Patents

Literature

1325results about How to "Low curing temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

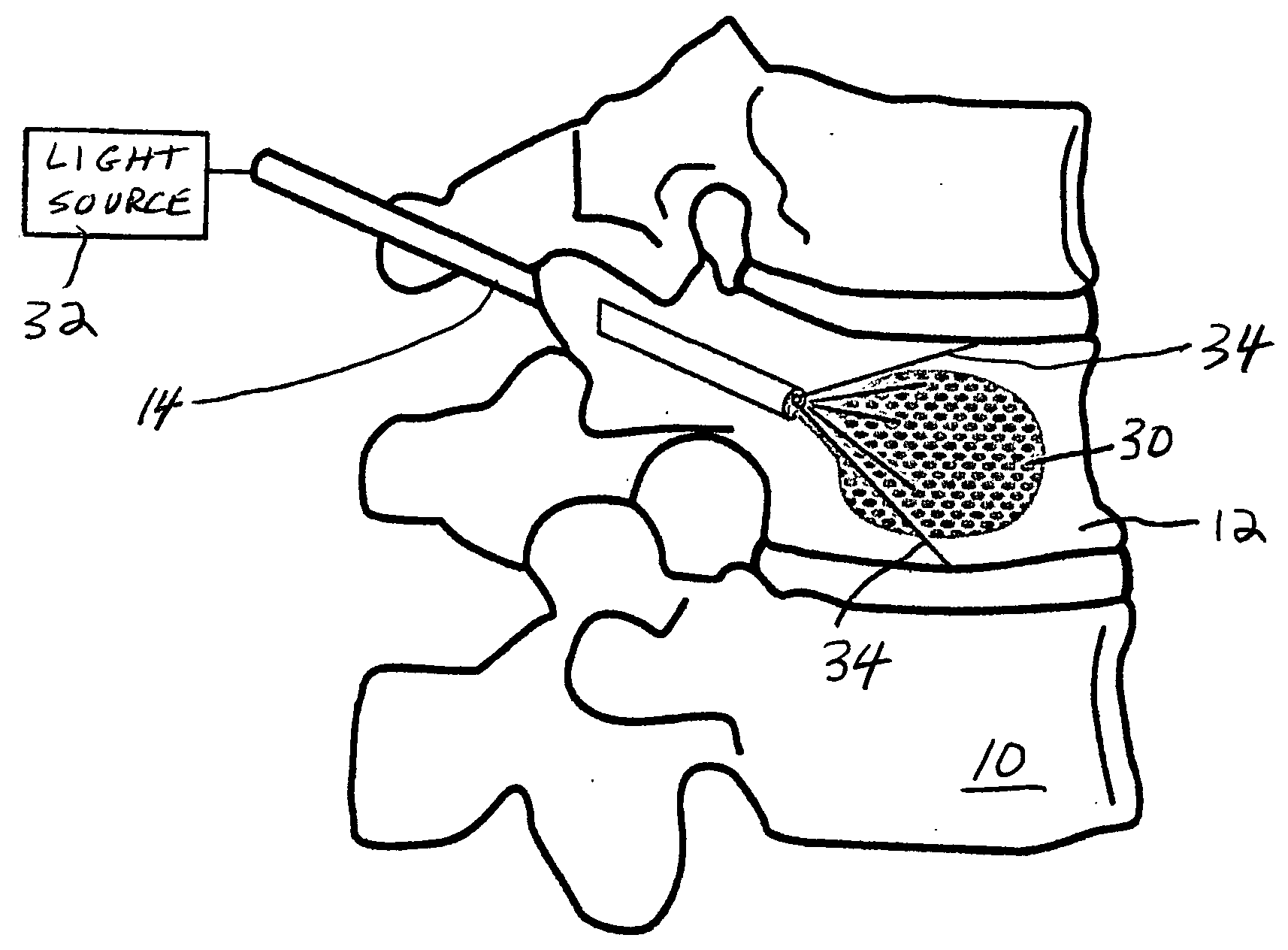

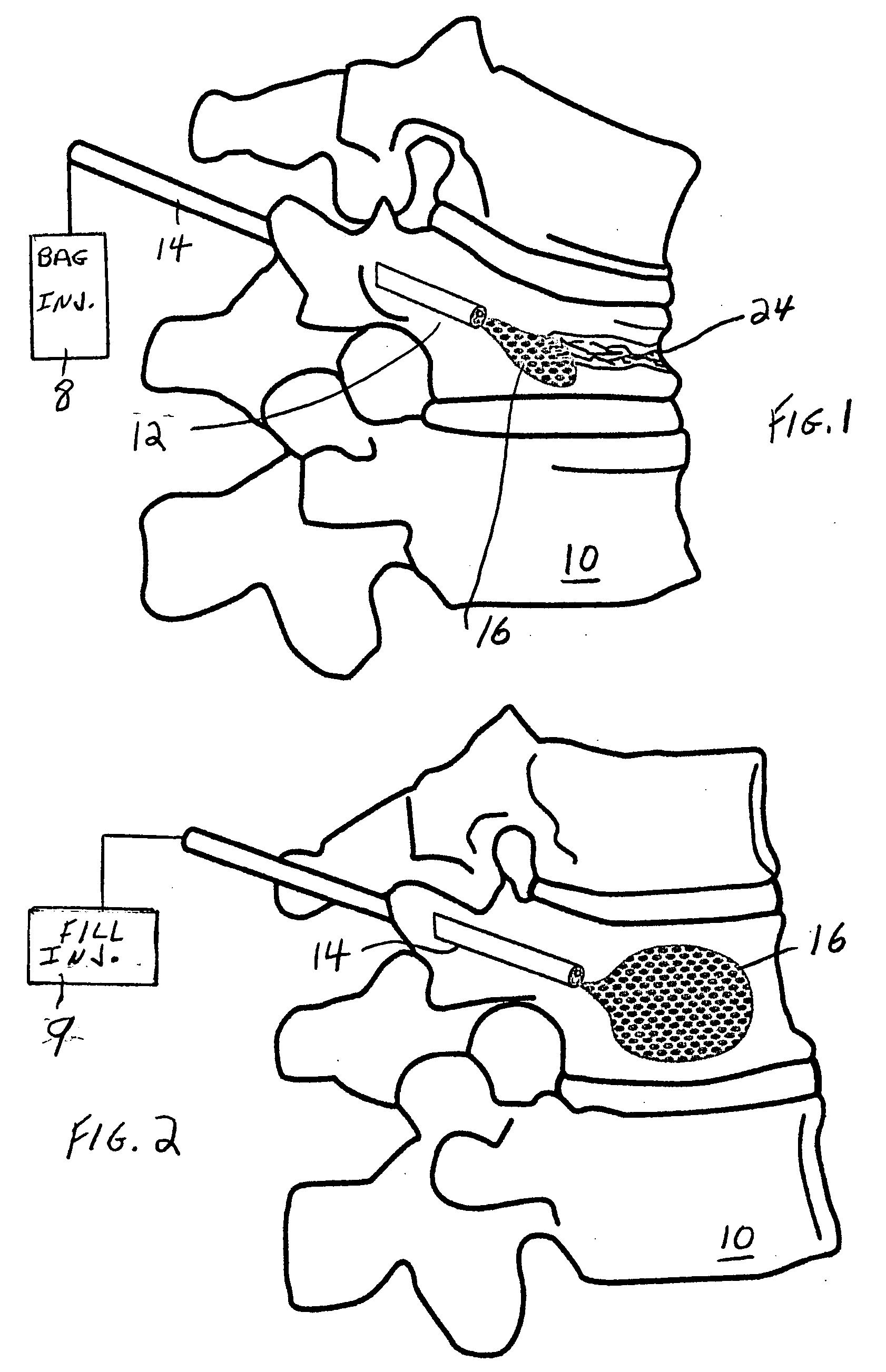

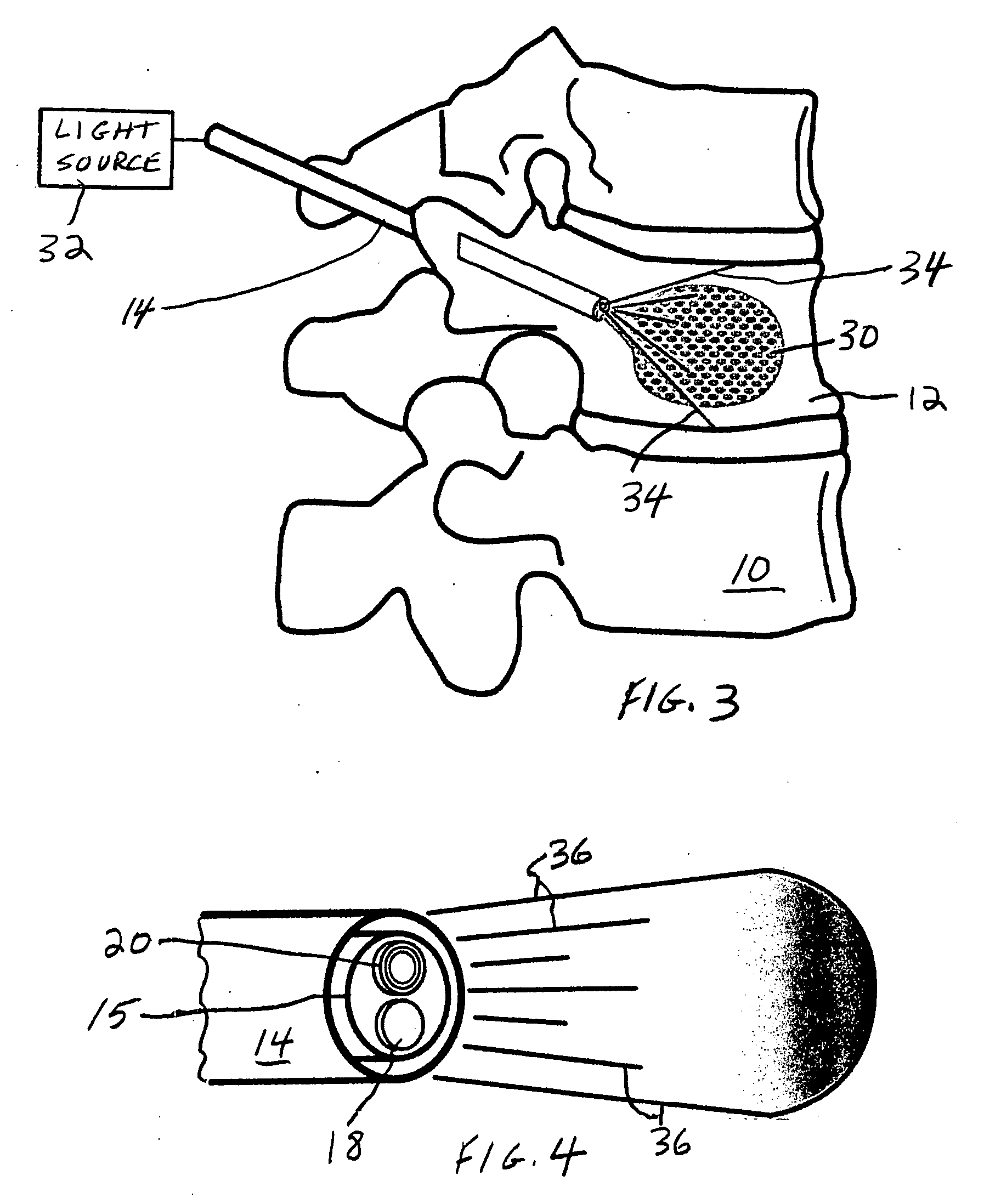

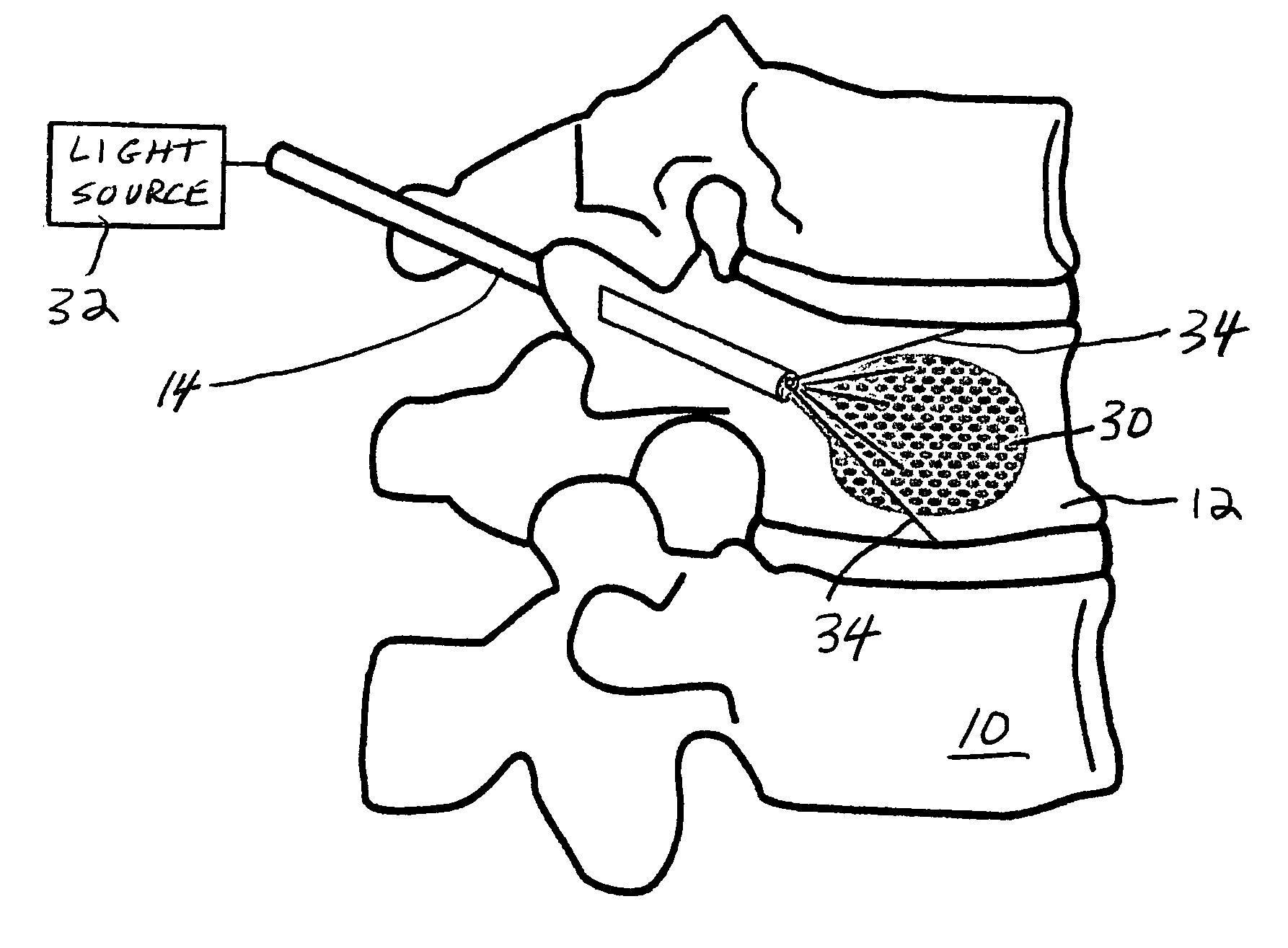

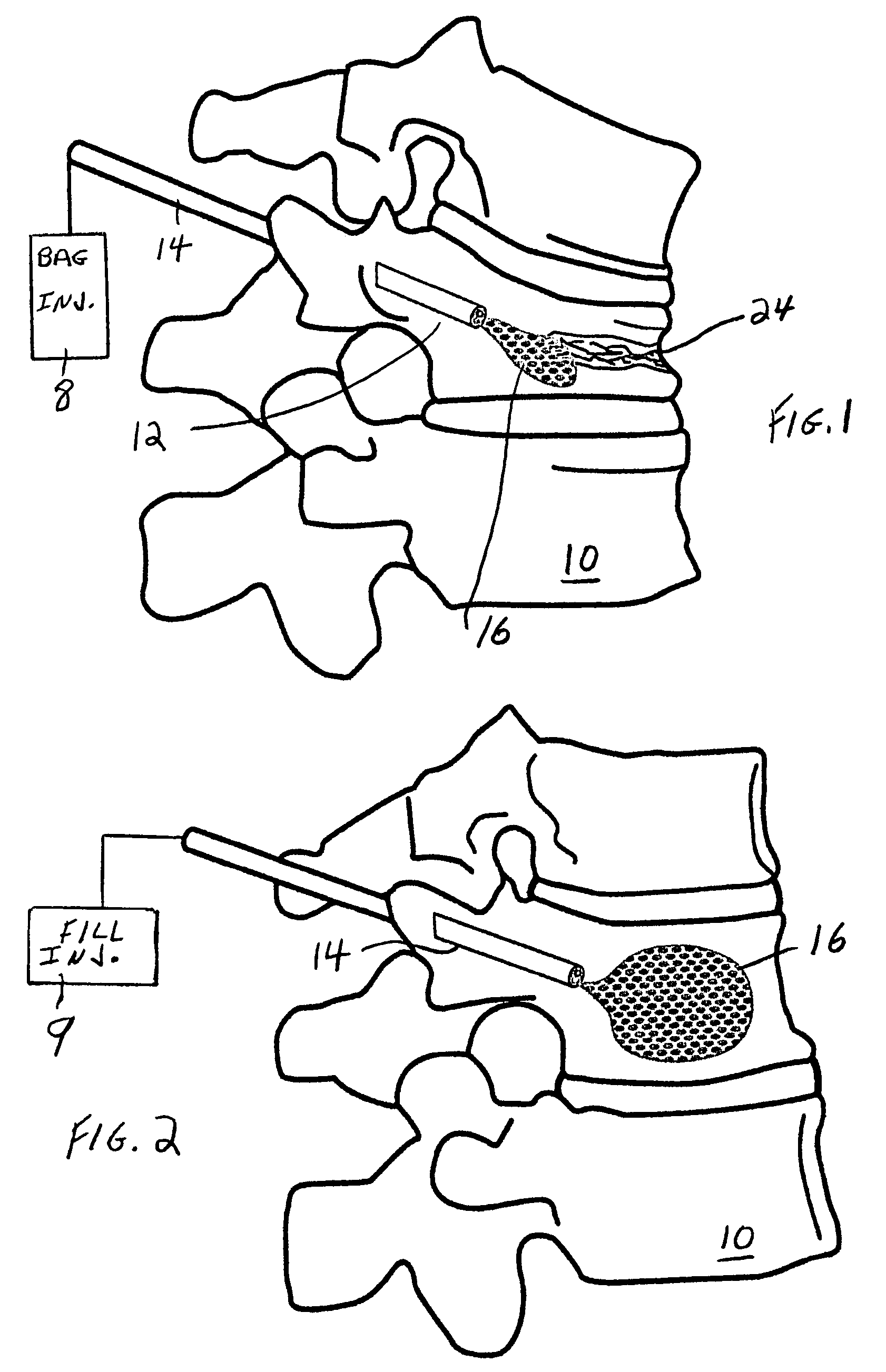

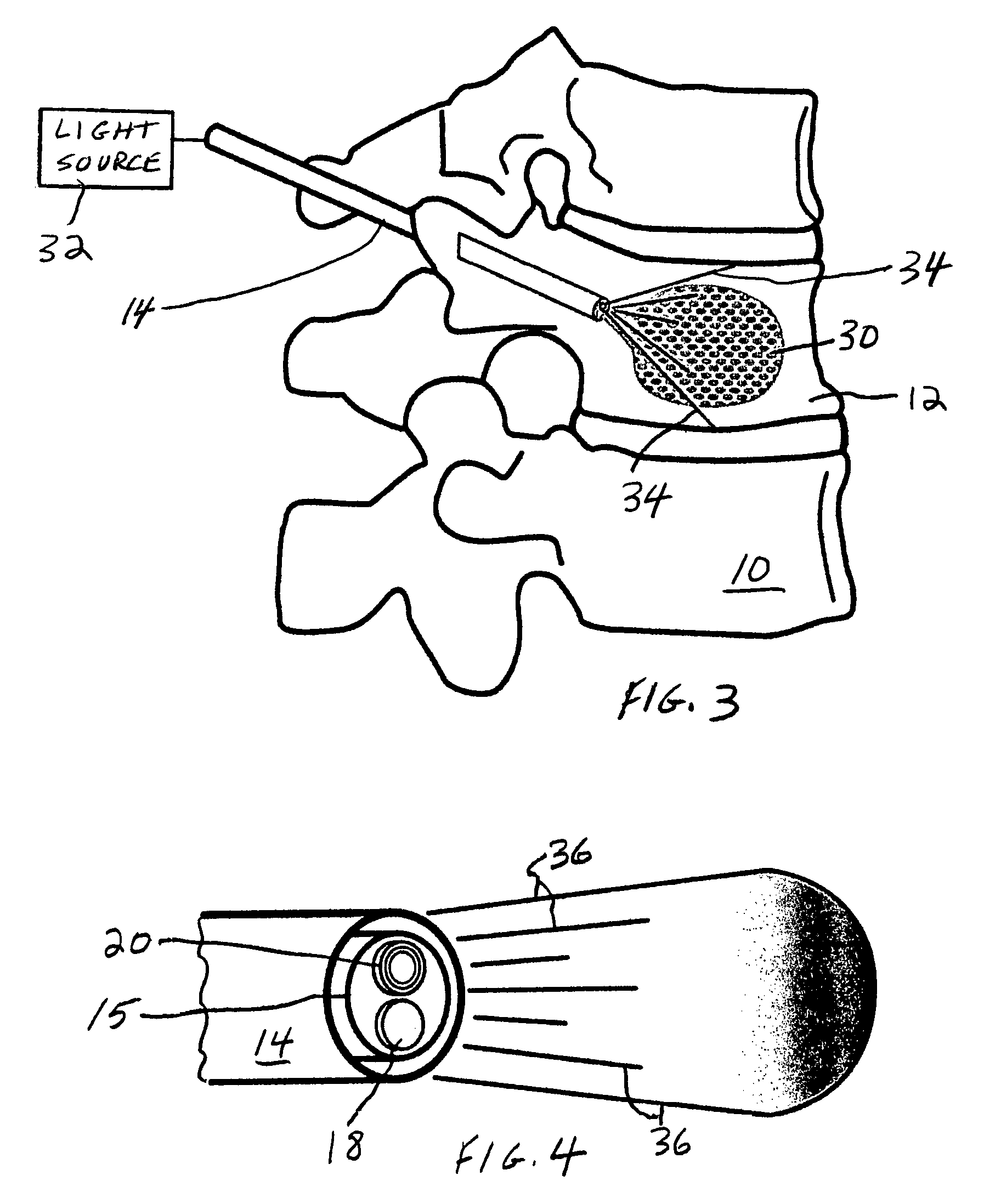

Spinal fill for disk surgery

The invention is based on the use of polyisobutylmethacrylate instead of PMMA as an adhesive or spinal fill material for treating diseases of the spine. Polyisobutylmethacrylate has several advantages over PMMA, mainly less heat is developed during the in situ polymerization process. When using any spinal adhesive of fill material that is light activated, a tube can be used to transmit activating light to the light-activated adhesive or spinal polymerizable fill material at the surgical site. In addition, a mesh bag comprising optical fibers or similar light transmitting material can be employed to receive the injected light-activated fill, with the mesh bag, irradiated externally, for directing the light via the bag to the polymerizable fill.

