Patents

Literature

1793 results about "Metallurgical industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

METALLURGICAL INDUSTRY. The metallurgical industry can be broadly divided into primary and secondary metal production operations. Primary refers to the production of metal from ore. Secondary refers to production of alloys from ingots and to recovery of metal from scrap and salvage.

Composite tailing non-fired and non-steamed building block brick and preparation method thereof

InactiveCN102093004AHigh waste rateSolve the problem of excessive dosageSolid waste managementBrickSlag

The invention discloses a composite tailing non-fired and non-steamed building block brick and a preparation method thereof. The brick comprises the following raw materials in parts by weight or volume: 50-300 parts of tailing and 3-30 parts of cement; and at least two components are selected from the active wastes such as fly ash, coal gangue, shale slag, alkaline residue, carbide slag, chemical gypsum and the waste residue of metallurgical industry to be mixed with the raw materials. The preparation method comprises the following steps: mixing to stir, compressing and shaping, performing natural curing or utilizing the solar heaing hydrating maintenance to prepare the composite tailing building block brick. By adopting the preparation method of the invention, the single performances of the tailings and slags can be changed, thus the product can have higher strength and quality owning to the interaction of materials; the technology does not adopt firing and steaming, the cost is low; different sizes of solid bricks, perforated bricks, hollow blocks, floor tiles, grass planting bricks, roadside bricks and artistic rails can be prepared by changing the mould; and various harmful slags such as tailings can become good, the Chinese development direction of the comprehensive utilization of resources is satisfied and the brick of the invention has development and application prospect.

Owner:郭东京 +2

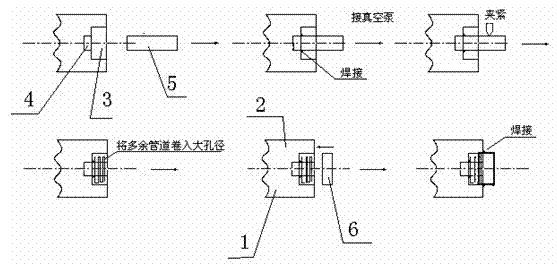

Technological process for producing super-thick plate

InactiveCN101439348AQuality improvementLow costTemperature control deviceElectron beam welding apparatusElectro-slag remeltingVacuum chamber

The invention relates to a process for producing an ultra-thick plate and belongs to the field of rolling and producing an ultra-thick steel plate in the metallurgical industry. The invention mainly overcome the defect of producing the ultra-thick steel plate by a traditional model casting manufacturing blank and an electro-slag remelting manufacturing blank. The method comprises the following steps: cutting and fixing lengths of the blanks, mechanically conditioning the blanks (eliminating, leveling and cleaning a single-surface oxide layer of a casting blank with a milling machine, a planer or a shot blast); clamping an assembly (relatively superposing the cleaning surfaces of the two blanks after processing, placing the two blanks oppositely and clamping the blanks); mounting the blanks in a vacuum chamber of an electronic beam welding machine for purpose of vacuuming; sewing the assembly on the electronic beam welding seal edge, heating the assembly in a furnace and rolling the assembly through temperature control; and then producing the ultra-thick steel plate. Compared with the traditional electro-slag remelting production process, the process has the advantages of high production efficiency, reduced electric power consumption, less investment of production devices and low production cost. Compared with the traditional die casting production process, the process solves the problem of segregation and looseness of a large-scale die casting ingot center part; the finished product ratio is high; and the finished product ratio of blank assembly is over 90 %.

