Patents

Literature

31results about How to "Increase water absorption area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

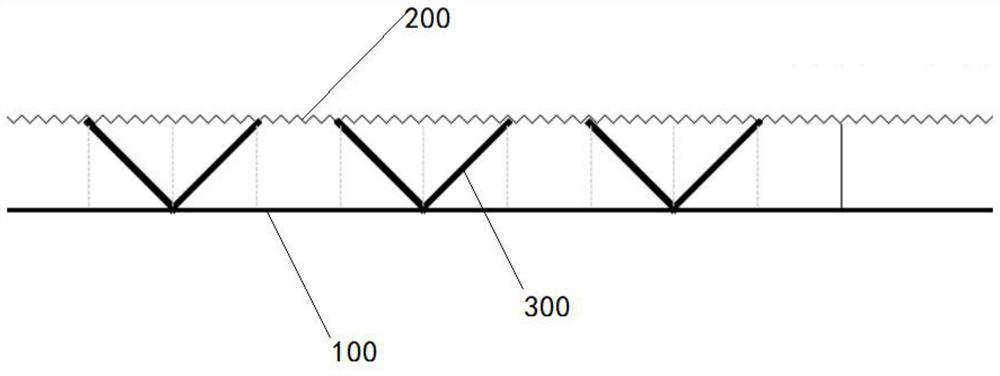

One-well multi-control method for offshore low-permeability reservoir thick oil layer exploitation

InactiveCN104818978ALow costReduce well construction costsFluid removalPrincipal stressDisplacement pressure

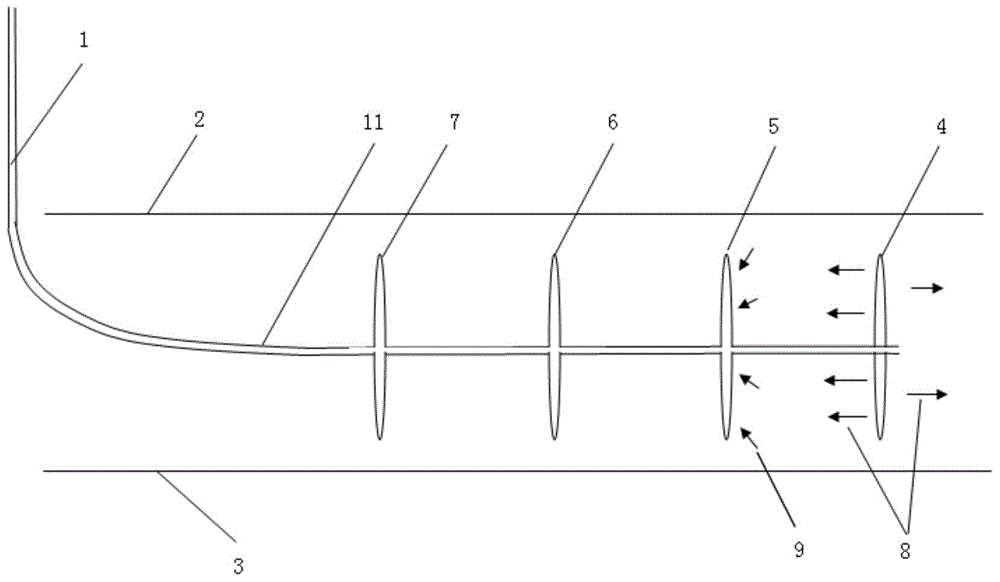

The invention relates to a one-well multi-control method for an offshore low-permeability reservoir single relatively thick oil layer. The method at least uses a long section horizontal well and a plurality of artificial fractures located between an oil layer top and an oil layer bottom, wherein the extension direction of a well section of the horizontal well is the maximum principal stress direction of a stratum; the artificial fracture surfaces are vertical to the horizontal well section and extend along the minor principal stress direction; injection and recovery are carried out simultaneously by implementing an offshore same-well injection and recovery technology in the horizontal well; injection water is firstly injected into the artificial fracture at the farthest end from the root of the horizontal well section; the injection water drives crude oil to enter the closest artificial fracture to enter a wellbore so as to be recovered; and when the far end artificial fractures are flooded by water in succession and water plugging is invalid, conversion is carried out in sequence from a far end to a close end. According to the method, the well building cost is reduced; the injection effect is improved; the distance between adjacent artificial fractures is adjusted, so that the small-well-distance water injection is realized, the displacement pressure gradient is favorably built, the start pressure difference is overcome, and the oil recovery effect is increased.

