Patents

Literature

185results about How to "Reduce arsenic levels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Holothurian peptide functional food and preparation method thereof

InactiveCN101341978AAvoid residueSave the hassleProtein composition from fishAnimal proteins working-upDiseaseAdditive ingredient

The invention discloses a sea cucumber polypeptide functional food and a preparation method thereof which not only remarkably improves the content of polypeptide, but also has no chemical residues; the contents of salt and arsenic are low; the food is healthier and safer to eat; simultaneously the food is simply operated, easily controlled, is effective and saves energies. The key technical scheme includes: selecting a compound protease of Protamex and needing not to adjust the pH value of materials; carrying out processes of desalting and arsenic removing on an enzymolysis liquid; more than 80 percent of the molecular weight of the product is between 100 to 6000Dalt; wherein, the small polypeptide of 100 to 2100Dalt is more than 70 percent; the product components and the content weight percentages are as follows: 50 to 60 percent of polypeptide, 5 to 10 percent of free amino acids, 2.5 to 7.5 percent of mucoitin as well as containing the inherent nutrition components of a plurality of minerals and vitamins of the sea cucumber. The product has the effects of resisting knub, reducing blood pressure, preventing cardio-cerebrovascular diseases, resisting fatigue, delaying senescence, improving the immunity. The food can be used as a healthy food to eat and can also be used as a food and a medicine additive.

Owner:DALIAN FEIDE BIOIND

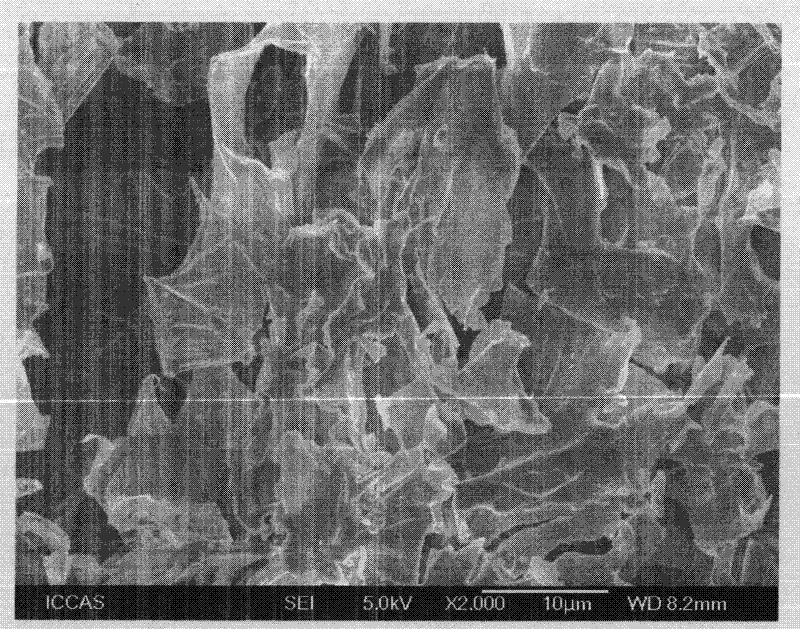

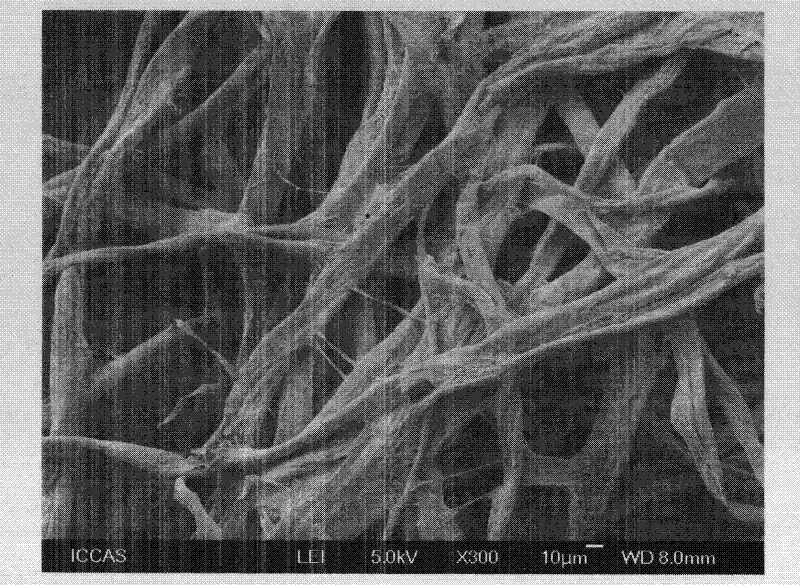

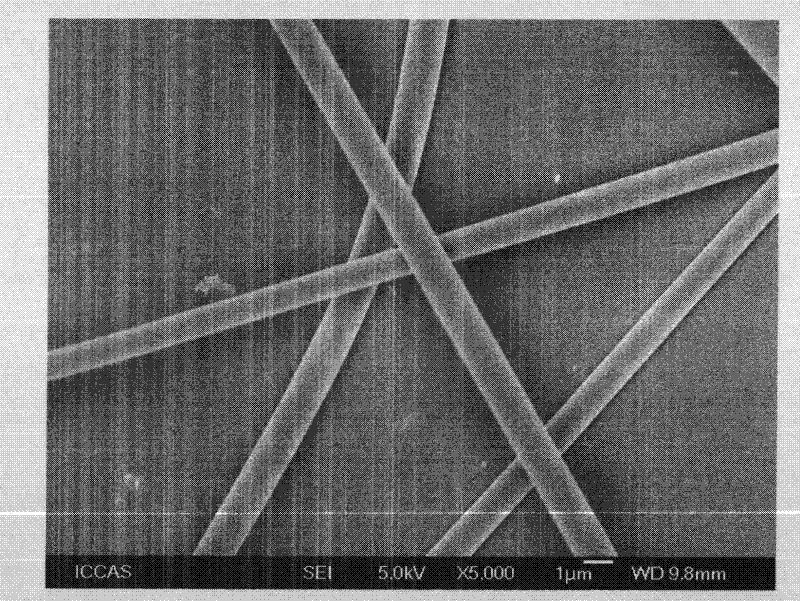

Cellulose base/Fe3O4 composite adsorption material used for removing arsenic in water and preparation method thereof

ActiveCN102476043AImprove adsorption capacityWide working pH rangeOther chemical processesWater/sewage treatment by sorptionAlkaline waterNational standard

The invention relates to a cellulose base / Fe3O4 composite adsorption material used for removing arsenic in water and a preparation method thereof. According to the invention, with fibers or powder of natural cellulose or fibers of a cellulose derivative as a cellulose matrix material for the composite adsorption material, in an alkaline water system provided by ammoniacal liquor, Fe3O4 particles are loaded on the surface of the cellulose matrix material through in-situ co-precipitation, and the loaded Fe3O4 particles enable the obtained cellulose base / Fe3O4 composite adsorption material to have magnetism and to be easily removed from water, and allow harmful ions like arsenate ions and arsenite ions in water to be absorbed. Compared to arsenic removal materials in the prior art, the invention has the following characteristics: a natural biomass is used as an adsorption carrier, and the natural biomass is cheap and highly efficient, enables the content of arsenic in water to be substantially lower than a national standard and is easy to remove and convenient to use.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

