Advanced treatment method for urban water of electric power plant

A technology for urban reclaimed water and advanced treatment, which is applied in multi-stage water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problem of organic matter content, high ammonia nitrogen content, and complex bacterial population , Corrosive microorganisms and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

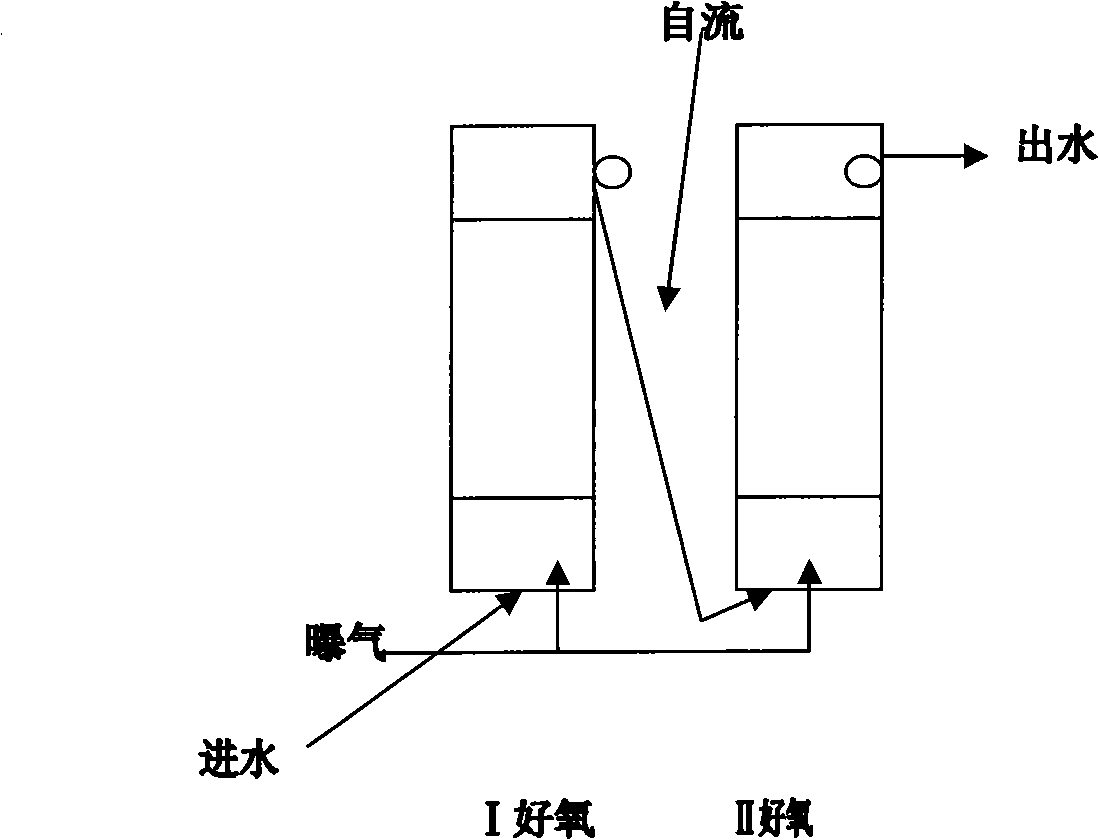

[0016] The urban reclaimed water advanced treatment method for power plants of the present invention relies on the reclaimed water advanced treatment project of Huadian International Zouxian Power Plant 2*1000MW expansion unit to carry out specific experiments. The source of reclaimed water is the secondary discharge water from Zoucheng Wastewater Treatment Plant.

