Patents

Literature

5470results about How to "Adequate response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adaptively controlled footwear

A method for controlling footwear, comprising cushioning a transient force during use of the footwear at a first period of a gait cycle, storing energy from said cushioning, and releasing the stored energy during use of the footwear at a second period of the gait cycle, and after said transient force has subsided. The control can be electronic, mechanical or hydraulic, and is preferably dependent on a sensed gait cycle phase. The control may be adaptive to the user or the use of the footwear. The stored energy can be used to assist in locomotion, to generate electrical energy, to drive a heat pump, or simply dissipated.

Owner:PROMDX TECH

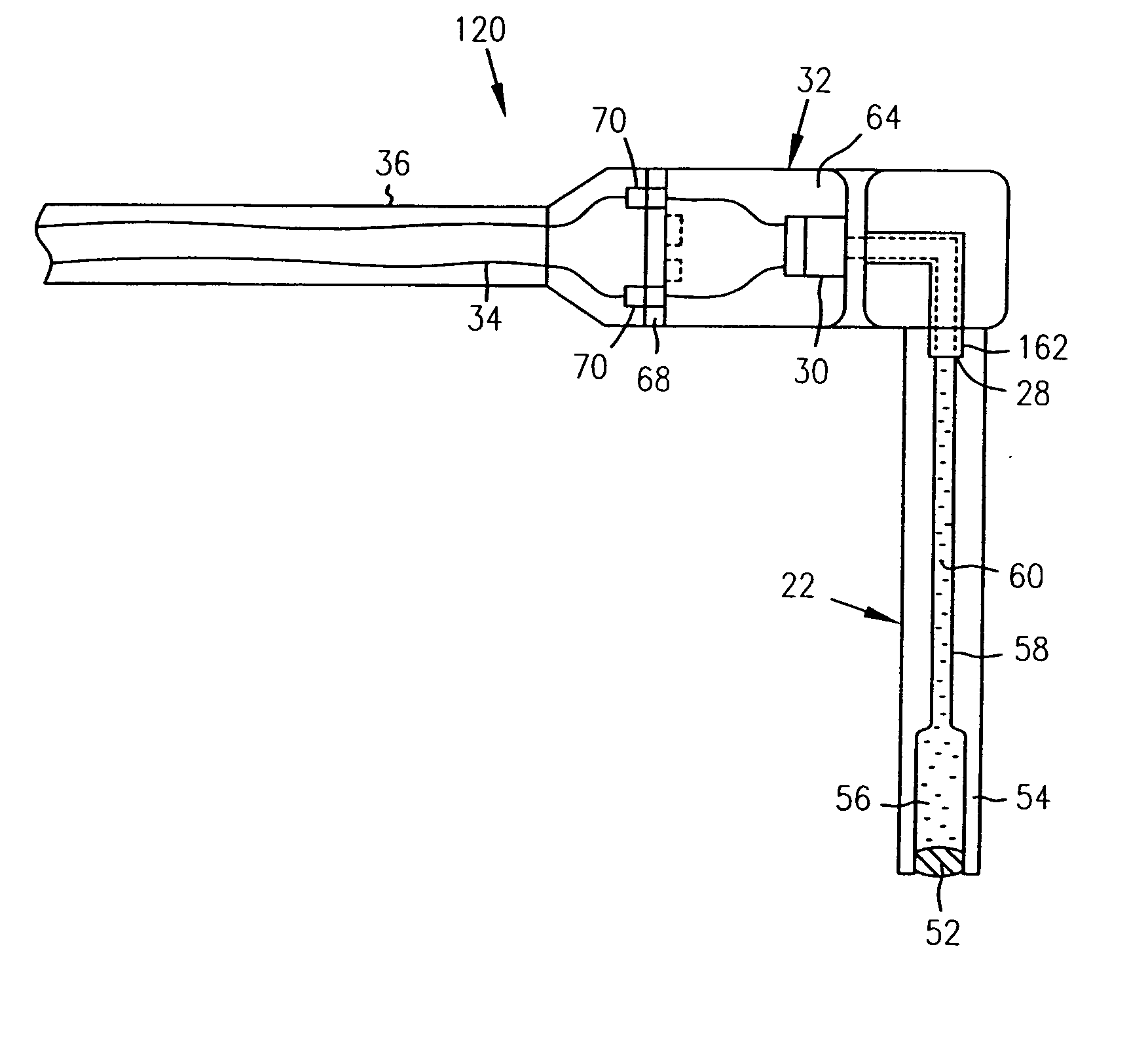

Pressure measurement device

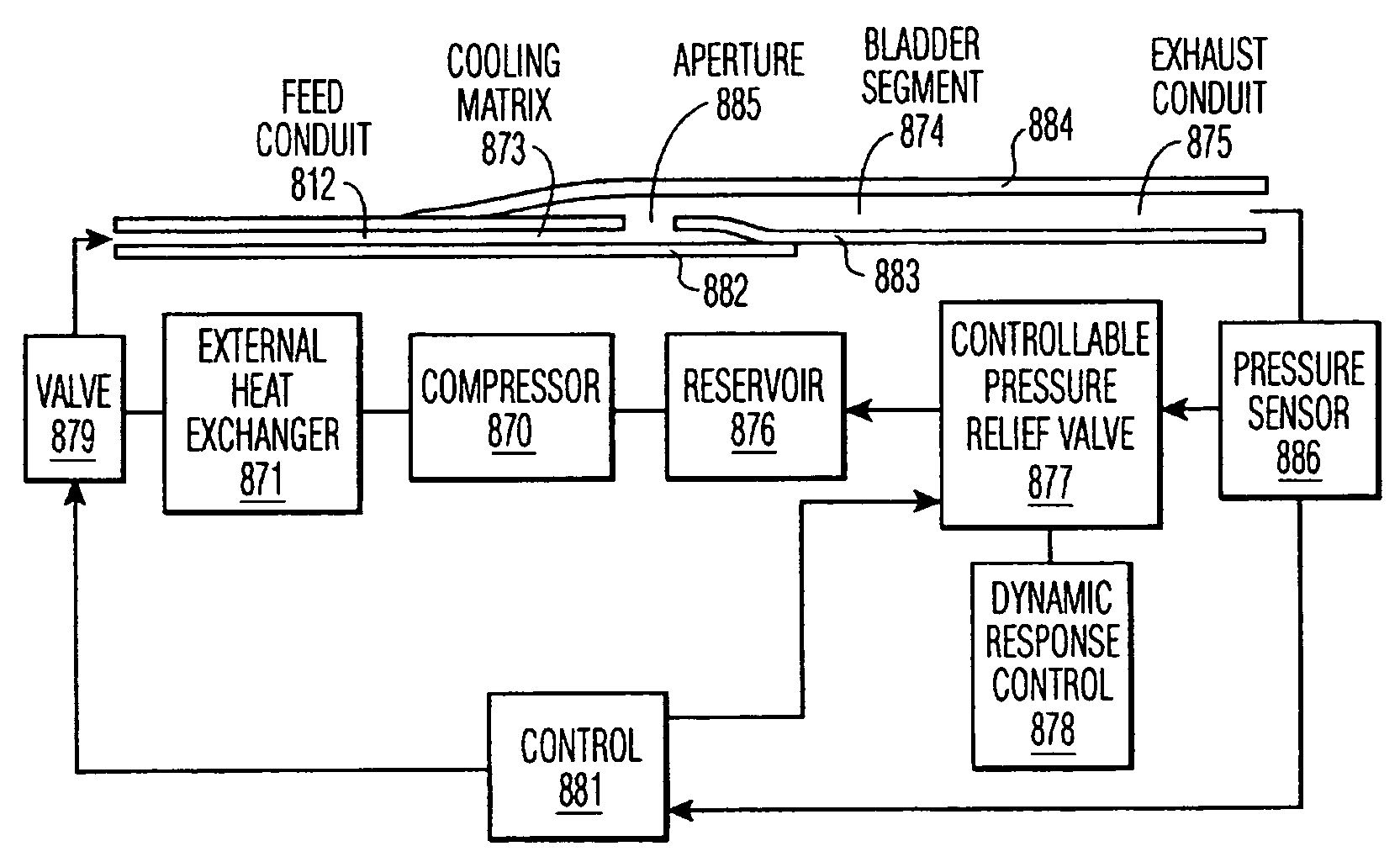

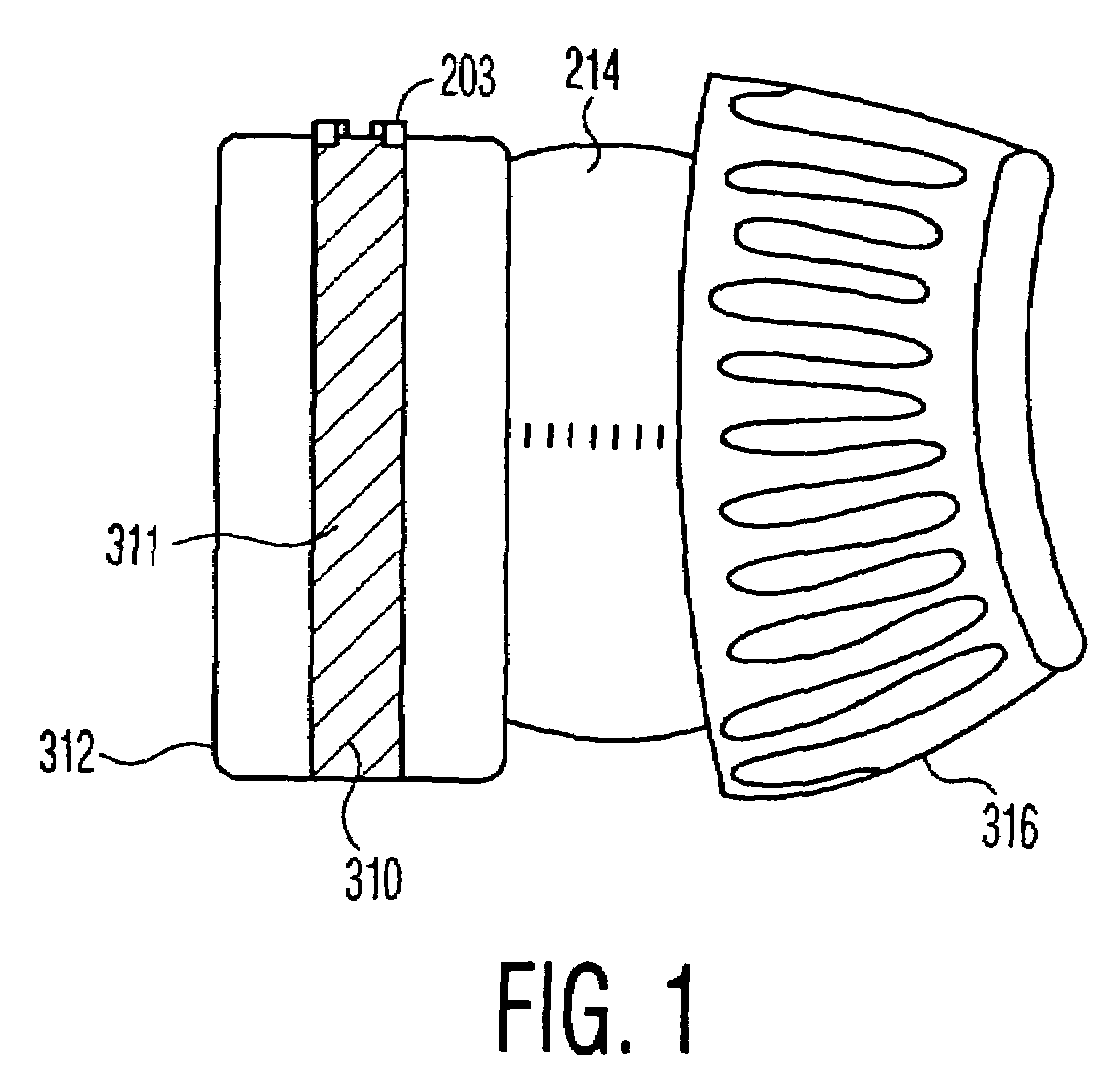

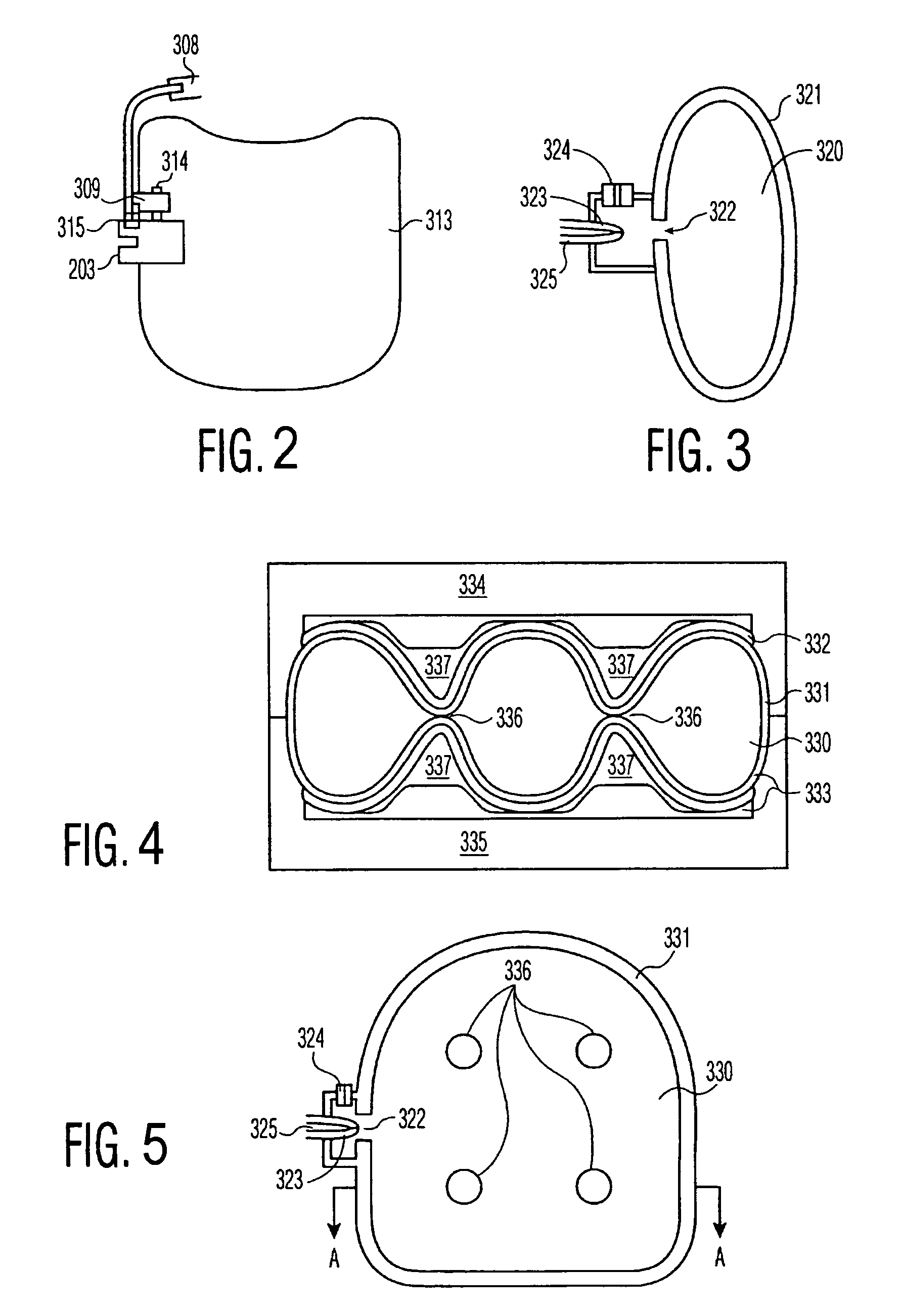

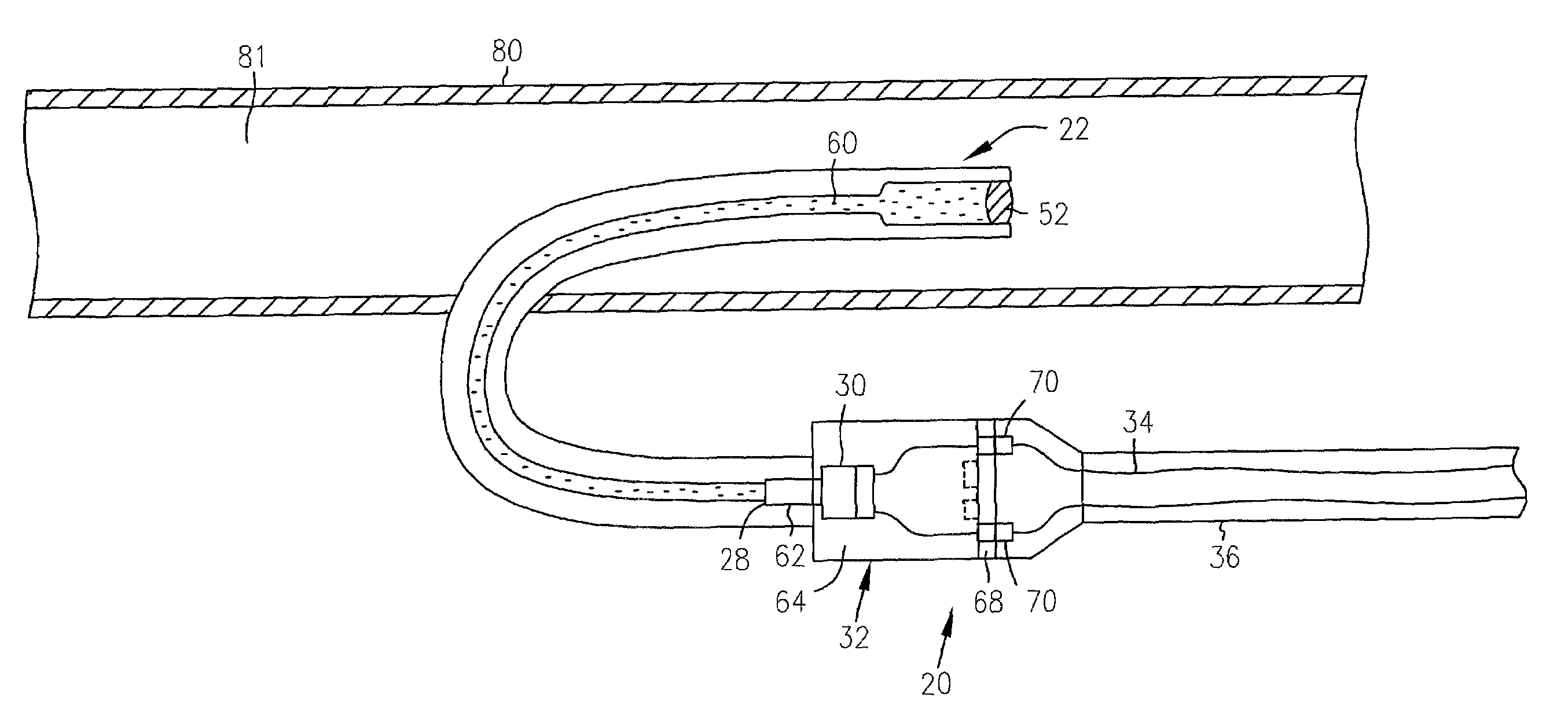

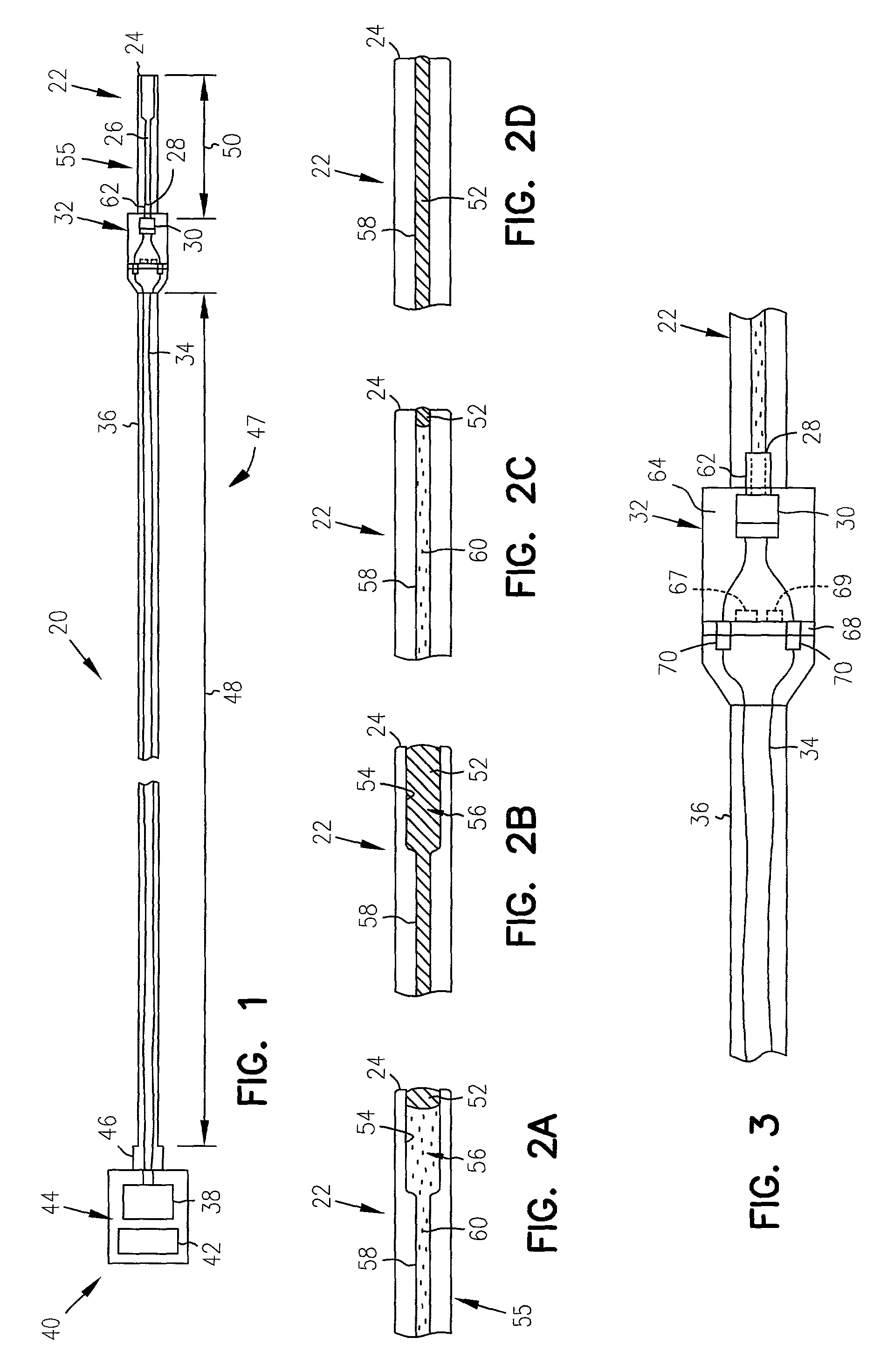

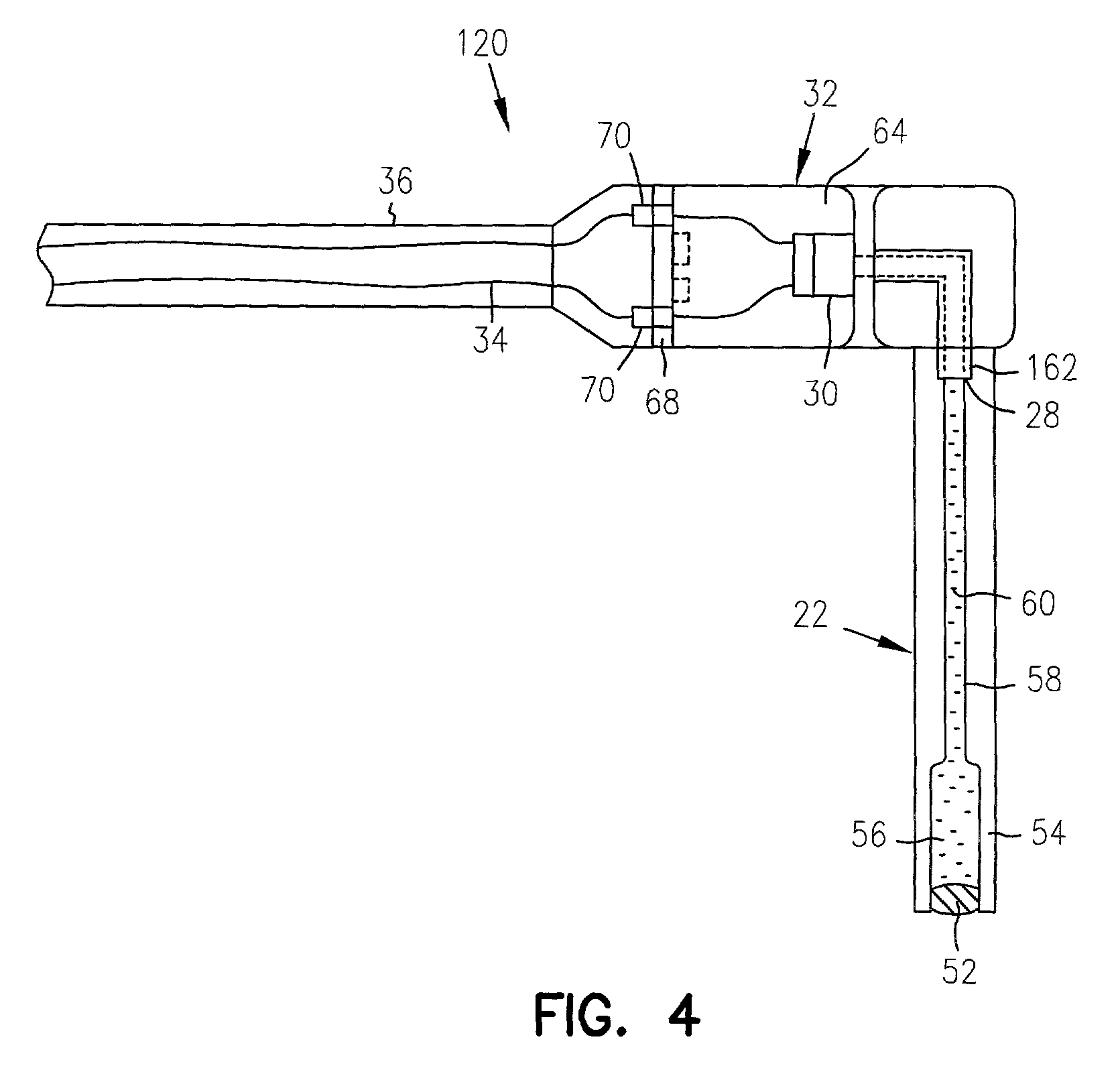

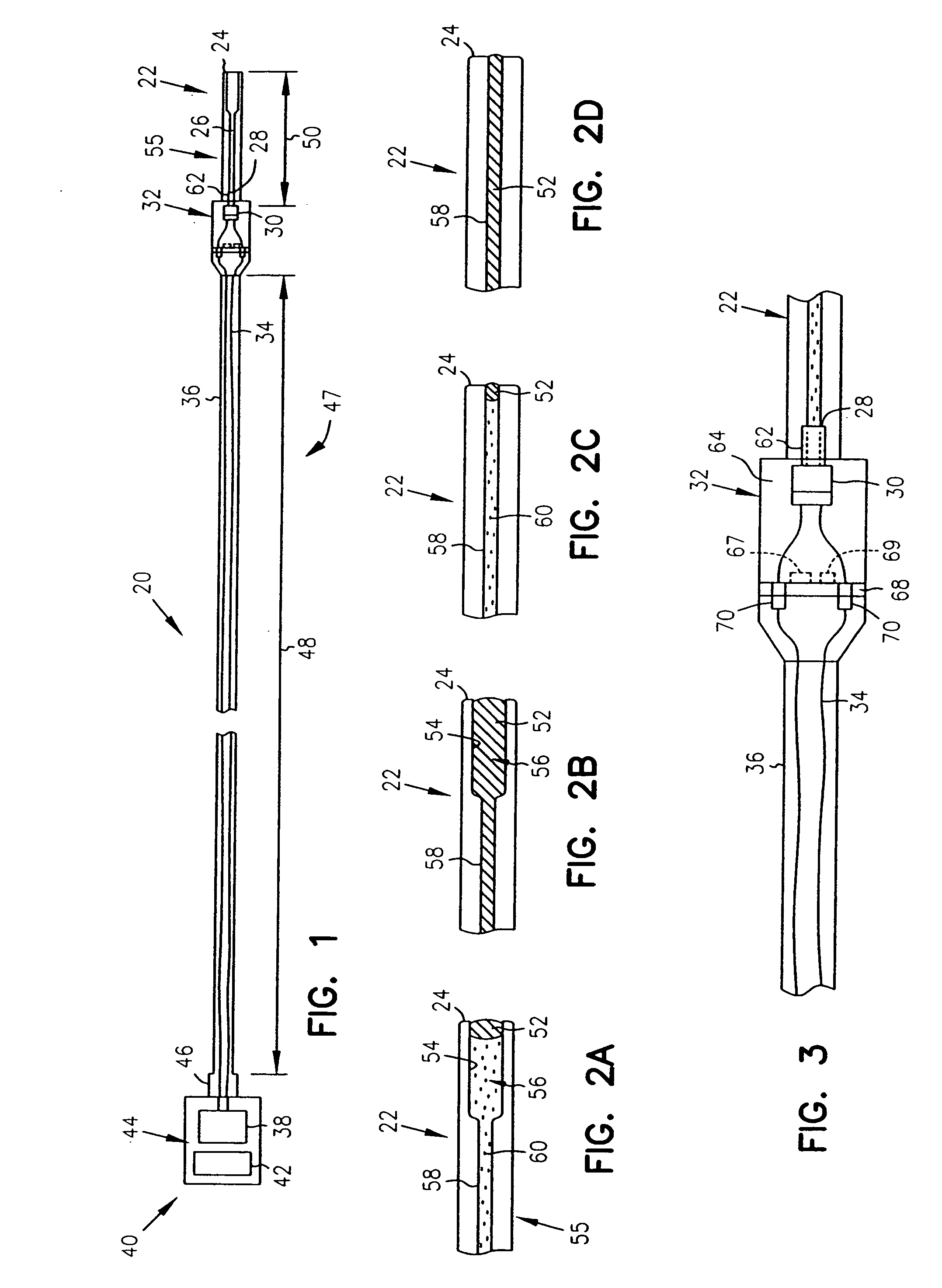

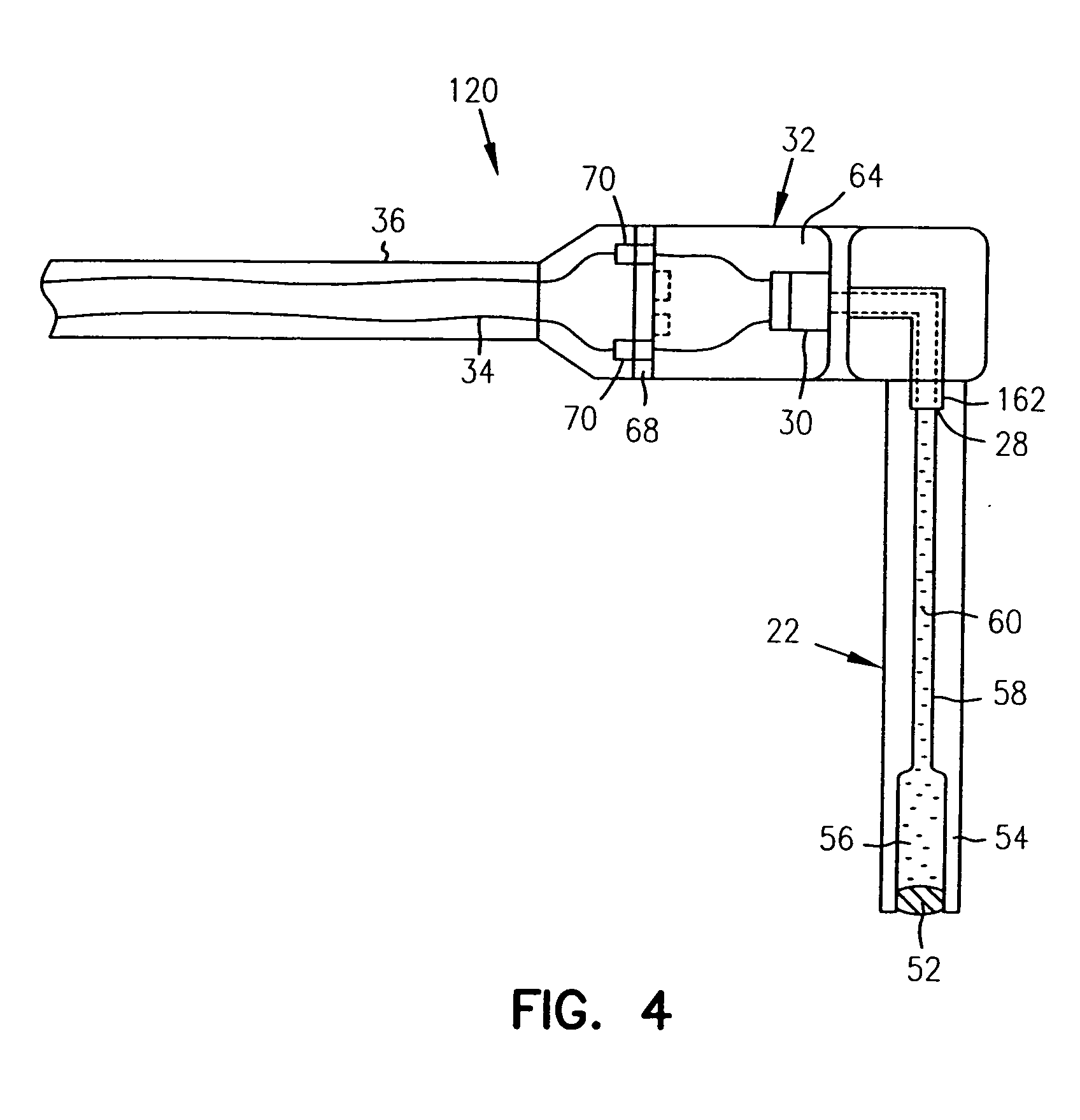

InactiveUS7025727B2Sufficient dynamic responseLow pressureCatheterIntracranial pressure measurementMeasurement deviceTelemetry

