Patents

Literature

1268 results about "Steam explosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A steam explosion is an explosion caused by violent boiling or flashing of water into steam, occurring when water is either superheated, rapidly heated by fine hot debris produced within it, or heated by the interaction of molten metals (as in a fuel–coolant interaction, or FCI, of molten nuclear-reactor fuel rods with water in a nuclear reactor core following a core-meltdown). Pressure vessels, such as pressurized water (nuclear) reactors, that operate above atmospheric pressure can also provide the conditions for a steam explosion. The water changes from a liquid to a gas with extreme speed, increasing dramatically in volume. A steam explosion sprays steam and boiling-hot water and the hot medium that heated it in all directions (if not otherwise confined, e.g. by the walls of a container), creating a danger of scalding and burning.

Method for processing lignocellulosic material

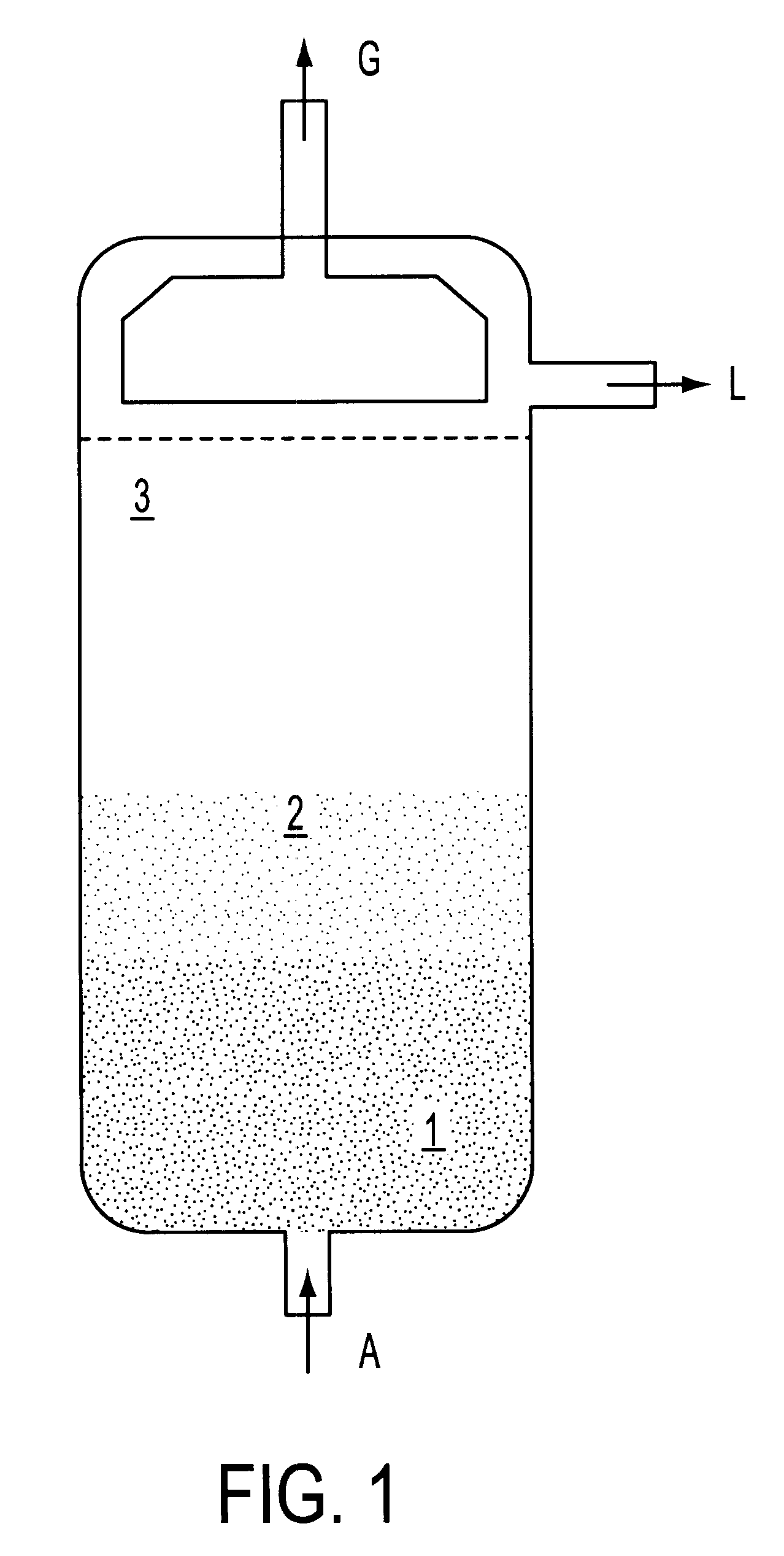

InactiveUS6555350B2High degreeReduce water consumptionSludge treatment by oxidationBiofuelsCelluloseWater flow

A method wherein lignocellulosic biomass materials are converted into combustible fuel products. In particular, the method is a continuous process, involving wet oxidation or steam explosion, for fermentatively converting such biomass materials into ethanol using a process design that permits all or part of the process water from the ethanol fermentation process to be recycled to reduce the consumption of process water. The effluent from the ethanol fermentation step may be subjected to an anaerobic fermentation step generating methane and a water effluent in which the amount of potentially inhibitory substances is at a sub-inhibitory level, which in turn permits all or part of the effluent water from the anaerobic fermentation step to be recycled into the process.

Owner:POET RES INC

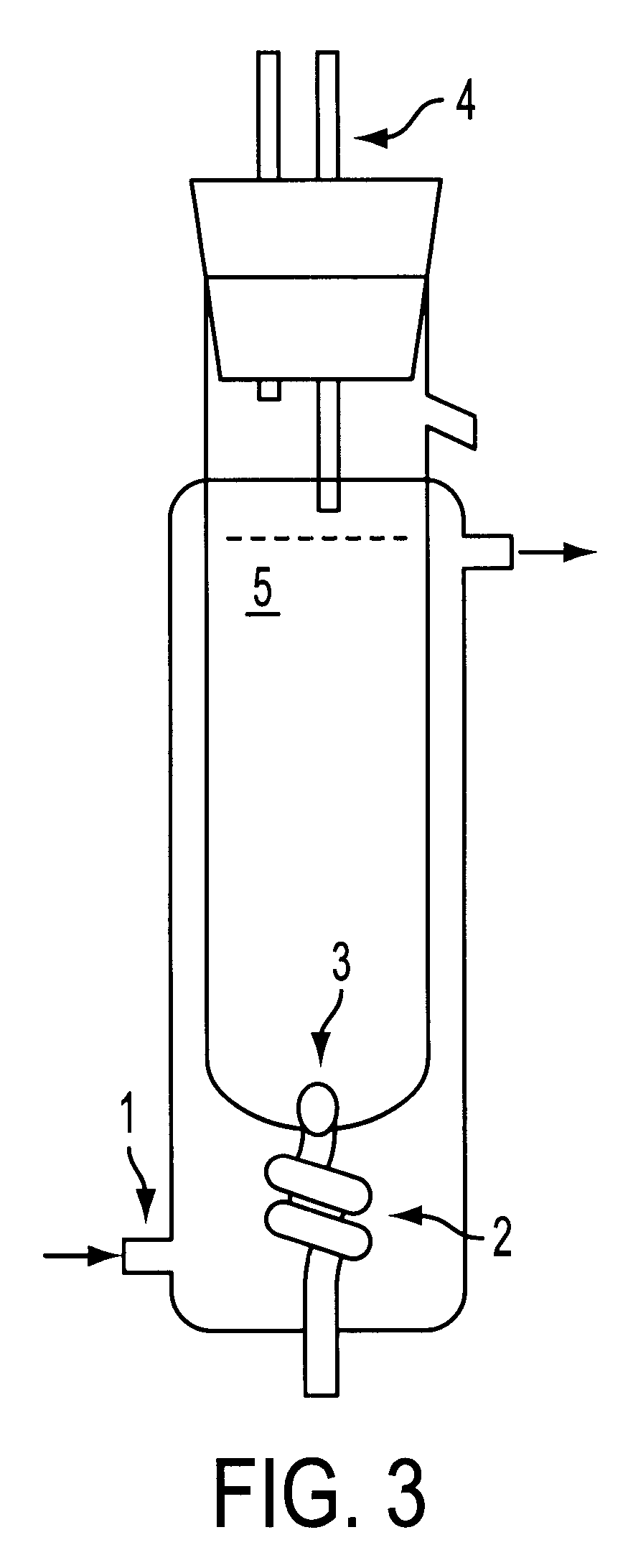

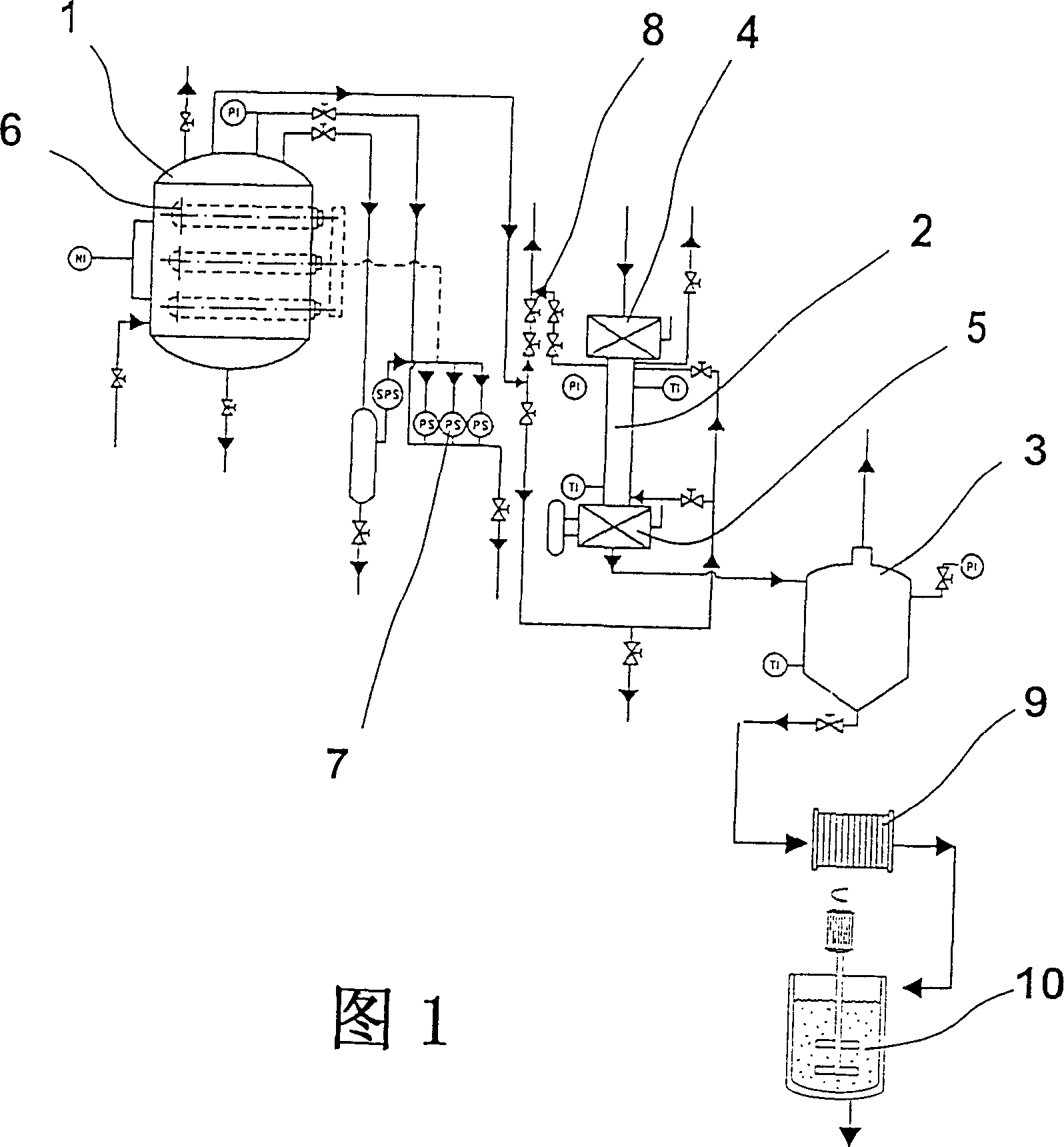

Procedure for the production of ethanol from lignocellulosic biomass using a new heat-tolerant yeast

InactiveUS20050069998A1Low conversion rateReduce yieldFungiBiological substance pretreatmentsFiltrationSolid fraction

It includes the stages of grinding the lignocellulosic biomass to a size of 15-30 mm, subjecting the product obtained to steam explosion pre-treatment at a temperature of 190-230° C. for between 1 and 10 minutes in a reactor (2), collecting the pre-treated material in a cyclone (3) and separating the liquid and solid fractions by filtration in a filter press (9), introducing the solid fraction in a fermentation deposit (10), adding a cellulase at a concentration of 15 UFP per gram of cellulose and 12.6 International Units of β-glucosidase enzyme dissolved in citrate buffer pH 4.8, inoculating the fermentation deposit (10) with a culture of the heat-tolerant bacteria Kluyveromyces marxianus CECT 10875, obtained by chemical mutagenesis from strain DER-26 of Kluyveromyces marxianus and shaking the mixture for 72 hours at 42° C.

Owner:CENT DE INVESTIGACIONES ENERGETICAS MEDIO AMBIENTALLES Y TECNOLOGICAS (C I E M A T)

