Clean chitosan production technology

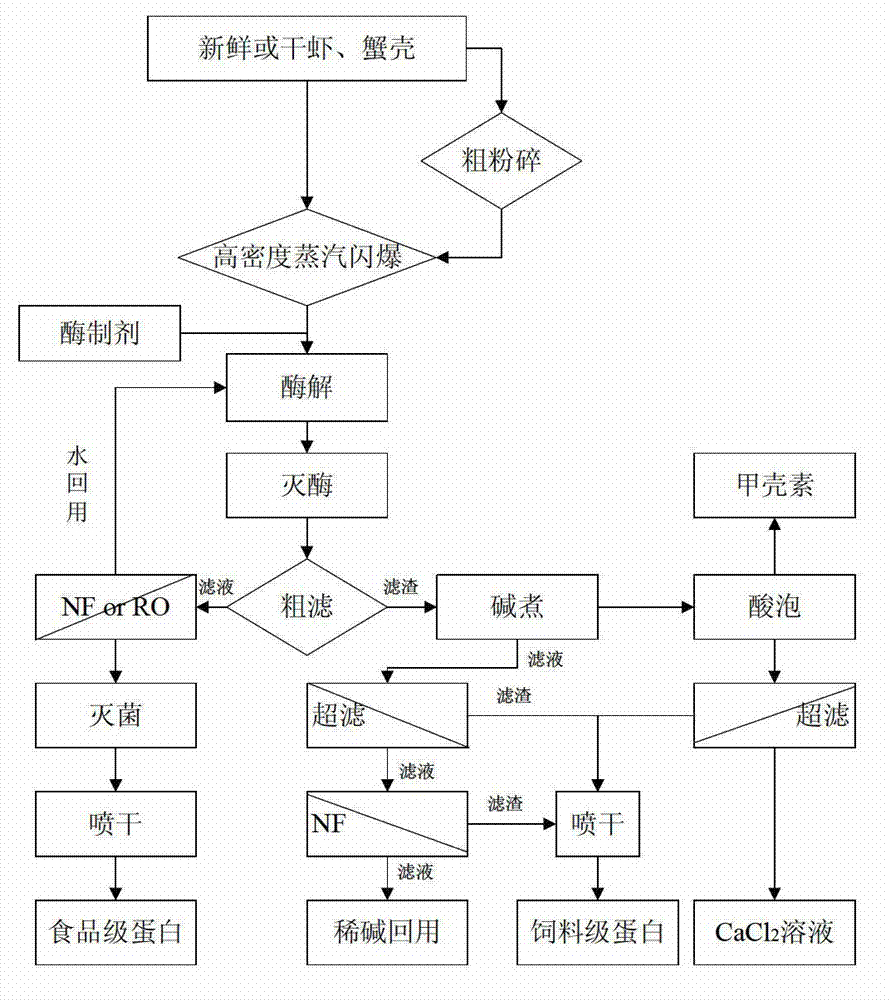

A clean production and chitin technology, applied in the preparation method of peptides, organic chemistry, peptides, etc., can solve the problems of environmental damage of chitin production technology, extensive process wastewater treatment methods, and non-standard discharge. It is of great significance to achieve environmental protection. The effect of reducing the amount of acid foam and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]Using 100Kg of shrimp shells and shrimp processing scraps as raw materials, without coarse crushing, they are directly transported to a high-density steam flash explosion (HDSFE) device, pressurized to 10MPa by steam, and then 0.0875s instantaneous pressure release flash explosion; after flash explosion Transfer the raw materials to a 316L stainless steel reaction tank, soak in 2 times (w / w) tap water, heat up to 60°C, stir and adjust the pH to 6.5, add 30g of neutral protease (100Kg×30%×1‰), and stir for 12 hours , inactivate the enzyme at 85°C, coarsely filter, pass the filtrate through NF or RO membrane to concentrate the proteolysis solution to 20%, and spray dry to obtain about 25Kg hydrolyzed protein powder. Reheat the filter residue with 7% NaOH solution to 100°C, soak for 1 hour with gas blowing, discard the waste caustic soda, wash the residue with water until it is neutral, then soak it with 6% hydrochloric acid for 12 hours with blowing gas at room temperature,...

Embodiment 2

[0029] 100Kg of Alaskan cod crab shells are used as raw material, after being coarsely crushed, it is transported to the HDSFE device, pressurized to 2MPa by steam, and then the flash explosion is instantaneously released in 0.0875s; the raw material after the flash explosion is transported to a 316L stainless steel reaction tank, and the (w / w) Soak in tap water, heat up to 40°C, stir and adjust the pH to 11, add 1.5Kg alkaline protease (100Kg×30%×5%), stir for 4 hours, inactivate the enzyme at 85°C, coarsely filter, and pass the filtrate through NF or RO membrane concentrates the proteolysis liquid to 8%, and sprays and dries it to obtain about 28Kg of hydrolyzed protein powder. Reheat the filter residue with 10% NaOH solution to 95°C, soak with air for 0.5h, discard the waste caustic soda, wash the residue with water until neutral, then soak with 8% hydrochloric acid for 1 hour with air blowing at room temperature, discard the waste acid solution, The slag was washed with wa...

Embodiment 3

[0032] 100Kg crayfish shells are used as raw materials, which are coarsely crushed and transported to the HDSFE device, pressurized to 4MPa by steam, and then instantaneously depressurized for 0.0875s to explode; the raw materials after flash explosion are transported to a 316L stainless steel reaction tank, and are used 5 times ( w / w) Soak in tap water, temperature 10°C, stir and adjust pH to 3, add 0.3Kg compound protease (containing papain, trypsin, pepsin) (100Kg×30%×1%), stir for 1h, 85°C Inactivate the enzyme, coarsely filter, and pass the filtrate through NF or RO membrane to concentrate the protein hydrolyzate to 18%, and spray dry to obtain about 26Kg of hydrolyzed protein powder. Reheat the filter residue with 7% NaOH solution to 95°C, soak for 2 hours with gas blowing, discard the waste alkali solution, wash the residue with water until it is neutral, then soak it with 8% hydrochloric acid for 12 hours with blowing gas at room temperature, discard the waste acid solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com