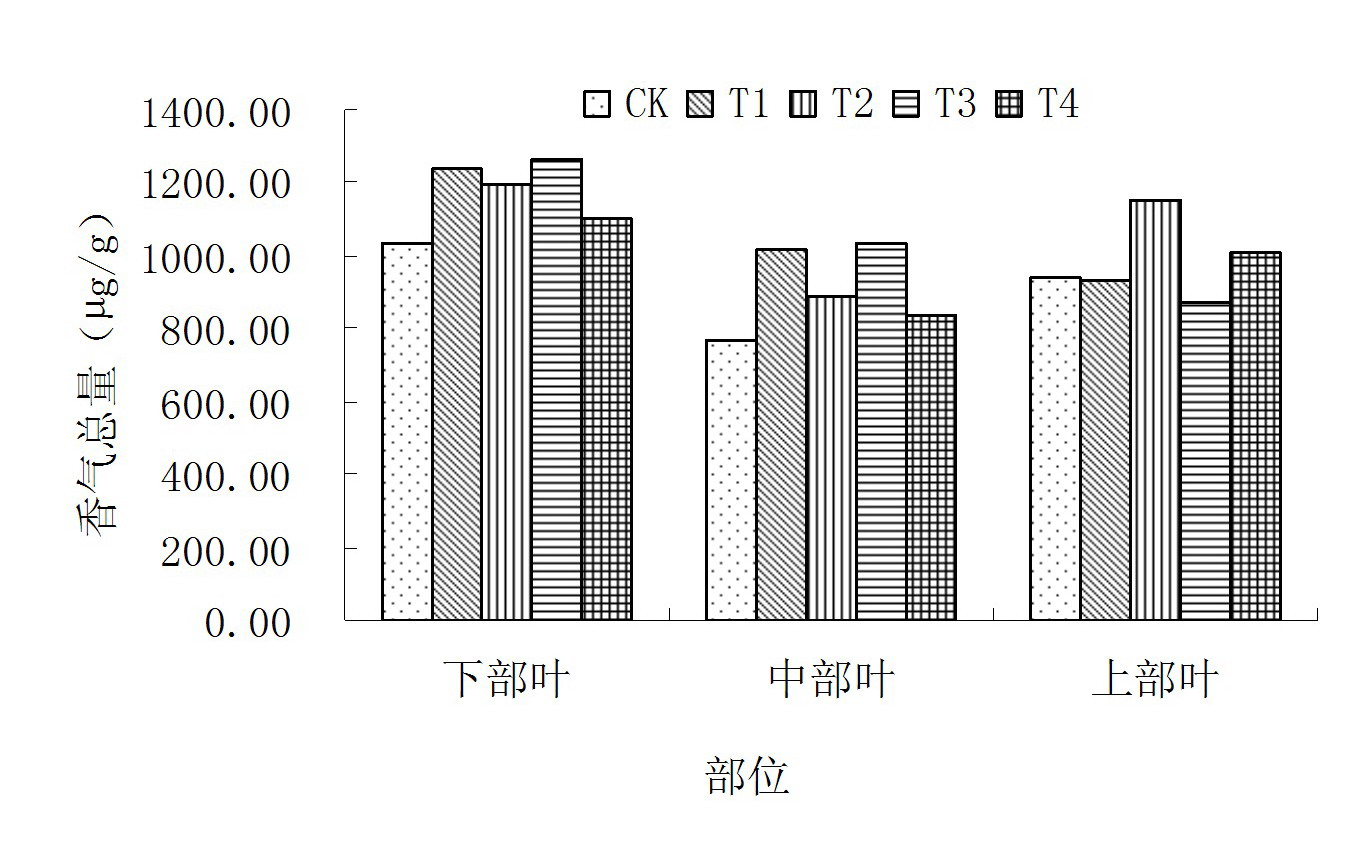

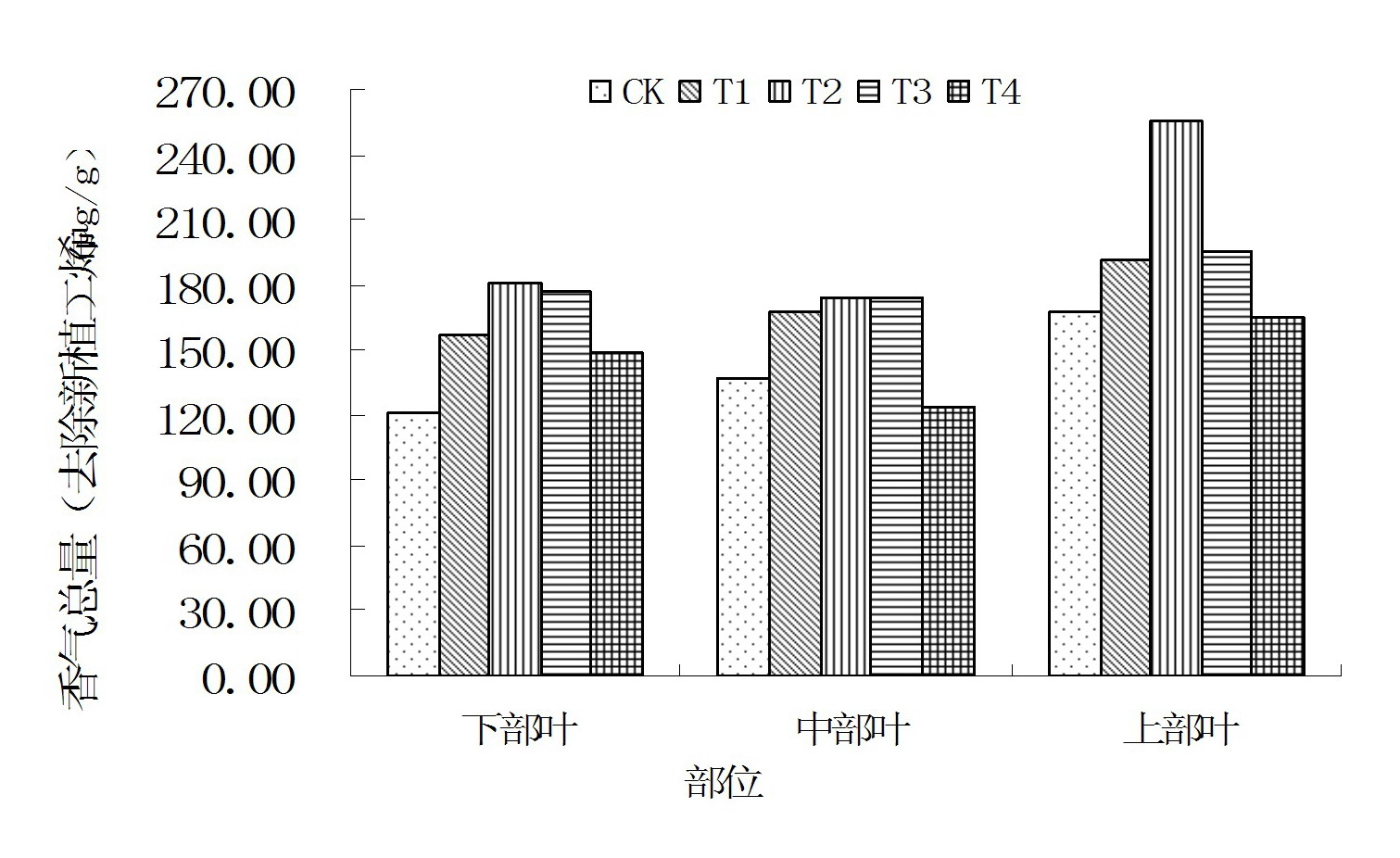

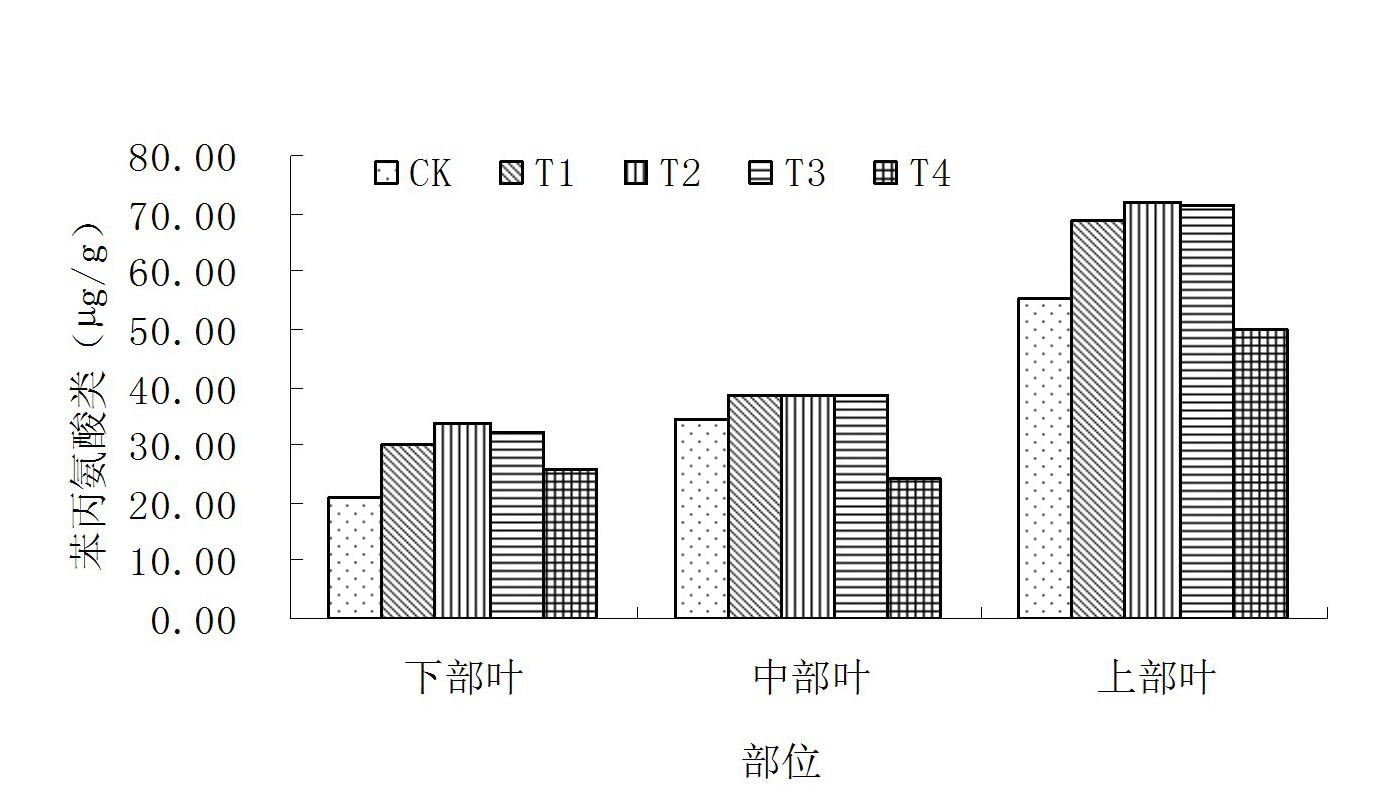

Fertilizer capable of improve tobacco soil and promote growth of root

ActiveCN101973824AIncrease soil organic matterPromotes plant root developmentFertilizer mixturesCuring of tobaccoNicotiana tabacum

The invention relates to a fertilizer capable of improve the tobacco soil and promote the growth of roots. The fertilizer comprises the following components by weight percent: 60-90% of humus type organic carrier, 4-10% of rooting powder or root growth promoter, 2-5% of plant growth hormone, 2-5% of potassium sulfate and 2-10% of secondary element / trace element fertilizer. By using the fertilizerof the invention, the soil can be improved, the soil organic matters can be increased, the soil organic and inorganic composites can be improved, the water-stable aggregate structure is easy to form,the supply of soil nutrients can be coordinated, the growth of plant roots can be promoted, the effectiveness of nutrients in soil can be increased, the potassium content of plant tissues can be increased, the organic matters of the tobacco soil can be increased, the effectiveness of nutrients in the tobacco soil can be increased, the growth of tobacco can be promoted, the potassium content of tobacco leaves can be increased, the quality of the flue-cured tobacco leaves can be improved, and the fragrance of tobacco leaves can be increased. By using a defined amount of the fertilizer of the invention, the absorption of the flue-cured tobacco to heavy metals such as arsenic can be reduced, the heavy metal enrichment factor of the flue-cured tobacco can be reduced and the contents of heavy metals such as arsenic in soot and smoke can also be reduced.

Owner:HENAN AGRICULTURAL UNIVERSITY

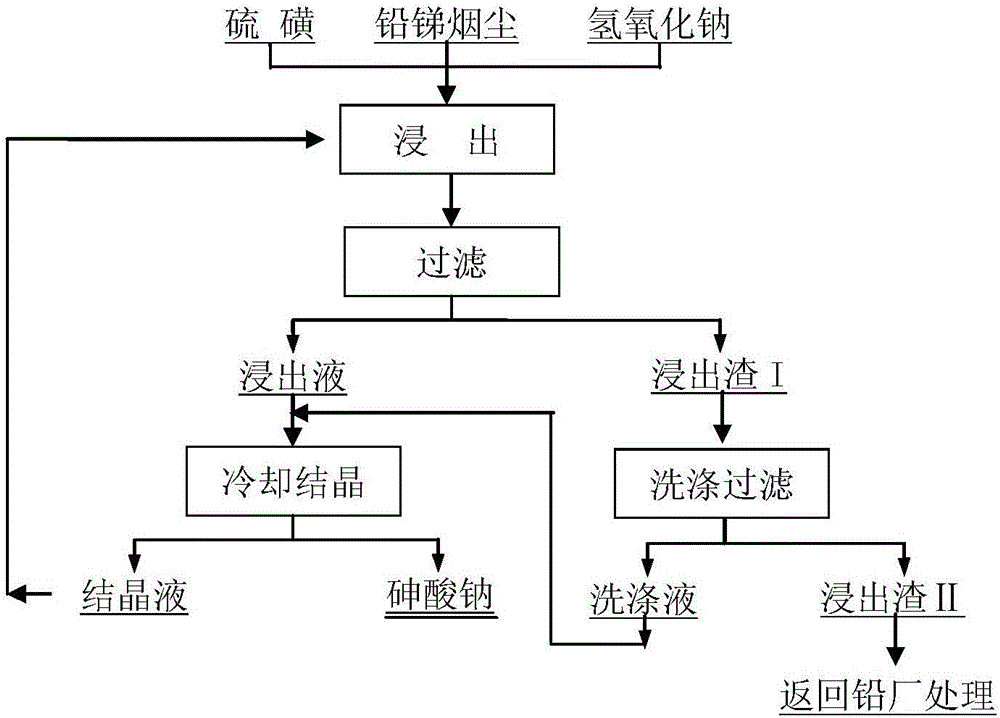

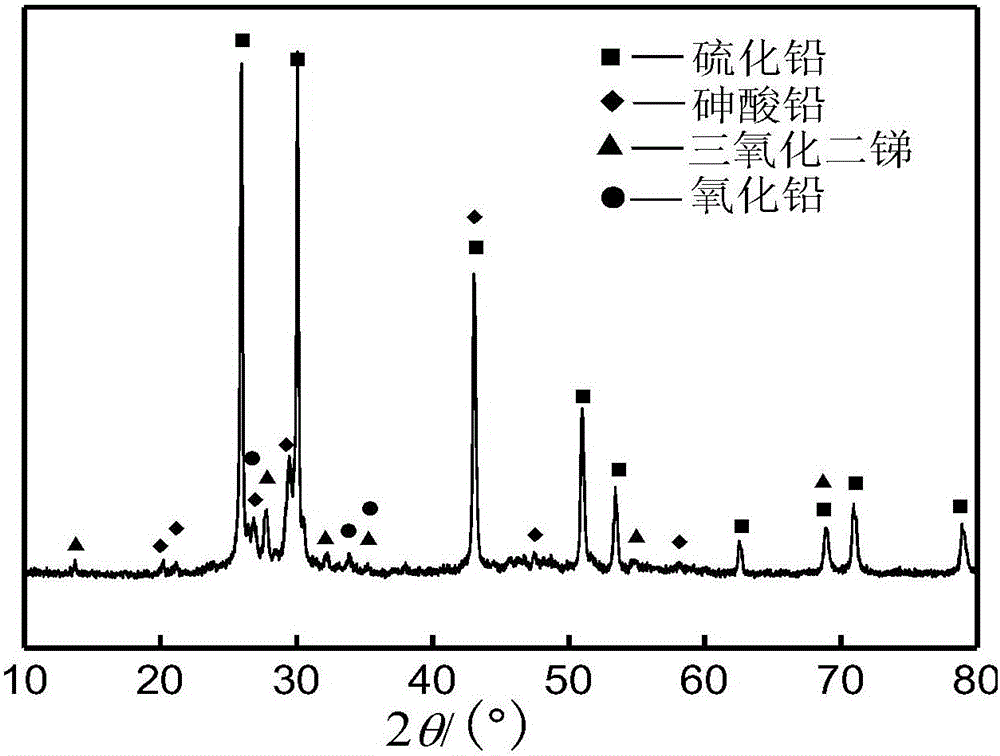

Method for preferably removing arsenic in lead and antimony smoke

ActiveCN105039722AHigh removal rateAchieve selective removalProcess efficiency improvementPregnant leach solutionRoom temperature

The invention discloses a method for preferably removing arsenic in lead and antimony smoke. The method comprises the following steps that firstly, sulphur and the lead and antimony smoke are mixed according to the mass ratio of 0.01-0.5:1, then the mixture is added into a sodium hydroxide solution to be leached, and meanwhile the temperature of the solution is kept within the range from 50 DEG C to 100 DEG C; secondly, liquid and solid separation is carried out on the solution leached in the first step, and a leaching agent and leaching residues are obtained; the leaching residues are washed, washing water obtained after washing is completed and the leaching agent are mixed and cooled to the room temperature, and filtering is carried out to obtain sodium arsenate crystal and crystalline liquid; and the crystalline liquid is used for leaching of the lead and antimony smoke in the first step. According to the technology method, the loss of valuable metal such as lead, antimony and zinc in the arsenic leaching and removing process is reduced through the adding of sulphur, meanwhile, the arsenic removing rate is increased, and selective removing of arsenic is achieved. The leaching rate of arsenic can reach 99% or more, and the content of arsenic in the leached residues can be reduced to 0.1% or lower.

