Patents

Literature

154 results about "Carbon.organic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon dioxide is considered by chemists as inorganic, along with carbon monoxide, carbonates and bicarbonates. Nature has not distinguished compounds into inorganic and organic compounds that clearly. These compounds of carbon are just assumed to be inorganic.

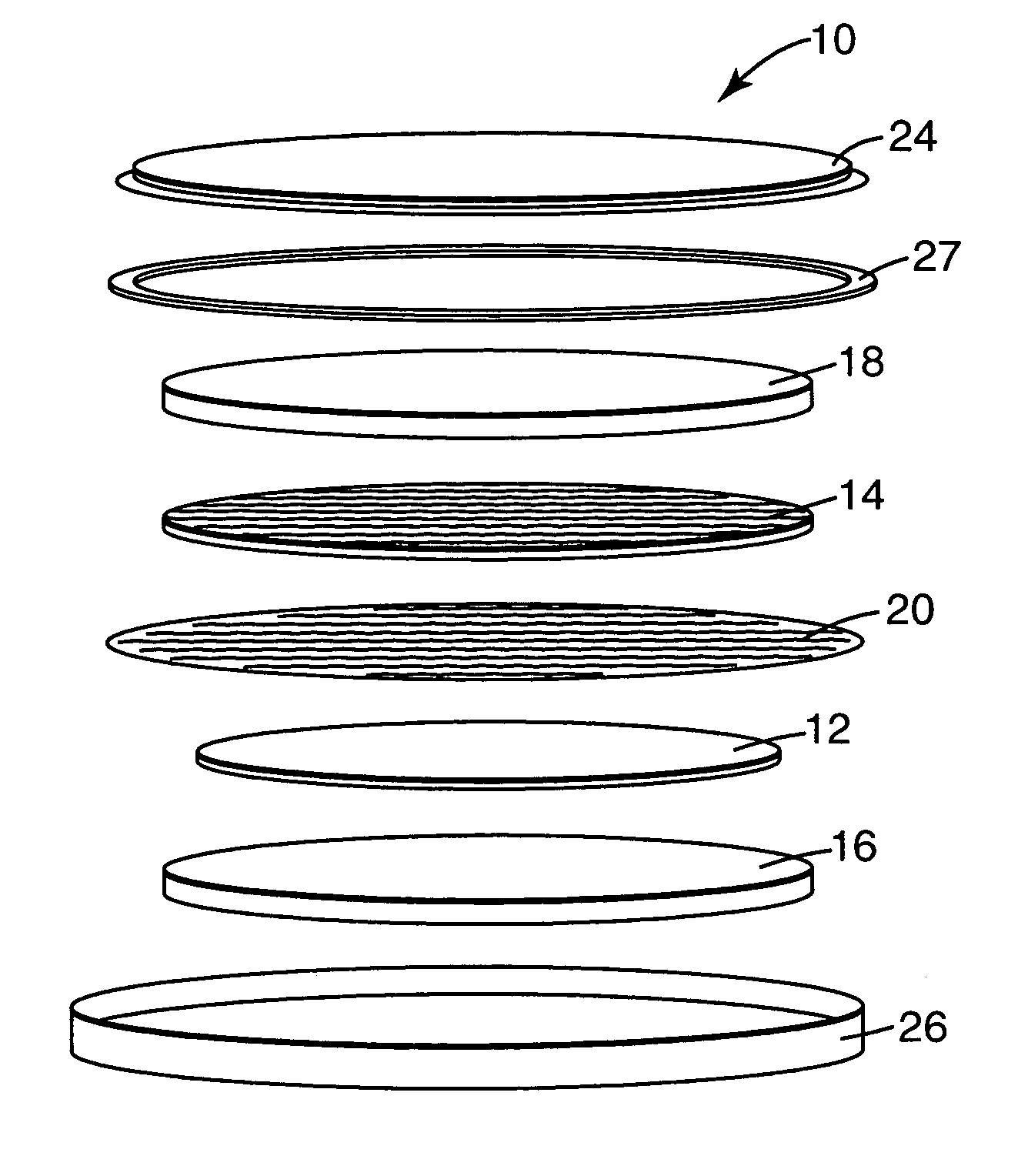

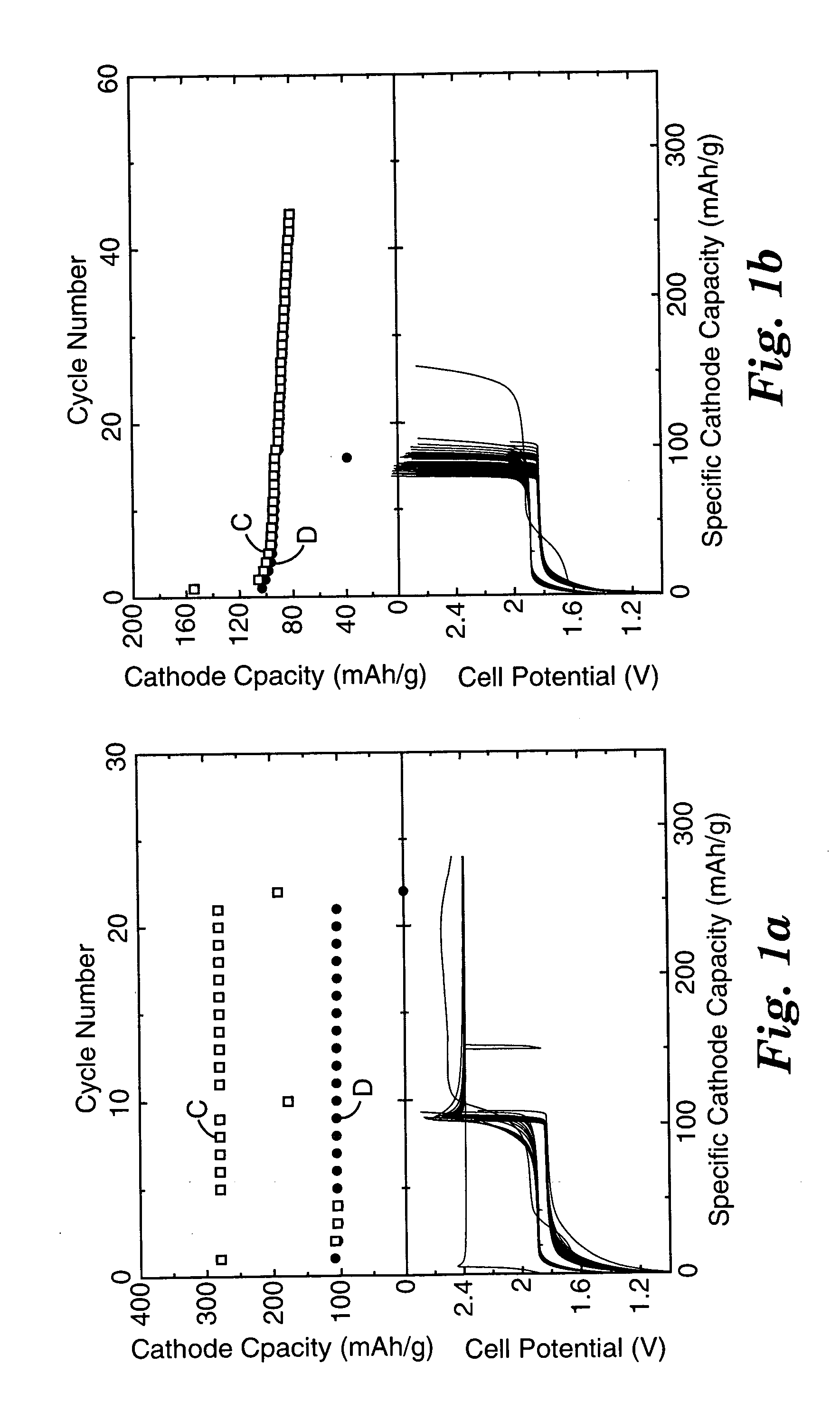

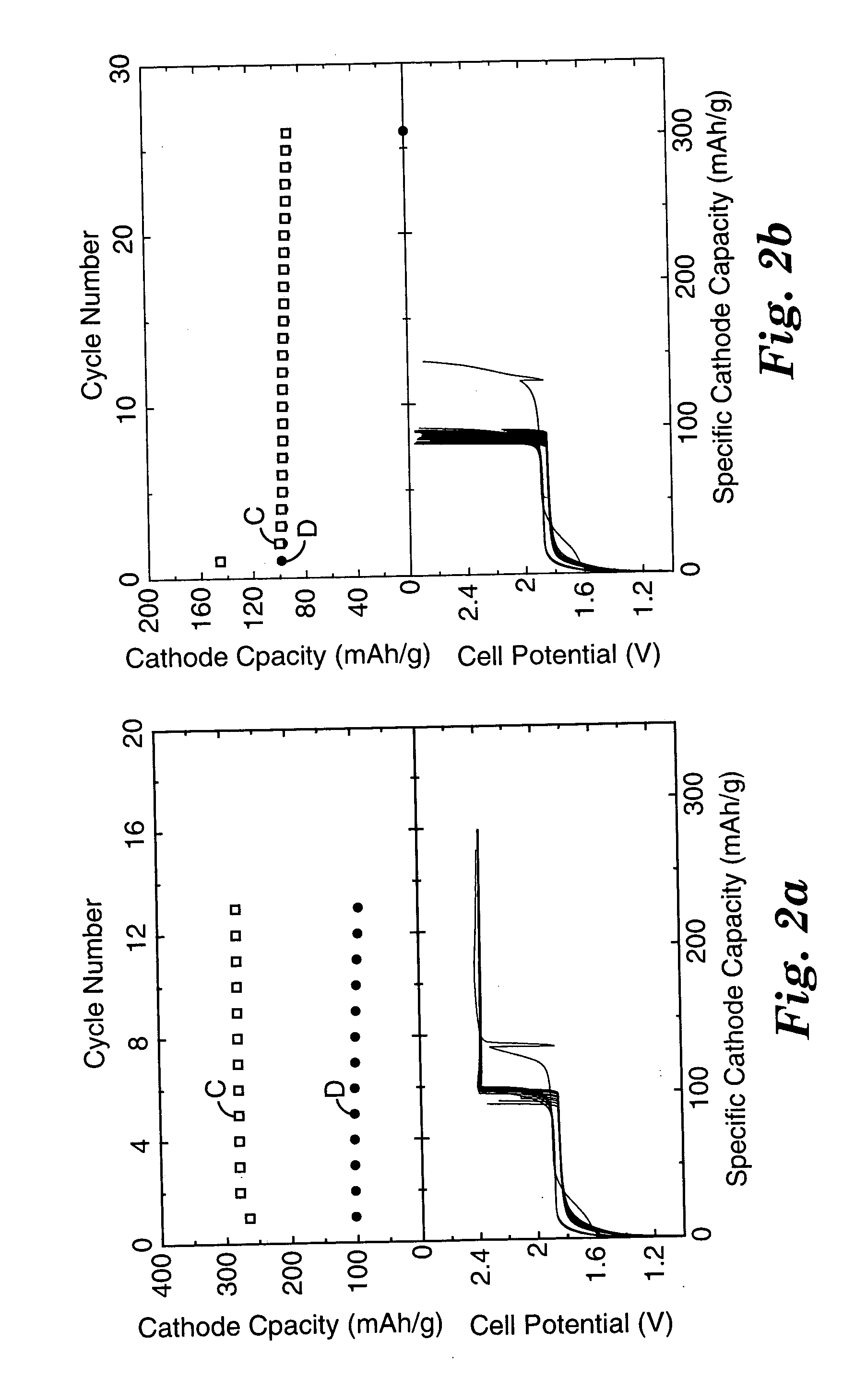

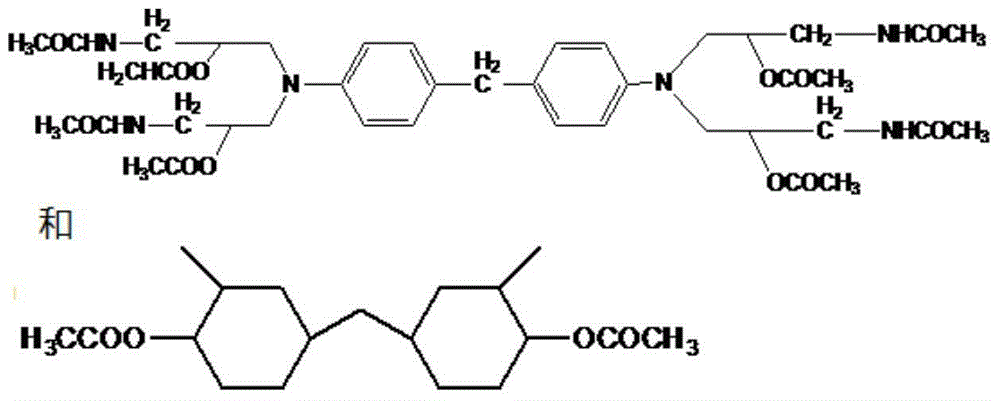

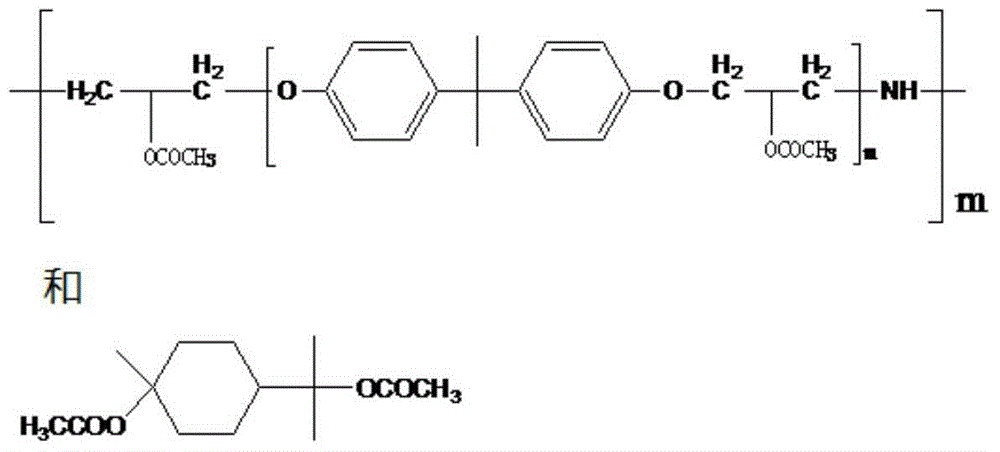

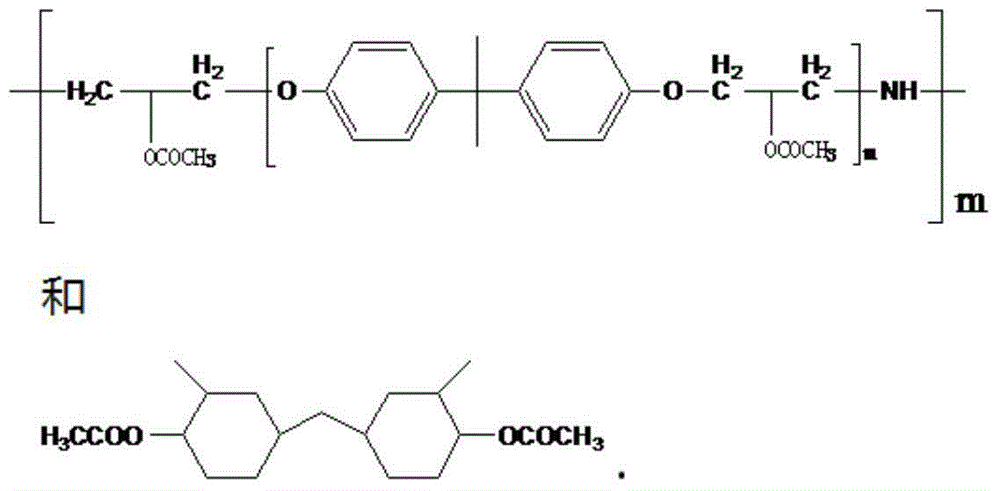

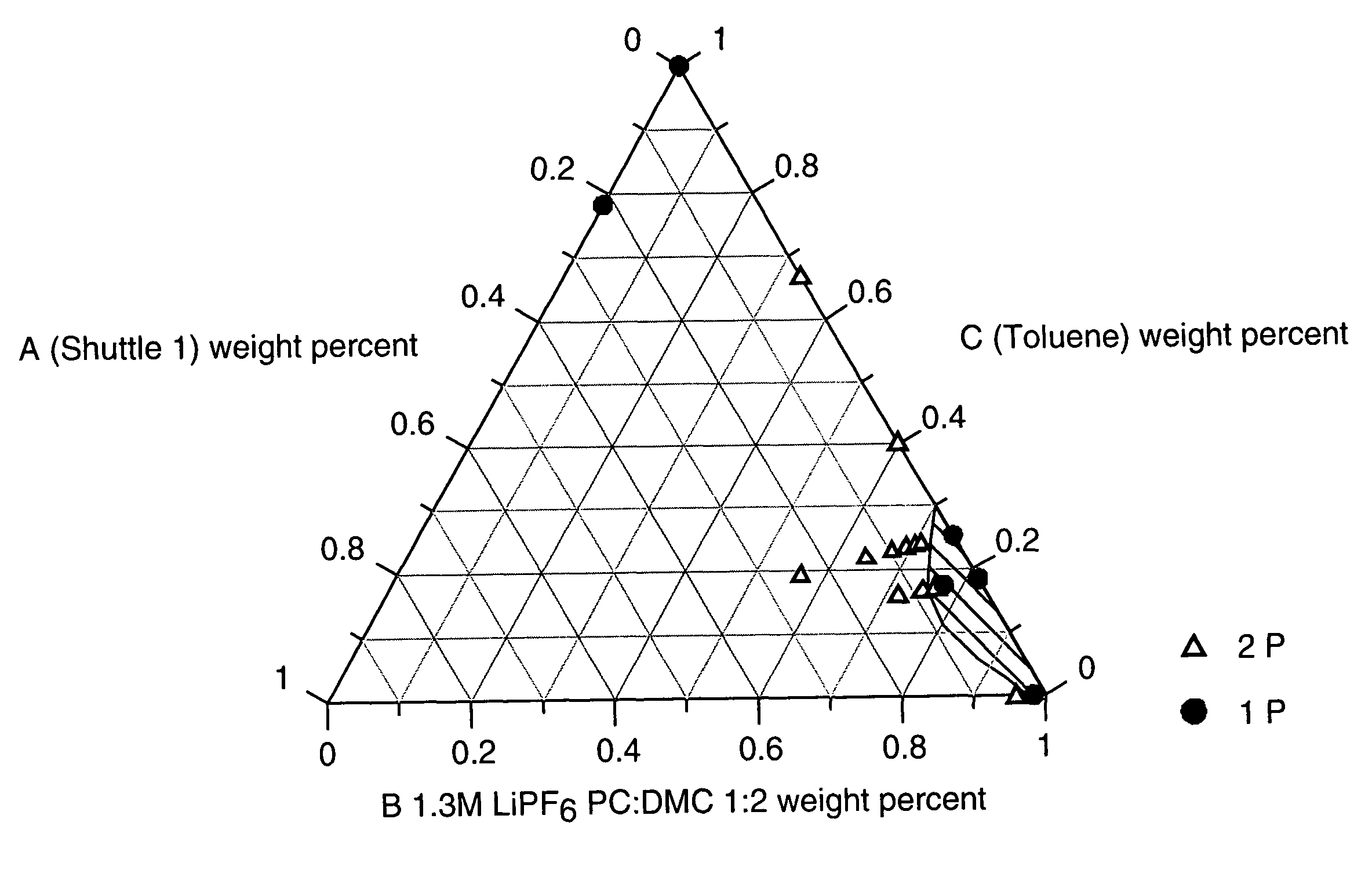

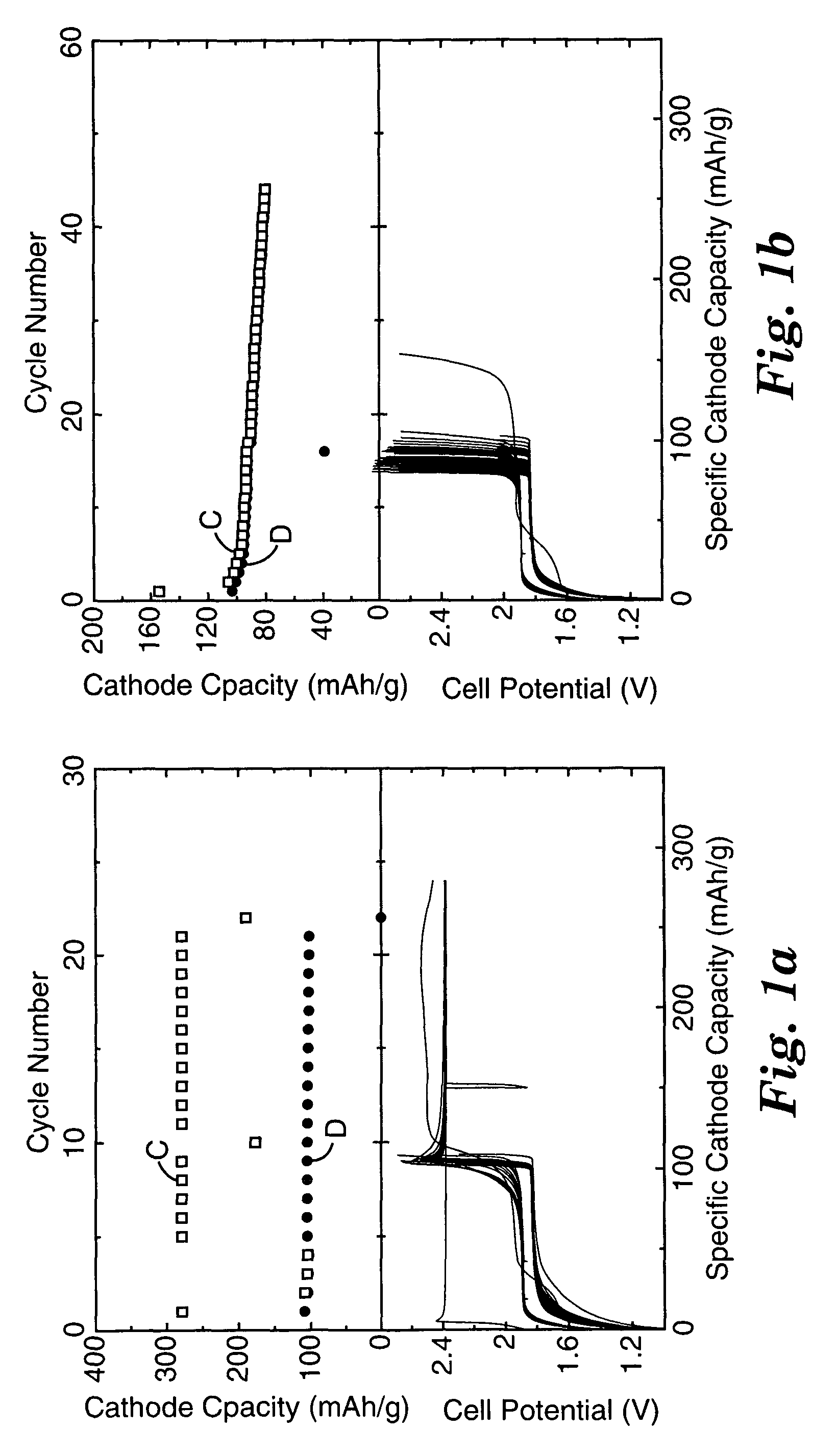

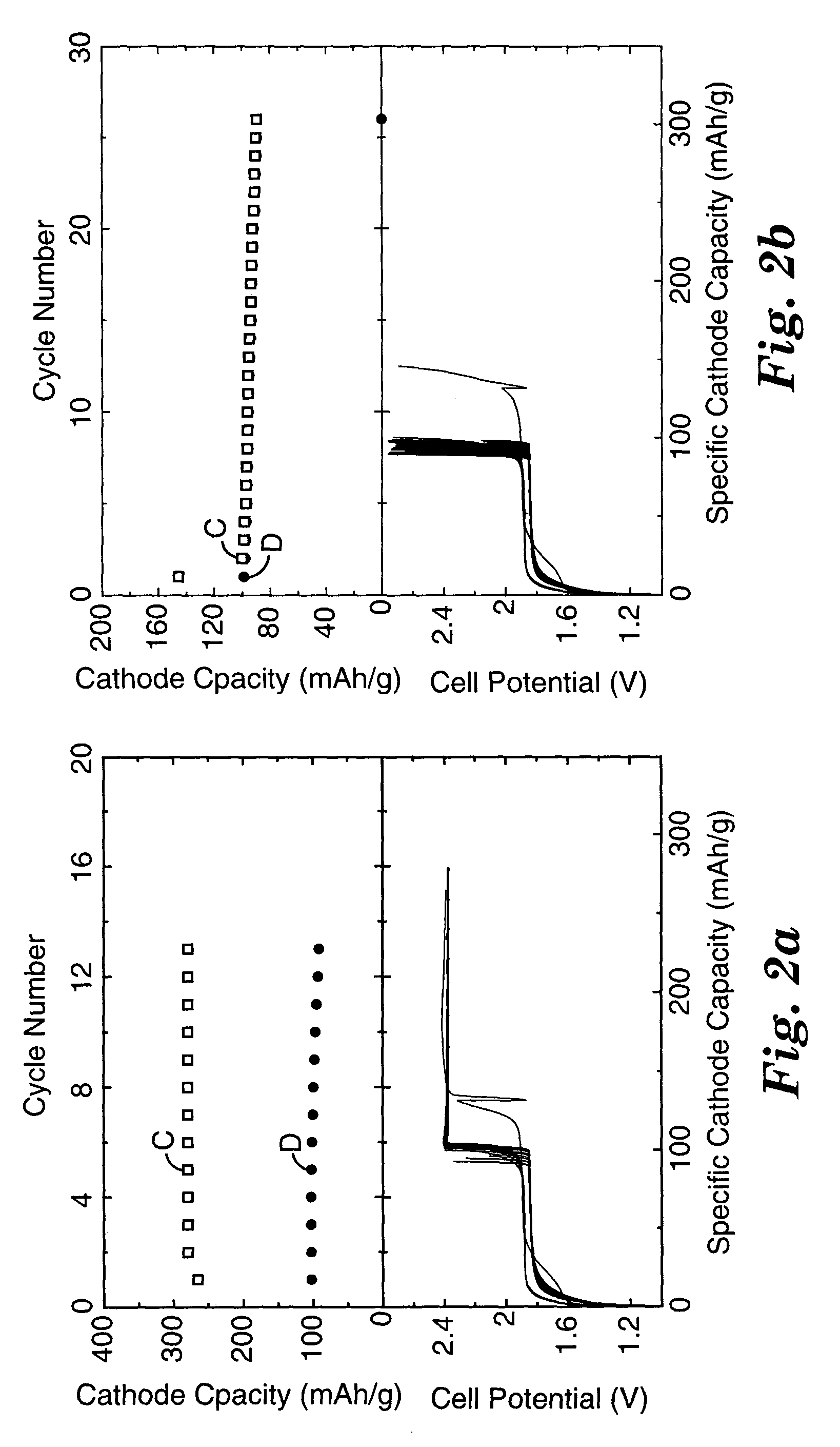

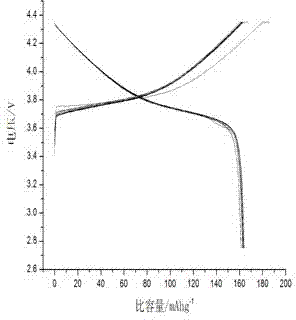

Redox shuttle for rechargeable lithium-ion cell

InactiveUS20050221196A1Excellent repeated overcharge stabilityNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsLithiumAlkoxy group

