Patents

Literature

684results about How to "Reduce looseness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

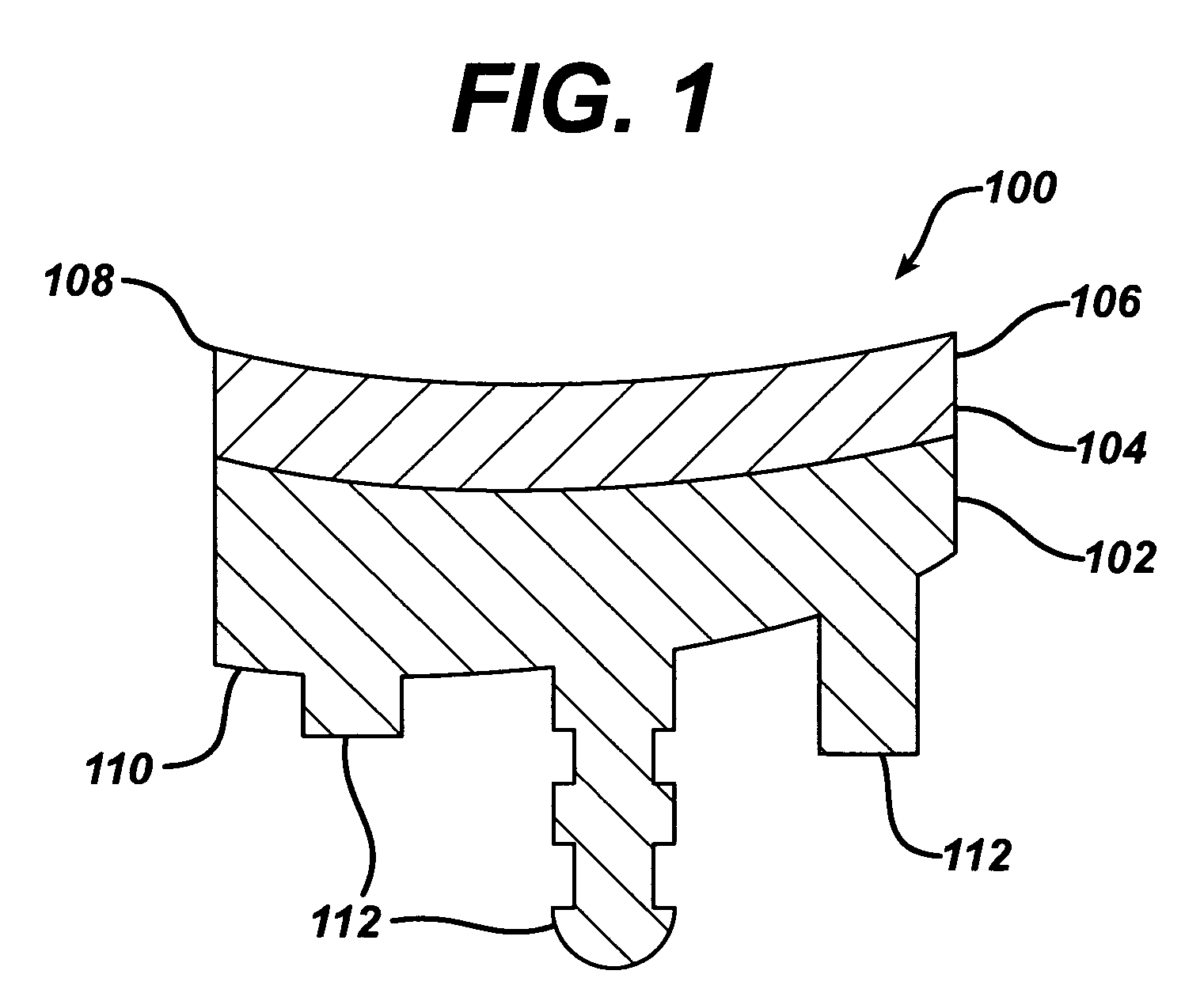

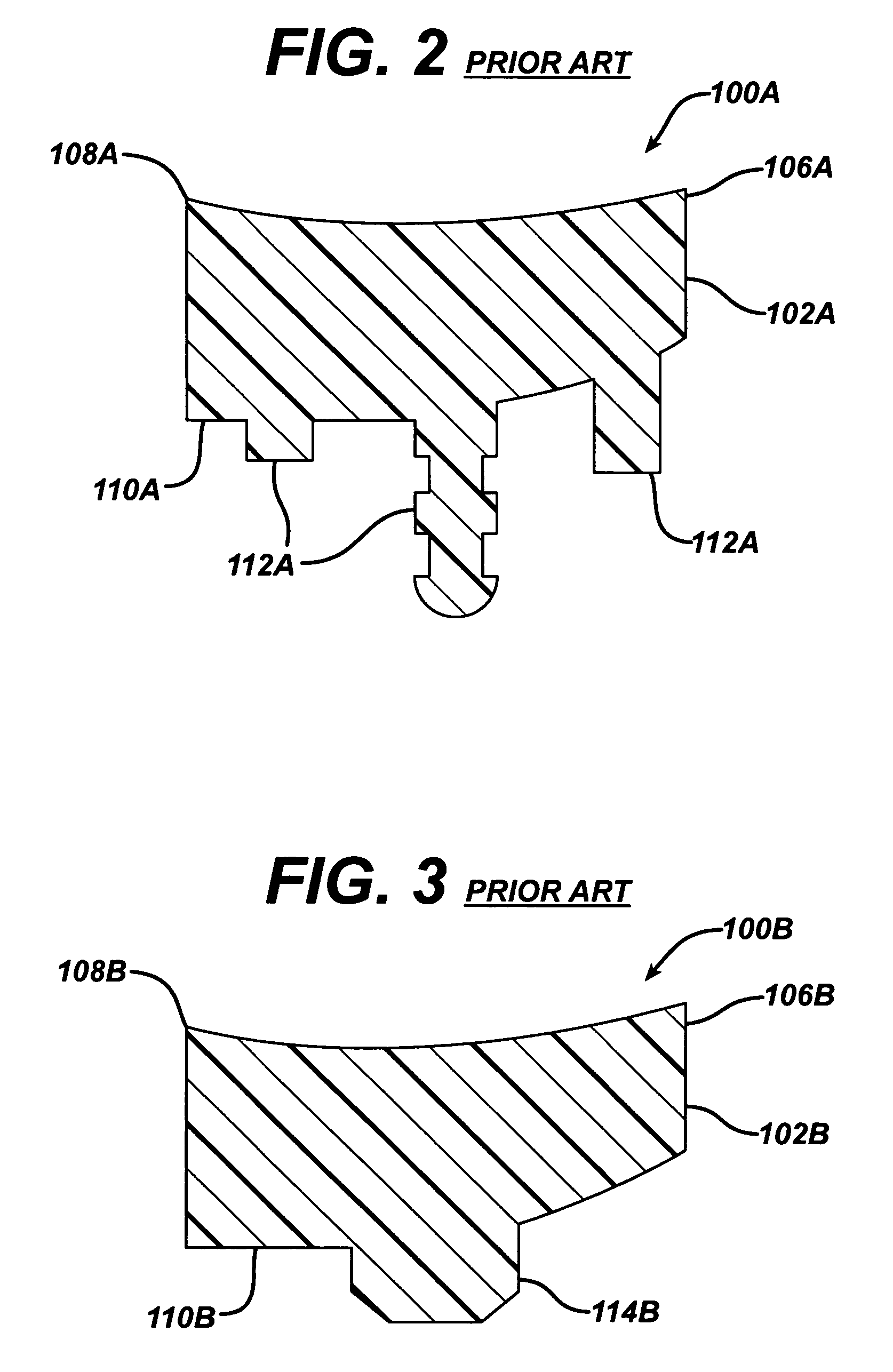

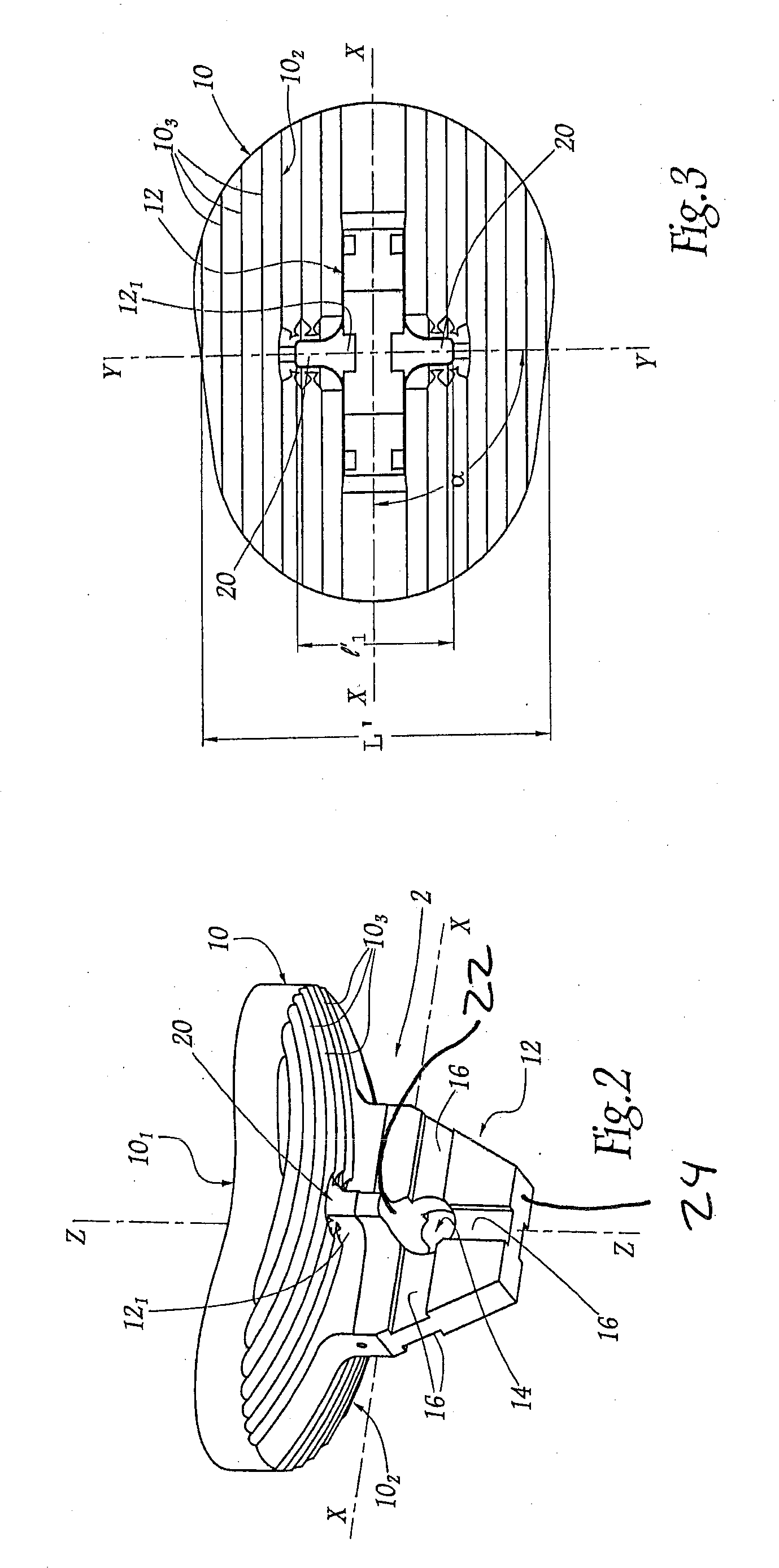

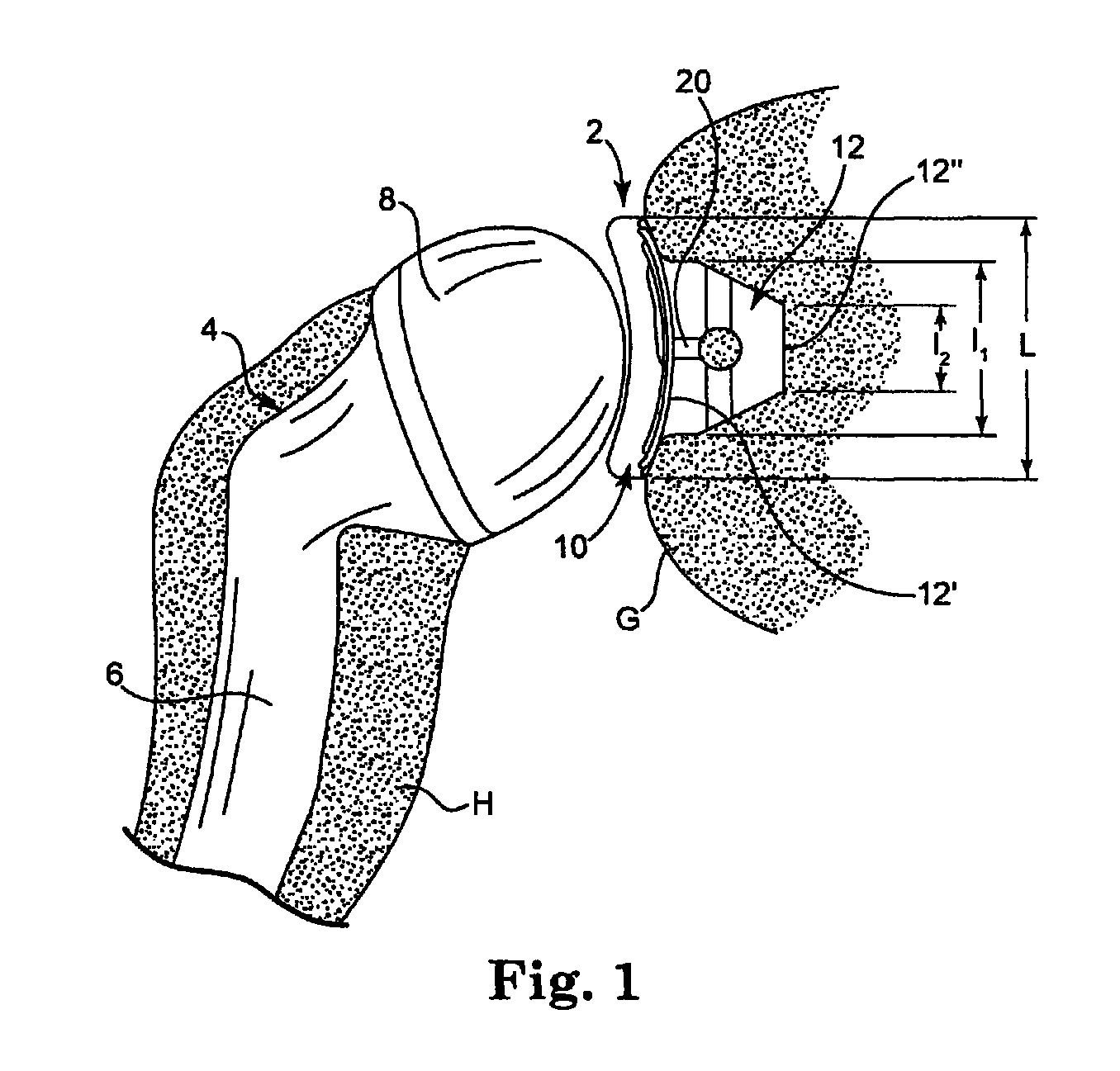

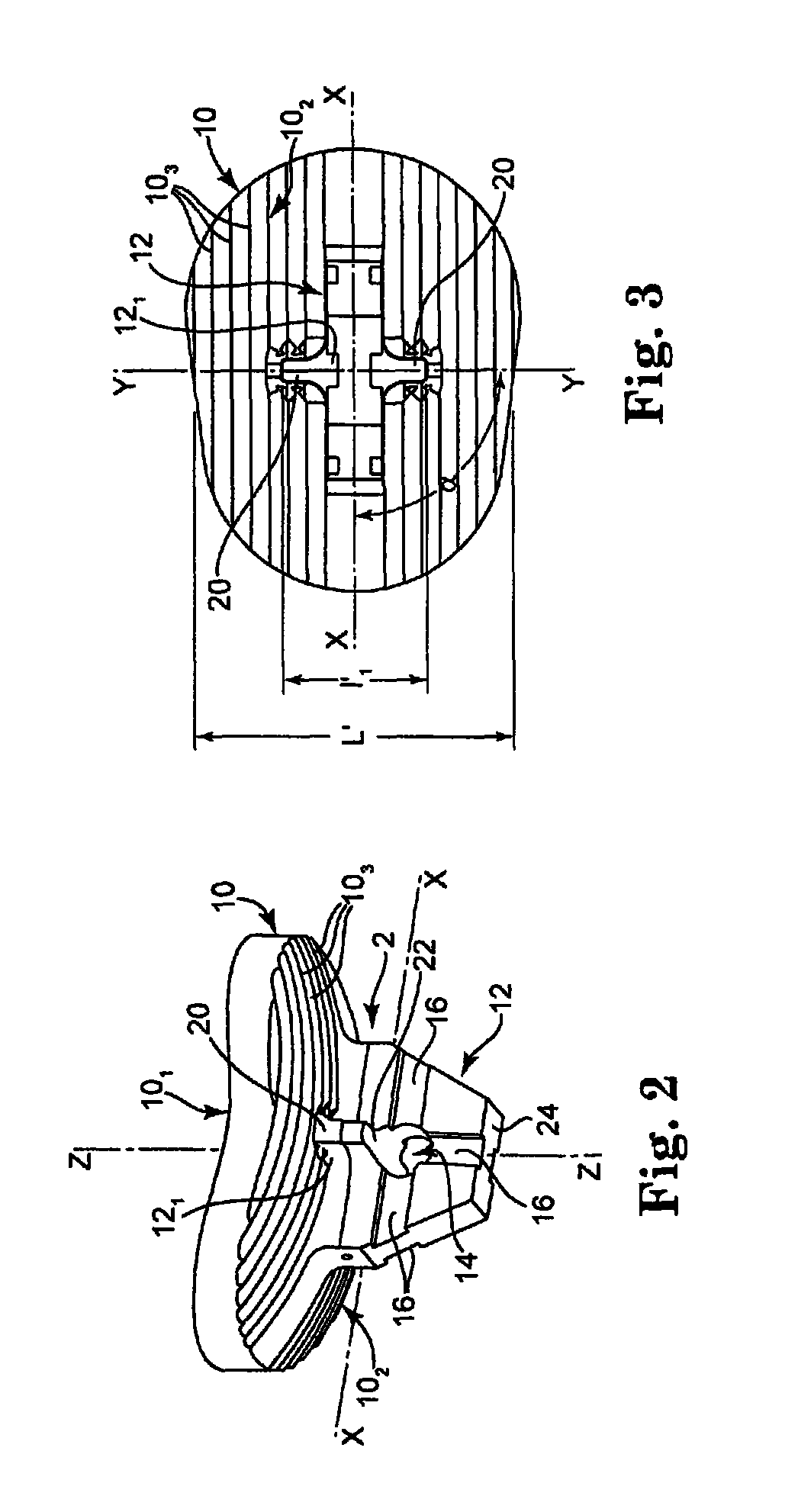

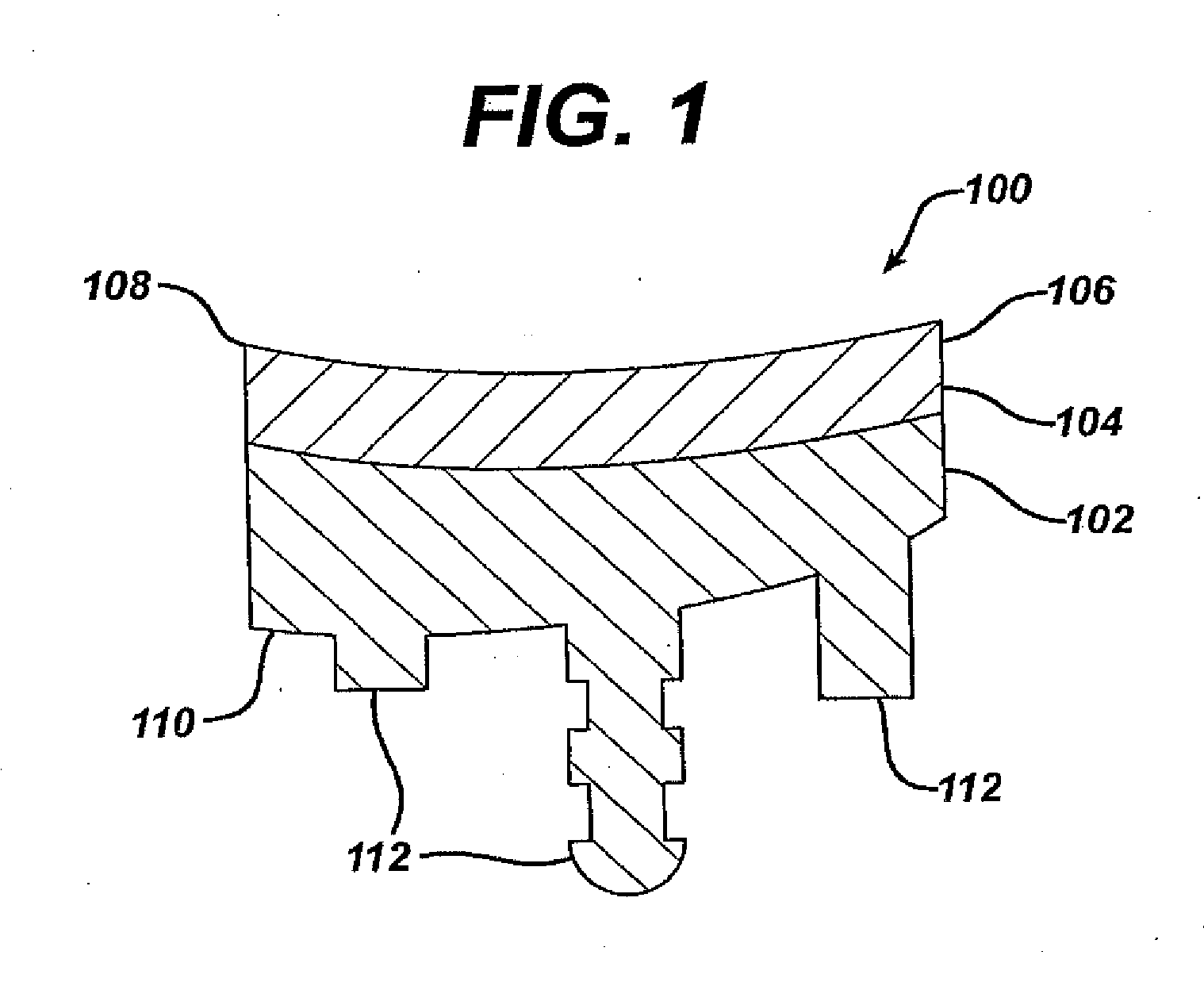

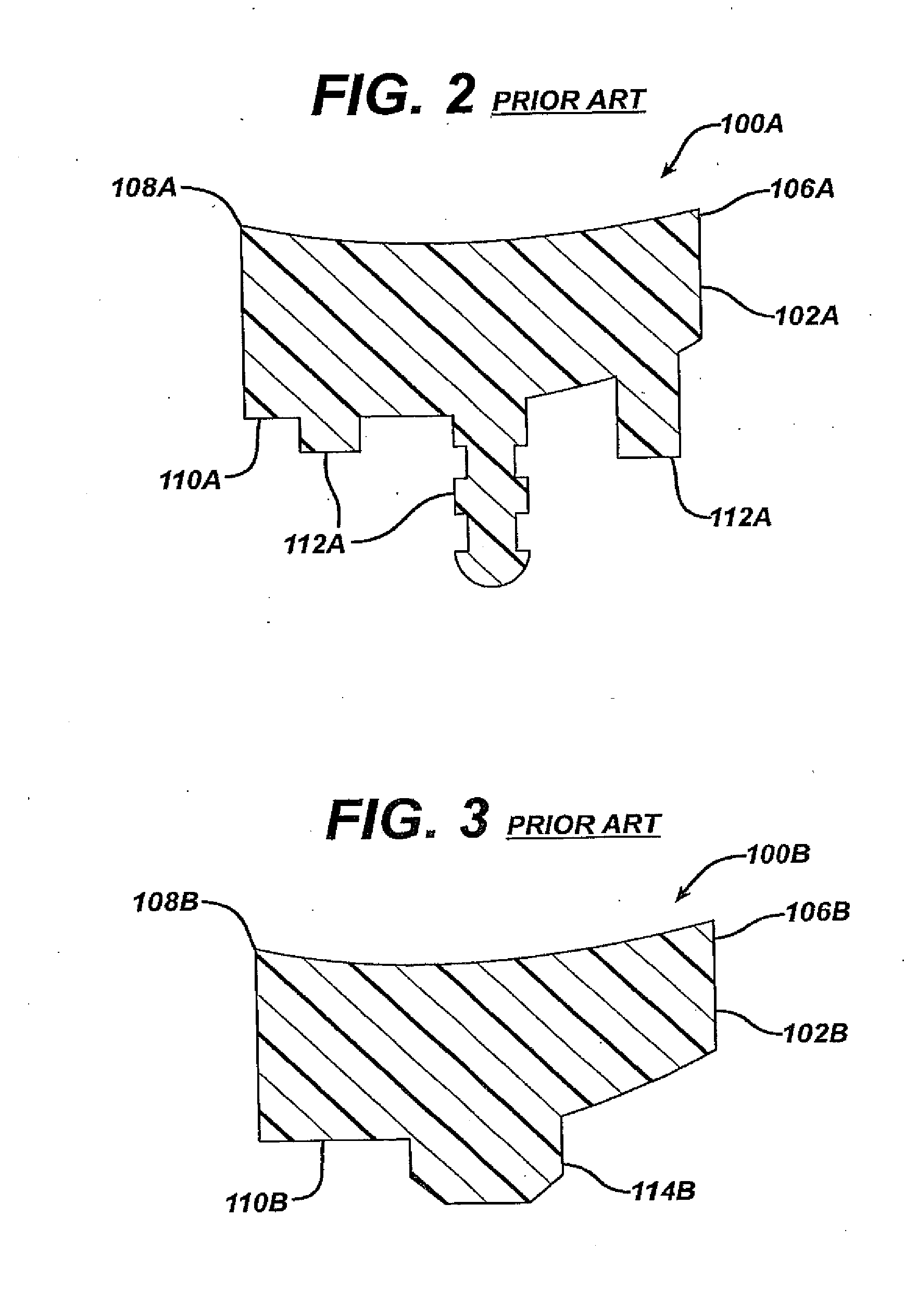

Glenoid augment and associated method

ActiveUS20060069444A1Reduce looseningEliminate shear forceJoint implantsShoulder jointsSacroiliac jointBiomedical engineering