Owner:SHANDONG IRON & STEEL CO LTD

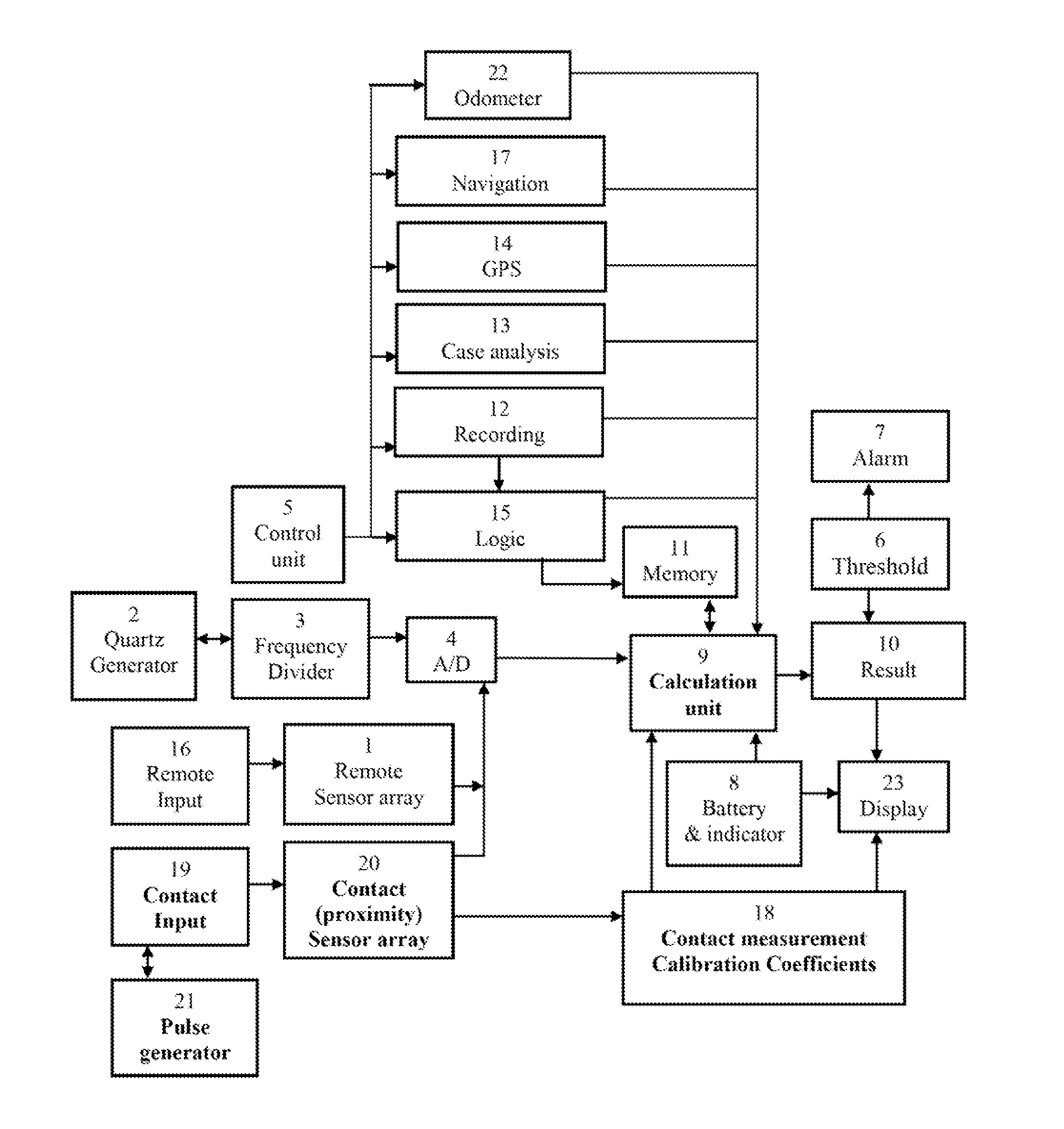

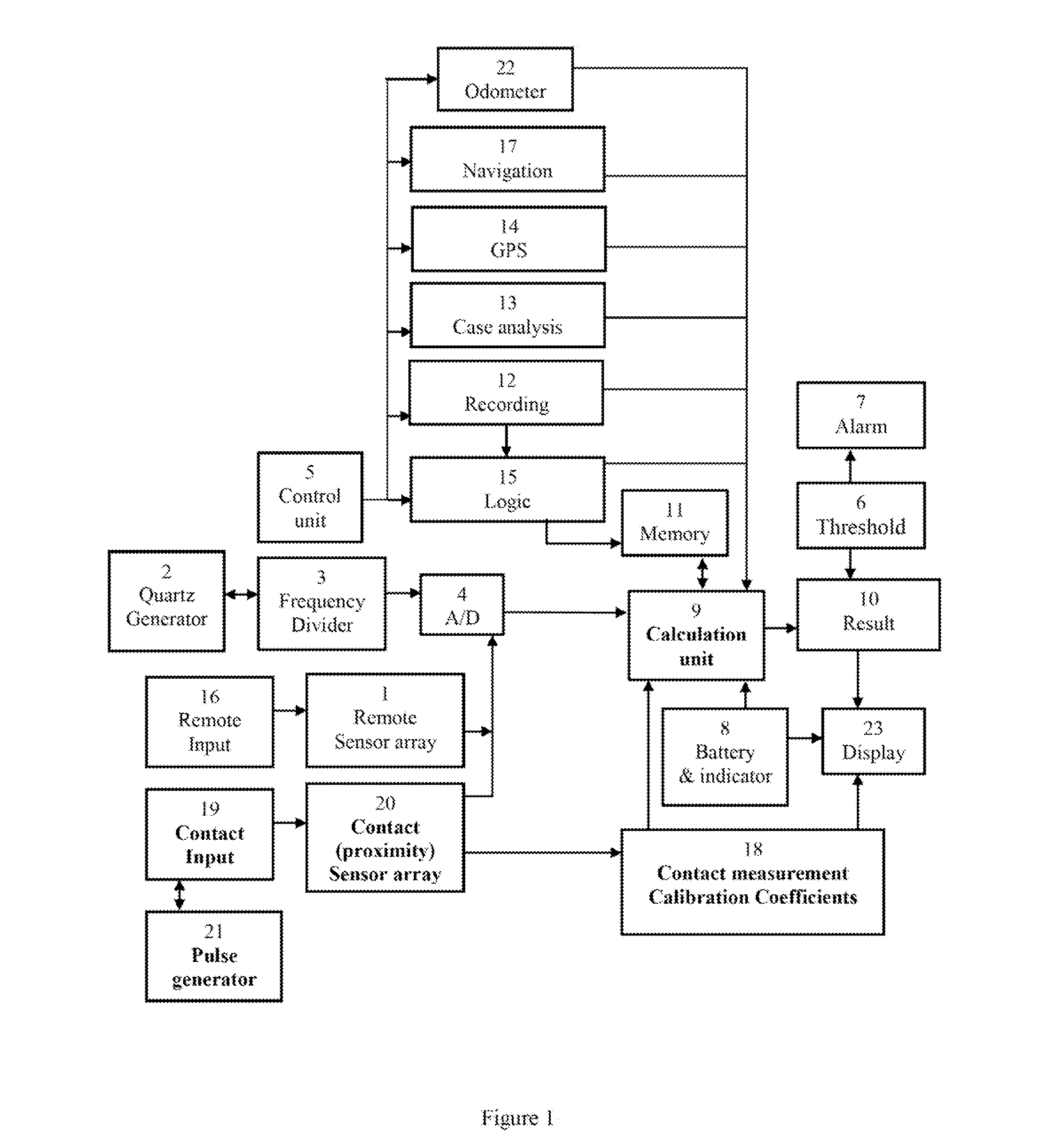

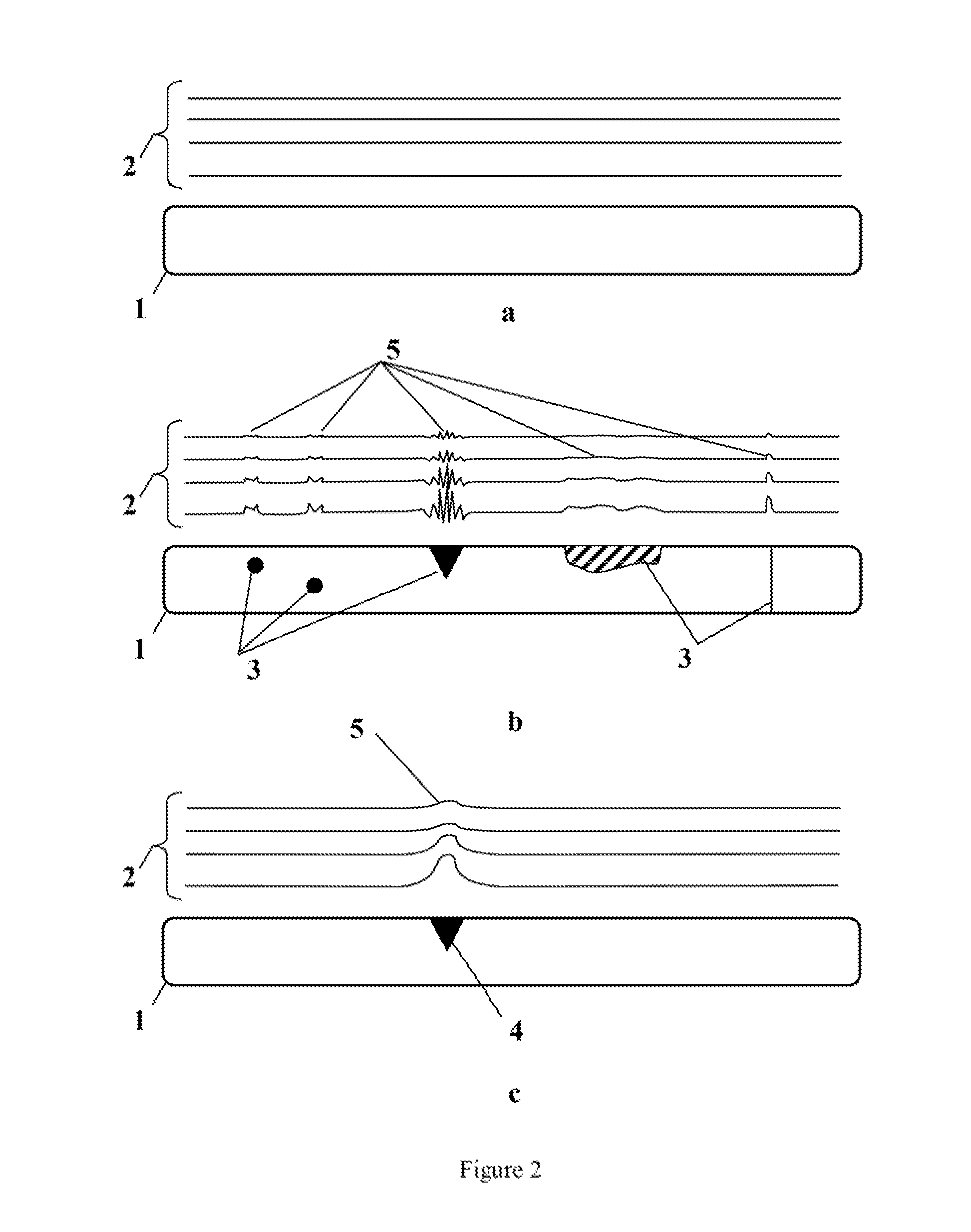

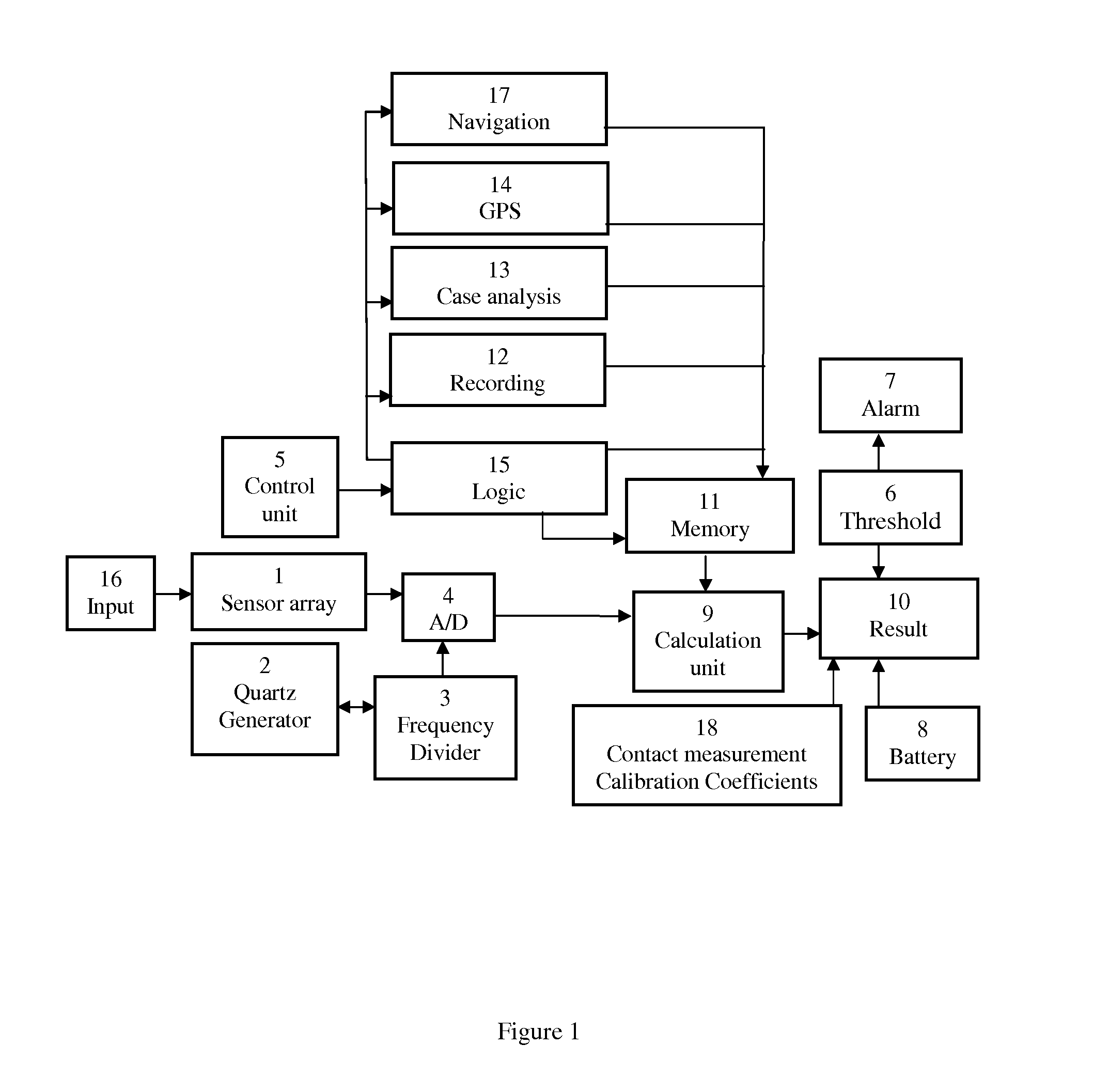

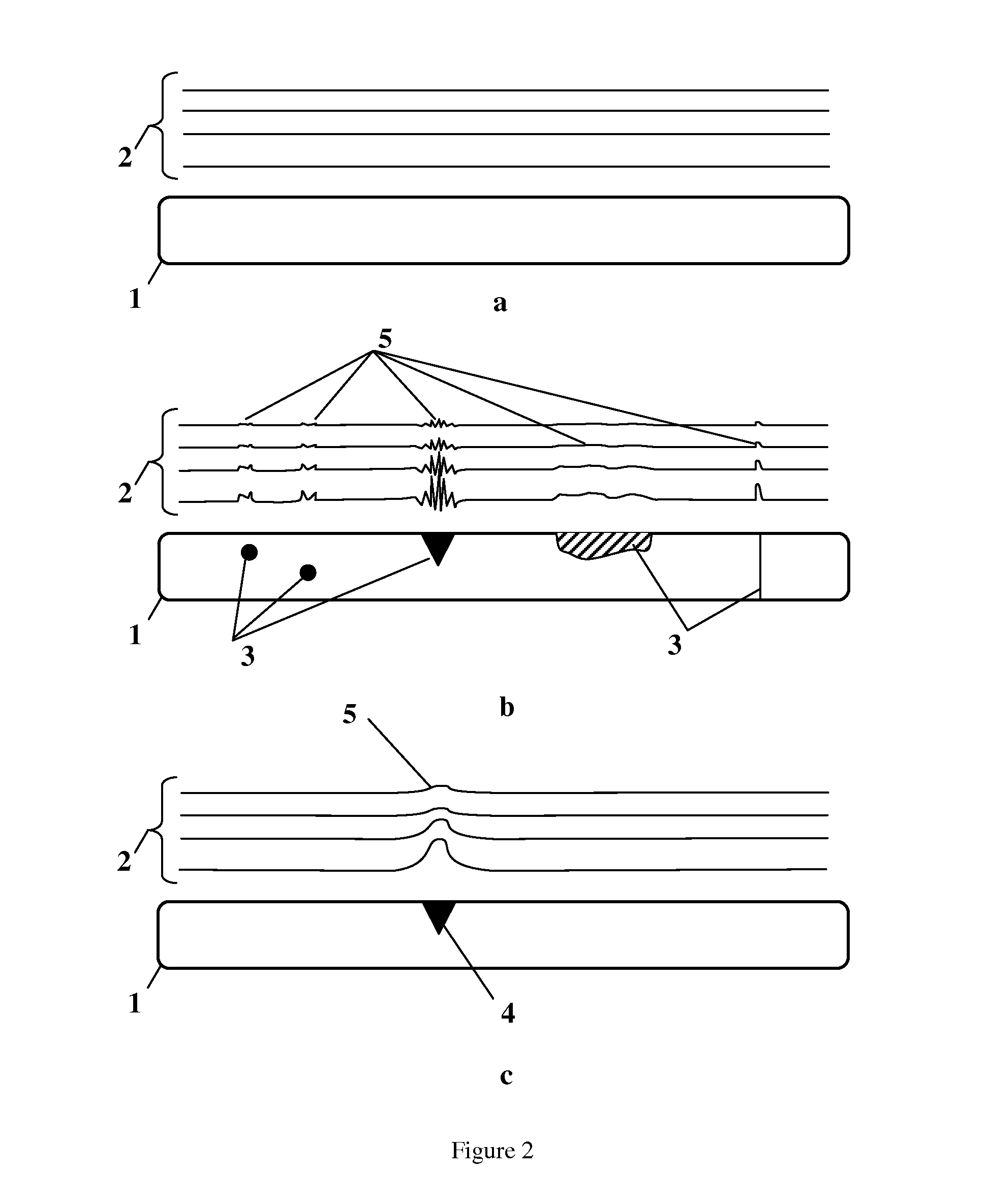

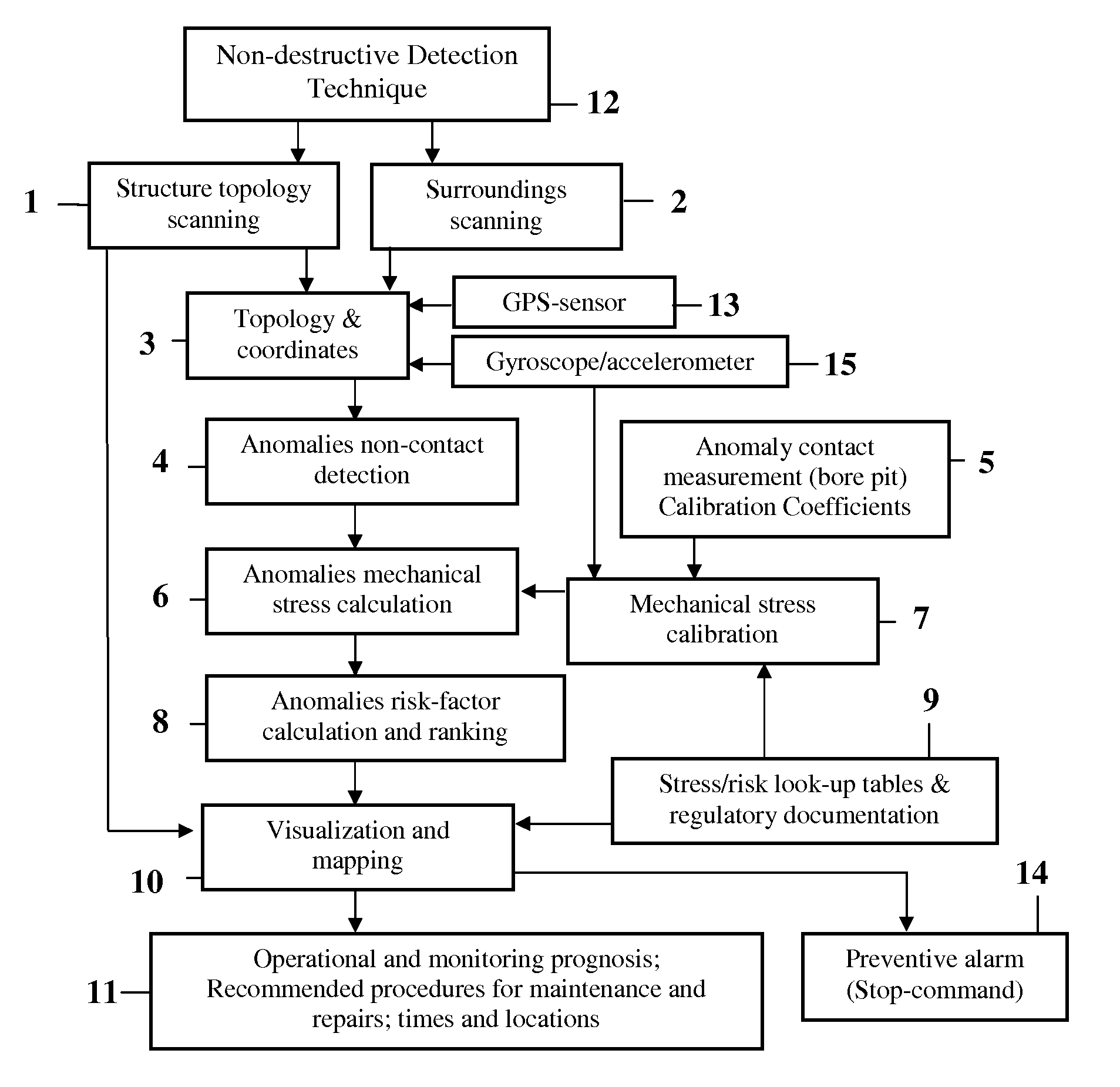

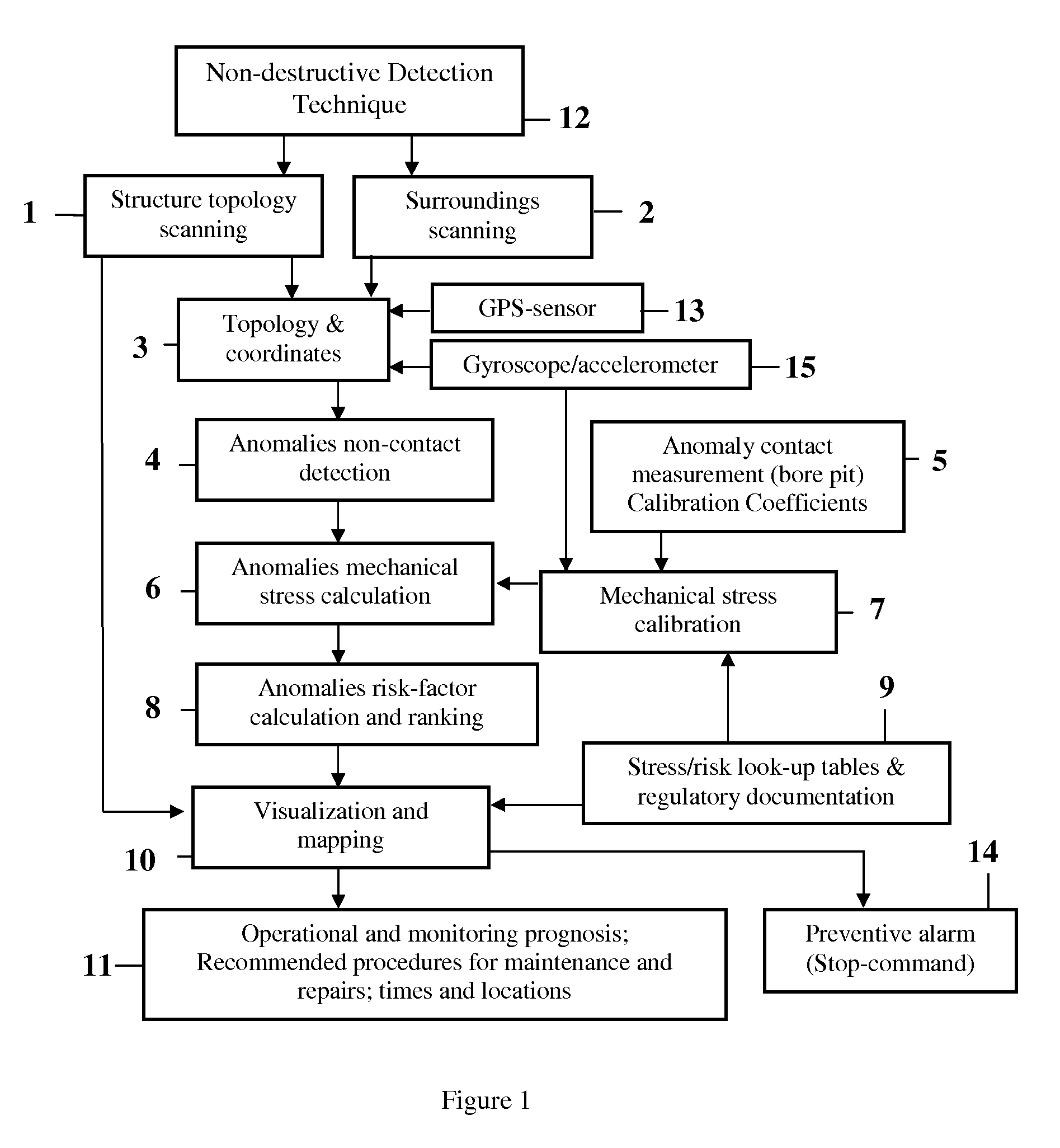

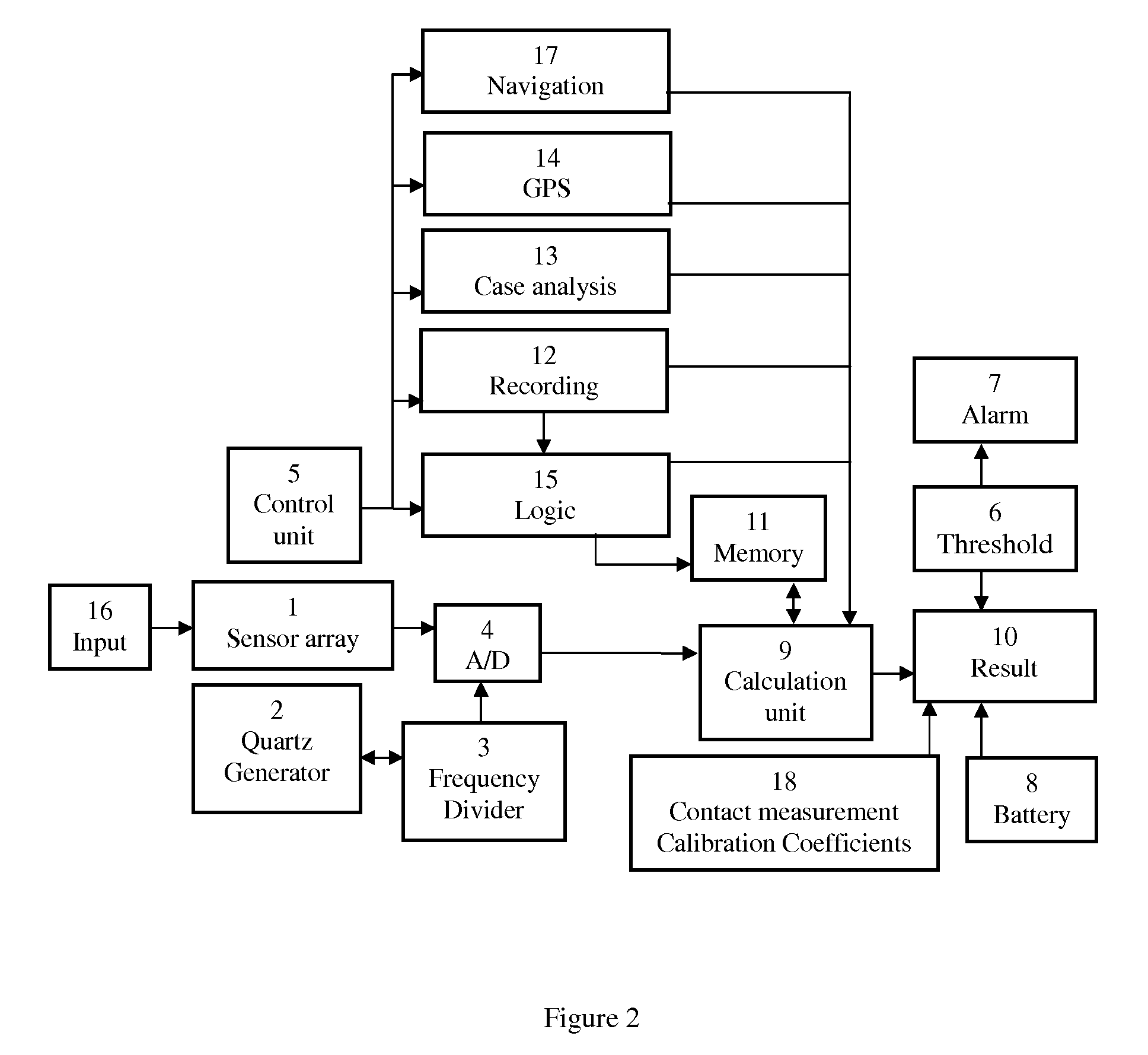

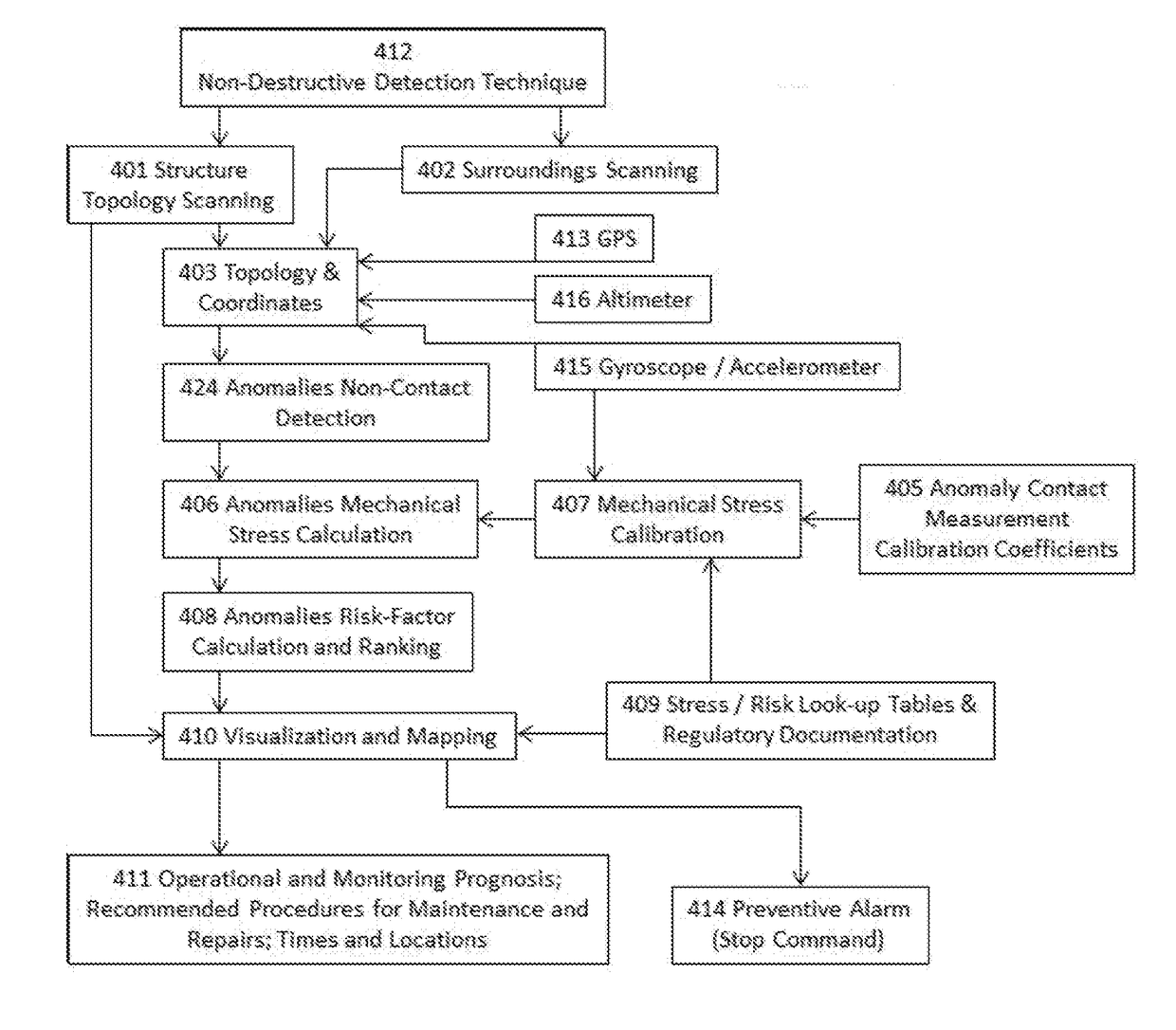

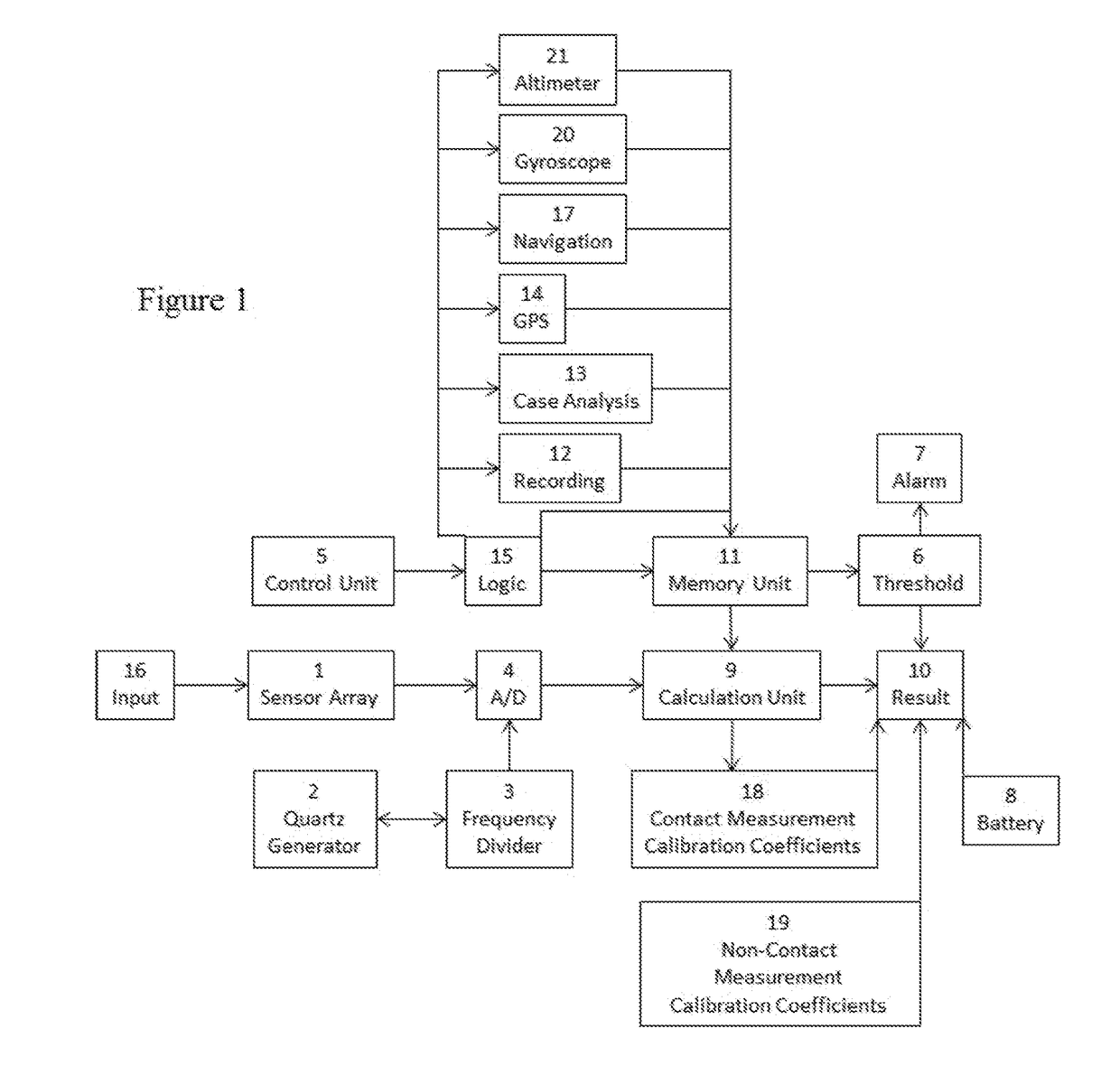

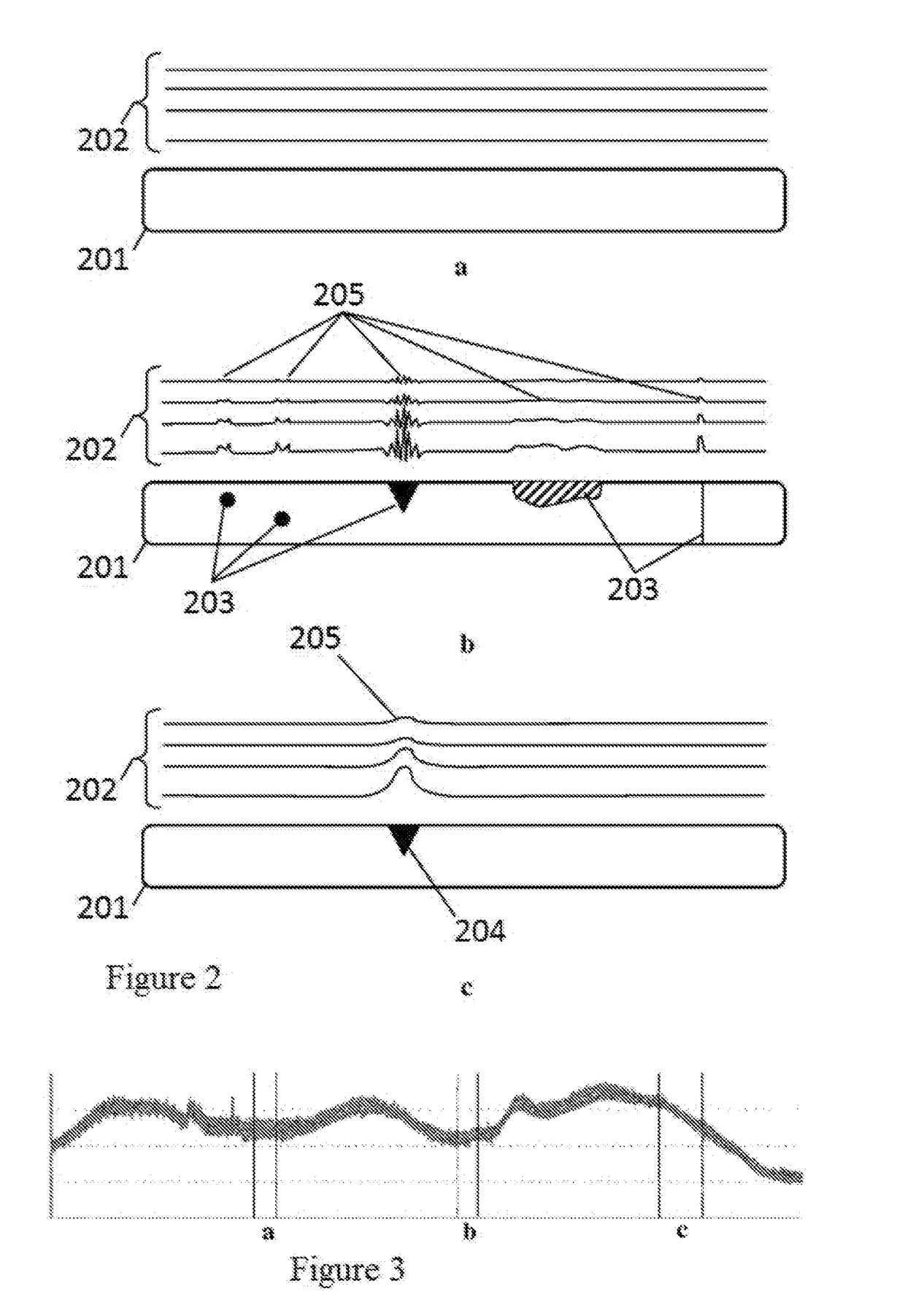

Apparatus and method for metallic constructions assessment

ActiveUS20140368191A1Improve accuracyEnsure qualitySusceptibility measurementsMaterial magnetic variablesEngineeringHeavy duty

A device for discovering, identification and monitoring, of mechanical flaws in metallic structures is disclosed, based on magneto-graphic / magnetic tomography technique to identify stress-related defects. The device includes registration means that optimized for use with metallic structures of various types, shapes and sizes. Applications include a real-time quality control, monitoring and emergency alarms, as well structural repairs and maintenance work recommendations and planning. Examples of the device implementation include pipes for oil and gas industry monitoring, detection of flaws in rolled products in metallurgical industry, welding quality of heavy duty equipment such as ships, reservoirs. etc. It is especially important for loaded constructions, such as pressured pipes, infrastructure maintenance, nuclear power plant monitoring, bridges, corrosion prevention and environment protection.

Owner:GOROSHEVSKIY VALERIAN +2

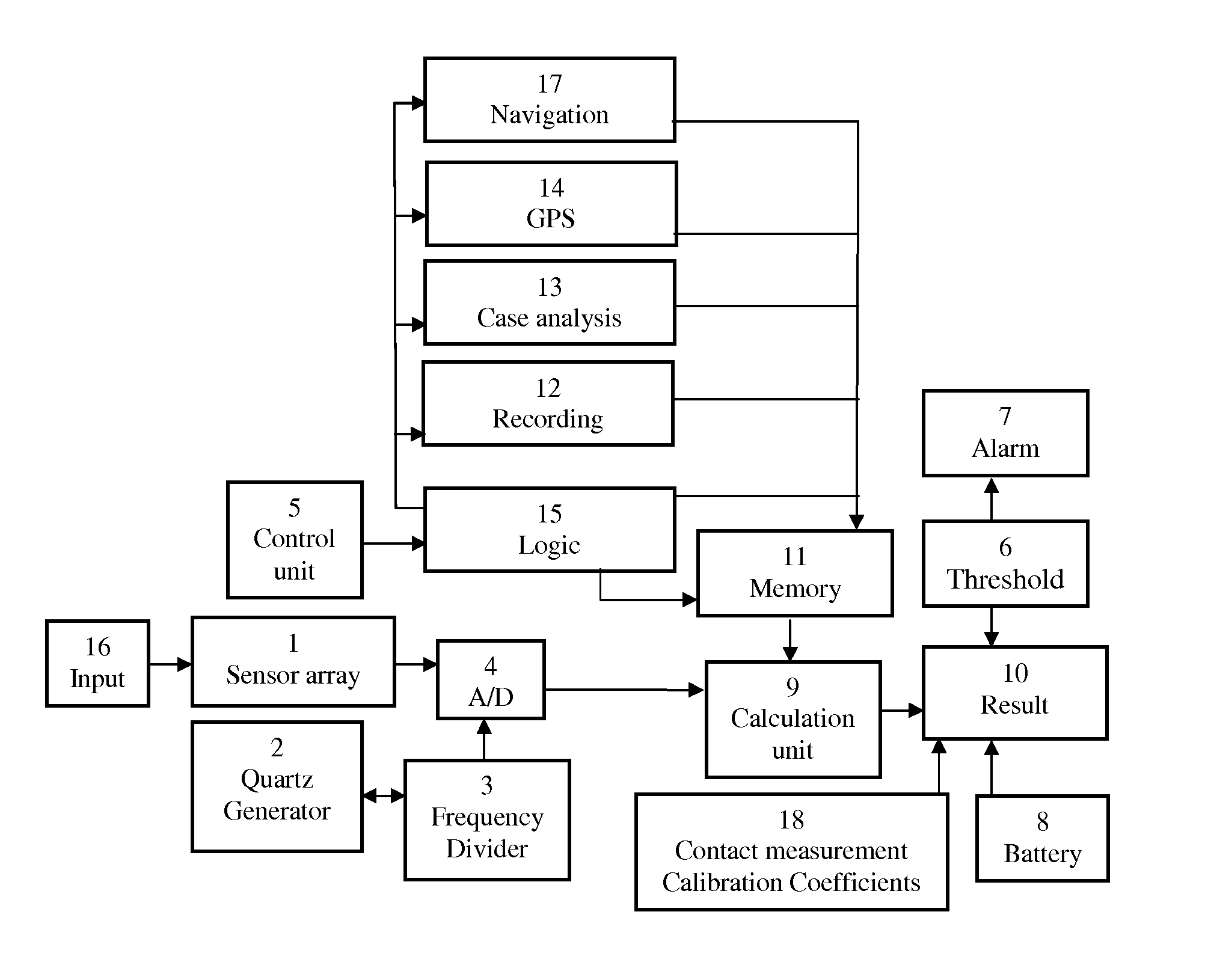

Apparatus for the non-contact metallic constructions assessment

ActiveUS8542127B1The result is accurate and reliableAnalysing solids using sonic/ultrasonic/infrasonic wavesElectrical measurementsHeavy equipmentHeavy duty

A device and method for discovering, identification and monitoring of mechanical flaws in metallic structures is disclosed, based on magneto-graphic / magnetic tomography technique to identify stress-related defects. The technique is specifically optimized for extended, not-accessible underground and underwater metallic structures quality control, emergency alarms as well as timeline planning for structural repairs and maintenance work. Examples of the technique implementation include pipes for oil and gas industry, detection of flaws in rolled products in metallurgical industry, welding quality of heavy duty equipment such as ships, reservoirs, etc. It is especially important for loaded constructions, such as pressured pipes, infrastructure maintenance, nuclear power plant monitoring, bridges, corrosion prevention and environment protection.