Owner:ELLIQUENCE

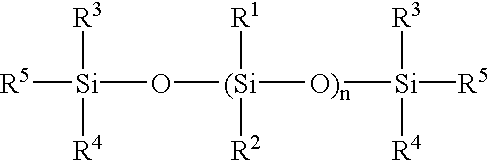

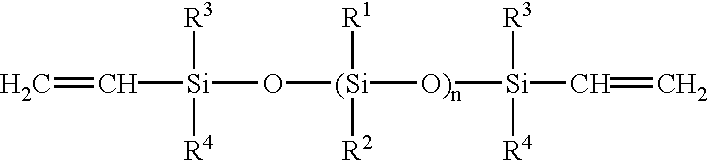

Low temperature, fast curing silicone compositions

InactiveUS6573328B2Low curing temperatureImproves of curedLayered productsSolid-state devicesPolymer sciencePtru catalyst

Heat-curable silicone compositions employing a reactive silicone, a silicone hydride crosslinker and a catalyst system which includes a rhodium-based catalyst, a stabilizing system are disclosed. A combination of rhodium and platinum-based catalysts are employed as well. The compositions are low temperature curing and are capable of providing low coefficient of thermal expansion compositions. A stabilizer system which includes in combination a peroxide and an acetylenic compound is also disclosed.

Owner:HENKEL LOCTITE CORP

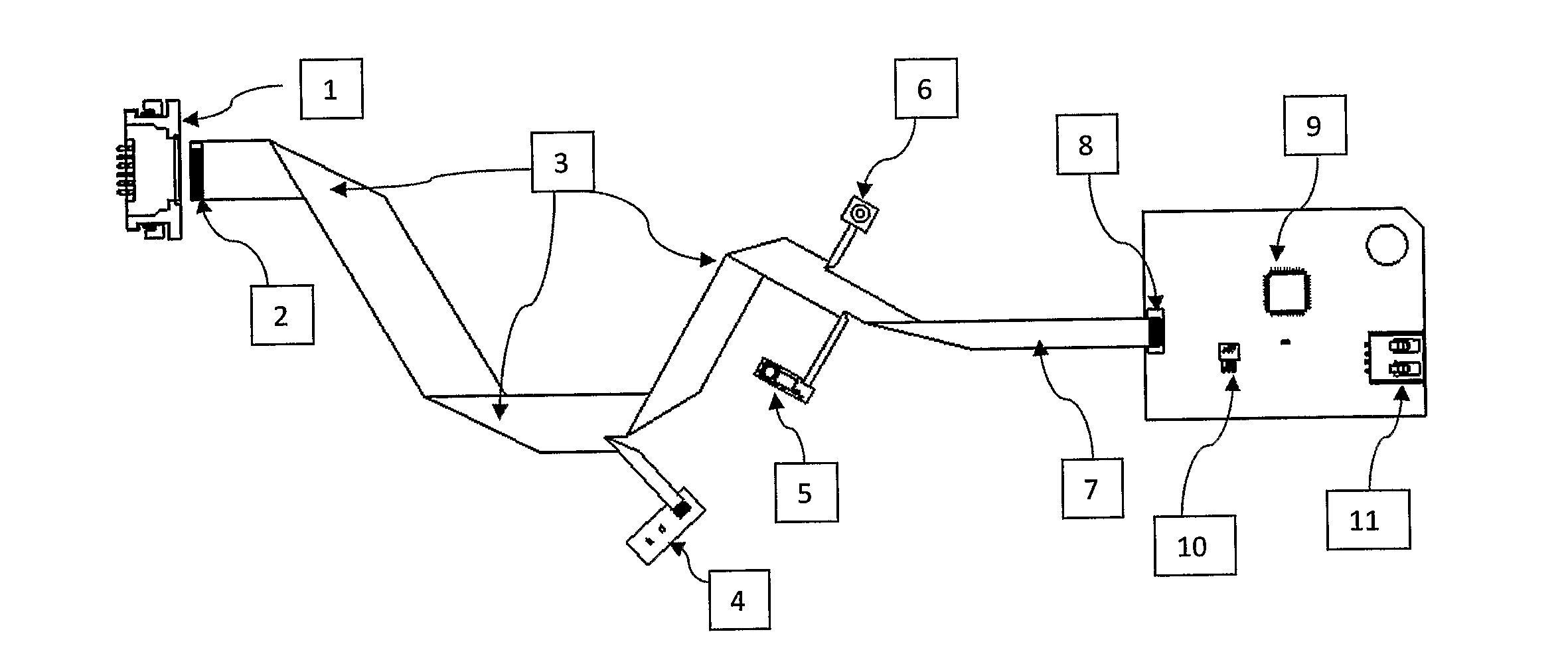

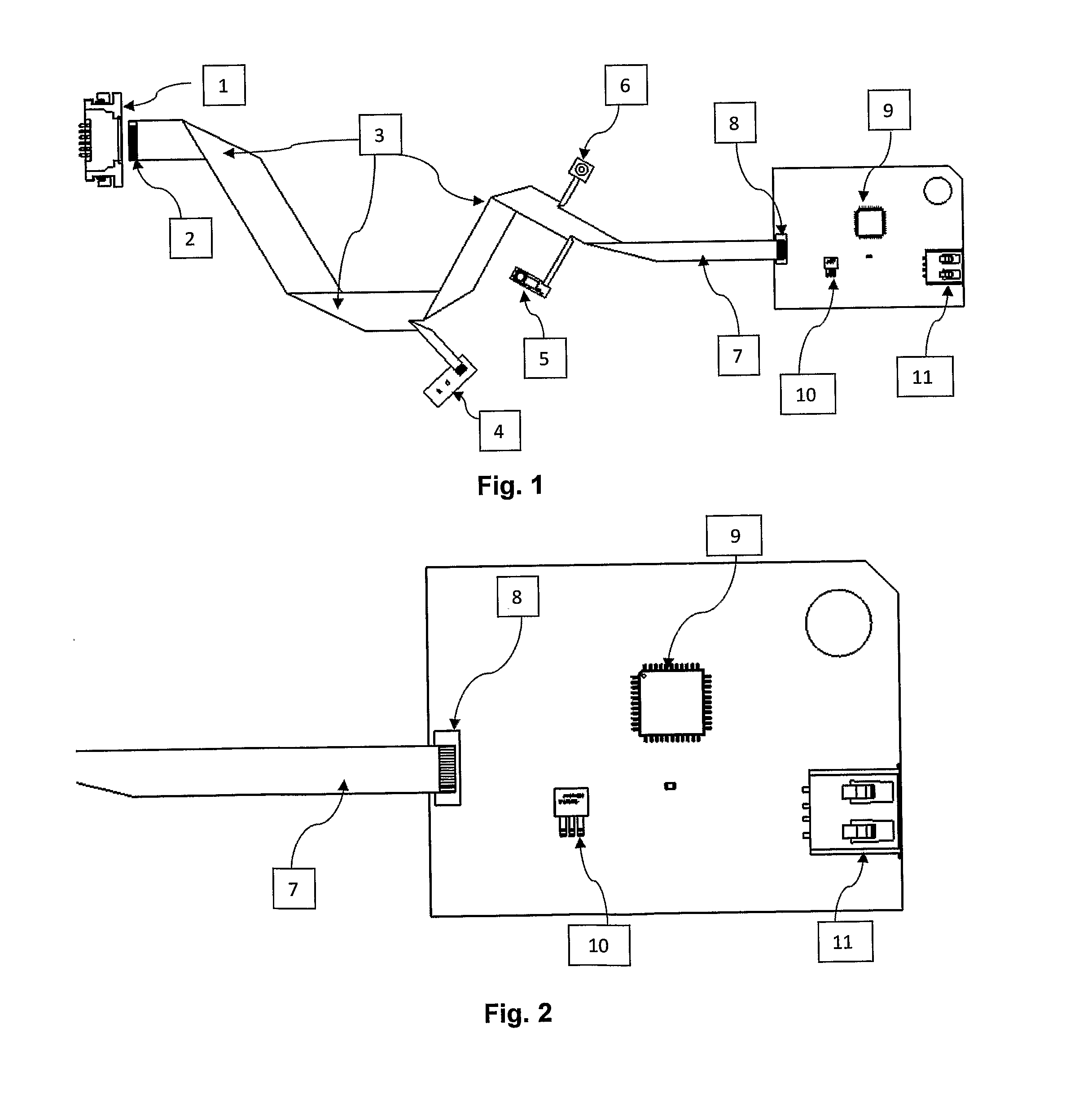

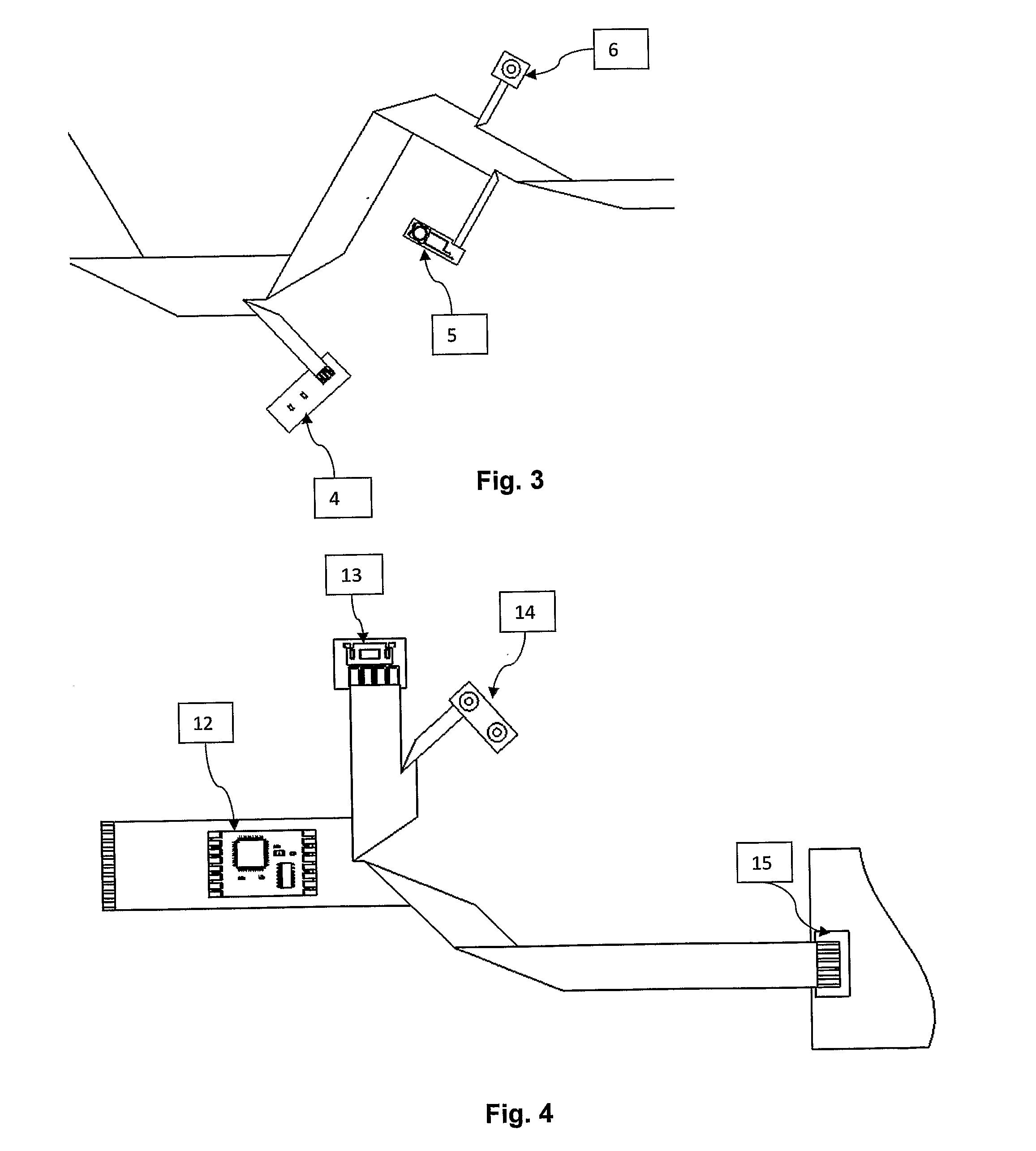

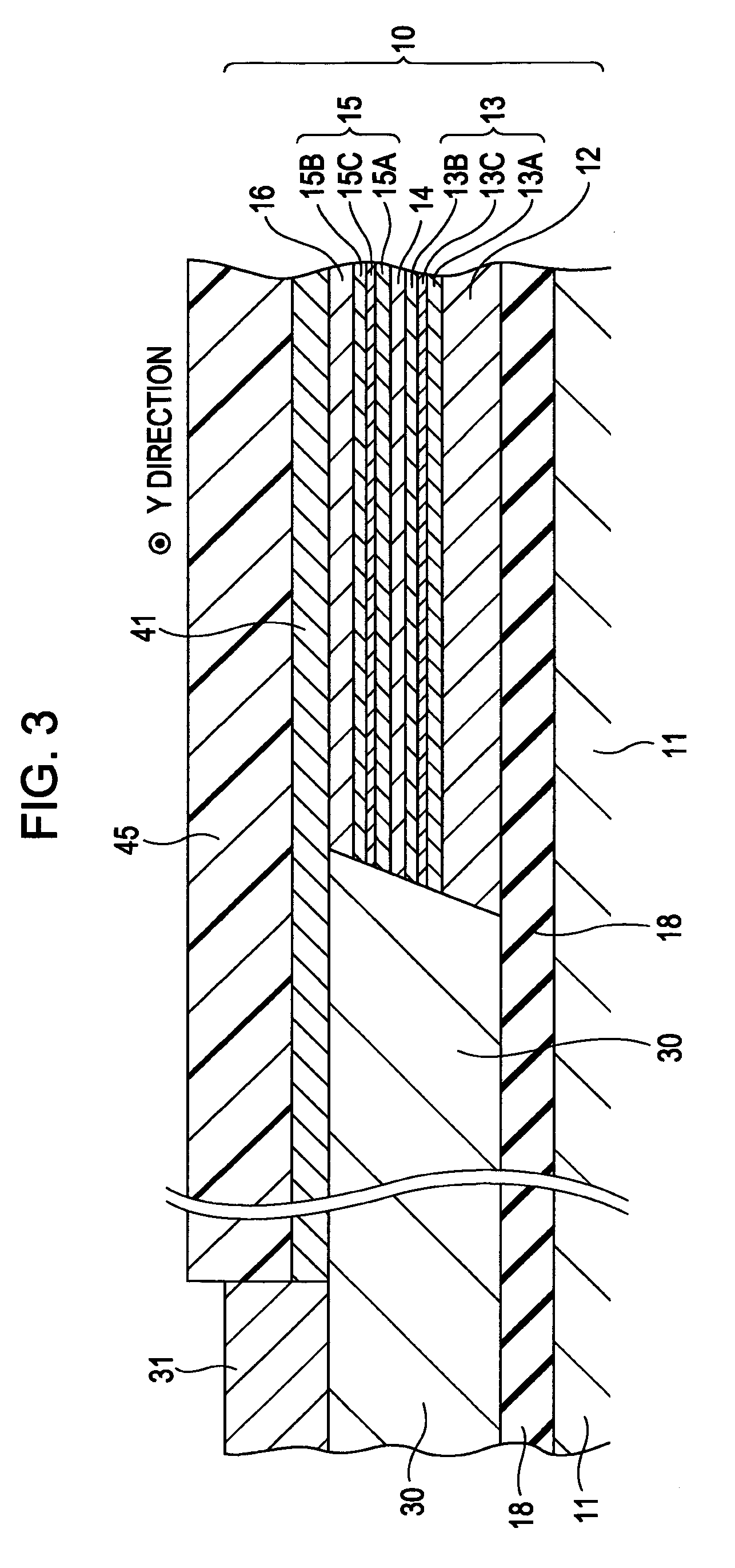

Rigid-flex circuit board and manufacturing method

InactiveUS20130161078A1Reduce complexityImprove mechanical stabilityContact member manufacturingCircuit bendability/stretchabilityEngineeringFlexible electronics

Disclosed herein is a cost effective rigid- flex circuit board comprising a flexible section which contents at least one flexible flat cable for interconnect, and a plurality of rigid sections which consists of at least one rigid printed circuit board (8) for components mounting. The improved flexible flat cable comprising at least one layer of flat wires laminated with a plurality of insulating material. The flat wires having non-uniform width and pitch are folded with different angle along the length to resemble wiring patterns of a typical flexible printed circuit board. The rigid section consists of at least one piece of rigid printed circuit board having at least one layer of circuit pattern.

Owner:DIGIPAS TECH INC

Spinal fill for disk surgery

Owner:ELLIQUENCE

Photo-curable conductive adhesive and method for making same

InactiveCN1699492ALow curing temperatureLow resistivityPolyureas/polyurethane adhesivesEster polymer adhesivesPolymer scienceSilver plate

Disclosed is a photo-curable conductive adhesive and method for preparation, which is prepared from light-sensitive high molecular polymer, reactive dilution monomer, conducting particles, light-summing heat initiating agent and anti-oxidant through mixing and grinding, wherein the light-sensitive high molecular polymer is epoxy acrylic resin or / and polyurethane-acrylate, the reactive dilution monomer is the single, double and multiple functional monomers of acrylic acid, the conducting particle is silver powder, copper powder or silver-plated copper powder, the light initiating agent is alpha-amine alkyl methyl ketone, benzoin (or substituted benzoin) ether or acyl phosphines, the heat initiating agent is azocompound or peralcohol, the antioxidant is hydroquinone, p-hydroxybenzene methyl ether, 2,6-ditertiary-butyl-4-methylphenol.

