Patents

Literature

464results about "Inert gas production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalytic reactive component reduction system and methods for the use thereof

ActiveUS7694916B2Minimizes ventingReduce riskOrganic chemistryIndirect heat exchangersGas phaseEngineering

Owner:PHYRE TECH

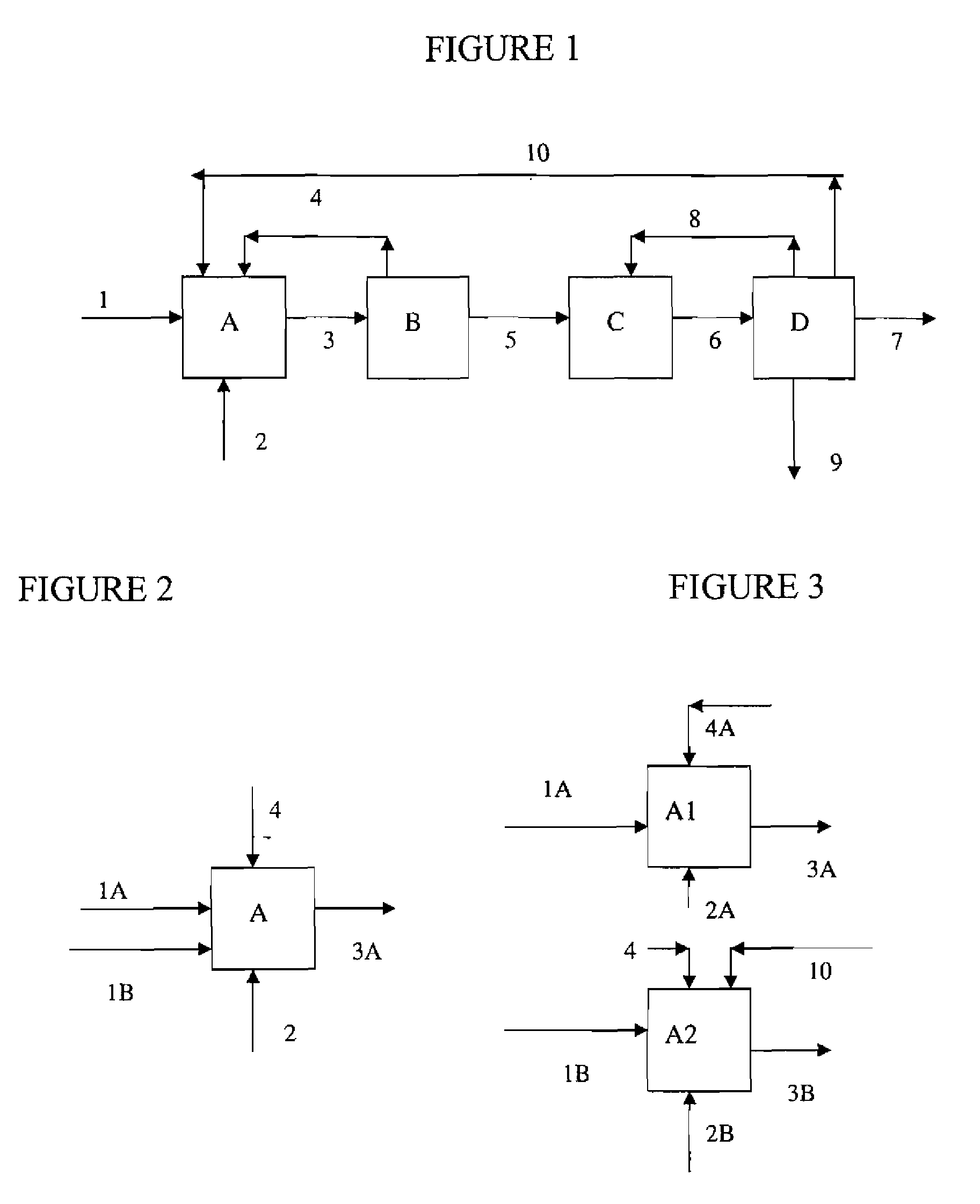

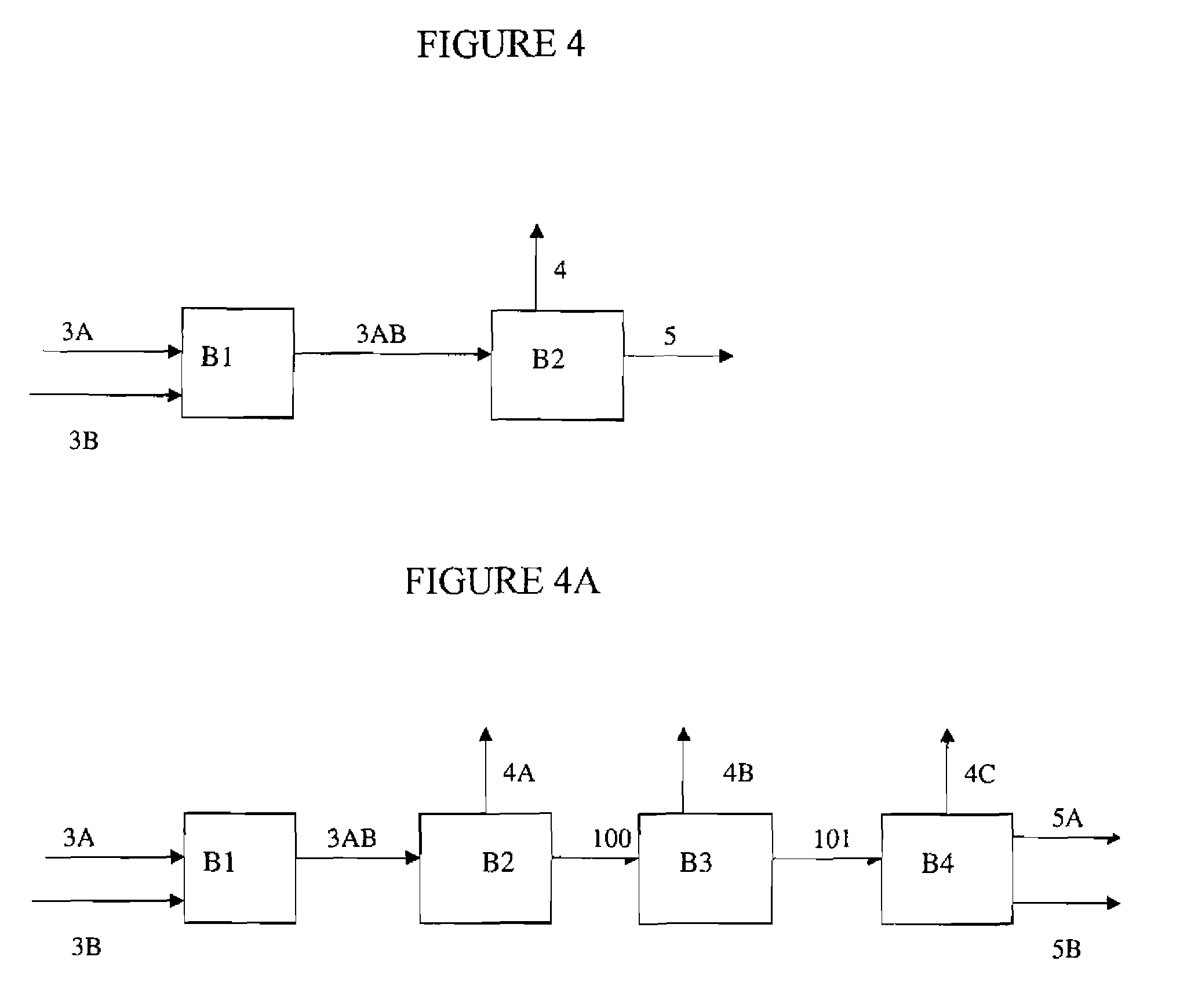

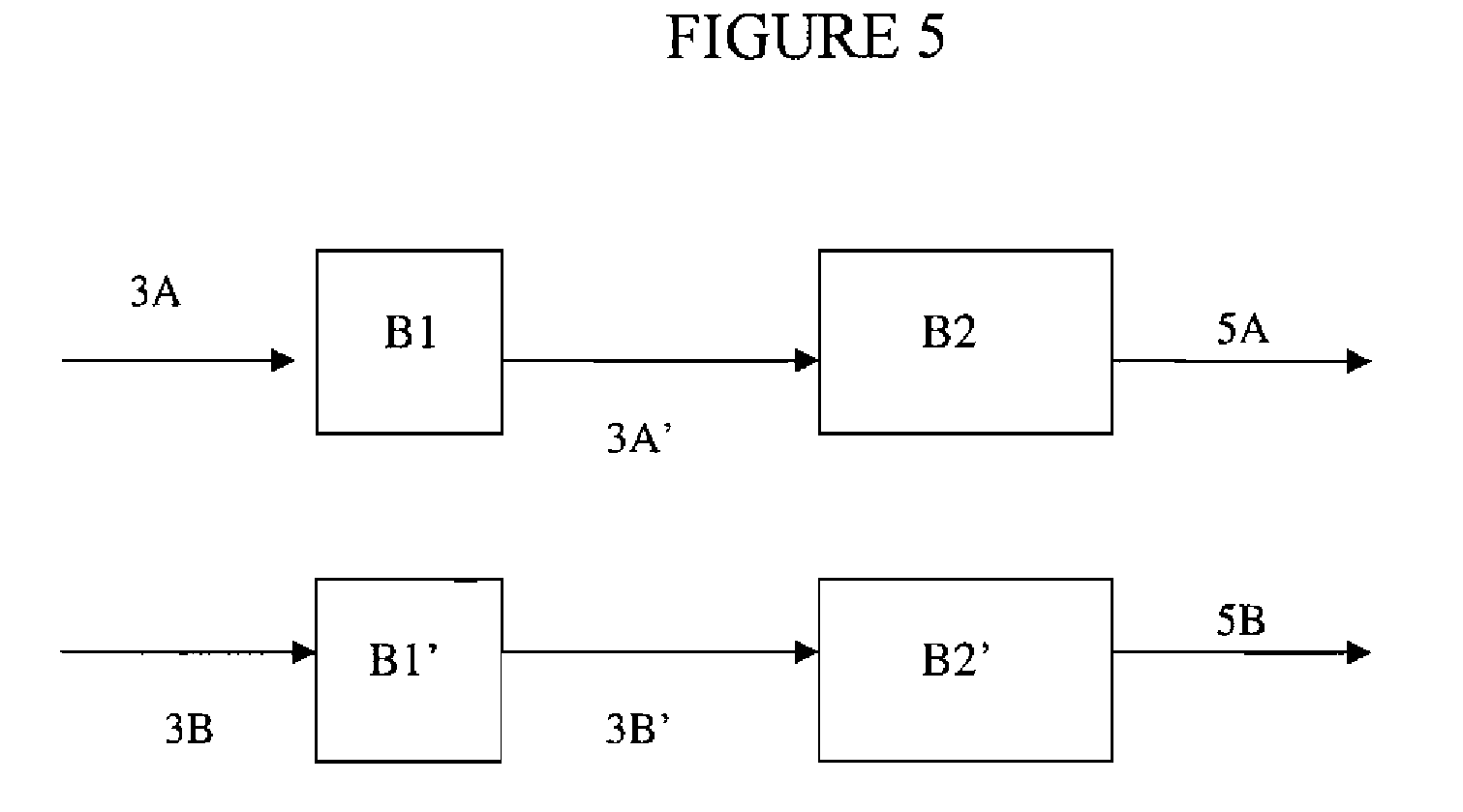

Process for the manufacture of fluorinated olefins

ActiveUS20090234165A1Good economic advantagePreparation by dehalogenationSequential/parallel process reactionsHexafluoropropylenePentafluoropropane

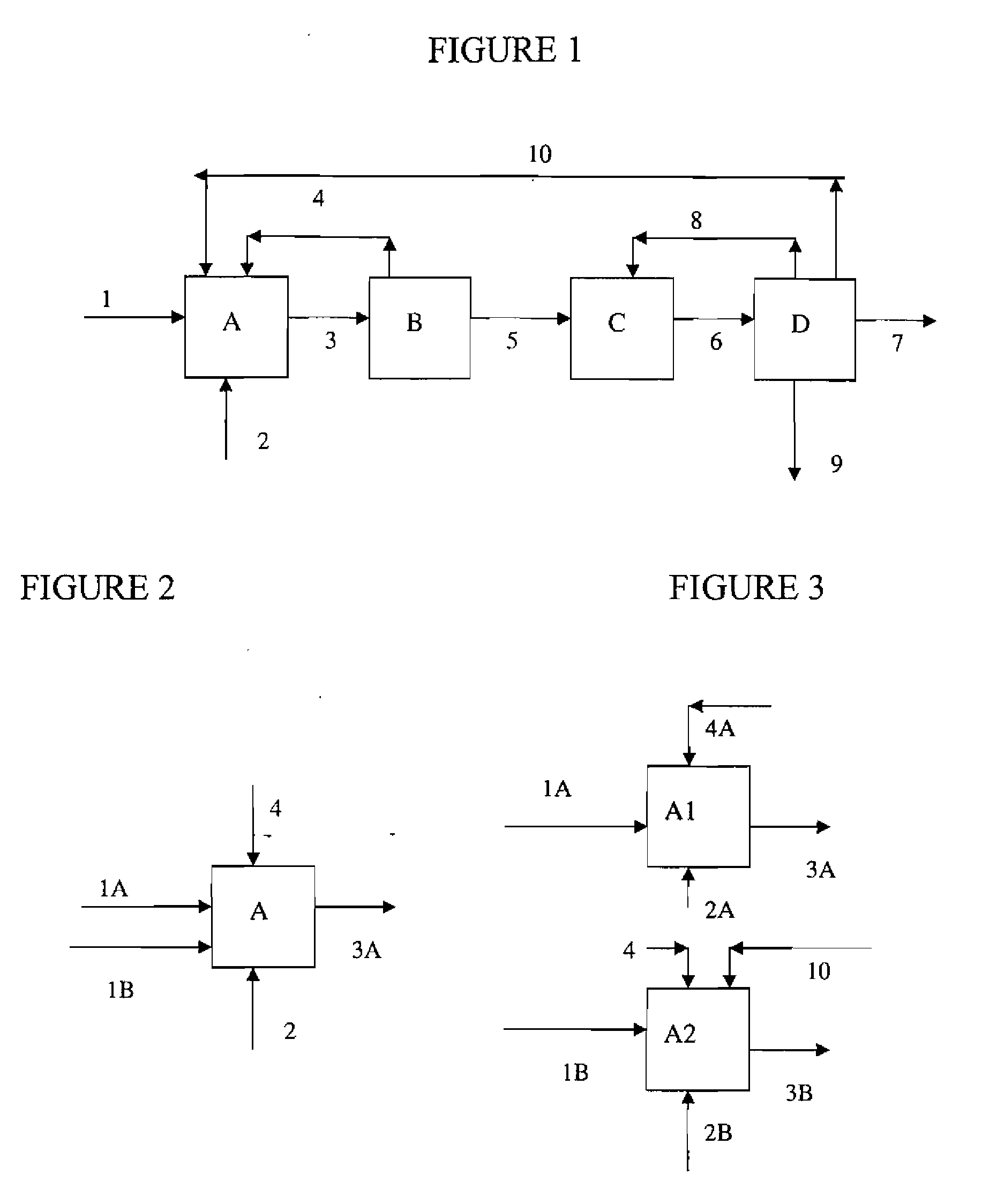

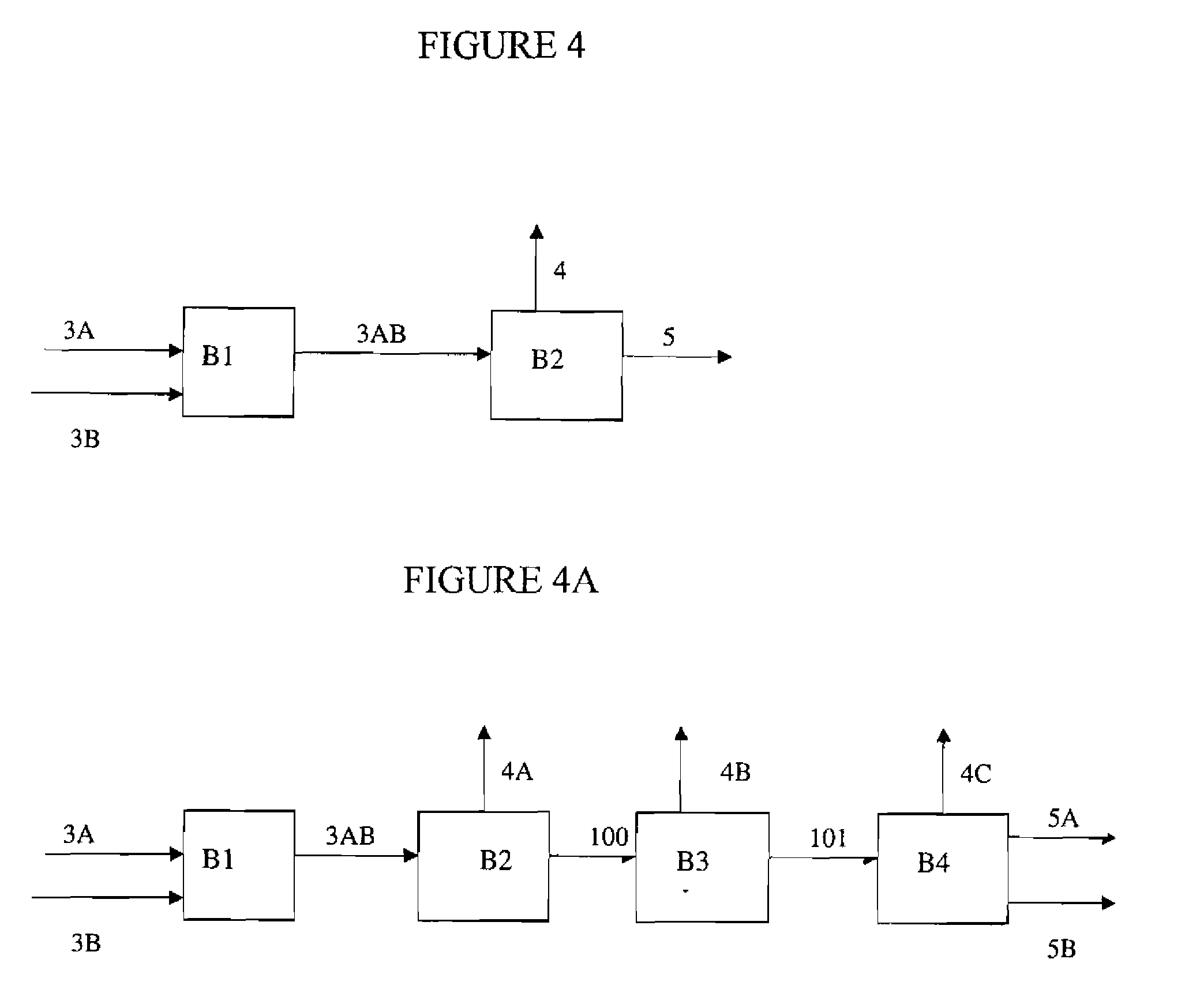

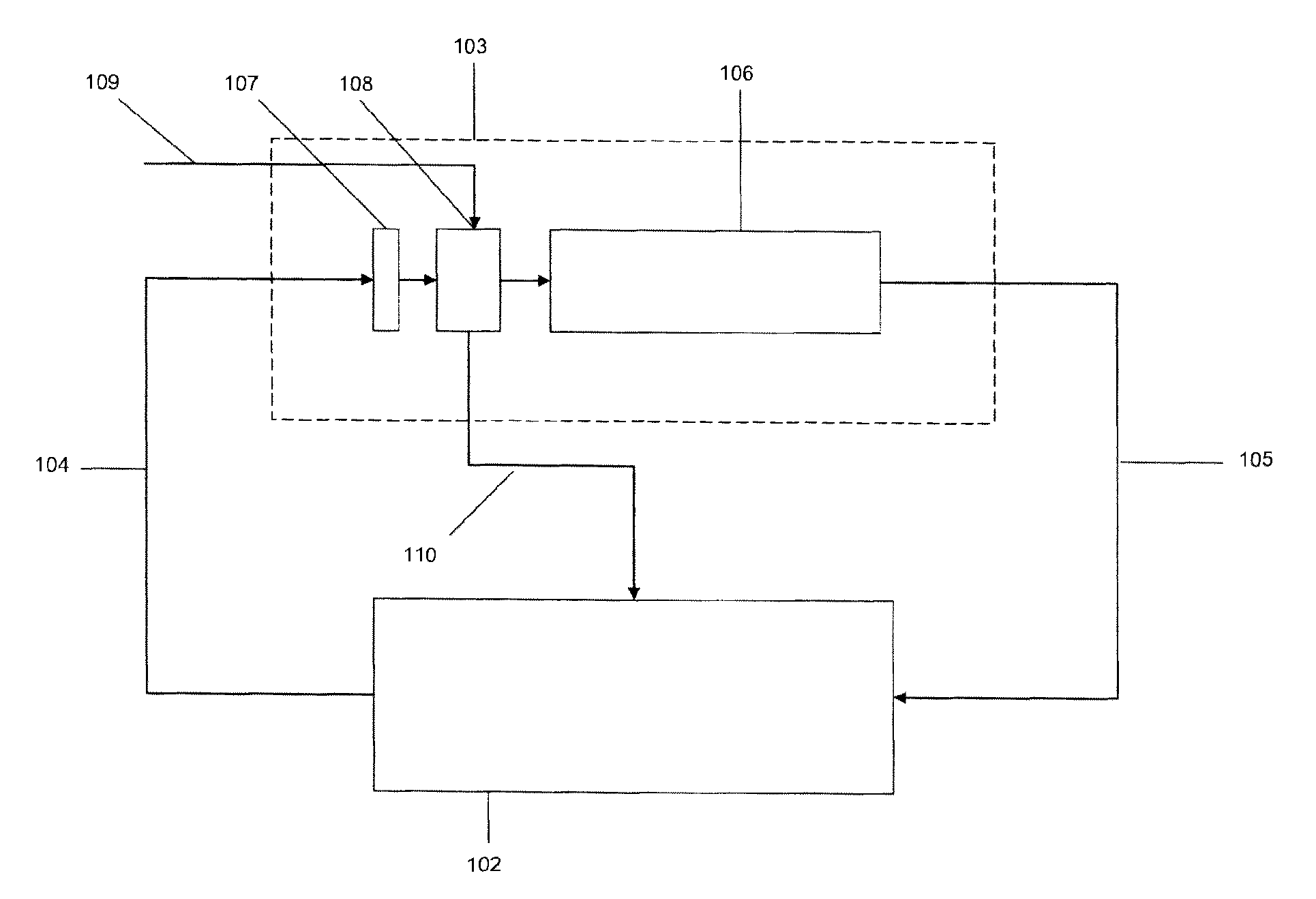

A method for producing 1,1,1,2-tetrafluoropropene and / or 1,1,1,2,3 -pentafluoropropene using a single set of four unit operations, the unit operations being (1) hydrogenation of a starting material comprising hexafluoropropene and optionally recycled 1,1,1,2,3-pentafluoropropene; (2) separation of the desired intermediate hydrofluoroalkane, such as 1,1,1,2,3,3-hexafluoropropane and / or 1,1,1,2,3-pentafluoropropane; (3) dehydrofluorination of the intermediate hydrofluoroalkane to produce the desired 1,1,1,2-tetrafluoropropene and / or 1,1,1,2,3-pentafluoropropene, followed by another separation to isolate the desired product and, optionally, recycle of the 1,1,1,2,3-pentafluoropropene.

Owner:HONEYWELL INT INC

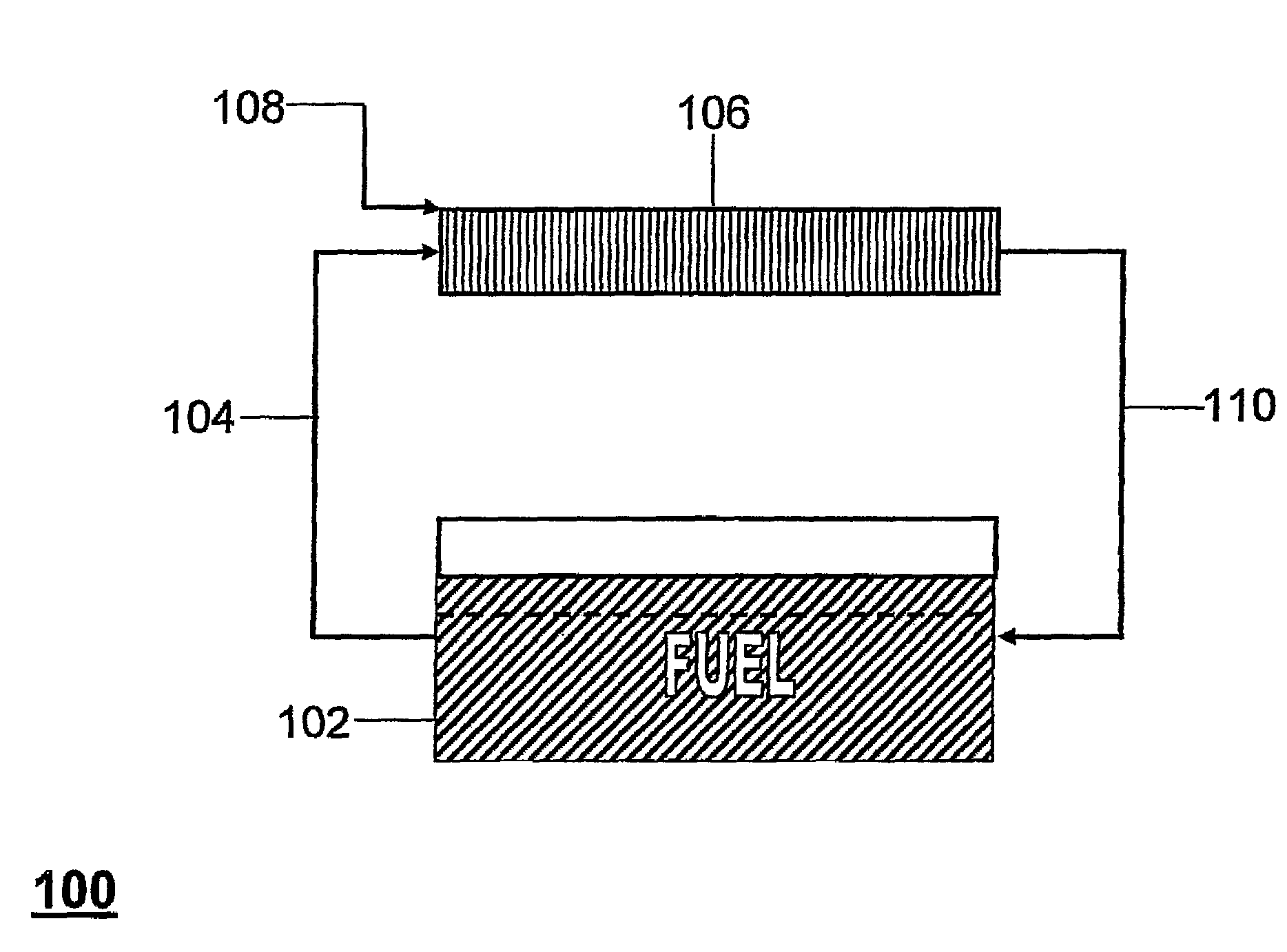

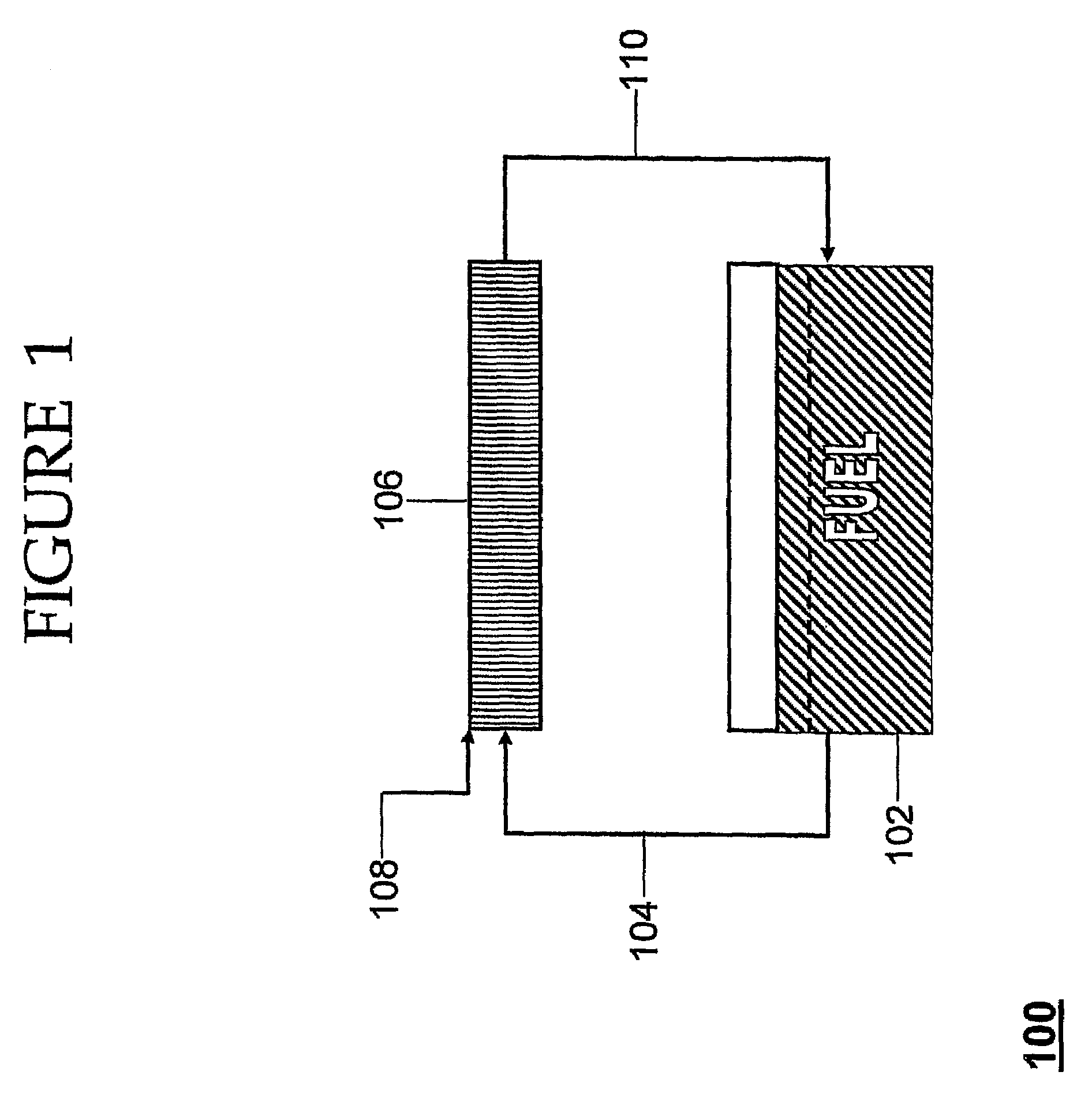

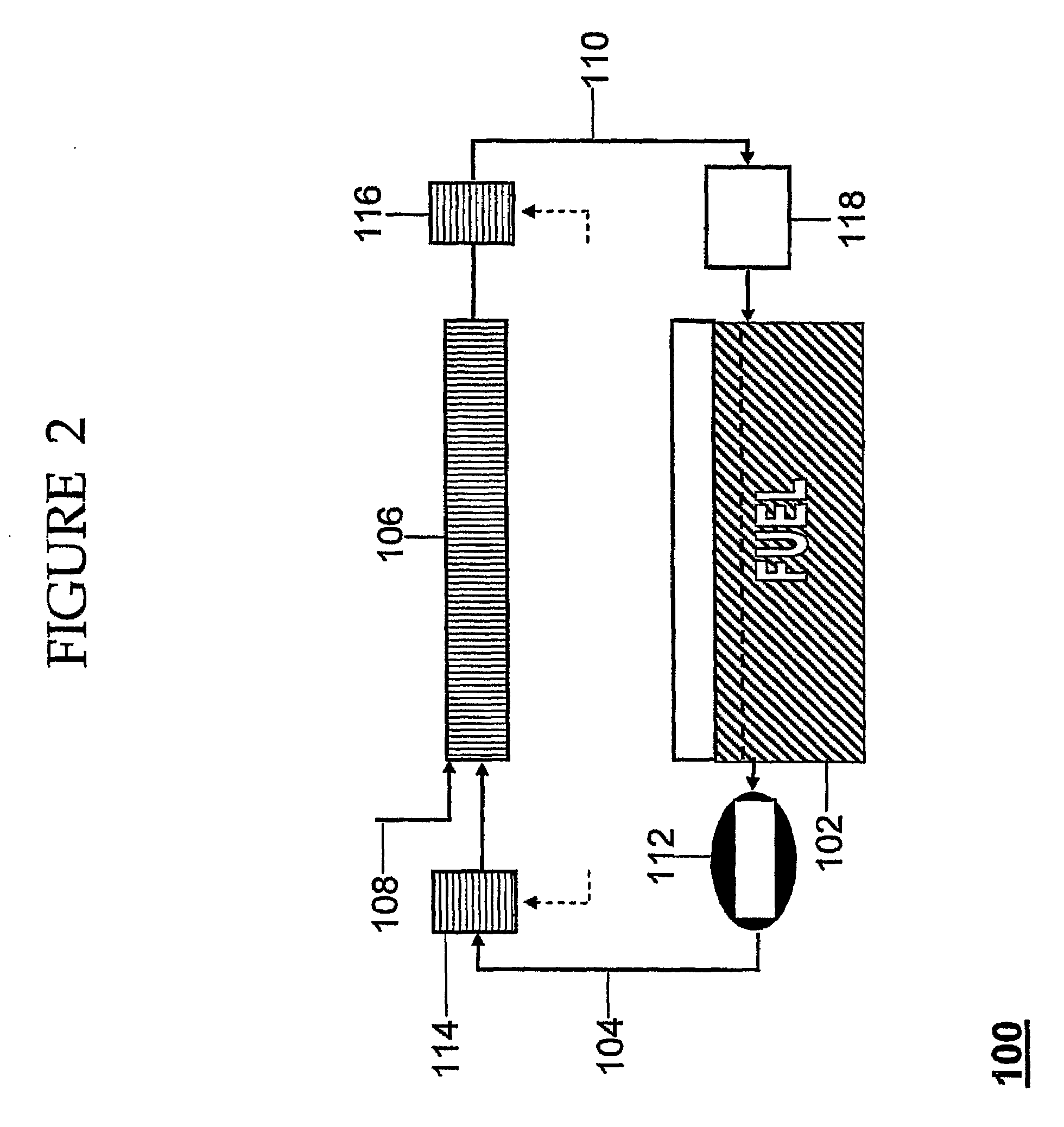

Reactive component reduction system and methods for the use thereof

ActiveUS7896292B2Reduce riskMinimizes ventingUsing liquid separation agentIndirect heat exchangersGas phaseEngineering

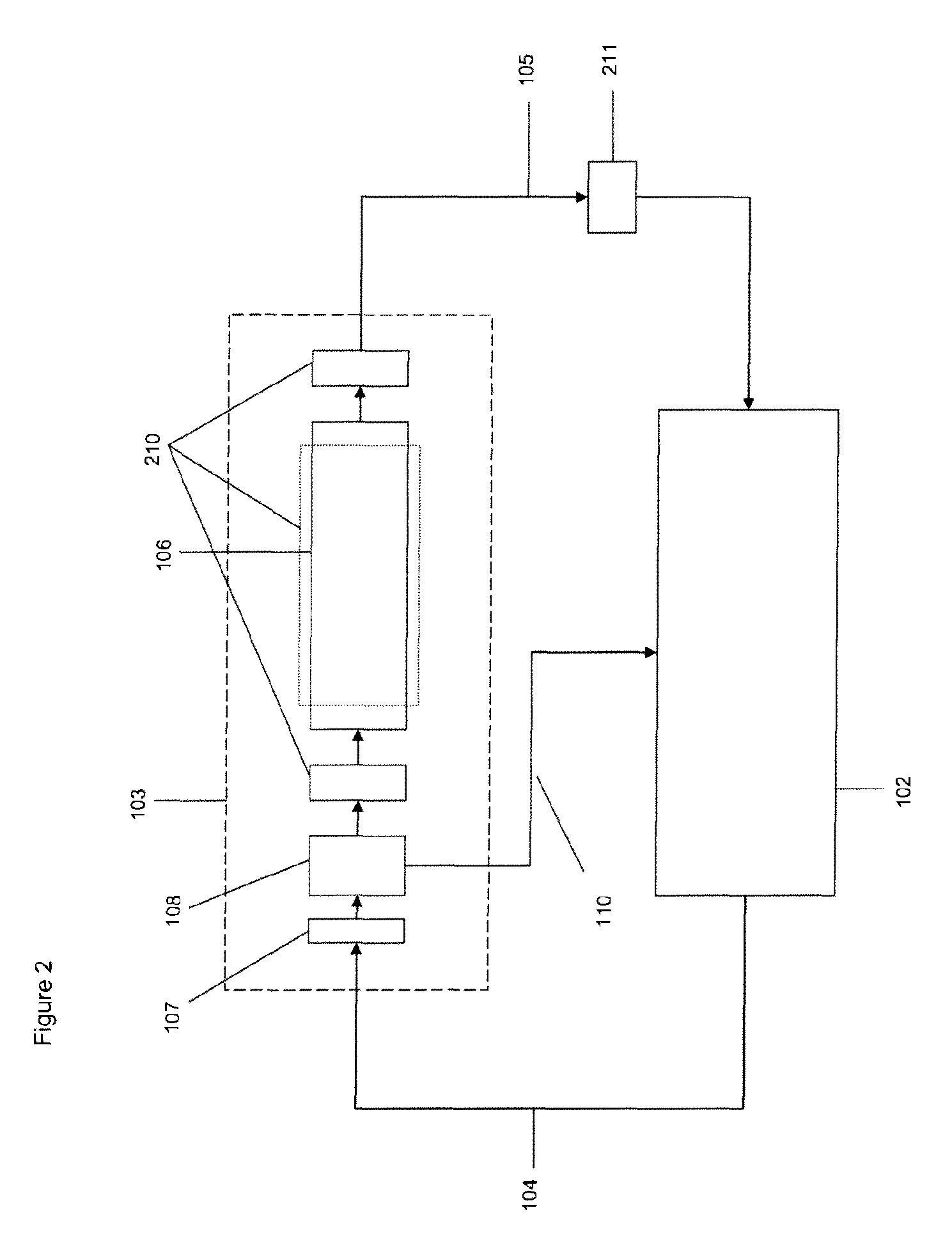

In accordance with the present invention, there are provided simplified systems and methods for catalytically deactivating, removing, or reducing the levels of reactive component(s) from the vapor phase of fuel storage tanks. The simple apparatus described herein can be utilized to replace complex systems on the market. Simply stated, in one embodiment of the invention, the vapor phase from the fuel tank is passed over a catalytic bed operated at appropriate temperatures to allow the reaction between free oxygen and the fuel vapor by oxidation of the fuel vapor, thus deactivating reactive component(s) in the gas phase.

