Patents

Literature

31 results about "Pyritic sulfur" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Commonly called fool’s gold, pyrite is the Earth’s most abundant sulfide mineral. Recognized for its brass-yellow color which resembles that of gold, pyrite is a source of iron and sulfur and is used for the production of sulfuric acid.

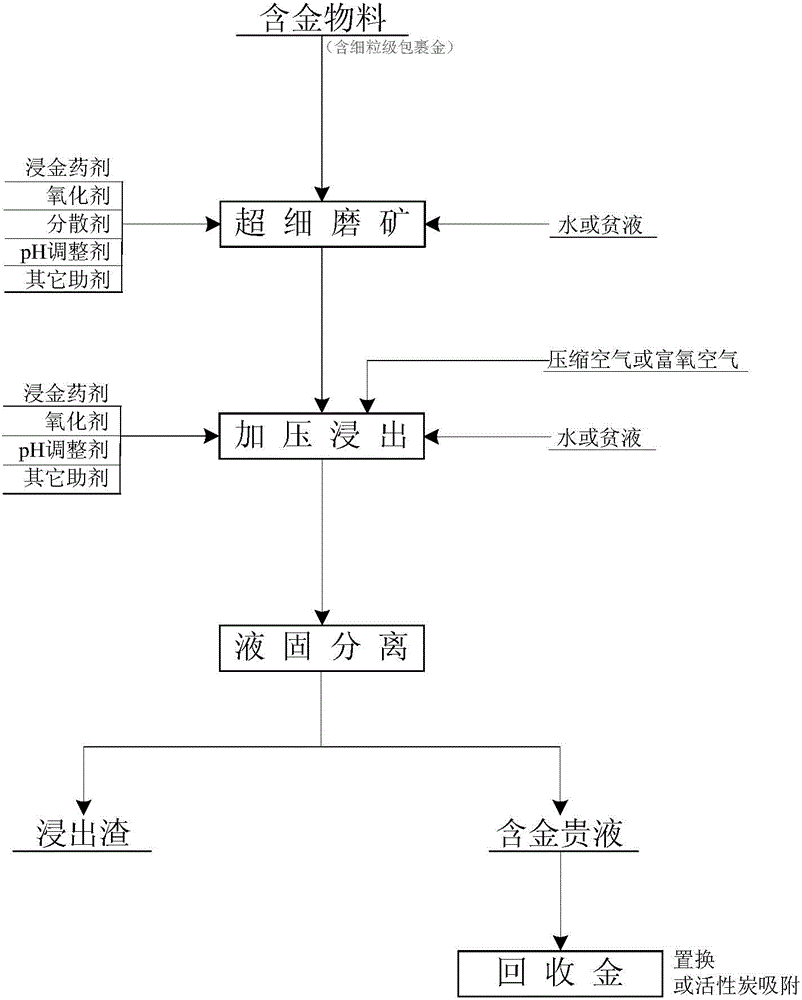

Reinforced leaching method of fine-grained encapsulated gold

ActiveCN104694764APromote complexation dissolution reactionIncrease dissolved oxygen contentProcess efficiency improvementWater basedElectrolysis

The invention discloses a reinforced leaching method of fine-grained encapsulated gold, which comprises the following steps: adding cyanation slag, calcined pyrite, pyrite cinder, auriferous sulfide ore roasted product or any other auriferous material, a gold leaching agent, a pH regulator, an oxidizer, a dispersing agent and the like into a water-base solvent, carrying out ball milling leaching to obtain extra-fine ground leaching slurry, transferring the extra-fine ground leaching slurry into a high-pressure reaction kettle, supplementing the gold leaching agent, oxidizer and water-base solvent, introducing air or oxygen-enriched air, carrying out pressure leaching, filtering and separating to obtain an auriferous pregnant solution and leaching slag. The method is simple in and convenient to operate, and can implement high-efficiency leaching of the fine-grained encapsulated gold; the obtained pregnant solution can be subjected to the existing technique composed of activated carbon adsorption, desorption, electrolysis, zinc powder (wire) reduction and the like to recover gold; and the method has high applicability and obvious economic benefits.

Owner:SHENZHEN RUICHENG SHIDAI IND CO LTD

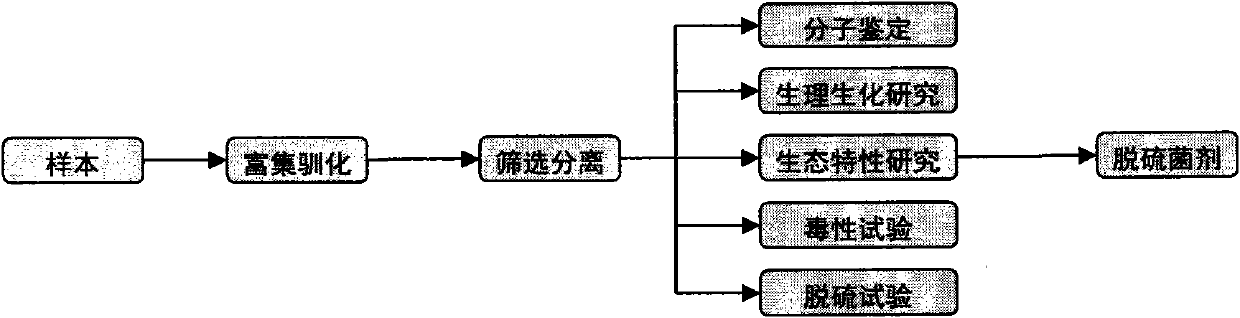

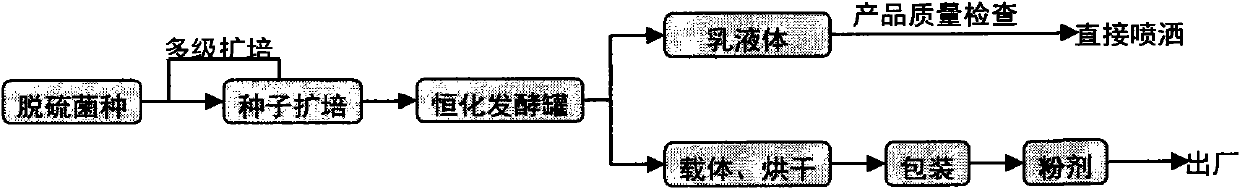

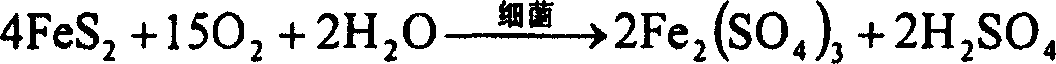

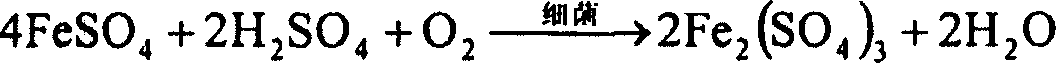

Combined microbial desulfurization method and its technology for coal

A combined desulfurization idea and process for coal removal, including the combination of high-efficiency core desulfurization bacteria agent and indigenous bacteria agent, as well as the combination of inorganic sulfur removal and organic sulfur removal technology, perfects the type and level of desulfurization, and can improve the desulfurization speed and efficiency. This invention considers and analyzes the differences in the state and content of sulfur in different coals, screens the indigenous microbial communities in the treated coal, and increases the local microbial populations’ influence on the core desulfurizing bacteria when the desulfurizing agents are expanded and applied in batches. Ecological support to form a combined desulfurization bacteria agent that is really suitable for the coal to be treated; at the same time, through the design and transformation of the traditional heap leaching method, the inorganic sulfur (mainly pyrite sulfur and elemental sulfur) and organic sulfur ( Dibenzothiophenes) are oxidized and decomposed into sulfuric acid by stage microorganisms and collected, so as to achieve the purpose of desulfurization. The combined microbial desulfurization method adopted in the present invention is a new technology pioneered at home and abroad.

