Patents

Literature

64results about How to "High bacterial content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound microbial bacterial preparation for degrading crop straw and preparation method and application of compound microbial bacterial preparation

ActiveCN102690755ASolve shipping problemsSolve storage difficultiesBio-organic fraction processingFungiMetabolitePhosphate

The invention relates to a compound microbial bacterial preparation for degrading crop straw and a preparation method and application of the compound microbial bacterial preparation. The compound microbial bacterial preparation is prepared from bacillus subtilis, bacillus cereus, aspergillus niger, aspergillus flavus, trichoderma reesei, trichoderma longibrachiatum, sporotrichum thermophile and phanerochaete chrysosporium through solid fermentation. The compound microbial bacterial preparation can shorten the decomposition time and improve the decomposition efficiency of the crop straw. Microorganisms generate various effective metabolic products with nitrogen fixation and phosphate solubilizing functions and a high disease and pest resistance effect in the fermentation process, so that the compound microbial bacterial preparation is favorable for improving the soil structure and the yield and the quality of crops.

Owner:DEZHOU YUANHE AGRI TECH DEVCO

Compound microbial bacterial preparation for efficiently degrading feces and preparation method and application of compound microbial bacterial preparation

InactiveCN102690769AShorten fermentation timeEfficient killingFungiBio-organic fraction processingMicroorganismFeces

The invention relates to a compound microbial bacterial preparation for efficiently degrading feces and a preparation method and application of the compound microbial bacterial preparation. The compound microbial bacterial preparation is prepared from bacillus subtilis, bacillus cereus, bacillus megaterium, geobacillus stearothermophilus, aspergillus oryzae, trichoderma longibrachiatum, sporotrichum thermophile and streptomycesmicroflavus through solid fermentation. The compound microbial bacterial preparation can shorten the fermentation time of feces, and effectively kill larva, eggs and pathogens in the feces, and further improves the content of organic matters, total nitrogen, total phosphorus, and total potassium in the fermented materials.

Owner:DEZHOU YUANHE AGRI TECH DEVCO

Bacteria immobilization particles for water purification and preparation method of bacteria immobilization particles

ActiveCN104894099AImprove adsorption capacityReduce harmOn/in organic carrierOn/in inorganic carrierActivated carbonEnvironmental chemistry

The invention discloses bacteria immobilization particles for water purification and a preparation method of the bacteria immobilization particles, and belongs to the technical field of water treatment. The preparation method comprises the following steps: preparing a bacteria concentrate through flocculation by utilizing activated carbon, diatomite and a chitosan acetic acid solution; adding diatomite, bentonite, silicon dioxide and a polyvinyl alcohol-sodium alginate mixed solution into the concentrate for stirring; carrying out granulation with a granulator to prepare the bacteria immobilization particles. The prepared bacteria immobilization particles are high in biological activity, high in bacteria content (5*10<9>-1*10<10> CFU / g), short in starting time, and high in reaction speed, has a honeycomb structure (100-300 m<2> / g in specific surface area) suitable for bacteria apposition growth and mass transfer, and can be used for immobilizing bacteria for long, prohibiting the invasion of external hazardous materials, and permanently and efficiently treating sewage in different environments and of different water quality types; meanwhile, industrialized production is available for a whole bacteria immobilization particle preparation process, and the prepared bacteria immobilization particles are high in mechanical property, long in service life, and convenient to store and convey.

Owner:CENT LAB FUJIAN ACADEMY OF AGRI SCI +1

Water quality purification bacterium agent from mix fermentation production with multiple bacterials and production method thereof

The invention relates to a water purification microbial inoculum which is produced by blending and fermenting a plurality of bacteria. Straws are taken as raw materials and then seed solutions of a plurality of bacteria, a straw fermention medium and a concentrated nitrifying bacteria solution are added, thus obtaining the water purification microbial inoculum. A preparation method of the water purification microbial inoculum comprises the steps as follows: the straws are sent to a material steam explosion system and then a steam explosion is conducted to the straws; after the steam explosion, the straws are sent to a chelated reaction storage for reaction; after reacting in the chelated reaction storage, the straws are sent to a fermention storage for fermentation; 5 percent of the seed solution of a plurality of sporos and 30 percent to 40 percent of the straw fermention medium are added to the fermention storage; and before the straws are taken out of the storage, 2 percent to 3 percent of the concentrated nitrifying bacteria solution is added and stirred evenly, thereby obtaining the water purification microbial inoculum. The water purification microbial inoculum has the advantages that the valid viable bacteria number of the produced water purification microbial inoculum reaches 2 billion / g (slab) and nitration and subnitration can be realized; a purifier has comprehensive water purification functions which can effectively restrain the harmful bacteria of a cultured water body, thereby realizing the disease prevention and survival rate improvement; the degradation of the organic pollutant in the water body can be accelerated; and ammonia nitrogen can be decreased and dissolved, and oxygen can be increased, thereby achieving the aims of increasing production and income.

Owner:河南省龙腾高科实业有限公司

Production process for bioorganic fertilizer with high bacteria content

InactiveCN106631248AIncrease contentReduce pollutionFungiBio-organic fraction processingBiotechnologyBacillus amyloliquefaciens

The invention relates to a production process for bioorganic fertilizer with high bacteria content. The production process comprises the following steps: separately activating a trichoderma viride strain and a trichoderma pseudokoningii strain; separately activating a bacillus amyloliquefaciens strain, a bacillus subtilis strain and a candida utilis strain; carrying out step-by-step enlarged culture and the like. A preparation method provided by the invention has the advantages of low cost, simple process, high operability and convenience in popularization and application; the obtained bioorganic fertilizer is high in content of effective living bacteria; a large amount of corn stalk resources can be really and efficiently converted, soil is remediated, the fertility of the soil is improved, and wastes are changed into valuables; in addition, the problem of environmental pollution caused by straw burning can be relived to a certain degree.