Owner:PHYRE TECH

Active gases and treatment methods

InactiveUS20120064016A1Optimise populationNegative side effectCosmetic preparationsBiocideKryptonNoble gas

A method of making an active gas by generating a glow discharge, non-thermal plasma, in a gas mixture of a carrier gas and a more readily ionisable gas. The gas mixture is exposed to water vapour at or downstream from the generator to form the active gas. The gas mixture includes helium as the carrier gas and up to 40% by volume of at least one noble gas such as argon, krypton, or xenon as the more readily ionisable gas. The gas mixture is ejected at a temperature between 5° C. to 42° C. The active gas may be used for oral treatment such as cosmetic whitening of teeth, medical or non-clinical cleaning of teeth or for cleaning laundry or dishwashing items.

Owner:LINDE AG

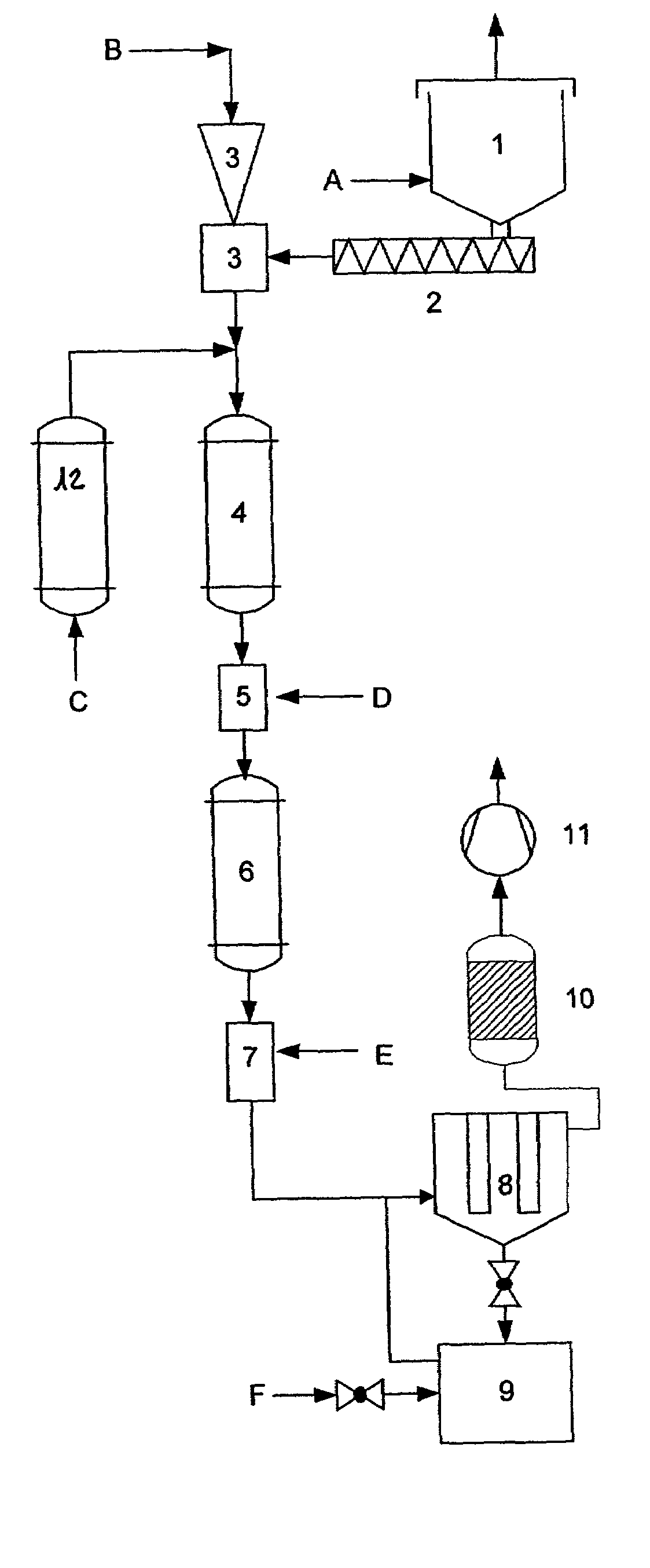

Process and apparatus for the thermal treatment of pulverulent substances

InactiveUS7288501B2Safe handlingMaterial nanotechnologyCatalyst activation/preparationGas solidThermal treatment

Process and apparatus for the thermal treatment of pulverulent substances, in which the pulverulent substance is dispersed in a carrier gas and is passed in a continuous manner through a heated reactor where it is thermally treated and is then quenched by a cooling medium and is collected in a gas-solids separating unit.

Owner:UMICORE AG & CO KG

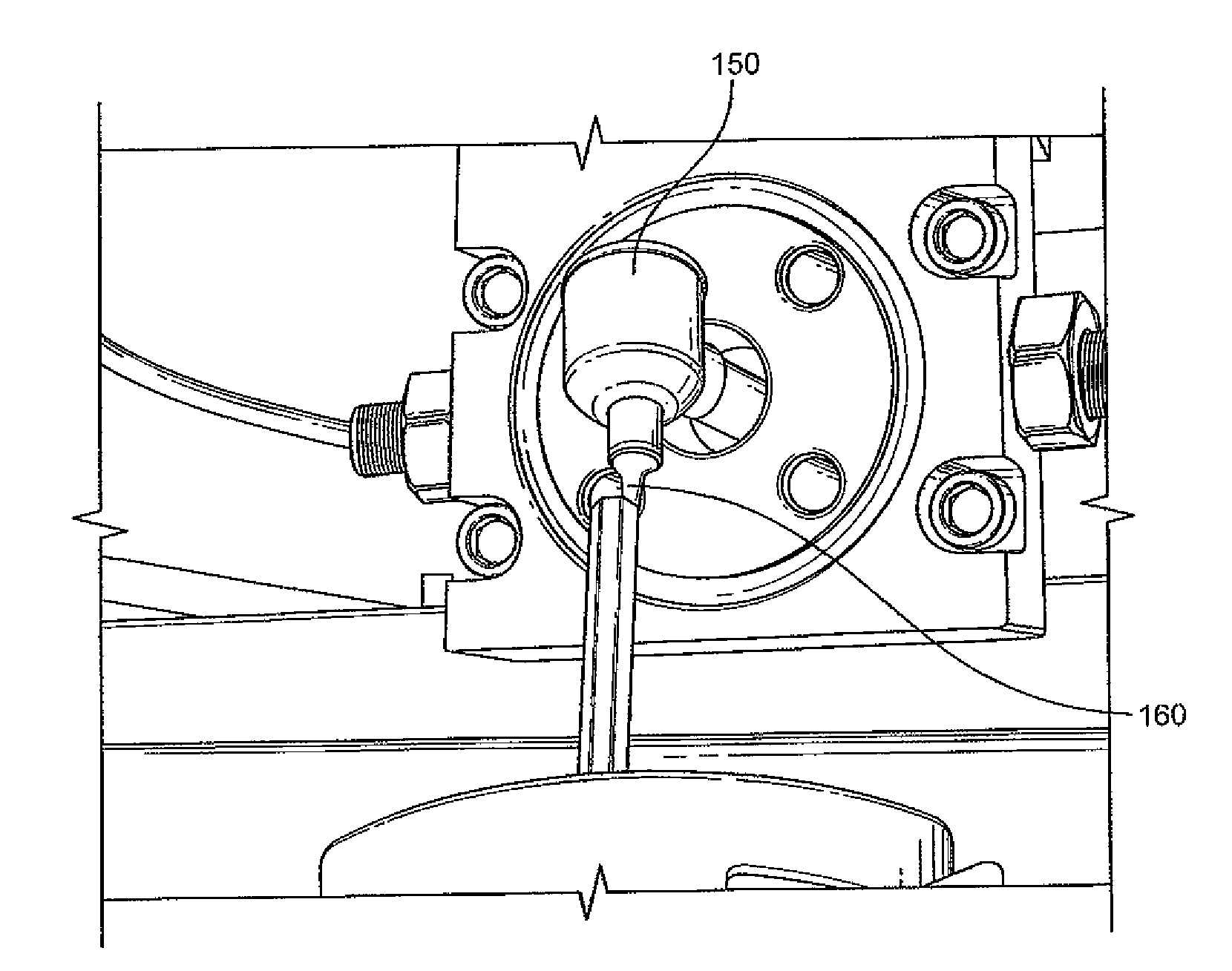

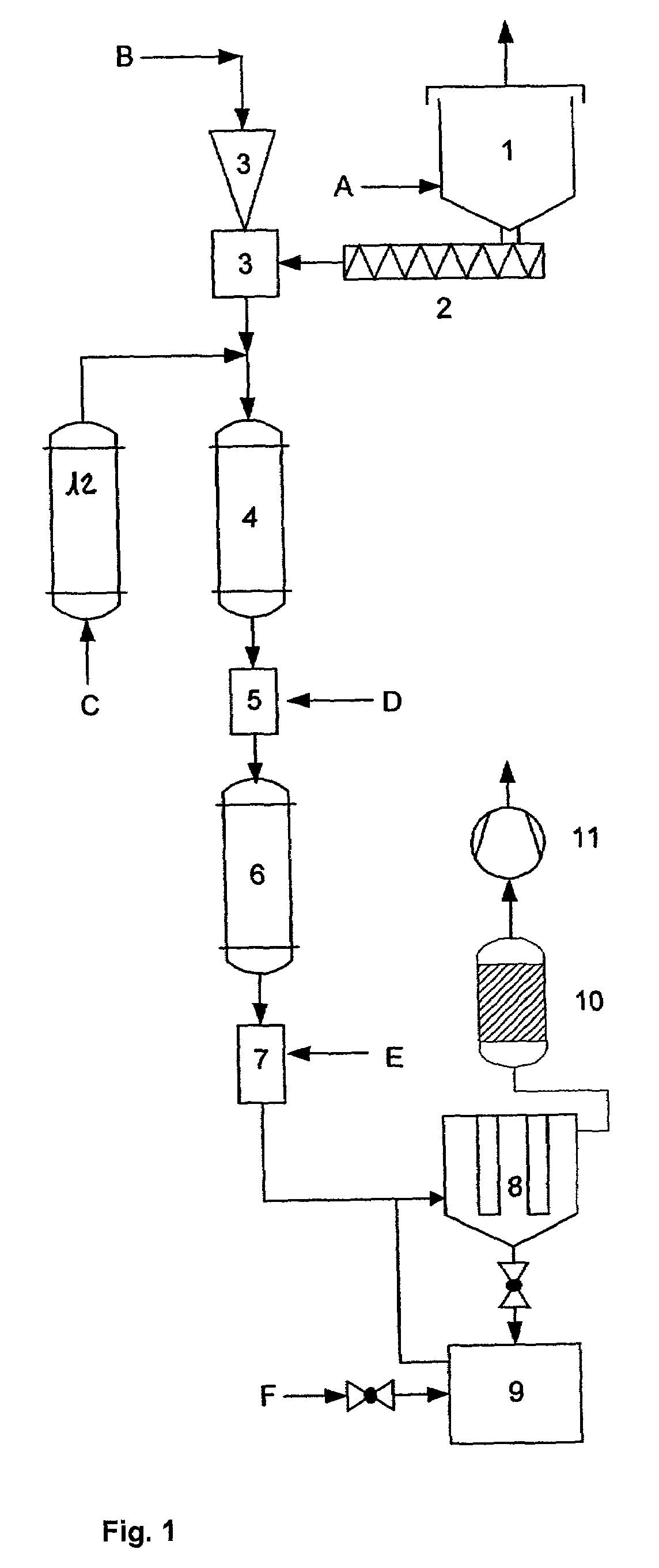

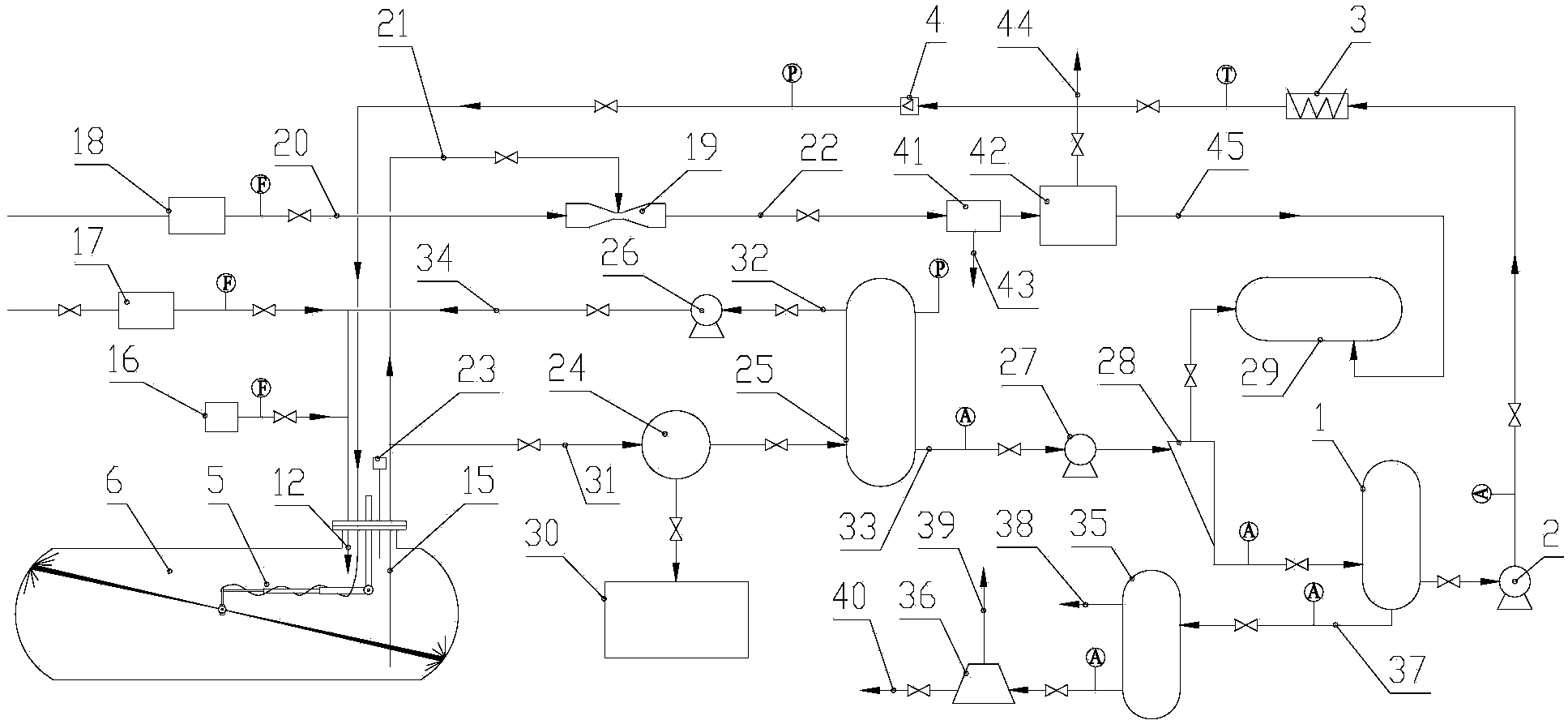

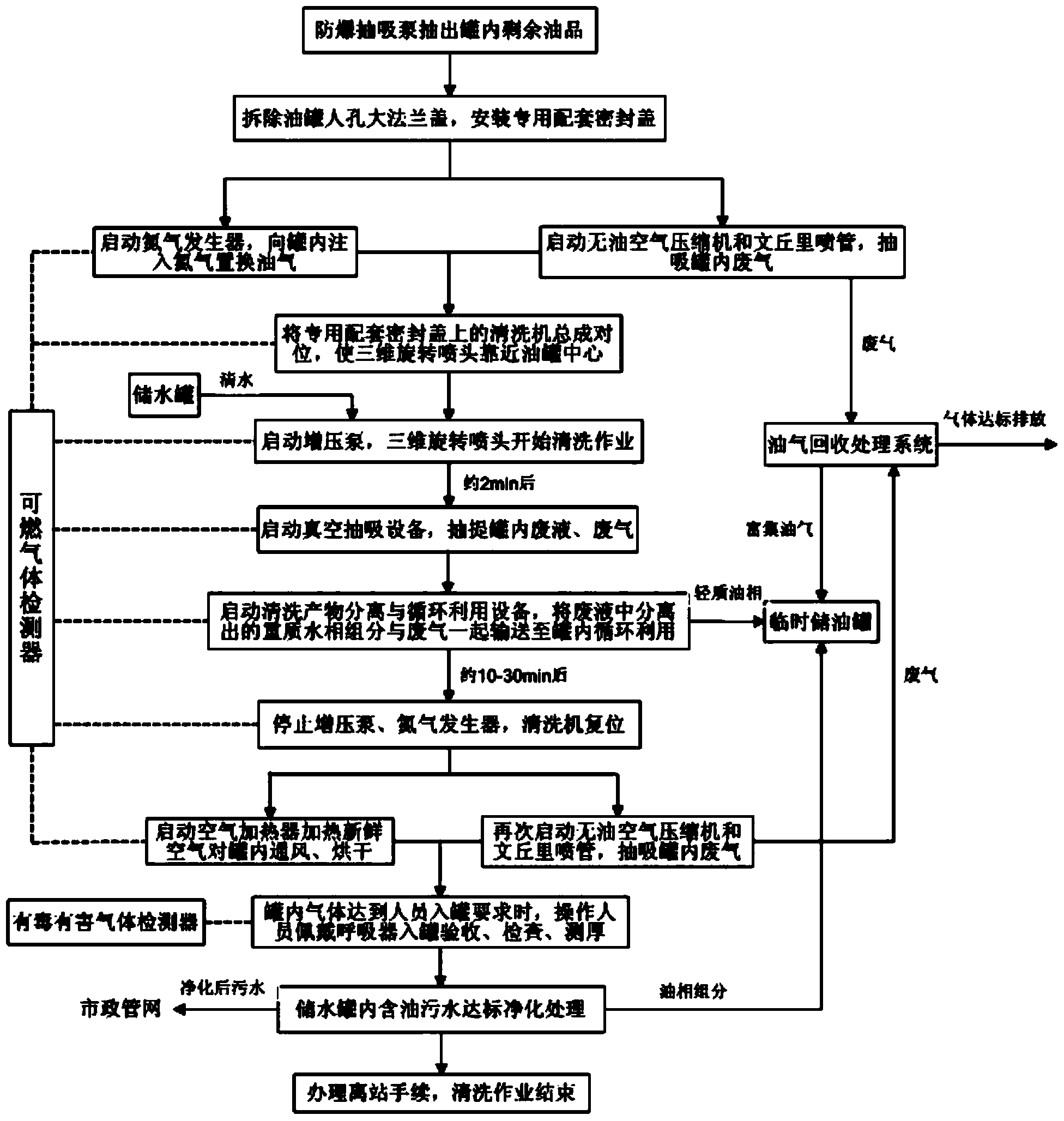

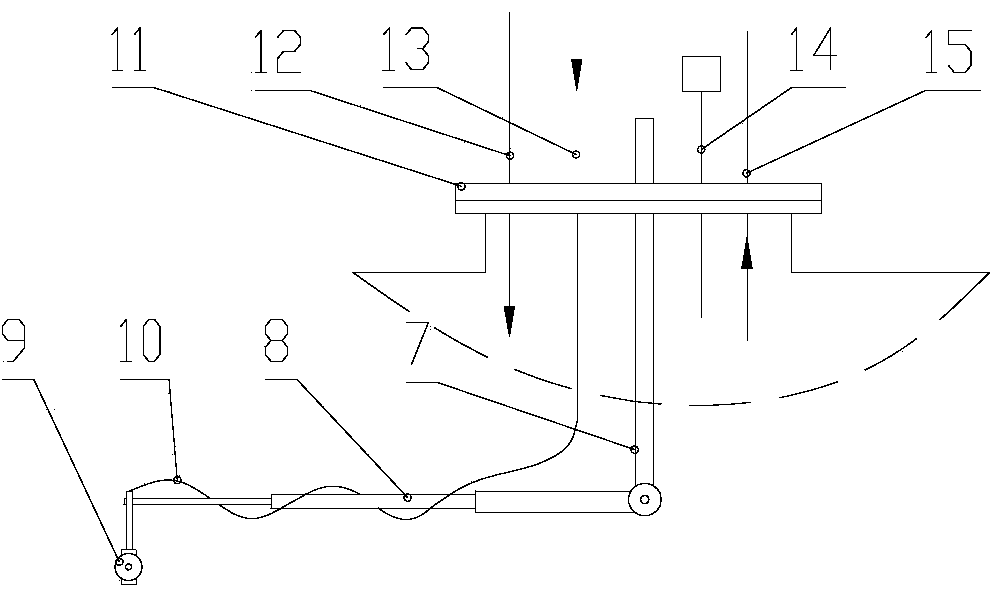

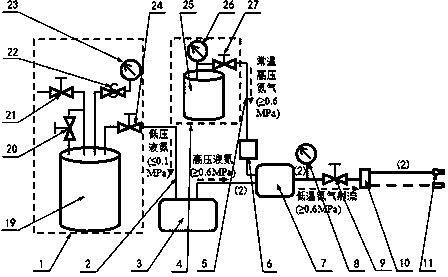

Mechanical cleaning system for underground storage tank of filling station

ActiveCN104001702ACompact structureWater/sewage treatment by centrifugal separationHollow article cleaningNitrogen generatorWater storage tank

The invention discloses a mechanical cleaning system for an underground storage tank of a filling station. The mechanical cleaning system comprises a low-pressure jet cleaning device, an air replacement device, a gas atmosphere monitoring device, a cleaned-away dirt separation and recycling device, an oily sewage discharge standardization treatment device and an oil and gas recovery treatment device. The low-pressure jet cleaning device comprises a water storage tank, a booster pump, a heater, a turbine flowmeter and a cleaning machine, wherein the water storage tank, the booster pump, the heater, the turbine flowmeter and the cleaning machine are connected in sequence through pipelines. The air replacement device comprises a nitrogen generator, an air heater and an oilless air compressor. The oil and gas recovery treatment device comprises a precooler and an activated carbon adsorption tank, wherein the precooler and the activated carbon adsorption tank are connected with each other. The cleaned-away dirt separation and recycling device comprises a filter, a vacuum suction tank, a suction pump and an axial inlet hydrocyclone. The oily sewage discharge standardization treatment device comprises a compact vertical swirling air-floatation separation tank and a disk centrifuge. The mechanical cleaning system is intrinsically safe, efficient, environmentally friendly, compact in structure and capable of meeting related discharge requirements.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

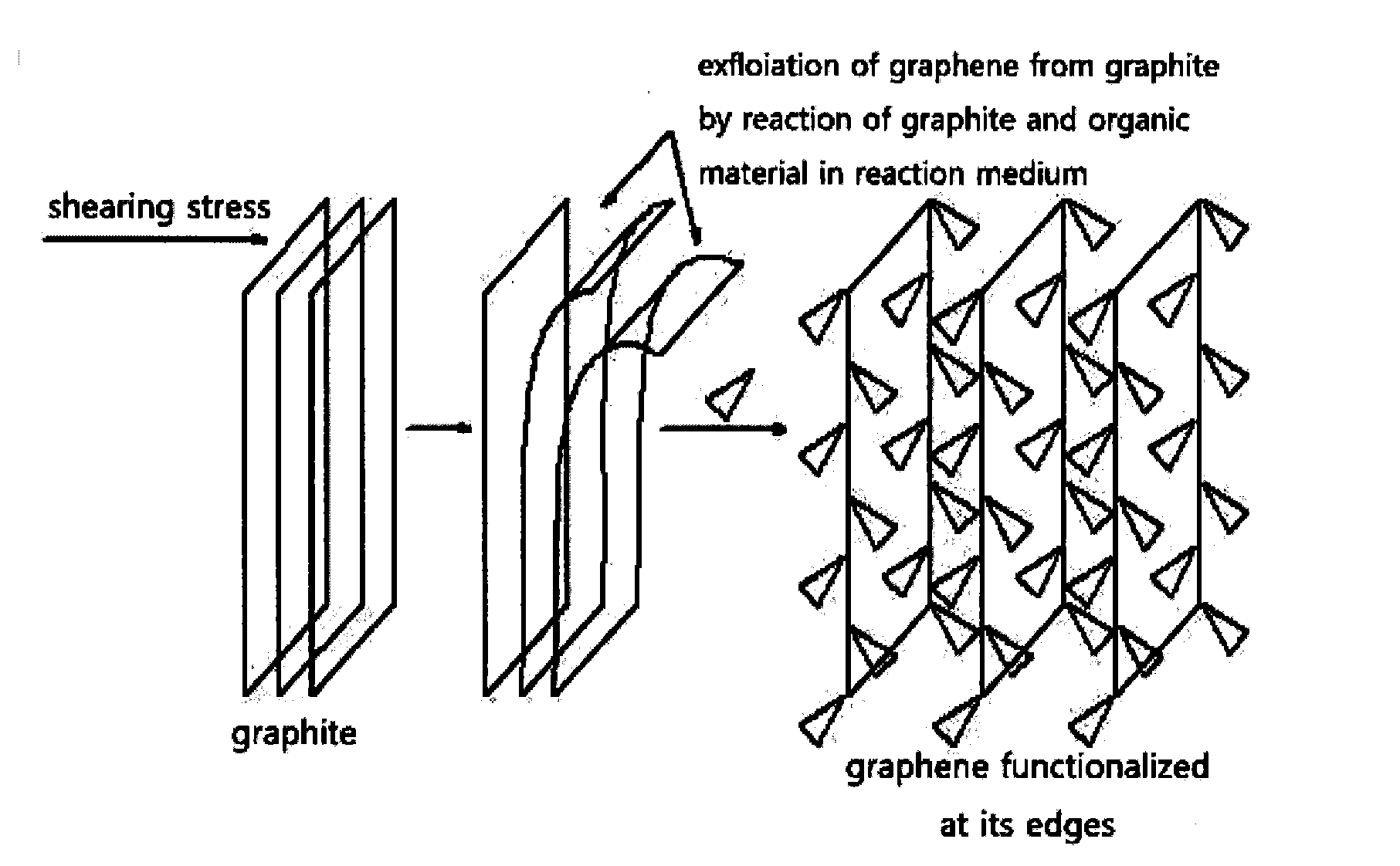

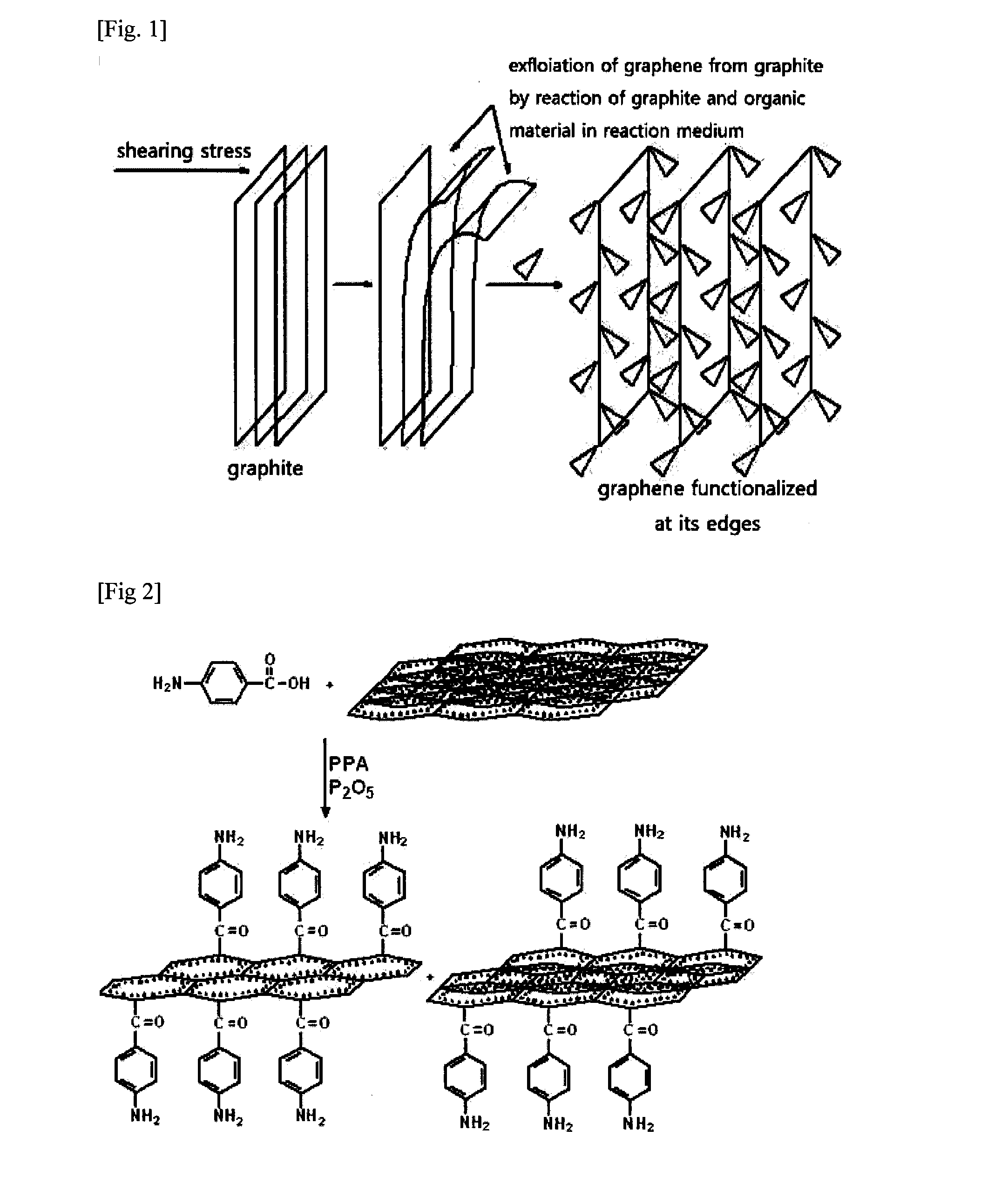

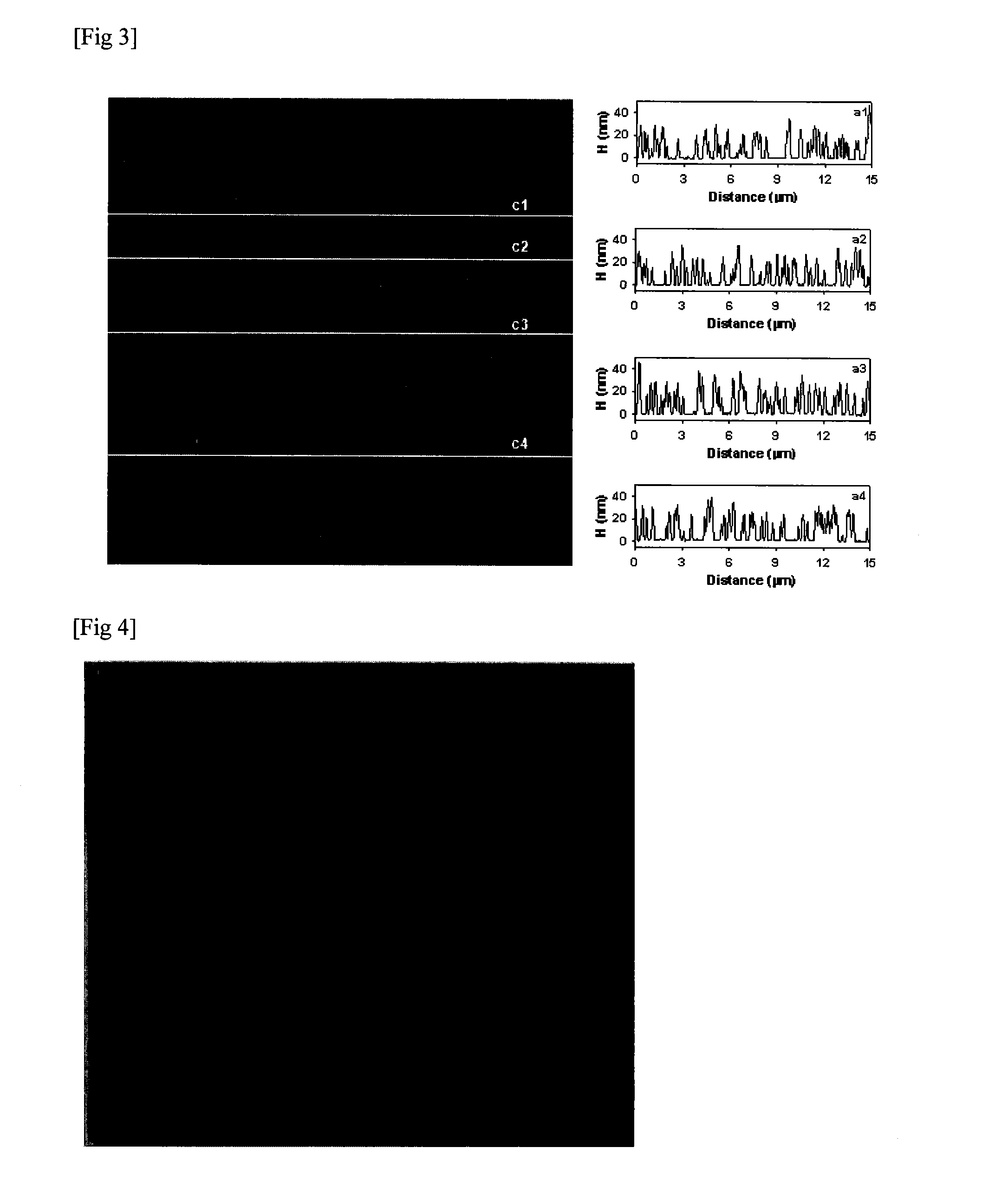

Graphene prepared by using edge functionalization of graphite

Disclosed is a method for producing graphene functionalized at its edge positions of graphite. Organic material having one or more functional groups is reacted with graphite in reaction medium comprising methanesulfonic acid and phosphorus pentoxide, or in reaction medium comprising trifluoromethanesulfonic acid, to produce graphene having organic material fuctionalized at edges. And then, high purity and large scaled graphene and film can be obtained by dispersing, centrifugal separating the functionalized graphene in a solvent and reducing, in particular heat treating the graphene. According to the present invention graphene can be produced inexpensively in a large amount with a minimum loss of graphite.

