Polyurethane foam with high water absorption performance and high water retention performance and preparation method of polyurethane foam

A technology of polyurethane foam and high water absorption, which is applied in the fields of high water retention polyurethane foam and its preparation, high water absorption, polyurethane foam and its preparation field, can solve the problems of low grafting rate, uneven distribution of components, and water absorption of grafts. The problem of low magnification is to achieve the effect of light weight, good mechanical properties and strong water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

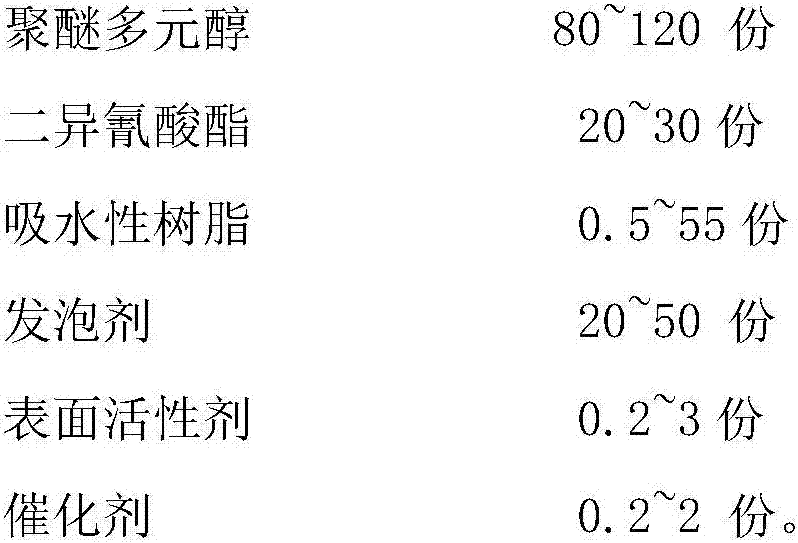

Method used

Image

Examples

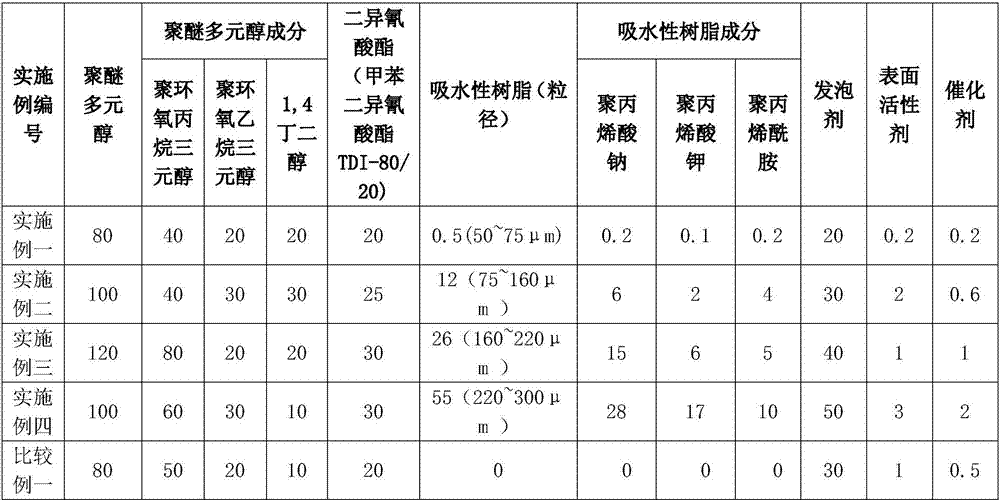

Embodiment 1

[0031] A kind of high water absorption, high water retention polyurethane foam, its preparation process is: Step 1: the preparation of prepolymer: take polyether polyol by mass parts, vacuum dehydration at 120 ℃ for 2 hours; cool down to 40-50 ℃; add diisocyanate, catalyst and surfactant, stir evenly at 75 ℃ for 2 hours to obtain a prepolymer, the isocyanate content of the prepolymer is 1wt%, cool to 30-40 ℃ for use; step 2: foam material Preparation: quickly add water-absorbent resin to the prepolymer prepared in step 1, stir at a high speed for 3 minutes, and rotate at a speed of 1600r / min. After the liquid material is evenly mixed, quickly pour the foaming agent and stir at a high speed until the material turns white After slightly bubbling, pour it into the prepared mold quickly to fill the mold with foam, let it stand for 10 minutes, put it in a 60°C oven for 1 hour, cool and demould, and then the polyurethane foam with high water absorption and high water retention is obt...

Embodiment 2

[0034] A kind of high water absorption, high water retention polyurethane foam, its preparation process is: Step 1: the preparation of prepolymer: take polyether polyol by mass parts, vacuum dehydration at 120 ℃ for 2 hours; cool down to 40-50 ℃; add diisocyanate, catalyst and surfactant, stir evenly at 75 ℃ for 2 hours to obtain a prepolymer, the isocyanate content of the prepolymer is 6wt%, cool to 30-40 ℃ for use; step 2: foam material Preparation: quickly add water-absorbent resin to the prepolymer prepared in step 1, stir at a high speed at a speed of 1600r / min, after the liquid material is evenly mixed, quickly pour the foaming agent into it and stir at a high speed, until the material turns white slightly After foaming, quickly pour it into the prepared mold to fill the mold with foam, let it stand for 15 minutes, then put it in a 60°C oven to mature for 1 hour, cool and demould, and then the polyurethane foam with high water absorption and high water retention is obtain...

Embodiment 3

[0037] A kind of high water absorption, high water retention polyurethane foam, its preparation process is: Step 1: the preparation of prepolymer: take polyether polyol by mass parts, vacuum dehydration at 120 ℃ for 2 hours; cool down to 40-50 ℃; add diisocyanate, catalyst and surfactant, stir evenly at 80 ℃ for 2 hours to obtain a prepolymer, the isocyanate content of the prepolymer is 10wt%, cool to 30-40 ℃ for use; step 2: foam material Preparation: quickly add water-absorbent resin to the prepolymer prepared in step 1, stir at a high speed at a speed of 1600r / min, after the liquid material is evenly mixed, quickly pour the foaming agent into it and stir at a high speed, until the material turns white slightly After foaming, quickly pour it into the prepared mold to fill the mold with foam, let it stand for 20 minutes, put it in a 60°C oven for 2 hours, cool and demould, and then the polyurethane foam with high water absorption and high water retention is obtained.

[0038]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com