Patents

Literature

79results about How to "Product quality is not affected" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technology of transforming common magnesium hydrexide into hexagonal sheel shaped magnesium hydroxide by hydrothermal method

ActiveCN1830788AImprove conversion rateImprove product qualityMagnesium hydroxideLithium hydroxidePotassium hydroxide

A process for preparing hexagonal flake type magnesium hydroxide from ordinary one by dydrothermal method includes such steps as proportionally mixing ordinary magnesium hydroxide with lithium hydroxide and / or potassium hydroxide, or their mixture with sodium hydroxide, stirring, hydrothermal reaction at 140-200 deg.C for 2-6 hr, cooling, filtering, washing, drying, and pulverizing.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Sea-buckthorn instant tea and preparation thereof

InactiveCN101238842AComply with hygienic standardsIncrease productionTea substituesFood preparationInstant teaAdditive ingredient

The invention provides a method for preparing sea buckthorn instant tea, the method includes the following steps: extracting and concentrating the collected sea backthern leaves by extracting agent to obtain the concentrated extracting solution; spray drying the concentrated extracting solution to obtain powder shaped water-soluble sea backthern leaf extract; preparing the sea backthern leaf extract with accessories in a certain ratio to for producing the sea buckthorn instant tea with needed flavor and taste. The invention also provides a sea buckthorn instant tea prepared by the upper method, containing the water-soluble sea backthern leaves extract extracted from sea backthern leaves, the flavone content of the instant tea is 0.2-10 mg / bag, preferably 1-5mg / bag. The merits of the invention reside in that: picking time of the material sea backthern leaves or tender and fresh degree are not requested; the process is industrial producing process, the output of the products is large, the product is safe and health; at the same time because the matter added into the sea backthern teabag is 100% water-soluble sea backthern leaves extract, once the tea bag is soaked, all the effective active ingredients in the sea backthern tea are dissolved.

Owner:高原圣果沙棘制品有限公司

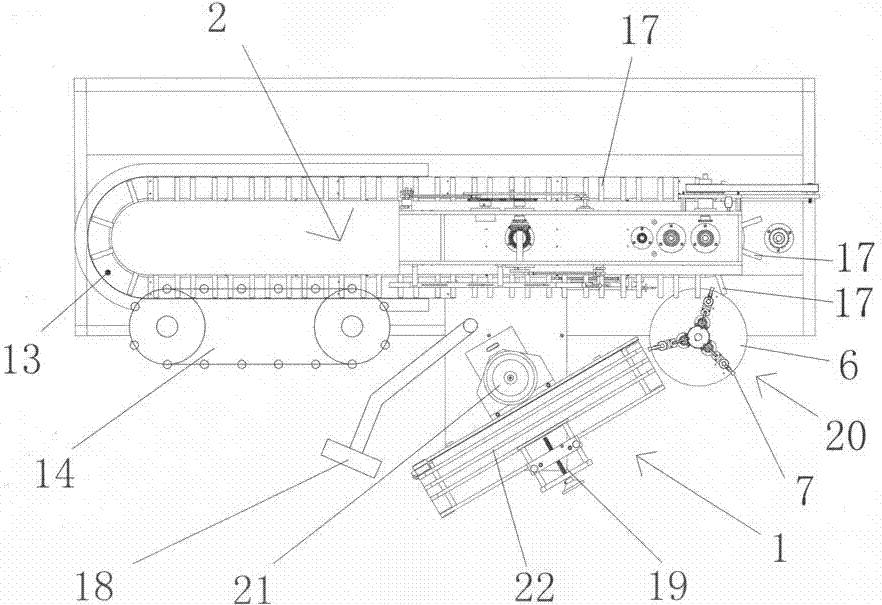

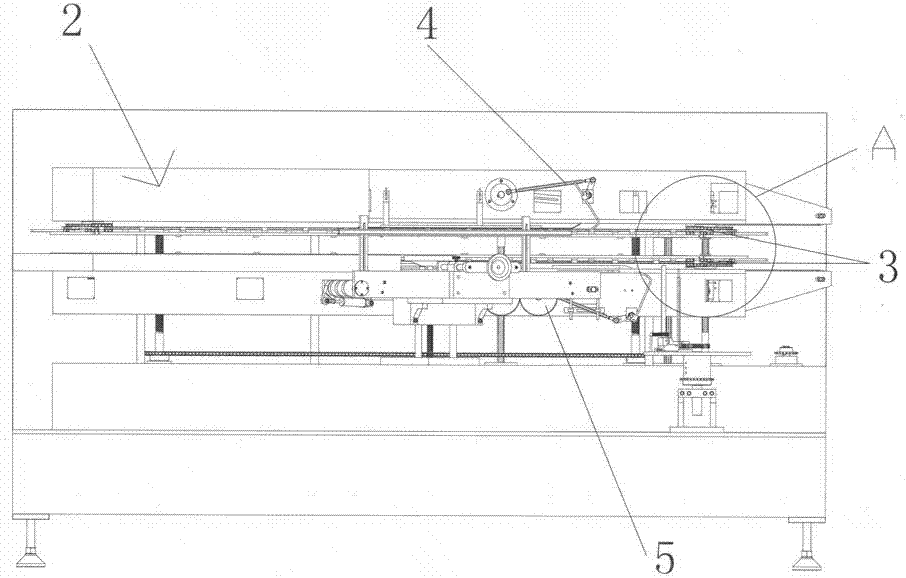

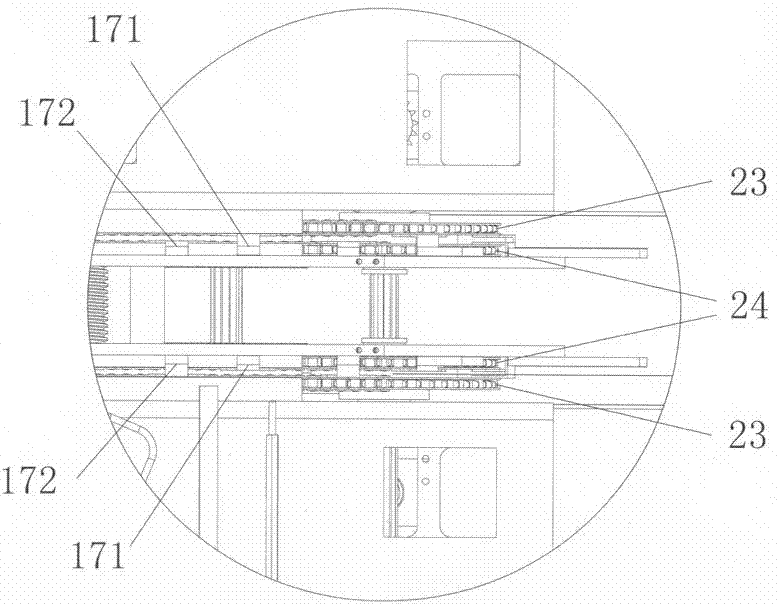

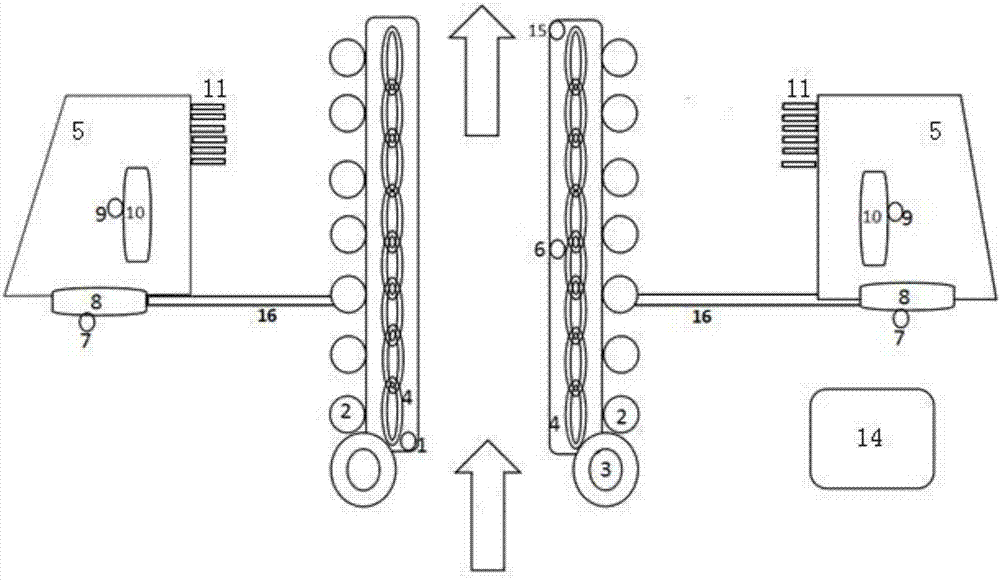

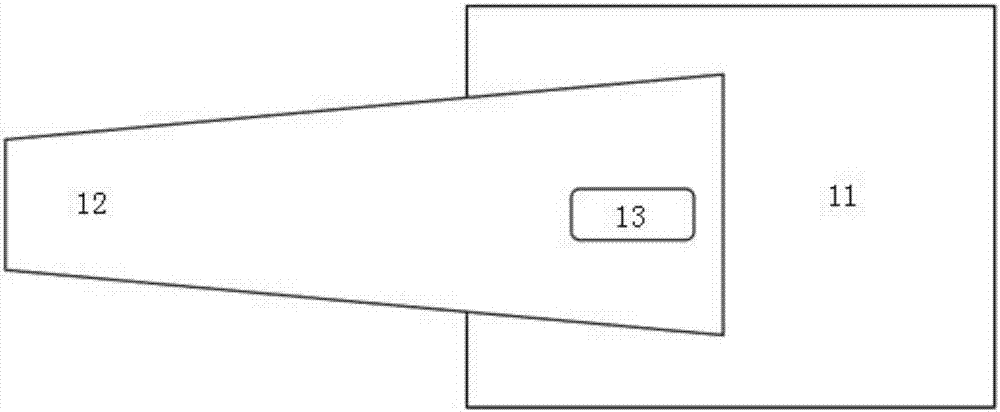

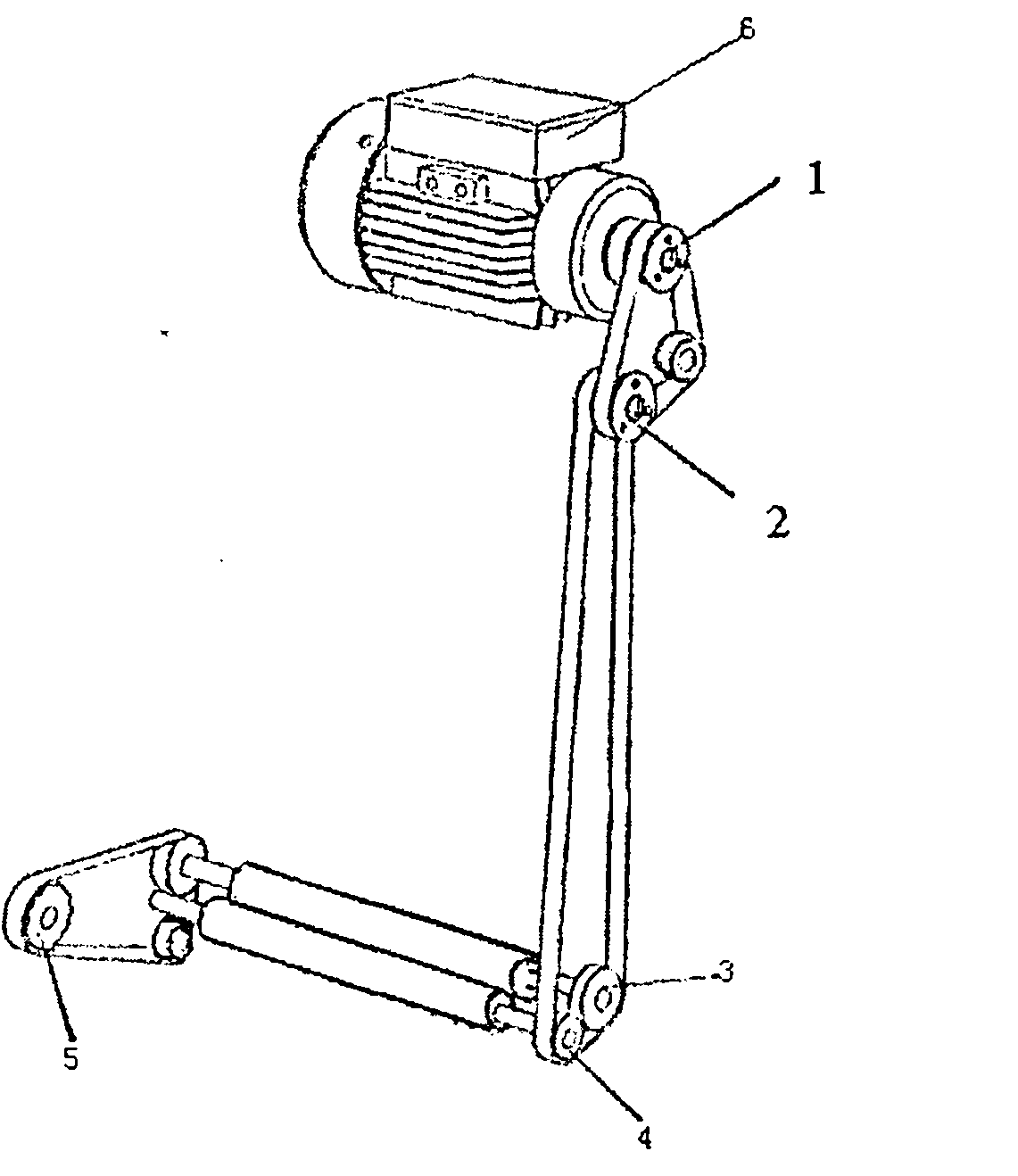

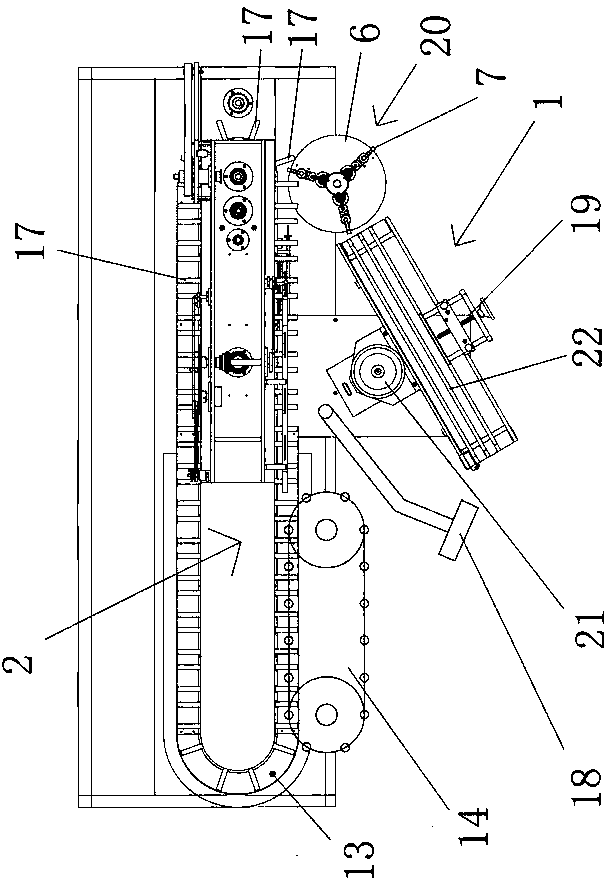

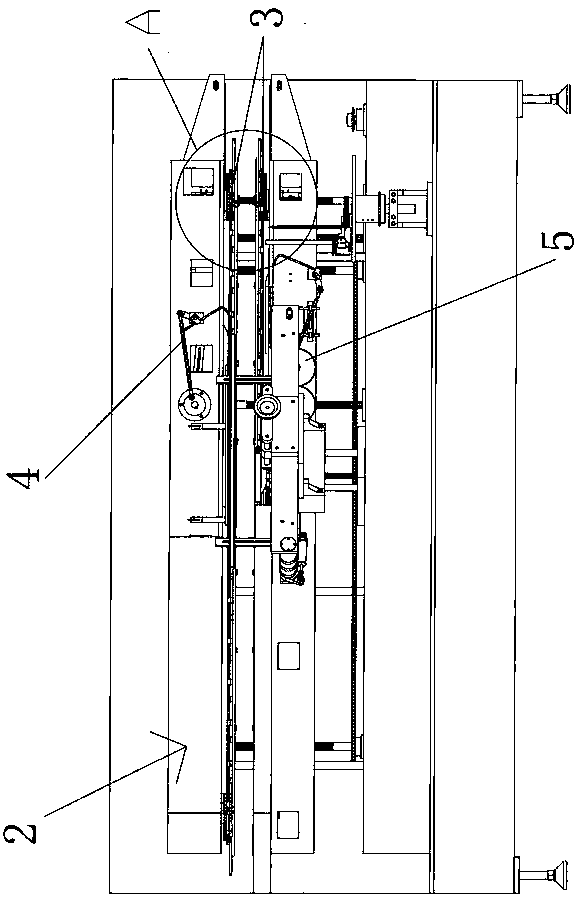

Vertical boxing machine and rotary box-sucking mechanism thereof

ActiveCN103204266AAvoid contactAvoid affecting product qualityPackagingMechanical devicesCartoning machine

The invention provides a vertical boxing machine and rotary box-sucking mechanism thereof, and belongs to the mechanical devices or equipment of packing objects or materials. The vertical boxing machine comprises a paper box storeroom (1) and a paper box delivery and convey chain mechanism (2) which comprises a convey chain assembly (3), a tongue driving mechanism (4) and a tongue inserting mechanism (5). The vertical paper boxing machine is characterized in that the rotary box-sucking mechanism (20) is arranged between the paper box storeroom (1) and the convey chain mechanism (2) and is matched with the same; the rotary box-sucking mechanism comprises a turntable (6) connected with a power device in a transmission manner. A radial reciprocating-moving box-sucking unit assembly is arranged on the turntable (6) and mainly comprises a sucking head (7) connected with an air source; and the vertical boxing machine capable of completing material vertically boxing and sucking and releasing the paper boxes successfully without additional paper box opening mechanisms.