Owner:CHINA NAT OFFSHORE OIL CORP +1

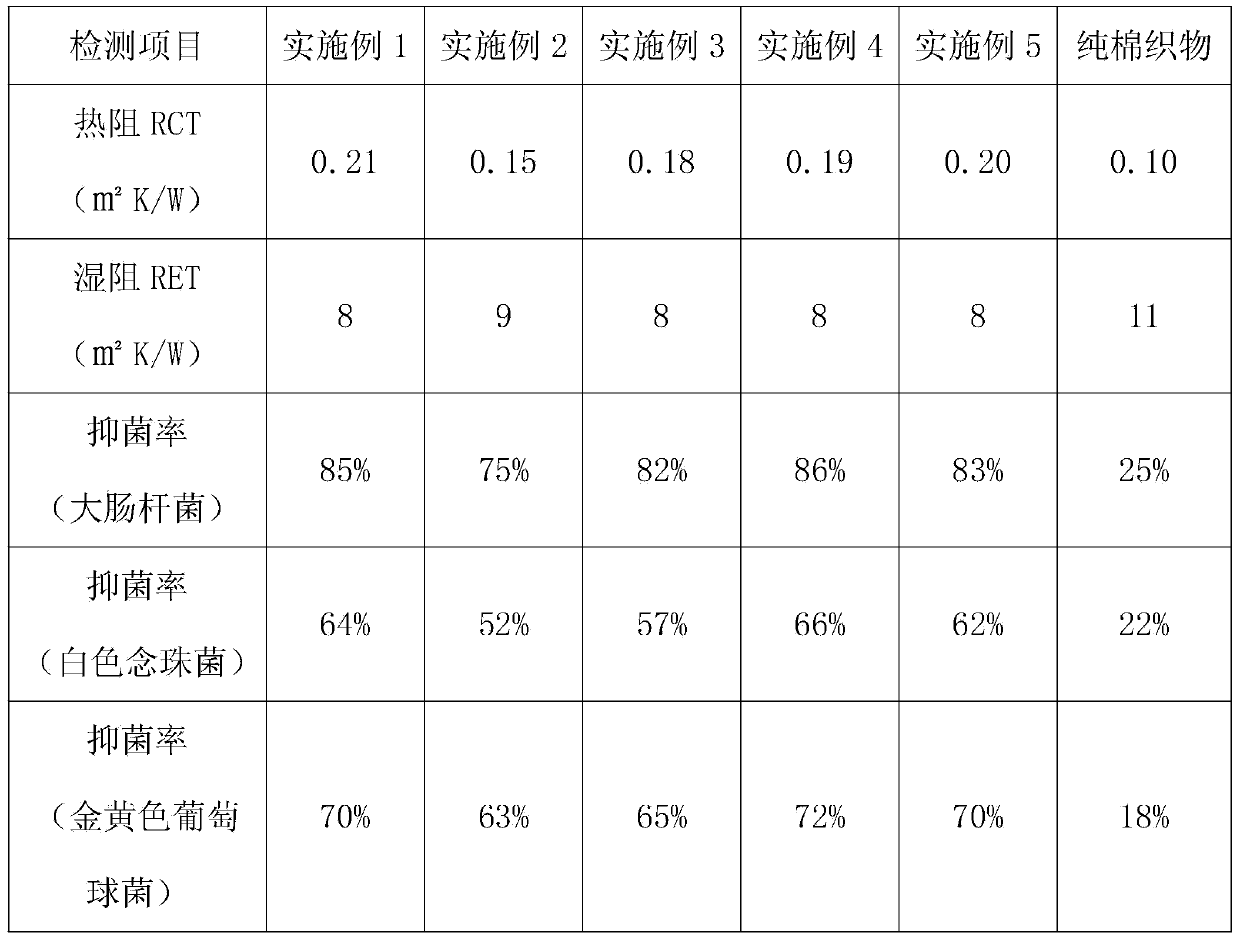

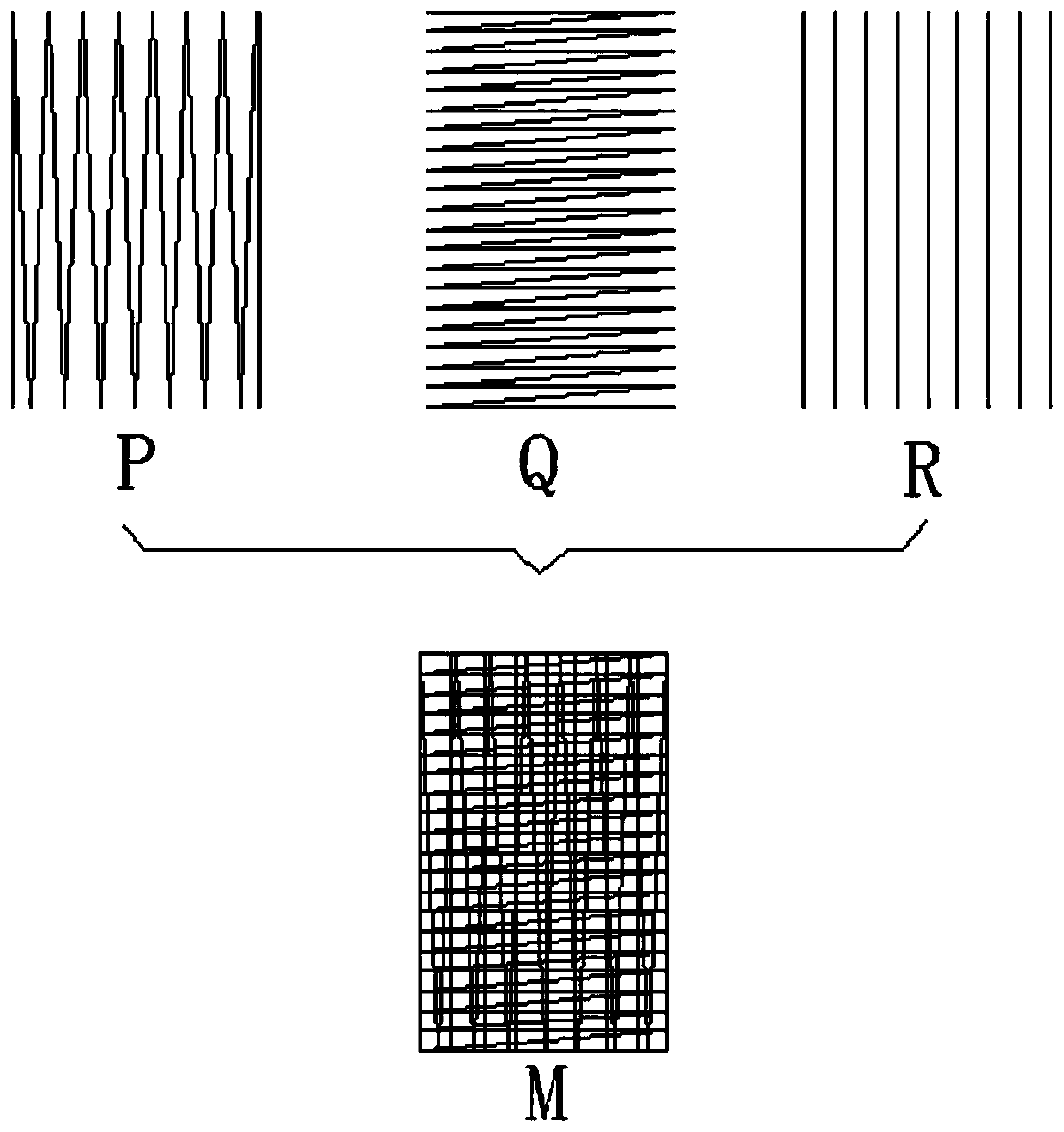

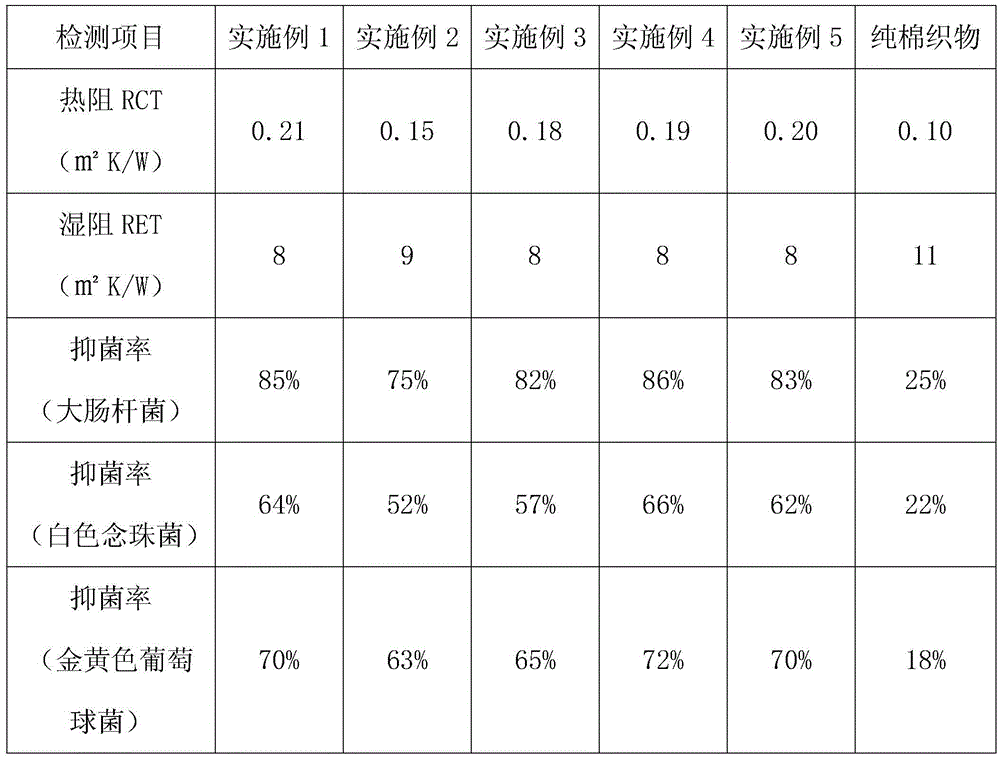

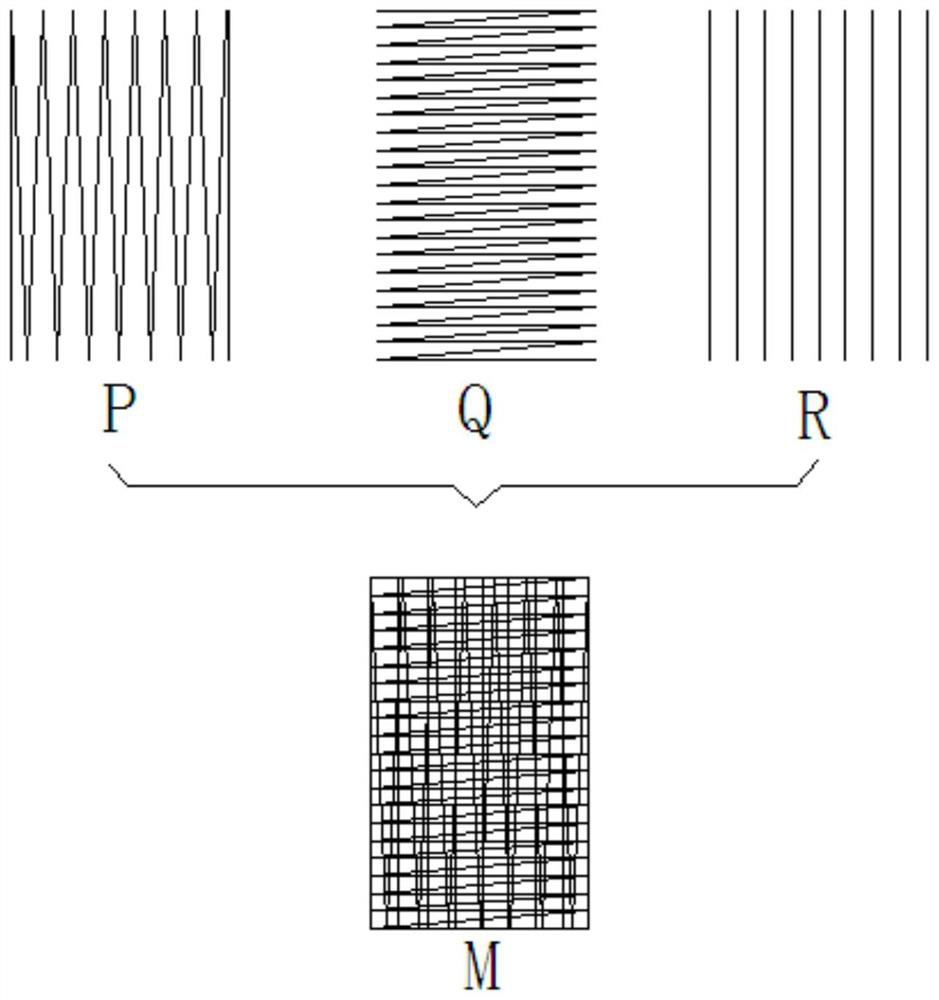

Novel antibacterial and aromatic bed sheet fabric and preparation method thereof

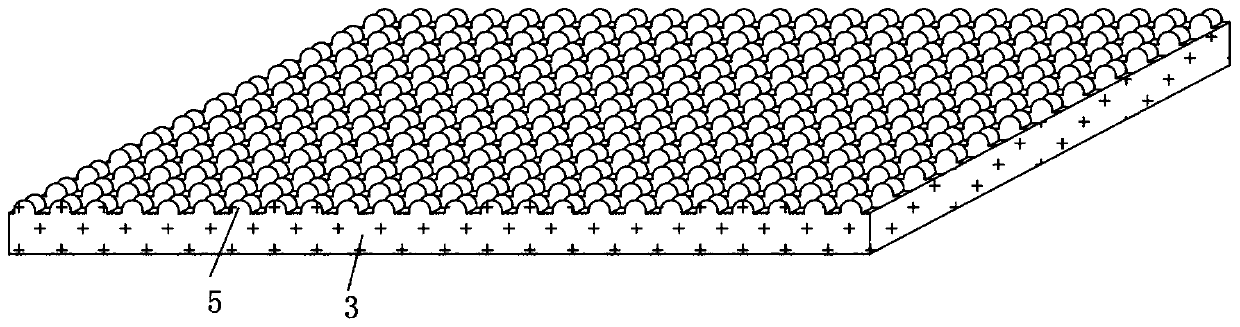

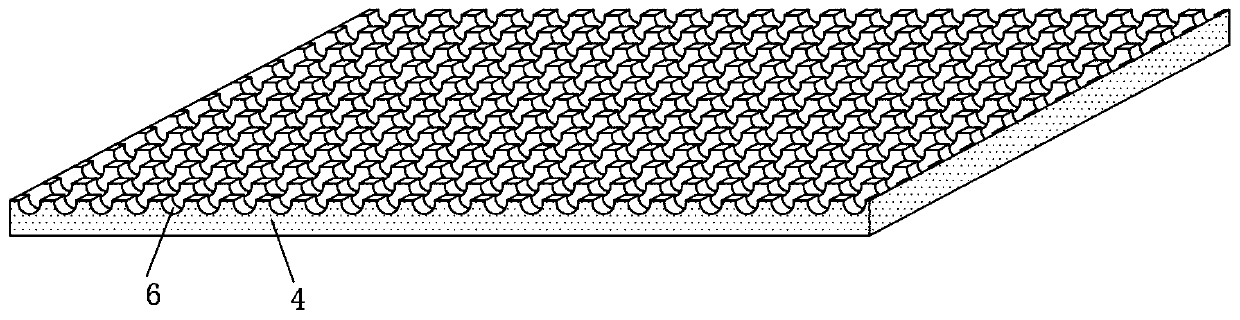

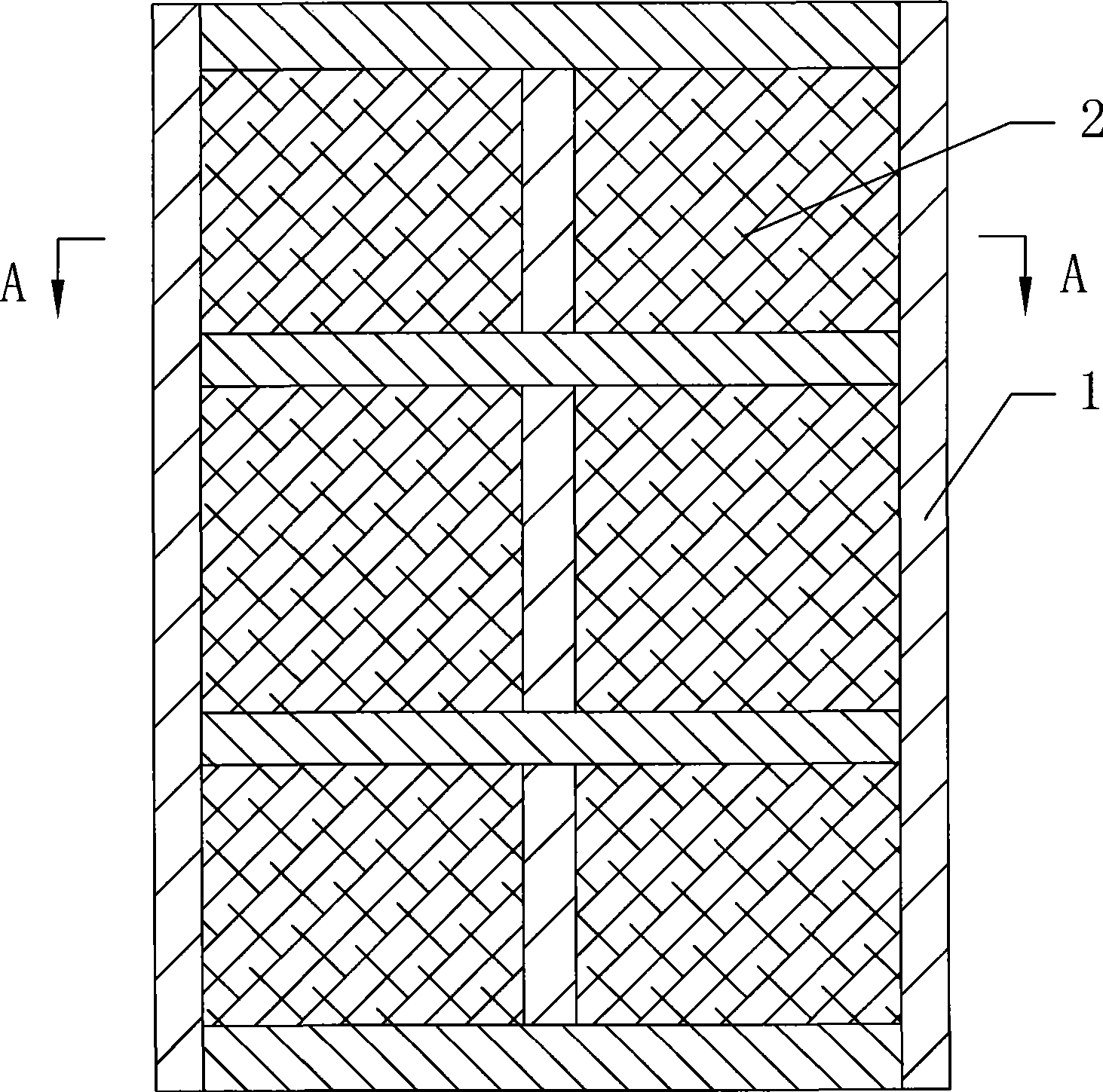

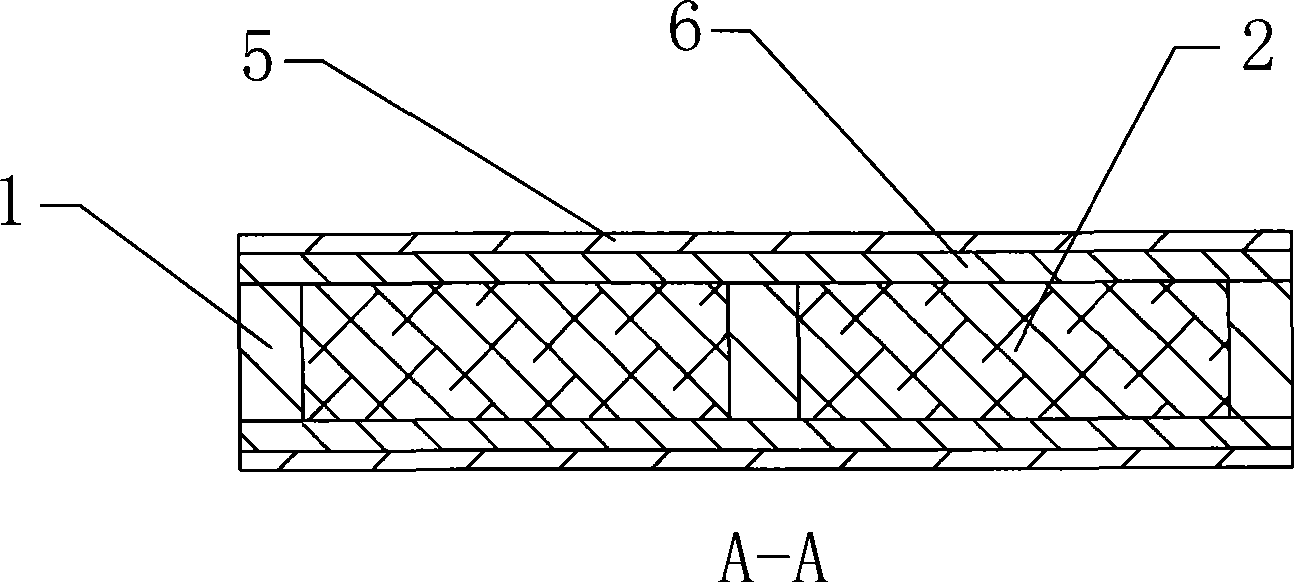

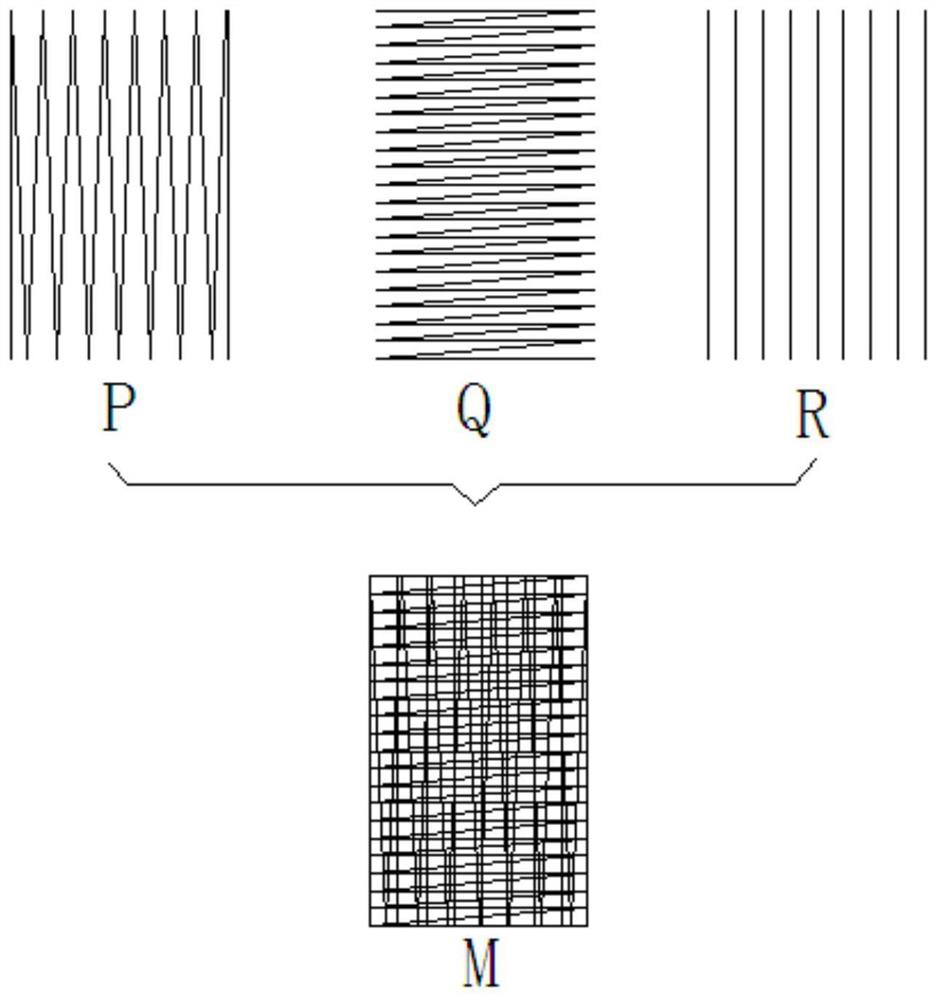

ActiveCN104213306AIncrease water absorption areaStrengthen antibacterial and deodorizing effectSucessive textile treatmentsWoven fabricsPolyesterFiber

The invention discloses a novel antibacterial and aromatic bed sheet fabric and a preparation method thereof. The novel antibacterial and aromatic bed sheet fabric is prepared by weaving blended yarns of polyester high F yarns, bamboo fibers and copper ammonia fibers in the preparing process, so that the fabric has excellent deodorization and bacteriostasis performance, heat insulation property and antistatic property; due to the adoption of a microcapsule aroma finishing agent, aromatic microcapsules are uniformly distributed on a fiber surface layer of the fabric and an aromatic contained in the polymer capsules can be slowly released, so that fragrance duration of the fibers is greatly prolonged.

