Patents

Literature

512 results about "Membrane method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Membrane method or mixing by gas separation is a method of gas blending to produce nitrox, a breathing gas mostly used for scuba diving. Nitrox systems use semi-permeable membranes to separate out a portion of the nitrogen in air. Nitrox mixtures, containing between 24% and 40% oxygen (O₂), are then delivered to a high-pressure compressor to fill scuba cylinders or storage tanks, or to a low-pressure compressor for pumping to surface-supply divers. Although this compressor is described as the “nitrox compressor”, it is also used for air.

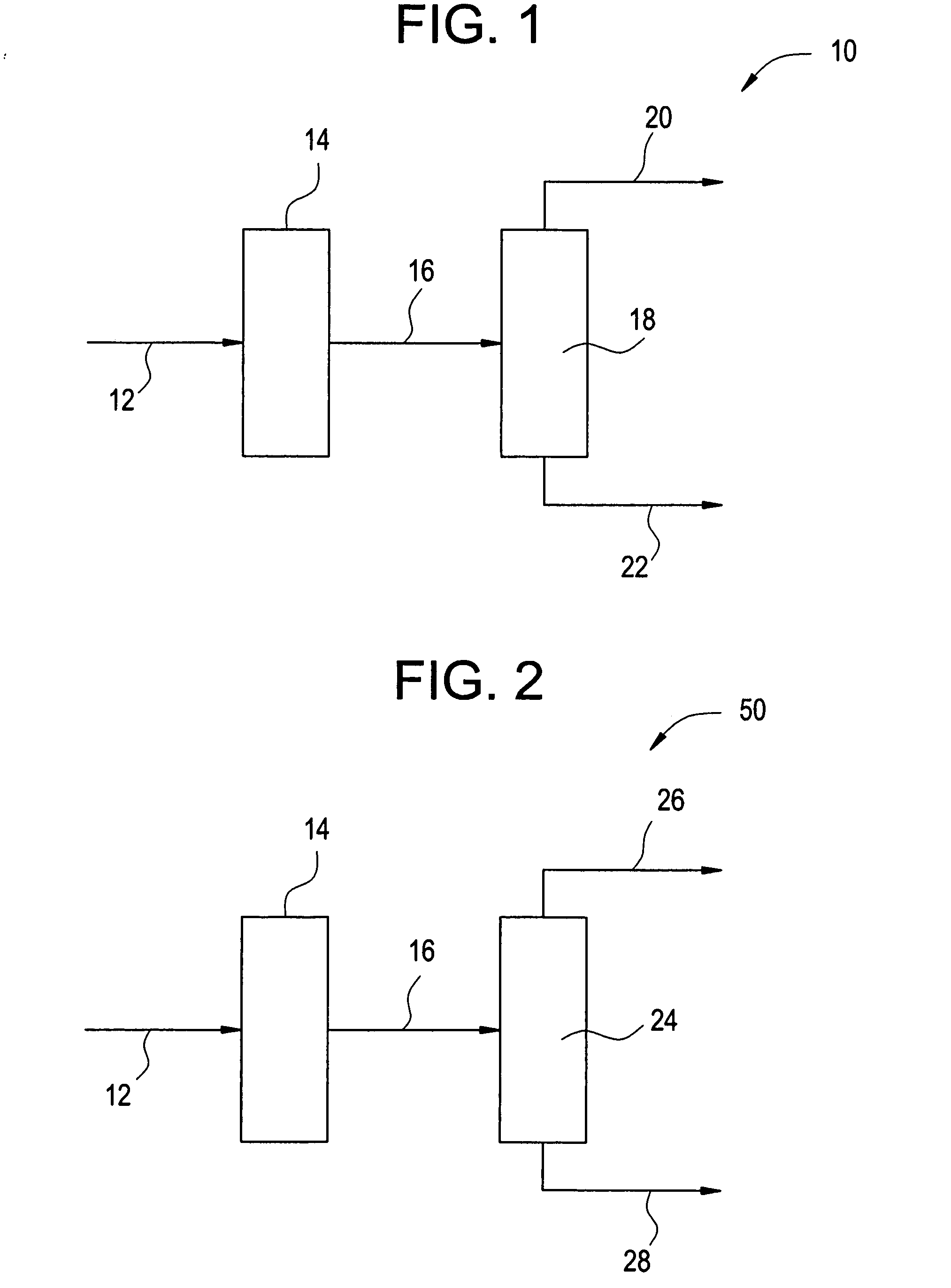

Methods and apparatus for treating wastewater employing a high rate clarifier and a membrane

