Reinforced leaching method of fine-grained encapsulated gold

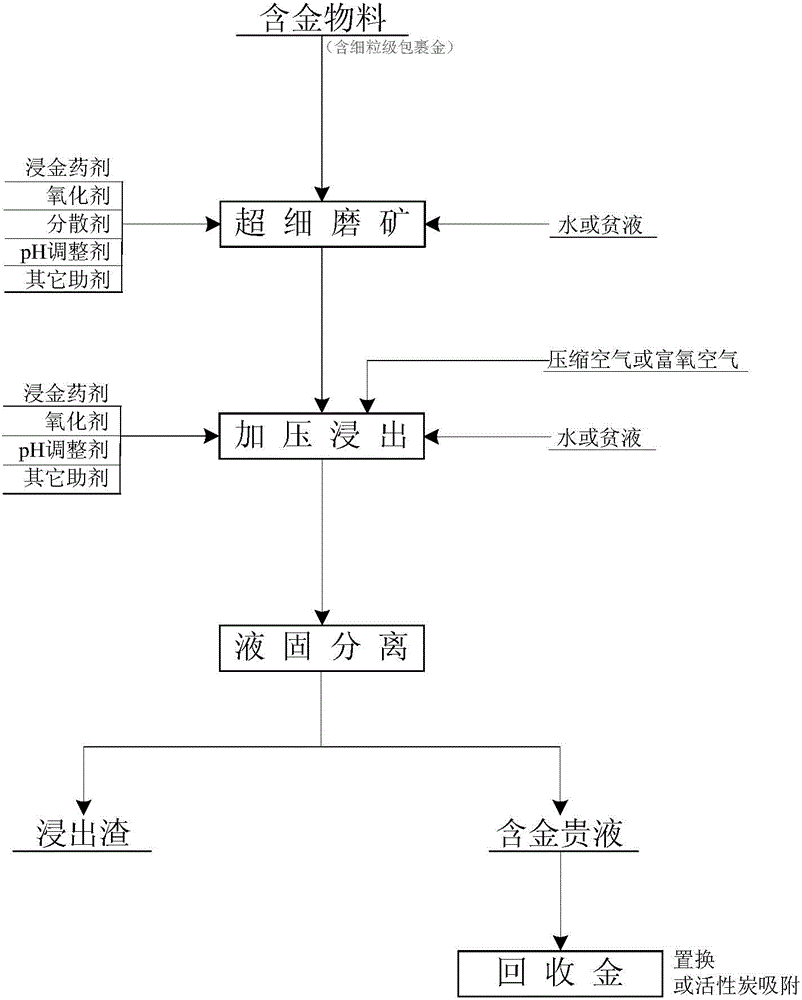

A technology for strengthening leaching and wrapping gold, applied in the direction of improving process efficiency, can solve the problems of difficult to achieve recovery, difficult to recover by cyanidation, and achieve the effect of convenient operation, high gold leaching rate, and enhanced leaching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The cyanide slag is taken from a gold mine in Yueyang, Hunan, containing 12.8g / t of gold, and the fineness is -0.074mm, accounting for 70.5%. Take 1000 parts of cyanide slag, 1.5 parts of golden cicada medicine, 0.3 part of oxidant calcium peroxide, 0.1 part of organic dispersant Pingpingjiao, 0.1 part of inorganic dispersant sodium hexametaphosphate, 4.0 parts of lime, and 2000 parts of water into the stirring mill , the grinding medium is 2mm steel balls, and the grinding time is 60 minutes. As measured by the laser particle size analyzer, the particle size distribution of the pulp is between 0.5 μm and 20 μm, and d(50)=3.35 μm.

[0046] Put the ground pulp into a high-pressure reaction kettle, add 1000 parts of water, 1.0 parts of Jinchan medicine, 1.5 parts of lime (pH value of the pulp = 11.5), 0.2 parts of oxidant calcium peroxide, and start stirring; Unicom air compressor, put The reaction kettle was pressurized to 0.4MPa (gauge pressure), and the reaction was s...

Embodiment 2

[0049] The cyanide slag is taken from a gold mine in Yueyang, Hunan, containing 12.8g / t of gold, and the fineness is -0.074mm, accounting for 70.5%. Take 1000 parts of cyanide slag, 1.5 parts of sodium cyanide, 0.3 part of oxidant potassium ferricyanide, 0.2 part of organic dispersant P-5040 (commercially available, a kind of modified polyacrylate), 3.5 parts of sodium hydroxide, water Add 1000 parts to the stirring mill, the grinding medium is 2mm steel balls, and grind for 30 minutes. As measured by the laser particle size analyzer, the particle size distribution of the pulp is between 0.5 μm and 36 μm, and d(50)=10.98 μm.

[0050] Put the ground pulp into a high-pressure reactor, add 1000 parts of water, 1.0 parts of sodium cyanide, 1.2 parts of sodium hydroxide (pH value of the pulp = 10.5), 0.2 parts of potassium ferricyanide, and start stirring; Unicom air compressor , pressurize the reactor to 0.6MPa (gauge pressure), set the temperature of the reactor to 80°C; stir an...

Embodiment 3

[0052] The cyanide slag is taken from a gold mine in Zhaoyuan, Shandong, with a gold content of 3.8g / t and a fineness of -0.074mm, accounting for 80.6%. Take 1000 parts of cyanide slag, 1.0 part of golden cicada medicine, 0.10 part of oxidant hydrogen peroxide, 0.5 part of dispersant sodium hexametaphosphate, 2.0 parts of ammonia water, and 1000 parts of water and add them to the stirring mill. The grinding medium is 2 mm steel balls, and grind for 60 minutes. As measured by the laser particle size analyzer, the particle size distribution of the pulp is between 0.5 μm and 15 μm, and d(50)=1.39 μm.

[0053] Transfer the ground pulp into a high-pressure reactor, add 2500 parts of water, 0.5 parts of Jinchan medicine, 1.5 parts of lime (pH value of the pulp = 12.0), 0.2 parts of oxidant hydrogen peroxide, and start stirring; Pressurize to 1.1 MPa (gauge pressure), stir and react at 40° C. for 12 hours; stop the reaction, filter to obtain leaching liquid and leaching residue. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com