Owner:UNIST ULSAN NAT INST OF SCI & TECH

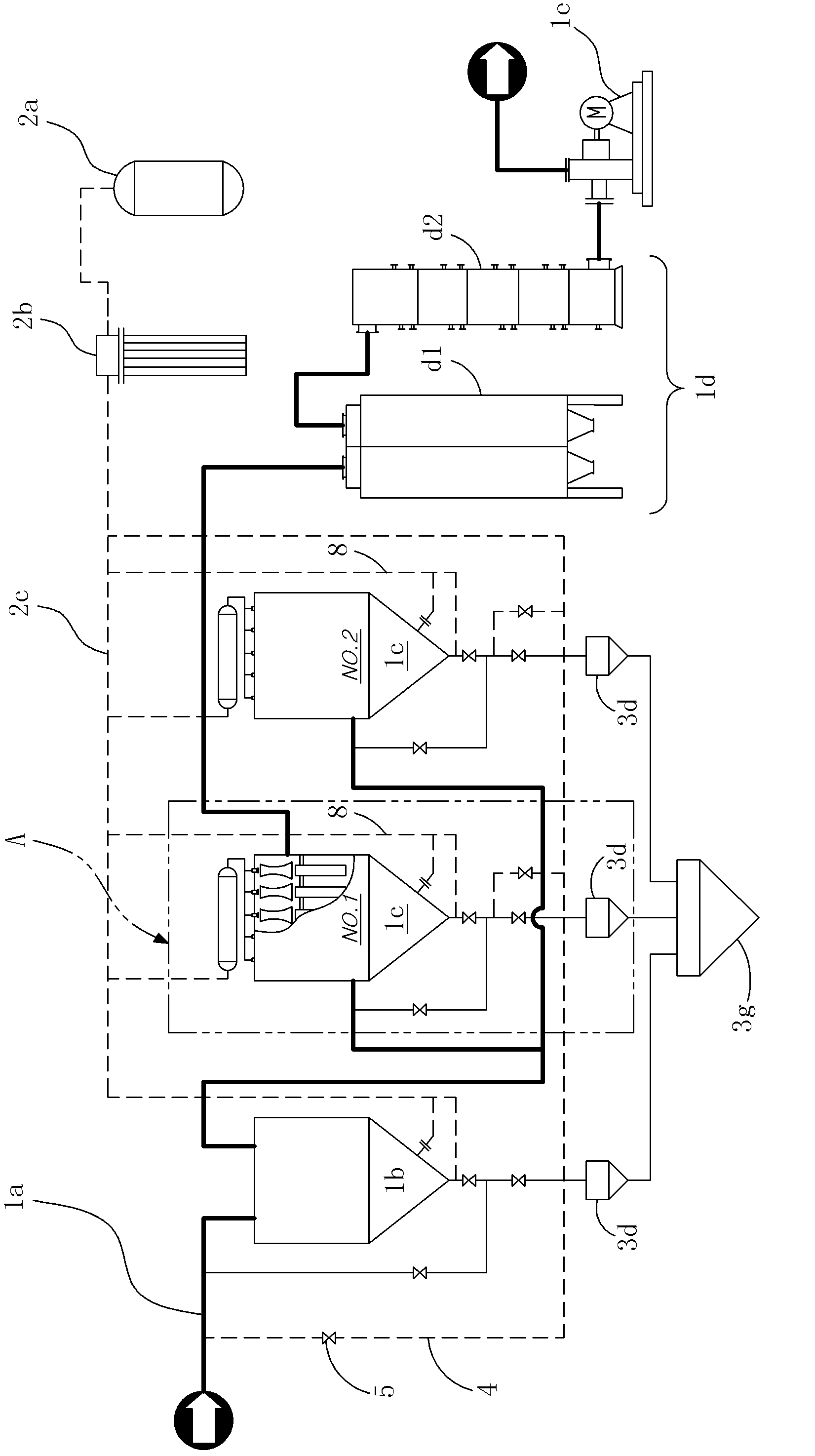

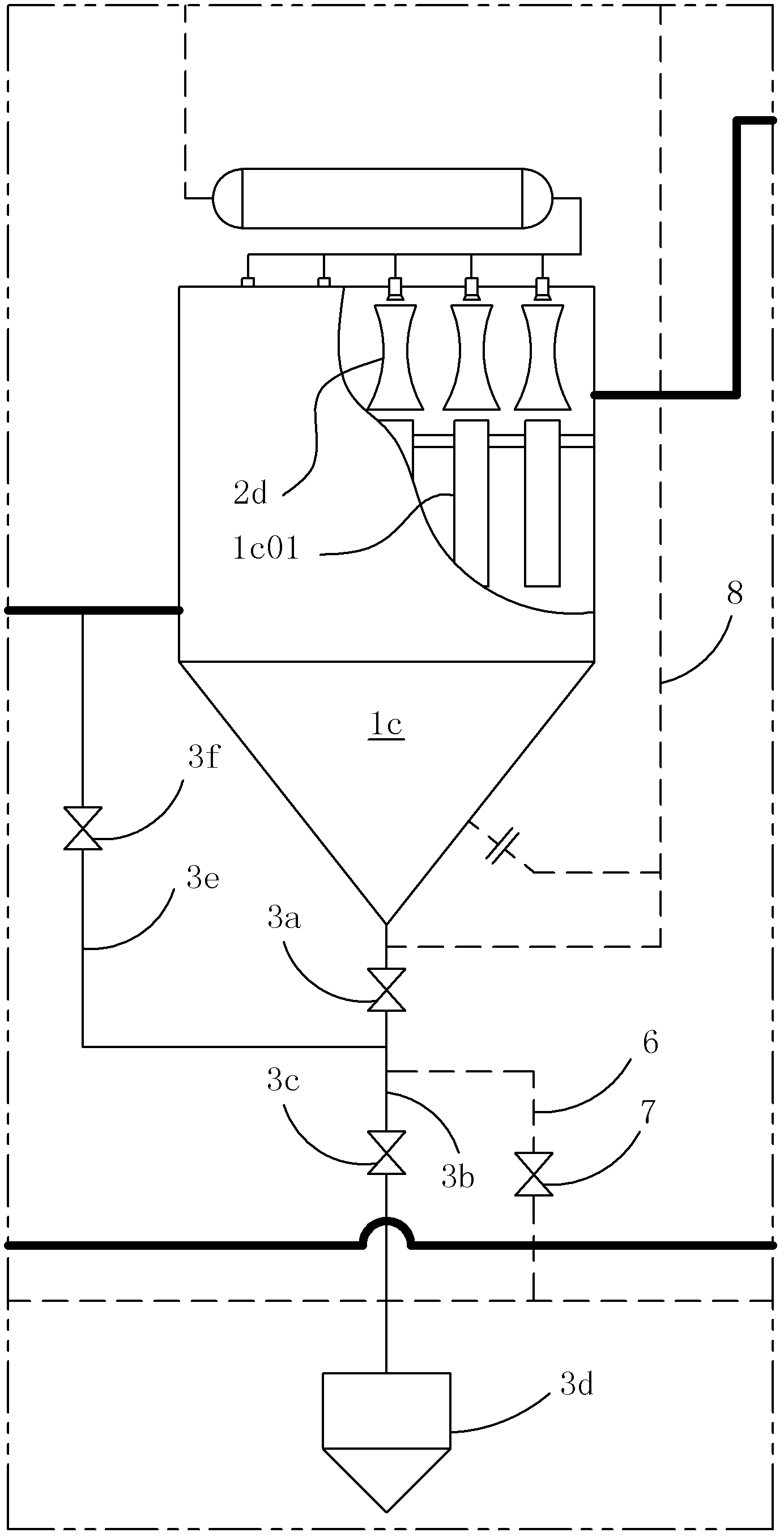

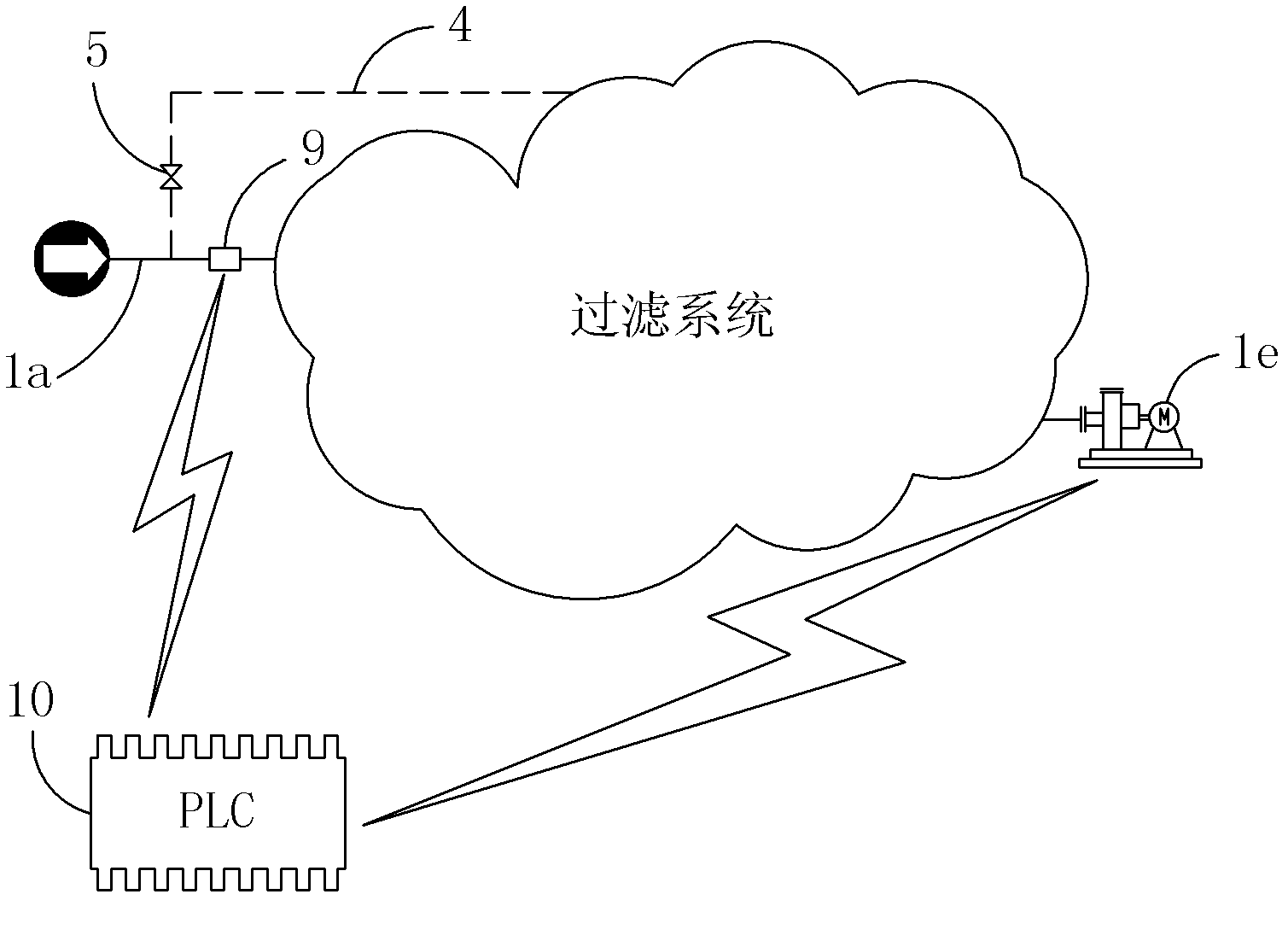

High-temperature flue gas cleaning system

InactiveCN102631820AAvoid condensationAvoid tar filmingCombination devicesDispersed particle filtrationFlue gasMoisture condensation

The invention discloses a high-temperature flue gas cleaning system which is moisture condensation resistant, and tar film pasting resistant. The system comprises a filtering system, a blowback system and an ash discharging system, wherein the filtering system comprises a high-temperature flue gas connecting pipe, at least one part of a filter connected with the high-temperature flue gas connecting pipe and a fan driving the gas to be cleaned to pass through the filter, the filter is respectively connected with the blowback system and the ash discharging system, the blowback system takes protective gas as a blowback medium, and the blowback system is internally provided with a protective gas heater; and when the high-temperature flue gas cleaning system is turned on, the blowback system is taken as a filter core moisture condensation-resistant system for preheating a filter core in the filter in a blowing way, and when the high-temperature flue gas cleaning system is turned off, the blowback system is further taken as a protective gas displacement system for displacing the original gas in the filter in a blowing way. In the stage that high-temperature flue gas cleaning system is turned on, the filter core is preheated by the protective gas, so that the phenomena of moisture condensation and tar film pasting on the surface of the filter core can be avoided.

Owner:CHENGDU INTERMENT TECH

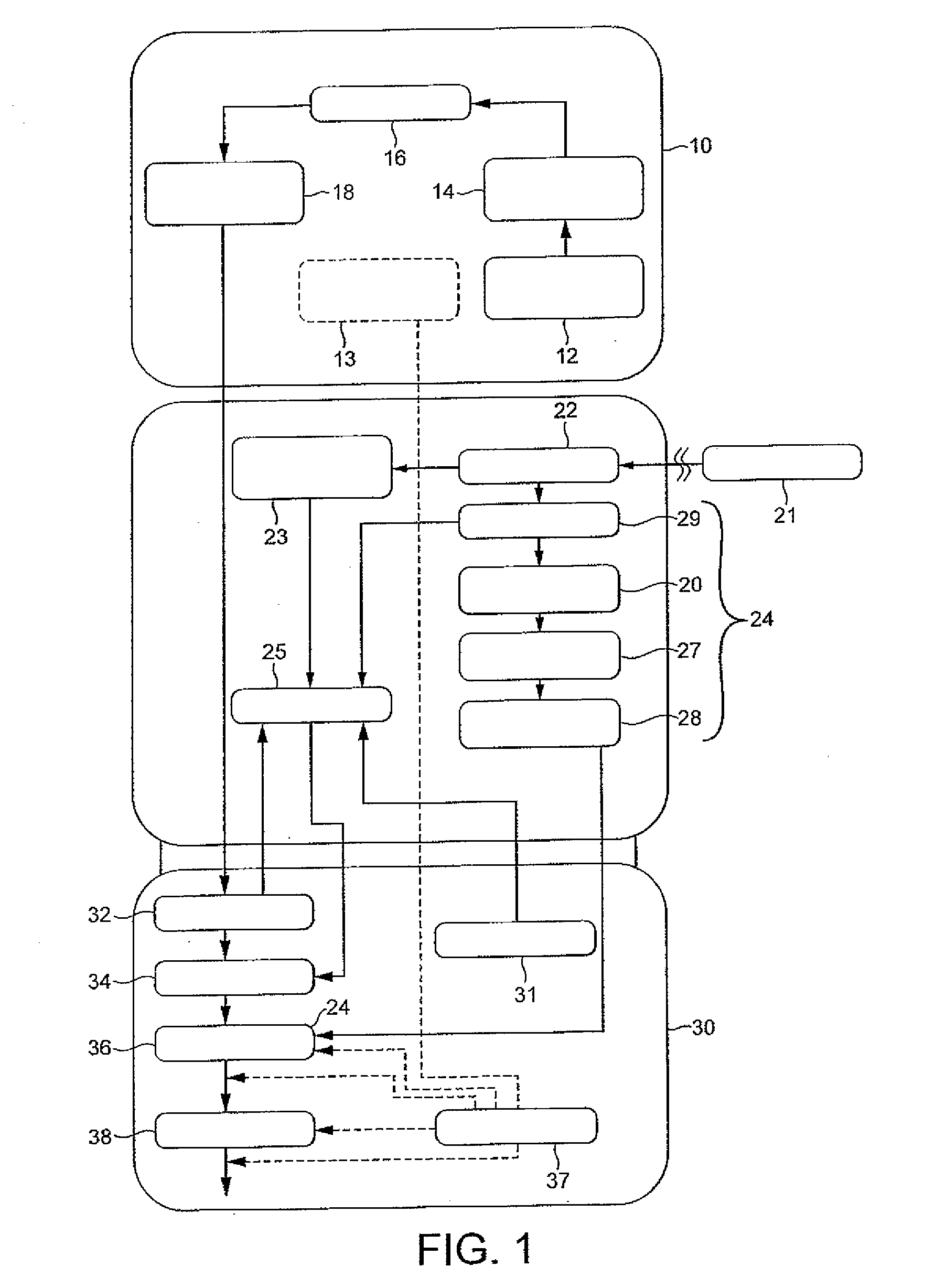

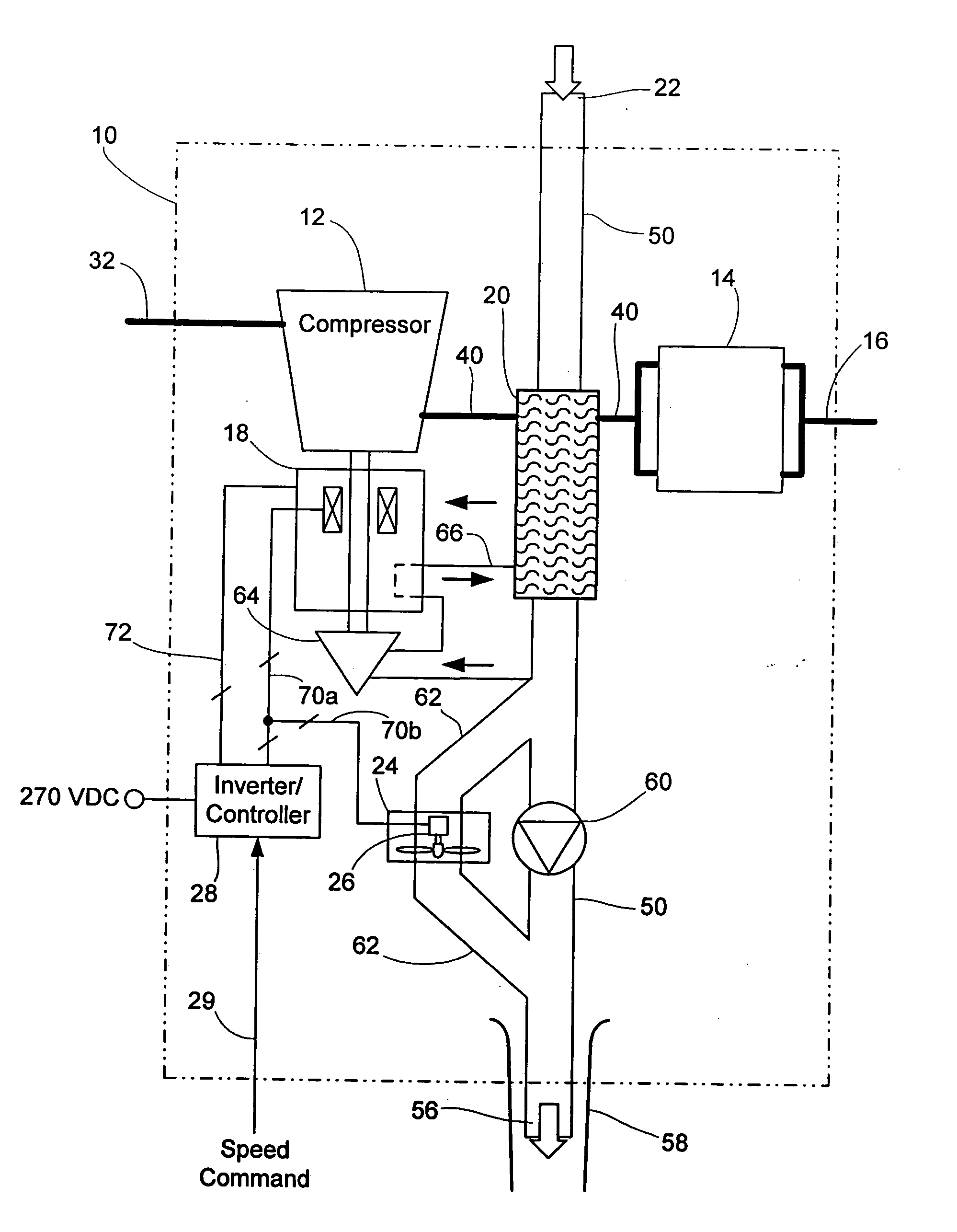

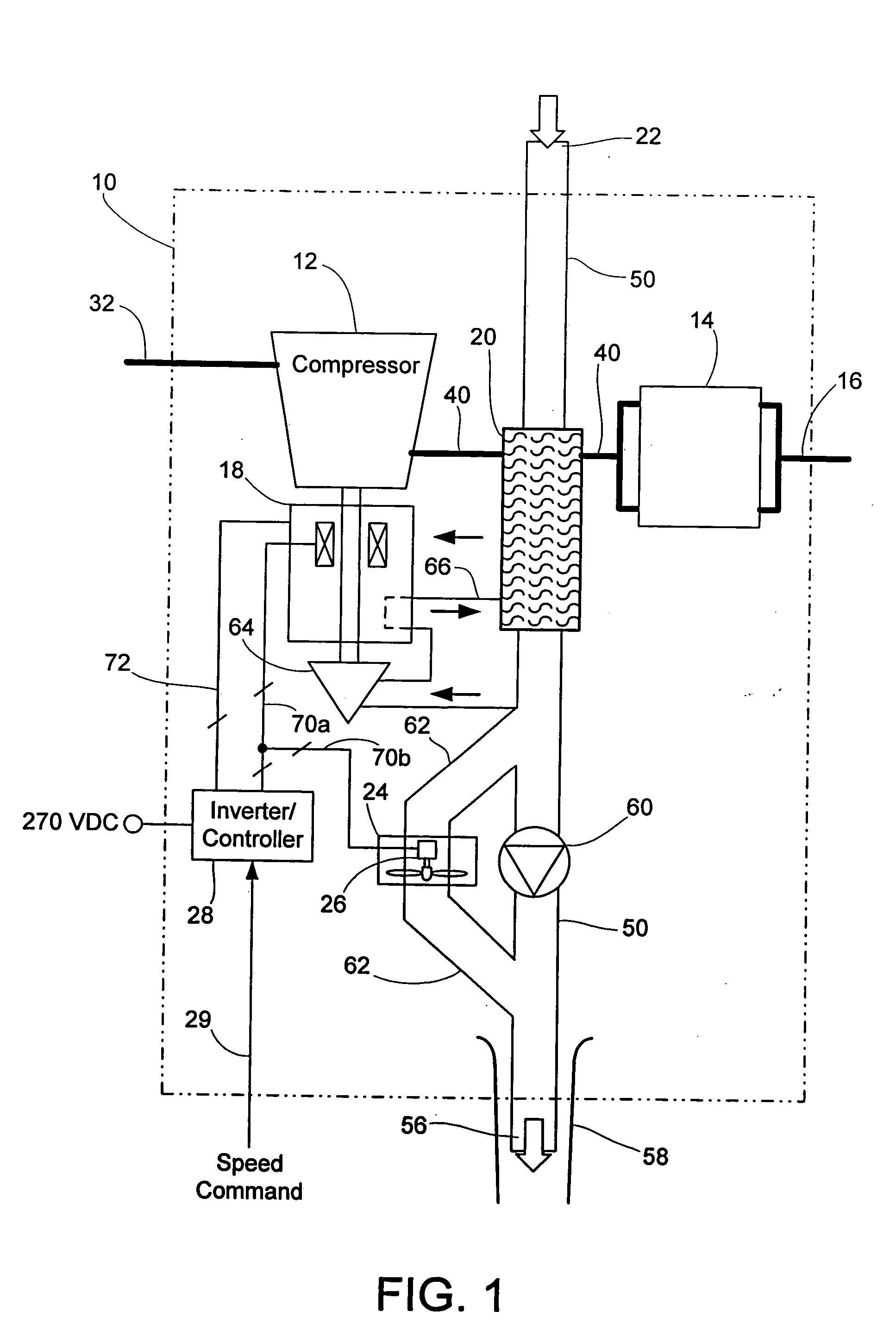

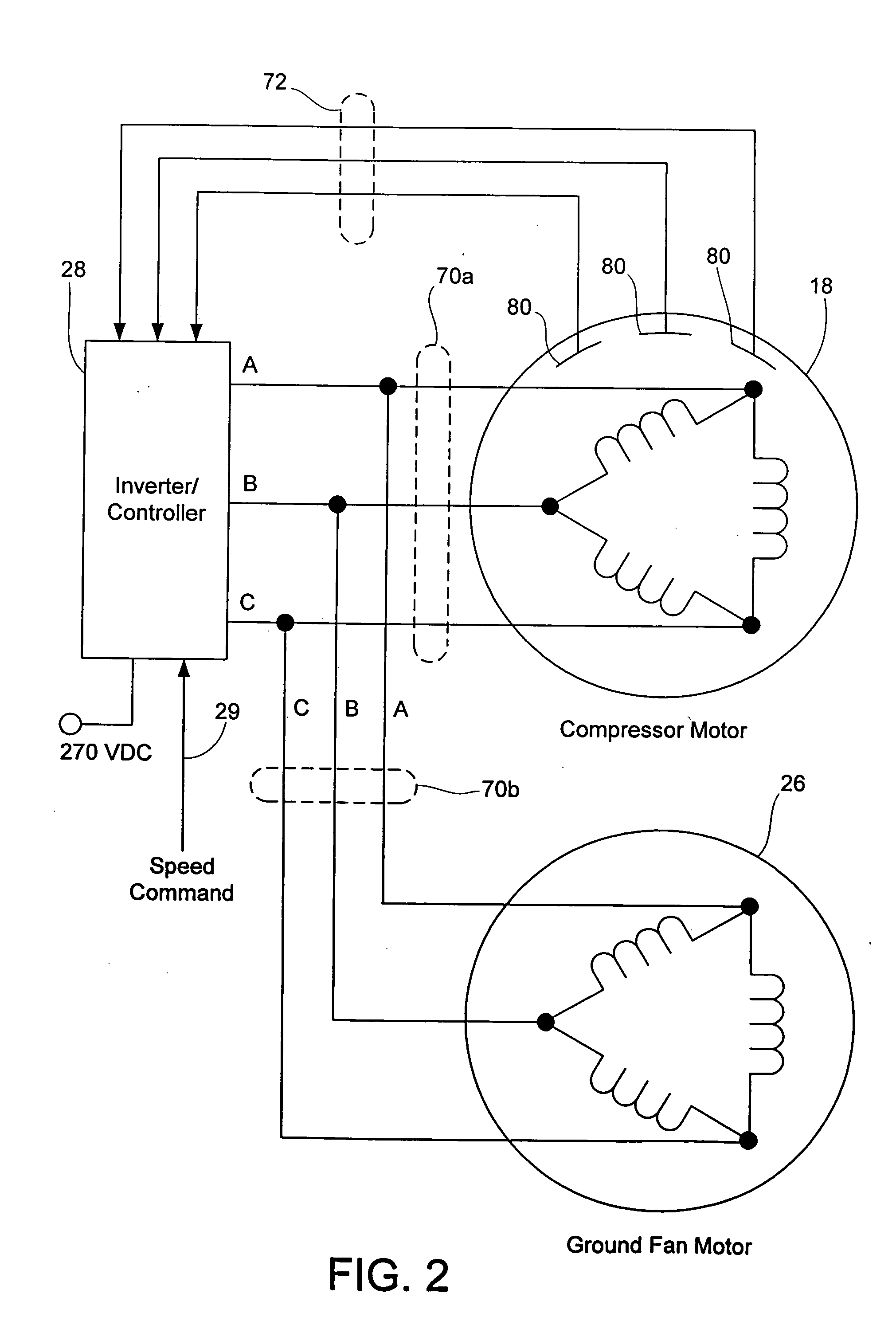

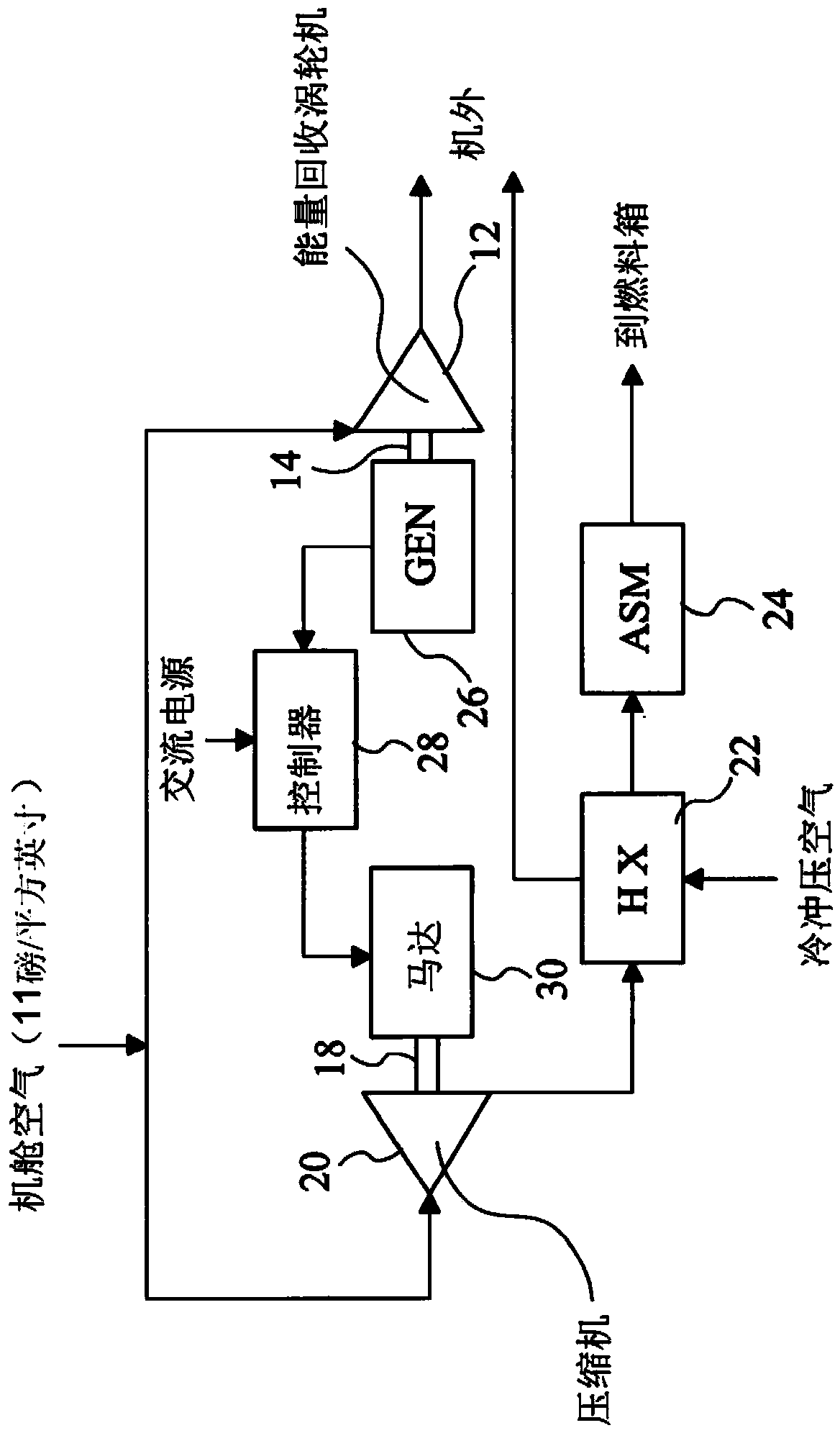

Electrically pressurized on-board inert gas generation system

InactiveUS20050151019A1Oxygen depletionPower plant fuel tanksFuel tank safety measuresElectricityOn board

An on-board inert gas generation system that provides inert gas to a fuel tank of an aircraft. The system includes an air compressor for providing a supply of compressed air, the air compressor being driven by a compressor motor. The system further includes a separator for separating the inert gas from the compressed air provided by the air compressor, the inert gas being substantially oxygen depleted. In addition, the system includes an output for delivering the inert gas from the separator to the fuel tank, and a ground fan for providing air flow to cool the compressed air prior to the compressed air being separated by the separator, the ground fan being driven by a ground fan motor. Still further, the system includes an inverter / controller circuit for providing controlled electrical power to the compressor motor to control at least one of speed and torque of the compressor motor based on feedback provided from the compressor motor, and also providing the controlled electrical power to drive the ground fan motor.

