Patents

Literature

460 results about "Production pipeline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

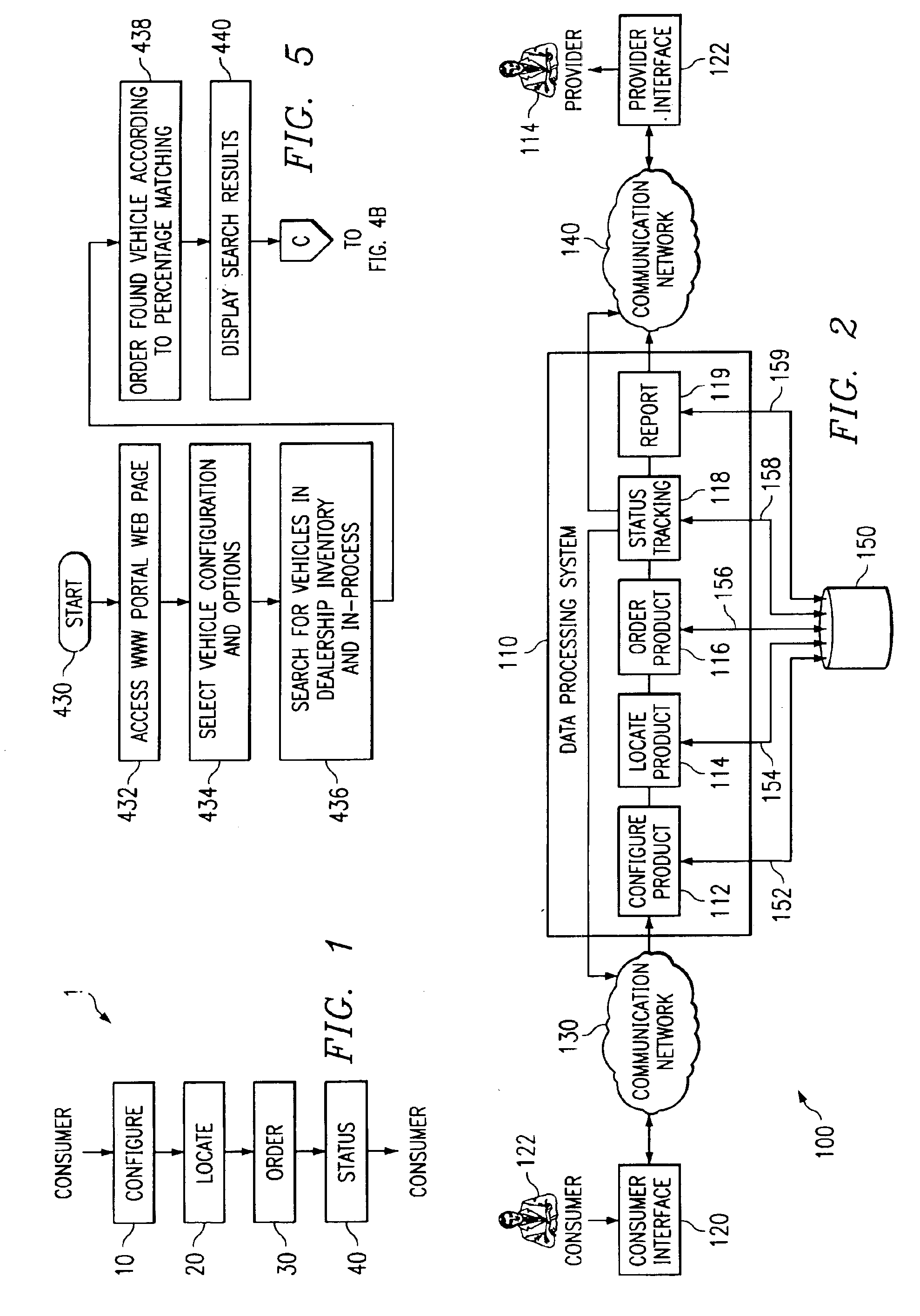

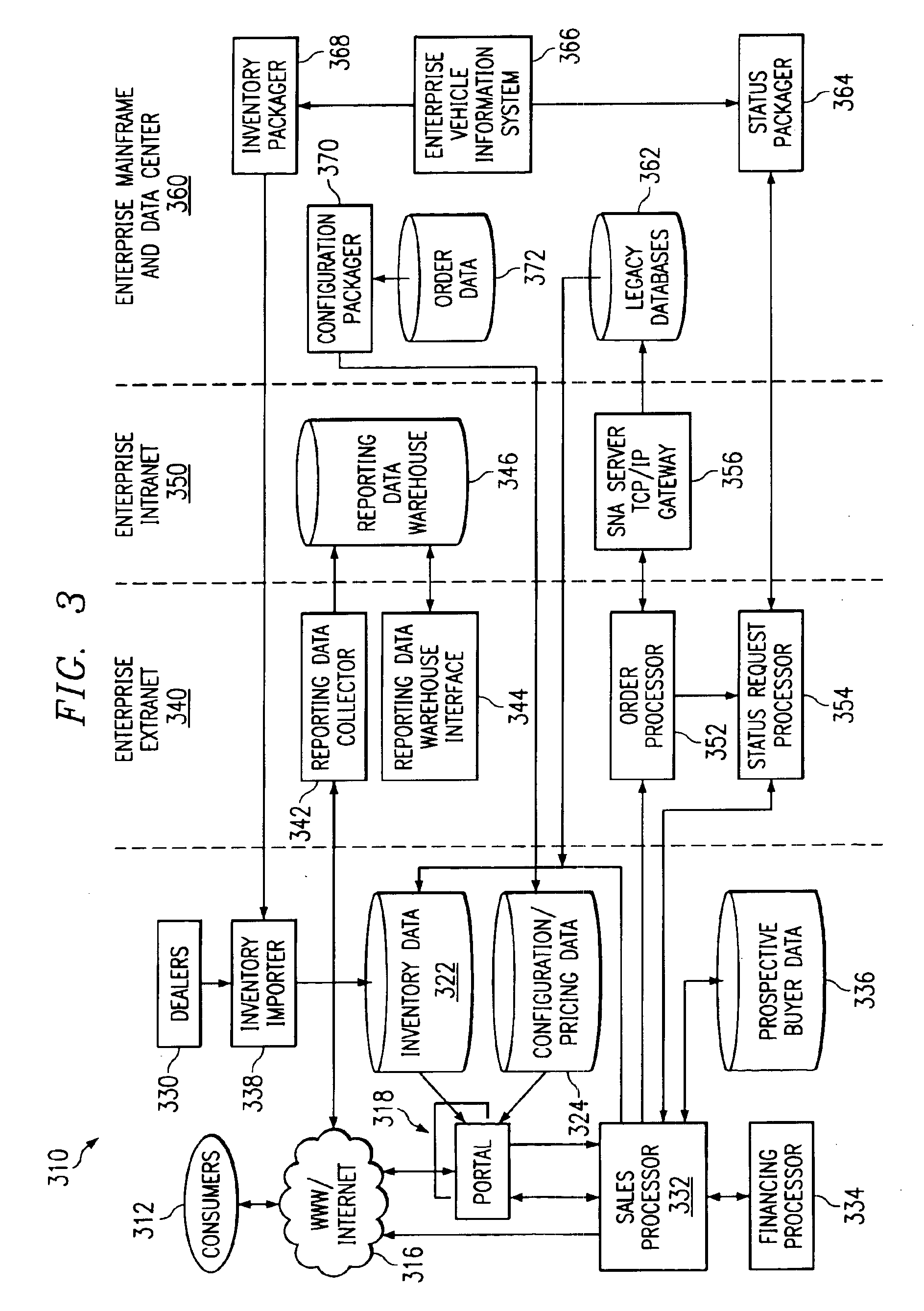

Online system and method of locating consumer product having specific configurations in the enterprise production pipeline and inventory

InactiveUS6901430B1Shorten delivery timeHand manipulated computer devicesDigital data processing detailsData matchingUser input

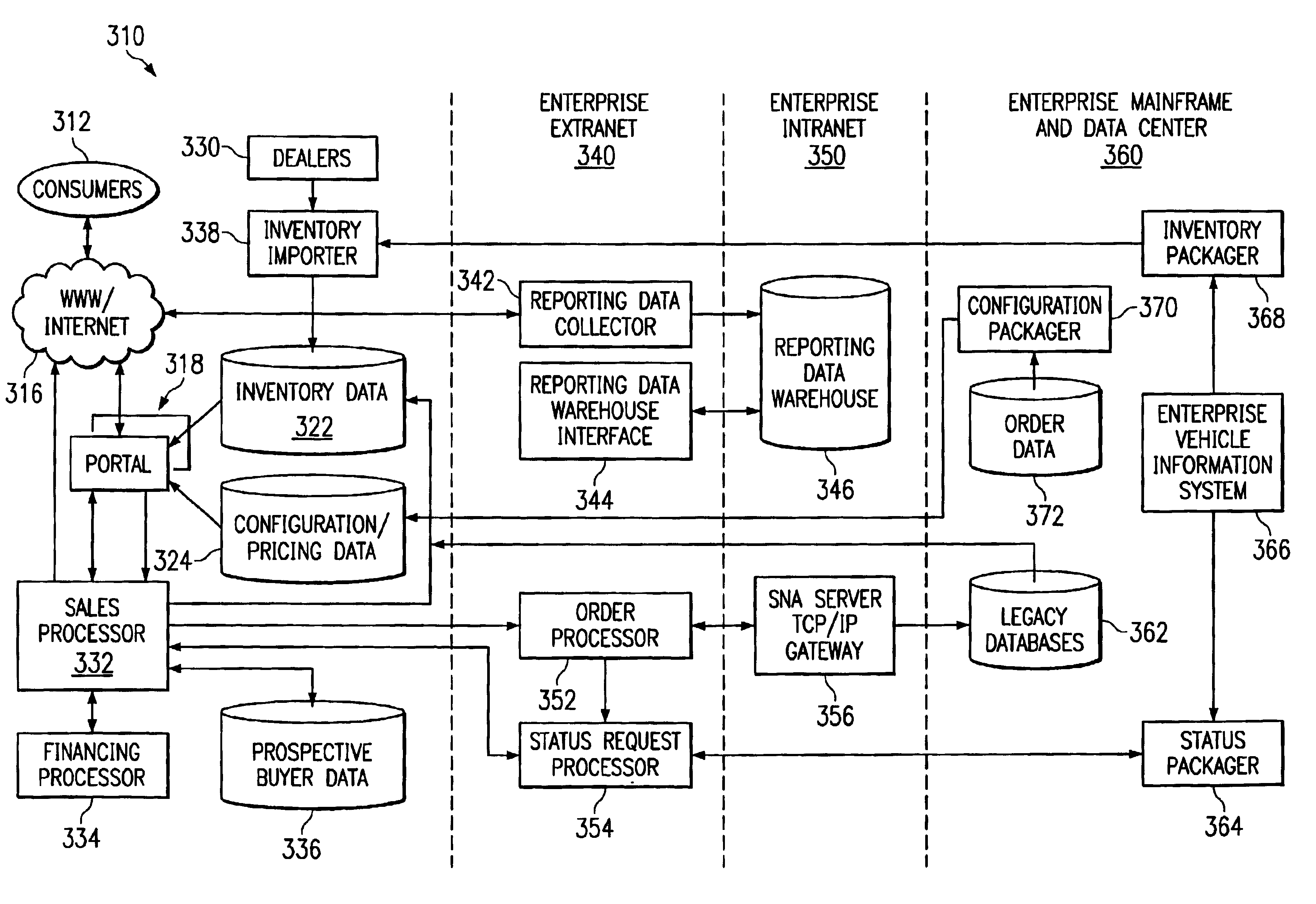

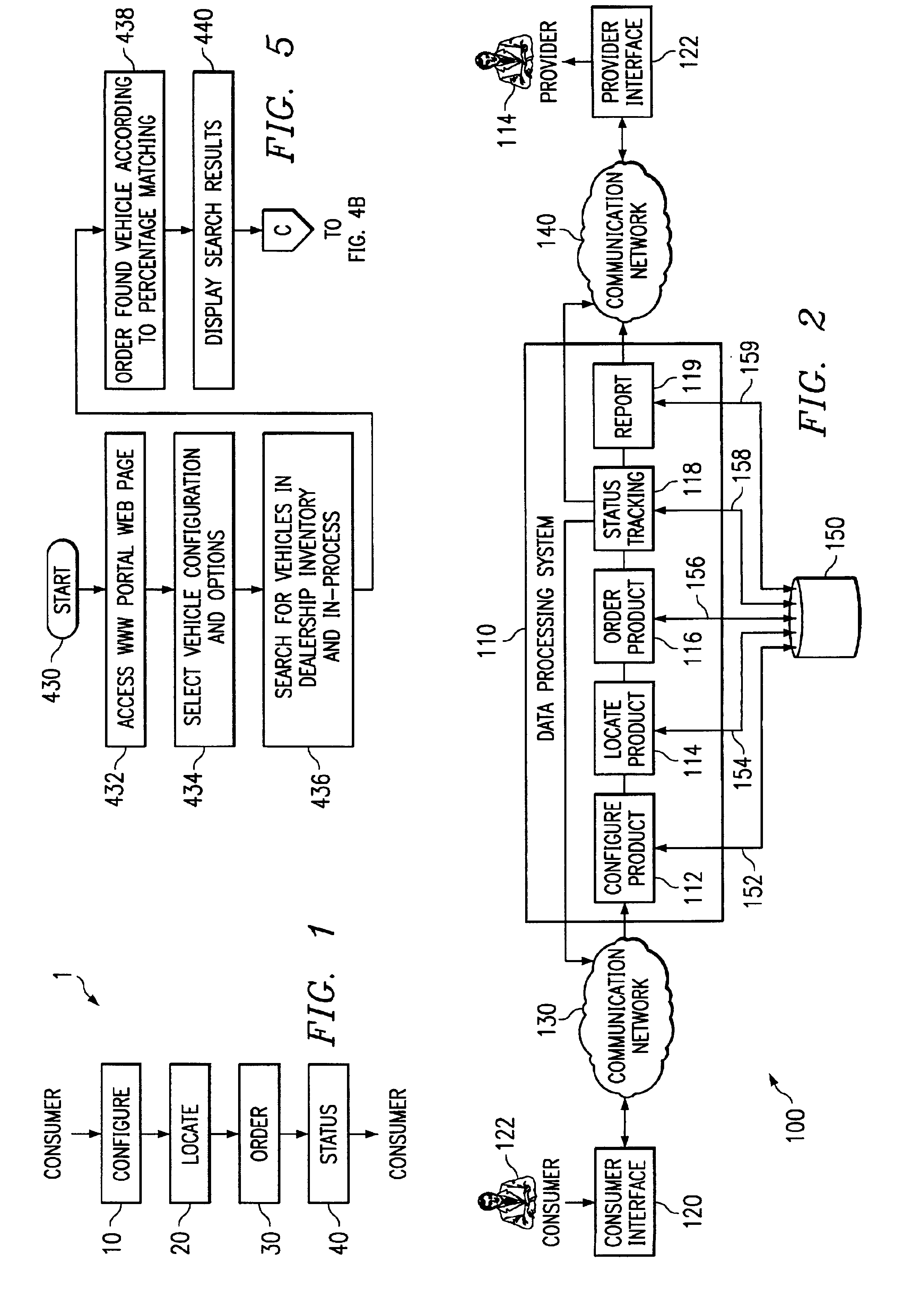

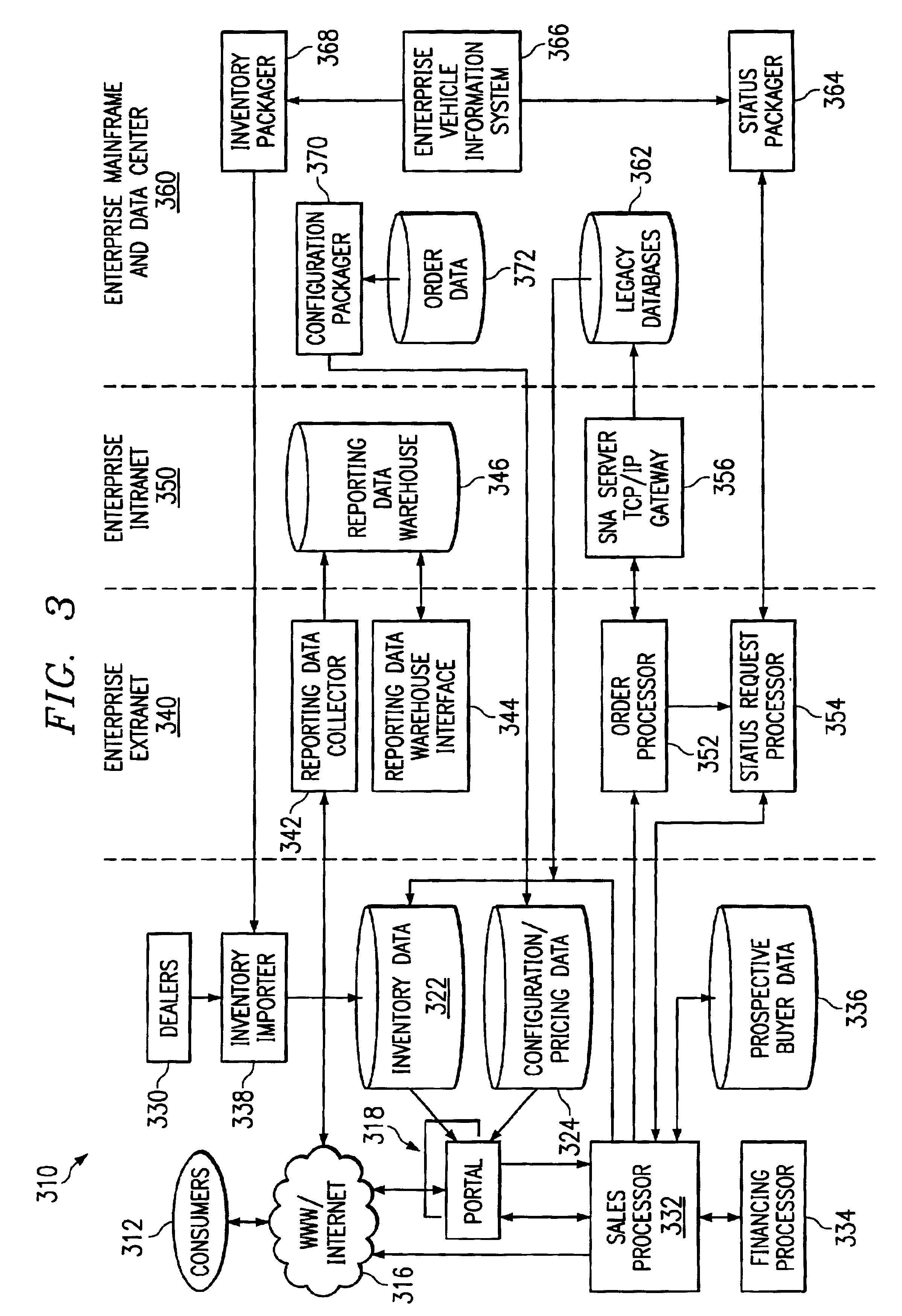

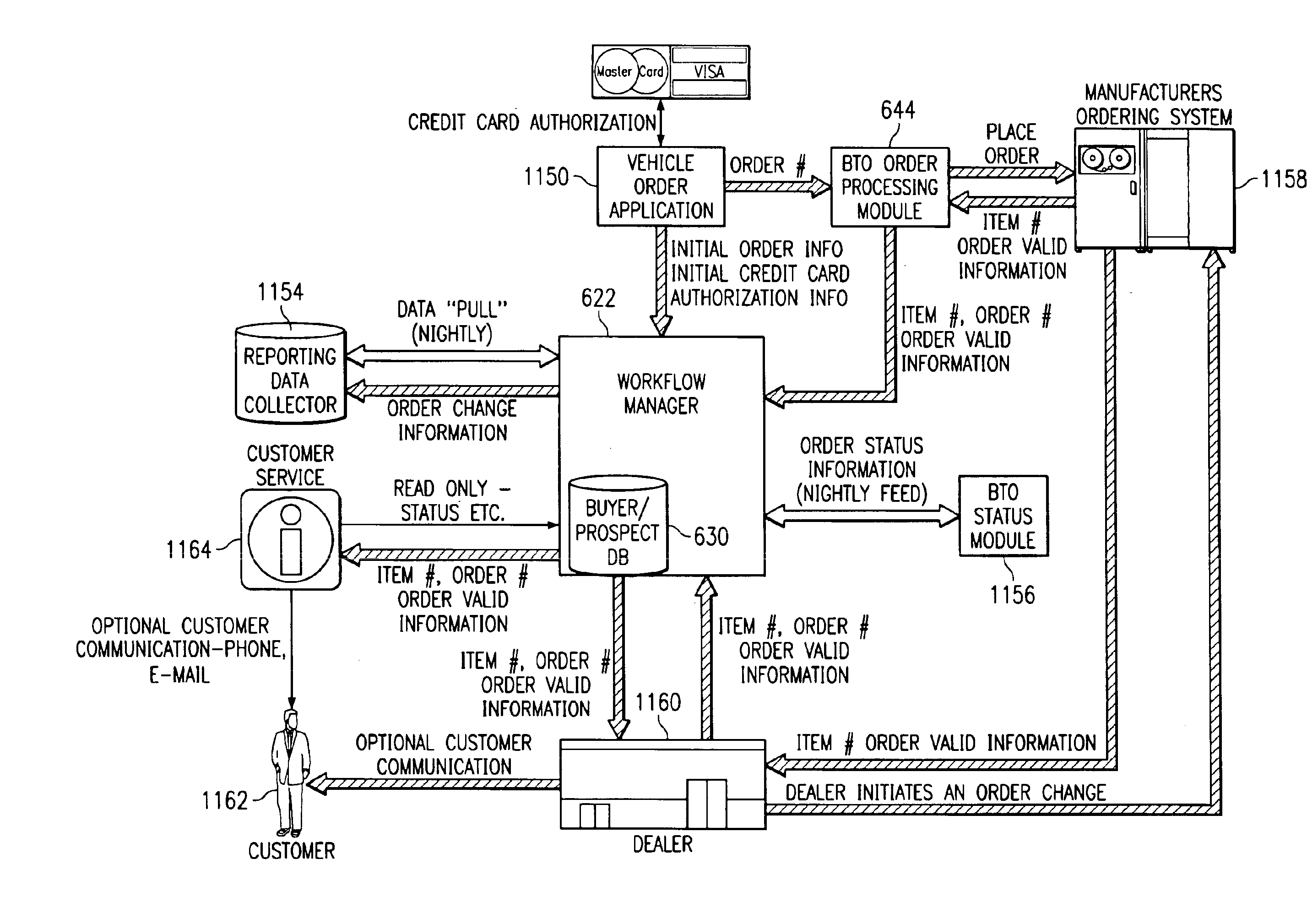

An online system of locating consumer product having specific configuration in an enterprise production pipeline and inventory is provided. The system includes a locate client process operable to receive product configuration data and generate a search request message incorporating the product configuration data in response to user input, and an inventory database storing product availability data in the enterprise production pipeline and in inventory. A locate server process is operable to receive the search request message from the locate client process, and search the product availability data in the inventory database for products matching and substantially matching the product configuration data. The locate server is further operable to generate a search reply message containing the matching products and return the search reply message to the locate client process.

Owner:FORD MOTOR CO

Communication schema of online system and method of locating consumer product in the enterprise production pipeline

InactiveUS6895388B1Shorten delivery timeBuying/selling/leasing transactionsSpecial data processing applicationsModel NumberWorld Wide Web

An online communication schema for an online vehicle ordering and tracking system is provided. The communication schema includes a search request message and a search reply message. The search request message includes at least one search criteria, including make and model of a vehicle, and a weighting of each criterion. The search reply message includes a list of vehicles substantially matching the search criteria, and a plurality of vehicle configuration parameters of the vehicles substantially matching the search criteria, including make, model, dealer identifier, price, and color.

