Patents

Literature

276 results about "Underground storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

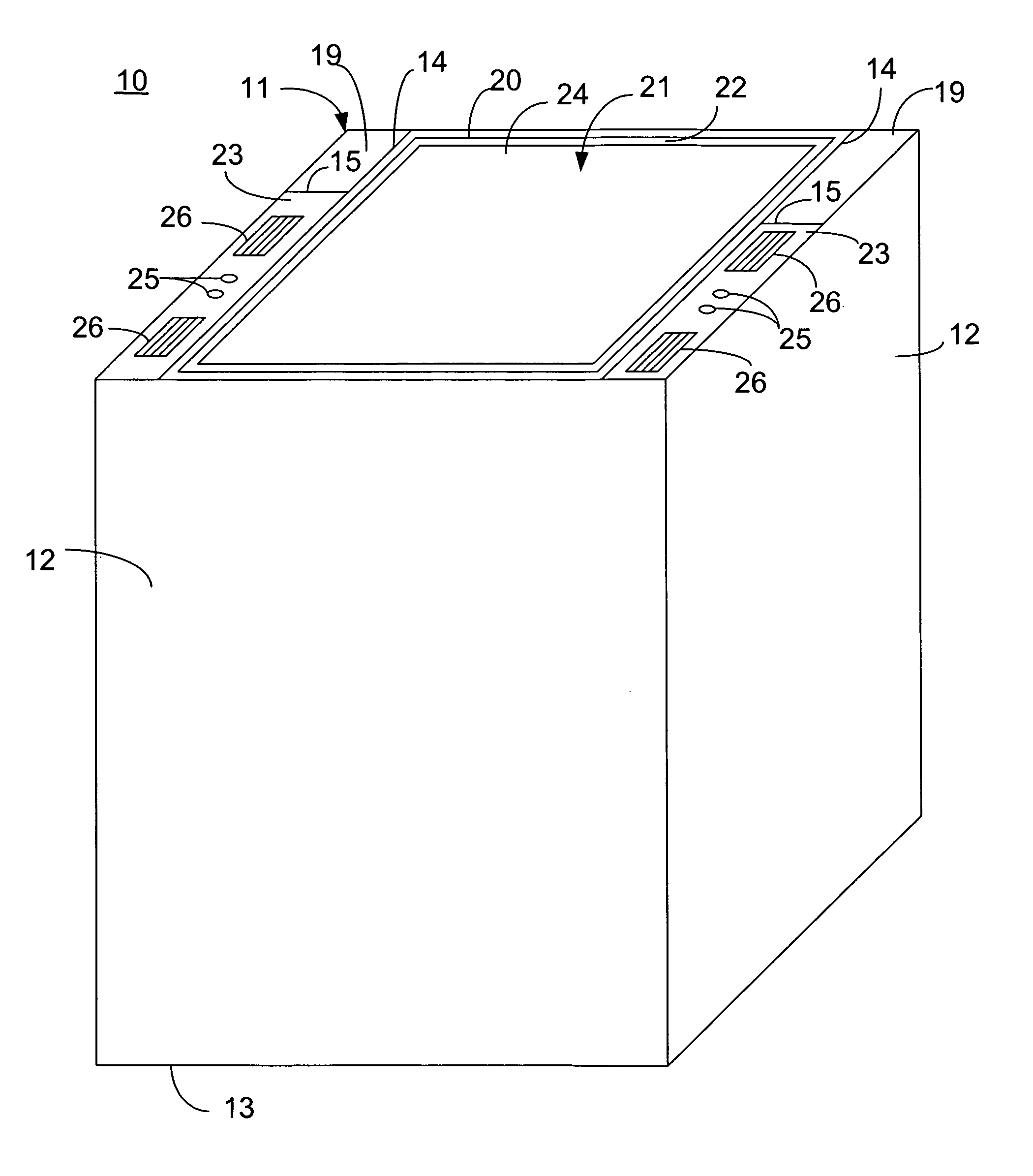

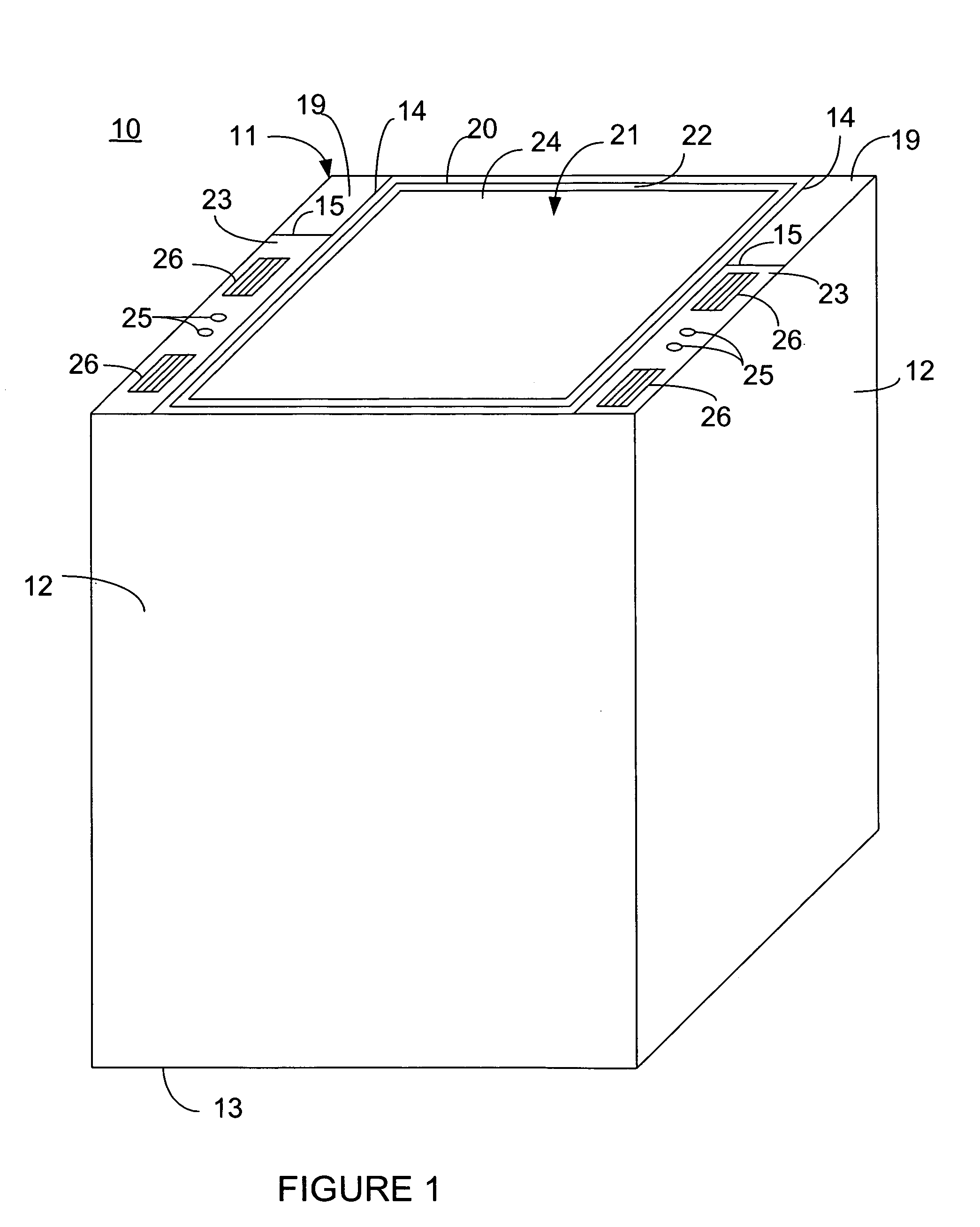

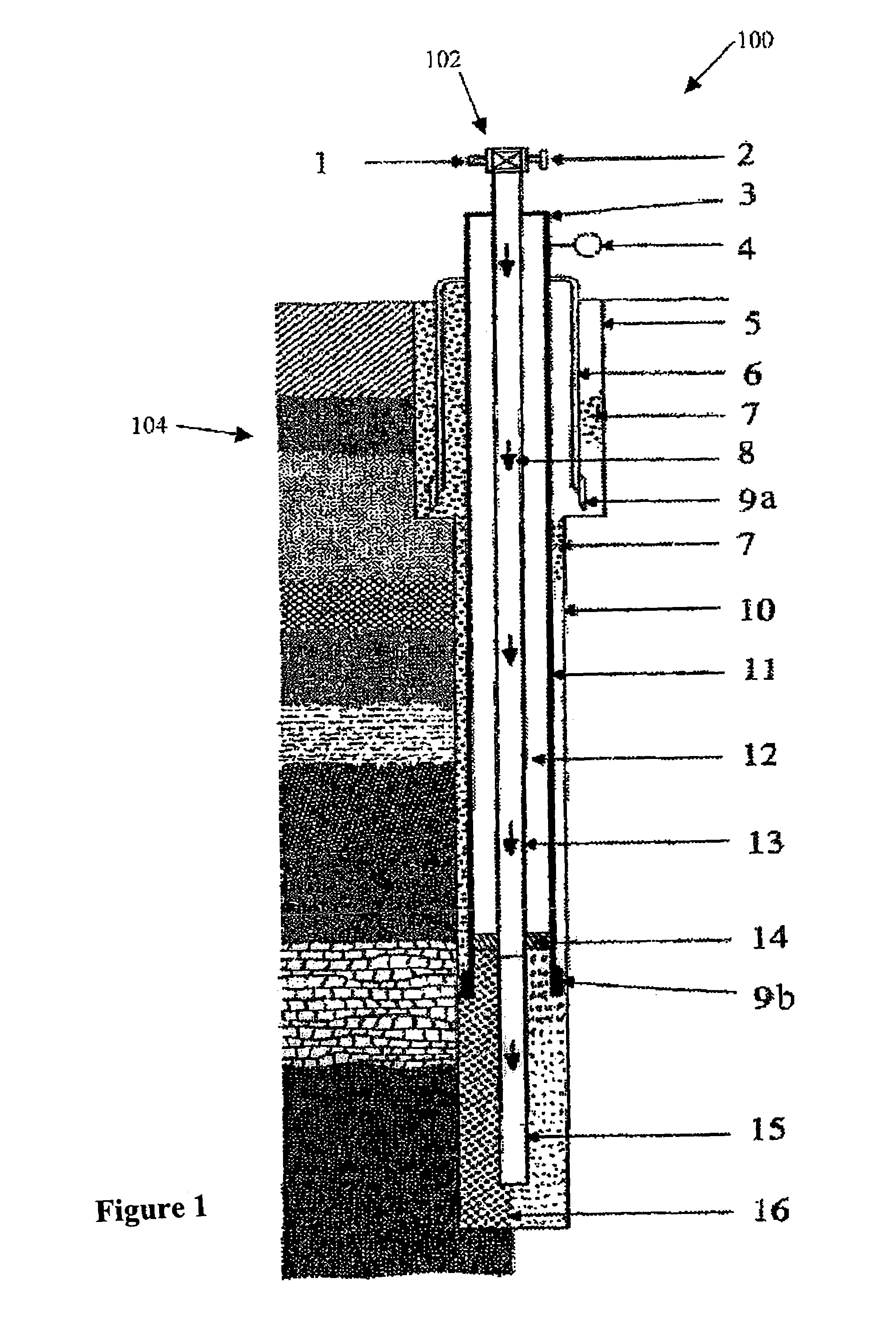

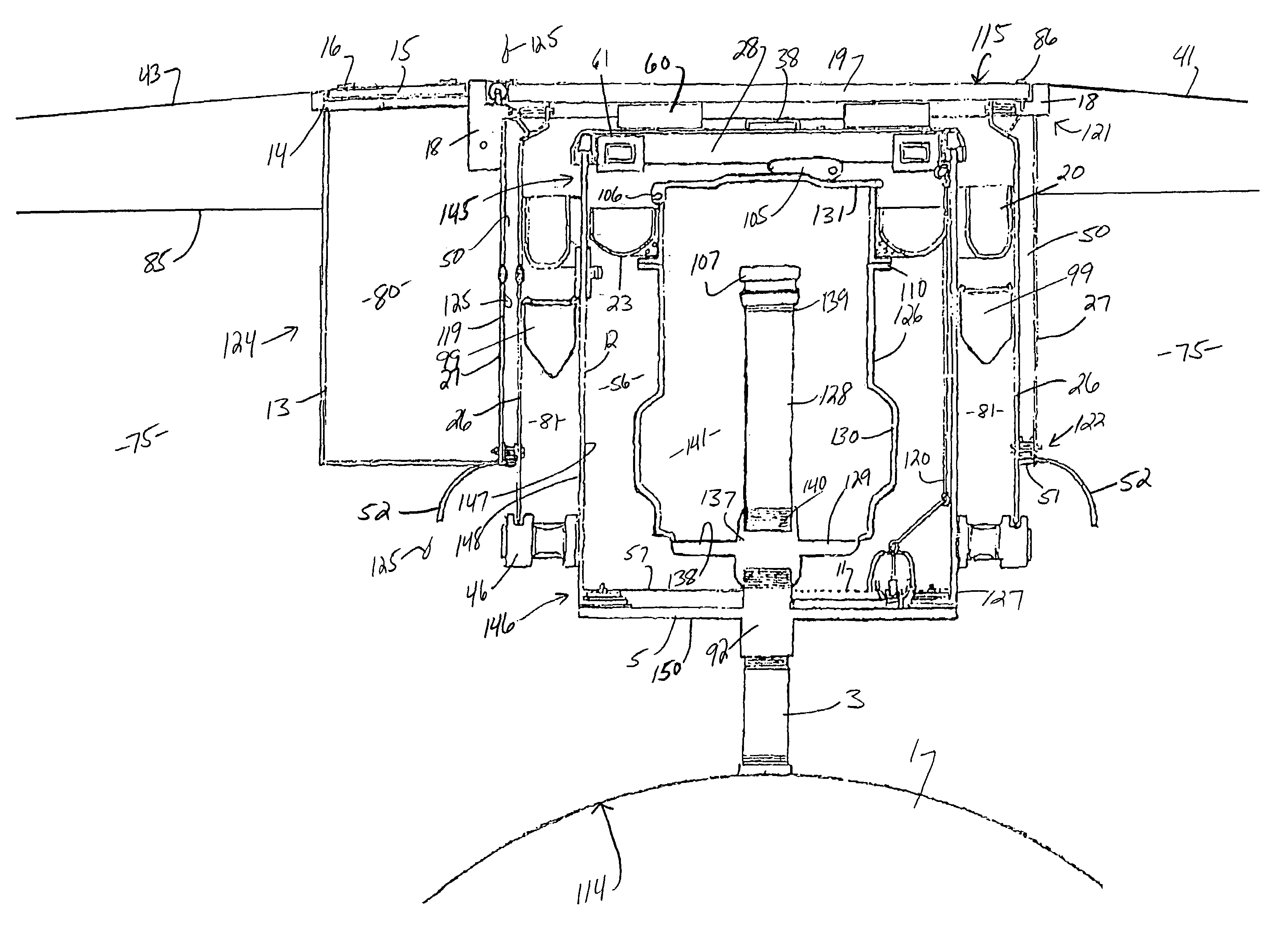

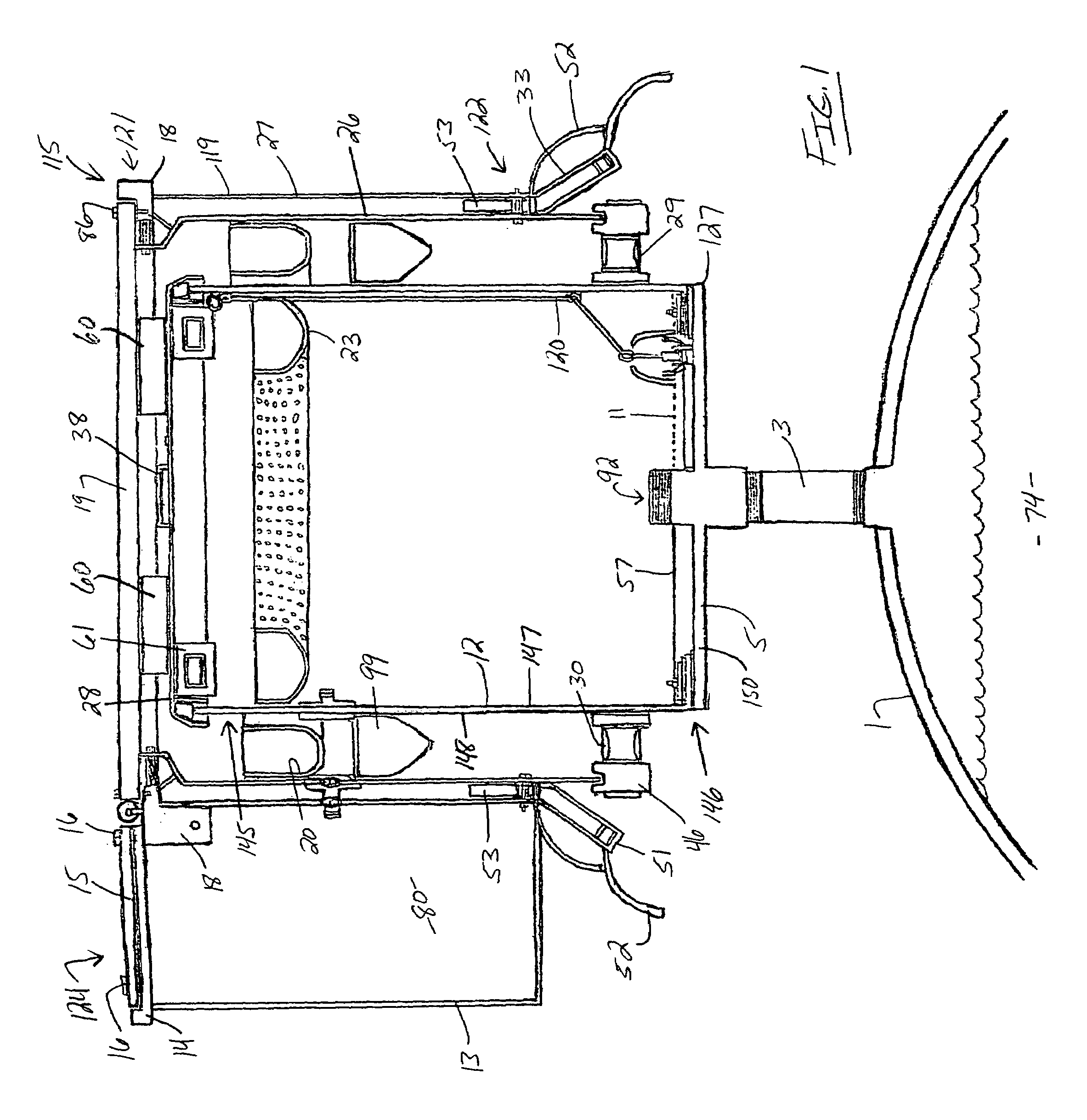

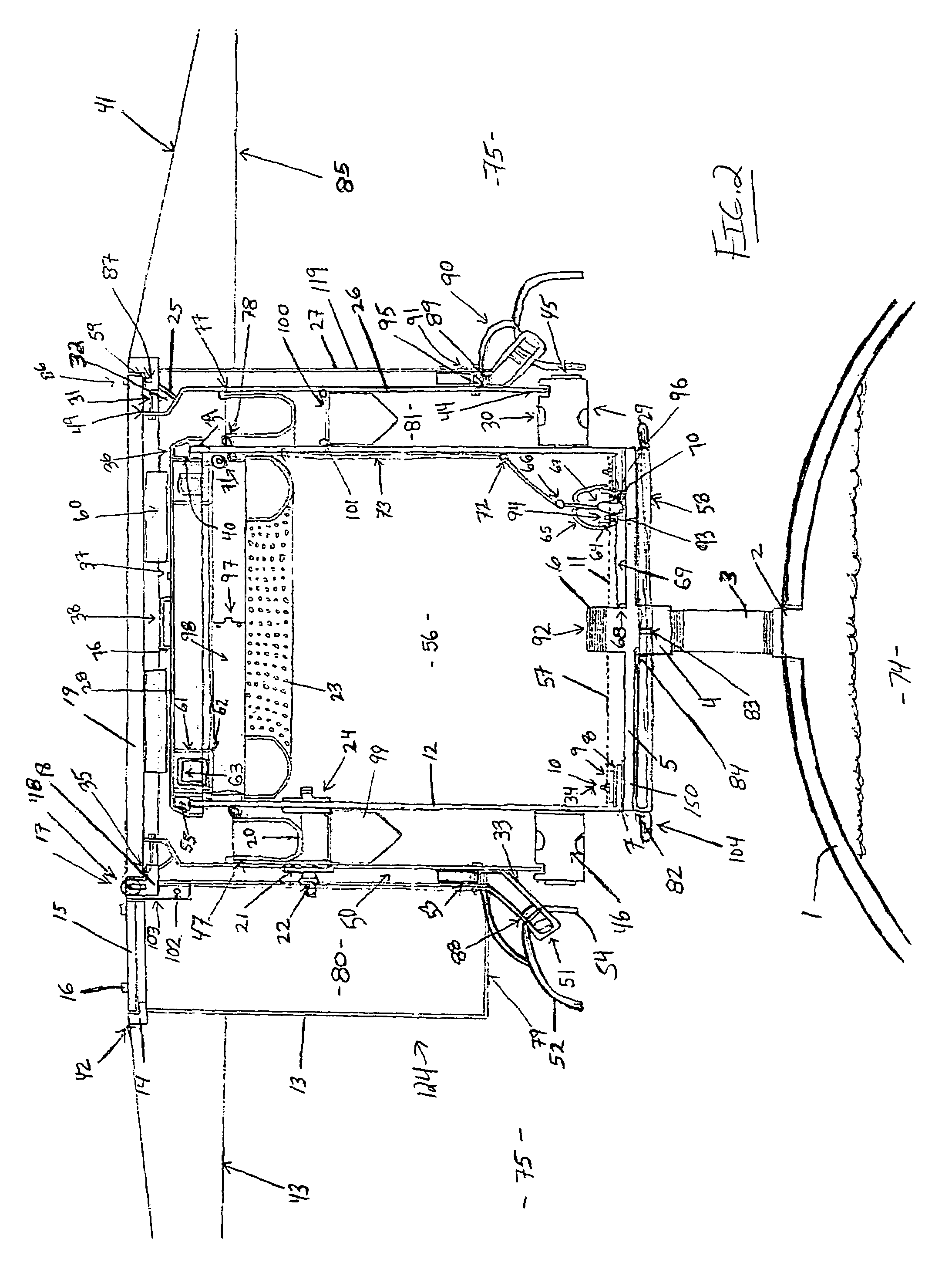

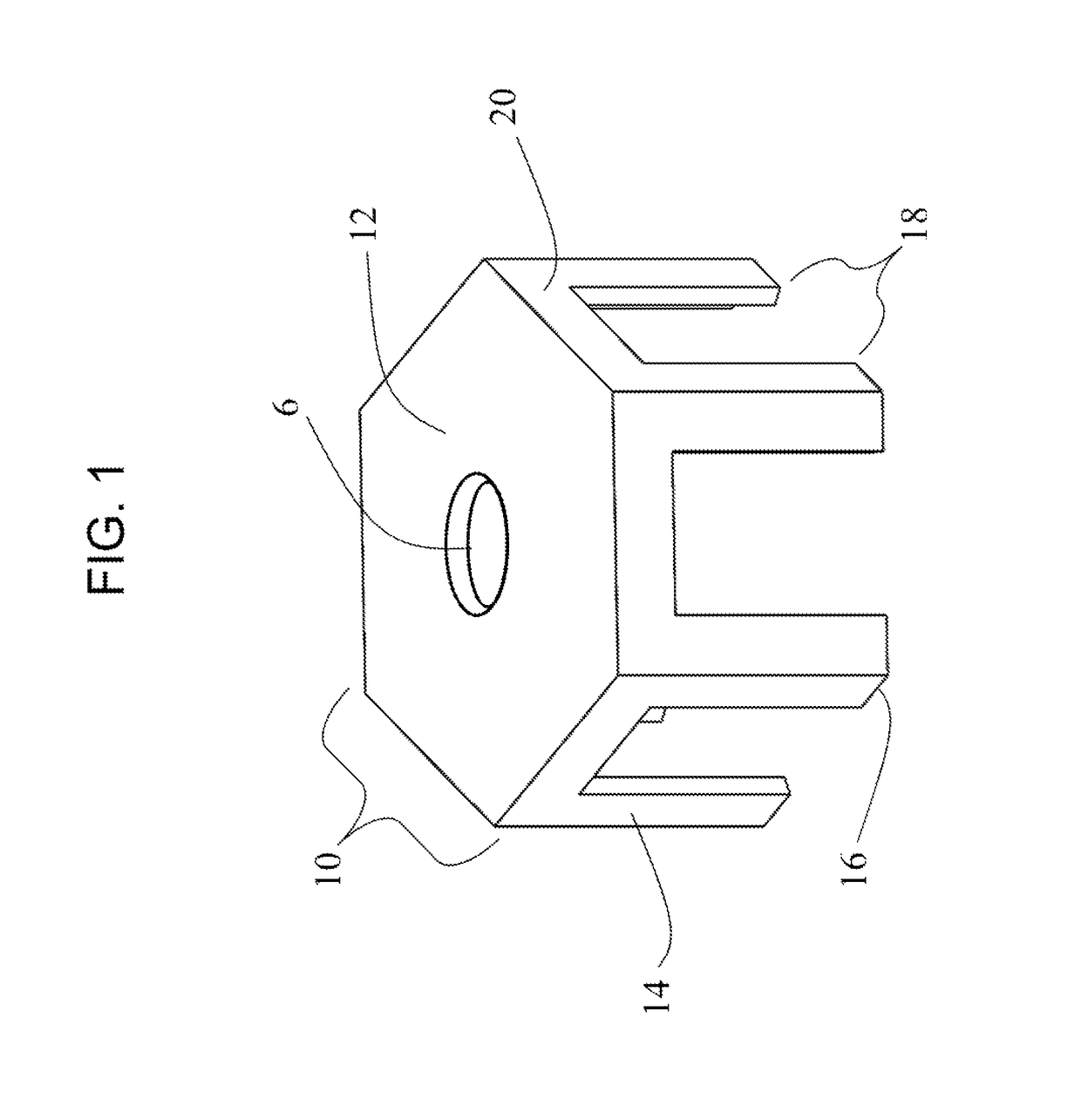

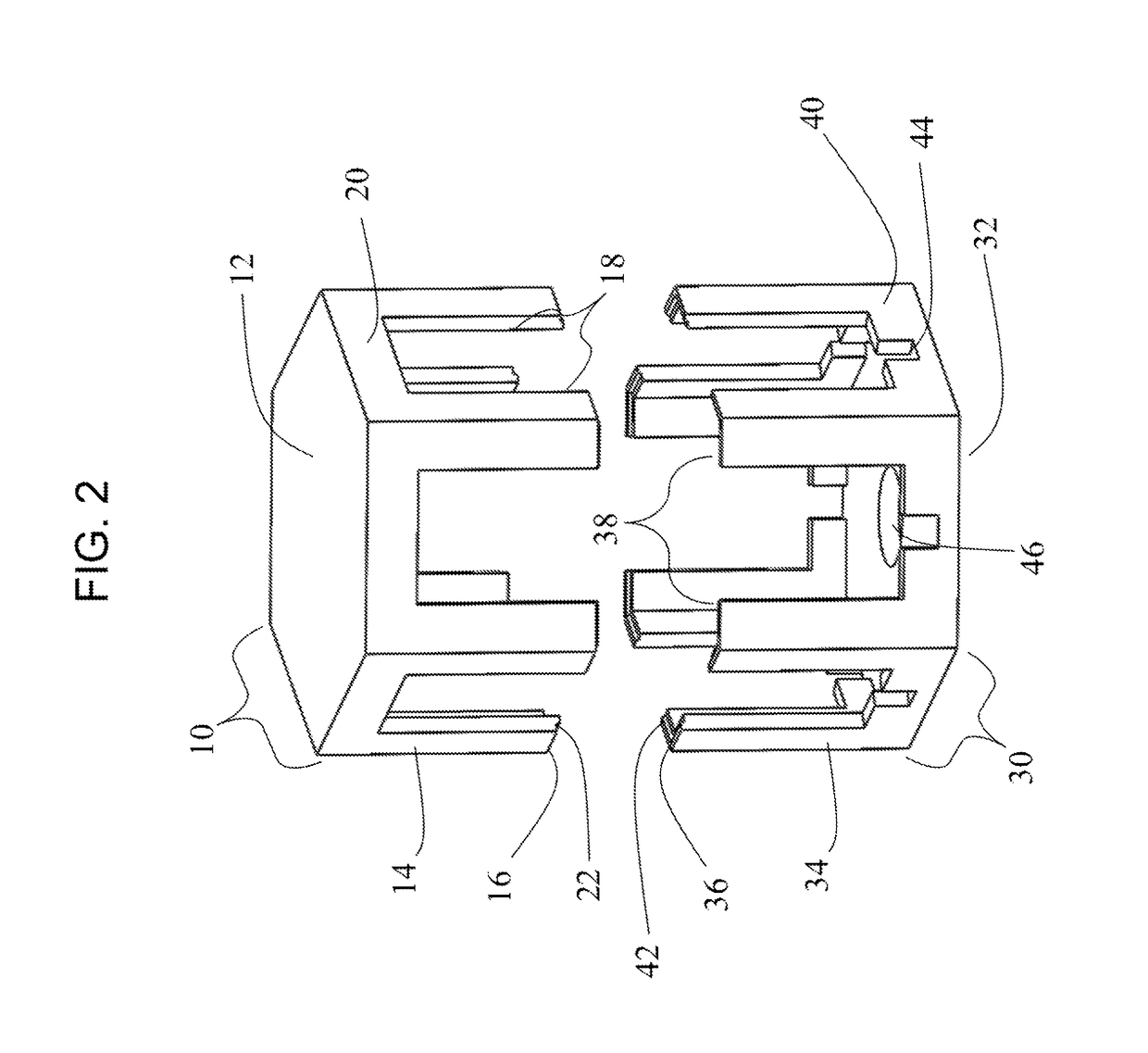

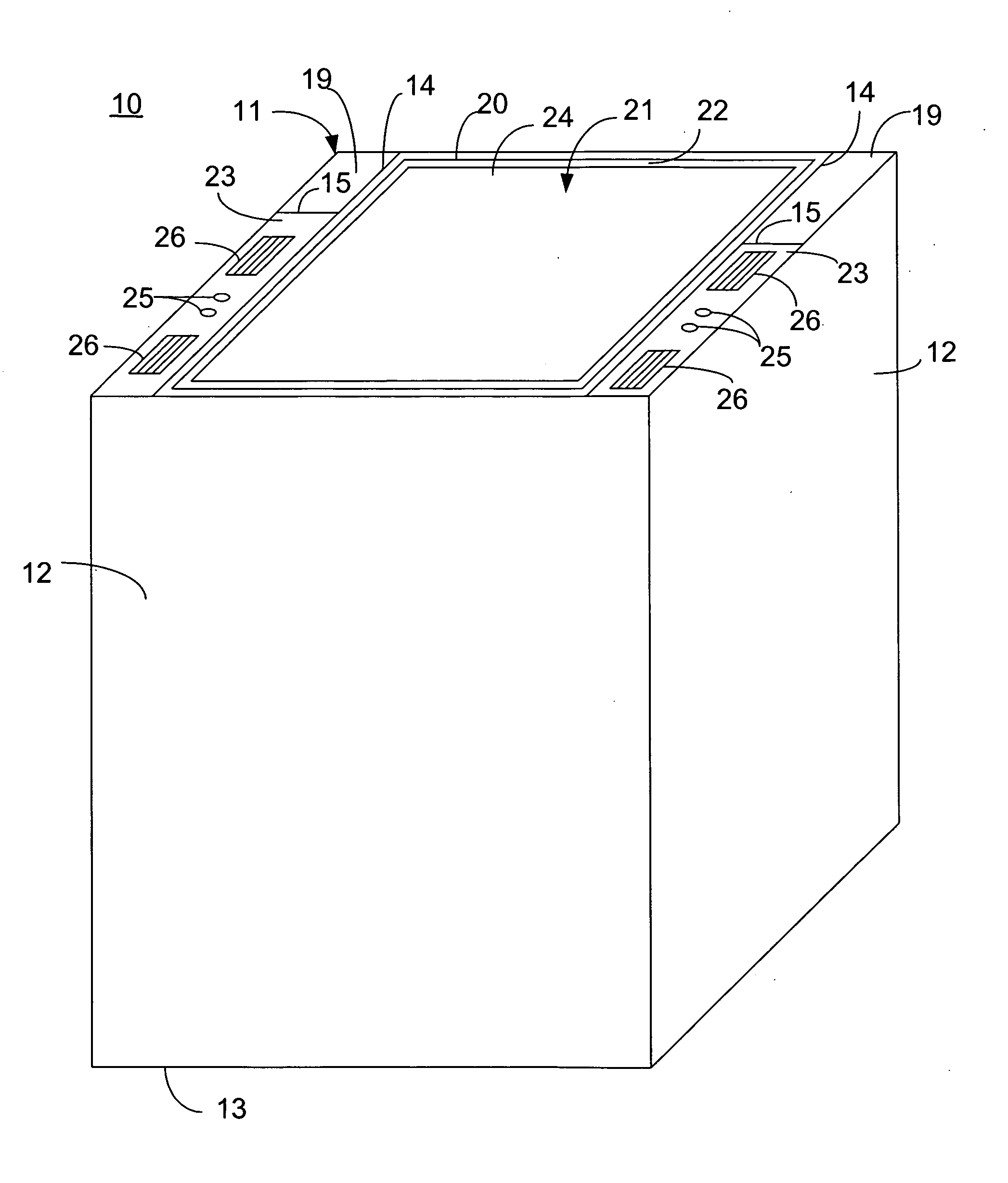

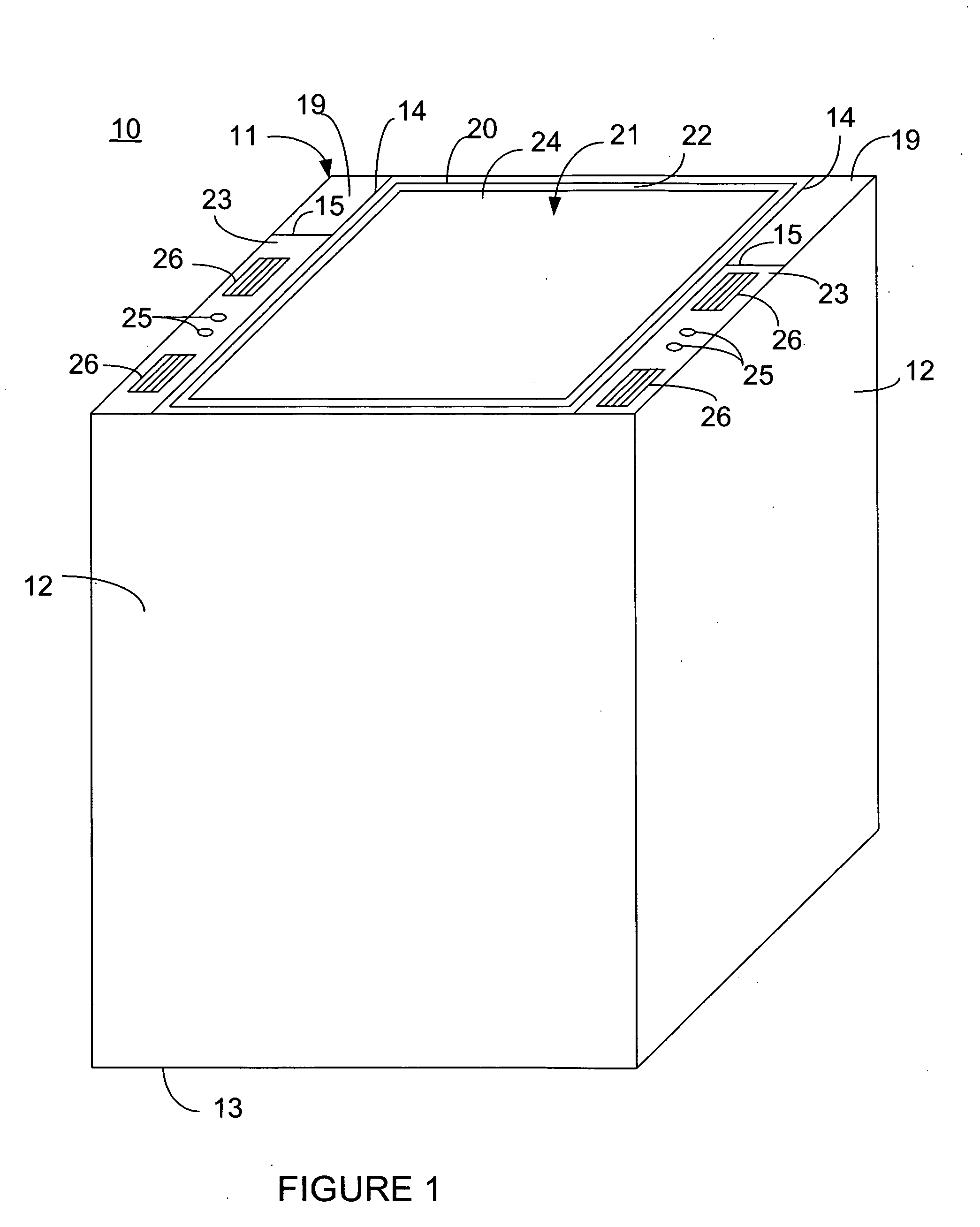

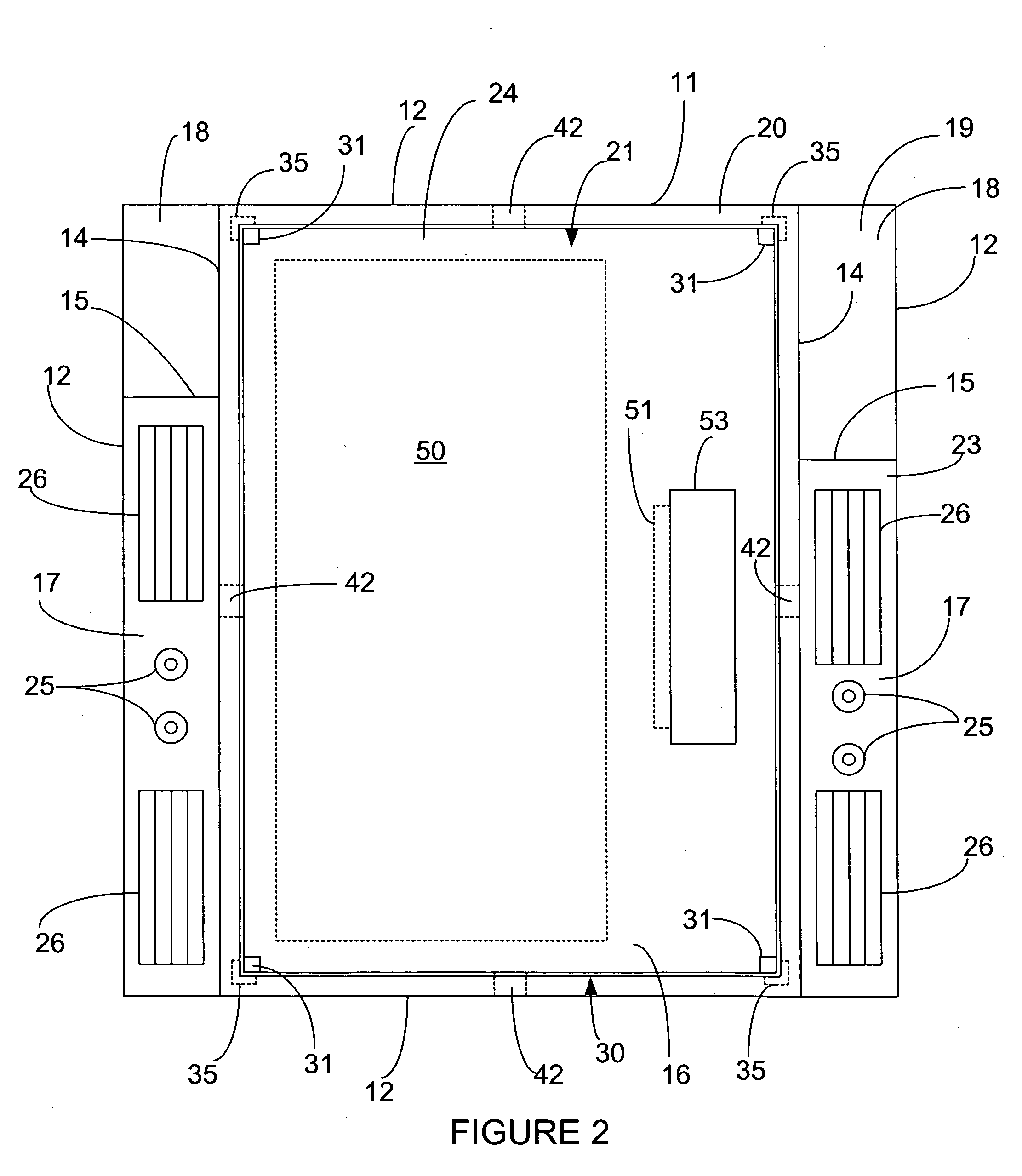

Flood evacuation system for subterranean telecommunications vault

ActiveUS8275417B2Prevent and minimize injuryLarge containersSubstation equipmentTelecommunicationsInstrumentation

An improved vault that facilitates the underground storage of electronic equipment, such as instrumentation for wireless telecommunications antenna systems. The vault preferably includes an flood evacuation system that prevents the electronic equipment from being submerged under water when the vault floods, a break-away lid to reduce or minimize injury, and a grated lid to prevent water from entering the main equipment chamber.

Owner:INTEL CORP

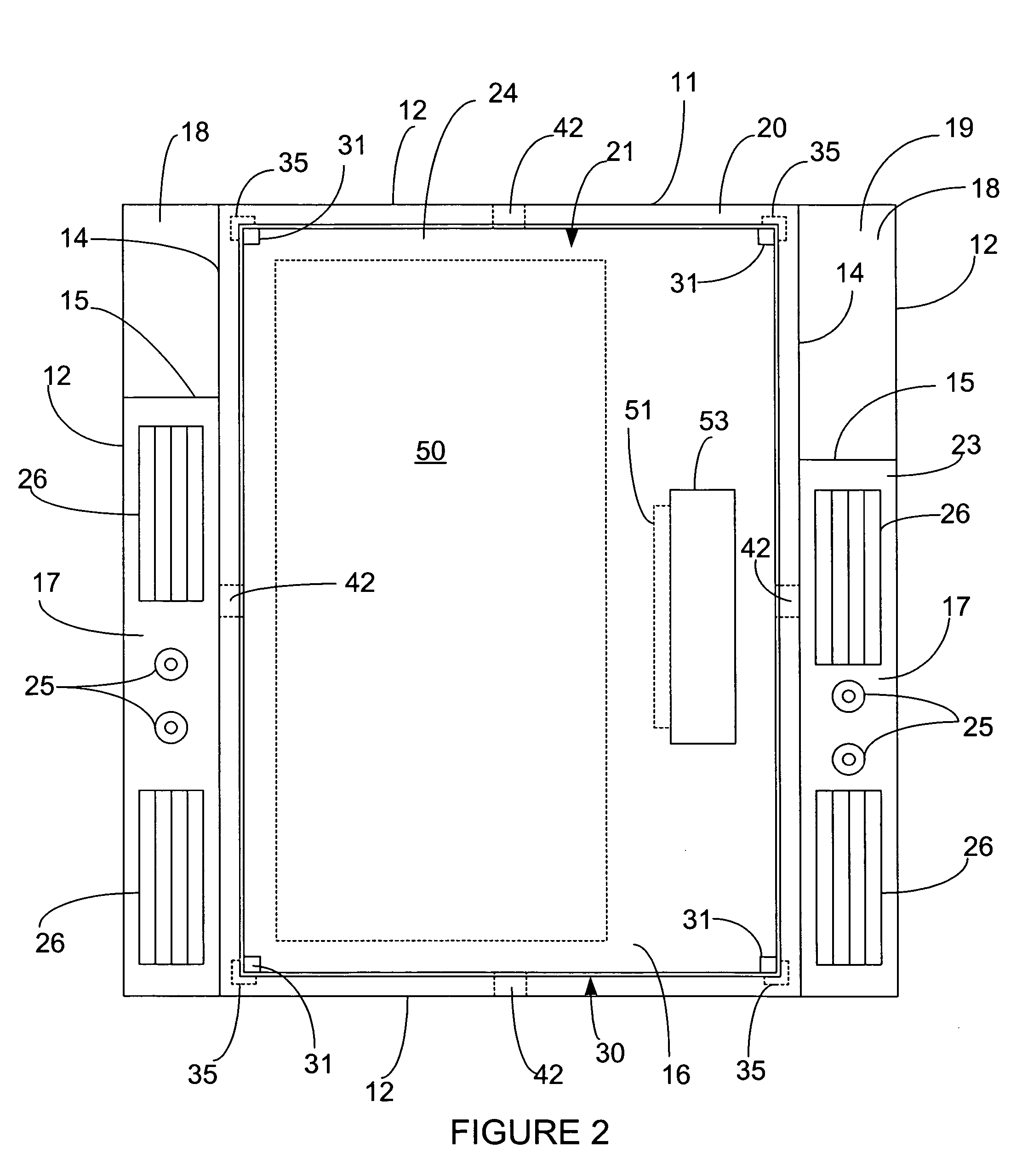

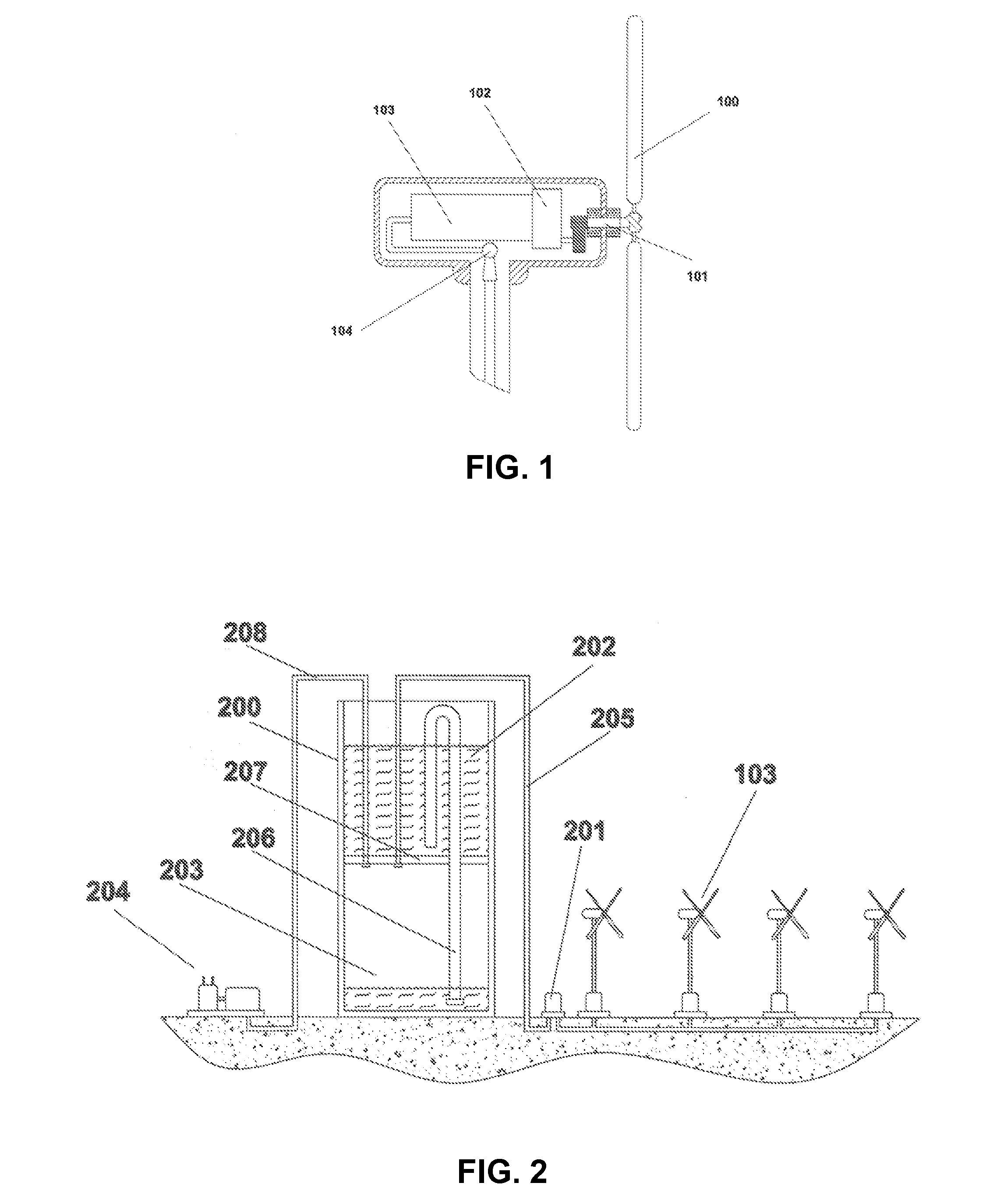

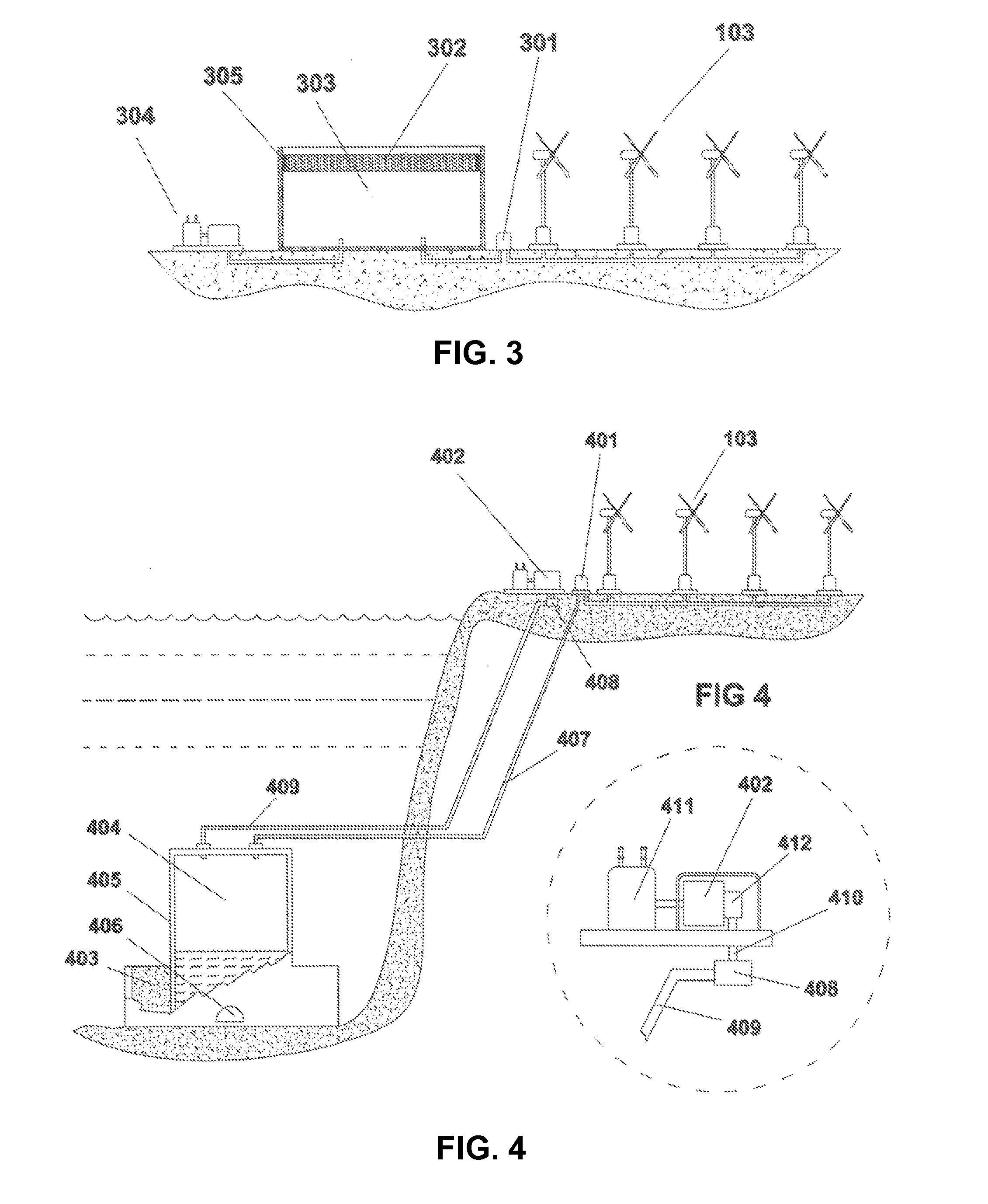

Integrated wind-power electrical generation and compressed air energy storage system

InactiveUS20090021012A1Prevent over-pressurization of the storage unitFrequency stabilityWind energy with garvitational potential energySteam accumulatorsThermal energy storageEngineering

The present invention relates to a method and apparatus for using wind energy to compress air or pressurize a fluid as a means of storing energy. Compressed air or pressurized fluid is generated directly by the wind turbines, thereby avoiding the energy losses that occur when wind power is used first to generate