Owner:上海彤微环保科技有限公司

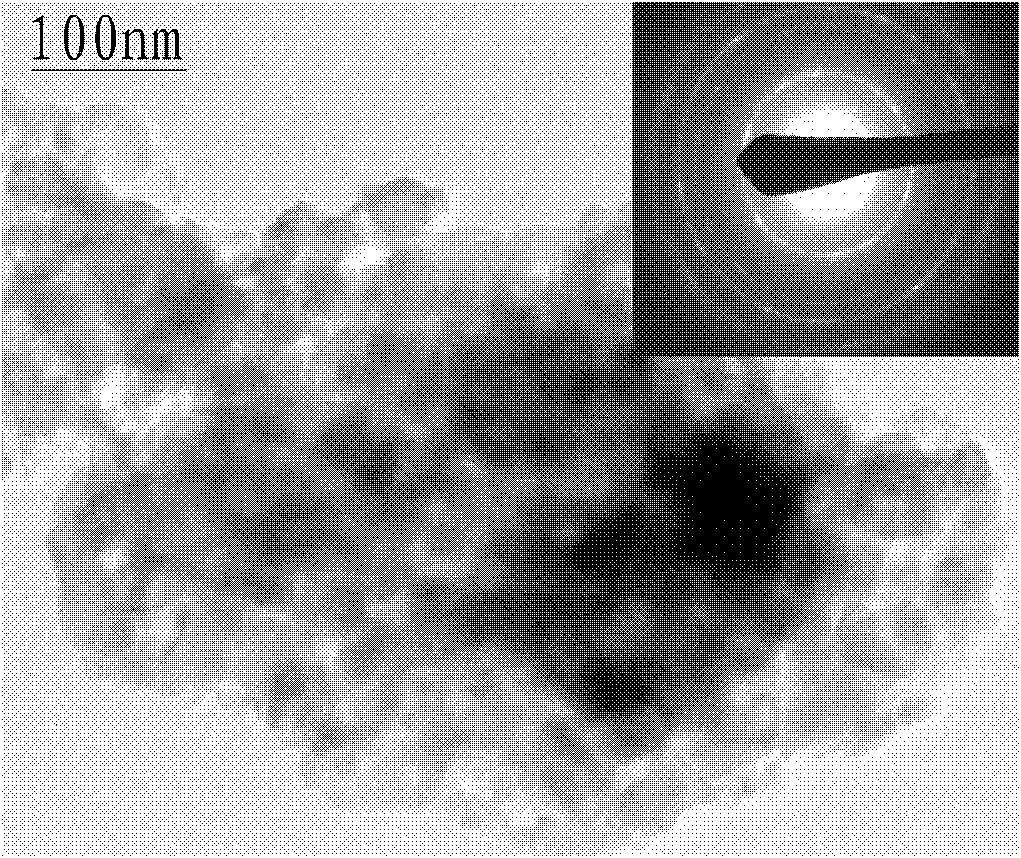

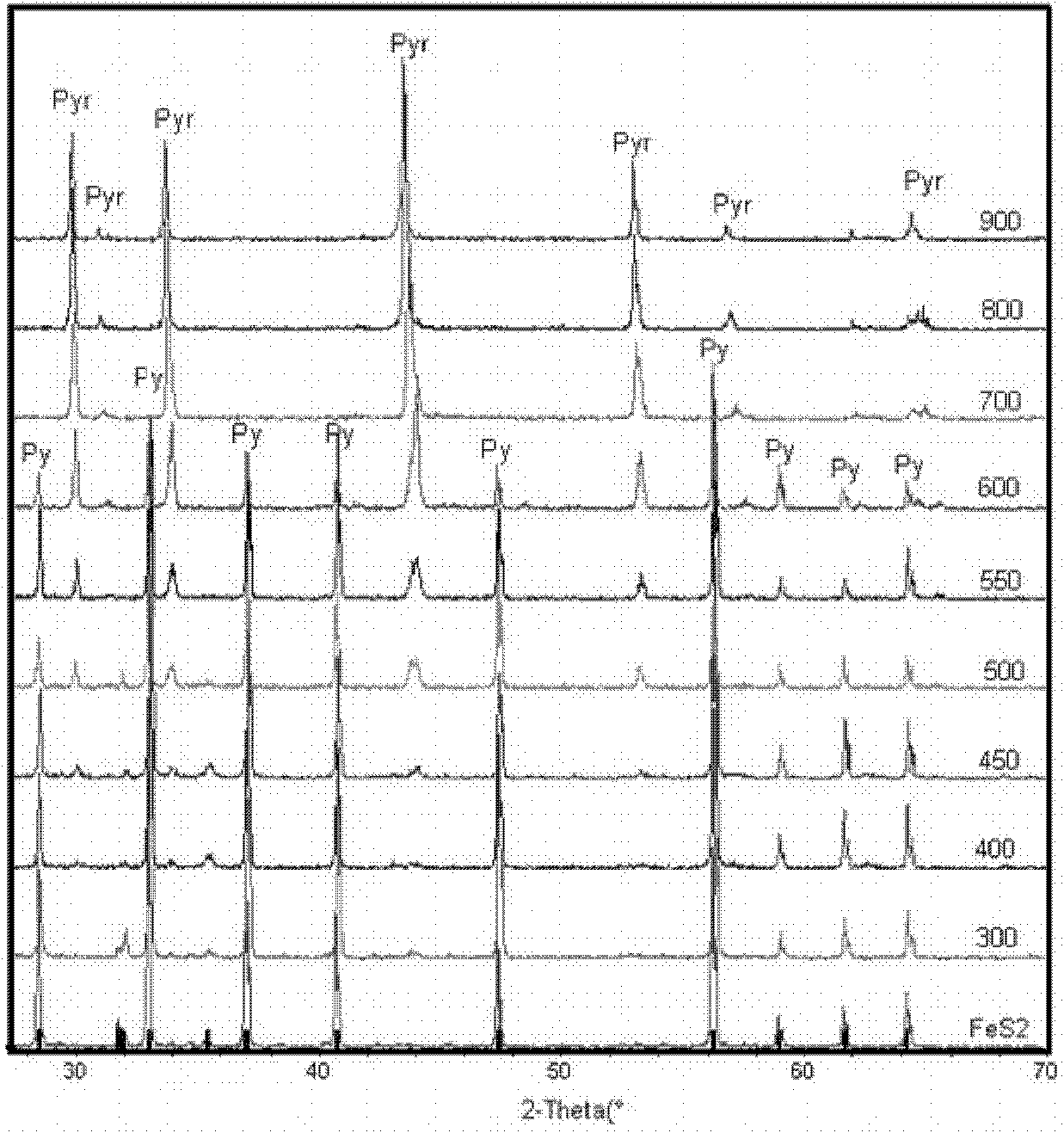

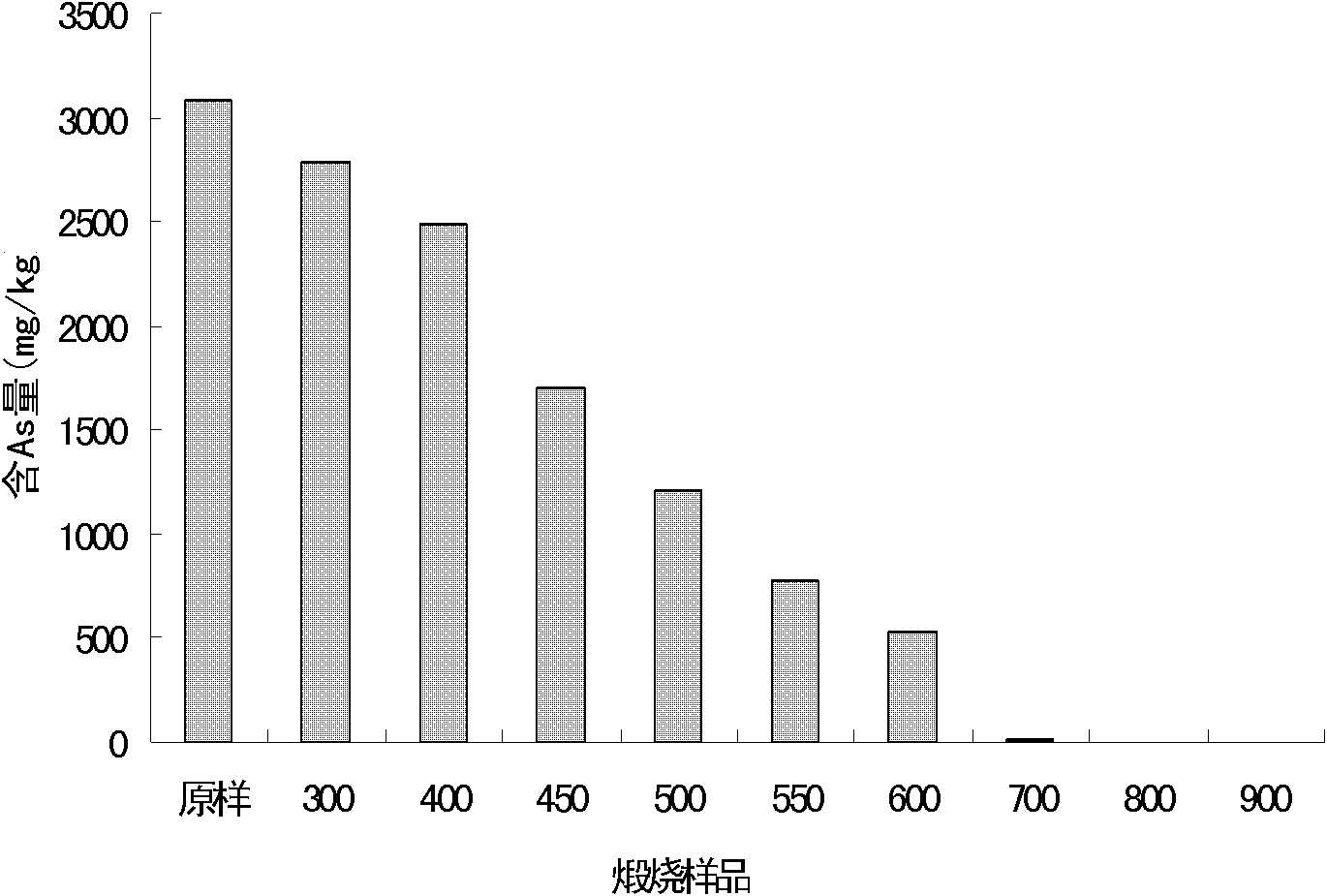

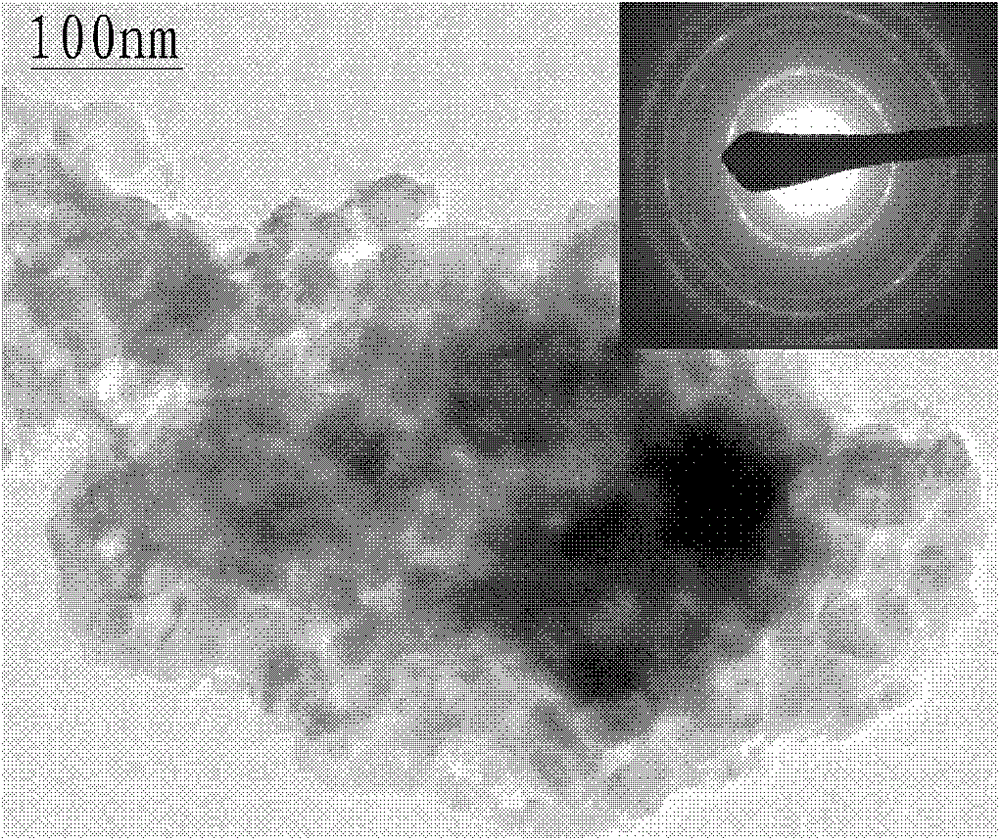

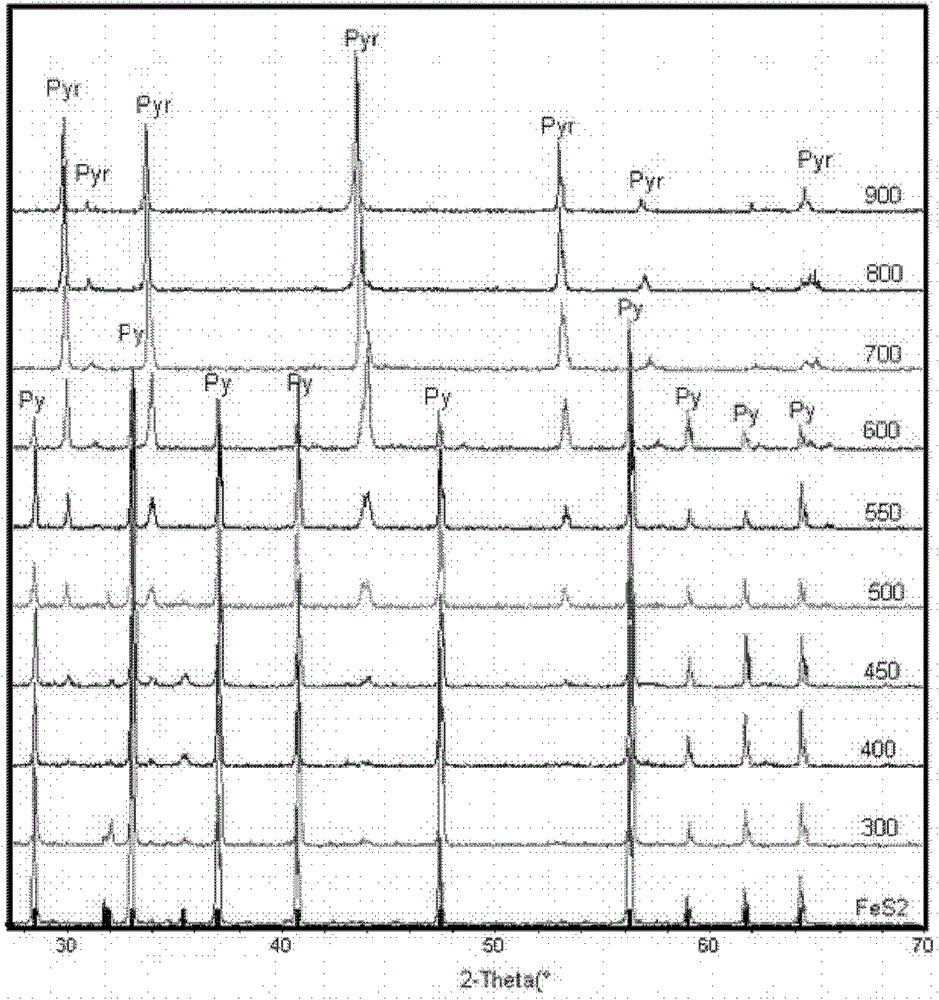

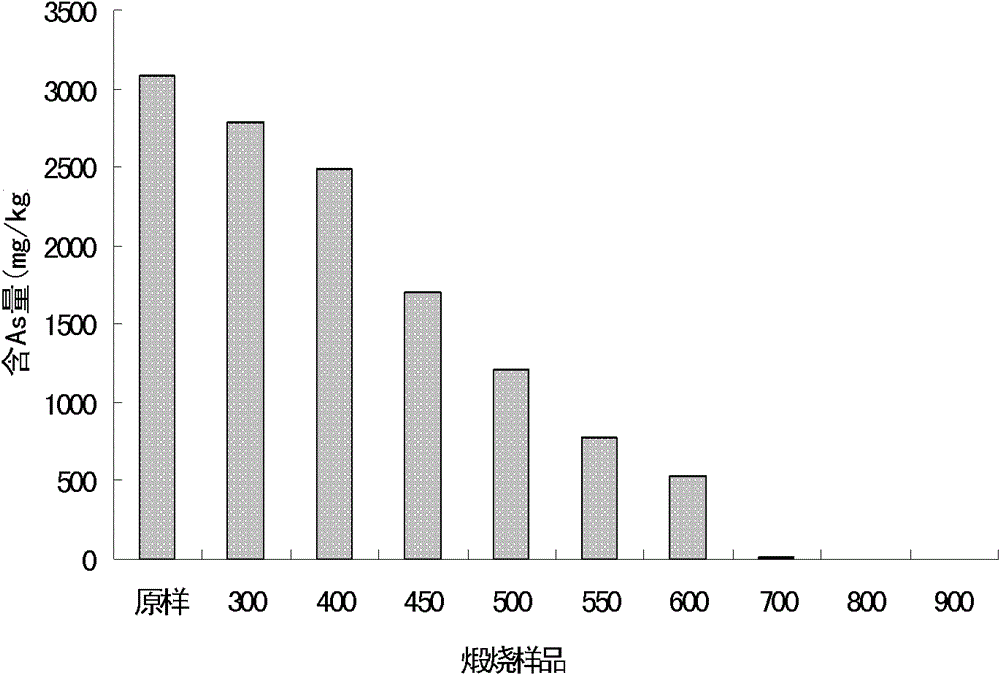

Pyrite nano mineral material and preparation method thereof

ActiveCN102320668ARegulatory structure stateRegulate physicochemical propertiesSulfur preparation/purificationNanotechnologyChemical reactionRoom temperature

The invention discloses a pyrite nano mineral material and a preparation method thereof. The pyrite nano mineral material uses pyritic sulfur and sulphide concentrate as raw materials, the mass percent of pyrite in the pyritic sulfur is not smaller than 50%, and the mass percent of the pyrite in the sulphide concentrate is not smaller than 90%. The preparation method comprises the following stepsof: crushing pyritic sulfur ores, sieving with a sieve of 100 meshes to obtain powder or directly selecting the sulphide concentrate with the particle diameter which is smaller than 0.165mm as powder, adding a bonder to the powder, pelletizing and molding to obtain particles with the particle diameter of 1-3mm, calcinating the particles at a temperature of 500-1000DEG C for 0.5-30min under anaerobic conditions, separating gas from solids, condensating the gas, recovering sulfur, and cooling the solids under oxygen isolation conditions to a room temperature to obtain a finished product. The material has the advantages of large specific area, strong magnesium, high chemical reaction activity, simple preparation technology, low cost and wide raw material resources.

Owner:HEFEI UNIV OF TECH

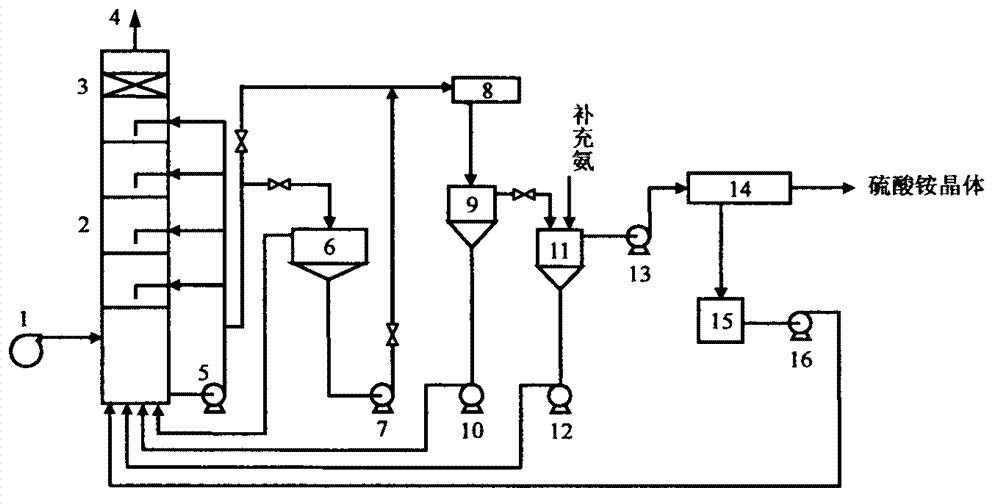

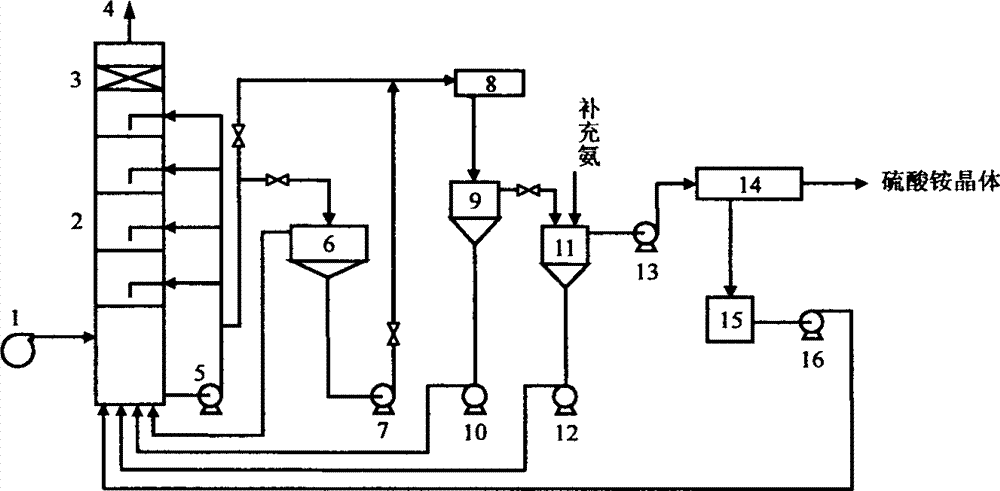

Method for desulfurization and denitrification of fume and coproduction of ammonium sulfate

ActiveCN103041688AInhibition of oxidative degradationReduce sulfur contentDispersed particle separationAmmonium sulfatesSulfate radicalsNitric oxide

The invention discloses a method for desulfurization and denitrification of fume and coproduction of ammonium sulfate. The method comprises the steps that slurry is prepared by a solution containing hydroxy carboxylic acid ligands and pyrite powder, the slurry is used for washing the fume containing sulfur dioxide and nitric oxide, sulfur dioxide and oxygen in the fume react with pyrite, sulfur dioxide and pyritic sulfur are oxidized into sulfate radicals, ferrous generated by leaching the pyrite is combined with aminocarboxylic acid ligands to generate a ferrous complexing agent, the ferrous complexing agent complexes and absorbs nitric oxide in the fume, a complexation product nitrosyl complex continues to react by the action of the pyritic to generate ammonium radicals, and the ammonium radicals are combined with the sulfate radicals to generate ammonium sulfate. According to the method, with the adoption of the pyrite, oxidation degradation of the ferrous complexing agent is inhibited, and the nitrosyl complex continues to react to generate the ammonium radicals. In addition, ferrous ions and the like leached from the pyrite have a catalyst effect in oxidizing sulfur dioxide.

Owner:青岛赛诺威尔工业水处理有限公司

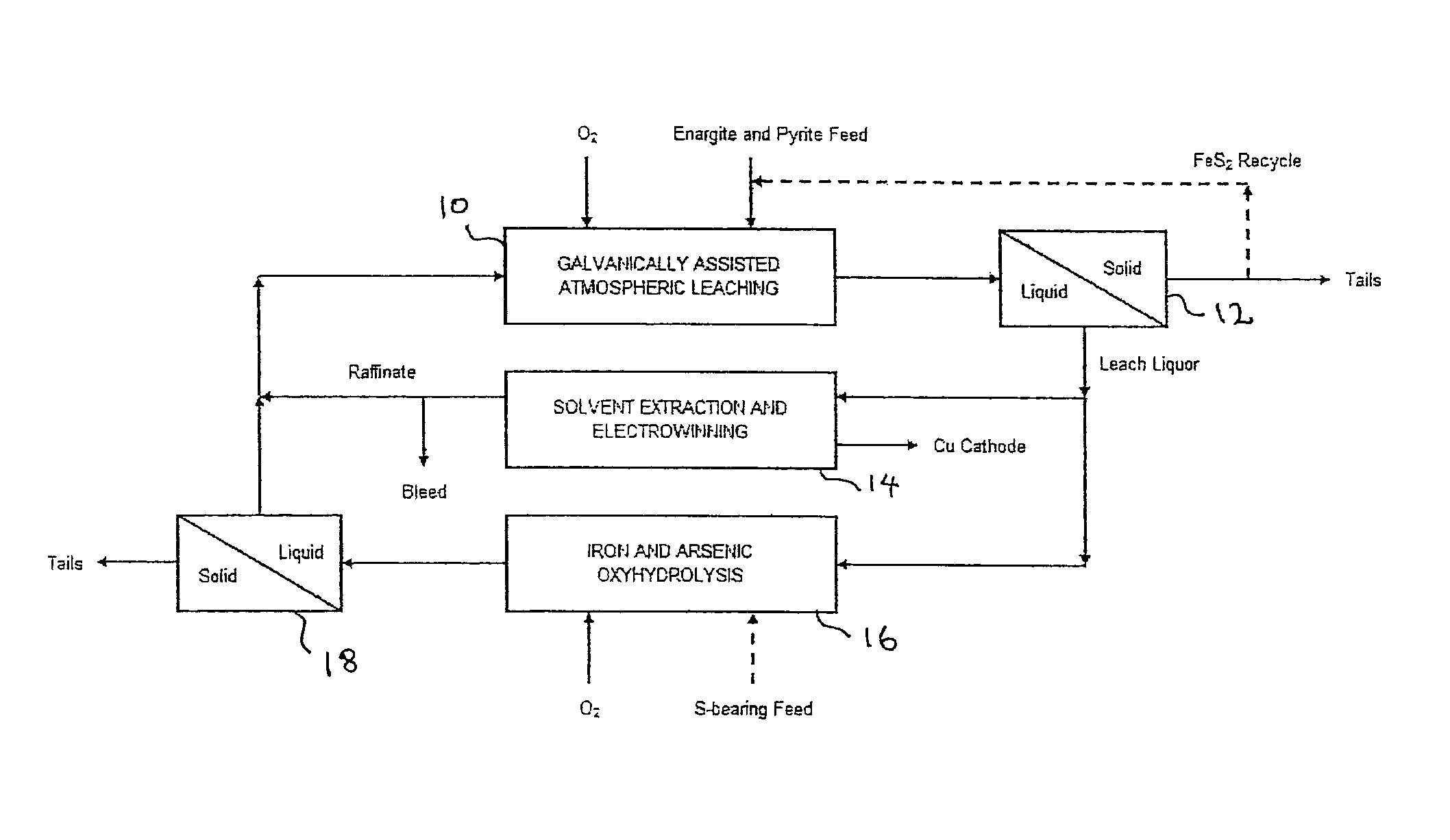

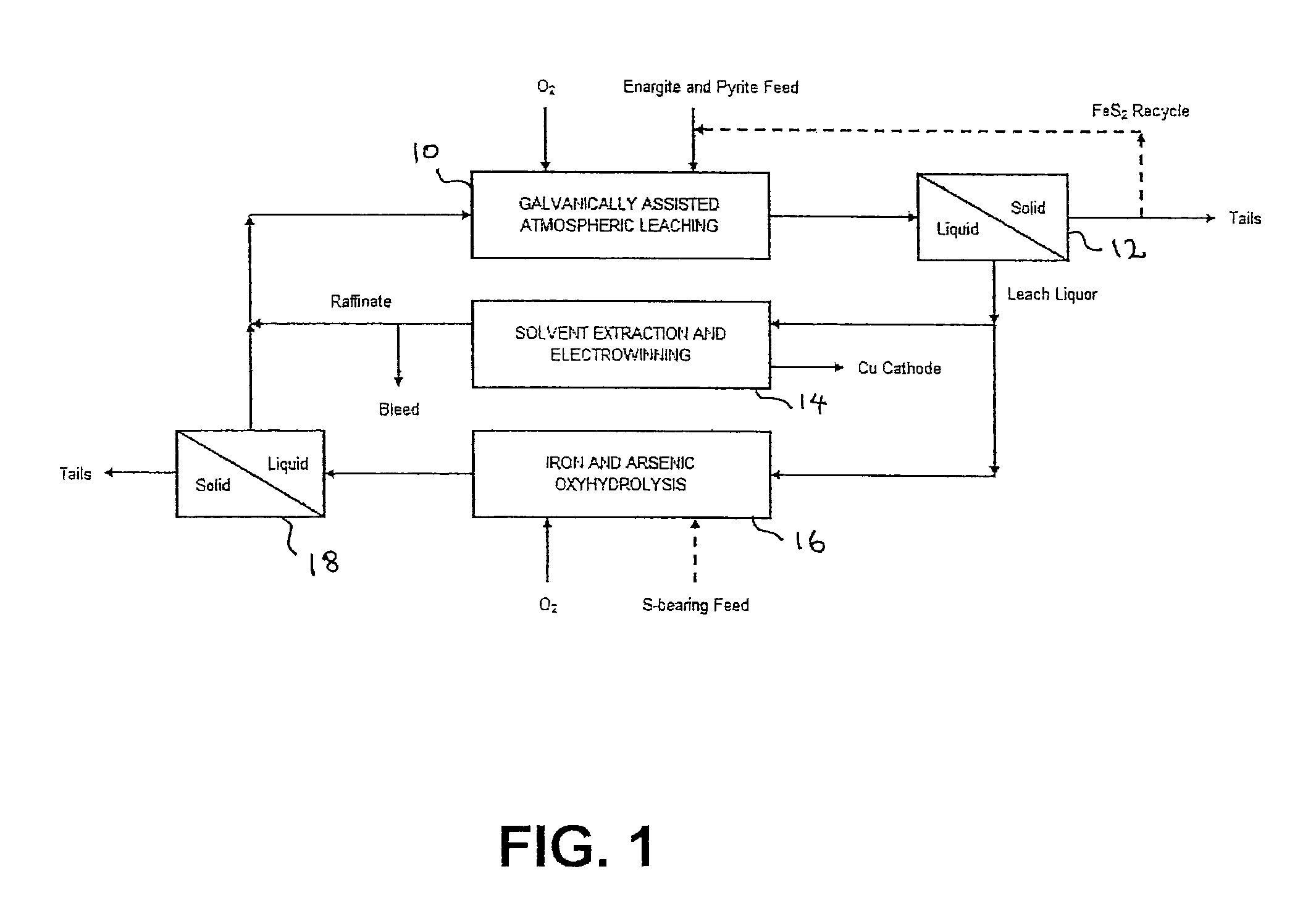

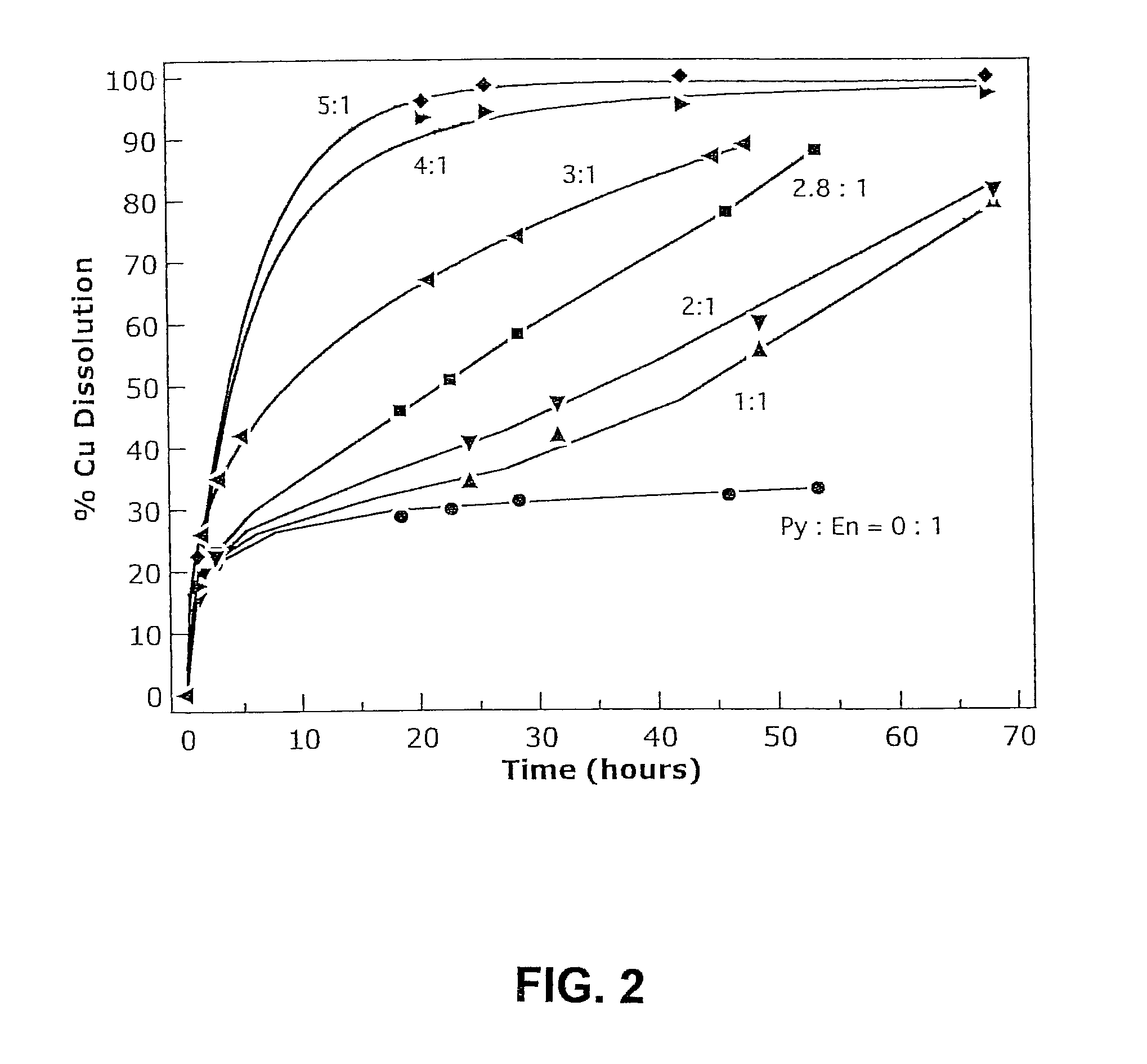

Leaching process for copper concentrates containing arsenic and antimony compounds

A method of recovering copper from a copper sulfide concentrate comprising a copper arsenic sulfosalt or a copper antimony sulfosalt, using pyrite as a catalyst. The concentrate and pyrite are added to an acidic sulfate leach solution. The copper is leached from the concentrate, in the presence of an oxygen-containing gas, under conditions whereby the pyrite is substantially unoxidized. The pyrite:copper sulfide ratio of the pyrite being added to the copper sulfide present in the concentrate being added is at least 1:3. The pyrite may be maintained at a concentration in the leach solution of at least 9 grams per liter. The leached copper is recovered from the solution by conventional methods.