A device measures pressures in animals and humans and includes a pressure transmission catheter (PTC) filled with a pressure transmitting medium and implantable in an area in having a physiological pressure. A transducer communicates with the pressure transmitting medium to provide a pressure signal representing variations in the physiologic pressure on electrical wires. A connecting catheter carries the electrical wires to signal processing and telemetry circuitry, which transmits a telemetry signal representing the pressure signal to a receiver external to the animal or human. A housing holds the signal processing and telemetry circuitry, but the transducer is remote from the housing. The device is particularly useful in measuring venous pressure, pulmonary pressure, bladder pressure, or intracranial pressure without significant head pressure artifact and with a sufficient dynamic response. One embodiment of the PTC includes a multi-durometer stem.

Owner:DATA SCI INT

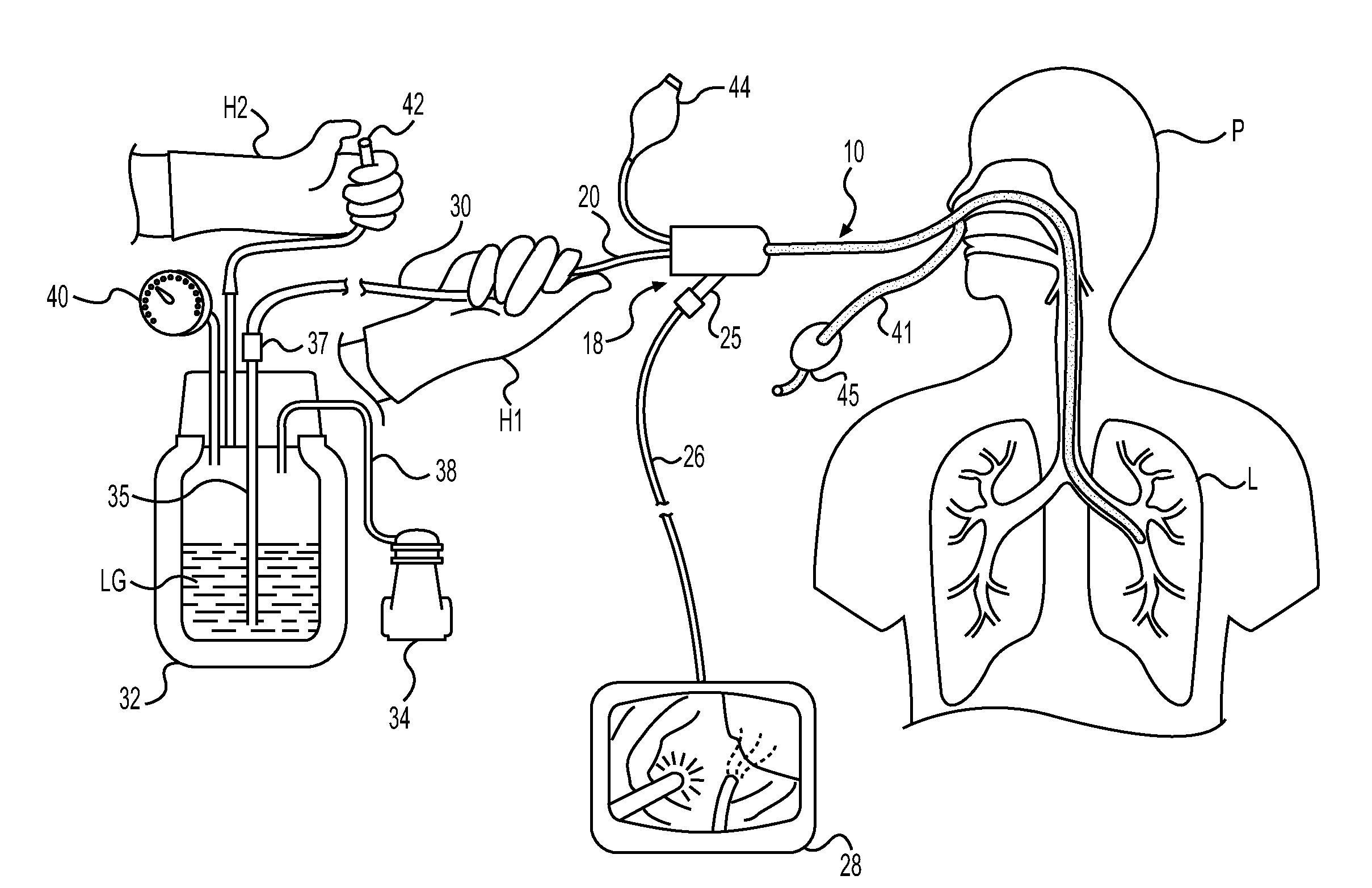

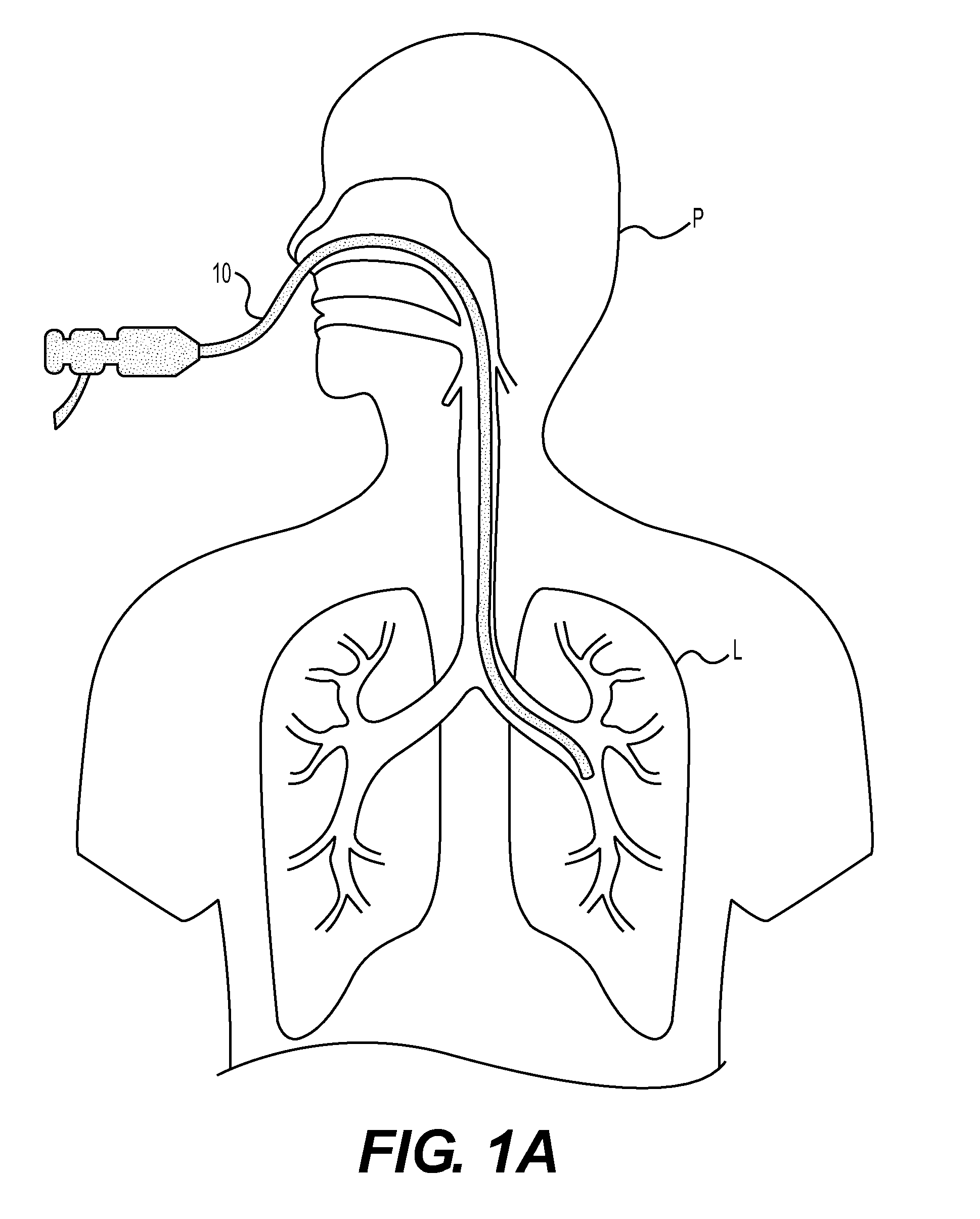

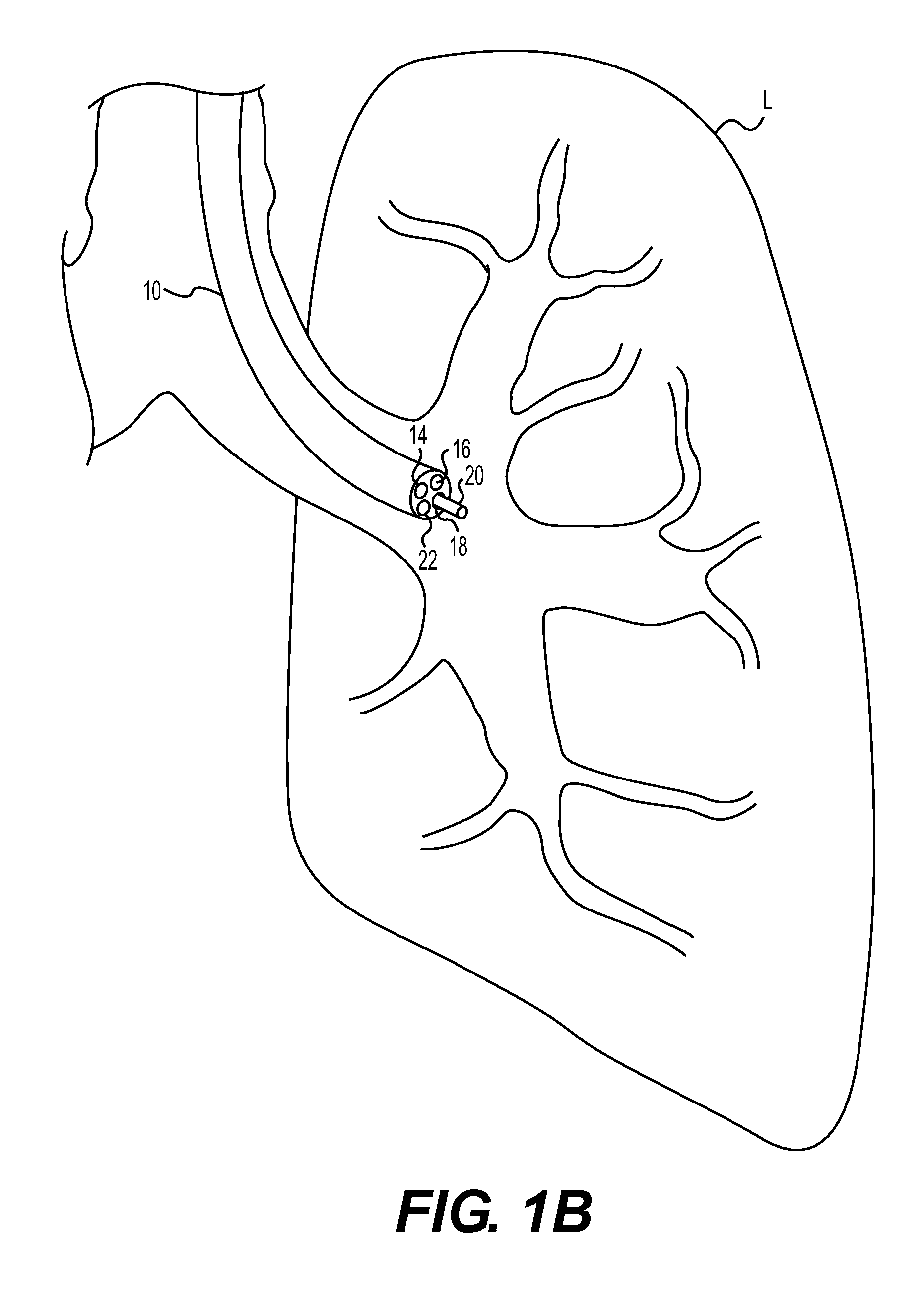

Method for cryospray ablation

InactiveUS20090192505A1Increase load capacityAdequate doseUltrasonic/sonic/infrasonic diagnosticsEchographic/ultrasound-imaging preparationsThoracic structureDisease

The present invention relates to methods for treating tissue in the thoracic cavity of a subject by the application of a cryogen, or using the cryogen to create an isotherm in proximity to the tissue to be treated. A wide variety of conditions may be treated using the methods of the invention including asthma, neoplastic disease and a variety of conditions characterized by inflammation in lung and chest tissue.