A redox chemical shuttle comprising an aromatic compound substituted with at least one tertiary carbon organic group and at least one alkoxy group (for example, 2,5-di-tert-butyl-1,4-dimethoxybenzene) provides repeated overcharge protection in rechargeable lithium-ion cells.

Owner:3M INNOVATIVE PROPERTIES CO

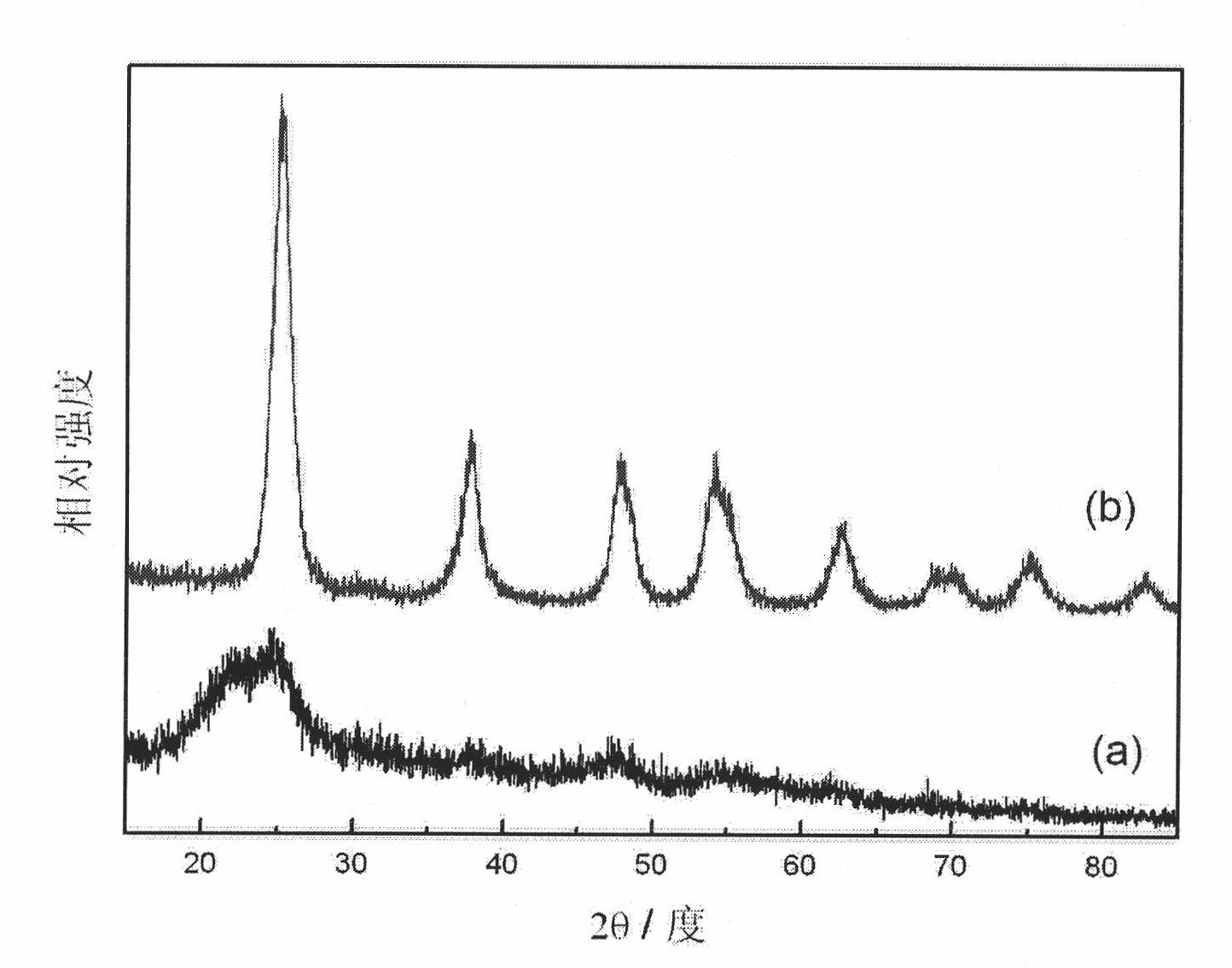

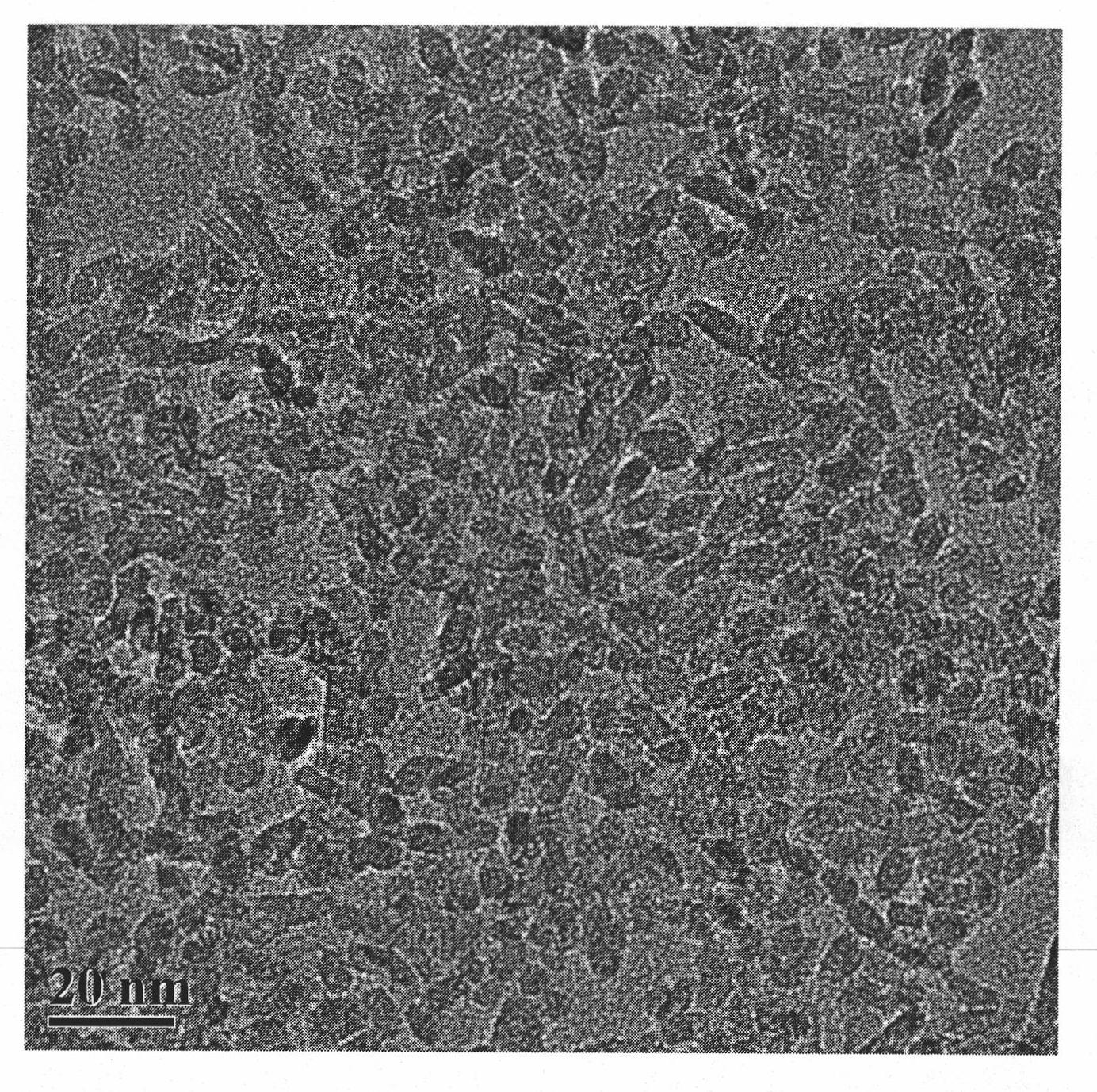

Method for mass preparing hollow nanometer carbon cages

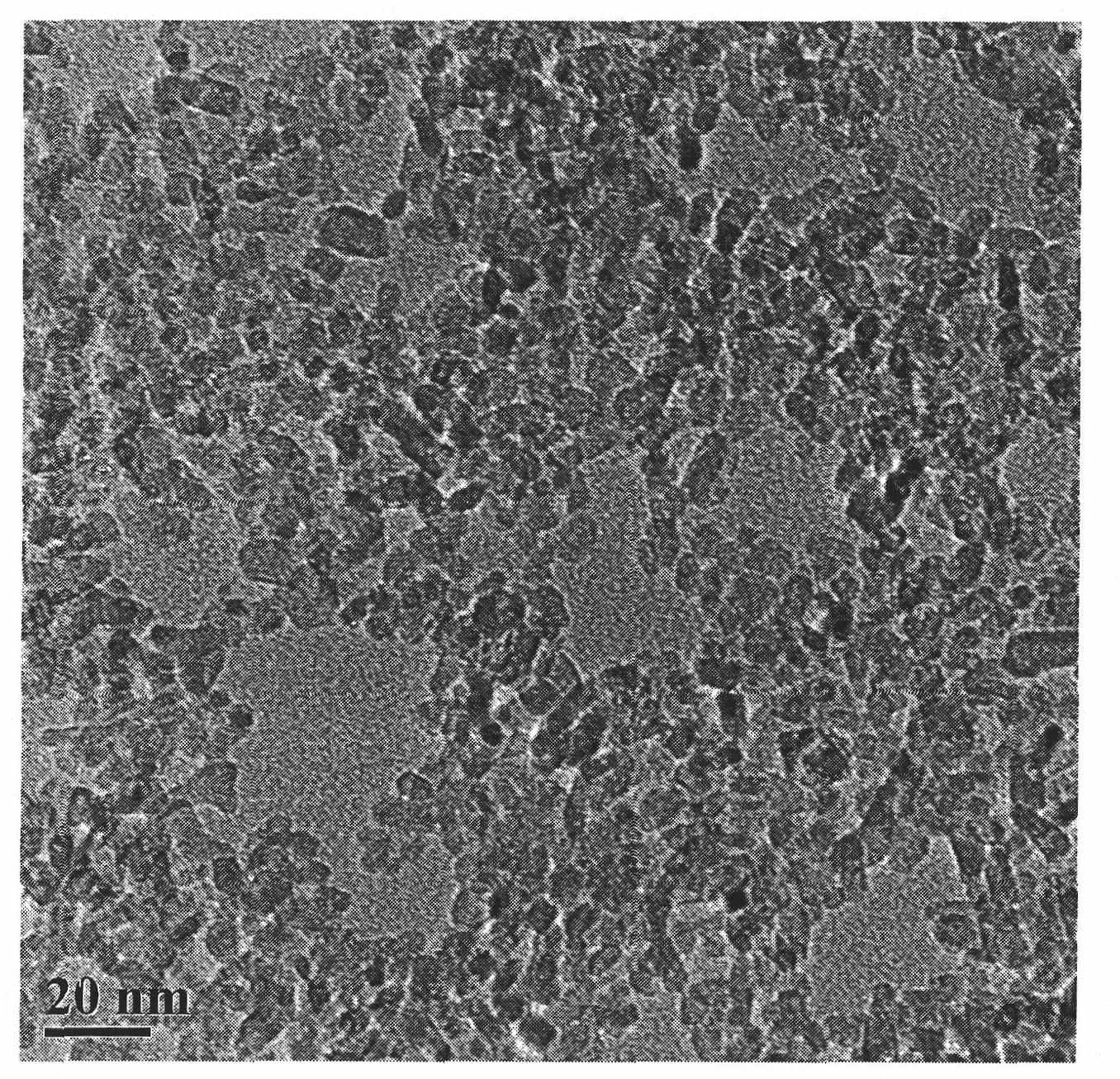

InactiveCN1583552AEasy to operateSuitable for large-scale industrial productionNano-carbonHigh volume manufacturingDistilled water

A process for preparing a lot of hollow carbone nanocages includes such steps as proportionally mixing metallic carbonyl liquid with low-carbon organic liquid to obtain reaction solution, heating reactor while introducing inertial gas to it, pumping said reaction solution into the reactor to obtain solid carbon nanocages, putting them in pure nitric acid or the mixture of nitric acid and distilled water, ultrasonic oscillating, heating, reflux cooling, diluting by distilled water, laying aside for deposition, and baking the deposited substance.