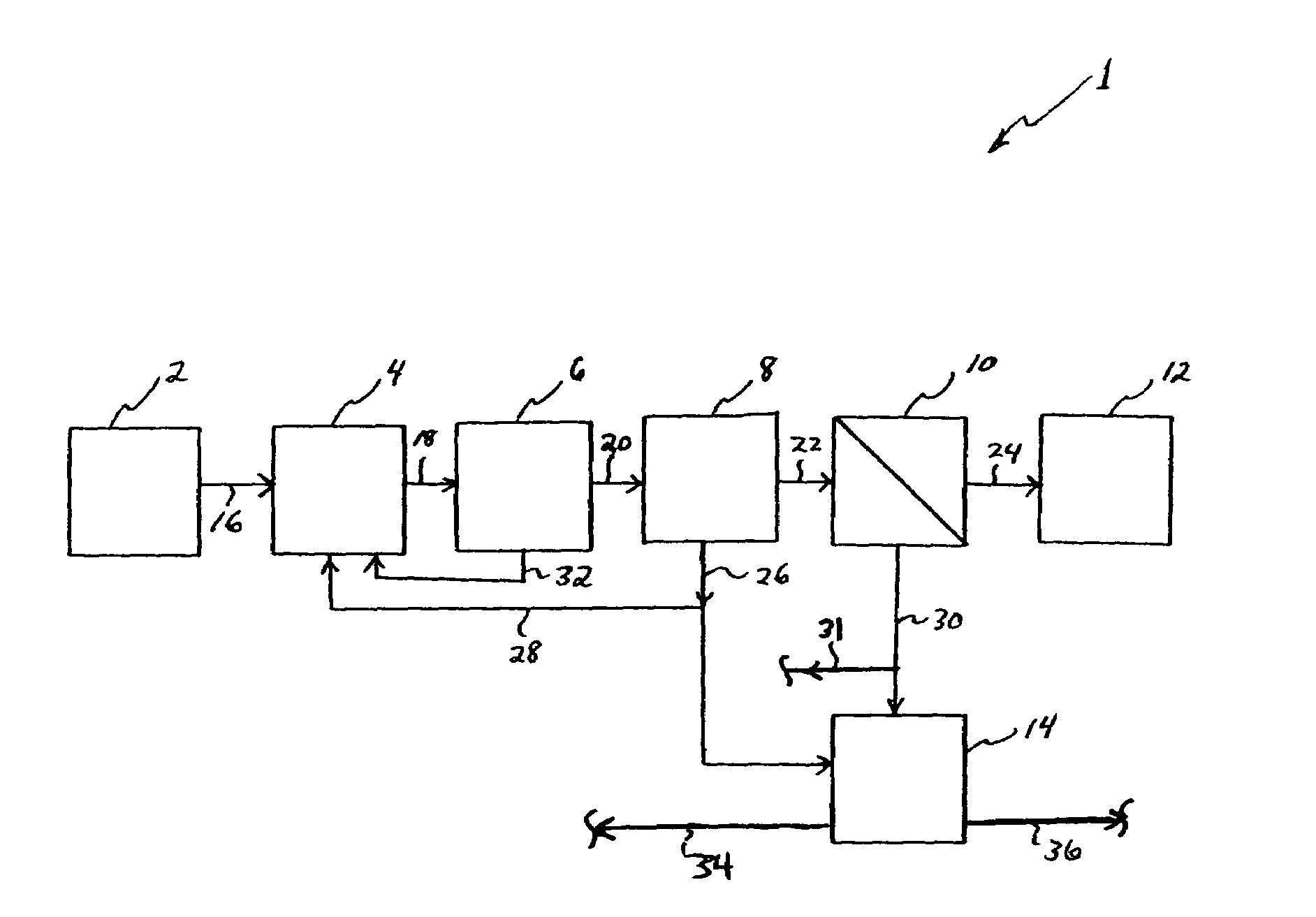

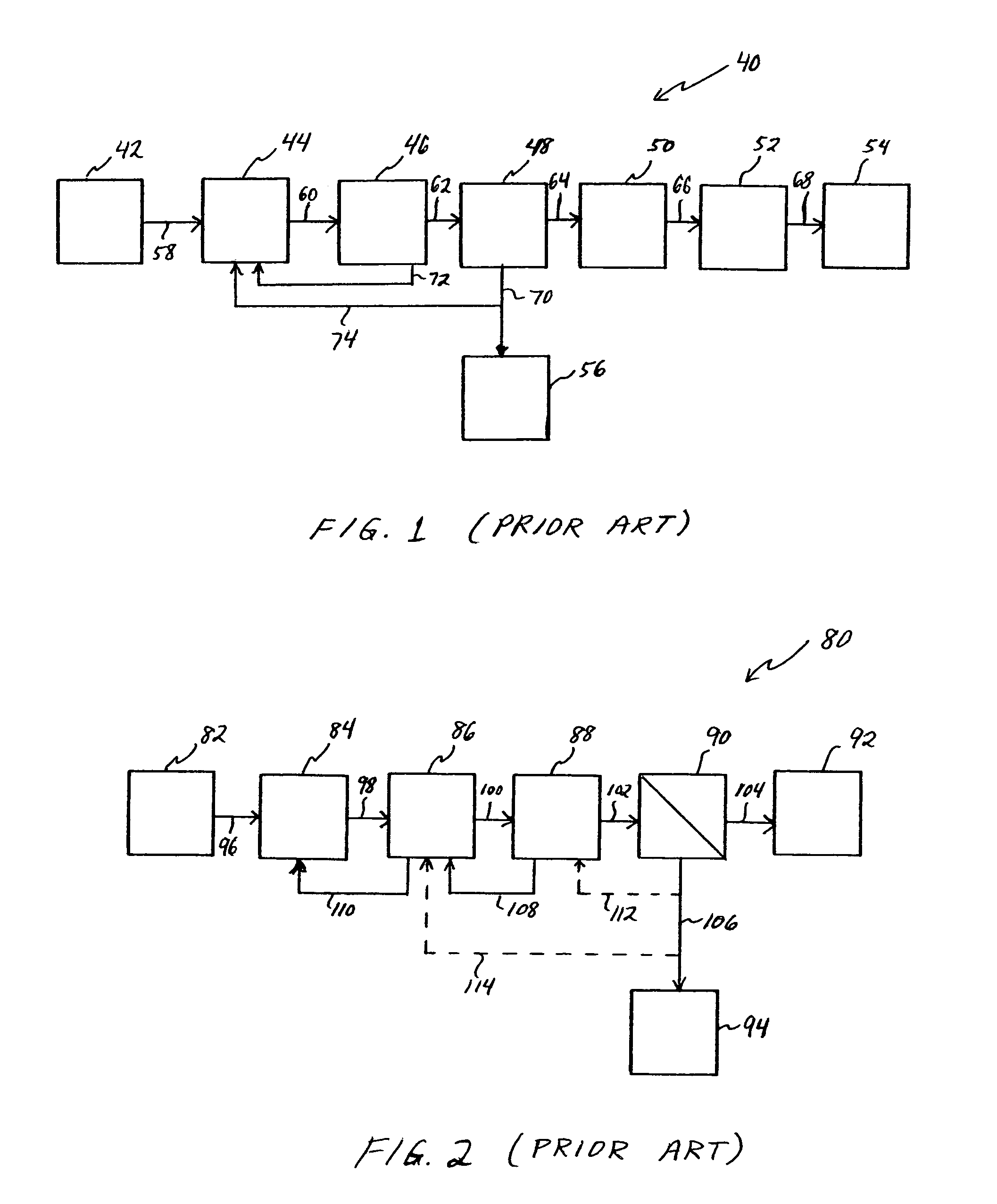

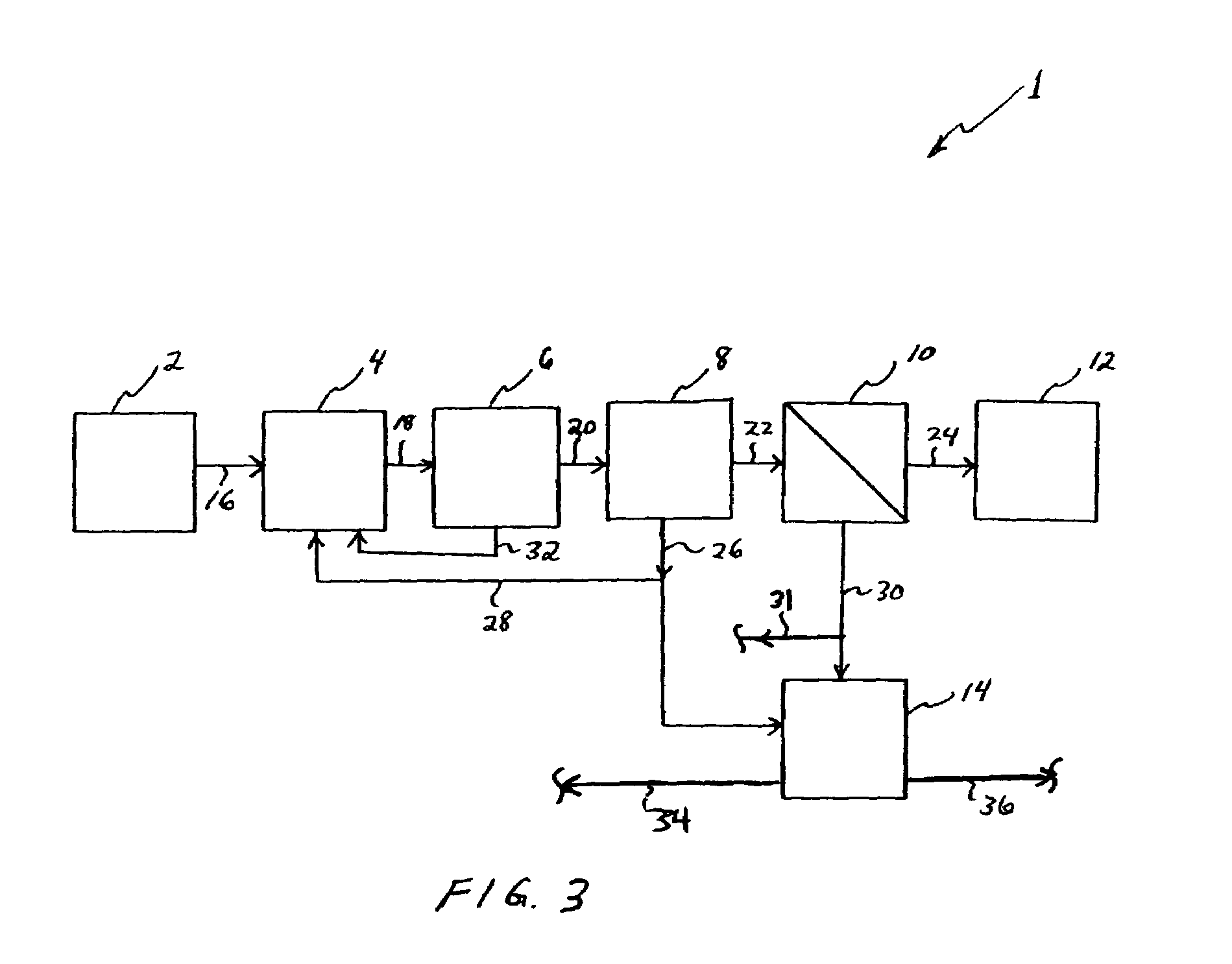

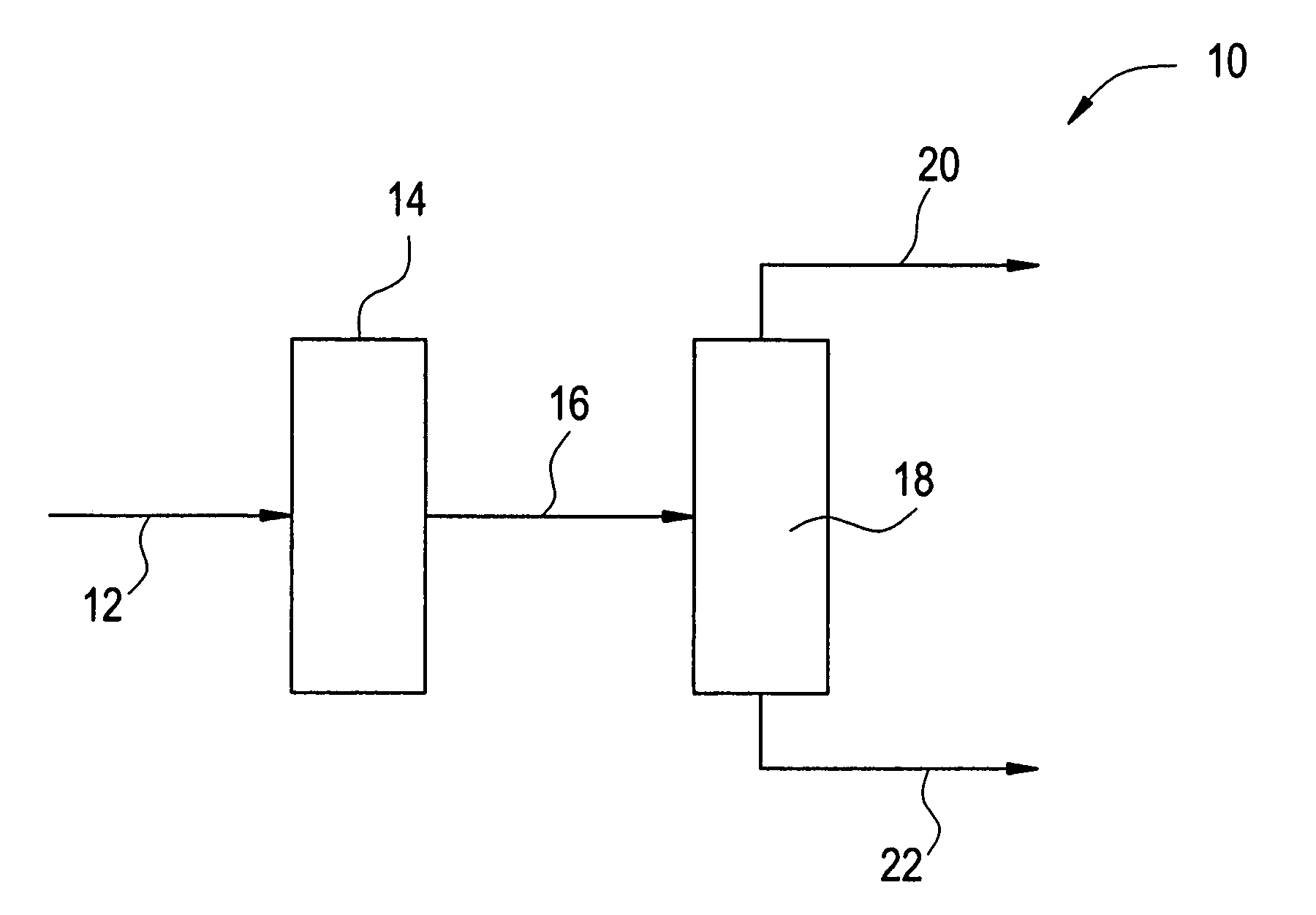

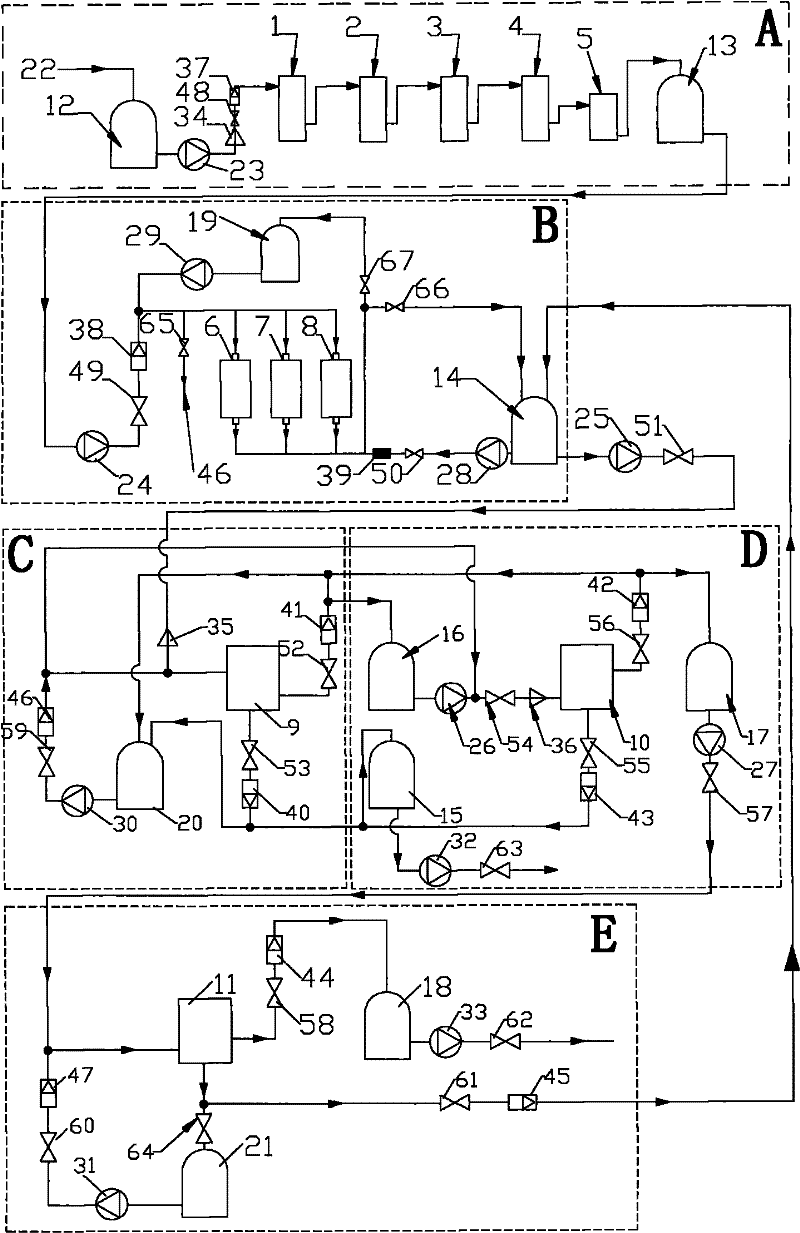

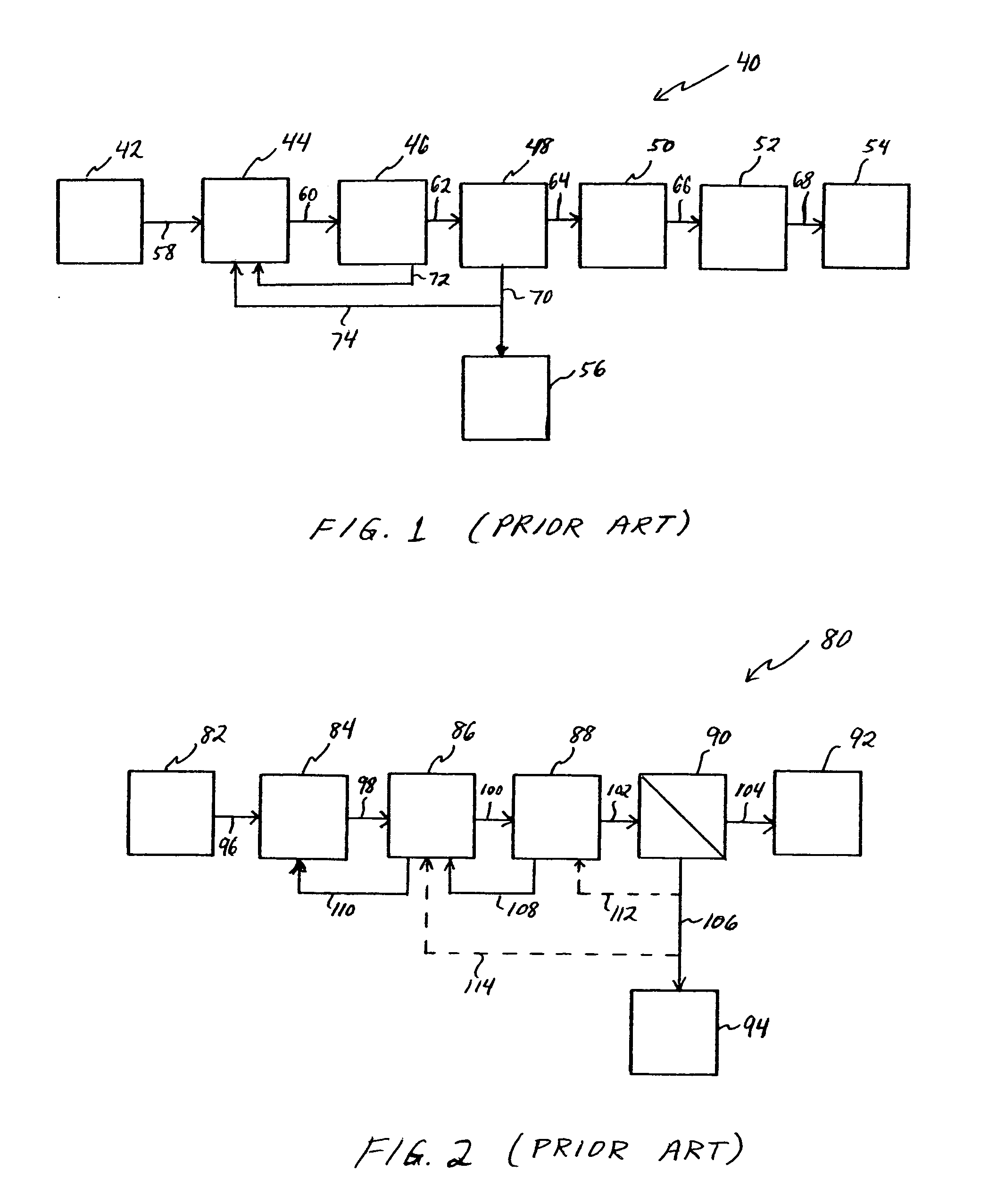

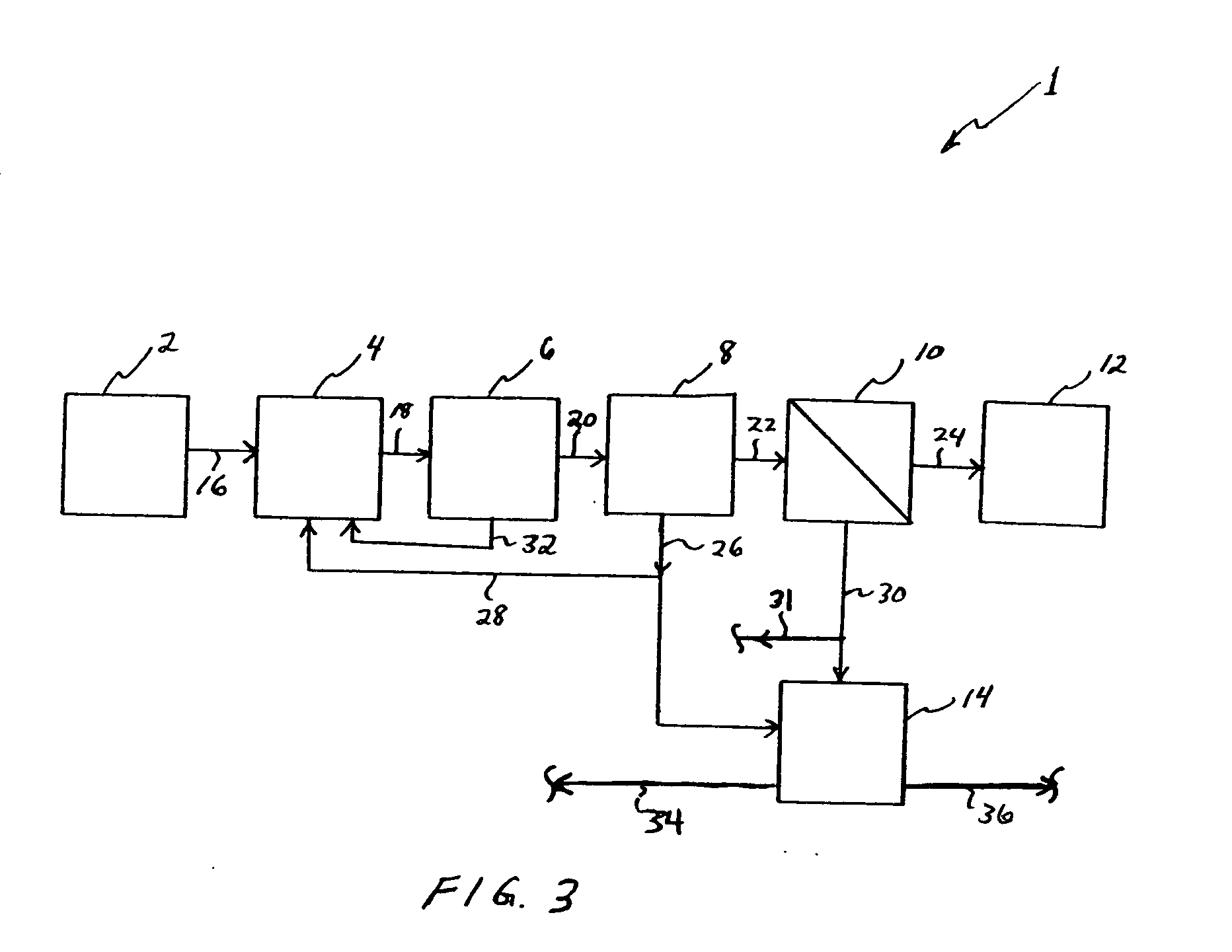

Methods and apparatus for treating wastewater are described, one method embodiment including the steps of flowing a mixed liquor suspended solids to a high rate clarification stage, forming a clarifier effluent, a first waste activated sludge stream, and a return waste activated sludge stream. The high rate clarifier effluent stream then flows to a membrane stage that includes a membrane media, producing a membrane reject (retentate) stream and a treated effluent (permeate) stream. Optionally, the methods include routing a screened raw wastewater to an anaerobic and / or aerated anoxic stage and introducing a gas comprising oxygen to the wastewater during the aerated anoxic stage, and optionally allowing the product of this stage to flow to an aeration stage prior to the high rate clarification stage.