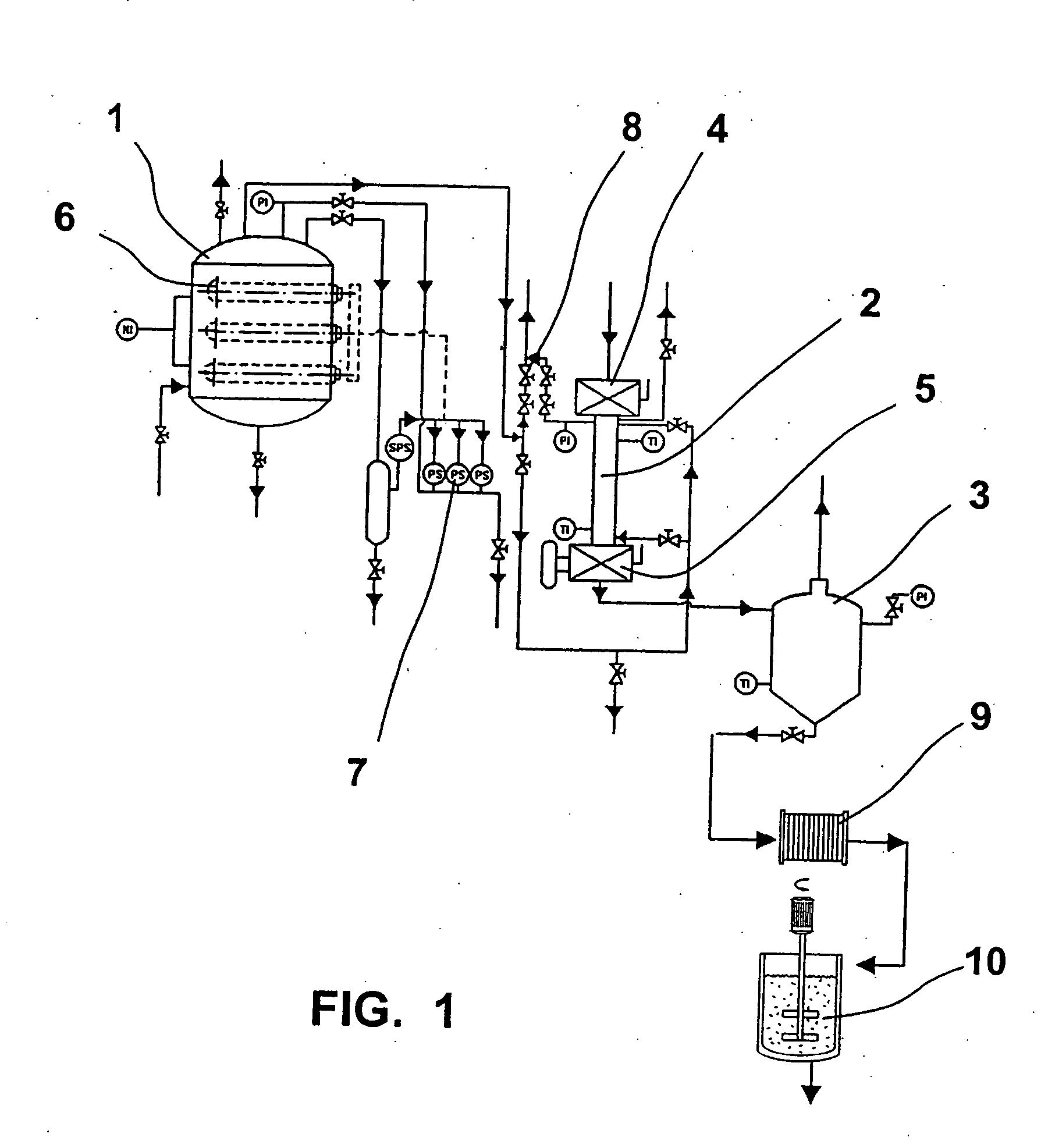

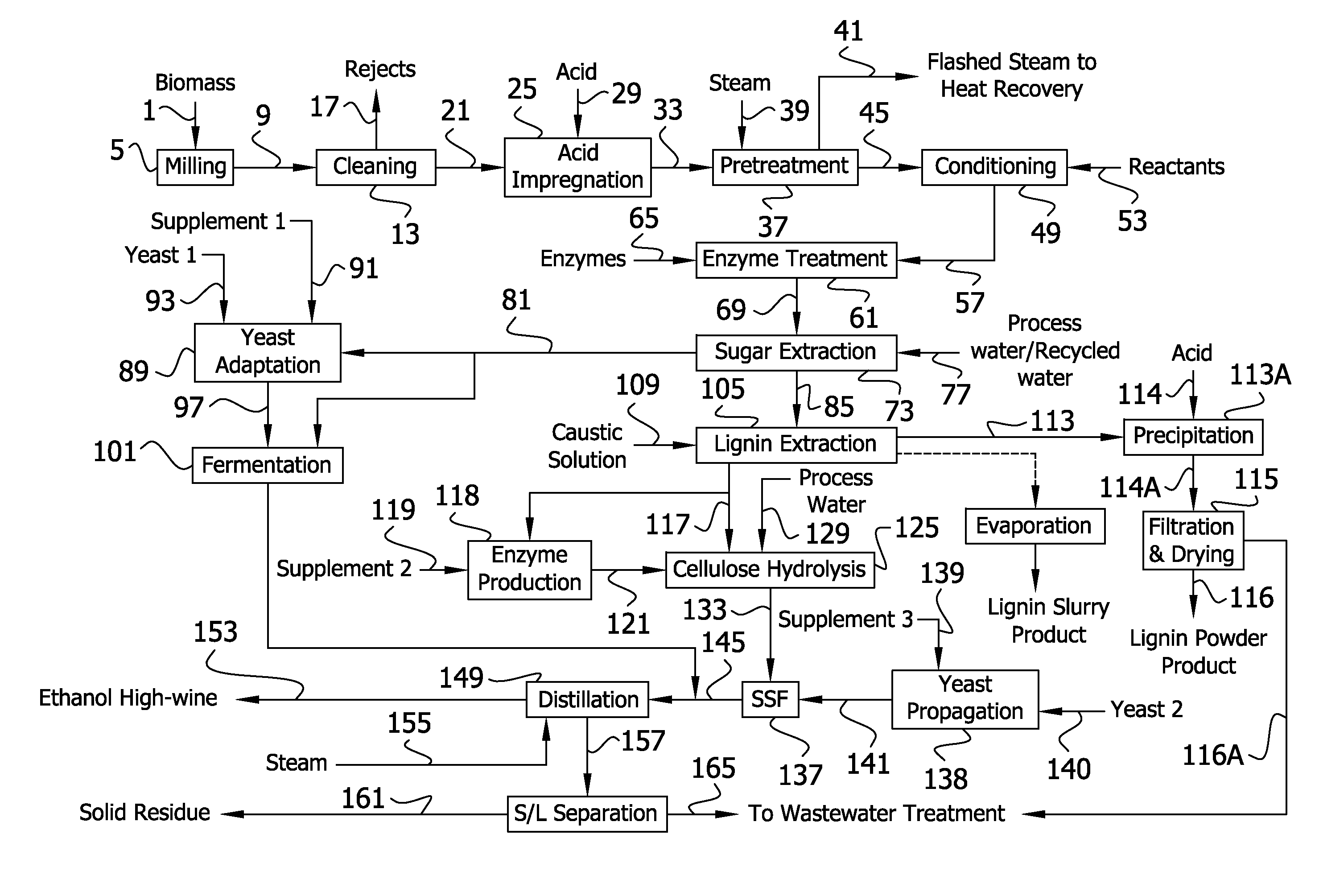

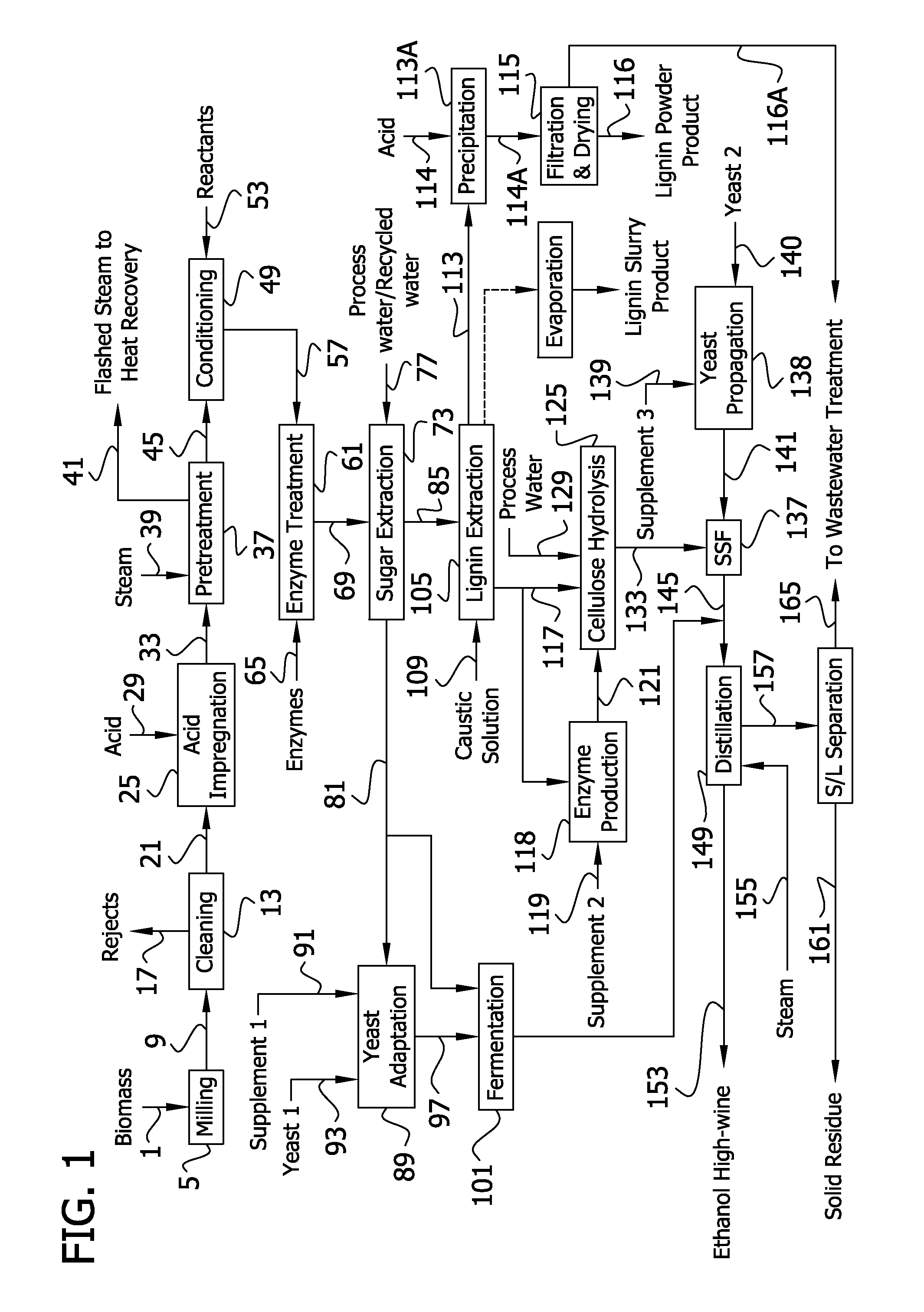

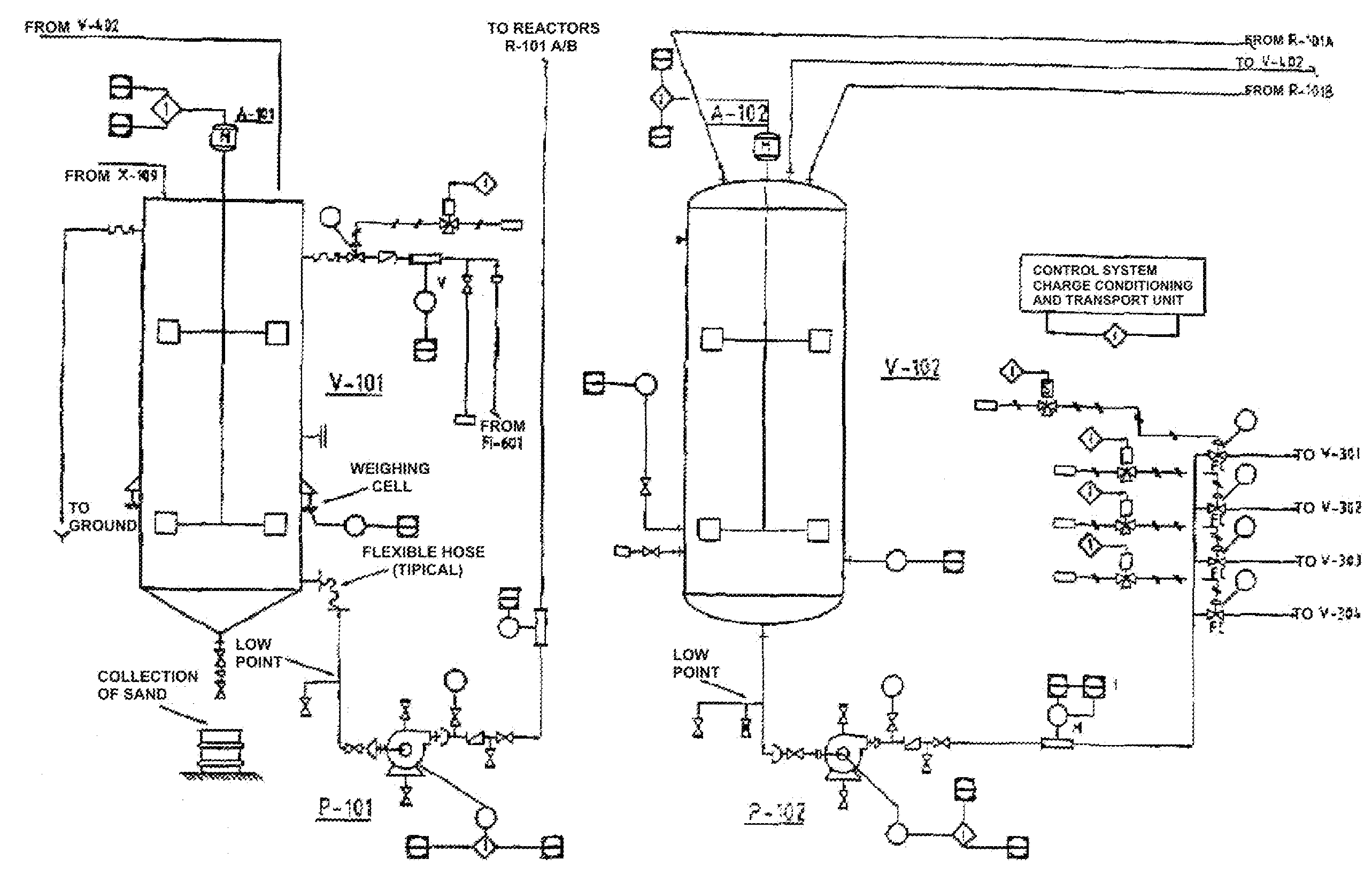

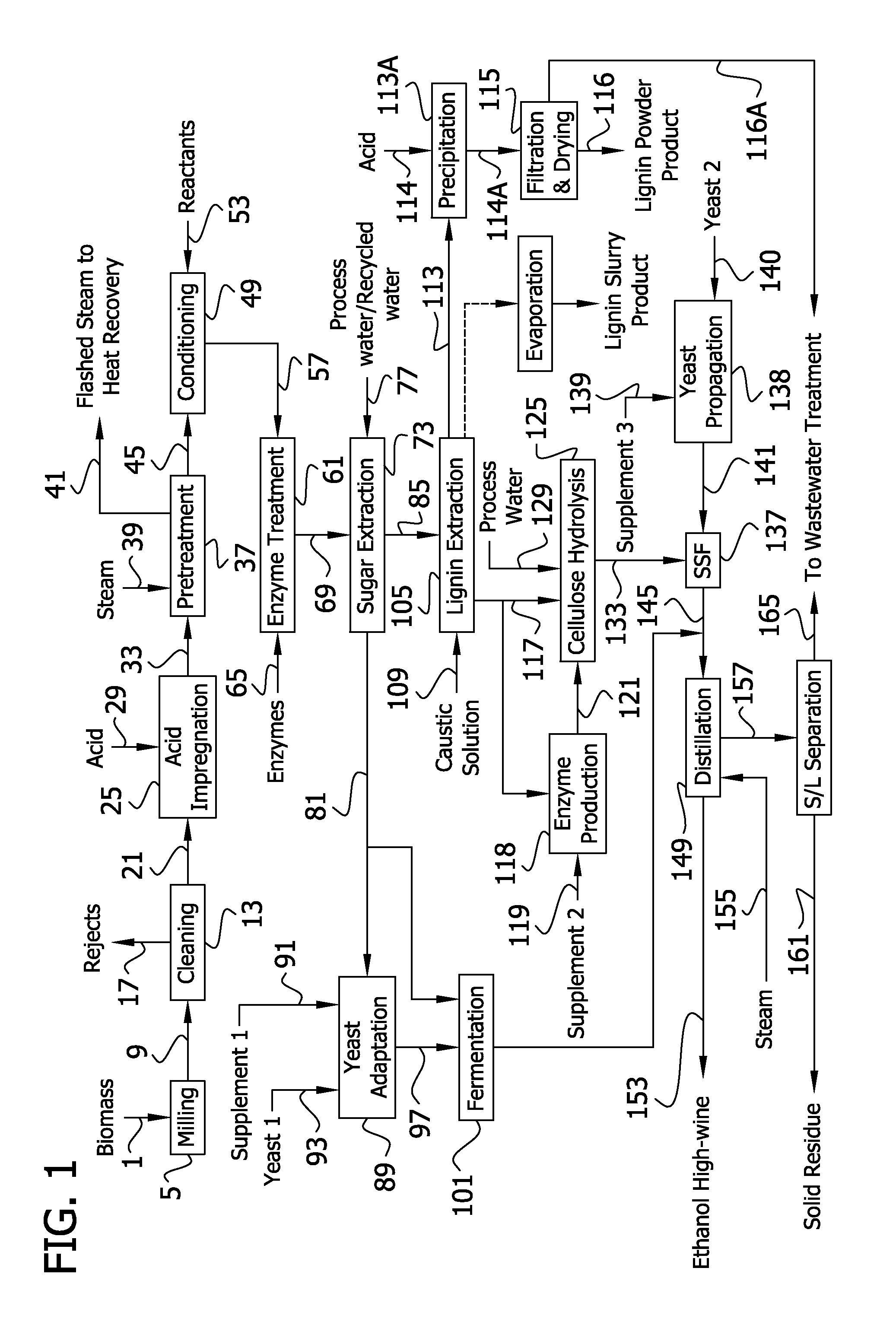

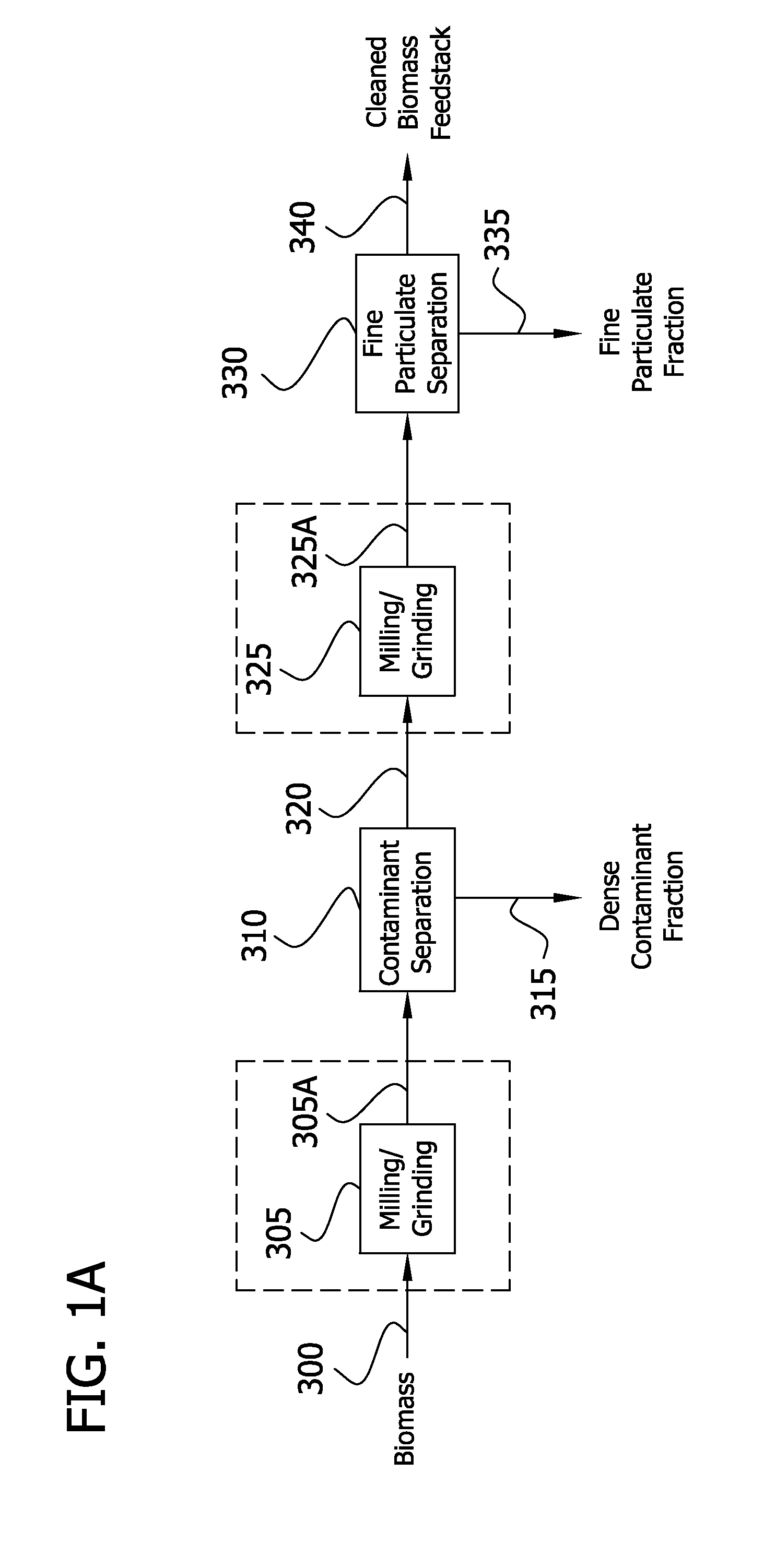

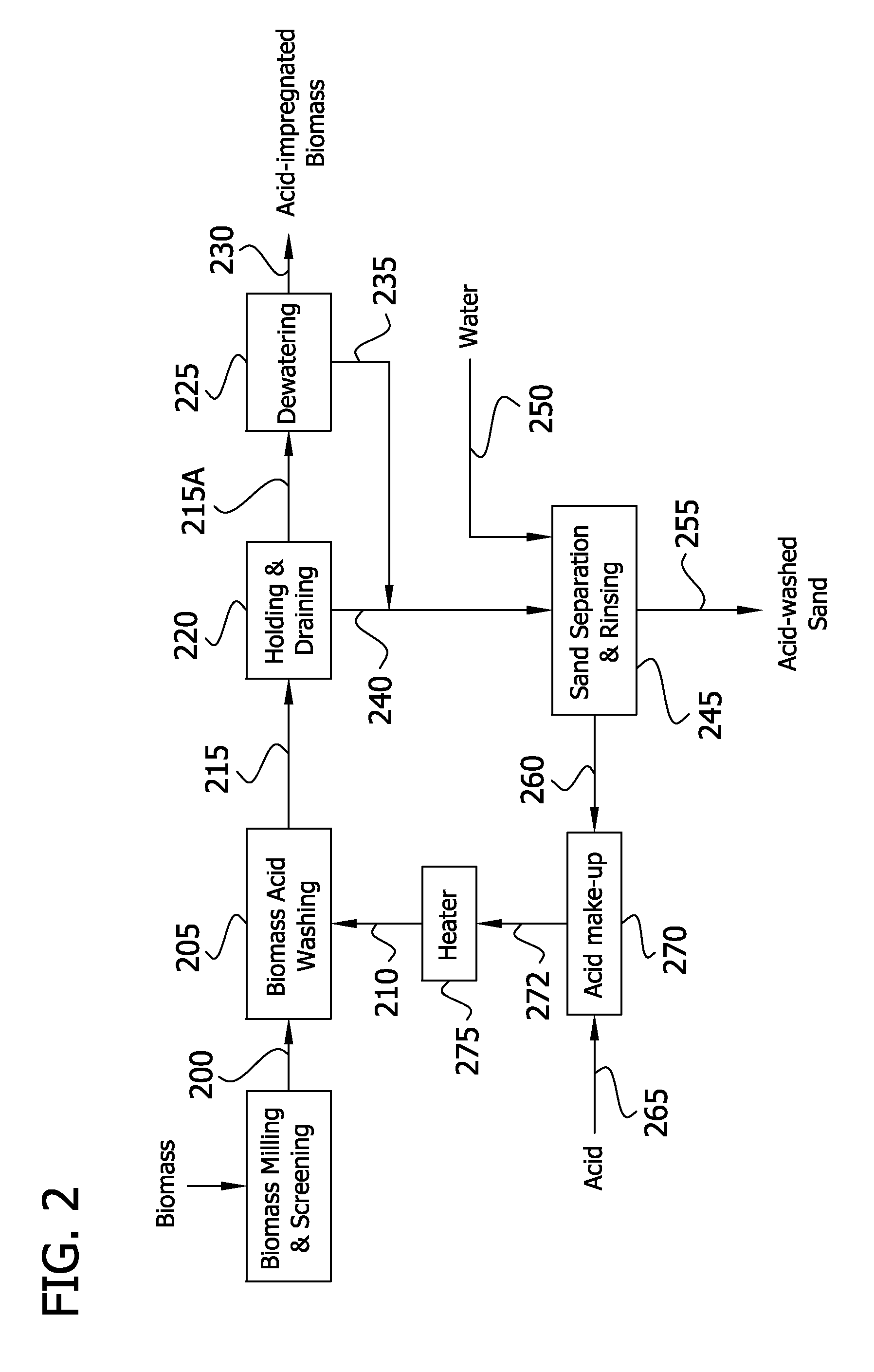

Method for producing ethanol and co-products from cellulosic biomass

InactiveUS20120006320A1Increased ethanol productionImproved co-productsFuel supply regulationPretreatment with acid reacting compoundsCelluloseLignocellulosic biomass

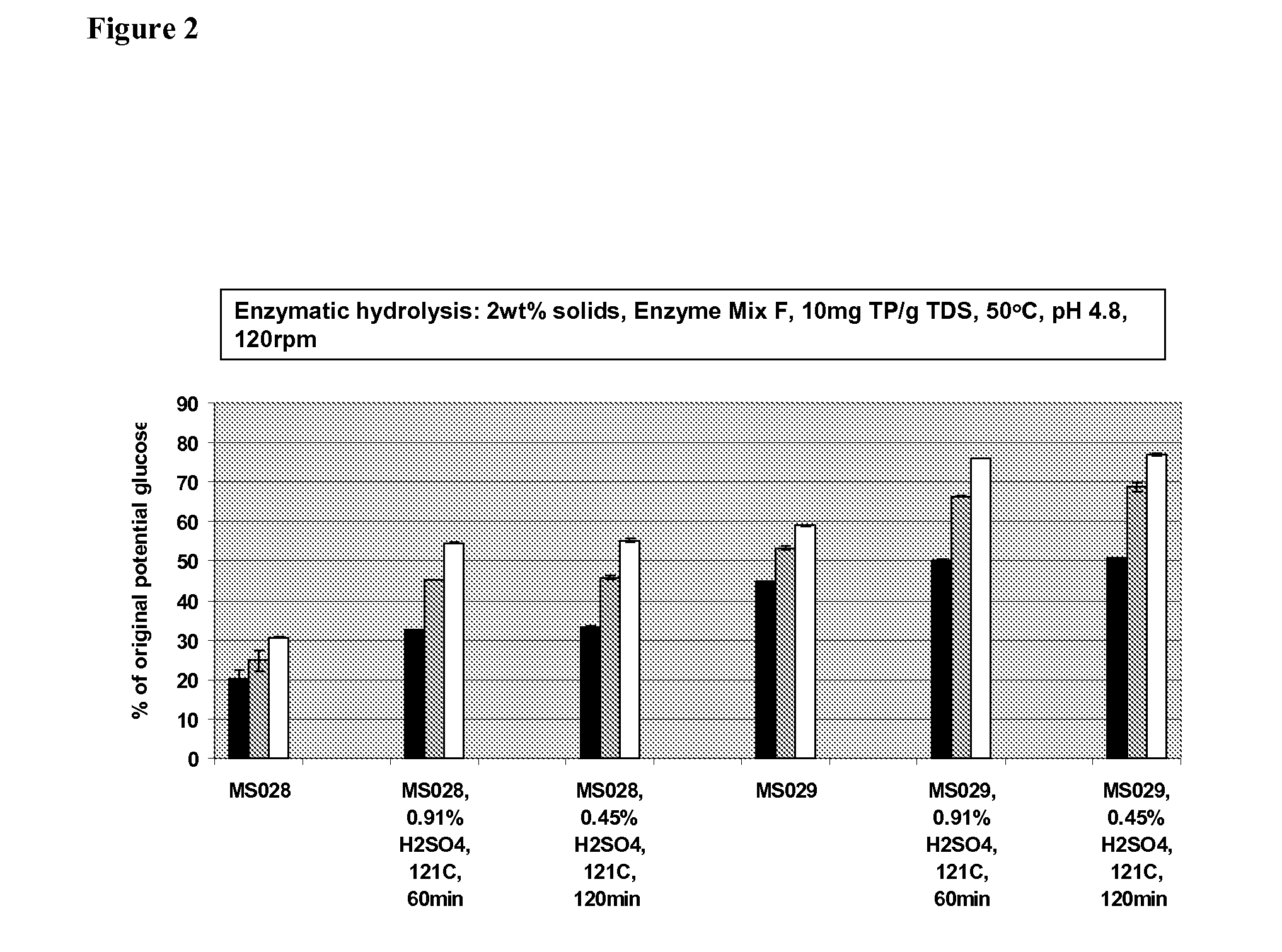

The present invention generally relates to processes for production of ethanol from cellulosic biomass. The present invention also relates to production of various co-products of preparation of ethanol from cellulosic biomass. The present invention further relates to improvements in one or more aspects of preparation of ethanol from cellulosic biomass including, for example, improved methods for cleaning biomass feedstocks, improved acid impregnation, and improved steam treatment, or “steam explosion.”

Owner:ABENGOA BIOENERGY NEW TECH

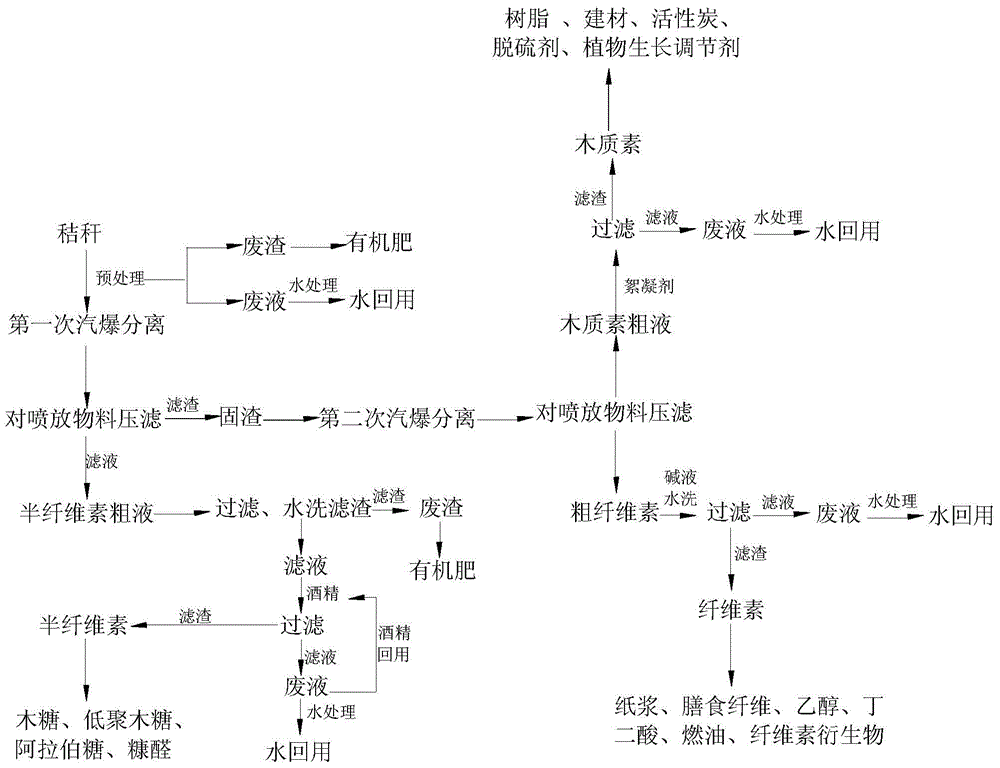

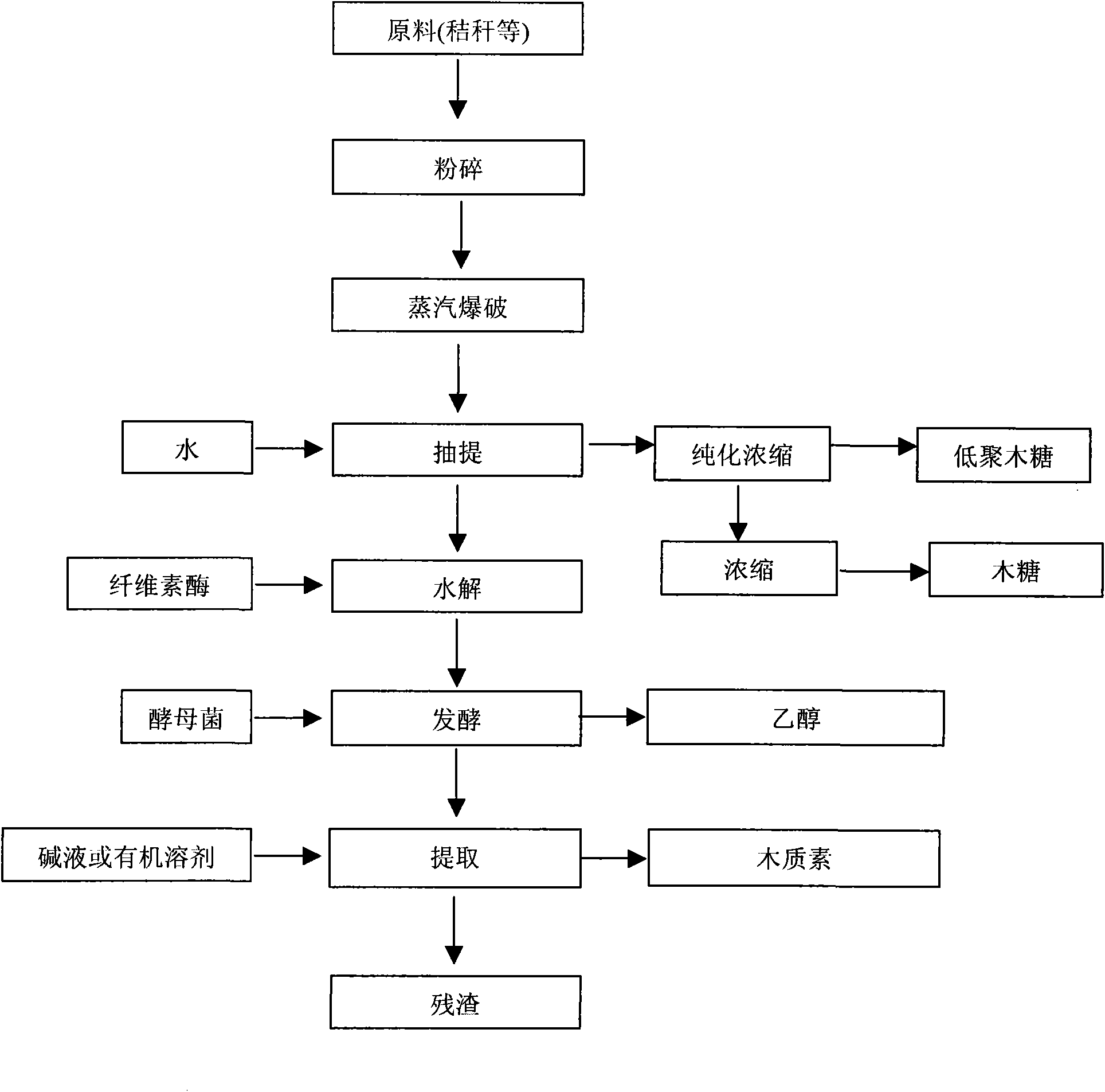

Straw component separation and straw component full utilization method

ActiveCN104404803AAchieve separationEasy to separateRaw material divisionSeparation technologyWastewater

The invention discloses a straw component separation and straw component full utilization method, and relates to the technical field of straw comprehensive utilization. According to the method, straws are subjected to a steam explosion treatment, such that hemicellulose is first separated; and the rest of the material after hemicellulose extraction is subjected to steam explosion treatment again, such that the separation of cellulose and lignin is realized. The method has the advantages of simple process, environment-friendliness, low cost, and thorough separation of hemicellulose, cellulose and lignin. With the method provided by the invention, an environment-friendly separation technology of cellulose and lignin is realized for the first time internationally, and a basis is provided for full-element, high-added-value and comprehensive utilization of straws. On the basis, products with higher added values can be derived or generated. With the production process provided by the invention, all wastewater is treated and is completely recycled, and all waste residue is used for producing organic fertilizers, such that straws are thoroughly utilized, and straw component full utilization is realized. Also, zero emission and zero pollution are realized, such that the difficulty of straw comprehensive utilization is solved.

