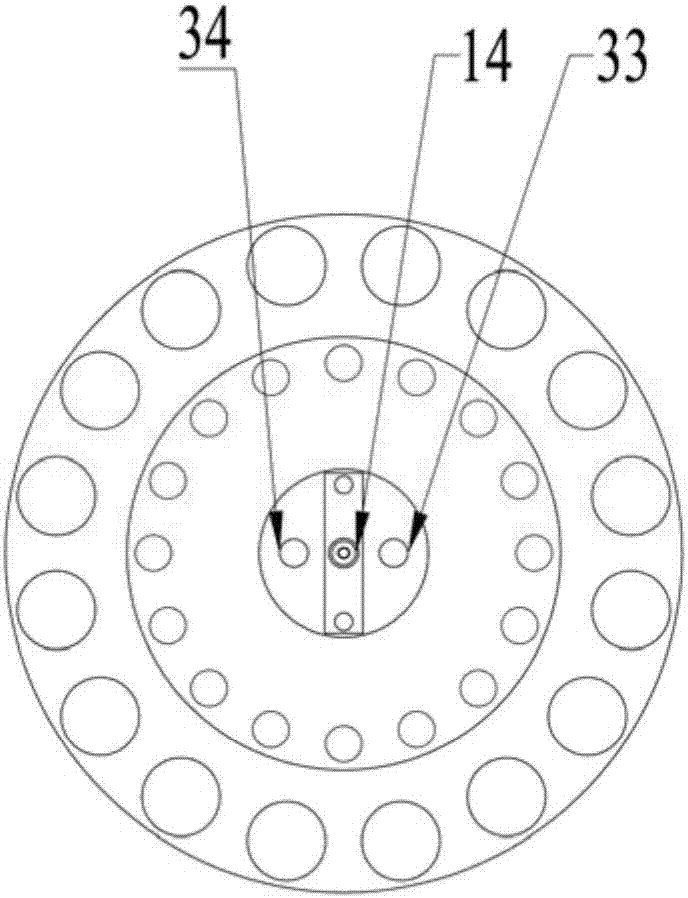

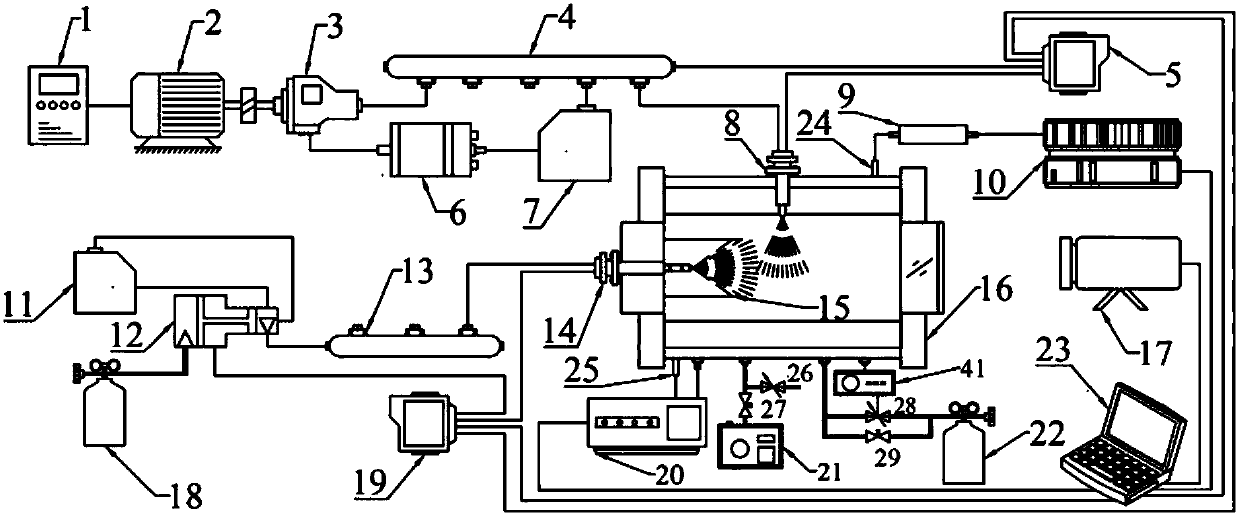

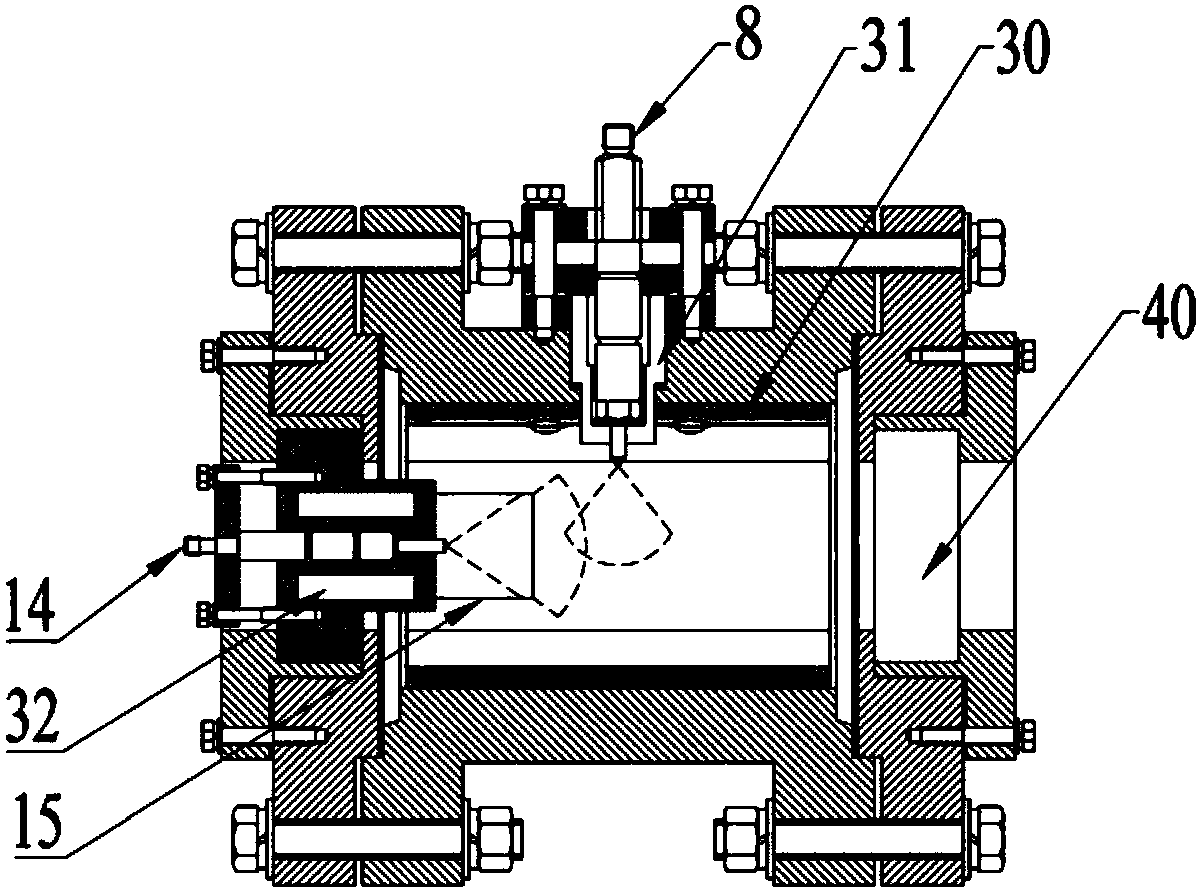

Constant volume combustion bomb system for simulating multiple combustion modes of methanol/diesel oil dual-fuel engine and method thereof

PendingCN107271193AWith heating functionHeating fully and evenlyInternal-combustion engine testingControllers with particular characteristicsOil canSystem pressure

The invention relates to a constant volume combustion bomb system for simulating multiple combustion modes of a methanol / diesel oil dual-fuel engine and a method thereof. The constant volume combustion bomb system for simulating multiple combustion modes of the dual-fuel engine comprises a constant volume combustion bomb, a diesel oil injector, a diesel oil injection system connected with the diesel oil injector, a methanol injector, a methanol injection system connected with the methanol injector, a gas inlet system, a gas exhaust system, a pressure sensor, a synchronous data acquisition card, a high-speed camera and an upper computer. Multiple combustion modes that the diesel oil ignites the methanol, the diesel oil and the methanol are on fire simultaneously and the methanol is self-ignited before the diesel oil can be realized by adjusting the injection moment of the methanol relative to the diesel oil, uniform premixing and concentration stratification of the methanol in the constant volume combustion bomb can also be realized and the injection pressure of the methanol is flexible and adjustable.