Owner:ALFA LAVAL ASHBROOK SIMON HARTELY INC

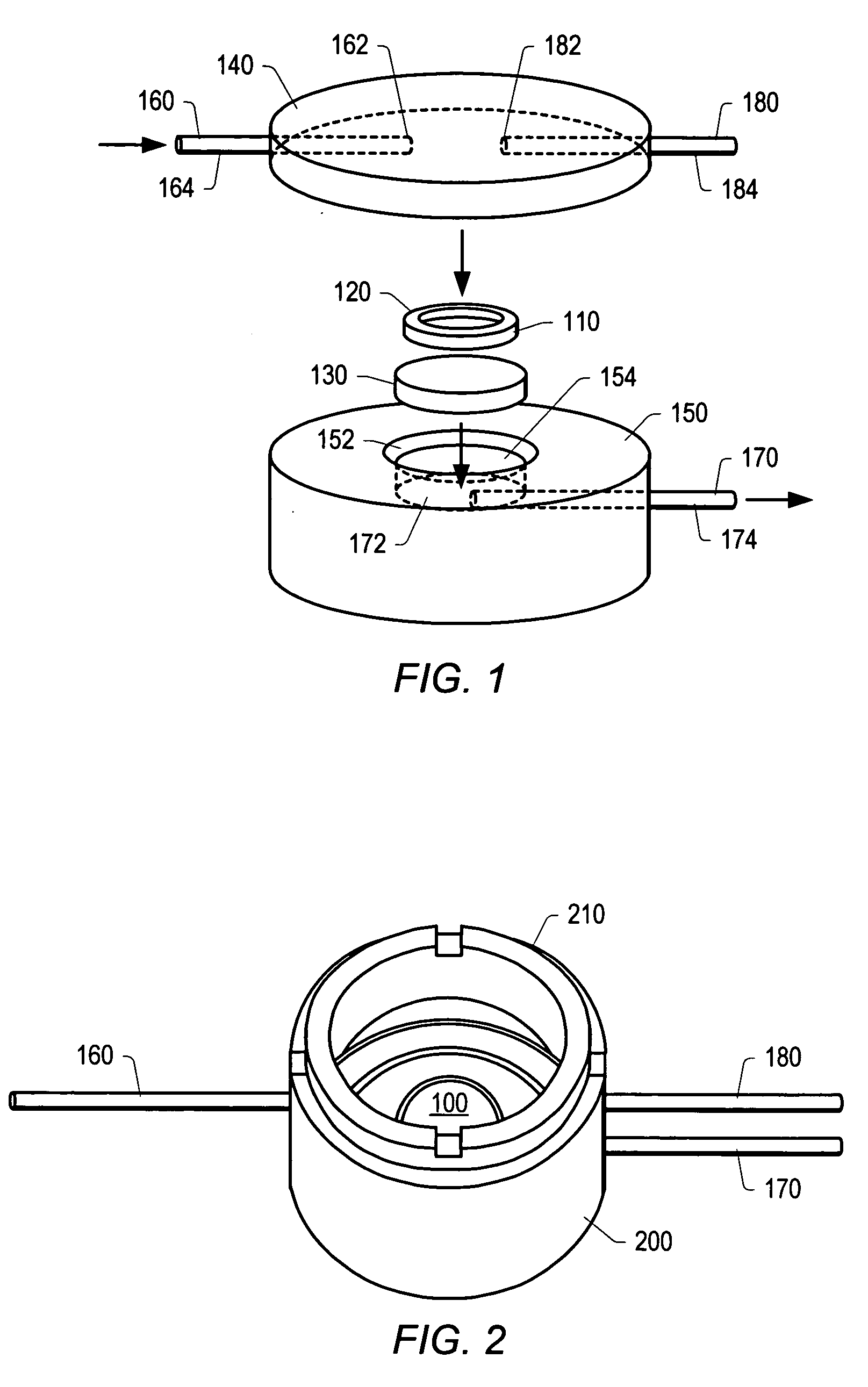

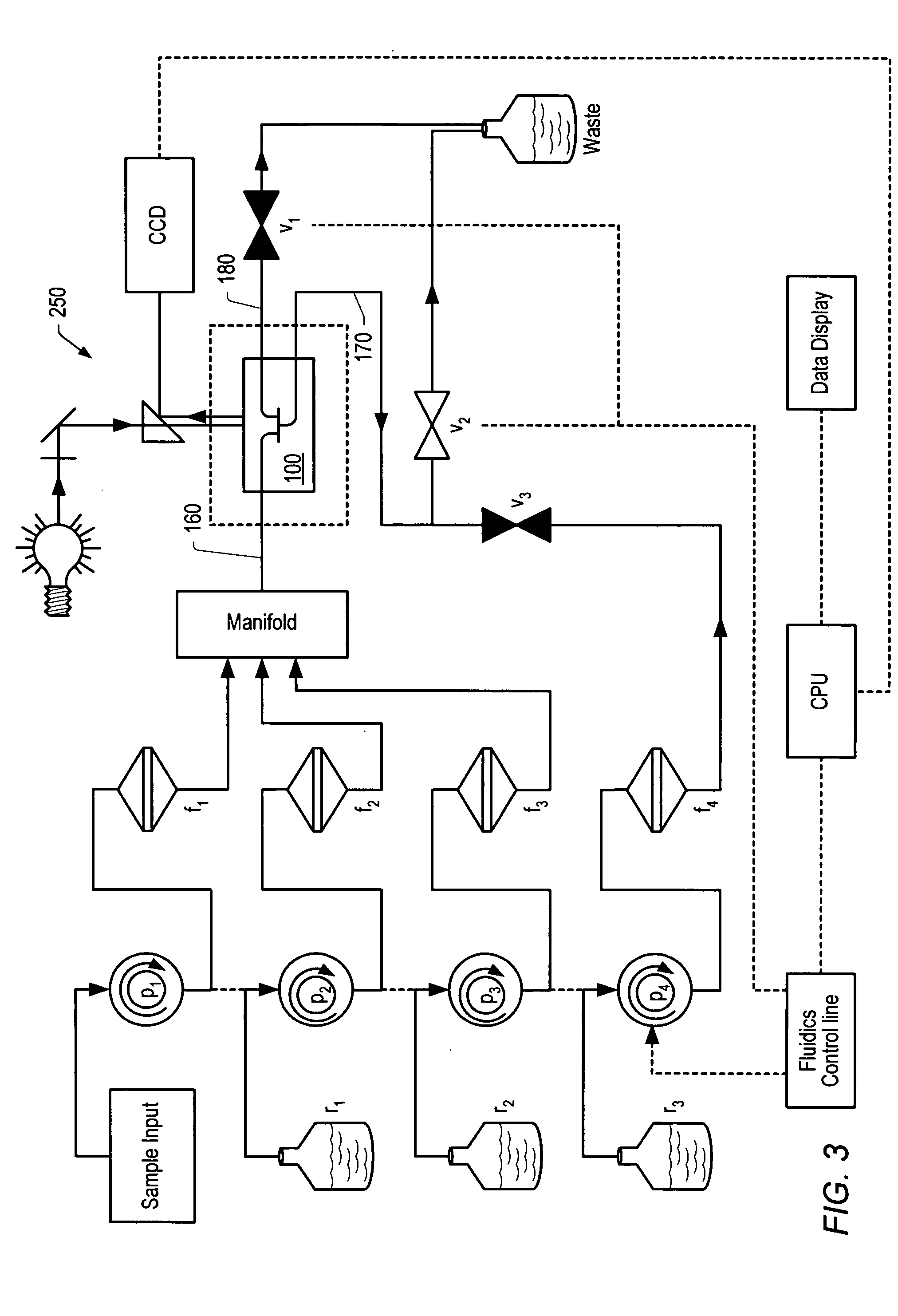

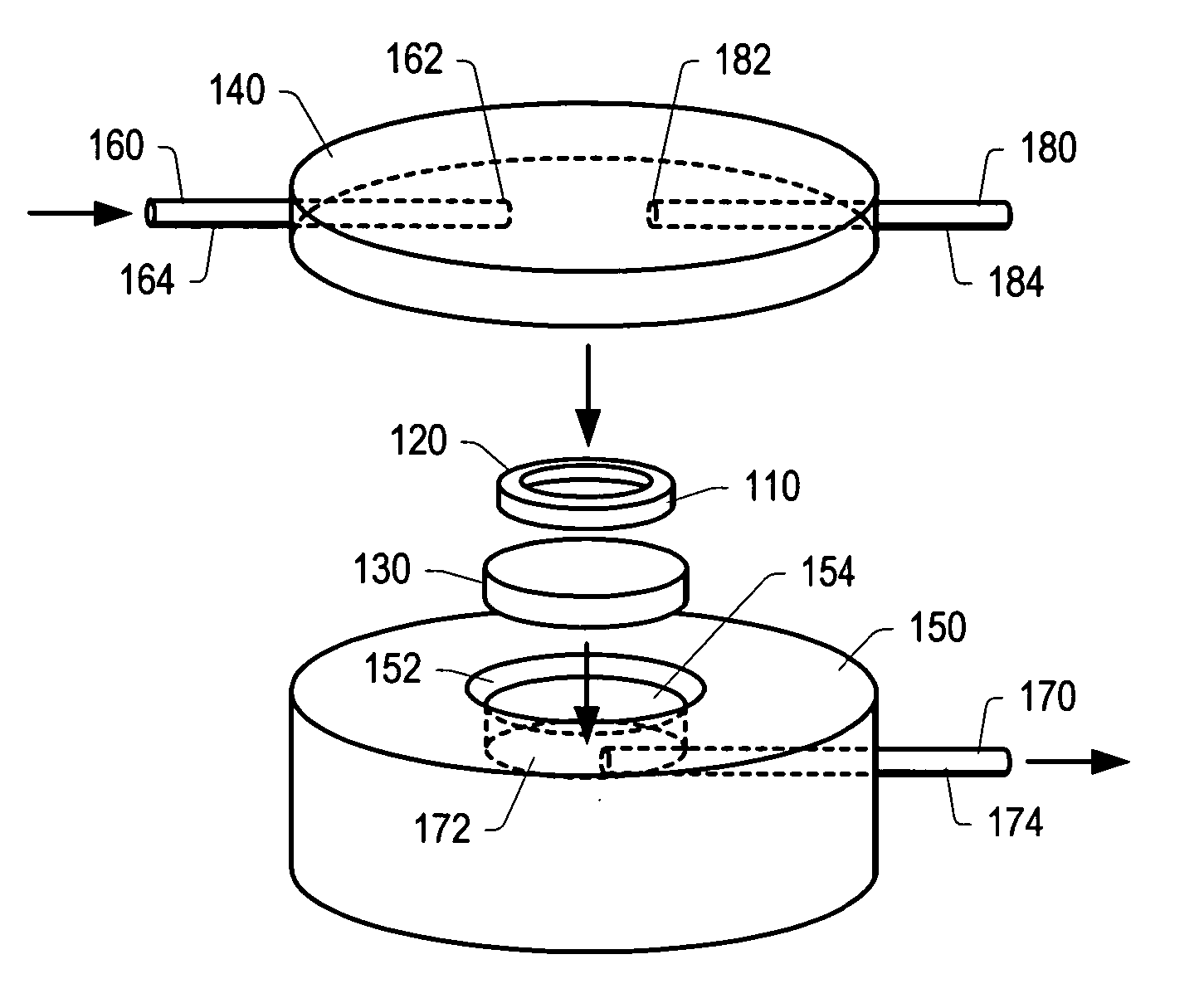

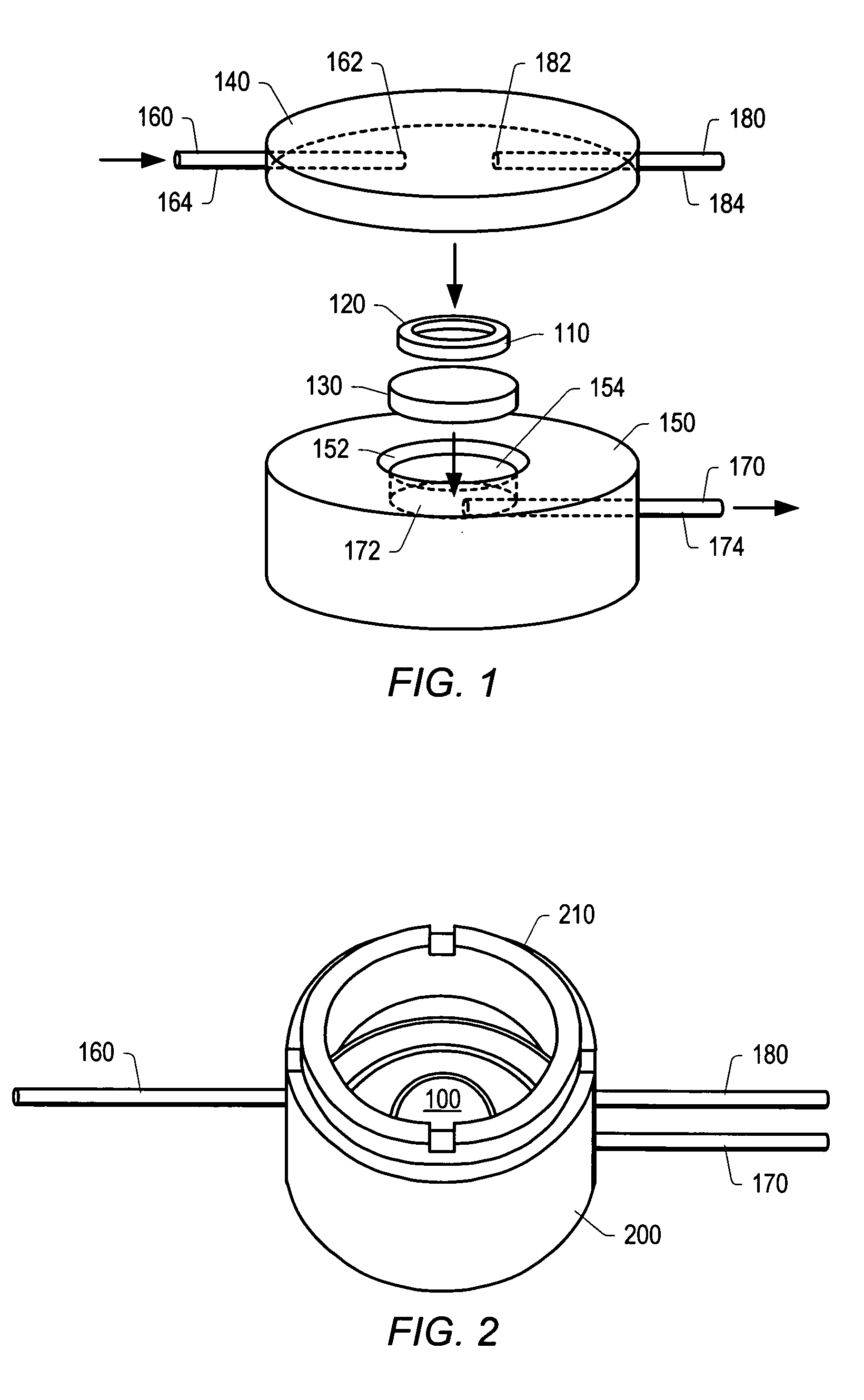

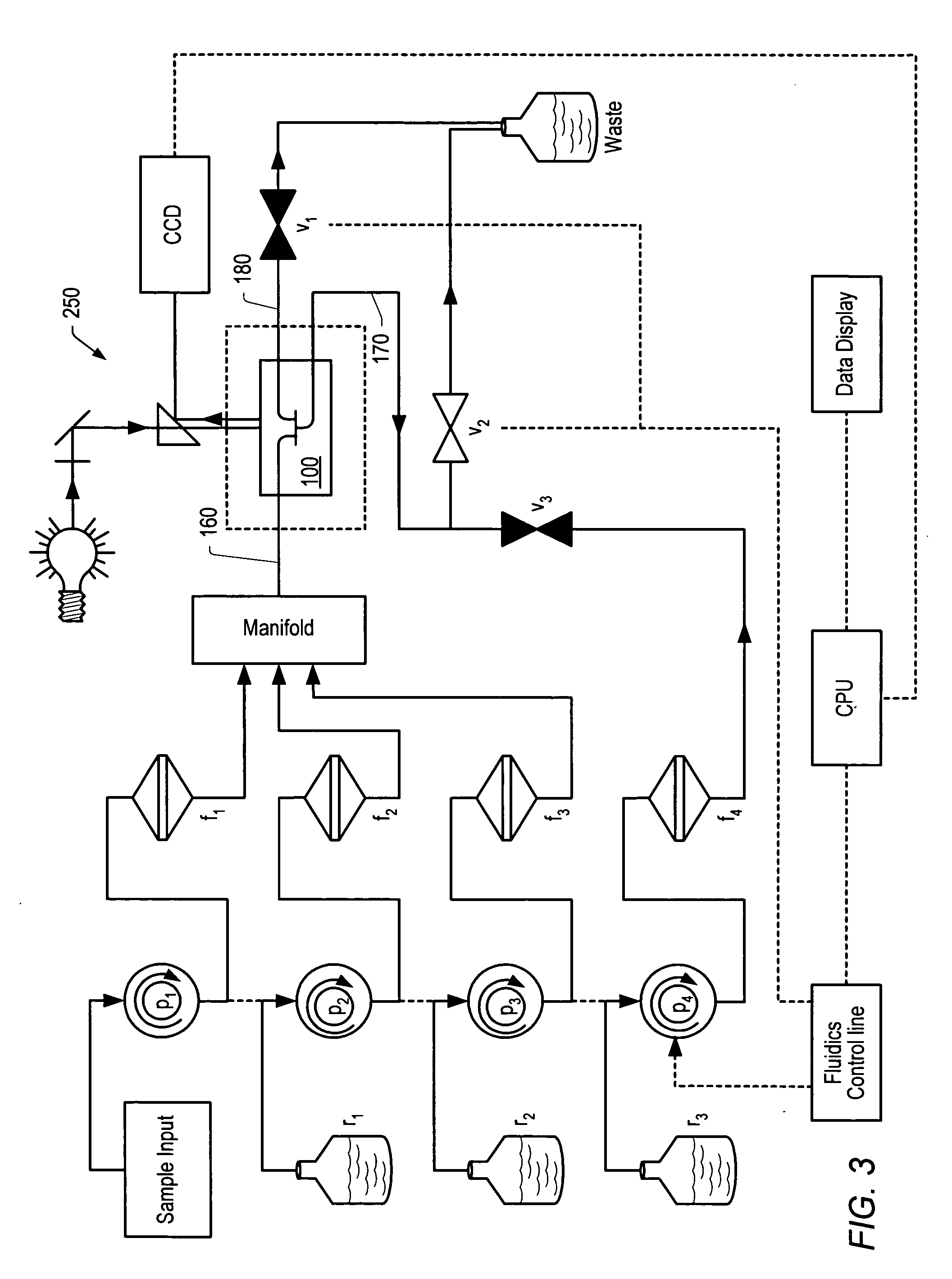

Capture and detection of microbes by membrane methods

InactiveUS20060073585A1Quick checkBioreactor/fermenter combinationsBiological substance pretreatmentsMembrane methodMicroorganism

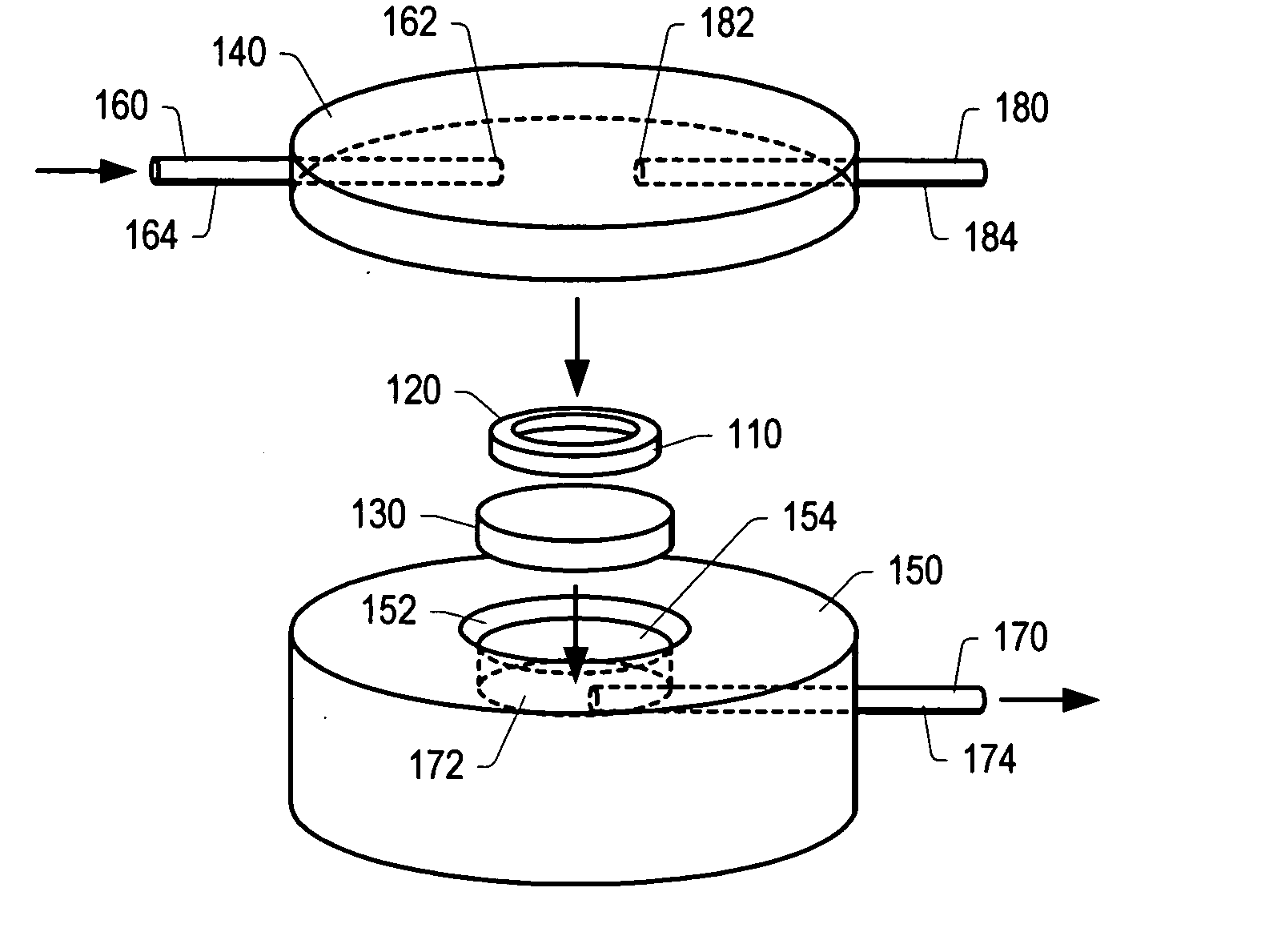

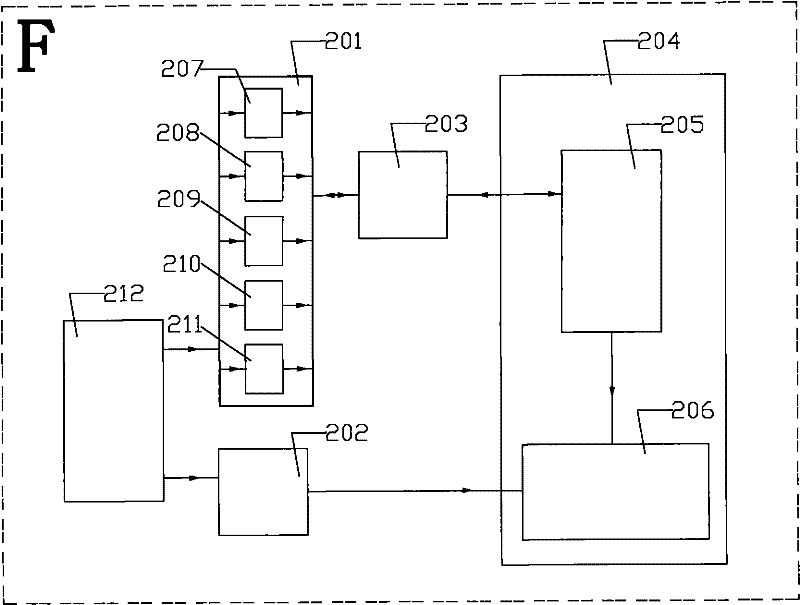

Methods and systems for detecting the presence of analytes using a membrane based detection system are described. A fluid sample is passed through a membrane based detection system (100). Particulate analytes (e.g., microbes) are captured by the membrane (110). Detection and analysis techniques may be applied to determine the identity and quantity of the captured analytes.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Capture and detection of microbes by membrane methods

InactiveUS20060079000A1Quick checkBioreactor/fermenter combinationsBiological substance pretreatmentsMembrane methodMicroorganism

Methods and systems for detecting the presence of analytes using a membrane based detection system are described. A fluid sample is passed through a membrane based detection system (100). Particulate analytes (e.g., microbes) are captured by the membrane (110). Detection and analysis techniques may be applied to determine the identity and quantity of the captured analytes.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

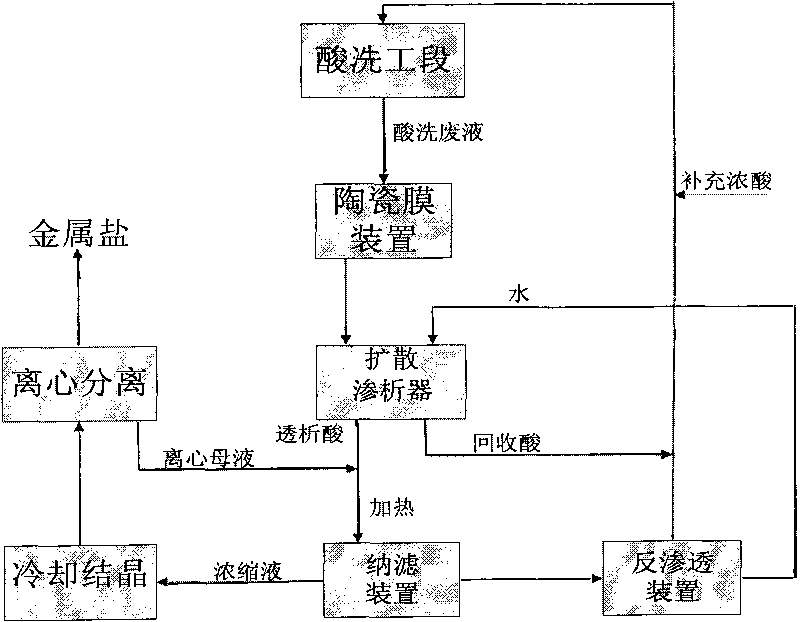

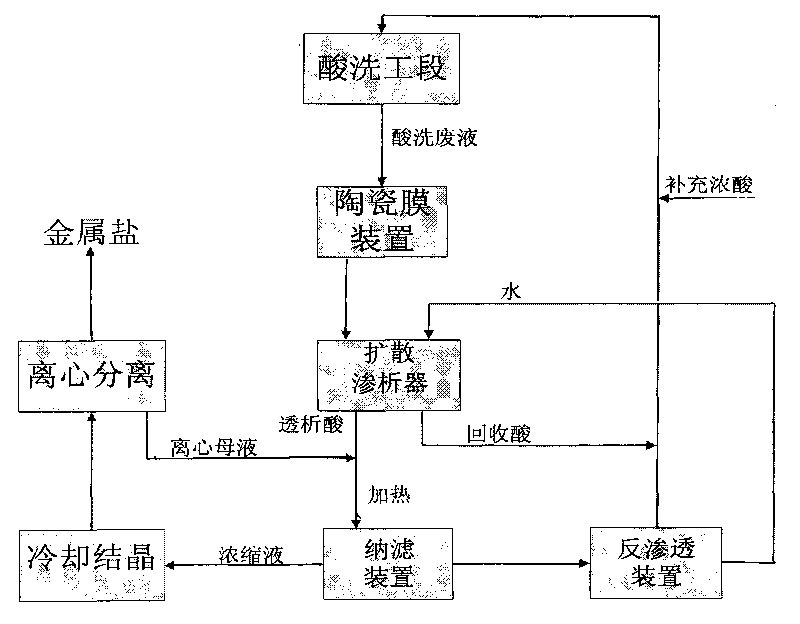

Process for recovering heavy metallic salt and inorganic acid in pickling waste liquid

ActiveCN101759250AOptimizing the integration processReduce pollutionSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisLiquid wasteIron salts

The invention relates to a process for separating and recovering heavy metallic salt and inorganic acid in pickling waste liquid by a membrane method, which comprises the following concrete steps: filtering and removing solid suspended substances in pickling waste liquid through an inorganic ceramic membrane; separating acid from salt in the ceramic membrane penetrating liquid through diffusion dialysis; and heating the dialysis liquid of a diffusion dialyzer, then introducing the dialysis liquid into a nanofiltration membrane, and cooling and crystallizing the concentrated liquid of a nanofiltration device and then centrifuging the crystal of the concentrated liquid to obtain iron salt, wherein the penetrating liquid of the nanofiltration device passes through a reverse osmosis membrane device, the concentrated liquid of the reverse osmosis device returns to a pickling section, and the water discharged from the reverse osmosis device enters a diffusion dialysis section for recycling. The invention has the characteristics that the pickling waste liquid is completely used as resources, the recovery process is simple, the recovery ratio of metallic salt and acid is high, and water is recycled. The process of the invention can be coupled with various pickling sections to realize continuous and stable automated operation, and the supplemented acid amount can be quantitatively controlled according to the acid amount consumed by the crystallized metallic salt.

Owner:NANJING UNIV OF TECH +1

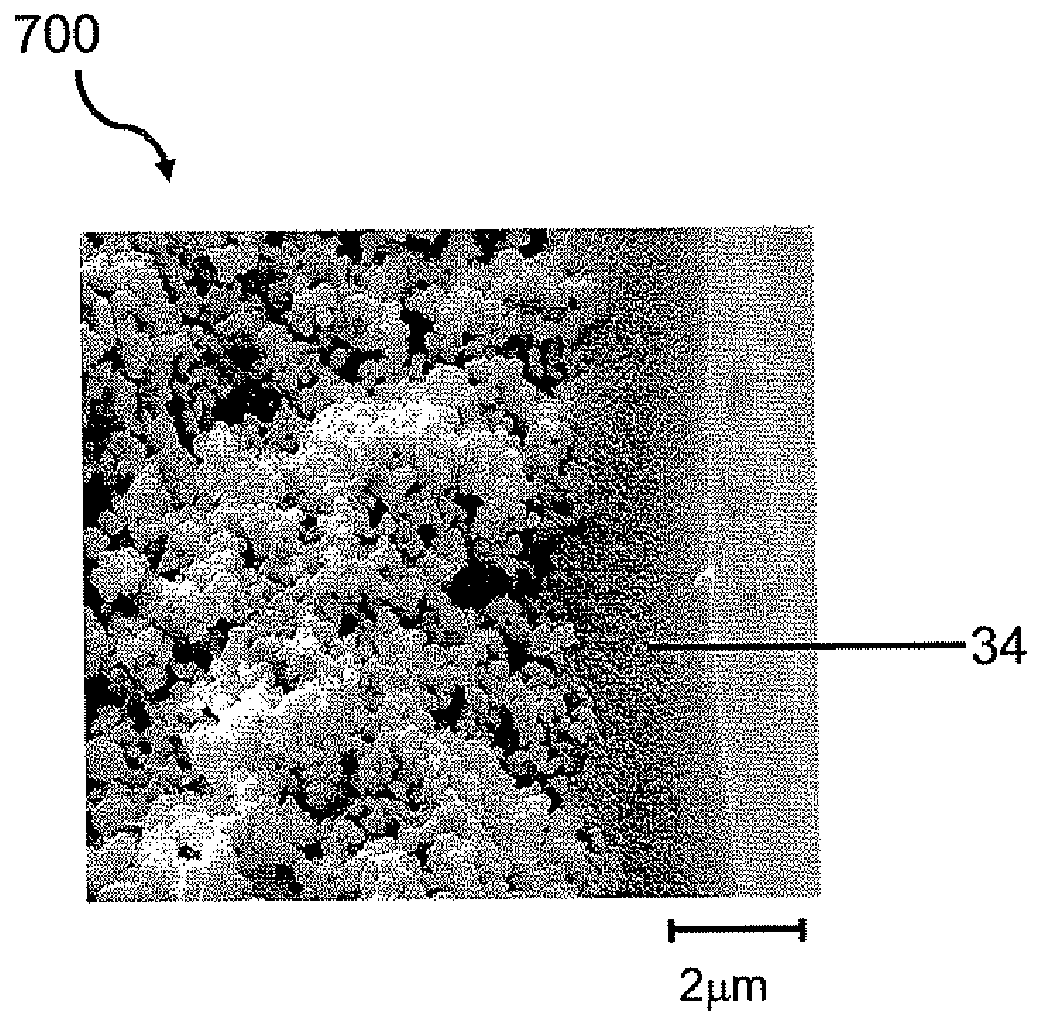

Graphene oxide-based composite membrane for treating radioactive wastewater

InactiveCN105664738AHigh retention rateAchieve enrichmentSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiltrationIon

The invention relates to a graphene oxide-based composite membrane for treating radioactive wastewater and a preparation method thereof.According to the membrane, a porous carrier is pre-modified through a silane coupling agent, and the graphene oxide-based composite membrane is prepared from a polydopamine and graphene oxide compound by adopting a vacuum filtration method.The method is characterized in that a polydopamine bionic self-assembly technology and a graphene oxide sheet are compounded, the size dimension of a membrane nanochannel is accurately adjusted, the selectivity or the rejection rate of the membrane on radionuclide ions is increased, and concentration and removal of radionuclide are achieved.According to the graphene oxide-based composite membrane for treating the radioactive wastewater and the preparation method thereof, the preparation process is simple and easy to operate, good repeatability is achieved, the water flux and ion rejection rate of the composite membrane are significantly increased, the separating property of a long-time operating membrane is stable, and a wide application prospect in the fields such as membrane-method radioactive wastewater treatment and heavy metal wastewater treatment is achieved.

