Patents

Literature

6986results about How to "Reduce water consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing lignocellulosic material

InactiveUS6555350B2High degreeReduce water consumptionSludge treatment by oxidationBiofuelsCelluloseWater flow

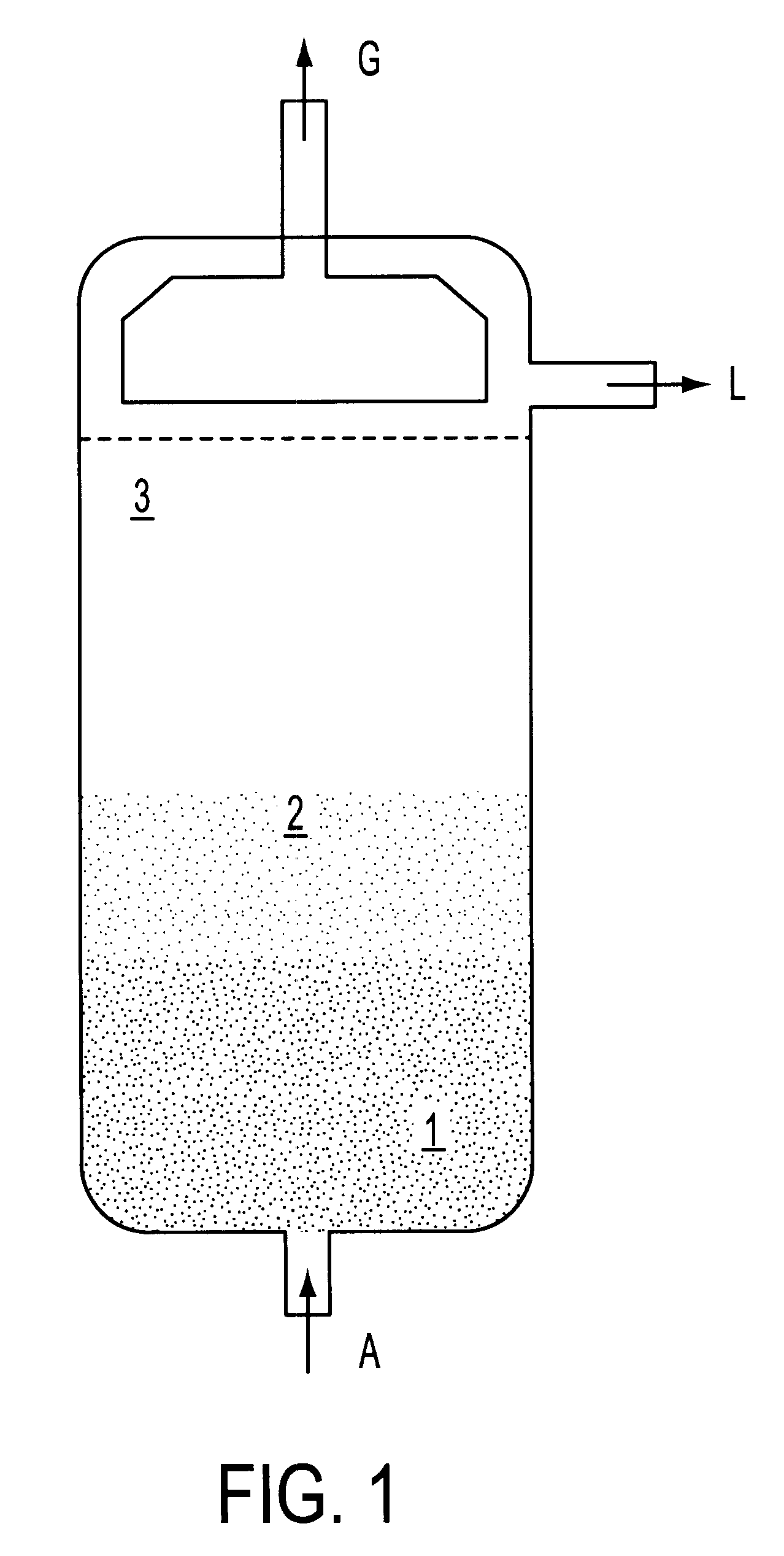

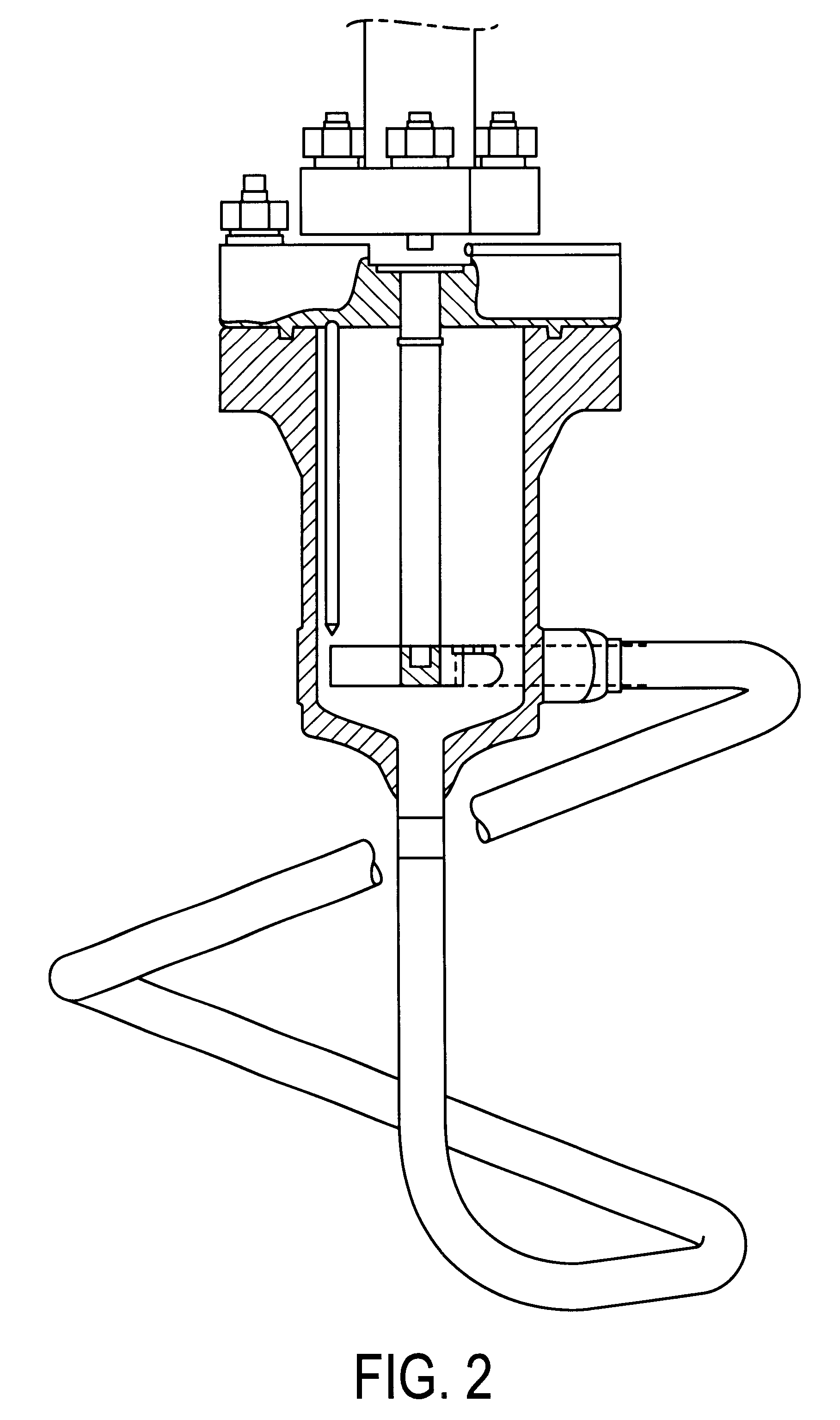

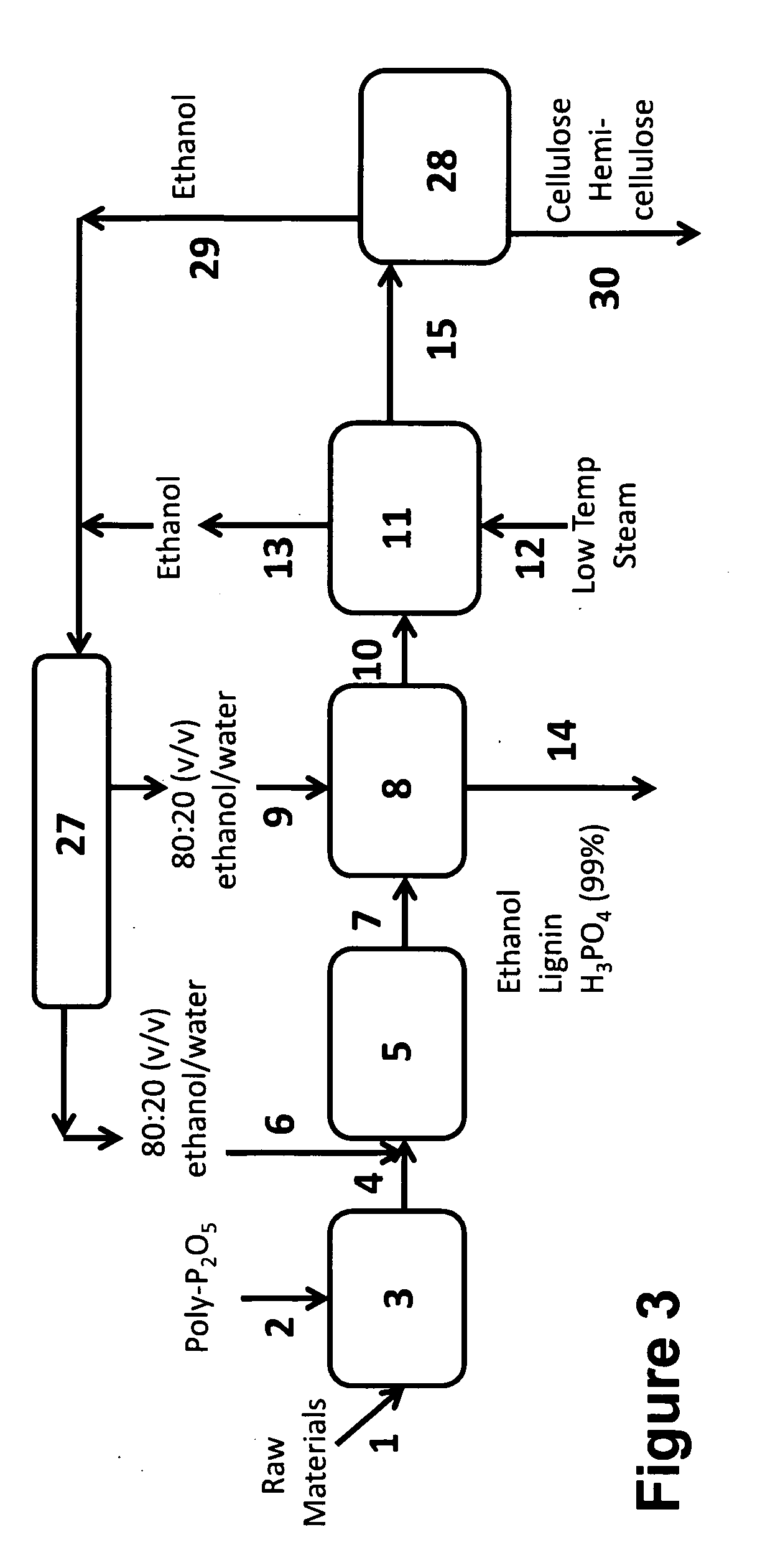

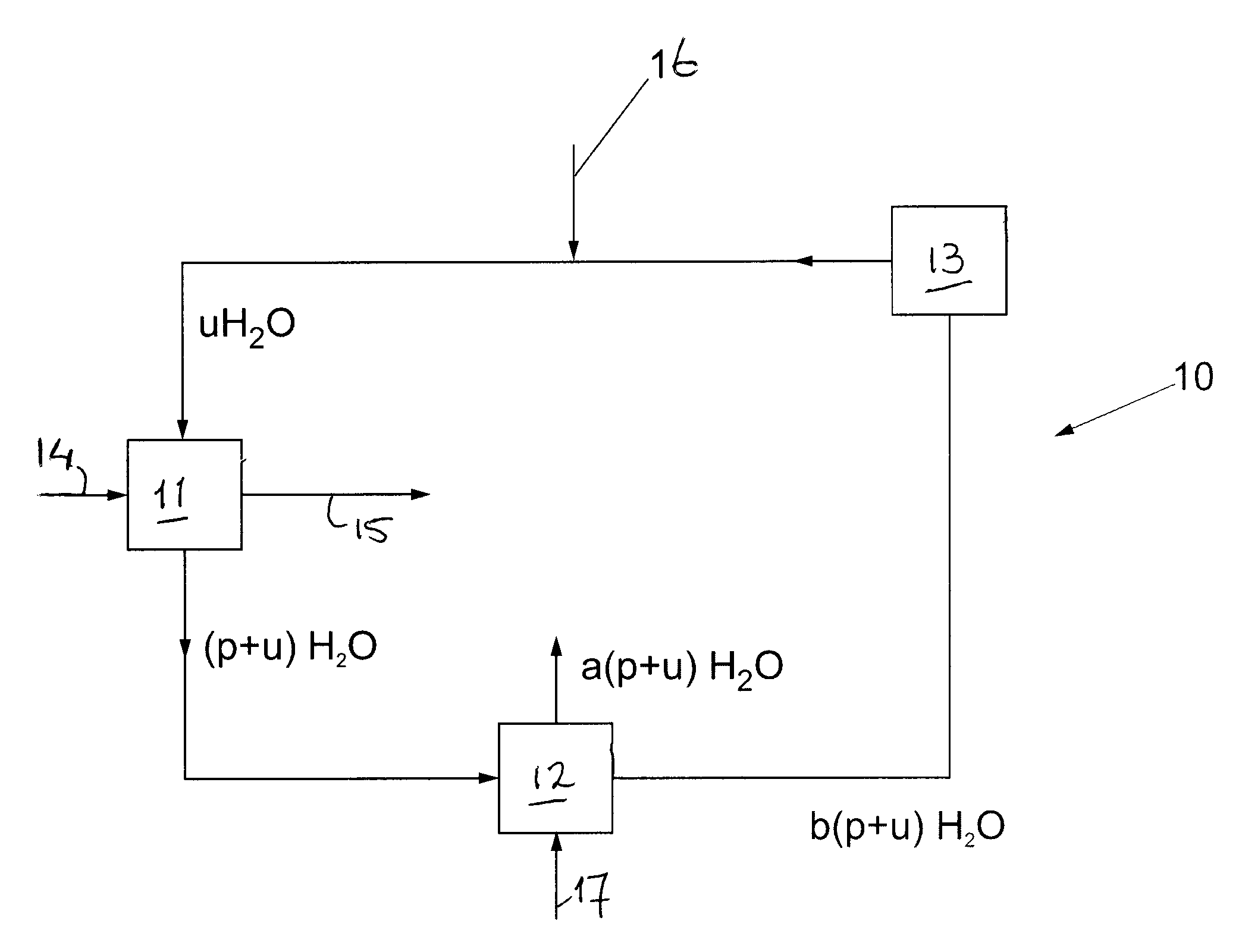

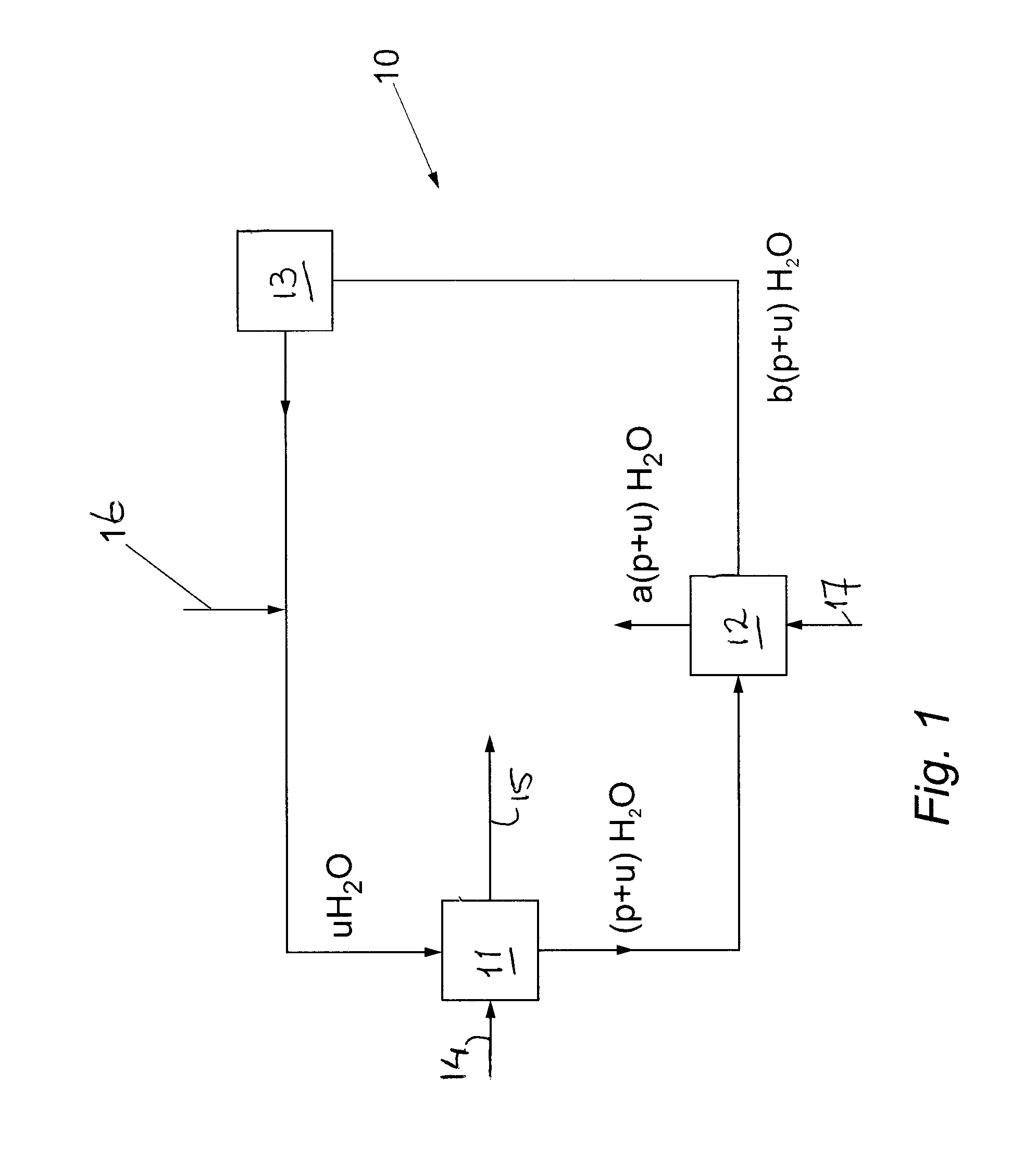

A method wherein lignocellulosic biomass materials are converted into combustible fuel products. In particular, the method is a continuous process, involving wet oxidation or steam explosion, for fermentatively converting such biomass materials into ethanol using a process design that permits all or part of the process water from the ethanol fermentation process to be recycled to reduce the consumption of process water. The effluent from the ethanol fermentation step may be subjected to an anaerobic fermentation step generating methane and a water effluent in which the amount of potentially inhibitory substances is at a sub-inhibitory level, which in turn permits all or part of the effluent water from the anaerobic fermentation step to be recycled into the process.