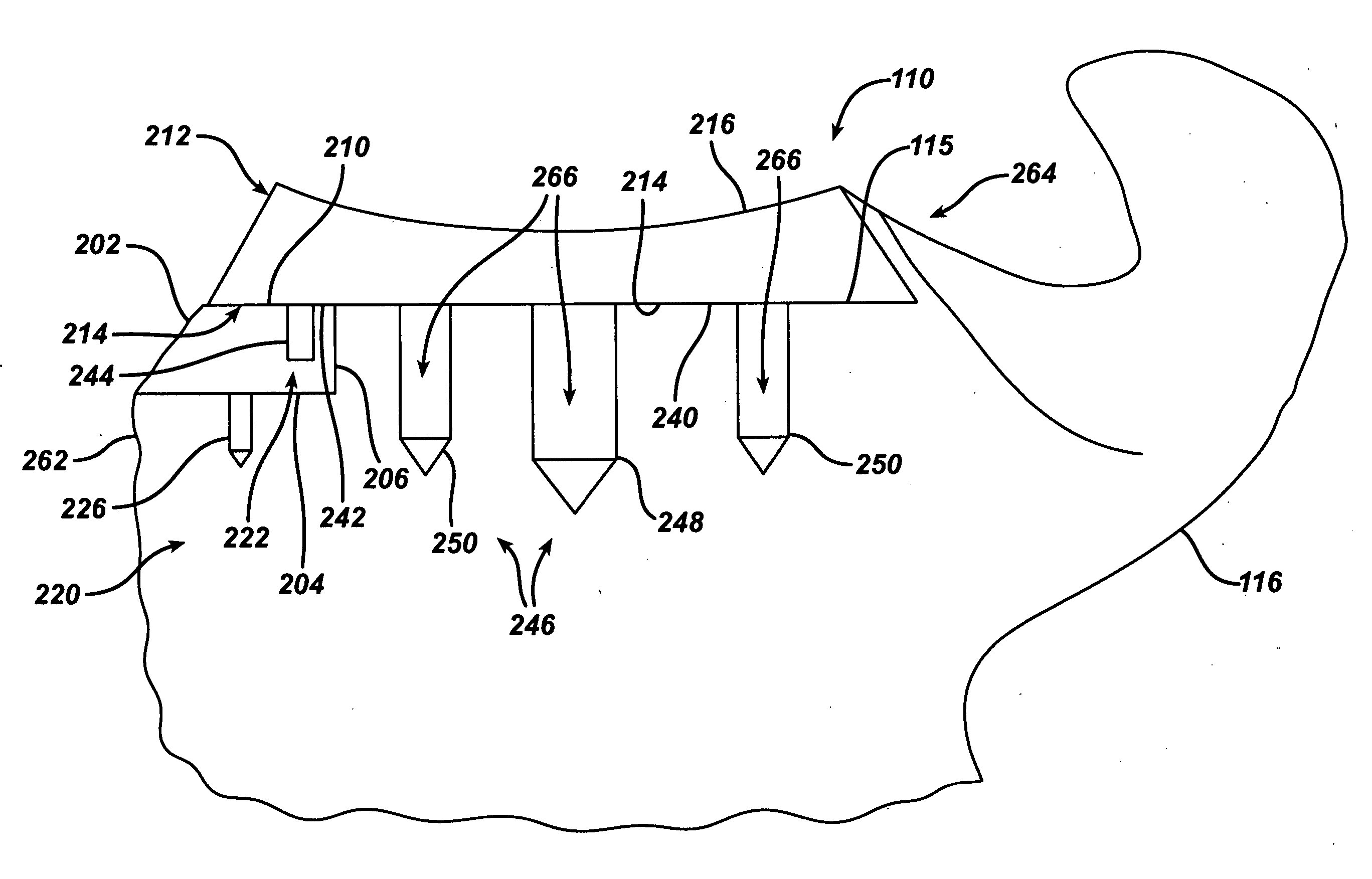

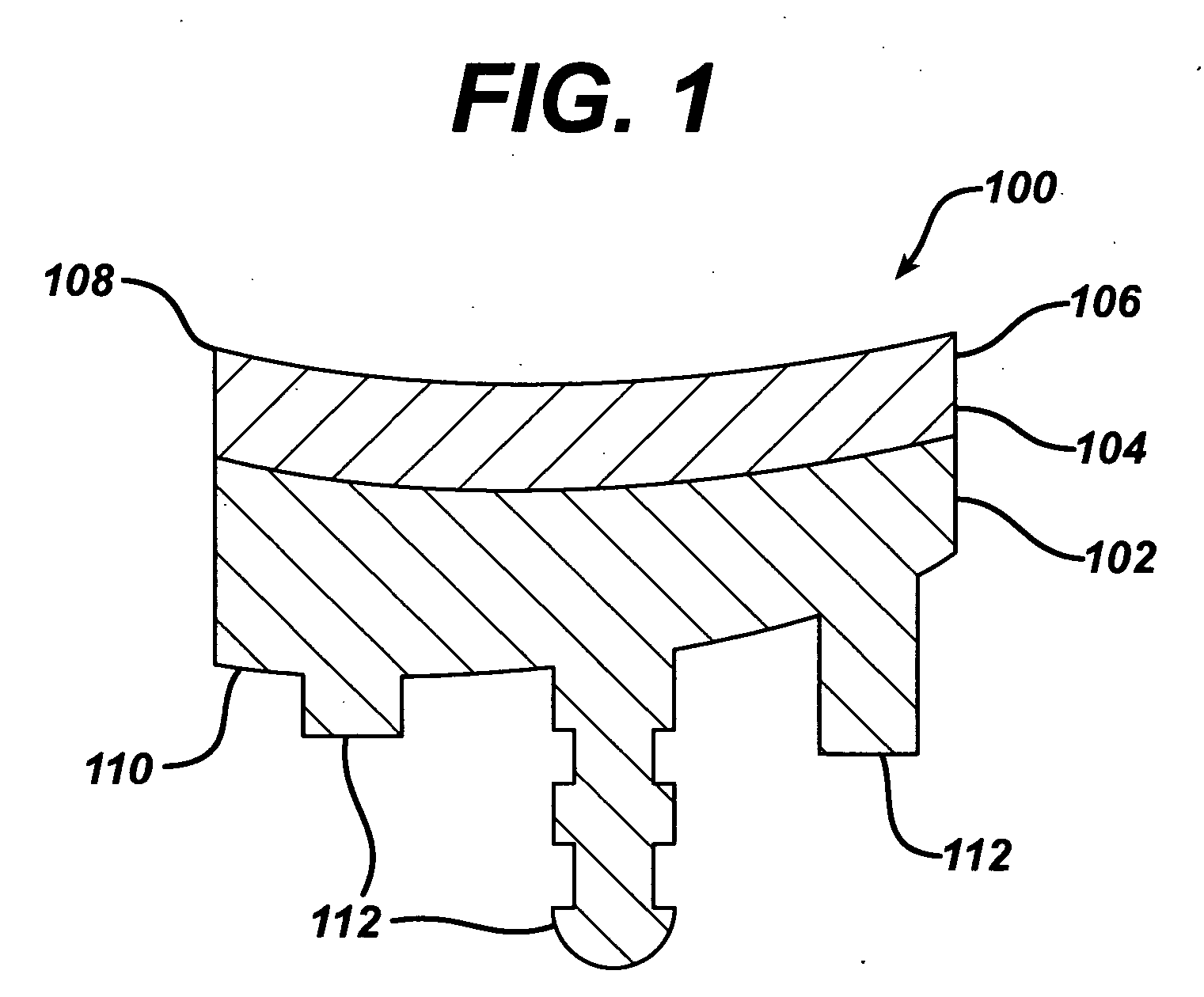

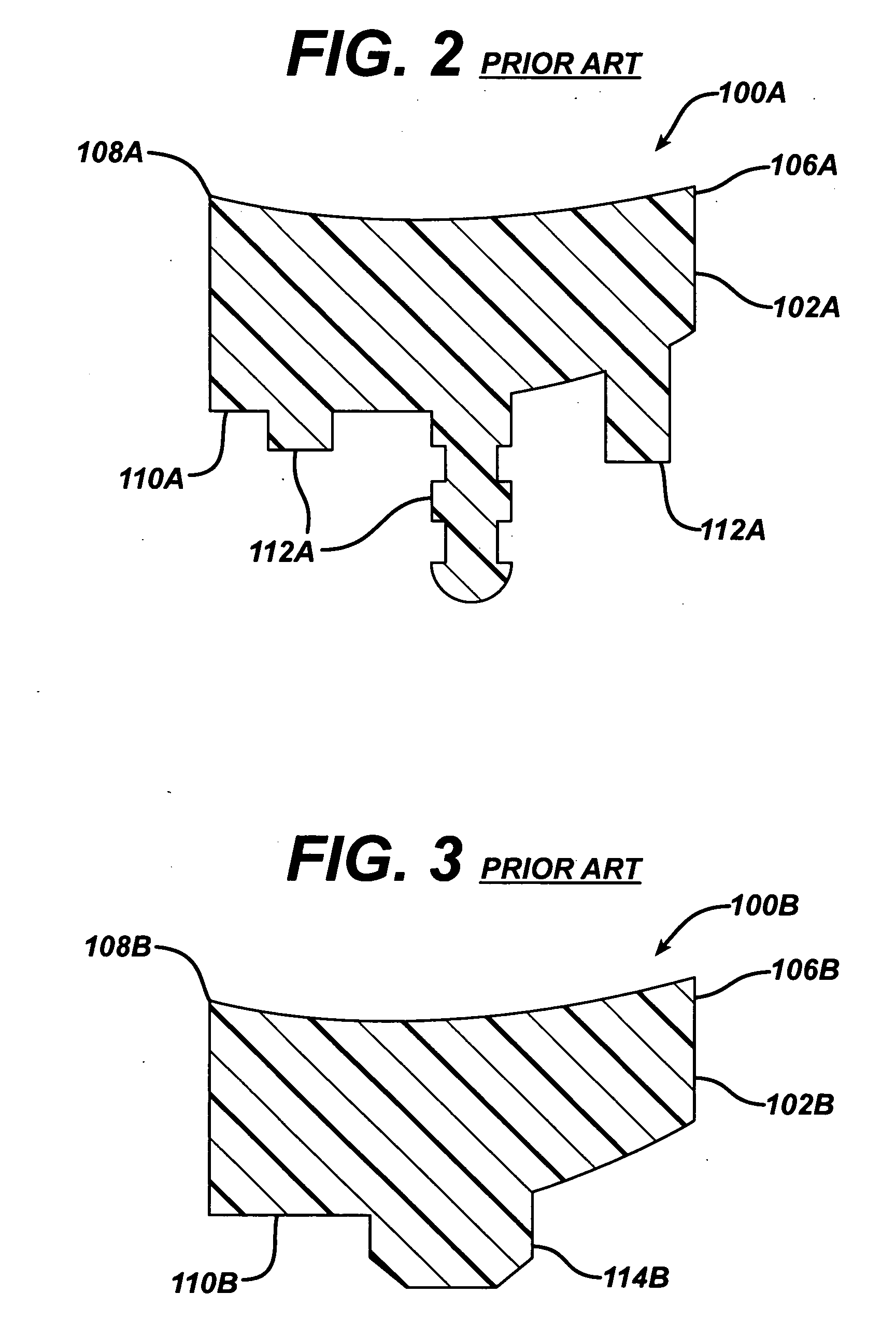

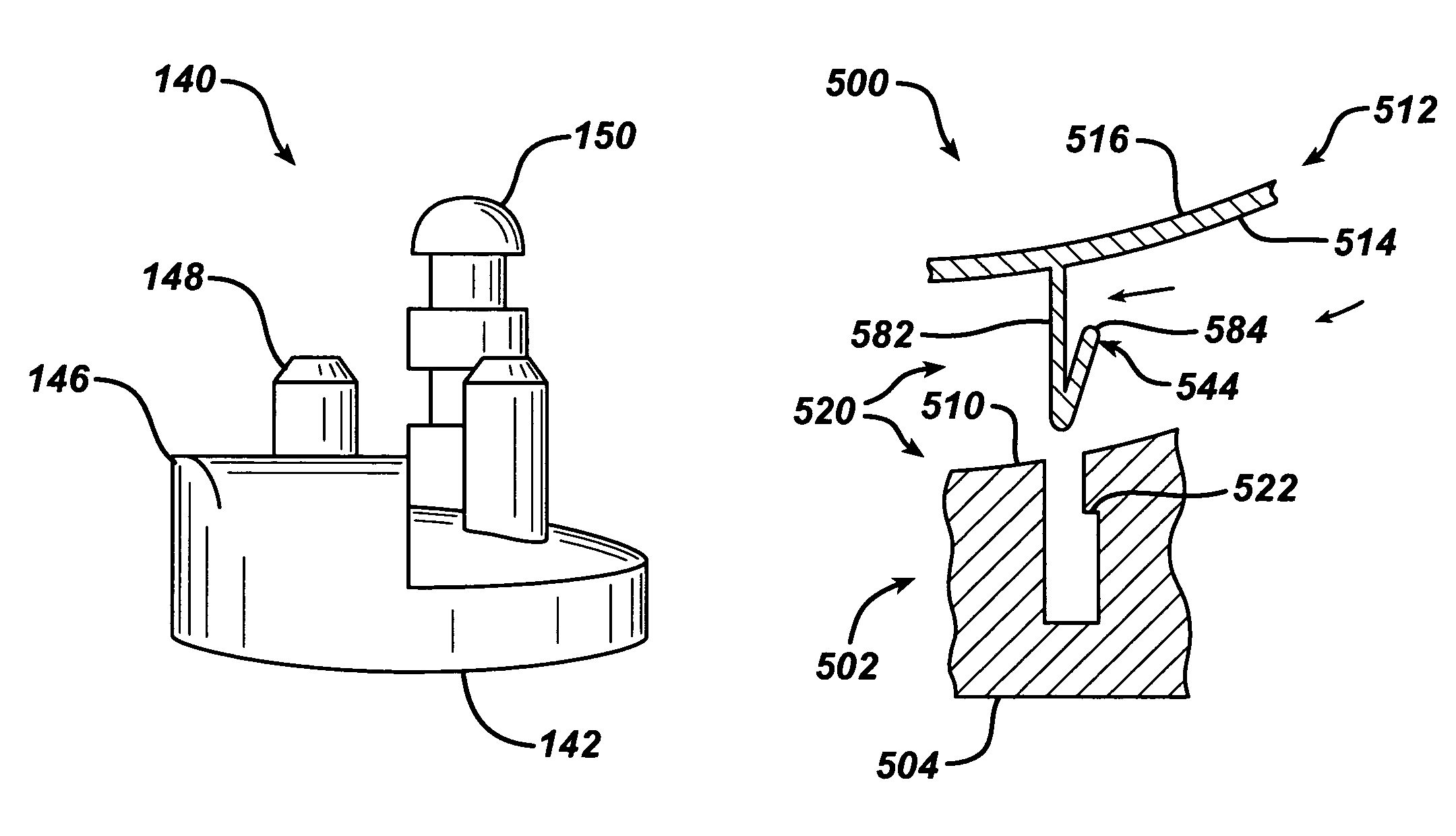

A augmented glenoid implant assembly for use in performing shoulder arthroplasty is provided. The augmented glenoid implant assembly is used for cooperation with the glenoid fossa of a scapula. The implant assembly includes a first component for attachment to the scapula. The first component defines a support surface for cooperation with the glenoid fossa, a second surface positioned adjacent a buttress formed in the glenoid fossa and an assembly surface. The implant assembly also includes a second component removably secured to the first component. The second component includes an assembly face of the second component. The assembly surface of the second component is in close approximation to the assembly surface of the first component. The second component further includes an articulating surface opposed to the assembly surface.

Owner:DEPUY PROD INC

Glenoid augment and associated method

ActiveUS7892287B2Reduce loosenessEliminate shear forceJoint implantsShoulder jointsButtressSacroiliac joint

A augmented glenoid implant assembly for use in performing shoulder arthroplasty is provided. The augmented glenoid implant assembly is used for cooperation with the glenoid fossa of a scapula. The implant assembly includes a first component for attachment to the scapula. The first component defines a support surface for cooperation with the glenoid fossa, a second surface positioned adjacent a buttress formed in the glenoid fossa and an assembly surface. The implant assembly also includes a second component removably secured to the first component. The second component includes an assembly face of the second component. The assembly surface of the second component is in close approximation to the assembly surface of the first component. The second component further includes an articulating surface opposed to the assembly surface.

Owner:DEPUY PROD INC

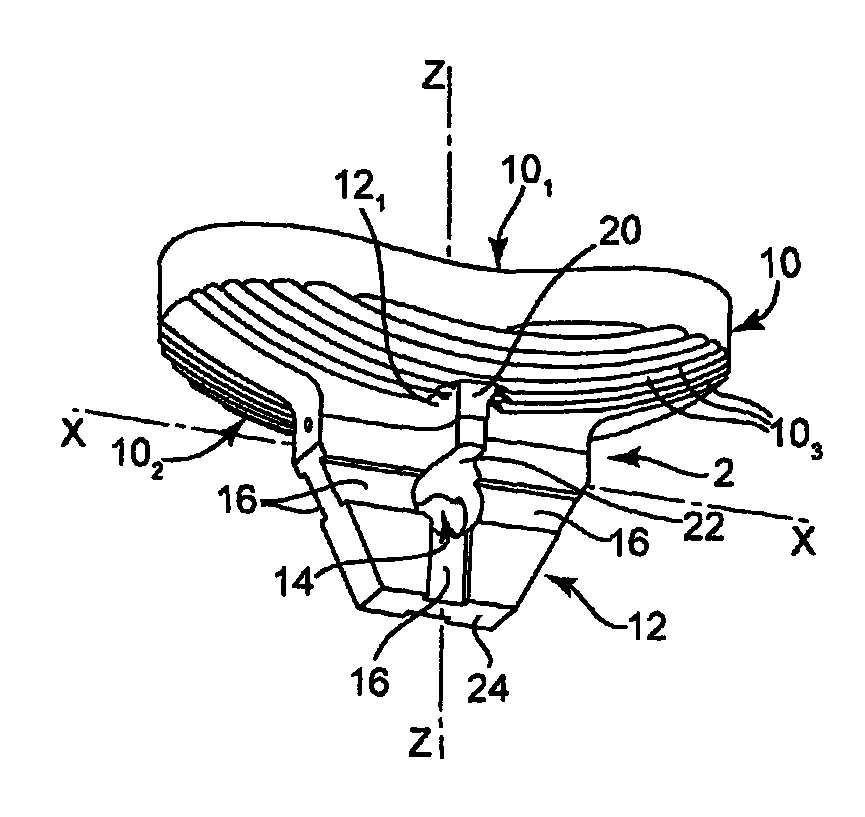

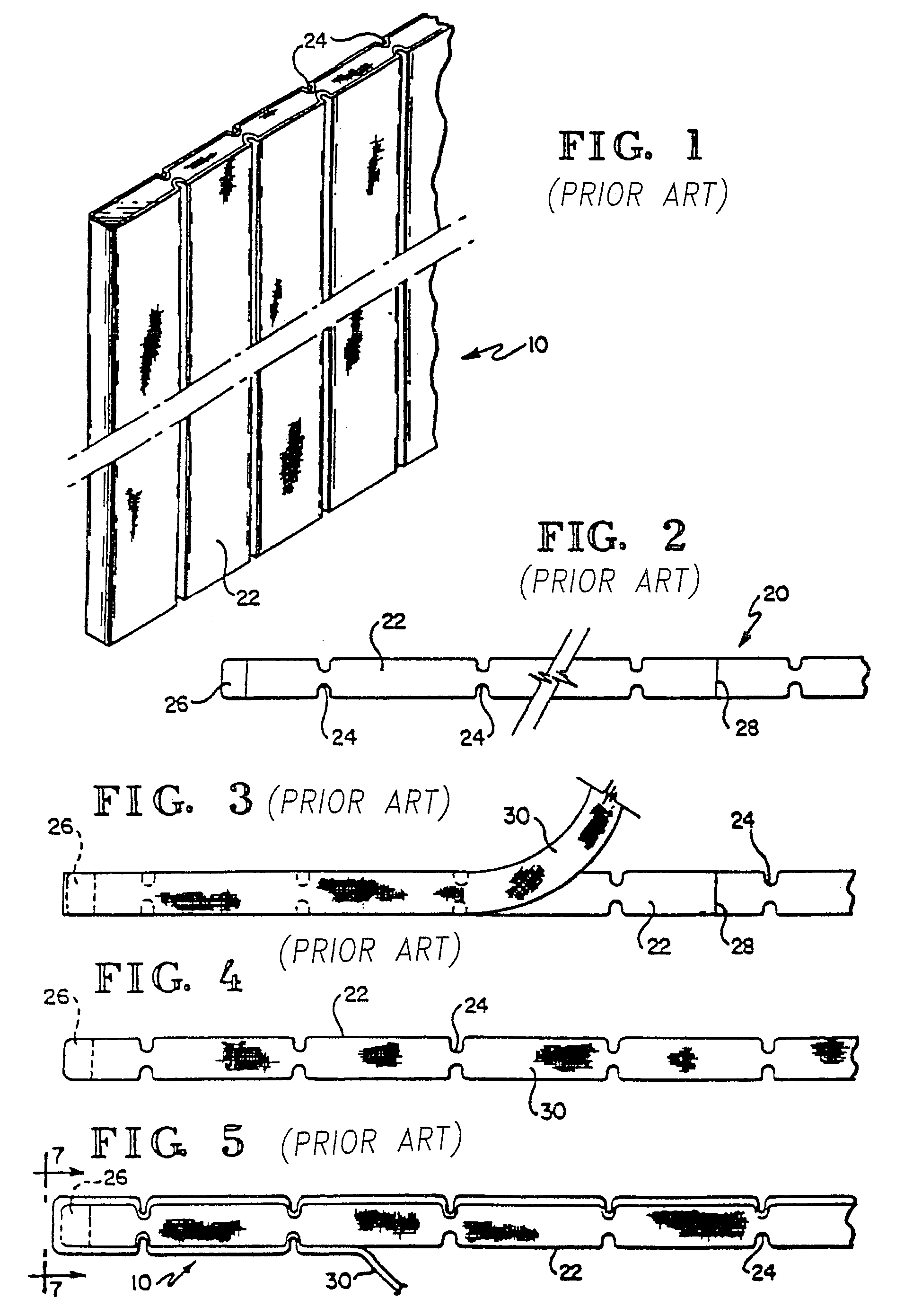

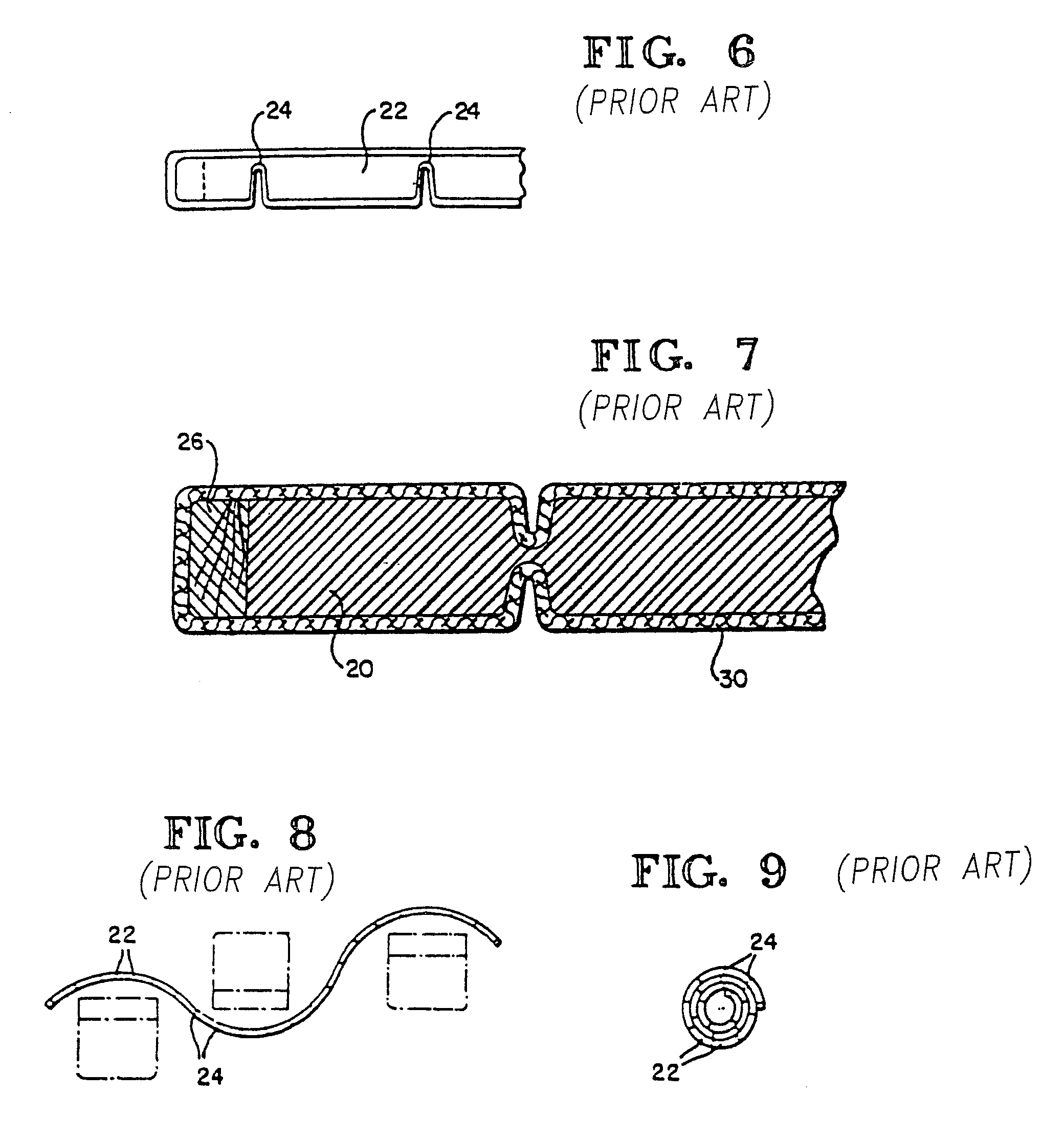

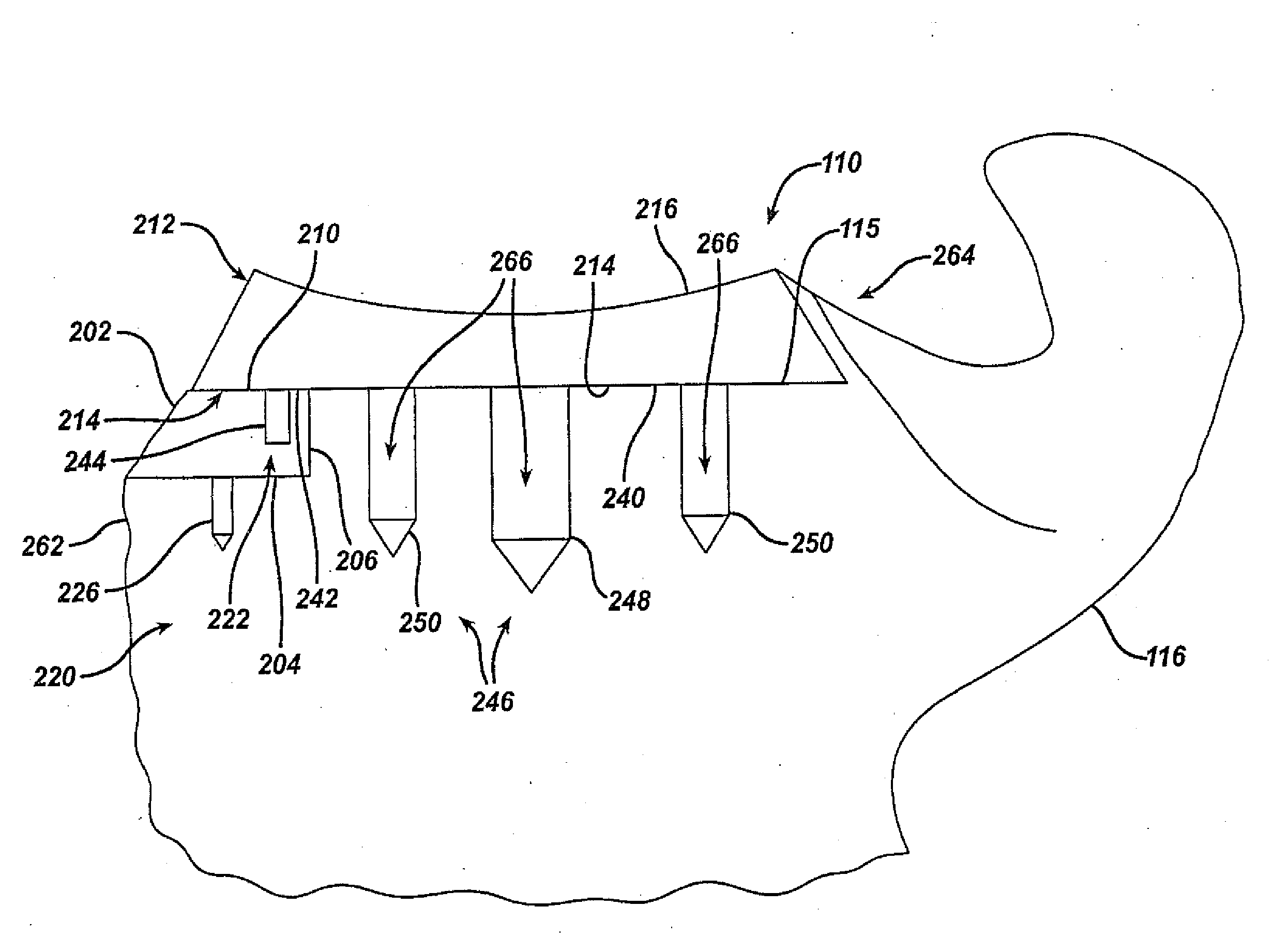

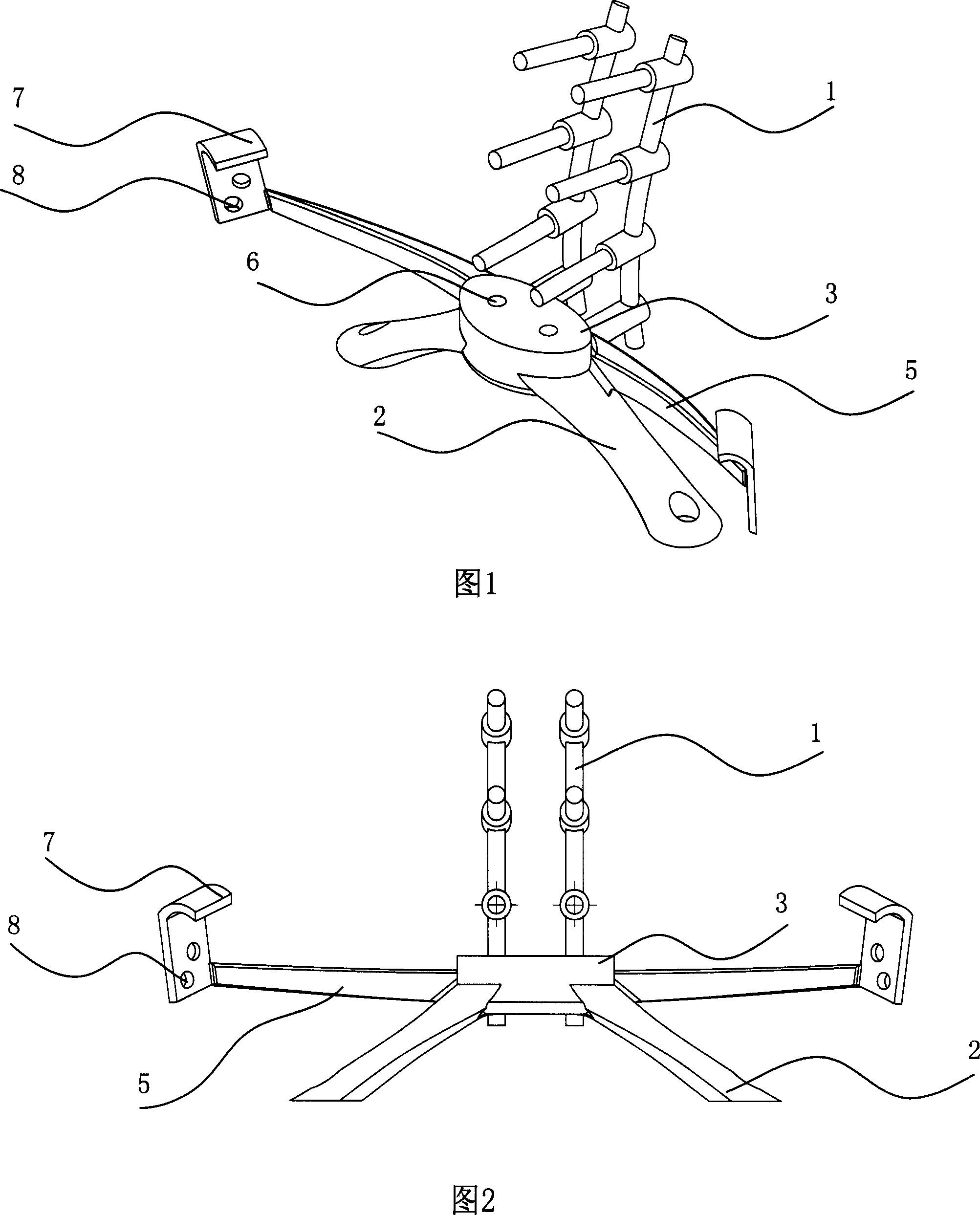

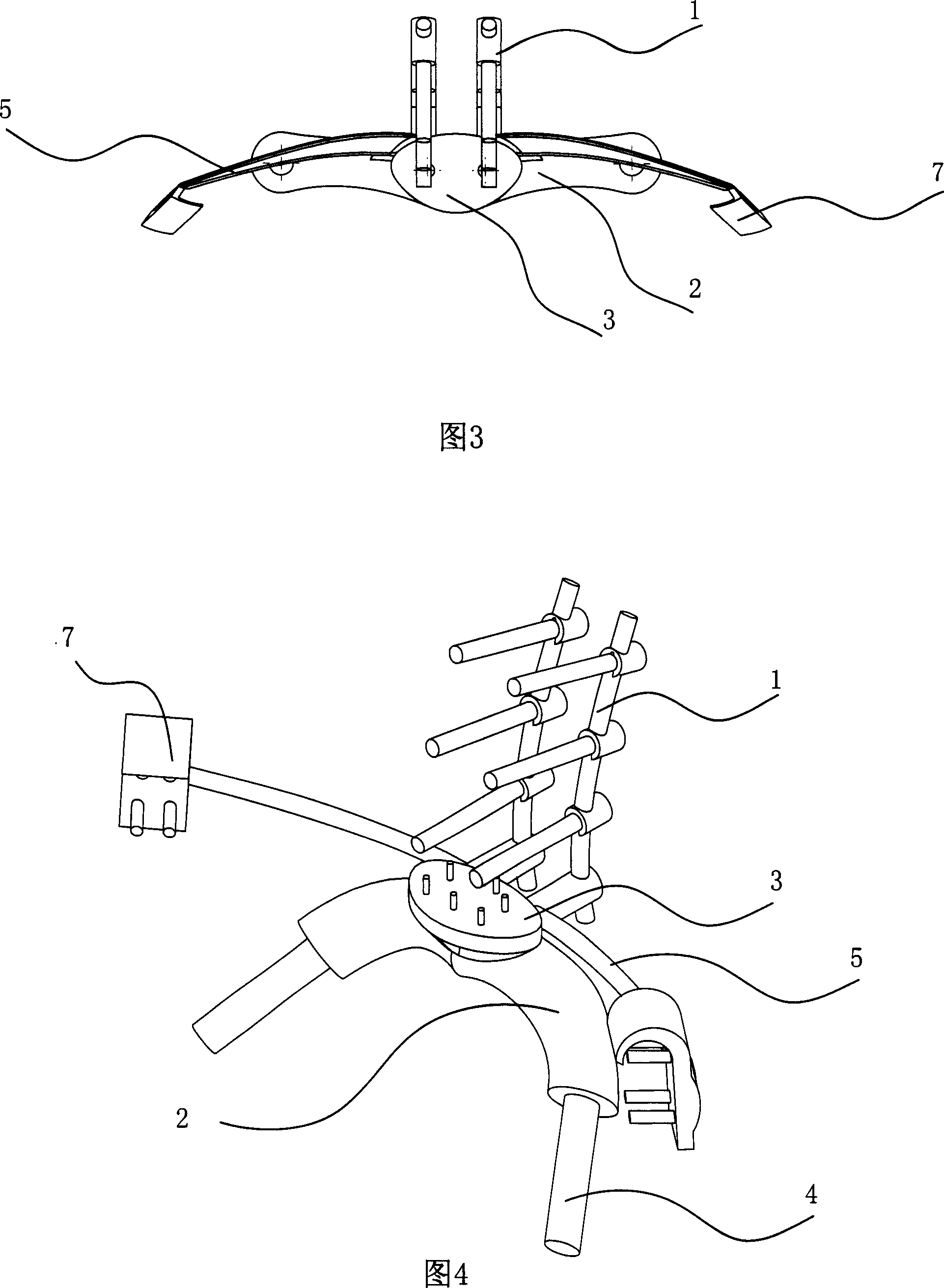

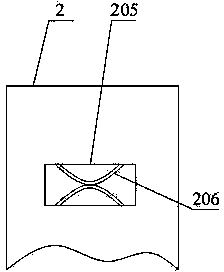

Glenoid component with an anatomically optimized keel

ActiveUS20070244564A1Improve stabilityHigh strengthJoint implantsShoulder jointsKeelBase of the sacrum

A glenoid component for a shoulder prosthesis adapted to be mounted in a glenoid cavity of a shoulder. An elongated keel adapted to engage with the glenoid cavity is attached to the internal surface of the base. The keel extends along a longitudinal axis of the base. The keel includes various configurations of transverse members extending away from the longitudinal axis. The surgeon selects a glenoid component with a keel and transverse member configuration that is anatomically optimized for the patient. Glenoid components properly optimized provide mechanical strength and stability superior to prior art devices. The glenoid components disclosed herein are particularly well suited for use in an anatomical total shoulder prosthesis, but may are also suited to partial shoulder prostheses and reverse shoulder prostheses.

Owner:TORNIER SA SAINT ISMIER

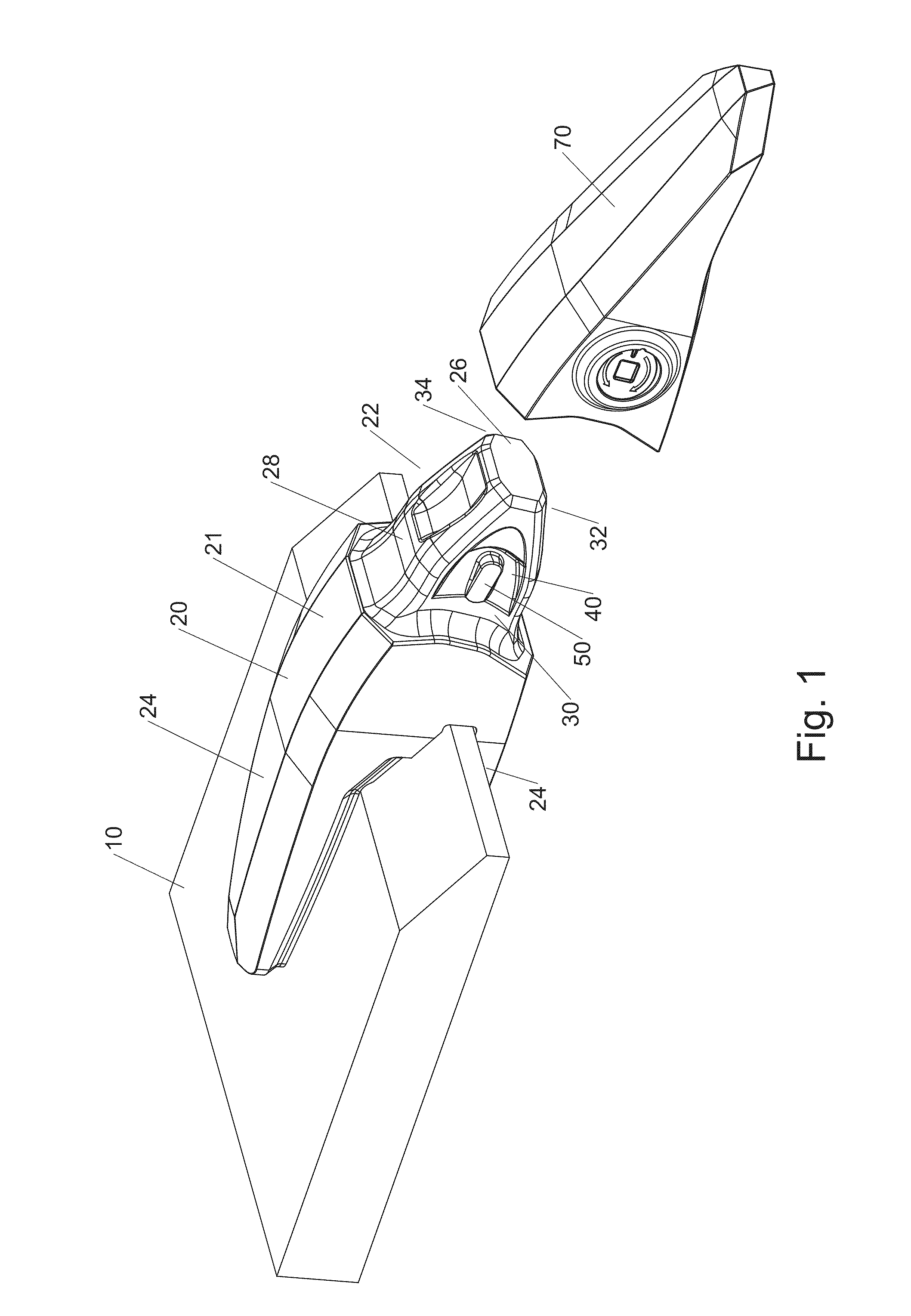

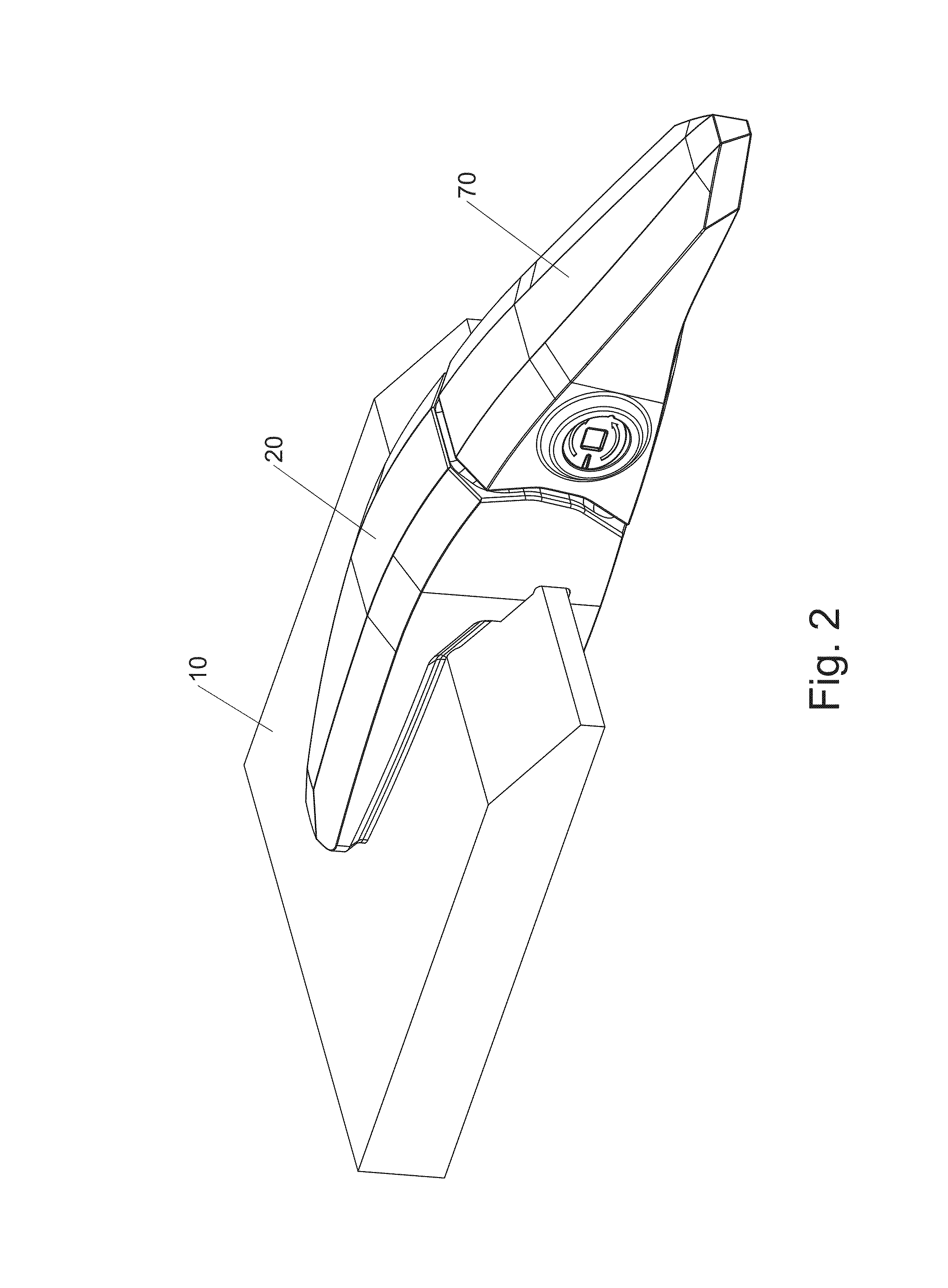

Anchor

An anchor for a wear assembly on an excavating bucket is disclosed. The excavator bucket lip has a base having a nose, and the wear assembly includes a wear member having a cavity in which the nose can be received, and an aperture extending between an outside surface of the wear member and the cavity, an internally toothed ring being located within the aperture; and a lock for releasably holding the wear member to the base. The lock includes an operable member and an externally toothed resilient ring, the resilient ring having a central aperture for engagement with the operable member. The operable member and resilient ring are jointly rotatable relative to the cavity and the internally toothed ring between a plurality of rotationally spaced locking positions where the lock secures the wear member to the base with varying tightness, and a release position rotationally spaced from the locking positions. The teeth of the internally toothed ring and the teeth of the resilient ring engage each other in each of the locking positions to reduce the loosening of the lock during use.