Owner:FORD MOTOR CO

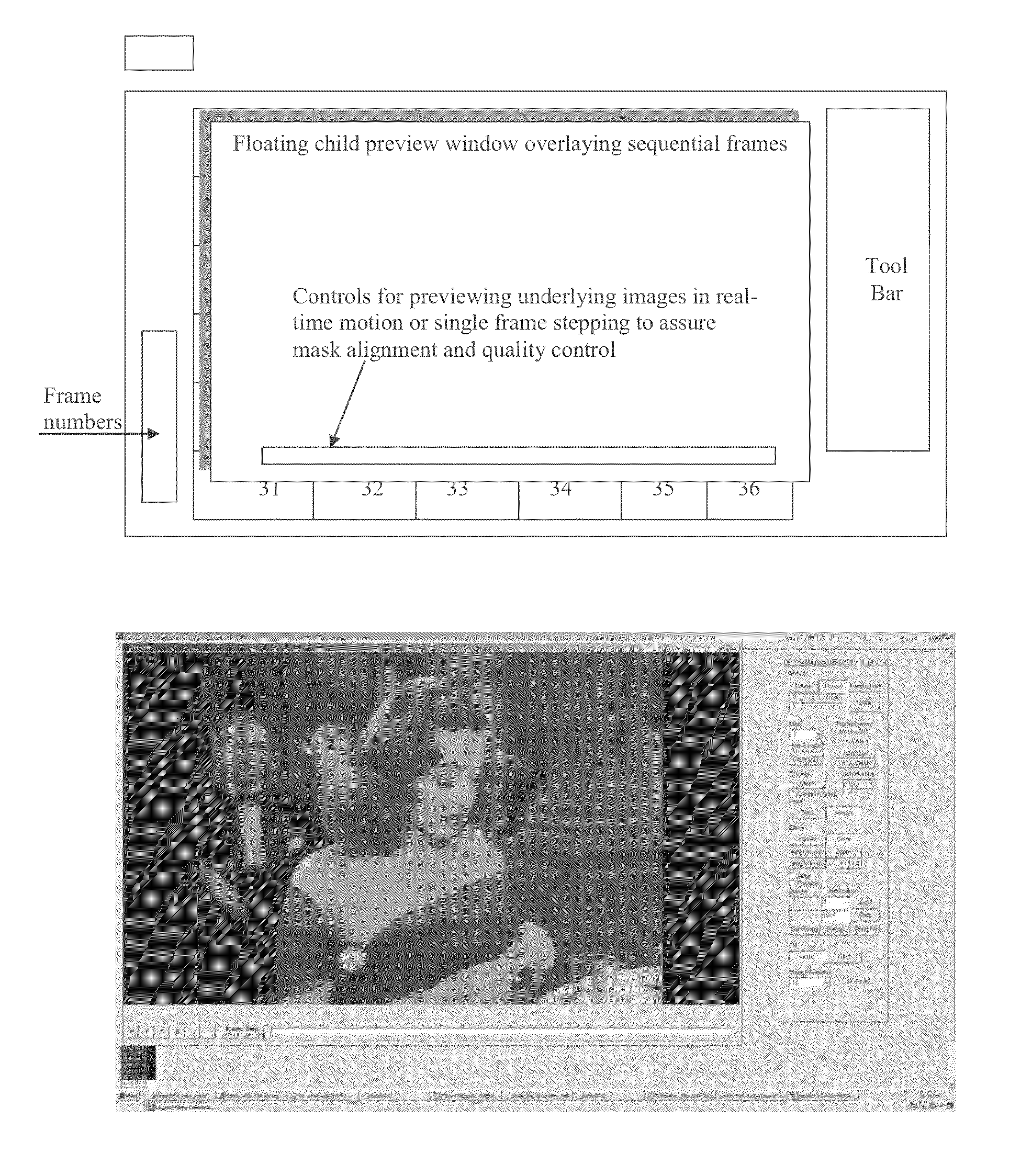

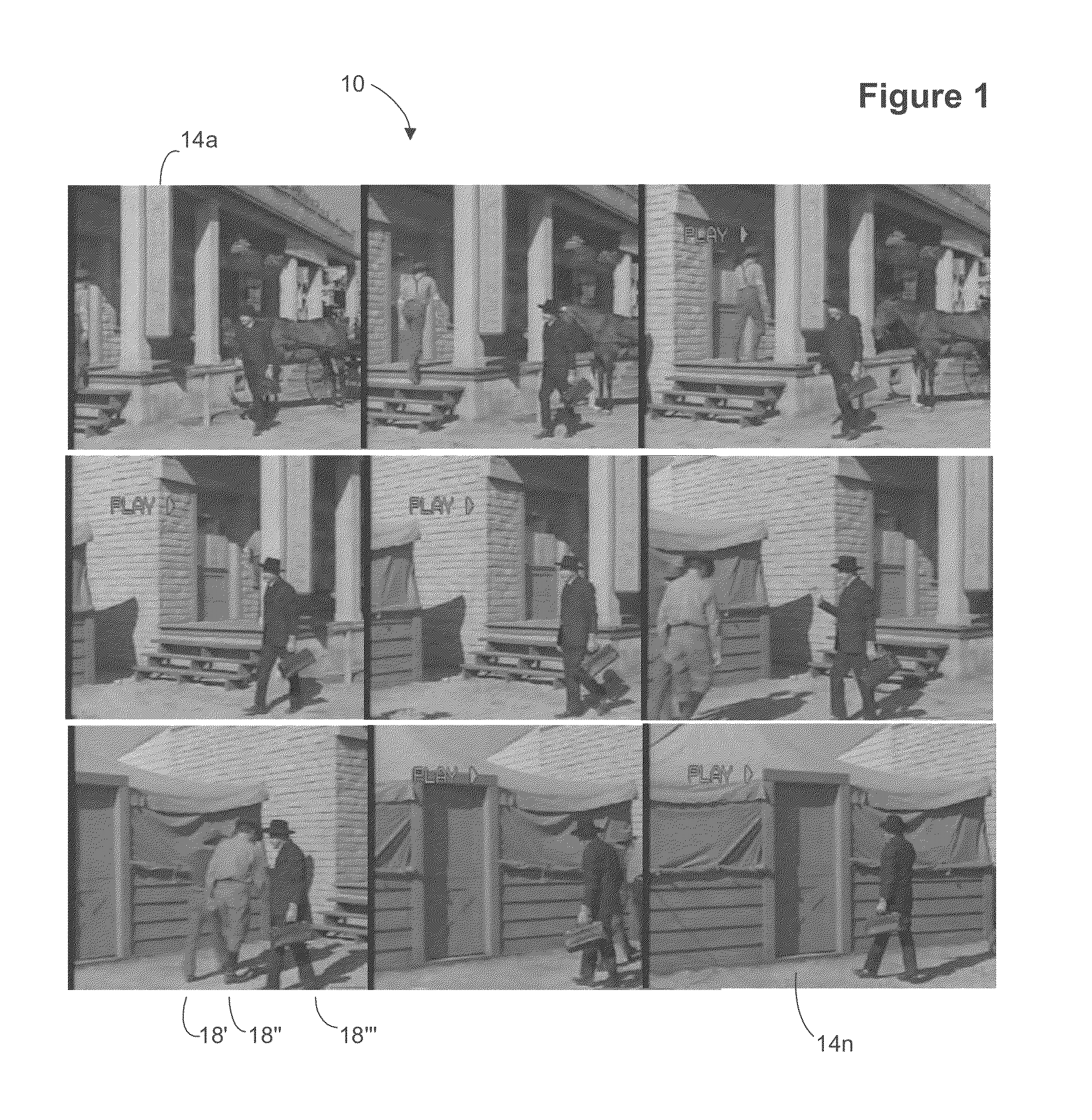

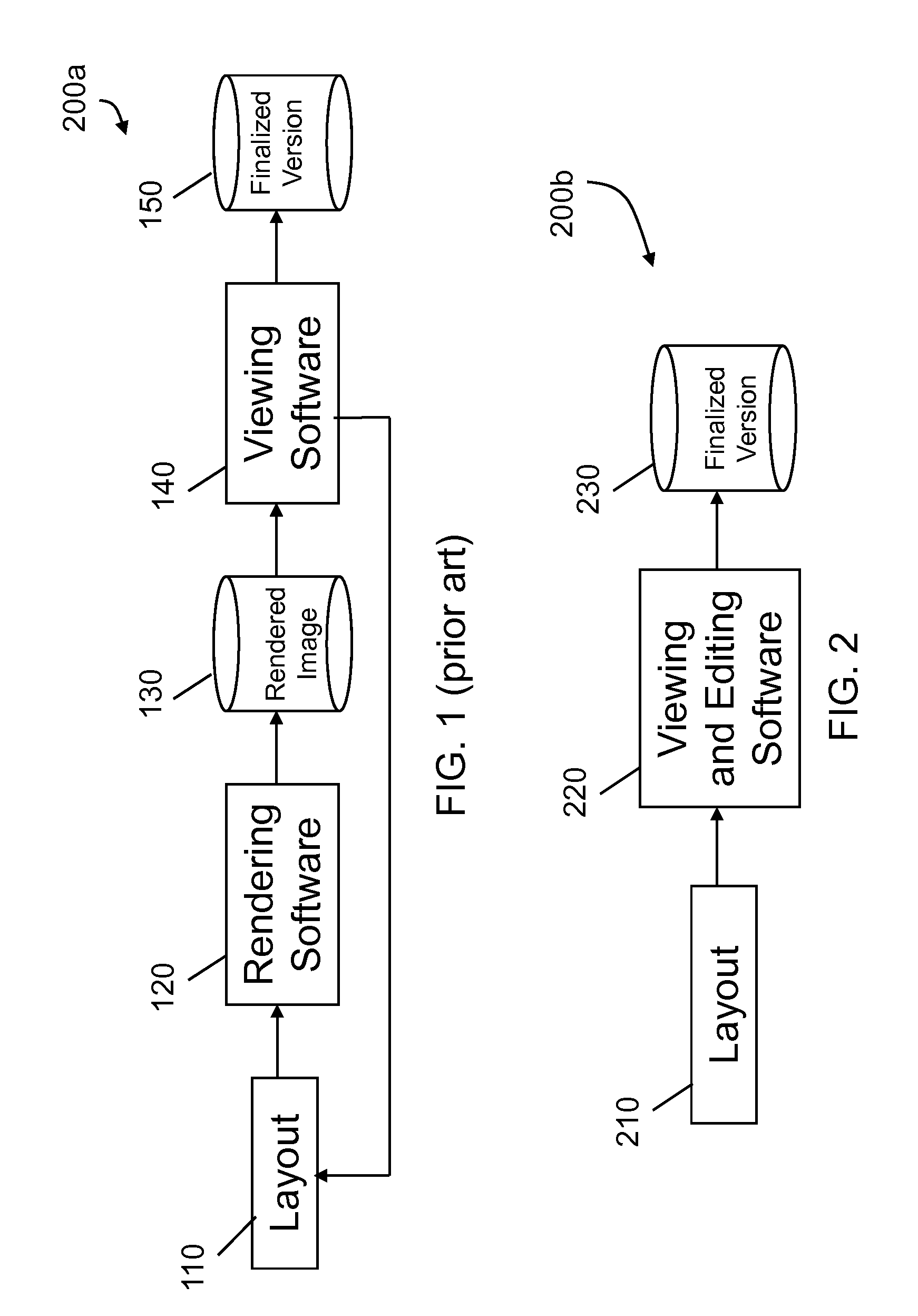

Multi-stage production pipeline system

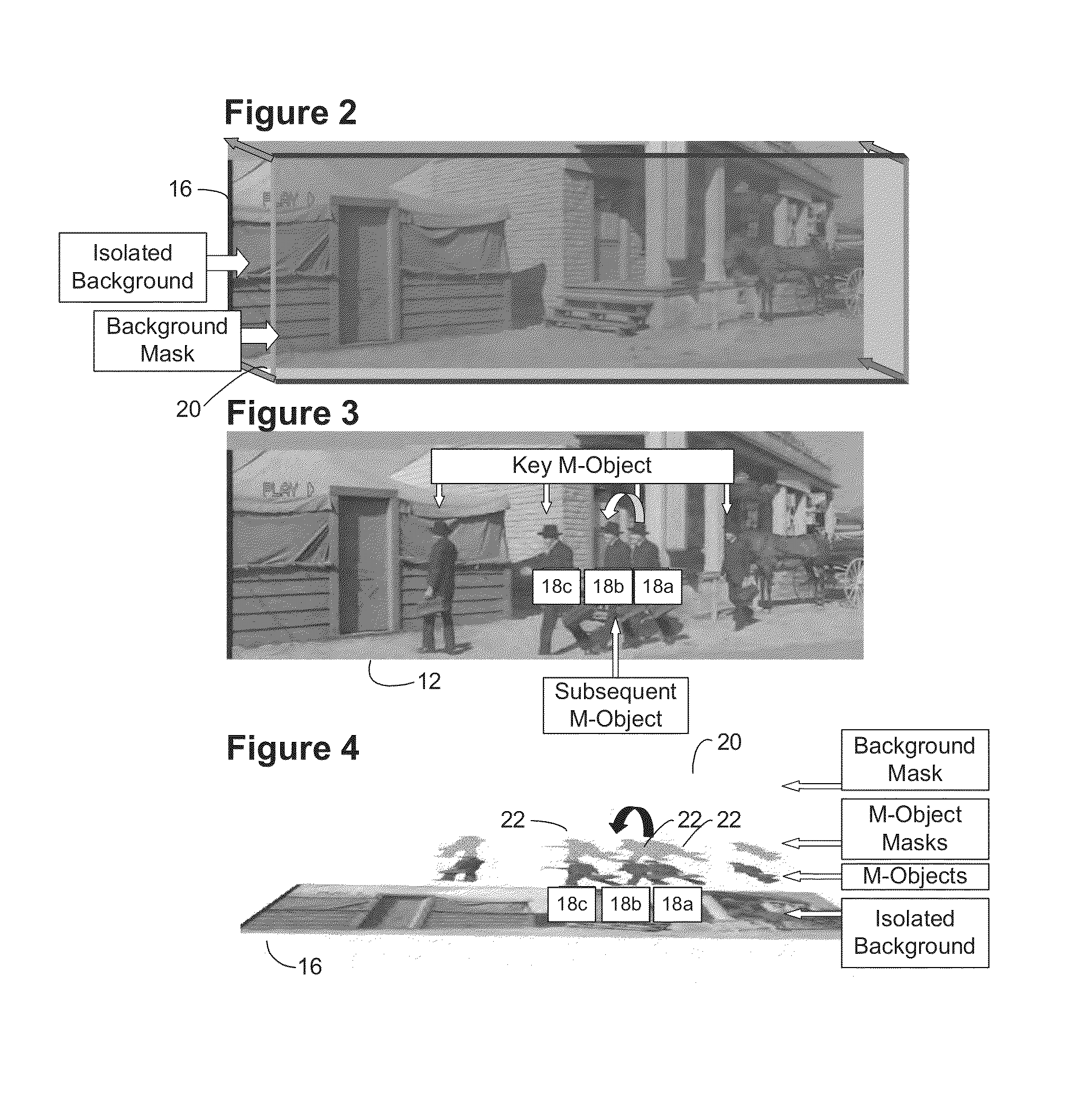

InactiveUS20130266292A1Improves project managementQuality improvementTelevision system detailsElectronic editing digitised analogue information signalsACROSS ProjectVisual perception

Multi-stage production pipeline system that may be utilized in conjunction with a motion picture project management system. The multi-stage production pipeline system includes a computer and a database. The database includes metadata associated with at least one shot or associated with regions within the plurality of images in the at least one shot, or both. The computer includes a grouping tool interface for presenting user interface elements and accepting input of the metadata associated with the at least one shot or regions within the plurality of images in the at least one shot, or both. The system enables a large studio workforce to work non-linearly on a film while maintaining a unified vision driven by key creative figures, allowing for more consistent, higher quality, faster, less expensive work product and more efficient project management techniques. The system also enables reuse of project files, masks and other production elements across projects.

Owner:LEGEND FILMS INC

High temperature resistance non halogen flame retardant cable sheath material and preparation method thereof

ActiveCN101613506AImprove temperature resistanceOvercome the problem of not being able to prepare high temperature resistant halogen-free flame retardant cable sheathing materialsRubber insulatorsPolymer scienceVulcanization

The invention discloses a high temperature resistance non halogen flame retardant cable sheath material and a preparation method thereof. The high temperature resistance non halogen flame retardant cable sheath material comprises the following components with the following parts by weight: 100 parts of ethylene-propylene-diene monomer (EPDM), 1.5-6 parts of vulcanizing agent, 1.5-6 parts of co-vulcanization agent, 0.5-5 parts of coupling agent, 4-20 parts of antiager, 4-30 parts of softener and 80-250 parts of inflaming retarding filling agent. In the invention, the halogen-free material is adopted, thick smoke, corrosive halogenide gas and other harmful substances are not generated in the process of burning; the cable sheath of the invention features excellent elasticity and tenacity, not only has obvious inflaming retarding effect, but also improves heat-resisting and anti-aging properties, can resist high temperature, and has high mechanical strength and wide application range; in addition, the production process is easy and is convenient for rubber-producing enterprises to achieve self-sufficiency.

Owner:SICHUAN MINGXING CABLE

Method for separating fluids

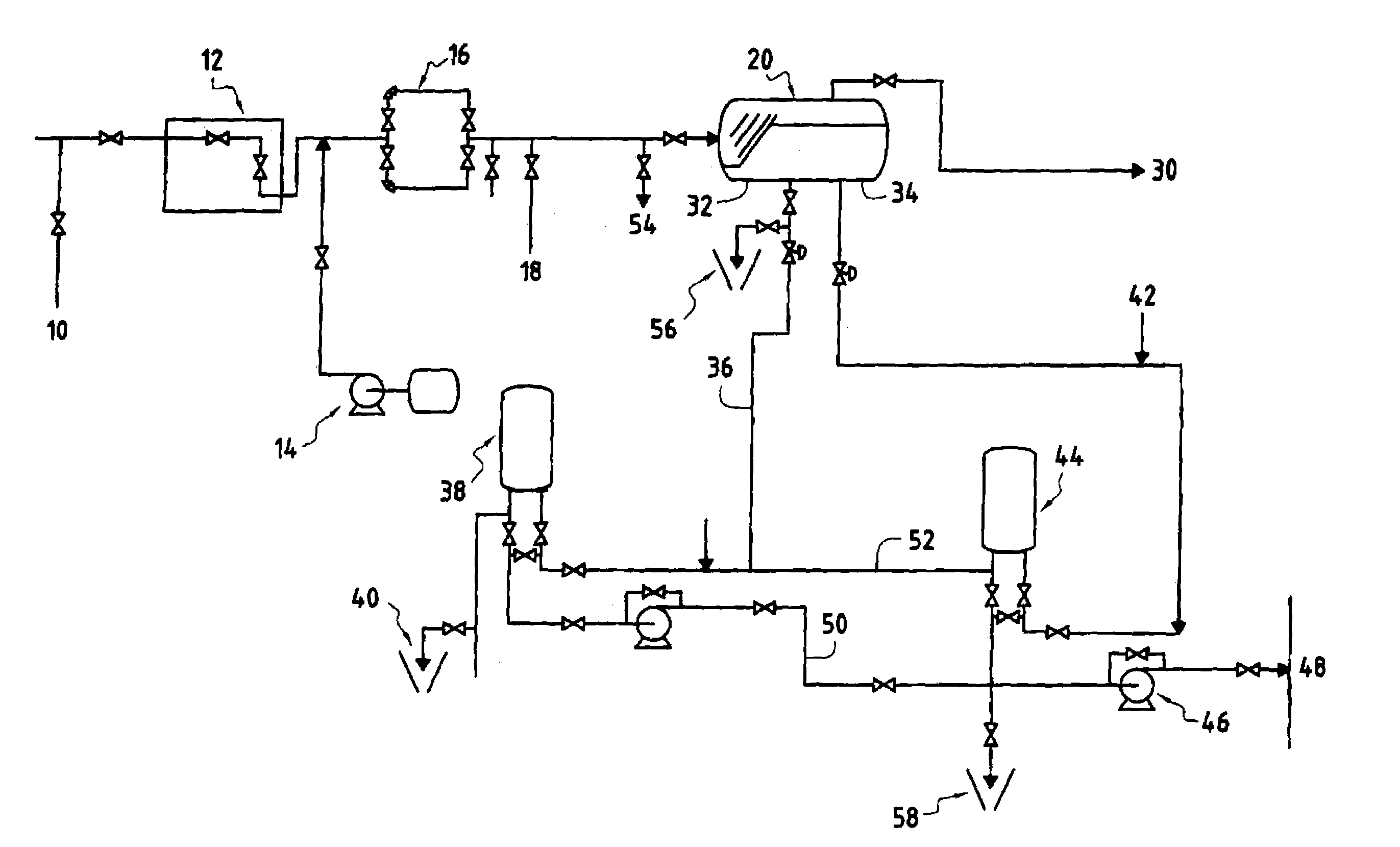

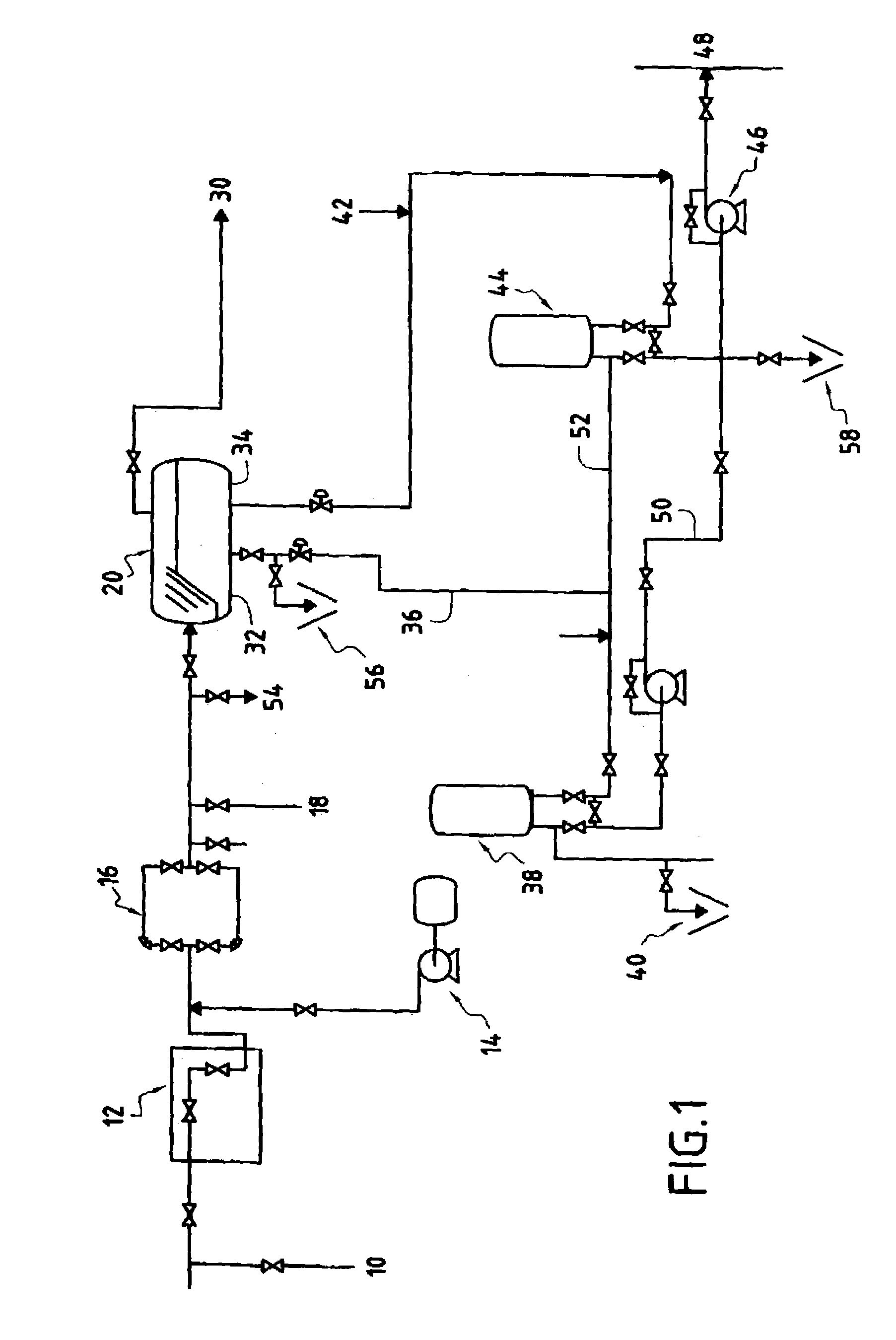

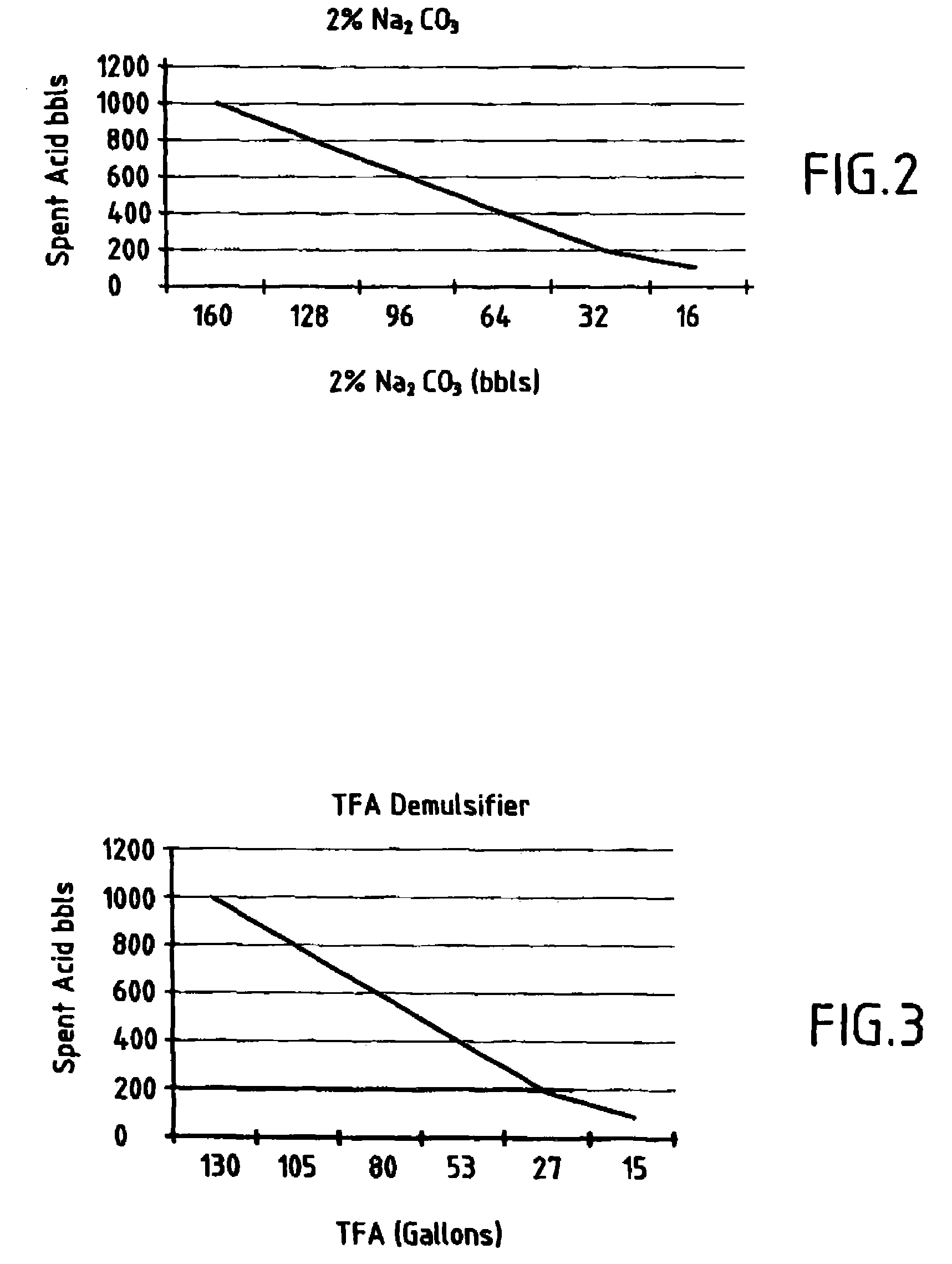

InactiveUS6989103B2Avoid flaringReduce oil contentFatty/oily/floating substances removal devicesWater cleaningEmulsionEnvironmental regulation

Methods of treatment of fluids produced by an oil or gas well following a stimulation operation, allowing separation from the fluids and re-injection of oil and gas hydrocarbons in a production pipeline under pressure, and allowing achievement of suitable quality for the residual fluids compatible with their rejection, for example into the sea, including the following three elements; neutralization of the fluids by mixing with a high pH chemical, until the resulting pH reaches a level compatible with the equipment and pipes; use of optimized emulsion breakers in a phase separator, selected for best results with the fluids produced by the well, to accelerate the separation of oil from the fluids, and to lower the residual oil content in the fluids to levels compatible with environmental regulations; and use of a multi-phase pump to pump the oil and gas hydrocarbons produced and reinject them in a pipeline under pressure.