Owner:中华全国供销合作总社天津再生资源研究所

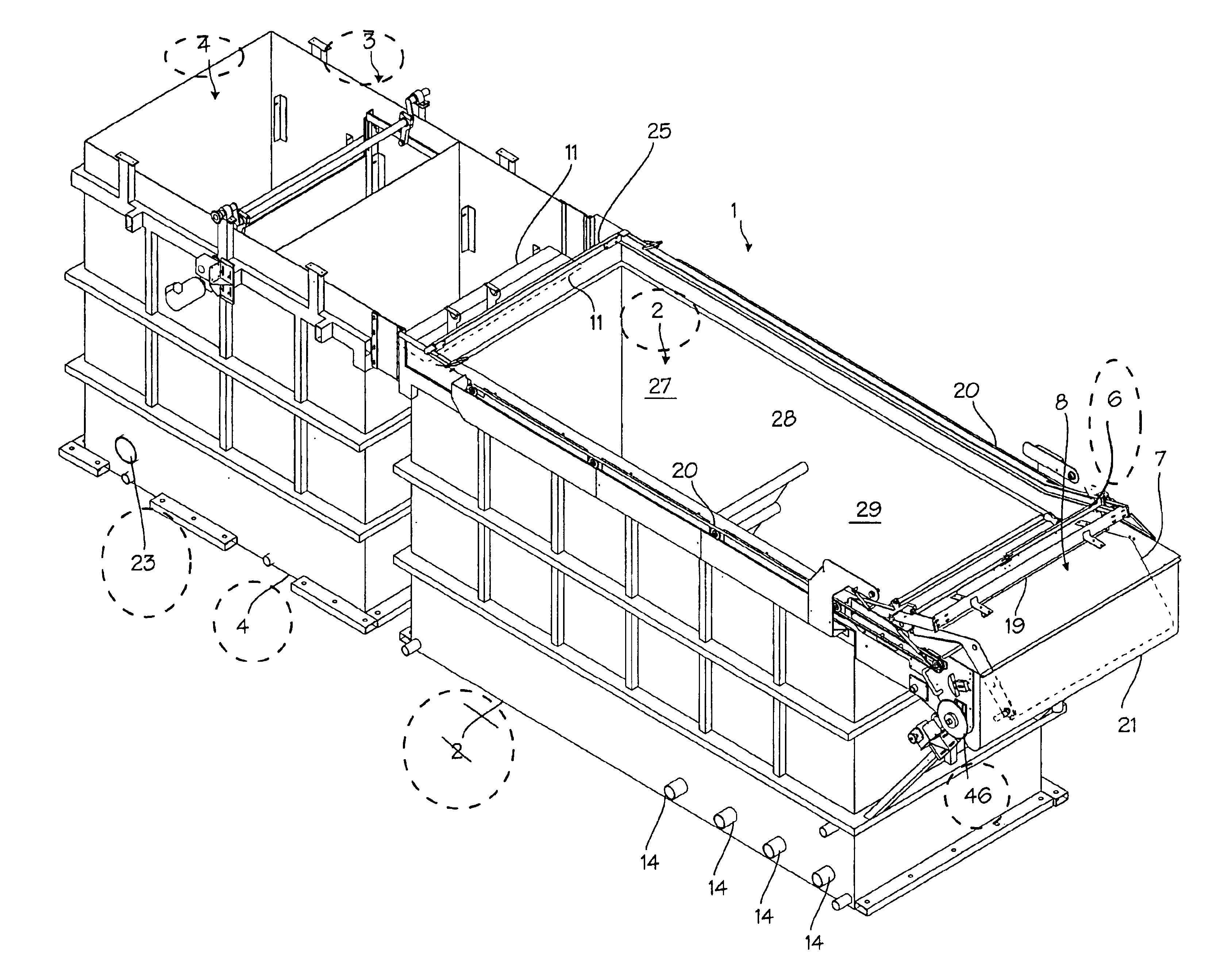

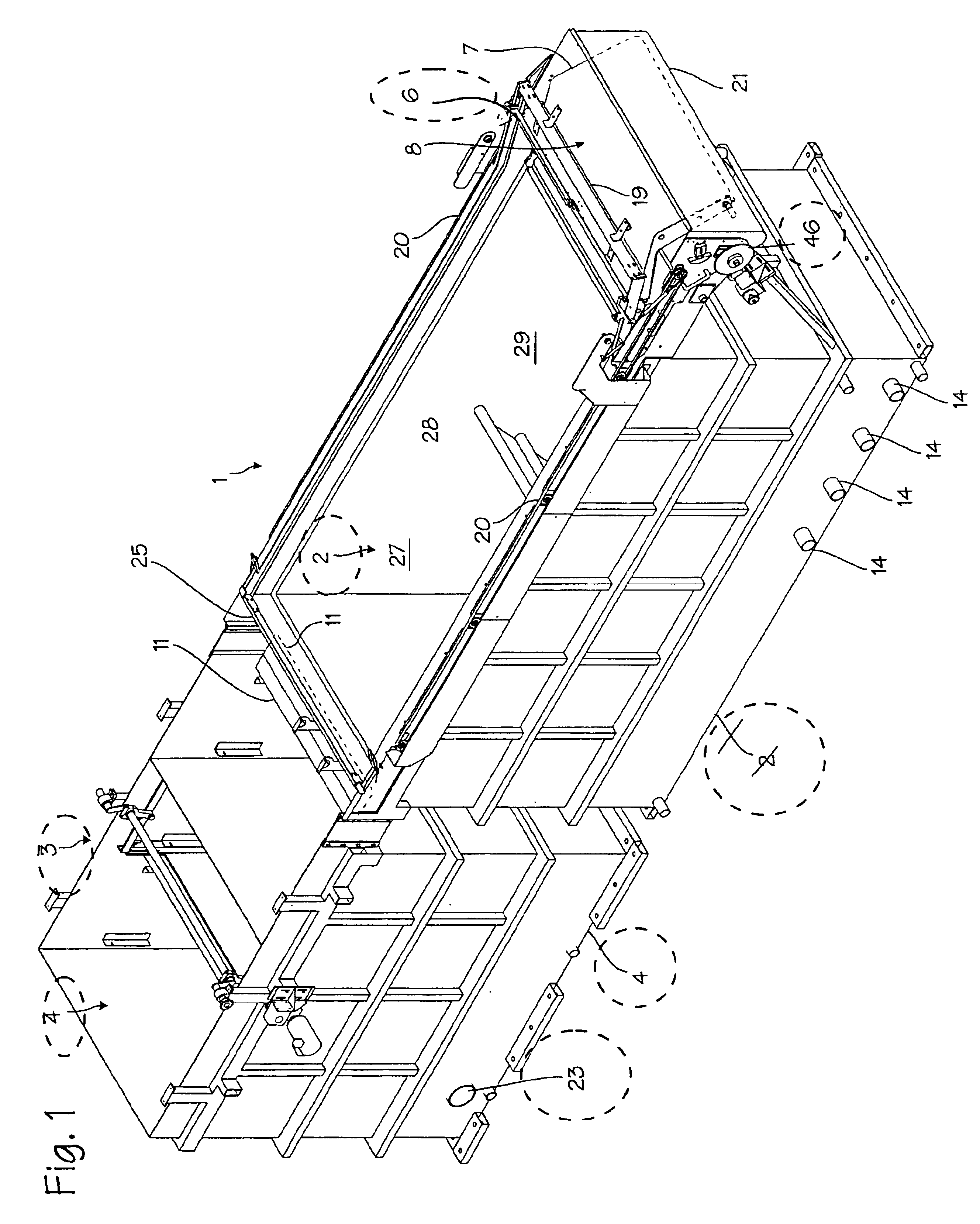

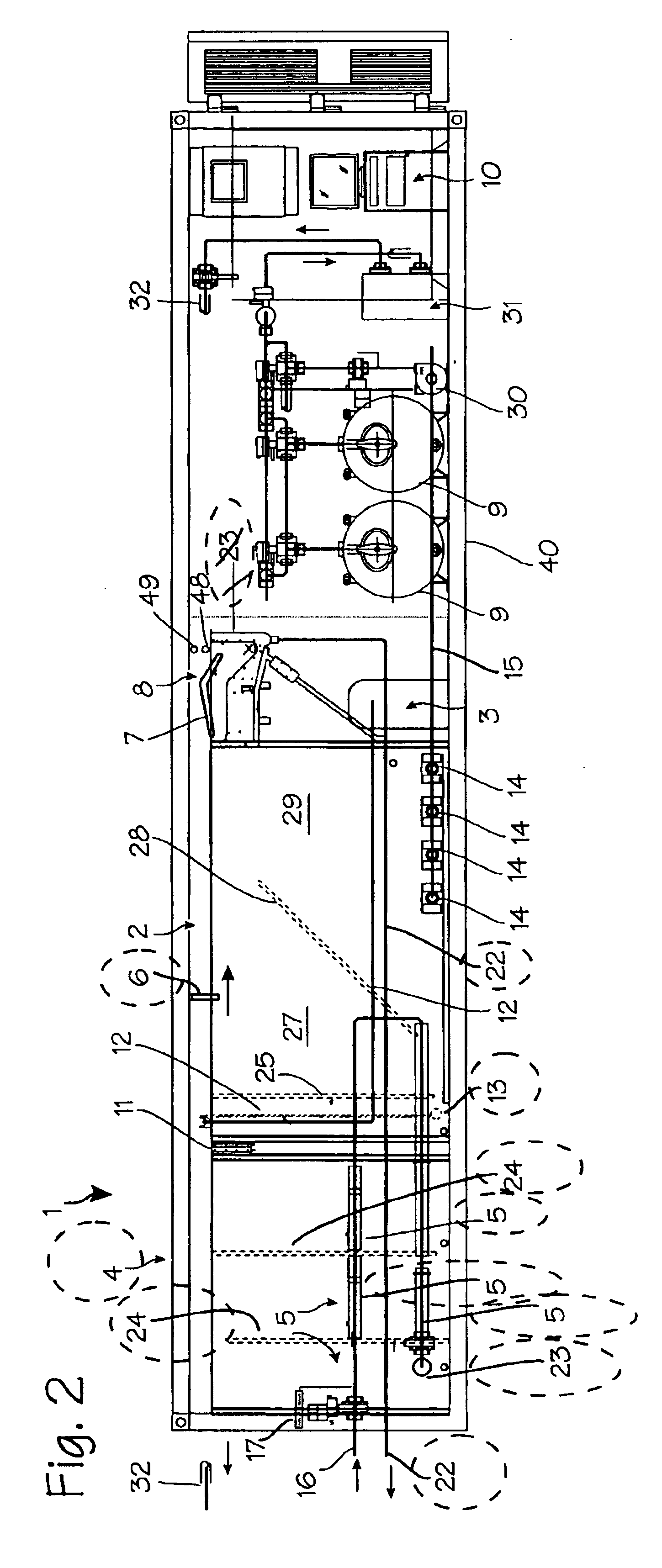

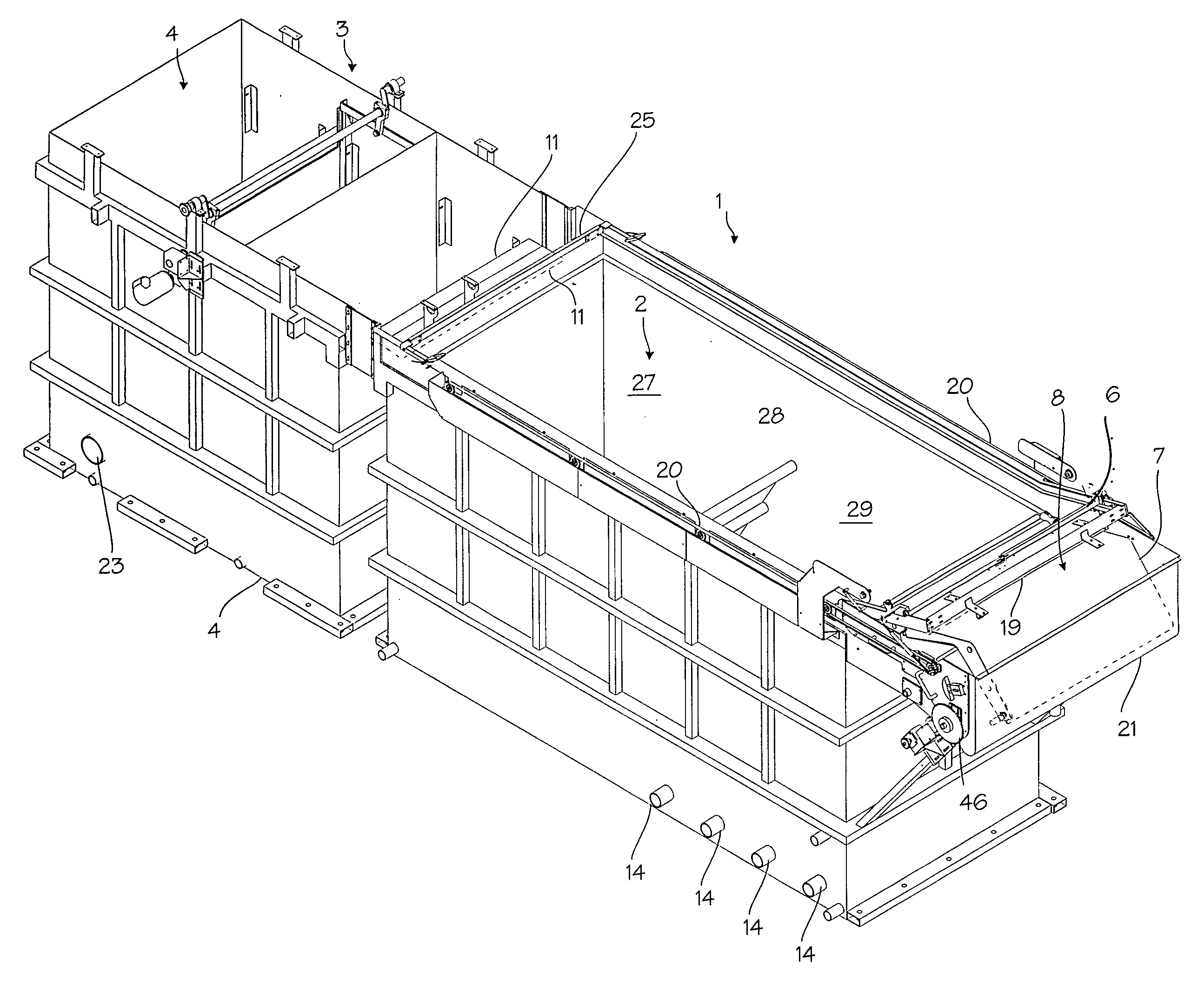

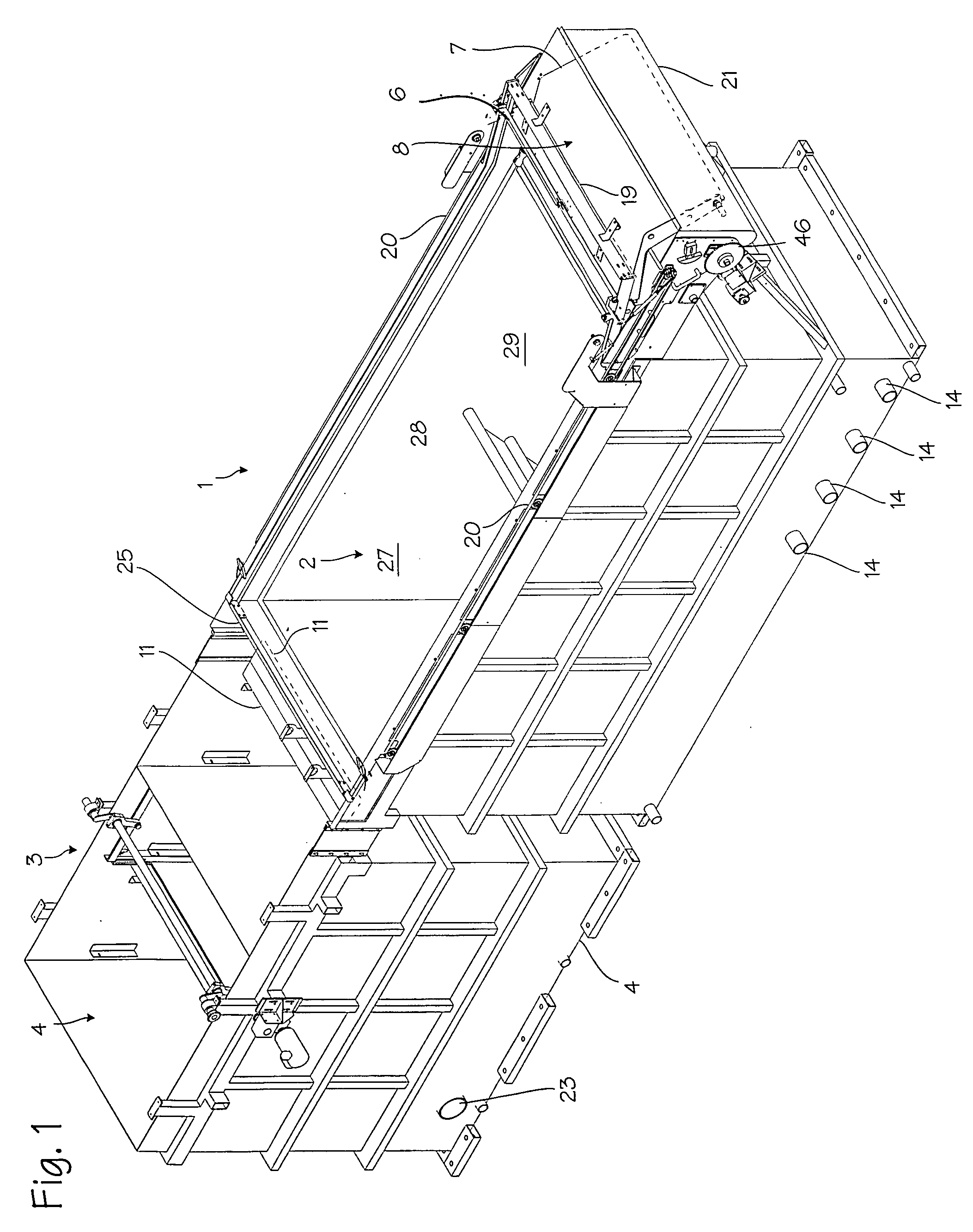

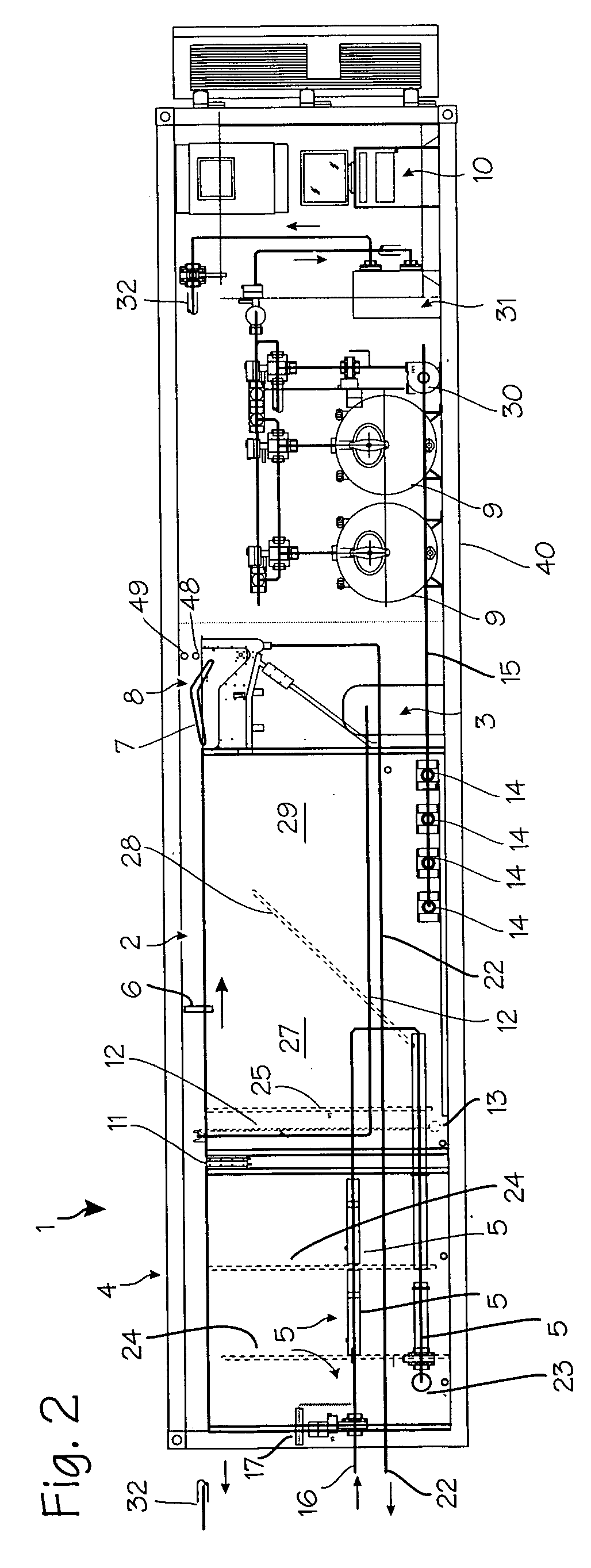

Dissolved air flotation system

InactiveUS6921478B2Continuous operationEasy disposalIon-exchanger regenerationSolid sorbent liquid separationFresh waterClean water

A dissolved air flotation system and method for purifying fresh water. The system is self-contained within a standard shipping container, with all components disposed in-line within the shipping container. Float is removed from the flotation tank with a skimmer that drives float downstream onto a conveyor belt, and the conveyor belt conveys float away from the flotation tank, in the downstream direction, and deposits the float in a collection tank. Clean water may be drawn from the flotation tank continuously, while float may be removed periodically.

Owner:SIONIX CORP

Microbial water-purifying agent and preparation method thereof

The invention relates to a microbial water-purifying agent and a preparation method thereof. The microbial water-purifying agent is prepared by fermenting corncobs, sugar cane residue, wheat bran, rapeseed meal, zeolite powder, potassium dihydrogen phosphate, sodium chloride, light calcium carbonate, water and liquid strains in a fermentation bin. The preparation method of the microbial water-purifying agent comprises the following steps: firstly, crushing the corncobs into particles with diameters smaller than 5 mm; proportionally adding and mixing the sugar cane residue, the wheat bran, therapeseed meal, the zeolite powder, the potassium dihydrogen phosphate, the sodium chloride and the light calcium carbonate; adding 25 percent of water; sending the mixture to an air steamer; adding high-pressure steam to the air steamer to increase the air pressure to 1-2 MPa and the temperature to 140-200 DEG C; keeping the pressure for 4-6 minutes; momentarily releasing the mixture in the air steamer; sending the mixture to the fermentation bin so that the temperature falls to 30-37 DEG C; then, inoculating 3-5 percent of strains; fermenting in the fermentation bin for 72 hours; and discharging from the bin to obtain a finished product. The product has good water-purifying effect, and air-steamed stalks are culture media for strain growth as well as excellent vectors. The invention can prepare strains by strains, stimulate the mass propagation of microorganisms to form dominant strains and have the yield-improving efficiency.

