Patents

Literature

448 results about "Salt lake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Great Salt Lake, located in the northern part of the U.S. state of Utah, is the largest salt water lake in the Western Hemisphere, and the eighth-largest terminal lake in the world. In an average year the lake covers an area of around 1,700 square miles (4,400 km 2), but the lake's size fluctuates substantially due to its shallowness. For instance, in 1963 it reached its lowest recorded ...

Method for separating magnesium and concentrating lithium from brine in salt lake

ActiveCN1626443AHighly selective extractionEfficient separationMagnesium halidesLithium halidesLithiumSalt lake

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Method for extracting lithium from salt lake brine by adsorption method

ActiveCN101928828ALow investment costHigh adsorption capacityProcess efficiency improvementSODIUM CATIONSalt lake

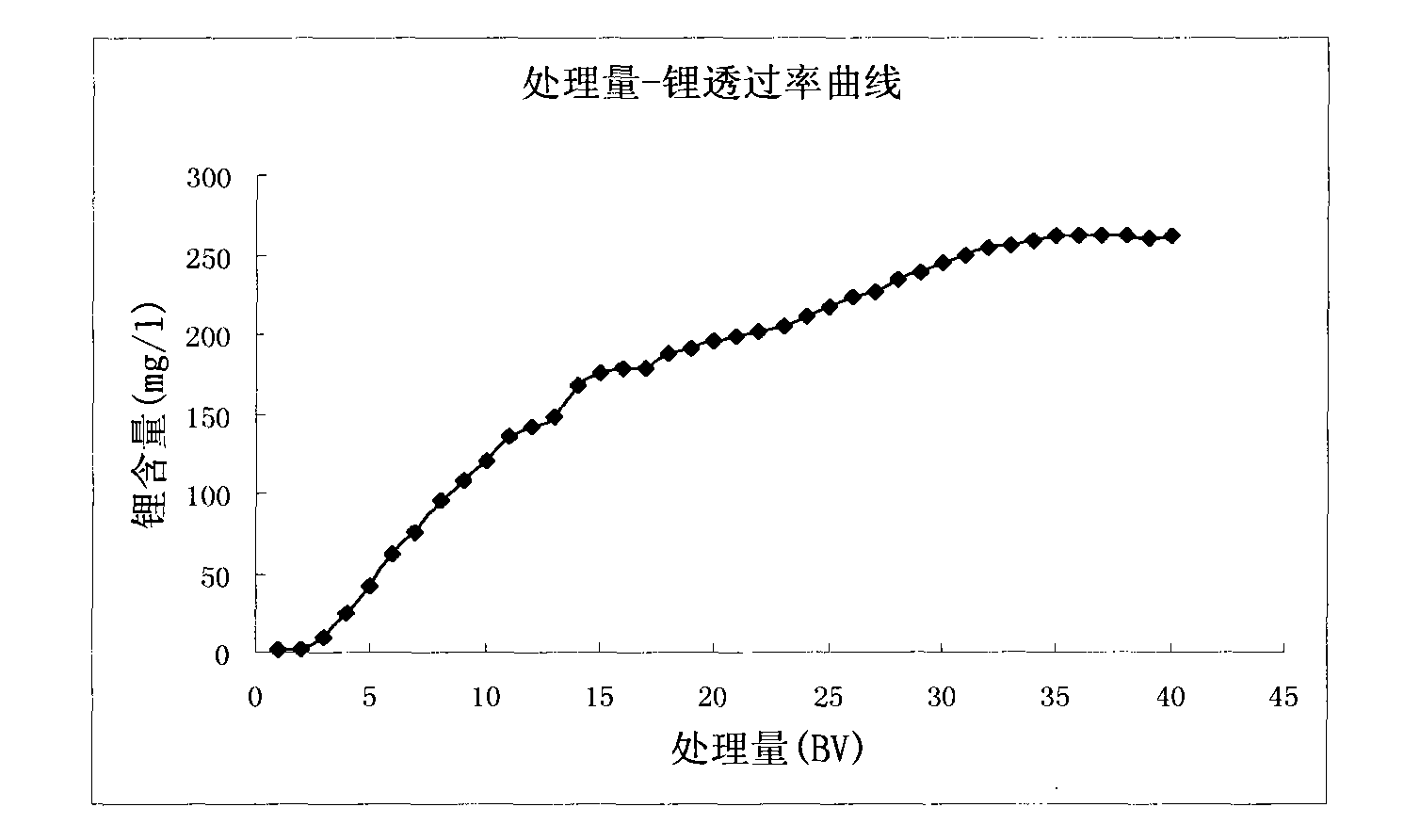

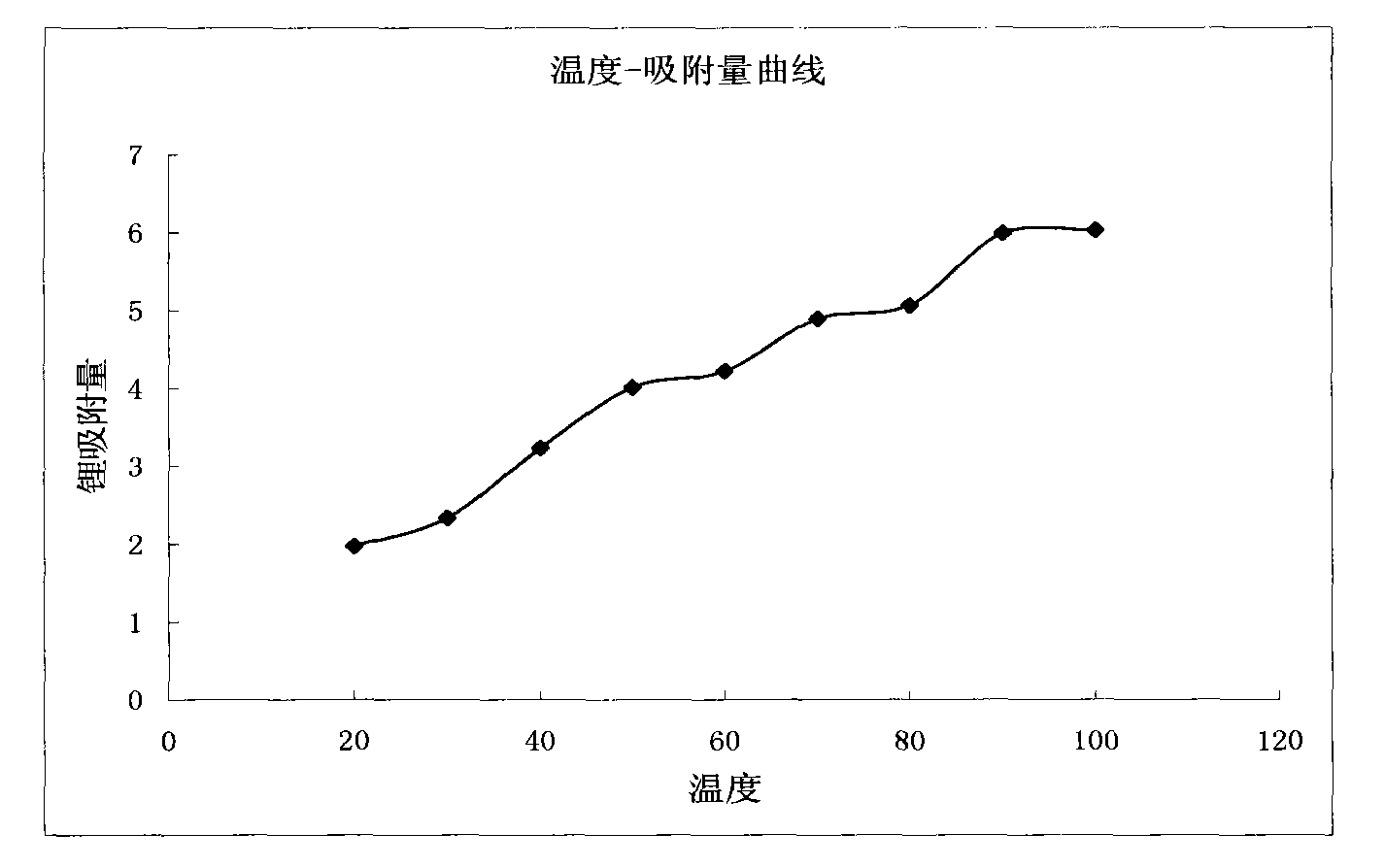

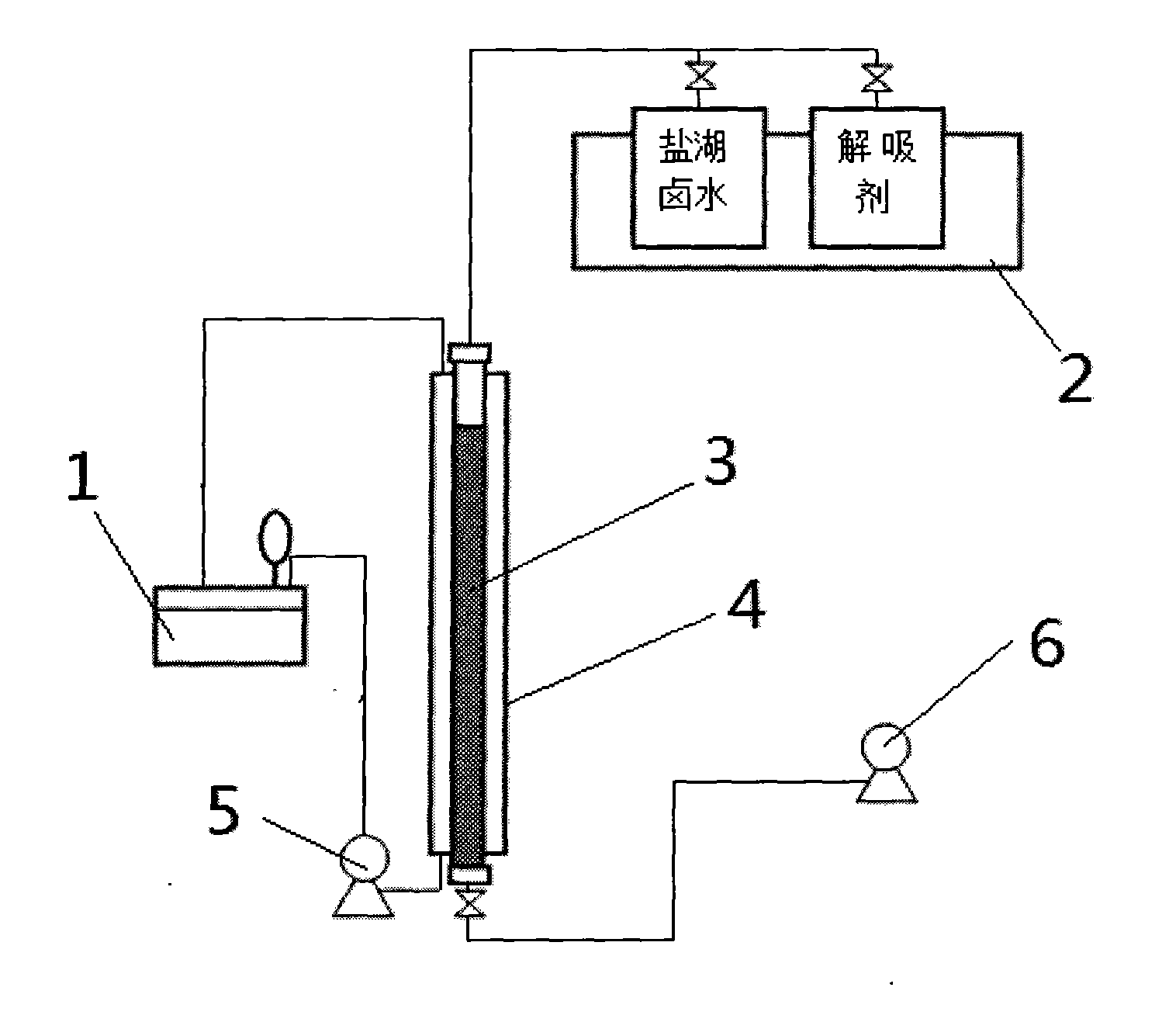

The invention discloses a method for extracting lithium from salt lake brine by an adsorption method. The method comprises the following steps of: (1) making the salt lake brine pass through aluminum salt-containing adsorption resin at a speed of between 5 and 10 BV / H at the temperature of between 20 and 100 DEG C to ensure that the lithium ions in the salt lake brine are adsorbed on the adsorption resin; (2) making lithium ion eluant pass through the aluminum salt-containing adsorption resin at a speed of between 5 and 10 BV / H at the temperature of between 20 and 100 DEG C to ensure that thelithium ions adsorbed on the aluminum salt-containing adsorption resin are eluted and desorbed into the eluant solution so as to obtain desorption liquid; and (3) making the desorption liquid pass through common sodium cation exchange resin at a speed of between 5 and 10 BV / H to remove magnesium from the desorption liquid, and then concentrating to obtain a lithium salt. The method has the advantages of low consumption of chemical materials, simple process, easy operation and no pollution.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

Method for efficiently extracting lithium from salt lake brine

ActiveCN103710549AAvoid interferenceHigh separation factorProcess efficiency improvementSeparation factorIonic liquid

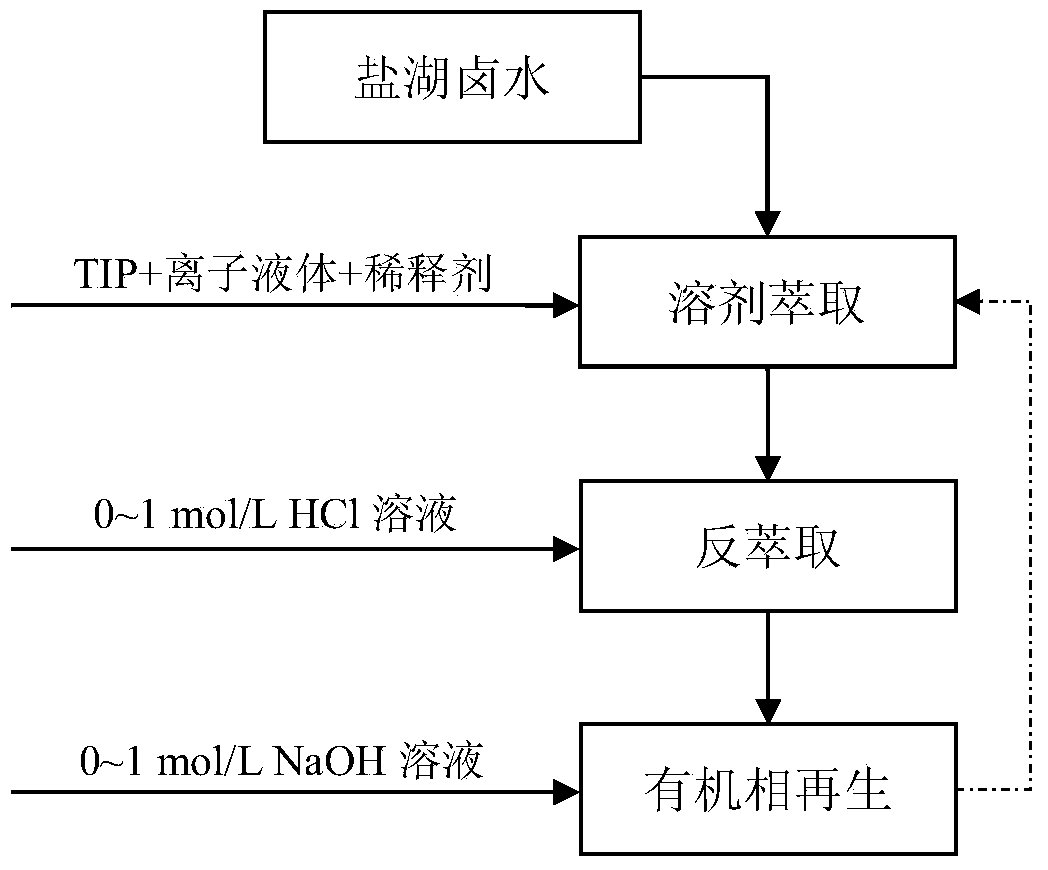

The invention relates to a method for efficiently extracting lithium from salt lake brine. The method comprises the following steps: (1) forming an extraction organic phase by an extraction agent, a co-extraction agent and a diluent, and then mixing the extraction organic phase with salt lake brine according to the volume ratio of (3-4):2 for three-stage extraction with single extraction time being 2-10 minutes to obtain an organic phase; and (2) mixing the organic phase obtained in step (1) with a reverse extraction acid solution (0-1 mol / L) for three-stage reverse extraction with single reverse extraction time being 2-10 minutes, and collecting an aqueous phase which is an aqueous solution containing lithium ions. The co-extraction agent of an extraction system of the method is hydrophobic ionic liquid, compared with conventional synergist ferric trichloride, the interference caused by iron ions is avoided, the reverse extraction acidity is greatly reduced, more importantly the lithium-magnesium separation factor is significantly improved, and the elution step of magnesium ions is reduced; in addition, the method provided by the invention is easy in process, easy to control, high in operation reliability, and good in recyclability of the organic phase, and greatly reduces the production cost for extracting the lithium from the salt lake brine.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

