Engine tail gas after-treatment control system and control method

A technology of exhaust gas post-treatment and control system, which is applied to the electronic control of exhaust treatment devices, exhaust treatment, engine components, etc. It can solve the problems of large measurement results, uncontrollable closed-loop strategy, ammonia cross-sensitivity, etc., and achieve enhanced Robustness, improving calculation accuracy and execution efficiency, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

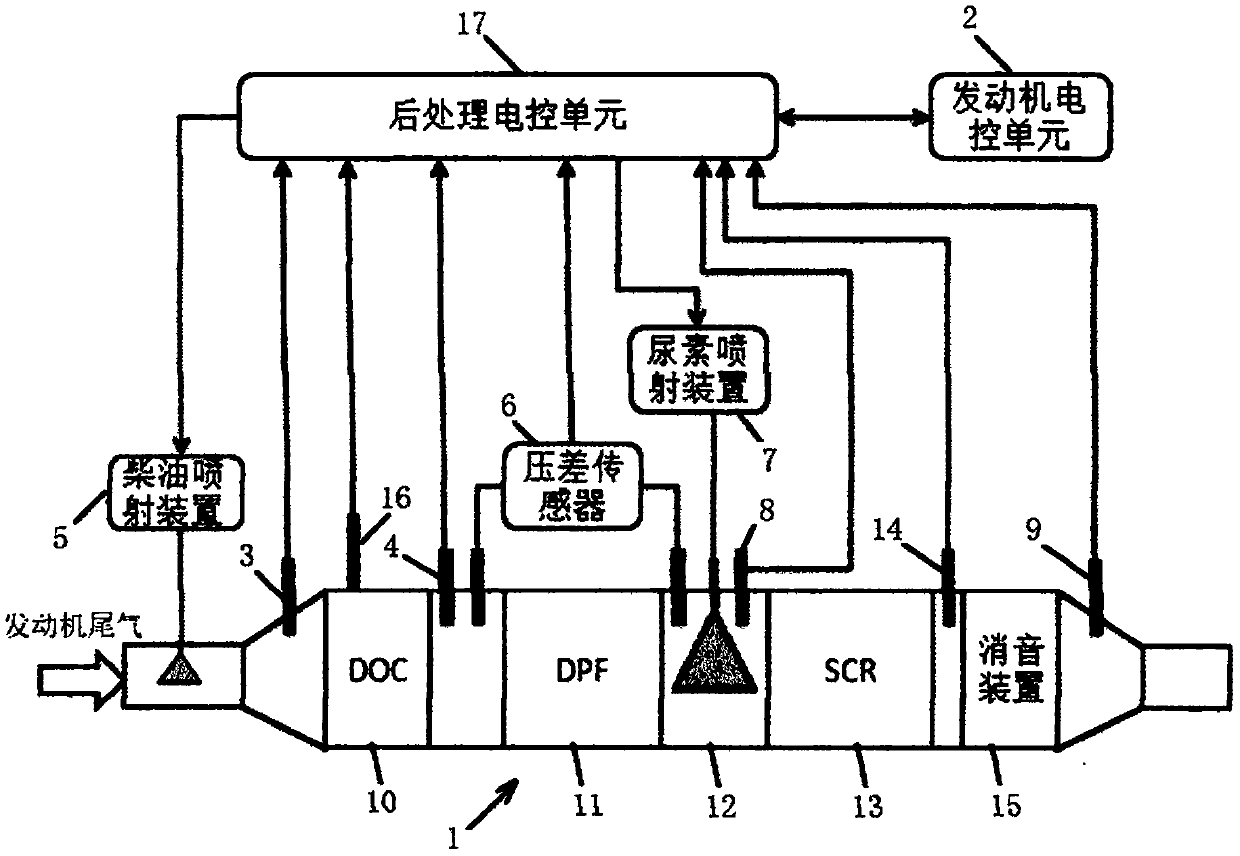

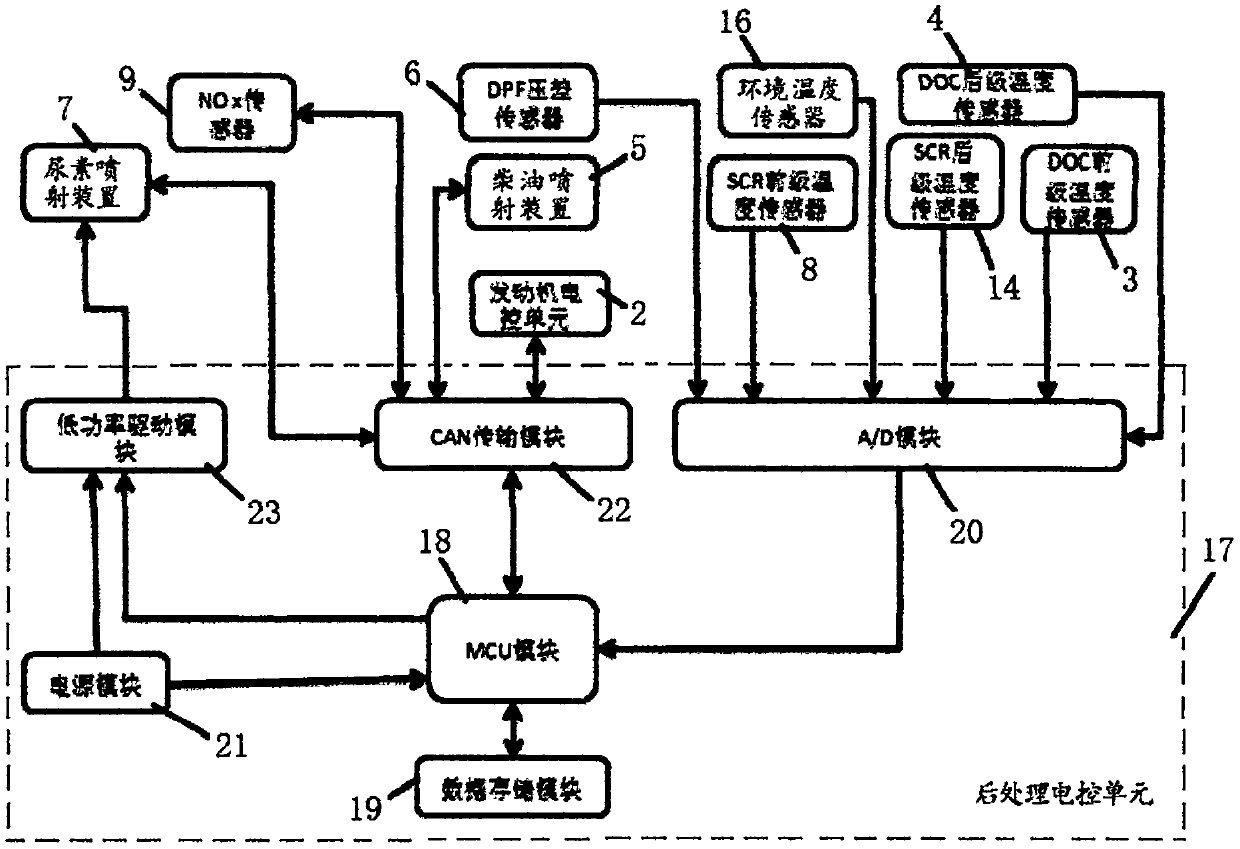

[0028] In order to make the purpose of the present invention, technical solutions and advantages clearer and more intuitive, the following will be combined with the present invention figure 1 and figure 2 , to clearly and completely describe the present invention.

[0029] In the first aspect, the present invention proposes an engine exhaust post-treatment control system, including an exhaust post-processor 1 , an engine electronic control unit 2 , a diesel injection device 5 , a urea injection device 7 , and an after-treatment electronic control unit 17 .

[0030]The exhaust gas post-processor 1 is connected to the exhaust pipe. In the exhaust gas post-processor 1, DOC10, DPF11, mixing chamber 12, SCR13 and muffler device 15 are packaged sequentially from front to back. Several sensors are installed on the exhaust gas post-processor 1 . The injection head of described diesel injection device 5 is installed in the exhaust pipe of DOC10 front end, and diesel oil is injected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com