Bacteriostatic deodorant super absorbent resin and absorbent products of super absorbent resin

A technology of superabsorbent resin and absorbent layer, which is applied in the field of antibacterial and deodorizing superabsorbent resin and absorbent products using antibacterial and deodorizing superabsorbent resin, which can solve the problem of limited antibacterial effect, affecting antibacterial durability, and Poor salt performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

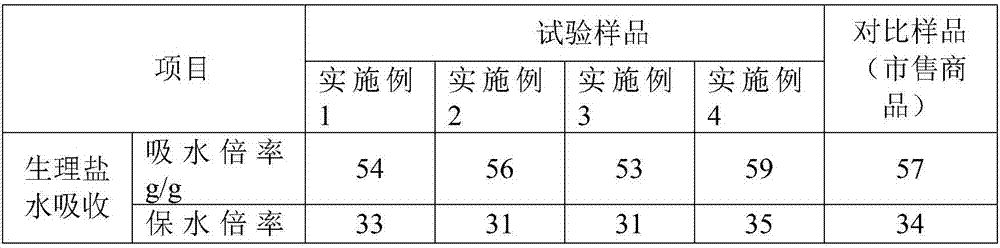

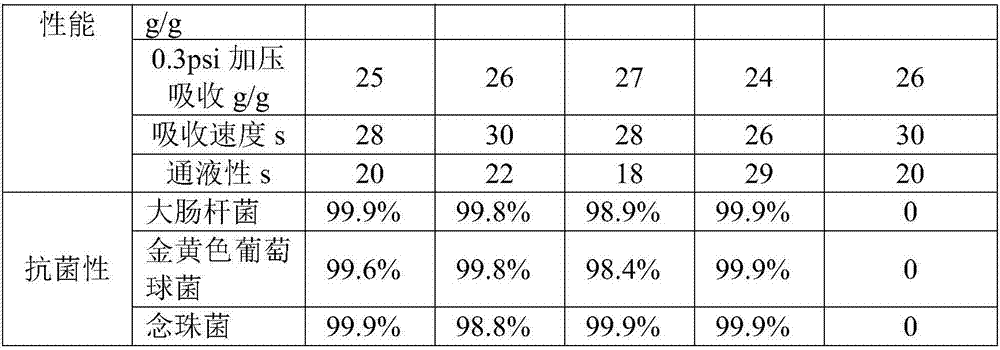

Examples

preparation example Construction

[0063] The method for preparing the antibacterial and deodorizing super absorbent resin of the present invention includes emulsion polymerization, reverse (reverse) suspension polymerization, bulk polymerization, and aqueous solution polymerization. The preparation method is preferably an aqueous polymerization method. The preparation process of the aqueous solution polymerization method includes the following steps: the super absorbent resin of the present invention is added to a mixed solution of acrylic acid / acrylic acid salt which is diluted with deionized water and neutralized by a basic compound and acrylic acid monomer solution. The initial crosslinking agent, initial dispersant and mixing uniformly, add 0-80% of the antibacterial agent and continue to stir evenly, heat up to 35℃-70℃, add the colloidal super absorbent resin polymerized by the initiator, the colloidal super absorbent resin The water-absorbent resin is sequentially granulated, dried, and surface treated wit...

Embodiment 1

[0076] Accurately weigh 200g acrylic acid, 70g sodium hydroxide, 210g deionized water, 0.2g N,N'-methylenebisacrylamide, 0.1g sodium bisulfite, 0.2g ammonium persulfate, 0.01g polyvinylpyrrolidone, and hydroxy 0.1g of methyl cellulose, 0.6g of composite crosslinking agent prepared in a 1:1 molar ratio of polyethylene glycol diglycidyl ether and polyethylene glycol 200, 10g of nano-silica, and 2g of antibacterial agent. Among them, the antibacterial agent of this embodiment is amino acid chelated nano silver, and 1g of antibacterial agent is added in the initial reaction crosslinking stage, and 1g of antibacterial agent is added in the surface crosslinking stage, using titanate coupling agent 0.2g, and then press The preparation of the steps:

[0077] 1) After mixing acrylic acid with deionized water, sodium hydroxide is added for neutralization.

[0078] 2) Add polyvinylpyrrolidone and amino acid chelated nano-silver to the reaction system, stir and mix and then ultrasonically sha...

Embodiment 2

[0085] Accurately weigh 200 g of acrylic acid, 80 g of sodium hydroxide, the degree of neutralization of the acrylic acid monomer solution in this example is 72%, deionized water 260 g, N,N'-methylenebisacrylamide 0.2 g, sodium bisulfite 0.1g, ammonium persulfate 0.2g, polyvinylpyrrolidone 8g, sodium pyrophosphate decahydrate 6g, polyethylene glycol diglycidyl ether, pentaerythritol in a 1:1 molar ratio of compound crosslinking agent 8g, nano titanium dioxide 15g, Antibacterial agent 20g. Among them, the antibacterial agent of this embodiment is composed of amino acid nano silver chelate and chitosan nano silver ion chelate in a ratio of 1:1 by mass, and 10g of antibacterial agent is added in the initial reaction crosslinking stage, and the surface is crossed. In the linking stage, 10 g of antibacterial agent was added, and 0.2 g of titanate coupling agent was used. Then, according to the steps of Example 1, a shell-core type antibacterial and deodorizing super absorbent resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com