Owner:CENT SOUTH UNIV

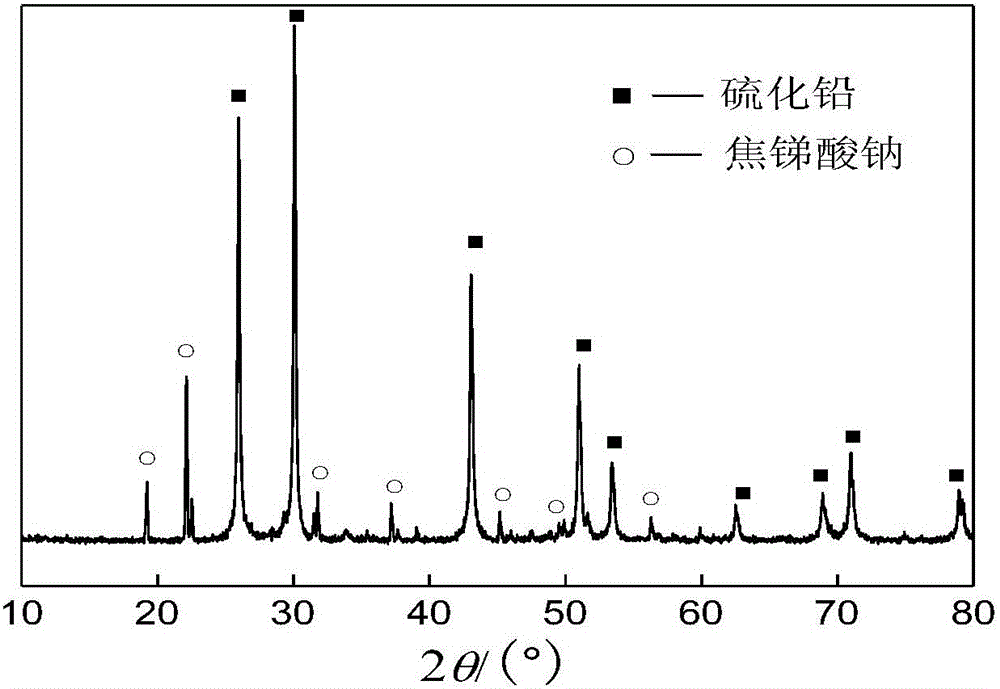

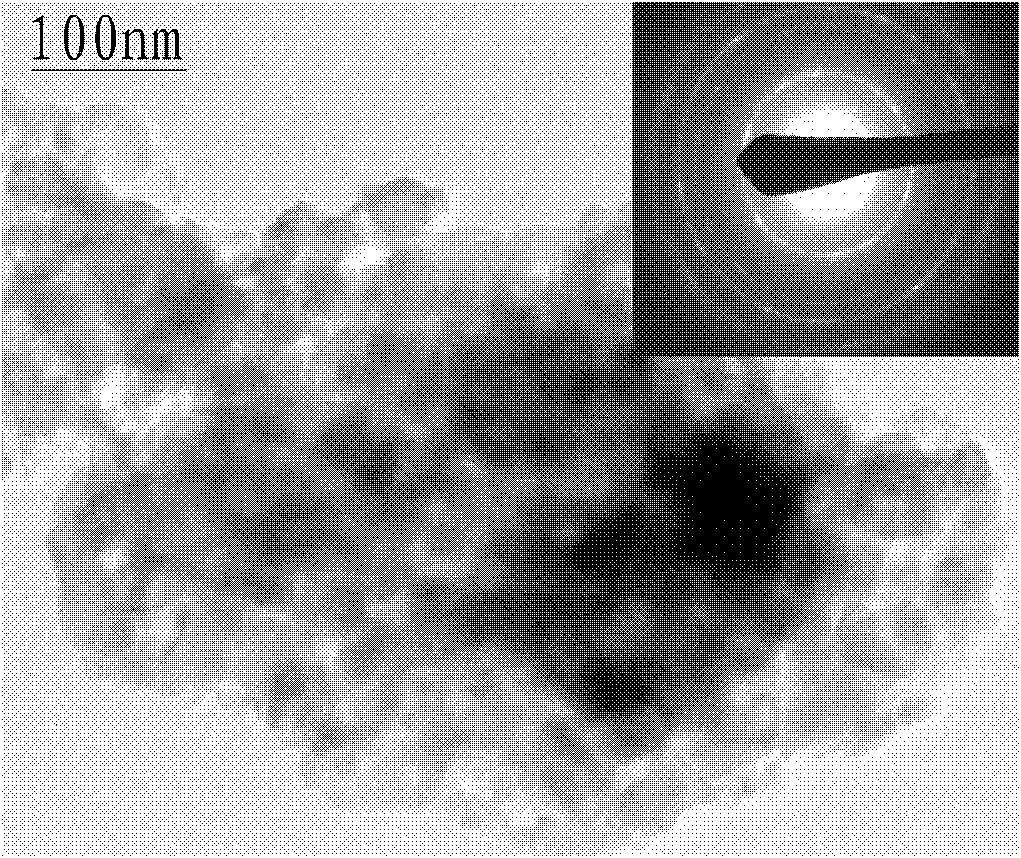

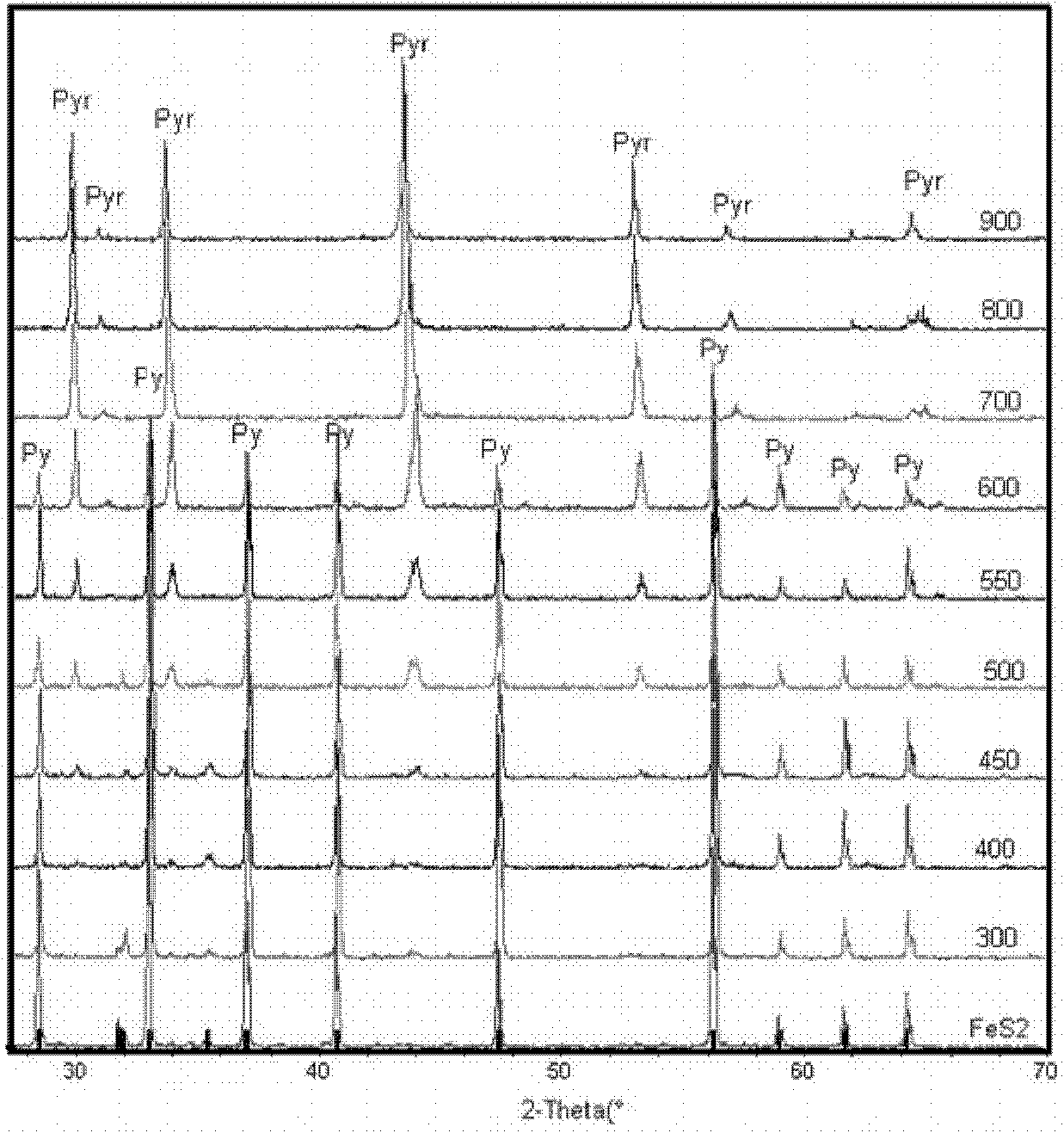

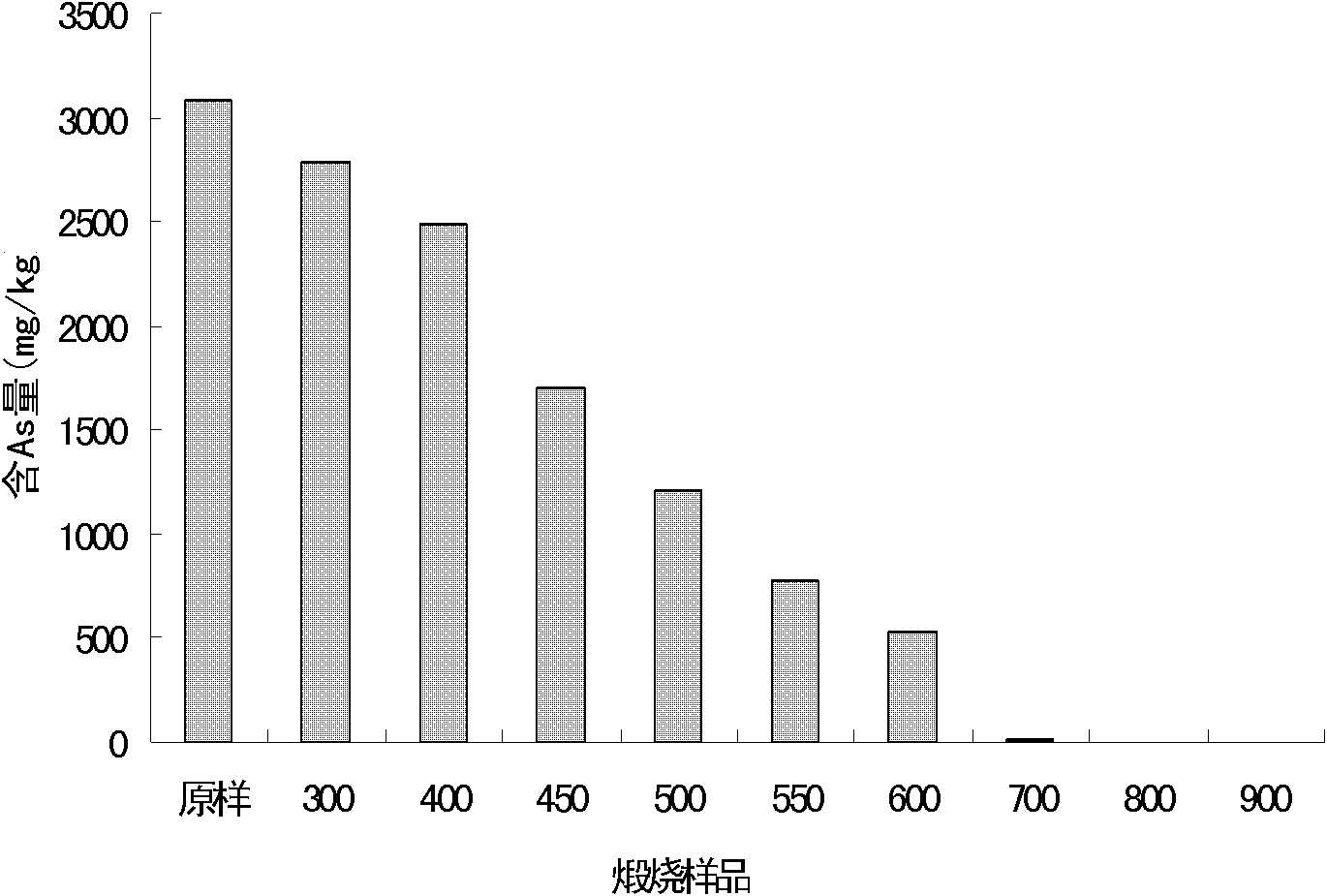

Pyrite nano mineral material and preparation method thereof

ActiveCN102320668ARegulatory structure stateRegulate physicochemical propertiesSulfur preparation/purificationNanotechnologyChemical reactionRoom temperature

The invention discloses a pyrite nano mineral material and a preparation method thereof. The pyrite nano mineral material uses pyritic sulfur and sulphide concentrate as raw materials, the mass percent of pyrite in the pyritic sulfur is not smaller than 50%, and the mass percent of the pyrite in the sulphide concentrate is not smaller than 90%. The preparation method comprises the following stepsof: crushing pyritic sulfur ores, sieving with a sieve of 100 meshes to obtain powder or directly selecting the sulphide concentrate with the particle diameter which is smaller than 0.165mm as powder, adding a bonder to the powder, pelletizing and molding to obtain particles with the particle diameter of 1-3mm, calcinating the particles at a temperature of 500-1000DEG C for 0.5-30min under anaerobic conditions, separating gas from solids, condensating the gas, recovering sulfur, and cooling the solids under oxygen isolation conditions to a room temperature to obtain a finished product. The material has the advantages of large specific area, strong magnesium, high chemical reaction activity, simple preparation technology, low cost and wide raw material resources.

Owner:HEFEI UNIV OF TECH

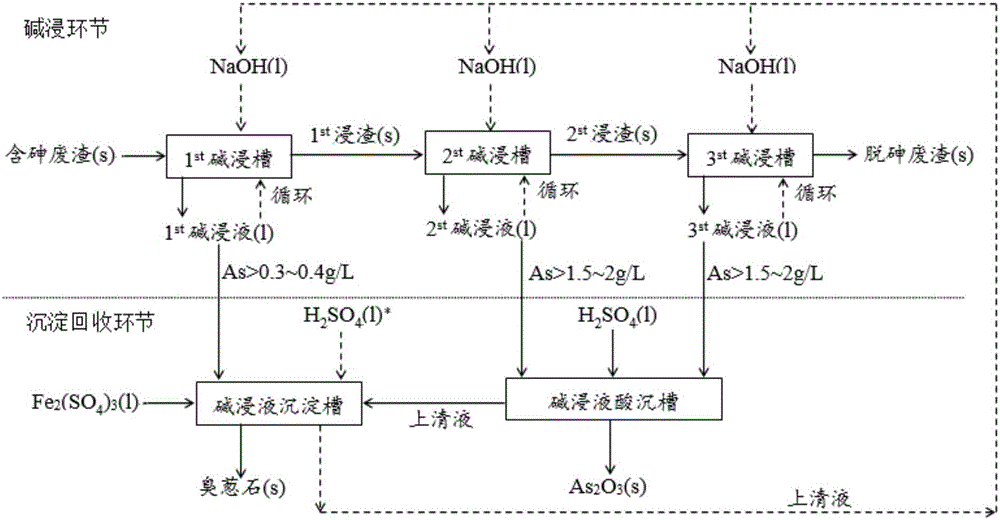

Method for innocent treatment of low-concentration arsenic-containing waste residue and recovery of arsenic

ActiveCN106011475AEfficient leachingReduce arsenic levelsArsenic oxides/hydroxides/oxyacidsIron compoundsResource utilizationMaterials science

The invention relates to a method for innocent treatment of low-concentration arsenic-containing waste residue and recovery of arsenic. Aiming at low-concentration arsenic-containing waste residue, according to the invention, a multistage alkaline leaching method is adopted, wherein mechanical stirring is performed for 10-12h in the environment of 60-80 DEG C, three-stage successive leaching is adopted, the arsenic leaching rate reaches more than 80%, the arsenic content of waste residue after treatment is less than 0.05%, which is lower than the hazardous waste identification limiting value, and therefore, the waste residue can be used as making material of building materials. As2O3 in an arsenic-containing alkaline leaching solution can be recovered by acid neutralization and sedimentation, and ferric sulfate is added to a leaching solution after filtering and sedimentation so as to produce FeAsO4.2H2O sedimentation, the comprehensive arsenic removing rate of the arsenic-containing alkaline leaching solution can reach 99%, and filter liquor can be recycled. Compared with the prior art, according to the invention, no wastewater discharge is caused in the whole process, the technology is simple, and the material is easily available, and the method can be widely popularized and applied to treatment and resource utilization of low-concentration arsenic-containing solid waste.