Owner:JINAN MIDUOTAN NEW ENERGY TECH

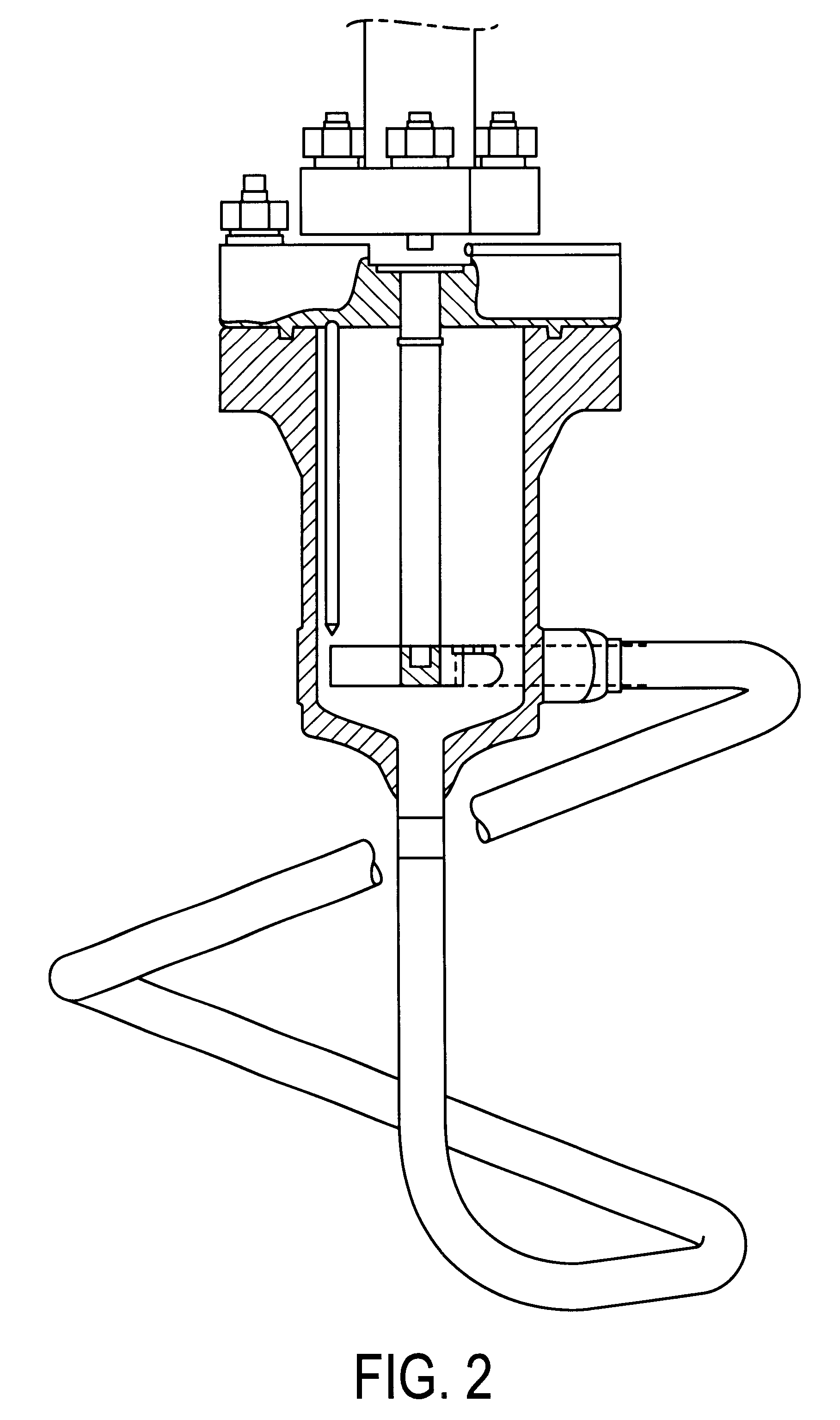

High pressure compressor and steam explosion pulping method

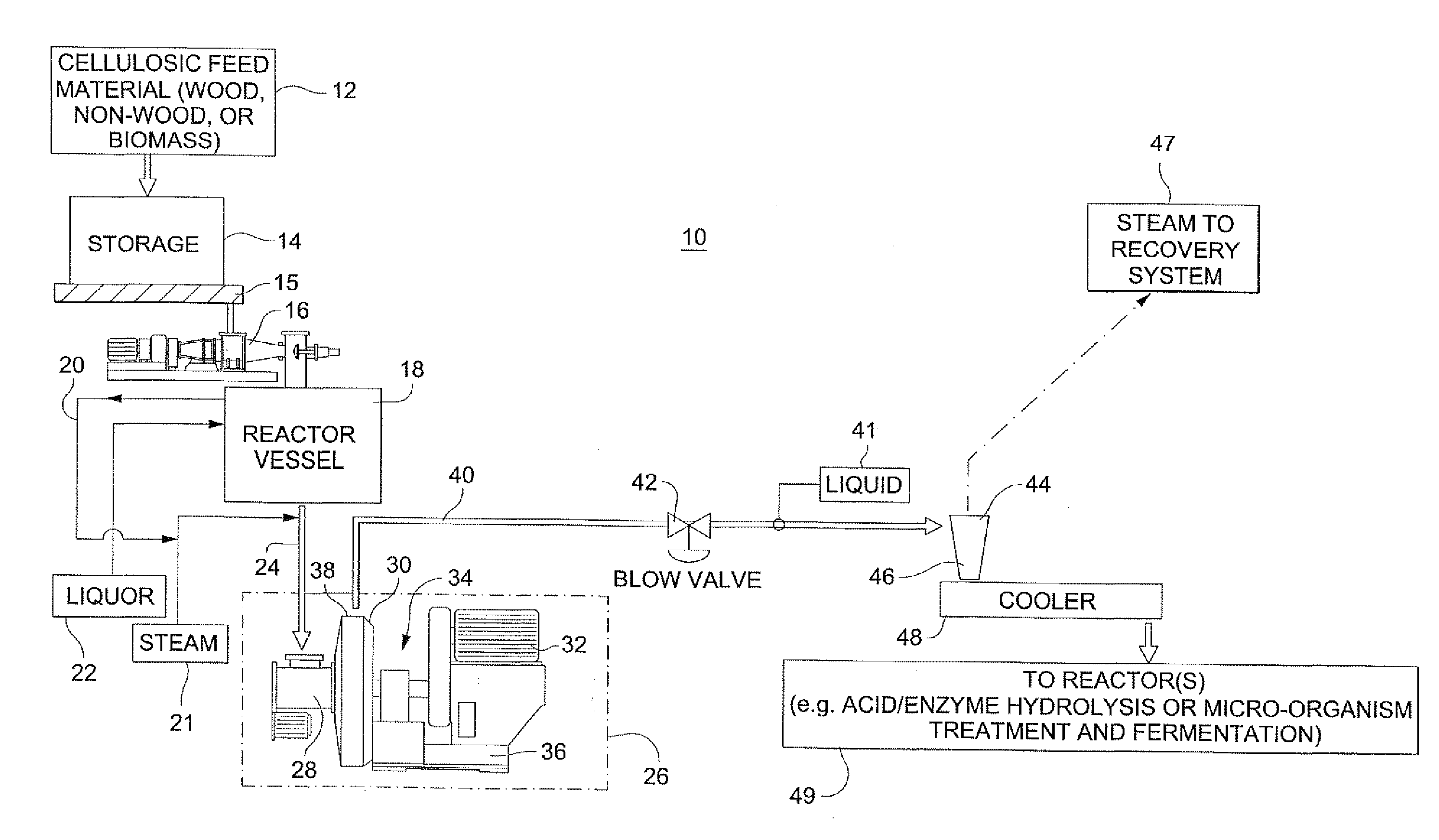

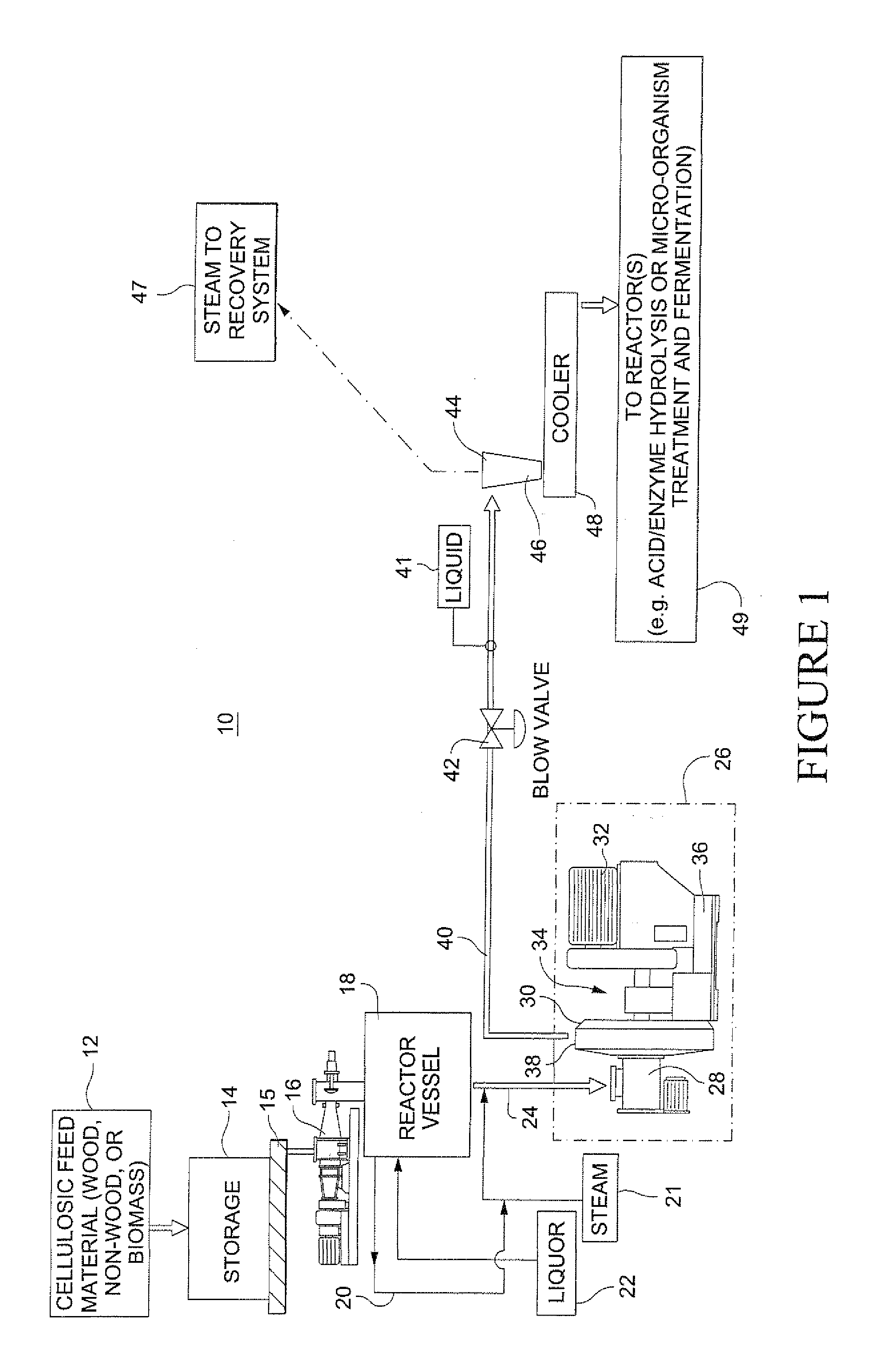

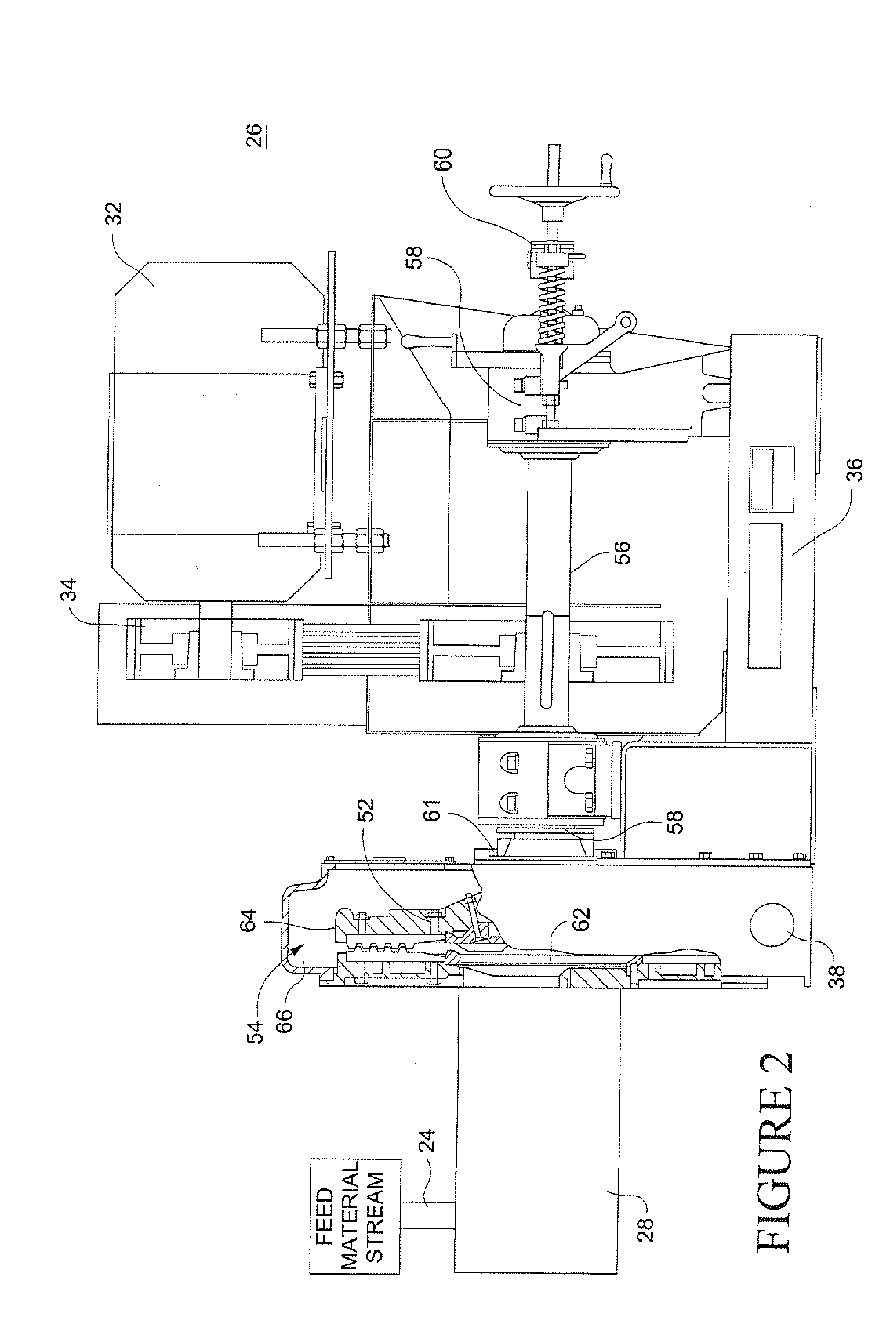

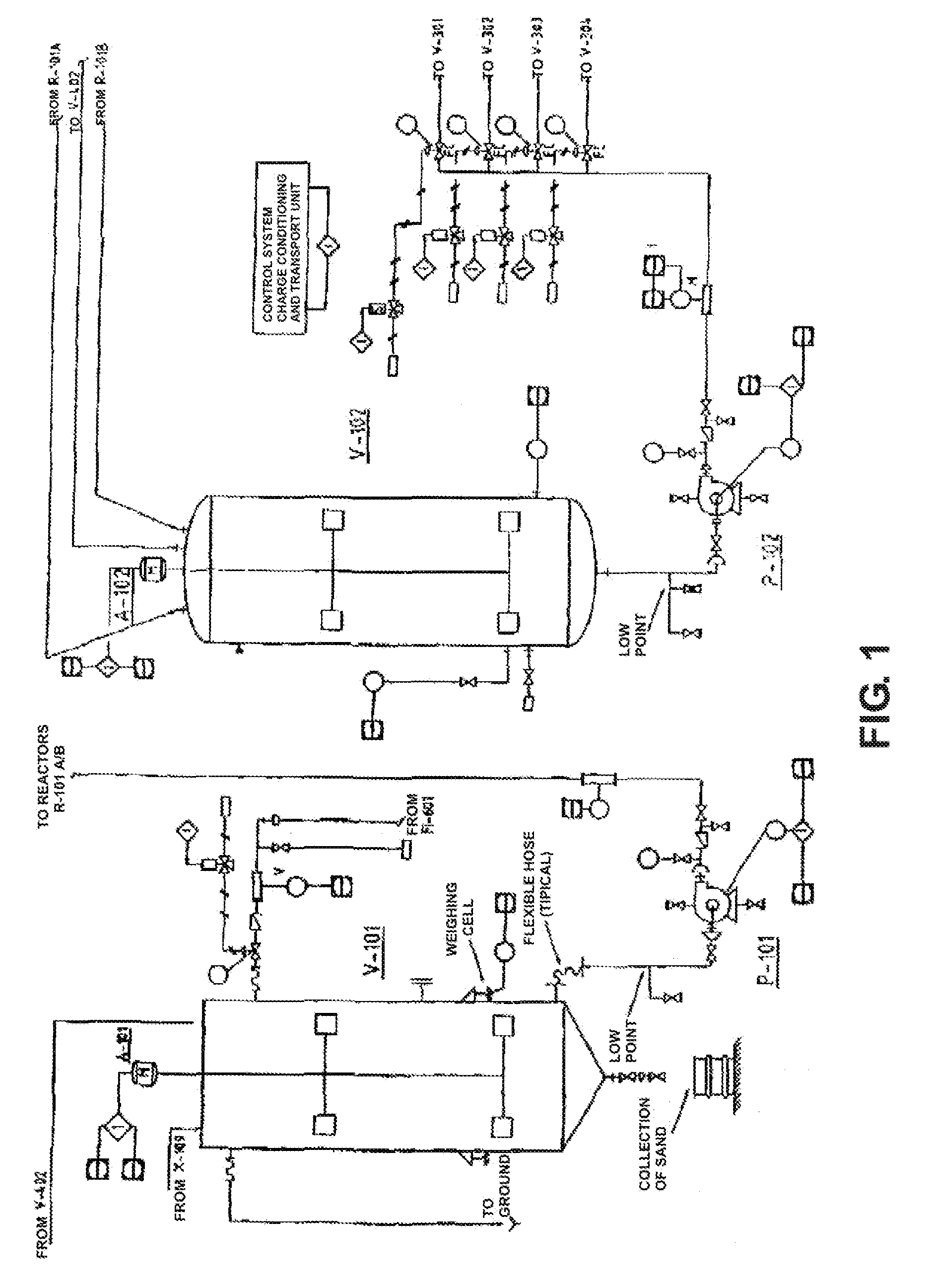

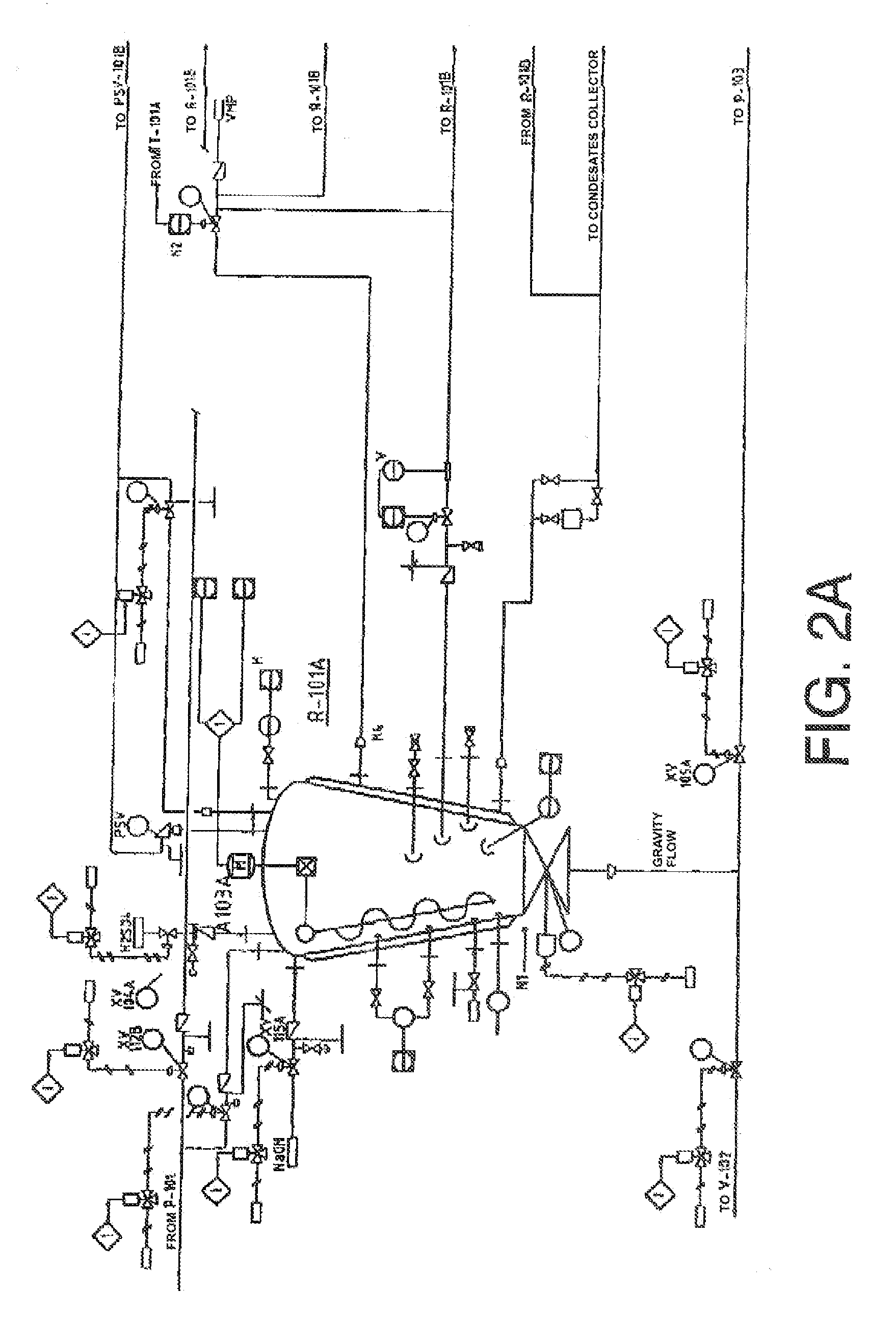

InactiveUS20080277082A1Reduce pressureRapid pressurePretreatment with water/steamPulp beating/refining methodsProcess engineeringHigh pressure

A steam explosion pulping method including: impregnating a cellulosic biomass feed material in a pressurized reactor vessel; discharging the impregnated feed material from the vessel to a high pressure compressor; elevating a pressure of the feed material in the compressor; discharging the pressurized feed material from the compressor to a conduit coupled to a blow valve; rapidly reducing pressure of the pressurized feed material as the feed material passes through the blow valve, and pulping the feed material by expansion of fluid in the feed material during the rapid pressure reduction.

