Method for extracting antimony from lead anode mud

A lead anode slime and anode slime technology, applied in the metallurgical industry, can solve the problems of long production cycle, increased environmental protection pressure, low recovery rate, etc., and achieve the effects of high recovery rate, high extraction efficiency and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

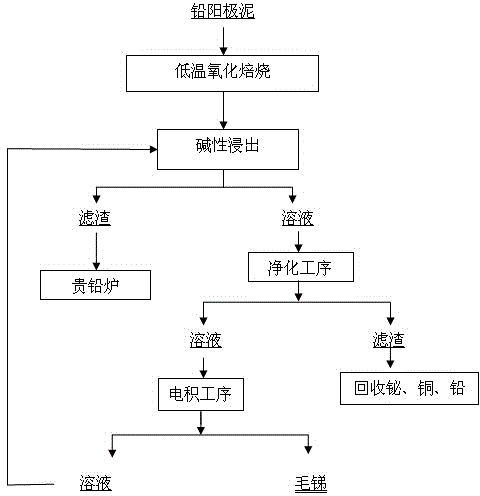

Image

Examples

Embodiment 1

[0015] The method for extracting valuable metal antimony from lead anode slime of the present invention comprises the following steps:

[0016] (1) Low-temperature oxidation roasting of lead anode slime: put the weighed lead anode slime in the roasting tray to ensure that the thickness of the anode slime is 20-25 mm and evenly distributed, and then put the roasting tray containing the lead anode slime into the oxidation roaster , the furnace temperature was maintained at 120°C, the roasting time was 24 hours, and the lead anode slime in the roasting furnace was rolled every 6 hours during the roasting period.

[0017] (2) Enrichment of antimony and precious metals in lead anode slime by alkaline leaching of low-carbon polyol + sodium hydroxide mixed solution: Weigh 20g of lead anode slime obtained after roasting in step (1) and pour it into a 400ml beaker, Prepare 100ml of 250g / L NaOH solution, then add 20ml of glycerin with a mass fraction of 99% into the NaOH solution, then ...

Embodiment 2

[0021] The method for extracting valuable metal antimony from lead anode slime of the present invention comprises the following steps:

[0022] (1) Low-temperature oxidation roasting of lead anode slime: put the weighed lead anode slime in the roasting tray to ensure that the thickness of the anode slime is 20-25 mm and evenly distributed, and then put the roasting tray containing the lead anode slime into the oxidation roaster , the furnace temperature was maintained at 100°C, the roasting time was 10 hours, and the lead anode slime in the roasting furnace was rolled every 3 hours during the roasting period.

[0023] (2) Enrichment of antimony and precious metals in lead anode slime by alkaline leaching of low-carbon polyol + sodium hydroxide mixed solution: Weigh 20g of lead anode slime obtained after roasting in step (1) and pour it into a 200ml beaker, Prepare 60ml of NaOH solution of 50g / L, then add 18g of xylitol with a concentration of 99% in the NaOH solution, then pou...

Embodiment 3

[0027] The method for extracting valuable metal antimony from lead anode slime of the present invention comprises the following steps:

[0028] (1) Low-temperature oxidation roasting of lead anode slime: put the weighed lead anode slime in the roasting tray to ensure that the thickness of the anode slime is 20-25 mm and evenly distributed, and then put the roasting tray containing the lead anode slime into the oxidation roaster , the furnace temperature was maintained at 100°C, the roasting time was 48 hours, and the lead anode slime in the roasting furnace was rolled every 5 hours during the roasting period.

[0029](2) Enrichment of antimony and precious metals in lead anode slime by alkaline leaching of low-carbon polyol + sodium hydroxide mixed solution: Weigh 20 g of lead anode slime obtained after roasting in step (1) and pour it into a 500ml beaker, Prepare 160ml of 300g / L NaOH solution, then add 48g of tartaric acid with a concentration of 99% into the NaOH solution, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com