Owner:TALON ENG

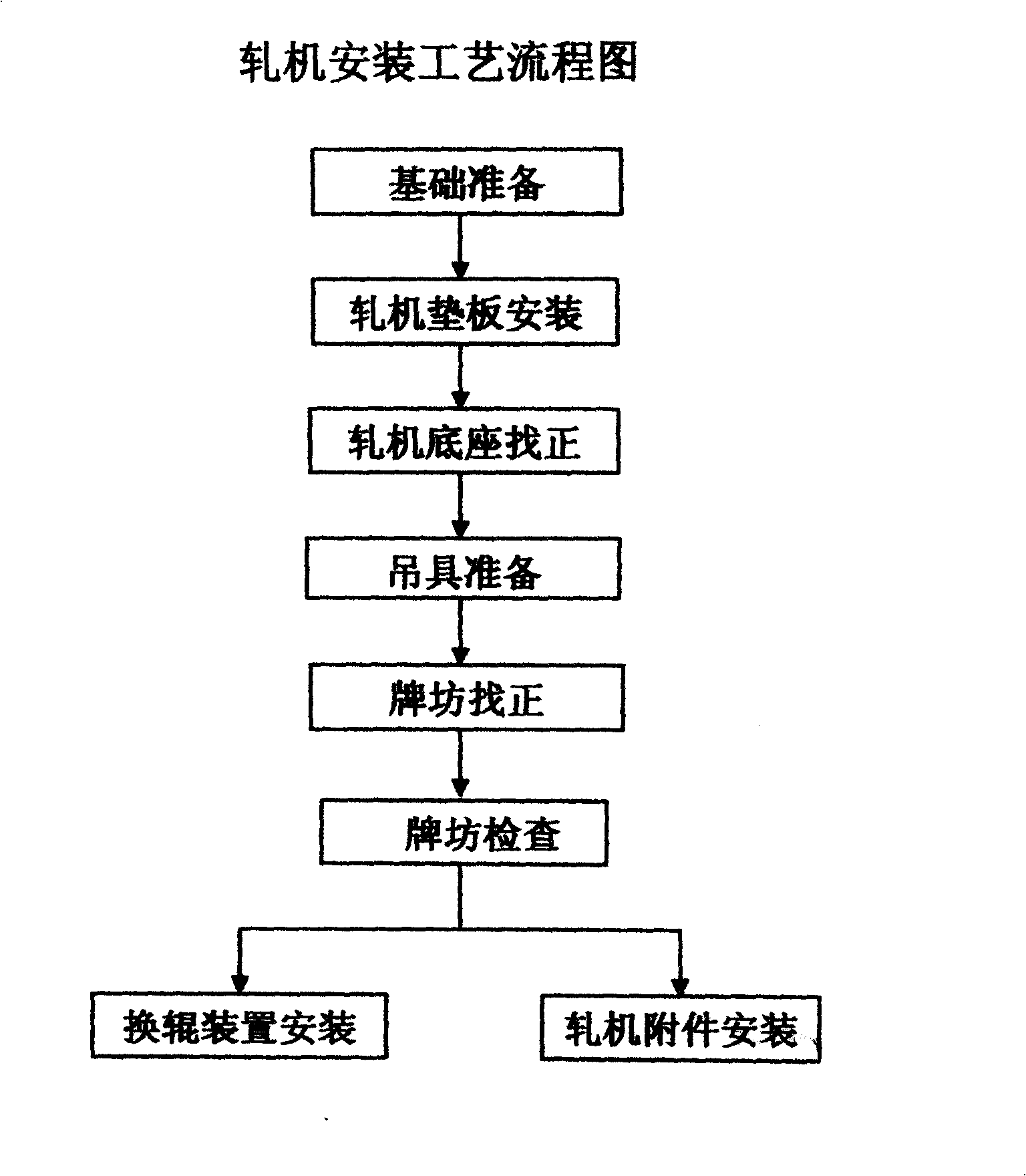

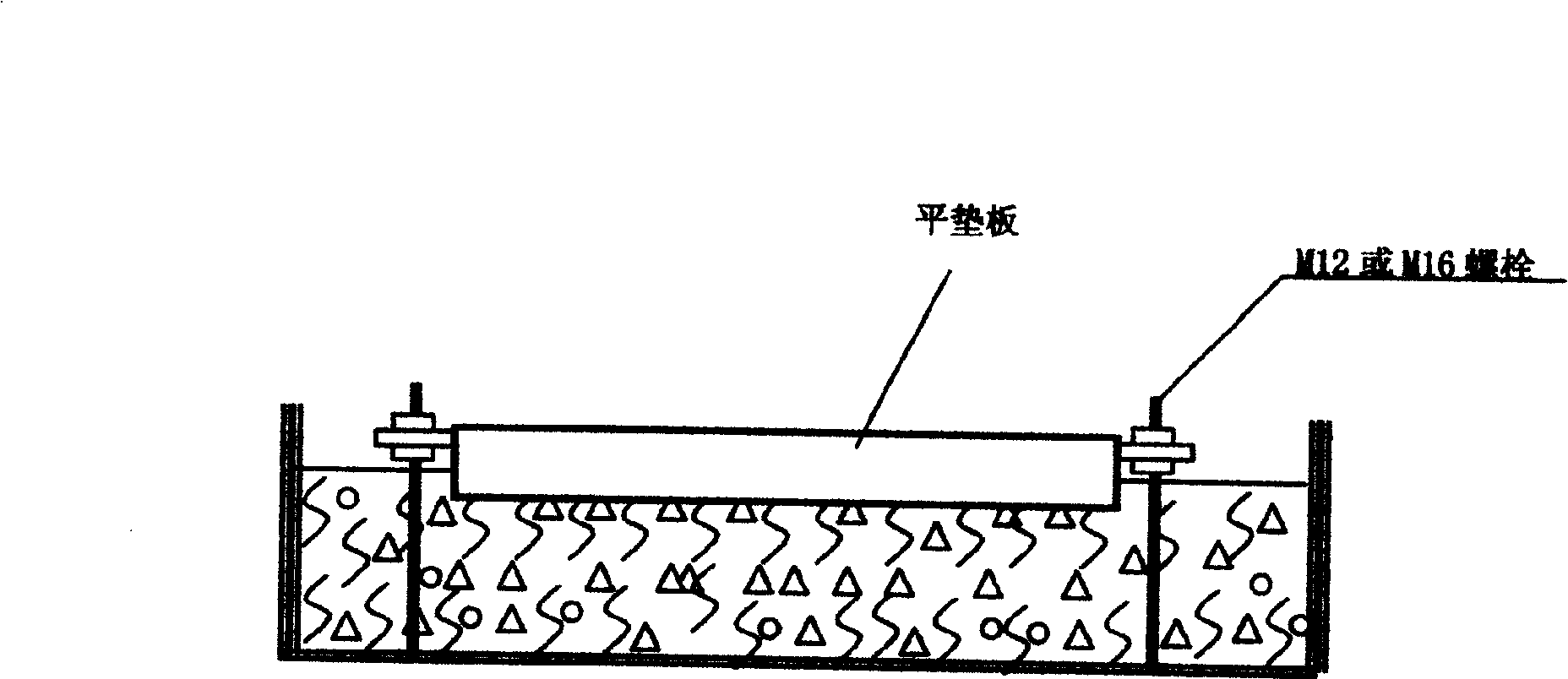

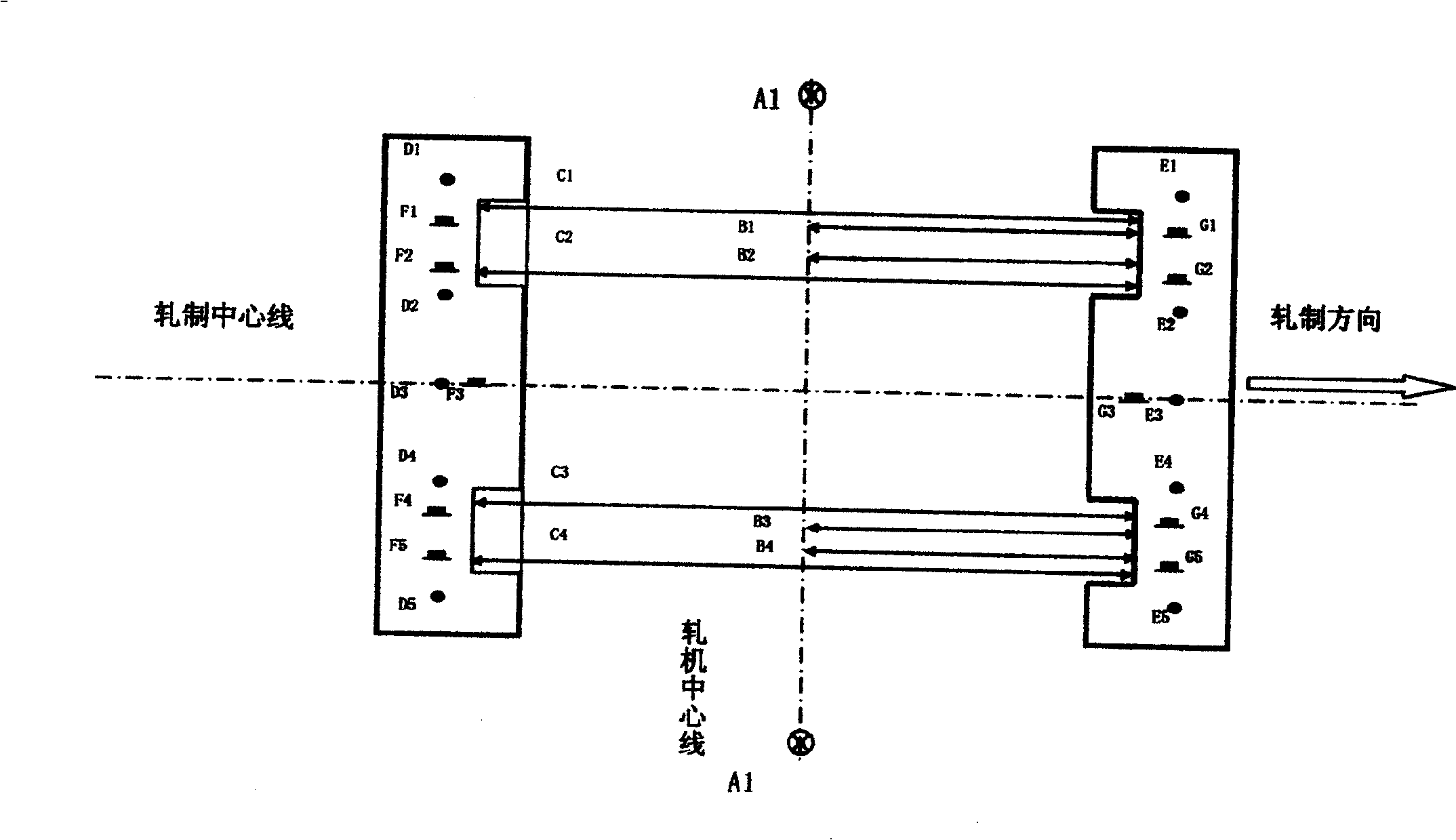

Method for mounting large-sized rolling mills

InactiveCN101275400AReduce loosenessAvoid damageFoundation engineeringBuilding material handlingStrip millMechanical equipment

The invention relates to an installation of metallurgy industry rolling mills, pinch pass mill, burnishing machines and the like large-scale mechanical equipment, especially to an installation method of a large-scale rolling mill, which is characterized in that the installation of a large-scale rolling mill is realized by the process steps of base preparation, rolling mills bearing plate installation, rolling mills motherboard transverse alignment, sling preparation, memorial archway transverse alignment, memorial archway check-up, roll-changer installation and rolling mill accessory installation. The invention satisfies all requirement of different construction sites, effectively resolves hanging difficult problem, saves work efficiency about 6-7 times, ensures installation quality, uses hydraulic bolt stretchers to avoid bolt up force moment from macrolesion bolt, and adopts small fastening force moment to allow rolling mills subbase to become flexible. Work difference bands are used to control the roll changing transmission device central line and the rolling mill central line to ensure installation quality. According to combination of calculation and on-site practicality, the invention not only can be used for rolling mills installation, but also can spread in mechanical equipment installation with common advising signification.

Owner:ANGANG CONSTR CONSORTIUM

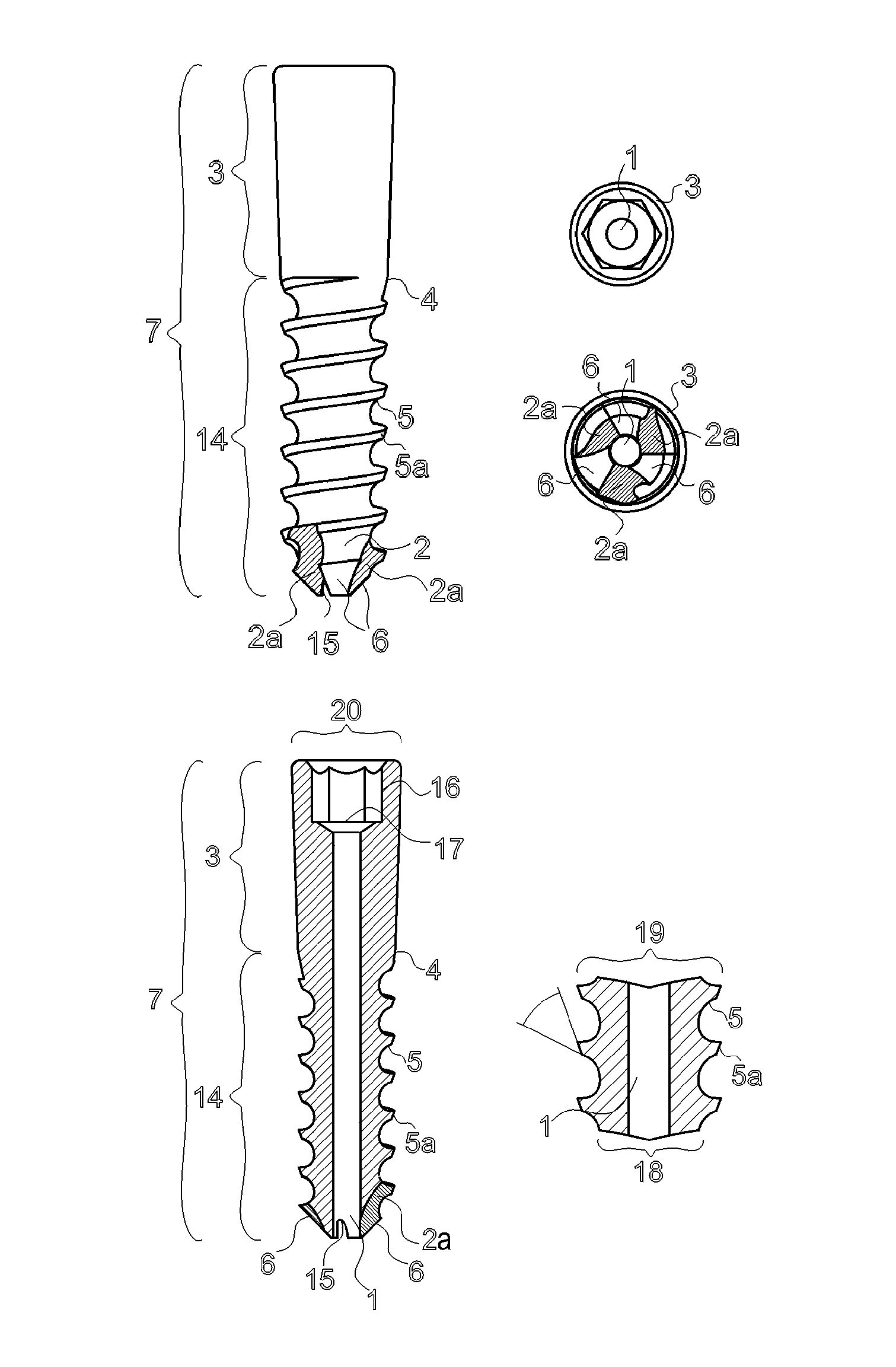

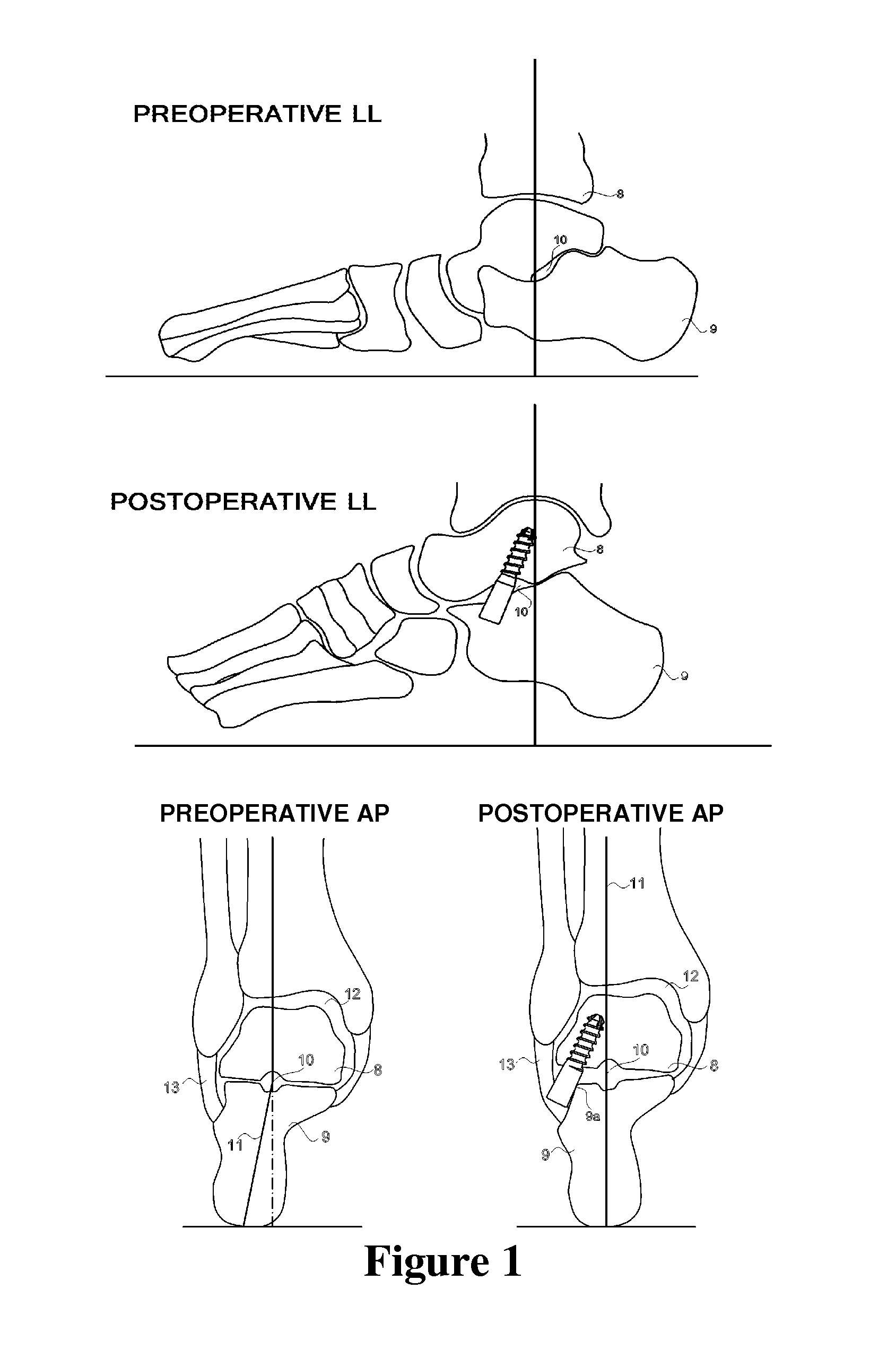

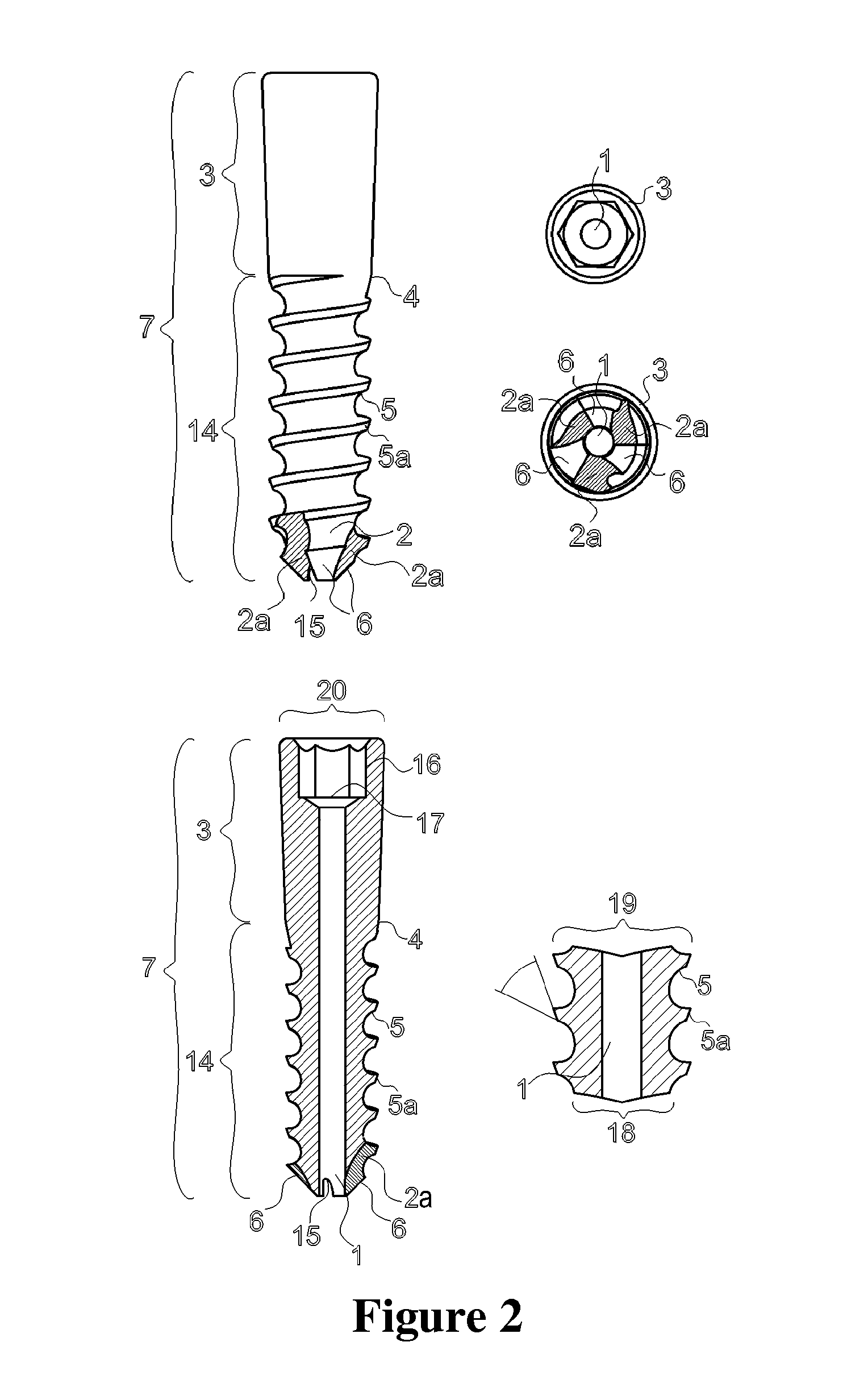

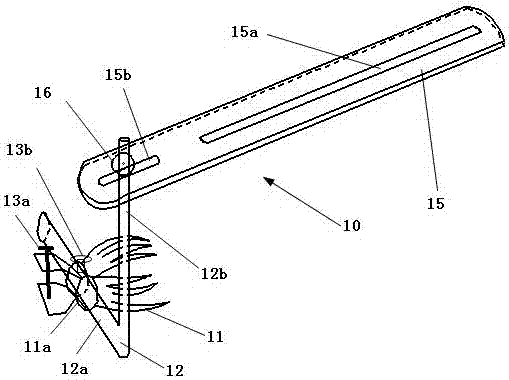

Canulated titanium implant for correcting flat feet in children

InactiveUS8267977B2Easier correctly placedHarming the surrounding tissueSuture equipmentsAnkle jointsMedicineTitanium

The cannulated titanium implant (screw) for correction of flat feet in children characterized by that: a) the diameter of the stem is D=4.8 mm±25%, recommended 4.8 mm±10%, and especially recommended 4.8 mm, b) it is cannulated, whose diameter is C=2 mm+25%, recommended 2 mm±10%, and especially recommended 2 mm, c) the screw-thread height is 1.15 mm±25%, recommended 1 / 15 mm±10%, and especially recommended 1.15 mm, d) on the point of the screw, which ends at the angle of 90°, on the apex thread are trisect cuts at the angle of 120°. The edges of the apex thread are cut at the angle of 55°. At the very top of the point of the screw, the trisect cuts of the apex thread go inward the tunnel in the length of the screw by 1.5 mm, e) this type of the point replaces the use of the drill and the tapping device.