Owner:THE UNIV OF BRITISH COLUMBIA

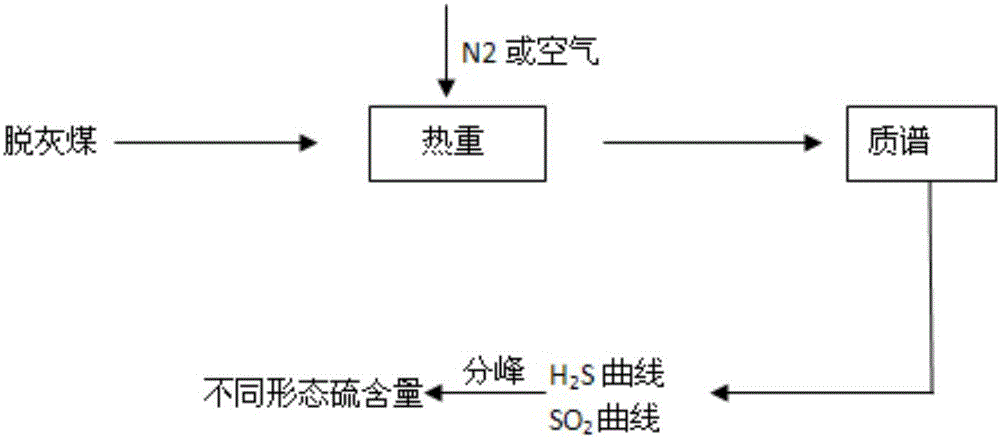

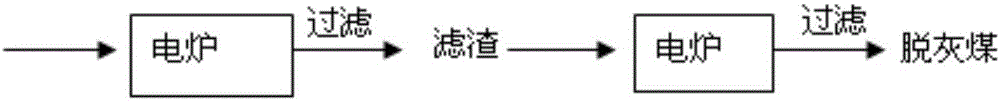

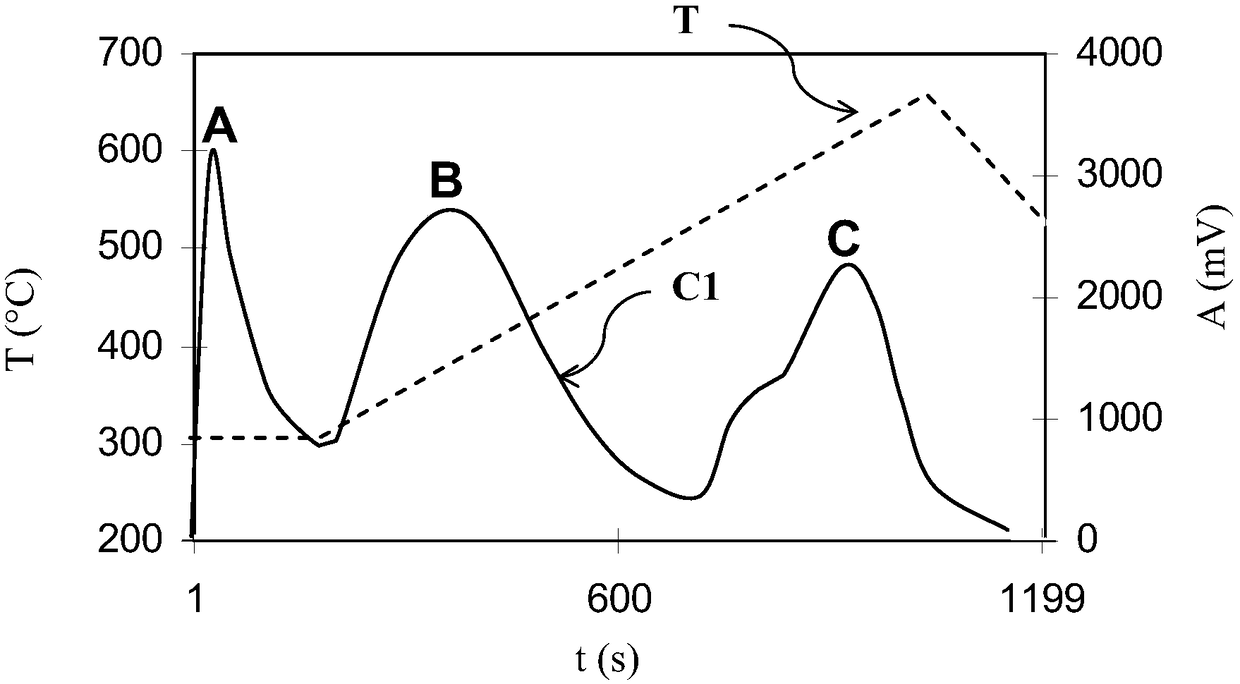

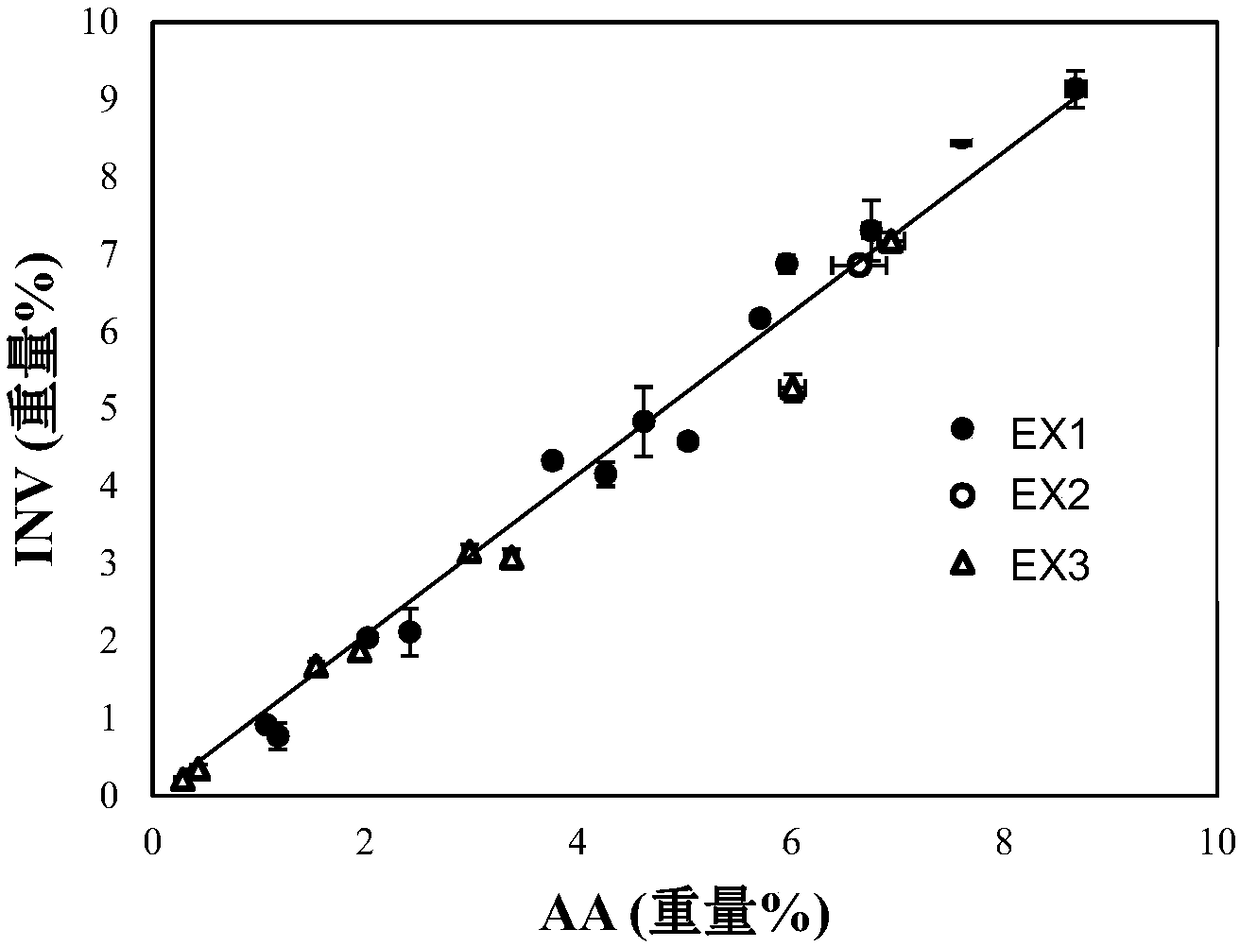

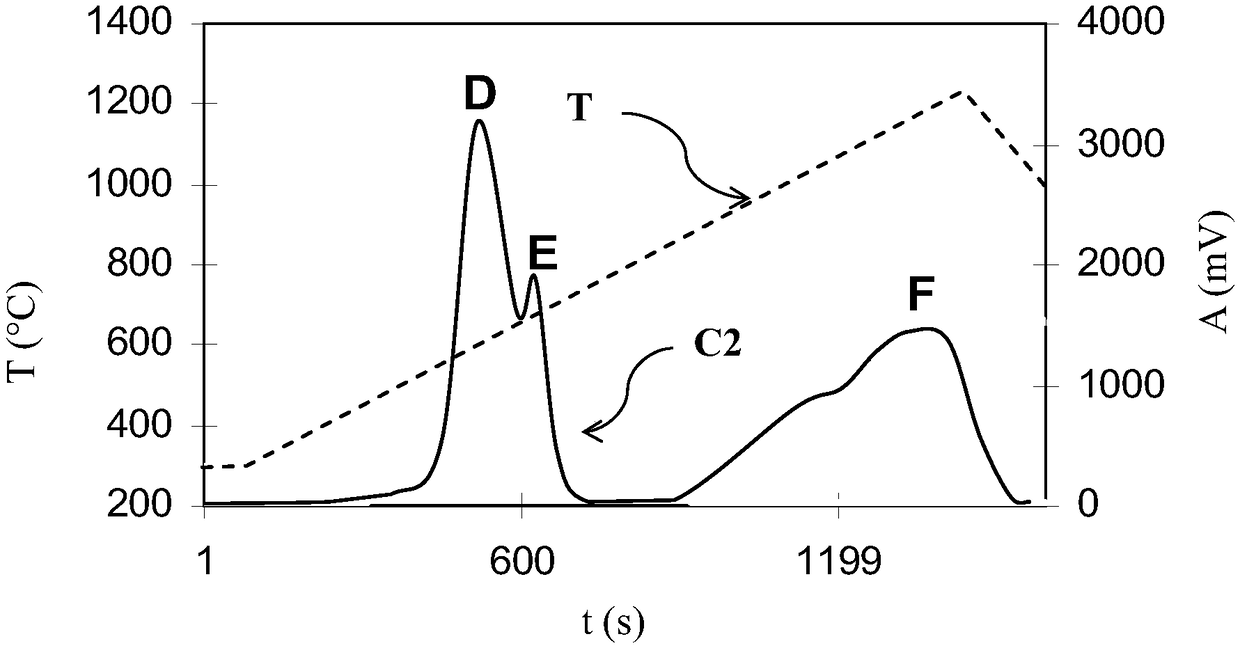

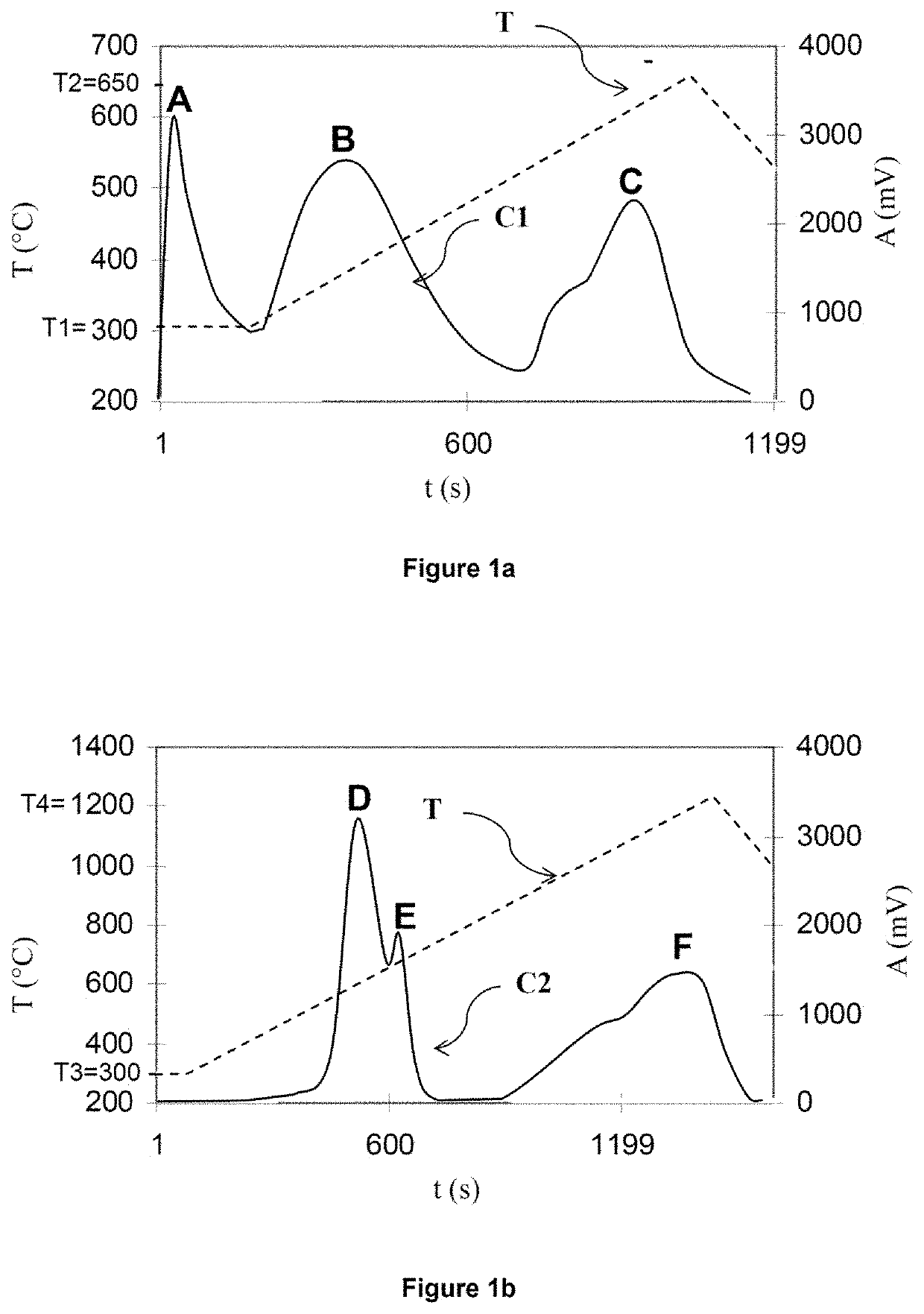

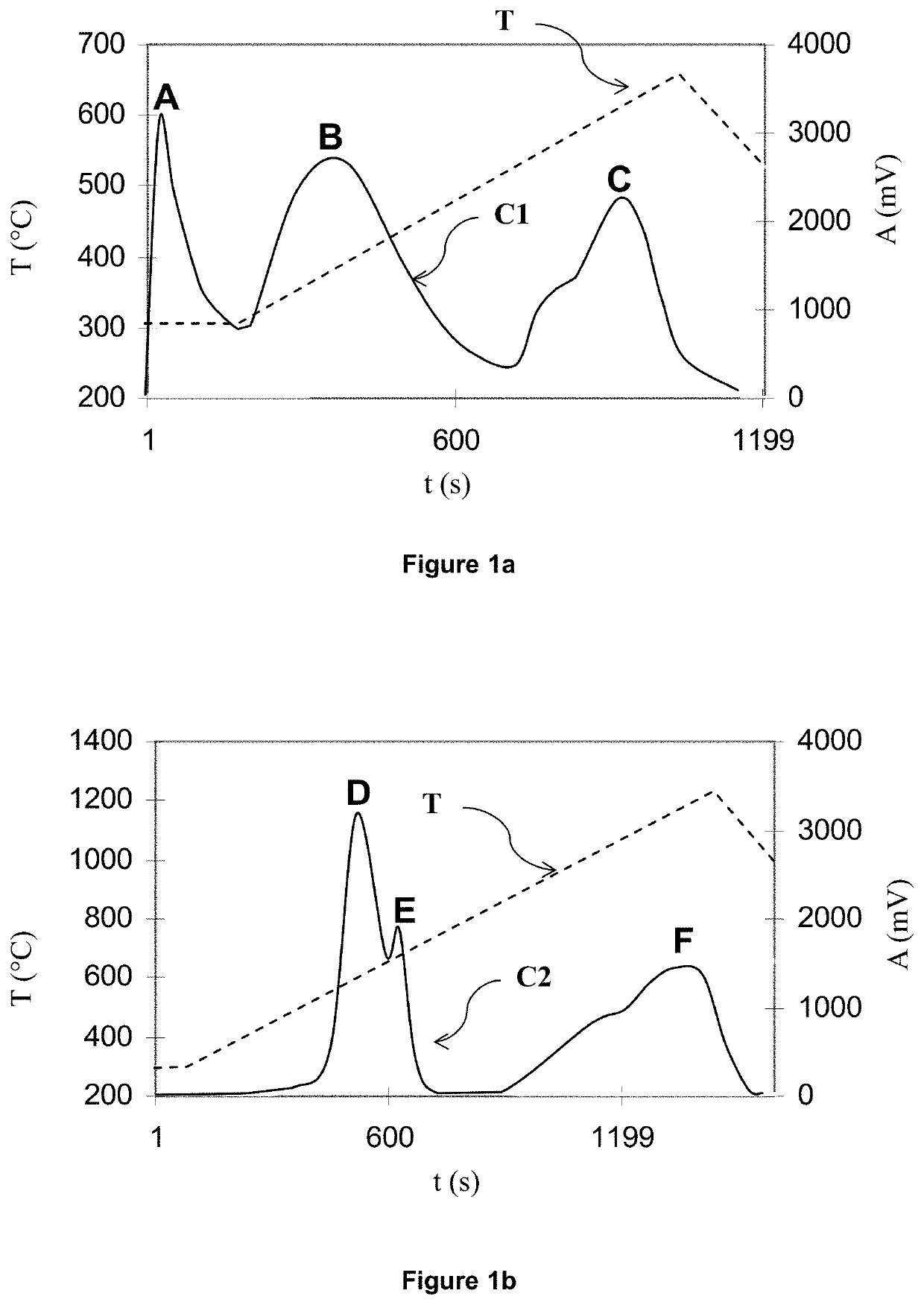

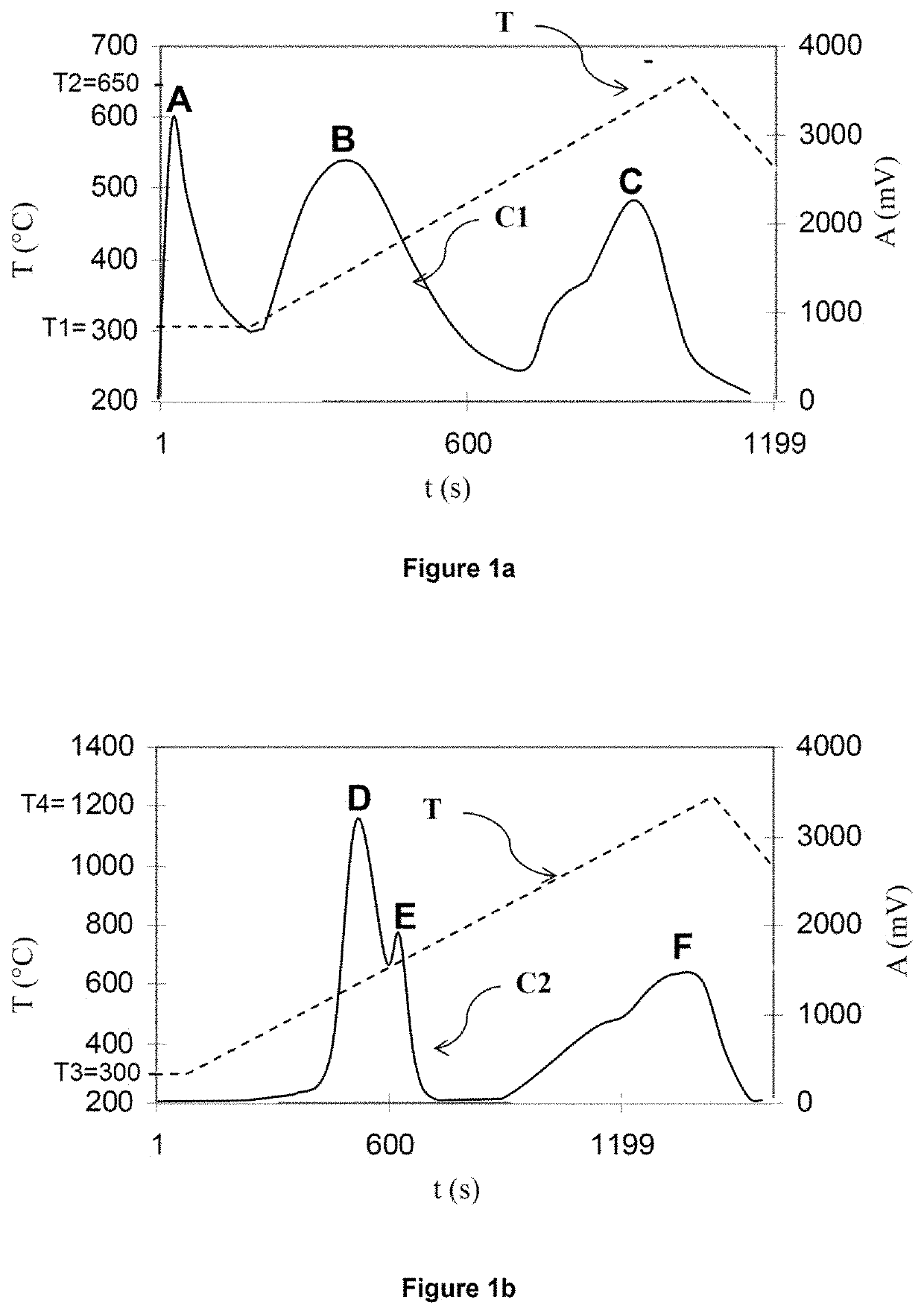

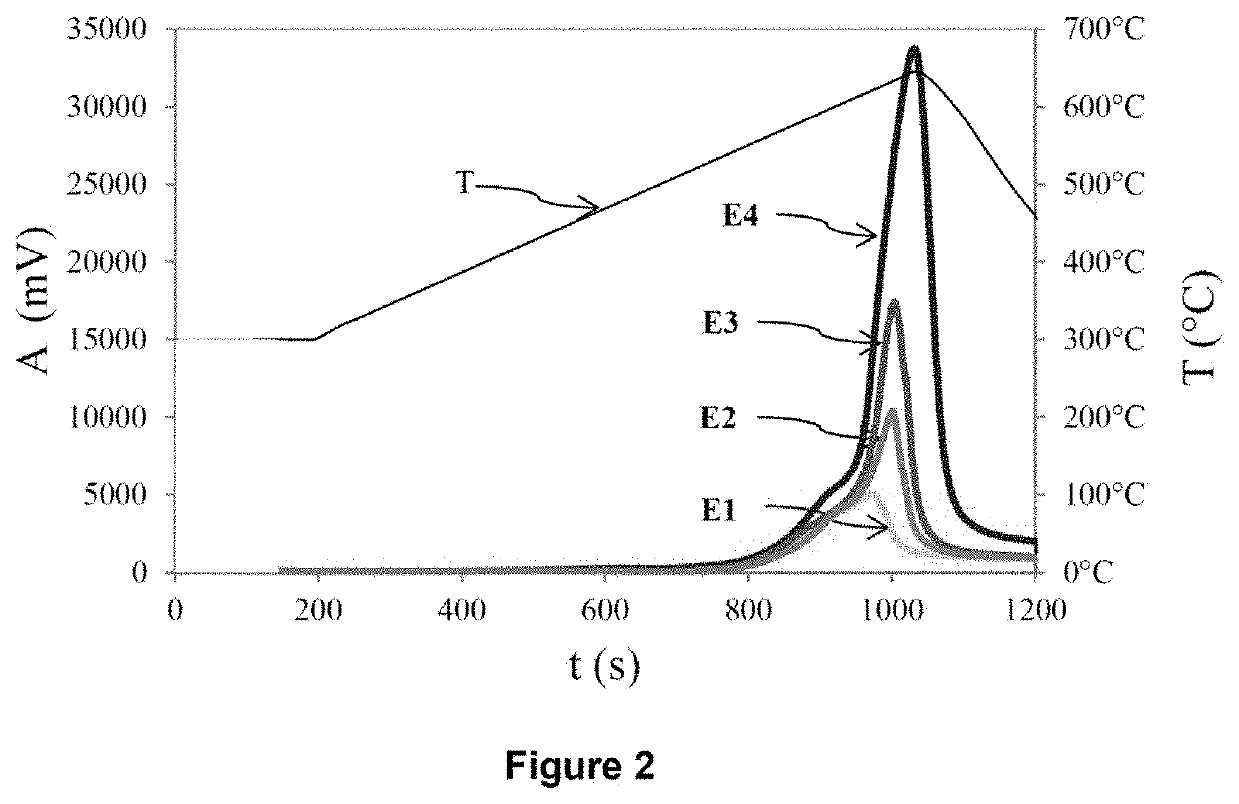

Determination method for applying demineralized coal to measure forms of sulfur in coal by temperature programming method

InactiveCN106596315AHigh precisionLow costMaterial analysis by electric/magnetic meansMaterial weighingPyritic sulfurTemperature-programmed reduction

The invention discloses a determination method for applying demineralized coal to measure forms of sulfur in coal by a temperature programming method. Coal is first demineralized, a temperature-programmed reduction