electricity to run an electrically powered air compressor. The compressed air or pressurized fluid is stored by means of expanding a volume at constant or nearly constant pressure. This method avoids energy losses that would otherwise result from compressional heating; while also allowing lower pressures to be employed, reducing the cost of the containment facility and avoiding the need to locate facilities in geographically favored locations where underground storage is available. The invention permits both large and small-scale storage at low cost per unit of energy stored, thereby avoiding the difficulty of using a highly variable and unreliable source of energy such as the wind for electrical power generation. The invention can be used for generation and storage on land, in shallow near-shore waters and in deep-water locations far from shore.

Owner:STULL MARK A +1

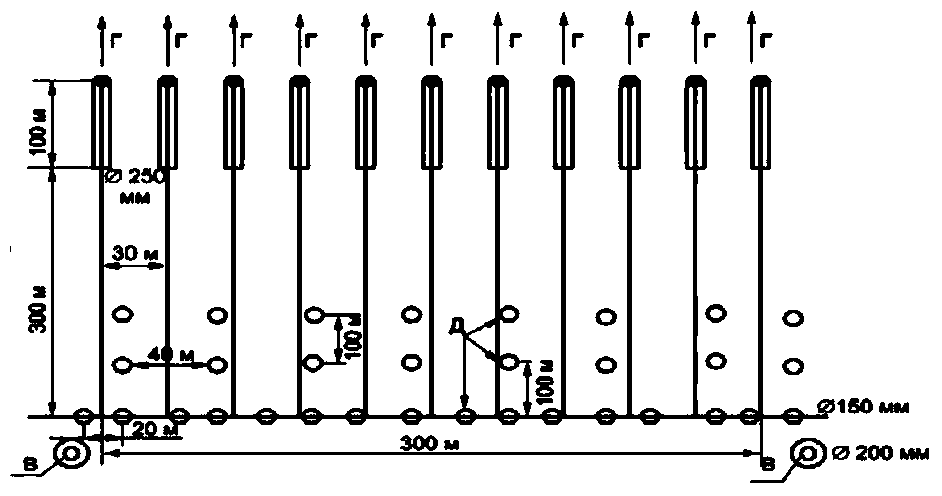

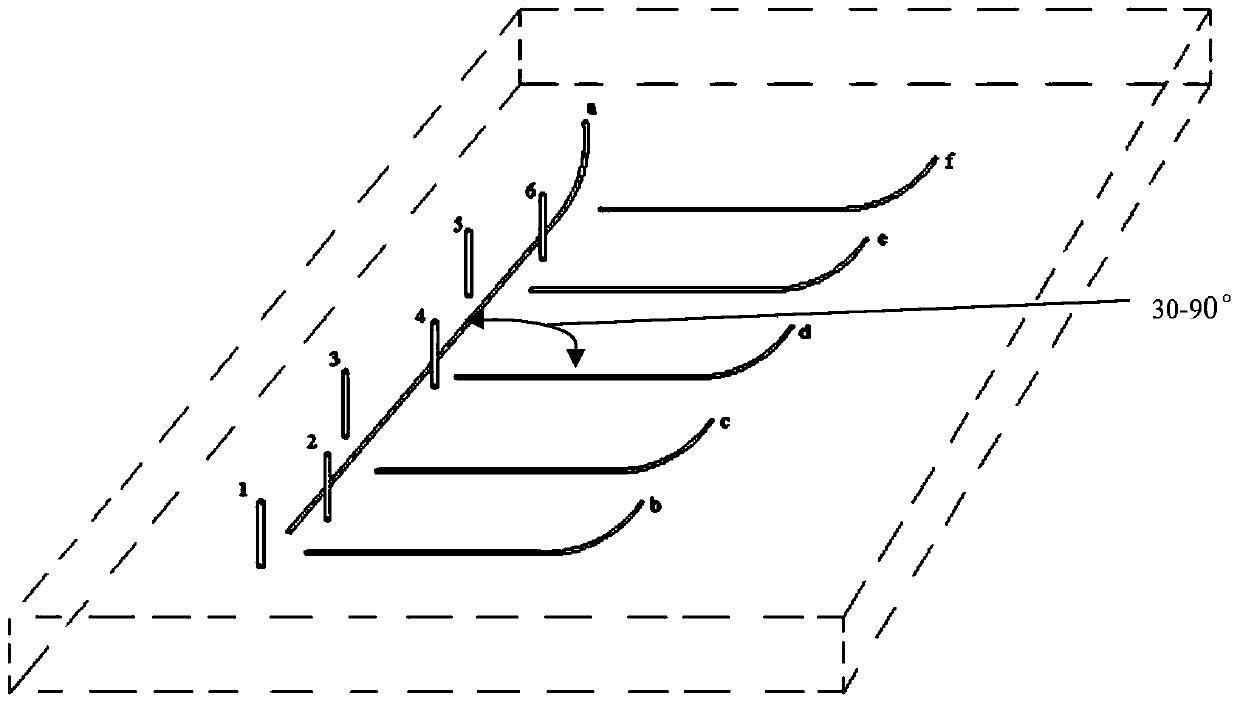

Underground coal gasifying furnace and underground coal gasifying method

The invention provides an underground coal gasifying furnace which comprises an ignition system and a gas injection system, wherein the ignition system is provided with a first vertical drilling well (1) and a first horizontal directional drilling well (a) communicated with the first vertical drilling well; the gas injection system is provided with a second drilling well communicated with a coal seam; at least one second horizontal directional drilling well (b, c, d, e and f) of a horizontal section in the coal seam serves as the second drilling well. The invention also provides an underground coal gasifying method. By adopting the underground coal gasifying furnace and the underground coal gasifying method provided by the invention, the defects of low cut-through speed and unstable structure in a gasifying production section of the prior art are eliminated.