Owner:JIANGXI NORMAL UNIV

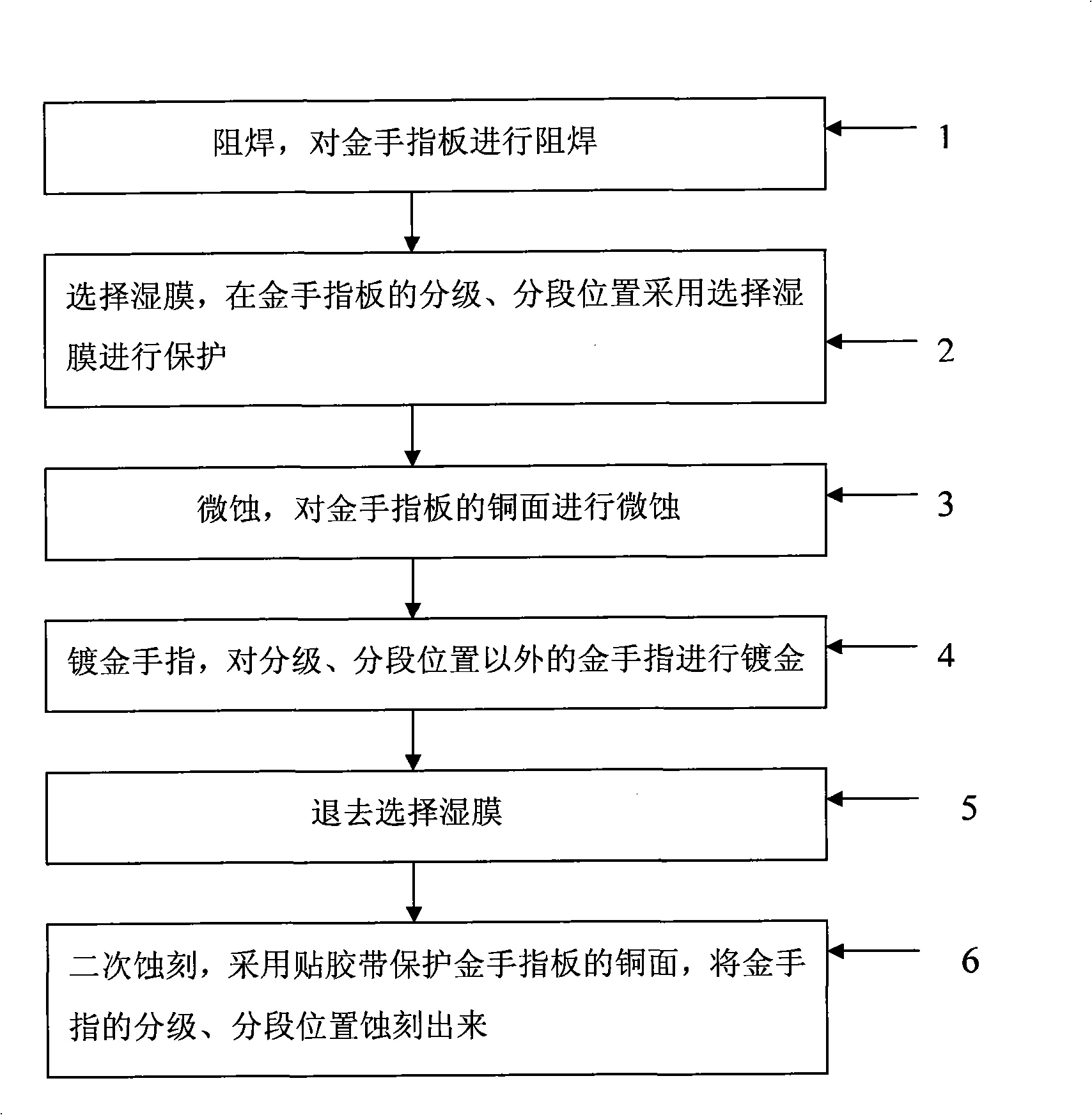

Method for preparing hierarchical and grading gold finger plate using method of selecting wet film

ActiveCN101355856AEasy to controlLow signal distortionPrinted element electric connection formationMembrane methodLow distortion

The invention relates to a method for manufacturing a sectional and segmented gold fingerplate by a selective wet membrane method, comprising the following: a step of resistance welding, in which the gold fingerplate is subjected to resistance welding; a step of selecting a wet membrane, in which the wet membrane is selected to protect the sectional and segmented position of the gold fingerplate; a step of microetching, in which the copper surface of the gold fingerplate is microetched; a step of plating a gold finger, in which the gold fingers except the sectional and segmented position is gilded; a step of removing the selective wet membrane; and a step of etching for the second time, in which an attach tape is adopted to protect the copper surface of the gold fingerplate, and the sectional and segmented positions of the gold finger are etched. The method manufactures the sectional and segmented gold fingerplate by the selective wet membrane method, is used for removing plating lead wires, has easily controlled production process, and has low distortion rate of the signal and high accuracy when a client uses the method on a core network.

Owner:DONGGUAN SHENGYI ELECTRONICS

Cross Linking Treatment of Polymer Membranes

InactiveUS20080214687A1Improve permeabilityImprove stabilitySemi-permeable membranesMembranesCross-linkMembrane method

Methods of forming a hydrophilic porous polymeric membrane which include preparing a porous polymeric membrane from a polymer blend which typically contains a hydrophobic non crosslinkable component (e.g. PVdF) and a component which is cross-linkable (for instance, PVP) and treating said porous polymeric membrane under cross linking conditions to produce a modified membrane with greatly improved water permeability and hydrophilic stability. Cross linking condition include chemical (e.g. peroxodisulfate species), thermal or radiation and / or combinations thereof. Non cross linked material may be washed out if desired.

Owner:SIEMENS IND INC

Application of Rejection Enhancing Agents (REAs) that do not have Cloud Point Limitations on Desalination Membranes

Methods of treating used or degraded reverse osmosis membranes post-production are provided. The membranes can be treated online or offline. The reverse osmosis membranes are cleaned and then contacted with a rejection enhancing agent solution that includes polyvinylpyrrolidone or polyvinylalcohol. The reverse osmosis membrane is then contacted with a tannic acid solution to produce a reconditioned reverse osmosis membrane having reduced defects. The treatment can take place at temperatures greater than 34° C. because the polyvinylpyrrolidone and polyvinylalcohol rejection enhancing agents used do not have cloud point limitations.

Owner:SAUDI ARABIAN OIL CO

Membrane method of removing oil-soluble metals from hydrocarbons

InactiveUS20080000809A1Semi-permeable membranesRefining by dialysisMembrane methodPhysical chemistry

A method of removing an oil-soluble metal from a hydrocarbon feedstock comprises passing the hydrocarbon feedstock through a nanofiltration membrane or a reverse osmosis membrane to produce a permeate stream having at least a vanadium concentration less than an initial vanadium concentration in the hydrocarbon feedstock, and a retentate stream having at least a vanadium concentration greater than the initial vanadium concentration in the hydrocarbon feedstock.

Owner:GENERAL ELECTRIC CO

Electronegativity membrane-method haze-removing agent and environment atmosphere haze-removing method

ActiveCN104147888AEfficient removalHigh mechanical strengthCombination devicesOther chemical processesMembrane methodFoaming agent

An electronegativity membrane-method haze-removing agent and an environment atmosphere haze-removing method. The electronegativity membrane-method haze-removing agent is mainly composed of 20-80% by mass of an electronegativity membrane-forming agent and 20-80% by mass of a foaming agent. The components are mixed uniformly to obtain the electronegativity membrane-method haze-removing agent which is in the form of a powder or a paste. The invention also includes the environment atmosphere haze-removing method through the electronegativity membrane-method haze-removing agent. The electronegativity membrane-method haze-removing agent is wide in raw material sources and is simple in process. The haze-removing method is simple. The electronegativity membrane-method haze-removing agent is high-efficient and economical in application. The invention provides a simple and feasible technology method for eliminating gas pollution, especially for eliminating environment atmosphere dust and haze pollution.

Owner:长沙紫宸科技开发有限公司

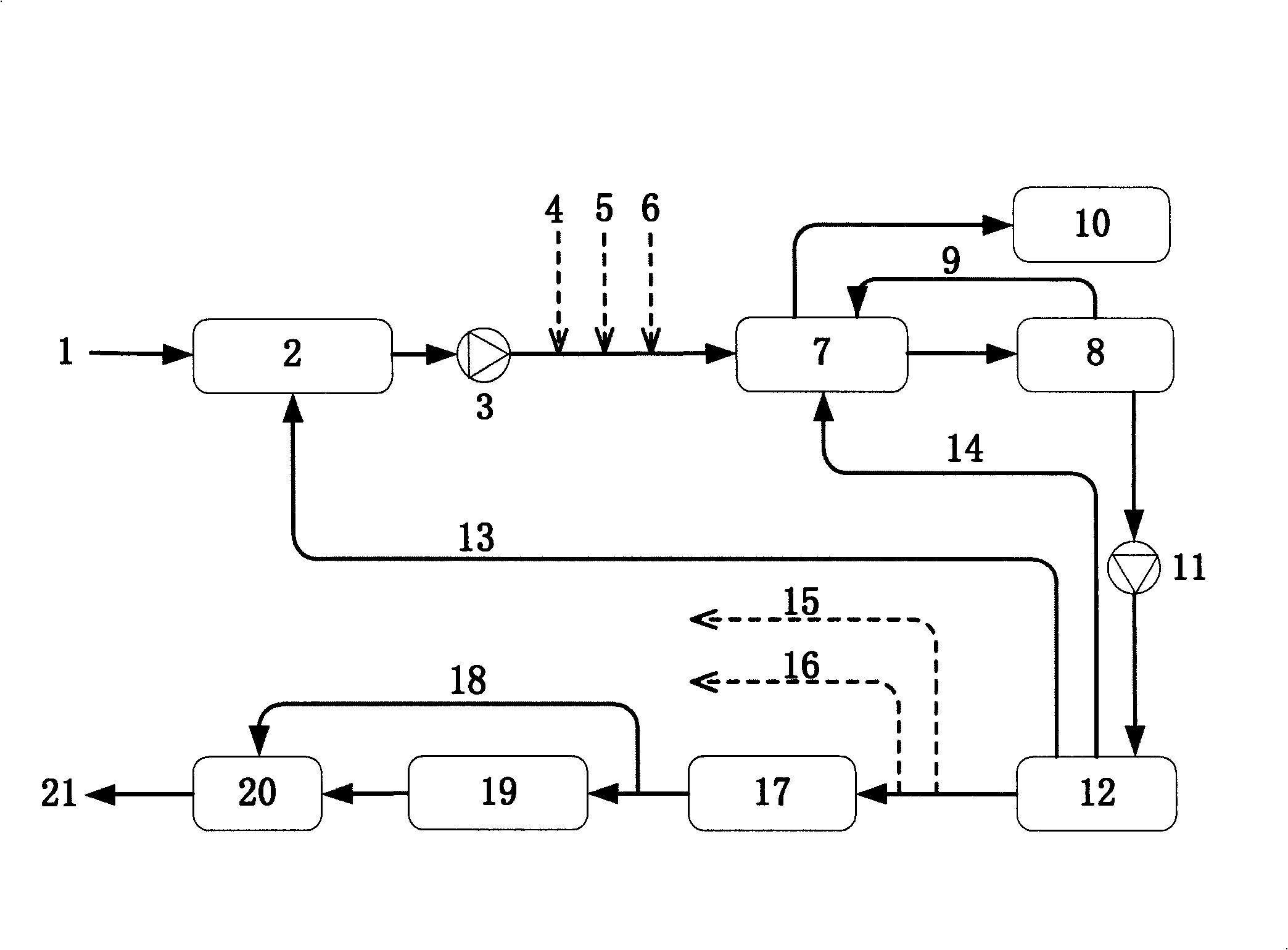

Method and device for treating a great variety of waste emulsion of high concentration using hyperfiltration membrane method

ActiveCN101311127AGood demulsification effectEasy to handleUltrafiltrationWater/sewage treatment bu osmosis/dialysisHigh concentrationLiquid waste

The invention discloses a method for treating the waste emulsion with high concentration and a plurality of varieties by an ultrafiltration membrane method and a device thereof, which belongs to the technical field of waste water and waste liquid treatment. The main technique of the invention is 'dissolved air flotation-ultrafiltration membrane-electrolysis floatation', which can effectively reduce the dosage of medicament and improve emulsion breaking effect by adopting an efficient dissolved air flotation system, moreover, the water for dissolved air flotation, which is taken from a subsequent intermediate water tank, can flexibly adjust and dilute the concentration of the waste water, thus improving the running stability and the shock resistant loading capability of the system. An ultrafiltration membrane with large flux, high separative efficiency and long service life is adopted in an ultrafiltration system to realize oil-water separation and to concentrate the emulsion for a plurality of times and then floating oil is recovered, the waste water generated in ultrafiltration washing is treated again after reflow, thus reducing waste liquid discharging. Electrolysis floatation can remove residual emulsified oil and dissolved oil in the waste water, thus further lowering the COD value of yielding water. When the quality of raw water is changed, an activated carbon adsorption unit can guarantee the quality of the yielding water to be standard. The method and the device of the invention can process waste emulsion with high concentration and a plurality of varieties and have simple and reasonable technique, good quality of yielding water, compact layout of the device, thus facilitating automatic control and realizing recovery of emulsion and recycle economy as well as changing waste to be profitable simultaneously.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

Cross linking treatment of polymer membranes

InactiveCN101203554AIncrease hydrophilic stabilityGood water permeabilityMembranesSemi-permeable membranesMembrane methodCross-link

Owner:SIEMENS IND INC

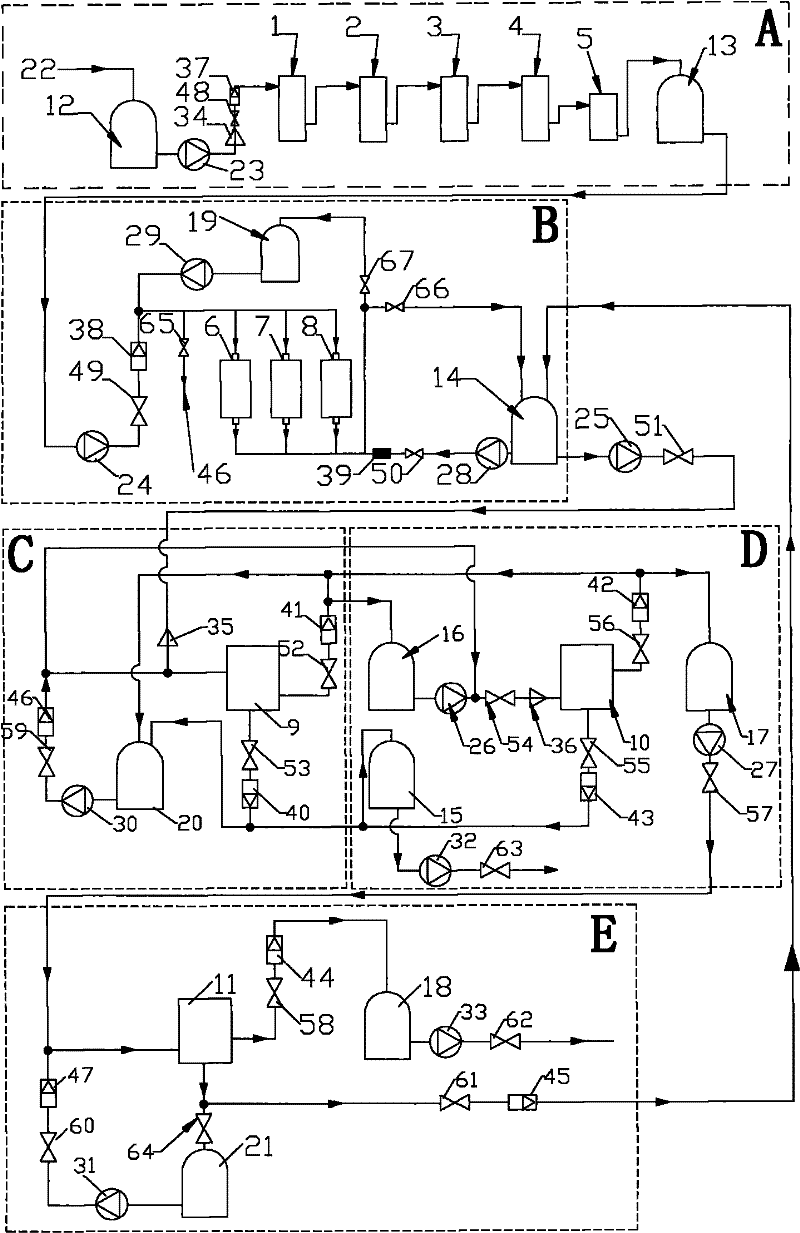

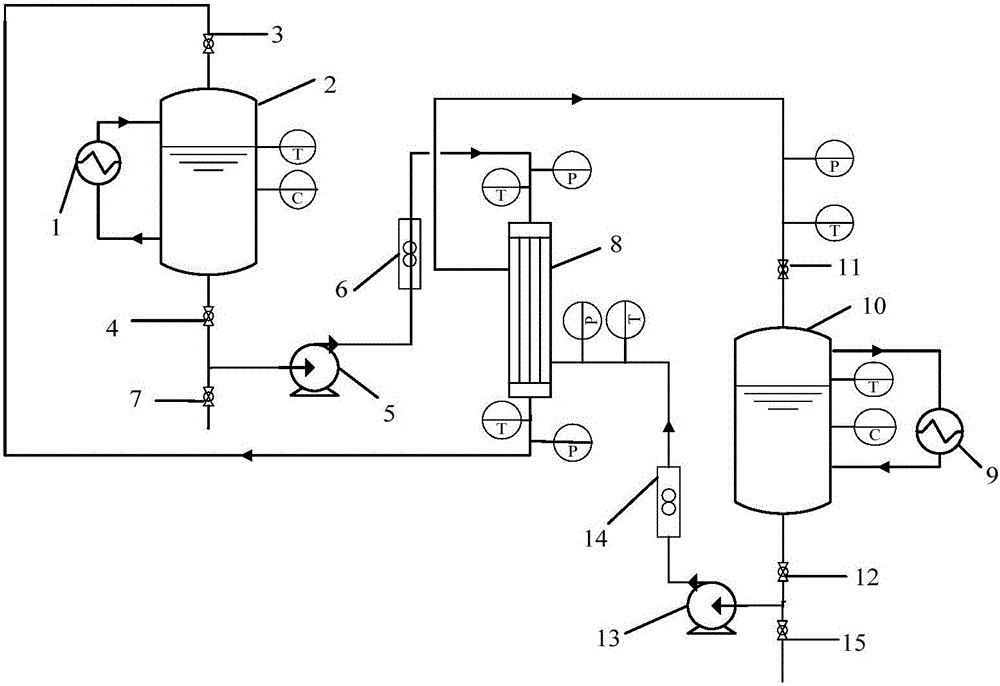

Movable industrial wastewater advanced treatment experimentation device

ActiveCN102050539AWater/sewage treatment by irradiationDispersed particle separationElectricityMembrane method

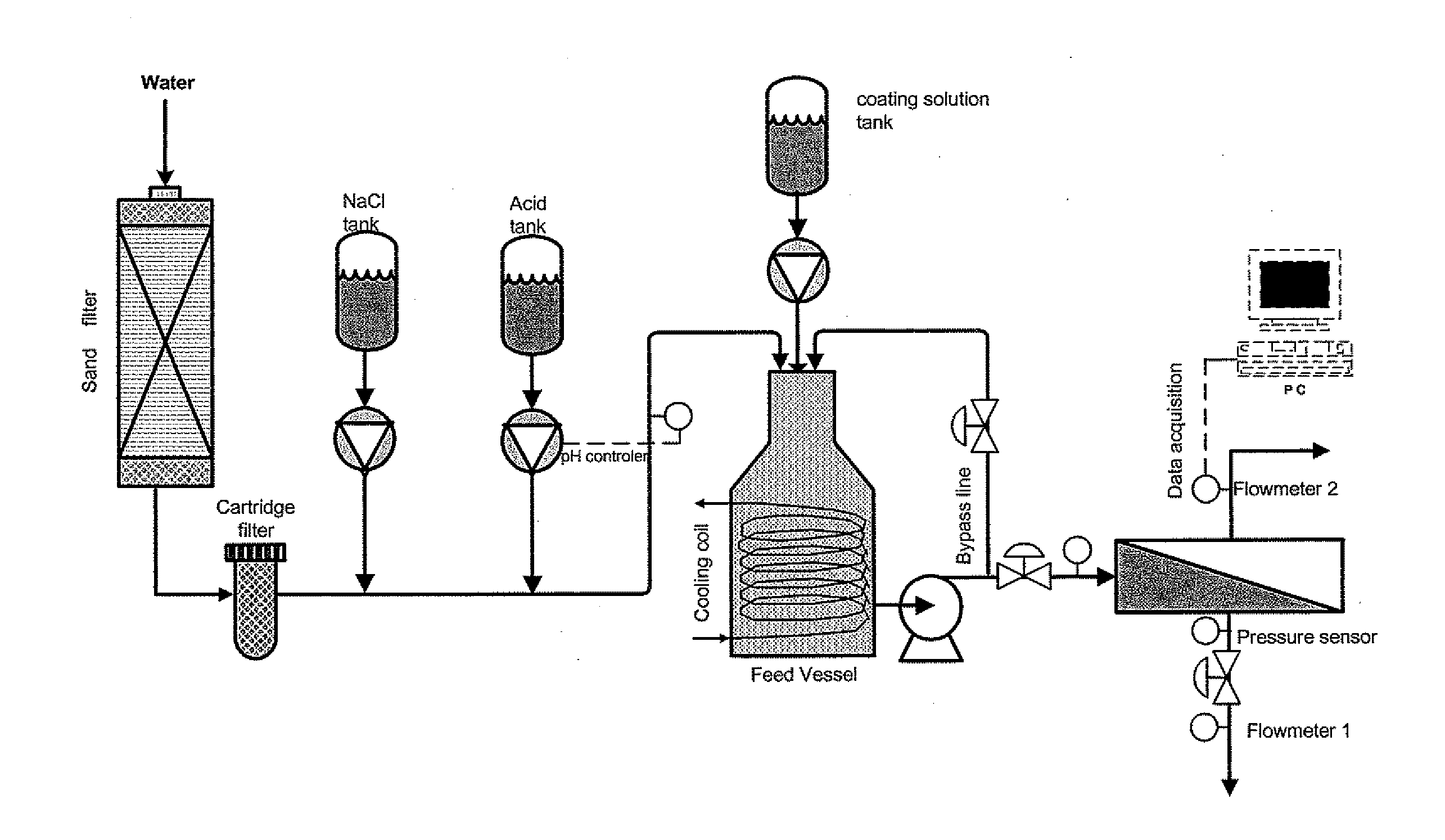

The invention relates to a movable industrial wastewater advanced treatment experimentation device, which mainly comprises a pre-treatment modular unit, a ceramic membrane ultrafiltration and micro filtration modular unit, a nanofiltration modular unit, a reverse osmosis modular unit, an electrodialytic modular unit, an automatic control system unit, and other equipment members. All the units are connected through a pipeline and then mounted in a 40ft (12.192m) container, and all the units are fixed at the bottom of the container to ensure that the experimentation device and the container are integrated. The device adopts membrane method advanced treatment and all other technologies at present, and the modules can operate independently as well as be combined at random, and different technological process can be chosen according to different inflow water quality, so as to realize preferred experimentation of various technological processes. Further, the device has the advantages of convenience in operation and reliable operational parameter.