Owner:SCHLUMBERGER TECH CORP

Oil spraying instant noodle production line and production technology thereof

InactiveCN101720890AFragrant and delicious tasteReduce oil contentFood preparationDough processingAlkaline waterHigh volume manufacturing

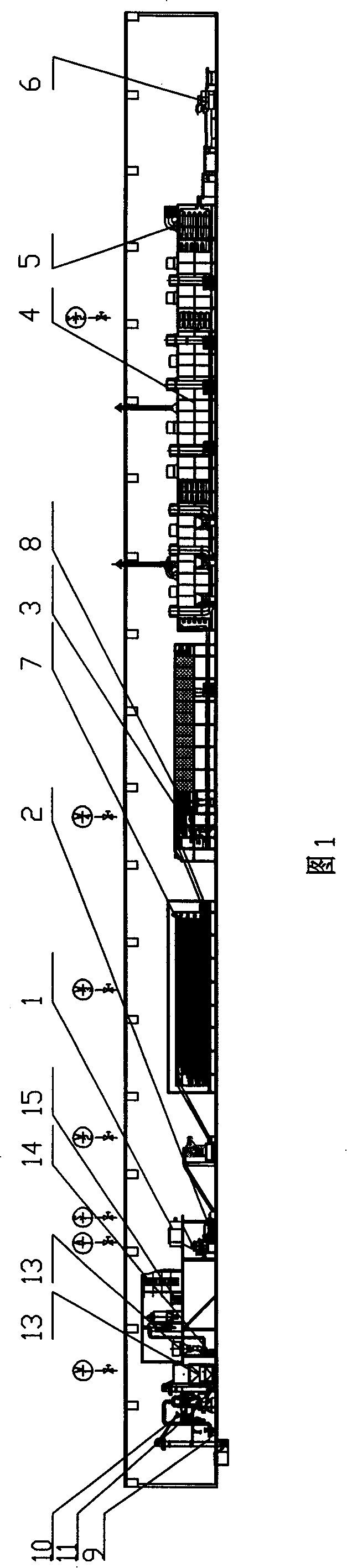

The invention relates to oil spraying instant noodle production line and production technology thereof. The production line is sequentially provided with an alkaline water bucket, a quantitative water adding bucket, a vibrating screen, a double shaft flour-mixing machine, a curing feeder, a composite tablet machine, a continuous tablet machine, a three-layer vaporizer, a cutting folder, a spraying flavouring machine, an oil spraying noodle frying machine, a microwave drying machine, an air cooling machine and an output packaging device. The equipment is full automatic, production efficiency is high, thus being applicable to mass production; in the production equipment, oil spraying device is adopted to carry out oil spraying treatment on noodle block, the noodle block has the flavour of common instant noodles while the oil content thereof is only about 5%, thus the noodle block is a good low oil content healthy food.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

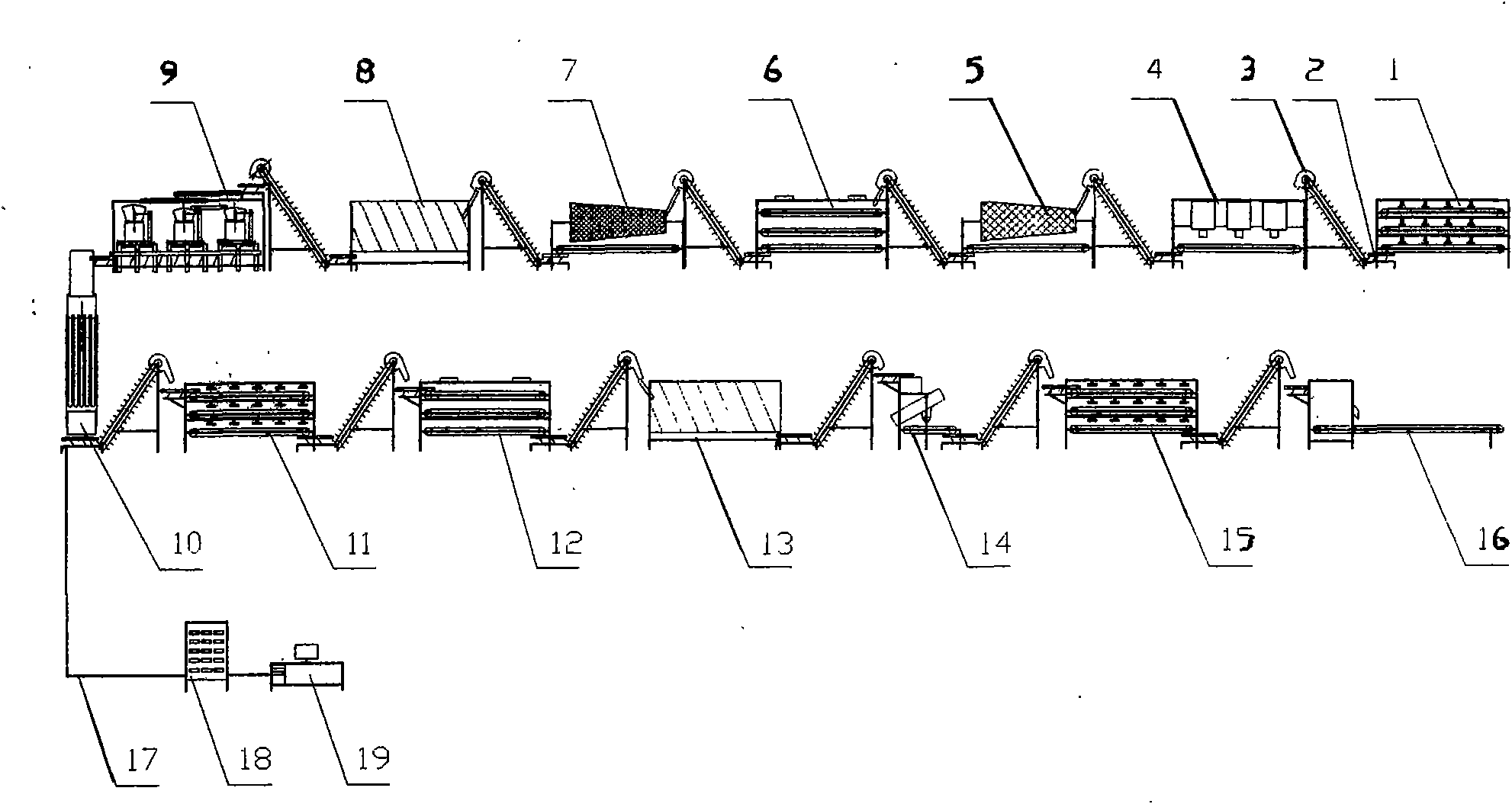

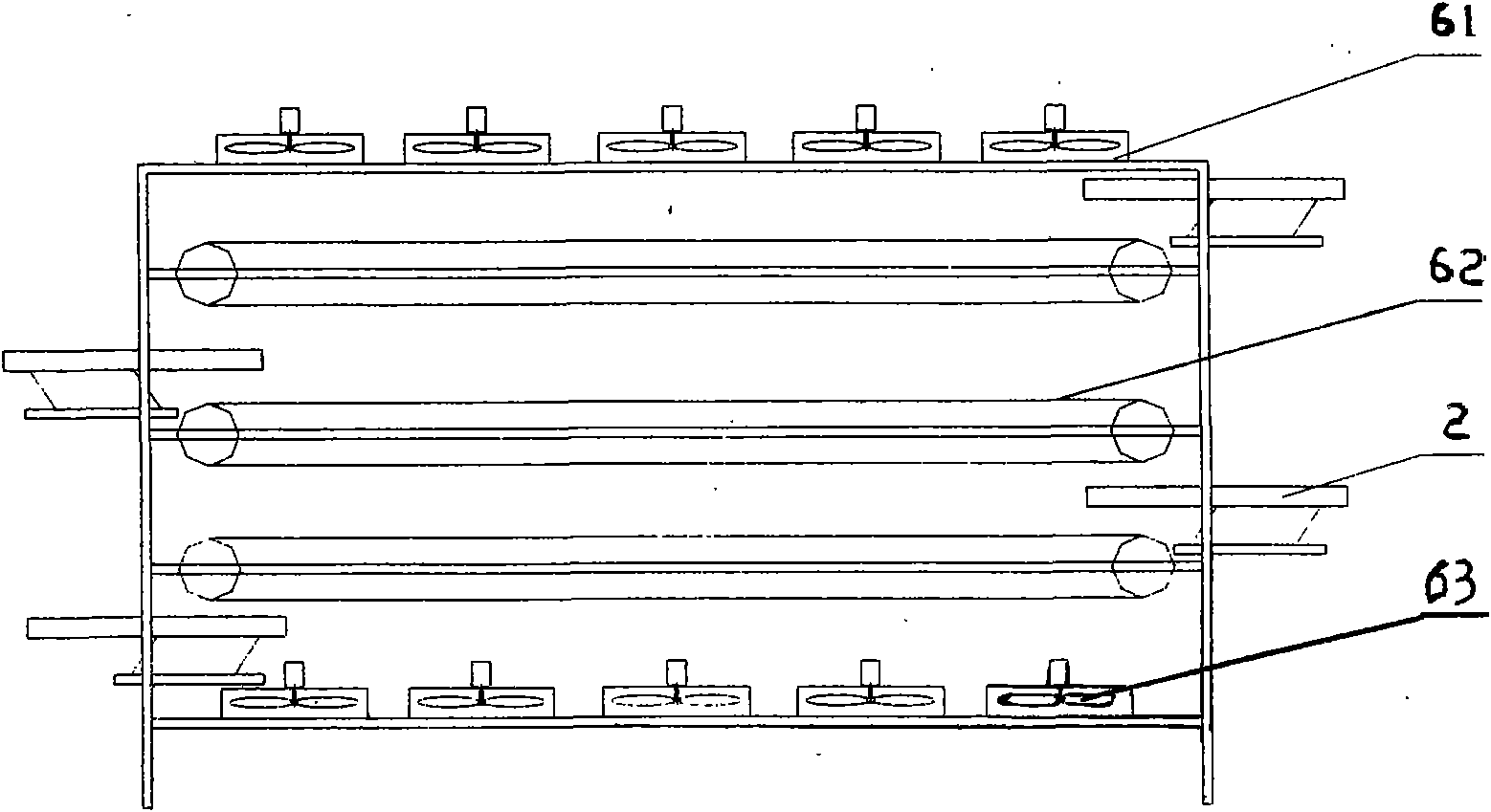

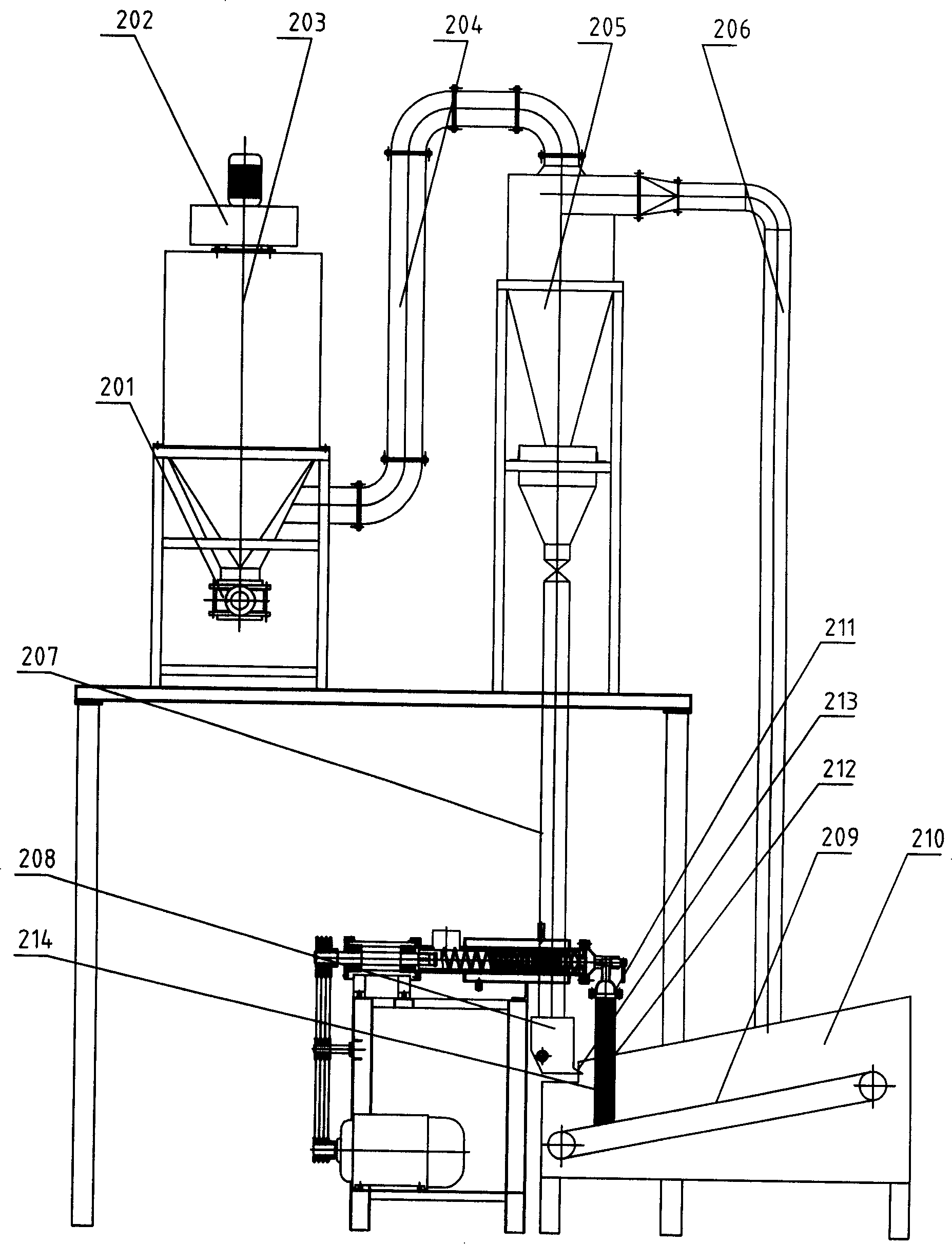

Tea mechanization and clean production line

InactiveCN101953405ASimple processing equipmentAvoid secondary pollutionPre-extraction tea treatmentMicrocomputerElectric machinery

The invention relates to a tea mechanization and clean production line, which belongs to the technical field of tea processing equipment. The invention provides a tea production line which is mechanized, standardized, automated, serialized, clean and dimensions scaled. The production line comprises various process devices which are composed of a cleaning machine, a dehydrater, a grader, a green-unfolding machine, a green-shaking machine, a rotary-drum removing green machine, a knead entwist machine, a multislot pot type continuous strip-managing machine, a low temperature far infared baker, a WXTL, a treating pot machine, a tea color sorter a high temperature far infared baker and a tea package mechanism, a material conveying mechanism composed of an elevator and a conveyor and a control mechanism composed of a microcomputer and a central control cabinet; the adjacent process devices are respectively connected by the conveyor and the elevator; electrical machines of the various process devices and the electrical machine of the material conveying mechanism both are variable frequency motors which are controlled by the control mechanism.

Owner:ANHUI AGRICULTURAL UNIVERSITY +1

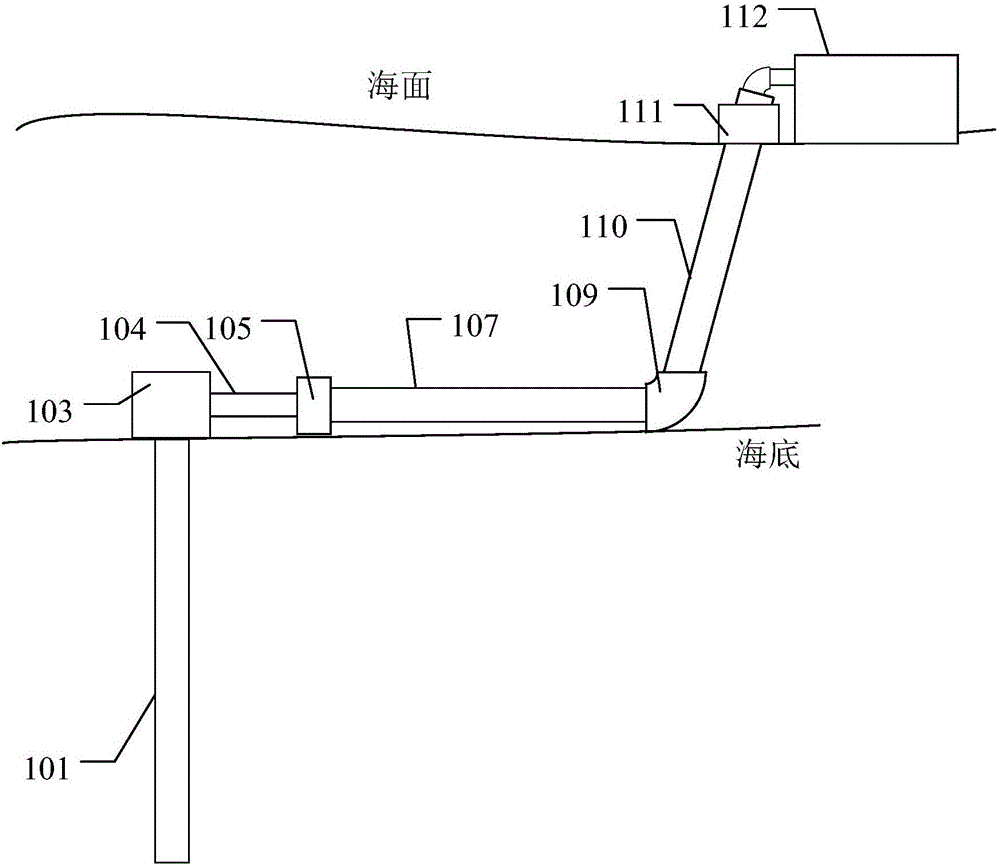

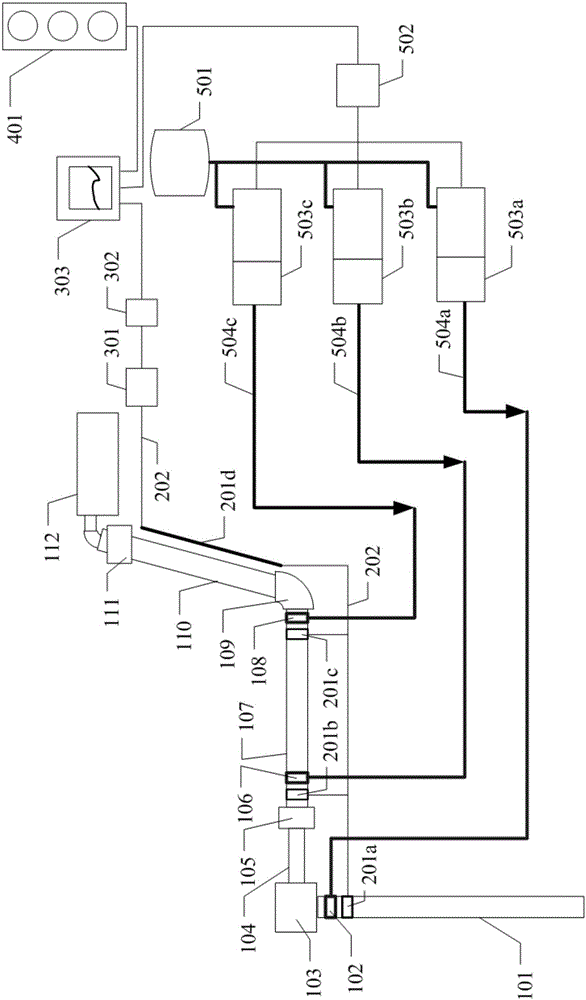

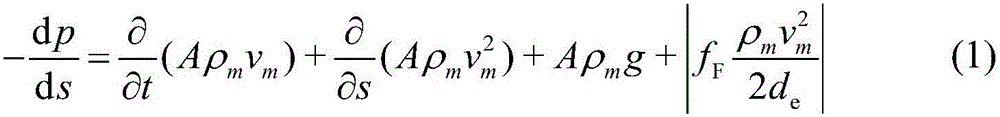

Early monitoring device and method for hydrate blockage of deep water gas well production pipeline

ActiveCN106322121AEarly warning of congestionHarm reductionFluid removalPipeline systemsData acquisitionTemperature and pressure

The invention relates to an early monitoring device for hydrate blockage of a deep water gas well production pipeline. The early monitoring device comprises a data collecting and transmitting system, a data analyzing and processing system and an automatic hydrate inhibitor injection system. The data collecting and transmitting system monitors temperature and pressure data in the production pipeline in real time and transmits the monitoring data to the data analyzing and processing system. The data analyzing and processing system stores, analyzes and processes the monitoring data, calculates and analyzes the natural gas hydrate blockage condition in the production pipeline and sends out an early warning signal and a hydrate inhibitor injection instruction. The automatic hydrate inhibitor injection system is arranged on a platform and injects hydrate inhibitor into the production pipeline according to the instruction sent by the data analyzing and processing system. By means of the early monitoring device, early monitoring can be achieved for the hydrate blockage position and the blockage severity degree in the production pipeline, sufficient time is provided for field workers to take the hydrate inhibitor injection measure, and more serious blockage conditions are avoided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

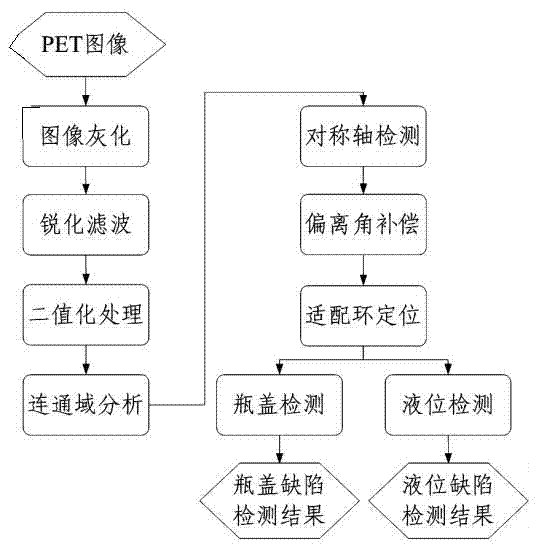

Detection method of PET bottle cap and liquid level

ActiveCN102519972AImprove detection efficiencyAvoid detection impactOptically investigating flaws/contaminationMachines/enginesEngineeringPre treatment

The invention discloses a detection method of a PET bottle cap and a liquid level. The method comprises steps of: segmenting an interested zone of an image and carrying out pretreatment on the image; carrying out segmentation on a PET bottle body and a background zone; carrying out PET bottle symmetry axis positioning on the image after the pretreatment; and carrying out detection according to the position of the symmetry axis and a line, which a PET bottle adapter ring is on, and coordinates of an adapter ring central point. The method of the invention can carry out real-time ongoing detection on PET bottle cap and liquid level defect on a high speed automatic production pipeline and realize high detection efficiency.

Owner:SHANDONG MINGJIA TECH

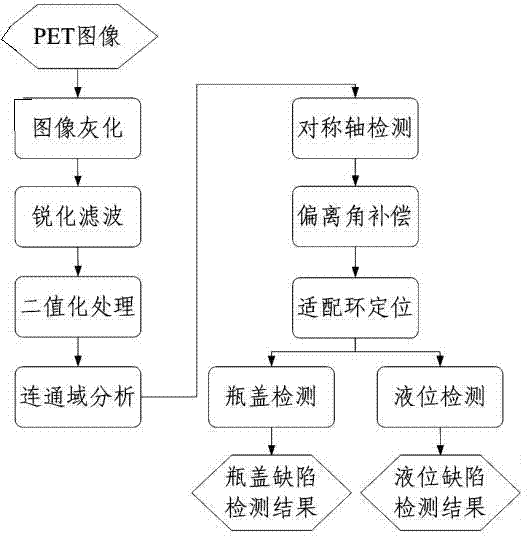

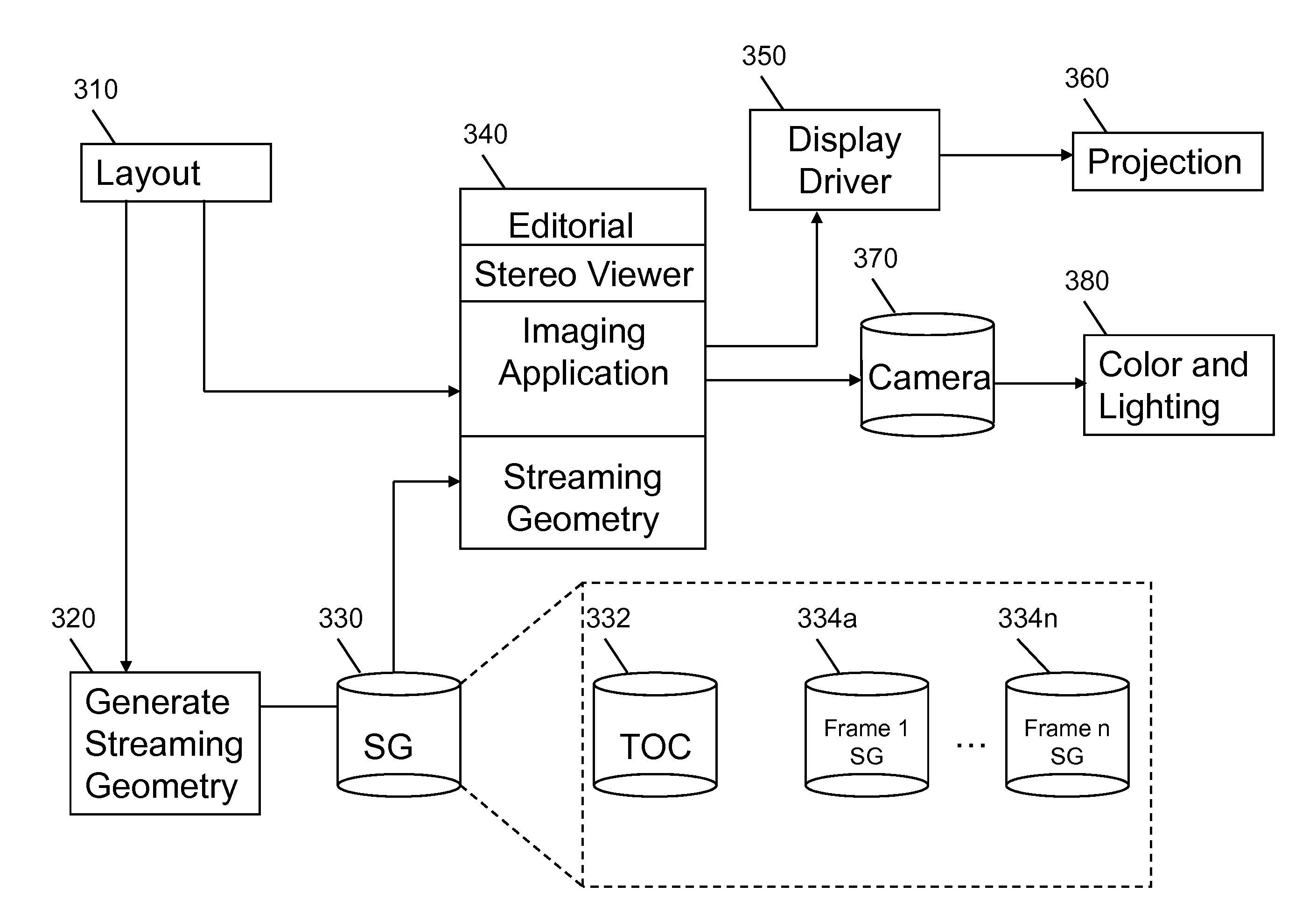

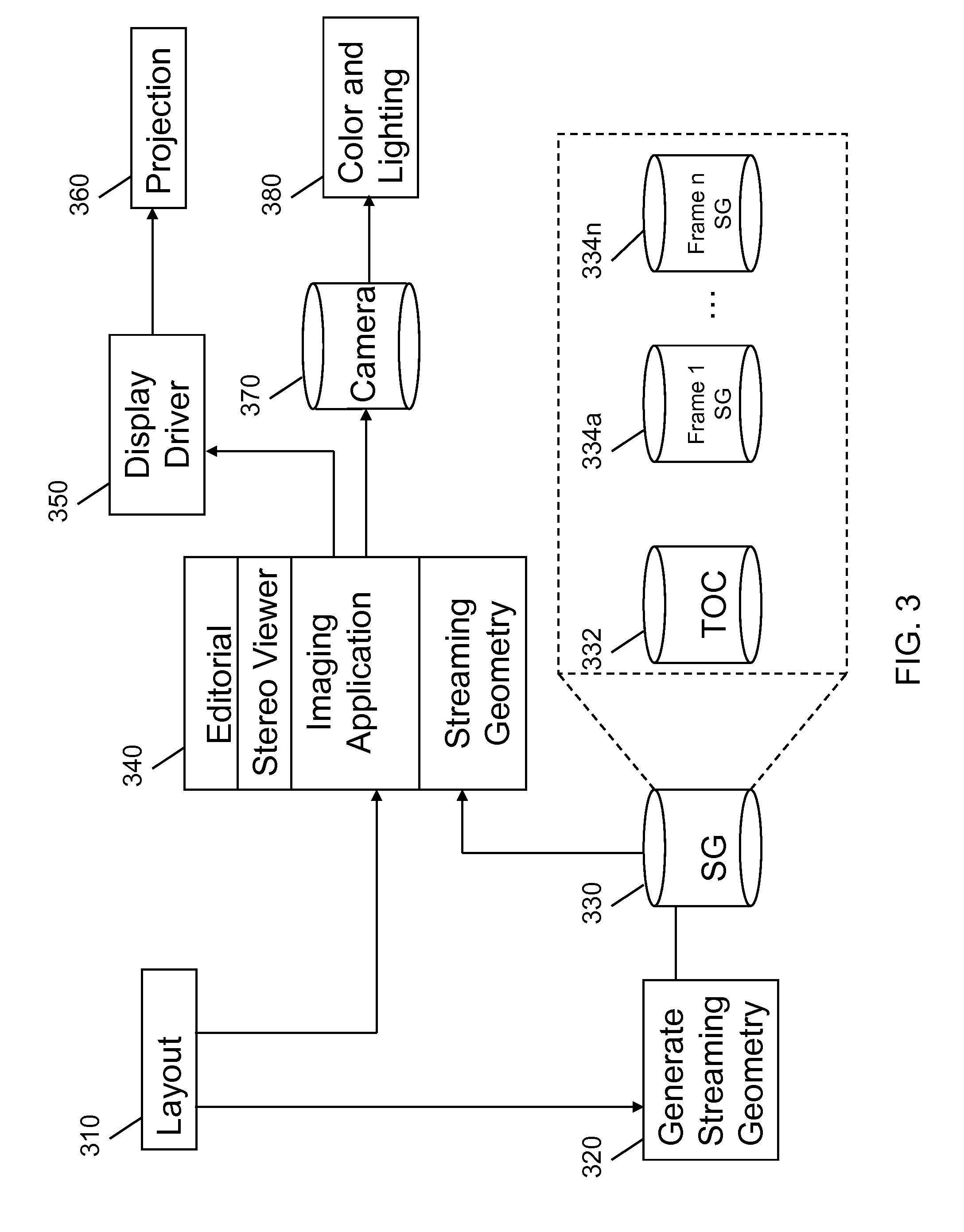

Streaming geometery for use in displaying and editing 3D imagery

Method and systems are provided using streaming geometry in 3D imagery production. In one implementation a method for use in the display of 3D video images comprises receiving a first set of data corresponding to an output from a layout in a production pipeline, generating geometry data for one or more objects represented within the first set of data, merging the geometry data for each of the one or more objects to create one or more merged files, generating a table of contents, wherein the table of contents specifies the location of the geometry data for each of the one or more objects within the one or more merged files and storing the geometry data and the table of contents to a memory device for subsequent retrieval

Owner:SONY CORP +1

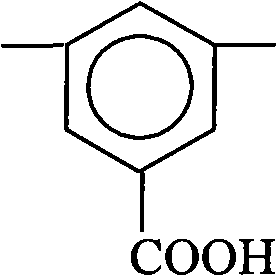

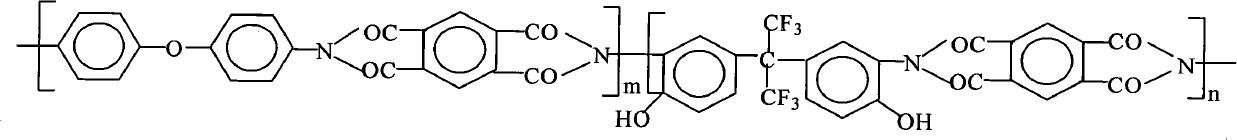

Polyimide fiber and preparation method thereof

InactiveCN101922061AGood organic solvent solubilityChemically reactiveMonocomponent synthetic polymer artificial filamentHigh resistanceFiber

The invention relates to a polyimide fiber. The polyimide fiber has a molecular structure general formula shown in the specifications, wherein -Q1- is an aromatic binary primary amine residue without a phenolic hydroxyl group; =Ar= is an aromatic binary anhydride residue; and -Q2- is a phenolic hydroxyl group-containing linker of aromatic binary primary amine. The preparation of the polyimide fiber comprises the following steps of: firstly, stirring the aromatic binary primary amine and aromatic binary anhydride in an organic solvent system at room temperature and reacting for 2 to 4 hours toobtain homogeneous, transparent and viscous polyamic acid solution; secondly, pouring the solution into a spinning machine, performing screw extrusion, forming the fiber by using a spinneret and a coagulating bath, drawing and winding to obtain an as-spun fiber; and finally, treating the as-spun fiber at a high temperature to obtain the polyimide fiber. The polyimide fiber has high resistance to high temperature and high mechanical property; and the preparation process has the advantages of no need of special production equipment, capability of producing on the conventional polyimide resin production line and the spinning machine, easy recycling of an organic solvent, environmental friendliness and suitability for industrial production.