method or a temperature-programmed oxidation method is then carried out on the demineralized coal, sulfur in the demineralized coal is converted into H2S or SO2, peaks of an H2S or SO2 evolution curve are resolved, and different forms of sulfur contents (including pyritic sulfur, aliphatic sulfur, aromatic sulfur and thiophene) in the coal are then derived reversely. The invention can effectively measure the contents of different forms of sulfur in coal, results are more accurate, and measurement is easy.

Owner:HUANENG POWER INTERNATIONAL +2

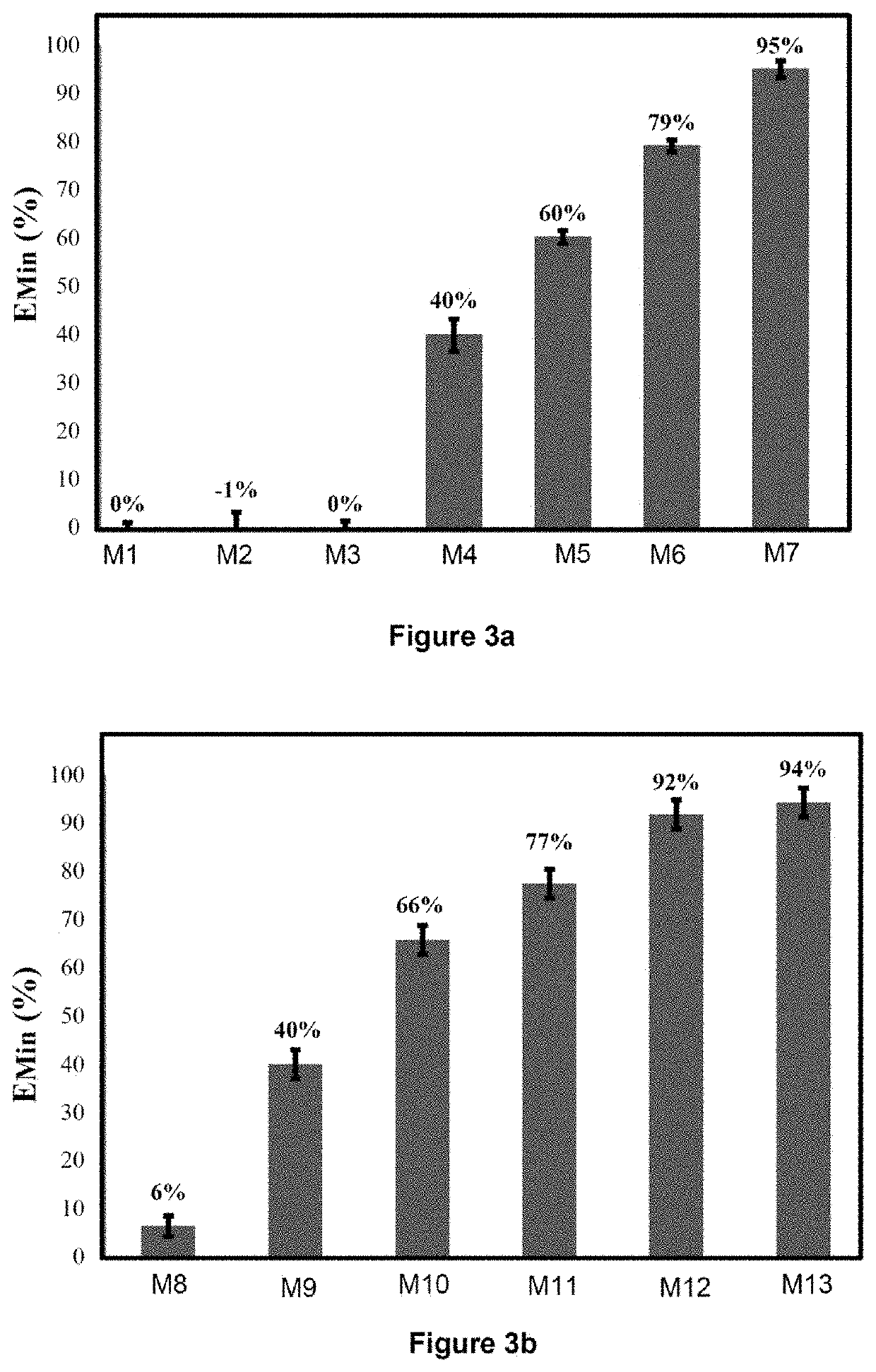

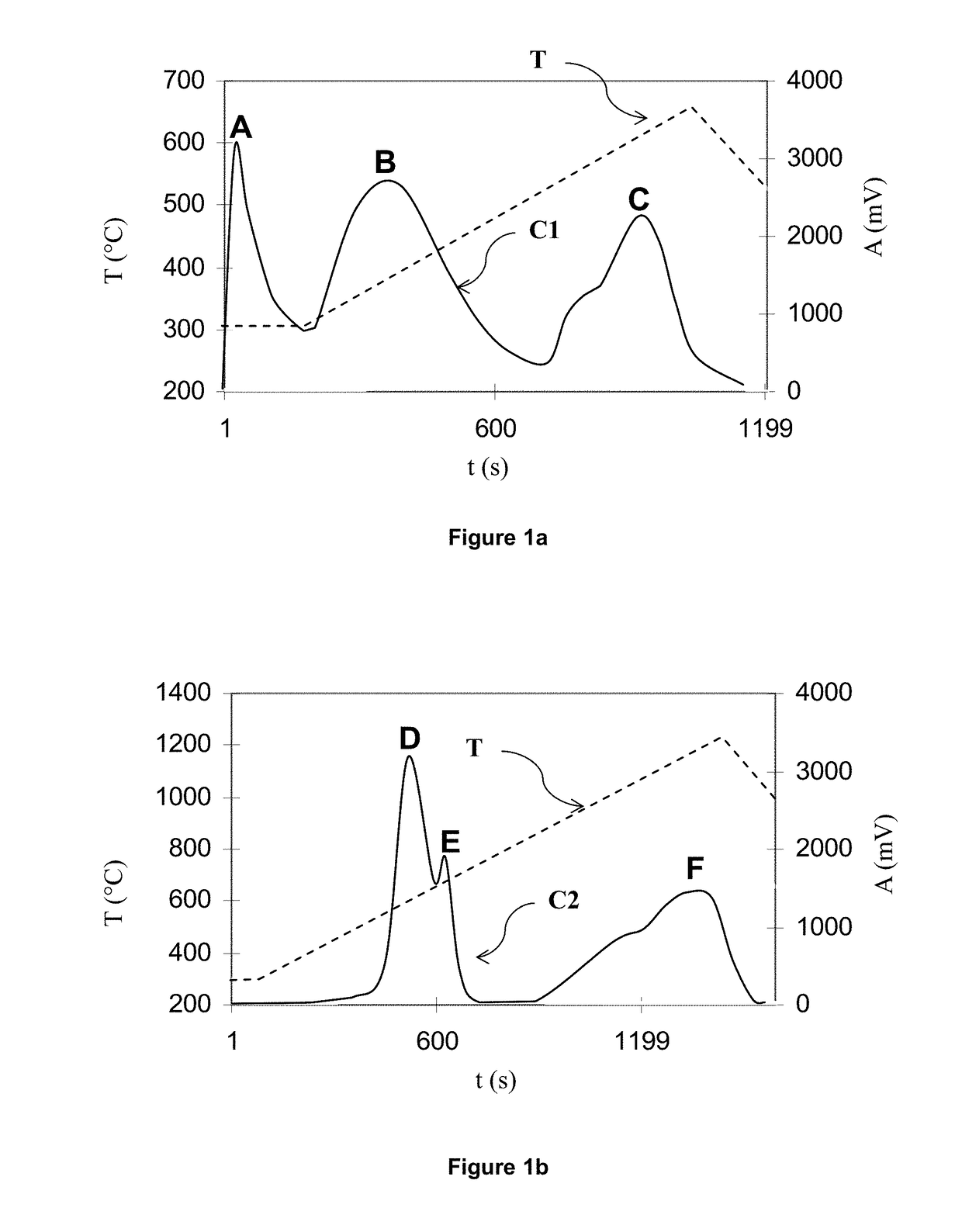

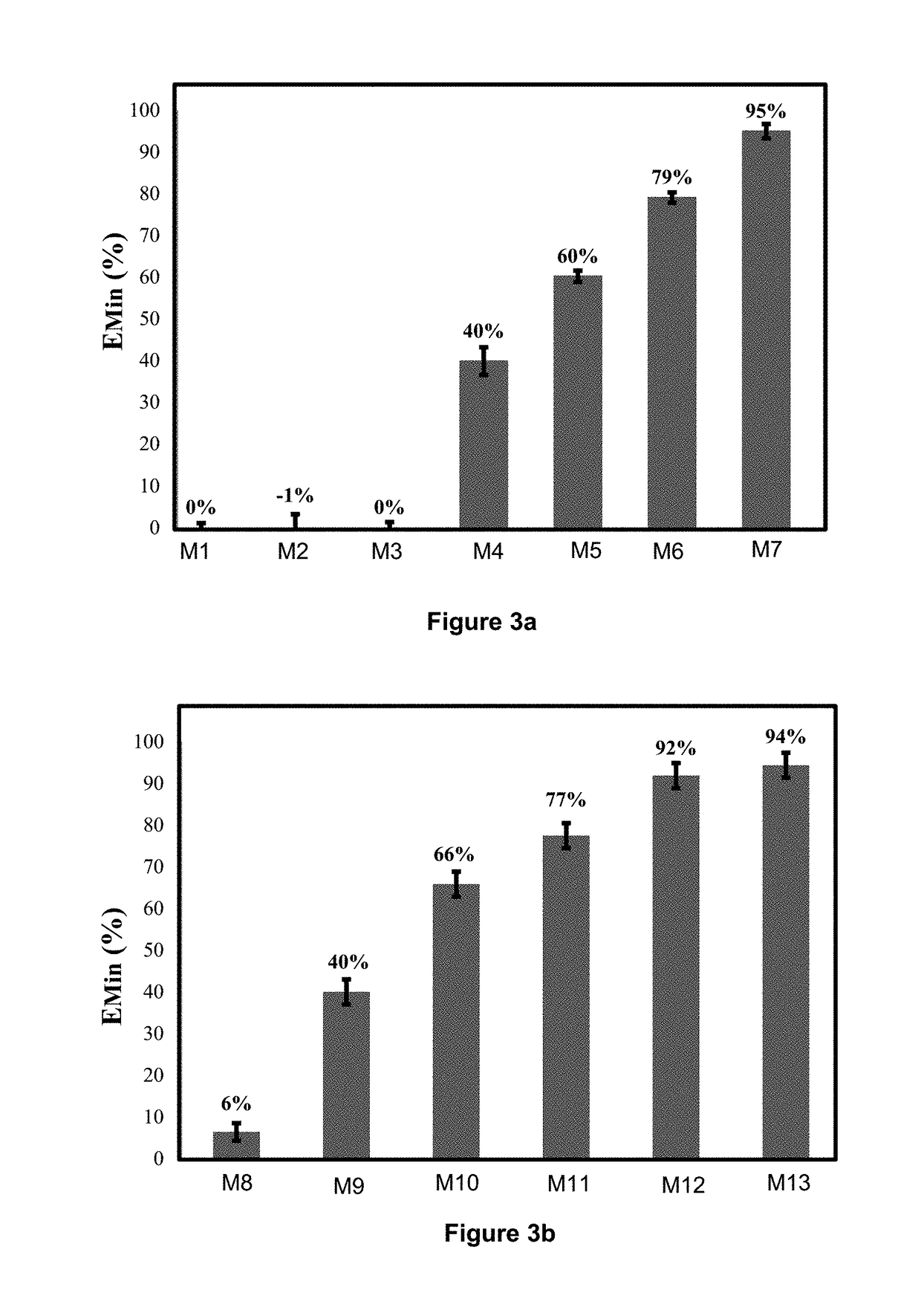

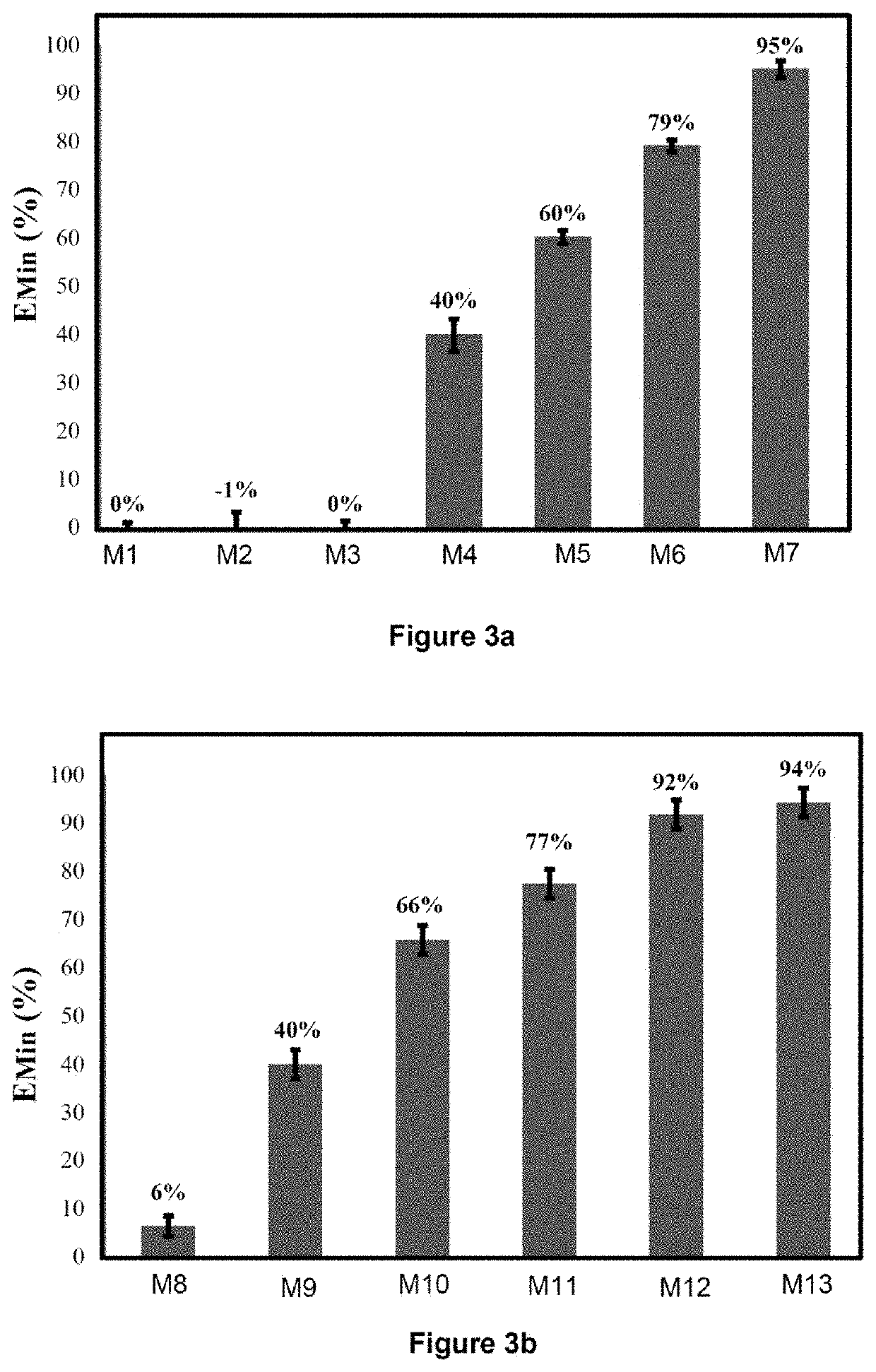

Method for quantifying pyritic sulfur and organic sulfur of rock sample

ActiveCN109490505AChemical analysis using combustionEarth material testingSoil sciencePetroleum exploration