Owner:POET RES INC

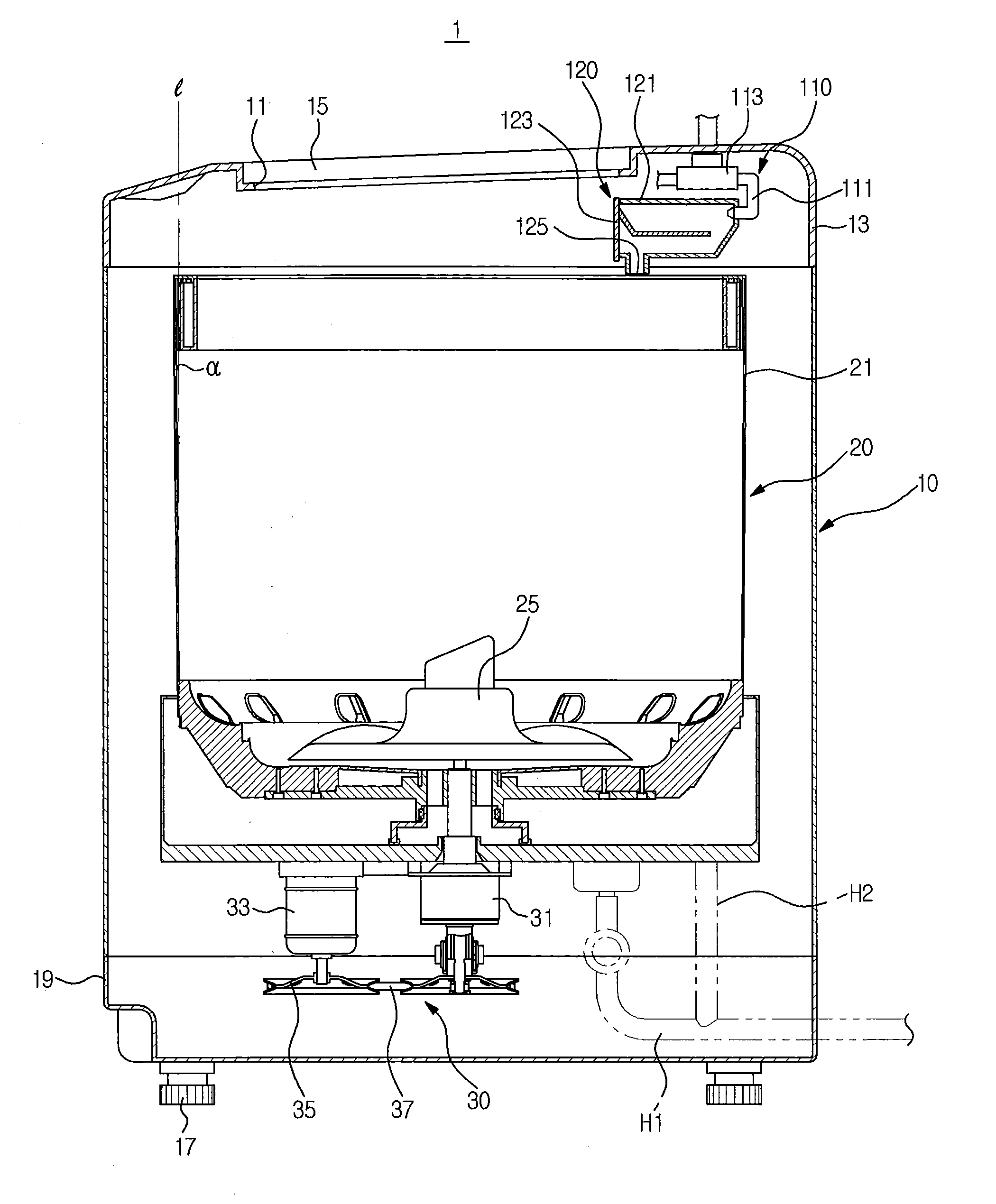

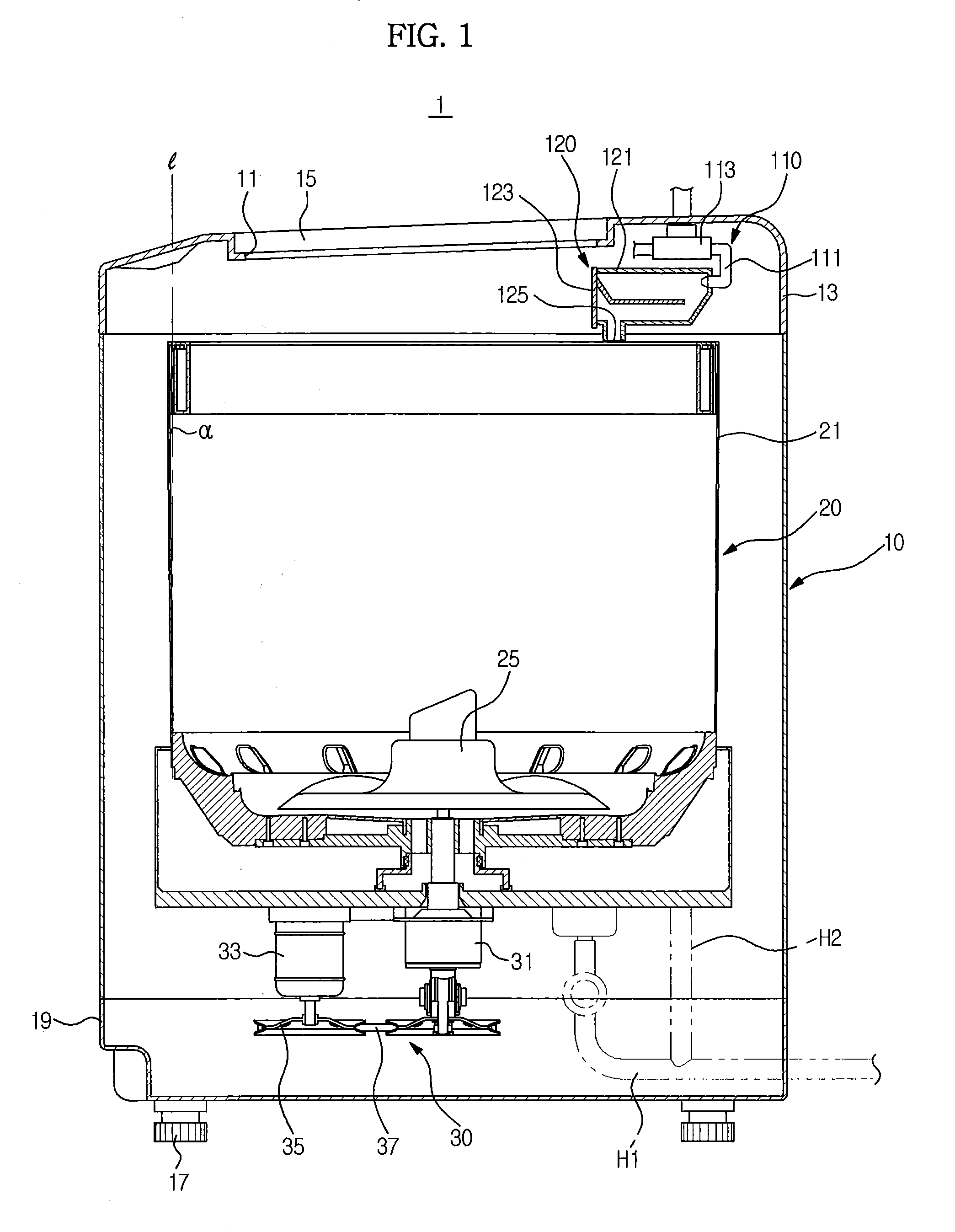

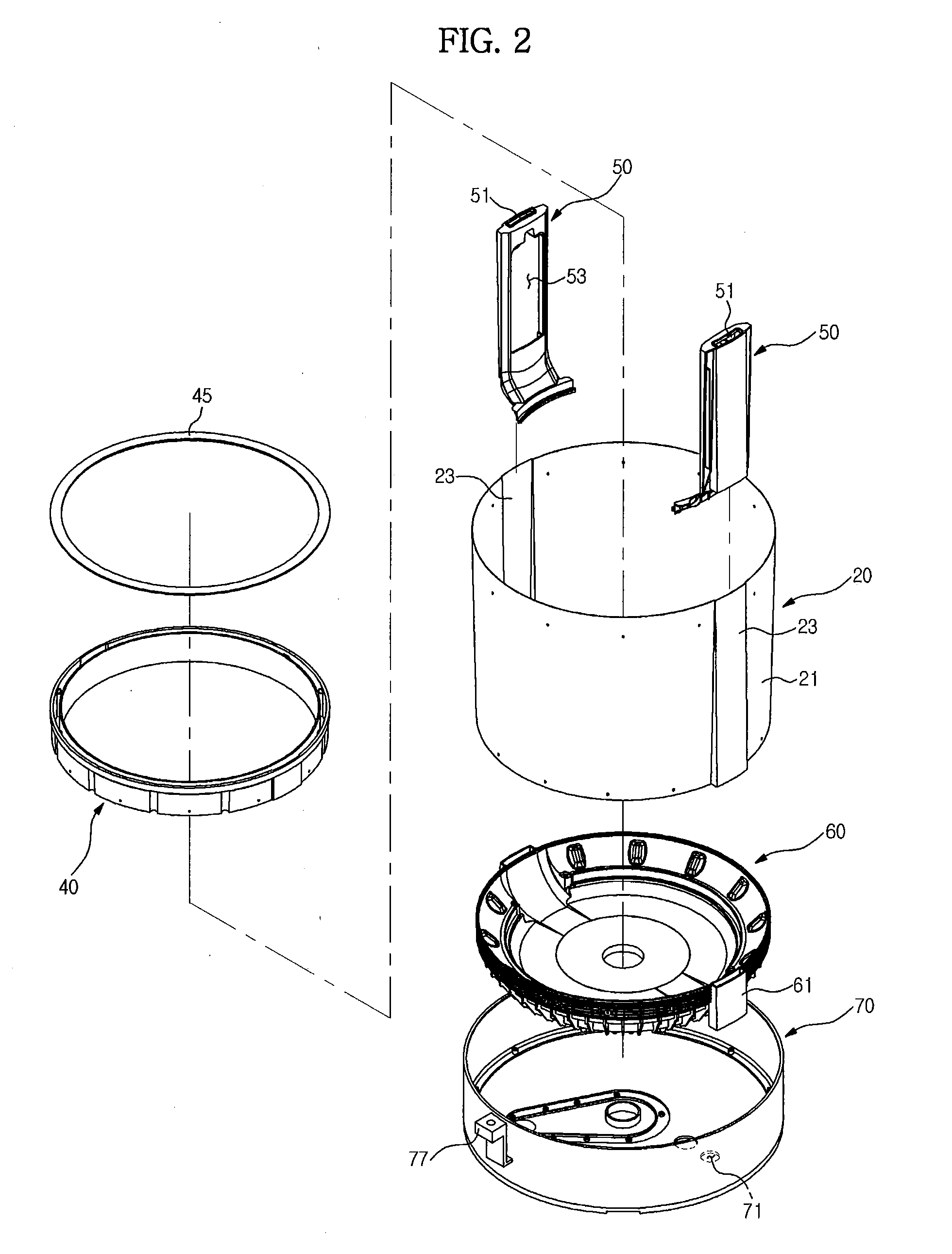

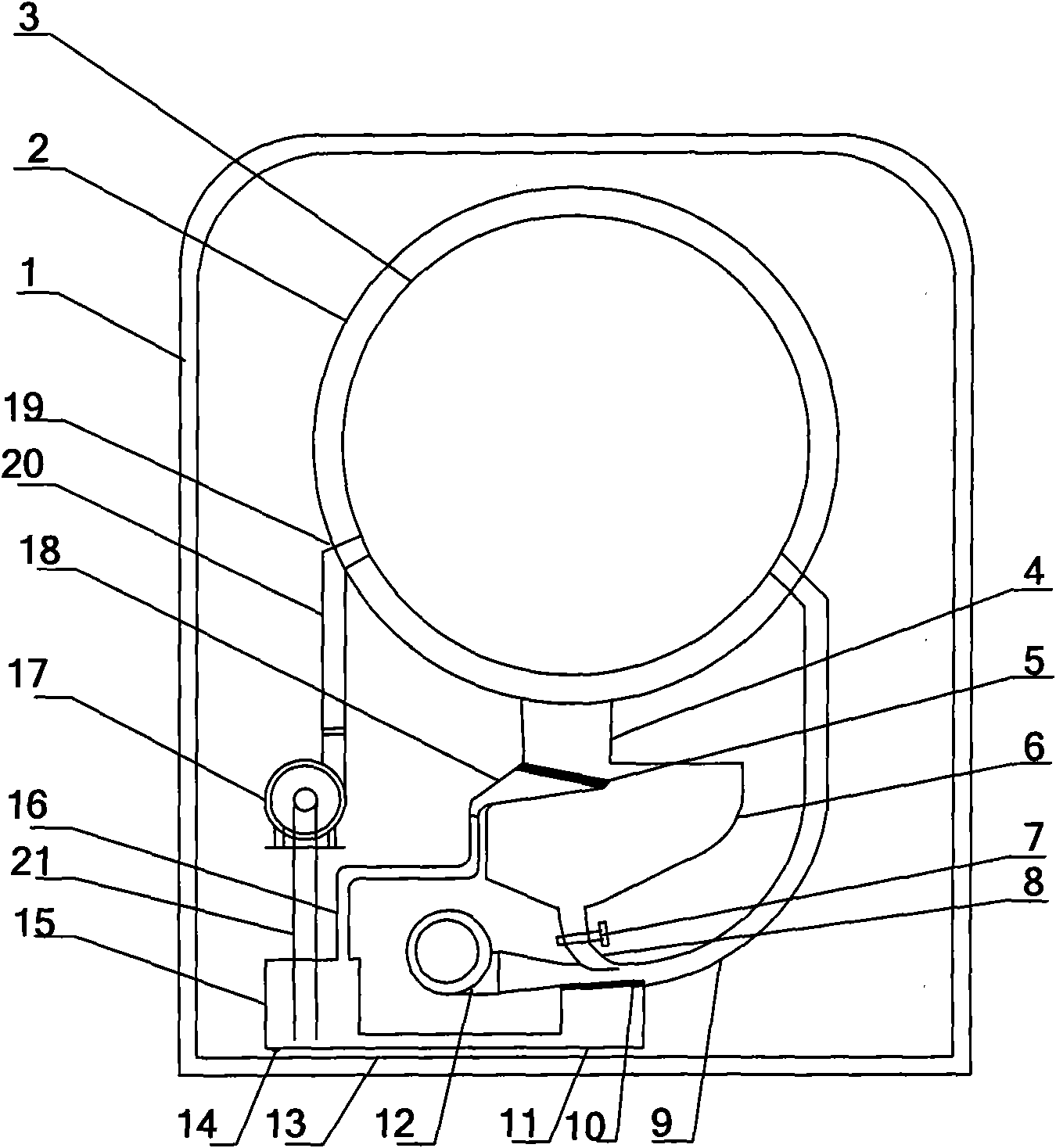

Washing machine

InactiveUS20130036776A1Reduce water consumptionImprove washing effectOther washing machinesInterengaging clutchesWater dischargeDrive shaft

A washing machine includes a cabinet forming an external appearance of the washing machine, a rotary tub disposed to rotate around a driving shaft vertically provided inside the cabinet and including a sidewall, which extends with inclination to have a diameter increasing from a lower side to an upper side of the washing machine, and at least one protrusion part, which protrudes from the sidewall with inclination to have a diameter increasing from an upper side to a lower side of the sidewall. A guide water filter is mounted on at least one protrusion part inside the rotary tub and provided at a rear surface thereof with a drain passage to discharge the washing water discharged from the balance ring to outside. A base is installed at the lower side of the rotary tub and includes a guide part and a support plate.

Owner:SAMSUNG ELECTRONICS CO LTD

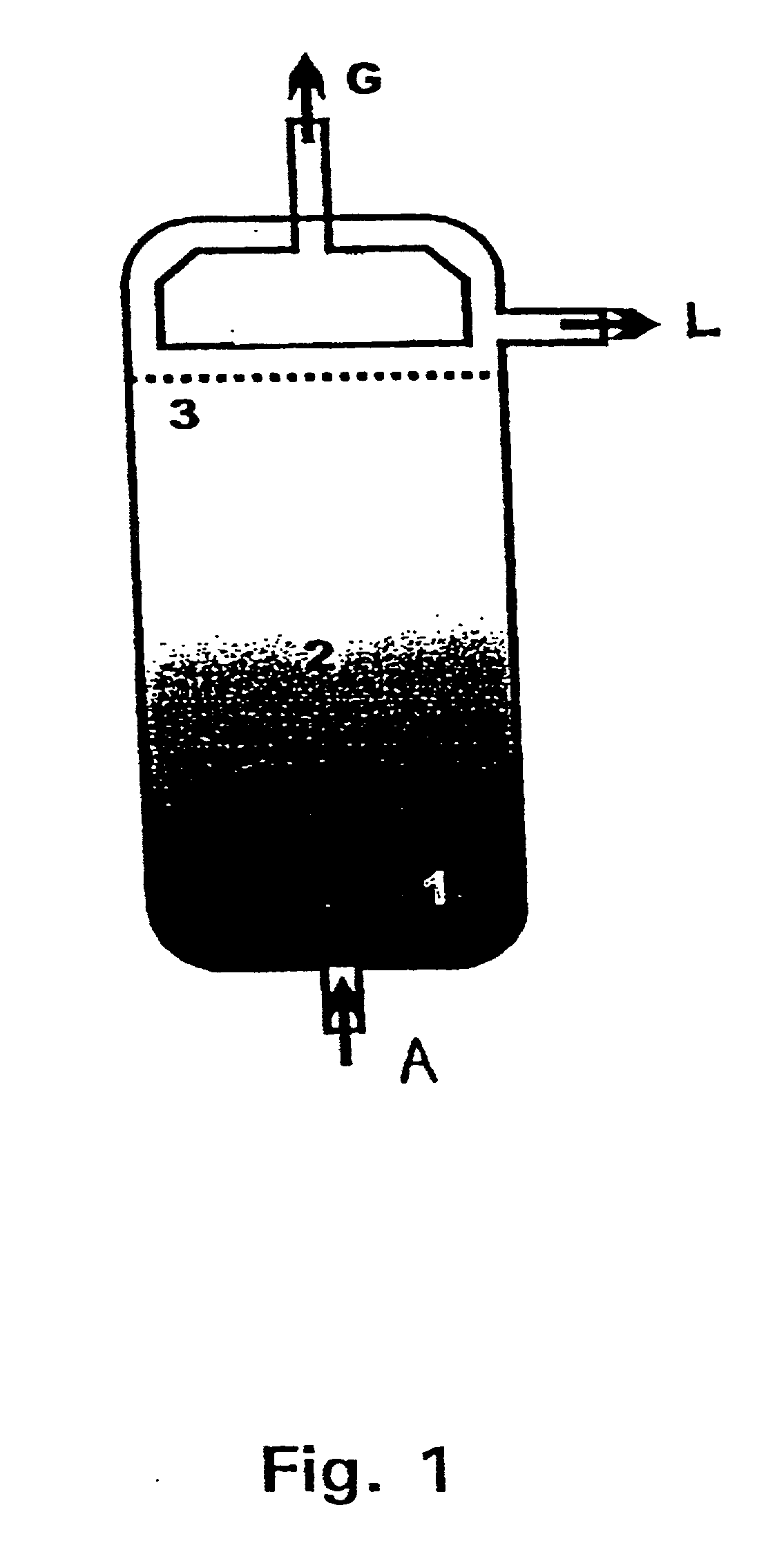

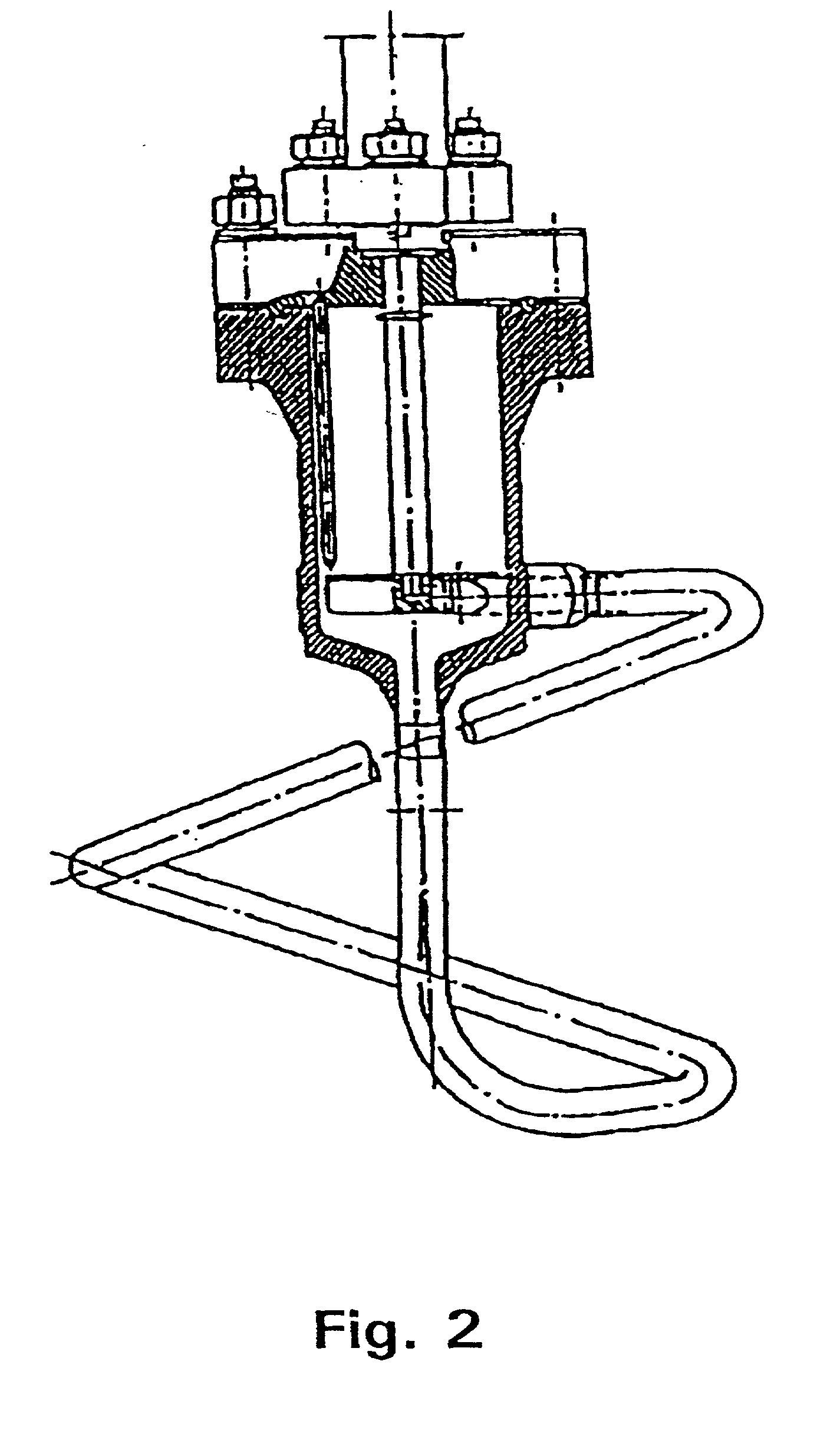

Method for processing lignocellulosic material

InactiveUS20020192774A1High degreeReduce water consumptionSludge treatment by oxidationBiofuelsCelluloseEnvironmental engineering

A method wherein lignocellulosic biomass materials are converted into combustible fuel products. In particular, the method is a continuous process. involving wet oxidation or steam explosion, for fermentatively converting such biomass materials into ethanol using a process design that permits all or part of the process water from the ethanol fermentation process to be recycled to reduce the consumption of process water. The effluent from the ethanol fermentation step may be subjected to an anaerobic fermentation step generating methane and a water effluent in which the amount of potentially inhibitory substances is at a sub-inhibitory level, which in turn permits all or part of the effluent water from the anaerobic fermentation step to be recycled into the process.

Owner:POET RES INC

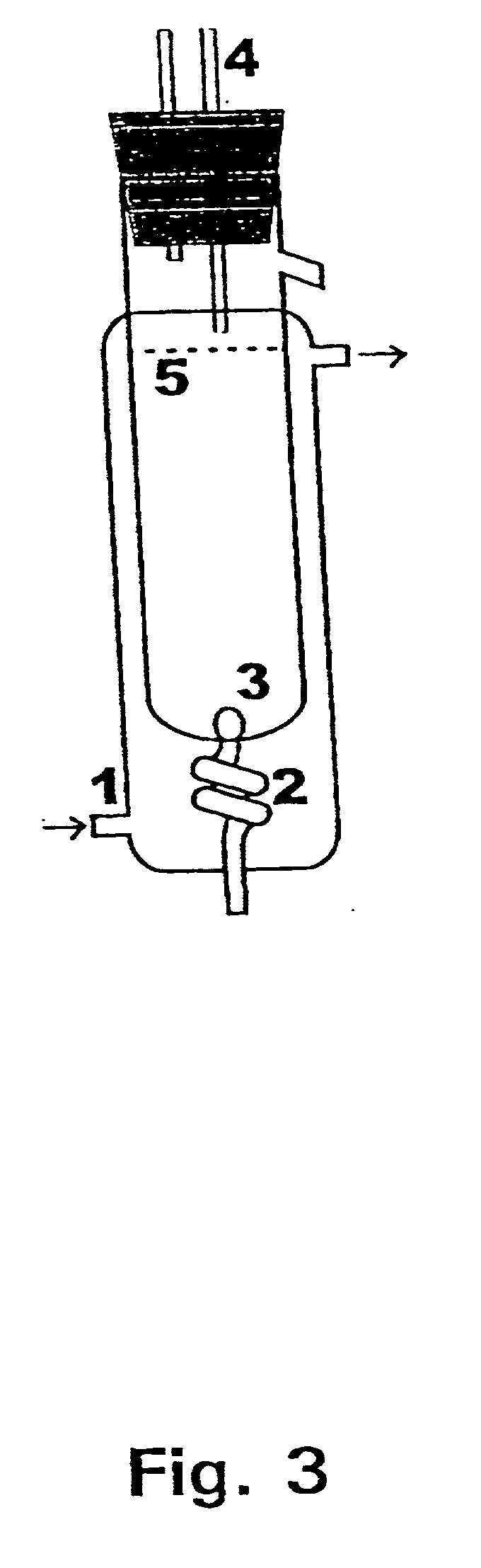

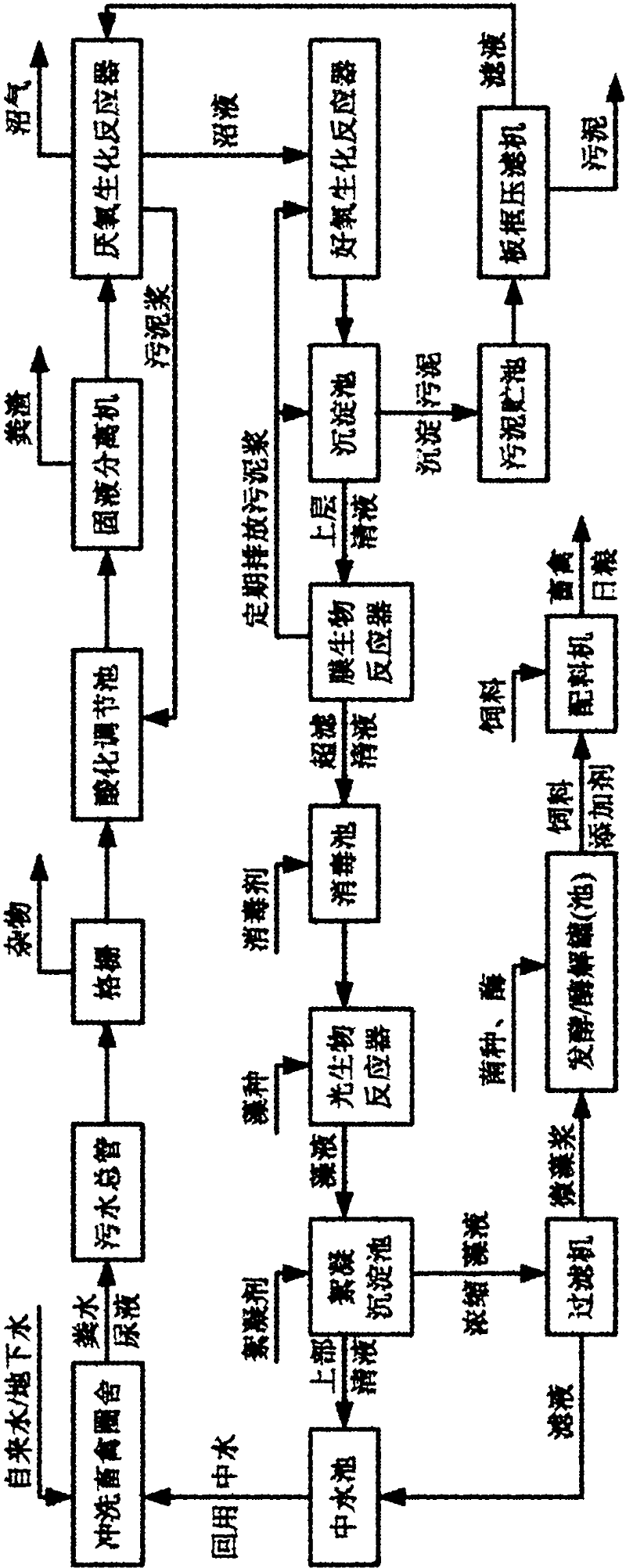

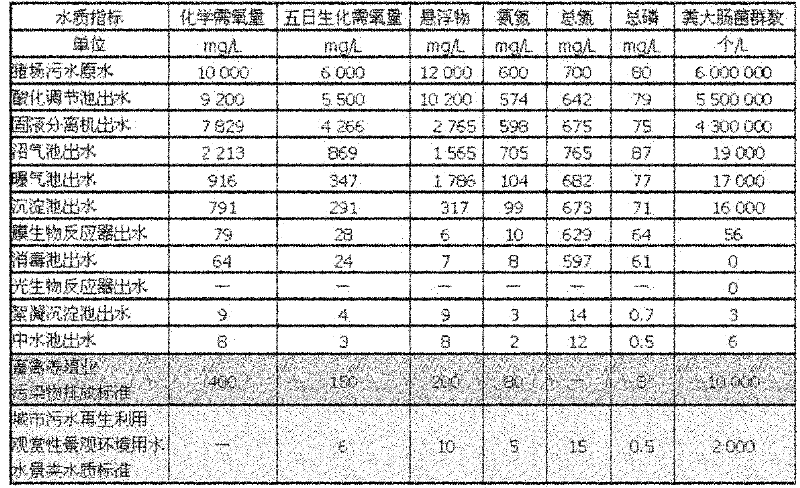

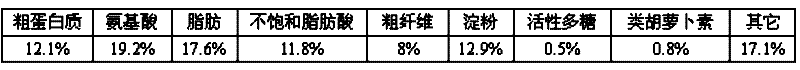

Method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water

InactiveCN102161550AReduce water consumptionAchieving zero emissionsWaste water treatment from animal husbandryAnimal feeding stuffUltrafiltrationSlurry

The invention relates to the fields of environmental technology and the breeding and processing of microalgae, in particular to a method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water. The method is characterized by comprising the following steps that: wastewater enters an acidification adjusting tank through a grille, and the acidified wastewater enters an anaerobic biochemical reactor for treatment and then enters an aerobic biochemical reactor; after the aerobic biochemical treatment, the obtained biogas slurry enters a settling tank for settling, the supernatant enters a membrane bioreactor for further aerobic treatment and is filtered by an ultrafiltration membrane, the generated ultrafiltration clear liquid is sterilized and neutralized and then enters a photobioreactor, algae are added into the photobioreactor to perform microalgae cultivation, and the algae liquid is discharged from the photobioreactor and then enters a flocculation and settling tank; and after flocculation and settling, the supernatant is used for water recycling, the concentrated algae liquid at the bottom enters a filter, and the separated microalgae slurry enters a fermentation / enzymolysis pot (tank) to perform fermentation / enzymolysis to be used as the feed additive. The invention has the advantages of high economic adaptability, zero discharge and the like.

Owner:蔡志武 +1

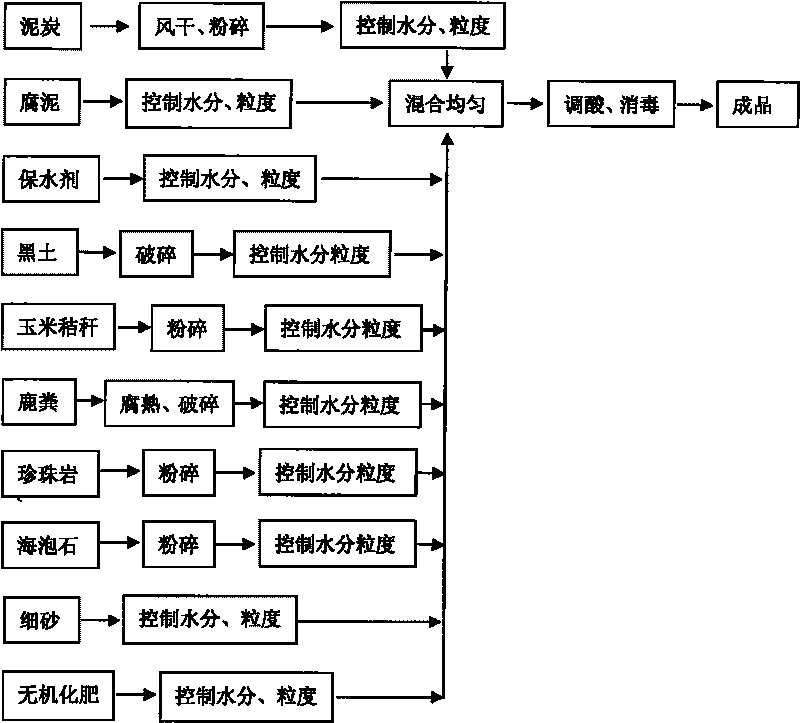

Moisture-preserving nutritious soil for growing herbaceous flower seedlings and preparation method thereof

InactiveCN101715714AReasonable structureLoose structureRenewable energy machinesCultivating equipmentsSoil sciencePlant nutrition

The invention belongs to plant nutritious soil and a preparation method thereof and particularly relates to flower nutritious soil and a preparation method thereof. The flower nutritious soil contains the components of biomass water-retaining agent, turf, sapropel, black soil, corn straw, perlite, meerschaum, deer feces, fine sand, inorganic fertilizer, and the like and is processed by the steps of raw material selection, crushing, screening, disinfection, mixing, pH regulation and the like. By adopting the method of mixing organic materials and inorganic materials, the flow nutritious soil has the advantages of reasonable and loosened structure, complete nutrients, stable property, easily obtained raw materials, easy processing and low cost. In addition, the biomass water-retaining agent contained in the flow nutritious soil is a novel, multifunctional and natural macromoleclar polymer and has a three-dimensional space reticular structure, not only can absorb water and fertilizer, but also can retain water and fertilizer, and. the water absorbing capacity of the flower nutritious soil is more than 1000 times the weight thereof, a small reservoir of water and fertilizer is formed in the soil, and the water and the fertilizer are slowly released, thereby the flow nutritious soil has the functions of saving both water and fertilizer. The invention can be used for growing seedlings and planning seedlings.