Owner:DONGHUA UNIV +1

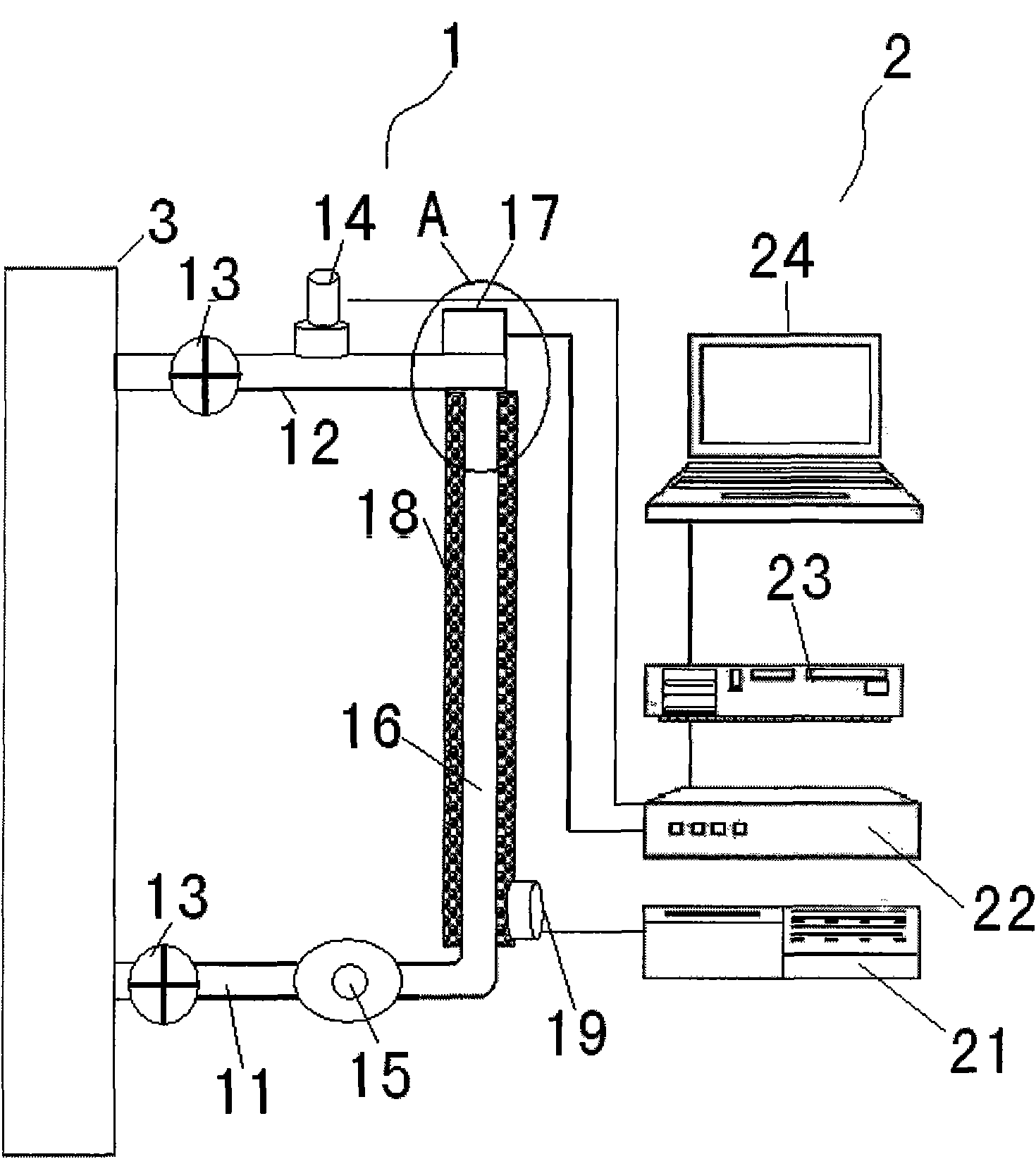

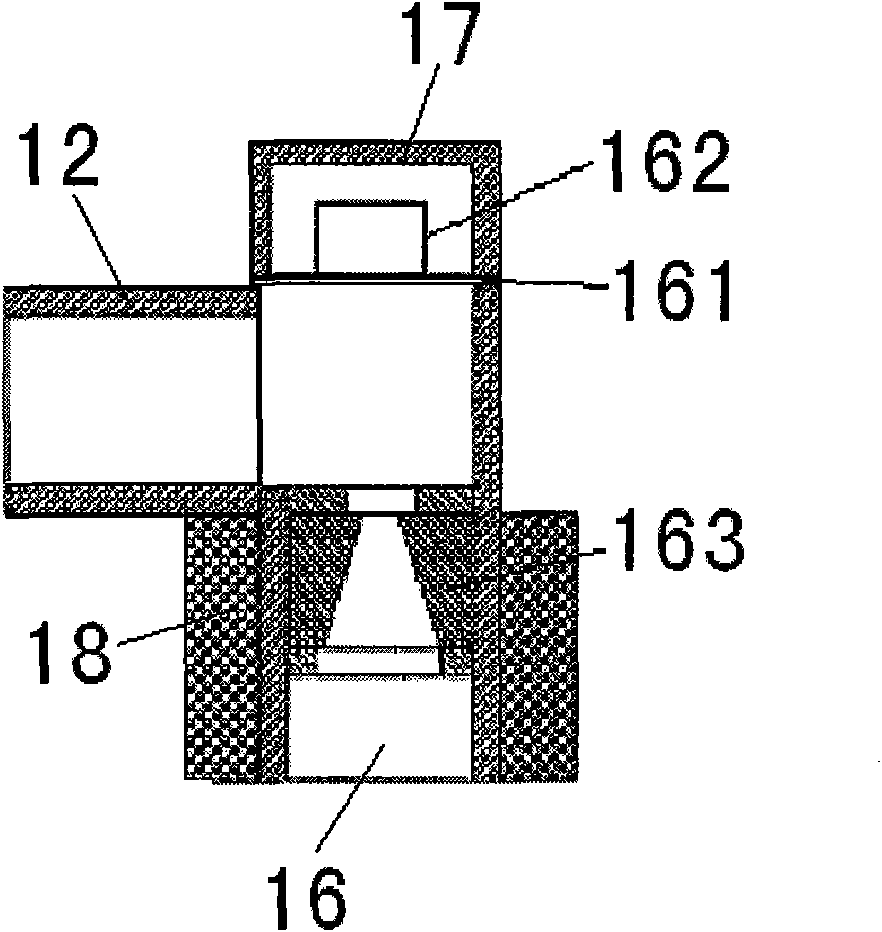

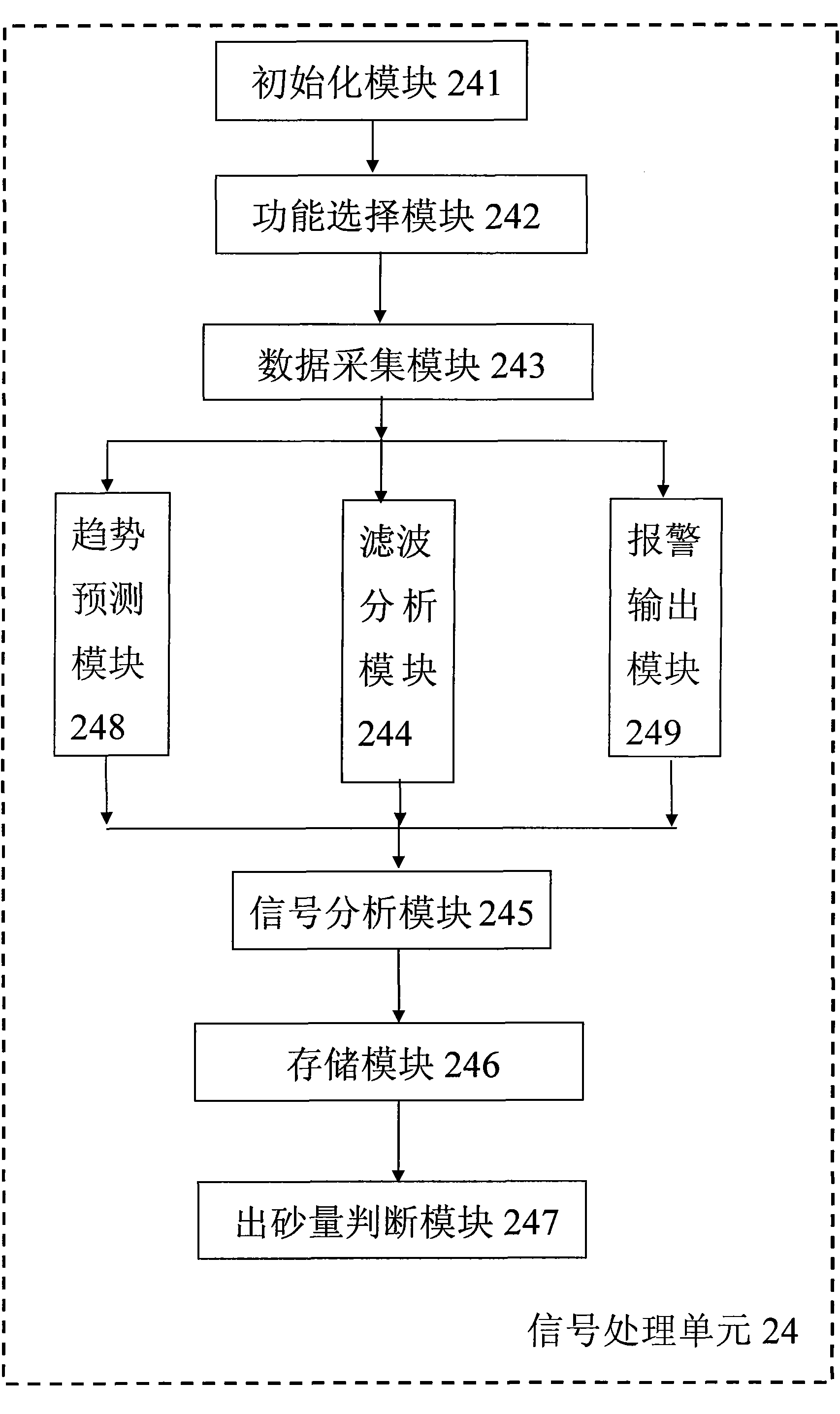

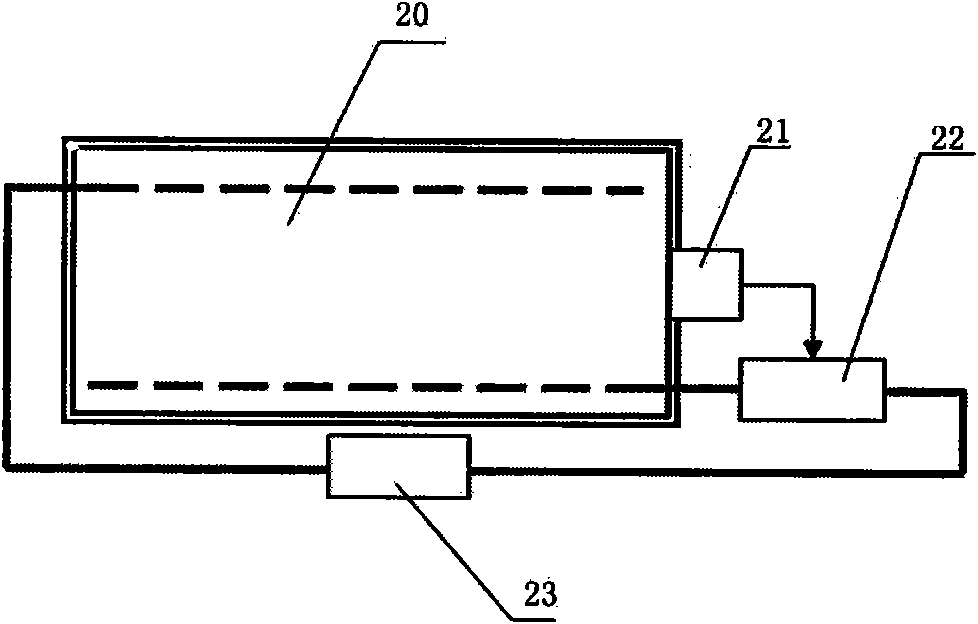

System and method for monitoring sand production rate of oil-gas well

ActiveCN101915090ALow viscositySolution to short lifeSurveyMining devicesProduction rateAudio power amplifier

The invention relates to a system and a method for monitoring the sand production rate of an oil-gas well. The system comprises a high-frequency signal sensing device and a control device, wherein the high-frequency signal sensing device comprises an oil stream introducing pipeline and an oil stream returning pipeline which are arranged in parallel on an oil-gas production pipeline of the oil-gaswell; the oil stream introducing pipeline is provided with a fixed displacement pump; the oil stream returning pipeline is provided with a pressure sensor; an oil stream monitoring pipeline is arranged between the oil stream introducing pipeline and the oil stream returning pipeline; a signal sensing drum is arranged between the oil stream monitoring pipeline and the oil stream returning pipelineand bonded with a high-frequency signal sensor; the control device comprises a data acquisition system which acquires pressure and impact signals monitored by the pressure sensor and the high-frequency signal sensor, transmits the acquired signals to a filter amplifier for filtering and signal amplifying and transmits the filtered and amplified signals to a signal processing unit; and the signal processing unit analyzes and judges the impact signals monitored by the high-frequency signal sensor so as to monitor the sand production rate of oil-gas stream in real time. The system and the methodare suitable for the field of oil-gas well development engineering.

Owner:CHINA NAT OFFSHORE OIL CORP +1

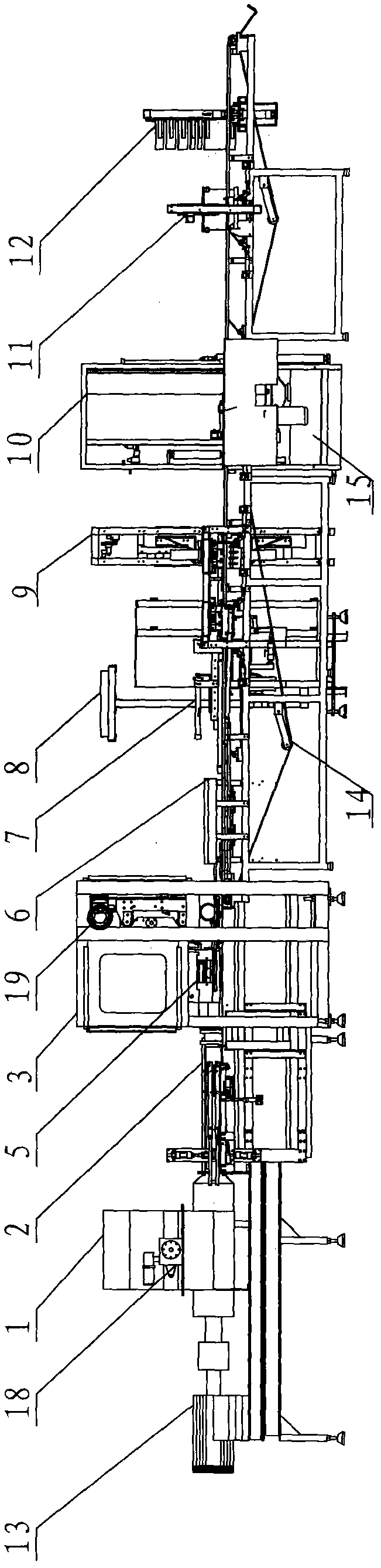

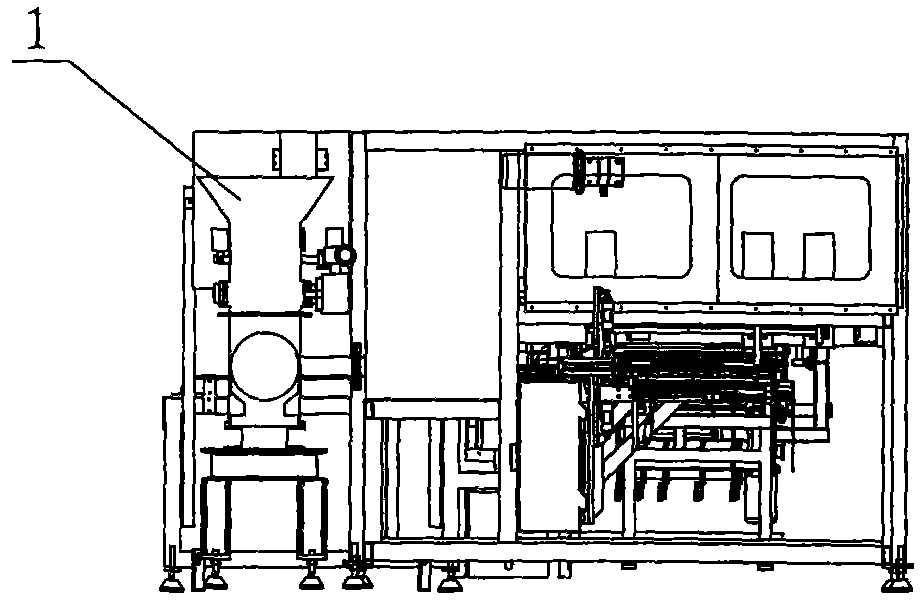

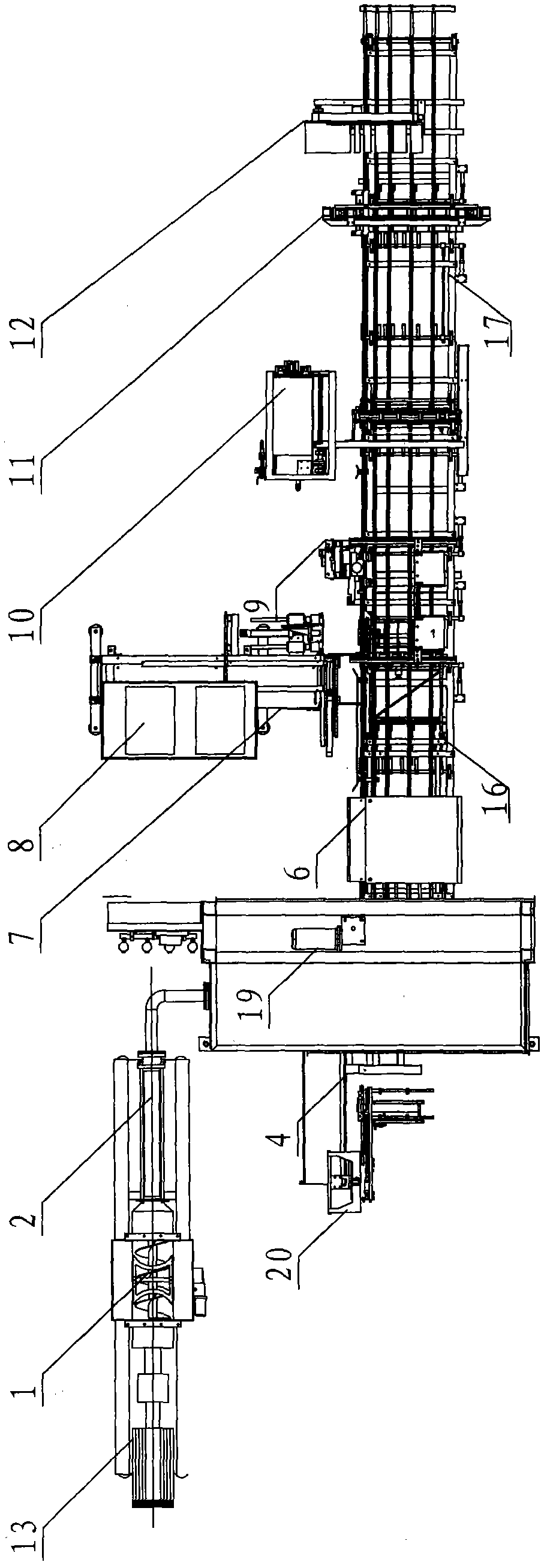

Fully-automatic convenient instant rice flour noodle production line and production technology thereof

InactiveCN101167541AQuality productionGreat tasteSeed preservation by freezing/coolingFood shapingEngineeringFully automatic

The invention relates to a production line of convenient instant rice flour and process technology, wherein the production line of the convenient instant rice flour comprises a rice treatment device, a cooking flour-mixing machine, a self-mature wire-extruding device, an aging device, a quantitative disconnecting device, a boxing shaping device, a powder block drying device, a powder block cooling device, and a packaging conveying device, which are orderly arranged according to the transfer direction of materials. The aging device comprises a rice vermicelli refrigerator, an aging machine and a continuous fluffer. The invention has the advantages of excellent product quality, wide adaptability, high performance, automaticity, low consumption, energy saving, high yield, health and environmental protection.