Owner:ANDRITZ INC

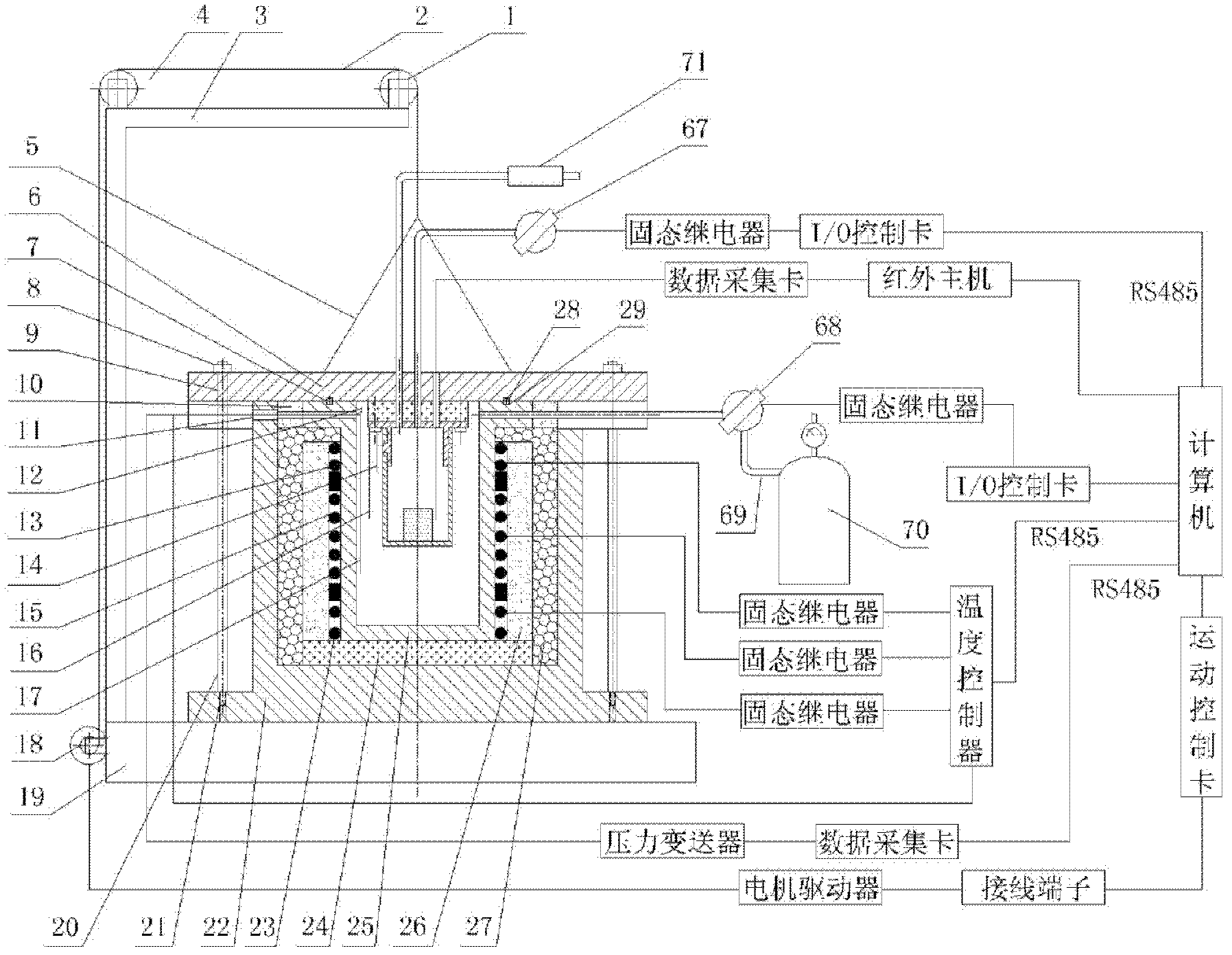

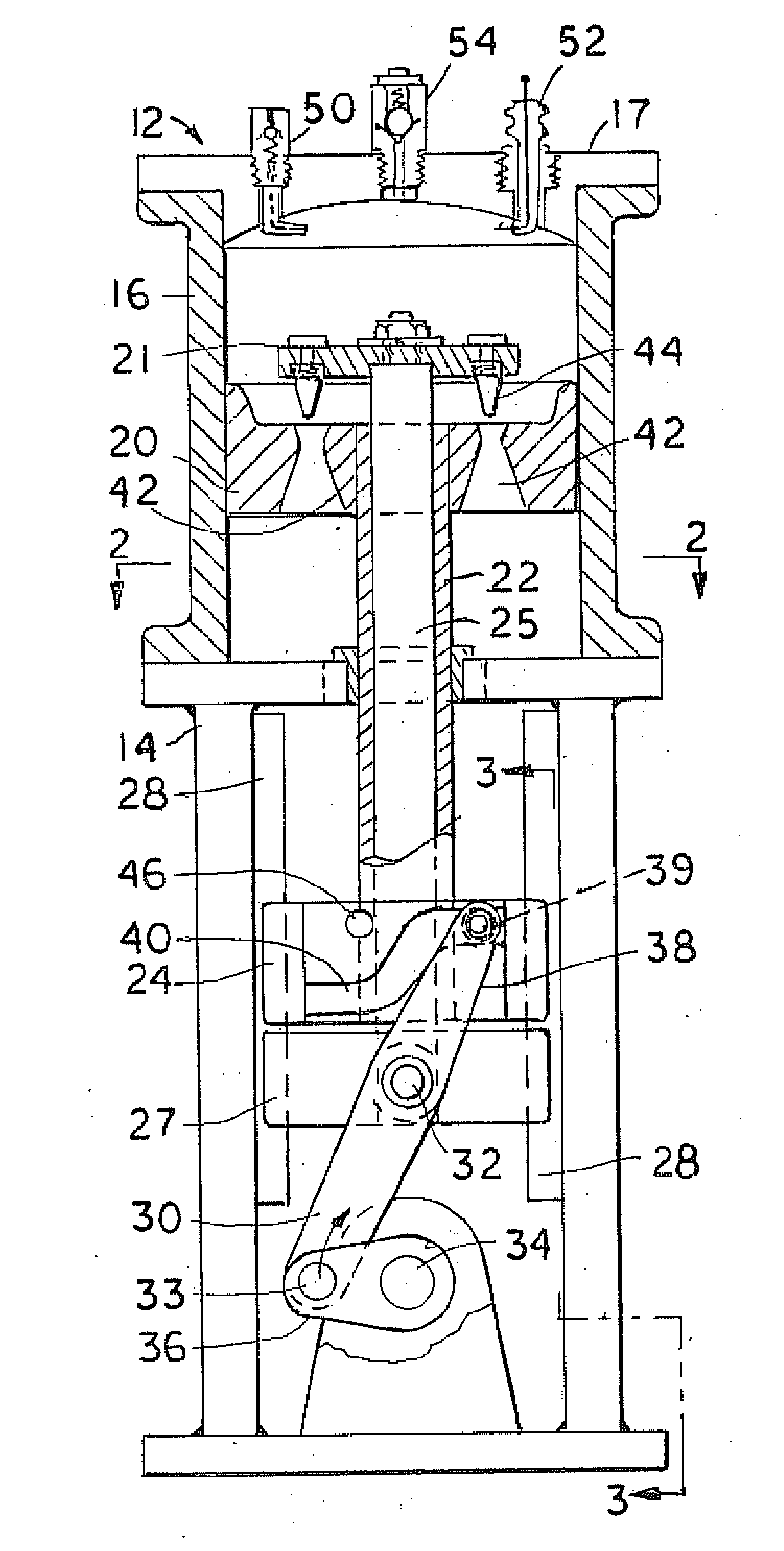

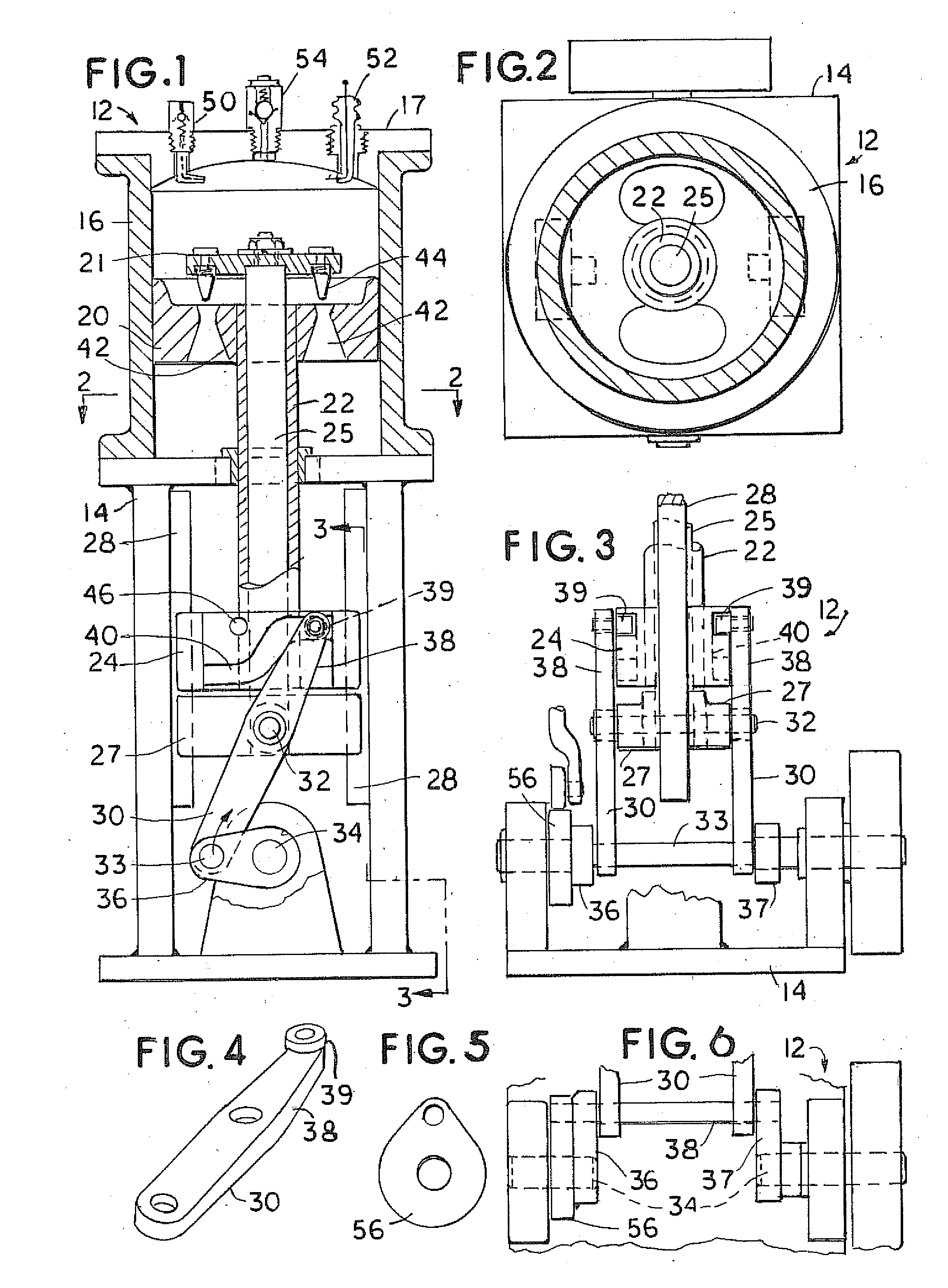

Testing system for critical pressure during thermal explosion of explosives

InactiveCN102608160ARealize multi-point temperature controlImprove uniformityMaterial exposibilityData acquisitionData treatment

The invention discloses a testing system for critical pressure during thermal explosion of explosives. The testing system comprises a pressure-resistance heating unit, a pressure control unit, a sample loader unit, a decomposed product detection unit and a computer; the pressure-resistance heating unit comprises a single-cavity heating furnace body, wherein a temperature sensor which is connected with the computer is arranged in a furnace cavity, and temperature, temperature rise speed and pressure of the single-cavity heating furnace body are controlled by the computer; the pressure control unit comprises a high-pressure gas cylinder, a pressurizing gas channel pipe, a pressurizing electromagnetic valve, a heat conduction layer extension edge pressurizing pipe, a pressure-releasing gas channel pipe, a pressure-releasing electromagnetic valve, a safety valve gas channel pipe, a safety valve and a pressure sensor; the sample loader unit comprises an L-shaped bracket, a stepping motor, two fixed pulleys, a steel wire rope, a furnace cover, a sample reservoir bracket and a sample reservoir; the decomposed product detection unit comprises an infrared sensor which is arranged in the sample reservoir; and the computer is provided with a data acquisition card, a graphic display control and a data processing unit and can be used for identifying the critical state of thermal decomposition to combustion or explosion and acquiring a critical pressure parameter.

Owner:XIAN MODERN CHEM RES INST

Multi-bacterial fermentation production of protein feedstuff with steam exploration of vegetables dregs and cotton dregs and method thereof

InactiveCN101401614ADisease resistantLow costFood processingAnimal feeding stuffBiotechnologyDisease

The invention relates to protein feed produced by multi-fungus fermentation with steam explosion rapeseed meal and cotton meal and a method. Rapeseed meal and cotton meal are used as main materials, meat and bone meal, straw and pomace are used as auxiliary materials, and a group of oxic liquid strain and anaerobic liquid strain are inoculated, so the protein feed is obtained. The preparation method is as follows: raw materials are delivered to a steam explosion system to be exploded, and then are released to normal pressure quickly after steam explosion; the materials after steam explosion are delivered to chelation reaction granary and cooled to 30 DEG C, and then are sterilized by microwave. The sterilized materials are delivered to a fermentation granary and the group of the oxic liquid strain is inoculated at the same time, the inoculum concentration is 5 percent, the intermittent ventilation and oxygen supplying are performed, the oxic fermentation time is between 36 and 48 hours; after the oxic fermentation, an anaerobic strain is inoculated, the inoculum concentration is 5 percent, and the sealed anaerobic culture is performed; and when the peptides content reaches 3 percent, the fermentation ends. The protein feed produced by multi-fungus fermentation with steam explosion rapeseed meal and cotton meal and the method have the advantages that toxin of miscellaneous mealis degraded completely after the steam explosion and microorganism fermentation treatment; the protein feed has flavor taste, and contains active substances, such as large amount of B vitamins, a plurality of vezyme and peptides, and so on; in addition, the protein feed has the functions of promoting growth development, resisting diseases.