Owner:NORTHEAST NORMAL UNIVERSITY

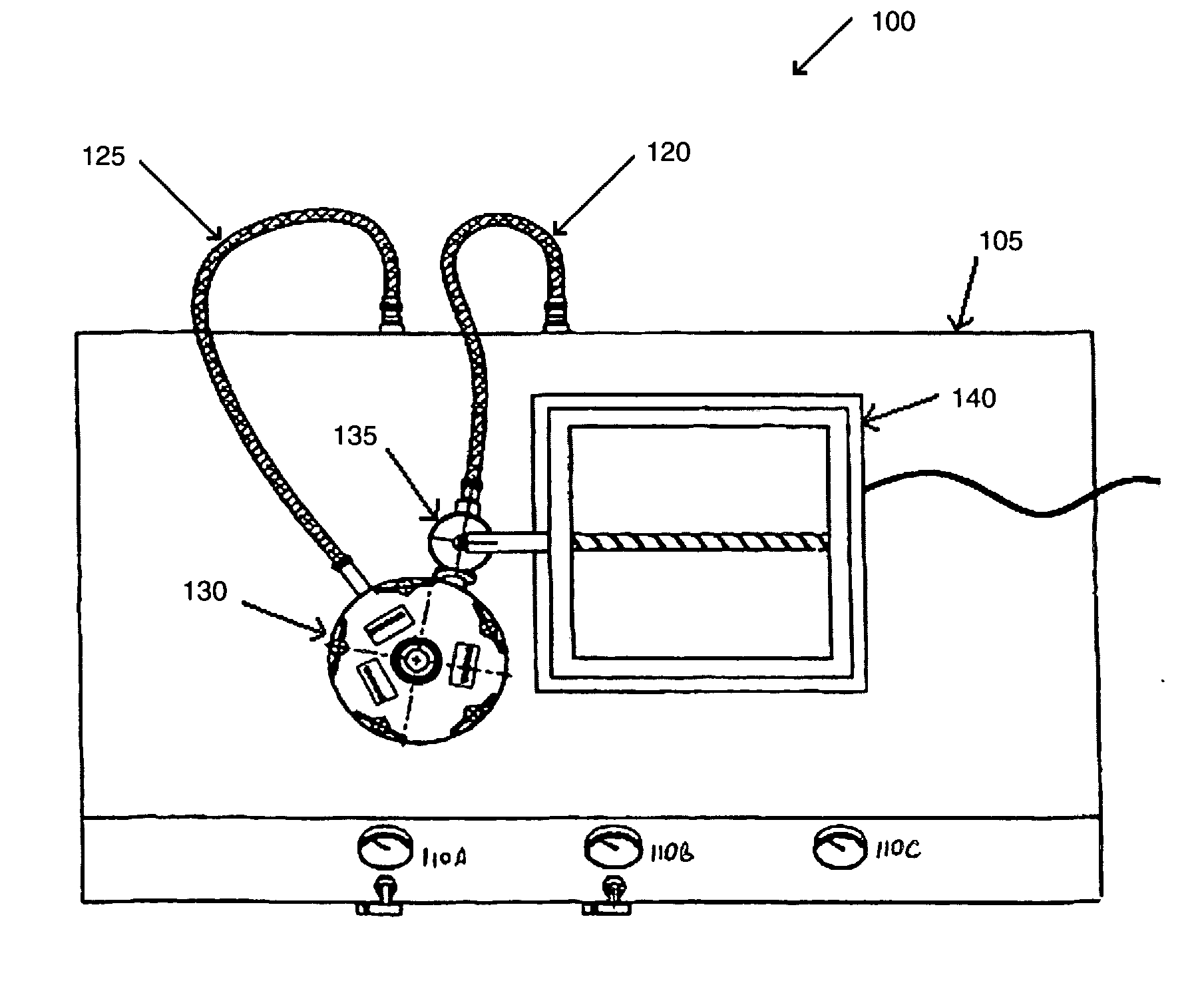

Dry-particle based adhesive and dry film and methods of making same

InactiveUS20070122698A1Reduce water consumptionHigh yieldElectrode rolling/calenderingFinal product manufactureAdhesiveEngineering

Dry process based energy storage device structures and methods for using a dry adhesive therein are disclosed.

Owner:TESLA INC

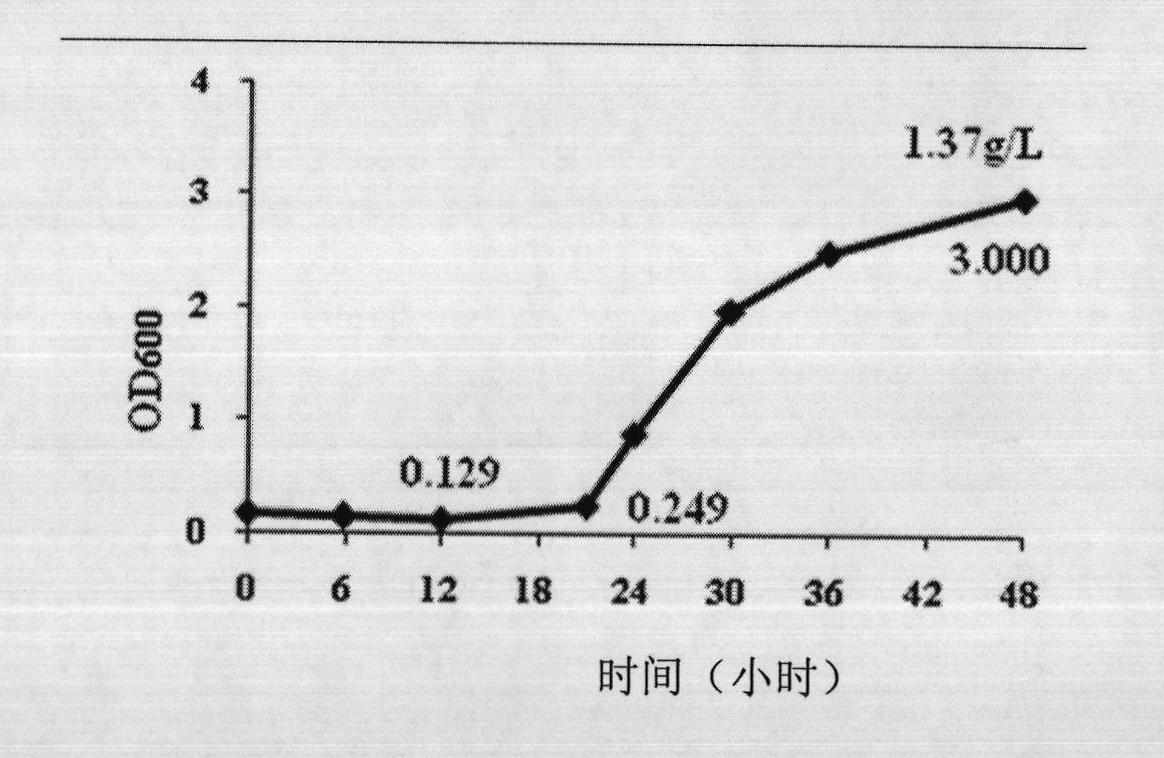

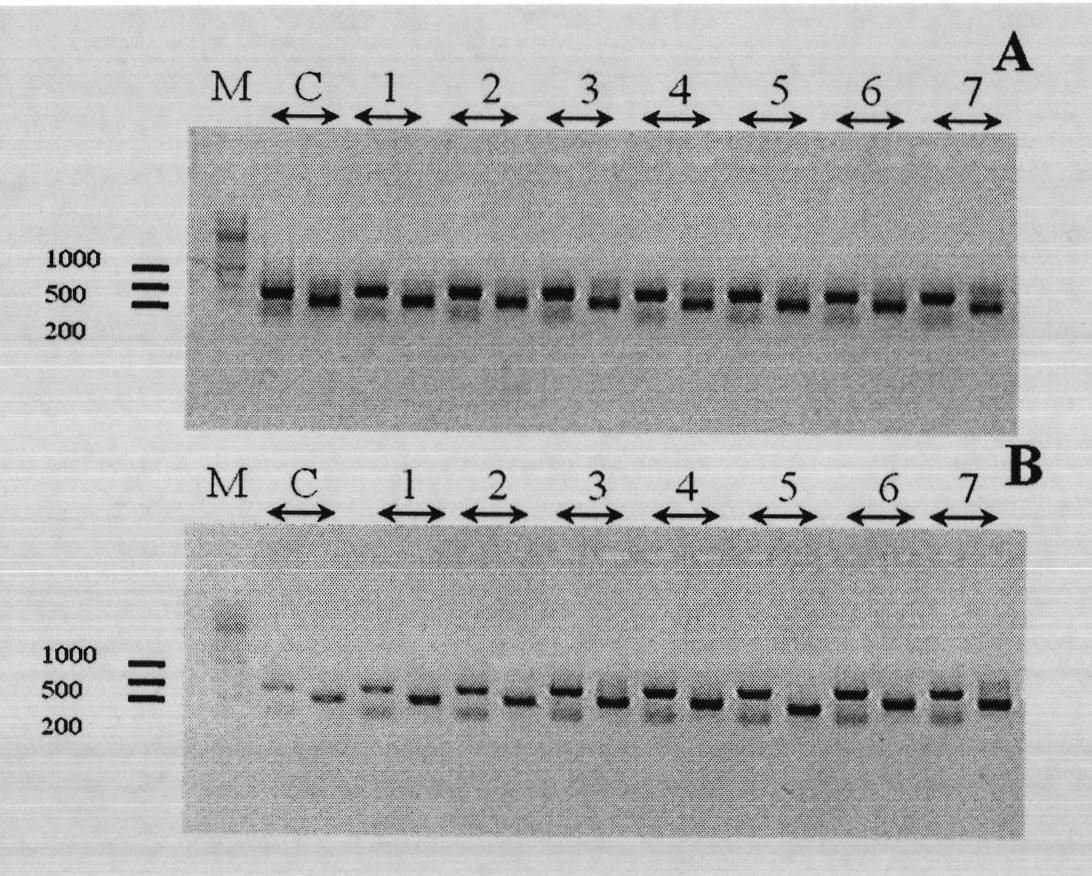

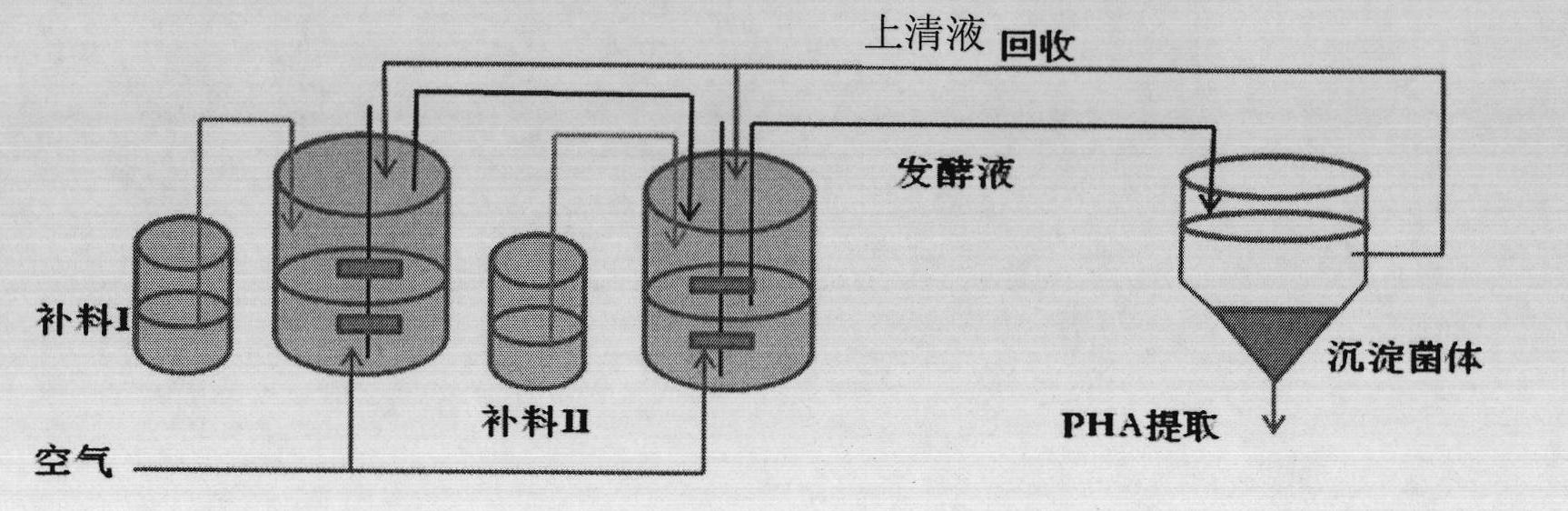

Halomonas strain and application thereof

ActiveCN102120973AIncrease productionReduce manufacturing costBacteriaFermentationBiotechnologyNutrient

The invention discloses a halomonas strain and application thereof. The halomonas strain is a halomonas sp. TD01 with a preservation number of CGMCC NO.4353. Experiments indicate that the halomonas sp. TD01 can effectively accumulate polyhydroxyalkanoates (PHA) in a mineral medium (MM) and provides a better guarantee for the biosynthesis of the PHA and PHBV (poly(hydroxybutyrate-hydroxyvalerate)). The halomonas strain has the advantages of simple nutrient requirement, no need of sterilization in a fermenting process, capability of continuous implantation and simpleness and easiness in control. Methods for preparing the PHA by using the halomonas sp. TD01 all lower the production cost from varying degrees and increase the yield of the PHA; and the obtained PHA has the molecular weight of above 500kDa and has an industrial application value.

Owner:BLUEPHA CO LTD

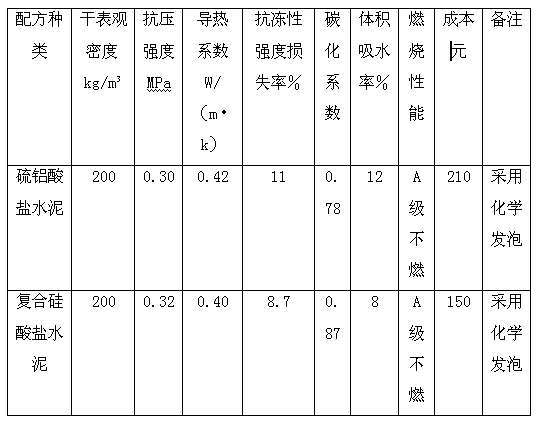

Lightweight high-performance foam concrete and preparation method thereof

ActiveCN104108912AHigh CaO contentHigh glass bead contentSolid waste managementCeramicwareFoam concreteFiber

The invention discloses a lightweight high-performance foam concrete, which is composed of the following components in parts by weight: 50 to 60 parts of cement, 20 to 35 parts of mineral slag, 15 to 20 parts of fly ash, 5 to 10 parts of gypsum, 60 to 80 parts of fine aggregate, 2.7 to 7.3 parts of additive, 0.1 to 0.2 part of fiber, 32 to 45 parts of water, and 5 to 25 parts of foam. The invention also discloses a preparation method of the foam concrete. The foam concrete has the advantages of small volume-weight, high strength, low water absorption, and small contraction rate, and has the waterproof and anti-cracking functions at the same time.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

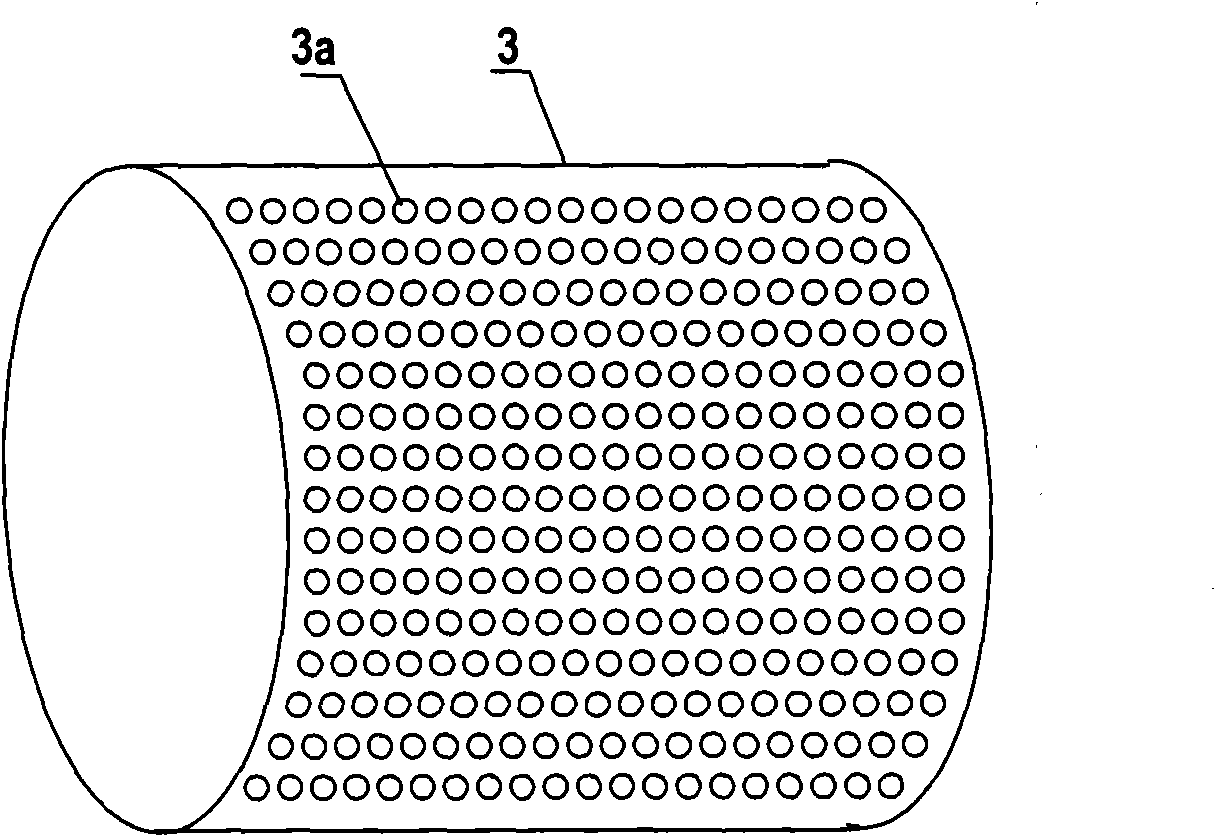

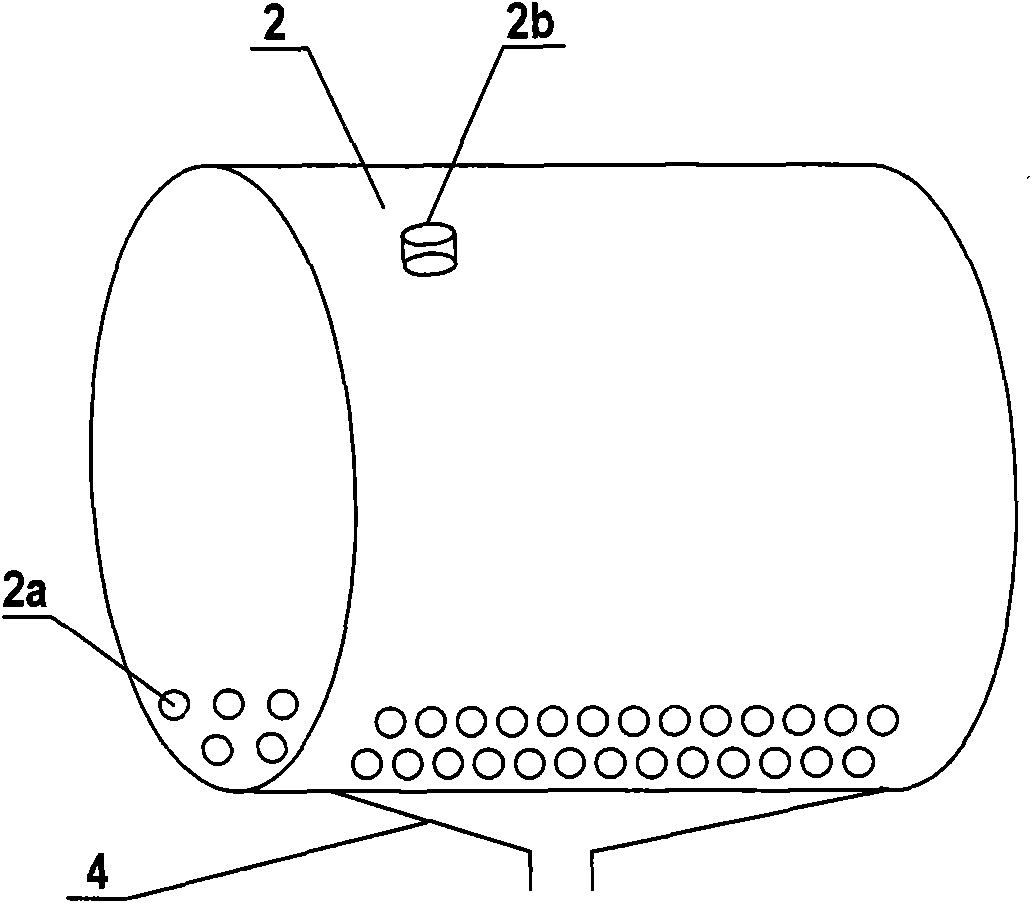

Washing machine

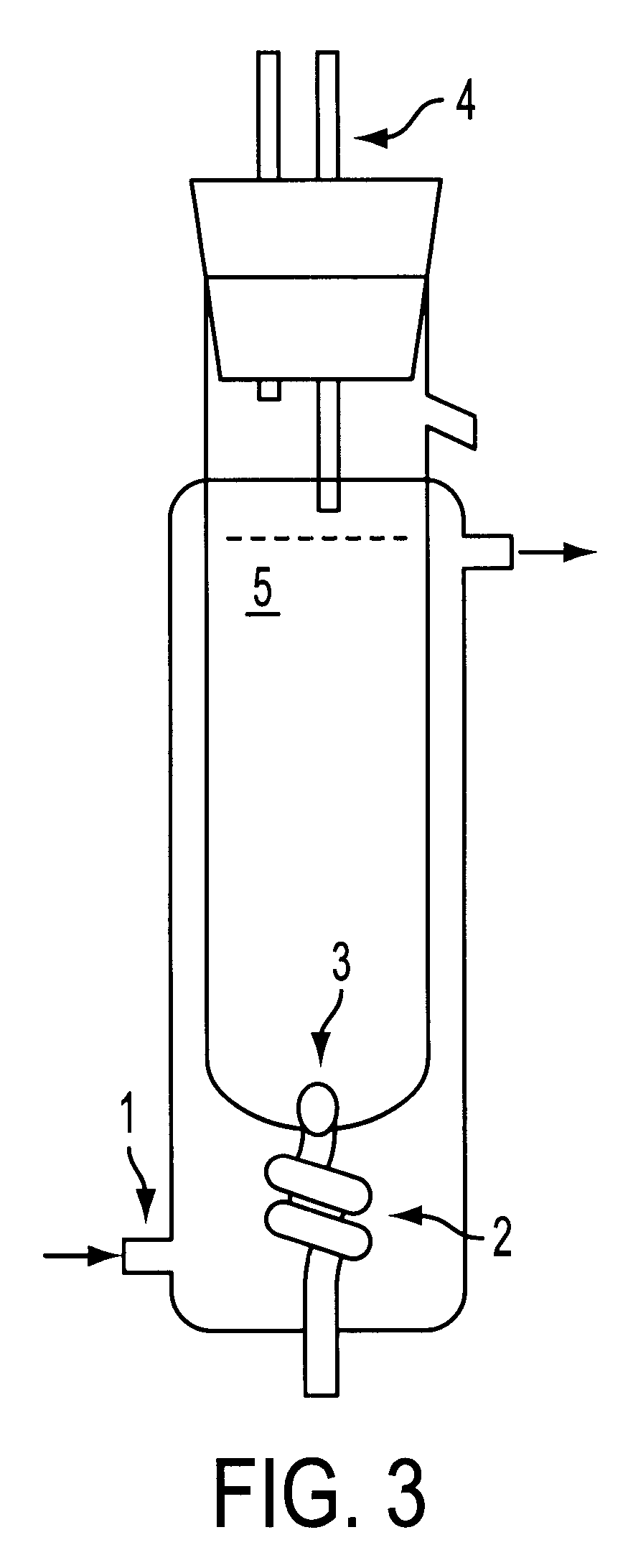

ActiveCN102061589AReduce water consumptionEasy to moveOther washing machinesWashing machine with receptaclesEngineeringMaterial storage

The invention provides a washing machine, comprising an inner cylinder (3) and an outer cylinder (2) arranged at the outer side of the inner cylinder (3). The washing machine is characterized by also comprising a material storage box (6), a particle circulating pipeline (9) and a circulation power plant (12), wherein the walls of the inner cylinder (3) and the outer cylinder (2) are provided with holes (3a,2a) from which solid particles can be leaked; the bottom of the outer cylinder (2), the material storage box (6), the particle circulating line (9) and the inner cylinder are sequentially communicated; a discharging control valve (7) is arranged at the position at which the material storage box (6) is connected with the particle circulating line (9); and the circulation power plant (12) is used for delivering the solid particles entering the particle circulating line (9) to the inner cylinder. Through using the washing machine provided by the invention, clothes can be washed by using a mixture of particles and water, thereby reducing water consumption.