Owner:PARKER HANNIFIN CORP

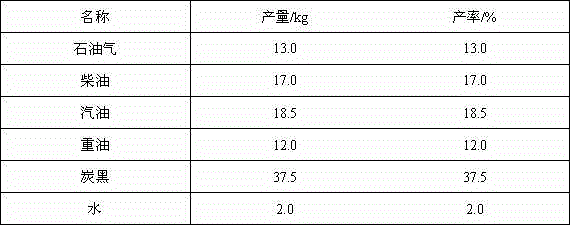

Process for thermal cracking of waste tires

InactiveCN104531198AEasy to buyAchieve reusePigmenting treatmentChemical industryResource recoveryNitrogen

The invention discloses a process for thermal cracking of waste tires. The process comprises the following steps: preheating a whole waste tire with a catalyst in a preheating bin by using flowing nitrogen of which the temperature is 300-450 DEG C; then putting the waste tire into a cracking bin, and performing cracking in a flowing nitrogen atmosphere of which the temperature is 600-1000 DEG C; and finally separating steel wires and carbon black after cracking, separating a cracking gas from hot nitrogen, and introducing the cracking gas into a condenser for condensation. In the whole cracking process, oxidation is isolated by the nitrogen, a high-value oil product is obtained, and meanwhile, the recovery rate of pyrolysis oil is improved. The nitrogen used in the process disclosed by the invention is a byproduct from a steel plant, and the heat of the nitrogen is reused in the whole process. The thermal cracking cost of the waste tires is reduced by adopting the waste nitrogen of the steel plant, the cracking quality is improved, and meanwhile, the recovery utilization of the cracking gas ensures that self-sufficiency of energy is realized by the process disclosed by the invention. By adopting the process, the reutilization of industrial waste gases and waste tires is realized, and the aims of resource recovery and energy efficiency are achieved.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

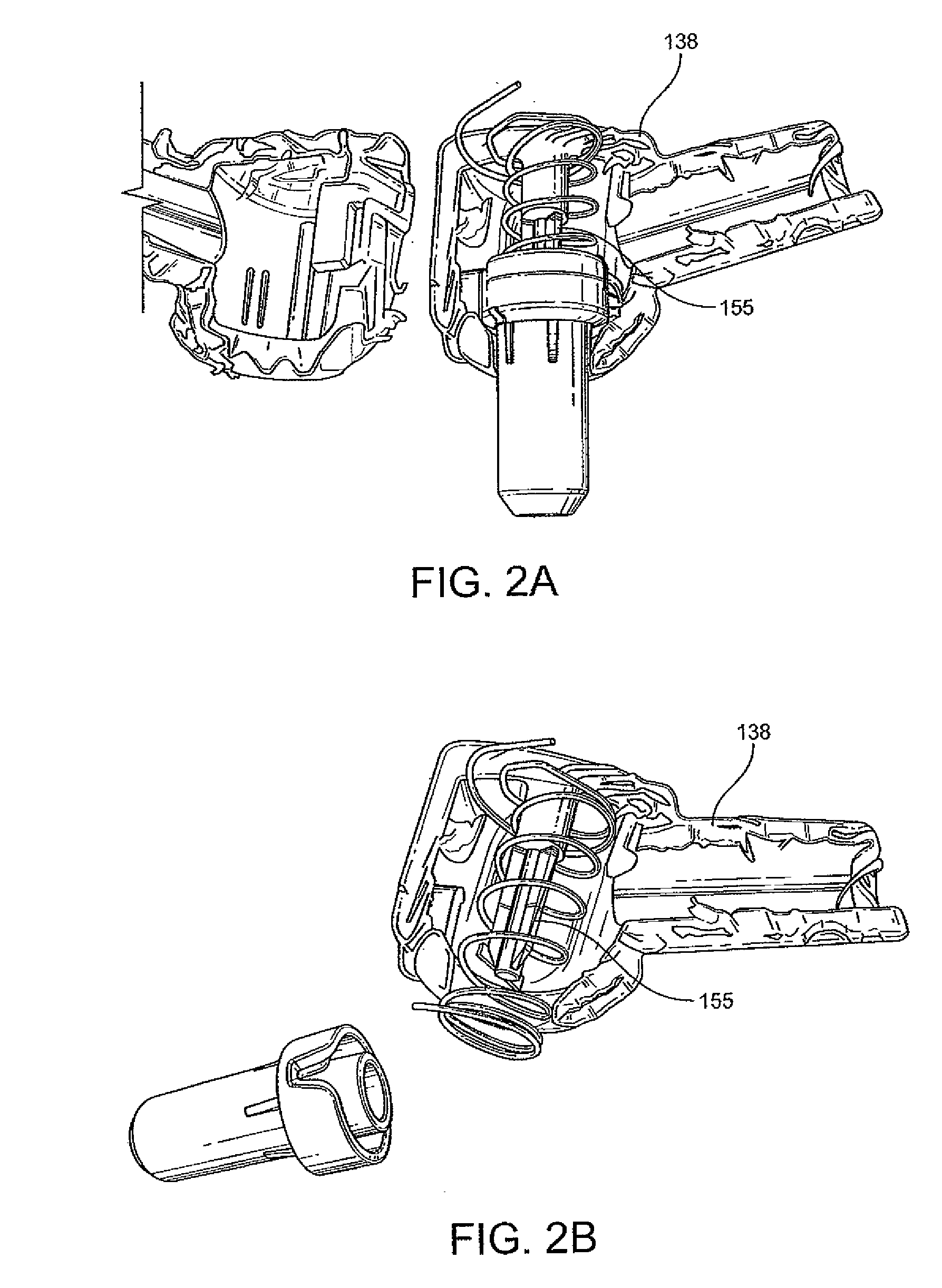

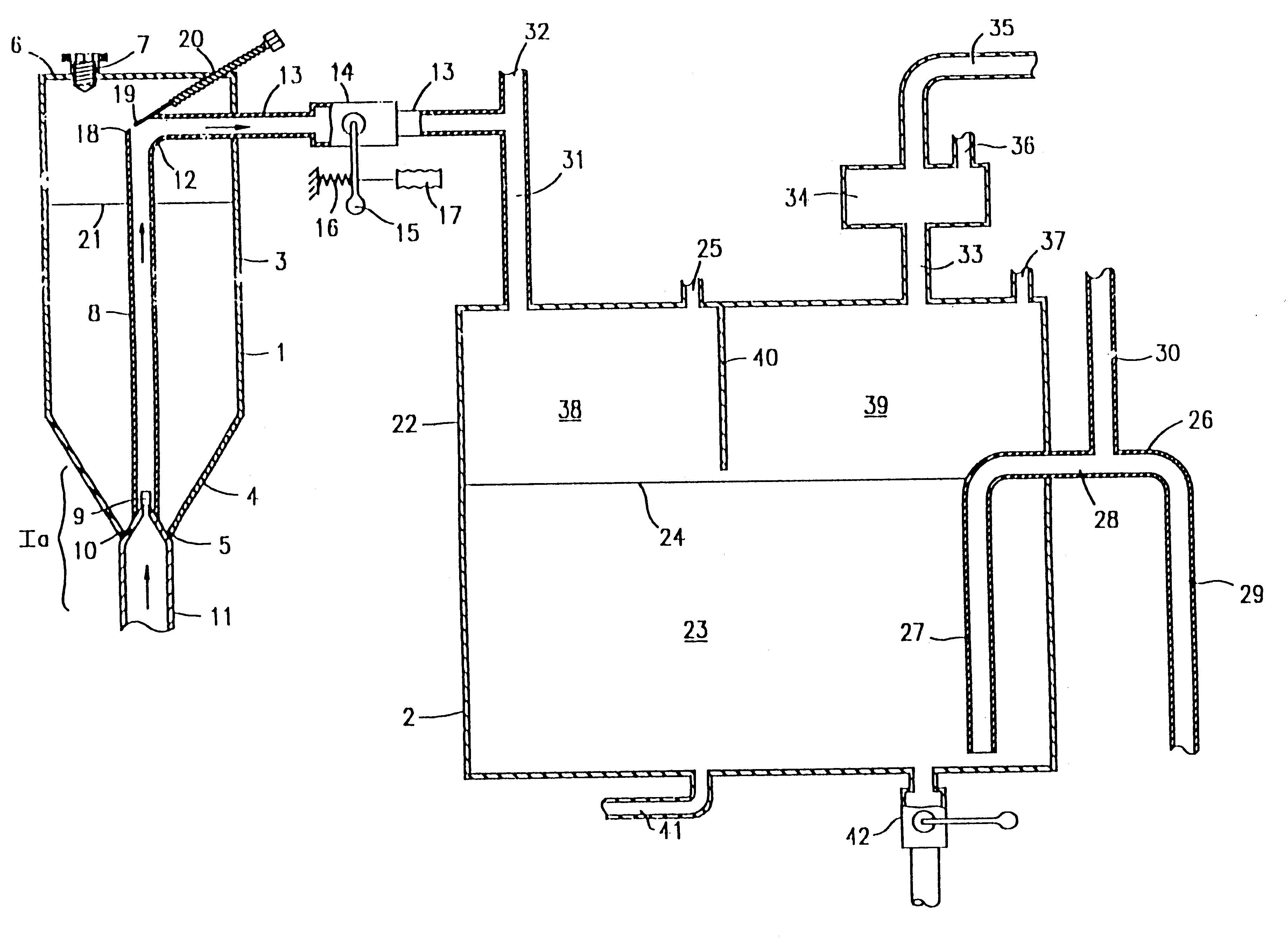

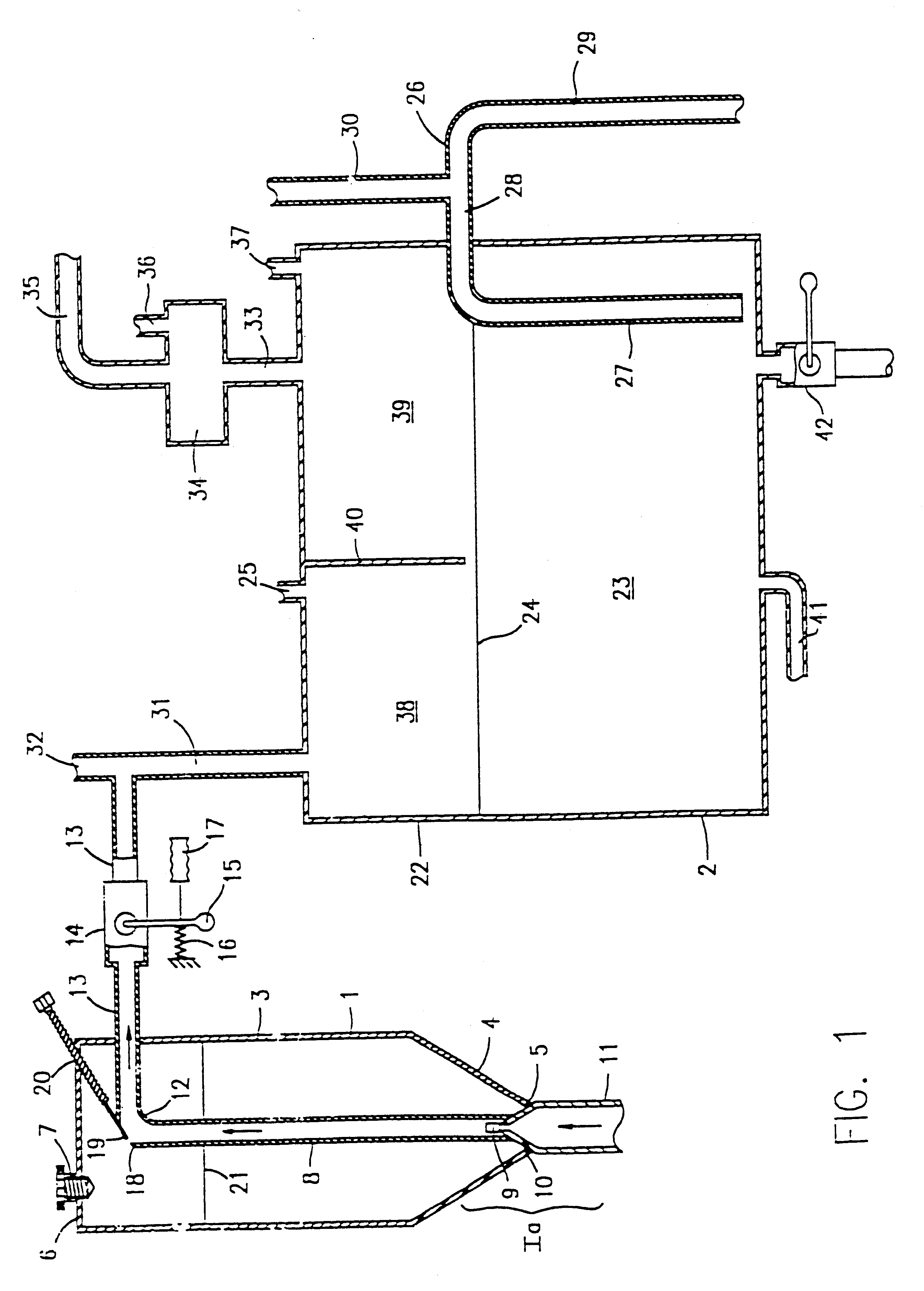

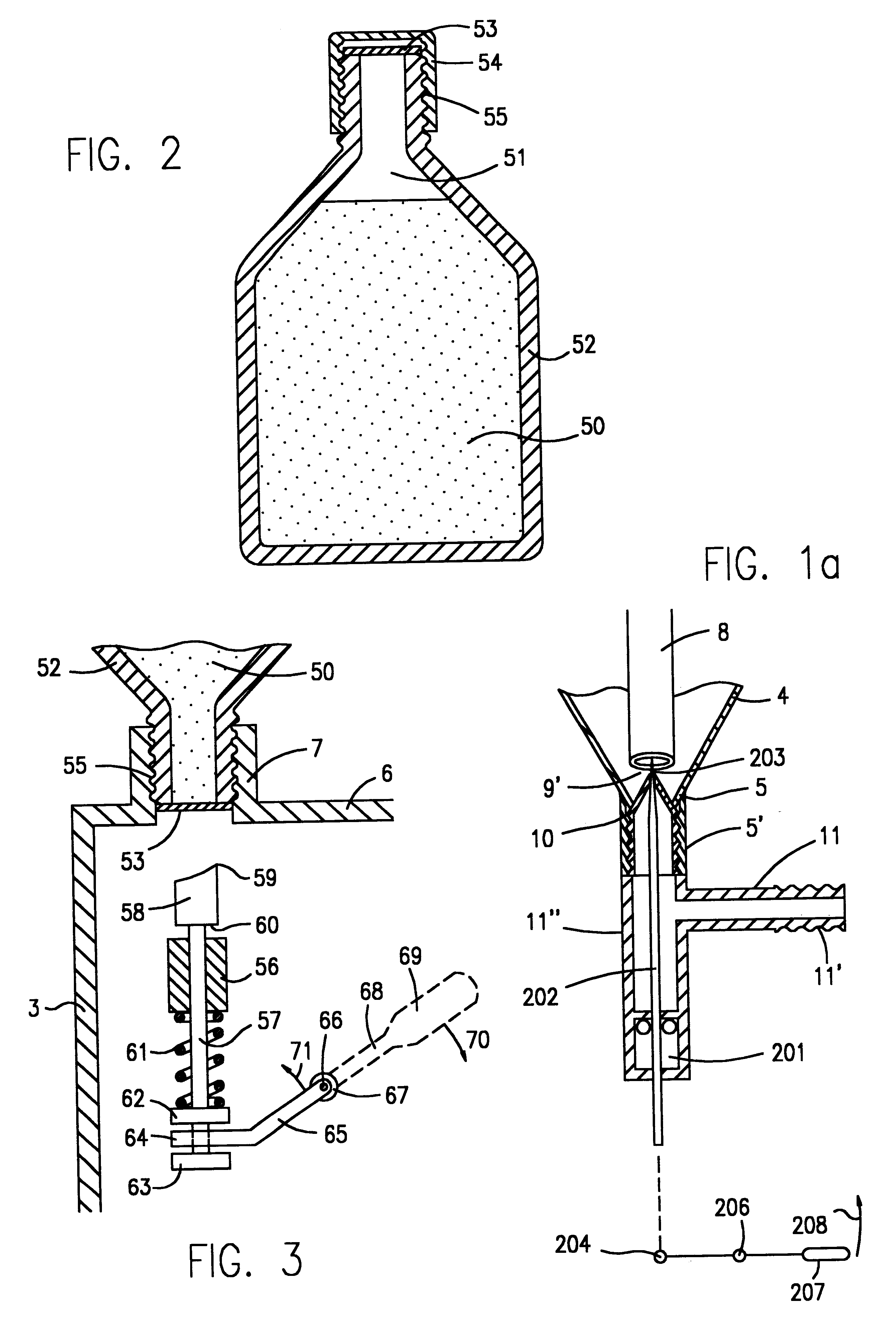

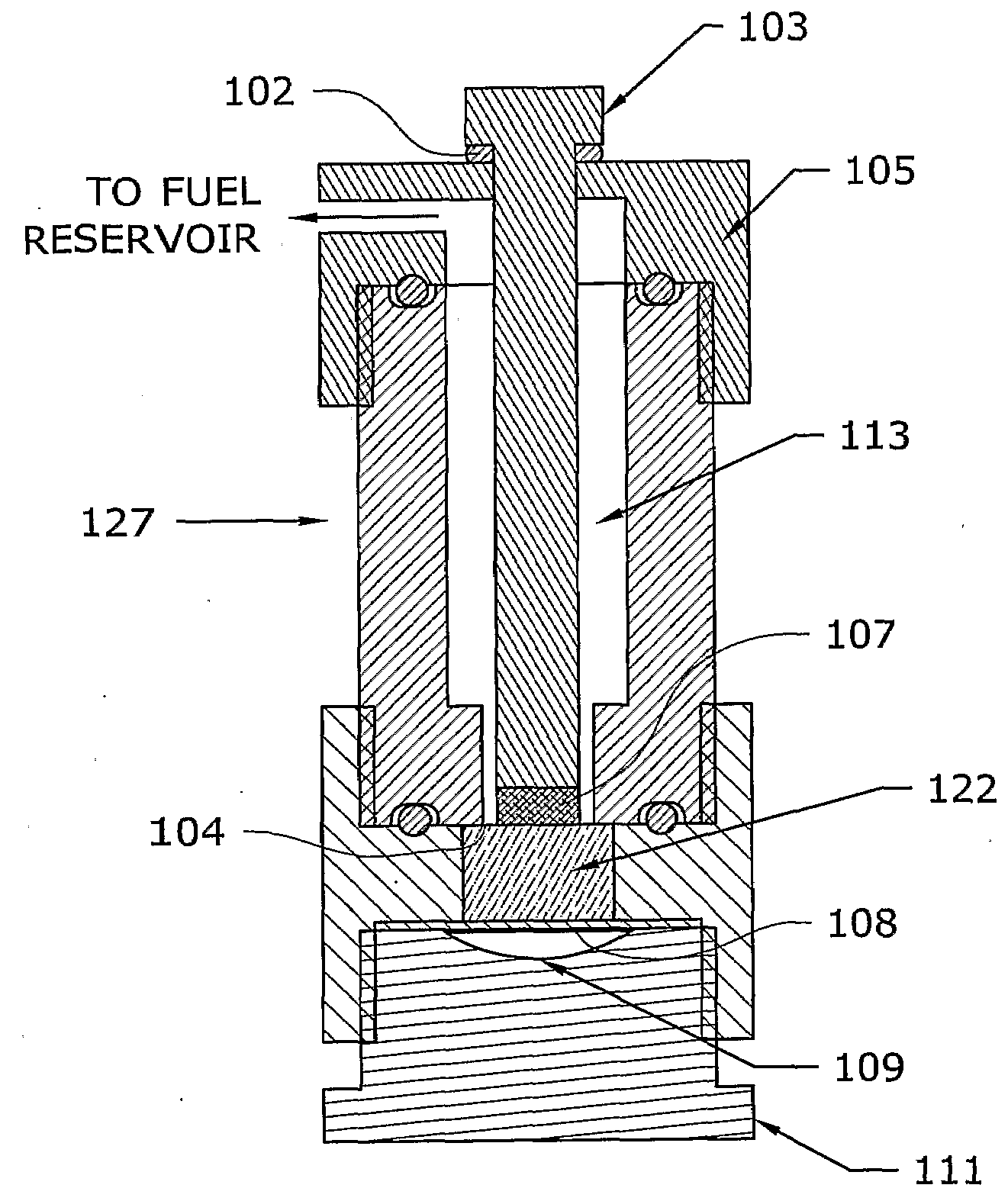

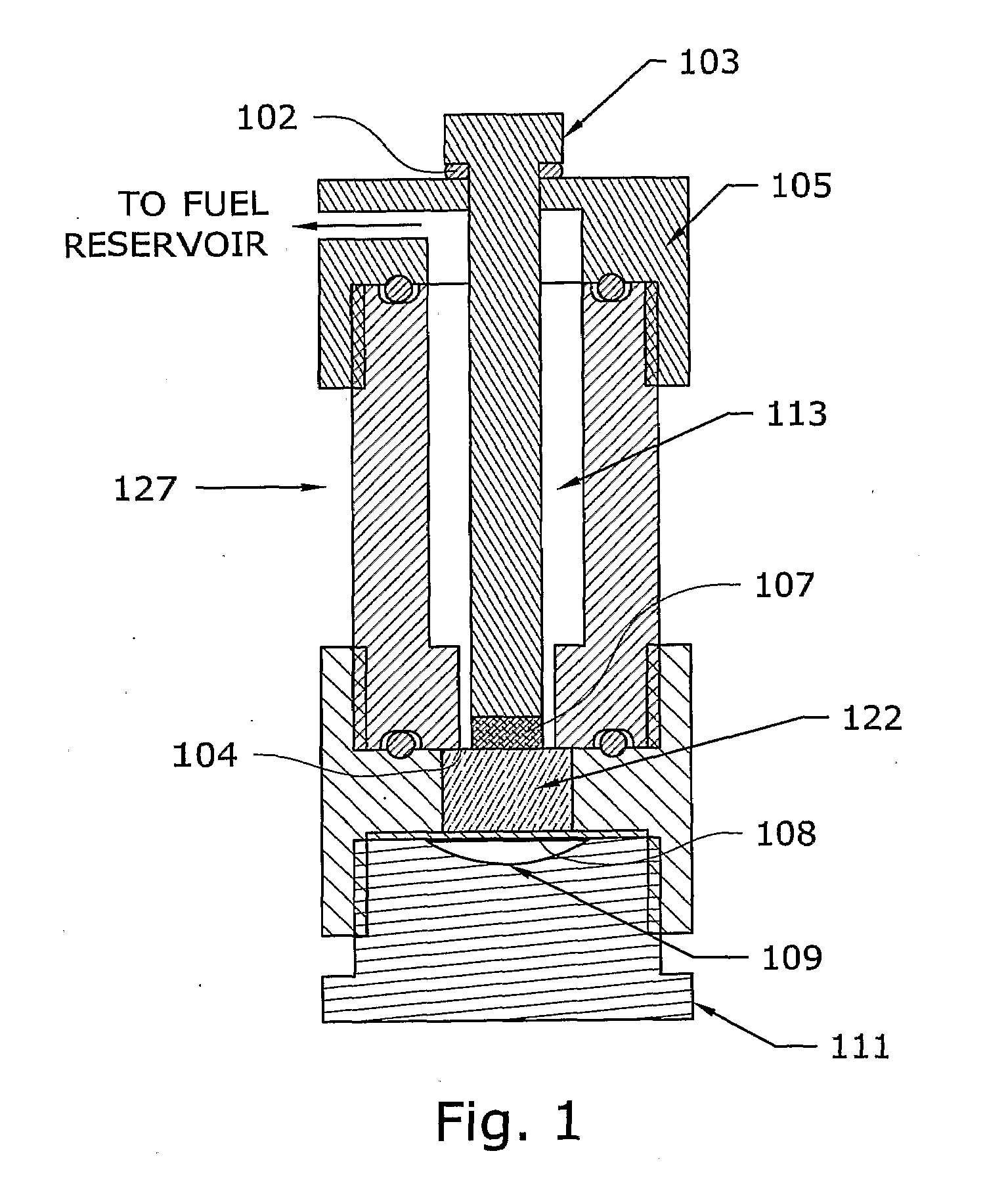

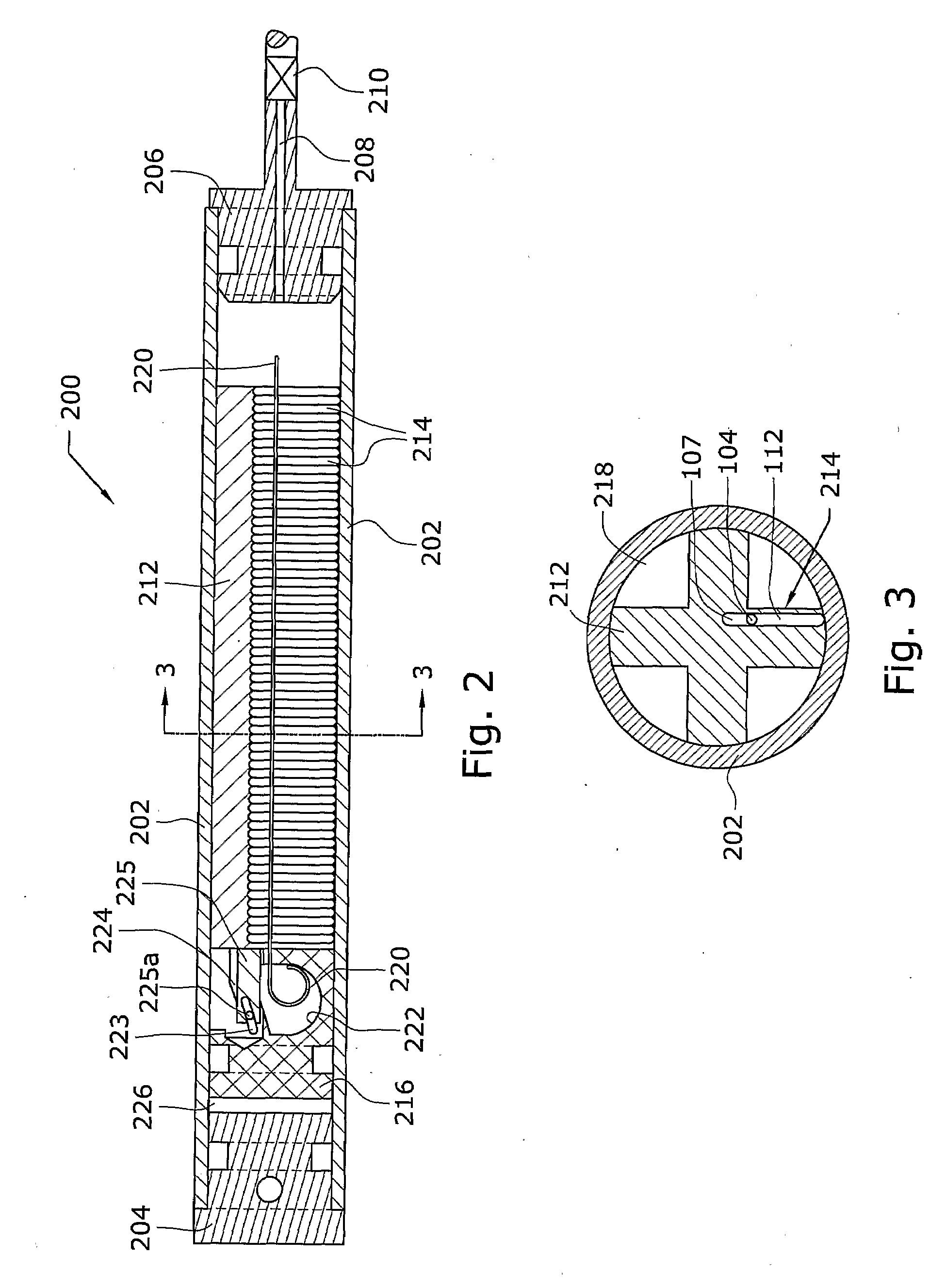

Phosphine generator for producing phosphine-containing gas

InactiveUS6315965B1Promote safe productionImprove storage characteristicsBiocideMixing methodsParticulatesLiquid water

A process and apparatus is disclosed for generating a mixture of phosphine and diluent gas(es). A hydrolysable metal phosphide, preferably magnesium phosphide, is released directly into liquid water under an atmosphere of gas inert to phosphine and in a free-flowing particulate form, composed of loose metal phosphide particles. The generated mixture of phosphine and inert carrier gas, e.g. CO2, is used as such or is diluted into a gas mixing chamber with air to a concentration below the ignitability limit before being used in fumigation. Using argon as a carrier gas the phosphine mixture is suitable for semiconductor doping.

Owner:DECH DE CHILE

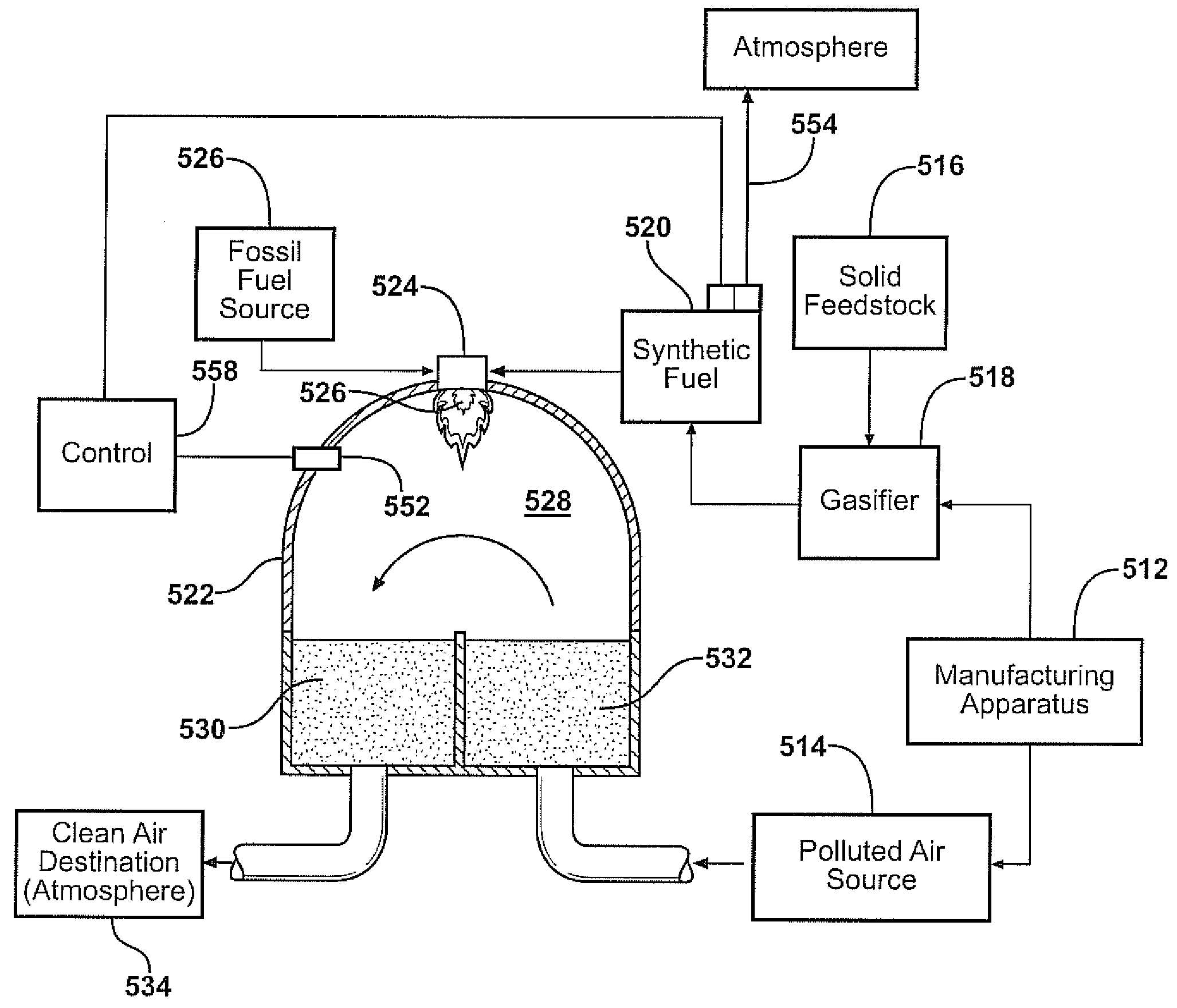

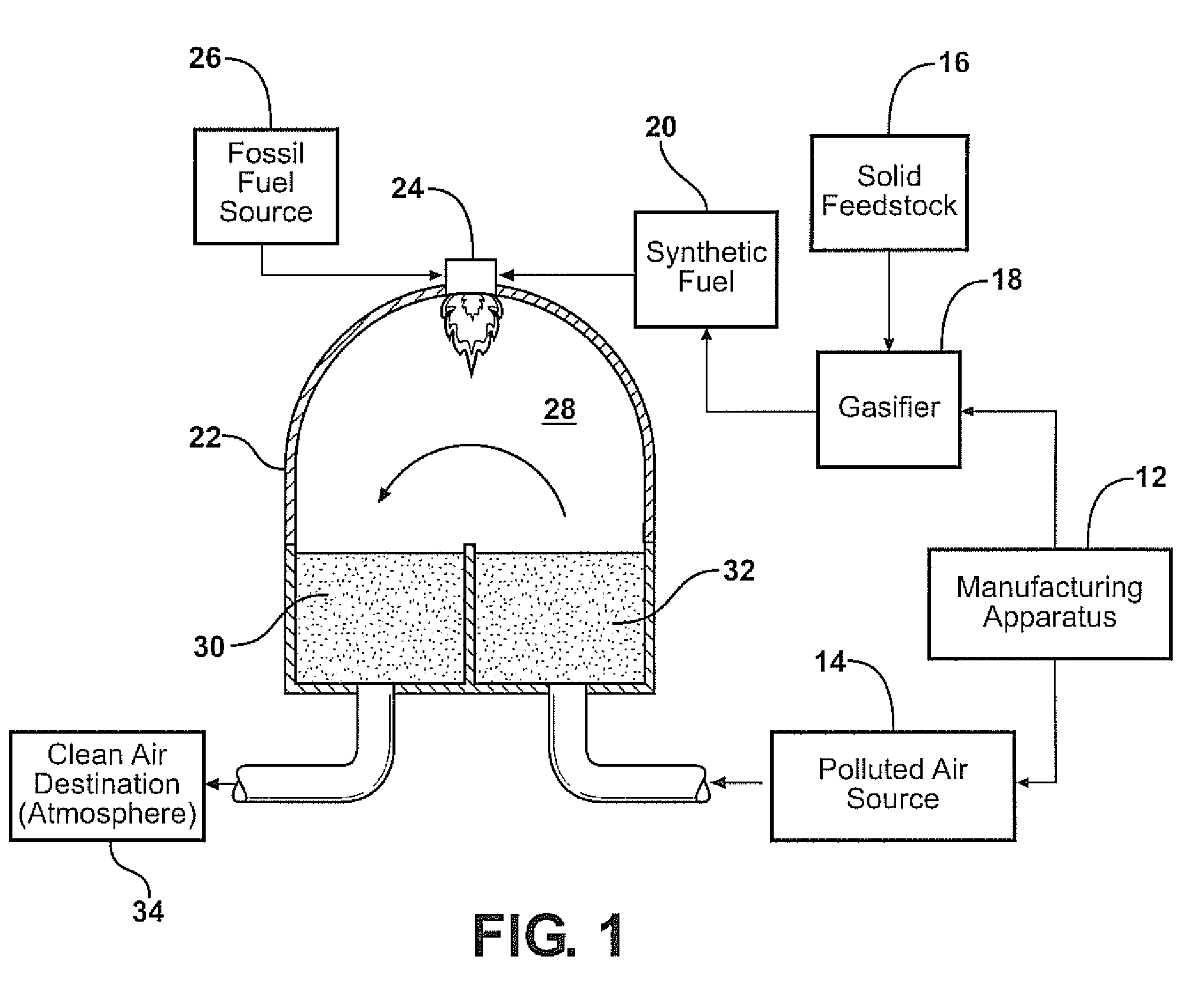

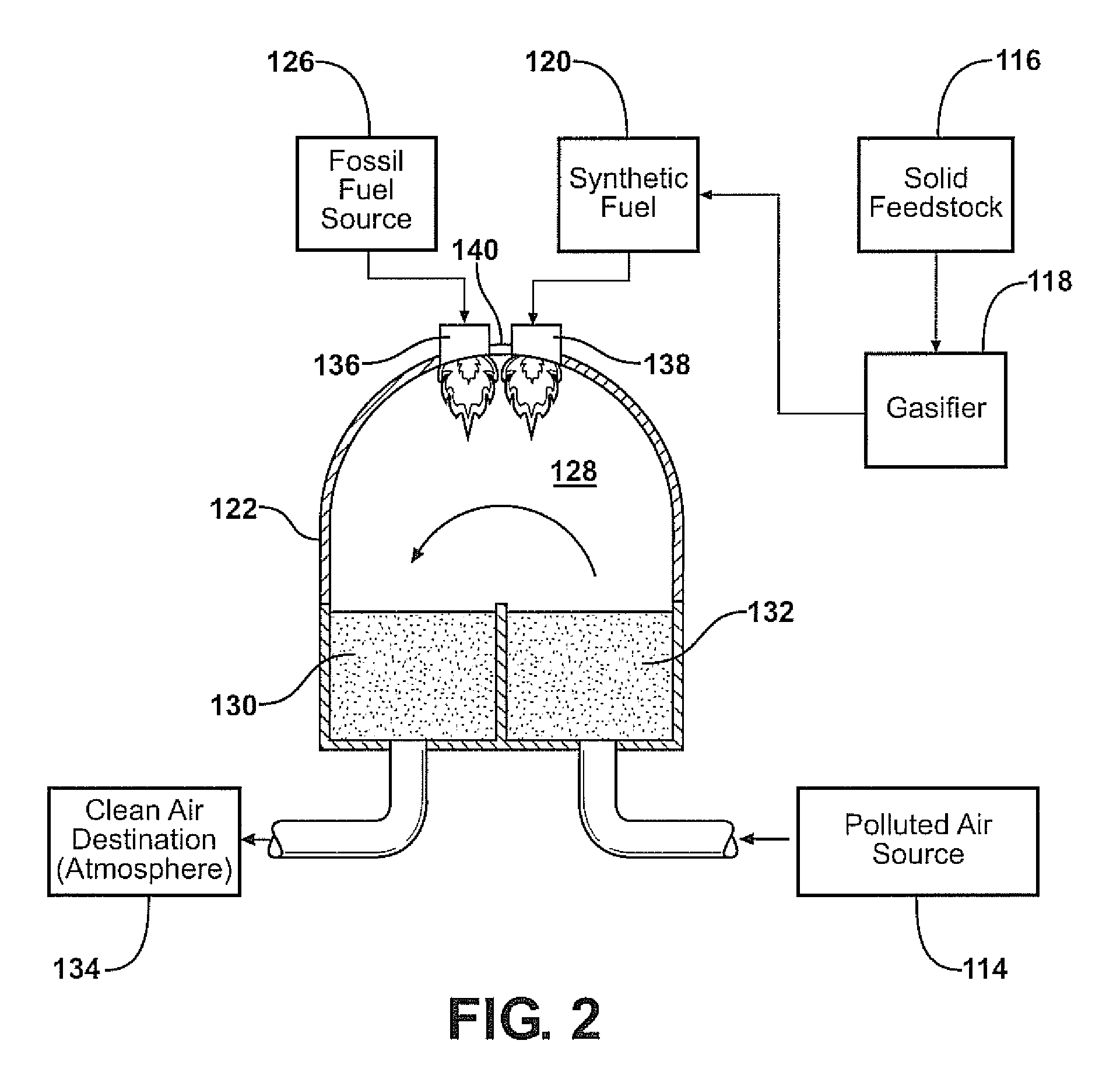

Thermal oxidizer with gasifier

InactiveUS20090221866A1Reduce the amount requiredReduced organic wasteCarbon compoundsExhaust apparatusThermal energyForming gas

A manufacturing apparatus for producing products results in solid waste and organic waste disposed in an air stream. The organic waste is subject to oxidation by a thermal oxidizer receiving the air stream from the manufacturing apparatus for oxidizing the organic waste. The thermal oxidizer includes a clean air outlet for venting the oxidized air stream to the atmosphere. A gasifier receives solid waste from the manufacturing apparatus for gasifying the solid waste and producing synthetic gas. The synthetic gas is introduced to the thermal oxidizer for providing additional thermal energy to the thermal oxidizer reducing the amount of fossil fuel required to provide thermal energy to the thermal oxidizer that is necessary for oxidizing the organic waste disposed in said air stream.