Owner:SHANGHAI JIAO TONG UNIV

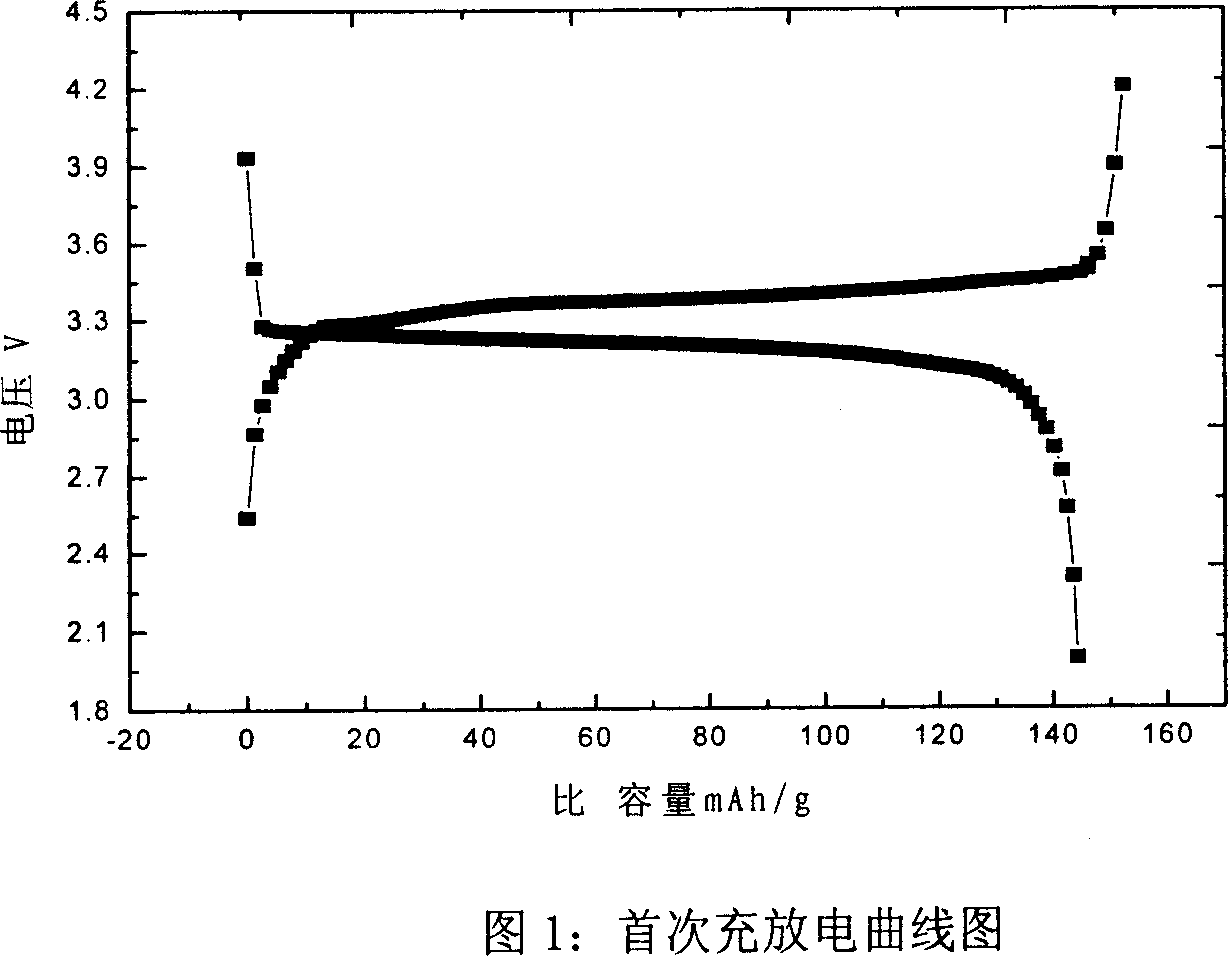

High density ultrafine composite ferric lithium phosphate anode material and preparation method

ActiveCN1907844AChemical composition is easy to controlEasy to dopeCell electrodesPhosphorus compoundsIron saltsOrganic compound

This invention belongs to battery field, which relates to ultra-micro compound lithium iron phosphate cathode material with high density and its fabrication method. Said cathode material is prepared by mixing iron salt, lithium salt and phosphates at a P / Li / Fe ratio of 1-1.1:1-1.1:1-1.1, adding conductive additives containing dopant element and carbon-bearing organic compound, adding organic acid as carrier, adjusting pH, controlling solution temperature in reactor to form sol, separating the sol to obtain nano-precursor and placing it into micorwave oven under protection of inert gas, and obtaining the final product. It is easy to control the chemical component, phase composition and particle size distribution. The conductive additive can be well-distributed. The method also has the advantages of short reaction time, low energy consumption during synthesis process and low cost. The obtained composite has high purity and good compatibility with electrolyte, excellent conductive property and charge and discharge property with large current, and good structure stability,thermal stability and cycle performance.

Owner:GUANGZHOU GREAT POWER ENERGY & TECH CO LTD

Method for preparing UHTC (Ultra-High Temperature Ceramic) matrix composite material through modification of UHTC powder basal body

InactiveCN103058711AImprove mechanical propertiesGuaranteed mechanical propertiesFiberVacuum pressure

The invention discloses a method for preparing an UHTC (Ultra-High Temperature Ceramic) matrix composite material through modification of a UHTC powder basal body. The method comprises the steps of: introducing UHTC powder and a carbon organic precursor into C / SiC with a gas hole ratio of 30 vol% to 40 vol% by adopting a vacuum pressure impregnation way; and performing in-situ reaction on melting silicon and splitting carbon in the basal body, and compacting the material through the combination of RMI (Reactive Melt Infiltration) so as to prepare a C / SiC-UHTC composite material. For one aspect, the SiC basal body protects fibers from being eroded by the melting silicon so as to improve mechanical properties of the material as the C / SiC with the gas hole ratio of 30 vol% to 40 vol% is adopted as a prefabricated body; and for the other aspect, a certain amount of the UHTC powder is introduced into the prefabricated body to improve anti-ablation performances.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

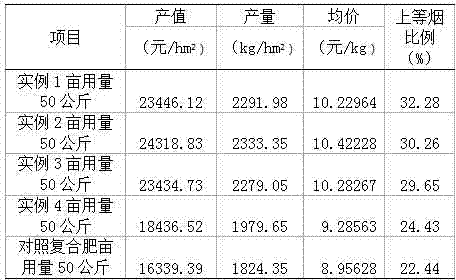

Biological carbon organic fertilizer and preparation method thereof

InactiveCN102850120AIncrease profitIncrease productionFertilizer mixturesSocial benefitsTrace element

The invention discloses a biological carbon organic fertilizer and a preparation method thereof. The biological carbon organic fertilizer comprises, by weight, 32.12%-34.60% of biological carbon, 62.83%-64.12% of organic matter and 2.28%-5.05% of trace elements, and preferably biological carbon produced form flue-cured tobacco stalk. According to the invention, characteristics of the biological carbon prepared from flue-cured tobacco stalk are fully utilized to produce a novel fertilizer with a variety of effects, so as to increase the utilization rate of fertilizer, and improve the absorption and utilization of trace elements by crops. A reasonable and scientific approach for utilization of tobacco stalk is also provided to reduce the environmental pressure of planting area, has good economic benefit, social benefit and ecological benefit, and can enhance the yield and quality of crops.

Owner:LUZHOU CO LTD SICHUAN TOBACCO

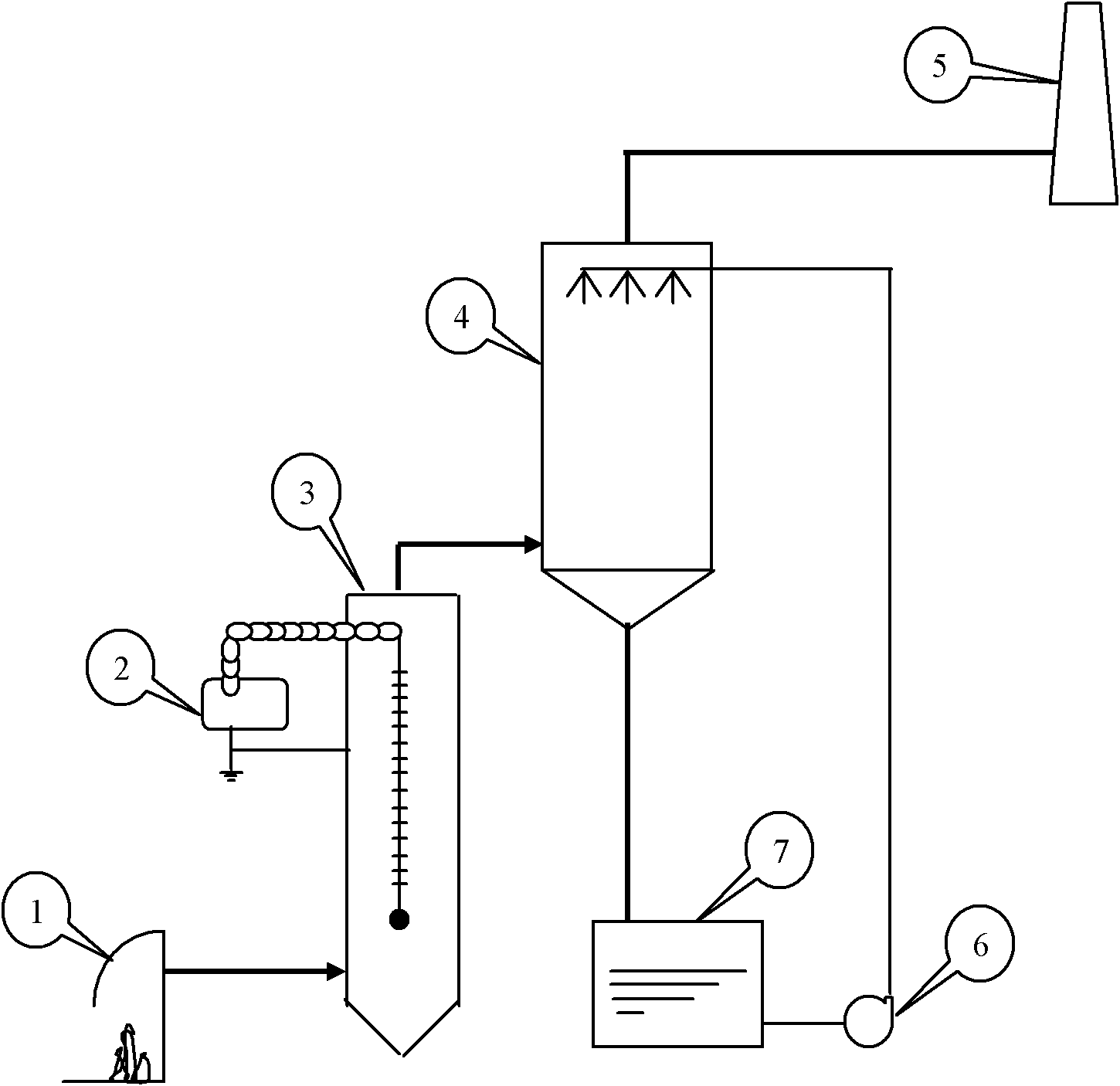

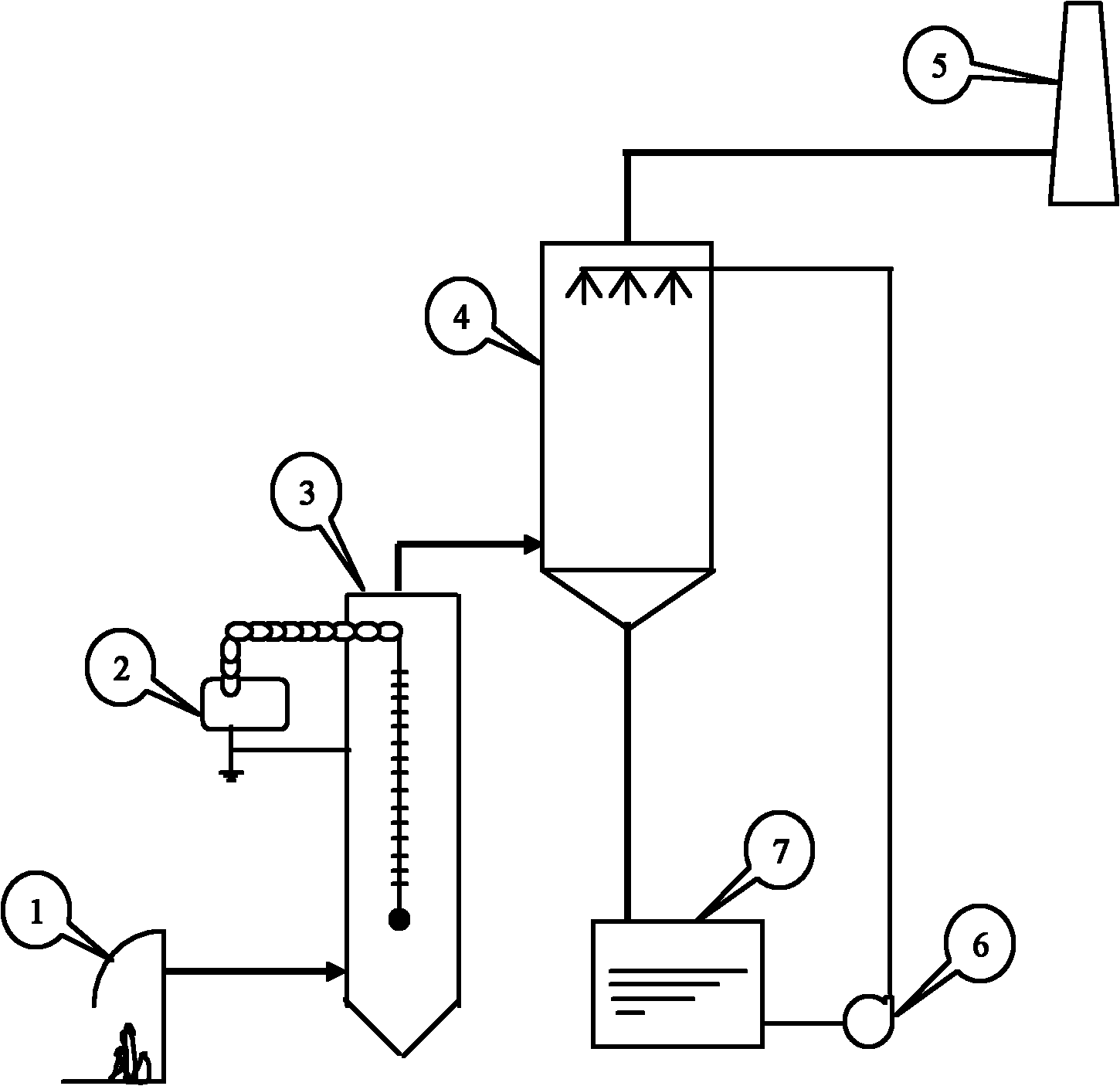

Method and device for treating nondegradable organic waste gas by combining low-temperature plasma with organisms

ActiveCN102059047AAchieve purificationMeet emission requirementsDispersed particle separationAtmospheric airHigh energy

The invention discloses a method and device for treating nondegradable organic waste gas by combining low-temperature plasma with organisms. After being collected, organic waste gas is sequentially treated through a low-temperature plasma reactor and a biological treatment reactor and finally exhausted to the atmosphere through a chimney. In the low-temperature plasma reactor, polycyclic aromatichydrocarbon, halogenated hydrocarbon, heterocycle compounds and an organic nitrile compound which are insoluble in water and nonbiodegradable are oxidized into low-carbon organic acid, alcohol, esterand other organic compounds which are soluble in water and biodegradable by utilizing substances with strong oxidizing property, such as O3, OH., H2O2, O. and high-energy electrons generated by high voltage discharge. In the biological treatment reactor, the organic acid, the alcohol, the ester and other organic compounds are further converted into CO2, H2O and other inorganic compounds under theaction of microorganisms. Through the treatment, the total purification efficiency of nondegradable organic compounds containing benzene, methylbenzene, dimethylbenzene, phenol and the like in waste gas can be up to over 90 percent.