Owner:RESET MEDICAL

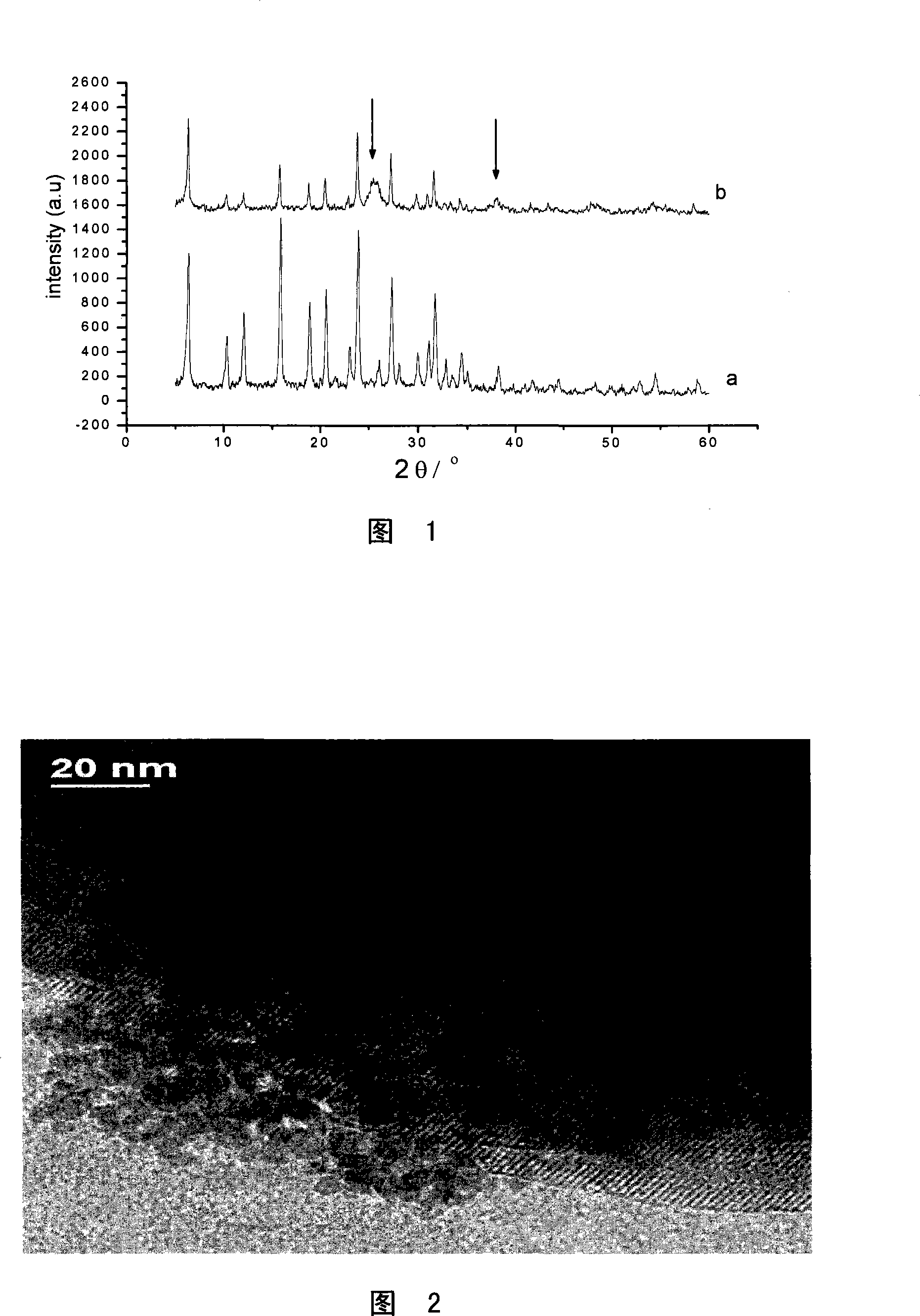

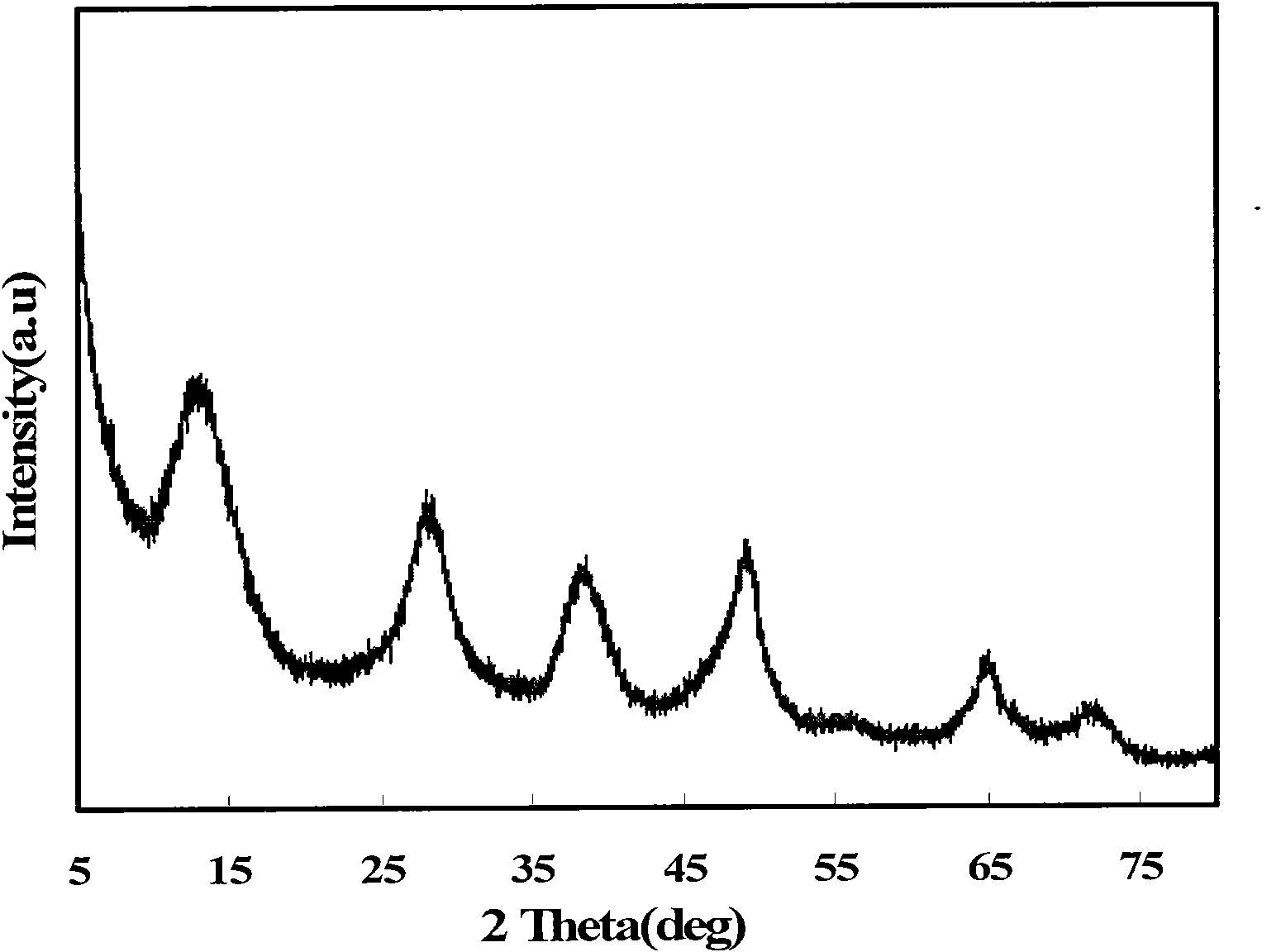

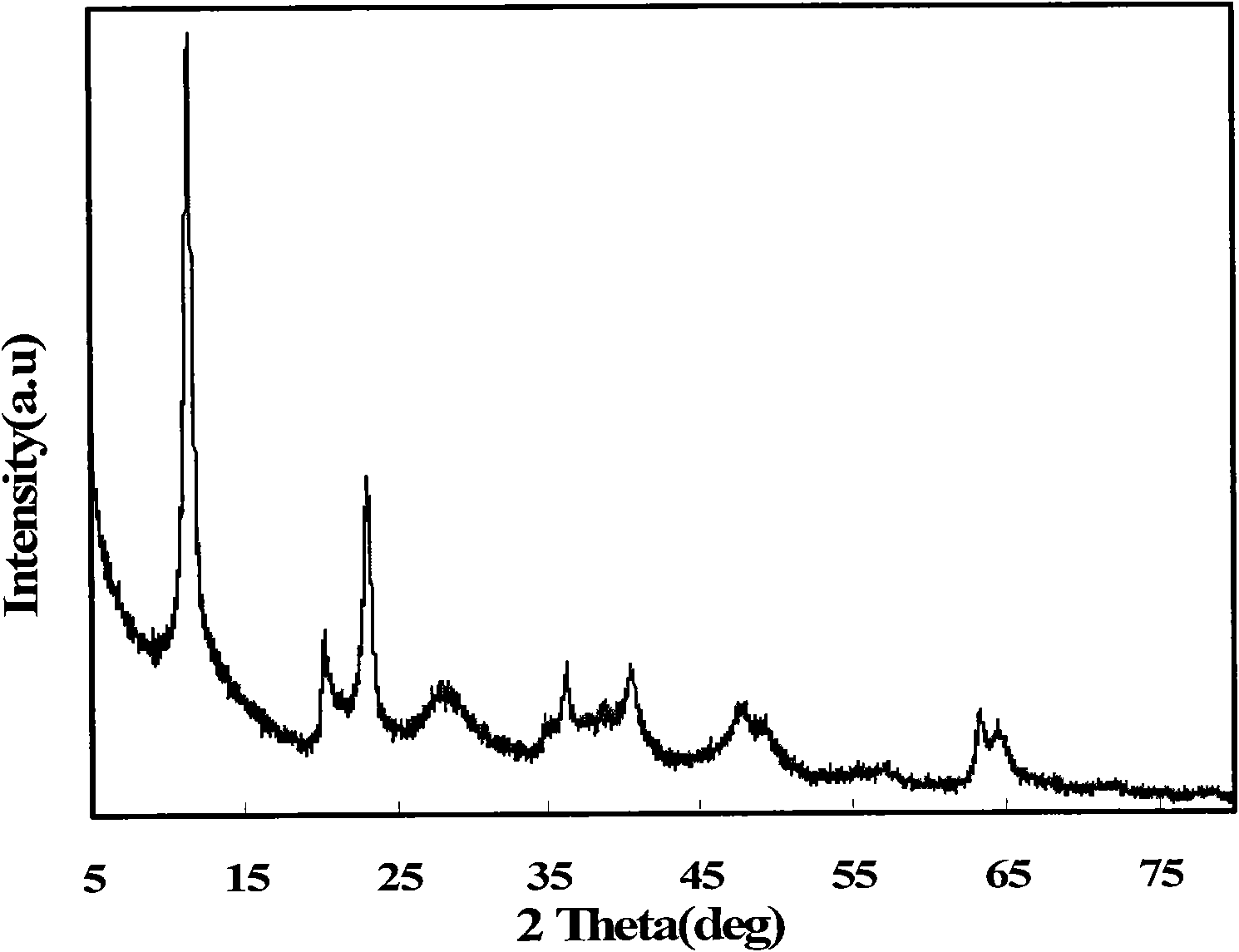

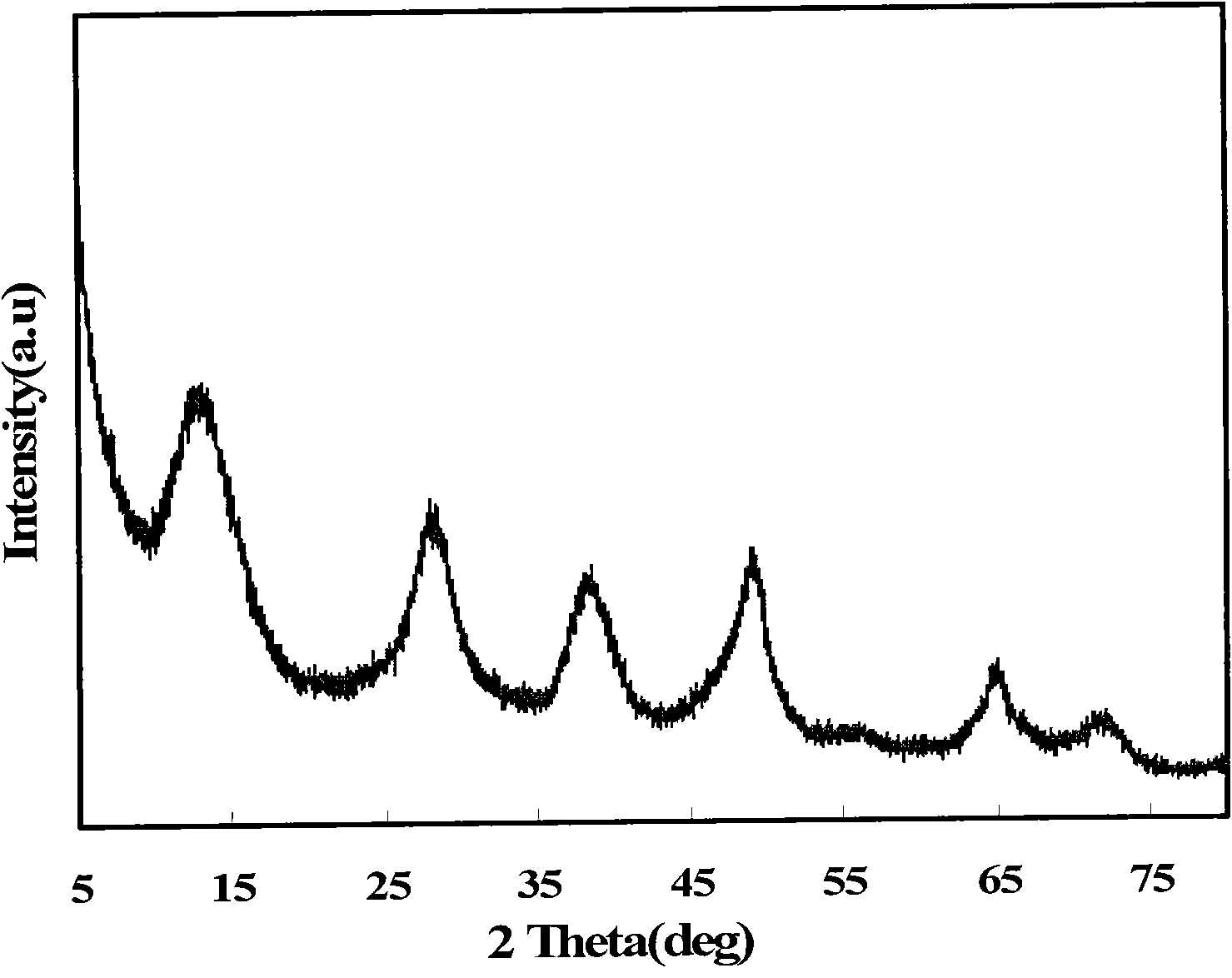

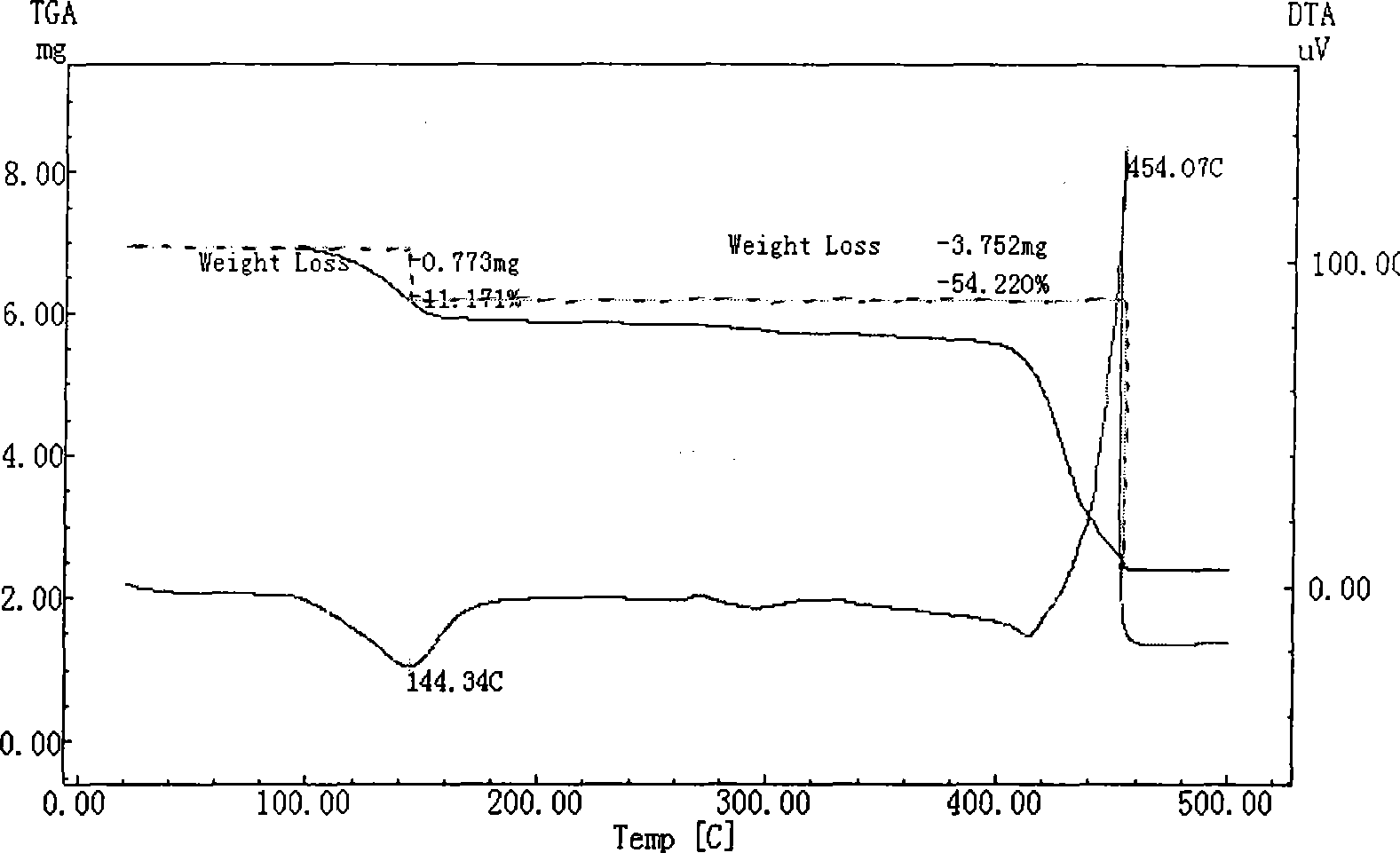

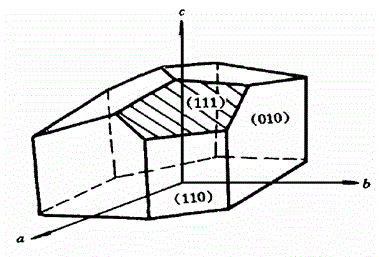

Lithium ion battery positive pole material cobalt nickel oxide manganses lithium and method for making same

ActiveCN101202343AHigh specific capacityExcellent cycle characteristicsElectrode manufacturing processesLithium compoundsLithium oxideAntioxidant

The invention relates to a nickel cobalt manganese lithium oxide material used for an anode of a li-ion battery and a preparation method. The invention belongs to the li-ion battery technical field. The nickel cobalt manganese lithium oxide material used for the anode of the li-ion battery is a li-rich laminated structure with the chemical component of Li1+zM1-x-yNixCoyO2; wherein, z is less than or equal to 0.2 and more than or equal to 0.05, x is less than or equal to 0.8 and more than 0.1, and y is less than or equal to 0.5 and more than 0.1. The preparation method of the invention is that dissoluble salt of the nickel, cobalt and manganese is taken as the raw material; ammonia or ammonium salt is taken as complexing agent; sodium hydroxide is taken as precipitator; water-dissoluble dispersant and water-dissoluble antioxidant or inert gas are added for control and protection; in a cocurrent flow type the solution is added to a reaction vessel for reaction; after alkalescence disposal, aging procedure, solid-liquid separation and washing and drying, the nickel cobalt manganese oxide is uniformly mixed with the lithium raw material; the nickel cobalt manganese lithium oxide powder is obtained by sintering the mixed powder which is divided into three temperature areas. The invention has the advantages of high specific capacity, good circulation performance, ideal crystal texture, short production period, low power loss, and being suitable for industrial production, etc.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

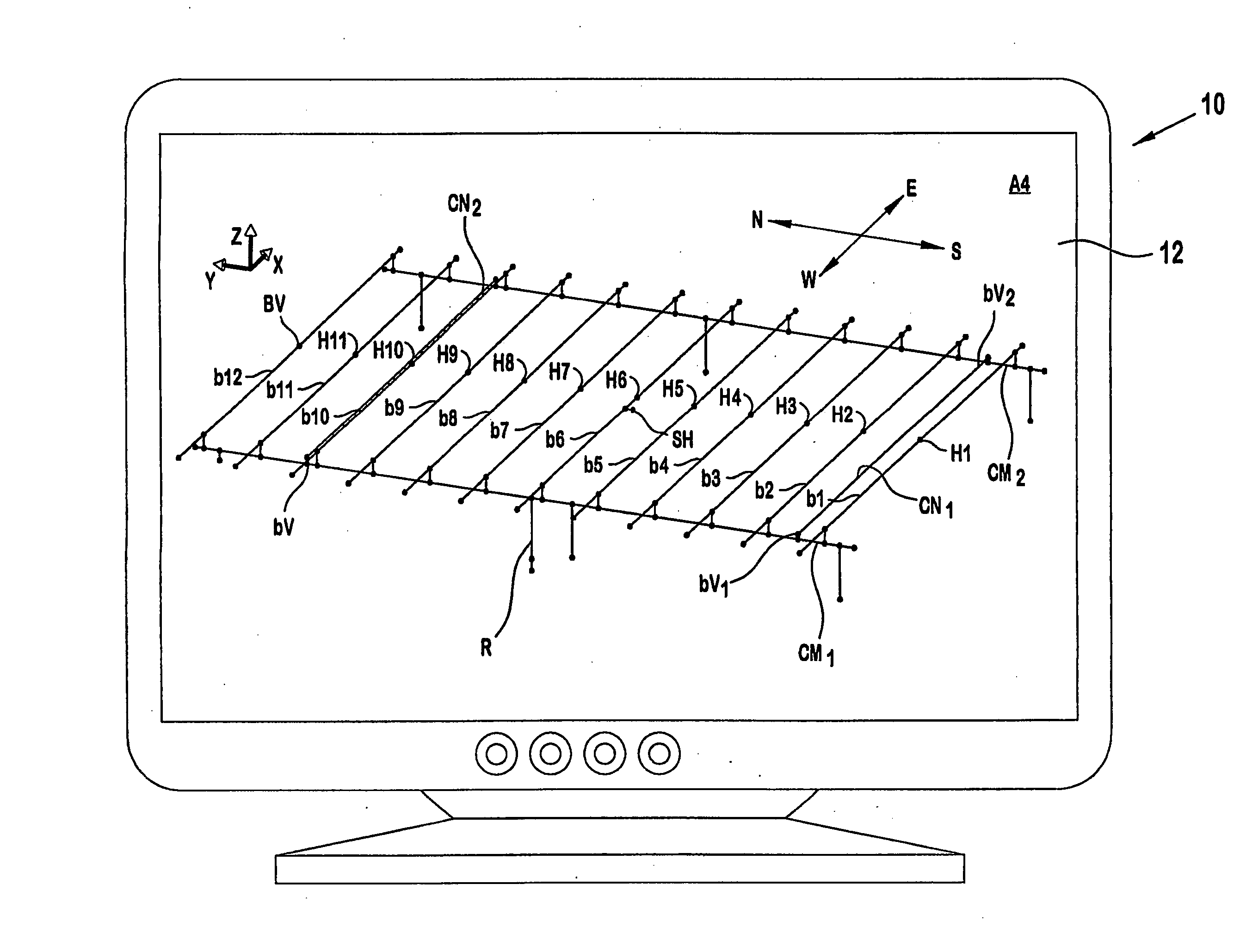

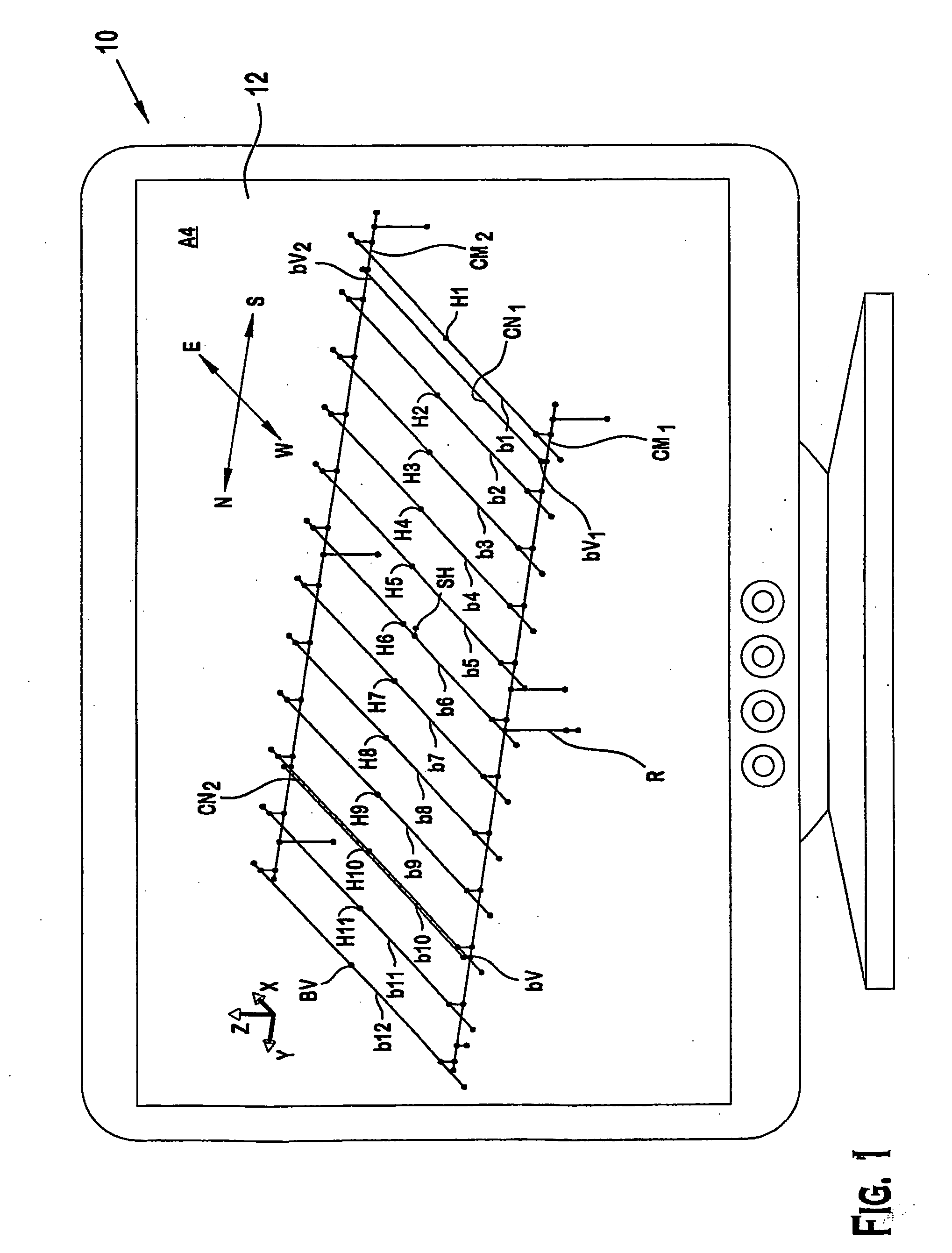

System and method for evaluation of fluid flow in a piping system

A method to model a complex system of pipes. The model takes into account the physical processes in a tree-type piping system and provides for an accurate modeling of a real world tree-type piping system. In a preferred embodiment, a computer program is provided for analyzing models of dry pipe systems. The computer program includes a user interface and a computational engine. The user interface allows a model of a dry pipe system to be defined and the computational engine determines a liquid flow time through the model of the dry pipe system. The computational engine provides a verification of the liquid flow time in a model of a referential dry pipe system within 20% of an actual liquid flow time in the referential dry pipe system.