Owner:XEROS LTD

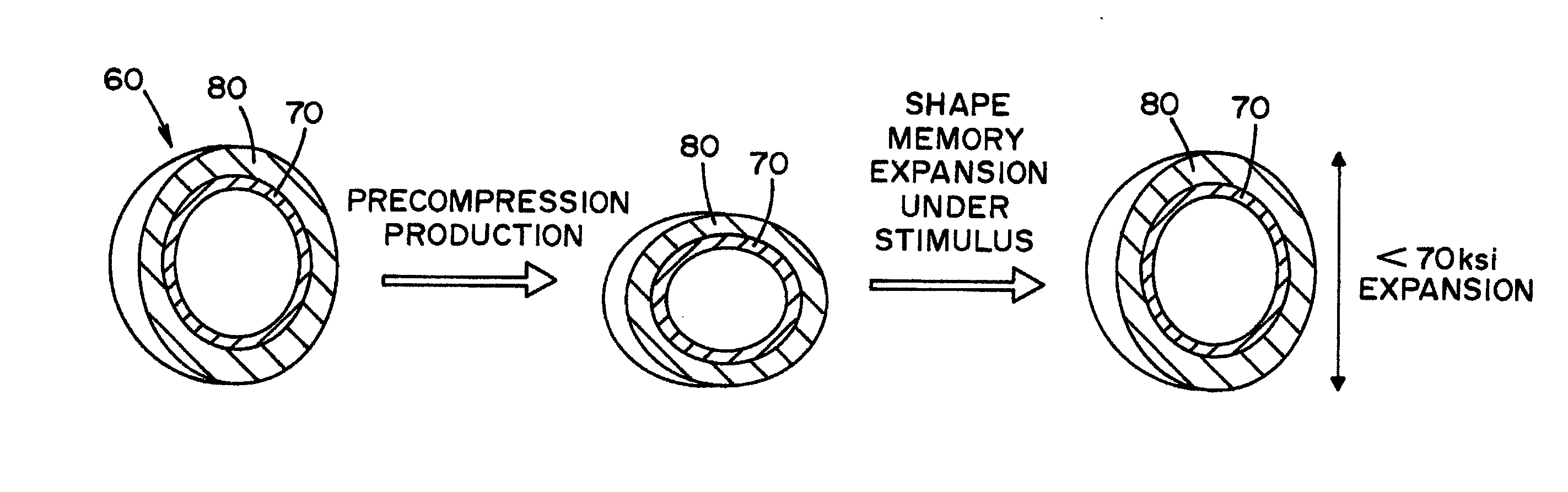

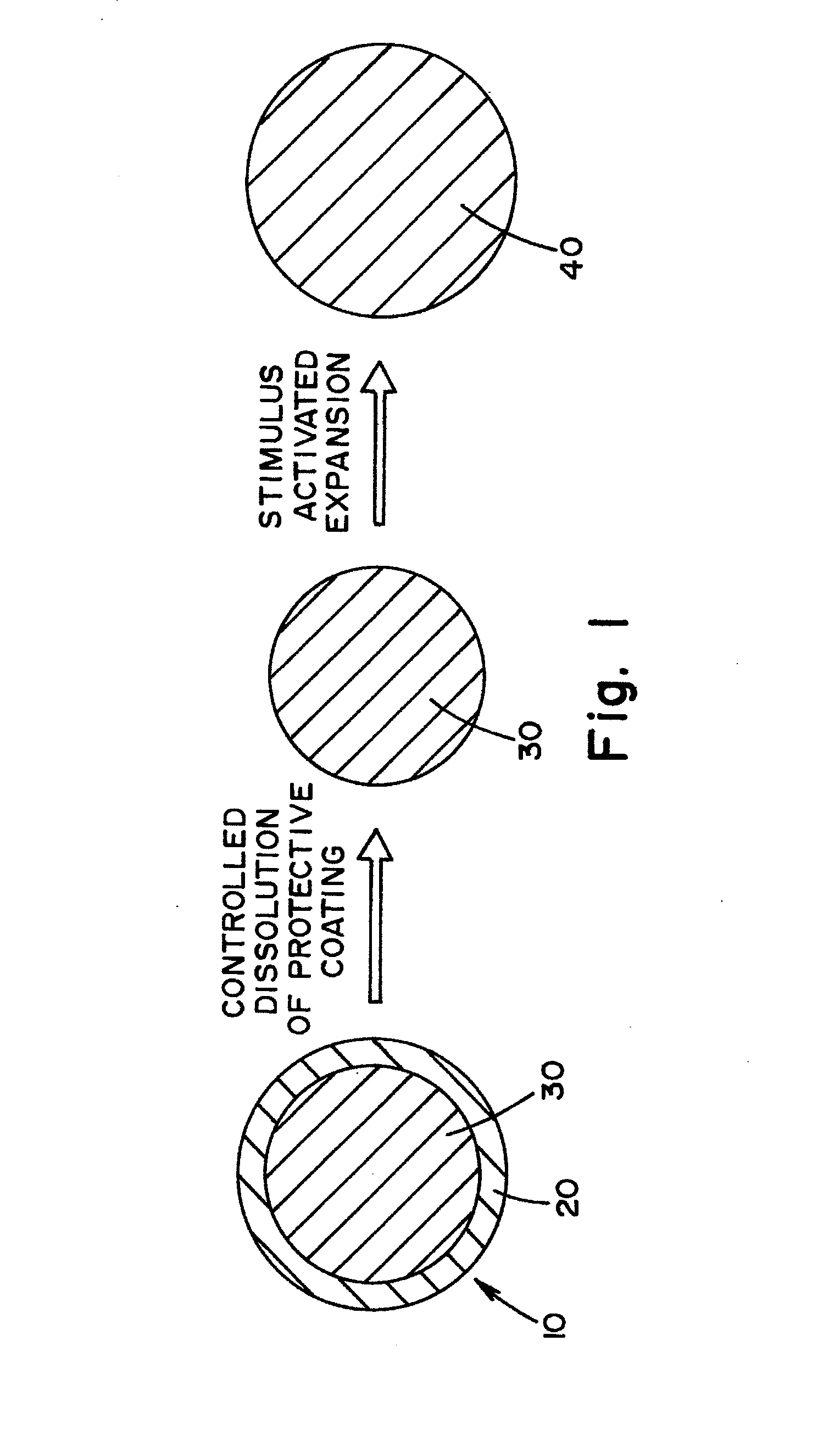

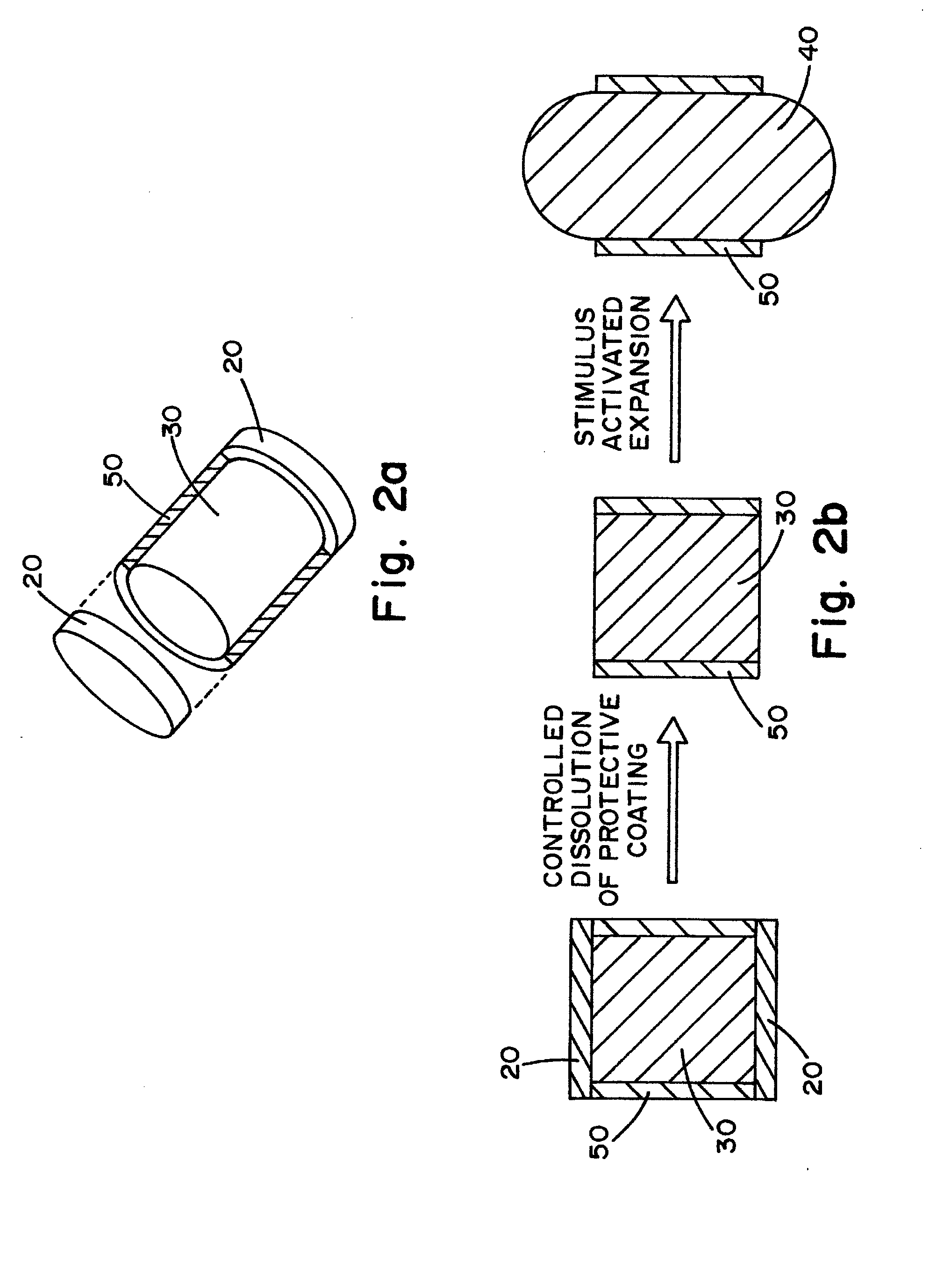

Structural Expandable Materials

ActiveUS20160137912A1Control expansionReduce the amount of waterFluid removalFlushingMaterials scienceChemical change

A composite particle that incorporates a material and is designed to undergo a reaction and / or mechanical or chemical change with the environment to increase in volume. The composite particle can be combined with a constraining matrix to create an expandable particle upon reaction. These particles can be used in stimulating wells, including oil and gas reservoirs.

Owner:POWDERMET

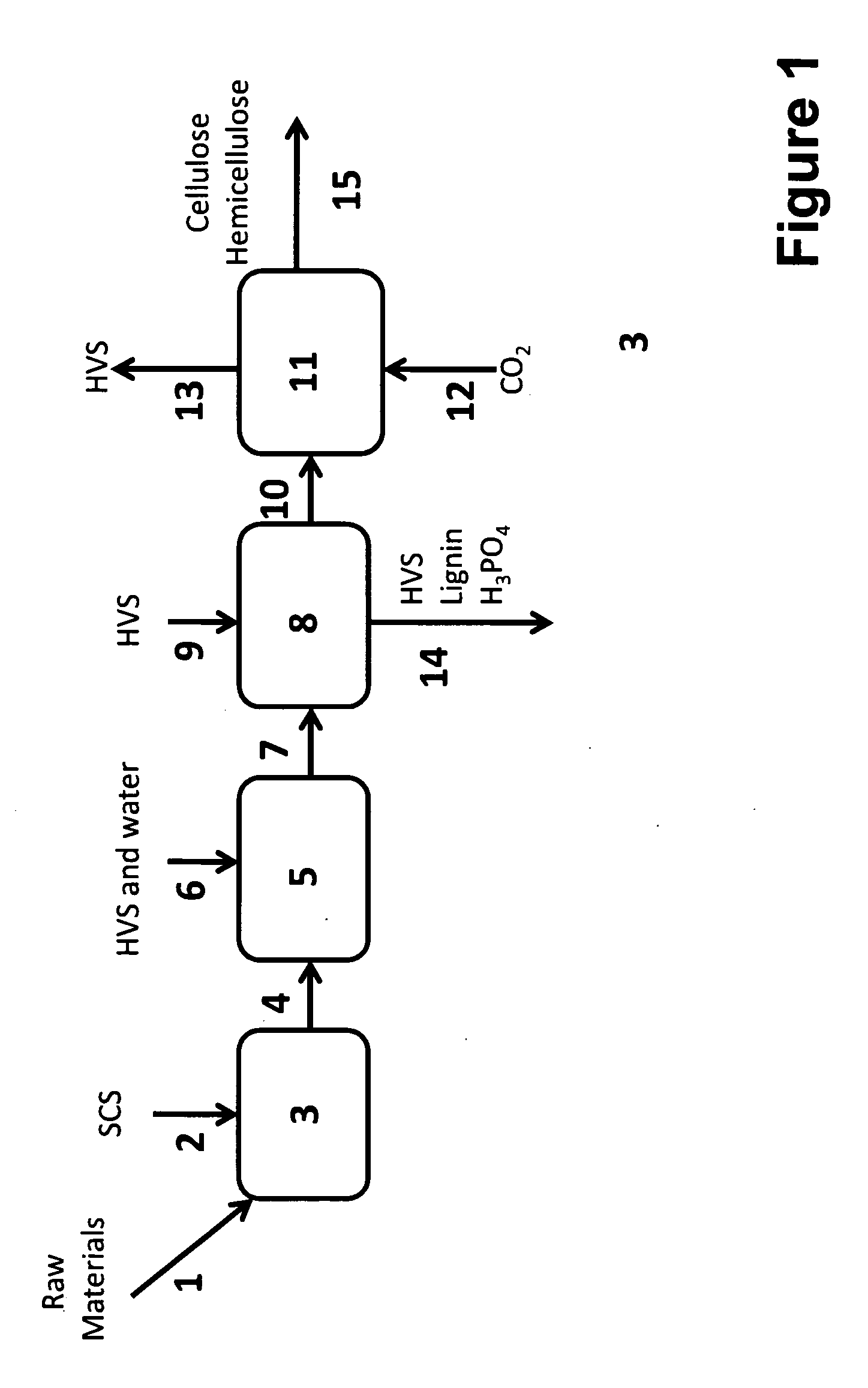

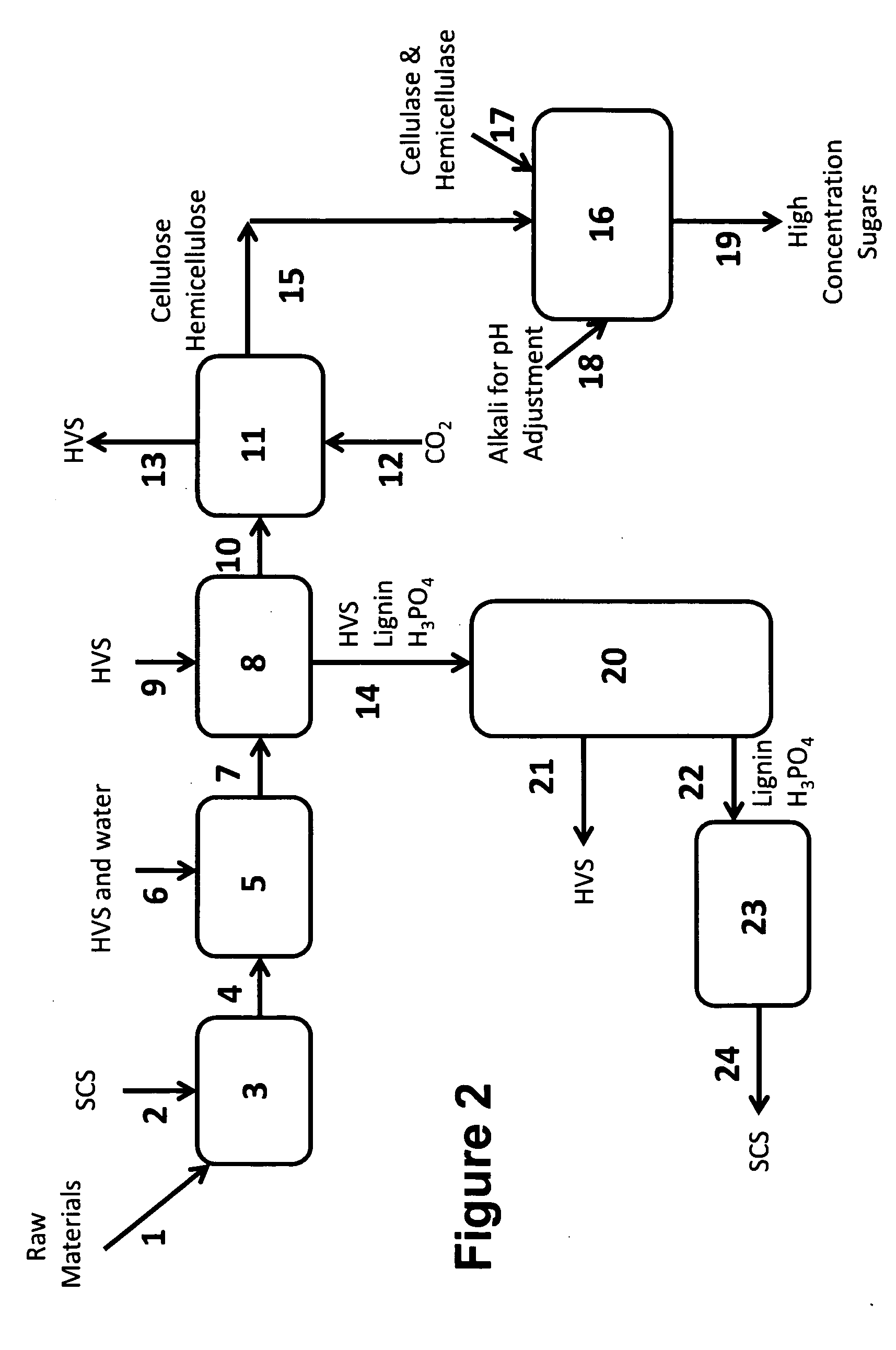

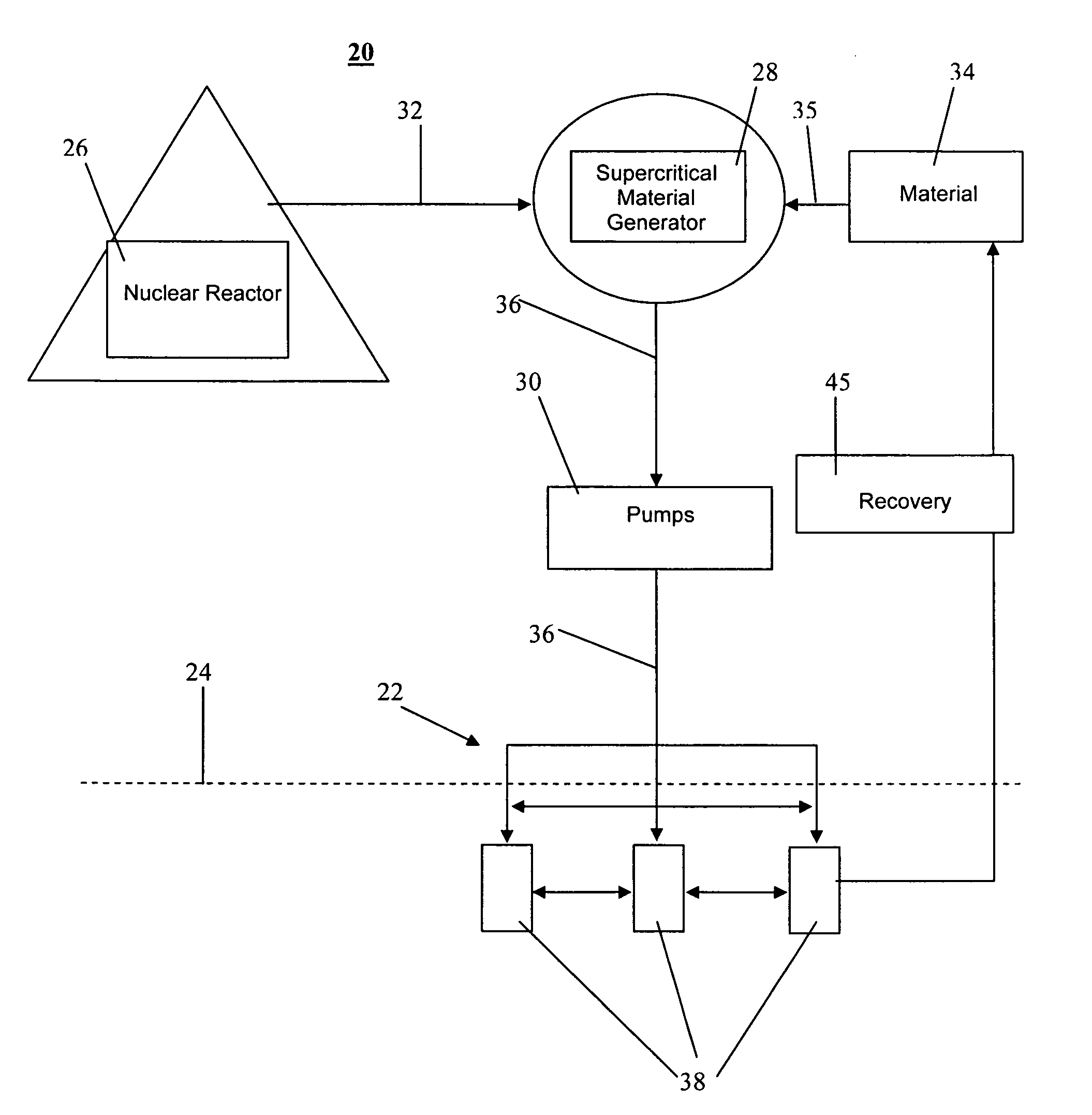

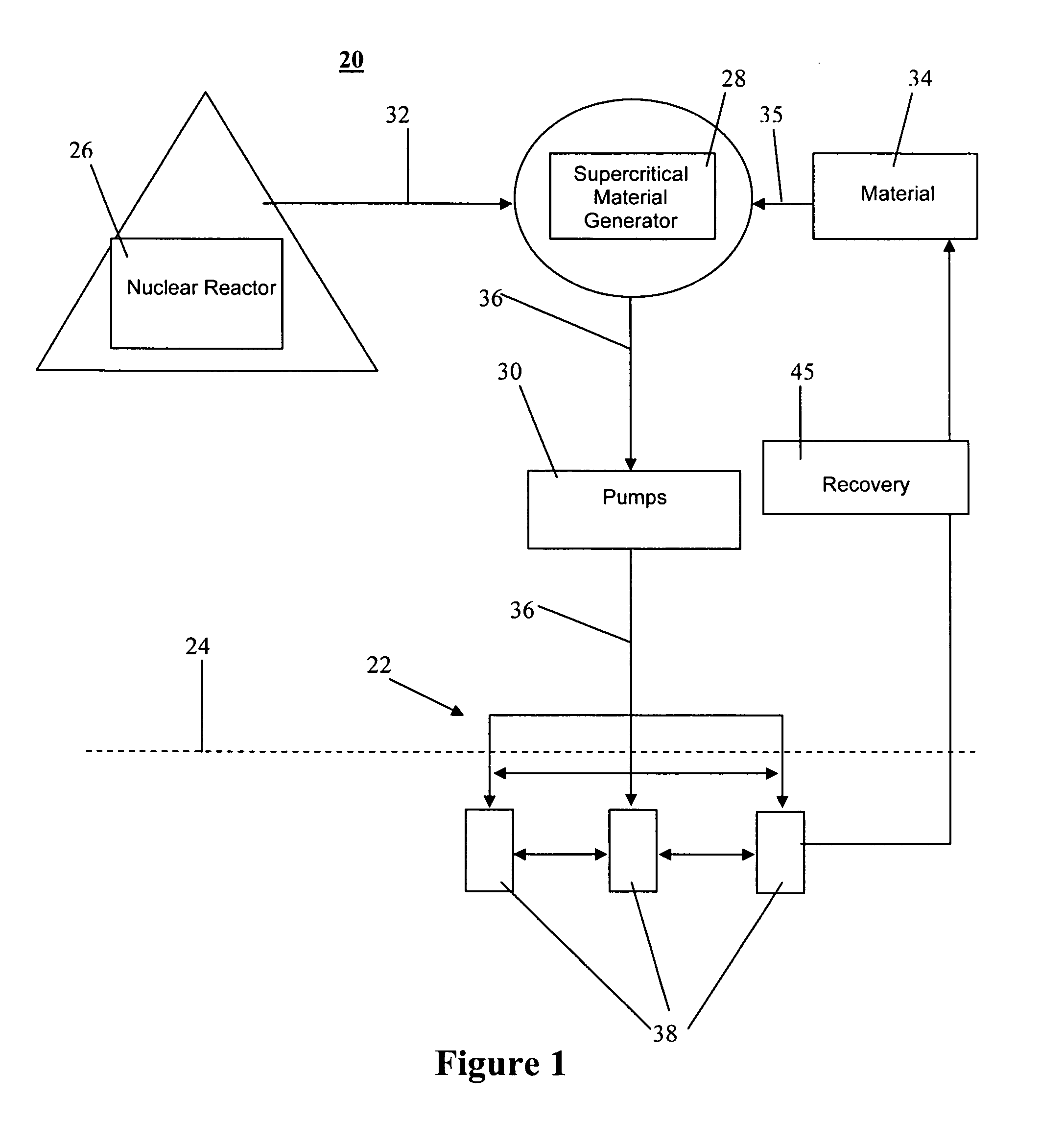

Method and apparatus for lignocellulose pretreatment using a super-cellulose-solvent and highly volatile solvents

InactiveUS20090229599A1Overcome shortcomingReduce solvent usagePressurized chemical processBiofuelsAlcoholGram

Embodiments of the present invention overcome the well-known recalcitrance of lignocellulosic biomass in an economically viable manner. A process and a system are provided for the efficient fractionation of lignocellulosic biomass into cellulose, hemicellulose, and lignin. The cellulose and hemicellulose thus obtained are highly amorphous and can be readily converted into highly concentrated mixtures of five and six carbon sugars using known methods. Typical yields of sugars exceed 100 grams of sugars per liter of sugar solution. Other products, such as alcohols, can easily be prepared according to methods of the invention. The modest process conditions and low solvent / solid ratios of some embodiments of the invention require relatively low capital and processing costs.

Owner:VIRGINIA TECH INTPROP INC

Process for cooling down a hot flue gas stream

InactiveUS7655071B2Reduce water consumptionConserve waterMethane captureCarbon compoundsFlue gasEvaporation

A process for cooling down a hot flue gas stream comprising water vapour and carbon dioxide, the process including: (a) heat exchange between the hot flue gas stream and a cooling water stream so that the hot flue gas stream is cooled to a cooled down gas stream at a temperature at which at least part of the water vapour therein has condensed and the cooling water stream increases in temperature; (b) combining the condensed water vapour and the cooling water stream to produce a combined water stream; (c) separation of the cooled down gas stream from the combined water stream; (d) cooling the combined water stream by contact with air from the atmosphere and by evaporation of a portion of the combined water stream; (e) using at least part of any non-evaporated and cooled water of the combined water stream as at least part of the cooling water stream for cooling the hot flue gas stream in step (a); and (f) storing any non-evaporated and cooled water of the combined water stream that is not used in step (e) and using the stored water later as at least part of the cooling water stream in step (a).

