Patents

Literature

771 results about "Polyferric sulfate" patented technology

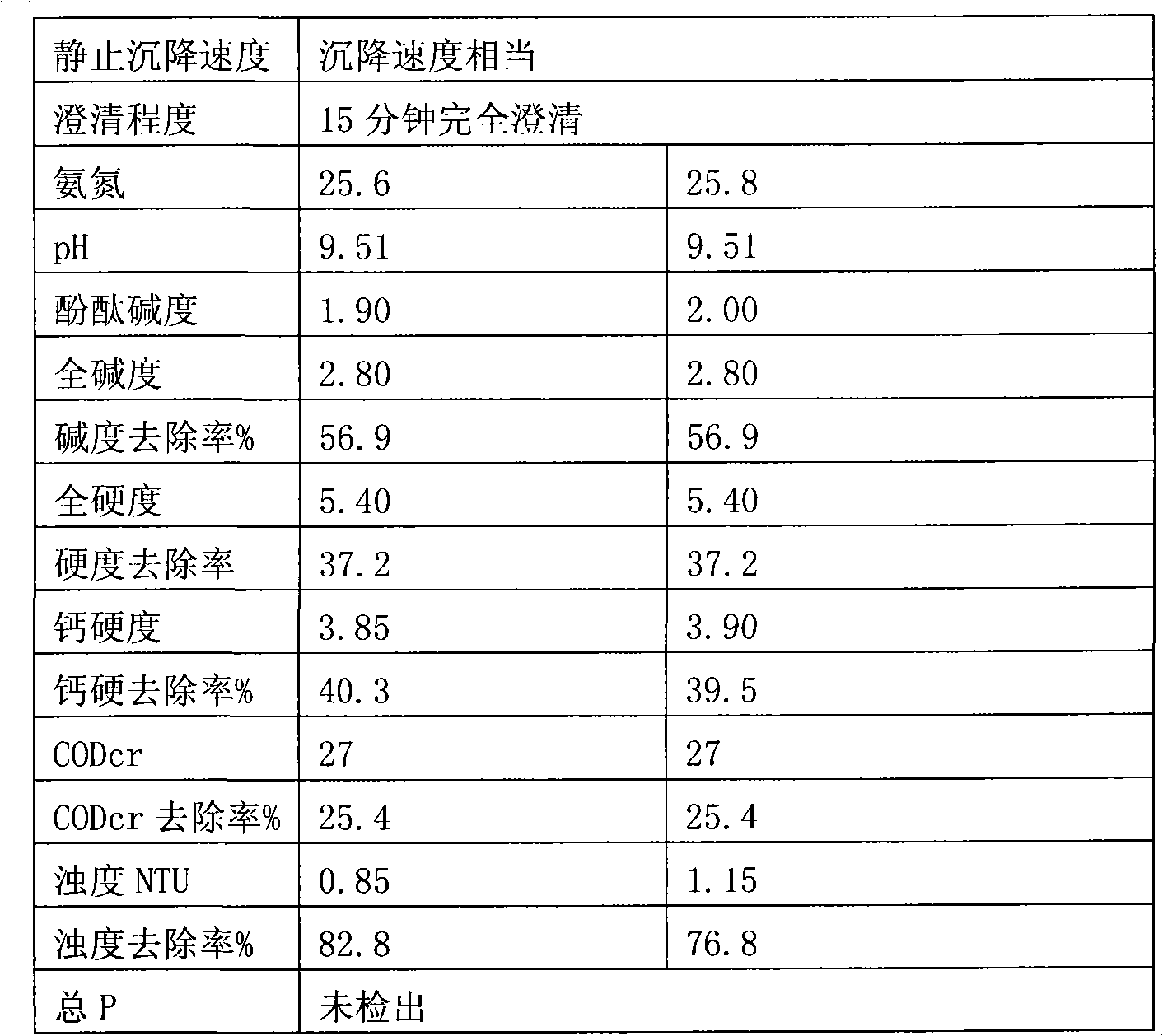

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyferric sulfate (PFS) is a new type of environmental product and belongs to inorganic high mlecular flocculating agent. [Properties:] 1, New type, high quality, high iron salts of inorganic polymer flocculants.

Polymeric ferric sulfate-poly-dimethyl-diallyl-ammonium chloride composite flocculent, preparation and use method thereof

InactiveCN101323472AGuaranteed performanceGuaranteed stabilityWater/sewage treatment by flocculation/precipitationSulfateWater quality