Owner:GOROSHEVSKIY VALERIAN +2

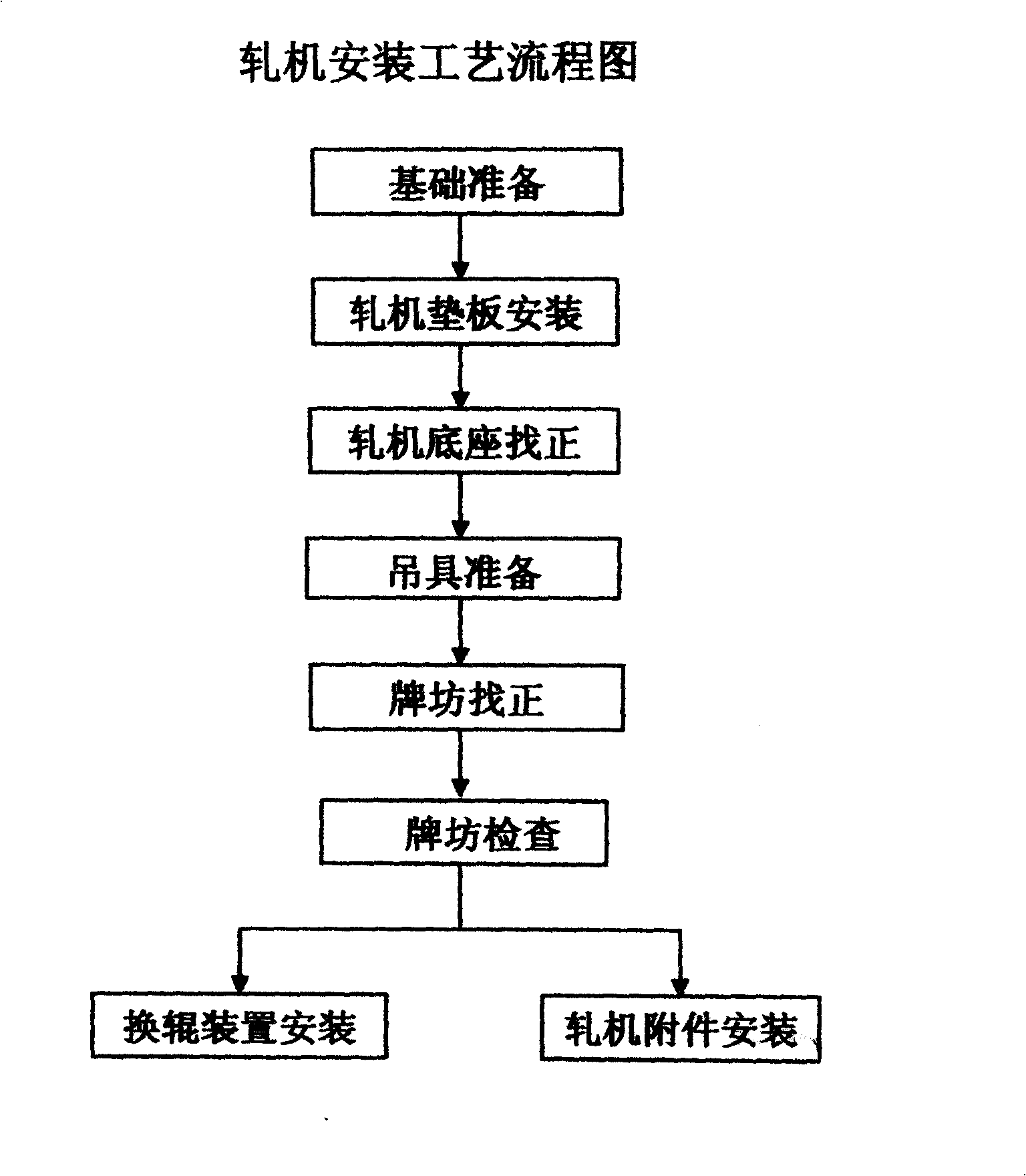

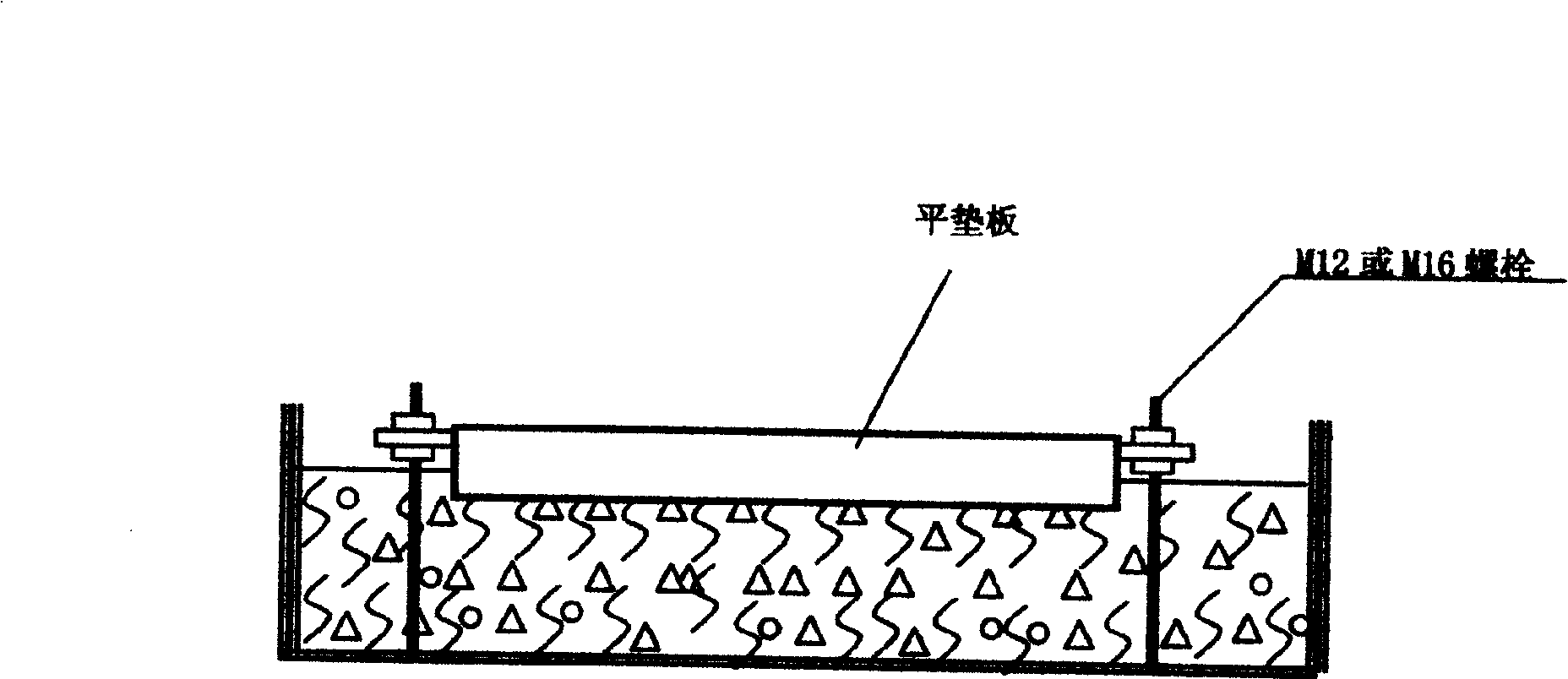

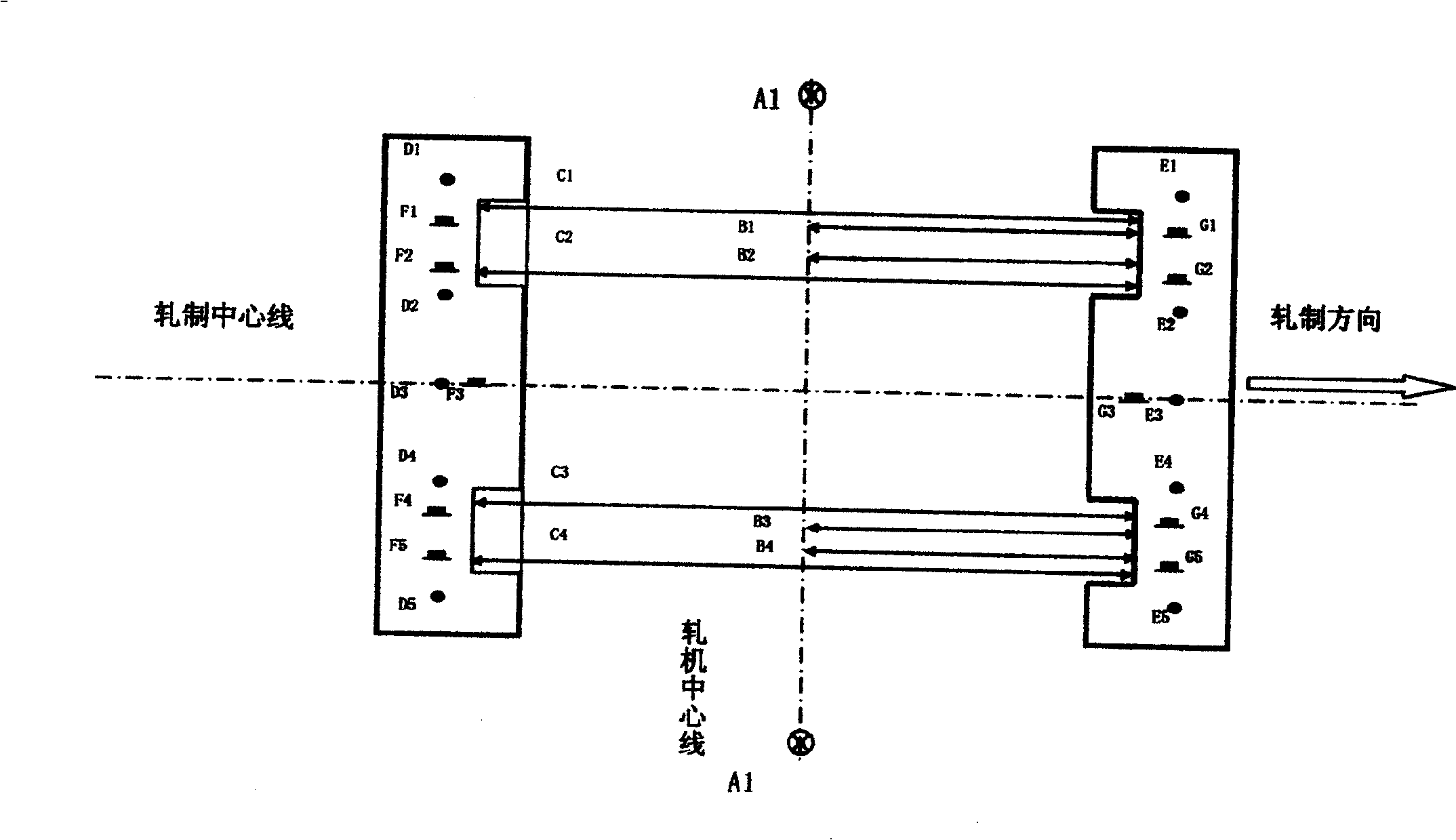

Method for mounting large-sized rolling mills

InactiveCN101275400AReduce loosenessAvoid damageFoundation engineeringBuilding material handlingStrip millMechanical equipment

The invention relates to an installation of metallurgy industry rolling mills, pinch pass mill, burnishing machines and the like large-scale mechanical equipment, especially to an installation method of a large-scale rolling mill, which is characterized in that the installation of a large-scale rolling mill is realized by the process steps of base preparation, rolling mills bearing plate installation, rolling mills motherboard transverse alignment, sling preparation, memorial archway transverse alignment, memorial archway check-up, roll-changer installation and rolling mill accessory installation. The invention satisfies all requirement of different construction sites, effectively resolves hanging difficult problem, saves work efficiency about 6-7 times, ensures installation quality, uses hydraulic bolt stretchers to avoid bolt up force moment from macrolesion bolt, and adopts small fastening force moment to allow rolling mills subbase to become flexible. Work difference bands are used to control the roll changing transmission device central line and the rolling mill central line to ensure installation quality. According to combination of calculation and on-site practicality, the invention not only can be used for rolling mills installation, but also can spread in mechanical equipment installation with common advising signification.

Owner:ANGANG CONSTR CONSORTIUM

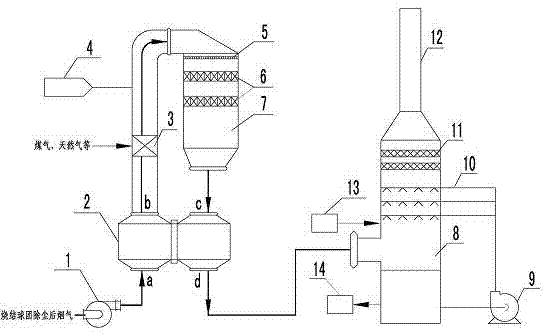

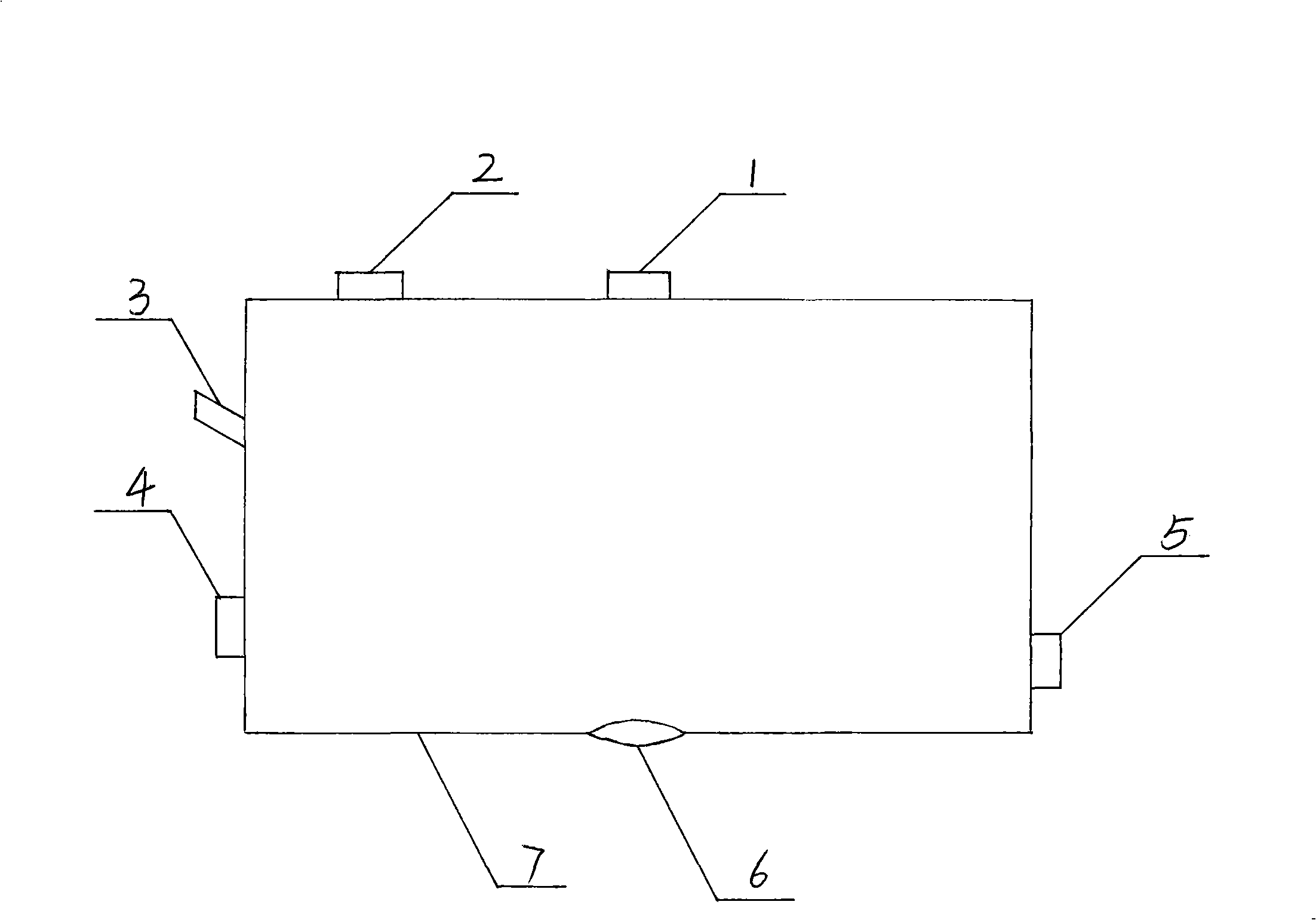

Sintering and pelletizing flue gas desulfurization and denitrification coordinating management system and process

InactiveCN103785290AGuaranteed uptimeLess investmentDispersed particle separationMetallurgical industryOperating cost

The invention relates to a coordinating management system and process for sulfur dioxide, oxynitride, heavy metal, dioxin and other pollutants in flue gas emitted in the sintering and pelletizing processes in the metallurgical industry. The system comprises a booster fan 1, a flue gas heat exchanger 2, a combustor 3, a denitrification reactor 7 and a desulfurization tower 8. The flue gas heat exchanger 2 is a rotary type or tubular heat exchanger. Sintering and pelletizing flue gas after dust removal enters the booster fan 1. The booster fan 1 is connected with an inlet a of the flue gas heat exchanger 2 through a flue. An outlet b of the flue gas heat exchanger 2 is connected with the combustor 3. An outlet of the combustor 3 is connected with the denitrification reactor 7 through a flue. A denitrification reductive agent injector 4 is arranged on the flue through which the combustor 3 is connected with the denitrification reactor 7. An outlet of the denitrification reactor 7 is connected with an inlet c of the flue gas heat exchanger 2. An outlet d of the flue gas heat exchanger 2 is connected with the desulfurization tower 8. The sintering and pelletizing flue gas desulfurization and denitrification coordinating management system and process have the advantages that operation is stable and reliable, investment is lowered, operating cost is low, and by-products can be comprehensively utilized, thereby being a sintering and pelletizing flue gas desulfurization and denitrification coordinating management technology suitable for national conditions of China.

Owner:中钢集团天澄环保科技股份有限公司

Metallic constructions integrity assessment and maintenance planning method

ActiveUS8447532B1Easy maintenancePromote repairPlug gaugesForce measurement by measuring magnetic property varationMaintenance planningHeavy duty

A method for metallic structure maintenance is disclosed. The method includes a magneto-graphic / Magnetic Tomography technique to identify stress-related defects. The method is specifically optimized for extended, non-accessible underground and underwater metallic structures in providing quality control, emergency alarms as well as timeline planning for structural repairs and maintenance work. Examples of the method implementation include pipes for oil and gas industry, detection of flaws in rolled products in metallurgical industry, welding quality of heavy duty equipment such as ships reservoirs, etc. It is especially important for loaded constructions, such as pressured pipes, infrastructure maintenance, nuclear power plant monitoring, bridges, corrosion prevention and environment protection.

Owner:GOROSHEVSKIY VALERIAN +2

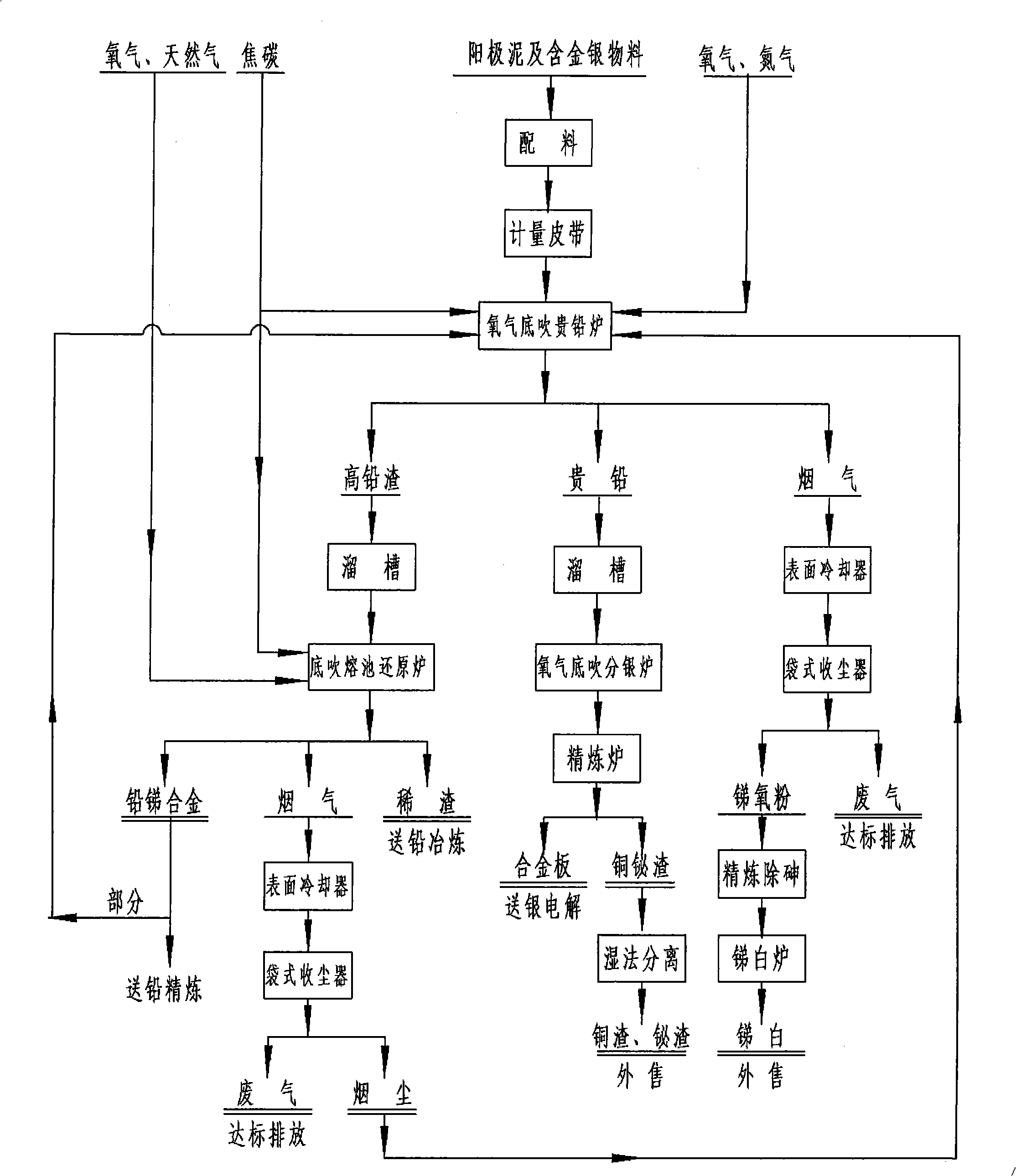

Smelting method for separating value metals from anode mud by firing process and device thereof

The present invention relates to a smelting method for separating and extracting noble and base metals during anode mud pyrogenic attack process and the device thereof, belonging to the field of nonferrous metallurgical industry. The smelting compositions only includes anode mud and nut coke, continuous oxidation-reduction smelting is carried out on the anode mud by oxygen bottom blown smelting method, gold, silver, copper and bismuth are enriched, arsenic and stibium are volatilized, silicon and lead are slagged, the smelting process is divided into two processes: one is the process of bottom oxidative slagging of oxygen and noble lead or bottom lead; the other is the process of reducing volatilization of coke on the slag surface, the two processes are two continuous combined cycle smelting processes finished in a same furnace and during the same time, the smelting process is non-alkali low-silicon high-lead-slag type, the mass ratio of the SiO2 to PbO is 0.2 to 0.5. The invention has the advantages of low cost, large handling capacity, low energy comsuption, long using period of refractory lining, high direct recovery rate of gold, silver, copper, stibium and bismuth, strong adaptability to raw materials, high automation level, etc.

Owner:HENAN YUGUANG GOLD & LEAD

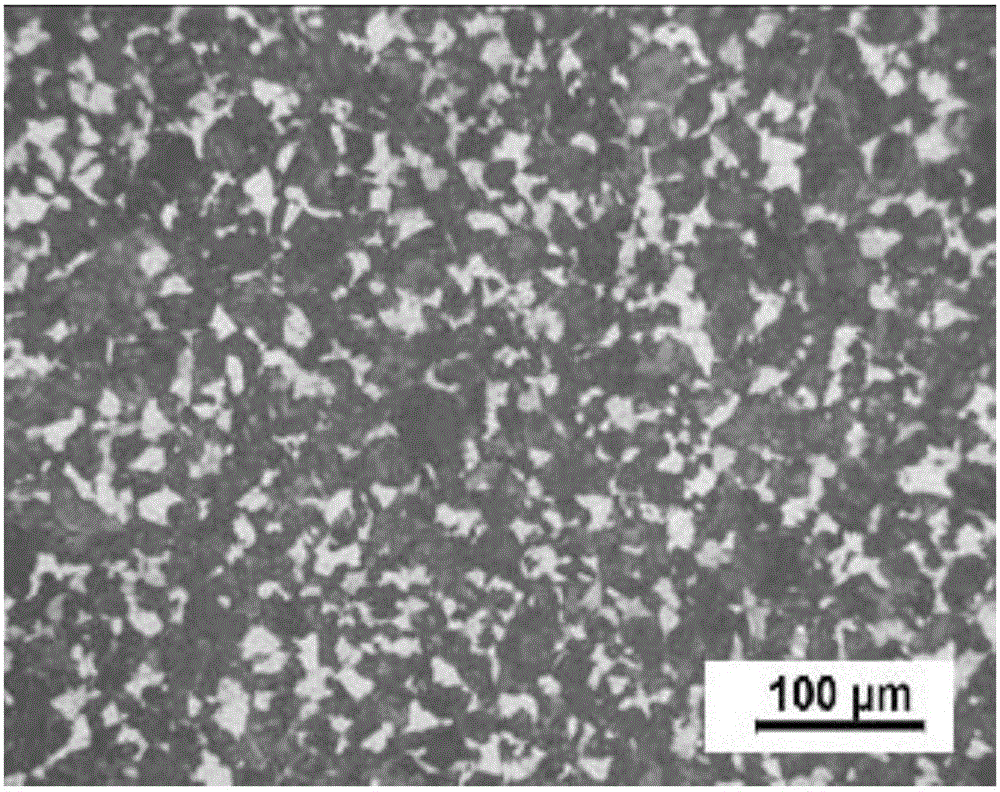

Rolling production method capable of reducing hardness of 42CrMo

ActiveCN106216391AMeet the national standardMeet user needsTemperature control deviceWork treatment devicesAutomatic controlContinuous rolling

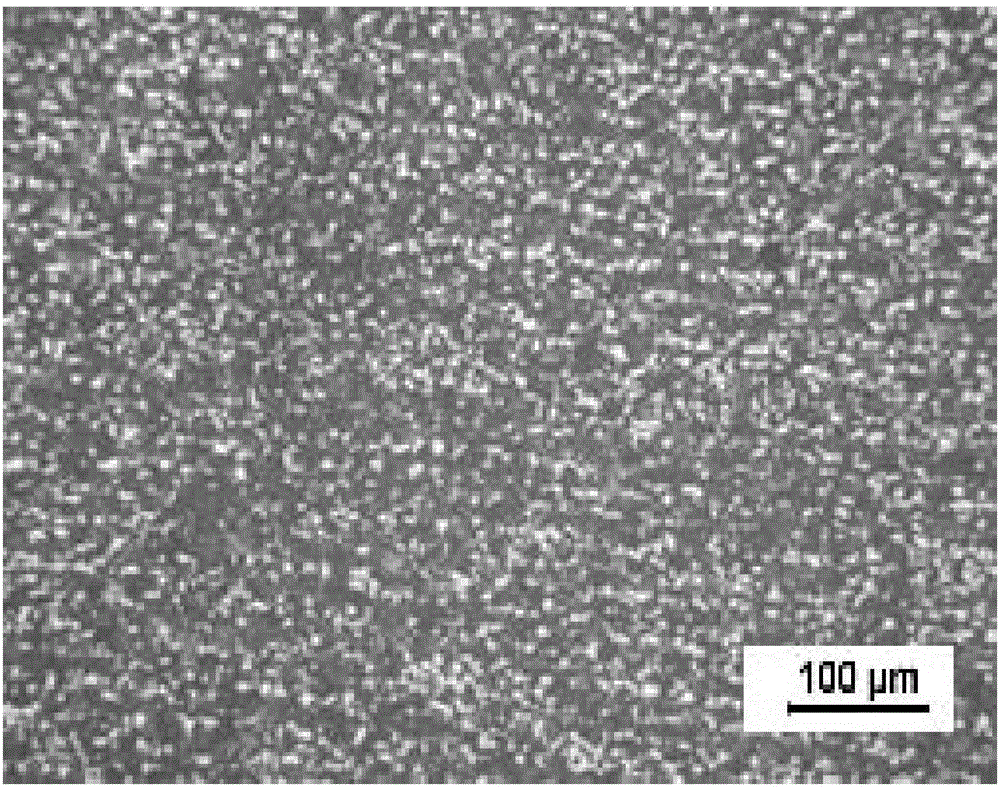

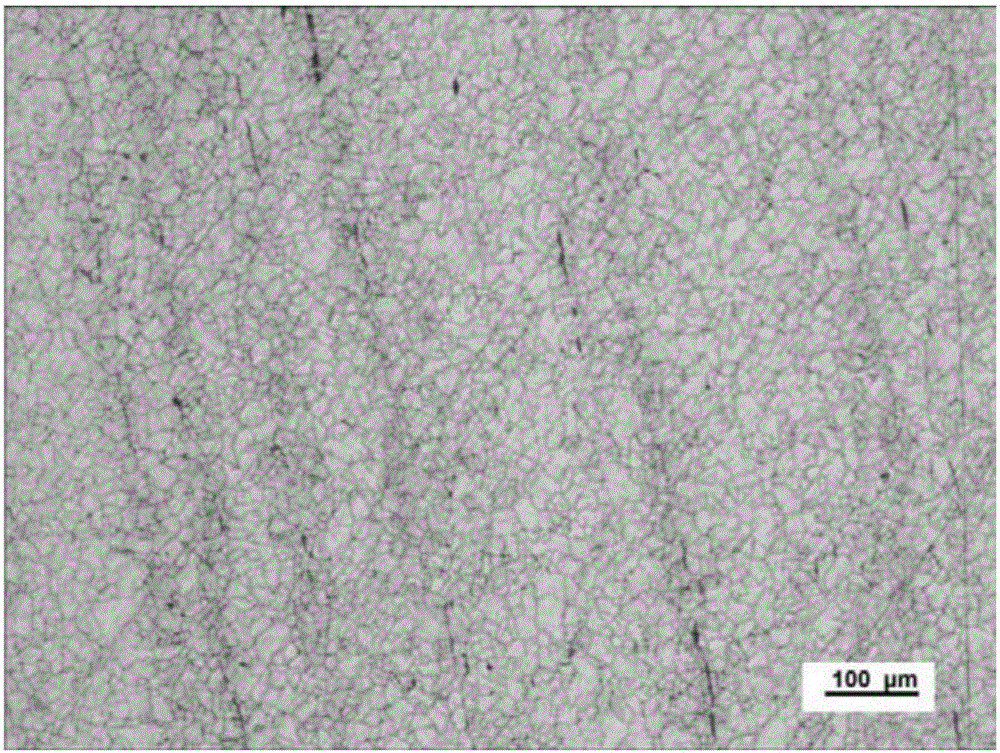

The invention belongs to the field of production machining of special steel of the metallurgical industry, and relates to a rolling production method capable of reducing hardness of 42CrMo. A 42CrMo casting blank serves as a raw material, and the method sequentially comprises following working procedures of heating, descaling, a rough rolling, cooling after rough rolling, continuous rolling, through water cooling, bar reducing sizing mill finish rolling, cooling bed cooling and finally obtaining a finished product bar; by the adoption of the technology, the site operation is simple, online automatic control is easily achieved, and operation labor intensity of a worker is reduced; through the online controlled rolling controlled cold technology, straightness of the 42CrMo steel grade is greatly improved; the subsequent heat treatment technology (annealing technology) is reduced, production cost is saved, the production period is shortened, and the steel market competitiveness is improved; the hardness value range of the obtained 42CrMo steel ranges from 220 HBW to 260 HBW; a metallographic structure comprises ferrite and pearlite; the banded structure is smaller than or equal to 2 levels; the grain size is larger than or equal to 8 levels; and the mechanical property can meet the national standard and user needs.