Owner:TIANJIN UNIV

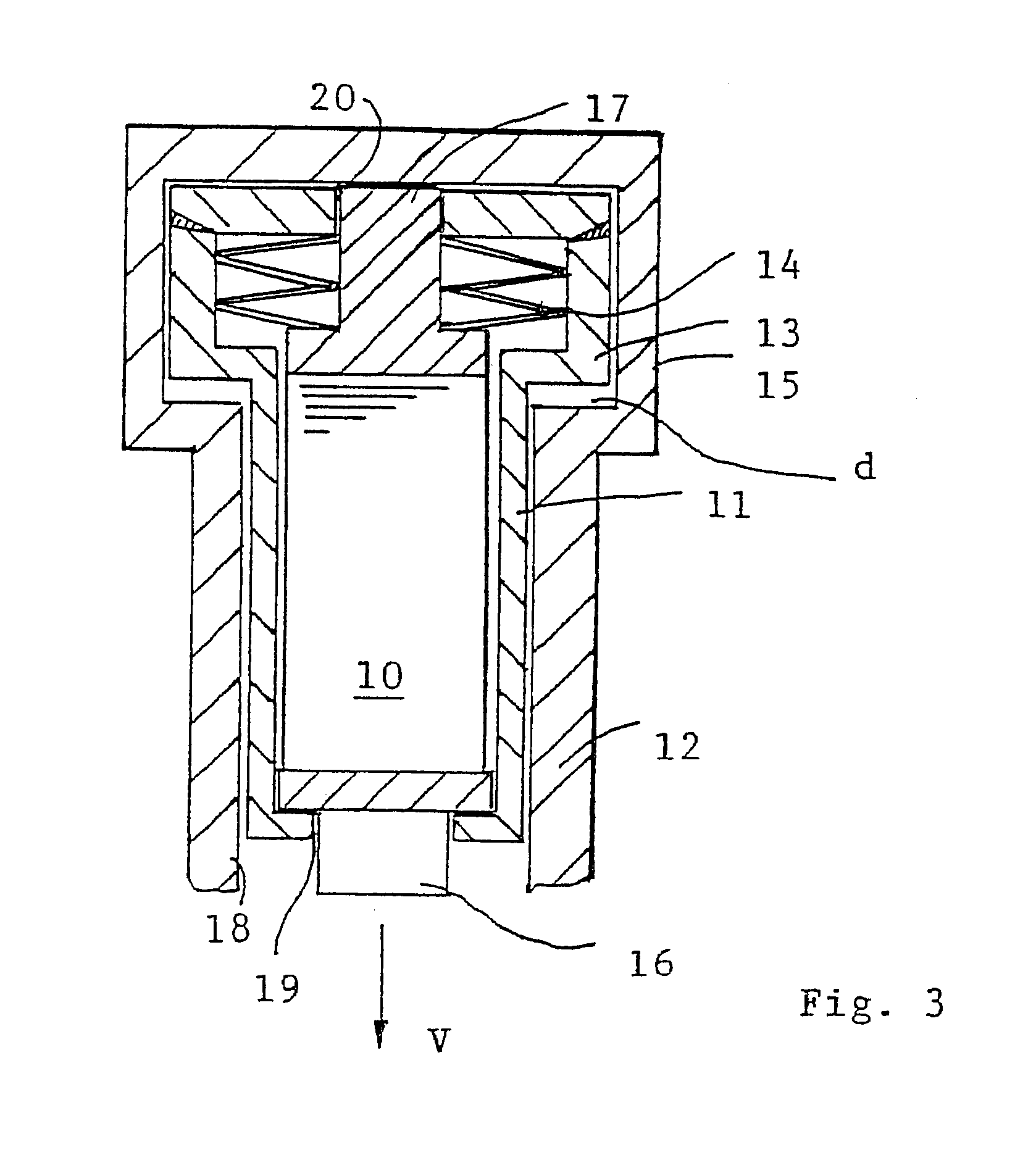

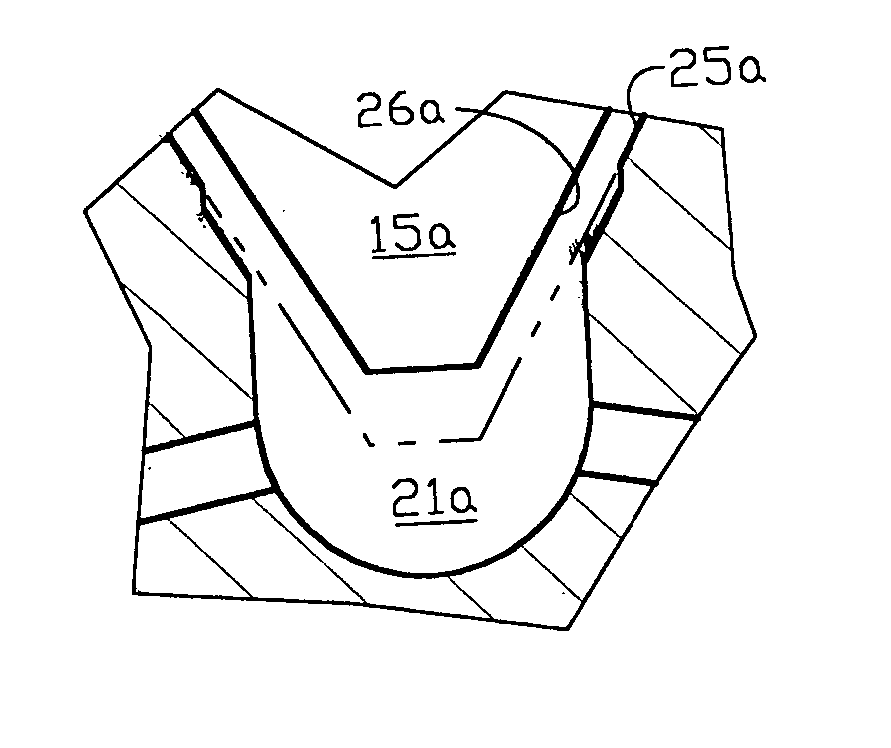

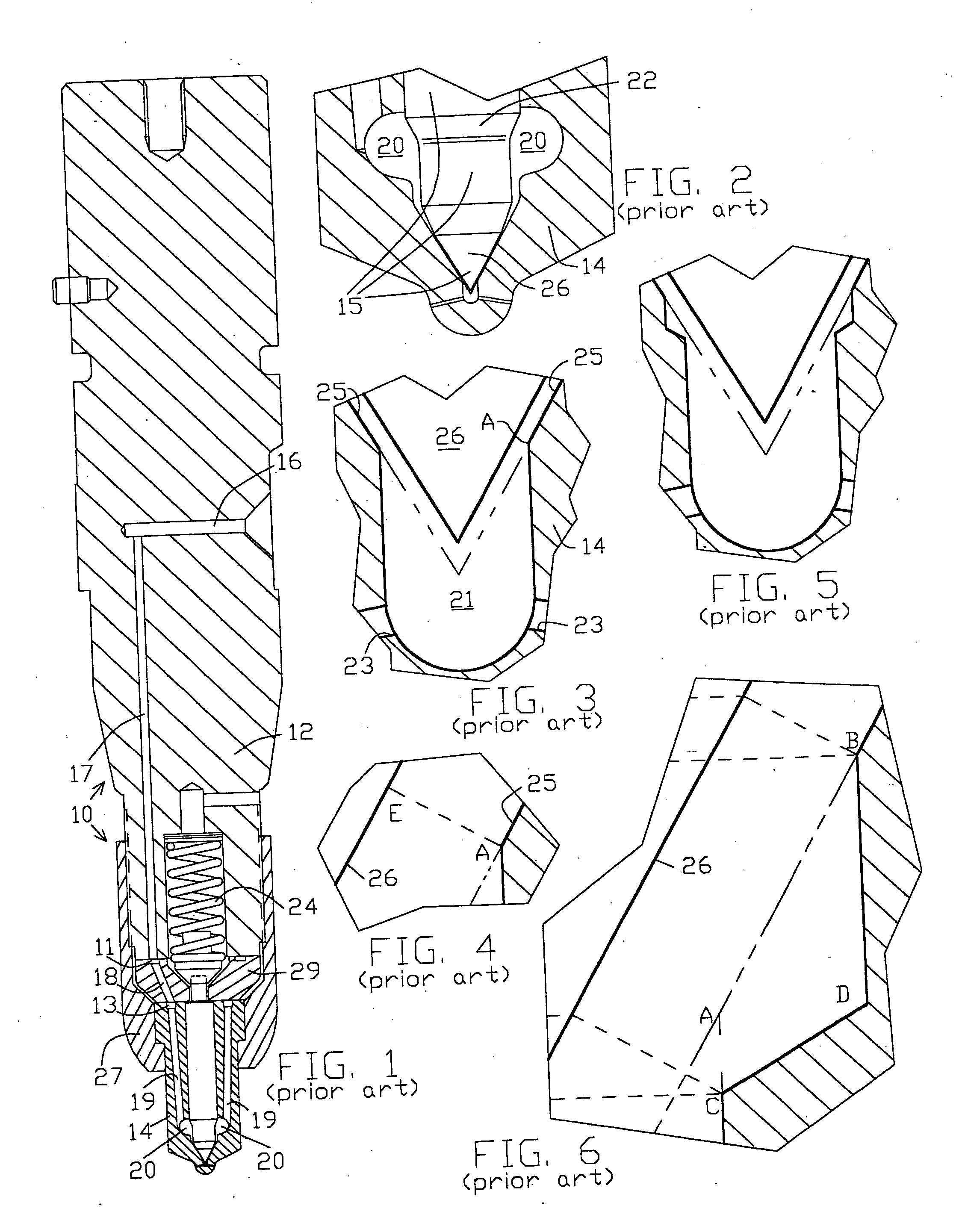

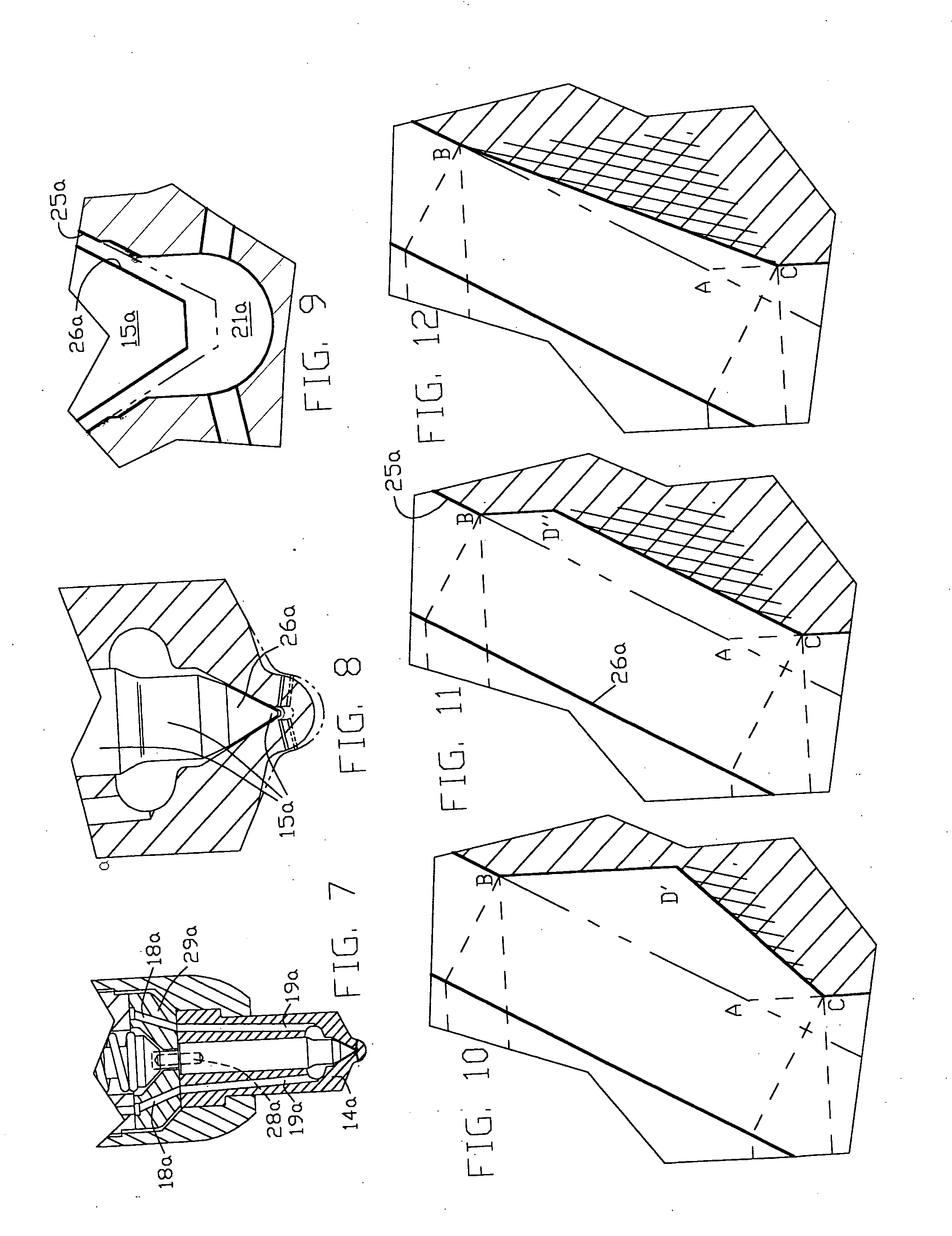

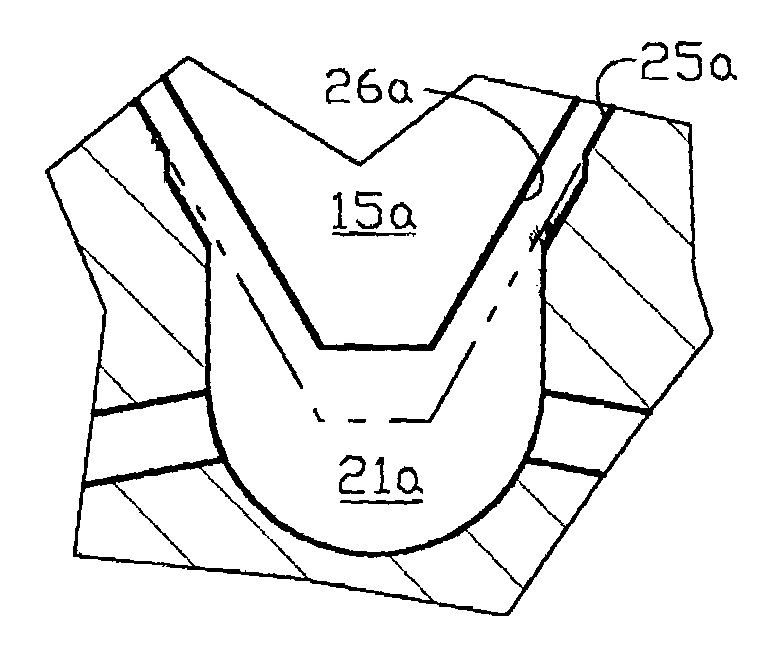

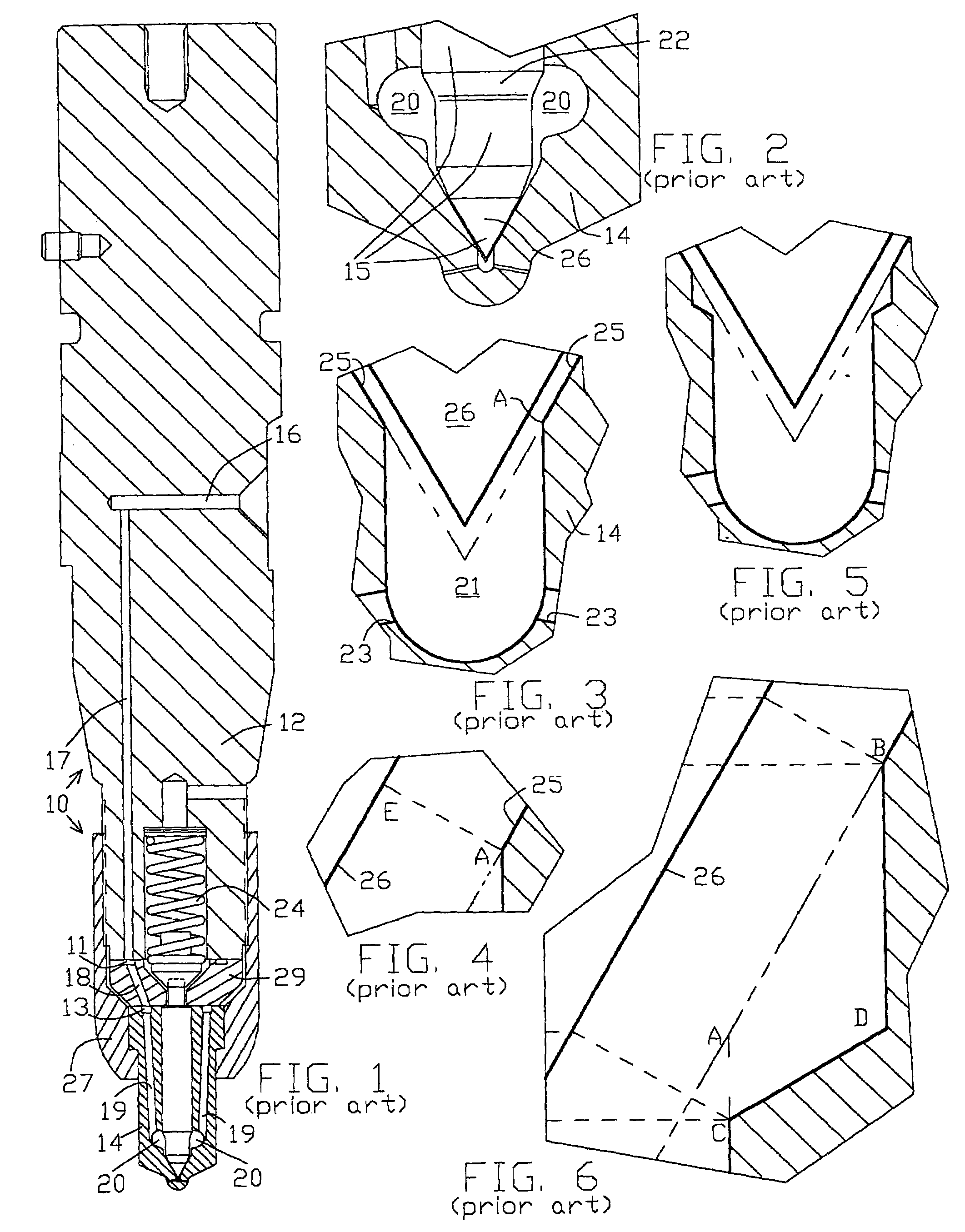

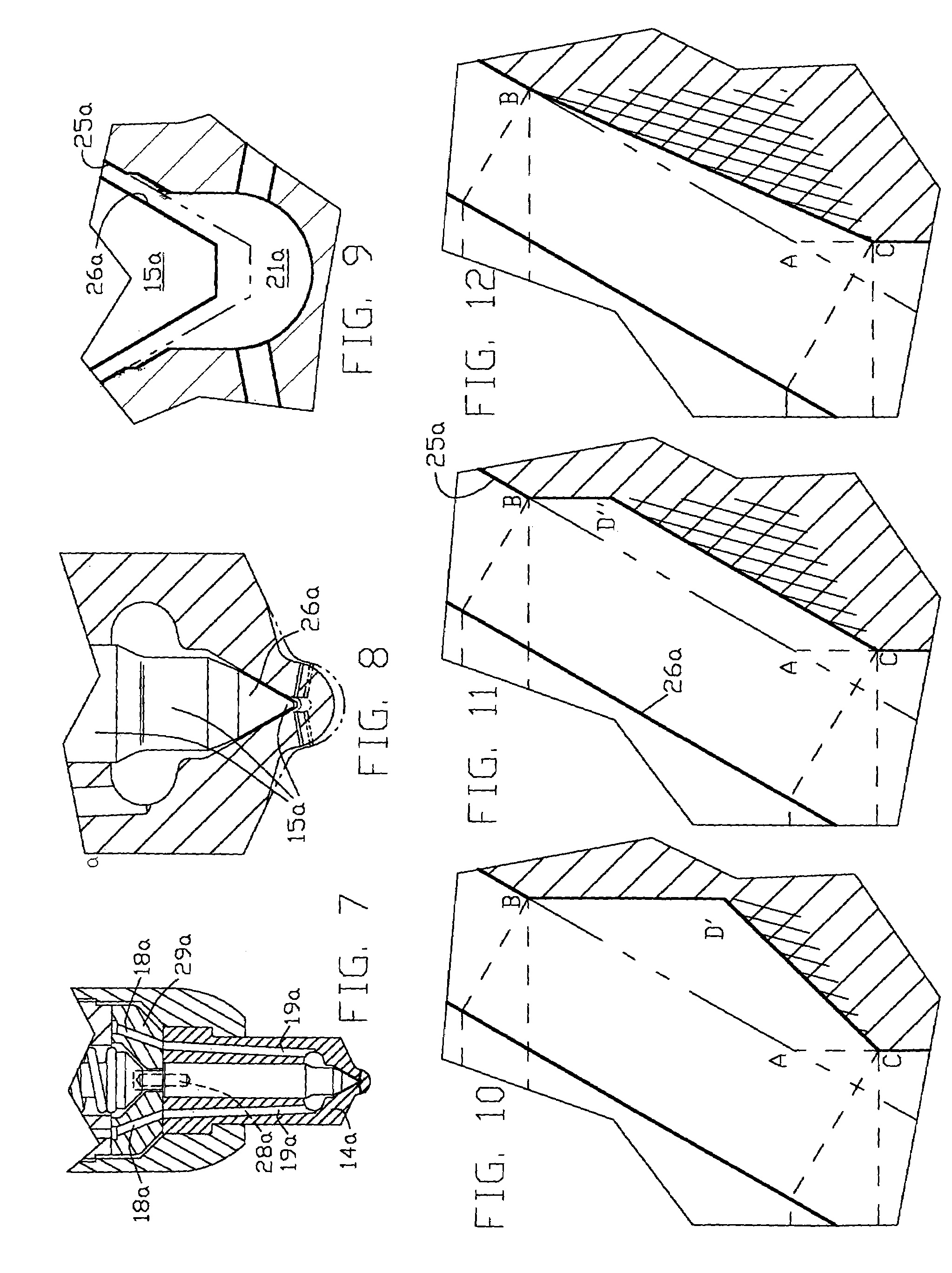

Diesel injection nozzle

An annular notch is provided in the body seat associated with the nozzle valve of an ALCO-type diesel injector. The notch extends from (i) an upper edge that is on the seat and is above the imaginary edge that would have been the sac inlet edge had the notch not been provided to (ii) a lower edge below such imaginary edge. The notch has a lowest wall that, at least at the portion of its length where such lowest wall approaches such lower edge, has a given angle-to-vertical of less than 60°.

Owner:BUESCHER DEV

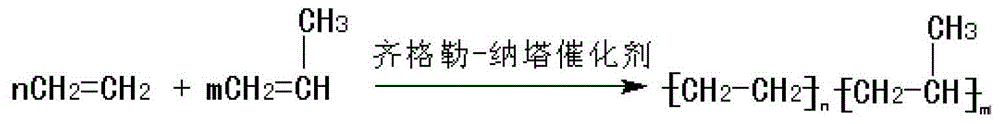

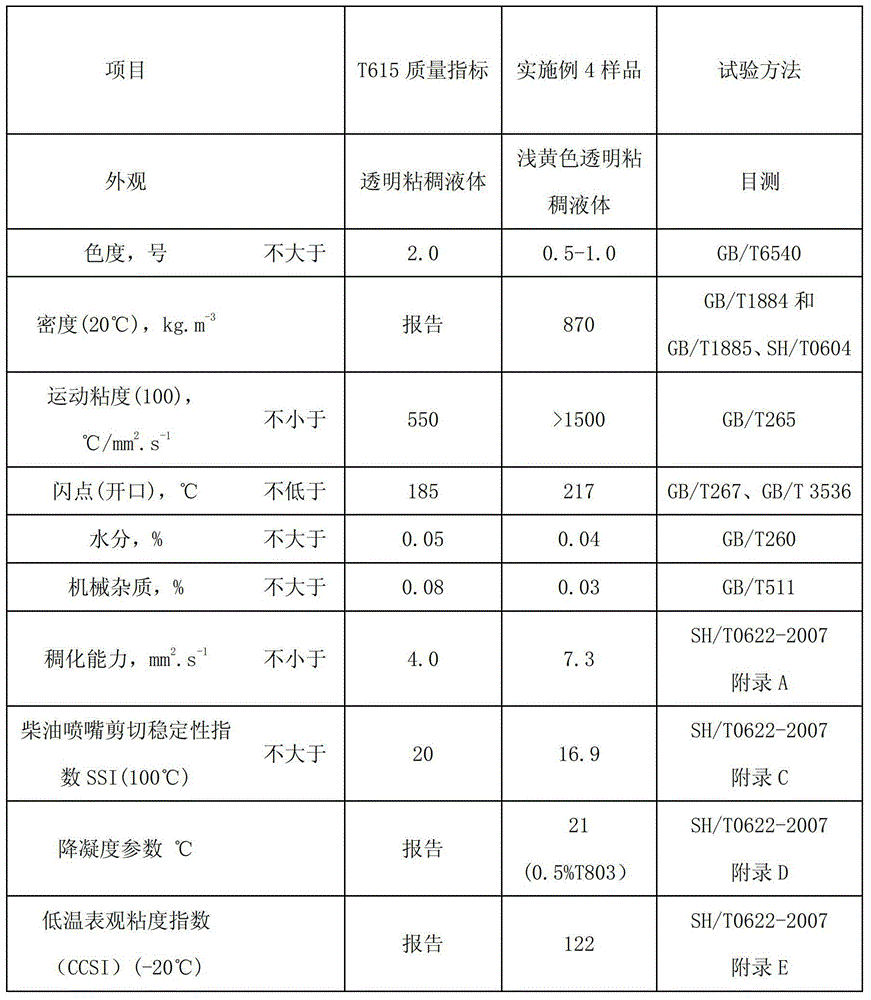

Preparation method for viscosity index improver

The invention discloses a preparation method for a viscosity index improver used for lubricating oil. The method mainly conducts exploratory research on the production technology of an ethylene-propylene copolymer viscosity index improver. Under low temperature, the method utilizes a peroxide oxidation degradation process, effectively controls the product quality, fully optimizes the anti-shearing performance and thickening performance of the product, and effectively improves the product cost performance. For the product, the mass content of the ethylene-propylene copolymer is 10-20%, the mass content of an accelerator is 0.01-8%, and the balance is base oil. The product has a thickening ability of 6.0-9.0mm<2>.s<-1>, and the diesel injection nozzle shear stability index SSI (100DEG C) is 16-20. Being in accord with the T615 product quality indexes of the national petrochemical industry standard SH / T0622-2007, the product is applicable to high range internal combustion engine oil products. The process involved in the invention has the characteristics of simple operation, mild condition, and environmental friendliness.

