Method for recycling purified terephthalic acid wastewater

A technology of purified terephthalic acid and wastewater, applied in chemical instruments and methods, natural water treatment, biological water/sewage treatment, etc. problems, to achieve the effect of alleviating water shortage, stable treatment effect and convenient operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

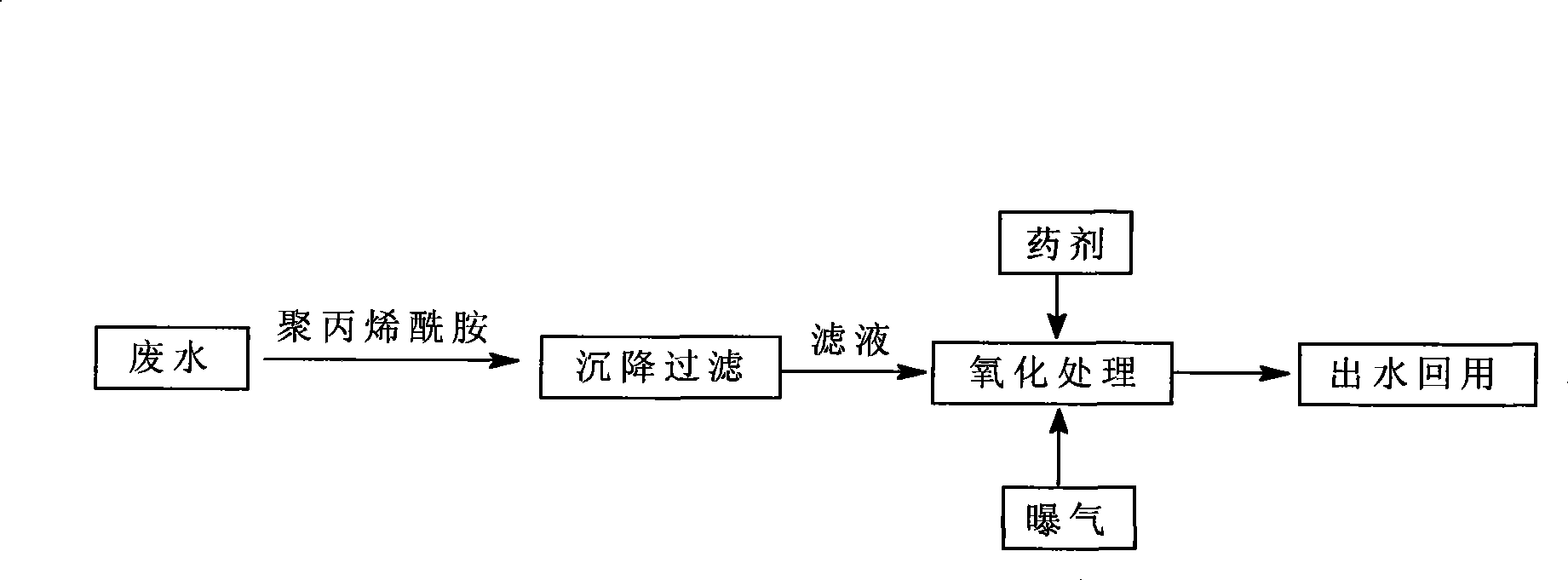

Image

Examples

Embodiment 1

[0024] Weigh 1000mL of wastewater to be treated and put it into the container, add 5mL of the prepared polyacrylamide solution with a concentration of 1‰, flocculate and settle for 60min, and then filter. Add 10g of 15% hydrogen peroxide, 1g of industrial-grade sodium chlorate, and 0.1g of industrial-grade potassium persulfate to the wastewater that has been filtered to remove solid matter and mix evenly. The time is 90 minutes. The residence time of wastewater in the reaction tank is 8h. The treated wastewater COD drops to 10mg / L, BOD 5 Reaching 8mg / L, the chroma can be reduced to about 10 times, which meets the requirements of workshop reuse water.

Embodiment 2

[0026] In the same device as in Example 1, weigh 1000 mL of waste water to be treated and put it into a container, add 6 mL of a prepared polyacrylamide solution with a concentration of 1.2‰ to flocculate and settle for 65 minutes, and then filter. Adding concentration is 11g of 20% hydrogen peroxide, 1.2g of industrial grade sodium chlorate, 0.12g of industrial grade potassium persulfate to the waste water that has been filtered to remove solid matter and mix evenly. Gas time is 100min. The residence time of wastewater in the reaction tank is 8.5h. The treated wastewater COD drops to 9mg / L, BOD 5 The chromaticity is about 10 times lower than 8mg / L, which meets the requirements for reused water in workshops.

Embodiment 3

[0028] In the same device as in Example 1, weigh 1000mL of wastewater to be treated and put it into a container, add 7mL of a prepared polyacrylamide solution with a concentration of 1.4‰, flocculate and settle for 70min, and then filter. Adding concentration is 12g of 25% hydrogen peroxide, 1.4g of industrial grade sodium chlorate, 0.14g of industrial grade potassium persulfate to the waste water that has been filtered to remove solid matter, and stir and mix evenly. Gas time is 105min. The residence time of wastewater in the reaction tank is 9h. The treated wastewater COD drops below 9mg / L, BOD 5 It can reach 7.5mg / L, and the chroma can reach less than 10 times, which meets the requirements of workshop reuse water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com