Owner:河南省龙腾高科实业有限公司

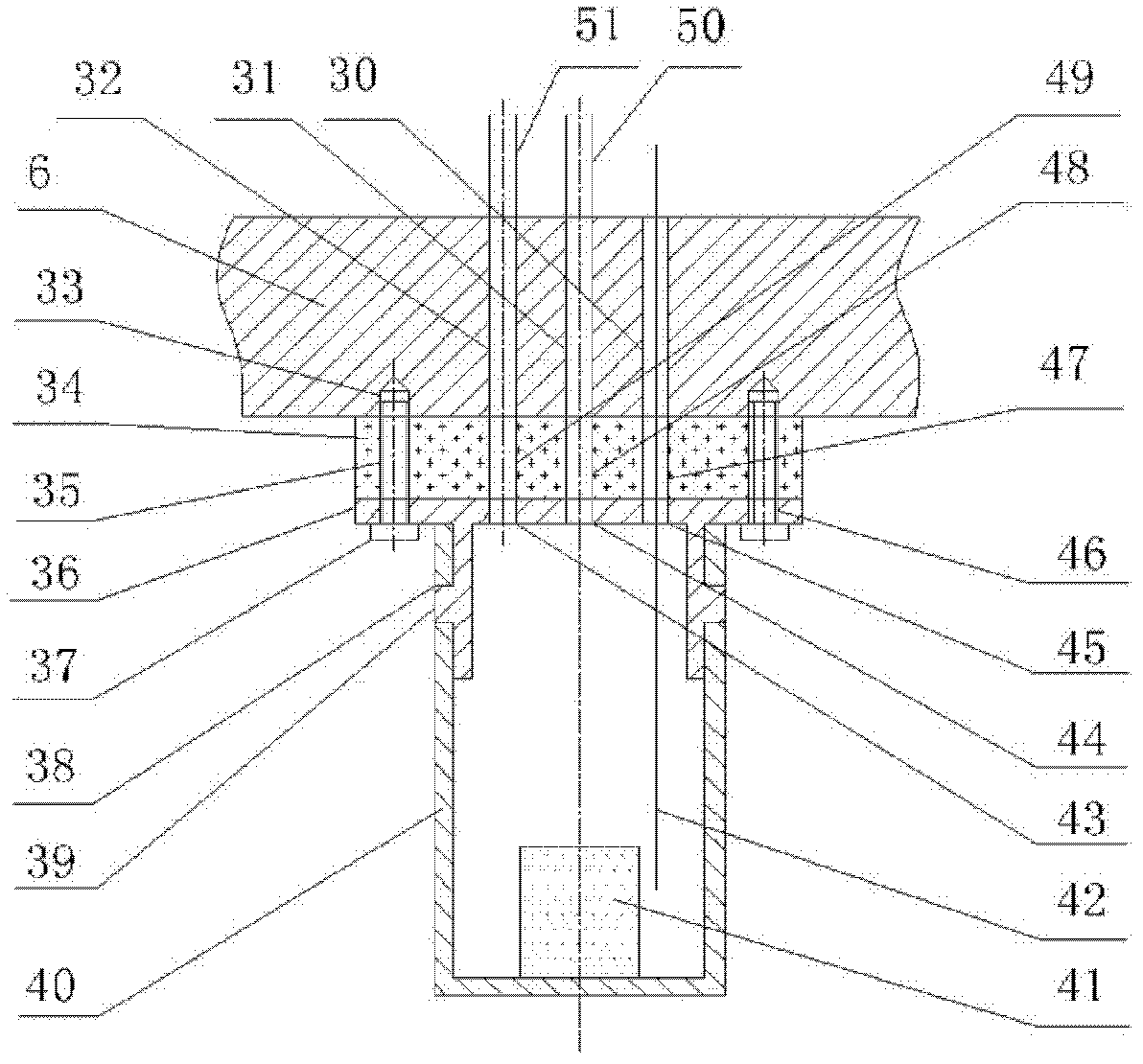

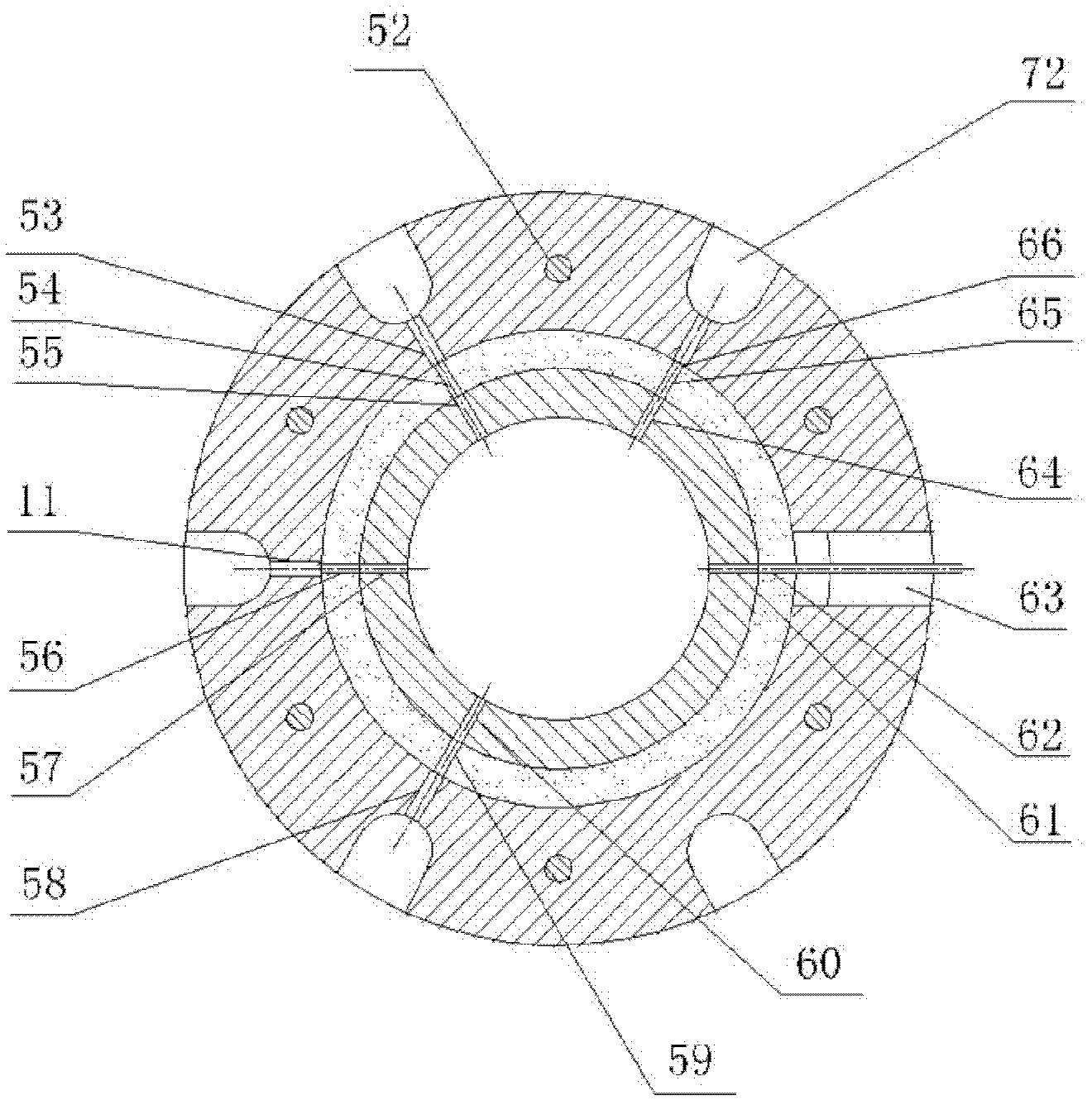

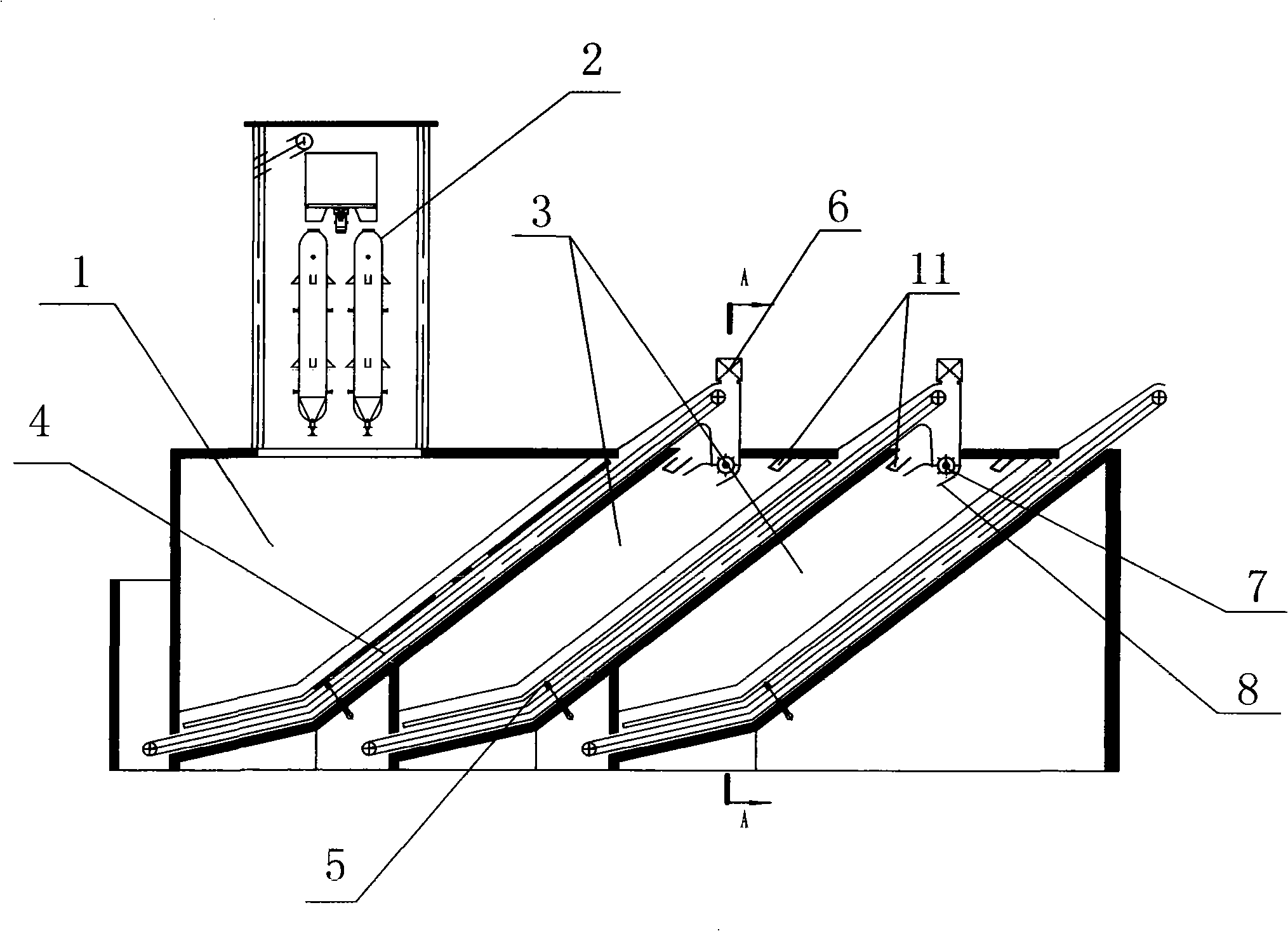

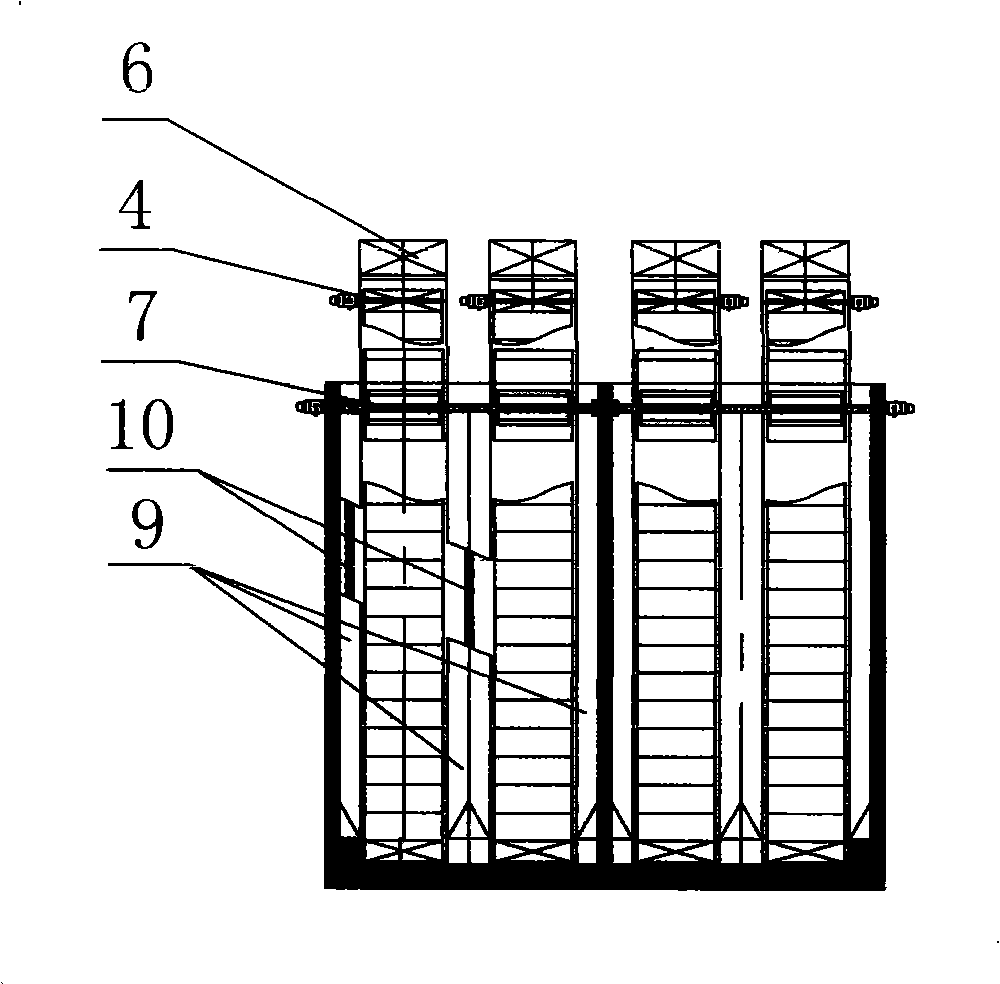

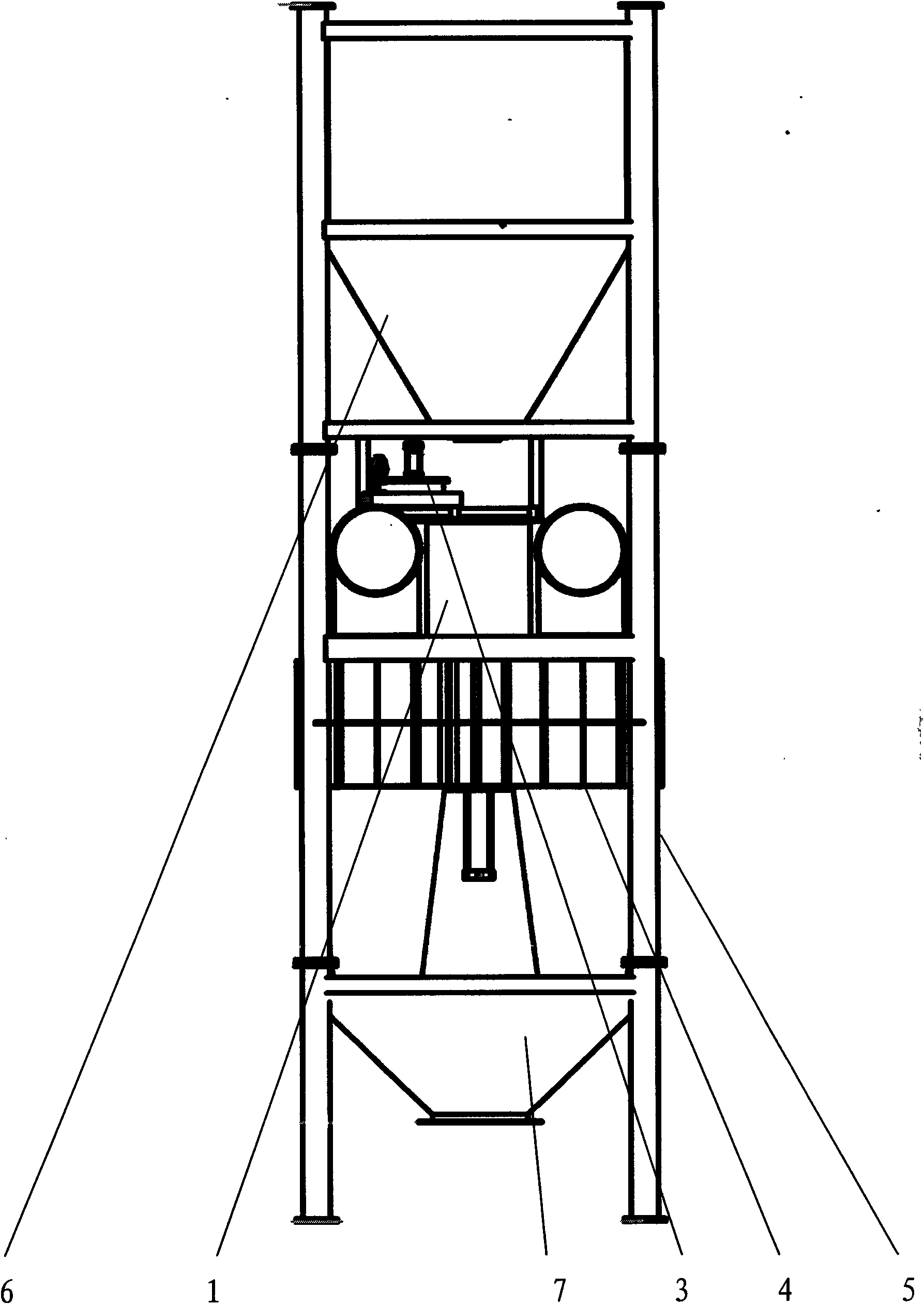

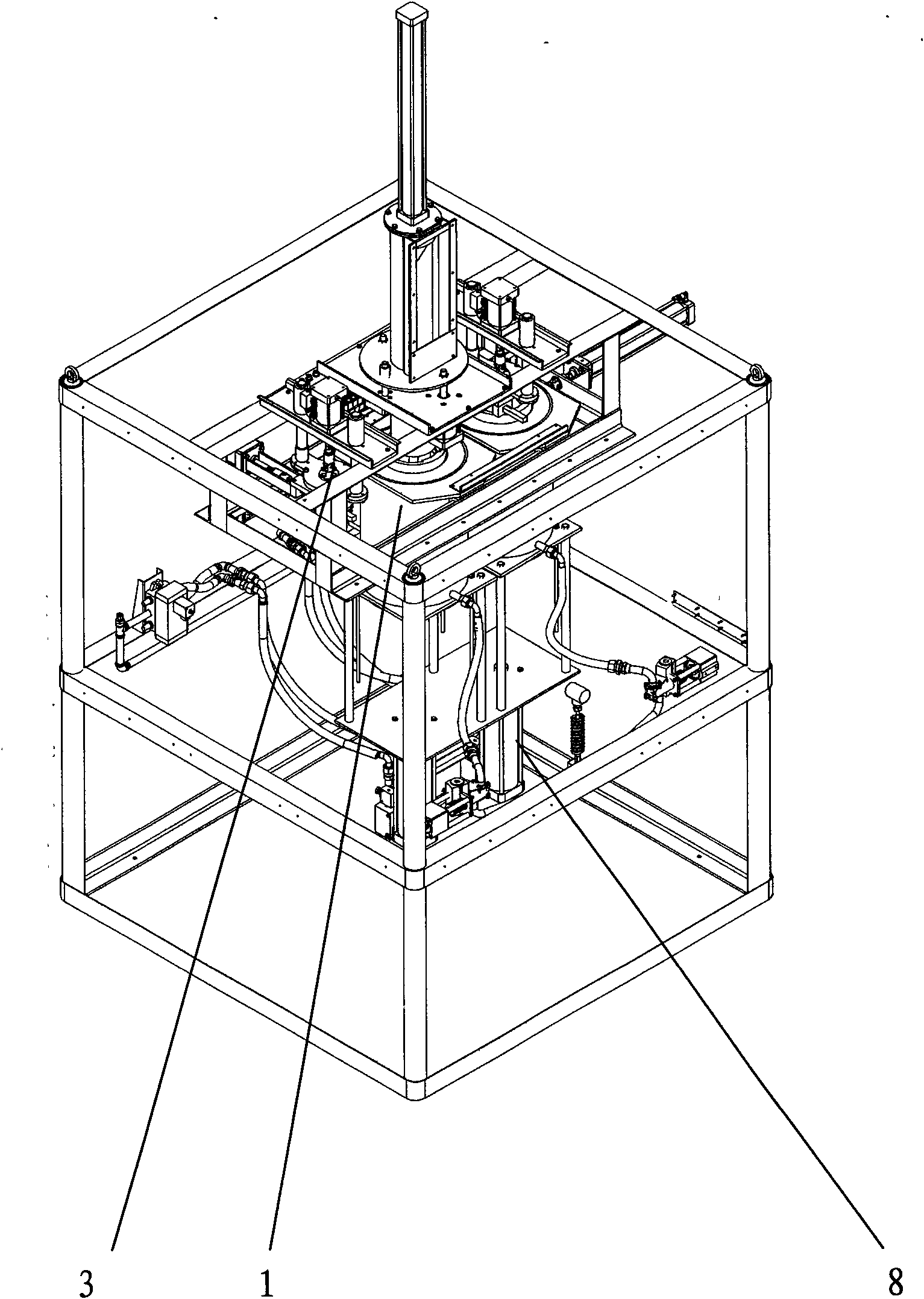

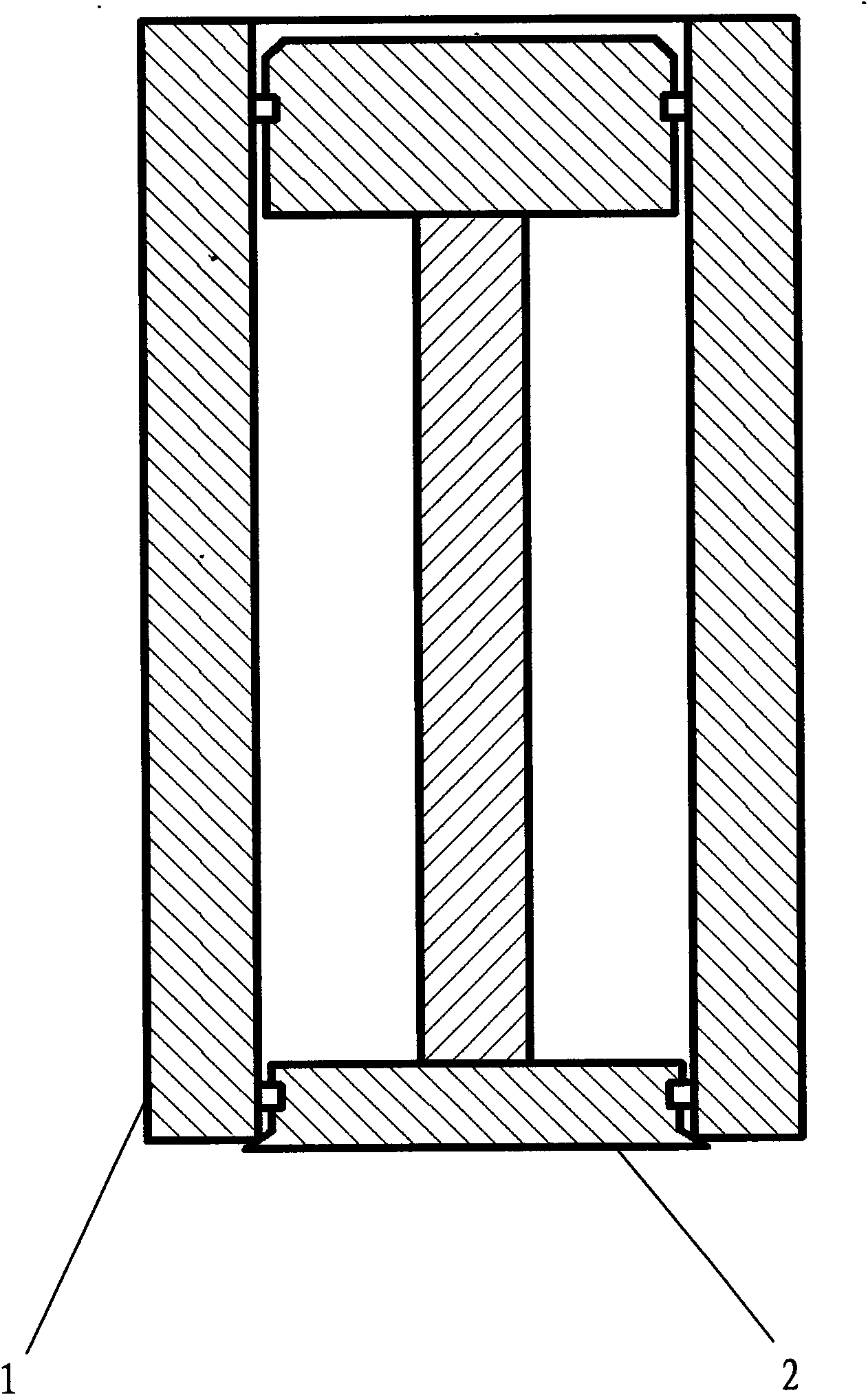

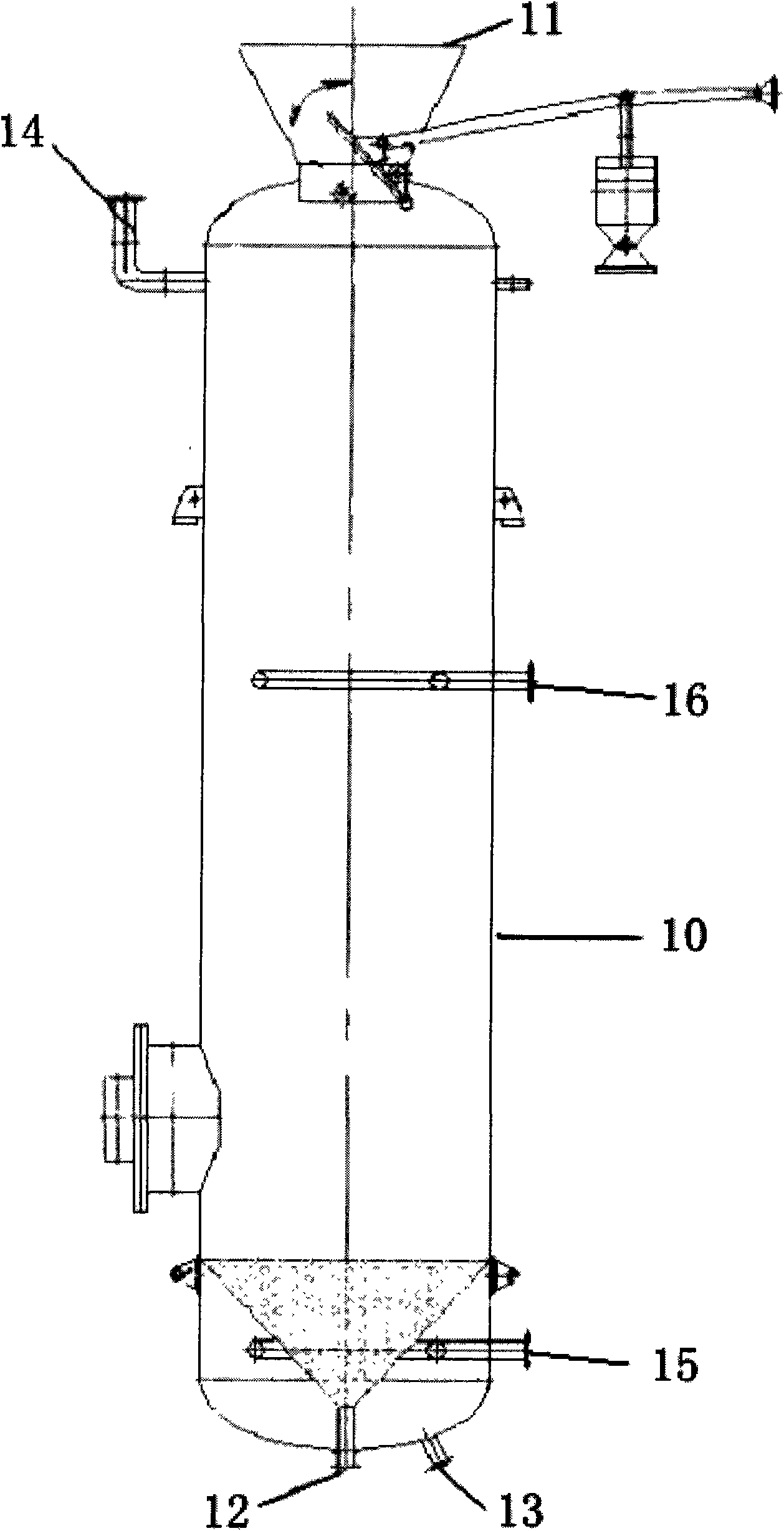

Numerically controlled continuous steam explosion machine

InactiveCN102600763AAchieving suddennessGuarantee the same effect of steam explosionPressurized chemical processFixed ratioEngineering

The invention relates to a production device for steam explosion pretreatment of biomass, in particular to a pretreatment device for the industry of biomass utilization, and provides a numerically controlled continuous steam explosion machine, which can complete supersonic steam explosion in milliseconds (0.00875s) based on the principle of a sliding cover. Since the cross-sectional area of the steam explosion machine for gas discharging, i.e. the cross-sectional area of the sliding cover, is equal to the cross-sectional area of a high-pressure cylinder, the cross-sectional area of the steam explosion machine for gas discharging and the steam explosion treatment volume form a fixed ratio, the problem that the gas discharging time is prolonged along with increase in the treatment volume in the traditional hot blowing process can be solved, and the power and density of steam explosion can be increased by three orders of magnitude. Moreover, the 'rawness and maturity' of materials which are subjected to batch treatment can be kept identical, and a foundation is laid for the consistency of industrial biochemical treatment. Meanwhile, the machine has the function of feeding and discharging materials automatically and the continuous steam explosion production can be realized.

Owner:于政道

Method for recovering energy from the organic fraction of solid urban waste and associated facility

ActiveUS20100151550A1High organic contentAvoid enteringBioreactor/fermenter combinationsBiological substance pretreatmentsDistillationSlurry

The invention relates to a method for recovering energy from the organic fraction of urban solid waste comprising the following steps: a) the organic fraction is pre treated with mineral acids, preferably sulfuric acid, during which the fraction is heated by an outer thermal jacket with no steam injection or steam explosion, thereby producing a first slurry containing an insoluble solid susceptible to enzymatic attack by cellulases; b) a step comprising enzymatic hydrolysis using cellulases and simultaneous fermentation, using an ethanologenic microorganism, of the first slurry in order to obtain a second slurry containing diluted ethanol; and c) distillation of the second slurry such as to obtain wet ethanol, a recyclable liquid effluent and a solid.

Owner:PERSEO BIOTECHNOLOGY SL +1

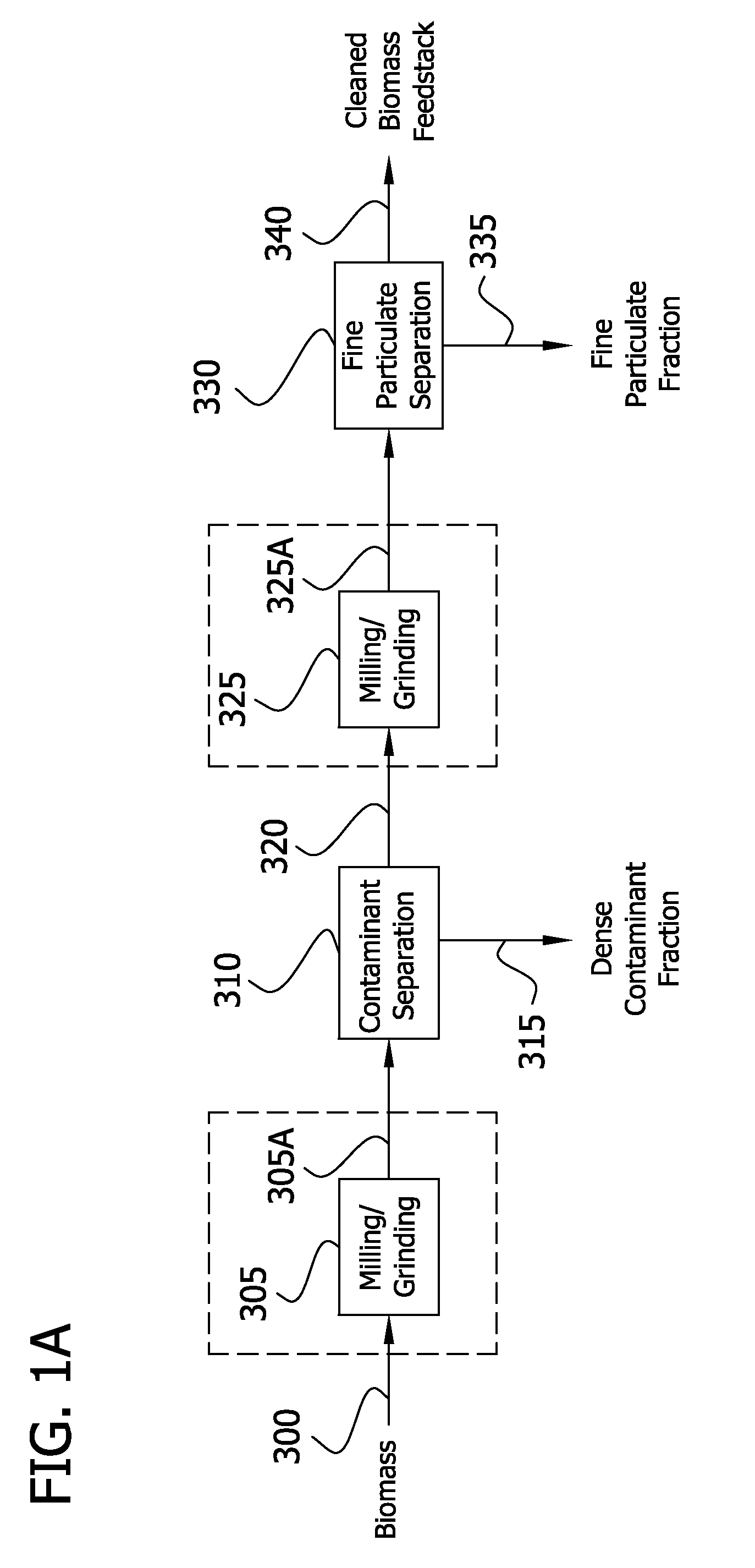

Method for producing ethanol and co-products from cellulosic biomass

InactiveUS20110262984A1Increased ethanol productionImproved co-productsPretreatment with acid reacting compoundsBiofuelsCelluloseCo product

The present invention generally relates to processes for production of ethanol from cellulosic biomass. The present invention also relates to production of various co-products of preparation of ethanol from cellulosic biomass. The present invention further relates to improvements in one or more aspects of preparation of ethanol from cellulosic biomass including, for example, improved methods for cleaning biomass feedstocks, improved acid impregnation, and improved steam treatment, or “steam explosion.”

Owner:ABENGOA BIOENERGY NEW TECH

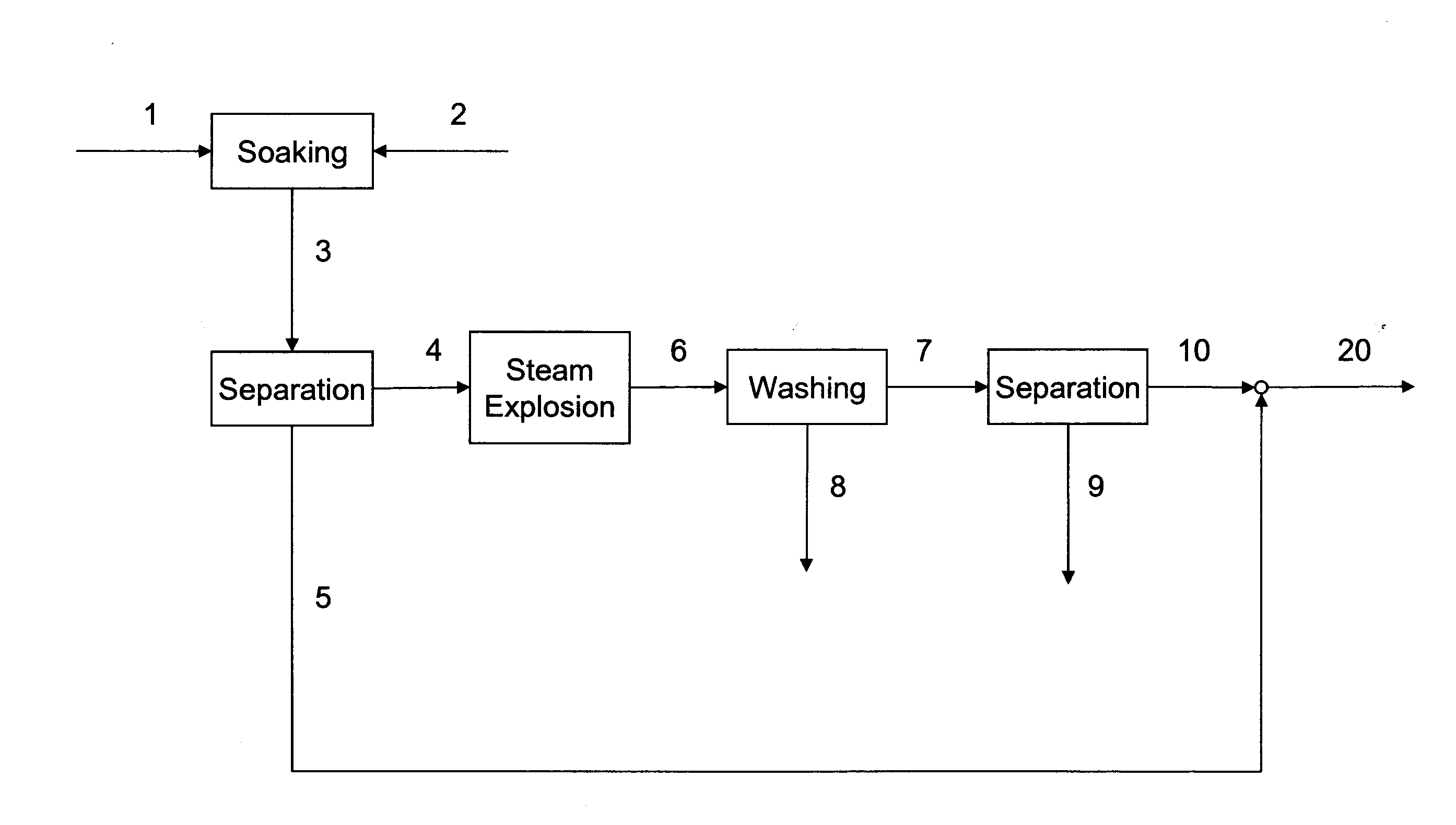

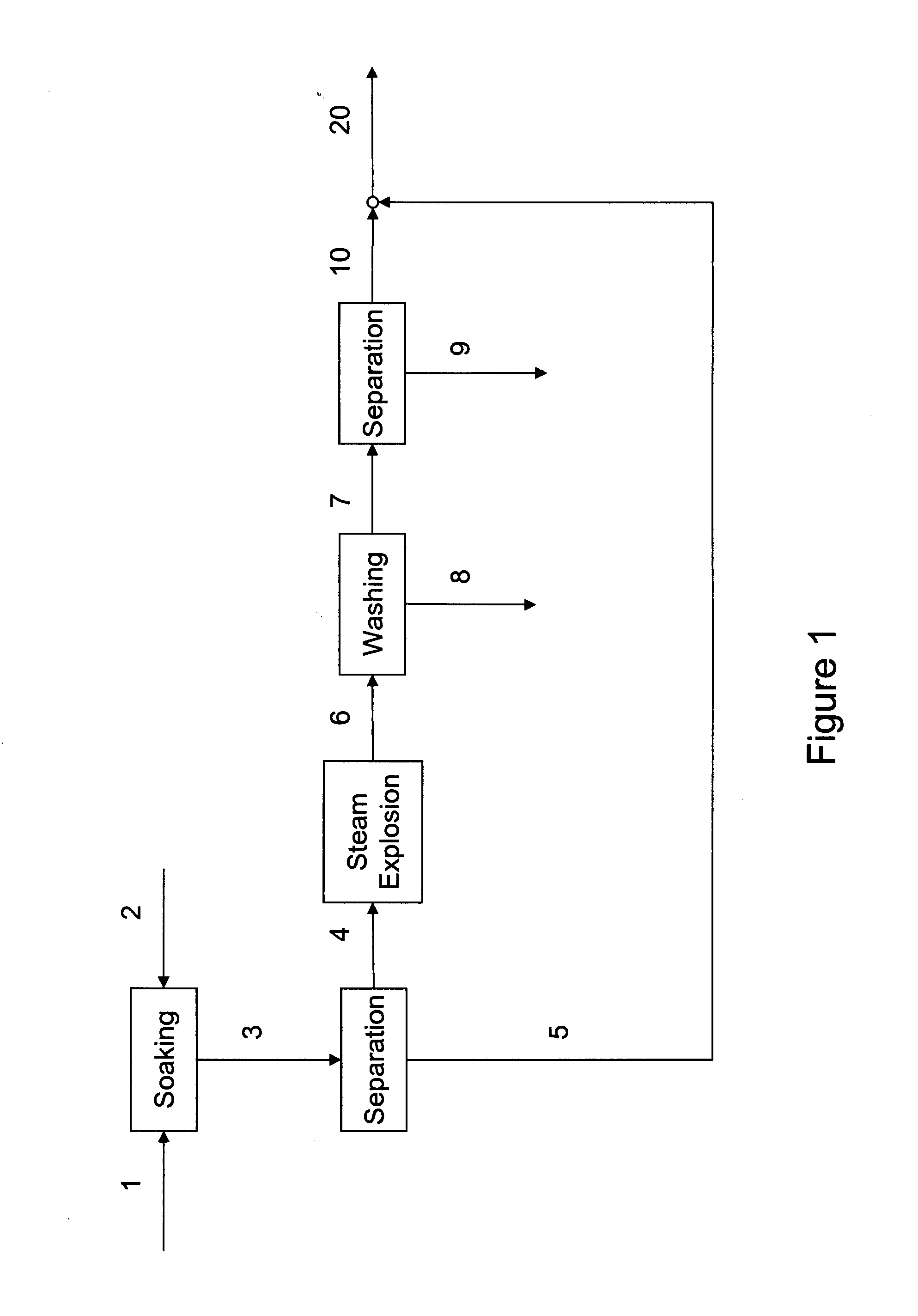

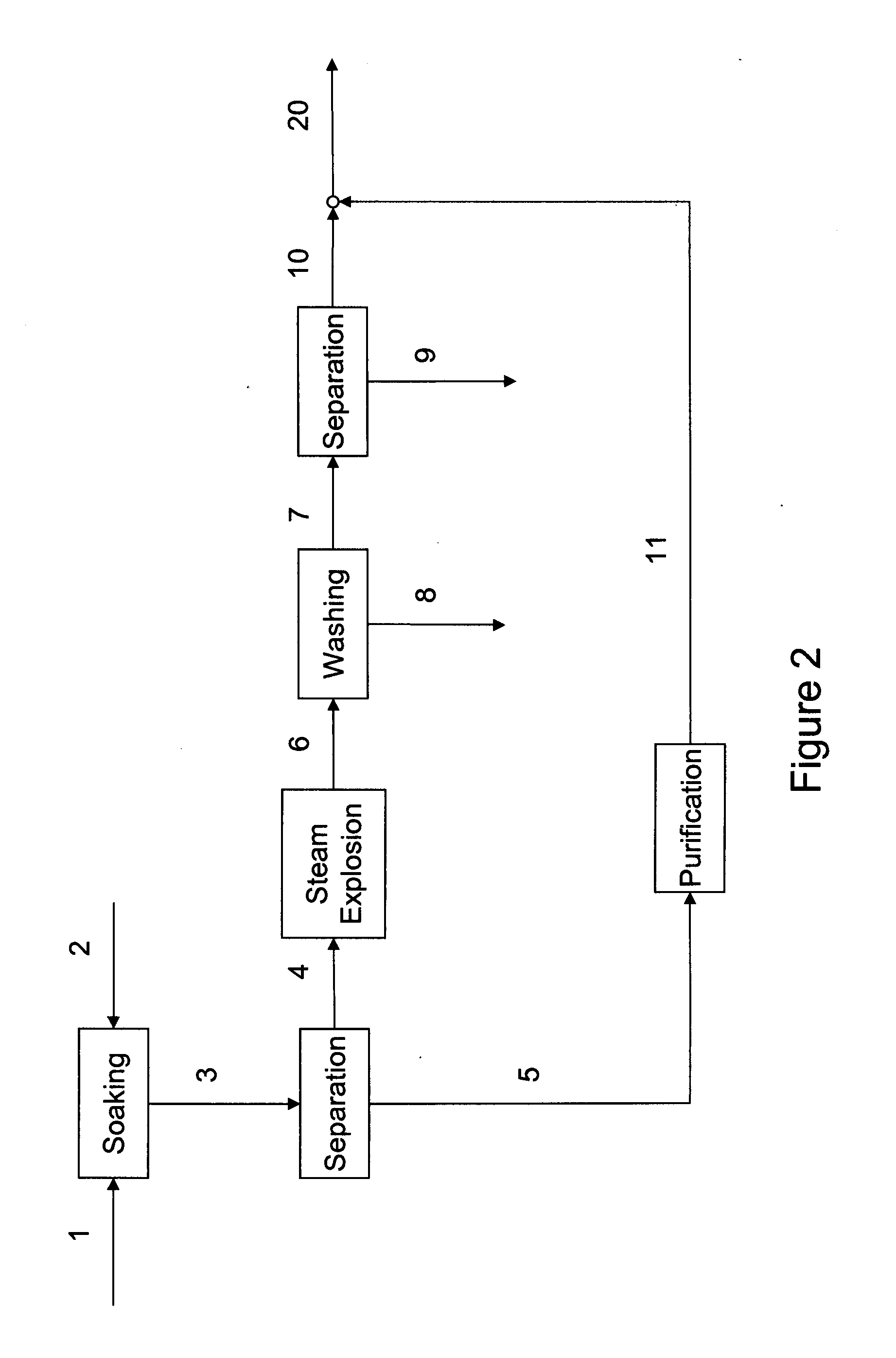

Biomass pretreatment process

Owner:CHEMTEX ITAL +1

Straw densification briquetting fuel preparation method for biomass power generation and boiler combustion

InactiveCN101768494ARaise the ash melting pointImprove combustion effectBiofuelsSolid fuelsSolid fuelPotassium ions

The invention provides a straw densification briquetting fuel (SDBF) preparation method for biomass power generation and boiler combustion, solving problems of low ash fusion point, easily coking, serious corrosion to boilers and the like of direct straw combustion. In the invention, straw is pre-processed through steam explosion or with diluted acid then is subjected to enzyme hydrolysis with cellulose, and the enzyme hydrolysis residue is briquetted to be used as fuel for biomass power generation or boiler combustion. The pre-processed and enzyme-hydrolysis straw can be briquetted easily; cellulose and hemicellulose in the pre-processed and enzyme-hydrolysis straw are removed basically, lignin content and calorific value increase, potassium ion, sodion and chloridion are removed, thereby improving ash fusion point of straw, reducing coking and boiler corrosion in combustion process, and improving combustion performance of straw. The straw solid fuel prepared by the invention can be used as fuel for common domestic boilers. Sugar produced by enzymolysis can be used as a fermentation carbon source for large-amount fermented products, so as to improve comprehensive utilization value of straw.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for utilizing straw biomass by grades

InactiveCN101643796AMaximize utilizationOvercome costsBiofuelsLignin derivativesWater insolubleWater soluble

The invention discloses a method for utilizing straw biomass by grades, comprising the following steps: carrying out steam explosion to straw biomass; extracting and separating water soluble constituents and water insoluble constituents in steam exploded straw by water, wherein the water soluble constituents are purified and concentrated to obtain active low polyxylose and xylose and the water insoluble constituents are used for further fermentation to generate ethanol; and extracting lignin from the fermentation residue. The invention realizes the maximization of utilization of biomass and overcomes the disadvantages of high production cost, low efficiency and environmental pollution and the like in the prior art.