A method is provided for characterizing and quantifying the pyritic sulfur and the organic sulfur separately in a sedimentary rock sample. A rock sample is subjected to a heating process in an inert atmosphere, the effluents resulting from the heating in the inert atmosphere are continuously oxidized, the released SO2 is continuously measured, and a pyrolysis sulfur content and a pyrolysis pyriticsulfur content are deduced. The residue heated in the inert atmosphere is heated in an oxidizing atmosphere, the released SO2 is continuously measured, and at least oxidation sulfur content is deduced therefrom. The pyritic sulfur content is determined from the pyritic pyrolysis sulfur content and a weighting function taking account of a first parameter representing a thermal degradation rate ofthe pyrite, a second parameter representing the impact of the mineral matrix, and a third parameter representing the impact of the organic matrix. In addition, the organic sulfur content can be determined from at least the oxidation sulfur content, the pyrolysis sulfur content and the pyritic sulfur content. Application: in particular to oil exploration and exploitation.

Owner:INST FR DU PETROLE

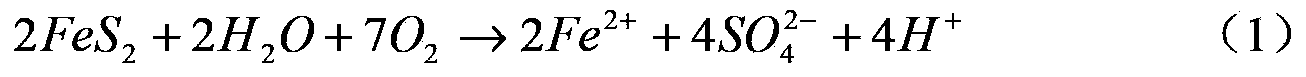

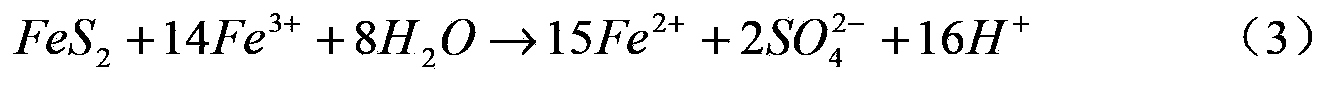

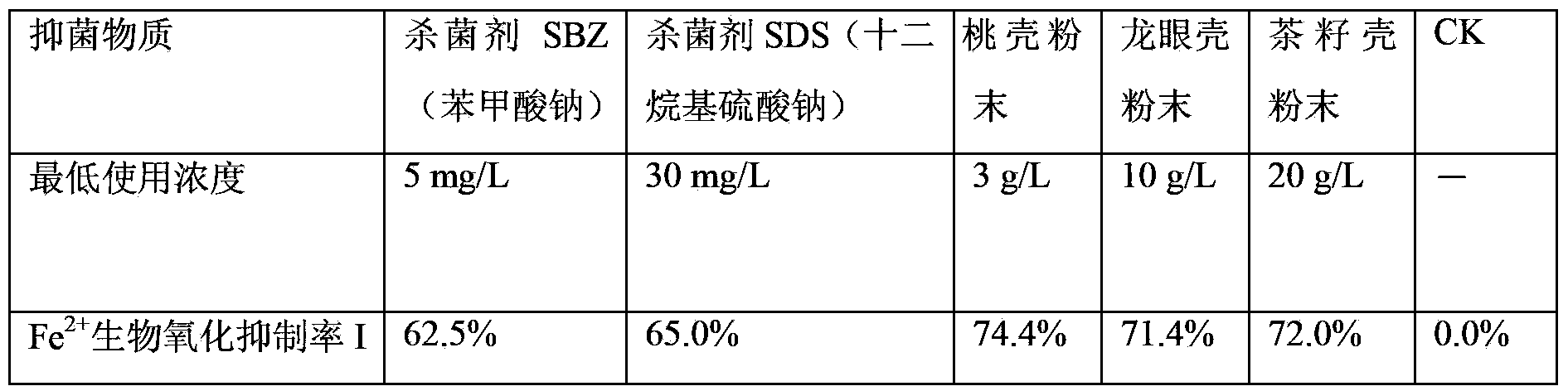

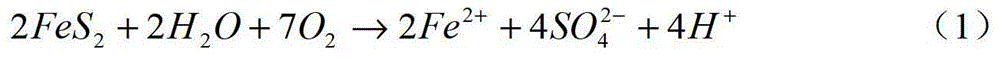

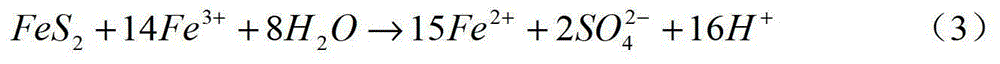

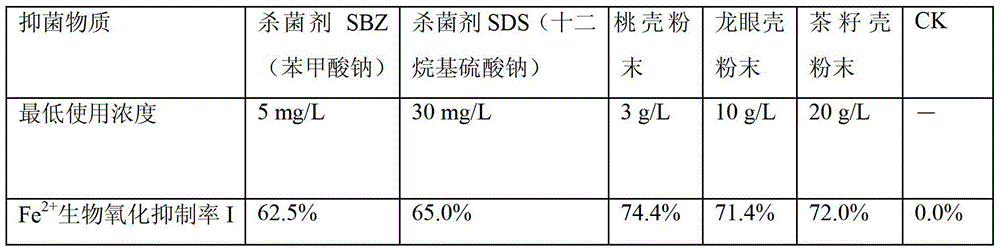

Method for performing in situ treatment on acid mine water by using crop seed husks

InactiveCN103362550AProduction slows down and suppressesExtend design service lifeMining devicesFerric hydroxidePollution

The invention provides a method for performing in situ treatment on acid water of a mine by using crop seed husks. The method comprises the steps that an acid generation point or a fissure surface where the acid water seeps in a mine shaft is detected; a biological inhibitor and alkali flocculation mixed liquor are prepared; the surface of the acid water of the mine shaft is sprayed by the biological inhibitor or subjected to brushed in batch; and continuous seepage of the acid water in the shaft can be eliminated by spraying the alkali flocculation mixed liquor onto an inhibitor layer at intervals for 1-3 times finally. According to the method, the oxidative activity of acidophilic bacteria in an acid water generation environment is inhibited by the biological inhibitor, generation of the acid water is slowed down or inhibited, and the alkali flocculation mixed liquor is used for spraying continuously to form ferric oxide or ferric hydroxide flocculent settling to form a protective film on the surface of pyritic sulfide, so that the acid water generated due to biological and chemical oxidation of sulfur-bearing minerals is avoided completely. The method has the advantages that waste is recycled, neither poison nor secondary pollution to an environment is caused, and the method is low in cost and simple to apply and operate.

Owner:HEFEI UNIV

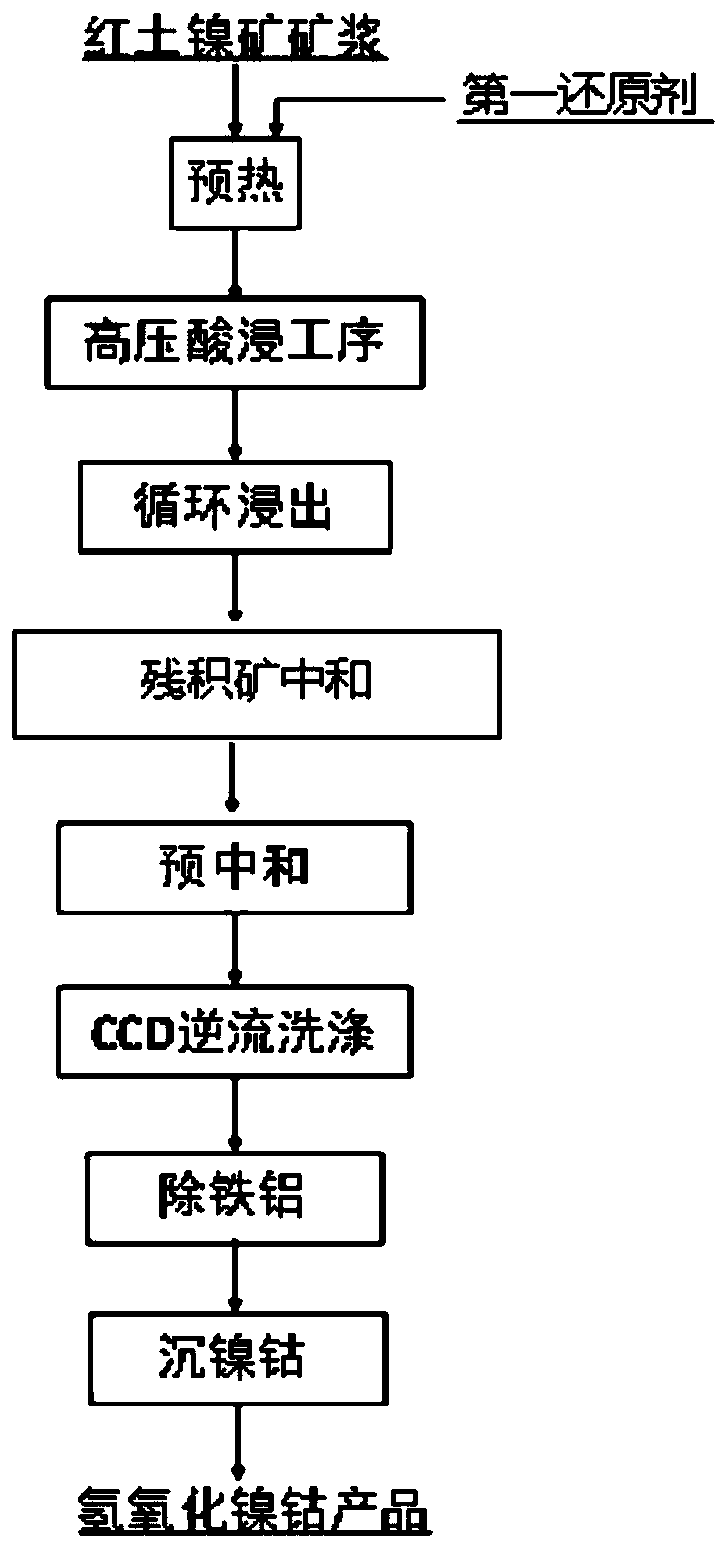

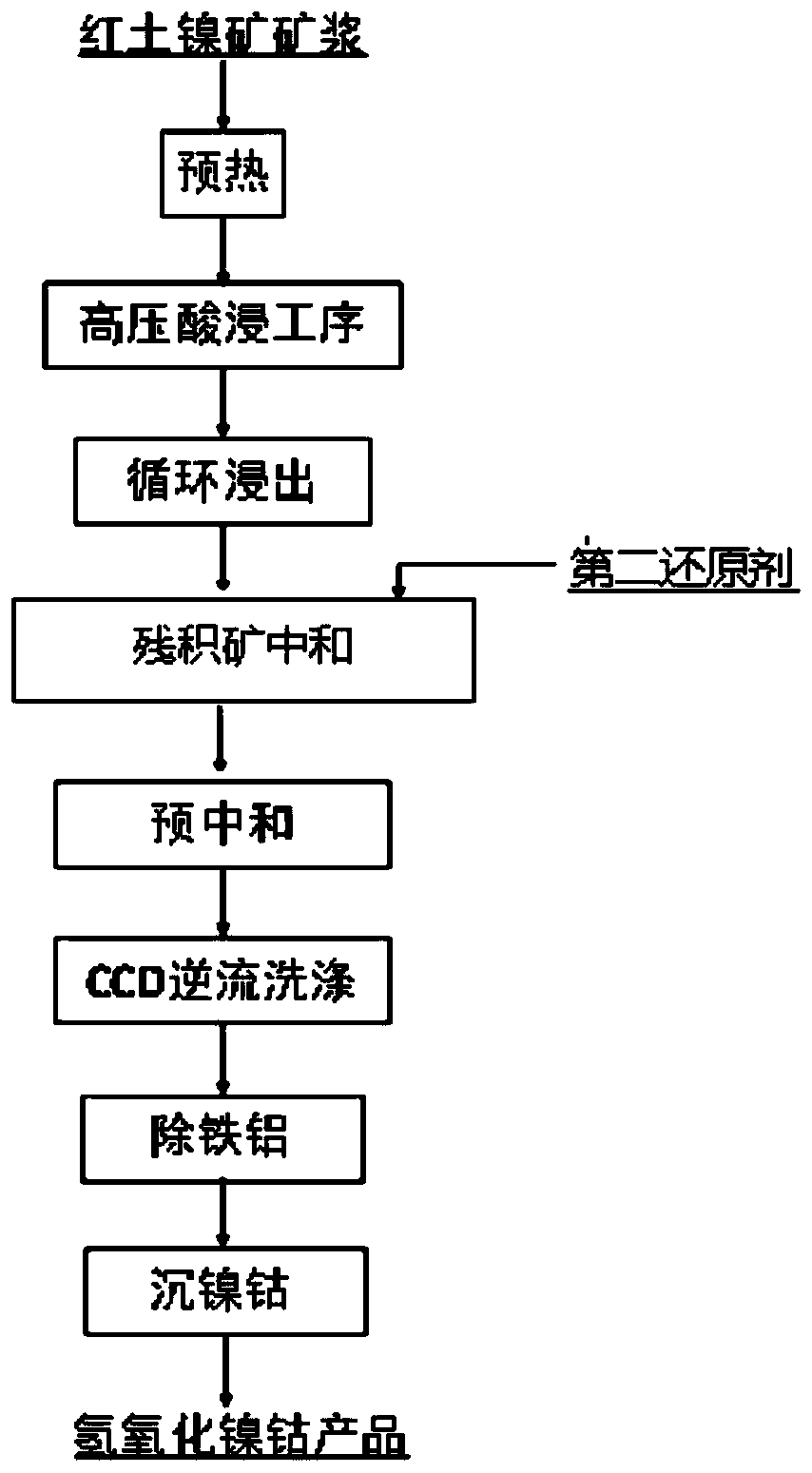

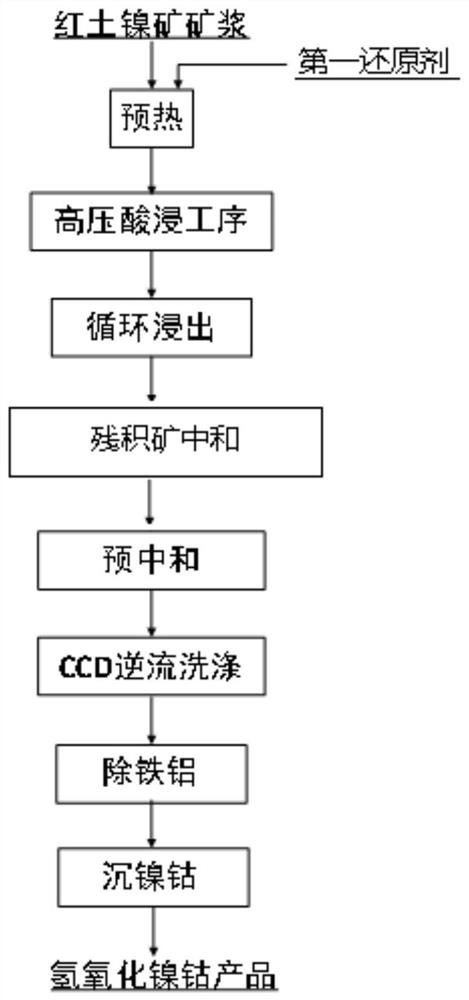

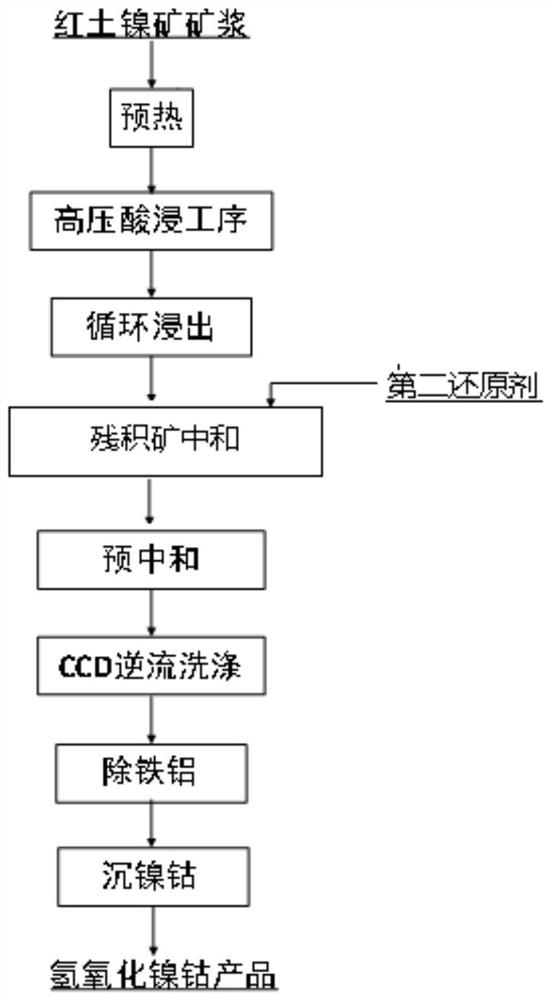

Method for removing hexavalent chromium in process of preparing cobalt nickel hydroxide from laterite-nickel ore

The invention provides a method for removing hexavalent chromium in the process of preparing cobalt nickel hydroxide from laterite-nickel ore. The method comprises the steps that before the high-pressure acid leaching step, laterite-nickel ore pulp is preheated, before the preheating step, a first reducing agent is added into the laterite-nickel ore pulp, and then the laterite-nickel ore pulp added with the first reducing agent is made to enter the high-pressure acid leaching step; wherein the first reducing agent is one or more of pyrite, sulfur and chromite, or organic wastewater; or, a second reducing agent is added into the leachate obtained in the cyclic leaching step, and then the residual ore neutralization step is executed; and the second reducing agent is one or more of sulfite, pyrosulfite, ferrite, thiosulfate, sulfide salt and bisulfite of alkali metal or alkaline-earth metal. By utilizing the method provided by the invention, hexavalent chromium can be removed from the source on the basis of not changing the high-pressure leaching procedure of the laterite-nickel ore, so that the nickel-cobalt hydroxide product is prevented from being carried out, and the original steps are not influenced.