Owner:PETROCHINA CO LTD

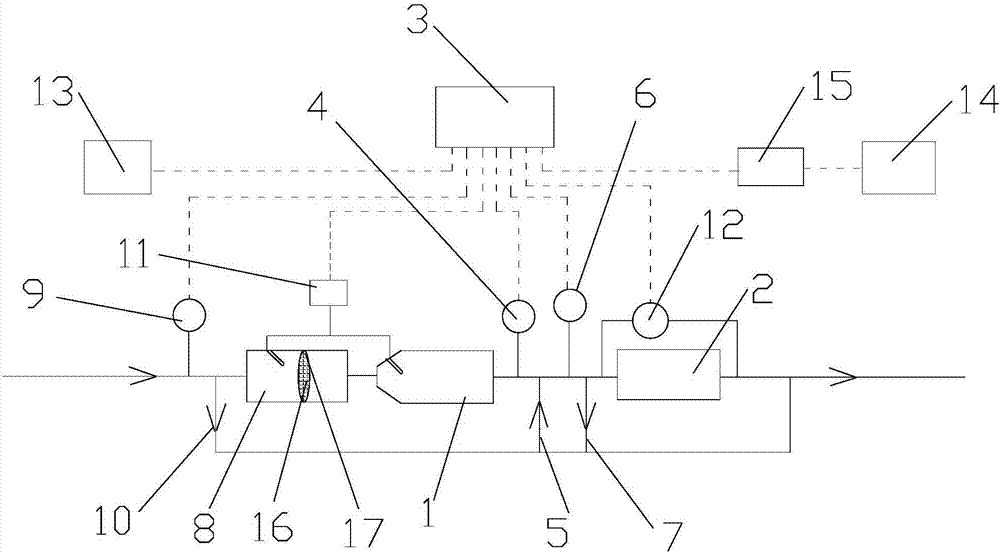

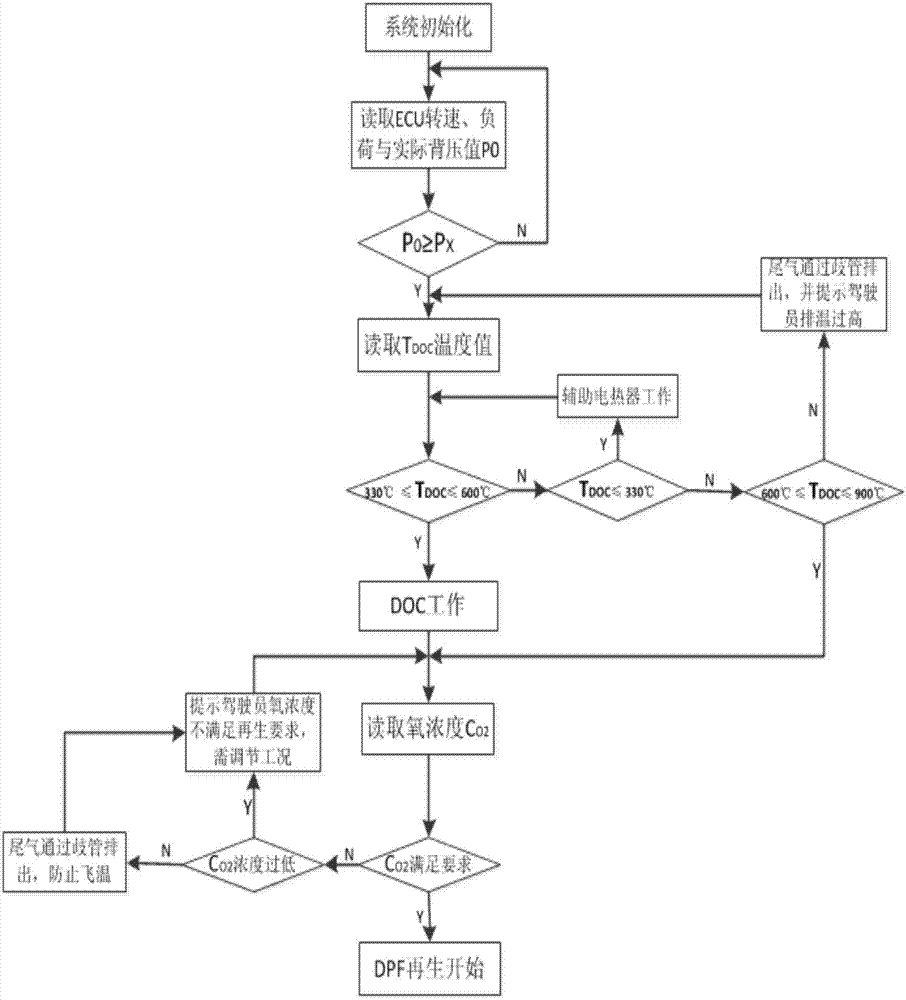

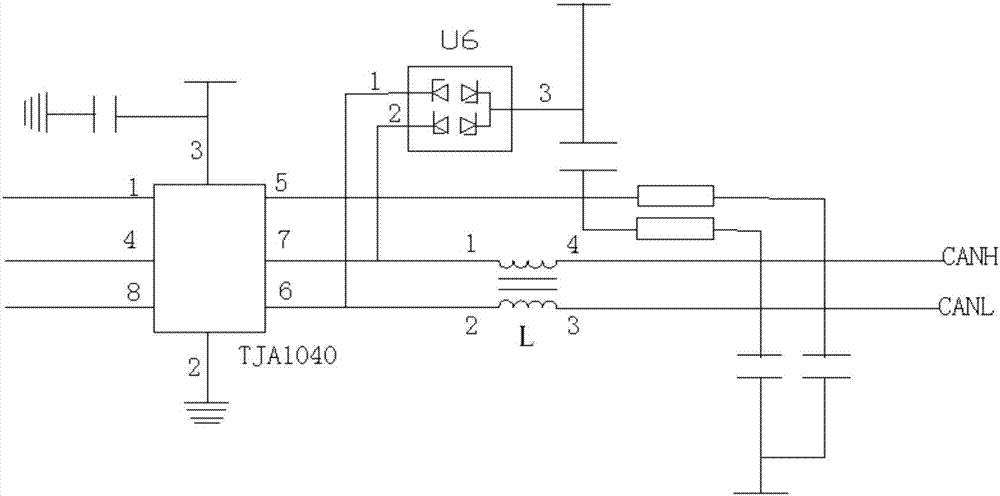

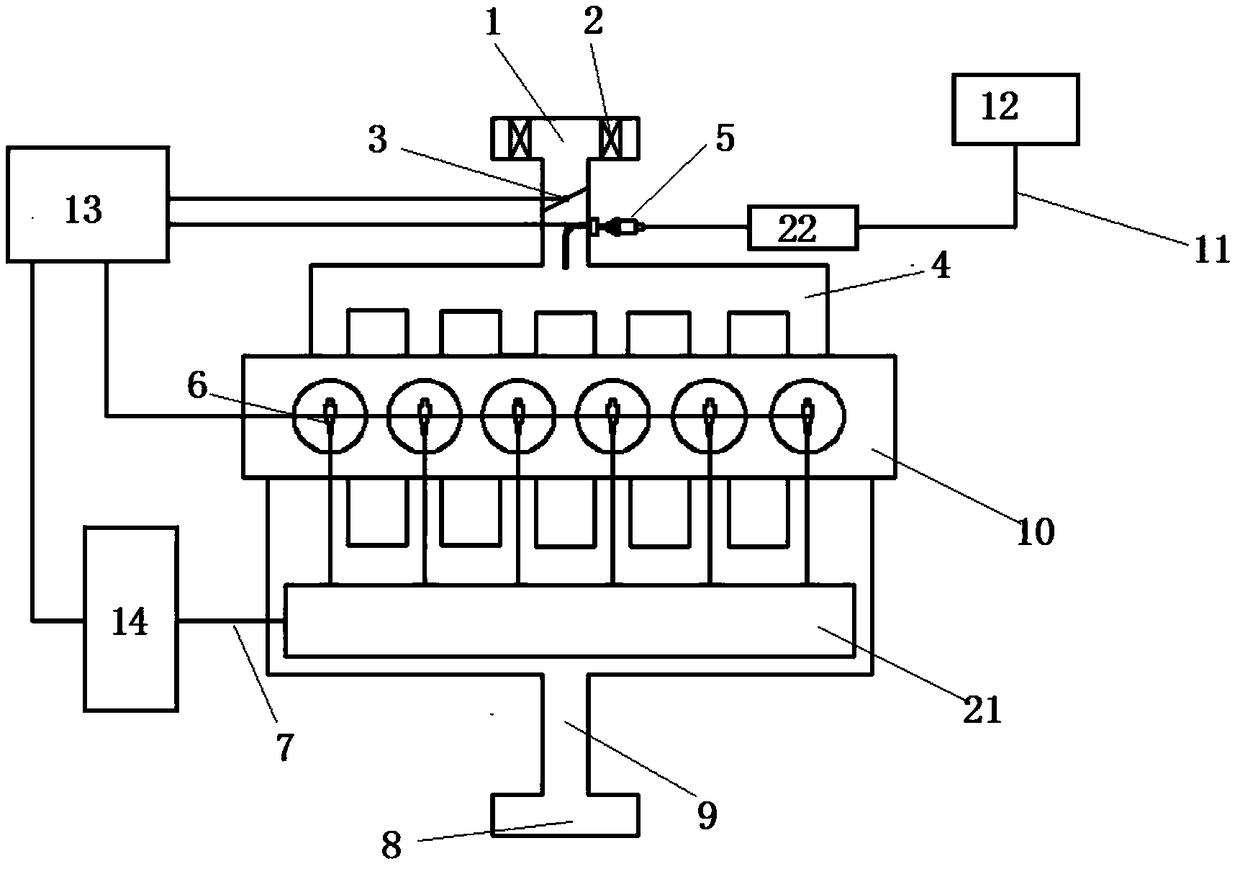

Diesel particulate filter regeneration control system based on CAN communication

InactiveCN107461249ARealize full working condition regenerationIncrease exhaust temperatureInternal combustion piston enginesExhaust apparatusDifferential pressureOxygen sensor

The invention relates to a diesel particulate filter regeneration control system based on CAN communication. The diesel particulate filter regeneration control system comprises a catalytic oxidizer DOC, a diesel particulate filter DPF and a regeneration control unit DCU; the inlet end of the catalytic oxidizer DOC is provided with an auxiliary electric heater, and the other end of the auxiliary electric heater is sequentially provided with a first temperature sensor and a first exhaust manifold; a second temperature sensor, a second exhaust manifold, an oxygen sensor and a third exhaust manifold are sequentially connected between the catalytic oxidizer DOC and the diesel particulate filter in series, the auxiliary electric heater and the catalytic oxidizer DOC are connected with a diesel injection metering unit, and a differential pressure sensor and the diesel particulate filter are connected in parallel. According to the diesel particulate filter regeneration control system based on CAN communication, through an auxiliary electric heating and oil injection combustion-supporting combined treatment method, full-work-condition regeneration of the diesel particulate filter is achieved, and the condition that the DPF device is burnt due to high temperature can be effectively prevented.