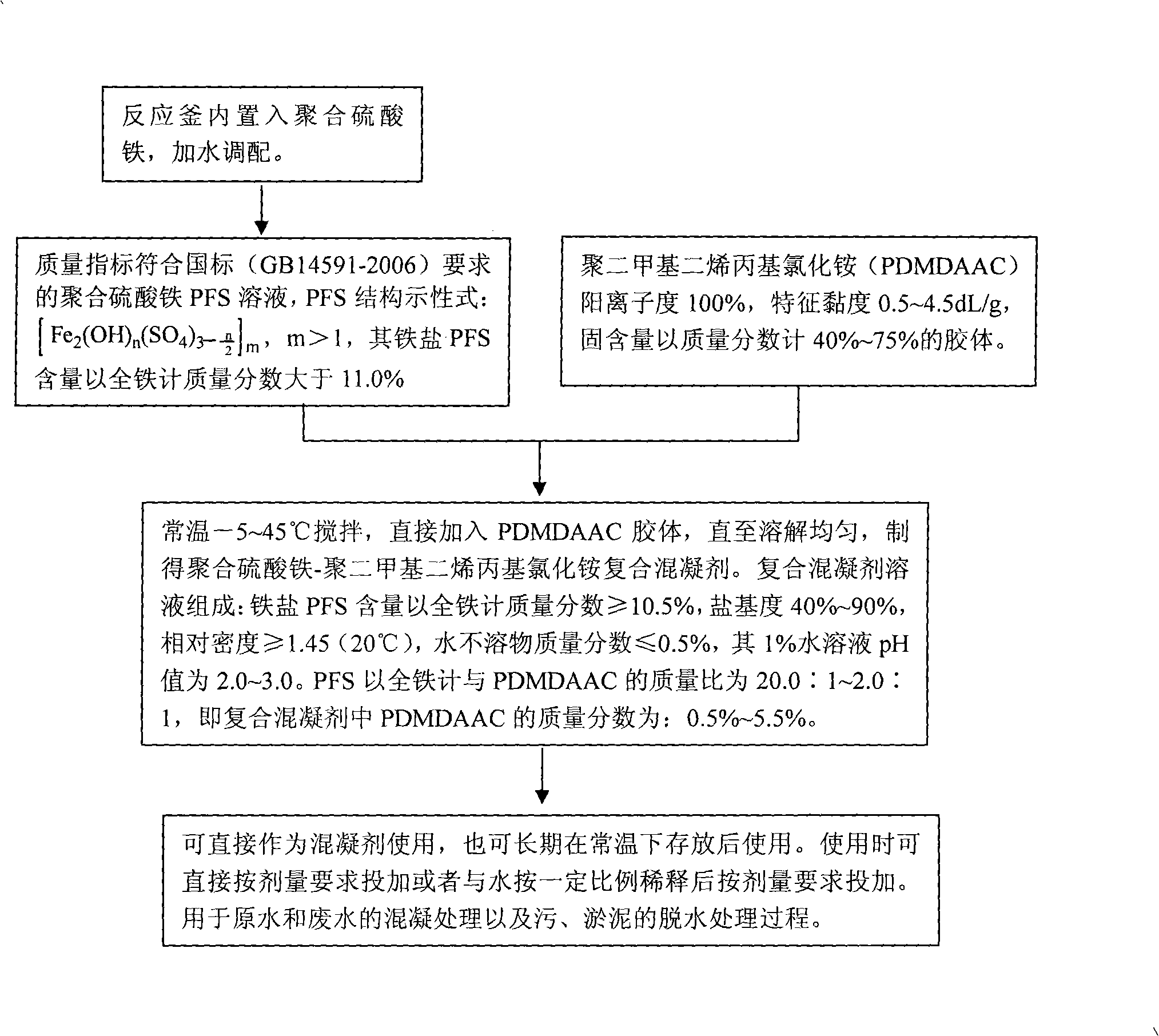

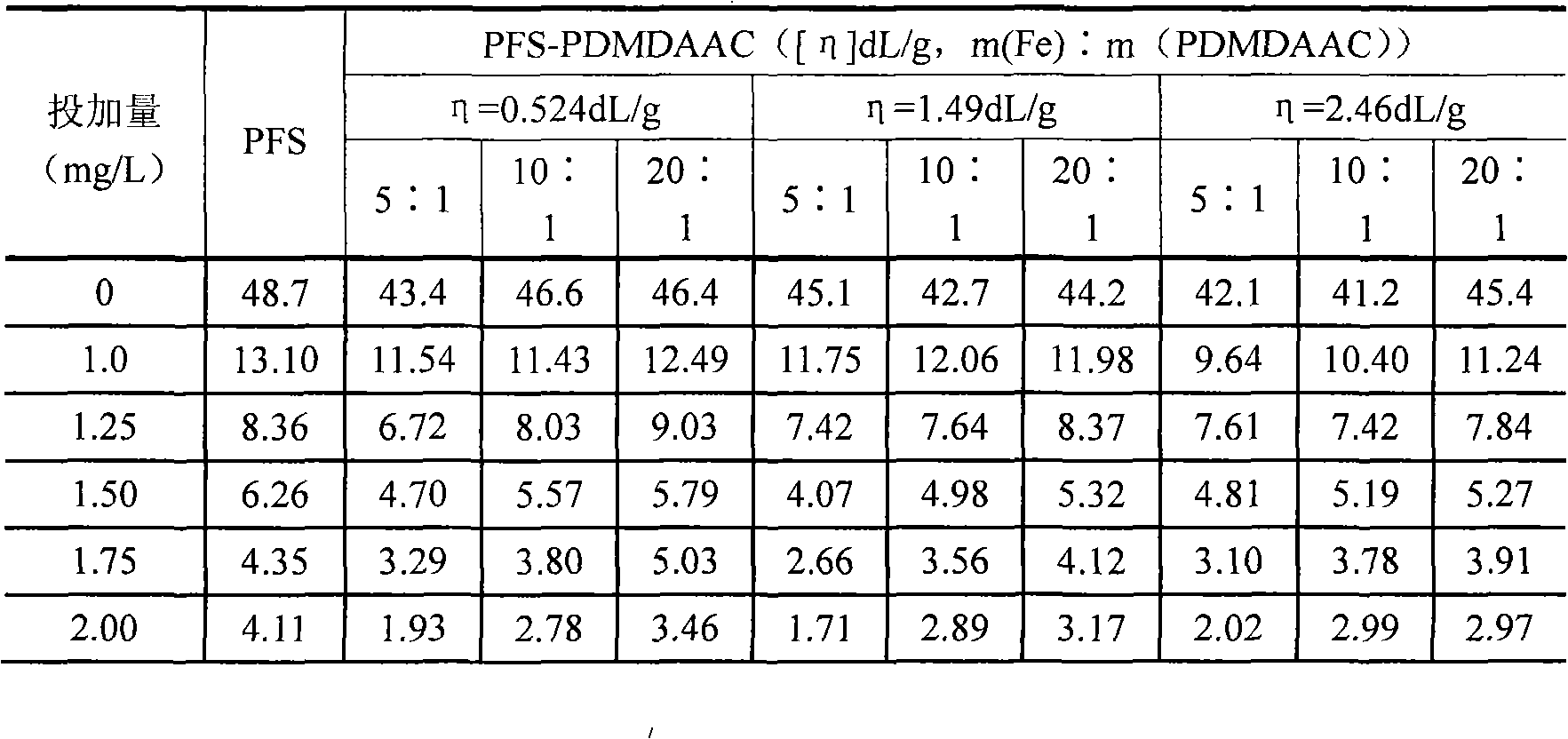

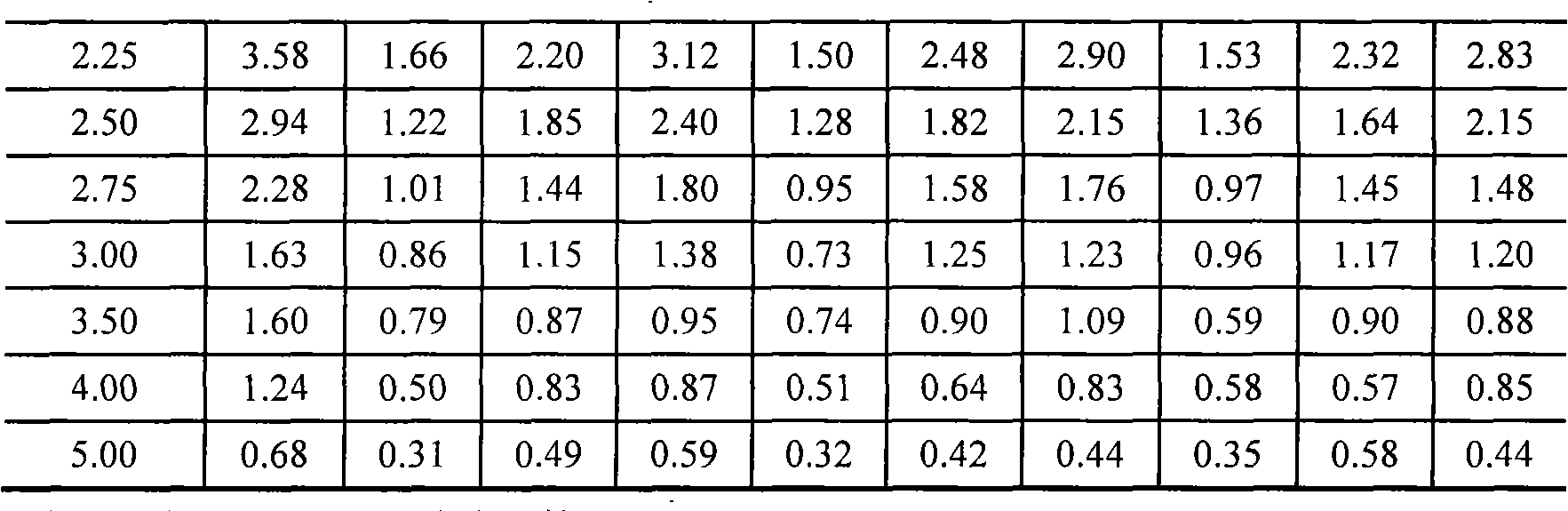

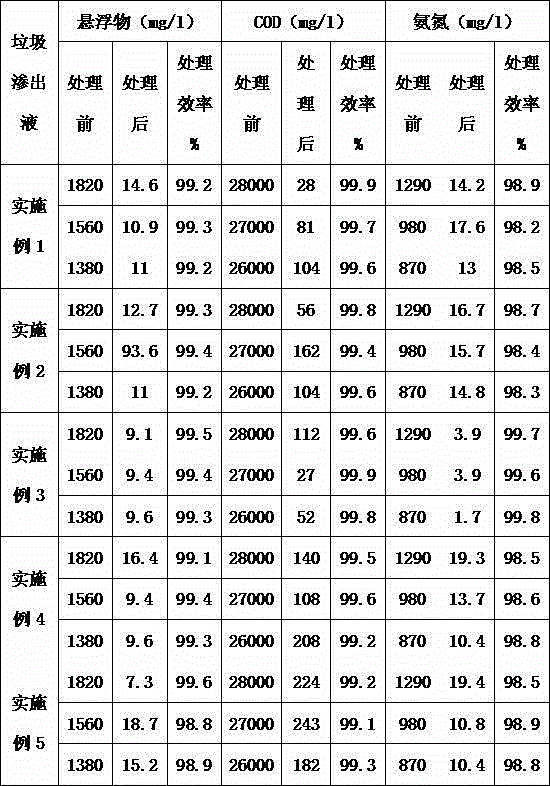

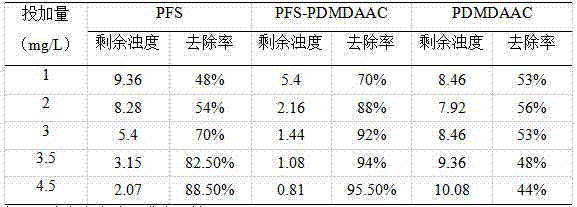

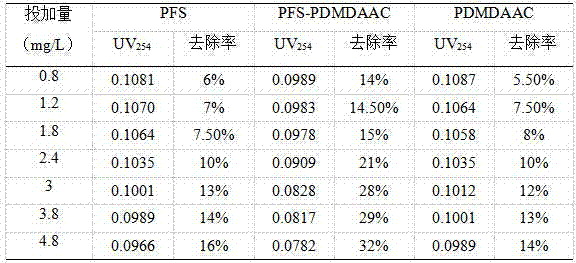

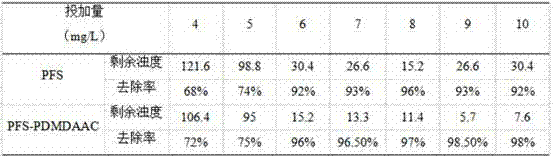

The invention discloses a PFS-PDMDAAC compound coagulant, a corresponding preparation method and an application method. The PFS-PDMDAAC compound coagulant is prepared as the following steps: the PFS dry powder or solution is arranged in a mixing reactor, and water is added to obtain a ferric-salt PFS solution which is stirred under normal temperature and a PDMDAAC colloid is added into the solution; the mixed solution is stirred under normal temperature till the PDMDAAC colloid is completely dissolved to obtain a stable PFS-PDMDAAC. The application of the PFS-PDMDAAC compound coagulant is to adopt the PFS-PDMDAAC compound coagulant for the coagulation treatment to raw water and waste water and sewage and the dehydration treatment to sludge or silt directly or after dilution with water by any proportion. The component structure and content scope of the invention are distinct to guarantee the capability and stability of the obtained PFS-PDMDAAC compound coagulant, and the materials on industrial manufacturing are available. The various functions of the PFS-PDMDAAC compound coagulant can be adjusted during water treatment with high adaptability so as to reduce cost, reinforce coagulation effect and dramatically enhance the quality of obtained water.

Owner:NANJING UNIV OF SCI & TECH

Modifying agent for soda-alkalized paddy field soil

InactiveCN102517027AImprove efficiencyLower unit costOrganic fertilisersSoil-working methodsIron sulfateBiology

The invention discloses a modifying agent for soda-alkalized paddy field soil. The modifying agent is prepared by mixing polyferric sulfate with polyaluminum sulfate according to the weight ratio of 1:(0.6-1.4) and is suitable for modifying severe soda-alkalized soil into a paddy field; and the modifying method comprises the following steps of: applying the modifying agent to the paddy field soil of the field prior to soil preparation, wherein the application rate is 5.6-18 tons per hectare of soil; carrying out normal soil preparation; and soaking and leaching the soil after the modifying agent is sufficiently mixed with the soil. Compared with the polyferric sulfate, the unit cost of the modifying agent for the soda-alkalized paddy field soil disclosed by the invention is reduced by 9.4-15% under the condition that the same effect is maintained; and compared with the aluminum sulfate soil modifying agent, the macromolecular polymer of the modifying agent has a better flocculation effect and higher modifying efficiency, and meanwhile, the concentration of activated aluminum of soil is controlled to be in a low-concentration level, which is harmless to crops.

Owner:JINAN UNIVERSITY

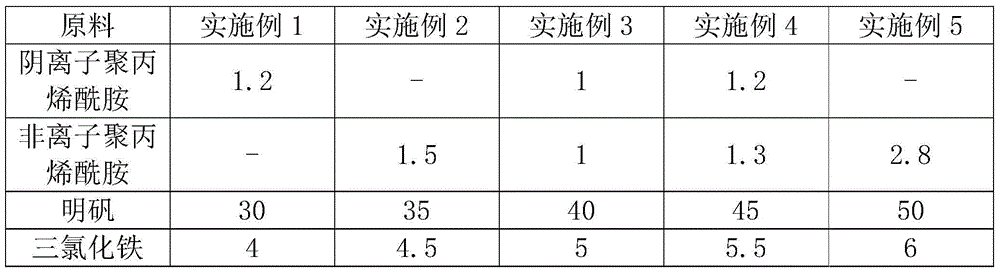

Industrial wastewater treating agent

InactiveCN104591362AGood effectImprove water qualityWater/sewage treatment by flocculation/precipitationSodium bicarbonateIron sulfate

The invention relates to the technical field of sewage treatment and particularly relates to an industrial wastewater treating agent. The industrial wastewater treating agent comprises the following components in parts by mass: 0.8-3 parts of polyacrylamide, 25-35 parts of aluminium polychlorid, 25-55 parts of alums, 3-8 parts of iron trichloride, 0.8-3.4 parts of polymeric ferric sulfate, 1.2-2.5 parts of a coagulant aid, 2-10 parts of plant fiber, 10-30 parts of coal ash, 0.8-2.5 parts of sodium silicate, 2.5-5 parts of sodium sulfite, 0.5-3.5 parts of sodium hypochlorite, 5-10 parts of hydrogen peroxide, 8-15 parts of a sodium carbonate-sodium bicarbonate buffer system and 10-20 parts of sodium-based bentonite. The treating agent has the beneficial effects of wide treated pollutant range, good effect, wide production raw material source, environmental friendliness, no toxicity, good discharged water quality, short process flow, and high process operating safety. The treating agent disclosed by the invention can treat various kinds of wastewater such as chemical wastewater produced in oil fields, mining, steel, electroplating wastewater, dyes, pesticides, wine-making and chemical engineering, and sanitary sewage, papermaking wastewater, river and lake water, rubbish seeping water, leather-making wastewater, and the like; and the treating agent is good in treatment effect.

Owner:湖北源绿高科技节能环保有限公司

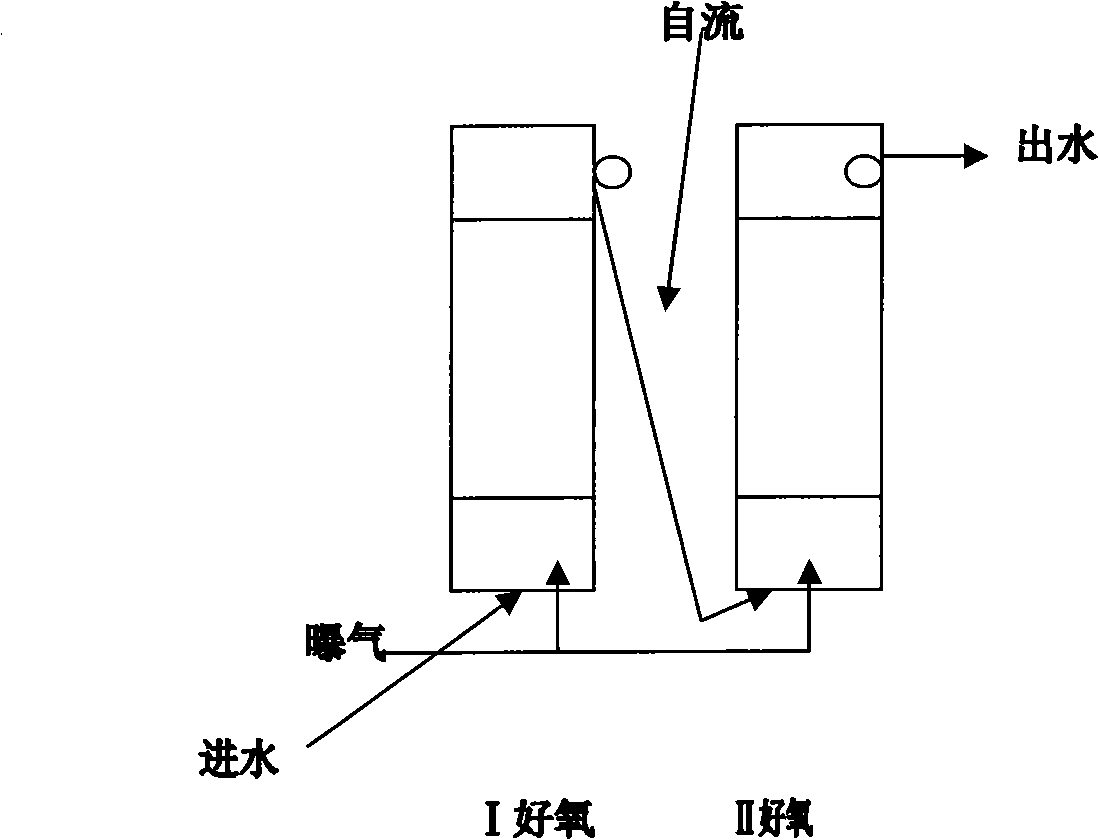

Treatment process and device for wastewater containing benzene

InactiveCN103102042AReduce reuse operating costsExtended operating cycleGeneral water supply conservationMultistage water/sewage treatmentMoving bedSuspended solids

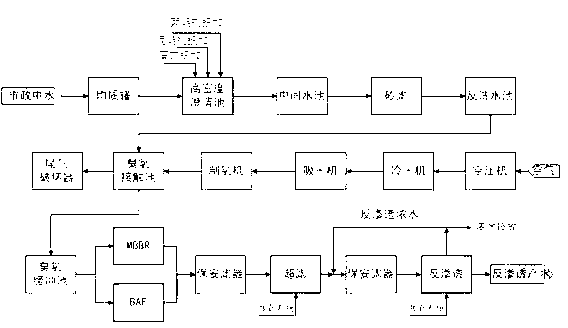

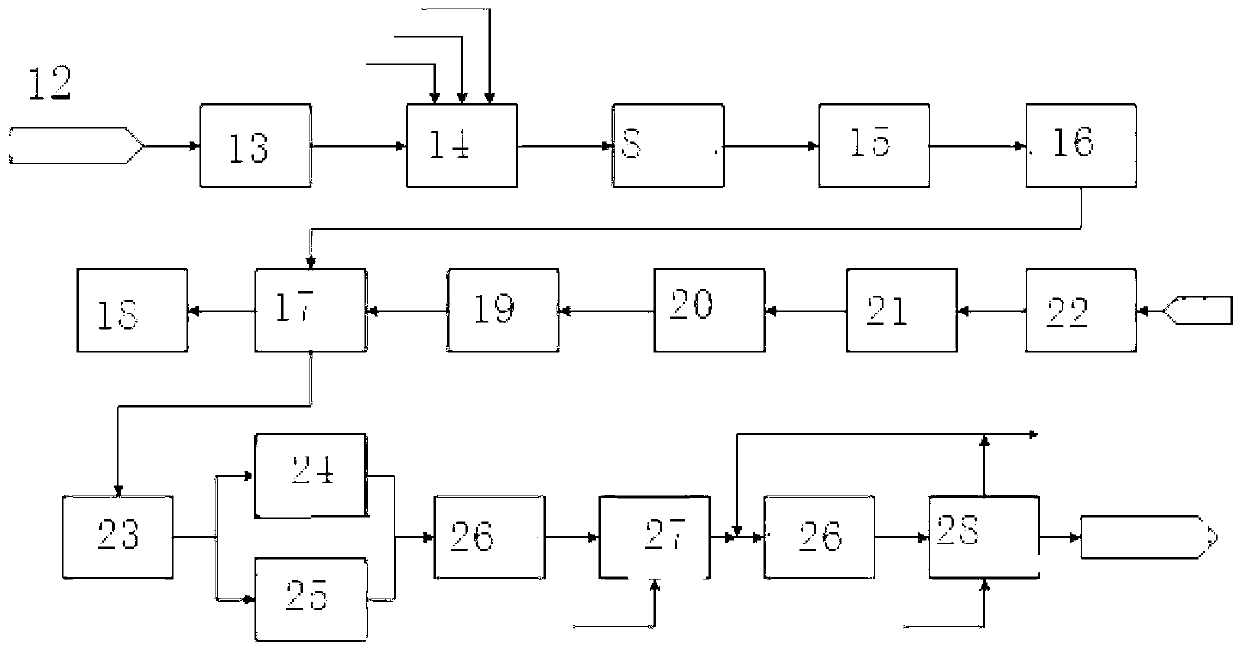

The invention relates to a treatment process and device for wastewater containing benzene. The device comprises a pretreatment unit, an ozone oxidation unit, a biochemical treatment unit and a double-membrane advanced treatment unit which are sequentially connected. The treatment process comprises the steps of: firstly adding lime to the wastewater for softening the wastewater, then adding a coagulant for polyferric sulfate coagulation, adding a flocculating agent for flocculation, precipitating and clarifying, and then sending clear liquid into a sand filtering layer, wherein yielding water enters an ozone contact tank for ozone aeration and oxidation, carrying out biochemical treatment on the wastewater subjected to ozone oxidation by adopting a biological aerated filter treatment process and a moving bed biomembrane reactor so as to further degrade COD (Chemical Oxidant Demand), and carrying out ultra-filtration and reverse osmosis double-membrane treatment on the wastewater for desalination. According to the invention, through combination of the treatment units, the removal rate of CODcr with benzene rings in the fed water can be up to above 80%, and the removal rate of SS (Suspended Solids) is about 90%, and the removal rate of ammonia nitrogen is above 85% before fed water enters a RO (Reverse Osmosis) membrane. For a double-membrane system, the cleaning period is increased by 3-4 times, and the service life of the membrane is prolonged by 1-2 years.