Owner:广州尧先机械有限公司

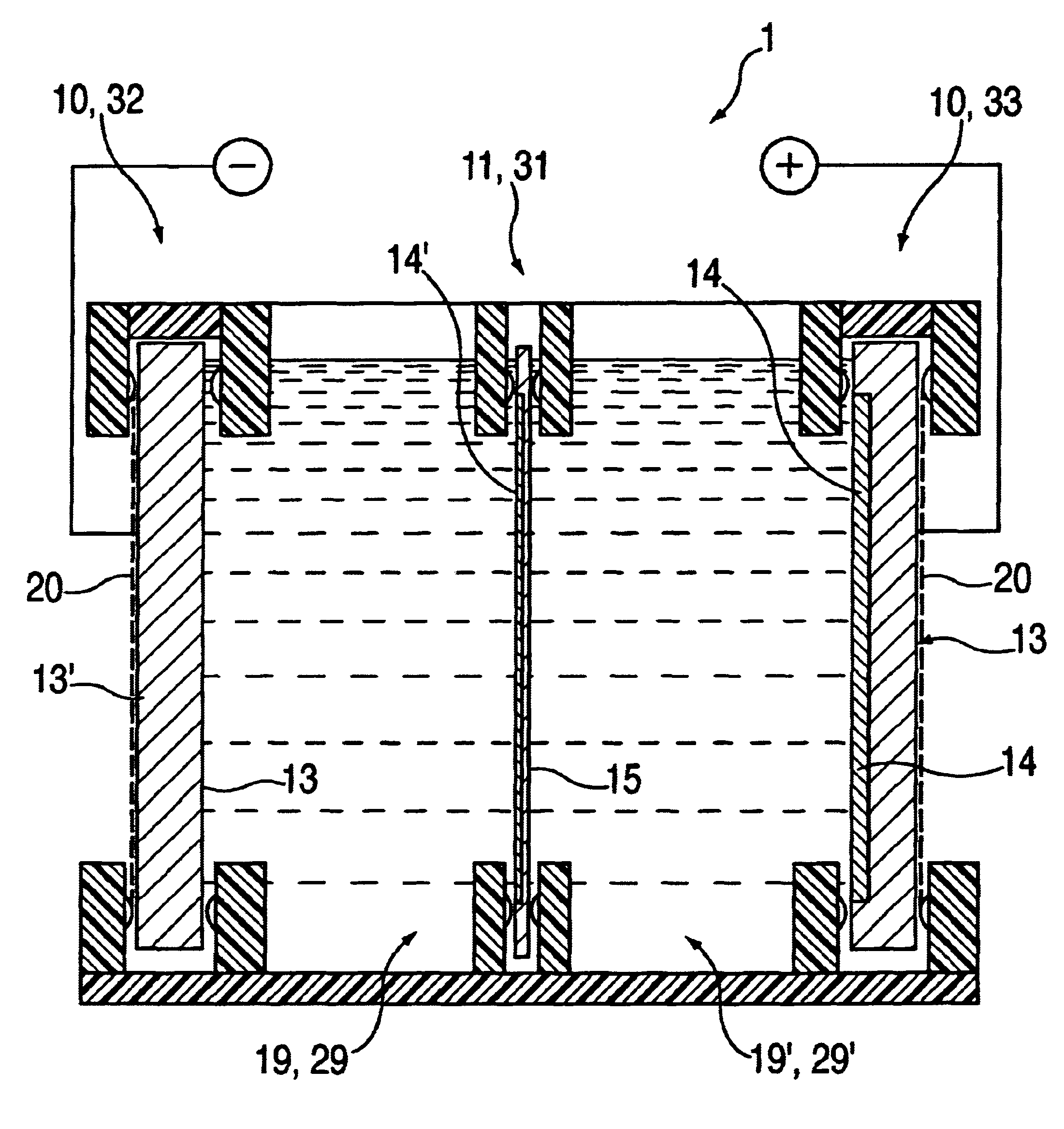

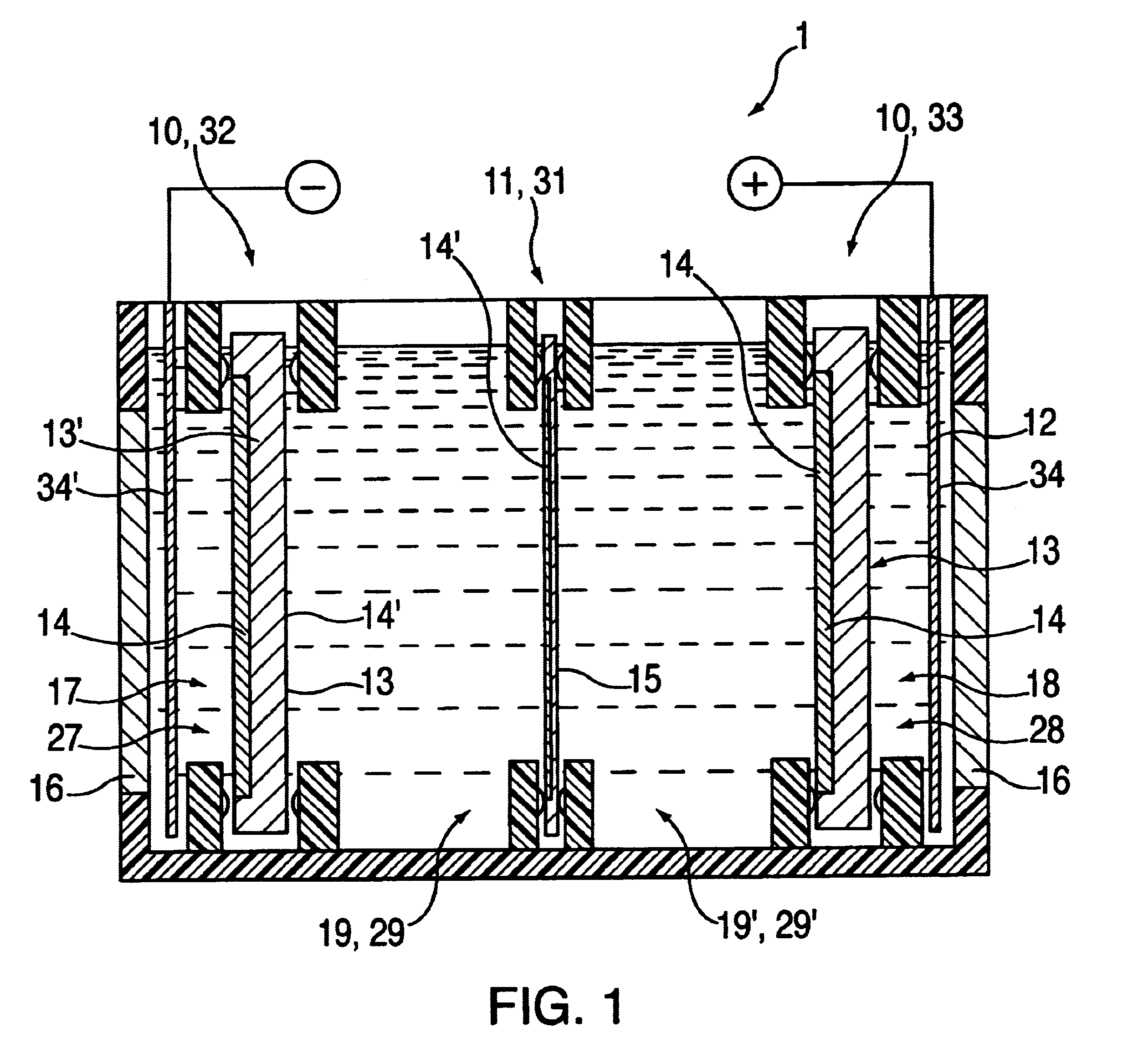

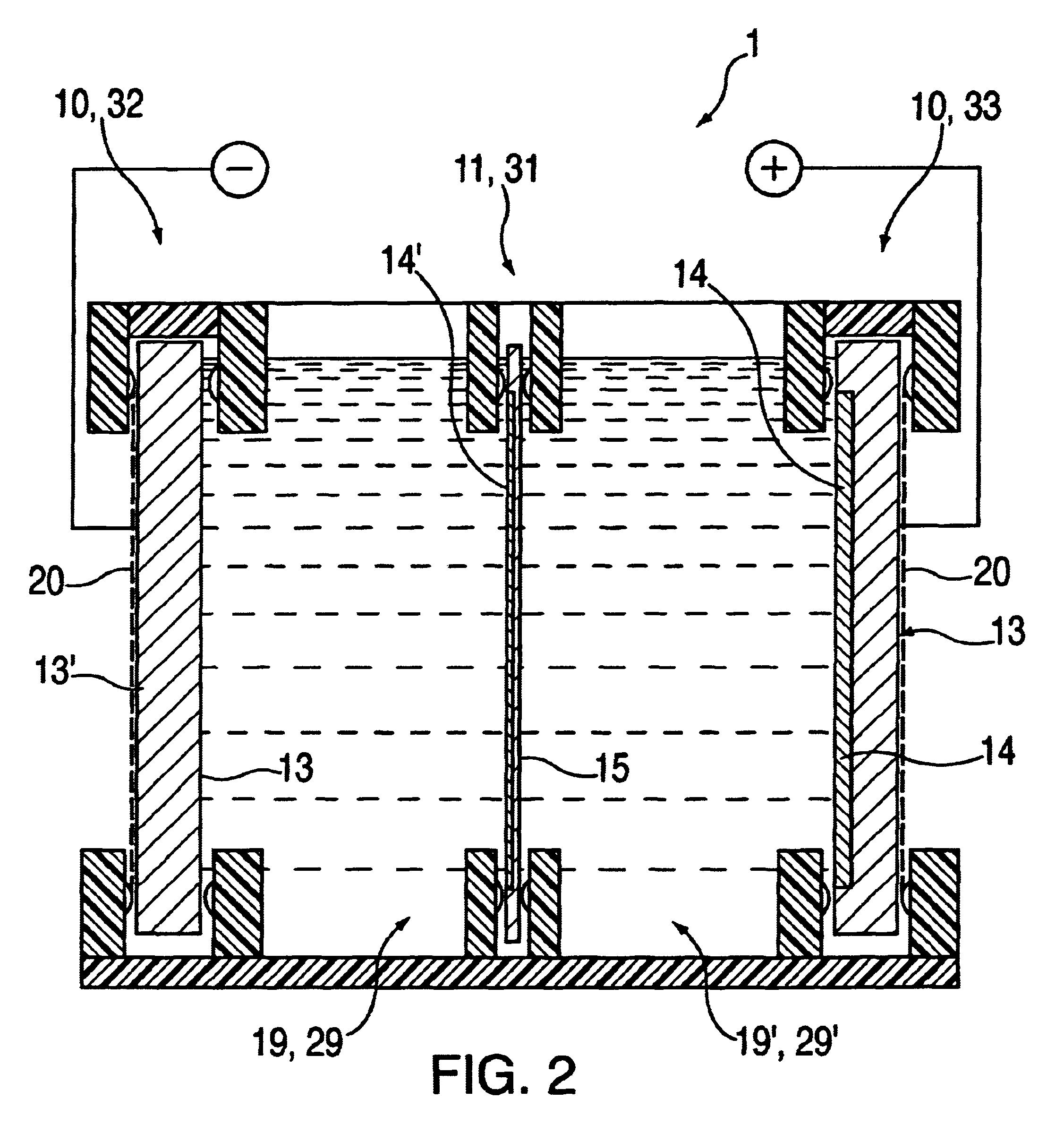

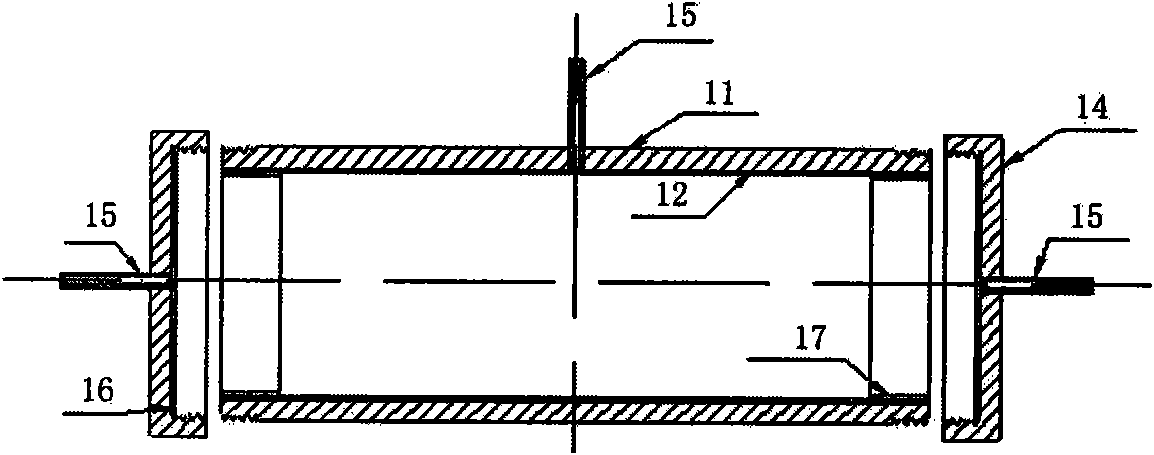

Electrochemical etching cell

InactiveUS6726815B1Simplifies electrical contactSimple structure designCellsCell componentsElectrolyteElectrochemical etching

An electrochemical etching cell (1) is proposed for etching an etching body (15) made at least superficially of an etching material. The etching cell (1) has at least one chamber filled with an electrolyte, and is provided with a first electrode (13), which at least superficially has a first electrode material, and with a second electrode (13') which at least superficially has a second electrode material. Furthermore, the etching body (15) is in contact, at least region-wise, with the electrolyte. In this context, the first electrode material and the second electrode material are selected such that, after the etching, the etching body (15) is not contaminated and / or is not impaired in its properties by the electrode materials. In particular, the electrode materials are the same materials as the etching material. Also proposed is a method for etching an etching body (15) using this etching cell (1), the first and / or the second electrode (13, 13') being used as a sacrificial electrode. The proposed etching cell is particularly suitable for etching silicon wafers in a CMOS-compatible production line.

Owner:ROBERT BOSCH GMBH

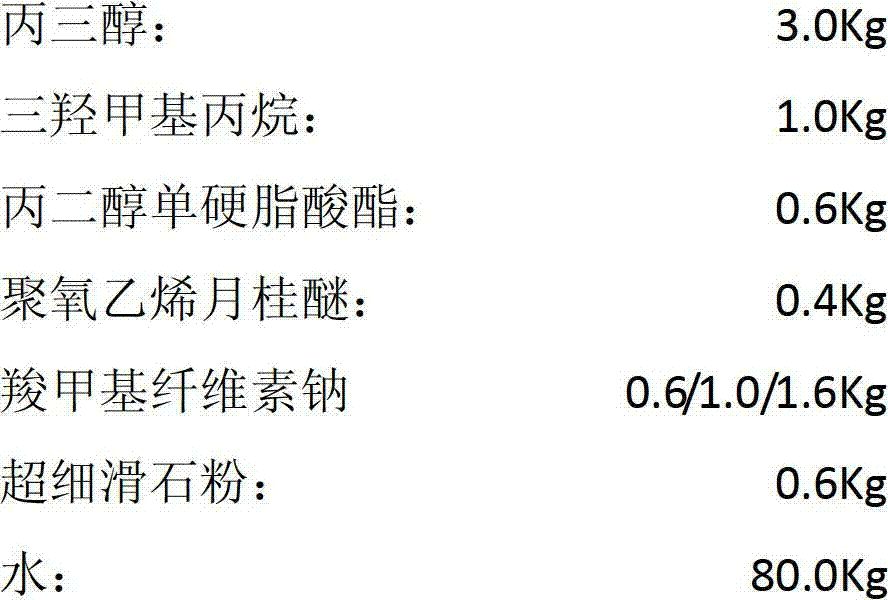

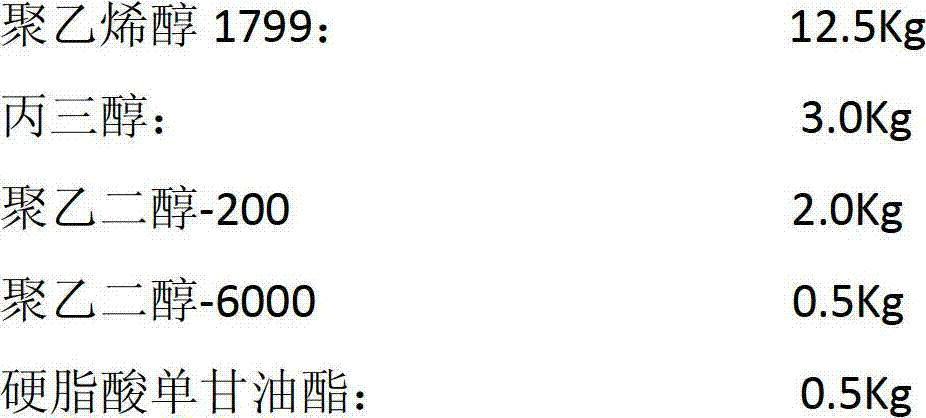

Controllable-respiration preservative film and preparation method thereof

InactiveCN102924855AAchieve free breathingImprove barrier propertiesFruit and vegetables preservationPolymer sciencePolyvinyl alcohol

The invention discloses a controllable-respiration preservative film and a preparation method thereof. The method comprises the following steps: dissolving a water-soluble polyhydroxy plasticizer in water, adding the reaction raw material, heating until the raw material is completely dissolved in water, dispersing at high speed, and cooling to 50-70 DEG C to prepare a solution for running filming; and running the solution for running filming onto a steel belt on a running production line via a die head, and drying to obtain the controllable-respiration preservative film. The controllable-respiration preservative film is prepared from the reaction raw materials in percentage by mass: 60-80% of polyvinyl alcohol, 10-30% of water-soluble polyhydroxy plasticizer, 1-5% of moisture respiration regulator, 1-3% of compatilizer, 3-10% of water retention agent and 0.5-3% of assistant. The preservative film has high barrier property for oxygen and nitrogen sources; the bidirectional permeation exchange power for moisture can be effectively regulated and controlled through the raw material formula; and thus, the preservative film can ensure free respiration and moisture exchange of fruits and vegetables in the preservation process.

Owner:SOUTH CHINA UNIV OF TECH

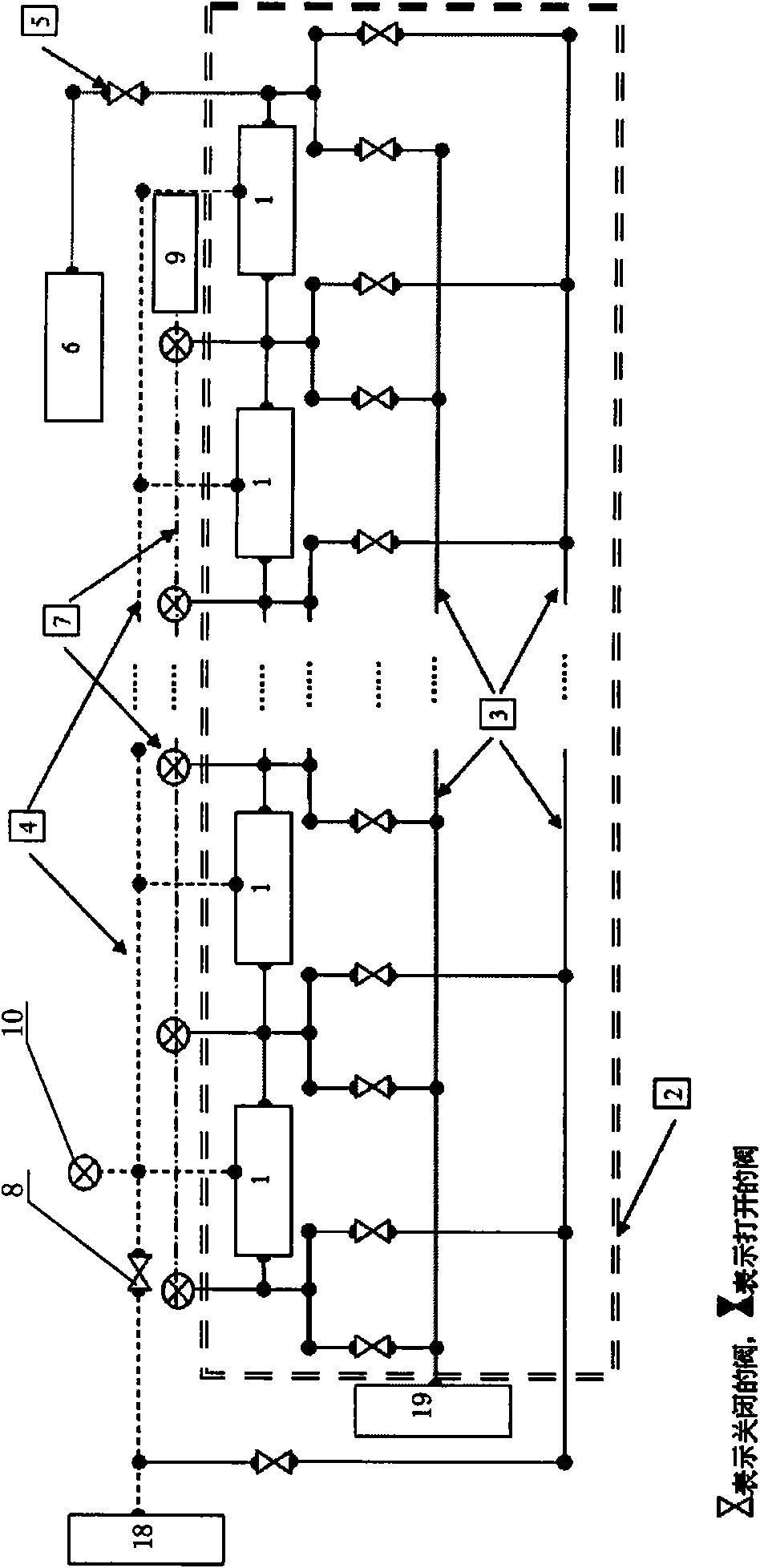

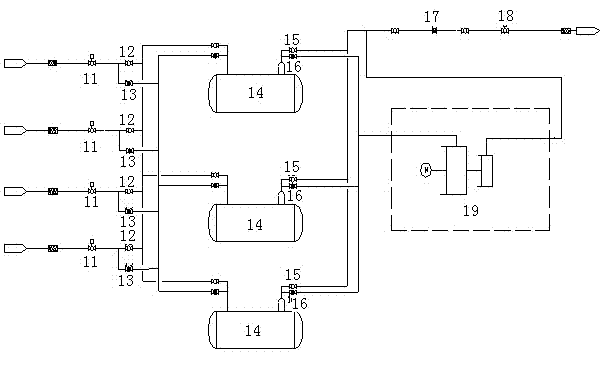

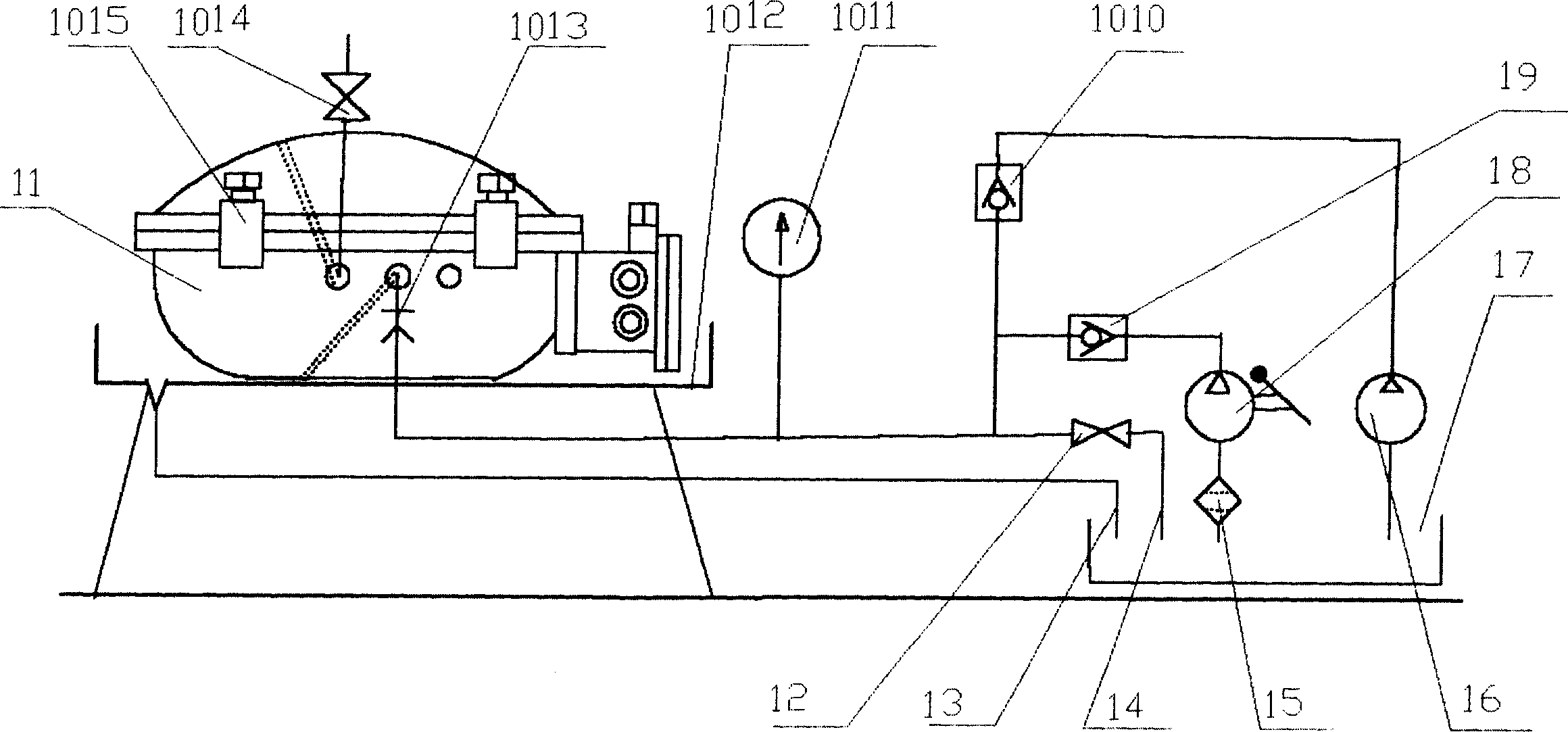

Physical simulation device and simulation method for coal bed methane production

InactiveCN101799466ARealize automatic collectionReal-time display of node pressureFuel testingGeological measurementsWater bathsMethane production

The invention relates to a physical simulation device and a simulation method for coal bed methane production. In the process of production simulation of the current production experiment well and numerical simulation, the cost is high and the accuracy of the numerical simulation can not be ensured. In the physical simulation device and the simulation method for coal bed methane production of the invention, the device comprises sample bins, a thermostatic water bath system, a gas / water metering system and a pressure monitoring system, wherein the sample bins are mutually connected through gas / water configuration production pipelines to form a simulation system; the thermostatic water bath system is arranged around the simulation system; the sample bins of the simulation system are all connected with confining pressure simulation pipelines; the pressure monitoring system is arranged on the gas / water configuration production pipelines at the ends of the sample chambers; simulation well mouths are connected with the gas / water configuration production pipelines at the tail ends of the simulation system; and the simulation well mouths are connected with the gas / water metering system. Through the device and simulation method of the invention, the gas filling, water injection and production states are simulated, thereby optimizing the gas well production working system, reducing the cost, and simultaneously ensuring safe high-efficiency exploitation of the coal bed methane.