Owner:SHELL OIL CO

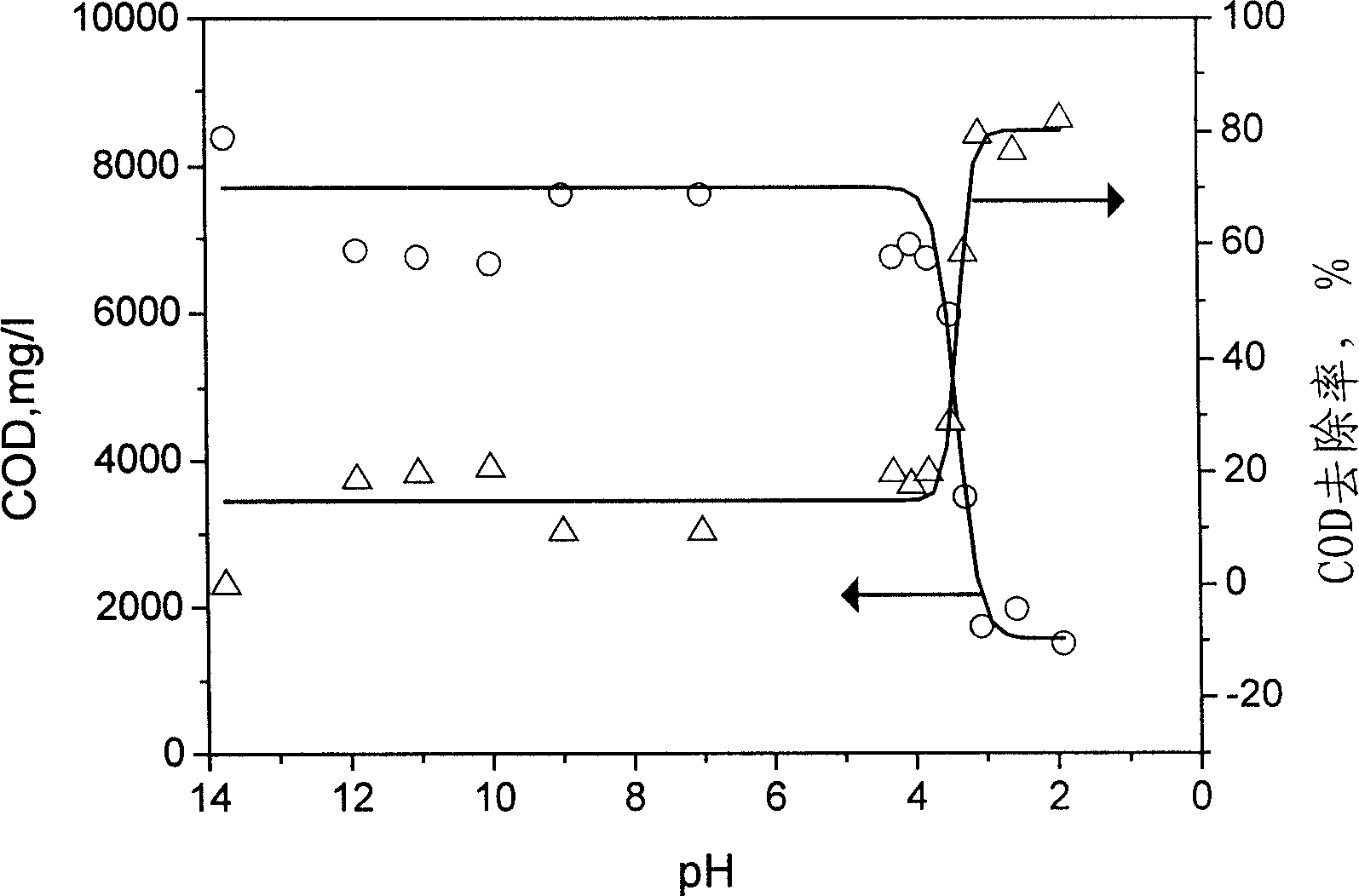

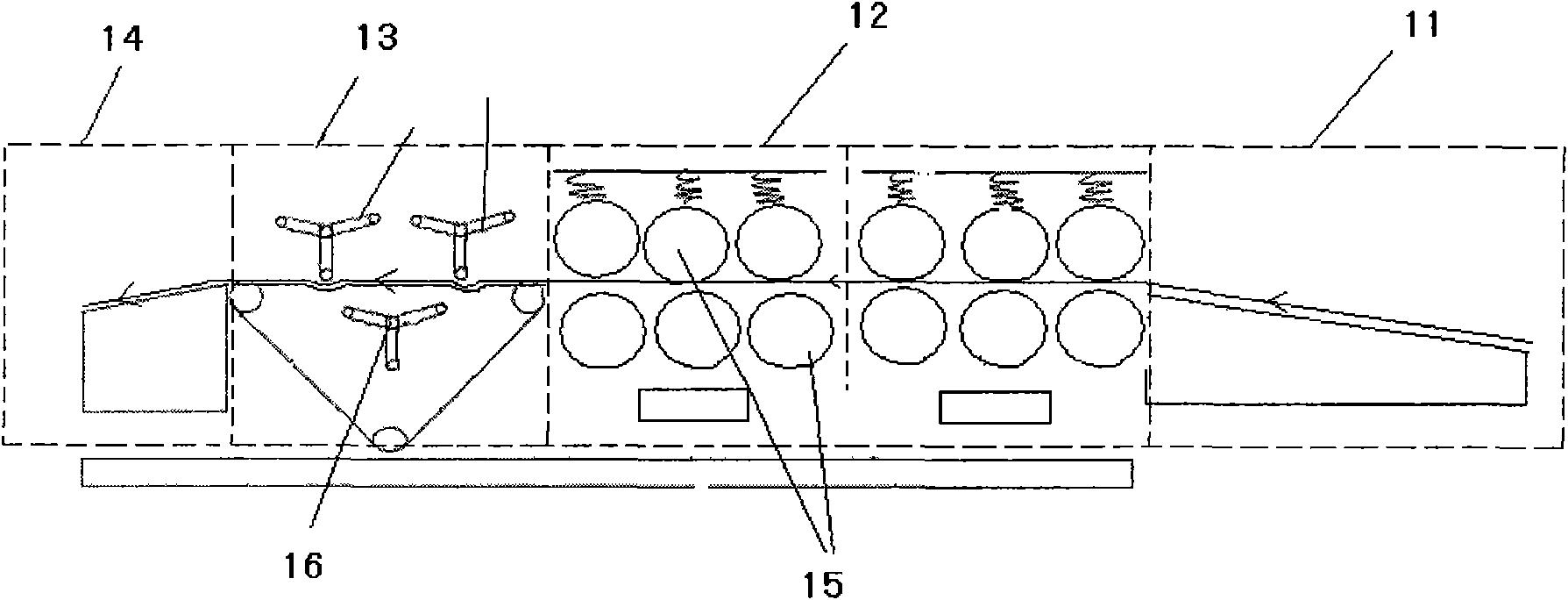

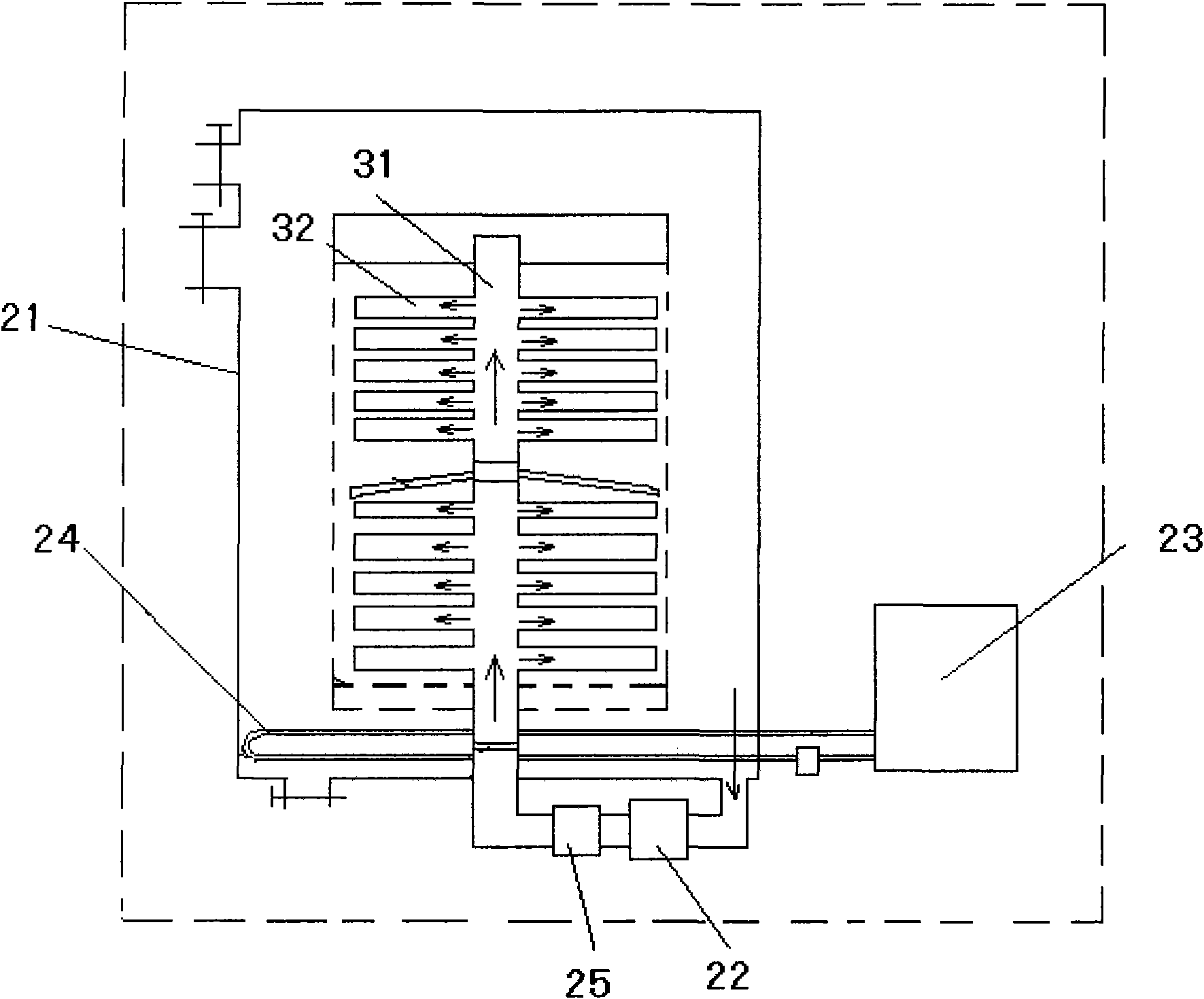

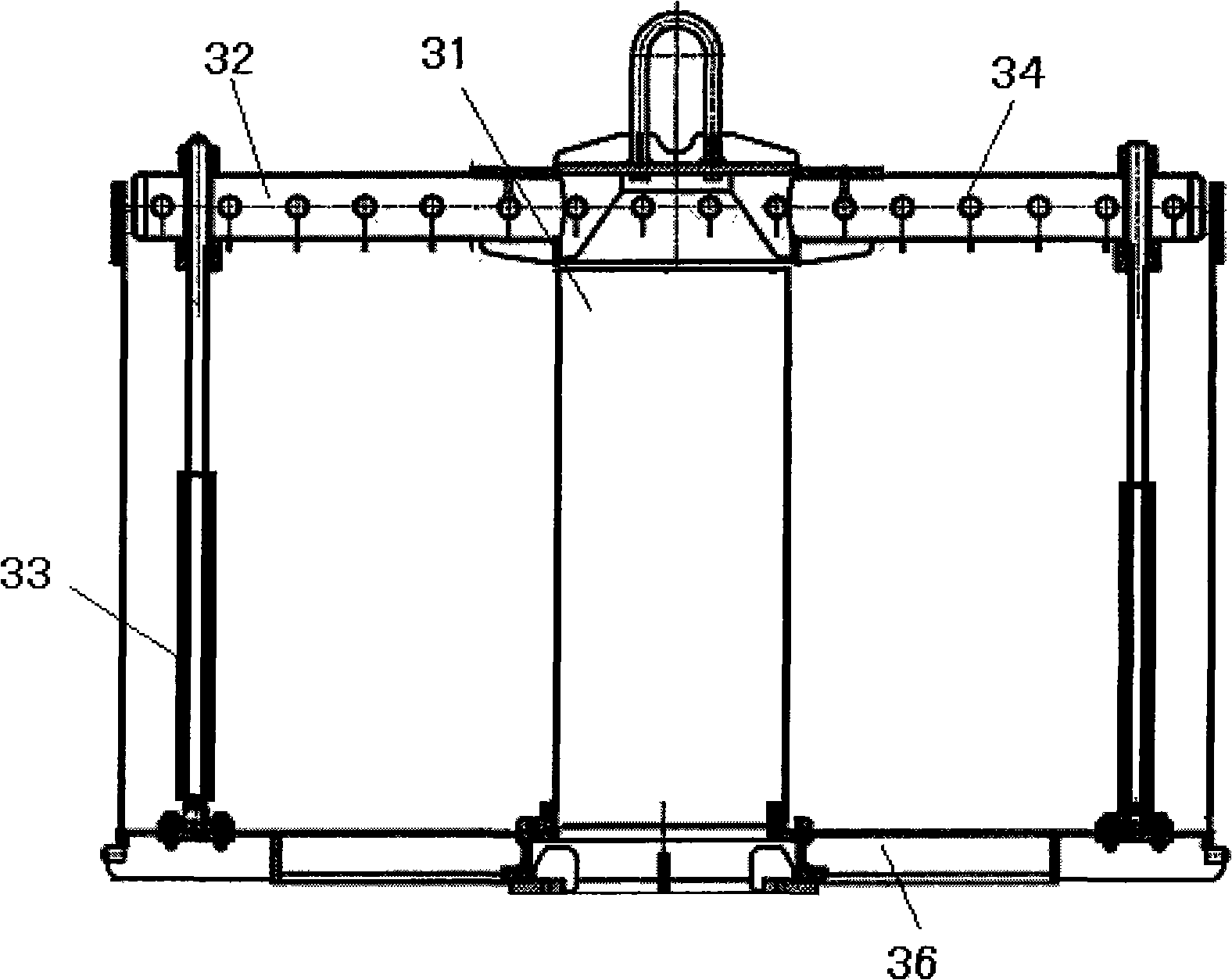

Printing and dyeing wastewater recovery and disposal method

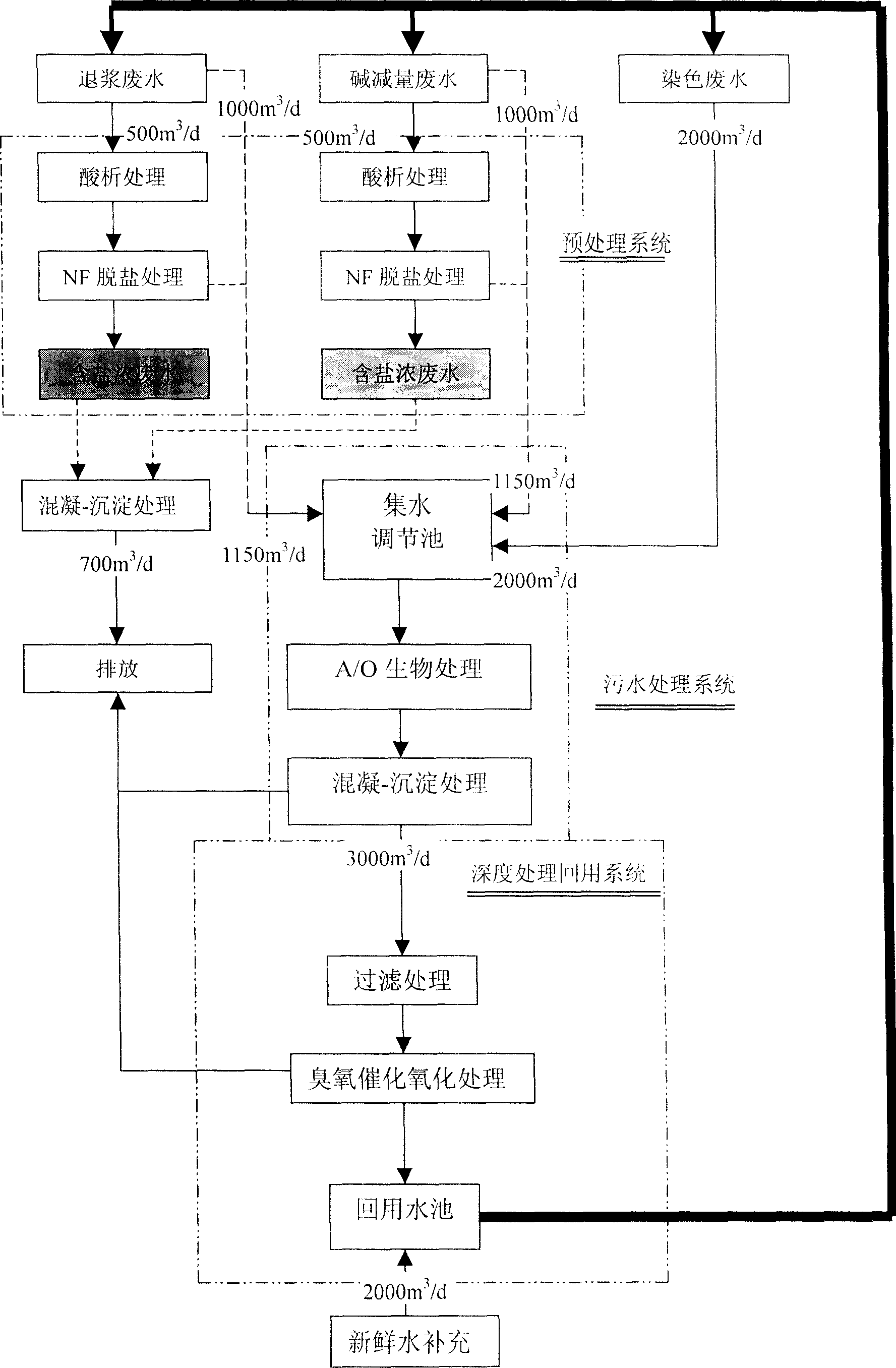

InactiveCN1765779AImprove recycling economicsProduct quality is not affectedTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentResource recoveryWastewater

The recycle treatment method for printing and dyeing wastewater aims to providing a system technique to recycle and treat the desizing, base-decrement, dyeing sewage with no effect to dyeing product quality and high yield and low cost, which comprises: taking acid-out pre-treatment to sewage for recycling slurry; then, taking A / O biochemical treatment with dyeing sewage and ozone catalytic advance treatment to recycle more than 60% water. This invention can release greatly water-resource pressure with the facility payback period less than five years.

Owner:ZHEJIANG UNIV

Technological process of ramie bast fiber

ActiveCN101824658AImprove processing uniformityImprove qualityCombing machinesDrafting machinesBiochemical engineeringCombing

The invention relates to a technological process of a ramie bast fiber, which comprises a basic degummed ramie production route: raw ramie skin-sorting and derooting-mechanical ungluing-cage loading-biological ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-radio frequency drying- degummed ramie. Long ramie can be growth through the mechanical hemp oiling- infiltration and health care-stretch breaking and carding-pre-gilling-combing and sorting-final gilling of the degummed ramie. Short ramie can be produced through the combing and the sorting of combed noil. Oakum can be produced through biological ungluing-high-temperature stewing and ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-dehydration and drying-radio frequency drying-mechanical hemp oiling- infiltration and health care-opening and edulcoration- combing and sorting. Improving methods are adopted for the mechanical ungluing, biological ungluing, high-temperature rinsing, sub-fiber washing, stretch breaking and carding, combing and sorting and the like. The preparation process has the advantages of short process, high production efficiency, high mechanical automation degree, stable product quality, excellent fiber quality and strong operability of fiber length and fineness, and can be used in the production processes of various bast fiber raw material, gramineae fiber raw material, leaf fiber raw material and other fibers.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

Lightweight aggregate foam concrete and production method thereof

The invention discloses a lightweight aggregate foam concrete which is composed of the following materials in parts by weight: 100-300 parts of cement, 1-150 parts of admixture, 60-250 parts of water, 1-10 parts of additive and 1-11 parts of foaming agent, as well as a lightweight material by a dosage accounting for 5%-60% of the total volume. The admixture comprising PC32.5 cement, coal ash and the like is produced from industrial waste materials such as coal ash, slag powder and clinker, so that discharge and bulk deposition of the industrial waste materials are effectively reduced and the environmental pollution is greatly reduced; therefore, good environmental protection benefit and social benefit are achieved. More importantly, expensive sulfoaluminate cement is replaced by low-cost materials, so that the cost of producing the lightweight aggregate foam concrete is greatly reduced; the performance effect of the product is extremely obvious and the physical properties of the cement is greatly improved; as a result, the outside erosion resisting capability of the concrete is effectively improved.