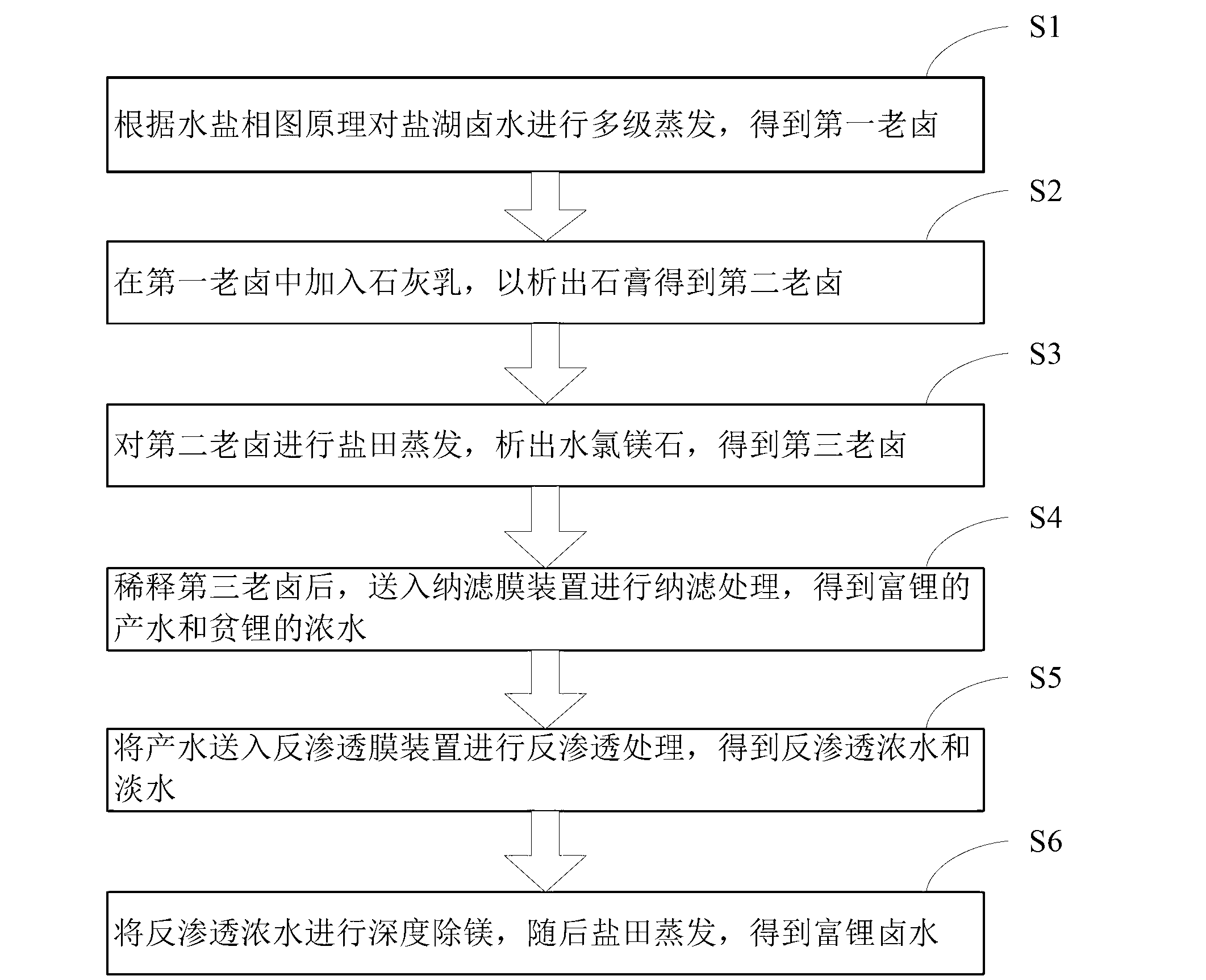

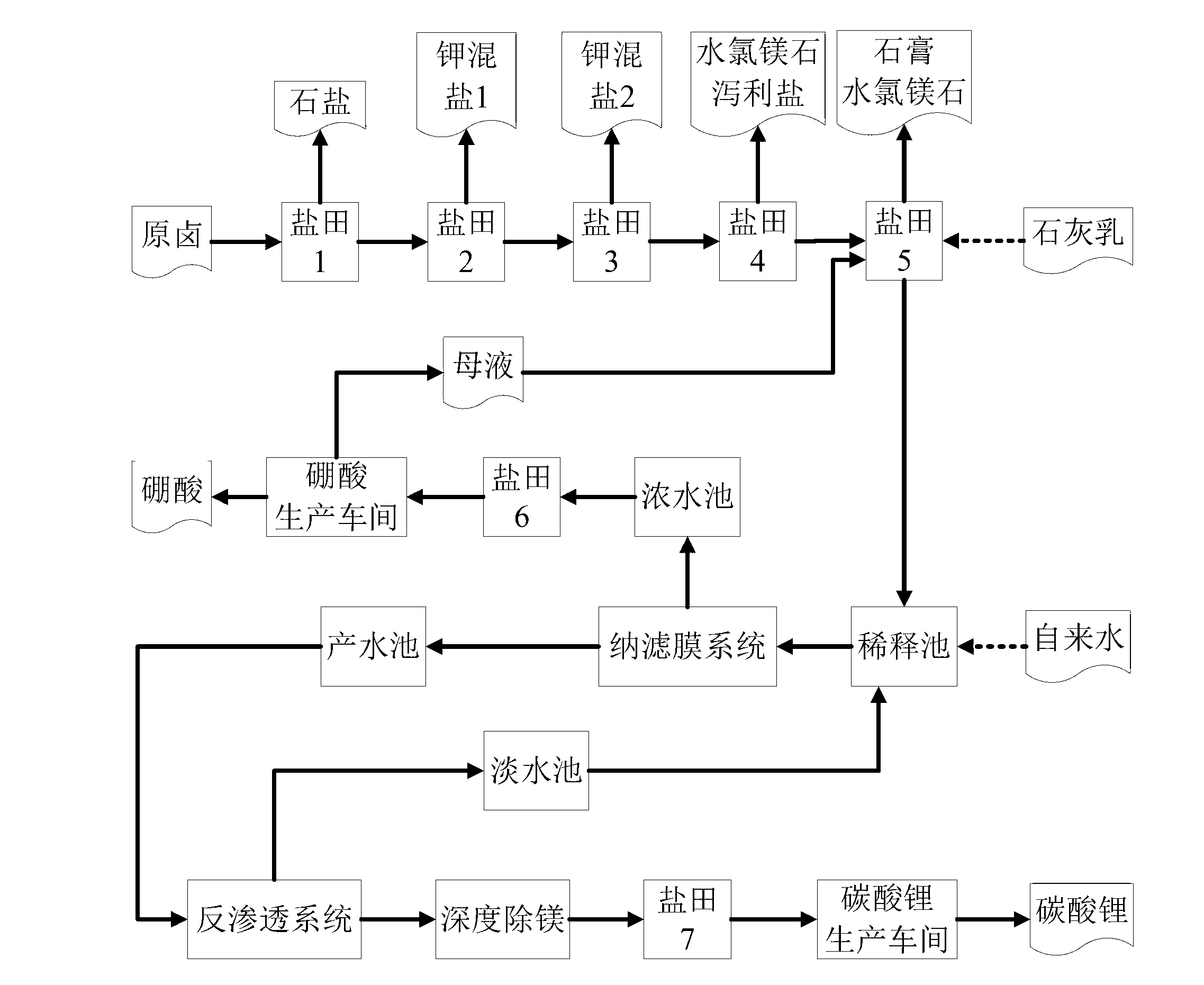

Salt lake brine treatment method for separating lithium from high-magnesium-lithium-ratio salt lake brine

ActiveCN103074502ATake advantage ofHigh recovery rateProcess efficiency improvementReverse osmosisEvaporation

The invention discloses a salt lake brine treatment method for separating lithium from high-magnesium-lithium-ratio salt lake brine. The treatment method comprises the steps that S1, the salt lake brine is subjected to multistage salt pan evaporation to form first old brine; S2, sulphur removal is conducted: lime milk is added to the first old brine for separating out gypsum, and second old brine is obtained; S3, the second old brine is subjected to salt pan evaporation, bischofite is separated out, and third old brine is obtained; S4, the third old brine is diluted, and sent to a nanofiltration membrane device for nanofiltration treatment, and contributing water rich in lithium and thick water poor in lithium are obtained; and S5, the contributing water in Step S4 is sent to a reverse osmosis membrane device for reverse osmosis treatment, and reverse osmosis thick water and fresh water are obtained. The method combines a salt pan technology with a membrane system, makes full use of solar energy, and reduces energy consumption; a technological process is simple; equipment is easy to configure, mount and transfer; popularization and an application are very easy.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

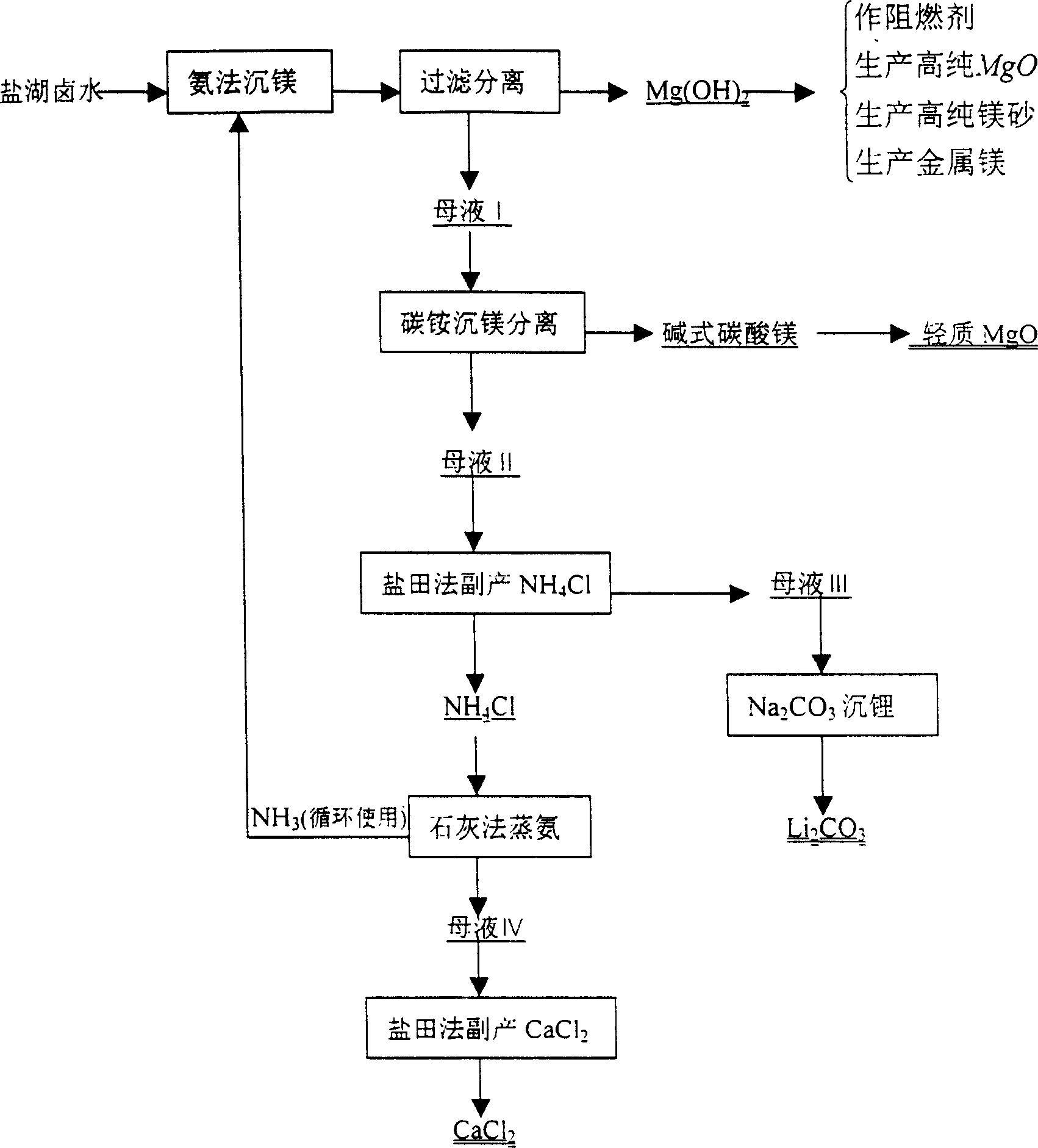

Method of combined extraction of magnesium and lithium in salt lake bittern

A process for extracting Mg and Li from the brine of salt lake features that the ammonia and ammonium dicarbonate are used to implement two stages of magnesium deposition. For the first stage, the crystal seeds (5-10%) are added and the efficiency of magnesium deposition is controlled to 80-85%. For the second stage, the solid ammonium dicarbonate is added for reaction to obtain more than 98% of Mg extraction rate. The ammonium chloride in the mother liquid can be converted to ammonia for reuse. The lithium chloride solution enriched from the mother liquid can be used to prepare lithium carbonate. The extraction rate of Li is more than 95%.

Owner:CENT SOUTH UNIV

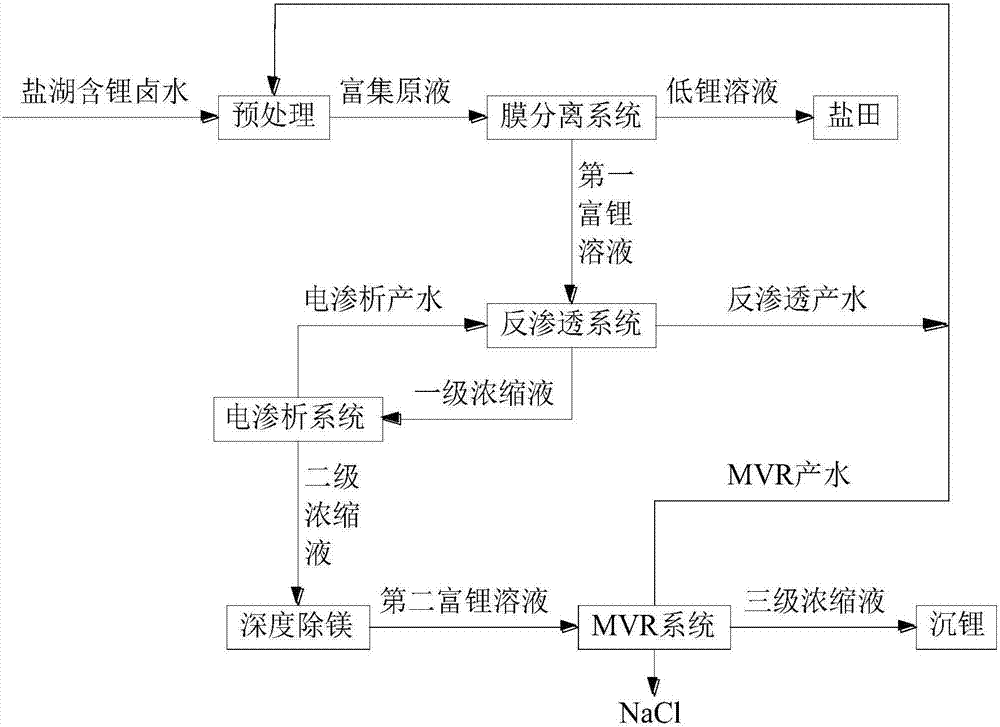

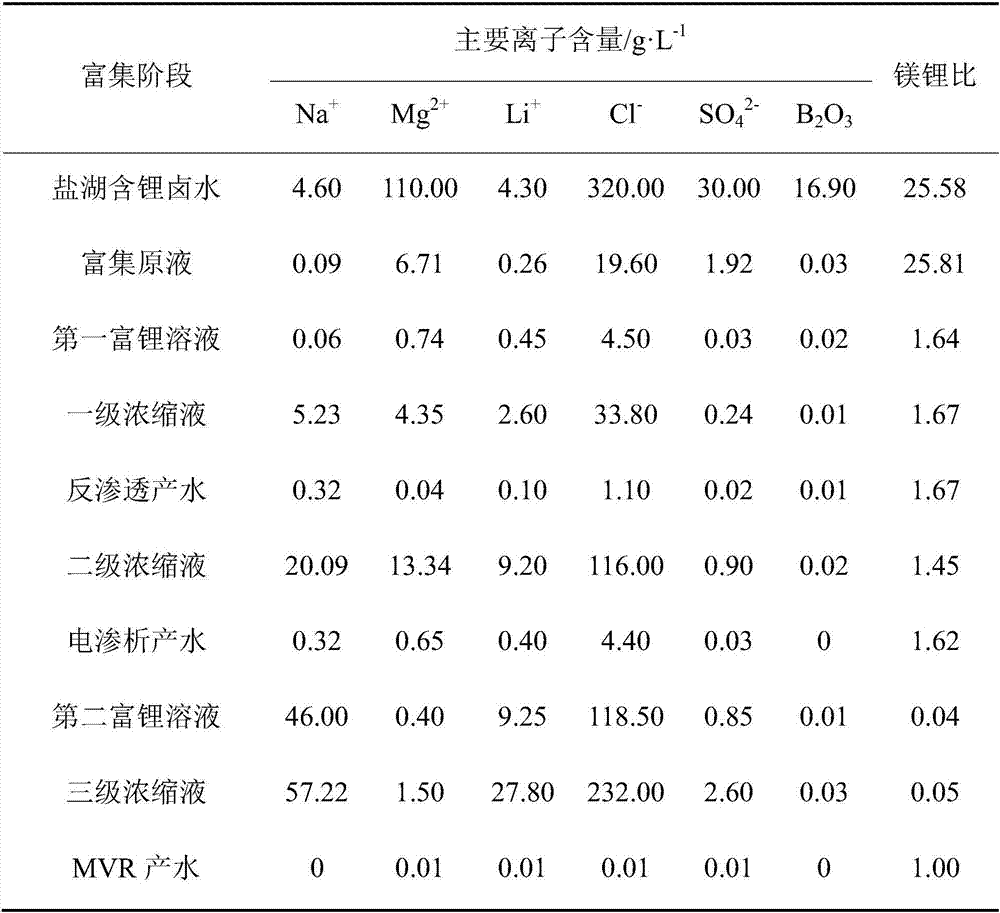

Method for enriching lithium in lithium-containing brine of salt lake

ActiveCN106865582AHigh yieldReasonably control the degree of enrichmentChemical industryAlkali metal chloridesLithiumSalt lake

The invention discloses a method for enriching lithium in lithium-containing brine of a salt lake. The method comprises the following steps of firstly, performing impurity removal and thinning pretreatment on the lithium-containing brine of the salt lake; then, sequentially treating the obtained enriching concentrated liquid by a membrane separation system, a reverse osmosis system, an electrodialysis system, a deep magnesium removal system and an MVR (mechanical vapor recompression) system; finally, obtaining third-level concentrated liquid, wherein the content of Li<+> can reach the concentration required by lithium precipitation, and the third-level concentrated liquid can be directly used as a precipitate to prepare a lithium product. The method has the advantages that in each enriching phase, the concentrations of Li<+> and the magnesium-lithium ratios in correspondingly obtained first lithium-rich solution, first-level concentrated liquid, second-level concentrated liquid, second lithium-rich solution and third-level concentrated liquid are strictly controlled; by effectively coupling the separating systems, the lithium ions in the lithium-containing brine of the salt lake can be efficiently enriched, and the high recycling rate of lithium in the process is guaranteed; furthermore, the reverse osmosis produced water, electrodialysis produced water and MVR produced water produced in different enriching phases can be reasonably recycled, the high recycling rate of fresh water is guaranteed, the energy consumption is decreased, and the cost is reduced.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