Owner:山东航源环境科技有限公司

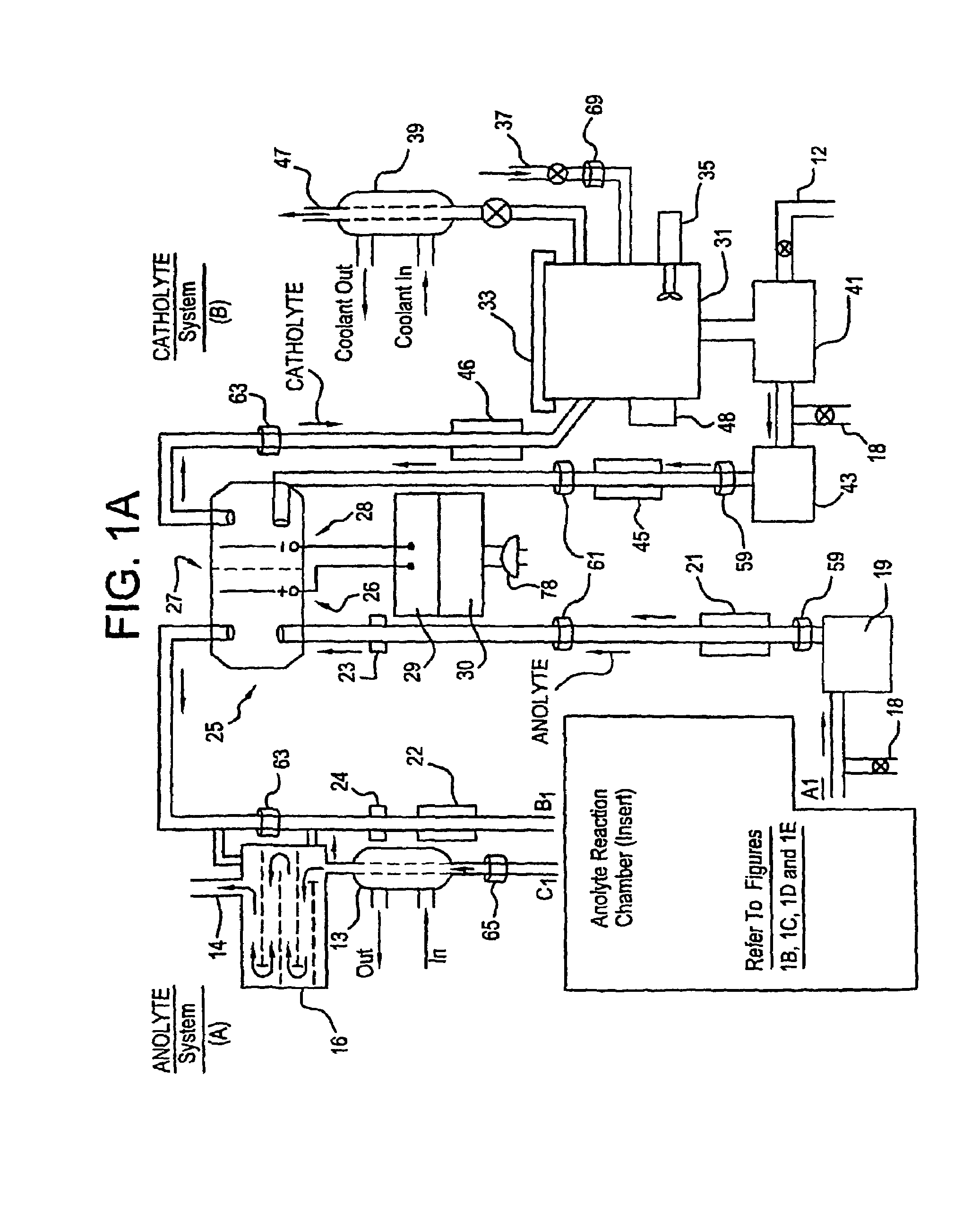

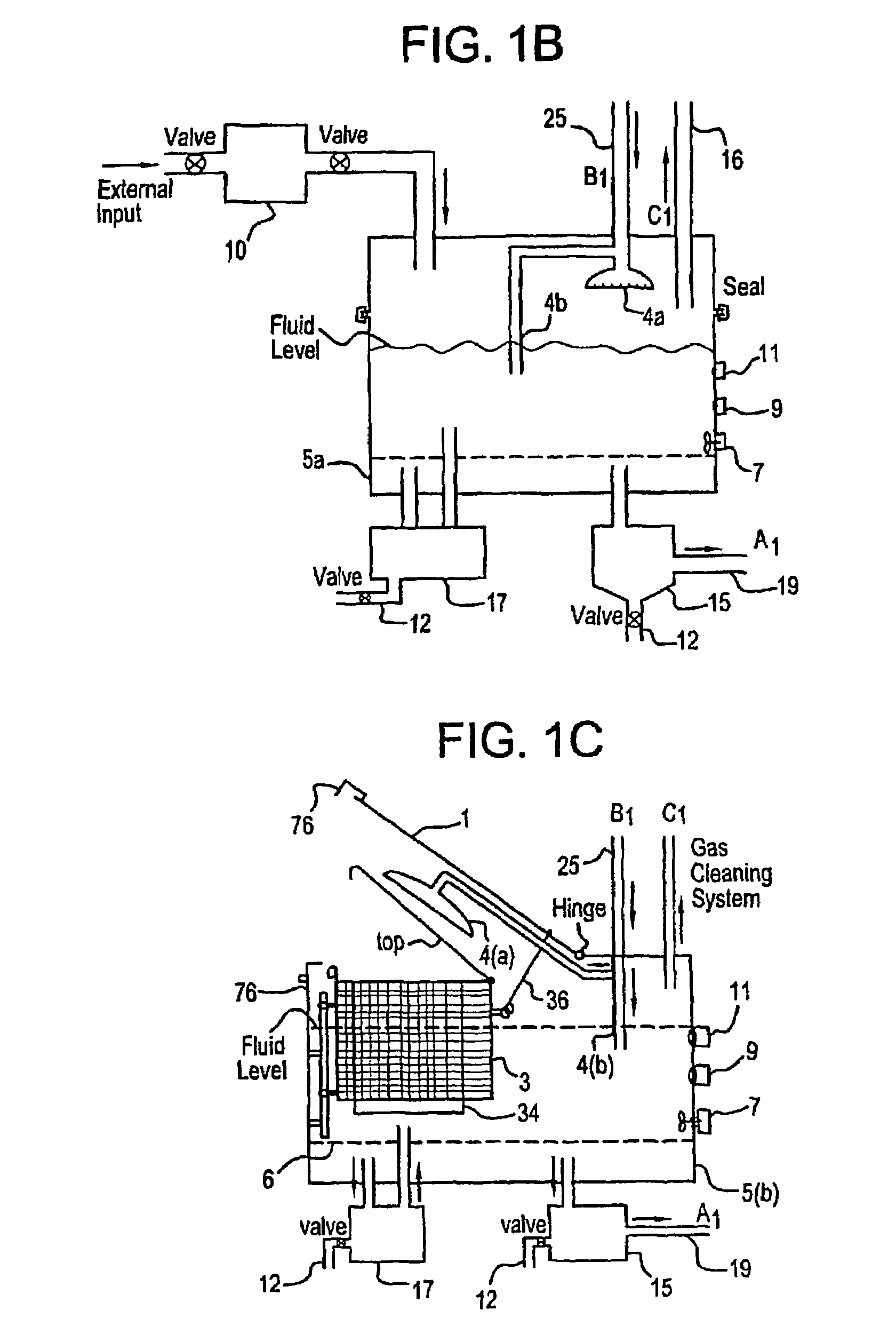

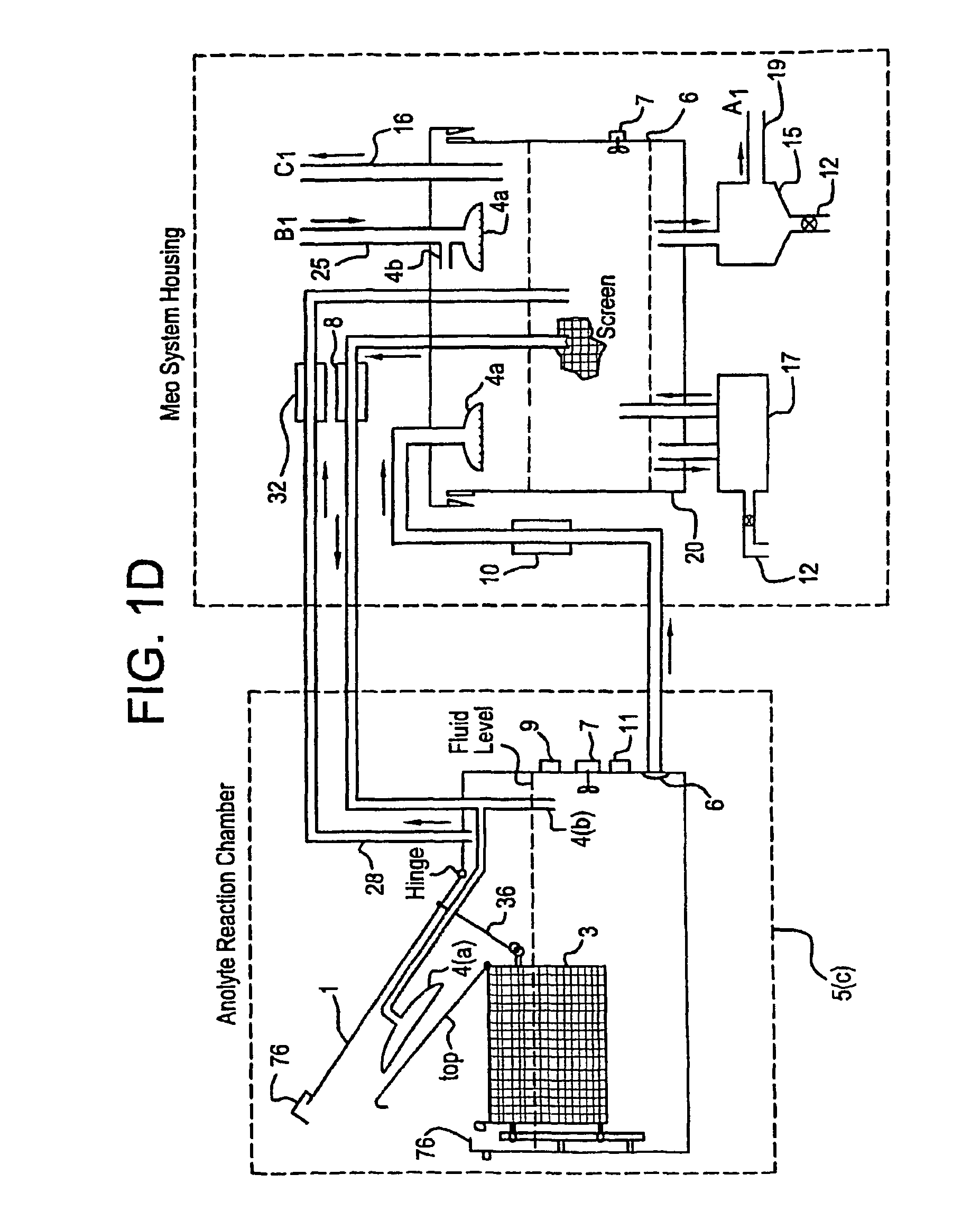

Mediated electrochemical oxidation for decontamination

InactiveUS7531708B2Improve efficiencyElectrolysis componentsPhotography auxillary processesLow-level wasteContaminated equipment

A mixed waste mediated electrochemical oxidation process (MEO) process and apparatus for the dissolution of transuranic elements, and / or compounds thereof in transuranic waste, low level waste (LLW), low level mixed waste, special case waste, and greater than class C LLWS, and also the destruction of the non-fluorocarbon organic component in the waste. The MEO process and apparatus operates in three different modes: dissolution, destruction, and decontamination. In the first mode, dissolution, the process runs until the transuranics such as a mixed oxide or carbide, and / or mixture of oxides or carbides of uranium and plutonium are totally dissolved into solution. The second mode, destruction, the process is operated such that the mixed waste materials are reduced to CO2, water and small amounts of inorganic salts. The third mode, decontamination, involves contaminated equipment. In the decontamination mode the MEO process destroys the mixed wastes that have contaminated the equipment.

Owner:SCIMIST LNC

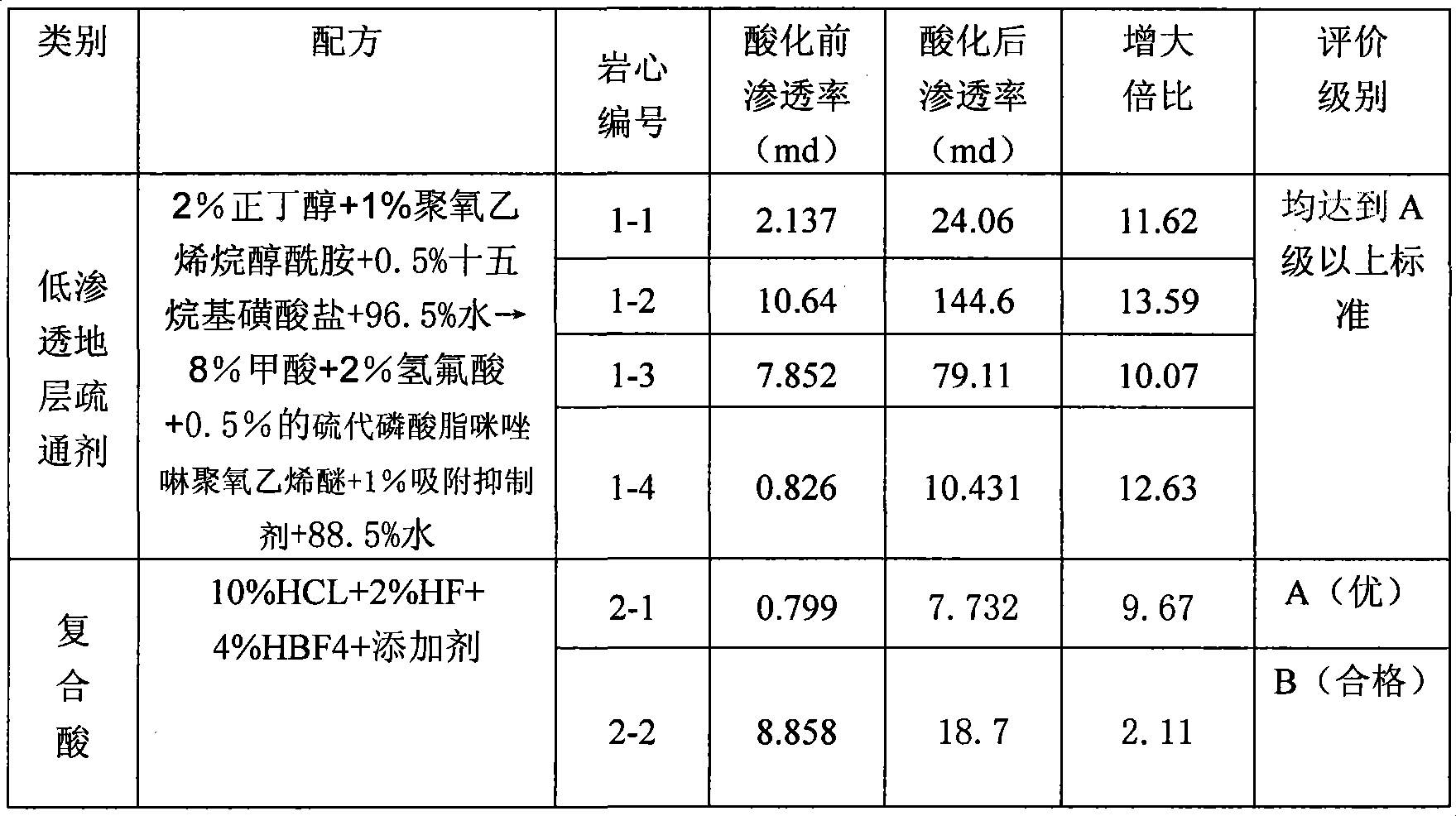

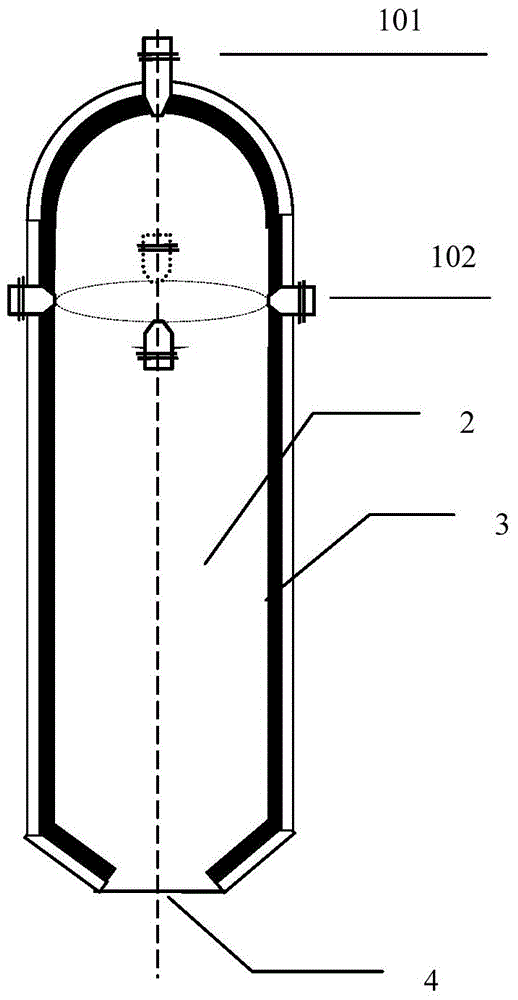

Formation opener agent for low permeable reservoir of oilfield

The invention relates to a stratum opener agent which is applied to oilfield low permeability reservoir. The stratum opener agent comprises two parts: pre-disposal liquid and acid inhibitor system; according to the weight percentage, the pre-disposal liquid consists of solvent and surfactant as follows: 1-3% of organic solvent such as higher alcohol, 0.2-1% of non-ionized surfactant polyoxyethylene alkylolamide, 0.3-0.5% of tenthfive alkyl sulfonate, and the residual quantity of stratum water; according to the weight percentage, the acid inhibitor system comprises 5-10% of low-carbon organic acid, 1-3% of hydrofluoric acid, 0.5% of inhibitor thio-phosphate imidazoline polyoxyethylene ether, 1% of adsorption inhibitor and the residual quantity of water; the adsorption inhibitor comprises 0.5-2% of ethyl dimethylene-bi-cetyltrimethylammonium ammonium bromide, 0.2-1% of quaternary ammonium salt small kation, 2-5% of inorganic salt, 0.2% of 1,3-amine group propyl alcohol N-methyl sodium phosphate or potassium dihydrogen phosphate or sodium hexametaphosphate. The opener agent can effectively improve the seepage capability of reservoir and achieve the objects of decompression and augmented injection and improving the yielding.