Owner:ZHENGZHOU JIANGHE ENVIRONMENTAL PROTECTION TECH

Oxidization coagulant for treating coking wastewater

InactiveCN101734780AWide pH rangeGood removal effectWater/sewage treatment by flocculation/precipitationWater/sewage treatment by oxidationChemical oxygen demandAqueous solution

The invention discloses an oxidization coagulant for treating coking wastewater, which consists of two parts of an oxidization flocculant and a coagulant aid. The oxidization flocculant comprises the following components according to proportion by weight: 8-20% of flocculant polyferric sulfate, 0.1-2.0% of oxidant ferrate and the balance of water; and the coagulant aid is polyacrylamide aqueous solution. In the invention, the double functions of oxidization and flocculation are available, the removal rate of the coking wastewater CODcr (Chemical Oxygen Demand) can reach more than 70%, the draining water is clear, the colority is less than 80 times, the adding amount is little, and the cost is low, wherein the medicament cost of advanced treatment is only 0.5 RMB / ton; the condition is easy to control and the operation is convenient. The invention provides an economical and efficient method and powerful assurances for the draining standard of advanced treatment of the coking wastewater.

Owner:娄底市裕德科技有限公司

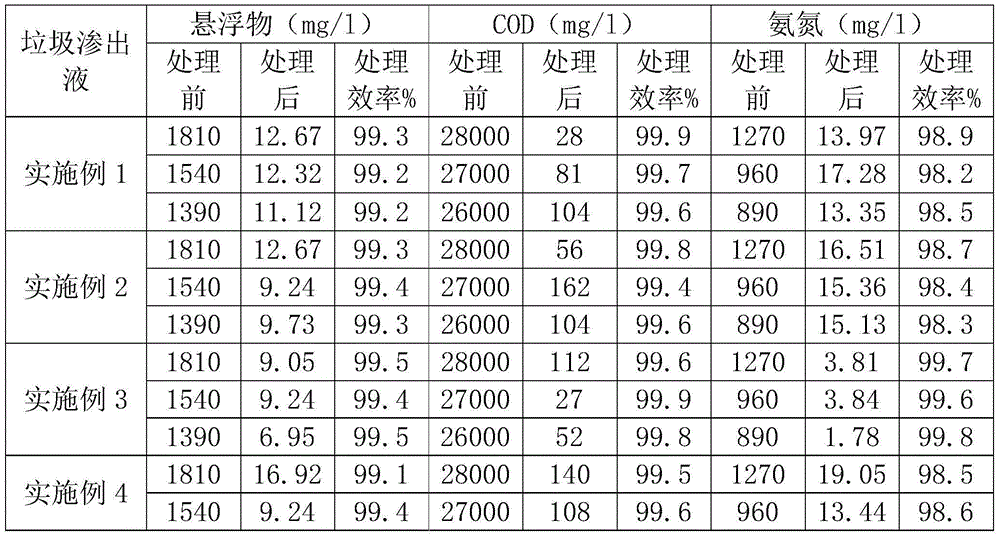

Efficient ecological type sewage and sludge treating agent and preparation method thereof

ActiveCN101811764AOvercoming High Carryover ProblemsIncrease productivityWater/sewage treatment by flocculation/precipitationSodium BentoniteSludge

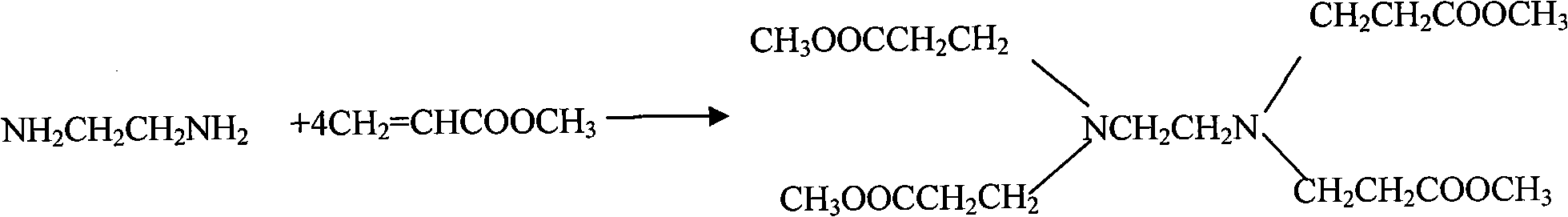

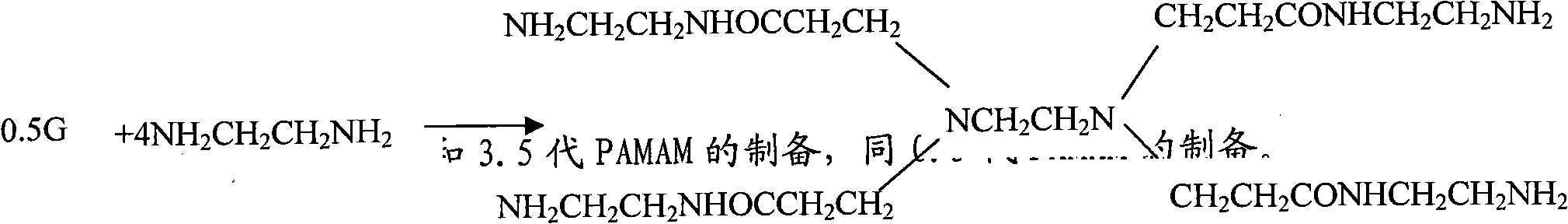

The invention relates to an efficient ecological type sewage and sludge treating agent and a preparation method thereof. A flocculant X consists of sodium carboxymethyl cellulose, polyferric sulfate and sodium bentonite with the weight ratio of 2:7:1; and a coagulant aid Y consists of starch, 2nd generation polyamide-amine, sodium hydroxide and ammonium persulfate with the weight ratio of 10:8:2:0.05. The invention overcomes the defects that the production process of multi-generation PAMAM dendritic polymer needs to be repeated many times, and the cycle time of each generation is overlong, which seriously affects the production process and greatly reduces the production efficiency, so the contamination control enterprises can not apply the multi-generation PAMAM dendritic polymer. The invention does not have the defects of high amide monomer residue in wastewater treatment by polyacrylamide and low production efficiency of the 4th generation polyamide-amine dendritic polymer, greatly increases the production efficiency, and enables the treating agent to have handleability and contamination removal and control effects.

Owner:NANJING SHENKELONG ENVIRONMENTAL PROTECTION

Method for preparing and using polymeric flocculant polyferric silicate sulfate

ActiveCN101974566AWide variety of sourcesSimple production equipmentMicroorganism based processesFermentationThiobacillus ferrooxidansSilicic acid

The invention discloses a method for preparing inorganic polymeric flocculant polyferric silicate sulfate and a wastewater treatment method. Ferrous sulfate is oxidized into polyferric sulfate through the acclimated thiobacillus ferrooxidans; polymerization reaction is conducted between the polyferric sulfate and the active polysilicic acid solution; and then the polymerization reaction product is left to stand and ageing to obtain the brownish red liquid polyferric silicate sulfate. The product brownish red liquid polyferric silicate sulfate is applicable to the purification of domestic sewage, printing and dyeing wastewater and heavy metal wastewater and COD removal rate, decoloring rate and heavy metal removal rate can reach more than 90%.

Owner:CENT SOUTH UNIV

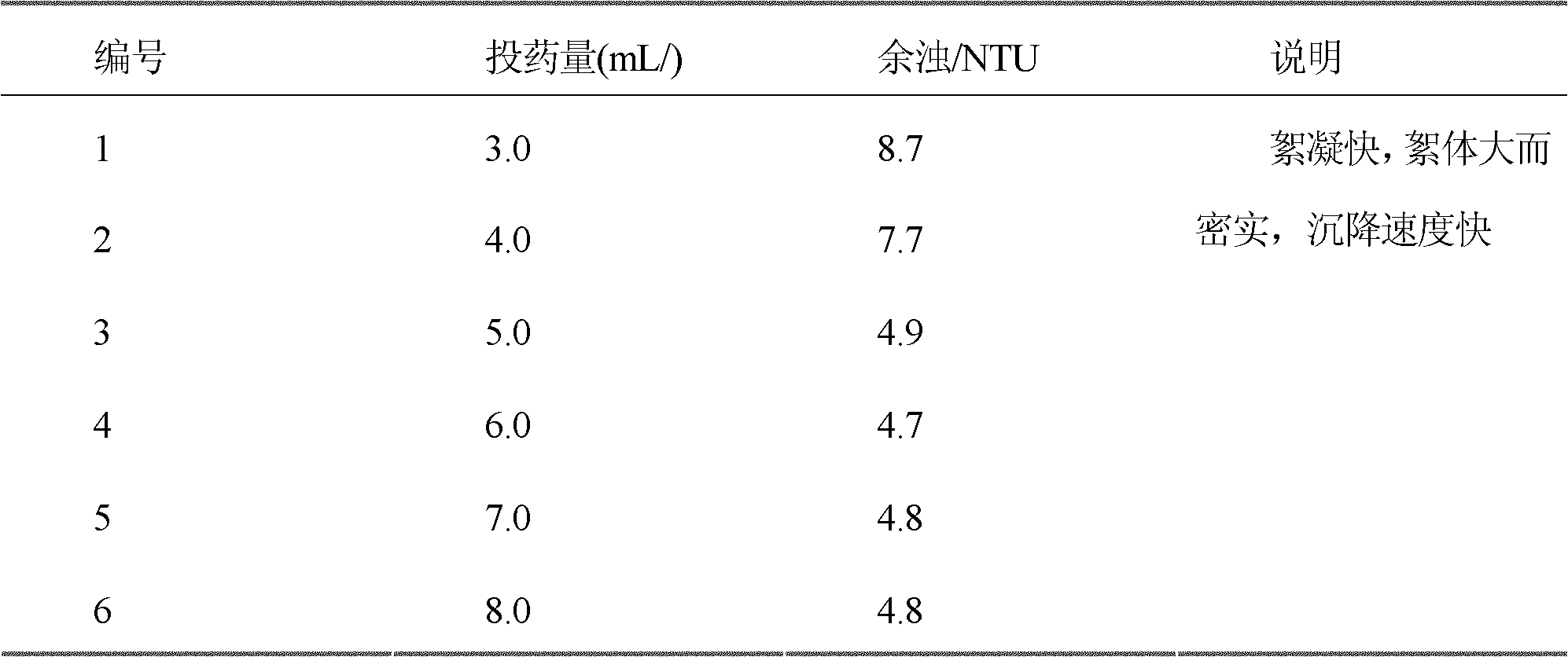

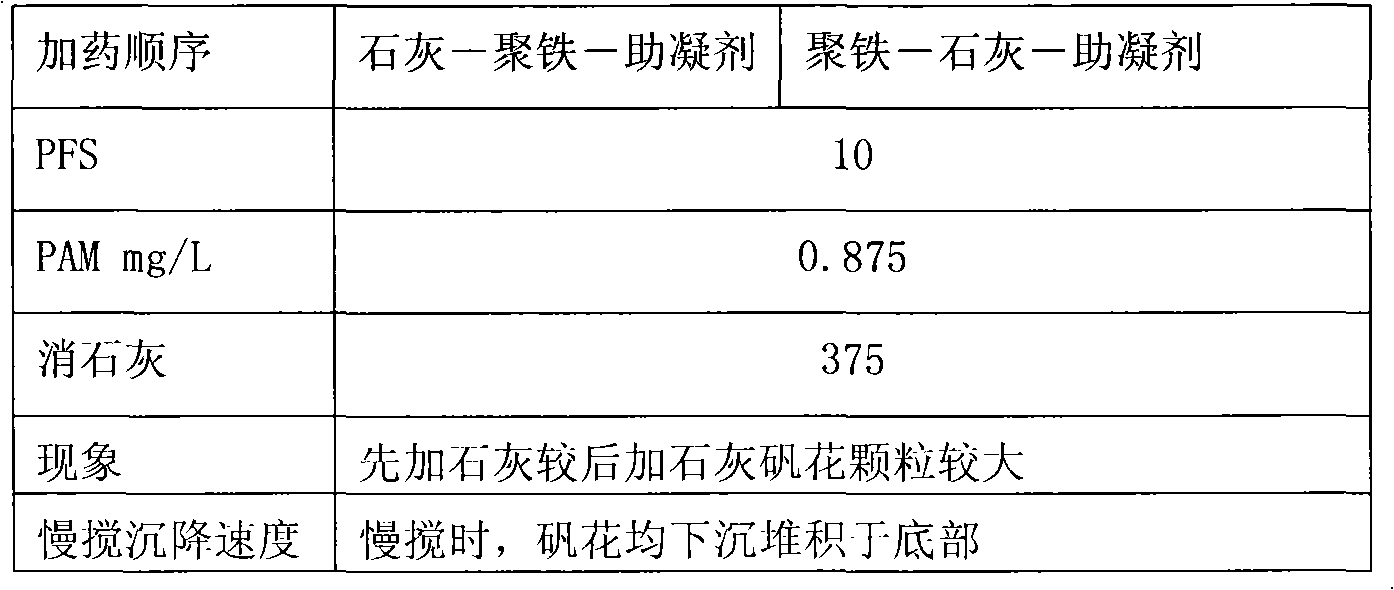

Advanced treatment method for urban water of electric power plant

InactiveCN101318747AScale removal and water softeningMultistage water/sewage treatmentIron sulfateWater use