Owner:浙江新千禧纺织股份有限公司

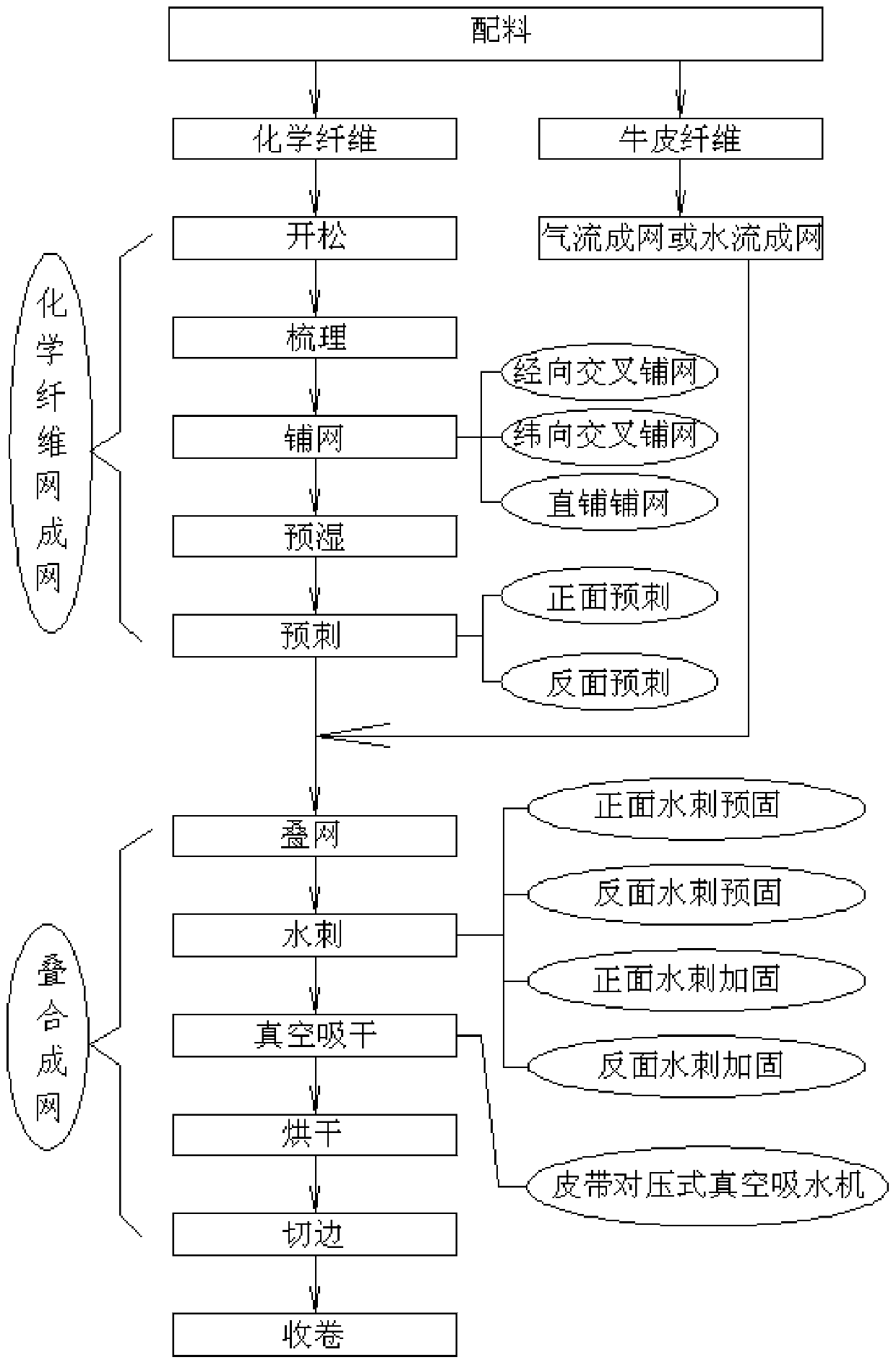

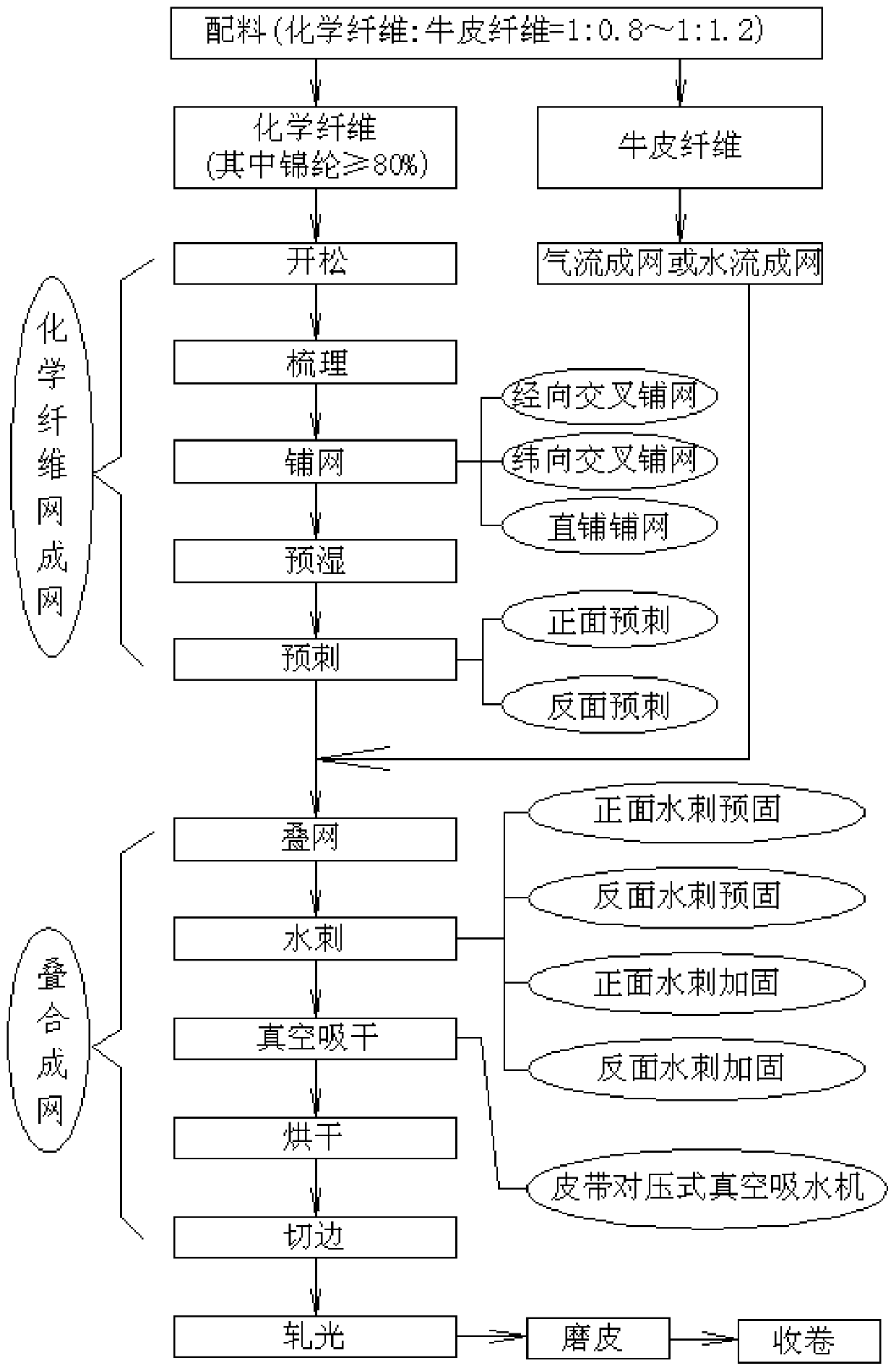

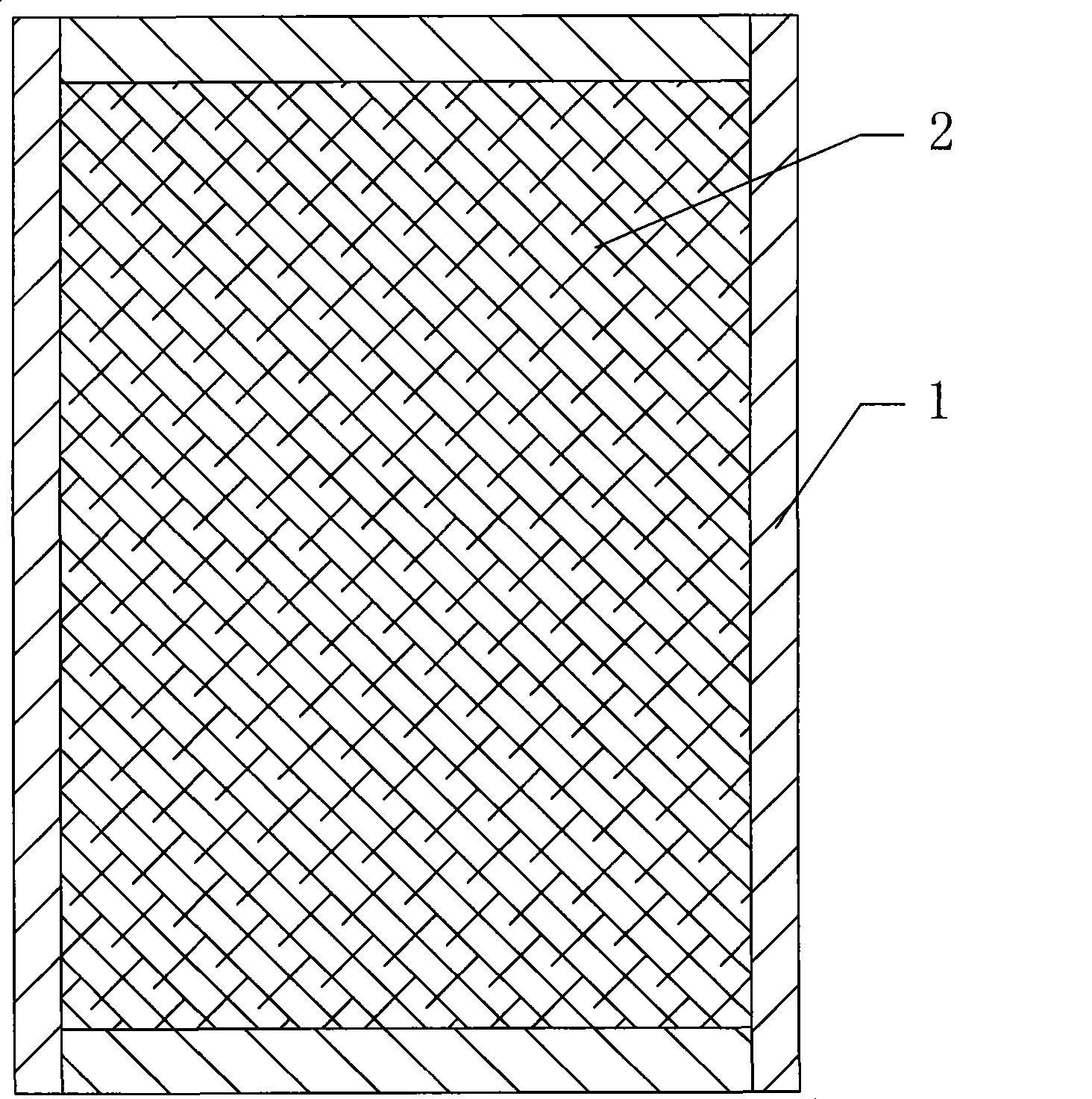

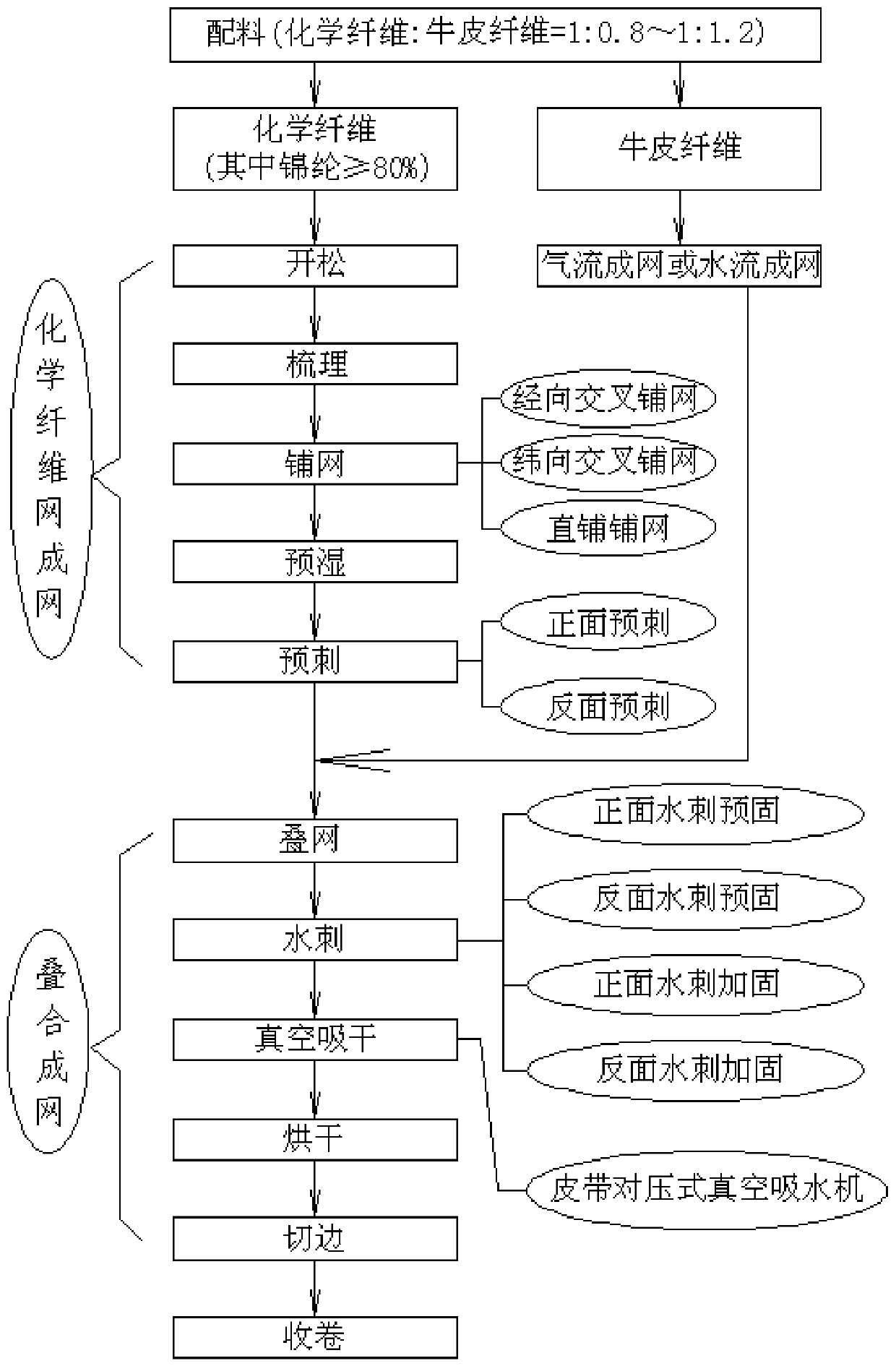

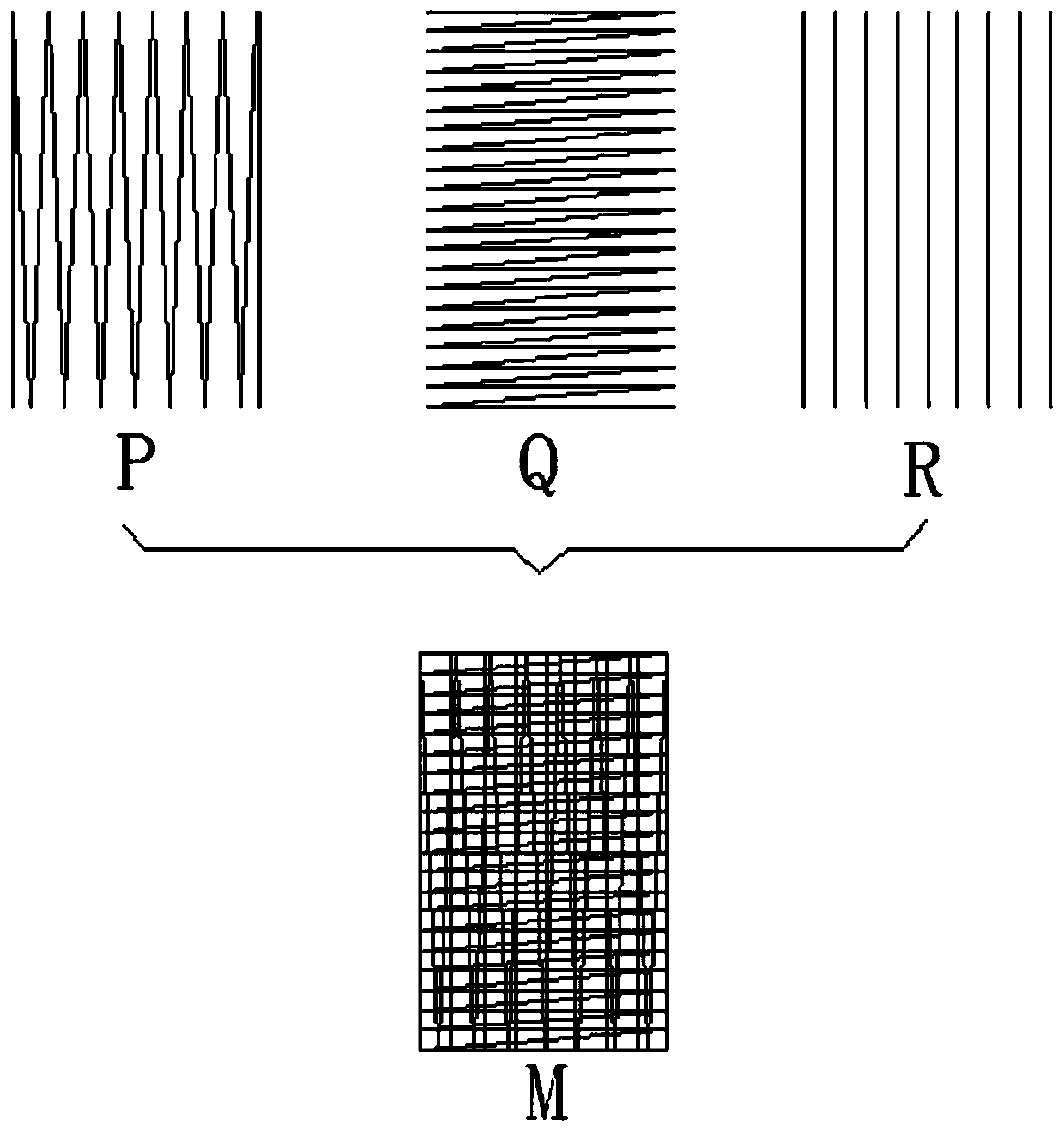

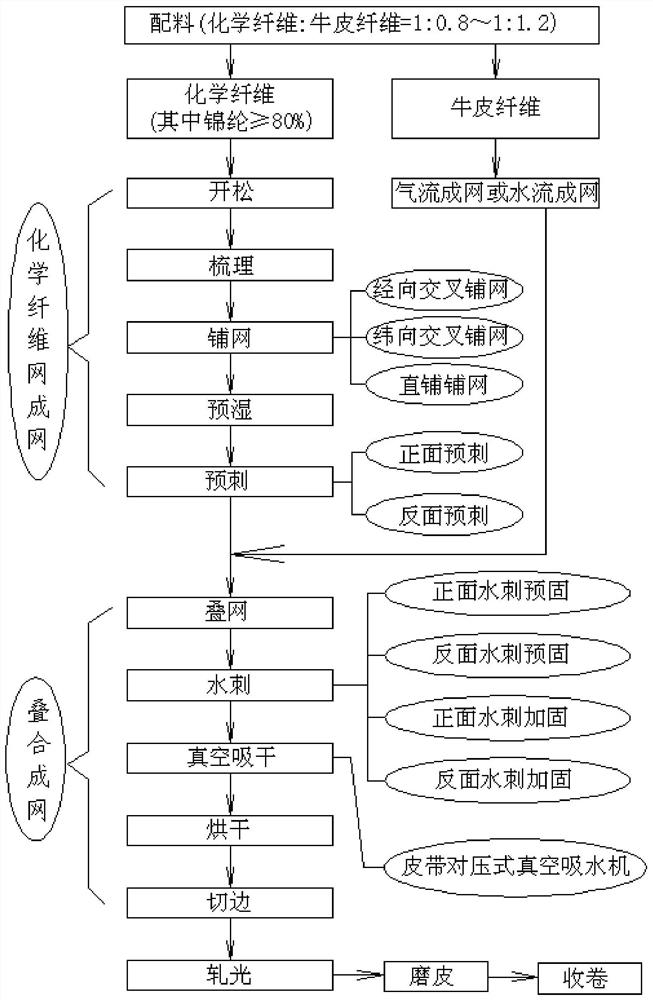

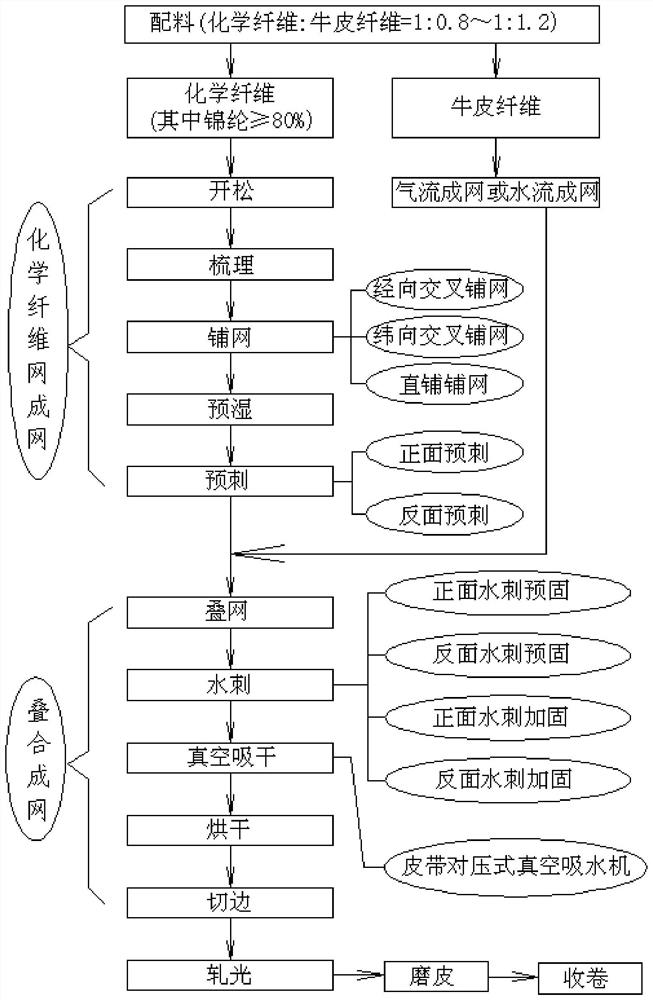

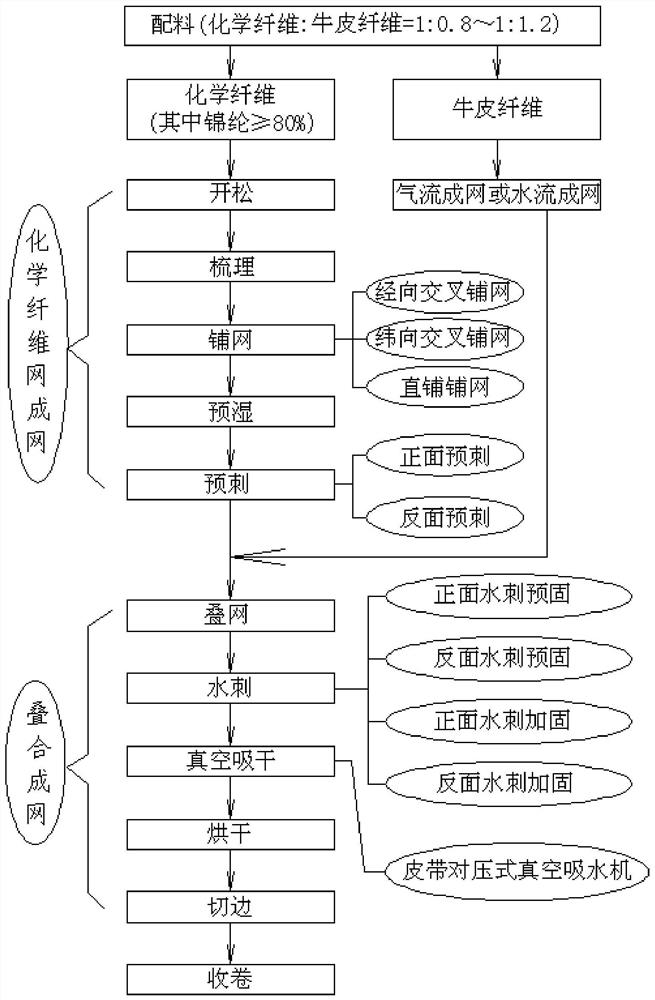

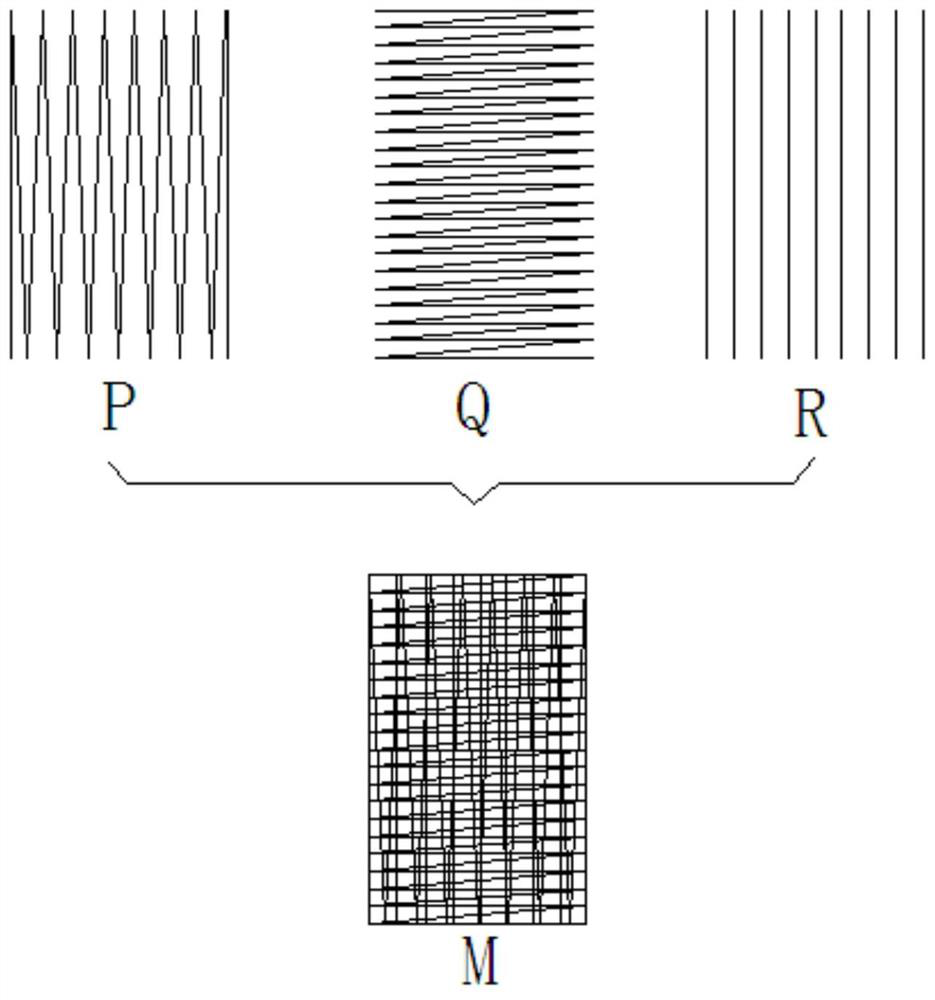

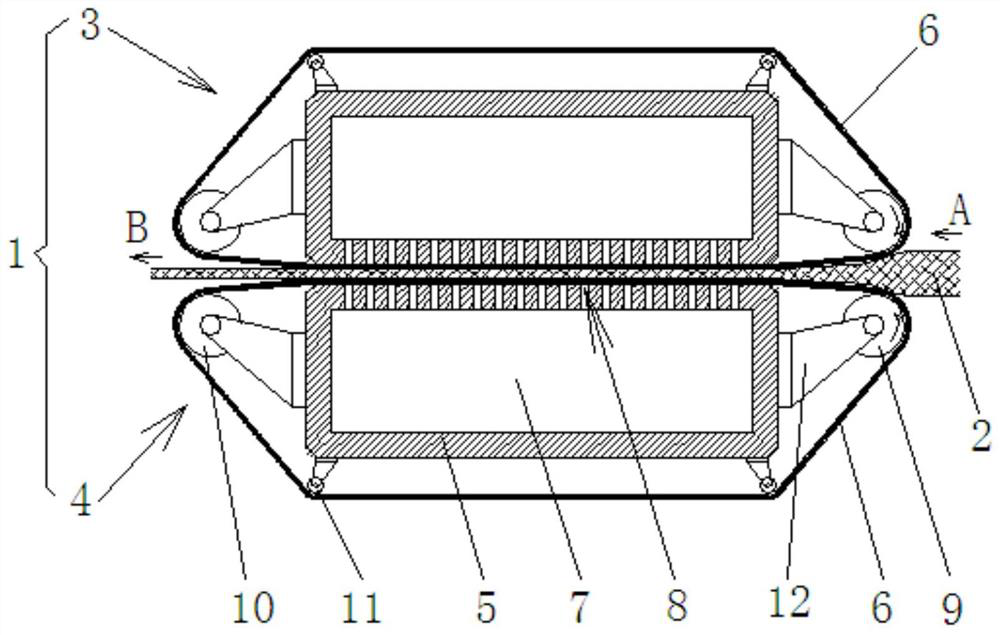

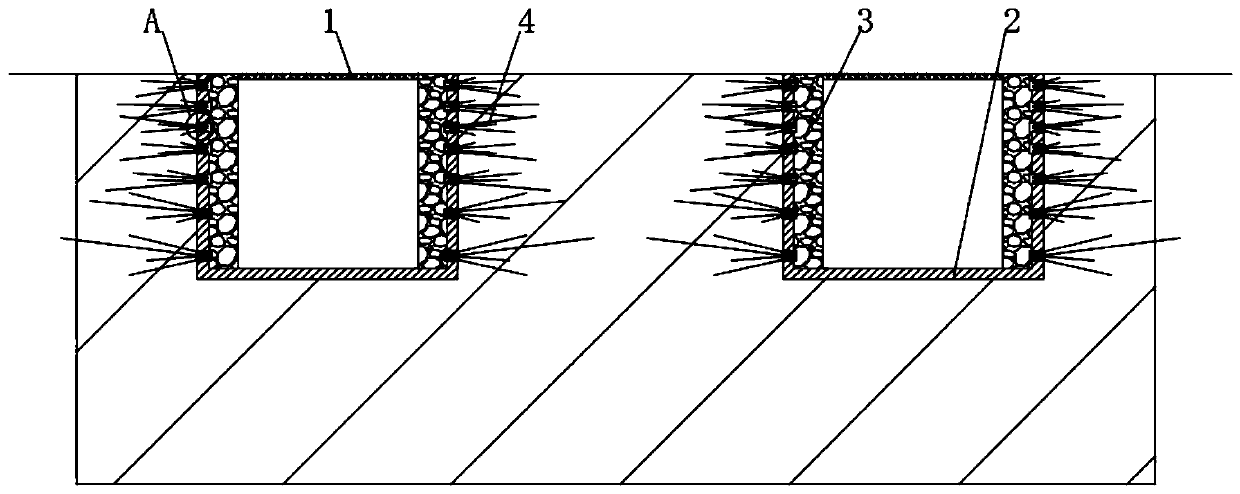

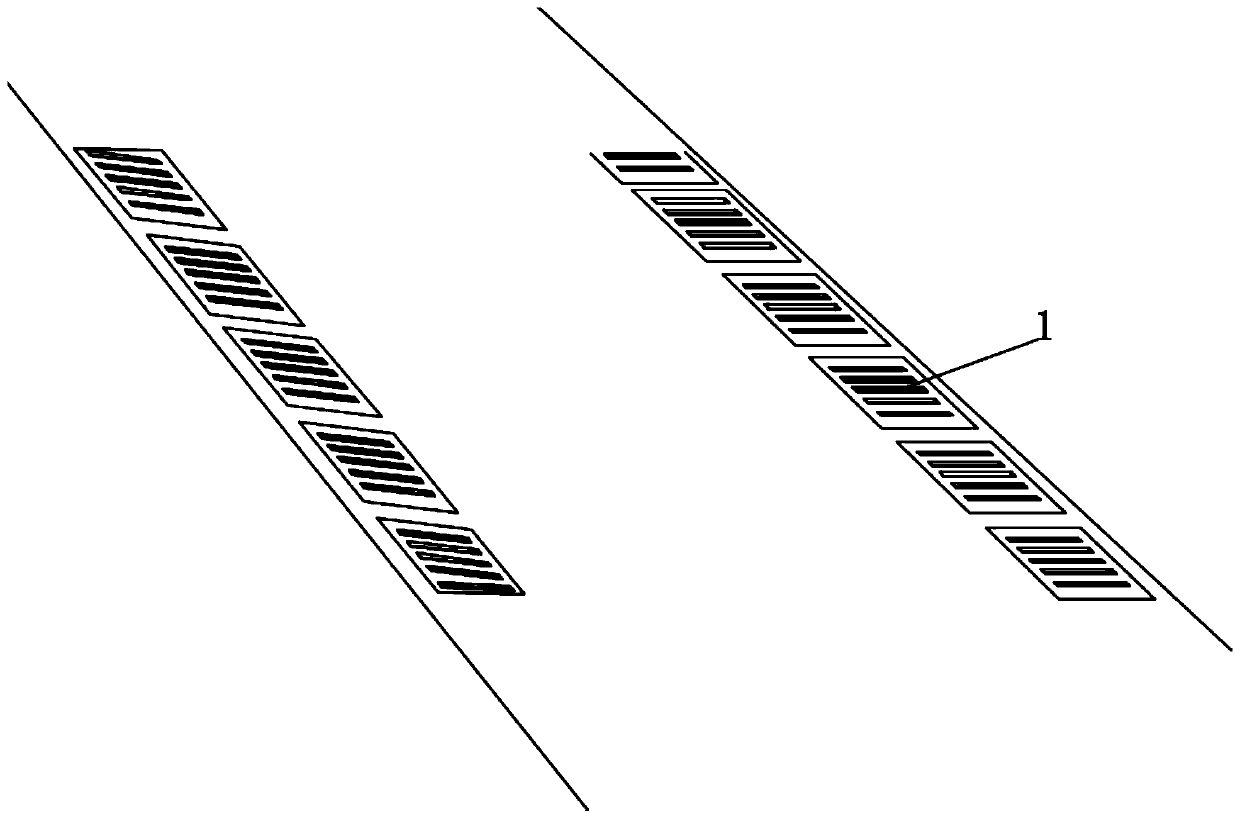

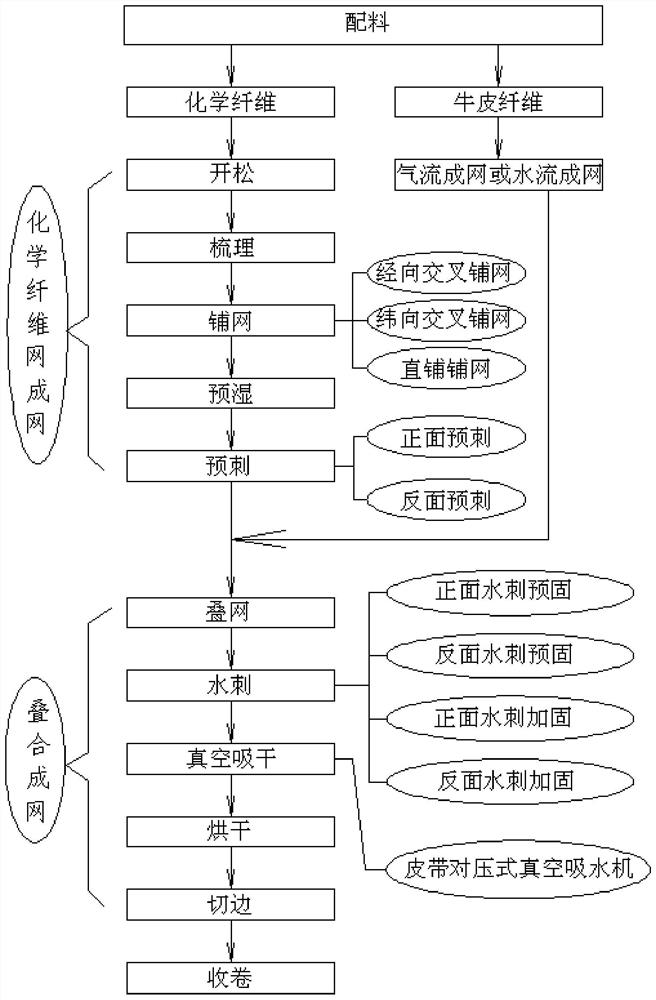

Preparation process of fully-penetrated cow fiber leather base cloth

ActiveCN110258023ASolve the disadvantages that are not easy to penetrateHigh tensile strengthDrying solid materials without heatNon-woven fabricsFiberManufacturing technology

The invention relates to the technical field of leather manufacturing, and discloses a preparation process of fully-penetrated cow fiber leather base cloth. The preparation process includes a batching process, a chemical fiber net forming process, a cow leather fiber net forming process, and a process of laminating the chemical fiber net and the cow leather fiber net into a net, wherein the batching process includes taking chemical fibers and cow leather fibers as raw materials for preparing fully-penetrated cow fiber leather base cloth, and batching according to a proportion; the chemical fiber net forming process sequentially includes the working procedures of opening, carding, net laying, pre-wetting and pre-penetrating: in the cow leather fiber net forming process, making cow leather fiber raw materials into a cow leather fiber net by adopting airflow net forming or water flow net forming; and the process for laminating the chemical fiber net and the cow leather fiber net into a net sequentially includes the working procedures of laminating the net, spunlacing, vacuum suction and drying, and the net laying working procedure includes warp cross laying and weft cross laying. The preparation process improves the physical properties of the cow fiber leather base cloth and reduces the production cost.