Owner:河南华泰新材科技股份有限公司

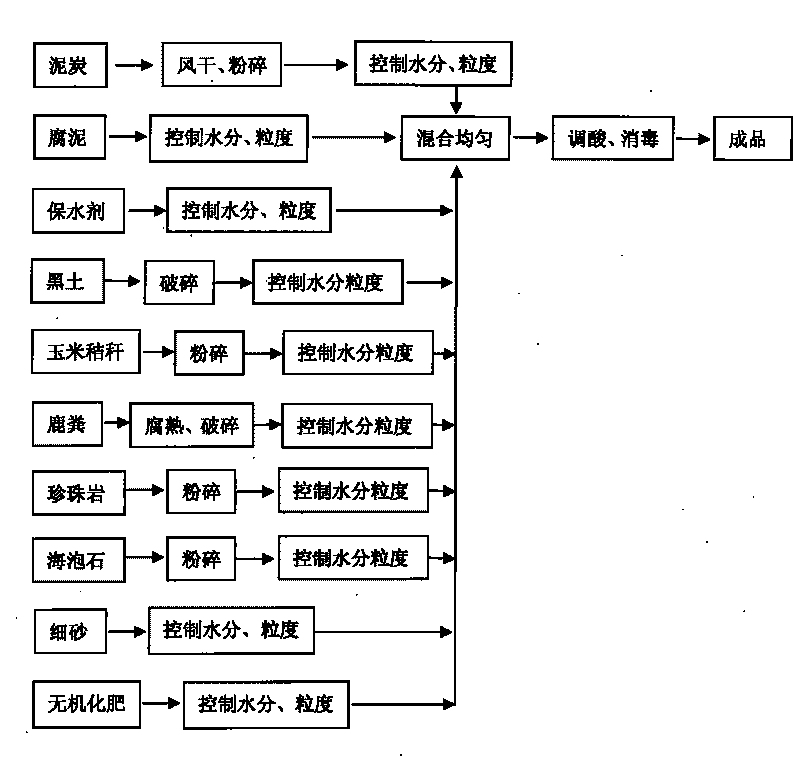

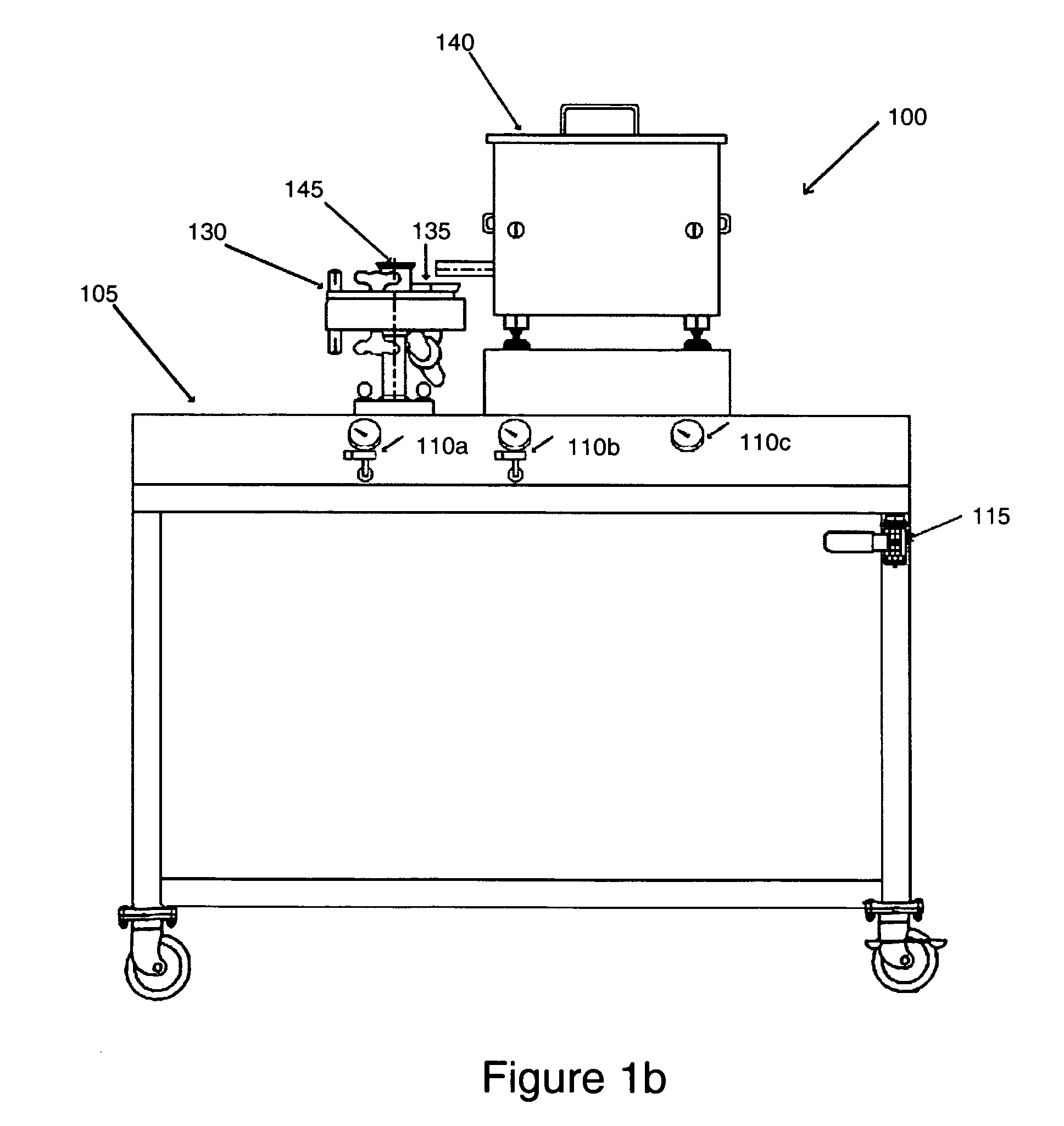

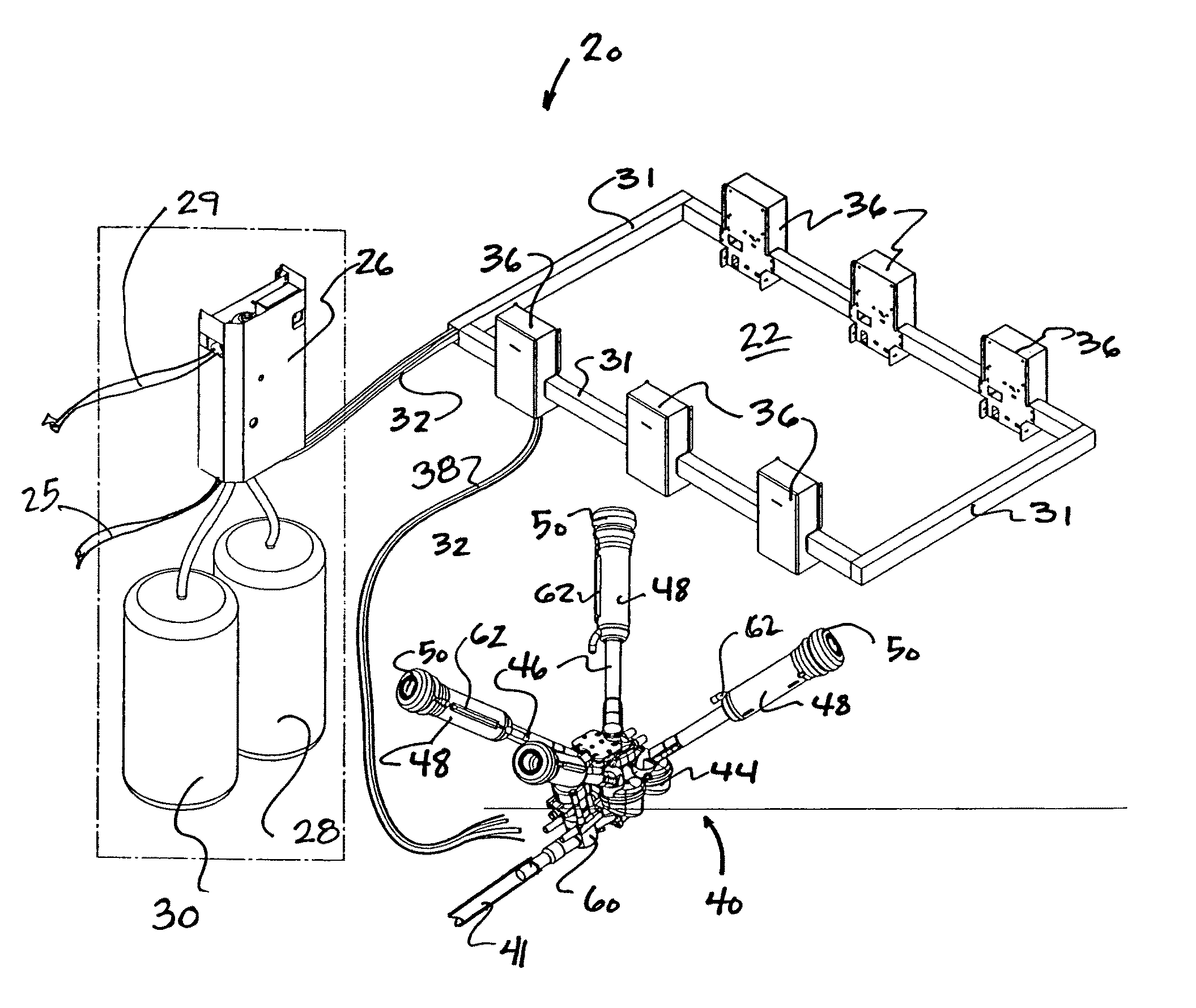

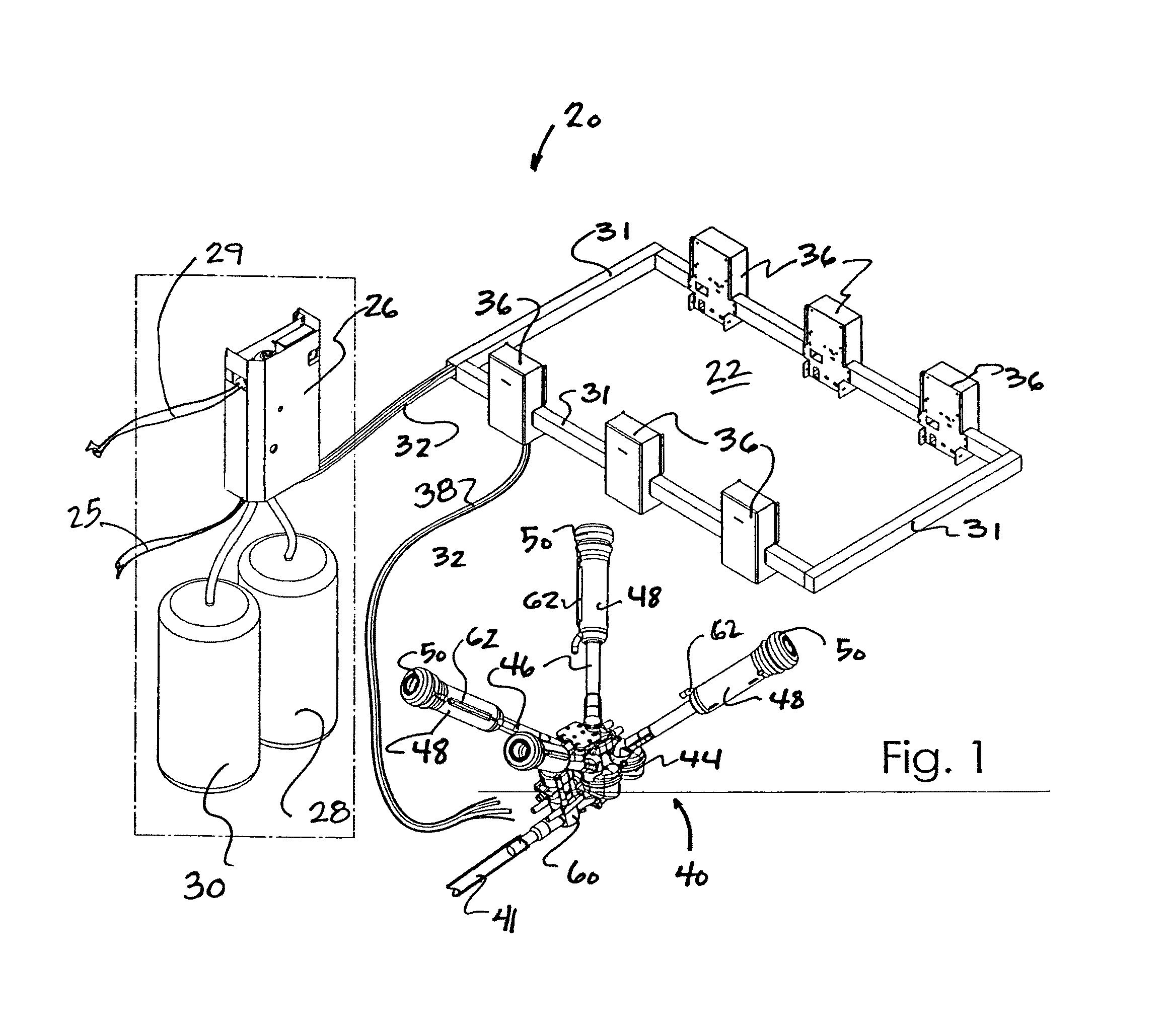

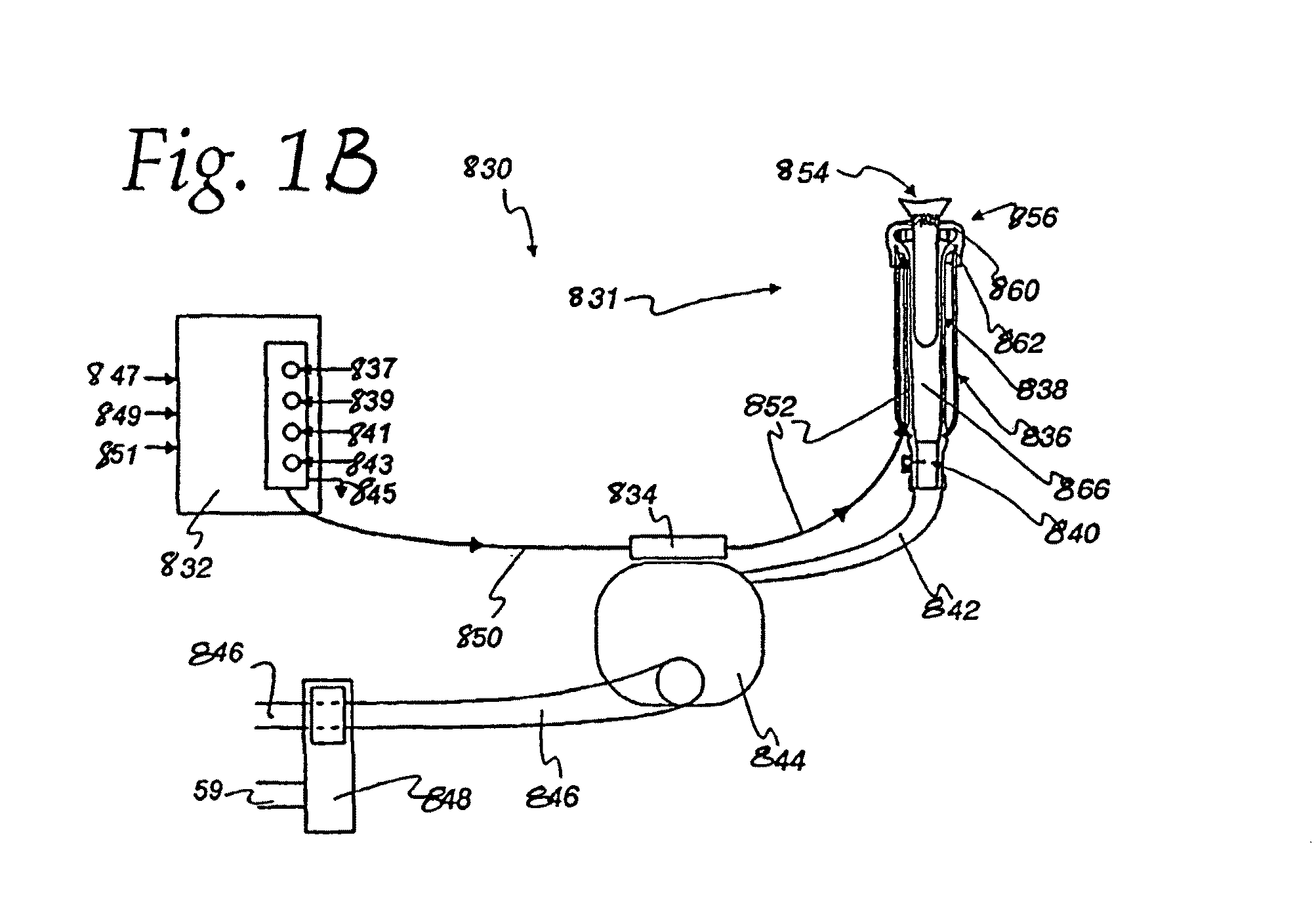

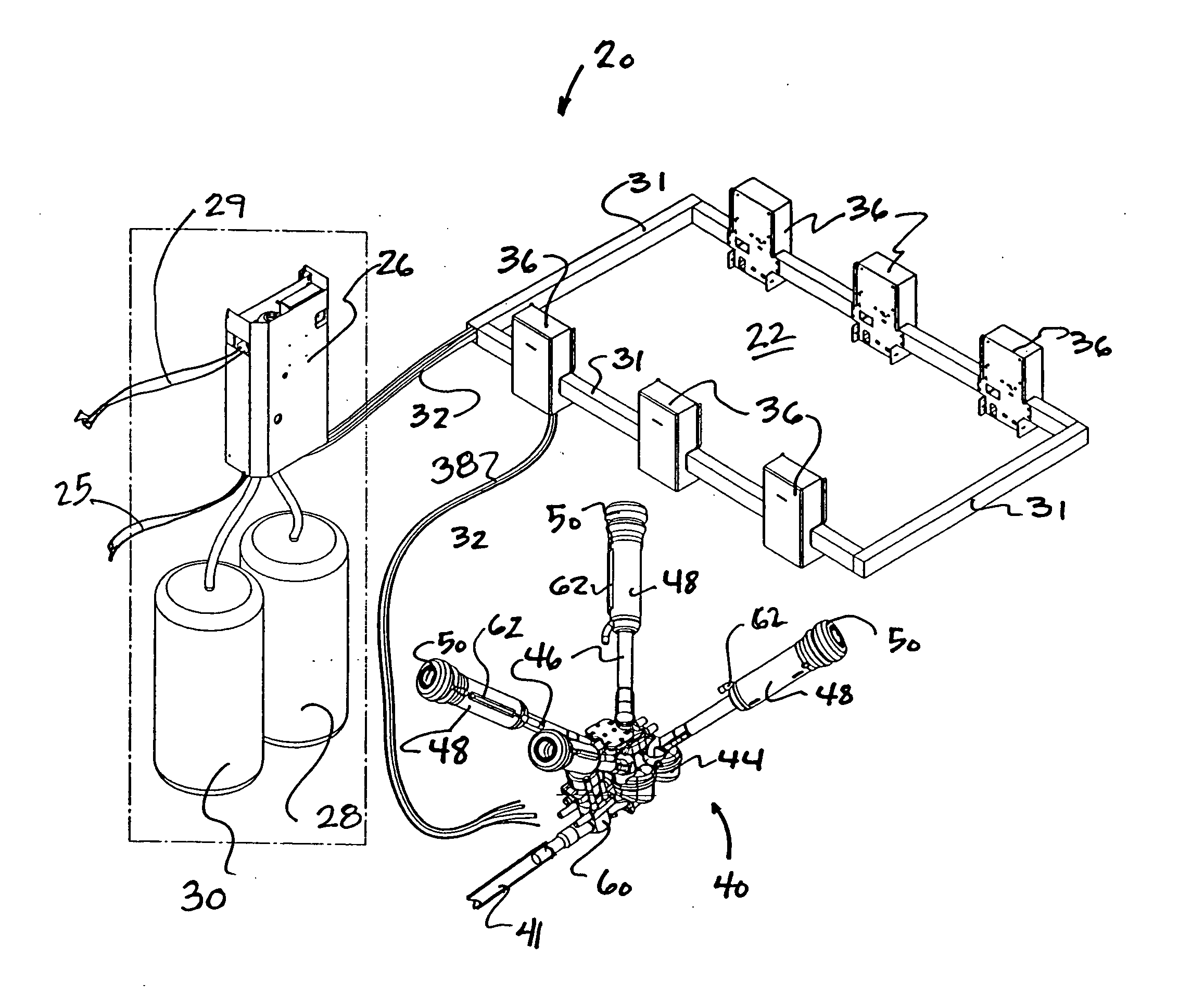

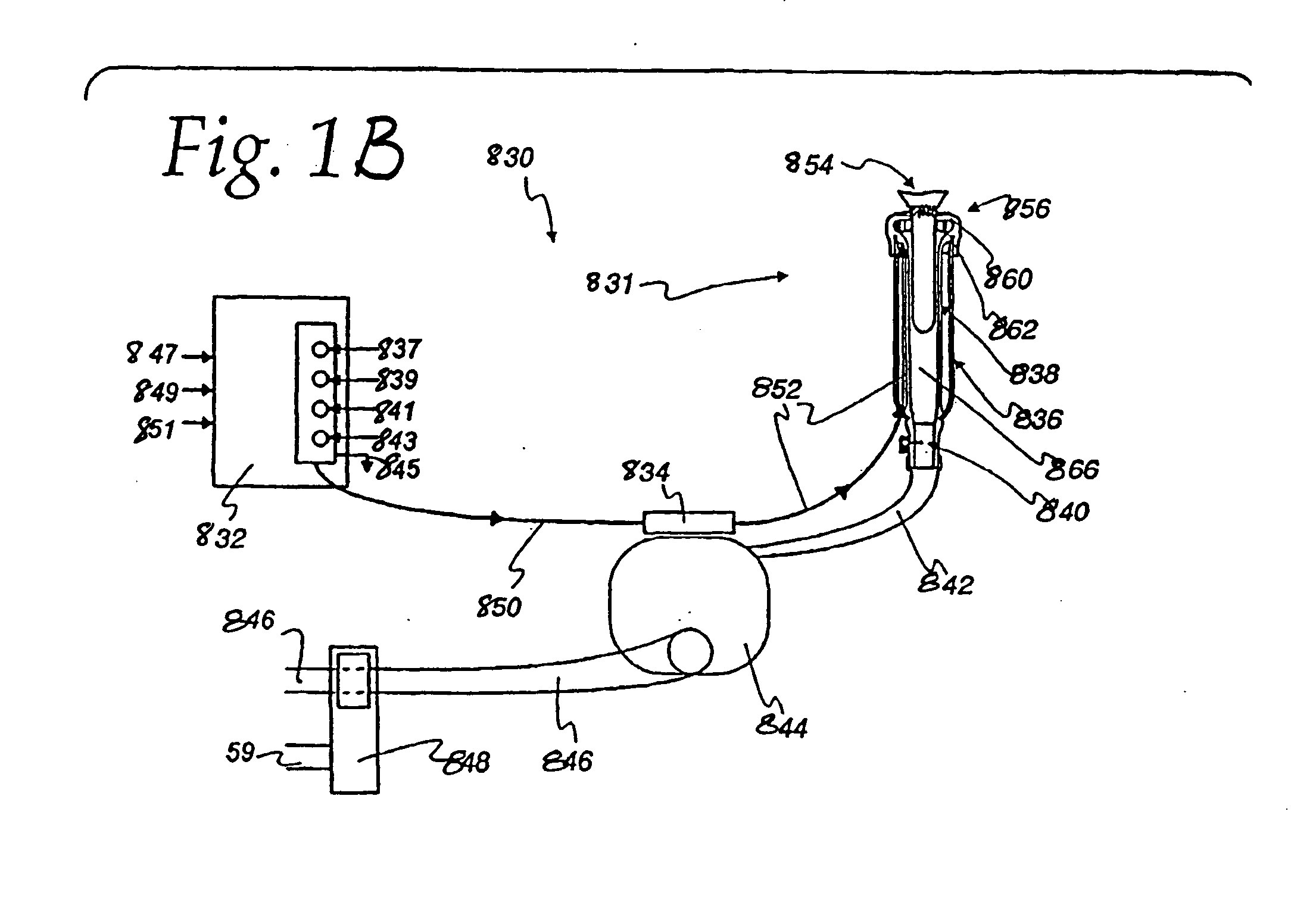

Automatic dairy animal milker unit backflusher and teat dip applicator system and method

A system for cleaning a dairy animal milker unit and applying dip to a dairy animal, the system includes a main control, an air supply, a water supply, a backflush fluid supply, a dip supply, a stall control for receiving the air, water, backflush fluid and dip supplies, and a safety valve that is adjacent to a downstream portion of the milker unit to control backflush and dip fluids being fed to the milker unit.

Owner:GEA FARM TECH

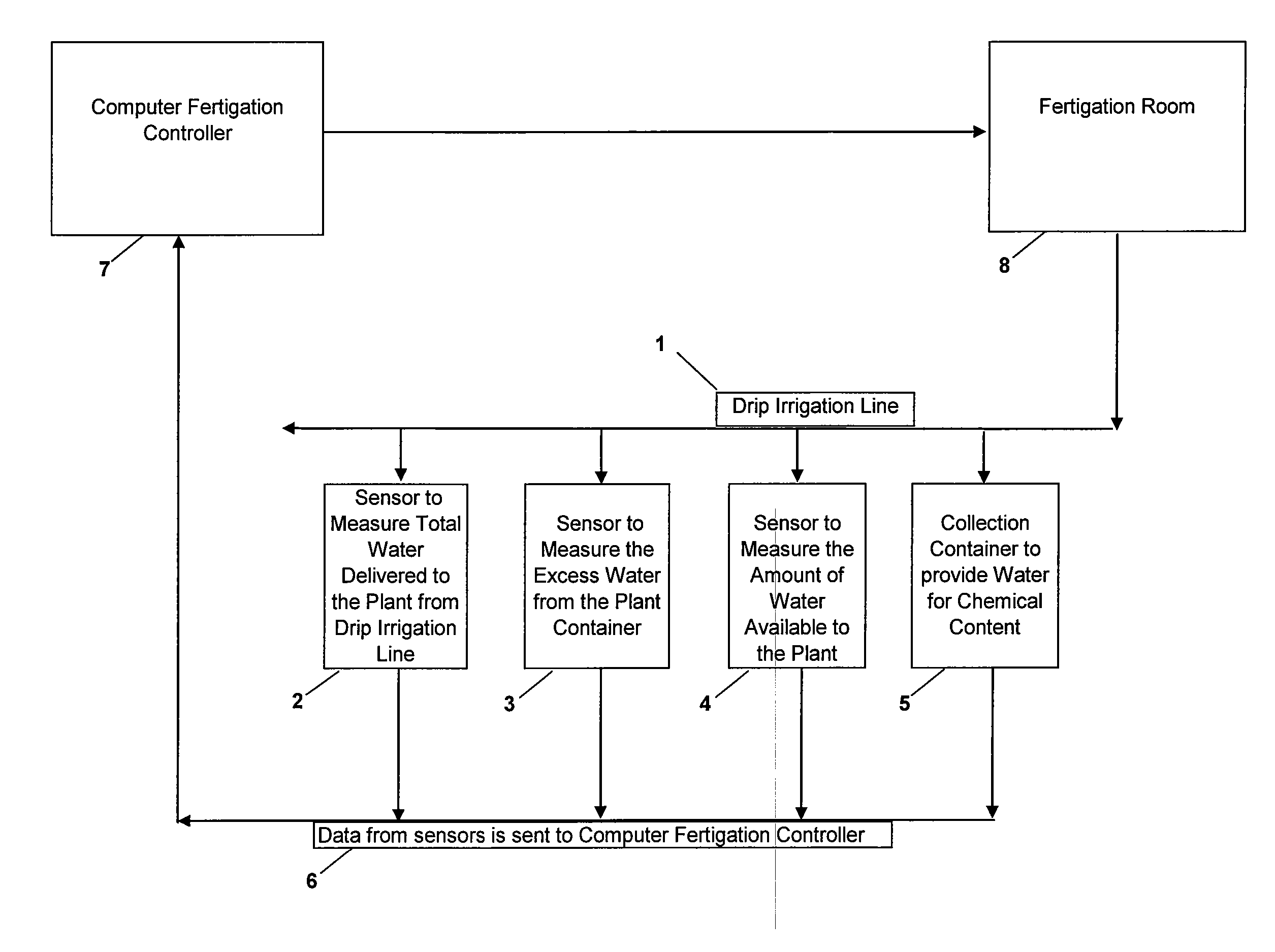

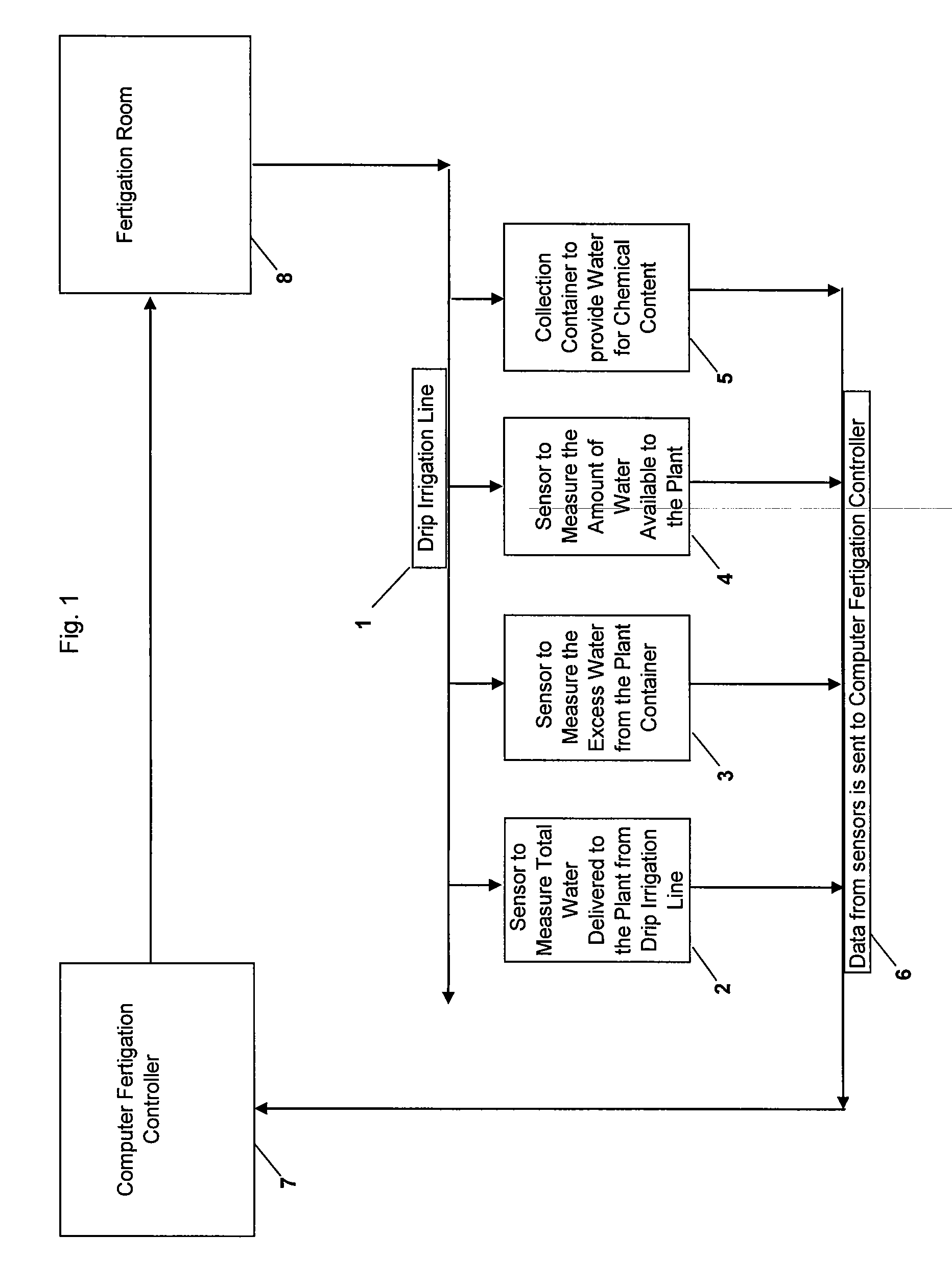

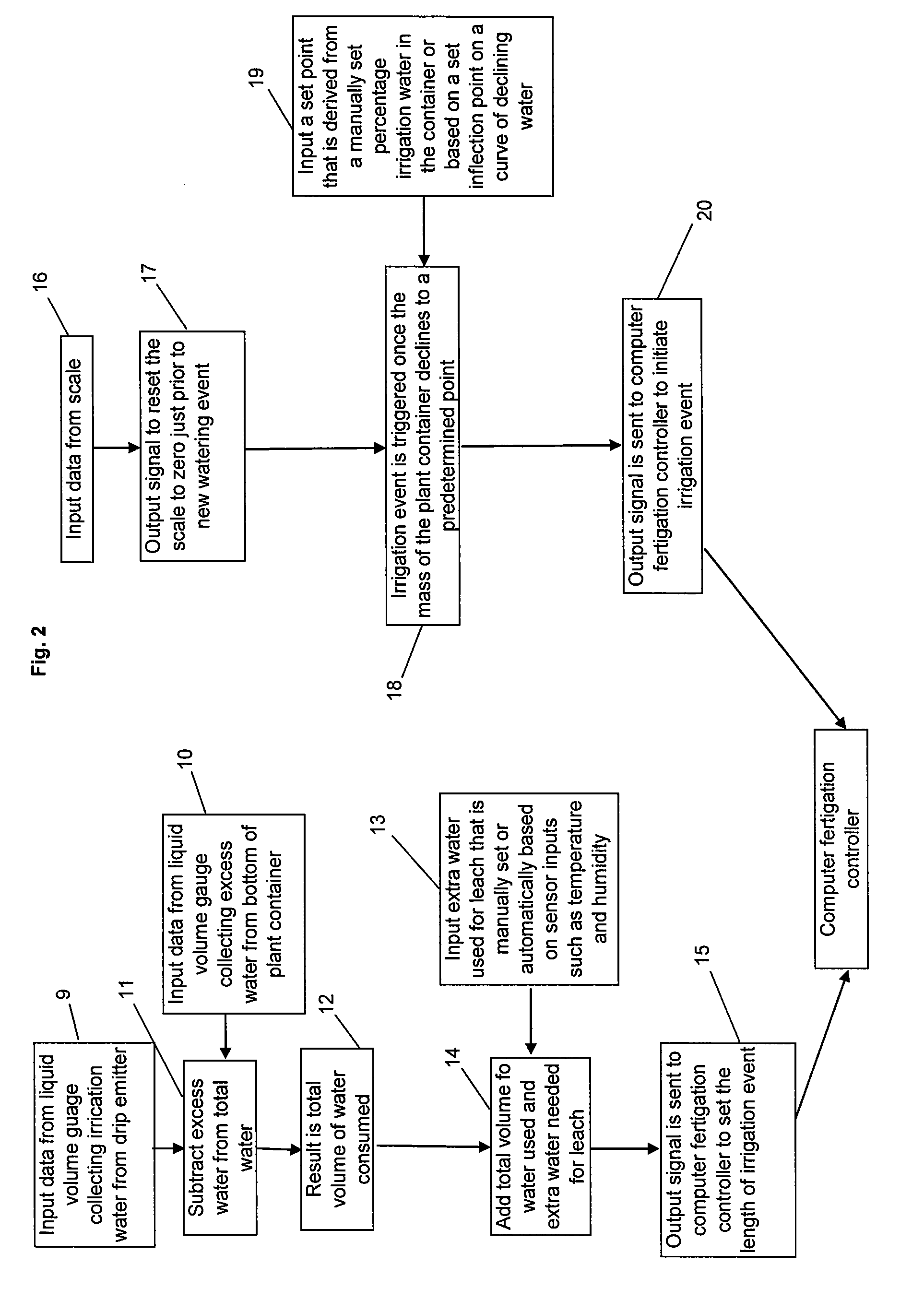

Computer Controlled Fertigation System and Method

InactiveUS20070220808A1Reduce water consumptionReduce fertilizer useRoot feedersSelf-acting watering devicesFertigationEngineering

A system and a method of computer controlled irrigation and fertigation composed of one or more sensors positioned in order to quantify the amount of water and / or nutrients that a plant is consuming. By controlling the fertigation, the plant or a part thereof, has improved yield and quality,

Owner:FW ENVIRO

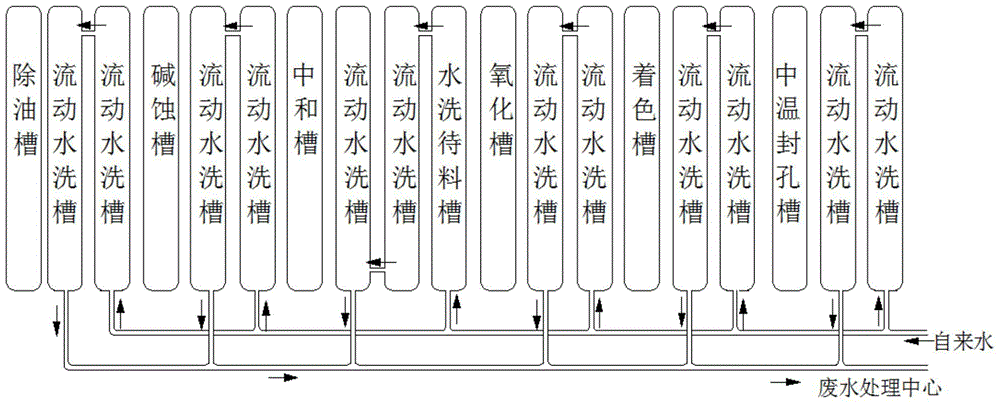

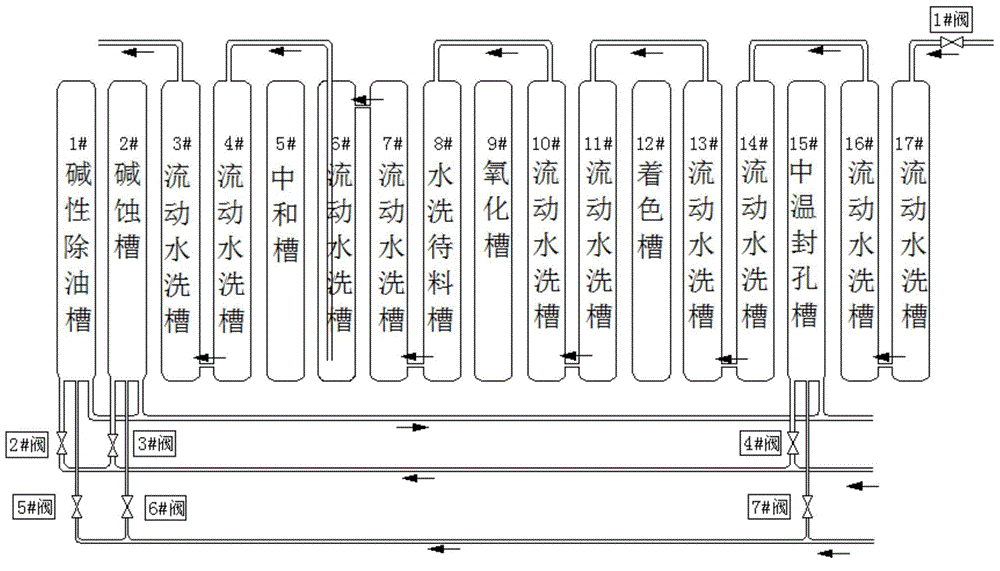

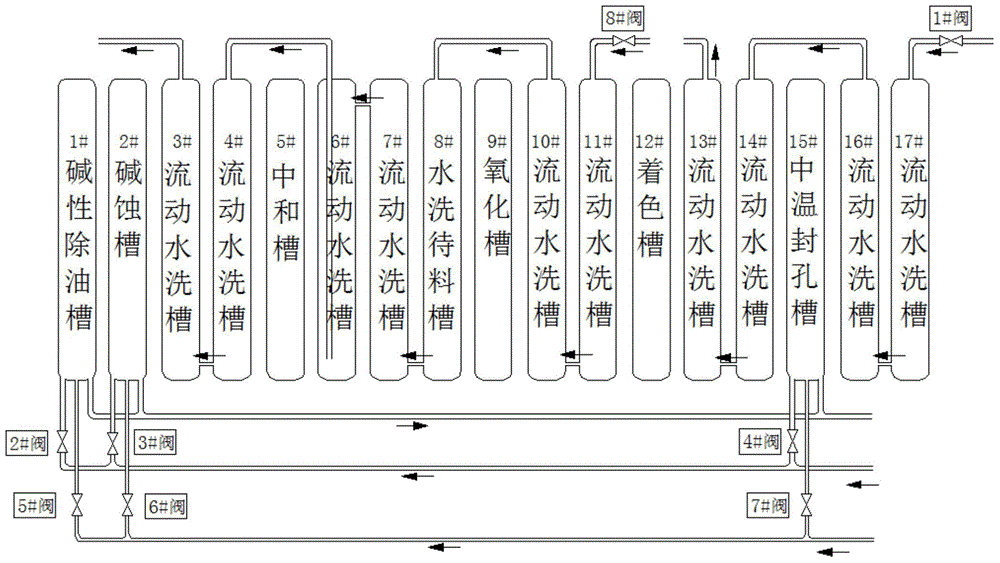

Aluminum alloy anodizing line treatment process

ActiveCN103952741AAchieve large-scale water conservationAvoid pollutionAnodisationAnodizingMaterials science