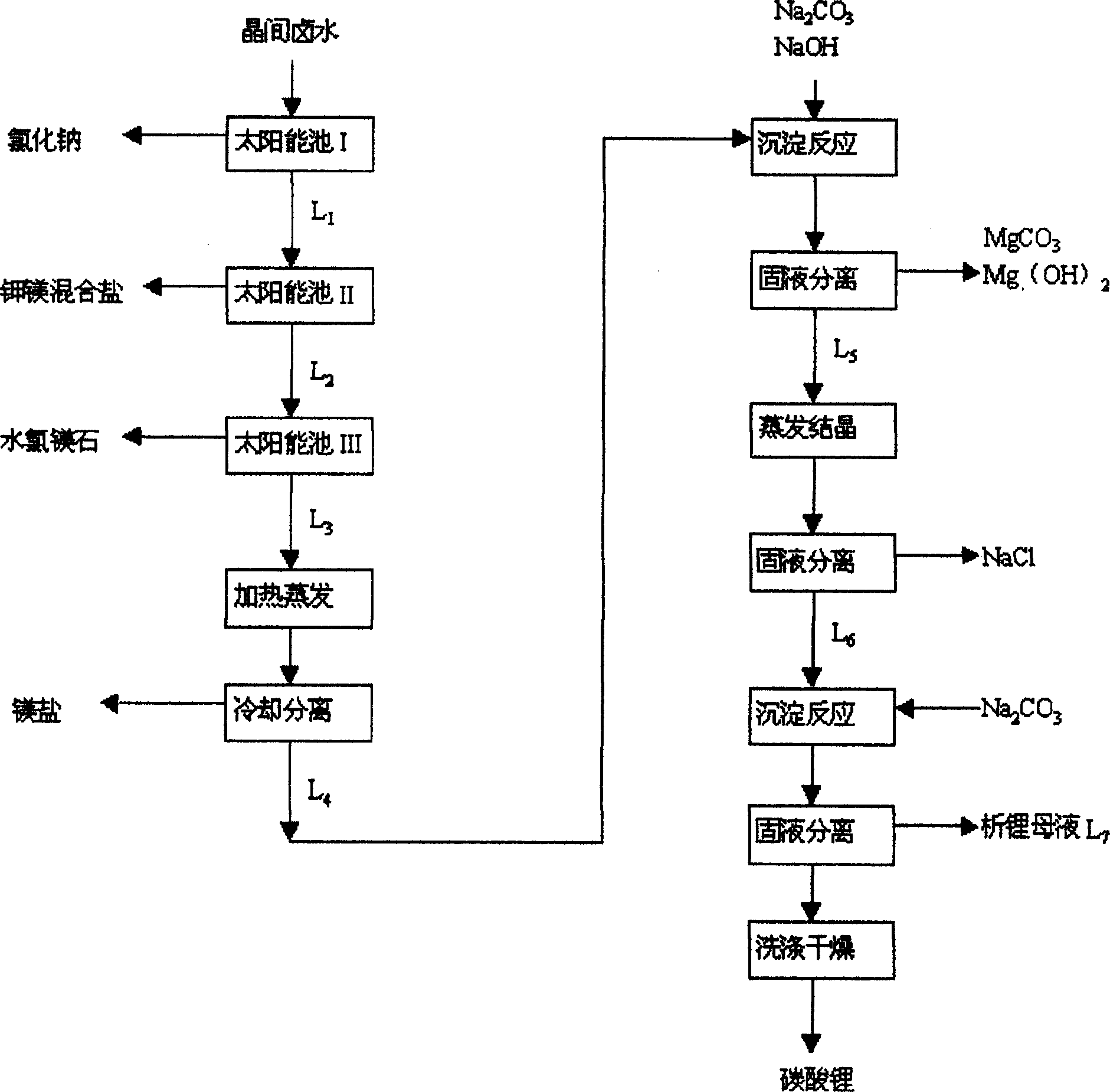

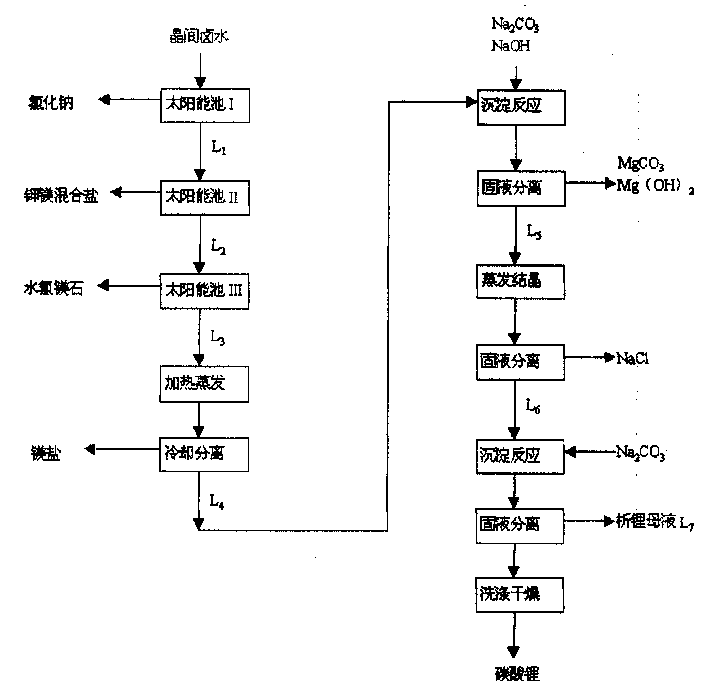

Method of extracting lithium carbonate from salt lake saline with high Mg/Li ratio

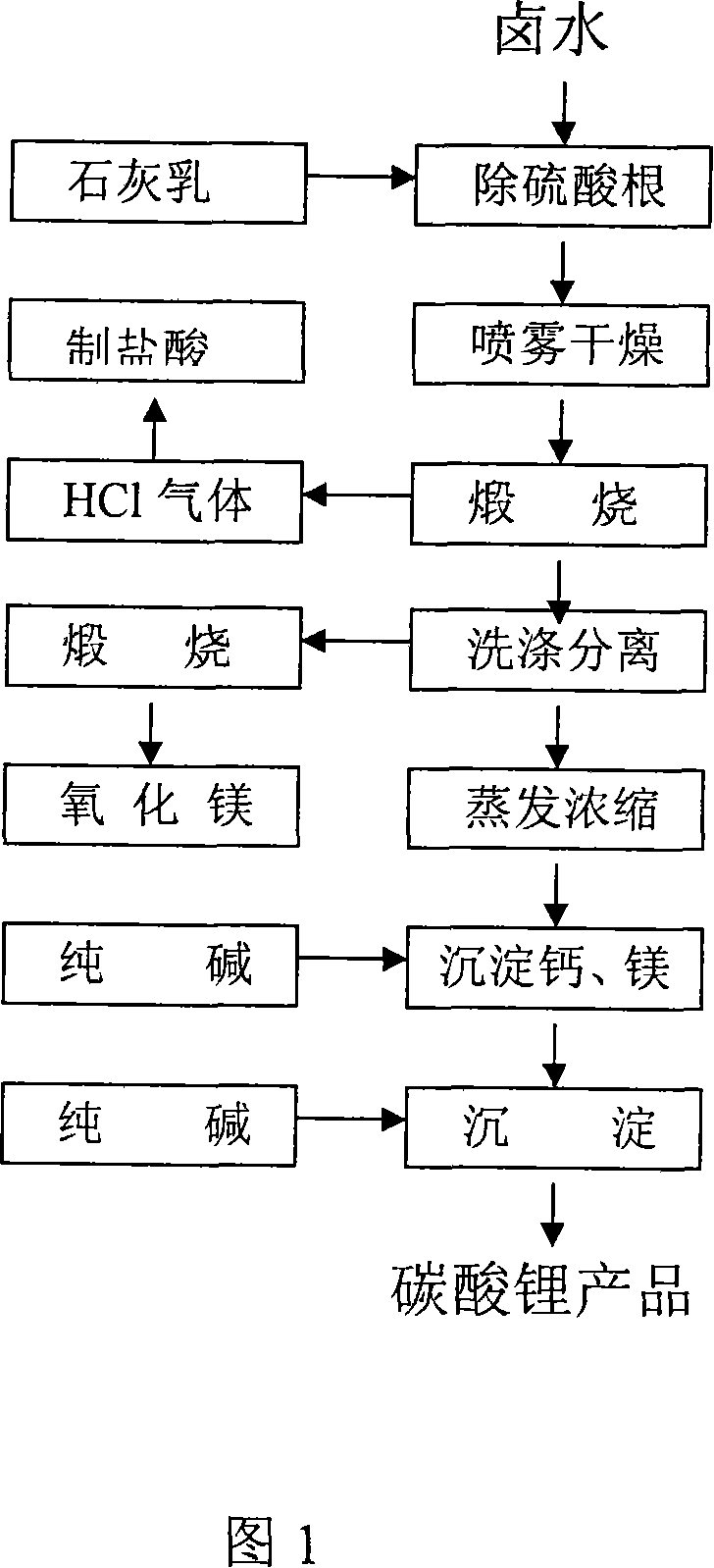

InactiveCN1398785AIncrease profitEasy to operateLithium carbonates/bicarbonatesSalt lakeLithium carbonate

A process for extracting lithium carbonate from salt lake saline with high Mg / Li ratio includes natural evaporation to concentrate in a sunshine evaporating pond, sectional crystalization while adding precipitator to make magnesium ion to form insoluble salt, solid-liquid separation, elimianting magnesium from liquid phase, regulation of pH value and evaporation to separate NaCl and obtain LiCl solution of over 100 g / l concentration, deposition of lithium carbonate by using sodium carbonate as precipitator, and separation and drying to obtain lithium carbonate product. The said technological process is suitable for industrial use.

Owner:陆增 +2

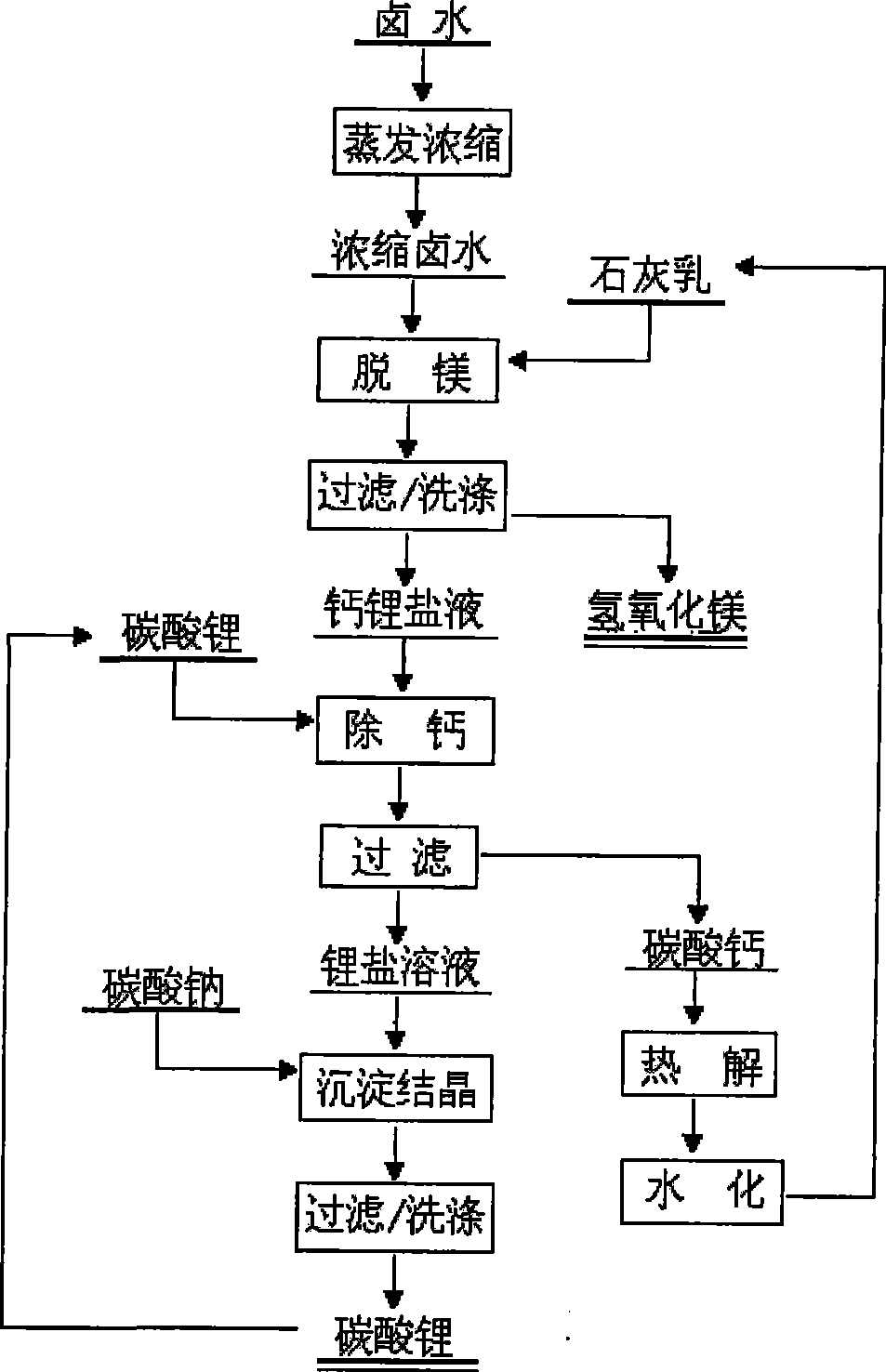

Method for extracting lithium salt from salt lake bittern with low-magnesium-lithium ratio with calcium circulation solid phase conversion method

ActiveCN101508450AReduce lossesPrecipitation crystal form is goodCalcium/strontium/barium carbonatesProcess efficiency improvementSolid phasesRaw material

The invention relates to a method for extracting lithium salts from saline salt brine with a low magnesium-lithium ratio through a calcium cycling solid-phase conversion method. The method is to take the saline salt brine with the low magnesium-lithium ratio as a raw material and adopt the technological flows of brine concentration, magnesium and sulfur removal through lime cream, calcium separation through lithium carbonate, lithium extraction through sodium carbonate, thermal decomposition of calcium carbonate, hydration of quicklime into cream, and the like to extract lithium carbonate products. The main technical points of the method comprises that: the method is based on a solid-phase conversion principle of anions (OH, CO3) and realizes magnesium and calcium removal of the brine, purification of the lithium salts and closed cycle of calcium through solid-phase conversion of Ca(OH)2, Mg(OH)2, Li2CO3, Ca(OH)2, CaCO3, CaO, Ca(OH)2. The method comprehensively utilizes magnesium resources and lithium resources of saline lakes, has the characteristics of high magnesium removal efficiency, good purification effect of the lithium salts, high recovery rate of lithium and magnesium, low energy consumption, low cost, closed cycle of the calcium, small project investment, and the like, and is particularly suitable for industrial production on a large scale. In addition, the whole process is simple, clean and environment-friendly.

Owner:CENT SOUTH UNIV

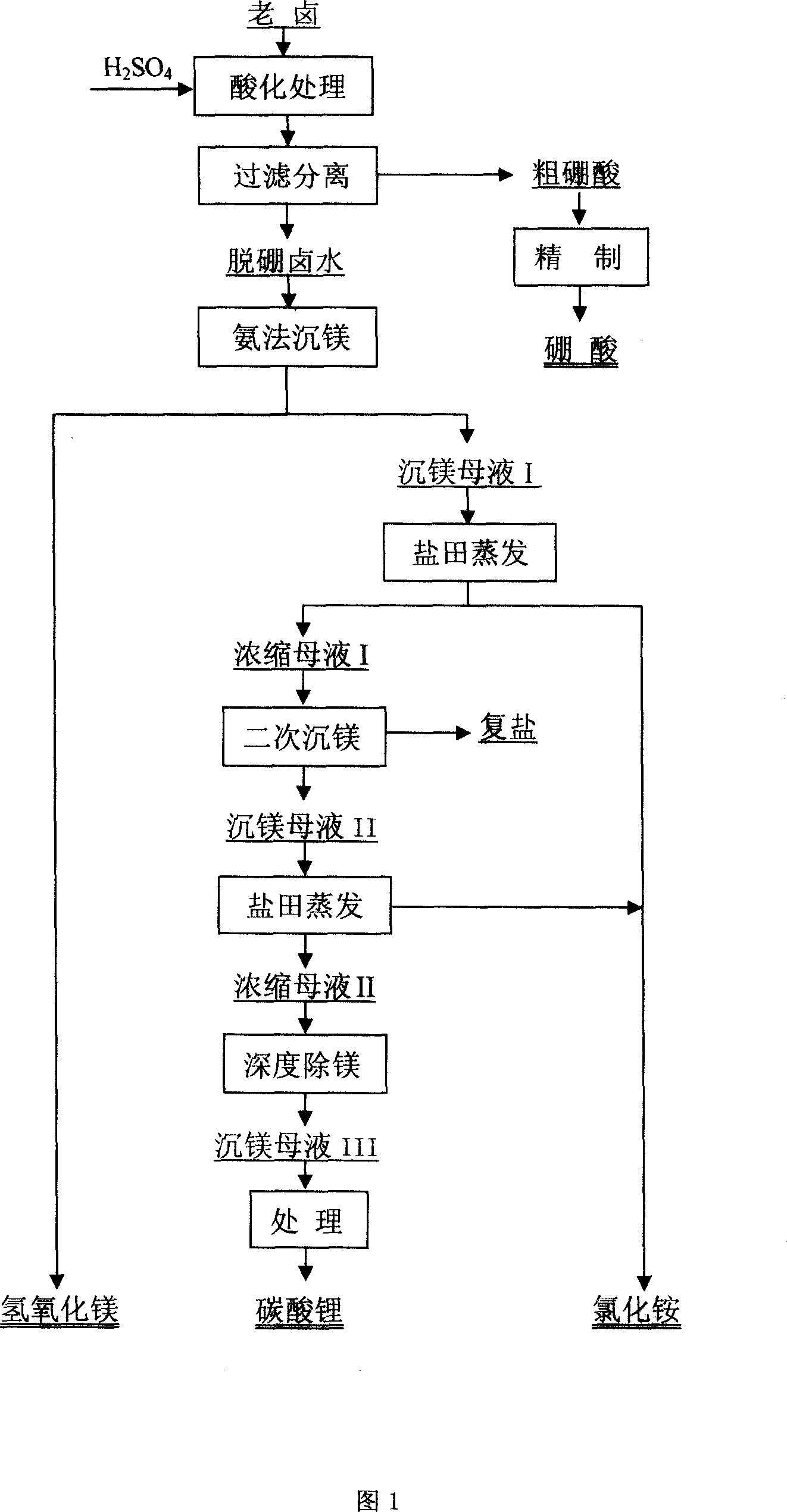

Method for combined extracting boron, magnesium and lithium from salt lake bittern

InactiveCN101024502AEfficient use ofIncrease profitBoron-oxygen compoundsNitrogen and non-metal compoundsResource utilizationPotassium

The invention relates to salt lake resource developing and comprehensive utilization. It uses boron, magnesium and lithium bittern as raw material, adopting combination distilling technology to make boric acid, magnesium hydroxide, lithium carbonate, and ammonium chloride. The recycling ratio of boron, magnesium and lithium reach 87%, 95%, and 92%. It has the advantages of simple technology, little device investment, high utilization coefficient of resource, high yield, good product quality, low producing cost and no pollution.