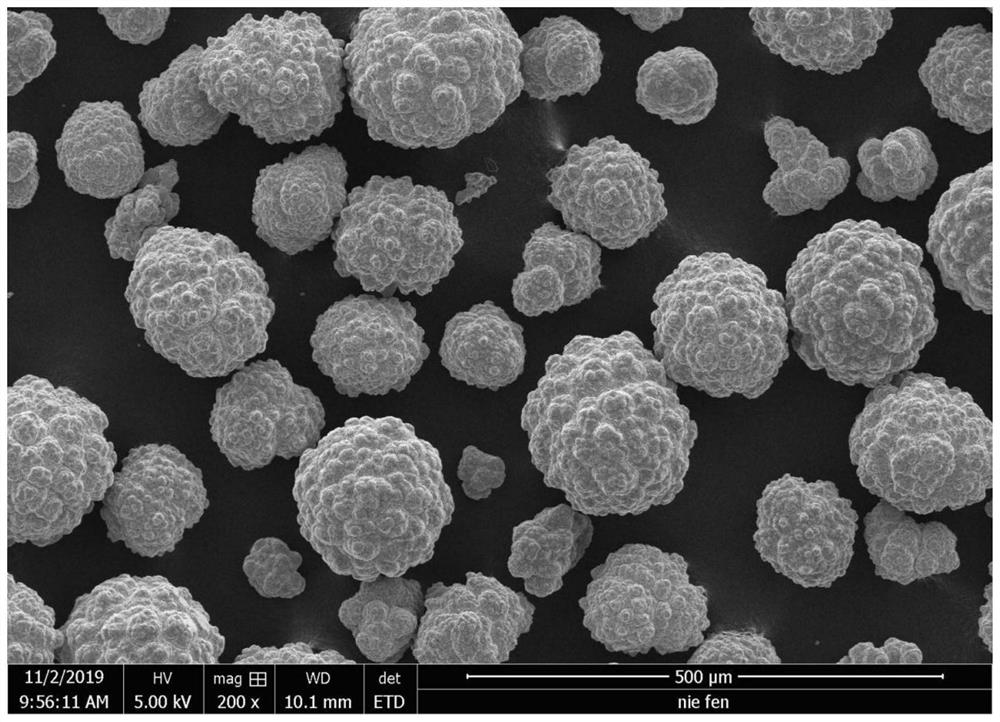

Preparation technology of hexagonal plate magnesium hydroxide

InactiveCN101544387AUniform particle sizeImprove flame retardant performanceMagnesium hydroxideLithium hydroxidePotassium hydroxide

The invention provides a preparation technology of hexagonal plate magnesium hydroxide. Magnesium hydroxide products are prepared into slurry mass concentration of which is 7.5 percent to 15 percent, the slurry is added into transforming agent solution to enable the total alkali concentration of the transforming agent solution to be 2-4mol / L; then all the mixture is mixed uniformly and placed in a high-pressure reaction kettle to react at 140-160 DEG C for 2-6h; and after being cooled, the reaction product is washed by water, dried and crashed to obtain the hexagonal plate magnesium hydroxide. The transforming agent is a composite transforming agent formed by mixing lithium hydroxide and sodium hydroxide or potassium hydroxide according to mol ratio of 1:1-1:4. Observed by a low vacuum laser scanning electron microscope, the magnesium hydroxide prepared in the invention is a hexagonal plate magnesium hydroxide with complete crystal formation and uniform granularity; the grain diameter of the magnesium hydroxide is correlative to raw materials; and the specific surface of the magnesium hydroxide is 3.0-20 m<2> / g. Due to the adoption of the new transforming agent, the invention has high transformation ratio, good product quality, stable crystal formation and low cost.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

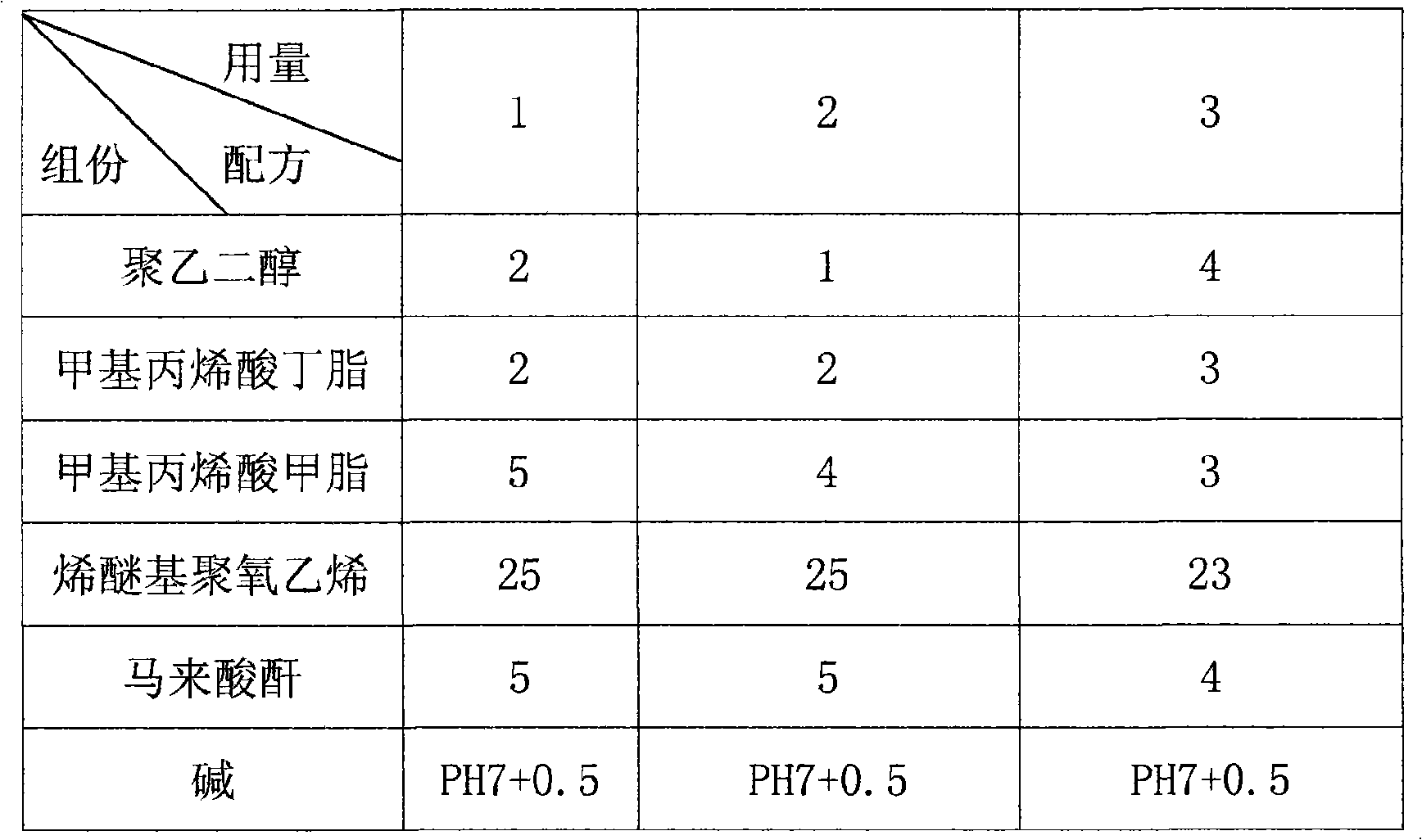

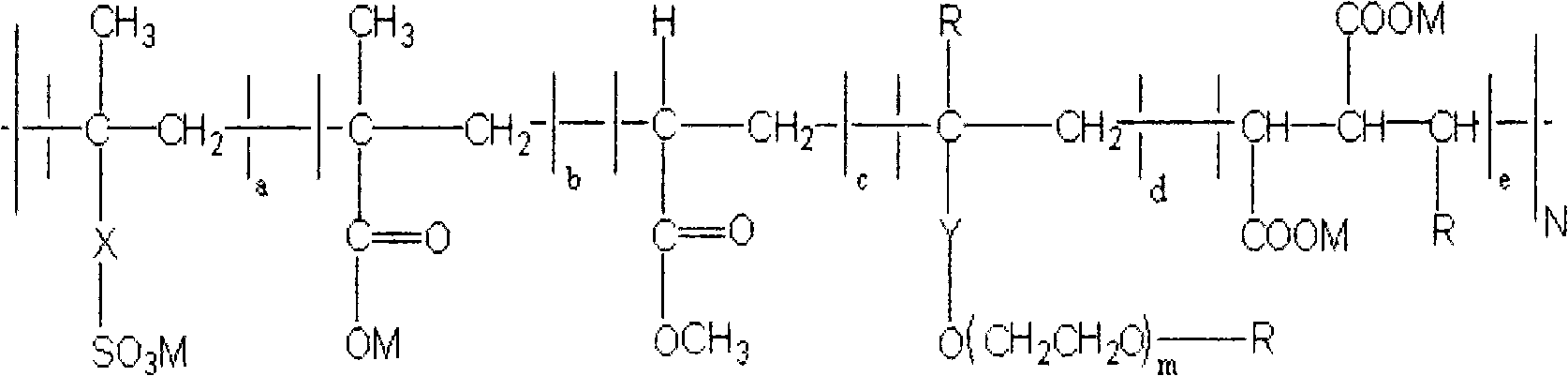

Process for synthesizing high performance water reducing agent of polyocarboxy acid

A synthesis process for a polycarboxylate high performance water reducing agent is characterized in that the polycarboxylate high performance water reducing agent is made from the raw materials with the following weight portions of 1 to 4 portions of polyethylene glycol, 2 to 3 portions of butyl methacrylate, 3 to 5 portions of methyl methacrylate, 23 to 25 portions of vinyl ether polyoxyethylene and 4 to 5 portions of maleic anhydride. Water is heated to 70 DEG C to 100 DEG C in a reaction kettle, part of the reactants is taken to pour into the reaction kettle to stir, melt, mix evenly and heat, alkali with 0.5 weight portions is added to neutralize after the reaction is completed, and the process is completed. The synthesis process has no nitrogen protection and does not use de-ionized water equipment, does not need separate titration, and can simultaneously carry out the addition and the mixture. The process has the characteristics of simple flow, simple and convenient operation, excellent performance-price ratio, safety, environment protection, etc.