Owner:DALIAN POLYTECHNIC UNIVERSITY

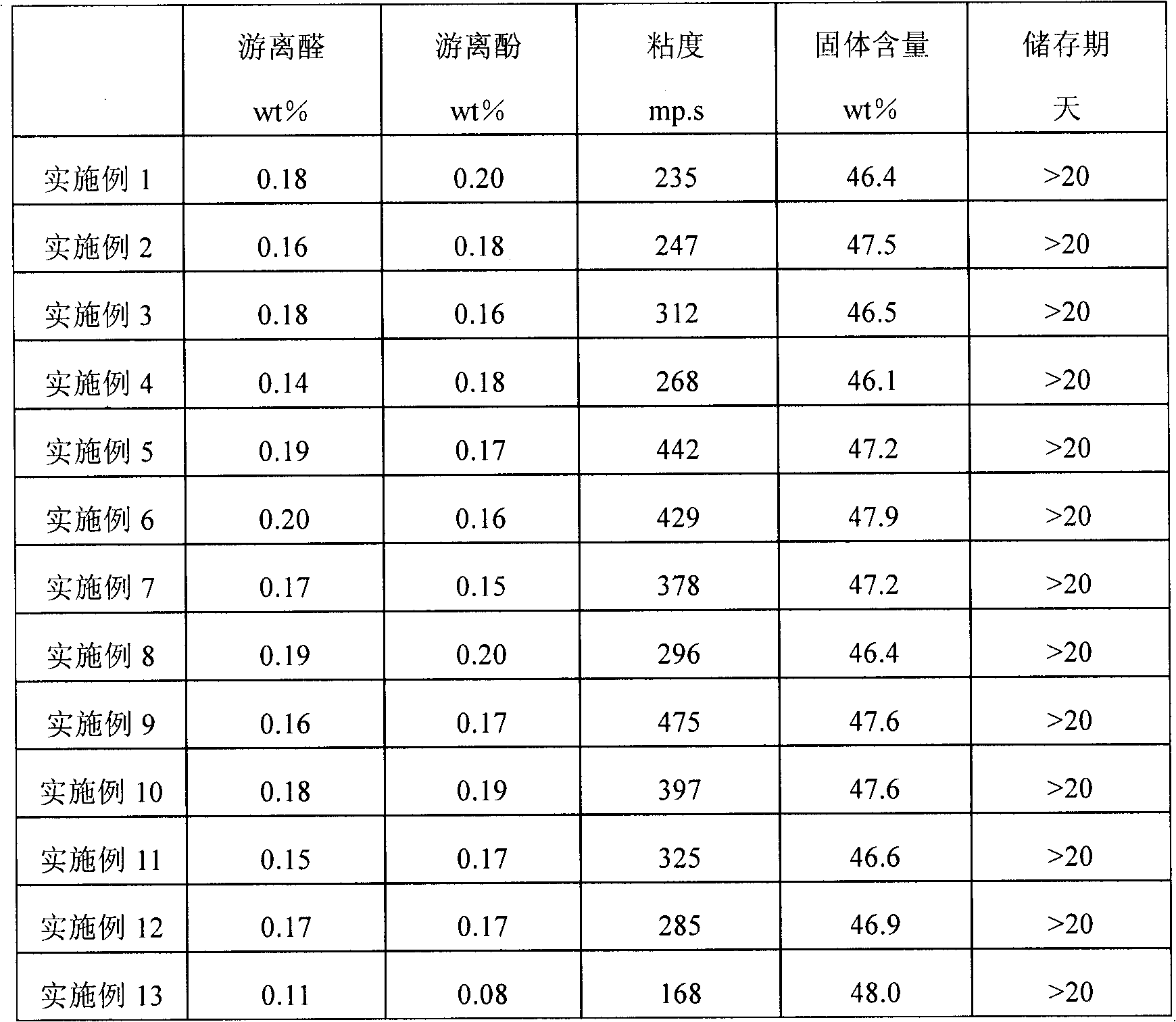

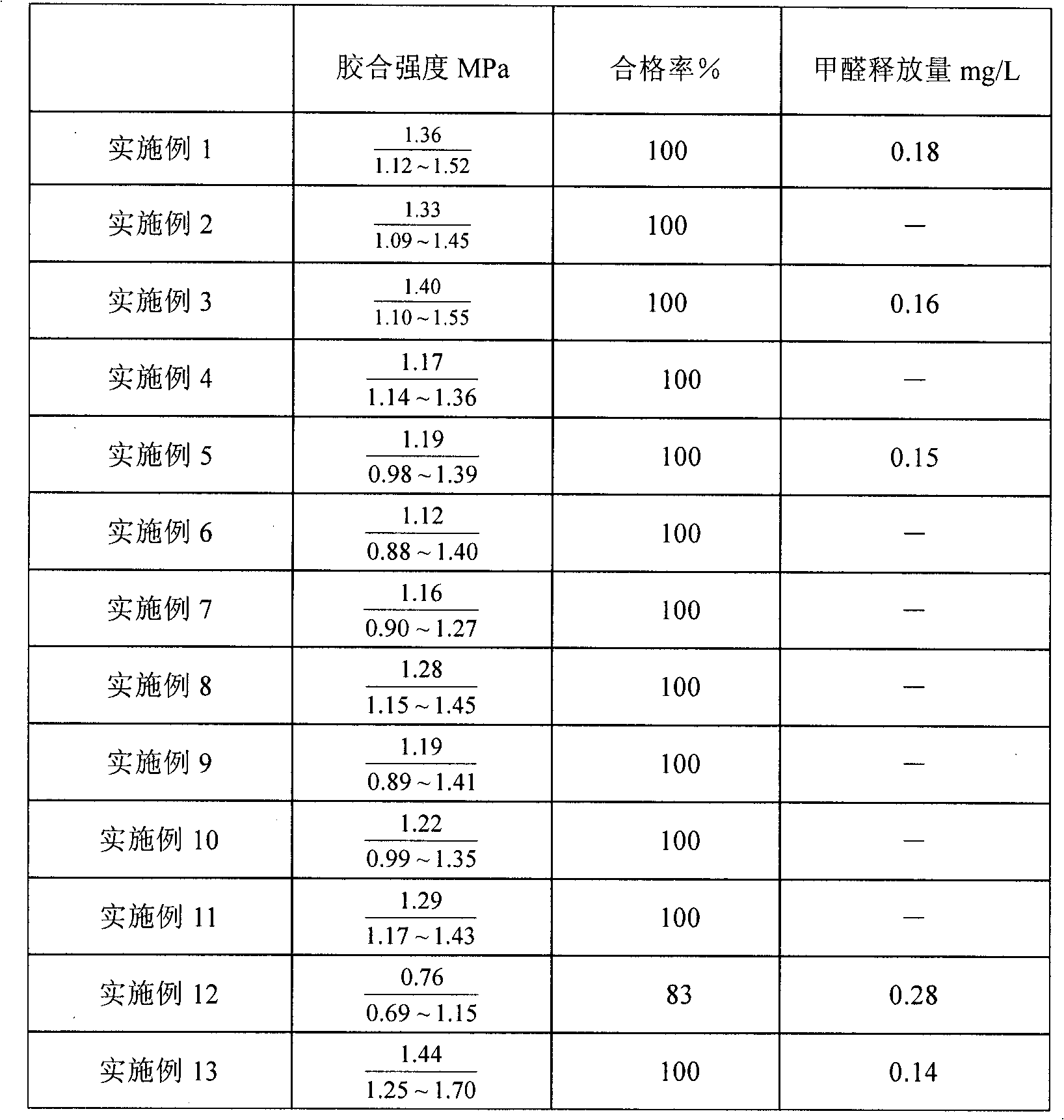

Method for preparing environmentally-friendly adhesive for lignin-based timber

ActiveCN102061141AAdequate responseLow in free phenolsAldehyde/ketone condensation polymer adhesivesAdhesiveTime ratio

The invention discloses a method for preparing an environmentally-friendly adhesive for a lignin-based timber. The method comprises the following steps of: 1) adding phenol, formaldehyde solution, lignin, first alkali liquor and diluting water into a reactor, heating to the temperature of between 75 and 85 DEG C and reacting for 2.5 to 3.5 hours, wherein the molar ratio of formaldehyde to the phenol is 2.20:1-2.40:1; the formaldehyde solution is added for three times in a mass ratio of 1.5 to 1.0 to 1.0; and the reaction time ratio of the added formaldehyde solution is 1.2 to 1.0 to 1.0; 2) cooling to 70 DEG C, adding a formaldehyde collector and second alkali liquor, and reacting at the temperature of between 65 and 70 DEG C for 20 to 50 minutes; and 3) cooling to the temperature of between 30 and 40 DEG C, adding an intensifier, stirring for 10 to 30 minutes, cooling and discharging. In the method, a 50 to 60 percent petroleum-based phenol raw material can be substituted; the methodis stable in reaction, easy to control and easy for industrial production; formaldehyde emission of a plywood reaches E0 level; adhesive strength meets the requirements of national class I plates; and a new approach is provided for the development of an environmentally-friendly biomass-based timber adhesive and recycling of wastes.

Owner:青岛生物能源与过程研究所

Method of preparing low temperature solidifying environment protection type cathode electrophoresis coating

InactiveCN101054487AImprove stabilityLow curing temperaturePaints for electrolytic applicationsPolyamide coatingsEpoxyLow temperature curing

The invention discloses an environment-friendly cathode electrophoretic coating with a low heating loss and low solvent content which can be cold cured. The method includes following steps and craft conditions: (1) preparation of curing agent and modification of mainbody resin. The curing agent is prepared by reaction of isocyanate, ketoximes solvent and trimethylolpropane so as to produce multifunctional group for closing the isocyanate curing agent. The whole reaction of mainbody resin modification includes chain extension reaction of epoxide resin, ring-opening reaction of amine and polyamide to the epoxide resin, the preparation of semi enclosed isocyanate and grafting reaction steps; (2) preparation of the catalytic curing agent slurry; (3) preparation of cathode electrophoretic coating latex and color paste. The invention improves the epoxide resin stability, reduces the resin curing temperature, and declines the heating loss of the dope and the discharge of the solvent. It applies extracting method in the latex producing process to reduce the solvent content so as to produce a environment-friendly cathode electrophoretic coating which can be cold cured.

Owner:佛山科富科技有限公司

Low-temperature-curable, solid polyurethane powder coating compositions containing uretdione groups

InactiveUS6914115B2Low curing temperatureAccelerate the cleavage of uretdione groupsSynthetic resin layered productsPretreated surfacesArylPolymer science

Polyurethane powder coating compositions containing uretdione groups and curing at low temperatures are provided, along with processes for preparing such compositions, and their use as powder coatings, wherein the compositions generally contain: A) a uretdione-containing powder coating hardener derived from aliphatic, (cyclo)aliphatic, cycloaliphatic or aromatic polyisocyanates and hydroxyl-containing compounds, and having a melting point from 40 to 130° C., a free NCO content of less than 5% by weight, and a uretdione content of 6-18% by weight; B) a hydroxyl-containing polymer having a melting point from 40 to 130° C., and an OH number between 20 and 200 mg KOH / gram, and C) a catalyst of the formula [NR1R2R3R4]+[R5]−, in which R1-R4 simultaneously, or independently of one another, are alkyl, aryl, aralkyl, heteroaryl or alkoxyalkyl radicals, and each R1-R4 is aromatic, linear or branched, unbridged or bridged with other radicals, R1-R4.

Owner:EVONIK DEGUSSA GMBH

Environment-friendly low-temperature curing pure polyester powder paint and preparation method thereof

InactiveCN101985538AGood physical and mechanical propertiesLow curing temperaturePowdery paintsPolyester coatingsChemistryLow toxicity

The invention discloses an environment-friendly low-temperature curing pure polyester powder paint, comprising the following components in parts by weight: 100-200 parts of hydroxyl polyester resin, 1-20 parts of HAA curing agent, 0-30 parts of auxiliaries, 0-16 parts of inorganic filler and 0-30 parts of pigment. The invention also discloses a preparation method of the powder paint. The environment-friendly low-temperature curing pure polyester powder paint provided by the invention has simple formula, low toxicity, environment protection and low curing temperature, and contains no TGIC in the raw material components by adopting the novel carboxyl-terminated polyester resin to be combined with beta-hydroxyalkylamides, and the cured coating has the characteristics of excellent physical and mechanical properties, chemical resistance, outdoor weather fastness and the like; in addition, the powder paint provided by the invention can be used in outdoor appliances and is a real energy-saving environment-friendly paint product.

Owner:CHINA NAT ELECTRIC APP RES INST +1

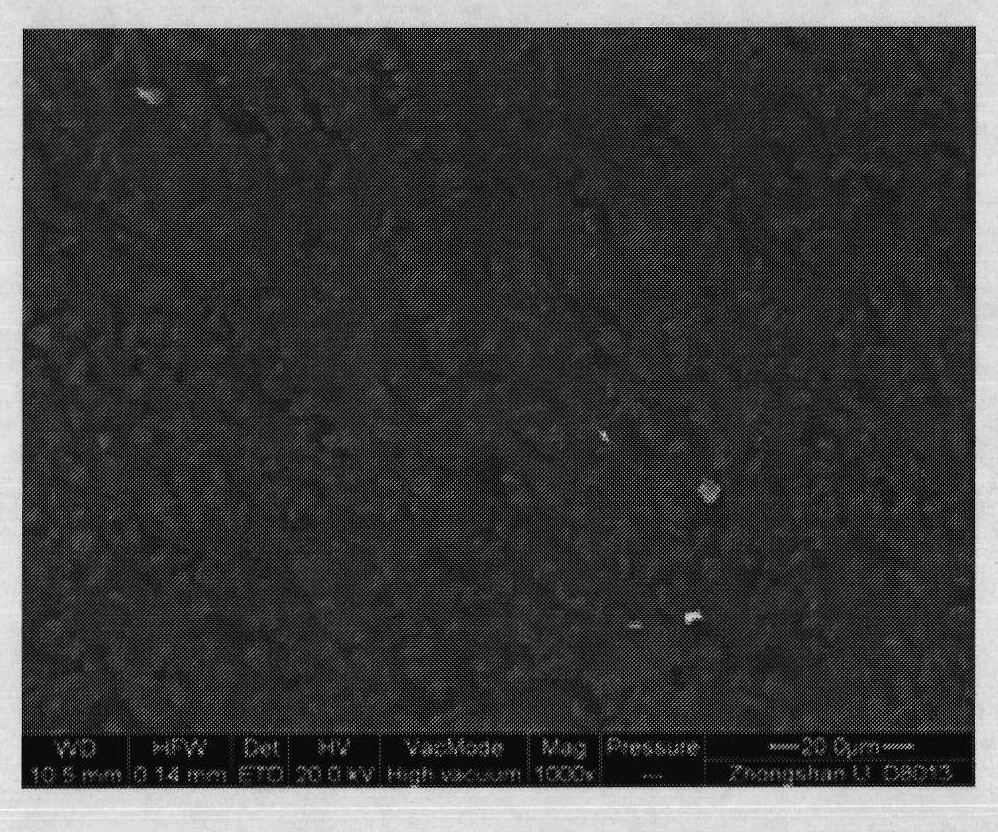

Conductive graphene printing ink and preparation method thereof

The invention provides a conductive graphene printing ink. The conductive graphene printing ink is composed of 0.001-80wt% of graphene, 1-60wt% of a linking material, 0.1-30wt% of an assistant, and the balance solvent. The invention also provides a preparation method of the conductive graphene printing ink. The conductive graphene printing ink has the advantages of good toughness, good die molding performance, good adhesion and good impact resistance; chemically doped graphene and chemically modified graphene in the graphene have good conductive, mechanical and thermal performances. The molecules of the chemically doped graphene comprise one or more of polyaniline, polyacetylene, polythiophene, polyparaphenylene and polypyrrole, and the functional groups of the chemically modified graphene comprise one or more of an anilino group, a pyrryl group, an imidazolyl group, a benzenesulfonic acid group, a thienyl group, a furyl group, a phenyl group, a hydroxy group, an ester group and derivative groups thereof, so the conductive performance, the mechanical performances and the dispersion stability of graphene in the printing ink are improved.