Owner:WUHAN UNIV OF TECH

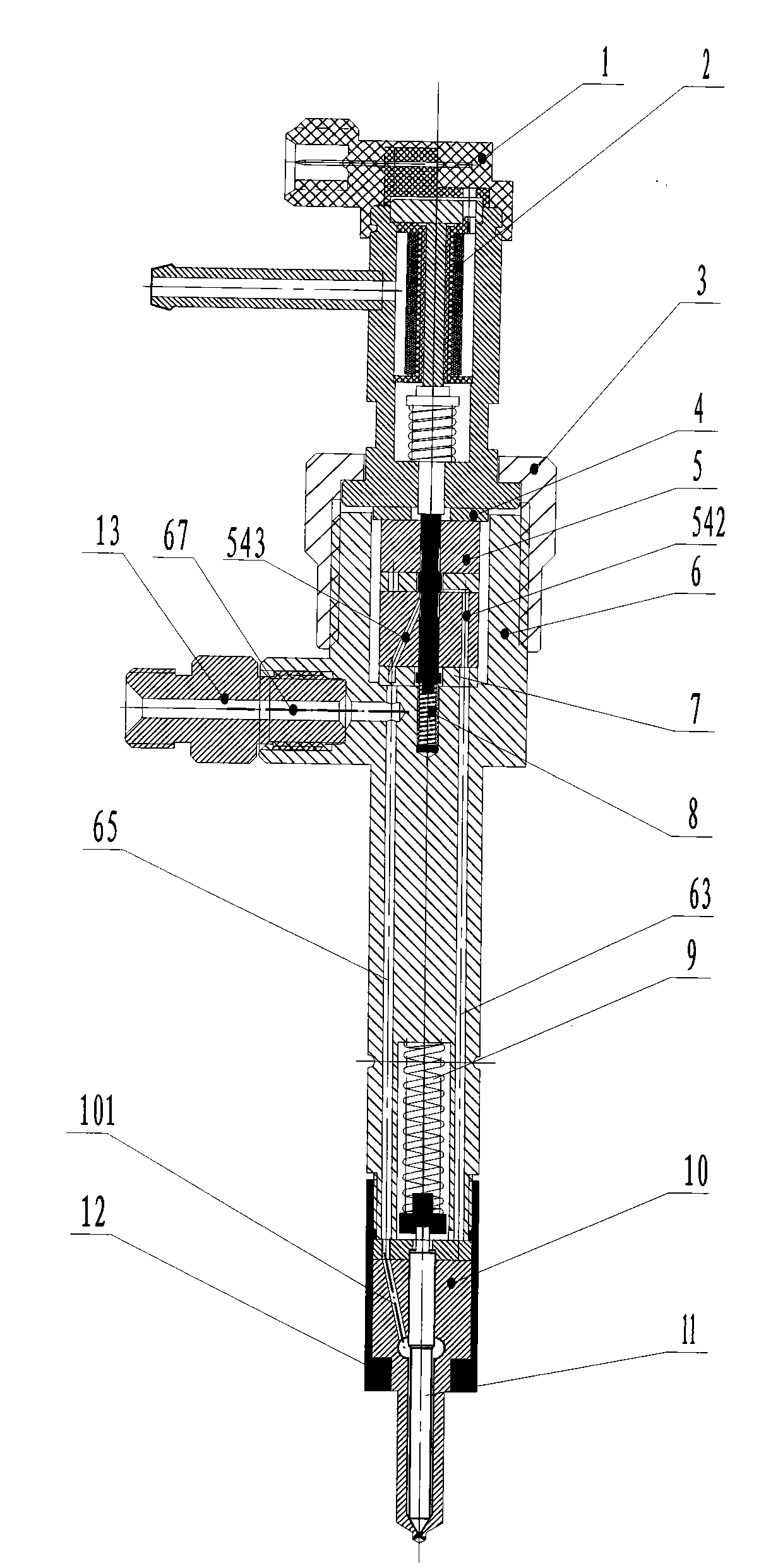

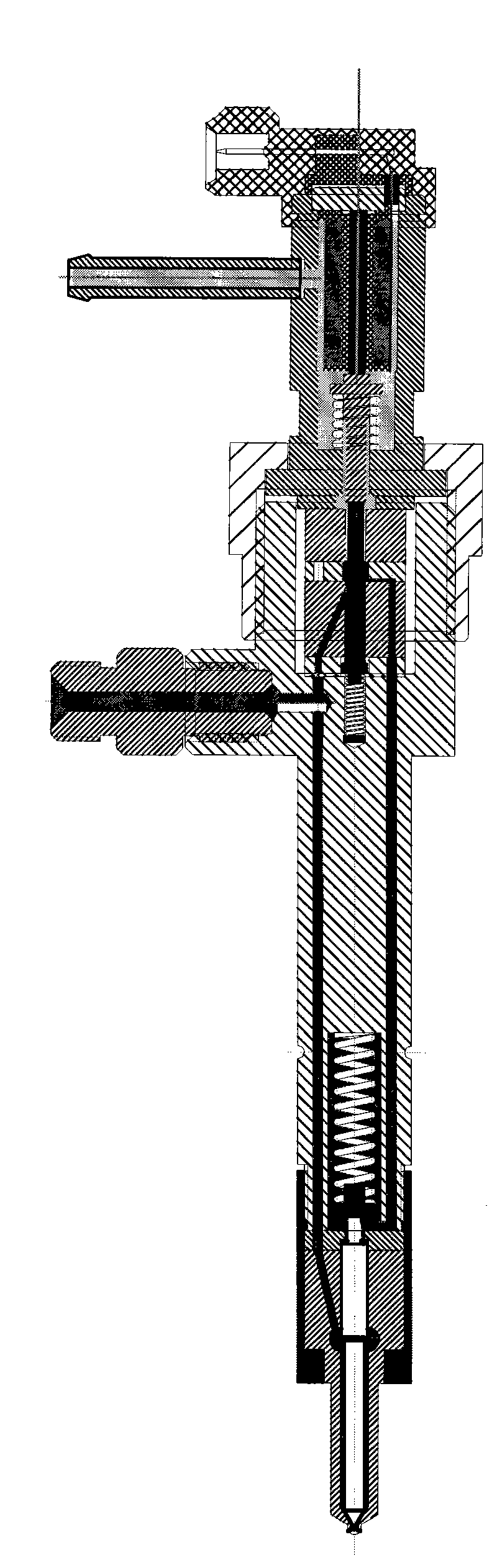

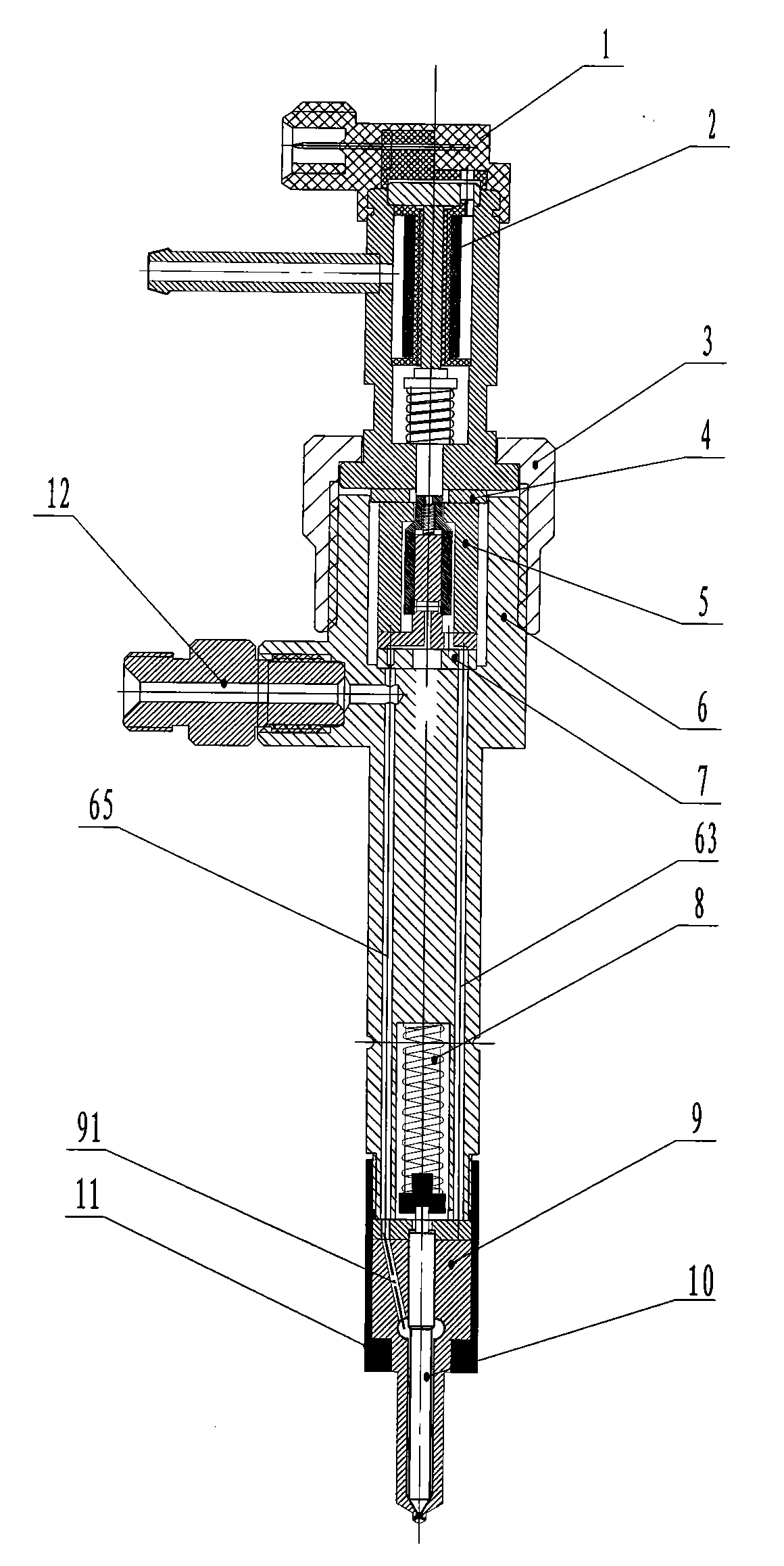

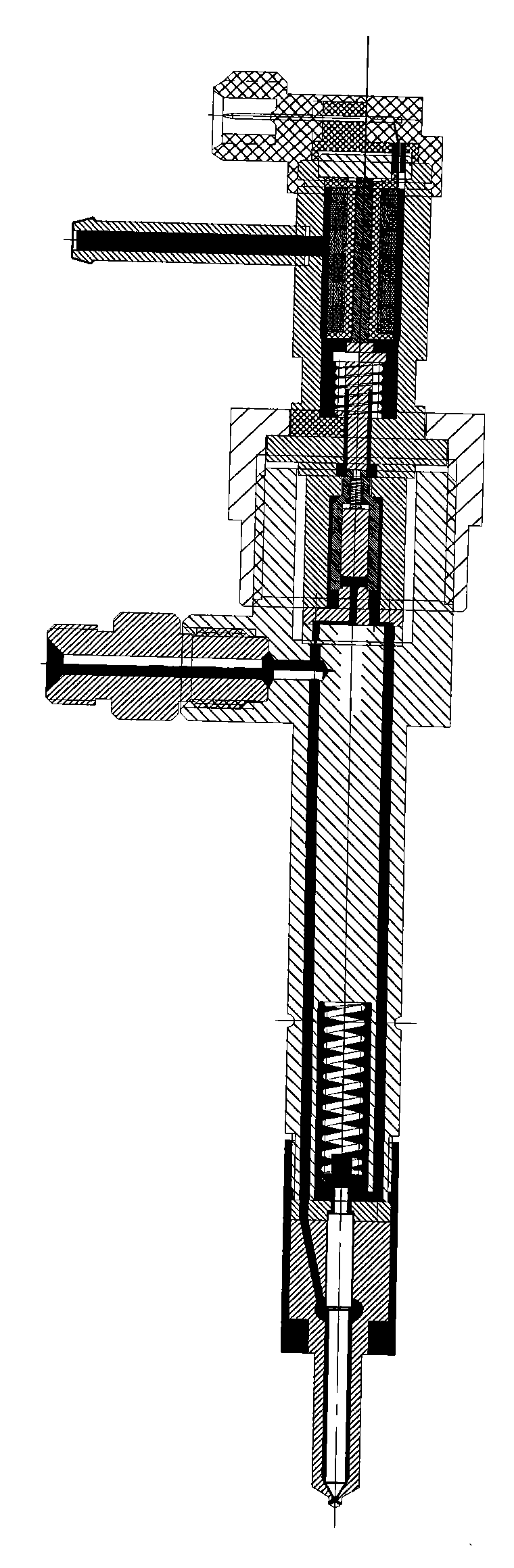

Zero-backpressure electronically-controlled diesel injector driven by magnetostrictive component

InactiveCN101649796APrecision injectionJet easyFuel injection apparatusMachines/enginesMagnetostrictive actuatorDiesel injector

The invention discloses a zero-backpressure electronically-controlled diesel injector driven by a magnetostrictive component, which comprises a diesel injector shell provided with a diesel inlet passage and a diesel return passage, a nut cap, a magnetostrictive actuator, a zero-backpressure two-position three-way valve, a lock nut, an adjusting shim, a transition block, a return spring, a pressure spring and injection nozzle matching parts. The return spring, the transition block, the zero-backpressure two-position three-way valve, the adjusting shim, the lock nut, and the magnetostrictive actuator are orderly arranged in the diesel injector shell along the axial direction. The pressure spring and the injection nozzle matching parts are orderly arranged in the nut cap. The upper end surface and the lower end surface of the diesel injector shell, the two end surfaces of the transition block, the two end surfaces of the zero-backpressure two-position three-way valve, the two end surfaces of the adjusting shim and the lower end surface of the magnetostrictive actuator are high flatness plane; and the end surfaces of the components are connected tightly with one another to form a seal. Thus, a mechanism of which the magnetostrictive actuator controls the axial movement of a valve needle of an injection nozzle of the zero-backpressure two-position three-way valve under high-pressure diesel condition is formed. The diesel injector can realize more precise and high-frequency high pressure diesel injection.