Owner:DURR SYST INC

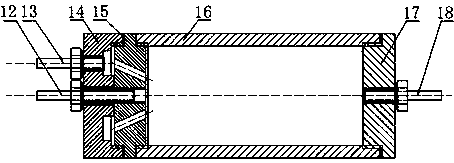

Gas-liquid two-phase mixed low-temperature nitrogen gas jet flow generation apparatus

ActiveCN105498566AAdjustable temperatureAdjustable jet pressureFlow mixersInert gas productionRoom temperatureSpray nozzle

The present invention discloses a gas-liquid two-phase mixed low-temperature nitrogen gas jet flow generation apparatus, which comprises a self-pressurization liquid nitrogen supply system, a high-pressure-resistant low-temperature soft pipe, a reciprocating low-temperature pressurization pump, a room-temperature nitrogen gas supply system, a high-pressure-resistant room-temperature soft pipe, an inner mixing chamber, an interception valve, a three-way valve and a spraying nozzle, wherein the self-pressurization liquid nitrogen supply system outputs low-pressure liquid nitrogen, the low-pressure liquid nitrogen is pressurized through the reciprocating low-temperature pressurization pump, the obtained high-pressure liquid nitrogen is output to the inner mixing chamber, the room-temperature nitrogen gas supply system outputs room-temperature and high-pressure nitrogen gas and conveys the high-pressure nitrogen gas to the inner mixing chamber, the high-pressure liquid nitrogen and the room-temperature and high-pressure nitrogen gas form low-temperature nitrogen gas in the inner mixing chamber, and the low-temperature nitrogen gas is conveyed to the three-way valve and the spraying nozzle to form the low-temperature nitrogen gas jet flow. According to the present invention, the flow rates and the ratio of the low-temperature liquid nitrogen and the room-temperature nitrogen gas are controlled, such that the adjustable low-temperature nitrogen gas jet flow temperature from the room temperature to -196 DEG C can be achieved, and the jet flow pressure and the jet flow rate can be adjusted.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Fuels for Hydrogen Generating Cartridges

ActiveUS20090123342A1Facilitated releaseLower the volumeReactant parameters controlExhaust apparatusReagentHydride

Owner:INTELLIGENT ENERGY LTD

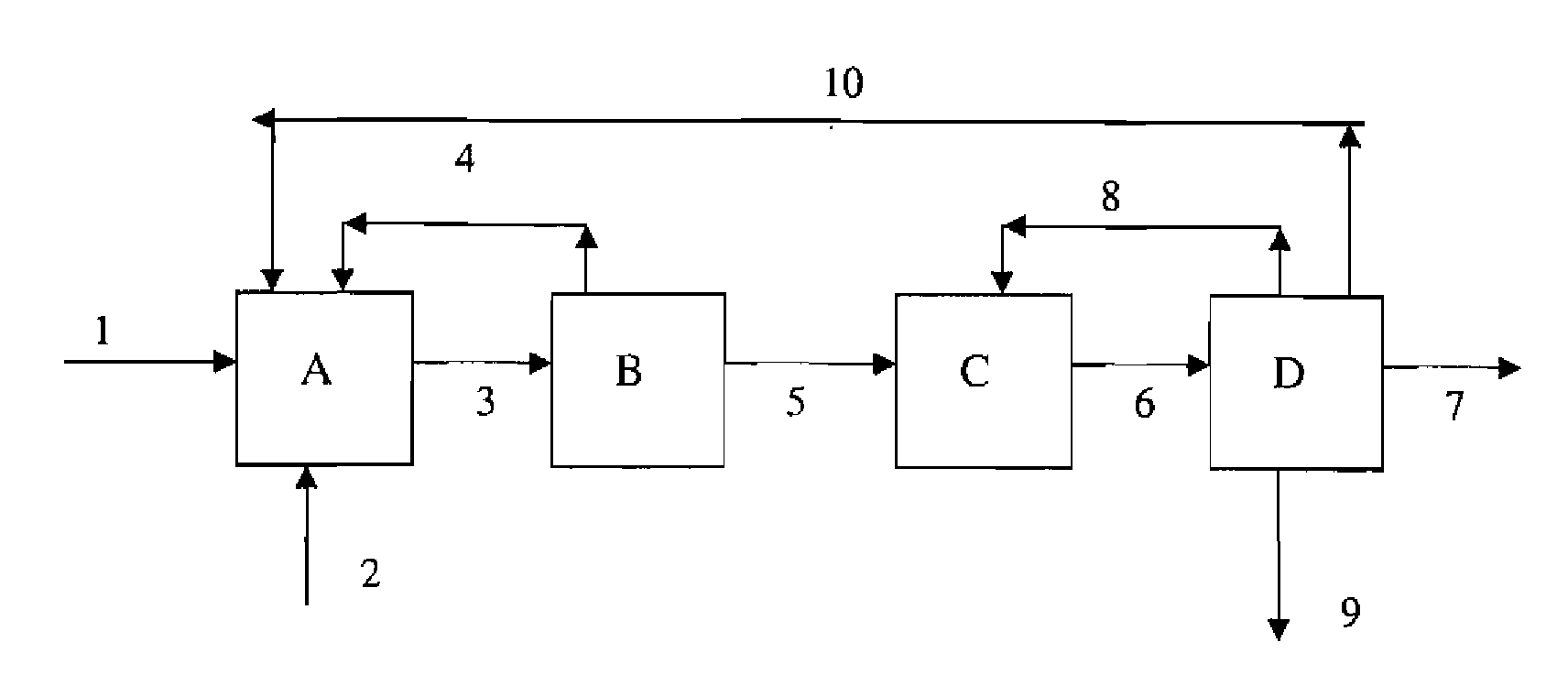

Process for the manufacture of fluorinated olefins

ActiveUS8013194B2Preparation by dehalogenationSequential/parallel process reactionsHydrogen fluorideAlkane

A method for producing 1,1,1,2-tetrafluoropropene and / or 1,1,1,2,3-pentafluoropropene using a single set of four unit operations, the unit operations being (1) hydrogenation of a starting material comprising hexafluoropropene and optionally recycled 1,1,1,2,3-pentafluoropropene; (2) separation of the desired intermediate hydrofluoroalkane, such as 1,1,1,2,3,3-hexafluoropropane and / or 1,1,1,2,3-pentafluoropropane; (3) dehydrofluorination of the intermediate hydrofluoroalkane to produce the desired 1,1,1,2-tetrafluoropropene and / or 1,1,1,2,3-pentafluoropropene, followed by another separation to isolate the desired product and, optionally, recycle of the 1,1,1,2,3-pentafluoropropene.

Owner:HONEYWELL INT INC

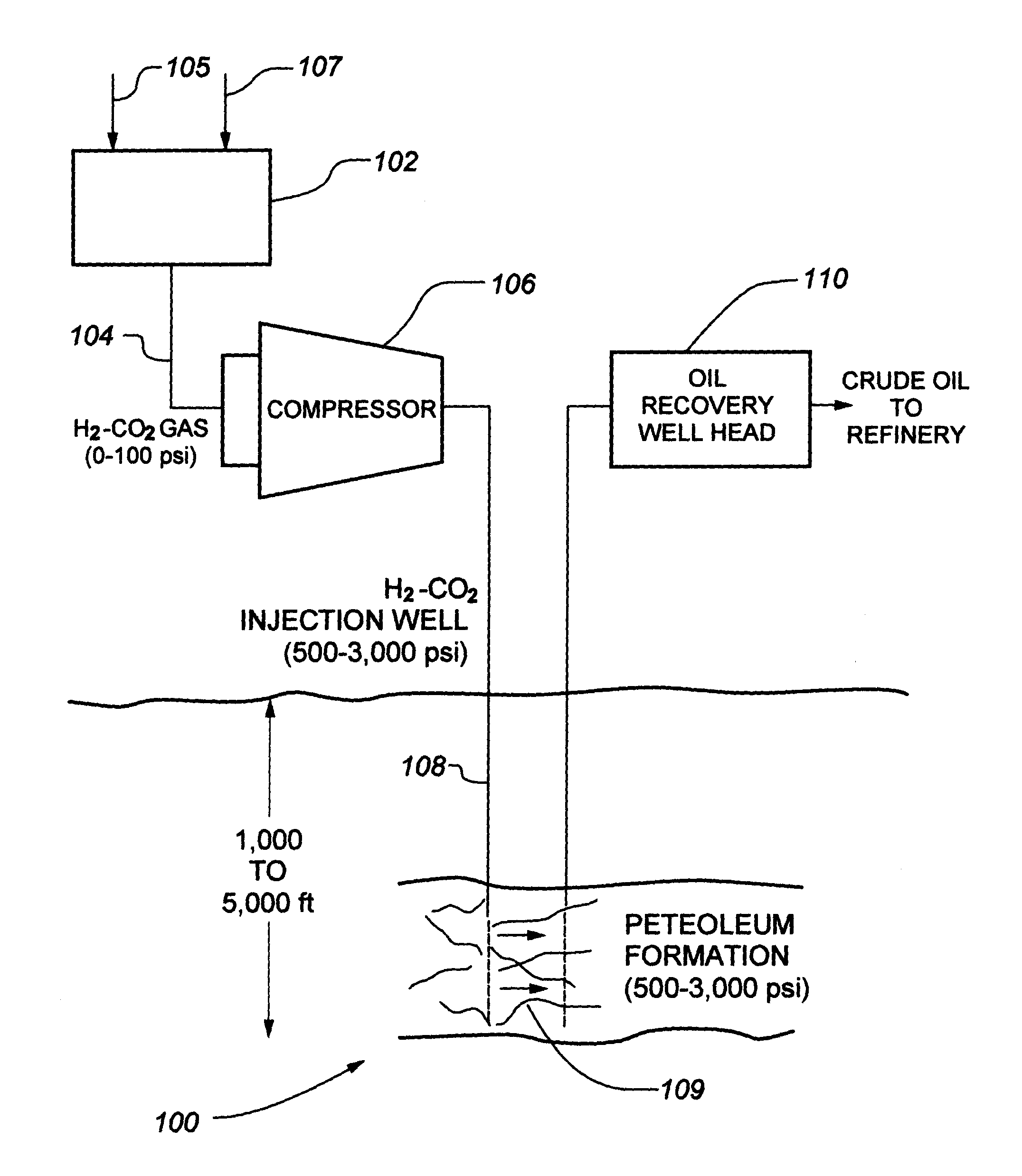

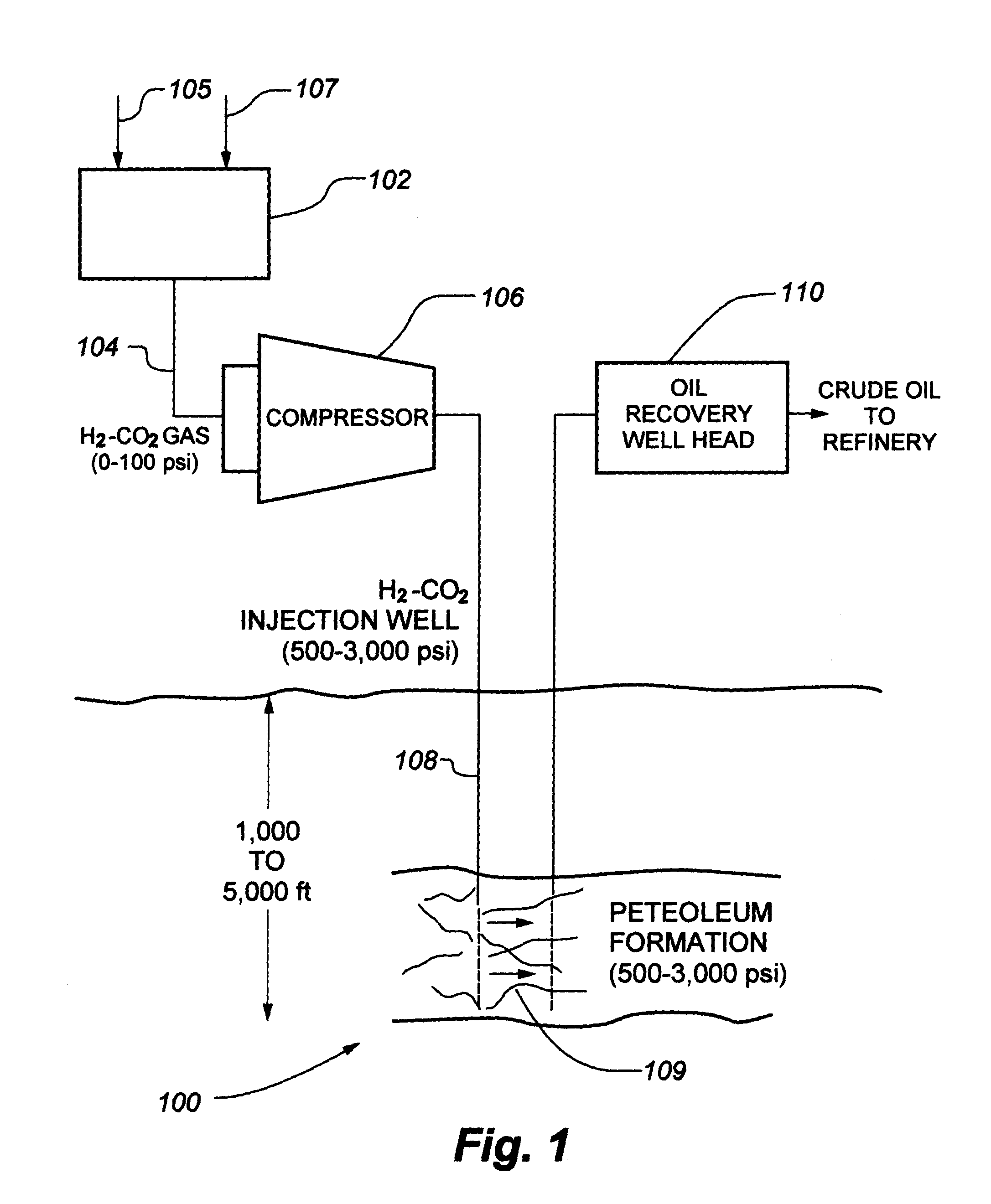

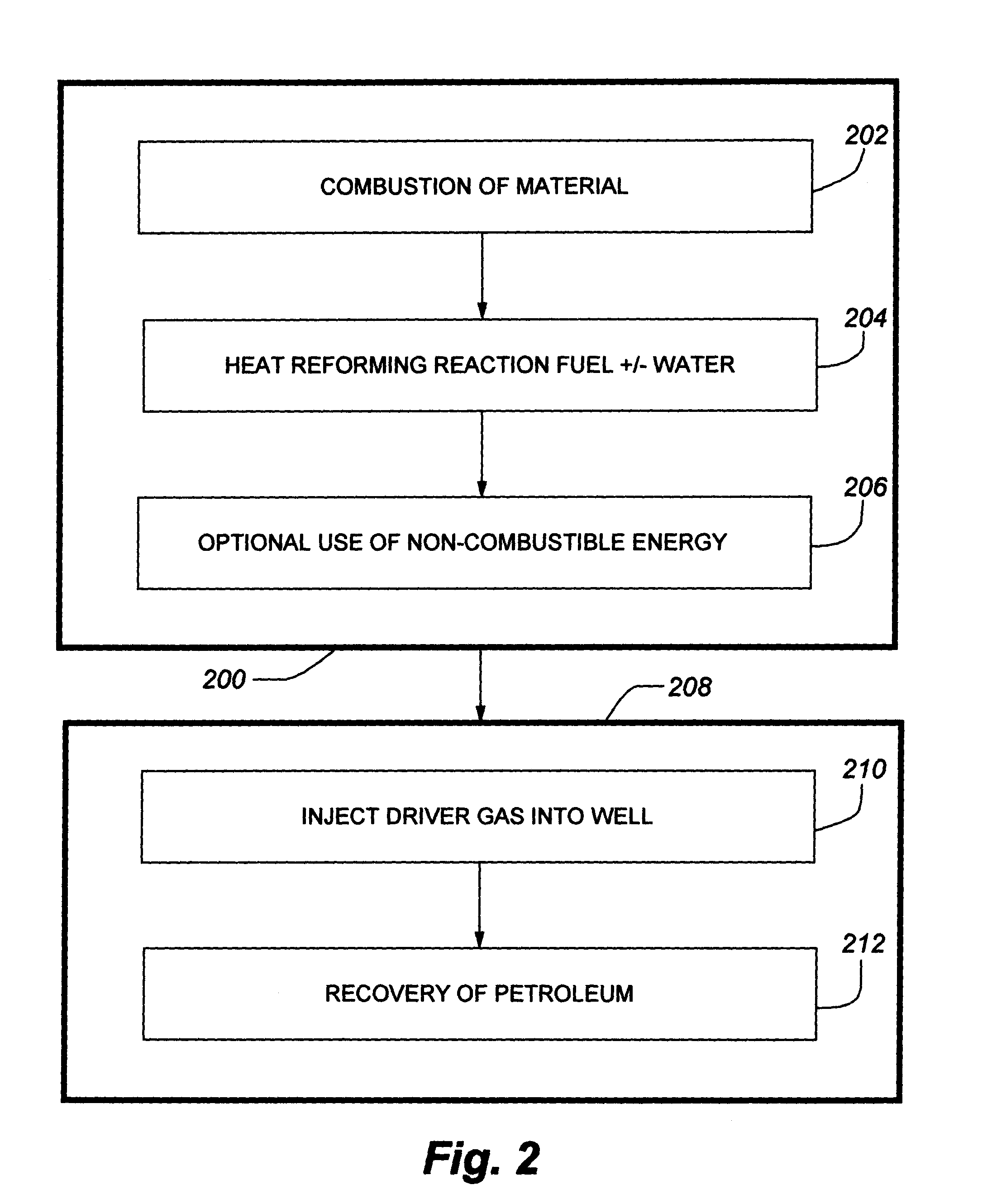

Apparatus and method for extracting petroleum from underground sites using reformed gases

InactiveUS7506685B2Low temperature requirementReduce the amount requiredDrilling rodsOther gas emission reduction technologiesCombustionWater source

Methods and apparatus for removing oil or natural gas from the ground. In one example, the method may include reforming a fuel source by reaction with water to generate driver gas, and injecting the driver gas into the oil well. The reforming operation may include causing the combustion of a combustible material with ambient oxygen for the release of energy; and heating a reforming reaction fuel and water sources, with the energy released from the combustion of the combustible material, to a temperature above that required for the reforming reaction wherein the fuel and water sources are reformed into driver gas. In one example, the amount of the combustible material combusted is sufficient to result in the release of enough energy to heat an amount of the reforming reaction fuel and water sources to the temperature above that required for the reforming reaction to proceed. The driver gas may be used to help extract oil from the ground and especially oil from depleted oil wells. It may also be used to drive natural gas trapped underground or in coal beds to the surface.

Owner:PIONEER ENERGY

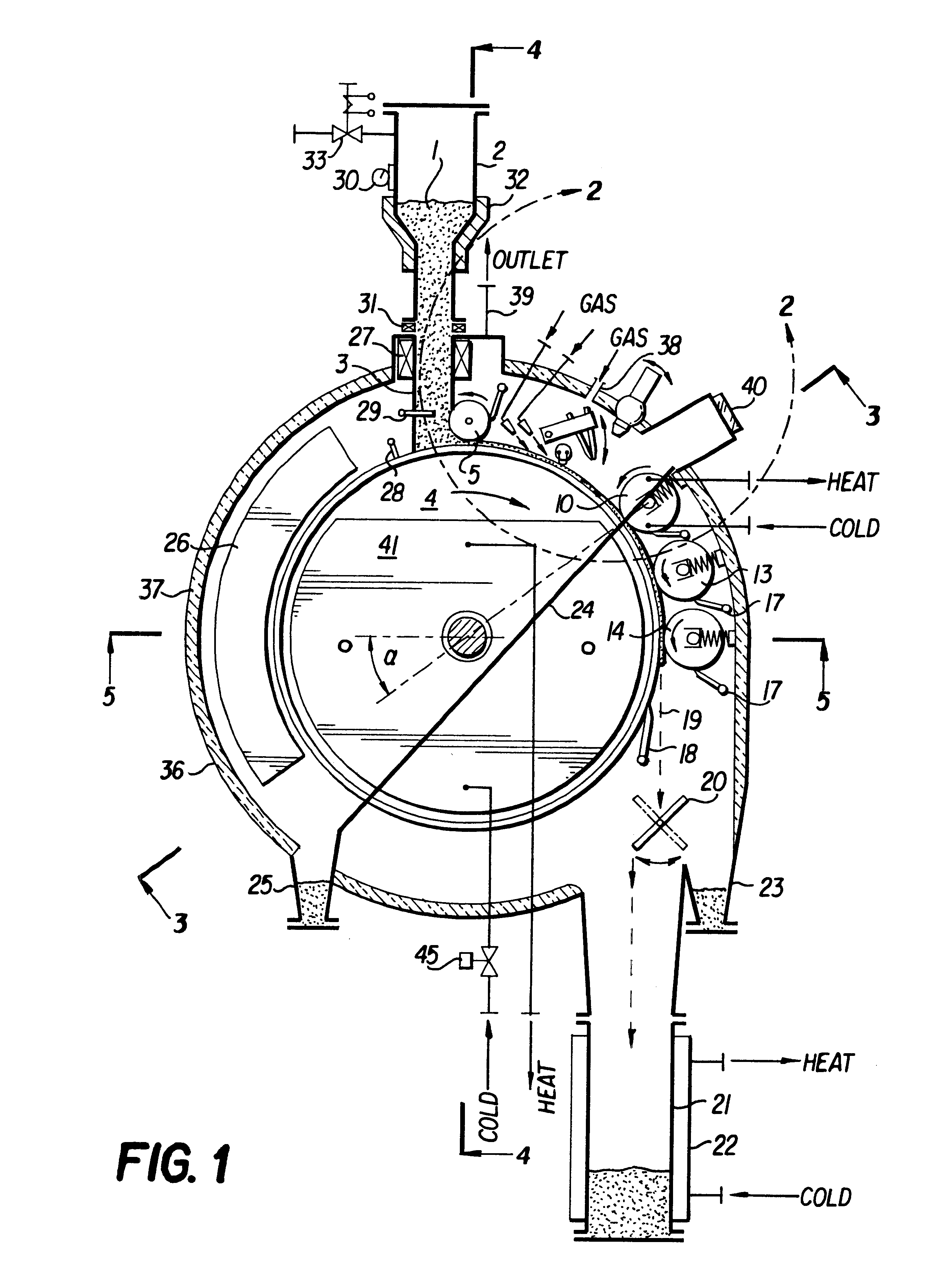

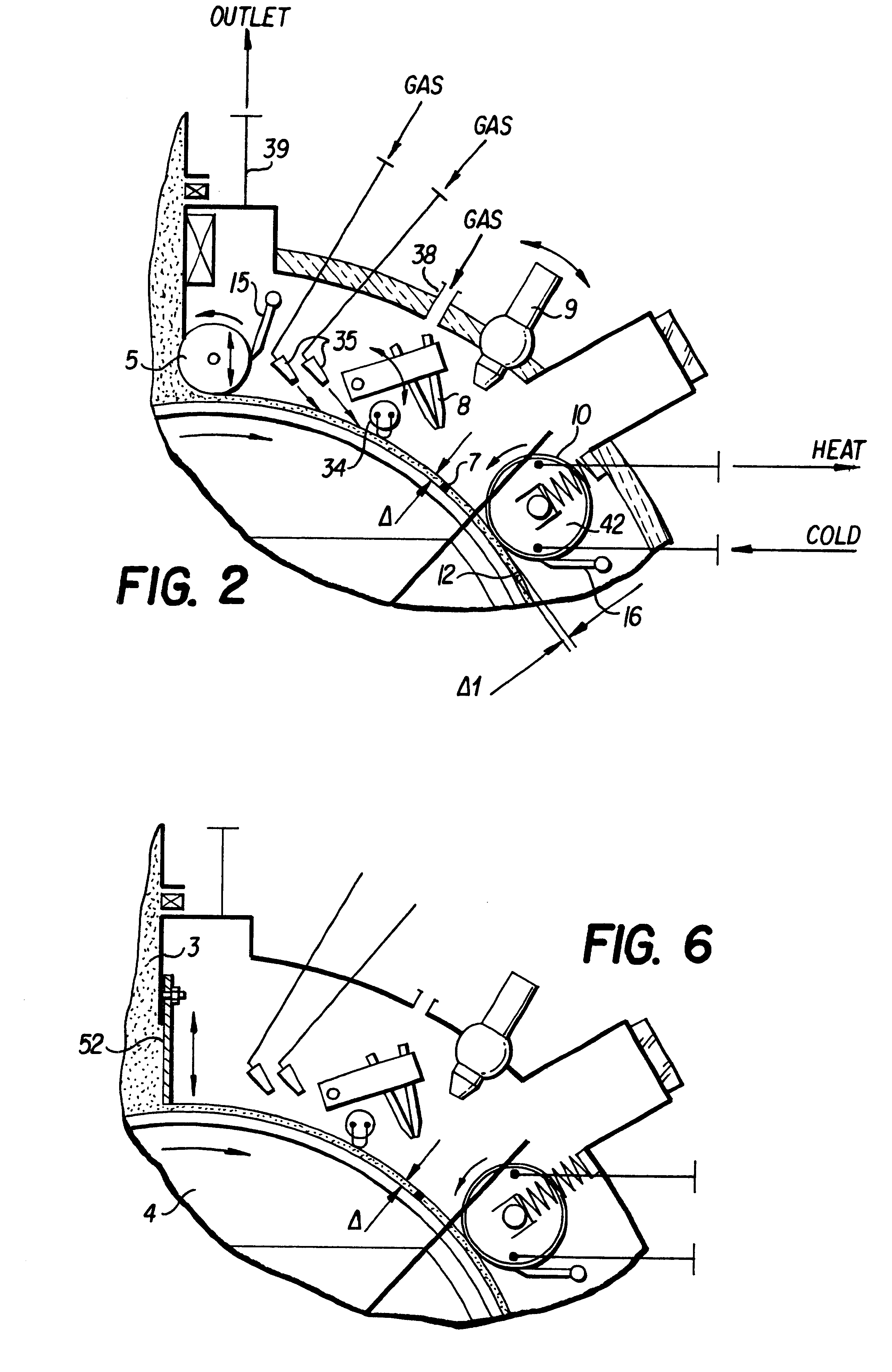

Apparatus for self-propagating high temperature synthesis

InactiveUS6436356B1Carry-out safelyAvoid expansionOxygen/ozone/oxide/hydroxideNitrogen compoundsSelf-propagating high-temperature synthesisInorganic compound

The present invention relates to an apparatus for self-propagating high temperature synthesis of an inorganic compound from a combustible charge mixture of initial ingredients. The apparatus comprises mechanisms for continuously feeding the combustible charge into a reaction chamber and removing the synthesized compound therefrom. The apparatus also contains sensors to control and contain the combustion inside a combustion zone of the reaction chamber.

Owner:COMSYNTECH

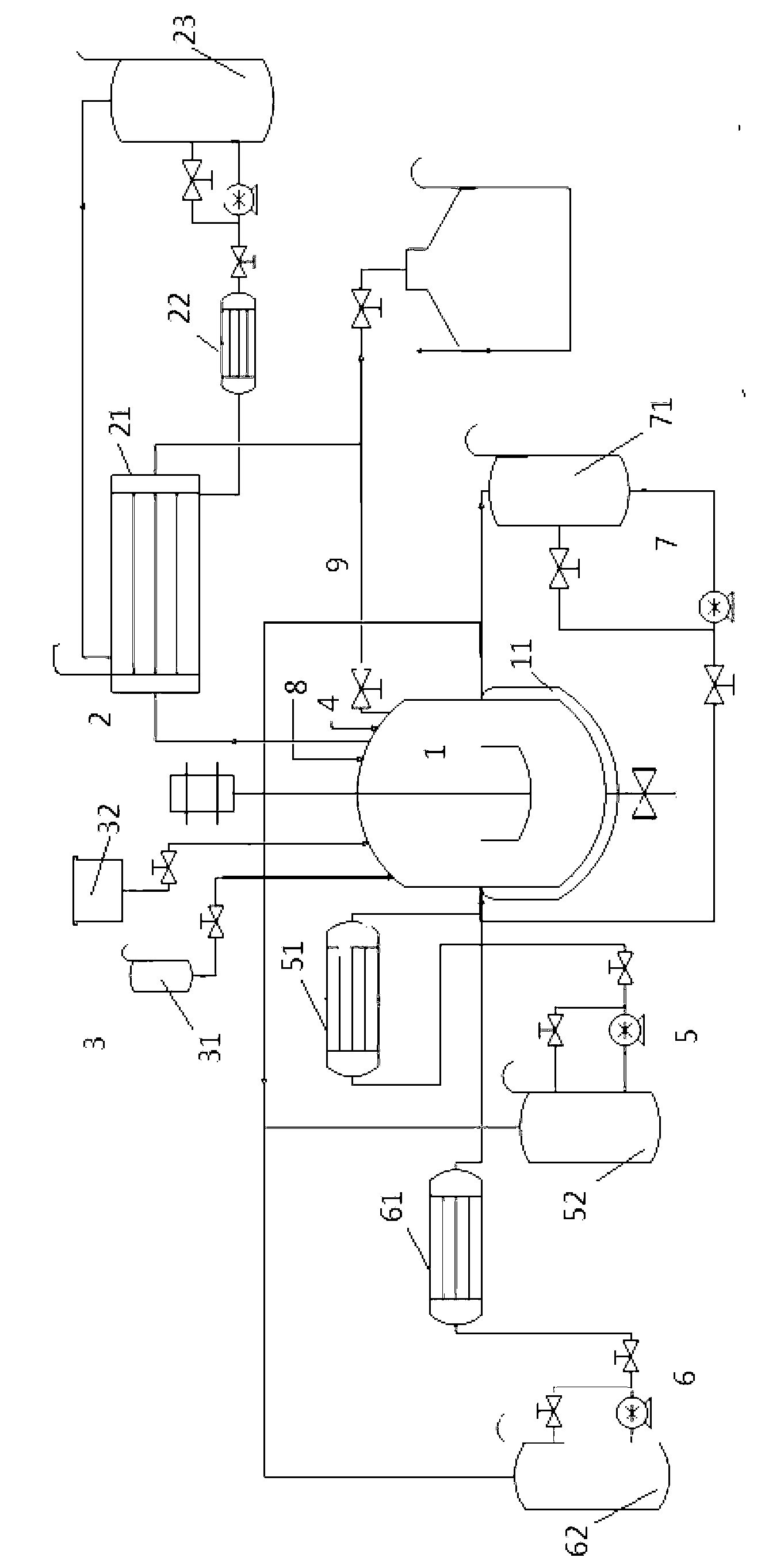

Industrial water-free oxygen-free production apparatus

InactiveCN103007857AAchieve coolingRealize the heating effectInert gas productionFeed devicesChemical industryIndustrial equipment

The invention relates to a water-free oxygen-free production apparatus used in the chemical industry. The apparatus comprises a reaction vessel which is respectively connected with a feeding system, an inert gas pressure supplementing system and a condenser cooling system, and a non-aqueous medium cooling system and a non-aqueous medium heating system are arranged out of the reaction vessel. The invention further relates to a preparation method for a chemical product by using the production apparatus. According to the invention, the technical problem of requirements for no water and oxygen in a reaction with participation of an active alkali metal is overcome, effects of heating and cooling are realized through indirect heating and cooling of all the heat sources and cold sources in the whole reaction vessel reaction vessel without a water medium, the advantages of safety, reliability, easy operation and a low manufacturing cost are obtained, and the apparatus is applicable both to common reactions with participation of active alkali metals and strict requirements for no water and oxygen and to a majority of water-free oxygen-free production systems and has a high popularization value in industrial equipment.

Owner:新岸诺亚(北京)催化科技有限公司

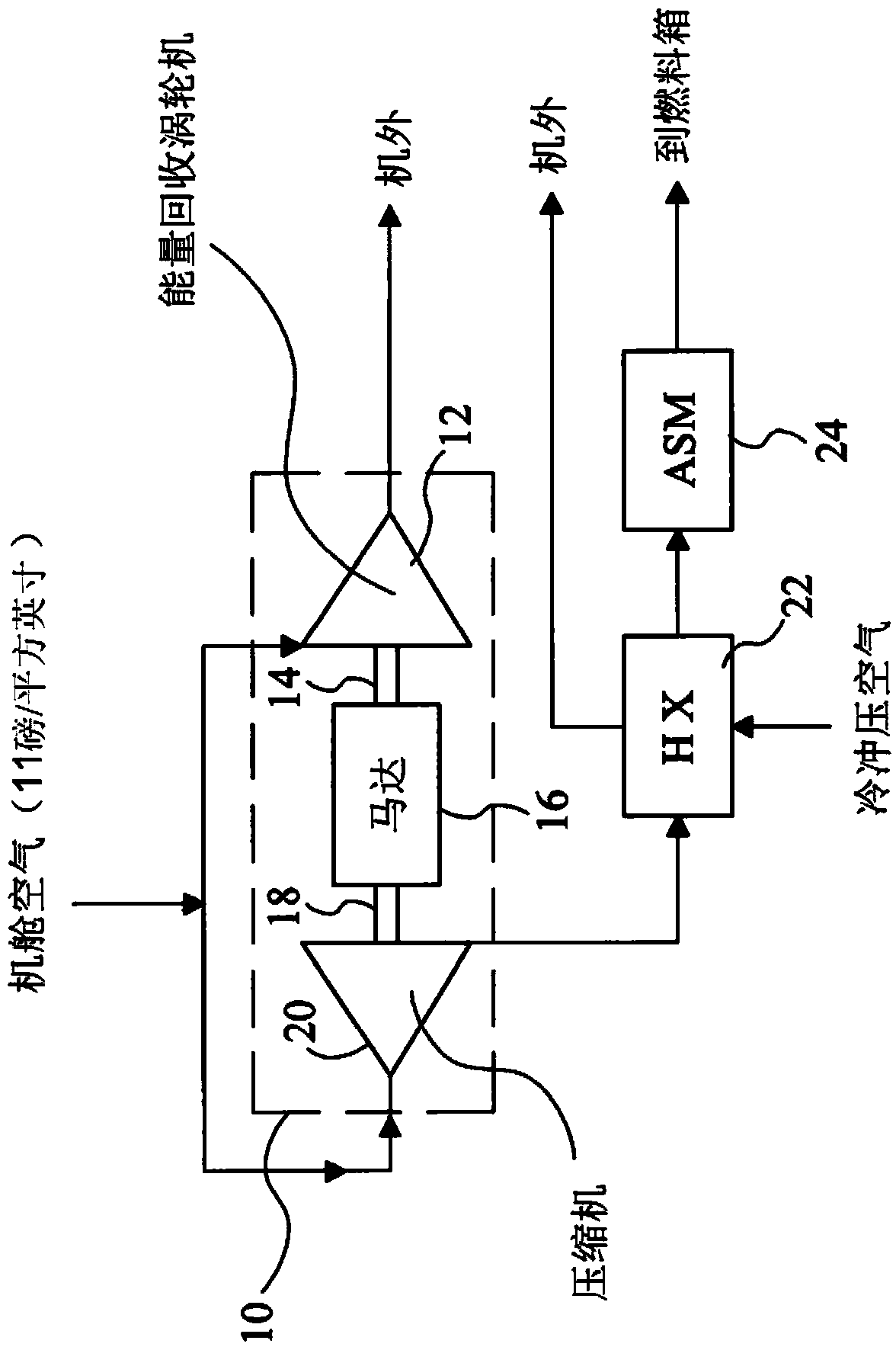

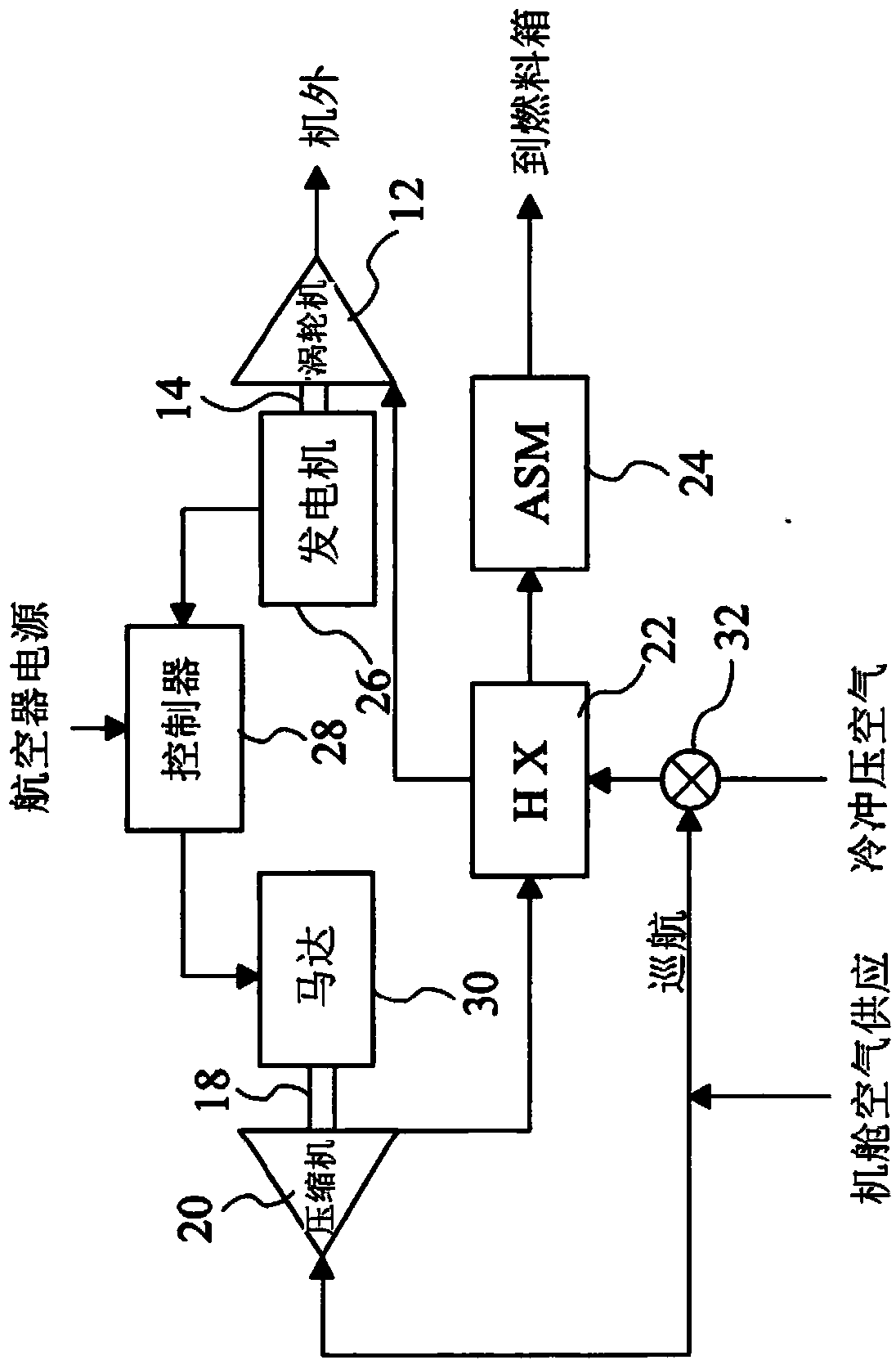

On board inert gas generation system

InactiveCN104080700AAir-treatment apparatus arrangementsDispersed particle separationGas compositionOn board

An on board inert gas generation system for an aircraft receives air from a relatively low pressure source such as low pressure engine bleed air or ram air and passes it to a positive displacement compressor (20) to increase the pressure thereof to be suitable for supply to an air separation module (24). The speed of the positive displacement compressor may be adjusted across a wide range in order to provide efficient operation in cruise and descent phases of aircraft flight. The operating speed of the compressor and / or the flow rate from the ASM to the space to be inerted may be controlled in accordance with at least one of the gas composition in the space to be inerted, the flight condition, and the ullage volume.