Owner:WESTERN MINING GROUP +1

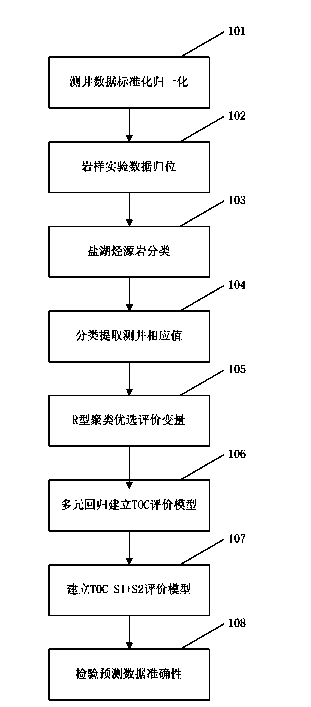

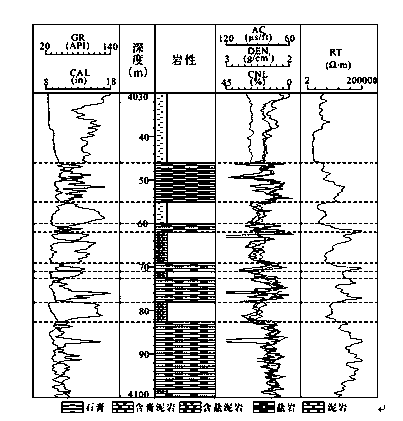

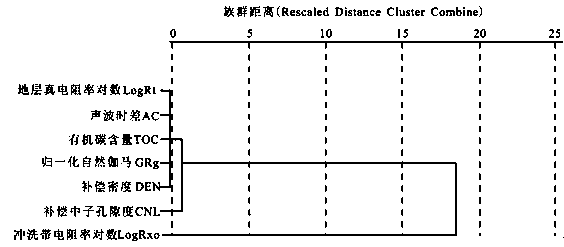

Multivariate well logging computing method for total organic carbon and hydrocarbon generating potential of hydrocarbon source rocks in salt-lake facies

The invention provides a multivariate well logging computing method for the total organic carbon and the hydrocarbon generating potential of hydrocarbon source rocks in salt-lake facies. The method comprises the steps of conducting standardization and normalization on logging curves of different wells, conducting core proper-horizon restoration on hydrocarbon source rock total organic carbon data measured through experiments, classifying the hydrocarbon source rocks in the salt-lake facies, reading logging curve data, obtained after core proper-horizon restoration correction, of total organic carbon experimental points, conducting R-type hierarchical clustering analysis on the logging data and the total organic carbon of the rocks, establishing logging evaluation models of the TOC according to different lithological characters, and conducting computing to obtain TOC data so as to work out rock pyrolysis data. The multivariate well logging computing method for the total organic carbon and the hydrocarbon generating potential of the hydrocarbon source rocks in the salt-lake facies can be used for evaluating the mass and the hydrocarbon generating potential of the hydrocarbon source rocks, of special lithological characters, in the salt-lake facies, and the method can be applied to provide a great number of evaluation data for hydrocarbon source rock evaluation and oil and gas resource quantity evaluation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production process of large grain anhydrous sodium sulfate with natural salt lake mirabilite

InactiveCN1986406AChange granularityControl the number of generatedSulfate/bisulfate preparationSalt lakeWarm water

The production process of large grain anhydrous sodium sulfate with natural salt lake mirabilite includes the steps of washing mirabilite, decomposing mirabilite, refining, settlement, neutralizing with sulfuric acid to obtain clear solution, evaporating, centrifuging to dewater, and drying with hot blast to obtain product. It features the addition of surfactant solution comprising sodium dodecyl benzene sulfonate, sodium ethoxy alkyl sulfate and warm water at about 40deg.c into the clear solution before evaporating. The production process can produce anhydrous sodium sulfate of granularity of 200-1000 microns and with high economic value.

Owner:乌鲁木齐市华高商贸有限公司

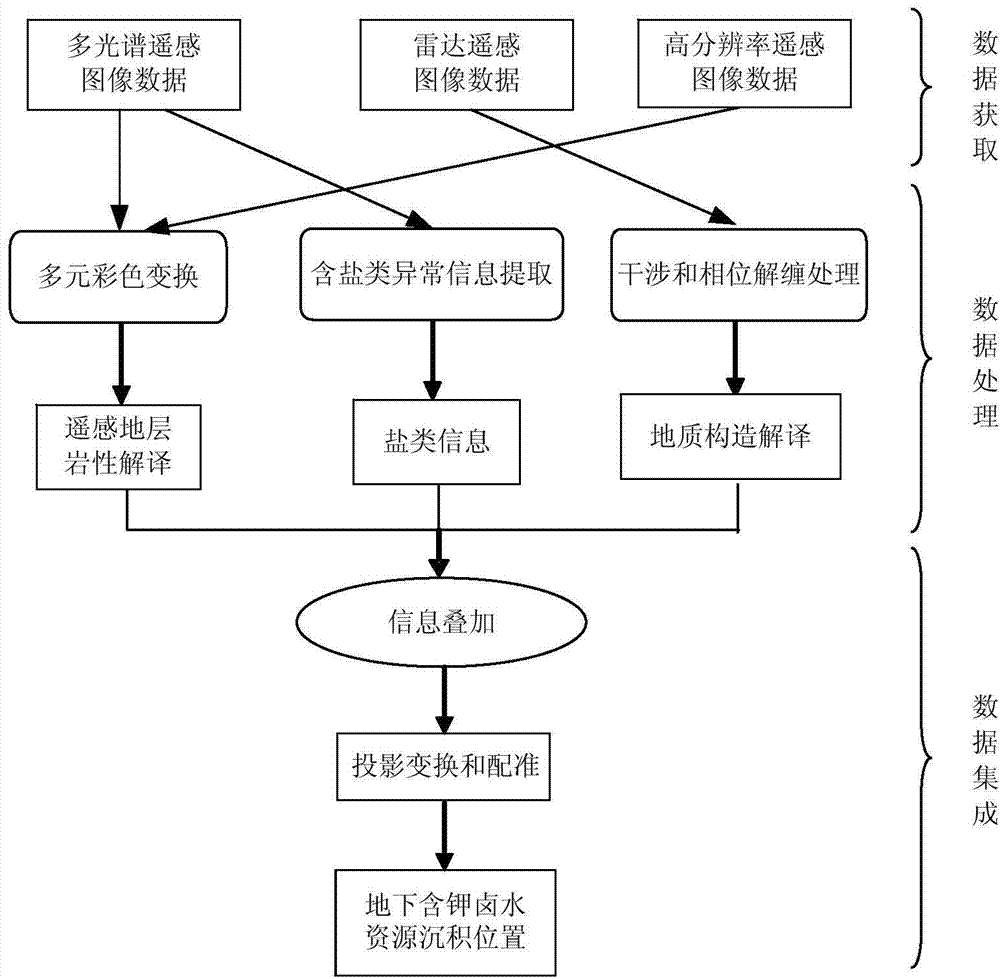

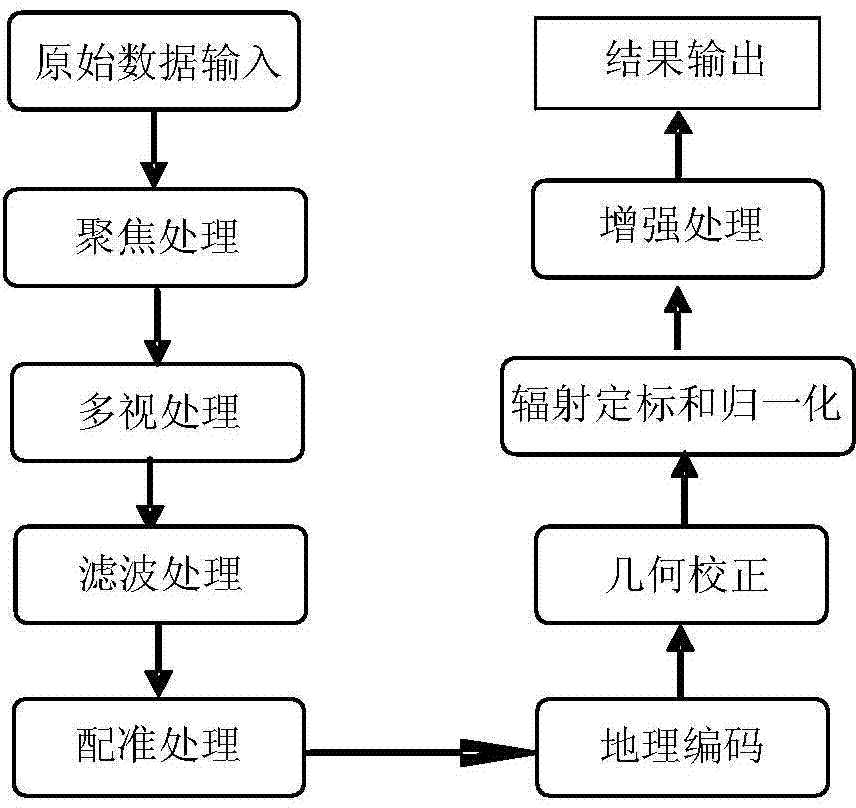

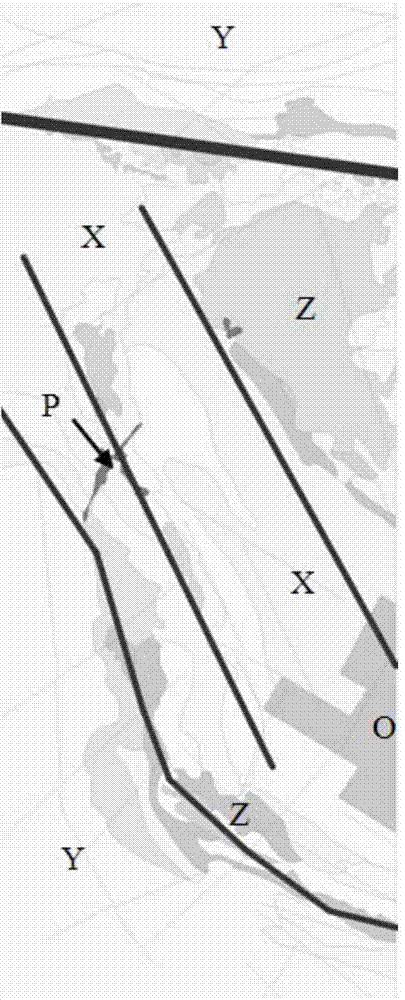

Multi-resource remote sensing distinguishing method and system of underground potassium- and halide-containing water resource in salt lake area

ActiveCN104123559AImprove accuracyAvoid the drawbacks of not being able to authenticate each otherImage analysisCharacter and pattern recognitionLithologyColor transformation

The invention relates to a multi-resource remote sensing distinguishing method and system of an underground potassium- and halide-containing water resource in a salt lake area. The method comprises the following steps: acquiring data, namely, acquiring multi-resource remote sensing image data; processing data, namely, processing multi-spectral remote sensing image data and high-resolution remote sensing image data by the multi-color transformation technology, building a remote sensing stratum lithology interpretation mark and performing remote sensing stratum lithology interpretation; extracting salt-containing abnormality information from the multi-spectral remote sensing image data by the main component analyzing technology; extracting the salt information by the interpretation extracting method; processing a radar remote sensing image data, building a geologic structure interpretation mark for potassium- and halide-containing water resource and performing geologic structure interpretation; integrating data, namely, processing three information obtained in data processing by overlapping, projection transformation and matching. According to the method, the multi-resource remote sensing image data are processed, interpreted and integrated to realize accurate distinguishing of the potassium- and halide-containing water resource.

Owner:INST OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

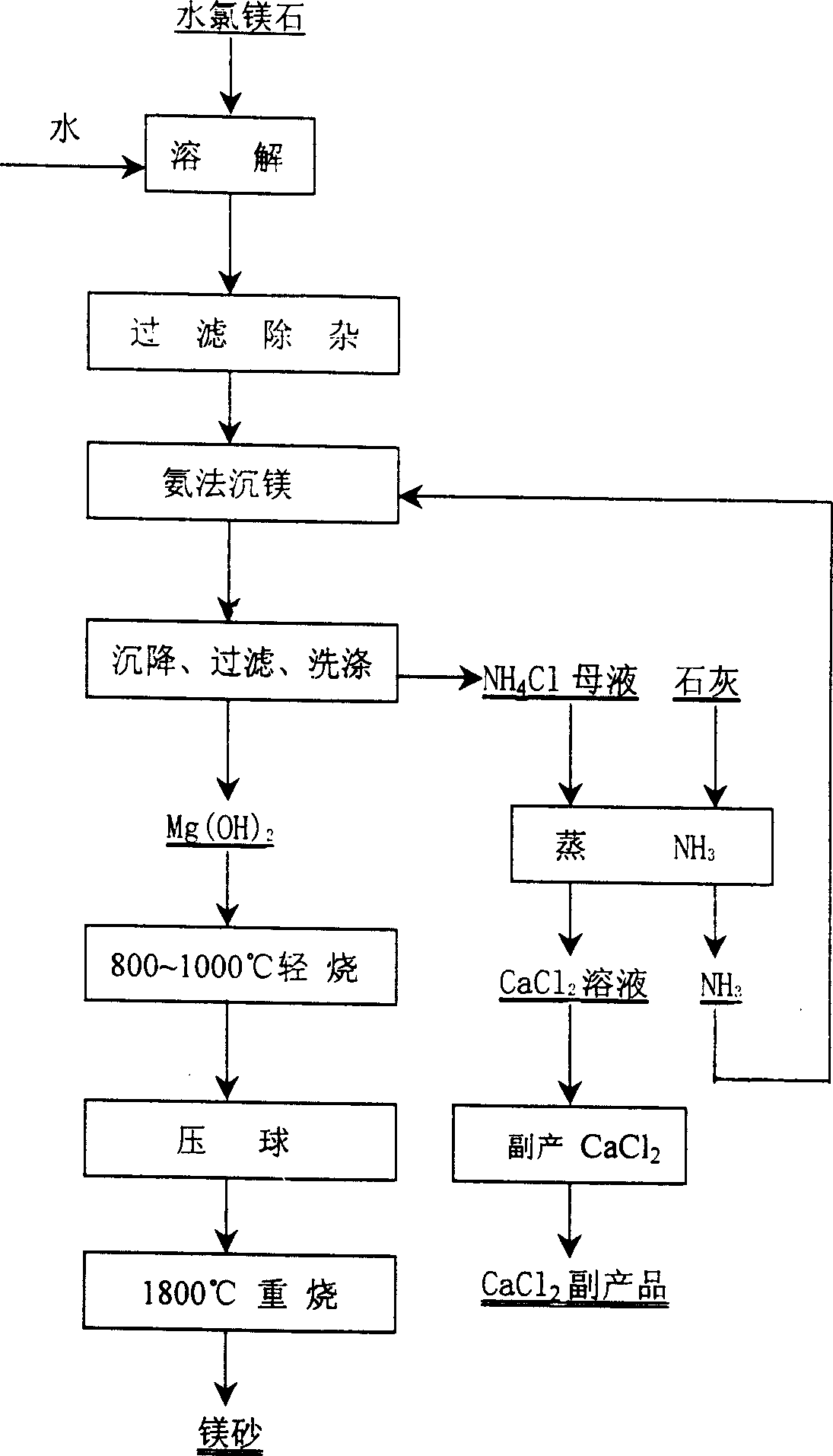

Method of preparing high purity magnesiun sand using salt lake bischofite as raw material

InactiveCN1618998ANo pollution in the processLow free ammonia concentrationMagnesiaHigh concentrationSalt lake

A process for preparing high-purity magnesium sand from the bischofite of salt lake includes such steps as preparing high-concentration saline from bischofite, depositing magnesium by ammonia method including adding crystal seeds, controlled reacting, depositing particles of magnesium hydroxide, filtering, washing, drying and two-step calcining to obtain target product containing MgO (more than 99.95%).