Owner:ENN SCI & TECH DEV

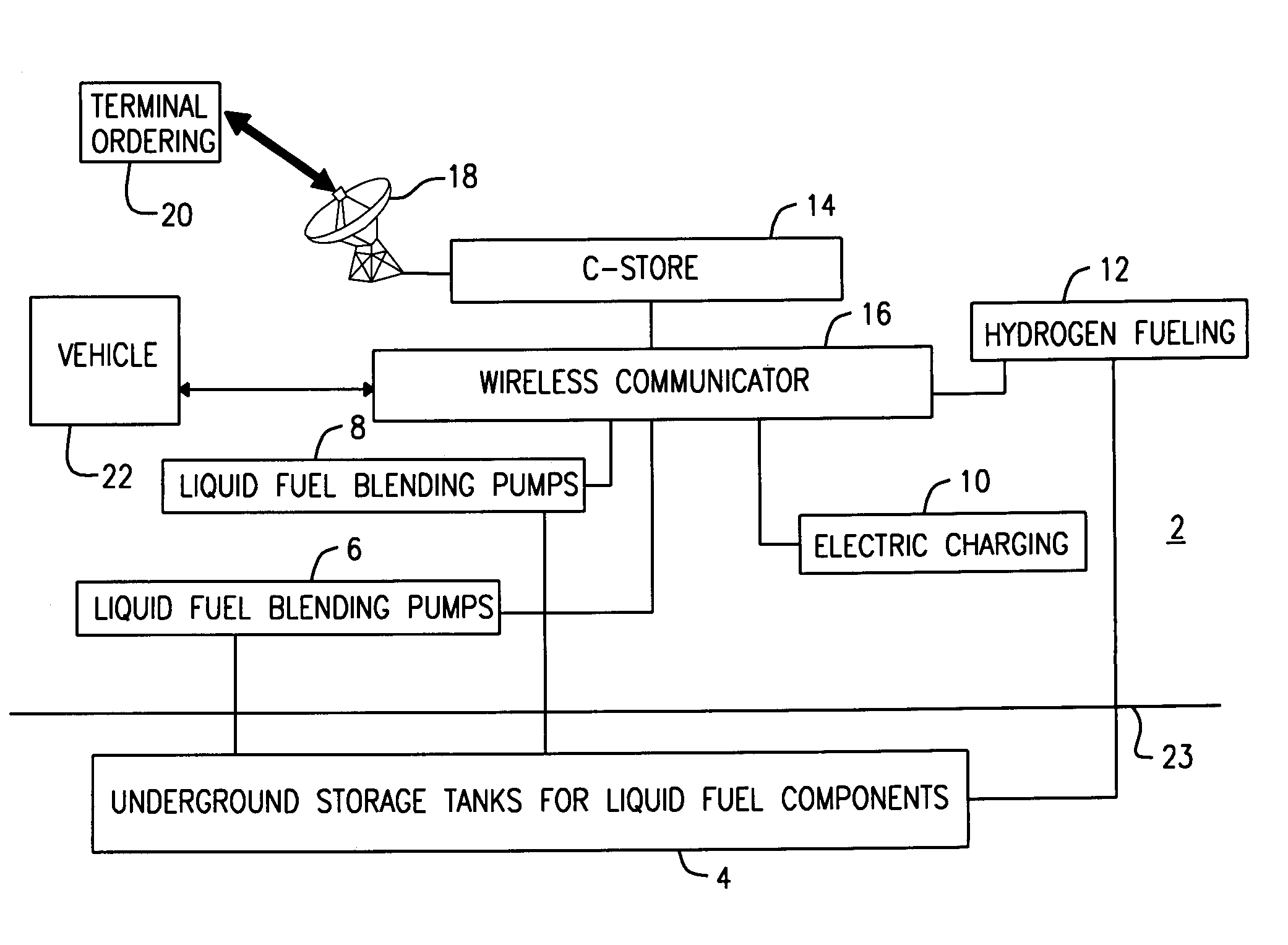

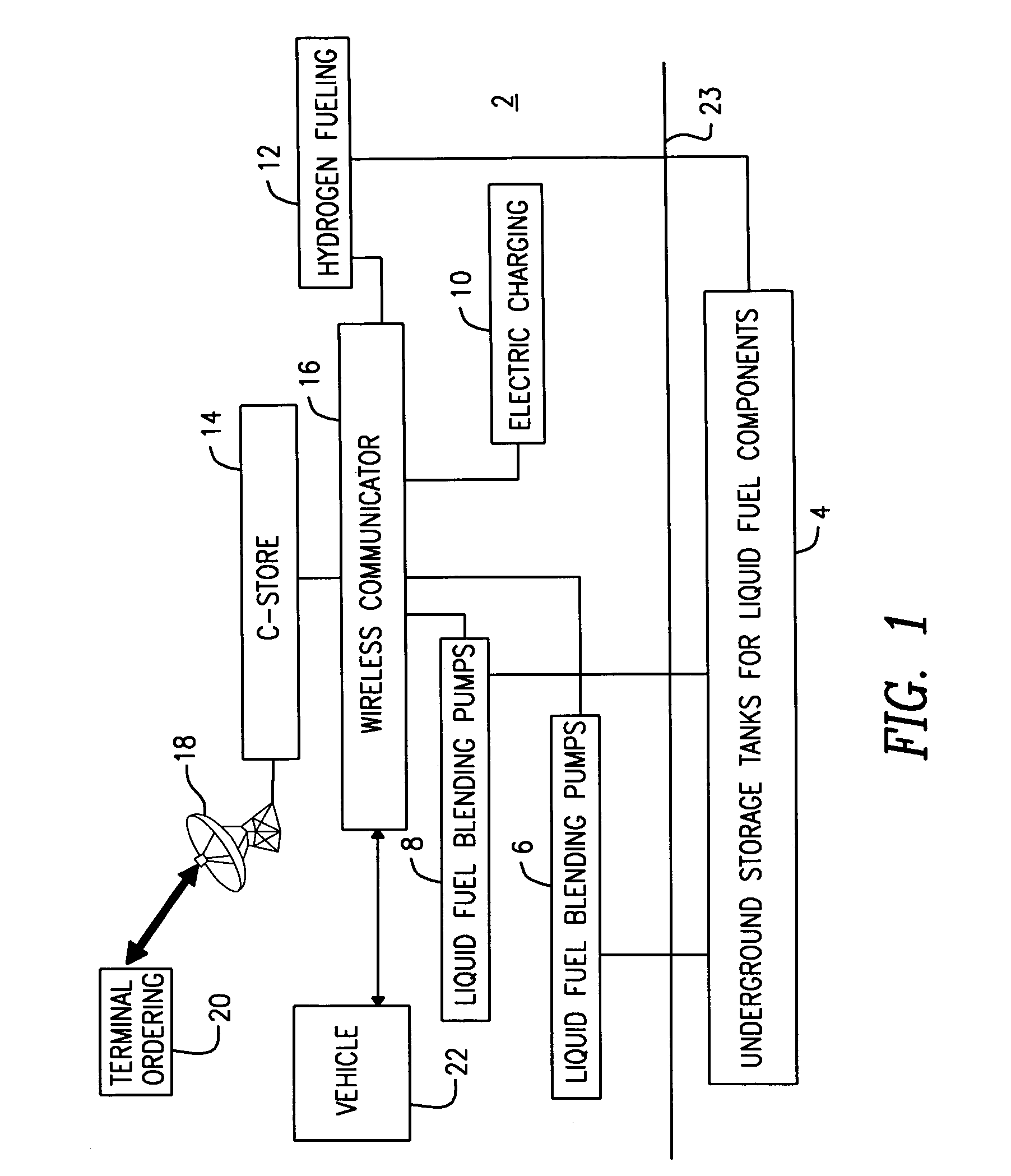

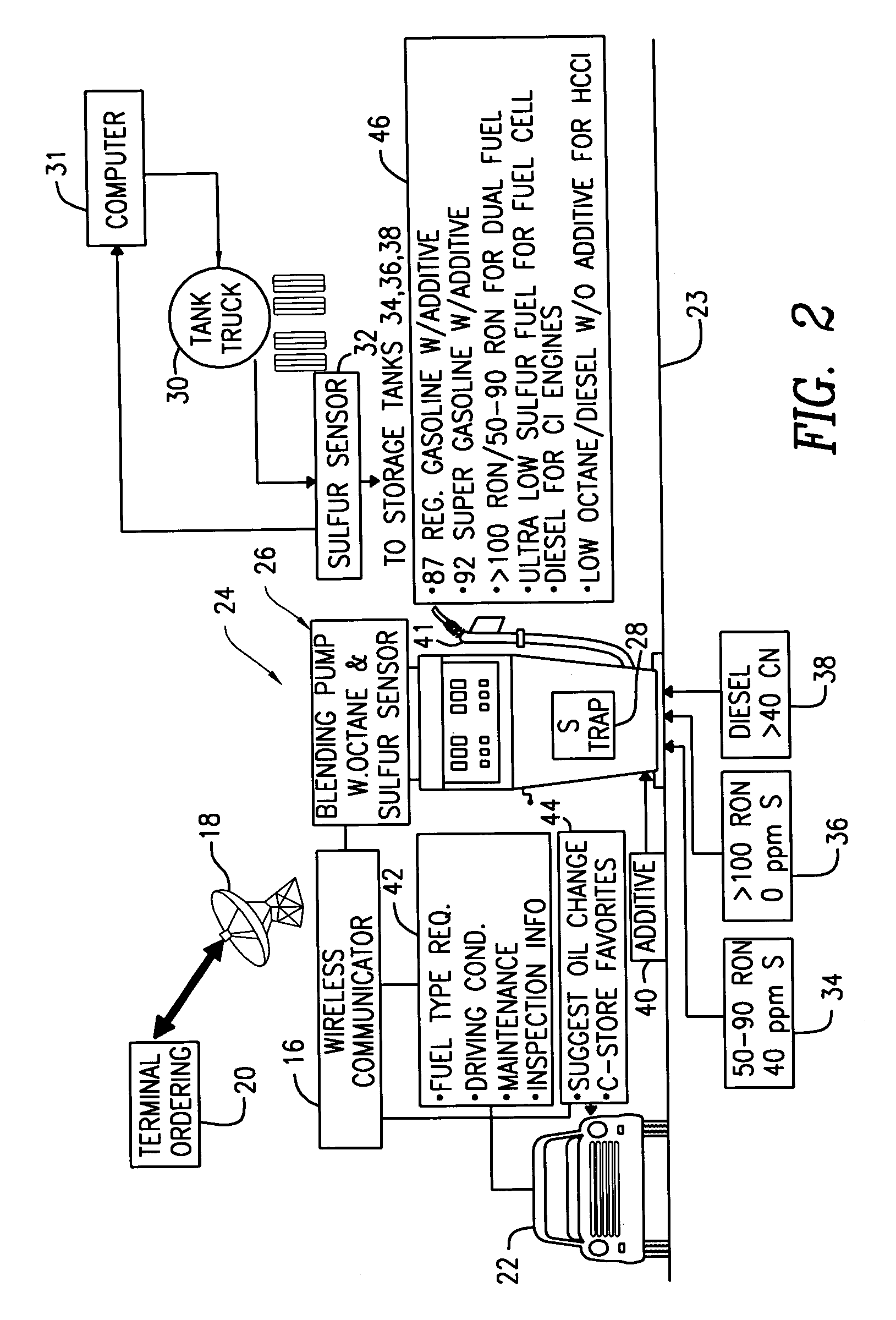

Service station for serving requirements of multiple vehicle technologies

A service station is provided with a plurality of vehicle servicing islands including liquid fuel blending pumps for dispensing and blending fuel components from underground storage tanks for refueling standard gasoline engine driven vehicles, standard diesel engine vehicles, vehicles with engines requiring dual fuels, vehicles with HCCL engines require low octane gasoline blended with standard diesel fuel, and fuel cell powered vehicles having onboard reformers. Other service islands include pumps for dispensing compressed hydrogen to fuel cell powered vehicles that do not include onboard reformers. In addition, service islands are provided for recharging the batteries of pure electric powered vehicles. A service station is further provided with a wireless communicator for receiving signals indicative of a vehicle's fuel requirements and transmitting signals to direct the vehicle to a service island capable of servicing the vehicle.

Owner:EXXON RES & ENG CO

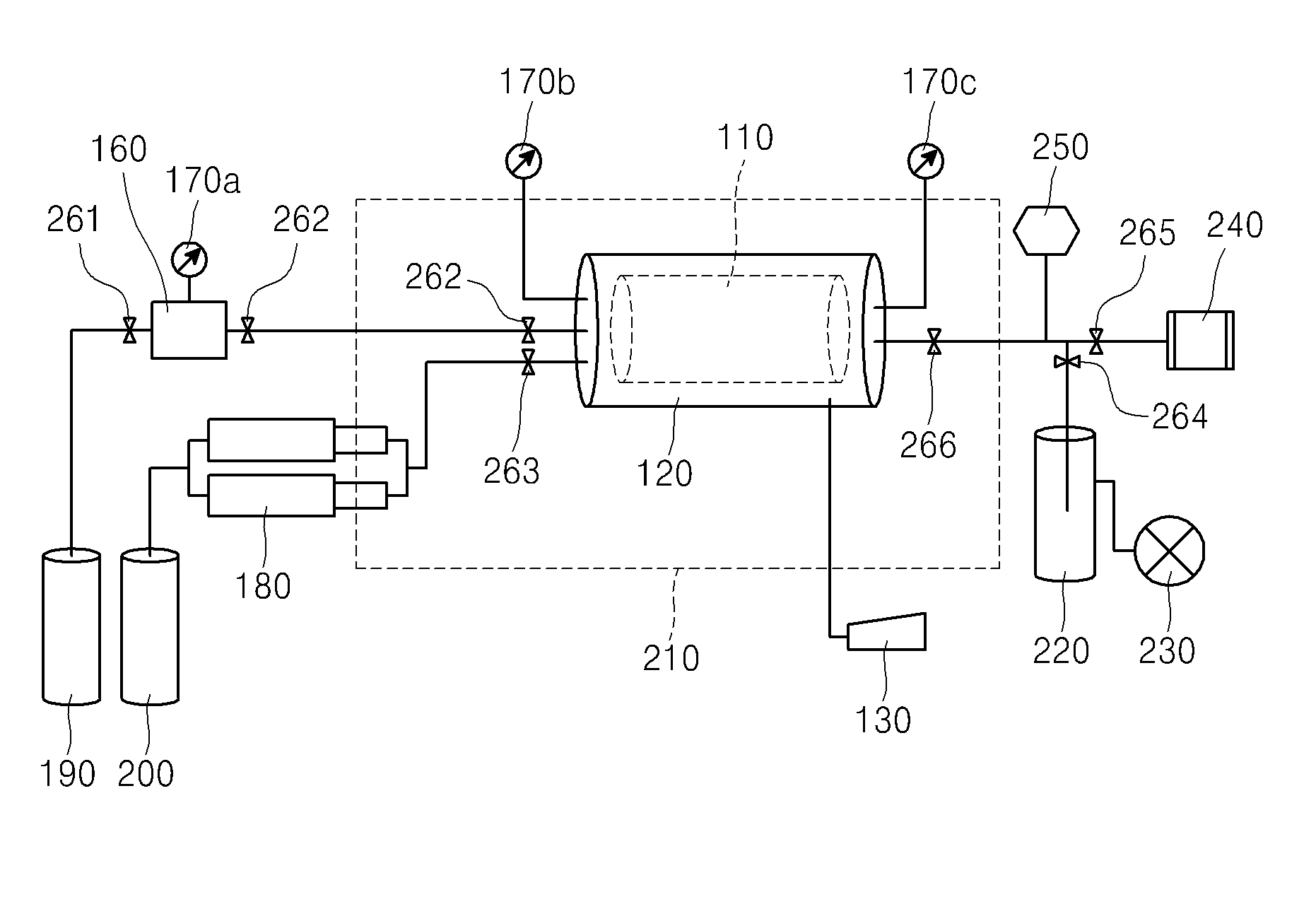

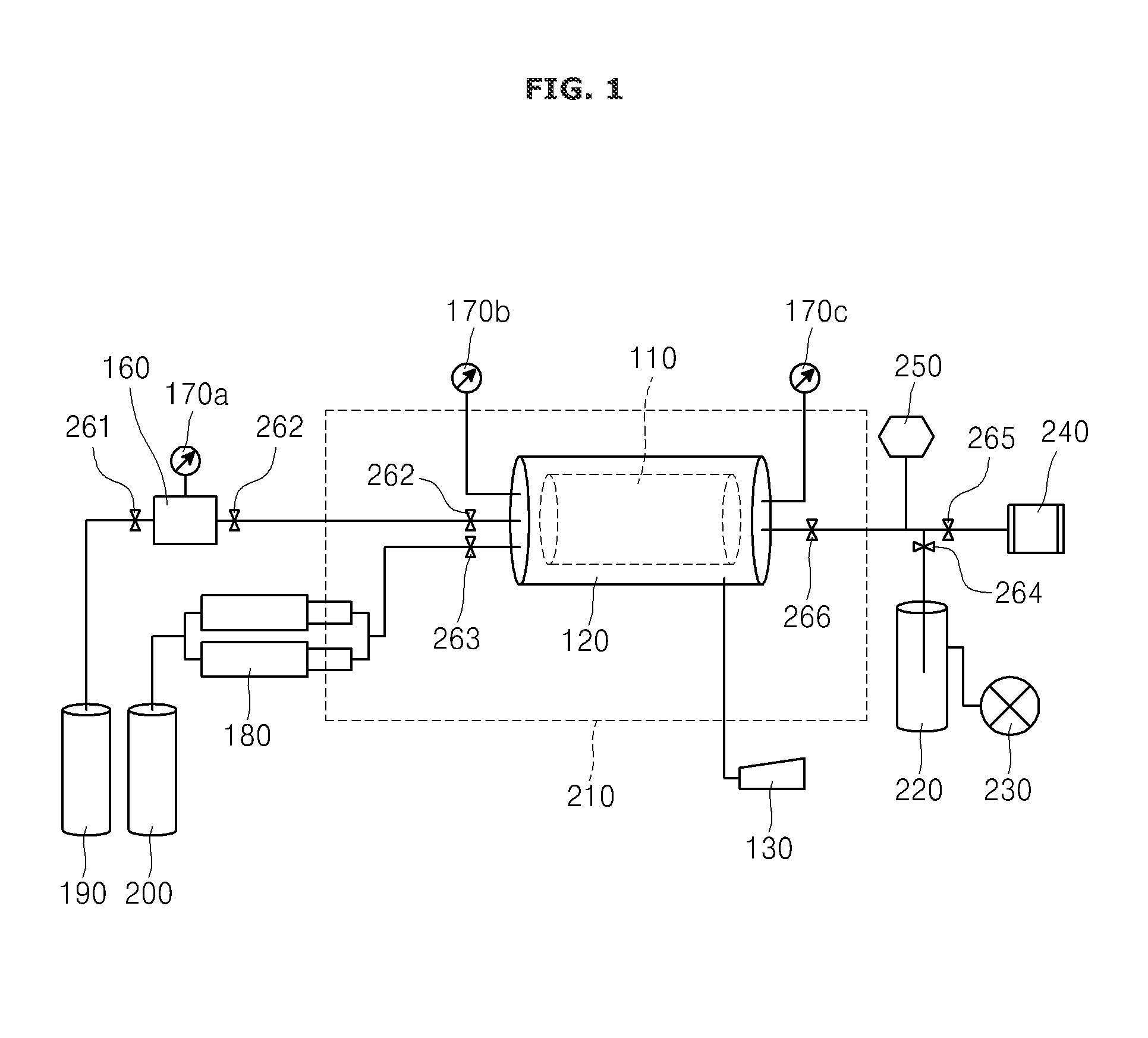

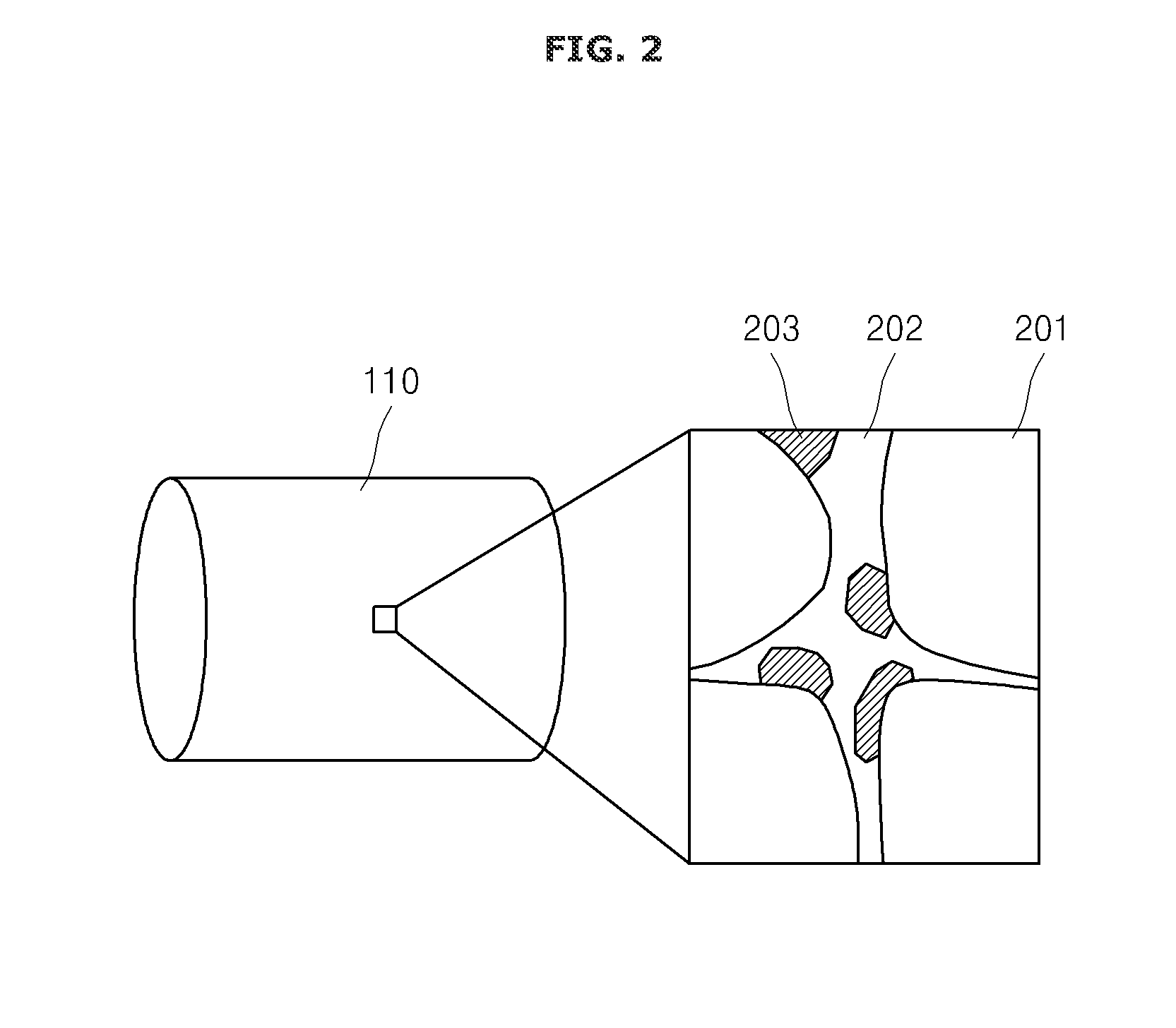

Apparatus and method of measuring porosity and permeability of dioxide carbon underground storage medium

ActiveUS20130144533A1Avoid sex changeEfficient measurementElectric/magnetic detection for well-loggingPermeability/surface area analysisInternal pressurePorosity

Disclosed are an apparatus and a method of measuring porosity and permeability of a carbon dioxide underground storage medium. Both of the porosity and the permeability are measured in the state that the confining pressure is applied once. The variation characteristic in the porosity and the permeability of the core sample according to the salt precipitation occurring when supercritical carbon dioxide is injected is continuously measured. The apparatus includes a holder receiving a core sample, a pressure pump applying a confining pressure to the core sample, a gas chamber storing gas and supplying supply the stored gas to the core sample, first to third pressure gauges measuring an internal pressure of the gas chamber and front and rear portions of the holder, and a gas flow meter measuring a flow rate of gas.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