Owner:JIANGYIN JUNHUA TEXTILE TECH

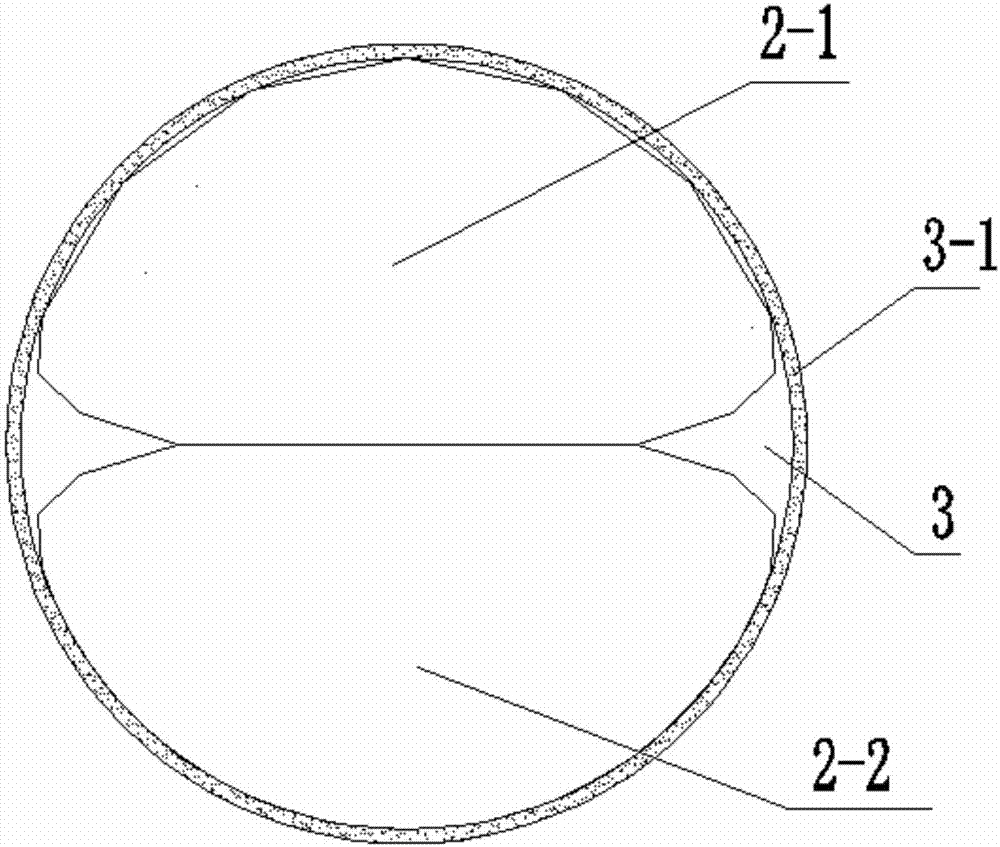

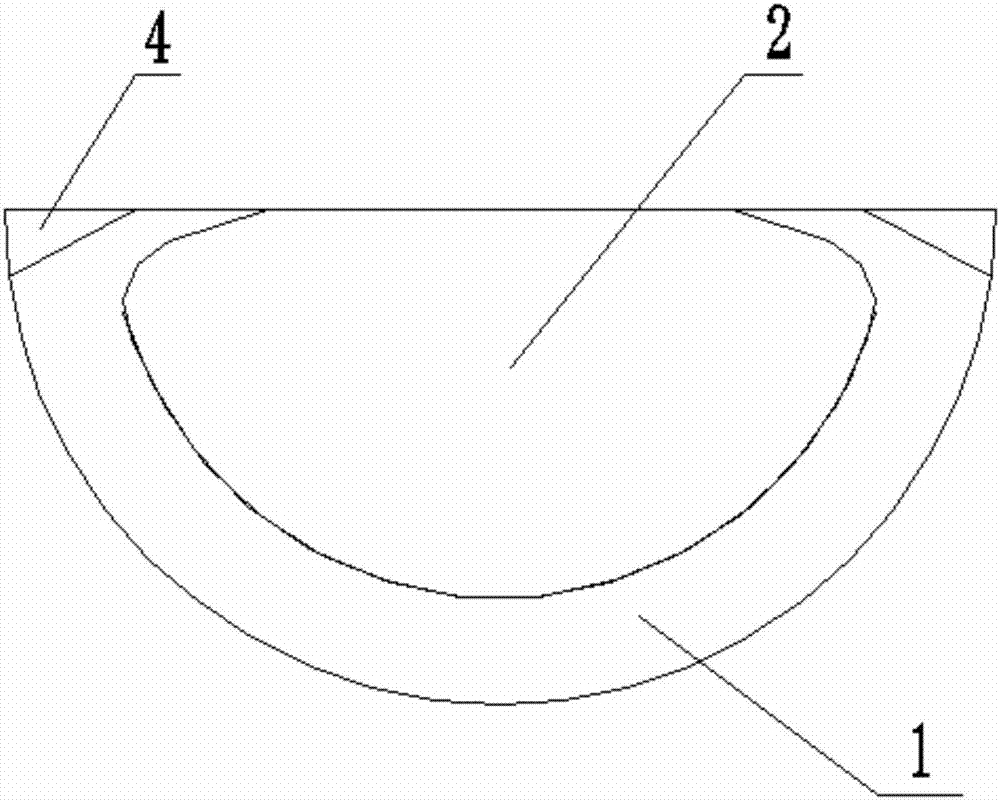

Anti-spill breast pad and its manufacturing method

InactiveCN107440838AHigh water absorption characteristicsPrevent random walkingBreast bandagesBrassieresWater layerMaterials science

The invention discloses an anti-spill breast pad. A water absorbing layer comprises a water absorbing material and a coating layer located at an upper surface or a lower surface or upper and lower surfaces of the water absorbing material; the water absorbing material is in the shape of a shell and comprises an upper shell and a lower shell; the coating layer is a circular flaky structure and covers on the water absorbing material; the coating layer and the water absorbing layer are commonly formed to be a circular water absorbing layer; a water permeable layer, a waterproof layer and the water absorbing layer can be folded up along with a folding trace; under a folding state, the overlapped water permeable layers at both ends of the folding trace are jointed so that the breast pad is arched. The invention further discloses a manufacturing method of the anti-spill breast pad, which includes steps of manufacturing the water absorbing layer, and covering one layer or several layers of water permeable materials at the upper surface or the lower surface or upper and lower surfaces of the shell type water absorbing material as the coating layer; covering the water permeable layer and the waterproof layer at both sides of the water absorbing layer; crimping to form a jointing side; folding up; jointing the overlapped water permeable layers at both ends of the folding trace. The manufactured anti-spill breast pad can prevent the water absorbing material from leaking from the edge of the breast pad; meanwhile, the water absorbing property is enhanced.

Owner:CHANGZHOU DAILYS CARE PROD

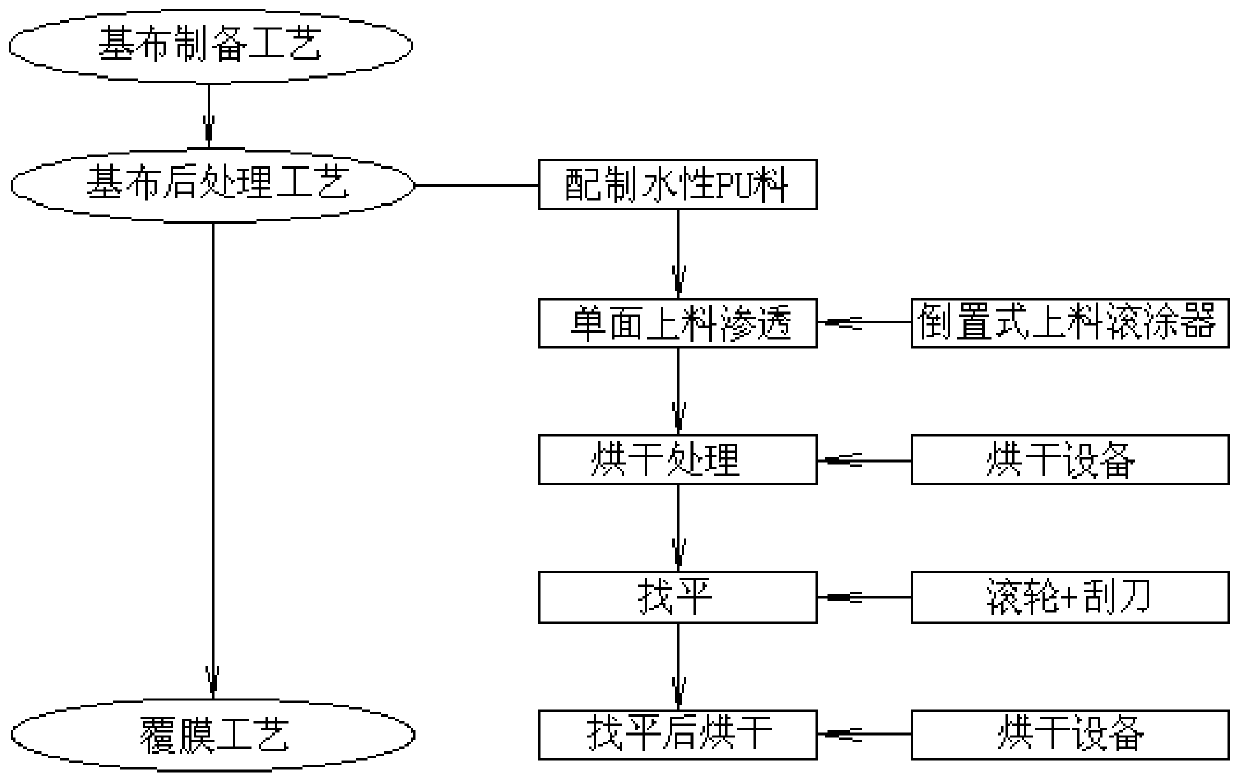

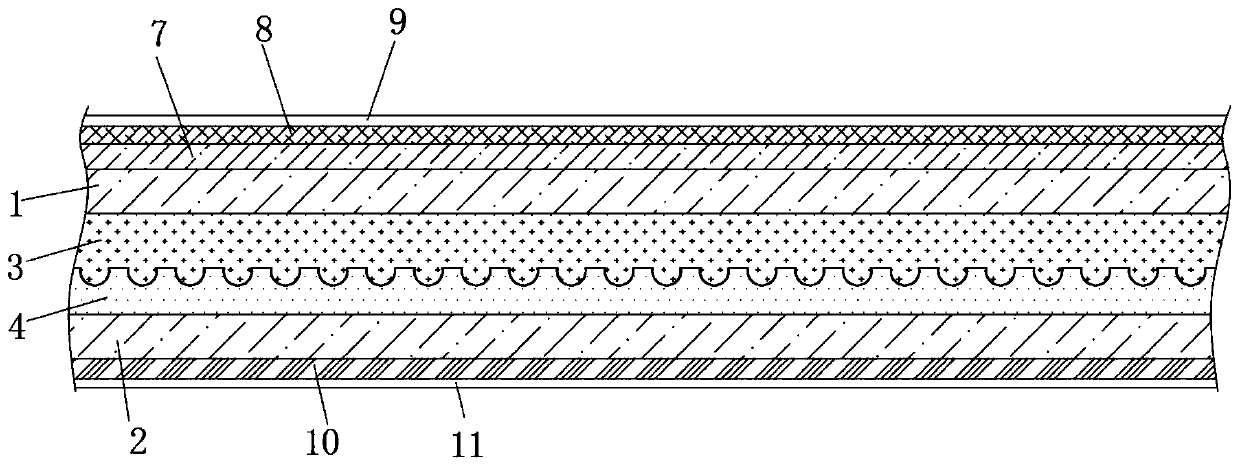

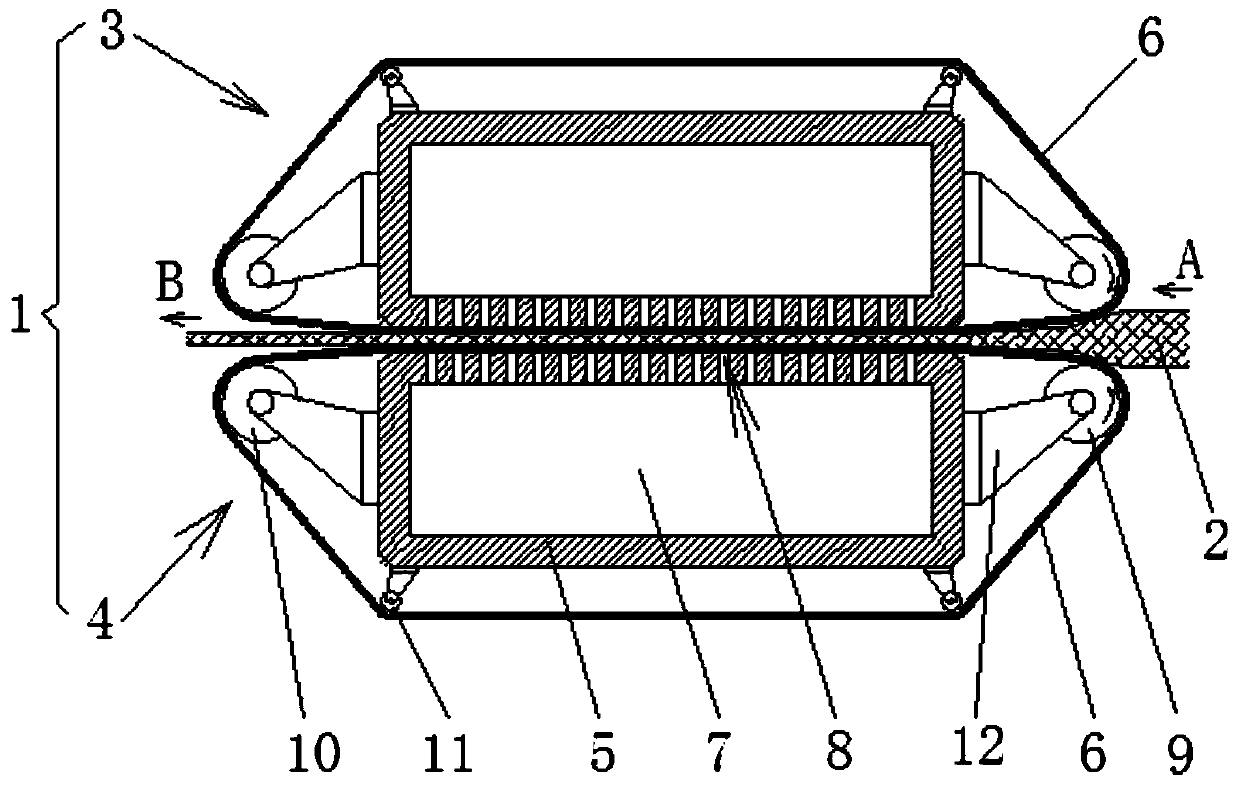

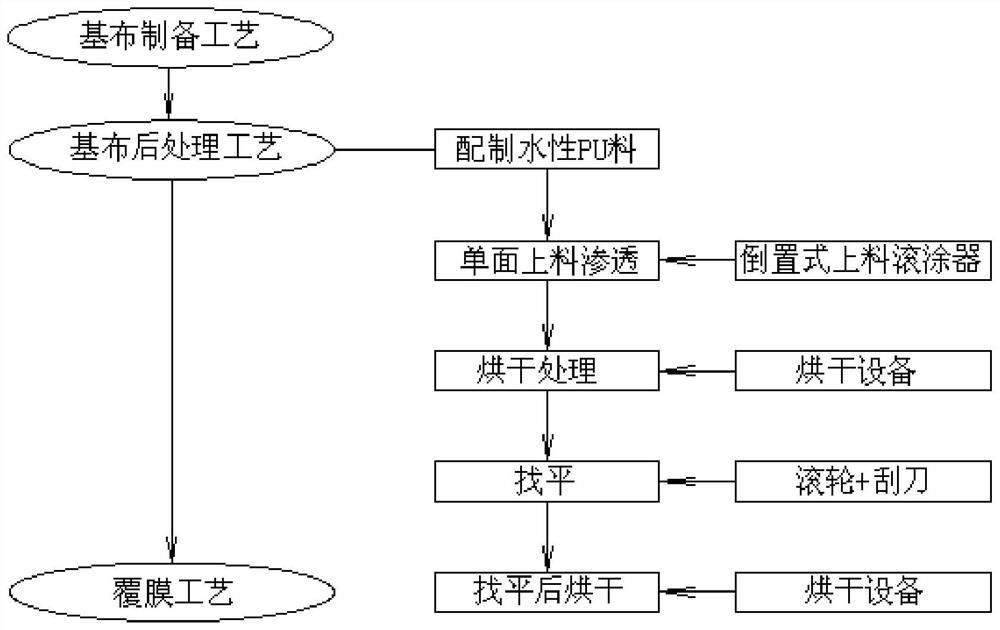

Preparation process of fully water-based cattle hide fiber leather with high physical properties

ActiveCN110331517AFeel goodGood physical propertiesLamination ancillary operationsLaminationWater basedFiber

The invention relates to the technical field of leather manufacture and discloses a preparation process of fully water-based cattle hide fiber leather with high physical properties. The preparation process sequentially comprises a base cloth preparation process, a base cloth aftertreatment process and a film covering process, wherein the base cloth preparation process comprises process steps as follows: chemical fiber and cattle hide fiber are taken as raw materials respectively, the chemical fiber is lapped and then spunlaced in advance into a chemical fiber net, a cattle hide fiber net is prepared from the cattle hide fiber with an air laying or waterflow net formation method, then, the chemical fiber net and the cattle hide fiber net are stacked for spunlacing curing, vacuum suction anddrying, and cattle hide fiber leather base cloth is prepared; the base cloth aftertreatment process comprises process steps as follows: single-sided loading, seepage and drying of a water-based PU material are performed on a PU film binding surface of the cattle hide fiber leather base cloth, wherein the single-sided seepage depth of the water-based PU material in the base cloth aftertreatment process is 1 / 3-2 / 3 of the thickness of the cattle hide fiber leather base cloth. The physical properties of the fully water-based cattle hide fiber leather are improved, and the production cost is reduced.