Owner:张培举

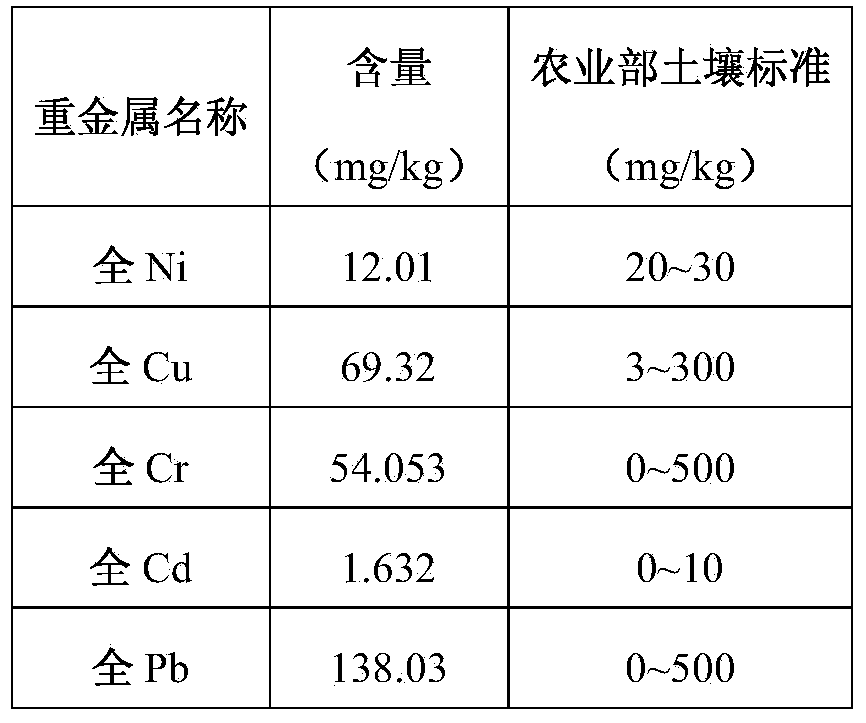

Iron tailing residue reclaimed soil and preparation method thereof

The invention provides iron tailing residue reclaimed soil and a preparation method thereof. The reclaimed soil is obtained by curing a reclaimed mixture. The reclaimed mixture comprises air-dried particles of the iron tailing residue and air-dried particles of sludge from a tap water plant which accounts for 20-30% of the mass of the air-dried particles of the iron tailing residue. Since the reclaimed soil provided by the invention comprises the iron tailing residue and the sludge from the tap water plant, various bacteria contained in the sludge from the tap water plant can improve the amount of bacteria in the iron tailing residue, and meanwhile, bacteria contained in the sludge from the tap water plant have the effect in decomposing harmful substances in the residue and the farming performance of the reclaimed soil is the same as or close to that of the conventional soil. Due to adoption of the preparation method, the utilization ration of the residue can be improved and the problem of the stockpiling of the residue can be alleviated. The soil is simple in composition and the stockpiling amount of the existing residue can be effectively reduced.

Owner:湖南鑫生矿冶废弃物综合利用科技有限公司

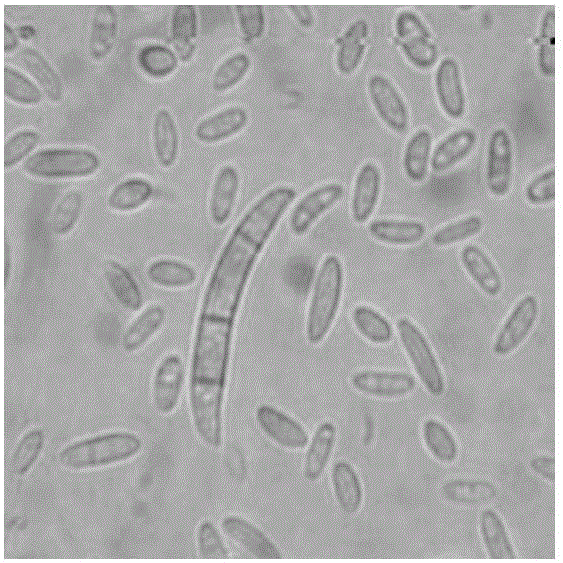

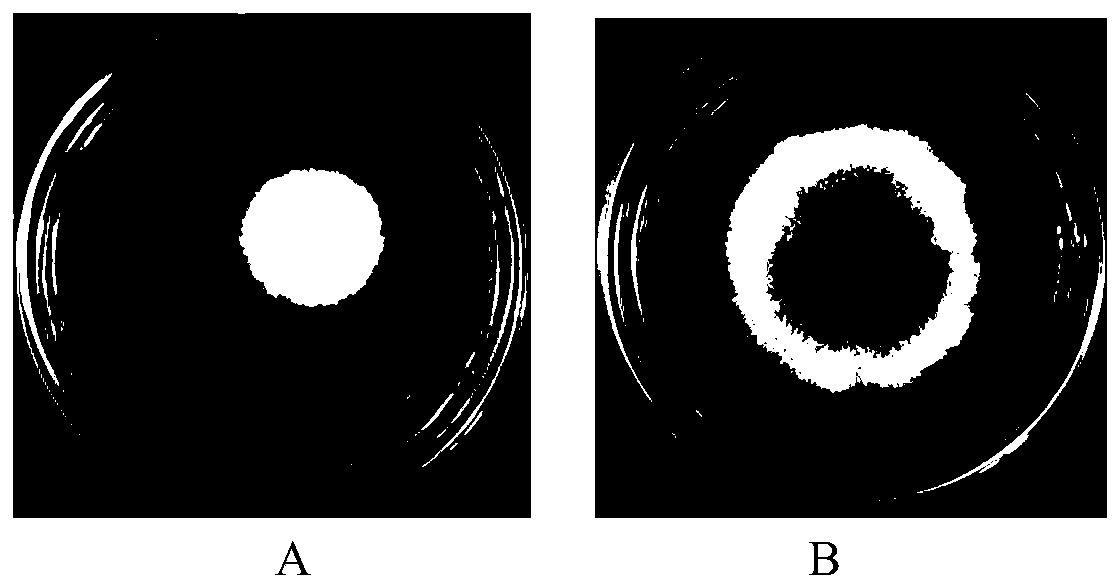

Method for producing fungal granular formulation for preventing and treating pest

InactiveCN101502271AGuaranteed decentralizationGood recovery growthBiocideArthropodicidesBiotechnologyInsect disease

The present invention relates to a method for manufacturing a fungal granule for controlling insects. The invention provides a method for preparing an entomopathogenic fungi sodium alginate granule and a granular formulation prepared through the method. Compared with the prior art, the invention not only preserves the normal advantages of long-time shape keeping of algae colloidal particle and growth recovering of fungus in the particles, but also has other innovations and improvements on other aspects. The algae colloidal particles containing fungus are used for being sprinkled to the farmland or woodland for controlling insects.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

Paenibacillus polymyxa pesticide-fertilizer for farm onsite fermentation and applications thereof

InactiveCN105439725APromote germinationImprove bud germination efficiencyAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersEscherichia coliCorn steep liquor

The invention relates to a paenibacillus polymyxa pesticide-fertilizer for farm onsite fermentation, a preparation method, and applications thereof. The pesticide-fertilizer comprises the following raw materials: paenibacillus polymyxa powder, colistin sulfate, natamycin, L-alanine, valine, yeast powder, corn steep liquor powder, disodium hydrogen phosphate, sodium chloride, fructose, and brown sugar. The colistin sulfate and natamycin in the insecticide-fertilizer can inhibit the growth of fungi (such as pathogenic fungi, yeast, etc.) and gram negative bacteria (such as colibacillus, salmonella, etc.) during the fermentation process. The spore germinator (alanine, fructose, and valine) can rapidly promote the germination of spores of paenibacillus polymyxa and improve the germination rate of spores. The provided pesticide-fertilizer can be applied to the onsite fermentation and propagation in a simple and crude farm. The required equipment is simple. The using amount of bacterium is little. The cost is low. The fermentation broth obtained through onsite fermentation has the advantages of high content and good activity. The insecticide-fertilizer can prevent disease, promote growth, and increase output and improve product quality, and can be used as a microbial pesticide, and the effect is stable.

Owner:FOSHAN YANHUI BIOTECH CO LTD

Bacillus amyloliquefaciens insecticide-fertilizer for farm onsite fermentation and applications thereof

InactiveCN105439723AFermentation reproduces rapidlyHigh bacterial contentBio-organic fraction processingAlkali orthophosphate fertiliserBiotechnologyDisease

The invention relates to a bacillus amyloliquefaciens insecticide-fertilizer for farm onsite fermentation, a preparation method and applications thereof. The insecticide-fertilizer comprises the following raw materials: bacillus amyloliquefaciens, colistin sulfate, natamycin, L-alanine, asparagine, yeast extract powder, peptone, disodium hydrogen phosphate, sodium chloride, glucose, fructose, and brown sugar. The colistin sulfate and natamycin in the insecticide-fertilizer can inhibit the growth of fungi (such as pathogenic fungi, yeast, etc.) and gram negative bacteria (such as colibacillus, salmonella, etc.) during the fermentation process. The spore germinator (alanine, fructose, and asparagine) can rapidly promote the germination of spores of bacillus amyloliquefaciens and improve the germination rate of spores. The provided insecticide-fertilizer can be applied to the onsite fermentation and propagation in a simple and crude farm. The required equipment is simple. The using amount of bacterium is little. The cost is low. The fermentation broth obtained through onsite fermentation has the advantages of high content and good activity. The insecticide-fertilizer can prevent disease, promote growth, and increase output and improve quality, and can be used as a microbial pesticide, and the effect is stable.

Owner:FOSHAN YANHUI BIOTECH CO LTD

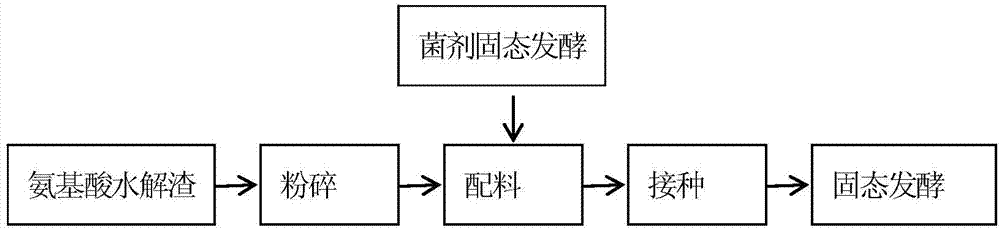

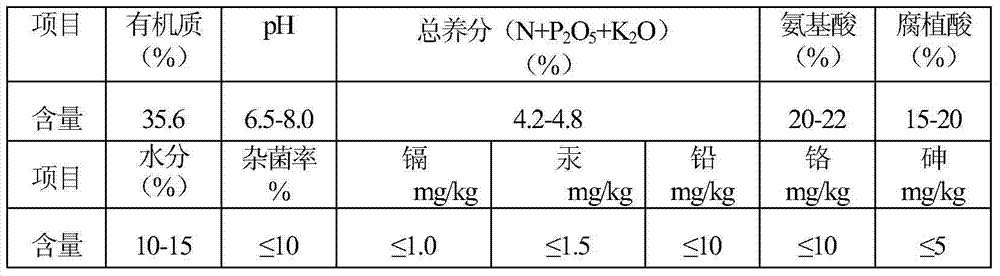

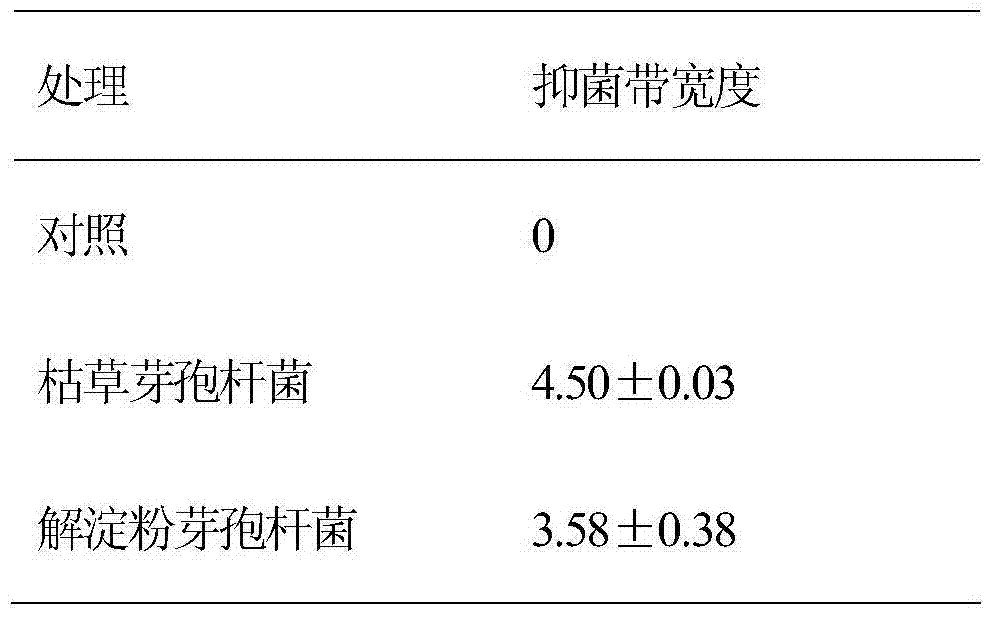

Special biocontrol compound microbial fertilizer for grapes and production method and application

ActiveCN104496573AComprehensive nutritionImprove micro-ecological floraBioloigcal waste fertilisersFertilizer mixturesFertilizerChemistry

The invention discloses a special biocontrol compound microbial fertilizer for grapes. An organic raw material is amino acid hydrolysis residue, and a bacterial agent is a mixed bacterial agent of bacillus subtilis and bacillus amyloliquefaciens; the strain in the bacterial agent is subjected to factory fermentation; the initial pH value of the culture medium is 6.5-7.5, and the fermentation temperature is 30-35 DEG C; and a nitrogen source comprises 140.0-106.0g / L corn flour, 0.6-1.3g / L glucoamylase, 1.2-1.8g / L alpha-amylase, 4.0-6.5g / L KH2PO4 and 3.0-6.0g / L CO(NH2)2. The invention also discloses a production method of the compound microbial fertilizer. In the special compound microbial fertilizer for grapes, disclosed by the invention, the microorganisms and the fertilizer enter the soil at the same time and are colonized at the root of a grape plant, and the growth of pathogenic bacteria of coniothyrium diplodiella is inhibited so as to reduce the morbidity of coniothyrium diplodiella.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

Prepn process of acidophilic lactobacillus milk tablet

InactiveCN1672538AReduce cell deathHigh bacterial activityMilk preparationLactobacillus acidophilusLaboratory culture

The preparation process of acidophilic lactobacillus milk tablet adopts inducing mutation breeding method to breed high temperature mutant acidophilic lactobacillus strain, i. e., acidophilic lactobacillus LA201 strain. Meanwhile, matter capable of lowering the death rate of acidophilic lactobacillus is extracted from the Chinese herbal medicine extract liquid and microbe culture liquid. The breeding of high temperature acidophilic lactobacillus strain and the protecting agent make it possible to produce acidophilic lactobacillus milk tablet in available milk powder producing high temperature spray drying apparatus and conventional tabletting.