Owner:CHINA NAT OFFSHORE OIL CORP +1

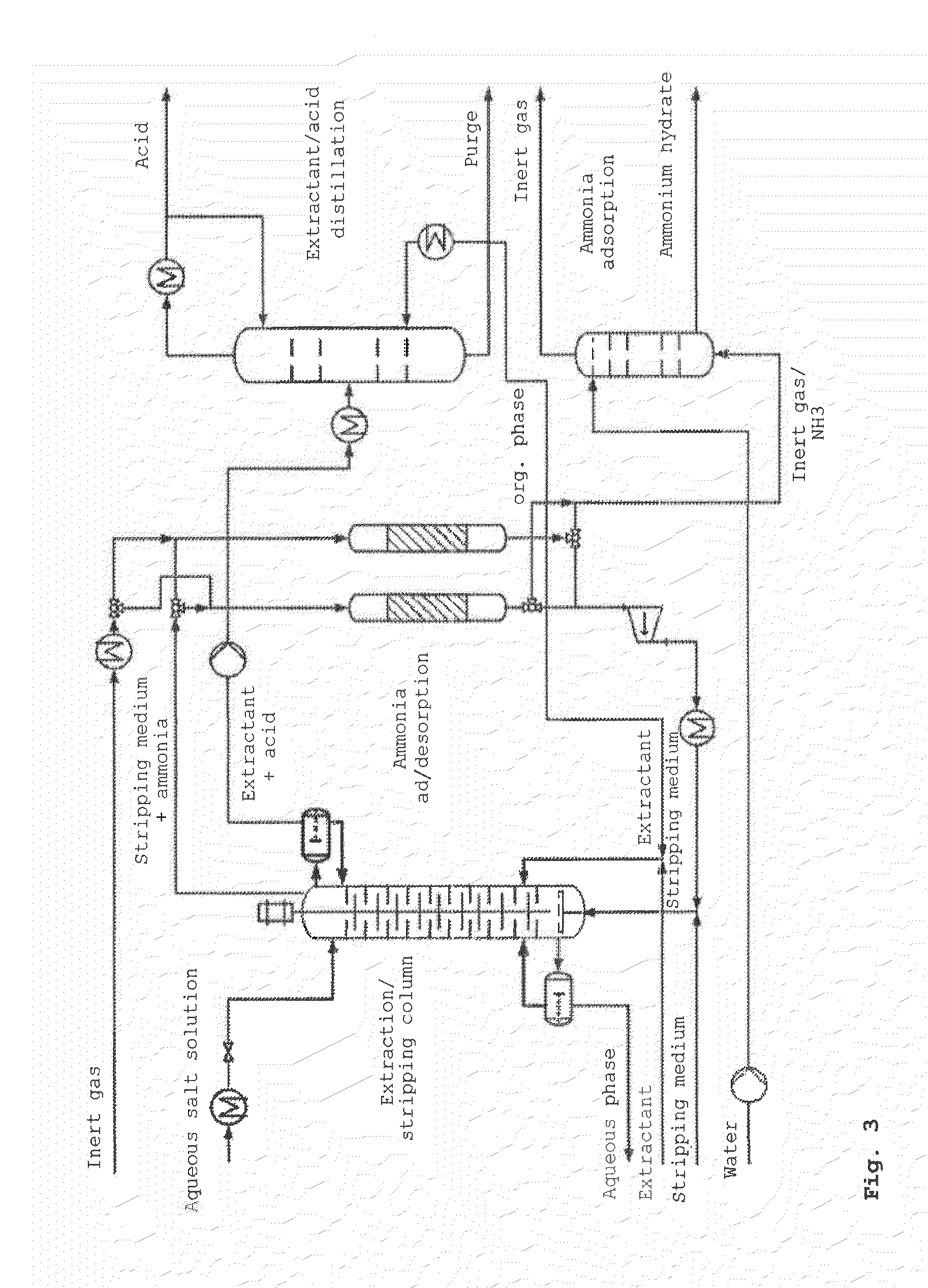

Method for producing a free acid from the salt thereof

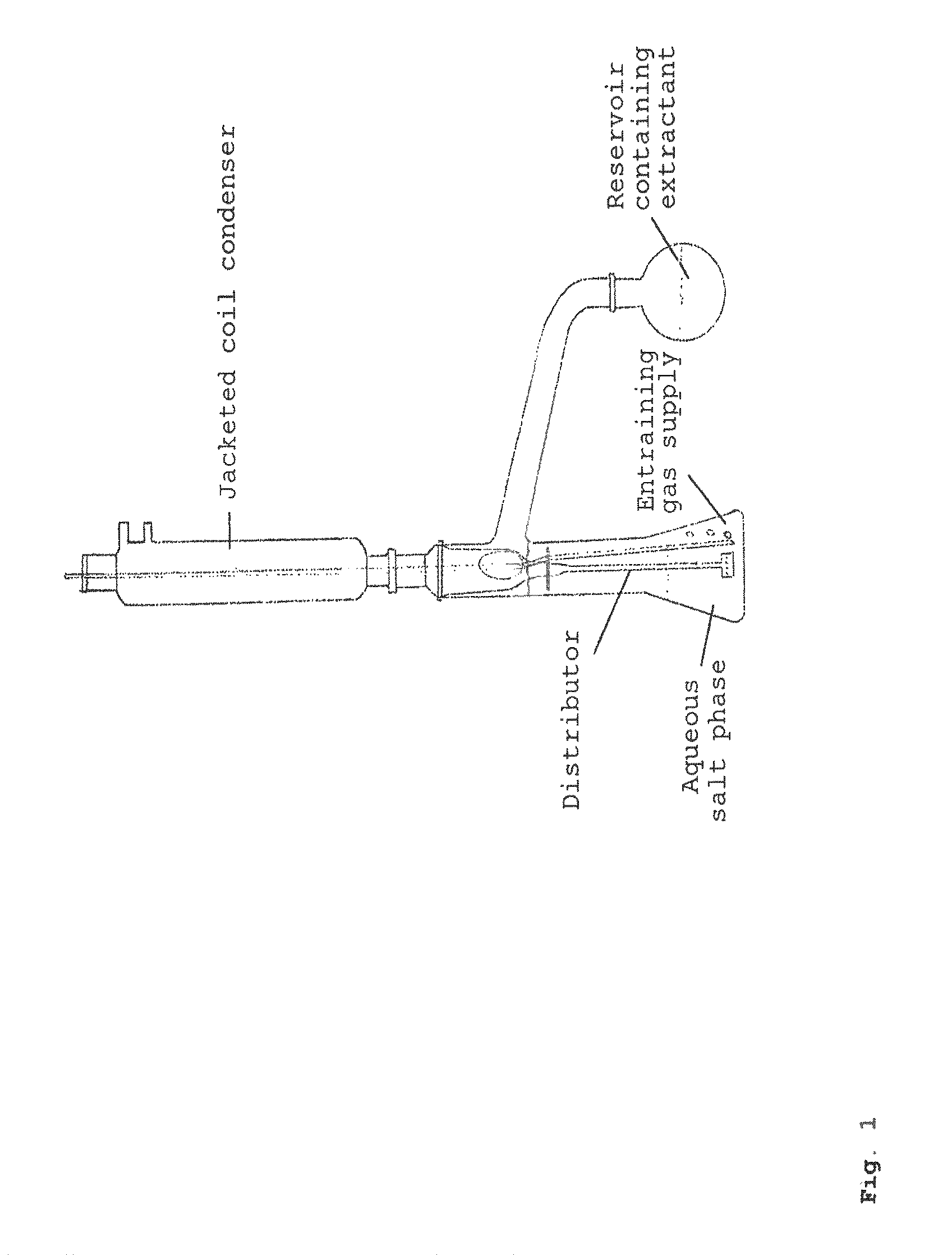

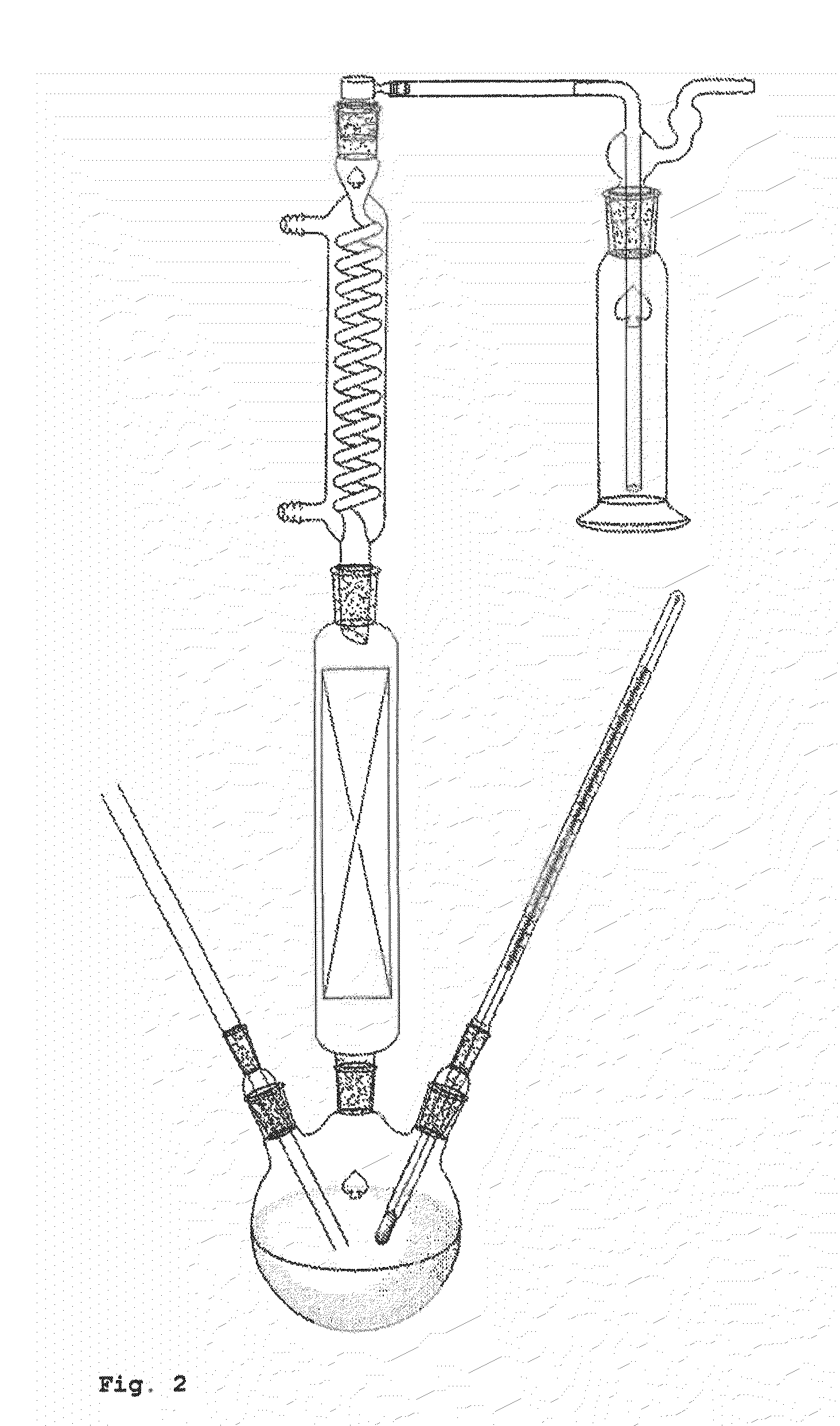

InactiveUS8809576B2Less expensiveLow costPreparation from carboxylic acid saltsGroup 5/15 element organic compoundsWater vaporDistillation

The invention relates to an improved method for releasing an organic acid, preferably a carbon, sulfone or phosphone acid, particularly an alpha or beta hydroxycarbon acid, from the ammonia salt thereof by releasing and removing ammoniac and simultaneous extraction of the released acid, having an amine as a suitable extraction means from the aqueous phase. This method corresponds to a reactive extraction. The reactive extraction of an organic acid from the aqueous ammonia salt solution thereof can be significantly improved by the use of a strip medium or carrier gas, such as nitrogen, air, water vapor or inert gases such as argon. The released ammoniac is removed from the aqueous solution by the continuous gas flow and can be resupplied into a production process. The free acid can be obtained by a method such as distillation, rectification, crystallization, reextraction, chromatography, adsorption or by a membrane method from the extraction means.

Owner:EVONIK DEGUSSA GMBH

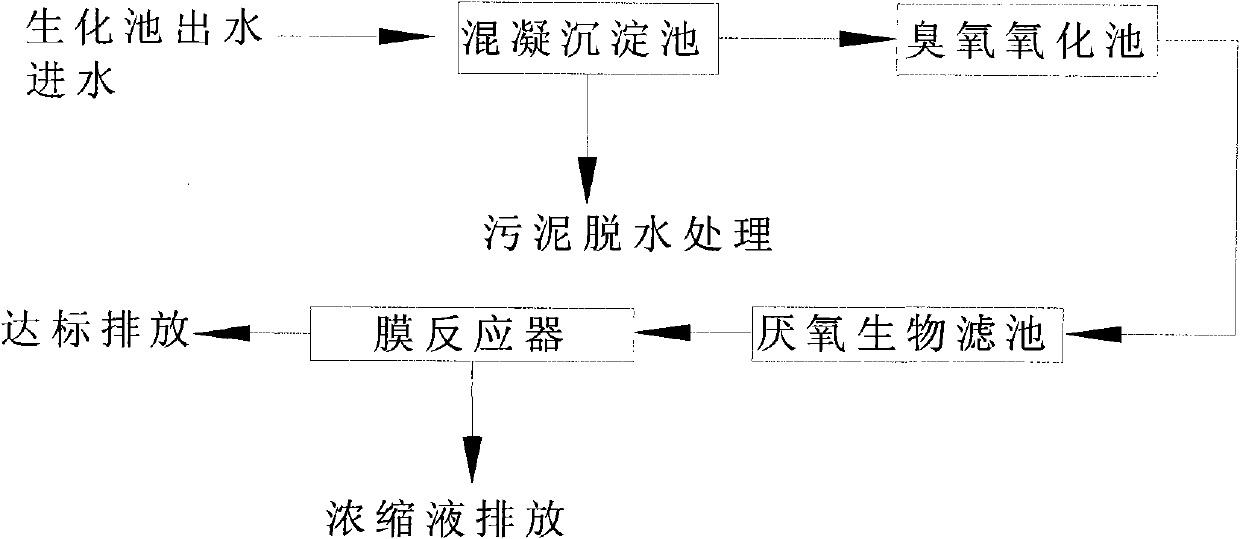

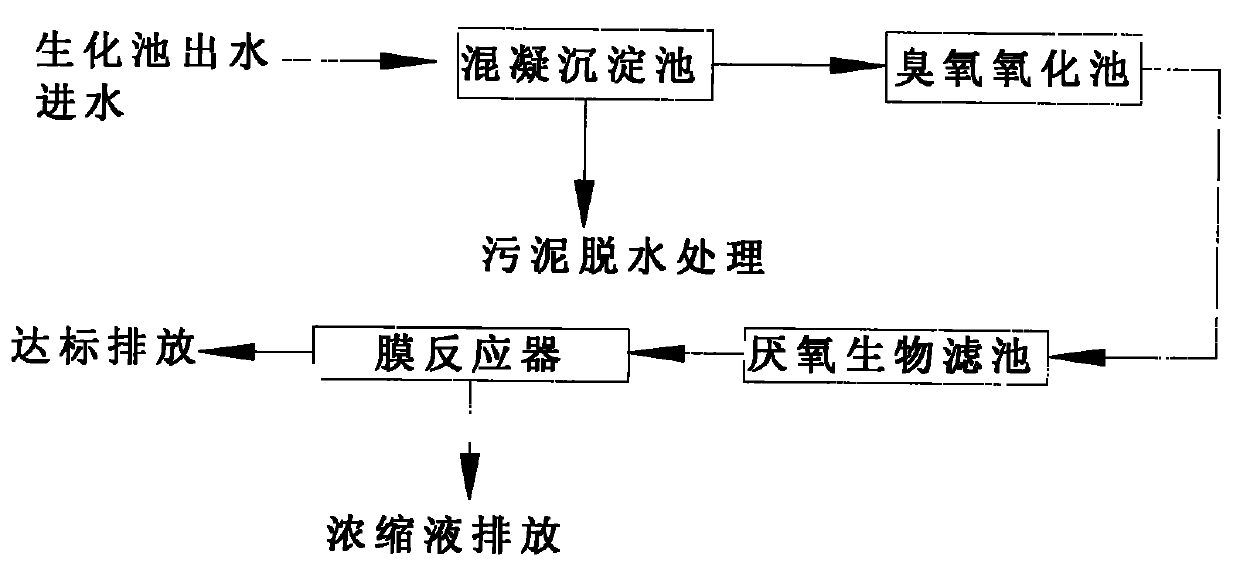

Deep treatment process of landfill leachate

ActiveCN102086075ALow priceLow costWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesSeparation technologyBiological filter

The invention relates to a deep treatment process of landfill leachate. The effluent of landfill leachate subjected to biochemical treatment is used as influent. The process adopts a coagulative precipitation tank, an oxidation tank, an anaerobic biological filter and a membrane treatment device and comprises the following steps of: (1) removing partial organic matter through coagulative precipitation to reduce chroma; (2) further removing refractory and non-biochemical organic matter with an oxidizer formed by ozone, and the like and improving the biodegradability of the effluent; (3) removing SS (Suspended Solid), organic matter and nitrate in the leachate through an anaerobic filter; and (4) ensuring that the effluent stability of the whole system through a membrane separation technology reaches the emission standard and canbe recyclable. The process has the advantages of lower operation cost, stable effluent, less quantity of generated concentrated liquid, less salt content in theconcentrated liquid, and the like, and the process of biochemistry and materialization of the pretreatment, which is used before using the membrane method, can prolong the service life of the membrane.

Owner:BMEI

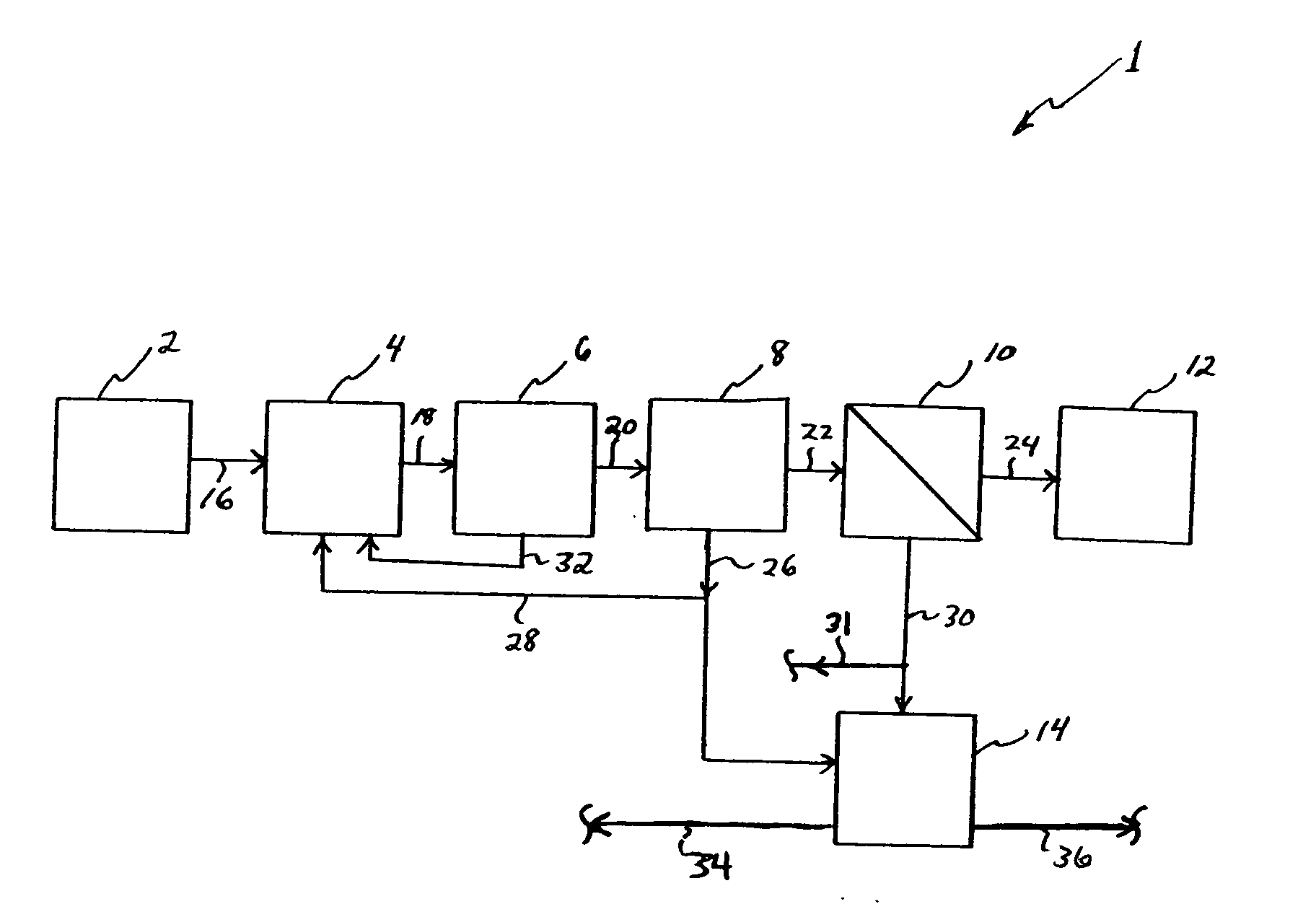

Methods and apparatus for treating wastewater employing a high rate clarifier and a membrane

InactiveUS20060169636A1Reduce and overcomeMembranesTreatment using aerobic processesMembrane methodMixed liquor suspended solids

Methods and apparatus for treating wastewater are described, one method embodiment including the steps of flowing a mixed liquor suspended solids to a high rate clarification stage, forming a clarifier effluent, a first waste activated sludge stream, and a return waste activated sludge stream. The high rate clarifier effluent stream then flows to a membrane stage that includes a membrane media, producing a membrane reject (retentate) stream and a treated effluent (permeate) stream. Optionally, the methods include routing a screened raw wastewater to an anaerobic and / or aerated anoxic stage and introducing a gas comprising oxygen to the wastewater during the aerated anoxic stage, and optionally allowing the product of this stage to flow to an aeration stage prior to the high rate clarification stage.