Owner:JIANGYIN JUNHUA TEXTILE TECH

Nano-wet wipe with rain, fog, and water scale proof functions

PendingCN110450474AIncrease water absorption areaImprove water absorption efficiencyOther chemical processesSynthetic resin layered productsAbsorption capacityWoven fabric

The invention relates to a nano-wet wipe with rain, fog, and water scale proof functions. The nano-wet wipe includes an inner non-woven fabric substrate and an outer non-woven fabric substrate. A water barrier film is disposed at the upper end of the inner non-woven fabric substrate in the wet wipe, so that the upper and lower end faces of the wet wipe becomes two independently usable individuals,when water spots on glass need to be wiped, the wet wipe end face with the outer non-woven fabric substrate is employed to wipe the glass, the cooperative use of inner absorbent cotton and outer absorbent cotton and the effect of the absorbent cotton are conducive to improving the water absorption capacity of the outer non-woven fabric substrate, thus realizing rapid water absorption of the wet wipe, at the end of wiping, the other end face of the wet wipe is utilized to wipe the glass, after contact wiping of an efficient rain and fog proof nano-coating on the other end face of the wet wipeto the glass, the surface tension of water molecules is changed, and a very thin water film is formed on the glass surface, thereby realizing the rainwater and fog proof functions of the glass, afterwiping, rainwater does not stay on the glass surface easily, so that dust cannot be adhered easily, and water scale can be hardly produced.

Owner:深圳伊尚纳米科技有限公司

Magnesite composite board and method for producing the same

InactiveCN101413320AReduce moisture retentionInhibit reversionBuilding componentsMagnesiteWater vapor

The invention relates to a composite magnesite board and a production method. The composite magnesite board comprises a frame and magnesite boards adhered to both sides of the frame, wherein the inside of a cavity enclosed by the frame and the magnesite boards is fully clamped with a foam board, and contact surfaces of the foam board and the magnesite boards are adhered to each other. According to the proposal, the inside of a hollow structure of the frame is filled with the foam board which is loose and porous and can absorb water vapor in the air to the ambient environment, thereby effectively inhibiting the recurrent halogen and the recurrent milk; in addition, no hollow structure exists between two layers of the magnesite boards after the foam board is filled, so the strength of the boards is increased.

Owner:王建平

Preparation process of high-physical-property cowhide base cloth

ActiveCN110258022ASolve the disadvantages that are not easy to penetrateHigh tensile strengthDrying solid materials without heatNon-woven fabricsPolyesterWater flow

The invention relates to the field of leather and discloses a preparation process of high-physical-property cowhide base cloth. The preparation process includes: blending, forming a chemical fiber net, forming a cowhide fiber net, and superimposing the chemical fiber net and the cowhide fiber net to form a net; the blending process refers to blending chemical fiber and cowhide fiber according to a weight ratio of 1:0.8-1:1.2, the process of forming the chemical fiber net sequentially includes opening, combing, lapping, pre-wetting, and pre-needling, the process of forming the cowhide fiber net refers to adopting airflow net forming or water flow net forming to make the cowhide fiber into the cowhide fiber net, the process of superimposing the chemical fiber net and the cowhide fiber net to form the net sequentially includes superimposing the nets, spunlacing, vacuum sucking, and drying, the chemical fiber is fiber formed by mixing polyester fiber and aramid fiber, and the aramid fiber accounts for higher than 80% of total weight of the mixed fiber. By the preparation process, physical performance of the cowhide base cloth is improved, and production cost is lowered.

Owner:JIANGYIN JUNHUA TEXTILE TECH

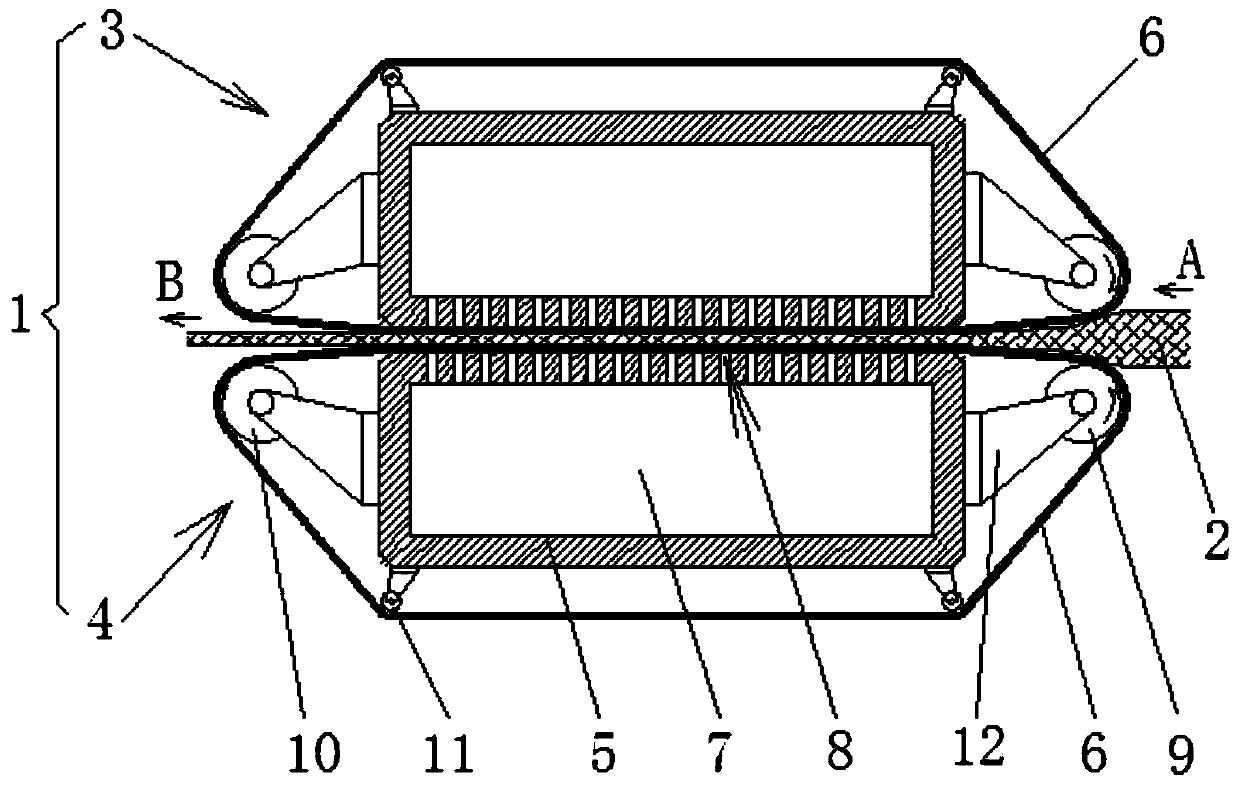

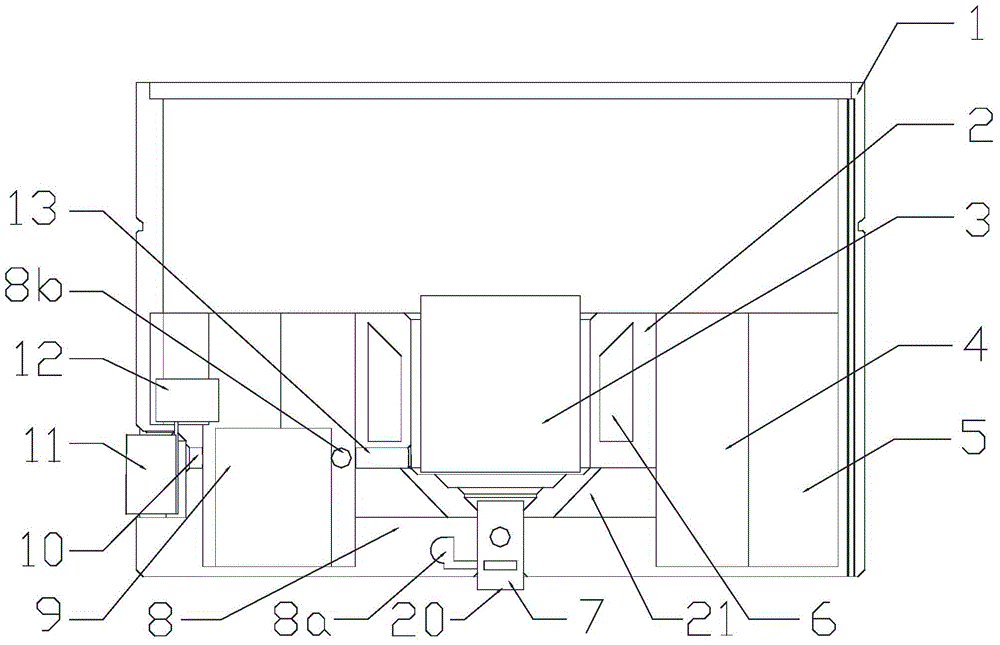

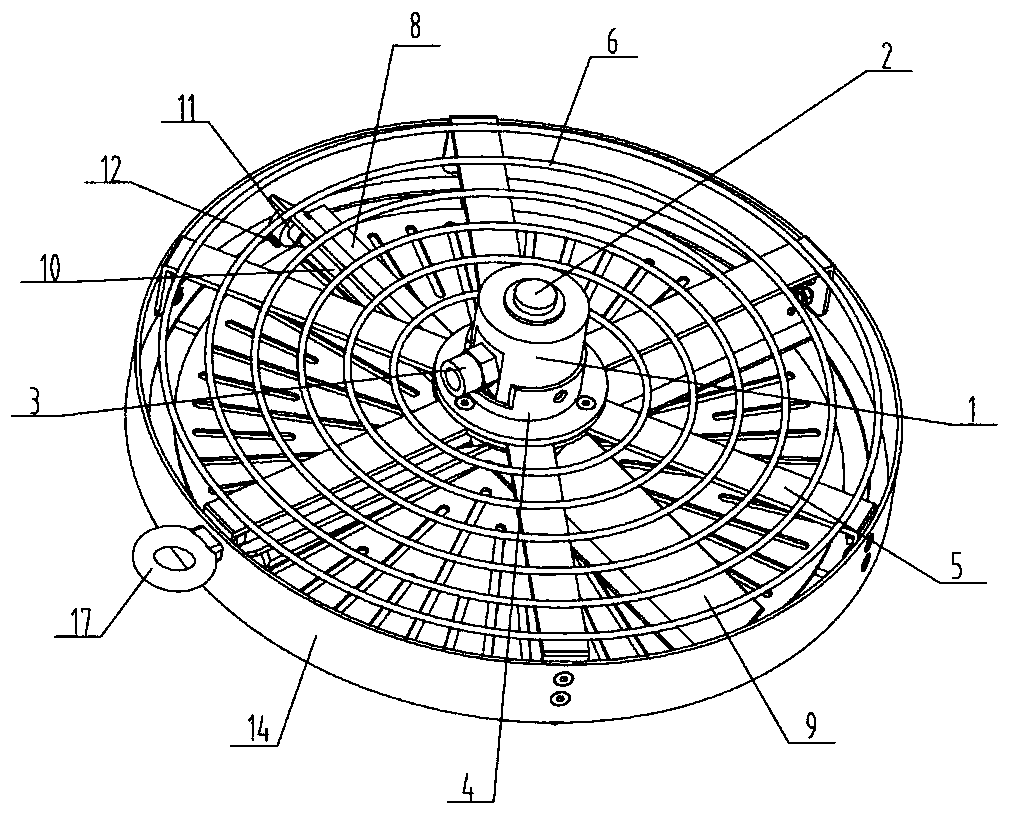

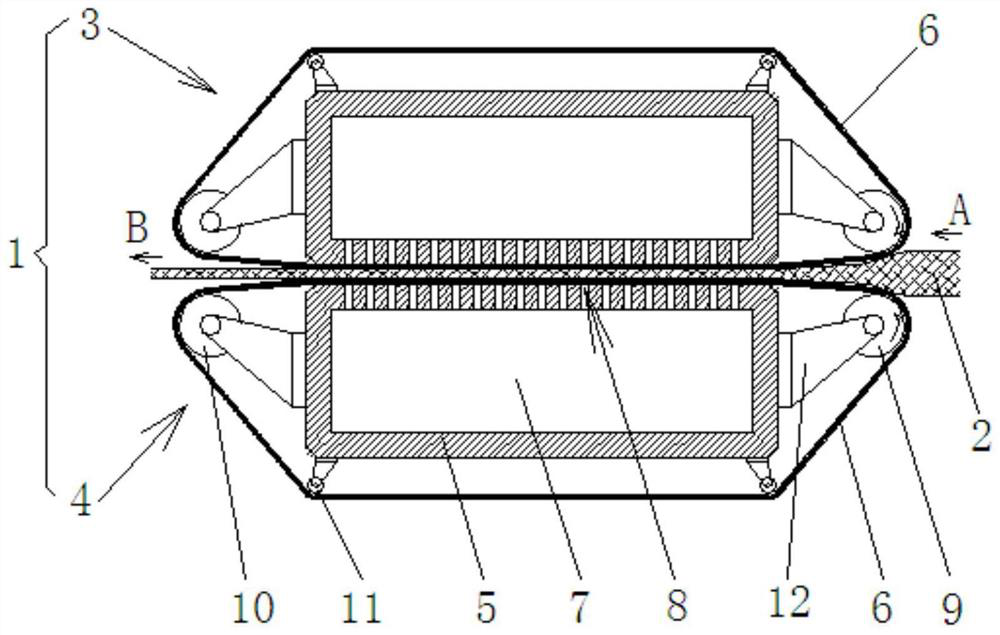

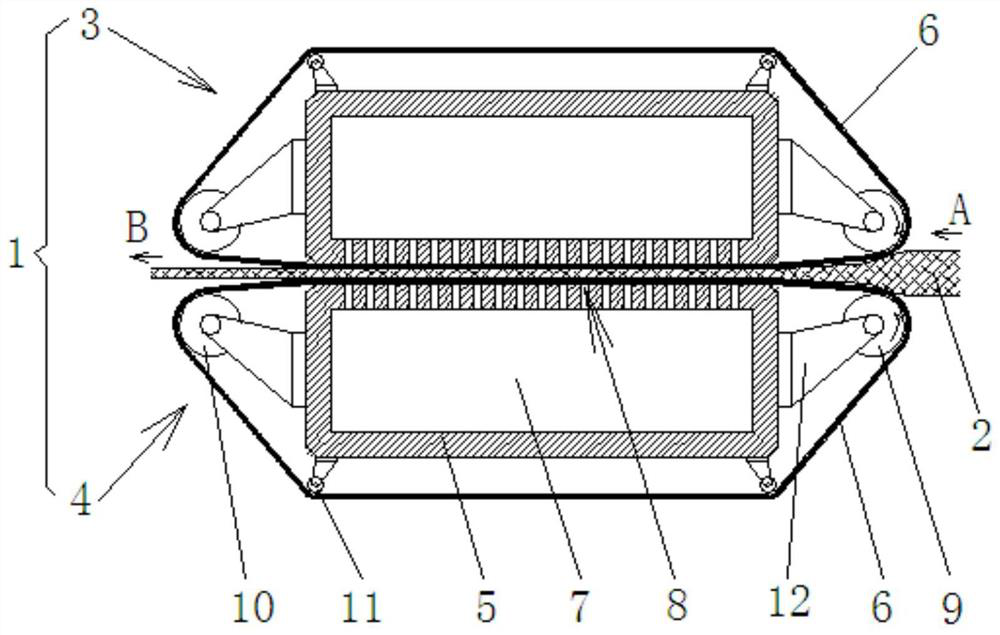

Omnibearing cleaning and filtering robot for swimming pool

ActiveCN104790696AReduce costs and power consumptionIncrease water absorption areaGymnasiumSwimming poolsEnergy consumptionWater quality

The invention relates to an automated water quality cleaning and filtering technology for swimming pools, and discloses an omnibearing cleaning and filtering robot for a swimming pool. The cleaning and filtering efficiency of the robot is improved, and the energy consumption of the robot is lowered by optimizing the structure. According to the technical scheme, the omnibearing cleaning and filtering robot for the swimming pool comprises a shell, an electric water pump, a control module, a battery, a filterer, a multi-channel rotating switch, a water storage bin, an air storage tank, a solenoid valve, a water outlet, a steering blade, a steering engine, a water channel, a water surface water inlet and a water bottom water inlet. According to the omnibearing cleaning and filtering robot, the water volume of the water storage bin is controlled through compressed air in the air storage tank, and the robot can float on the water surface of the swimming pool or submerged into water to conduct water quality cleaning and filtering; the battery is adopted to supply power to the robot, cable connection is omitted, and the robot moves flexibly and freely; when the robot is on the water surface, the robot can conduct operation through a remote command or conduct operation according to internal programming.

