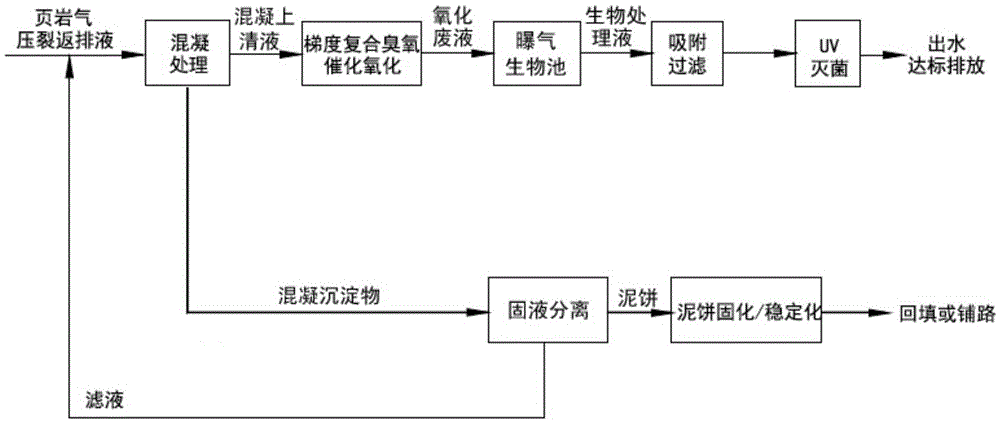

Treatment method of shale gas fracturing flowback liquid

A treatment method and flowback liquid technology, which can be used in sludge treatment, water/sewage treatment, aerobic process treatment, etc., and can solve problems such as surface water pollution, deterioration of well site environment, and ecological environment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The appearance of the flowback liquid is dark green, with floating oily substances on the surface and high suspended solids. The pH value is 7.62 after testing, and the COD Cr It is 15118mg / L, TDS is 13823mg / L, SS is 2030mg / L, total alkalinity (as CaCO 3 Count) is 1304mg / L.

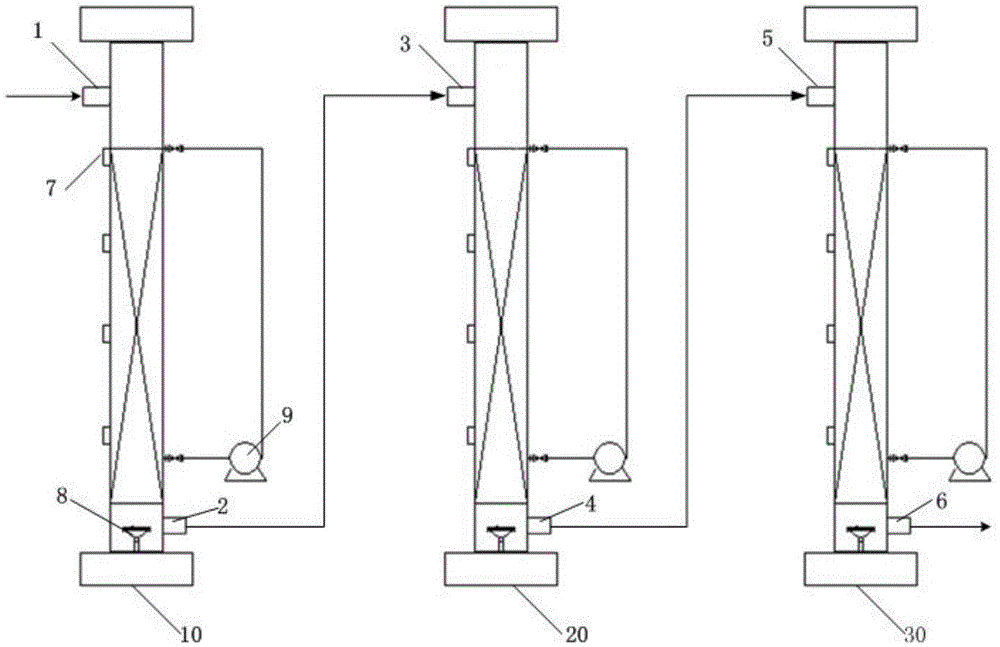

[0062] The gradient ozone catalytic oxidation reaction device includes three oxidation towers, which are respectively named as the first oxidation tower, the second oxidation tower and the third oxidation tower according to the sequence in which the flowback liquid flows through.

[0063] (1) Add polyaluminum chloride to the flowback liquid through a metering pump, so that the concentration of polyaluminum chloride reaches 3000mg / L, stir at a speed of 300 rpm for 1 minute, then add CPAM, and the molecular weight is 1000 10,000-20 million polyacrylamide; the concentration of CPAM is 15 mg / L, and the concentration of polyacrylamide with a molecular weight of 10 million-20 million is 5 mg / L. Continue...

Embodiment 2

[0069] The appearance of the flowback liquid is grayish brown, with floating oil-like substances on the surface, and high suspended solids. The pH value is 8.25 after testing, and the COD Cr It is 4890mg / L, TDS is 12197mg / L, SS is 1330mg / L, total alkalinity (as CaCO 3 Count) is 978mg / L.

[0070] The gradient ozone catalytic oxidation reaction device includes three oxidation towers, which are respectively named as the first oxidation tower, the second oxidation tower and the third oxidation tower according to the sequence in which the flowback liquid flows through.

[0071] (1) Add polyaluminum ferric chloride to the flowback liquid through a metering pump, so that the concentration of polyaluminum ferric chloride reaches 1000 mg / L, stir at 250 rpm for 1.5 minutes, add CPAM, and molecular weight 10 million-20 million polyacrylamide; the concentration of CPAM is 3 mg / L, the concentration of polyacrylamide with a molecular weight of 10 million-20 million is 2 mg / L, and after sti...

Embodiment 3

[0077] The appearance of the flowback liquid is milky white, there is no floating oily substance on the surface, and the suspended solids are low. The pH value is 8.63 after testing, and the COD Cr It is 3450mg / L, TDS is 6197mg / L, SS is 253mg / L, total alkalinity (as CaCO 3 Count) is 378mg / L.

[0078] The gradient ozone catalytic oxidation reaction device includes three oxidation towers, which are respectively named as the first oxidation tower, the second oxidation tower and the third oxidation tower according to the sequence in which the flowback liquid flows through.

[0079] (1) Add polyferric sulfate to the flowback liquid through a metering pump, so that the concentration of polyferric sulfate reaches 2000mg / L, stir at a speed of 150 rpm for 2 minutes, then add APAM, and the molecular weight is 10 million- 20 million polyacrylamide; the concentration of APAM is 30mg / L, the concentration of polyacrylamide with a molecular weight of 10 million-20 million is 20mg / L, continu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com