Owner:ROTH SANDOR UMLAUT OVER

Glenoid component with an anatomically optimized keel

Owner:TORNIER SA SAINT ISMIER

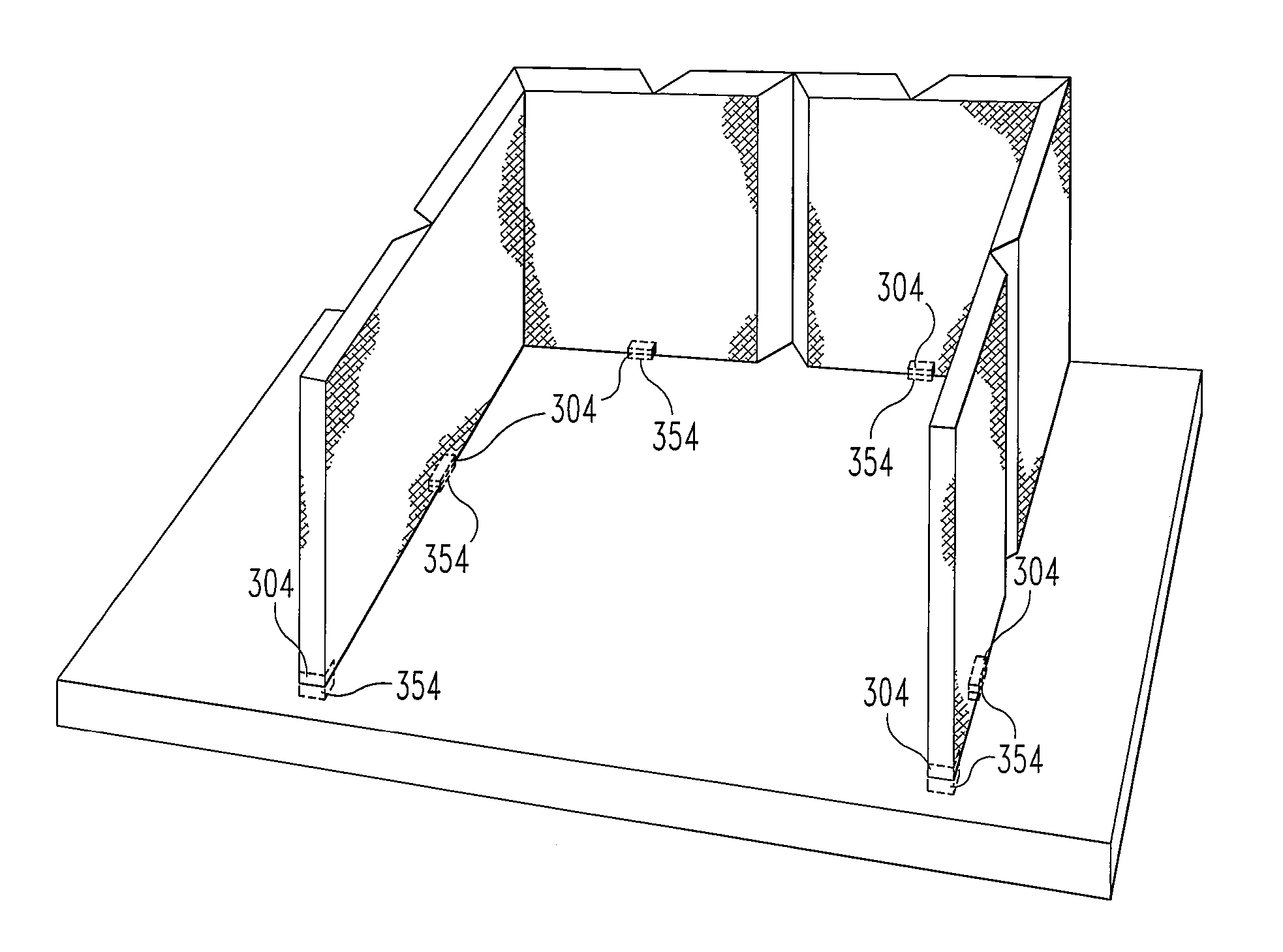

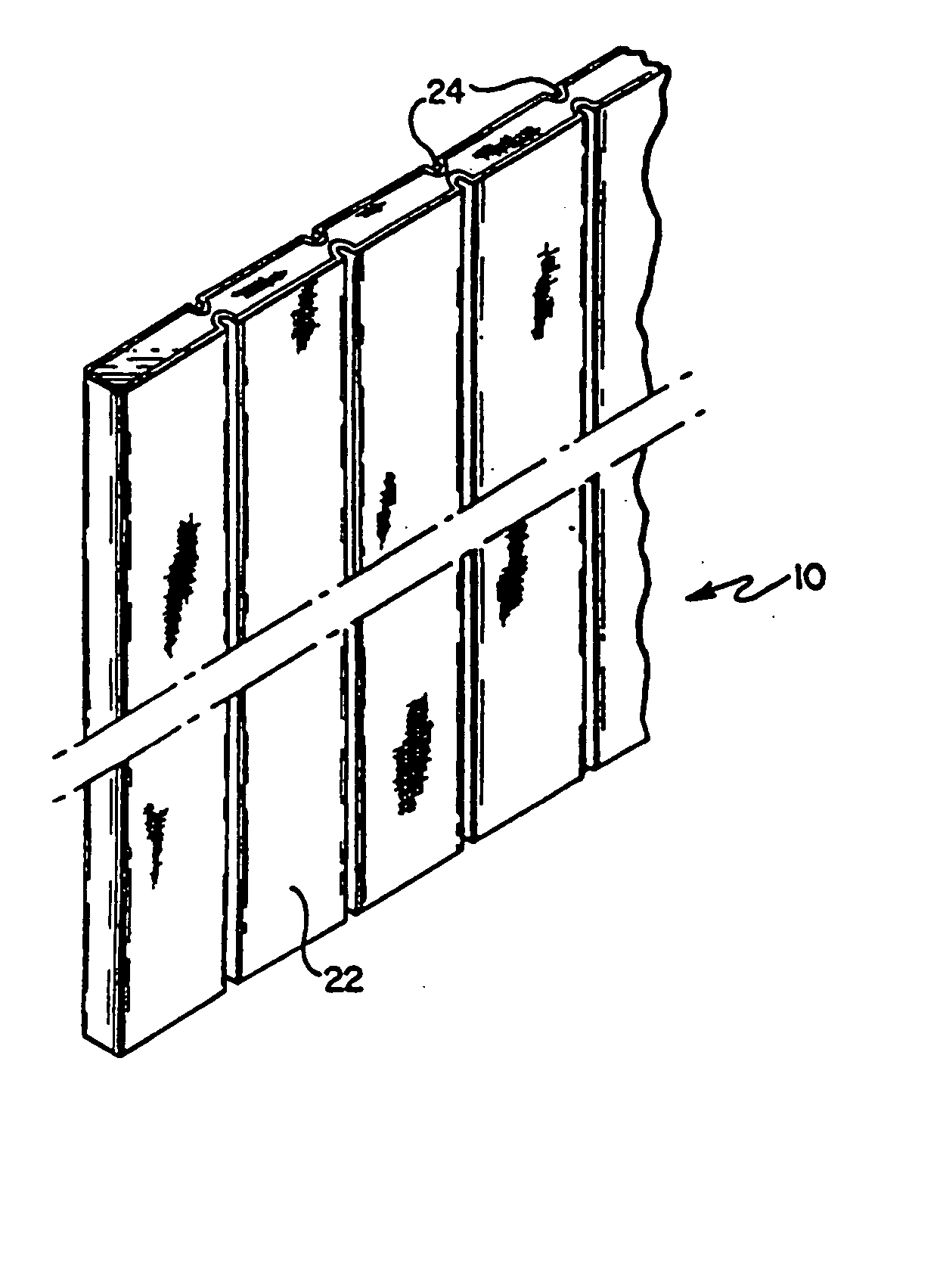

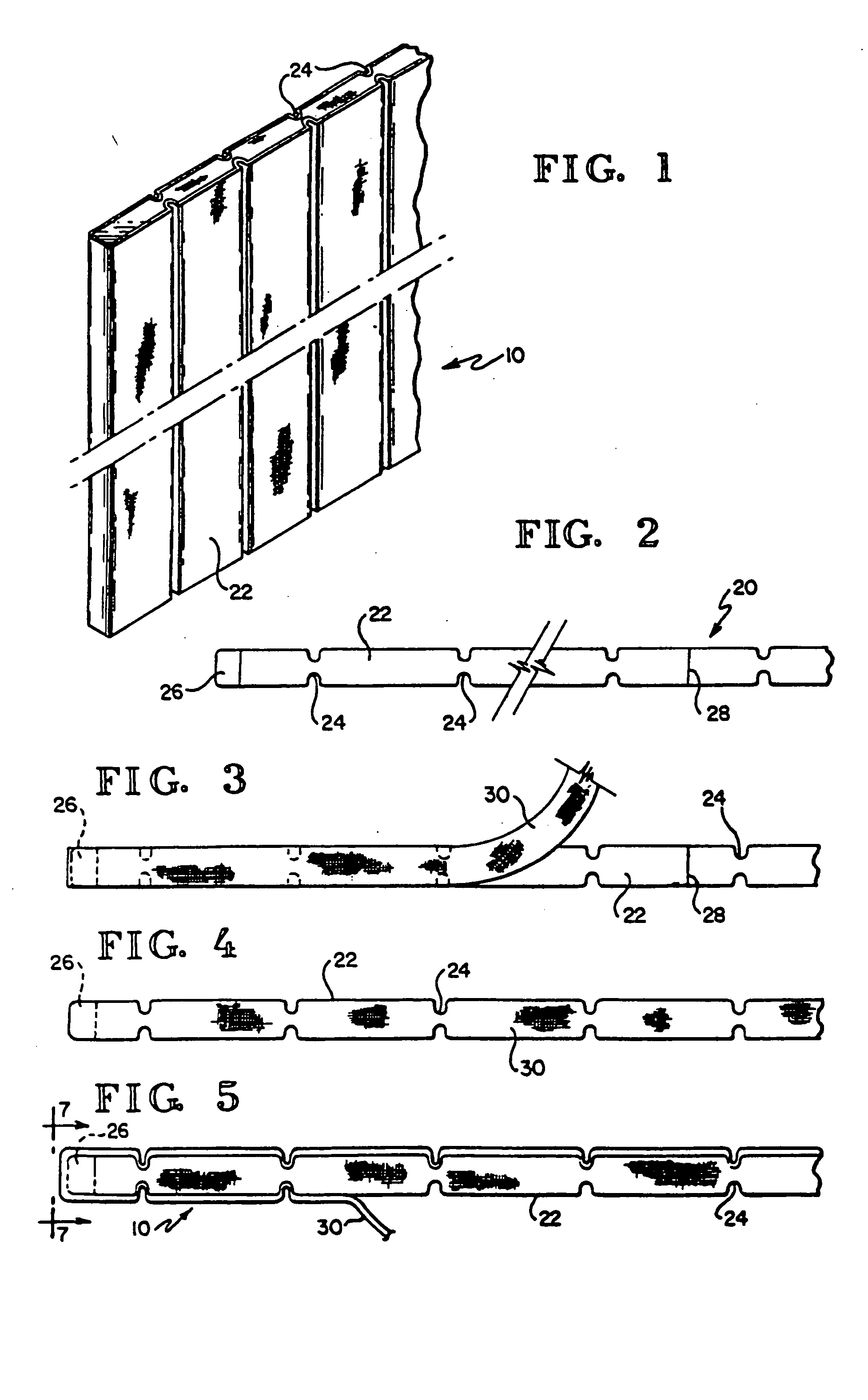

Sight and sound barrier

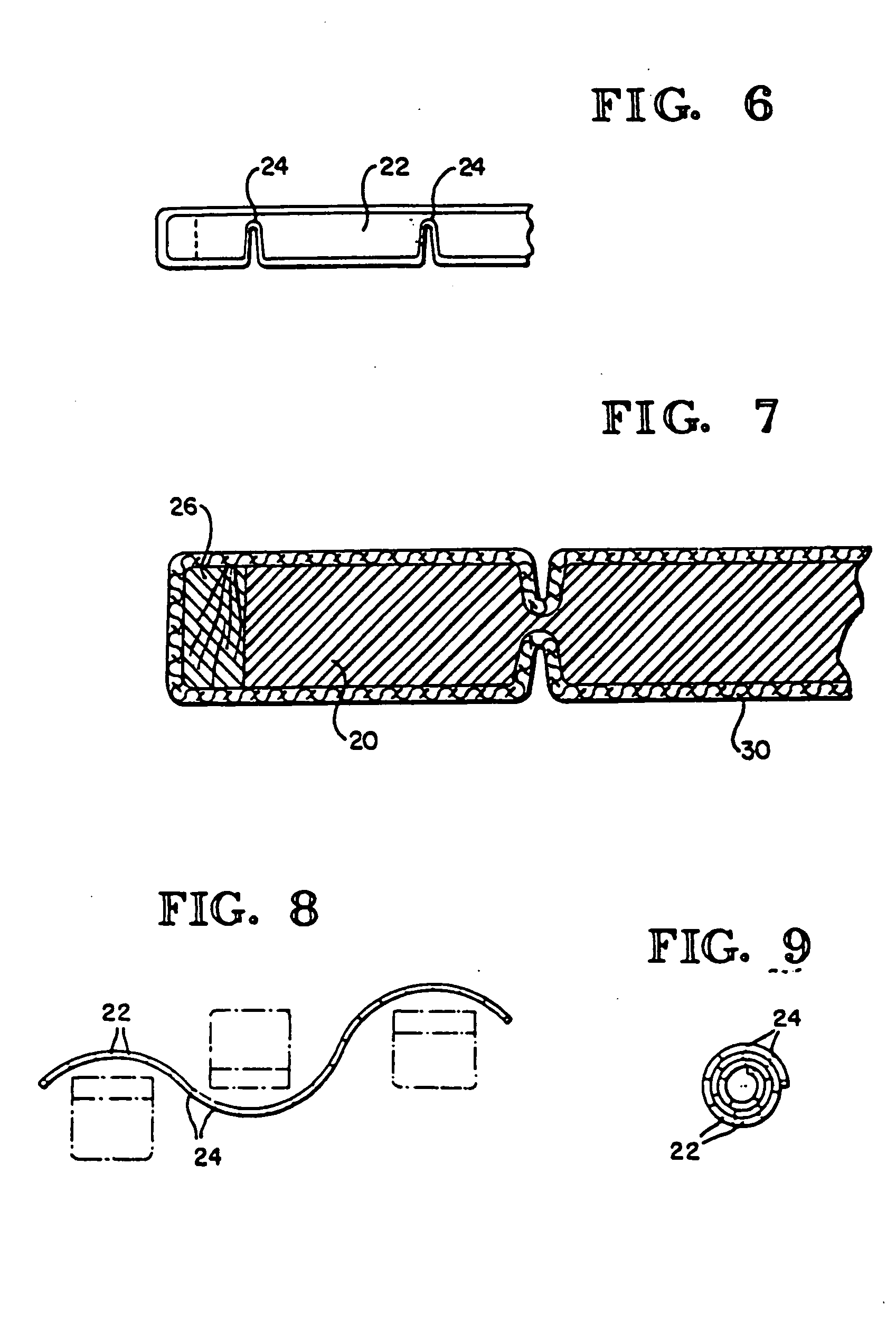

ActiveUS7690158B2Room for improvementImprove acoustic propertiesBuilding roofsWallsSound barrierPolystyrene

Owner:CHILDRENS FACTORY LLC

Glenoid augment and associated method

ActiveUS20110144758A1Reduce loosenessEliminate shear forceJoint implantsShoulder jointsButtressSacroiliac joint

A augmented glenoid implant assembly for use in performing shoulder arthroplasty is provided. The augmented glenoid implant assembly is used for cooperation with the glenoid fossa of a scapula. The implant assembly includes a first component for attachment to the scapula. The first component defines a support surface for cooperation with the glenoid fossa, a second surface positioned adjacent a buttress formed in the glenoid fossa and an assembly surface. The implant assembly also includes a second component removably secured to the first component. The second component includes an assembly face of the second component. The assembly surface of the second component is in close approximation to the assembly surface of the first component. The second component further includes an articulating surface opposed to the assembly surface.

Owner:DEPUY SYNTHES PROD INC

Quick pipeline connecting method and joint using same

The invention discloses a quick pipeline connecting method and a joint using the same. The joint comprises a joint body, wherein a clamping ring, a conical base and an O-shaped sealing ring are sequentially arranged inside the joint body along the pipeline insertion direction; when the pipeline is inserted into the joint, a flange arranged on the clamping ring is deflected; and when the pipeline expands under increased pressure after the introduction of a liquid, the O-shaped sealing ring expands axially under the action of pressure, and the clamping ring is driven to move along a direction opposite to the pipeline insertion direction by pushing the conical base to clamp the pipeline. The invention also discloses a quick pipeline joint adopting the quick connecting method. The joint has the advantages of capabilities of making an elastic pipe body (such as a PEX pipe body) easier to insert and ensuring that the elastic pipe body does not loosen easily after being inserted and expanded due to increased pressure caused by the introduction of the liquid, high air tightness and connecting reliability.

Owner:LA CASA ANGELA HLDG

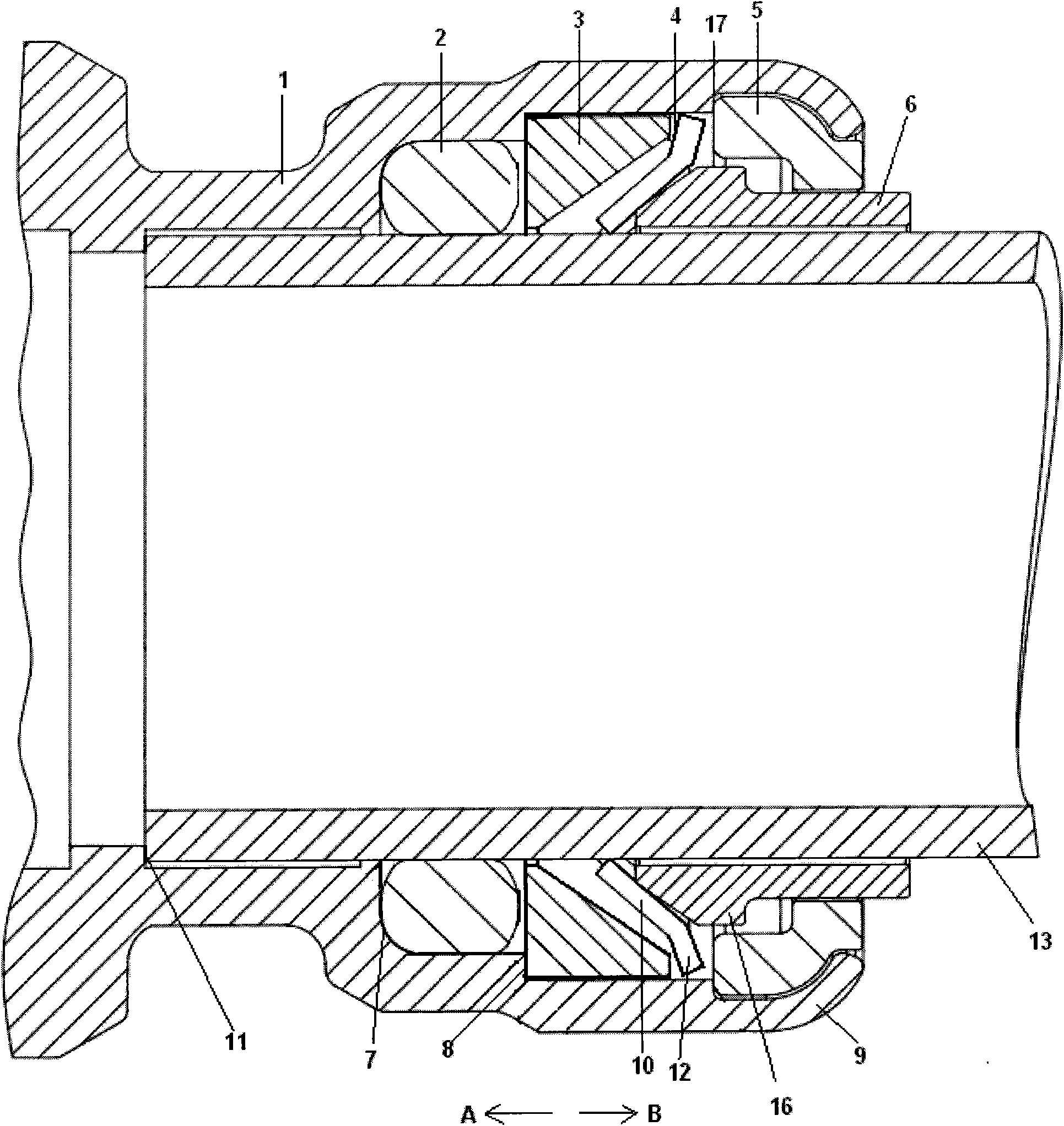

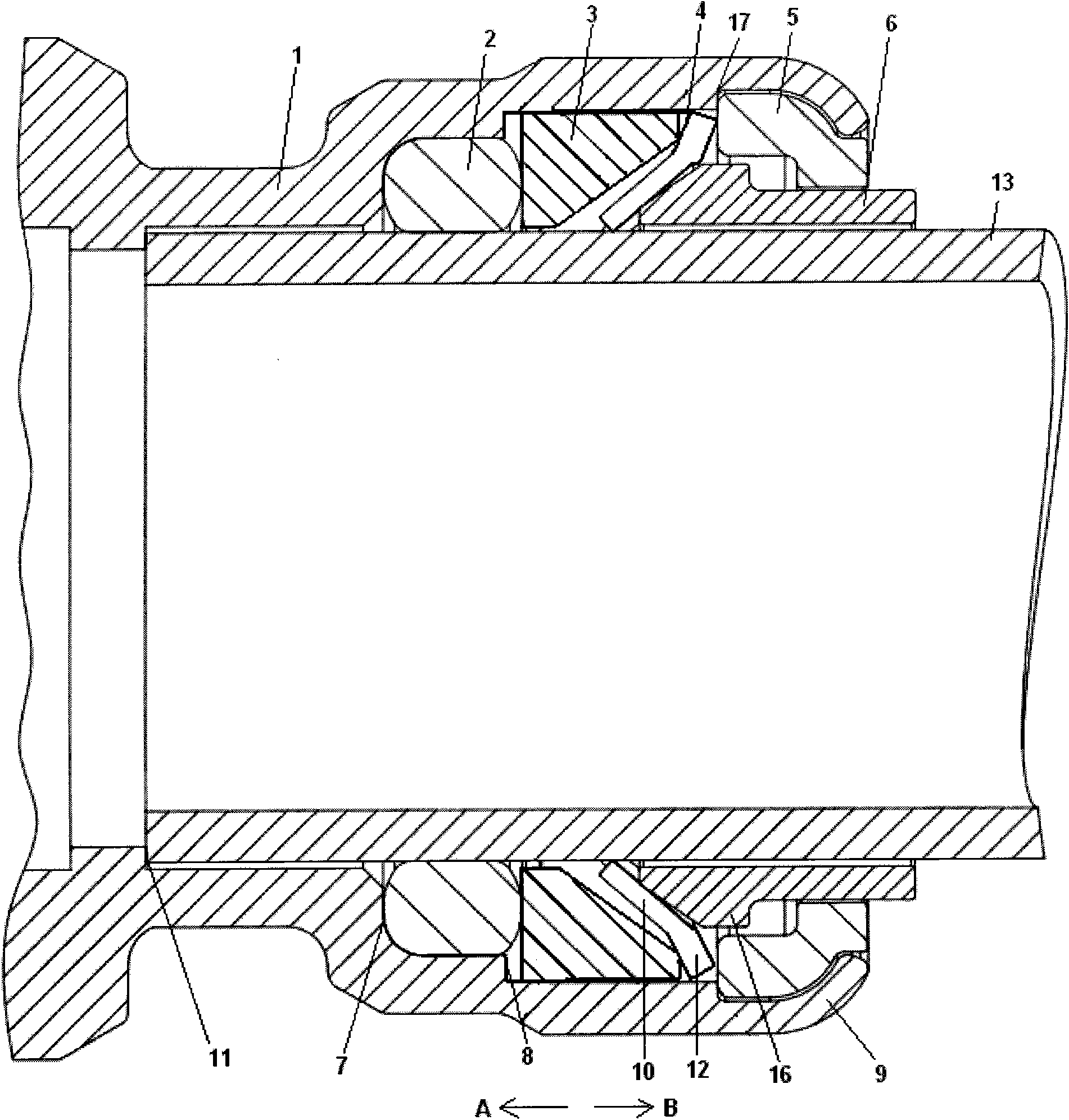

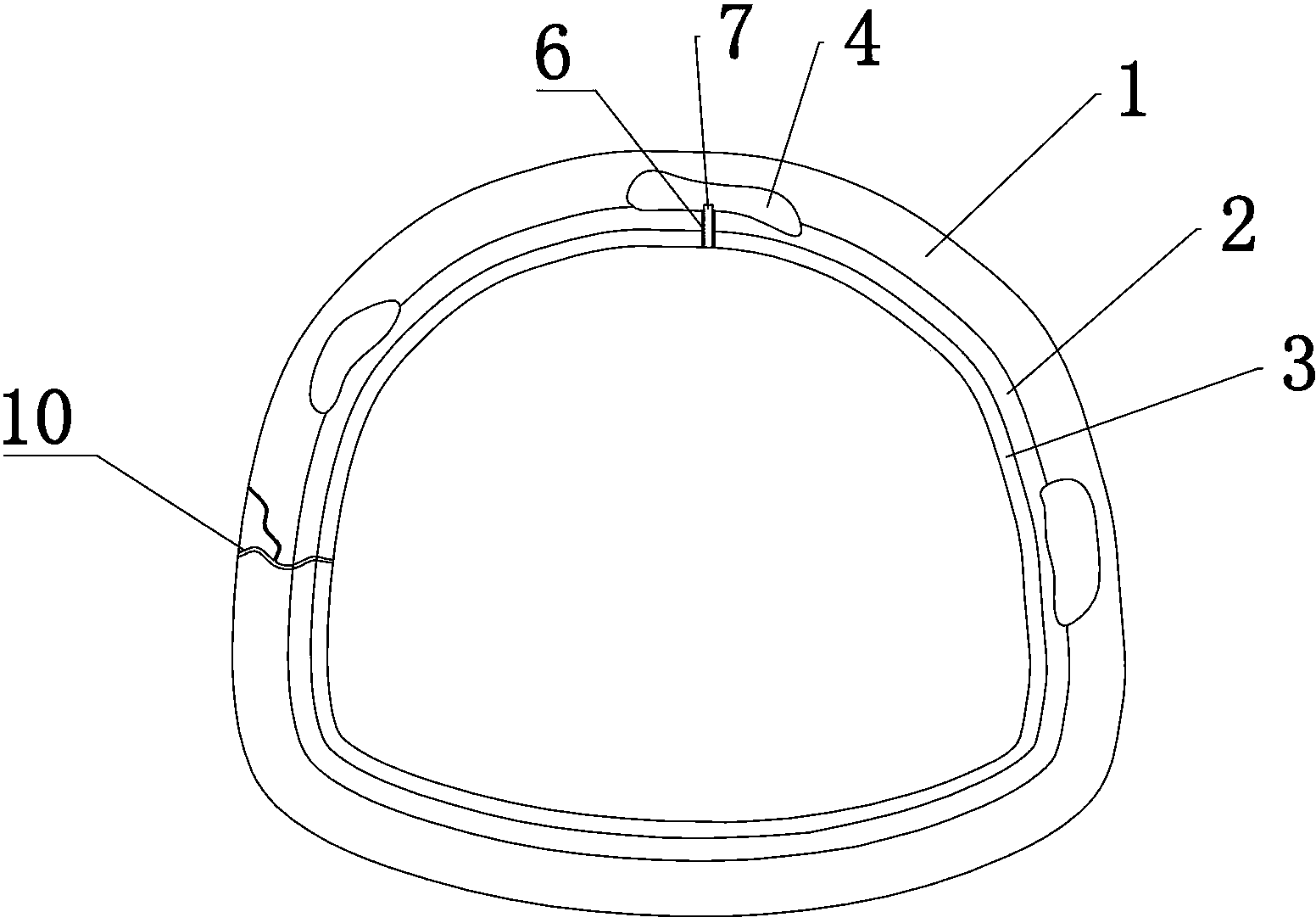

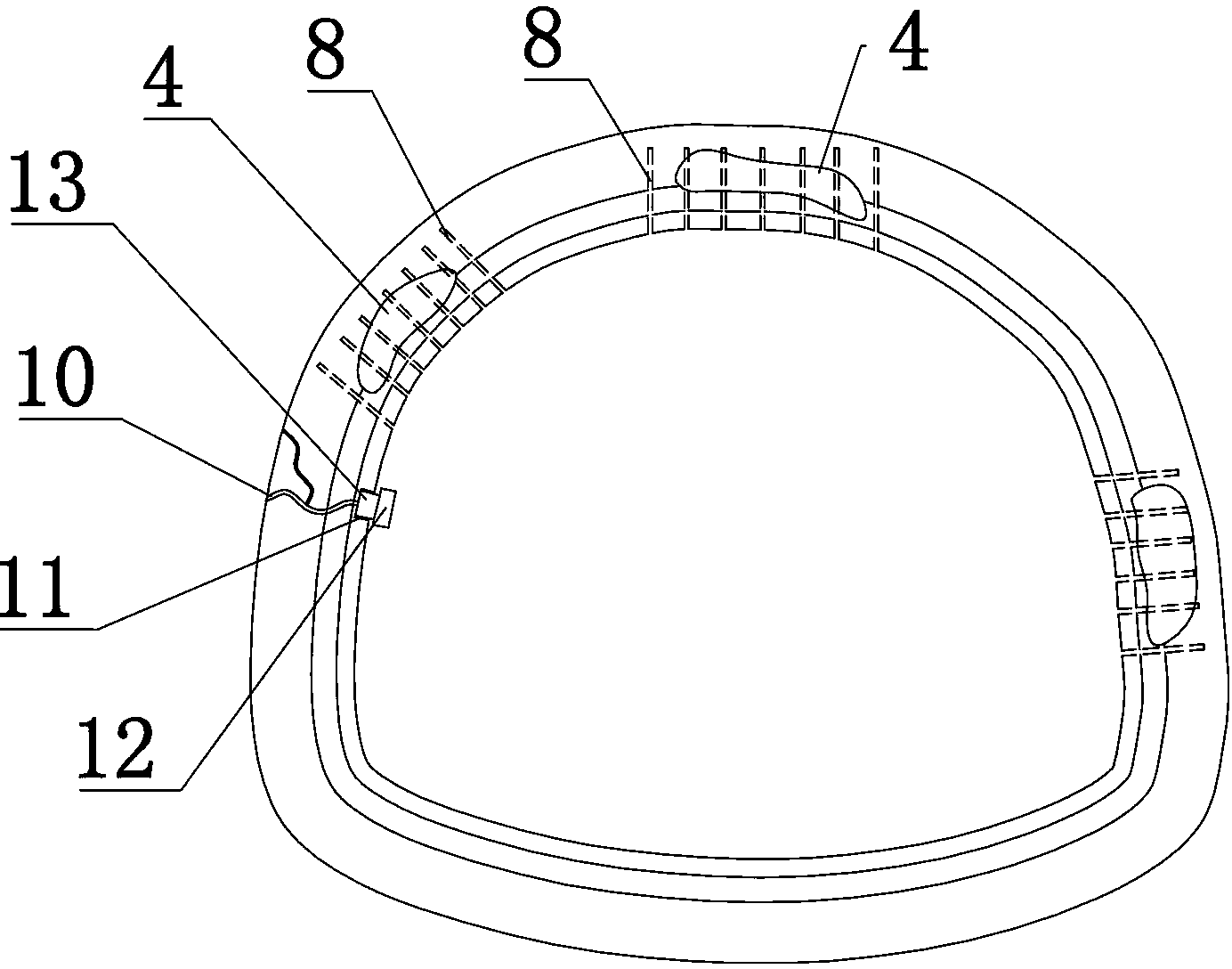

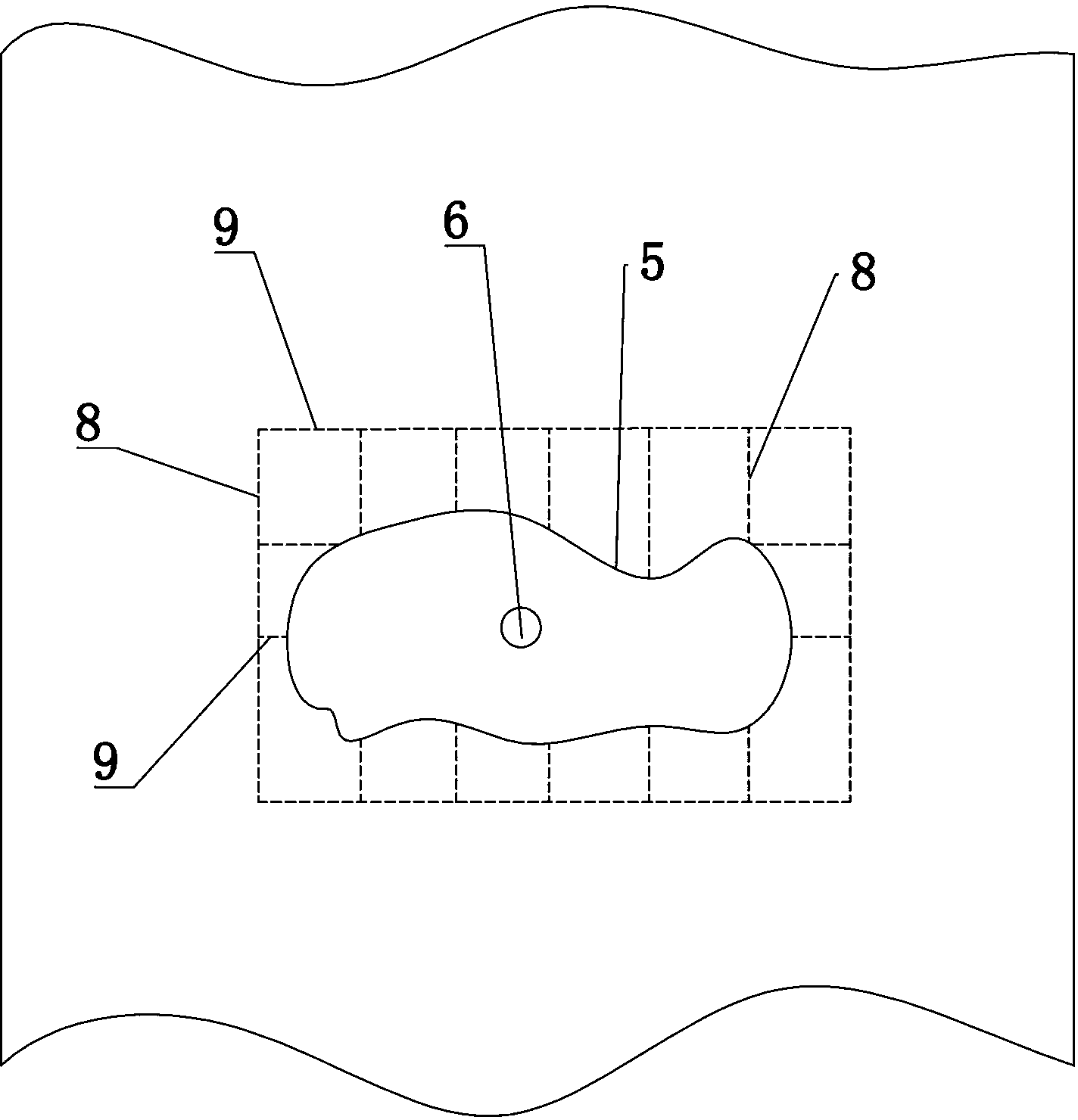

Method for solving disengagement and water seepage of internal arch of tunnel

ActiveCN104033164AReduce loosenessImprove stabilityUnderground chambersTunnel liningGroutWater seepage

The invention relates to a method for overcoming tunnel defects, in particular to a method for solving disengagement and water seepage of an internal arch of a tunnel. The method includes the steps that a detection radar is utilized for detecting the disengagement position and the position of a water seepage channel in a damaged tunnel, a grouting hole is obtained by drilling a hole in the surface of a lining of the disengagement position, a grouting pipe is installed in the grouting hole and extends into the disengagement position, a first grouting hole of which the diameter is greater than that of an outlet of the water seepage channel is obtained by drilling a hole in the outlet of the water seepage channel, and a first grouting pipe is arranged in the first grouting hole in a sealed and matched mode; grout is injected into the grouting hole and the first grouting hole, the grout filling situation inside the disengagement position and the water seepage channel is detected in real time through the detection radar, and grouting is stopped when the disengagement position and the water seepage channel are filled with the grout; after the grout is solidified and reaches the final strength, multiple longitudinal slots and multiple transverse slots which extend from the outline to the periphery are formed in the surface of the lining; all the slots are filled with grout, the grout is solidified; the disengagement position and the adjacent portions surrounding the disengagement position are fixed and strengthened, and water accumulated in the water seepage channel is drained.