Owner:柳州福尔曼汽车电子有限公司

Diesel injection nozzle

An annular notch is provided in the body seat associated with the nozzle valve of an ALCO-type diesel injector. The notch extends from (i) an upper edge that is on the seat and is above the imaginary edge that would have been the sac inlet edge had the notch not been provided to (ii) a lower edge below such imaginary edge. The notch has a lowest wall that, at least at the portion of its length where such lowest wall approaches such lower edge, has a given angle-to-vertical of less than 60°.

Owner:BUESCHER DEV

Constant-volume combustion bomb system and method with simulation of various combustion modes of methanol/diesel dual-fuel engine

ActiveCN107796629AWith heating functionHeating fully and evenlyInternal-combustion engine testingDiesel injectorData acquisition

The invention relates to a constant-volume combustion bomb system and method with simulation of various combustion modes of a methanol / diesel dual-fuel engine. The system is composed of a constant-volume combustion bomb, a diesel injector, a diesel injection system connected to the diesel injector, a methanol injector, a methanol injector system connected to the methanol injector, an air intake system, an exhaust system, a pressure sensor, a synchronous data acquisition card, a high-speed camera, and an upper computer. According to the invention, with adjustment on the injection time of methanol relative to the diesel, several kinds of different combustion modes such as methanol ignition by diesel, simultaneous ignition of diesel and methanol, and autoignition of methanol earlier than diesel are realized; uniform premixing and concentration layering of methanol in the constant-volume combustion bomb are realized respectively; and the injection pressure of methanol is adjusted flexibly.

Owner:TIANJIN UNIV

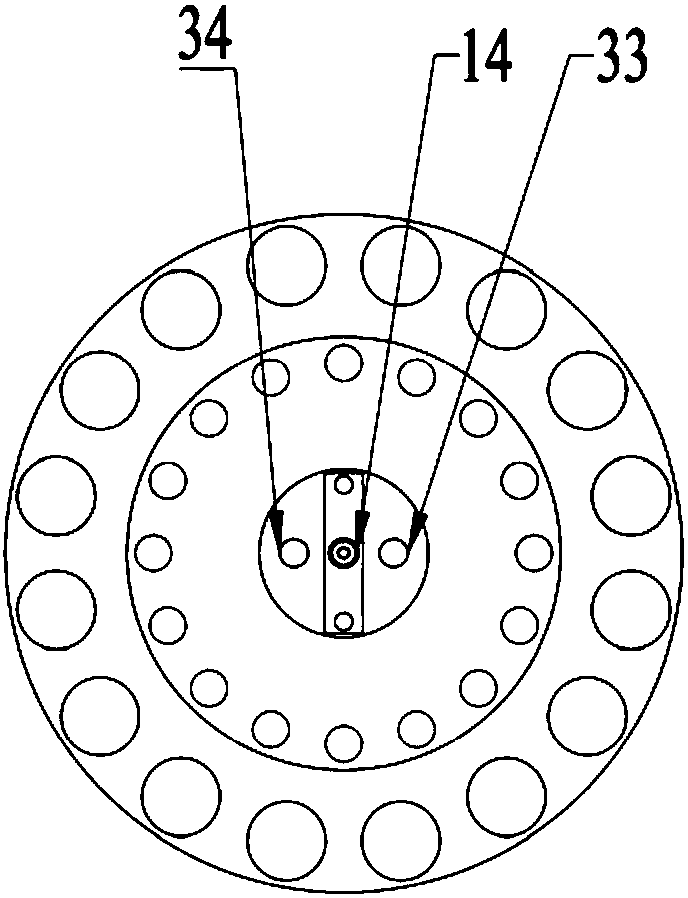

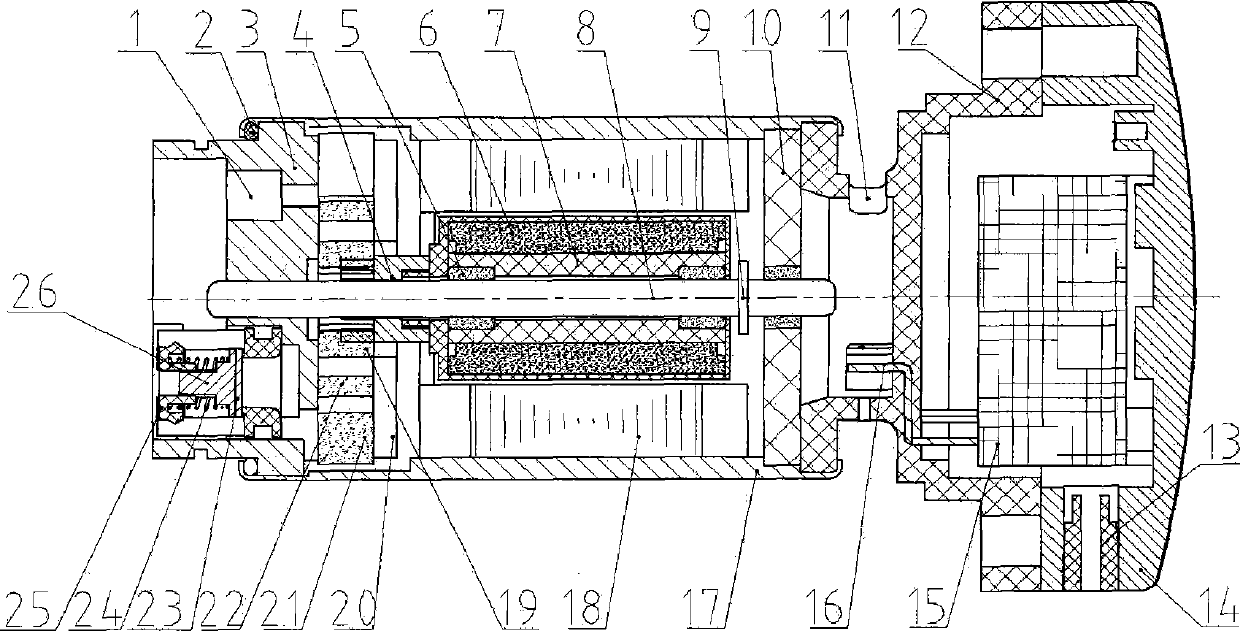

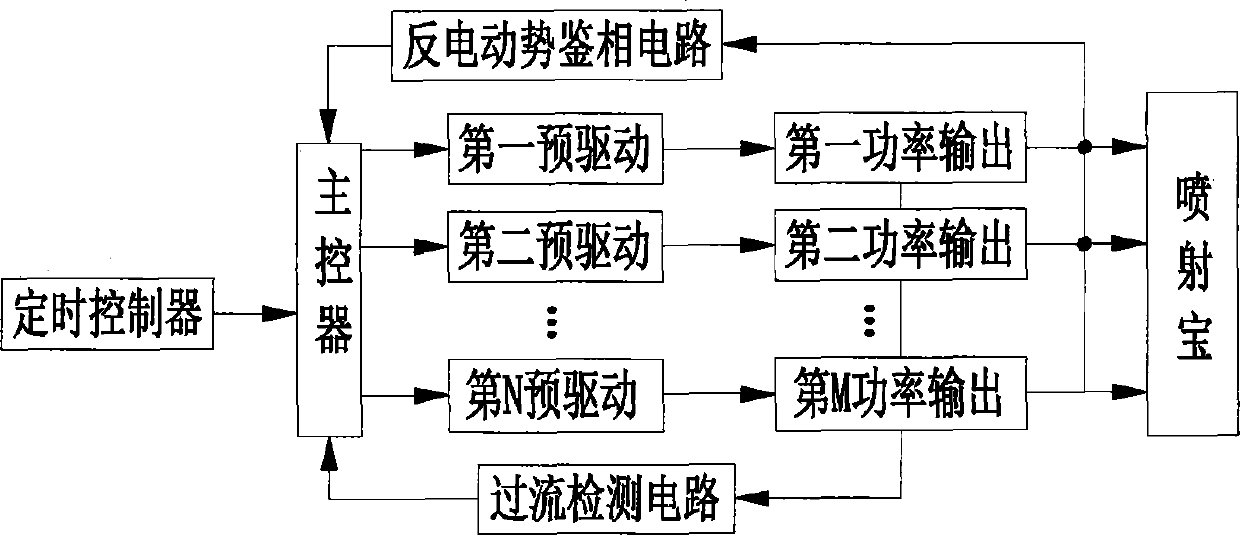

High-efficiency large-flow brushless diesel oil injector

ActiveCN103362798AIncrease oil supply pressureIncrease fuel flowRotary piston pumpsRotary piston liquid enginesEngineeringStreamflow

The invention discloses a high-efficiency large-flow brushless diesel oil injector, comprising a casing, a rear cover, a decompression valve, a rotor, a rotor core, a connector, a dead axle, a jump ring, a locking plate, a controller, a controller seat, a circuit cover plate, a supply socket, a stator assembly and a gear. According to the invention, the high-efficiency large-flow brushless diesel oil injector employs a five-roller pump body structure, so oil supply pressure and oil supply flow of the injector are greatly improved; intermittent working time of the injector can be set through a timing controller of the intelligent controller, so work efficiency of the injector is substantially enhanced; moreover, the injector has the advantages of a compact structure, small noise and a prolonged service life.

Owner:浙江康松动力科技有限公司

Natural gas-diesel dual-fuel layered combustion engine combustion control method based on reactivity control

ActiveCN109296469ALow emission combustionElectrical controlMachines/enginesChemical reaction kineticsActive component

The invention aims to provide a natural gas-diesel dual-fuel layered combustion engine combustion control method based on reactivity control. Fuel gas single-time injection is adopted under the smallload, the multi-time injection strategy is adopted under the medium load, the fuel gas single-time injection strategy is adopted under the high load, and the timing and injection quantity of fuel gasinjection are flexibly adjusted according to the different loads. Diesel is pre-mixed through diesel large-advance-angle injection, active components are formed in a cylinder in the compression process, and the ignition starting point is controlled through ignition diesel injection, so that the dual-fuel engine layered combustion strategy based on chemical reaction kinetics activity control is achieved. According to fuel gas concentration distribution formed in the cylinder through the fuel gas injection strategies under the different loads, the timing and the injection quantity of diesel injection are reasonably matched, reasonable fuel oil and fuel gas coupling stratification is formed in the cylinder, and the optimal in-cylinder combustion effect is achieved under the different loads, so that efficient, stable and low-emission combustion of an engine is achieved.

