Method for preparing lithium carbonate through salt lake brine

A technology of salt lake brine and lithium carbonate, applied in the direction of lithium carbonate;/acid carbonate, etc., can solve the problems of high extraction cost and high energy consumption by direct evaporation and concentration of analytical solution, so as to reduce energy consumption, easy to operate, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

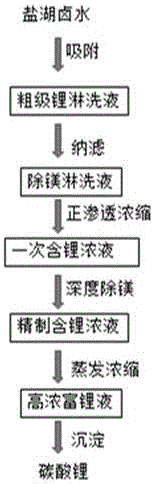

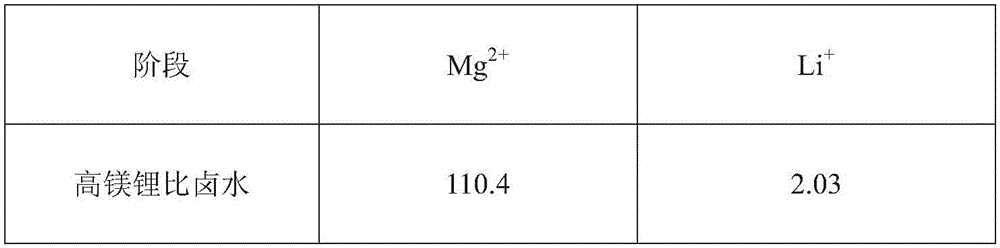

[0026] The process of extracting lithium carbonate from salt lake brine with high magnesium-lithium ratio is as follows:

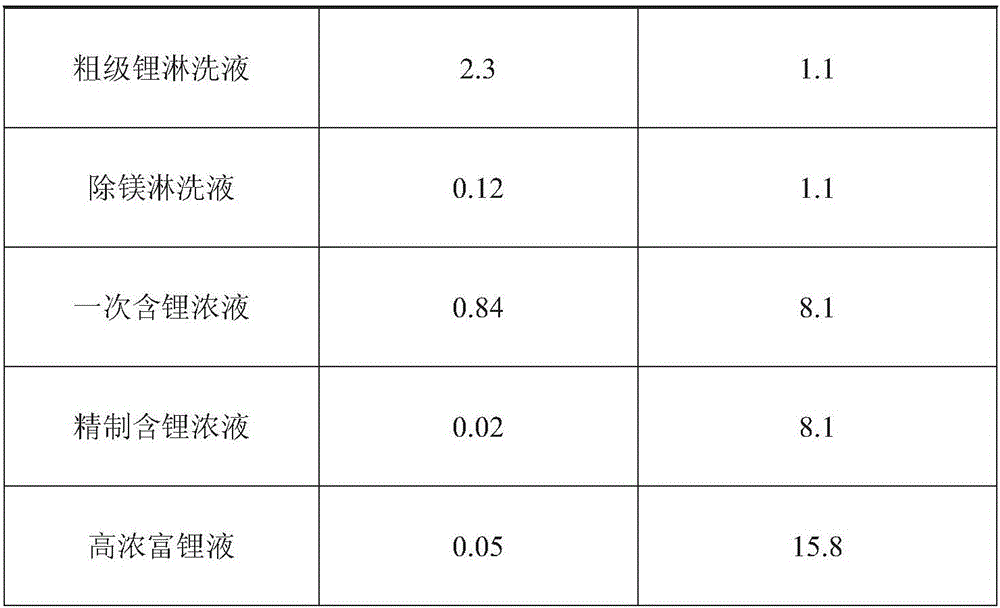

[0027] (1) Add 24L of hybrid nanocrystalline lithium extraction adsorbent (patent number 201410065121.4) into the adsorption column, add 48L of brine for adsorption, after the adsorption is saturated, add 24L of pure water for desorption, and obtain 24L of coarse lithium eluent.

[0028] (2) 24L coarse-grade lithium eluent is passed into the nanofiltration system. If the magnesium content is higher than 2g / L, a second-stage nanofiltration is used to obtain the magnesium-removing eluent.

[0029] (3) The 17L magnesium removal eluent is passed into the forward osmosis system, and 4mol / L ammonium bicarbonate is used as the drawing solution. Ammonium bicarbonate has a high solubility in water, so a high osmotic pressure is generated, and lithium-rich The water molecules in the solution are attracted to the other side of the permeable membrane, so as to achieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com