Owner:JIANGSU DINGTAI ENG MATERIAL

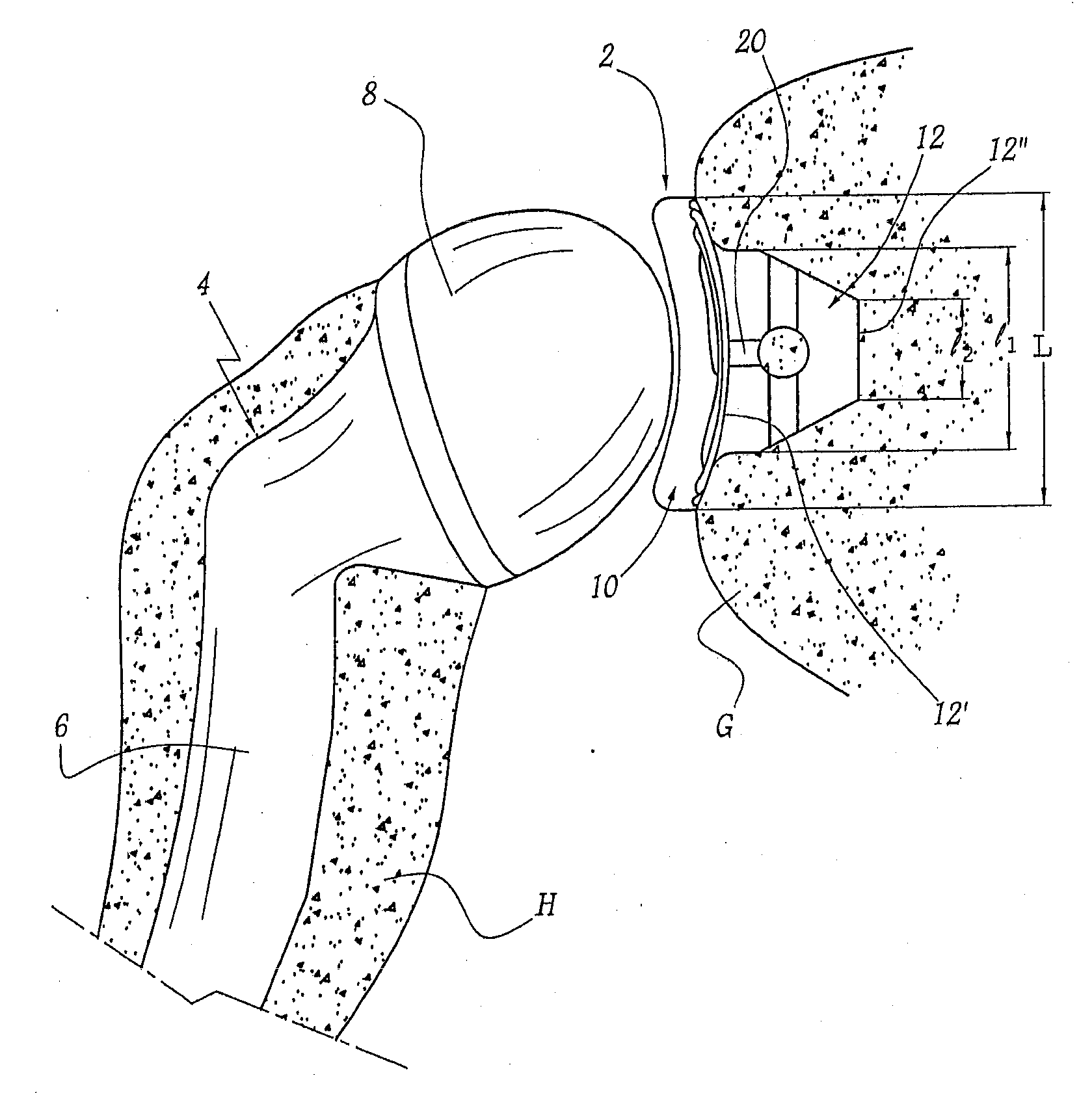

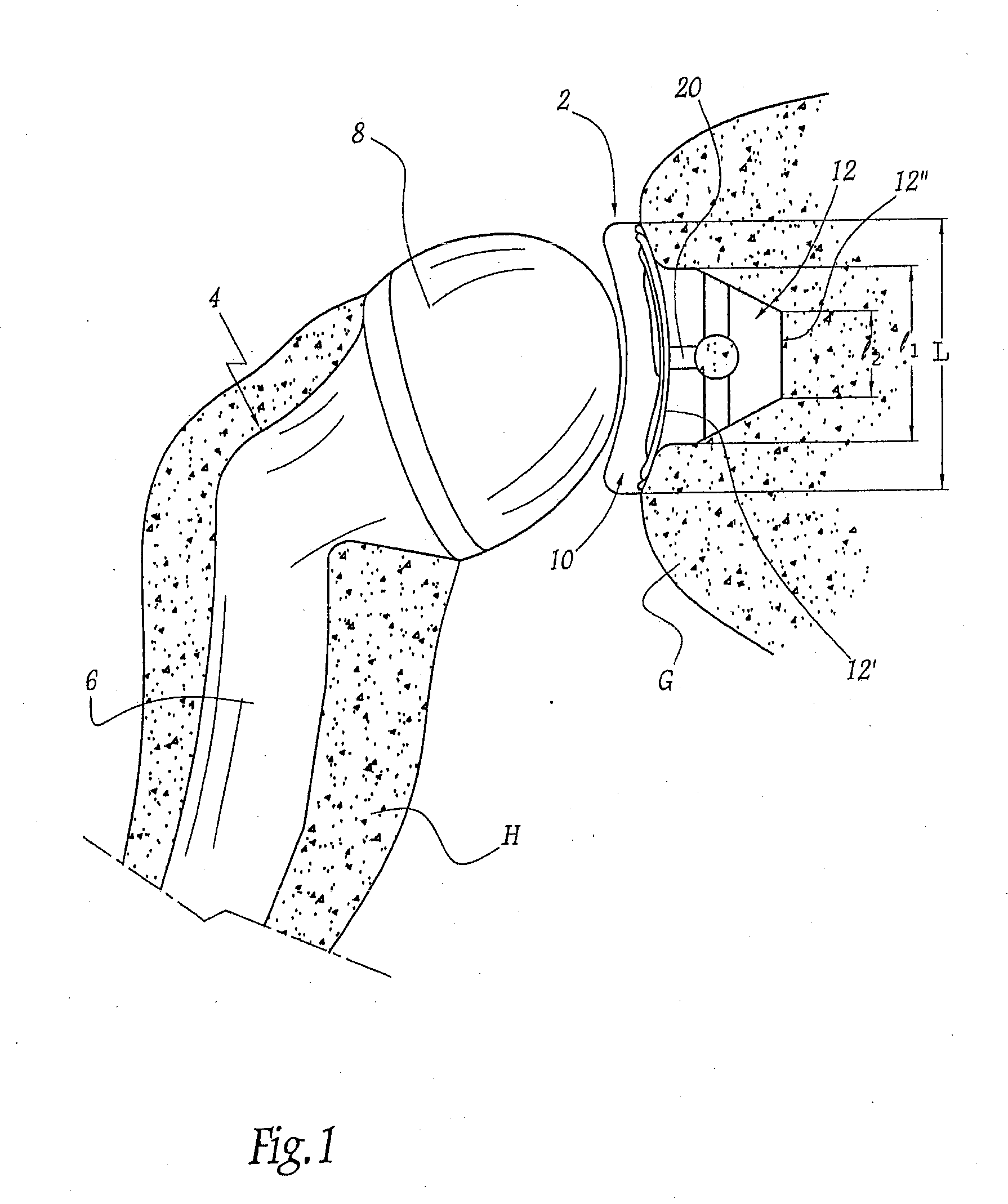

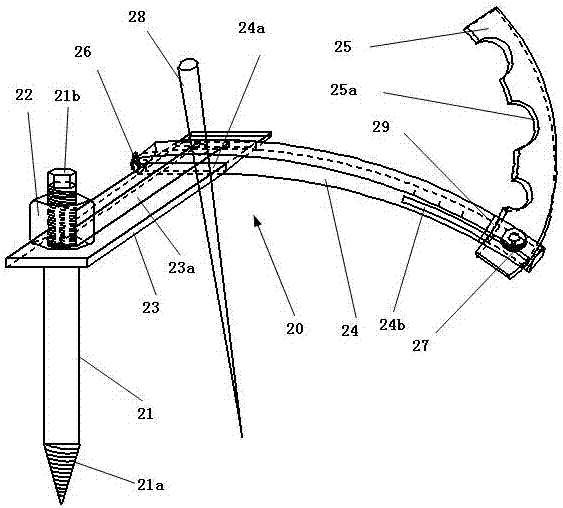

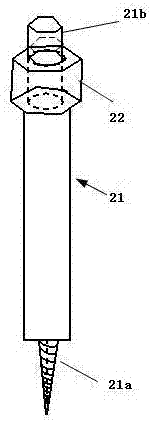

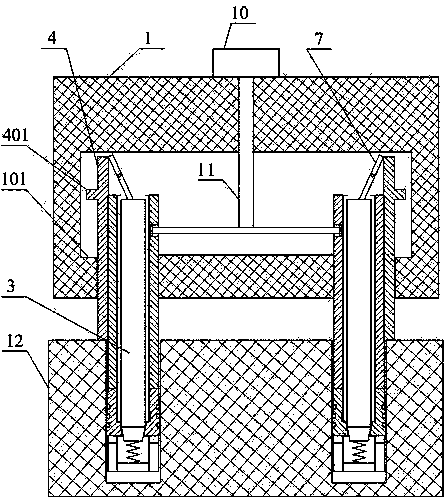

Complete locating device for total hip arthroplsty

PendingCN107149490AReduce the chance and degree of loosening or saggingGuaranteed stabilitySurgical sawsBone drill guidesMedullary cavityCalcar

The invention discloses a complete set of positioning device for artificial total hip joint replacement, which belongs to the field of medical equipment. The positioning device is conducive to the accurate osteotomy of the femoral neck with the oscillating saw, the accurate positioning of the use direction of the acetabular file, the square head bone knife, and the medullary cavity file, and the insertion of the femoral prosthesis into the femoral marrow at the original position and original angle. The cavity is beneficial to preserve the femoral calcar and the length of the femoral neck, which is conducive to the correct placement of the acetabular cup, shortens the operation time, reduces intraoperative bleeding, improves the success rate of the operation, relieves joint pain, corrects deformity, restores and improves joint movement Function.

Owner:汤向阳

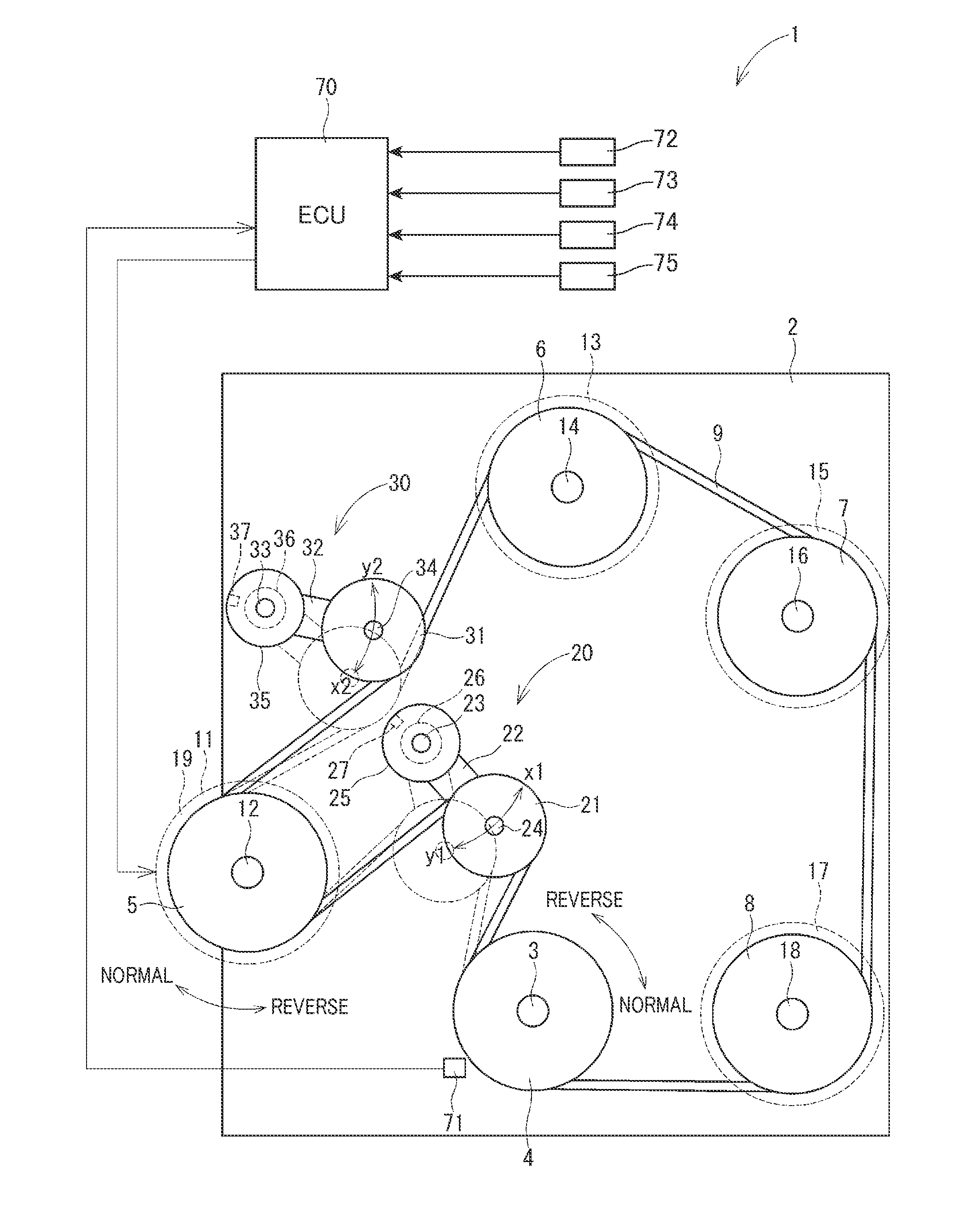

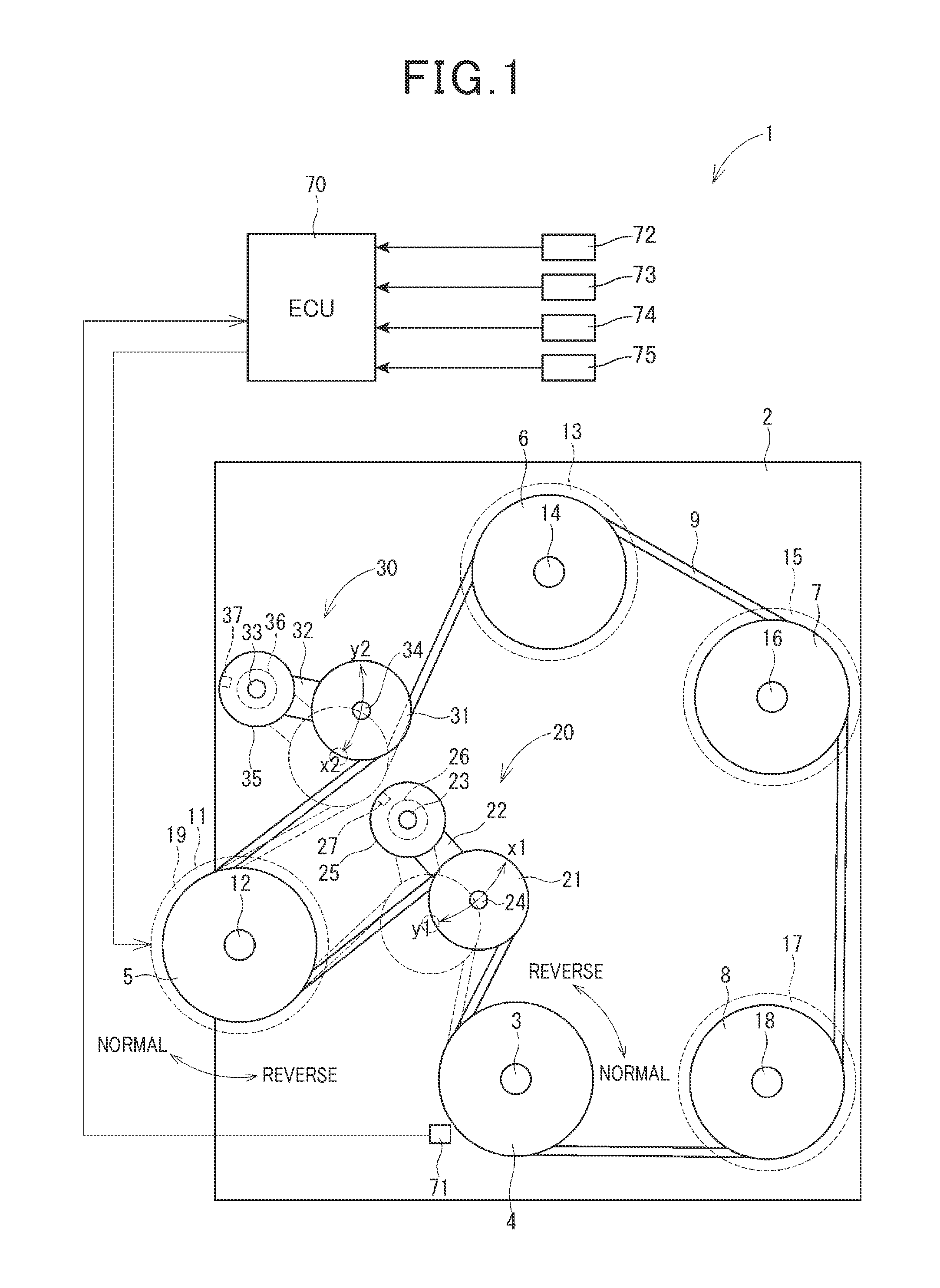

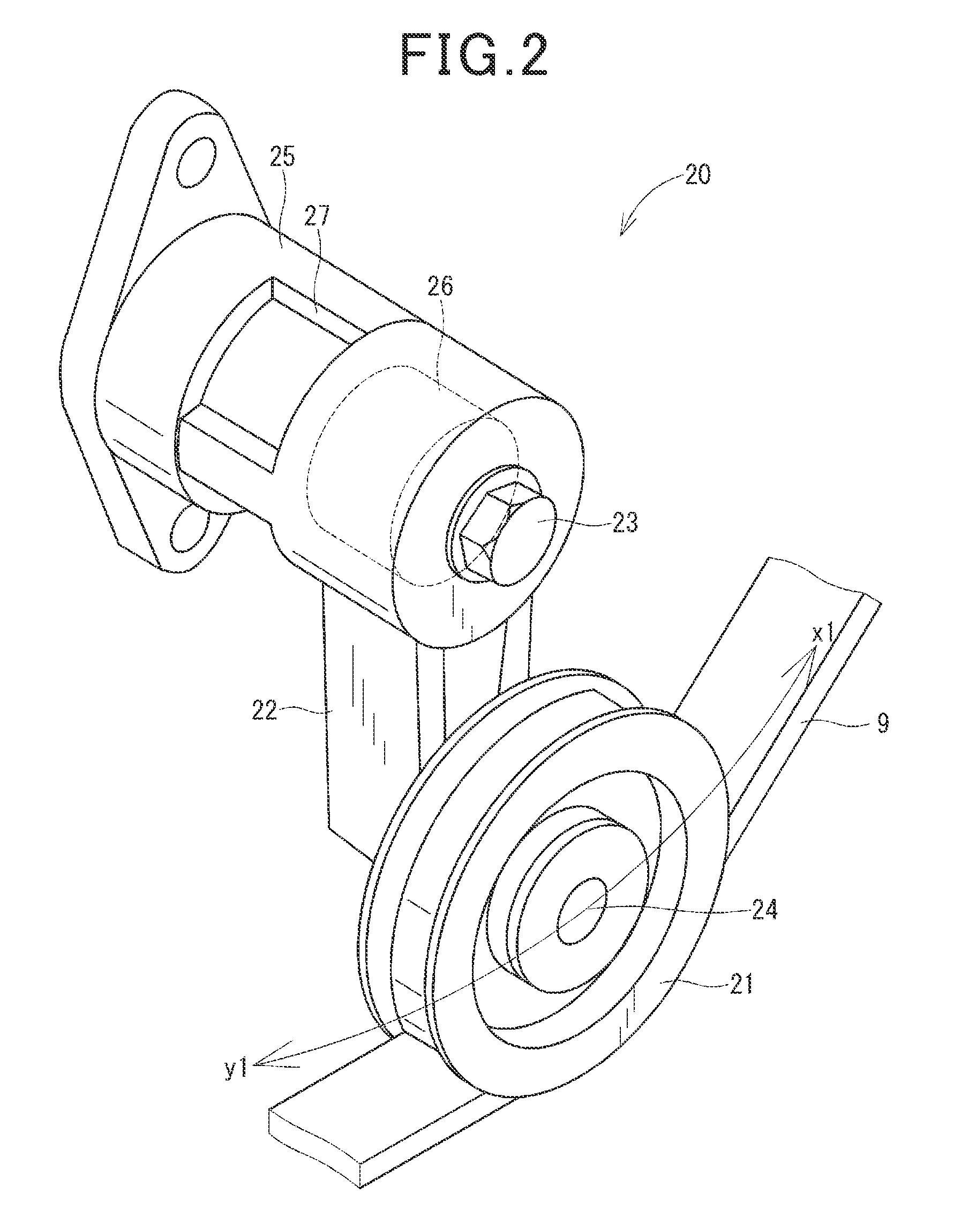

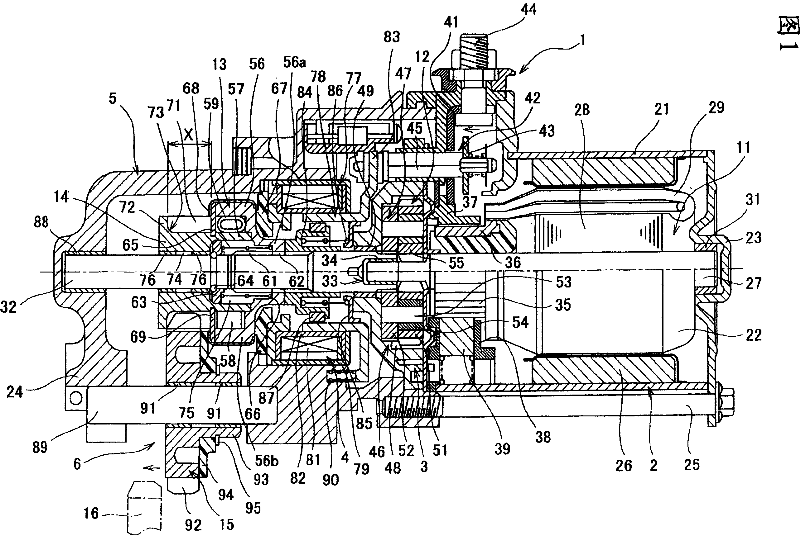

Structure of power transmission apparatus

ActiveUS20150167797A1Simple structureMinimize timeHybrid vehiclesPower operated startersTransmitted powerDrivetrain

A power transmission system transmits power from an internal combustion engine to a first and a second auxiliary device through an endless transmitting member. Prior to issuing of an engine start request, the first auxiliary device is actuated to move a tensioner pulley to a given position to increase the degree of tension of the endless transmitting member. The actuation of the first auxiliary device as an engine starter upon the issuing of the engine start request, therefore, enables a drive shaft of the engine to be rotated immediately within a required time to crank the engine. This achieves a quick start of the engine and results in a decrease in amount of time between the issuing of the engine start request and the actual start of the engine.

Owner:DENSO CORP

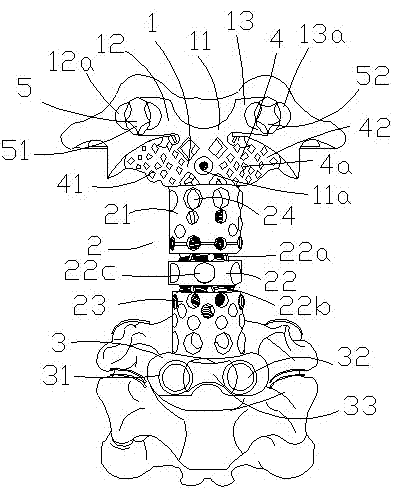

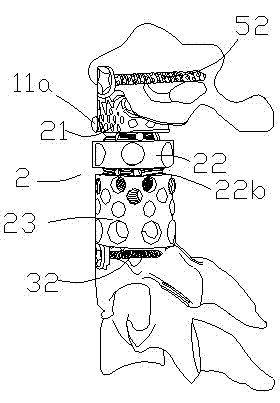

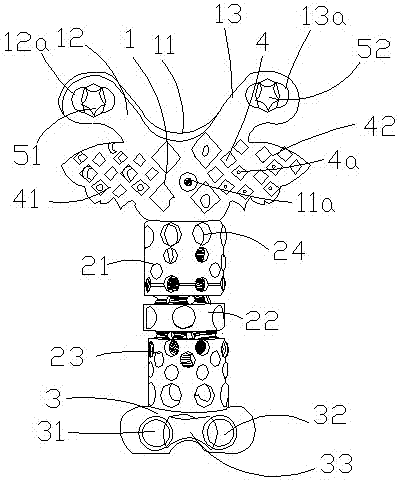

Second cervical vertebra displacer with merging structure

InactiveCN102860864AImprove stabilityReduce loosenessInternal osteosythesisSpinal implantsSpinal cageGynecology

The invention relates to a second cervical vertebra displacer with a merging structure. The second cervical vertebra displacer comprises an atlas connecting part, a fixed connector and a third cervical vertebra connecting part, wherein the atlas connecting part is fixedly connected with the atlas through a hollow atlas bolt, at least one merging hole is arranged on the bolt body of the hollow atlas bolt, the merging hole is internally provided with bone particles, and a support merging device matched with the shape of the lower surface of the atlas is arranged at the lower part of the atlas connecting part. The second cervical vertebra displacer can integrate a vertebral merging device bolt and a vertebral body, and greatly enhance the connecting performance and the fixation performance of the displacer. The second cervical vertebra displacer has the advantages that the displacer is more reliable, and the length of the displacer can be adjusted as required.

Owner:胡勇

Sight and sound barrier

ActiveUS20050076585A1Room for improvementImprove acoustic propertiesBuilding roofsWallsSound barrierPolystyrene

In one embodiment, the sight and sound barriers of this invention have a flexible sheet of lightweight, resilient foam as a core. This core is covered by a fabric or other suitable covering to further enhance the acoustic properties and to make the walls attractive. In this embodiment the core of polyethylene, polystyrene, urethane, or a mosaic thereof, for example, is made flexible with alternating wall and hinge portions. In an alternate preferred embodiment, the barriers or panels are formed with mitered grooves to allow the panel to be bent into larger degree corners, such as 90 degrees in one direction or 180 degrees in the opposite direction. Preferably the grooves have a depth extending substantially through the thickness of the core. In one embodiment, the covering material on one side of the panel is laid into the groove so that the covering material of a wall portion approaches, or preferably touches, the covering material on the opposite side. In an optional feature, grooves can be placed on alternating sides of the panel or barrier. In an optional feature, groove inserts may be sized and shaped to be placed in the grooves. The groove inserts may include a face which is flush with, recessed or protrudes from the adjacent wall portions. The groove inserts and mitered grooves may use various connectors such as Velcro® hook and loop fasteners or magnets.

Owner:CHILDRENS FACTORY LLC

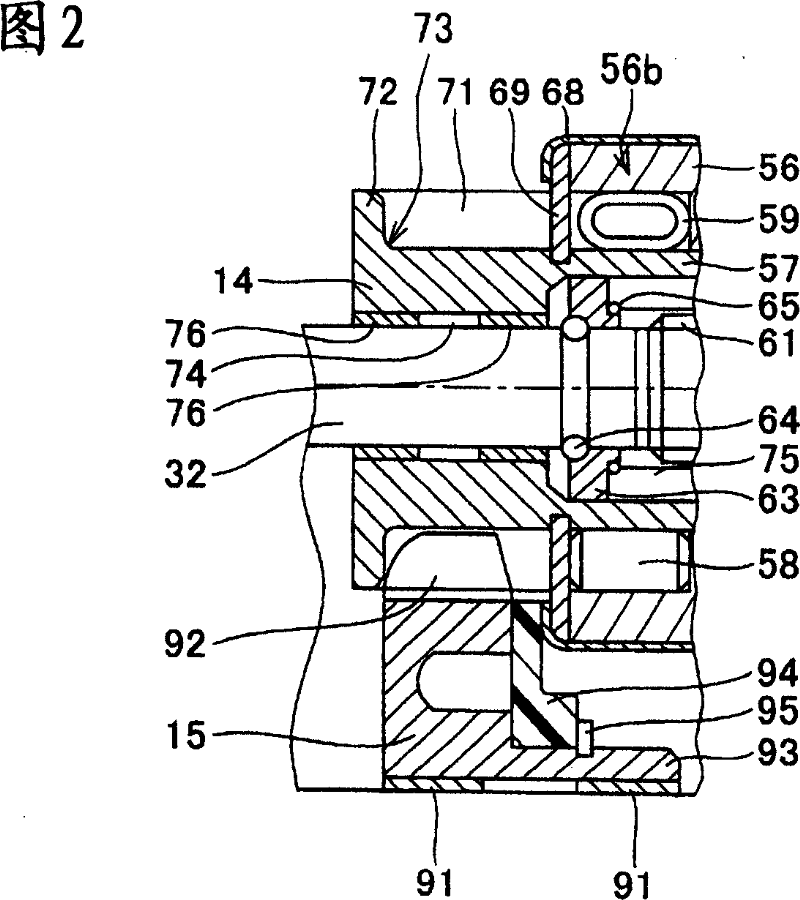

Starter motor with idle gear

InactiveCN101044316AAchieve simplicityMiniaturizationPower operated startersMachines/enginesDrive shaftEngineering

The present invention provides a starter motor with an idle gear, wherein a helical spline part (61) is formed on a drive shaft (32) rotated by a motor (11) through a planetary gear mechanism (12) and an over-running clutch (13) movable in the axial direction is mounted thereon. A pinion (14) meshing with the idle gear (15) is formed integrally with the clutch inner (57) of the over-running clutch (13). A feeding flange (72) engaged with the idle gear (15) and disengaging the idle gear (15) from a ring gear (16) according to the axial movement of the pinion (14) is formed at the tip of the pinion (14). The bottom outer diameter of the gear part (71) of the pinion (14) is smaller than the outer diameter of the clutch inner (57), and the pinion (14) is formed integrally with the feeding flange (72) and the clutch inner (57) by cold forging. Thus, the starter motor simply formed, manufacturable at low cost, having high reliability and capable of engaging and disengaging the gear with and from the ring gear can be provided without increasing the number of parts.

Owner:MITSUBA CORP

Artificial crystalline lens

InactiveCN101011300AConform to the physiological structureReduce loosenessBone implantSpinal implantsLamina terminalisProsthesis

The invention relates to an artificial sacrum prosthese, formed by an iliac bone connecting structure and a low lumbar vertebral arch nail rod. The invention is characterized in that the main body of the iliac bone connecting structure is in arc shape, whose middle is arranged with a lumbar bottom support table engaged with the cut lower plate of lumbar; the lower ends of two sides of arc are engaged with the cut sacrum joint and arranged with the iliac bone nail; two upper sides of the arc are arranged with both one sacrum rod whose end is arranged with the connecting part engaged with the upper part of iliac bone. The invention sets the iliac bone connecting structure in arc shape to meet the sacrum physiological structure, to stabilize the basin ring, improve the stress transmission and reduce the nail loosen. When in use, the two side sacrum joint cut are less, to avoid damaging the ear face, to be used to rebuild the basin.

Owner:杨惠林 +2

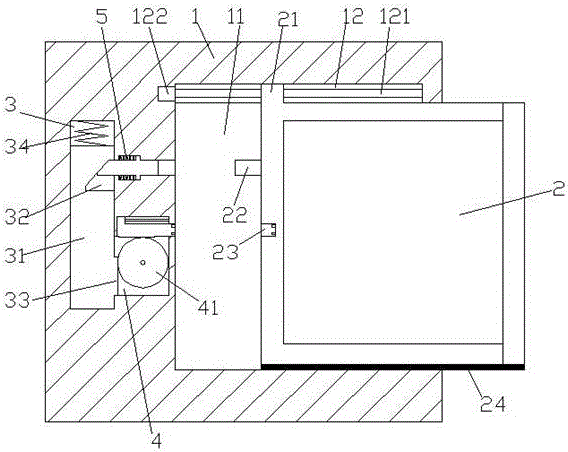

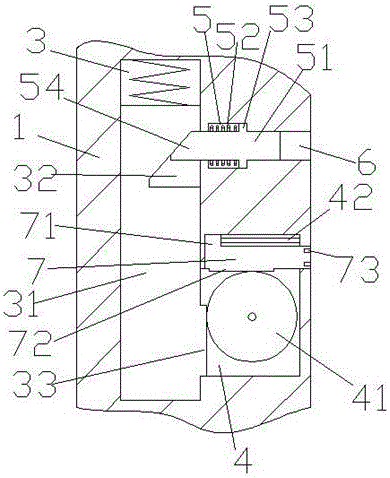

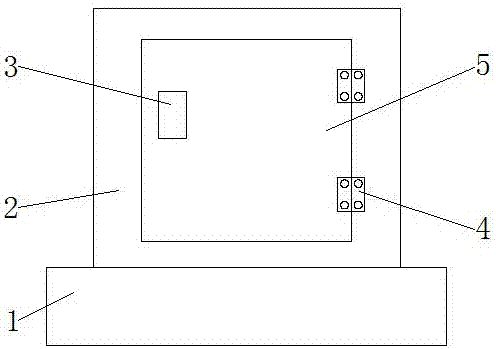

Power control cabinet achieving safe power supply

InactiveCN106848876AImprove stabilityReduce loosenessSubstation/switching arrangement detailsSwitchgear with withdrawable carriageEngineeringElectric power

The invention discloses a power control cabinet achieving safe power supply. The power control cabinet comprises a cabinet body which is internally provided with a containing cavity and a drawer part arranged inside the containing cavity, the left end face of the drawer part is provided with an insertion and connection rod and a power supply connection hole formed in the lower portion of the insertion and connection rod, a through hole is formed in the portion, opposite to the insertion and connecting rod, inside the cabinet body, a first transmission cavity is formed in the portion, below the through hole, inside the cabinet body, a second transmission cavity is formed in the portion, at the left side of the through hole and the first transmission cavity, inside the cabinet body, the second transmission cavity is internally provided with a transmission sliding block, a first spring is arranged on the top of the transmission sliding block, an inclined sliding groove is formed in the right end face of the transmission sliding block, a first rack is arranged on the portion, below the inclined sliding groove, of the transmission sliding block, the first transmission cavity is internally provided with an external gear plate which is connected with the first rack in a meshed mode, a guide sliding rod is arranged on the upper portion of the external gear plate, a sliding block is arranged on the guide sliding rod, and a power supply insertion and connection rod is connected to the bottom of the sliding block. By means of the power control cabinet achieving safe power supply, the safety of maintenance is improved.

Owner:广州迅速光电科技有限公司

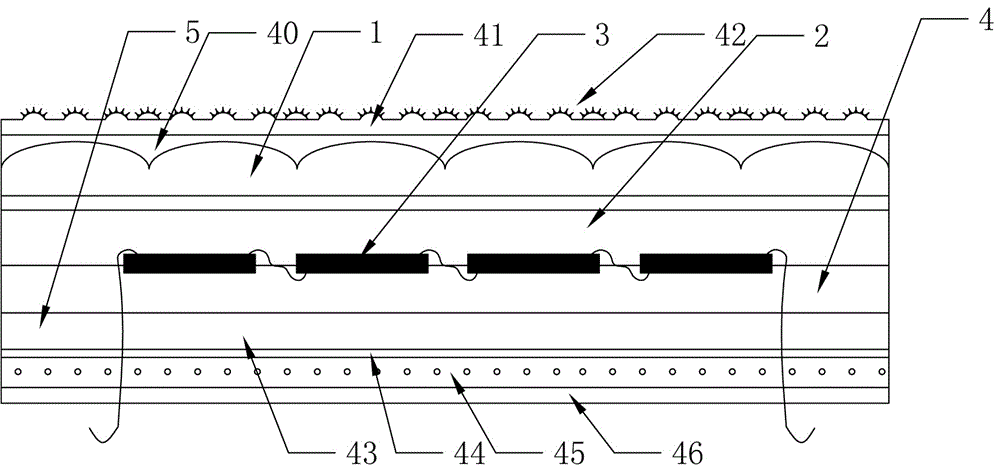

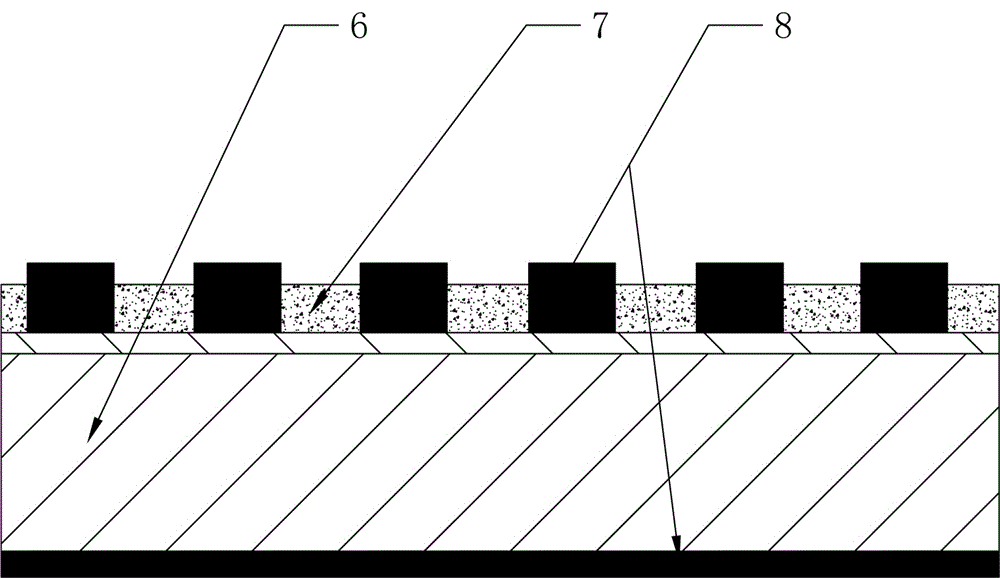

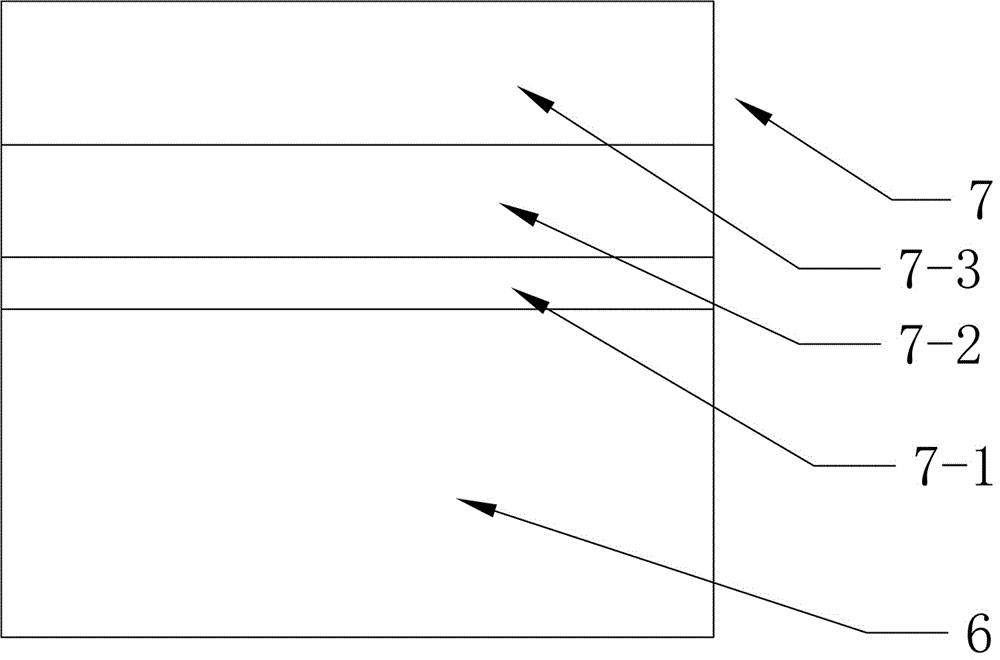

Solar panel component and processing technology

ActiveCN106206758AReduce widthReduce thicknessFinal product manufacturePhotovoltaicsEngineeringPhotoelectric conversion

The invention discloses a solar panel component and a processing technology. The solar panel component mainly comprises components, wherein the components comprise a battery piece, a glass layer, a backboard and a frame on the outer side, wherein the upper end of the battery piece is provided with a silicon nitride passivation antireflection layer; the electrode grid lines of the battery piece are formed in a way that fragmented main grid lines and grouped thin grid lines are arranged in parallel and are connected by auxiliary grid lines; and the frame comprises an integral frame and a detachable frame. By use of the solar panel component and the processing technology provided by the invention, the internal laminated structure and the external frame structure of the solar panel are improved to lower power loss, improve a photoelectric conversion rate and prolong the service life of the solar panel component.