The invention relates to a method for treating municipal intermediate water, in particular to an advanced treatment method for treating the municipal intermediate water which is used as cooling water for a power plant. The method comprises the following specific steps that: water in a municipal sewage treatment plant is introduced into a pool, respectively added with lime hydrate, polymeric ferric sulfate as a coagulant and polyacrylamide as a coagulant aid and clarified; a clarifying solution is added with an disinfectant for disinfection, added with sulphuric acid for adjusting the PH value of the clarifying solution to between 8 and 8.5 and filtered; and intermediate water after filtration is added with a composite scale corrosion inhibitor, evenly mixed and added to circulating water in the power plant. The advanced treatment method solves the relevant technological difficult problems of advanced treatment, disinfection, scale inhibition, anticorrosion, ammonia nitrogen treatment, etc. of the intermediate water recycled by the power plant and provides technological support for the safe and economic use of the intermediate water in the power plant; and the intermediate water in the power plant is used as circulating water and replenishing water for recycling and has remarkable economic, social and environmental benefits.

Owner:SHANDONG ELECTRIC POWER RES INST

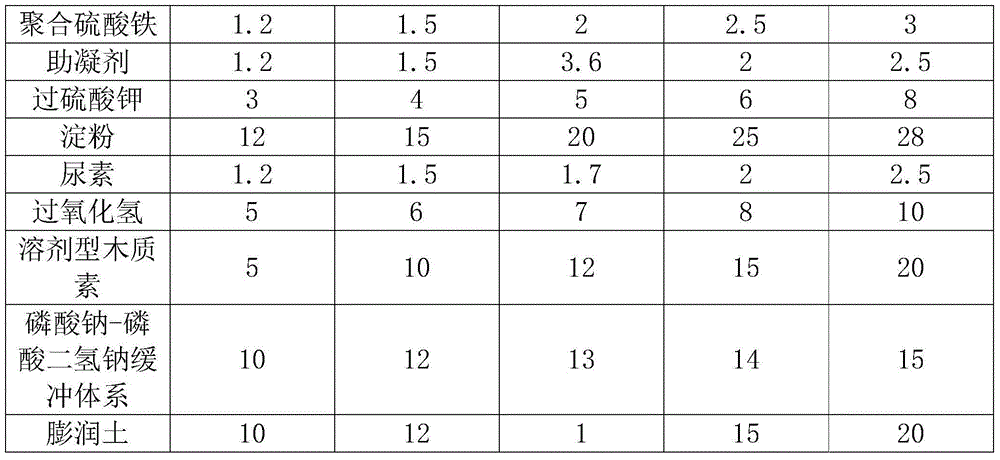

Industrial sewage treating agent

InactiveCN104817125AGood effectImprove water qualityWater/sewage treatment by flocculation/precipitationPotassium persulfateChemical industry

The invention relates to the technical field of sewage treatment, particularly an industrial sewage treating agent. The industrial sewage treating agent is composed of the following components in parts by mass: 1.2-2.8 parts of polyacrylamide, 30-50 parts of alum, 4-6 parts of iron trichloride, 1.2-3 parts of polyferric sulfate, 1.2-2.5 parts of coagulant aid, 3-8 parts of potassium persulfate, 12-28 parts of starch, 1.2-2.5 parts of urea, 5-10 parts of hydrogen peroxide, 5-20 parts of solvent-type lignin, 10-15 parts of sodium phosphate-sodium dihydrogen phosphate buffer system and 10-20 parts of bentonite. The industrial sewage treating agent has the advantages of wide pollutant treatment range, favorable effect, wide production raw material sources, environment friendliness, no toxicity, good effluent water quality, short technical process and high technical operation safety. The treating agent can treat various types of sewage, such as chemical wastewater in oilfields, mines, iron and steel, electroplating, dyes, pesticides, wine making, chemical industry and the like, and domestic sewage, paper mill wastewater, rivers and lakes, garbage seep water, tanning wastewater and the like. The treating agent has favorable treatment effect.

Owner:ZHANGJIAGANG SHANMU NEW MATERIAL TECH DEV

Microwave demulsifying and purifying method for emulsifying liquid waste water

InactiveCN1648058ASignificant separationEasy to controlWater/sewage treatment by flocculation/precipitationLiquid wasteMicrowave method

The microwave method of demulsifying and purifying emulsifying liquid waste water in water processing field features that microwave irradiation is adopted in processing emulsifying liquid waste water. The flocculating demulsifier solution is compounded with calcium chloride, aluminum chloride, ferric chloride, aluminum sulfate, ferric sulfate, polyaluminum sulfate, polyferric sulfate and polyacrylamide and the added amount is 0.5-25.0 g / L. The microwave has frequency 2450 MHz or 915 MHz, power 0.4-64 kw, and irradiation time 1-5 min. The microwave demulsifying reactor consists of mainly microwave generator and demulsifying reactor. The present invention has the advantages of oil content lowering rate over 95 %, CODCr lowering rate of about 80 %, short reaction time, low reaction power consumption and easy oil-water separation.

Owner:DALIAN UNIV OF TECH

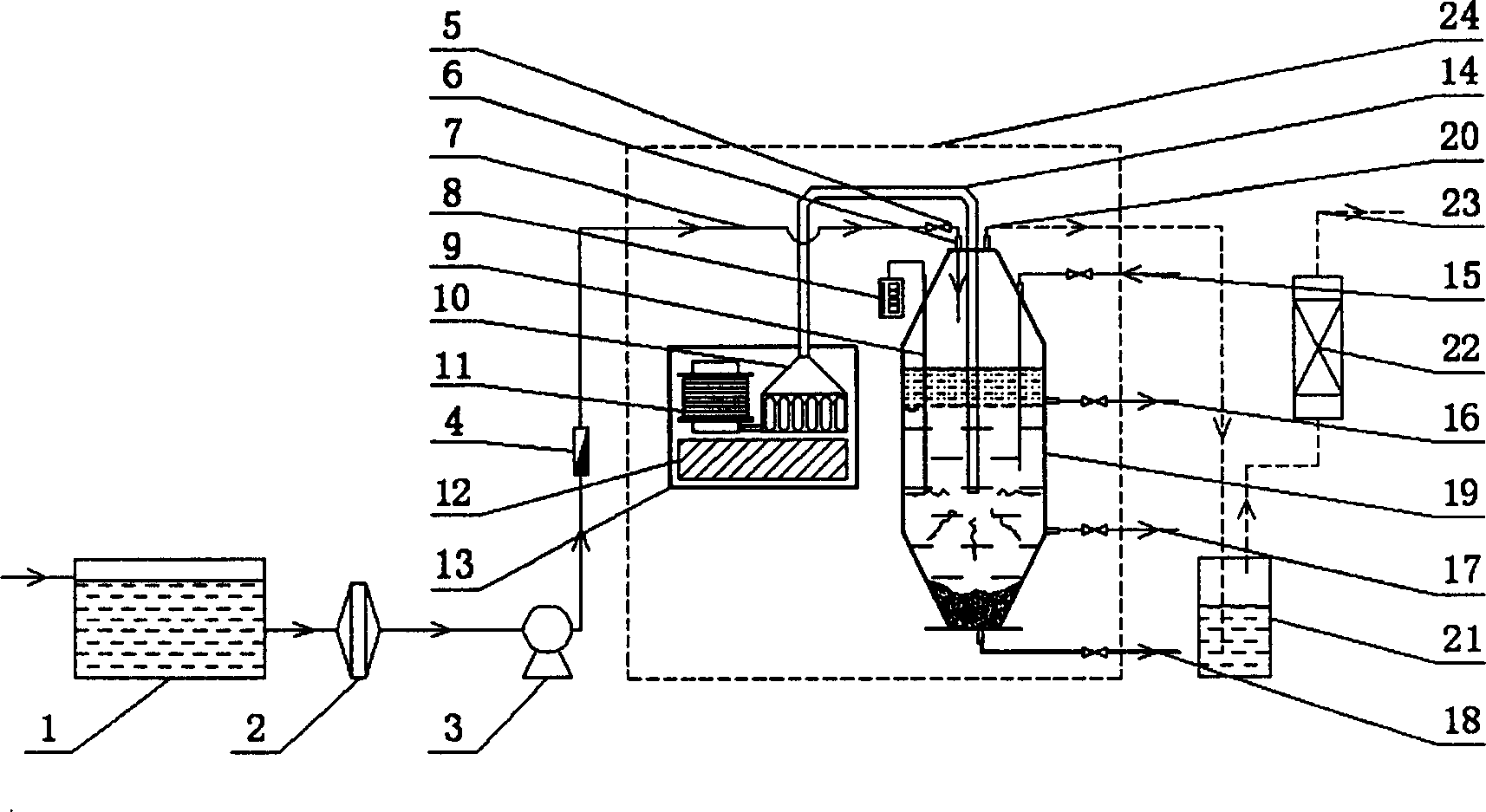

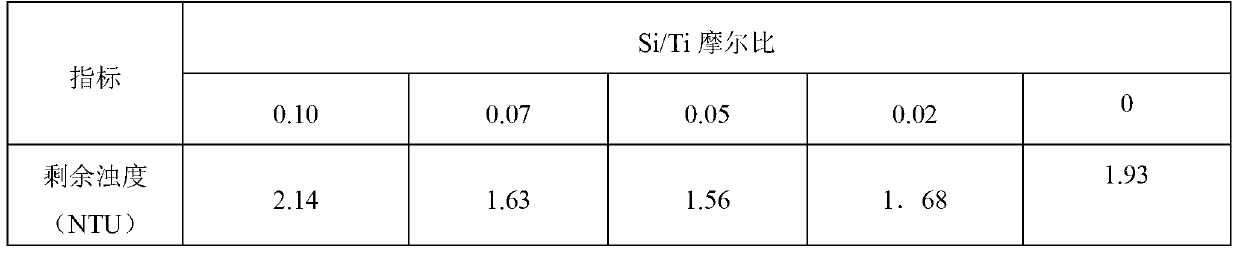

Polymeric silicic acid-polyferric sulfate titanium inorganic macromolecular composite flocculant and preparation method and application thereof

ActiveCN103342406AImprove stabilityGood flocculation effectWater/sewage treatment by flocculation/precipitationChemical industryAlkalinity