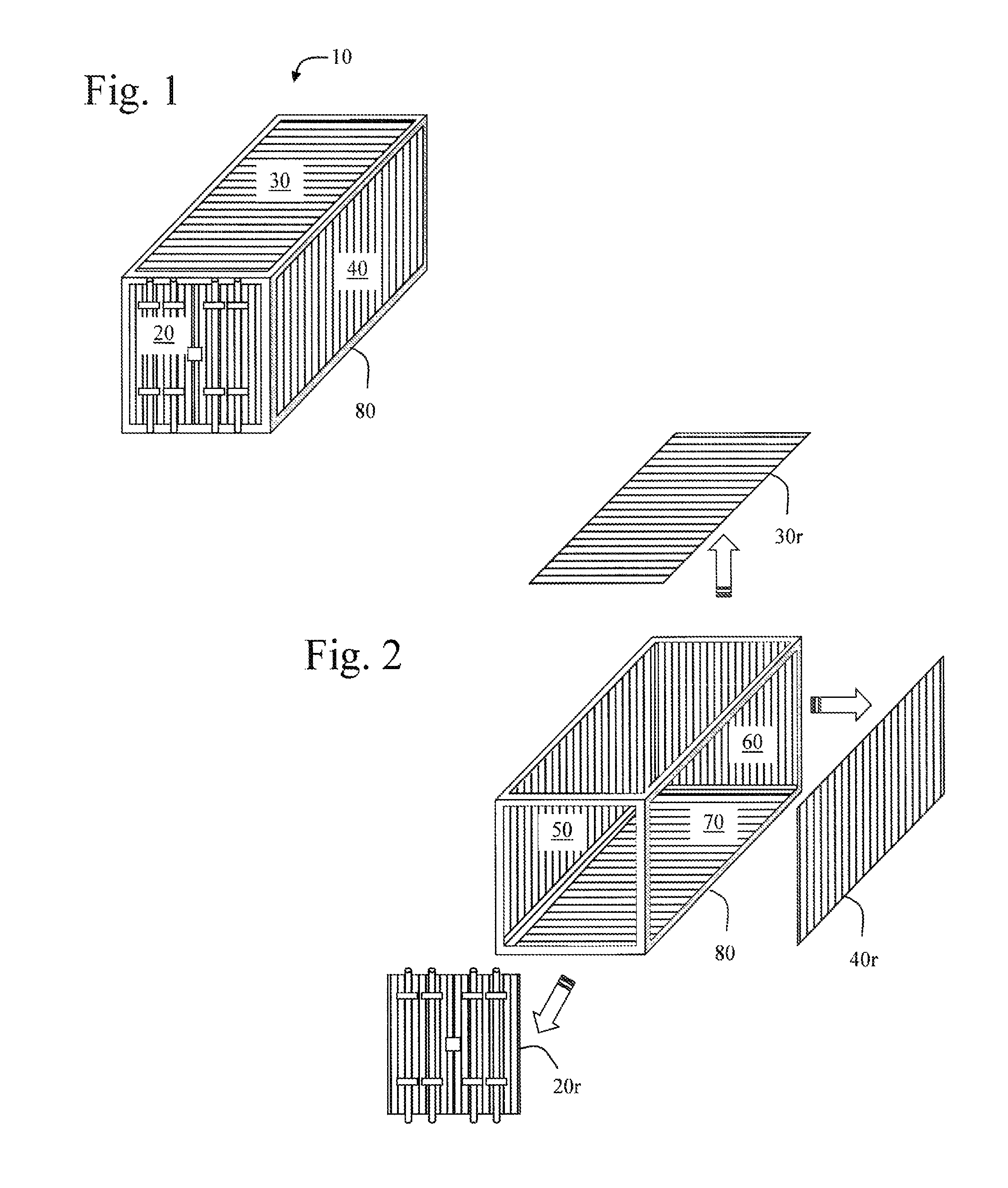

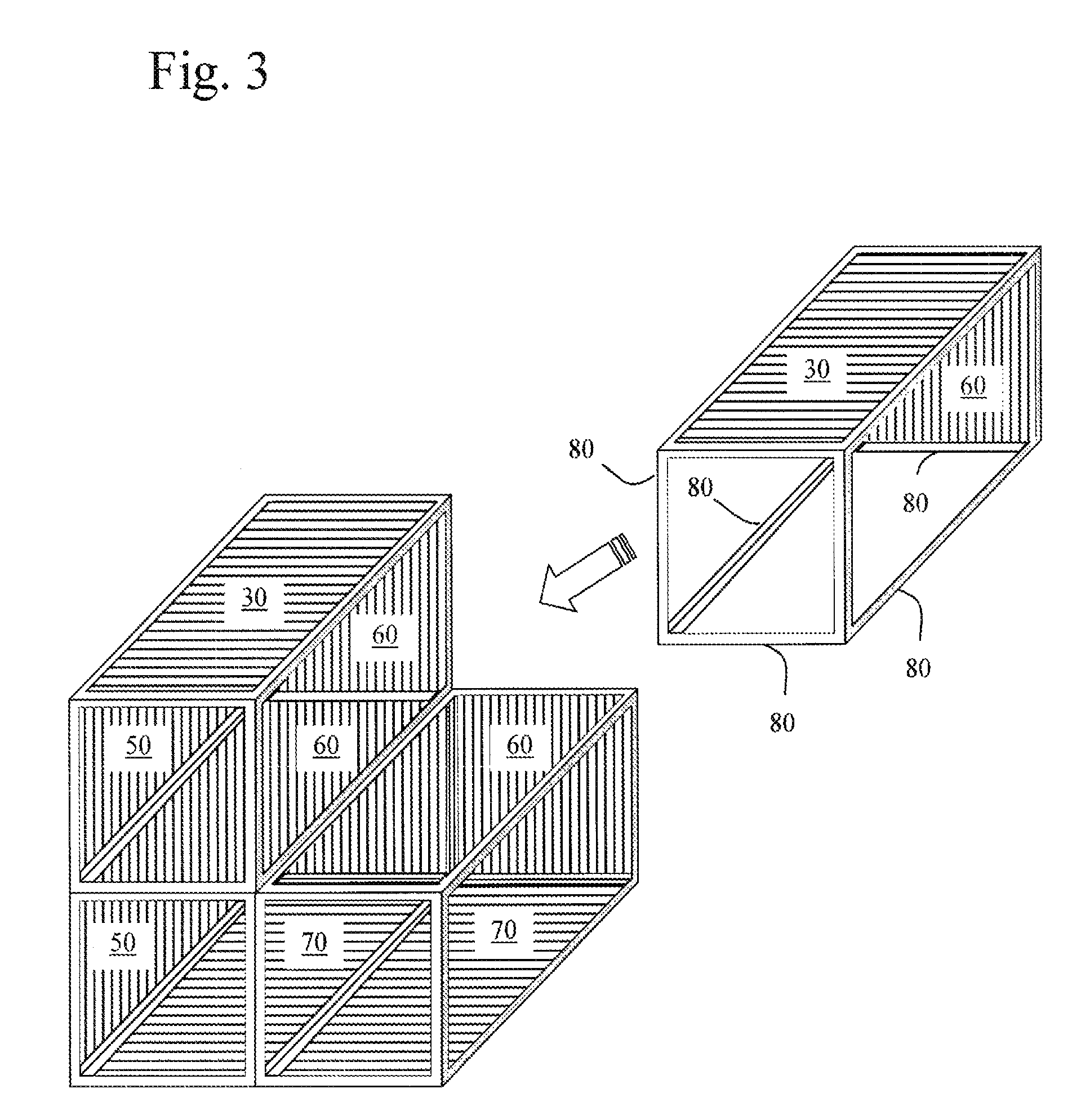

Construction of modular underground storage facilities

Owner:BEGDOURI HAMZA

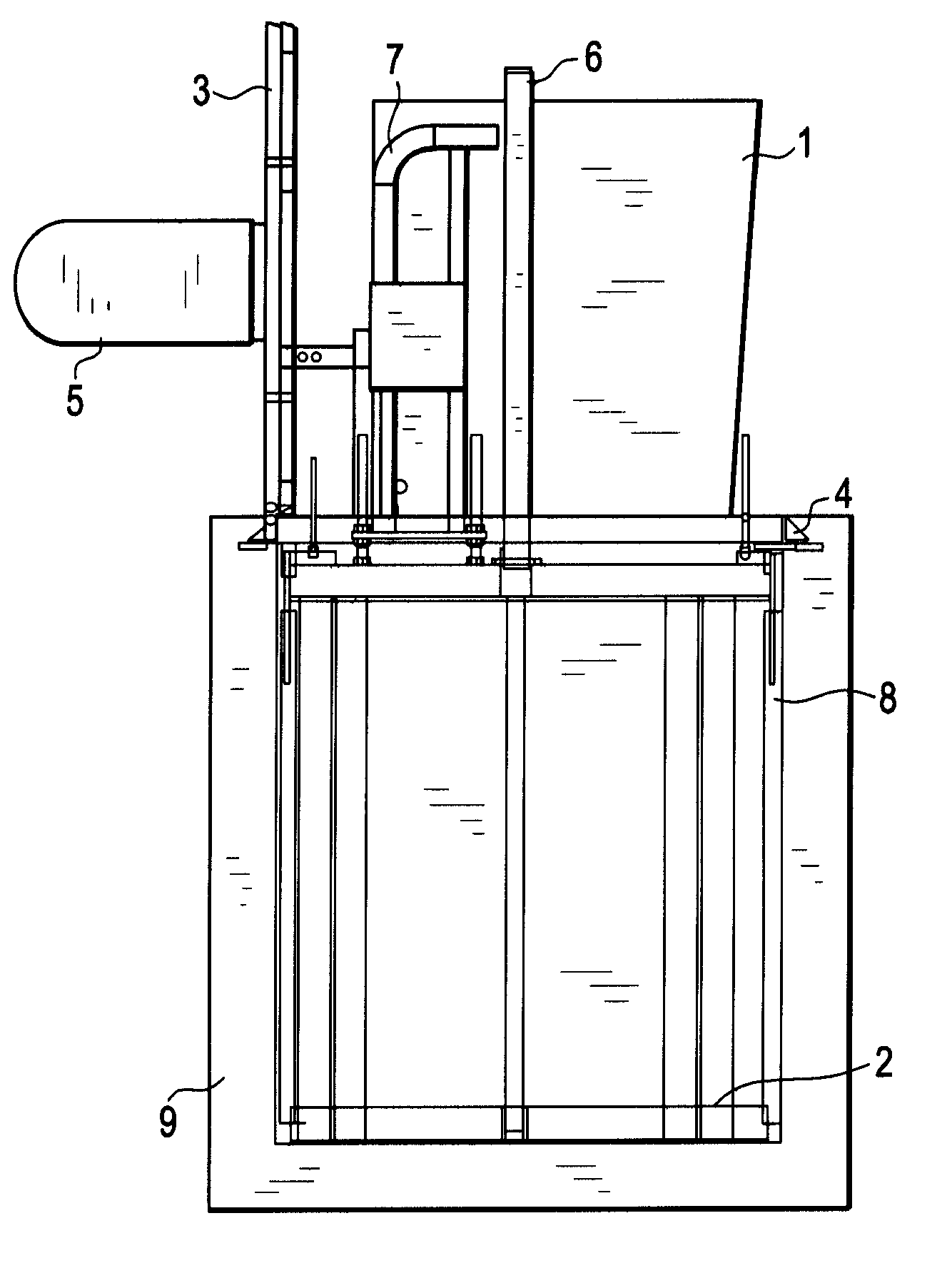

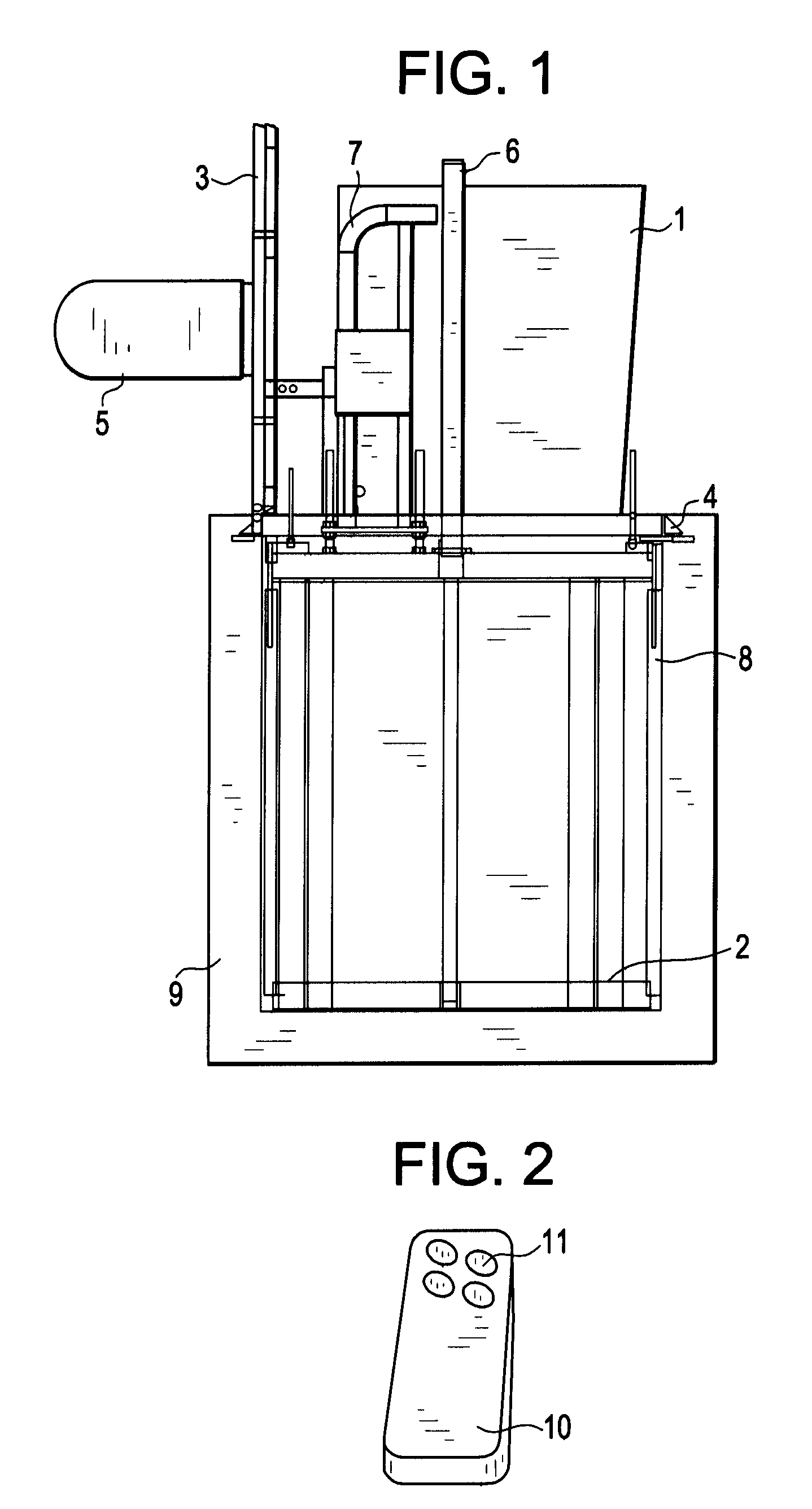

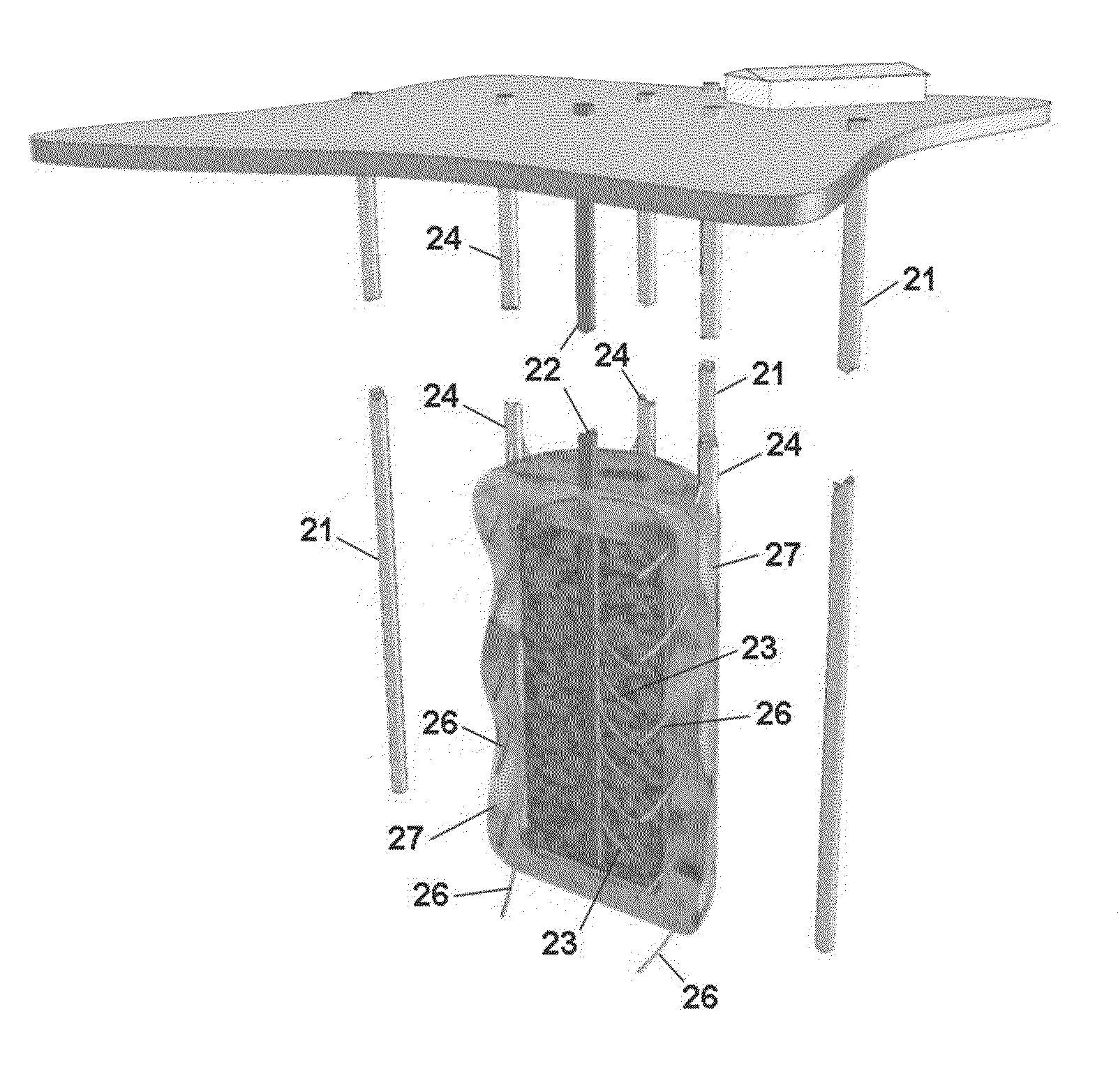

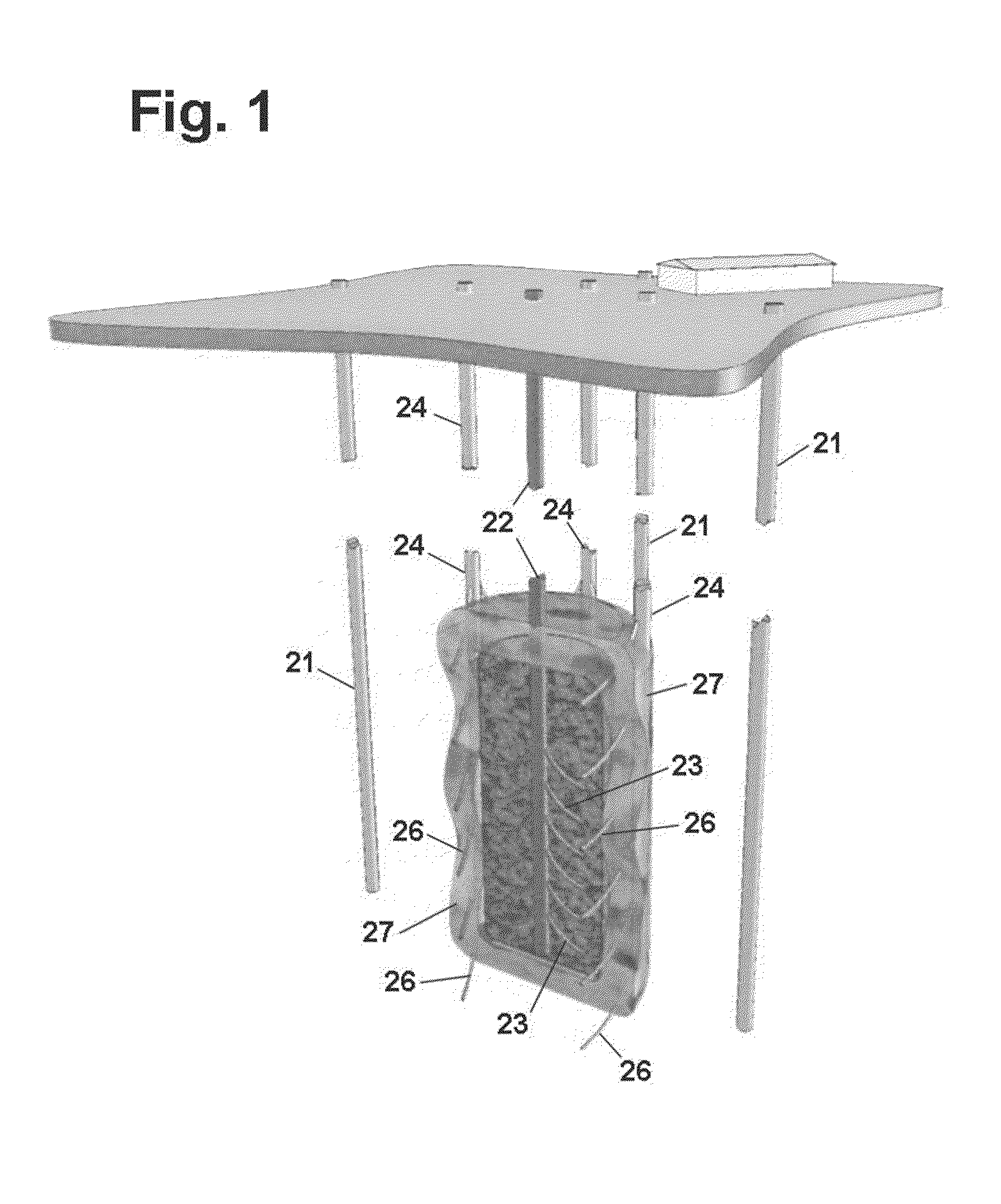

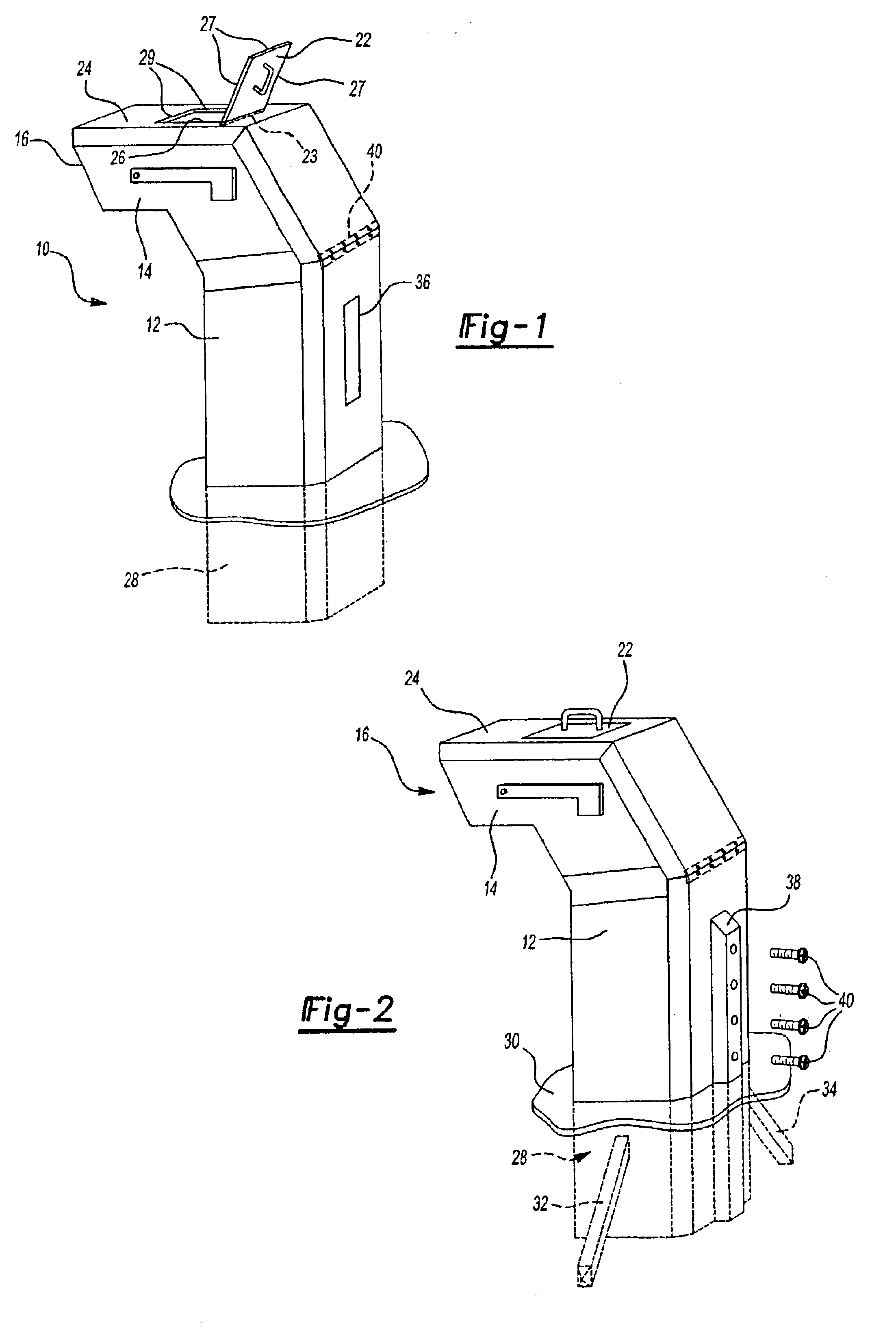

Universal system for underground storage and elevation of solid waste containers

InactiveUS20080203097A1Minimizing potential odorsFacilitate the collection of the waste containersLarge containersRefuse receptaclesHydraulic cylinderSolid waste collection

The present invention applies to the collection of solid waste into underground equipment and it refers to a system by which an underground pit is used to house one or more solid waste container(s).The system for the collection of solid waste as described by the current invention has a hydraulically activated platform on which one or more waste containers can be placed. It is made up of a bottom structure, a lid, an external surface, one or more deposit bins, two or more hydraulic cylinders, two or more structures that push and support the lid and a leveling structure. This platform, which can match the slope of the surrounding surface, is leveled and secured to a concrete pit.

Owner:TNL - SOC DE EQUIPAMENTOS ECOLOGICOS E SISTEMAS AMBIENTAIS LDA

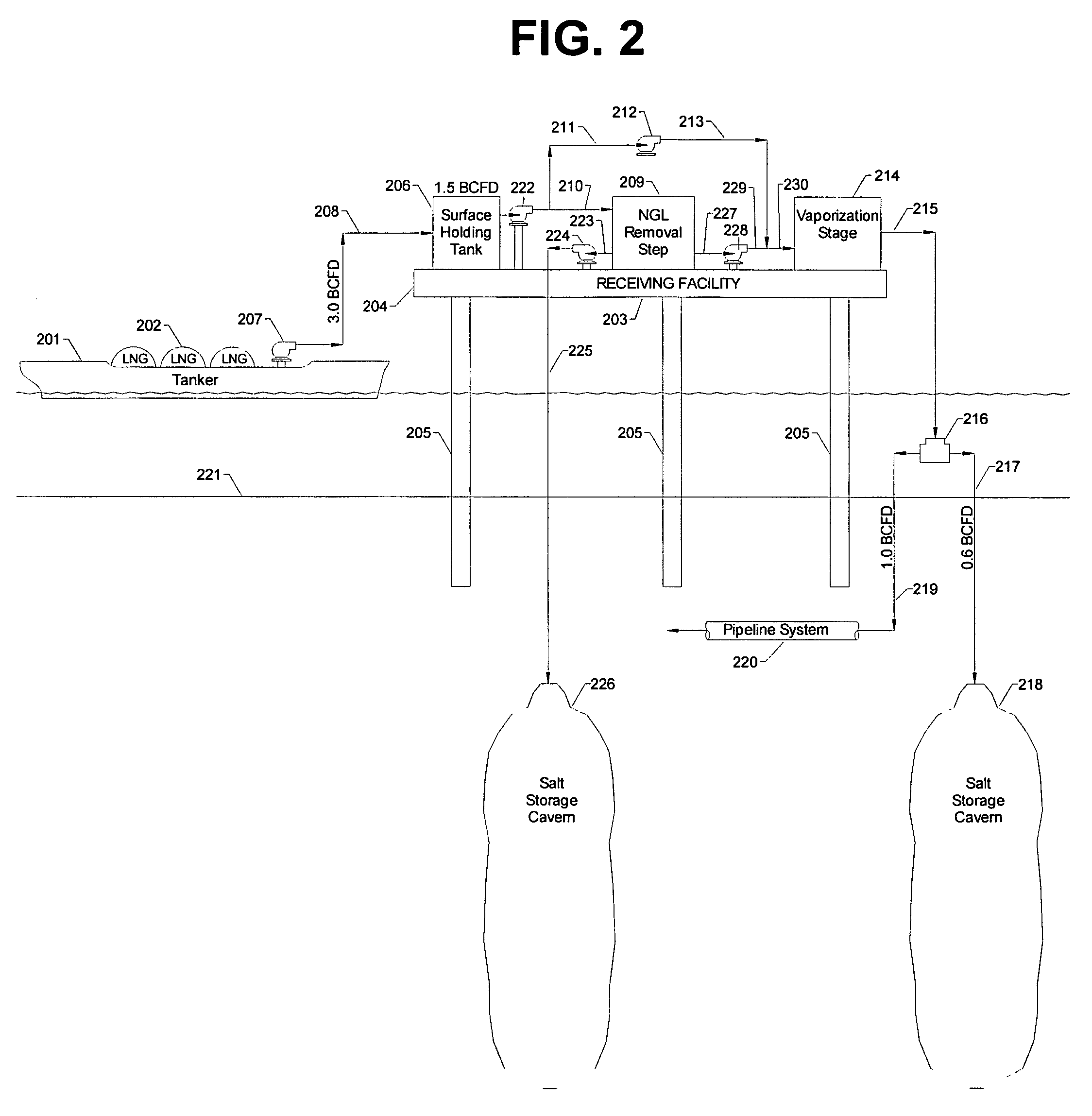

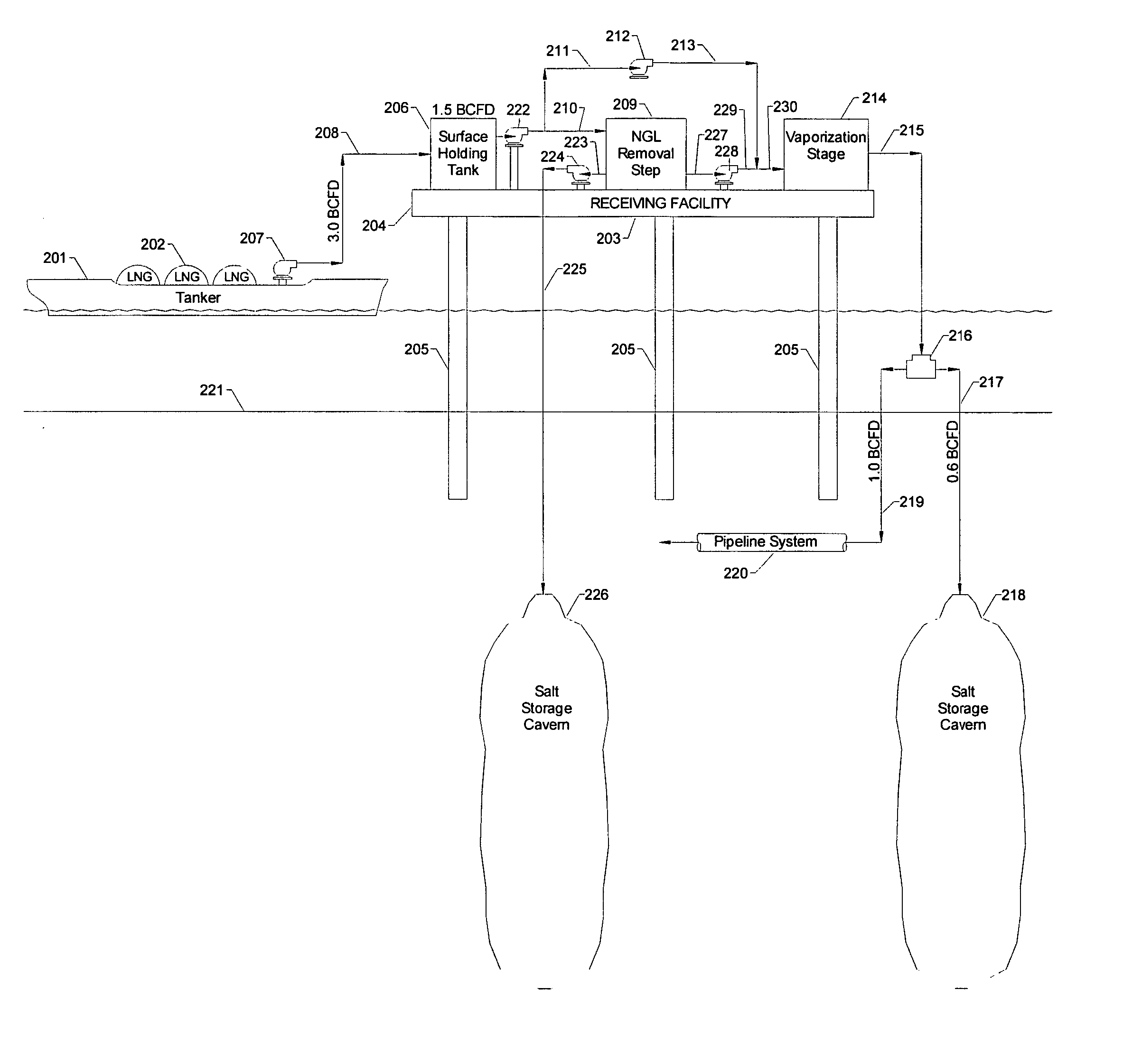

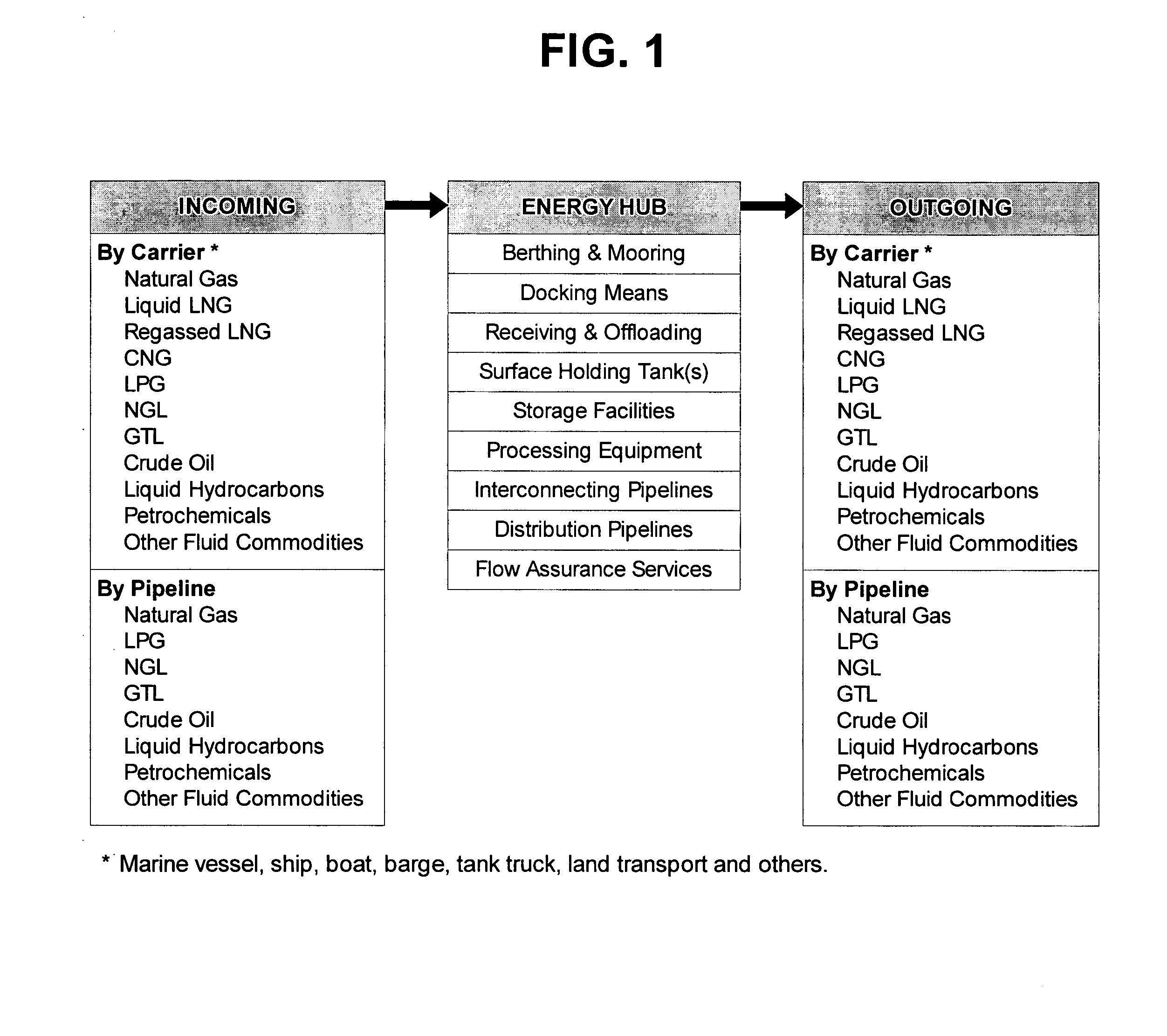

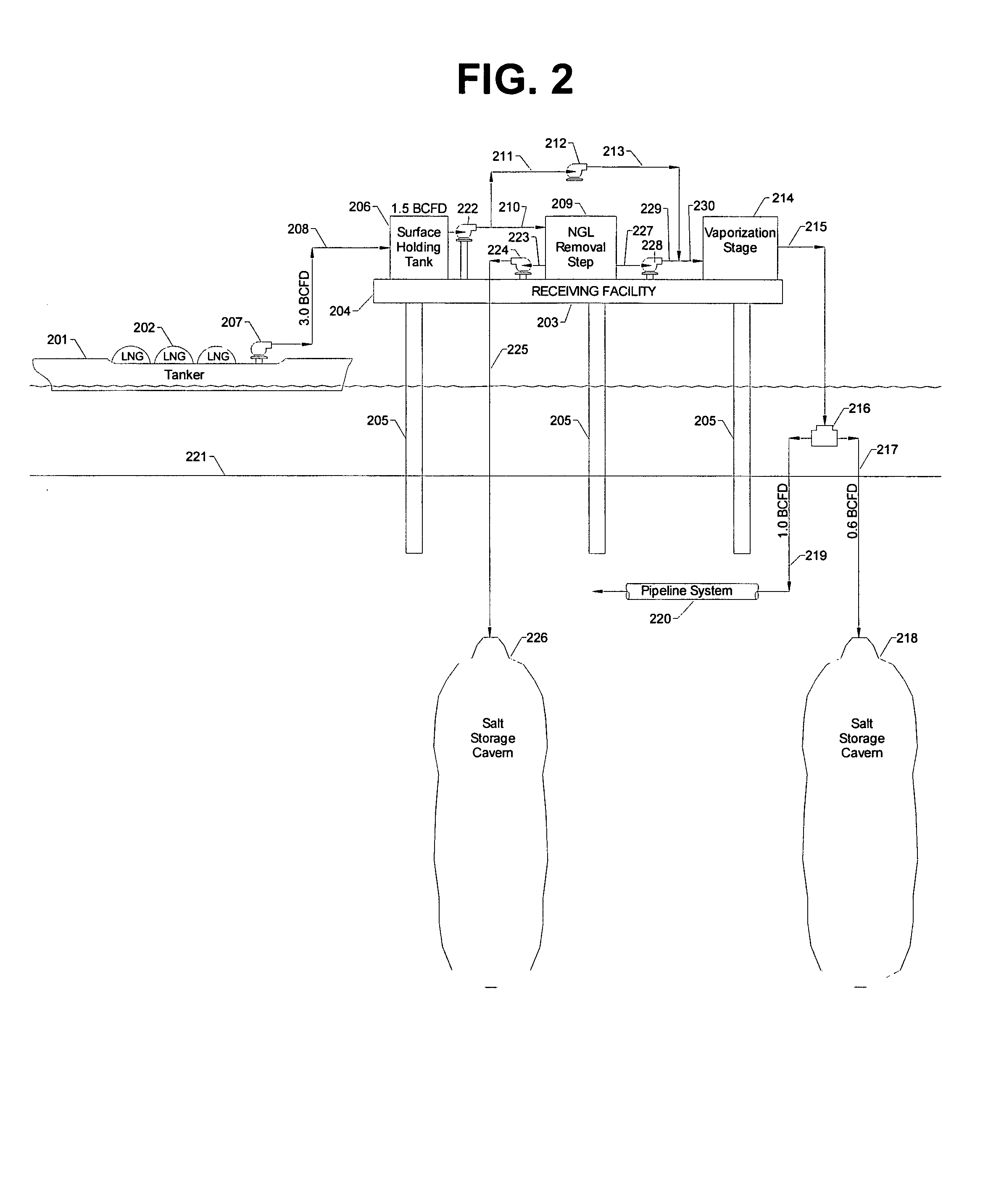

Reception, processing, handling and distribution of hydrocarbons and other fluids

InactiveUS7322387B2Reduce probabilityQuick uninstallSolidificationLiquefactionProcess engineeringHolding tank

An integrated energy hub facility capable of bringing together all aspects of hydrocarbon and other fluid product movement under controlled conditions applicable to the reception, storage, processing, collection and transmission downstream is provided. Input to the energy hub includes natural gas and crude from a pipeline or a carrier, LNG from a carrier, CNG from a carrier, and carrier-regassed LNG, as well as other products from a pipeline or a carrier. Storage can be above surface, in salt caverns or in subterranean formations and cavities, and include petroleum crude, natural gas, LPG, NGL, GTL and other fluids. Transmission downstream may be carried out by a vessel or other type of carrier and / or by means of a pipeline system. Cryogenic fluids are offloaded and sent to the energy hub surface holding tank, then pumped to the energy hub vaporizers and sent to underground storage and / or distribution.