Owner:青海西部镁业有限公司

Prepn process of lithium ion sieve adsorbant

InactiveCN1810353AReduce manufacturing costImprove hydrophilicityOther chemical processesLithium compoundsLithiumSalt lake

The preparation process of lithium ion sieve adsorbent for adsorbing lithium from salt lake bittern, well bittern, sea water and other lithium containing solution adopts ammonia leached residue of polymetallic nodule as skeleton material, and includes the following steps: mixing ammonia leached residue of polymetallic nodule and lithium salt, calcining the mixture to obtain ion sieve precursor, acid treating the precursor to leach out the lithium precursor and convert into H-type ion sieve, filtering slurry, washing with water and drying to obtain adsorbent with lithium ion sieving effect. The present invention adopts ammonia leached residue of polymetallic nodule, rather than expensive manganese reagent, in preparing the adsorbent, and has the advantages of simple technological process, low production cost, and forming ion sieve with high hydrophilicity and fast adsorption.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Method for preparing lithium carbonate through salt lake brine with high ratio of magnesium to lithium

ActiveCN105152191ALow costAddress process complexityLithium carbonates/bicarbonatesSalt lakeHydrotalcite

The invention relates to the field of salt lake resource comprehensive utilization, in particular to a method for preparing lithium carbonate through salt lake brine with the high ratio of magnesium to lithium. The salt lake brine with the high ratio of magnesium to lithium serves as a raw material, a certain amount of soluble trivalent metal salt is added, the ratio of magnesium to lithium in the salt lake brine is reduced by synthesizing magnesium-based stratified functional materials, magnesium and lithium in the salt lake brine with the high ratio of magnesium to lithium are separated, and then lithium carbonate is prepared through hydrotalcite mother liquor with the low ratio of magnesium to lithium. The technical problems that an existing method is complex in process, cost is high, and the magnesium and lithium separation effect is not ideal can be effectively solved through magnesium and lithium separation and lithium carbonate preparation methods, the lithium carbonate preparation process is simplified, cost is reduced, waste magnesium resources are fully utilized, and meanwhile the cost of the magnesium-based functional materials is reduced; high-valued and comprehensive utilization of salt lake magnesium, lithium and boron resources is achieved, and good industrialization prospects are achieved.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

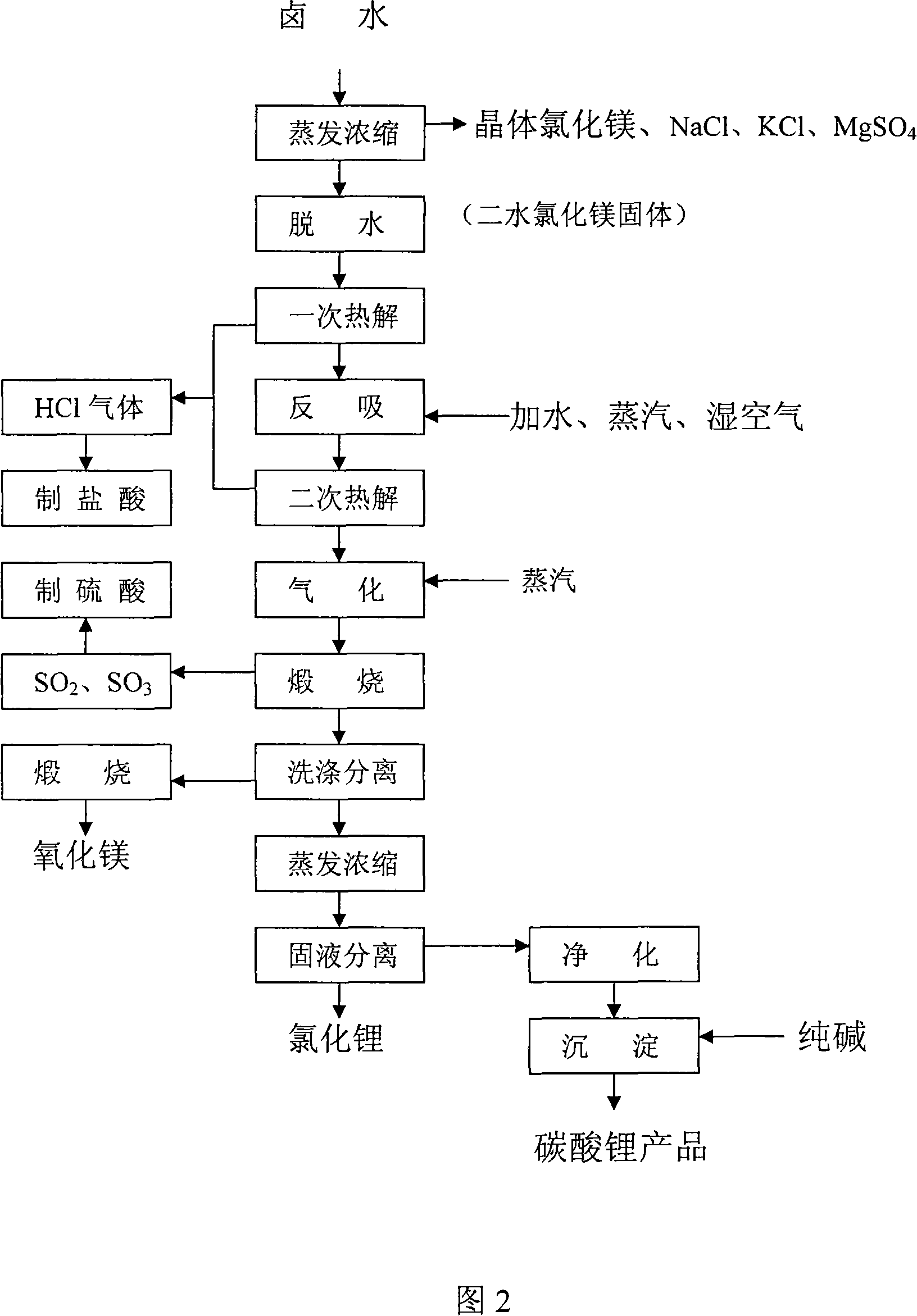

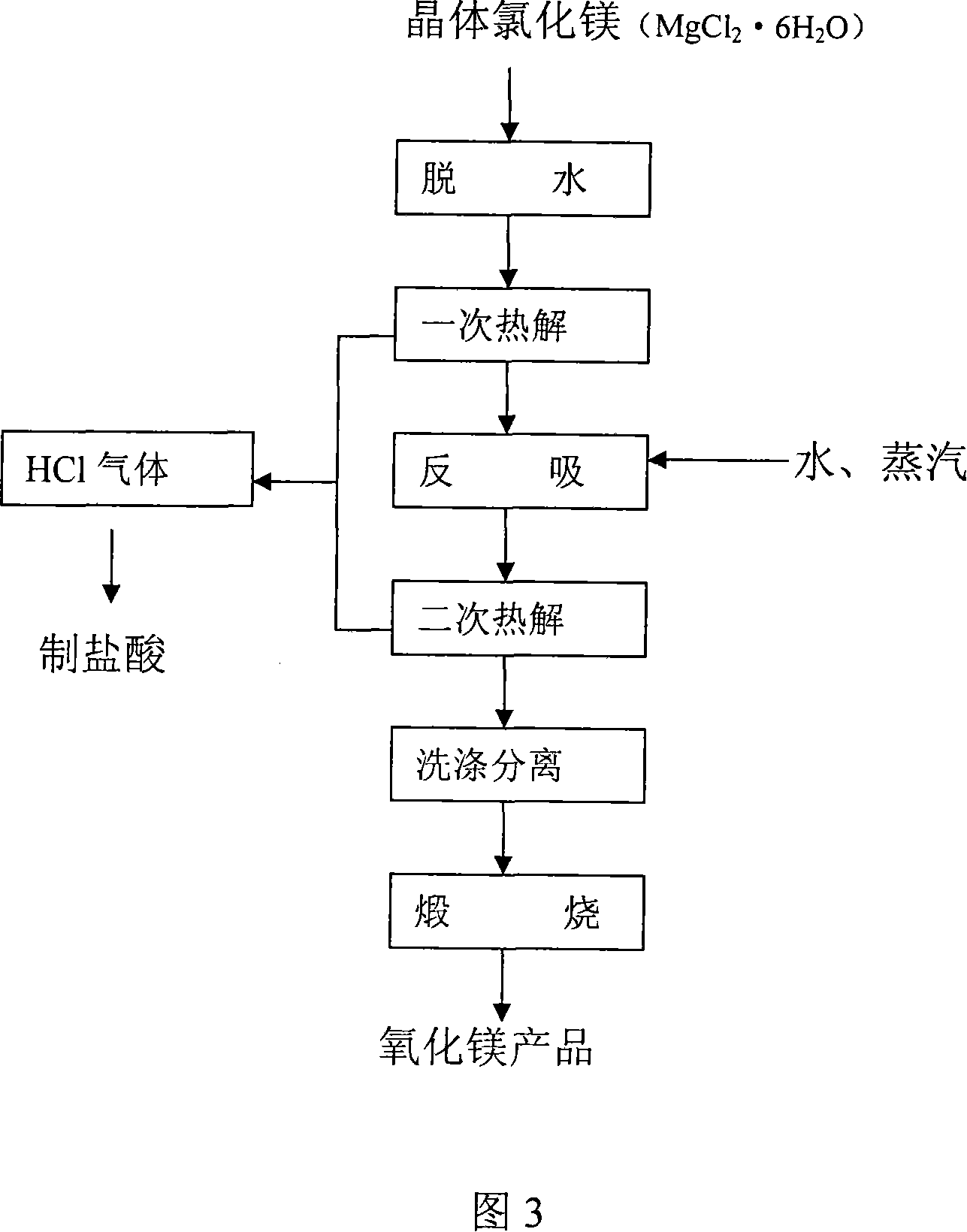

Process for producing high-purity magnesium oxide and lithium salt by using salt lake old brine

InactiveCN101117225ADon't talk about loss rateThe production process is easy to operateAlkali metal chloridesMagnesiaRequirements processMoisture absorption

The invention discloses a process for producing a high purity magnesium chloride, which is as follows: the crystal magnesium chloride separated from the salt lake old brine which is evaporated and concentrated or the residual liquid after the crystallization is processed by primary pyrolysis, counter moisture absorption and secondary pyrolysis. The invention also discloses a process for jointly producing the high purity magnesium chloride and the lithium salt, which is as follows: after the salt lake old brine is evaporated, concentrated and crystallized, the obtained residual liquid is processed by dehydration, primary pyrolysis, counter moisture absorption, secondary pyrolysis, gasification and calcination. The invention is widely adapted to the different salt lake brine, the extraction ratio of magnesium chloride and lithium salt is high. The invention is applied to magnesium chloride production alone, and is also applied to lithium salt joint production, thus the presently difficult technology problem of magnesium-lithium separation is completely resolved at home and abroad. The invention has the advantages of low requirement process, simple equipment, simple principle and easy mastery, short process for single product, low cost for comprehensive productions, .The invention is adapted to the production requirement of different size, and provides the new approach for comprehensive development of the salt lake in Chinese western region.

Owner:陈兆华

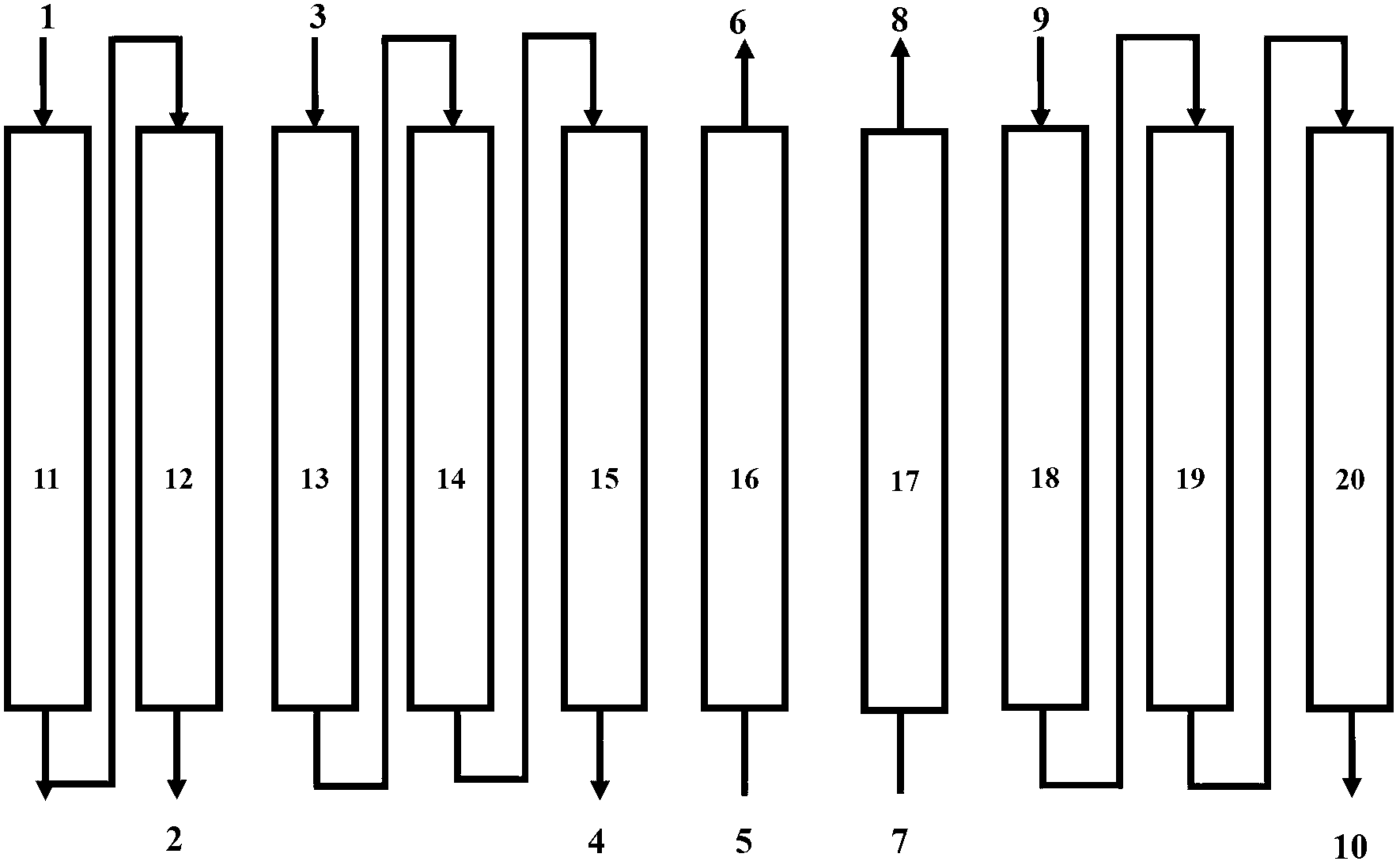

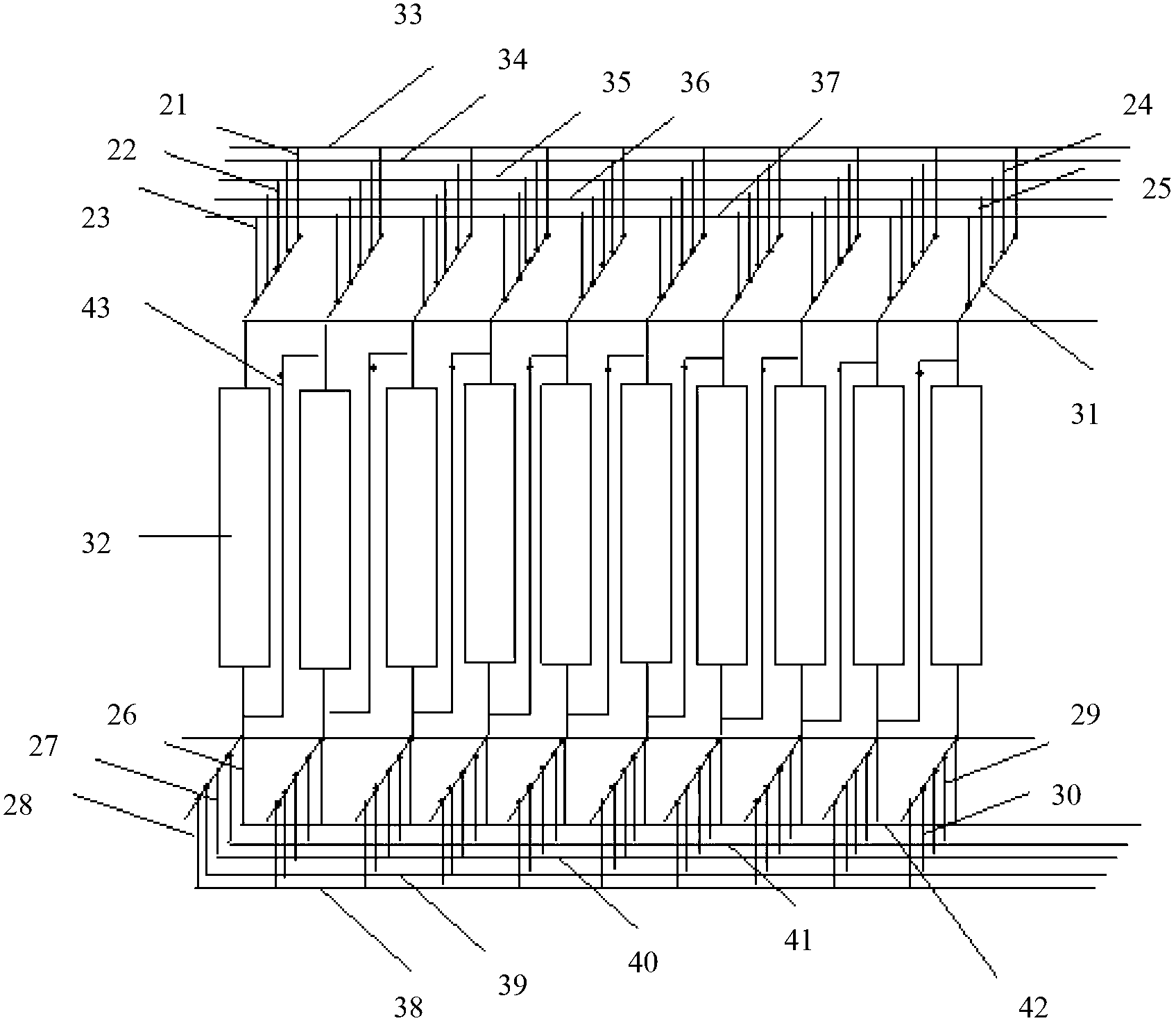

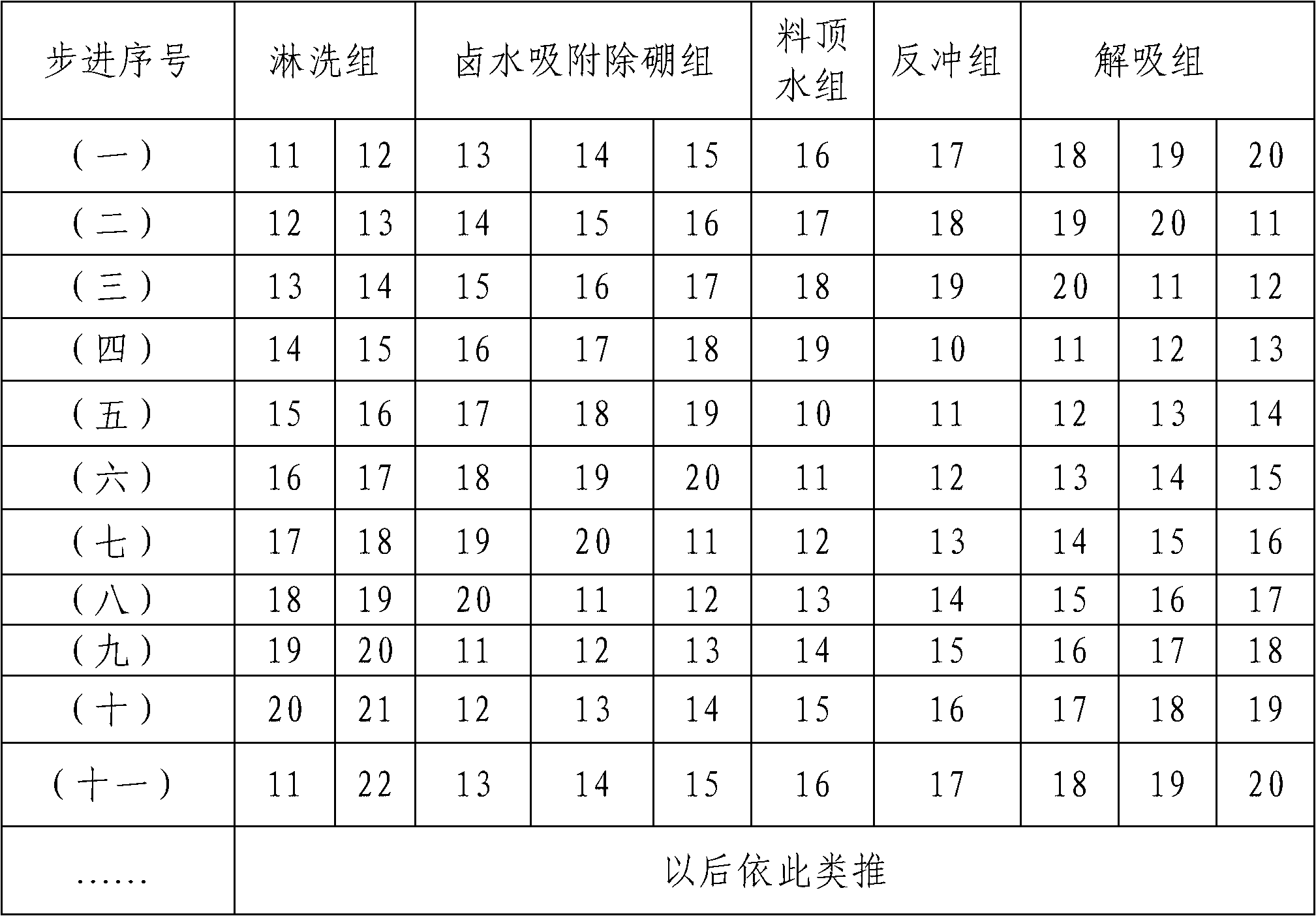

Continuous ion exchange device and method for removing boron from salt lake magnesium chloride brine