Owner:宫世全

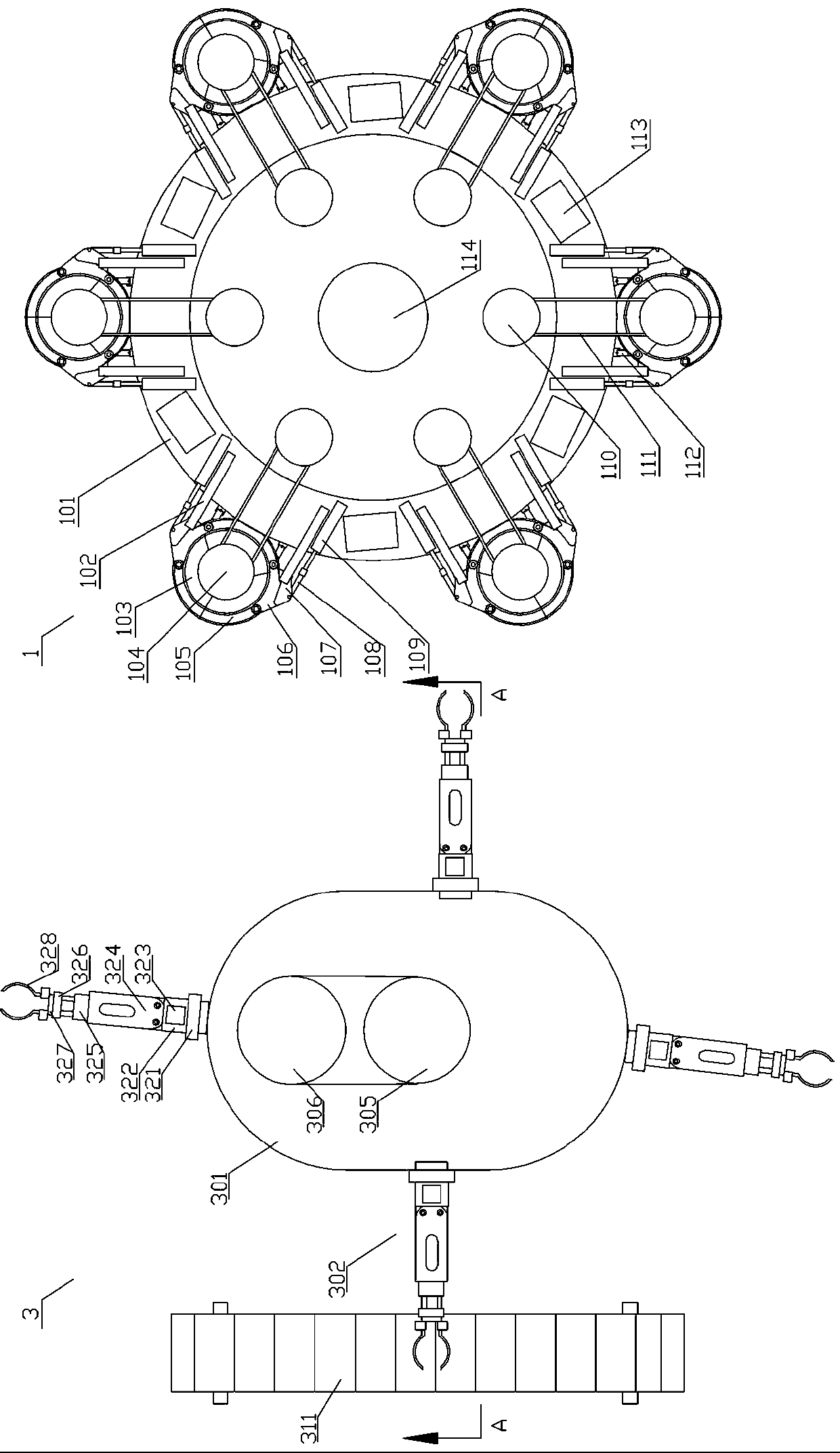

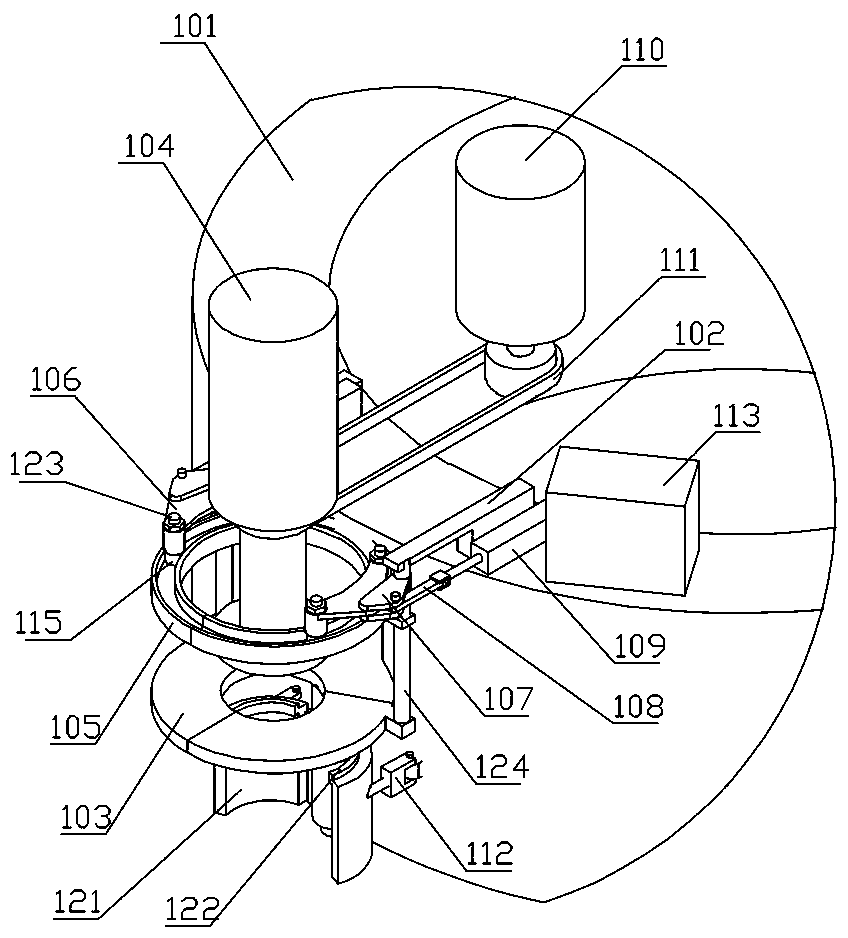

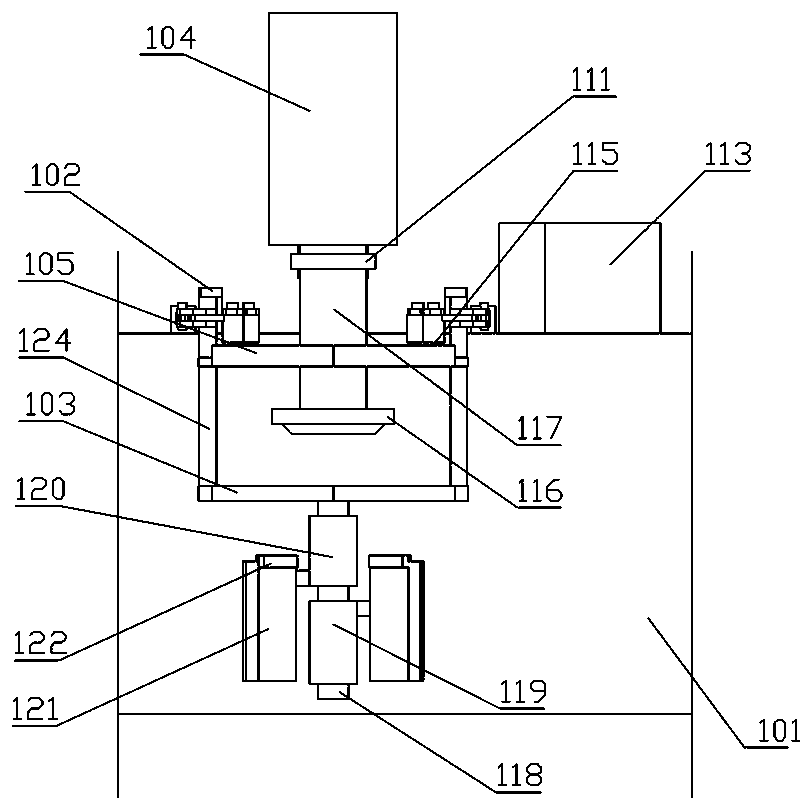

Automatic production system of high borosilicate glass kettle

PendingCN107902874AImprove efficiencyIncrease productivityBlowing mouldsRolling-element bearingMechanical drive

The invention provides an automatic production system of a high borosilicate glass kettle. The automatic production system comprises blower molding equipment, a molding mold and a discharging device,wherein the blower molding equipment comprises an annular rack; the annular rack is provided with at least three blowers; each blower comprises a glass blank clamping plate and connecting column sleeves are arranged at two sides of each glass blank clamping plate; an annular sliding channel is arranged above each glass blank clamping plate and a rolling bearing is arranged in each annular slidingchannel; each rolling bearing is mechanically driven through an air cylinder to open the corresponding glass blank clamping plate; an openable mold hanging plate with an arc-shaped bulge is arranged below each glass blank clamping plate; each mold hanging plate is pushed through the air cylinder; the molding mold comprises a kettle wall mold and a kettle bottom mod; one circle of L-shaped reversedhooks are arranged on an outer wall surface of the kettle wall mold and are matched with the arc-shaped bulges; the discharging device comprises discharging equipment; a conveyor belt is arranged ona side face of the discharging equipment; at least three mechanical arms are uniformly distributed on the discharging equipment. The automatic production system of the high borosilicate glass kettle is high in automation degree and high in production efficiency and influences on quality in a product transportation process are not caused.

Owner:HUBEI RUIXIN HEALTH CARE PROD SCI & TECH CO LTD

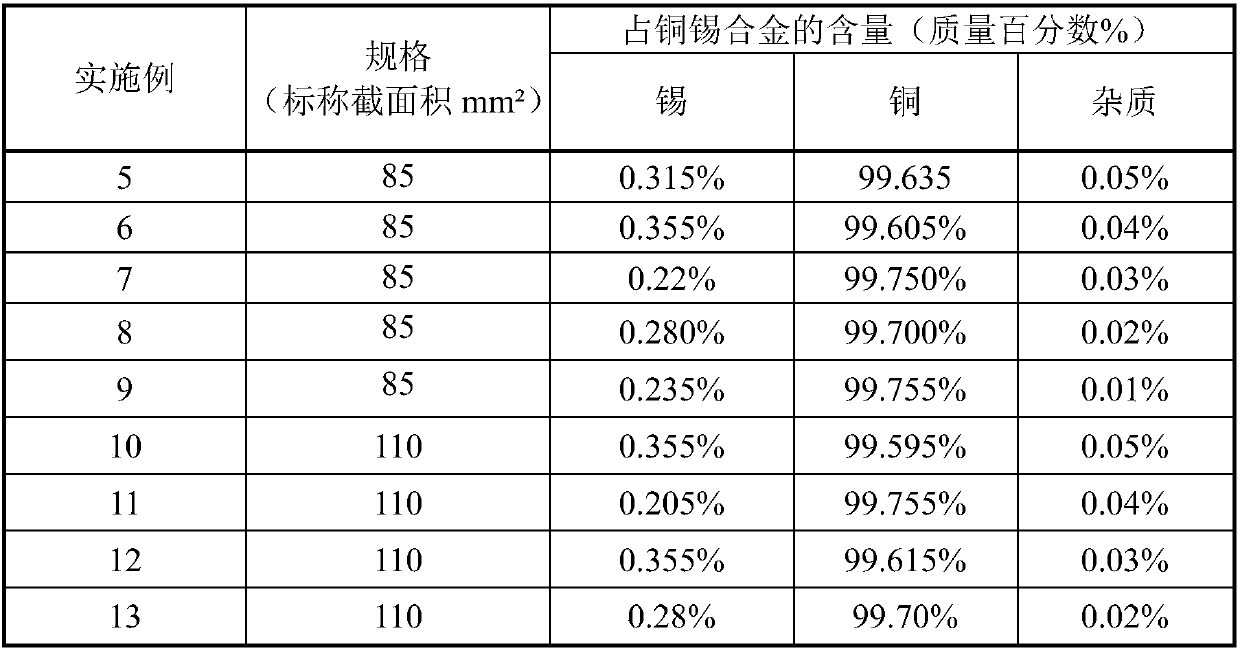

Copper-tin alloy contract wire for electrified railway and continuous manufacturing process thereof

ActiveCN107723504ARealize continuous productionMeet physical and chemical performance requirementsSingle bars/rods/wires/strips conductorsConductive materialButt weldingAlloy

The invention discloses a copper-tin alloy contract wire for an electrified railway and a continuous manufacturing process thereof. The alloy of the copper-tin alloy contract wire comprises the following components in weight ratio: 0.195-0.435% of metallic tin, 99.755-99.515% of metallic copper and 0.05% of other impurities. The continuous manufacturing process aims at different types of copper-tin alloy contract wires to produce and controls the content range of tin of a copper-tin alloy extrusion stem, so that the copper-tin alloy extrusion stem can conduct flash butt welding, and then continuous production is realized. The continuous manufacturing process can ensure the one-time success rate of continuity of the copper-tin alloy extrusion stem and the production efficiency.

Owner:西安西电光电缆有限责任公司 +1

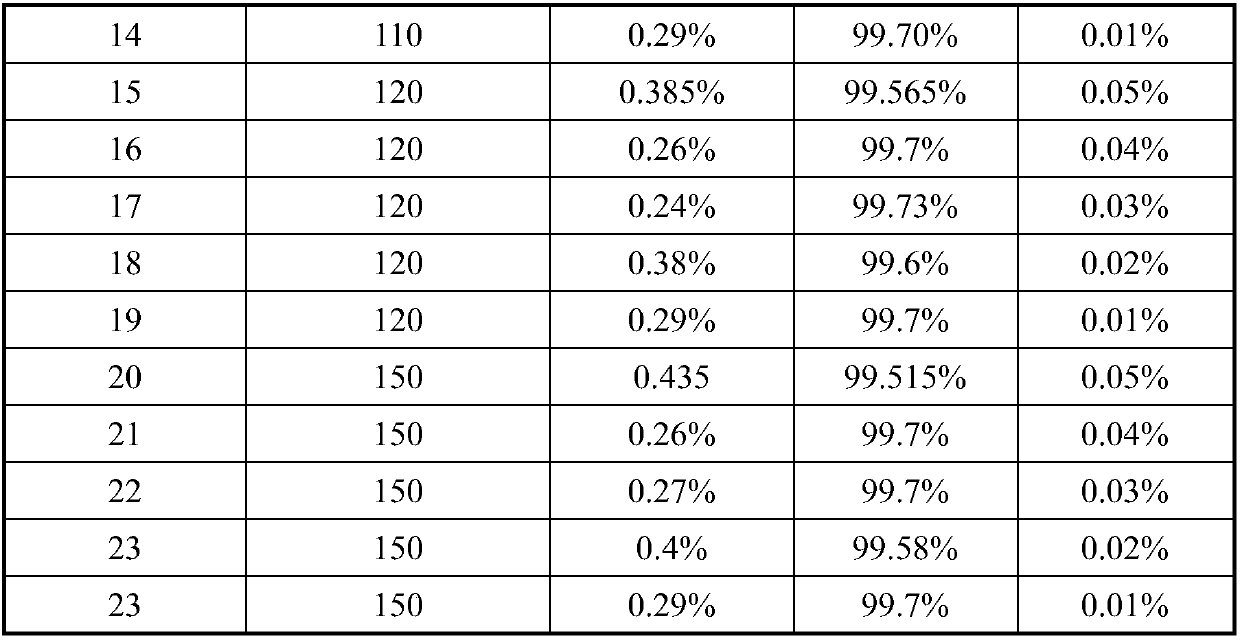

Method for recycling purified terephthalic acid wastewater

ActiveCN101428944AAchieve recyclingProduct quality is not affectedMultistage water/sewage treatmentNature of treatment waterPotassium persulfateIndustrial waste water

The invention provides a treatment method for the reuse of purified terephthalic acid (PTA) waste water, which belongs to the technical field of environment engineering and industrial waste water treatment. The particular method is as follows: polyacrylamide solution with mass concentration of between 1 and 2 thousandth is adopted for flocculate sedimentation pretreatment on the PTA waste water, the adding amount of the polyacrylamide solution is 1.5 to 1 percent of the volume of the waste water; the waste water after treatment enters an oxidation tank for advanced oxidation degradation reaction; in the reaction, a fan is used to blow air to a reaction tank; and the waste water after treatment can be directly used for production of workshop, wherein the concentration of the main oxidizing agent which is hydrogen peroxide is between 20 and 30 percent; auxiliary oxidants of sodium chlorate and potassium persulphate are industry graded; and the adding amount of sodium chlorate and potassium persulphate is 0.1 to 0.2 percent and 0.1 to 0.2 thousandth of the weight of the waste water respectively. Compared with the prior waste water reuse process, the method has the advantages of low investment, simple and convenient operation, high treatment efficiency and the like. The method realizes the reuse of the PTA waste water, relieves the pressure of insufficient water resources and meets the general policy of China on energy conservation and emission reduction.

Owner:溧阳常大技术转移中心有限公司

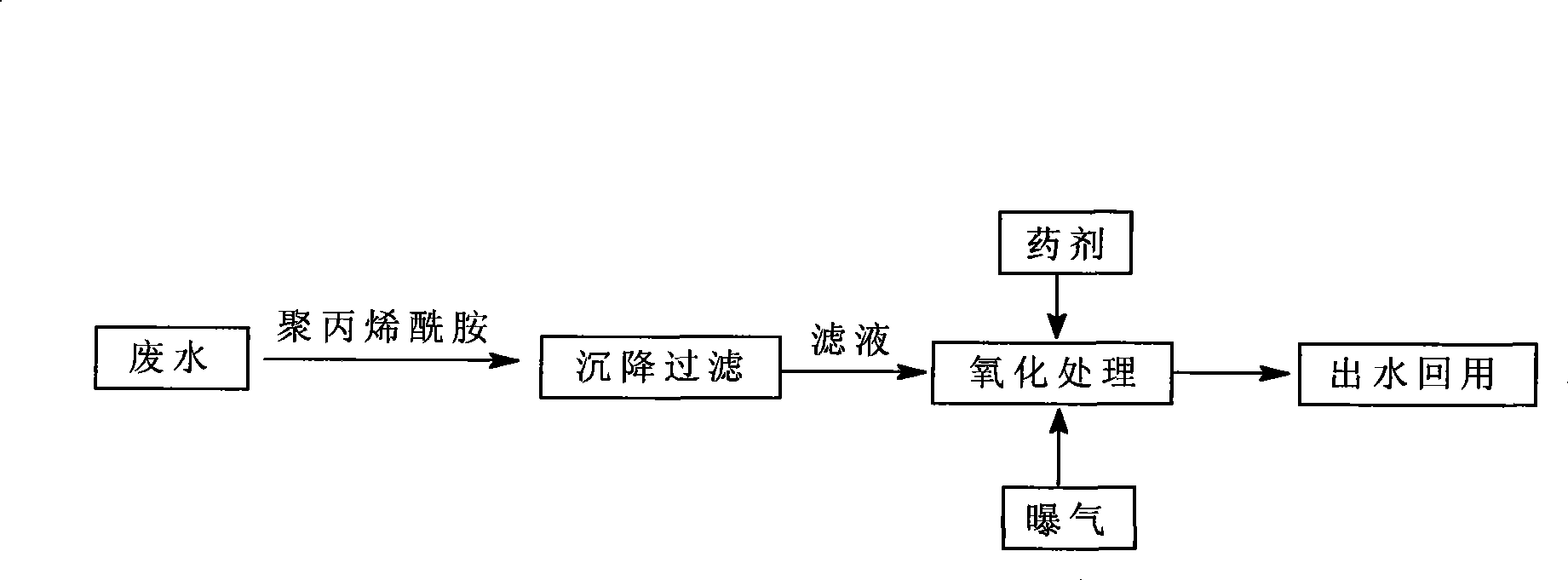

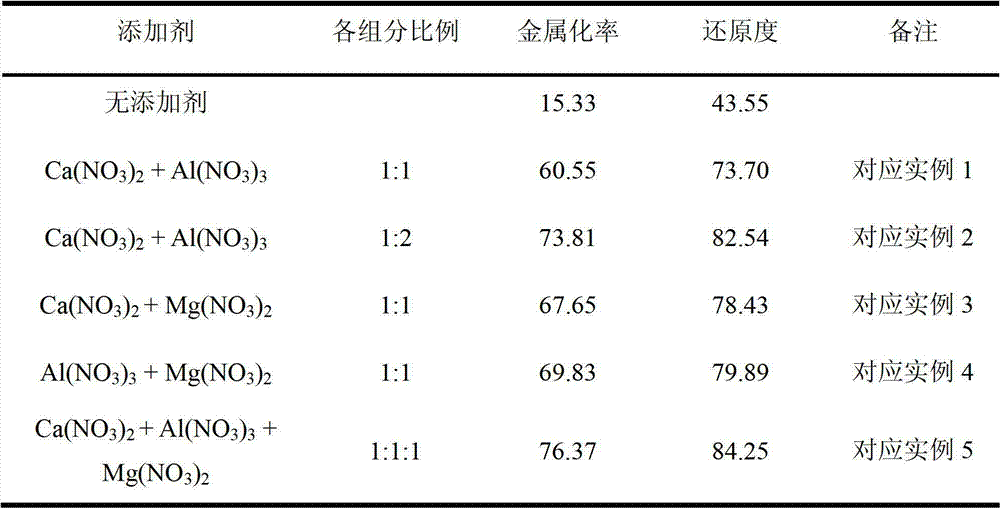

Method for modifying iron ore powder by composite additive to prevent sticking and defluidizing during fluidization reduction

InactiveCN102925611AImprove reduction efficiencyInhibition of cohesive lossFluidised-bed furnacesIron powderMaterials science

The invention relates to a method for modifying iron ore powder by utilizing a composite additive to prevent sticking and defluidizing during fluidization reduction. The method comprises the following steps of: modifying the iron ore powder before a fluidization reduction process step, firstly preparing a 0.5%-60% additive solution, then dipping the iron ore powder in the additive solution, adsorbing the additive onto the surface of the iron ore powder or a pore canal by utilizing the adsorption performance of the iron ore powder, and performing fluidization preheating treatment on the modified iron ore powder. According to the method disclosed by the invention, the occurrence of sticking and defluidizing during the fluidization reduction can be effectively inhibited, and the reduction degree and the metallization rate are respectively improved by 45%-55% and 30%-40%. Simultaneously, the additive can realize cyclic utilization by magnetic separation so as to ensure product quality. The method disclosed by the invention has the advantages of a wide range of applications of ore, and capability of adjusting the composition of the composite additive against the characteristics of the type of the iron ore powder to achieve the best anti-sticking effect; and simultaneously, the process flow of the fluidization reduction process is not changed, and the method is simple to operate and economic and practical.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

2,4-D choline water-soluble granules and preparation method thereof

InactiveCN103081909ASimple processPromote environmental protectionBiocideAnimal repellantsOrganic solventAqueous solubility

The invention discloses 2,4-D choline water-soluble granules. The 2,4-D choline water-soluble granules comprise the components in percentage by weight: 5-99.5% of 2,4-D choline and the balance of water-soluble packing. The invention also discloses a preparation method of the 2,4-D choline water-soluble granules. The preparation method comprises the steps of: mixing the 2,4-D choline and the water-soluble packing, kneading, extruding, pelletizing and drying to obtain the 2,4-D choline water-soluble granule product, effective constituents of which are up to 99.5%. The preparation method is simple in process, economic and safe; hazardous chemical substances are not used in the whole production process, no dust is generated, and organic solvents are not needed; the preparation method is environment-friendly and easy in control and operation; and safety factors of the preparation method are high.