Owner:TYCO FIRE PRODS LP

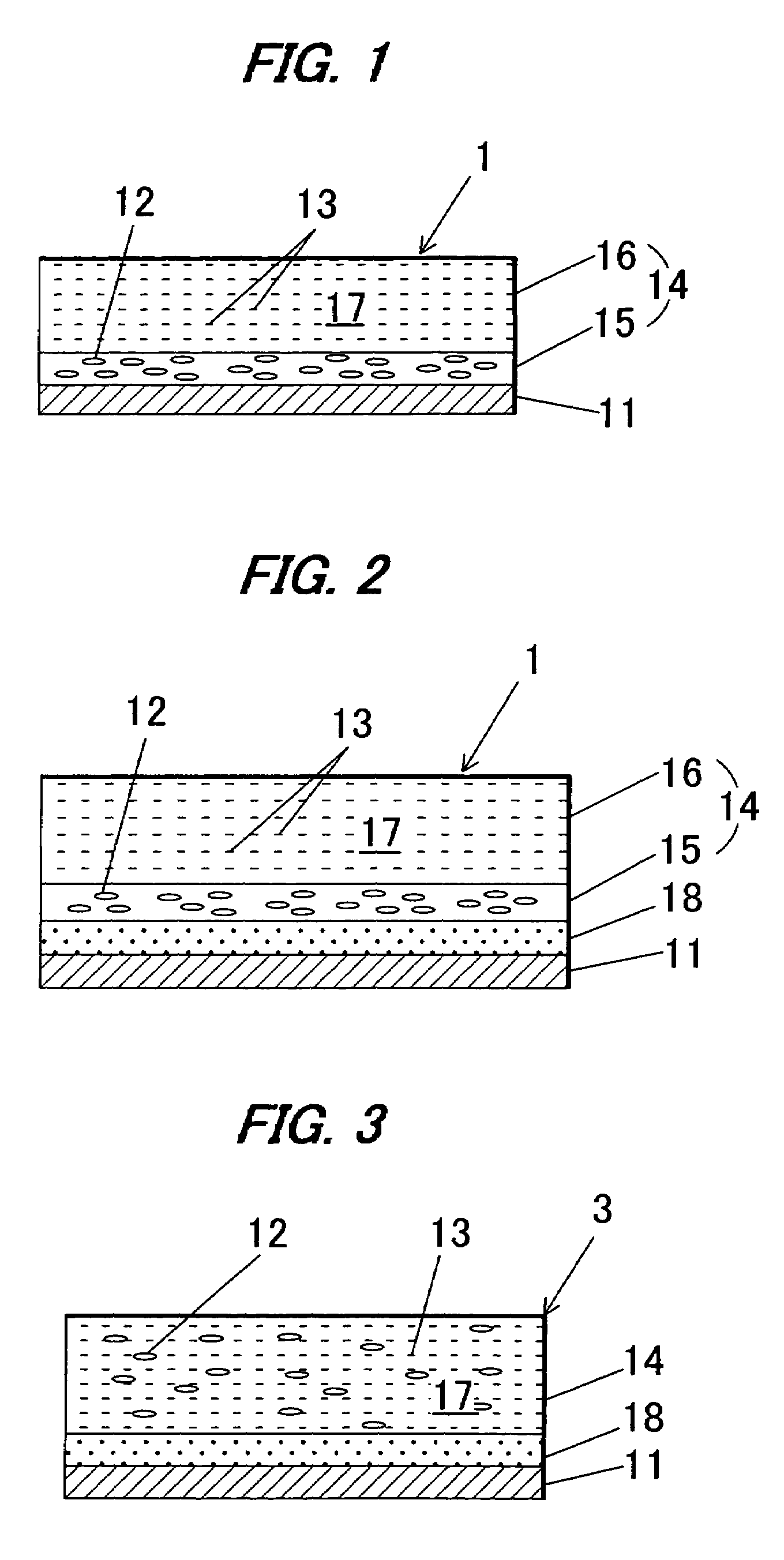

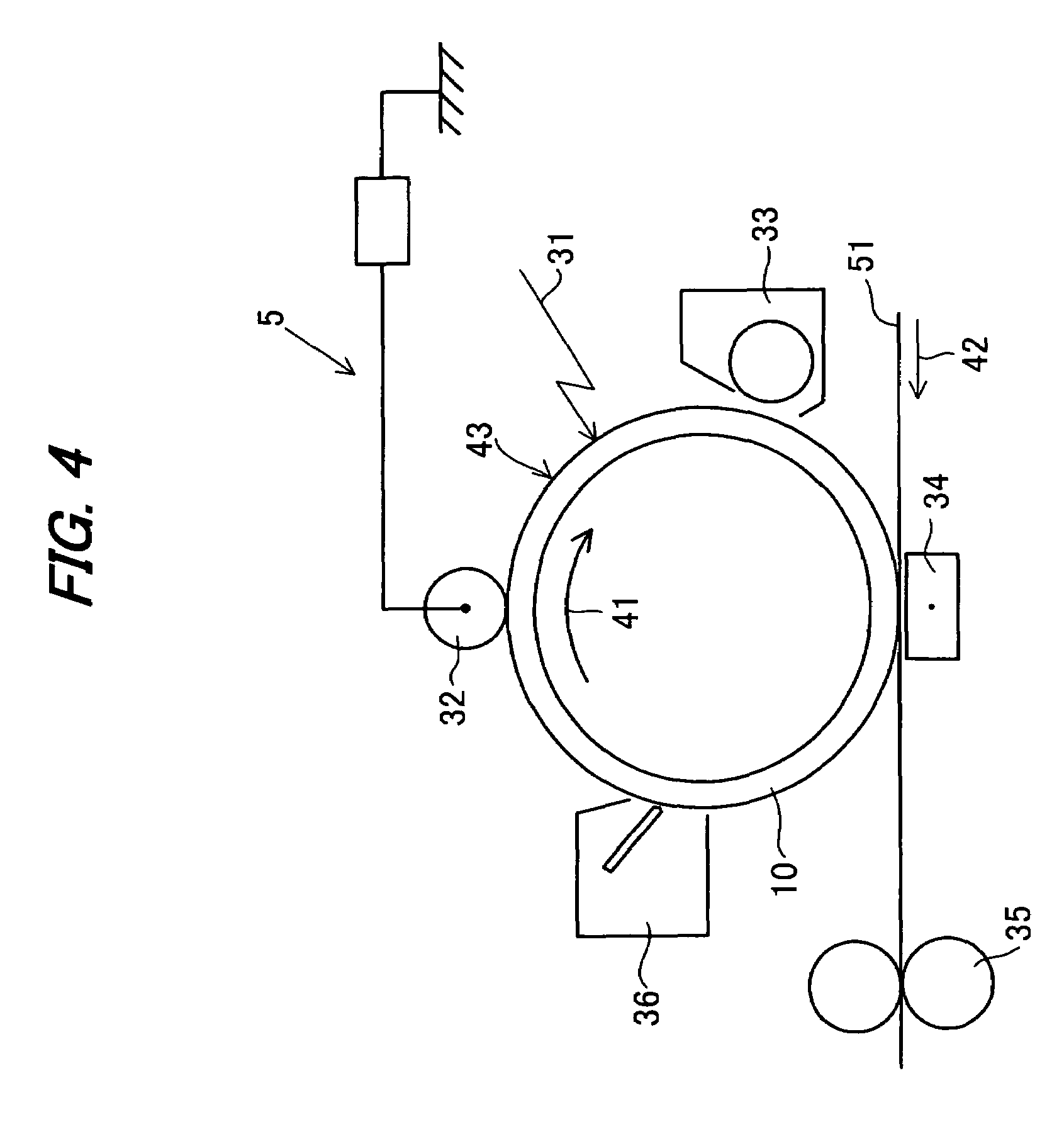

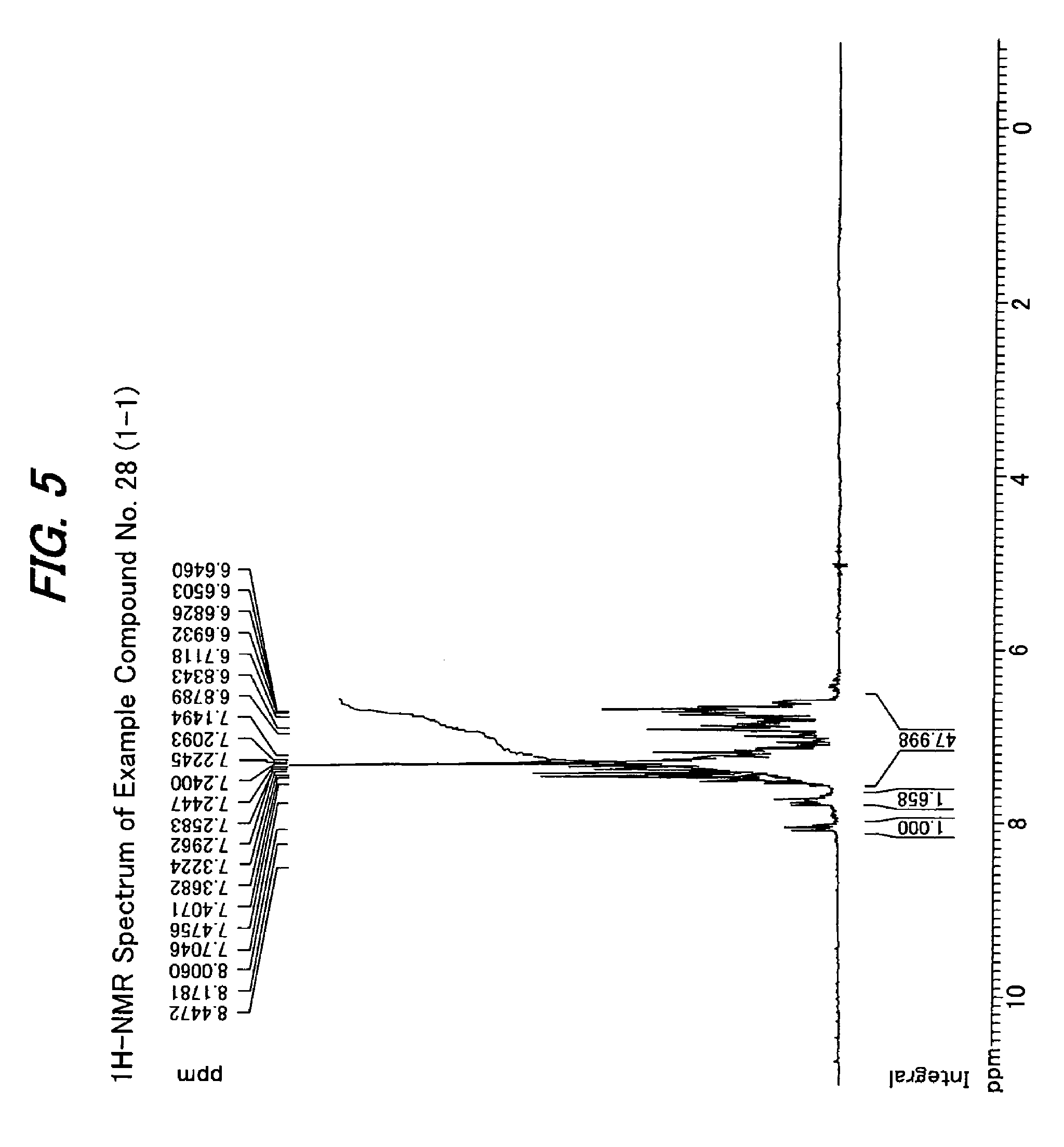

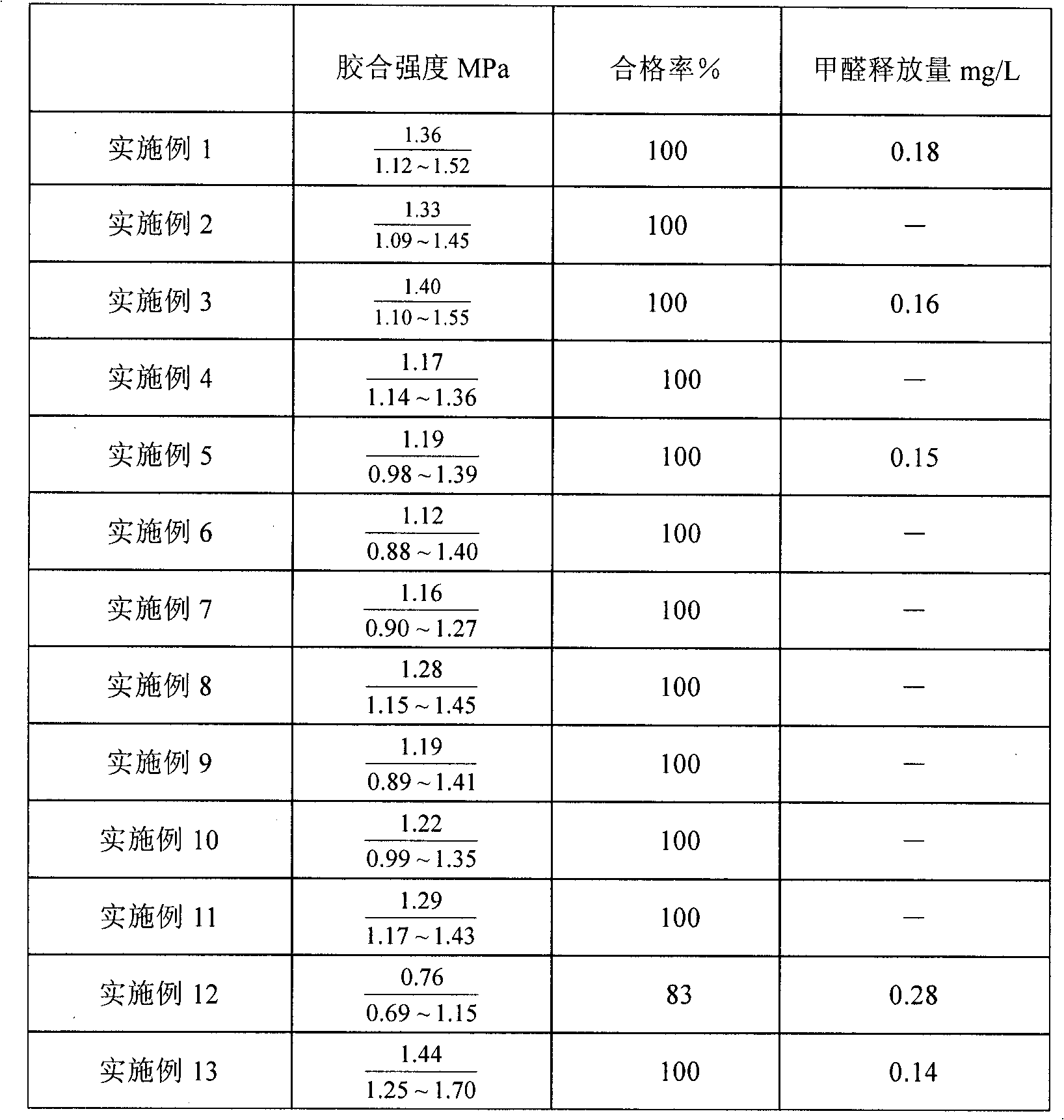

Organic photoconductive material electrophotographic photoreceptor and image forming apparatus using the same

ActiveUS7416824B2Highly reliable electrophotographic photoreceptorHigh sensitivityOrganic chemistryOrganic compound preparationEnaminePhenyl group

According to the present invention, an enamine compound having a specific structure is used as an organic photoconductive material. This enamine compound is obtained based on asymmetrical secondary naphtylamine which is readily available at a lowest price, by introducing phenyl groups containing substituents, as constituents units of the enamine part and presents excellent compatibility with binder resins, will not present detrimental effects such as partial crystallization at film forming and have a high charge mobility. The compound is able to realize highly reliable electrophotographic photoreceptor and an image forming apparatus which present a high electrostatic potential, high sensitivity and high enough light response and are excellent in durability and will not degrade in these characteristics under a low-temperature environment or in a high-speed process and will not lower in these characteristics even due to exposure to light.

Owner:SHARP KK

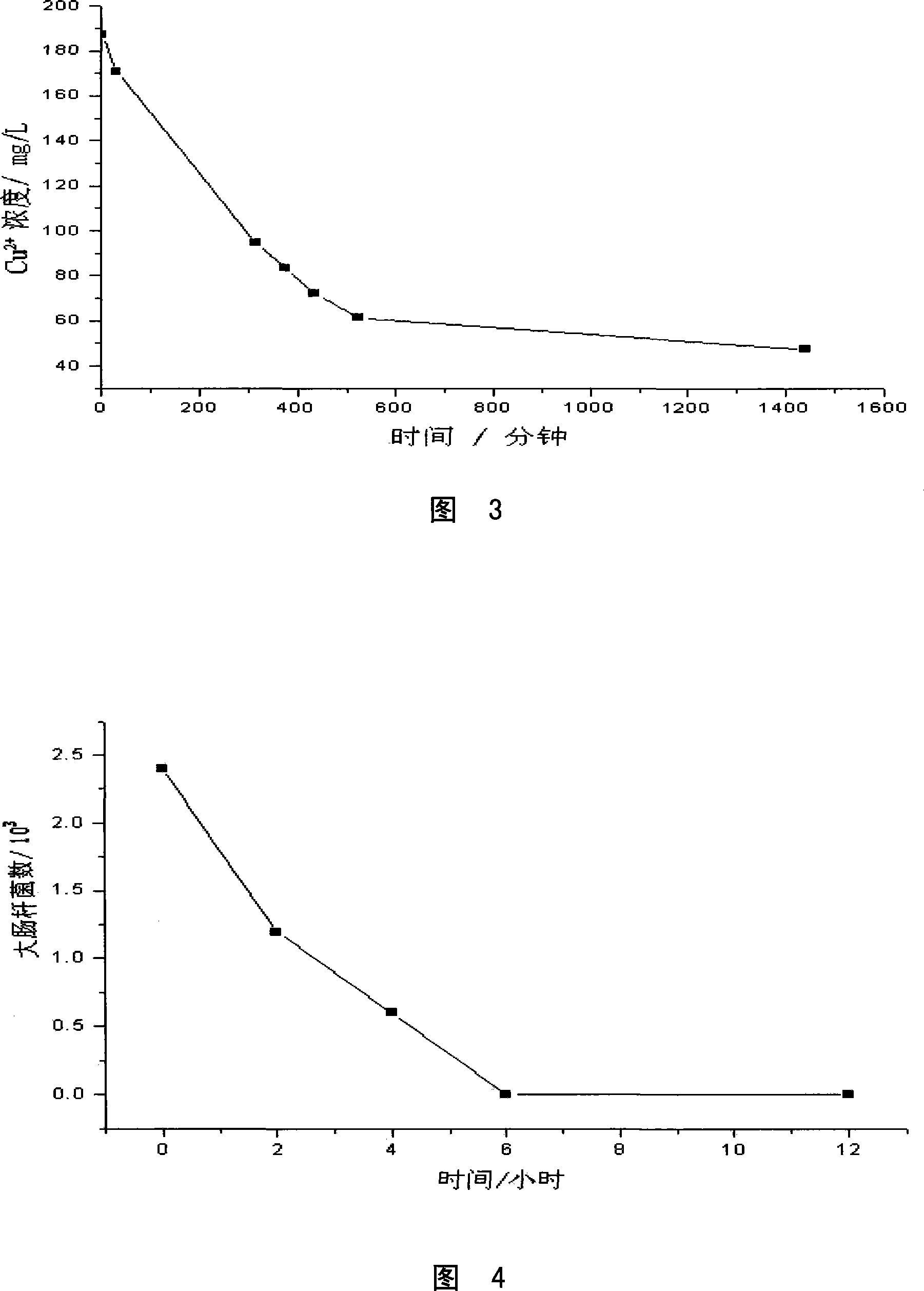

Zeolite base composite antibiotic material and its preparation method

InactiveCN101167451APrevent seepageImprove thermal stabilityBiocideDisinfectantsIon exchangeSilver ion

The invention relates to zeolite-based composite antibiotic material and a process for preparation, the material of which is low-silicon-aluminum-ratio zeolite molecular sieve which is used as the base and carrier, the outer surface of the invention is covered with nanometer titanium dioxide particles, and the pore passages or cages of the invention are provided with metallic ions which have antibiotic effect. The process for preparing the material is that low-silicon-aluminum-ratio zeolite molecular sieve absorbs organic amine to saturation and then is dipped into soluble titanates for roasting to generate nanometer titanium dioxide on the outer surface of zeolite, and metallic ions such as silver ions, copper ions and the like which have antibiotic effect are exchanged to zeolite by the ion exchange process to form the novel composite antibiotic material. The composite antibiotic material not only has the antibiotic effect of metallic ions but also has the antibiotic effect of nanometer titanium dioxide, and thereby the antibiotic effect is strengthened. The composite antibiotic material is easy to prepare, low in price and suitable for industrial production.

Owner:SUZHOU UNIV OF SCI & TECH

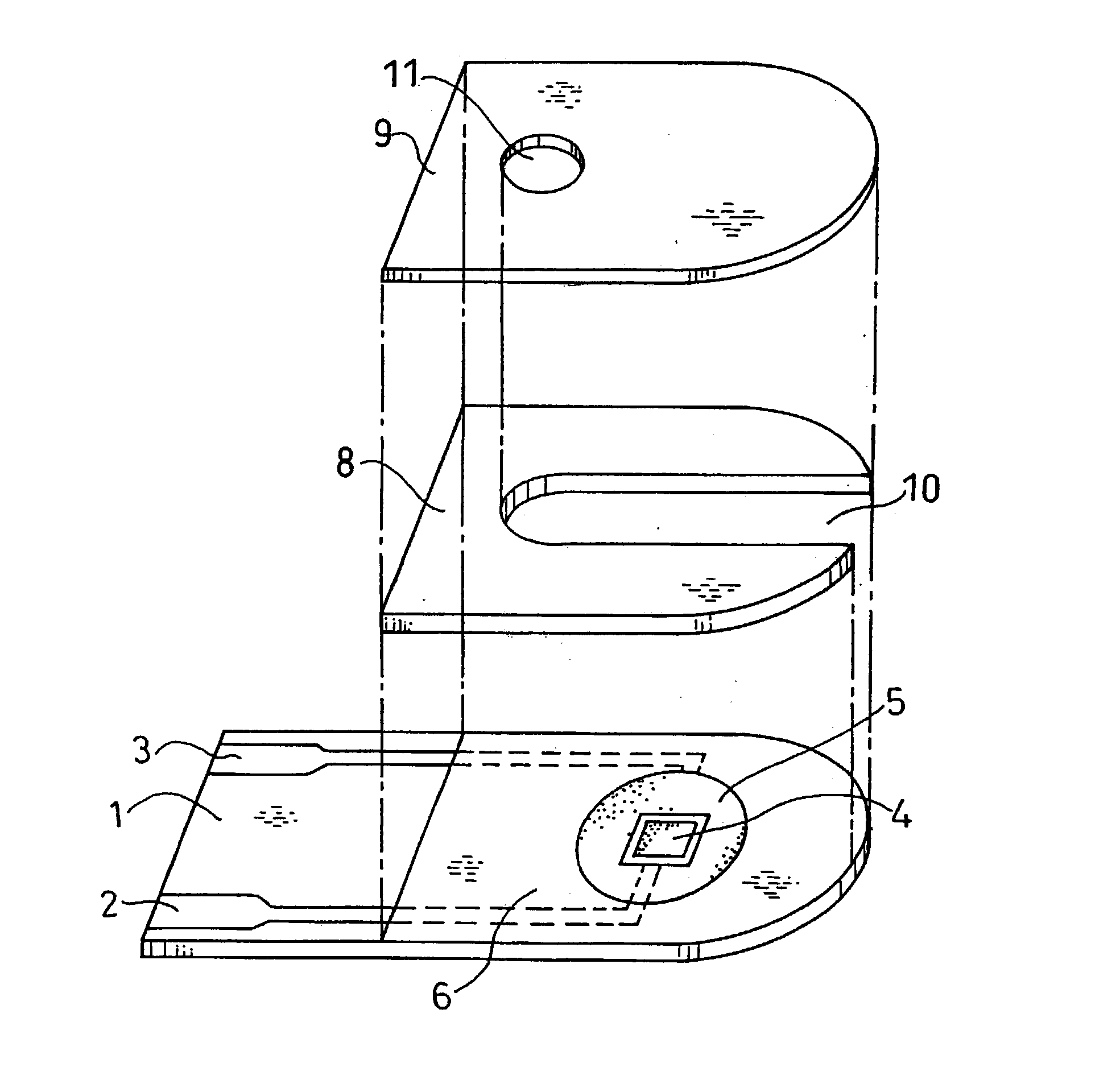

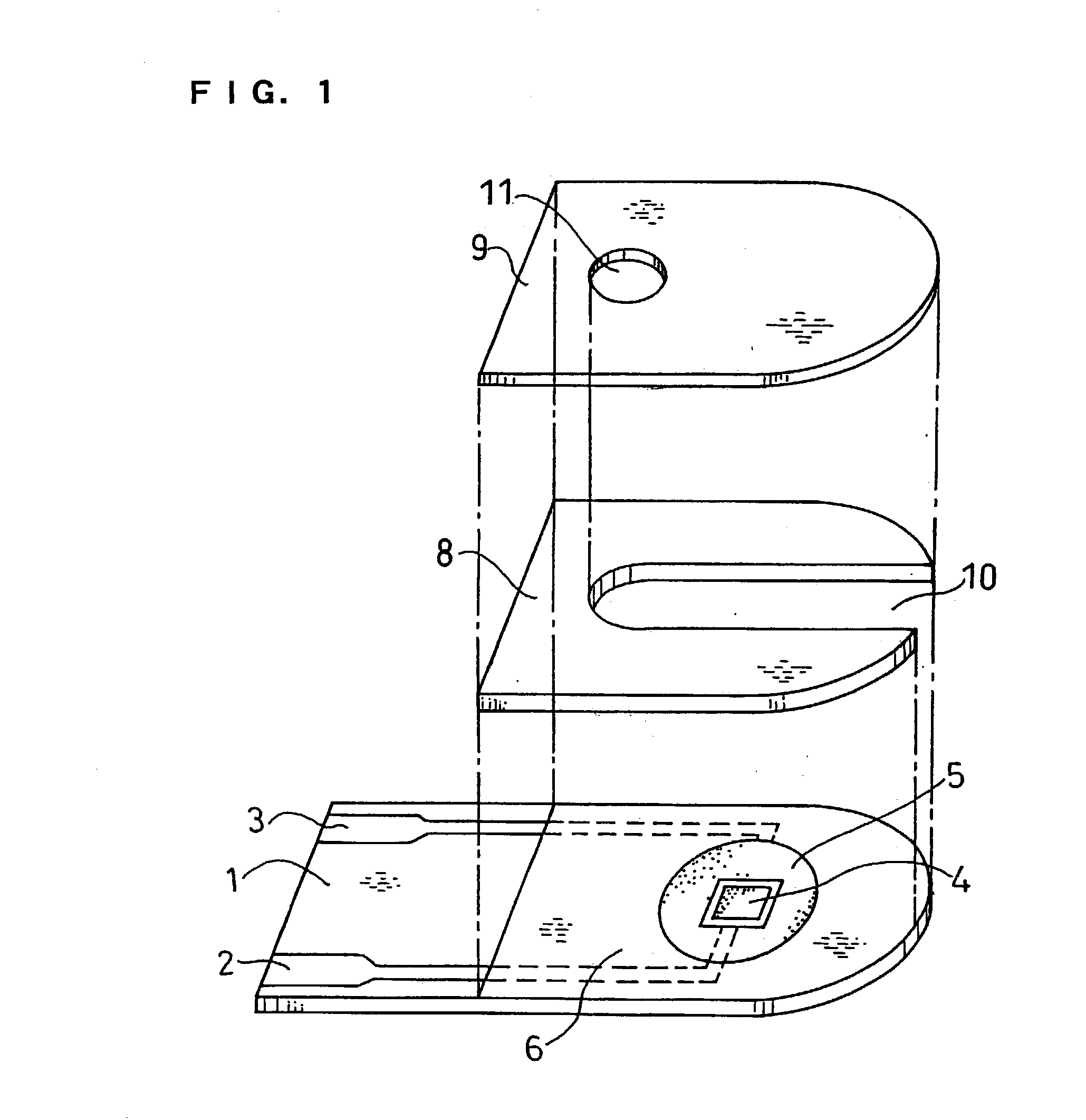

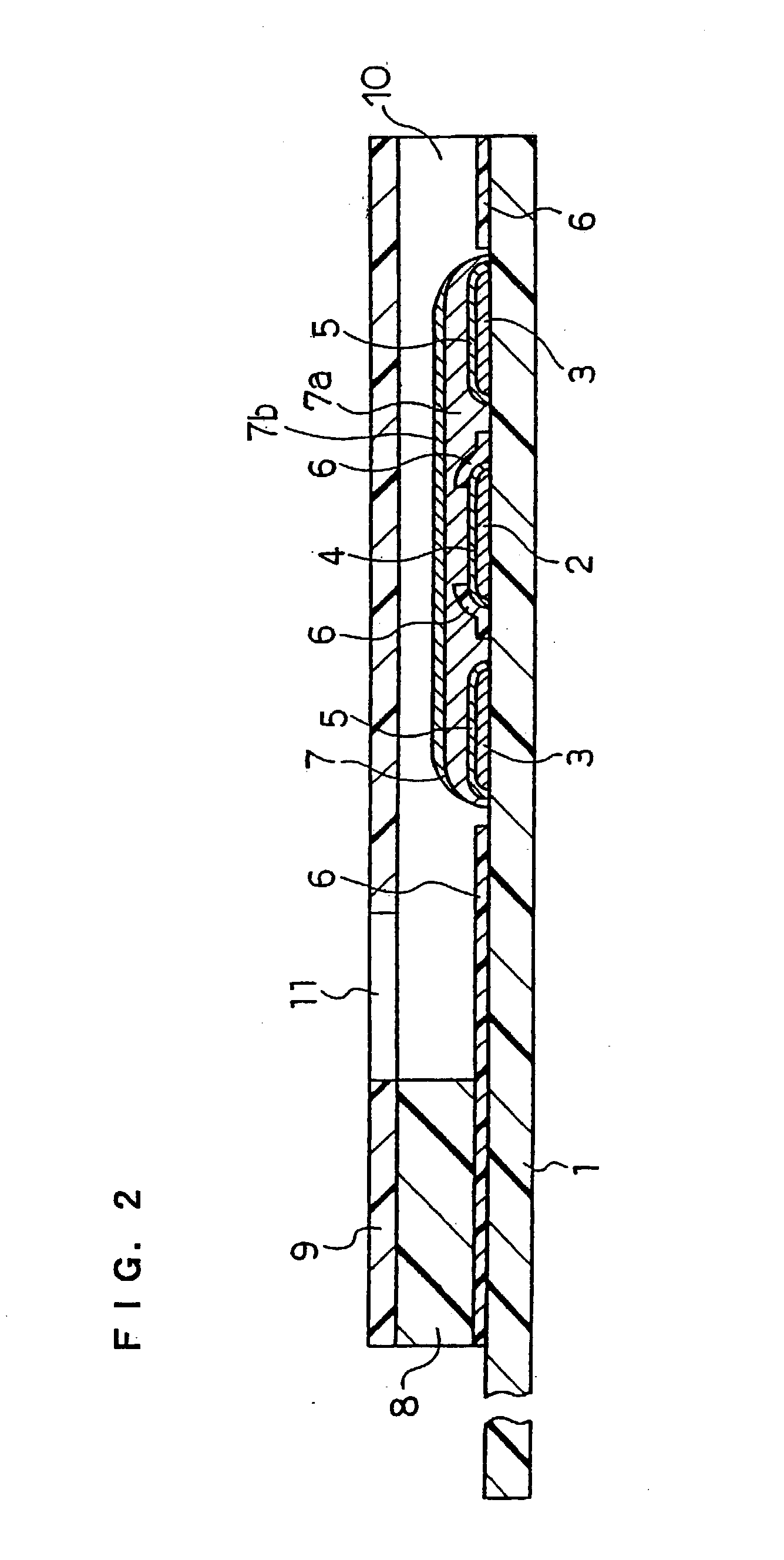

Biosensor

InactiveUS20030175841A1Avoid influenceReduce solubilityImmobilised enzymesBioreactor/fermenter combinationsGluconolactonaseSuccinic acid

A biosensor that is highly responsive and capable of rapid and highly sensitive quantification of a specific component contained in a sample is provided. The biosensor of this invention comprises: an electrically insulating base plate; an electrode system comprising a working electrode and a counter electrode disposed on the base plate; and a reagent system comprising an oxidoreductase which catalyzes the oxidation reaction of glucose, gluconolactonase and a buffer. The buffer is selected from the group consisting of phthalic acid and its salts, maleic acid and its salts, succinic acid and its salts, phospholic acid and its salts, acetic acid and its salts, boric acid and its salts, citric acid and its salts, glycine, tris(hydroxymethyl)aminomethane, piperazine-N,N'-bis(2-ethane sulfonic acid) and the like.