The invention relates to an aluminum alloy anodizing line treatment process. The aluminum alloy anodizing line treatment process comprises a functional trough system and water washing trough systems arranged between functional troughs. The functional trough system is arranged along the flow direction of washing water in a manner that an upstream functional trough is compatible with a downstream functional trough, and the water washing trough systems are arranged in an overall phase-reversing in-series-connection manner. According to the aluminum alloy anodizing line treatment process, a mode in which a flowing water washing tank is separately configured for each functional trough in the traditional anodizing line is changed. Since all water washing troughs are connected in series in a phase-reversing manner, the number of the water inlets and outlets is greatly reduced and the water consumption is decreased from 25.0-35.0 tons per ton material to 5.0-6.0 tons per ton material and the water is saved by more than 80%. The treatment process disclosed by the invention has the advantages of low production cost, high efficiency and environmental friendliness and is suitable for industrial application.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

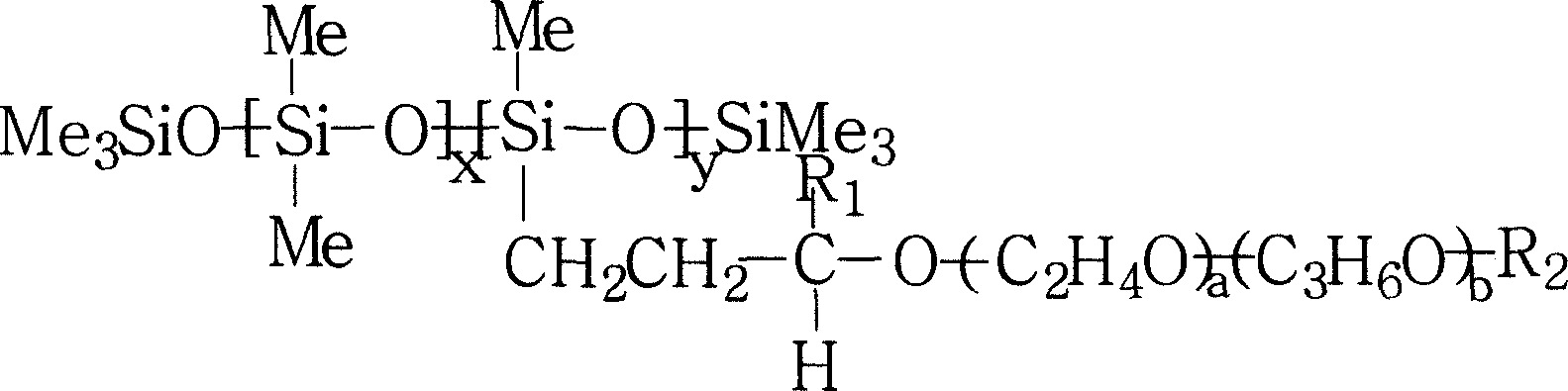

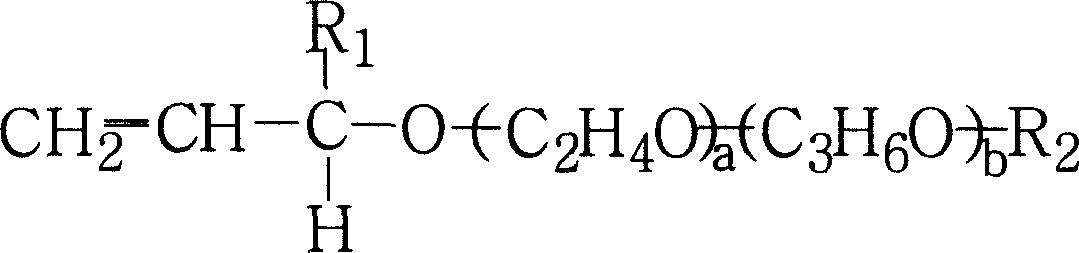

Organosilicon pesticide booster and preparing method thereof

InactiveCN101011062ALower the surface tension of the liquidGood physiological safety performanceBiocideAnimal repellantsSodium bicarbonatePlatinum

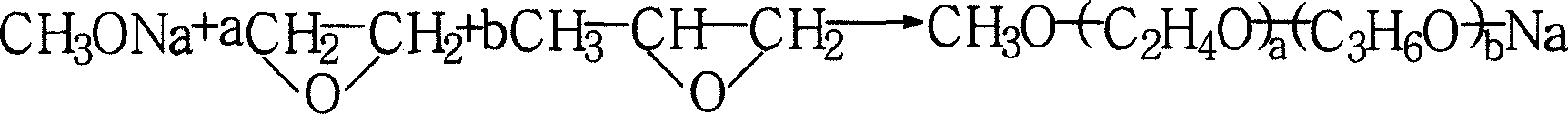

The invention relates to an organic silicon pesticide booster with low surface tension, less side effect and high yield. The chemical formula of invention is as following one, wherein, Me=CH3, R1=CH3, R2=H, CH3, C4H9, -O(O)CCH3, x=0-10, y=1-20, a=5-25, b=0-15. And the preparation comprises that putting the hydrogen siloxane and polyalkenylethers into reaction kettle, protected by N2, to increase temperature and be mixed quickly; then adding some platinum-1.3-divinyl tetramethyl disilyloxy-acetylacetone as catalyst, naturally increasing temperature to 110Deg. C, making solution transparent, adding baking soda, compressing and filtering, to obtain needed organic silicon pesticide booster. The invention has wide application in variable pesticides.

Owner:ZHANGJIAGANG JUNBO NEW MATERIAL

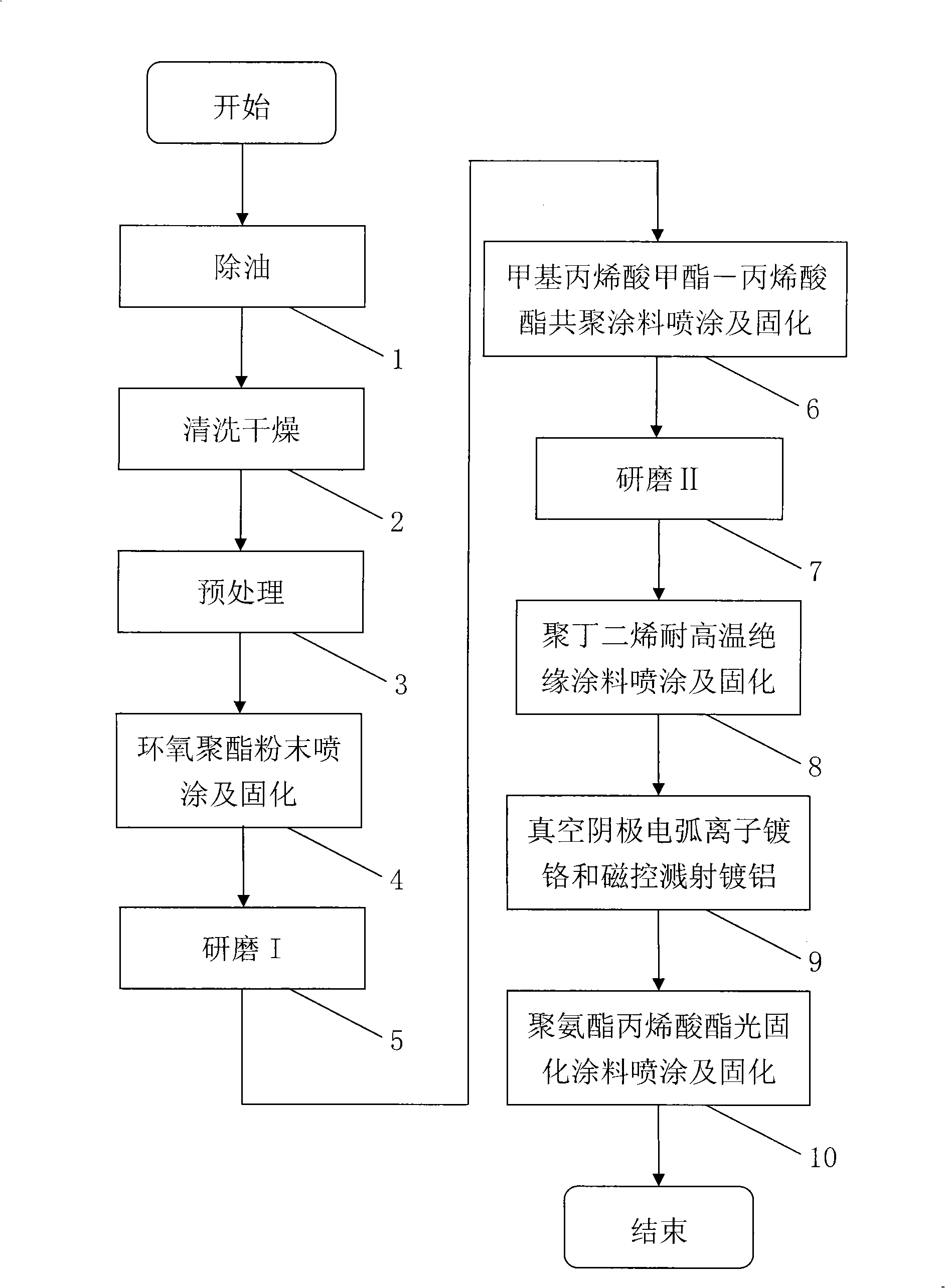

Film coating process for aluminium alloy wheel hub

InactiveCN101343740AReduce pollutionReduce energy consumptionVacuum evaporation coatingSputtering coatingPolyesterFilm coating

The invention discloses an aluminum alloy wheel hub coating technology. The aluminum alloy wheel hub coating technology comprises the procedures of oil removing, cleaning and drying, pre-treating, epoxy polyester powder spraying and solidifying, grinding I, methyl methacrylate-acrylate copolymer paint spraying and solidifying, grinding II, polybutadiene high temperature resistant insulating coating spraying and solidifying, vacuum cathode arc ion chromium plating and magnetism control sputtering aluminum plating, and polyurethane methacrylate light solidifying paint spraying and solidifying in sequence. The aluminum alloy wheel hub coating technology adopts dry electric plating to replace the traditional wet electric plating, the plating layer surface quality and the physical and chemical properties are approximately equivalent to the wet electric plated aluminum alloy wheel hub, the chromium consumption is reduced to about one fifth of the wet electric plating, the water consumption is reduced to about one seventh of the wet electric plating, precious nickel and copper are not utilized, the poisonous metal substance such as hexavalent chromium is not contained, the pollution to the environment is reduced, the energy, water and precious metal consumption is remarkably reduced, the technological flow is simplified, the production efficiency is enhanced, the heavy polishing working sequence is omitted, the working condition is remarkably improved, and the cost is reduced.

Owner:HUZHOU JINTAI PLATING IND

Automatic dairy animal milker unit backflusher and teat dip applicator system and method

ActiveUS20100132626A1Clean thoroughlyNot to wasteCathetersHollow article cleaningEngineeringForced-air

A method for applying teat dip to a dairy animal and backflushing a milker unit using a safety valve. The method includes the steps of: closing the safety valve to seal off the milker unit from a dairy pipeline system, forcing teat dip through the safety valve and a dip channel to a teat dip applicator on a milker unit teat cup, forcing backflush fluid through the safety valve and the milker unit, forcing water through the safety valve and milker unit, forcing air through the safety valve and the milker unit, and opening the safety valve so that the milker unit is in fluid communication with the dairy pipeline system.

Owner:GEA FARM TECH

Tobacco sheet producing process using improved paper making method

ActiveCN101011182AProminent smoke and smoke smellWoody smell is not obviousTobacco preparationPaper forming aids additionSlagUltra fine

The invention relates to a method for producing the tobacco sheet via improved paper making method, which comprises that preparing the tobacco slag, tobacco powder and ash via grinding machine to the tobacco powder at 60-80 deals and the ultra-fine tobacco powder at 120-800 deals; immerging the tobacco stem in water for 1-2 hours, separating the solid and liquid, concentrating the extractive solution into 15-25 degree / Be', adding the ultra-fine tobacco powder at 5-30% of the weight of concentrated solution, to obtain the coat liquid of sheet; the solid extracted from the tobacco stem is decomposed to prepare pulp, to be mixed with external pulped fiber, adjusting the density to 0.05-0.8%, to be mixed with the tobacco powder at 60-80 deals; preparing via paper machine, compressing, dewatering, drying to obtain the base sheet; immerging and coating the base sheet in the coat liquid, drying, breaking to obtain the final product. The invention can improve the smell of sheet tobacco.

Owner:CHINA TOBACCO HUNAN INDAL CORP

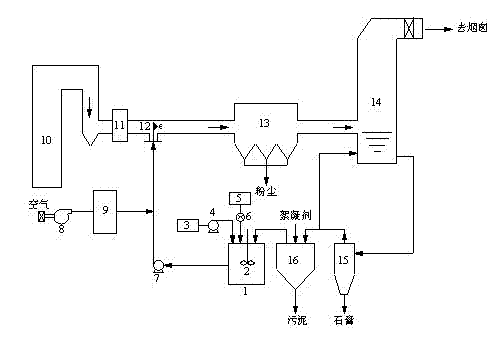

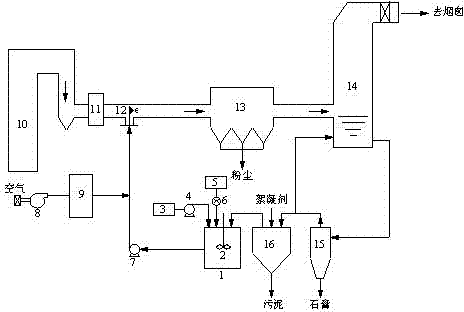

Method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in evaporation manner and device of method

InactiveCN102380278ALow running costConvenient sourceCombination devicesWater/sewage treatmentAir preheaterFlue gas

The invention discloses a method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in an evaporation manner and a device of the method. The method particularly includes steps that agglomeration liquor prepared by desulfuration wastewater, high polymer adhesive and wetting agent is sprayed into an inlet flue of an electric precipitator and is evaporated by the aid of heat of flue gas, in an evaporation process, the wetting agent promotes dust to enter drops of the agglomeration liquor, the high polymer adhesive is connected with PM2.5 via a polymer chain with polar groups, the grain diameter of the PM2.5 is prompted to be enlarged, so that the PM2.5 can be gathered by the follow-up electric precipitator, the desulfuration wastewater is evaporated completely, suspended matters and dissolvable pollutants in the wastewater are converted into solid to be dissolved out, and the suspended matters and the dissolvable pollutants in the wastewater, together with dust in the flue gas, are gathered by the electric precipitator. The device consists of a boiler, an air preheater, the electric precipitator, a desulfurizing tower, a hydraulic cyclone, a desulfuration wastewater clarification tank and an agglomeration liquor preparation tank, and a double-fluid atomizing nozzle is arranged in the flue between the air preheater and the electric precipitator.

Owner:SOUTHEAST UNIV

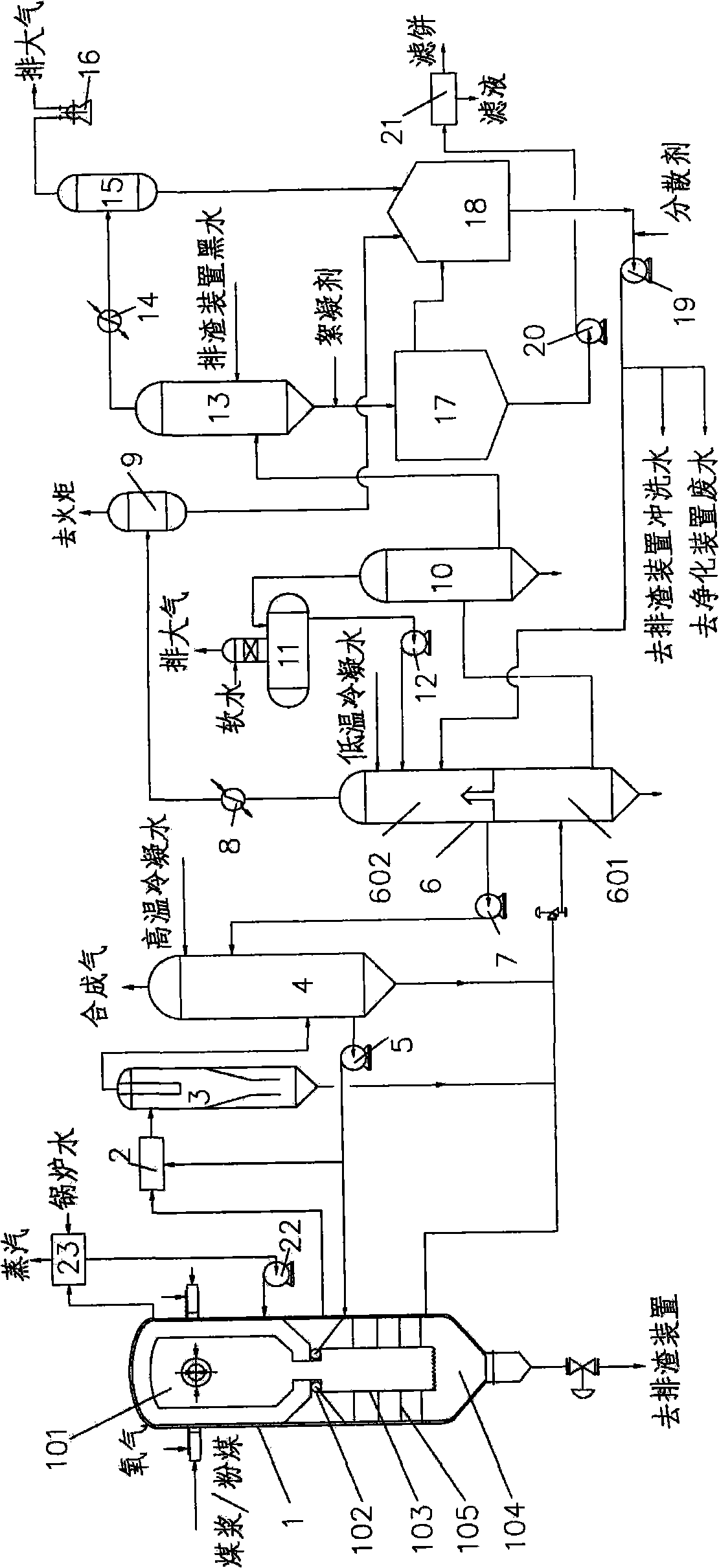

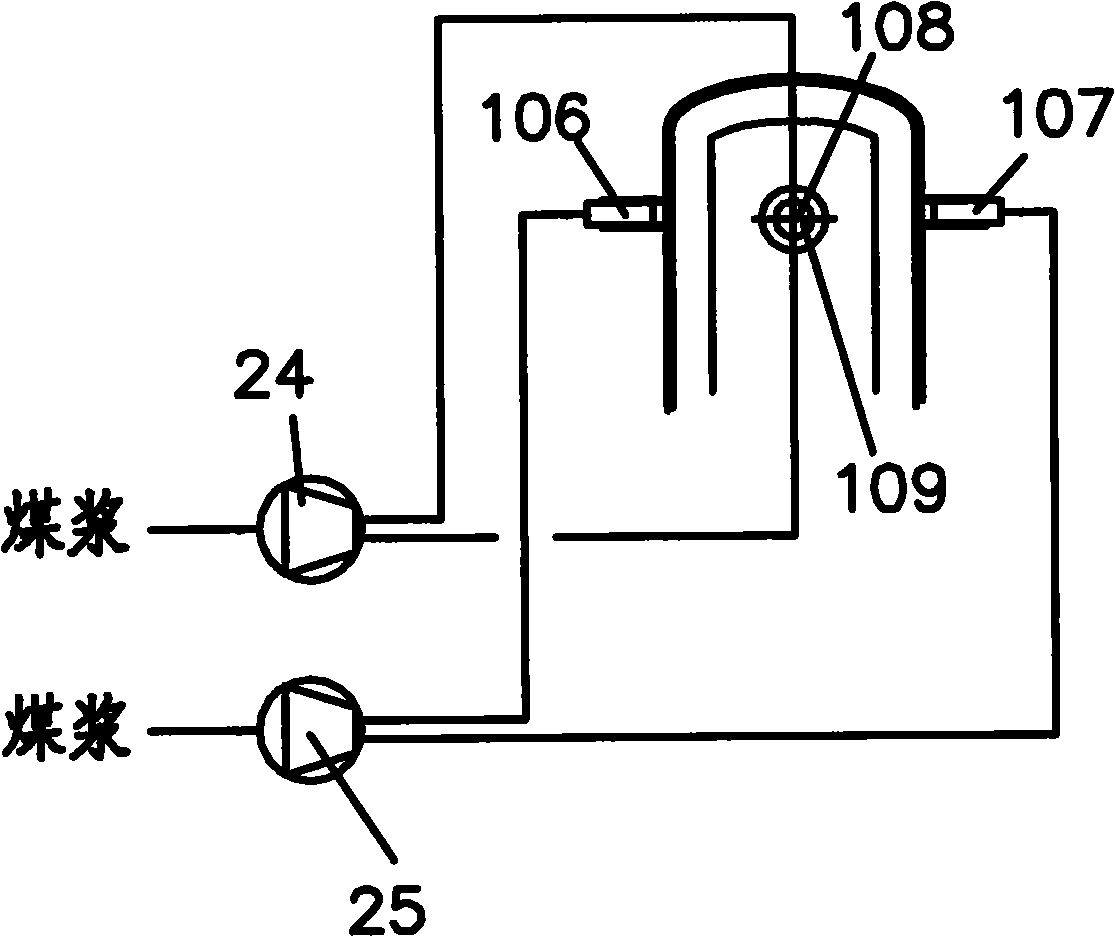

Gasification method of shock chilling type pulp or powder carbonaceous material

ActiveCN101298569AImprove water qualityReduce or eliminate emissionsChemical industryCombined combustion mitigationWater vaporWater quality

The invention discloses a gasification method of chilling slurry or powdery carbonic material. The method mainly consists of four technologies which are gasification in opposed multi-burner type, primary purification of synthetic gas, heat recovery and the treatment and recycling of black water, wherein, a gasification furnace is the core device of the method in the gasification process, which is provided with at least two pairs of opposed burners in uniform distribution and realizes the full gasification of the material under the operation pressure of 3-8 MPaG and the operation temperature of below 1200 DEG C-1700 DEG C. The invention has the following advantages: the carbon conversion rate in the gasification furnace is up to more than 90 percent, the effective gas content during slurry feeding is more than 84 percent and the effective content during powdery feeding is more than 90 percent; the ash content of the synthetic gas after primary purification is low, which can be lowered to below 1 mg / Nm<3>, thus having better water-gas ratio, i.e. the volume ratio of steam / synthetic gas (dry basis) is 1.3-1.5 / 1; the heat of the black water is totally recovered, the quality of ash water after purification is good and no fouling and clogging phenomena occur; the energy consumption, the oxygen consumption and the water consumption of the whole gasification process are relatively low, thus being capable of realizing long period stable operation with high efficiency.