Owner:CENT FOR CLEAN ENERGY TECH OF SHANGHAI

Method for separating straw components by carrying steam explosion-microwave coupling treatment to plant straw

The steam blasting and microwave treating process for separating plant stalk components includes the following steps: steam blasting plant stalk, expanding and washing in hot water at 40-60 deg.c and letting stand to deposit semi-cellulose; dewatering semi-cellulose, mixing with glycerin and microwave treating intermittently; dissolving in hot water for 30-90 min; washing with 40-60 deg.c water and filtering for 3-5 times to obtain filter cake as the coarse fiber; and depositing the filtrate to obtain lignin. The process has coarse cellulose yield of 52-70 %, semi-cellulose yield and lignin yield in 67-80 % and 70-85 % of content in the stalk separately; and glycerin recovered and reused. The process has high efficiency, environment friendship and other advantages.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

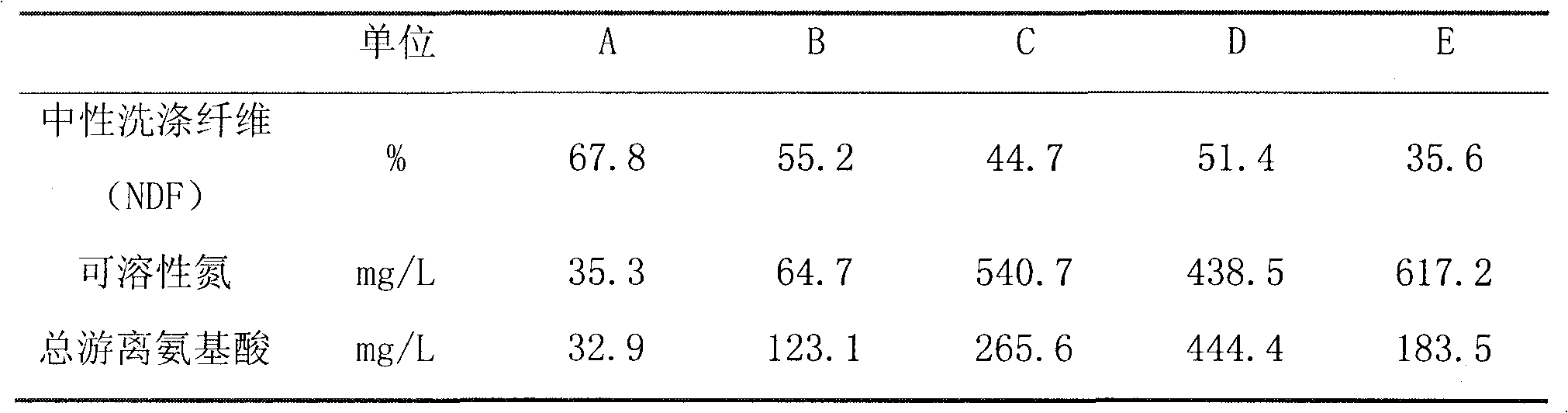

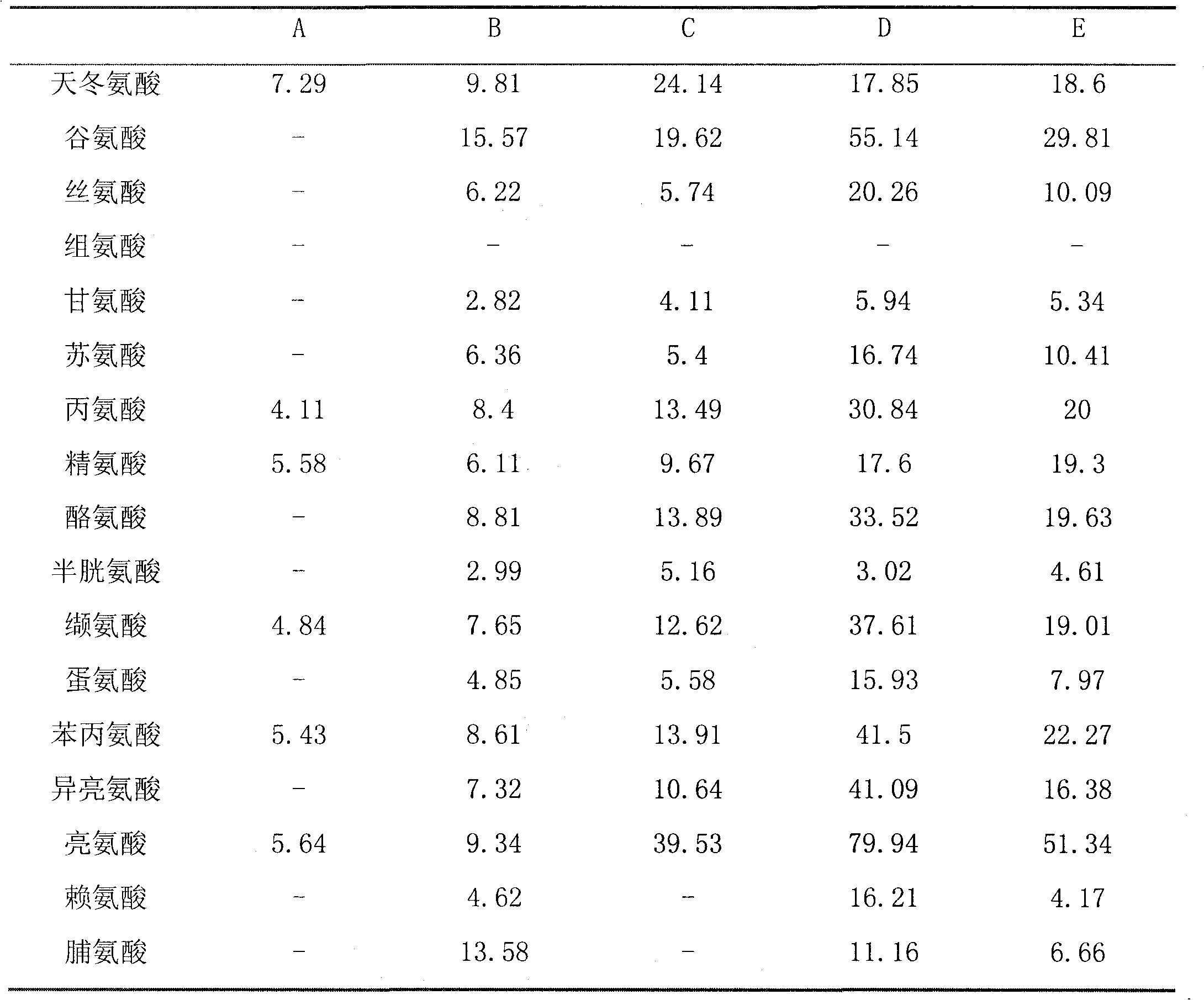

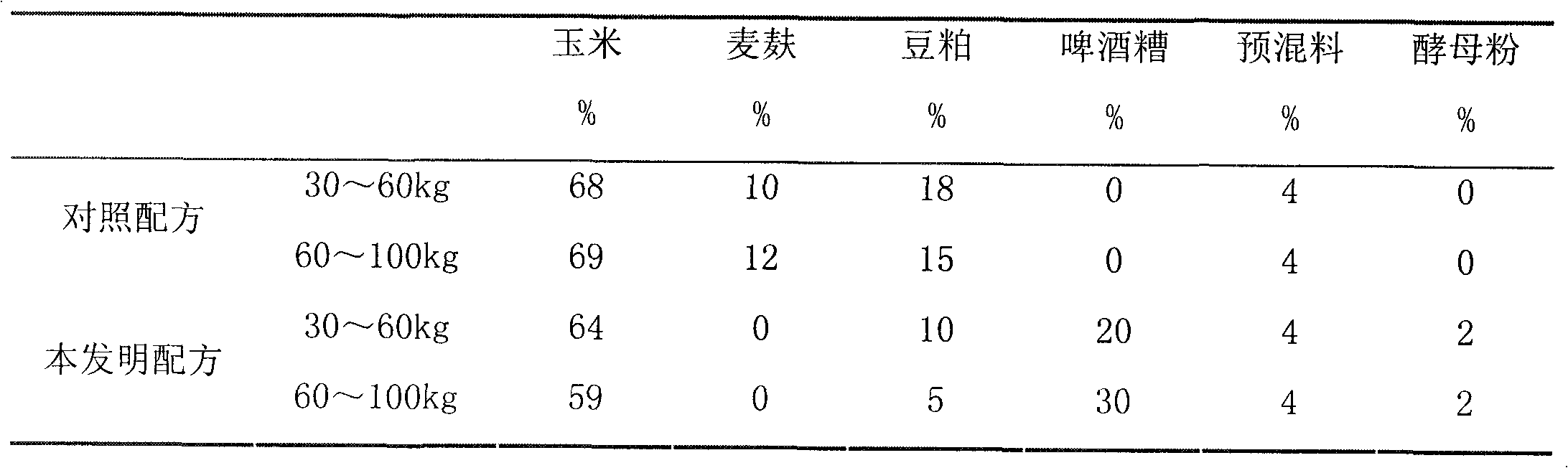

Production method for adding brewer grain fattening pannage

ActiveCN101779749ARich varietyLow costFood processingAnimal feeding stuffAdditive ingredientCorn meal

The invention belongs to a production method for adding brewer grain fattening pannage, which belongs to the technical field of the feed processing. The production method comprises the following steps that: the brewer grain is undertaken the steam explosion pretreatment and is added with mixed bacteria and / or complex enzyme to be undertaken the solid anaerobic fermentation so as to degrade the fiber content in the brewer grain and to improve the soluble nitrogen content of the brewer grain, so the quality is better, and the nutrition is more balanced; then the fermented brewer grain, waste yeast powder, corn meal, soybean meal and pre-mixed material are uniformly mixed to obtain the fattening pannage being added with brewer grain. The source of the brewer grain and the waste yeast is abundant, the nutrition for matching the brewer grain and the waste yeast is balanced, and the cost of the feed can be reduced; and the brewer grain is processed with the steam explosion pre-treatment technology, the enzymolysis technology and the biological fermentation technology, so the fiber content is reduced, the protein quality is improved, and the type of the aminoacid is more abundant; and the production method can reduce the grain ratio, improves the daily gain, reduces the feed compositions, and is free from influencing the feed intake and the growth of the fatty pigs.

Owner:BEIJING YANJING BREWERY

Method for treating lignocellulose raw material through steam explosion and producing biogas, cellulose and lignin simultaneously

InactiveCN102051383ASolve the problem of component separationAchieve separationWaste based fuelFermentationHigh concentrationIndustrial Additive

The invention relates to a method for treating lignocellulose raw material through steam explosion and producing biogas, cellulose and lignin simultaneously. The traditional utilization of the lignocellulose raw material only uses a single component and aims to produce a single product, thus the function of each component can not realized and the economic benefit is low. The method in the invention uses the steam explosion technology as a core, wherein hemicellulose, cellulose and lignin are separated from the lignocellulose raw material for high-value use. The method comprises the following steps: performing steam explosion on the lignocellulose raw material; degrading hemicellulose to soluble sugar; extracting soluble sugar with water for biogas fermentation, wherein lignin and cellulose are easy to separate when hemicellulose is removed; extracting high-concentration lignin with low concentration base; and leaving high concentration cellulose when hemicellulose and lignin are removed. The biogas produced by the method has low sulfur content and can be directly used; the extracted lignin can be used to produce resins, adhesives, rubber industry additives and the like; cellulose can be used for papermaking and preparing products such as polyol, carboxymethyl cellulose, cellulose acetate and textile fibre. By adopting the method in the invention, the biomass of lignocellulose can be completely utilized and no pollutant is discharged; and the method is easy for industrialization operation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

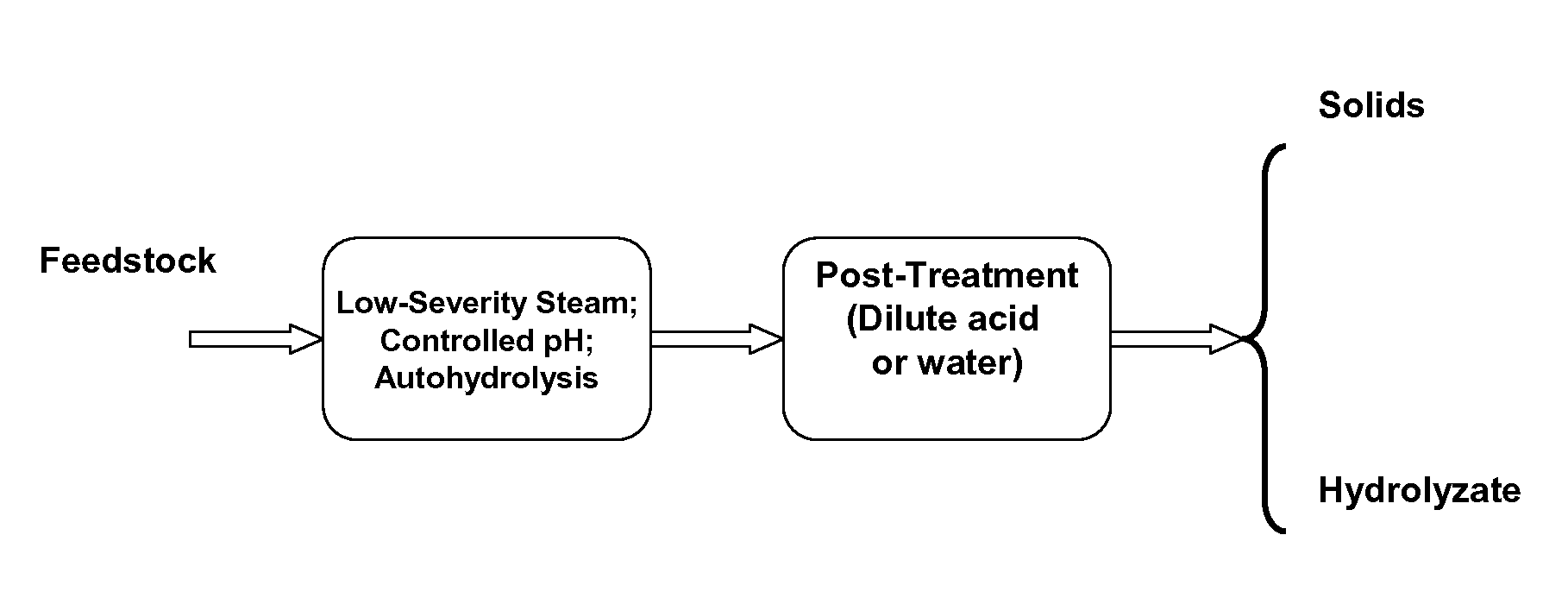

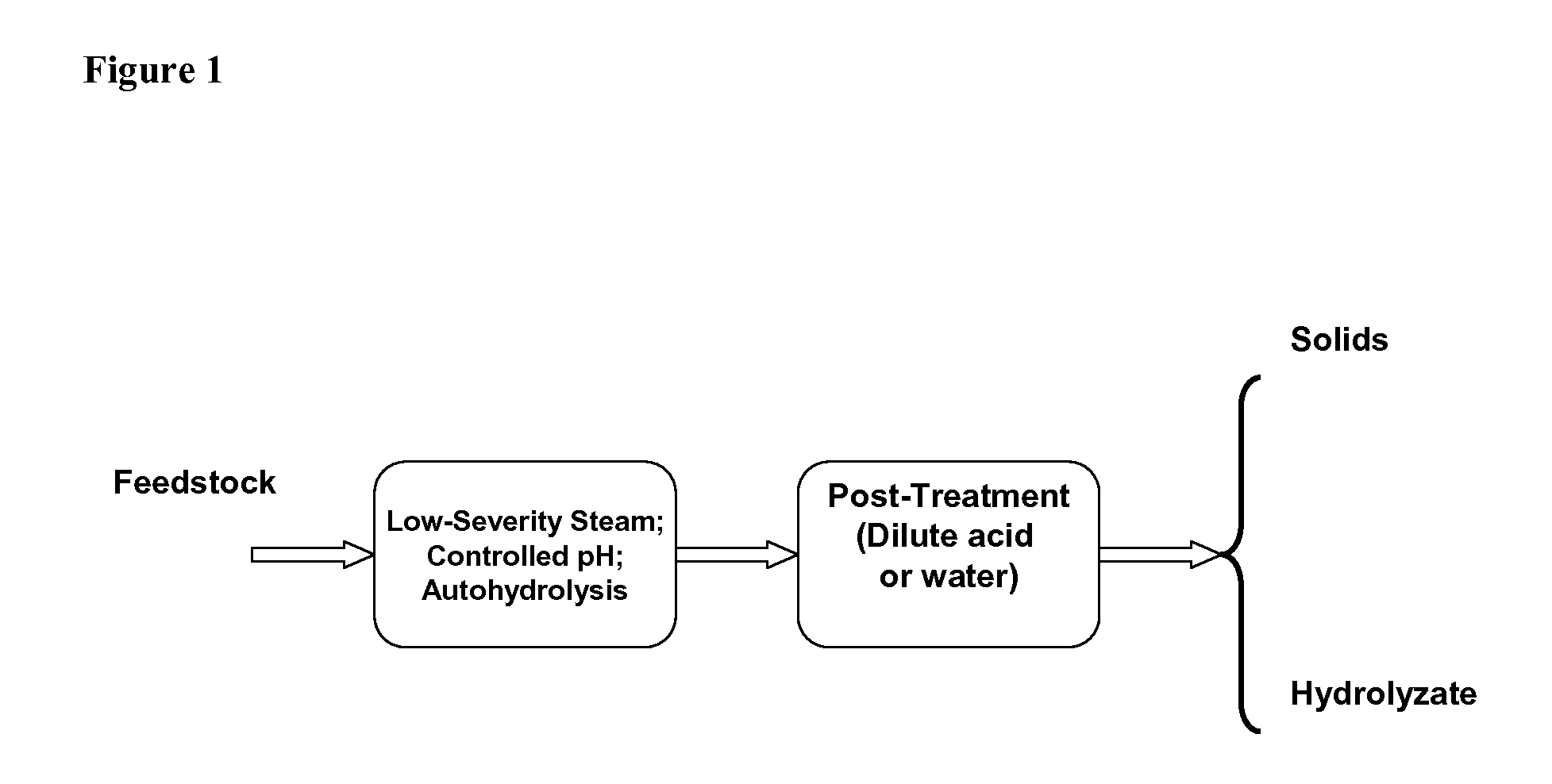

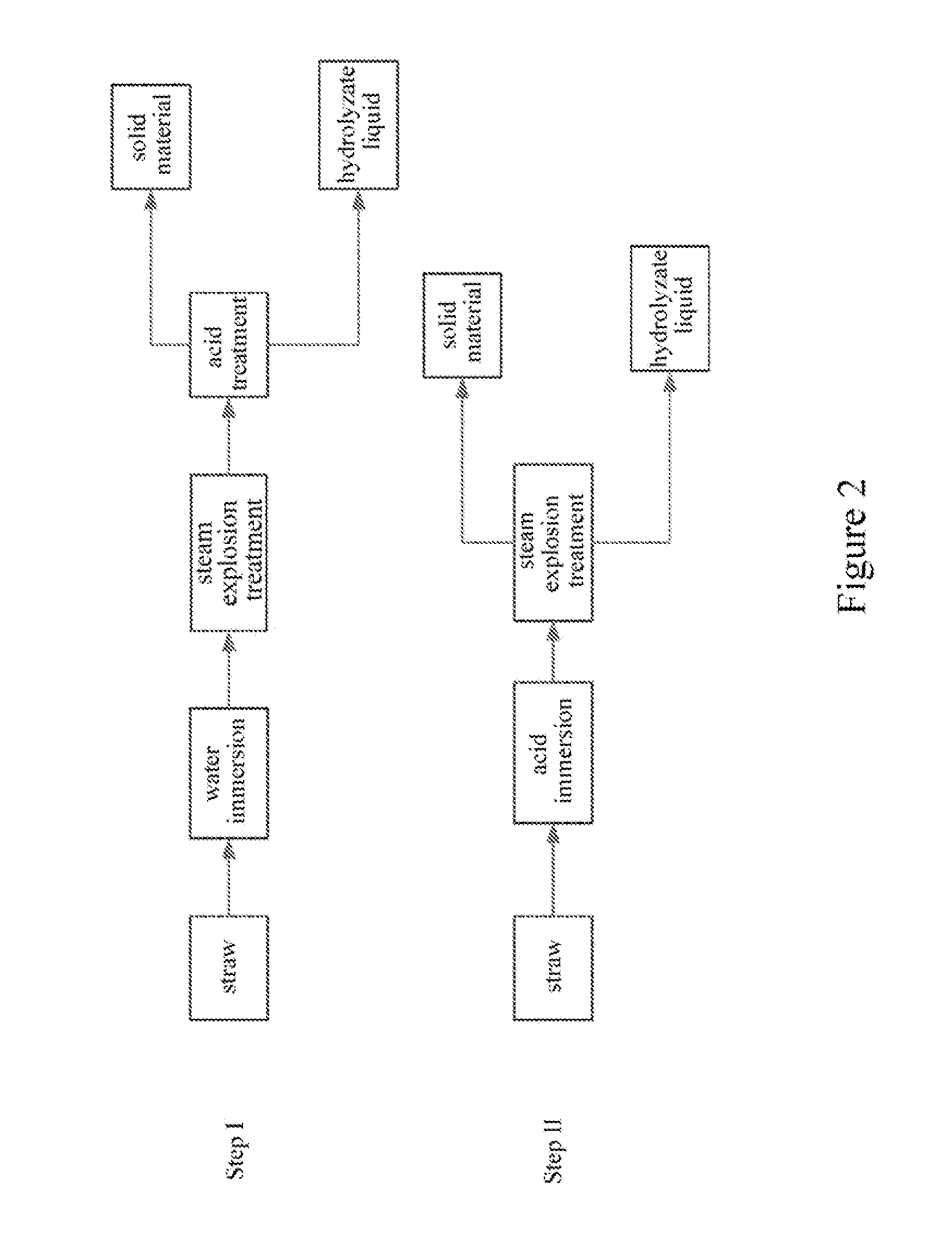

Two-Stage Process for Biomass Pretreatment

InactiveUS20110300586A1Increase rangeImprove digestibilityBiofuelsPulping with acid salts/anhydridesAcid hydrolysisLignocellulosic biomass

Described herein are improved methods of pretreating lignocellulosic biomass. One aspect of the invention relates to a two-stage pretreatment process comprising a relatively low severity steam treatment, a controlled pH pretreatment, or autohydrolysis, followed by hydrolysis with dilute acid or hot water at a relatively low temperature. In certain embodiments, the methods increase hemicellulose sugar yields, substrate digestibility, and suitability for fermentation as compared to steam explosion or acid hydrolysis alone. The two-stage pretreatment processes also employ few chemicals, minimizing the costs associated with pretreatment of lignocellulosic biomass. Moreover, the two-stage pretreatment process may expand the range of suitable feedstocks for bioethanol production.

