Water quality purification bacterium agent from mix fermentation production with multiple bacterials and production method thereof

A technology of water purification and mixed fermentation, applied in biochemical equipment and methods, methods based on microorganisms, chemical instruments and methods, etc., can solve the problem of increased breeding costs for disease prevention and treatment, poor purification effects, and deterioration of breeding water bodies and other issues to achieve the effect of improving survival rate, accelerating degradation and preventing diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

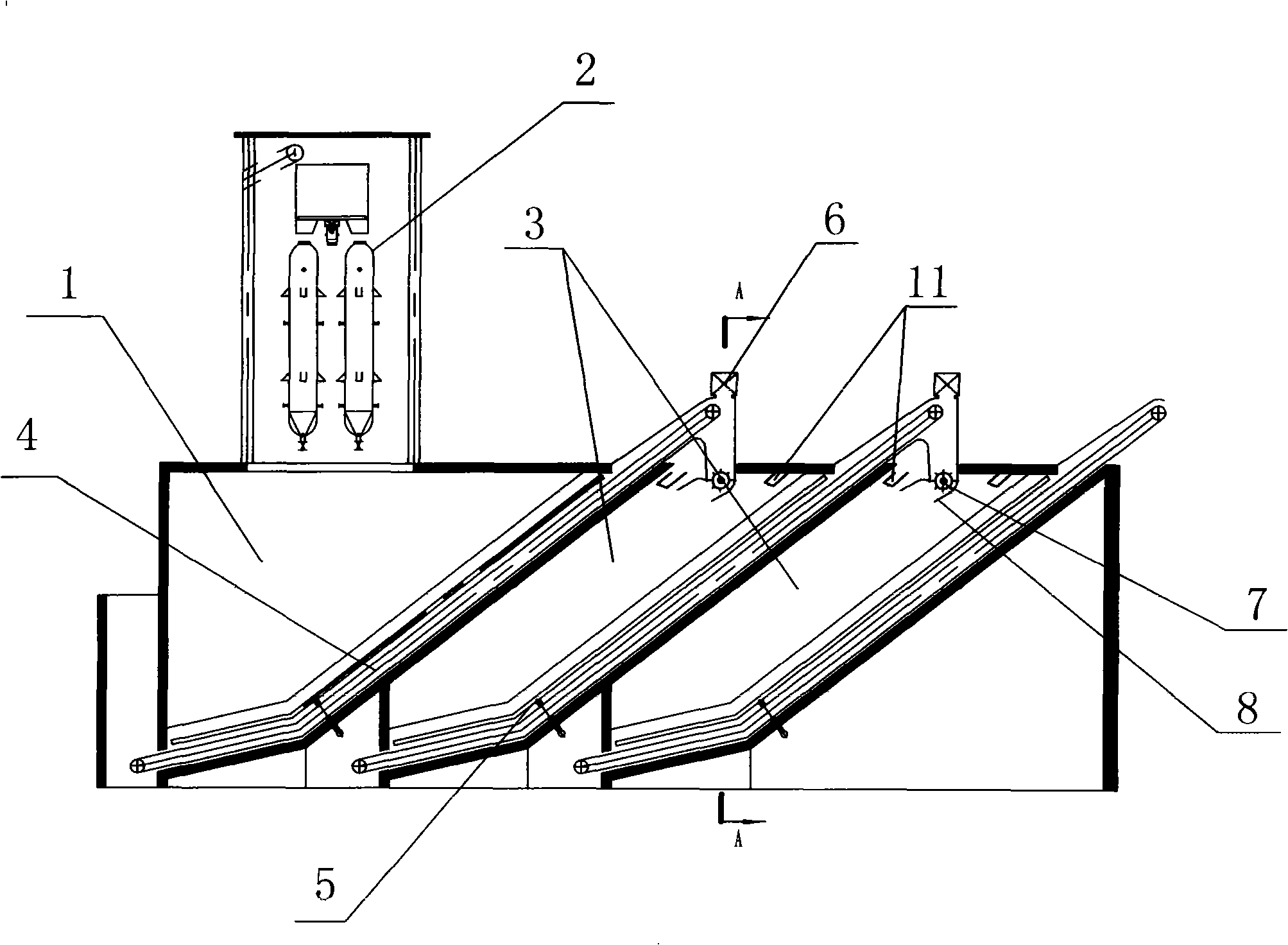

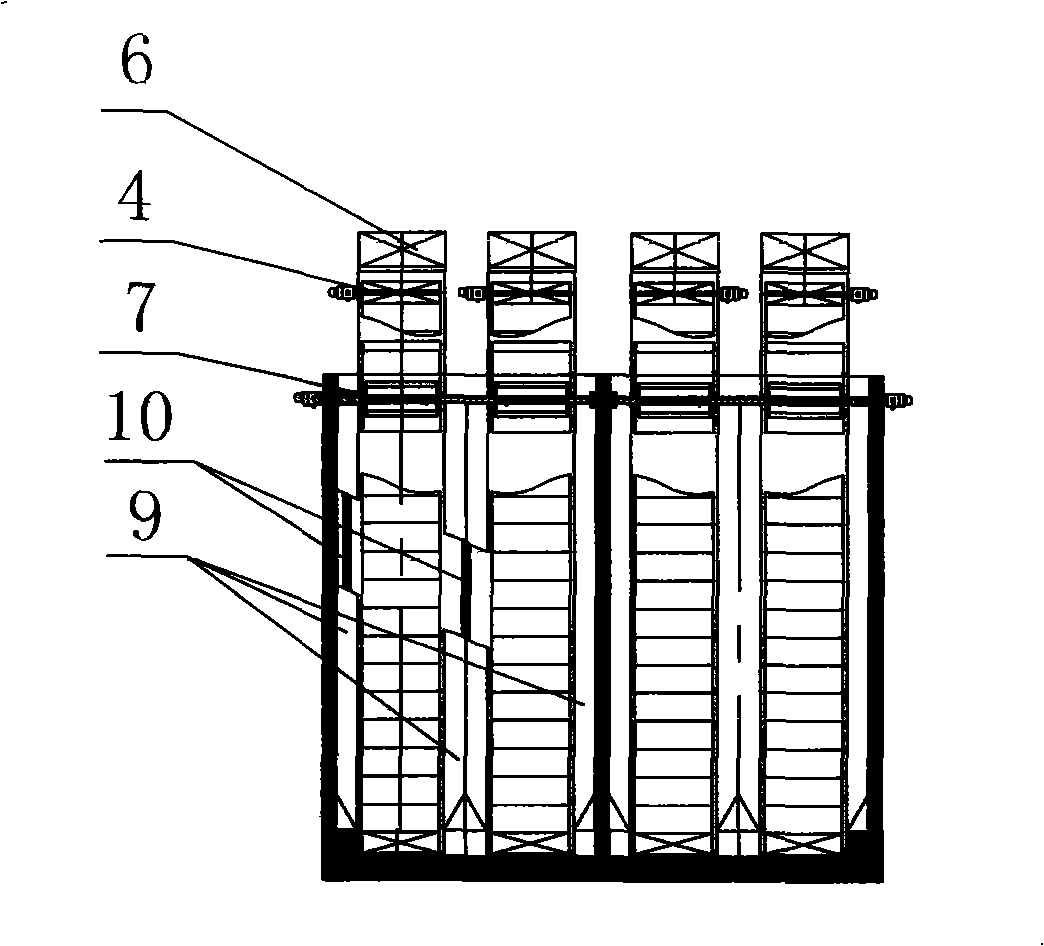

Image

Examples

Embodiment Construction

[0028] The water purification bacterial agent produced by the mixed fermentation of multi-strain uses straw as raw material, inserts multi-strain seed liquid, straw fermentation medium and concentrated nitrifying bacteria liquid to prepare water purification bacterial agent, straw, multi-strain seed liquid , the parts by weight and the addition ratio of straw fermentation medium and concentrated nitrifying bacteria liquid are: 60-65% of straw, 5% of multi-bacteria seed liquid, 30-40% of straw fermentation medium, and the adding ratio of concentrated nitrifying bacteria liquid is 2-3% of the total weight of straw, multi-strain seed solution and straw fermentation medium.

[0029] The multi-species seed solution is composed of Bacillus cereus, Bacillus subtilis, Pseudomonas fluorescens, Bacillus licheniformis, actinomycetes, Candida utilis, white rot fungus, Trichoderma listeri, photosynthetic bacteria and The original strains of Lactobacillus plantarum are mixed and then insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com