Controllable-respiration preservative film and preparation method thereof

A technology of fresh-keeping film and water-retaining agent, which is applied in the fields of fruit and vegetable preservation, food preservation, food science, etc., which can solve unsafe and unhygienic problems and achieve high barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 (aqueous solution casting method)

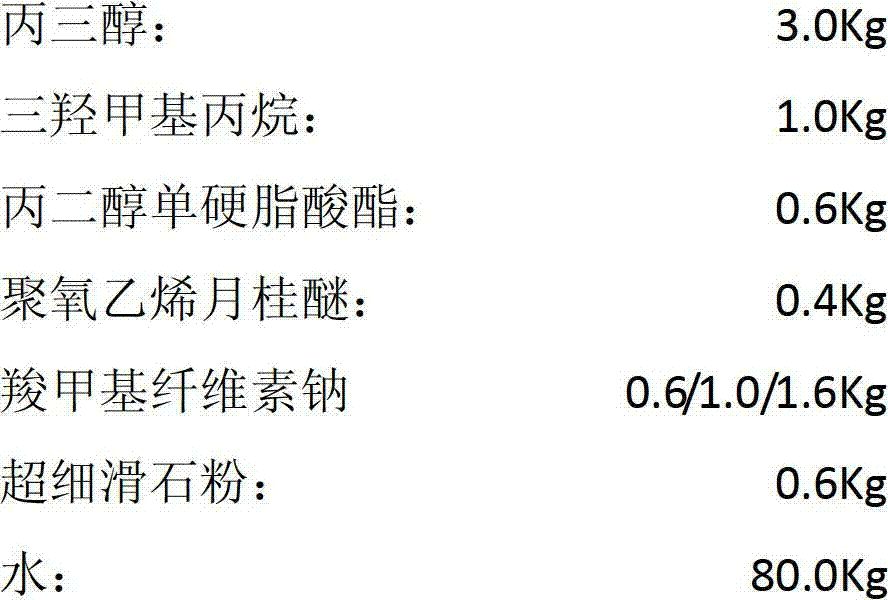

[0038]

[0039]

[0040] The above groups are measured separately, first dissolve glycerin and trimethylolpropane in water, then dissolve polyvinyl alcohol 2099 and polyvinyl alcohol 1788, propylene glycol monostearate, polyoxyethylene lauryl ether, carboxymethyl cellulose Add sodium and superfine talc powder into water, and heat to 95°C to completely dissolve in water, disperse at high speed for 30 minutes, cool to 60°C, and prepare a solution for casting film. The prepared solution is cast onto a steel belt through a casting die, and dried in a drying tunnel at 120-180° C. to form a film. 120-180°C drying tunnel drying and film formation refers to the range of segmental temperature control of the drying tunnel. The temperatures of the four drying zones are: 120°C, 150°C, 180°C and 160°C.

[0041] In the above formula, the consumption of sodium carboxymethyl cellulose is three kinds of situations, add respectively...

Embodiment 2

[0044] Embodiment 2 (aqueous solution casting method)

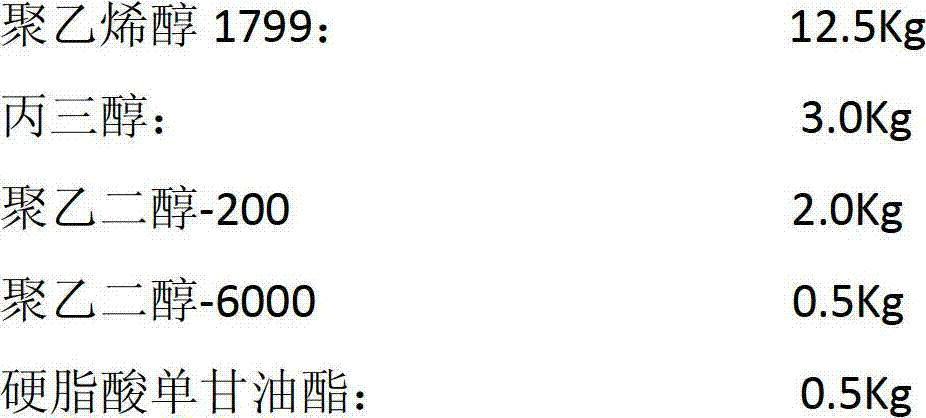

[0045]

[0046]

[0047] The above groups are measured separately, first dissolve glycerin, polyethylene glycol-200 and polyethylene glycol-6000 in water, then dissolve polyvinyl alcohol 1799, monoglyceride stearate, polyoxyethylene monolaurate , gelatin, and ultra-fine precipitated white carbon black were added to water, and heated to 95 ° C to completely dissolve in water, dispersed at high speed for 30 minutes, cooled to 50 ° C, and a solution for casting film was prepared. The prepared solution is cast onto a steel belt through a casting die, and dried in a drying tunnel at 120-180° C. to form a film. 120-180°C drying tunnel drying and film formation refers to the range of segmental temperature control of the drying tunnel. The temperatures of the four drying zones are: 120°C, 150°C, 180°C and 160°C.

[0048] In the above-mentioned formula, the consumption of gelatin is three kinds of situations, add respective...

Embodiment 3

[0051] Embodiment 3 (melt extrusion method)

[0052]

[0053] The above groups are measured separately, and then put into a high-speed mixer to stir and mix for 20 minutes, and then extrude and granulate through a twin-screw extruder at 160-180°C after discharge. Then it is extruded and blown into a film through an extruder at 160-180°C. Extrude and granulate through the twin-screw extruder at 160-180°C after discharging, which means that the temperature control ranges of each section of the twin-screw extruder sleeve and die head are: zone 1: 160°C; zone 2: 165°C ℃; Zone 3: 170℃; Zone 4: 175℃; Zone 5: 180℃; Zone 6: 180℃; Touch head: 170℃. The extrusion blow molding of the extruder at 160-180°C means that the temperature of the blown film extruder is divided into four stages of heating and temperature control: 160°C, 170°C, 180°C and 175°C.

[0054] Under the condition that other raw materials and the preparation method of the above formula remain unchanged, 10Kg, 16Kg an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com