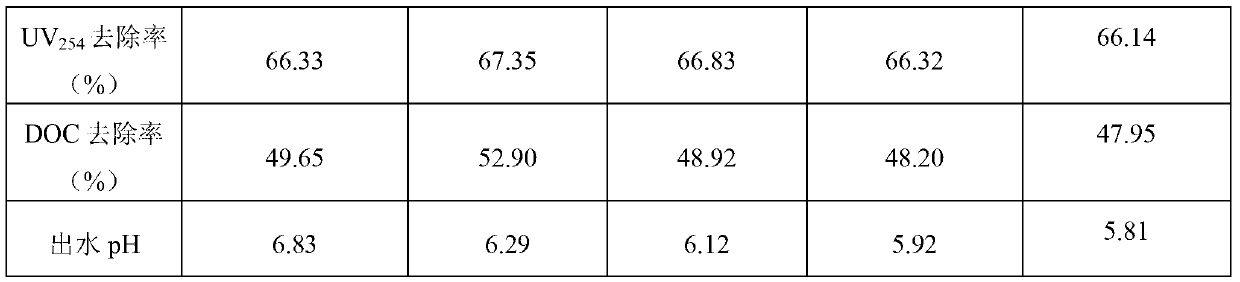

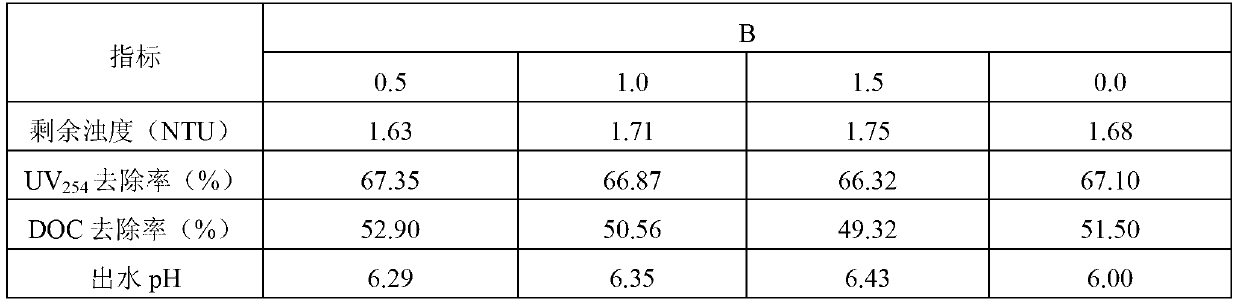

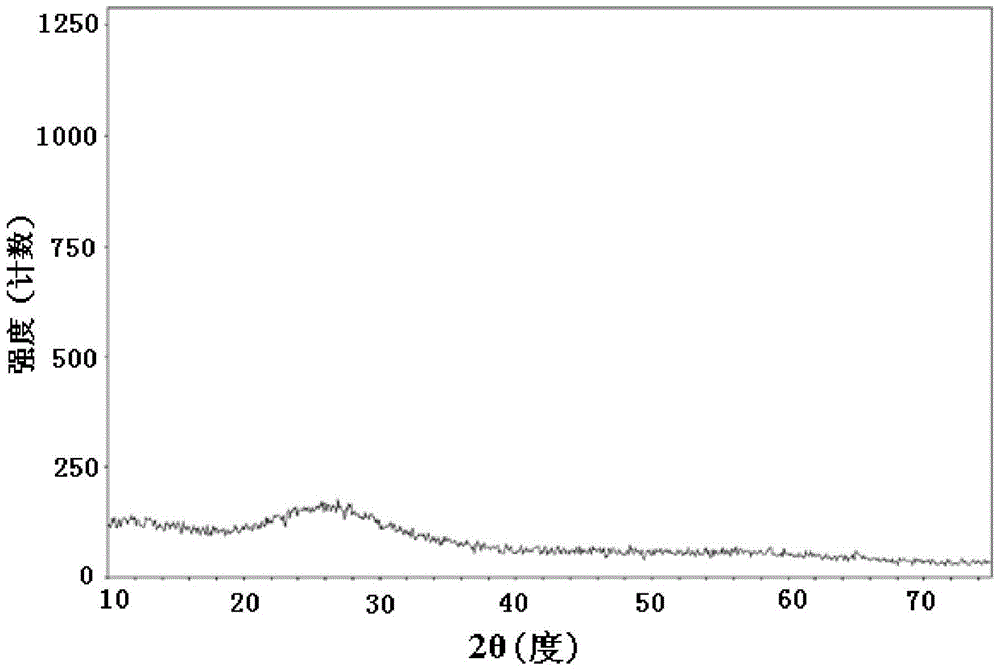

The invention relates to a polymeric silicic acid-polyferric sulfate titanium inorganic macromolecular composite flocculant and a preparation method and an application thereof. The alkalinity (B) of the composite flocculant is 0.5-1.5, and the composite flocculant is prepared by mixing a polymeric silicic acid solution with concentration of 0.08-0.12 mol / L with a polyferric sulfate titanium solution with concentration of 8-15 g / L according to a Si / Ti mol ratio of (0.02-0.1):1. The composite flocculant has the advantages of strong adsorption bridging ability on colloid matters, good flocculation effect, wide application range, less sludge generation amount and the like, thereby being capable of being extensively applied in such fields as water supply, waste water treatment, papermaking, textile dyeing and finishing and daily-use chemical industry, and the water treatment effect is good.

Owner:SHANDONG UNIV

Sewage treatment agent special for printing and dyeing wastewater and preparation method of sewage treatment agent

InactiveCN105967261AReduce COD

<sub>Cr</sub>Reduce ammonia nitrogenWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationSodium BentonitePolyacrylamide

The invention discloses a sewage treatment agent special for printing and dyeing wastewater. The sewage treatment agent is prepared from, by weight, coal ash, wooden activated carbon, poly aluminium chloride, polyferric sulfate, polyacrylamide, ammonium persulfate, sodium carbonate, poly-ferric aluminum sulfate, aluminum sulfate, yttrium oxalate, manganese sulfate, sodium bentonite, zeolite, sepiolite, modified lignin sulfonate, alkylphenol ethoxylates, amino trimethylene phosphonic acid, menthone, thiourea, cationoid starch derivatives, sodium dodecyl benzene sulfonate, dimethyl diallyl ammonium chloride, octaphenyl polyoxyethyiene, glycerin monostearate, peroxiredoxin and microbial bacterial liquid. The microbial bacterial liquid is prepared from saccharomycetes, fusarium oxysporum, proteusbacillus vulgaris, neurospora and mycoplana. The invention further provides a preparation method of the sewage treatment agent. The prepared sewage treatment agent is good in treatment effect on the printing and dyeing wastewater, the preparation method is simple, and no secondary pollution exists.

Owner:许婷

Solid composite polymeric ferric sulfate flocculant and preparation thereof

InactiveCN101348294AImprove performanceEasy to storeWater/sewage treatment by flocculation/precipitationIron sulfateFerrous sulfate iron

The invention provides a solid composite polymeric ferric sulfate flocculating agent used in the treatment of high-concentration organic starch wastewater. The flocculating agent takes ferrous sulfate and sodium bentonite as raw materials and sulphuric acid and hydrogen peroxide as oxidizing agents, is obtained after oxidative polymerization, aging, concentrating and settling, and is a straw yellow solid which has stable performance and is convenient for storage and transportation; during the treatment of high-concentration organic starch wastewater, the flocculating agent ensures quick settling velocity of floc, compact floc, excellent deodorization effect, relatively high removal rate of COD and large removal value of COD, and has high use value; the flocculating agent has low energy consumption during preparation; moreover, the flocculating agent has the advantages of cheap and easily obtained raw materials, low cost, simple device and process and convenient operation, and is easy to realize industrial production.

Owner:NORTHWEST NORMAL UNIVERSITY

Compound phosphoric polyferric sulfate flocculant and production method thereof

ActiveCN101805051AReduce turbidityReduce CODWater/sewage treatment by flocculation/precipitationPhosphorus compoundsLiquid wasteInorganic compound

The invention provides a novel inorganic compound phosphoric polyferric sulfate flocculant and a production technology thereof. The flocculant can be used in both water treatment and sewage treatment thereby being multifunctional. The phosphoric polyferric sulfate of the invention takes the by-products generated in titanium pigment production, such as ferrous sulfate, phosphoric acid and the like for producing titanium pigment as raw materials thereby having the characteristics of utilization of waste products, simple components, low cost and the like. The production technology of the invention is convenient, has simple operation and can be carried out at normal temperature and normal pressure. In the production process, no liquid waste, waste gas and waste residue can be generated, and the production technology belongs to the cleaner production technology. The invention can be widely applied in water treatment and sewage treatment. Especially in water treatment, the phosphoric polyferric sulfate flocculant of the invention is added to effectively remove soluble phosphorus and phosphorus in other forms in water as well as algae in algae waste water, lower chemical oxygen demand (COD), total phosphorus (TP), suspended solid (SS), chlorophyll (chl-a) and the like.

Owner:善水(南通)工业技术有限公司

Treatment method of industrial arsenic wastewater

InactiveCN104787932ARaw materials are easy to getReduce processing costsMultistage water/sewage treatmentArsenateIron sulphate

The invention relates to a treatment method of industrial arsenic wastewater, which comprises the following steps: neutralizing industrial arsenic wastewater with an antalkali to control the end pH value to be greater than or equal to 5.0, and carrying out solid-liquid separation to obtain primary treated water; adding polyferric sulfate and H2O2 into the primary treated water to control the end pH value to be greater than or equal to 5.0, wherein the polyferric sulfate accounts for 0.01-1 wt% of the arsenic wastewater to be treated, and the H2O2 accounts for 0.01-1 wt% of the arsenic wastewater to be treated; and carrying out solid-liquid separation on the product to obtain secondary treated water with the arsenium content of less than 0.5 ppm. The primary treatment adopts lime or any other antalkali, and thus, has the advantages of accessible raw material and low treatment cost. The secondary treatment adopts the H2O2 and polyferric sulfate as reagents, and can convert residual arsenium in the primary treated water into an insoluble ferric arsenate precipitate, thereby achieving the effect of deep dearsenication. The secondary treated water can be further treated by a sewage treatment cyclic utilization system, thereby reducing the subsequent treatment cost for arsenic wastewater.

Owner:TONGLING CHEM IND GRP

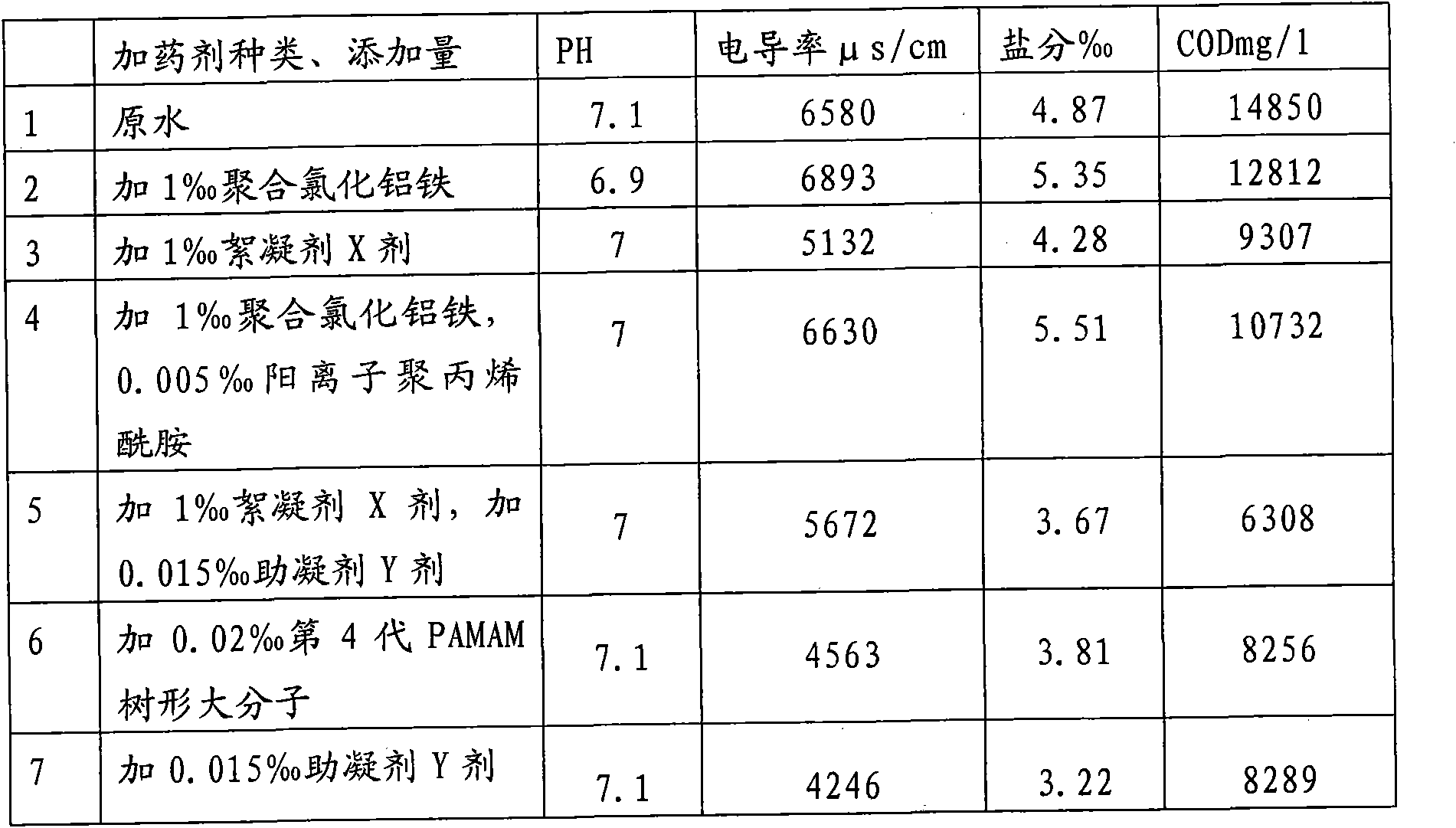

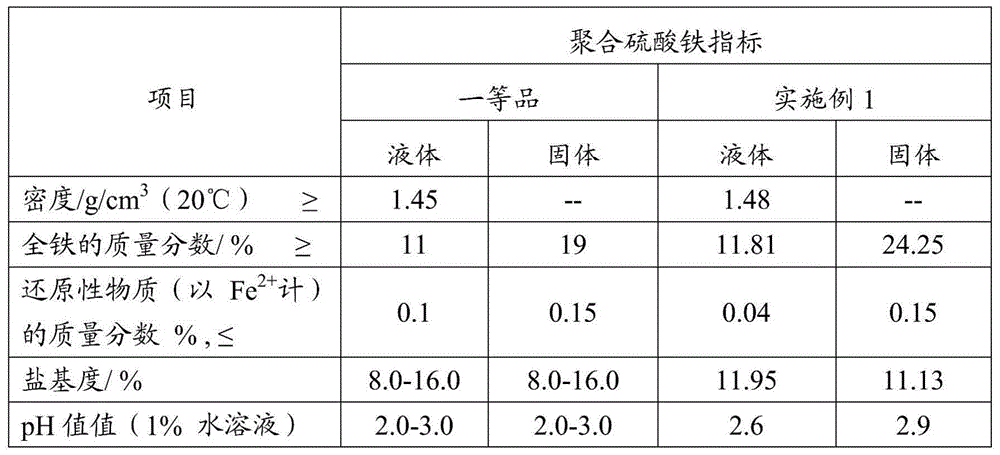

Preparation method of polyferric sulfate

ActiveCN104692467AImprove oxidation capacityReduce dosageIron sulfatesWater/sewage treatment by flocculation/precipitationIron sulfateStrong acids