Owner:EATON CORP

Method and device for preparing oxygen-free protective gas by removing oxygen and impurities from air

InactiveCN102319555AThe overall structure is simple and reliableInert gas productionAir pumpProduct gas

The invention provides a method for preparing a gas by removing oxygen and impurities from air, which comprises the steps of: roasting a solid reducing agent to consume oxygen in the air; and purifying the generated gas to form a clean gas. The invention also provides a device for preparing a gas by removing oxygen and impurities from air; and the device comprises a sealed container that is full of air, an air pump, a roasting chamber, a cooling and water washing pool, a dust removal room and a pipeline. In the technical scheme of the invention, through the method and device for roasting the solid reducing agent to consume the oxygen in the air and purifying the residual gas after the oxygen is consumed, the gas that has inactive chemical properties and is used for protecting files and cultural relics is generated; and the product is simple and reliable in structure.

Owner:吴焕松 +1

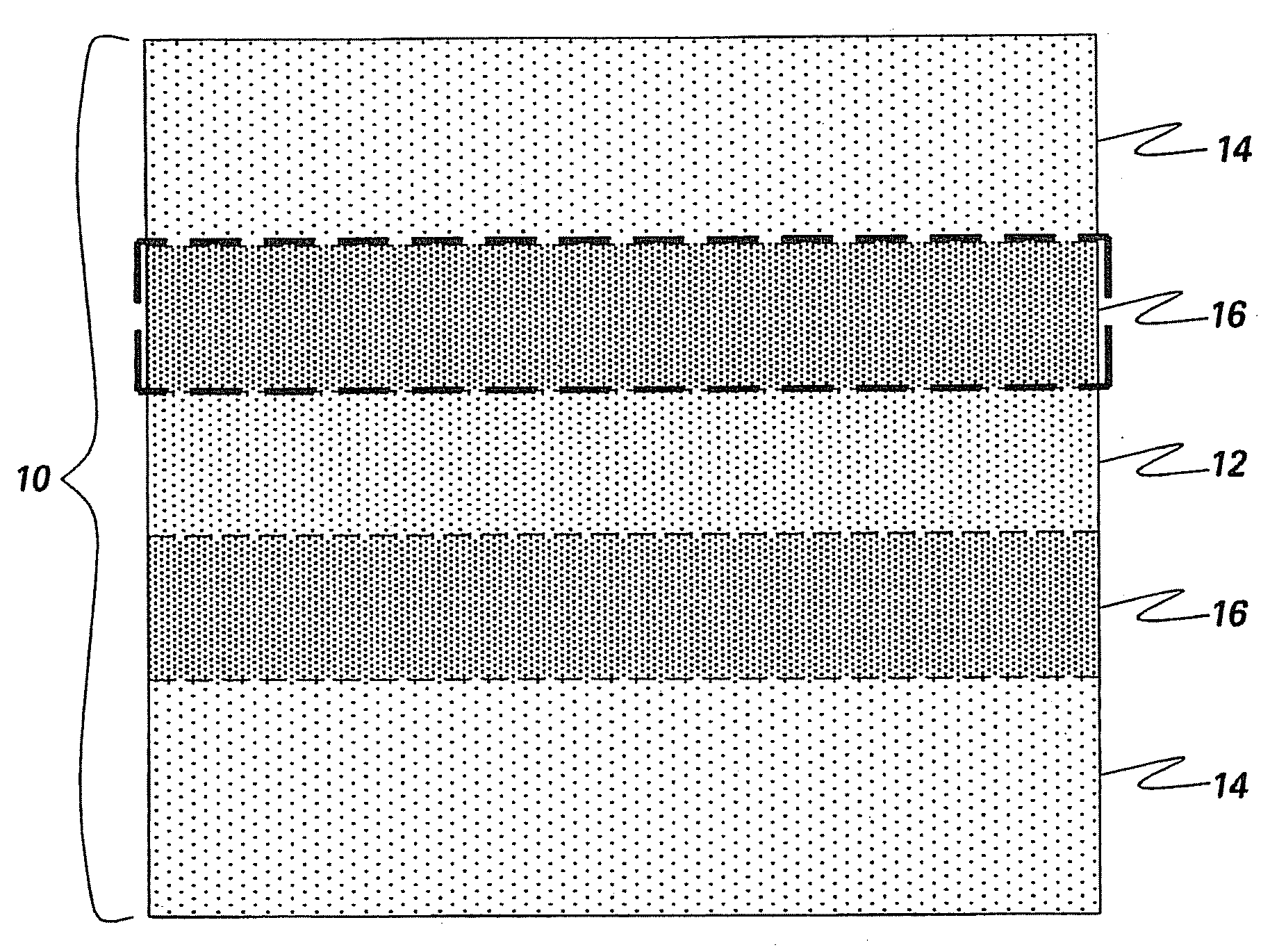

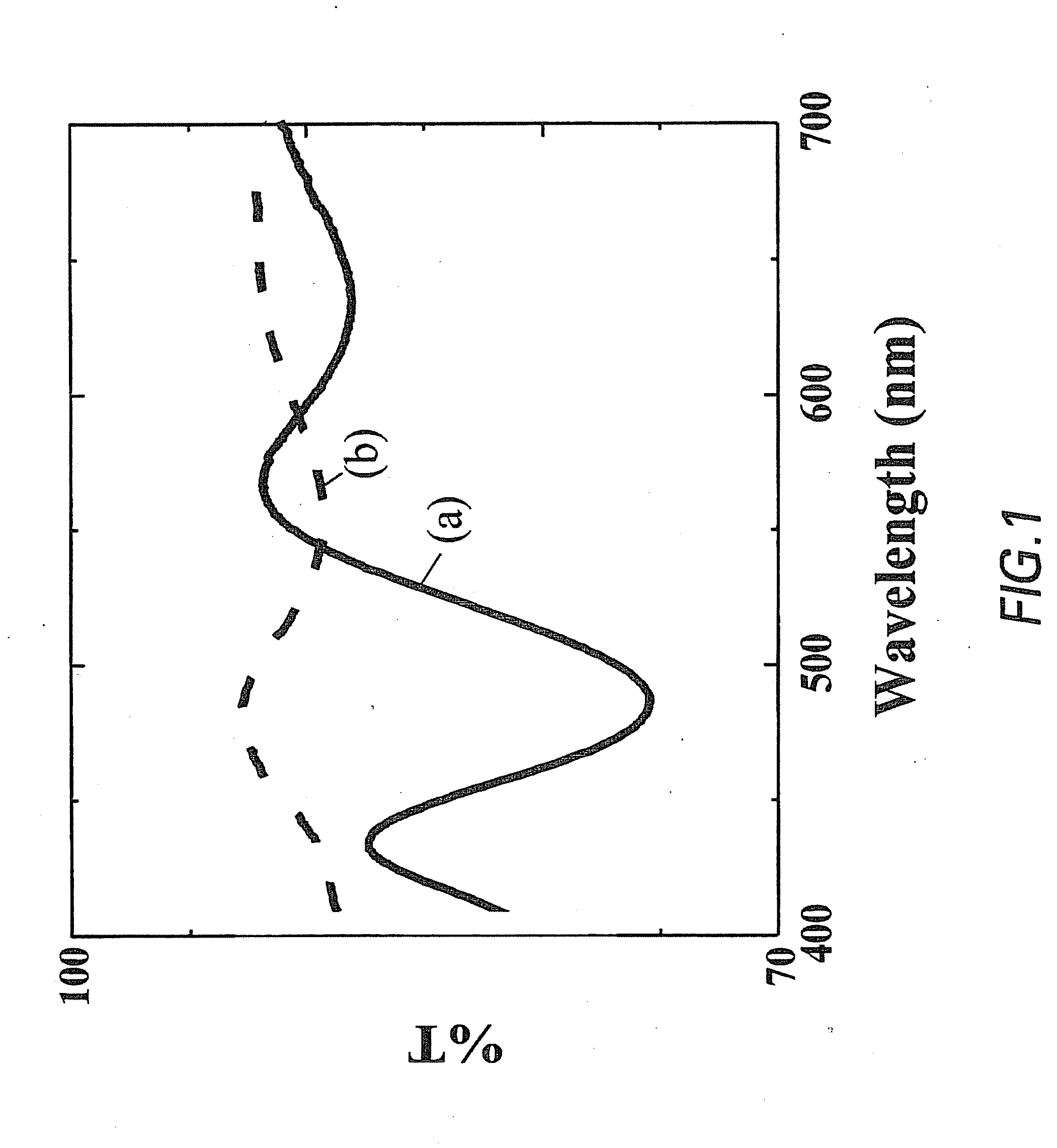

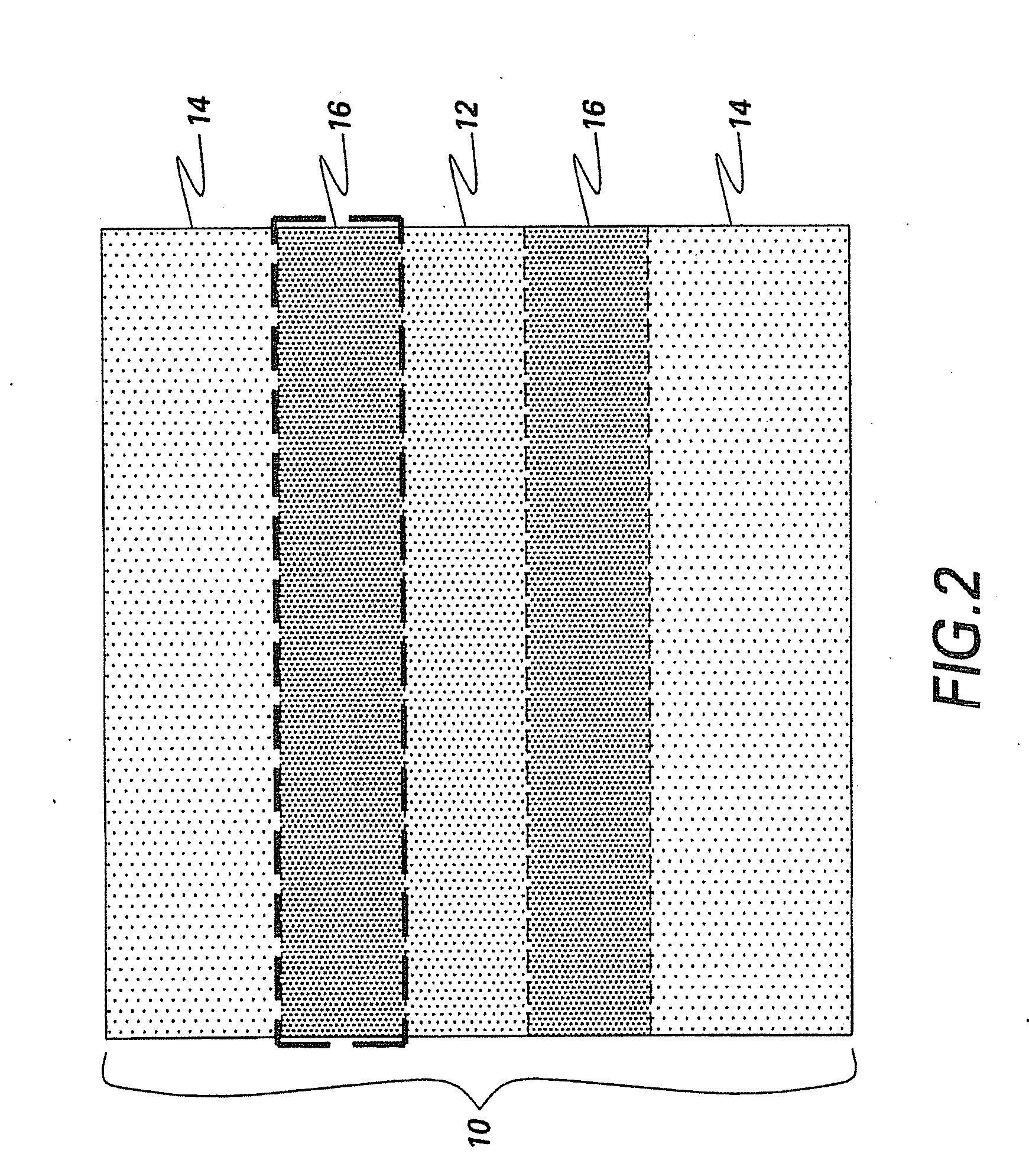

Barrier coatings

Owner:GENERAL ELECTRIC CO

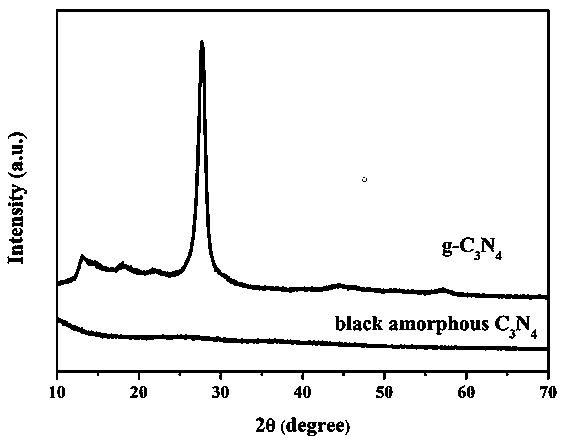

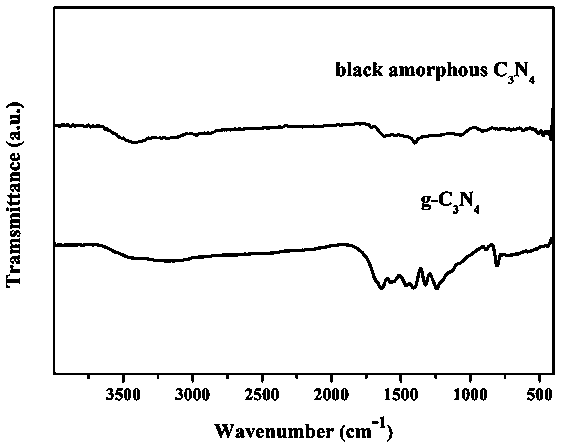

Preparation method of metal-doped black amorphous-state carbon nitride photocatalytic material

InactiveCN108889327AEasy to operateLow costOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationVisible light photocatalyticMetal salts