Owner:MASCOMA CORPORATION

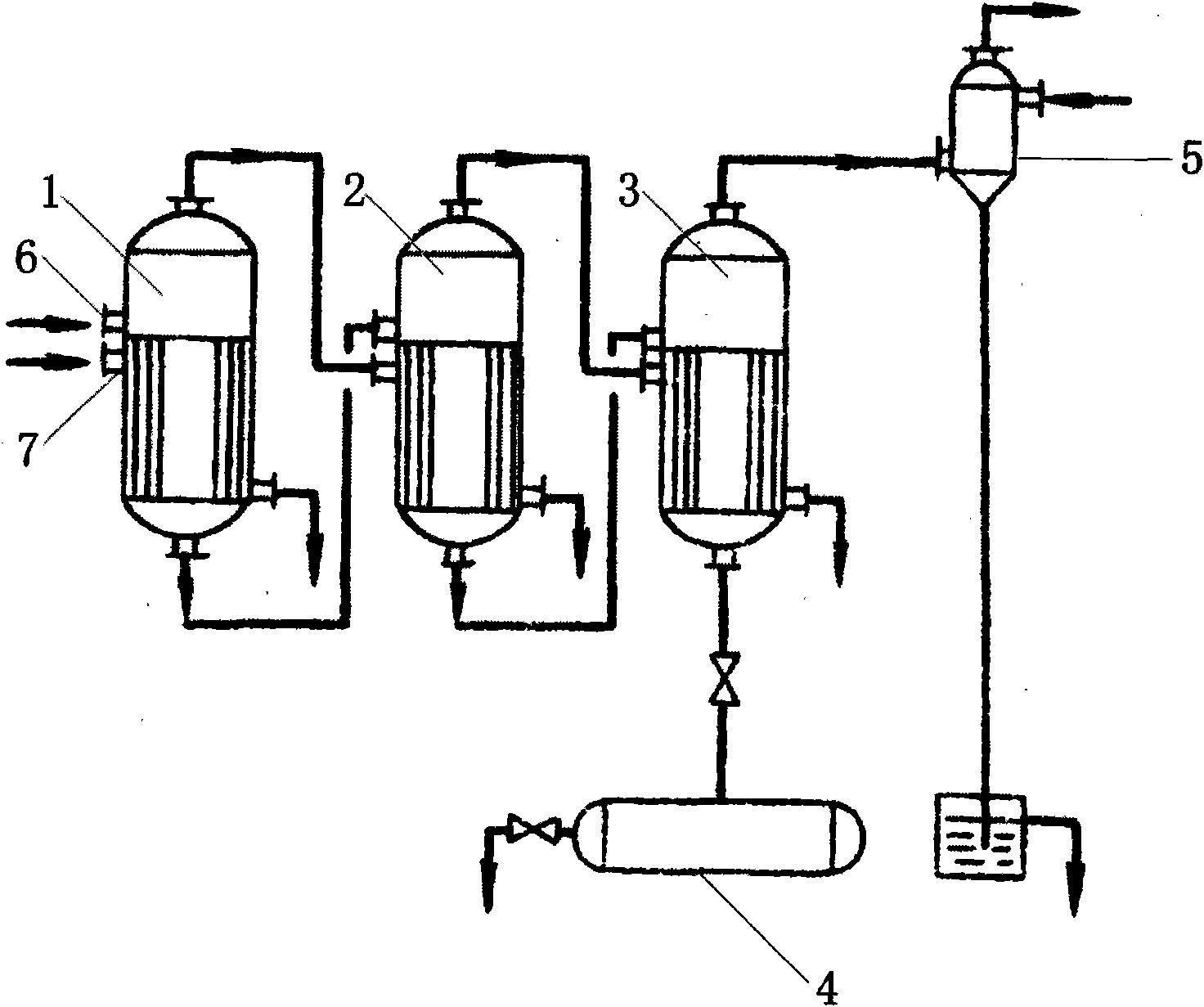

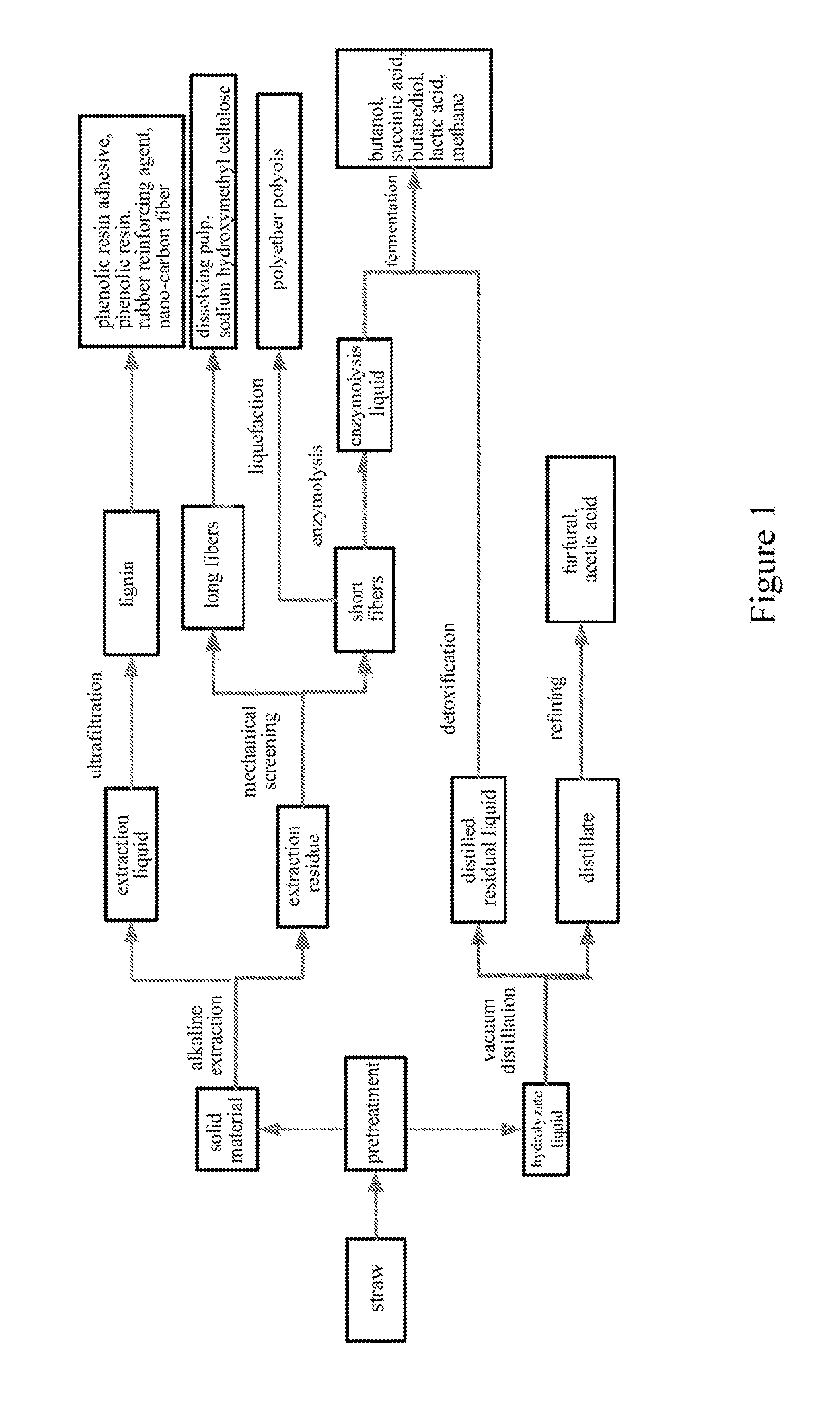

Process for producing bio-based product from straw hemicellulose and fully utilizing the components thereof

ActiveUS20130252293A1Low costHigh value utilizationPretreatment with water/steamBacteriaHigh concentrationSuccinic acid

Provided is a process for producing biomass-based product from straw hemicellulose and utilizing the components thereof thoroughly. Steam-explosion and acid-hydrolysis are combined in the pre-treatment of straw in the process, thus a higher concentration of a sugar liquid can be obtained, and furfural and acetic acid can be recovered. The hemicellulose obtained by the pre-treatment can be used directly as ferment materials for producing butanol, succinic acid, butylene glycol, lactic acid, hydrogen and firedamp, which reduces the cost of these biomass-based products. The cellulose and lignin obtained by extracting the straw with an alkaline solution can produce products, such as sodium hydroxymethyl cellulose etc. In the process, all components in the straw can be utilized thoroughly and waste and pollutant will not be produced.

Owner:HAINAN SUPER HEALTHY GRAIN CO

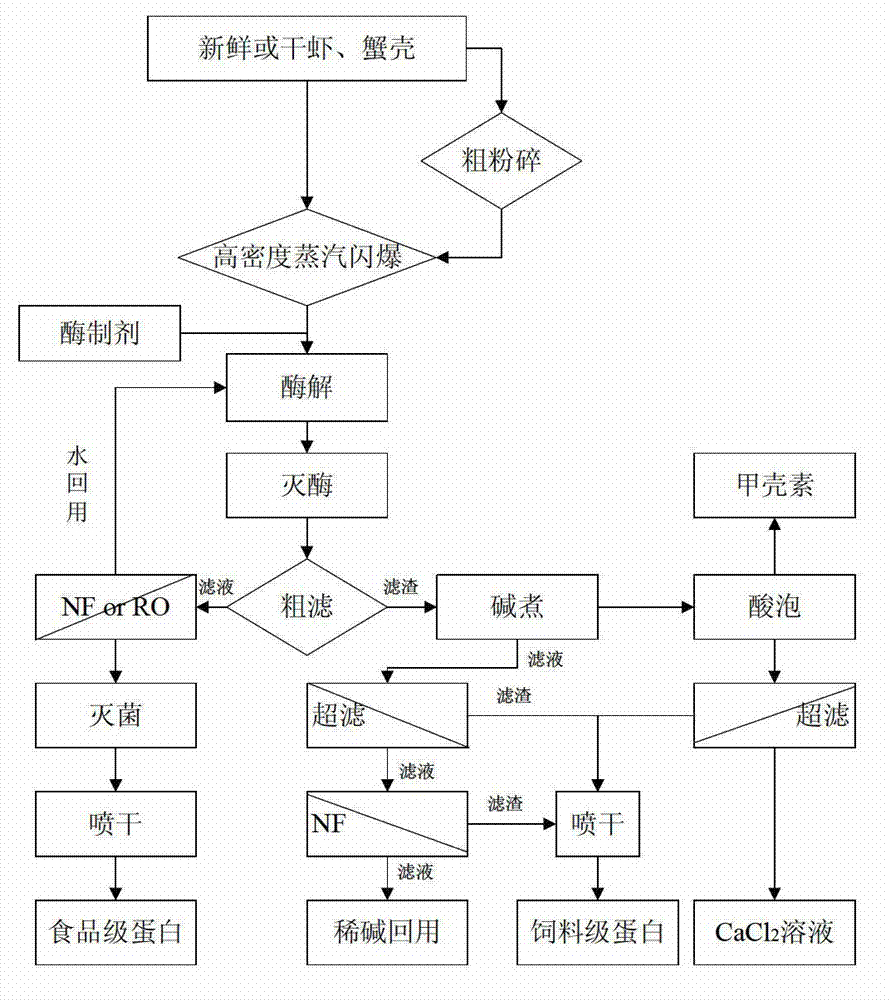

Clean chitosan production technology

ActiveCN103113496ATake advantage ofImprove qualityPeptide preparation methodsFermentationFiltrationUltrafiltration

The invention relates to a clean chitosan production technology and relates to the technical field of comprehensive utilization of wastes generated in a process of aquatic product processing and treatment and comprehensive utilization of food processing wastewater. The clean chitosan production technology comprises the following steps of: carrying out instant high-pressure steam explosion pretreatment on shrimps and crab shells taken as raw materials through a high-density steam explosion device, dissolving and extracting most of protein in the raw materials through enzymatic hydrolysis to prepare food-grade protein hydrolysate; sequentially soaking enzymolysis residues in NaOH and hydrochloric acid to prepare the high-quality chitosan; sequentially carrying out filtration treatment on an alkali waste liquid through a security filter, a carbon carbide ultrafiltration membrane and an alkali-resisting NF (Nanofiltration) membrane to obtain feed-grade protein and recycled dilute alkali liquid; treating the waste liquid soaked in acid through the security filter and the carbon carbide ultrafiltration membrane to obtain the neutral CaC12 clear water which is discharged after reaching the standard. Compared with the prior art, the clean production technology has the advantages that the whole new technology is clean and environmentally-friendly, a seperation and purification technology is simple, reasonable, short in working procedures and convenient in operation, simultaneously resources are fully and comprehensively utilized, secondary pollution is avoided, economic benefits are obviously improved, and industrialized application value is fulfilled.

Owner:EAST CHINA UNIV OF SCI & TECH

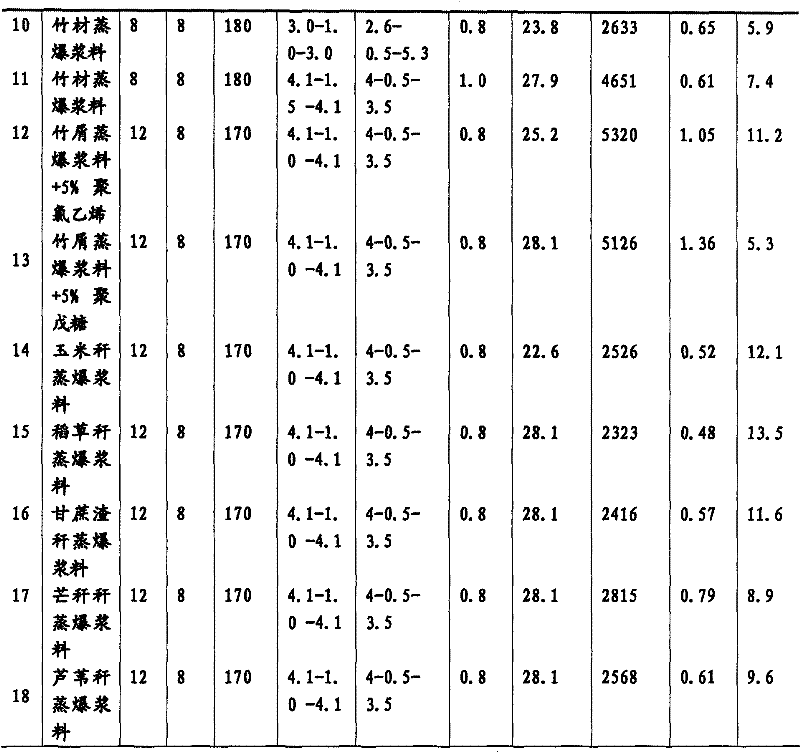

Method for producing steam exploded stalk binder-less artificial boards by alkali process

InactiveCN103358381AAchieve glue-free gluingLow additional costDomestic articlesFlat articlesCell wallWater content

The invention belongs to the field of binder-less environment-friendly artificial board production, and particularly relates to a method for producing binder-less environment-friendly artificial boards by means of hot pressing with steam exploded stalks as raw materials. The method includes steps of chopping the stalks, dipping the chopped stalks into alkali solution and then taking out with water content controlled, performing a steam explosion process on the stalks to obtain steam exploded stalks, drying the steam exploded stalks until reaching a certain water content, and finally performing hot press molding. In the method, alkali lignin is dissolved out during high-temperature digesting of the alkali-process steam explosion, and is blown instantly to damage cell wall structures, so that active groups of three components in the raw materials are exposed fully. In the later hot press molding process, the lignin dissolved out is subjected to condensation reaction with polysaccharide and lignin of the raw materials at a high temperature so as to form a binding effect. By the method, binder-less binding of the stalks is realized, cost for adding binders is saved, processing and production lines are simplified, environmental pollution caused by synthetic resin binders is reduced, production cost is lowered, and a new effective way is provided for artificial board production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

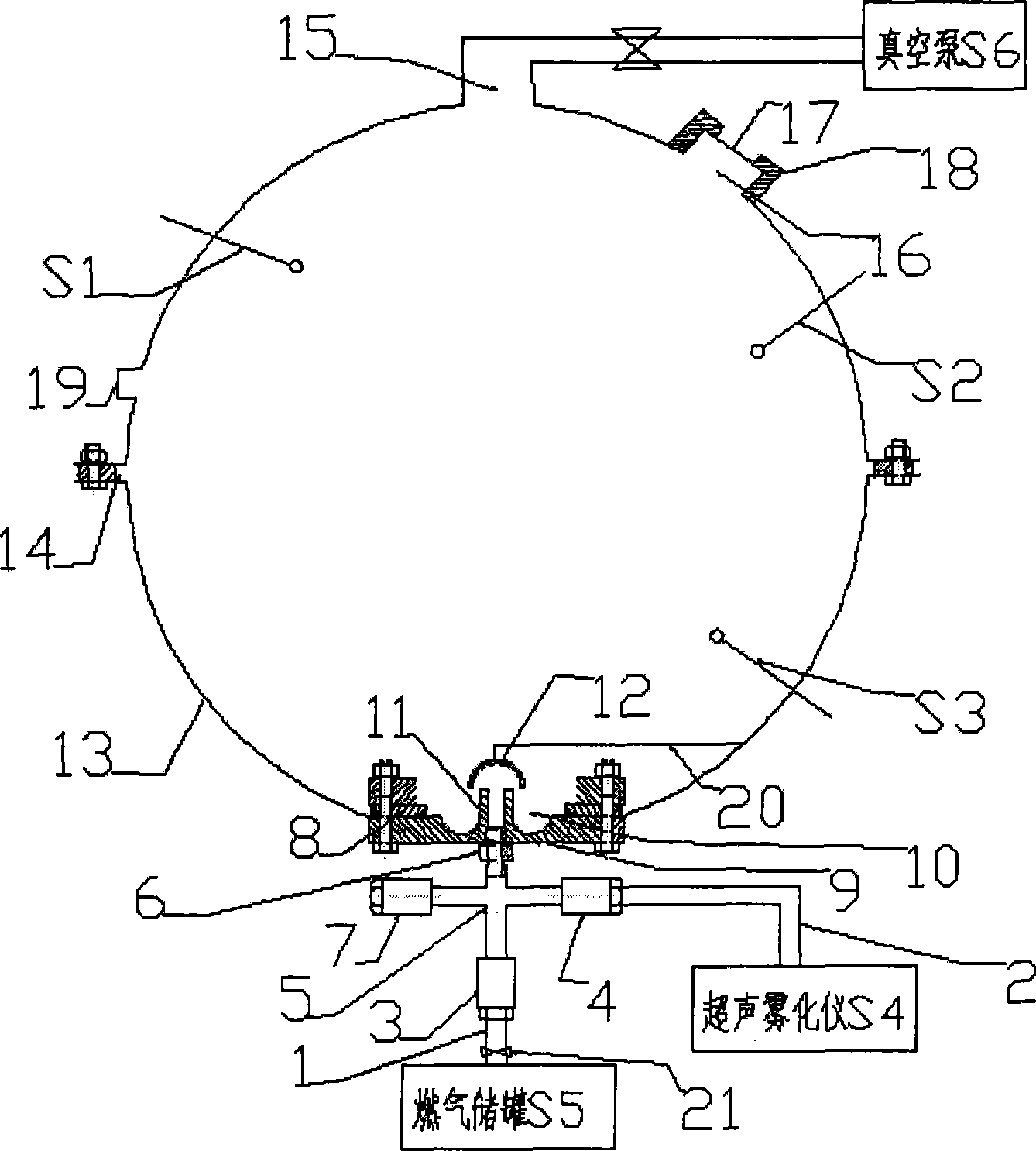

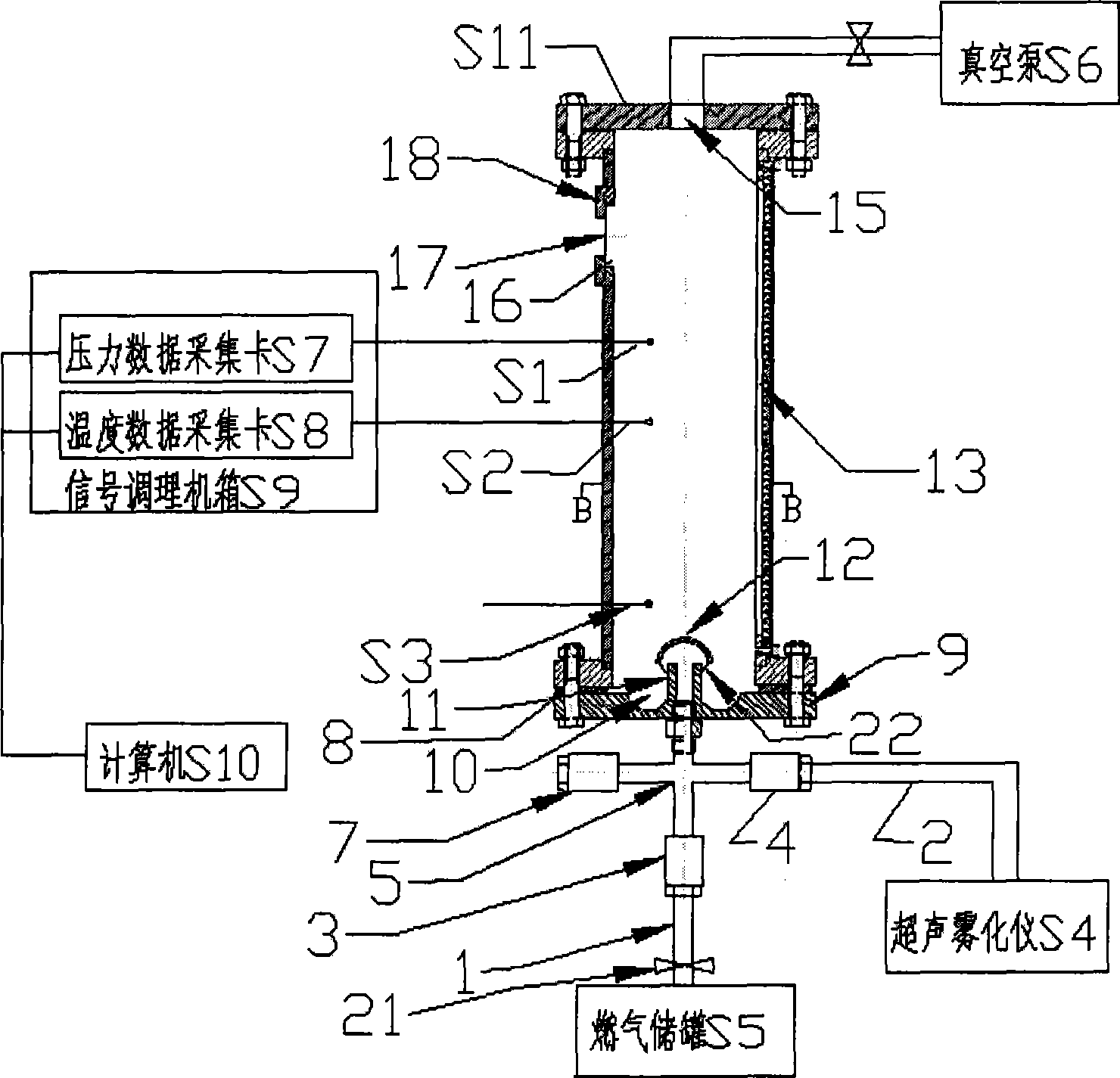

Experimental device for restraining gas and dust explosion by water mist

InactiveCN101477094AControl limit test pressureGood for optical observationChemical methods analysisAtmospheric airInlet pressure

The invention discloses an experimental device adopting fine water mist to suppress gas and dust explosion. The experimental device is characterized in that a pressure-resisting airtight burner of the device is provided with a temperature sensor, a pressure sensor and an ignition device inside; the wall of the burner is provided with a transparent observation window and a pressure release hole pasted with an explosion-proof piece; the top of the burner is connected with a vacuum pump through a gas suction pipe with a valve; a flange base on the bottom of the burner is provided with a gas inlet pipe protruding inwards; a hollow hemispherical cover body with the spherical top protruding inwards is fixed above a nozzle of the gas inlet pipe; the flange base encircling the bottom of the outer wall of the gas inlet pipe is provided with an annular groove inside; the gas inlet pipe is respectively connected with a gas storage tank through a valve via an adjusting valve and an ultrasonic atomizer through a fine water mist inlet pipe, and is also communicated with the atmospheric environment; and dust inside the bottom flange groove is raised and suspended in the burner by means of inlet pressure. The experimental device can carry out explosion suppression experiment of gas, dust or gas-dust composite explosion and research on flame spreading rule and microstructure.

Owner:UNIV OF SCI & TECH OF CHINA

Method for preparing dietary fiber from bean dregs serving as raw material by combining steam explosion and enzymolysis

The invention discloses a method for preparing dietary fiber from bean dregs serving as a raw material by combining steam explosion and enzymolysis. In the method, a pure natural and fully water-soluble dietary fiber product is obtained through pretreatment of the bean dregs, steam explosion, ultrafine grinding, enzymolysis and drying of enzymolysis slurry. In the method, conversion rate of the soluble dietary fiber can be quickly and effectively increased by performing the steam explosion before the enzymolysis. Other chemical substances are not required to be added due to the adoption of the steam explosion, and the product is the pure natural dietary fiber. Cellulase, pectinase or xylanase can be separately used as an enzyme used in the method. Compared with a method for producing the fully water-soluble dietary fiber, the method for producing the mixed dietary fiber with high water-soluble dietary fiber content has the advantages of reduced investment, low production cost and capability of solving the problem of pollution of three wastes (waste water, waste gas and industrial residues).

Owner:GUANGXI UNIV

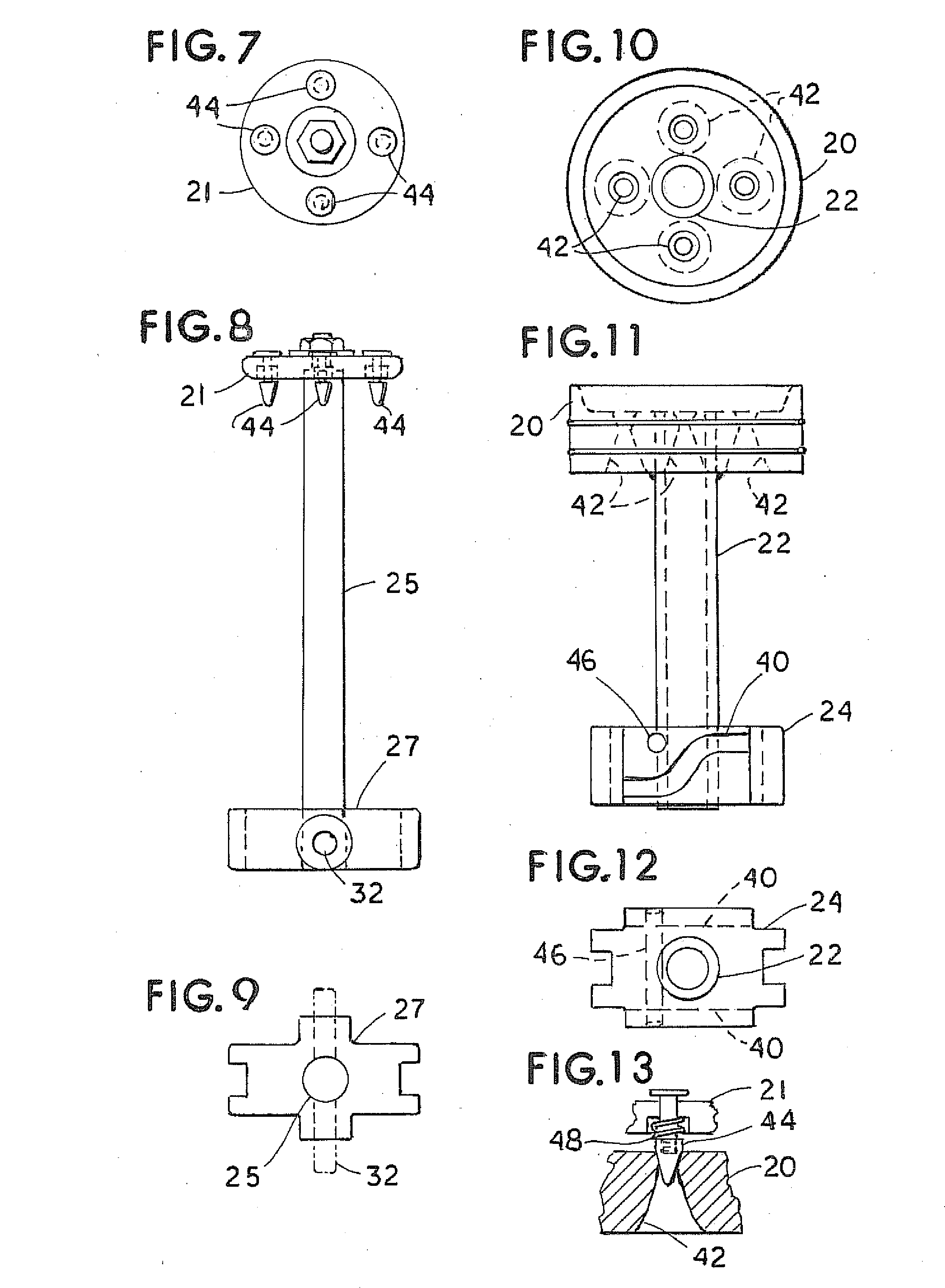

Jet exhaust piston engine

InactiveUS20110030646A1Reduce and eliminate return stroke pressureEliminate compression strokePistonsPiston pumpsEngineeringPiston

This invention is a piston in cylinder engine using water injection into a relative vacuum heated to steam by expanding in the cylinder and by an electric arc or other heat source. The resulting steam explosion applies a work force on the piston. The piston has jet nozzles uncovered at the end of its work stroke to jet the piston to help propel it during the return stroke and to form a vacuum in place of the usual compression stroke. The piston has a cover plate with tapered pins depending into jet nozzles through the piston to block the jet nozzles during the main work stroke.