Owner:DAQING PETROLEUM ADMINISTRATION +1

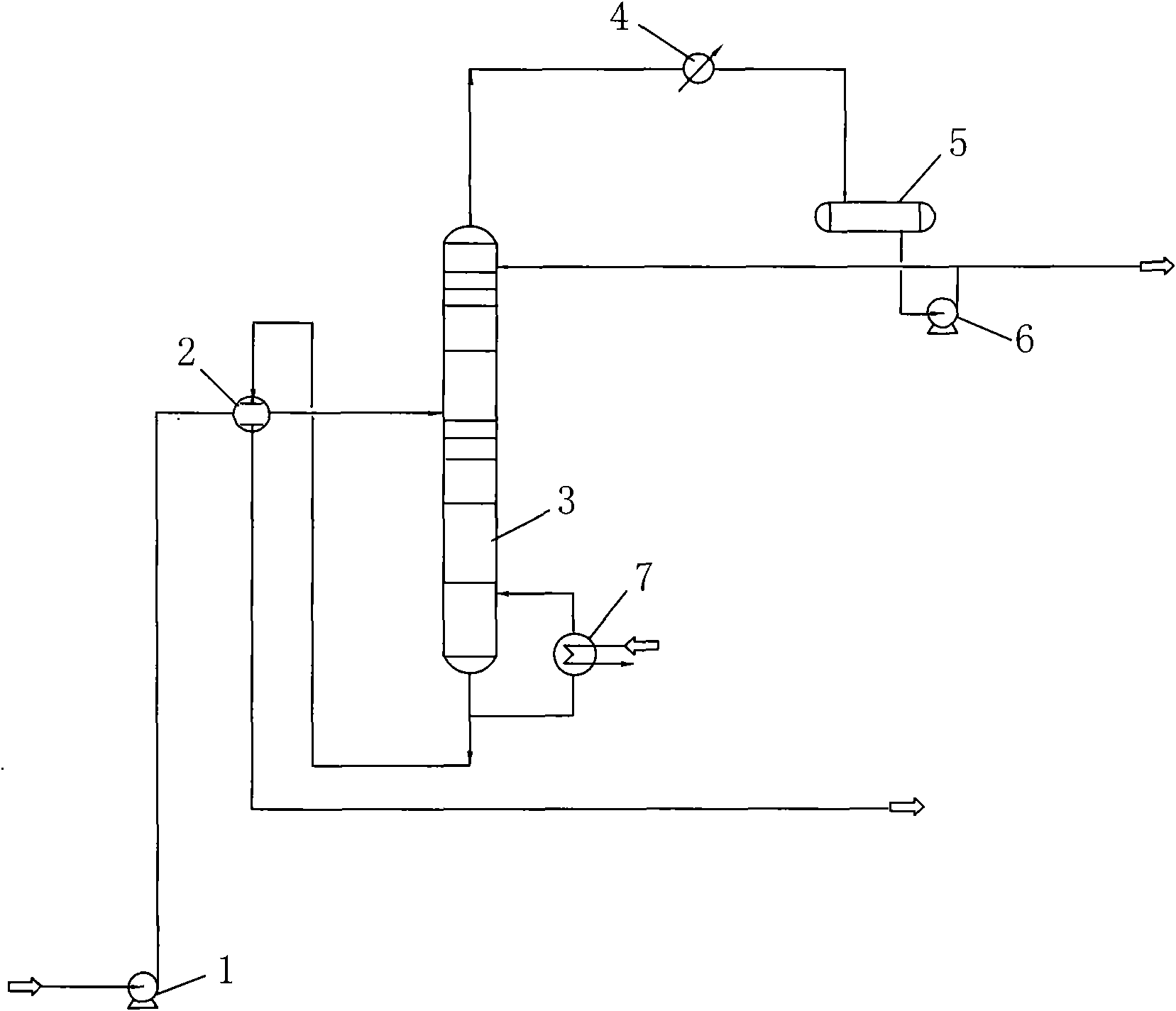

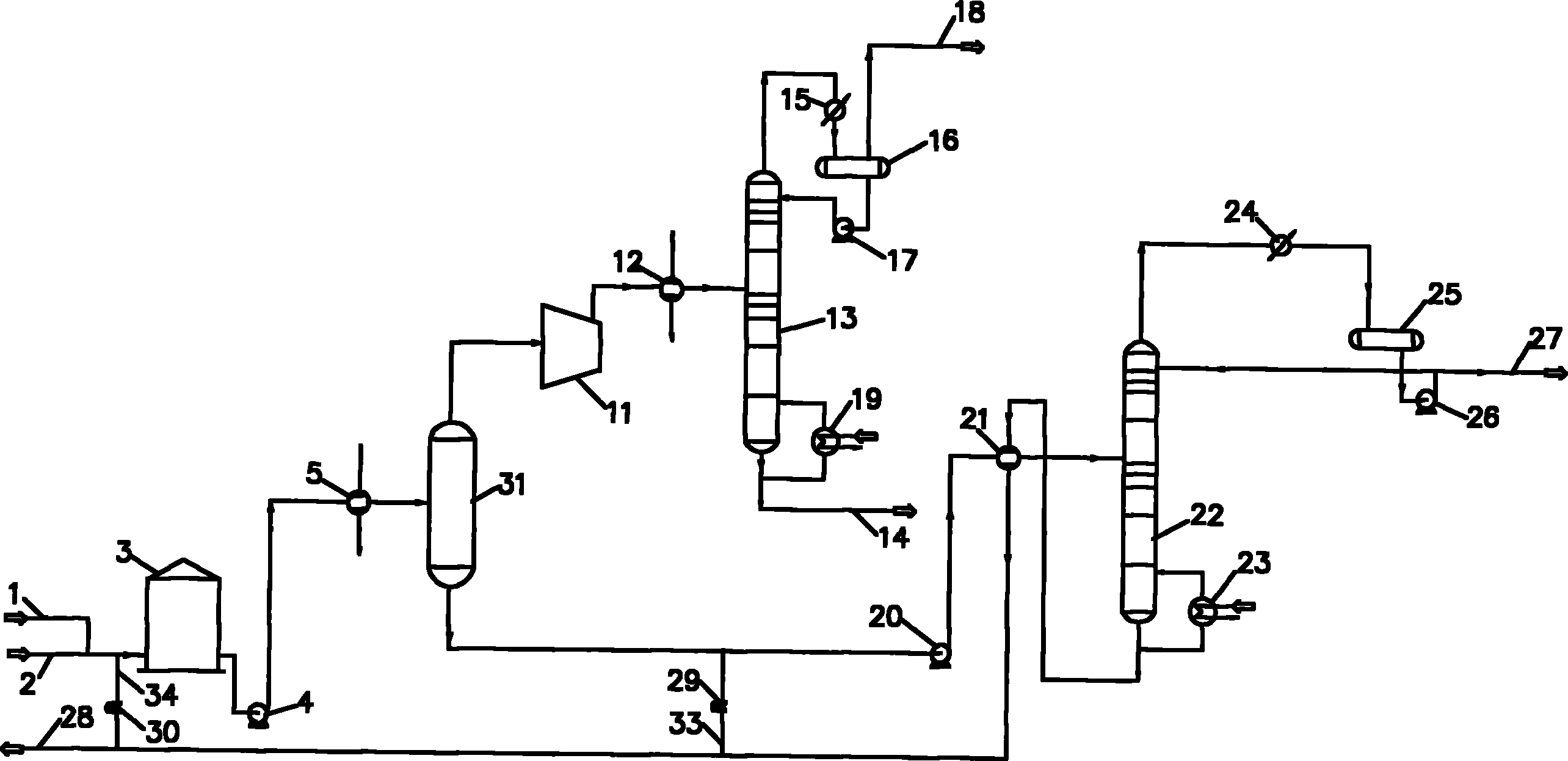

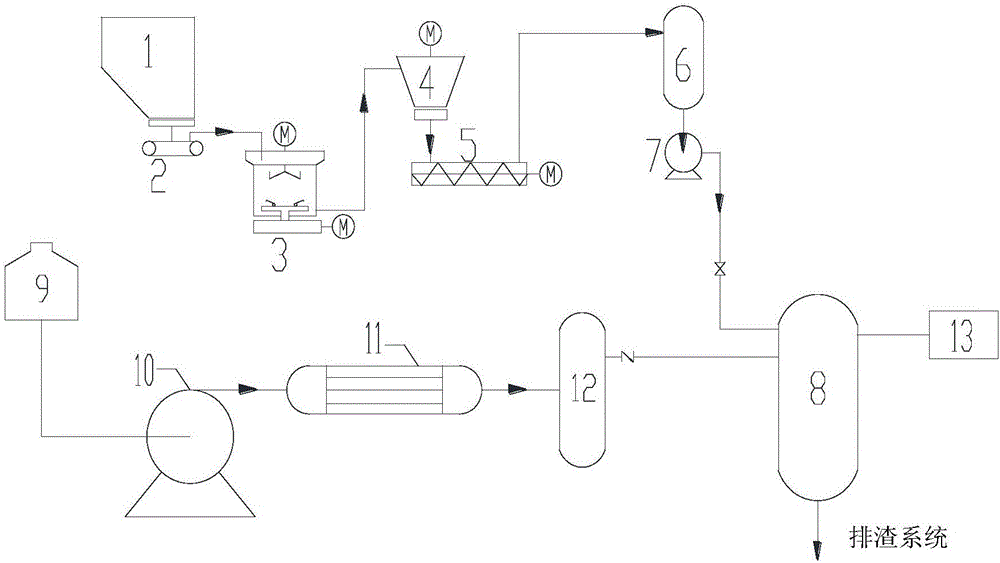

Method for gasifying carbonaceous organic materials and gasification furnace

ActiveCN103555370AReduce consumptionRaise the reaction temperatureGranular/pulverulent flues gasificationMetallurgyReaction temperature

The invention provides a method for gasifying carbonaceous organic materials. The method comprises a co-gasification step of simultaneously gasifying a slurry carbonaceous organic material and a powder carbonaceous organic material in a same gasification furnace according to a certain proportion, and a co-gasification fine adjustment step of adjusting the material conveying proportion of a gasifying agent, the powder carbonaceous organic material and the slurry carbonaceous organic material according to the coal gas temperature at an outlet of the gasification furnace. The invention also provides a gasification furnace used in the method for gasifying the carbonaceous organic materials, and the gasification furnace comprises a temperature feedback control module. By adopting the method and the gasification furnace provided by the invention, the consumption of water is reduced, the gasification efficiency is improved, the reaction temperature of the gasification furnace is improved at the same time, and then a number of gasification raw materials which can not be gasified by the prior art due to a high ash fusion point can be gasified, so that the selection range of coal types can be improved through the method and the gasification furnace provided by the invention. Furthermore, by adopting the gasification furnace, the injection ratio of the gasifying agent to each gasification raw material according to the temperature of the outlet coal gas can be adjusted, so that the fine adjustment of co-gasification can be realized.

Owner:ENN SCI & TECH DEV

Method for degrading and recycling thermosetting epoxy resin material

The invention discloses a method for degrading and recycling a thermosetting epoxy resin material. The method comprises the following steps: adding a catalyst into a solvent to prepare a reaction solution, wherein the solvent is a low-carbon organic acid or a mixed solution of a low-carbon organic acid and water; dipping epoxy resin material in the reaction solution, and degrading at 100-280 DEG C for 10min-72min; adding a separating agent to the reaction solution obtained after degradation so as to separate inorganic packing out of the catalyst and the resin, filtering, and drying and recycling the solid; and drying filtrate by distillation to obtain a resin degradation product. The method has the advantages of high efficiency and high selectivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Redox shuttle for rechargeable lithium-ion cell

InactiveUS7811710B2Excellent repeated overcharge stabilityNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsLithiumAlkoxy group

A redox chemical shuttle comprising an aromatic compound substituted with at least one tertiary carbon organic group and at least one alkoxy group (for example, 2,5-di-tert-butyl-1,4-dimethoxybenzene) provides repeated overcharge protection in rechargeable lithium-ion cells.

Owner:3M INNOVATIVE PROPERTIES CO

Method for preparing anatase-phase titanium dioxide sol

InactiveCN101955222AIncrease concentrationImprove stabilityTitanium dioxideCarbon.organicCrystallinity

The invention relates to a method for preparing anatase-phase titanium dioxide sol. The method comprises the following steps: preparing a titanium-containing inorganic substance into aqueous solution; heating the aqueous solution to 40 to 100 DEG C; dripping inorganic base solution to be taken as precipitant and keeping the temperature for 2 to 24h to obtain white titanium dioxide hydrated precipitate; washing the precipitate with deionized water to obtain gelatinous hydrated titanium dioxide; adding two-carbon organic acid solution, stirring, performing ultrasonic dispersion for 2 to 48h and peptizing; and performing hydrothermal treatment on the obtained sol for 1 to 24h in a hydrothermal kettle at the temperature of 100 to 200 DEG C, wherein the crystallinity and crystallite dimension of the titanium dioxide in the sol can be regulated. The preparation method has the advantages of simplicity, low cost, wide raw material resources and good application prospects and is suitable for industrial production; moreover, the crystallite dimension of the prepared titanium dioxide sol is the dimension of a few of nanometers, therefore the problem of fast growth of crystallites caused by phase change in the high-temperature calcination and crystallization of amorphous titanium dioxide sol is solved.

Owner:DONGHUA UNIV

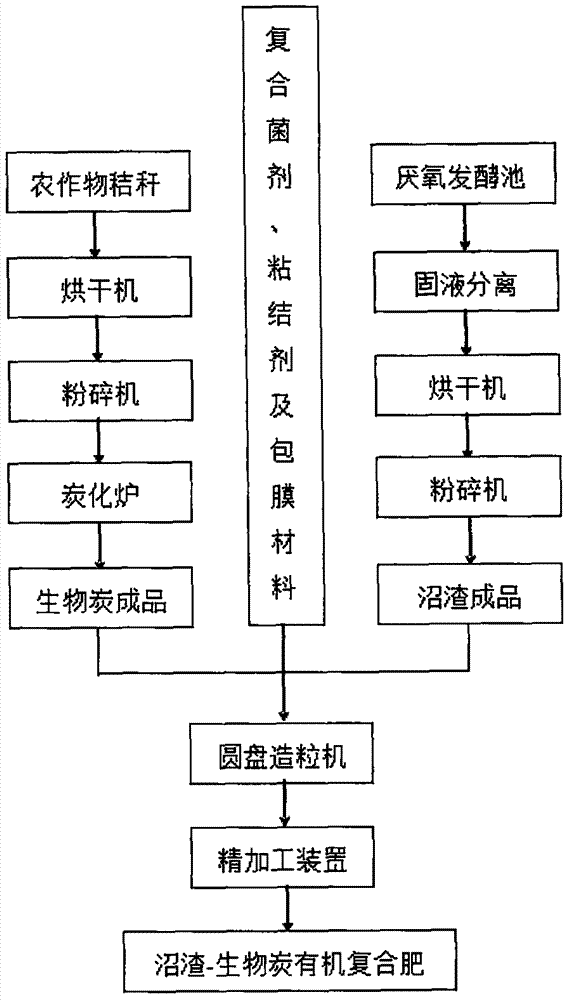

Biogas residue-biological carbon organic compound fertilizer and preparation method thereof

InactiveCN107285846AMeet different nutritional needsIncrease pHAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAdhesiveCarbon.organic

The invention provides biogas residue-biological carbon organic compound fertilizer and a preparation method thereof. The biogas residue-biological carbon organic compound fertilizer is prepared from the following raw materials: biogas residue, biological carbon, conventional fertilizer, a mineral powder adhesive, a compound microorganism bacterium agent, a granulation adhesive and a film coating material; the preparation method of the compound fertilizer comprises the following steps: carrying out high-temperature cracking on straws to prepare the biological carbon; collecting the biogas residues which are generated in an anaerobic fermentation process of organic wastes; after mixing the prepared biological carbon with the biogas residues and the conventional fertilizer and melting, granulating; carrying out screening and film coating on grains to prepare the biogas residue-biological carbon organic fertilizer. The organic compound fertilizer provided by the invention sufficiently utilizes the residual straws and biogas residues and has the advantages of slowly releasing the fertilizer, improving soil, fixing carbon and reducing emission and the like; the biogas residue-biological carbon organic compound fertilizer is nutritional and is scientifically matched; when the biogas residue-biological carbon organic compound fertilizer is matched with conventional chemical fertilizer and then is applied, the fertilizer efficiency and the utilization rate can be further improved and the yield and quality of crops are remarkably improved. The method provided by the invention has the advantages of relatively low cost, a simple and feasible proces, and is suitable for large-scale popularization.

Owner:NORTHWEST A & F UNIV

Culture medium for selenium-rich organic edible fungi and culture method thereof

InactiveCN105110954AEasy to operateMild operating conditionsCultivating equipmentsMushroom cultivationBiotechnologyCarbon.organic

The invention provides a culture medium for selenium-rich organic edible fungi, which is mainly prepared from the following raw materials in parts by mass: 60-90 parts of culture main material, 10-25 parts of carbon organic fertilizer, 1-5 parts of selenium-rich nutrient element, 1-6 parts of root irrigation culture agent, 0.2-0.5 part of compound probiotic fertilizer and 0.1-0.5 part of plant growth promoter. The method for culturing selenium-rich organic edible fungi by using the culture medium comprises the following steps: mixing the plant growth promoter and compound probiotic fertilizer, and dissolving in water to prepare a liquid; mixing the rest raw materials, adding the liquid, and fermenting to obtain the culture medium; and uniformly mixing a strain with the culture medium for inoculation, culturing for 10-15 days until the hypha are overgrown, and reinoculating the hypha. The culture medium has the advantages of reasonable component proportioning and high growth speed of hypha.

Owner:重庆市曾东燃纳米科技合伙企业(有限合伙)

Methods and compositions for increasing solubility of azole drug compounds that are poorly soluble in water

The combination of any two of a polyol, a polyol ether, and a low carbon organic alcohol provides a synergistic effect on the solubility of azole compounds, such as metronidazole, in aqueous fluid.

Owner:BAUSCH HEALTH IRELAND LTD

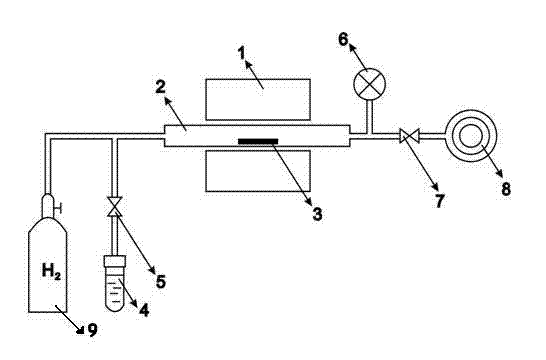

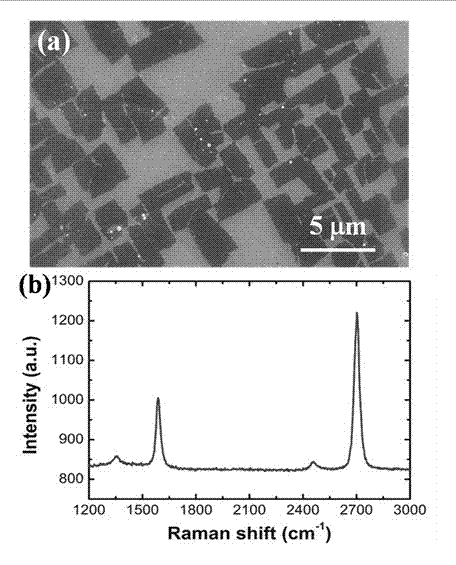

Method for preparing graphene strip by adopting low-temperature chemical vapour deposition

InactiveCN103086370ALow growth temperatureNo shape clipping requiredGrapheneNanotechnologySemiconductor materialsElectrolysis

The invention belongs to the field of preparation of semiconductor materials and in particular relates to a method for preparing a graphene strip by adopting low-temperature chemical vapour deposition. The method provided by the invention comprises the following steps of: firstly carrying out electrolytic polishing on a copper foil, then placing the copper foil into a quartz tube reactor, annealing under the condition of hydrogen, and then adjusting flow velocity of the hydrogen to be 2.4-3.0sccm and introducing a liquid carbon source at the temperature of 500-580 DEG C, and growing a graphene strip on the copper foil while pressure is controlled to be 2.0-10.0Torr and growth time is controlled to be 10-50 minutes, so that the graphene strip growing on the copper foil is obtained. According to the method, the copper foil subjected to electrolytic polishing is adopted, so that chemical activity of the surface of the copper foil is higher; and the adopted carbon source is a carbon-containing organic solvent which has the characteristics of aromatic compounds and aliphatic compounds and the characteristics between the characteristics of the aromatic compounds and the characteristics of the aliphatic compounds, and compared with a gas carbon source commonly used in the prior art such as methane, the carbon-containing organic solvent is more beneficial to low-temperature growth of the graphene strip.

Owner:NORTHEASTERN UNIV

Preparation method of hydrogenation catalyst

ActiveCN103100384AExtended service lifeAvoid PolymerizationHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsCarboxylic acidCarbon.organic

The invention discloses a preparation method of a hydrogenation catalyst. The hydrogenation catalyst takes activated carbon as a carrier, and adopts palladium as an active metal component. The catalyst has a palladium content of 0.1wt%-0.7wt%. An impregnation method is employed to prepare the catalyst. Specifically, a palladium-containing impregnation solution is prepared by: dissolving palladium acetylacetonate in an organic solvent, and using a low carbon organic carboxylic acid to regulate the pH value of the impregnation solution. The method adopts a special process to prepare the palladium acetylacetonate impregnation solution, can make palladium crystal grains highly dispersed and loaded on the inner and outer surfaces of the activated carbon carrier, and at the same time, no inorganic ion is introduced, no high-temperature roasting is needed, and migration and grain growth of the palladium metal are effectively controlled, thus improving the activity and selectivity of the catalyst. Moreover, the utilization rate of noble metal palladium is enhanced, noble metal waste is avoided, and the cost is reduced. The hydrogenation catalyst is applicable to a selective hydrogenation process of unsaturated C4 hydrocarbon fraction. The polymerization reaction of unsaturated hydrocarbon on the catalyst surface can be effectively inhibited, and the service life of the catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