Owner:MPEH LLC

Spillage containment system and kit for underground storage tanks

InactiveUS7171994B1Large collection pointEliminate potentialArtificial islandsLiquid fillingControl systemMonitoring system

A matter-isolating system for use in combination with an underground storage tank assembly comprises primary and secondary spillage containment assemblies and a double-walled manhole assembly. The manhole assembly comprises a manhole lid, an outer skirt wall, and an inner skirt wall. The inner skirt wall defines an inner manhole cavity and an outer manhole channel. The outer manhole channel directs moisture from the lid to certain backfill material thus isolating the inner manhole cavity from channel-directed moisture. The spillage containment assemblies form concentric primary and secondary spillage-containing chambers in radial adjacency to a tank access conduit of the underground tank assembly. The inner manhole cavity functions to isolate the secondary spillage containment chamber from the outer manhole channel and the primary spillage containment chamber isolates the secondary spillage containment chamber from the tank access conduit. A chamber-monitoring system may be incorporated into the system for monitoring the isolated chambers.

Owner:OBRIEN PATRICK E

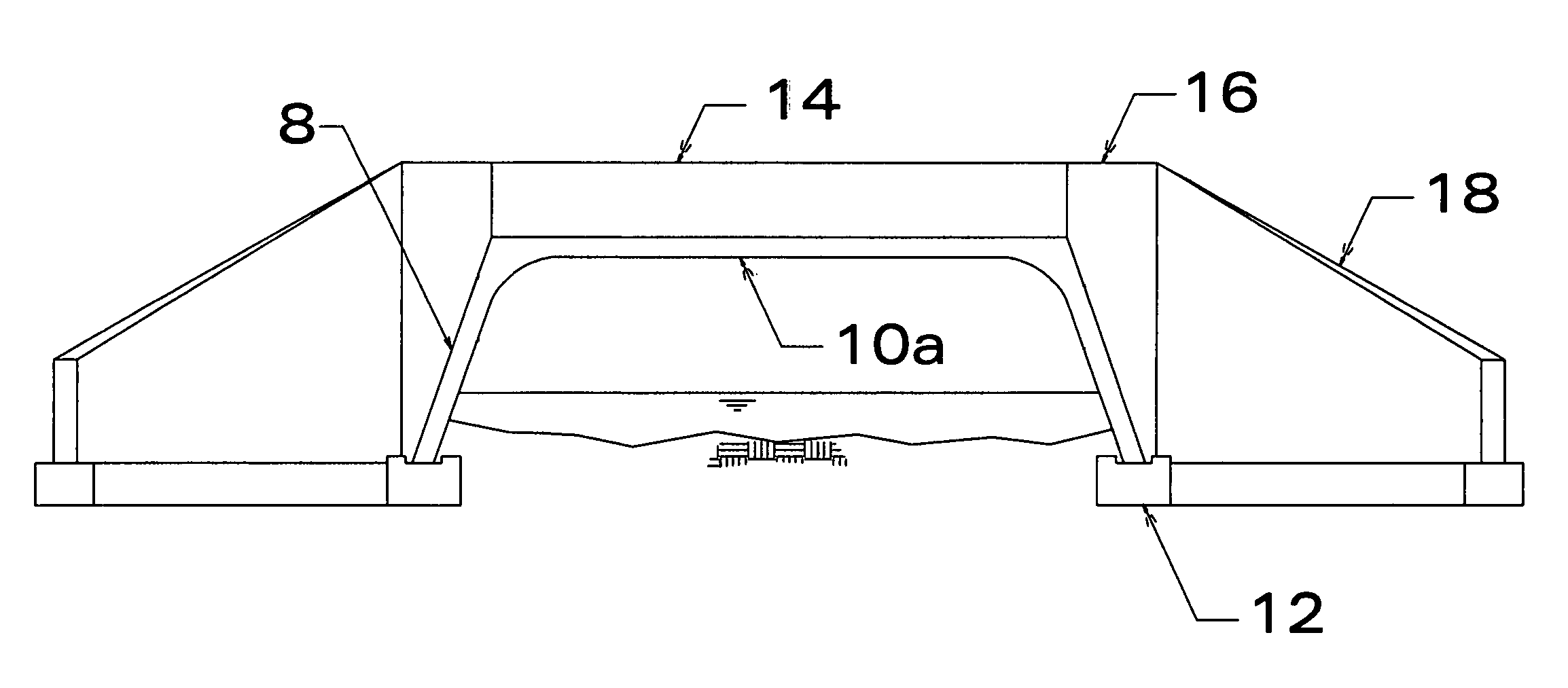

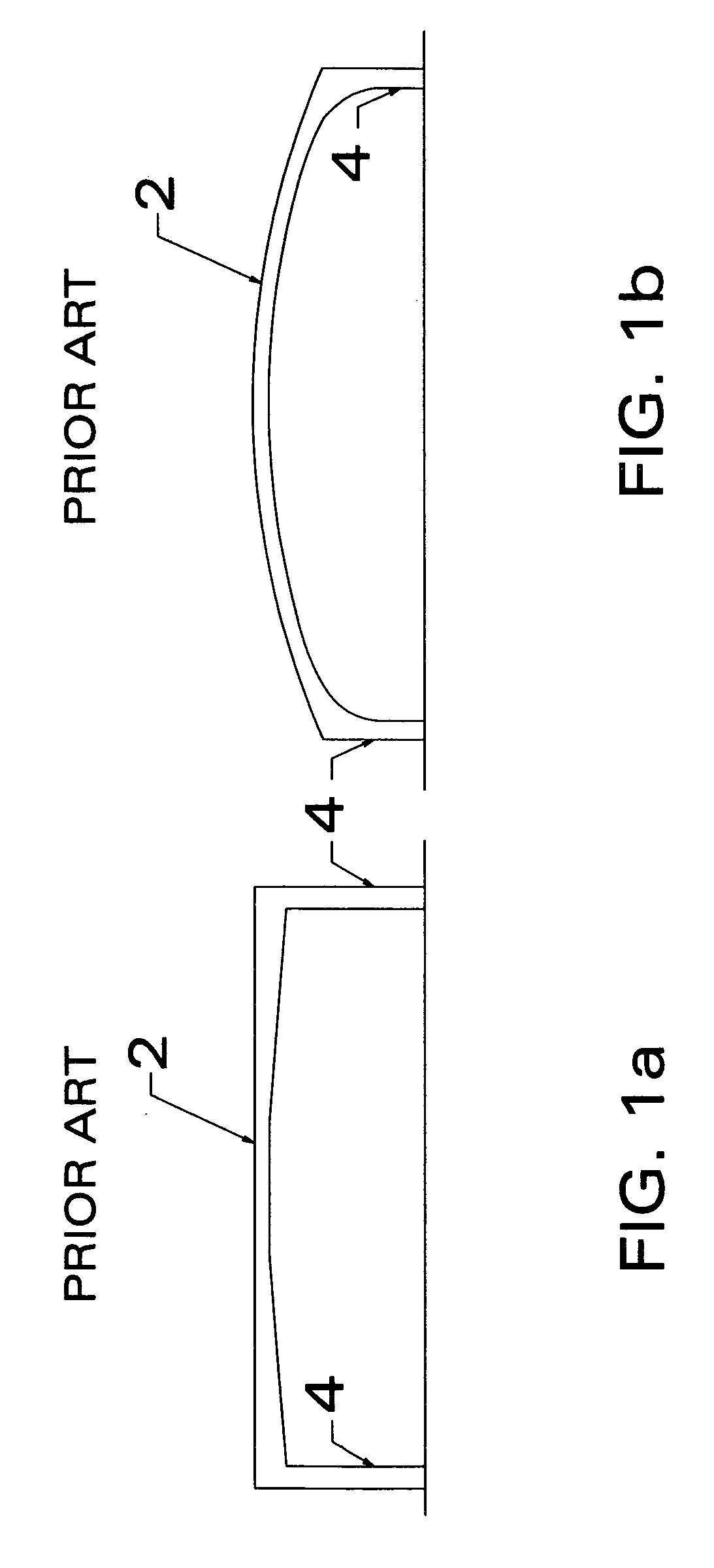

Flared leg precast concrete bridge system

InactiveUS20090183321A1Simple structureRealized benefitsGround-workTruss-type bridgeEngineeringSpandrel

A concrete building system includes a set of parallel spaced apart strip footers and one or more precast concrete sections supported by the footers in a predetermined alignment. Each precast concrete section has a top slab integrally connected to a pair of equally flared legs. Each leg depends from an end of the top slab at an effective flare angle to form a corner. The precast section includes haunch sections formed between the top slab and each leg resulting in a corner thickness greater than the uniform thickness of the angled leg to which it is integrally formed and the top member. The length of the effective span of each section varies between 60 and 90 percent of the distance between the bottom-of-leg span. The sections can be used to construct bridges, culverts, underground storage units, fluid detention units and dam structures.

Owner:COUNTY MATERIALS CORP +1

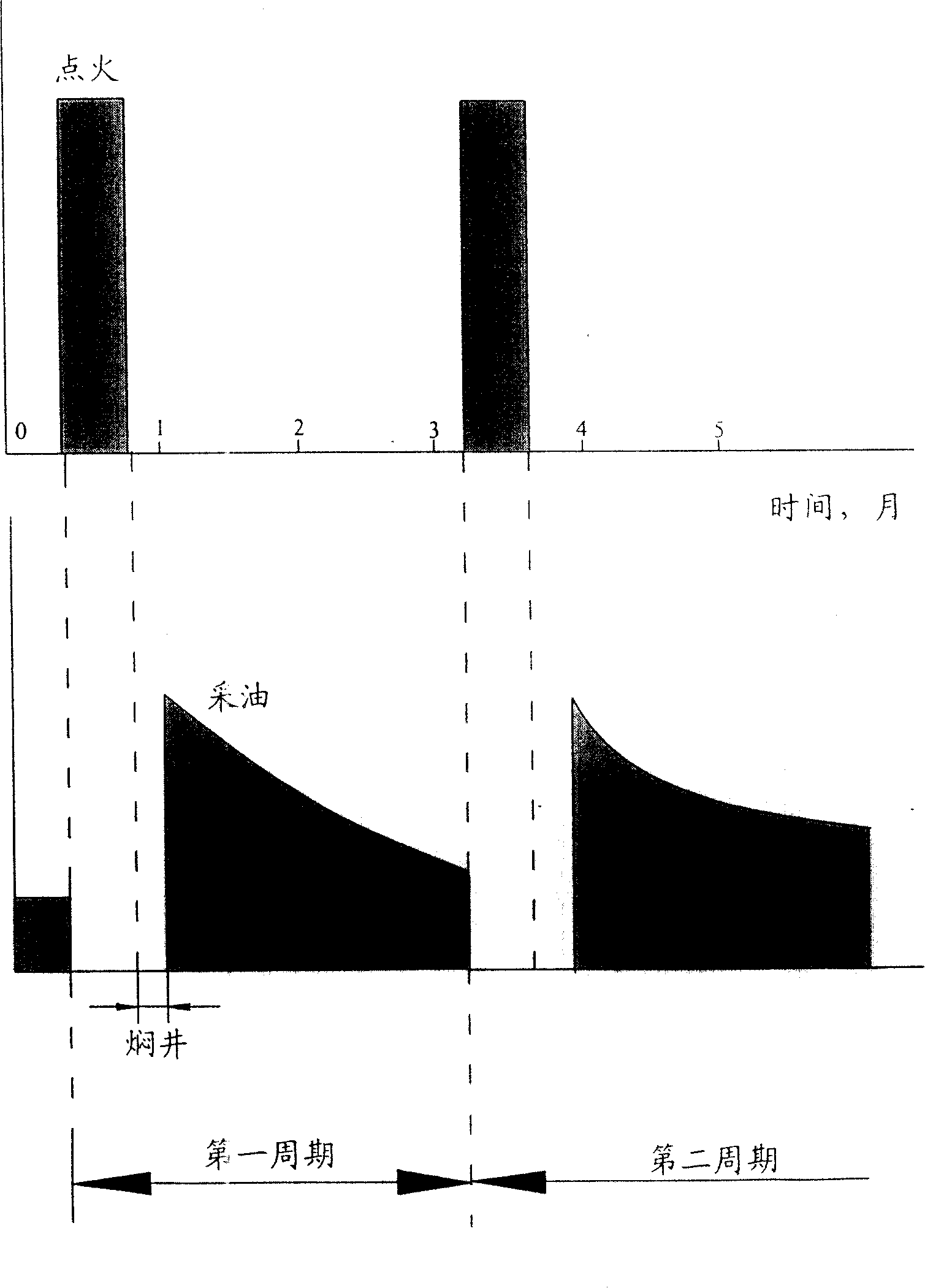

Combustion soaking heavy crude producing technique

InactiveCN101161987ALow viscosityImprove production dynamicsIncandescent ignitionFuel lightersOil productionAir compressor

The invention relates to a craftwork technology of pumping thick oil by firing and sorking. The pumping craftwork by firing, sorking is that ignition technologies such as ignition with a radiator, ignition with natural gas or spontaneous ignition are adopted; an oil-well oil layer or a water-well oil layer is heated to have a temperature of over 450 DEG C; the oil well or the water well is continuously injected with oxygen enrichment through an air compressor for 15 to 25 days and ignition is stopped; the oil well or the water well is soaked for 5 to 10 days and opened to be injected with water, thereby reaching the aims of increasing production and injection. The pumping by firing and soaking is mainly used for the pumping of high-turn soaking pumping wells; as the underground storage capacity of the oil well is high and the strata pressure is low, the pumping by firing and soaking can improve daily oil production of per well or moisture pickup of per well to reach the aims of increasing production and injection. The technology is also applicable for oil wells or water wells in which the pumping of steam soaking is not implemented.

Owner:富象油气技术服务有限公司

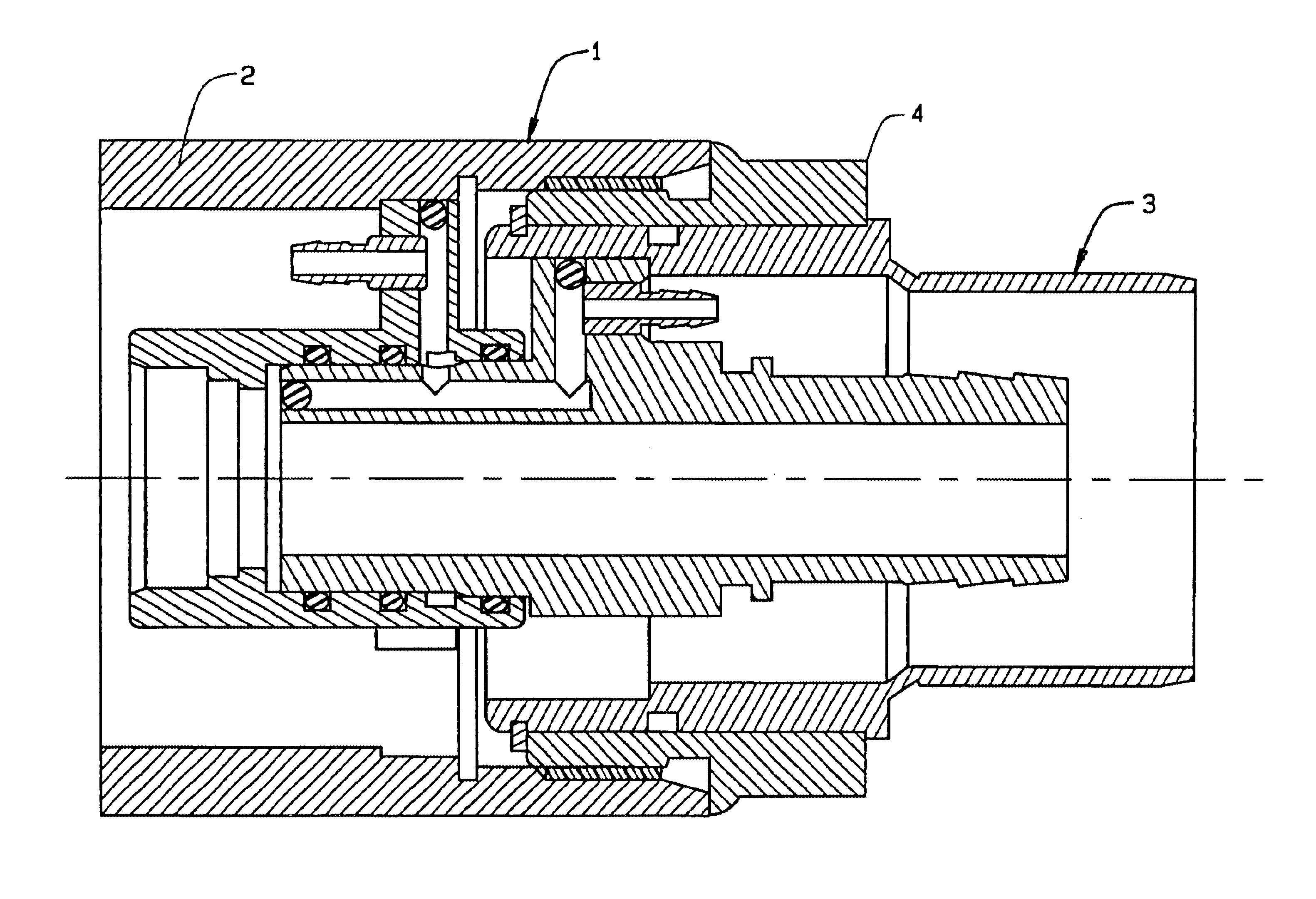

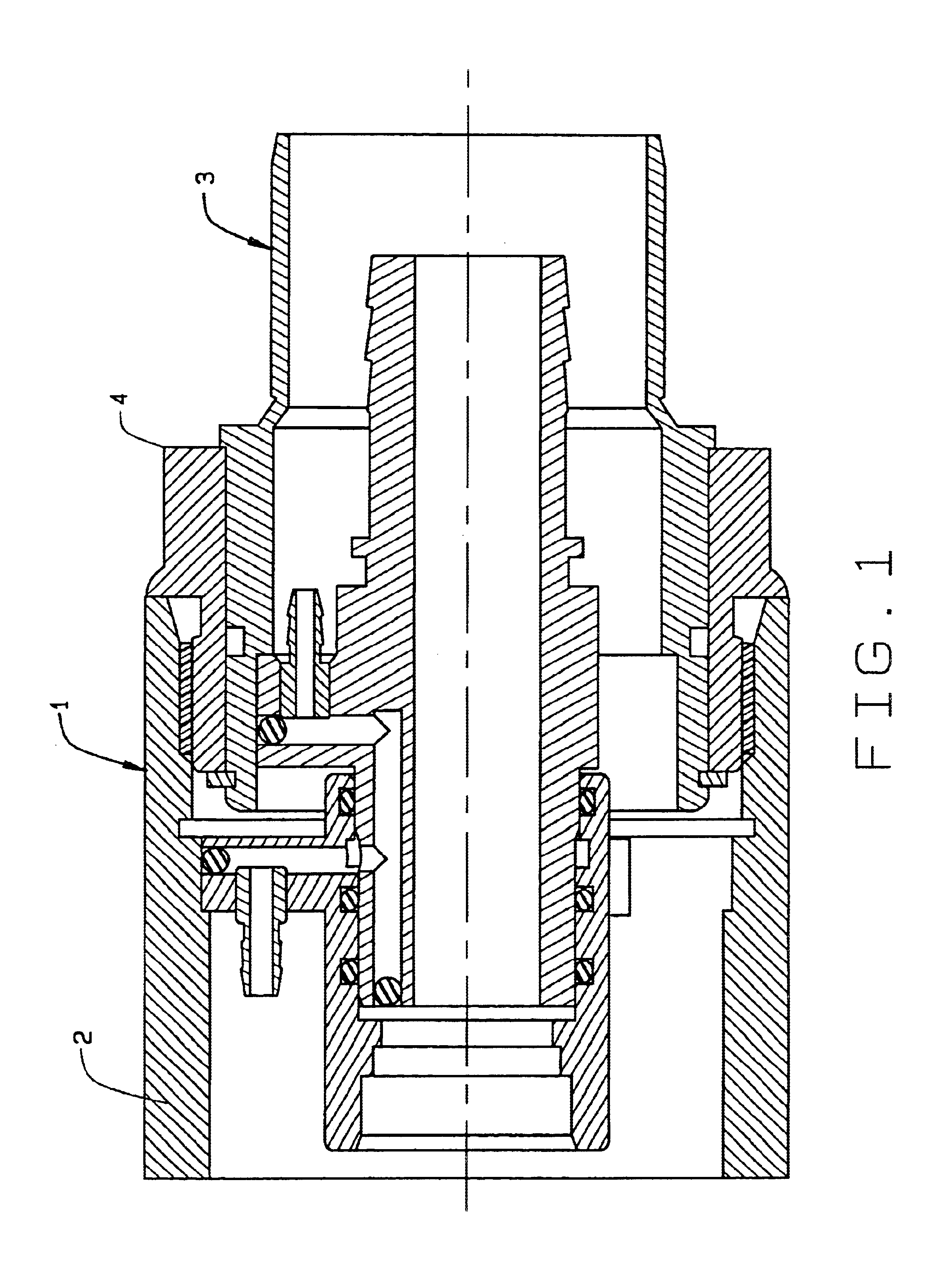

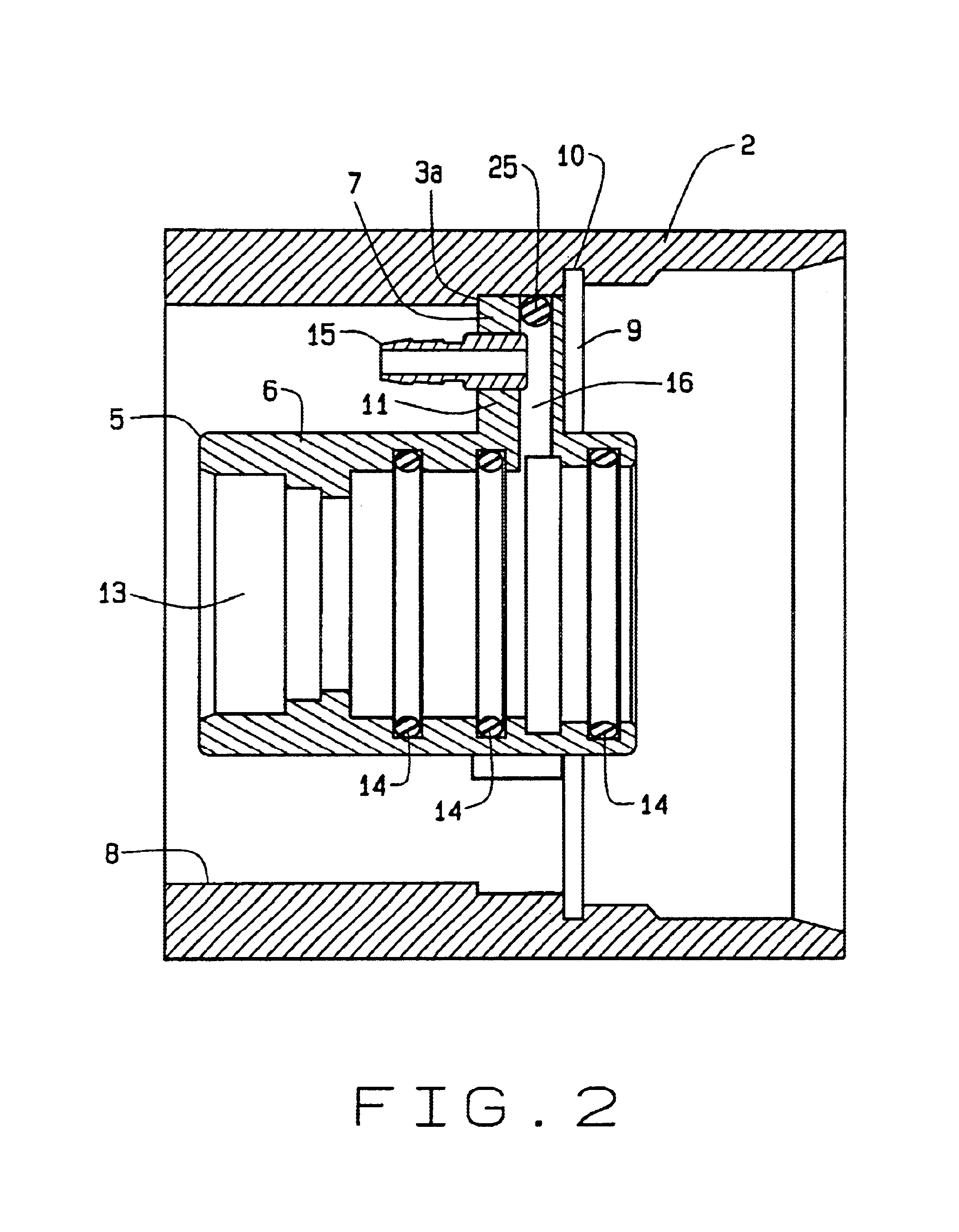

Slurpie hose connection

ActiveUS6866299B2Quickly and facilely connectedQuick installationPipe supportsFluid pressure sealed jointsLeading edgeEngineering

A slurpie hose connection, for attachment between the coaxial hose and the back end of a fuel dispensing nozzle, including two parts, a connector part that fits within the back end of the nozzle, a hose part that secures with the leading edge of the hose, such that when these two parts are brought together, and pushed into sealed engagement, a nut is fastened within the back end of the nozzle, to tightly and snuggly secure the hose connection together, available for prompt usage. A slurpie tube may fasten to tube fittings and extend forwardly in the nozzle, as known, and extend to the bottom of the coaxial hose, to act as a slurpie to remove any accumulated or condensed fuel, from this location, and to prevent its blockage of the return of vapors to the dispenser and for underground storage.

Owner:HUSKY

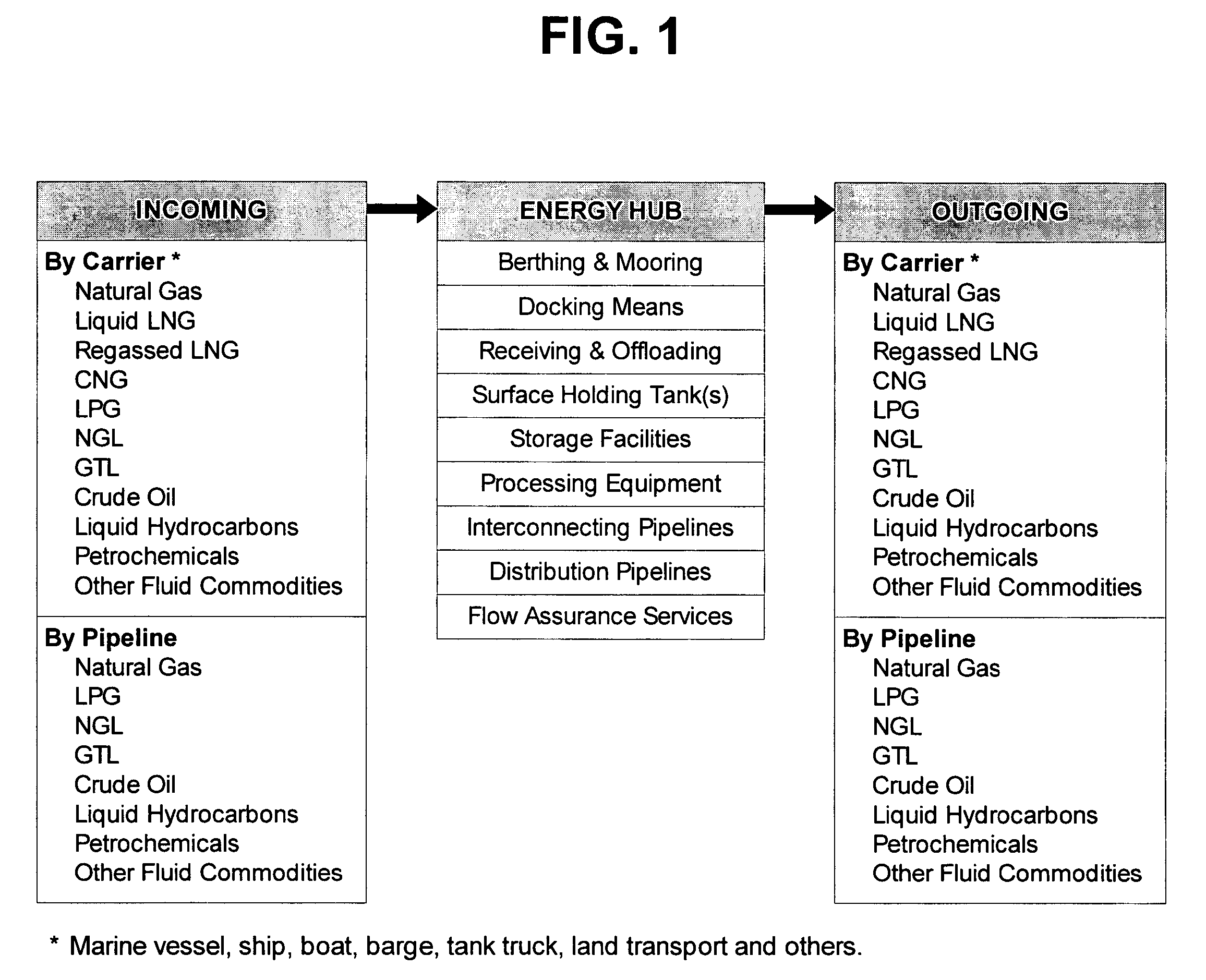

Reception, processing, handling and distribution of hydrocarbons and other fluids

InactiveUS20050061396A1Reduce probabilityQuick uninstallSolidificationLiquefactionCompressed natural gasHydrocotyle bowlesioides

An integrated energy hub facility capable of bringing together all aspects of hydrocarbon and other fluid product movement under controlled conditions applicable to the reception, storage, processing, collection and transmission downstream is provided. Input to the energy hub includes natural gas and crude from a pipeline or a carrier, LNG from a carrier, CNG from a carrier, and carrier-regassed LNG, as well as other products from a pipeline or a carrier. Storage can be above surface, in salt caverns or in subterranean formations and cavities, and include petroleum crude, natural gas, LPG, NGL, GTL and other fluids. Transmission downstream may be carried out by a vessel or other type of carrier and / or by means of a pipeline system. Cryogenic fluids are offloaded and sent to the energy hub surface holding tank, then pumped to the energy hub vaporizers and sent to underground storage and / or distribution.