Owner:TONGJI UNIV

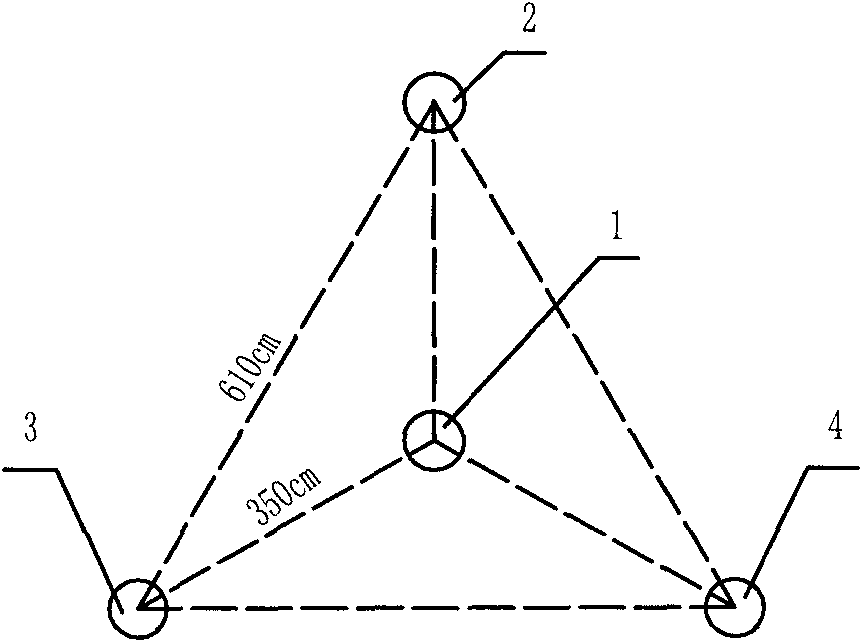

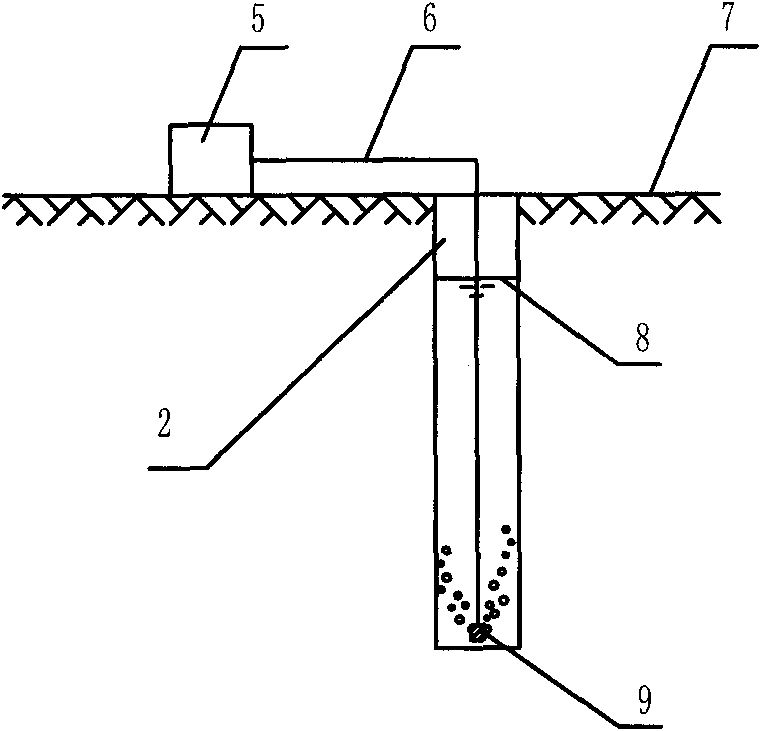

In-situ arsenic removing method of underground water

InactiveCN101830551AIncrease oxygen contentReduce arsenic levelsWater/sewage treatmentIonInjection well

The invention relates to an in-situ arsenic removing method of underground water, which is characterized by comprising the following steps of: (1) arranging a pumping well in an earth surface area containing arsenic in the underground water, arranging a liquid-injection and gas-injection well around the pumping well, and arranging an aeration head of an aeration device at the bottom inside the liquid-injection and gas-injection well; (2) firstly completely pumping well water inside the pumping well and the liquid-injection and gas-injection well, then injecting a ferrous chloride solution into the liquid-injection and gas-injection well, and then injecting the water into the liquid-injection and gas-injection well till the water surface aligns to the ground, and starting to pump the water by the pumping well after the water is completely injected into the liquid-injection and gas-injection well; (3) alternately injecting the ferrous chloride solution and air; and (4) stopping injecting the ferrous chloride solution and the air when the content of the arsenic contained in the underground water pumped by the pumping well is stabilized at a value less than or equal to 10 micrograms / L and the content of chloride ions does not exceed the standard. The in-situ arsenic removing method of underground water has low cost and obviously reduced content of the arsenic contained in the processed underground water.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

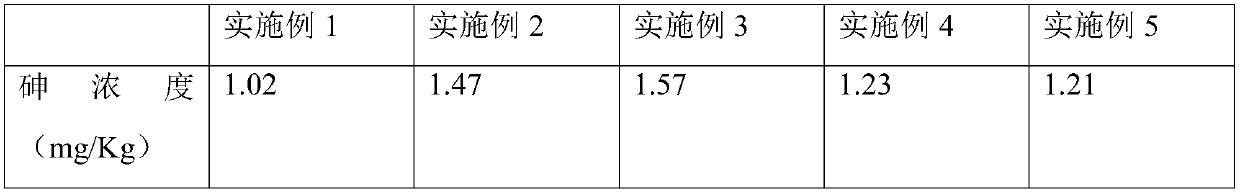

Preparation method of soil remediation agent for remediating arsenic contaminated soil

InactiveCN107805138AStir wellIncrease productionBio-organic fraction processingExcrement fertilisersFiberArsenic pollution

The invention discloses a preparation method of a soil remediation agent for remediating arsenic contaminated soil. Firstly, the selected wheat straws, teosinte and pennisetum hydridum are high in yield and low in price, and lots of plant fibers can be provided, so that soil nutrients can be effectively fixed; secondly, the wheat straws, teosinte and pennisetum hydridum are mixed with EM bacteriaand animal manure, and nutrients which are easily absorbed by plants are formed by adopting an anaerobic fermentation method, so that the yield of the crops can be greatly improved; and thirdly, zeolite, fly ash, coal cinder and kaolin are matched with one another, so that metal arsenic in the soil can be effectively adsorbed, and the effect of reducing the arsenic content in the soil is further achieved.

Owner:林良兵

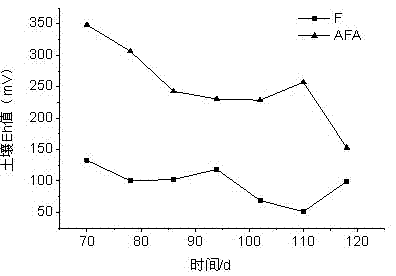

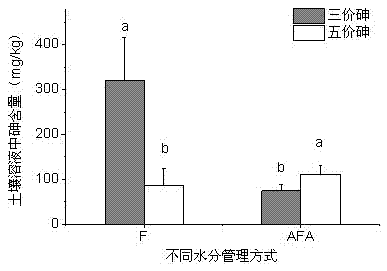

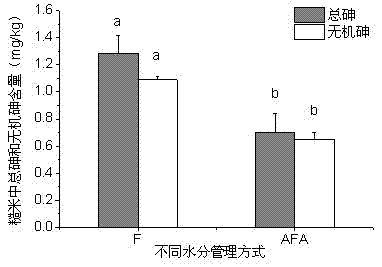

Rice cultivation water management method for moderate and mild arsenic pollution paddy field

InactiveCN103477927AReduce absorption accumulationReduce arsenic levelsRice cultivationInorganic arsenicArsenic pollution

The invention belongs to the technical field of paddy field arsenic pollution treatment, and particularly discloses a rice cultivation water management method for a moderate and mild arsenic pollution paddy field. The water content of the arsenic pollution paddy field is reasonably adjusted by alternately performing waterflooding-moistening irrigation in the whole growth period of rice, the arsenic content of soil solution is remarkably reduced, and trivalent arsenic in soil can be transformed into low-toxicity pentavalent arsenic. By changing the form and the valent state of the arsenic in the soil, arsenic absorption and accumulation of the rice are reduced, so that the arsenic content of the rice is reduced. Measurement proves that the arsenic content of the rice cultivated by the method meets the pollutant limit standard (inorganic arsenic<0.2mg / kg, GB2726-2012) of national food.

Owner:曾敏 +1

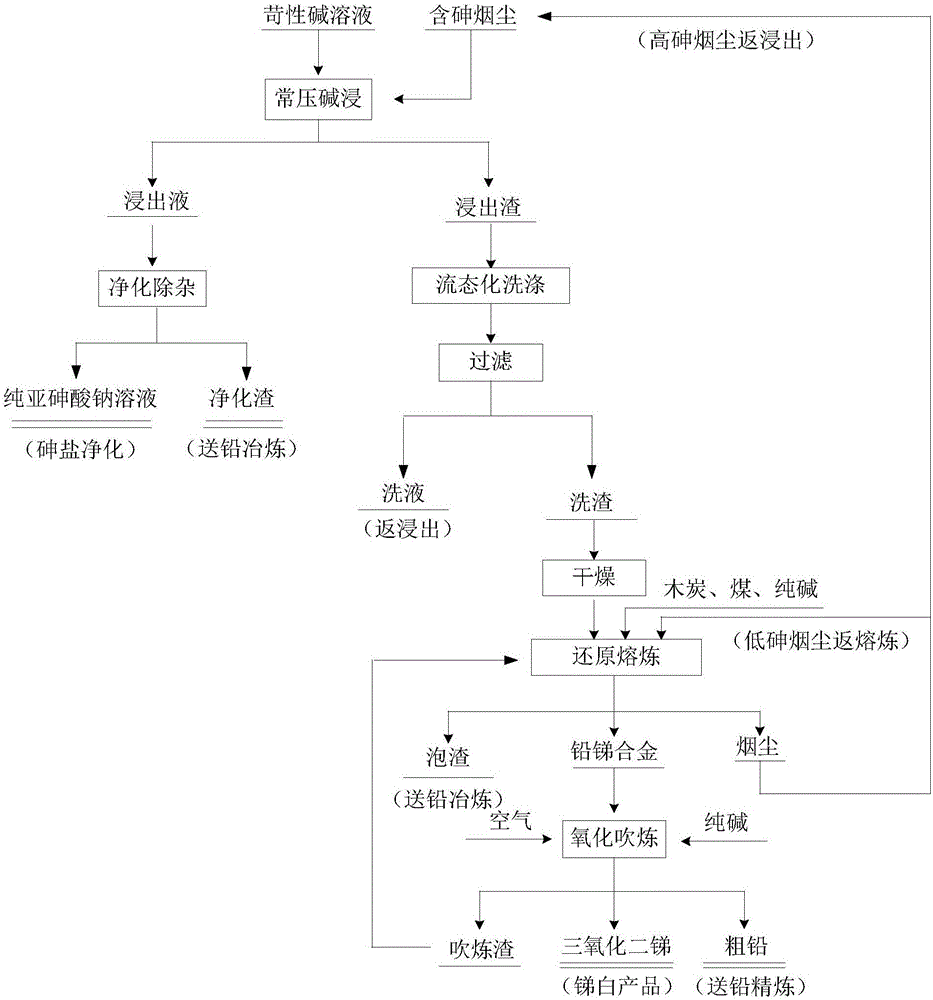

Comprehensive utilization method of arsenic-containing materials

ActiveCN106834715AHarmlessImprove resource utilizationProcess efficiency improvementLead smeltingHydrometallurgy

The invention relates to a comprehensive utilization method of arsenic-containing materials. According to the method, production of comprehensive recovery of valuable metals such as arsenic, antimony, lead, bismuth and the like from smelting dust containing the arsenic, the antimony and the lead is performed, accumulation of the arsenic in the system is reduced, and harmless treatment is performed on the arsenic. With the method, through normal pressure alkaline leaching, soluble arsenic in the dust is removed, leaching residues are subjected to procedures of washing, reduction smelting, oxidizing blowing and the like, and various valuable elements are recycled. With the method, the arsenic is removed from the dust and enters a leaching solution, and impurities such as antimony, lead, tin and the like are separated out in the form of precipitates through purification and impurity removal of the leaching solution. A purified solution is used for arsenic salt purification of a zinc sulfate solution during zinc hydrometallurgy, and purification residues are sent for lead smelting, so that separation and harmless treatment of the arsenic and the valuable metals are realized. According to the method, the comprehensive utilization rate of resources is high, the raw material application range is wide, the problem of pollution in the extraction process of the traditional technology is solved, and the method has the more obvious advantages for the dust produced in the lead and zinc smelting process particularly.

Owner:CENT SOUTH UNIV +1

Treatment method of arsenium-containing polluted acid wastewater generated by smelting flue gas

ActiveCN105152448ASave medicineReduce consumptionWater contaminantsMultistage water/sewage treatmentChemistryFlue gas

The invention relates to a treatment method of arsenium-containing polluted acid wastewater generated by smelting flue gas, which comprises the following steps: pretreatment for sulfate removal; preneutralization; primary neutralization; secondary neutralization; tertiary neutralization; and circulating treatment. The pretreatment for sulfate removal, preneutralization and primary neutralization are sequentially operated to remove the sulfates and fluorine in the system in the precipitation form, wherein the removal rate is up to 95% or above, and the precipitate arsenium content is less than 0.1%. The secondary neutralization can enable more than 85% of the Cu, Fe, Pb, Zn and other metals to form a hydroxide precipitate, so that the high-content metals can be recycled. The tertiary neutralization can enable more than 95% of As to be enriched in the filter residue in the forms of calcium arsenate and calcium arsenite and to be recycled. The method can not generate unmanageable neutralization slag to form secondary pollution, and uses fewer reagents in the whole process; the calcium chloride only needs to be purchased at the time of starting; the operating process can be satisfied by circulation; and the method only consumes small amounts of lime and flocculant, is simple to operate, and has the advantages of low cost and favorable treatment effect.

Owner:JIANGXI UNIV OF SCI & TECH

Method for performing microwave arsenic removal on high-arsenic iron ore

The invention discloses a method for performing microwave arsenic removal on high-arsenic iron ore and belongs to the technical field of mineral separation. The method comprises the following steps: crushing the high-arsenic iron ore until the granularity is less than 1mm, adding a proper amount of pulverized coal, uniformly mixing, performing microwave roasting in an industrial microwave oven, controlling the temperature at 800-1200 DEG C, wherein the roasting time is 5-30 minutes, the arsenic is separated from the iron ore in a gas state form, low-arsenic iron ore concentrate which meets the industrial requirements is obtained, and the generated arsenic-containing tail gas is recycled by virtue of a flue gas absorption device arranged on the industrial microwave oven. According to the method, effective separation between the arsenic and the iron ore is promoted by utilizing selective heating of microwave on the iron ore, the arsenic removal rate is over 90 percent, and the method is a high-efficiency low-cost method for removing arsenic from the iron ore.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for safely and efficiently treating arsenic waste water generated from arsenic hydride production

InactiveCN103663779AHighlight substantive featuresSignificant progressWater contaminantsEnergy based wastewater treatmentSorbentWastewater

The invention relates to a method for safely and efficiently treating arsenic waste water generated from arsenic hydride production. The method comprises the steps of adding alkaline substance into the arsenic waste water, and neutralizing the waste water until the waste water is alkaline; adding oxidant into alkaline waste water, and oxidizing and transforming volatile arsenic hydride dissolved in the waste water into non-volatile arsenate AsO4<3->; adding metal ions M<n+> and forming a precipitate Mx(AsO4)y from the soluble arsenate AsO4<3->; adding a flocculating agent and an adsorbent, further reducing arsenic content in the waste water through adsorption and coprecipitation, filtering and collecting arsenic solid waste after the solid gets complete precipitation. Through the combination of physical and chemical methods, arsenic content in the waste water generated from arsenic hydride production is effectively reduced, and a great amount of virulent waste water is transformed into recycling industrial water; as arsenic solid waste collected from the treating process is small in size, the arsenic solid waste water can be safely and conveniently treated as the solid waste.