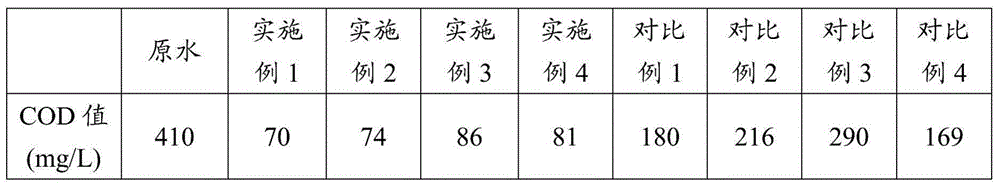

The invention provides a preparation method of polyferric sulfate. The method is that a sulfuric acid aqueous solution and ferrous sulfate are mixed to obtain a mixing solution of which the pH is 0.5 to 1.5; the mixing solution and hydrogen peroxide respectively individually flow through independent flowing channels and then are synchronously poured into a reaction system to react to obtain polyferric sulfate. With the adoption of the method, the oxidizing capacity of hydrogen peroxide can be improved, the rate of converting ferrous ions into ferric ions can be increased, and moreover, ferrous ions and hydrogen peroxide can fully contact and rapidly react; therefore, the problem of decomposing of hydrogen peroxide at a high temperature or strong acid condition in the prior art can be effectively solved, the dosage of hydrogen peroxide can be reduced, the cost input can be decreased, the operation process is simplified, and the reaction time is greatly reduced. The quality of polyferric sulfate prepared by the method meets indicators as specified by national standard on top quality goods; with the adoption of the polyferric sulfate to treat wastewater, the COD of drained water can be stabilized to be less than or equal to 86mg / L, so that the method is applicable to industrial production.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Efficient sewage treatment agent and preparing method thereof

InactiveCN106145381AEasy to handleGood processing effectWaste water treatment from metallurgical processBiological water/sewage treatmentActivated sludgePectinase

The invention discloses an efficient sewage treatment agent. The efficient sewage treatment agent is prepared from polymeric aluminium, polyferric sulfate, activated sludge, pectinase, quaternary ammonium salt lignin flocculant, 1,3,5-triazine-2,4,6-(1H,3H,5H)-trithione trisodium salt, polyacrylamide, ferric trichloride, amino trimethylene phosphonic acid, sodium dodecyl benzene sulfonate, phosphorus pentoxide, plant ash, poly(ethylene imine), cross-linked rectorite, sodium bentonite, zeolite powder, cocoanut active charcoal, kieselguhr, anhydrous magnesium sulfate and microorganism bacteria solution. The microorganism bacteria solution is composed of saccharomycetes, flavobacterium, nocardia and aspergillus ustus. The invention further provides a method for preparing the efficient sewage treatment agent. The efficient sewage treatment agent has a remarkable steel making wastewater treatment effect and can become effective quickly, steel making wastewater treatment cost can be reduced, and treated water can meet the discharge standard so as to be directly discharged or recycled.

Owner:MAANSHAN SHUNDA ENVIRONMENTAL PROTECTION EQUIP

New technology for preparing electrolytic manganese metal solution and recycling iron by reducing pyrolusite with iron scraps

InactiveCN101988154ASimple processMild conditionsProcess efficiency improvementElectrolysisPyrolusite

The invention discloses a new technology for preparing manganese sulfate solution which is used for electrolyzing manganese metal and recycling iron through the atmospheric pressure leaching of pyrolusite and iron scraps. The technology comprises the following steps: adding pyrolusite in a certain concentration of sulphuric acid solution, mixing evenly; adding iron scraps used as the reductant in a reaction tank, performing mechanical agitation for 1h-3h under different reaction temperatures to obtain reaction leachate; according to the changes of the reaction time and the pH value, adding heavy calcium carbonate and ammonia water in turn to adjust the pH value of the solution to 6.3-6.7; then adding sodium N,N-dimethyl dithiocarbaminate (SDD) to remove impurities such as heavy metal ions and purify; filtering, adding additive to obtain manganese sulfate solution used for electrolyzing manganese; and recycling iron from filter residue through alkali leaching and acid leaching to produce polyferric sulfate. The invention has the advantage that iron scraps are used as the reductant which have wide sources and rich raw materials and can be leached out under the atmospheric pressure; and iron scraps can be recycled to produce the water purification agent and have great economic benefit.

Owner:HUNAN UNIV OF SCI & TECH +1

Water quality improving method by algae control of compound ecological environment-protection algae control agent

InactiveCN101880100ASettling operation is convenientQuick resultsMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationEcological environmentWater quality

The invention discloses a water quality improving method by algae control of a compound ecological environment-protection algae control agent, which comprises the following steps: A. area selection: girding an experimental zone; B. algicide preparation: diluting hydrogen peroxide with tap water and arranging the hydrogen peroxide in the shade; C. flocculant preparation: preparing industrial-grade polyferric sulfate into a solution and diluting with water; D. lake sediment preparation: taking pythmic sediments, drying and crushing the sediments, preparing a turbid liquid, and stirring silt sunk into the bottom to the upper layer; E, the dosage and spraying condition of the algicide: uniformly spraying the diluted H2O2 in proportion in an enclosure with surface water bloom and spraying; F. sediment turbid liquid spraying: spraying the turbid liquid in proportion on the water surface in an atomization mode; and G. flocculation sedimentation implementation: sprinkling the polyferric sulfate solution into the water, stirring, standing still and settling. The method is simple and convenient to operate, has low cost, increases transparency, has obvious substrate improvement effect, has zero pollution on the water remediation, and has high environmental, social and economic benefits.

Owner:INST OF AQUATIC LIFE ACAD SINICA

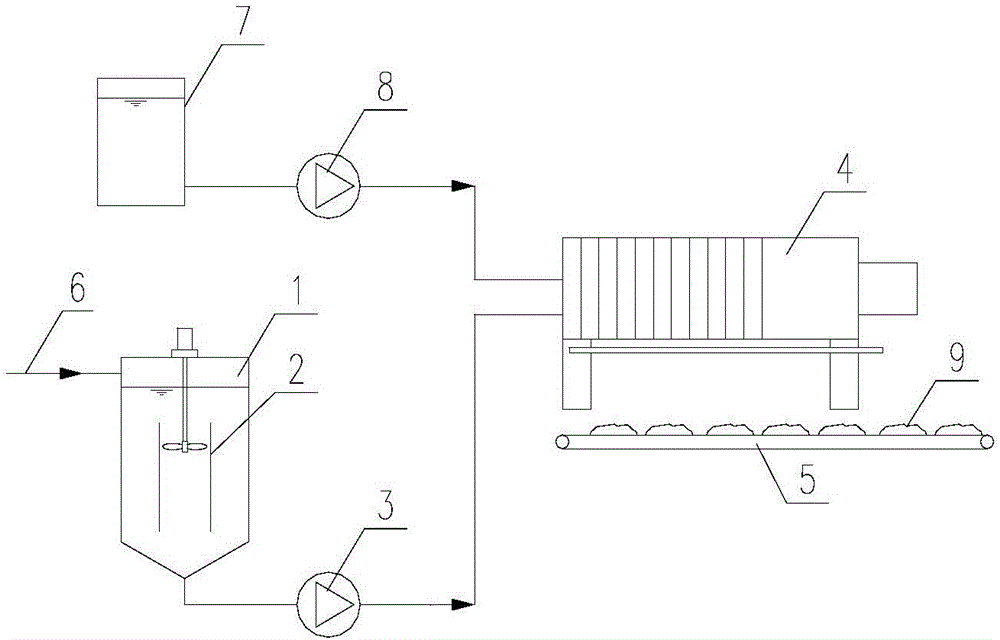

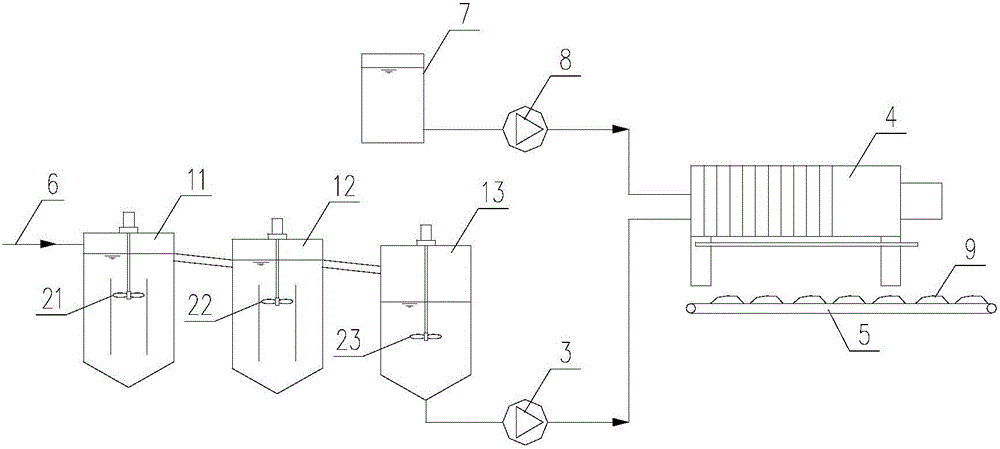

Method and equipment for dewatering municipal sludge with high dryness

InactiveCN105776812AImprove ventilationSuitable for growth and reproductionSludge treatment by de-watering/drying/thickeningDewatered sludgeMicrobiological growth

The invention relates to a method and equipment for dewatering municipal sludge with high dryness. The method comprises the following steps: putting to-be-treated sludge in a sludge treatment machine, and mixing and stirring with ferric sulfate or polymerized ferric sulfate; adding quick lime, and keeping on mixing and stirring to obtain treated sludge having neutral pH; and starting a feed pump of a filter press, pumping the treated sludge in the high-pressure diaphragm frame filter press, squeezing to obtain dewatered sludge cake, opening a filter plate, and delivering the dewatered sludge cake on a belt conveyer to the outside. The equipment comprises the sludge treatment machine, a sludge inlet pipe, the feed pump of the filter press, the high-pressure diaphragm frame filter press, a squeezing water pump, a squeezing water tank and the belt conveyor. According to the method, the dewatered sludge cake has a water content of less than 60 percent, has good ventilation after being ground, is suitable for growth and reproduction of microorganisms, can be directly subjected to aerobic fermentation, can be used for directly realizing reduction, harmlessness and resource of sludge, and is beneficial to sustained development.

Owner:王树岩

Advanced treatment method of urban reclaimed water for power plant

InactiveCN101985382ASolve processingSolve the bactericidalMultistage water/sewage treatmentWater useIron sulfate

The invention relates to an urban reclaimed water treatment method, in particular to an advanced treatment method of urban reclaimed water used as cooling water for a power plant. The advanced treatment method of urban reclaimed water for the power plant of the invention comprises the following steps: carrying out aeration treatment and filtering; adding slaked lime, coagulant polyferric sulfate and efficient coagulant aid; adding bactericide for sterilizing; and adding composite scale and corrosion inhibitor, and after mixing the mixture evenly, adding the mixture to circulating water of the power plant. The advanced treatment method of the invention solves the related technical problems of advanced treatment, sterilization, scale inhibition, corrosion prevention, ammonia nitrogen treatment and the like of the reclaimed water involved by reclamation of the reclaimed water in the power plant, and provides technical support for safe and economical use of the reclaimed water in the power plant, and the reclaimed water is used as make-up water for the circulating water in the power plant, and has very obvious economical, social and environmental benefits.

Owner:STATE GRID OF CHINA TECH COLLEGE

Water quality modifier

InactiveCN103588274AQuality improvementReduce harmful effectsWater/sewage treatment by neutralisationWater/sewage treatment using germicide/oligodynamic-processSolubilityWater source

A disclosed water quality modified is composed of disodium ethylene diamine tetraacetate, citric acid, potassium monopersulfate triple salt, polyferric sulfate and phytic acid according to a weight ratio. The water quality modifier is good in water solubility, helps to purify water, improve water quality, reduce the mortality and elimination rate and increase breeding income, is widely applicable to modification on poultry and livestock drinking water and aquaculture animal water source.

