Mixed cooperative fermentation process of bacillus subtilis

A technology of Bacillus subtilis and fermentation process, which is applied in the field of mixed bacteria synergistic fermentation process of Bacillus subtilis, can solve problems such as instability, poor control effect, and few biological control products and varieties, so as to enhance adaptability, improve inhibition Bacterial effect, enhanced effect of antibacterial potency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

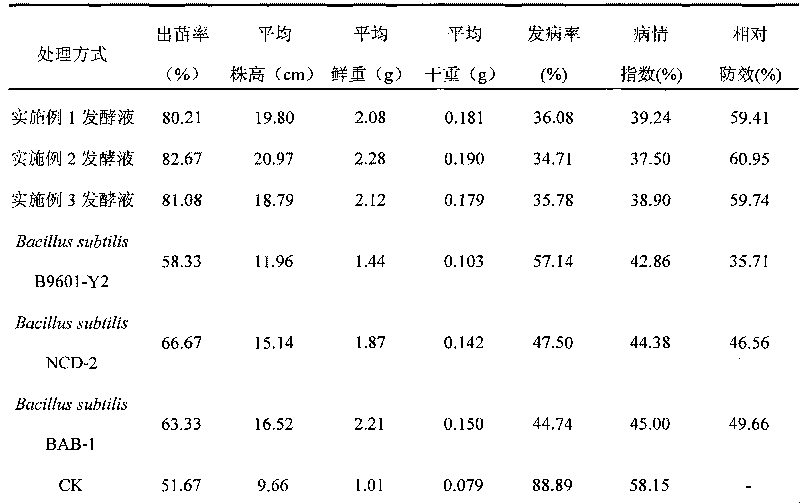

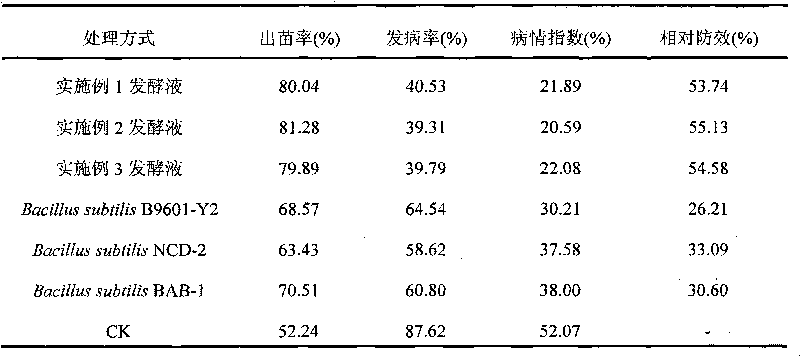

Examples

Embodiment 1

[0025] Step 1. Seed activation

[0026] The three fermentation strains that will be stored in the seed tube: Bacillus subtilis B9601-Y2, Bacillus subtilis NCD-2 and Bacillus subtilis BAB-1 were respectively streaked on the slant of the seed activation medium test tube and cultivated in a 28°C incubator 24h, obtain the inclined-plane bacterial classification for production;

[0027] Seed activation medium: beef extract 3g / L, peptone 5g / L, sodium chloride 5g / L, glucose 10g / L, agar 15g, pH 7.0-7.2, medium sterilization conditions: 0.15MPa steam sterilization for 30min, Sterilization temperature 121°C;

[0028] Step 2, preparation of primary seed solution

[0029] Use the inoculation loop to pick the single colonies of the slant strains of each strain of Bacillus subtilis for production respectively, and inoculate them in three 250ml Erlenmeyer flasks with 50ml primary seed culture medium respectively, at 28~30°C, 180~ Shake culture at 200r / min for 18h to obtain the first-grade...

Embodiment 2

[0041] Steps one, two and three are the same as steps one, two and three in Example 1;

[0042] Step 4. Seed tank cultivation

[0043] Add 20L seed tank culture medium in the 25L stirring type fermentation tank as seed tank, cool to 30 ℃ after the culture medium is sterilized, pH adjustment is 7.0, the secondary seed liquid of each strain Bacillus subtilis single strain, Inoculate into the seed tank respectively, the inoculation ratio is Bacillus subtilis B9601-Y2: Bacillus subtilis NCD-2: Bacillus subtilis BAB-1 equals 2: 1: 3, and the total inoculum amount is 8% (v / v) of the medium of the seed tank ; The control conditions for the mixed bacteria fermentation in the seed tank are 30°C, the ventilation rate is 10L / min, the tank pressure is 80kPa, the stirring speed is 200r / min, the aerobic mixed bacteria fermentation culture is cultivated for 20 hours, and the third-grade seed liquid is obtained;

[0044] Seed tank medium is: bean cake powder 10g / L, beef extract 5g / L, yeast e...

Embodiment 3

[0049] Steps one, two and three are the same as steps one, two and three in Example 1;

[0050] Step 4. Seed tank cultivation

[0051] Add 20L seed tank culture medium in the 25L stirring type fermentation tank as seed tank, cool to 30 ℃ after the culture medium is sterilized, pH adjustment is 8.0, the secondary seed liquid of each strain Bacillus subtilis single strain, Inoculate into the seed tank respectively, the inoculation ratio is Bacillus subtilis B9601-Y2: Bacillus subtilis NCD-2: Bacillus subtilis BAB-1 is equal to 3: 1: 4, and the total inoculum amount is 10% (v / v) of the medium of the seed tank ;The control conditions of the mixed bacteria fermentation in the seed tank are 30°C, the ventilation rate is 8L / min, the tank pressure is 80kPa, the stirring speed is 200r / min, the aerobic mixed bacteria fermentation culture is cultivated for 18 hours, and the third-grade seed liquid is obtained;

[0052] Seed tank culture medium: bean cake powder 10g / L, beef extract 4g / L,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com