Owner:SHANDONG WEIFANG RAINBOW CHEM

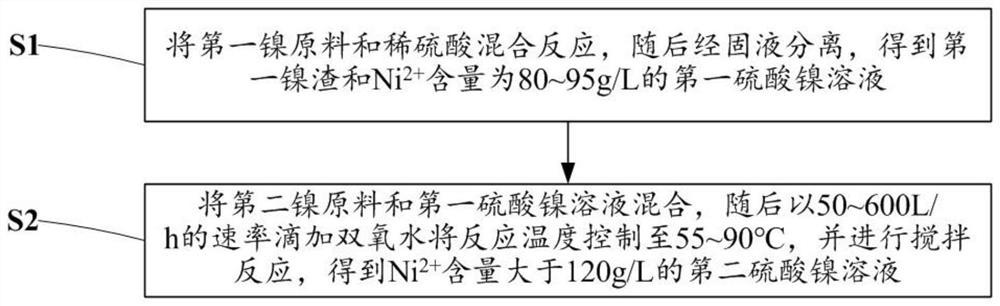

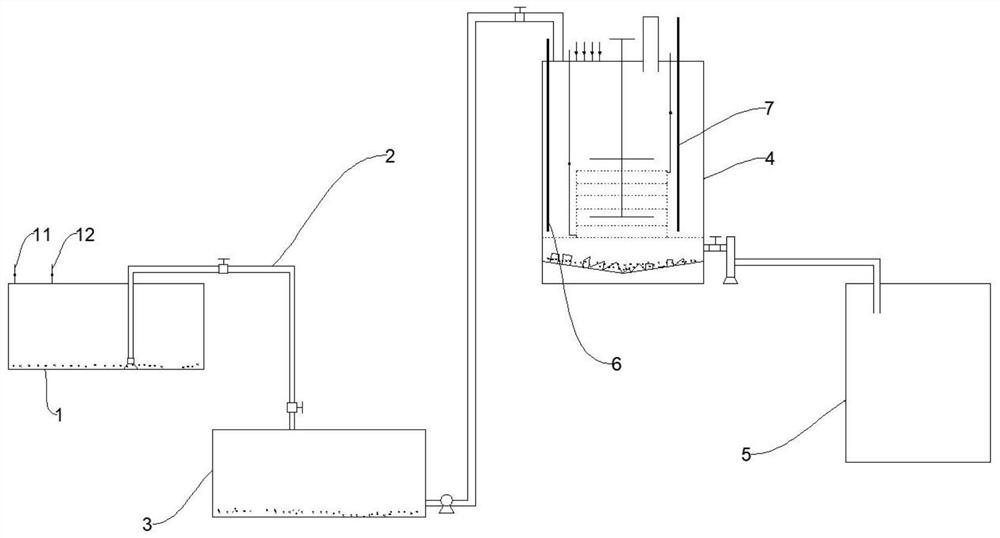

Production method and device of nickel sulfate solution

ActiveCN111689530AIncrease dissolution rateProduct quality is not affectedNickel sulfatesProcess efficiency improvementSulfatePhysical chemistry

The invention discloses a production method and device of a nickel sulfate solution. The production method comprises the following steps: mixing a first nickel raw material with dilute sulfuric acid for reaction, and then performing solid-liquid separation to obtain first nickel slag and a first nickel sulfate solution with the Ni<2+> content of 80-95 g / L; mixing a second nickel raw material withthe first nickel sulfate solution, then dropwise adding hydrogen peroxide at the rate of 50-600 L / h to control the reaction temperature to be 55-90 DEG C, and carrying out stirring reaction to obtaina second nickel sulfate solution with the Ni<2+> content being greater than 120 g / L. According to the method, the hydrogen peroxide is dropwise added to promote the reaction, heat generated by reaction heat release is used for heating the system, the reaction rate is increased, the nickel sulfate solution with the Ni<2+> content larger than 120 g / L can be obtained within a short time, the subsequent production requirement is met, heating is not needed in the process, and energy consumption and production cost can be remarkably reduced. On the basis of an existing production device, simple modification is carried out, the dissolution rate of the nickel raw material is greatly increased, energy consumption and production cost are reduced, and the product quality of the nickel sulfate solution is not affected.

Owner:JINGMEN GEM NEW MATERIAL +1

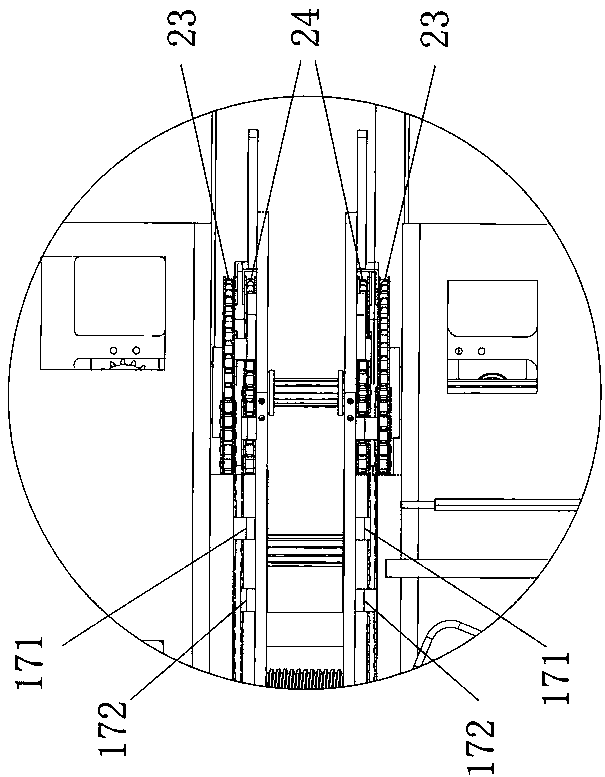

Polyester filament single filament cake fixed weight batch weighing device and weighing method thereof

InactiveCN107389162ASolve the quality requirements of monitoring fixed weightProduct quality is not affectedWeighing apparatus for continuous material flowPolyesterInductor

The invention discloses a polyester filament single filament cake fixed weight batch weighing device comprising conveying belts used for conveying a filament trolley. There are two conveying belts which are arranged in parallel. The conveying belts are driven by a conveying motor. The input end and the output end of the conveying belts are respectively provided with an inlet inductor and an outlet induction switch. The external side of the conveying belts is also provided with filament holding supports, filament holding support guide rails, a horizontal moving cylinder which drives the filament holding supports to horizontally slide on the filament holding support guide rails and an elevating cylinder which drives the filament holding supports to vertically move on the filament holding support guide rails. The filament holding supports are provided with filament holding rods which are matched with the filament cakes of the filament trolley. The number of the filament holding rods on each filament holding support is not less than the number of the filament cakes of one side of the filament trolley. Each filament holding rod is provided with an electronic scale used for weighing the filament cakes and a weighing timer. According to the polyester filament single filament cake fixed weight batch weighing device, the whole operation can be completed by one person, and the enterprise of the same scale of production and the same position can save 4-8 persons in comparison with conventional sampling monitoring so as to be time-saving and labor-saving and high in efficiency.

Owner:TONGKUN GRP ZHEJIANG HENGTONG CHEM FIBER

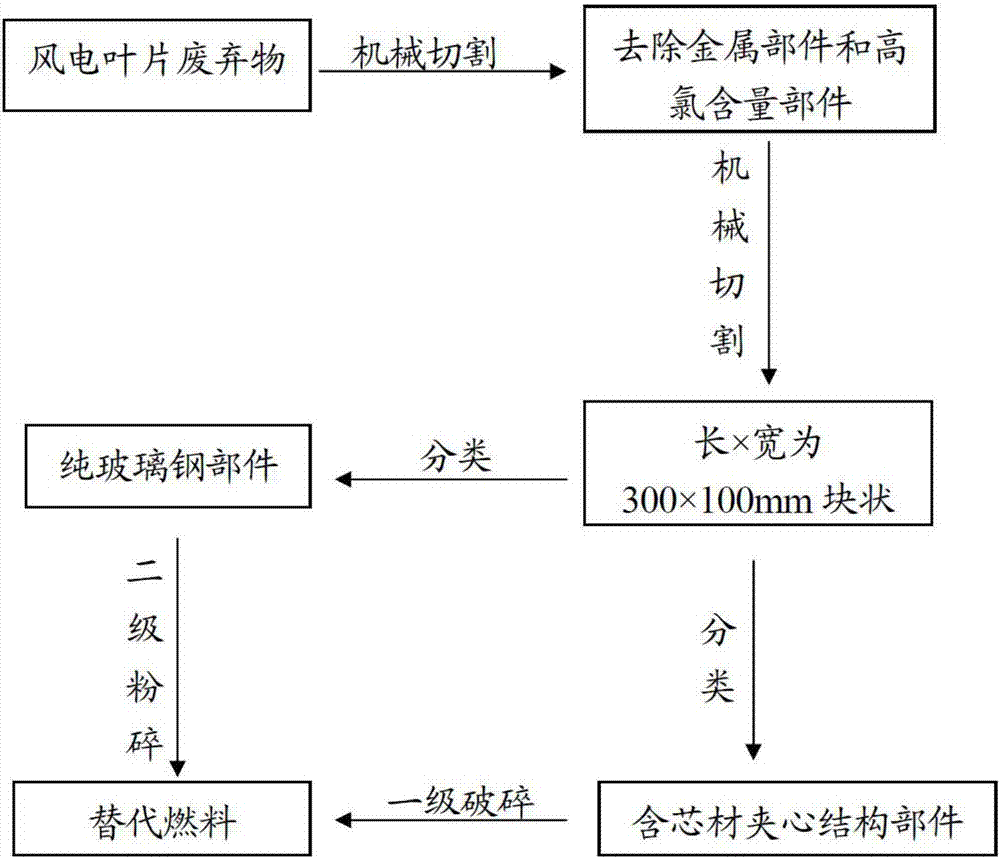

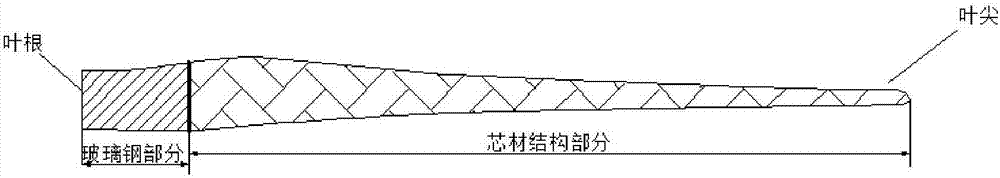

Method for absorbing wind turbine blade wastes in cement kiln

InactiveCN107305010AConsumptionReduce wearIncinerator apparatusCombined combustion mitigationAlternative fuelsHigh energy

The invention provides a method for absorbing wind turbine blade wastes in a cement kiln. The method comprises the following steps: separating metal parts and high-chlorine content parts in the wind turbine blade wastes, and segmenting the remaining wind turbine blade wastes as massive wastes; grinding the massive wastes into particles so as to obtain ground materials; and taking the ground materials as alternative fuel of the cement kiln, and combusting the fuel in a cement kiln decomposing furnace. The method disclosed by the invention is simple, practical, less in initial investment and subsequent maintenance cost, environment-friendly and harmless, belongs to a circular economy manner, accords with the treatment policy of 'reduction, recycling and harmlessness' of municipal wastes, can thoroughly implement and carry out the national policy of cooperatively treating non-medical wastes and industrial wastes in the cement kiln, solves the thermosetting material waste disposal difficulty problem troubling the society for a long time, provides alternative fuel and raw materials for the high-energy-consumption cement industry and has wide application prospects.

Owner:SINOMATECH WIND POWER BLADE

Solvent-free waterborne polyisocyanate curing agent and preparation method and application thereof

ActiveCN108659191AGood dispersionGood storage stabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDispersityPolyurethane adhesive

The invention discloses a solvent-free waterborne polyisocyanate curing agent and a preparation method and application thereof. The solvent-free waterborne polyisocyanate curing agent is polyisocyanate prepolymer containing sulfonic acid groups. The preparation method includes: dissolving dicarboxyl sulfonate into an organic solvent, allowing the solution to have reaction with polyisocyanate prepolymer, and distilling to remove the organic solvent to obtain the solvent-free waterborne polyisocyanate curing agent. The solvent-free waterborne polyisocyanate curing agent is truly free of VOC discharge, excellent in water dispersity and storage stability, high in NCO content, low in viscosity, capable of being coordinated with various resin containing hydroxyl, carboxyl or amino to prepare double-component polyurethane coating and double-component polyurethane adhesive, and capable of allowing a product to be good in water resistance and high in strength.