Owner:煤炭科学研究总院有限公司西安研究院

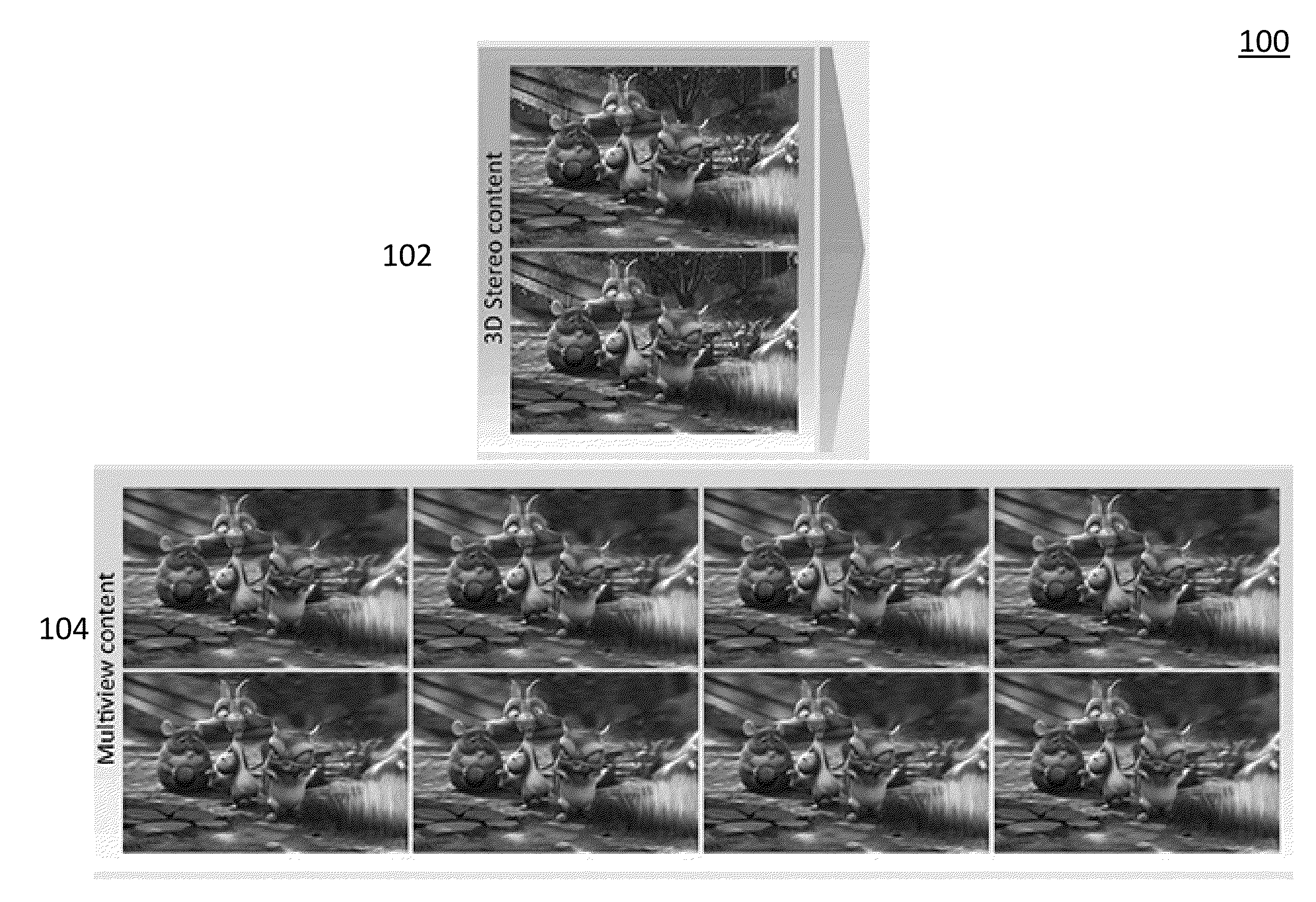

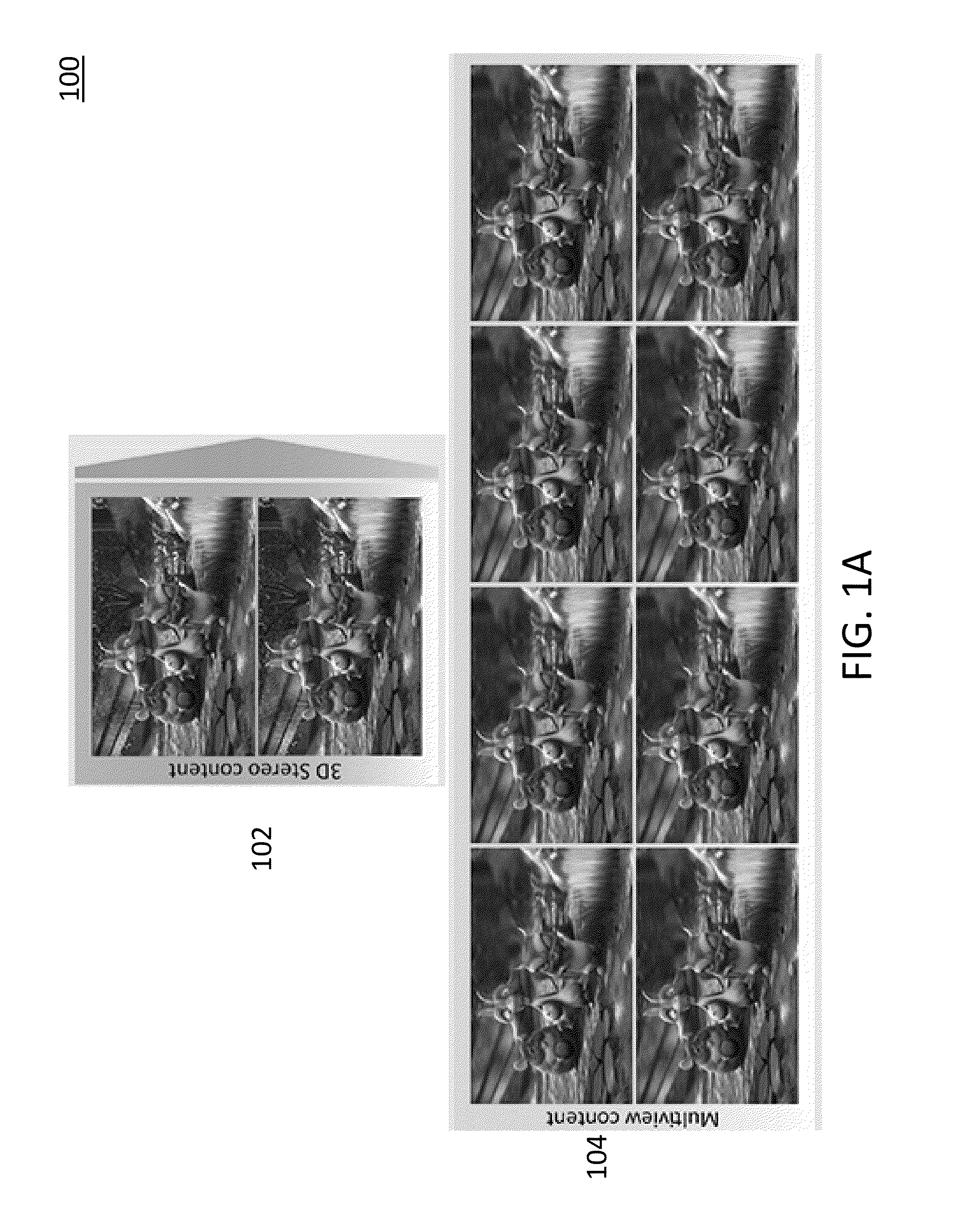

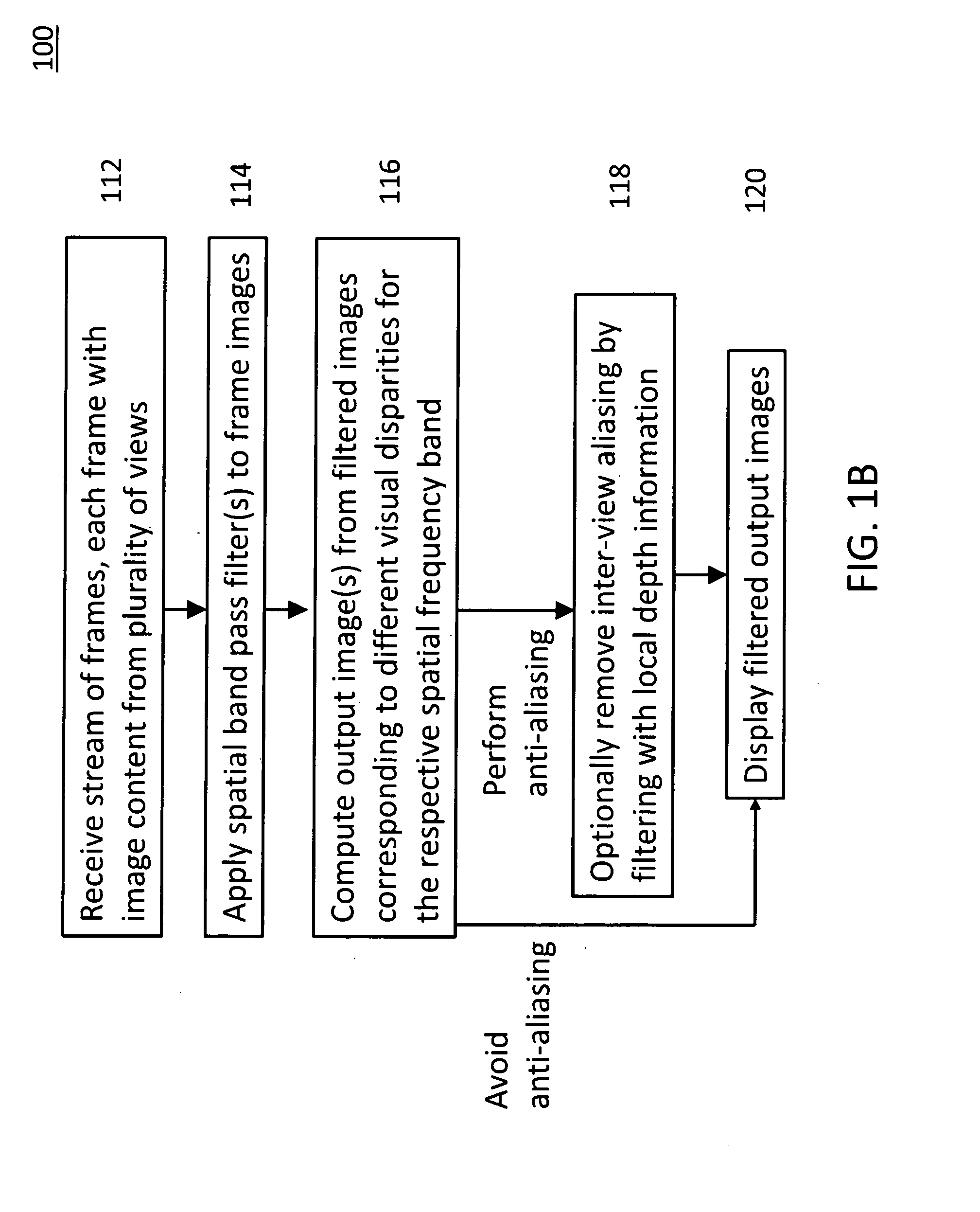

Joint View Expansion And Filtering For Automultiscopic 3D Displays

ActiveUS20150124062A1Good effectReduce the numberSteroscopic systemsStereoscopic videoDisplay device

Multi-view autostereoscopic displays provide an immersive, glasses-free 3D viewing experience, but they preferably use correctly filtered content from multiple viewpoints. The filtered content, however, may not be easily obtained with current stereoscopic production pipelines. The proposed method and system takes a stereoscopic video as an input and converts it to multi-view and filtered video streams that may be used to drive multi-view autostereoscopic displays. The method combines a phase-based video magnification and an interperspective antialiasing into a single filtering process. The whole algorithm is simple and may be efficiently implemented on current GPUs to yield real-time performance. Furthermore, the ability to retarget disparity is naturally supported. The method is robust and works transparent materials, and specularities. The method provides superior results when compared to the state-of-the-art depth-based rendering methods. The method is showcased in the context of a real-time 3D videoconferencing system.

Owner:MASSACHUSETTS INST OF TECH

Anticorrosive sealant for hems in automobile manufacturing

InactiveCN104327783ASimple preparation processGood storage stabilityNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyCar manufacturing

The invention relates to an anticorrosive sealant for hems in automobile manufacturing, particularly an anticorrosive sealants for hems of car doors, boot lids, hood shields and the like in the automobile manufacturing process, which has the functions of sealing, corrosion resistance and rust prevention. The anticorrosive sealant is a composition composed of an epoxy resin, a thermoplastic resin, synthetic rubber, a plasticizer, a latent curing agent, a vulcanizing agent, an accelerator, a preservative, a thixotropic agent and a filler. The sealant has the advantages of simple preparation technique, identical curing temperature and automobile production pipeline temperature, high storage stability, high toughness of the curing product, low cost and environmental protection. When being used for sealing, rust prevention and corrosion resistance of hems of car doors, boot lids, hood shields and the like, the sealant can greatly enhance the overall reliability and durability of the automobile. When in use, the sealant can be directly coated on the edge in need of sealing by an automatic coater or pressure spray gun, has the advantages of higher peel strength and lower internal stress, and is convenient to use.

Owner:三友(天津)高分子技术有限公司 +1

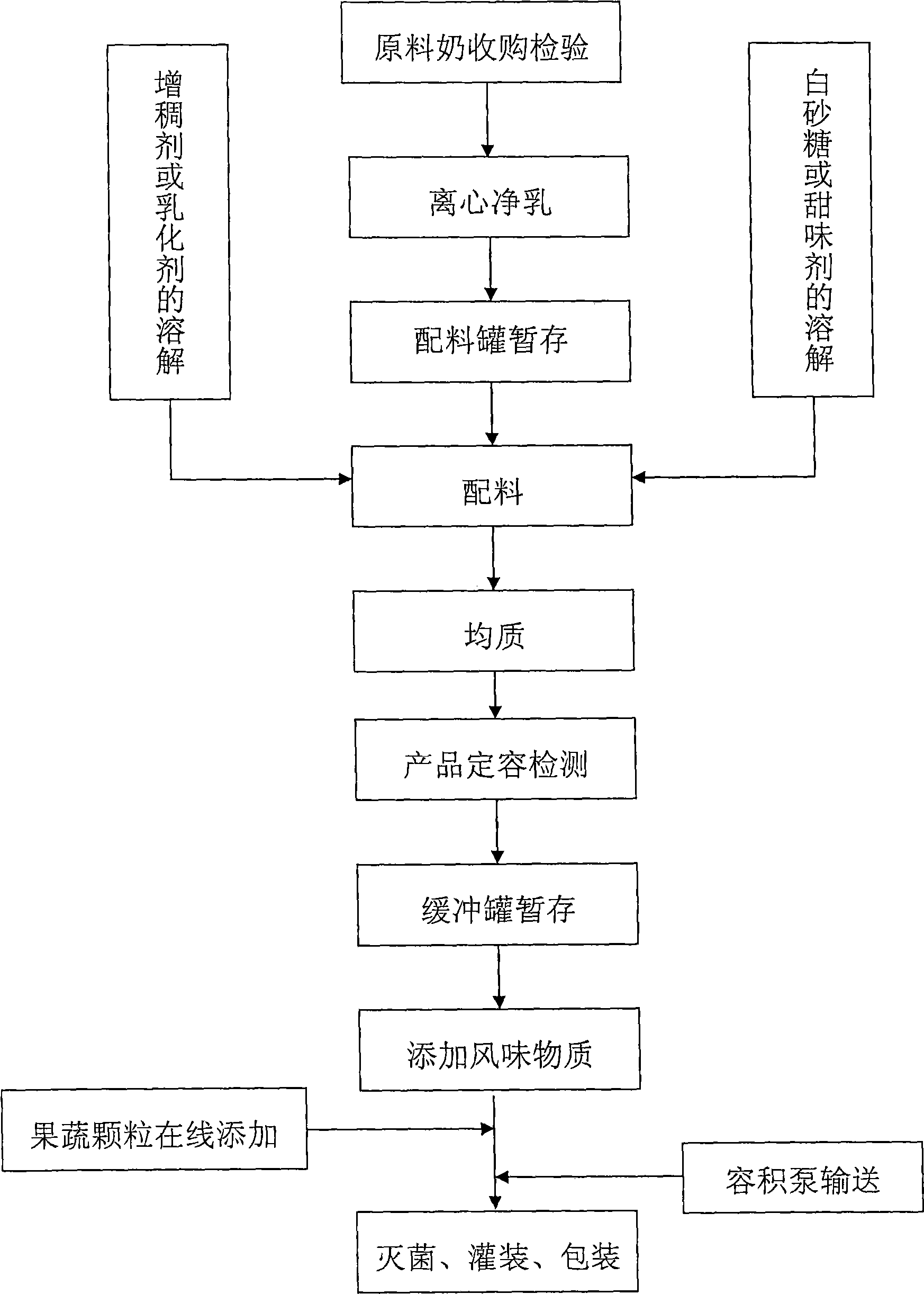

Method for producing liquid milk product containing fruit-vegetable granules

ActiveCN101543246AAvoid mechanical damageReduce breakage rateMilk preparationFood preparationMixed materialsLiquid milk

The invention relates to a method for producing a liquid milk product containing fruit-vegetable granules, wherein the compositions of raw materials of the liquid milk product comprises milk, fruit-vegetable granule material liquid, a stabilizer and water. The production method comprises the following: 1) a step of preparing a base material, which is to mix the milk, the stabilizer and the water well, homogenize the mixture and obtain the base material; 2) a step of adding the fruit-vegetable granules, which is to convey the fruit-vegetable granule material liquid to a production pipeline, mix the fruit-vegetable granule material liquid with the base material on line, obtain mixed material liquid and convey the mixed material liquid to a sterilization machine for sterilization; and 3) a step of canning the material liquid, which is to can the sterilized mixed material liquid and obtain the liquid milk product. The production method does not need to temporarily store or delay storing the material liquid and does not need agitation, thereby reducing the destruction of the fruit-vegetable granules which is caused by mechanical agitation, protecting the shape and size of the fruit-vegetable granules from destruction and reducing the broken rate of the fruit-vegetable granules. In addition, as the liquid milk product is uniform in the content of the fruit-vegetable granules in every unit package and good in taste, the method improves product quality.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

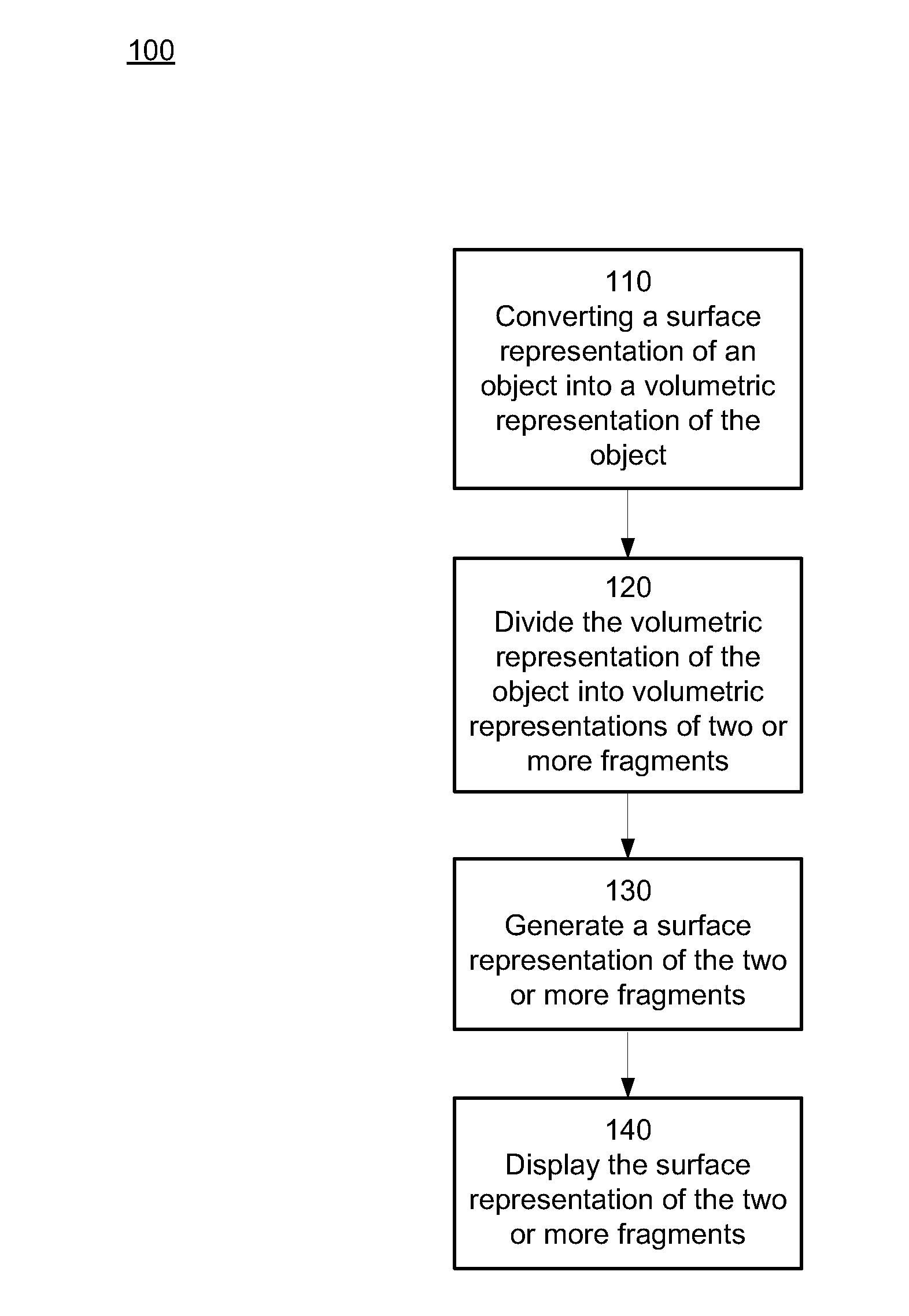

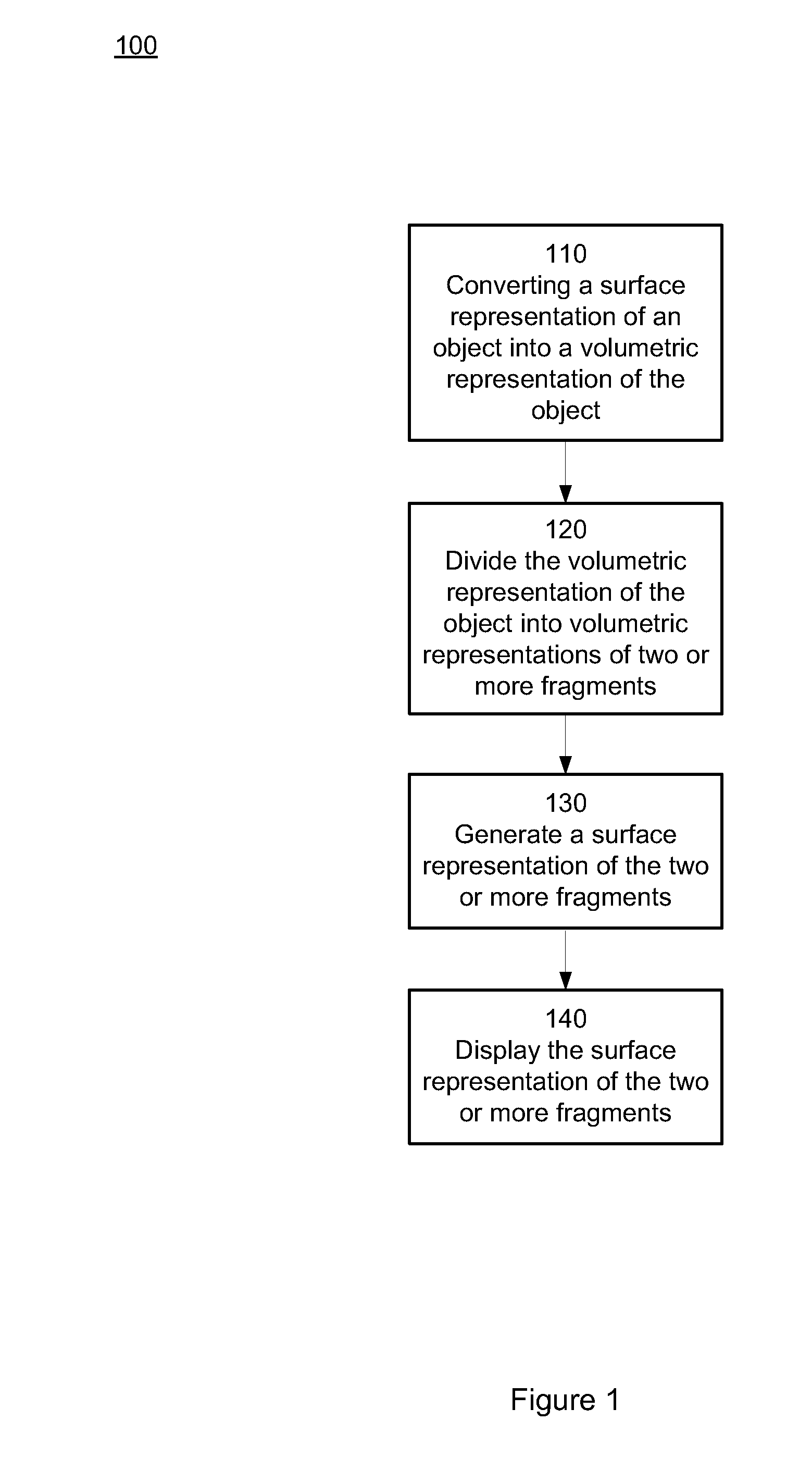

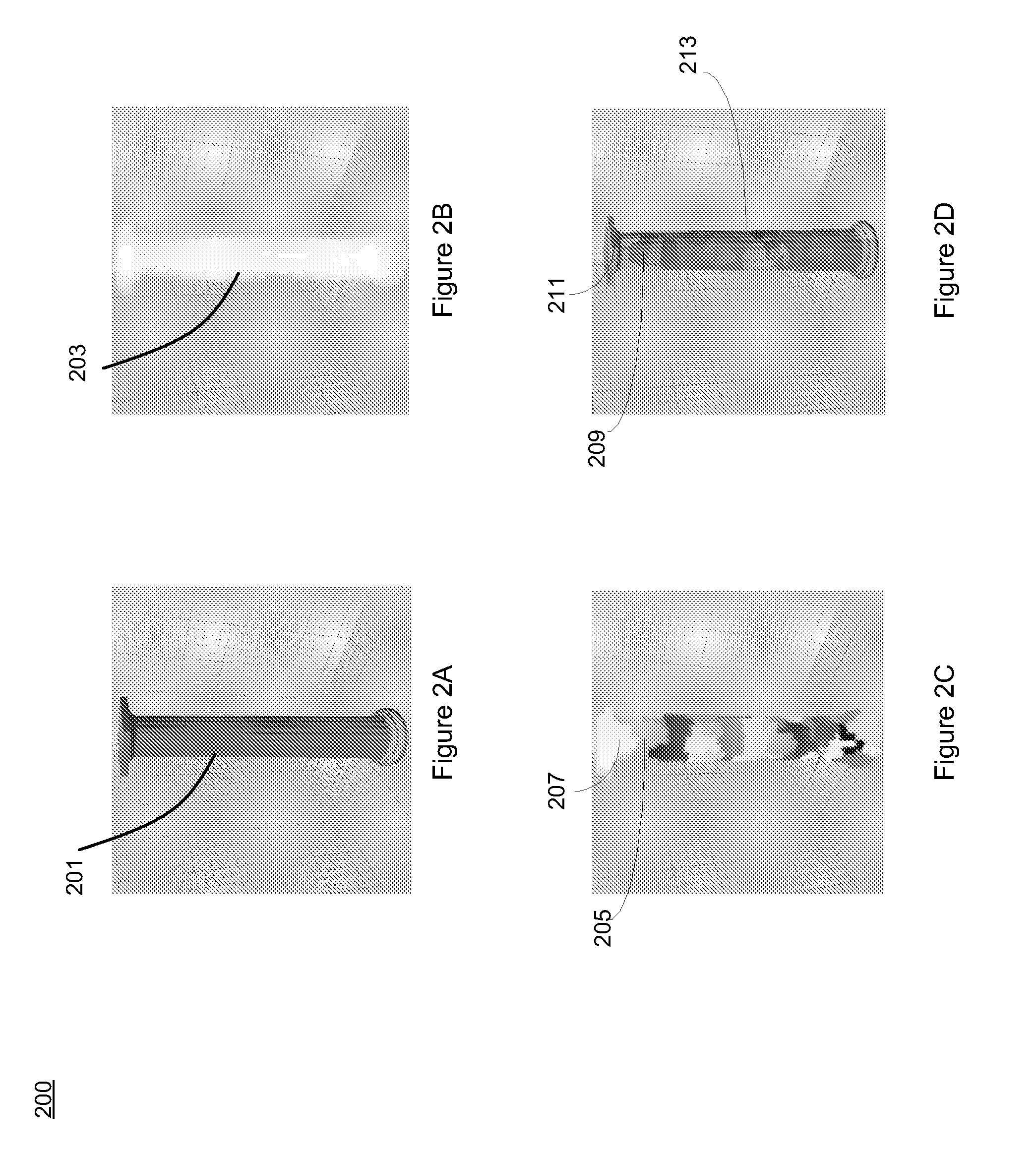

Seamless fracture in a production pipeline

ActiveUS20120001909A1Cathode-ray tube indicatorsAnimationComputer graphics (images)Production pipeline

Owner:DREAMWORKS ANIMATION LLC

Low-permeability gas field gathering and transmitting system and gathering and transmitting method thereof

ActiveCN104728604AReduce injection volumeLow investment costPipeline systemsProcess engineeringHigh pressure

The invention relates to a low-permeability gas field gathering and transmitting system and a gathering and transmitting method of the low-permeability gas field gathering and transmitting system. The low-permeability gas field gathering and transmitting system comprises a plurality of gas gathering stations, a plurality of well clusters and a processing factory, wherein the well clusters are communicated with the gas gathering stations through independent gas production pipelines, the gas gathering stations are communicated to the processing factory sequentially through gas gathering branch lines and a gas gathering main line, and a gas gathering system is arranged in the gas gathering stations and sequentially comprises a plurality of gas gathering station inlet pipelines, a plurality of separators, a compressor and a gas gathering station outlet pipeline. According to the low-permeability gas field gathering and transmitting system and the gathering and transmitting method of the low-permeability gas field gathering and transmitting system, high-pressure production is performed while the transmitting and processing requirement is met at the early stage of the well clusters, pressure energy and temperature energy at the early stage of a gas well are fully utilized, the pipe diameter of a pipeline and the injection amount of hydrate inhibitors are reduced, low-pressure production is performed at the middle-later stage, concentrated pressurization is performed on the gas gathering stations, concentrated processing is performed in the processing factory, gas field development ground investment and running cost are reduced, and construction of a gas gathering pipe network is more reasonable.

Owner:XIAN CHANGQING TECH ENG

High-temperature-resistance oxidation coating for predry-free full-descaling steel billet

InactiveCN1935921AApply evenlyDoes not affect the application effectLiquid surface applicatorsAnti-corrosive paintsEpoxySurface oxidation

The invention discloses total scale removal billet using high temperature resistance oxidation paint without pre-drying. It includes the following steps: using high temperature melt film screen and oxidation reduction doubling protection mechanism, cross blend modified resin ofmetlbond, epoxy, organic silicon resin, high temperature oxide, high melting point reducing metal, flame resisting silicate material, auxiliary agent as raw material, processing complexing, cross linking, curing, drying. The using of the paint is not need billet surface pretreatment, pre-drying, has self stripping total scale removal performance, can reduce billet ratio of burnt area, effectively increase steel surface quality, reduce steel surface post processing workload, has no pollution for environment. And it can be used in heating furnace, heat treatment furnace under 1500 degree centigrade etc.