Owner:HARBIN ENG UNIV

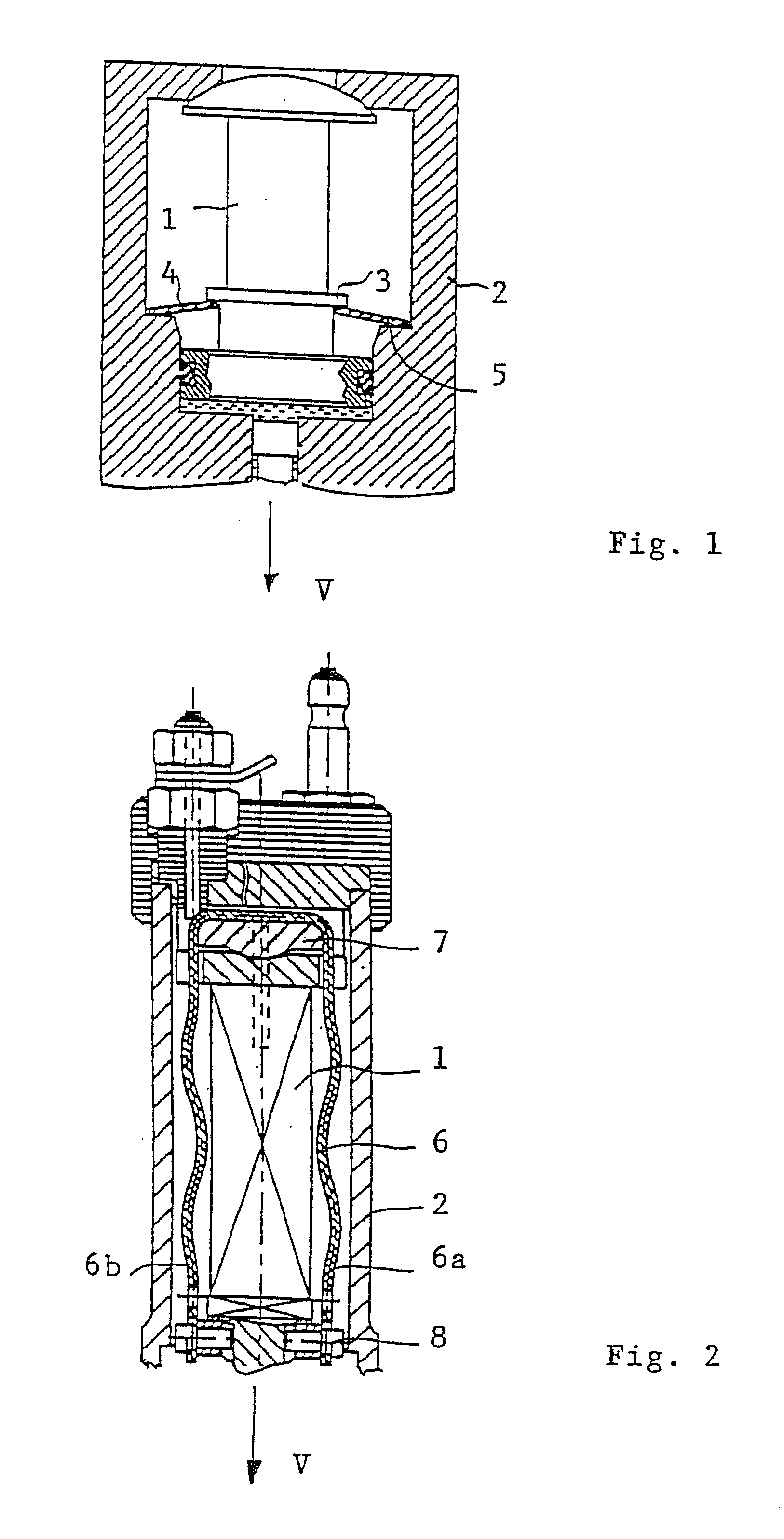

Method for setting the nozzle opening pressure for an injection nozzle and arrangement for carrying out the method

InactiveUS6976389B2Short cycleTechnique is simple and quickDetection of fluid at leakage pointEngine testingSpring forceEngineering

In order to set the nozzle opening pressure for an injection nozzle, in particular for a diesel injection nozzle, to an accuracy of around ±1%, the method provides that the injection needle is first pressed against the valve seat with a closing force (Fz), and then when two different test pressures (pU, p1, p2) are applied to the injection nozzle the test forces (Fz, F1, F2) effective on the injector needle are measured, with the pressure stage (A) being determined from the measured test forces and the test pressures applied, and finally using the pressure stage (A) a nozzle valve with a suitable valve spring force (Fv) is selected to correspond to the desired nozzle opening pressure (pD).

Owner:SIEMENS AG

EGR venturi diesel injection

InactiveUS8453626B2Non-fuel substance addition to fuelInternal combustion piston enginesMixed flowEngineering

An arrangement for mixing a first and a second gas flow, for example, an inlet flow with an exhaust gas return flow in a diesel engine. An air conduit has an inlet for the first flow and an inlet for the second flow, in order to achieve the mixing. A valve body is arranged to be displaced in the longitudinal direction of the air conduit at the inlet for the second flow in order to achieve a variable venturi effect and in this way a variable suction effect and mixture of the mixed flow. One or more fuel injectors inject fuel into the air conduit to pre-mix fuel with the first and second gas flows before reaching the engine cylinders for combustion.