Owner:苏州市振渭城镇建设发展有限公司

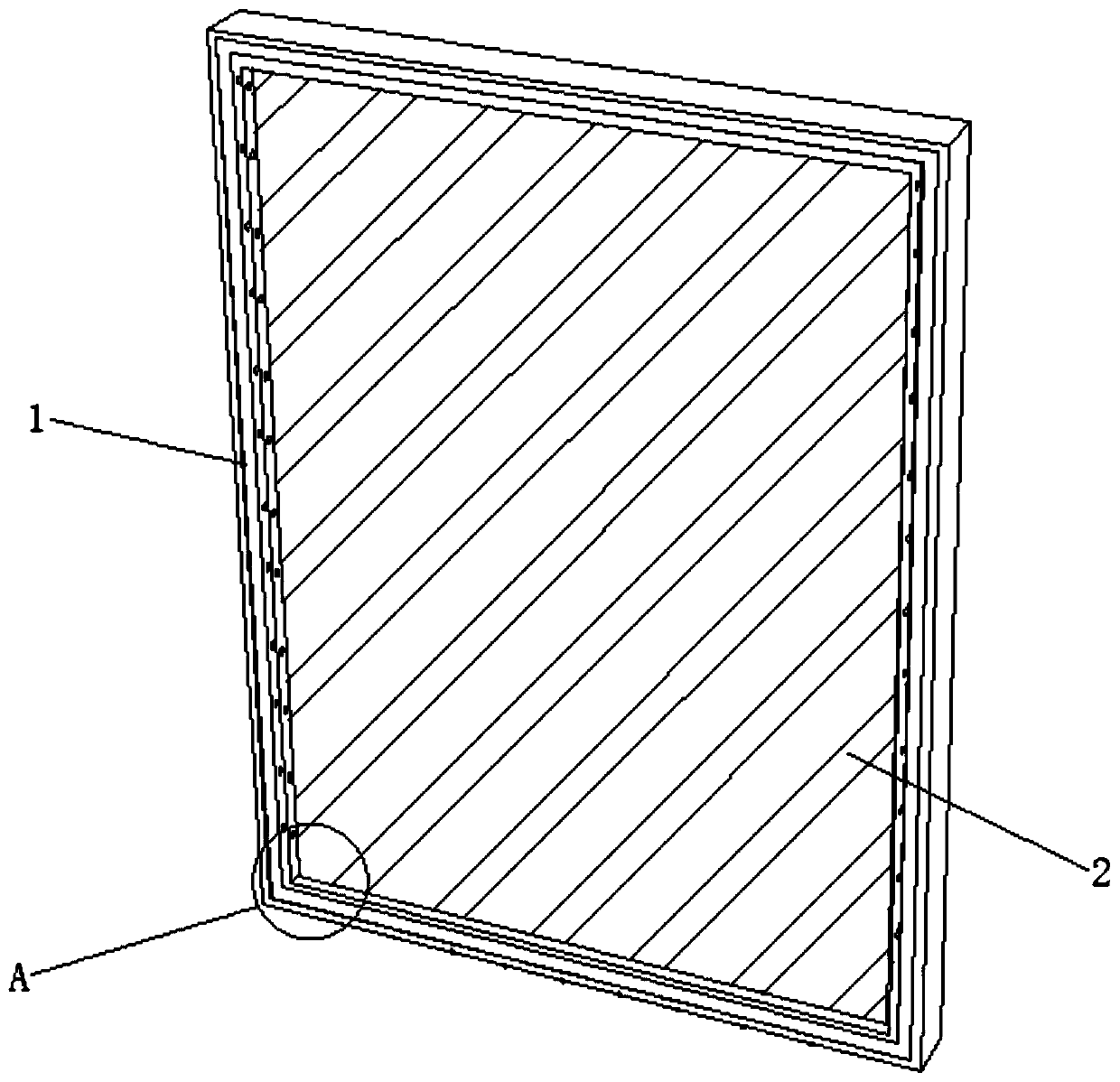

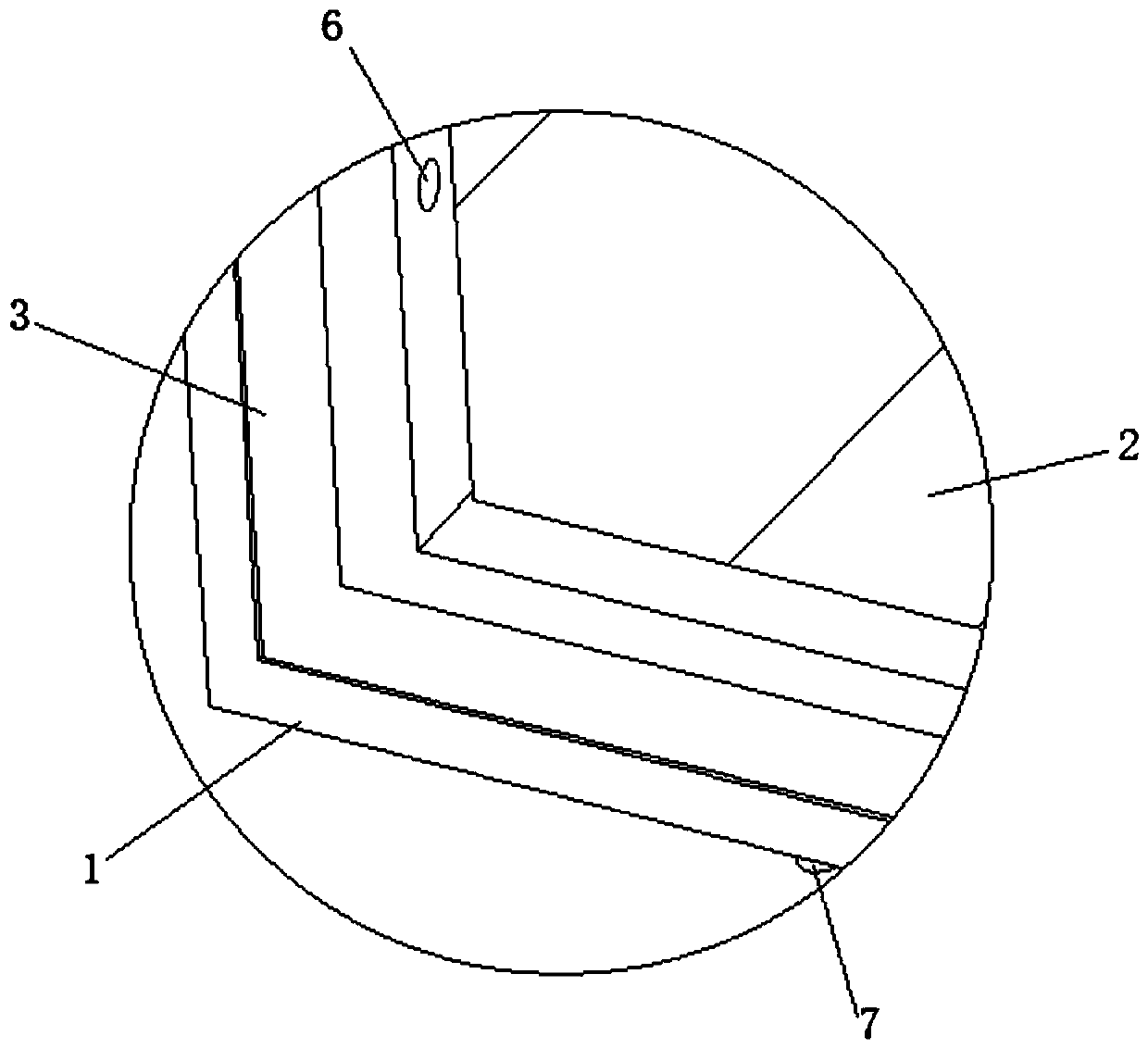

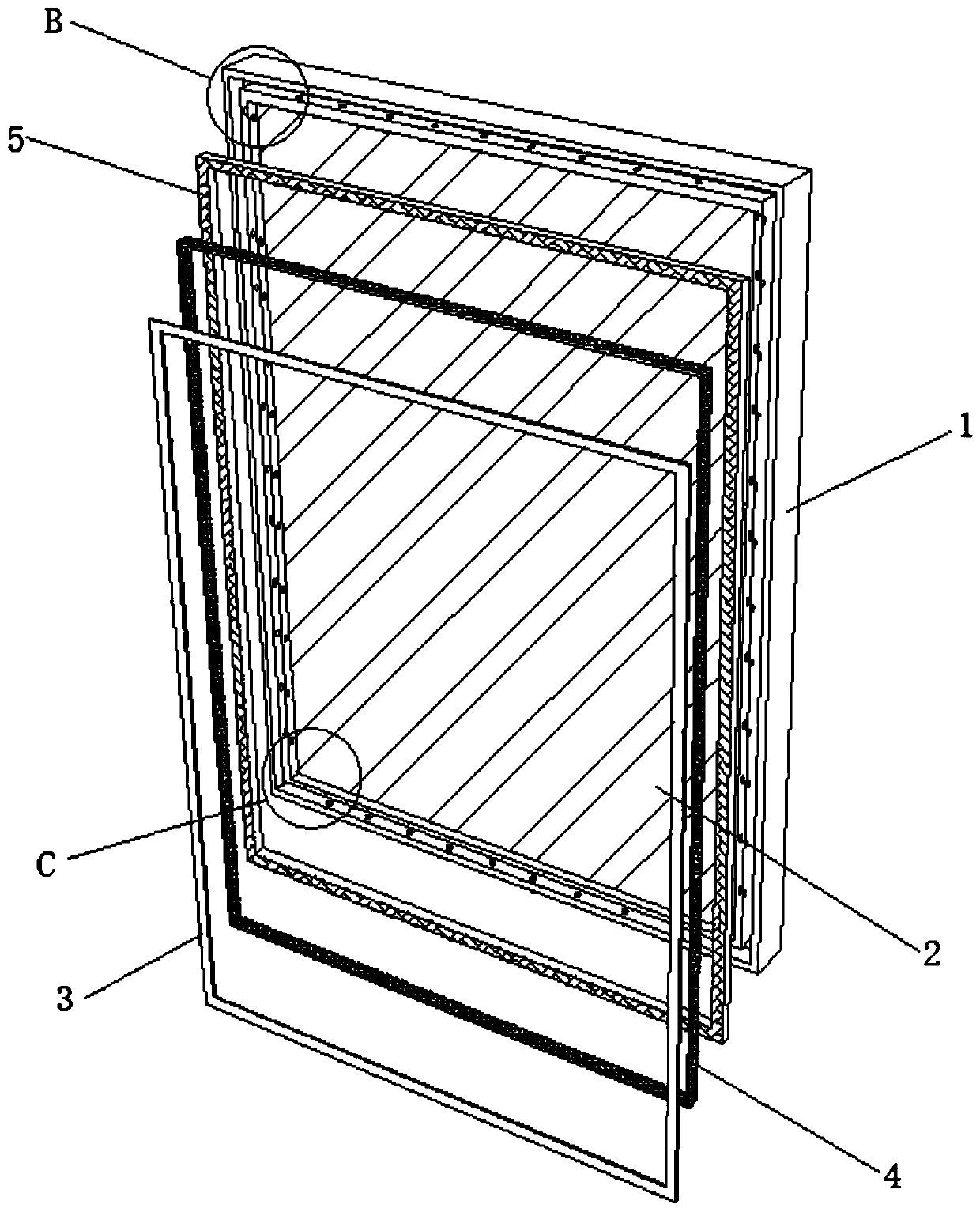

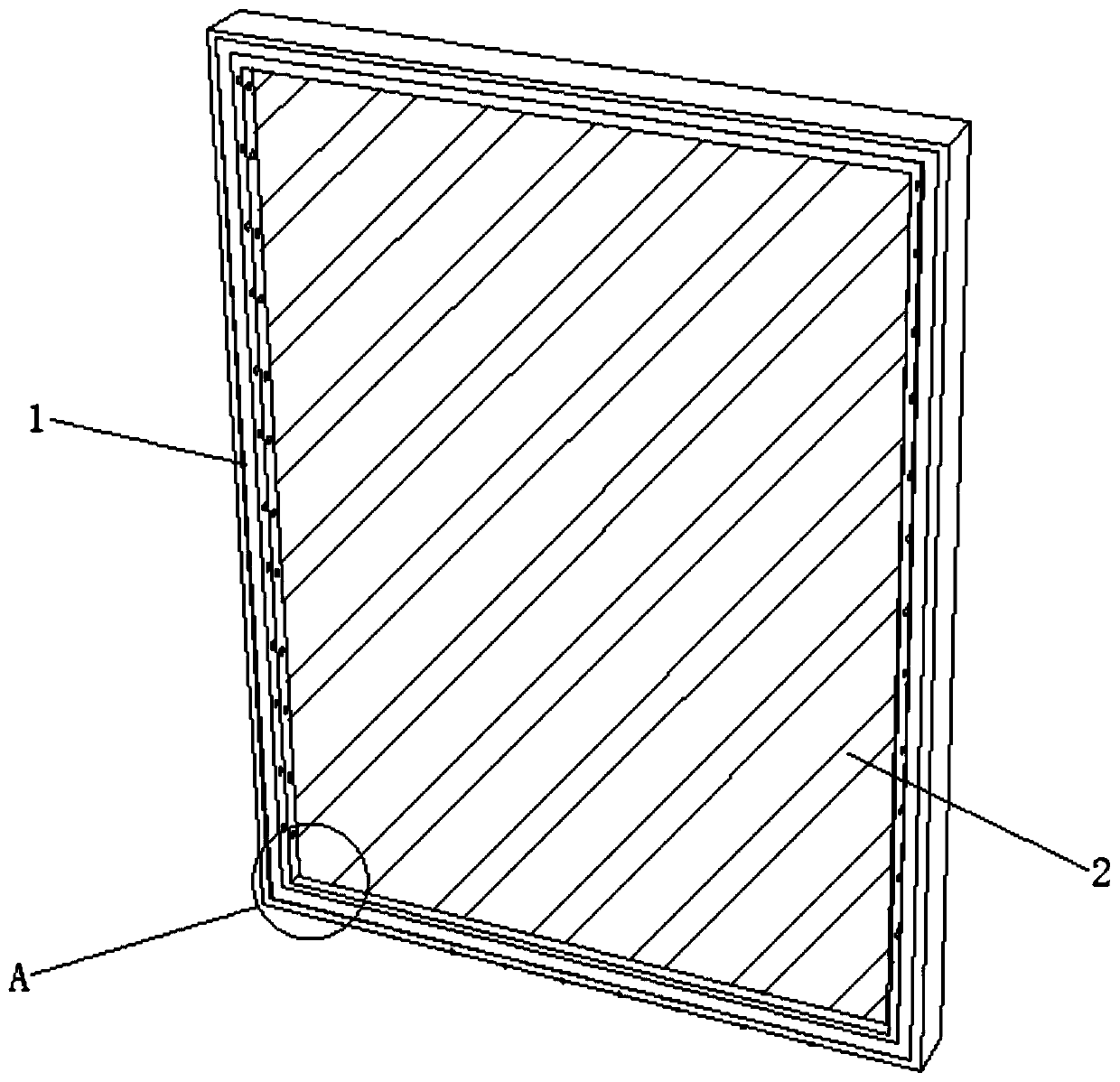

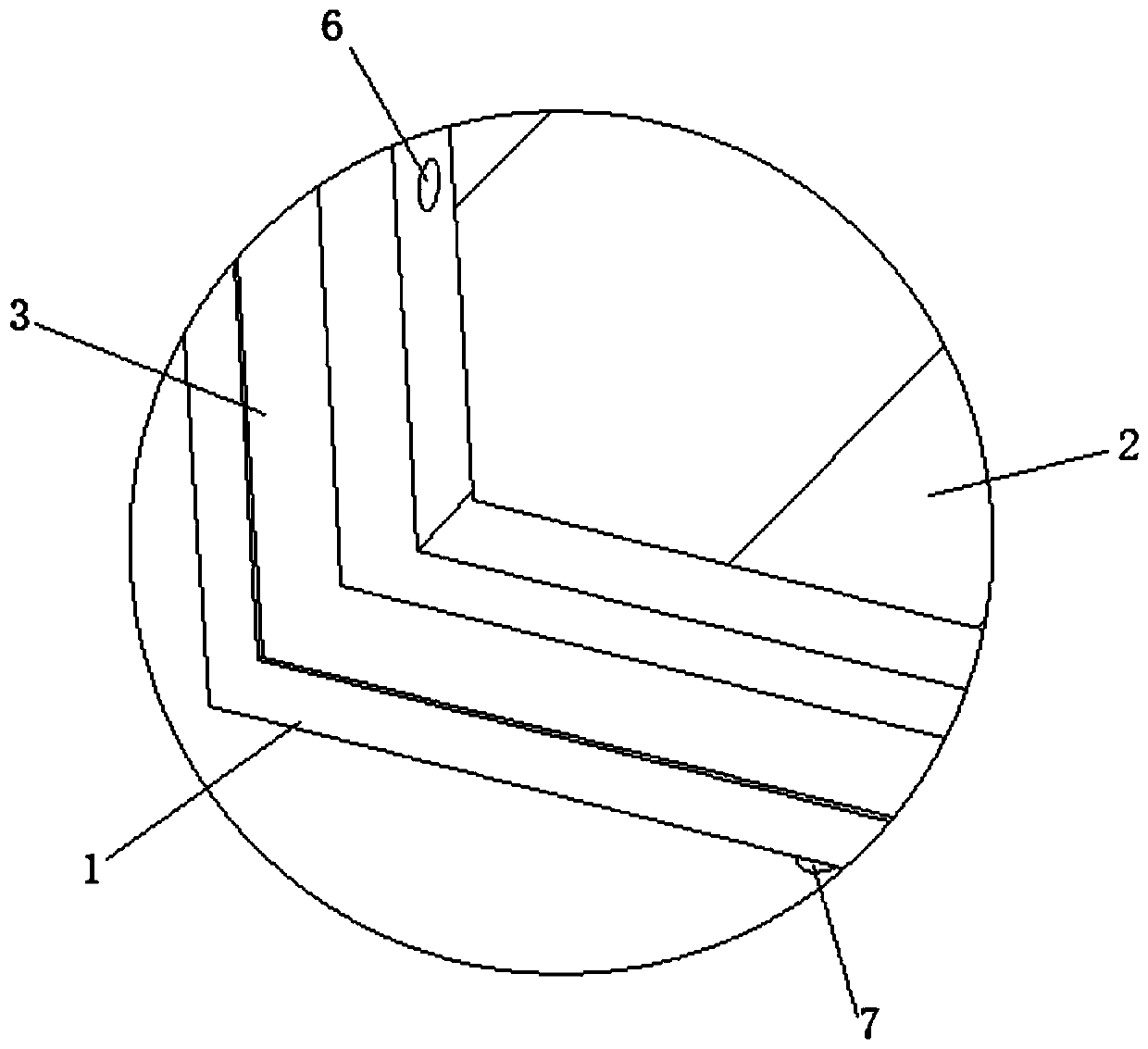

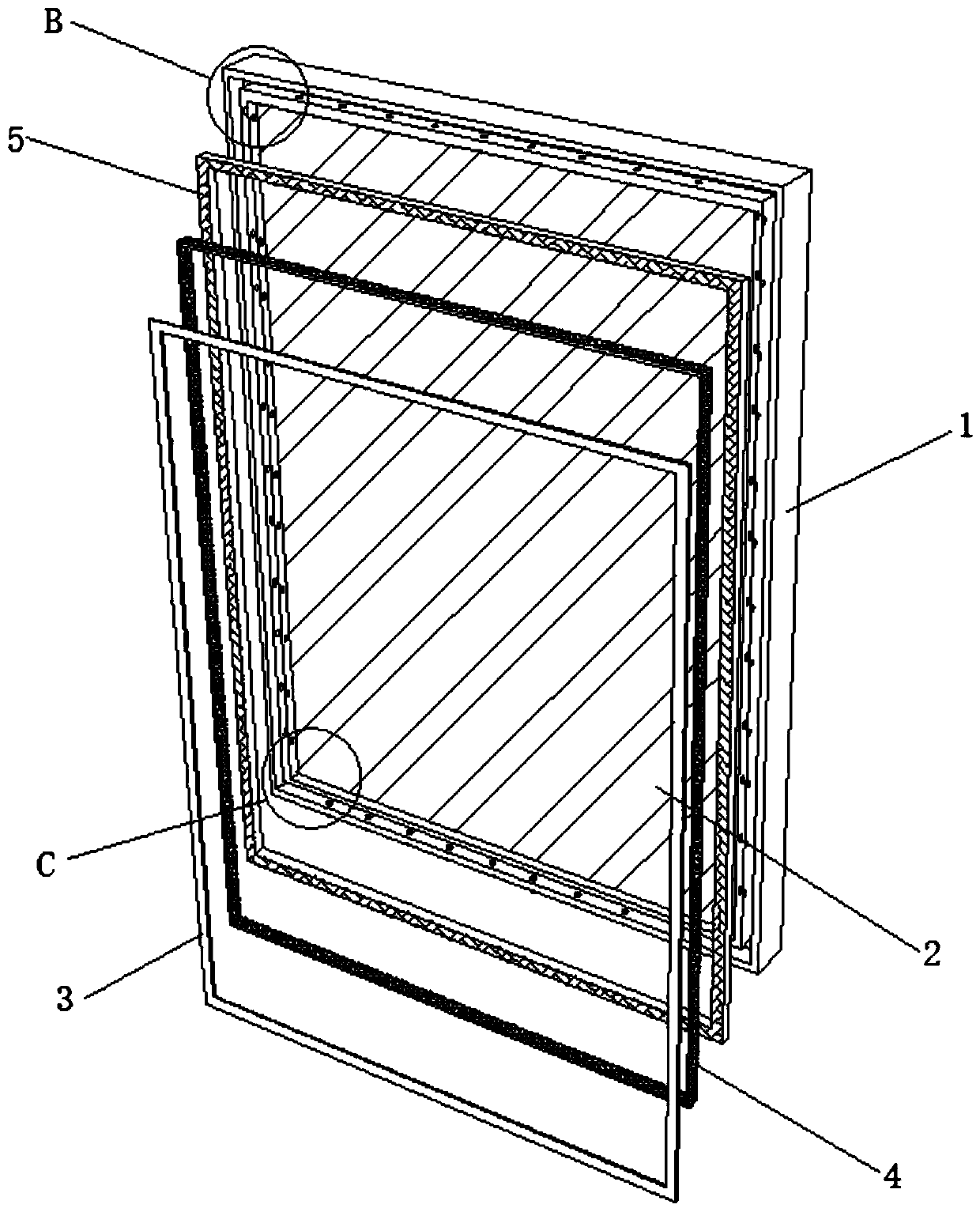

Aluminum alloy door and window achieving hidden type trace water drainage

ActiveCN110485857AGuaranteed flexibilityPrevent rustCondensed water drain-offCondensed water formation preventionWindow openingGlass sheet

The invention discloses an aluminum alloy door and window achieving hidden type trace water drainage and belongs to the field of aluminum alloy doors and windows. The aluminum alloy door and window achieving hidden type trace water drainage comprises an aluminum alloy door and window outer frame with a glass plate installed on the inner side. A hidden type water drainage groove is formed in the front end of the aluminum alloy door and window in a digging manner. A water absorbing frame is arranged in the hidden type water drainage groove. A sealing cover frame is connected to a groove openingof the hidden type water drainage groove. Multiple water guide holes are uniformly formed in the lower end of the aluminum alloy door and window outer frame in a digging manner. Embedded type water absorbing bars are fixedly connected into the water guide holes. Multiple side air drying holes are formed in the left inner side end and the right inner side end of the aluminum alloy door and window in a digging manner correspondingly. Upper air drying holes distributed uniformly are formed in the upper inner side end of the aluminum alloy door and window outer frame in a digging manner. Accordingto the aluminum alloy door and window, the multiple embedded type water absorbing bars are utilized for absorbing trace water spots on the surface of a sliding rail of the aluminum alloy door and window, the absorbed water is transferred and dried through the water absorbing frame, the surface of the sliding rail is effectively prevented from rusting, and flexibility of the door and window opening and closing is ensured.