Owner:QUANJIAO NANDA PHOTOELECTRIC MATERIAL

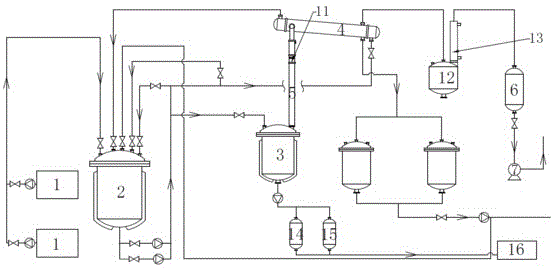

High arsenicum gold ore roasting smoke gas treatment system and method for recovering arsenicum and desulfurating

ActiveCN102350163AReduce loadGuaranteed operational safetyCombination devicesSublimationWater jacketGold ore

The invention discloses a high arsenicum gold ore roasting smoke gas treatment system and a method for recovering arsenicum and desulfurating, which can be used for mainly solving the problems that the arsenicum resource in the high arsenicum gold ore roasting smoke is wasted, and the environment is polluted by a large amount of hazardous wastes containing the arsenicum generated in wet processing. The high arsenicum gold ore roasting smoke gas treatment system comprises an arsenicum recovery system which comprises a settling chamber, a primary cyclone dust collector, a secondary cyclone dust collector, an electric dust collector, a water jacket cooler, a water circulating pump, a water circulating pond and a cloth bag arsenic collector. The high arsenicum gold ore roasting smoke gas treatment system provided by the invention also comprises a desulfurization system; and the method for recovering the arsenicum provided by the invention comprises the following steps of roasting smoke and dedusting, smoke drying cooling and arsenicum collecting by a cloth bag. The desulfurating method comprises the steps of rushing and washing. The invention has the advantages of being stable in process, high in arsonium recovery rate, high in product purity, low in gypsum arsenicum content and less in environmental pollution.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Method enhancing oxidization leaching with arsenic in arsenic-cobalt-nickel containing slag

The invention relates to a method for enhancing oxidization leaching of low-valence arsenic existed as an alloy form of arsenic copper, arsenic cobalt and arsenic nickel in arsenic-cobalt-nickel containing slag by taking NaOH or KOH solution as a leaching medium and taking a copper oxide as an oxidizing agent. In the method, on one hand, an alkali medium is taken as the leaching medium, thereby the risk of generation of arsine gas with severe toxicity can be avoided during acid leaching; on the other hand, the copper oxide is taken as the oxidizing agent, by comparing with oxygen pressure leaching of the alkali medium, operation pressure of a system is reduced, copper in the copper oxide can not be dissolved in the alkali medium, and can follow with copper in the arsenic-cobalt-nickel containing slag into a copper smelting system. The method is the further improvement of a pressure oxidation leaching-out method for the alkali medium.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Arsenic-free glass bottle

The invention discloses an arsenic-free glass bottle, which solves the problems that the conventional food packing glass is not favorable for human health and environmental protection and cannot reach state specified standards due to higher arsenic and antimony dissolution amount. The arsenic-free glass bottle is prepared from raw materials comprising the following components in part by weight: 51 to 63 parts of quartz sand, 3 to 9 parts of lithium (or sodium or potassium) feldspar, 12 to 19 parts of calcite, 0 to 20 parts of dolomite, 1 to 3 parts of calcium sulfate, 0 to 2.2 parts of fluorite, 0 to 3 parts of sodium fluosilicate, 15 to 21 parts of soda ash, 0.1 to 0.5 part of sodium sulfate, 0.3 to 1 part of calcium sulfate and 0.1 to 0.5 part of cerium oxide. The components are mixed uniformly, melted, molded and annealed to form the arsenic-free glass bottle according to the conventional glass bottle manufacturing method. The arsenic of the arsenic-free glass bottle is far below the state specified dissolution permissible amount, so the arsenic-free glass bottle has no toxic or side effect on the human body and does not produce environmental pollution; and at the same melting temperature, the clarifying time is shortened to half time of using arsenic and antimony oxides, and the production capacity is improved by 10 percent.

Owner:忻州鑫洋玻璃制品有限公司

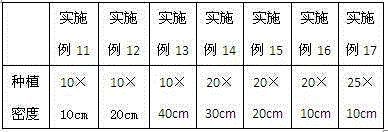

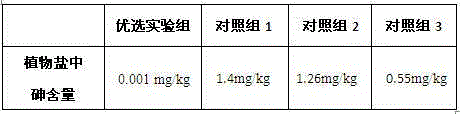

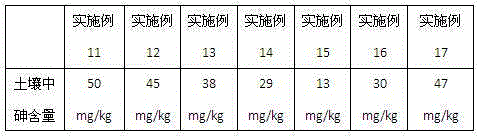

Method for planting Suaeda salsa on medium-low-arsenic saline and alkaline land and extracting plant salts

InactiveCN105027877AReduce arsenic levelsIncrease contentPlant cultivationCultivating equipmentsAlkali soilNephrolepis cordifolia

The invention discloses a method for planting Suaeda salsa on medium-low-arsenic saline and alkaline land and extracting plant salts. The method comprises the step of adsorption treatment on arsenic in soil. In the step of adsorption treatment on the arsenic in the soil, the arsenic is adsorbed by interplanting nephrolepis cordifolia (L.) presl and Chinese milk vetch, the interplanting proportion of the nephrolepis cordifolia (L.) presl to the Chinese milk vetch is preferably 4:2, and the planting density of the nephrolepis cordifolia (L.) presl and the Chinese milk vetch is preferably 20cm*20cm. According to the plant salts prepared by the method disclosed by the invention, the content of the arsenic is remarkably reduced, particularly the content of the arsenic is 0.001mg / kg; the content of sodium chloride is 35 percent, the content of potassium chloride is 13 percent, the content of Ca is 8 percent, and the content of Fe is 700mg / kg; the problem that the arsenic content in the plant salts extracted by using the Suaeda salsa planted on the medium-low-arsenic saline and alkaline land is over high is solved.

Owner:WEIFANG YOURONG IND

Method for preparing inhibitor for arsenic-containing ores

The invention provides a method for preparing an inhibitor for arsenic-containing ores. The method comprises the following steps of: according to the mass ratio of tannin to ethanol of 1-1.5:1.5-3, adding the tannin in a three-neck bottle, adding 95 percent ethanol in the three-neck bottle, placing the three-neck bottle in a thermostatic waterbath at the temperature of 45 DEG C, dispersing the mixing solution for 2 to 3h by stirring, adding 0.4 to 0.6 g / mL NaOH solution for alkalization according to the molar ratio of the NaOH to the hydroxyl group in the tannin of 1.5-3:1-1.5, heating the mixed solution up to the temperature of between 50 and 60 DEG C for full reaction for 1 to 2h, adding chloroactic acid in the three-neck bottle according to the molar ratio of the chloroactic acid to the hydroxyl group in the tannin of 2-3:1-6, heating the mixed solution up to the temperature of between 75 and 85 DEG C for reflux reaction for 4 to 6h, and drying the mixed solution by vaporization toobtain a solid product, namely the inhibitor for arsenic ores. The inhibitor provided by the invention can better inhibit the arsenic-containing ores during the antimony-arsenic separation, and lowerthe arsenic content in the antimony concentrate; moreover, the method also has the advantages of less consumption of the inhibitor, good solubility, no toxicity and no pollution.

Owner:GUANGXI UNIV

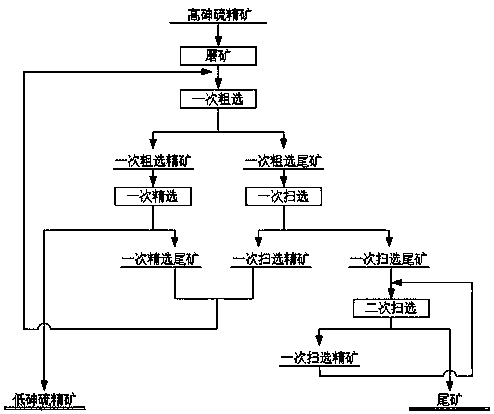

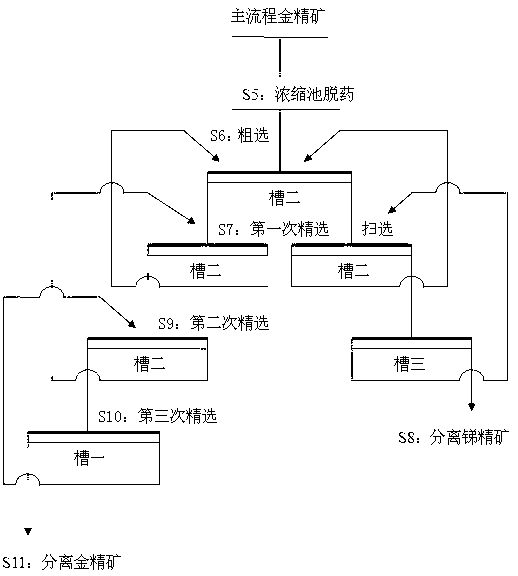

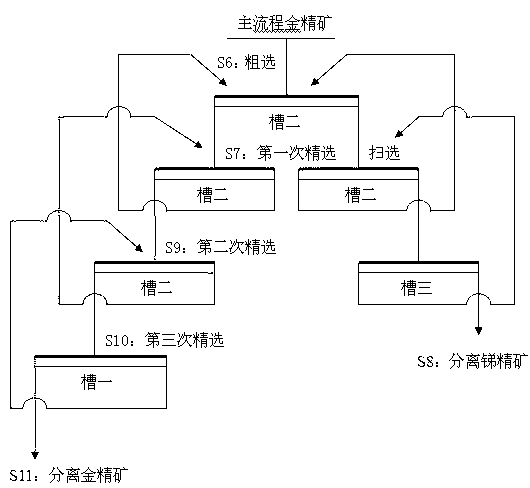

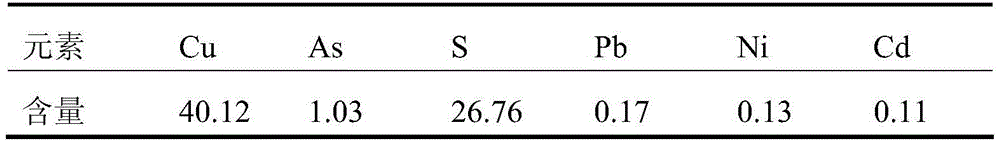

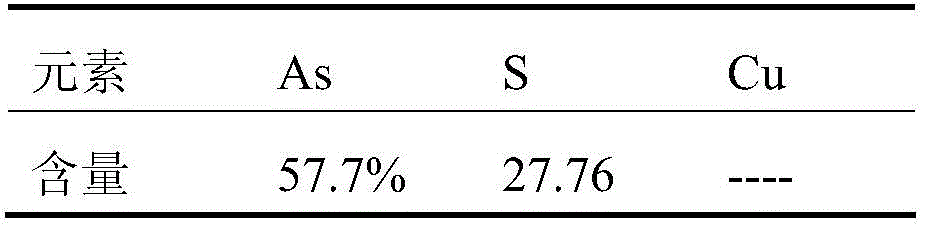

Arsenic removing flotation method for high-arsenic-content sulfur concentrate

The invention discloses an arsenic removing flotation method for high-arsenic-content sulfur concentrate, and belongs to the technical field of beneficiation. The arsenic removing flotation method comprises the steps that water and sodium carbonate are added into the high-arsenic-content sulfur concentrate for pulp mixing; ball milling is conducted on concentrate pulp; a rough flotation chemical agent is added into the milled concentrate pulp to be uniformly mixed, first-time rough flotation is conducted for 3-5 min, and rough flotation concentrate and rough flotation tailings are obtained; first-time concentration is conducted on the rough flotation concentrate for 2-4 min, and low-arsenic-content sulfur concentrate and first-time concentration tailings are obtained; a first-time scavenging flotation chemical agent is added into the rough flotation tailings to be uniformly mixed, first-time scavenging flotation is conducted for 3-5 min, and first-time scavenging flotation concentrateand first-time scavenging flotation tailings are obtained; the first-time scavenging flotation concentrate and the first-time concentration tailings are mixed, and first-time rough flotation is conducted; a second-time scavenging flotation chemical agent is added into the first-time scavenging flotation tailings to be uniformly mixed, second-time scavenging flotation is conducted for 2-4 min, andsecond-time scavenging flotation concentrate and second-time scavenging flotation tailings are obtained; and the second-time scavenging flotation concentrate is returned for first-time scavenging flotation. According to the method, the content of arsenic in the sulfur concentrate can be decreased, and resources such as arsenic and sulfur can be recycled.