Owner:TAIAN DAIYUE DISTRICT SHANNONG GAOKE VETERINARY MEDICINE RES INST

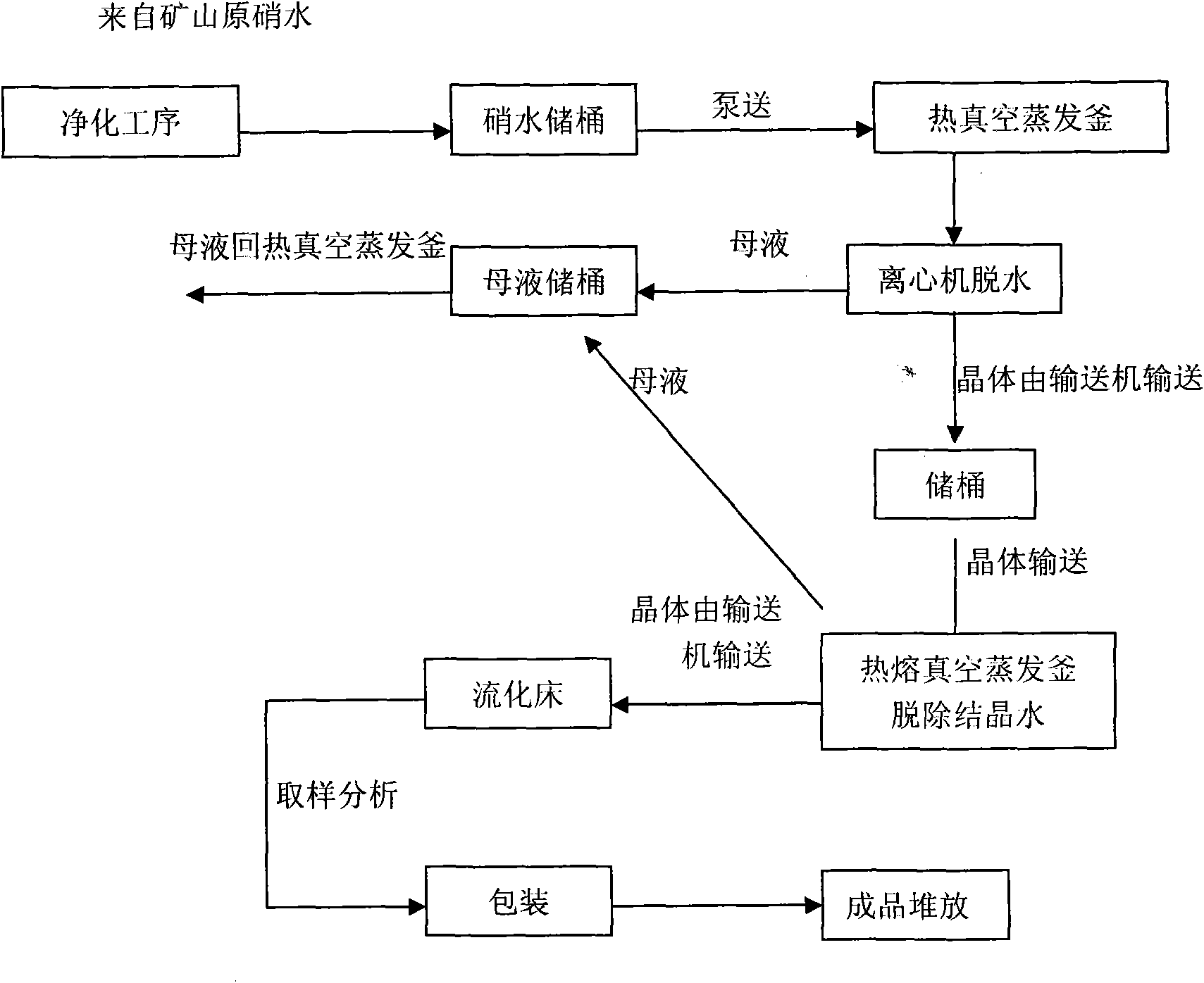

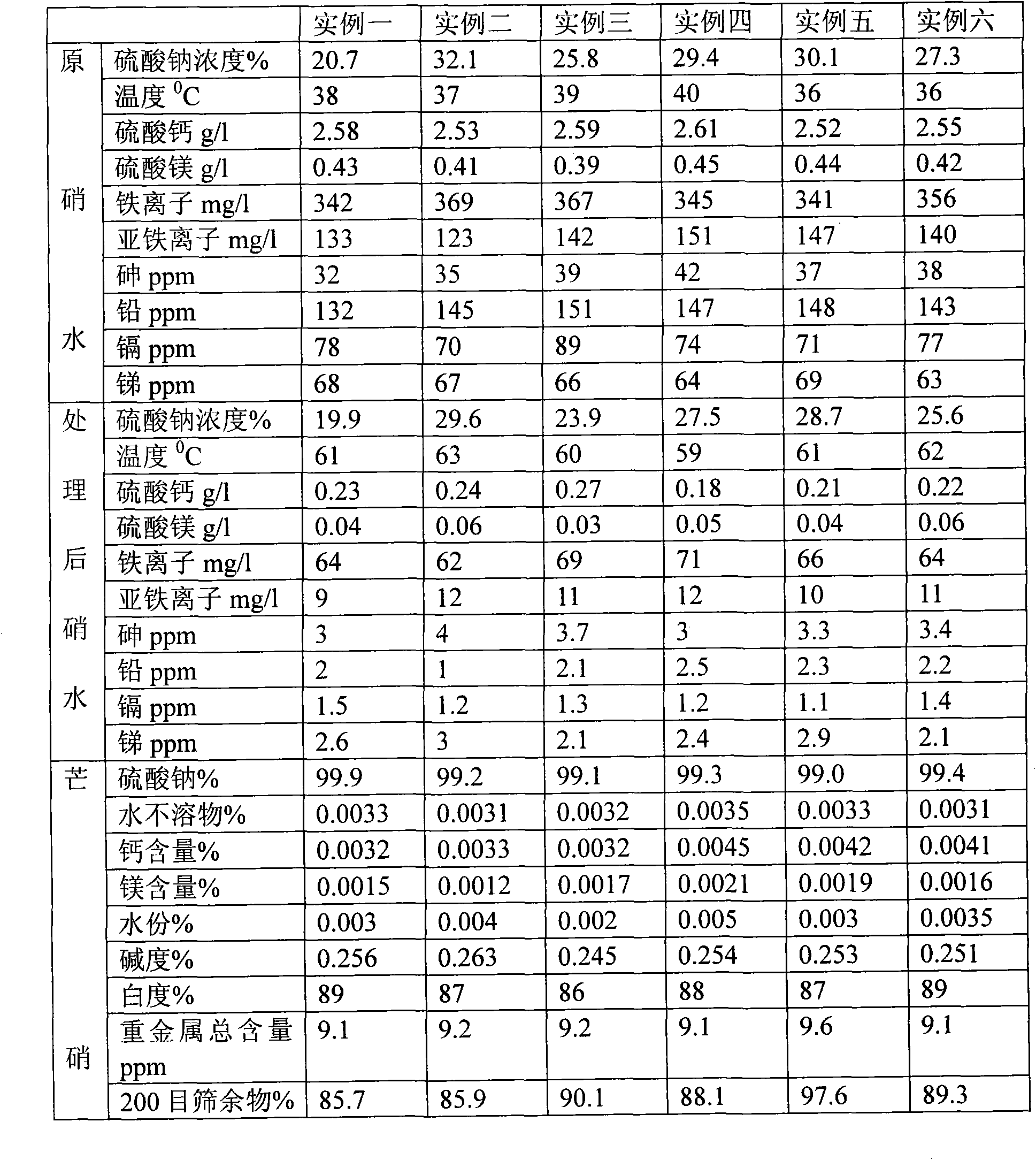

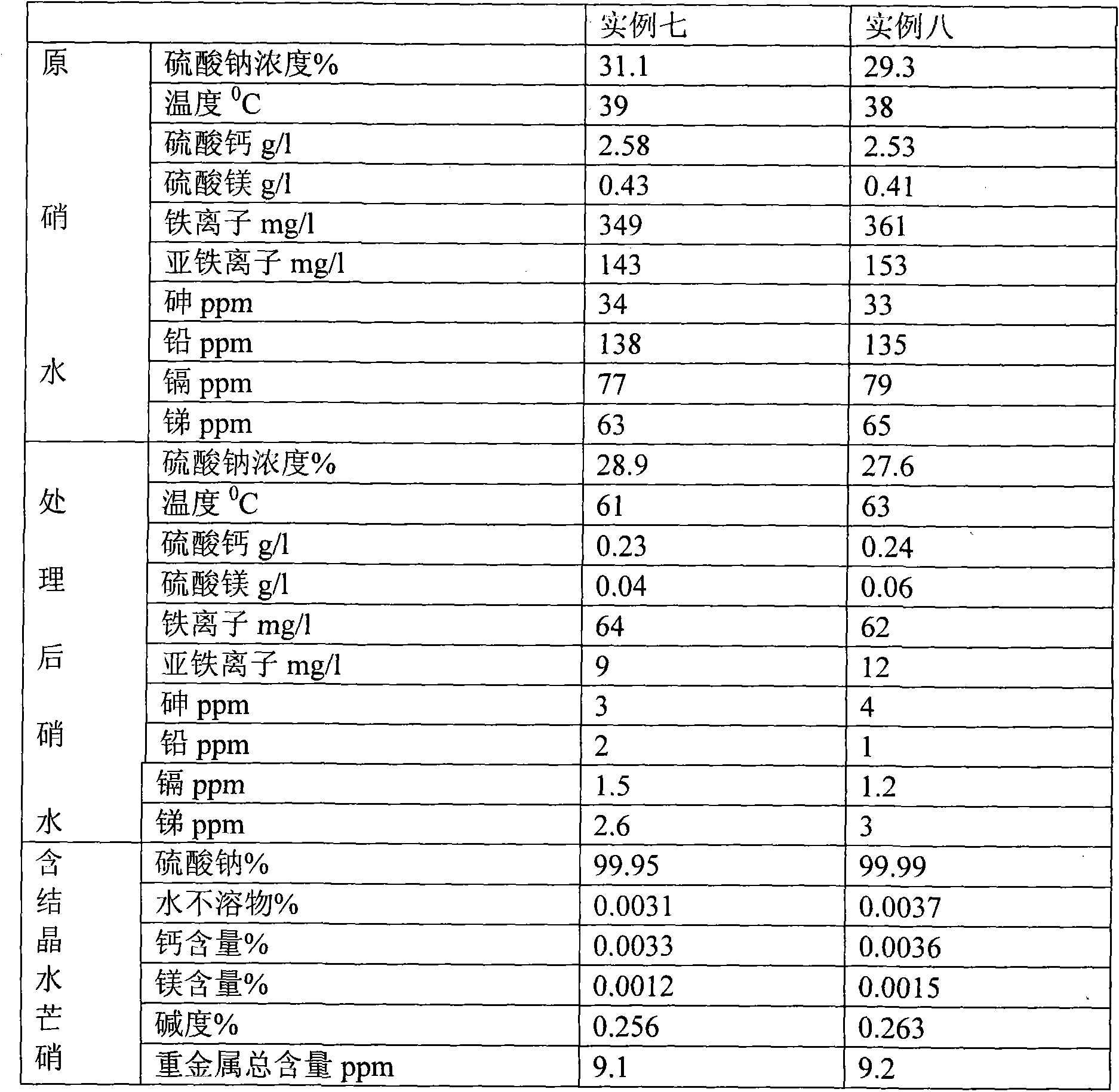

Method for preparing special mirabilite with high purity

The invention provides a method for preparing special mirabilite with high purity, which comprises the following steps: pumping hot water at 40 DEG C-70 DEG C by a pump and dissolving mirabilite in ore to form niter water containing various impurities; calculating the content of added sodium carbonate with the excess of 10 percent-20 percent according to the detected content of calcium and magnesium ions in the original niter water during chemical impurity removal processing; calculating the content of added sodium sulfide with the excess of 20 percent-30 percent according to the detected content of heavy metal ions including ferrum, arsenic, lead, cadmium, antimony, and the like in the original niter water; then adding sodium hydroxide to lead the pH value of the niter water to reach 9-11; adding 0.1-0.3 percent by weight of polyferric sulfate and polyaluminum-ferric chloride sulfate to enable various generated sediments to settle; and finally adding sulfuric acid to adjust the pH value of the niter water to reach 7-7.5. The wet niter containing crystal water is processed by a fluidized bed after standing at 45 DEG C-80 DEG C for 0.5 hour-3 hours in a heat preservation way, thereby obtaining anhydrous special mirabilite with high purity. The mirabilite can not be caked during long-term placement at room temperature and can be widely applied to industries of foods, medicines, and the like.

Owner:四川川眉特种芒硝有限公司

Waste water processing medicine capable of realizing high efficiency decolouring, decyanation, and degradation of COD

ActiveCN109384276AEfficient decolorizationEffective decolorizationWater contaminantsSustainable biological treatmentAluminum silicateWater processing

The invention relates to a waste water processing medicine capable of realizing high efficiency decolouring, decyanation, and degradation of COD. The waste water processing medicine capable of realizing high efficiency decolouring, decyanation, and degradation of COD comprises, by weight, 10 to 70 parts of active carbon, 10 to 60 parts of diatomite, 1 to 30 parts of a ferric salt, 1 to 30 parts ofan aluminum ferric salt, and 0.5 to 15 parts of a strong oxidant; the ferric salt is one selected from polymeric ferric sulfate, polymerization ferric chloride, and ferrous sulphate; the aluminum ferric salt is one selected from polyaluminum ferric chloride, polymeric ferric aluminum silicate, and polymeric aluminum ferric sulfate. The advantages are that: excellent flocculation, adsorption, andhigh oxidation functions are achieved; the waste water processing medicine can be used for removing cyanides and COD in waste water at the same time, and is capable of realizing effective decolouring;obtained processed water is low in chroma; efficiency is high; no equipment corrosion is caused; and the preparation method is simple.