Owner:DAYE SPECIAL STEEL CO LTD

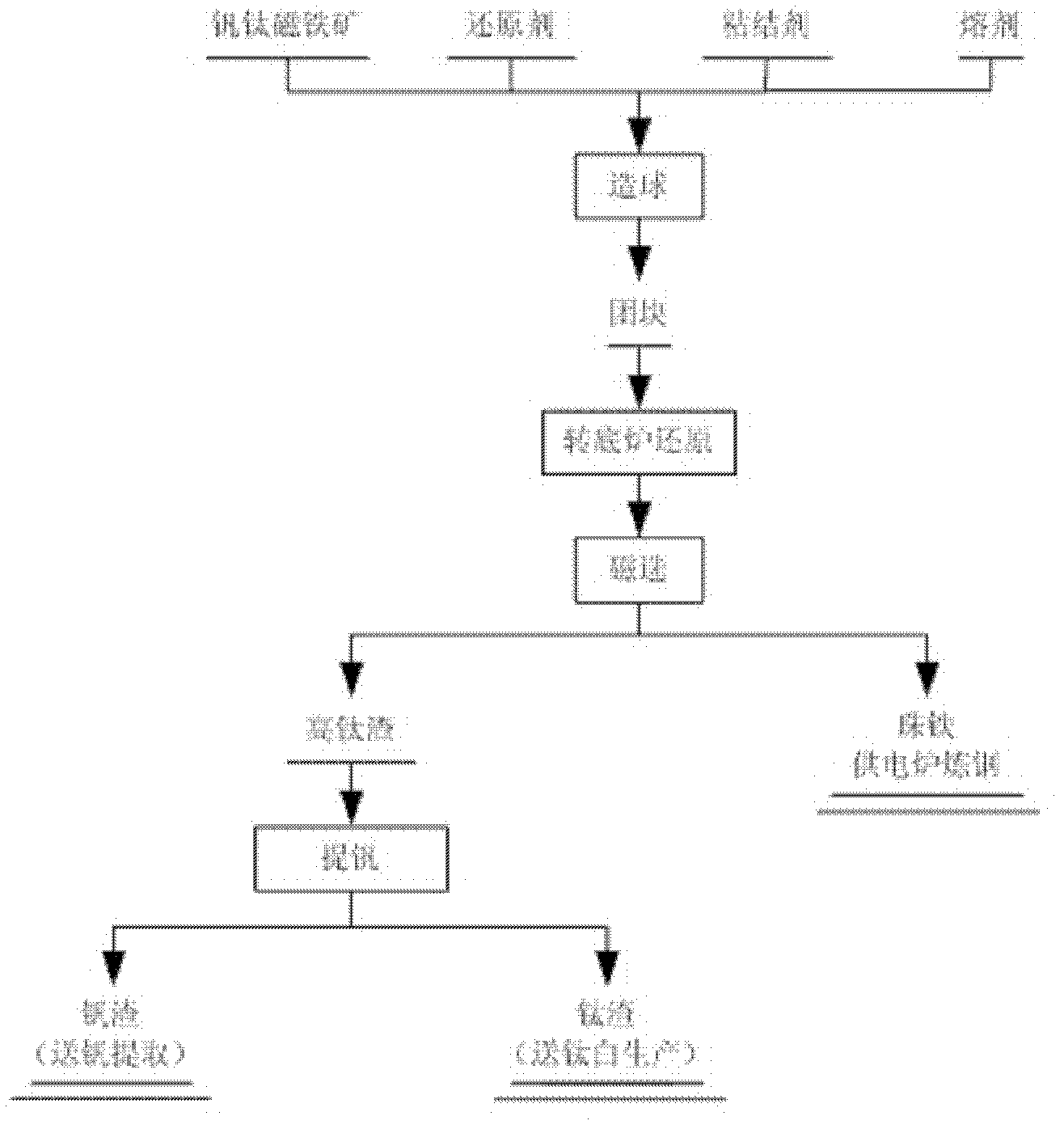

A method for comprehensive utilization of vanadium-titanium magnetite

InactiveCN102277462AReasonable useLess investmentMagnetic separationProcess efficiency improvementSteelmakingFurnace temperature

The invention relates to a method for comprehensive utilization of vanadium-titanium magnetite, which belongs to the field of new technology of direct reduction ironmaking in the metallurgical industry. In order to solve the problems of low utilization of iron, vanadium and titanium in vanadium-titanium magnetite, at the same time, due to the sintering process of traditional technology, the comprehensive energy consumption of the overall smelting process is relatively high, and the environmental pollution is serious. The invention provides a method of agglomerating vanadium-titanium magnetite and producing high-titanium slag and pearl iron by high-temperature reduction and melting in a rotary hearth furnace. The technical solution includes pelletizing of vanadium-titanium magnetite, high-temperature reduction in rotary hearth furnace, magnetic separation, and high-temperature reduction in rotary hearth furnace to directly produce high-titanium slag and pearl iron. Applying this method to process vanadium-titanium magnetite can not only effectively solve the problem of recovery of titanium and vanadium resources, but also obtain qualified iron pearls for steelmaking in electric furnaces, making full use of the iron, vanadium, and Valuable elements such as titanium.

Owner:UNIV OF SCI & TECH BEIJING

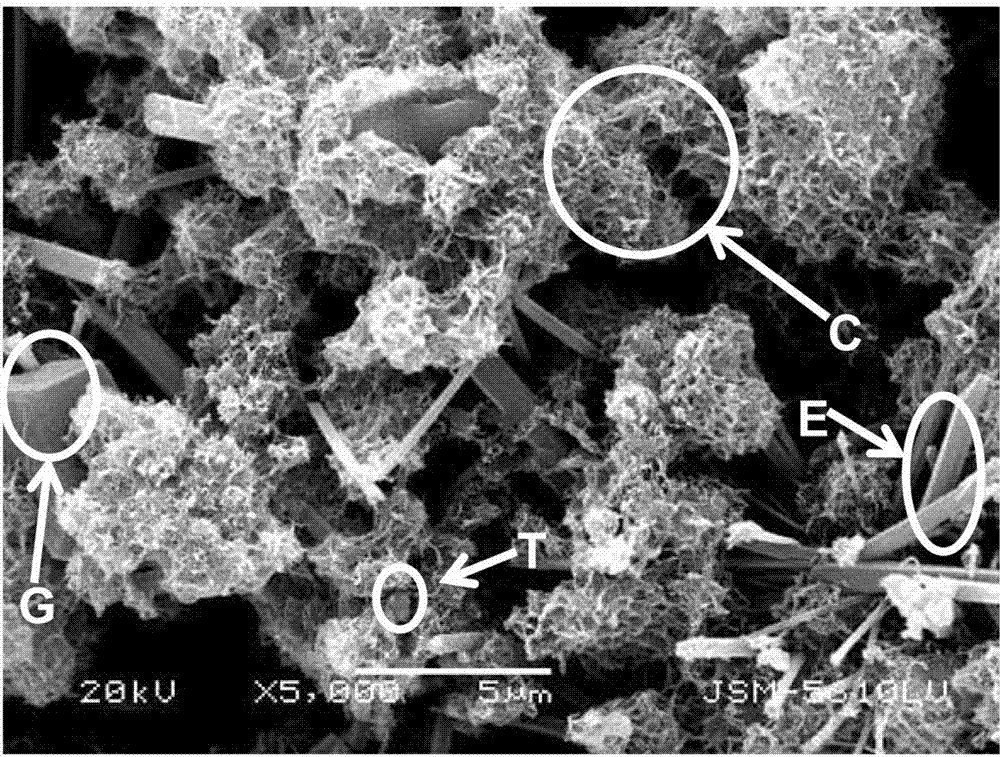

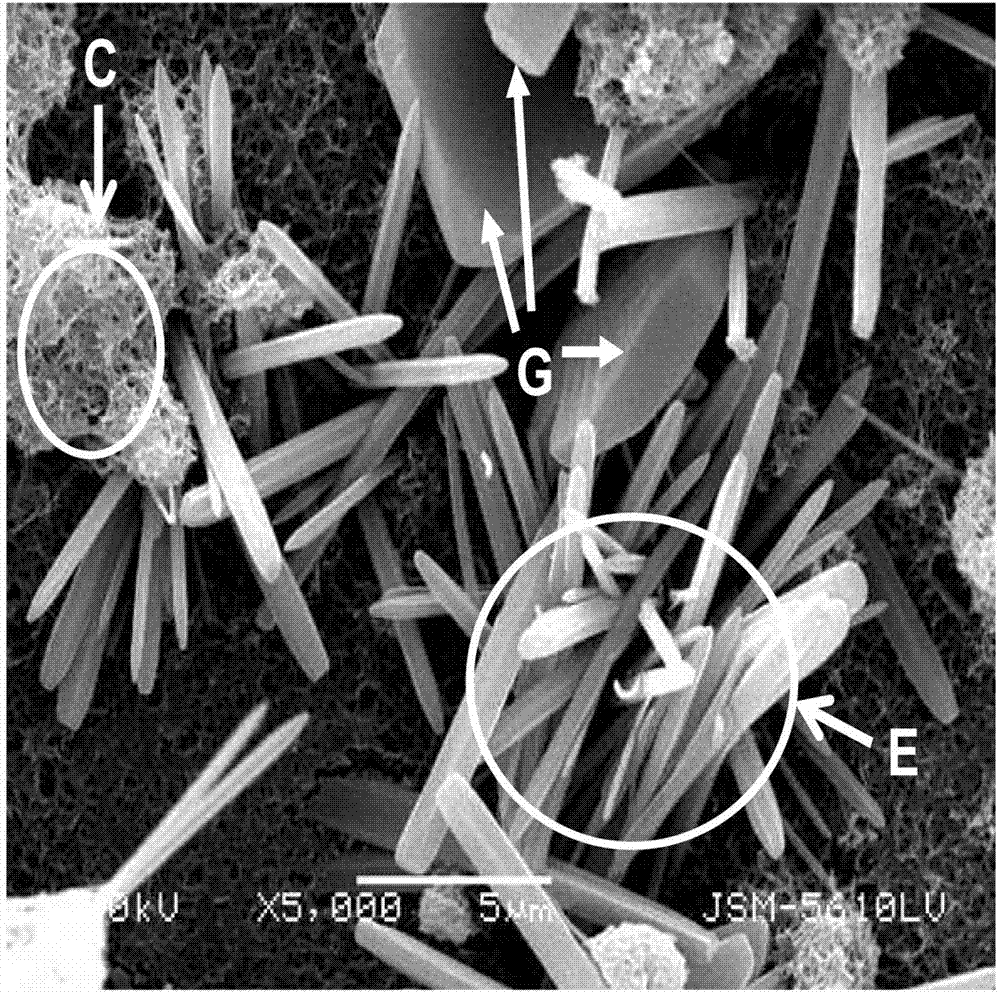

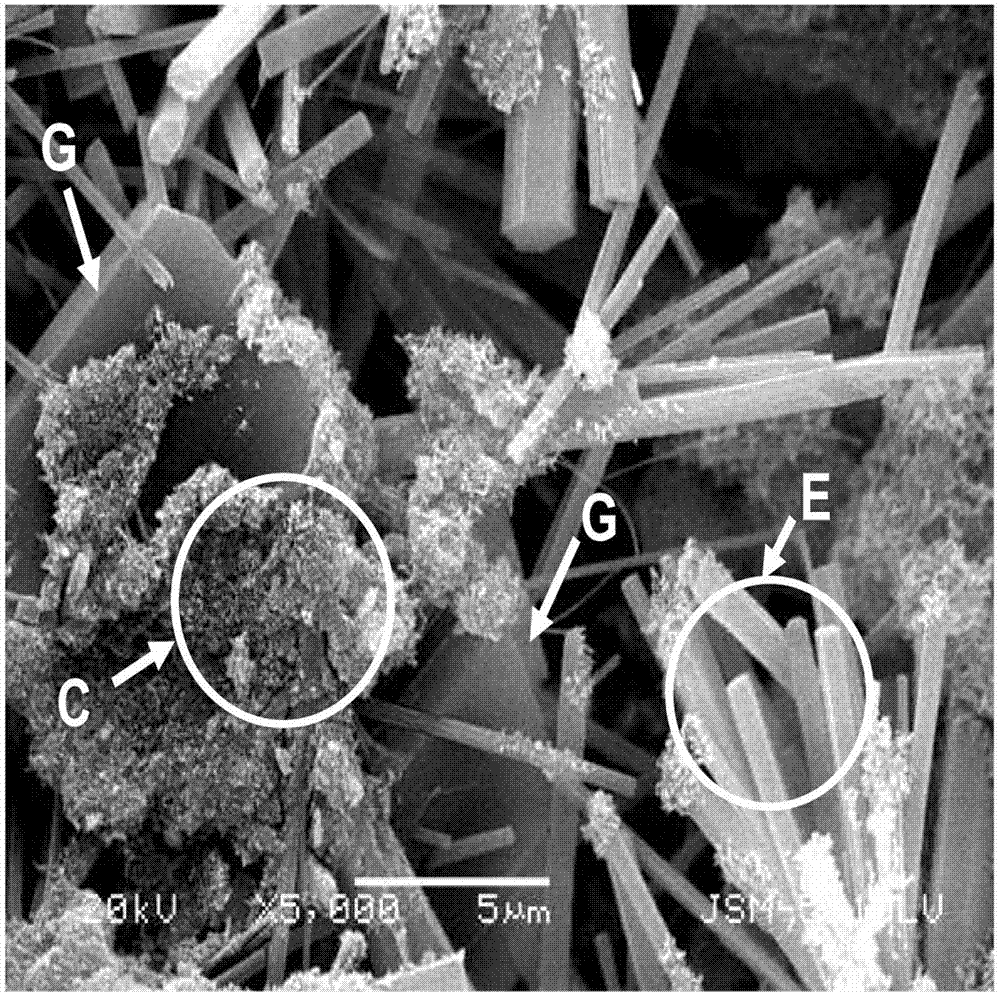

Tungsten alloy composite plating coat material and manufacturing method thereof

InactiveCN101210305AImprove wear resistanceImprove corrosion resistanceMetallic material coating processesFiberMining industry

The invention relates to a tungsten alloy composite coating material and a manufacture method. The tungsten alloy composite coating material is a multi-phase composite structure material composed of a tungsten alloy and a large number of particles or fibers dispersed in the tungsten alloy. The tungsten alloy composite coating contains tungsten of 5 to 98wt% and particles or fibers of 0.05 to 80wt%, and the diameter of the particle or the fiber is 3nm to 5 micrometer. The coating has low internal stress, excellent normal-temperature and high-temperature hardness and abrasion resistance, excellent high-temperature oxidization resistance and excellent corrosion resistance. The tungsten alloy composite coating has important use in machinery industry, chemical and medicine industry, metallurgy industry, aerospace industry, weapons and ammunitions, petroleum exploitation, mining industry, electronic industry, etc, and is particularly suitable for the occasions with high-temperature strength and high corrosion resistance.

Owner:CHENGDU SHENJIA MACHINERY MFG +2

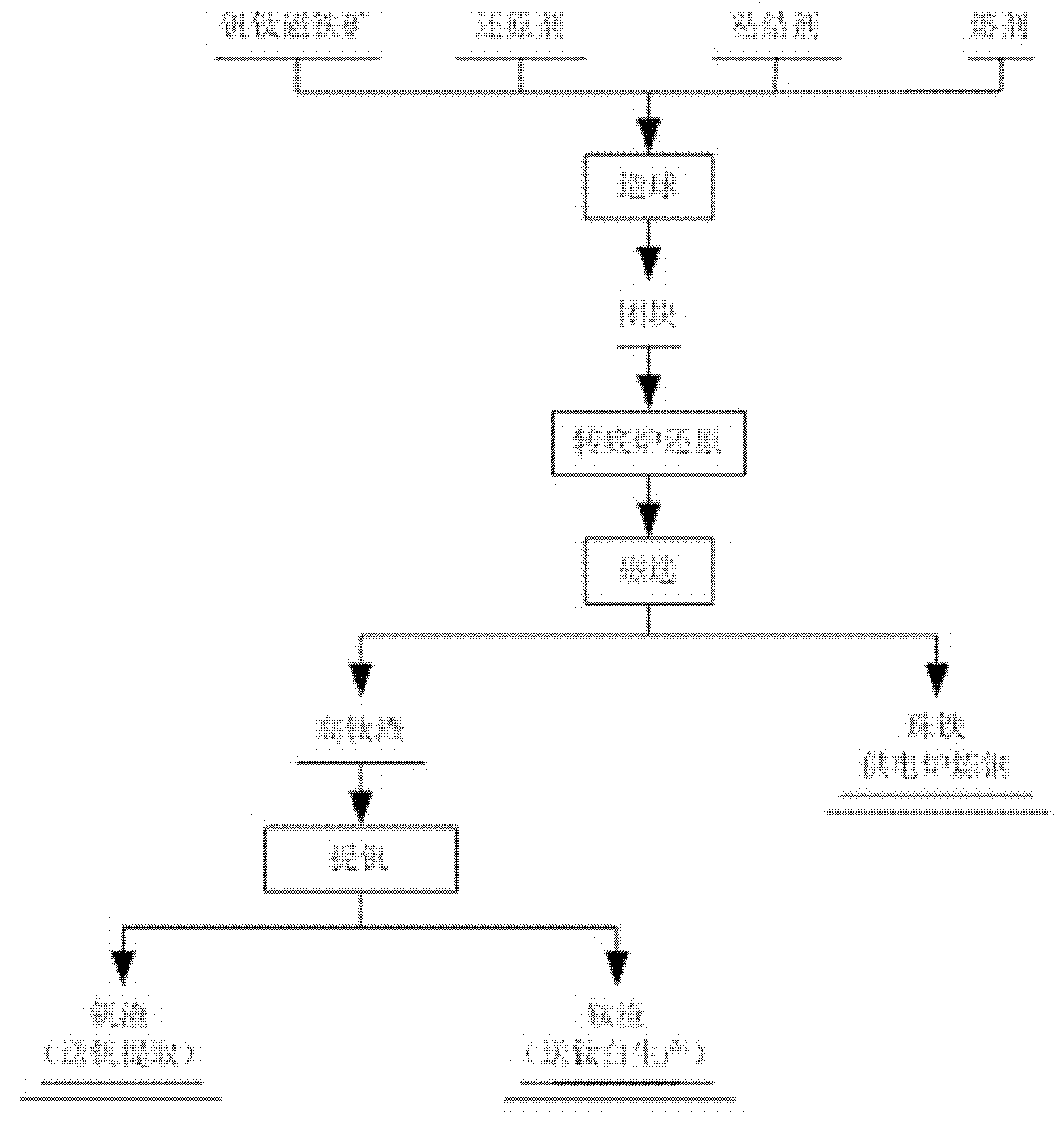

Direction reduction and electric furnace smelting-separation preparation process of vanadium-titanium magnetite cold bound pellet

The cooled agglomerated carbon-contained pellet prepared with vanadium titano magnetite concentrate and opposite direct reduction with former pellet comprises: mixing the concentrate, reducer and bonding agent, drying, grinding, and pelletizing to obtain the cooled agglomerated carbon-contained pellet drying and sieving into the reduction furnace with reducer for reduction atmosphere; loading the reduced pellet into electric furnace to melt and separate the iron liquid, V, Ti and Cr. This invention is fit to the pellet on wide application temperature and low energy consumption, has well efficiency and low running cost, and can also extract V, Ti Fe and Cr from electric furnace with high yield and obvious environmental protection.

Owner:鲜帆 +2

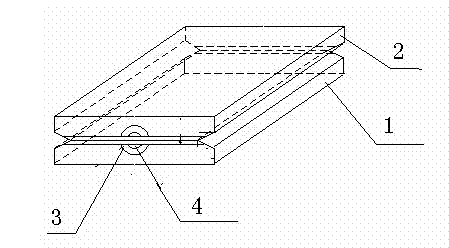

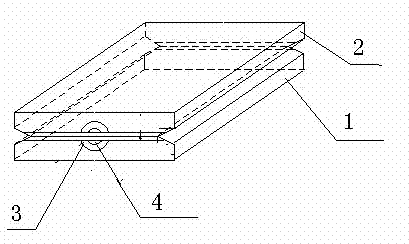

Composite manufacturing method of ultra-thick steel plate

InactiveCN102240894AOvercome the problems existing in the production of extra-thick steel plates above 100mmThe internal quality of the product is goodSheet steelHydrogen

The invention relates to a composite manufacturing method of an ultra-thick steel plate, which adopts a method of high-temperature hydrogen reduction and hot rolling for producing an ultra-thick steel plate and belongs to the field of steel rolling in the metallurgical industry. The technical scheme is as follows: the composite manufacturing method sequentially comprises the following process steps: preparing a base material and a covering material; carrying out surface treatment on the base material and the covering material; carrying out welding and combined blanking on the side part of a composite surface; carrying out high-temperature hydrogen reduction; vacuumizing and sealing a composite cavity; heating and rolling; carrying out hot straightening; cooling and inspecting; and collecting and warehousing the finished product. The composite manufacturing method has the following benefits: the ultra-thick steel plate with the thickness of greater than 100mm can be manufactured by the composite manufacturing method, stratification and cracking can be avoided during shearing, drilling and other processing operations, the method overcomes the problems existing in the production of ultra-thick steel plates with the thickness of greater than 100mm in the background art, and the composite manufacturing method has the characteristics of good internal quality of the product, reasonable process steps, high efficiency, low investment, convenient operation process and the like.