Owner:PHC HLDG CORP

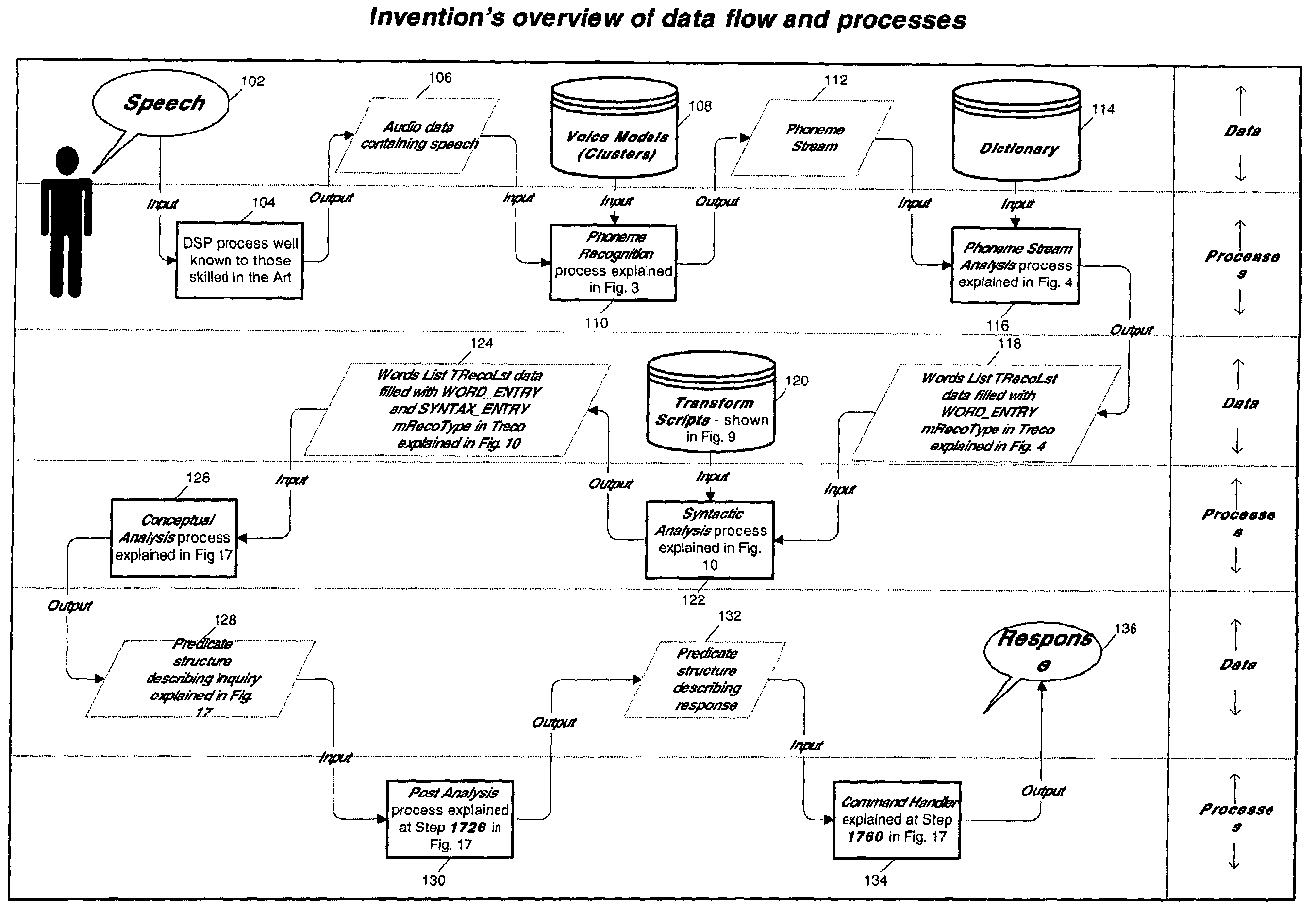

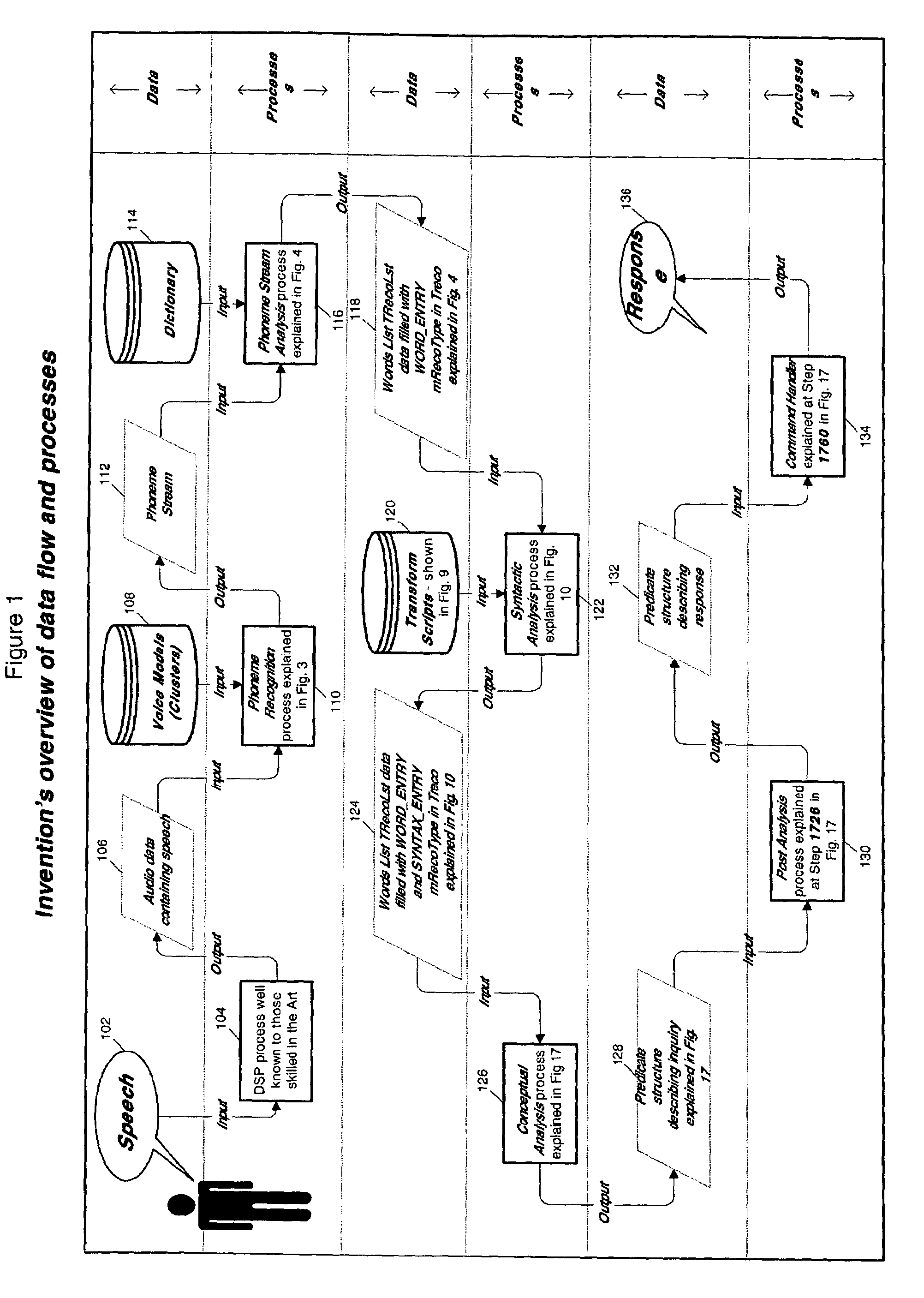

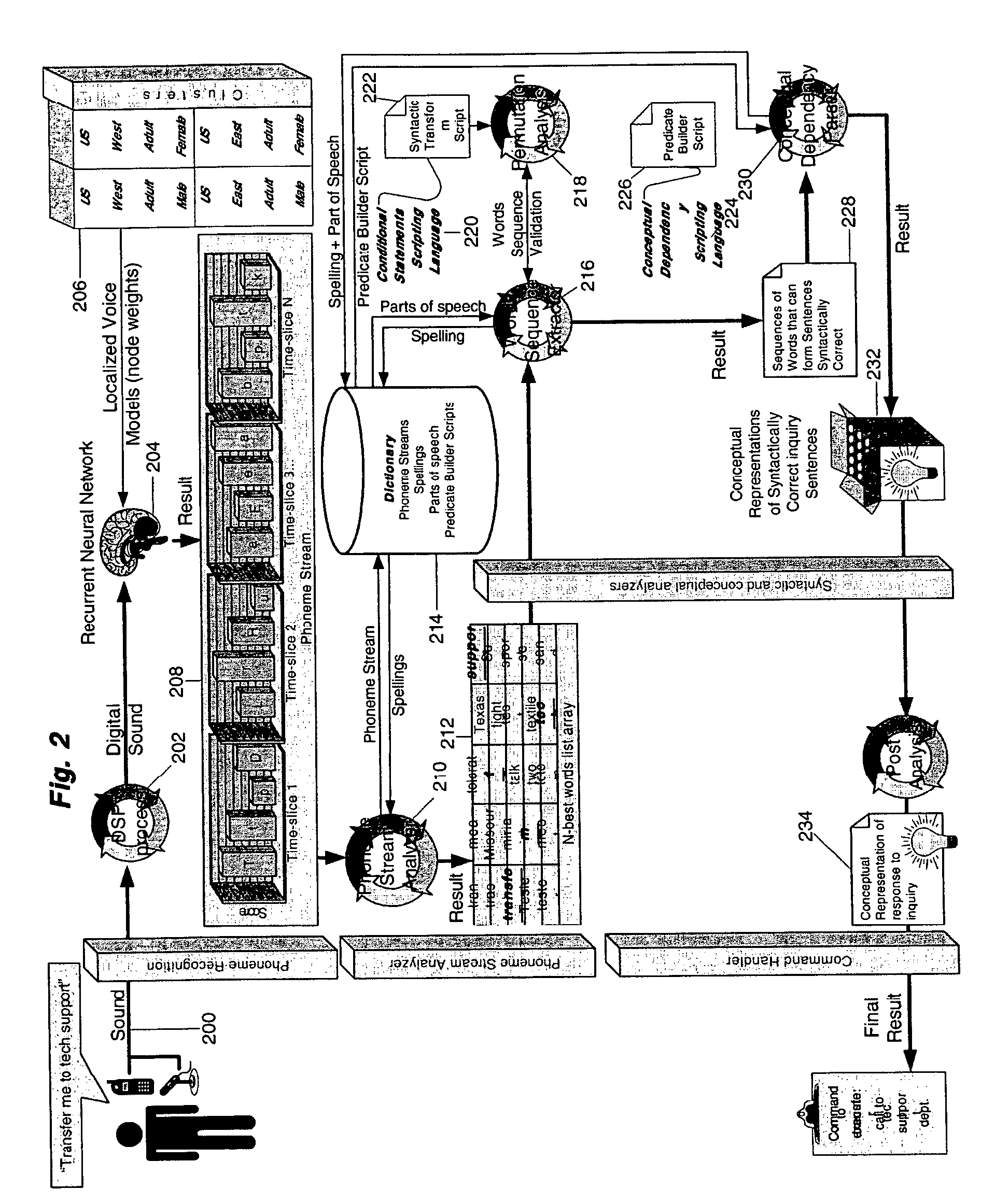

Multi-phoneme streamer and knowledge representation speech recognition system and method

ActiveUS7286987B2Adequate responseImprove power balanceSpeech recognitionSpeech identificationCall routing

A system and method related to a new approach to speech recognition that reacts to concepts conveyed through speech. In its fullest implementation, the system and method shifts the balance of power in speech recognition from straight sound recognition and statistical models to a more powerful and complete approach determining and addressing conveyed concepts. This is done by using a probabilistically unbiased multi-phoneme recognition process, followed by a phoneme stream analysis process that builds the list of candidate words derived from recognized phonemes, followed by a permutation analysis process that produces sequences of candidate words with high potential of being syntactically valid, and finally, by processing targeted syntactic sequences in a conceptual analysis process to generate the utterance's conceptual representation that can be used to produce an adequate response. The invention can be employed for a myriad of applications, such as improving accuracy or automatically generating punctuation for transcription and dictation, word or concept spotting in audio streams, concept spotting in electronic text, customer support, call routing and other command / response scenarios.

Owner:CHEMTRON RES

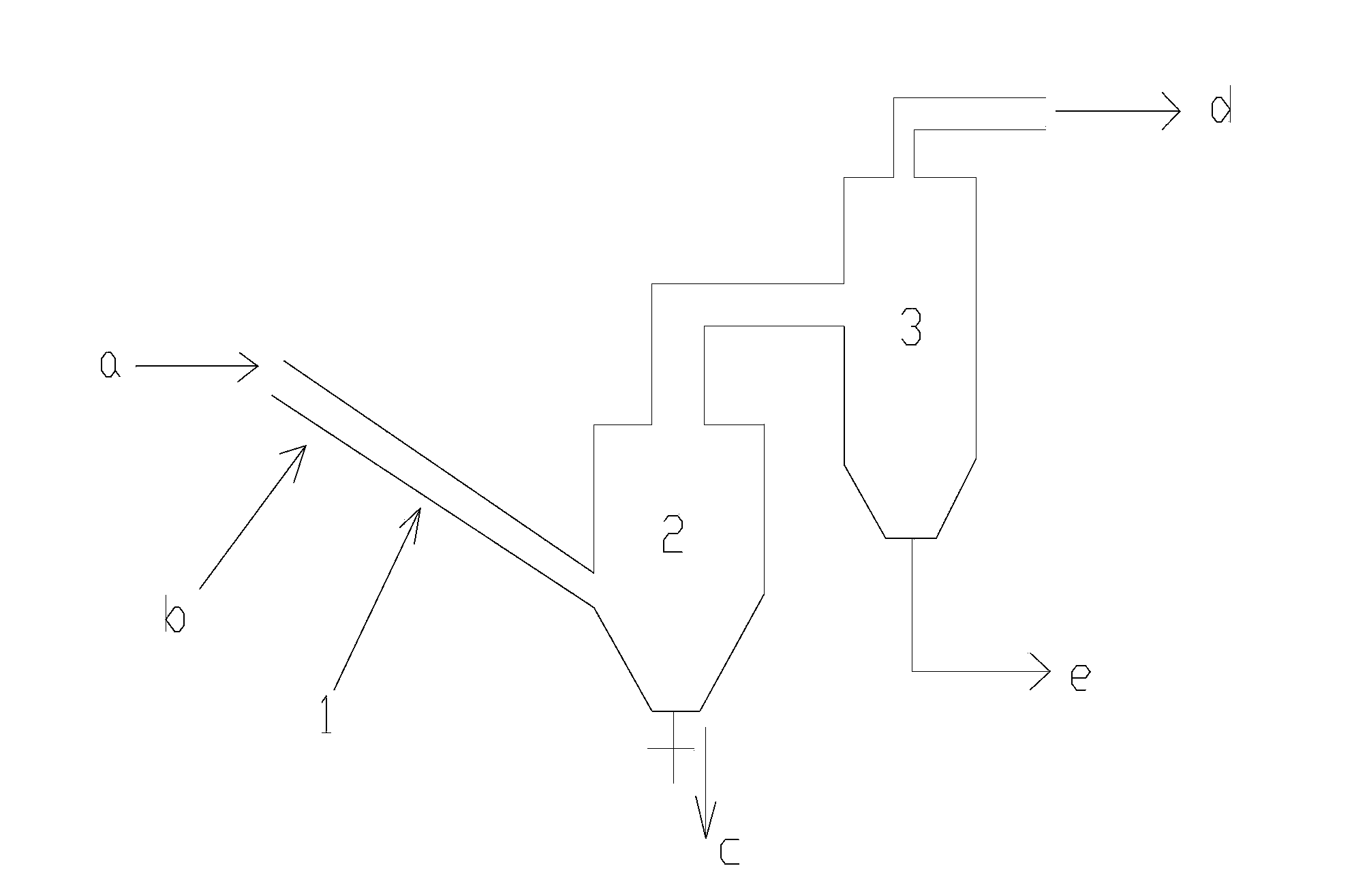

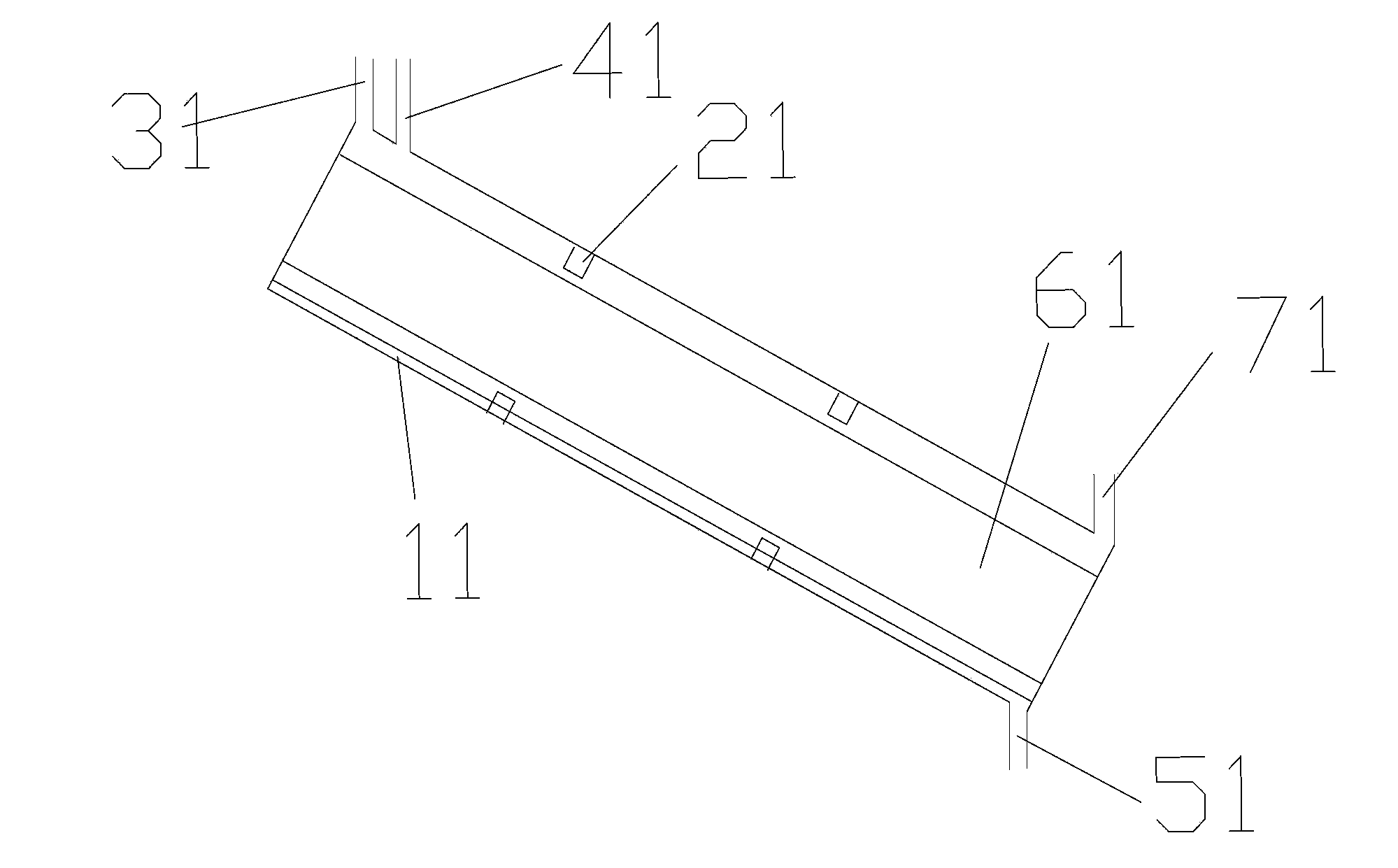

Method for preparing molecular sieve

ActiveCN103787352AFull residence timeFull contact timeCrystalline aluminosilicate zeolitesMolecular sieveGas phase

The invention relates to a method for preparing a molecular sieve, which comprises the following steps: the molecular sieve is introduced in a gas phase ultra-stable reactor, the gas phase ultra-stable reactor is capable of moving the molecular sieve from the molecular sieve inlet of the gas phase ultra-stable reactor to the molecular sieve outlet of the gas phase ultra-stable reactor under the condition that carrying gas is not used for conveying, and the molecular sieve and gas-phase silicon tetrachloride are contacted for reacting in the gas phase ultra-stable reactor. The conveying of the molecular sieve does not require inertia carrying gas, the technology flow is simplified, carrying gas amount is saved, and the consumption of silicon tetrachloride can be greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