Owner:CONCENTRIC SKANES FAGERHULT

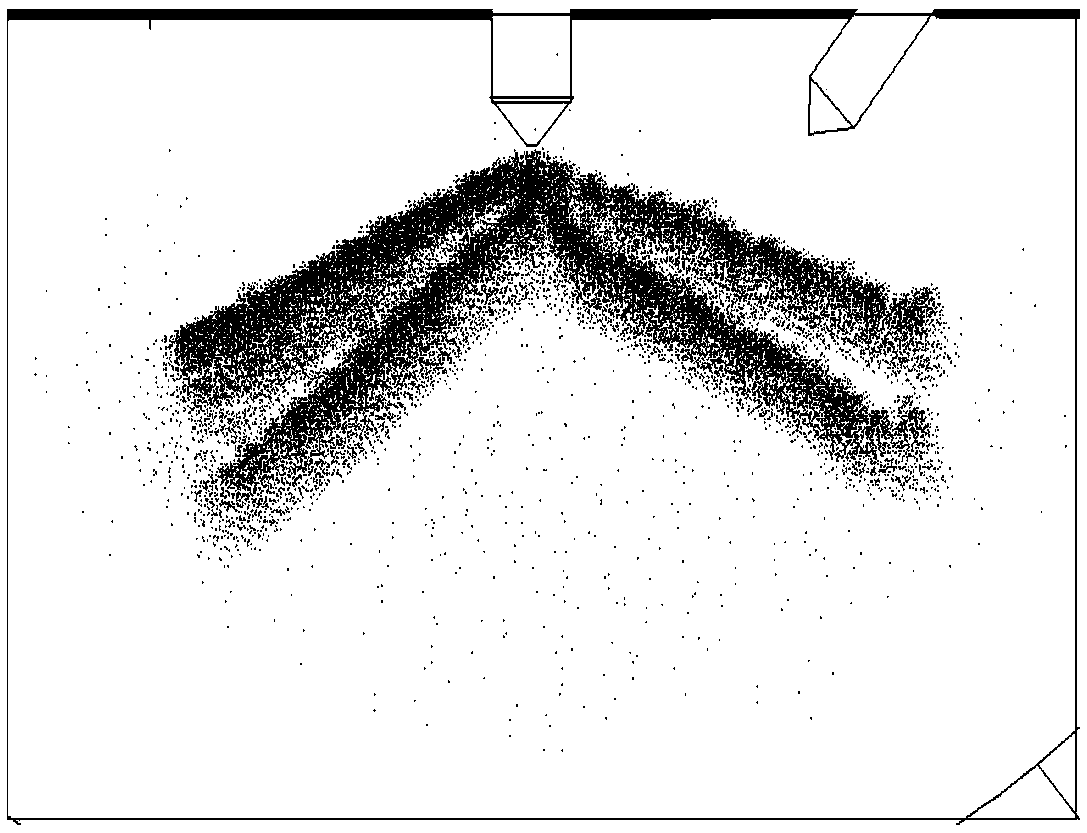

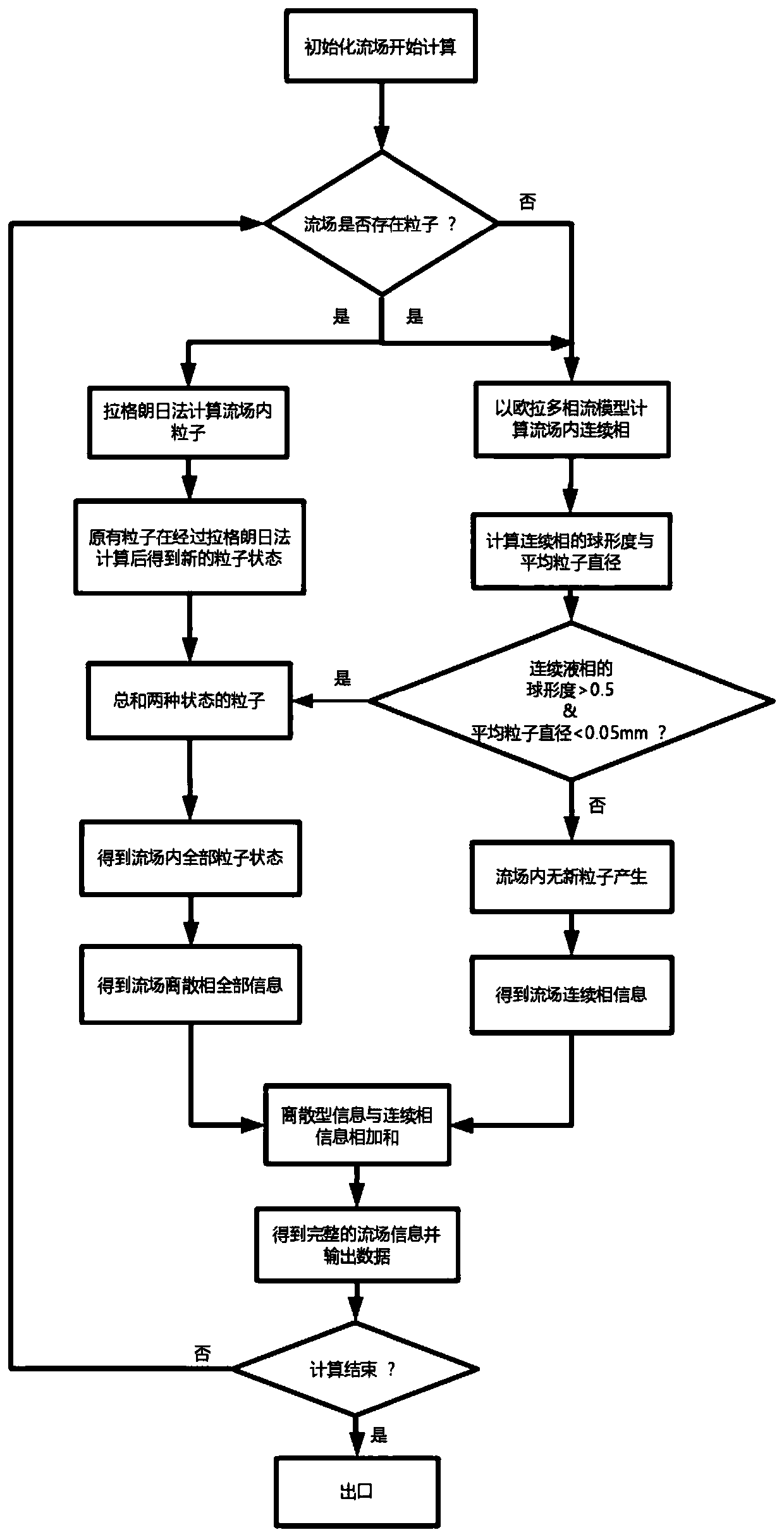

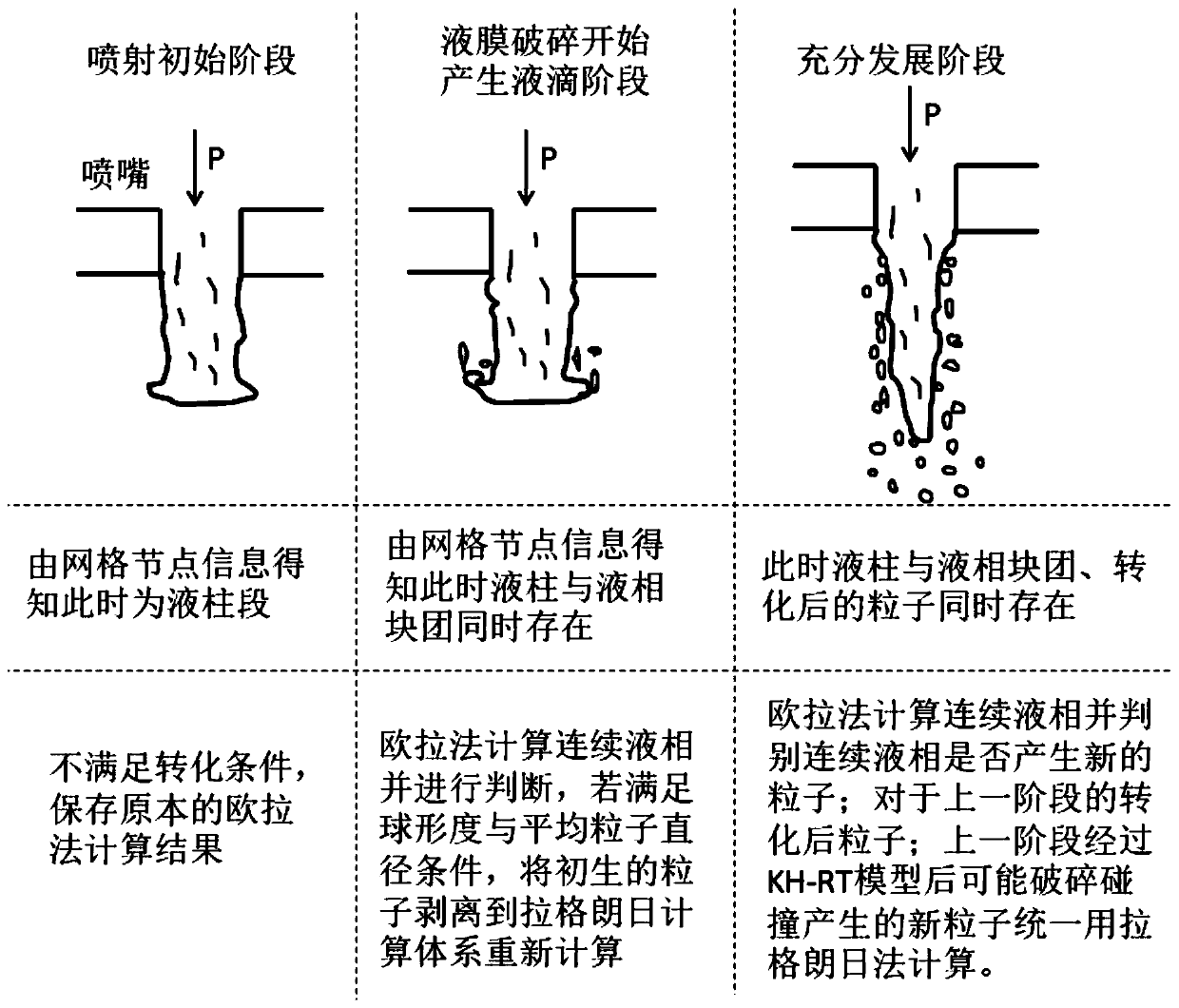

Method for automatically identifying diesel spray crushing process and automatically realizing spray continuous calculation

The invention discloses a method for automatically identifying a diesel spray crushing process and automatically realizing the spray continuous calculation. The method automatically judges the processthat a liquid film is crushed into liquid drops in the diesel injection process, and realizes a SD-ELSA algorithm of the spray continuous calculation. The SD-ELSA algorithm is characterized in that the sphericity degree and the average particle diameter of liquid phases in grids are calculated and taken as judgment bases, the information of particles in a flow field are calculated through a Lagrangian method, the information of the grids belonging to continuous liquid phases in the grid node information in the full-flow field is calculated by using an Euler model, and Euler block masses meeting two bases for determination are converted into particles and re-calculated through the Lagrangian method. According to the method, dynamic converting coupling of the Euler-Lagrangian model is realized, the complete information of discrete phases and continuous phases in the flow field can be automatically obtained and subjected to iterative computation, three stages of a liquid column, primarycrushing and secondary crushing of the diesel injection are obtained, and the diesel spray process is completely represented.

Owner:BEIJING UNIV OF TECH

Zero-backpressure electronically-controlled diesel injector driven by magnetostrictive component

InactiveCN101649797APrecision injectionJet easyFuel injection apparatusMachines/enginesMagnetostrictive actuatorDiesel injector

The invention discloses a zero-backpressure electronically-controlled diesel injector driven by a magnetostrictive component, which comprises a diesel injector shell provided with a diesel inlet passage and a diesel return passage, a nut cap, a magnetostrictive actuator, a zero-backpressure two-position three-way valve, a lock nut, an adjusting shim, a transition block, a pressure spring and injection nozzle matching parts. The transition block, the zero-backpressure two-position three-way valve, the adjusting shim, the lock nut, and the magnetostrictive actuator are orderly arranged in the diesel injector shell along the axial direction. The pressure spring and the injection nozzle matching parts are orderly arranged in the nut cap. The upper end surface and the lower end surface of the diesel injector shell, the two end surfaces of the transition block, the two end surfaces of the zero-backpressure two-position three-way valve, the two end surfaces of the adjusting shim and the lower end surface of the magnetostrictive actuator are high flatness plane; and the end surfaces of all components are connected tightly with one another to form a seal. Thus, a mechanism of which the magnetostrictive actuator controls the axial movement of a valve needle of an injection nozzle of the zero-backpressure two-position three-way valve under high-pressure diesel condition is formed. The diesel injector can realize more precise and high-frequency high pressure diesel injection.

Owner:柳州福尔曼汽车电子有限公司

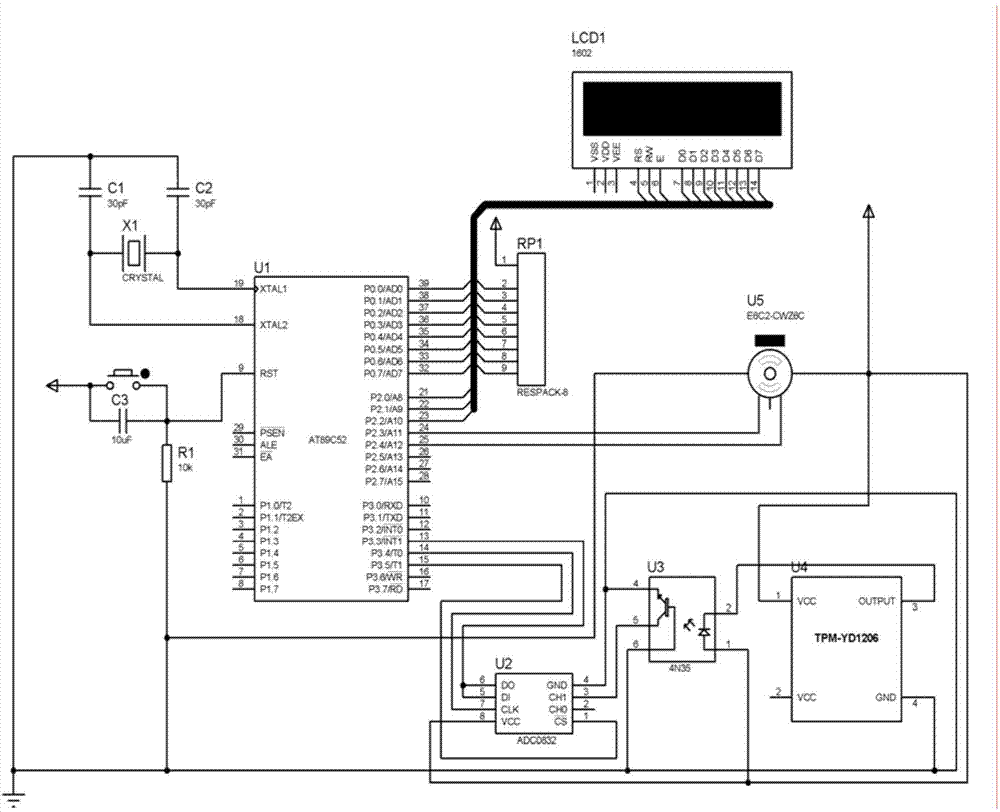

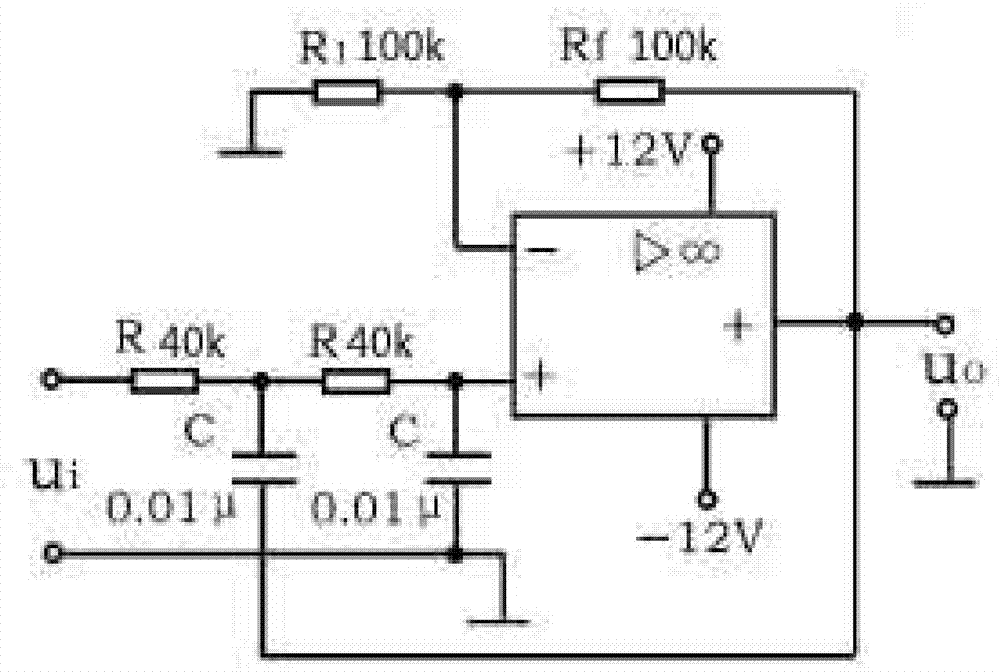

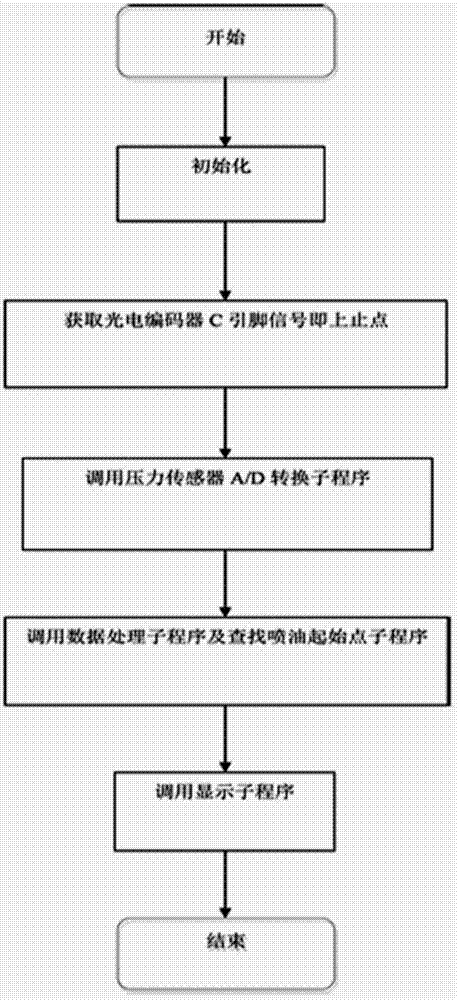

Diesel injection timing detection method based on AT89C52 single-chip microcomputer

The invention provides a diesel injection timing detection method based on an AT89C52 single-chip microcomputer. The method includes the steps that a clamping type pressure sensor is clamped on a high pressure fuel pipe, output signals of a photoelectric encoder which is installed at the free end of a crankshaft are detected, and phase angle signals of a crank of a diesel are acquired through algorithm calculation; the pressure of the high pressure fuel pipe is detected, the moment fuel pressure begins to rise is judged according to a developed algorithm, corresponding crankshaft angle signals are read according to the signals and displayed as diesel injection timing outputs. The factors of elasticity of the fuel pipe, fuel compressibility and the like are eliminated through measured engine injection timing, and compared with a traditional injection timing measurement method, the diesel injection timing detection method has the advantages that injection timing detection is in real time and accurate, and is not limited by the working state of the diesel.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com