Owner:CHINA ENFI ENGINEERING CORPORATION

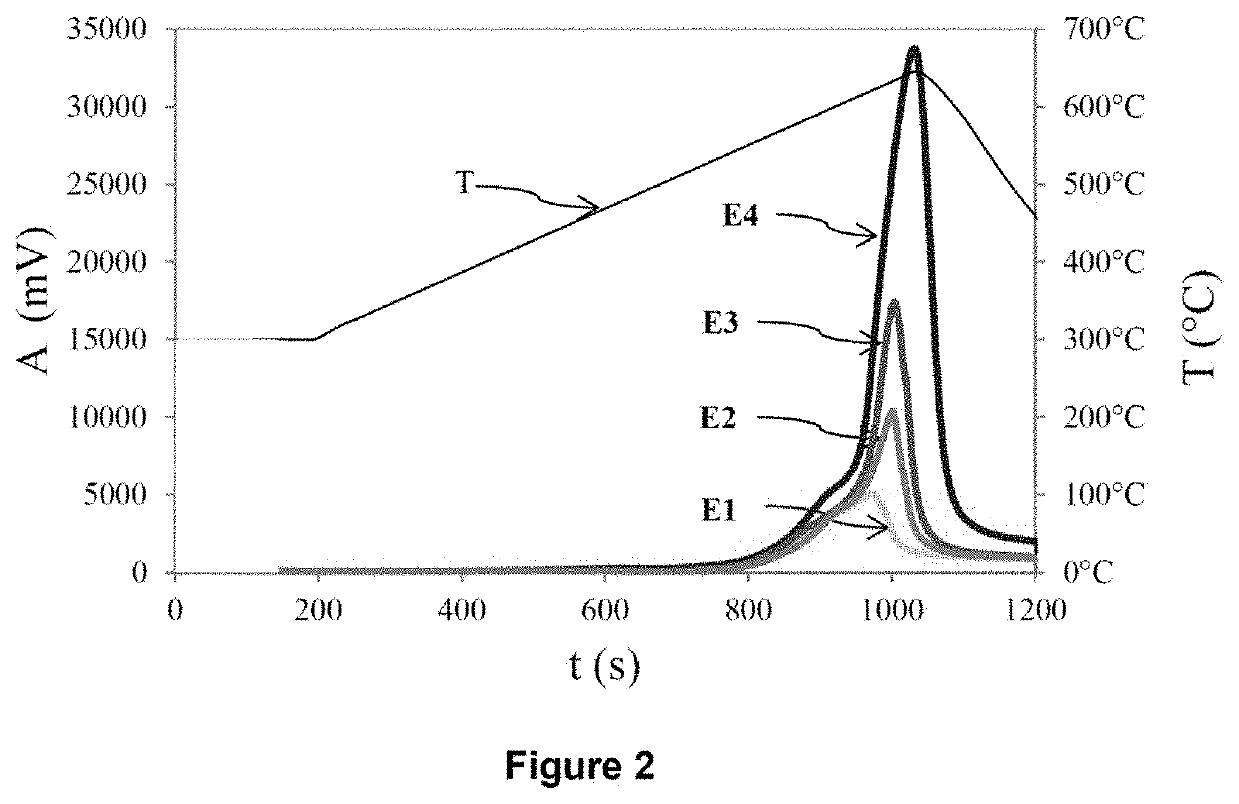

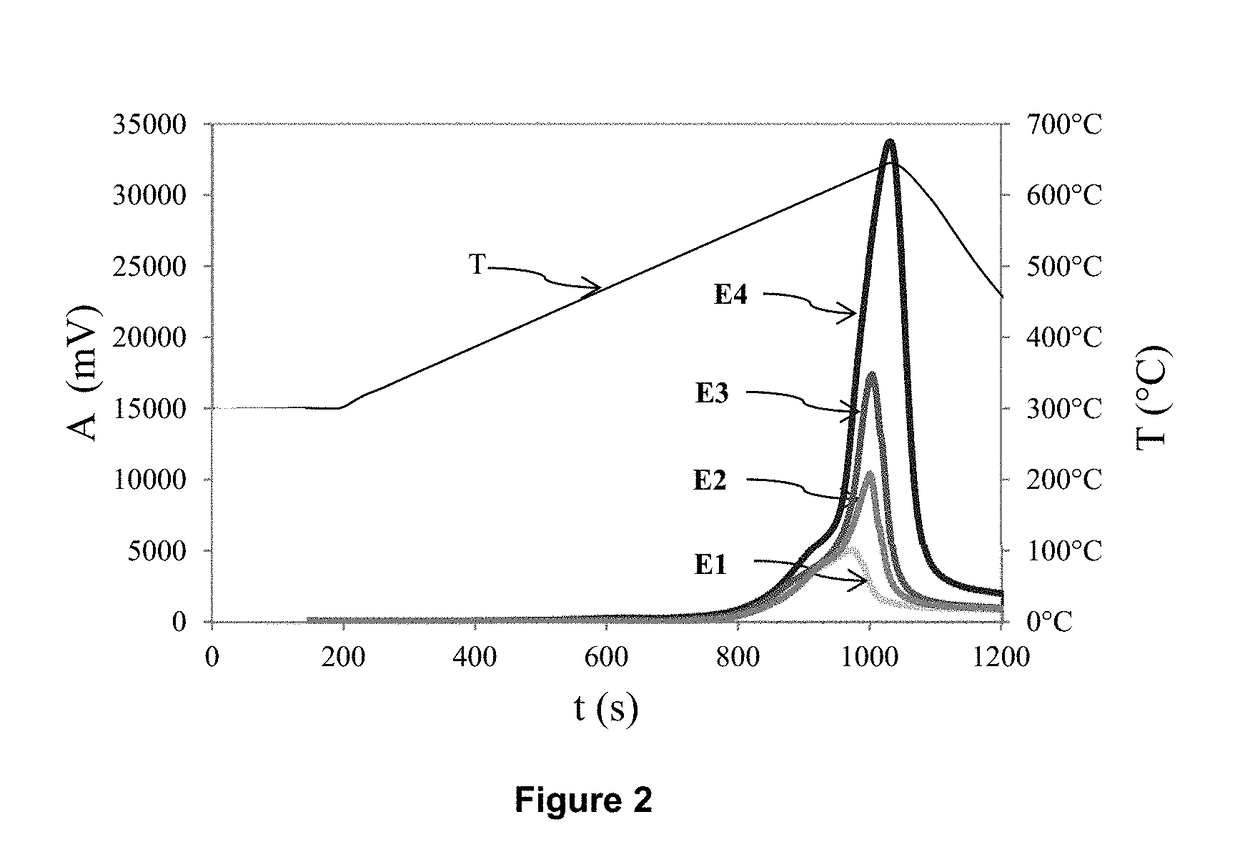

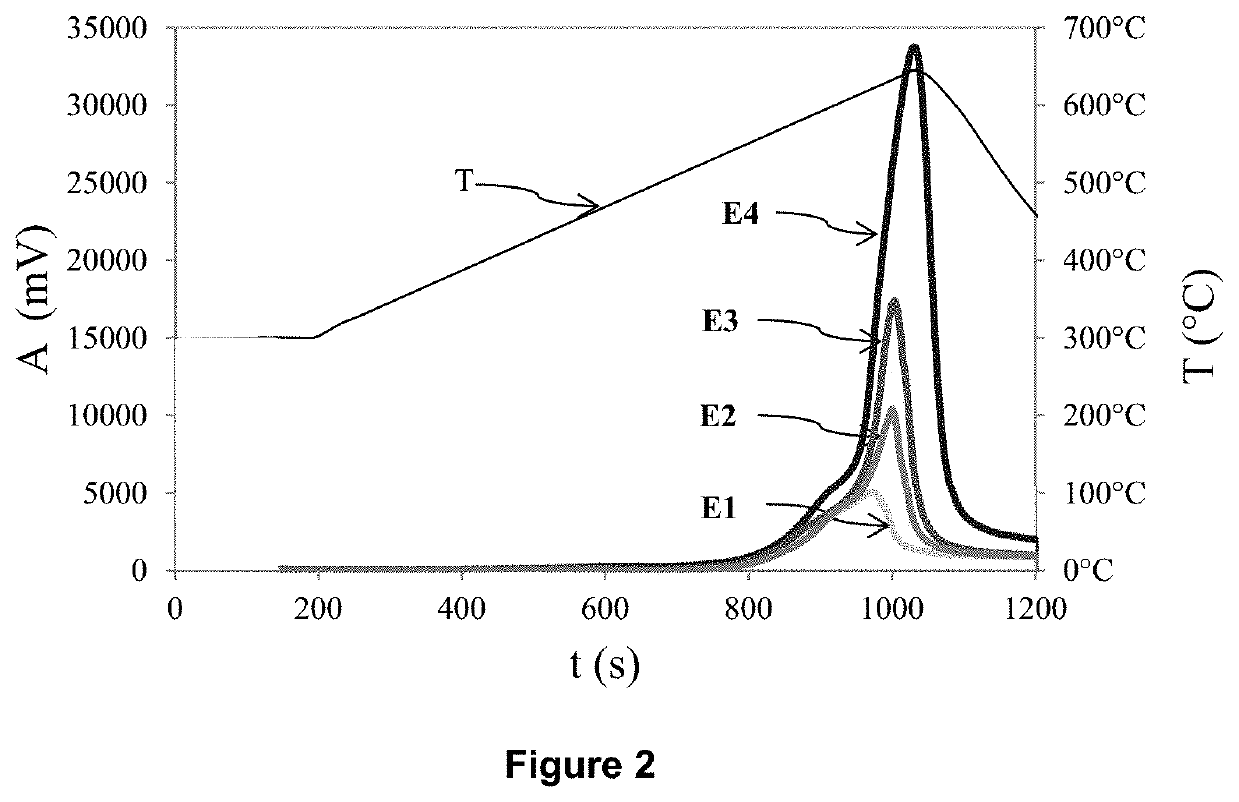

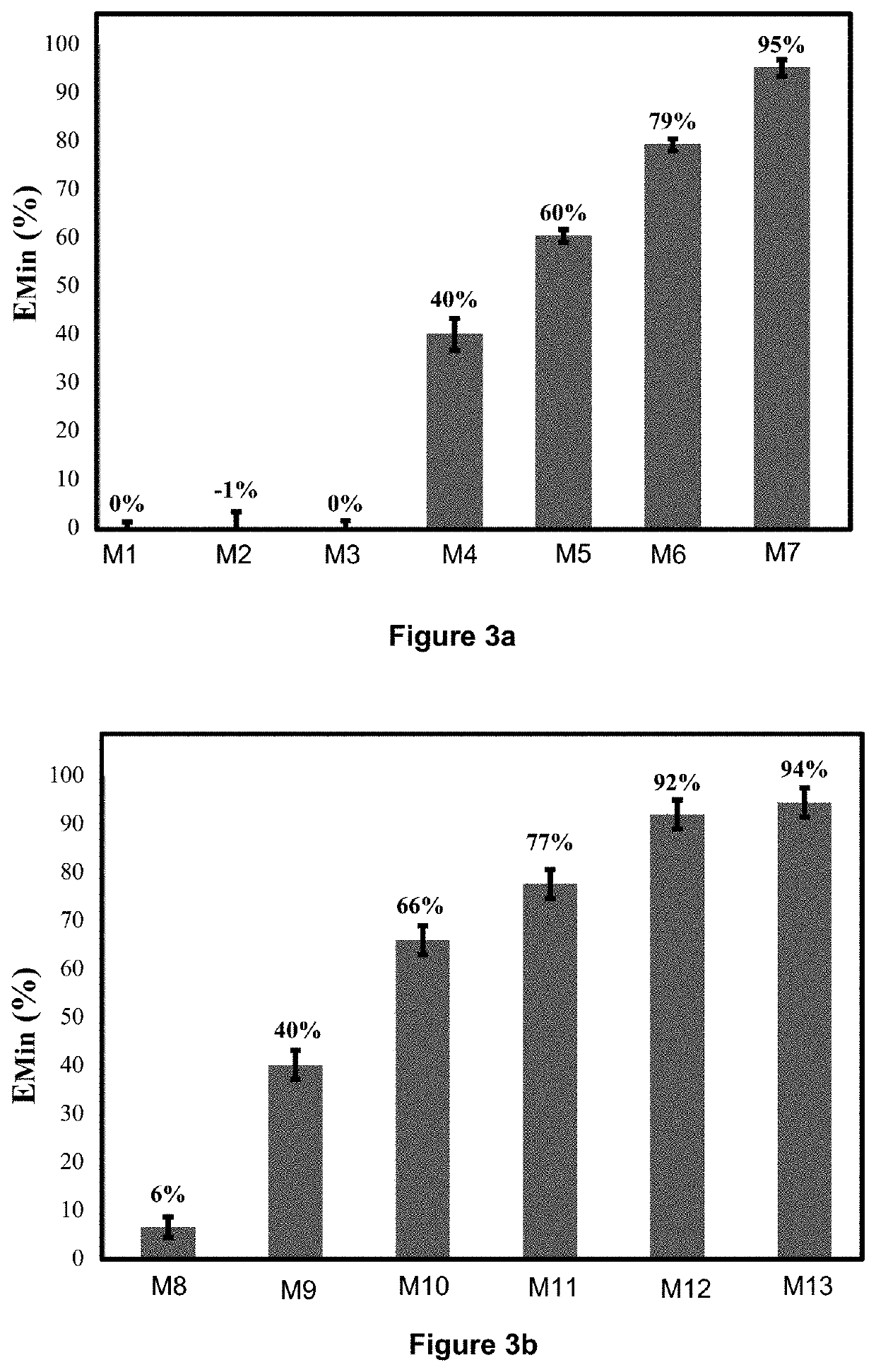

Process for quantifying the pyritic sulfur and the organic sulfur of a rock sample

ActiveUS20200003750A1Chemical analysis using combustionPreparing sample for investigationSoil scienceHydrocotyle bowlesioides

A rock sample is subjected to a heating sequence in an inert atmosphere, the effluents resulting from this heating are oxidized, the hydrocarbon-based compounds, the CO, the CO2 and the SO2 released are measured, and a pyrolysis pyritic sulfur content is deduced therefrom. The residue resulting from the heating in an inert atmosphere is then heated in an oxidizing atmosphere and the CO and the CO2 released are measured. The pyritic sulfur content is determined at least from the pyrolysis pyritic sulfur content and from a parameter which is a function of the hydrogen content and of the oxygen content of the organic matter of the sample. It is also possible to determine the organic sulfur content from the pyritic sulfur content and from a measurement of the SO2 during the heating sequence in an oxidizing atmosphere.

Owner:INST FR DU PETROLE

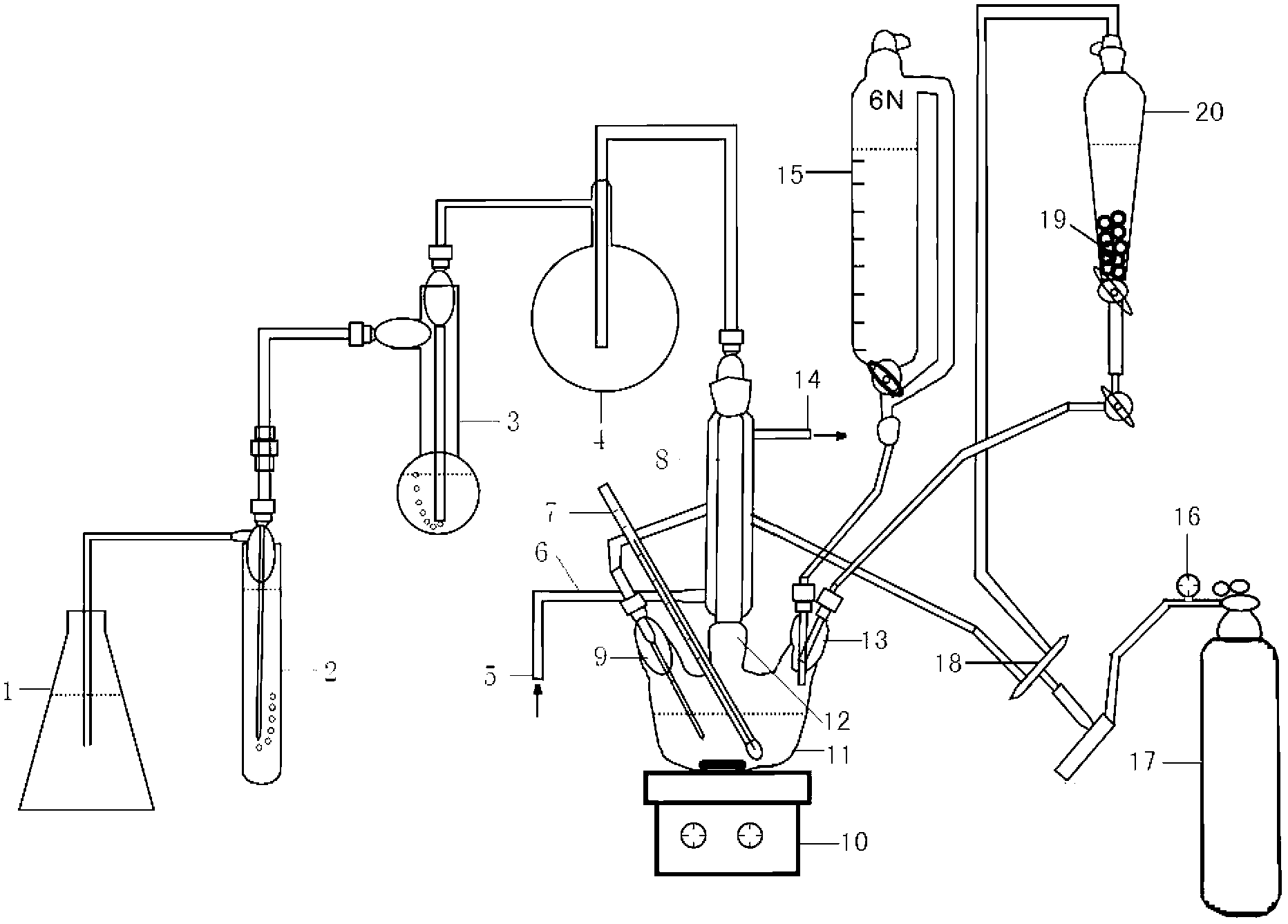

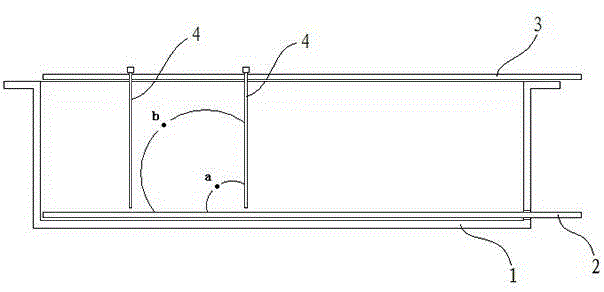

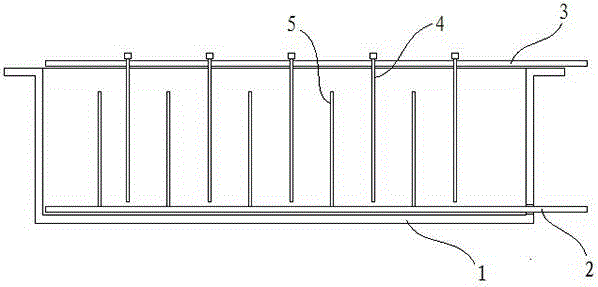

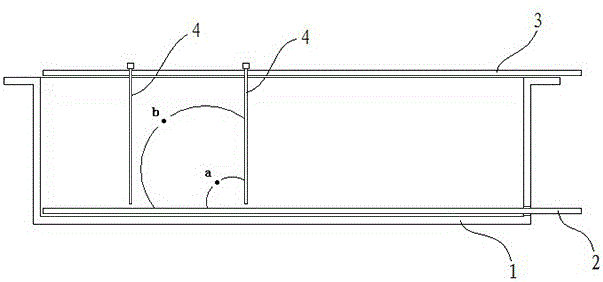

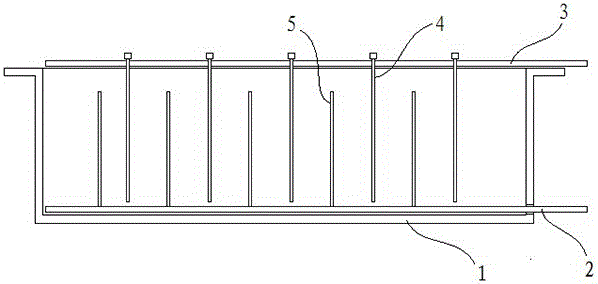

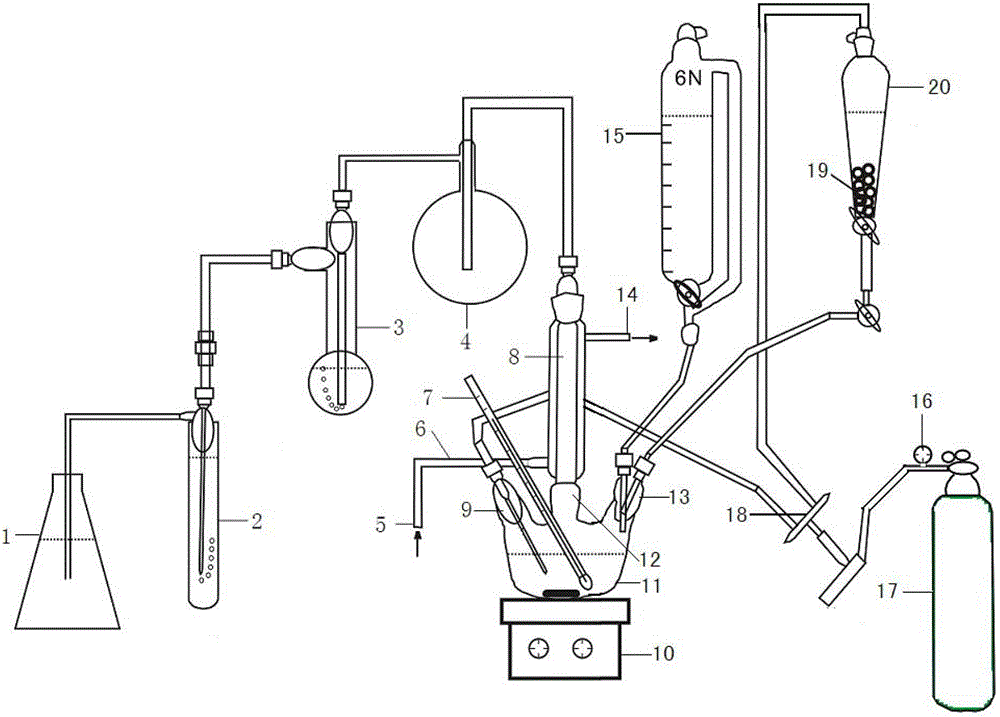

Device for extracting pyritic sulfur contained in geological sample

InactiveCN103018084ALow costFirmly connectedPreparing sample for investigationMaterial weighingMagnetic stirrerRound-bottom flask