Owner:MPEH LLC

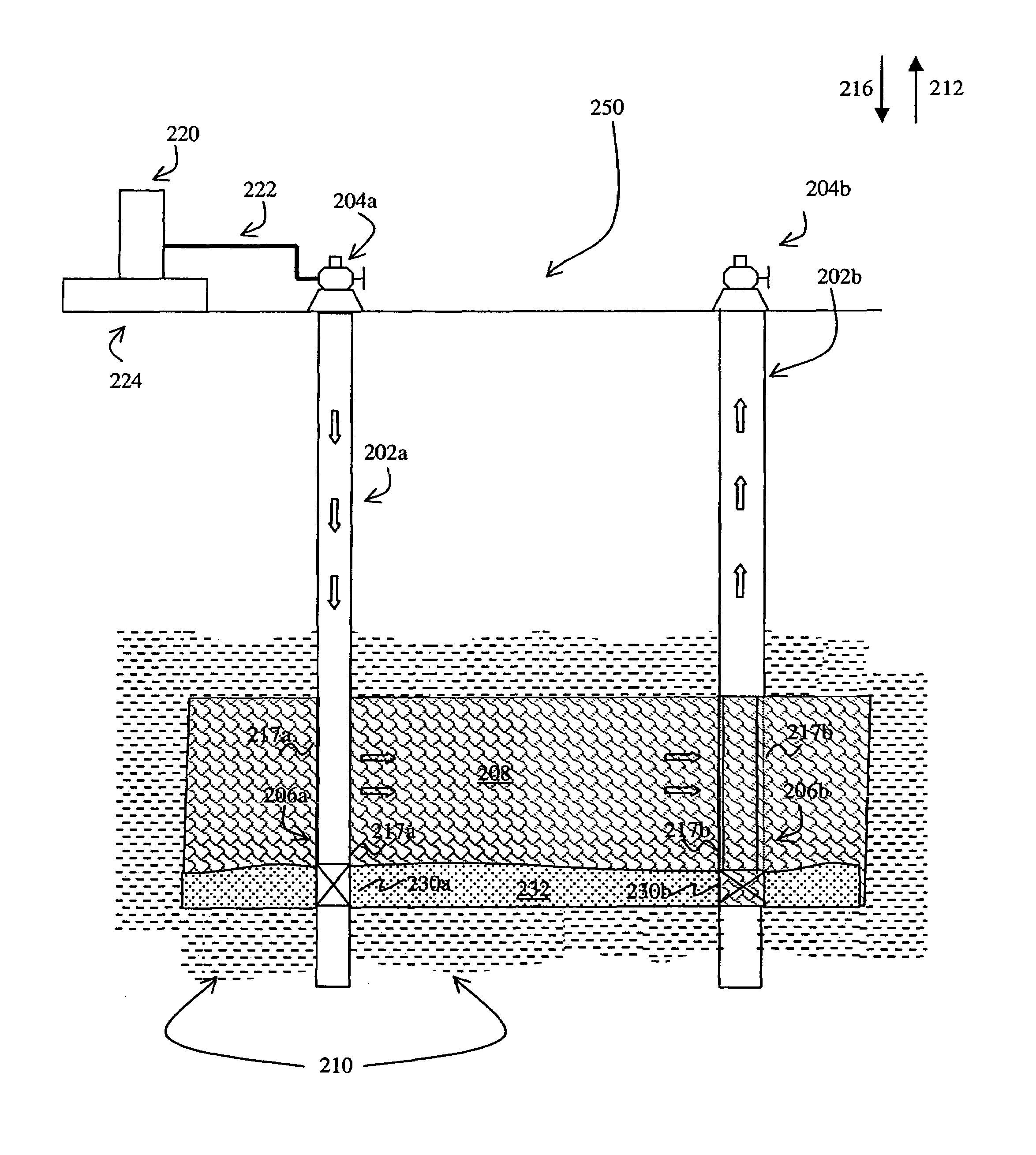

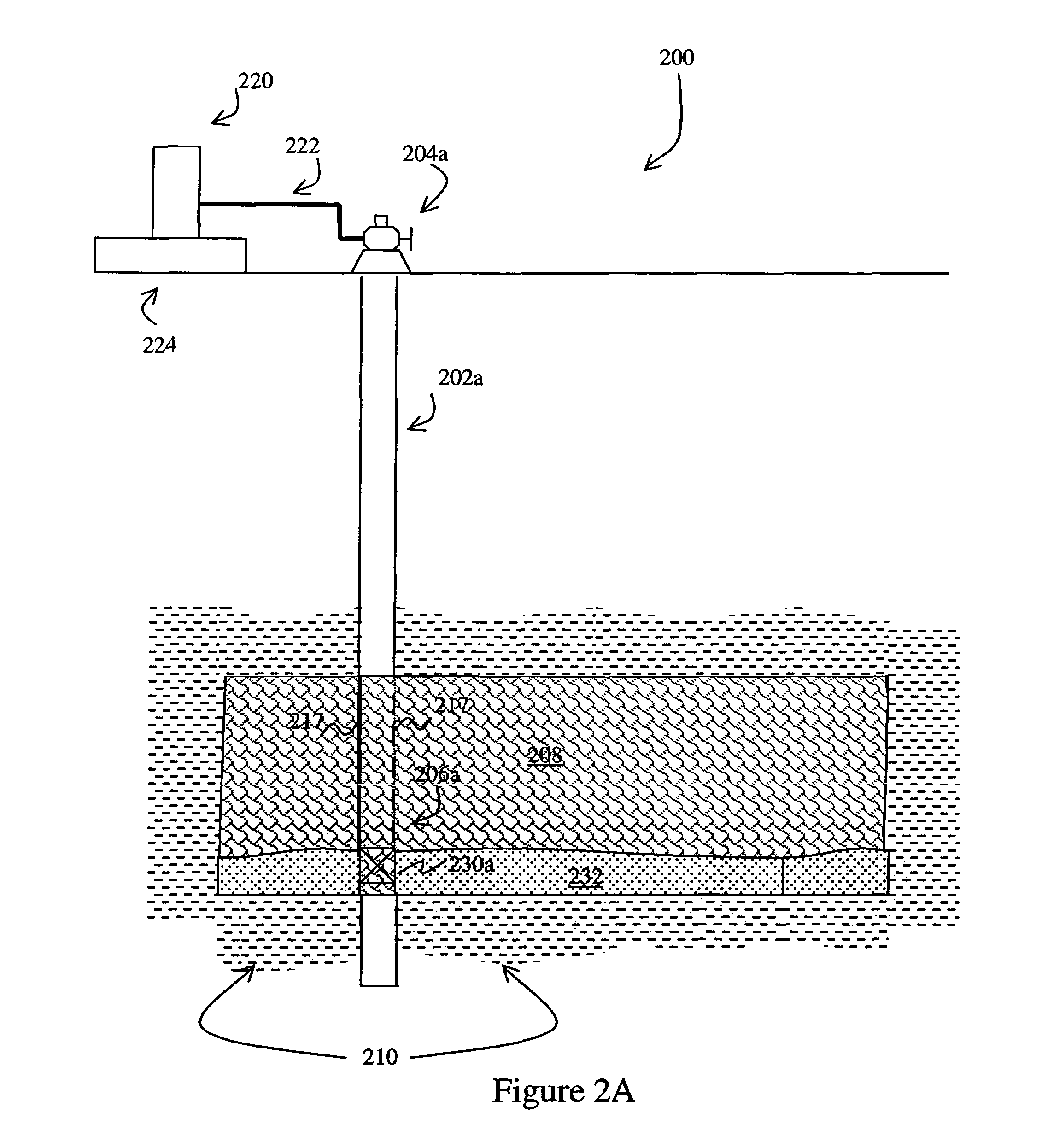

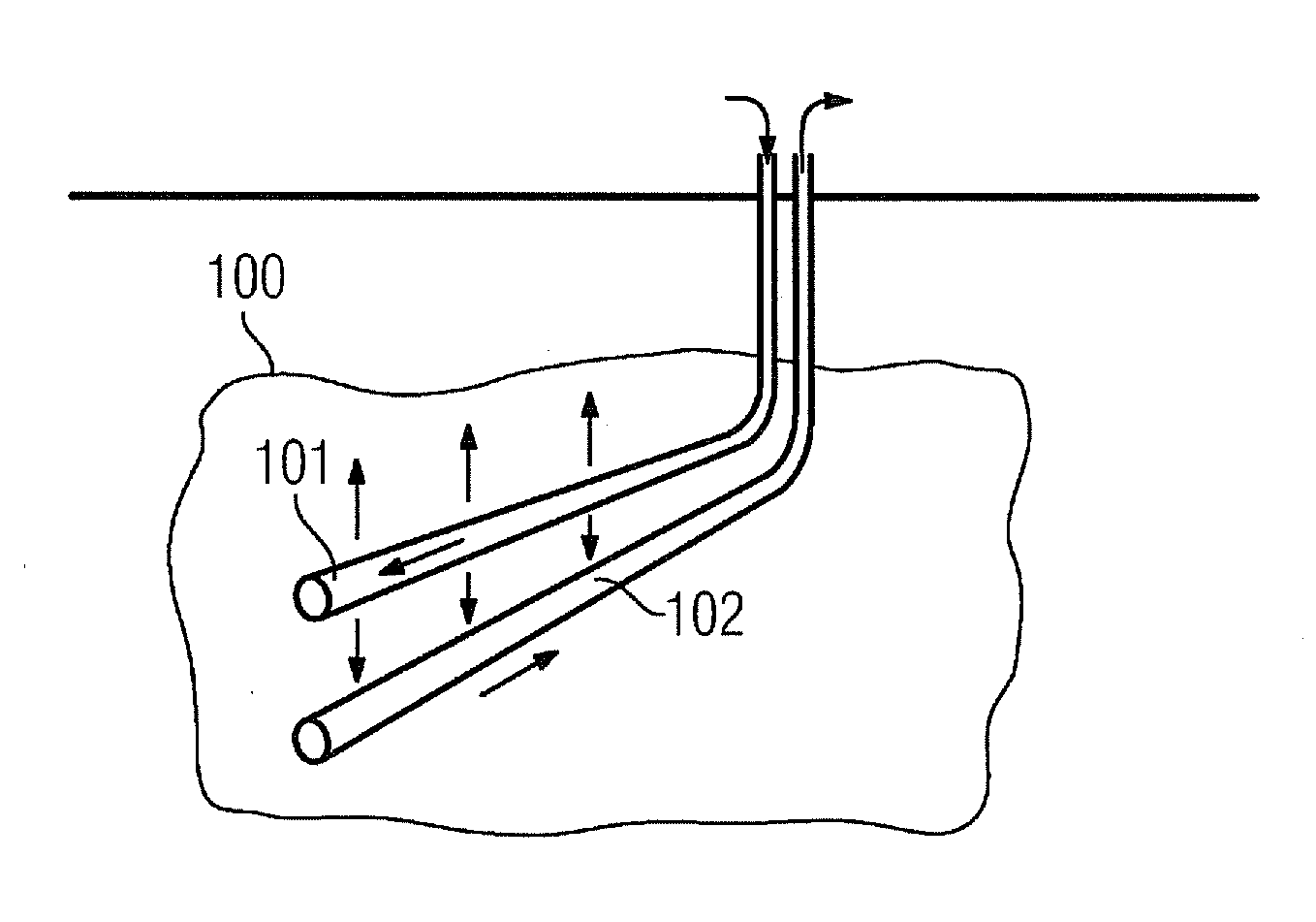

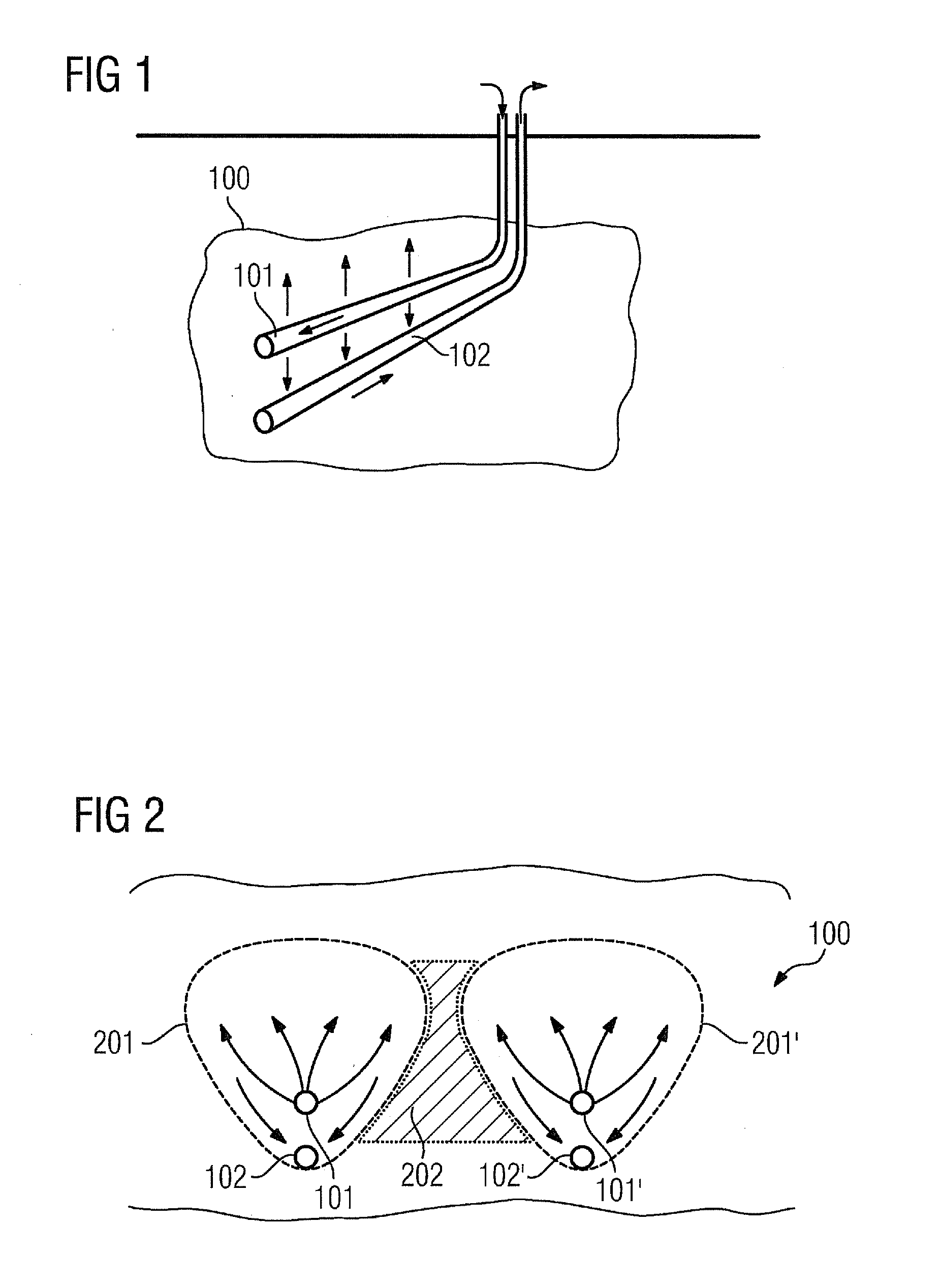

Engineered, Scalable Underground Storage System and Method

InactiveUS20100101789A1Improve reliabilityImprove permeabilityMining devicesSolid waste disposalPorosityGeomorphology

An engineered, scalable underground containment system and method for storing compressed gases or liquids in permeable rock formations using conventional drilling techniques. The porosity and permeability of the formation may be enhanced to maximize reservoir capacity and increase the rate at which gases and liquids can be introduced into and removed from the reservoir. In some embodiments, layers of cap rock in the formation are utilized as containment barriers, and in some, containment barriers are constructed around the storage zones.

Owner:SEQENERGY

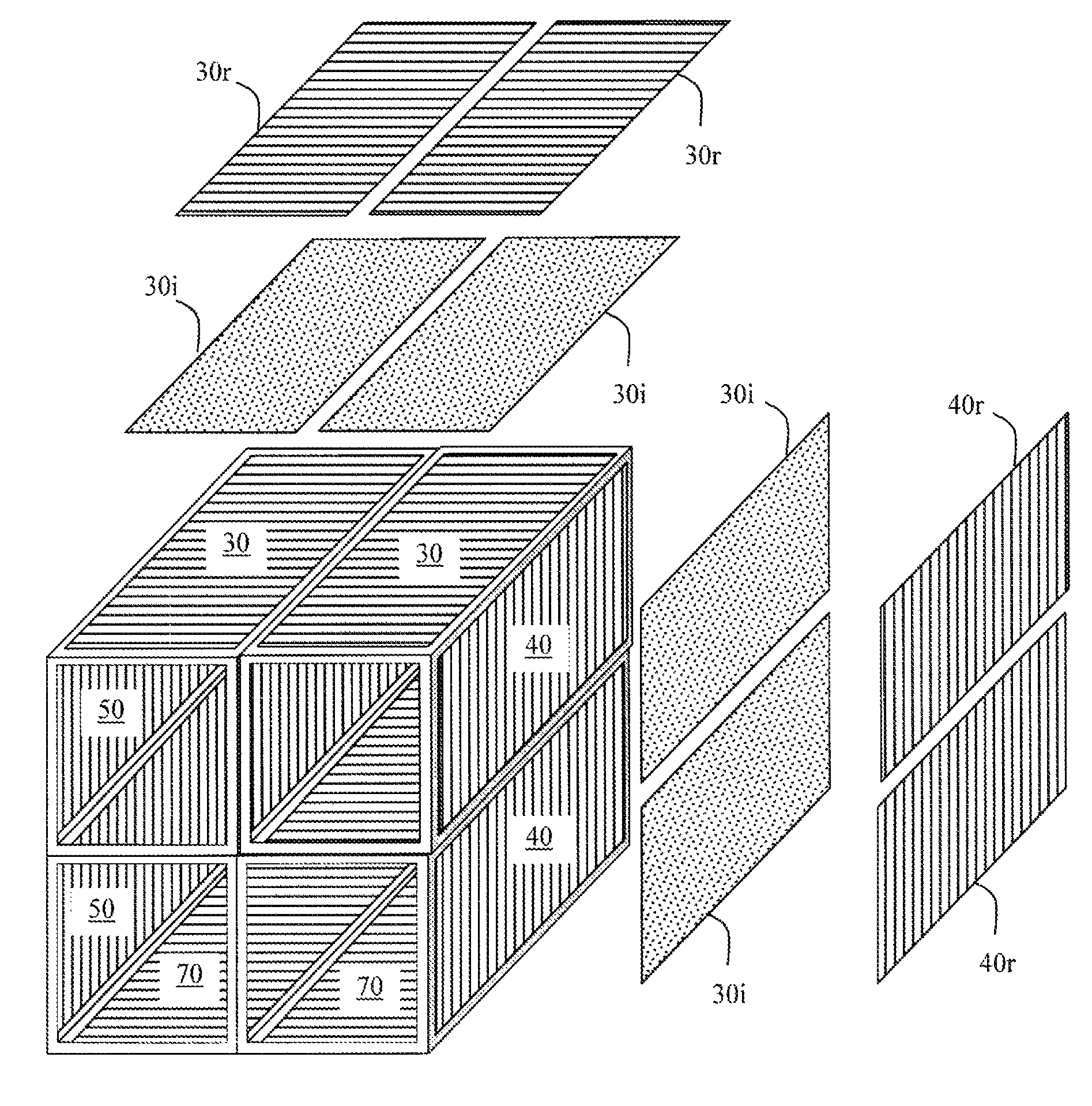

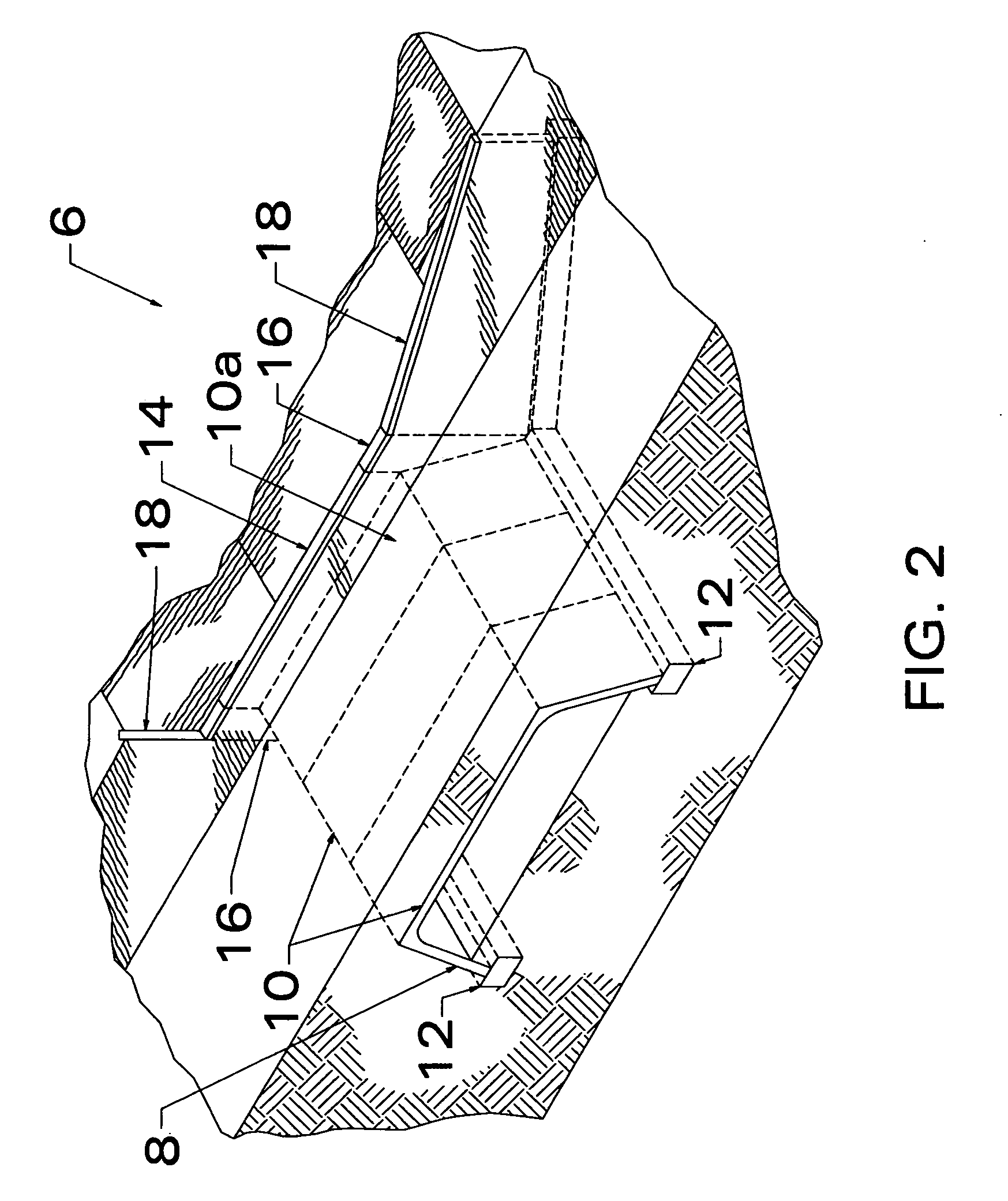

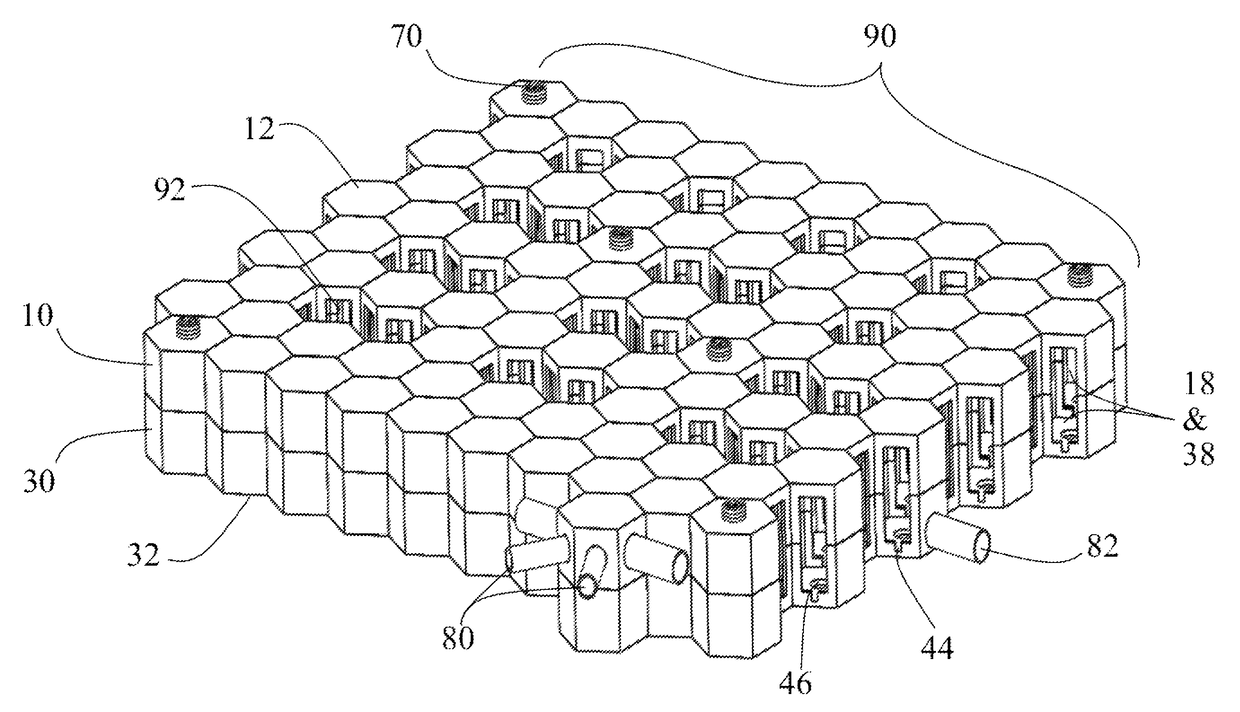

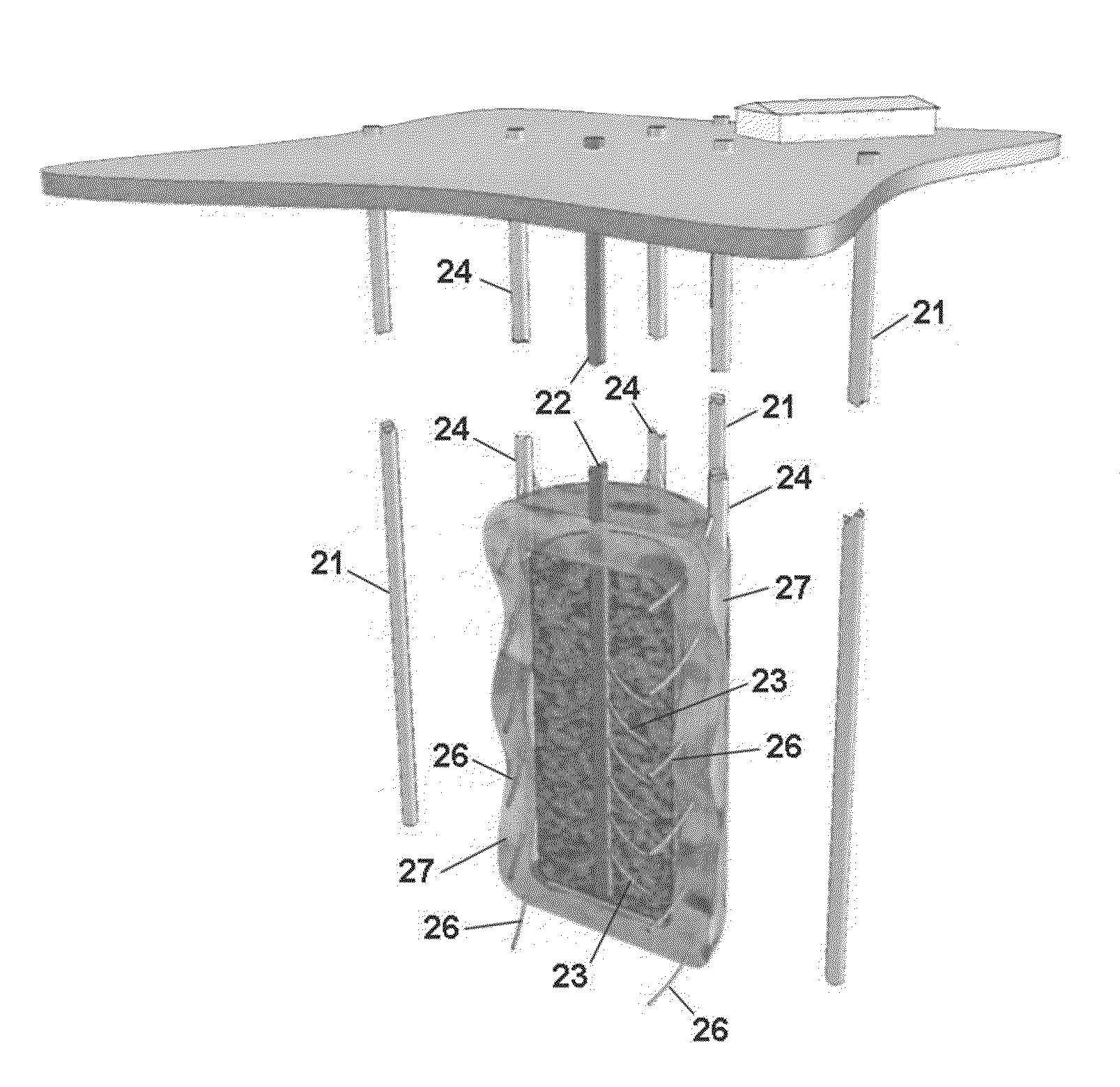

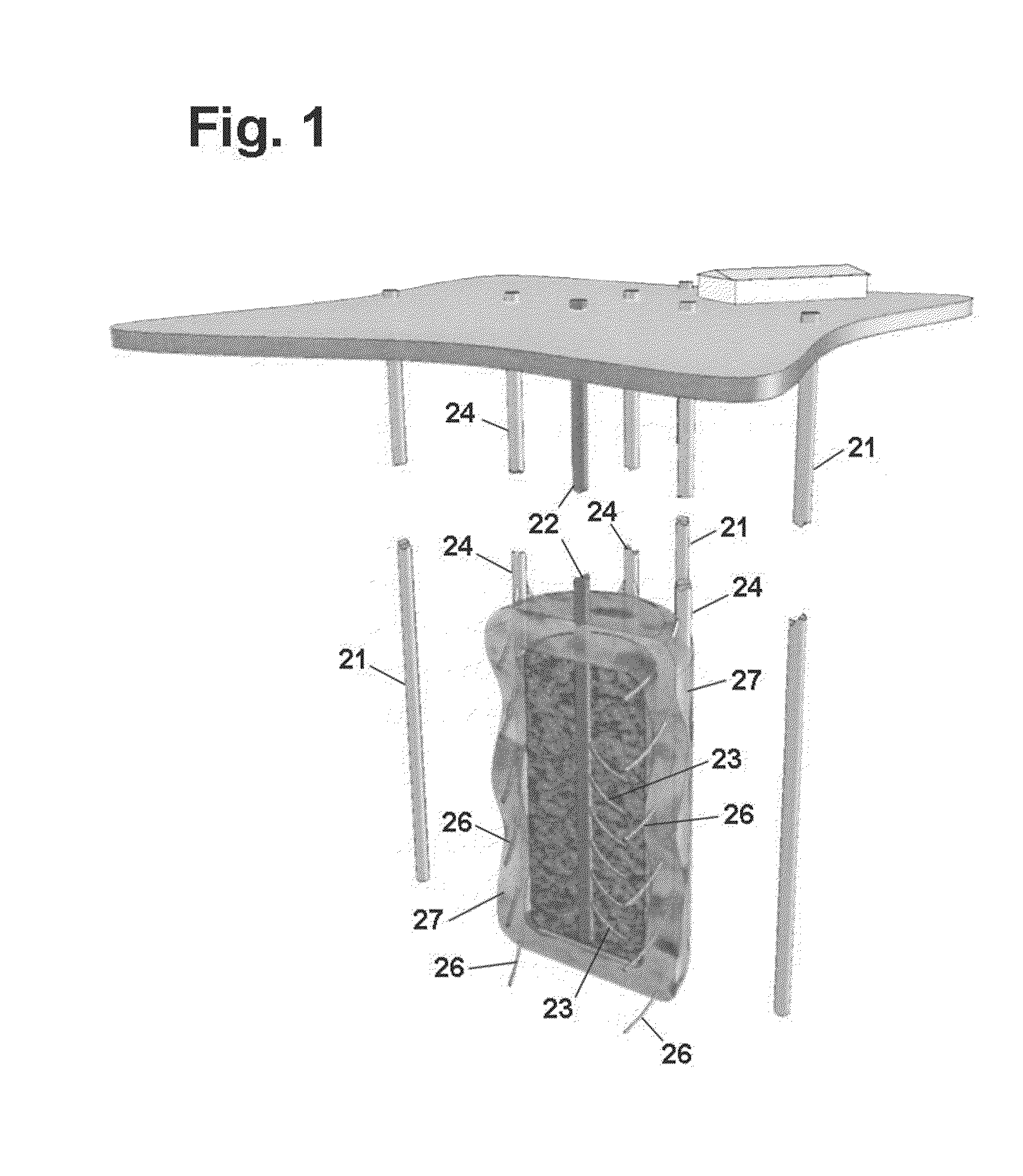

Hexagonal module and assembly for storage of water underground

ActiveUS9732508B1Avoid smallEnsure efficient flowSoil drainageStorage devicesHoneycombComputer module

Individual hexagonal shaped modules used in an assembly for underground storage of storm water and other fluid storage needs. Modules are assembled into a resultant honeycomb shape for maximized structural strength and material use efficiency. Adjacent modules are in direct fluid communications with one another via openings or windows in module side walls. Assemblies include various top and side pieces along with access ports for entry into said assembly.

