Method for material concentrating in ternary precursor synthesis reaction

A synthesis reaction and precursor technology, which is applied in the field of material concentration in the synthesis reaction of ternary precursors, can solve the problems of reflux growth of concentrated particles, loss of material particles, unqualified products, etc., and achieve the goal of reducing clogging, avoiding leakage and reducing pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

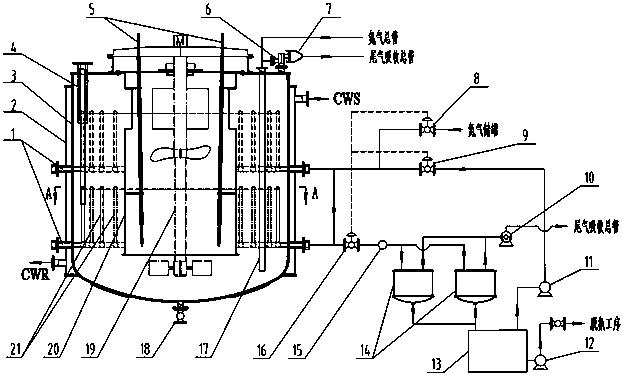

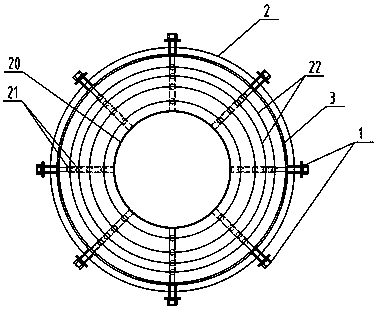

[0032] Refer to attached Figure 1-2 , a method for concentrating materials in a ternary precursor synthesis reaction, comprising a reactor, a negative pressure tank, and a mother liquor pool connected in sequence; a reactor jacket is arranged outside the reactor, a breathing valve is arranged on the upper part of the reactor, and the inlet of the breathing valve is It is connected to the nitrogen main pipe, and the outlet of the breathing valve is connected to the exhaust gas absorption main pipe. Inside the reactor, there are agitator, draft tube, feeding pipe, nitrogen conduit, liquid level gauge, pigging pipe, filter rod; the agitator is composed of reaction The top of the center of the kettle extends to the bottom of the reactor, and the upper part of the draft tube connects to the top of the reactor and covers the outside of the agitator; one end of the feed pipe is connected to the upstream batching process, and the other end extends into the reactor through the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com