Owner:九州方园新能源股份有限公司

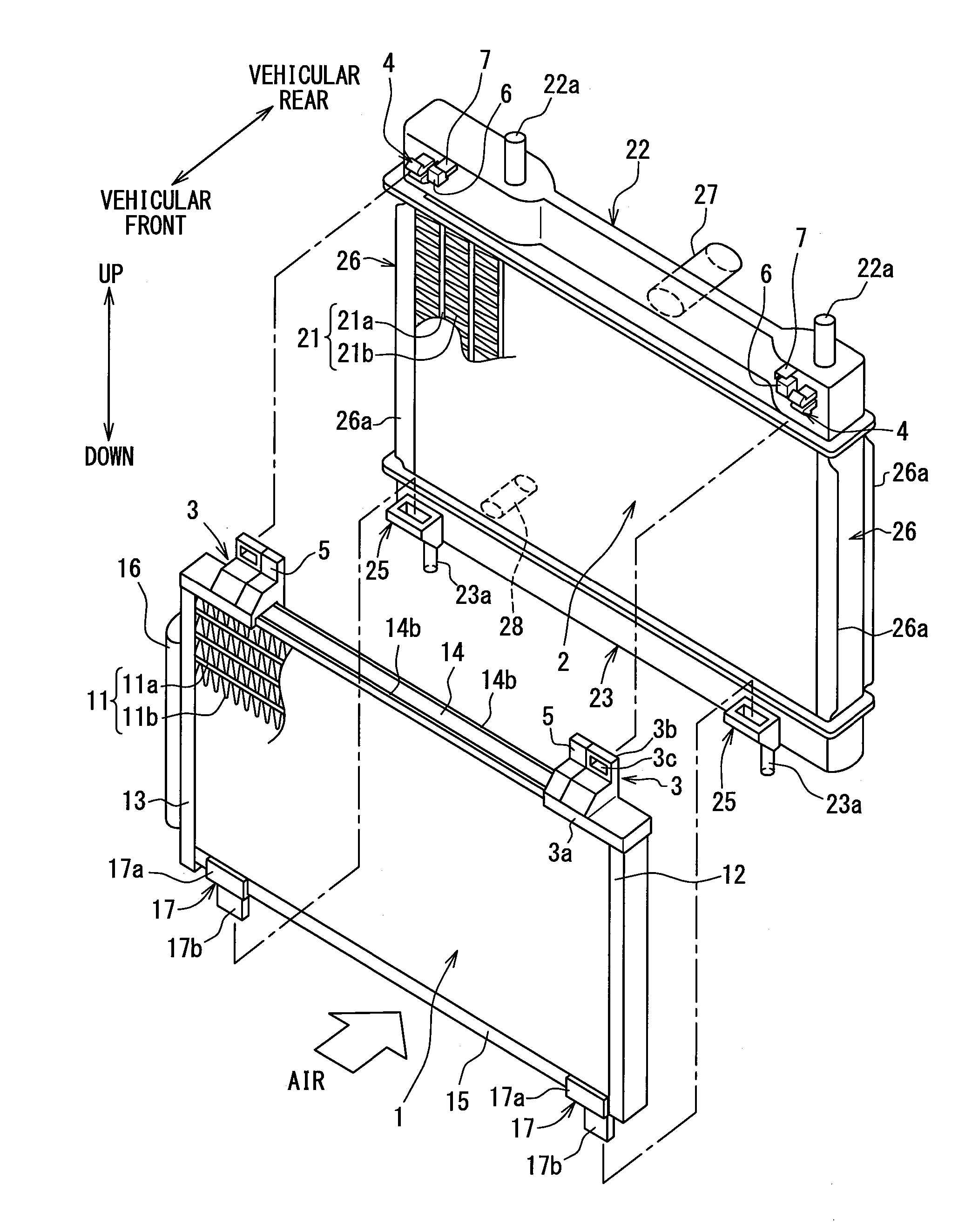

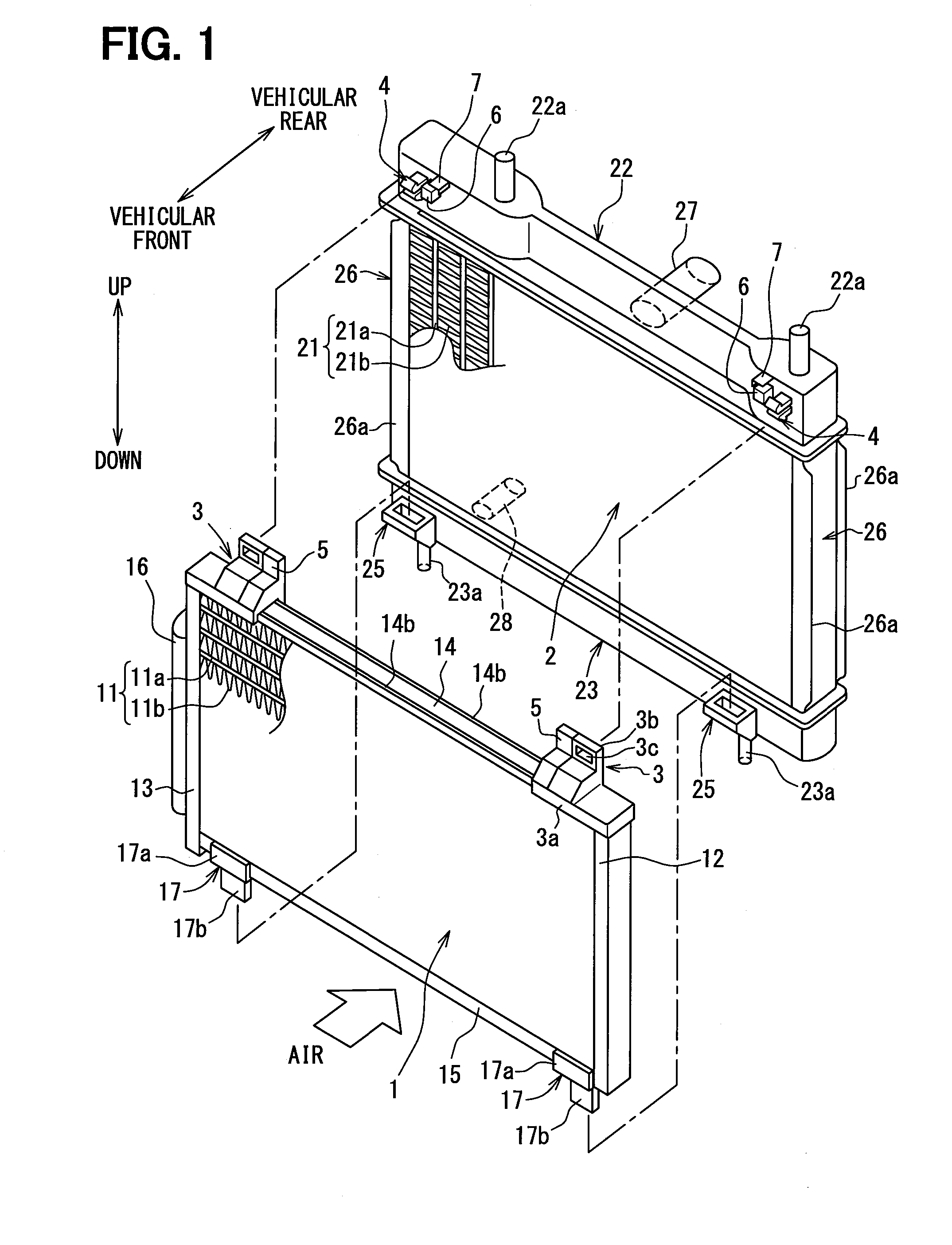

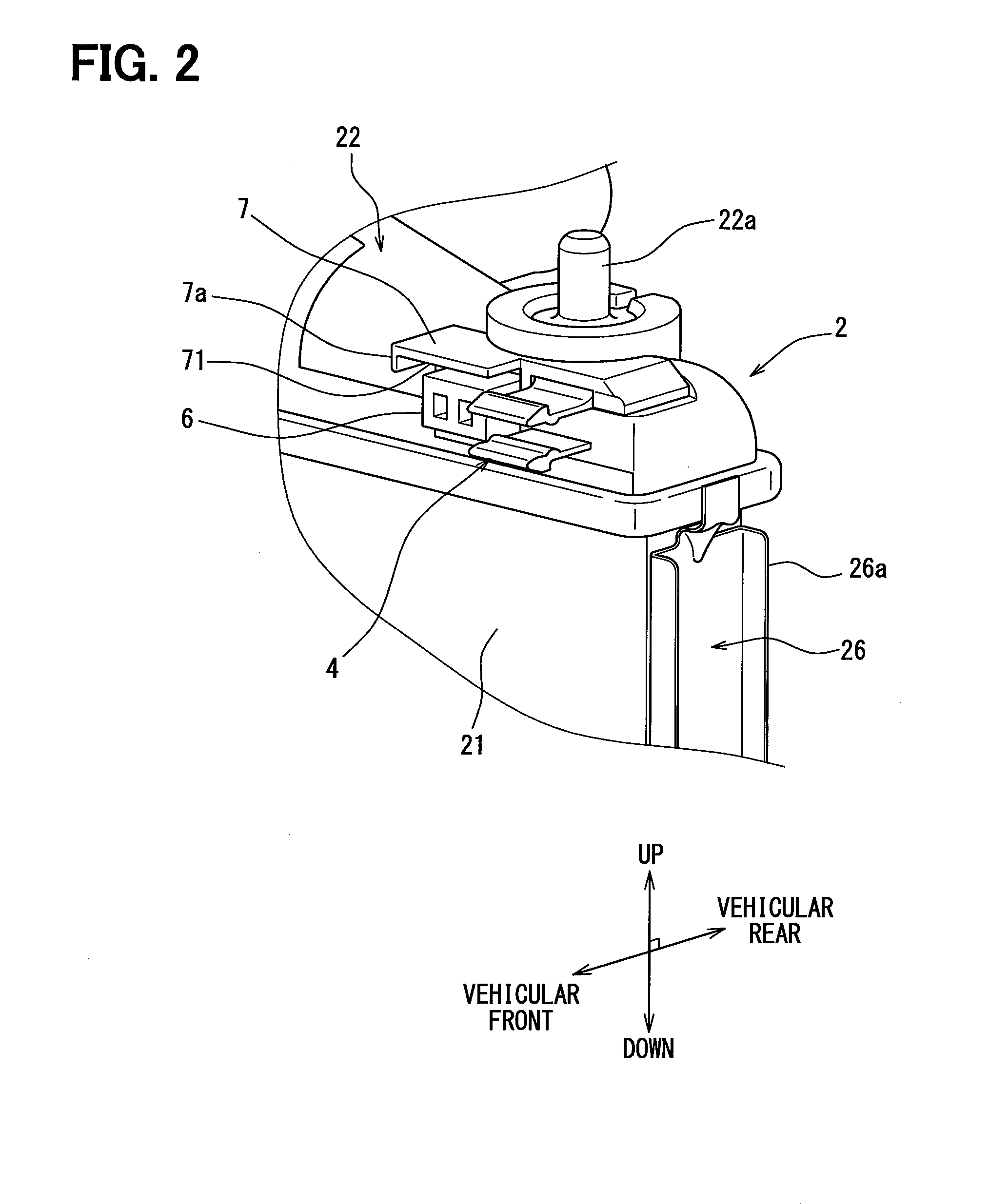

Heat exchanger mounting structure

ActiveUS20150047808A1Stable stateLooseness can be reducedLiquid coolingMachines/enginesPlate heat exchangerEngineering

A heat exchanger mounting structure is provided with a bracket, a load supporting section, a fitting member, and a contact section. The bracket is provided to one of a first heat exchanger and a second heat exchanger. The load supporting section is provided to the other heat exchanger to which the bracket is not provided, and supports a load transmitted from the one of the first heat exchanger and the second heat exchanger. The fitting member is provided to the one of the first heat exchanger and the second heat exchanger, to which the bracket is provided, and is fitted over the load supporting section. The contact section is in contact with at least a part of the upper portion of the bracket.

Owner:DENSO CORP

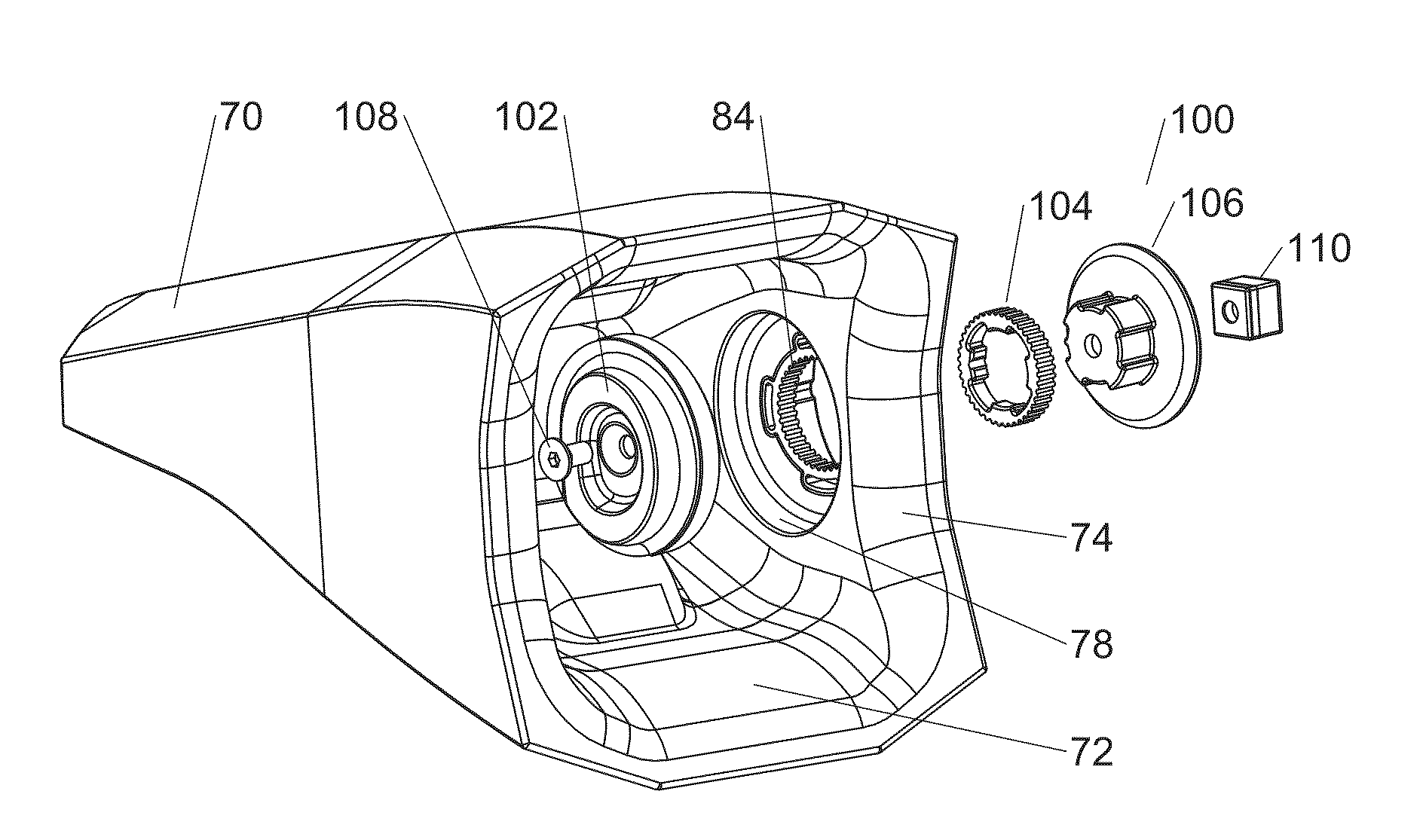

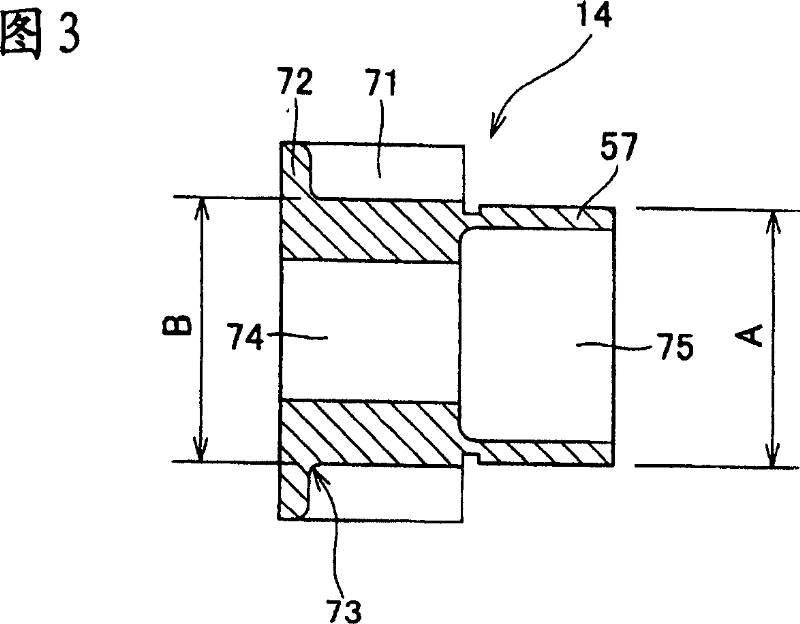

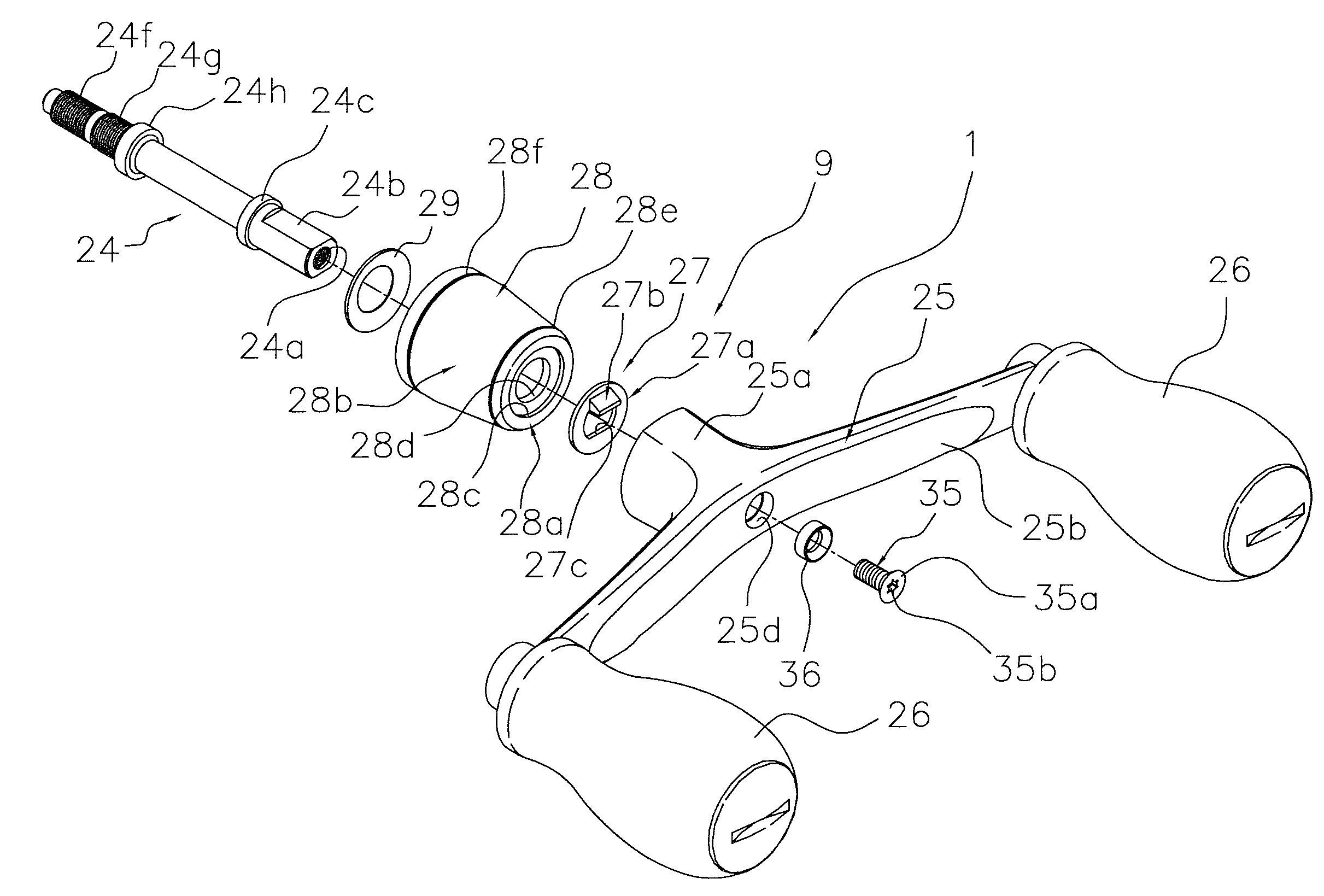

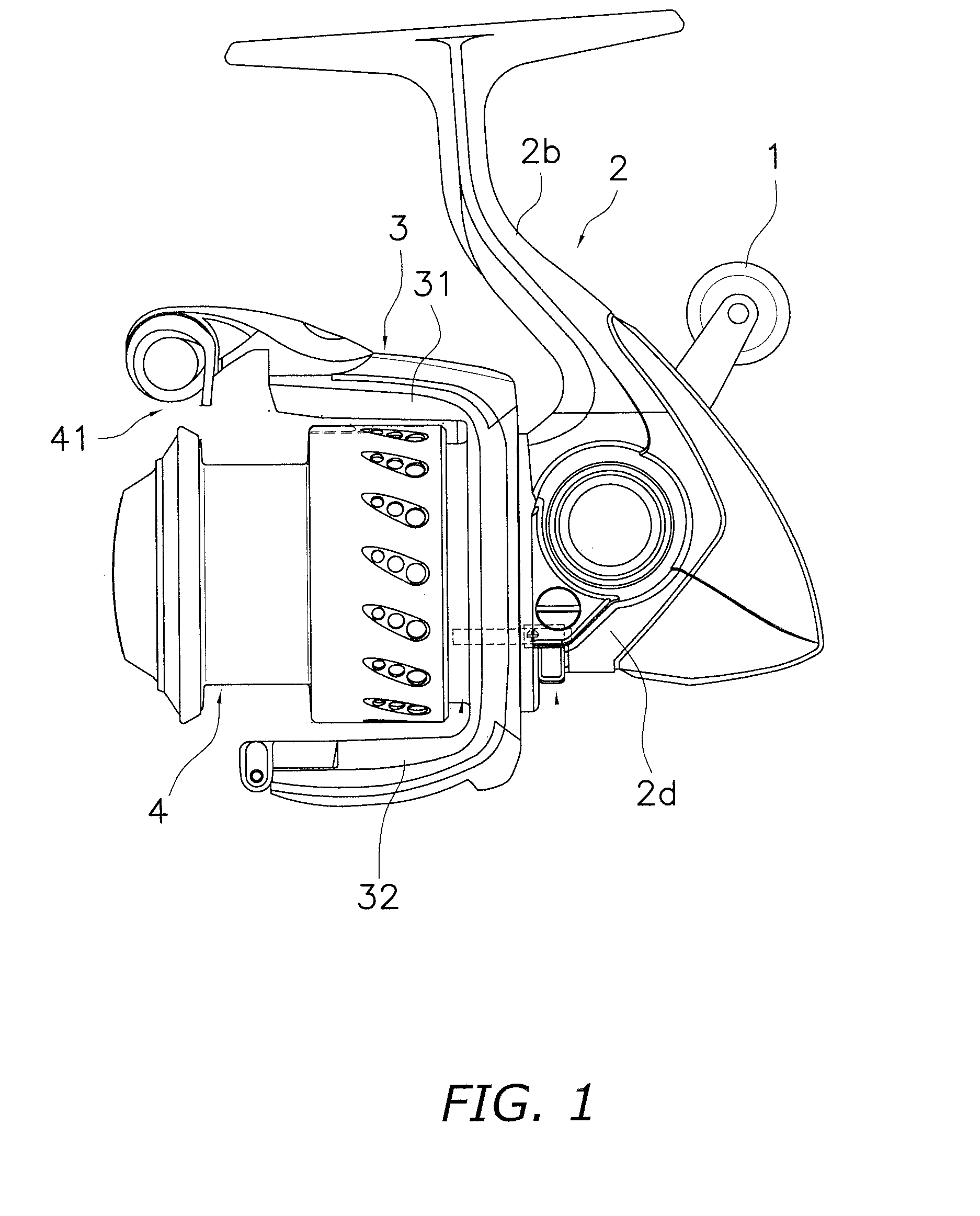

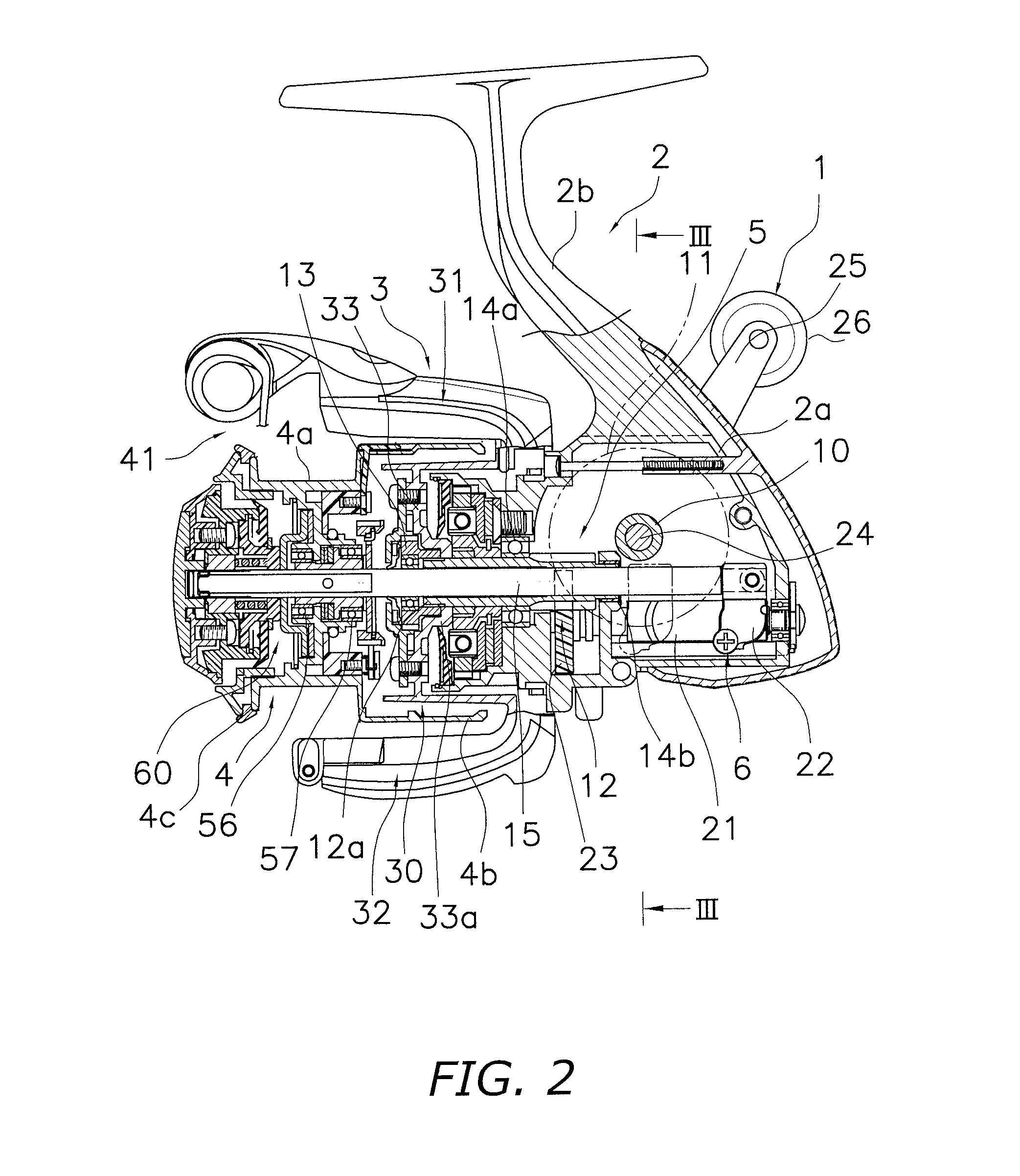

Handle arm mounting structure for fishing reel

ActiveUS20100243781A1Reduce amount of loosenessReduce loosenessControlling membersYielding couplingCircular sectionEngineering

A handle arm mounting structure for a fishing reel includes a fastening section and a washer member. The fastening section has a first non-circular hole configured to engage non-rotatably with a non-circular section of a handle shaft. The washer member has a circular disk-like section and an engaging protrusion and is configured to be mounted in an axial direction on the handle shaft. The circular disk-like section has a second non-circular hole that engages with the non-circular section. The engaging protrusion protrudes toward the first non-circular hole from a periphery of the second non-circular hole. The engaging protrusion has an inside surface configured to engage with the non-circular section and an outside surface having a first tapered surface that tapers toward a tip end and engages with the first non-circular hole.