Owner:陈历泽

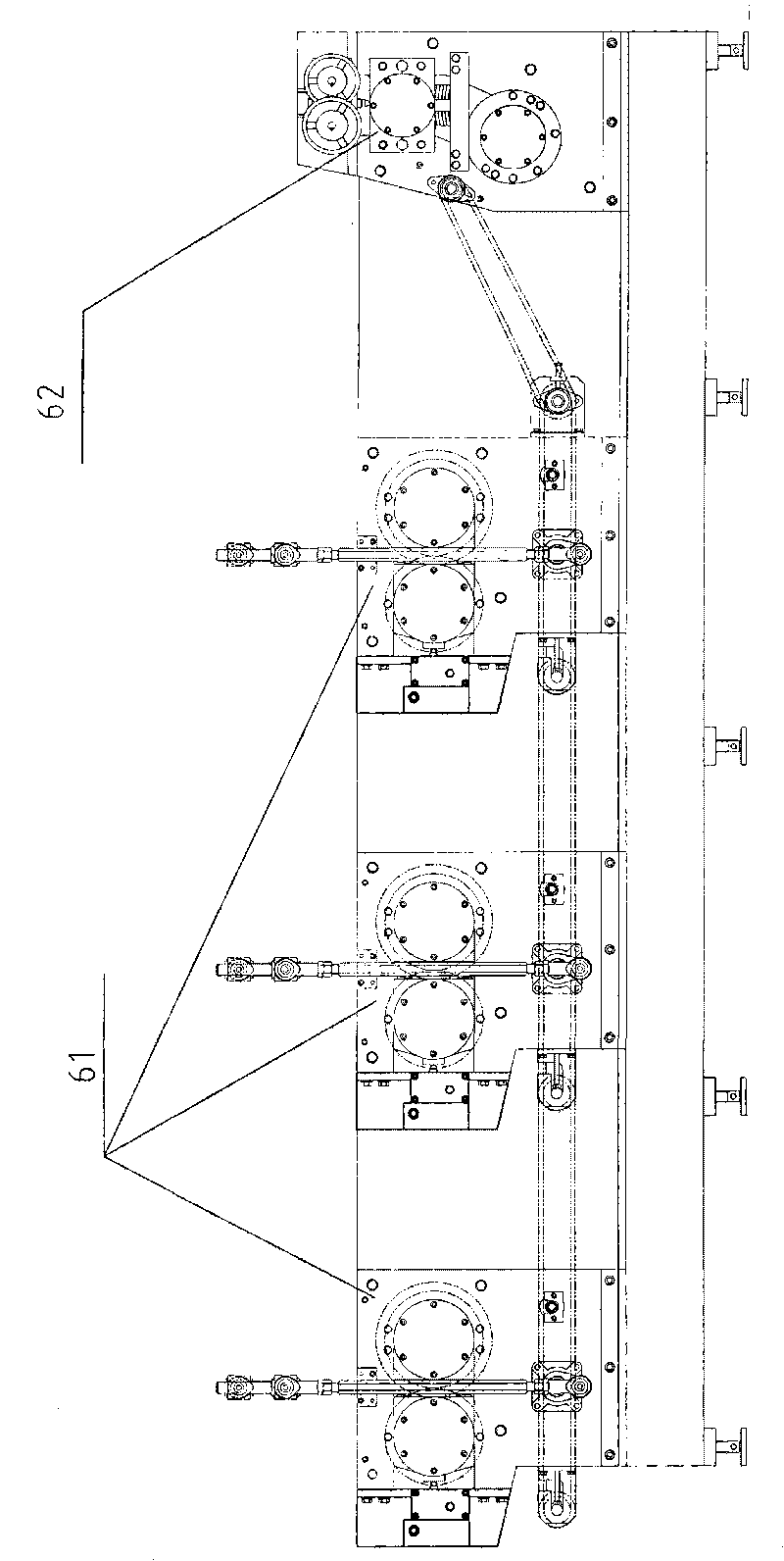

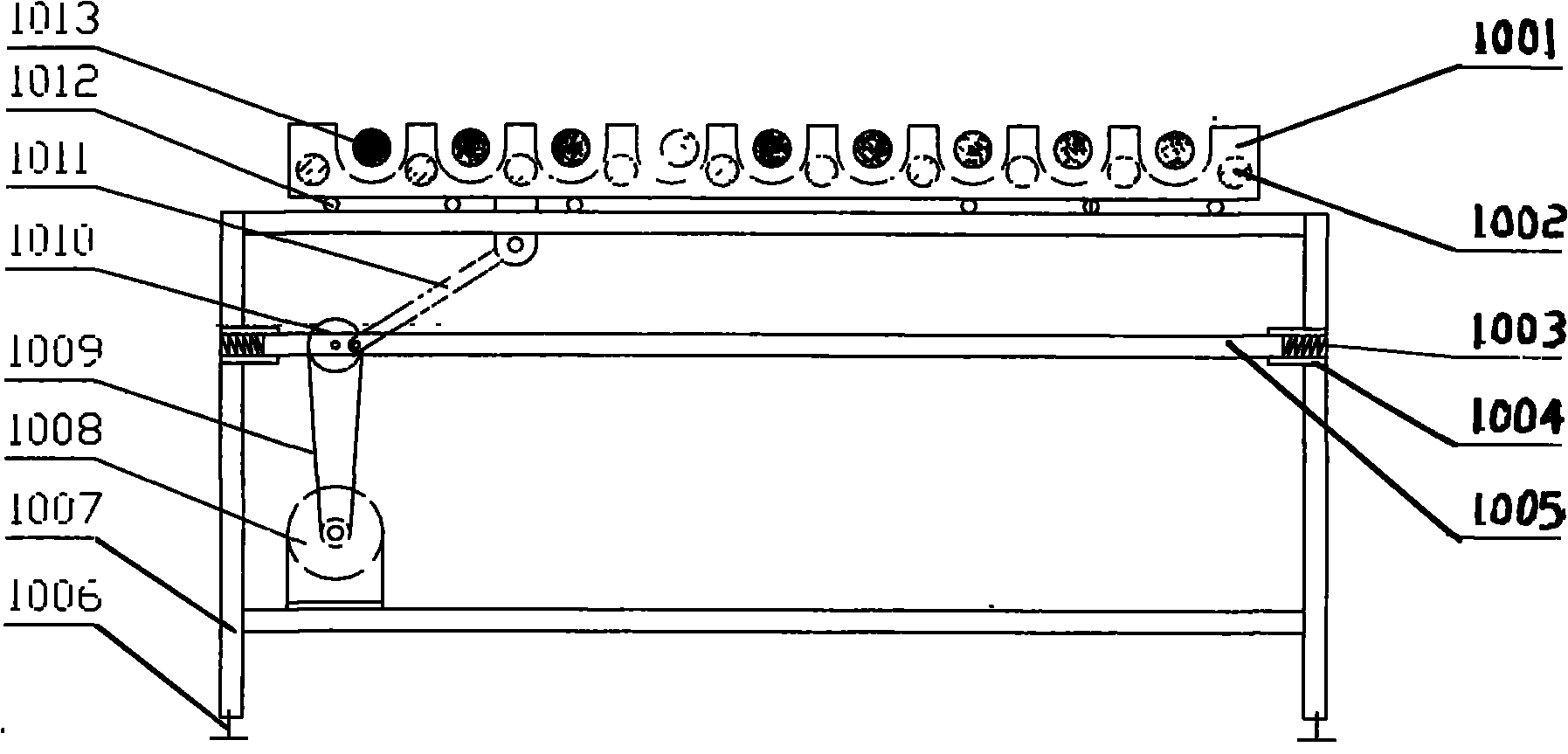

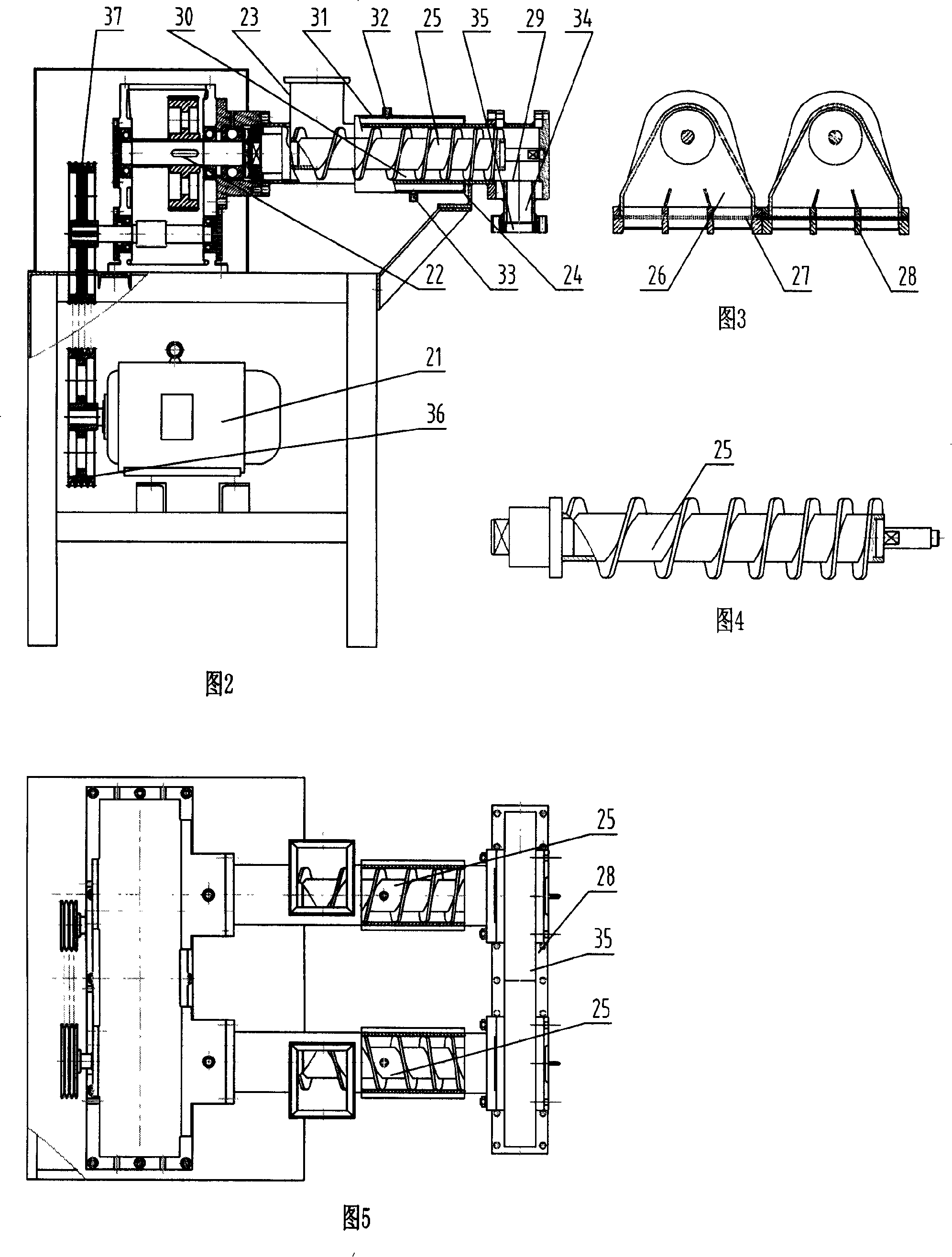

Tube-type slab lattice paste extrusion production line

ActiveCN102136571AGuaranteed performanceAvoid flyingLead-acid accumulator electrodesControl systemUltrasonic welding

The invention relates to a tube-type slab lattice paste extrusion production line. The tube-type slab lattice paste extrusion production line is characterized in that: a lead paste stirring motor is arranged in a paste extrusion bucket; the paste extrusion bucket is arranged on a paste extrusion rack; the lead paste delivery pipe is arranged on the lower part of the paste extrusion bucket and is connected with a paste extrusion head; and a slab lattice clamp device, a sliding table moving device, a primary paste extruding and washing device, a 1# polar plate delivery device, a back cover delivery device, a welding control system, an ultrasonic welding device, a secondary paste extruding and washing device, a 2# polar plate delivery device, a paste weighing device and a waste plate removing device are arranged behind the lead paste delivery pipe in turn. The tube-type slab lattice paste extrusion production line is improved on the basis of an original storage battery tube-type slab lattice which extrudes lead paste directly, and has the characteristics of reliable performance, environment friendliness, and capacity of filling a row gate tube of a storage battery with the lead pasteuniformly and the like.

Owner:ZIBO XINXU POWER SUPPLY TECH

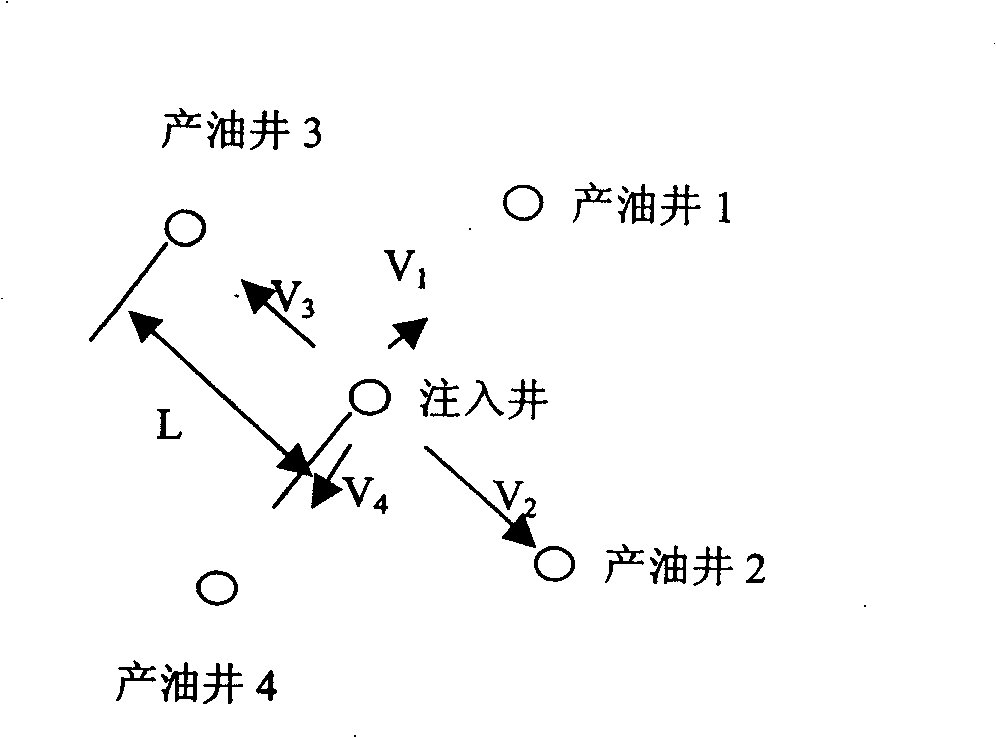

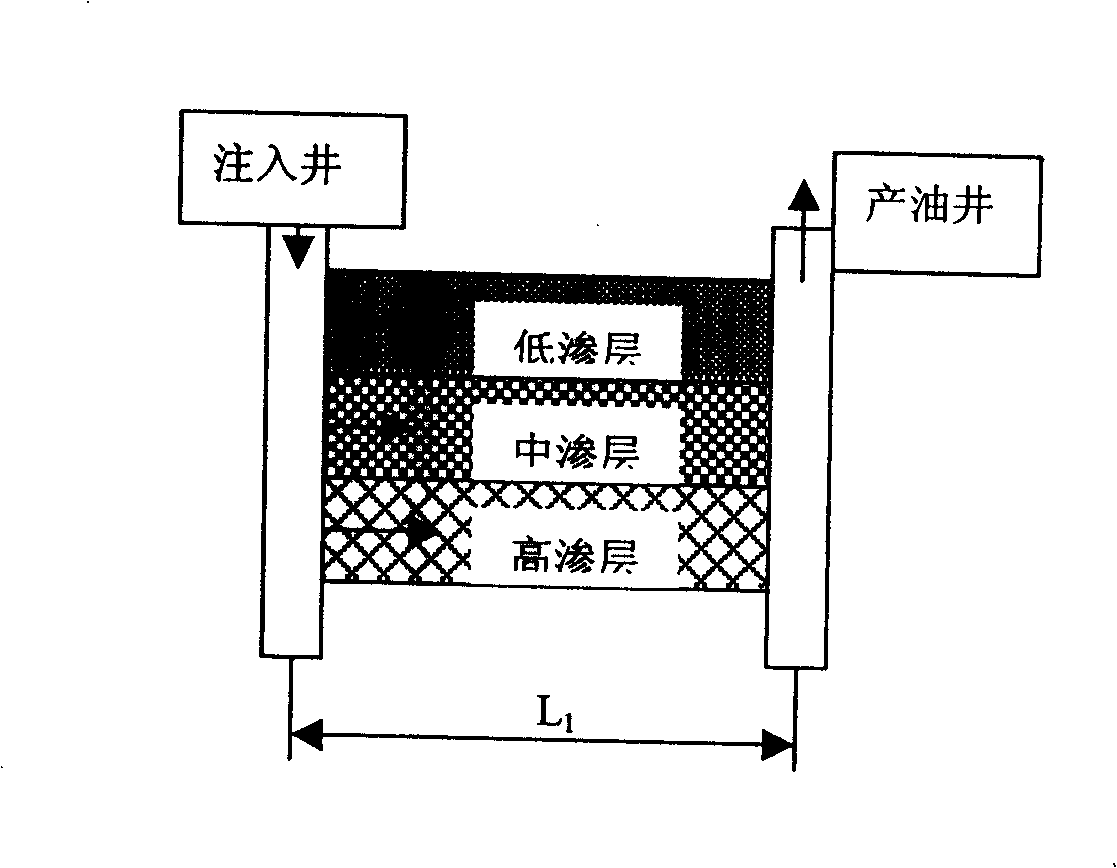

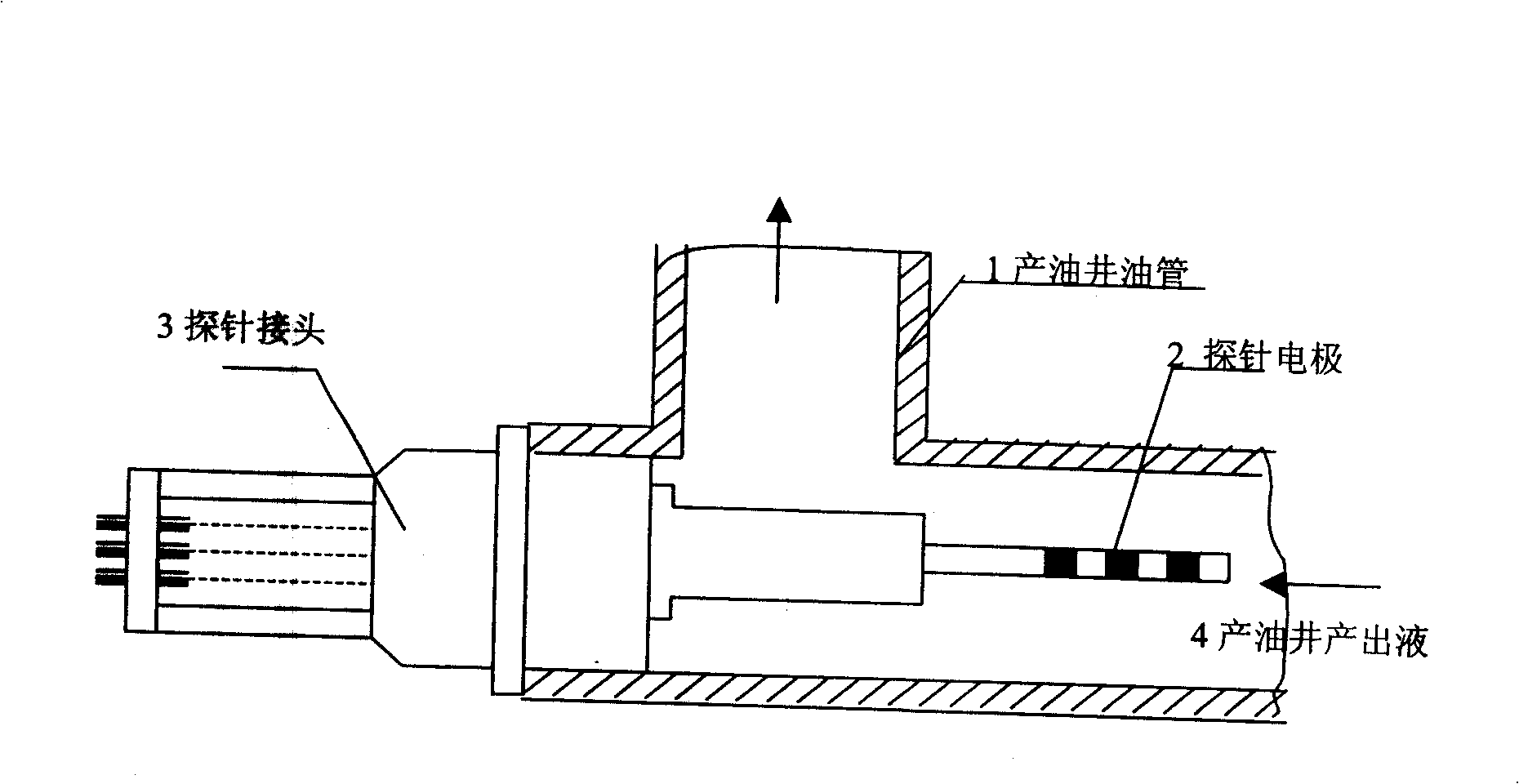

Method for monitoring oilfield high infiltration strip

InactiveCN101260803AQuickly monitor heterogeneityRapid monitoring of hypertonic bandsSurveyEngineeringProduction pipeline

The invention relates to a method for rapidly monitoring a high permeable strip in an oil field; a microprobe is arranged on production pipelines of more than two oil producing wells in a reservoir block which needs monitoring; an electrode of the probe is connected with a voltage measuring apparatus which is connected with a data collecting computer through cables; salt water is injected into a water injection well; measuring data is continuously read in the oil producing wells; and the data variability of specific resistance is calculated to determine stratum pore canals of the oil producing well and the water injection well. The method for rapidly monitoring the high permeable strip in the oil field has high degree of automation and convenient operation, overcomes the disadvantages of manual sampling in the prior interwell tracing and monitoring technology and rapidly and accurately monitors the high permeable strip and non-homogeneity of the reservoir; the measuring and analyzing result has an important effect on predicting the surplus oil distribution in an old oil field, adjusting a developing proposal and implementing the measures to improve the recovery rate.

Owner:PETROCHINA CO LTD

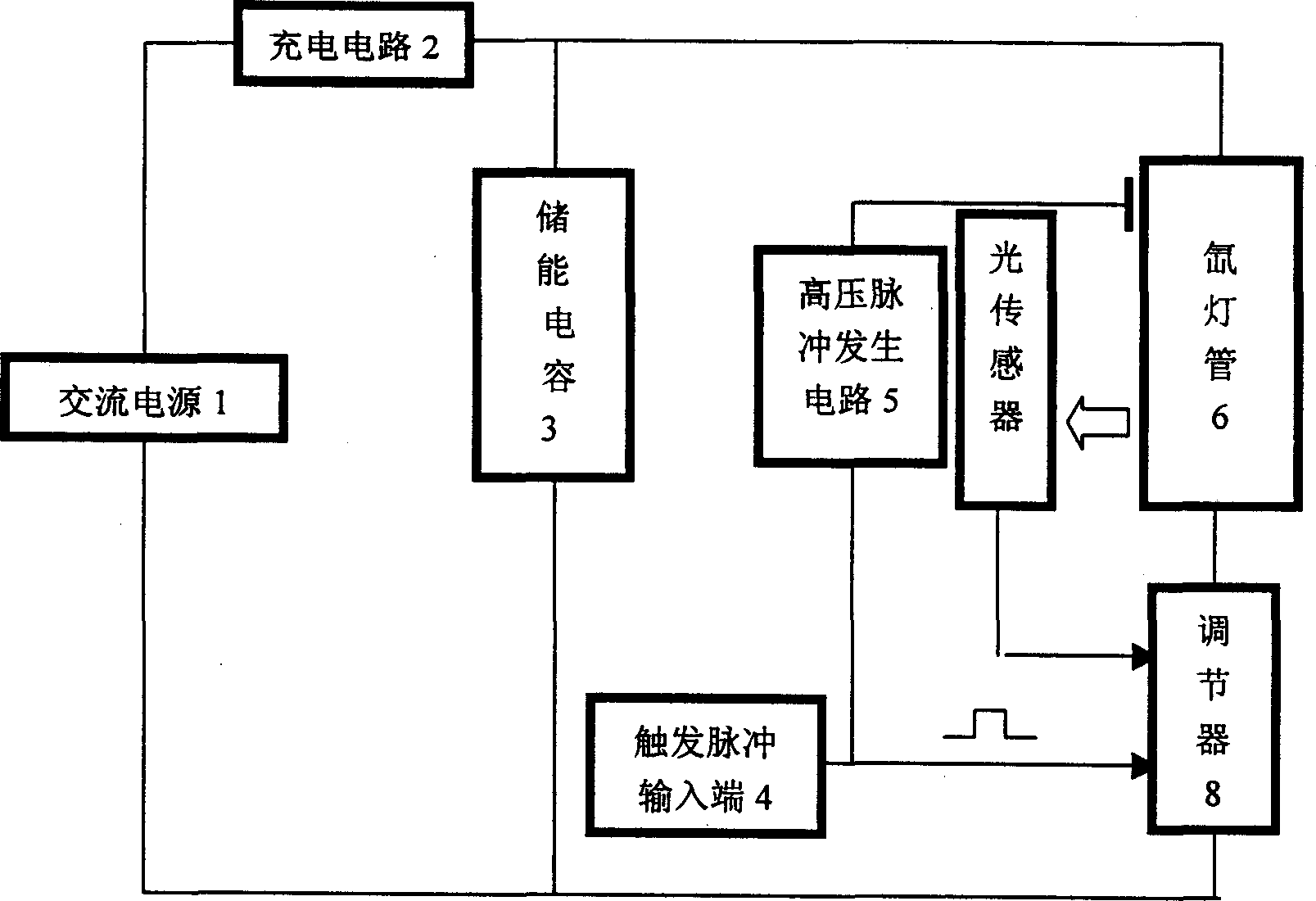

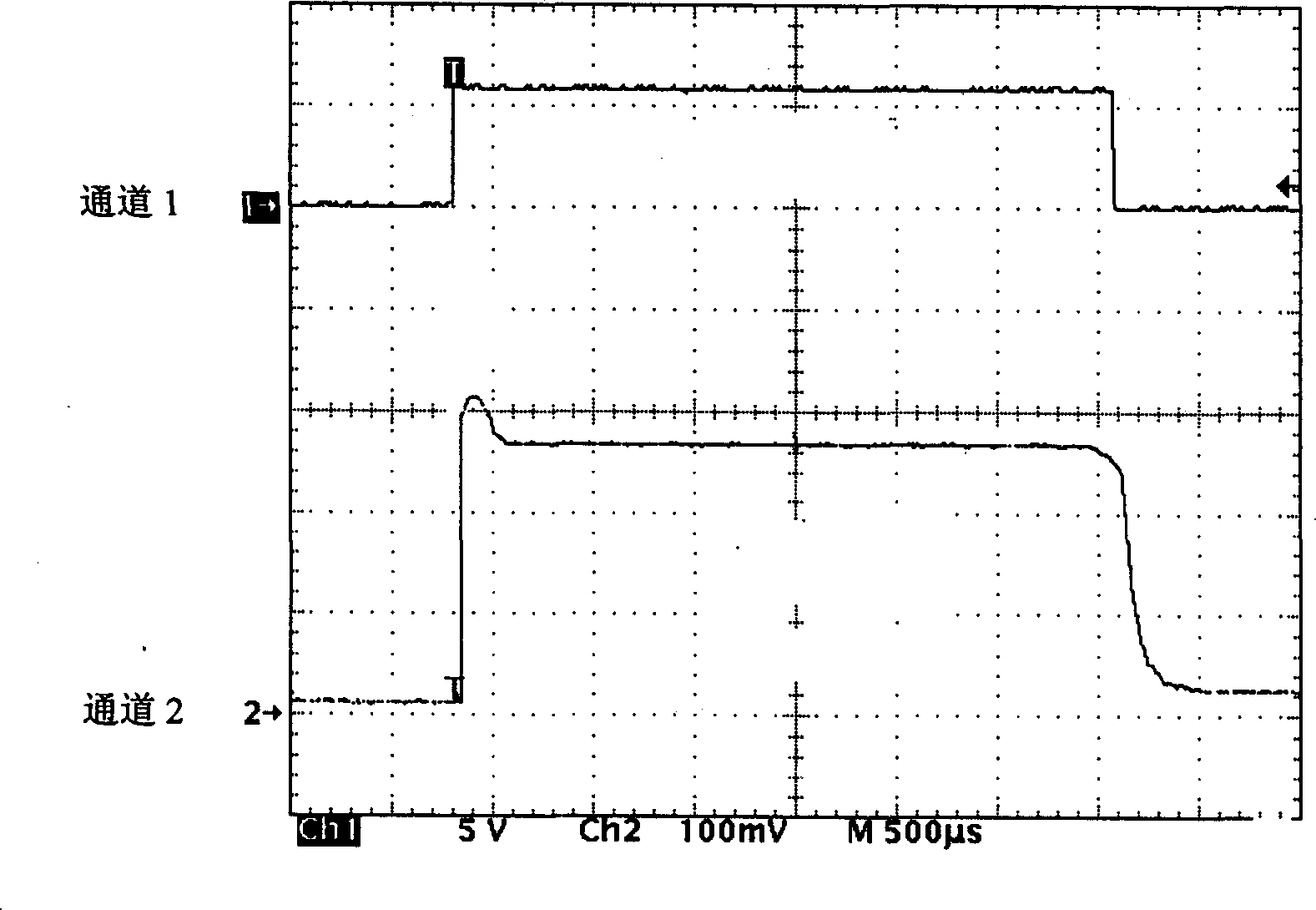

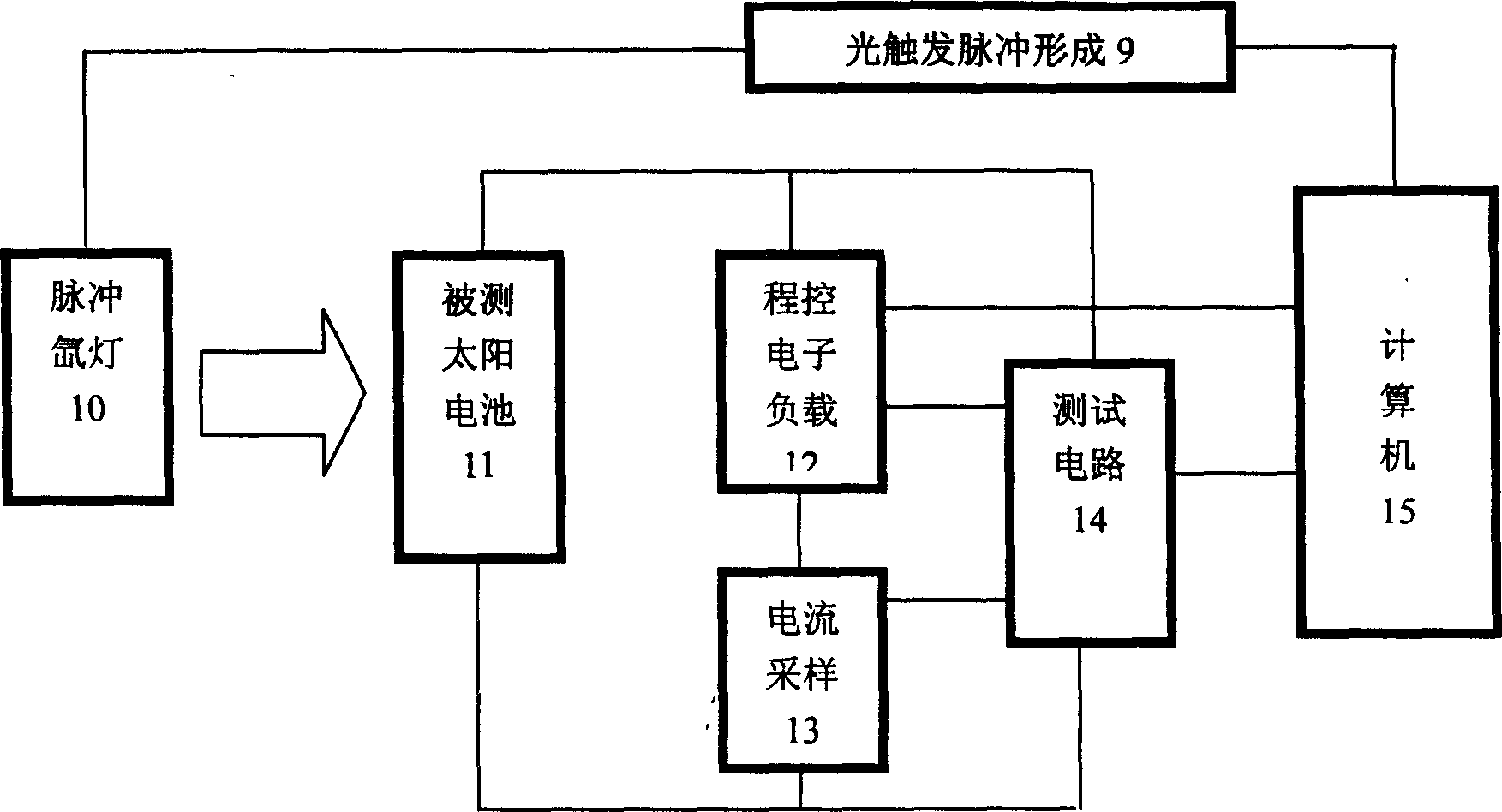

Constant pulsed light xenon lamp solar cell testing method

InactiveCN1456899AQuick testSimple structurePhotovoltaic monitoringPhotovoltaic energy generationSingle flashAutomatic control

A testing method utilizes light feedback and automatic control technique to modify camera used flash light or similar ones to be impulse xenon lamp with constant light strength in addition to conventional program-controlled electron load, testing circuit and computer. The light impulse with several milliseconds of constant light strength can be obtained at each flash of the light source and I-V curve data collection of solar energy battery can be finished by computer-controlled testing circuit within the period of single flash and to finalize test of solar battery electric parameter in several seconds. The method also can be used to test solar battery component as well as can be utilized to manufacture the testing device for both of one-body solar battery and solar battery component.