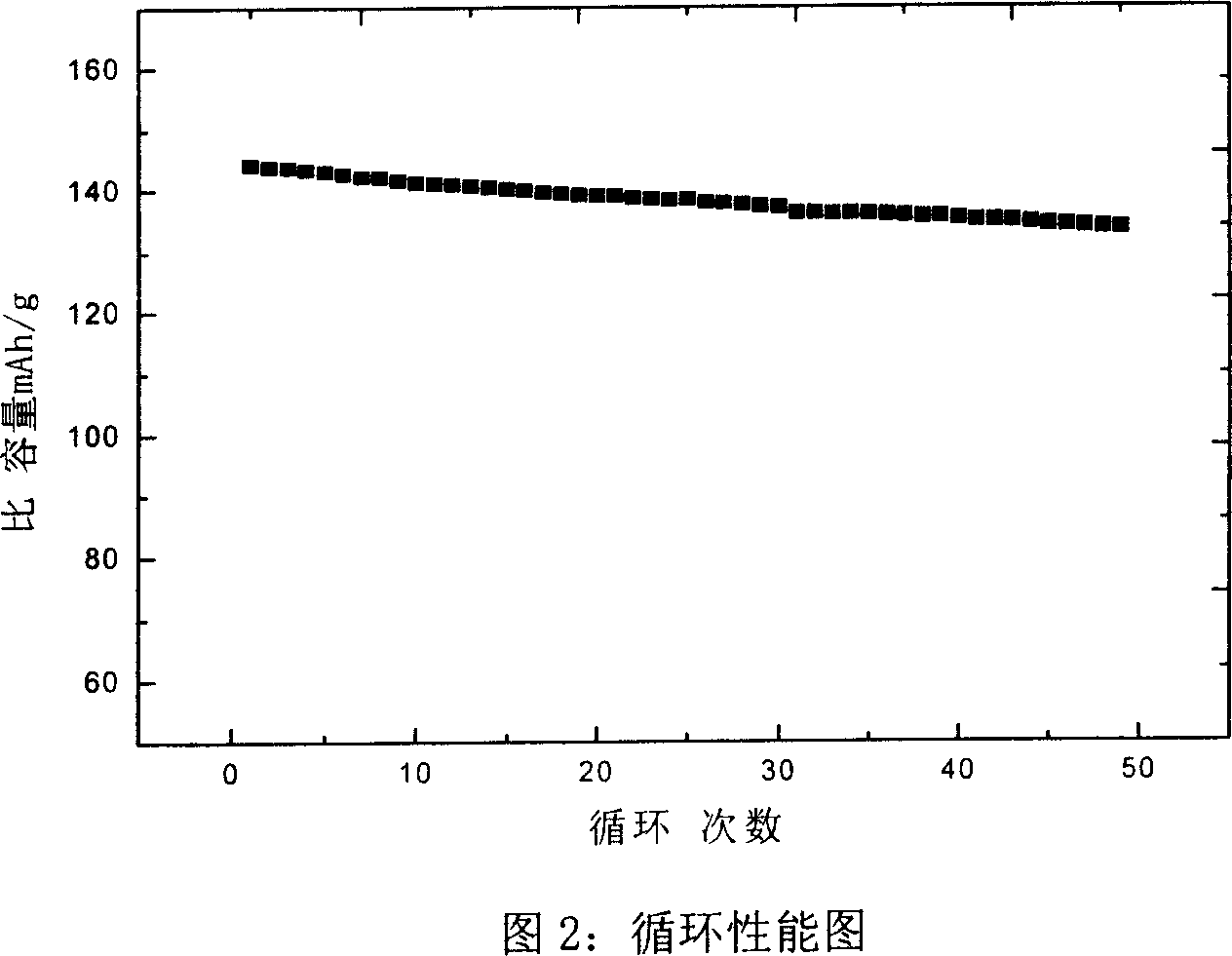

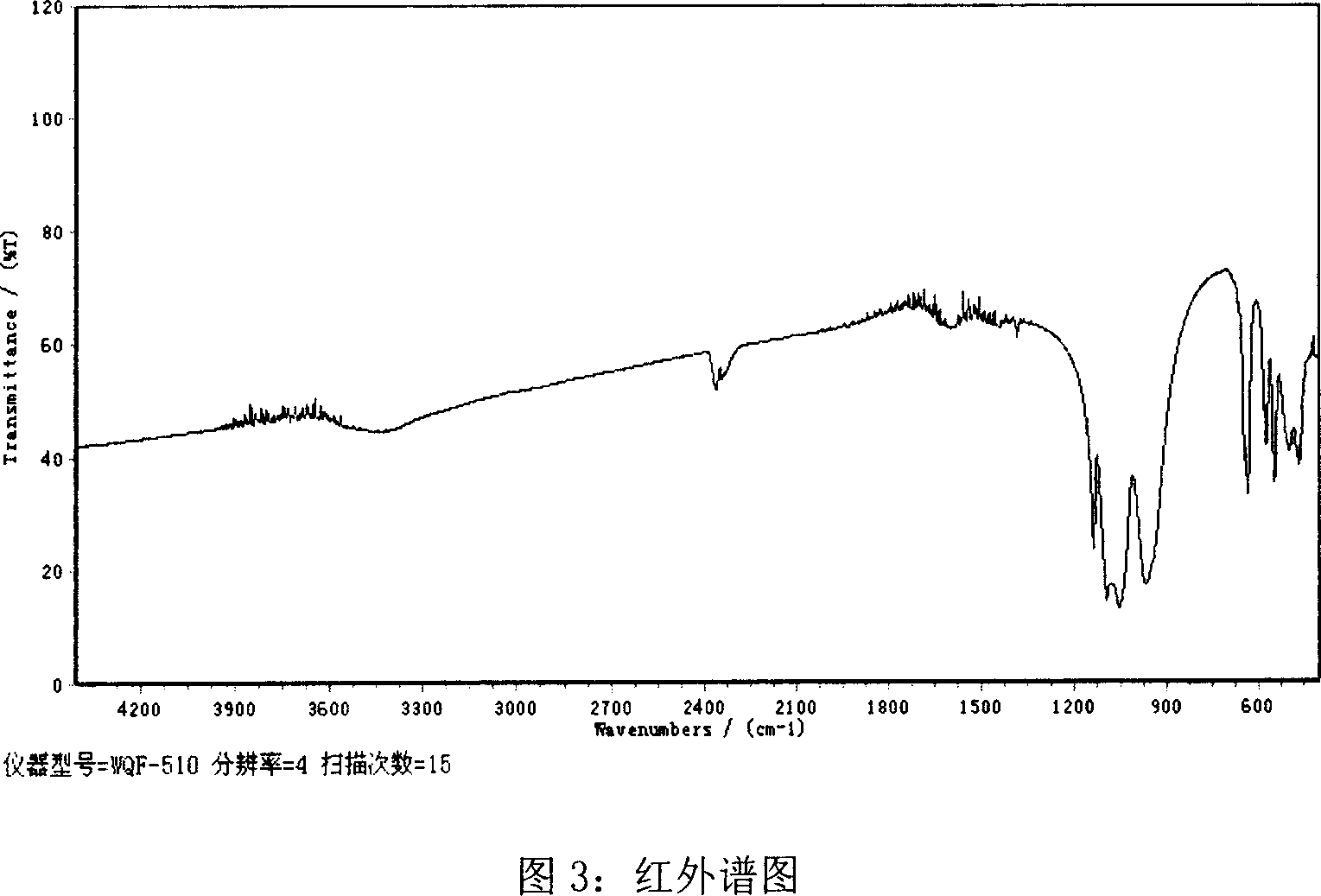

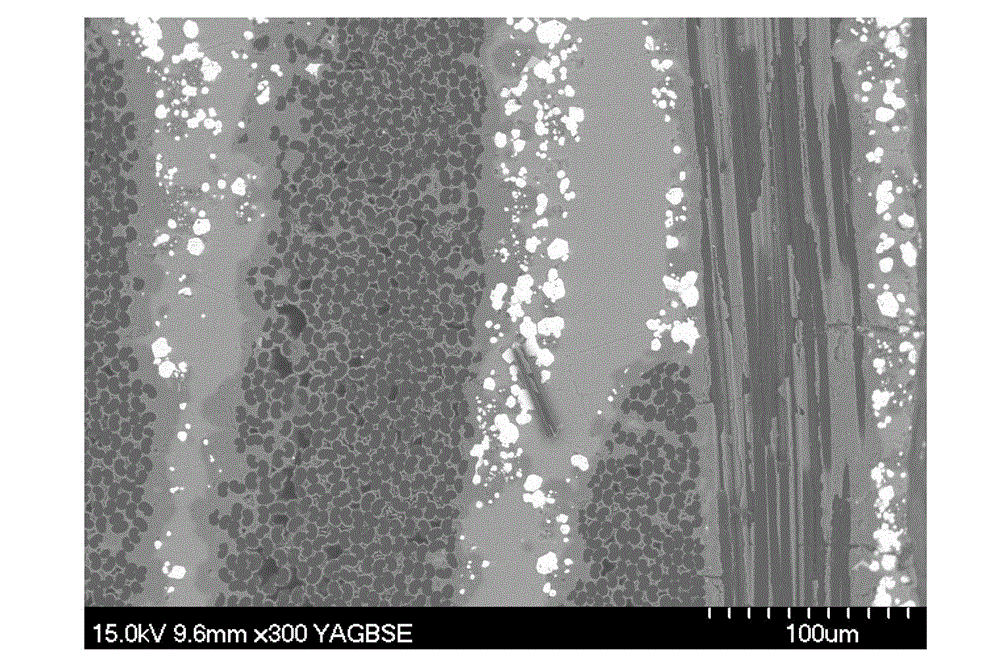

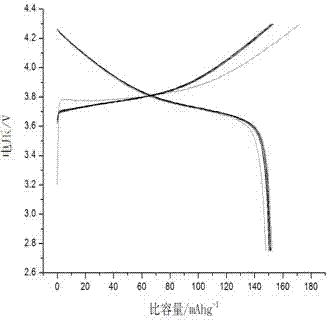

Method for preparation of composite anode material of carbon-coated lithium-ion battery

InactiveCN102403495ASimple processLow firing temperatureCell electrodesLithium carbonatePhysical chemistry

The invention provides a method for preparation of a composite anode material of a carbon-coated lithium-ion battery, which comprises the following steps: weighing lithium carbonate, nickel hydroxide, manganese hydroxide and cobalt hydroxide with the molar ratio of the lithium carbonate, nickel hydroxide, manganese hydroxide and cobalt hydroxide being (3 / 2):1:1:1, adding excessive lithium carbonate of 6 percent of the mass of the lithium carbonate, mixing the materials, adding distilled water, and milling for 16 hours; drying at 50 DEG C; carrying out microwave roasting for 60 minutes at 830-970 DEG C to obtain ash black LiNi1 / 3Mn1 / 3Co1 / 3O2 powder; adding carbon-containing organic substances and distilled water of 1.5-4 percent of the mass of the LiNi1 / 3Mn1 / 3Co1 / 3O2 powder, milling until the materials are well mixed, and drying at 50 DEG C; and finally carry out microwave roasting to obtain LiNi1 / 3Mn1 / 3Co1 / 3O2 / C powder. Compared with non-carbon-coated LiNi1 / 3Mn1 / 3Co1 / 3O2 powder, the discharge cycle stability of the obtained LiNi1 / 3Mn1 / 3Co1 / 3O2 / C powder is enhanced under high magnification. The power can be used as an anode material to be applied in high-power lithium-ion batteries and power lithium-ion batteries.

Owner:KUNMING UNIV OF SCI & TECH

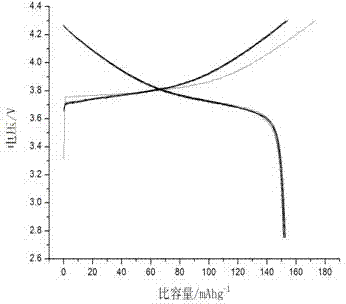

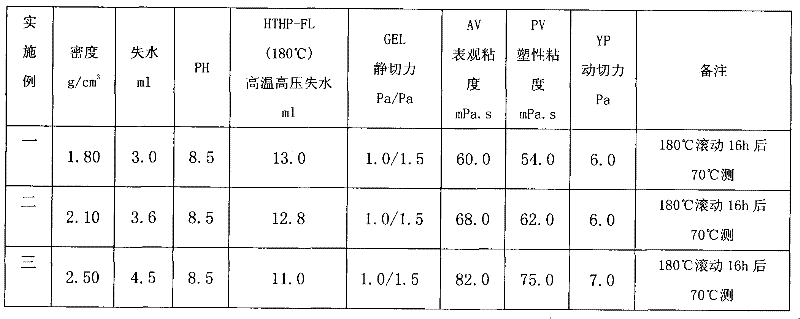

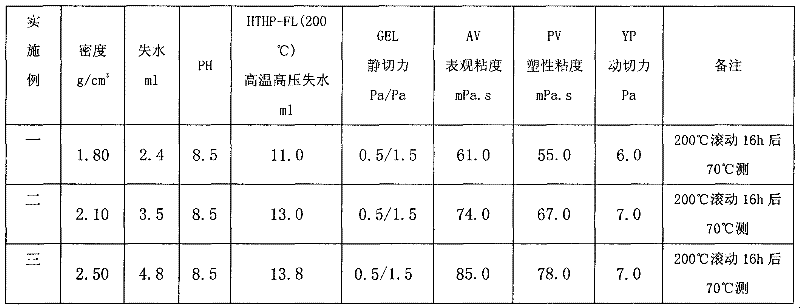

Formula and preparation method of 180 DEG C temperature and salt resistant drilling fluid with strong inhibition and high density

The invention relates to a formula and preparation method of a 180 DEG C temperature and salt resistant drilling fluid with strong inhibition and high density. The formula is characterized in that in the formula, a high temperature salt resistant shear strength improving agent is a silicate modified substance; fluid loss additives A and B are products with carbon-carbon chains as main chains and sulfonic acid groups, pyrrolidone groups or alkane groups as branched chains; an inhibiting / anti-collapse agent is a modified natural vegetable pitch derivative with a high softening point; an inhibiting / lubricating agent is a high polymer nonionic surfactant; and a water soluble heavy weight additive is a compound of low carbon organic acid salts of alkali metals, organic acid ammonium and organic acid quaternary ammonium. The preparation method is characterized by successively adding corresponding components with determined concentrations to the fresh water at a certain stirring speed according to the formula, thus obtaining the drilling fluid. The formula and the preparation method have the following beneficial effect: the problems of difficulty in control of viscosity, high fluid loss, low solid phase capacity and poor pollution resistance of the drilling fluid with high density are solved.

Owner:CNPC BOHAI DRILLING ENG

Low-cost deodorizing desiccant and its preparing method

InactiveCN1470320AHas secondary commercial valueSimple structureOther chemical processesAluminium silicatesDesiccantAdditive ingredient

The invention provides a kind of low cost deodorization desiccant, the proportion is: coal ash 45í½75%, plaster (CaSO4) 18í½53%, lime 2í½7%. 0.1íÙí½0.4íÙ activating agent, the ingredients are: CaO 67í½70%, MgO10í½12%, Al2O3 2í½5%, SiO2 10í½15%, Fe2O3 0.12í½0.3%, K2O0.2í½2.5%. Besides, the activating agent also may has other calcium salt, carbon organic compound. Adds 30í½45 water into 100 compound and forms them into column with radius of 3í½10mm, and length of 5~30mm, and then they are dried into product.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

Methods and compositions for increasing solubility of azole drug compounds that are poorly soluble in water

The combination of any two of a polyol, a polyol ether, and a low carbon organic alcohol provides a synergistic effect on the solubility of azole compounds, such as metronidazole, in aqueous fluid.

Owner:BAUSCH HEALTH IRELAND LTD

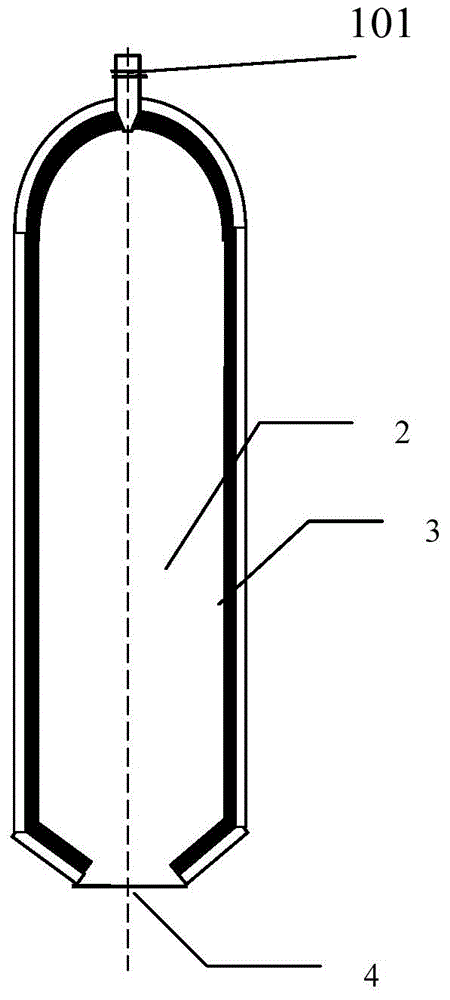

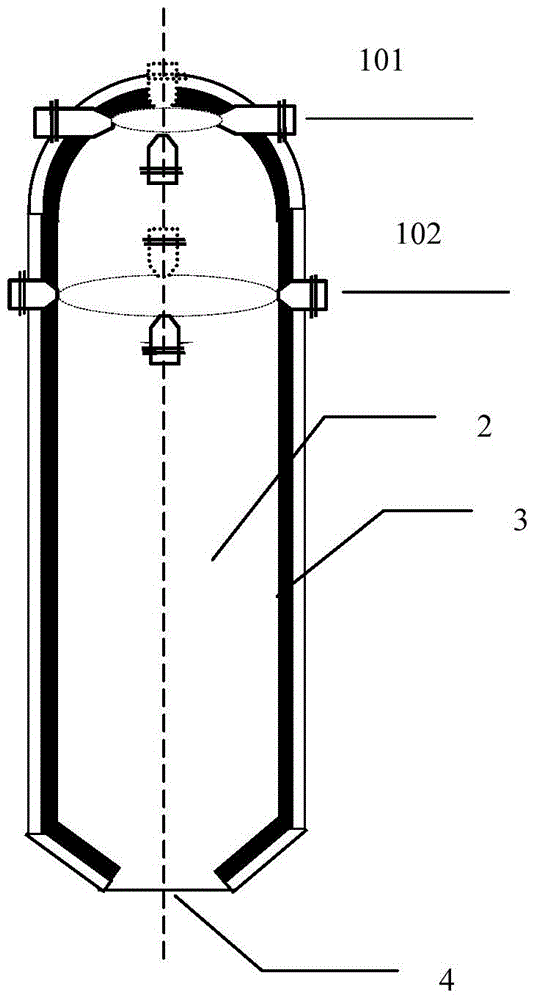

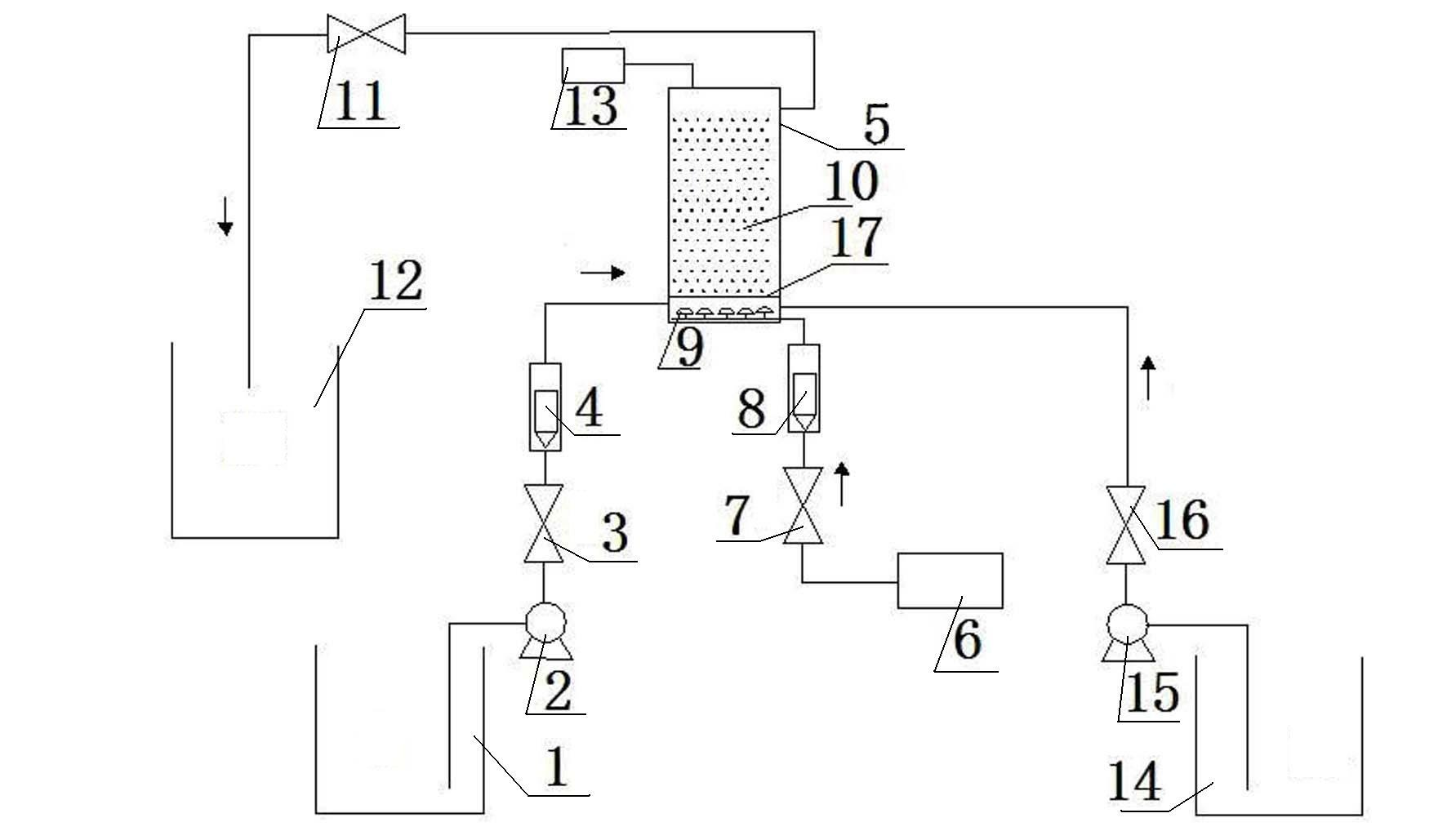

A method and device for treating organic sewage

The invention provides a method for treating organic sewage. The organic sewage enters the reactor from the lower part of the reactor, and the reactor is filled with iron and carbon; Reduction degradation; a microporous aeration system is installed at the bottom of the reactor, and ozone is passed into the reactor from the bottom of the reactor through the microporous aeration system, and a liquid oxidant is added into the reactor through the lower part of the reactor. , ozone and liquid oxidant to complete the treatment of organic sewage. The present invention also provides a sewage treatment device using the above treatment method. The method and the treatment device of the invention have good treatment effect on organic sewage, wide application range of pH, overcome the defect that iron and carbon are easy to agglomerate, and reduce operating cost.