Owner:HEBEI IRON & STEEL GRP

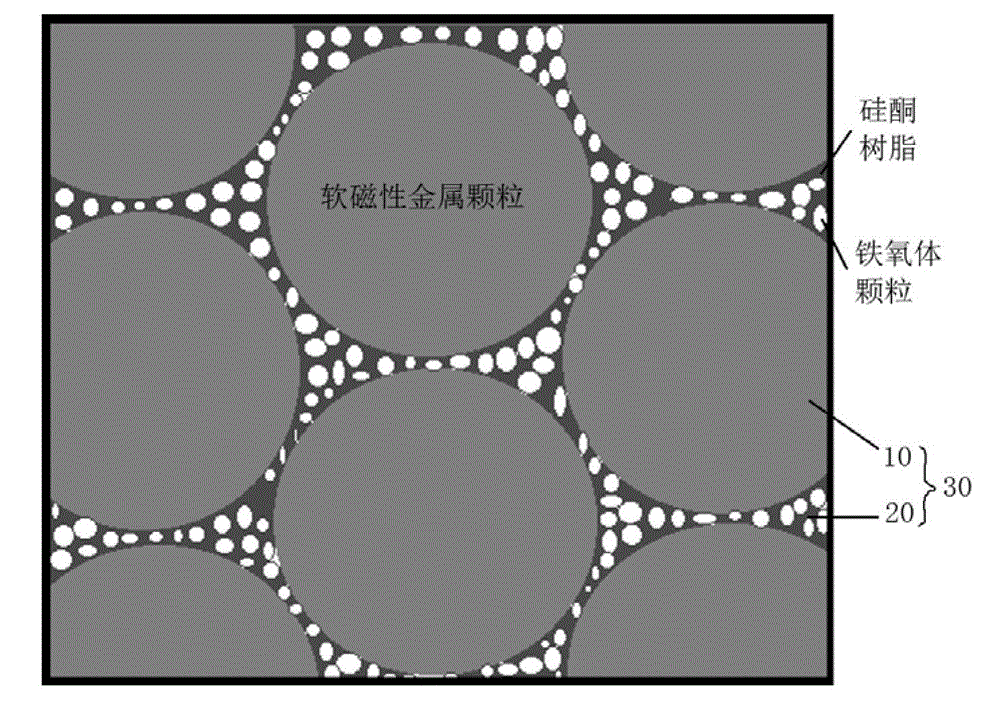

Composite silicone rein-ferrite-coating soft magnetic powder core and preparation method thereof

InactiveCN103151134AImprove adhesionHigh resistivityInorganic material magnetismInsulation layerVolumetric Mass Density

The invention discloses a composite silicone rein-ferrite-coating soft magnetic powder core and a preparation method thereof, and belongs to the metallurgical industry of magnetic functional material and powder. The soft magnetic powder core is formed by pressing and forming composite magnetic particles, wherein each composite magnetic particle comprises a soft magnetic metal particle and a composite insulation film, and each composite insulation film is coated on the surface of each soft magnetic metal particle. The preparation method of the soft magnetic powder core comprises the following steps of surface modification and coupling treatment of the soft magnetic metal particles, forming of the composite insulation coating around each soft magnetic metal particle, pressing and forming, and high-temperature heat treatment at 300 DEG C to 650 DEG C. Compared with the prior art, the soft magnetic powder core and the preparation method have the advantages that the adopted organic resin can resist the high temperature of 600 DEG C; since the soft magnetic ferrite power is added into the composite coating agent, the damage of the insulation layer to the magnetic performance of a substrate is reduced; and the magnetic conductivity is high, the density is high, the rapture strength is high, the loss is low, and the industrial production is easy.