Owner:BIO CLEAN ENVIRONMENTAL SERVICES

Engineered, Scalable Underground Storage System and Method

InactiveUS20100098492A1Improve reliabilityMaximize reservoir capacityMining devicesFluid removalPorosityGeomorphology

An engineered, scalable underground containment system and method for storing compressed gases or liquids in permeable rock formations using conventional drilling techniques. The porosity and permeability of the formation may be enhanced to maximize reservoir capacity and increase the rate at which gases and liquids can be introduced into and removed from the reservoir. In some embodiments, layers of cap rock in the formation are utilized as containment barriers, and in some, containment barriers are constructed around the storage zones.

Owner:SEQENERGY

Method for fix carbon underground using biomass

The invention discloses a method for underground carbon storage by making use of biomass, which is characterized in that the biomass is dried in advance before being buried underground. The invention is that carbon dioxide is buried underground in a form biomass, and compression and anti-erosion treatments are continuously carried out on the biomass during the process to avoid the carbon dioxide being released caused by erosion. Obviously, the treatment method can suppress the discharge of carbon oxide on the earth from root, and save storage volume, relieve threaten to the crust and underground water by being compared with the existing liquid underground storage method of carbon oxide. The method of the invention is comparatively safe, with simple process and easy to perform, which is suitable for being prompted widely in environment-friendly enterprises.

Owner:许晓春

Underground cavern group layout method

ActiveCN103291331AReduce deformation and damageReduce the cost of reinforcement supportUnderground chambersUnderground cavernTransformer

The invention discloses a large-scale underground cavern group layout method applied to water conservancy and hydropower engineering and underground storage cavern engineering. The underground cavern group layout method can give overall consideration to major factors having influences on underground cavern adjoining rock stability, particularly gives overall consideration to the crucial factor of the rock strength-stress ratio, enables a large-scale underground cavern group layout designing scheme to be scientific, and is overall in considered factors. The method includes the following steps: firstly, determining the positions of main caverns, then determining the axis directions of the main caverns, determining the thickness of a rock pillar between the main caverns, and finally determining cavern shapes of the main caverns. When the cavern shapes of the main caverns are determined, each main cavern is divided into an underground main power house, a main transformer chamber and a tail water surge chamber according to functions, the hole shape of each underground main power house and the hole shape of each main transformer chamber are in circular arch straight wall shapes or egg shapes, and each tail water surge chamber is in a cylinder shape or a gallery shape.

Owner:POWERCHINA CHENGDU ENG

Transverse tunnel cover method for shallow-buried underground excavation large underground space construction

ActiveCN104863597AReduce spanMany working surfacesUnderground chambersTunnel liningSpatial structureGround settlement

The invention discloses a transverse tunnel cover method for shallow-buried underground excavation large underground space construction. Foundation pits or pilot tunnels are formed, in the longitudinal direction of underground space, of the tops of side walls of the underground space to be constructed, temporary transverse stress structures are formed inside the foundation pits or the pilot tunnels at a time and located above a top plate of the underground space to be constructed and are controllable in rigidity, the temporary transverse stress structures are connected with piles inside the foundation pits or the pilot tunnels to form a temporary transverse top cover-pile bearing system, and under protection of the transverse top cover-pile bearing system, a single-span or multi-span and a single-layer or multi-layer underground space structure can be constructed in a sequential construction mode or in an inverse construction mode. In shallow-buried underground excavation large underground space structure construction, ground settlement is effectively controlled, constructed building deformation is reduced, the construction risks are reduced, the construction period is shortened, and the construction cost is lowered.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST +1

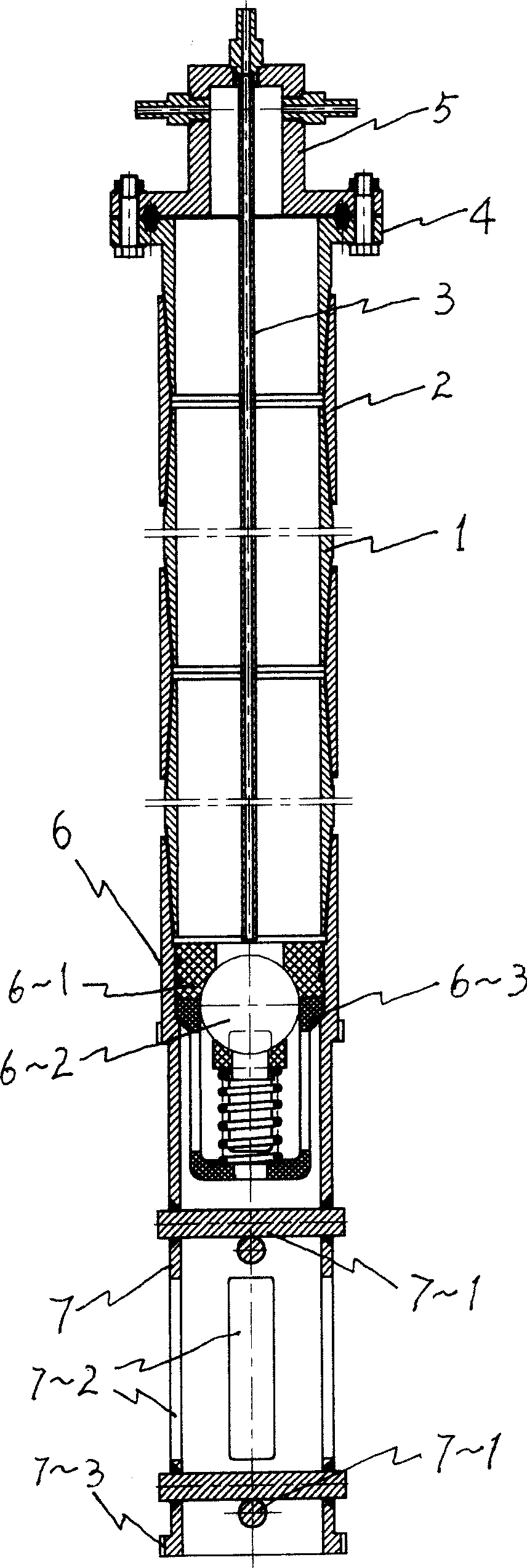

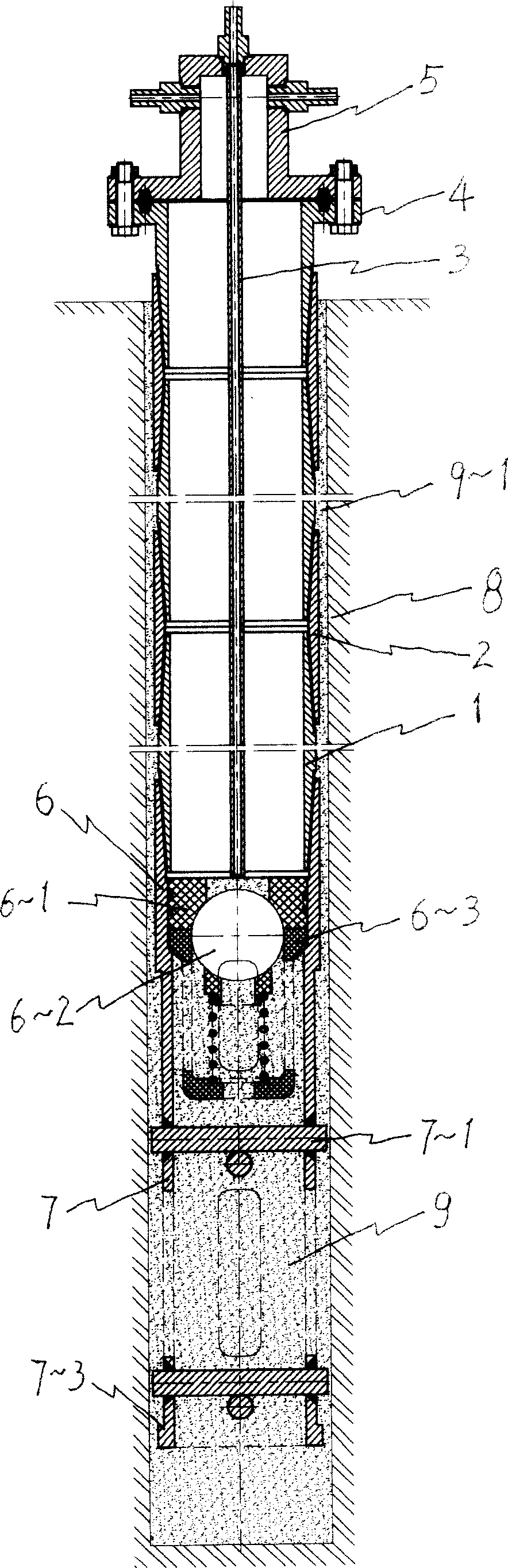

Underground gas storage well shaft and its fixing method

InactiveCN1952466AReasonable structural designEasy grouting and fixingContainer filling methodsPressure vesselsCement slurryHigh pressure

The invention relates to a mine shaft of high-pressure gas underground storage well and the fixed method. The mine shaft comprises shaft body, connecting sleeve, four-way control head, one-way sealing head and foundation fixed bracket on the bottom, and drainage pipe. The fixed method comprises drilling base well, setting shaft body, producing cement slurry, cement slurry perfusion along inner cavity of mine shaft and one-way valve, installing drainage pipe and four-way control head. Because of one-way valve applied as bottom sealing head of mine shaft, base fixed bracket added, and cement slurry perfusion improved, it is provided with reasonable structure design, convenient and stable operation for perfusion, fixed connection between the mine shaft and well wall, good safety, convenient repair and maintenance, and longer service life so on. Inconvenient assembling and fixing well shaft, small attachment force with cement, bad stability of perfusion fixing technology, uneasy operation, mine shaft rotating or moving in working and bad safety are conquered.

Owner:自贡力源科技有限公司

Layout design method of underground cavern group

ActiveCN103266902AReduce damage and deformationReduce the cost of reinforcement supportUnderground chambersDesign planUnderground cavern

The invention discloses a layout design method of an underground cavern group applied to a water conservancy and hydropower project and an underground storage. According to the layout method, main factors influencing the stability of surrounding rock of the underground caverns, especially, the rock strength stress ratio which is the essential factor can be fully taken into consideration. The method comprises the following steps of: firstly determining the positions of main caverns, determining the axial line directions of the main caverns, determining the thicknesses of rock pillars among the main caverns, and finally determining the shapes of the main caverns, wherein in the process of determining the thicknesses of the rock pillars among the main caverns, the thicknesses of the rock pillars are 1.0-2.5-time mean than excavation span between two adjacent main caverns and are 0.5-0.8 times that of the height of the big one in the adjacent two main caverns. Compared with the layout design with a design plan provided by a using traditional layout method, the layout design with the layout method disclosed by the invention is more scientific; and especially, in a highland stress environment and in a condition with relatively low surrounding rock strength, the phenomena of the deformation and destruction of the surrounding rock after the surrounding rock of the underground cavern group is excavation-unloaded can be greatly reduced or the deformation and destruction degrees of the surrounding rock can be reduced.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

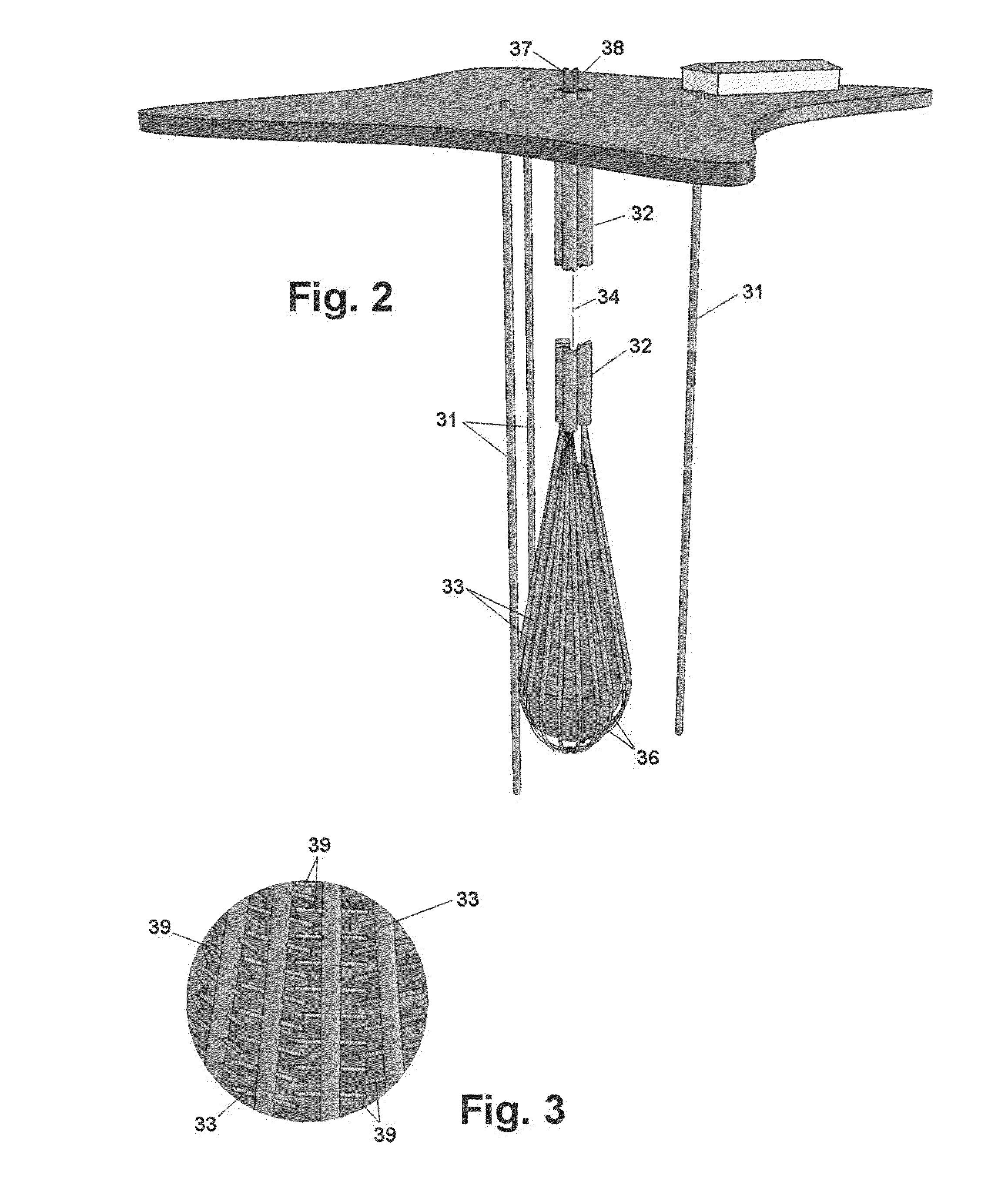

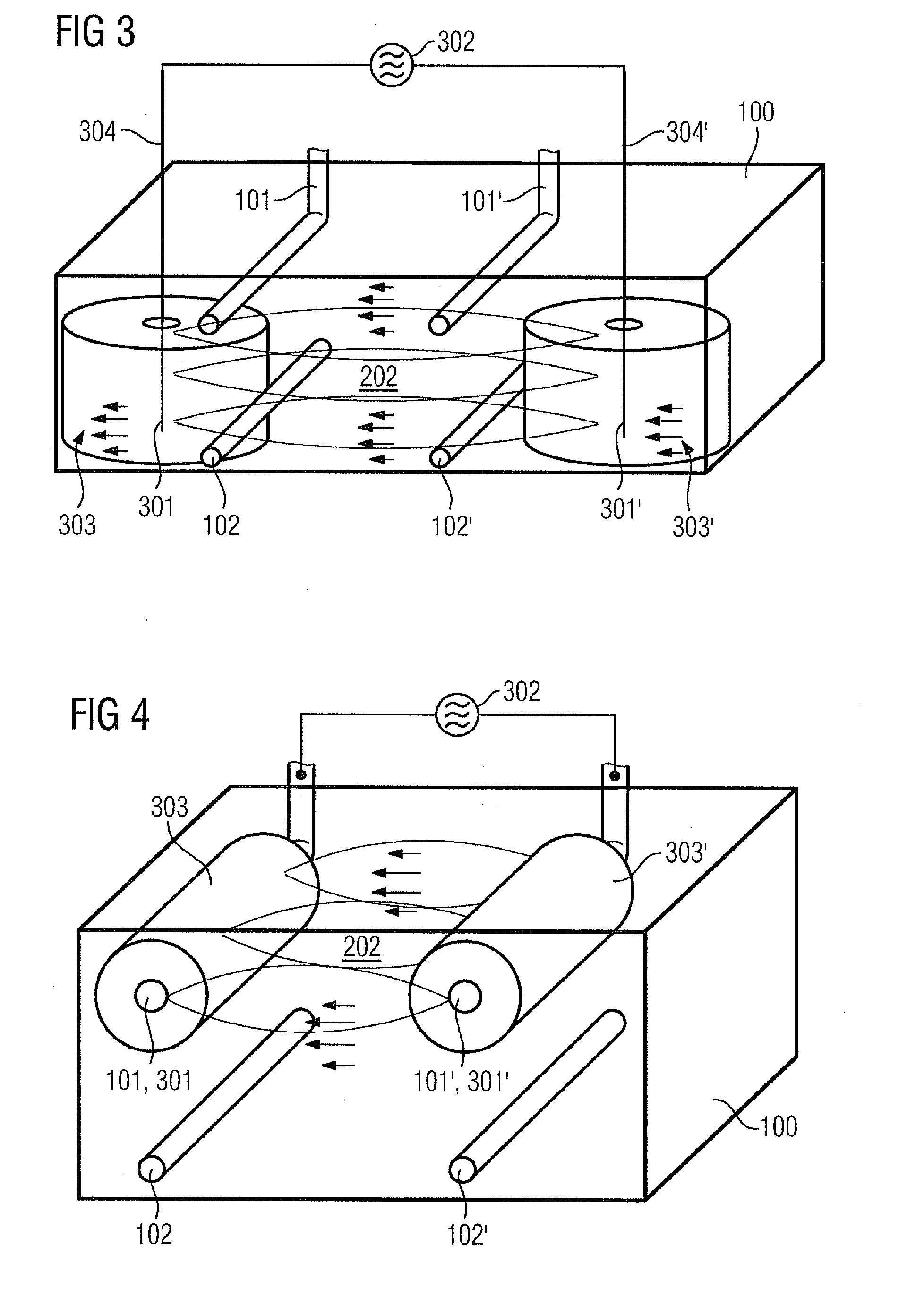

Device for in situ extraction of a substance comprising hydrocarbons

InactiveUS20100252249A1Improve electrical reliabilityGuaranteed uptimeInsulationFluid removalElectrical resistance and conductanceViscosity

A device for in situ extraction of a substance including hydrocarbons while reducing the viscosity thereof from an underground storage site is provided. The device includes at least one production pipeline leading out of the storage site, and at least two electrodes which are inductively and resistively effective relative to at least parts of the storage site.

Owner:SIEMENS AG

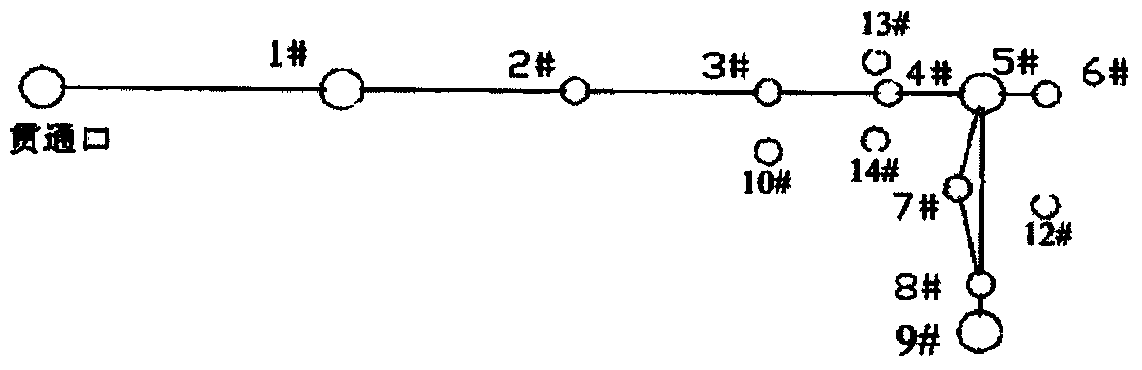

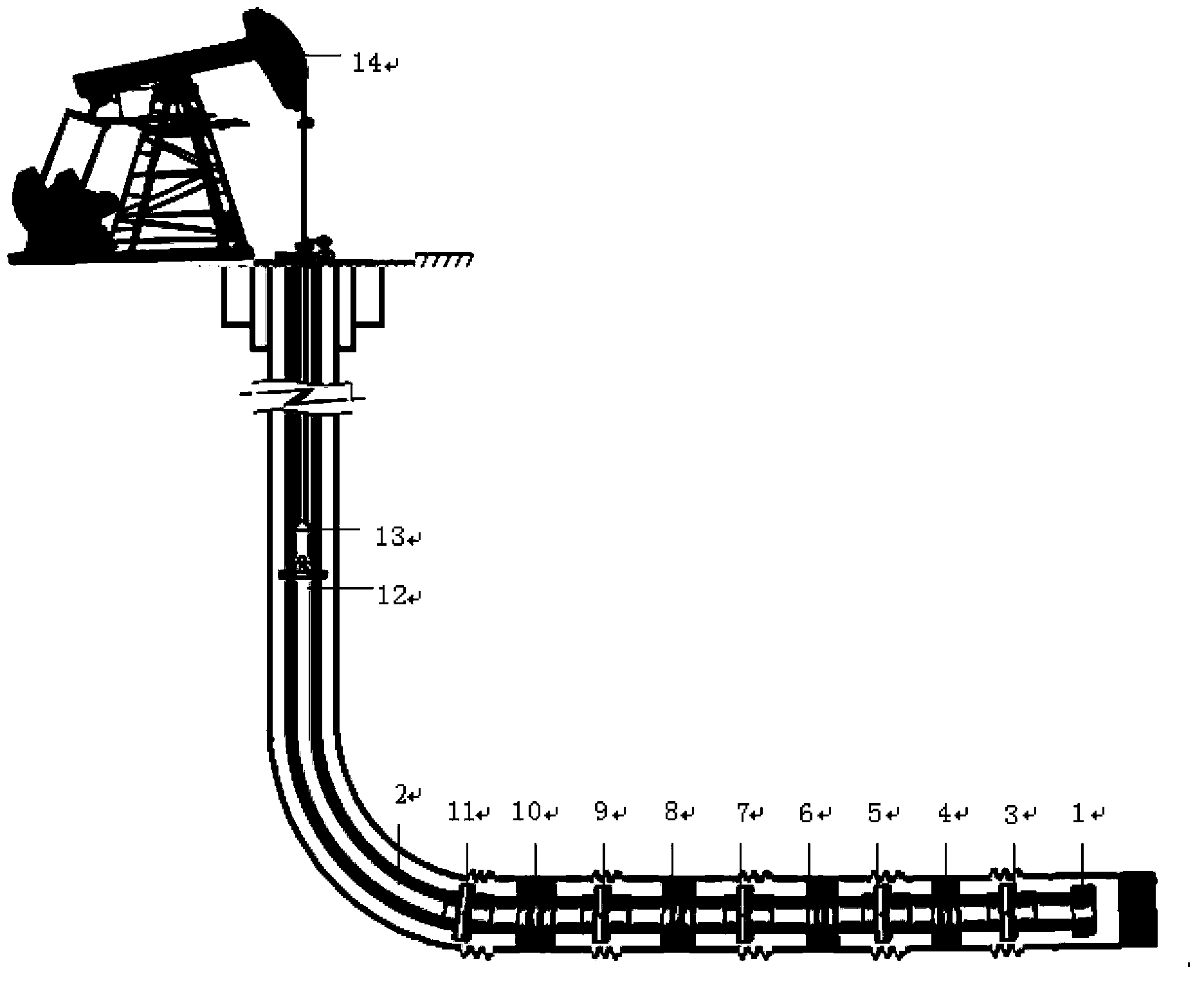

Sectional synchronous flow rate and water content monitoring and water exploration tubular column of multi-section fracturing horizontal well and working method thereof

InactiveCN104100254AShorten the water search cycleImprove water search efficiencySurveyWater dischargeOil production

The invention discloses a sectional synchronous flow rate and water content monitoring and water exploration tubular column of a multi-section fracturing horizontal well and a working method thereof, and the tubular column is designed for realizing synchronous monitoring and water exploration for all intervals of the horizontal well through one trip of the tubular column. The tubular column is arranged between a screwed plug and an oil well pump, multiple stages of connecting units consisting of underground storage flow rate and water content monitors and packers are connected through oil pipes, and each stage of connecting unit corresponds to one interval respectively; the upper end of the underground storage flow rate and water content monitor at the top stage is connected with the oil well pump through an oil pipe, the oil pipe is connected to a wellhead, and the oil well pump is connected to a ground pumping unit through a sucker rod. The tubular column adopts the underground storage flow rate and water content monitors, so that synchronous flow rate and water content monitoring and water exploration for multiple intervals through one trip of the tubular column can be realized, the original manner that production and water exploration for each interval are separated is converted into the manner of synchronous production and water exploration, the water exploration period can be significantly shortened, the water discharge interval and the water discharge rate can be determined, the water exploration efficiency is improved, and a reliable basis can be provided for water control and oil production enhancement measures for the horizontal well.