Owner:SHAANXI UNIV OF SCI & TECH

Microbial water purifying agent

InactiveCN104828958AHigh bacterial contentAchieve the purpose of purificationBiological water/sewage treatmentDiseaseYeast extract

The invention relates to the technical field of water treatment, particularly a microbial water purifying agent. The microbial water purifying agent is prepared from a culture medium and a liquid microbial inoculant. The culture medium is composed of the following components in parts by mass: 50-70 parts of rice hull, 8-15 parts of bagasse, 15-30 parts of wheat bran, 5-10 parts of bean pulp, 5-15 parts of peanut pulp, 2-6 parts of sodium dihydrogen phosphate, 0.2-0.8 part of sodium chloride, 0.5-1.2 parts of trace element solution, 3-8 parts of rock powder, 5-20 parts of glucose, 2-6 parts of ammonium chloride solution, 1.2-5.8 parts of beef leaching substance and 2-6 parts of yeast extract. By adopting the combination of multiple bacteria and using mixed fermentation, the microbial water purifying agent can well remove nitrogen, phosphorus and other eutrophic substances in water, can effectively inhibit other harmful bacteria in the water body, achieves the effects of preventing diseases and enhancing the survival percent, and achieves the goal of water purification.

Owner:ZHANGJIAGANG SHANMU NEW MATERIAL TECH DEV

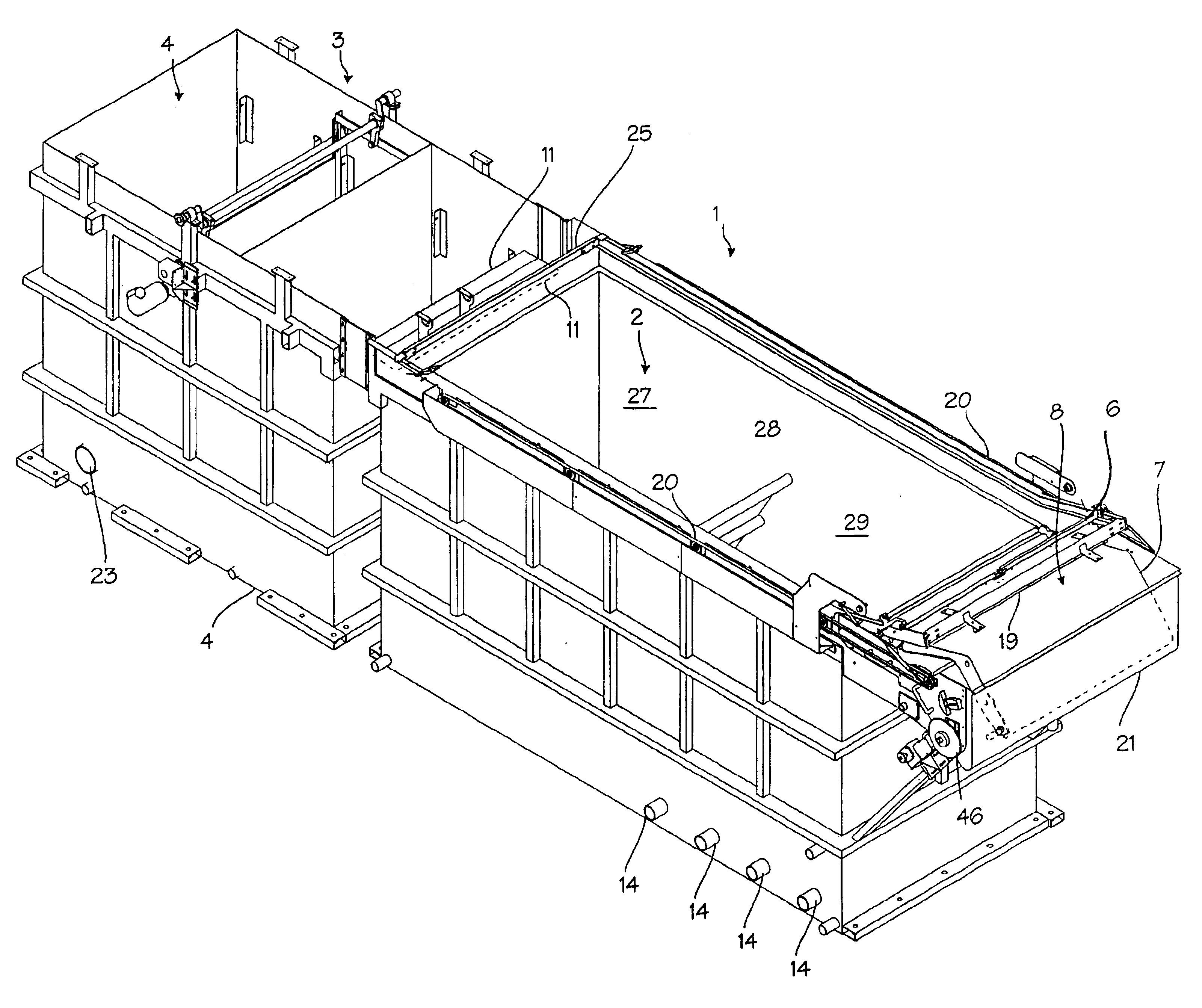

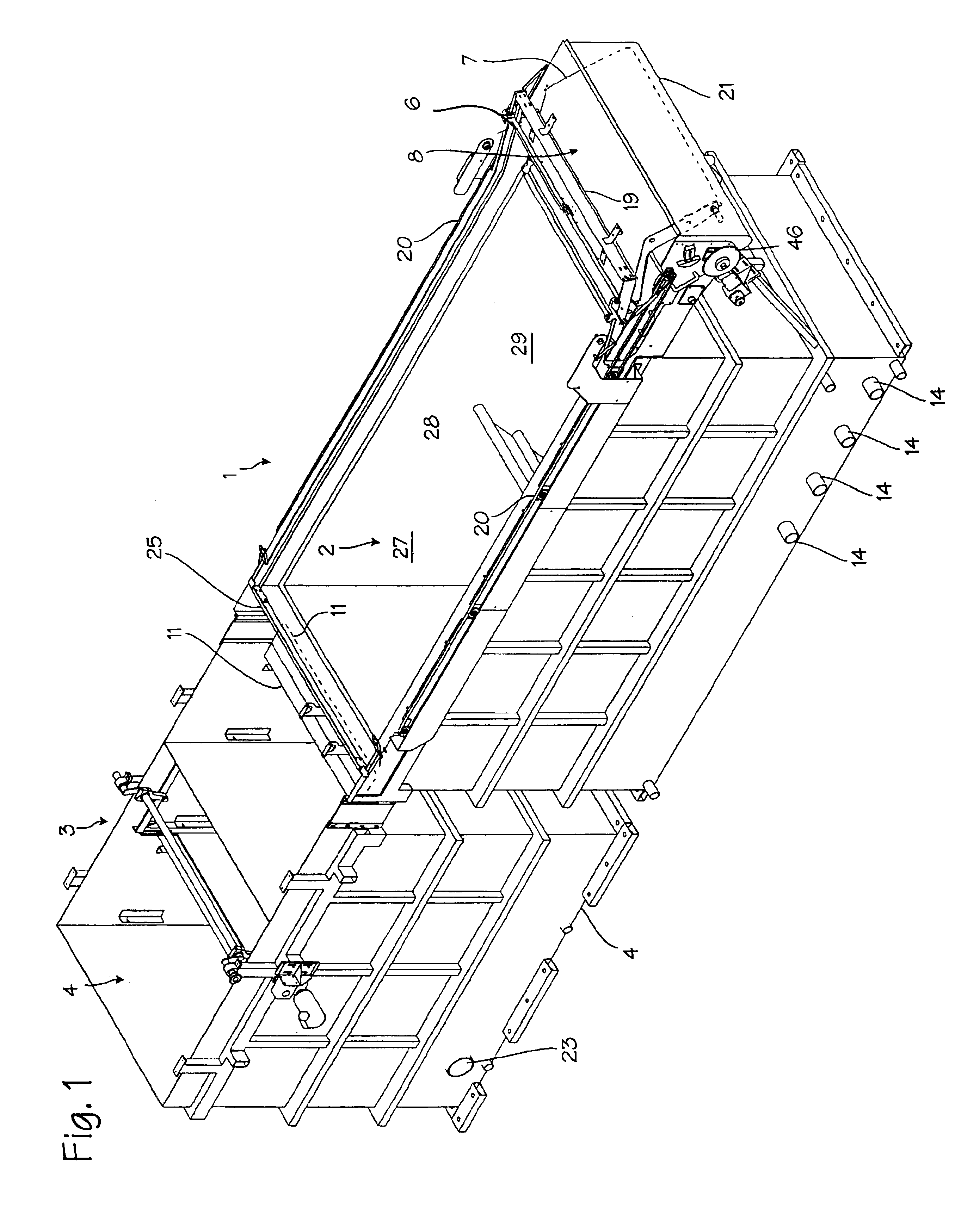

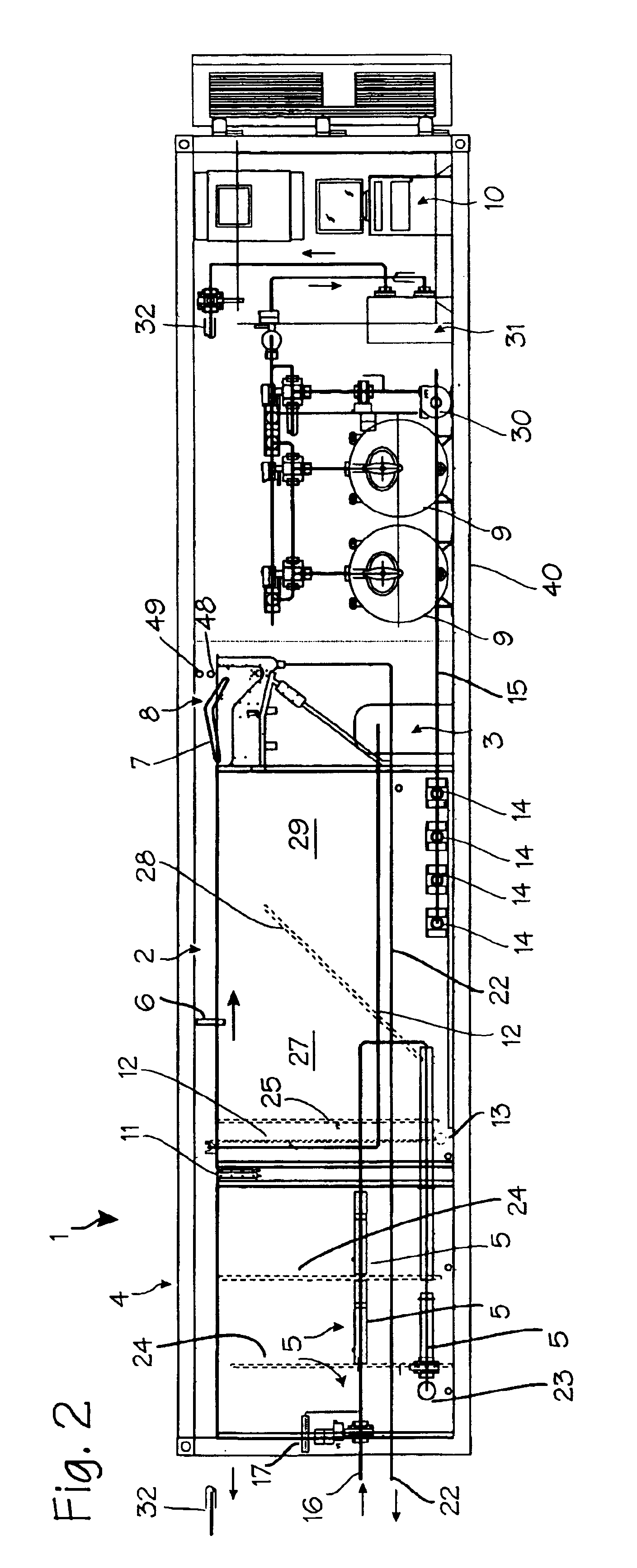

Self contained dissolved air flotation system

InactiveUS7033495B2Continuous operationEasy disposalIon-exchanger regenerationSolid sorbent liquid separationFresh waterConveyor belt

A dissolved air flotation system and method for purifying fresh water. The system is self-contained within a standard shipping container, with all components disposed in-line within the shipping container. Float is removed from the flotation tank with a skimmer that drives float downstream onto a conveyor belt, and the conveyor belt conveys float away from the flotation tank, in the downstream direction, and deposits the float in a collection tank. Clean water may be drawn from the flotation tank continuously, while float may be removed periodically.