Owner:UNIV OF SCI & TECH BEIJING

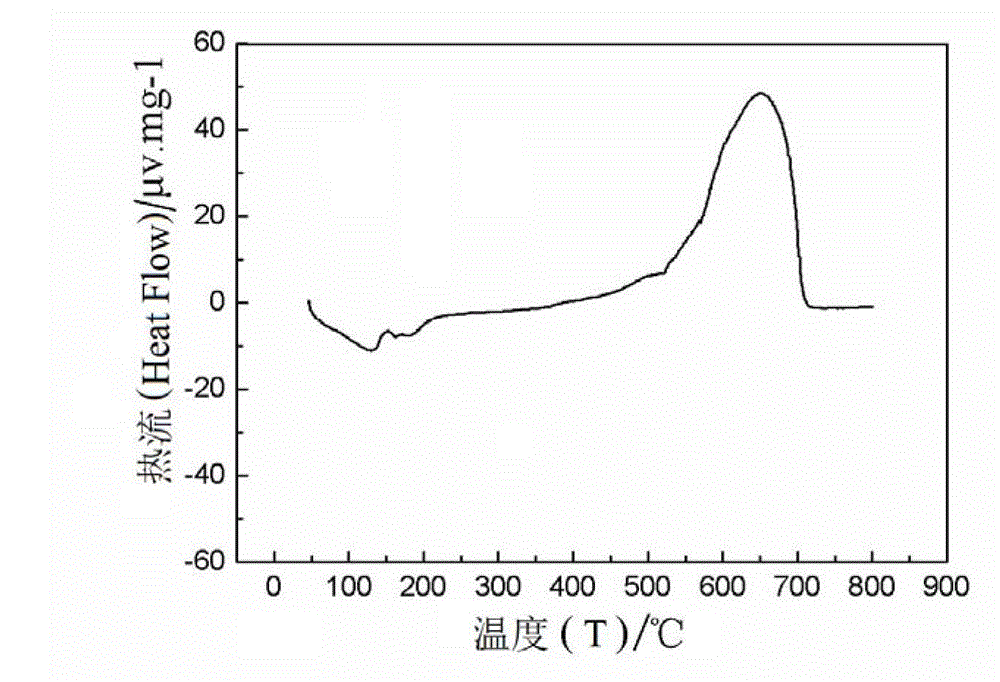

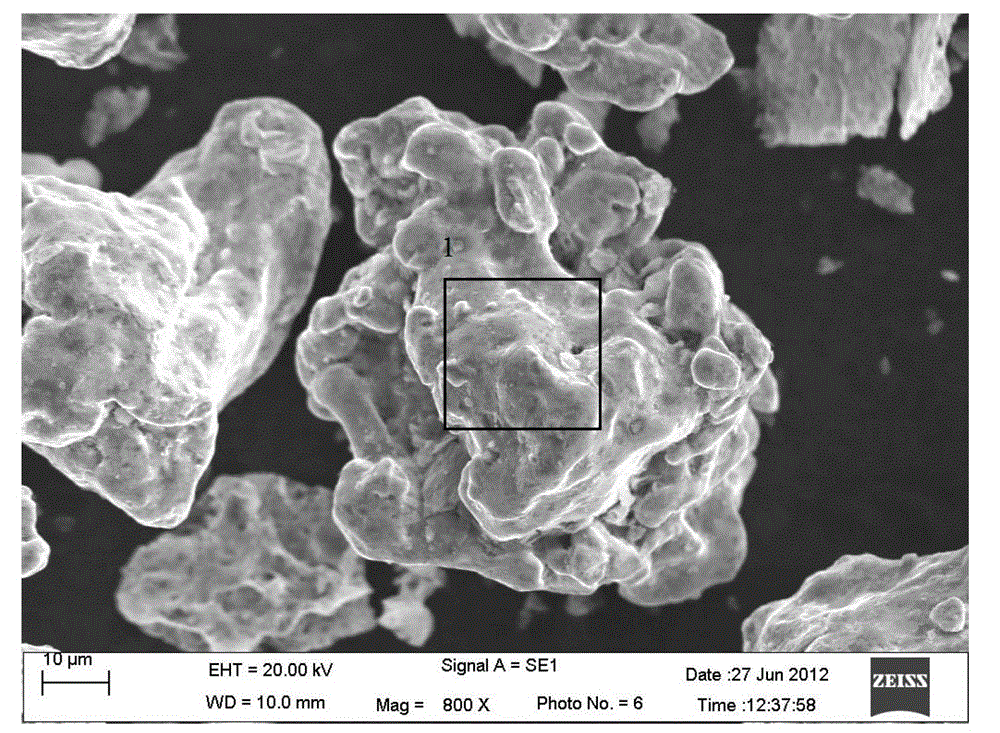

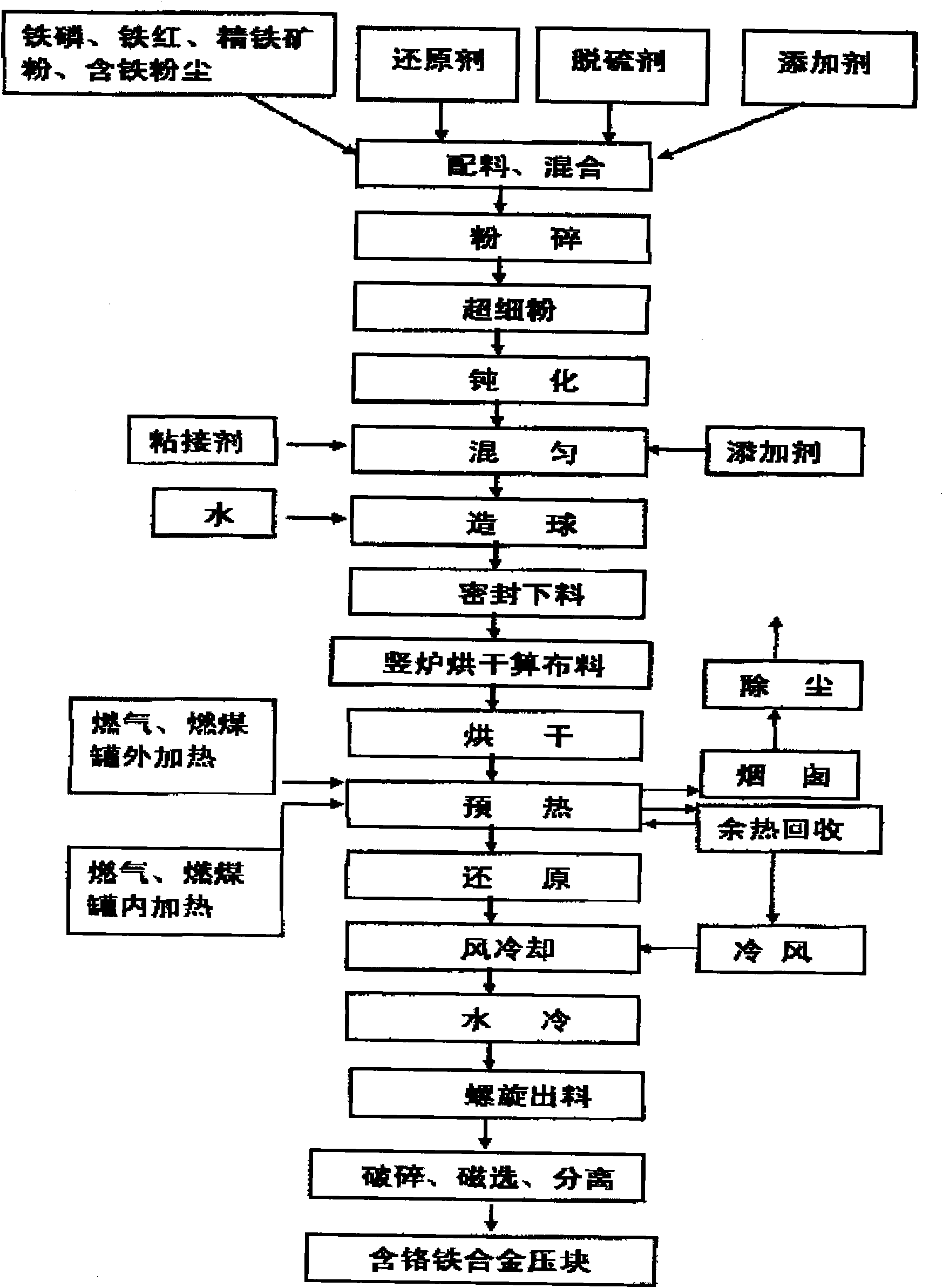

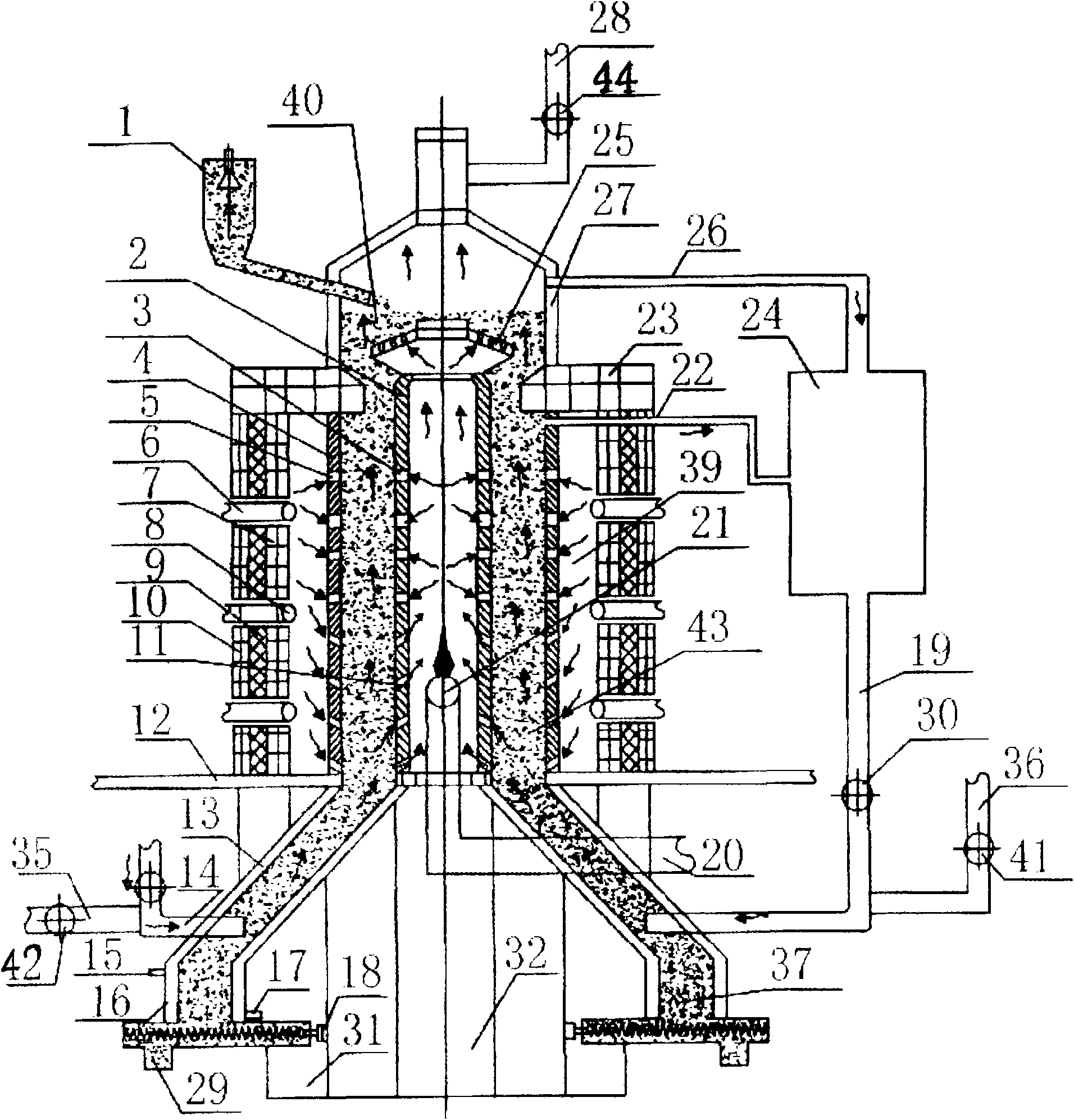

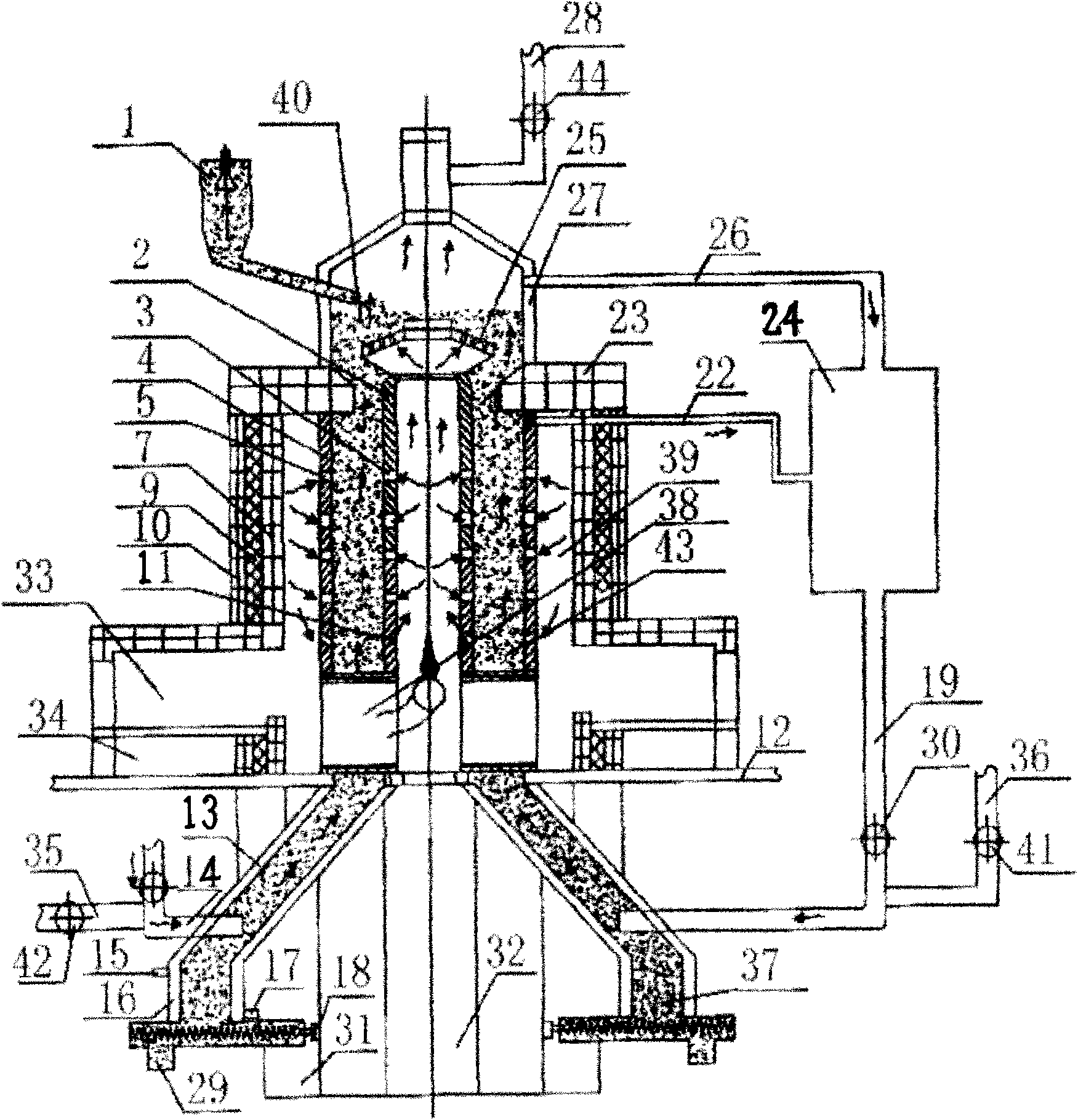

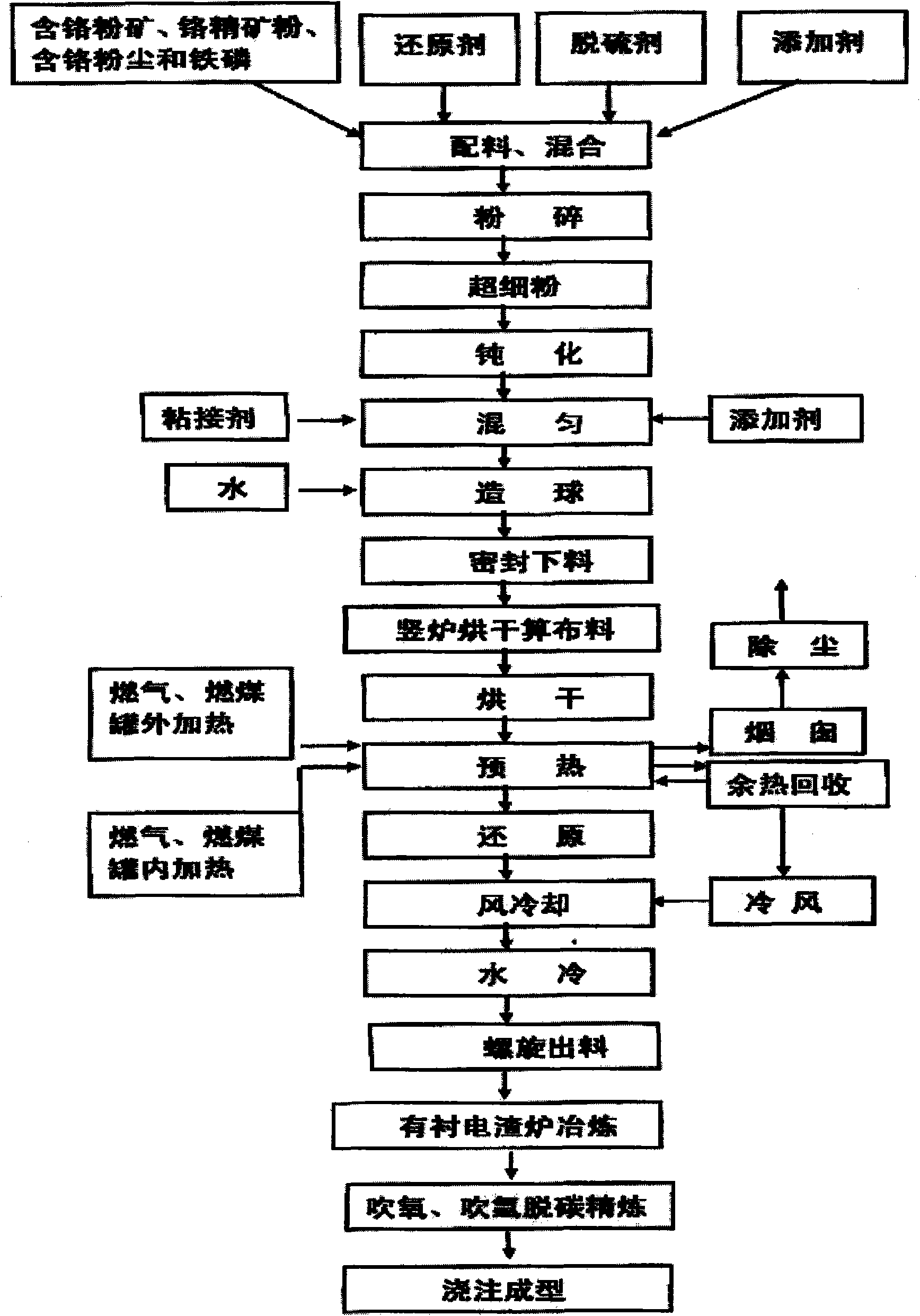

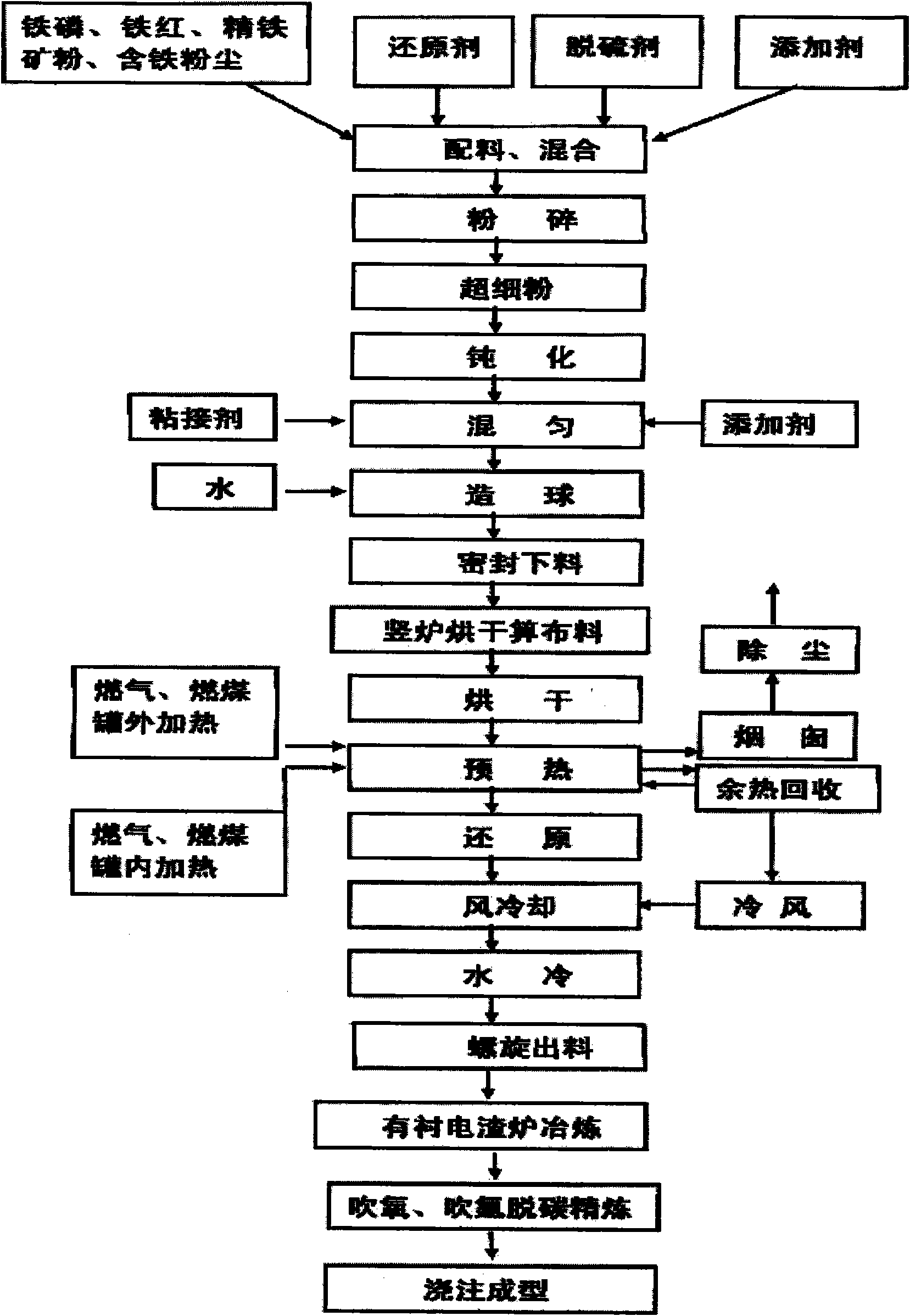

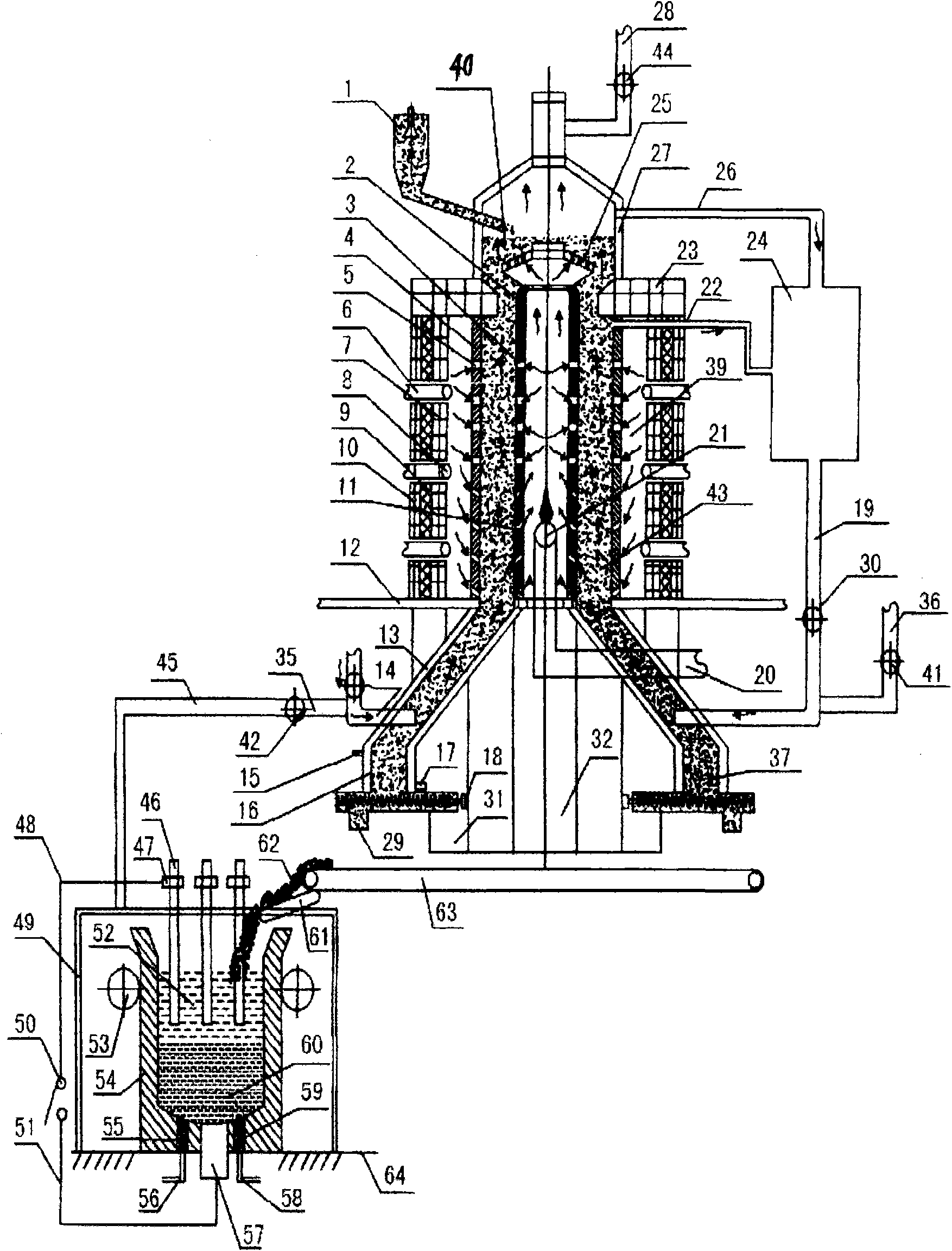

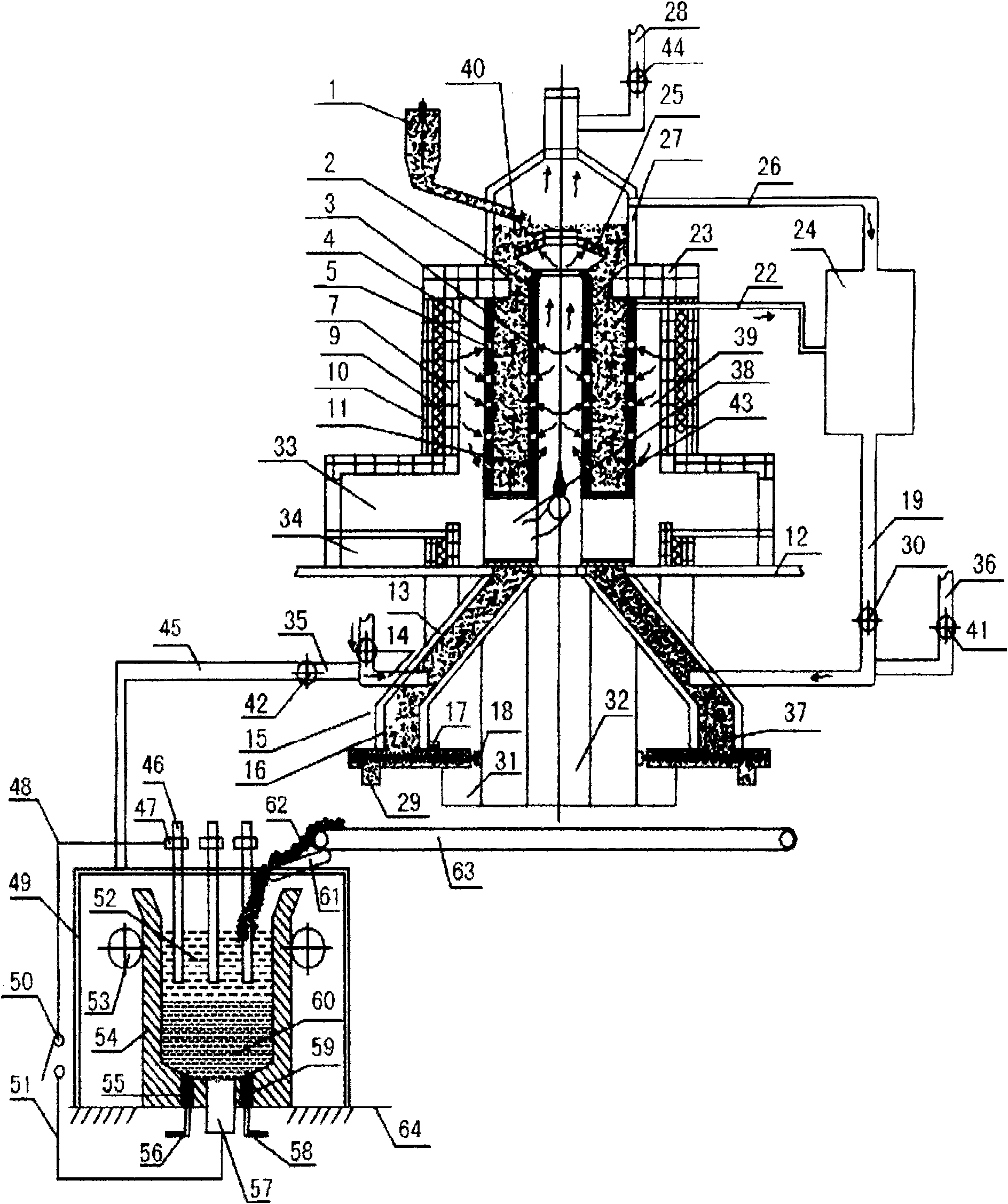

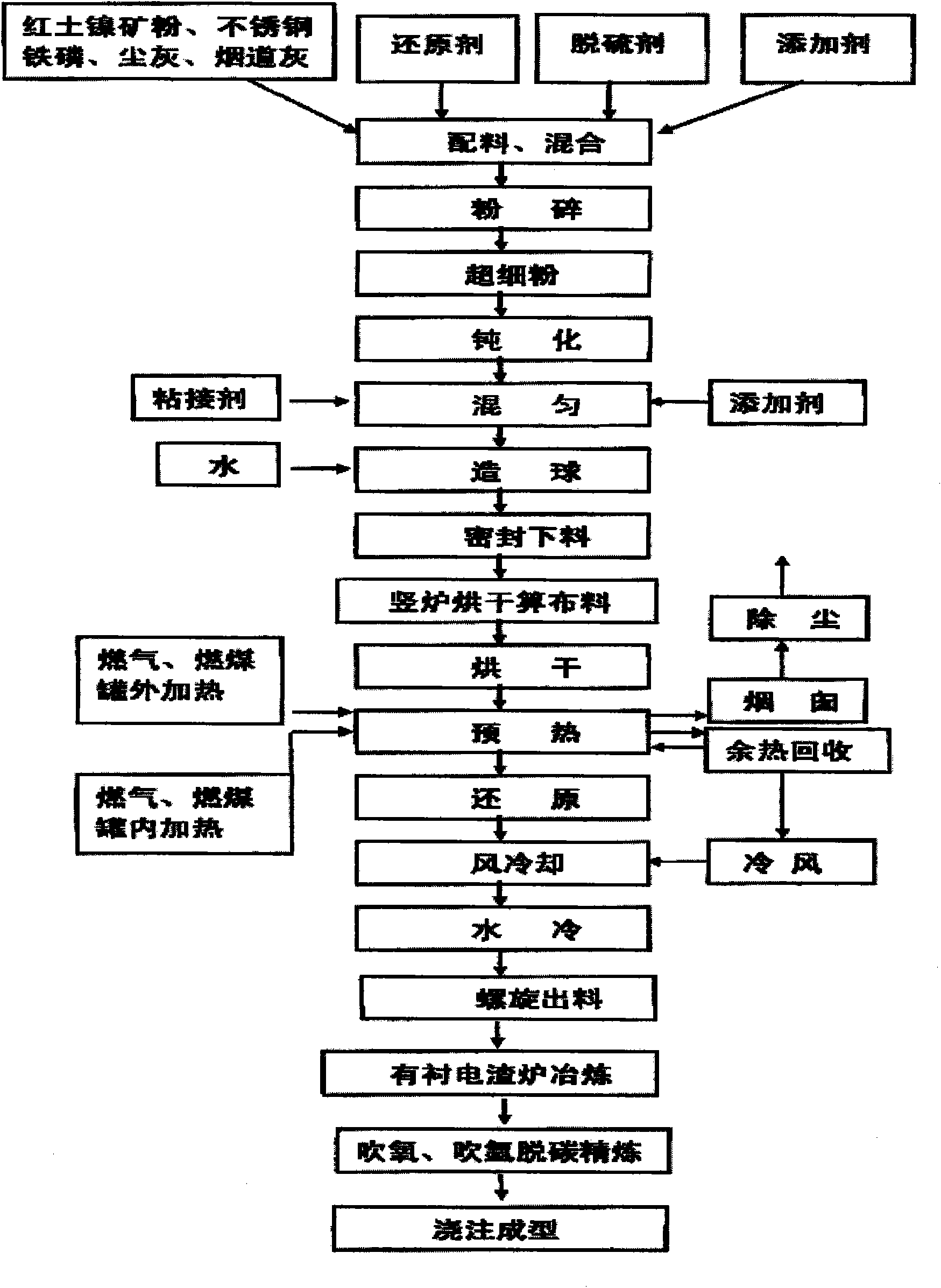

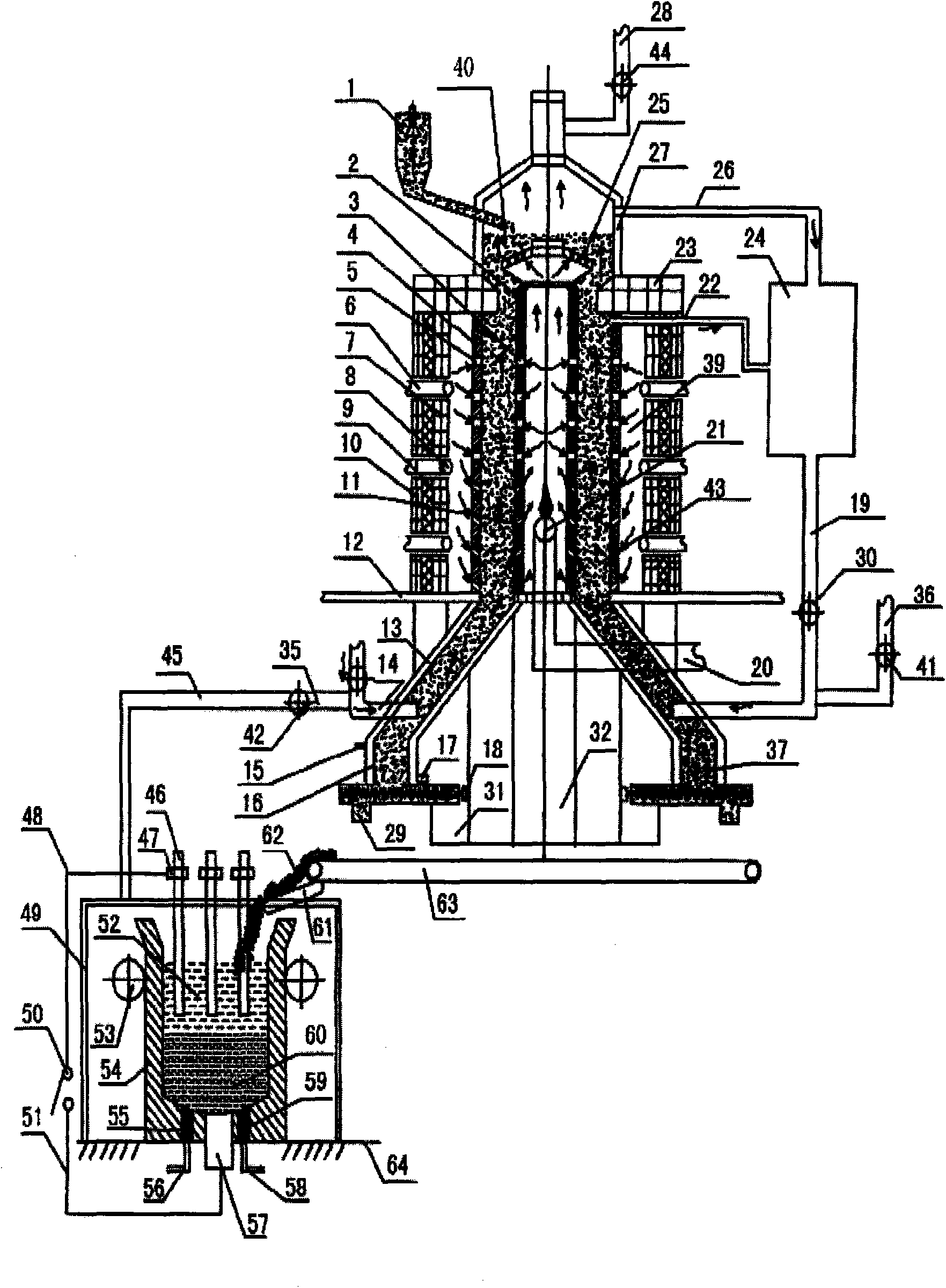

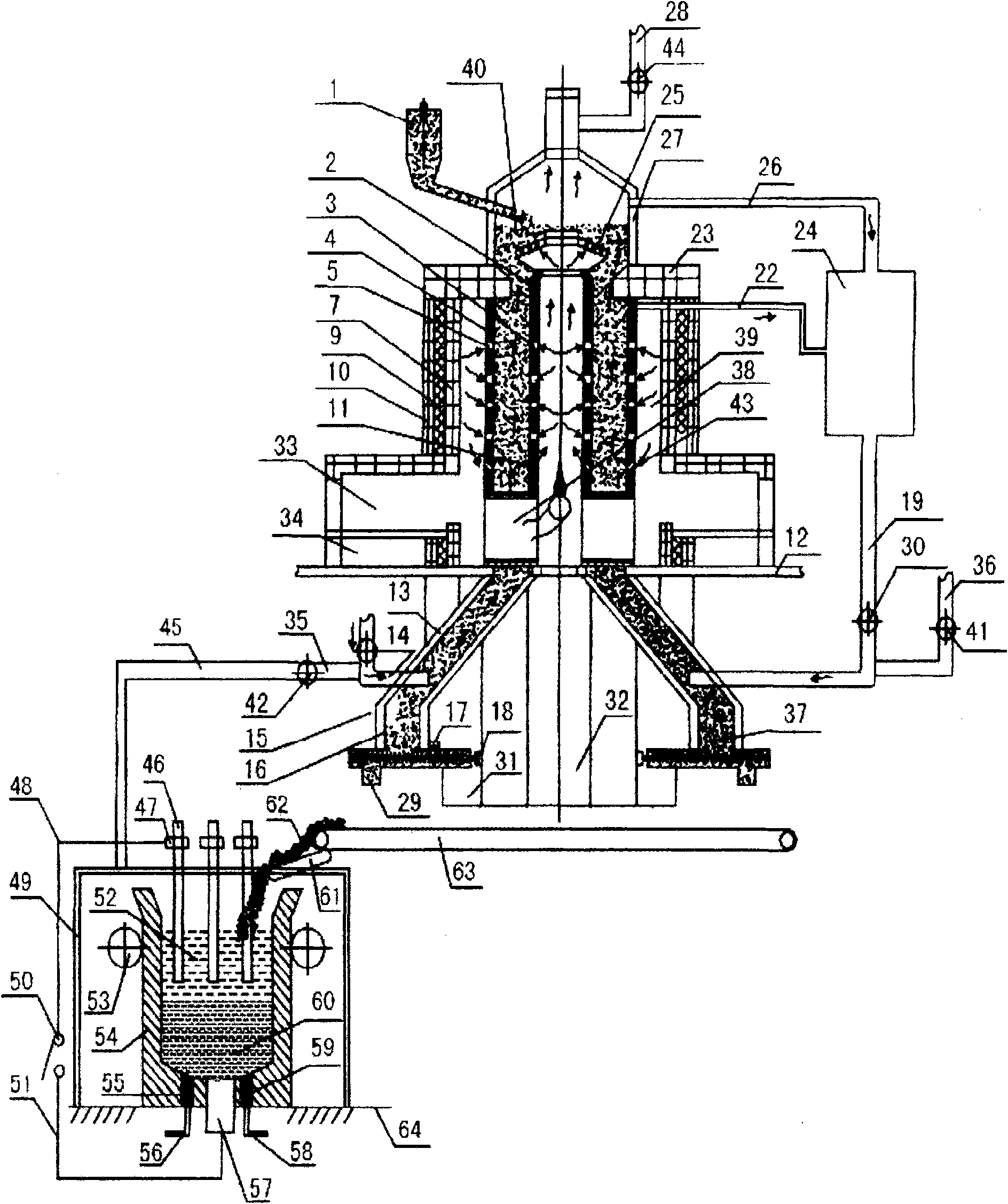

Preparation process and device of sponge iron

InactiveCN101538632AGuaranteed uniformityReduce wasteProcess efficiency improvementShaft furnaceResource consumptionUltra fine

The invention relates to a preparation process and a device of sponge iron, belonging to metallurgical industry steel-making raw material. The process comprises the following steps: mixing iron-containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, passivating and mixing to make pelletizing materials, sending the prepared pelletizing materials into a reducing furnace, drying and roasting, and obtaining sponge iron after the reduction reaction. The reducing device is connected with an upper furnace above a furnace base, a lower furnace body is connected to the downside of the furnace base, the upper end of the upper furnace body is connected with an upper furnace mantle, a drying bed grate is positioned at the upper end in the upper furnace body, a purifying device is connected with the upper furnace body and the lower furnace body through pipelines, and a residual heat circulating device is connected with the lower furnace body. The invention has the advantages that: firstly, the reduction temperature is reduced, the reduction speed is increased, the energy consumption is reduced, the production cost is lowered, the production efficiency is improved, and the uniformity of the quality is ensured; secondly, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is lowered, the environment pollution is reduced; and fourthly, the waste resource can be recycled so as to save the resource consumption.

Owner:丁家伟 +1

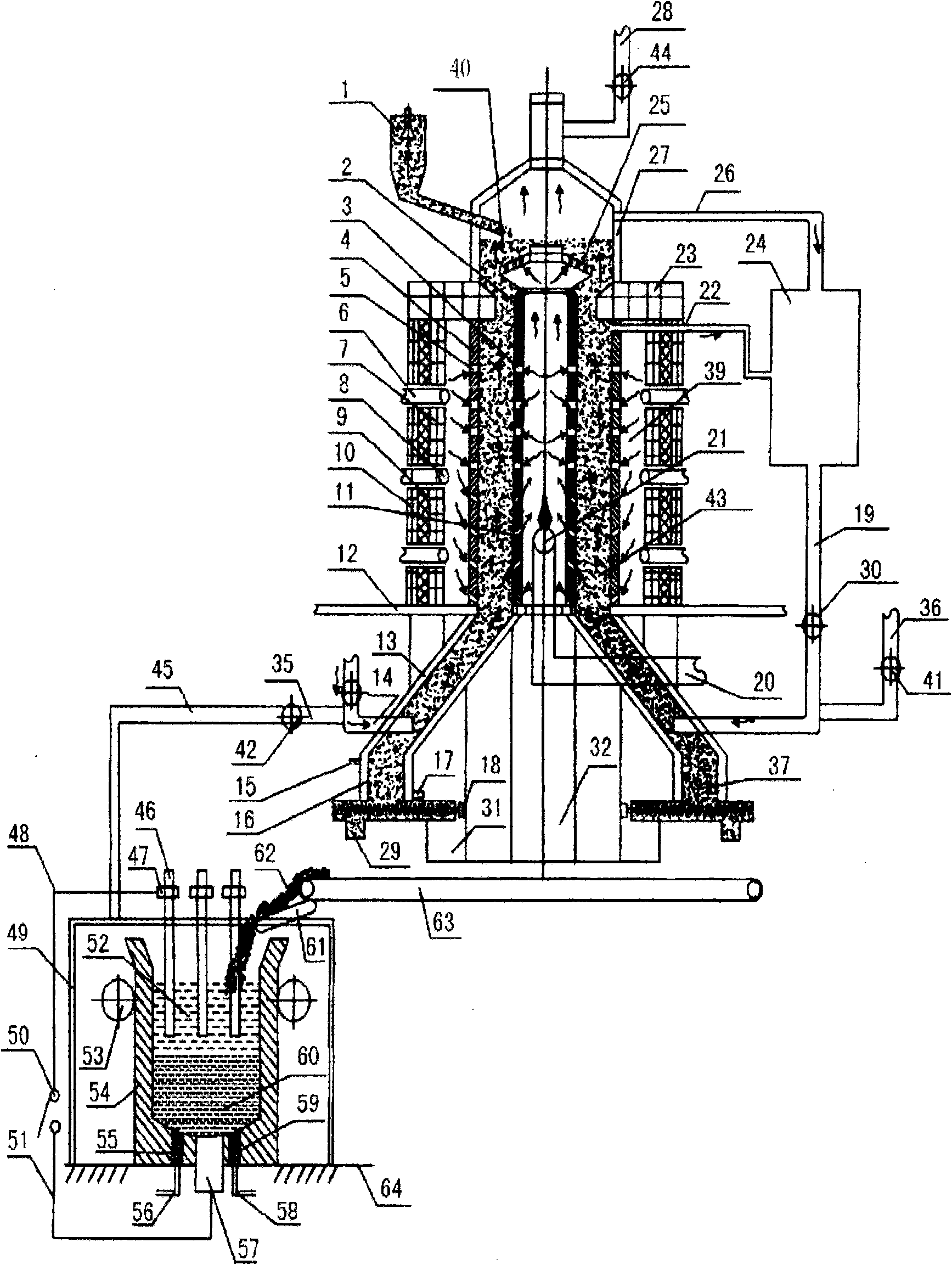

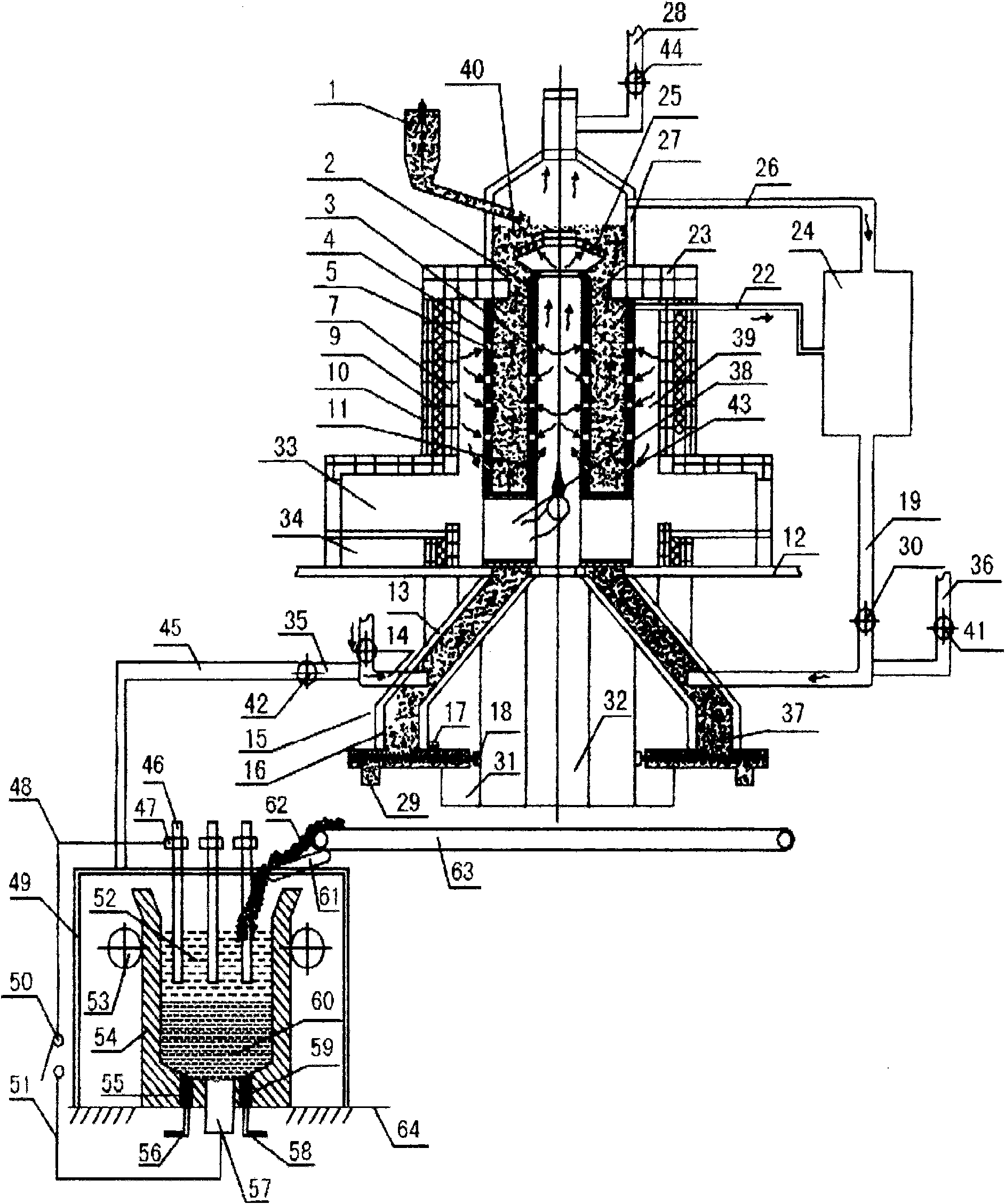

Process and device for smelting chromium irons and chromium-containing molten iron by using chromium ore powder

InactiveCN101538629AImprove applicabilityHigh recovery rateProcess efficiency improvementShaft furnaceUltra fineSolvent

The invention relates to a process and a device for smelting chromium irons and chromium-containing molten iron by using chromium ore powder, which belongs to metallurgical industry steel-making raw material. The process comprises the following steps: mixing chromium iron containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, mixing to make pelletizing materials, sending the pelletizing materials into a reducing furnace, obtaining chromium irons pellets after the reduction reaction, and directly adding reduced pellets into a lining electroslag furnace for being smelted into the chromium-iron alloy or the chromium-containing molten iron. The device comprises an internal-external heating vertical reducing furnace, a lining electroslag furnace and a residual heat recovery system. The invention has the advantages that: firstly, the reduction temperature is low, the speed is high, the energy consumption is reduced, the production cost is lowered, the production efficiency is high, and the uniformity of the quality is good; secondly, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is reduced, the environment pollution is lowered; fourthly, the source of raw materials adopting the chromium ore powder and chromium-containing waste, the cost is low; fifthly, the waste resource can be recycled so as to save the resource consumption; and sixthly, the high-temperature pellets are directly smelted by adopting the lining electroslag furnace, the heat efficiency is high, the energy consumption is low, the material purity is high and the quality is good, and the device is simple with less investment.