Owner:BARRY LEONARD D

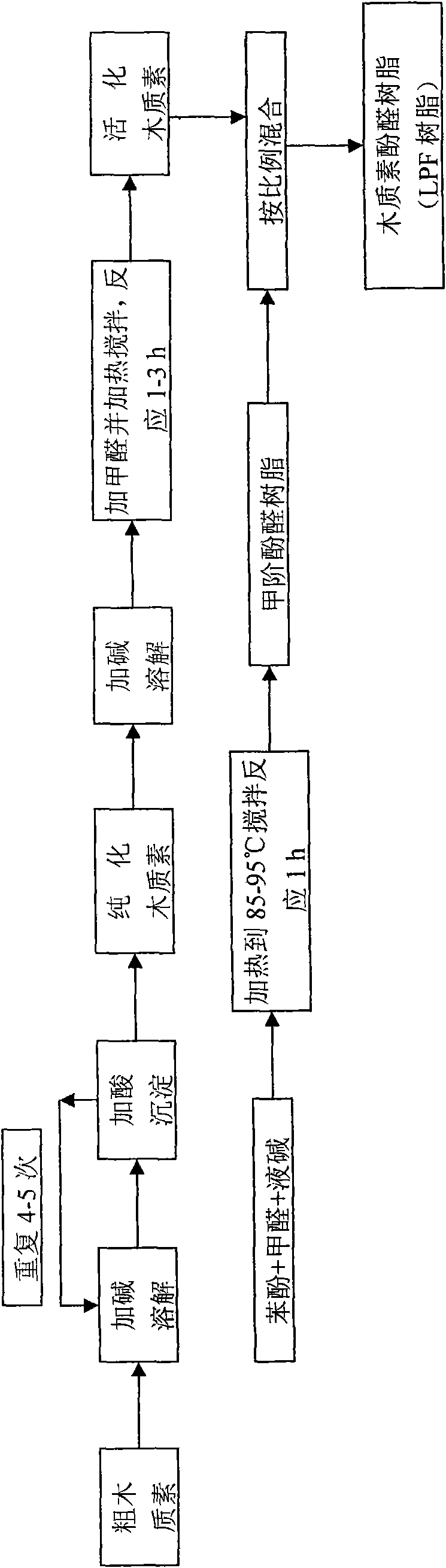

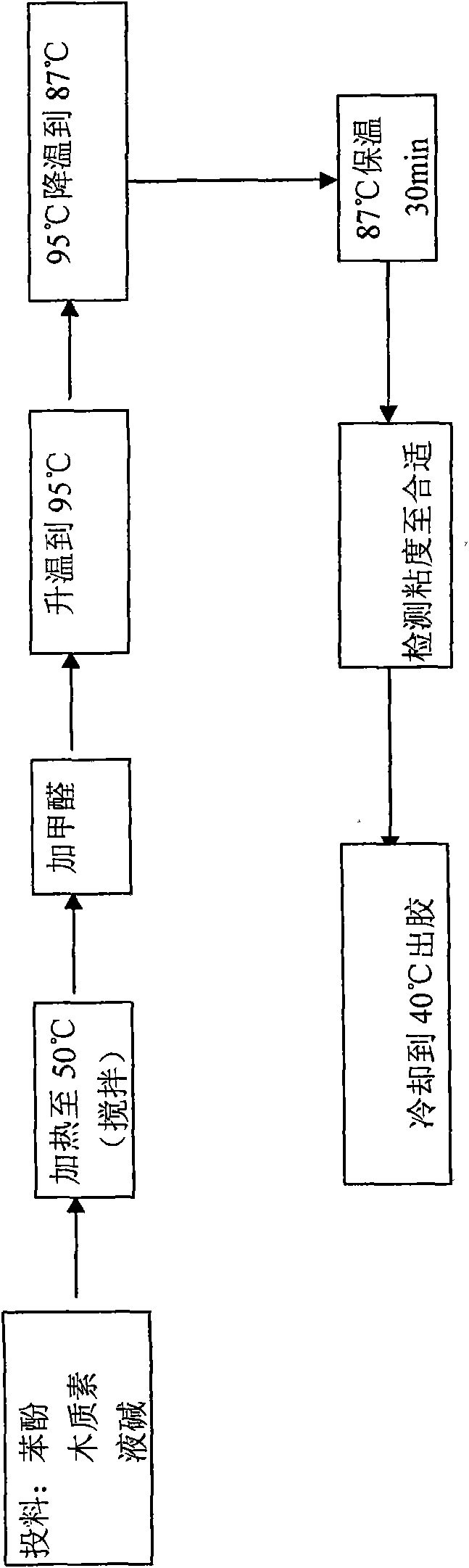

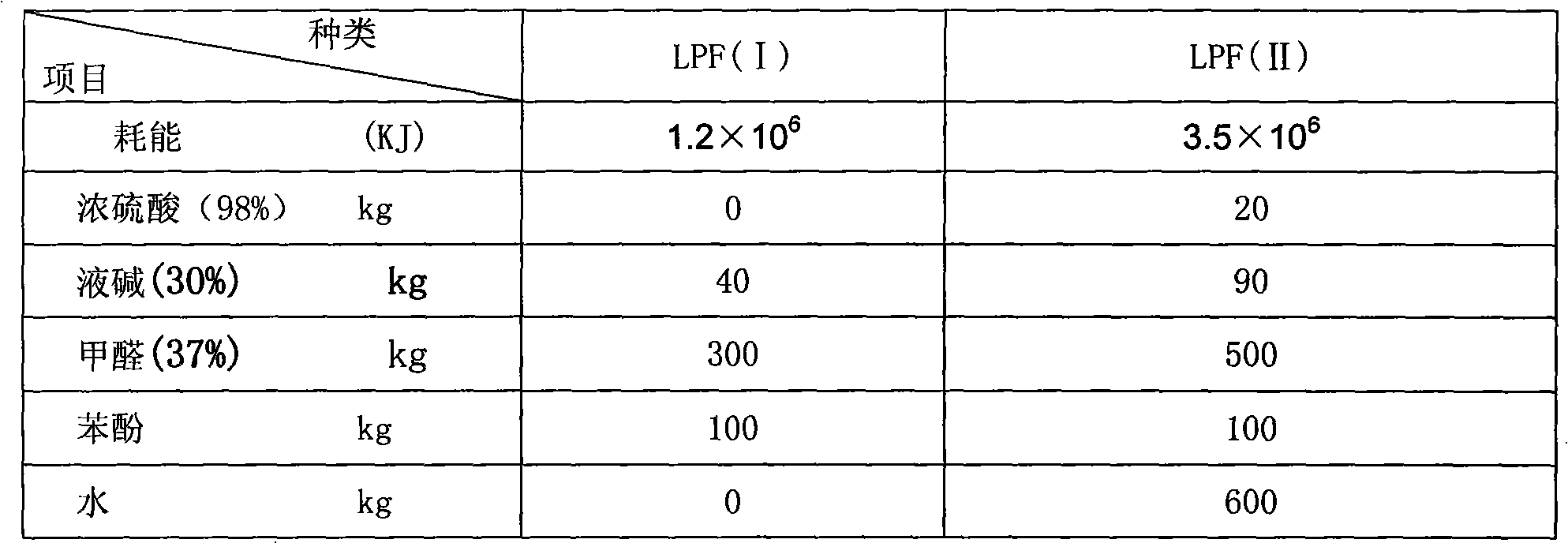

Preparation method of lignin phenolic resin

ActiveCN101942068AQuality improvementReduce energy consumptionAldehyde/ketone condensation polymer adhesivesBlack liquorBiological activation

The invention relates to a preparation method of lignin phenolic resin, which comprises the steps of directly stirring liquid lignin, phenol and formaldehyde for reaction under the action of liquid caustic soda at the temperature of 70-100 DEG C and obtaining the lignin phenolic resin. The liquid lignin is lignin alkaline solution obtained by stage-by-stage separation through steam explosion, stewing by adding alkali, film treatment and other technological processes of grasses or / and ligneous plants, the solid content is 10-25%, and the pH is 10.5-13.5. The preparation method can avoid the purification and the activation treatment by using the high-pure liquid lignin in comparison with coarse lignin powder taken from paper pulp black liquor, thereby not only improving the product quality, but also simplifying the process, saving the equipment investment, simultaneously greatly reducing the energy consumption, the consumption of raw materials and the production cost and being more environment-friendly.

Owner:ANHUI GEYI CYCLIC ECONOMY IND PARK

Recovery of fibers from a fiber processing waste sludge

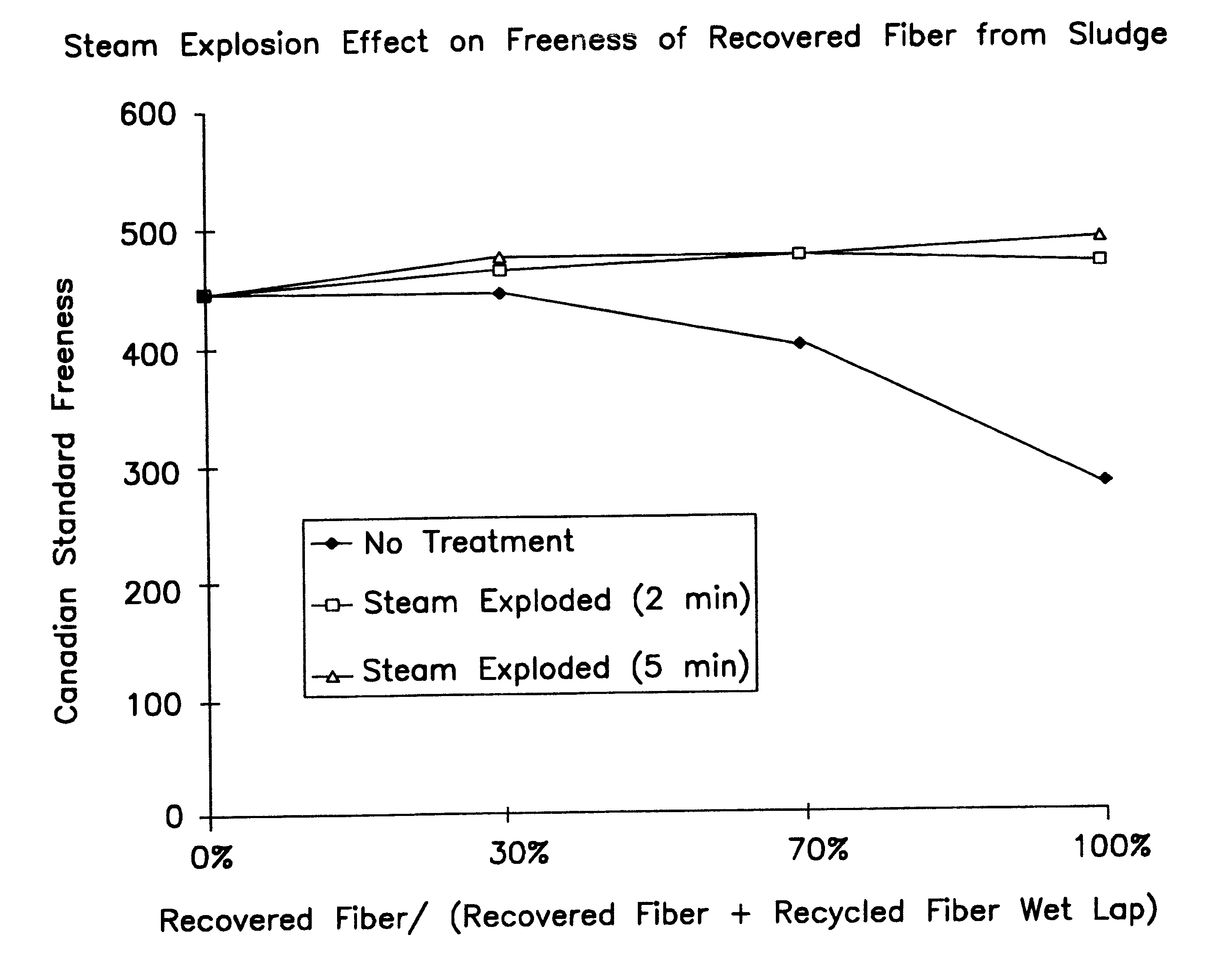

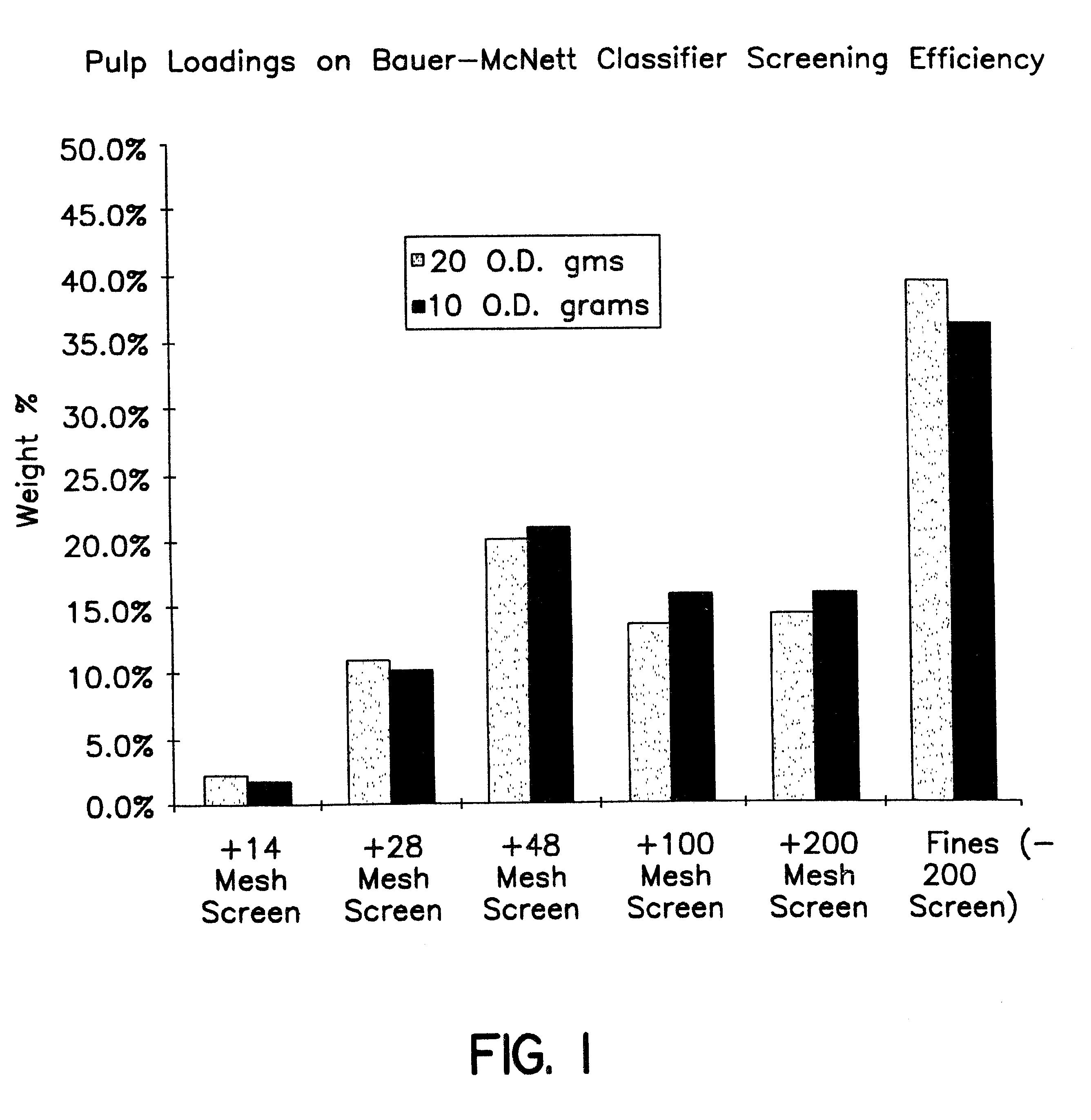

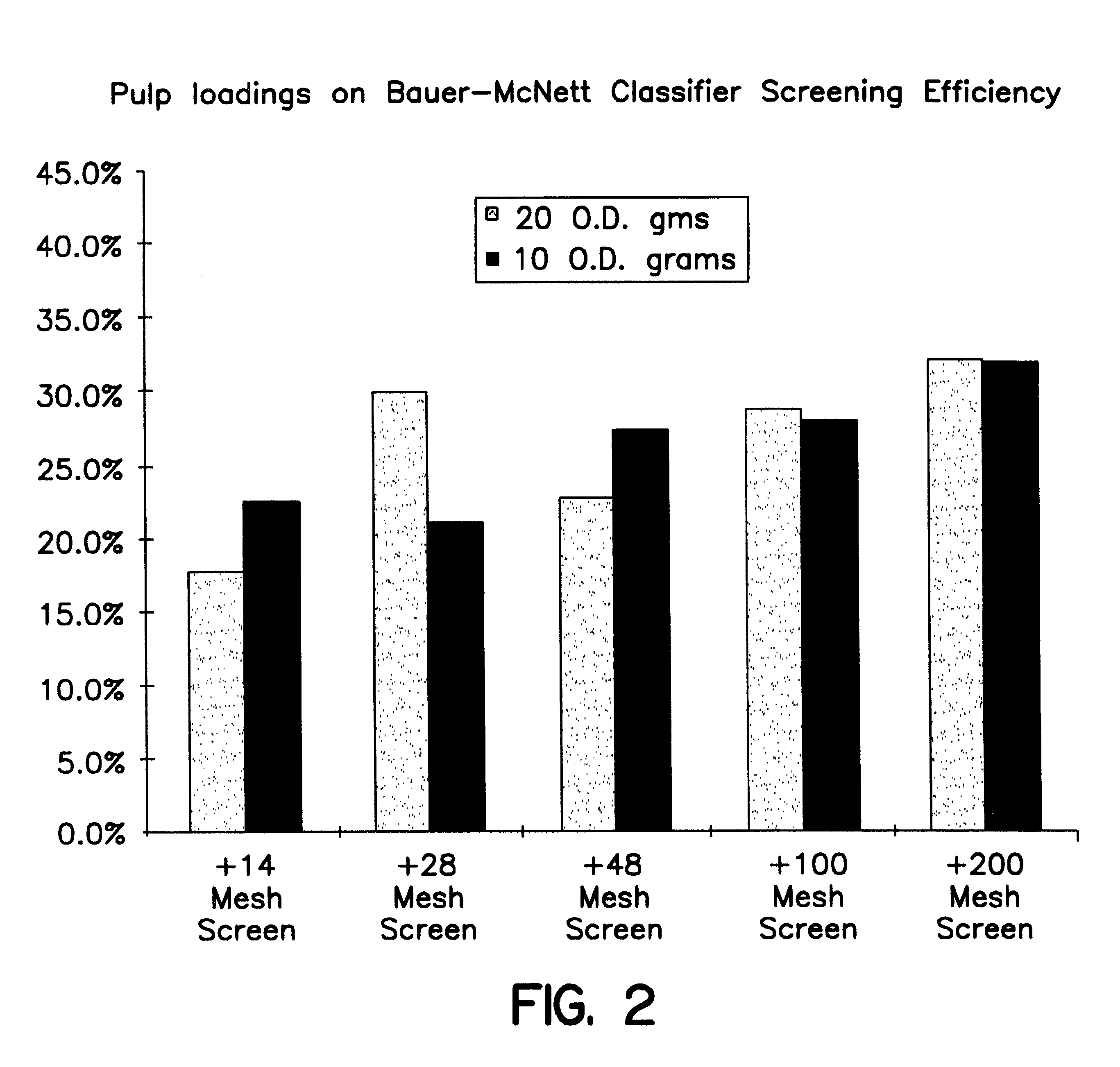

InactiveUS6372085B1Superior fiber quality characteristicIncrease percentagePaper recyclingWaste paper working-upFiberSludge

A process of recovering a useful population of fibers and fines from the waste stream of fiber processing facility is disclosed. Steam explosion of the fiber-containing waste stream is used to increase the separation efficiency of the fibers from the ash. The steam explosion also enhances the quality of the recovered fibers and fines, providing a population of recovered fibers which can be incorporated into the fiber component of a tissue or absorbent paper product.

Owner:PAPER TECH FOUND INC

Feather albumen powder and preparation method thereof

ActiveCN101653188ASimple production methodReduce manufacturing costAnimal feeding stuffSmall peptideSpatial structure

The invention relates to a preparation method of feather albumen powder and the feather albumen powder prepared by the method. The method comprises the following steps: firstly carrying out pretreatment of washing, drying and cutting; then effectively carrying out steam explosion on feather by a steam explosion technique to damage the stable space structure of feather keratin; and finally carryingout zymohydrolysis treatment to enable the feather to become dissoluble small peptide and amino acid, thereby enhancing the digesting rate of pepsin of feather albumen and largely enhancing the biologic valence. The preparation method has the advantages of simplicity, low production cost, short processing period and high equipment efficiency. The content of crude albumen in the feather powder achieves more than 90%, and the digesting rate of in vitro pepsin achieves more than 88%.

Owner:JIANGNAN UNIV

Method for producing ethanol from lignocellulose biomaterial by use of neu-heat-resistant enzyme

It includes the stages of grinding the lignocellulosic biomass to a size of 15-30 mm, subjecting the product obtained to steam explosion pre-treatment at a temperature of 190-230 DEG C for between 1 and 10 minutes in a reactor (2), collecting the pre-treated material in a cyclone (3) and separating the liquid and solid fractions by filtration in a filter press (9), introducing the solid fraction in a fermentation deposit (10), adding a cellulase at a concentration of 15 UFP per gram of cellulose and 12.6 International Units of beta -glucosidase enzyme dissolved in citrate buffer pH 4.8, inoculating the fermentation deposit (10) with a culture of the heat-tolerant bacteria Kluyveromyces marxianus CECT 10875, obtained by chemical mutagenesis from strain DER-26 of Kluyveromyces marxianus and shaking the mixture for 72 hours at 42 DEG C.

Owner:RES CENT OF ENERGY SOURCE ENVIRONMENT & TECH

Boiling-off method for bast fibre and bast fibre produced by the same

InactiveCN1772976AAchieve economyFully reflect the scientific concept of developmentVegetable materialEngineeringWater content

The present invention discloses a degumming method of bast fibre. Said method includes the following steps: soaking bast fibre in water for 40-80 min, making its water content is 60-100%, then placing the water-contained bast fibre into a steam explosion tank, making steam explosion under the condition of that its pressure is 1.3-1.7 MPa and the pressure-retaining time is 3-8 min, taking out the bast fibre, washing said bast fibre with water and drying so as to obtain the invented degummed bast fibre.

Owner:北京赛特瑞科技发展有限公司

Method for producing glue-free fiber board by using dry method of steam explosion slurry

InactiveCN102225571AEasy to separateDoes not consume energyWood working apparatusDomestic articlesFiberWater soluble

The invention discloses a method for producing a glue-free fiber board by using a dry method of steam explosion slurry, and relates to a method for producing a glue-free fiber board by using a dry method of slurry prepared by gramineous plant fiber steam explosion. The method comprises the following seven steps of: 1, preparing raw materials; 2, preparing the steam explosion slurry; 3, separating, accurately grinding and mixing; 4, drying the slurry; 5, paving; 6, performing hot pressing in high-water low-temperature and low-water high-temperature modes; and 7, performing post treatment. The glue-free fiber board prepared by the method has no free formaldehyde or phenol and does not harm the environment; the raw materials do not need to be treated by catalysts of acid, alkali and the like, so acid and alkali pollution and equipment corrosion are not caused; and the water-soluble resin in the steam explosion slurry is not separated or concentrated, and the separated residues are not subjected to secondary steam explosion, so the process is not required, the energy is saved, and the production efficiency is high. The manufactured glue-free fiber board has high strength and low cost.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Method for quickly producing bio-organic fertilizer by using tobacco stalks and bio-organic fertilizer

InactiveCN103058725ARealize resourcesEfficient killingBio-organic fraction processingOrganic fertiliser preparationEcological environmentFlora

The invention discloses a method for quickly producing a bio-organic fertilizer by using tobacco stalks and the bio-organic fertilizer. The raw materials for producing the bio-organic fertilizer in the method comprise the following substances in percentage by weight: 30 to 70 percent of tobacco stalks subjected to steam explosion treatment, 20 to 50 percent of mixed accessories, 5 to 15 percent of conditioning agent and 1 to 5 percent of microbial flora; and the bio-organic fertilizer is prepared through an aerobic composting process, wherein the stacking C / N ratio is adjusted to be 25 to 35 / 1, the water content is adjusted to be 50 to 65 percent, the pH is controlled to be 5.0 to 8.5, the strip stamping height is 1.0 to 1.5 m, and the tobacco stalks are crushed, screened and packaged after reaching a maturity index. The method has the characteristics of fast treatment, high efficiency and fast maturity, and has an important practical significance for fully using wasted tobacco stalk resources, improving the ecological environment of tobacco planting areas and reducing environmental pollution. The bio-organic fertilizer has high organic content, has the effects of improving the soil structure and improving the soil fertility, and can be widely used for planting economic crops of tobaccos, vegetables and the like.

Owner:HENAN AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com