ActiveCN102703703AImprove efficiencyIncrease profitProcess efficiency improvementHigh concentrationSalt lake

The invention discloses a continuous ion exchange device and method for removing boron from salt lake magnesium chloride brine. The device comprises resin, a plurality of resin columns used for loading the resin, a feeding header pipe and a discharging header pipe, wherein the feeding header pipe is communicated with the upper end of the same resin column; the discharging header pipe is communicated with the lower end of the same resin column; the resin columns are successively connected in series by a serial pipeline; a brine adsorption boron removal group, a leaching group, a desorption group, a back-washing group and a material top water group which are moved and circularly operated in sequence are formed therebetween; and each feeding branch pipe and each discharging branch pipe are respectively provided with a control valve used for harmoniously controlling all groups of resin columns to realize ion exchanging, leaching and desorbing processes in turn. Compared with the prior art, the continuous ion exchange device disclosed by the invention is simple, is convenient to operate, and has the advantages of high automation degree, small resin use amount, high use ratio, stable product concentration and high concentration of qualified liquid.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

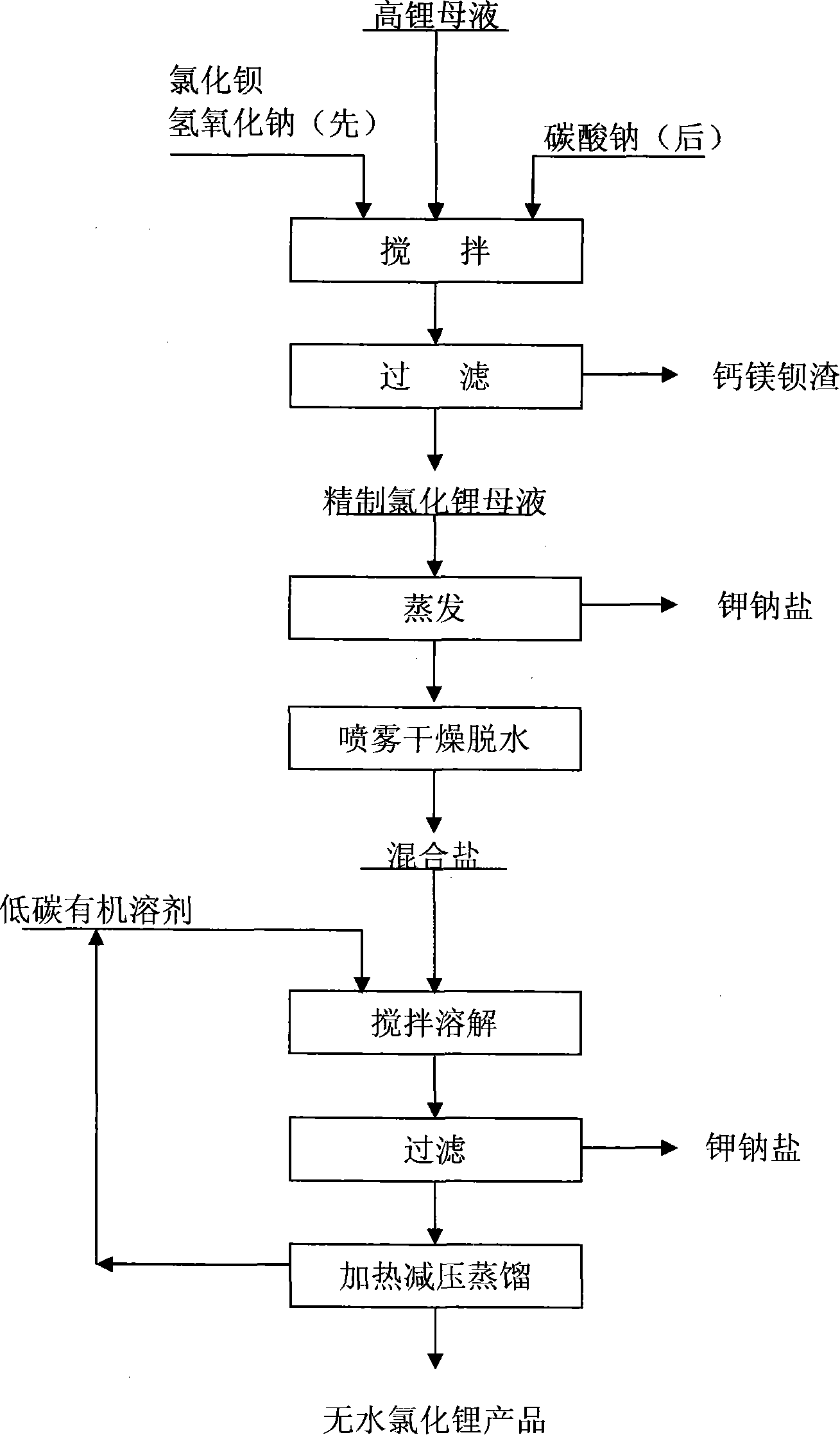

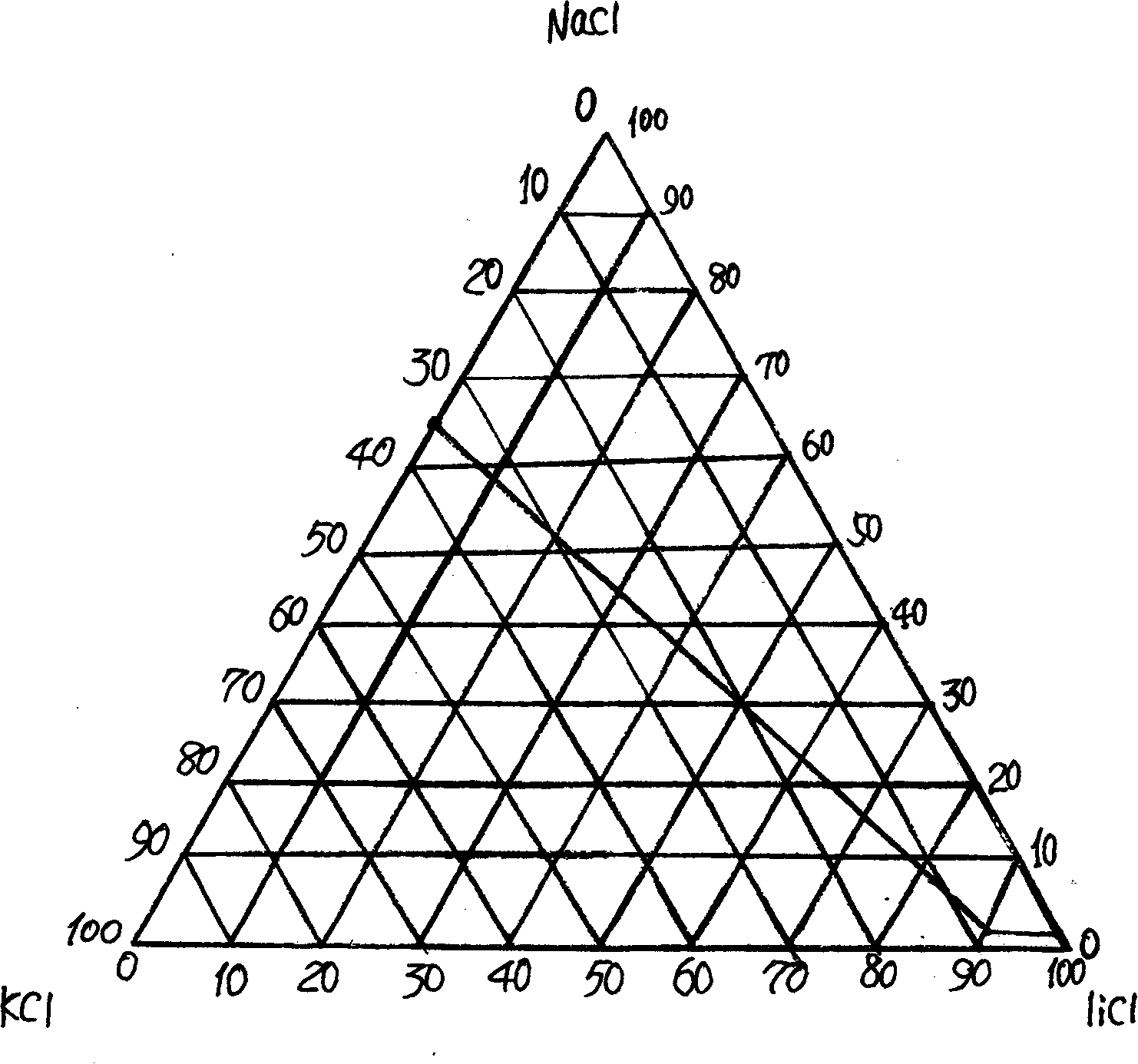

Method of producing high-purity anhydrous lithium chloride

InactiveCN101172624AEfficient separationEfficient purificationAlkali metal chloridesLithium chlorideSolvent

The invention belongs to the chemical field of inorganic salts, in particular to a preparation method of high-purity anhydrous lithium chloride; wherein, sodium hydroxide and barium chloride are added into the high-potassium sodium brine containing lithium chloride which is used as a raw material; the mixture is stirred and filtered to eliminate a great amount of Mg 2 <+> and SO 4 <2->; and the micro Mg 2 <+> and the SO 4 <2-> can be eliminated by adding sodium carbonate into the mixture, and then is filtered to get a refined mother liquid. The refined mother liquid can be evaporated and filtered to eliminate potassium chloride and sodium chloride; and high-potassium mixed salt containing 60 to 95 percent of lithium chloride can be achieved by spraying and drying the refined mother liquid. After adding low-carbon organic solvent, the high-potassium mixed salt is stirred to extract lithium chloride and filtered to eliminate potassium sodium salt. High-purity anhydrous lithium chloride with the purity of over 99.5 percent can be achieved by depressurizing and distilling the mother liquid. The invention is applicable to the extraction art of the lithium chloride used in all present low-magnesium salt lakes containing lithium, and the extraction process of the lithium chloride from the mother liquid achieved after pressing solid lithium ore. The invention not only has the advantages of simple process and low cost, but also is easy to be operated and used in industrialization and has no three-waste pollution.

Owner:青海中信国安科技发展有限公司

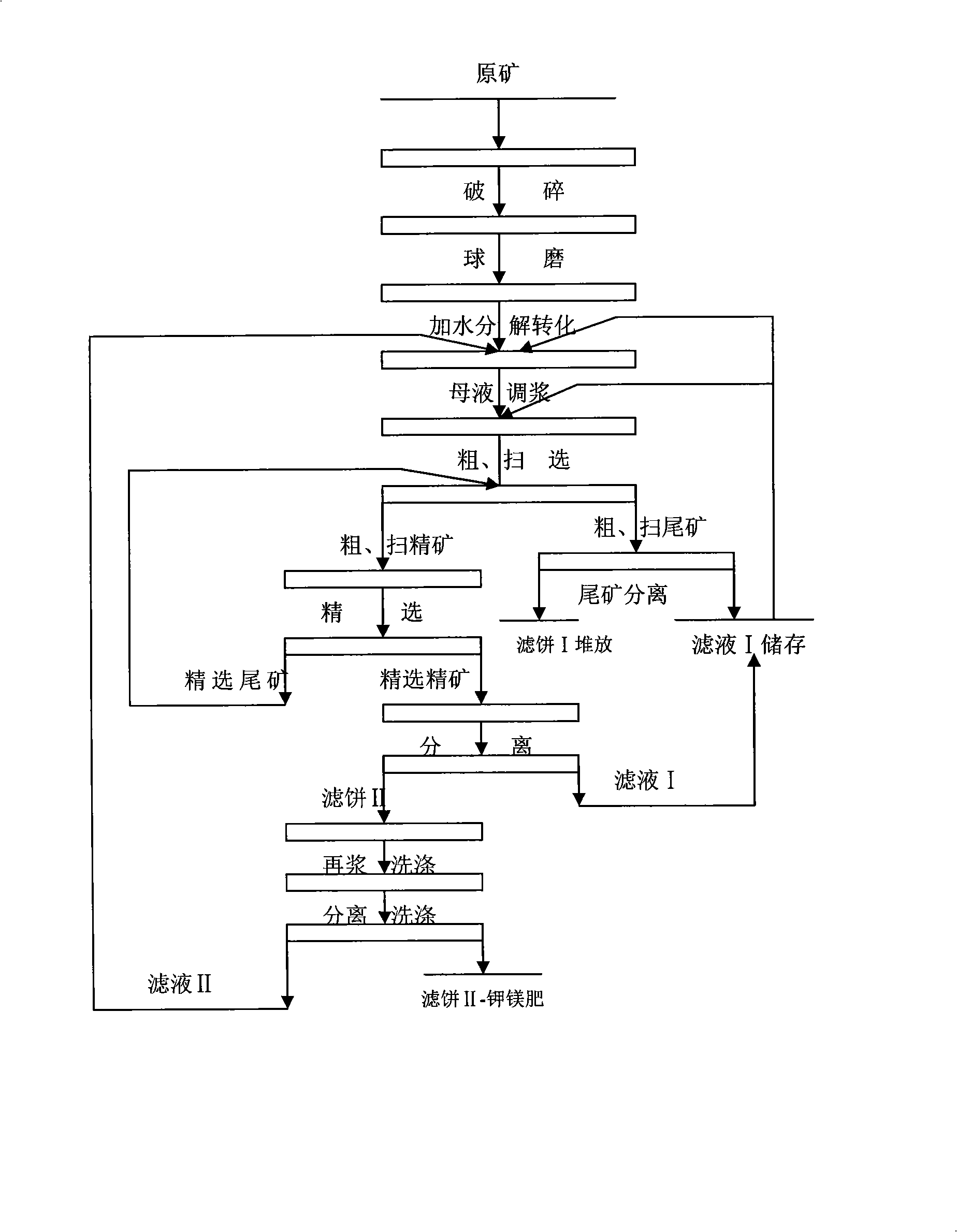

Process for preparing potash magnesium sulphate fertilizer with kalium containing sulfate

InactiveCN101318845AImprove Potassium YieldHigh yieldMagnesium fertilisersPotassium fertilisersDecompositionTemperature and pressure

The invention provides a method for preparing a potash magnesium sulphate fertilizer by utilizing potassium-bearing sulfate mineral, which takes the potassium-bearing sulfate mineral obtained by solarization of sulphate type salt lake potassium-containing brine water as a raw material to prepare potash magnesium sulphate fertilizer products in accordance with national potash magnesium sulphate fertilizer product standard, through processes such as crushing, grinding ore, decomposing and converting, floatation and separation, secondary pulp washing and so on. The method utilizes decomposing mother liquor and secondary pulp washing liquid to decompose raw material ores, the circulating utilization ratio of the decomposing mother liquor is more than or equal to 80 percent, and the circulating utilization ratio of the secondary pulp washing liquid reaches 100 percent, thereby improving yield of potassium, reducing water amount for decomposition and reducing the water consumption of ton-product by 30 to 70 percent compared with other methods for producing the potash magnesium sulphate fertilizer. The whole production process is carried out at normal temperature and pressure, which reduces energy consumption; and the quality of the potash magnesium sulphate fertilizer products meets or exceeds national standard (GB / T20937-2007) for potash magnesium sulphate fertilizer qualified products.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