Owner:SIONIX CORP

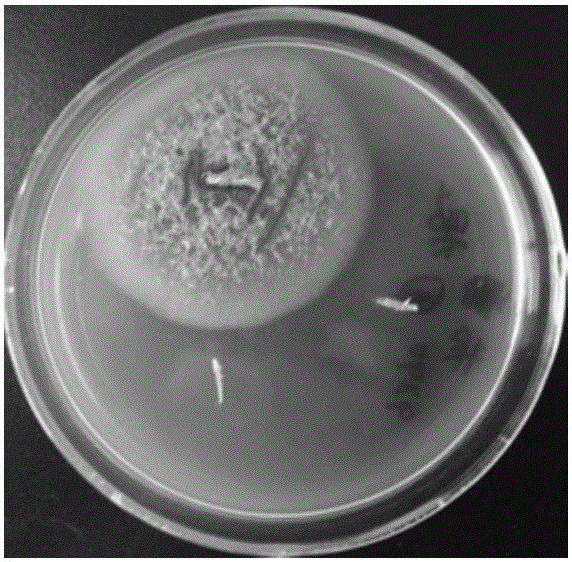

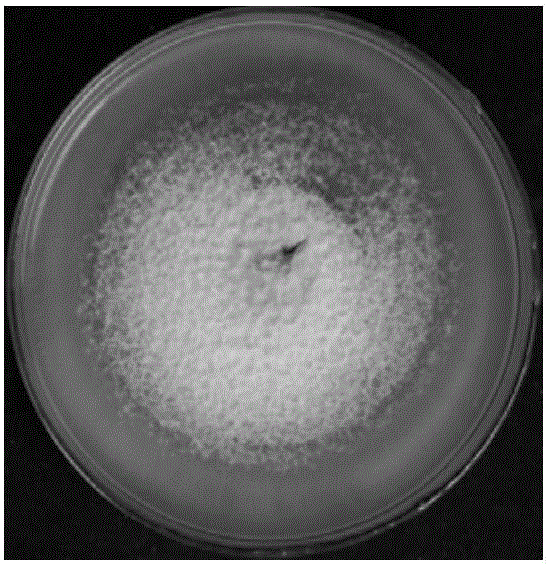

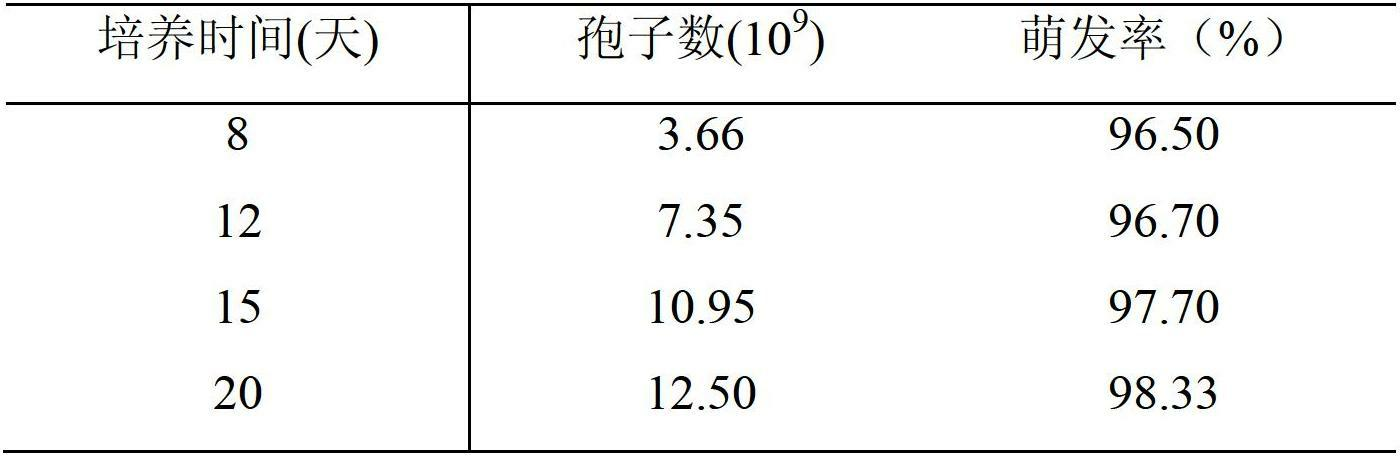

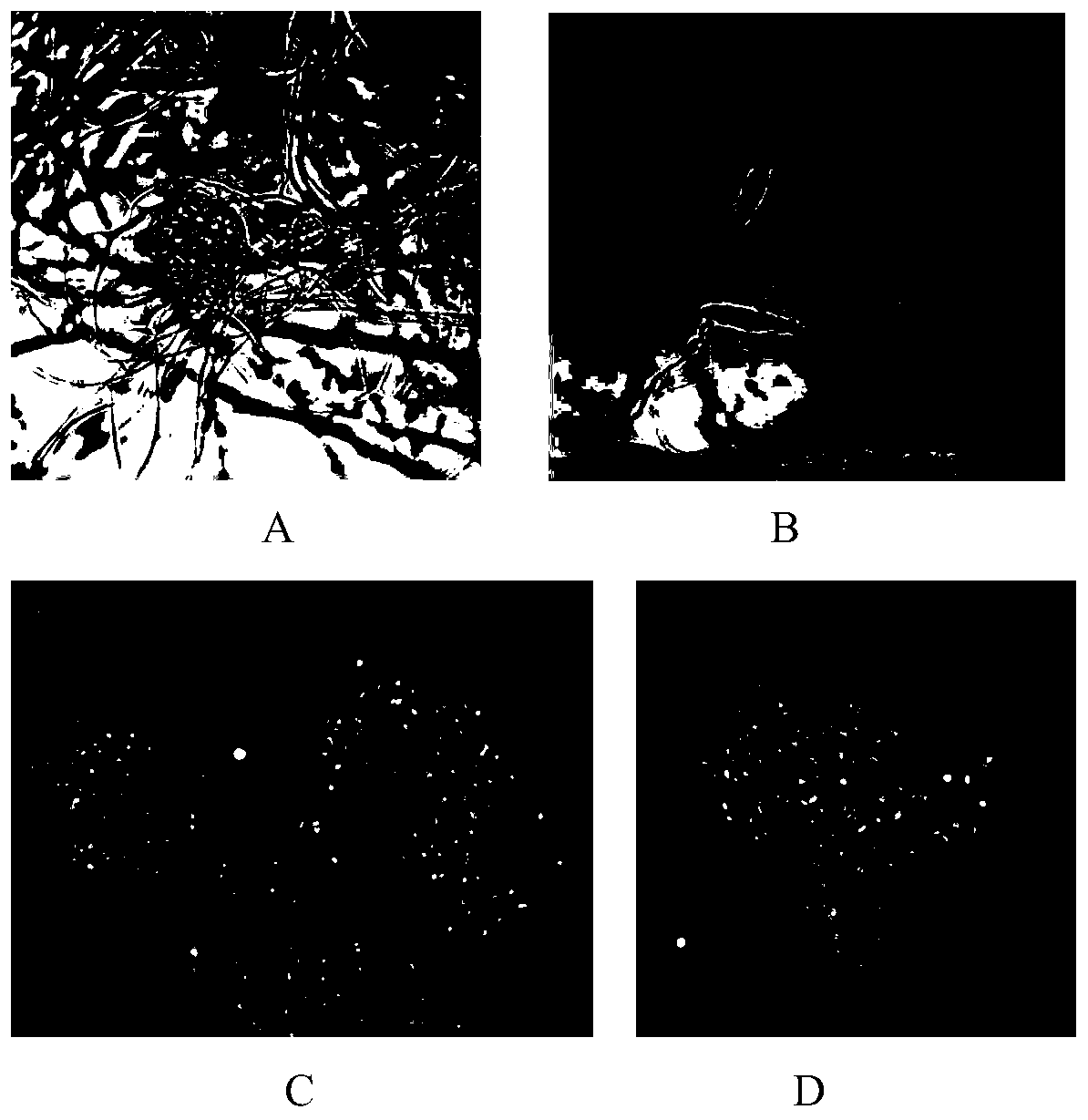

Production method of nonpathogenic fusarium oxysporum-containing plant vaccine preparation

InactiveCN105767009AImprove resource reuse efficiencySolve the problem of fusarium wilt that is difficult to controlBiocideDisinfectantsBiotechnologyVaccine Production

The invention provides a production method of a nonpathogenic fusarium oxysporum-containing plant vaccine preparation. The method comprises the following steps: preparing liquid strain for production by taking nonpathogenic fusarium oxysporum FJAT-9290 as strain and using a potato dextrose agar (PDA) culture medium and a Czapek yeast culture solution as a culture medium for the liquid strain; preparing a solid culture medium substrate for plant vaccine production by taking pig manure waste as a main component, mixing the prepared solid culture medium substrate with bran and wheat grains, respectively packaging the mixture into polypropylene plastic bags, sterilizing and then inoculating the liquid strain, culturing and fermenting for 18-20 days at the constant temperature of 28-30 DEG C to prepare a solid fermentation product of a plant vaccine, and evenly mixing the product after fermentation to obtain the nonpathogenic fusarium oxysporum-containing plant vaccine. The plant vaccine preparation prepared by the method has effects of promoting growth of crops and resisting diseases, can solve the problem that tomato fusarium wilt is difficult to control, and achieves the aim of reducing the use of chemical pesticides.

Owner:福建省农业科学院农业生物资源研究所

Beauveria bassiana preparation for controlling peach fruit borers and preparation method thereof

InactiveCN102690760AHigh bacterial contentImprove the effect of prevention and controlBiocideFungiMicrobiologyLeachate

The invention provides a beauveria bassiana preparation for controlling peach fruit borers and a preparation method thereof. The preparation method comprises the following steps of: inoculating a strain of beauveria bassiana with the collection number of CGMCC No. 4526 into a test tube loaded with a PDA (potato dextrose agar) slant culture medium containing a healthy peach fruit borer corpse leachate for culture, further performing second-stage strain culture and third-stage solid amplification culture, and finally preparing a bacterial powder preparation. The bacterial powder preparation provided by the invention has a better effect on controlling the peach fruit borers, the control effect can be up to 90.5%, and the fruit-boring rate of an orchard in the same year can be reduced by 83.8% -93.6%. The bacterial powder preparation provided by the invention is particularly suitable for controlling the peach fruit borers in dry and low-temperature regions in the north.

Owner:SHANXI UNIV

Self contained dissolved air flotation system

InactiveUS20070000840A1Continuous operationEasy disposalIon-exchanger regenerationSolid sorbent liquid separationFresh waterConveyor belt

A dissolved air flotation system and method for purifying fresh water. The system is self-contained within a standard shipping container, with all components disposed in-line within the shipping container. Float is removed from the flotation tank with a skimmer that drives float downstream onto a conveyor belt, and the conveyor belt conveys float away from the flotation tank, in the downstream direction, and deposits the float in a collection tank. Clean water may be drawn from the flotation tank continuously, while float may be removed periodically.

Owner:SIONIX CORP

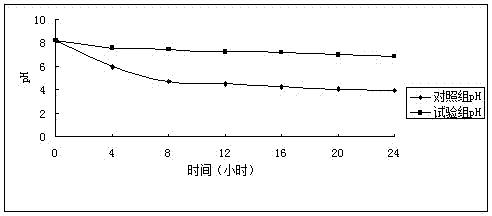

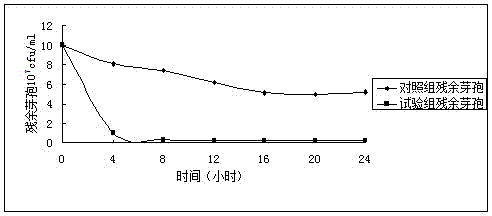

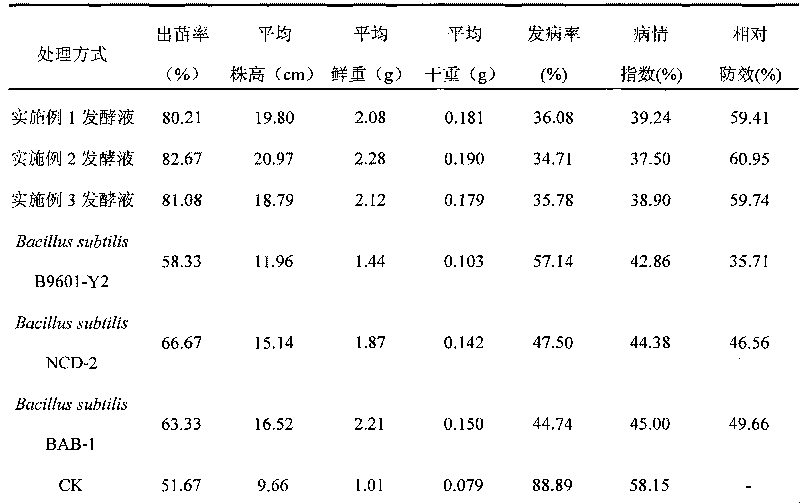

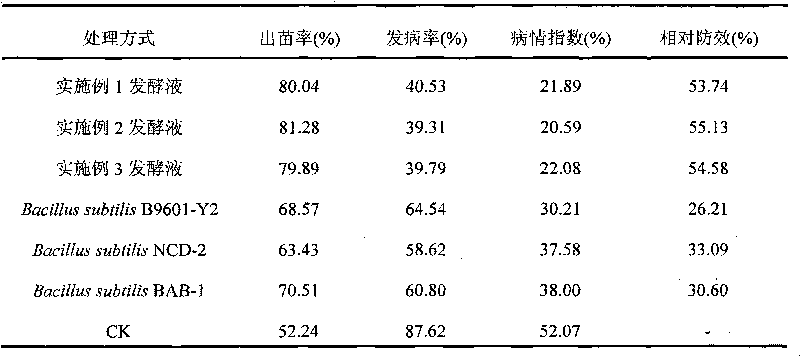

Mixed cooperative fermentation process of bacillus subtilis

InactiveCN101717723AImprove adaptabilityPromote growthBacteriaMicroorganism based processesMicroorganismBacterial strain

The invention relates to the mixed cooperative fermentation method of bacillus subtilis, and belongs to the field of microbe engineering. The scheme comprises the following steps of: selecting three different kinds of bacillus subtilis having strong inhibiting effects on different pathogenic bacteria; performing slant cultivation and shaking cultivation on the three kinds of bacillus subtilis respectively by using the mixed fermentation method; inoculating the three kinds of bacillus subtilis in certain proportion; and performing seeding tank cultivation and fermentation tank cultivation on the mixed bacteria. Methods such as culture medium selection, pH value, temperature, ventilatory capacity and inoculum concentration proportion of the three strains of bacteria are optimized during fermentation. Compared with the conventional single bacterial strain fermentation method, the mixed cooperative fermentation method is simplified, improves efficiency, reduces production cost and has effective bacteria quantity in a fermentation liquor of more than or equal to 1,012 cfu / ml.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Bacillus megaterium bacterial fertilizer for onsite fermentation in farm and applications thereof

InactiveCN105439726AHigh bacterial contentPhosphate dissolving activity is goodBio-organic fraction processingBacteriaEscherichia coliBacillus megaterium

The invention relates to a bacillus megaterium bacterial fertilizer for onsite fermentation in a farm and applications thereof. The bacterial fertilizer comprises the following raw materials: bacillus megaterium powder, colistin sulfate, natamycin, inosine, lysine, corn flour, soybean cake powder, disodium hydrogen phosphate, potassium chloride, and brown sugar. The bacillus megaterium bacterial fertilizer can be applied to onsite fermentation and propagation in a farm. The colistin sulfate and natamycin in the bacterial fertilizer can inhibit the growth of fungi (such as pathogenic fungi, yeast, etc.) and gram negative bacteria (such as colibacillus, salmonella, etc.) during the fermentation process. The spore germinator (inosine and lysine) can rapidly promote the germination of spores of bacillus megaterium and improve the germination rate of spores. The provided preparation can be applied to the onsite fermentation and propagation in a simple and crude farm. The required equipment is simple. The using amount of bacterium is little. The cost is low. The fermentation broth obtained through onsite fermentation has the advantages of high content, good activity and few contaminating microorganisms. The bacterial fertilizer can decompose phosphorus, prevent disease, promote growth, increase output, and improve product quality. The effect is stable.