Owner:SOUTHWEST PETROLEUM UNIV

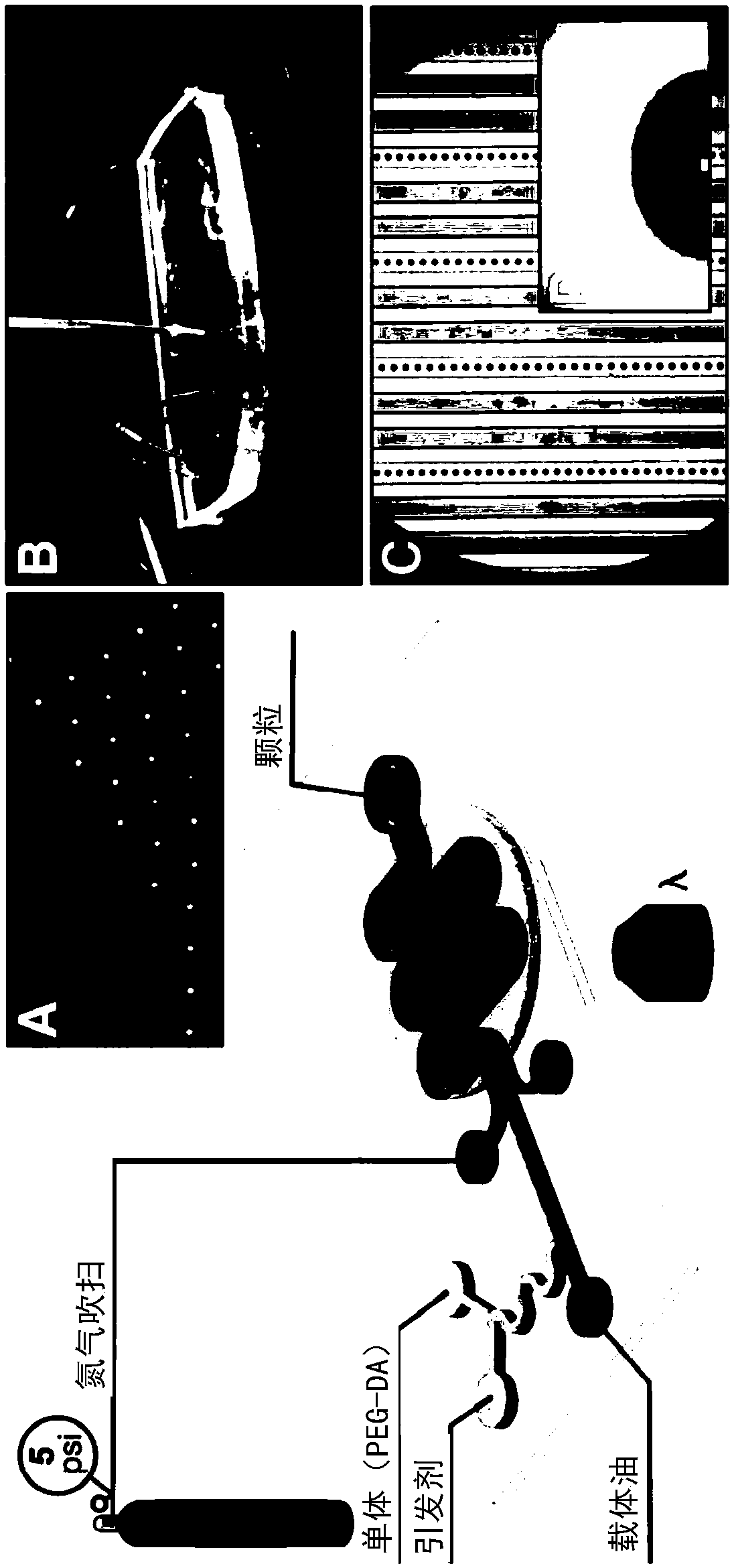

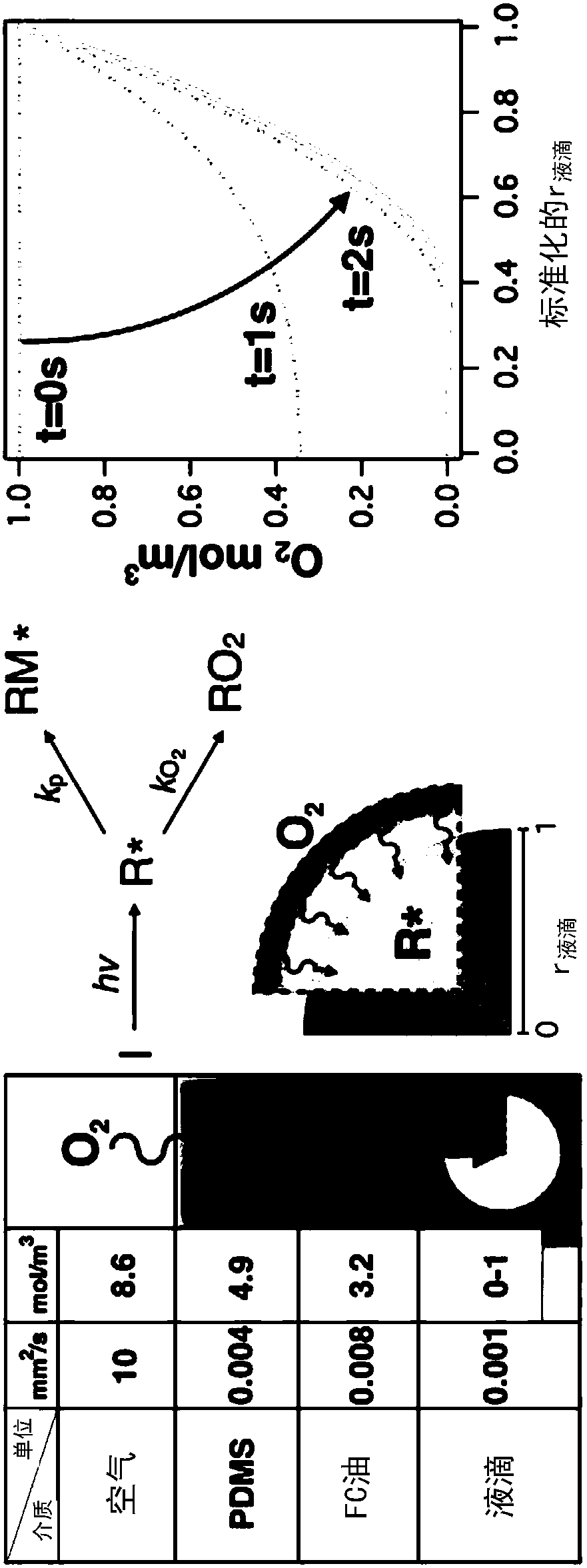

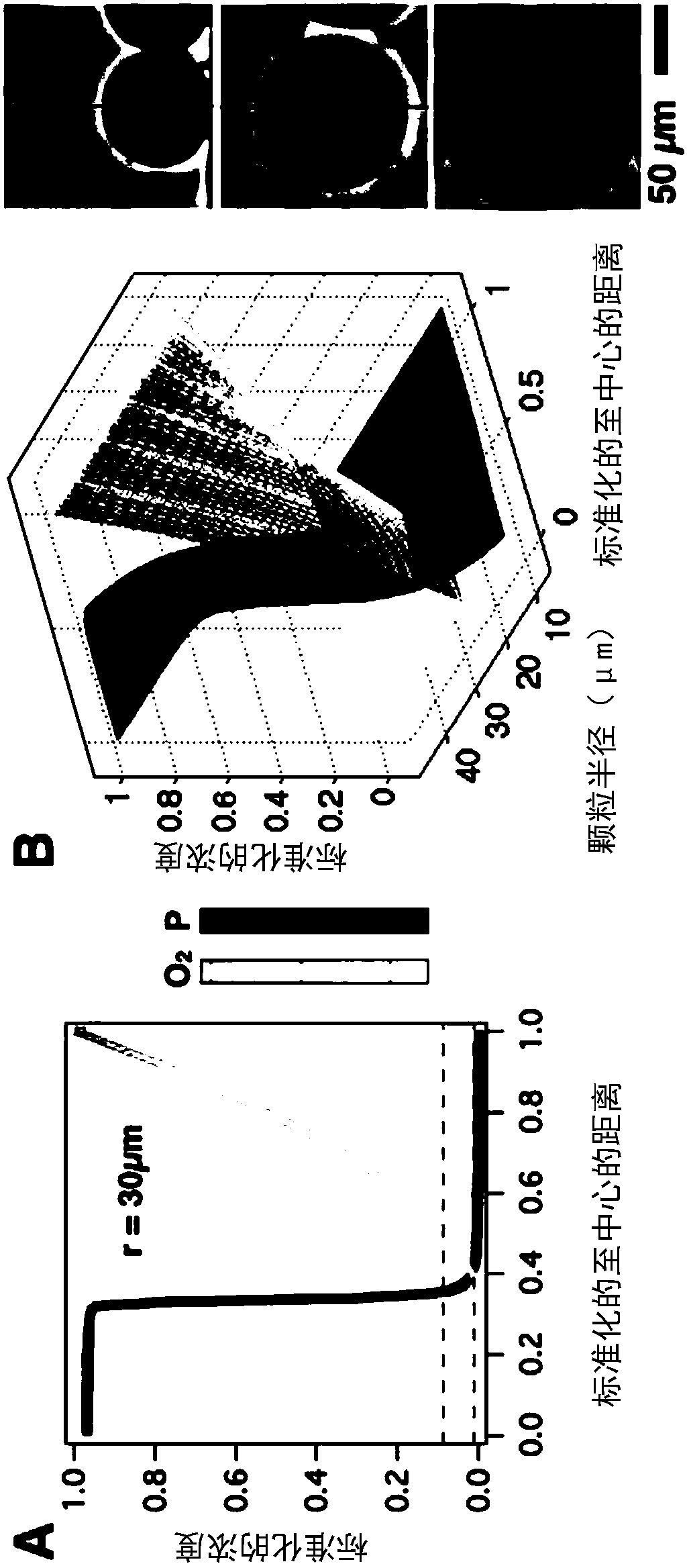

Methods of generating microparticles and porous hydrogels using microfluidics

Owner:UNIVERSITY OF WYOMING

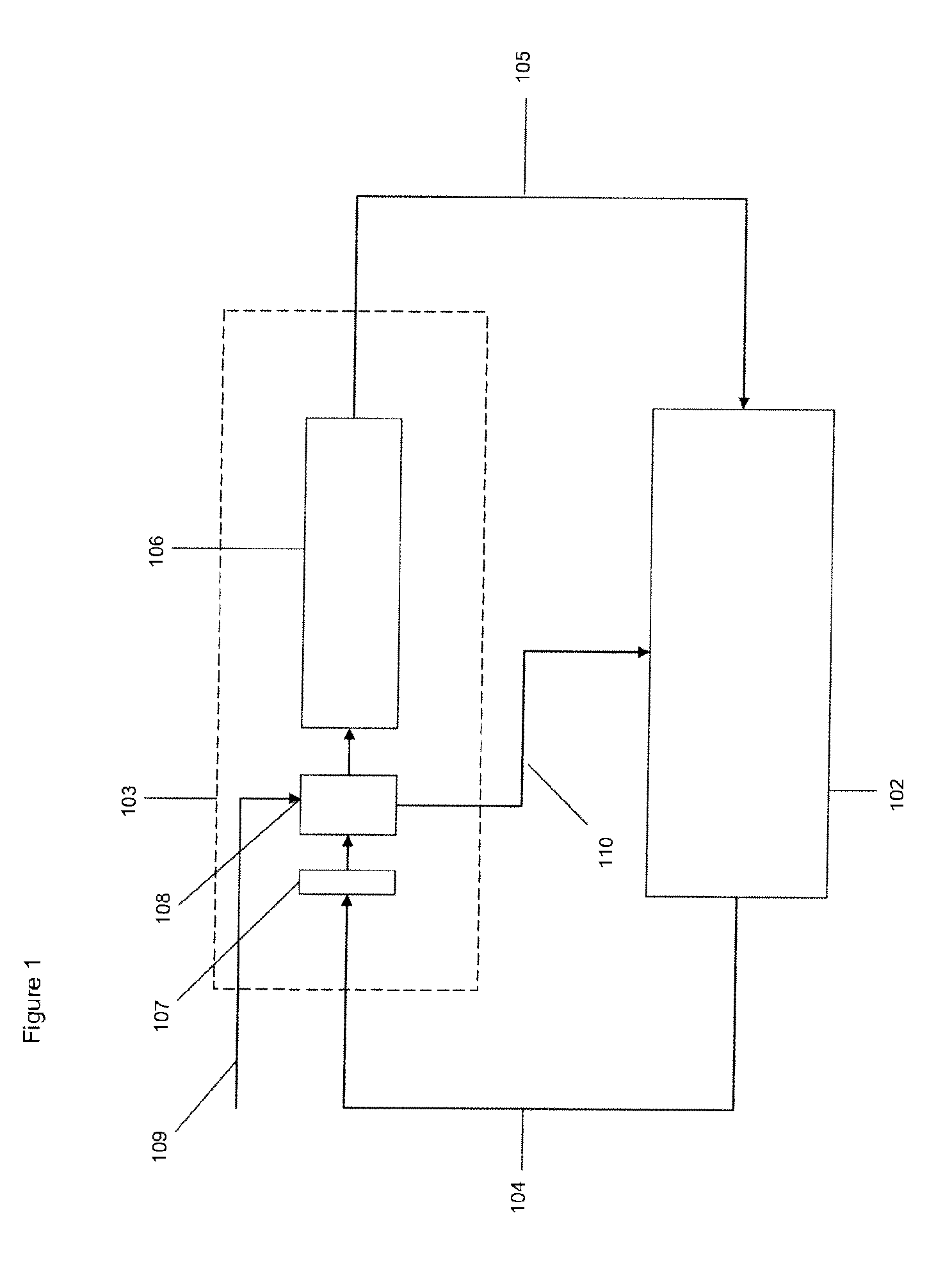

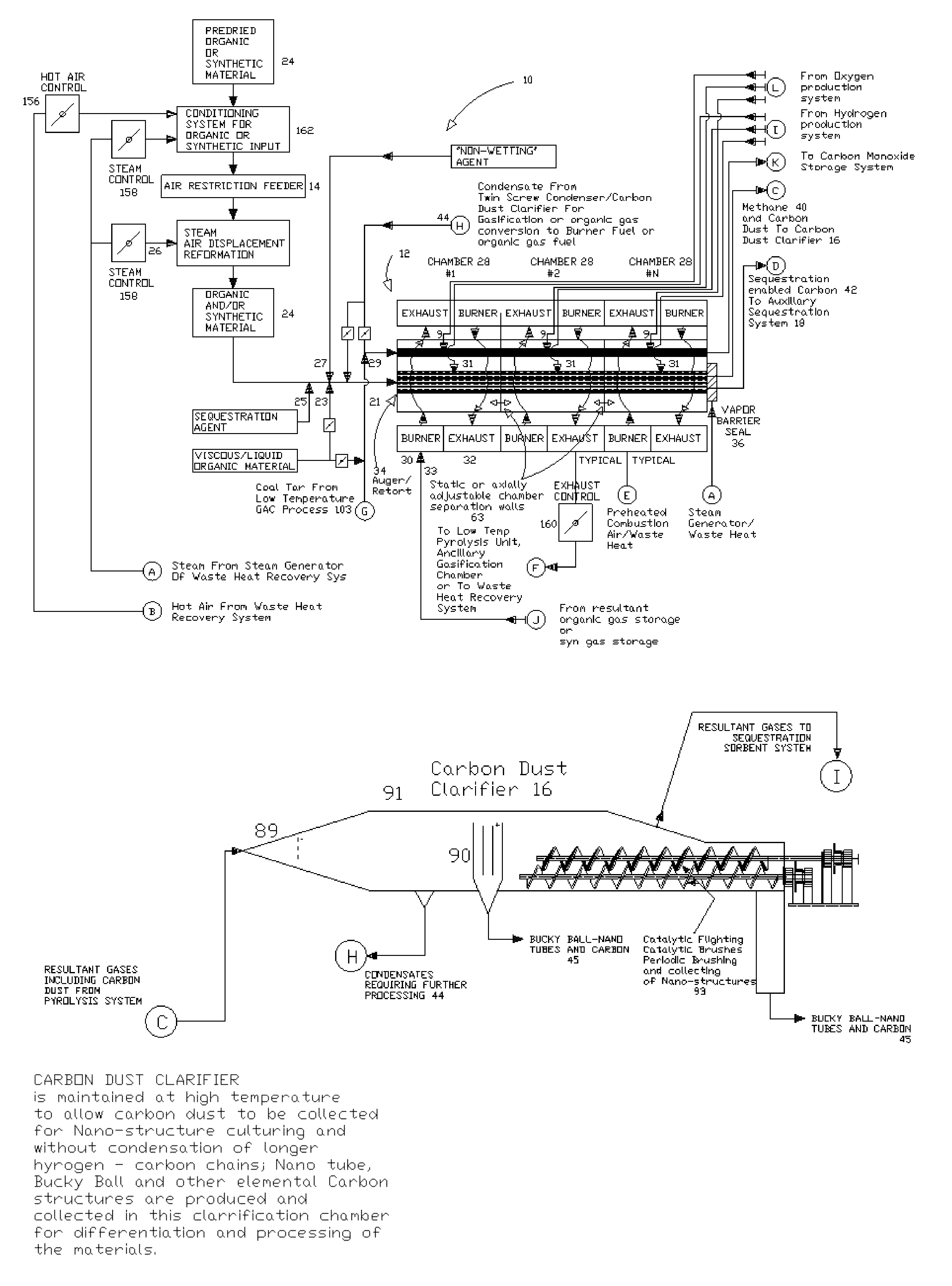

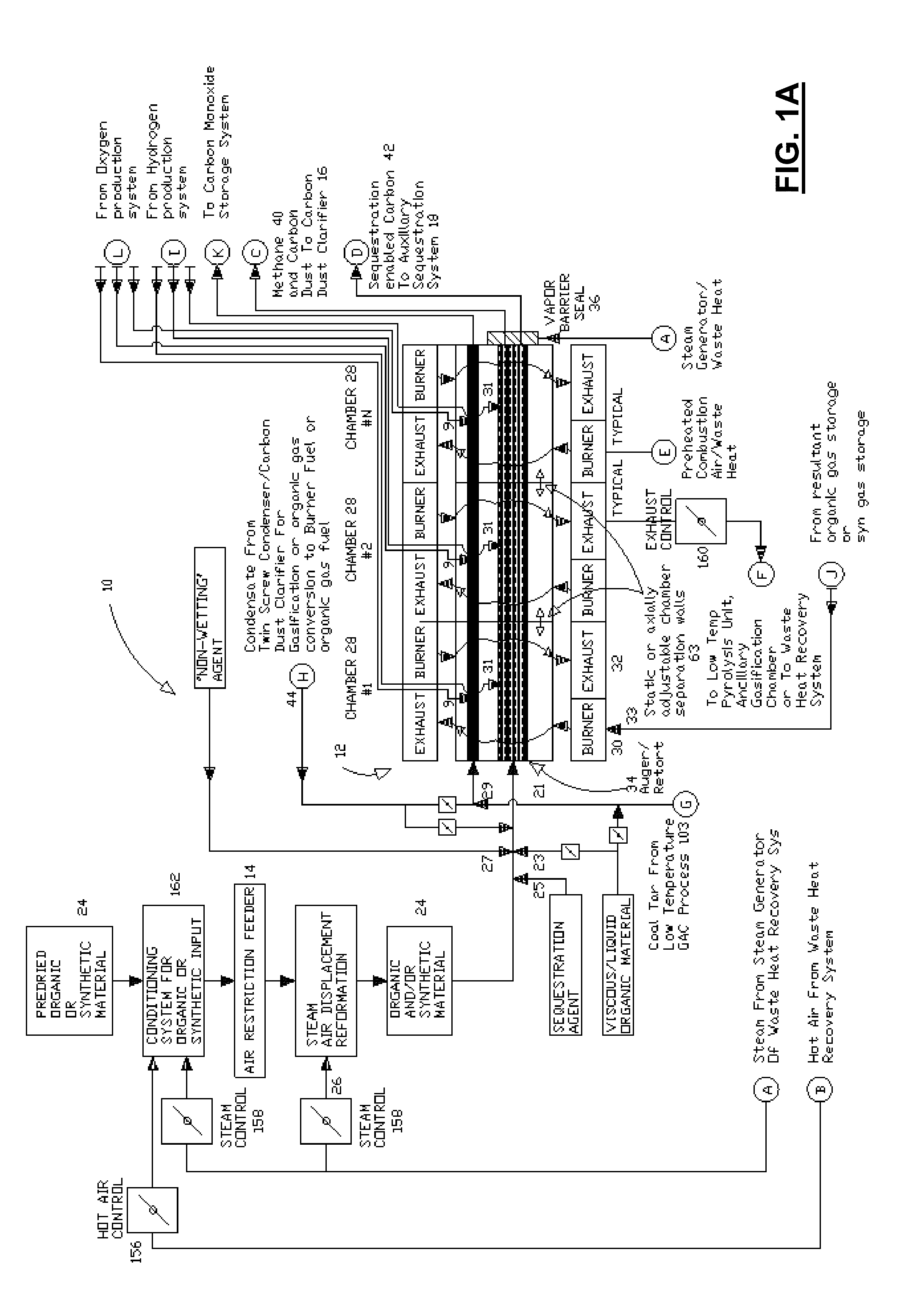

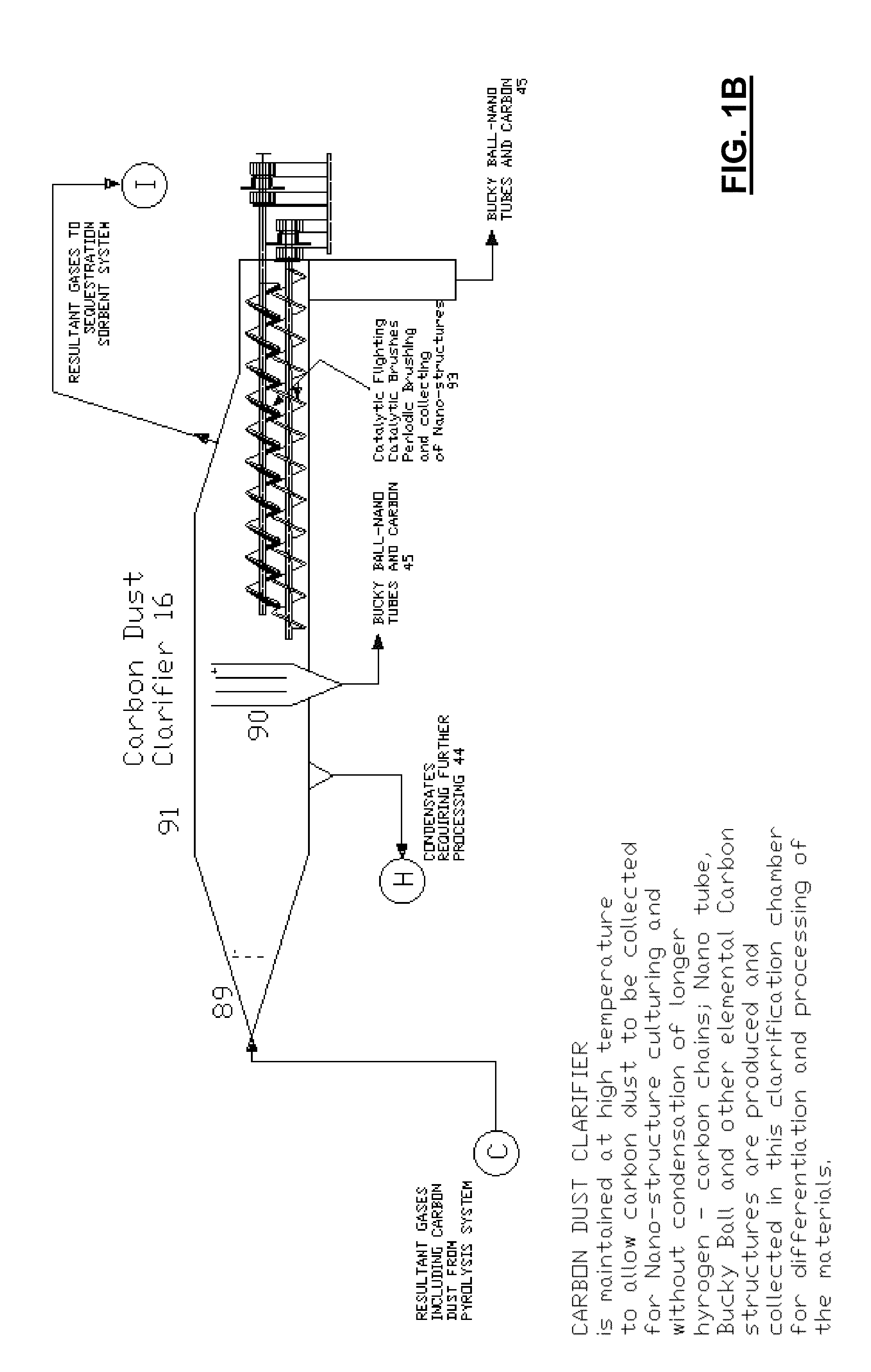

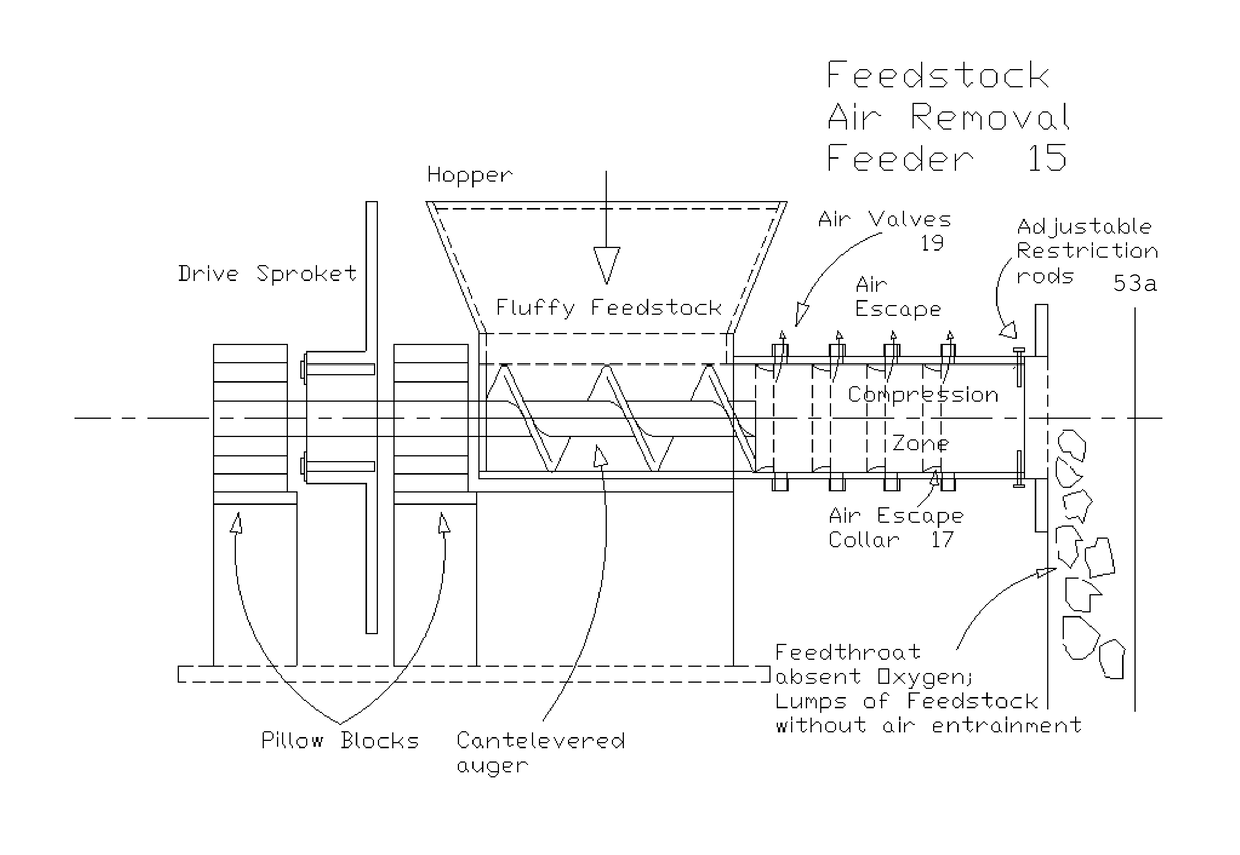

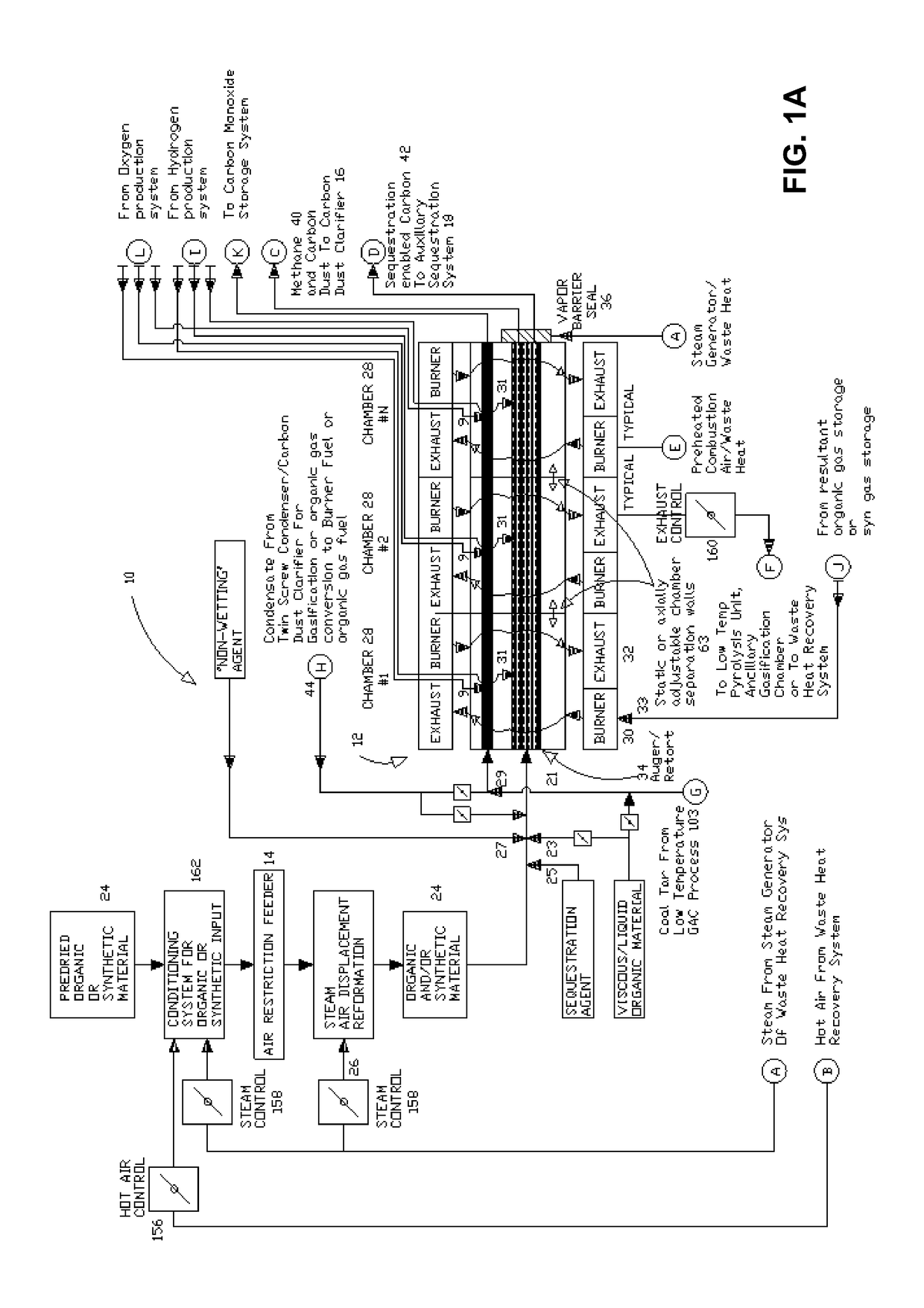

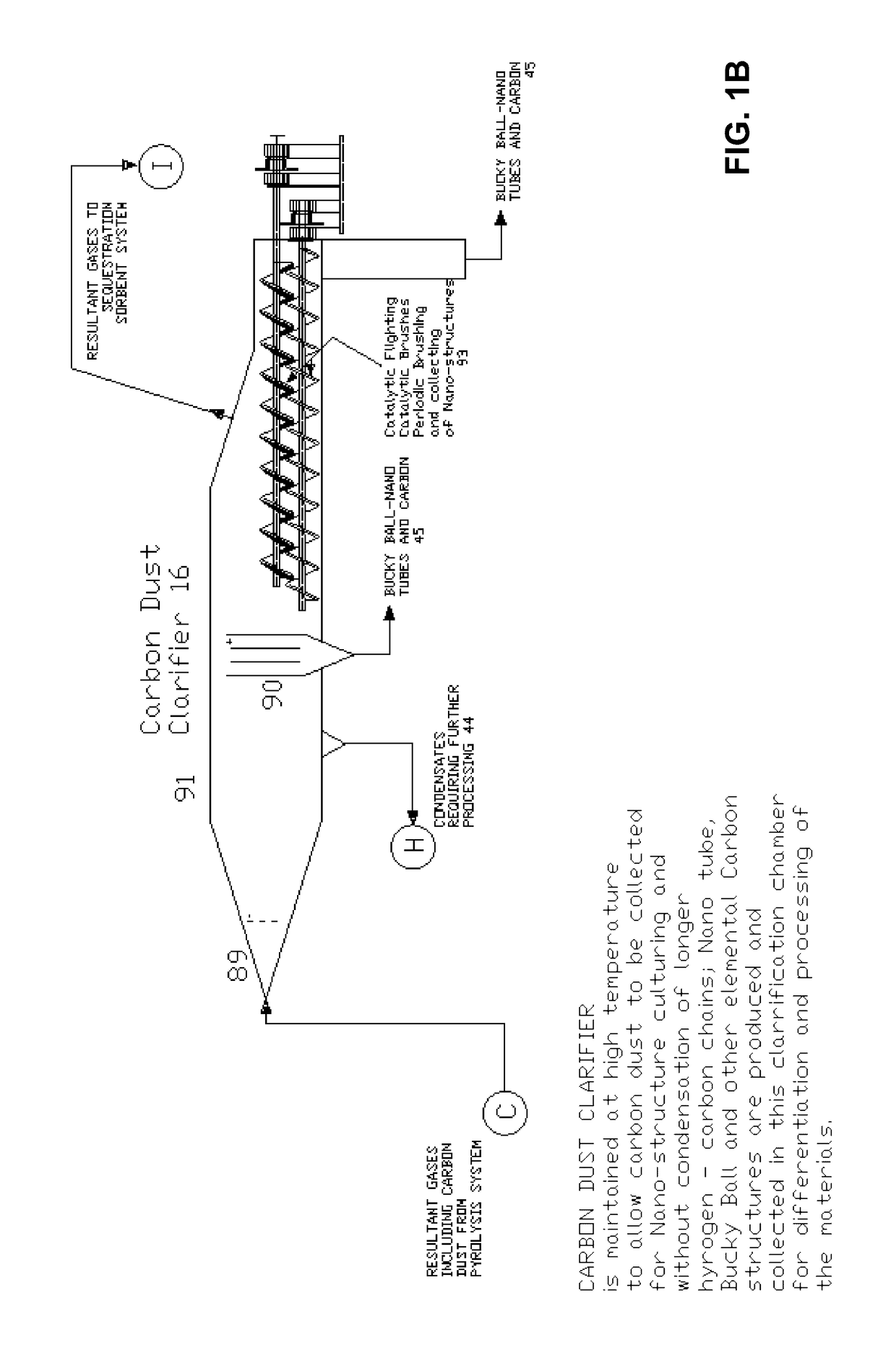

Pyrolysis and gasification systems, methods, and resultants derived therefrom

ActiveUS20140301934A1Fit closelyIncrease energy densityFullerenesDiffusing elementsHydrogenNano structuring

A process and system for the controlled thermal conversion of a carbonaceous feedstock, including: exposing the feedstock to one or more predetermined temperatures and one or more predetermined pressures for one or more predetermined amounts of time in one or more chambers to produce a gas product and a solid product, wherein the gas product includes one or more of methane, Carbon monoxide, Hydrogen, and one or more noxious chemicals and the solid product includes Carbon and Carbon nano-structures; sequestration enabling at least a portion of the Carbon by creating associated Lewis Acid Sites; sequestering at least one of the one or more noxious chemicals in the one or more chambers using the sequestration enabled Carbon; and controlling the constituents of the gas product using feedback, thereby providing a predictable and stable gas product from an unknown and / or variable feedstock and communicating data via SmartGrid communications protocols.

Owner:TUCKER RICHARD D

Pyrolysis and gasification systems, methods, and resultants derived therefrom

A process and system for the controlled thermal conversion of a carbonaceous feedstock, including: exposing the feedstock to one or more predetermined temperatures and one or more predetermined pressures for one or more predetermined amounts of time in one or more chambers to produce a gas product and a solid product, wherein the gas product includes one or more of methane, Carbon monoxide, Hydrogen, and one or more noxious chemicals and the solid product includes Carbon and Carbon nano-structures; sequestration enabling at least a portion of the Carbon by creating associated Lewis Acid Sites; sequestering at least one of the one or more noxious chemicals in the one or more chambers using the sequestration enabled Carbon; and controlling the constituents of the gas product using feedback, thereby providing a predictable and stable gas product from an unknown and / or variable feedstock and communicating data via SmartGrid communications protocols.

Owner:TUCKER RICHARD D

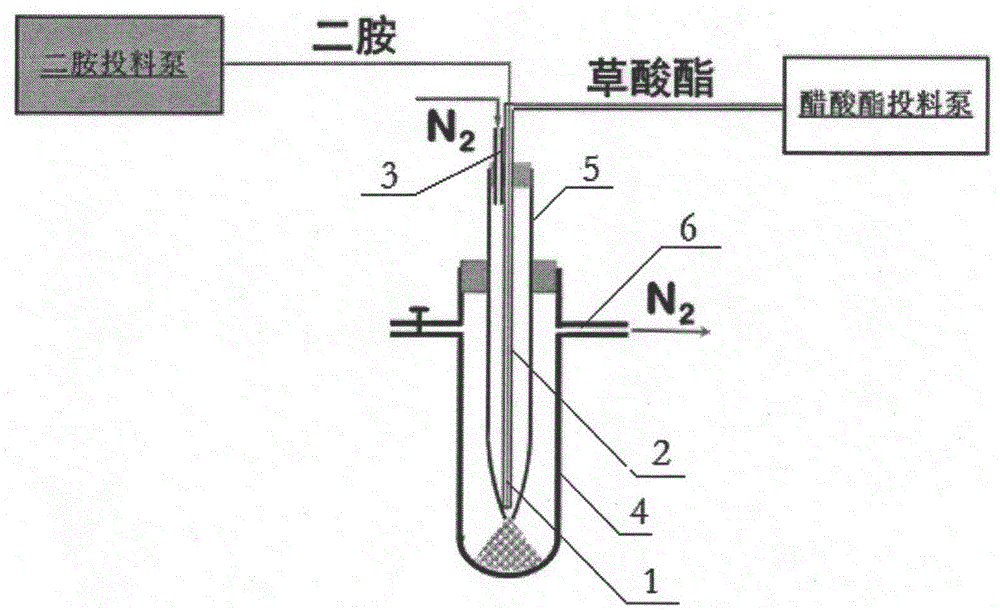

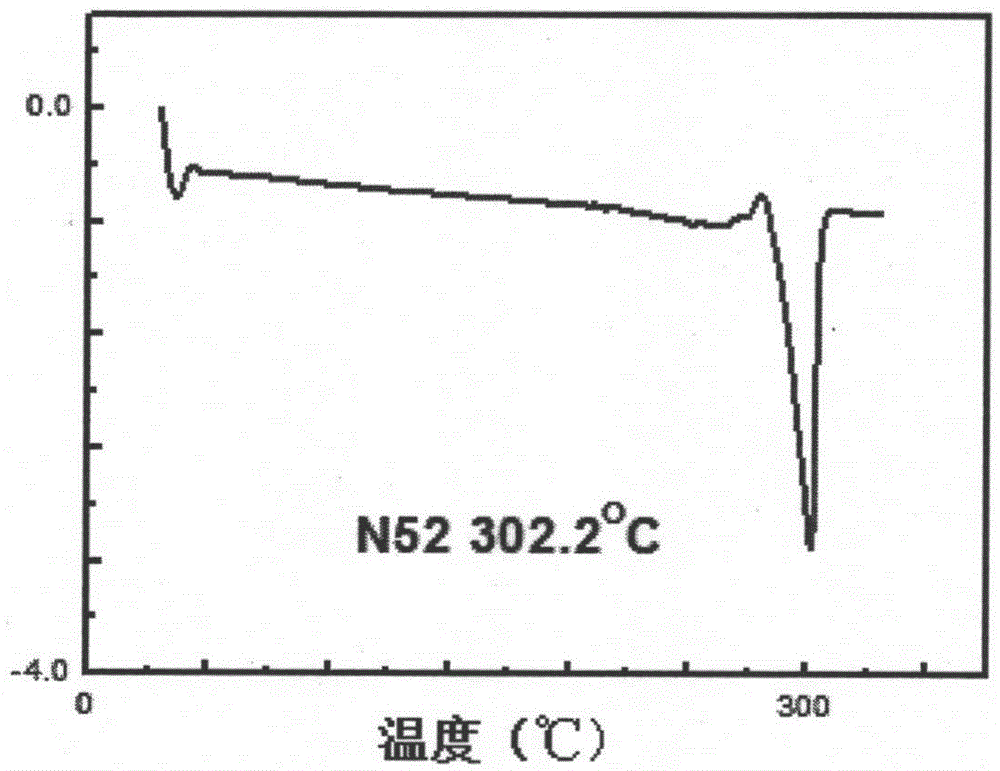

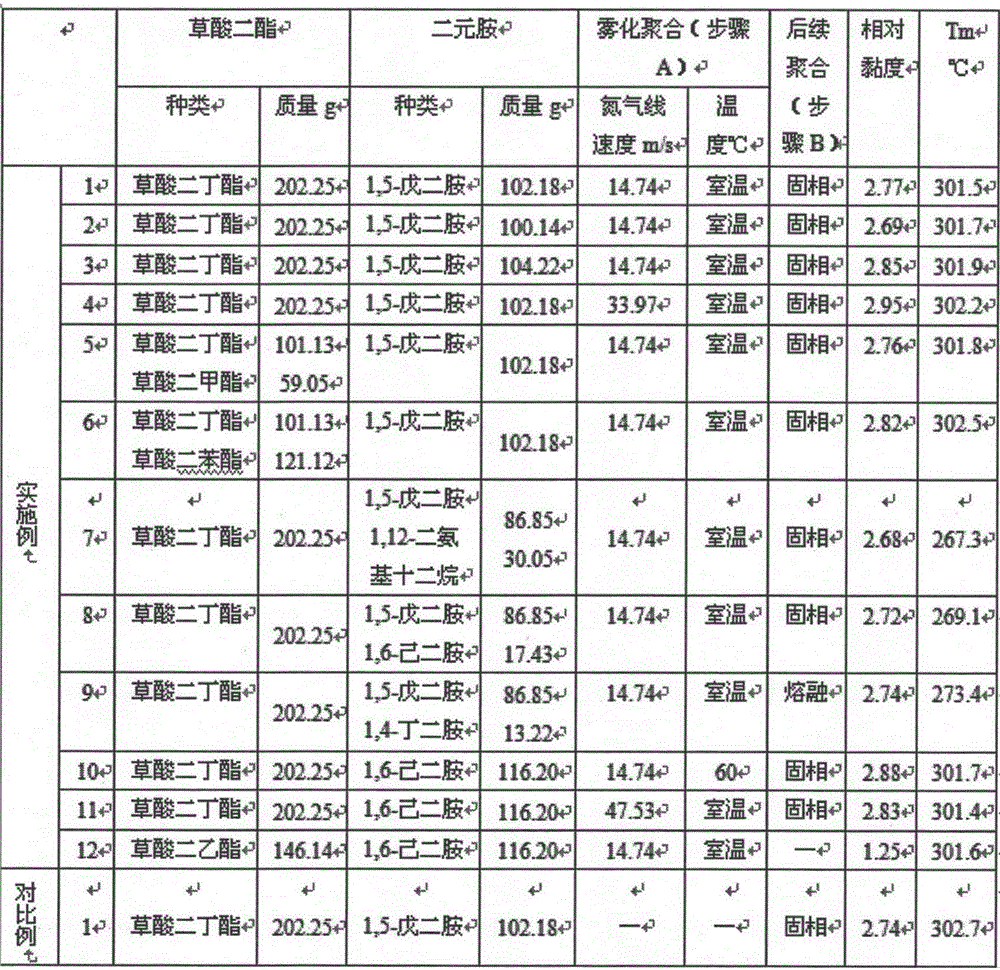

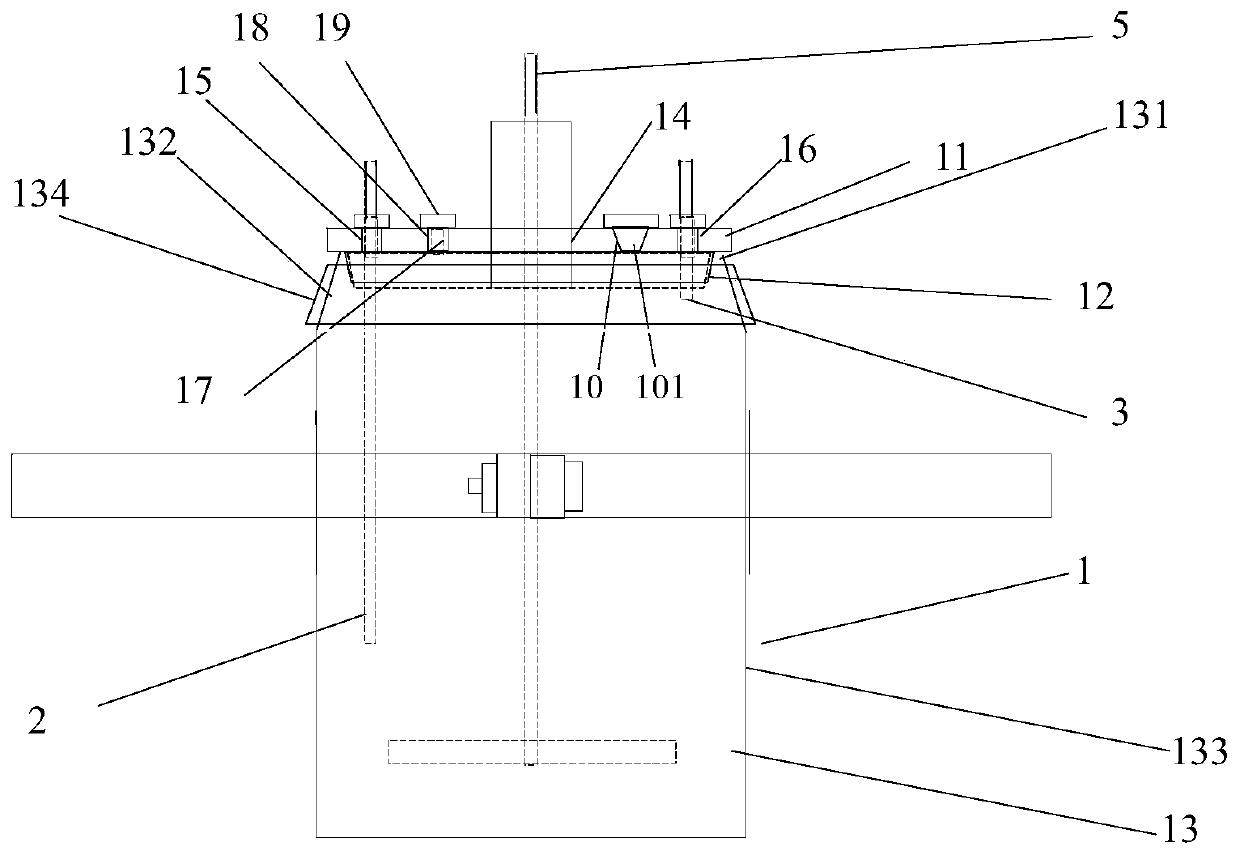

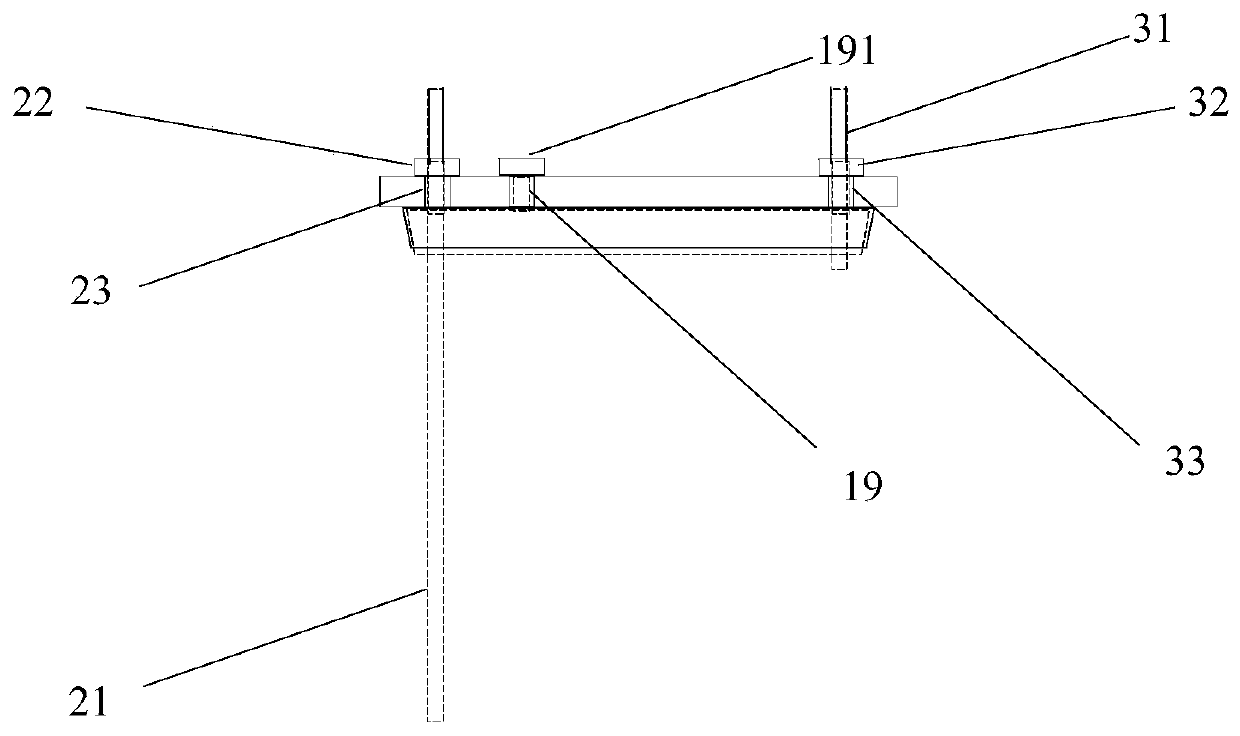

Atomization and polymerization method and device of polyoxamide

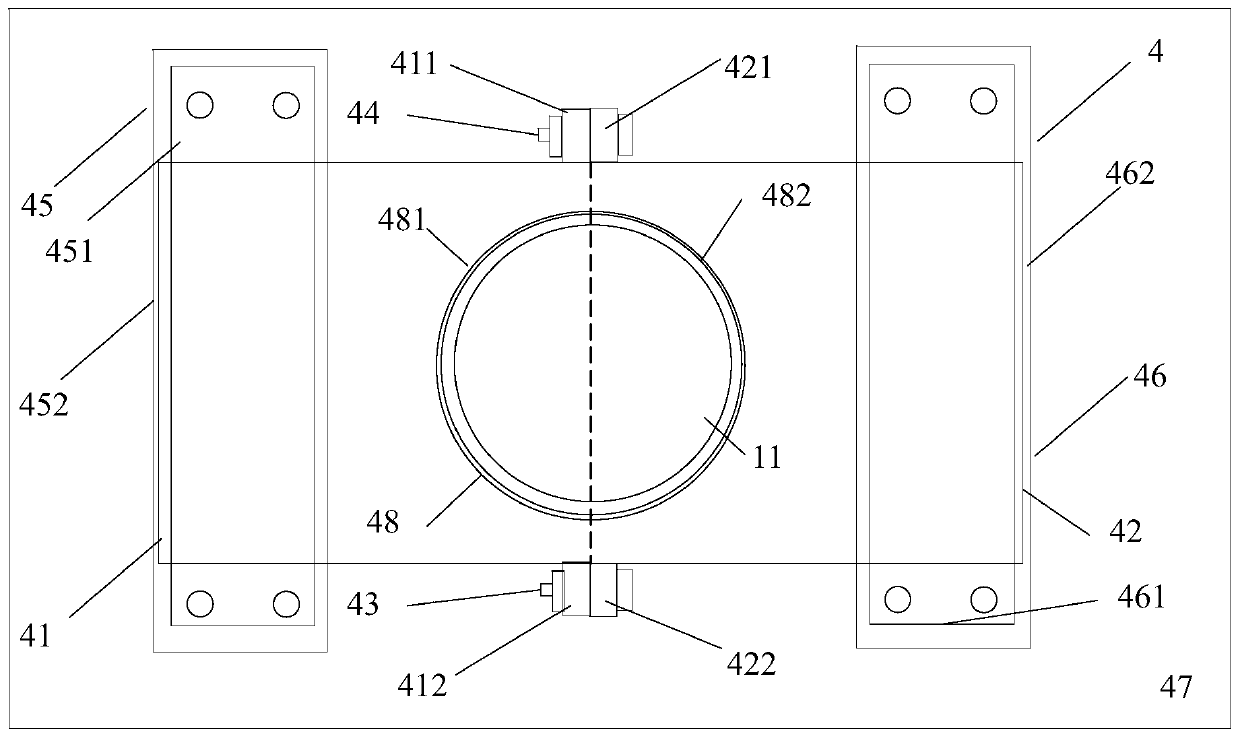

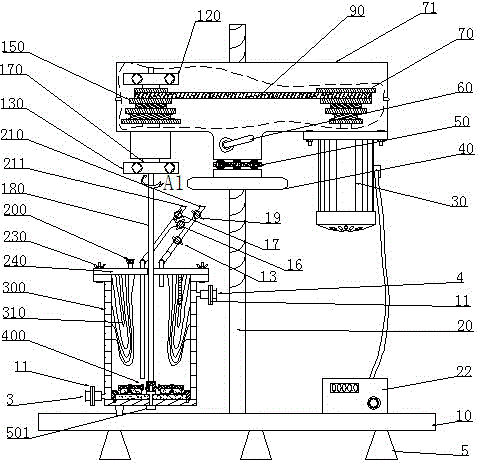

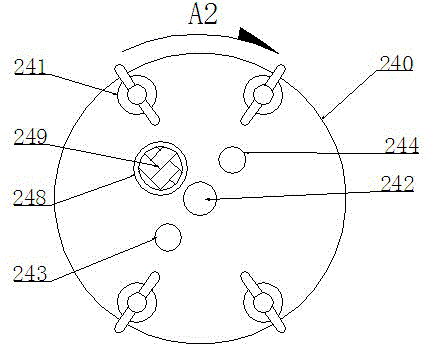

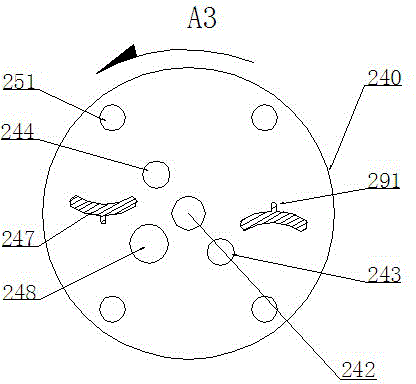

ActiveCN105461919AGuaranteed viscosityHigh molecular weightChemical/physical/physico-chemical nozzle-type rreactorsInert gas productionPolymer scienceSpray nozzle

The invention provides an atomization and polymerization method of polyoxamide. The method is characterized by including the steps that, diester oxalate and diamine are pumped into the same nozzle or different nozzles through a feeding pump, atomized, mixed and polymerized in inert gas flow, and polyoxamide is obtained. The atomization and polymerization method of polyoxamide is suitable for large-scale industrial production, has the advantages that operation is easy, conditions are moderate, solvents are not used, processing is easy and cost is low, and meanwhile guarantees viscosity and high molecular weight of polyoxamide.