Owner:FOSHAN JINGXIN HUIMING TECH CO LTD

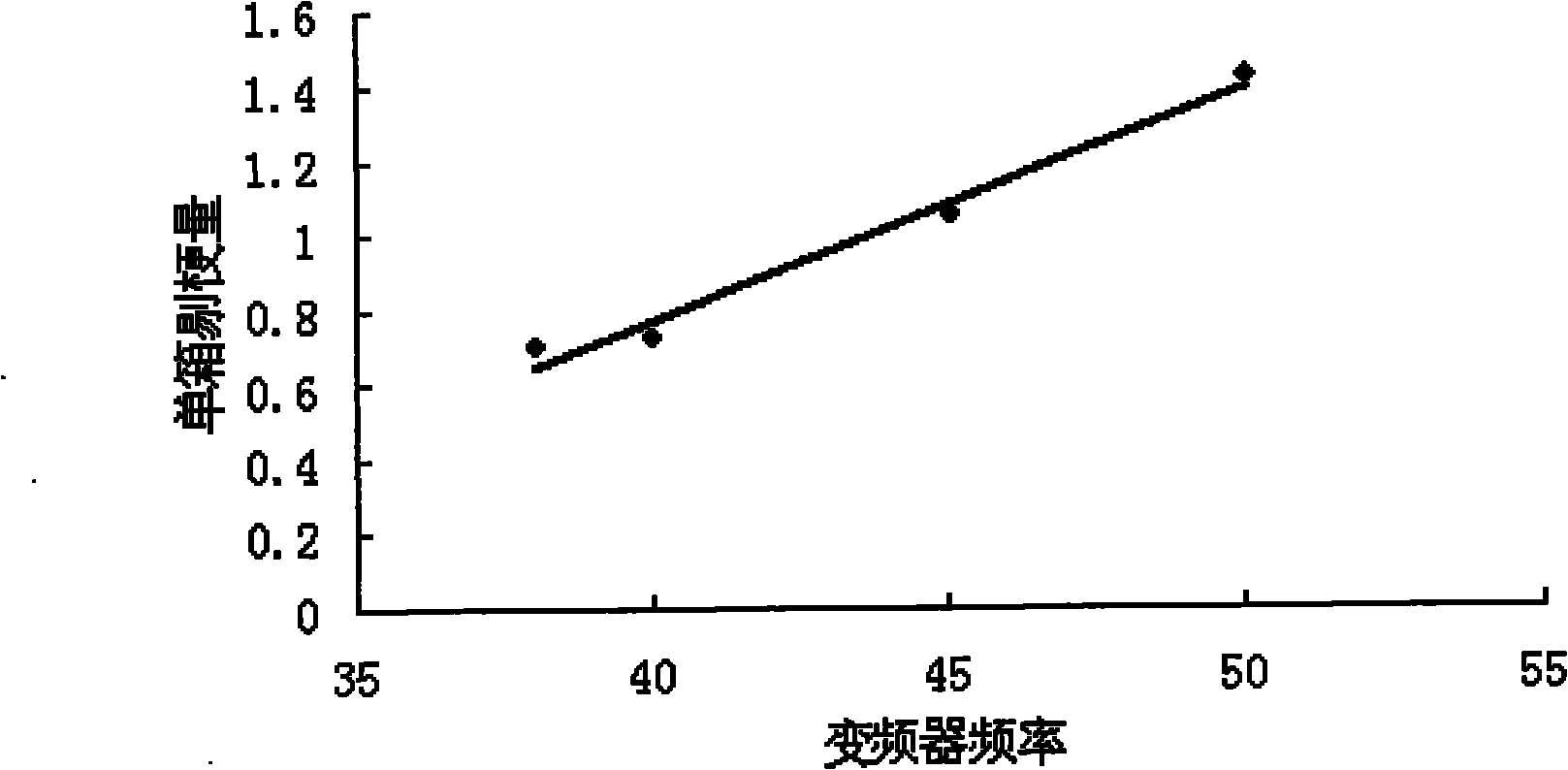

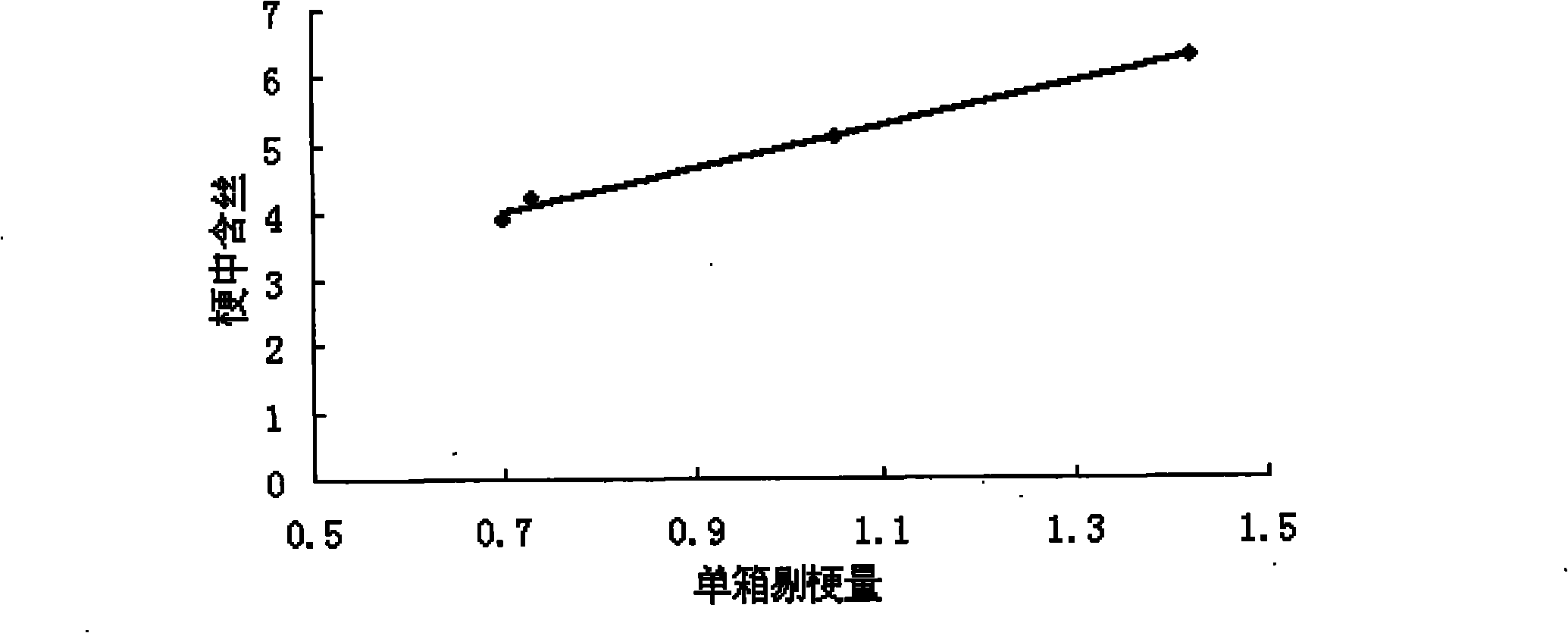

Control method for conveniently adjusting stem-removing quantity of cigarette making machine

The invention discloses a control method for conveniently adjusting stem-removing quantity of a cigarette making machine, belonging to the field of cigarette manufacturing. The method comprises the following steps: firstly, installing a frequency converter on a fan roll control motor, carrying out adjustment tests by using the frequency converter, then determining an appropriate frequency range of the frequency converter based on the technology demands for the stem-removing quantity; and finally, replacing belt pulleys of a tobacco shred-bouncing roller with ones of a different size as required, wherein if the bouncing effect of tobacco shreds is not influenced by the variation of the fan speed, the belt pulleys of the tobacco shred-bouncing roller do not need to be replaced; and if the bouncing effect of tobacco shreds is influenced by the variation of the fan speed, the belt pulleys of the tobacco shred-bouncing roller should be replaced to ensure the constant speed of a tobacco shred-bouncing roll so as to ensure the tobacco shred-bouncing effect. The method has the advantages of low investment and simple and flexible operation, can quickly and accurately adjust the stem-removing process by a wide margin based on the variation of incoming tobacco shreds, and is especially applicable to the condition that the stem-removing rate remains stubbornly high. Production proves that the consumption-reducing and quality-improving effects are obvious and the economic benefits are considerable, thereby ensuring favorable industrial application value and popularization prospects.

Owner:CHINA TOBACCO HENAN IND

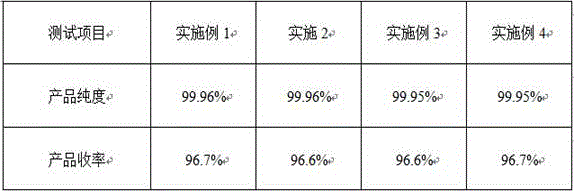

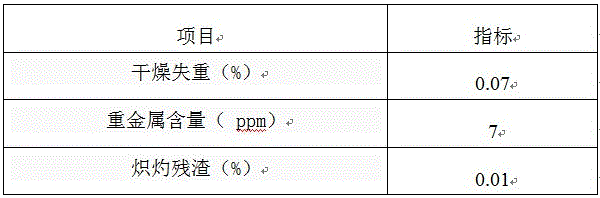

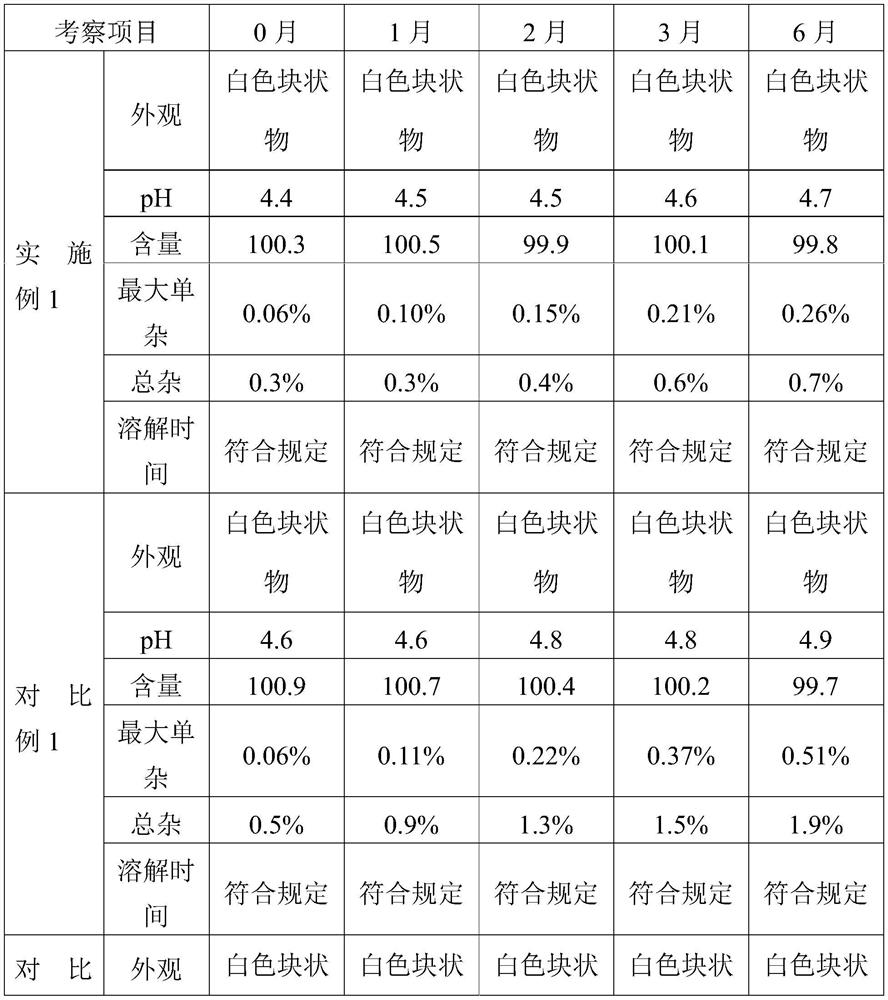

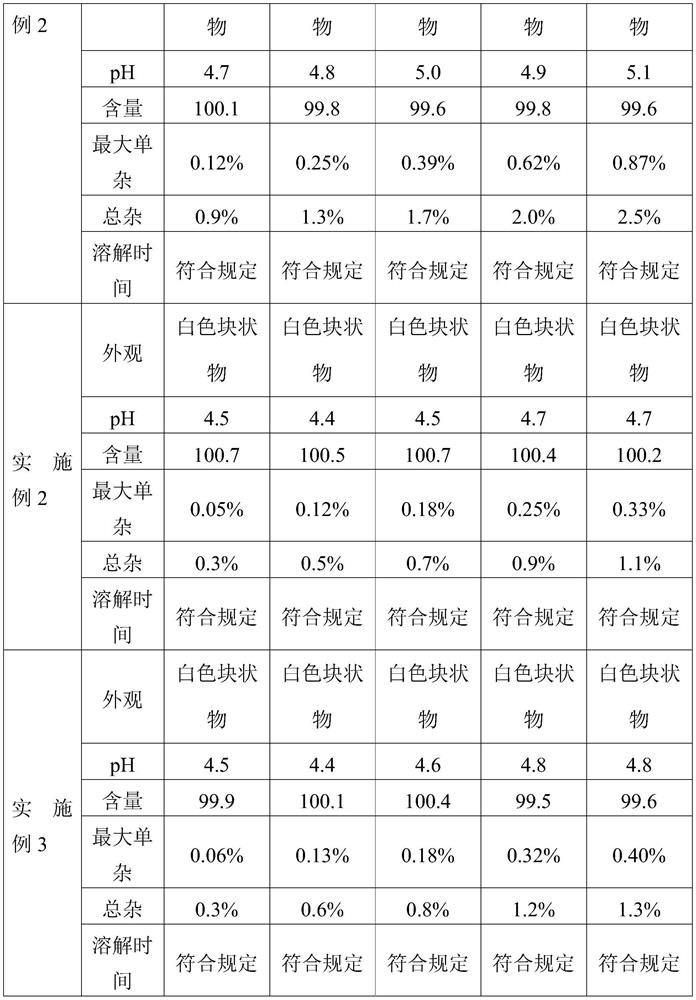

A kind of production method of high-purity metformin hydrochloride

InactiveCN104788345BLower the temperature of the addition reactionLow impurity contentOrganic chemistryOrganic compound preparationMetformin HydrochlorideHydrochloride

The invention discloses a high-purity metformin hydrochloride preparation method. N-methyl pyrrolidone is used as a solvent, dicyandiamide and dimethylamine hydrochloride are taken as a solute, the solvent and the solute are added into a synthesis kettle for reaction, and metformin hydrochloride is prepared through steps of stirring, cooling, spin-drying, washing, crystallizing and drying. The metformin hydrochloride prepared through the preparation method provided by the invention has the advantages that the yield is higher than 96.4 percent, and the product purity is higher than 99.93 percent.

Owner:TAISHAN MEDICAL UNIV

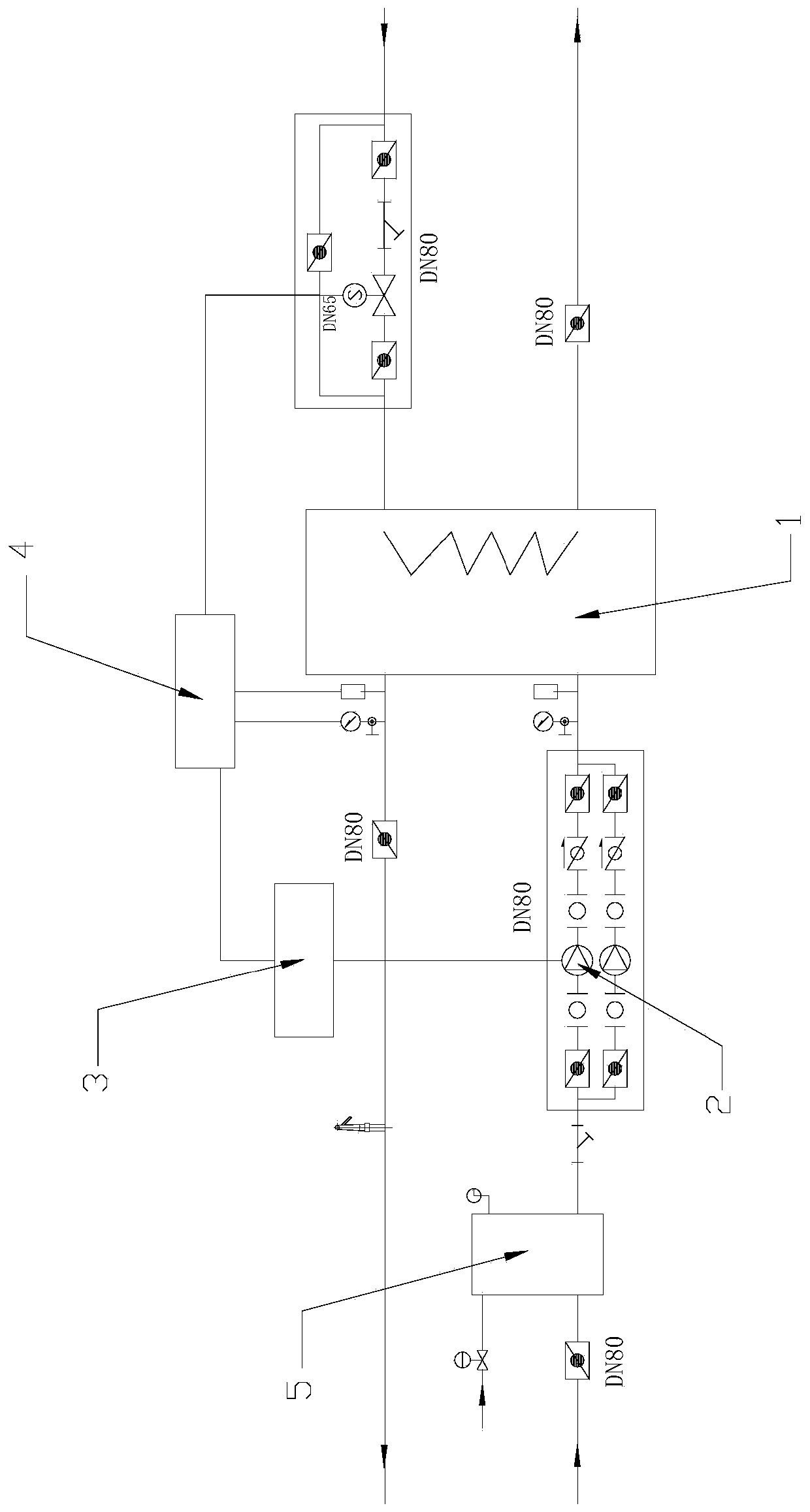

Heat exchange system seamless alternation type frequency conversion constant-pressure constant-temperature adjusting system and method

ActiveCN109751901AControl inputConstant pressure water supply is stableHeat exchange apparatusStationary plate conduit assembliesFrequency changerElectricity

The invention discloses a heat exchange system seamless alternation type frequency conversion constant-pressure constant-temperature adjusting system and method. The system comprises a plate heat exchanger, the plate heat exchanger is provided with a heat source input port, a cold source input port, a heat source output port and a cold source output port, the heat source input port is connected with at least two water supply pumps connected in parallel, the front ends of the water supply pumps are provided with a water tank, the front end of the cold source input port is provided with an electric regulating valve and a temperature sensor, each water supply pump is connected to a frequency converter, and the frequency converter and the cold source input port and the heat source output portof the plate heat exchanger are electrically connected to a control cabinet. According to the heat exchange system seamless alternation type frequency conversion constant-pressure constant-temperatureadjusting system and method, since the frequency converter for enabling the water supply pump connection power to be larger than water supply pump operation power is arranged, the rotating speeds ofthe water pumps are controlled in a frequency conversion mode through the control cabinet, constant-pressure water supply stabilization is achieved, meanwhile, the control cabinet can directly controlthe opening of the electric regulating valve, the cold source input quantity is controlled, stable water supply temperature is ensured, and it is ensured that product quality is not affected in the production process.