Owner:鞍山市鑫诚水处理有限公司

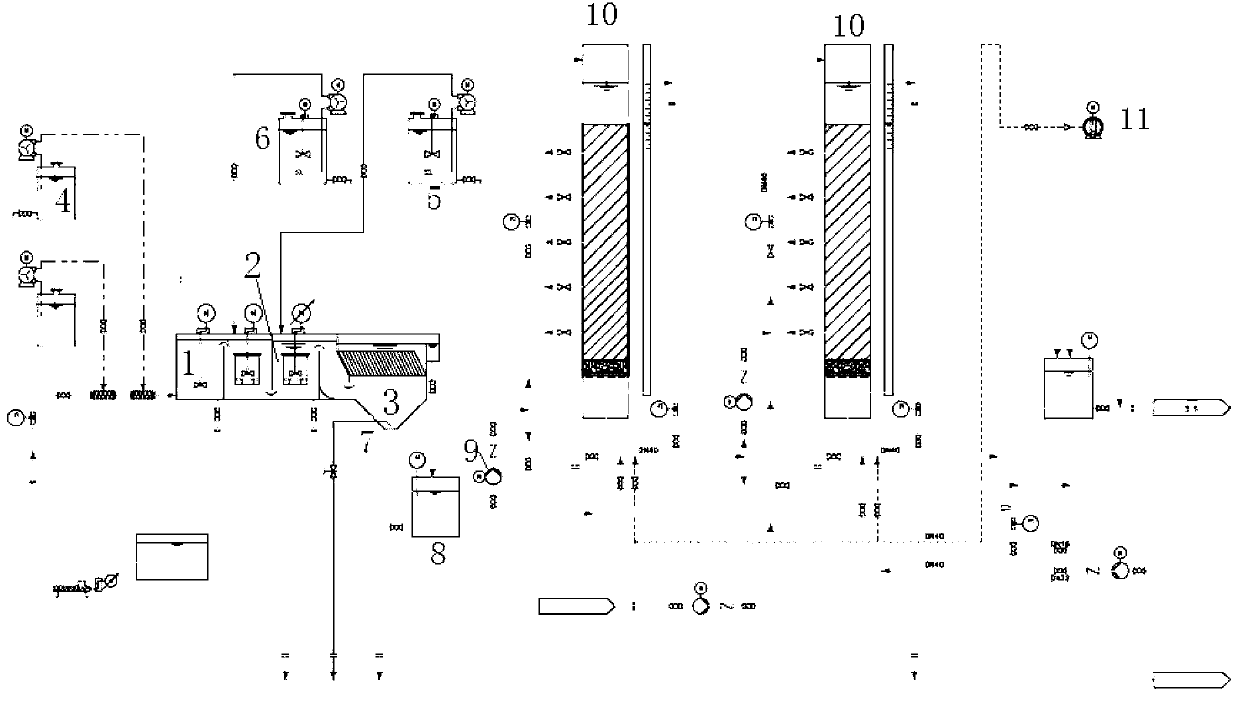

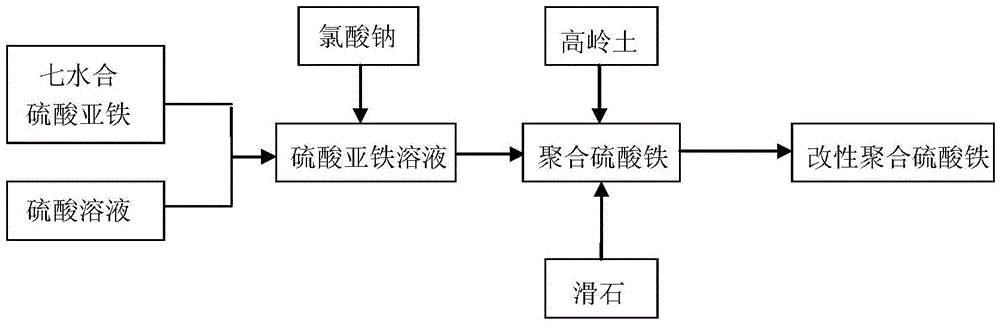

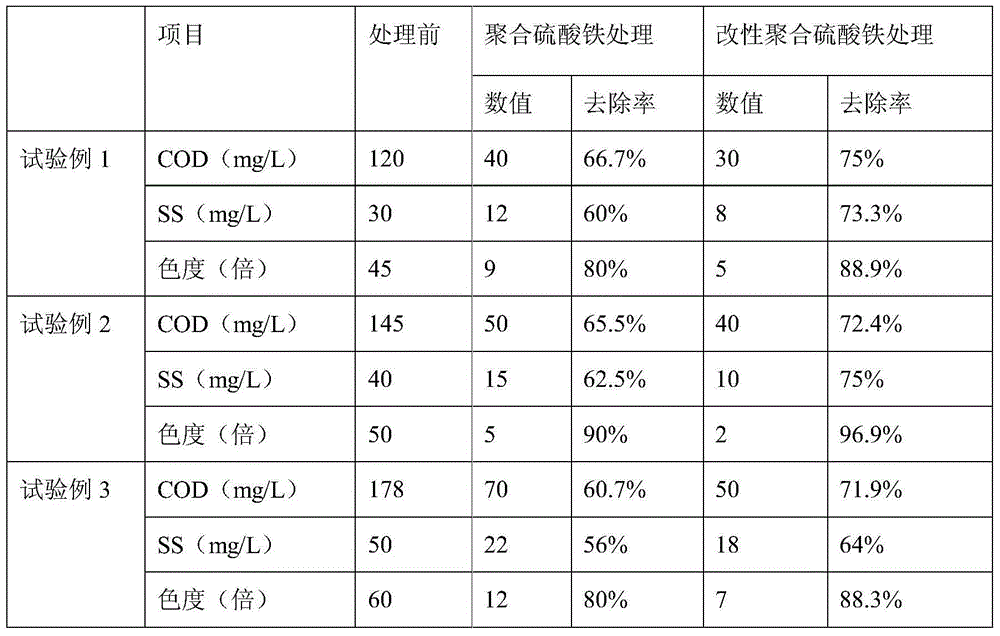

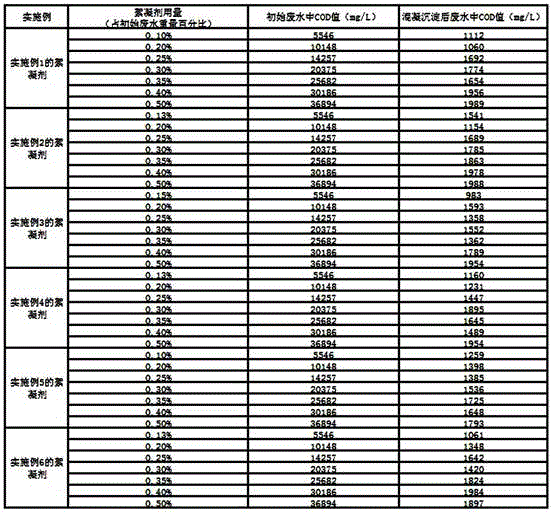

Preparation method and application of modified polyferric sulfate for treating industrial wastewater

ActiveCN104478050ASimple processLow priceIron sulfatesWaste water treatment from plant processingChemical oxygen demandIndustrial waste water

The invention provides a preparation method of modified polyferric sulfate. Kaolin and talcum are utilized to perform modification treatment on the polyferric sulfate. When the modified polyferric sulfate is used in a waste paper papermaking advanced wastewater treatment technique, the pollutant removal ratio is high, and the chroma removal effect is good: the removal ratio of the modified polyferric sulfate for COD (chemical oxygen demand) in wastewater is up to 71.9-75%, the SS (suspended sediment) removal ratio is up to 64-75%, and the chroma removal ratio is up to 88.3-96.9%. Under the same conditions, compared with the polyferric sulfate, the COD removal ratio is enhanced by 8.3-11.2%, the SS removal ratio is enhanced by 9-12.5%, and the chroma removal ratio is enhanced by 6.9-8.3%. The modified polyferric sulfate has high flocculation speed and has the same decolorization effect; and the consumption of the modified polyferric sulfate is greatly lower than that of the polyferric sulfate, so the generated chemical sludge quantity is low, thereby saving the cost and simplifying the technique.

Owner:ZHENGZHOU UNIV

Preparation method of organic high-polymer flocculant, and preparation method and application of inorganic-organic high-polymer composite coagulant

InactiveCN104761038AGood effectSimple processWater/sewage treatment by flocculation/precipitationEngineeringPolymer composites

The invention discloses a preparation method of an organic high-polymer flocculant, and a preparation method and application of an inorganic-organic high-polymer composite coagulant. The preparation method of the organic high-polymer flocculant comprises the following step: in the presence of an initiator and a chelator, carrying out solution polymerization on dimethyl diallyl ammonium chloride monomer to obtain a polydimethyl diallyl ammonium chloride colloidal solution which is the organic high-polymer flocculant. The preparation method of the composite coagulant comprises the following steps: 1) heating and mixing a polyferric sulfate solution with the colloidal solution to obtain a colloid mixed solution; and 2) keeping the temperature, and dispersing until the mixed solution forms a homogeneous system. The invention also discloses application of at least one of the prepared flocculant and inorganic-organic high-polymer composite coagulant in coagulative purification or sludge dewatering treatment of polluted water bodies. The technique is simple, and the prepared composite flocculant has favorable effect. The flocculant and coagulant can be used for micropolluted water source-water coagulative purification, special wastewater treatment, sludge dewatering and the like, and are simple and quick to operate.

Owner:DONGGUAN UNIV OF TECH +1

Compound treatment agents for oily sludge containing polymers and usage method thereof

ActiveCN108911447AEasy to oozeHigh recovery rateWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningOil sludgeSodium sulfate

The invention discloses compound treatment agents for oily sludge containing polymers and a usage method thereof, and belongs to the technical field of polymer-containing oily sludge treatment in petroleum oilfield. The compound treatment agents for the oily sludge containing the polymers comprise an agent A, an agent B, an agent C and an agent D; the agent A is composed of sodium carbonate, sodium silicate and sodium hydroxide; the agent B is composed of an OP emulsifier, Peregal, Triton X-100 and sodium dodecyl benzene sulfonate; the agent C is composed of sodium hypochlorite and hydrogen peroxide; and the agent D is composed of aluminum sulfate, sodium sulfate and polyferric sulfate. The usage method of the compound treatment agents for the oily sludge containing the polymers comprisesthe following steps: a, putting oily sludge containing polymers into a reaction kettle, adding water, and carrying out heating with stirring; b, adding the agent A and carrying out uniform stirring, adding the agent B and carrying out uniform stirring, adding the agent C and carrying out uniform stirring, and adding the agent D and carrying out uniform stirring; and c, performing standing-precipitating on the mixture of the oily sludge and the water, and separately retrieving oil, sludge and water after stratification. The compound treatment agents for the oily sludge containing the polymers and the usage method thereof are capable of realizing effective separation on the three phases of oil, sludge and water in the oily sludge containing the polymers so as to achieve reduction and resource recycling; and thus, the problem of performing harmless treatment and resource recycling on hazardous solid waste from oilfield is effectively solved.

Owner:中科亿诚(珠海)环保技术有限公司

Emulsified liquid waste water treatment method

InactiveCN101700951AEasy to separateLess sludgeSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesThree levelActivated sludge

The invention discloses an emulsified liquid waste water treatment method; in the method, active life sludge culture is carried out to domestic sewage, the life sludge generated in the domestic sewage treatment process is utilized to carry out adsorption treatment to pollutants of the emulsified liquid waste water, so as to skillfully use nutritive materials in the domestic sewage and the active sludge generated in the domestic sewage treatment process. Heating treatment and the operation of feeding the combination of lime milk and polyacrylamide PAM are carried out in the emulsified liquid breaking and solid-liquid separation links, aluminium polychlorid or polyferric sulfate or other coagulant is not used, the sludge amount is less and the solid-liquid separation effect is good when sedimentation is carried out. A chemical method, a microorganism method and a physical method are systematically combined, by adopting skillful process combination and on the basis of low cost operation, the oil content of the generated solid sludge is low, so as not to need to treat the solid sludge as hazardous waste and lead the emulsified liquid waste water to reach the three-level discharge standard requirements of GB8978-1996 integrated wastewater discharge standard.

Owner:无锡市林信环保工程有限公司

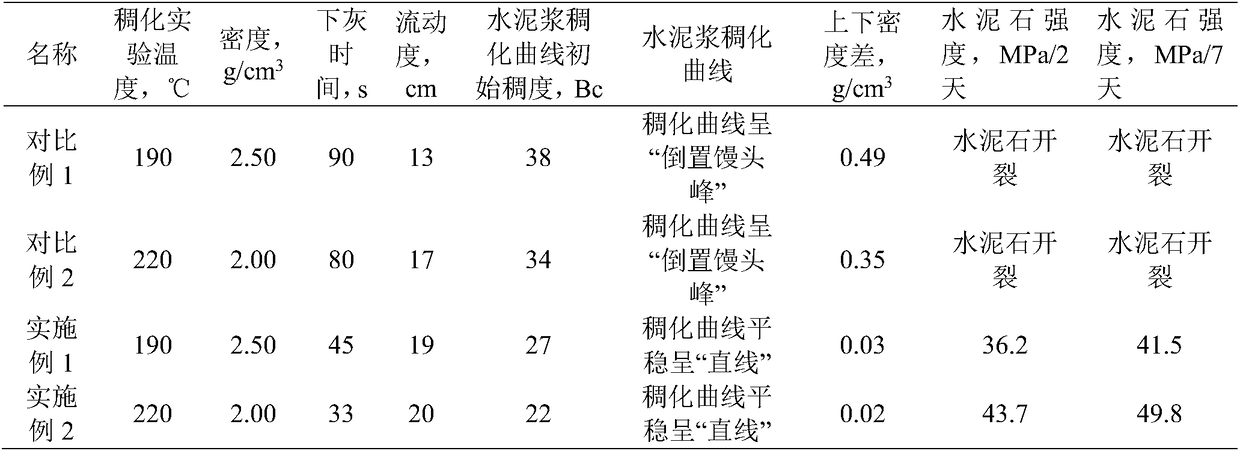

Suspension stabilizer for high-temperature cement paste and high-temperature-resistant cement paste prepared by same

ActiveCN108706927AIncrease surface tensionEnhance structural strengthDrilling compositionAluminium chlorideIron sulfate

The invention discloses a suspension stabilizer for high-temperature cement paste and high-temperature-resistant cement paste prepared by the same. The suspension stabilizer is formed by the followingcomponents according to the parts by weight: 0.5-4 parts of a fiber material, 1-5 parts of a surfactant powder material, and 0.5-2 parts of a flocculant powder material. The fiber material is a mixture of one or two materials in whisker, sepiolite, ceramic fibers, basalt fibers, and brucite fibers. The surfactant powder material is one of lauryl sodium sulfate, sodium dodecyl sulfate, hexadecylsulfonic acid sodium salt, sodium octadecyl benzene sulfonate, petroleum sodium sulfonate, white dextrin and yellow dextrin. The flocculant powder material is one of polyferric sulfate, aluminum polychlorid, and poly-aluminum ferric silicate sulfate. The high-temperature-resistant cement paste prepared by using the suspension stabilizer is low in initial consistence, and good in sedimentation stability. The suspension stabilizer is capable of improving the high-temperature suspension stability and the set cement strength of the cement paste, and providing technical support for the exploration and development of deep oil and gas resources.

Owner:CNPC DRILLING RES INST +2

Potato starch waste water macro-molecule organic matter separation treatment special-purpose flocculating agent

InactiveCN105540805APlay a synergistic roleHigh removal rateWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionIron sulfatePotato starch

The invention provides a potato starch waste water macro-molecule organic matter separation treatment special-purpose flocculating agent. The flocculating agent comprises, by mass, 20-30% of ultrafine attapulgite, 18-22% of polyacrylamide, 5-10% of iron chloride, 8-12% of urea, 15-19% of polyaluminum chloride, 17-21% of polyferric sulfate and 1-2% of natural cation polysaccharide chitosan. The organic matters and inorganic matters are compounded and produce synergism so that flocculation effects are obviously improved and a COD clearance rate is improved to 90%. Through the special-purpose flocculating agent, after one flocculating settling process, the potato starch waste water has a COD concentration reduced to 1000-2000mg / L from 10000-30000mg / L and the black waste water becomes clear and transparent.

Owner:GANSU BUILDING MATERIALS DESIGN & RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com