Owner:KUNMING UNIV OF SCI & TECH

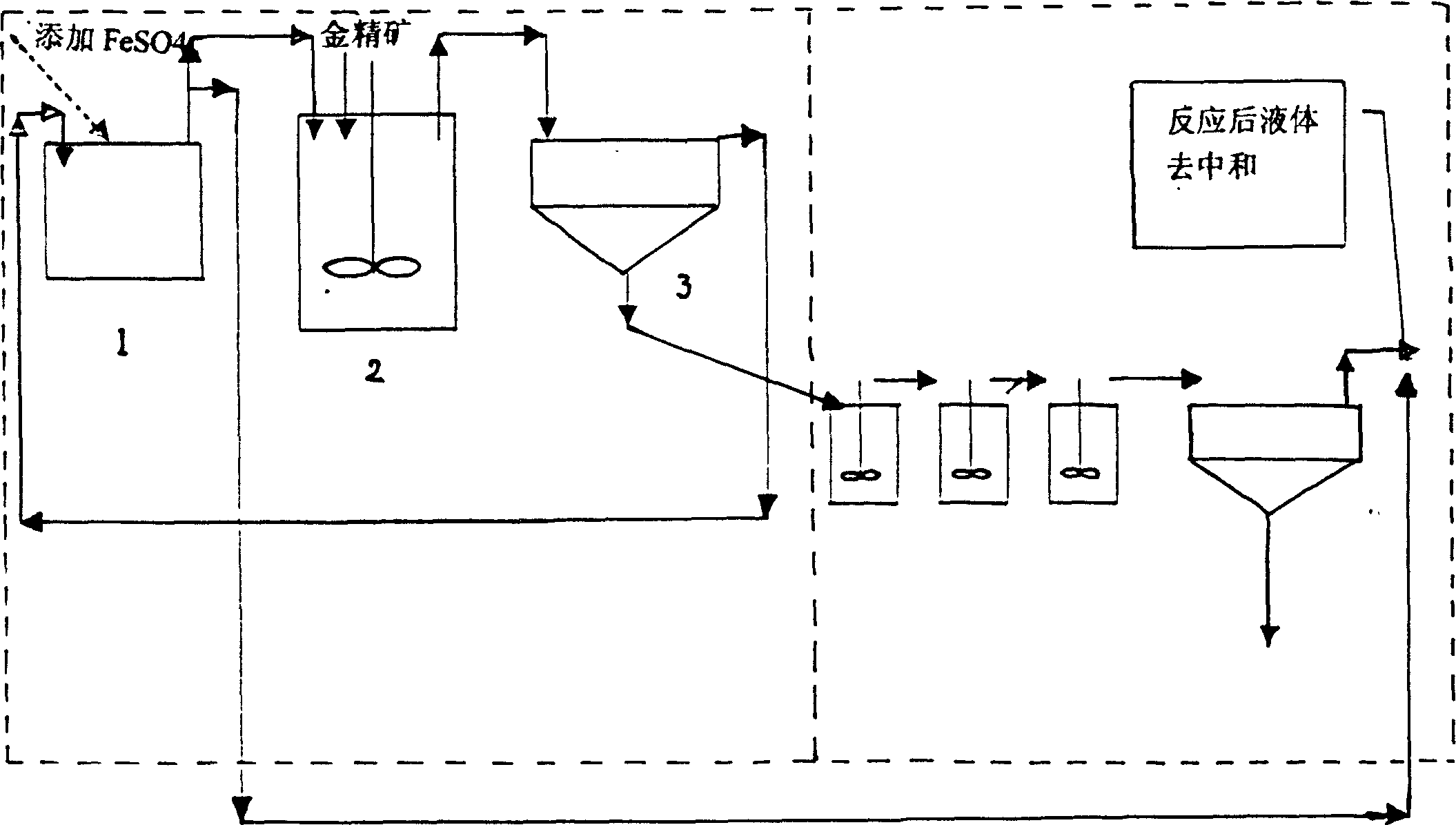

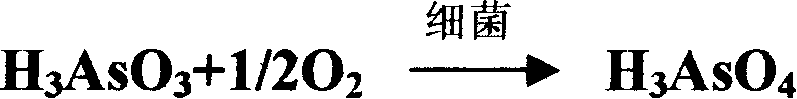

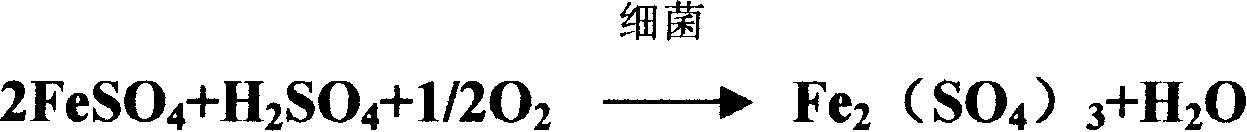

Gold extracting process for high arsenic gold mine

InactiveCN1683571AReduce contentBio-withdrawal went smoothlyProcess efficiency improvementOxidative treatmentMaceral

The present invention discloses a kind gold extracting process from high arsenic gold ore. High arsenic gold ore is first high iron pre-treated to make As content lowered to below 8 %, reaching the requirement of bacteria oxidation to extracting gold, and then gold is extracted biologically. The present invention has simple and effective technological process, can oxidize toxic sand in raw ore in short time and has low apparatus investment.

Owner:莱州泰源冶金技术有限公司

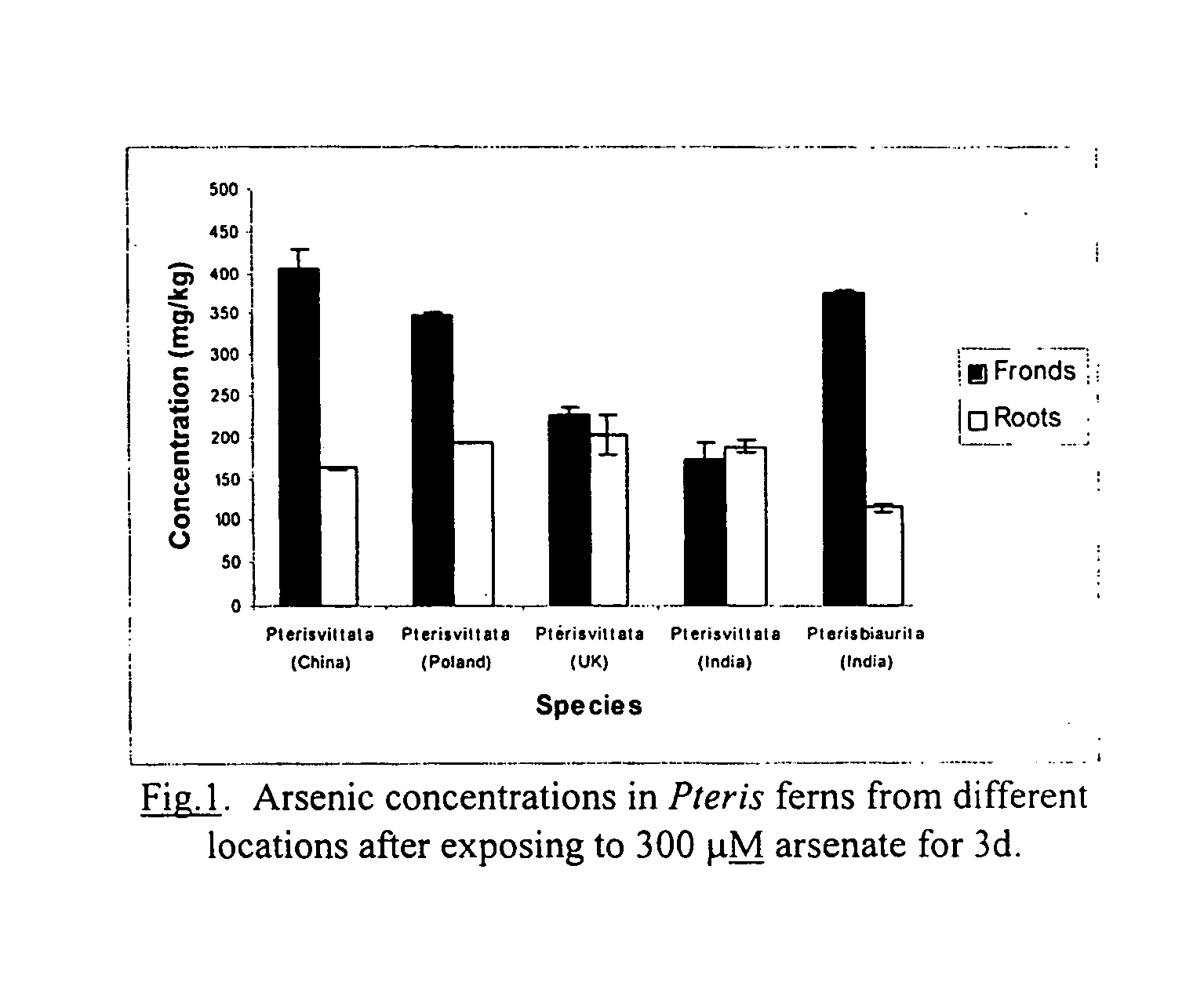

Contaminant removal by additional ferns

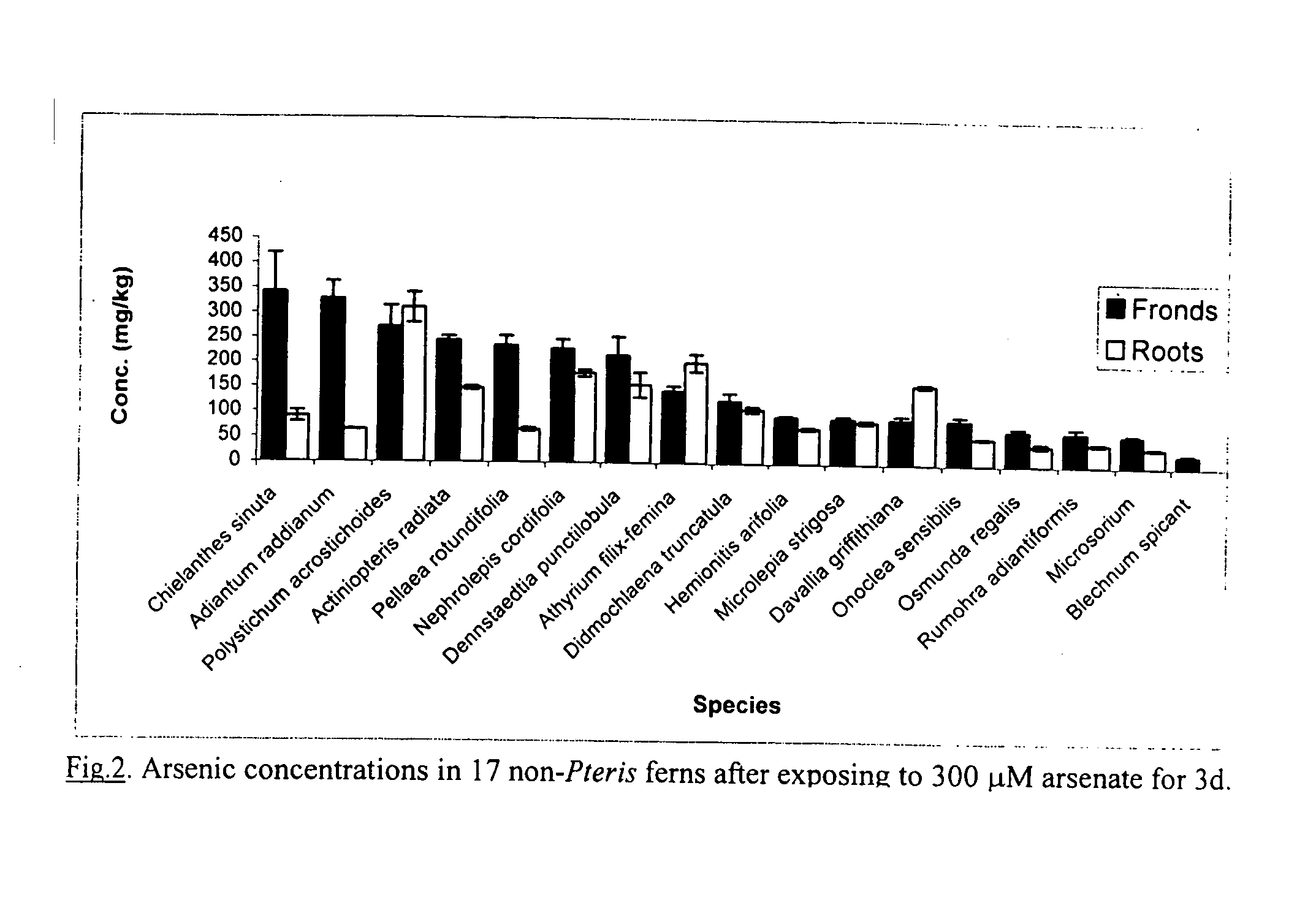

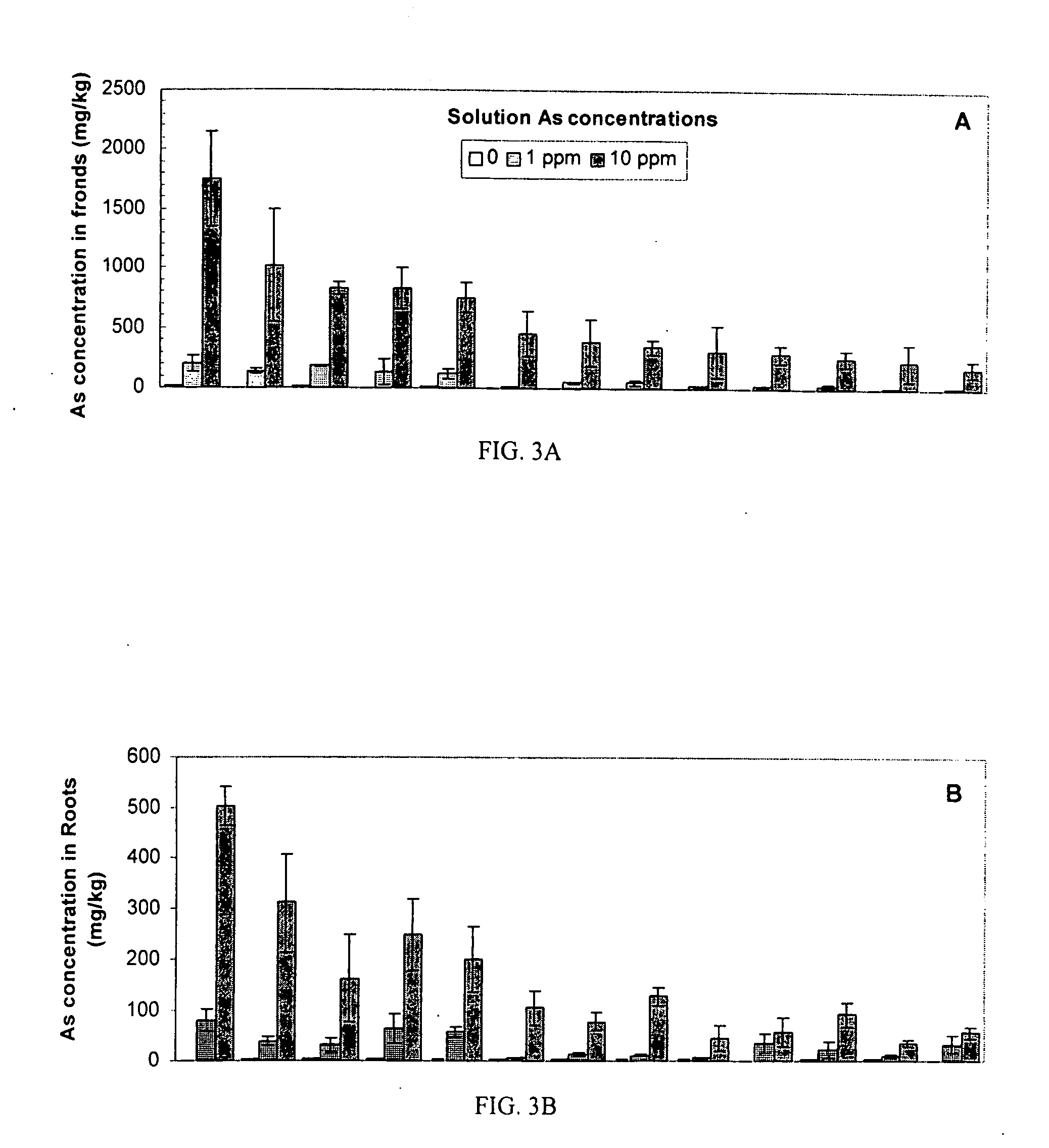

InactiveUS20050082221A1Efficient repairEasy disposalContaminated soil reclamationBlast furnace detailsFrondPteris