Owner:EAST CHINA UNIV OF SCI & TECH

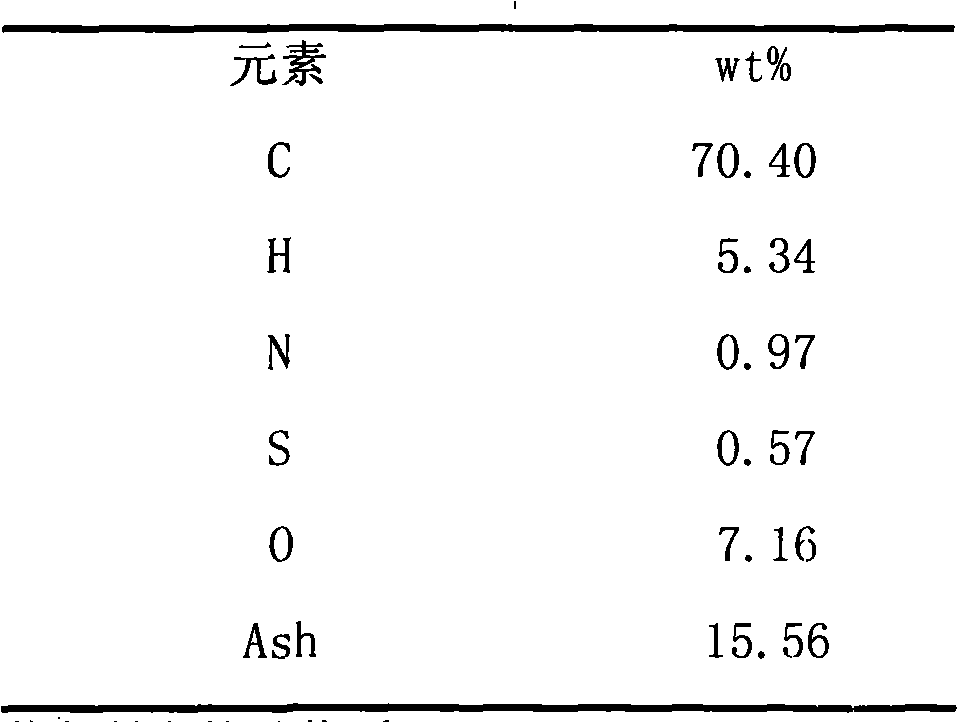

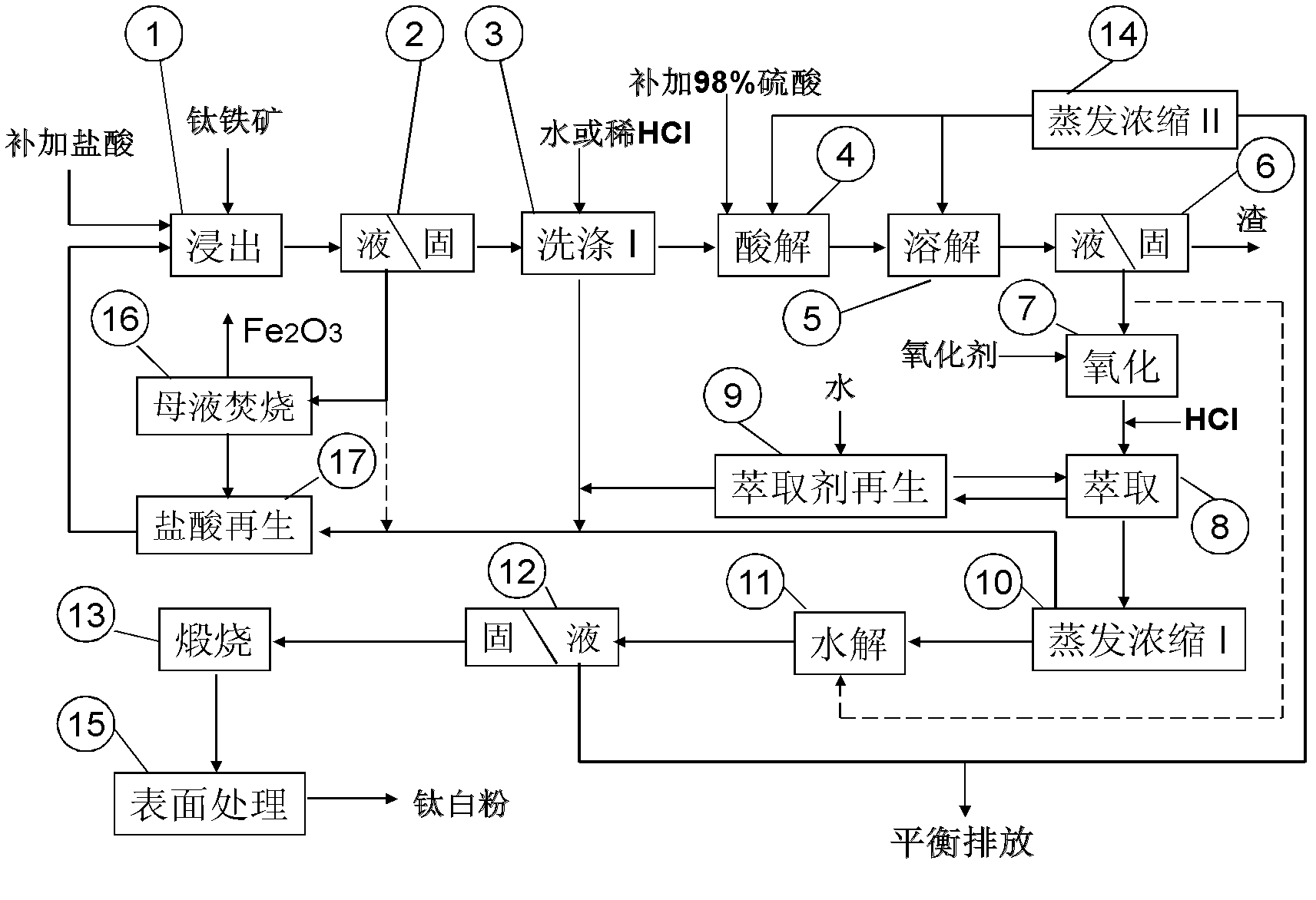

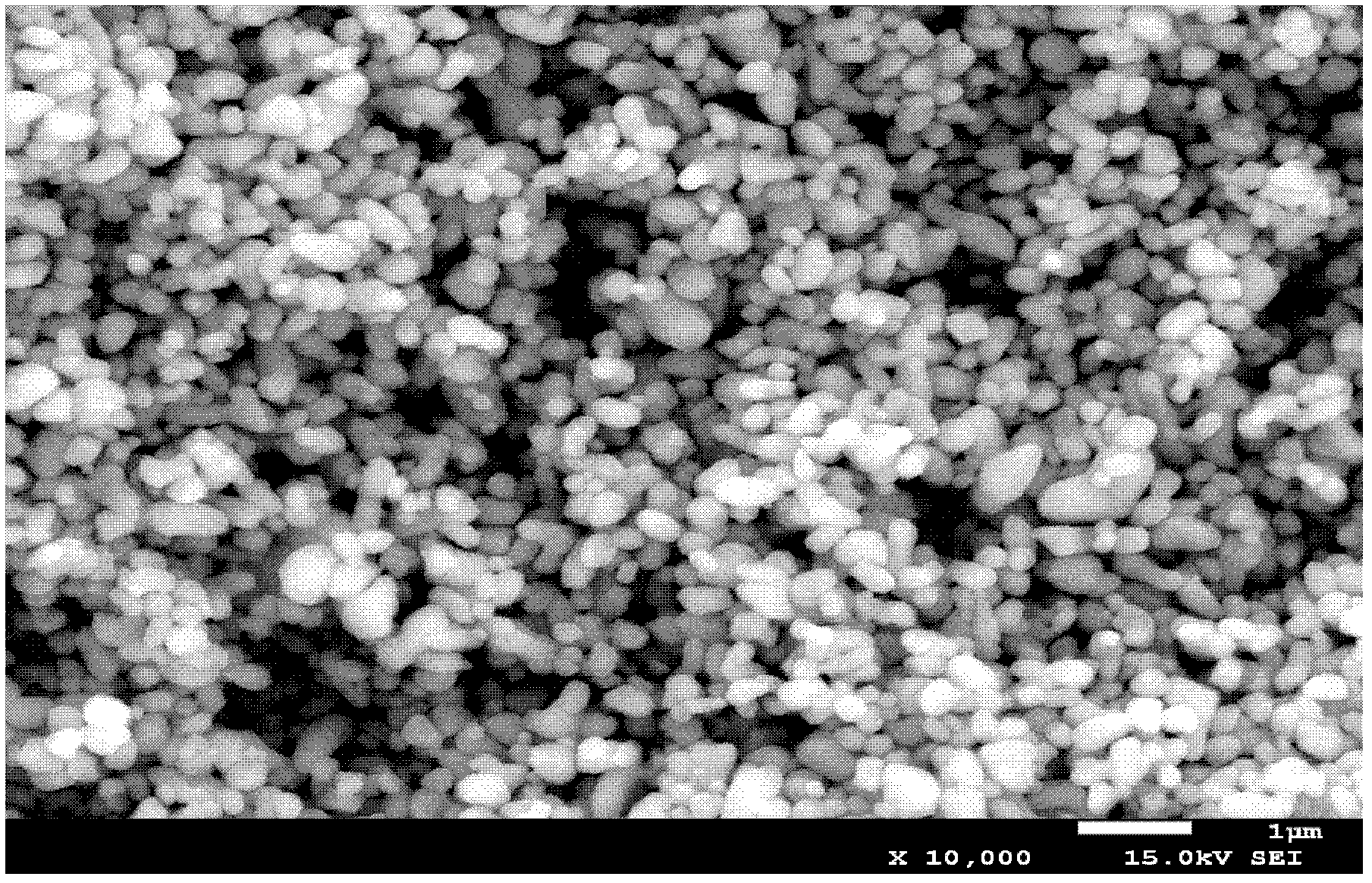

Method for preparing titanium white

The invention provides a method for preparing titanium white. The method comprises the following steps of: preparing titanium solution from high titanium hydrochloric acid leaching residue, which is prepared from a titanium iron material through a hydrochloric acid leaching method, serving as a raw material or one of raw materials through acidolysis by using sulfuric acid; oxidizing the titanium solution, performing organic extraction and purification, and hydrolyzing to obtain metatitanic acid; and performing washing, salt treatment, calcination and surface treatment on the metatitanic acid to prepare the titanium white. According to the method, hydrochloric acid composite system solution containing chlorate is subjected to diffluent disposal and is recycled after the titanium iron material is leached, and is organically matched with a cyclic process of an organic extraction and purification and sulfuric acid system of the titanium solution, so that the titanium solution treatment process and the cost are reduced; and since the used hydrochloric acid, sulfuric acid and organic extraction agent can be recycled, ferrous sulfate (green vitriol) is not produced; and thus, the discharge of dilute sulfuric acid and acidic wastewater is effectively reduced, and the quality of the titanium white is obviously improved. According to the method provided by the invention, high efficiency, cleanness, low cost, low energy consumption and low waste discharge effects of an entire flow are realized; a novel process technology is provided for producing the titanium white by a sulfuric acid method; and fine grained rock type ilmenite with high calcium and magnesium content at the Panxi area can be effectively utilized.

Owner:攀枝花新中钛科技有限公司

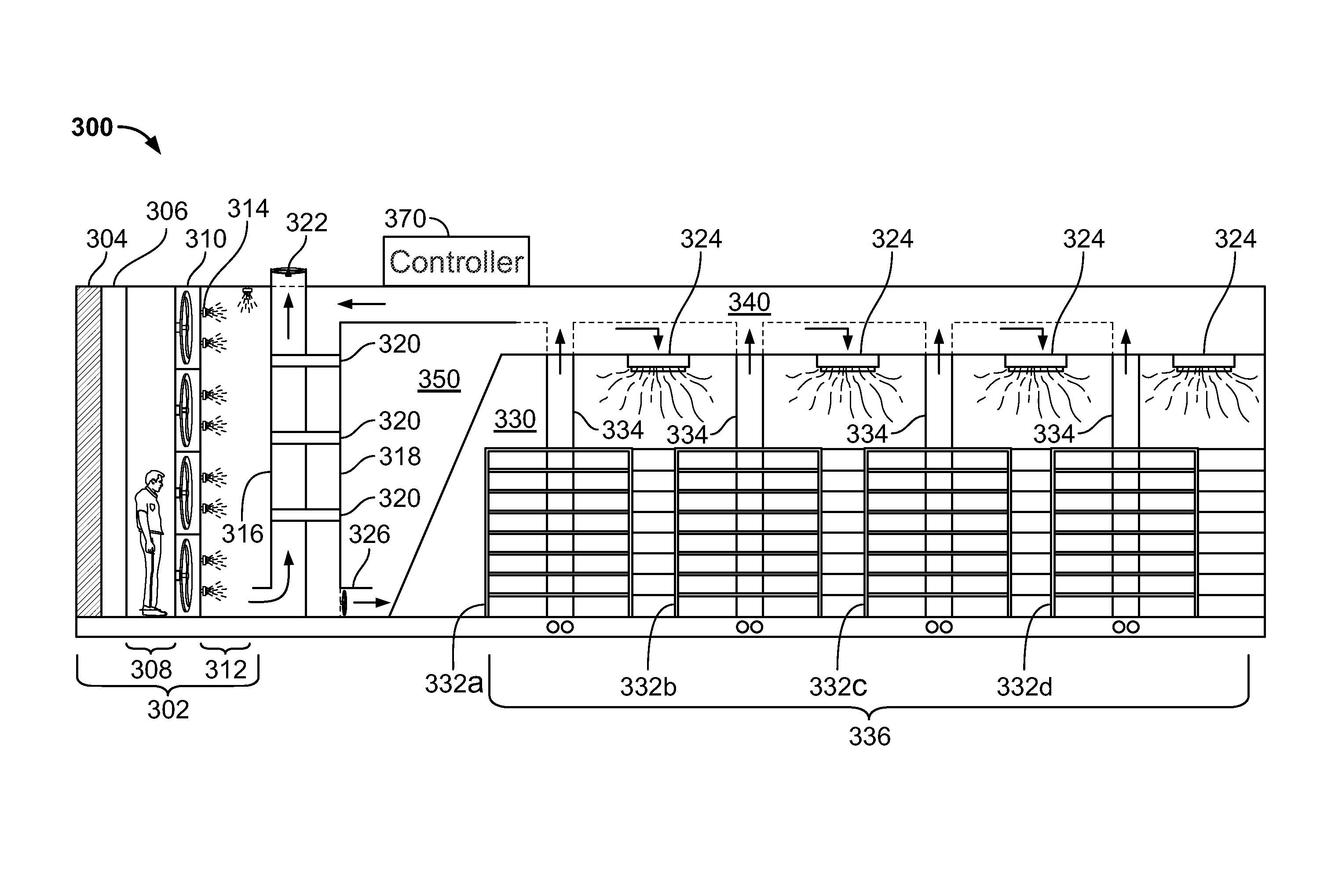

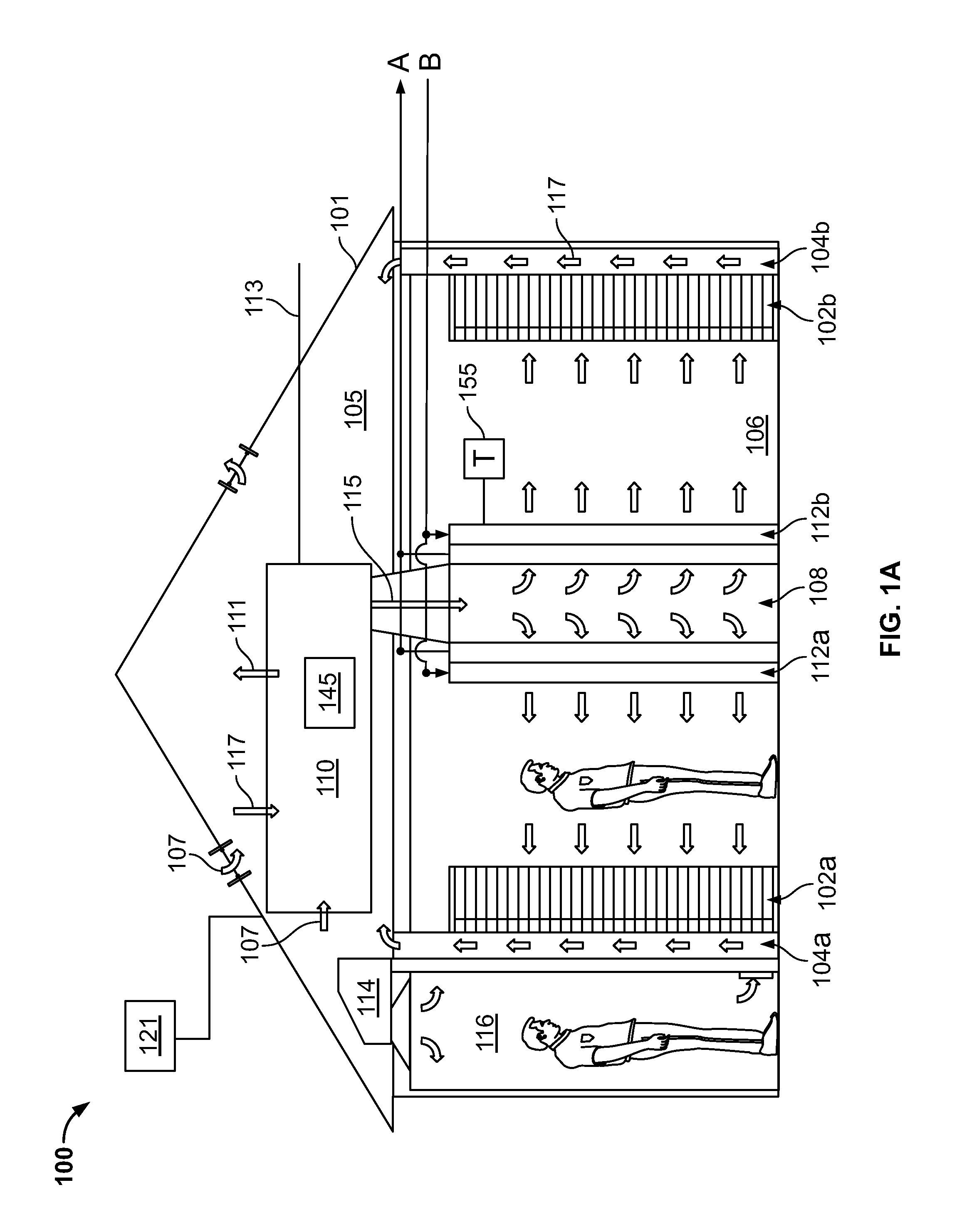

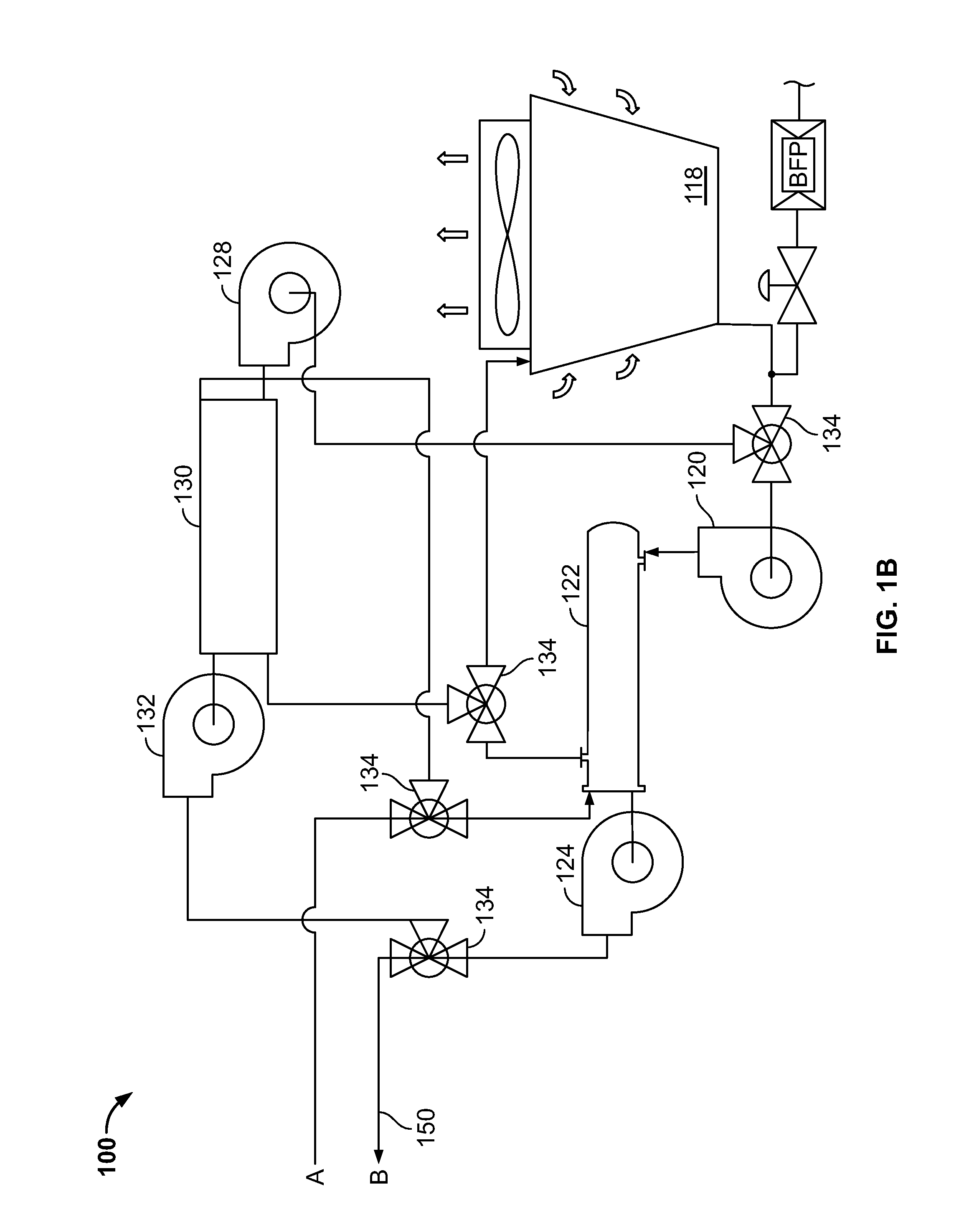

Managing data center airflow

ActiveUS9313929B1Reduce dry bulb temperatureEasy to cleanCooling/ventilation/heating modificationsAir contaminantData center

Techniques for cooling a data center include operating an air handling system in a first mode of operation to provide an outside airflow cooled through a direct evaporative cooling module to a data center without substantial mixing of the cooled outside airflow with another airflow; determining that a measured outside air contaminant level exceeds a setpoint contaminant level; and based on the determination, operating the air handling system in a second mode of operation to provide a datacenter return airflow cooled through an indirect evaporative cooling module to the data center without substantial mixing of the cooled return airflow with another airflow.

Owner:GOOGLE LLC

Cigarette core material free of burning during heating and preparation method thereof

InactiveCN107212467AGood physical propertiesGood processing adaptabilityTobacco treatmentTobacco devicesFlavorAirflow

The invention discloses a cigarette core material free of burning during heating and a preparation method thereof. The cigarette core material comprises, by weight, 5-30 parts of plant fiber, 40-85 parts of tobacco raw material, 5-40 parts of smoke agent, 0-20 parts of tobacco flavor and 1-10 parts of auxiliary material. The cigarette core material is formed through dry-process airflow forming technology, thereby having high loading performance; high-proportion adding of the smoke agent is realized; high reducibility and porous physical structure of tobacco active ingredients that dry-process reconstituted tobacco leaves have are combined, so that efficient smoking of formed cigarettes free of burning during heating can be guaranteed, high-level sensory quality of formed cigarette products free of burning during heating and effective volatilization of formed smoke can be guaranteed, and the cigarette products are enabled to have good sensory quality and user experience.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

Fiber-reinforced composite material cement board and preparation method thereof

ActiveCN101508133ALow water absorptionReduce moisture contentConstruction materialSurface layering apparatusFiberglass meshGlass fiber

The invention discloses a method for preparing a fiber composite material concrete board, which comprises the following steps: laying a first layer of slurry in a mould; laying a first layer of glass fiber grid cloth on the laid first layer of the slurry; laying a second layer of slurry on the laid first layer of the glass grid cloth; laying a second layer of glass fiber grid cloth on the laid second layer of the slurry; laying a third layer of slurry on the laid second layer of the glass fiber grid cloth; vibrating the mould by a vibration device; putting the mould into a steam autoclave; and performing autoclave leaving, demoulding, airing and final treatment to form the concrete board made of the fiber composite material. The invention also discloses a concrete board made of a fiber composite material. The method has the advantages of simple manufacturing process, little capital and equipment input and low cost; and the concrete board made of the fiber composite material has the advantages of low water absorbing rate, high strength, good toughness, high durability, and the like.

Owner:广德衡峰新型建材有限公司

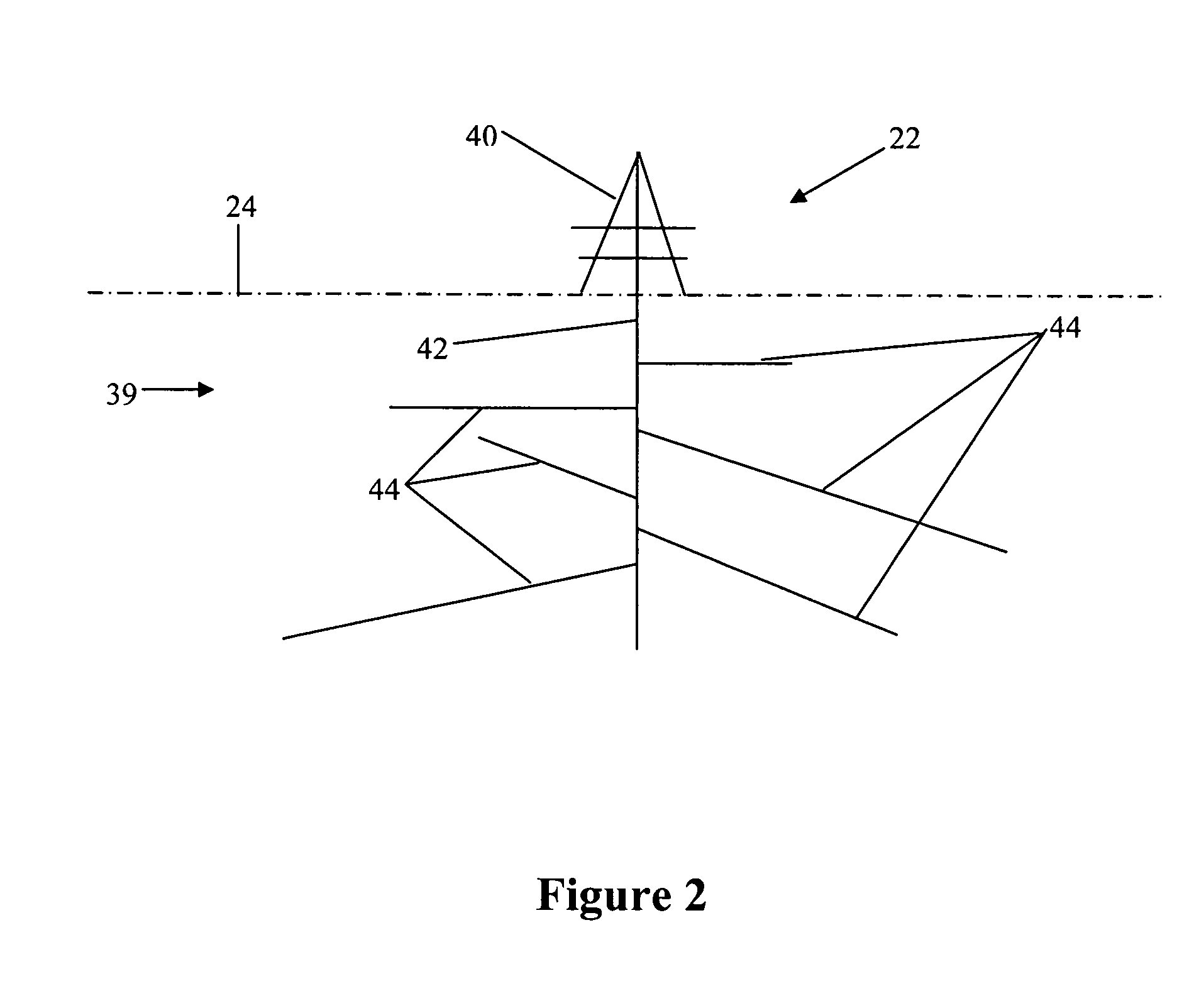

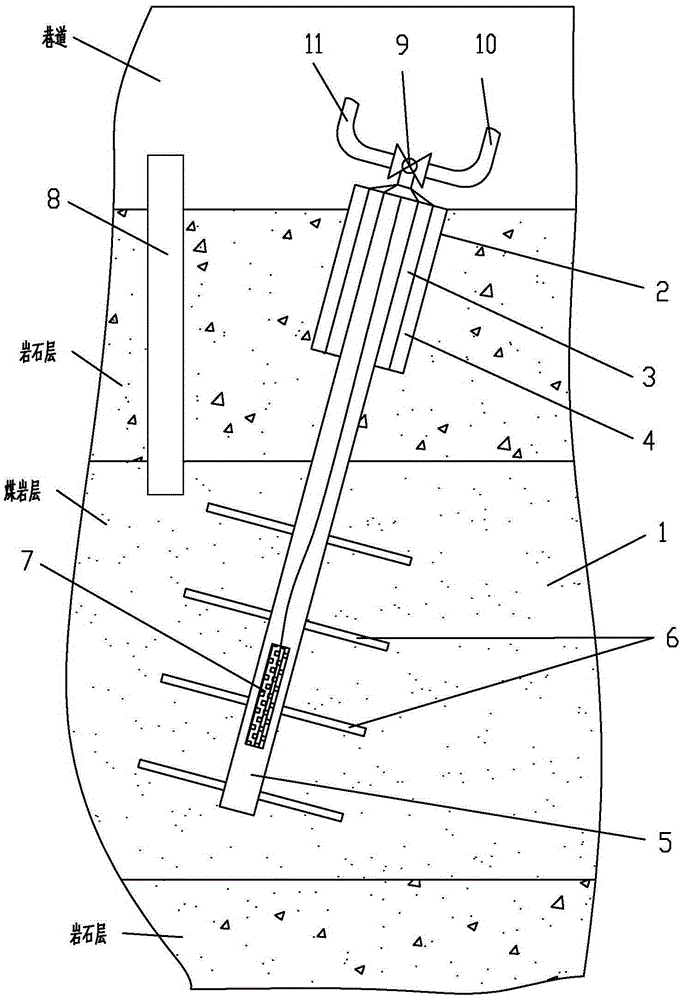

Method and system for extraction of hydrocarbons from oil shale

InactiveUS20070181301A1Improve permeabilityHigh porosityInsulationFluid removalOil shale gasEnergy source

A system and method for extracting hydrocarbon products from oil shale using nuclear energy sources for energy to fracture the oil shale formations and provide sufficient heat and pressure to produce liquid and gaseous hydrocarbon products. Embodiments of the present invention also disclose steps for extracting the hydrocarbon products from the oil shale formations.

Owner:ULTRA SAFE NUCLEAR CORP

High-pressure water burst and CO2 fracturing combined coal bed gas displacement extraction technology

InactiveCN105332684AAccurately determine the scope of influenceWide variety of sourcesFluid removalGas removalHigh pressure waterHigh pressure

The invention discloses a high-pressure water burst and CO2 fracturing combined coal bed gas displacement extraction technology. The high-pressure water burst and CO2 fracturing combined coal bed gas displacement extraction technology comprises the following steps: ground stress state determination, hole sealing section drilling and sealing, hole drilling and slitting, charging, water injection hole sealing, high-pressure water burst crack starting, supercritical or liquid CO2 fracturing and gas extraction. A ceramsite proppant is mixed in the supercritical or liquid CO2, in a continuous fracturing process of the liquid CO2, extension conditions of burst cracks can be monitored in real time by a microseism monitoring instrument, and fracturing is stopped after an expected effect of extension in a set range is achieved. During guided slitting, slitting can be carried out step by step after holes are drilled according to the number of slits and a set distance between each two adjacent slits, and a mode of drilling holes and slitting alternately can also be adopted. The high-pressure water burst and CO2 fracturing combined coal bed gas displacement extraction technology has the advantages that the permeability of a low-permeability coal bed gas reservoir can be increased effectively, construction amount is reduced, and coal bed gas extraction efficiency is high.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com