Owner:ZHUHAI LETONG NEW MATERIAL TECH CO LTD

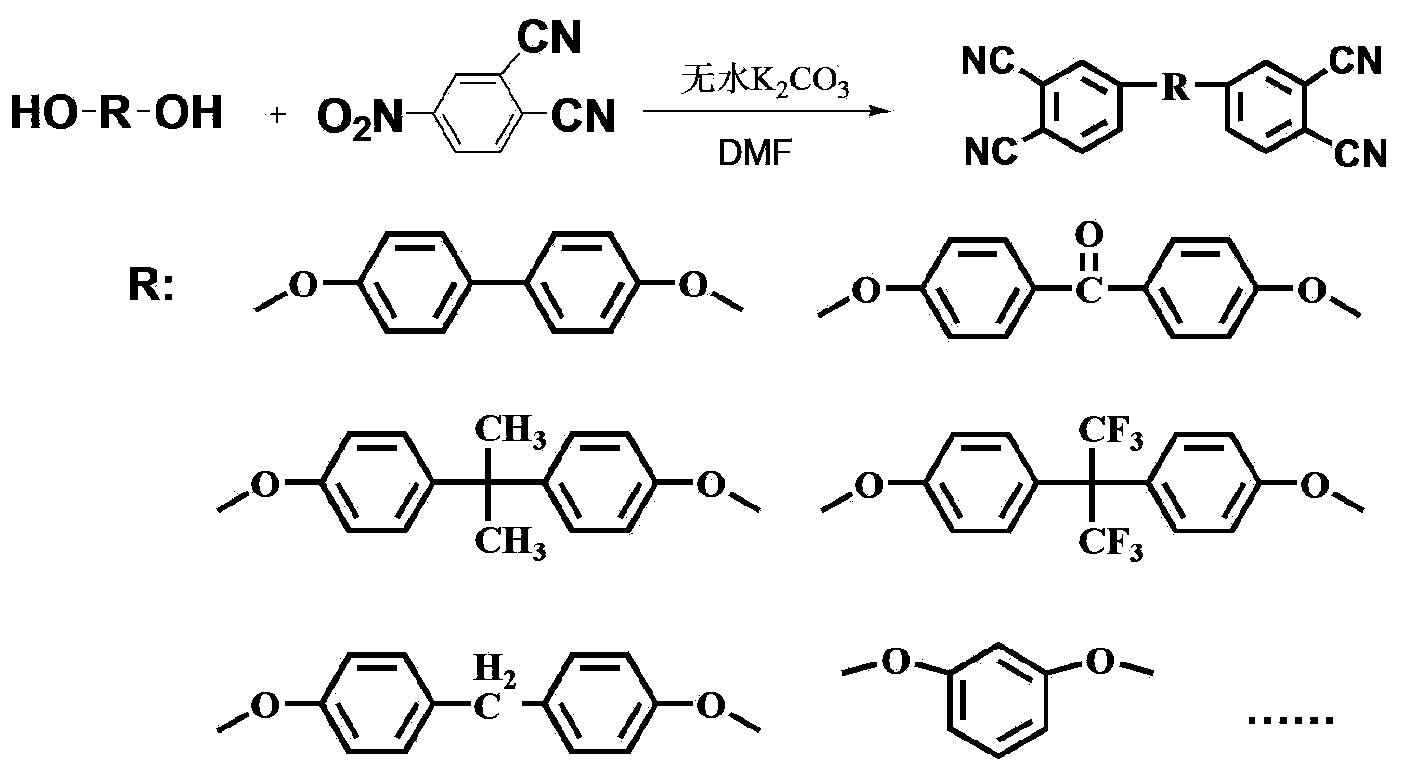

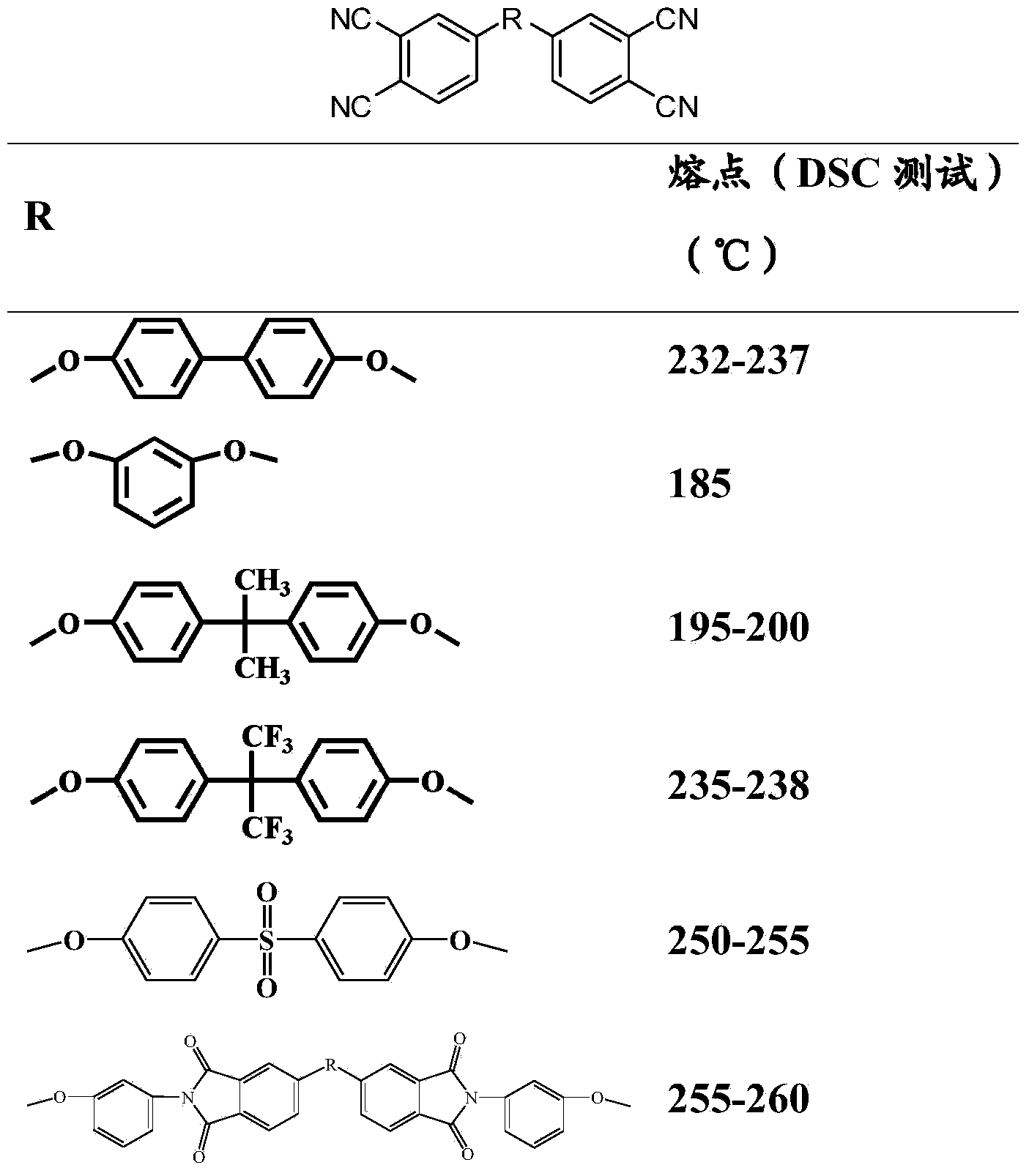

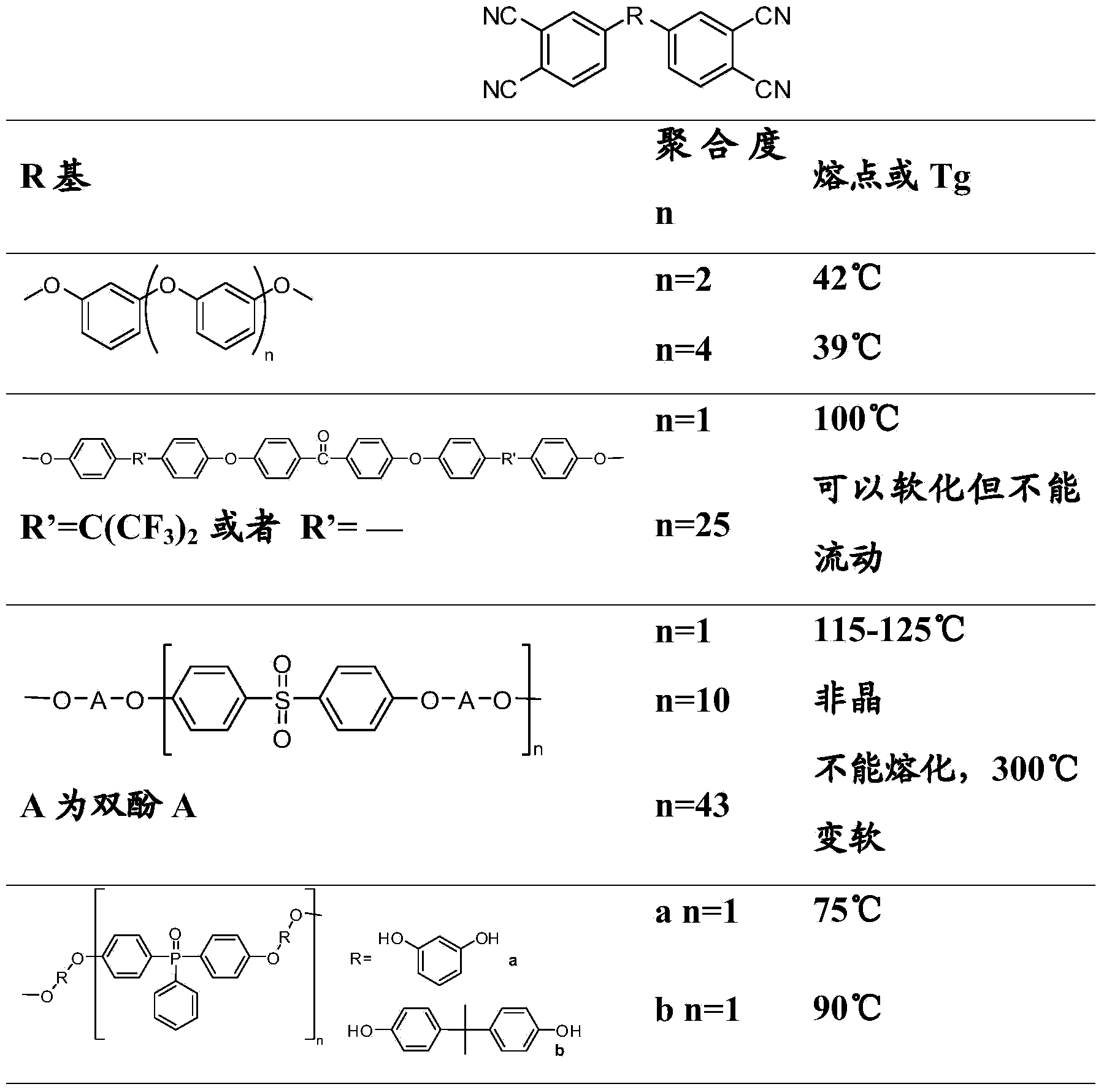

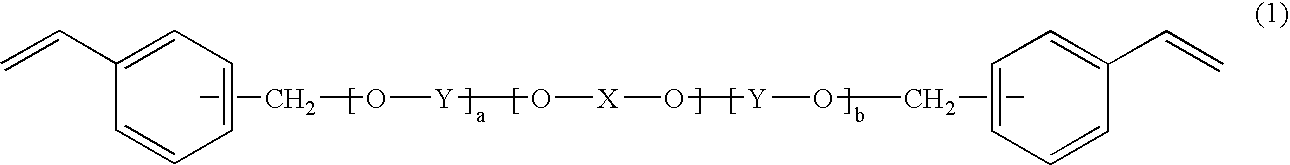

Novel phthalonitrile resin and preparation method thereof

ActiveCN103834008AIncrease asymmetryIncrease confusionSynthetic resin layered productsPhthalonitrileChemistry

The invention discloses a novel phthalonitrile resin and a preparation method thereof. Compared with a conventional phthalonitrile resin (only 4-nitro phthalonitrile as an end-capping reagent, the novel phthalonitrile resin is introduced with 3-nitro novel phthalonitrile resin to cooperate end capping, and thus the asymmetry of a resin structure is increased and the turbidity of a resin component is increased (see a formula 1). Compared with the conventional phthalonitrile resin, the novel phthalonitrile resin disclosed by the invention has the characteristics of low melting temperature, good solubility, wide processing window, low curing temperature and the like; a prepared resin molded part and a resin-based composite material are low in porosity, excellent heat-resistant quality, and high in mechanical property, and can be applied to the fields of aerospace, a space technology, machine manufacturing, and the like as a light-weight and high-temperature resistant part. The formula is described in the specification.

Owner:INST OF CHEM CHINESE ACAD OF SCI

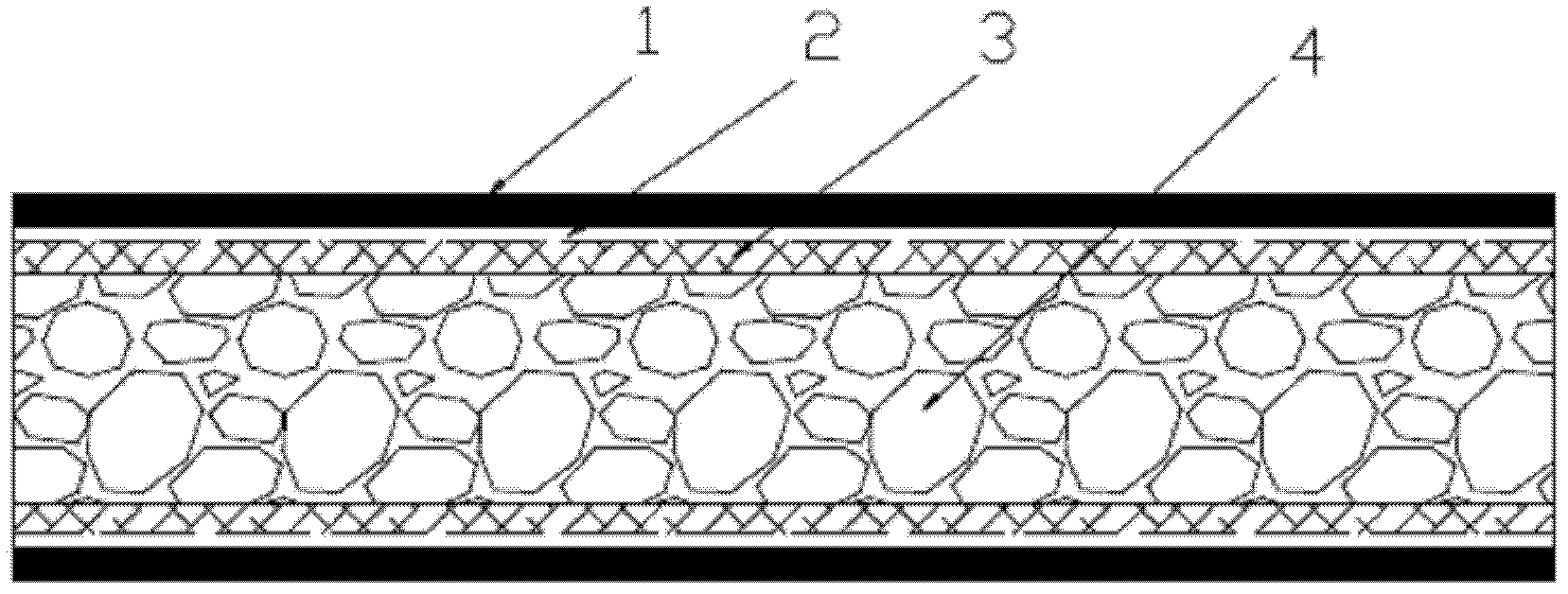

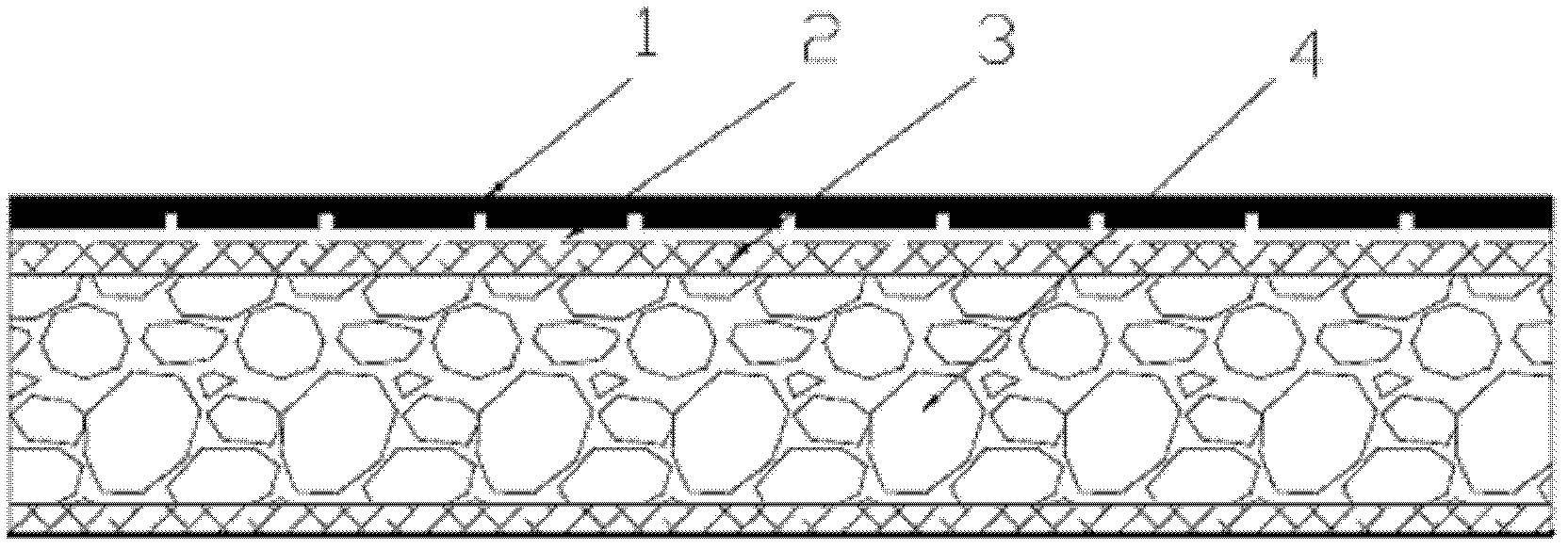

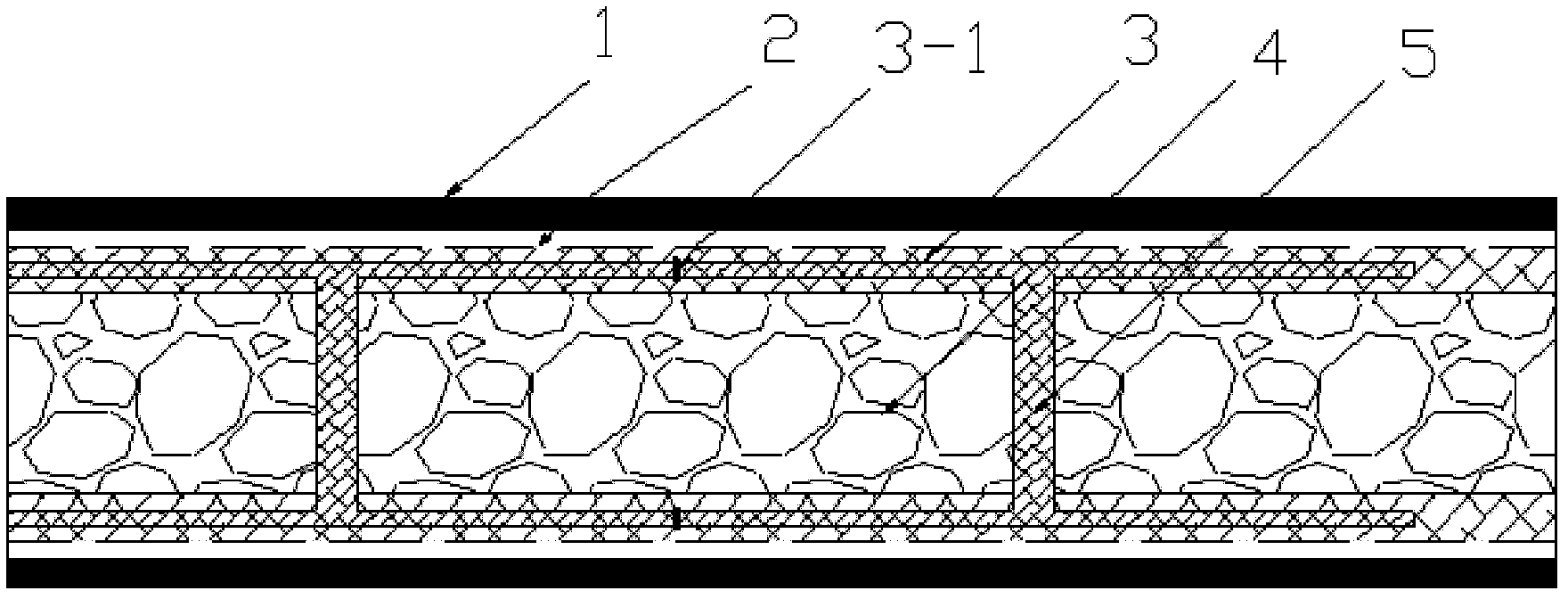

Resin bendable grinding wheel and preparation method and device

InactiveCN101804602AAvoid carbonizationIncrease contentFlexible-parts wheelsGrinding devicesFiberglass meshCarbide silicon

The invention discloses a resin bendable grinding wheel and a preparation method and a device thereof. The resin bendable grinding wheel consists of brown aluminium oxide, calcined alumina, white alundum, black silicon carbide, phenolic resin powder, phenolic resin liquid, cryolite, barium sulphate, pyretic, iron oxide red, Hunori gel, alkali-free high tensile glass fiber mesh and non-woven black cloth. Compared with the prior art, through the optimization configuration on the aspect of the material selection and working procedures, the strength, the flexibility and the aging resistance of the grinding wheel are greatly improved, and at the same time, the resource and the energy are saved; and the strength of the grinding wheel is more than 80m / s, the grinding ratio is more than or equal to 1:15, the maximum bendable angle can reach 40 degrees, the tensile strength is greatly improved, the service life is prolonged by two times, the energy consumption is reduced by 5 to 10 percent, and the yield of the finished product can reach more than 99 percent.