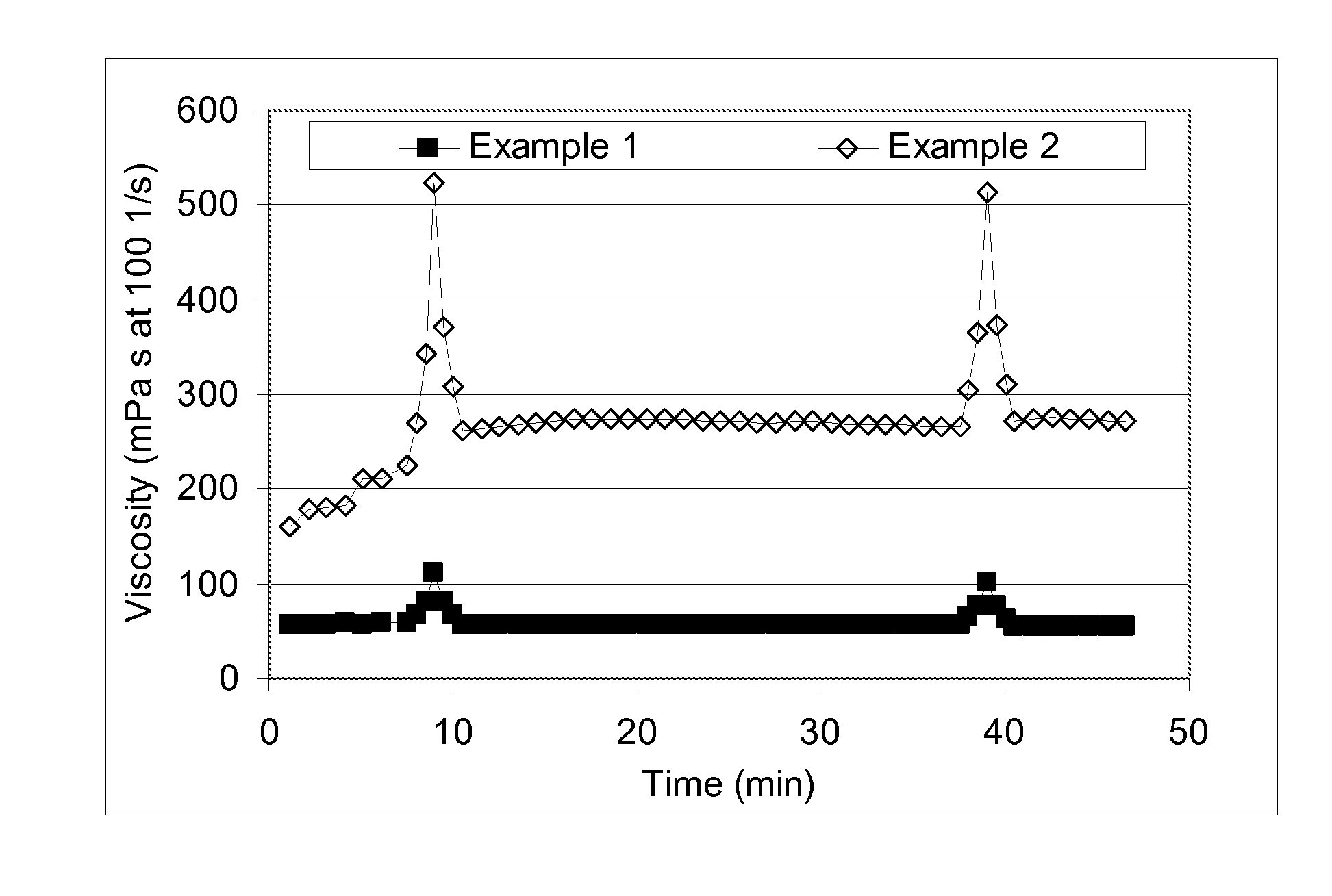

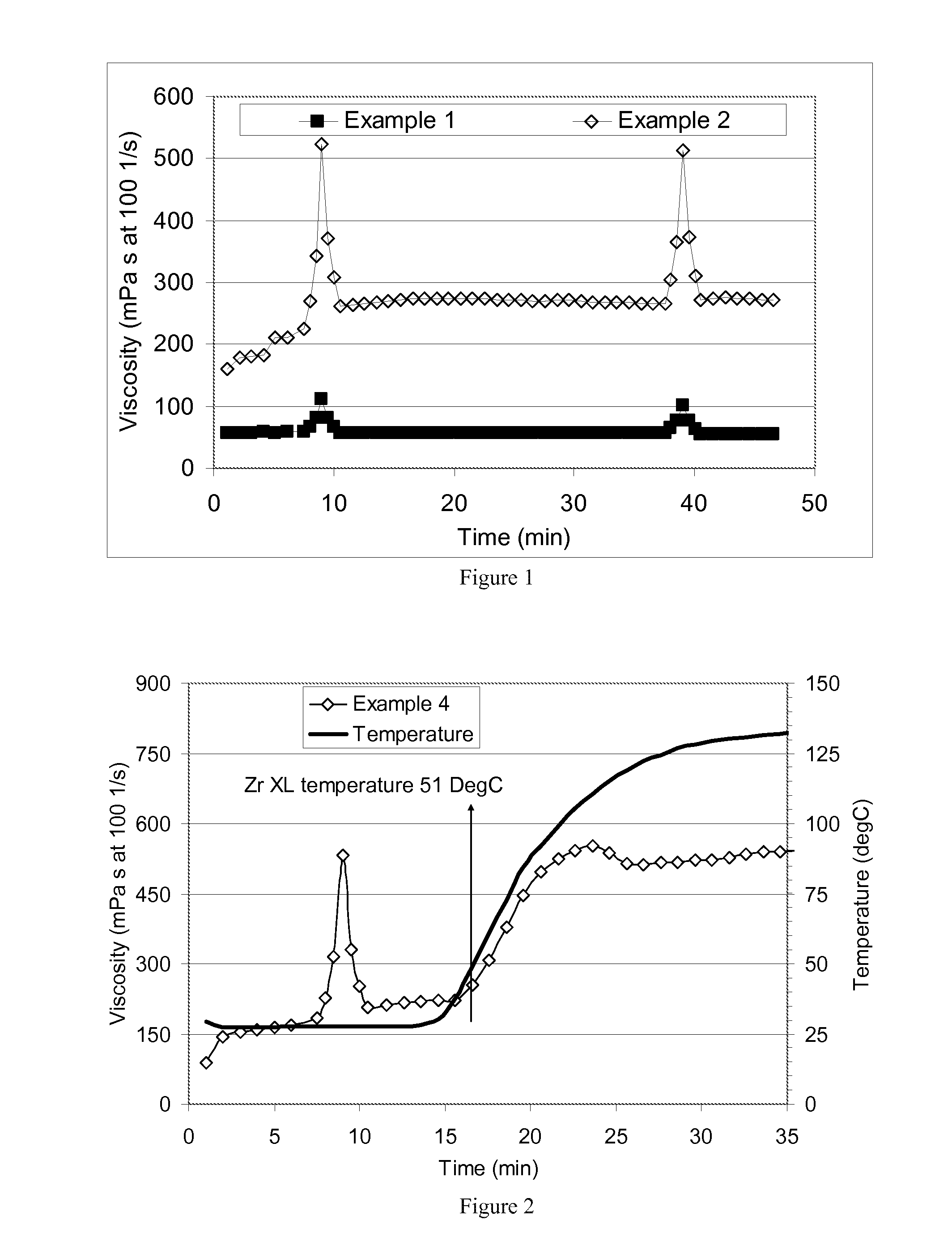

Well Treatment with Ionic Polymer Gels

Methods comprising preparing an aqueous mixture of an anionic polymer, a charge screening surfactant, and a borate crosslinker, wherein the mixture has a conductivity less than 10 mS / cm, injecting the mixture down a wellbore, and gelling the mixture. An embodiment of the aqueous mixture can also include tetramethylammonium chloride as a clay stabilizer and a metal crosslinker such as a complex of zirconium and an amino acid ligand system. An embodiment can effectively provide borate crosslinking of an anionic polymer in a low-ionic-strength fluid system, without sacrificing ultimate gel strength or thermal persistence of the metal crosslinked polymer.

Owner:SCHLUMBERGER TECH CORP

Method for preparing environmentally-friendly adhesive for lignin-based timber

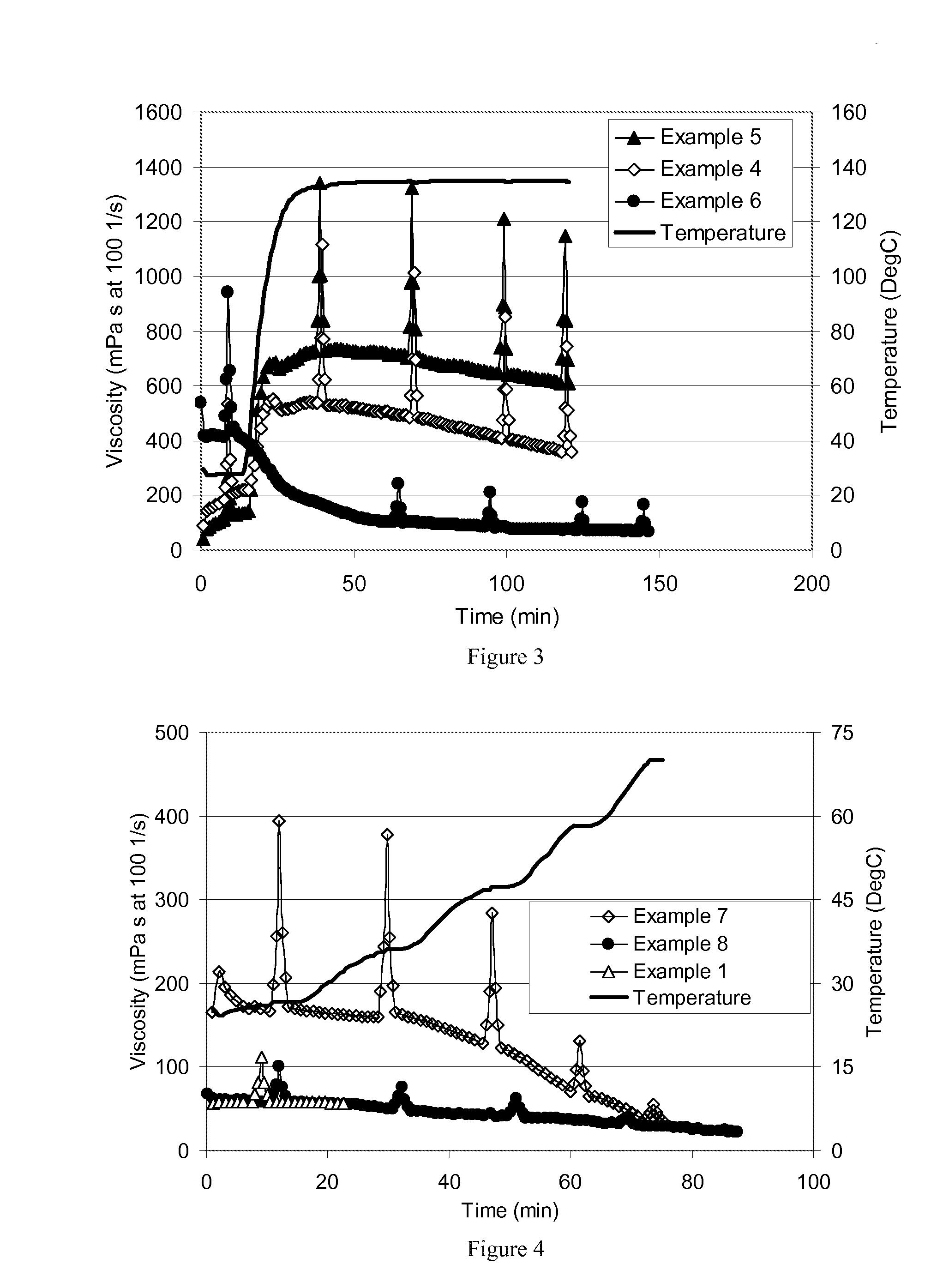

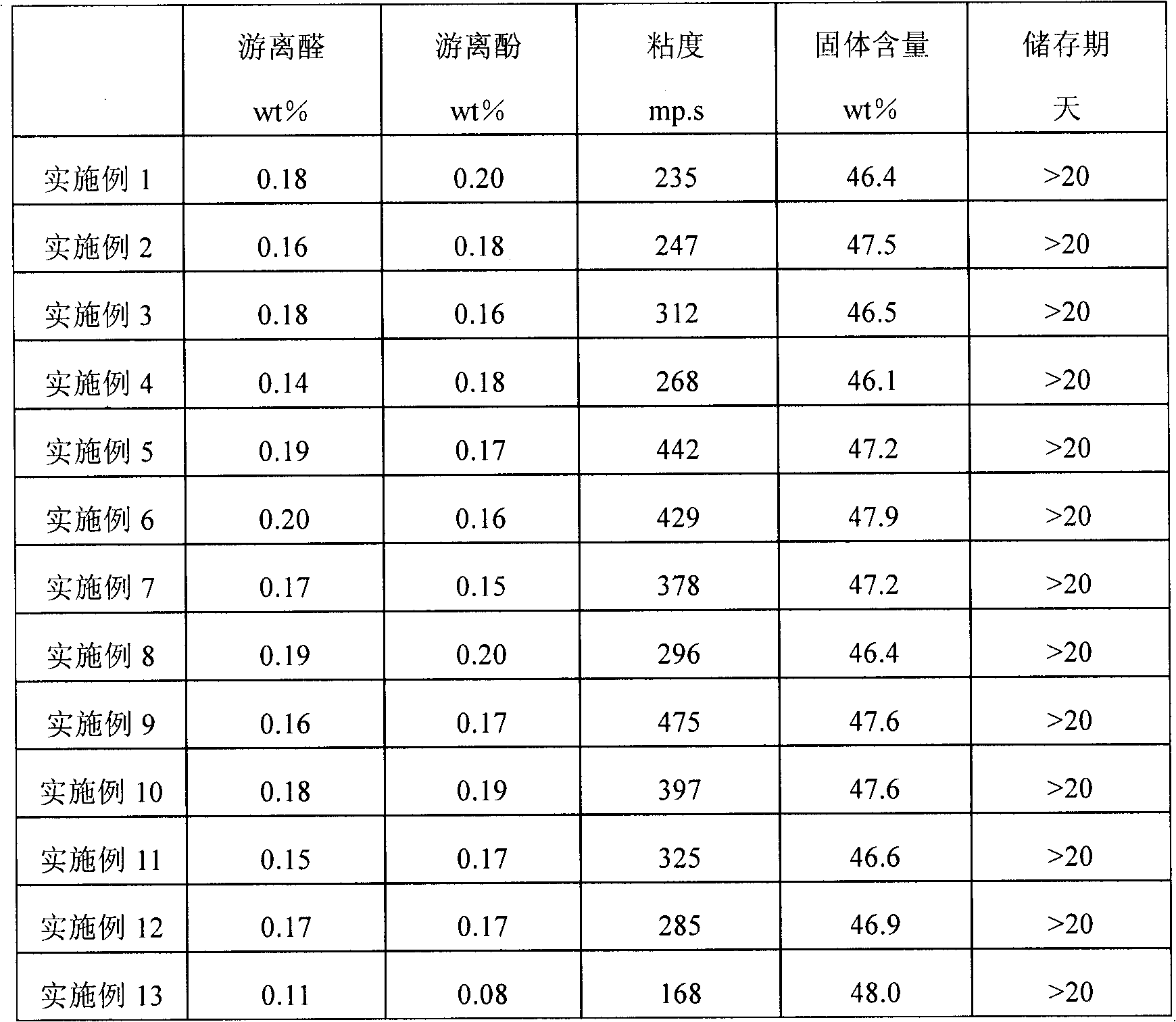

ActiveCN102061141AAdequate responseLow in free phenolsAldehyde/ketone condensation polymer adhesivesAdhesiveTime ratio

The invention discloses a method for preparing an environmentally-friendly adhesive for a lignin-based timber. The method comprises the following steps of: 1) adding phenol, formaldehyde solution, lignin, first alkali liquor and diluting water into a reactor, heating to the temperature of between 75 and 85 DEG C and reacting for 2.5 to 3.5 hours, wherein the molar ratio of formaldehyde to the phenol is 2.20:1-2.40:1; the formaldehyde solution is added for three times in a mass ratio of 1.5 to 1.0 to 1.0; and the reaction time ratio of the added formaldehyde solution is 1.2 to 1.0 to 1.0; 2) cooling to 70 DEG C, adding a formaldehyde collector and second alkali liquor, and reacting at the temperature of between 65 and 70 DEG C for 20 to 50 minutes; and 3) cooling to the temperature of between 30 and 40 DEG C, adding an intensifier, stirring for 10 to 30 minutes, cooling and discharging. In the method, a 50 to 60 percent petroleum-based phenol raw material can be substituted; the methodis stable in reaction, easy to control and easy for industrial production; formaldehyde emission of a plywood reaches E0 level; adhesive strength meets the requirements of national class I plates; and a new approach is provided for the development of an environmentally-friendly biomass-based timber adhesive and recycling of wastes.

Owner:青岛生物能源与过程研究所

Ventilated polyurethane plastic race-track surface layer cementing material

ActiveCN103666233AGuaranteed bonding strengthGood weather resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMass ratioEnd-group

The invention discloses a ventilated polyurethane plastic race-track surface layer cementing material, and belongs to the technical field of race-track construction. The ventilated polyurethane plastic race-track surface layer cementing material consists of a component I and a component II at the mass ratio of 1:(3-4), wherein the component I is prepolymer containing isocyanate end group prepared from environment-friendly polyisocyanate, polyether glycol and an addition agent by reacting in a reaction kettle for 3 to 4 hours at the temperature of 70 to 80 DEG C, and the component II comprises polyether glycol with three functionalities, inorganic filler, pigment, a plasticizing agent, a curing agent, an antioxygen, an ultraviolet light absorber and the like. The obtained plastic race-track has the advantages that surface particles are not easy to fall out, the surface is smooth, the quality of the plastic race-track is improved, the service life of the plastic race-track is prolonged, the qualification rate of the plastic race-track is increased to more than 95% as compared with the conventional 82%, the production cost and the use cost are reduced. Moreover all of the used raw materials are environmental protection materials, and belongs to environment friendly materials, the environmental pollution is avoided, and security is provided for the health safety of sporters.

Owner:金华市一家建设工程有限公司

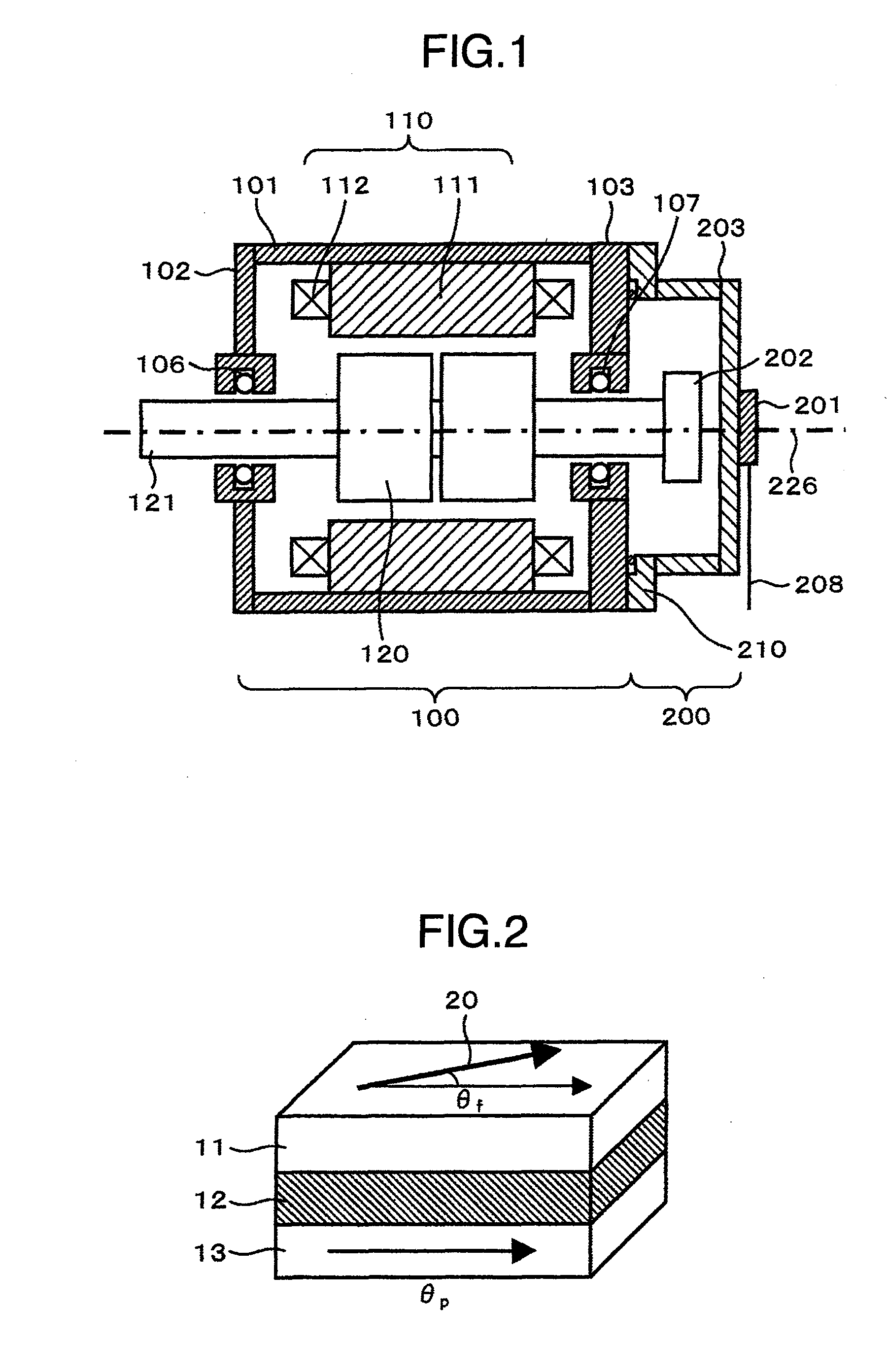

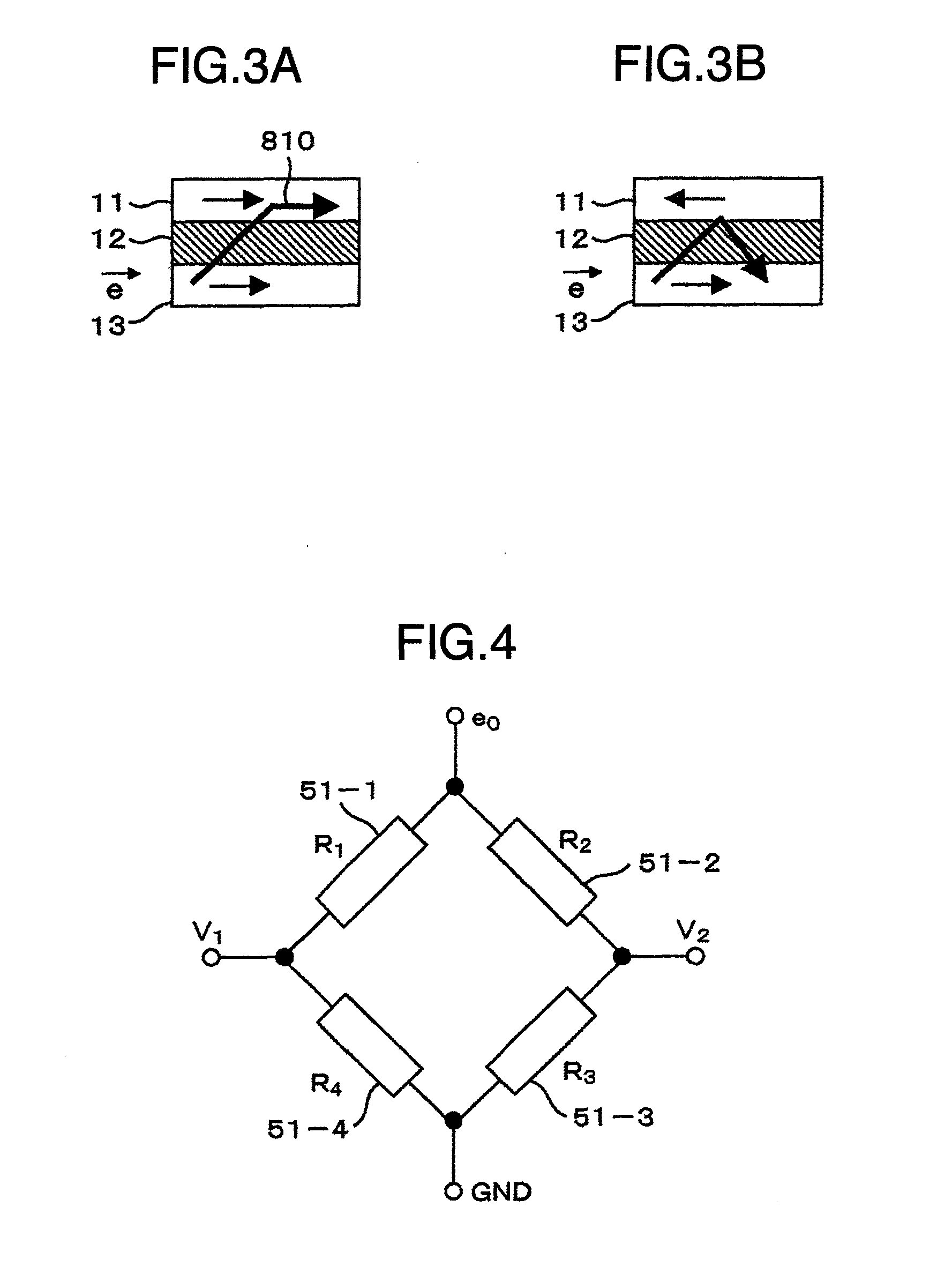

Rotational Angle-Measurement Apparatus and Rotational Speed-Measurement Apparatus

ActiveUS20100321006A1Improve accuracyHigh precision measurementMagnetic-field-controlled resistorsSolid-state devicesMeasurement deviceClassical mechanics

A rotational angle-measurement apparatus with high accuracy is provided through the electric correction of the rotational angle-measurement apparatus by rotating the rotation shaft at a constant speed.

Owner:HITACHI LTD

Low-smoke superthin expansion steel structure fireproof coating and its preparing method

The invention relates to a kind of new-style low smoke super thin inflating steel structure fire protection dope and its producing method. Its components have coordinated effect when encountering fire. It inflates and froths to isolate oxygen and has good heat insulation performance. It can slow down the speed of heat transmitting to protected basic material, and prevent flame fast overspreading. The dope of the invention is mainly comprised of basic material resin, carbon forming agent, vesicant and activator. It uses certain proportion of resin as main membrane forming substance, and improves height and intensity of frothing layer through adding china padding. The frothing height can get to over 50 times. It uses china padding and smoke inhibitor to have coordinated effect and reduce smoking quantity. Advantages: simple to smear, good fire protection performance, small smoking quantity, high frothing height and high frothing intensity.

Owner:FUDAN UNIV

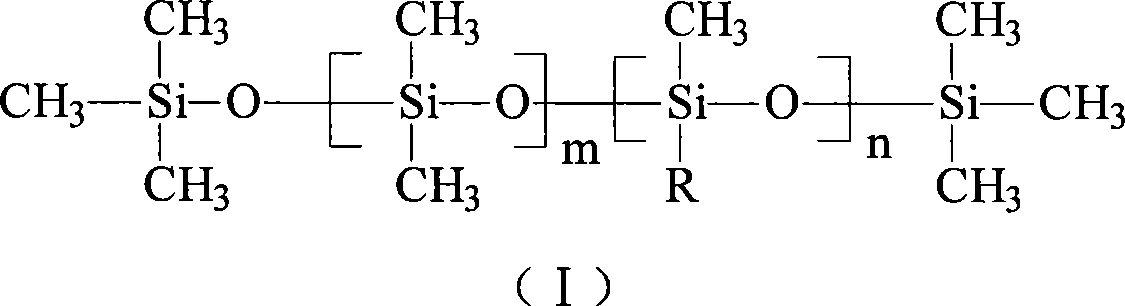

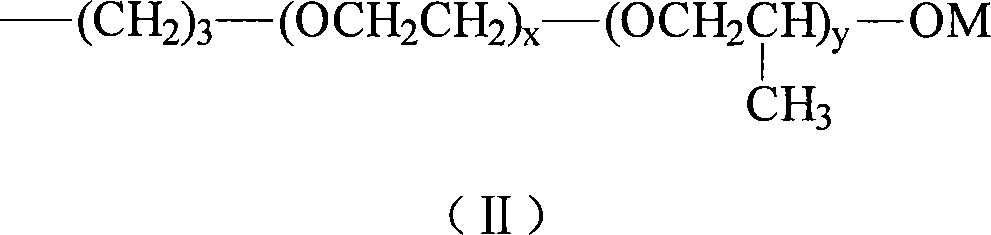

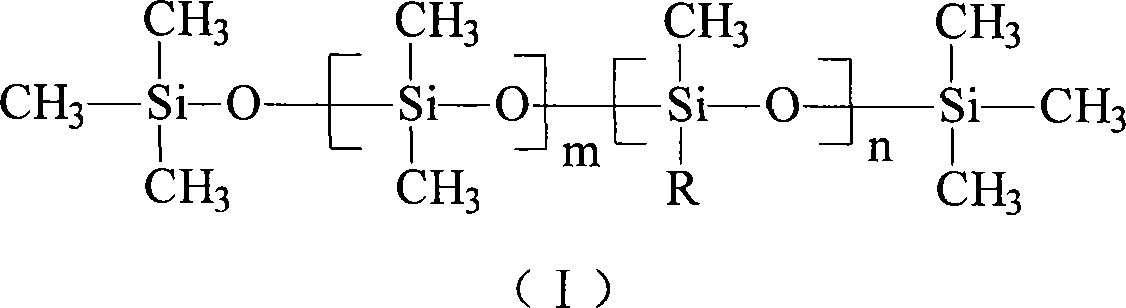

Masked non-ionic surfactant, preparation method and application thereof

ActiveCN101099926AMolecular weight controllableNarrow molecular weight distributionTransportation and packagingMixingPolymer scienceDouble bond

The present invention discloses one kind of terminated non-ionic surfactant and its preparation process and application. The surfactant is allyl terminated polyether with molecular weight controllable in 700-9500 Da, narrow molecular weight distribution and high reaction activity. It has methylol terminating rate up to 95 % and double bond terminating rate up to 93 %, and possesses structure as shown.