Owner:丁家伟

Phosphogypsum-based gelling material and its application in mine tailing filling

ActiveCN104211313ARealize high-quality utilizationWide variety of sourcesMaterial fill-upRed mudPhosphogypsum

The invention relates to a gelling material for mine tailing filling. The gelling material for mine tailing filling used for improving the early stage strength of a filler and having good water segregation performance is obtained through the steps of respectively milling phosphogypsum, red mud, phosphorus residues and clinker to 800m<2> / kg, 700m<2> / kg, 300m<2> / kg and above 300m<2> / kg respectively, uniformly mixing the above milled raw materials, and adding an exciting agent. The gelling material is used to carry out mine tailing filling, and the raw materials are from various industrial waste residues, so the gelling material has the advantages of low cost, simple technology, strong maneuverability, low filling cost, effective utilization of various industrial waste residues of the metallurgy industry, energy saving, emission reduction and environmental protection.

Owner:CHINA THREE GORGES UNIV

Stainless steel weldless steel tube for ship and producing technique

InactiveCN101220443AHigh mechanical strengthGood extensibilityFurnace typesHeat treatment furnacesNo productionUltimate tensile strength

The invention relates to a stainless steel seamless pipe in metallurgical industry and the manufacturing process for the stainless steel seamless pipe; wherein, the steel pipe is made of 00Cr24Ni6Mo2N dual phase stainless steel; the manufacturing process for preparing the ship borne stainless steel seamless pipe comprises the following production steps of a. round steel preparation; b. heating; c. hot-puncturing process; d. end cropping; e. pickling; f. repair grinding; g. lubrication; h. cold rolling processing; i. degreasing; j. solution heat treatment; k. straightening; l. pipe cutting; m. pickling; n. inspection of finished products. The invention solves the problems of lower mechanical strength and extensibility, shorter service life and high prices in present 316L stainless steel pipes used in ship seawater channels and provides a novel ship borne dual phase stainless steel seamless pipe and the manufacturing process and has the advantages of no production of pitting corrosion and grain boundary corrosion of the steel pipes, higher mechanical strength and extensibility, longer service life as well as low price and low cost.

Owner:江苏长盈不锈钢管有限公司

Non-destructive system and method for detecting structural defects

ActiveUS20170122909A1Stable positionImprove accuracyForce measurement by measuring magnetic property varationUnmanned aerial vehiclesEngineeringHeavy duty

A device for discovering, identification and monitoring, of mechanical flaws in metallic structures is disclosed, based on magneto-graphic / magnetic tomography technique to identify stress-related defects. The device can determine the position of the defect or stress including depth information. The device includes registration means that optimized for use with metallic structures of various types, shapes, and sizes. Applications include a real-time quality control, monitoring and emergency alarms, as well structural repairs and maintenance work recommendations and planning. Examples of the device implementation include pipes for oil and gas industry monitoring, detection of flaws in roiled products in metallurgical industry, welding quality of heavy duty equipment such as ships, reservoirs, bridges, etc. It is especially important for loaded constructions, such as pressured pipes, infrastructure maintenance, nuclear power plant monitoring, bridges, corrosion prevention and environment protection.

Owner:GOROSHEVSKIY VALERIAN +2

Repair method of backup roll surface of steckel mill and special repair powder used thereon

InactiveCN101358344AThe bonding strength is not lowLow costMetallic material coating processesBackup rollMachining

The invention relates to a machinery part surface repairing method in the metallurgical industry, in particular to a repairing method of steekle mill supporting roller surface and specially used repairing powder; the repairing powder contains the components with the following weight percent: 0.2 percent to 0.5 percent of C, 14 percent to 20 percent of Cr, 6 percent to 12 percent of Ni, 0 percent to 1.5 percent of Mn, 1 percent to 2.5 percent of Mo, 0.5 percent to 2.5 percent of W, 1.5 percent to 2.5 percent of Si, 2.0 percent to 3.0 percent of B, and the rest is Fe. When a supporting roller cannot be used any more because the roller surface is worn or locally falls off, areas to be repaired are molten through a laser process with the repairing powder, so that the missing and damaged parts are repaired and the performance of the repaired parts can meet the use requirements; and then, the shape of the roller surface is recovered through mechanical processing, and a reusable supporting roller can be obtained without heat treatment.

Owner:NANJING IRON & STEEL CO LTD +1

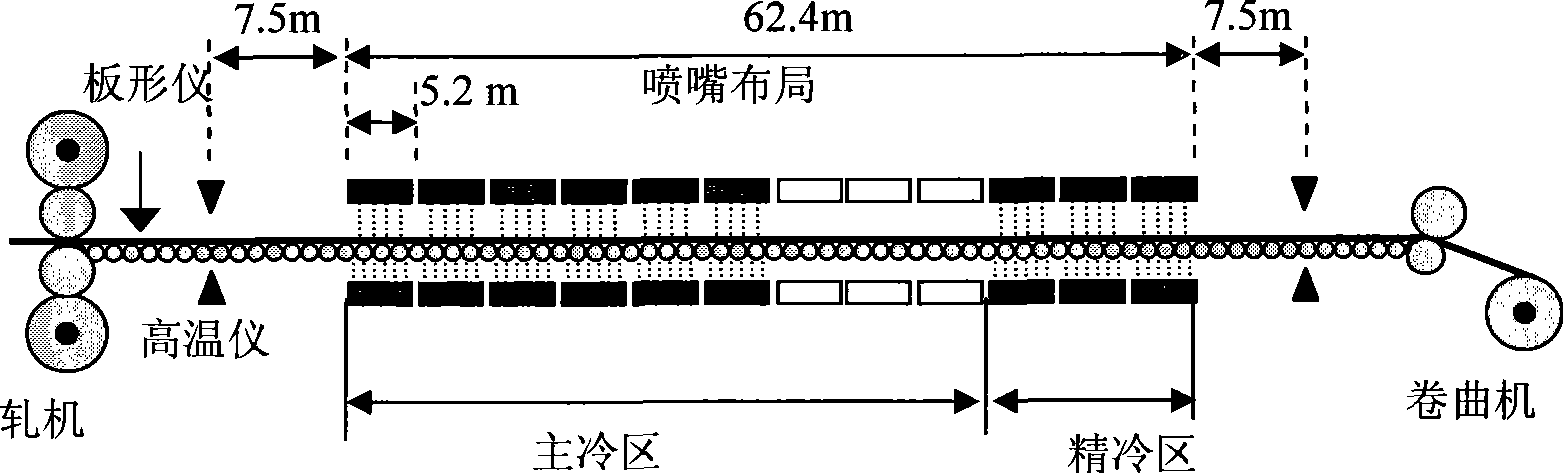

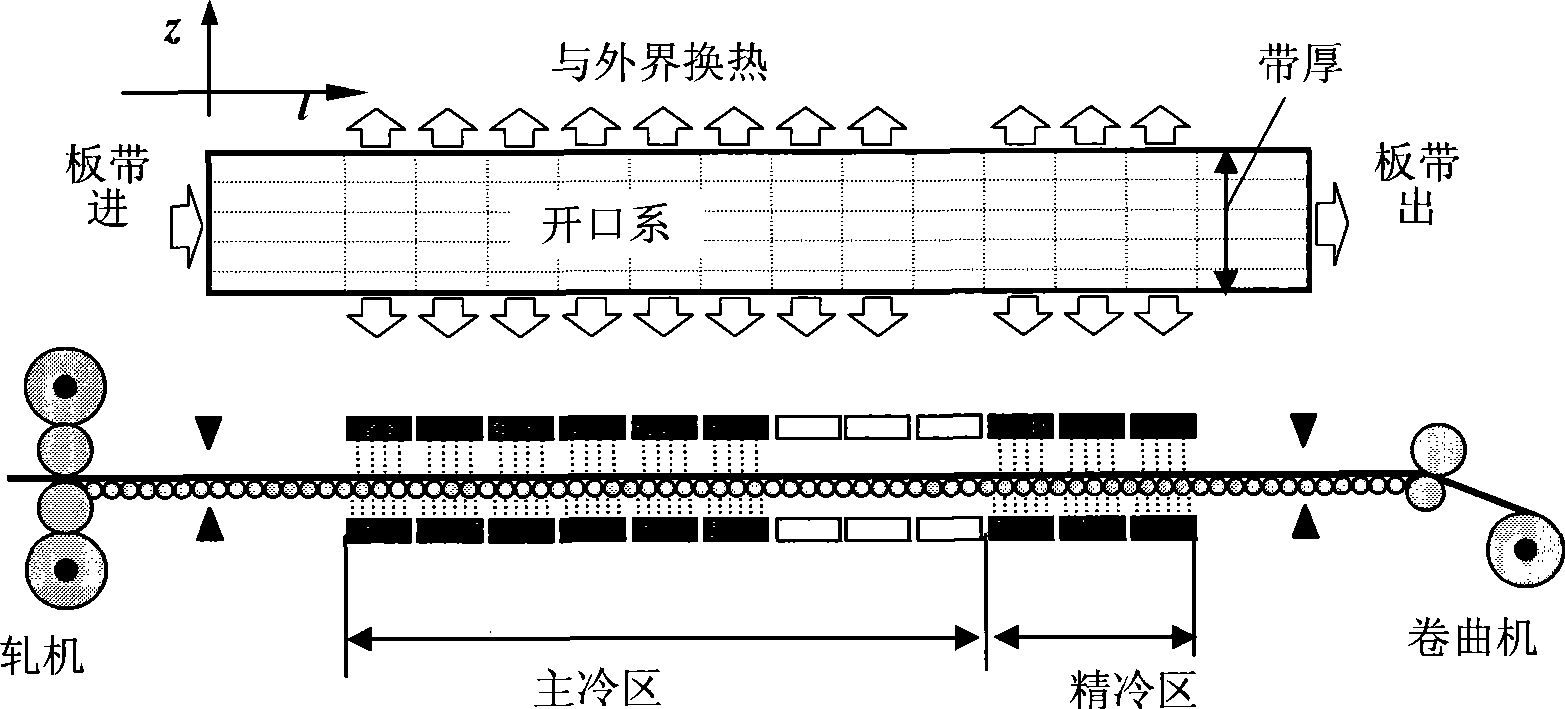

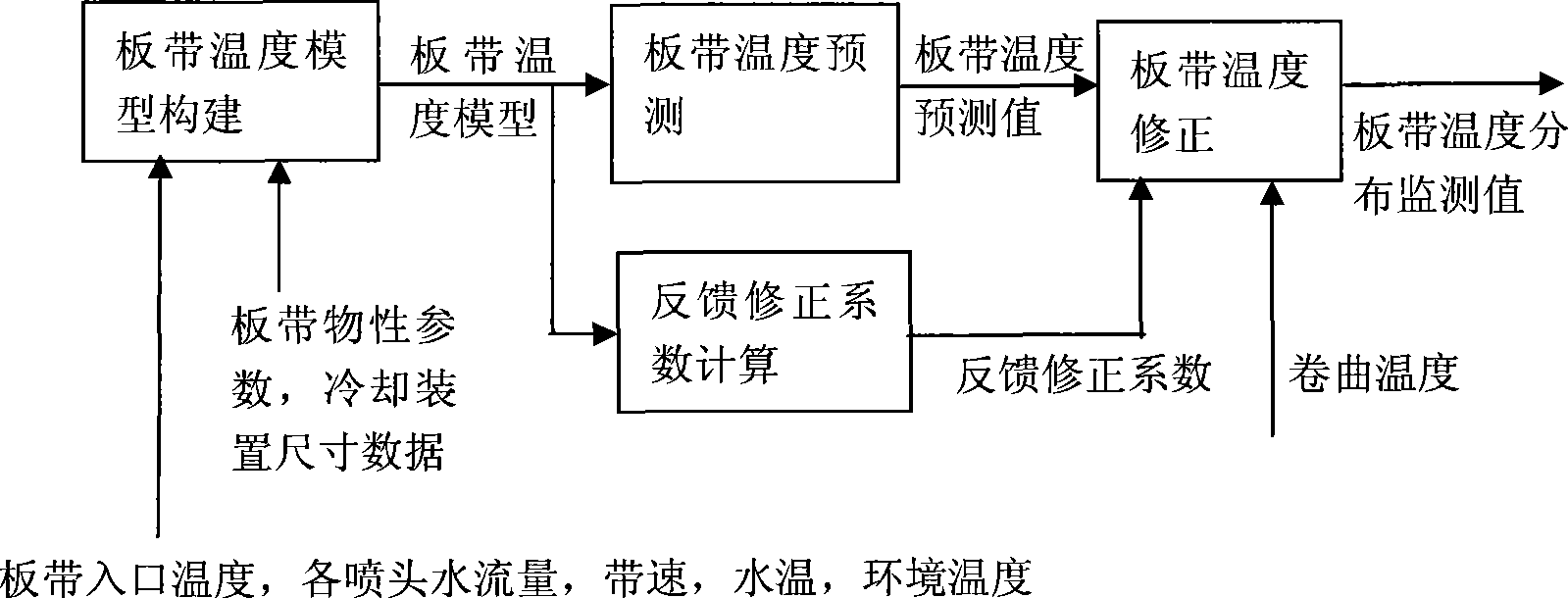

Plate-belt temperature monitoring method during hot-rolled strip steel stream cooling process

InactiveCN101456038AFast convergenceSuppress noiseTemperature control deviceMeasurement pointState space

The invention relates to a method for monitoring the temperature of a hot rolled ribbed steel layer flow cooling process slab band in the field of metallurgical industry. The invention monitors the slab band temperature distribution at each position between an outlet of a finishing mill and a curling temperature measuring point aiming to the hot rolled ribbed steel layer flow cooling process. The invention adopts the slab band physical property parameter and the parameter of a cooling device to directly write initial predicted slab band temperature distribution of a slab band temperature model in the form of state space. According to the curling temperature of the upper surface and the lower surface of the slab band, the initial predicted value is corrected by adopting the method for expanding Kallman filtering so as to obtain the slab band temperature monitoring value. The method has convenient application, is suitable for various steel grades, improves the monitoring accuracy of the slab band temperature distribution and reduces the requirement on the model accuracy.

Owner:SHANGHAI JIAO TONG UNIV

Smelting process and device of pure iron

InactiveCN101538634AImprove applicabilityHigh recovery rateShaft furnaceProcess efficiency improvementUltra fineSolvent

The invention relates to a smelting process and a device of pure iron, belonging to metallurgical industry steel-making raw material. The process comprises the following steps: mixing iron-containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, mixing to make pelletizing materials, sending the prepared pelletizing materials into a reducing furnace, obtaining metallic pellets after the reduction reaction, and directly adding the reduced pellets into a lining electroslag furnace for being smelted into pure iron. The device comprises an internal-external heating vertical reducing furnace, a lining electroslag furnace and a residual heat recovery system. The invention has the advantages that: firstly, the reduction temperature is low, the speed is high, the energy consumption is reduced, the production cost is lowered, the production efficiency is high, and the uniformity of the quality is good; secondly, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is reduced, the environment pollution is lowered; fourthly, the source of raw materials adopting iron ore concentrate powder and iron-containing metallurgical waste, the cost is low; fifthly, the waste resource can be recycled so as to save the resource consumption; and sixthly, the high-temperature pellets are directly smelted by adopting the lining electroslag furnace, the heat efficiency is high, the energy consumption is low, the material purity is high and the quality is good, and the device is simple with less investment.

Owner:丁家伟 +1

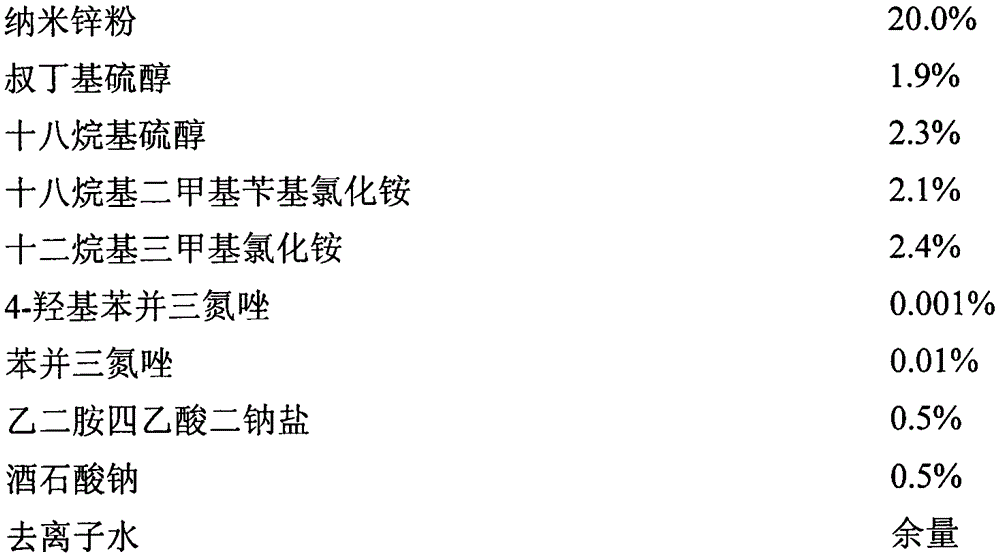

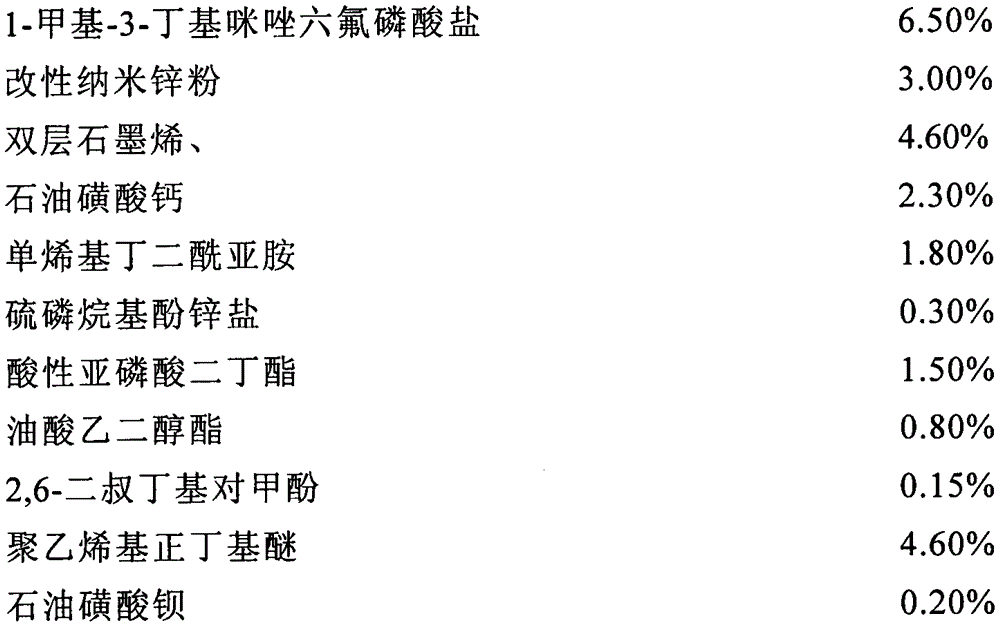

Preparation method of lubricating oil composition containing ionic liquid, modified nano-zinc powder and graphene

The invention discloses a preparation method of a lubricating oil composition containing ionic liquid, modified nano-zinc powder and graphene. According to the method, base oil, a cleaning agent, a dispersing agent, a preservative, an extreme pressure anti-wear agent, an oiliness agent, an antioxidant, a viscosity index improver, an anti-rust agent, a pour point depressant, an antifoaming agent, ionic liquid, modified nano-zinc powder and graphene are adopted for compounding to obtain the lubricating oil composition. The method has the advantages of simple and easy production process, low equipment investment, low energy consumption and no environmental pollution, and is conductive to popularization and application. The lubricating oil composition product containing the ionic liquid, modified nano-zinc powder and graphene can be widely applied in the industrial fields of mechanical industry, automobile industry, precision instruments, power industry, metallurgical industry, mold manufacturing and application industry, steel and iron industry, machine tool industry and the like, and has broad application prospects.

Owner:大庆招远圣通机械设备有限公司

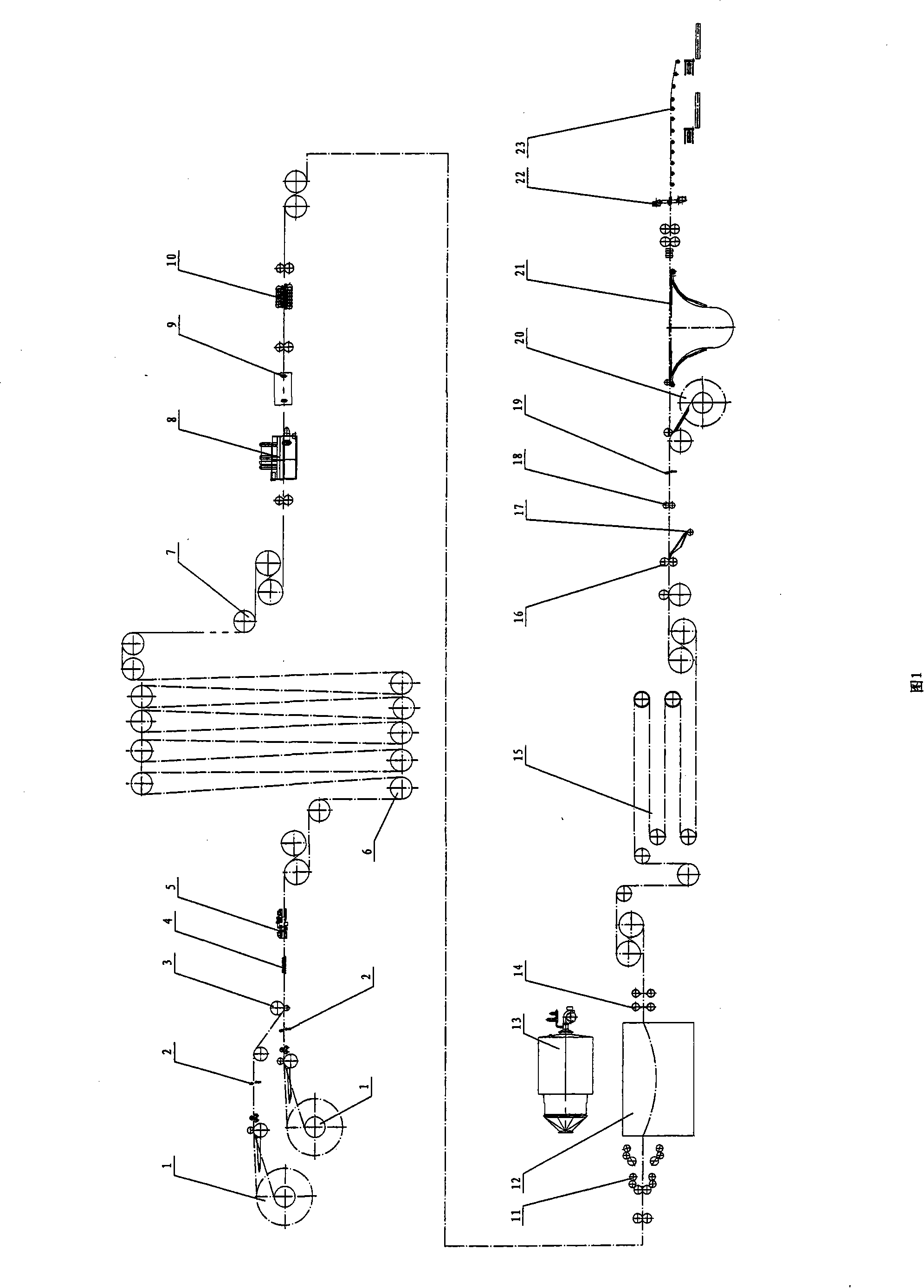

Method for continuous producing rust-inhibiting primer coating steel plate

ActiveCN101249605AIncrease productivityReduce wastePretreated surfacesSheets/panelsCircular discSheet steel

The invention provides a method for continuously producing rust-proof primer coated steel plate applied to the coating production field in the metallurgical industry. The method is characterized in that the defect of discontinuous former production is overcome and all processes are continuously completed on line. The method comprises the following steps: the head and tail of a hot-rolled steel band are welded together; the steel band enters a pickling tank to remove the oxide of the surface, and enters a hot air drying segment to remove the moisture of the surface; the steel band enters a roll coater 11 to coat the surface of the steel band and is then transmitted to a paint curing furnace 12 to cure and dry the band; the steel band with a certain temperature is blown by cold wind 14 to reduce the temperature; the steel band enters a horizontal type loop 15, is corrected an error through a loop 21, and then enters a flying shear 22 for definite distance cutting in order to be cut into the required plate according to the requirement; and then the steel band enters a dual stacking 23 to be stacked into a sheet bar with the defined height. When coiled materials are required, the steel band is longitudinally sheared into strip by a disc shear, then is coiled separately by a dividing shear, and enters a rolling machine 20 to form a coiled steel band.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH

Laser cladding Co-based alloy powder for conductor roll

InactiveCN101187023AImprove performanceModerate hardnessMetallic material coating processesRare-earth elementChemical composition

Provided is nickel-based alloy powder for laser cladding electricity conducting roller, the chemical components of the material mainly comprise the following elements including Ni, Cr, Mo, W, Co, V, Fe, Si, and Mn, the alloying components further comprise at least two rare earth elements among Y2O3, La2O3, Ce and Hf with proper amount, the weight percentages of the material of Cr 23-25%, Mo 14-16%, W 5-8%, Fe 6-10%, Co 3-5%, V 0.1-0.6%, Mn 0.5-2%, Si 0.2-2%, Y2O3 0.1-0.5%, Hf 0.1-0.5%, La2O3 0.1-0.5%, Ce 0.1-0.5%, and the rest is Ni. The alloy substrate of the invention is strengthened through multiple strengthened methods, and the crystal boundary quality is improved, which enables the alloy to achieve perfect combination property, thereby achieving medium rigidity and relatively high intensity of the alloy, simultaneously reducing alloy melting point and increasing properties of oxidation resistance, abrasion resistance, corrosion resistance, and certain electricity conduction. The invention provides an effective and convenient process for successful restoration of disabled electricity conducting roller parts of metallurgy industry.