Owner:湖南力和海得热能技术有限公司

Preparation method of nano-cellulose

The invention discloses a preparation method of nano-cellulose, comprising the following steps of: firstly, swelling the raw material cellulose by aqueous alkali, soaking for a while, centrifugally separating out cellulose, and washing by deionized water till the filter liquor is neutral; dispersing the separated cellulose in water, adding sodium bromide, 2, 2, 6, 6-tetramethyl piperidine-1-oxide and sodium hypochlorite solution, carrying out an oxidation reaction under sonic oscillation, centrifugally separating after reaction, and carrying out freeze drying treatment on suspension liquid to obtain the nano-cellulose powder. Compared with the prior art, the preparation method is incompact in cellulose structure, can enlarge the unit cell distance, and can improve the reaction accessibility after the raw material cellulose is pretreated, so that the oxidation reaction efficiency can be improved, and the product yield can be obviously improved; the oxidation reaction conditions are mild, and are easy to control, and the product quality can not be influenced due to the fact that only a small quantity of sodium chloride and minute quantity of oxidizing agent are mixed in a reaction system after the reaction; and the sonic oscillation is adopted in the process of reaction, so that the oxidation reaction speed can be accelerated, and the reaction time can be obviously shortened.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Emulsifiable paste stamp-pad ink for reticular lamina printing decoration of ceramic brick for wall and ground

The invention relates to cream stamp-pad ink for printing patterns on mesh plates of ceramic tiles, which is a mixture consisting of the following compositions by weight: 20 to 35 percent of ethylene glycol, 20 to 35 percent of glycerol, 30 to 45 percent of sorbitol, 1 to 7 percent of cellulose, 2 to 8 percent of a macromolecule polymer, and 0.2 to 1.0 percent of an exciting agent. The appearance of the cream stamp-pad ink is of milk white cream shape without off flavor; the viscosity is between 4,800 and 5,200 MPa.S; the density at 20 DEG C is between 1.040 and 1.050; the pH value is between 6 and 8; the water-soluble residue with 360 meshes is less than or equal to 0.2 percent; and the freezing point is 10 DEG C below zero. The burnt ash content of products is low without residues; the stability and the suspending power are good without layering; the proportion and the viscosity are adjustable; pattern-printing glaze slurry prepared from the cream stamp-pad ink can be used normally on-line after storage without the appearances of color differences and pinholes; and the cream stamp-pad ink is applicable to the pattern-printing requirements for various high-grade, middle grade and low grade ceramic tiles produced by different ceramic building factories. The pattern-printing glaze slurry prepared from the cream has certain fluidity, the performances of moisture, lubrication, mesh brightening and the like, and increases the adhesive force of the pattern-printing glaze slurry on blanks; besides, the surface of a sintered tile finished product is smooth and has no defects of unevenness, pinholes and the like, and the patterns are clear and bright.

Owner:淄博宜龙实业有限公司

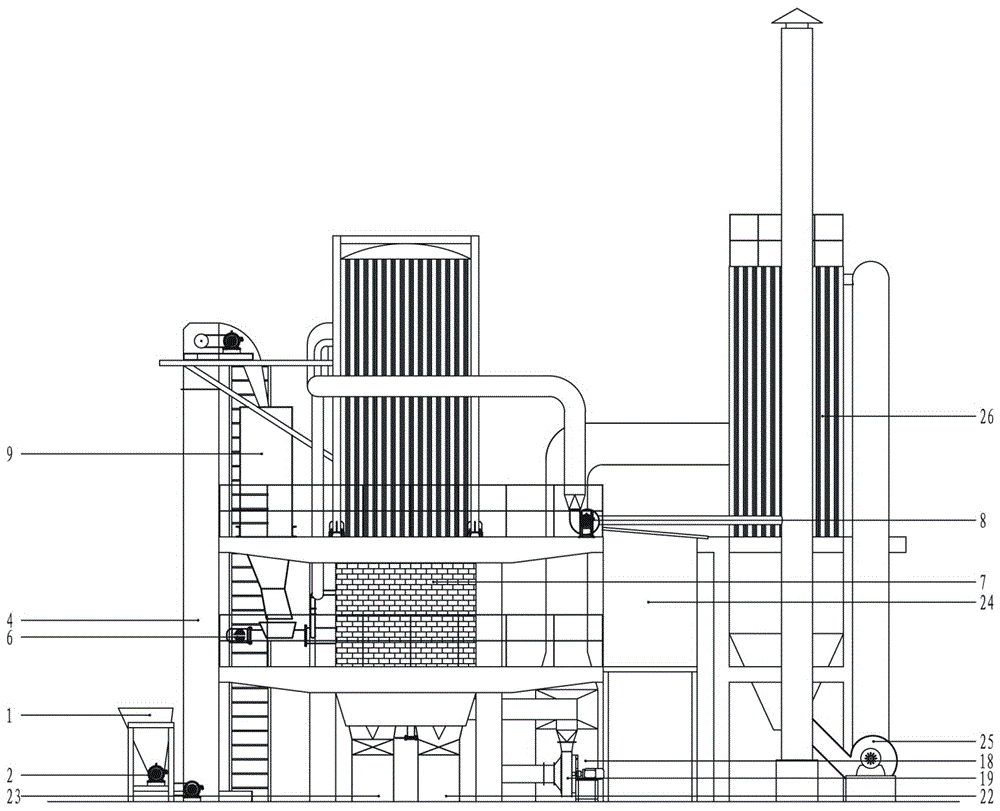

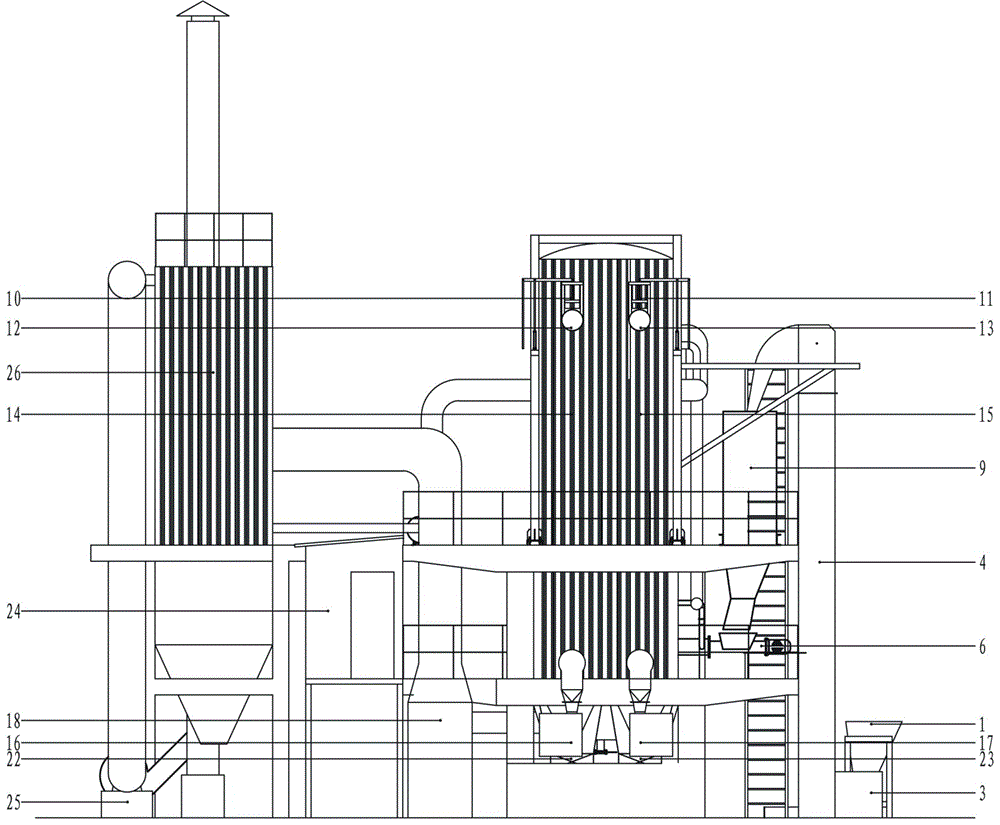

Activated aluminum oxide producing device and technology

ActiveCN106115752AHigh degree of automationProduct quality is not affectedEnergy inputAluminium oxide/hydroxide preparationSocial benefitsAutomatic control

The invention relates to an activated aluminum oxide producing device and a technology. The whole of the activated aluminum oxide producing device consists of a heat source device, a smashing device, a flash evaporation device, a shaping device, an activating and sieving device and a control center; and besides, aluminum hydroxide is used as raw material, and the technology is completed through the working procedures of crushing, dehydrating, pelletizing, preserving, activating and roasting, sieving and packaging. The activated aluminum oxide producing device and technology disclosed by the invention have the advantages that the stable quality of products is in automated control, the device is simple in structure, the investment is low, the safety coefficient is large, the floor space is small, the activated aluminum oxide producing device and technology are environmentally-friendly and energy-saving, and various aluminum oxide products can be produced. The producing device has a good popularization value and a good practical value, and after the producing device is widely popularized and applied, favorable economic benefits and social benefits can be generated.

Owner:江西中旭科技有限公司

Vertical boxing machine and rotary box-sucking mechanism thereof

The invention provides a vertical boxing machine and rotary box-sucking mechanism thereof, and belongs to the mechanical devices or equipment of packing objects or materials. The vertical boxing machine comprises a paper box storeroom (1) and a paper box delivery and convey chain mechanism (2) which comprises a convey chain assembly (3), a tongue driving mechanism (4) and a tongue inserting mechanism (5). The vertical paper boxing machine is characterized in that the rotary box-sucking mechanism (20) is arranged between the paper box storeroom (1) and the convey chain mechanism (2) and is matched with the same; the rotary box-sucking mechanism comprises a turntable (6) connected with a power device in a transmission manner. A radial reciprocating-moving box-sucking unit assembly is arranged on the turntable (6) and mainly comprises a sucking head (7) connected with an air source; and the vertical boxing machine capable of completing material vertically boxing and sucking and releasing the paper boxes successfully without additional paper box opening mechanisms.

Owner:ZHEJIANG HOPING MACHINERY

Preparation method of 1, 3-propanediol

InactiveCN103709004AProduct quality is not affectedLow costAlkali metal chloridesHalogenated hydrocarbon preparationBenzoyl peroxideReaction temperature

The invention relates to a preparation method of 1, 3-propanediol, belonging to the field of synthesis of chemical products. The preparation method of 1, 3-propanediol comprises the following steps: (1) synthesizing 1-bromo-3-chloropropane: enabling 3-chloro-1-propene, hydrogen bromide and benzoyl peroxide to react according to the molar ratio of 1: 1: (0.001-0.03) to obtain 1-bromo-3-chloropropane; (2) synthesizing 1, 3-propanediol: enabling 1-bromo-3-chloropropane, sodium hydroxide and water to react according to the molar ratio of 1: (1.9-2.5): (4-15) under the conditions that the reaction pressure is not more than 0.5MPa and the reaction temperature is 120-140 DEG C. According to the preparation method provided by the invention, although bromine is taken as a reaction raw material, bromine can be recycled, the production of three wastes is low, and the obtained product has the advantages of low cost and high benefits and can completely realize large-tonnage production.

Owner:DALIAN LONGTAI TECH DEV

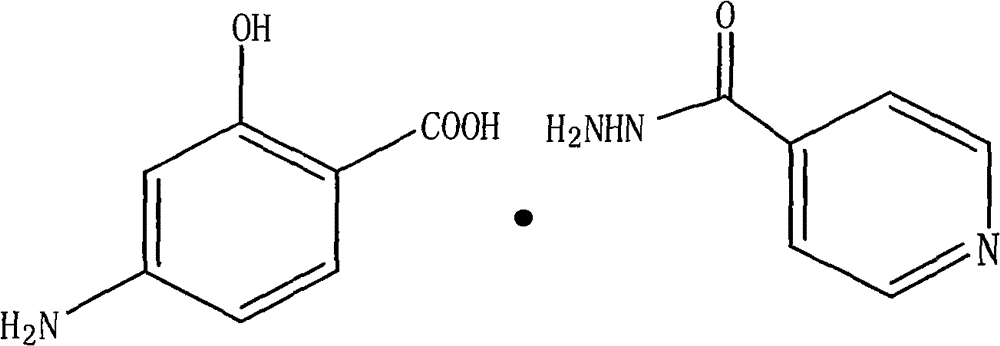

A kind of preparation method of isoniazid p-aminosalicylate

ActiveCN102344412BGood water solubilityHigh purityOrganic compound preparationAmino-carboxyl compound preparationIsoniazidOrganic solvent

The invention discloses a preparation method of isoniazid para-aminosalicylate. The preparation method comprises that a sodium para-aminosalicylate solution is added with an acid and then is extracted by an organic solvent and isoniazid is added into the extract to produce a desired product. The isoniazid para-aminosalicylate product prepared by the preparation method has isoniazid para-aminosalicylate purity above 98%. Through the preparation method, a yield of 90 to 98% is obtained. The preparation method adopts simple and environmentally friendly processes, realizes recycle of an extraction solvent and saves greatly costs.