Owner:SHIMANO INC

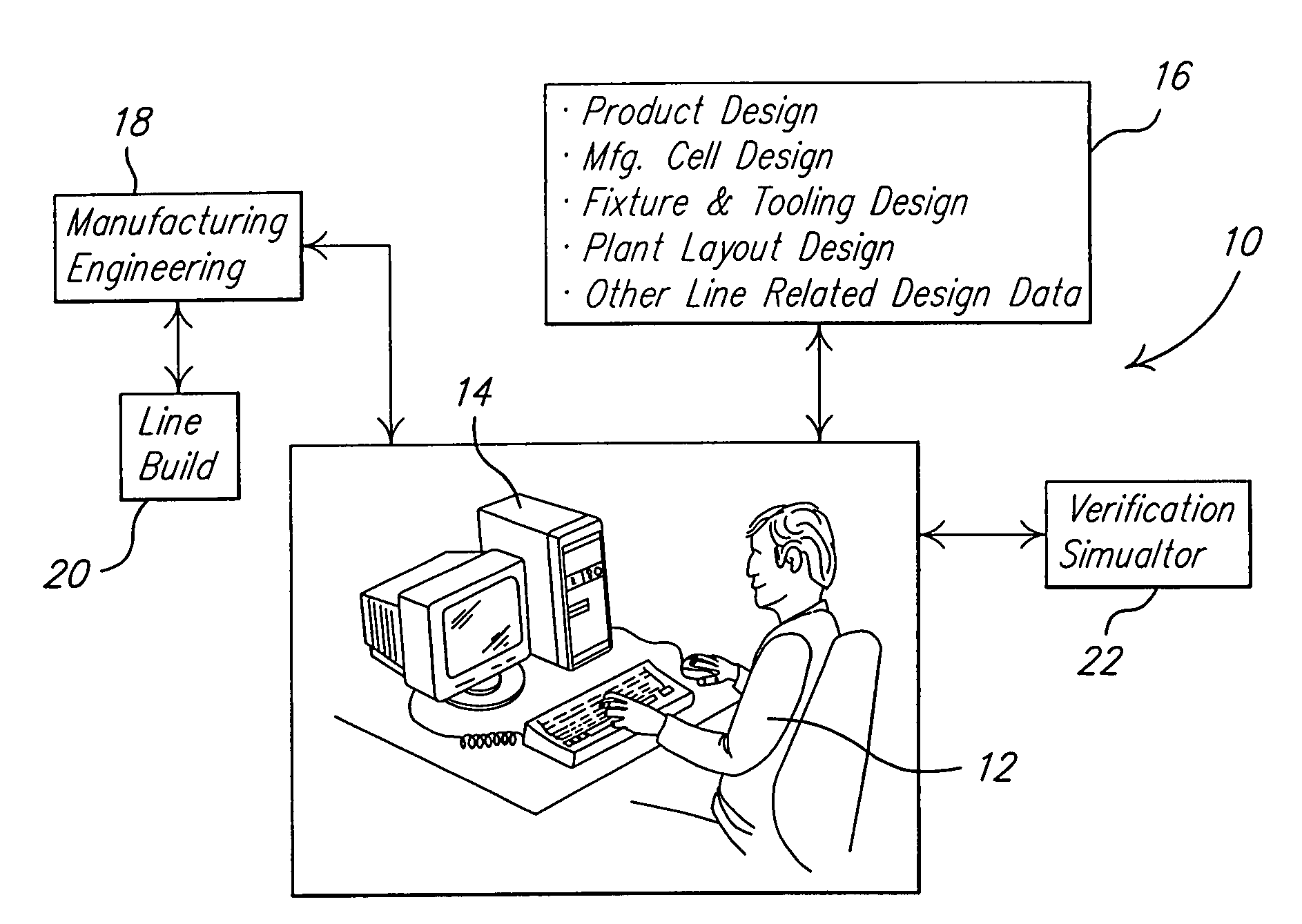

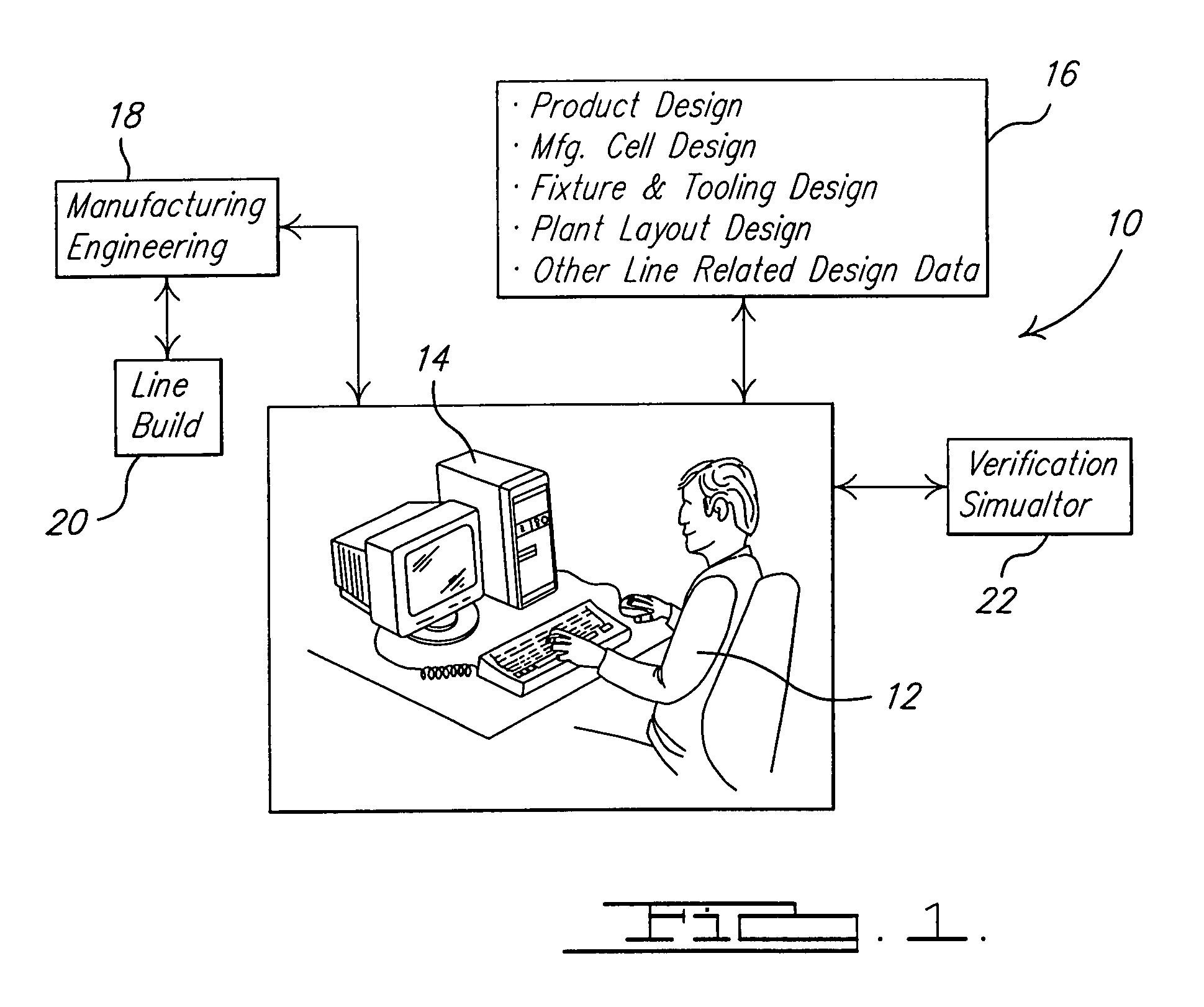

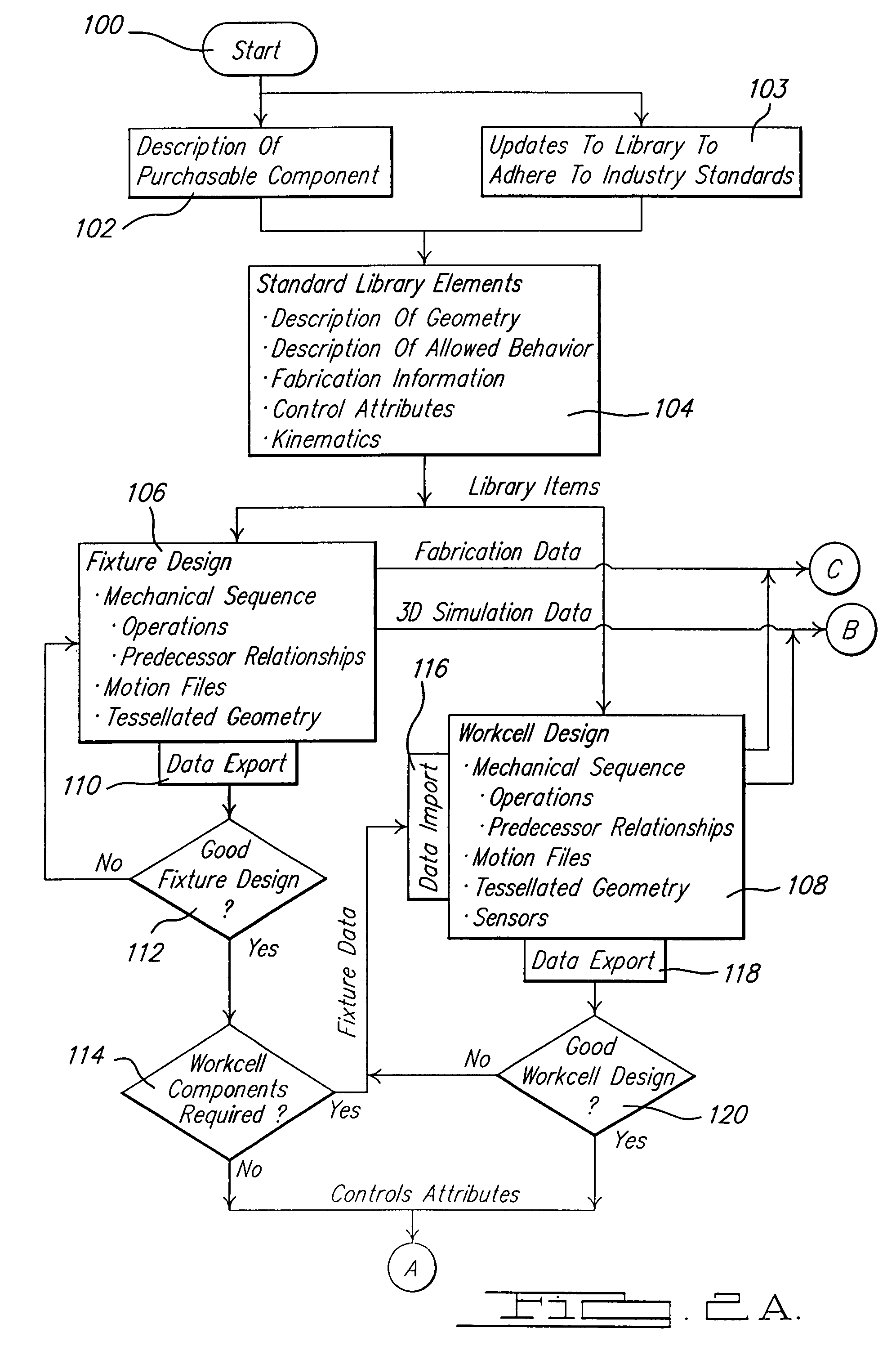

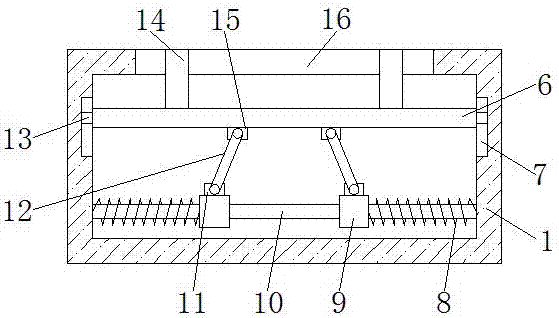

Method of embedding tooling control data within mechanical fixture design to enable programmable logic control verification simulation

InactiveUS7346478B2Amount of timeImprove accuracyProgramme controlAnalogue computers for electric apparatusWorkcellComputer architecture

A method is provided of embedding tooling control data within a mechanical fixture design to enable programmable logic control verification simulation. The method includes the steps of constructing at least one of a mechanical fixture design, a workcell design, and a controls design. The method also includes the steps of executing a virtual programmable logic control (VPLC) simulation with a VPLC verification simulator to verify the at least one of the mechanical fixture design, the workcell design, and the controls design.

Owner:FORD MOTOR CO

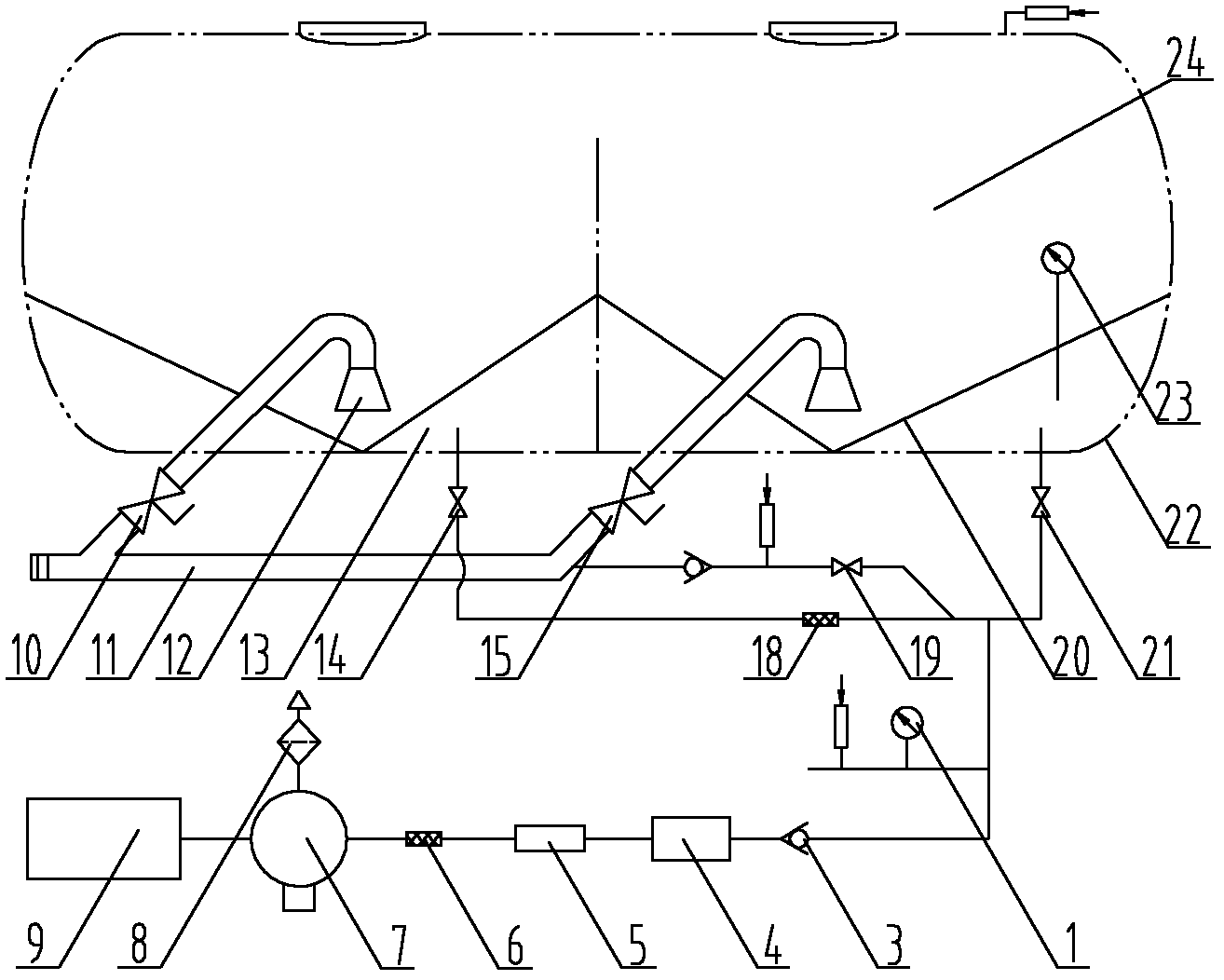

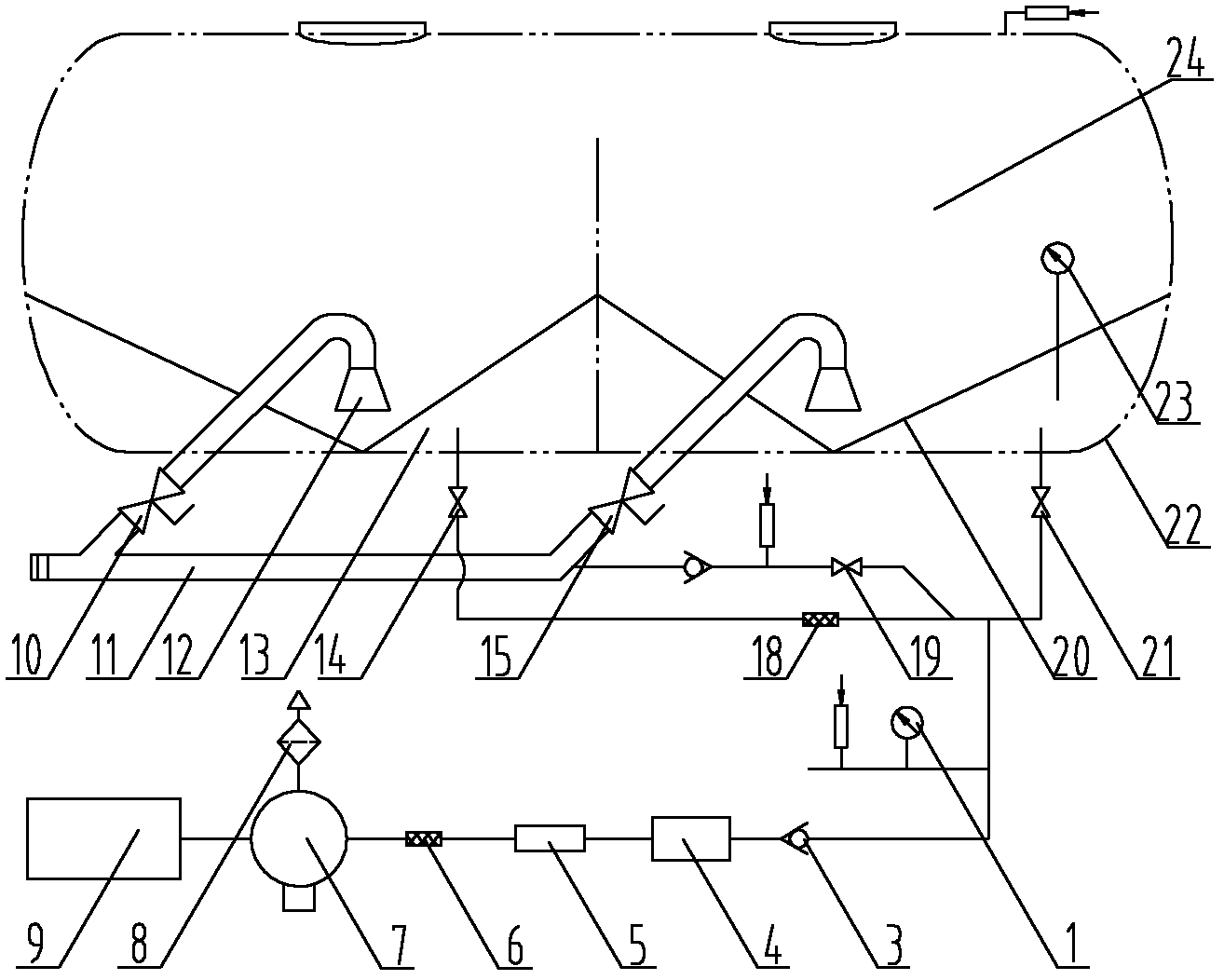

Tank type powder material carrier vehicle and discharging device thereof

ActiveCN102491013ADetect pressure differenceBest unloading speedLarge containersInternal pressurePressure difference

The invention discloses a discharging device of a tank type powder material carrier vehicle, which comprises an air compressor (7). An air outlet of the air compressor (7) is communicated with an air inlet of an air chamber of a tank body (22) of the tank type powder material carrier vehicle, and a discharging port of the tank body (22) is communicated with a storage tank. The discharging device of the tank type powder material carrier vehicle further comprises a first pressure detection device (23) detecting internal pressure of the tank body (22) and a second pressure detection device (1) detecting pressure of an air inlet pipeline. The first pressure detection device (23) is installed inside the tank body (22), and the second pressure detection device (1) is installed on the air inlet pipeline. Accordingly, pressure in an air inlet pipe and pressure difference between the inside of the pipe and the inside of the tank body can be detected conveniently, a pressure state of the inside of the pipeline can be detected in real time, and potential safety hazards are avoided. The invention further provides the tank type powder material carrier vehicle comprising the discharging device.

Owner:SANY AUTOMOBILE MFG CO LTD

Short connecting device

ActiveCN104009356AQuick conversionImprove work efficiencyCoupling contact membersEngineeringSliding contact

The invention discloses a short connecting device which comprises a fixing body, inserting connection rods, expansion rods, a sliding semicircular sleeve, a breakover bar and a rotary knob. Holes are formed in the outer surfaces of the inserting connection rods, the expansion rods are arranged in the holes, and protrusion parts are arranged on the expansion rods. The expansion rods are arranged in the inserting connection rods in a sliding mode, the top ends of the inserting connection rods are fixed in the fixing body, and the sliding semicircular sleeve is in sliding contact with the outer surfaces of the inserting connection rods. A rotating shaft is fixed in the fixing body, and the rotating shaft is placed above the inserting connection rods. The middle portion of a pressing bar is fixed on the rotating shaft, and the two ends of the pressing bar are in contact with the top end of the sliding semicircular sleeve and the top ends of the expansion rods respectively. The number of the inserting connection rods is two. A connecting shaft is vertically arranged in the fixing body, and the connecting shaft is placed between the two inserting connection rods. The middle portion of the breakover bar is connected with the connecting shaft, and the rotary knob is arranged on the top of the fixing body and is connected with the connecting shaft. The inserting connection rods are further provided with connecting grooves and arc-shaped metal pieces. The short connecting device can be firmly mounted, and quick switching of a short connection state and a non-short connection state can be achieved.

Owner:STATE GRID SICHUAN ELECTRIC POWER

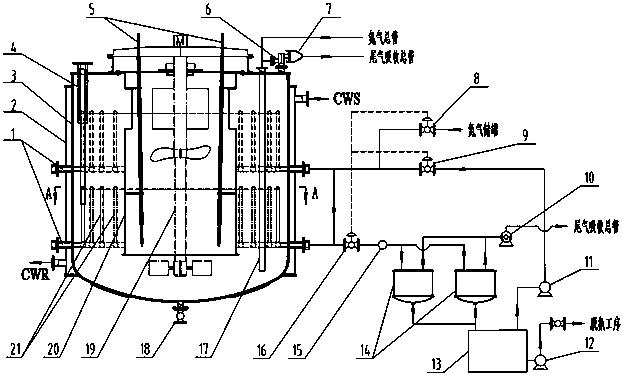

Method for material concentrating in ternary precursor synthesis reaction

ActiveCN110756140AReduce cloggingRelieve pressureChemical/physical/physico-chemical stationary reactorsInert gas productionCentrifugal pumpMother liquor

The invention relates to a method for material concentrating in a ternary precursor synthesis reaction. According to the method, a reaction vessel, a negative-pressure tank and a mother liquor tank are connected sequentially; a stirrer, a guide flow cylinder, a charging pipe, a nitrogen gas guide pipe, a liquid level meter, a clear-out pipe and a filter stick are arranged inside the reaction vessel; a vacuum pump is arranged at the top of the negative-pressure tank; and a centrifugal pump and a metering pump are arranged at the bottom of the mother liquor tank. According to the method, the problems of a ternary precursor synthesis reaction at present that concentrated particles are subjected to refluxing growth and the product is lost are solved. According to the method for material concentrating in the ternary precursor synthesis reaction, provided by the invention, reaction mother liquor can be directly drained outside the vessel, the problem of loss of the material particles is avoided, the particles are not required to be subjected to refluxing growth after concentration, and the problem that unaccepted products are produced due to secondary growth is avoided.

Owner:HUAYOU NEW ENERGY TECH (QUZHOU) CO LTD +1

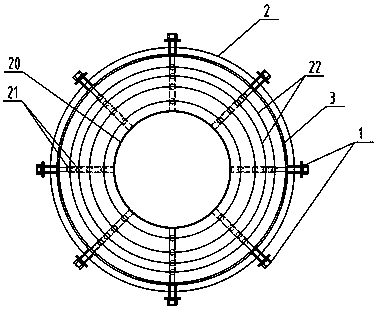

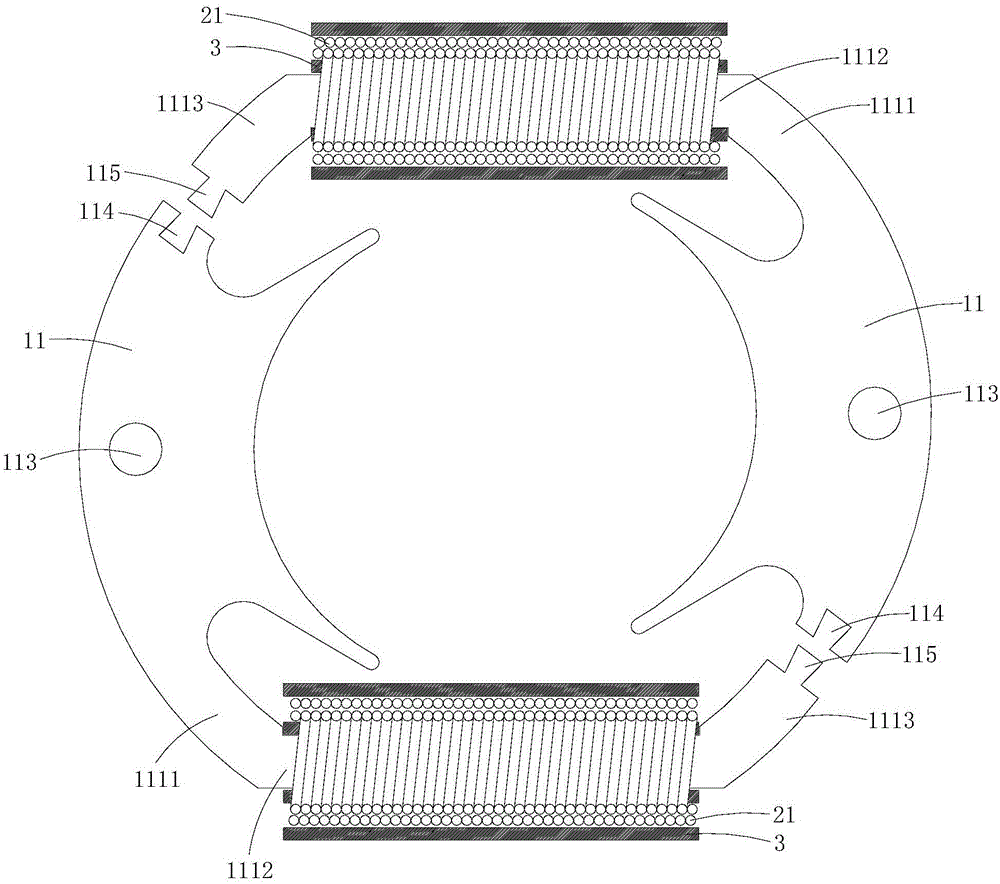

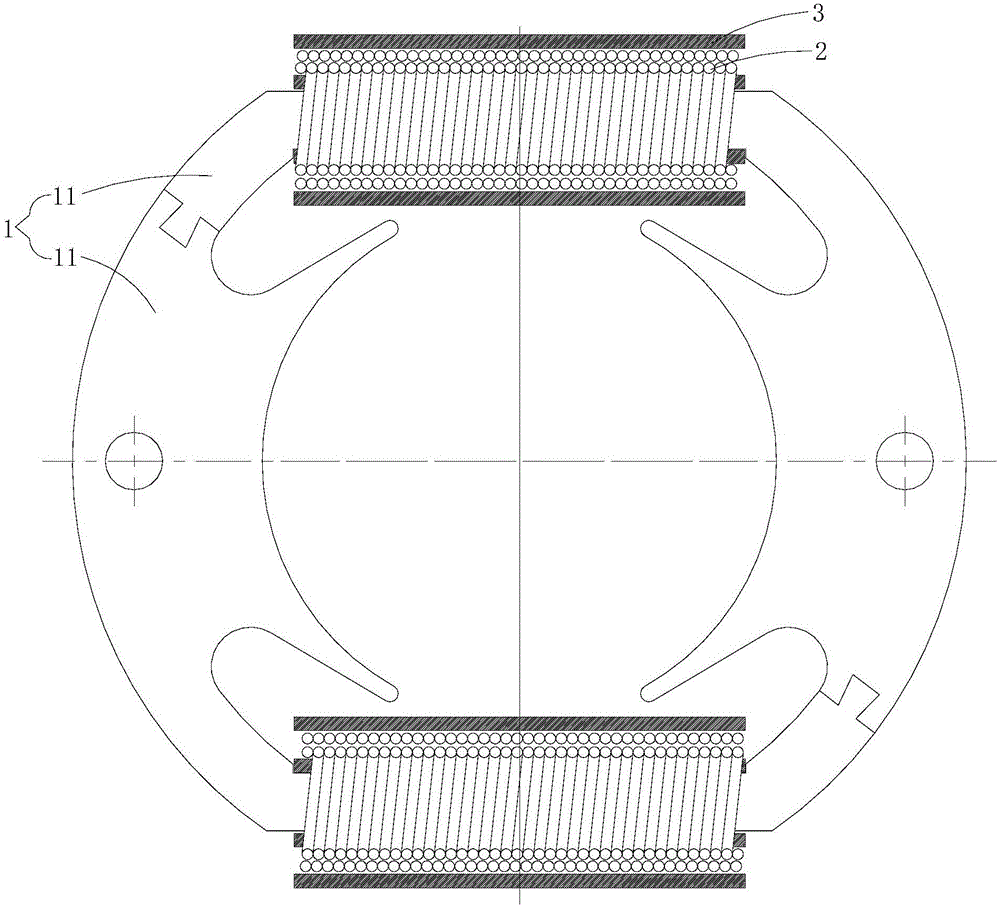

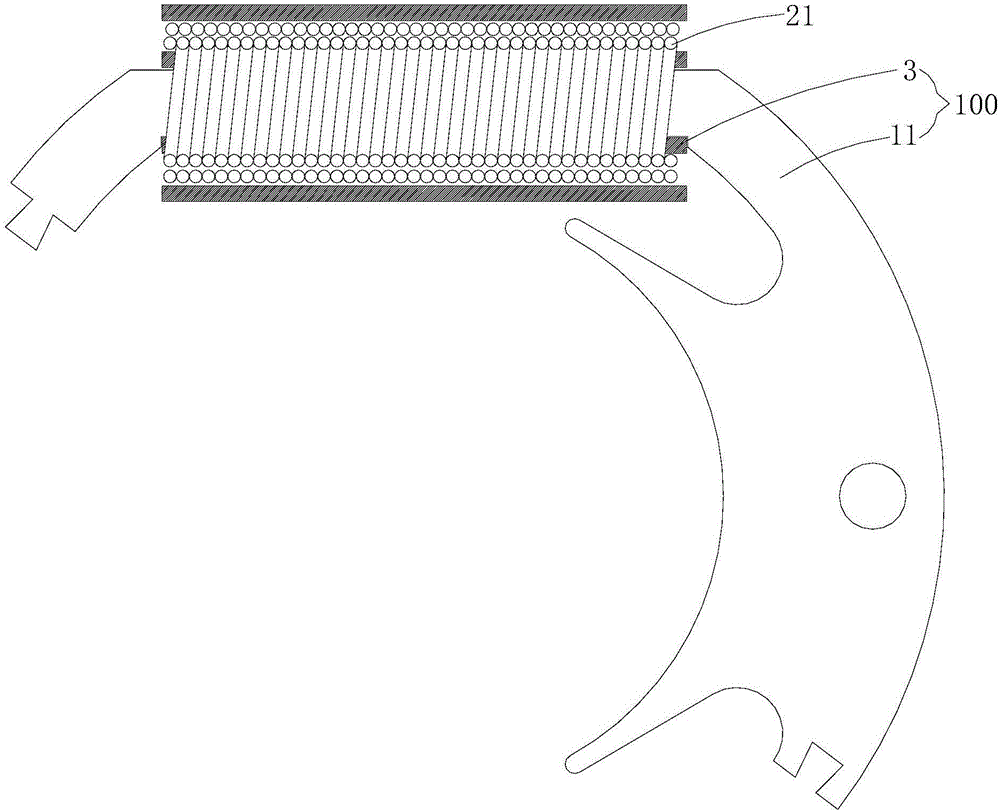

Series motor, stator iron core and stator thereof, and manufacturing method of stator

ActiveCN105024464AIncrease productivityReduce sizeWindings insulation shape/form/constructionMagnetic circuit stationary partsConductor CoilPhysics

The invention is suitable for the field of motors and provides a series motor stator iron core, a series motor stator, a manufacturing method of the series motor stator, and a series motor, wherein two iron core parts are spliced along the circumferential direction along the series motor stator iron core, each iron core part comprises a sub stator yoke and a stator tooth arranged on the sub stator yoke in a projected manner. The sub stator yoke comprises a first arc-shaped yoke part, a straight yoke part whose one end is connected with one end of the first arc-shaped yoke part, and a second arc-shaped yoke part whose one end is connected with the other end of the straight yoke part. The stator tooth is arranged on the first arc-shaped yoke part in a projected manner. The first arc-shaped yoke part and the second arc-shaped yoke part of one iron core part are respectively connected with the second arc-shaped yoke part and the first arc-shaped yoke part of the other iron core part. According to the invention, the winding efficiency of a stator winding is improved; sizes of end parts, projected from two ends of the stator iron core along the axial direction of the stator iron core, of the stator winding are reduced; the coil perimeter of the stator winding is reduced, the utilization rate of the stator winding is improved, and the cost of the series motor is lowered.

Owner:FOSHAN WEILING WASHER MOTOR MFG

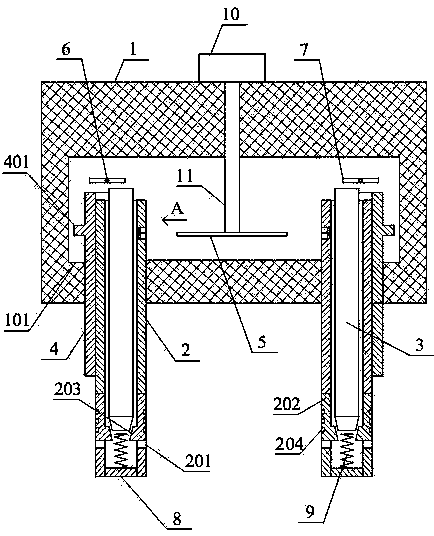

Electrical cabinet with good damping effect

InactiveCN107317237AImprove shock absorptionImprove practicalitySubstation/switching arrangement casingsAnti-seismic devicesComputer engineering