Owner:ALFA LAVAL ASHBROOK SIMON HARTELY INC

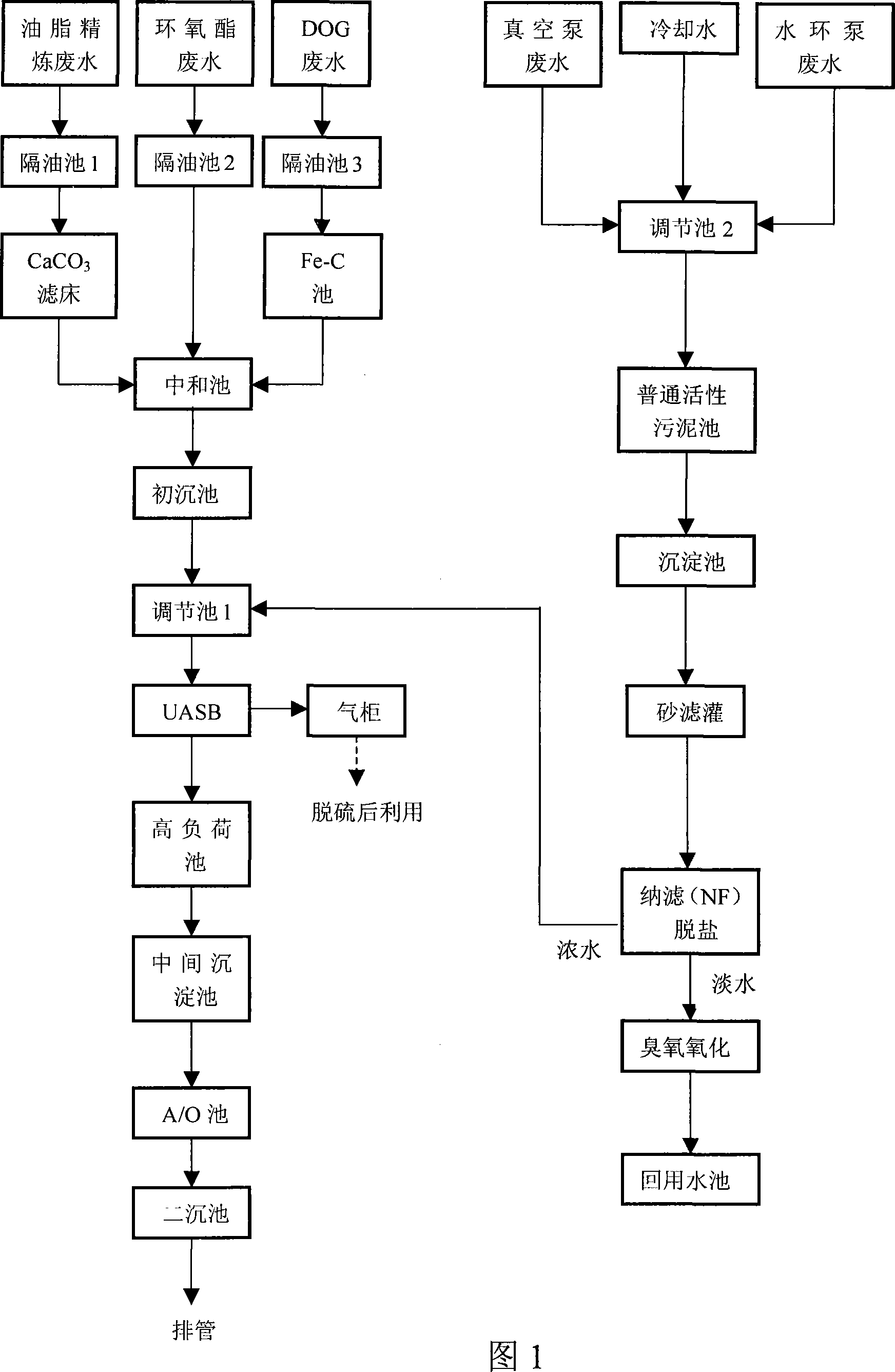

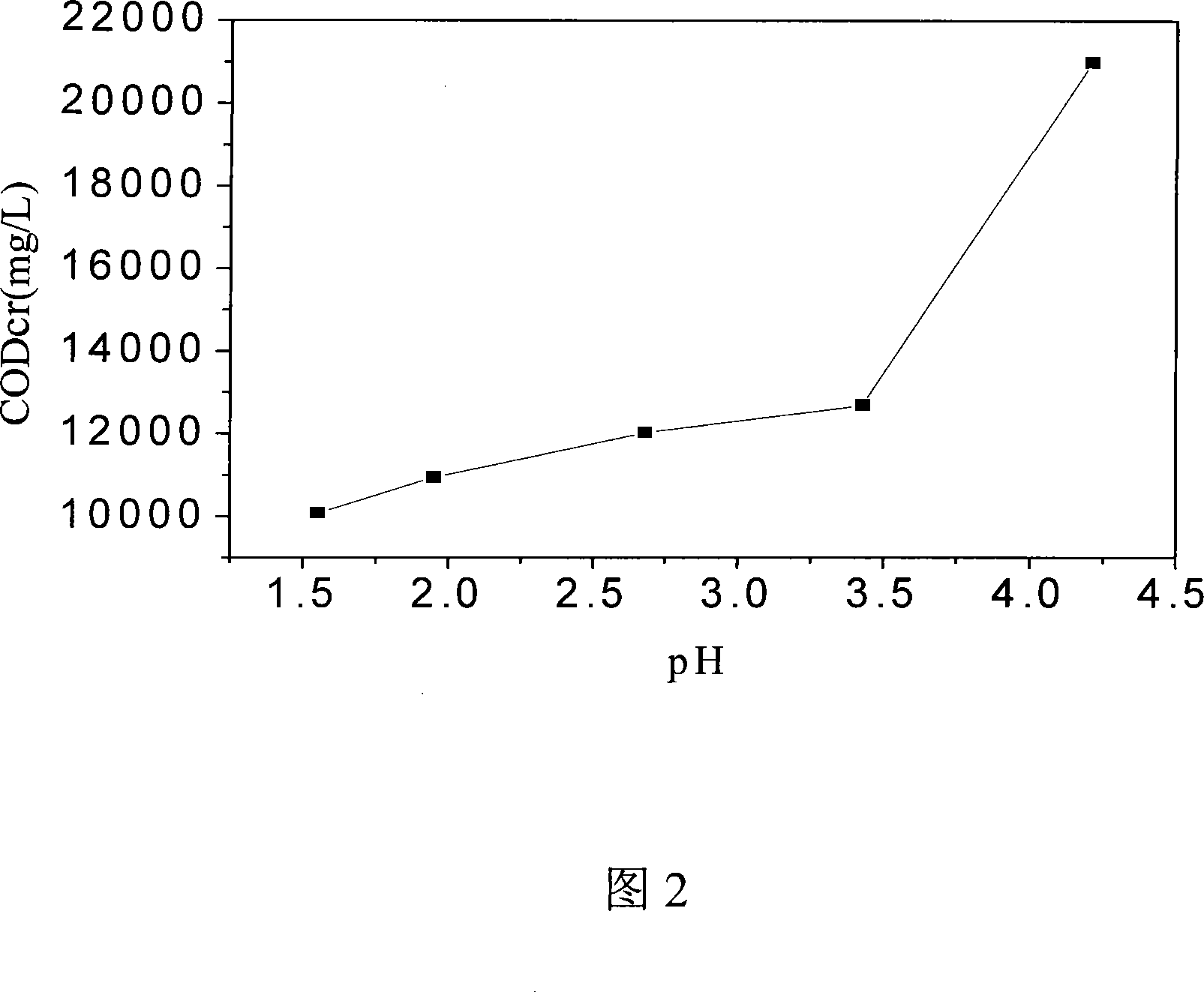

Reuse treating method for chemical industrial plasticizer waste water

ActiveCN101224937APrevent overflowSufficient hydraulic retention timeFatty/oily/floating substances removal devicesWater/sewage treatment bu osmosis/dialysisEpoxyMembrane method

The invention relates to a recycling and processing method of waste water of a chemical plasticizer, which pertains to the technical field of waste water treatment and resource recycling. The basic proposal is that: the waste water that belongs to high COD (COD is 6000-30000mg / L; BOD is 2000-10000mg / L; pH is 4-12) such as DOG waste water, the caustic washing waster water of epoxy-ester and oil and fats refining waste water, after being respectively pretreated, is mixed with TOTM waste water and enters into a biological and chemical system for processing. The waste water with low COD (COD is 500-2000mg / L; pH is 4-12) is done with aerobic biological treatment after being collected uniformly, then goes through advanced treatment with a membrane method and ozonation catalytic oxidation after coagulation, deposition and filtration and is reused in production. The effluent processed by the invention has stable water quality and can discharge up to standards. The waste water after purification can be reused in production, does not influence the product quality of the plasticizer and has economical and reasonable investment, operation cost and practical and feasible technique.

Owner:浙江嘉澳环保科技股份有限公司

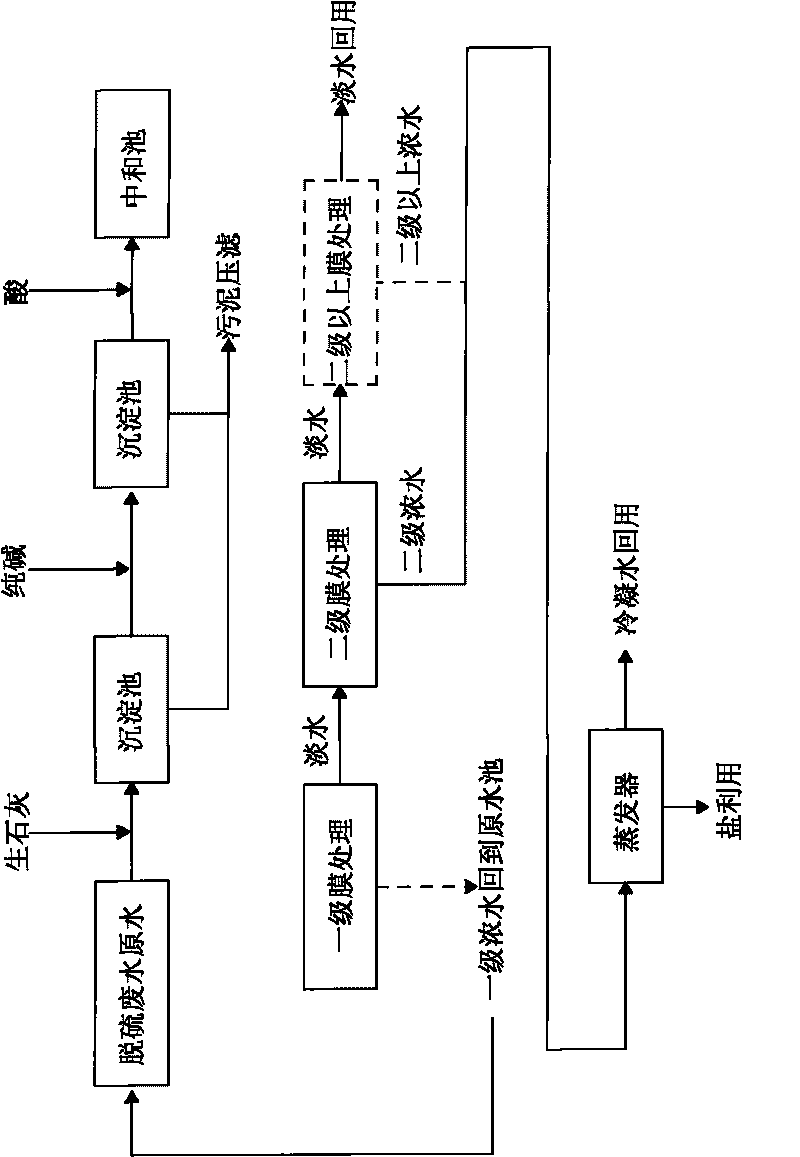

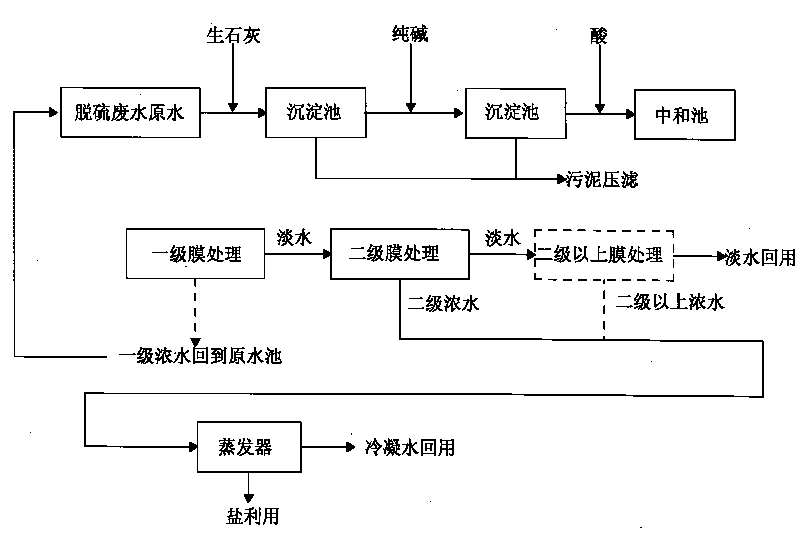

Desulfuration waste water treatment process with membrane method

InactiveCN101708911AHigh recovery rateEmission reductionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentProcess equipmentEvaporation

The invention discloses a desulfuration waste water treatment process with a membrane method, comprising the following steps: pre-treatment, one-level membrane treatment and two-level membrane treatment; the treatment process has the advantages that the waste water amount of evaporation treatment can be effectively reduced while fresh water is recycled, industrial salt can be recycled, the energy consumption is greatly reduced, waste water discharge is reduced, the problem of cyclic utilization of desulfuratin waster water can be effectively solved, and the process has good economic and social benefits; by adopting the membrane method, the desulfuration waste water has high recovery rate, and the reused water volume can reach more than 50-70 percent through two-level membrane treatment or multi-level membrane treatment, and an evaporation method is combined, zero discharge of the waste water can be realized; lower operating pressure is adopted, the investment and operating cost is reduced, the process equipment is simple, the occupying area is small, full-automatic operation is realized, and the operation is simple and convenient.

Owner:苏州凯新分离科技有限公司

Preparation method for sulphuric acid glucosamine

ActiveCN101343294ASimple structurePromote safe productionSkeletal disorderAminosugarsPotassiumPrecipitation

The invention discloses a preparation method of glucosamine sulfate, relating to a compound containing aminosugar. The preparation method of glucosamine sulfate has the advantages that a great deal of sulfate precipitation by-product is avoided being generated and a great deal of organic solvent is avoided being used, the operation is in complete aqueous phase, the production processes are safe, the sulfuric acid removed by the membrane method can be recovered and used, the production cost is reduced, exhaust and waste residue are not produced, the prepared product does not contain sodium, potassium or chlorine, the purity of the product reaches over 95 percent, and the glucosamine sulfate can be used to treat osteoarthritis without usage taboo. The preparation method is characterized in that chitin is adopted as the raw material, and a degradation agent of concentrated sulfuric acid is used to cause the chitin to generate degradation reaction; diluted sulfuric acid is used as a deacetylation agent to cause the degraded chitin to generate deacetylation reaction; the chitin which is not reacted after the deacetylation reaction is filtered, and the unreacted sulfuric acid is removed by the membrane method; and the solution, in which the unreacted sulfuric acid is removed, is decolorized, concentrated and dried, and glucosamine sulfate is obtained.

Owner:厦门蓝湾科技有限公司

Method for selectively removing calcium ions from concentrated water byproduct of sea water desalination process and other high-calcium-magnesium-content concentrated brines

InactiveCN102936067AHigh removal rateQuick responseGeneral water supply conservationMultistage water/sewage treatmentLoss rateWater desalination

The invention relates to a method for selectively removing calcium ions from a concentrated water byproduct of a sea water desalination process and other high-calcium-magnesium-content concentrated brines, which comprises the following steps: regulating the pH value of the concentrated water to 7.0-8.5, and then heating to a certain temperature; introducing the concentrated water into a heat-insulating apparatus capable of realizing sealed stirring, adding a sodium sulfite or sodium carbonate solution having a certain concentration while stirring, reacting for 1-40 minutes while sufficiently stirring, standing for 5-10 minutes, and then filtering to remove calcium sulfite or calcium carbonate precipitate; and adding hydrochloric acid into the filtrate to regulate the pH value back to 6. According to the invention, the problems of low calcium removal rate, high magnesium loss rate, long stirring time and the like during the concentrated water treatment based on the traditional normal-temperature sodium carbonate precipitation method are overcome, the operation is convenient, the investment is low, and the operation cost is low; and the concentrated water liquid subjected to decalcification treatment can be further deeply concentrated through a membrane method or hot method, thereby improving the fresh water recovery rate and realizing the reutilization and zero discharge of the resources. The method provided by the invention is suitable for selectively removing calcium ions from sea water, sea water or brackish water subjected to other treatment processes such as reverse osmosis or multiple-effect evaporation and concentration, underground salt brines and concentrated water of industrial waste water subjected to reverse osmosis treatment.

Owner:天津凯铂能膜工程技术有限公司

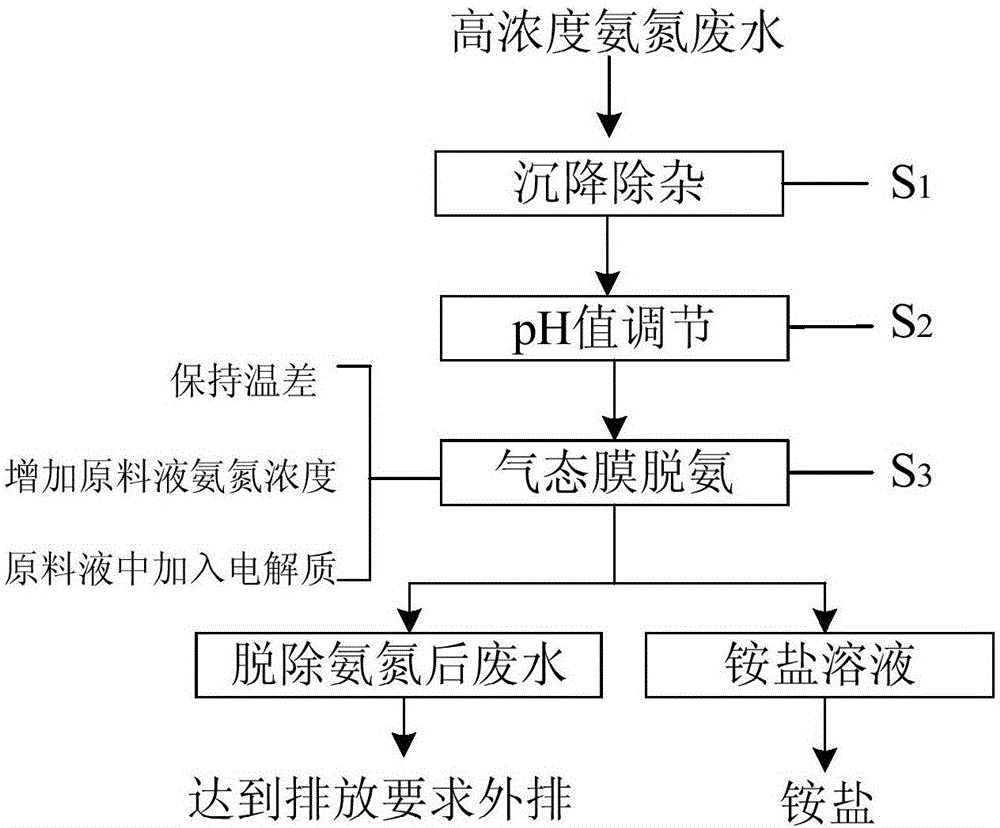

Ammonia nitrogen removal and ammonium salt enrichment method for high-concentration ammonia-nitrogen wastewater through membrane method

InactiveCN106186492AEliminate the concentration stepSimple processWater contaminantsMultistage water/sewage treatmentHigh concentrationDistillation

The invention discloses an ammonia nitrogen removal and ammonium salt enrichment method for high-concentration ammonia-nitrogen wastewater through a membrane method. The ammonia nitrogen removal and ammonium salt enrichment method comprises the steps that firstly, impurity removal through sedimentation is conducted to obtain purified high-concentration ammonia-nitrogen wastewater; secondly, the pH of the wastewater is regulated to be 10-11 by adding alkali to enable ammonia nitrogen to exist in the form of volatile NH3; finally, ammonia nitrogen in the wastewater is removed through the gas membrane process, the operation conditions are strictly controlled, the osmotic distillation process of water which has the same mass transfer direction as ammonia and is accompanied in the gas membrane process is effectively inhibited, the condition that an absorption solution is diluted is avoided, a high-concentration ammonium salt solution is obtained, and the step of concentration of the diluted absorption solution is omitted. According to the method, efficient and low-consumption ammonia removal of the high-concentration ammonia nitrogen wastewater can be achieved, no secondary pollution is generated, and environmental friendliness is achieved.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