Processes, methods, materials and compositions for phytoremediating contaminated waters, which have been contaminated with pollutants such as arsenic. Fern plants that include Pteris and non-Pteris fern plants can be used to accumulate pollutants from contaminated water, including aqueous solution, waste water, ground water, surface water, combinations thereof. Pollutants and contaminants can be removed from the water, soil and wetland type environment via phytoremediation through roots and fronds as well as by applying excised portions of plants such as leaflets (cut-off fronds). The biomass can be harvested and readily disposed of, or can be treated to recover the pollutants and contaminants.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

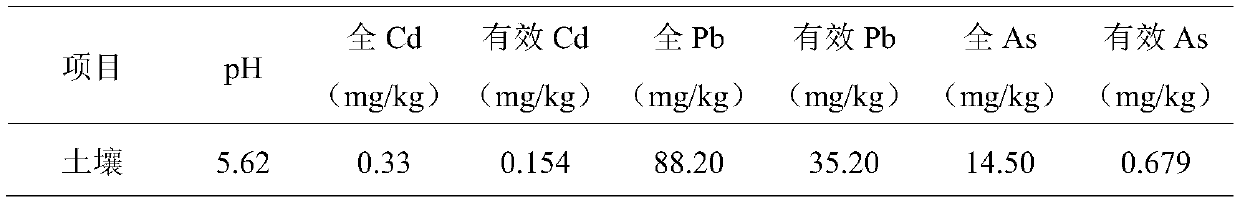

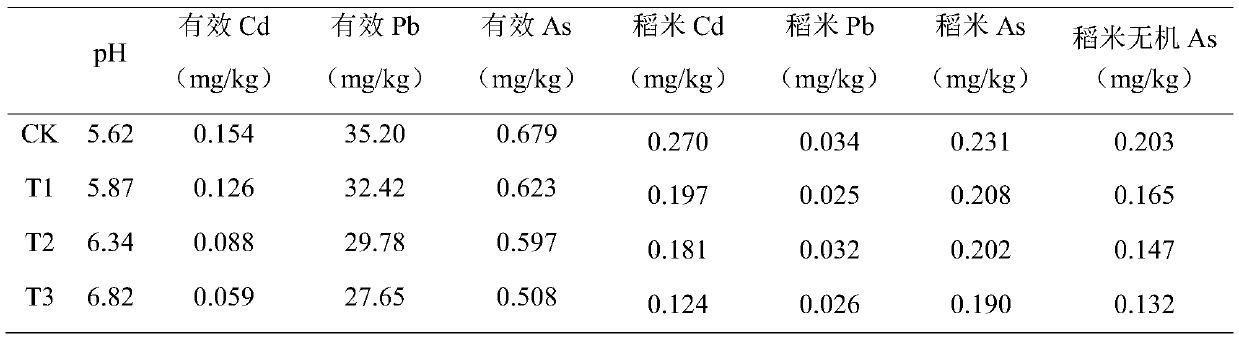

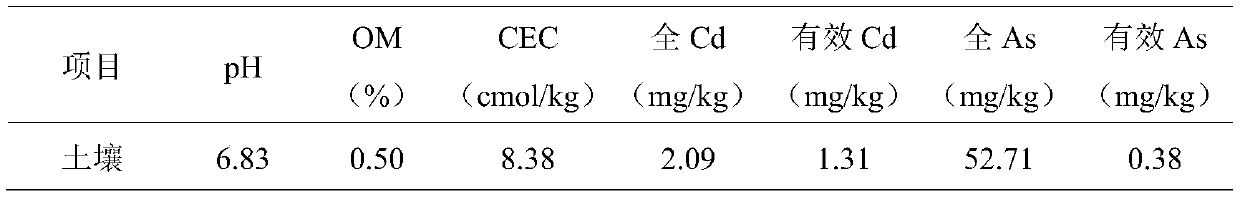

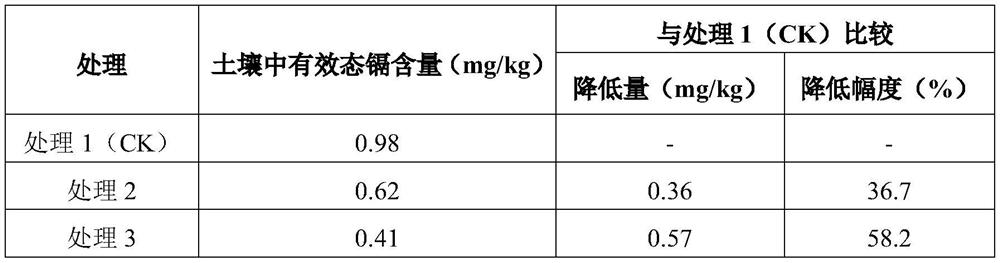

Slow-release repairing agent for treating cadmium-arsenic composite polluted rice field soil and preparation method thereof

ActiveCN111269722AImplement synchronous passivationOptimizing the ratio parametersAgriculture tools and machinesOther chemical processesSilicic acidPotassium silicate

The invention discloses a slow-release repairing agent for treating cadmium-arsenic combined pollution rice field soil and a preparation method thereof. The preparation method comprises the followingsteps: (1) fully and uniformly stirring calcium carbonate and calcium magnesium phosphate fertilizer and calcining under nitrogen protection, and obtaining a compound A after the calcined mixture is ground and smashed; (2) adding potassium silicate into water, fully stirring to dissolve potassium silicate, uniformly spraying the dissolved potassium silicate solution onto the surface of the iron powder, and then granulating on a granulator to obtain mixture granules B; (3) putting the compound A and the mixture granules B into the granulator, and gradually spraying pure water until the surfacelayers of the mixture granules B are uniformly coated with the compound A to form granules with the diameter of 3-5 mm; and (4) drying the particles obtained in the step (3) until the water content isless than or equal to 5% to obtain the slow-release repairing agent. The slow-release repairing agent can implement cadmium-arsenic synchronous passivation resistance control in the key growth periodof rice and is small in dosage and effectively reduces the cadmium-arsenic content of the rice and is remarkable and stable in effect.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