Owner:GUIZHOU FUSUN INDAL

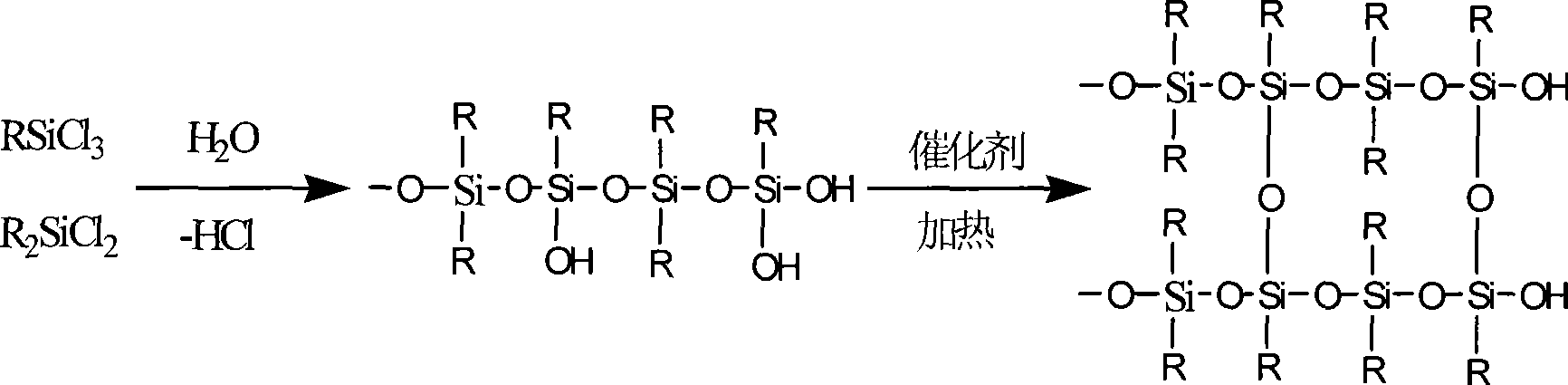

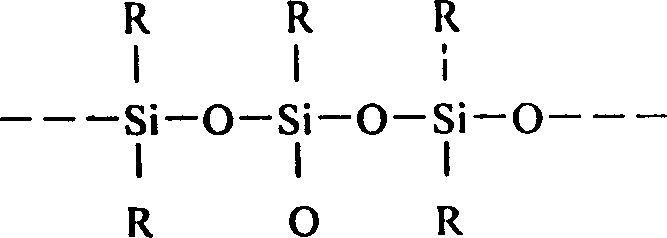

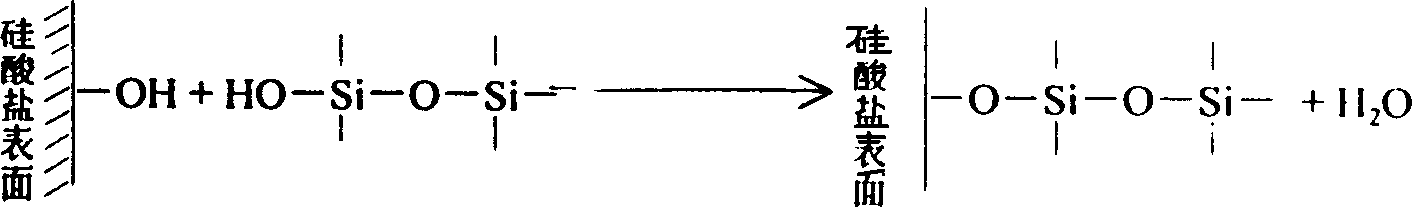

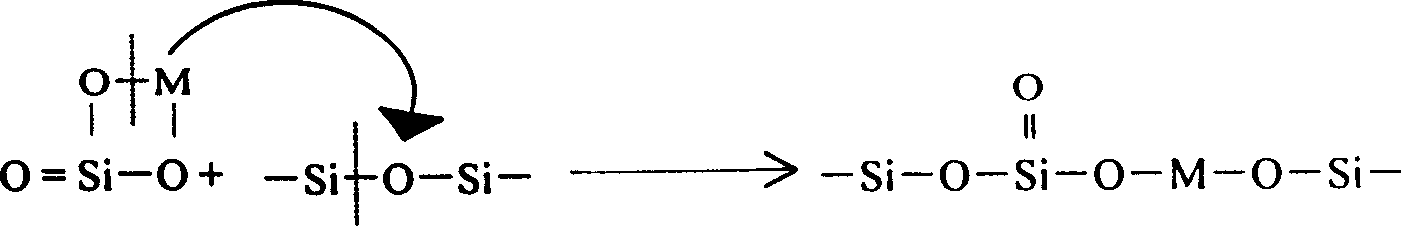

Method of preparing methyl phenyl polysiloxane

ActiveCN101508776AWith high and low temperature resistanceWeather resistantReaction temperatureMethyl phenyl polysiloxane

The invention discloses a method for synthesizing organic silicon, in particular provides a method for preparing methyl phenyl silicone resin which has low curing temperature by self and is not sticky repeatedly. The invention uses the monomers of methyl trichlorosilane, dimethyldichlorosilance, phenyl trichlorosilane, dichloromethylphenylsilane, diphenyl dichlorosilane and the like to obtain a methyl phenyl silicone resin with low curing temperature and a paint film which is not sticky repeatedly after being cured by the processes of adjusting the proportion of raw materials, controlling proper reaction temperature and polymerization time, carrying out hydrolysis reaction and polycondensation reaction, etc. The invention has the advantages that the methyl phenyl silicone resin prepared by the method has the characteristics of low curing temperature, being not sticky repeatedly, being clear and transparent, high and low temperature resistance, weather resistance, being insulating and the like; the methyl phenyl silicone resin is in particular fit for dip varnish higher than grade H; and the methyl phenyl silicone resin is used for confecting insulated paint, weather-resistant paint and heat resistant paint higher than grade H, is used for heat resistant parting agent and also can be used in the fields with rigorous using requirements, such as heat resistant water blocking and sand prevention for oil drilling, etc.

Owner:安徽比特海新材料股份有限公司

Environment-friendly heat conduction insulating glue used by high-power LEDs and preparation method

ActiveCN101812280AImprove cooling effectImprove work efficiencyNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyWorking temperature

The invention relates to an environment-friendly heat conduction insulating glue used by high-power LEDs, which is characterized by being prepared from the following raw materials in percentage by weight: 50-68 percent of micro-grade high-thermal conductive powder, 18-30 percent of epoxy resin, 4-10 percent of curing agent, 7-15 percent of solvent, 0.6-1.5 percent of accelerator and 1-2 percent of additive; and the micro-grade high-thermal conductive powder is selected from a mixture formed by one or more of micro-grade aluminum powder, palladium powder, platinum powder, gold powder, C powder, AlN powder and SiC powder. The invention also relates to a preparation method of the heat conduction insulating glue. The environment-friendly heat conduction insulating glue used by high-power LEDsis obtained by optimizing the matching ratio and the modification of the raw materials and improving and simplifying the preparation process. Besides high resistivity, the heat conduction insulating glue also has high thermal conductivity, higher working temperature, strong viscosity, high cutting strength and fine performance index.

Owner:连云港市昭华光电科技有限公司

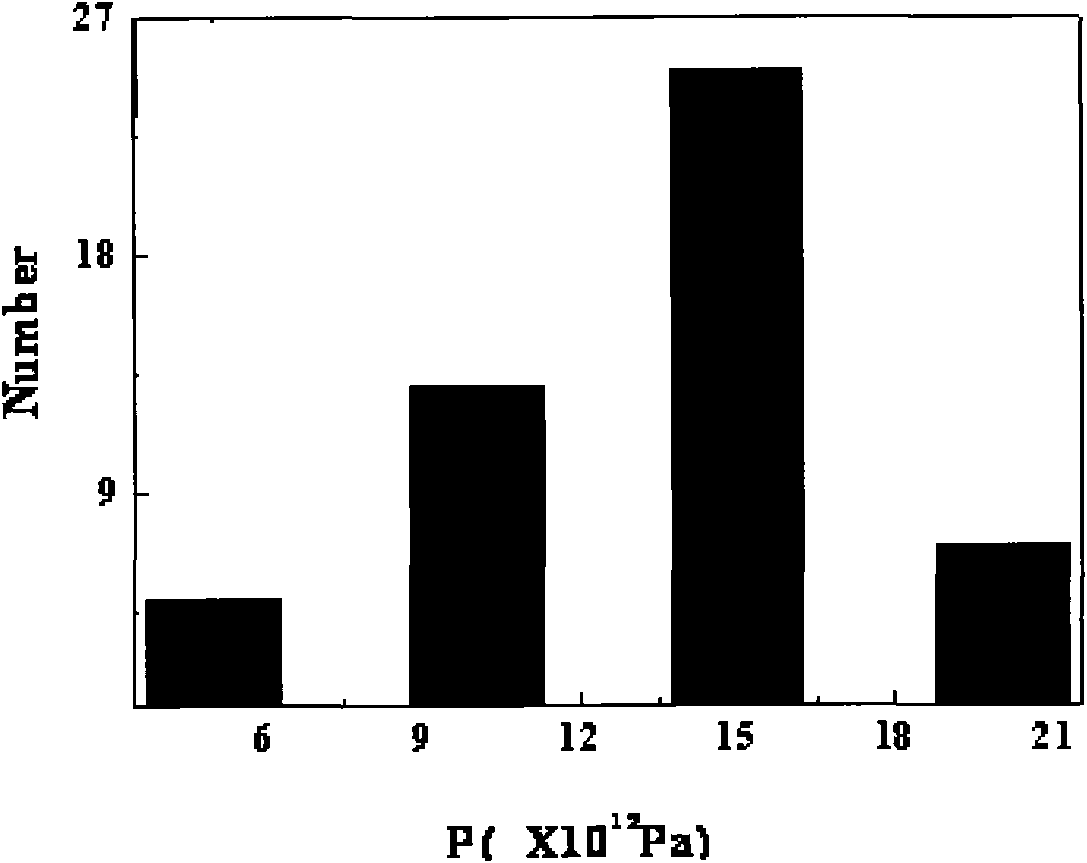

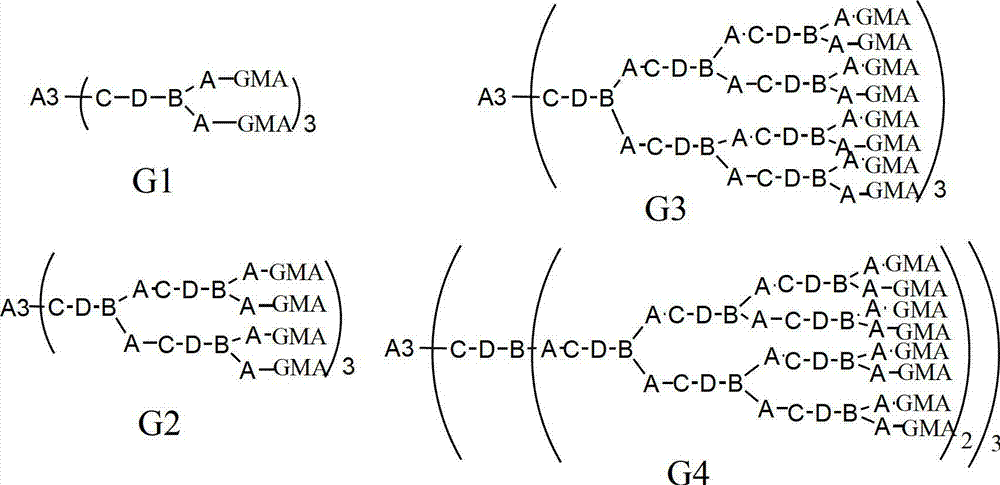

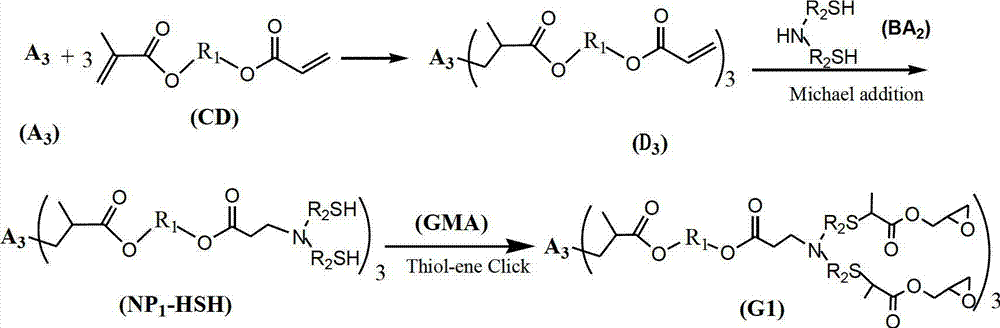

Sulfur-containing hyperbranched epoxy resin and preparation method thereof

The invention belongs to the technical field of epoxy resins and preparation method thereof and in particular discloses a sulfur-containing hyperbranched epoxy resin and a preparation method thereof. The preparation method comprises the following steps: stirring and reacting a trithiol compound and a diolefin compound at the temperature of 10 DEG C below zero and 20 DEG C for 2-5 hours and preparing an acrylate monomer with polyfunctionality; stirring and reacting the monomer and bithiol secondary amine at the temperature of 20-80 DEG C for 5-10 hours and obtaining a first generation mercapto-terminated hyperbranched polymer NP1-HSH; stirring and reacting the NP1-HSH and methacrylic acid glycidyl ester at the temperature of 10 DEG C below zero and 20 DEG C for 2-5 hours and obtaining a first generation sulfur-containing hyperbranched epoxy resin; and sequentially carrying out the previous three reactions on NP1-HSH to prepare a second-fourth generation sulfur-containing hyperbranched epoxy resin with the molecular weight of about 2,000-30,000 g / mol. The method is simple in process and low in reaction temperature, the obtained product can reduce the curing temperature and is expected to be applied to the fields of reinforcing and toughening of epoxy resins, solvent-free coatings and the like.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Aluminium phosphate sol used for catalyst and preparation method thereof

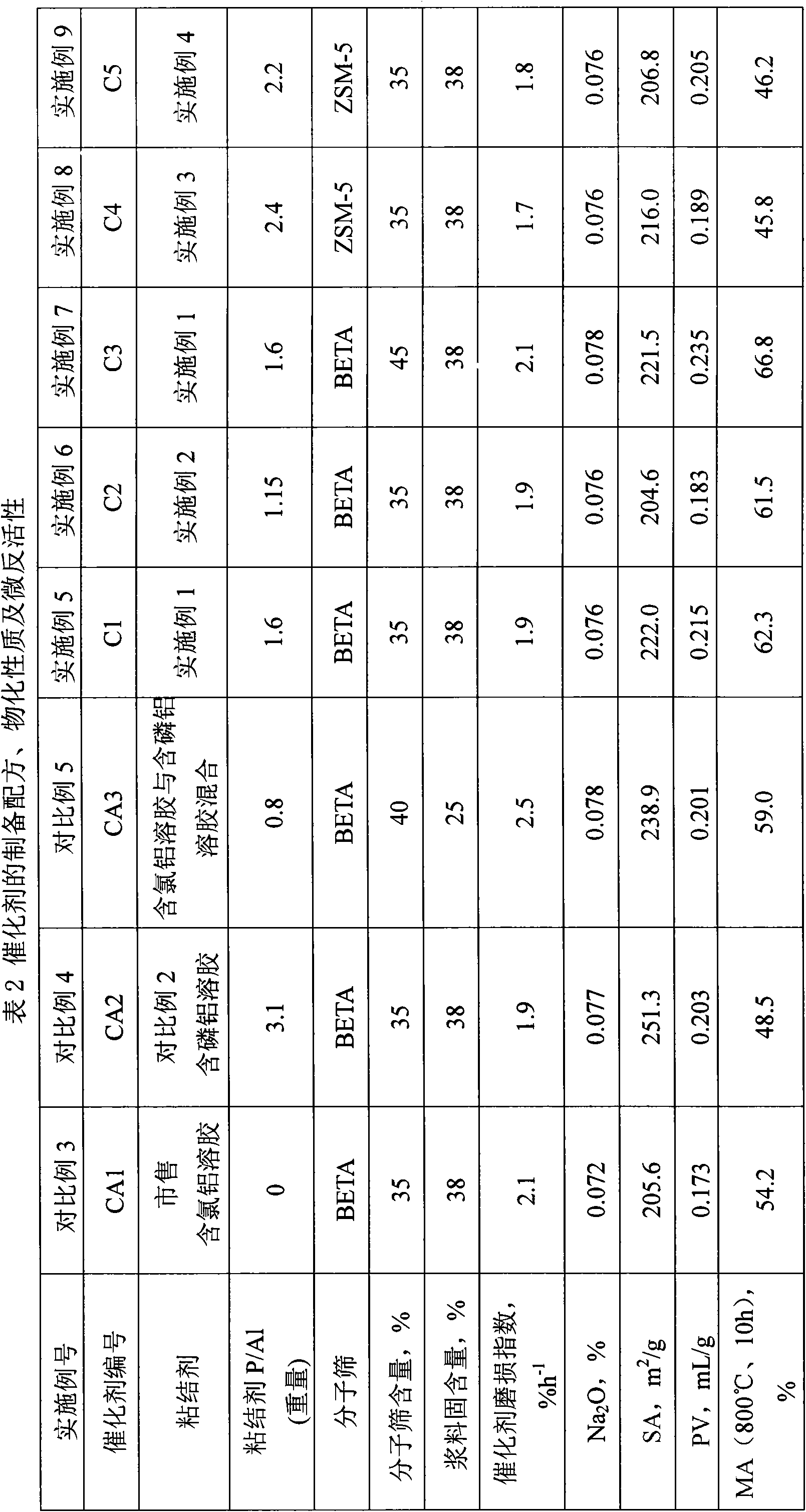

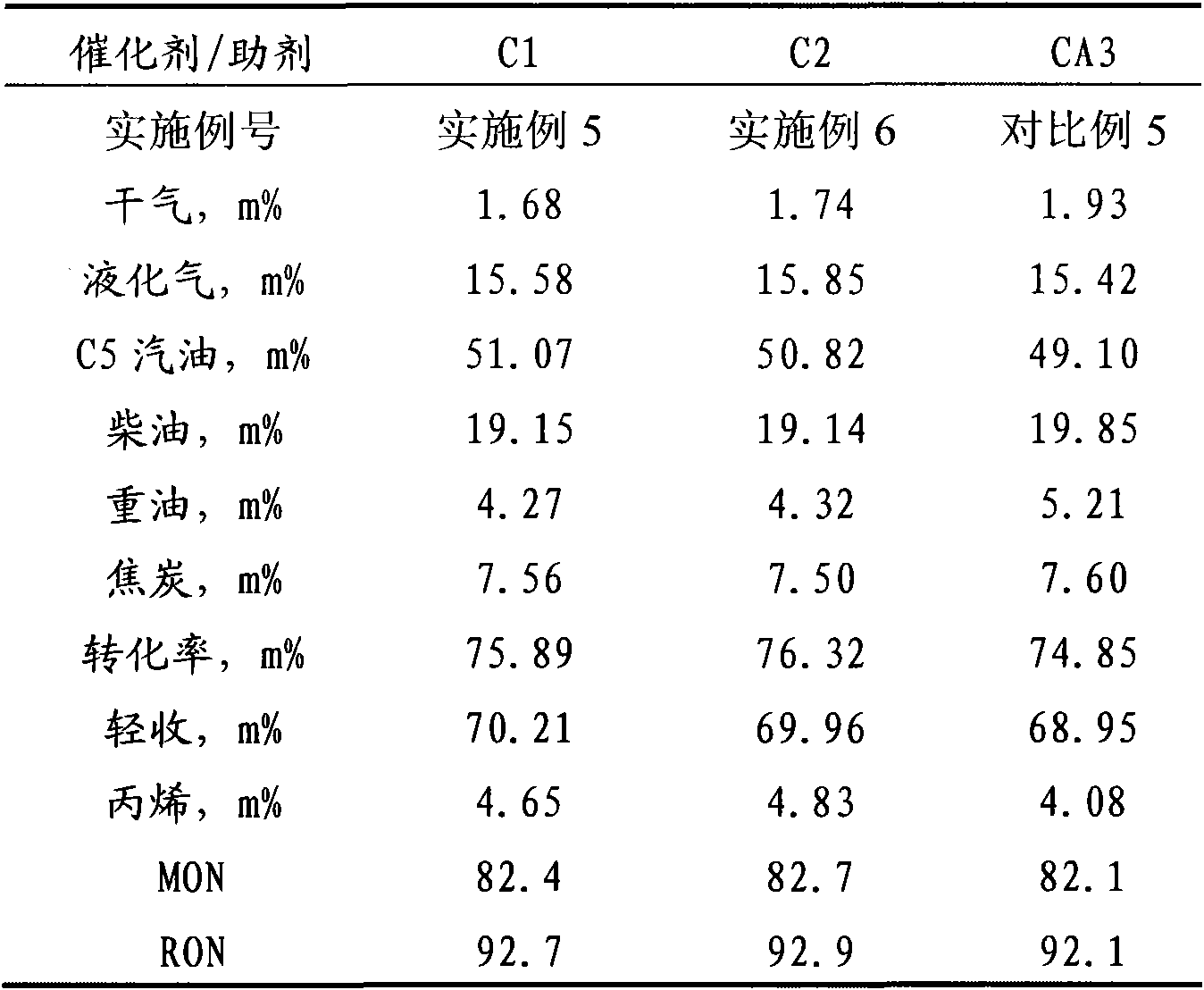

ActiveCN102050434AHigh activityHigh yieldPhysical/chemical process catalystsCatalytic crackingHydrogen NitratePhosphoric acid

The invention relates to a preparation method of aluminium phosphate sol used for a petroleum hydrocarbon cracking catalyst, which is characterized by comprising the steps of: mashing and dispersing an acid soluble aluminum precursor and decationed water into serous liquid with solid content of 15-35 percent, slowly adding phosphoric acid with concentration of 60-98 percent into the serous liquidunder the stirring according to the weight proportion of P / Al=1.0-2.5; then adding hydrogen nitrate with concentration of 40-98 percent according to the weight proportion of HNO3 / Al2O3=0.2-2.0, rapidly reacting and releasing a large quantity of heat; and generating colorless transparent thick liquid after the reaction. The microactivity of the catalytic cracking catalyst prepared by adopting the aluminium phosphate sol bonder provided by the invention is remarkably improved. The selectivity of the aluminium phosphate sol is improved, the yields of gas and coke are remarkably reduced, and the yields of light oil and propylene are improved.