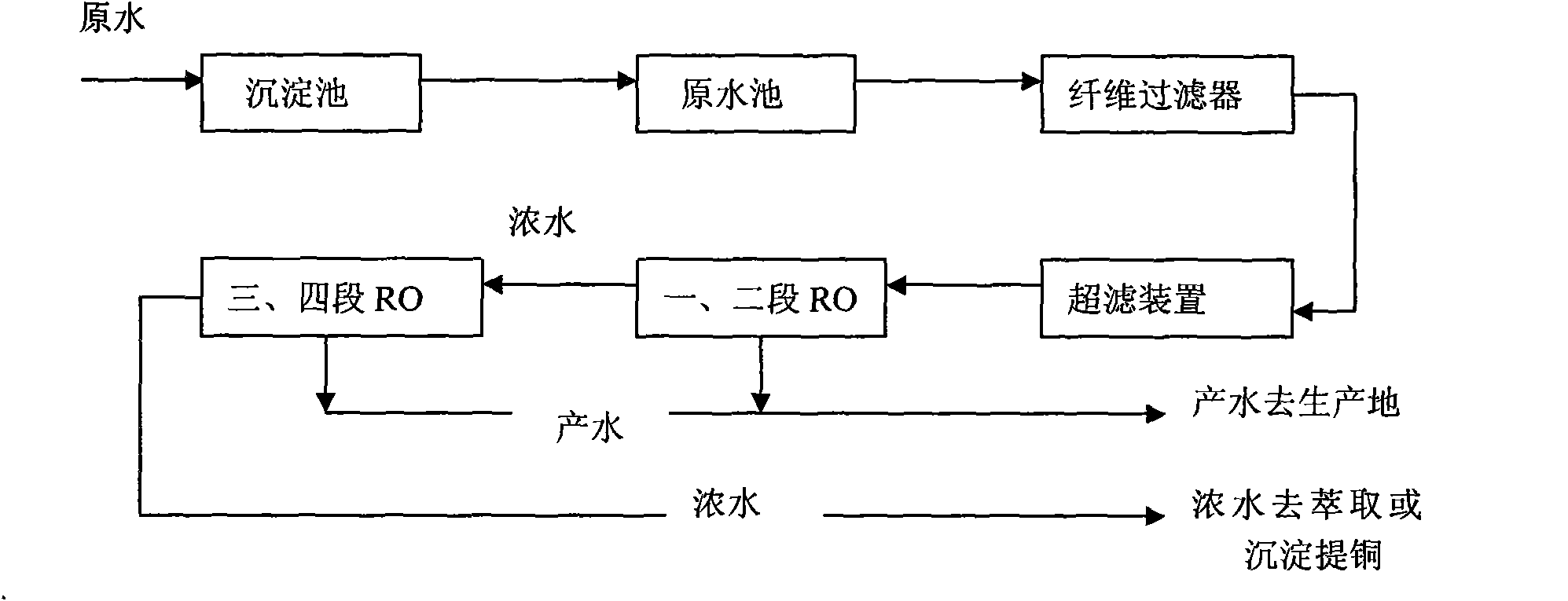

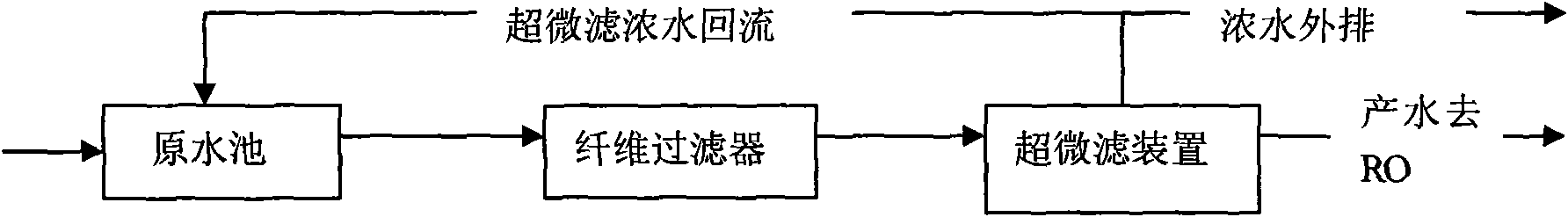

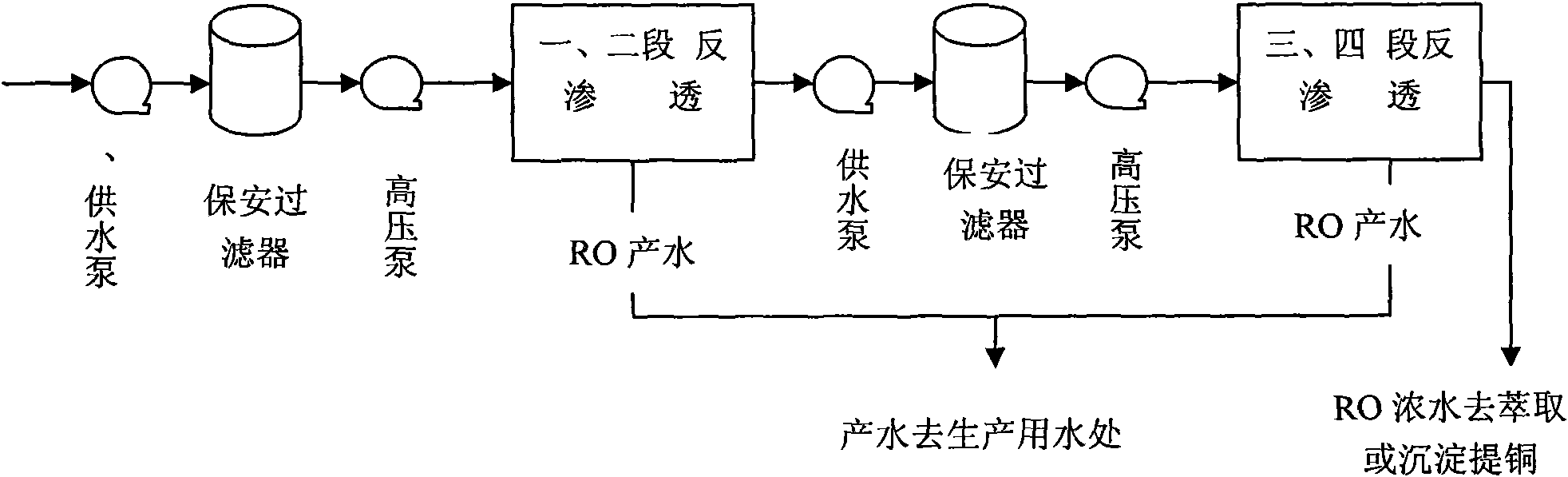

Process for treating acid waste water containing copper, nickel and the like by membrane method

InactiveCN101786734AWater contaminantsWater/sewage treatment bu osmosis/dialysisReverse osmosisProduced water

The invention provides a process for treating acid waste water containing copper, nickel and the like by a membrane method, discloses a process for treating and recycling acid waste water containing noble metal ions for non-ferrous metal mine, smelting, ore dressing and the like through a sedimentation tank, a fiber filter, ultra-micro filtration and reverse osmosis / nano filtration, and belongs to the technical field of waste water treatment and resource recycle. The process is characterized by treating the waste water and furthest reclaiming valuable metal ions and water resources in the waste water at the same time so as to achieve the purposes of treating and recycling the waste water and basically realizing zero emission of the waste water. Moreover, the water produced by the reverse osmosis / nano filtration is used as back washing water for the filter and the ultra-micro filtration so as to improve the cleaning effect of the filter and the ultra-micro filtration and the reclaiming rate of valuable metals; the pollution and plugging of iron and silicon in the water to the membrane are effectively overcome by adopting ultra-micro filtration treatment, adding a reducing agent and using the produced water flushing function of the device; and the scaling problem of sulfate such as calcium, strontium, barium and the like in the thick water is effectively solved by adopting special design of a desalting system and special scale inhibiting technology, and the long-term stable operation of the system is ensured.

Owner:刘春喜

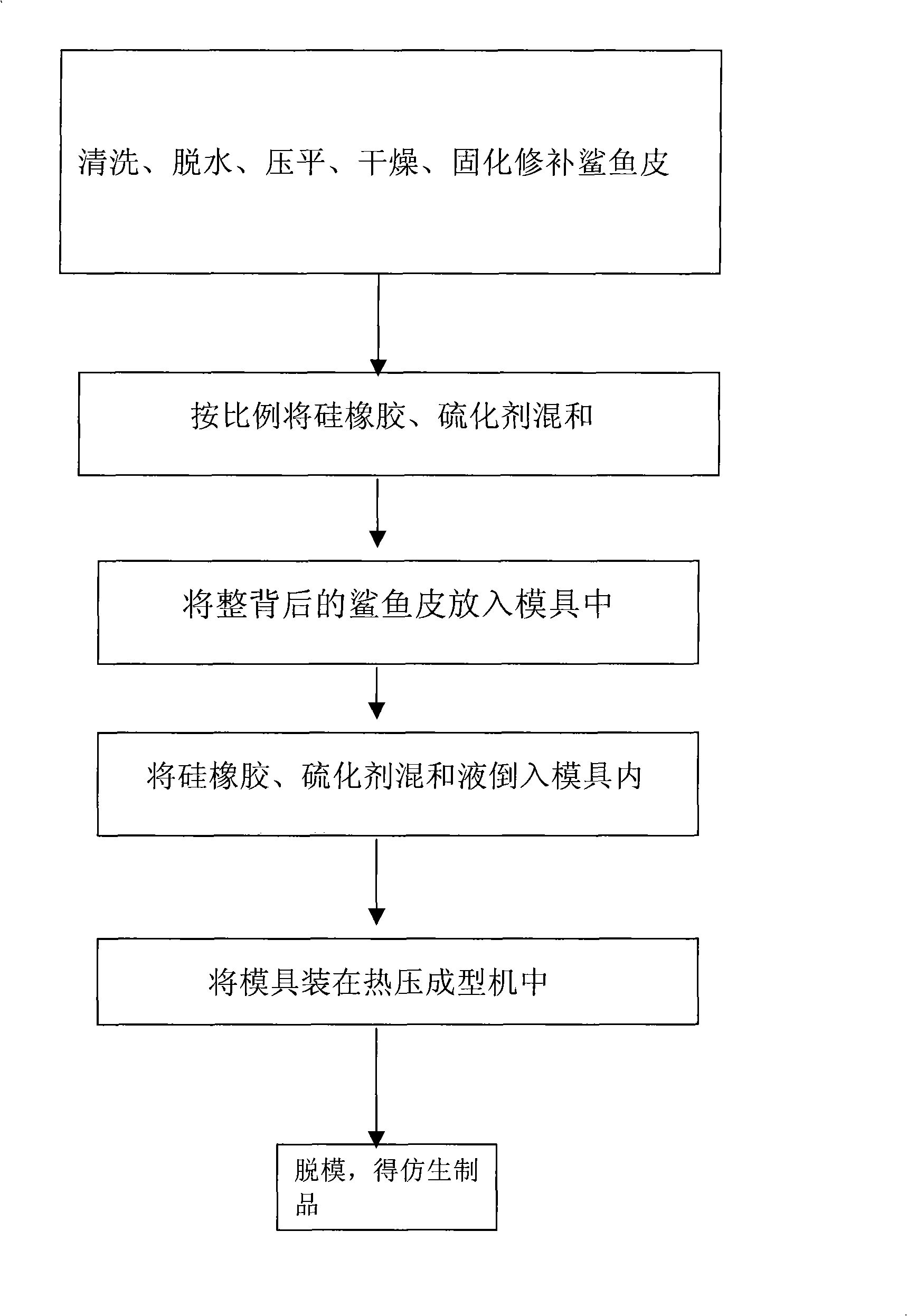

Preparation method for replicating shark skin surface micro-structure

InactiveCN101513760AGood anti-algae effectDecorative surface effectsLeather surface finishingChemical treatmentMembrane method

The invention provides a preparation method for replicating a shark skin surface micro-structure. The method is to take a shark skin which is cleaned and chemically treated as a template and obtain a silicone rubber membrane with a shark skin placoid scale micro-structure surface through silicone rubber hot pressing. The method comprises the following steps: 1, cleaning the shark skin; 2, dehydrating the shark skin; 3, flattening the shark skin; 4, drying the shark skin; 5, curing and repairing the shark skin; 6, mixing silicone rubber with a vulcanizing agent and vulcanizing the mixture; 7, placing the shark skin in a mold and injecting the silicone rubber into the mold; 8, placing the mold in a thermal pressure forming machine for curing; and 9, carrying out the demolding the shark skin to obtain the membrane with the shark skin placoid scale micro-structure surface. The products with the shark skin groove placoid scale structure which is replicated by a biological pouring membrane method can be widely applied in the industries such as shipping, and the like.

Owner:深圳市百安百科技有限公司

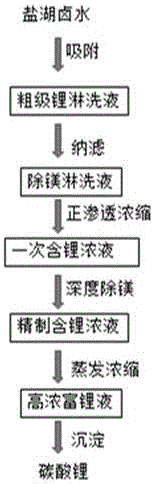

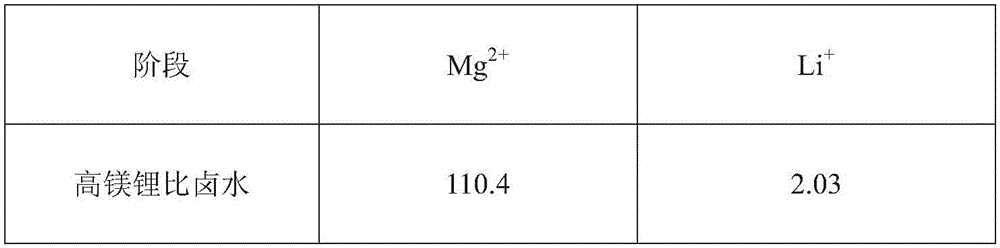

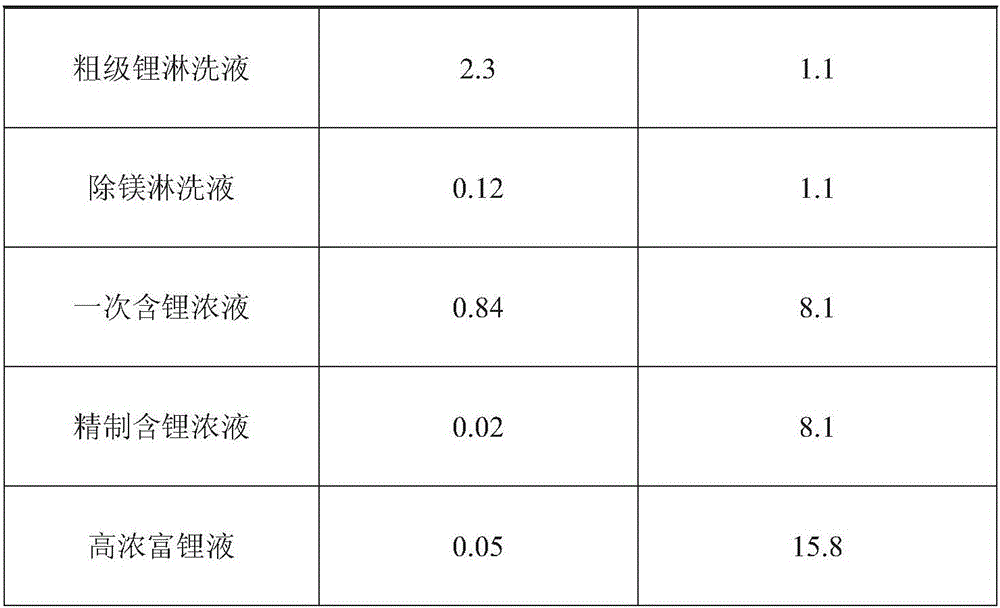

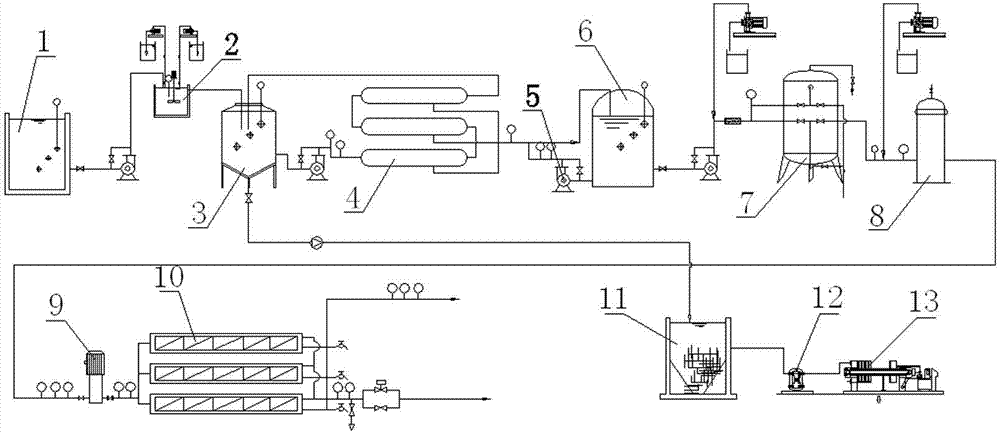

Method for increasing recovery rate of lithium separated with lithium-containing brine membrane method by using water as circulating working substance (water washing circulation method)

InactiveCN102433434AHigh recovery rateReduce recycling costsWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by heatingReverse osmosisMembrane distillation

The invention relates to a method for increasing the recovery rate of lithium in salt lake brine, in particular to a method for increasing the recovery rate of lithium in a membrane method for separating magnesium and lithium from the salt lake brine with high salt content and high magnesium / lithium ratio and concentrated lithium-containing old brine obtained after potash fertilizer production in a salt pan. In the method, water is used as a circulating working substance to dilute raw material brine with high salt content and high magnesium / lithium ratio to be below 180g / l; the diluted raw material brine is divided into concentrated liquid and permeated liquid by means of a separation membrane driven under one-stage or multistage pressure, wherein the salt content in the concentrated liquid is equivalent to or higher than that of the raw materials brine, and the lithium in the permeated liquid accounts for about 2 / 3 of the lithium resources of a feed solution; and a reverse osmosis membrane system or a membrane distillation system is used to perform concentration and separation to obtain fresh water and concentrated water, wherein the fresh water is circulated for diluting the raw material brine, the concentrated water is precipitated for lithium carbonate recovery, and supernate obtained after precipitation is partially returned for diluting the raw material brine. The method disclosed by the invention can be used for obviously reducing the load of a separation membrane system, reducing the operation cost and increasing the recovery rate, so that the recovery rate of the lithium in the brine with high salt content is increased.

Owner:王辉

Fiber reinforced plastic and method for producing sculpture from fiber reinforced plastic

The present invention relates to a fiber reinforced plastic and a method for producing sculpture from the fiber reinforced plastic, wherein the fiber reinforced plastic is prepared from a WSP6101 type epoxy resin, acetone or propylene oxide butyl ether, a curing agent, a curing accelerator, a demolding agent, a mineral filler and reinforcing fibers, and the method for producing the sculpture from the fiber reinforced plastic comprises mold preparing, molding process and finishing so as to obtain the finished product. According to the present invention, the fiber reinforced plastic has characteristics of good heat resistance, high strength and easy molding; the soft membrane method is used to prepare the mold, such that the high-quality work shape can be copied, and the smooth demolding can be ensured; and the resin glue liquid prepared by adding the curing agent and the curing accelerator is used to connect the reinforcing fibers to prepare the fiber reinforced plastic sculpture, and the reinforcing fibers are added at different positions according to different requirements, such that the obtained finished product does not generate deformation, and the precision and the integrity are significantly improved.

Owner:北京一和堂文化发展有限公司

Methods of Making Inorganic Membranes

Methods of making inorganic membranes, for example, methods of making gamma-alumina inorganic membranes which can be useful for, for example, molecular level gas separations and / or liquid filtration are described.