Owner:WUHAN TEXTILE UNIV

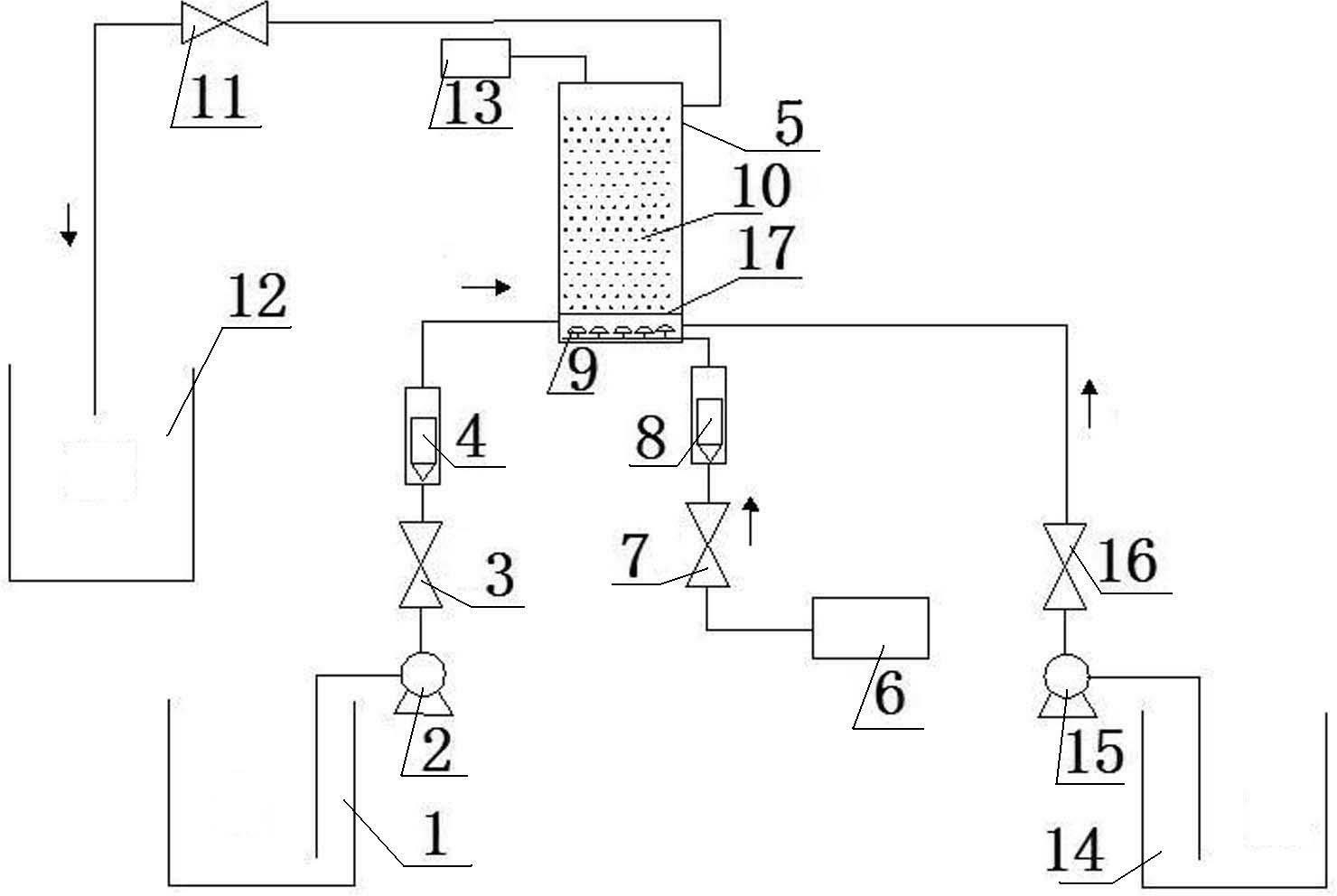

Sewage treatment process capable of recovering low-carbon hydrocarbons and low-carbon oxygen-containing organic matters

ActiveCN102060403AMeet the water quality requirementsAvoid harmEther separation/purificationHydrocarbon purification/separationWater qualityCarbon.organic

The invention discloses a sewage treatment process capable of recovering low-carbon hydrocarbons and low-carbon oxygen-containing organic matters. The process comprises the following steps: delivering a sewage raw material subjected to heat exchange into a flash evaporation separation tank; delivering a separated gas mixture containing ethene, propylene and low-carbon oxygen-containing organic matters into an oxide removing tower to obtain a low-carbon organic matter flow and a low-carbon hydrocarbon (such as ethene and propylene) flow; and delivering a separated liquid mixture into a stripping tower to obtain pure water. The total methanol and dimethyl ether content in pure water obtained by the method is not more than 100ppm. The pure water meets the inflow water quality requirement of sewage water treatment plant, and at the same time, the low-carbon hydrocarbon matters and low-carbon oxygen-containing organic matters in sewage are recovered.

Owner:CHINA PETROCHEMICAL CORP +1

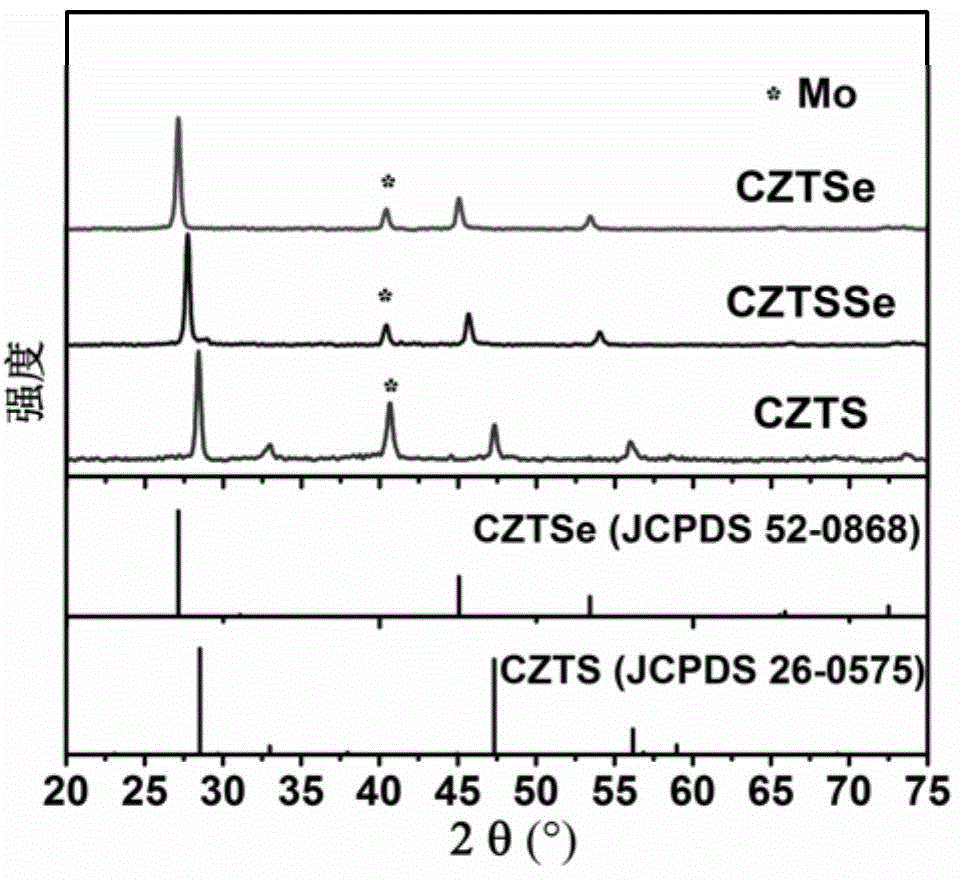

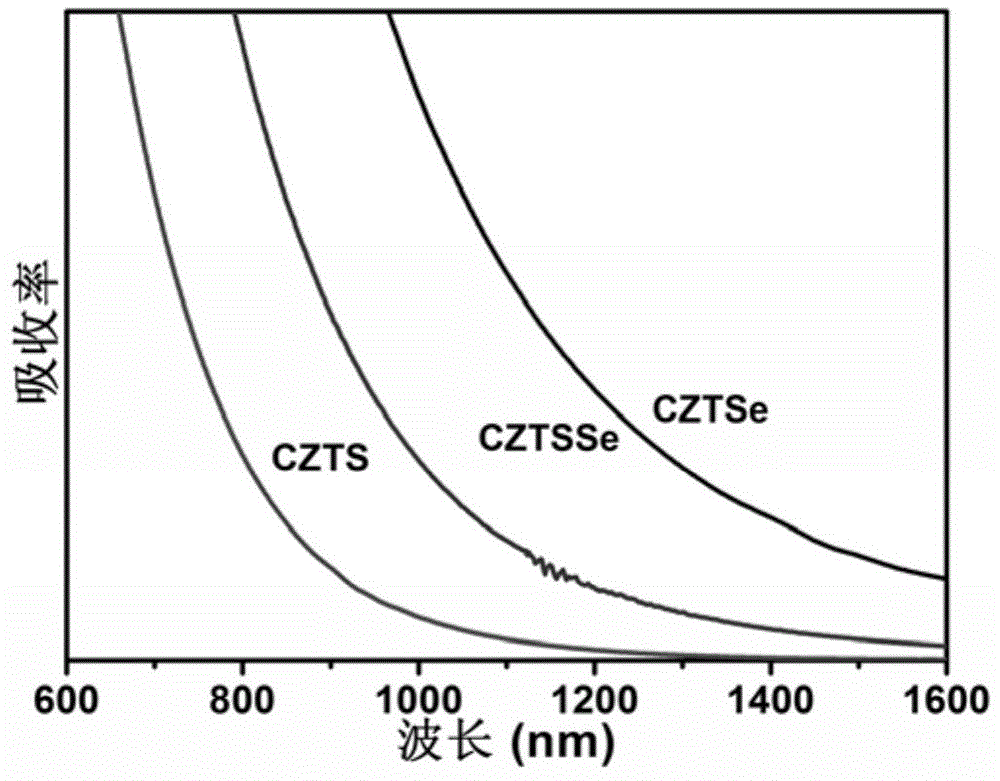

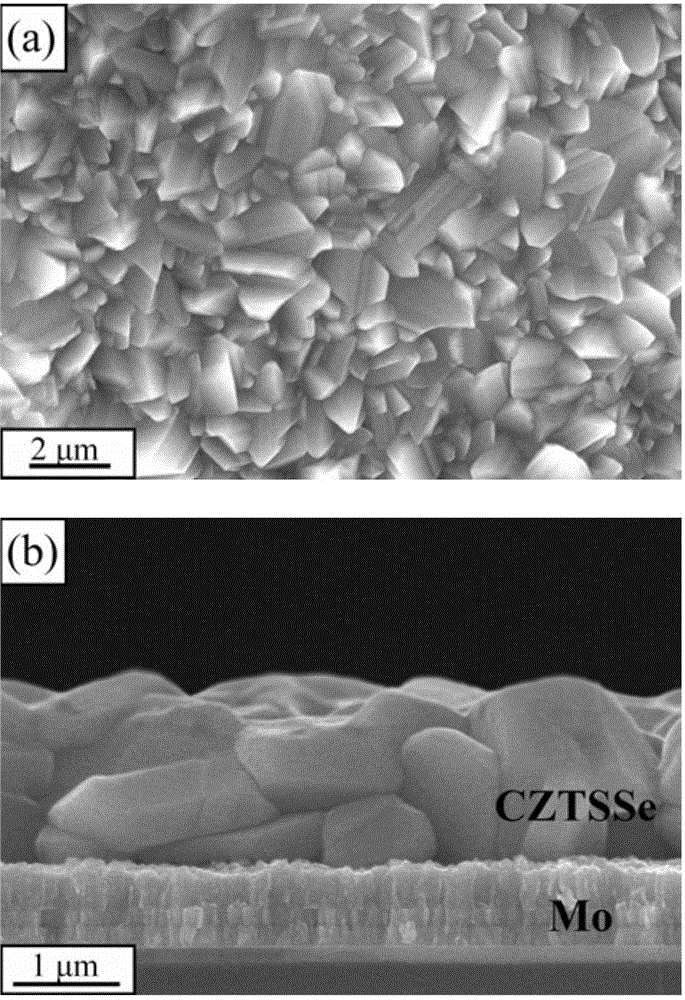

Method for preparing Cu2ZnSn(S,Se)4 solar cell absorbing layer film by using mercaptan-based ink

InactiveCN103560165AIncrease profitSafe preparationFinal product manufacturePhotovoltaic energy generationCarbon.organicSolvent

The invention provides a method for preparing Cu2ZnSn(S,Se)4 solar cell absorbing layer film by using mercaptan-based ink, belonging to the technical field of a solar cell absorbing layer film. The method comprises the steps of (a) stable precursor solution preparation under an air condition, (b) the preparation of a precursor film by using a spinning coating method, (c) drying, (d) multiple times of spinning coating and drying and (e) annealing processing. According to the film preparation method, the use of expensive original materials and devices is not needed, mercaptan which is a volatile, low carbon organic compound is taken as a solvent, and a problem of the introduction of carbon and oxygen elements in the previous copper zinc tin sulfide nanocrystal synthesis process can be overcome. The controllability of each process step is good, the preparation of the absorbing layer film with large grains, density and good photoelectric performance is facilitated, the process is simple, the repeatability is strong, and the large-scale production is easy to realize.

Owner:BEIJING UNIV OF TECH

Contacting Means and Method for Contacting Electrical Components

ActiveUS20120055978A1Contact stabilitySure easyTransportation and packagingSolid-state devicesOrganic acidSimple Organic Compounds

A method is provided for connecting at least two components, in which a sintering preform is used. This preform includes a carrier having a surface that has at least one structuring element containing hardened paste, wherein the hardened paste contains: (a) metal particles having a coating that contains at least one organic compound; and (b) at least one sintering aid selected from the group consisting of (b1) organic peroxides, (b2) inorganic peroxides, (b3) inorganic acids, (b4) salts of organic acids, wherein the organic acids have 1-4 carbon atoms, (b5) esters of organic acids, wherein the organic acids have 1-4 carbon atoms, and (b6) carbonyl complexes. The surface of the carrier having the hardened paste is not reactive to the constituents of the paste.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

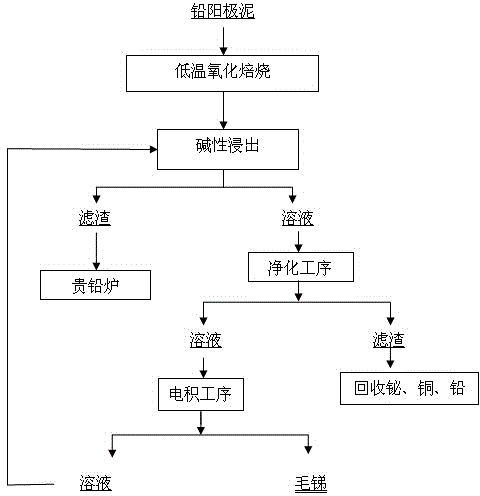

Method for extracting antimony from lead anode mud

InactiveCN104862484AHigh purityEasy to separatePhotography auxillary processesProcess efficiency improvementSulfideCarbon.organic

The invention discloses a method for extracting antimony from lead anode mud. The method comprises the steps of lead anode mud waste residue treatment, anode mud efficient leaching, purification of leaching liquid, electrodeposition antimony extracting of the purification liquid and the like. During leaching, mixed liquid of alcohol-ester-base-contained low carbon polyhydric alcohol organic matter and sodium hydroxide is used; the concentration of the sodium hydroxide and the concentration of the polyhydric alcohol low carbon organic matter in the leaching liquid are 50-300 g / L respectively; the ratio of the volume (mL) of the alkaline leaching liquid to the weight (g) of the lead anode mud is 3 : 1-8 : 1; leaching temperature is 20-93 DEG C; and leaching time is 0.5-5 h. In the leaching process, at least 90% of elements such as lead, antimony, bismuth, copper and arsenium in the anode mud can enter the leaching liquid; ions such as copper, lead, bismuth and arsenium in the leaching liquid, sulfide and calcium salt form insoluble precipitate to purify the leaching liquid. The leaching liquid is used as raw materials for carrying out electrodeposition antimony extracting in an electrolytic cell; cell voltage is 1.6-3.2 V; current efficiency can reach at least 55%. The method is simple; equipment cost is low; operation is convenient; purification residues obtained in the production process and electrodeposition liquid can be further recycled.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