Owner:罗必君

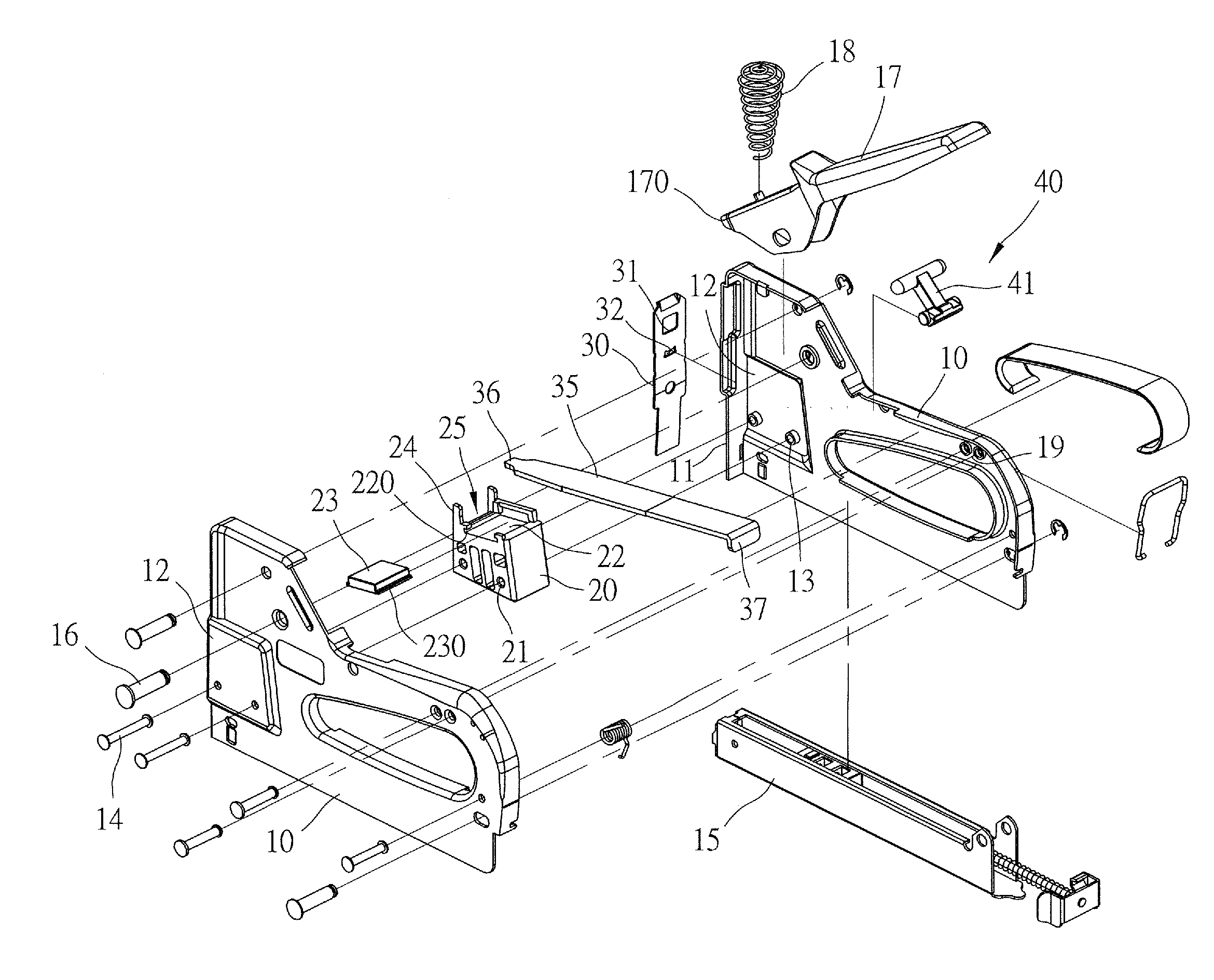

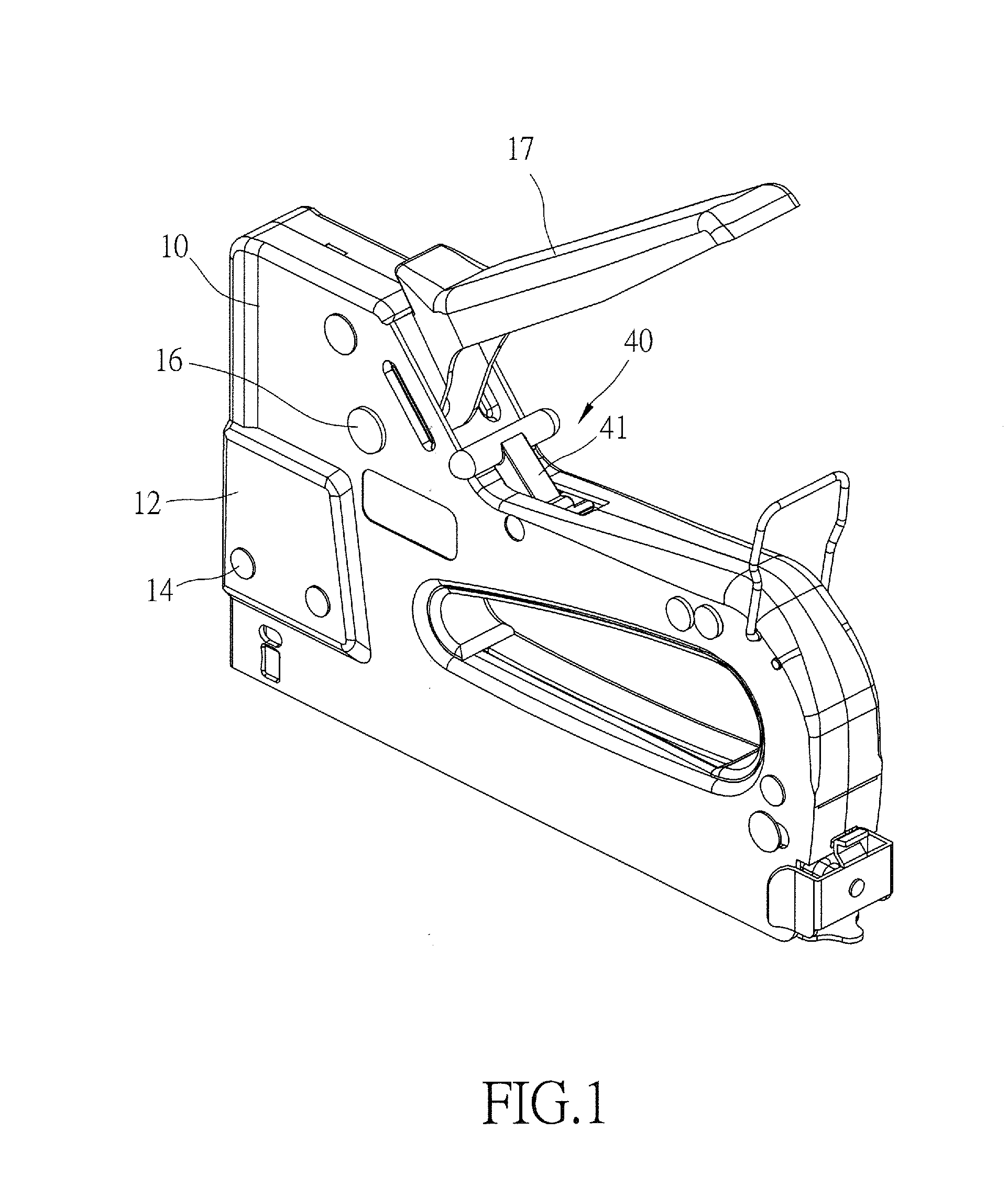

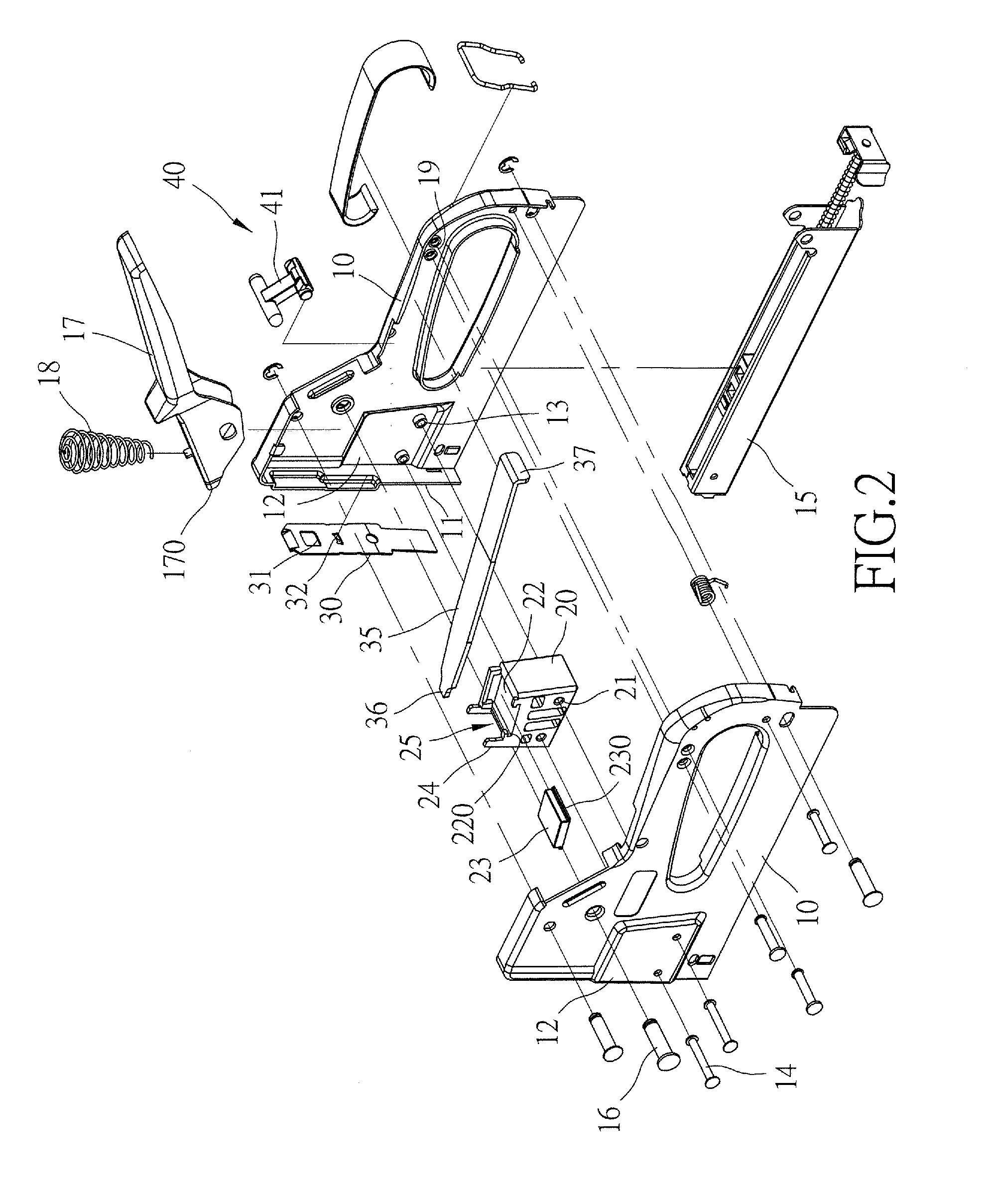

Structure of stapling device

InactiveUS20150041516A1Simple structureImprove securityStapling toolsDispensing apparatusEngineeringMechanical engineering

A stapling device includes two casing members, a pad seat, and a striker plate. The casing members, which can be combined together, have front ends respectively forming front-end plates abutting each other. The two casing members are rotatably coupled to a press-down handle that is selectively pressed down. The pad seat is set at the front end of the interior of the two combined casing members. The pad seat has a front end face, which define, collectively with the inside surfaces of the front-end plates of the two casing members, a striker plate channel. The striker plate is slidably received in the striker plate channel. The striker plate is selectively pulled by the press-down handle to move upward. The two casing members clamp and retain therebetween a spring plate for providing a striking pre-loading force to the striker plate.

Owner:JANN YEI IND

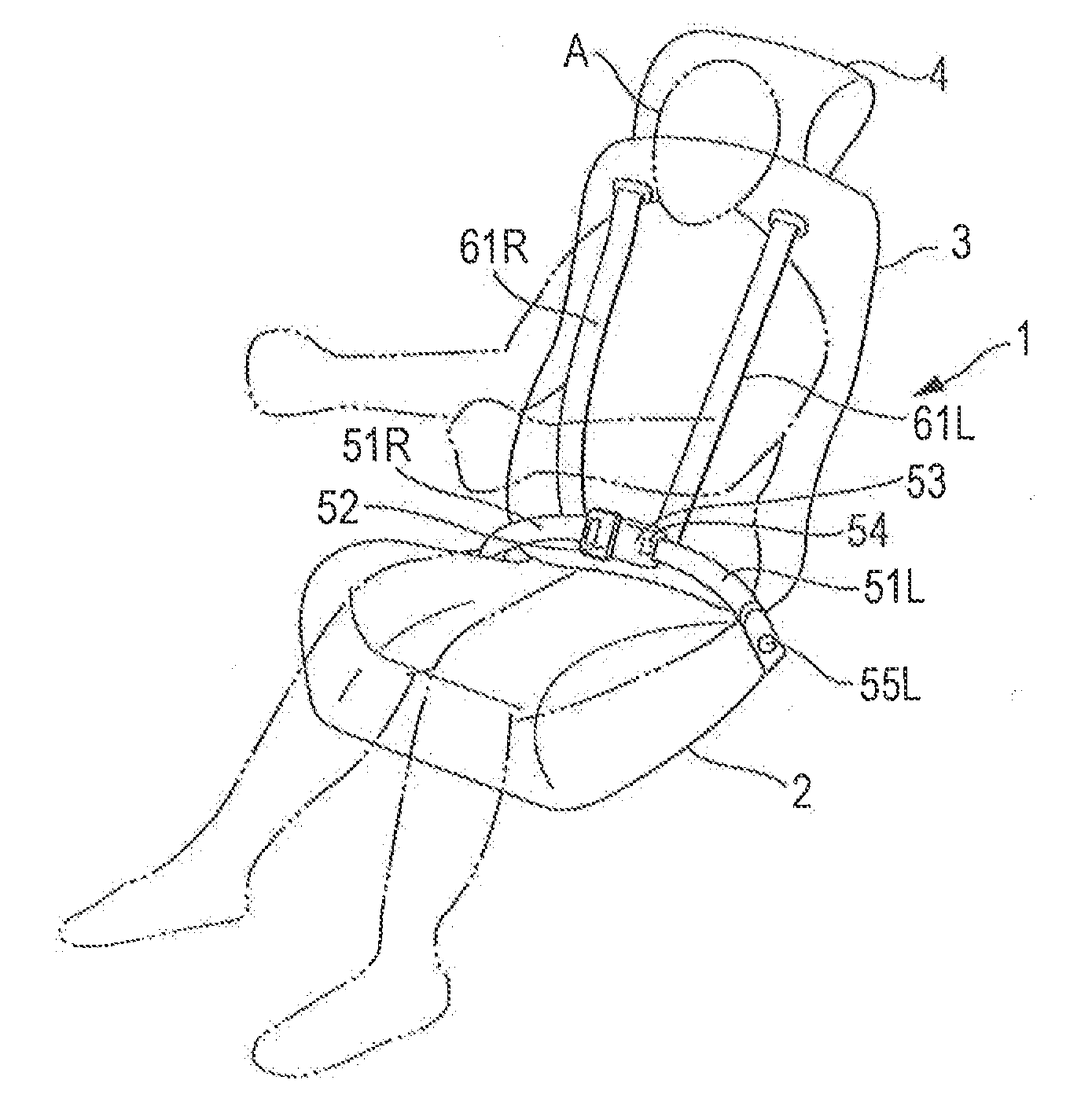

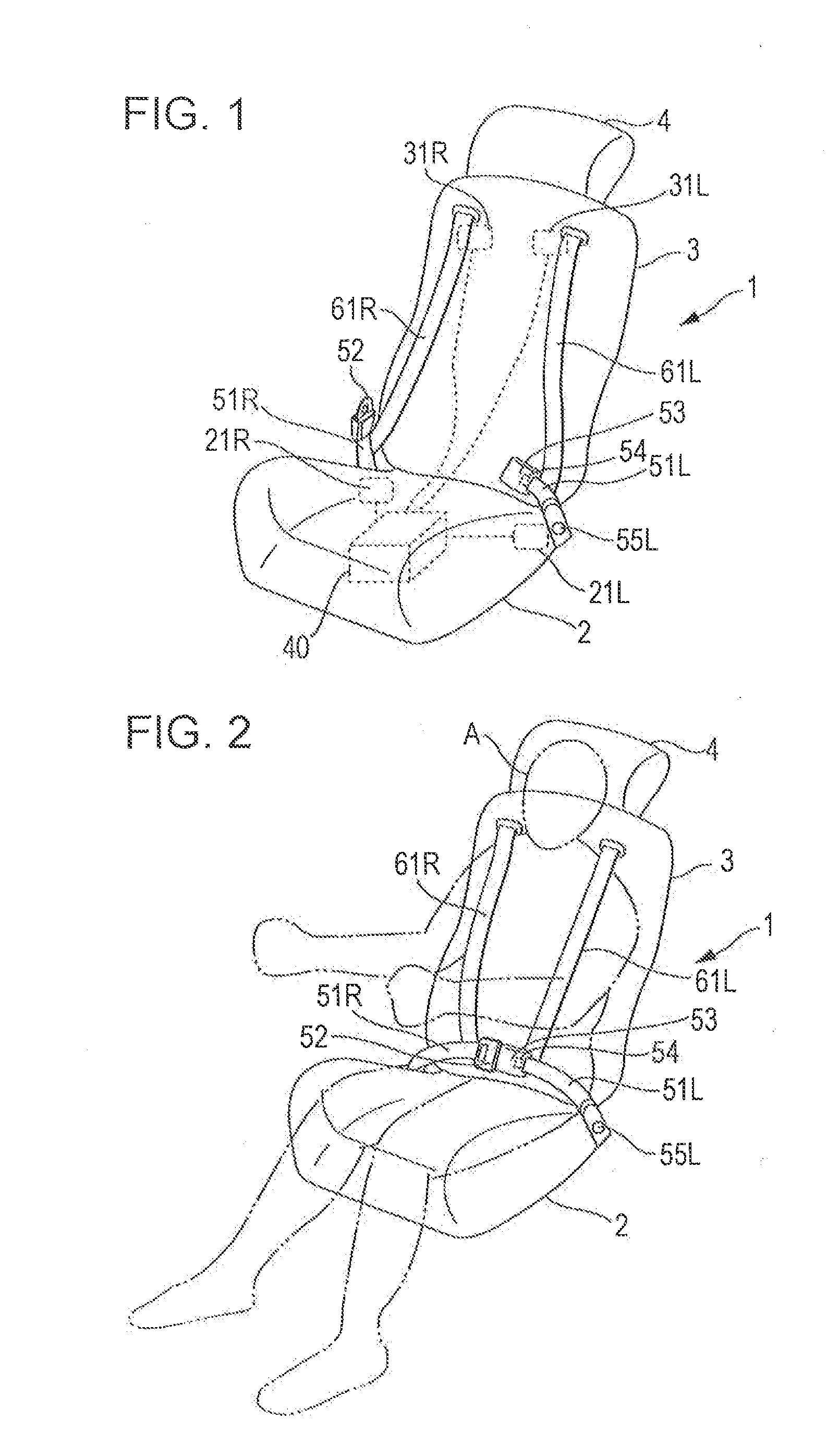

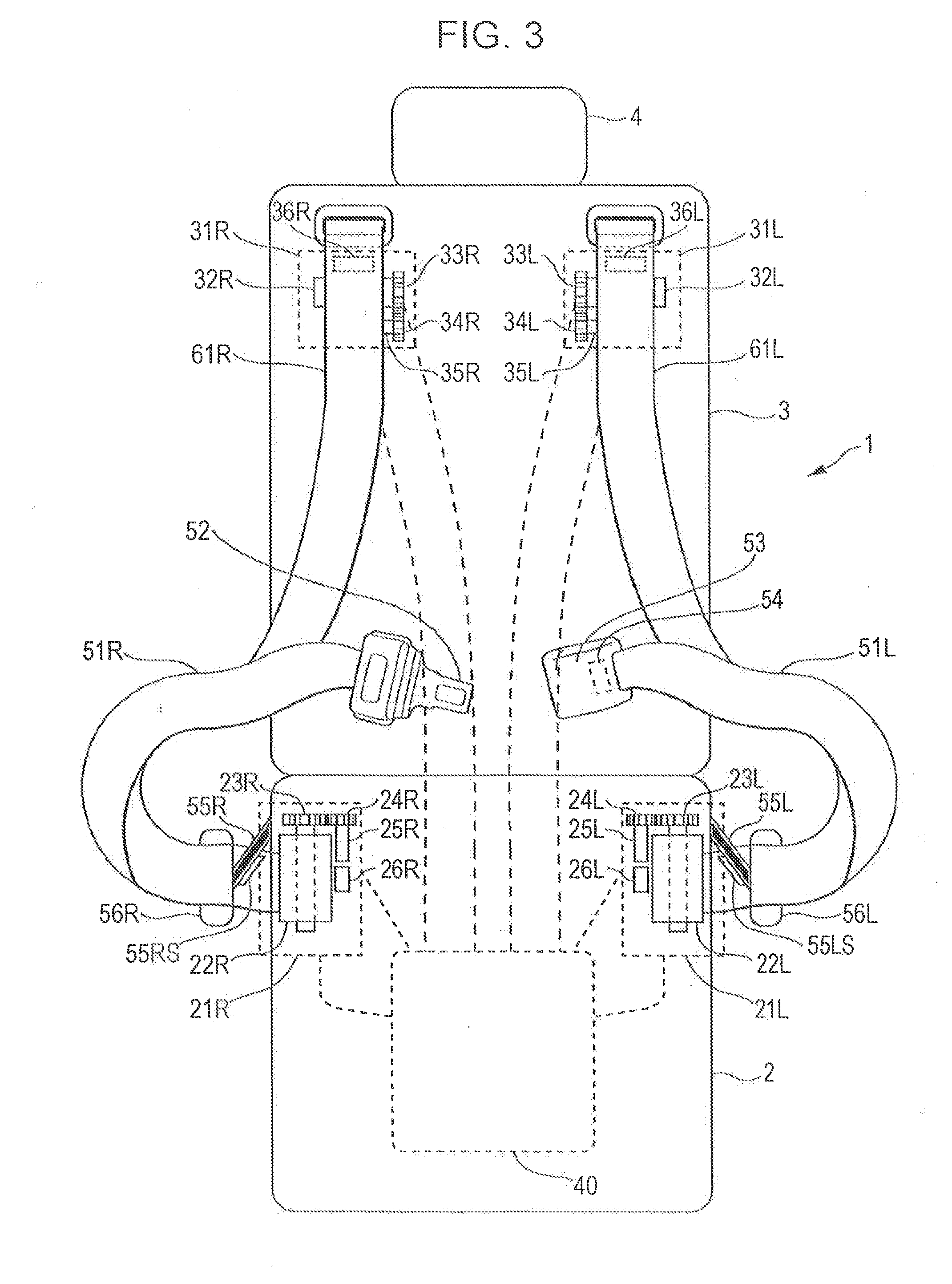

Four-point seat belt device

ActiveUS20140265292A1Reduce loosenessBody is inhibitedBelt retractorsBelt control systemsEngineeringConductor Coil

A four-point seat belt device includes right and left lap belts to press the hipbone of a passenger sitting in a seat, two shoulder belts to press both shoulders of the passenger, a driving unit to perform winding of the lap belts and the shoulder belts, and a latching detecting unit to detect a state in which the lap belts and the shoulder belts are latched via a buckle. The driving unit controls the lap belts in the case that the latching detecting unit has detected latching.

Owner:SUBARU CORP

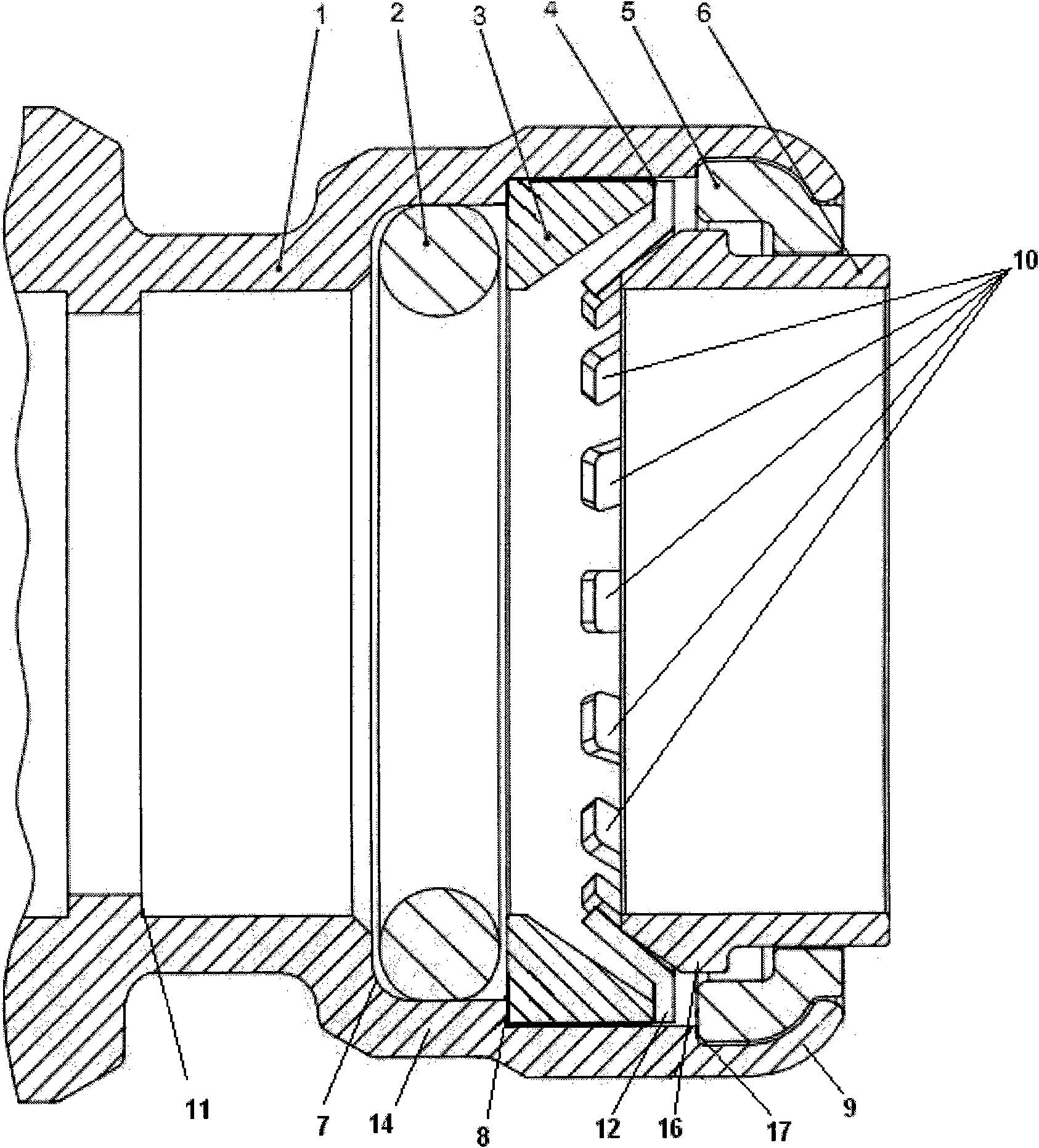

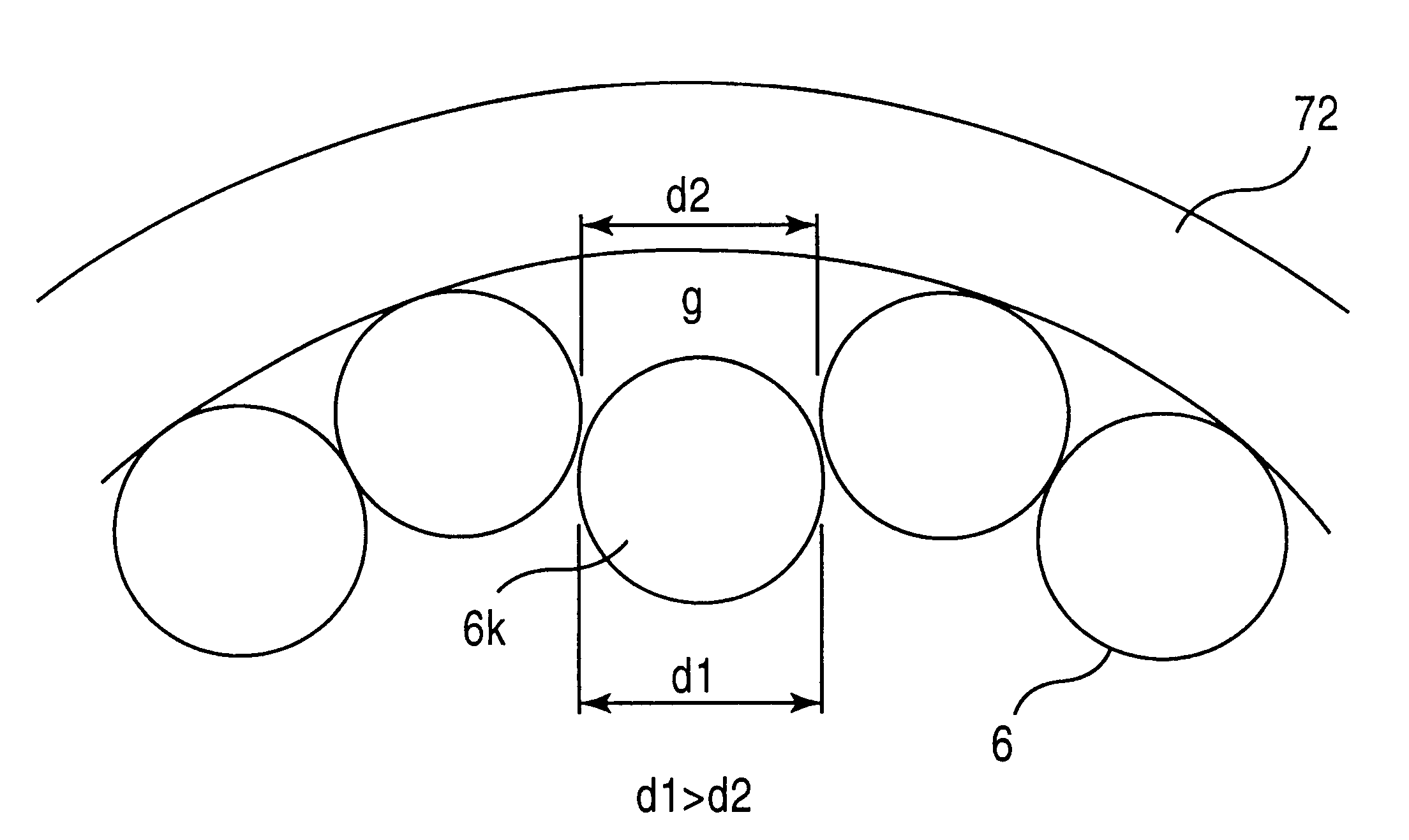

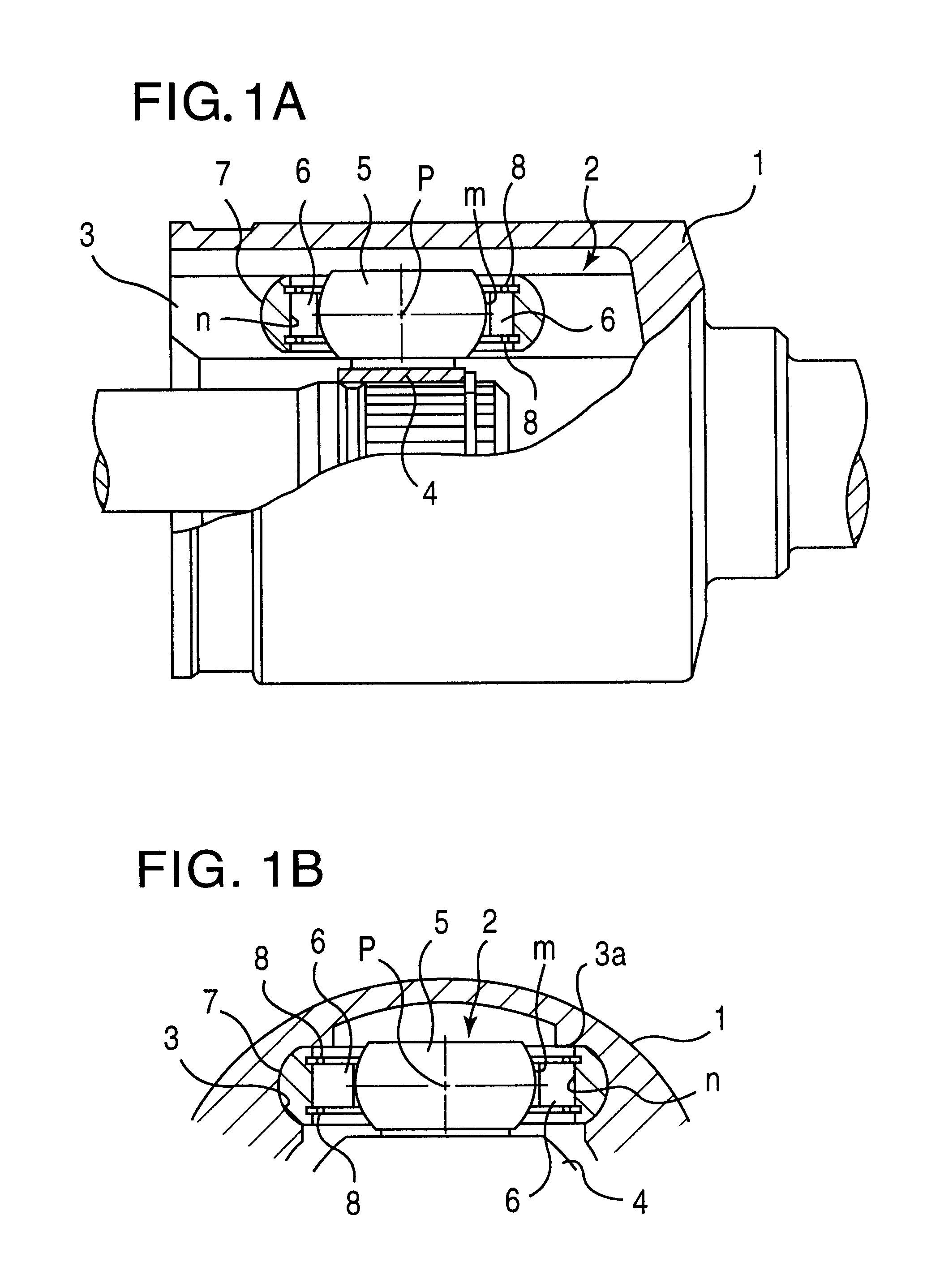

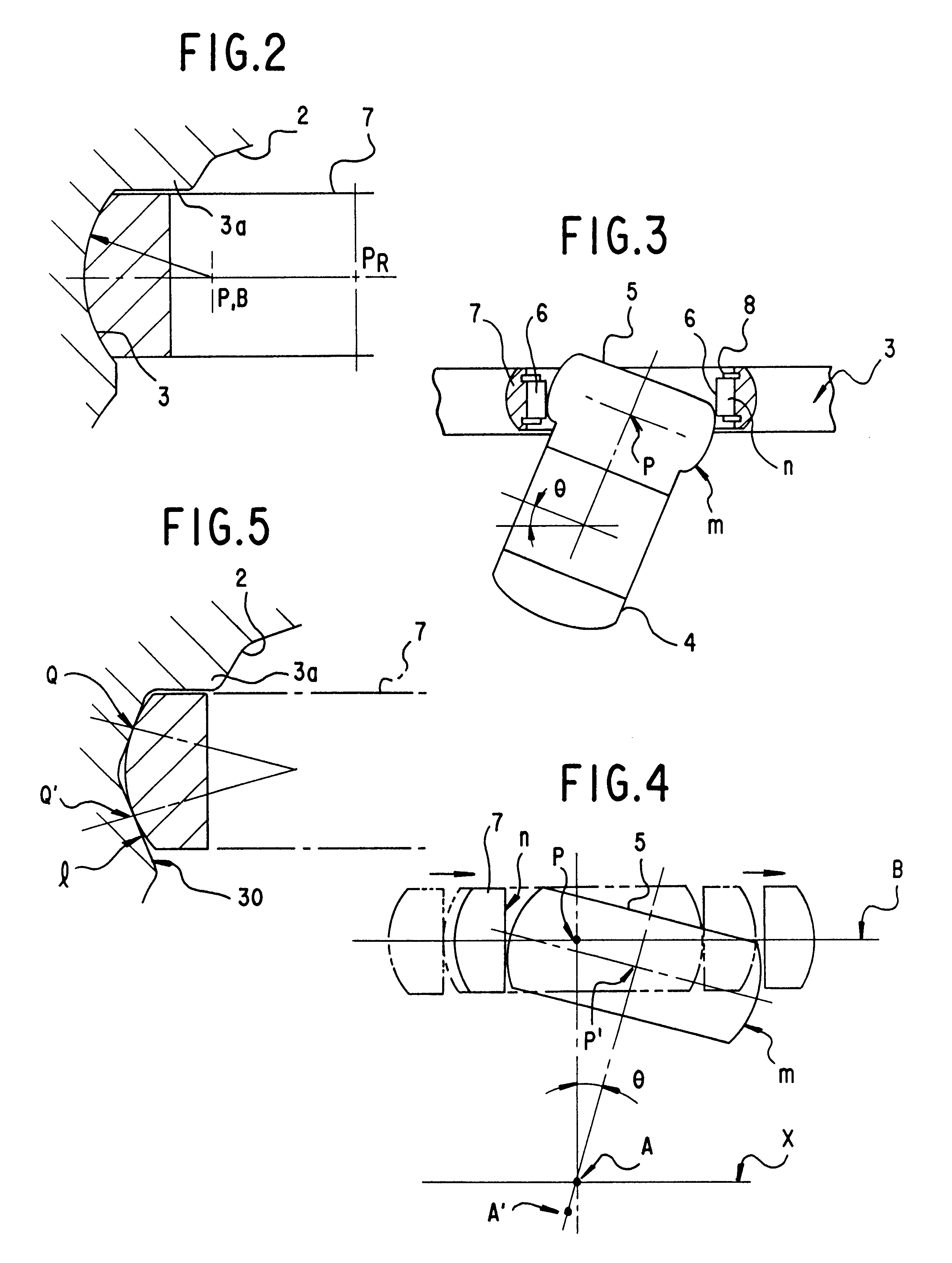

Tripod type constant velocity universal joint

A tripod type constant velocity universal joint which includes an outer member having three axially extending track grooves formed in an inner circumferential surface thereof, each of the track grooves having roller guide surfaces on a pair of opposing side walls thereof, a tripod member having three radially projecting trunnions, and rollers rotatably carried on the trunnions, respectively, through a series of cylindrical rolling elements, the rollers being accommodated in the track grooves, respectively, so that the rollers are movable axially of the outer member with each said roller rolling along one of the opposing roller guide surfaces. The cylindrical rolling elements roll directly on an outer circumferential surface of the trunnion. Each said roller has an annular radial projection at each axial end thereof. The roller with the annular projections and a series of the rolling elements retained along an inner periphery of said roller form an independent assembly capable of preventing the rolling elements from dispersing prior to mounting the assembly on the trunnion.

Owner:NTN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com