Owner:CORNING INC

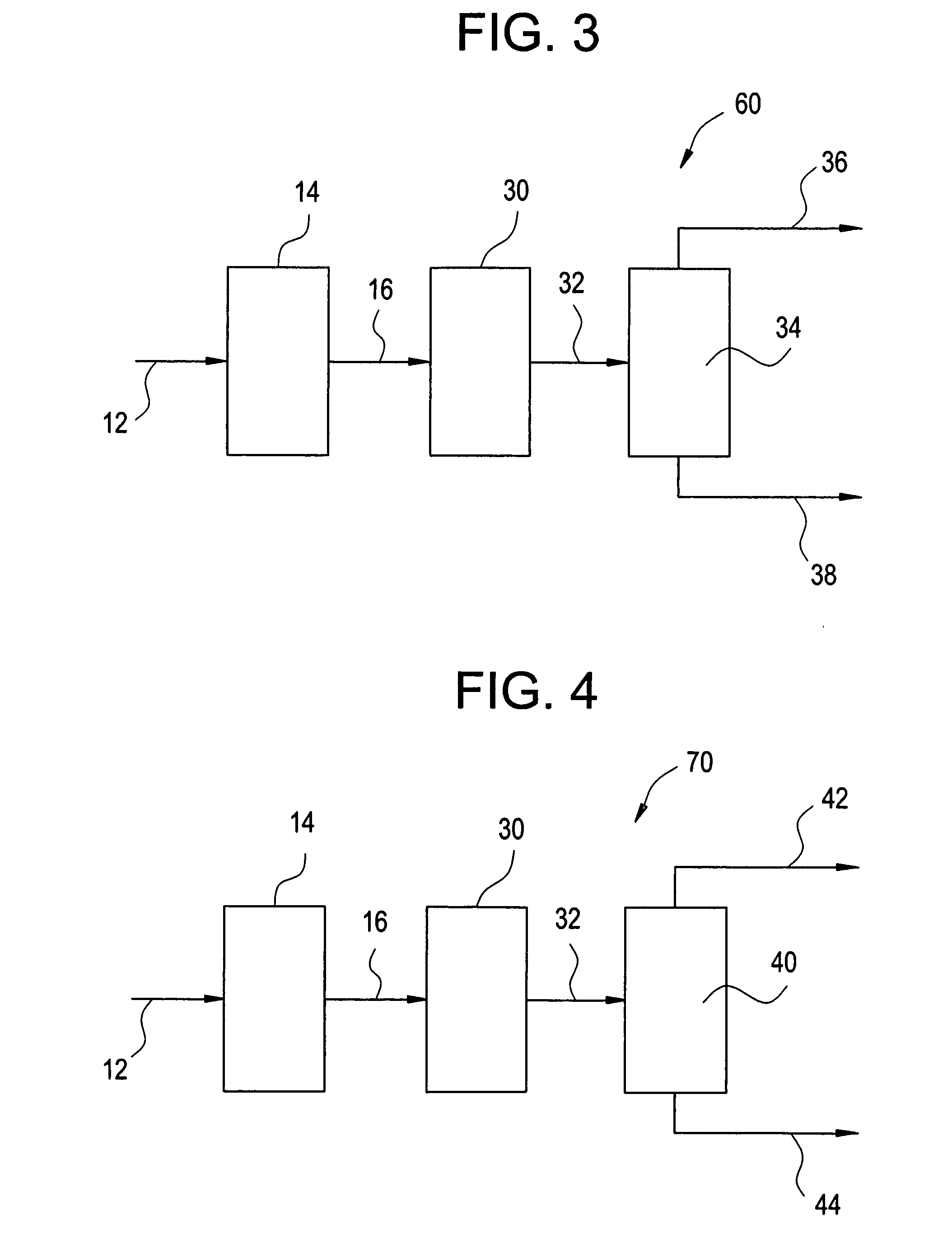

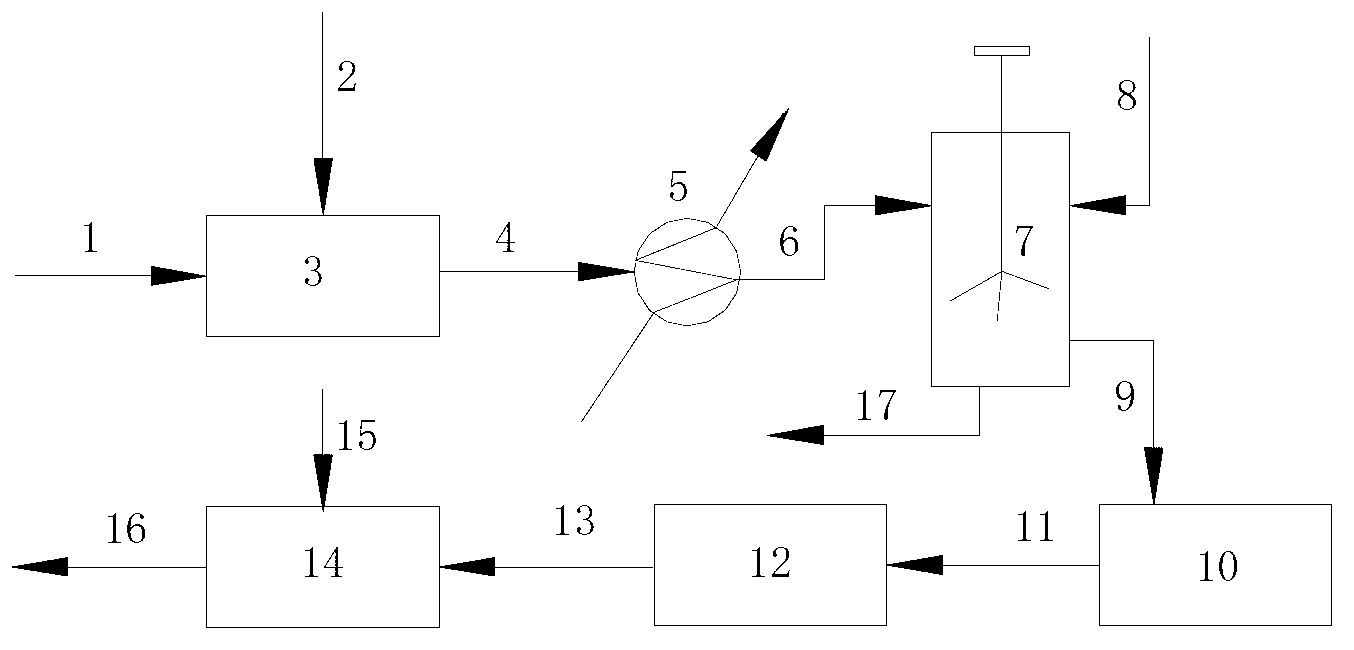

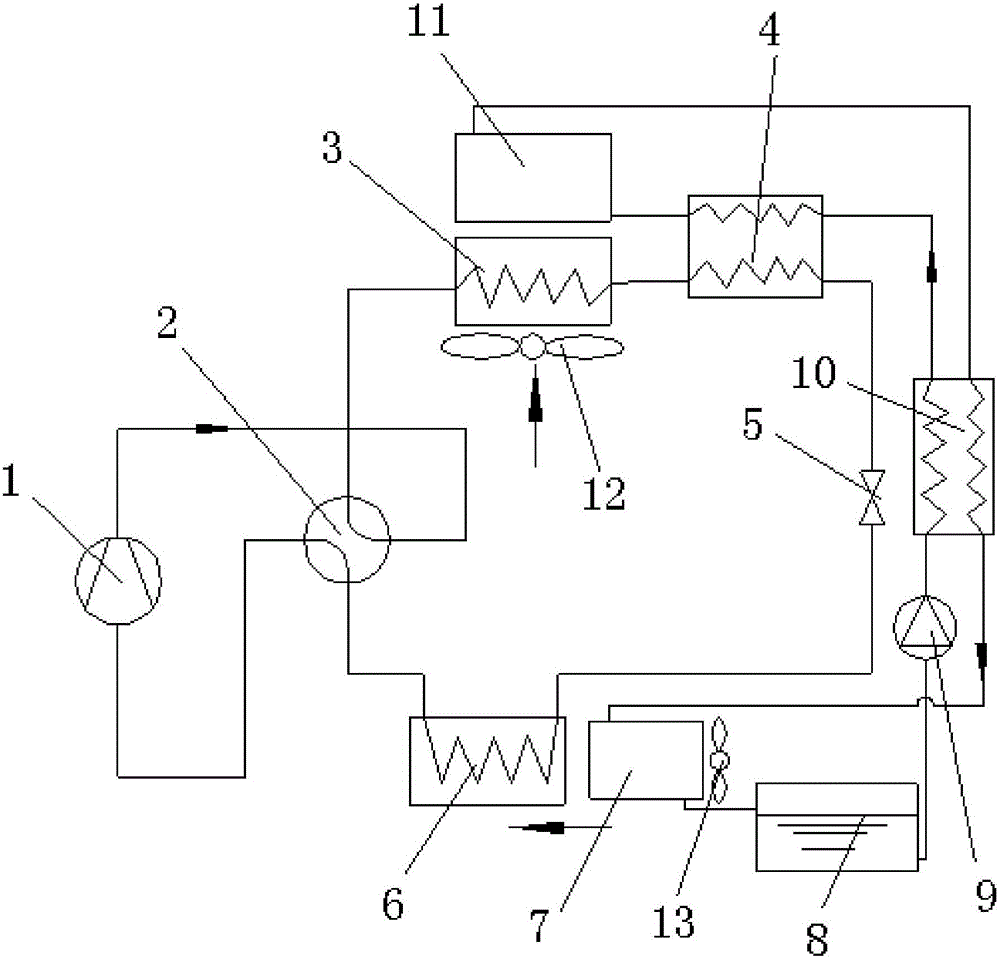

Frostless air source heat pump device and method based on membrane method dehumidification and indoor regeneration humidification

ActiveCN106051975APrevent heat pump from frostingAvoid pollutionAir treatment detailsHeat recovery systemsMembrane methodEngineering

The invention discloses a frostless air source heat pump device and method based on membrane method dehumidification and indoor regeneration humidification. The frostless air source heat pump device comprises a refrigerant circulation loop and a solution dehumidification / humidification circulation loop. The refrigerant circulation loop comprises a compressor (1), a four-way reversing valve (2), an indoor heat exchanger (3), a regeneration condenser (4), a throttling valve (5) and an outdoor heat exchanger (6) which are sequentially connected together in series through a first communication pipeline. The solution dehumidification / humidification circulation loop comprises a heat recovery heat exchanger (10), a regeneration condenser (4), an indoor humidification membrane assembly (11), a heat recovery heat exchanger (10), an outdoor dehumidification membrane assembly (7) and a dehumidification solution storage tank (8). According to the frostless air source heat pump device and method based on membrane method dehumidification and indoor regeneration humidification, outdoor air latent heat is converted into sensible heat through the dehumidification membrane assembly, frosting is avoided, and moisture introduced through a dehumidification solution is regenerated and used for indoor humidification.

Owner:SOUTHEAST UNIV

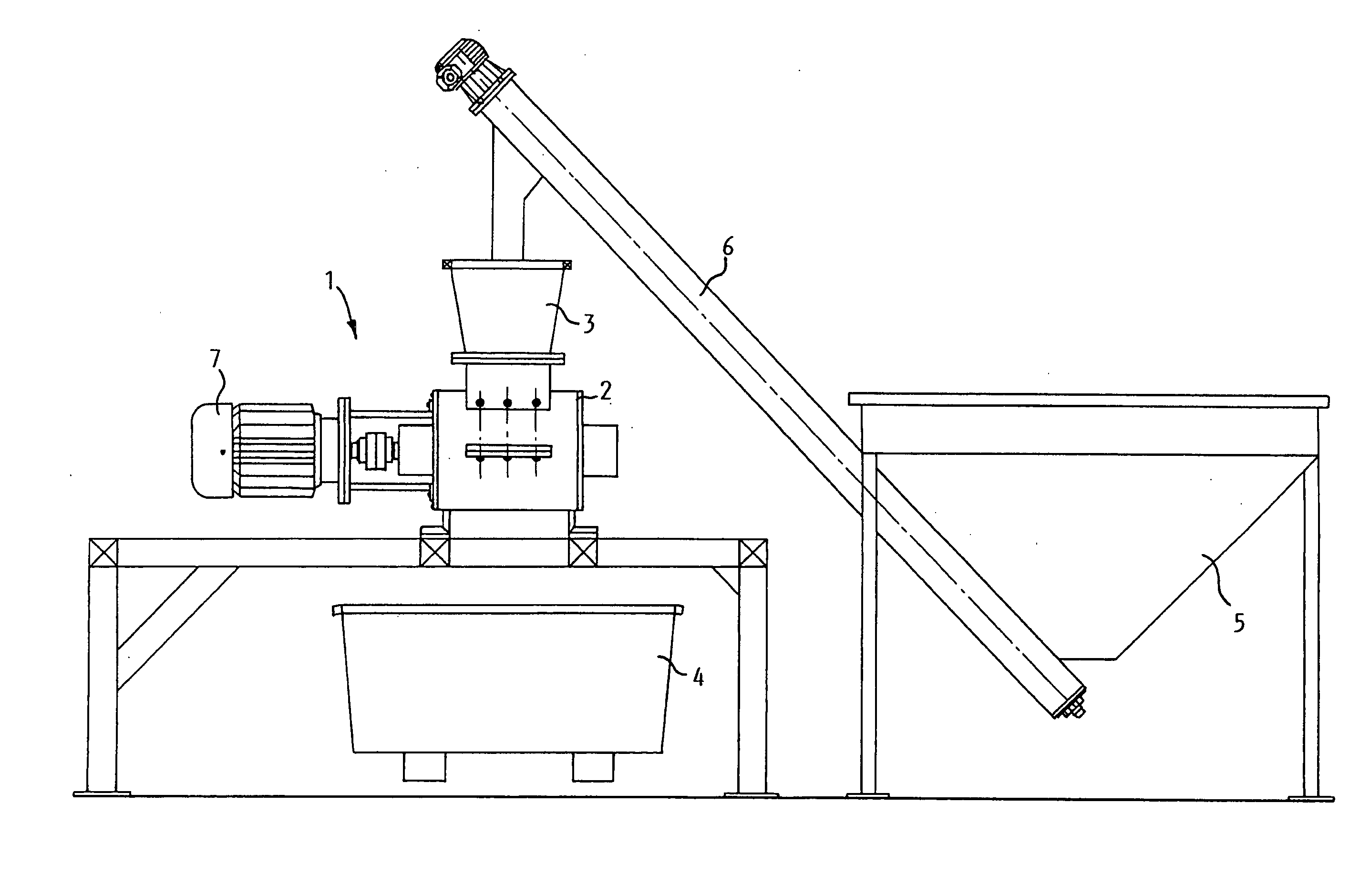

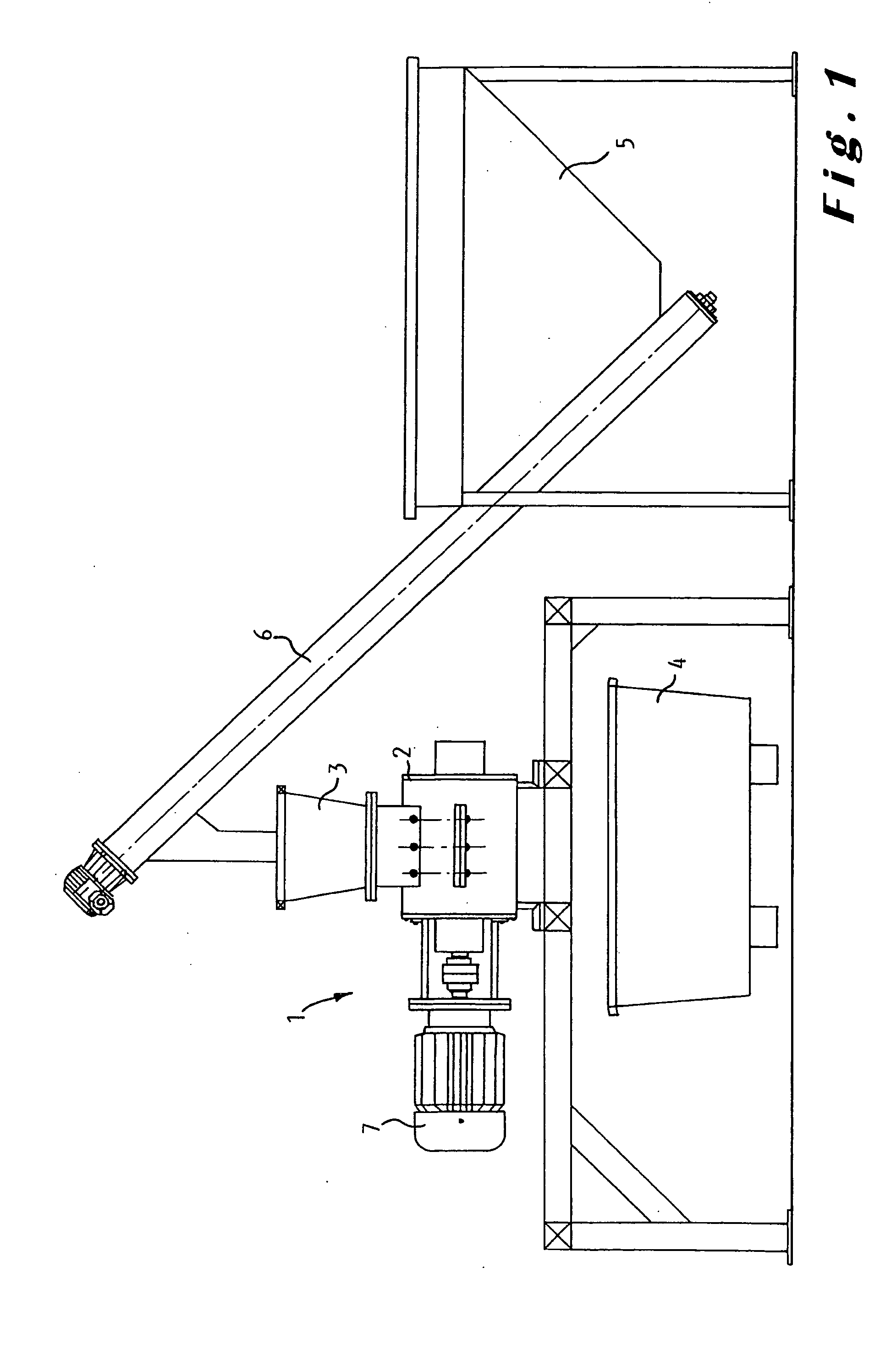

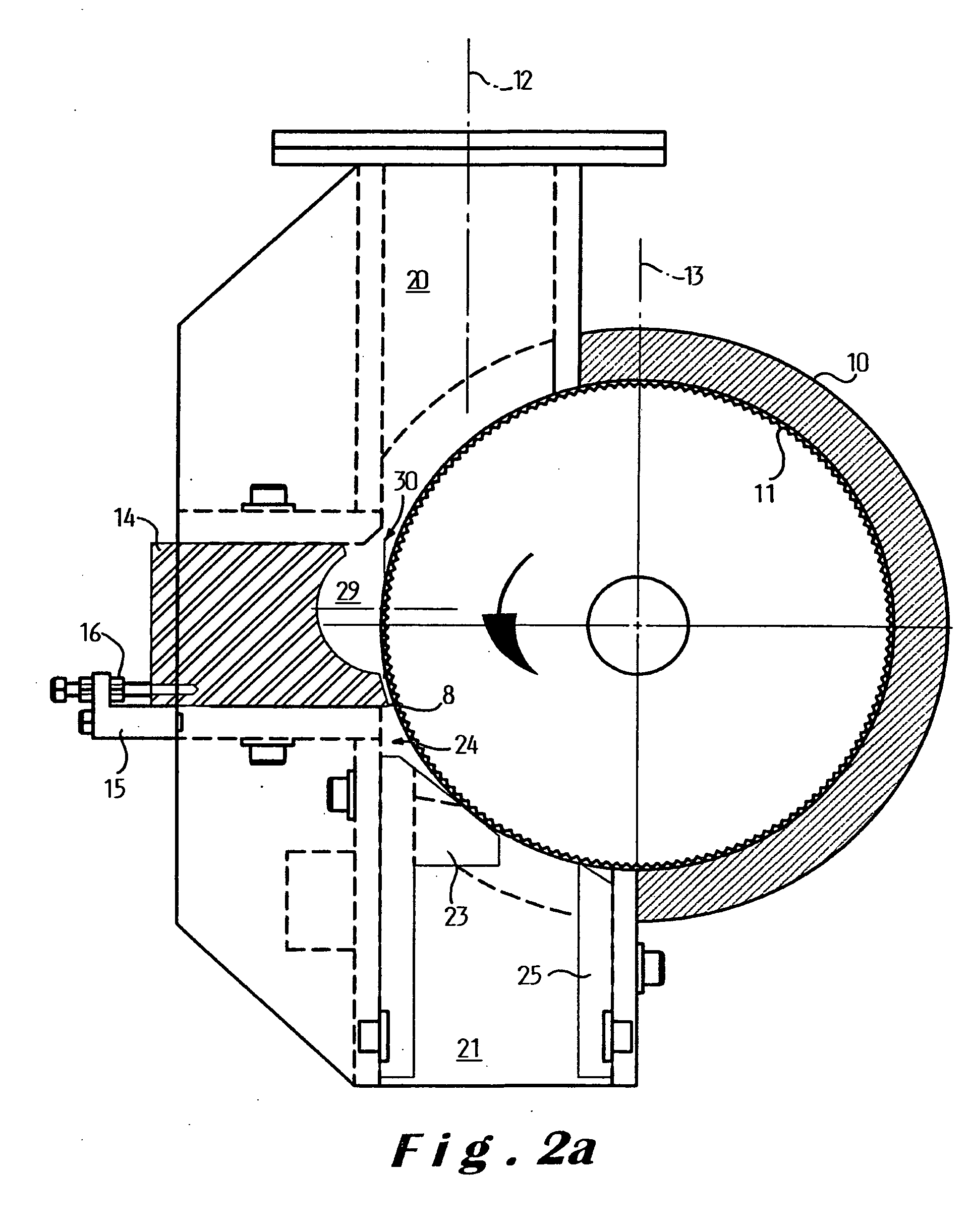

Unit and method for recycling a bituminous membrane

ActiveUS20050263625A1Simpler and less-expensive constructionEasy to usePlastic recyclingWorking-up pitch/asphalt/bitumen by solidifying/disintegratingMembrane methodTrituration

Method and unit for recycling a bituminous membrane provided with at least one reinforcement, which membrane is reduced to pieces which are introduced into a recycling unit, provided with a first rotor, housed in a first stator, and where they are heated and ground, said pieces being conveyed into a chamber, delimited by an external wall of the first rotor and a recess arranged in a counter-element mounted on the stator, where they are subjected to a trituration, the pieces thus triturated then being discharged from the chamber by flowing along said external wall of the rotor.

Owner:IMPERBEL

Method for preparing lithium carbonate through salt lake brine

ActiveCN106241841AHigh purityEasy to separateLithium carbonates/bicarbonatesMembrane methodLithium carbonate

The invention discloses a method for preparing lithium carbonate through salt lake brine. The method comprises the following steps of firstly adsorbing the salt lake brine through a high-property lithium extraction adsorbent, then performing nanofiltration for removing magnesium, performing forward osmosis and preliminary concentration, performing deep magnesium removal, performing multiple-effect evaporation, and performing sedimentation so as to obtain the battery-grade lithium carbonate. According to the method disclosed by the invention, an adsorption method, a membrane method and an evaporation method are organically combined together, so that the energy consumption is greatly reduced, and the cost is reduced; and besides, the lithium carbonate prepared by the method disclosed by the invention is high in purity and stable in quality. The method disclosed by the invention has the advantages of being simple and convenient to operate, low in energy consumption, stable in effects and the like.

Owner:JIANGSU HELPER FUNCTIONAL MATERIALS

System for recovering heavy metals and recycling wastewater through treating metal wastewater by using tube type filter membrane method

InactiveCN102923876AEasy to recycleSmall footprintSludge treatment by de-watering/drying/thickeningWater/sewage treatment bu osmosis/dialysisAutomatic controlFiltration membrane

The invention discloses a system for recovering heavy metals and recycling wastewater through treating metal wastewater by using a tube type filter membrane method. The system comprises a raw water collecting tank, a PH regulating tank, a concentration box, a micro-filtration membrane device, a micro-filtration water producing box, a carbon filer, a fine filter, a high-pressure pump and a reverse osmosis device which are sequentially communicated through pipelines, wherein the concentration box is also sequentially communicated with a sludge concentration tank, a sludge pump and a filter press through a pipeline. The system has the capacity of filtering particular pollutants without leaking sludge particles; a micro-filtration membrane can be cleaned with an acid agent, an alkaline agent, a bleaching agent and an oxidizing agent; and a membrane tube of the micro-filtration membrane is durable and has long service life. The system has the advantages that the process is simpler, more convenience is brought in operation, automatic control is easily realized, the occupation area is small, the investment of a foundation building period can be saved, the agent input can be reduced, the micro-filtration membrane can recover 99.9 percent of heavy metals, and is the best choice of recovering the heavy metals from the wastewater containing heavy metals.

Owner:上海瑞勇实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com