Owner:FOSHAN YANHUI BIOTECH CO LTD

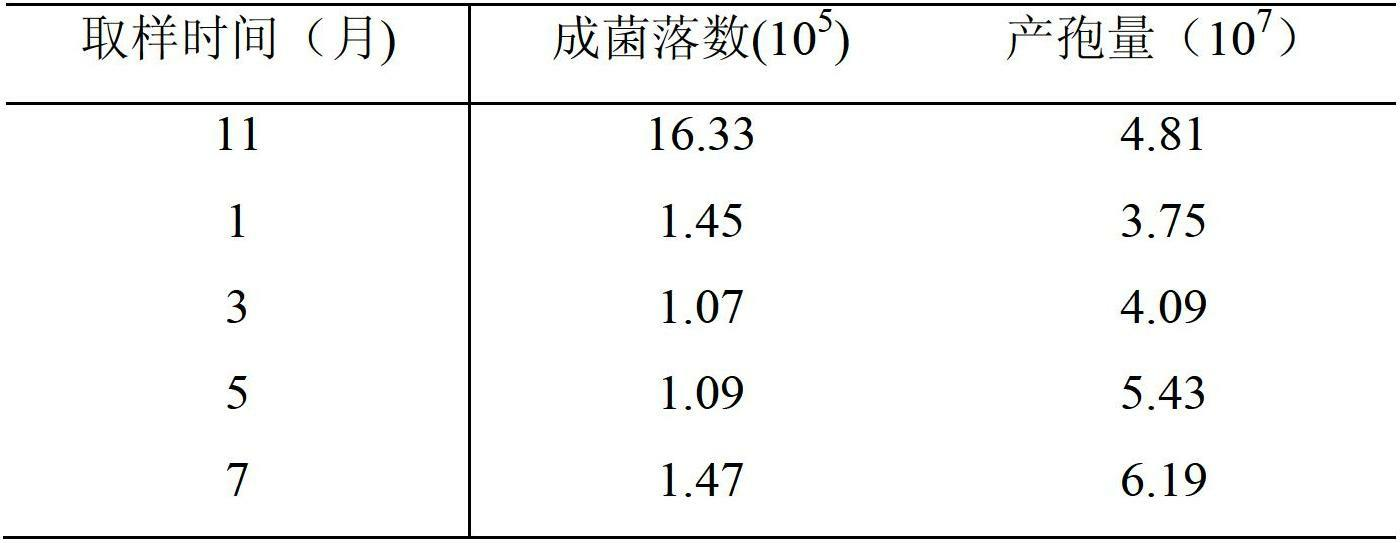

Semisolid fungus cultivation method for nitrifying bacteria

InactiveCN105002119AEliminate distractionsStable growth mediumBacteriaMicroorganism based processesBiotechnologyCulture fluid

The invention discloses a semisolid fungus cultivation method for nitrifying bacteria. The cultivation method comprises the following steps: 1, respectively inoculating purified ammonia oxidizing bacteria and nitrite oxidizing bacteria into triangular bottles, and putting the triangular bottles in a shaking bed for 12 days' heat-insulating cultivation; 2, respectively inoculating the strains into corresponding seed tanks, pumping gas into the seed tanks, stirring, and carrying out cultivation for 12 days; 3, mixing the strains with 99 times of corresponding culture solutions, mixing the mixtures with 3 times of carriers to obtain semisolids, putting the semisolids into containers for 20 days' heat-insulating and moisture-holding cultivation; step 4, heating the containers, and removing the moisture in the cultivated semisolids with exhaust fans, and smashing the dried cultivated semisolids; step 5, mixing the two semi-finished products according to the proportion of 1:1, and mixing uniformly to obtain the finished product. The semisolid fungus cultivation method is easy to operate, low in production cost, stable in product quality, and has the advantage that the finished product contains 0.2 billion or more bacteria per gram, and is easy to store and transport.

Owner:HAINAN CHIEF BIOLOGY TECHN EMPOLDER CO LTD

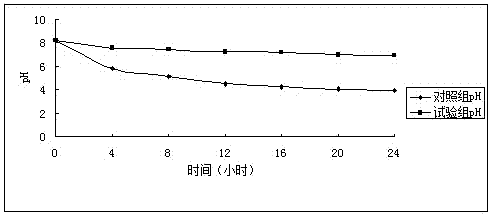

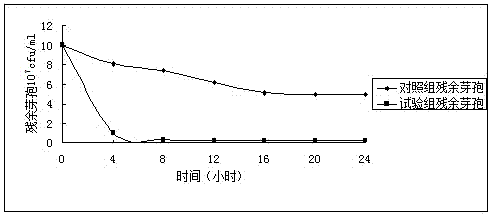

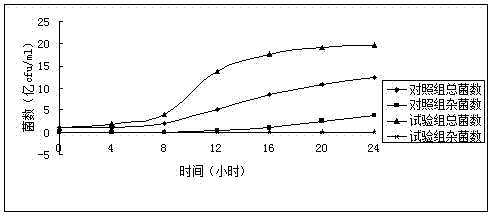

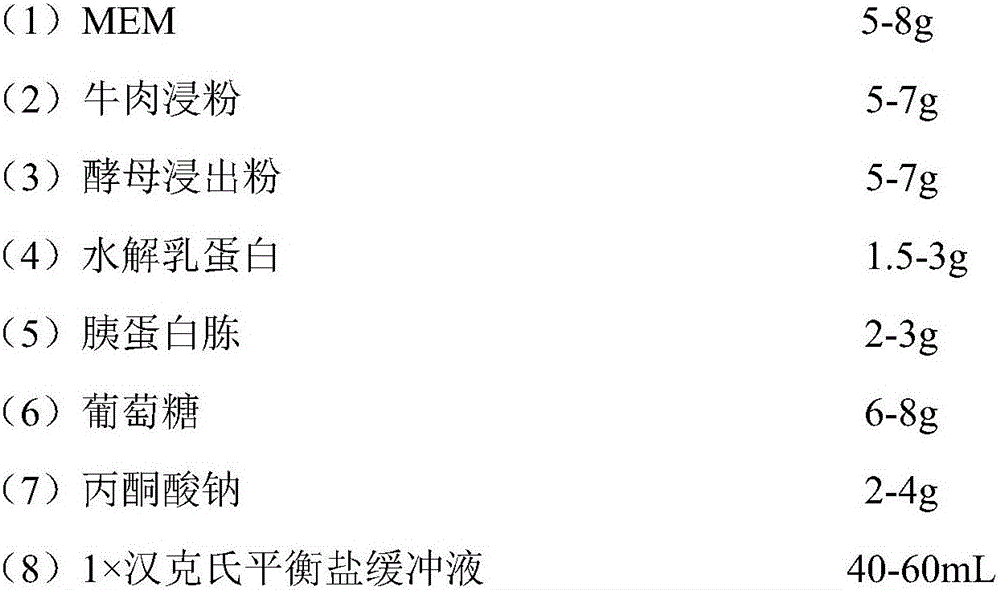

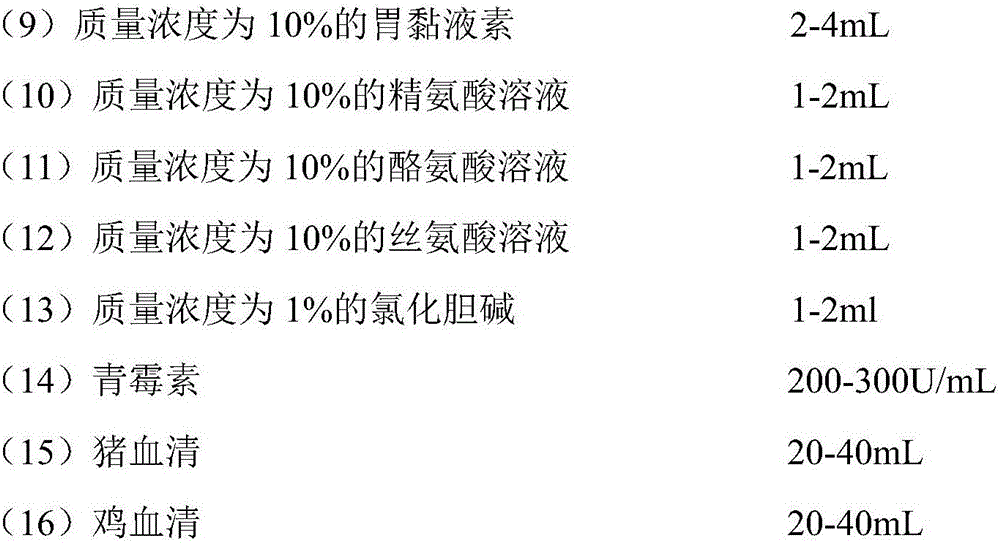

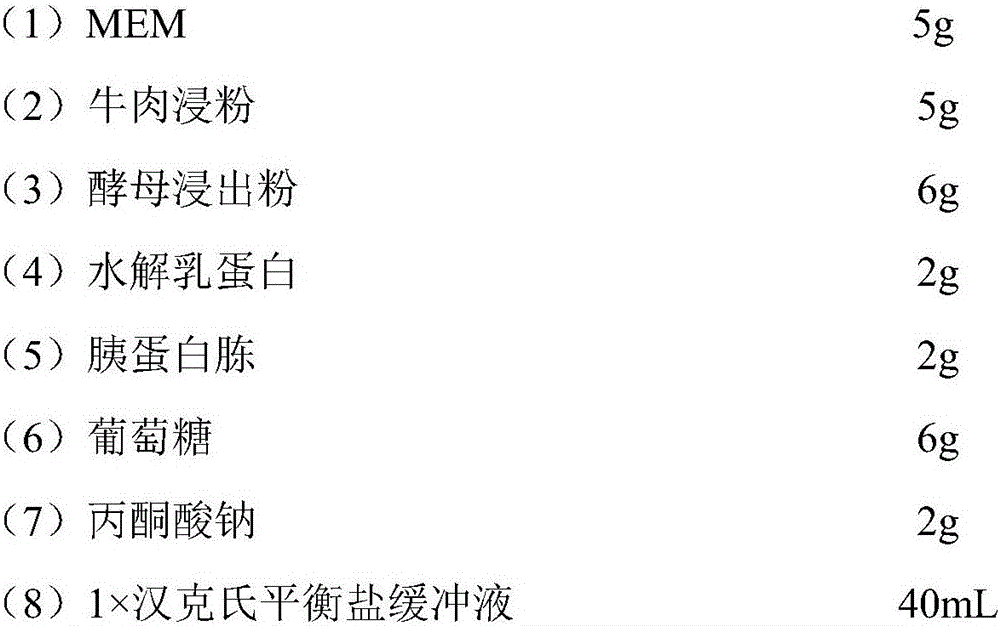

Swine mycoplasma hyopneumoniae culture medium and preparation method and application thereof

InactiveCN106434502ALow serum levelsLow side reaction rateBacteriaMicroorganism based processesMycoplasma cultureArginine

The invention provides a swine mycoplasma hyopneumoniae culture medium and a preparation method and application thereof and belongs to the technical field of bioengineering. The swine mycoplasma hyopneumoniae culture medium is prepared from a basal culture medium and an auxiliary culture medium, which are mainly prepared from ingredients such as MEM, beef extract powder, yeast leachate powder, lactoalbumin hydrolysate, gastric mucin, an arginine solution, pig blood serum and chicken blood serum. The swine mycoplasma hyopneumoniae culture medium is prepared through subjecting the basal culture medium and the auxiliary culture medium to sterile treatment, then, carrying out volume determination by using injection water, and adjusting the pH value of the solution. The culture medium provided by the invention is low in blood serum content and is applied to the preparation of vaccine antigens, the growth speed of swine mycoplasma hyopneumoniae is high, the culture cycle is short, the fungus content of a semi-finished product fungus solution is high, the production cost is low, and the prepared vaccines are good in immunization effect and low in side reaction occurrence probability, so that the culture medium is suitable for being industrially produced on a large scale.

Owner:RINGPU (BAODING) BIOLOGICAL PHARMACEUTICAL CO LTD

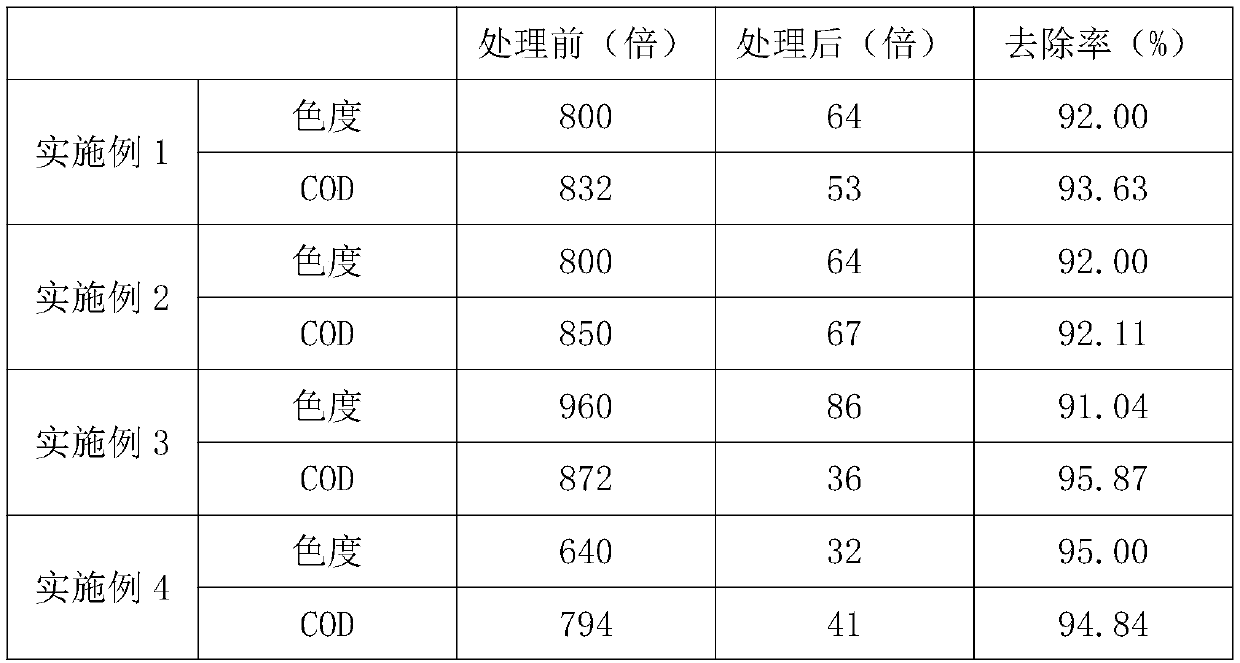

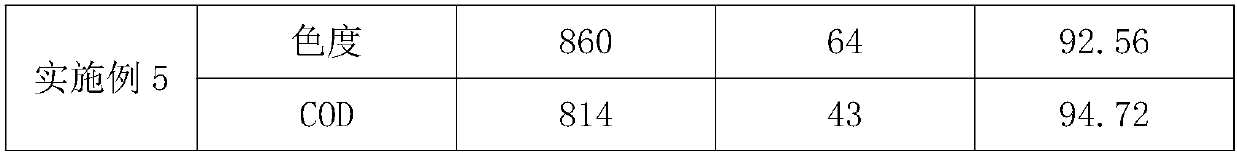

Low-temperature-resistant decoloring complex functional bacterial agent and preparation method thereof

InactiveCN110157629AHigh bacterial contentImprove biological activityFungiBacteriaChrysosporium speciesPhanerochaete chryosporium

The invention discloses a low-temperature-resistant decoloring complex functional bacterial agent and a preparation method thereof. The low-temperature-resistant decoloring complex functional bacterial agent is prepared from, by weight, 20-25% of a phanerochaete chrysosporium culture, 15-20% of a psychrobacillus psychrodurans culture, 15-20% of a bacillus decolorationis culture, 15-20% of a shewanella decolorationis culture, 10-15% of a coriolus versicolor culture, 10-15% of a klebsiella pneumoniae culture and 0.05-0.08% of multi-vitamins. The complex bacterial agent contains various strains,the compatibility is reasonable, the occurrence rate of sludge bulking in winter can be reduced, dyes in printing and dyeing waste water can be efficiently decolorized and degraded at a low temperature, the input cost is low, and the low-temperature-resistant decoloring complex functional bacterial agent can be applied and popularized on a large scale.