Owner:DONGHUA UNIV +1

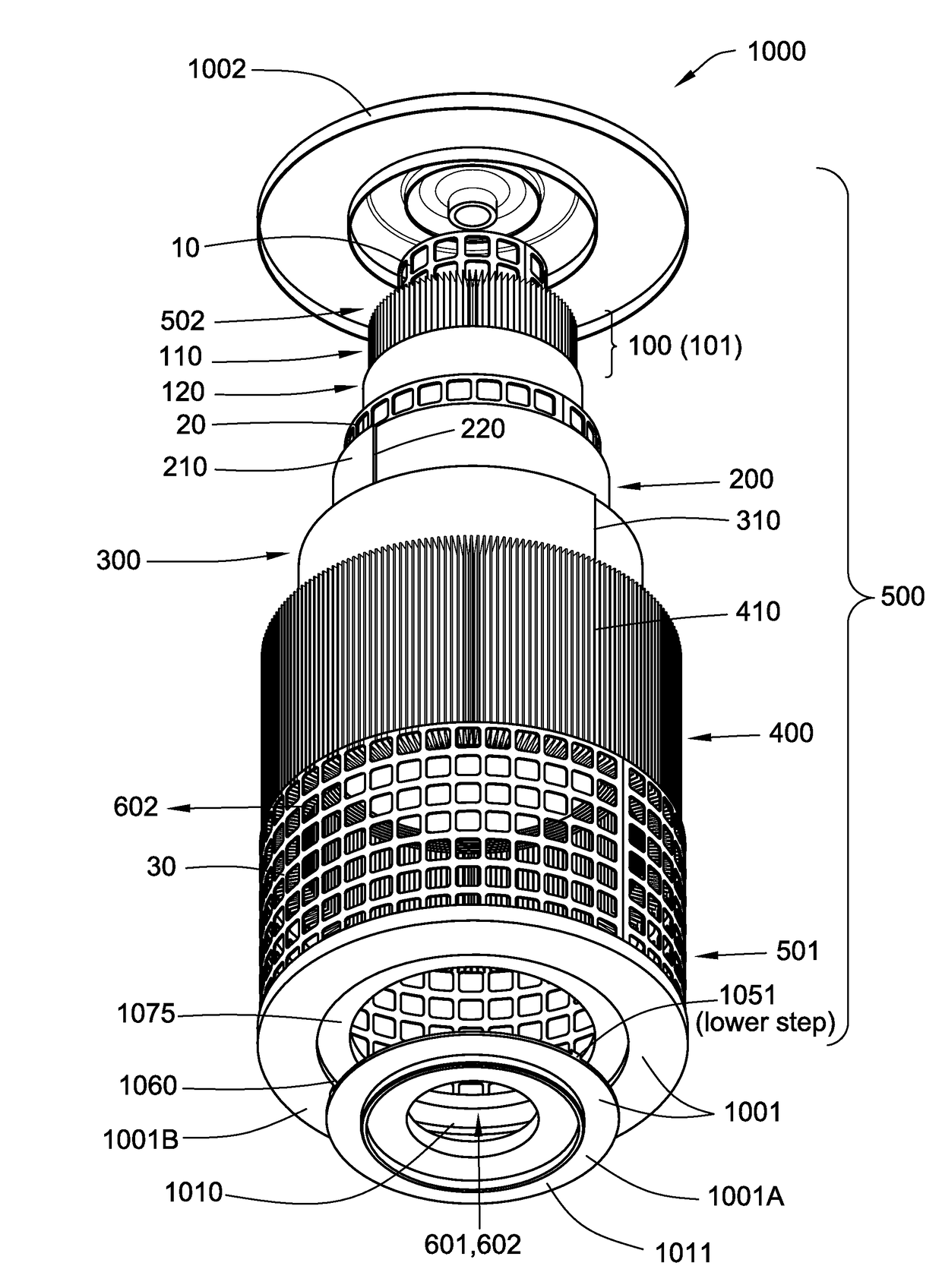

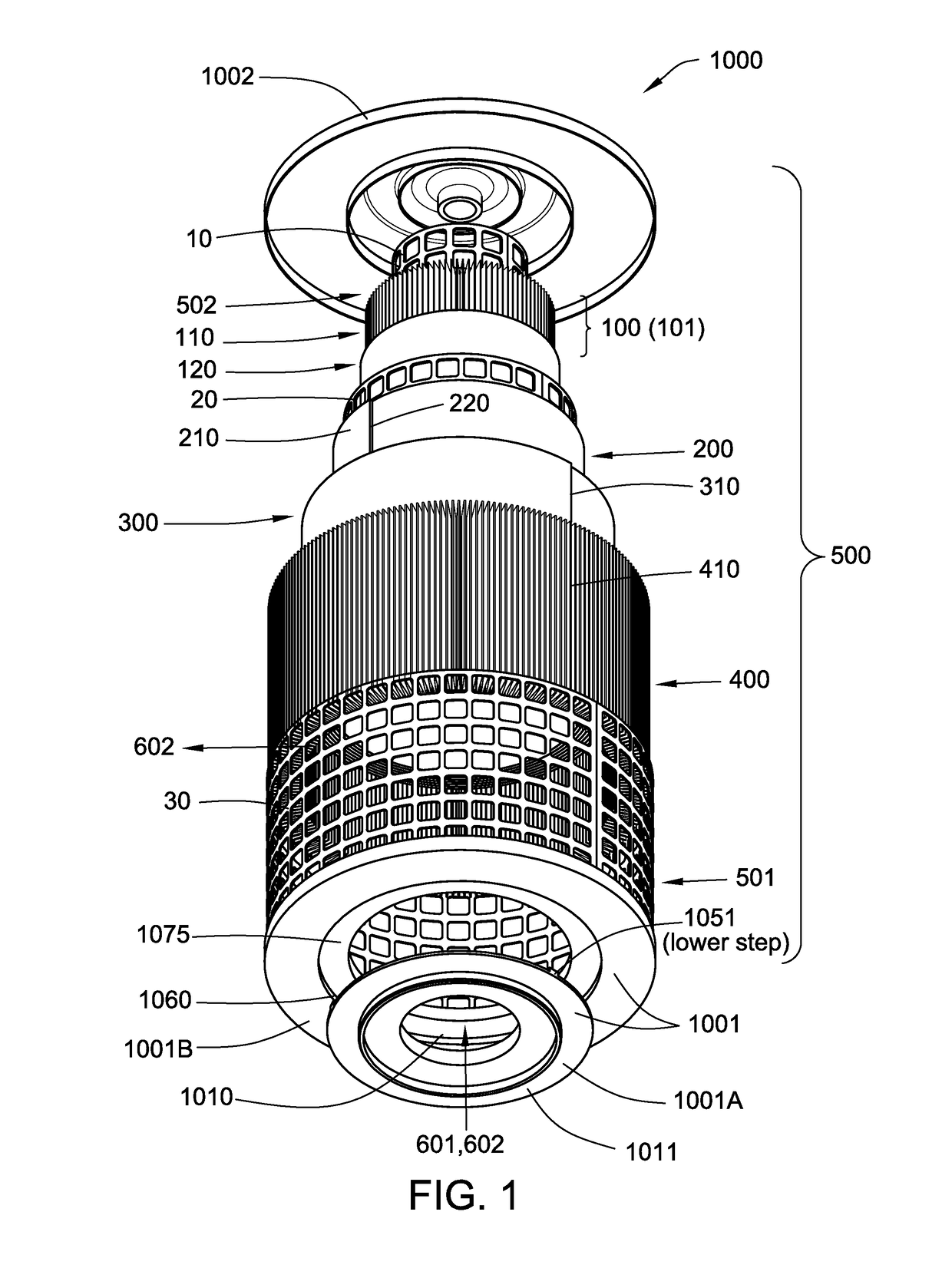

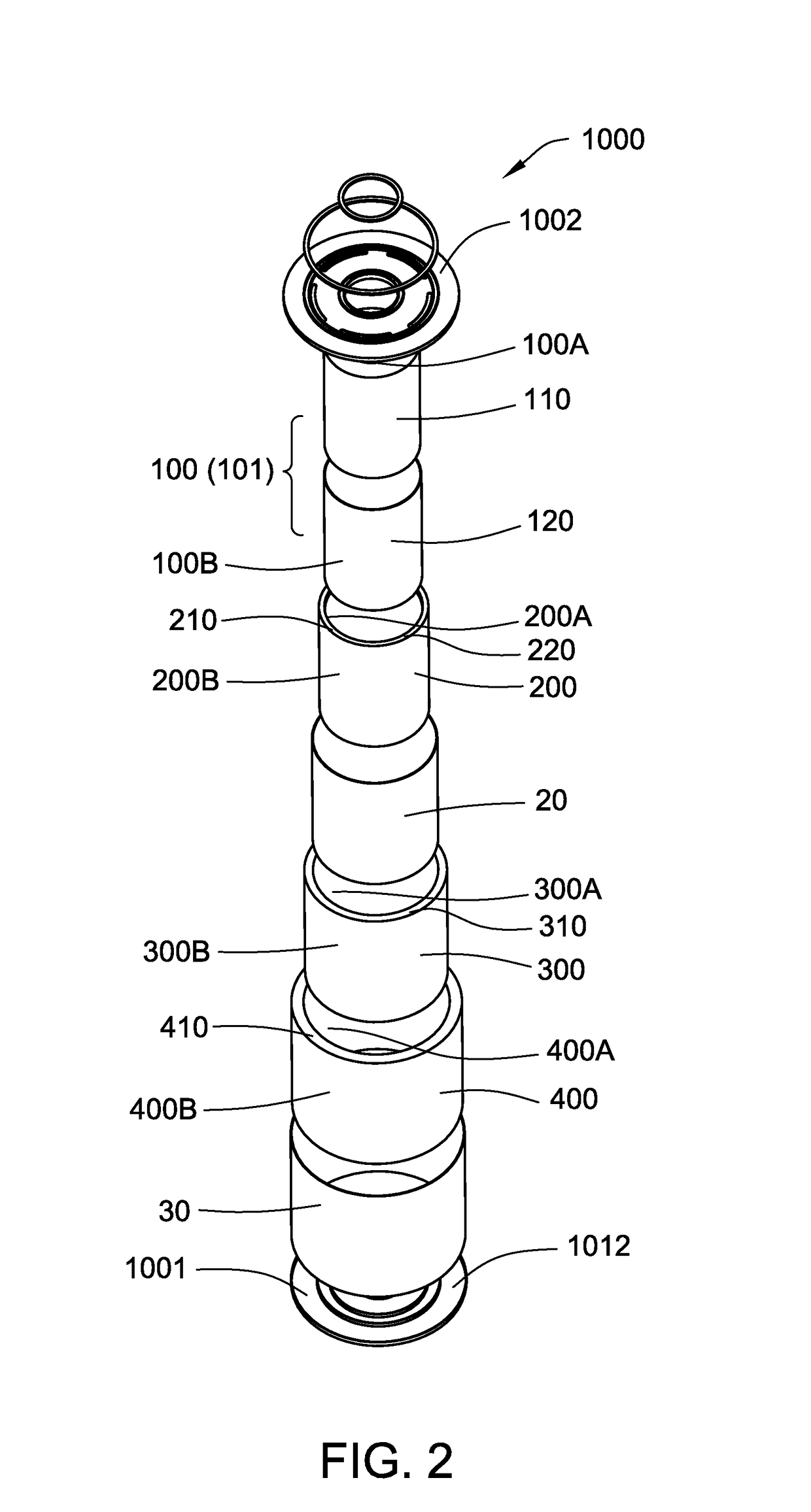

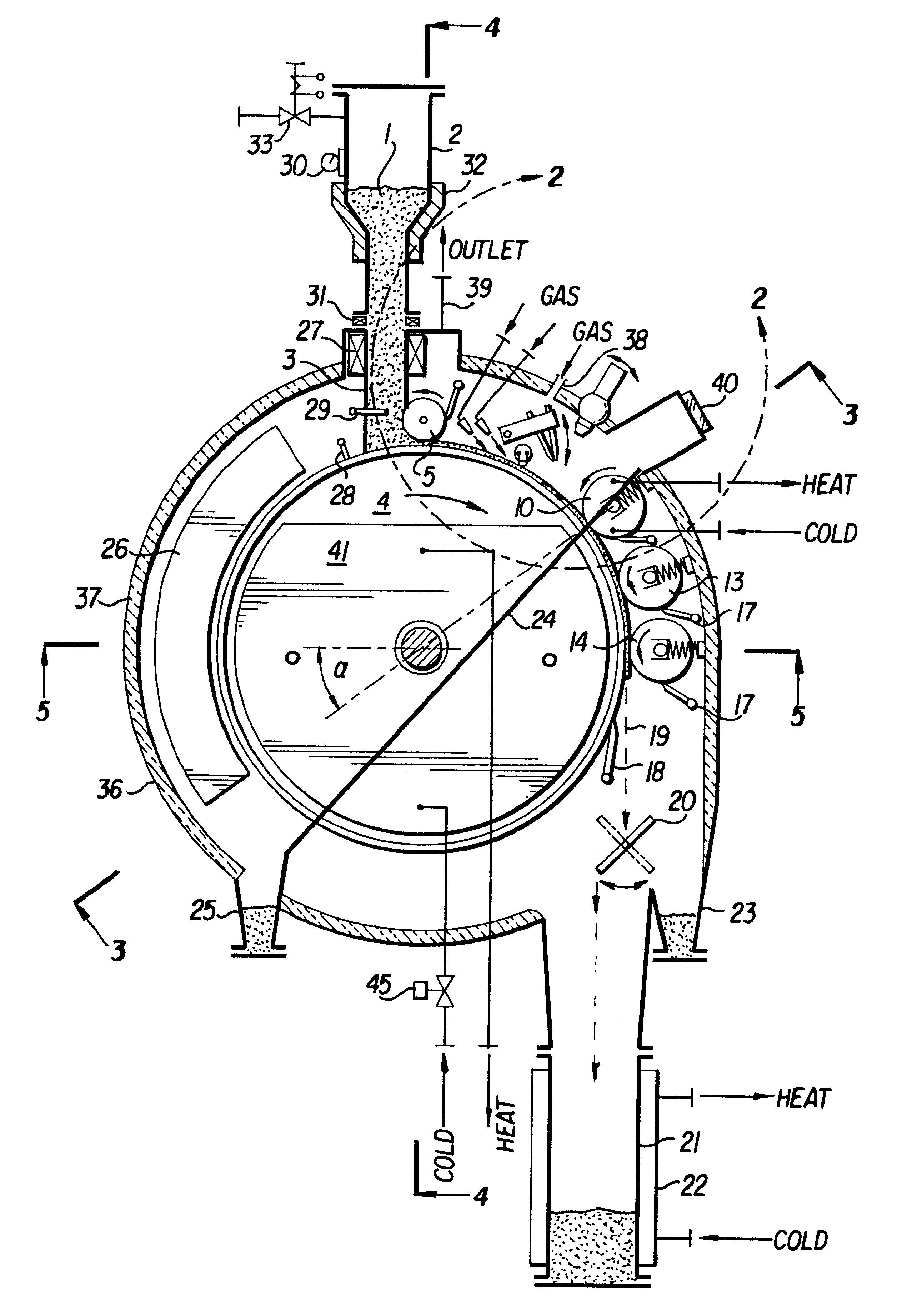

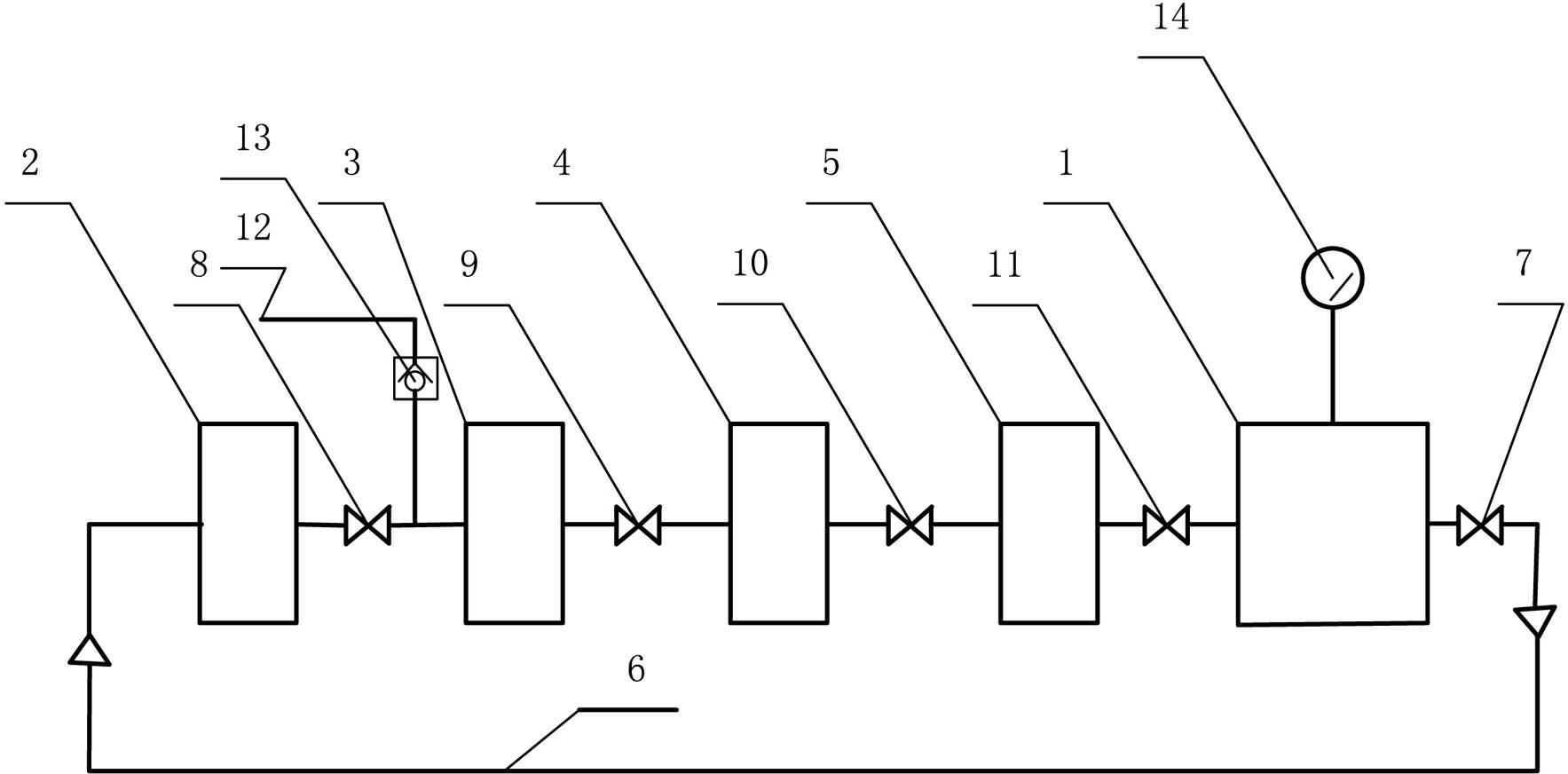

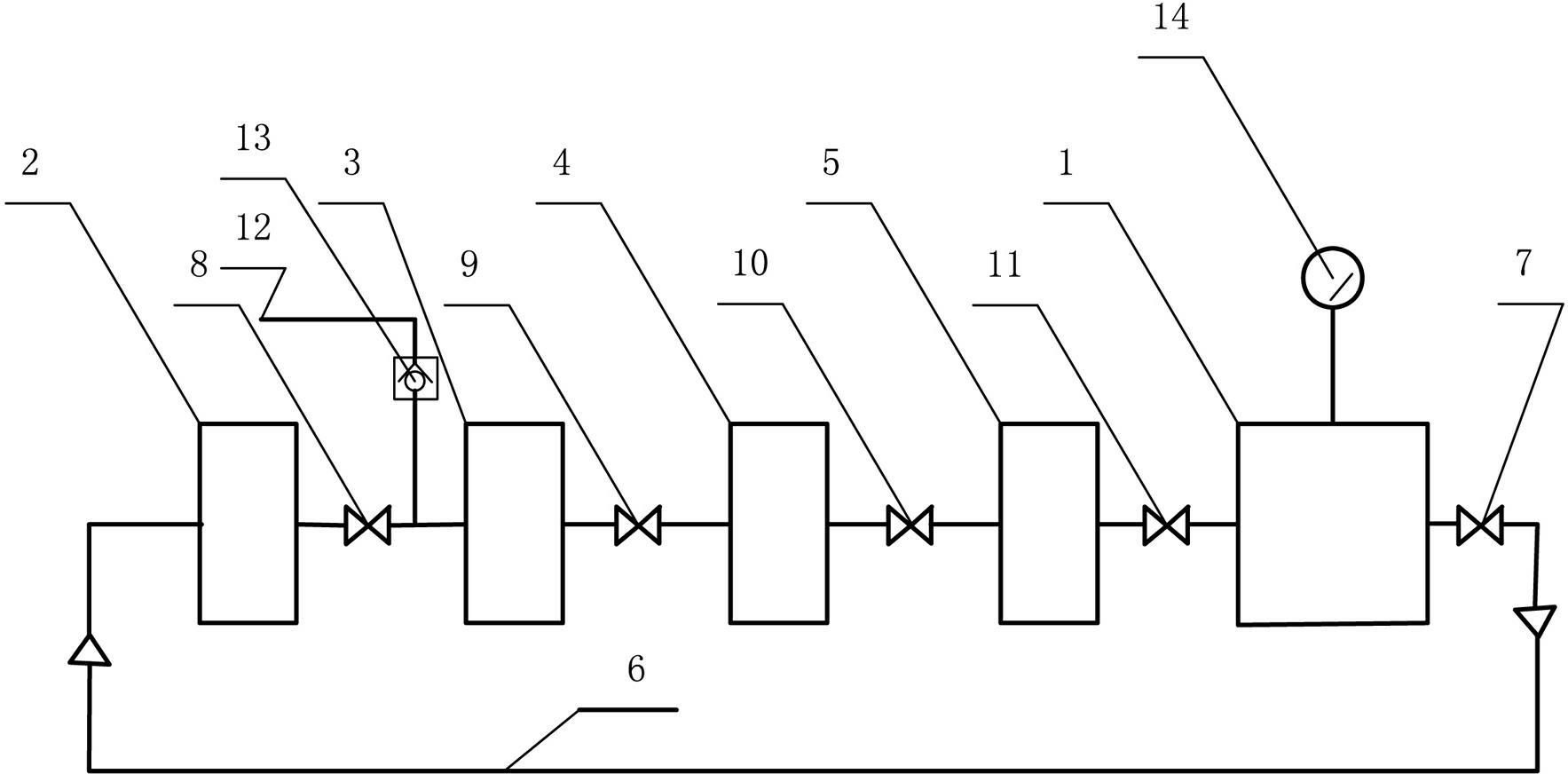

Preparation method of difluoromethoxy polysubstituted nitrogen-containing heterocyclic compound

ActiveCN110385096AImprove performanceImprove protectionOrganic chemistryChemical/physical/physico-chemical stationary reactorsNitrogenous heterocyclic compoundBoronic acid

The invention discloses a preparation method of a difluoromethoxy polysubstituted nitrogen-containing heterocyclic compound. The difluoromethoxy polysubstituted nitrogen-containing heterocyclic compound is prepared by using a special reaction kettle, the reaction kettle is provided with a glass body (1), the body is provided with a kettle cover (11), a lower flange (12) and a cylinder body (13) and further comprises an air intake assembly (2), an air outlet assembly (3), a fixing device (4), a stirring part (5) and a cooling pump tank (6); 2-bromo-3-fluoropyridine is used as a starting point to obtain 2-bromo-3-fluoropyridine-4-boronic acid, and 2-bromo-3-fluoropyridine-4-boronic acid is used for preparing 2-bromo-3-fluoro-4-hydroxypyridine; transition of 2-bromo-3-fluoro-4-difluoromethoxypyridine is performed; 3-fluoro-4-difluoromethoxypyridine-2-ethyl formate is prepared; a low temperature reaction under nitrogen protection is performed under protection of nitrogen to obtain 3-fluoro-4-di Fluoromethoxypyridine-2-methanol, a reaction is performed at a room temperature to obtain a final product of 3-fluoro-4-difluoromethoxypyridine-2-formaldehyde.

Owner:北京六合宁远医药科技股份有限公司

High-shear-force grinding reactor

InactiveCN104147995AEasy to createIncrease speedCocoaChemical/physical/physico-chemical stationary reactorsCircular discHigh density

The invention provides a high-shear-force grinding reactor. The high-shear-force grinding reactor comprises a power device, a transmission device, a grinding device, a stand column and a bottom plate, wherein the power device drives the grinding device to work through the transmission device; the transmission device is supported and mounted on the bottom plate through the stand column; a rotary disc in the device is connected with a driving shaft through a shaft sleeve arranged on a center line and is provided with a flow baffling ring; and a preformed hole through which a reactant conveniently enters a grinding gap is formed in a position between the flow baffling ring and the shaft sleeve. By adopting axial grinding, the rotary speed of reaction materials in a reaction container can be greatly accelerated under the driving of a movable grinding tool rotating at high speed; and the movement speed of particles with the same density and great particle diameter and particles with the same particle diameter and small density to a rotary center is accelerated along with the acceleration of the rotary speed according to a fluid dynamics principle, so that the high-shear-force grinding reactor has functions of automatically grading and regrinding the particles in a reaction mixture.

Owner:NANYANG NORMAL UNIV

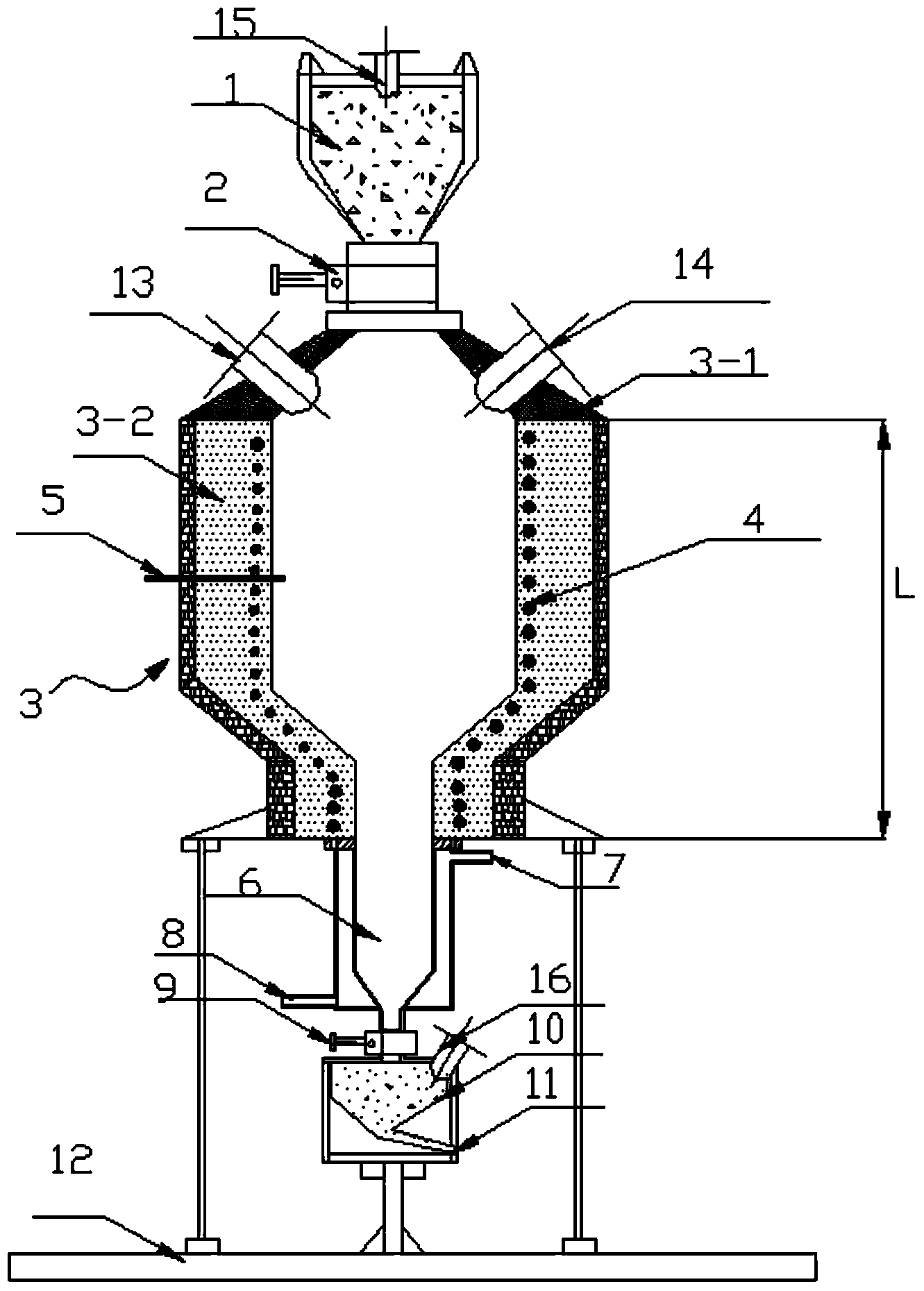

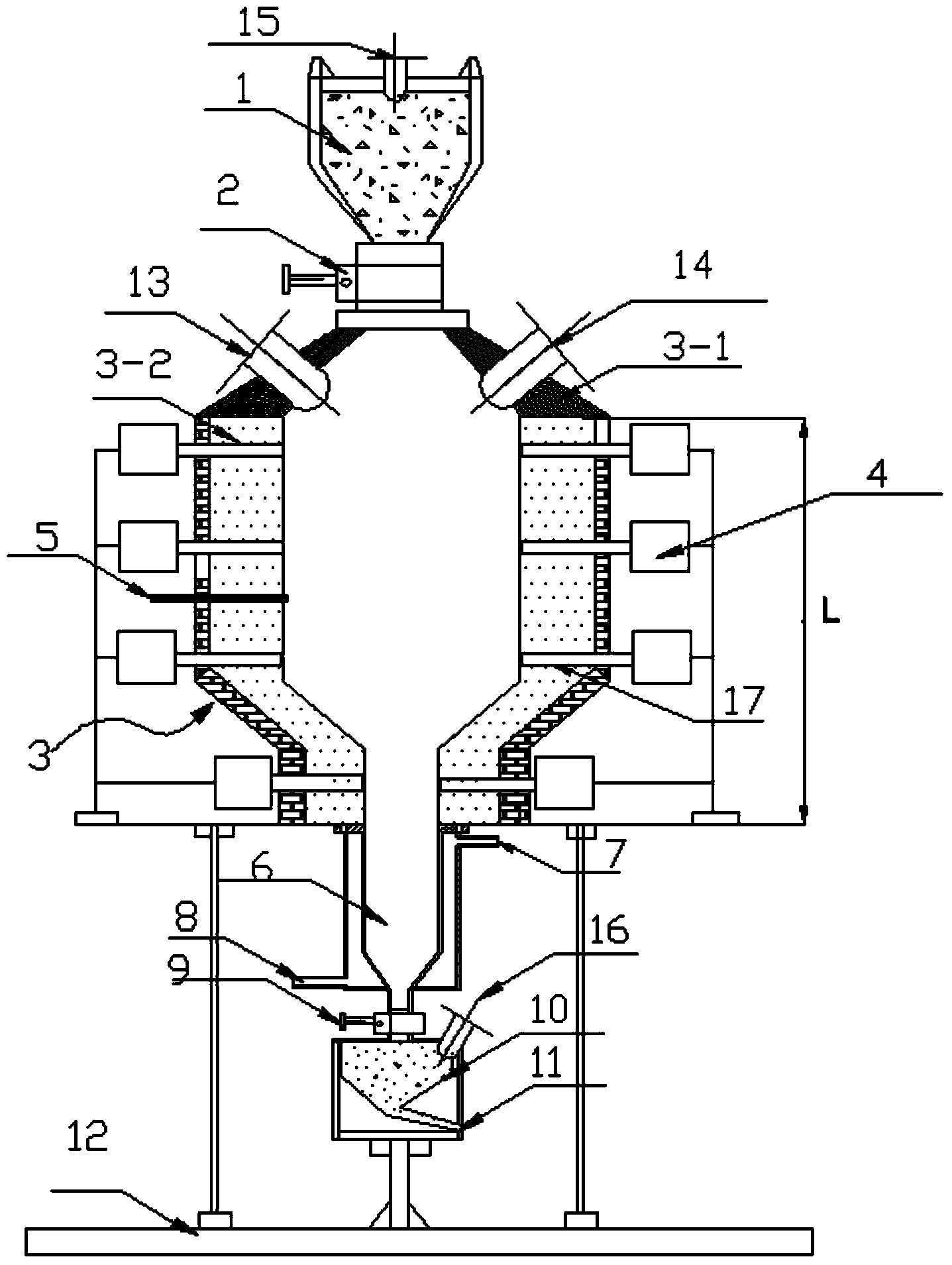

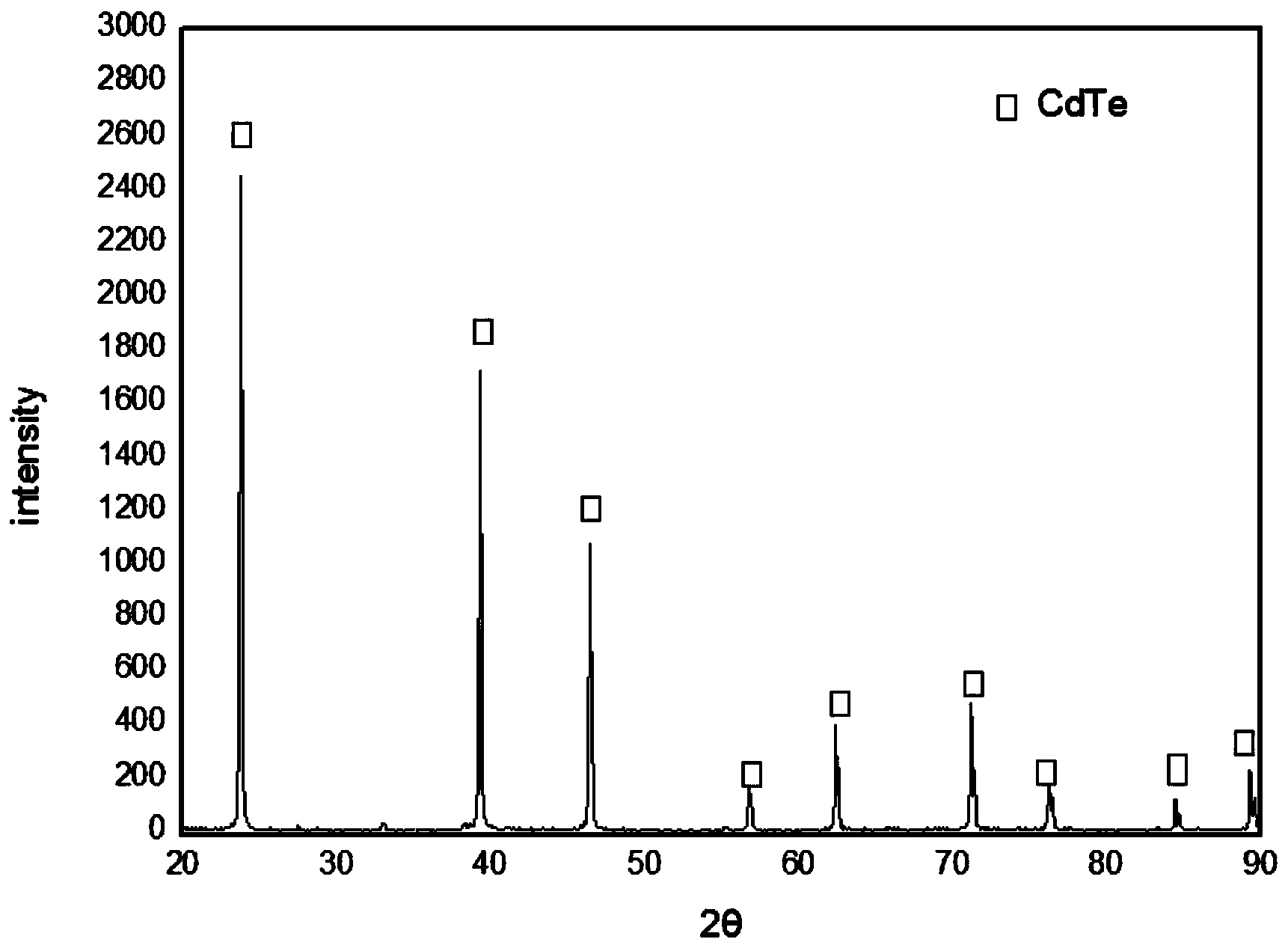

Free falling high-temperature synthesizing method and synthesizing device for IIB-VIA compound powder

ActiveCN104014284AEfficient synthesisAvoid introducingSulfide/polysulfide preparationInert gas productionFree fallingMaterial synthesis

The invention provides a synthesizing device for powder materials. The synthesizing device comprises a furnace body, a charging chamber, a first valve, a second valve, a condensation chamber and a collection chamber, wherein the furnace body is vertically mounted; a heat insulation section is arranged at the upper part, a heating section is arranged at the lower part and the heat insulation section and the heating section are supported by a bracket; the charging chamber is connected with the top of the heat insulation section of the furnace body through the first valve; the first valve is used for controlling the charging chamber to be communicated with or isolated from the inner cavity of the furnace body; the condensation chamber is connected with the bottom of the heating section of the furnace body; the inner cavity of the condensation chamber is communicated with the inner cavity of the furnace body; the collection chamber is connected with the condensation chamber through the second valve; the second valve is used for controlling the condensation chamber to be communicated with or isolated from the collection chamber. With the adoption of the synthesizing device for the powder materials, VIA non-metal powder in the charging chamber is mixed with IIB metal powder to form raw material powder and the raw material powder continuously enters the inner cavity of the furnace body in a free falling manner; a synthesizing reaction is finished after the raw material powder passes through the heating section of the furnace body and the raw material powder directly falls into the inner cavity of the condensation chamber to be condensed into IIB-VIA compound powder.

Owner:SICHUAN UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com