Owner:XI AN JIAOTONG UNIV

Modified polyvinyl butyral waterproof coiled material

InactiveCN101845186AReduce viscosityHigh mechanical strengthRoof covering using flexible materialsProtective foundationElastomerPolyvinyl butyral

The invention relates to a waterproof material for construction, in particular to a waterproof coiled material prepared from modified waste polyvinyl butyral materials as raw materials, belonging to the technical field of construction engineering waterproof materials. The modified polyvinyl butyral waterproof coiled material is prepared by using recovered waste PVB (Polyvinyl Butyral) as main raw materials and rubber or elastic bodies as main auxiliary materials and matching with a plasticizer, a releasing agent, a stuffing and other auxiliary materials, and a preparation method comprises the steps of: mixing the materials in an internal mixer according to a certain ratio, plasticating into strips or slabs in an open mill, entering a rubber single-screw extrusion molding machine for molding, and then processing on a tri-roll calender production line to obtain the coiled material of a determined thickness. The modified waste polyvinyl butyral waterproof coiled material has the properties of ageing resistance, good elasticity, bending resistance, ultraviolet radiation resistance, chemical corrosion resistance, water penetration resistance and the like.

Owner:ZHENGZHOU UNIV +1

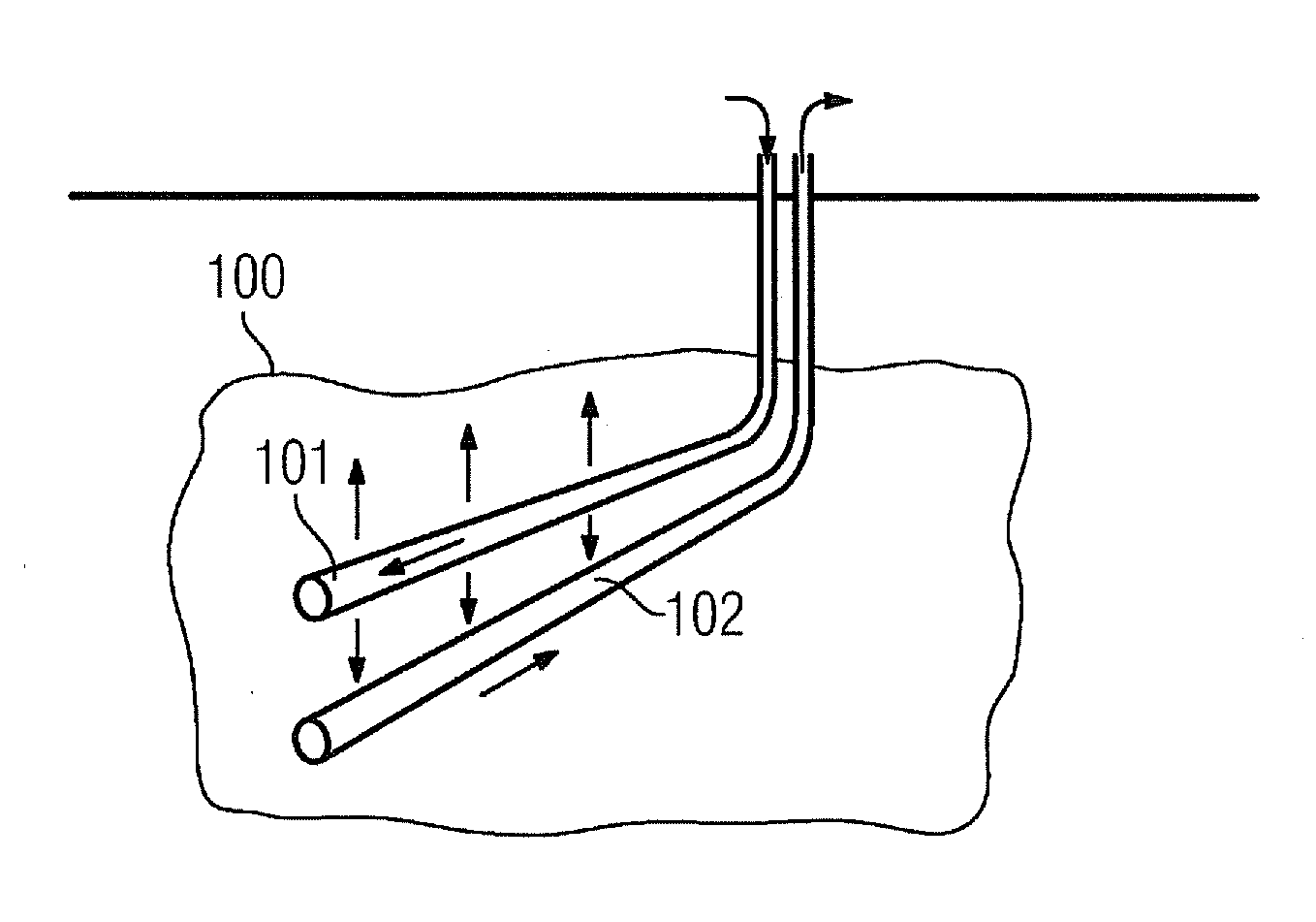

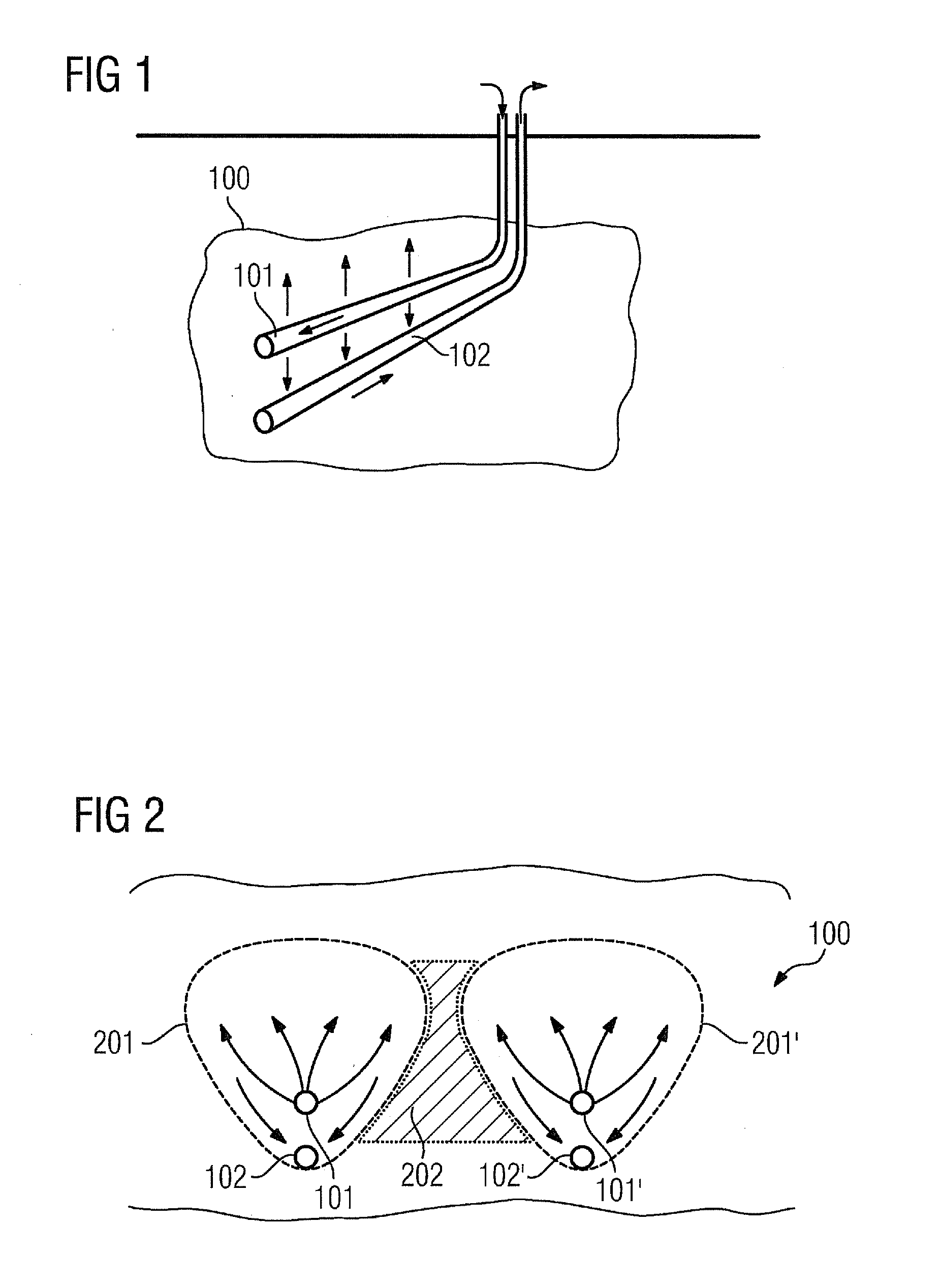

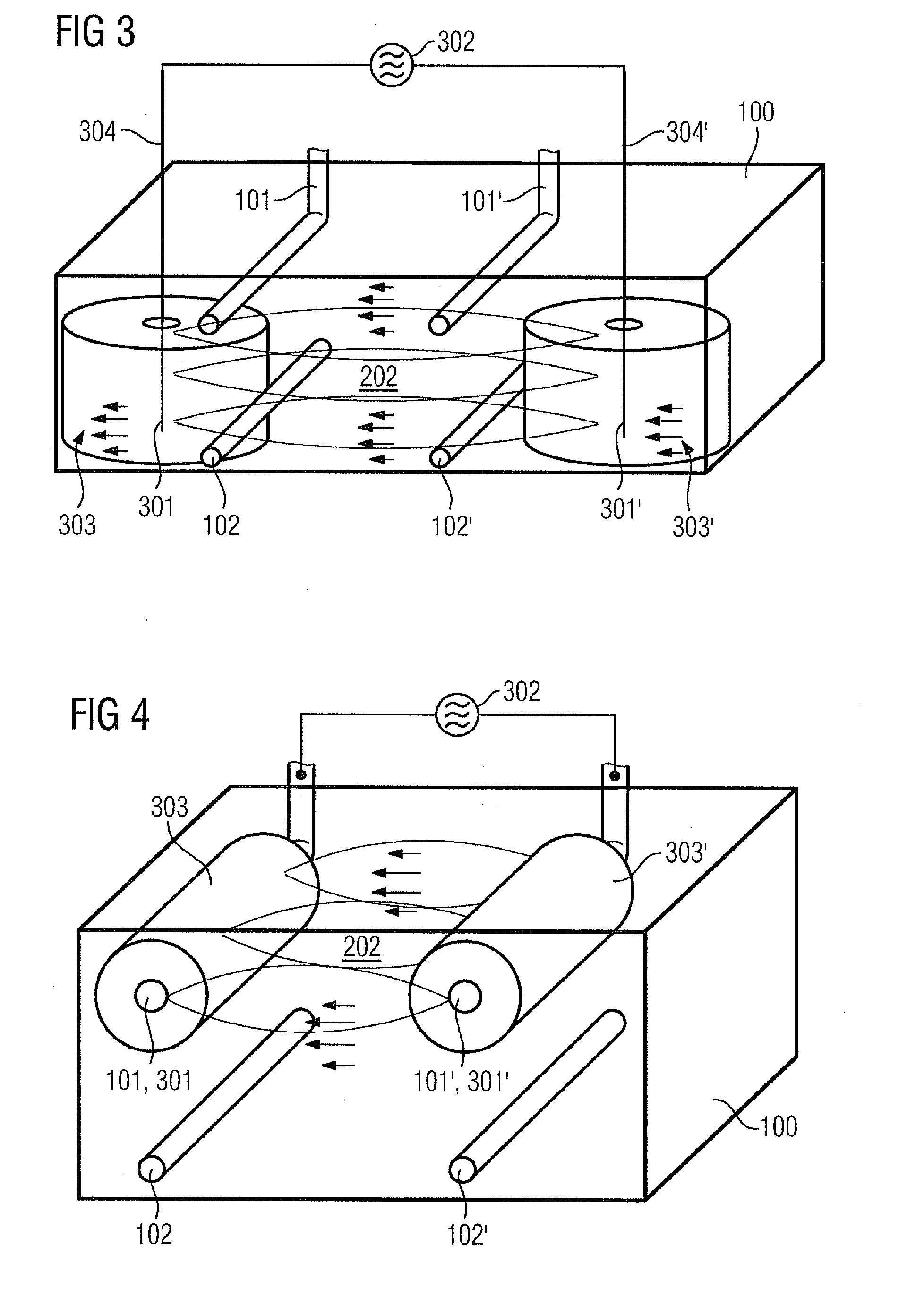

Device for in situ extraction of a substance comprising hydrocarbons

InactiveUS20100252249A1Improve electrical reliabilityGuaranteed uptimeInsulationFluid removalElectrical resistance and conductanceViscosity

A device for in situ extraction of a substance including hydrocarbons while reducing the viscosity thereof from an underground storage site is provided. The device includes at least one production pipeline leading out of the storage site, and at least two electrodes which are inductively and resistively effective relative to at least parts of the storage site.

Owner:SIEMENS AG

Method for re-manufacturing flame-proof outer shell

InactiveCN1468052ALong economic lifeMeet production needsSubstation/switching arrangement casingsManufacturing dynamo-electric machinesSurface engineeringHardness

A process for re-create the flame-proof hull characterized by that, a plurality of techniques are combined using the surface engineering technology as a key process to realize the re-creation using the wasted flame-proof hull as the blank, producing the long life multifunctional flame-proof hull with high hardness of flame-proof surface and high corrosion-resisting performance. The method by the invention can realize the multiple repeated application for the flame-proof hulls.

Owner:SHANXI QUANAN NEW TECH DEV CO LTD

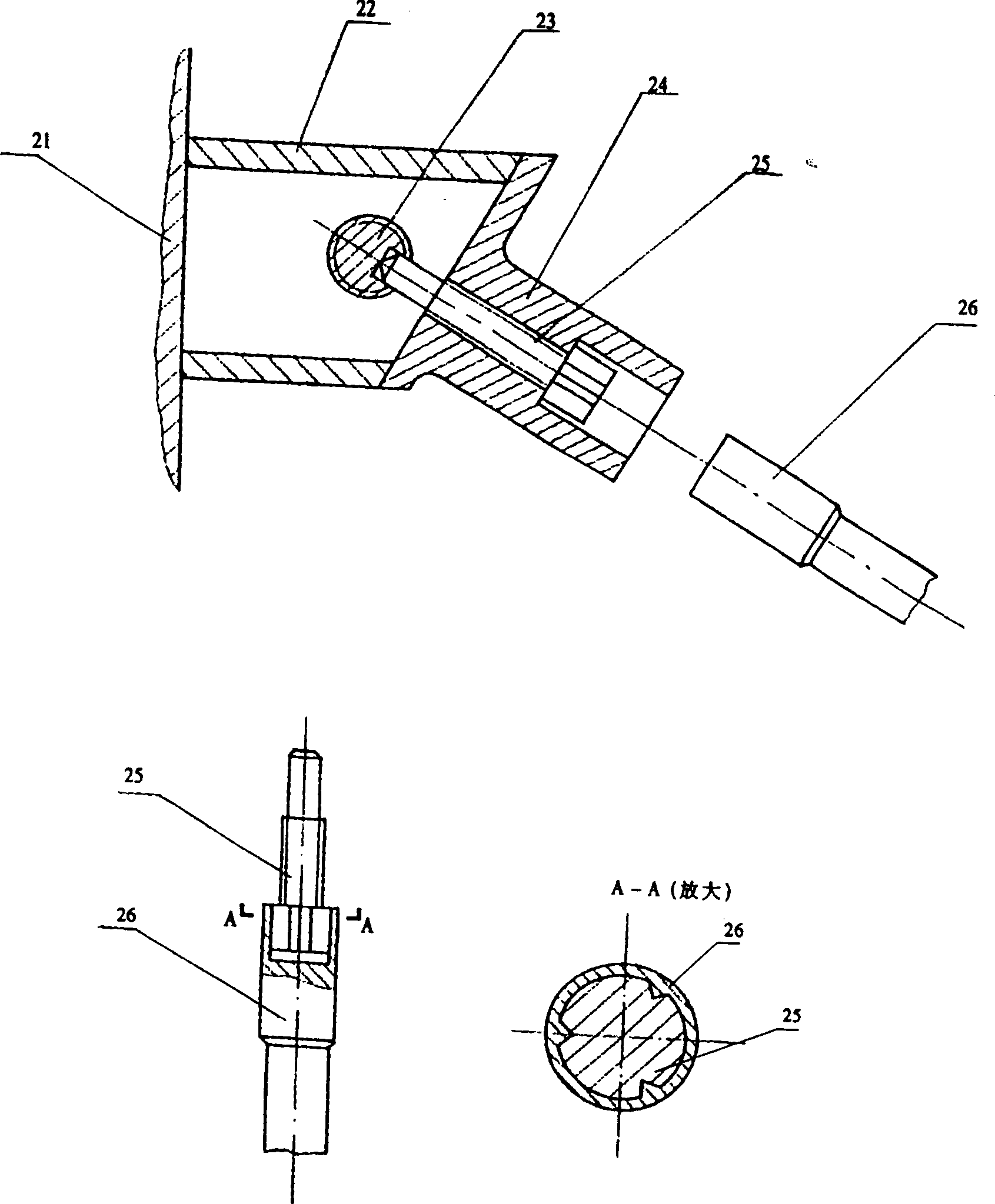

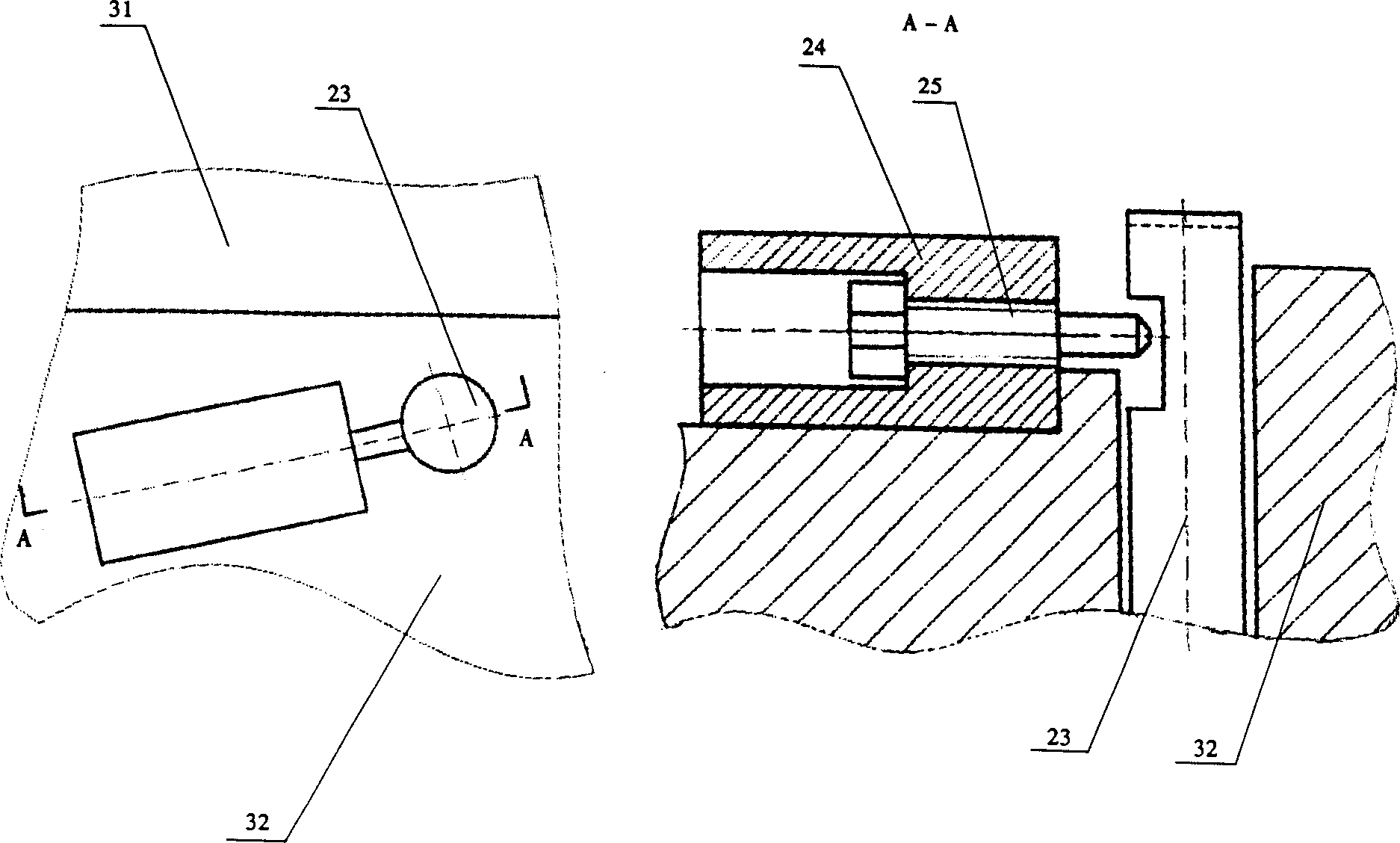

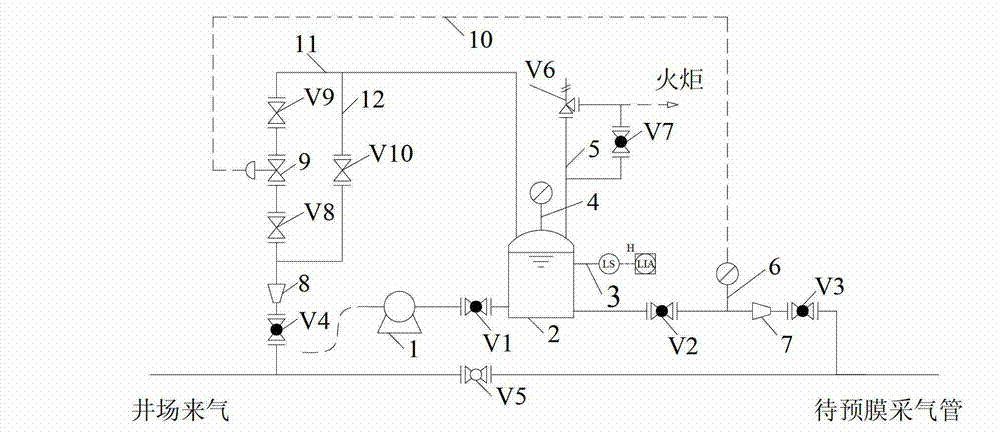

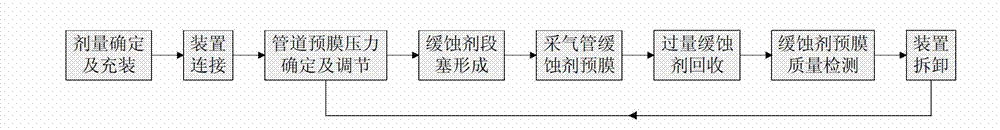

Forming device for gas production pipeline corrosion inhibitor slug pre-film

The invention discloses a forming device for a gas production pipeline corrosion inhibitor slug pre-film. The forming device comprises an injecting pump and a corrosion inhibitor storage tank, wherein an outlet of the injecting pump is communicated with an inlet of the corrosion inhibitor storage tank, an outlet pipeline of the corrosion inhibitor storage tank is provided with a valve and a pressure transmitter, the corrosion inhibitor storage tank is provided with a pressure gage, the pressure transmitter is communicated with a pressure regulating valve through a pipeline a, the pressure regulating valve is communicated with the corrosion inhibitor storage tank through a pipeline b, the pipeline b is communicated with a pipeline c, and the pipeline c is provided with a valve. According a method in the invention, through controlling of pressure difference at two ends of a corrosion inhibitor slug, the running speed of gas is controlled so as to allow the corrosion inhibitor to form slug flow in the pipelines, thereby realizing corrosion inhibitor pre-filming for the pipelines; the method has the advantages of a simple process, convenient operation and low cost for investment of capital construction and for operation management.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Preparation method of modified phenolic foam composite insulation board

InactiveCN101649653AGood fire resistanceImprove waterproof and thermal insulation performanceFibre typesSynthetic resin layered productsPolymer scienceComposite plate

The invention discloses a preparation method of modified phenolic foam composite insulation board. In the method, water resistance and flame resistance polymer cement sheet is prepared in advance andthe method is characterized in that a phenolic foaming machine continuous production line is adopted to foam the foaming raw material to modified phenolic foam composite insulation sheet while the water resistance and flame resistance polymer cement sheet is combined to the both sides of the modified phenolic foam composite insulation sheet. The foaming raw material comprises the following raw materials by weight percent: 60-80% of phenolic resin, 3-6% of foaming agent, 3-7% of polyurethane modifier, 12-32% of catalyst and 1-3% of foam stabilizer. The composite board prepared in the inventionhas excellent flame resistance and good water resistance and heat preservation effect; in addition, the insulation core material has high strength and toughness and does not drop residue so as to completely meet the national requirements of building engineering in energy-saving, water resistance, heat preservation, flame resistance and the like and be widely used for the large area heat preservation, flame resistance and water resistance inside and outside the external walls of building.

Owner:夏良强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com