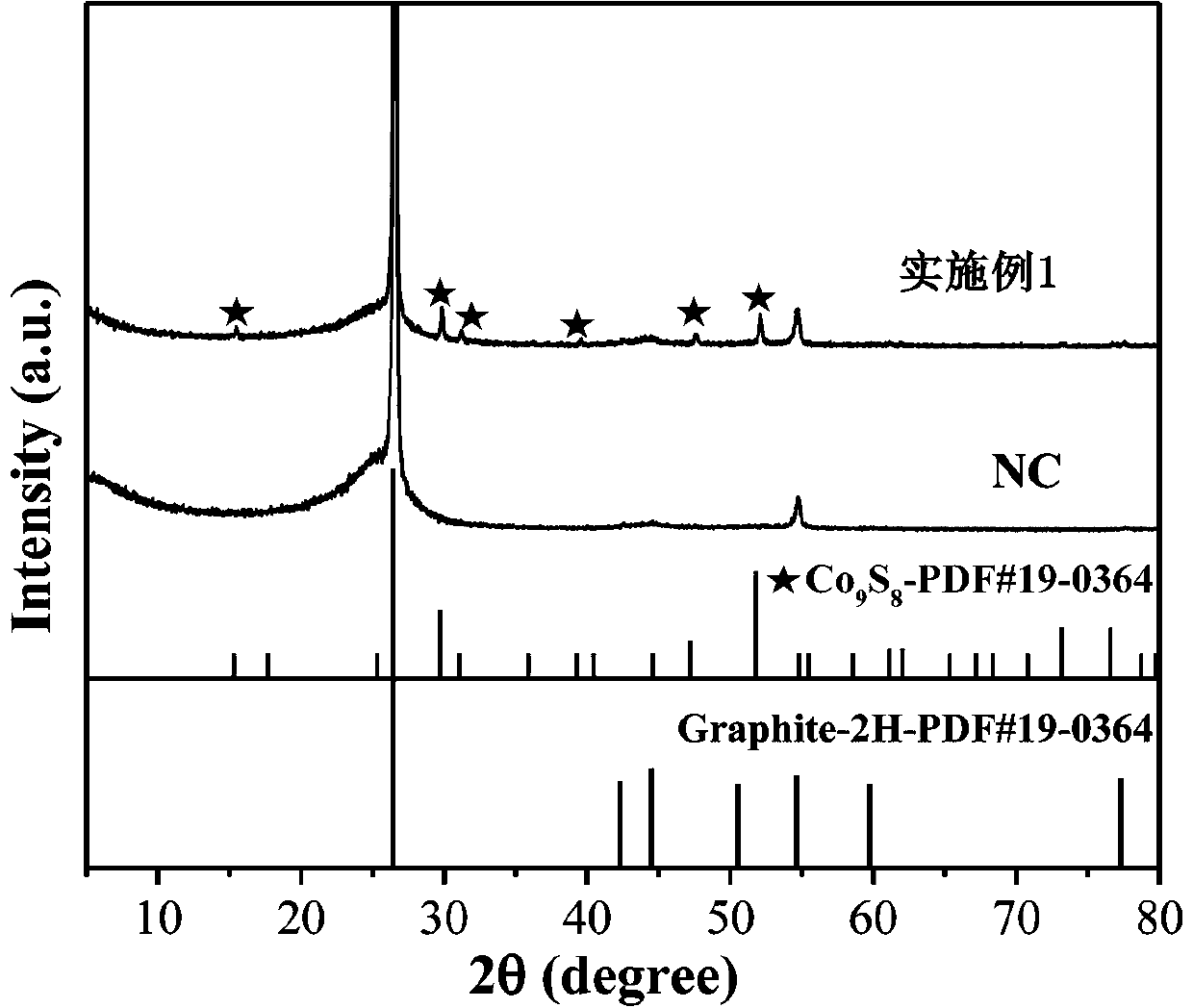

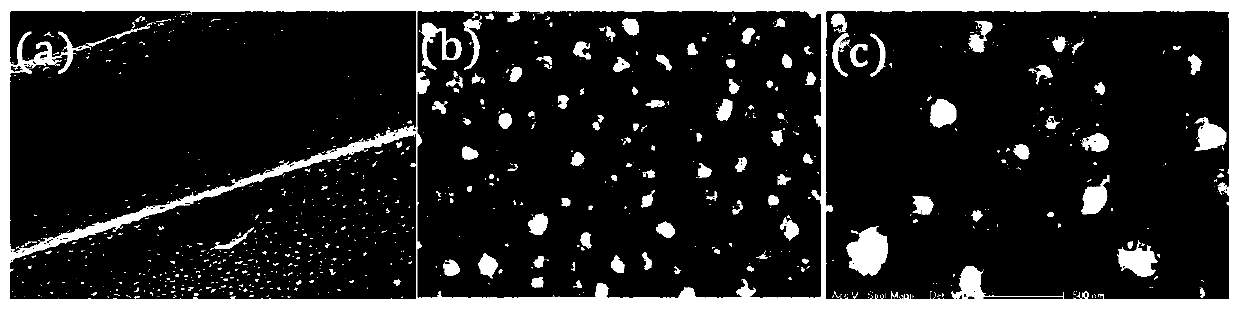

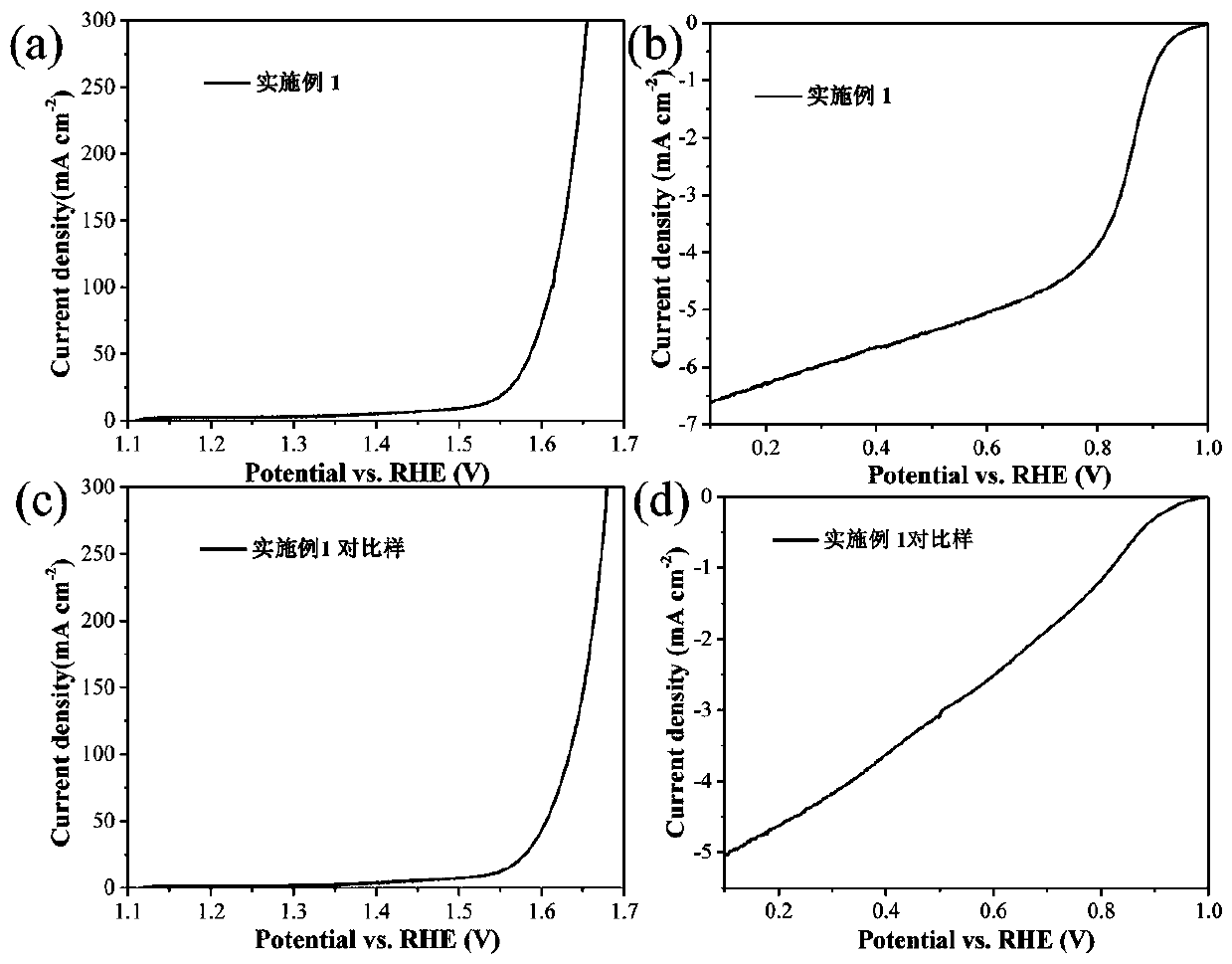

Preparation method of in-situ defect modified Co9S8-porous nitrogen-doped carbon electrode

ActiveCN110690469ARaise the ratioRaise the defect levelFuel and primary cellsCell electrodesPtru catalystThiourea

The invention provides a preparation method of an in-situ defect modified Co9S8-porous nitrogen-doped carbon electrode. The method comprises the steps of: dissolving cobalt salt, Tx-100, aniline and other carbon-containing organic matters in a volatile non-aqueous solvent, and adding thiourea as a sulfur source to obtain a Co-C-S precursor solution; and coating a carbon substrate with the precursor solution, performing drying and then annealing in Ar or N2 airflow to obtain an in-situ cobalt sulfide-carbon electrode, and continuously carrying out CVD calcination annealing on the in-situ cobaltsulfide electrode under dicyandiamide airflow to finally form the in-situ defect modified Co9S8-porous nitrogen-doped carbon electrode. The product obtained by the technical scheme provided by the invention has the advantages of the low equipment requirement, the low cost of required raw materials, the easily controlled reaction conditions, the simple production process, the good consistency of the formed product, the small environmental pollution and the like, and can be used for multifunctional electrocatalysts of OER and ORR.

Owner:CHINA THREE GORGES UNIV

Formula and preparation method of 200 DEG C temperature and salt resistant drilling fluid with strong inhibition and high density

The invention relates to a formula and preparation method of a 200 DEG C temperature and salt resistant drilling fluid with strong inhibition and high density. The formula is characterized in that in the formula, a high temperature salt resistant shear strength improving agent is a silicate modified substance; fluid loss additives A and B are products with carbon-carbon chains main chains and sulfonic acid groups, pyrrolidone groups or alkane groups as branched chains; an inhibiting / anti-collapse agent is a modified natural vegetable pitch derivative with a high softening point; an inhibiting / lubricating agent is a high polymer nonionic surfactant; and a water soluble heavy weight additive is a compound of low carbon organic acid salts of alkali metals, organic acid ammonium and organic acid quaternary ammonium. The preparation method is characterized by successively adding corresponding components with determined concentrations to the fresh water at a certain stirring speed according to the formula, thus obtaining the drilling fluid. The formula and the preparation method have the following beneficial effect: the problems of difficulty in control of viscosity, high fluid loss, low solid phase capacity and poor pollution resistance of the drilling fluid with high density are solved.

Owner:CNPC BOHAI DRILLING ENG

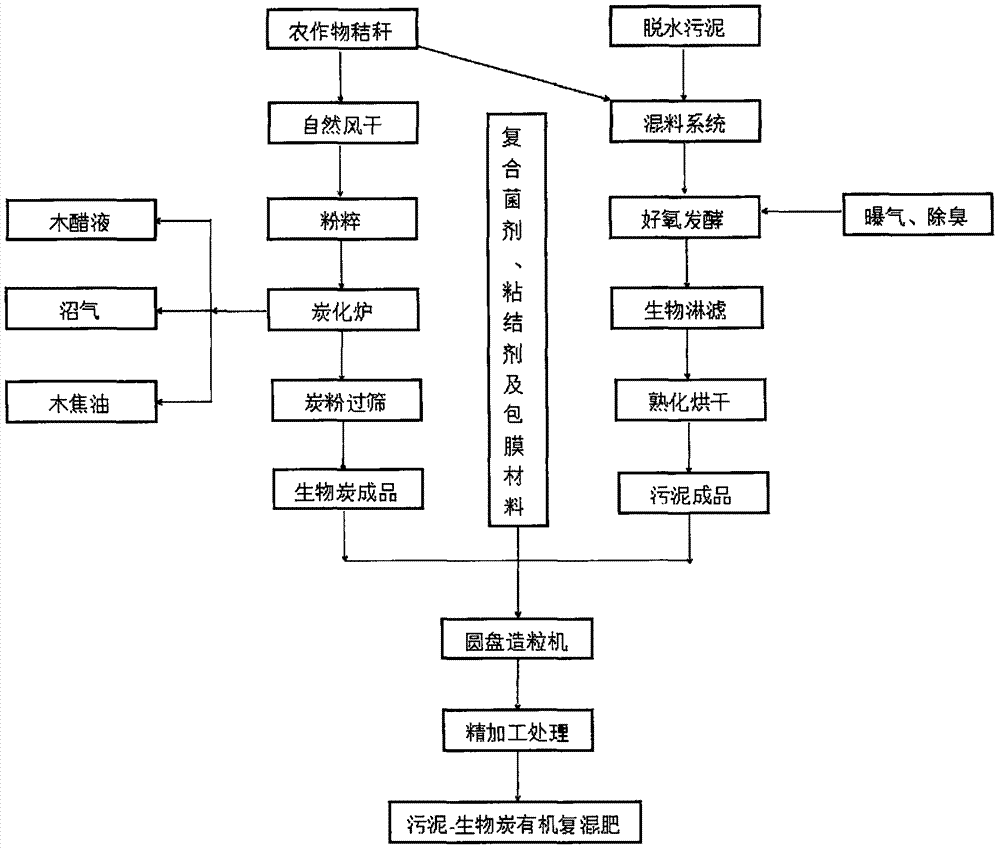

Sludge-biological carbon organic compound fertilizer and preparation method thereof

InactiveCN107285847AAvoid wastingSolve pollutionSewage/sludge fertilisersOrganic fertiliser preparationMicroorganismSludge

The invention provides sludge-biological carbon organic compound fertilizer and a preparation method thereof. The sludge-biological carbon organic compound fertilizer is prepared from the following raw materials: sludge, biological carbon, a mineral powder binding agent, a compound microorganism bacterium agent, a granulation binding agent and a film coating material; the preparation method of the compound fertilizer comprises the following steps: carrying out high-temperature cracking on crop straws to prepare the biological carbon; after mixing the sludge with the straws and composting, dehydrating, sterilizing and curing; removing heavy metal elements by utilizing a biological leaching method; after mixing and melting the prepared sludge and the biological carbon according to a reasonable ratio, melting and granulating; carrying out screening and film coating on grains to prepare the sludge-biological carbon organic compound fertilizer. The compound fertilizer provided by the invention sufficiently utilizes a lot of residual sludge and straw resources and has the advantages of fertilizer slow release, soil improvement, carbon fixation and emission reduction and the like; the nutrient matching is reasonable; after the sludge-biological carbon organic compound fertilizer is matched with conventional compound fertilizer and is applied, the fertilizer efficiency and the utilization rate can be effectively improved and the yield and quality of crops are remarkably improved. The method provided by the invention has relatively low cost and a feasible process and is suitable for large-scale popularization.

Owner:NORTHWEST A & F UNIV

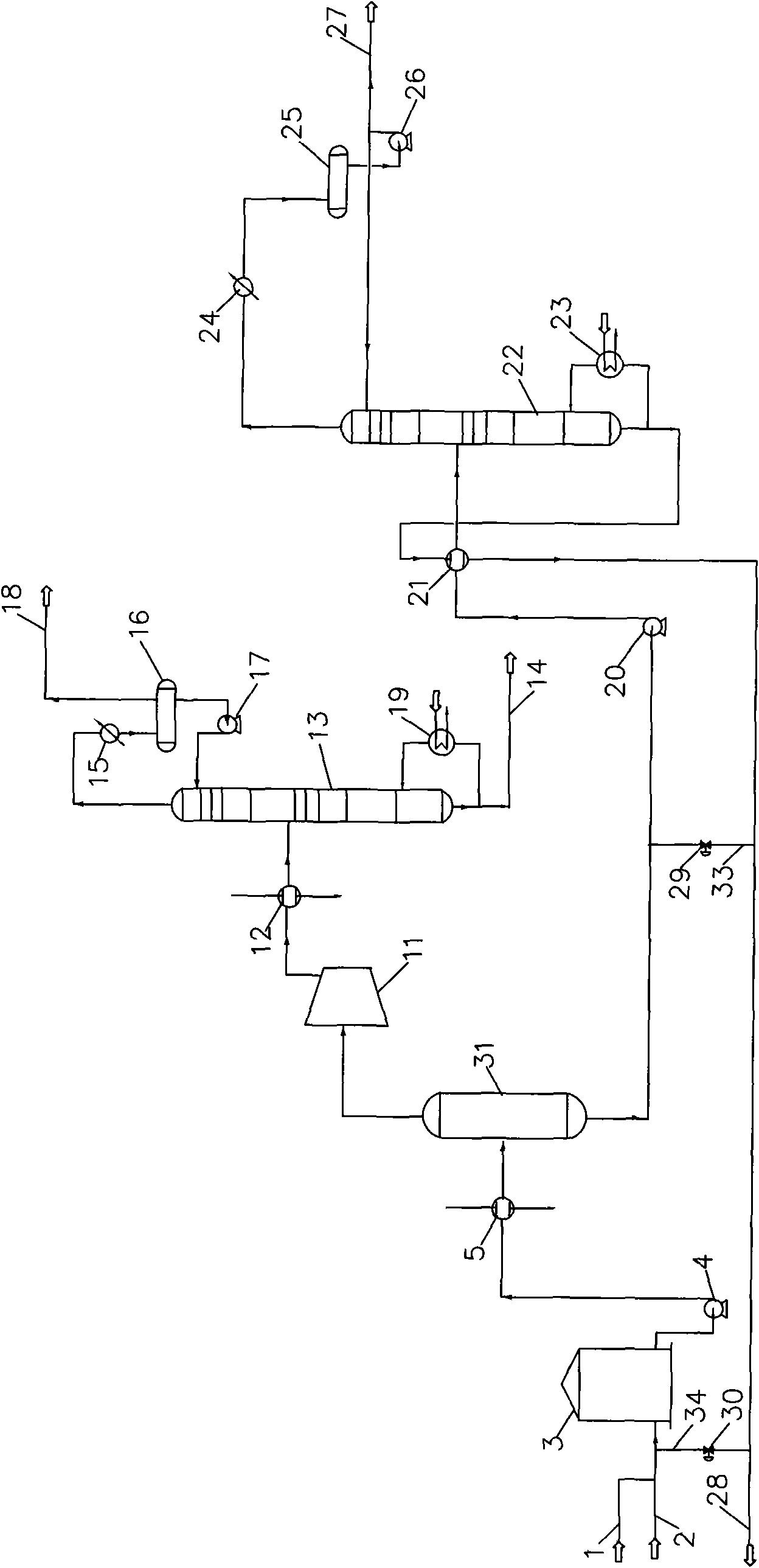

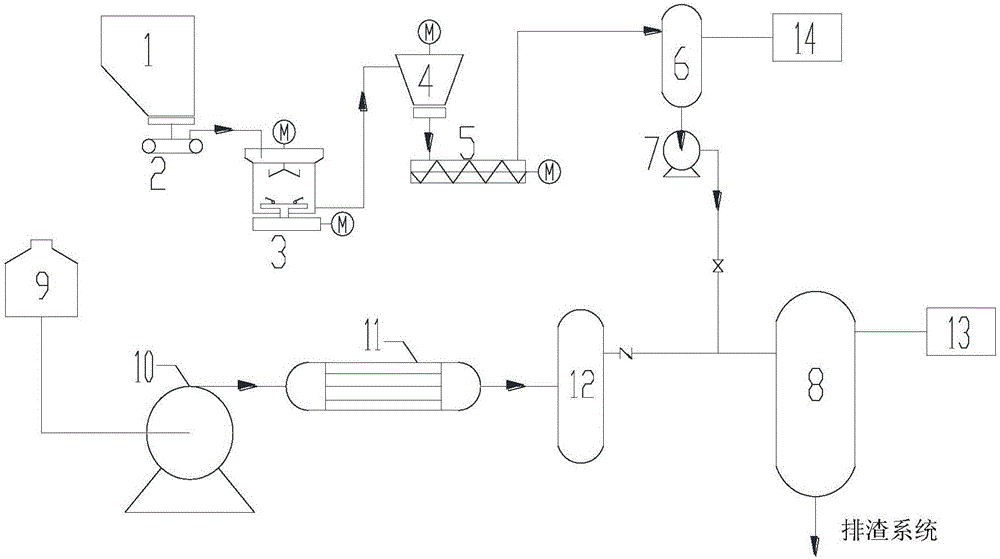

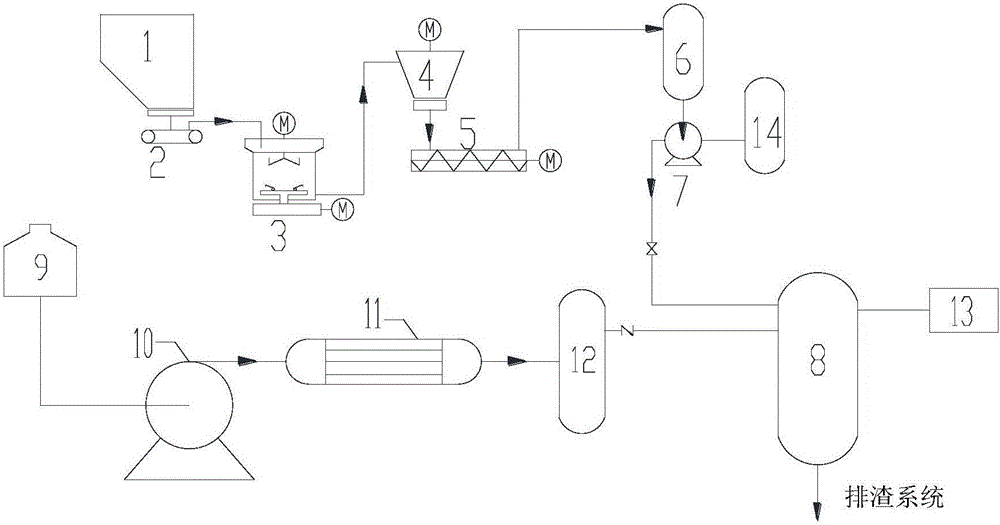

Supercritical sludge treatment system and treatment method

InactiveCN105859088ALarge amount of processingHigh calorific valueSludge treatment by oxidationByproduct vaporizationSludgeSlurry

The invention relates to a supercritical sludge treatment system, comprising a supercritical sludge treatment device as well as a sludge conveying device and a carbonaceous organic material adding device respectively communicated with the supercritical sludge treatment device, wherein the carbonaceous organic material adding device comprises a pressure device communicated with the supercritical sludge treatment device and a buffer pot connected with the pressure device. The aim of the supercritical sludge treatment system is that when the caloric value of sludge slurry is low in supercritical reaction, the caloric value of reactant burning is improved by a method of supplementing powdered carbonaceous organic materials to the sludge slurry, thereby increasing the sludge treatment capacity and improving the sludge treatment efficiency of a supercritical reactor. The invention also relates to a supercritical sludge treatment method.

Owner:ENN SCI & TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com