Owner:CHONGQING HUABANGSHENGKAI PHARM

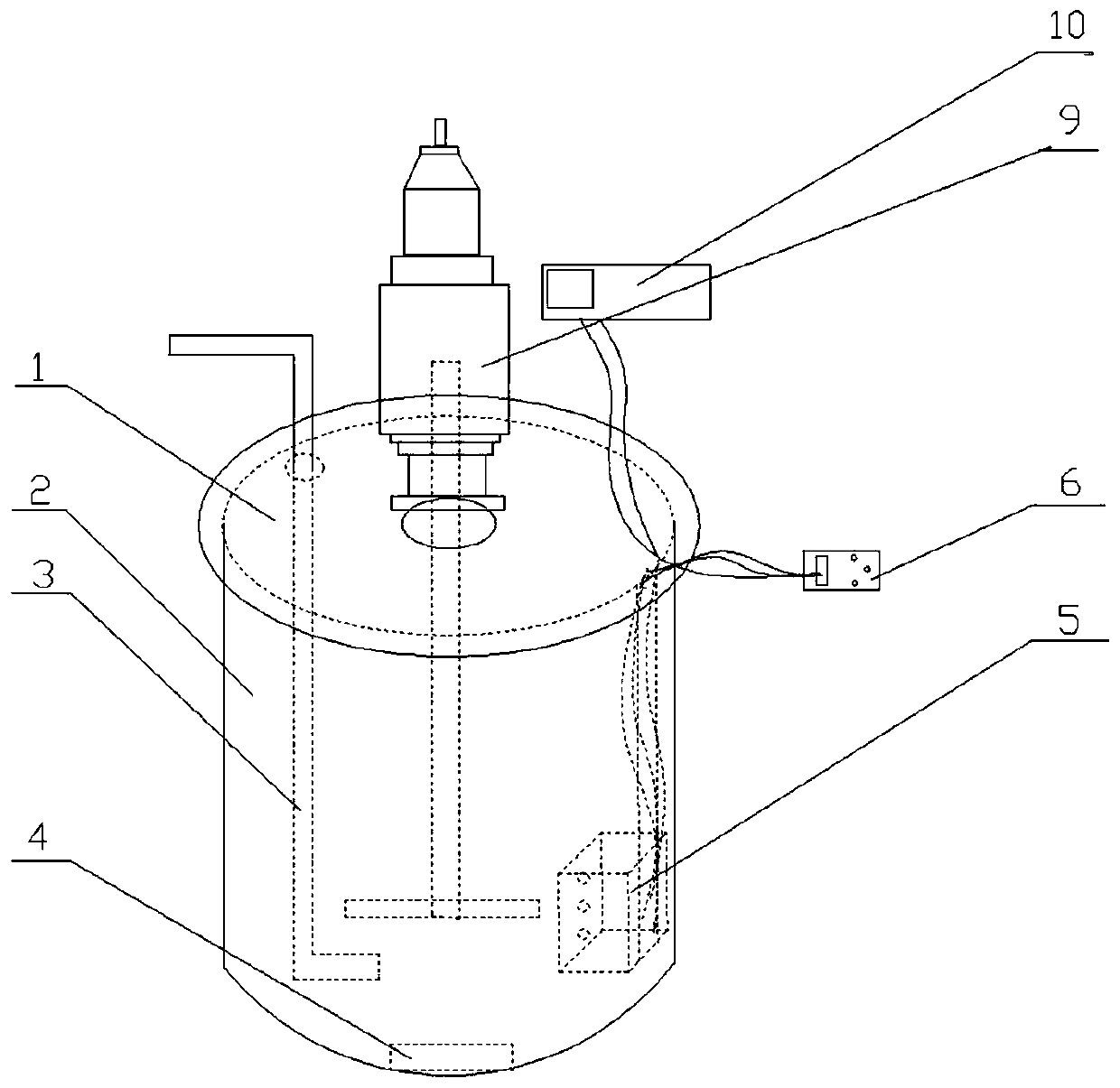

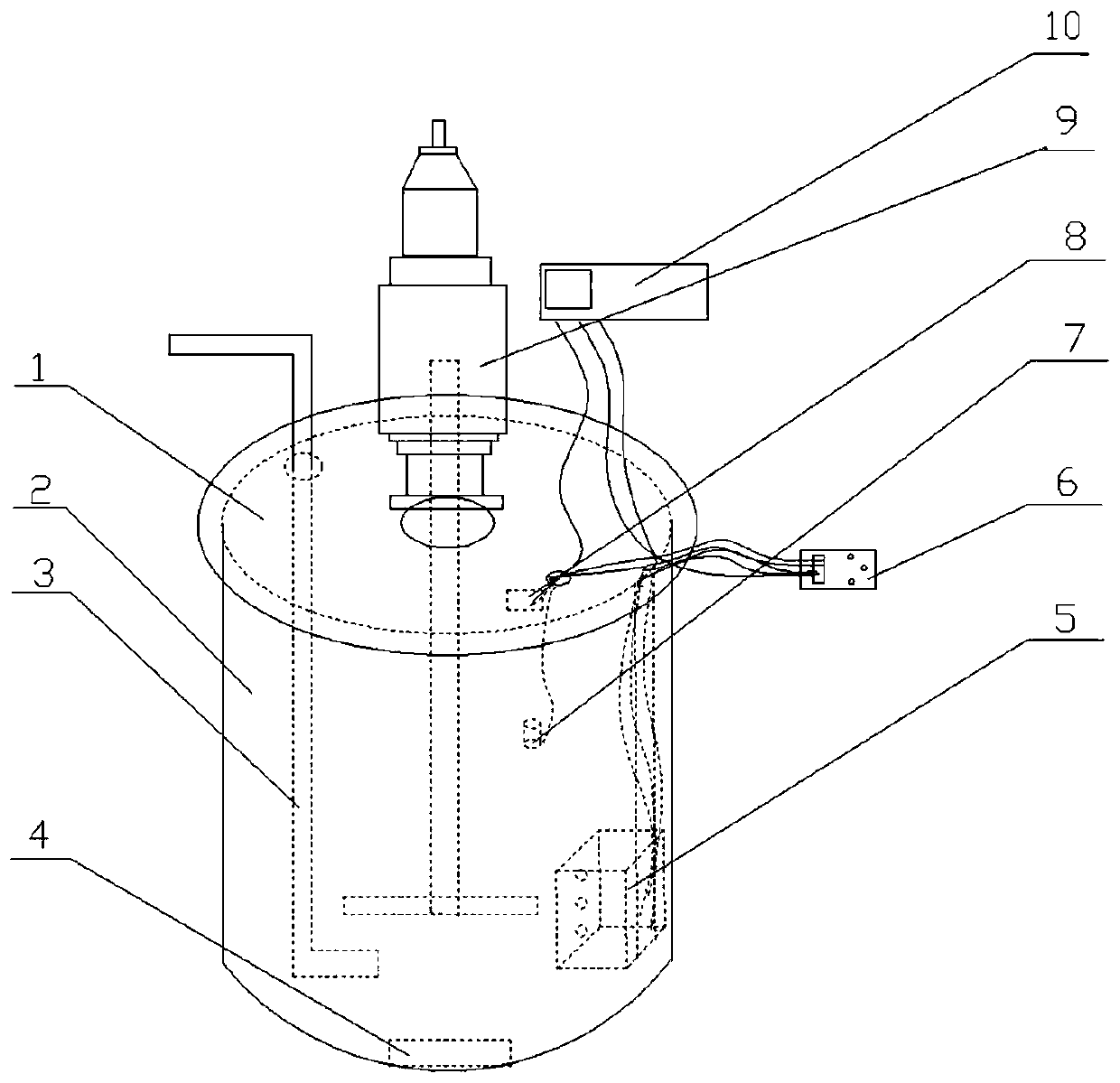

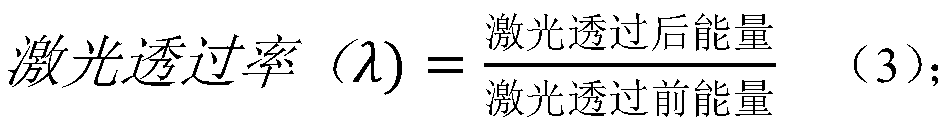

Preparation method for high-activity trimanganese tetraoxide

ActiveCN110422881AHigh specific surface areaEasy to operateManganese oxides/hydroxidesIonUltrasonic generator

The invention discloses a preparation method for high-activity trimanganese tetraoxide. The preparation method comprises the following steps: S1, mixing electrolytic manganese metal powder with a catalyst, carrying out wetting to form slurry, adding the slurry into warm deionized water to form a suspension, continuously introducing oxygen or pure air, and carrying out a stirring reaction; S2, starting an ultrasonic generator for treatment, adding a activator, and carrying out a reaction for 1.8-5 h to obtain the suspension slurry of high-activity trimanganese tetraoxide, wherein ultrasonic intensity is adjusted within the range of 20 kHz-40 kHz during the reaction; and S3, performing concentration, washing, dehydrating and drying to obtain the high-activity trimanganese tetraoxide. The method of the invention has the advantages of short production cycle, low cost, small environmental pollution and good safety, and can prepare high-activity trimanganese tetraoxide.

Owner:HUNAN SPECIAL METAL MATERIALS CO LTD

Destatic milling-assisting and yield-increasing technique for cement mill

The invention relates to a cement grinding mill static grinding increasing technique, which comprises the steps of drying, breaking, grinding and powder choosing. In the step of grinding, clinker and the mixing material are fed in a cement grinding mill, then water is infused in the wheel head of the cement grinding mill. The delivering proportion accords to the weight that the clinker: the mixing material: the water is 5000 to 8000:2000:5 to 8. The invention overcomes the technical bias of the prior art, greatly improves the output, and brings considerable economical benefit.

Owner:汪晓明

Cetrorelix preparation and preparation method thereof

PendingCN112807418AGuaranteed stabilityShorten drying timePowder deliveryPeptide/protein ingredientsHeat conservationCetrorelix

The invention discloses a cetrorelix preparation and a preparation method thereof, and relates to the technical field of biological medicines. The preparation method comprises the steps that a mixed solution containing mannitol and cetrorelix acetate is subjected to first-stage freezing, second-stage freezing and third-stage freezing, wherein the conditions of the first stage are that after the temperature is decreased to -20 DEG C to -40 DEG C, heat preservation is conducted for 0.1-2 h; the conditions of the second stage are as follows are that the temperature is raised to -20 DEG C to -5 DEG C, heat preservation is performed for 0.1-2 hours; and the conditions of the third stage are that after the temperature is reduced to -20 DEG C to -40 DEG C, heat preservation is performed for 0.1-2 hours. According to the method, the temperature is lowered to be close to the glass transition temperature of the solution, the temperature is kept for a period of time, and the temperature is lowered again until the solution is completely frozen after the temperature is raised to a certain temperature, so that the stability of the cetrorelix preparation product can be ensured to the greatest extent. Meanwhile, after the freezing treatment, a relatively high drying temperature can be selected for drying in the drying stage, so that the product quality is not influenced, the drying time is shortened, and the production cost is reduced.

Owner:南京康舟医药科技有限公司

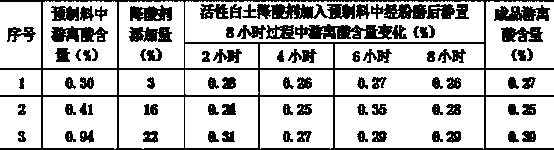

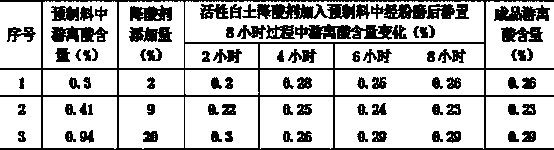

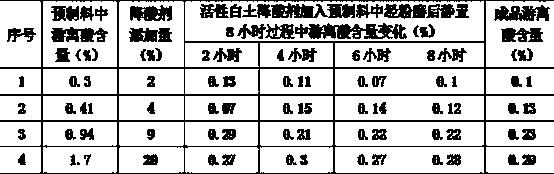

Preparation method of activated clay

InactiveCN109954485ASimple production processShort processOther chemical processesCombustible gas purificationElectricityClay minerals

The invention relates to the technical field of activated clay, and particularly relates to a preparation method of activated clay. The preparation method comprises the following steps: firstly, carrying out beneficiation, activation, pressure filtration and drying on clay minerals to prepare a prefabricated material with an free acid content of 0.30-2.5%, then adding the activated clay acidity-reducing agent into the prefabricated material, carrying out grinding, and then carrying out standing for 8 hours to obtain a finished product, wherein the content of free acid in the prefabricated material is 0.30-2.5%, and 1-20 parts of the activated clay acidity-reducing agent is added into every 100 parts of the prefabricated material. The method disclosed by the invention can be used for preparing an activated clay finished product meeting the national standard or specified standards of consumers, a conventional wet process production process flow is simplified, production water consumptionand electricity consumption are greatly reduced, acid water treatment and emission load are reduced, and production cost of enterprises is reduced.