The invention provides a device for extracting pyritic sulfur contained in a geological sample. The device comprises a nitrogen gas path unit, a CrCl2 gas preparation unit, a sample reaction unit and a gas absorption unit, wherein a reaction vessel inside the sample reaction unit is arranged on a heating type magnetic stirrer, and the reaction vessel is provided with a liquid inlet, a gas inlet and a gas outlet; a condensation pipe inner pipe is arranged above the gas outlet through a porous glass stopper, a condensation pipe outer pipe is wound outside the condensation pipe inner pipe; a separating funnel B and a separating funnel A are respectively communicated with the reaction vessel through sampling pipes which correspond to the separating funnel B and the separating funnel A and a sampling port; the sampling pipes are both inserted into the sampling port; a nitrogen cylinder inside the nitrogen gas path unit is communicated with the reaction vessel through a vent pipe and the gas inlet and communicated with the separating funnel B after being connected with the upper part of the separating funnel B through a two-port type gas-distributing pipe; and the gas absorption unit comprises a round-bottomed flask, a surge flask, a gas absorption test tube and a tail gas absorption bottle which are sequentially communicated through a pipeline. The device provided by the invention can effectively extract the pyritic sulfur contained in the geological sample and has the characteristics of economy, easiness, convenience and environmental friendliness.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for quantifying the pyritic sulfur and the organic sulfur of a rock sample

ActiveUS20190079065A1Chemical analysis using combustionEarth material testingRock samplePyritic sulfur

Method for distinctly characterizing and quantifying the pyritic sulfur and the organic sulfur of a sedimentary rock sample.A rock sample is subjected to a heating sequence in an inert atmosphere, the effluents resulting from this heating in an inert atmosphere are continuously oxidized, the SO2 released is continuously measured, and a pyrolysis sulfur content and a pyrolysis pyritic sulfur content are deduced therefrom. The residue from heating in an inert atmosphere is then heated in an oxidizing atmosphere, the SO2 released is continuously measured and at least an oxidation sulfur content is deduced therefrom. The pyritic sulfur content is determined from the pyrolysis pyritic sulfur content and from a weighting function taking account of a first parameter representing a pyrite thermal degradation rate, a second parameter representing the impact of the mineral matrix and a third parameter representing the impact of the organic matrix. The organic sulfur content can further be determined from at least the oxidation sulfur content, the pyrolysis sulfur content and the pyritic sulfur content.Application: notably petroleum exploration and exploitation.

Owner:INST FR DU PETROLE

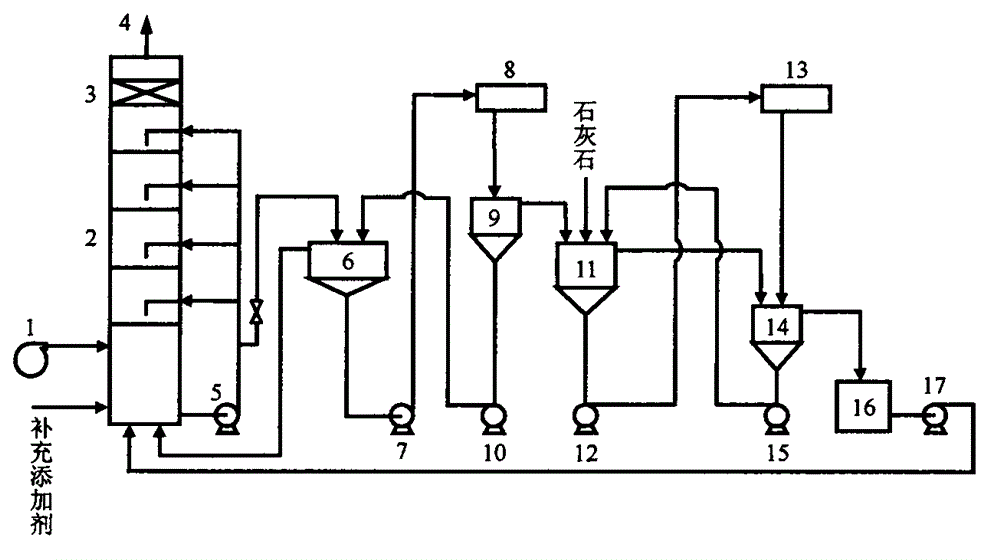

Flue gas desulfurization technology through additive enhanced coal slurry method

ActiveCN103071383AIncrease the mass transfer reaction rateImprove removal efficiencyDispersed particle separationSulfate radicalsReaction rate

The invention discloses a flue gas desulfurization technology through an additive enhanced coal slurry method, and belongs to the technical field of flue gas cleaning. The technology comprises the steps that coal powder or coal slime is prepared into a slurry liquid with water; at least one of aluminum ash, aluminum, aluminum oxide and aluminum sulfate is added to the slurry liquid and serves as an enhancing additive for washing flue gas containing sulfur dioxide; sulfur dioxide in the flue gas is oxidized into sulfate radical; pyritic sulfur in coal or the coal slime is also oxidized into sulfate radical; and generated sulfate radical reacts with limestone to form gypsum to be separated out. The adopted additive can increase a mass transfer reaction rate of sulfur dioxide in the slurry liquid, so that a flue gas desulfurization rate is increased. In addition, the additive can also increase a leaching rate of coal-series pyrite, so that a leaching efficiency is improved, and the sulfur content of the pyrite in the coal or the coal slime is reduced effectively.

Owner:青岛赛诺威尔工业水处理有限公司

Sample preparation method for pyrite sulfur isotope analysis of geological sample

InactiveCN102998156AFully separated and extractedReduce consumptionPreparing sample for investigationMaterial consumptionIsotope

The invention relates to a sample preparation method for pyrite sulfur isotope analysis of a geological sample. The sample preparation method comprises the following steps of: preparing CrCl2, removing non-pyrite sulfide in the geological sample, and extracting pyrite sulfur in the geological sample, wherein H2S gas generated in reaction is always at an enclosed environment. The method can be used for fully separating and extracting sulfur of pyrite in the geological sample, and the obtained Ag2S can effectively reflect the sulfur isotope composition of pyrite in the geological sample, can be used for quantitatively measuring the pyrite content, and is used for the research of pyritization and iron components and the like. The operation of the technical scheme provided by the invention is simple, and can be completed at one time according to reaction requirements and sequence, so the sample preparation method for pyrite sulfur isotope analysis of the geological sample has the advantages of material consumption conservation, reaction time reduction, high reaction efficiency and environment friendliness.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

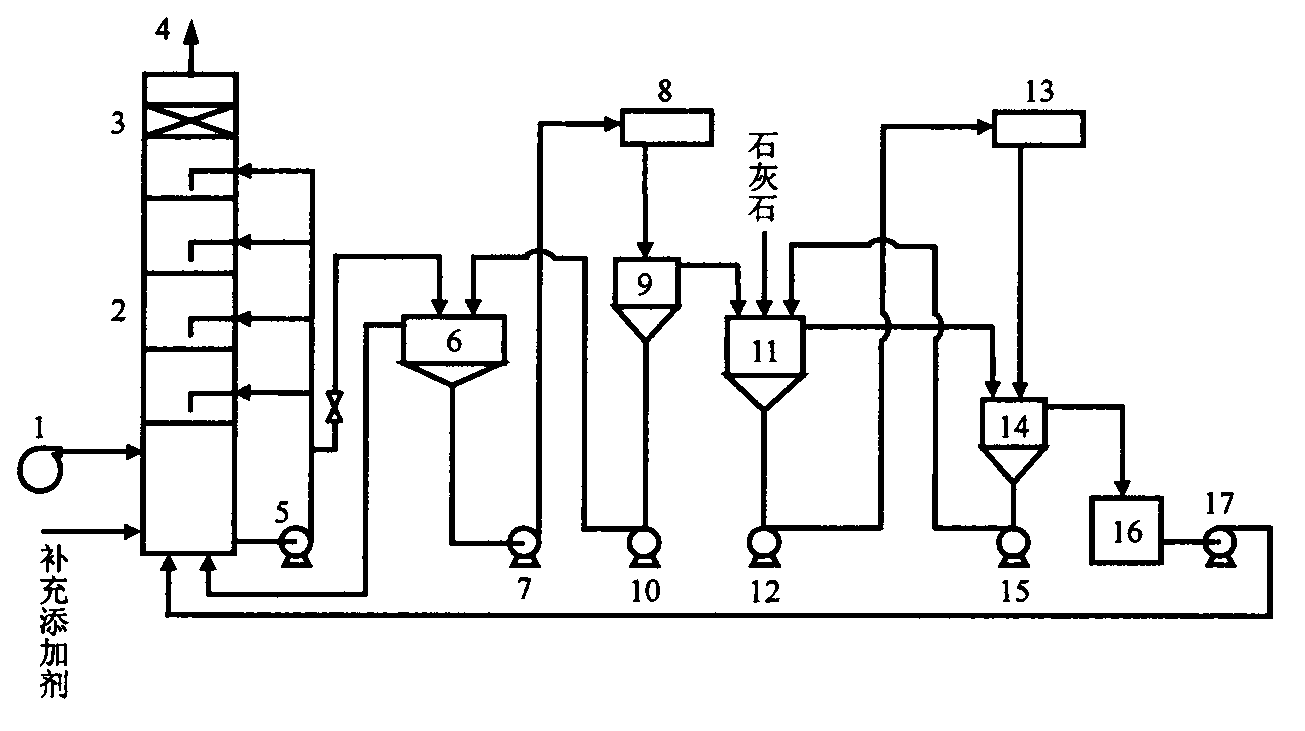

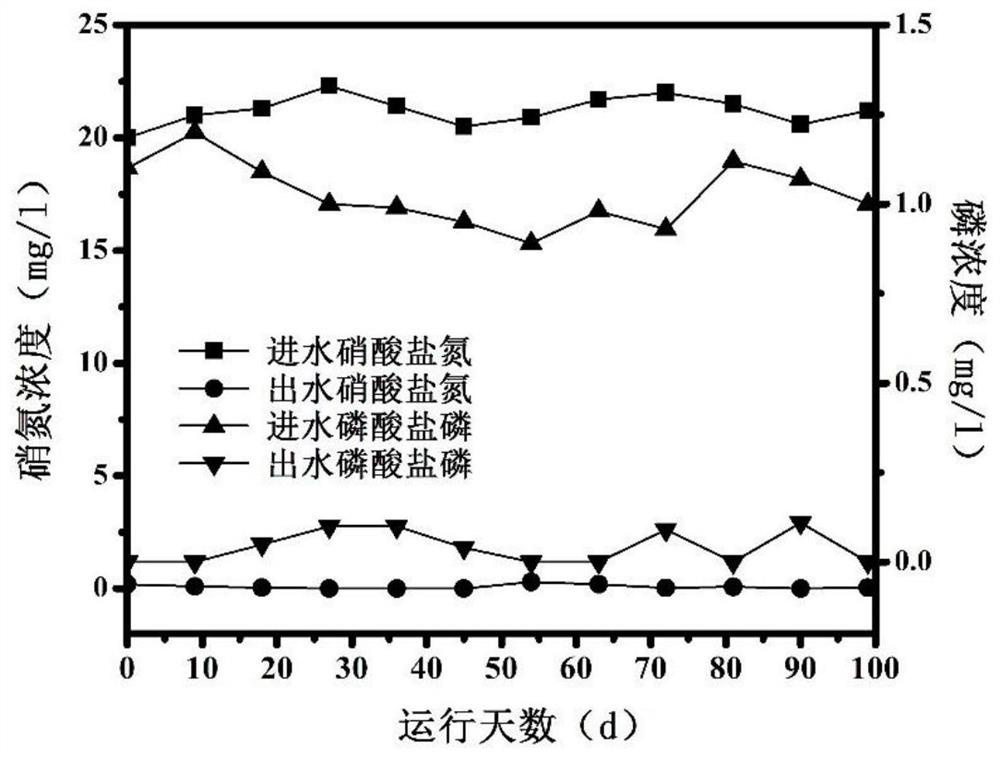

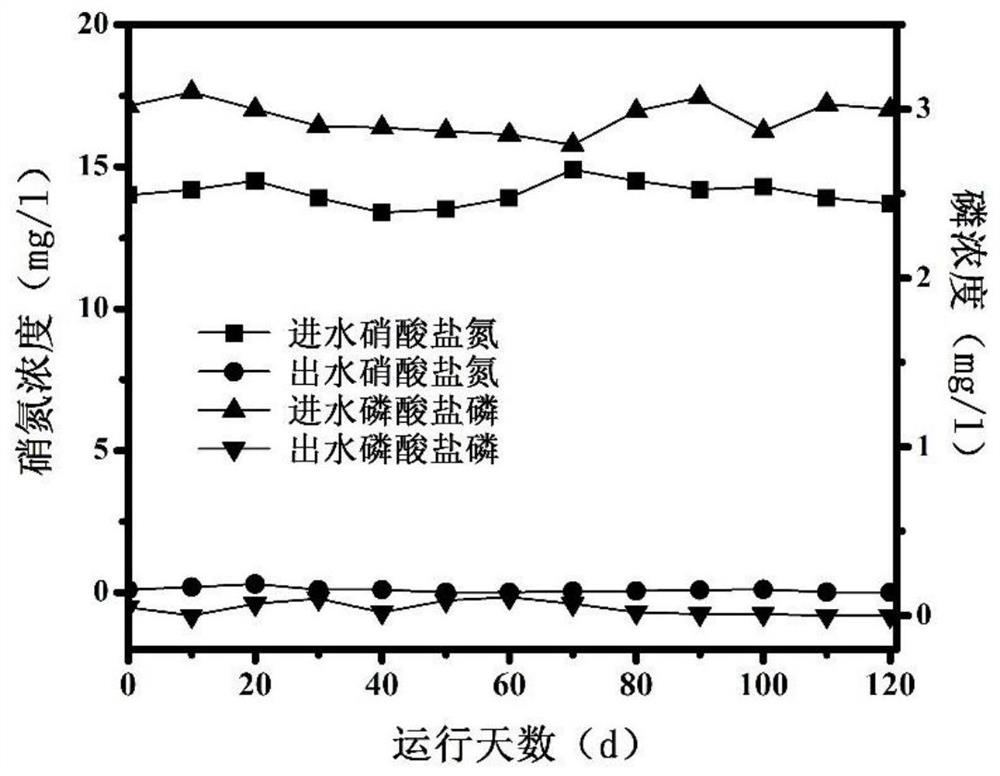

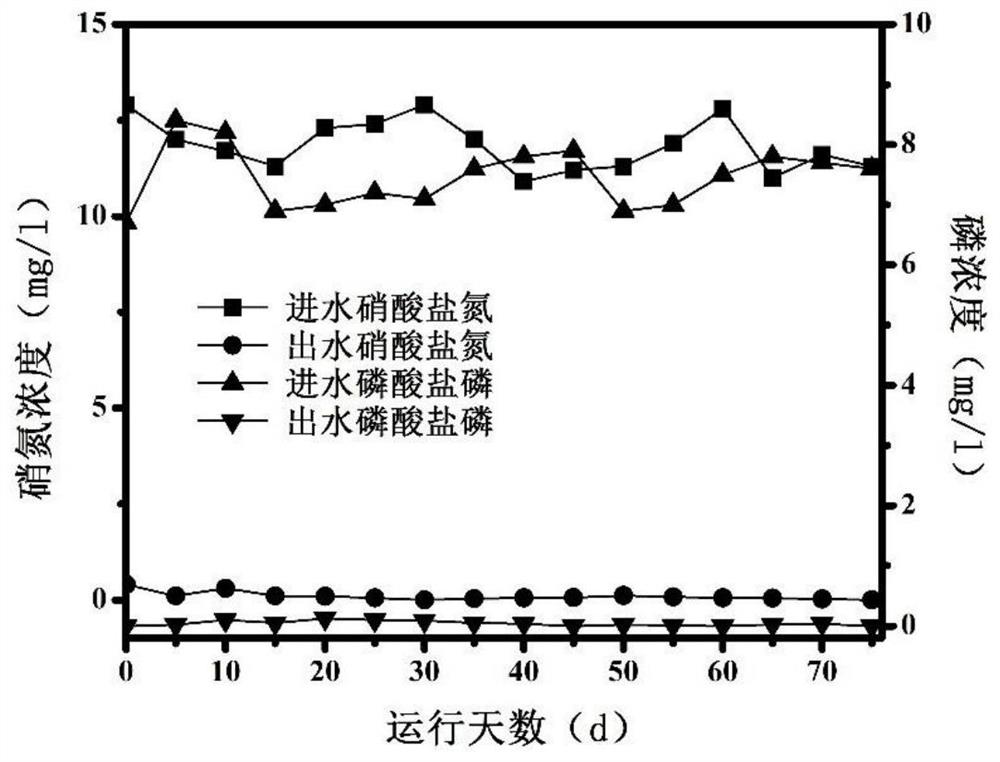

A coupling packing autotrophic denitrification biological filter and its application

ActiveCN109052641BDifficult to dissolveIncrease speedWater treatment compoundsTreatment with anaerobic digestion processesBiological filterPyritic sulfur

The invention discloses a coupling filler autotrophic denitrification biofilter and application and belongs to the technical field of sewage treatment. Pyrrhotite, sulfur and a carbon source are utilized to be mixed and coupled according to certain proportion; then the materials are put into a reactor, and the autotrophic denitrification biofilter can be formed after inoculating biofilm formation;sewage flows through the biofilter, and nitrogen and phosphorus in the water are removed. The biofilter disclosed by the invention has the advantages of simpleness, easiness, practicability and shortbiofilm formation time; when the biofilter is utilized to treat nitrogen and phosphorus containing sewage, hydraulic retention time is only 0.5 to 3 h, and yielding water can meet a requirement; furthermore, the biofilter has the advantages of excellent nitrogen and phosphorus removal effect, low cost and suitability for engineering application.