Owner:新疆水处理工程技术研究中心有限公司

Preparation method of microbiological water purifier

InactiveCN103663726AHigh bacterial contentEfficient removalBiological water/sewage treatmentMicroorganismCold air

The invention belongs to the technical field of environmental protection, and specifically relates to a preparation method of a microbiological water purifier. The method comprises the following steps: preparing and mixing materials and liquid bacterial strains, feeding the prepared mixture into a steam explosion boiler, closing the door of the steam explosion boiler, introducing high-pressure steam into the steam explosion boiler, wherein in this process the cold air in the steam explosion boiler is expelled out from the boiler in a very short time, and materials in the steam explosion boiler are brought out by the cold air; feeding the materials after the treatment of steam explosion into a sealed fermentation chamber, wherein in the fermentation chamber the liquid bacterial strains start to ferment, taking out the fermentation product after the fermentation reactions, and packing the fermentation product into bags so as to obtain finished products. The preparation method adopts a combination of a plurality of bacterium species to carry out mixed fermentation reactions so as to produce a water purifier which has the advantage of high bacterium content and has the functions of nitrifying, denitrifying, reducing nitrogen content, eliminating phosphor, and removing organic substances in water. The water purifier can well remove the nutritional substances such as nitrogen, phosphor, and the like, in the water, also can effectively inhibit other harmful bacteria in the water at the same time, and achieves the goals of preventing diseases and improving survival rate.

Owner:江苏乐尔环境科技股份有限公司

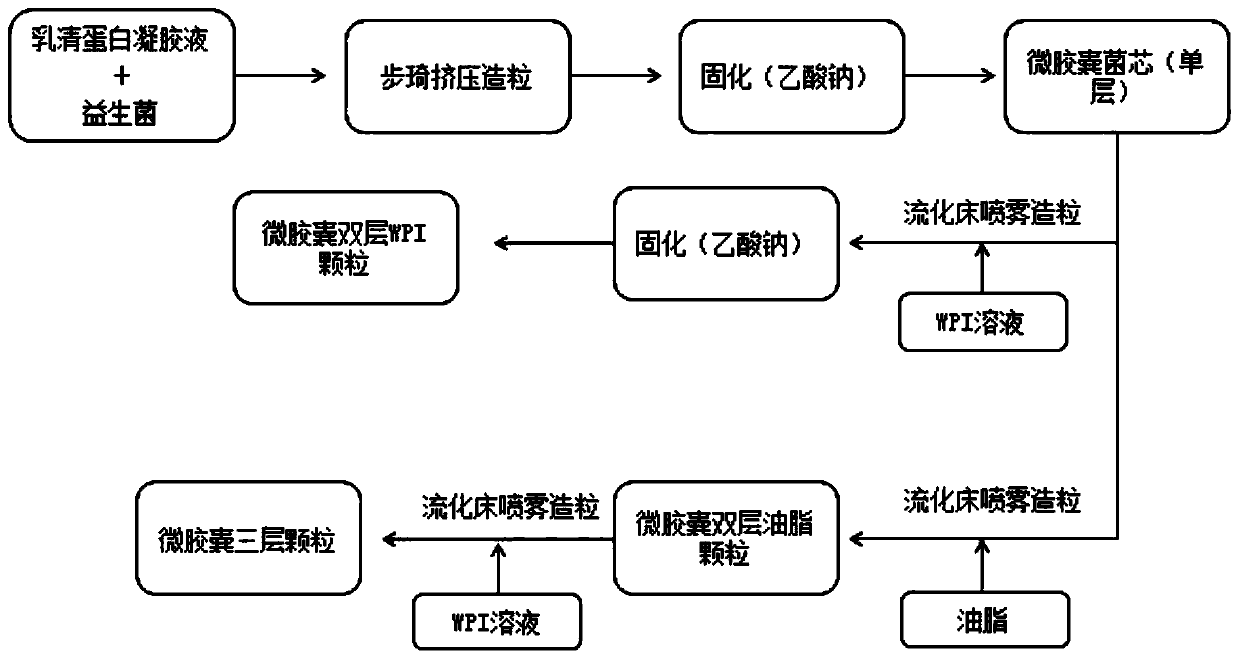

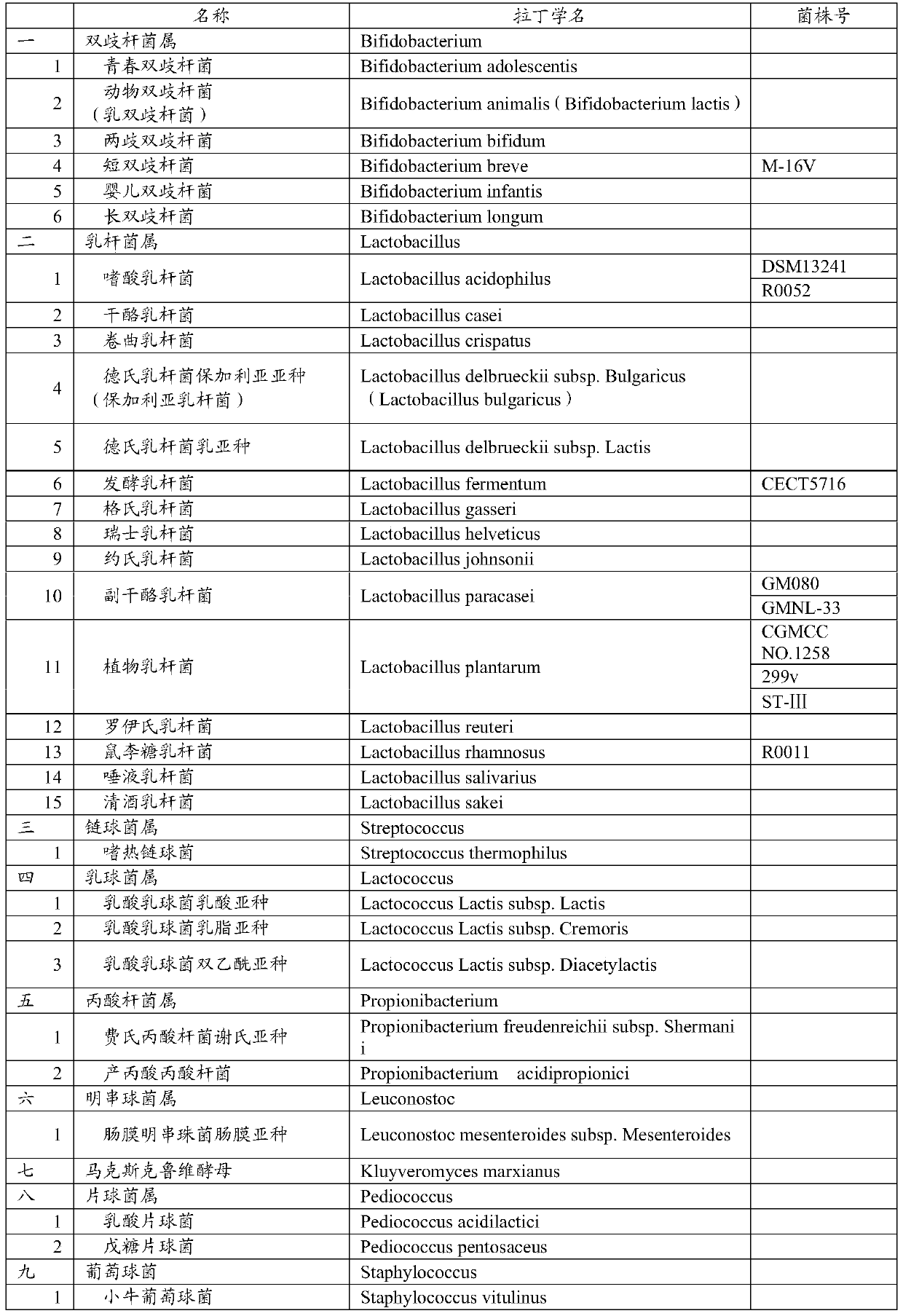

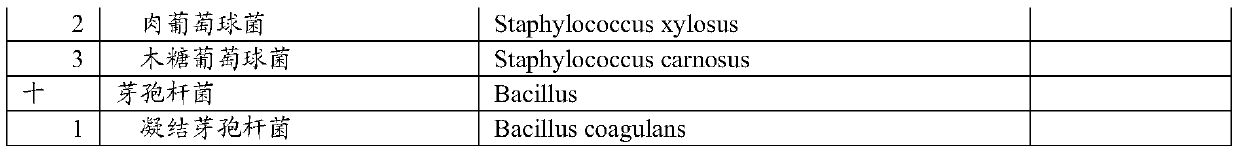

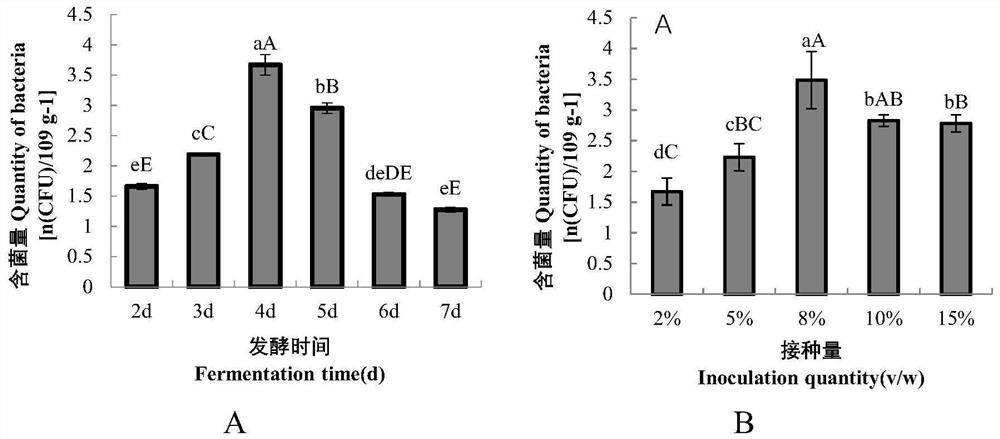

Preparation method ofprobiotic microcapsules by extruding granulation method and product prepared by method

PendingCN111134330ALow costHigh bacterial contentFood ingredient as solidifying agentLipidic food ingredientsSpray GranulationFluidized bed

The invention relates to a preparation method of probiotic microcapsules and the probiotic microcapsules prepared by the method. A method combining extruding granulation with spraying granulation through a fluidized bed is adopted. The preparation method comprises the following steps of: (1) performing coating of first-layer microcapsules; (2) optionally performing coating of second-layer microcapsules; and (3) optionally performing continuous coating for the third time or more times on the microcapsules obtained in the step (2).

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Bio-organic fertilizer containing dead bacillus vallismortis, and preparation method and application thereof

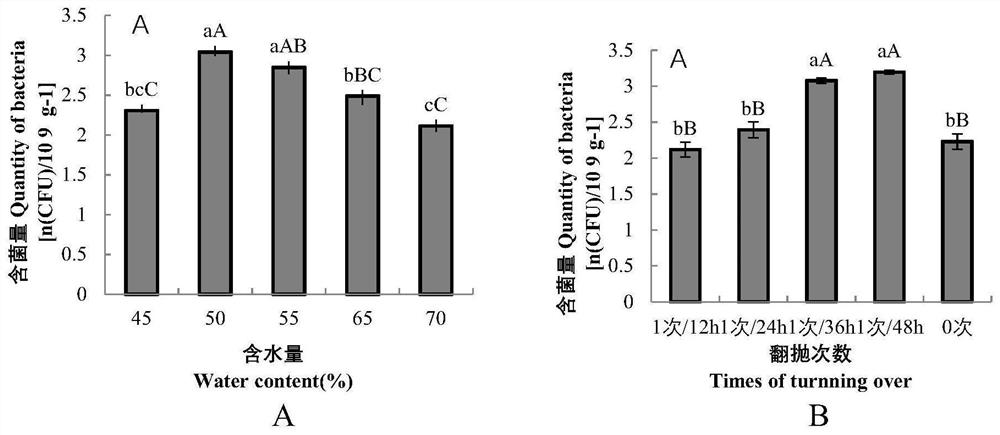

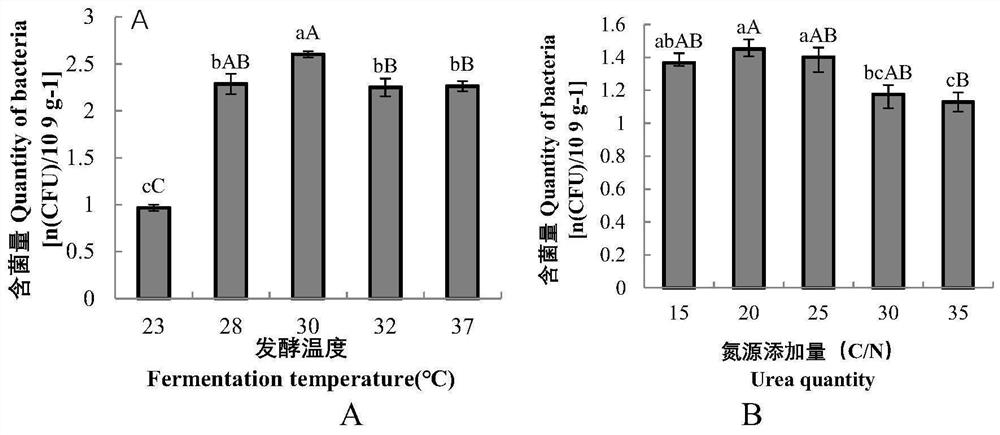

ActiveCN113213984AOptimal culture conditionsHigh bacterial contentBio-organic fraction processingBacteriaBiotechnologyRoot rot

The invention provides a bio-organic fertilizer prepared by combining dead bacillus vallismortis and a straw organic fertilizer through secondary solid fermentation, and a preparation method and application thereof. The content of dead bacillus vallismortis in the bio-organic fertilizer after the secondary solid fermentation is finished is taken as a detection index, the optimal culture condition combination of the bio-organic fertilizer is obtained by screening through a single-factor method and a multi-factor and multi-level orthogonal method, and the fermentation process of the bio-organic fertilizer is optimized. The BIO-4 bio-organic fertilizer, which is researched and developed by taking a corn straw organic fertilizer as a matrix and taking dead bacillus vallismortis SZ-4 as a biocontrol bacterium source, has a good prevention and control effect on root rot caused by fusarium solani, has a promoting effect on crop growth, and is beneficial to increase of crop yield and improvement of quality.