Owner:SHENYANG DALU LASER TECH

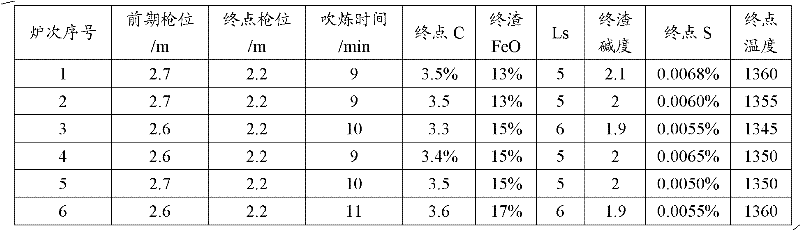

Production method of low-sulfur steel

ActiveCN102443675AAvoid increasing carbon and nitrogenReduce consumptionManufacturing convertersSteelmakingSulfur

The invention relates to the steelmaking technical field of the metallurgical industry, and in particular relates to a method for producing low-sulfur steel through the converter duplex technology. The production method comprises the following steps: (1) adding a desulfurizer in molten iron slagging iron slag to perform knotted reactor (KR) desulphurization treatment, skimming the desulfurized molten iron, and adding in a dephophorization furnace; (2) adding scrap steel and slag materials in the dephophorization furnace, blowing, and adding semisteel in a decarbonization furnace after the treatment; and (3) adding the slag materials in the decarbonization furnace, and blowing to ensure that S content in the molten steel is less than 0.005% after blowing. The method does not adopt low-frequency (LF) furnace refining to desulfurize; a converter can be directly used to stably produce the molten steel of which S content is less than 0.005%, thus better matching the production rhythm of continuous casting; for the production of the low-sulfur steel, S content is controlled to be less than 0.005% by the converter, thus the carburization and nitrogen increasing of molten steel caused by LF desulfurization can be avoided; and the total consumption amount of lime in the converter is less than 35kg / t and the total slag quantity is less than 70kg / t.

Owner:SHOUGANG CORPORATION

Process and device for smelting ferronickel and nickel-containing molten iron by using lower-nickel materials

InactiveCN101538631AImprove applicabilityHigh recovery rateShaft furnaceSolventMetallurgical industry

The invention relates to a process and a device for smelting ferronickel and nickel-containing molten iron by using lower-nickel materials, which belongs to metallurgical industry steel-making raw material. The process comprises the following steps: mixing ferro nickel containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, mixing to make pelletizing materials, sending the pelletizing materials into a reducing furnace, obtaining chromium irons pellets after the reduction reaction, and directly adding reduced pellets into an lining electroslag furnace for being smelted into ferro nickel alloy or the nickel-containing molten iron. The device comprises an internal-external heating vertical reducing furnace, a lining electroslag furnace and a residual heat recovery system. The invention has the advantages that: firstly, the reduction temperature is low, the speed is high, the energy consumption is reduced, the production cost is lowered, the production efficiency is high, and the uniformity of the quality is good; secondly, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is reduced, the environment pollution is lowered; fourthly, the source of raw materials adopting nickel oxide ore or nickel-containing waste, the cost is low; fifthly, the waste resource can be recycled so as to save the resource consumption; and sixthly, the high-temperature pellets are directly smelted by adopting the lining electroslag furnace, the heat efficiency is high, the energy consumption is low, the material purity is high and the quality is good, and the device is simple with less investment.

Owner:丁家伟

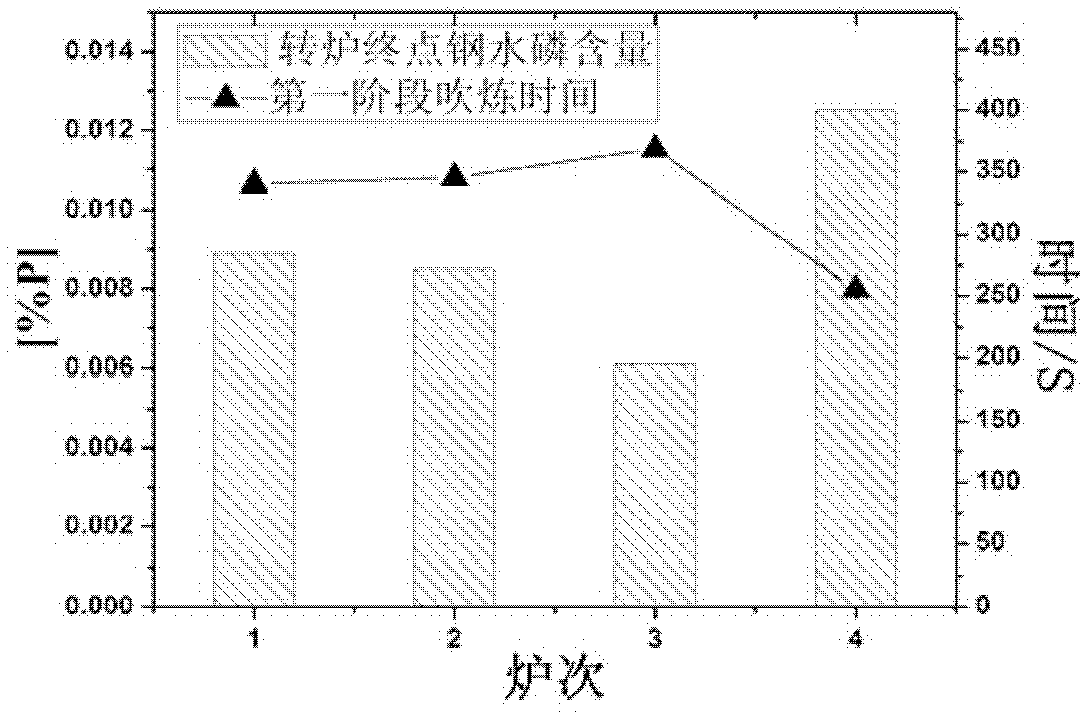

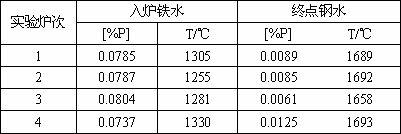

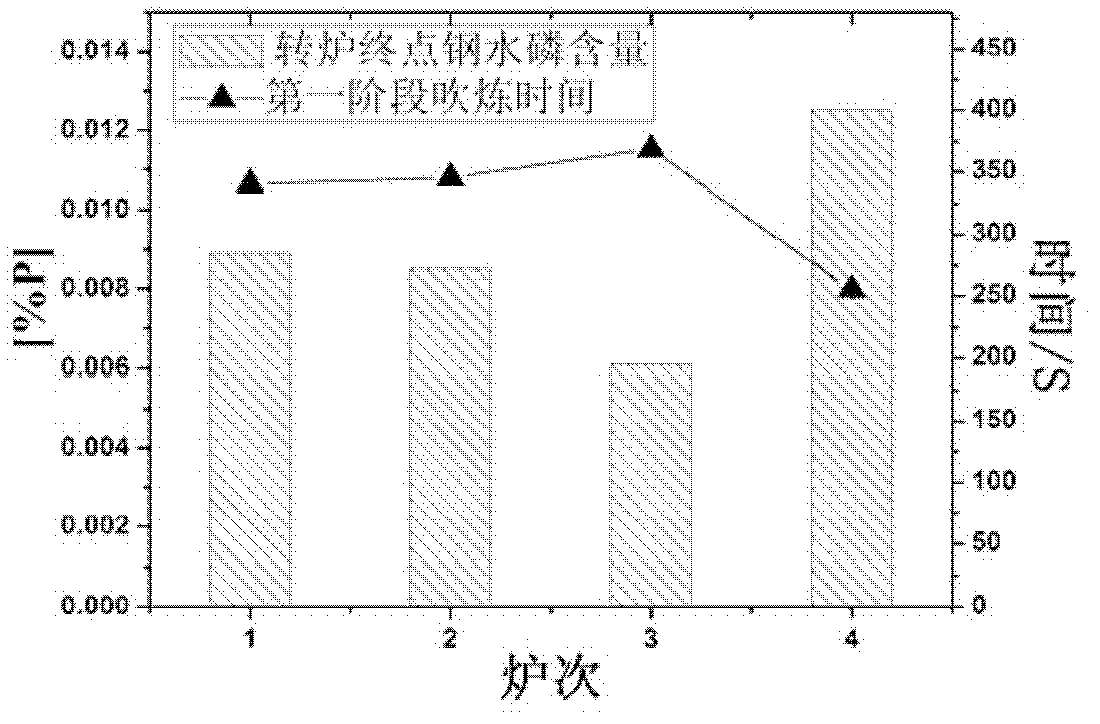

Convertor smelting technology method for producing low-phosphorous steel

InactiveCN102358912AReduce consumptionReduce water phosphorus contentManufacturing convertersSteelmakingMetallurgical industry

The invention relates to the technical field f convertor steel making in metallurgy industries, in particular to a method for smelting low-phosphorous steel through combined steel-tapping slag-left and double slag process technology, which aims at providing convertor technology for producing the low-phosphorous steel. The method prolongs previous dephosphorization blowing time, thereby prolonging reaction time of steel slag in a previous blowing stage, improving reaction temperature of dephosphorization steel slag in previous blowing, improving dynamics and thermodynamics conditions of steel slag reaction, improving dephosphorization effect in previous blowing and enabling phosphorus in steel liquid to be absorbed in slag as much as possible. Slag with high P2O5 content is poured out of a convertor so as to reduce phosphorus content of the whole convertor system, providing favorable conditions for dephosphorization in a later decarburization blowing stage and achieving the purpose of producing the low-phosphorous steel. Compared with other methods for producing the low-phosphorous steel, the method for producing the low-phosphorous steel has the advantages of being simple in operation methods, low in cost, easy to obtain and the like.

Owner:UNIV OF SCI & TECH BEIJING

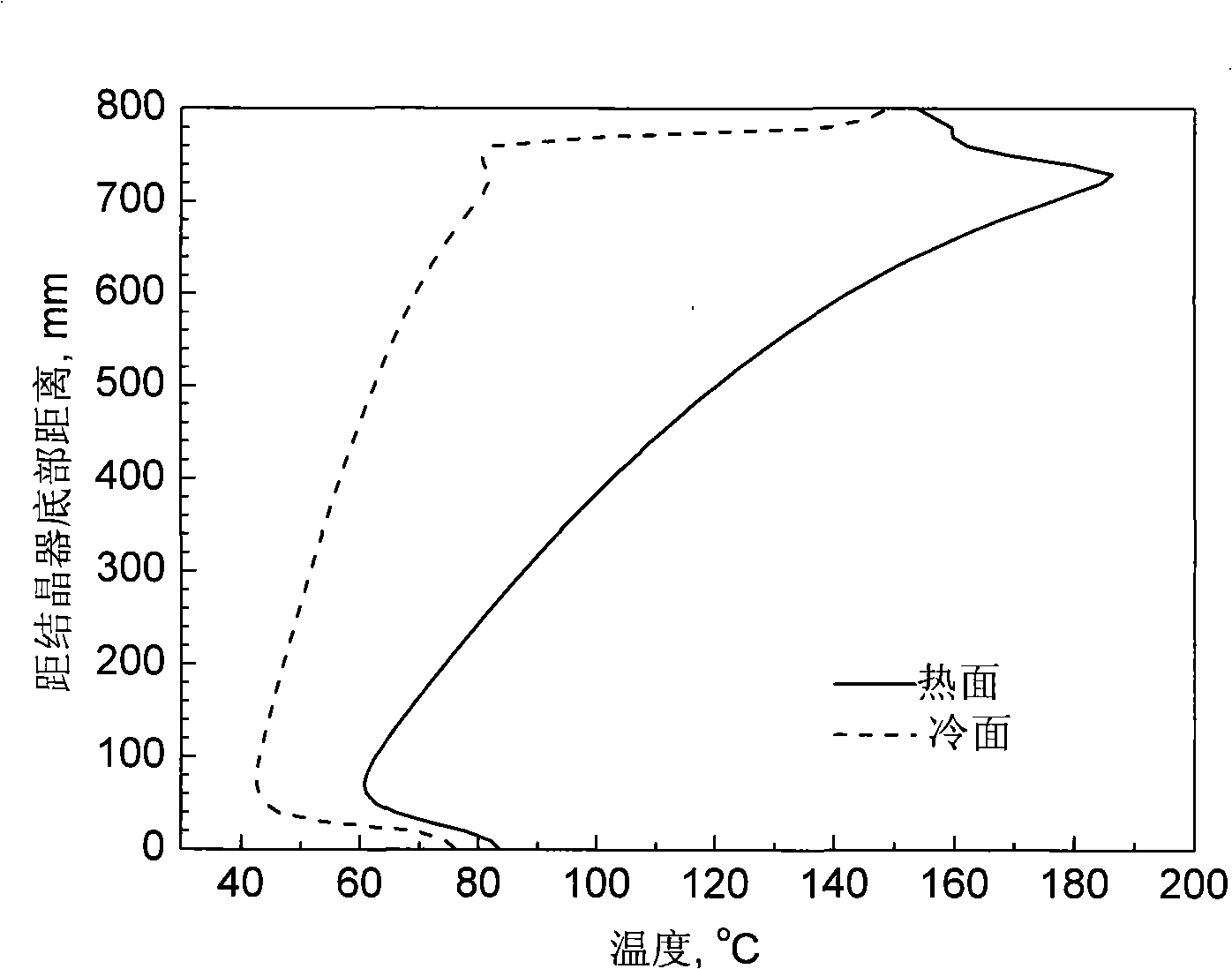

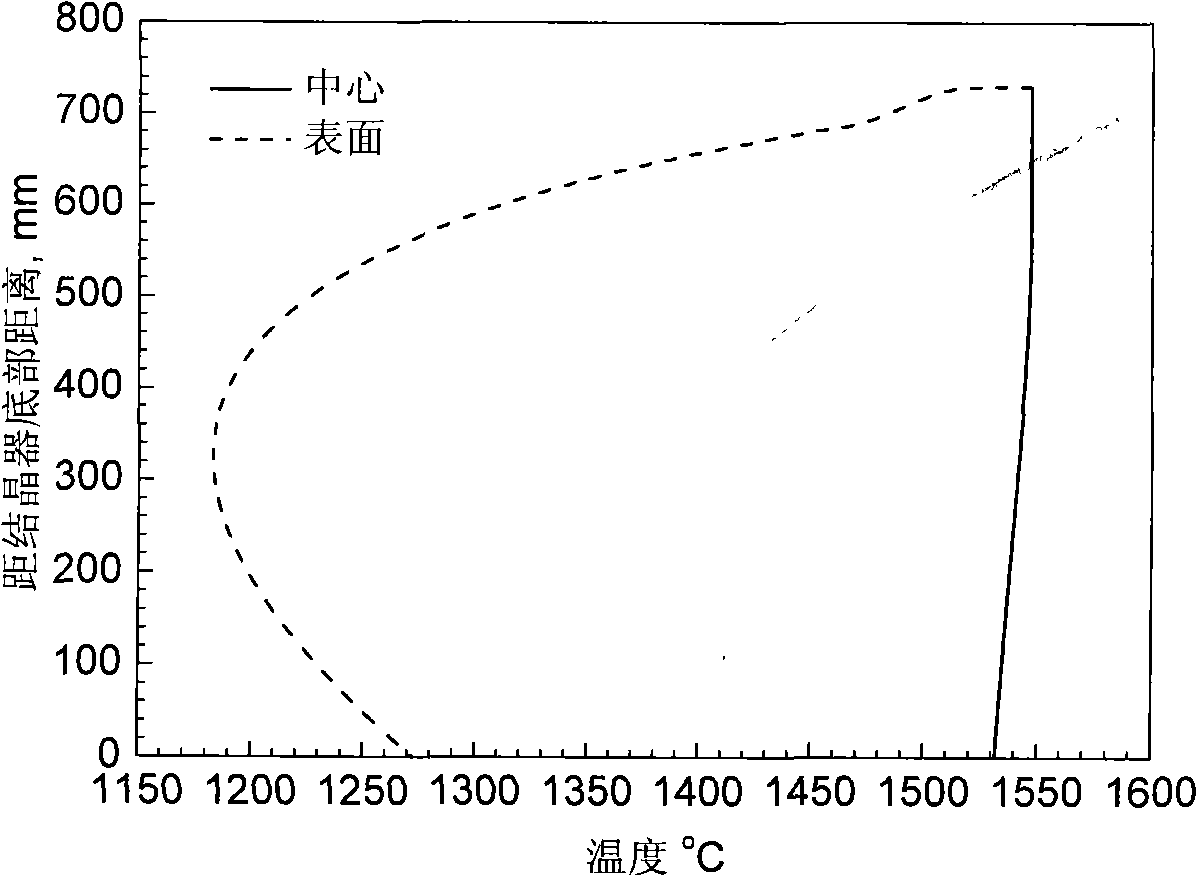

Method for producing low alloyed steel continuous casting circular tube blank with a diameter of 350-400mm

The invention provides a production method of a low alloy steel continuous casting round tube blank with the diameter of Phi 350 to Phi 400mm, comprising the following steps: the process conditions of a round tube blank crystallizer which is applicable to the ratio of the arc-shaped radius of a continuous casting machine and the diameter of the low alloy steel continuous casting round tube blank of 26.25 to 30 are selected; the parameters for low alloy steel casting blank cooling are selected; the low alloy steel casting blank secondary cooling system is prepared; and the parameters of the continuous casting process of the low alloy steel continuous casting blank are selected. The production method has the effects that the production method can ensure the quality of the low alloy steel casting blank to be in line with the requirements of the continuous casting process of the continuous casting round tube blank under the equipment condition that the ratio of the arc-shaped radius of the continuous casting machine and the diameter of the continuous casting round tube blank is 26.25 to 30.The non-round degree, the end-surface cut square, the curvature, the defects of the acid leaching macrostructures, the acid leaching macrostructures and the surface quality of the produced casting blank with the diameter of Phi 350 to Phi 400mm are all in line with the requirements of continuous casting round tube blank YB / T 4149-2006 of the black metallurgical industry standards of the People's Republic of China.

Owner:TIANJIN PIPE GROUP CORP

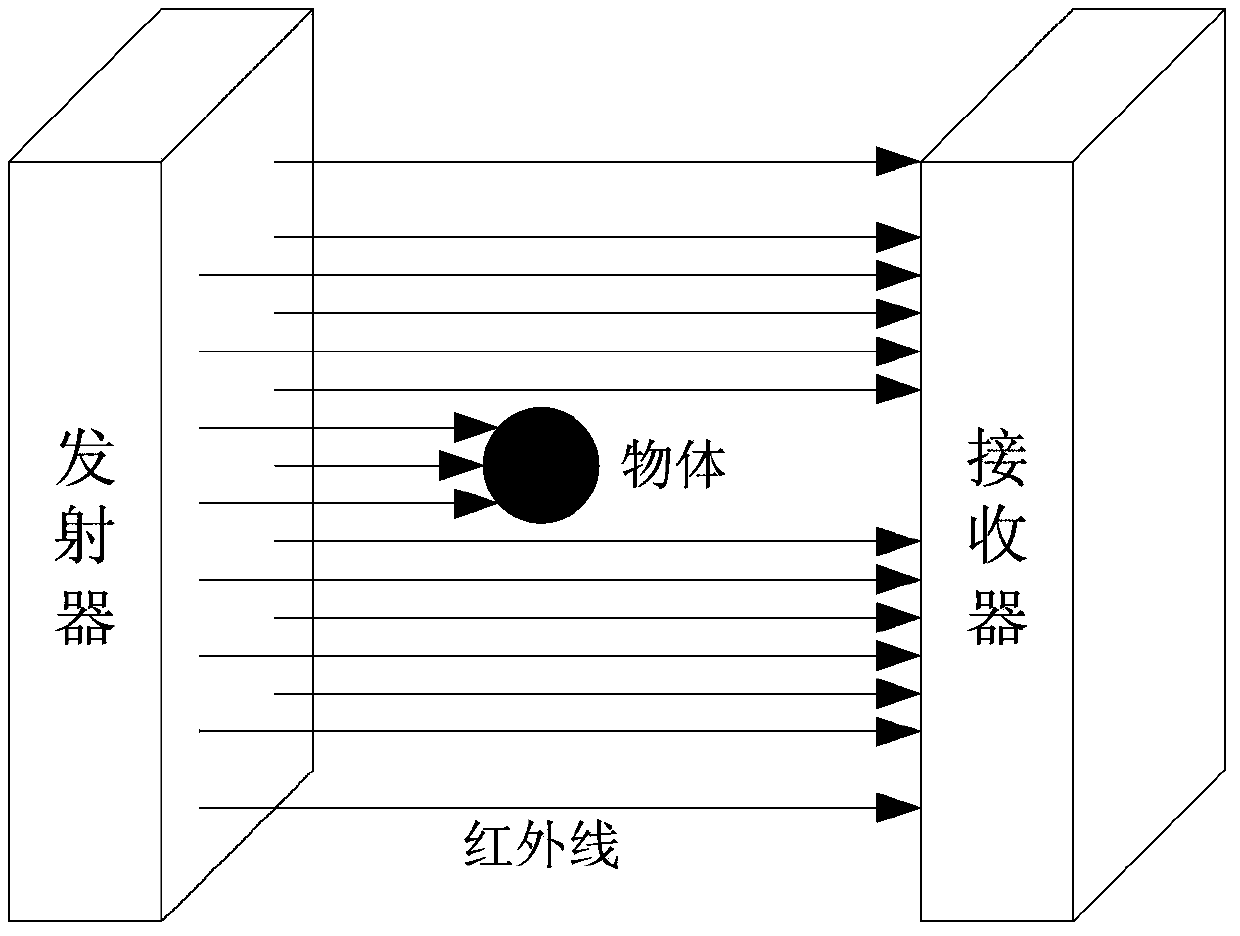

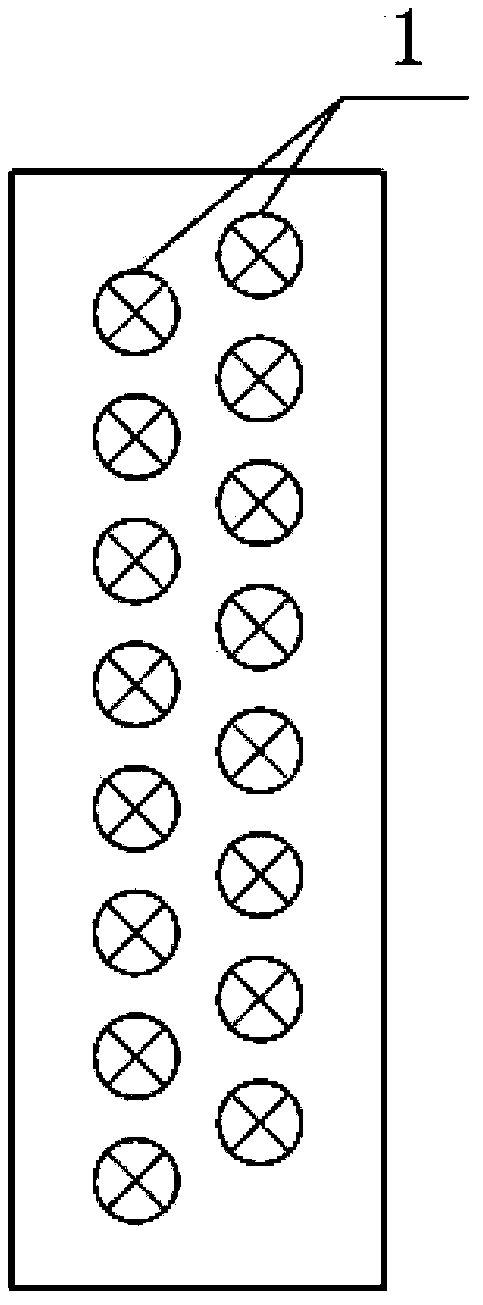

High-speed and high-precision light curtain detection device based on FPGA (field programmable gate array) and FPAA (field programmable analog array)

ActiveCN103389039AFast data processingQuick responseUsing optical meansSteel barField-programmable gate array

The invention discloses a high-speed and high precision light curtain detection device based on an FPGA and an FPAA. The device comprises a light curtain emitter and a light curtain receiver, wherein infrared transmitting tubes are arranged on the light curtain emitter; receiving photocells are arranged on the light curtain receiver; the infrared transmitting tubes, as well as the receiving photocells, are distributed in double rows and staggered in a plane; and a system core of the light curtain emitter and the light curtain receiver is based on two types (FPGA / FPAA) of super-large-scale digital / analog integrated circuits, that is, by means of a site reconfigurable characteristic of the FPAA and a parallel processing characteristic of the FPGA, the FPAA preprocesses a light envelope signal, and then the FPGA performs real-time in-place detection and edge detection on an object. With the adoption of the technical scheme, the high-speed and high precision light curtain detection device has the advantages as follows: the data processing speed and the system response speed are high, interference resistance is high, and the upgrade is convenient; the device can be applied to various industrial severe environments, in particular to a deformed steel bar production line of a bar production factory in the metallurgical industry; and in-place detection and size measurement performed on tiny objects moving at high speeds can be realized.

Owner:金湖县综合检验检测中心

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com