Owner:PETROCHINA CO LTD

Composite material plate, preparation method and use of composite material plate

InactiveCN103009728AIncrease stiffnessSolve wear resistanceSynthetic resin layered productsLaminationWear resistancePolydicyclopentadiene

The invention relates to a composite material plate. The composite material plate comprises a sandwich layer, two covering layers coating the outer surface of the sandwich layer, and a polydicyclopentadiene layer arranged on the outer surface of at least one of the covering layers. The invention also relates to a preparation method and a use of the composite material plate. According to the composite material plate, outside of a fiber reinforced material is coated by the polydicyclopentadiene layer, so that the problem that a conventional fiber reinforced resin-based composite material is easily suffered from layering failure and is poor in abrasive resistance when being subjected to an impact load is solved. The composite material plate can be widely applied to loading or load-bearing components on mine, railway and road transportation heavy vehicles and goods hoppers. The composite material plate material can be obtained through a reaction injection molding process combined with a vacuum auxiliary molding process, and is suitable for industrial production.

Owner:蓝星环境工程有限公司

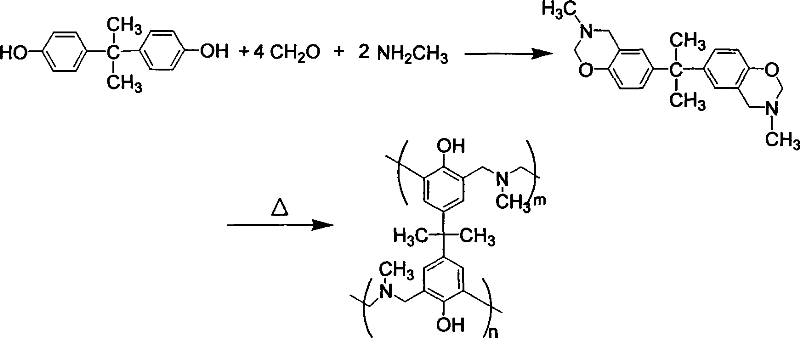

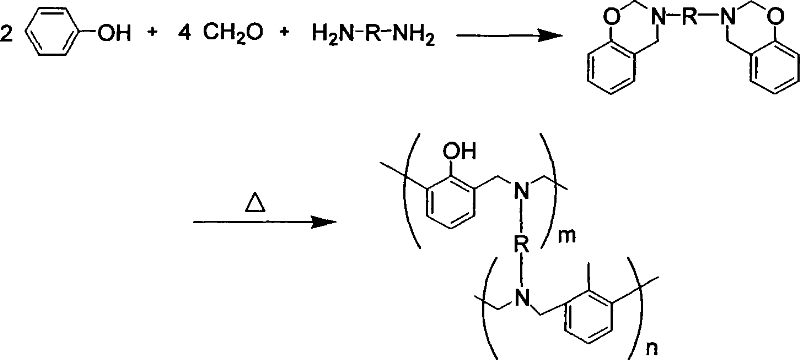

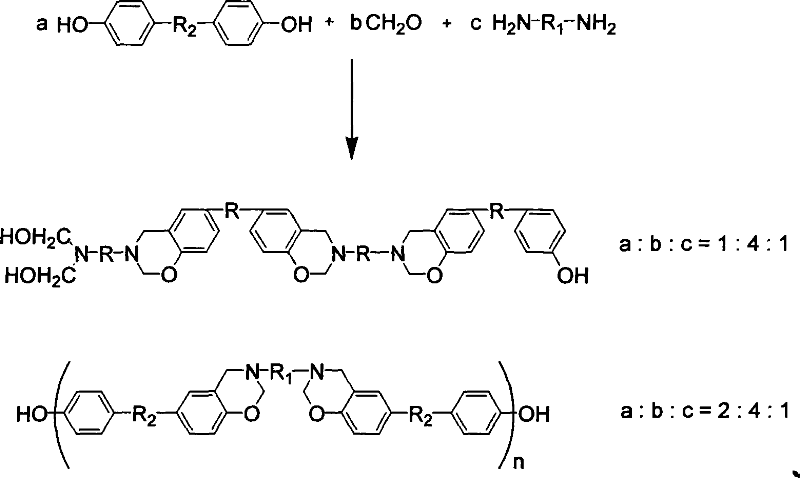

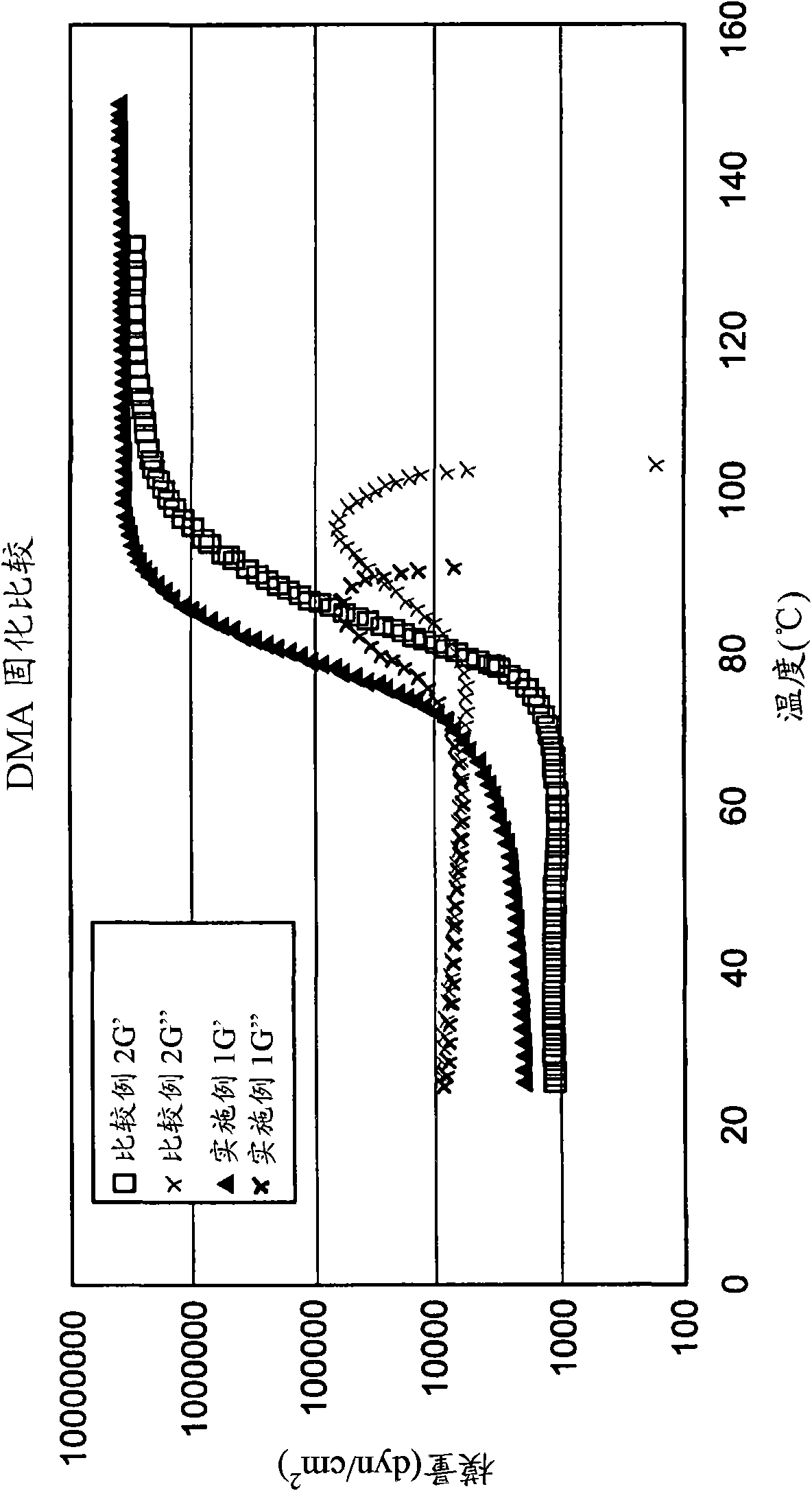

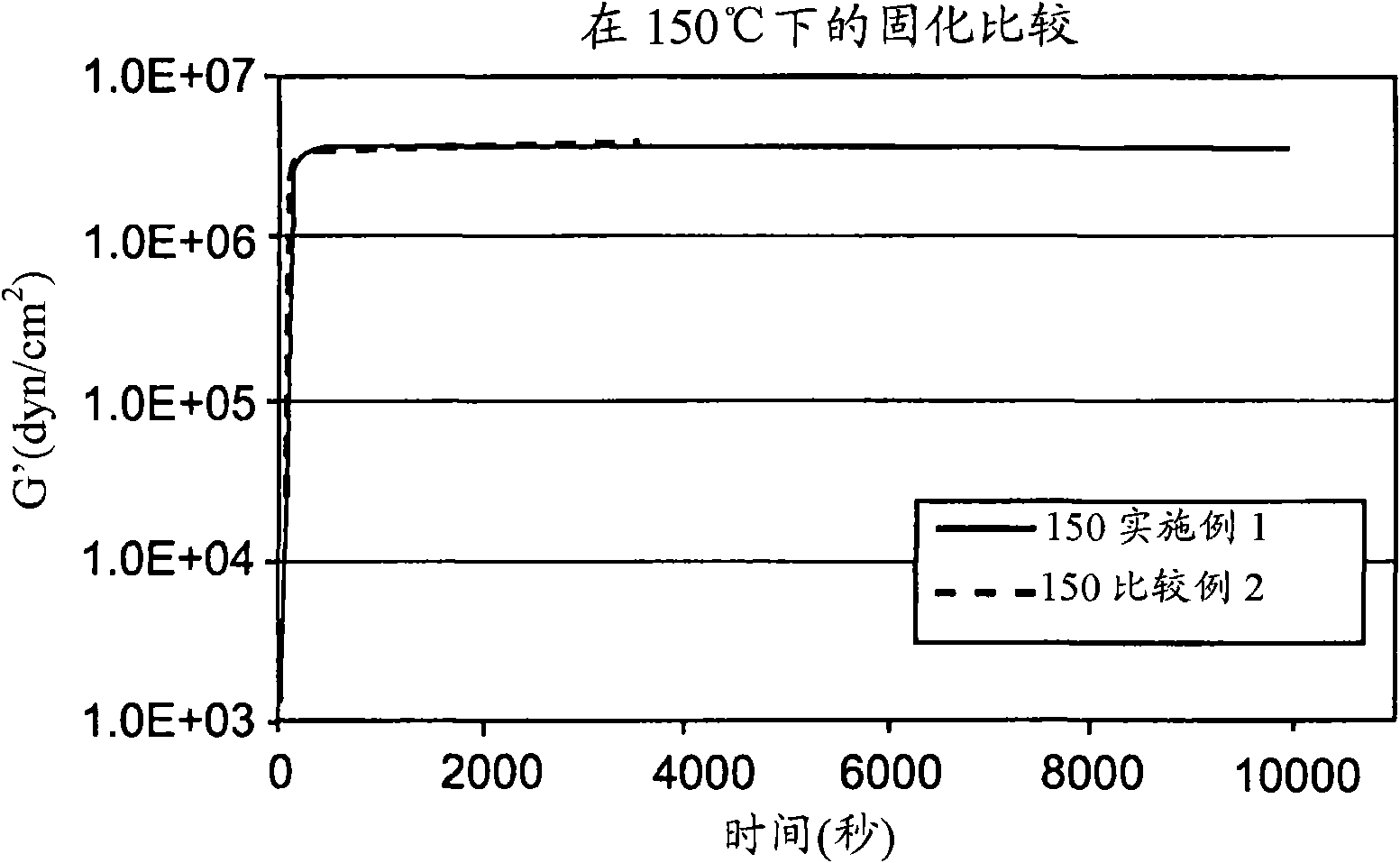

Preparation method of benzoxazine intermediate containing active function groups

The invention discloses a making method of benzoxazine intermediate with active functional group, which is characterized by the following: adopting diamine, dihydric phenol and formaldehyde as raw material; introducing the unit of diamine and dihydric phenol into the intermediate of benzoxazine; polymerizing under heating condition; reducing the ring-opening polymerizing temperature of benzoxazine; fitting for making high-property structural material, electric insulating material, electronic packing material, flame-proof material or braking material with temperature over 155 deg.c.

Owner:SHANDONG UNIV

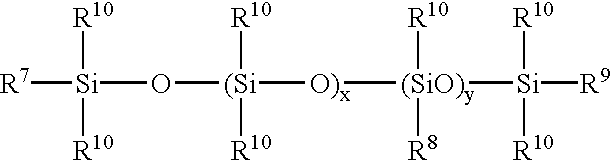

Silicone adhesive composition and method for preparing the same

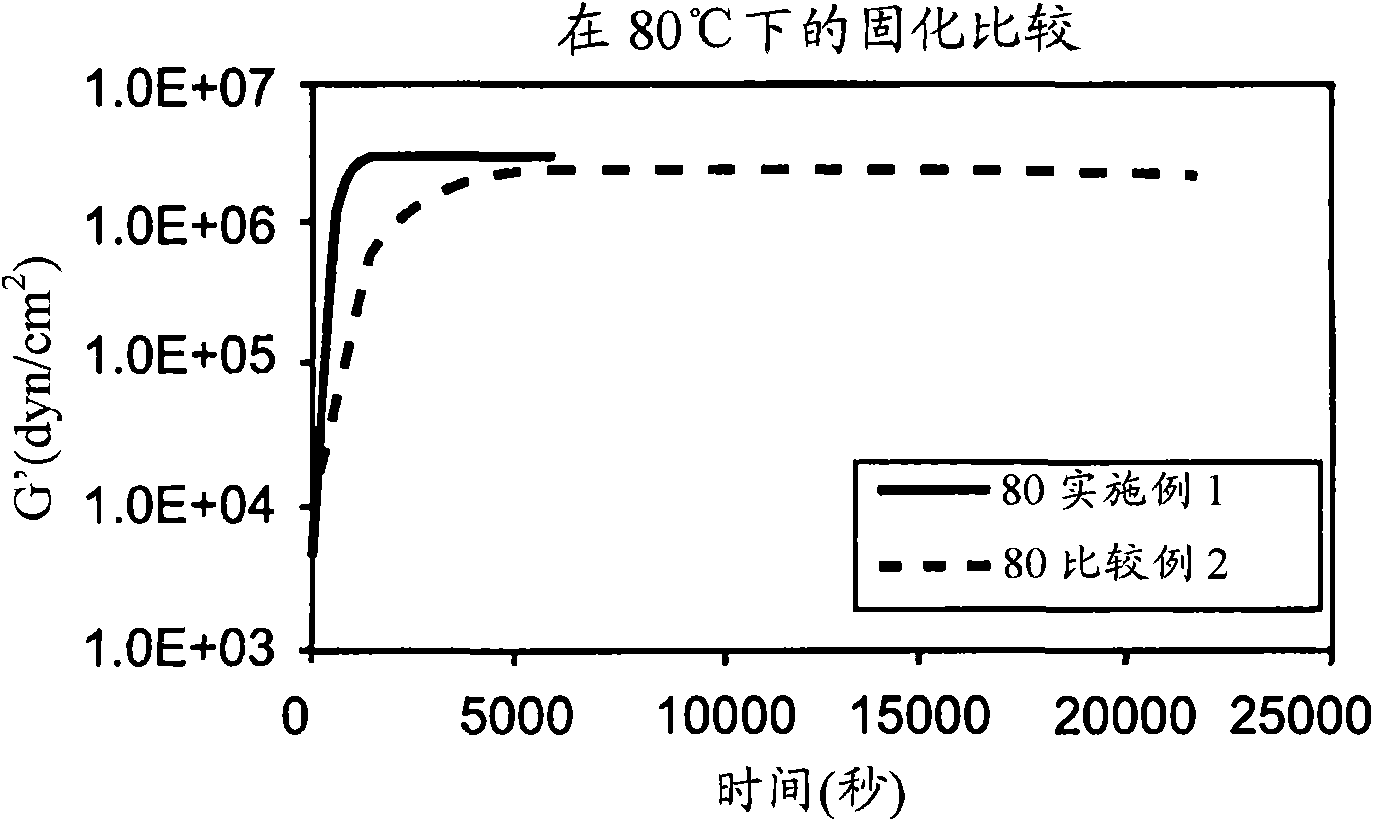

InactiveCN101627077AFast curing rateLow curing temperatureElectrically-conducting adhesivesPolymer scienceHydrogen atom

A thermal interface material composition including a blend of a polymer matrix and a thermally conductive filler having particles having a maximum particle diameter no greater than about 25 microns, wherein the polymer matrix includes an organopolysiloxane having at least two silicon-bonded alkenyl groups per molecule, an organohydrogenpolysiloxane having at least two silicon-bonded hydrogen atoms per molecule and a hydrosilyation catalyst comprising a transition metal, wherein the transition metal is present in an amount of from about 10 to about 20 ppm by weight based on the weight of the non-filler components and the molar ratio of the silicon- bonded hydrogen atoms to the silicon-bonded alkenyl groups ranges from about 1 to about 2. A method is also provided.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Low temperature curing epoxy low-gloss powder coating and preparation method thereof

InactiveCN101747826ASimple recipeLow curing temperaturePowdery paintsEpoxy resin coatingsPowder coatingEpoxy

The invention discloses a low temperature curing epoxy low-gloss powder coating, which comprises the following components in part by weight: 100 to 200 parts of epoxy resin, 1 to 10 parts of epoxy curing agent, 0 to 50 parts of delustering agent, 0 to 160 parts of inorganic filling and 0 to 10 parts of addition agent. The invention also discloses a method for preparing the powder coating. The low temperature curing epoxy low-gloss powder coating has the characteristics of simple formula, low curing temperature, stable gloss and free adjustment of a coat, good mechanical properties, good chemical resistance and the like.