Owner:金昌红泉膨润土有限责任公司

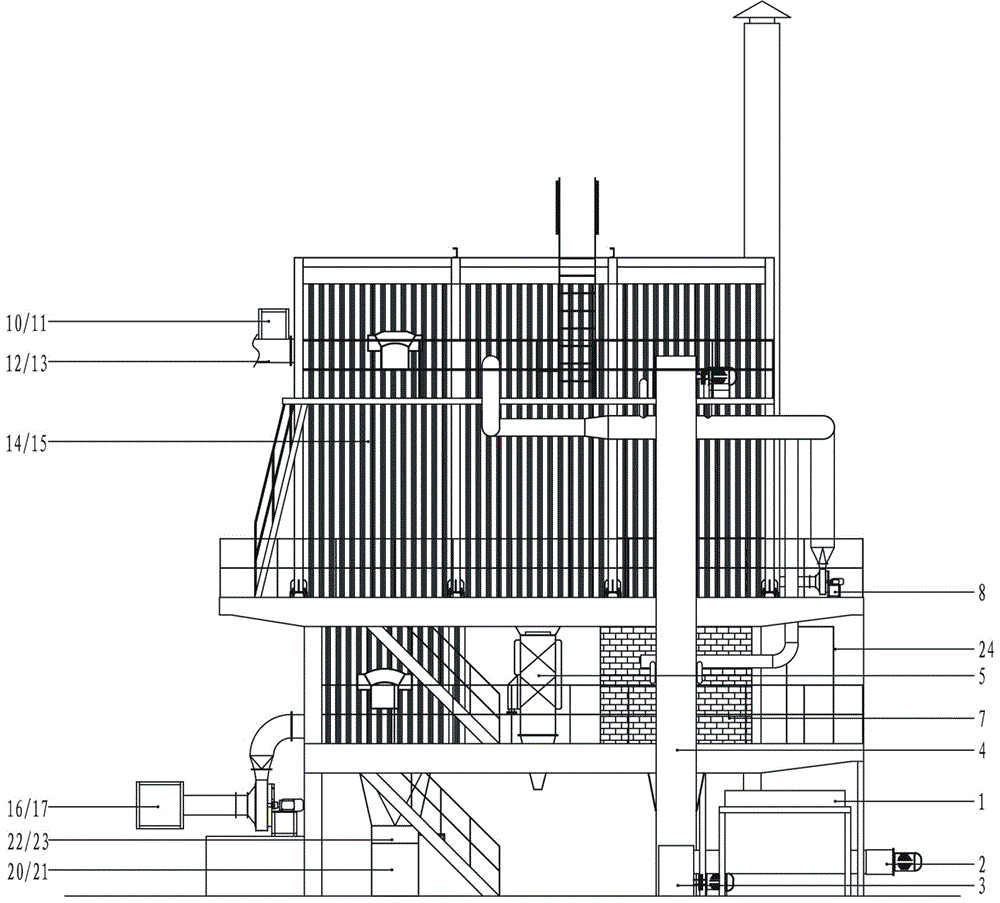

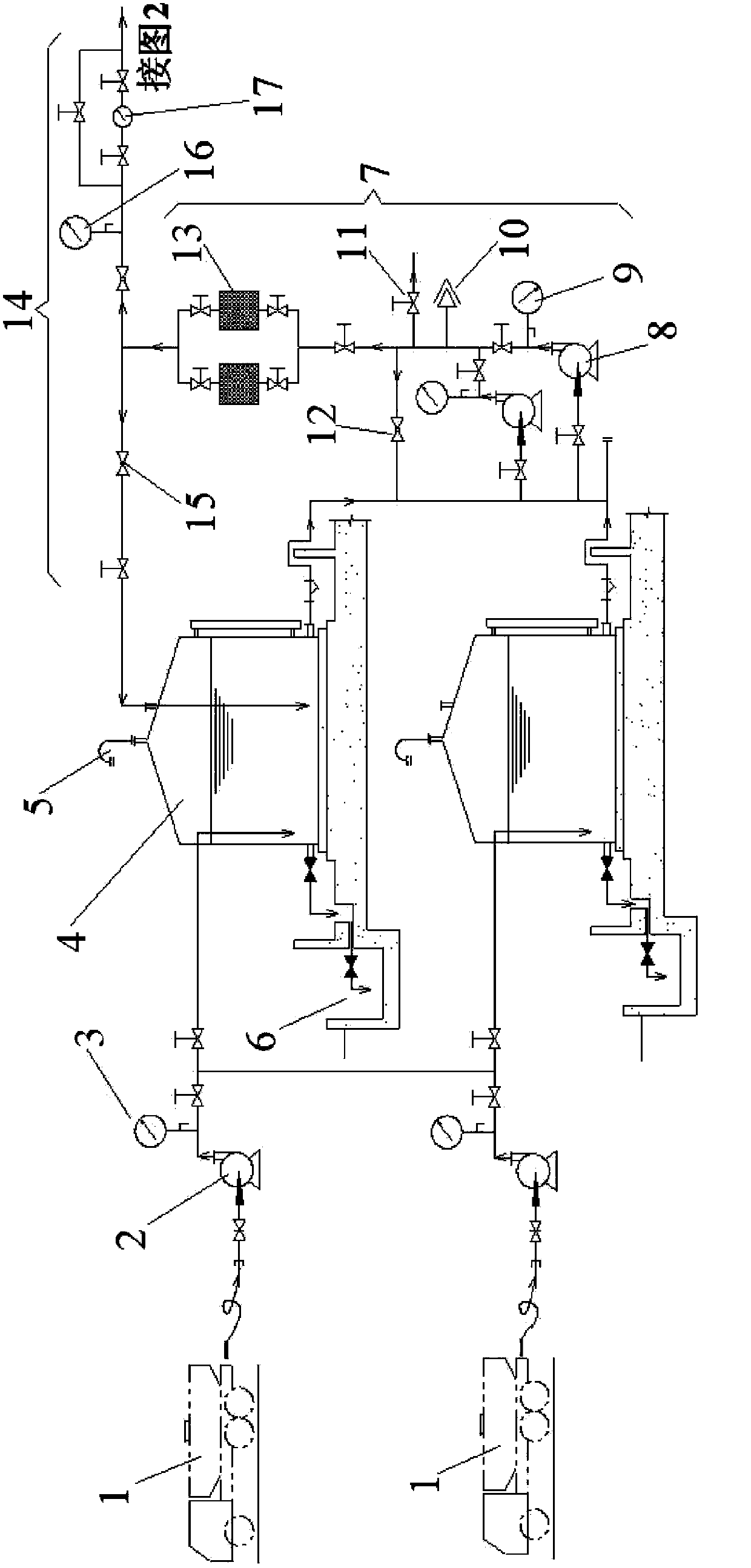

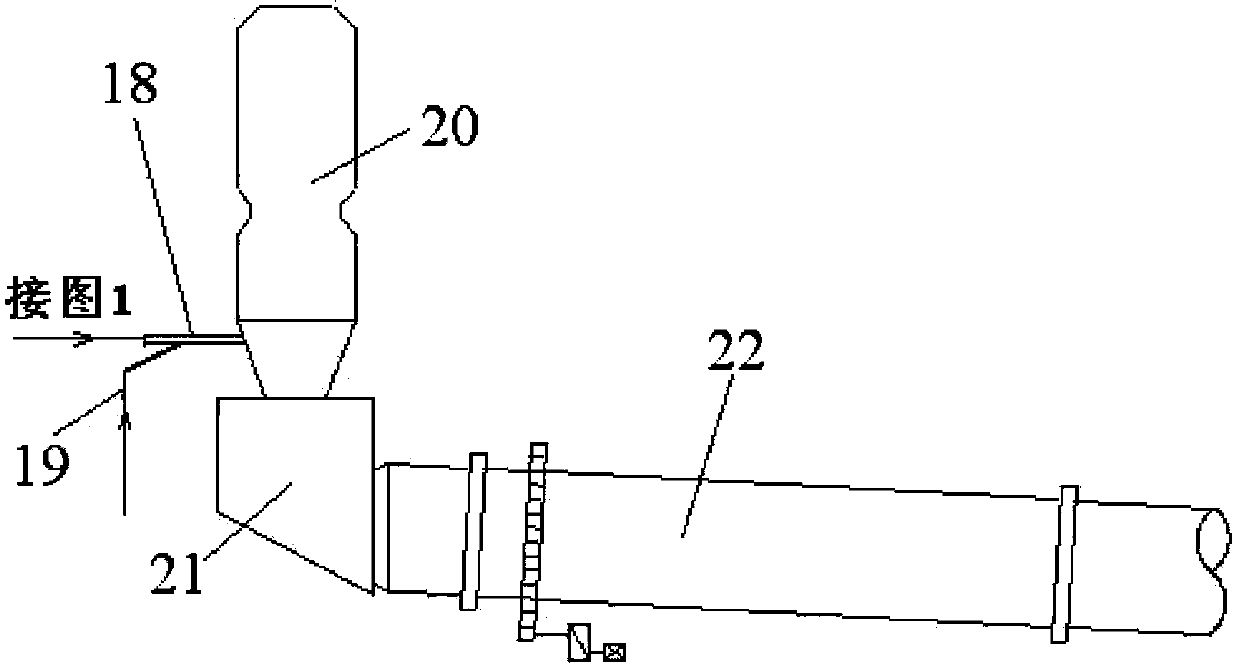

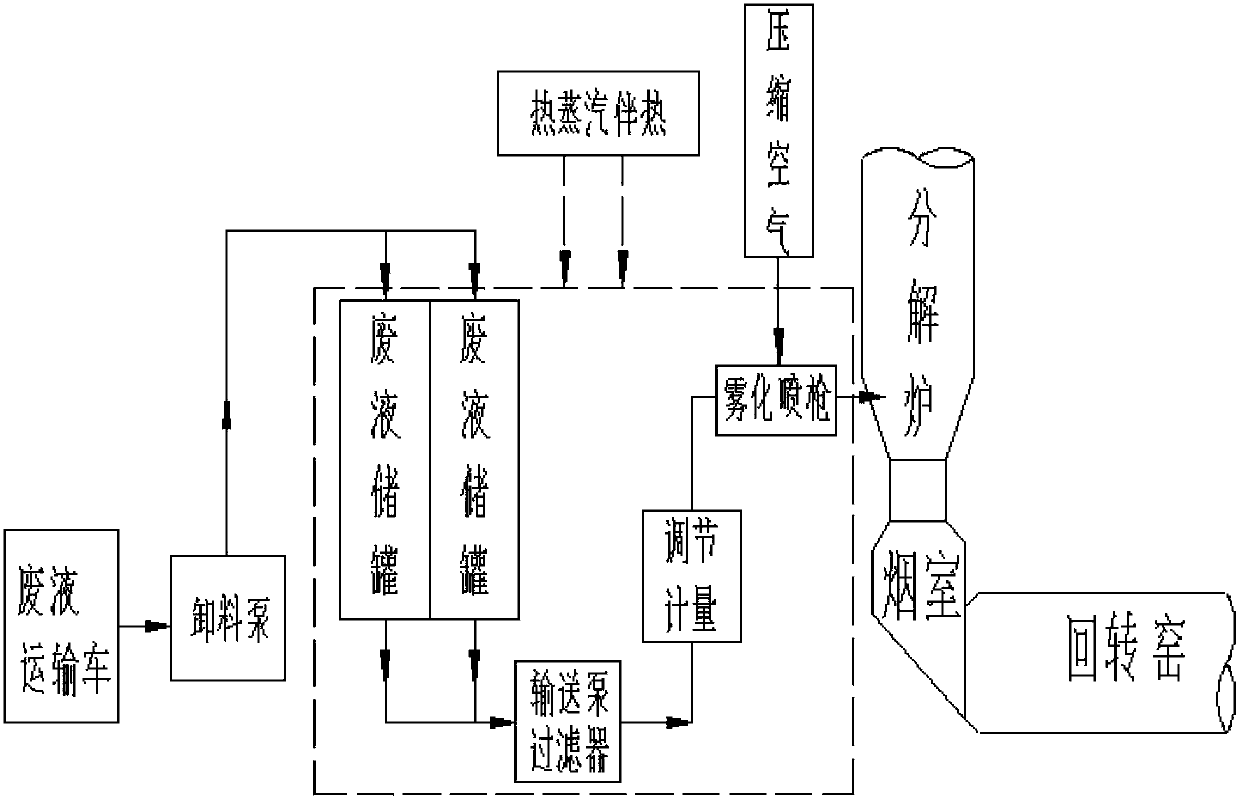

Chemical waste liquid disposal system

ActiveCN102718422BFully harmless treatmentProduct quality is not affectedWaste heat treatmentLiquid wasteSlag

The invention discloses a chemical waste liquid disposal system which is provided with a conveying and filtering system (7), an adjusting and measuring system (14) and an atomizing and spraying device (18); and the chemical waste liquid disposal system is connected with a pre-calcining kiln system of a cement new dry-process kiln through the atomizing and spraying device (18). With the adoption of the technical scheme, the chemical waste liquid disposal system has the beneficial effects that the technical characteristics of a cement firing system are fully utilized, chemical waste liquid is subjected to full and efficient innocent treatment, generated gas and ash are directly treated by utilizing the cement new dry-process kiln, no waste discharge exists, no complicated waste gas and waste slag treatment facility is required to be additionally arranged, and meanwhile, heat contained in the waste liquid is also completely utilized to achieve the purpose of carrying out innocent, resource and one hundred percent reduction on the waste liquid.

Owner:ANHUI CONCH GRP +2

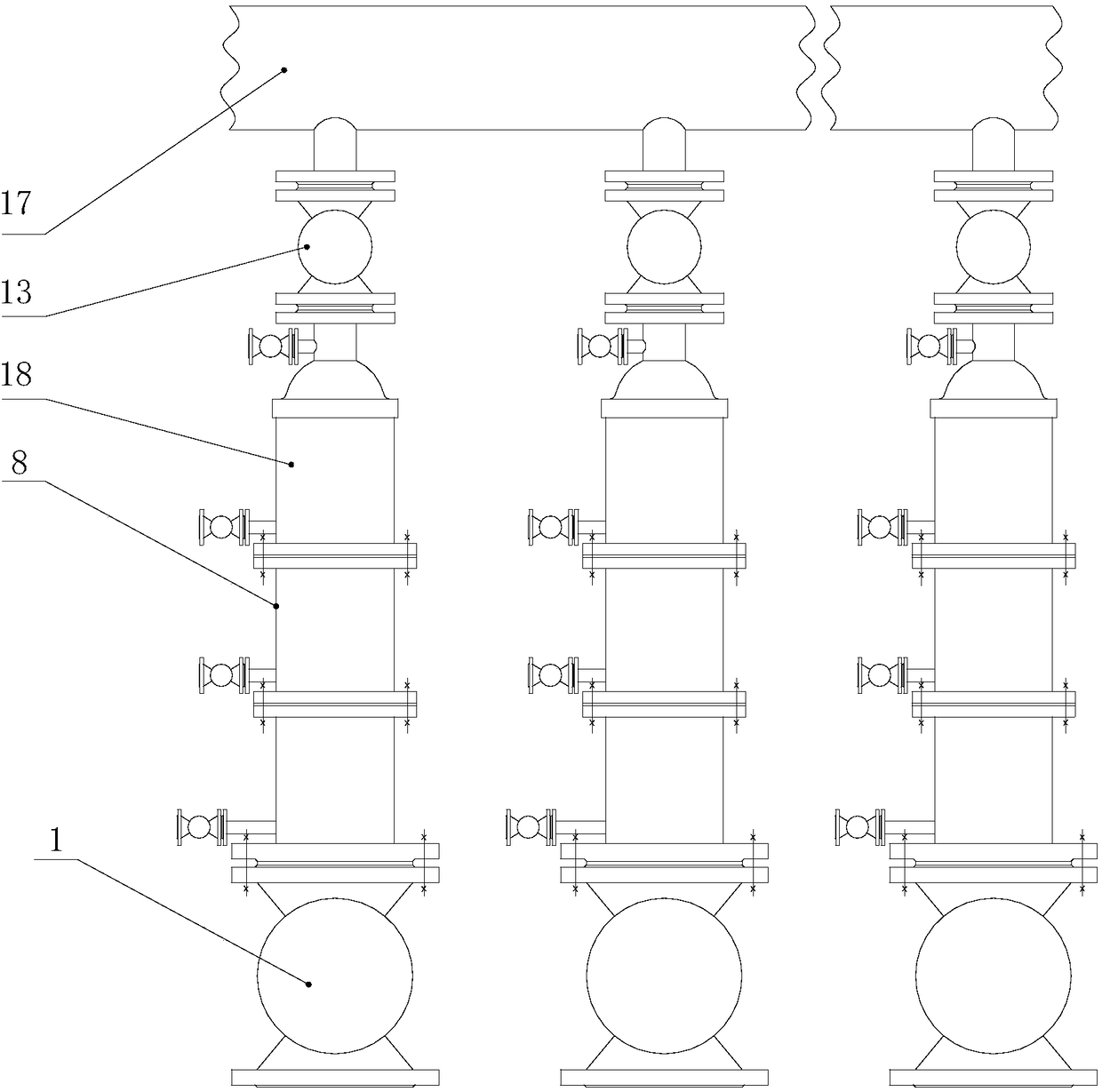

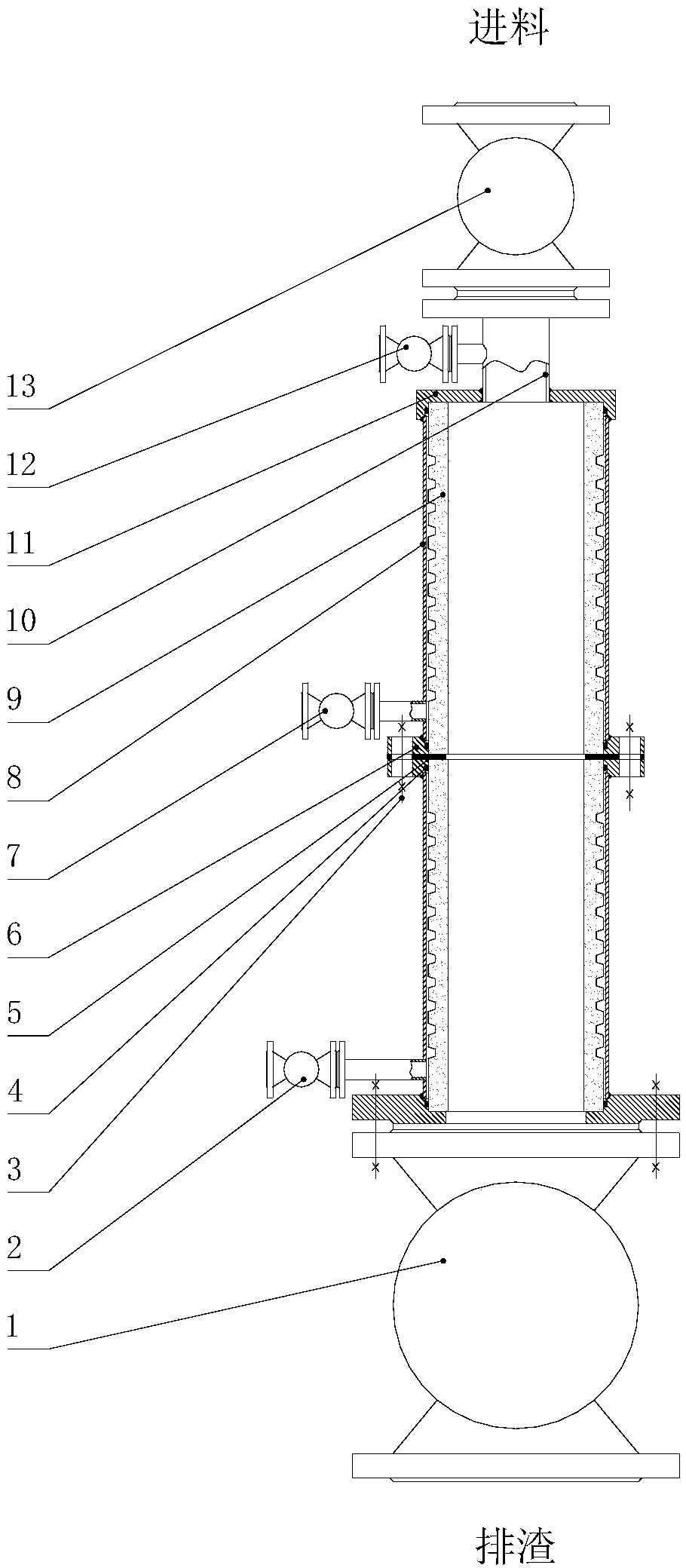

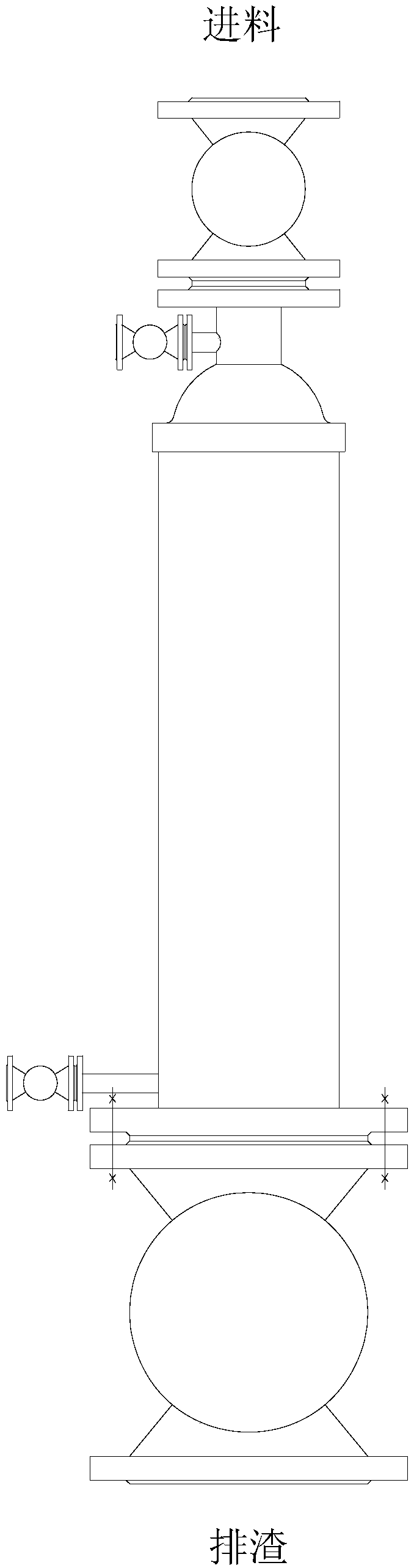

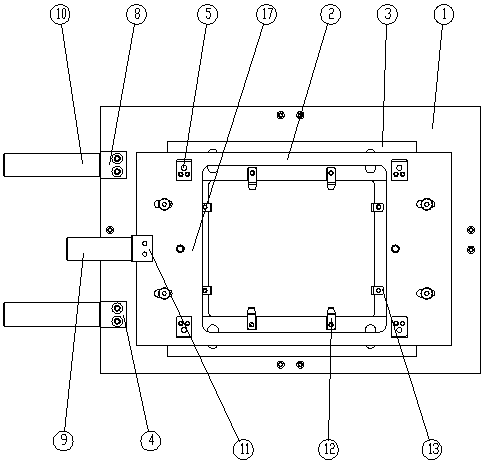

A filter and squeeze drying unit for easy-to-filter materials

ActiveCN106039803BClose in timePrevent unfavorable running water and other situationsStationary filtering element filtersEngineeringFilter material

The invention discloses a filtering and squeezing unit for filterable materials. The filtering and squeezing unit comprises a distribution pipe (17), which is connected to one or more filtering and squeezing machines (18) through feed valves (13). The filtering and squeezing machine comprises a barrel (8), the upper end of which is connected to the feed valve (13) and the lower end of which is provided with a discharge valve (1). An irregular-shaped filter pipe (9) is arranged inside each barrel (8). A positive blow valve (12) is disposed between the feed valve (13) and the barrel (8). The lower part of the barrel (8) is provided with a back-blow outlet valve (2). According to the invention, multiple materials can be filtered and squeezed at the same time, and the operation is carried out under airtight condition. In addition, filtering effect is good, squeezing efficiency is high, filter cakes can be continuously produced, and the operation can be effectively combined with production activities.

Owner:ZHEJIANG DONGOU FILTERING MASCH MFG CO LTD

High-temperature-resistant catching and releasing machine for semiconductor plastic package product

ActiveCN108336006ASimple structureEasy to operateSemiconductor/solid-state device manufacturingConveyor partsEngineeringMechanical engineering

The invention aims to provide a high-temperature-resistant catching and releasing machine for a semiconductor plastic package product, which is simple in structure, convenient and quick to operate andhigh in working efficiency. The high-temperature-resistant catching and releasing machine comprises a fixed plate, a moving plate and a moving block, wherein identical waist-shaped holes are correspondingly formed in the moving plate and the moving block; the moving plate and the moving block are fixed by bolts; tension springs and roller bearings are respectively arranged between the moving plate and the moving block; positions of the tension springs and a first shank are located on one horizontal line; mounting blocks are fixedly connected among the fixed plate, the moving block and the moving plate; a second shank is fixed on the fixed plate through shank mounting blocks, and limiting blocks L are arranged on the mounting blocks; the first shank is fixed on the moving plate through clamping blocks; a plurality of limiting blocks R are symmetrically and uniformly distributed on the moving plate along lengthwise directions of the waist-shaped holes; a plurality of locking blocks aresymmetrically and uniformly distributed on the fixed plate; a plurality of second supporting claws are symmetrically and uniformly distributed on the waist-shaped holes along the lengthwise directionof the moving plate; and a plurality of first supporting claws are symmetrically and uniformly distributed on the waist-shaped holes along a width direction of the moving plate.

Owner:TONGLING FUSHI SANJIA MACHINE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com