Owner:JIANGSU MAYSTA CHEM

Preparation method of high-performance lithium adsorbent

ActiveCN101829538AAvoid the problem of not easy to wash offActivity does not destroyOther chemical processesLithium compoundsLithiumHigh absorption

The invention discloses a preparation method of a high-performance lithium adsorbent. The method comprises the following steps of: (1) adding 100-500 ml of deionized water to a three-neck flask of 1L and adjusting a pH value to be 3-7; (2) adding 25-150g of organic aluminum to the flask at 40-70 DEG C and hydrolyzing to obtain active aluminum hydroxide, gradually dipping a lithium salt solution or a lithium salt solid three times of the organic aluminum 0.5h after hydrolyzation and reacting for 1-2h to obtain an active substance product of LiCl.2Al(OH)3.xH2O; (3) filtering the active substance containing the aluminum hydroxide and washing with 95 percent of ethanol twice to obtain solid precipitate and filtrate; and (4) drying the solid precipitate at 30-70 DEG C. The prepared active substance of aluminum hydroxide radically solves the problem of uneven reaction of a traditional method for preparing the active substance of aluminum hydroxide by utilizing solid-phase mixing, and the invention has the advantages of high absorption speed, greater specific surface area and longer adsorbent service life.

Owner:浙江海钛新材料科技股份有限公司

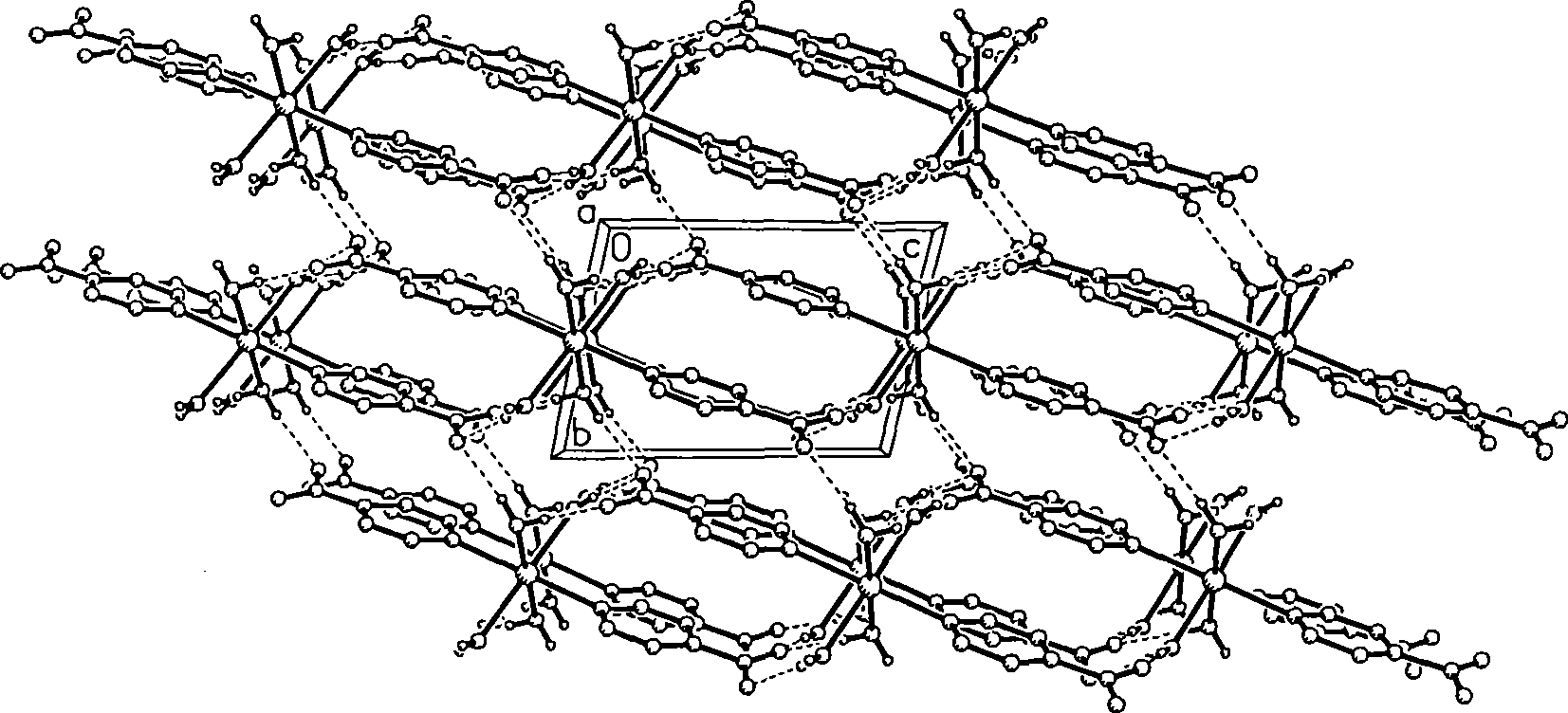

Method for low-temperature atmosphere-pressure hydrothermal synthesis of stephanoporate metal-organic framework

InactiveCN101429209AFully contactedQuality improvementCadmium organic compoundsZinc organic compoundsMetal-organic frameworkChemistry

The invention discloses a method for hydrothermally synthesizing a porous metal-organic framework under low temperature and normal pressure, which comprises the following steps: 1) bivalent transition metal salt is put into proper amount of distilled water to be dissolved; 2) a multidentate organic ligand is put into proper amount of distilled water, and ammonia (30 percent, W / W) is added into the solution until the organic ligand is dissolved; 3) solutions obtained in step 1) and step 2) are mixed, and diluted by the distilled water; 4) the solution obtained in step 3) reacts for 4 to 24h at a temperature of between 80 and 100 DEG C, and is naturally cooled to room temperature at an environmental temperature to obtain an MOF crystal product; and 5) the MOF crystal product obtained in step 4) is filtered, MOF crystals are colleted and washed by the distilled water and absolute ethyl alcohol respectively, and the product is obtained after the natural drying. By performing a hydrothermal reaction in an ammonia solution, the method has mild conditions needed by the synthesis, less energy consumption and time consumption, and does not need a voltage resistant reactor. Therefore, the method is simpler and has lower cost; and a porous crystal material obtained by the synthesis has potential application value in the fields of gas separation, gas storage and heterogeneous catalysis.

Owner:CHONGQING UNIV

High-energy-density Ni-Co-based lithium ion positive electrode material and preparation method thereof

The invention discloses a high-energy-density Ni-Co-based lithium ion positive electrode material. The chemical general formula of a base material is LipNixCo1-xMmO2, M is a doping agent, and a clad material is an active material N; a positive electrode material of a lithium ion secondary battery is composed of second particles formed by gathering of primary particles, or primary particles, or mixed particles of primary particles and second particles. A preparation method of the high-energy-density Ni-Co-based lithium ion positive electrode material comprises the steps of preparation of a precursor of the lithium ion secondary battery positive electrode material and preparation of the lithium ion secondary battery positive electrode material. The Ni-Co binary precursor of the positive electrode material is subjected to a continuous coprecipitation reaction, elements are evenly mixed, the reaction is sufficient, and morphology control is facilitated; the cation mixing phenomenon is reduced through doping of proper elements in a binary high-nickel material, the structure is stabilized, safety and high-temperature performance of the battery material are improved, and the cladding active material improves first-time charge and discharge efficiency and the energy density of the material to a certain extent.

Owner:NANTONG RESHINE NEW MATERIAL

Preparation method of functional polyester fiber

ActiveCN103789868AAdequate responseHigh apparent viscosityArtificial filament heat treatmentMelt spinning methodsPolymer scienceMoisture absorption

The invention relates to a preparation method of a functional polyester fiber. The preparation method comprises the following steps: performing esterification by stages, wherein dihydric alcohols, polyhydric alcohols and functional inorganic powder are mixed according to a certain mole ratio, in the first esterification stage, acid is slightly excess to ensure that monomers with low capability of participating in esterification reaction in the polyhydric alcohols fully react and are grafted into polyester molecular chains, and in the second esterification stage, the dihydric alcohols are replenished to control the terminal carboxyl group of copolyester. The preparation method has the advantages that polyhydric functional groups can improve the apparent viscosity of a system and play a role in wrapping the introduced functional inorganic powder (such as far infrared ceramic inorganic powder, titanium dioxide powder and zinc oxide antibacterial powder), thus improving the dispersion uniformity of particles; settlement is unlikely to happen in the polymerization process and then functional polyester is prepared through condensation polymerization; the functional polyester fiber is finally prepared by carrying out melt spinning on the prepared polyester, has good moisture absorption property and flexibility and can be widely used for preparing far-infrared moisture absorbing and sweat releasing antistatic and antibacterial fabrics next to the skin.

Owner:JIANGSU HENGZE COMPOSITE MATERIALS TECH

Pressure measurement device

InactiveUS20060094966A1Adequate responseReduce stressCatheterIntracranial pressure measurementPressure transmissionEngineering

A device measures pressures in animals and humans and includes a pressure transmission catheter (PTC) filled with a pressure transmitting medium and implantable in an area in having a physiological pressure. A transducer communicates with the pressure transmitting medium to provide a pressure signal representing variations in the physiologic pressure on electrical wires. A connecting catheter carries the electrical wires to signal processing and telemetry circuitry, which transmits a telemetry signal representing the pressure signal to a receiver external to the animal or human. A housing holds the signal processing and telemetry circuitry, but the transducer is remote from the housing. The device is particularly useful in measuring venous pressure, pulmonary pressure, bladder pressure, or intracranial pressure without significant head pressure artifact and with a sufficient dynamic response. One embodiment of the PTC includes a multi-durometer stem.

Owner:DATA SCI INT

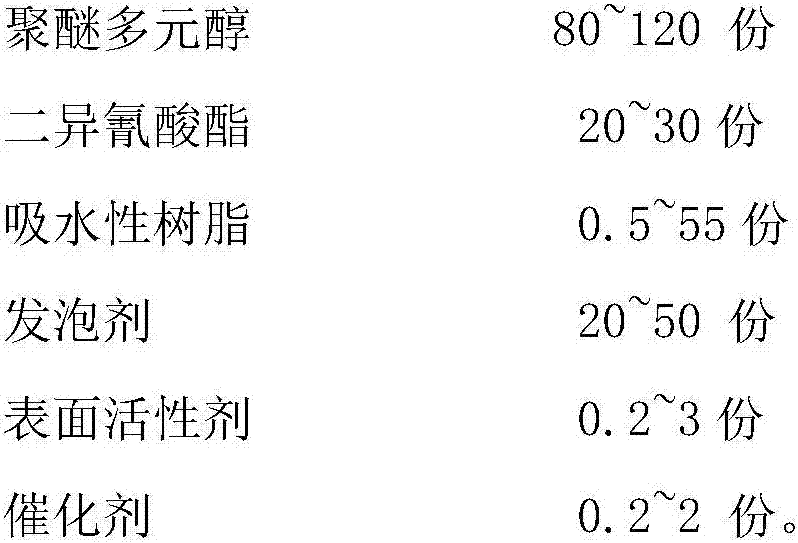

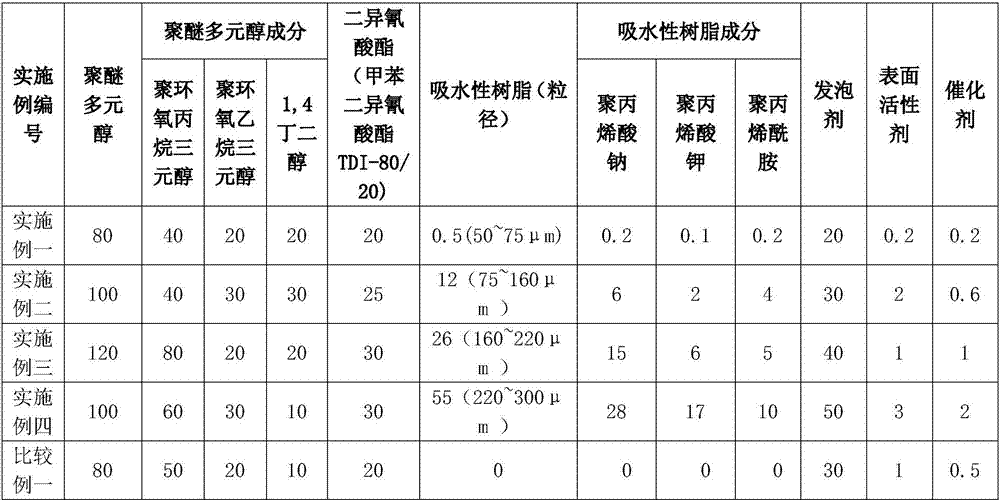

Polyurethane foam with high water absorption performance and high water retention performance and preparation method of polyurethane foam

The invention discloses polyurethane foam with high water absorption performance and high water retention performance and a preparation method of the polyurethane foam and belongs to the technical field of chemical engineering in high polymers. The polyurethane foam is prepared from components in parts by mass as follows: 80-120 parts of polyether glycol, 20-30 parts of diisocyanate, 0.5-55 parts of water-absorbent resin, 20-50 parts of a foaming agent, 0.2-3 parts of a surfactant and 0.2-2 parts of a catalyst through mixing. The preparation method comprises two steps of preparation of a prepolymer and preparation of a foam material. The polyurethane foam has the advantages of high water absorption performance, high water retention performance, high resilience, good compression performance and high stability.

Owner:NANJING UNIV OF TECH +1

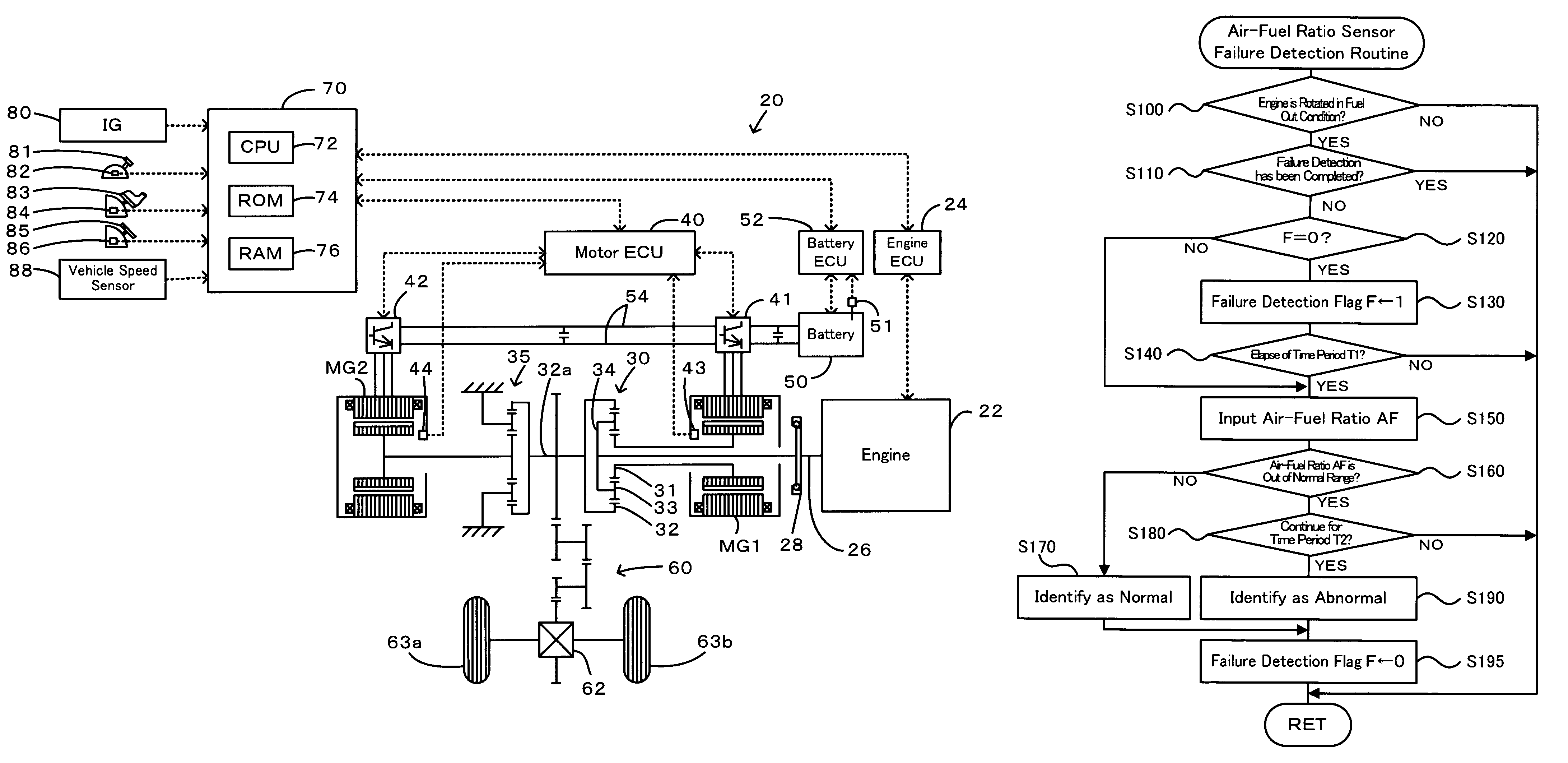

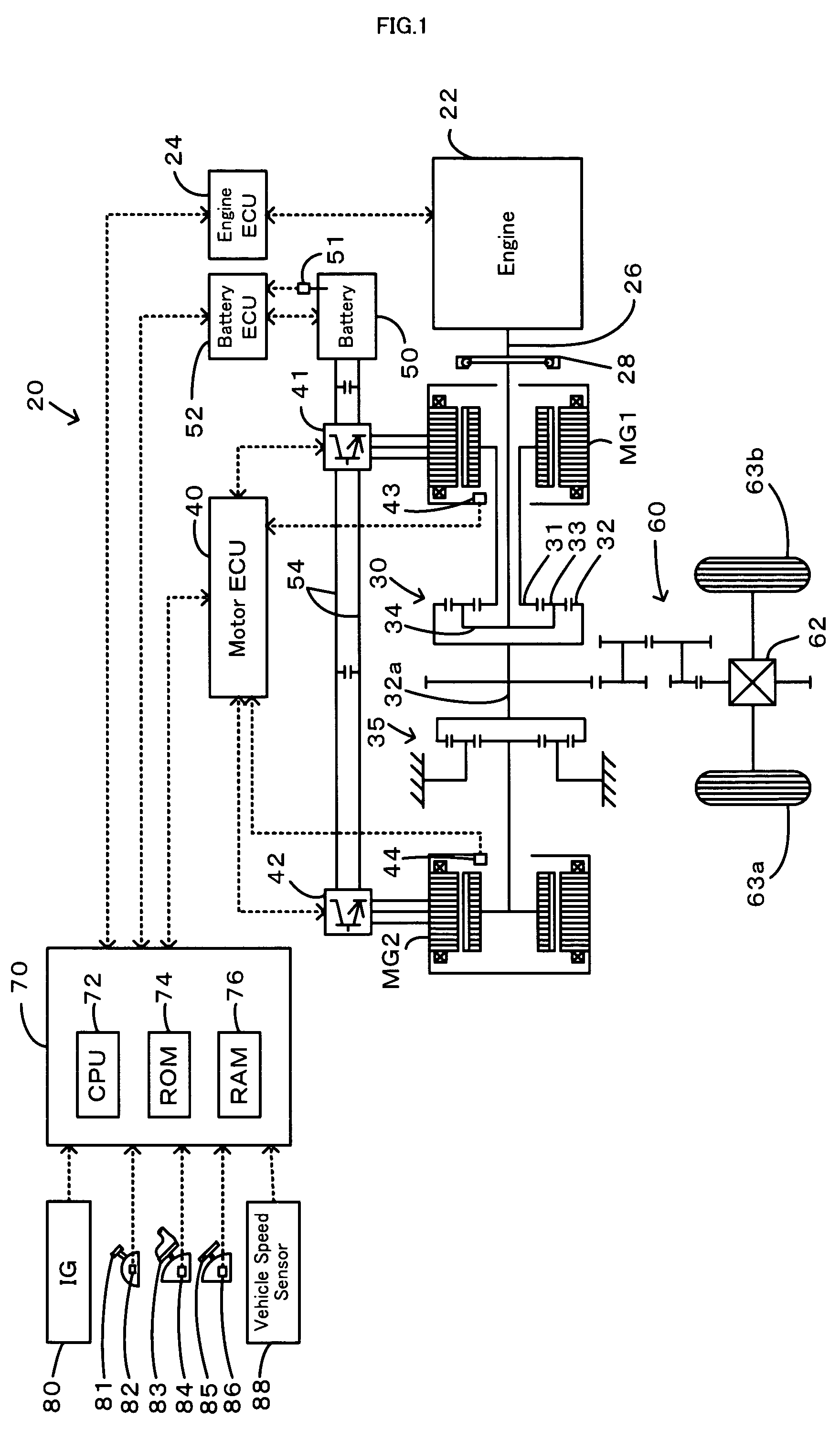

Power output apparatus, vehicle equipped with power output apparatus, and control method of power output apparatus

ActiveUS7599786B2Adequate responseAccurate detectionHybrid vehiclesAnalogue computers for vehiclesAir–fuel ratioAutomotive engineering

A vehicle is equipped with a planetary gear mechanism including a sun gear, a carrier, and a ring gear that are respectively connected to a first motor, an engine, and a driveshaft. A second motor is further linked to the driveshaft. An air-fuel ratio sensor located in an exhaust system of the engine detects the air-fuel ratio while the engine is rotated in a fuel cut state. Normality or abnormality of the air-fuel ratio sensor is identified, based on a result of determination whether the detected air-fuel ratio is out of a specified normal range. When engine stop conditions for stopping the operation (rotation) of the engine are satisfied during execution of failure detection of the air-fuel ratio sensor (steps S300 and S310), the drive control of the invention maintains the rotation of the engine in the fuel cut state until completion of the failure detection of the air-fuel ratio sensor and controls the first motor to motor the engine (step S330). The operation of the engine is stopped on completion of the failure detection (step S320).