Owner:GUANGZHOU QINGTIAN INDAL

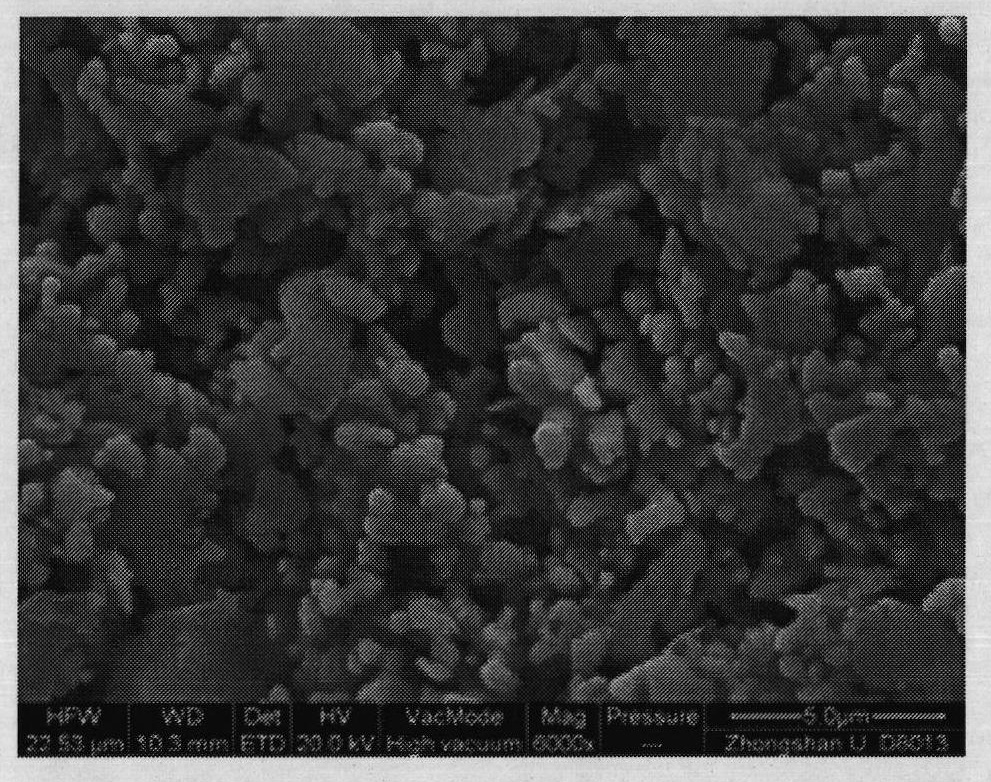

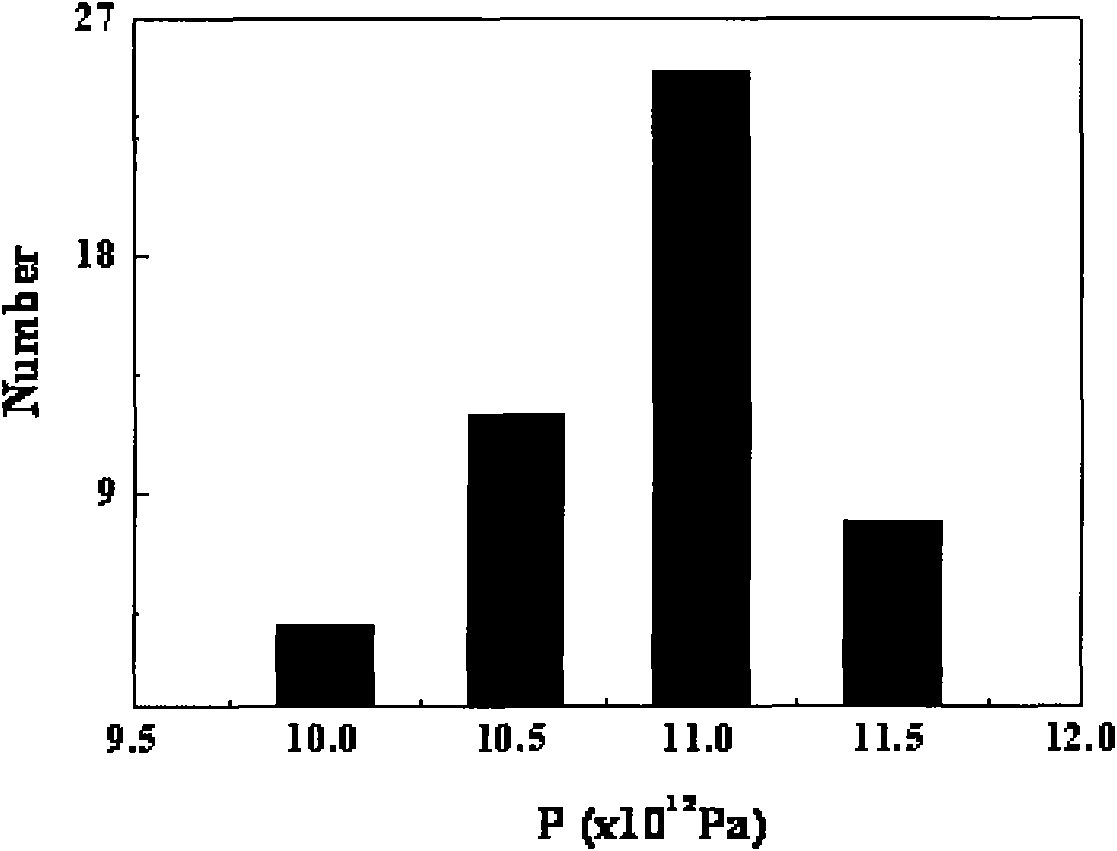

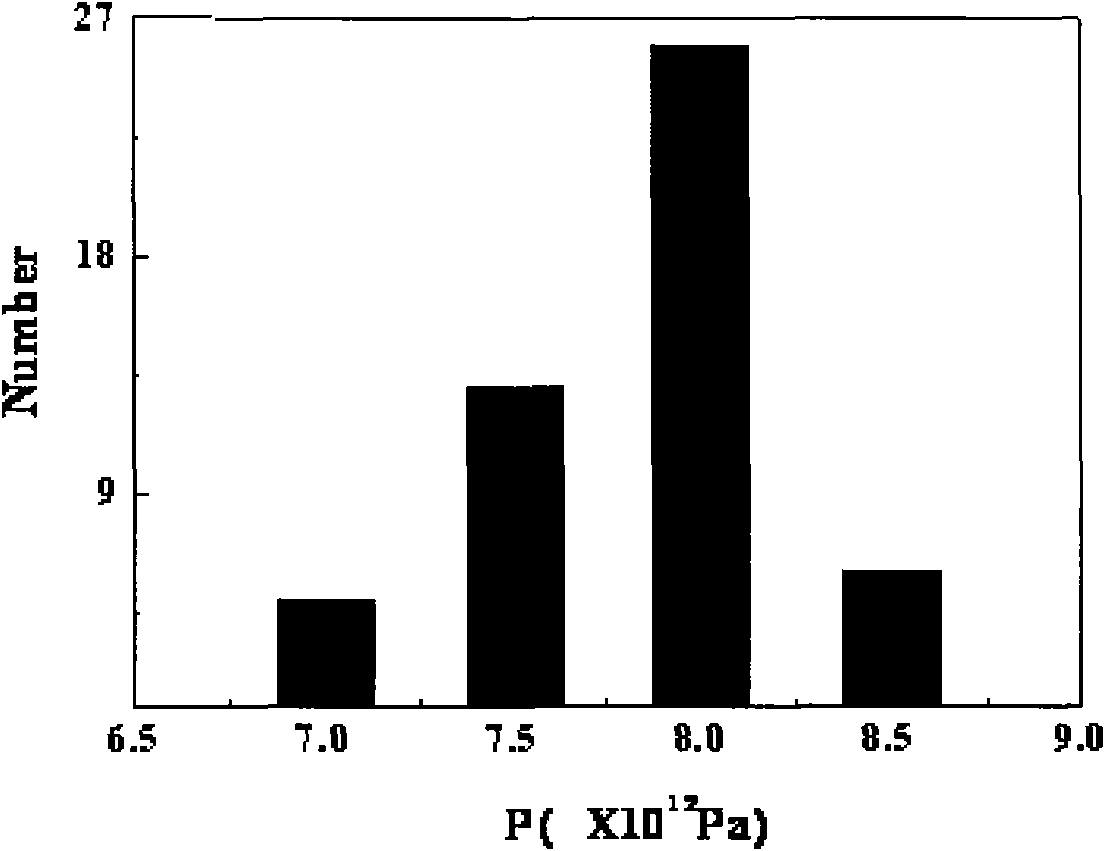

High-performance conductive silver paste and preparation method thereof

ActiveCN101805575AEvenly dispersedUniform size distributionNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyWorking temperature

The invention relates to a high-performance conductive silver paste, which is characterized by comprising the following raw materials in percentage by weight: 65-80% of micron-sized metal silver powder, 10-20% of epoxy resin, 1.4-3.5% of curing agent, 6-9% of solvent, 0.5-1.2% of accelerator, 0.05-0.1% of flexibilizer and 1-2% of additive. The invention also discloses a preparation method of the high-performance conductive silver paste. The conductive silver paste of the invention has high conductivity, very high thermal conductivity, high working temperature, strong viscosity and very high shear strength, and the performance indexes are apparently higher than the working performance of the conductive silver paste in the prior art, thereby solving the technical problems of poor shear performance, low working temperature, poorer thermal conductivity, long curing time, high curing temperature, poor viscosity, easy pollution of environment and the like in the field of the conductive silver paste in the prior art.

Owner:连云港市昭华光电科技有限公司

Vegetable oleic acid modified epoxy resin and preparation method thereof, polymer containing vegetable oleic acid modified epoxy resin, and preparation method and application of polymer

ActiveCN104710598AGood flexibilityImprove the level ofOrganic chemistryAnti-corrosive paintsPliabilityDouble bond

The invention discloses a vegetable oleic acid modified epoxy resin. The invention also discloses a preparation method for the vegetable oleic acid modified epoxy resin, a polymer containing the vegetable oleic acid modified epoxy resin, and a preparation method and application of the polymer. According to the invention, since vegetable oleic acid with an unsaturated double bond is introduced into the epoxy resin, post-curing of the unsaturated double bond improves comprehensive properties of a paint film. The polymer of the invention is applied in a cathodic electrophoretic coating material, and a formed coating has the characteristics of good flexibility, good leveling property, high gloss, low curing temperature, good corrosion resistance, etc., can be cured at 140 to 160 DEG C and is low in cost; and products using the coating has good storage stability.

Owner:NIPPON PAINT GUANGZHOU

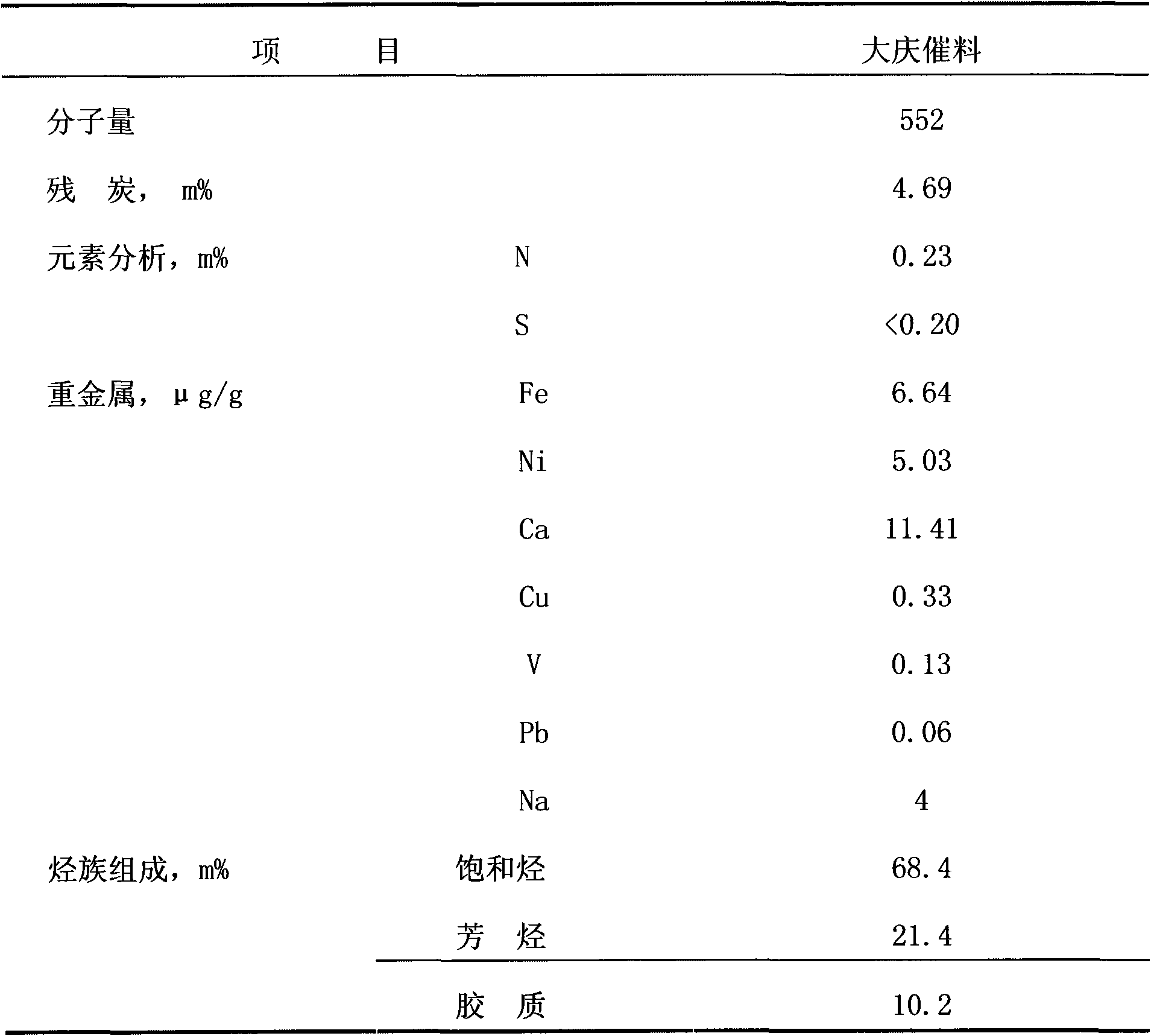

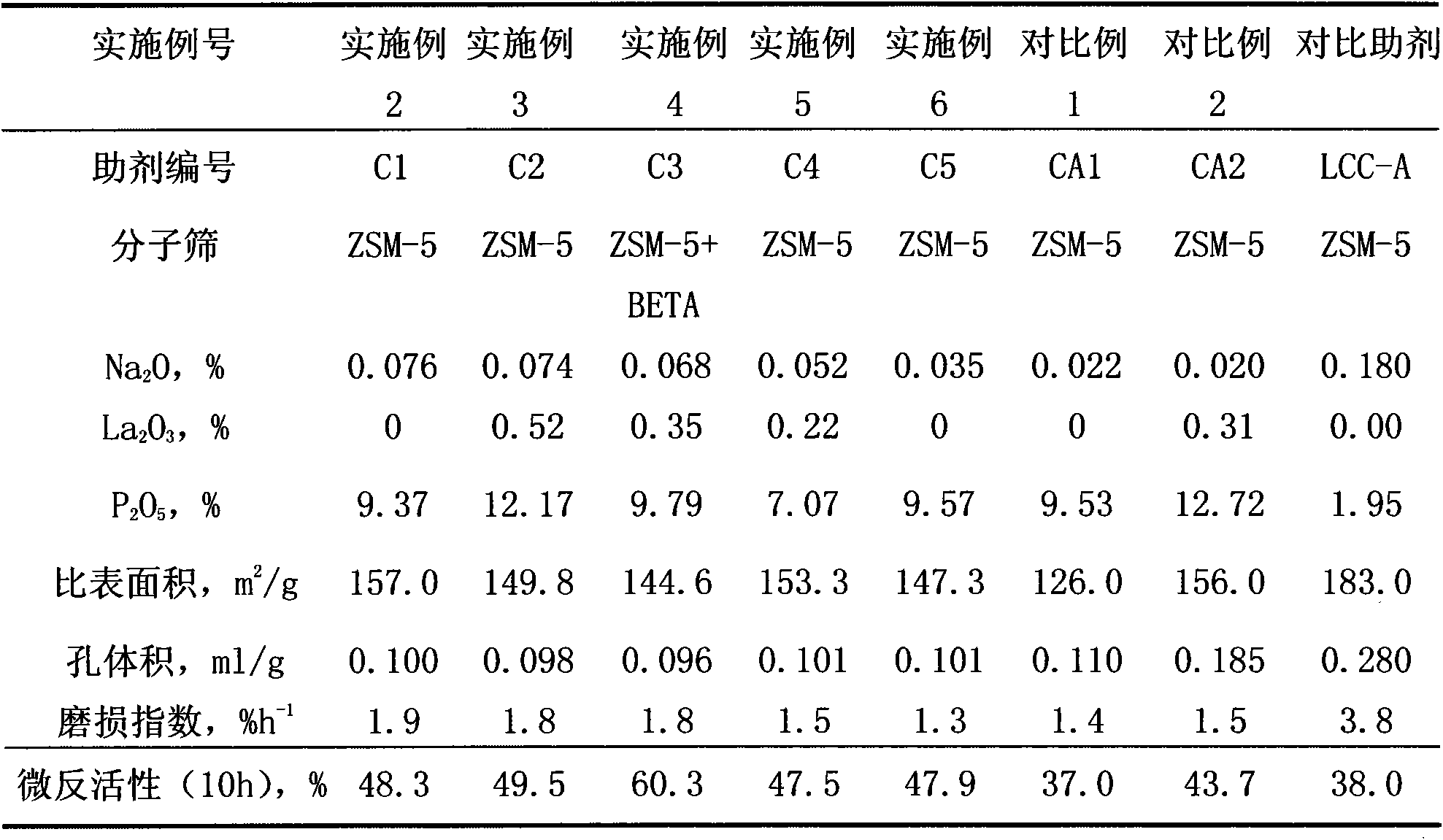

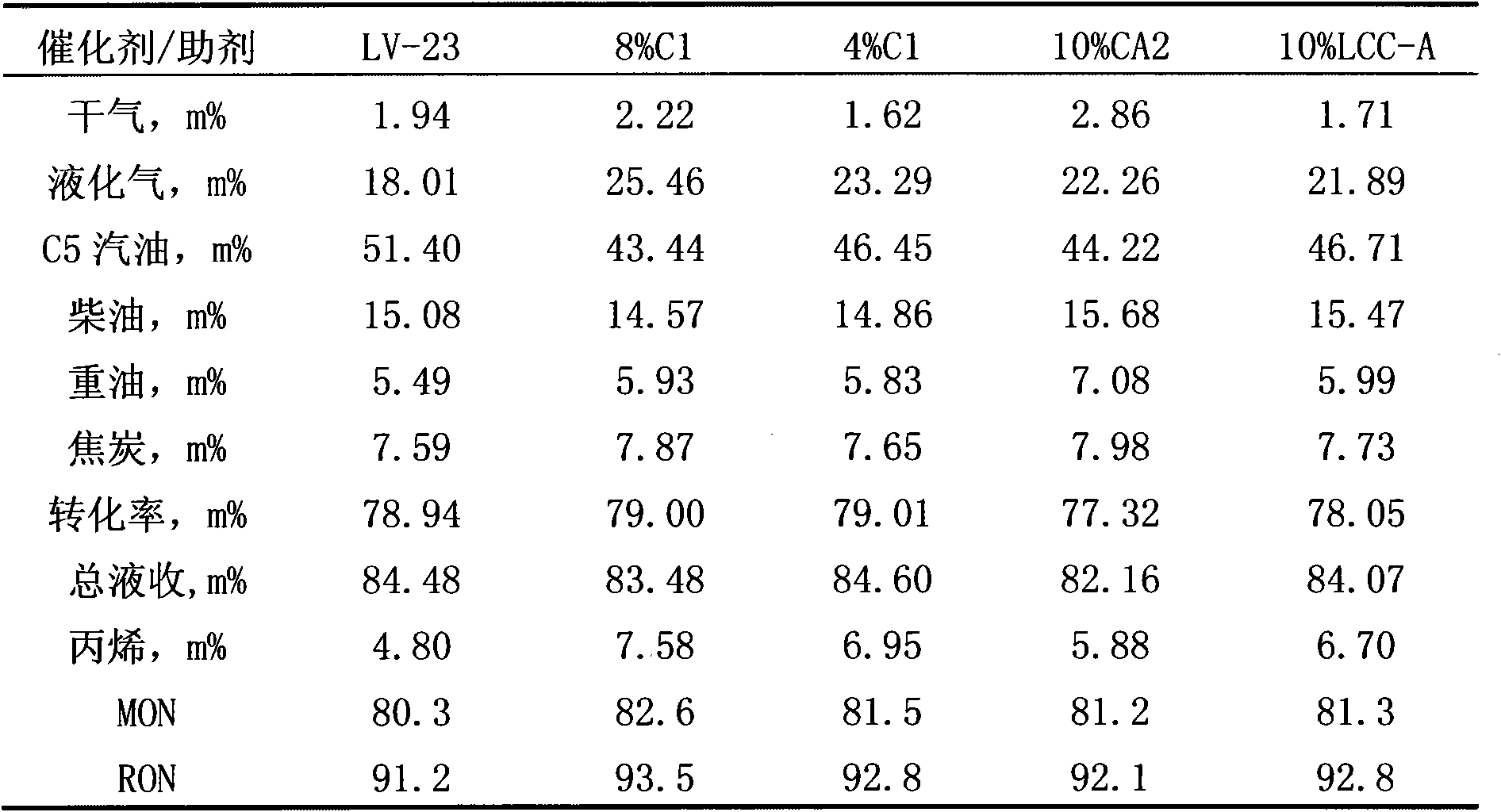

Catalytic cracking propylene additive and preparation method thereof

ActiveCN102049284AImprove stabilityReduce viscosityCatalytic crackingMolecular sieve catalystsAdhesiveALUMINUM PHOSPHATE

The invention relates to a catalytic cracking propylene additive. The additive measured in the total weight of 100 percent is characterized by being prepared from the following components in percentage by weight: 30-80 percent of molecular sieve including 28-78 percent of ZSM-5 zeolite, 10-65 percent of clay and 5.0-20.0 percent of P2O5, preferable 7.0-15.0 percent as well as 0-1.0 percent of La2O3. Aluminum phosphate sol is adopted as an adhesive to improve the abrasive strength of the additive, improve the solid content of spraying slurry and avoid the chlorine contents of the spraying slurry and the additive. The prepared catalytic cracking propylene additive remarkably improves the activity, slightly lessens the activity of a main catalyst when mixing with the main catalyst for use, can improve the product distribution, have favorable dry gas and coke selectivity and simultaneously improve the propylene yield and the gasoline octane number.

Owner:PETROCHINA CO LTD

Paint of silicon-ceramic capable of resisting 900-1200 deg.C. organic high temp

The invention relates to a high temperature 900-1200 deg.C resistant organic silicion-ceramic coating, using organic silicon resin as base material, mixing with high temperature-resistant pigment, metal oxide and silicate fillings as well as solvent to make it, converting the organic type to the inorganic type at high temperature by paint films so as to implement the high temperature protection of basal bodies. It combines two techniques of organic silicon coating and inorganic high temperature resistant coating to give play to their advantages and avoid their disadvantages, supplementing mutually, further obtaining the convenient-coated normal temperature-hardening high-temperature 900-1200 deg.C-resistant organic-inorganic coating. It has the characters of simple coating process, excellent coating properties, good high temperature resistance, excellent high-temperature anticracking property, ability of recycling, etc.