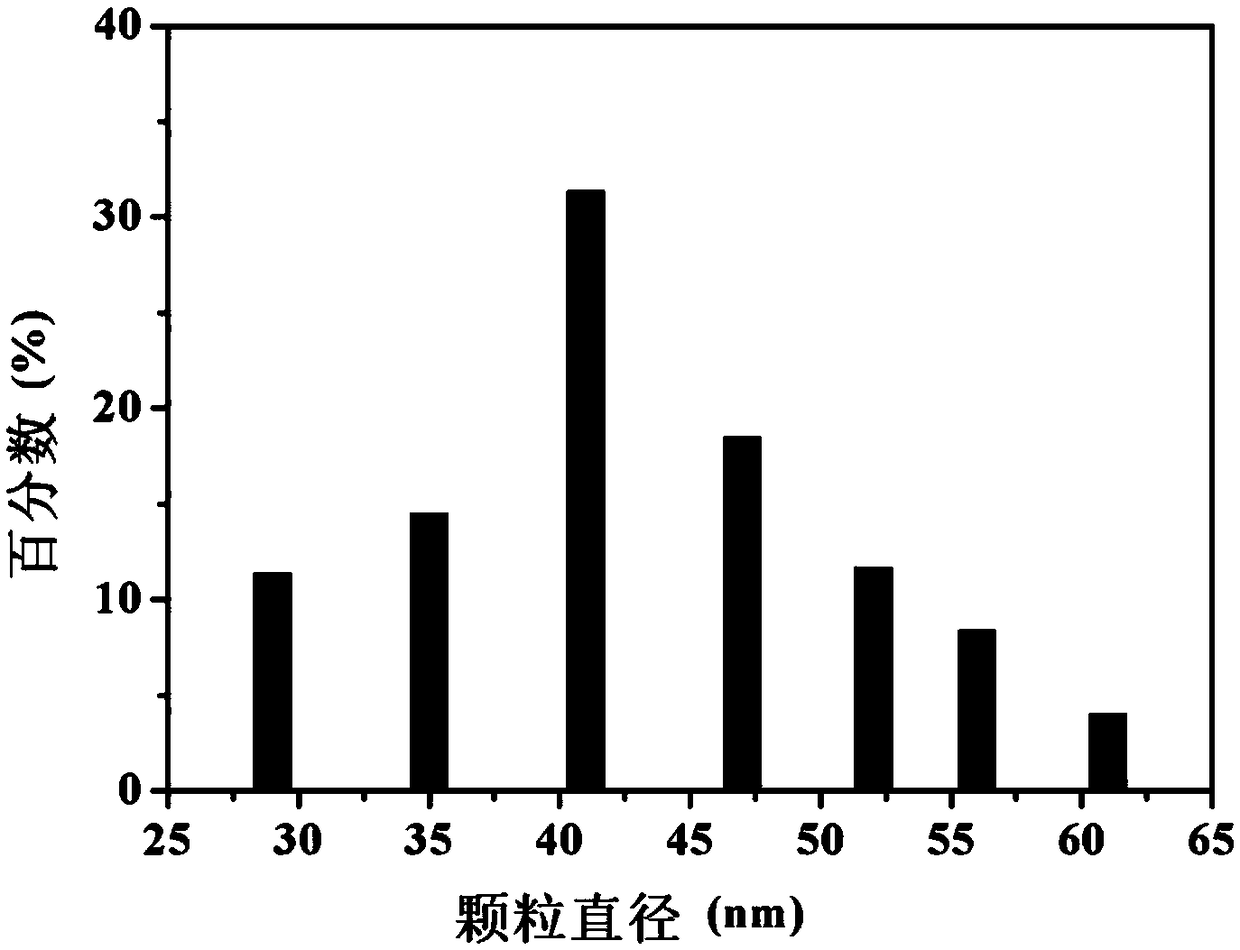

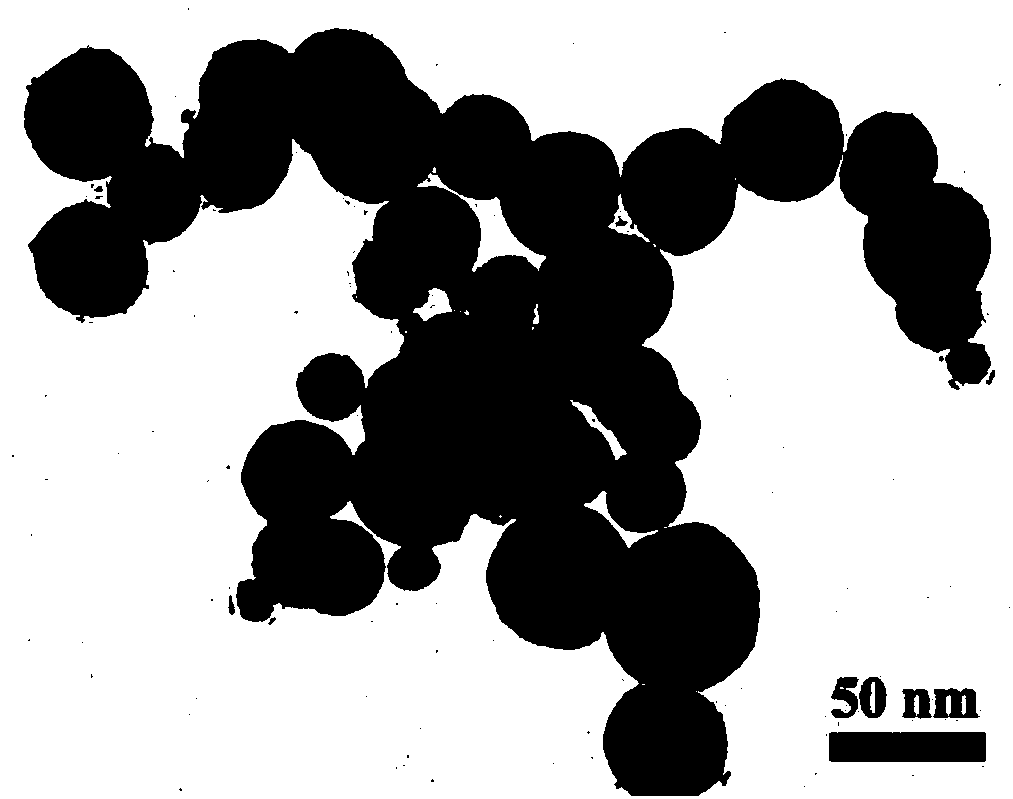

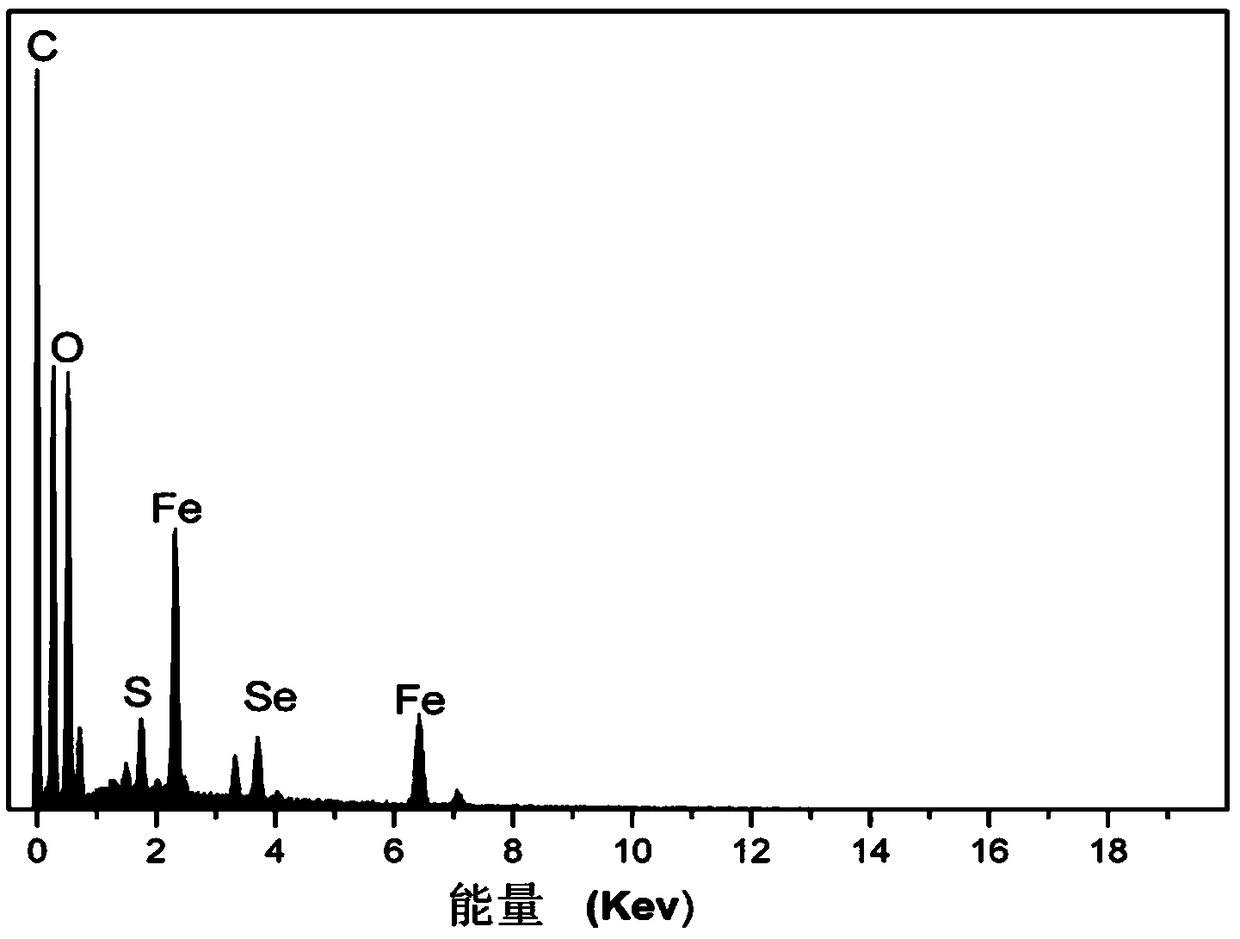

Ferrous modified selenium sol for inhibiting cadmium-arsenic accumulation of paddy rice as well as preparation method and application thereof

ActiveCN108967442ASimple preparation processCan be produced industrially on a large scaleBiocidePlant growth regulatorsSelenium CompoundCadmium Cation

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

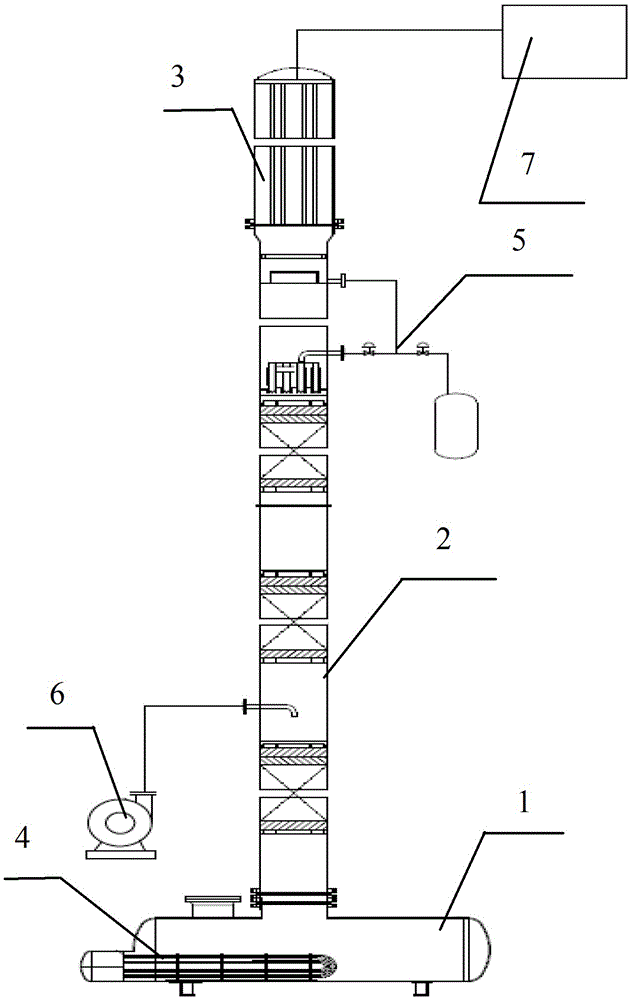

Method and device for preparing high-purity yellow phosphorus industrially and continuously

InactiveCN105600762AEfficient removalImprove the purification effectPhosphorus compoundsNitrogenNitrogen gas

The invention relates to a method for preparing high-purity yellow phosphorus industrially and continuously. The method comprises the steps that nitrogen is used for purging a rectifying tower at first so as to make the inert environment, and then a vacuum pump is used for vacuumizing a rectification system; an acid solution and liquid yellow phosphorus heated to 70-80 DEG C are mixed through a liquid mixer and then added into a tower kettle of the rectifying tower, yellow phosphorus flowing back from the tower top and yellow phosphorus steam ascending from the tower bottom make sufficient contact inside the tower to be subjected to gas-liquid exchange, and high-purity yellow phosphorus is extracted. A device comprises the tower kettle. The rectifying tower is arranged on the tower kettle. An integrated tower top cooler is arranged on the top of the rectifying tower. A vacuum skid mounted device is arranged on the integrated tower top cooler. A gravity type backflow extraction device is arranged at the upper portion of the rectifying tower and the lower portion of the integrated tower top cooler through guide pipes. Due to rectification, the content of arsenic in a tower top product is smaller than 30 ppb, and the content of antimony in the tower top product is smaller than 100 ppb.

Owner:湖北兴福电子材料股份有限公司

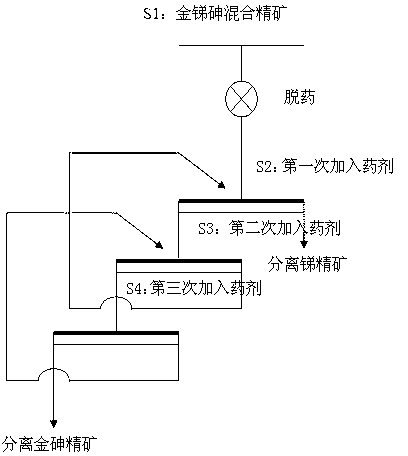

Separating method for antimony-gold-arsenic paragenetic ore

The invention relates to the field of metallic ore, particularly to a separating method for antimony-gold-arsenic paragenetic ore. The separating method comprises S1, preparing the antimony-gold-arsenic paragenetic ore of a certain weight; S2, adding 1.5kg / t of Na2S, 2.5kg / t of Na2CO3, 120g / t of CuSO4, 120g / t of MA-2 and 15g / t of 2# oil to the antimony-gold-arsenic paragenetic ore ; S3, adding 0.3kg / t of Na2S, 0.5kg / t of Na2CO3, 20g / t of CuSO4 and 20g / t of MA-2 to the antimony-gold-arsenic paragenetic ore continuously and separating antimony concentrate; S4, adding 0.5kg / t of Na2S and 0.75kg / t of Na2CO3 to the antimony-gold-arsenic paragenetic ore continuously and separating gold-arsenic ore. According to the separating method, the antimony-arsenic separating process through a sodium carbonate-sodium sulfide method is adopted, selective flotation of arsenic is achieved at the utmost through antimony suppression and arsenic flotation, the recovery rate of arsenic in gold-arsenic concentrate is improved, and the content of arsenic in the antimony concentrate is reduced.

Owner:湖南新龙矿业有限责任公司

Continuous refinement system and technology of ultra-pure phosphorus oxychloride of 5N grade

ActiveCN105016320AAvoid safety hazardsPurification equipment is safe and reliablePhosphorus halides/oxyhalidesFractional distillationHeat conductingNitrogen

The invention discloses a continuous refinement system of ultra-pure phosphorus oxychloride of a 5N grade. The continuous refinement system comprises feeding storage tanks, wherein the feeding storage tanks are communicated with a middle raw-material tank; a discharge opening of the middle raw-material tank is connected with a feed opening of a rectification kettle and a shell-side feed opening of a first condenser respectively; a discharge opening in the top end of the rectification kettle is connected with a tube-side steam feed opening of the first condenser through a rectification tower; a shell-side discharge opening of the first condenser is connected with a feed opening of the middle raw-material tank; a tube-side condensate-liquid discharge opening of the first condenser is connected with a finished-product collecting unit; a tube-side light-component discharge opening of the first condenser is connected with a light-component treating unit; a kettle-bottom heavy-component discharge opening of the rectification kettle is connected with a waste-liquid treating unit; a jacket of the raw-material middle tank and a jacket of the rectification kettle are connected with a circular heating unit of heat conducting oil; a vacuum pump for evacuation is arranged in the light-component treating unit. The continuous refinement system is protected by nitrogen. The invention further discloses a continuous refinement technology. The continuous refinement technology is short in engineering, and the purity of obtained products is high.

Owner:JIANGYIN JIANGHUA MICROELECTRONICS MATERIAL

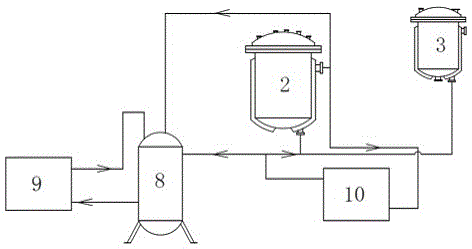

Method for separation and enrichment of copper and arsenic in copper smelting acidic wastewater

ActiveCN105543480AIncrease activation energyShort reaction timeProcess efficiency improvementSlagWastewater

The invention relates to a method for separation and enrichment of copper and arsenic in copper smelting acidic wastewater. The method includes the following steps that (1) the acidic wastewater is subjected to sulfide precipitation to generate sulfide slag containing the copper and the arsenic; (2) the sulfide slag is activated through mechanical ball milling; (3) the activated sulfide slag is added into the acidic wastewater according to a certain As / Cu mole ratio, and a reaction is conducted after ultrasonic dispersion; (4) solid-liquid separation is carried out after the reaction, so that copper-rich slag is obtained; and (5) liquid obtained after separation is subjected to deep sulfuration, so that arsenic-rich slag is obtained. According to the method, the sulfide slag is activated, is added into the acidic wastewater and then reacts after ultrasonic dispersion, so that not only are separation and enrichment of the copper and the arsenic in the acidic wastewater achieved, but also reaction time is greatly shortened, the reaction temperature is lowered, and reaction efficiency is improved; the method has good use value.

Owner:CENT SOUTH UNIV +1

Method for improving phytoremediation efficiency of heavy metal hyperaccumulation by using spraying agent

ActiveCN109127720ADoes not affect farming useReduce arsenic levelsContaminated soil reclamationPollution soilSoil remediation

The invention relates to the technical field of soil remediation, in particular to a method for improving the phytoremediation efficiency of heavy metal hyperaccumulation by using a spraying agent. The spraying agent is prepared from 25 mg*L<-1> of heteroauxin and 20 mg*L<-1> of kinetin, firstly, the spraying agent is cooperatively irrigated to plant leaves and soil around rhizosphere, and then the spraying agent is applied on the leaf surface every time after harvesting. The method for improving the phytoremediation efficiency of the heavy metal hyperaccumulation by using the spraying agent has the advantages that the investment and maintenance cost is low, the method is environmentally friendly, and can be widely used in the remediation of soil containing higher heavy metal, the cultivation use of subsequent soil is not affected, the phytoremediation efficiency is improved, the effect is quick, for medium-and-low pollution soil, the heavy metal pollution can be reduced to an ideal state through only several very short growth cycles, for example, the arsenic content in the soil can be reduced by 25% during first harvesting and can be reduced by 50% after one year; and lead and cadmium content in the soil can be reduced by 18% and 27% respectively after harvesting twice, so that the effect is significant.

Owner:KUNMING UNIV OF SCI & TECH

Soil conditioner for treating cadmium and arsenic combined pollution of farmland and application method of soil conditioner

PendingCN112939696AReduced bioavailabilityLarge specific surface areaAgriculture tools and machinesFertilising methodsSoil scienceSoil remediation

The invention relates to the field of farmland soil remediation, in particular to a soil conditioner for treating farmland cadmium and arsenic combined pollution and an application method of the soil conditioner. The soil conditioner is prepared from the following components in percentage by mass: 50%-60% of modified charcoal, 10%-30% of reduced iron powder, 10%-30% of calcium magnesium phosphate fertilizer and 10%-30% of sepiolite. When the soil conditioner is applied, the soil conditioner is uniformly mixed with water through a stirring box to form slurry, then the slurry is sprayed into a rice field through slurry spraying equipment, and then the soil conditioner is fully mixed with soil through ploughing. The soil conditioner provided by the invention can effectively reduce the bioavailability of cadmium and arsenic in farmland soil, reduce the content of cadmium and arsenic in agricultural products produced in a cadmium and arsenic combined pollution farmland, and avoid secondary pollution in the use process.

Owner:湖南中米环保科技有限公司

Adsorbent applicable to flue gas dearsenization and dearsenization method thereof

ActiveCN107930579AImprove adsorption capacityExtended stayGas treatmentOther chemical processesMetallurgical slagFlue gas

The invention provides an adsorbent applicable to flue gas dearsenization and a dearsenization method thereof, and belongs to the technical field of flue gas dearsenization. The adsorbent comprises calcium oxide, metallurgical slag, zeolite and pulverized fuel ash, wherein the amount of the added pulverized fuel ash is M4=gamma (M1+alpha M2-delta M3)-beta / (1-alpha) M2, wherein M 1 is the mass ofcalcium oxide; M2 is the mass of metallurgical slag; M3 is the mass of zeolite; gamma is 0.15-0.25; delta is 1.5-2; alpha is the mass percentage contents of CaO and MgO in the metallurgical slag; betais the mass percentage contents of Fe2O3 and MnO in the metallurgical slag. With the adoption of the adsorbent, the standing time of arsenic and oxide thereof on the surface of the adsorbent is prolonged, so that the reaction time of the adsorbent and arsenic and oxide thereof is prolonged, and as a result, the reaction process of calcium oxide and arsenic is accelerated; the pulverized fuel ashand the converter slag act together to promote the decomposing of ferric oxide, so that arsenic and oxide thereof can completely react with the ferric oxide or calcium oxide for improving the activityof metallurgical slag, and as a result, the effect of the adsorbent adsorbing arsenic can be improved.

Owner:扬州兄联冶金科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com