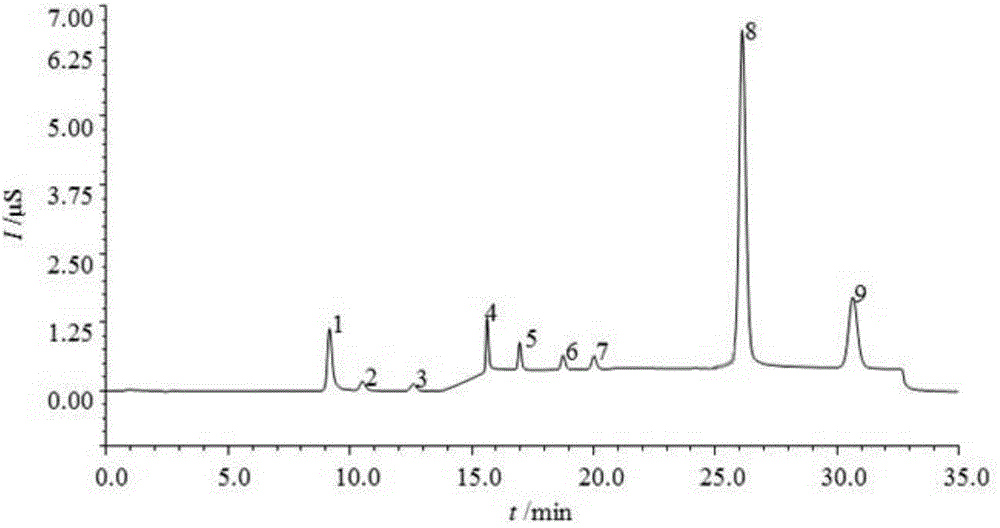

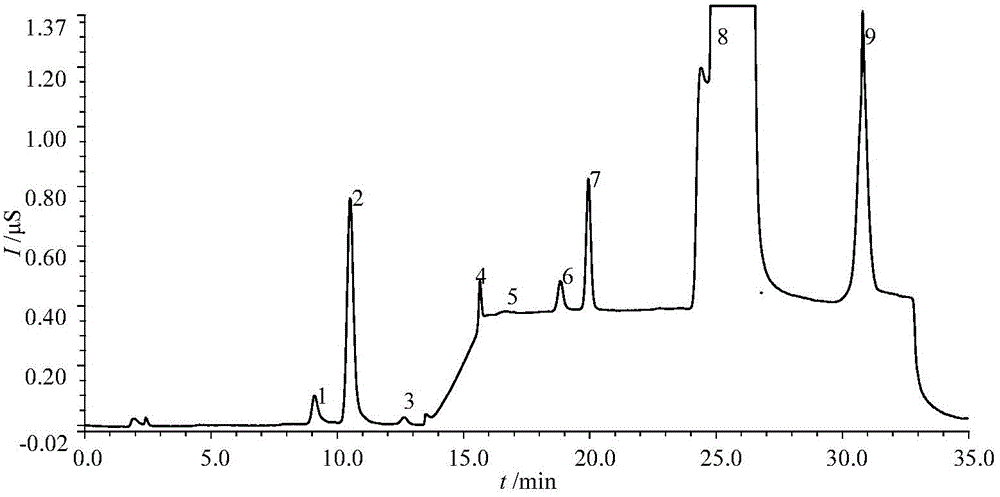

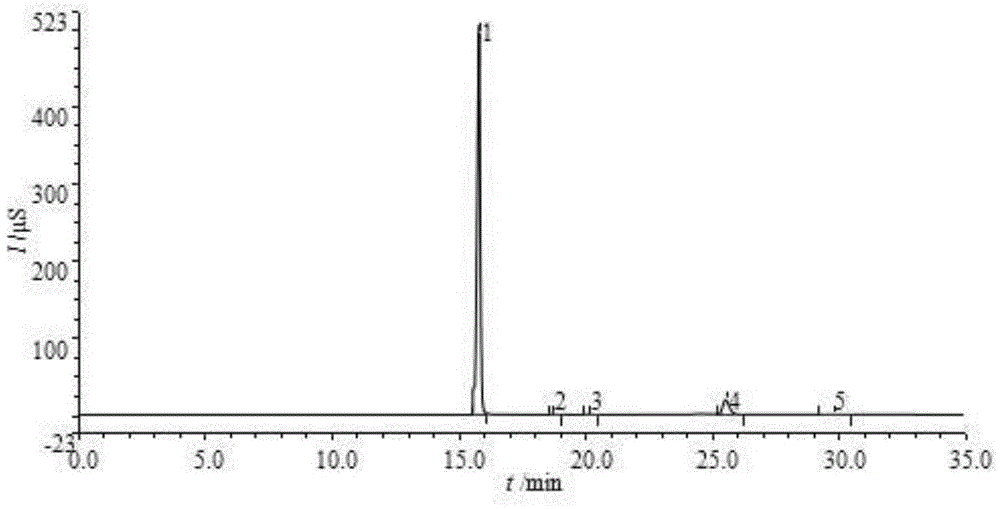

Method for simultaneously determining inorganic anions and organic acid radical ions in salt lake brine

The invention discloses a method for simultaneously determining inorganic anions and organic acid radical ions in salt lake brine. The method is characterized by preprocessing a certain quantity of samples of the salt lake brine, simultaneously separating and determining 6 types of inorganic anions comprising F<-1>, Cl<-1>, NO2<-1>, Br<-1>, NO3<-1> an SO4<2-> and 3 types of organic acid radical ions comprising CH3COO<-1>, HCOO<-1> and C2O4<2-> in the salt lake brine by carrying out secondary gradient elution through an ion chromatography. The result shows that the method is simple and convenient, high in accuracy and capable of providing the important reference basis for simultaneously separating and determining a plurality of anions in the salt lake brine and exploring resources of the salt lake.

Owner:QINGHAI UNIVERSITY

Method for extracting lithium from salt lake brine

InactiveCN104357677AEasy to operateReduce concentrationProcess efficiency improvementHigh concentrationSalt lake

The invention provides a method for extracting lithium from salt lake brine. The method comprises the following steps: adding HCl and FeCl3.6H2O to an extract water phase (an LiCl-MgCl2-H2O system), and controlling the ratio of amount of substances of iron and lithium to be 1.3 to 1; standing after fully mixing the extract water phase with an extract organic phase in a volume ratio of 1 to 2, and separating a liquid phase. By adopting the method, the problems that the corrosivity of high-concentration tributyl phosphate towards extraction equipment is stronger and the dissolution loss of an extracting agent in water is serious in long-term operation are solved, and the lithium extraction efficiency of the prior art is achieved. The extraction method is simple and reliable to operate.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Boron extraction technology

The invention discloses a boron extraction technology. Brine water after extracting lithium from salt lake is used as raw paderial and 2-thyl-1,3-hexanediol respectively with mixture alcohol of isooctal alcohol and isoamyl alcohol extracts borone from the brine water and optimum processing condition for extracting boron from brine water using the mixture alcohol is obtained after performing experiments from the aspects of extractant volume fraction, acidity, phase ratio, extraction time, extraction temperature, saturation extraction volume, back washing agent concentration and back washing time: extractant volume fraction 30%, water phase pH 3, phase ratio 1:1, extraction time 10min, maximum saturation capacity 61.4g / L(B2O3).

Owner:于网林

Preparation and application of 2-hydroxymethyl-12-crown 4-ether modified hierarchically-porous silicon material

ActiveCN106390912AHigh selectivityHigh adsorption capacityOther chemical processesSilicon compoundsCelluloseLithium

The invention relates to preparation of a lithium ion adsorption material, especially to a preparation method for a 2-hydroxymethyl-12-crown 4-ether modified hierarchically-porous silicon material, belonging to the technical field of synthesis of composite materials. The preparation method comprises the following steps: preparing nanocrystal cellulose at first; then with nanocrystal cellulose as a hard template and cetyl trimethyl ammonium bromide as a soft template, preparing a hierarchically-porous silicon material by using a template process; and then modifying the hierarchically-porous silicon material with 2-hydroxymethyl-12-crown 4-ether. The invention also discloses application of the modified hierarchically-porous silicon material to adsorption of alkali metal ions, especially to adsorption of lithium ions in salt lake bittern. According to the invention, the hierarchically-porous material with a high specific surface is employed, so the adsorption capacity of the modified hierarchically-porous silicon material is greatly improved; and the preparation process is simple and easy to operate. The lithium ion adsorption material prepared in the invention can realize high-efficiency high-selectivity adsorption and separation of alkali metal ions, especially lithium ions, and provides a feasible solution to sustainable development of the industry of extraction of lithium from a salt lake.

Owner:江阴智产汇知识产权运营有限公司

Method for enriching boron and lithium elements in sulfate type salt lake brine

ActiveCN103194622AReduce manufacturing costReduce the ratio of magnesium to lithiumBoron/boridesChemical industrySalt lakePotassium

The invention relates to a method for enriching boron and lithium elements in sulfate type salt lake brine. The method comprises the following steps of: (1) introducing the sulfate type salt lake brine into a pre-sunning pool, and regulating the concentration of sodium ions to a saturation state of sodium chloride; (2) introducing the brine with the sodium chloride in the saturation state into a mirabilite pool, and freezing in winter to precipitate mirabilite; (3) evaporating the brine after the precipitation of the mirabilite in spring and summer to precipitate the sodium chloride; (4) performing potassium removal treatment on the brine after the precipitation of the sodium chloride; (5) introducing the brine after potassium removal into an epsomite pool, and precipitating epsomite to obtain the brine with high content of magnesium chloride; and (6) mixing the brine with high content of magnesium chloride with the mirabilite for reaction, and performing solid-liquid separation to obtain a solution which is rich in boron and lithium elements.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

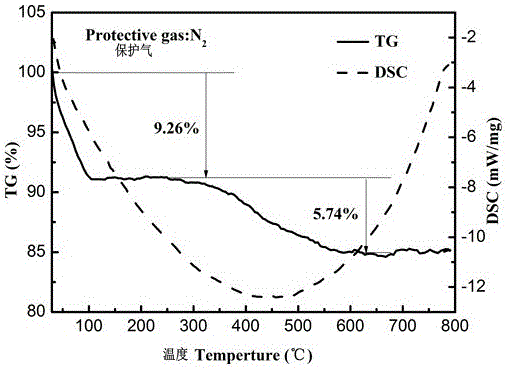

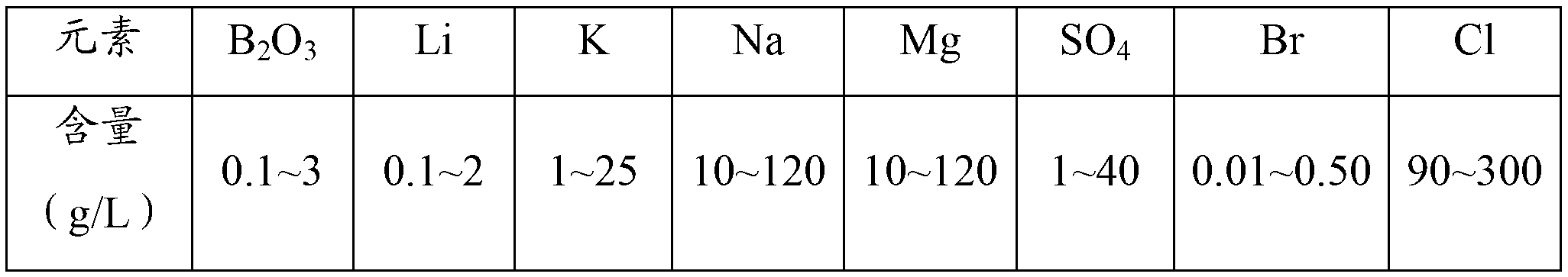

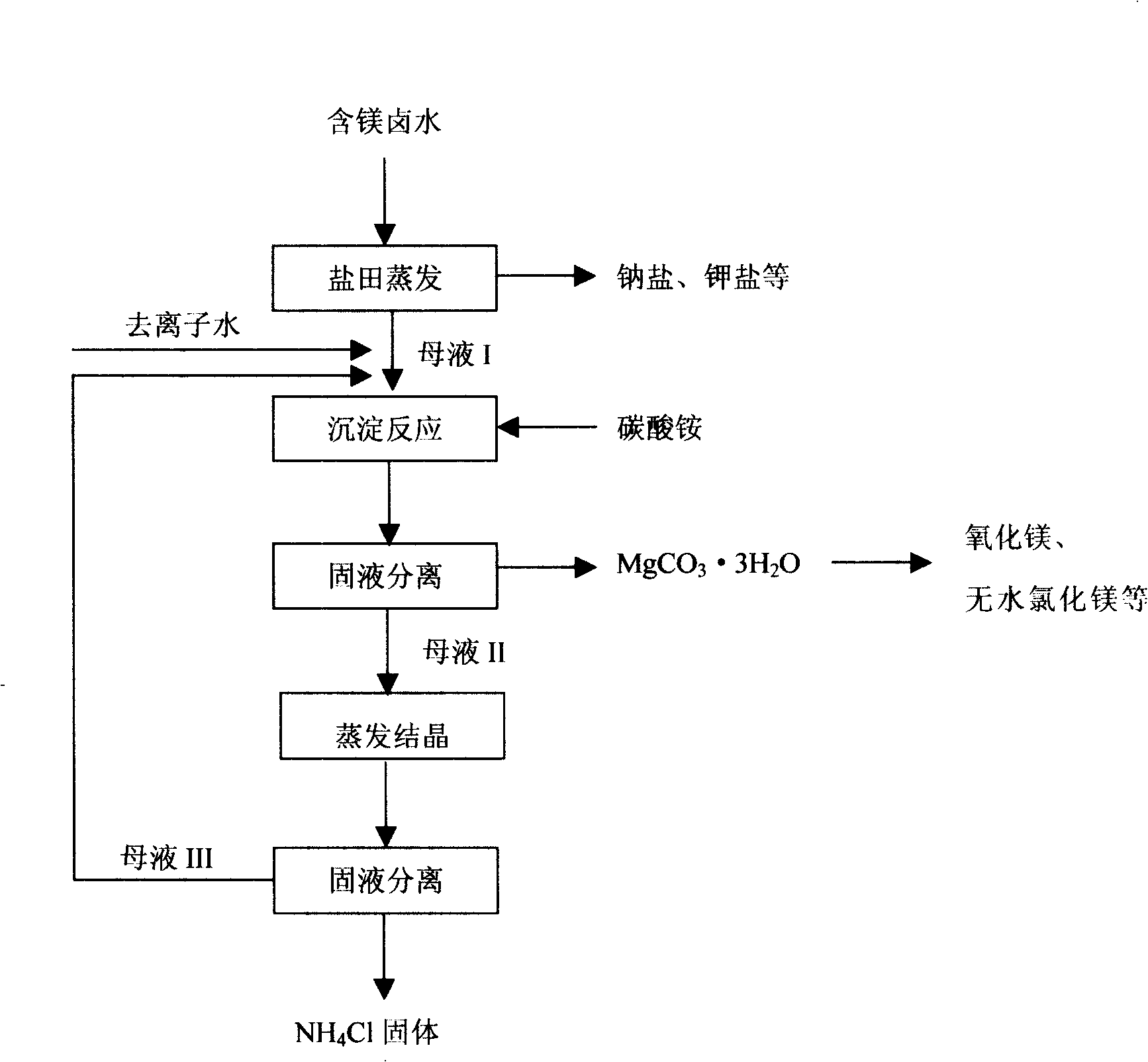

Method for preparing trihydrated magnesium carbonate from magnesium chloride-containing bittern by using ammonium carbonate

InactiveCN101259968AImprove the environmentSolve the use problemMagnesium carbonatesChemical industryHigh concentration

The invention belongs to the salt chemical industry technical field, in particular to a method for producing trihydrated magnesium carbonates and ammonium chlorides from magnesium chloride containing brine water by utilizing ammonium carbonates. The invention adopts the technical proposal that: the trihydrated magnesium carbonates are produced by taking the magnesium chloride containing brine water with high concentration as materials and the ammonium carbonates as precipitating agents. The trihydrated magnesium carbonate crystals with desirable shapes can be obtained by controlling technological conditions, so that the adsorption of impurities is reduced, and the products have relatively high purity; the trihydrated magnesium carbonate crystals obtained by reaction are big in volume and easy to filter, thereby lowering the energy consumption of filtering; moreover, the method of the invention has the advantages of strong operability, easy realization of industrialization, good economic benefits of byproducts and no environmental pollution, and realizes the comprehensive utilization of salt lake resources.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