Owner:江阴市大阪涂料有限公司

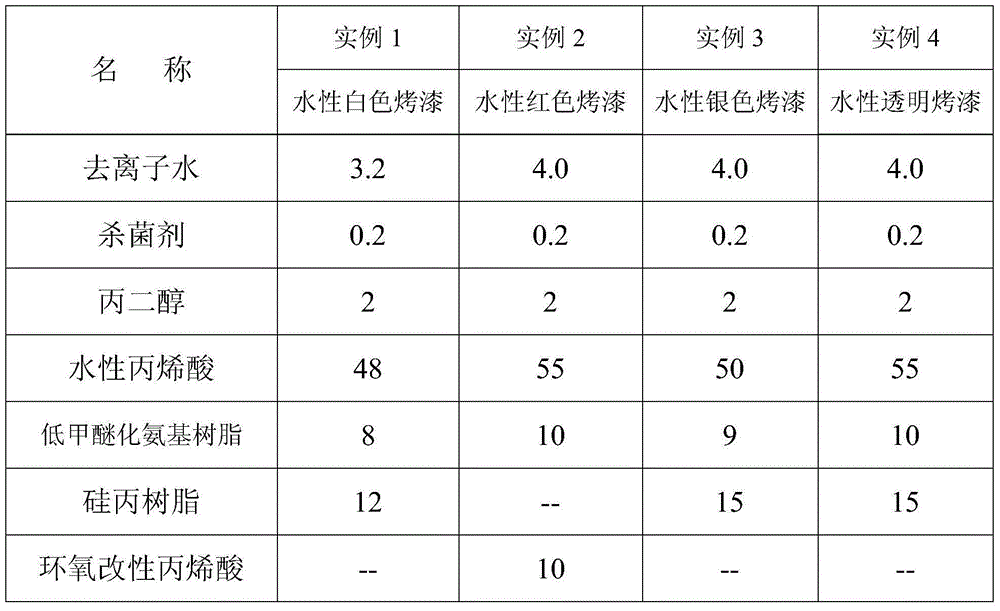

Preparation method of low-temperature curing water-based glass baking paint

ActiveCN103937360AIncrease the degree of cross-linkingLow curing temperatureCoatingsWater basedAcrylic resin

The invention relates to a preparation method of a low-temperature curing water-based glass baking paint composed of acrylic resin, amino resin, hydroxyl resin, a pigment or a colorant, a wetting agent, an adhesive agent, an acid catalyst, a film-forming auxiliary agent, a defoaming agent, an anti-scratch flatting agent, a thickening agent, a bactericide, a pH regulator, a cosolvent and water. The prepared low-temperature curing water-based glass baking paint has the advantages of low VOC, no pollution to the environment, no poison and harm to operators, strong coating film adhesive force, good flexibility, high hardness, excellent wear resistance, excellent water resistance, excellent alcohol resistance, excellent salt fog resistance, simple construction, and stable storage; and a prepared paint film has the hardness reaching 2 H or more, has excellent anti-scratch wear-resisting properties, and is widely used for surface protection and decoration of wine bottles, perfume bottles, glass products, lamps, woodware, metals, plastics and other products.

Owner:深圳市莱莉雅环保科技有限公司

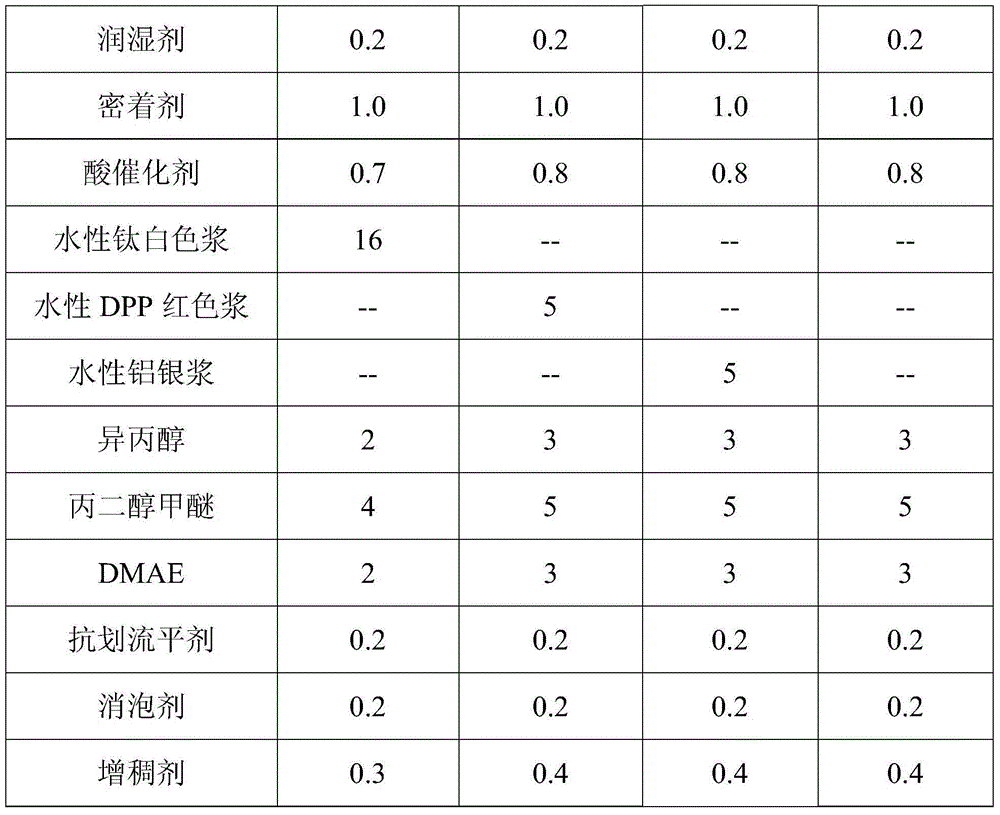

Canate-bimaleimide resin adhesive and preparation method

InactiveCN101531880ALow dielectric lossLow dielectric constantAdhesivesCyanate compoundResin adhesive

A cyanate-bimaleimide resin adhesive and a preparation method belong to the adhesive field, solving the problems of poor heat resistance, low dielectric property and poor adhesive property of current high-temperature adhesives. The adhesive of the invention is prepared by a cyanate ester resin, a bismaleimide resin, an internally toughened phenolic resin, an epoxy resin and a catalyst. The preparation method is as follows: 1. carrying out pre-reaction on the epoxy resin and the internally toughened phenolic resin to obtain a prepolymer resin B; 2. carrying out pre-reaction on the cyanate, the bimaleimide and the catalyst to obtain a prepolymer C; 3. carrying out pre-reaction on the prepolymer C and the prepolymer B to prepare the adhesive of the invention. The prepared adhesive has reasonable formulation, good heat resistance, dielectric property, adhesive property and curing process property, can be used for adhesion of high-temperature resistance composite materials with high dielectric property and used as a matrix resin, and is simple in method and easy operation.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Modified cyanate adhesive film and preparation method thereof

ActiveCN102876247AGood mechanical propertiesEasy to operateNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAdhesive

The invention relates to a modified cyanate adhesive film and a preparation method thereof, belonging to the field of modified cyanate adhesive films and preparation methods thereof. The invention aims at solving the technical problems that the surface of the cyanate adhesive film prepared by using the existing cyanate adhesive film preparation method is apt to be crystallized during placing at room temperature, the mechanical performance is low and the curing temperature is high. The modified cyanate adhesive film is prepared by using the following components in parts by weight: 60-100 parts of cyanate resin, 5-40 parts of epoxy resin, 1-50 parts of toughened resin, 1-10 parts of activated thinner and 1-5 parts of accelerator. The preparation method comprises the following steps of: 1) weighing raw materials; 2) preparing matrix resin; 3) preparing adhesive; and 4) preparing the modified cyanate adhesive film. The modified cyanate adhesive film and the preparation method thereof are used in the fields of aerospace and electronic information.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

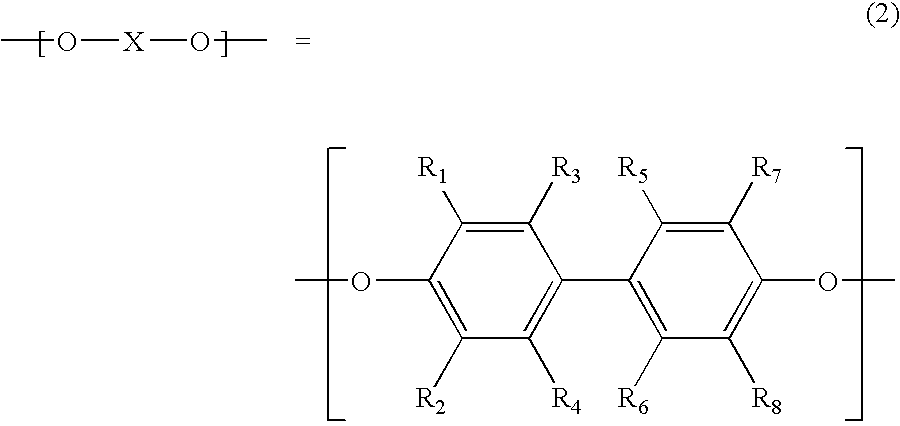

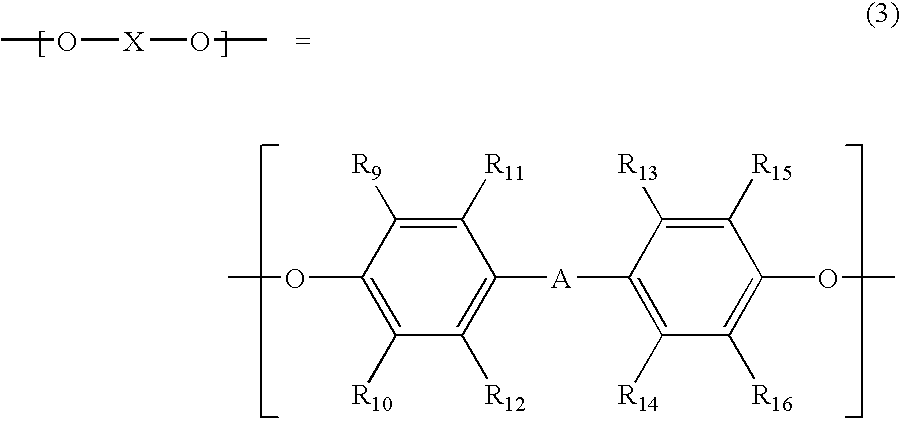

Curable resin composition, curable film and their cured products

A curable resin composition containing a specific vinyl compound obtained by vinylation of a terminal of a bifunctional phenylene ether oligomer having a polyphenylene ether structure in a molecule and a specific bismaleimide compound having at least two maleimide groups in a molecule, a curable film comprising the above composition, a cured product obtained by curing the above composition, and a film obtained by curing the curable film. The above resin composition is excellent in curability even in the presence of oxygen, is curable at a low temperature and is capable of giving a cured product having a low dielectric constant, a low dielectric loss tangent, high heat resistance, excellent mechanical properties, excellent chemical resistance and excellent flame retardancy.

Owner:MITSUBISHI GAS CHEM CO INC

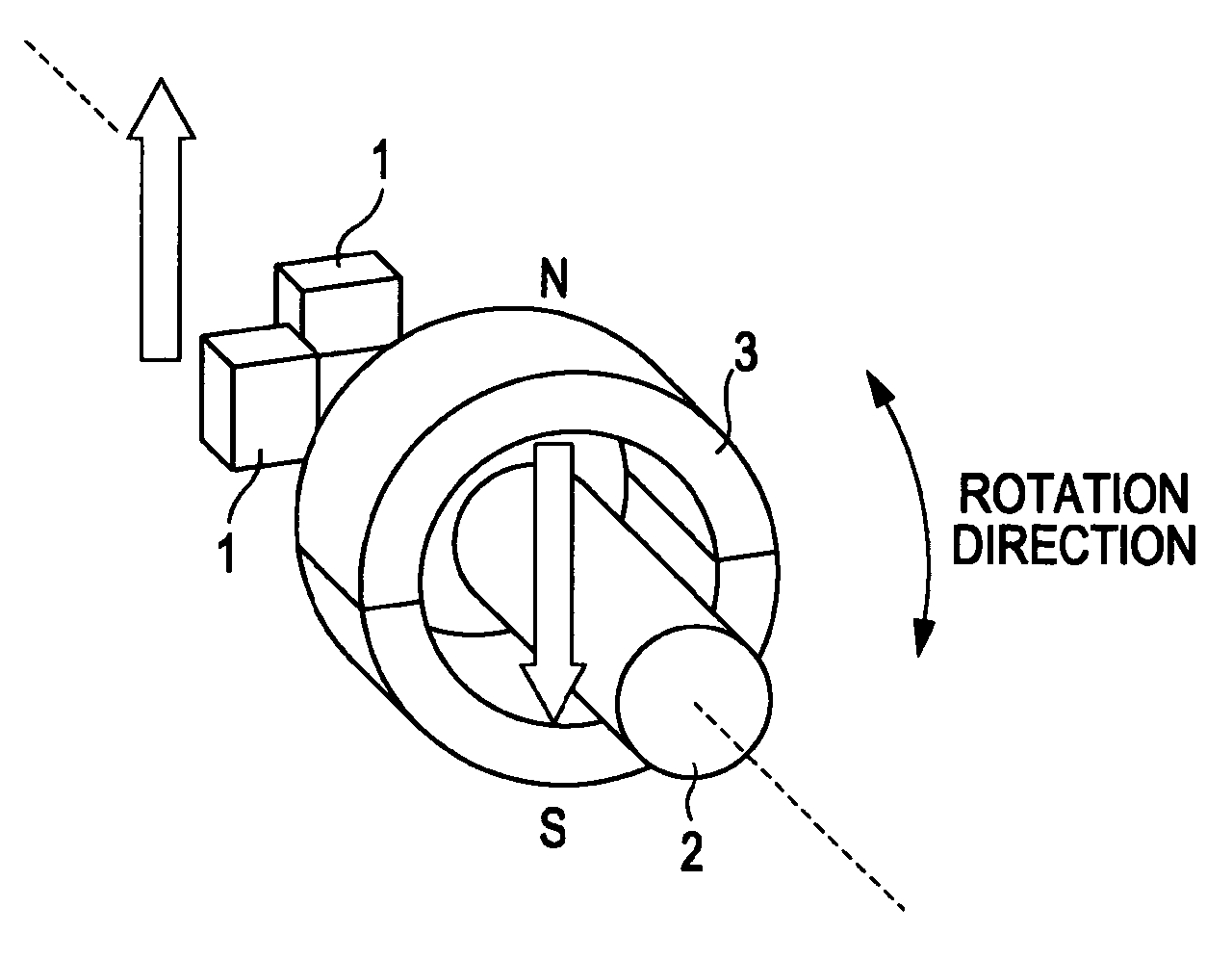

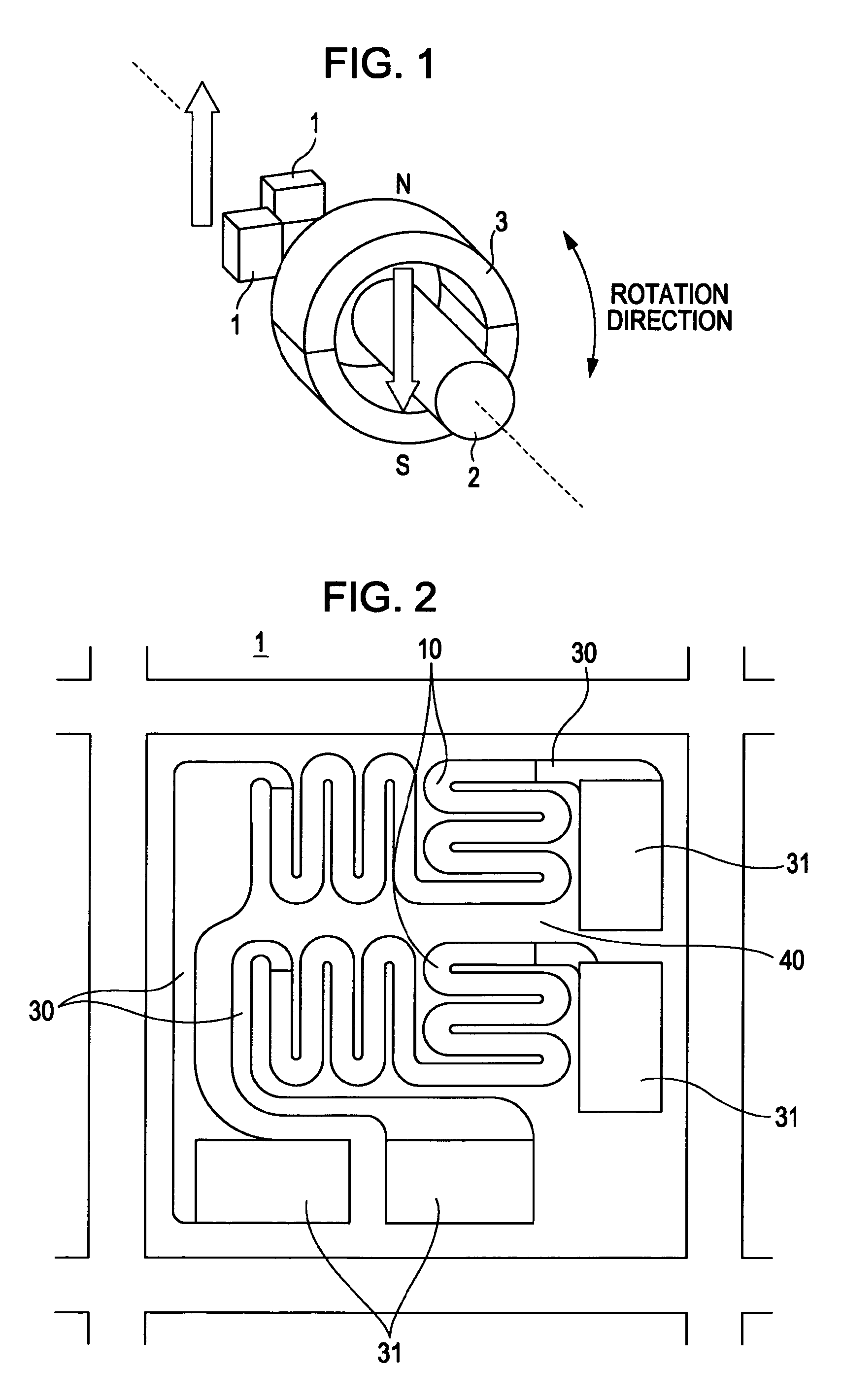

GMR angle sensor for vehicles

ActiveUS20070164734A1Suppress variationSuppress oxidationMagnetic-field-controlled resistorsSolid-state devicesOxidation resistantEngineering

A GMR angle sensor for vehicles includes a GMR element in which the element resistance is changed in response to an external magnetic field, lead conductors connected to either end of the GMR element, and a protective layer that seals the GMR element and the lead conductors, wherein the protective layer has a laminated structure including an oxidation-resistant inorganic film that ensures that the GMR element and the lead conductors are sufficiently insulated and a silicone-based organic film laminated on the inorganic film.

Owner:ALPS ALPINE CO LTD

Powder coating with low-temperature curing function

InactiveCN102993921AHigh transparencyBright colorPowdery paintsEpoxy resin coatingsEpoxyPolymer science

The invention relates to a powder coating with a low-temperature curing function. The powder coating comprises the following components in percentage by weight: 40-60 percent of unsaturated polyester resin, 20-25 percent of epoxy resin, 1-5 percent of photosensitizer, 0.5-1.5 percent of flatting agent, 0.1-1 percent of defoaming agent, 15-25 percent of filler, 8-15 percent of transparent iron oxide pigment and 0.1-0.5 percent of white carbon black. The powder coating with alow-temperature curing function is high in transparency, bright in color and low in curing temperature; when the powder coating is sprayed, the powder coating is preheated to 50-70 DEG C and maintained at the temperature for 5-8min, then subjected to electrostatic spraying, blown by hot air with the temperature being about 120 DEG C for 20min and then naturally cooled; and the powder coating is suitable for coating of wooden materials.

Owner:宿迁市英杰装饰材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com