Ventilating sole material and method for preparing ventilating sole

A technology for sole material and breathable shoes, which is applied to shoe soles, footwear, other household appliances, etc., can solve the problems of easy intrusion into the human body, weakened resistance, poor ventilation performance, sweat, etc., to achieve free breathing, maintain mechanical properties, Optimizing the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

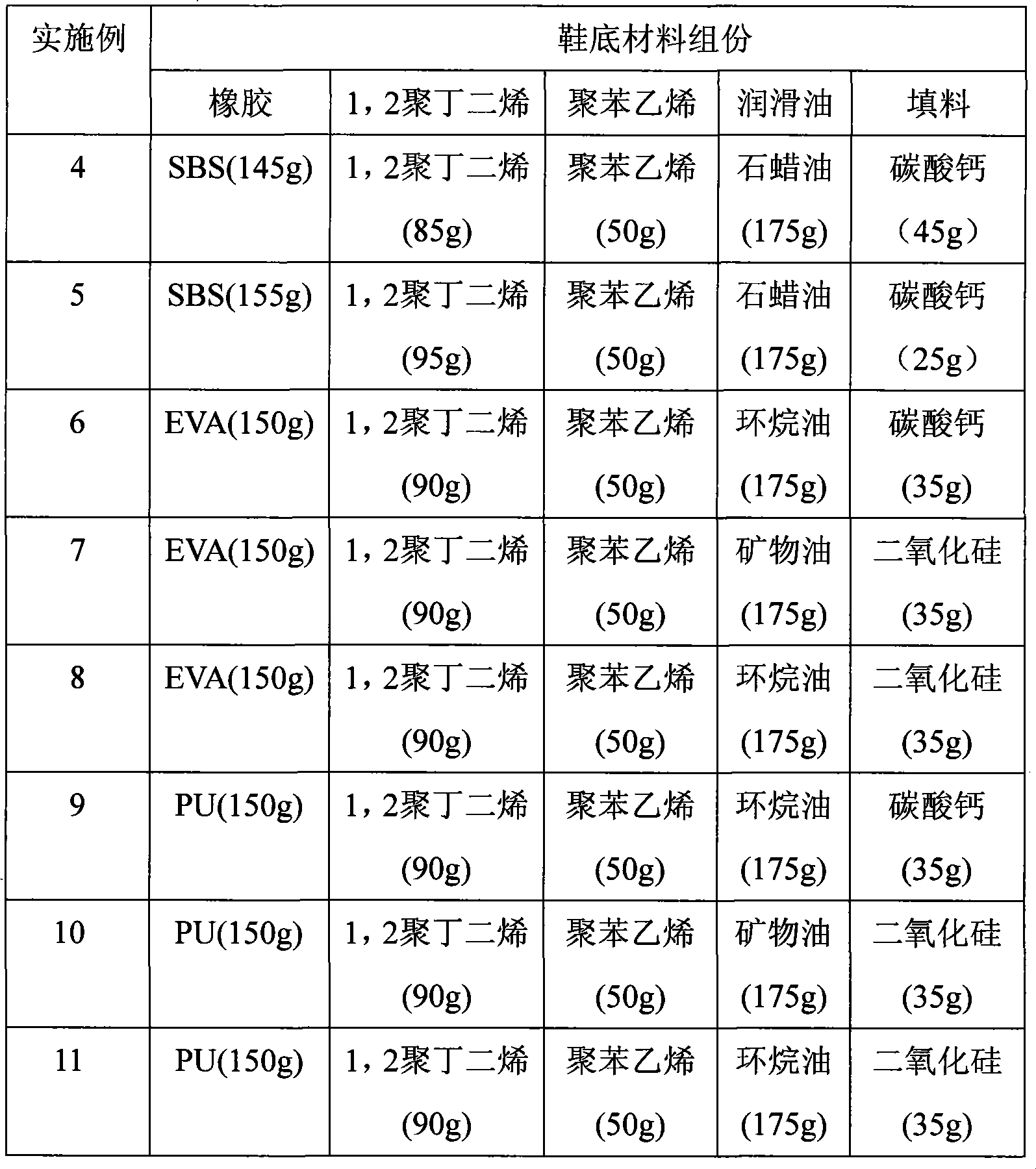

Examples

Embodiment 1

[0019] Put 150g of SBS, 90g of 1,2 polybutadiene, 50g of polystyrene, 175g of paraffin oil, and 35g of calcium carbonate with a particle size of 0.1-1μm into the compactor for compacting. The temperature is controlled at 130°C for 15 minutes. The refined mixture is put into a single-screw granulator for granulation (the temperature is controlled at about 100°C), and then the prepared granules are poured into the disc rotary injection molding machine through the feed hopper, and the temperature is controlled at the inlet temperature of 130°C. In a gradient field where the outlet temperature is 150°C, the injection pressure is 50kg / cm 2 , the back pressure is 5kg / cm 2 , injection molding.

[0020] Cut the foamed EVA sheet according to the size of the sole to make a bottom pad, and set air holes on the bottom pad, and then place the bottom pad on the above-mentioned sole to form a complete shoe sole. The ventilation holes in the bottom pad promote the free circulation and excha...

Embodiment 2

[0023] Put 140g of SBS, 80g of 1,2 polybutadiene, 45g of polystyrene, 170g of paraffin oil, and 65g of calcium carbonate with a particle size of 0.1 to 1 μm in a compact mixer. The temperature is controlled at 120°C for 15 minutes. The refined mixture is put into a single-screw granulator for granulation (the temperature is controlled at about 100°C), and then the prepared granules are poured into the disc rotary injection molding machine through the feed hopper, and the temperature is controlled at the inlet temperature of 130°C. In a gradient field where the outlet temperature is 150°C, the injection pressure is 45kg / cm 2 , the back pressure is 5kg / cm 2 , injection molding.

[0024] The air permeability detection method of the breathable sole is the same as that in Example 1, and the test results are shown in Table 1.

[0025] Table 1 Unit: m 2 ·(s·Pa) -1

[0026] Example 2 3 4 5 6 7 8 9 10 11 breathable

Embodiment 3

[0028] Put 160g of SBS, 100g of 1,2 polybutadiene, 55g of polystyrene, 180g of paraffin oil, and 5g of calcium carbonate with a particle size of 0.1 to 1 μm in a compact mixer. The temperature is controlled at 135°C for 10 minutes. The refined mixture is put into a single-screw granulator for granulation (the temperature is controlled at about 100°C), and then the prepared granules are poured into the disc rotary injection molding machine through the feed hopper, and the temperature is controlled at the inlet temperature of 130°C. In a gradient field where the outlet temperature is 150°C, the injection pressure is 50kg / cm 2 , the back pressure is 5kg / cm 2 , injection molding.

[0029] The air permeability detection method of the breathable sole is the same as that in Example 1, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com