[0017] 1: Static simulation test

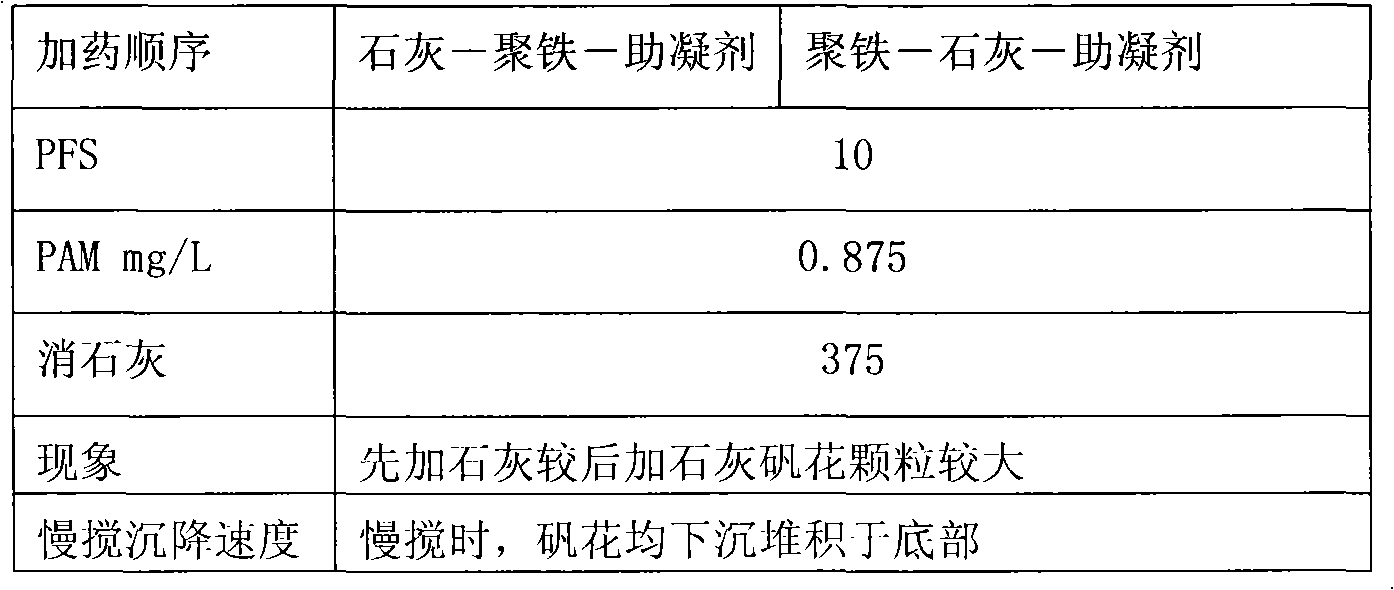

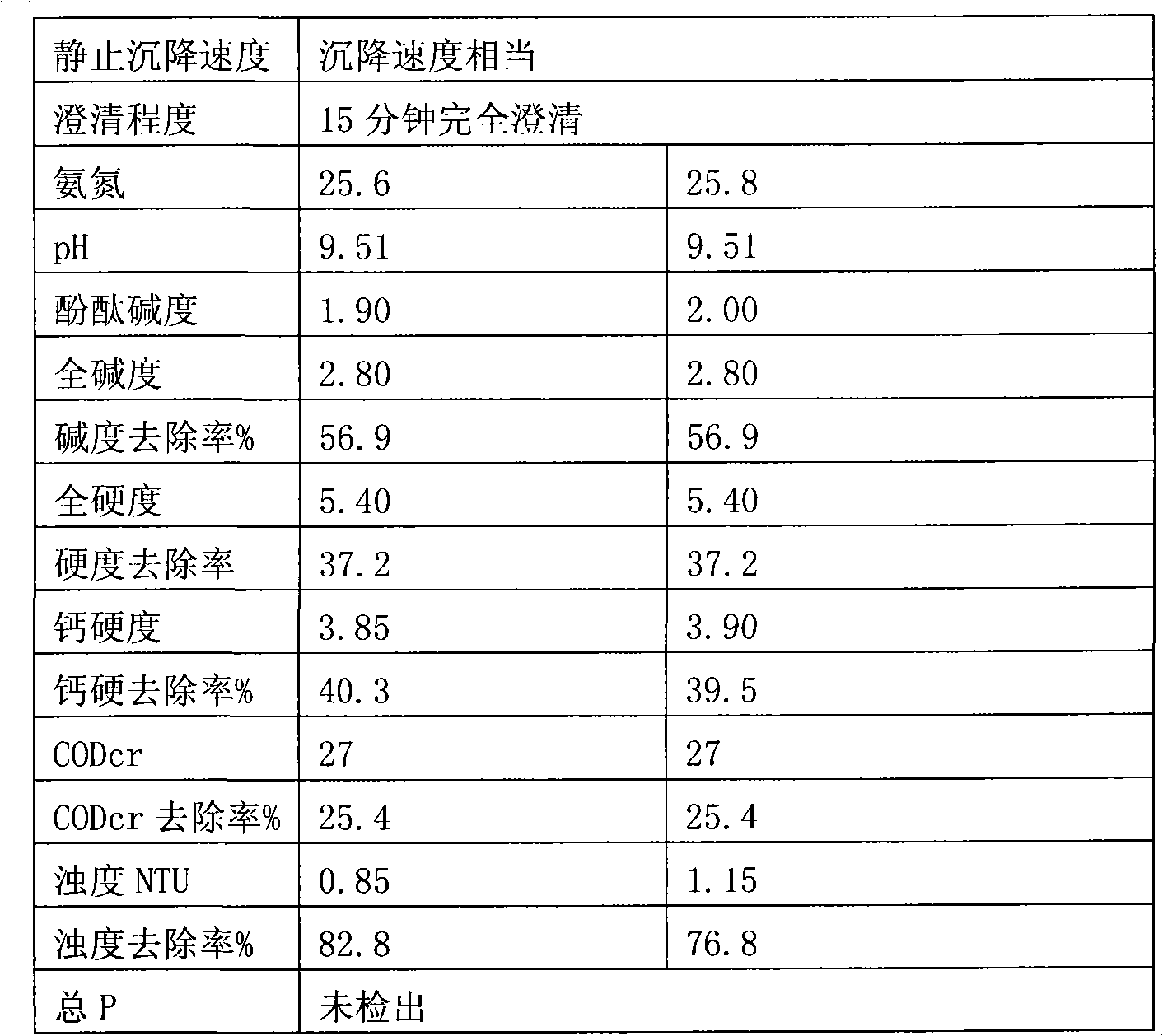

[0018] 1. Lime-coagulation treatment static simulation test of the present invention

[0019] The agents used in the static simulation test are slaked lime, coagulants and coagulants, etc.:

[0020] Slaked lime: solid powder, purity ≥ 94%, fineness: 325 mesh;

[0021] Coagulant: polyferric sulfate (PFS): liquid, total iron content ≥ 10%, density: ≥ 1.45g / cm 3 ;

[0022] Coagulant aid: anionic, cationic polyacrylamide (PAM), solid powder, solid content ≥ 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com