Owner:NANJING UNIV

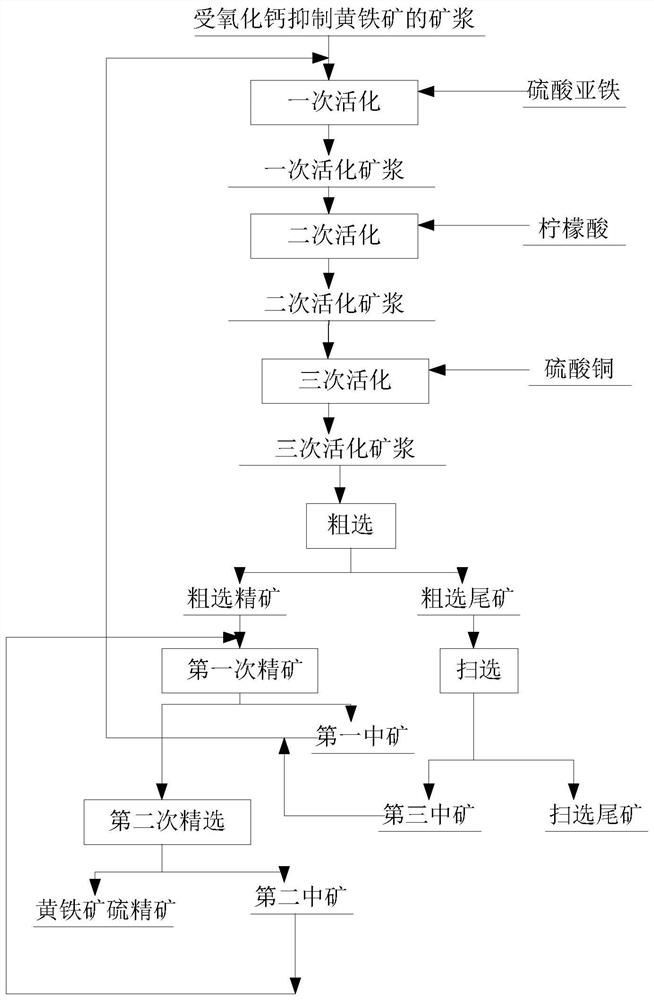

Flotation method of calcium-oxide-inhibited pyrite

The invention provides a flotation method of calcium-oxide-inhibited pyrite. The method comprises the following steps: S1, adding ferrous sulfate into ore pulp of pyrite inhibited by calcium oxide for primary activation to obtain primary activated ore pulp; S2, adding citric acid into the primary activated ore pulp for secondary activation to obtain secondary activated ore pulp; S3, adding copper sulfate into the secondary activated ore pulp for tertiary activation to obtain tertiary activated ore pulp; and S4, performing flotation on the third-time activated ore pulp to obtain pyrite sulfur concentrate. According to the method, the ferrous sulfate, citric acid and copper sulfate composite agents are adopted as activating agents for combined use, and the activating effect is enhanced through sequential adding and step-by-step activation, so that the flotation speed can be effectively increased, and the grade and the recovery rate of the sulfur concentrate are improved. Meanwhile, by selecting the composite agents, the cost is relatively low, ammonia gas and the like are not released, and the environmental protection property is higher.

Owner:CHINA ENFI ENGINEERING CORPORATION

Method for quantifying the pyritic sulfur and the organic sulfur of a rock sample

ActiveUS10895567B2Fast and simple and precise mannerChemical analysis using combustionEarth material testingRock sampleMineral matrix

A method which distinctly characterizes and quantifies the pyritic sulfur and the organic sulfur of a sedimentary rock sample. A rock sample is subjected to a heating sequence in an inert atmosphere which produces effluents resulting which are continuously oxidized. SO2 is continuously measured, and a pyrolysis sulfur content and a pyrolysis pyritic sulfur content are deduced therefrom. The residue from heating in an inert atmosphere is then heated in an oxidizing atmosphere. Released SO2 is continuously measured and at least an oxidation sulfur content is deduced therefrom. The pyritic sulfur content is determined from pyrolysis, a weighting function, a second parameter representing the impact of the mineral matrix and a third parameter representing the impact of the organic matrix.

Owner:INST FR DU PETROLE

Pyrite nano mineral material and preparation method thereof

ActiveCN102320668BRegulatory structure stateRegulate physicochemical propertiesSulfur preparation/purificationNanotechnologyChemical reactionRoom temperature

The invention discloses a pyrite nano mineral material and a preparation method thereof. The pyrite nano mineral material uses pyritic sulfur and sulphide concentrate as raw materials, the mass percent of pyrite in the pyritic sulfur is not smaller than 50%, and the mass percent of the pyrite in the sulphide concentrate is not smaller than 90%. The preparation method comprises the following stepsof: crushing pyritic sulfur ores, sieving with a sieve of 100 meshes to obtain powder or directly selecting the sulphide concentrate with the particle diameter which is smaller than 0.165mm as powder, adding a bonder to the powder, pelletizing and molding to obtain particles with the particle diameter of 1-3mm, calcinating the particles at a temperature of 500-1000DEG C for 0.5-30min under anaerobic conditions, separating gas from solids, condensating the gas, recovering sulfur, and cooling the solids under oxygen isolation conditions to a room temperature to obtain a finished product. The material has the advantages of large specific area, strong magnesium, high chemical reaction activity, simple preparation technology, low cost and wide raw material resources.

Owner:HEFEI UNIV OF TECH

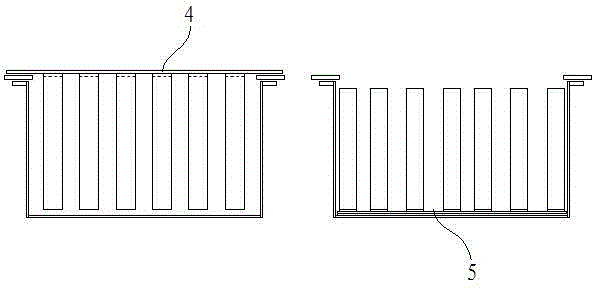

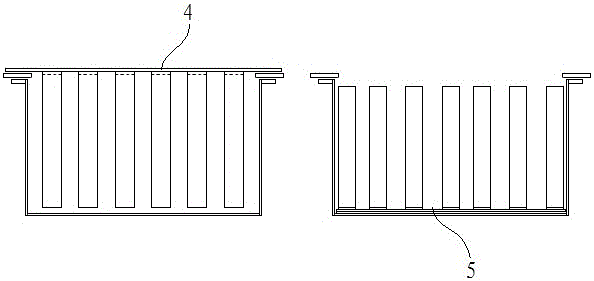

Three-dimensional balanced electric field decomposition tank and pre-desulphurization process of coals in absence of acid-alkali medium

ActiveCN104785182AReduce usageImprove decomposition efficiencySolid fuelsEnergy based chemical/physical/physico-chemical processesDecompositionConstant force

Owner:黄建高 +1

Method for removing pyritic sulfur in gangue by microbe

InactiveCN100370041CEliminate the risk of spontaneous combustionReduce adverse effectsProcess efficiency improvementParticulatesSocial benefits

The invention discloses a method of stripping pyrone sulfur from coal gangue using microorganism. The method includes disintegrating coal gangue to particulate of 0.1-300mm, inputting into culture liquid containing microorganism, and keeping extraction for 7-30 days; the extraction condition is: the proportion of the coal gangue and the culture liquid containing microorganism is 10-500g / L, the bacteriological density of the culture liquid containing microorganism reaches magnitude order of more than 107 per milliliter, the PH value of the culture liquid is 1.5-3.0, and the agitation mode, aeration mode, mode connecting agitation and aeration or sleep mode can be adopted for extraction. Performing biological treatment for coal gangue, the invention removes the self-inflammable hazard of coal gangue, solves the bad effect of coal gangue resource utilization because of the existence of sulfur, and can prevent water contamination and air pollution, which has distinctive environmental benefit and social benefit.

Owner:NANJING UNIV

Three-dimensional balanced electric field decomposition tank and coal pre-desulfurization process in an acid-base-free medium

ActiveCN104785182BReduce usageImprove decomposition efficiencySolid fuelsEnergy based chemical/physical/physico-chemical processesDecompositionConstant force

The invention discloses a three-dimensional balanced electric field decomposition tank and a pre-desulphurization process of coals in the absence of acid-alkali medium. According to the three-dimensional balanced electric field decomposition tank, two comb-shaped electrode plates are arranged in the decomposition tank in a balanced manner, and a conventional planar electric field is three-dimensional, so as to ensure that the molecule at any point in the decomposition tank can be ionized by constant force and greatly improve the decomposition efficiency. The invention further provides a set of process for coals to perform desulphurization by utilizing the three-dimensional balanced electric field decomposition tank in the absence of acid-alkali medium, so that pyritic sulfur can realize decomposition / aggregation in a neutral medium so as to achieve the purpose of polarization desulfurization, the desulfurization efficiency is high, the pollution is avoided, the sulfur aggregated on the electrode plates can further be recycled and processed into by-products. The three-dimensional balanced electric field decomposition tank and the three-dimensional balanced electric field pre-desulphurization process can be used for coal desulphurization and can further be applied to other electrochemical industry fields.

Owner:黄建高 +1

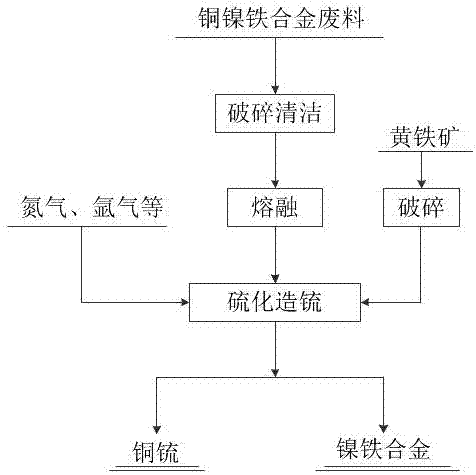

Method for producing copper sulphate and recycling ferro-nickel through vulcanization of albata waste by pyrite

InactiveCN107151743AIncrease added valueEfficient separationProcess efficiency improvementVulcanizationThermal insulation

The invention relates to a method for producing copper sulphate and recycling ferro-nickel through vulcanization of albata waste by pyrite and belongs to the technical field of secondary resource comprehensive utilization. The method comprises the following steps: at first, crushing and drying copper ferro-nickel waste, when the copper ferro-nickel waste completely fuse, adding pyrite with the water content less than 3% for vulcanization reaction under the condition of feeding inert gas, continuously feeding inert gas for thermal insulation reaction, and after copper sulphate and nickle molten iron are layered after reaction, discharging copper sulphate and nickle molten iron separately to obtain copper sulphate and ferro-nickel. According to the method, pyrite is adopted as a vulcanizing agent, the situation that affinity of the sulfur element and copper is far greater than that of nickle and iron is fully utilized, separation is realized by utilizing density difference of copper sulphate and nickle molten iron, and the copper sulphate is recycled, so that copper in copper ferro-nickel waste is effectively recycled, and qualified ferro-nickel can be directly produced at the same time.

Owner:KUNMING UNIV OF SCI & TECH

Method for performing in situ treatment on acid mine water by using crop seed husks

InactiveCN103362550BProduction slows down and suppressesExtend design service lifeMining devicesFerric hydroxidePollution

The invention provides a method for performing in situ treatment on acid water of a mine by using crop seed husks. The method comprises the steps that an acid generation point or a fissure surface where the acid water seeps in a mine shaft is detected; a biological inhibitor and alkali flocculation mixed liquor are prepared; the surface of the acid water of the mine shaft is sprayed by the biological inhibitor or subjected to brushed in batch; and continuous seepage of the acid water in the shaft can be eliminated by spraying the alkali flocculation mixed liquor onto an inhibitor layer at intervals for 1-3 times finally. According to the method, the oxidative activity of acidophilic bacteria in an acid water generation environment is inhibited by the biological inhibitor, generation of the acid water is slowed down or inhibited, and the alkali flocculation mixed liquor is used for spraying continuously to form ferric oxide or ferric hydroxide flocculent settling to form a protective film on the surface of pyritic sulfide, so that the acid water generated due to biological and chemical oxidation of sulfur-bearing minerals is avoided completely. The method has the advantages that waste is recycled, neither poison nor secondary pollution to an environment is caused, and the method is low in cost and simple to apply and operate.

Owner:HEFEI UNIV

A method for selecting sulfur by using sodium fluorosilicate mother liquor as iron sulfide ore activator

ActiveCN103567075BSave mineral processing costReduce pressure on environmental protectionFlotationSodium fluorideSodium fluorosilicate

The invention discloses a method for concentrating sulfur with sodium fluorosilicate mother liquor as activator of pyrite. The method includes the technological steps that first, the pyrite is obtained after flotation of lead and zinc is performed on lead, zinc and sulfur polymetallic sulfide ore, the pyrite contains a great amount of free CaO and 16-30% of FeS2, the pyrite is ground till the fineness of -200 meshes larger than 80%, and the solid content of ore pulp is 20-45%; second, the sodium fluorosilicate mother liquor is added into the ore pulp, activating reaction is carried out, the reaction time is 30-60min, and the pH of the ore pulp is 4.5-6.0 after the reaction is finished; third, the ore pulp after the reaction is fed into a flotation machine, meanwhile, flotation reagents are added, sulfur concentrate is obtained after air inflation and bubble scrapping are finished, and the adding method of the flotation reagents includes the steps that the flotation reagents accounting for 60-80% of the total amount are added before the flotation of the ore pulp, and the rest of the flotation reagents are evenly added stage by stage after every stage of flotation before discharge of tailings. With the method, the quality of the concentrated sulfur concentrate and the sulfur recovery rate can be guaranteed, activator cost is saved, and pressure on environmental protection is relieved.

Owner:KUNMING CHUAN JINNUO CHEM IND

Process for quantifying the pyritic sulfur and the organic sulfur of a rock sample

ActiveUS11442053B2Implementation is simple and rapidQuantitative precisionChemical analysis using combustionPreparing sample for investigationSoil scienceHydrocotyle bowlesioides

A rock sample is subjected to a heating sequence in an inert atmosphere, the effluents resulting from this heating are oxidized, the hydrocarbon-based compounds, the CO, the CO2 and the SO2 released are measured, and a pyrolysis pyritic sulfur content is deduced therefrom. The residue resulting from the heating in an inert atmosphere is then heated in an oxidizing atmosphere and the CO and the CO2 released are measured. The pyritic sulfur content is determined at least from the pyrolysis pyritic sulfur content and from a parameter which is a function of the hydrogen content and of the oxygen content of the organic matter of the sample. It is also possible to determine the organic sulfur content from the pyritic sulfur content and from a measurement of the SO2 during the heating sequence in an oxidizing atmosphere.

Owner:INST FR DU PETROLE

Device for extracting pyritic sulfur contained in geological sample

InactiveCN103018084BLow costFirmly connectedPreparing sample for investigationMaterial weighingMagnetic stirrerBottle

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

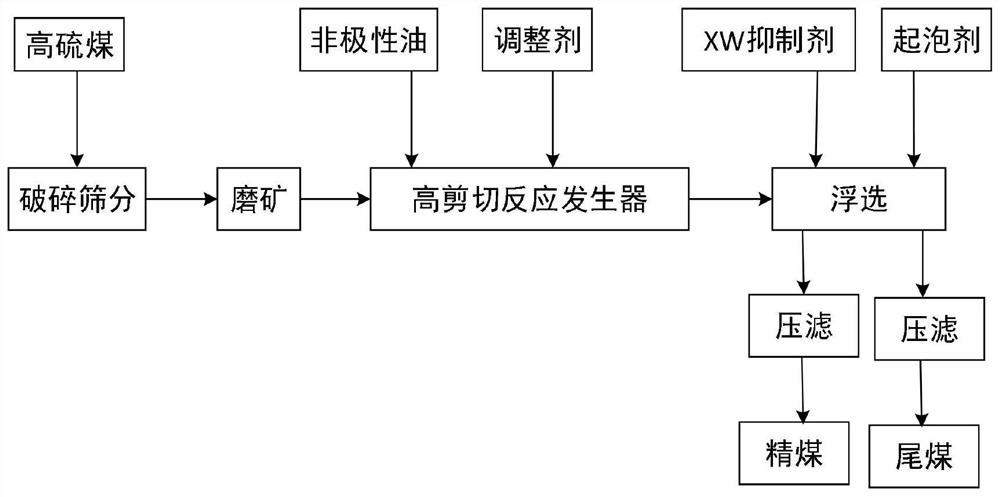

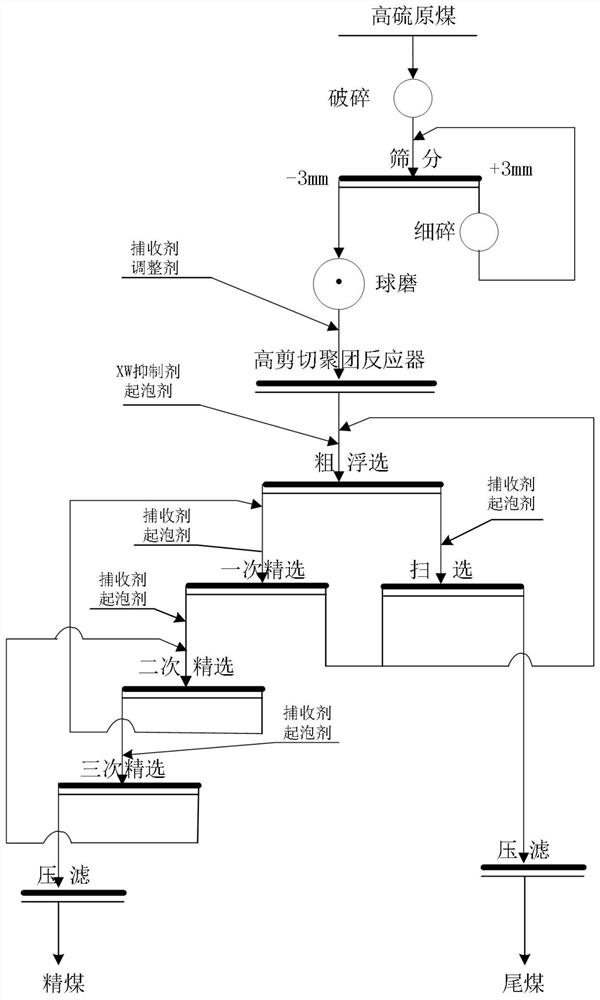

Desulfurization method of coal

The invention provides a desulfurization method of coal, and belongs to the field of coal treatment. The method comprises the following steps that high-sulfur raw coal is sequentially crushed, screened and ground to obtain coal particles; the coal particles, non-polar oil, a pH value regulator and water are mixed and then subjected to shear agglomeration, and coal slurry is obtained; the coal slurry, a foaming agent and a flocculation stabilizer are mixed and then subjected to desulfurization flotation, and clean coal is obtained. The method is an efficient flotation removal method for fine particles in the coal, especially pyrite sulfur finely dispersed and embedded in a coking coal matrix, shear agglomeration is adopted for treatment of the coal particles, quenching and tempering and hydrophobic strengthening treatment are carried out in the shear agglomeration process, and therefore the flotation false particle size similar to that under the conventional flotation condition of the coal particles is formed; the pH value regulator is adopted, so that minerals, especially pyrite, in the coal slurry are more hydrophilic; a flocculation inhibitor is adopted, the minerals, including pyrite, in the coal slurry are subjected to hydrophilic flocculation, and dissociated pyrite minerals in the coal slurry are effectively inhibited from entering tailings.

Owner:许泽胜

Additive Enhanced Coal Slurry Flue Gas Desulfurization Process

ActiveCN103071383BIncrease the mass transfer reaction rateImprove removal efficiencyDispersed particle separationSulfate radicalsReaction rate

The invention discloses a flue gas desulfurization technology through an additive enhanced coal slurry method, and belongs to the technical field of flue gas cleaning. The technology comprises the steps that coal powder or coal slime is prepared into a slurry liquid with water; at least one of aluminum ash, aluminum, aluminum oxide and aluminum sulfate is added to the slurry liquid and serves as an enhancing additive for washing flue gas containing sulfur dioxide; sulfur dioxide in the flue gas is oxidized into sulfate radical; pyritic sulfur in coal or the coal slime is also oxidized into sulfate radical; and generated sulfate radical reacts with limestone to form gypsum to be separated out. The adopted additive can increase a mass transfer reaction rate of sulfur dioxide in the slurry liquid, so that a flue gas desulfurization rate is increased. In addition, the additive can also increase a leaching rate of coal-series pyrite, so that a leaching efficiency is improved, and the sulfur content of the pyrite in the coal or the coal slime is reduced effectively.

Owner:青岛赛诺威尔工业水处理有限公司

Method for removing hexavalent chromium in the process of preparing nickel-cobalt hydroxide from laterite nickel ore

The invention provides a method for removing hexavalent chromium in the process of preparing nickel-cobalt hydroxide from laterite nickel ore. In the method: before the high pressure acid leaching step, the laterite nickel ore slurry is preheated, and before the preheating step, a first reducing agent is added to the laterite nickel ore slurry, and then the laterite nickel ore added with the first reducing agent is made to The pulp enters the high-pressure acid leaching step; the first reducing agent is one or more of pyrite, sulfur and chromite, or is organic waste water; or, the second reducing agent is added to the leachate obtained in the circulating leaching step, Then enter the residual ore neutralization step; the second reducing agent is one of alkali metal or alkaline earth metal sulfite, pyrosulfite, ferrous salt, thiosulfate, sulfide salt, hydrogen sulfite or several. Using the method provided by this method, hexavalent chromium can be removed from the source on the basis of not changing the high pressure leaching process of laterite nickel ore, so as to prevent it from producing nickel cobalt hydroxide products, and it will not affect the original steps.

Owner:CHINA ENFI ENGINEERING CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com