Owner:PETROCHINA CO LTD

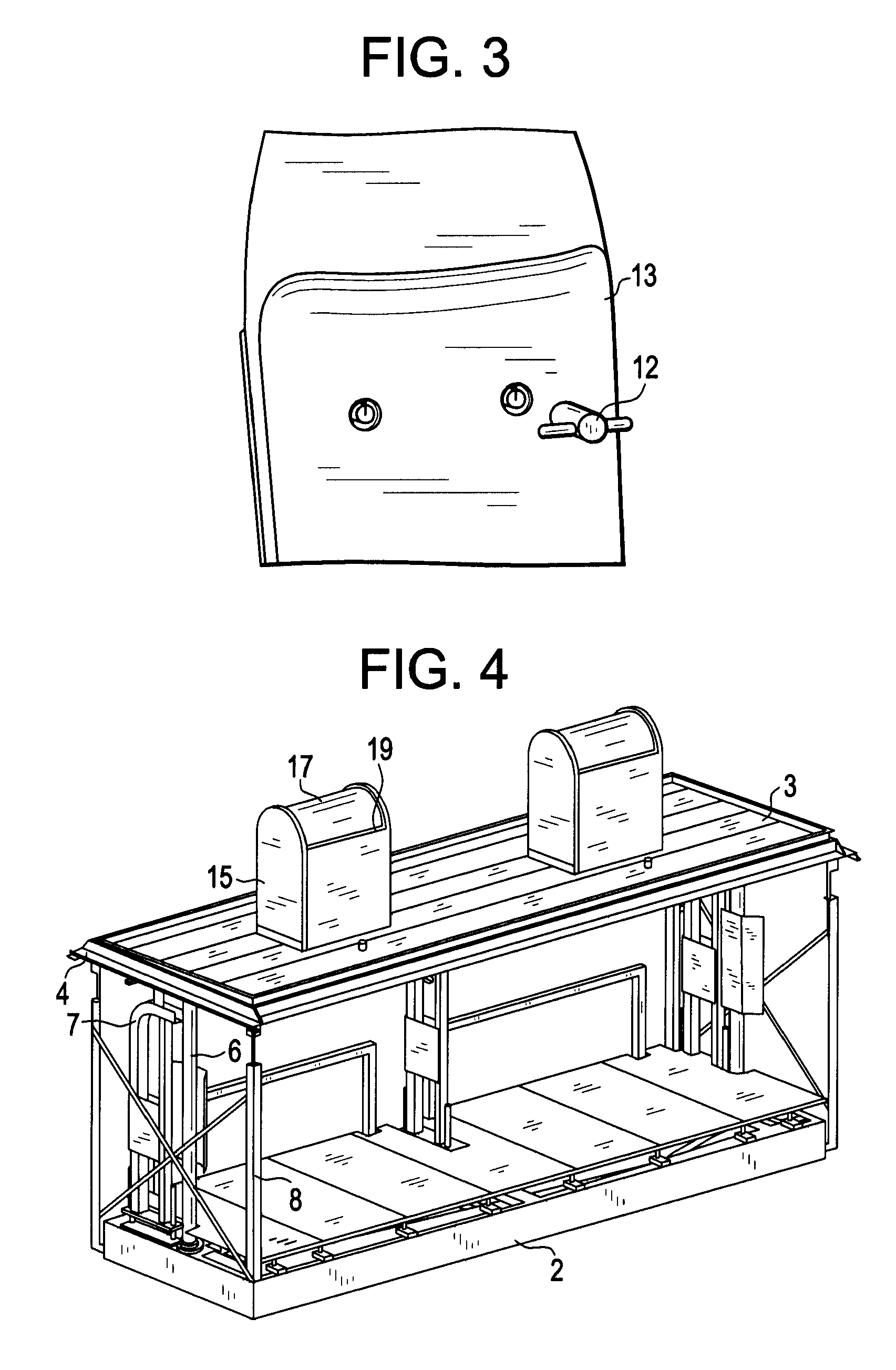

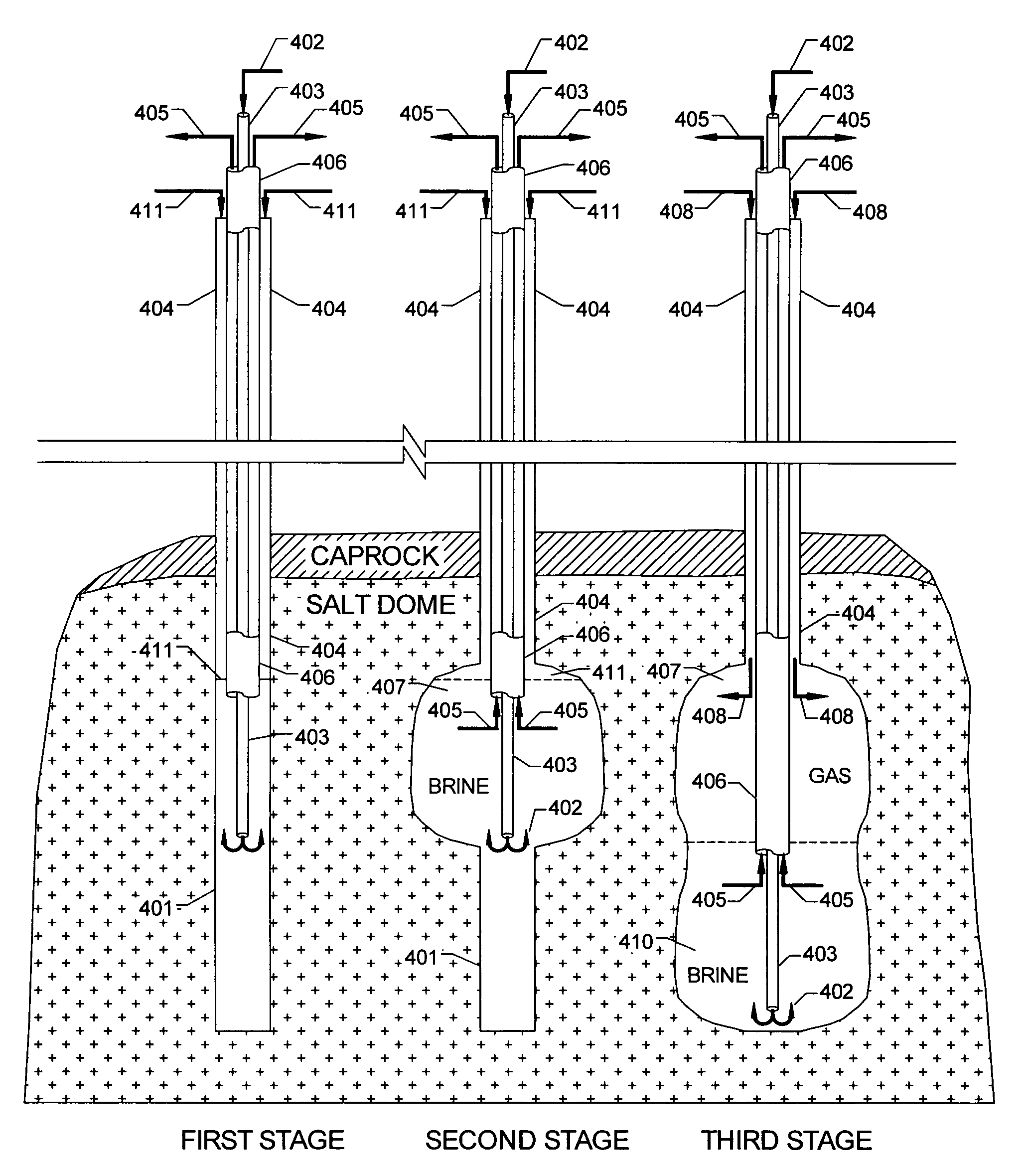

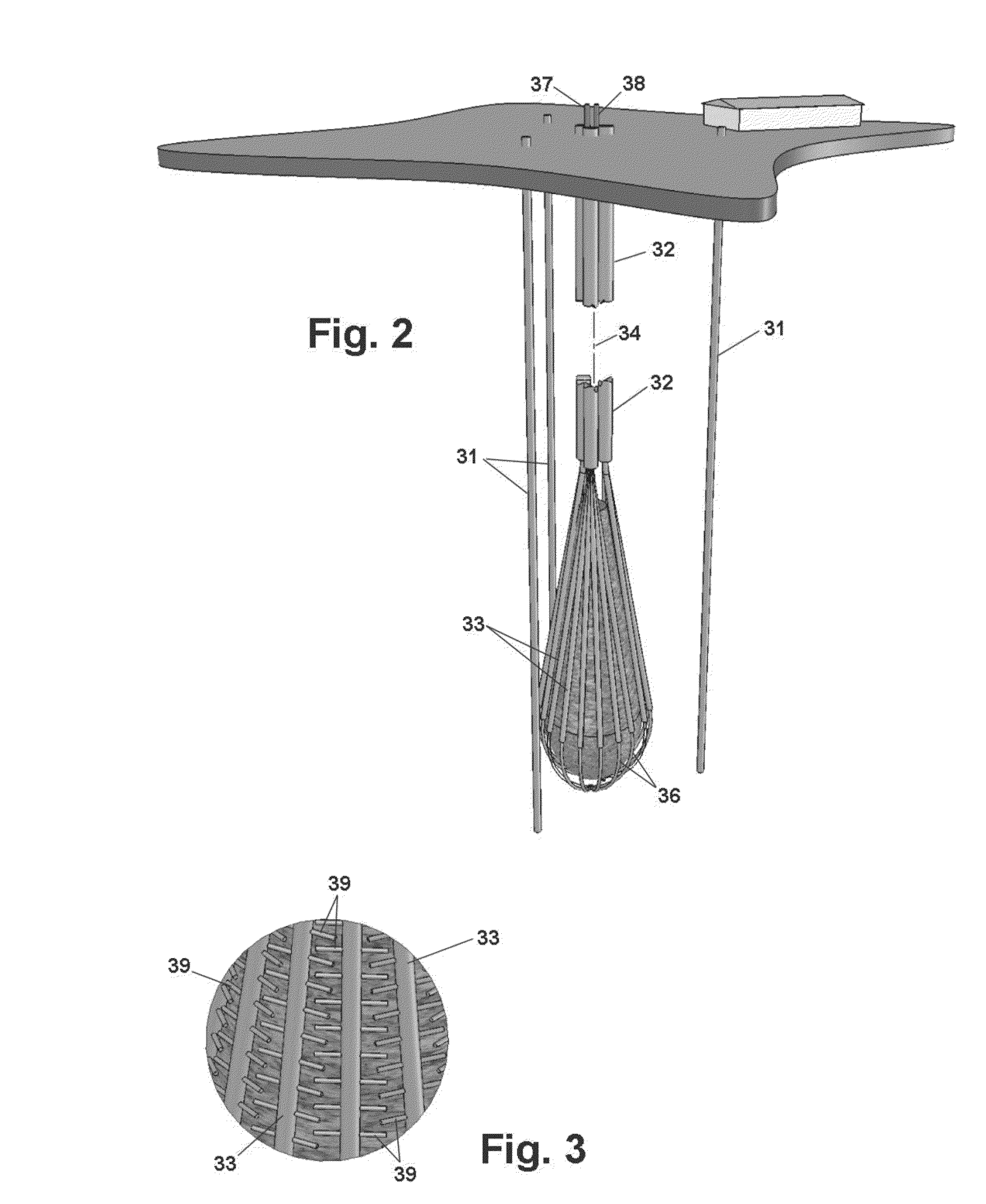

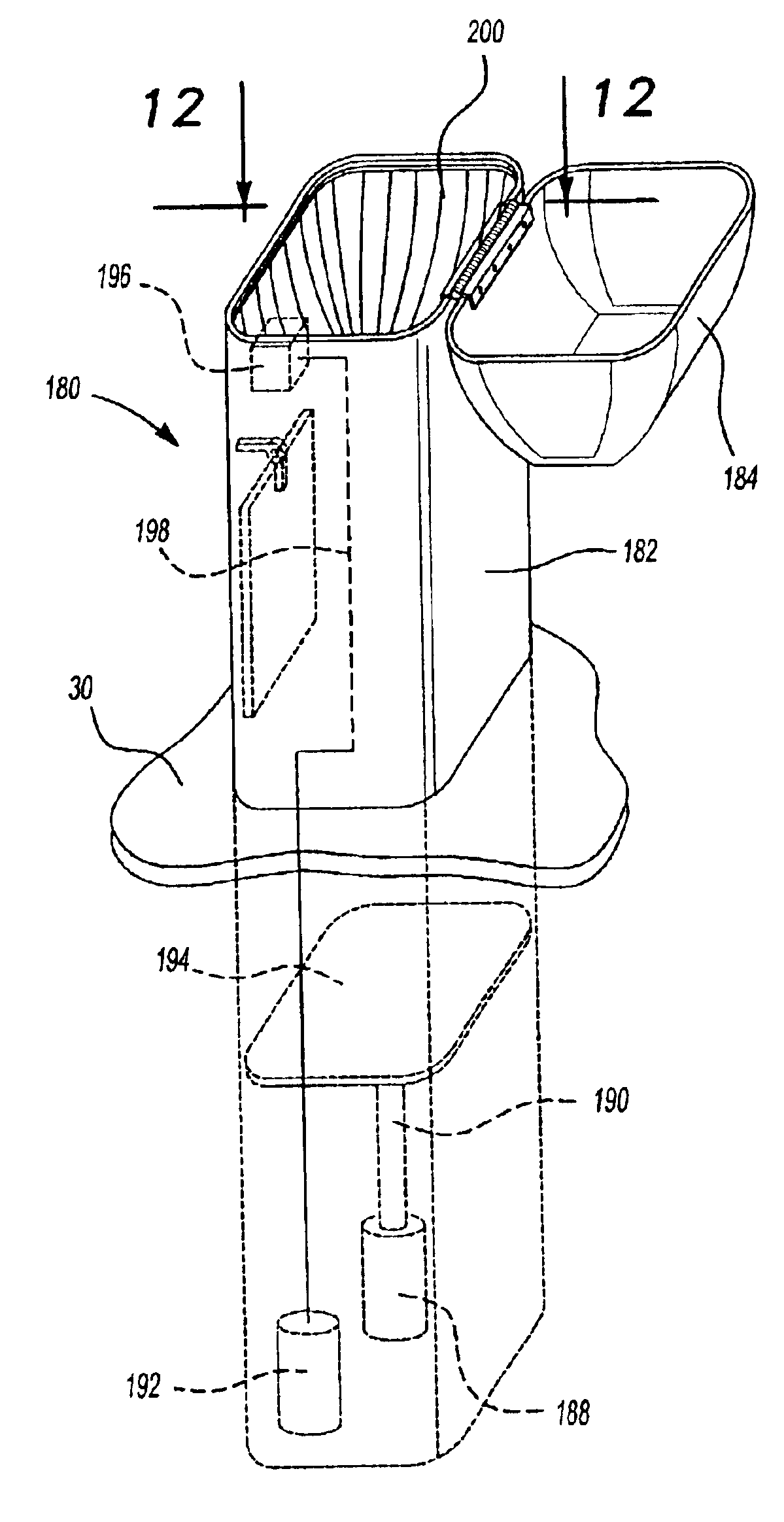

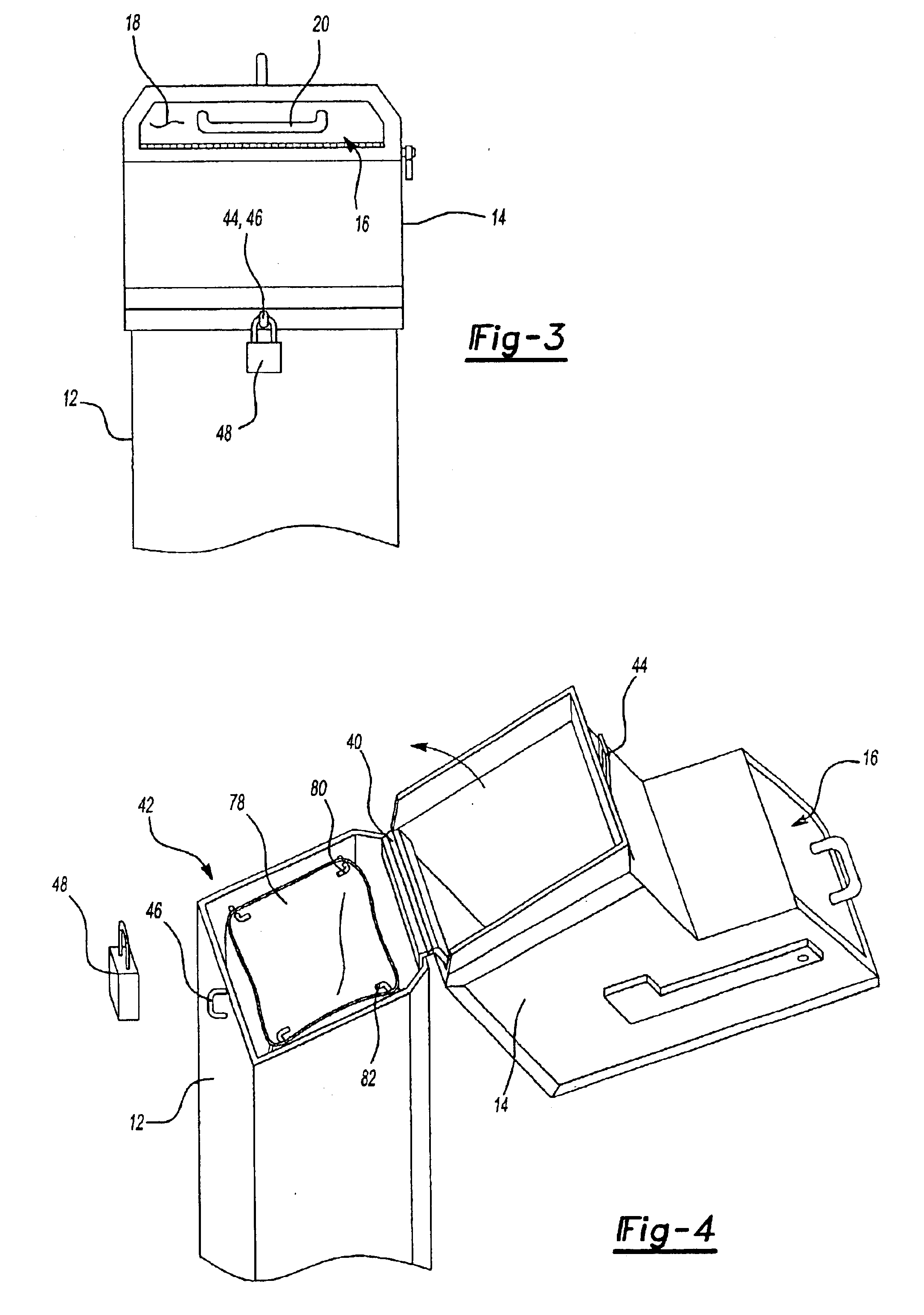

Theft preventative mailbox with underground storage capacity and mail retrieval mechanism

InactiveUS6840438B2Quick searchAvoid retrievingKitchen equipmentDomestic articlesEngineeringHolding room

A theft-preventative mailbox for holding various sizes of mail correspondence and mail parcels. The mailbox includes an elongate and internally hollowed body with a mail correspondence insertion slot at a generally upper end location. The body further includes a mail storage compartment, and the body is further fixedly anchored at a ground location so that at least a portion of the mail storage compartment extends below a surface of the ground location. An access door is defined within the body and permits the depositing of mail parcels into the storage compartment. A constriction skirt is secured to the interior of the mailbox body and includes a plurality of inwardly directed and pointed spear portions for permitting one-way depositing of mail correspondence and mail parcels. A mail retrieval mechanism acts in concert with the parcel access door to permit the retrieval of the mail correspondence and mail parcels deposited within the storage compartment.

Owner:HASSAN SHAWKY

Large-scale underground cavern group arrangement design method

ActiveCN103291316AReduce deformation and damageReduce the cost of reinforcement supportTunnelsUnderground cavernPrincipal stress

The invention discloses a large-scale underground cavern group arrangement design method applied to hydraulic and hydroelectric engineering and underground storage cavern engineering. According to the arrangement design method, principal factors, especially the essential factor of the rock strength-stress ratio, influencing underground cavern surrounding rock stability can be comprehensively taken into account, the designing scheme for large-scale underground cavern group arrangement can be more scientific, and considered factors are more comprehensive. The position of a main cave is determined at first, the orientation of an axis of the main cave is determined, then the thickness of a rock pillar in the main cave is determined, and at last the shape of the main cave is determined. When the orientation of the axis of the main cave is determined, the trend of a rock mass main structural surface on a construction site and the orientation of the maximum principal stress are measured at first, the orientation of the axis of the main cave is determined according to an included angle between the axis of the main cave and the trend of the rock mass main structural surface and an included angle between the axis of the main cave and the orientation of the maximum principal stress, the included angle between the axis of the main cave and the trend of the rock mass main structural surface is not less than 40 degrees, and the included angle between the axis of the main cave and the orientation of the maximum principal stress is 0-40 degrees.

Owner:POWERCHINA CHENGDU ENG

Large-sized underground cavern group arrangement designing method

ActiveCN104005777AEasy to operateHigh degree of quantificationUnderground chambersUnderground cavernStress ratio

The invention relates to the underground cavern designing method and discloses a large-sized underground cavern group arrangement designing method which is applied to water resources and hydropower engineering and underground storage cavern engineering to scientifically and reasonably confirm positions of the underground cavern group. According to the large-sized underground cavern group arrangement designing method, the rock strength stress ratio, site area crustal stress field characters, the cavern group effect, the main cavern size and the like key factors which influence arrangement of the underground cavern group are considered comprehensively according to the basis that the main cavern group longitudinal axis direction, the main cavern shape and size and the cavern distance are confirmed and the main cavern group valley wall slope rock mass thickness and the overlaying rock mass thickness are further confirmed. The valley slope crustal stress character quantitative analysis method, the valley slope side rock mass thickness computational formula and the cavern group overlaying rock mass thickness confirming method are scientific and reasonable, high in quantization degree, strong in operability, convenient for designer application and applicable to large-sized underground cavern group arrangement and design under various crustal stress levels and complete geological conditions.

Owner:POWERCHINA CHENGDU ENG

Large-scale underground cavern group arrangement method

ActiveCN103291332AReduce deformation and damageReduce the cost of reinforcement supportUnderground chambersUnderground cavernStress ratio

The invention discloses a large-scale underground cavern group arrangement method applied to hydraulic and hydroelectric engineering and underground storage cavern engineering. According to the arrangement method, principal factors, especially the essential factor of the rock strength-stress ratio, influencing underground cavern surrounding rock stability can be comprehensively taken into account, the designing scheme for large-scale underground cavern group arrangement can be more scientific, and considered factors are more comprehensive. The position of a main cave is determined at first, the orientation of an axis of the main cave is determined, then the thickness of a rock pillar in the main cave is determined, and at last the shape of the main cave is determined. When the position of the main cave is determined, the rock strength-stress ratio on a construction site is firstly measured, and when the rock strength-stress ratio is 2.0-4.0, the thickness from the outer edge of the main cave to a rock of a valley slope surface should be larger than 400m; when the rock strength-stress ratio is 4.0-7.0, the thickness from the outer edge of the main cave to the rock of the valley slope surface is 200-400m; when the rock strength-stress ratio is larger than 7.0, the thickness from the outer edge of the main cave to a rock of the valley slope surface is 150-200m.

Owner:POWERCHINA CHENGDU ENG

Flood evacuation system for subterranean telecommunications vault

ActiveUS20050130621A1Prevent and minimize injuryLarge containersSubstation equipmentTelecommunicationsInstrumentation

An improved vault that facilitates the underground storage of electronic equipment, such as instrumentation for wireless telecommunications antenna systems. The vault preferably includes an flood evacuation system that prevents the electronic equipment from being submerged under water when the vault floods, a break-away lid to reduce or minimize injury, and a grated lid to prevent water from entering the main equipment chamber.

Owner:INTEL CORP

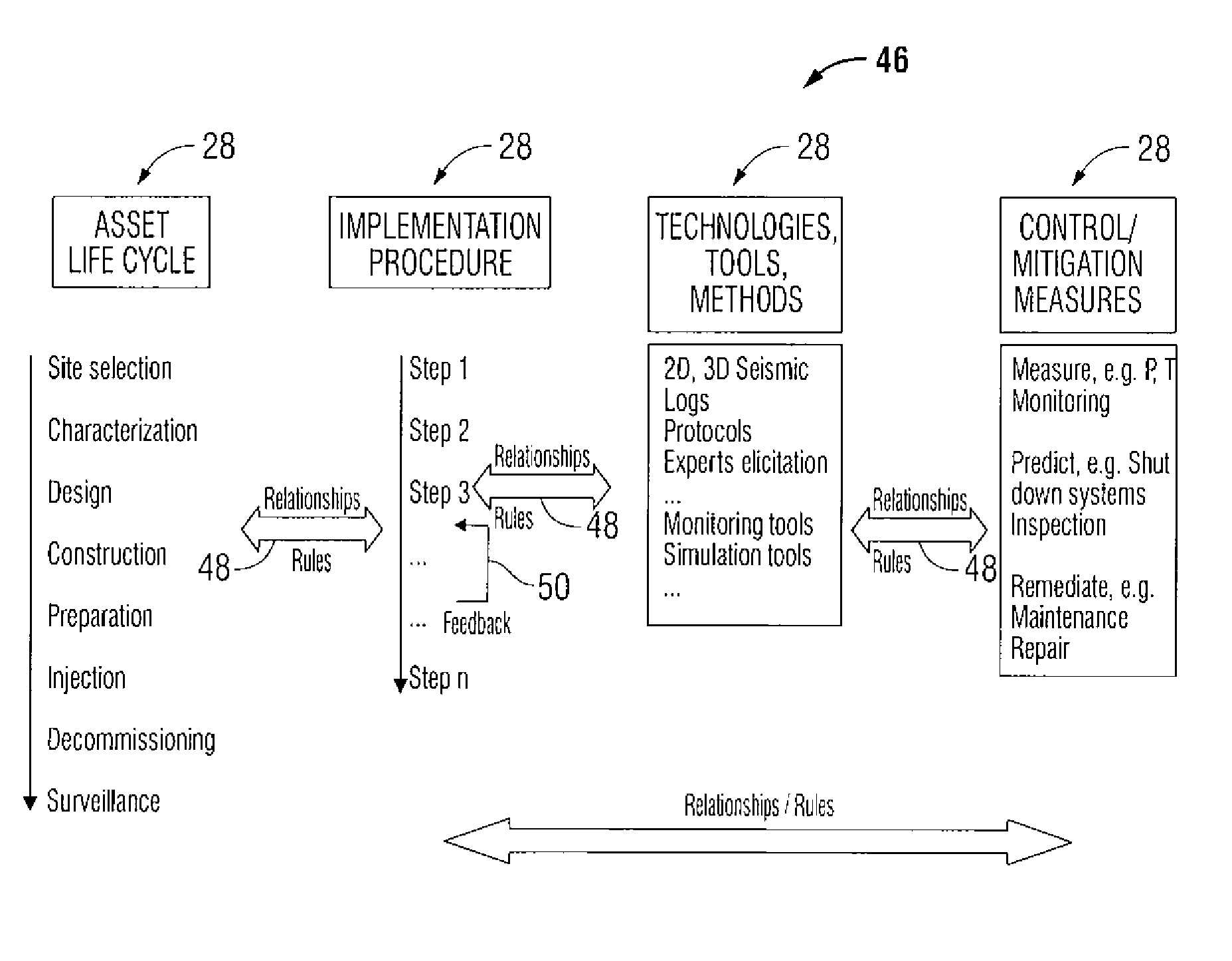

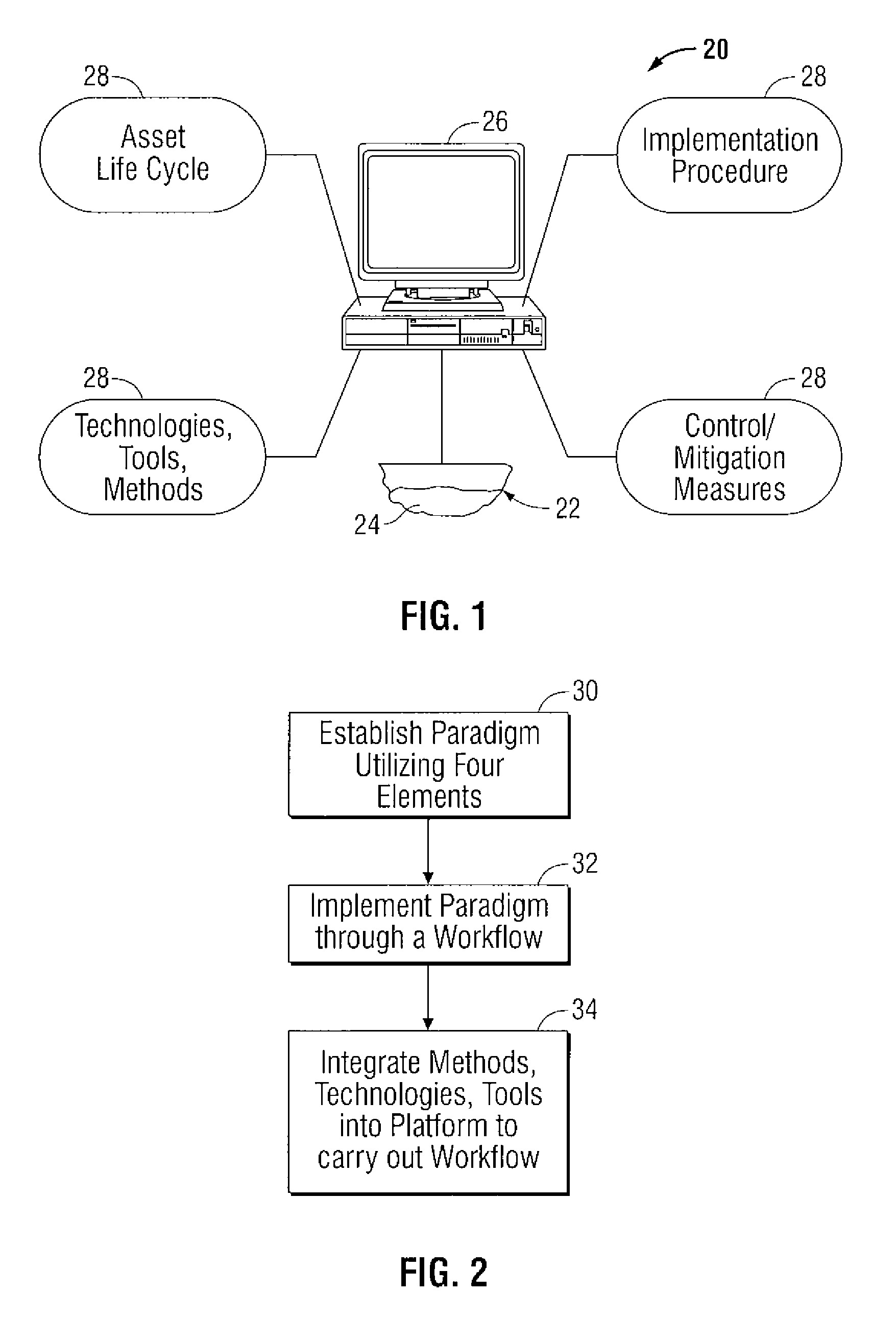

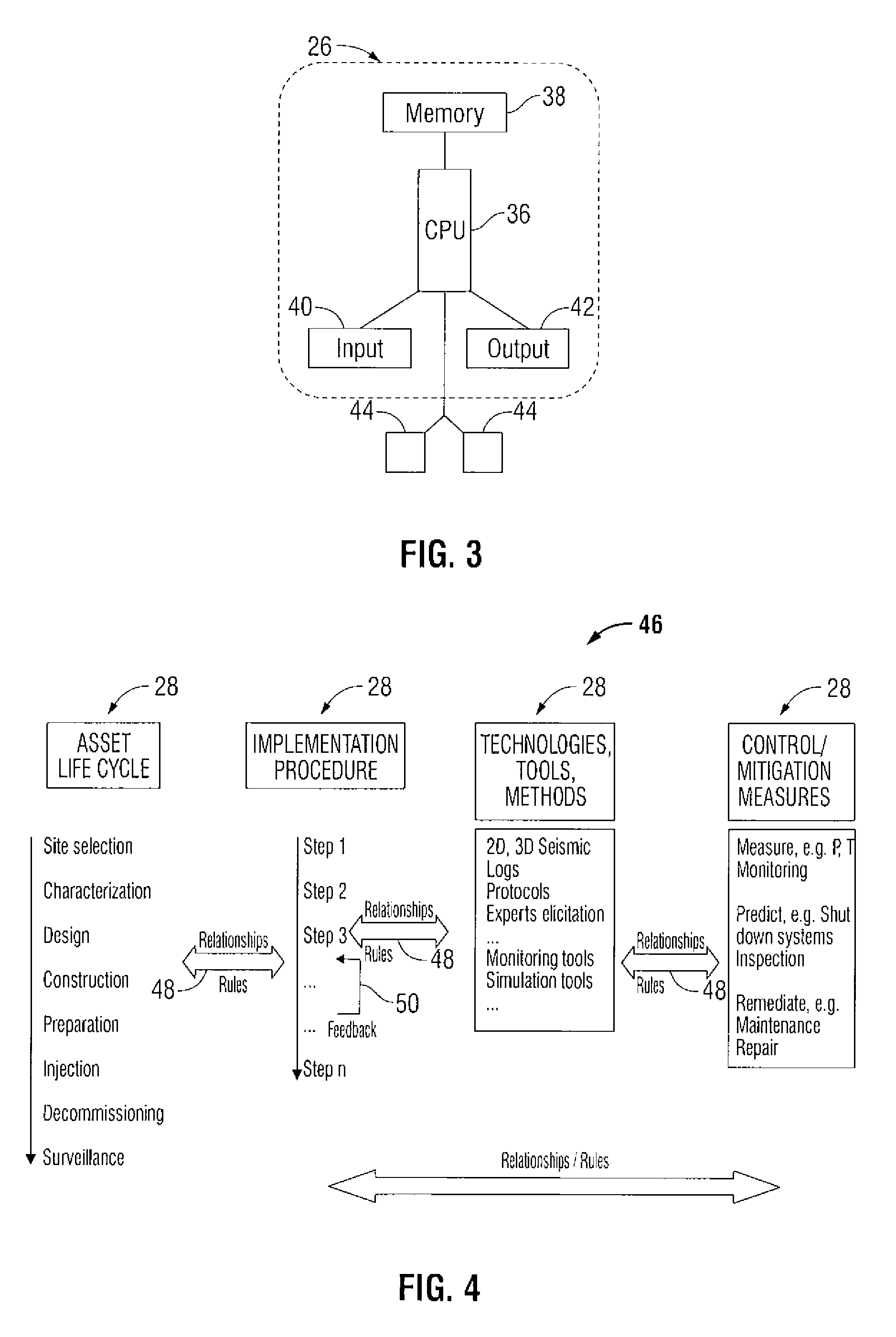

Asset integrity management system and methodology for underground storage

InactiveUS20100082375A1Carbon-dioxide storageSpecial data processing applicationsIntegrity managementManagement system

A technique facilitates asset integrity management of underground storage assets, such as underground carbon dioxide storage sites. The technique comprises establishing a paradigm for asset integrity management comprising element fields related to elements such as asset life cycle, implementation procedures, technologies, tools, and methods to obtain and evaluate data, and control / mitigation measures. Data related to the element fields is processed based on relationships established by the paradigm. Based on the analysis, information related to the integrity of the underground storage asset is output lot-use in managing the underground storage asset.

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com