Owner:TOYOTA JIDOSHA KK

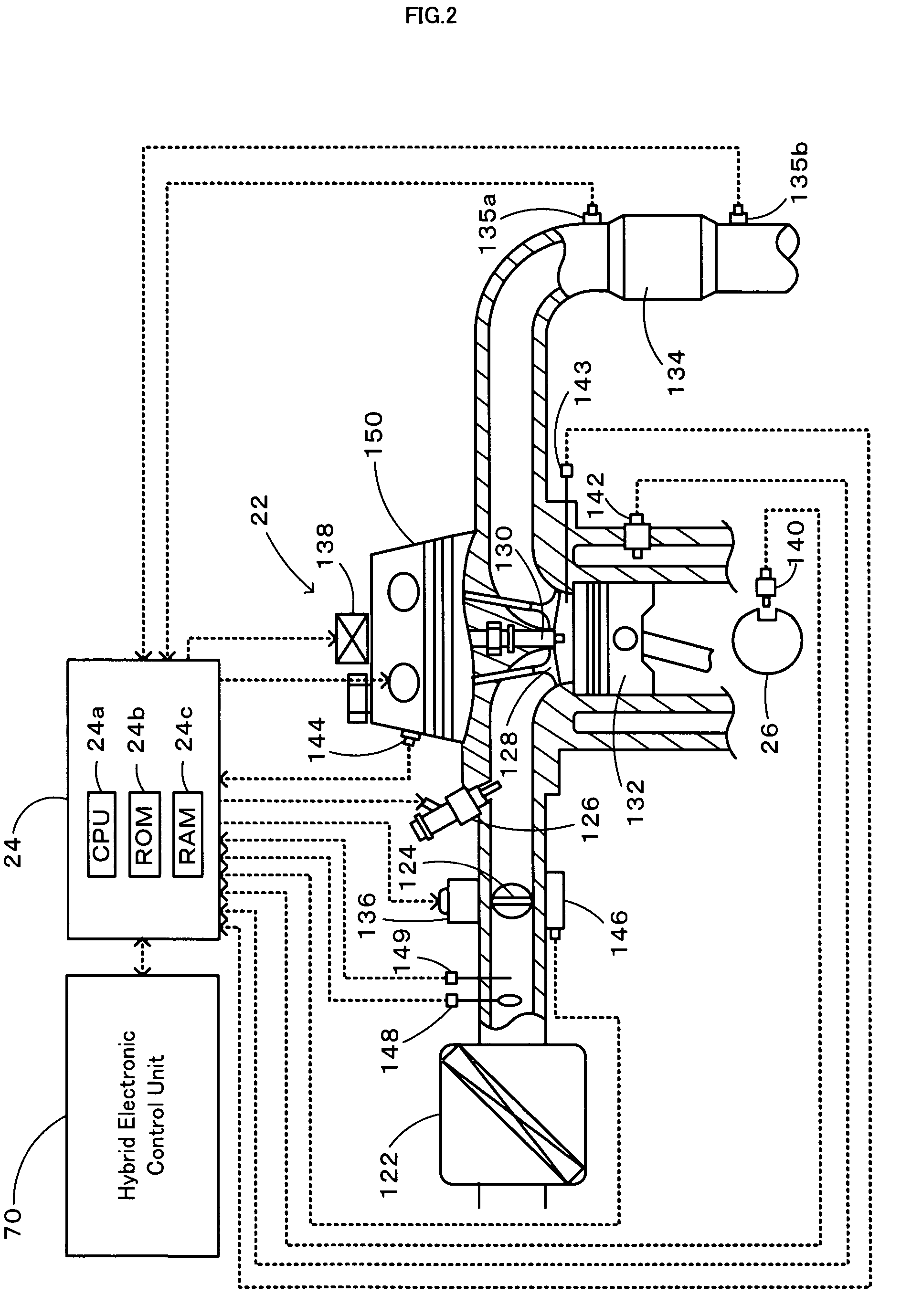

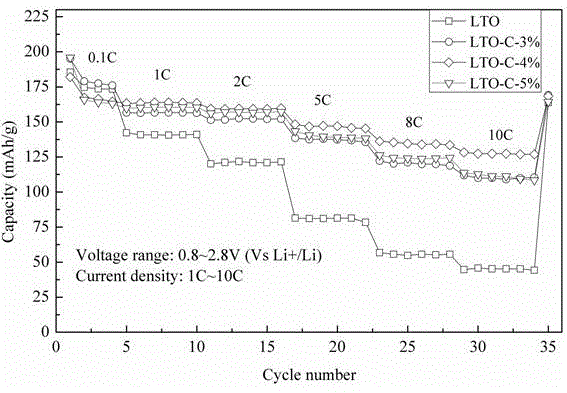

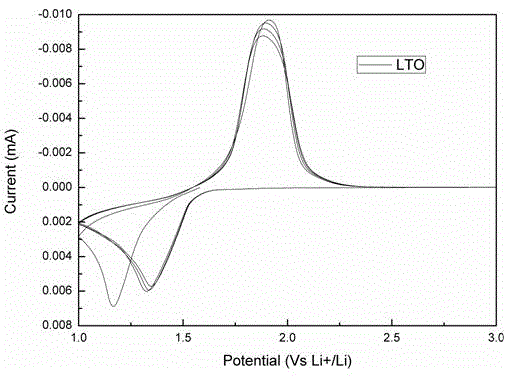

Preparation method of carbon-coated sodium-micron-scale lithium titanate composite anode material

ActiveCN105591079AGuaranteed stabilityLoose particle structureMaterial nanotechnologyCell electrodesMicron scaleOrganotitanium compound

The invention relates to a preparation method of a carbon-coated sodium-micron-scale lithium titanate composite anode material. The method comprises steps as follows: lithium salt is dissolved in an aqueous solution of absolute ethyl alcohol, and the solution is marked a solution a; an organic titanium compound and a carbon source are dissolved in absolute ethyl alcohol, and the solution is marked a solution b; a chelating agent M is dissolved in absolute ethyl alcohol, ultrasonic dispersion is performed, and the solution is marked a solution c; the solution c is slowly dropwise added to the solution b while stirring, and white sol is obtained; then the solution a is slowly dropwise added to the white sol; after the sol is aged, heating, stirring, drying, grinding, sieving and calcination are performed, and the carbon-coated lithium titanate composite anode material is obtained. Lithium titanate has narrower particle size distribution and more uniform particle distribution, and sodium-micron-scale particles are uniformly inlaid to form particles with high tap density; the particle structure is loose and porous, the specific surface area of a formed electrode is larger, getting off of lithium ions in the lithium titanate material is facilitated, and the stability of the crystal structure of the lithium ions in the charge and discharge process is guaranteed.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

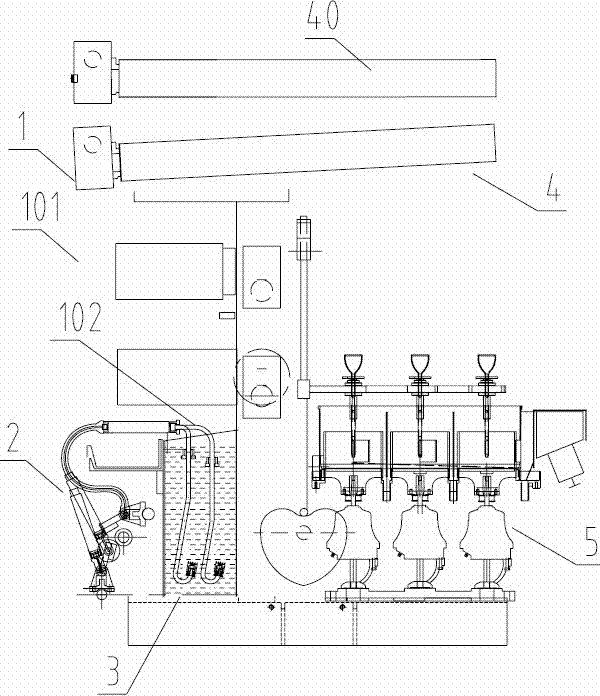

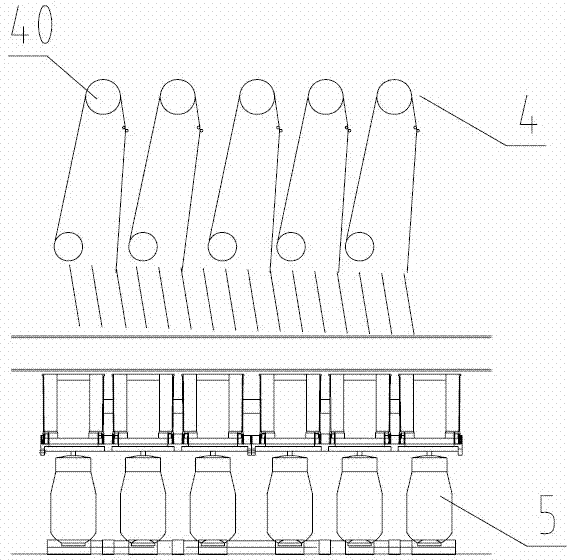

Spinning technology applied to semi-continuous high-speed spinning machine with spinning roller arranged horizontally

InactiveCN103290496ASmooth rotationNo shakingArtificial filaments from viscoseWet spinning methodsYarnSpinning

The invention relates to a spinning technology applied to a semi-continuous high-speed spinning machine with a spinning roller arranged horizontally. The spinning technology comprises glue measurement and supply, pre-spinning filtering, yarn strip forming, spinning and winding. The spinning technology aims at the specific semi-continuous high-speed spinning machine with the spinning roller arranged horizontally, under the mutual action of all processes and control of technological parameters, the spinning speed is ensured to be improved, independent walking of single yarn strips can be achieved, operations are simplified, the problems of doubling, burrs, breakage and the like are solved, the yarn strips are fully reacted and good in uniformity, the product quality is guaranteed, meanwhile, operations of workers are facilitated, and equipment maintenance is easy, overhaul costs are low, so that product costs are greatly reduced while the production efficiency is effectively improved.

Owner:YIBIN HIEST FIBER +2

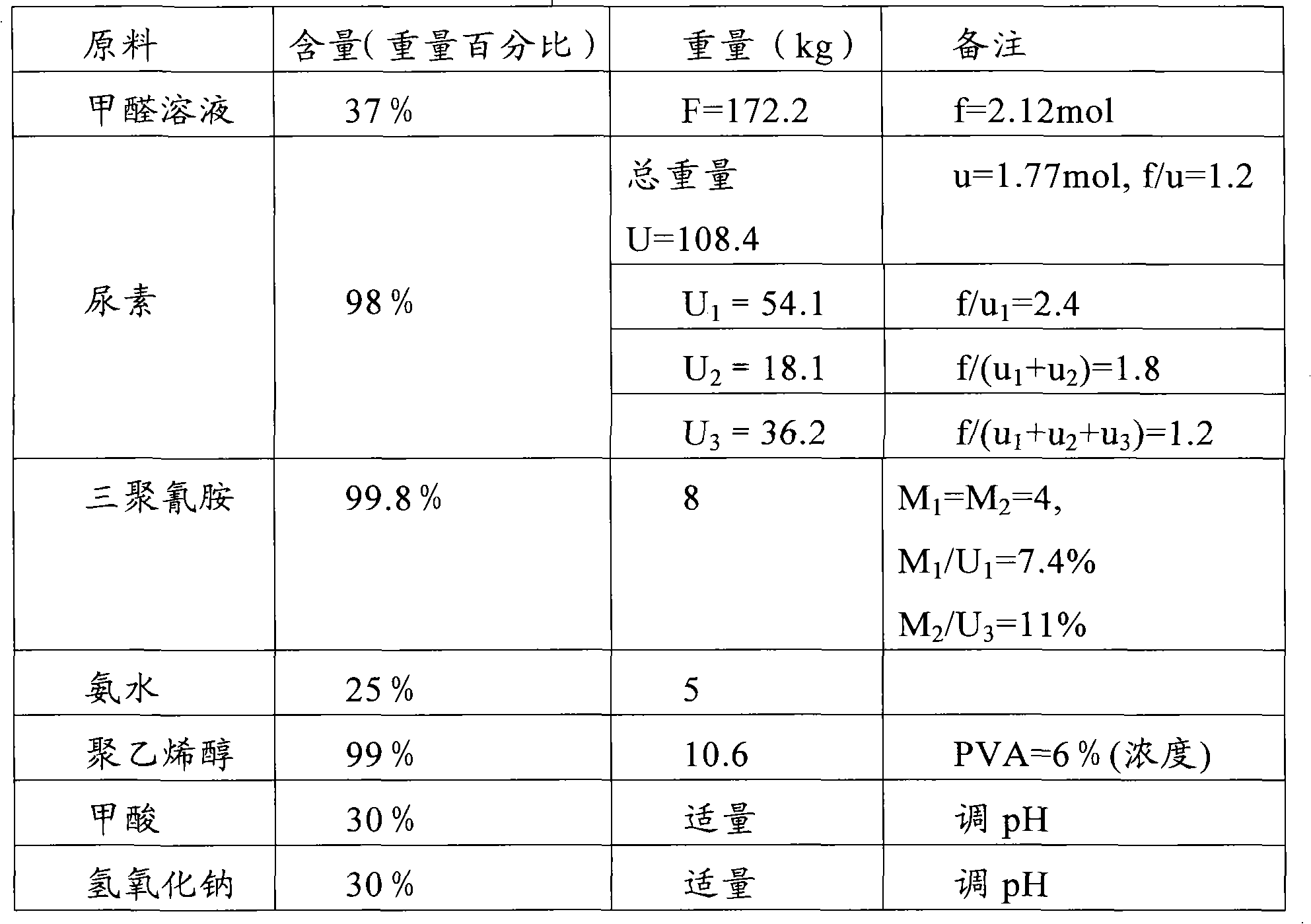

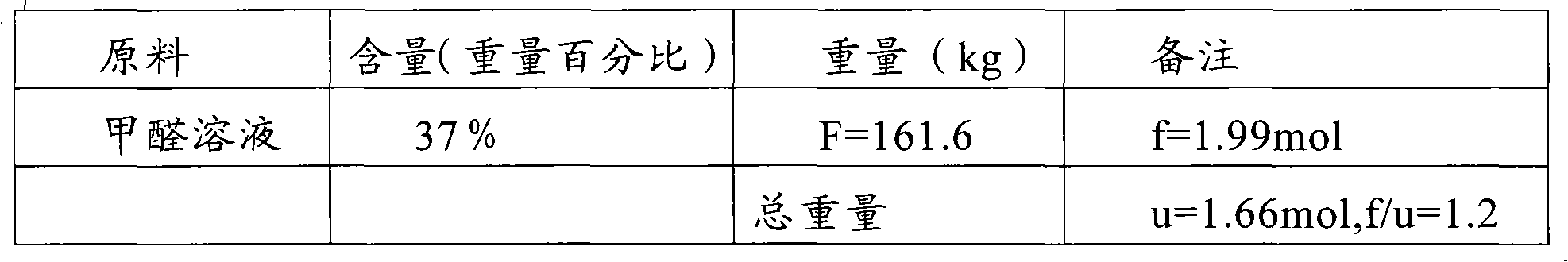

Environment-friendly urea resin for laminating plywoods from high water-content veneers and preparation and application thereof

ActiveCN102086257AThe polycondensation reaction is sufficientGood water solubilityAldehyde/ketone condensation polymer adhesivesHigh water contentUltimate tensile strength

The invention relates to a preparation method and application of environment-friendly urea resin for laminating plywoods from high water-content veneers. The method for synthesizing the resin is simple, and low in cost; the laminated plywoods can meet the national E1 grade and even E0 grade environmental protection requirements; and the problems of low prepressing performance and water resistance when the high water-content veneers are laminated into the plywoods are mainly solved. In the synthesis of the urea resin, an acid-base-acid-base process is adopted, formaldehyde and polyvinyl alcohol are added at one time, urea is added by three batches, melamine is added by two times, and after ammonia water is added, the ammonia water, the urea, the formaldehyde and urea-form condensate are reacted to generate a series of triazine ring compounds, and the microstructure of the resin is improved. When the resin is cured, the crosslinking density is improved, wet shear strength of the plywoods is obviously improved and the formaldehyde emission is obviously reduced.

Owner:广西鑫恒晶木业股份有限公司

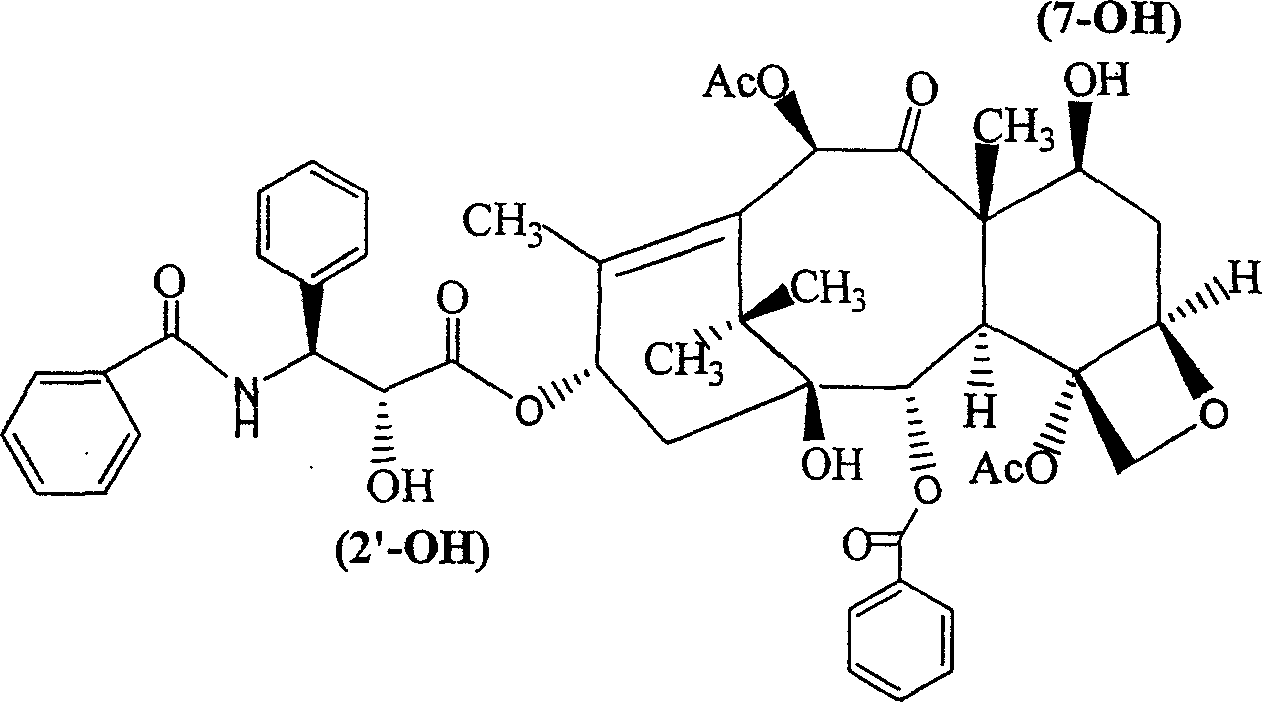

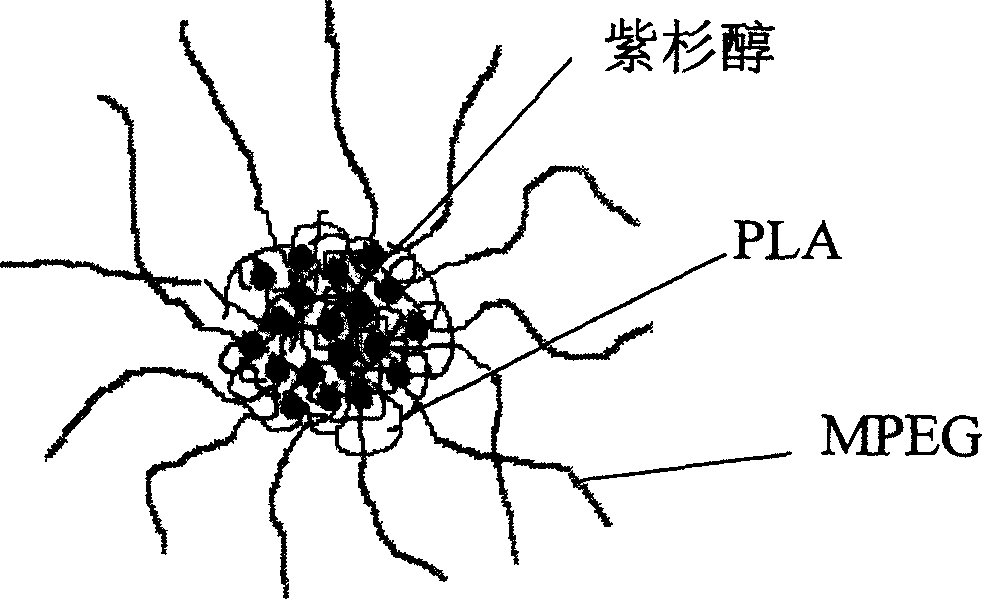

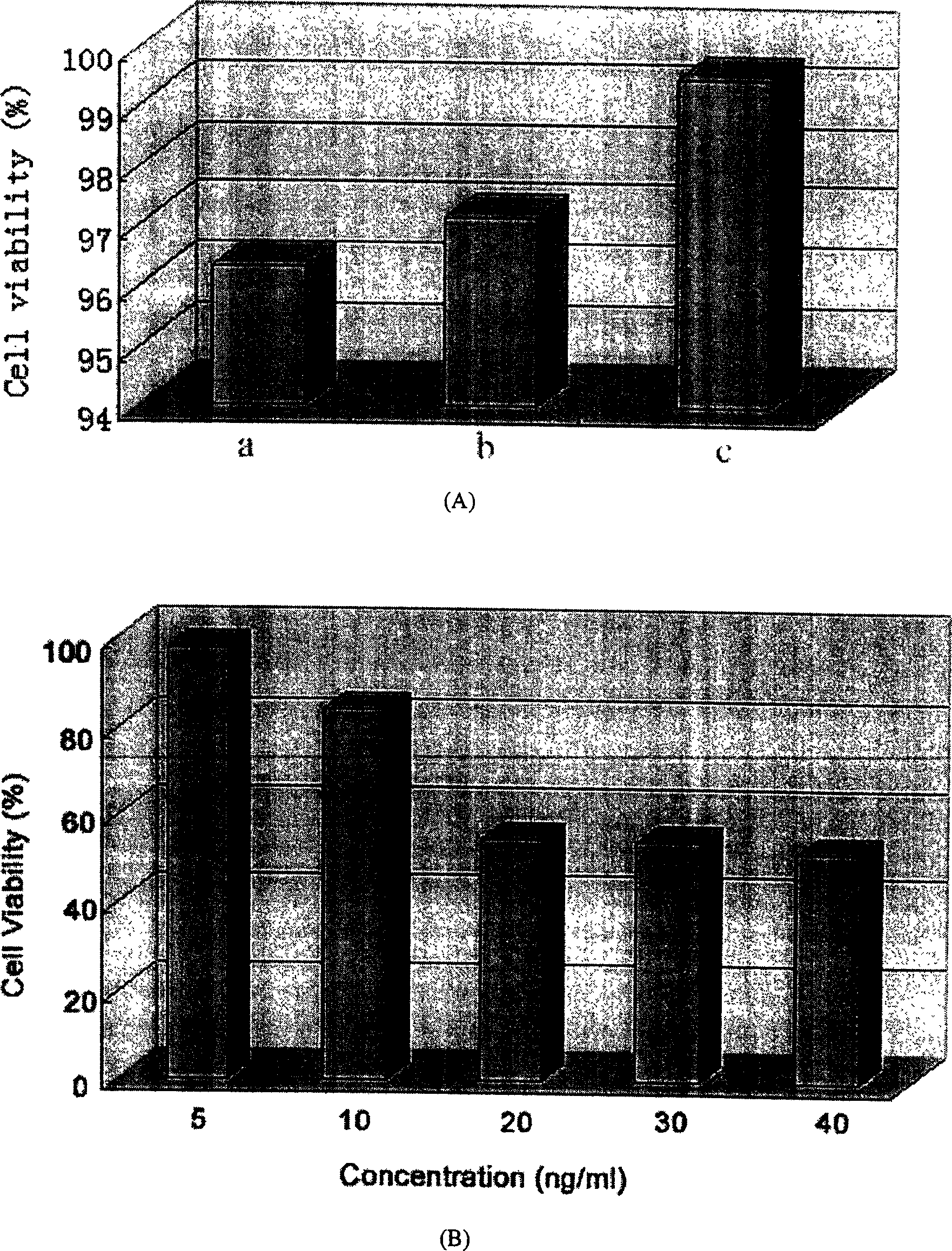

Paclitaxol predrug of biodegradable polymer and its synthesis method

The invention provides a paclitaxol predrug of biodegradable polymer and its synthesis method, which is bond from polyoxyalkylene-aliphatic polyester blocked copolymer and paclitaxol, the synthesizing process comprises, carrying out ring-opening polymerization of aliphatic cyclic esters at the presence of polyethylene glycol (PEG), solvent and catalyst, obtaining polyethylene glycol - aliphatic polyester blocked copolymer, then converting its end hydroxyl into end carboxyl, reacting with paclitaxol for esterification at the presence of condensing agent, the obtained paclitaxol predrug has amphiphilic, thus can be prepared into water based preparation.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

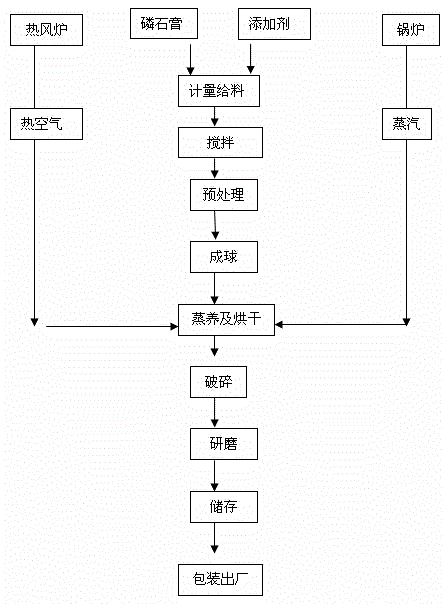

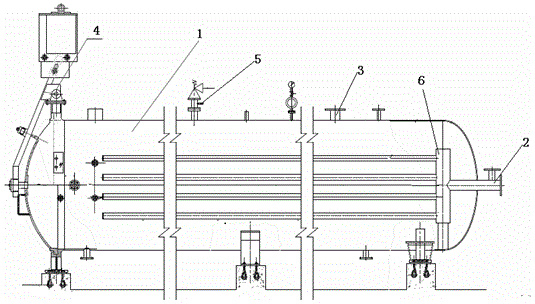

Method and device for preparing high-strength alpha hemihydrate gypsum by using phosphogypsum

The invention discloses a method for preparing high-strength alpha hemihydrate gypsum by using phosphogypsum. The method comprises the following steps of: mixing the phosphogypsum, a pretreatment additive, water and a crystal modifier, stirring to be uniform, forming balls after aging treatment, then finishing steam curing and drying in a stilling kettle, and preparing the high-strength alpha hemihydrate gypsum. The method disclosed by the invention has the advantages that the process flow is simple, the industrialization is easy, the phosphogypsum can be greatly utilized and consumed, and the conversion rate is high; and simultaneously, the invention provides the stilling kettle capable of realizing integration of steam curing and drying, the alpha hemihydrate gypsum can be better prepared, and the high-quality building material or wall-body material can be better prepared.

Owner:KUNMING UNIV OF SCI & TECH

Production method of ultrafine cell level ferric orthophosphate

InactiveCN101462704AIncrease response rateHigh purity of finished productPhosphatesCell electrodesChemistryPhosphate

The invention relates to a method for producing ultrafine battery-level positive ferric phosphate. The method comprises the following steps that: a ferrite solution is added into a catalytic reaction kettle, added with sulphuric acid to adjust the pH value and slowly added with hydrogen peroxide while stirring to perform oxidation reaction; the dissolved phosphate solution is added to the catalytic reaction kettle, added with soda ash or ammonia to control the pH value and strongly stirred to obtain slurry of the positive ferric phosphate; the slurry is water-washed, press-filtered and separated to obtain a positive ferric phosphate filter cake; a conversion reaction kettle is added with an aqueous solution of phosphoric acid and added with the filter cake, the pH value and the temperature of the obtained mixing solution are adjusted, and the mixing solution is stirred; the mixing solution is placed in a thermal insulation reaction kettle, heated and stirred for a few hours until the mixing solution becomes pink, and the slurry of the positive ferric phosphate is obtained; and the slurry is water-washed, press-filtered, dried and crushed to obtain a finished product of the positive ferric phosphate. The method has the advantages of complete reaction and high reaction ratio, 28 to 29 percent of the total iron content Fe<3+> of the obtained products and even and thin grain diameter, and the D50 is less than or equal to 2um, the P is more than or equal to 16 percent, the grain is ultrafine and high in purity, and has even grain diameter; and because waste slag discharged in the production of a titanium pigment or industrial acid pickling waste liquid is used as a raw material, the environment is protected, and the product cost is lowered.

Owner:刘世琦

Process for producing methane by dry-type fermentation of stalks

InactiveCN101338325ALess investmentReduce operating costsBio-organic fraction processingClimate change adaptationSlagSlurry

The invention provides a technique for producing biogas by utilizing stalk dry fermentation which includes the steps: I, cracking the stalks into 2 to 8mm by a cracking machine; II, transmitting the cracked stalks into a pre-treatment pool, adding hot water of 40 to 53 DEG C and a stalk fermentation agent in the pre-treatment pool to carry out pre-treatment; the cracked stalks and the biogas slurry refluxed by the anaerobic digester of the pre-treatment pool are mixed according to a proportion of 2 to 1; after stirring, the solid content rate of the stalk liquid is 20 to 35 percent; III, using a mud pump to equally transmit the stalk liquid to the top part of the anaerobic digester with a fermentation temperature of 40 to 53 DEG C; IV, the biogas generated by fermentation is purified to be clean fuel by gas-liquid separation. The technique can lead the stalks of 1.5kg to generate the biogas of 1m<3> (the content of methane is larger or equal to 55 percent); the degrading rate is more than 90 percent. The technique of the invention can continuously feed and discharge; the biogas slurry can be repeatedly used; only biogas slag is discharged; the biogas slag is manufactured into organic fertilizer by processing and can not cause any pollution to the environment.

Owner:HENAN FUCHENG ECOLOGICAL ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com