Owner:JILIN AGRICULTURAL UNIV

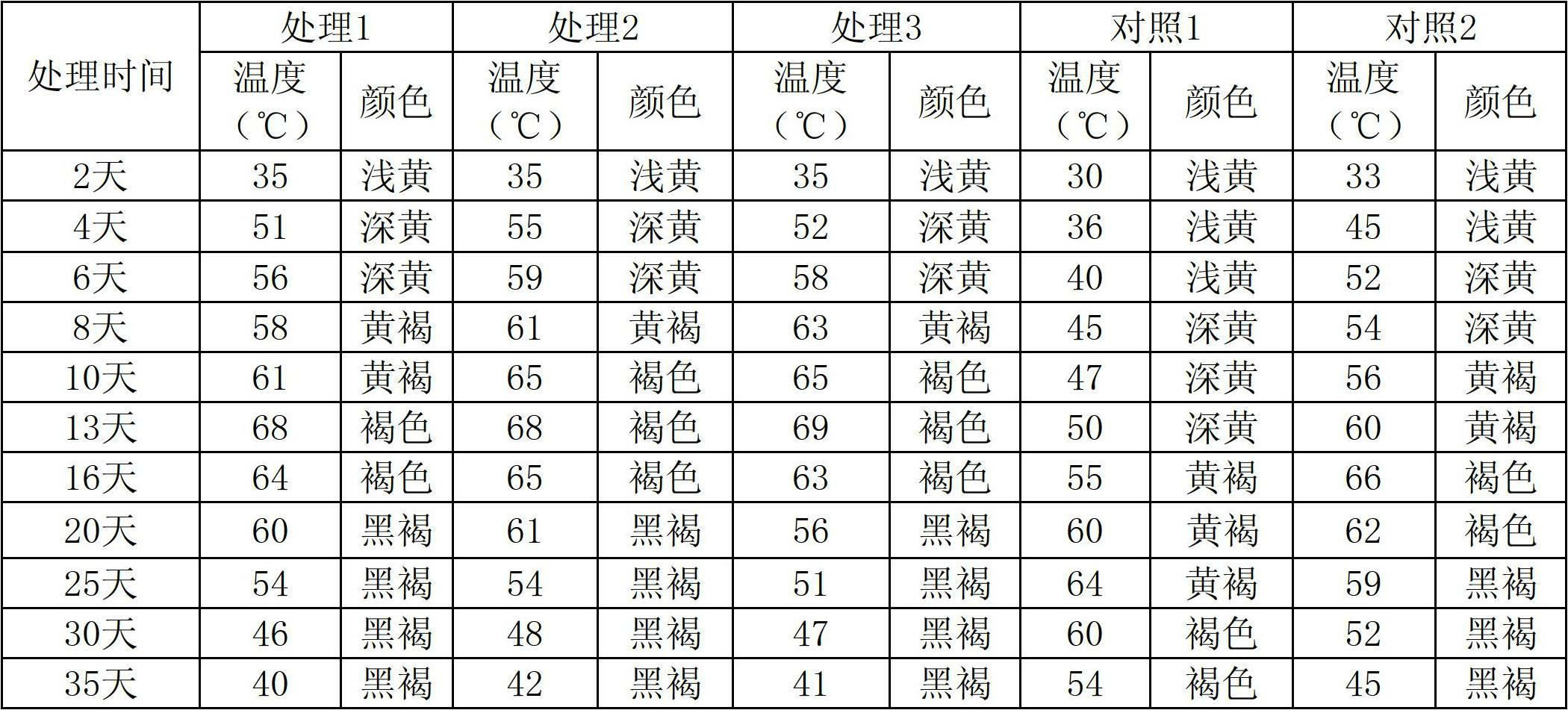

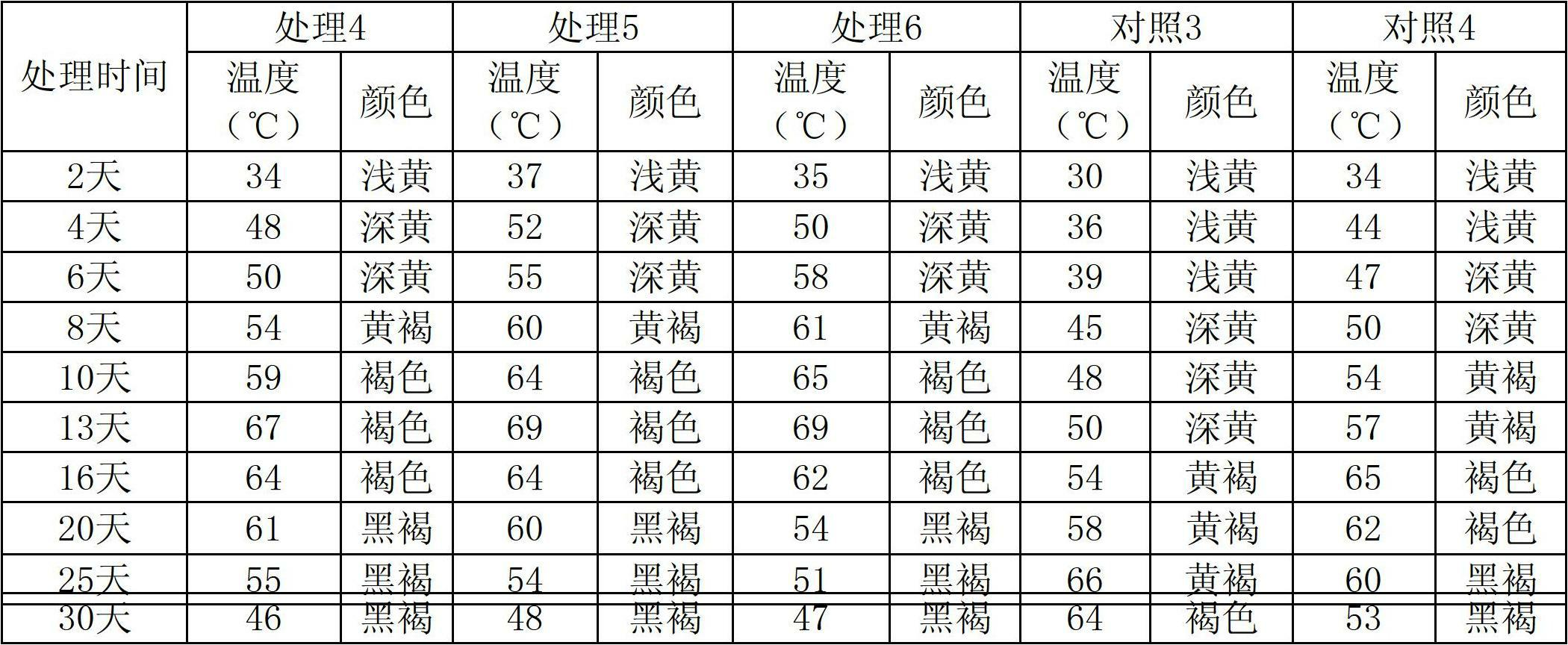

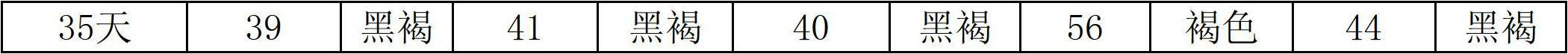

Method for making barbary wolfberry leaf tea by eurotium cristatum fermentation and special strain

The invention discloses a method for making barbary wolfberry leaf tea by eurotium cristatum fermentation. According to the method, screening and optimization of a series of conditions are implementedin fermented tea to obtain eurotium cristatum NCPS2018015 which is high in growth speed and fermenting capability, the strain is collected in a China Center for Type Culture Collection on December 12, 2018, and the collection number of the strain is CCTCC NO: M 2018882. According to the method, barbary wolfberry leaves are fermented by the strain to prepare daily drinking tea by particular process conditions, the appearance of the tea has an intersected color of jade green and golden yellow and is great beautiful, a color of tea soup is yellow brown, the fragrance of the tea is strong, raw green taste is omitted, the tea is little bitter and free from astringency and turns from bitterness to sweetness after being drunk, and the method solves the problems that 'the appearance color of traditional barbary wolfberry leaf tea is dark, the traditional barbary wolfberry leaf tea has raw green taste, the fragrance of tea soup is poor, the taste of the tea is astringent, and the stomach is easily irritated'.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI +1

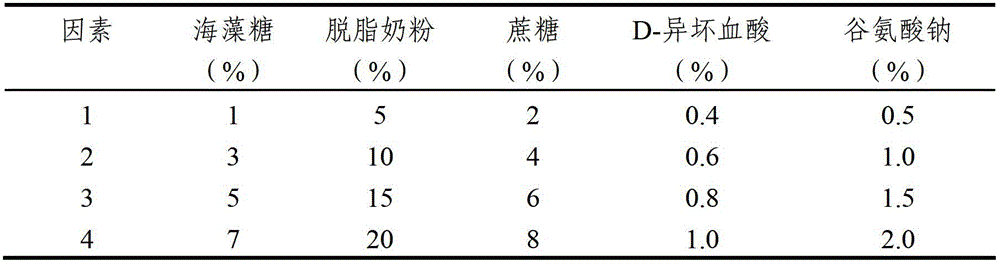

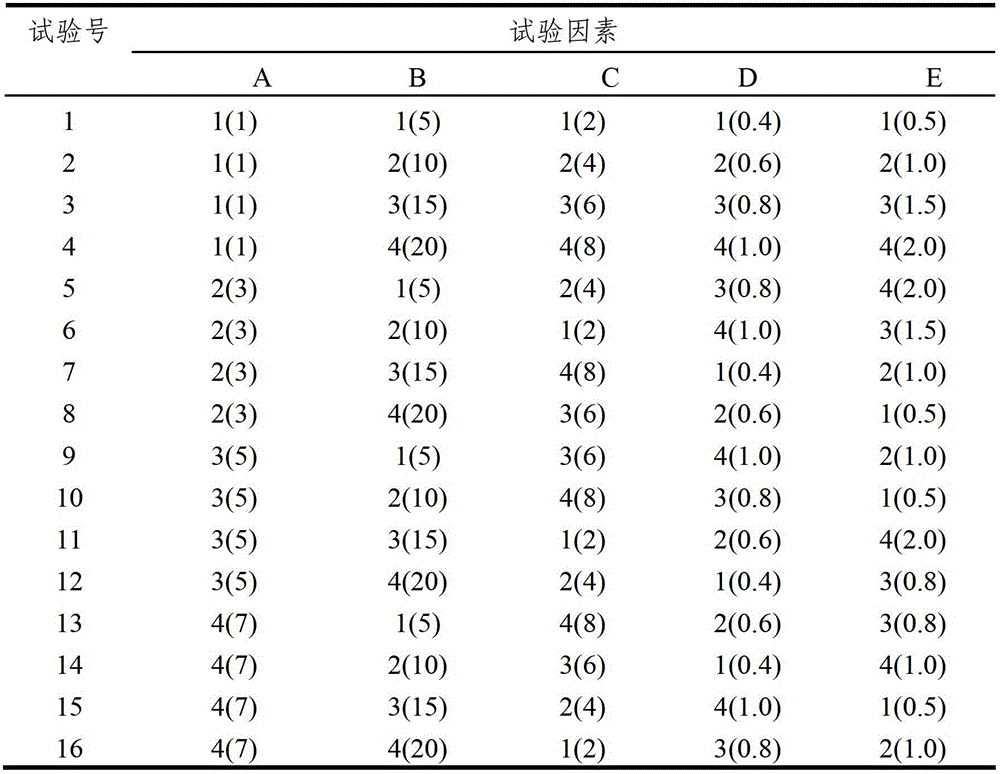

A kind of Lactobacillus acidophilus freeze-drying protective agent

ActiveCN102649945BReduce volumeHigh bacterial contentBacteriaMicroorganism based processesMonosodium glutamateSucrose

The invention discloses lactobacillus acidophilus cryoprotectant, which contains 1.0 to 5.0 percent of trehalose, 5.0 to 20.0 percent of defatted milk powder, 2.0 to 8.0 percent of cane sugar, 0.4 to 1.0 percent of D-isoascorbic acid and 0.5 to 2.0 percent of monosodium glutamate. The lactobacillus acidophilus cryoprotectant has the advantages of small size, high bacteria content, low pollution, convenience in preservation, transportation and use and the like. The viable count of the actobacillus acidophilus dry powder prepared by utilizing the lactobacillus acidophilus cryoprotectant can reach more than 4.0*10<11> CFU / g.

Owner:BEIJING DABEINONG TECH GRP CO LTD +1

Calf serum 'double resistant' culture medium

InactiveCN101012476AAvoid deathHigh bacterial contentMicrobiological testing/measurementPolymyxin BMedical microbiology

The invention discloses a liquid culture medium, which is allocated by calf serum, glucose peptone water, vancocin and polymyxin B to prevent non-target bacterial fertility.

Owner:盐城市疾病预防控制中心

Method for preparing viable bacillus subtilis preparation for feed

The invention discloses a method for preparing a viable bacillus subtilis preparation for feed. The viable bacillus subtilis preparation for the feed is prepared by the following steps of: (1) performing activation culture on bacillus subtilis strains; (2) mutagenizing and screening the activated bacillus subtilis strains; (3) performing propagation culture on the screened bacillus subtilis strains; (4) preparing bacillus subtilis liquid from the bacillus subtilis strains subjected to the propagation culture; (5) mixing the bacillus subtilis liquid and an absorption carrier, wherein the absorption carrier is a mixture of maize alcohol lees and maize cob meal; and (6) pneumatically drying the bacillus subtilis liquid-absorbed carrier to obtain the finished product. By the method, the low-cost and stable-quality viable bacillus subtilis preparation can be prepared.

Owner:辽宁邦成曙光生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com