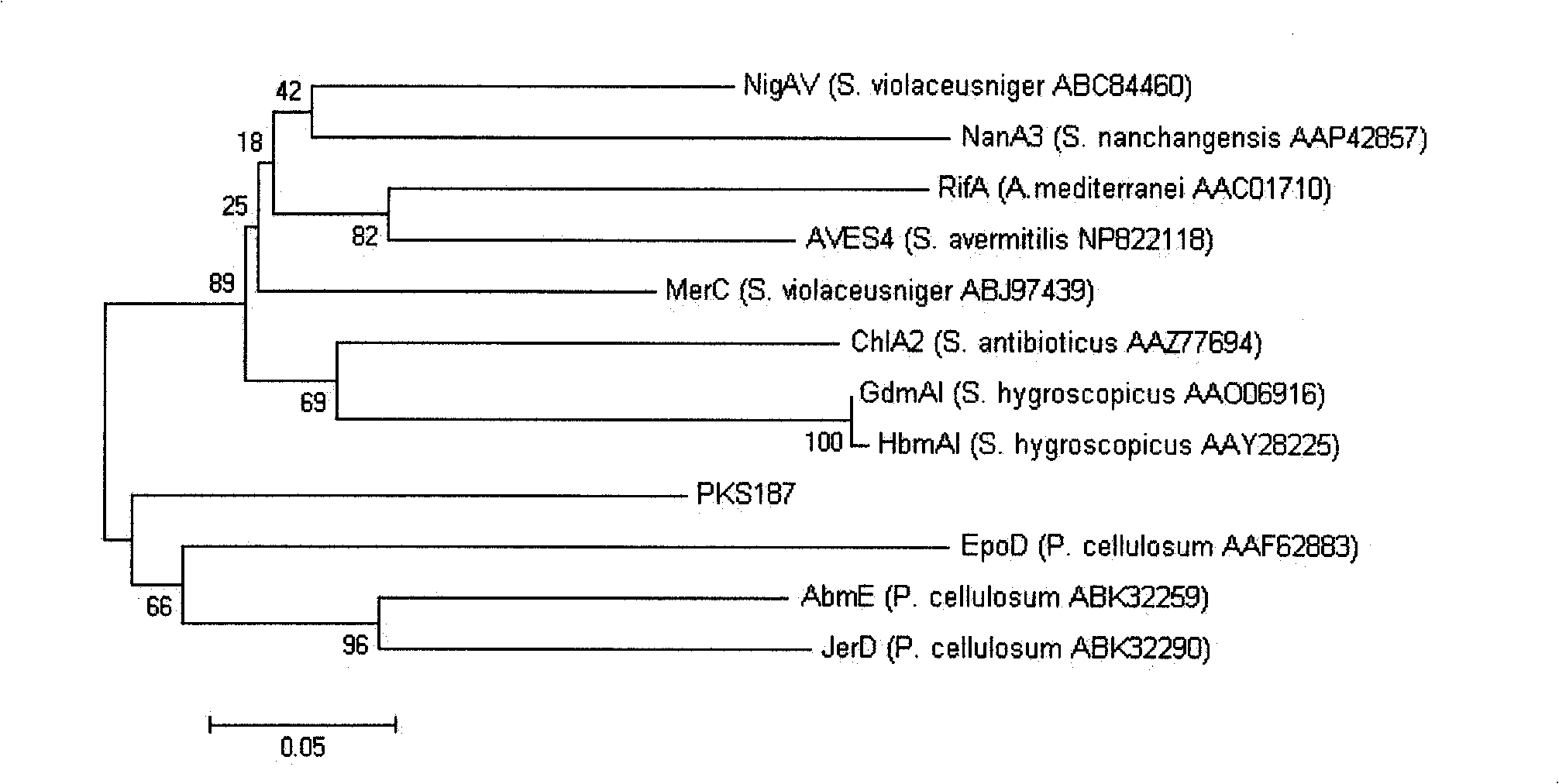

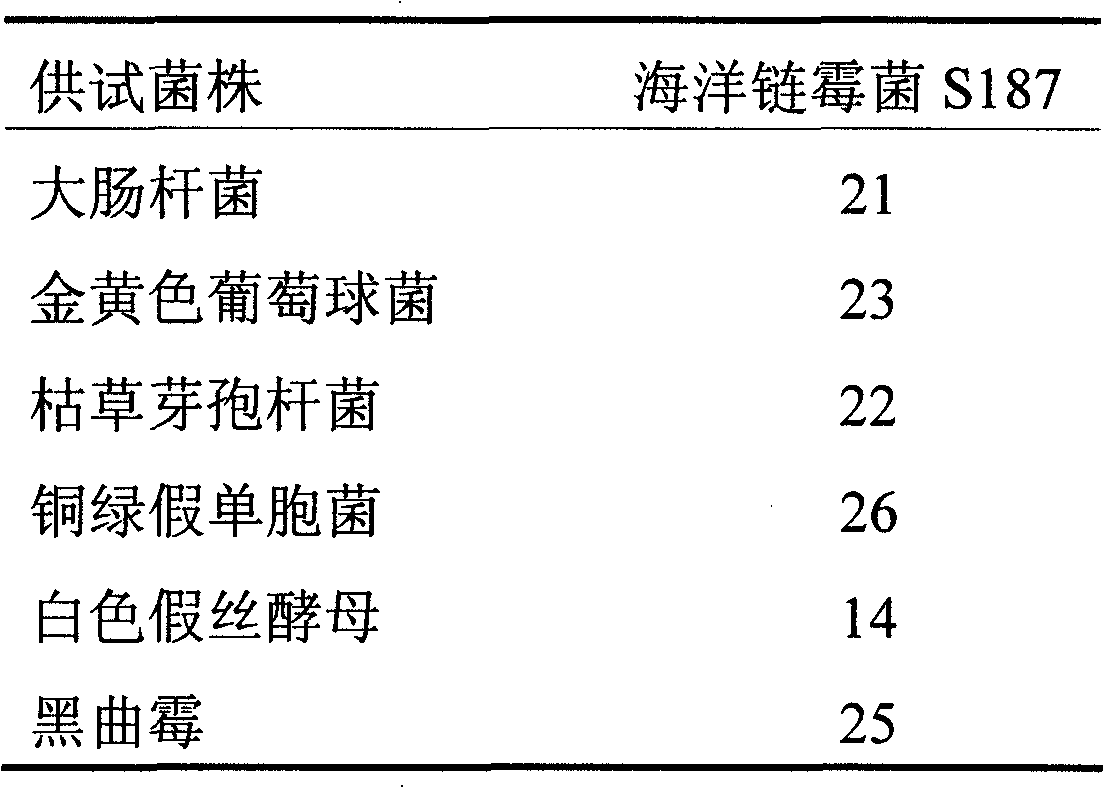

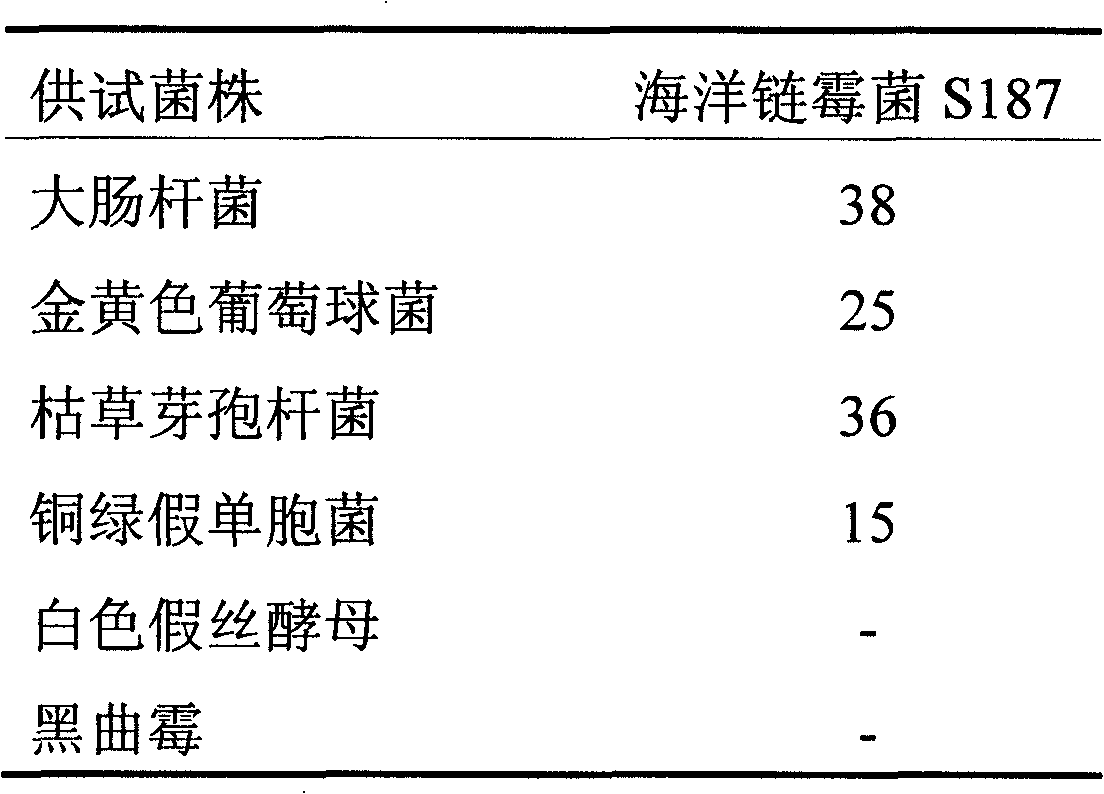

Marine streptomyces S187 having wide-spectrum antibacterial activity

InactiveCN101302482AHas broad-spectrum antimicrobial activityHigh antibacterial activityBiocideBacteriaEscherichia coliStaphylococcus aureus

The invention relates to marine streptomyces S187 having broad-spectrum antibacterial activity, belonging to the microbiological actinomycetes field. The marine streptomyces S187 is separated from a sea mud sample at a depth of 20 meters underwater in coastal waters. Primary screening through an agar block method proves that the bacterial strain has very strong antibacterial activity to Escherichia coli, Staphylococcus aureus, Bacillus subtilis, Pseudomonas aeruginosa, Candida albicans and Aspergillus niger; the result of fermentation liquid secondary screening confirms good activity for antagonizing the Escherichia coli, the Staphylococcus aureus and the Bacillus subtilis. The analysis for 16S rDNA shows that the only actinomycetes having the homology as high as 99 percent with the marine streptomyces S187 is the salt lake bacterial strain Streptomyces chungwhensis (DSM41483) separated by Korean scholars, but the bacterial strain is separated from the sea mud sample for the first time. I type polyketide synthase (PKSI) is successfully amplified out from the streptomyces S187, which indicates that the streptomyces S187 has the potential ability of generating polyketide.

Owner:DALIAN UNIV OF TECH

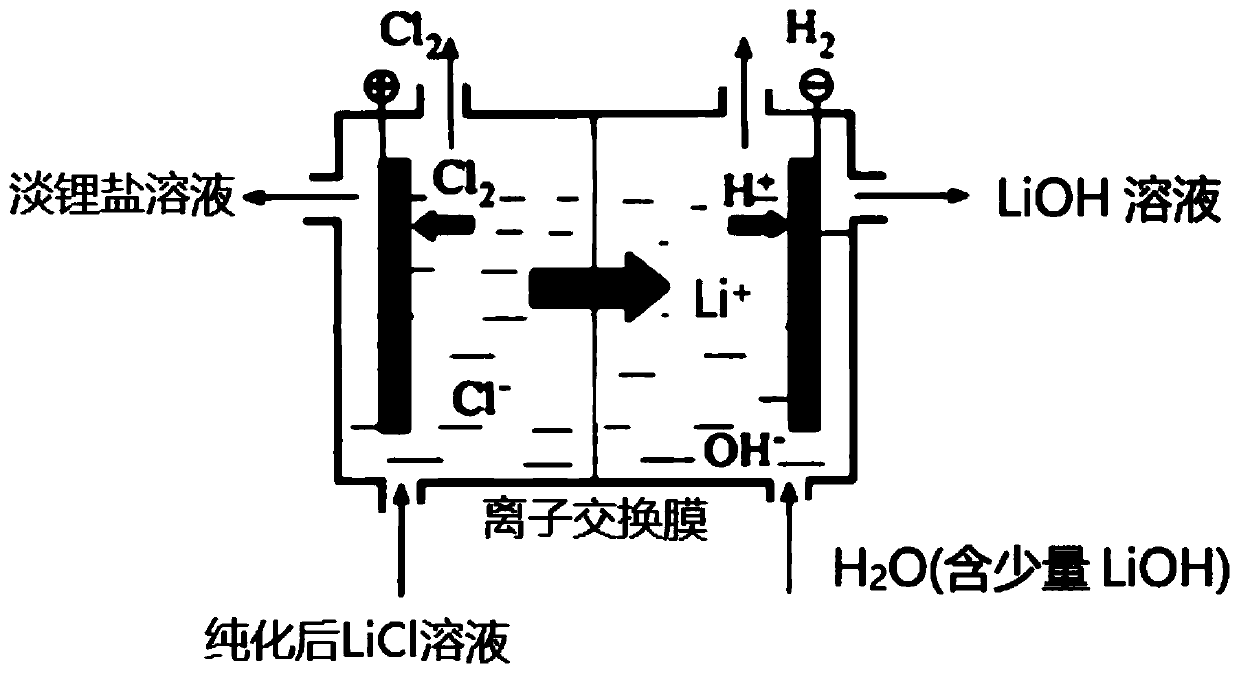

Method for preparing lithium hydroxide from lithium-containing low-magnesium brine

PendingCN111394745ALow costReduce shipping costsCellsProcess efficiency improvementLithium oxideSalt lake

The invention provides a method for preparing lithium hydroxide from lithium-containing low-magnesium brine, and relates to the technical field of salt lake lithium extracting. The method comprises the following steps: adjusting the pH value of the lithium-containing low-magnesium brine to be more than 10 by adopting an inorganic base to precipitate calcium and magnesium to obtain calcium and magnesium removed lithium-containing brine; extracting lithium in the calcium and magnesium removed lithium-containing brine by adopting an organic extracting agent to obtain raffinate containing sodium and potassium and a lithium-containing loaded organic phase; carrying out reverse extracting on the lithium-containing loaded organic phase by using an inorganic acid solution to obtain a lithium saltsolution; purifying the lithium salt solution and then electrolyzing to obtain a lithium hydroxide solution; and concentrating and crystallizing the lithium hydroxide solution to obtain lithium hydroxide and lithium hydroxide precipitation mother liquor. The method disclosed by the invention is simple and convenient to operate, high in lithium hydroxide product yield, high in purity, high in material cyclic utilization rate, low in cost, capable of continuously preparing the lithium hydroxide, and particularly suitable for extracting lithium from salt lakes of Tibet, Qinghai and South America,which are remote in geographical position, high in raw material transportation cost and low in photovoltaic power generation and energy storage cost.

Owner:YIDING SHANGHAI INFORMATION TECH CO LTD

Method for preparing lithium magnesium silicate montmorillonite using salt lake brine water

InactiveCN1789124AAvoiding Separation Technical DifficultiesReduce the introductionSilicon compoundsSeparation technologyMetasilicate

The invention provides a method for synthesizing magnesium metasilicate swinefordite by directly using salt lake saline water, which comprises: adding the soluble metasilicate into the salt lake condensed saline water, adjusting the mixing solution to make it not less than 11 with queous alkali, and adjusting the stoichiometric ratio of the magnesium, lithium and metasilicate in the mixing solution by using primary magnesium product and lithium product, then putting the mixing solution in the pressure reacting pan to react under high pressuer and high water temperature, rotary scrubbing or sucting after cooling, drying and getting the magnesium metasilicate lithium powder. The invention employs the abundant lithium, magnesium resource in the salt lake to synthesize magnesium metasilicate lithium, without the separation of magnesium and lithium, which passes the technological problem of separating magnesium and lithium, and the invention is characterized by simple process, short producing period, low cost, high product added value and suitable for industrialization; the raw material is nontoxic and harmless, there is no pollution during the whole process and no side product; the invention provides a new idea and way for comprehensive development and use of the salt lake resource.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Method for preparing lithium carbonate with high-lithium salt lake bittern

InactiveCN105036159AReduce contentHigh purityLithium carbonates/bicarbonatesInorganic saltsLithium chloride

The invention relates to the field of inorganic salt chemical engineering and discloses a method for preparing lithium carbonate with high-lithium salt lake bittern. The method comprises the steps of adding inorganic salt into the salt lake bittern for removing impurities, extracting lithium chloride, and then adding addition agents, complexing agents and precipitating agents into a lithium chloride solution for preparing the lithium carbonate. By means of the added complexing agents, micro calcium and magnesium ions remaining in the bittern can be effectively removed, and the content of the calcium and magnesium ions in a lithium carbonate product is reduced; by means of the addition agents, the lithium carbonate purity is effectively raised.

Owner:韦海棉

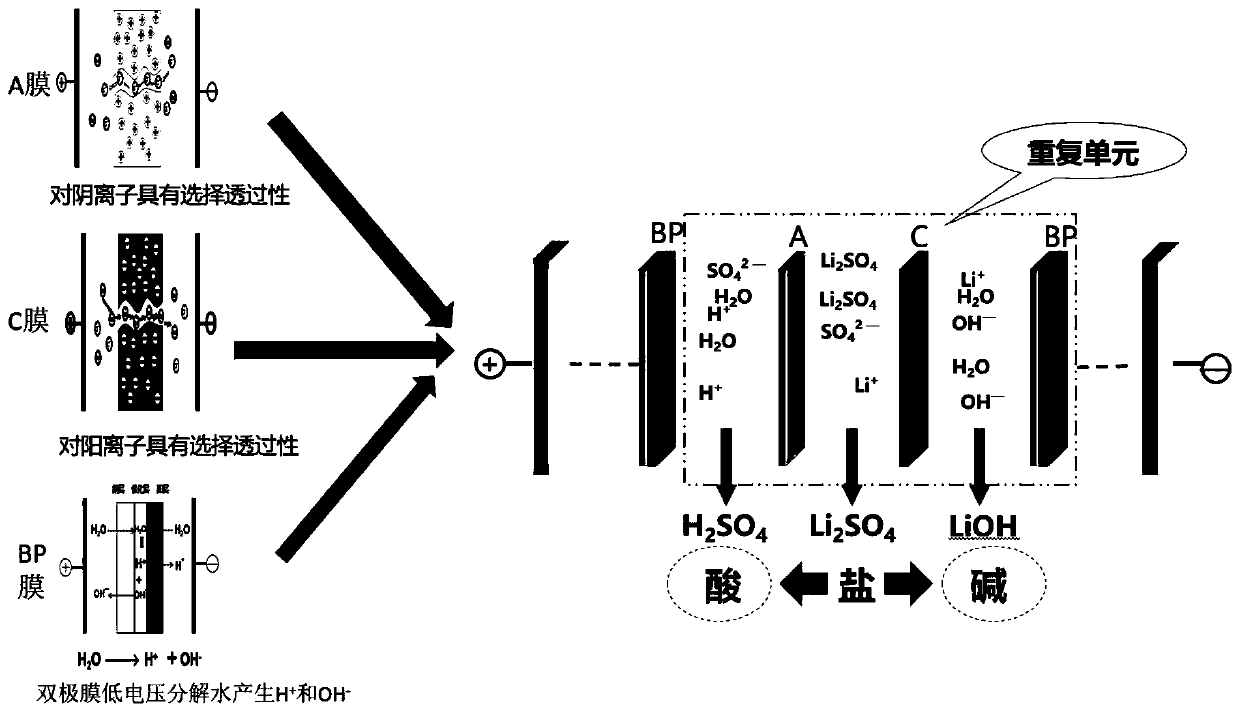

Novel process for producing high-purity lithium hydroxide by salt lake brine

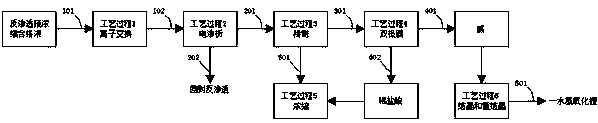

InactiveCN108385128AOptimize acid and alkali consumptioOptimize product lossElectrolysis componentsProcess efficiency improvementLithium chlorideElectrolysis

The invention discloses a novel process for producing high-purity lithium hydroxide by salt lake brine. The process comprises the following steps that A, and the process comprises the following operation mode that the process adopts continuous operation, wherein the scale of each device is optimized through the data calculated by the process, the operation mode is optimized, so that continuous operation is achieved; and B, the salt lake brine is subjected to lithium extraction (by an adsorption method or an electrodialysis method), lithium-magnesium separation, purification and reverse osmosispre-concentration to obtain a lithium chloride qualified solution, and the reverse osmosis pre-concentration qualified solution comprise the following raw materials of, 35-50 g / L of lithium chloride,lower than 10 mg / L of calcium-magnesium ions, and lower than 200 mg / L of boron ions. According to the method, (an adsorption method or a membrane method) ), the magnesium chloride solution subjectedto lithium extracting by brine, magnesium removal and reverse osmosis pre-concentration is taken as the raw material, the electrodialysis technology, a reverse osmosis technology, a resin adsorption technology, an ion membrane electrolysis technology, an evaporative crystallization technology and the like are adopted, so that the high-purity lithium hydroxide product is produced, and therefore cyclic utilization of salt lake lithium resources is guaranteed.

Owner:何朋飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com