Owner:江苏海鹰德拉图节能科技有限公司

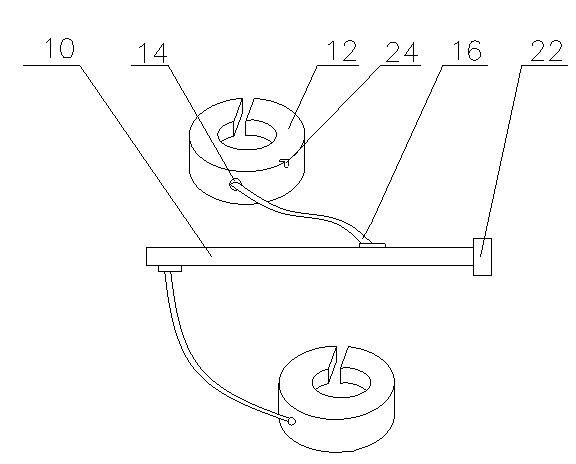

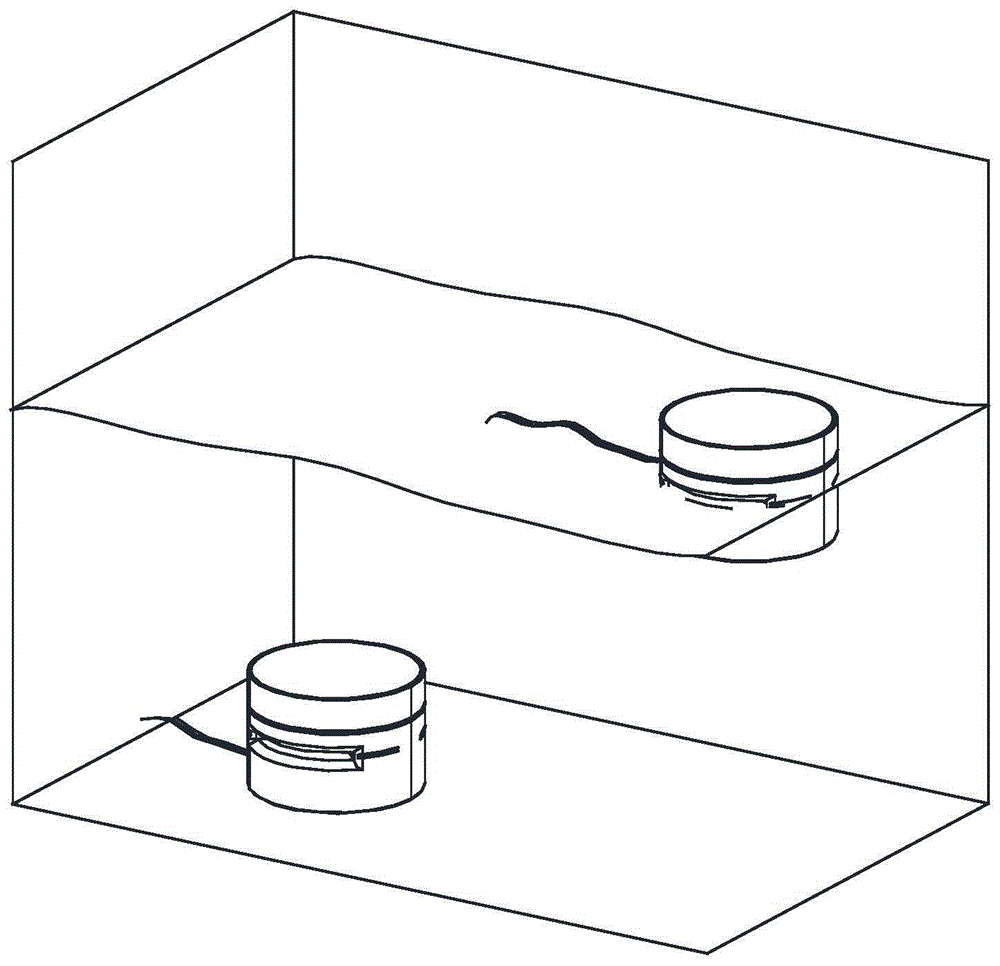

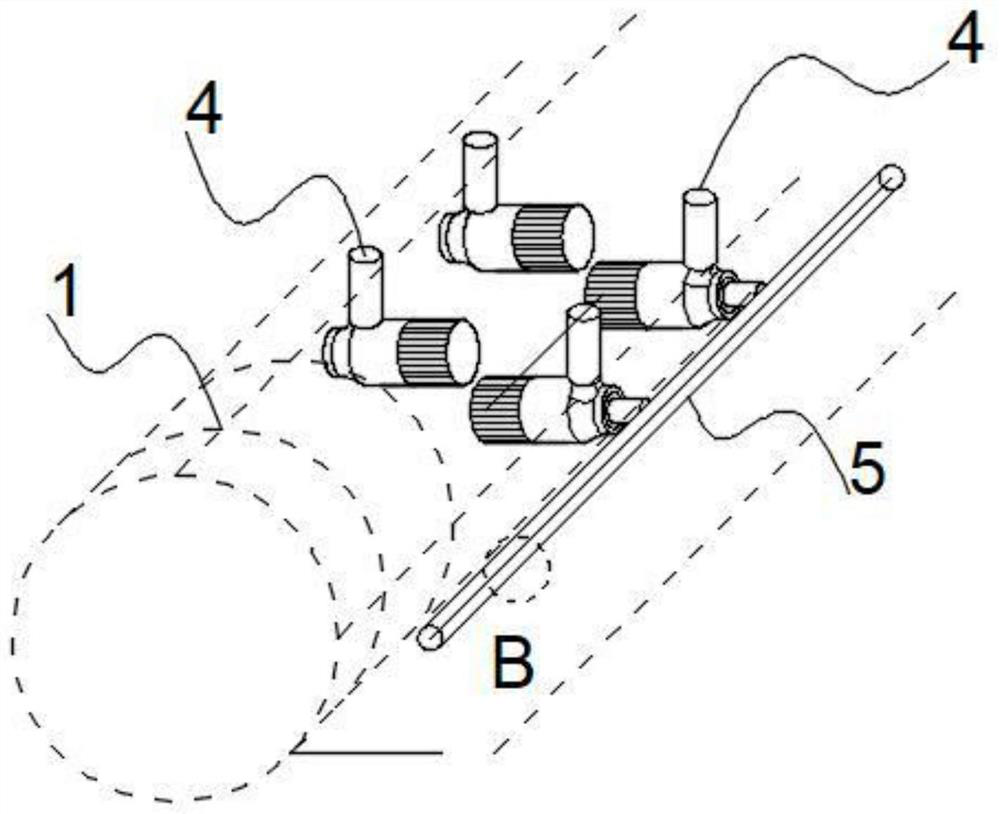

Novel tree permeating trickle irrigation system

InactiveCN102696452AIncrease profitPrevent evaporationWatering devicesCultivating equipmentsEngineeringMoisture

The invention discloses a novel tree permeating trickle irrigation system, which comprises a water main. The novel tree permeating trickle irrigation system is characterized in that at least one sponge cushion is arranged on the water main. Since the novel tree permeating trickle irrigation system adopts the sponge cushions to replace conventional trickle irrigation nozzles, the moisture utilization rate is high, blockage can be prevented, moreover, the water-absorbing area is large, and soil cannot be easily hardened.

Owner:苏州市绿韵园林工程有限公司

An aluminum alloy door and window with concealed micro drainage

ActiveCN110485857BGuaranteed flexibilityPrevent rustCondensed water drain-offCondensed water formation preventionWindow openingWater spot

The invention discloses an aluminum alloy door and window achieving hidden type trace water drainage and belongs to the field of aluminum alloy doors and windows. The aluminum alloy door and window achieving hidden type trace water drainage comprises an aluminum alloy door and window outer frame with a glass plate installed on the inner side. A hidden type water drainage groove is formed in the front end of the aluminum alloy door and window in a digging manner. A water absorbing frame is arranged in the hidden type water drainage groove. A sealing cover frame is connected to a groove openingof the hidden type water drainage groove. Multiple water guide holes are uniformly formed in the lower end of the aluminum alloy door and window outer frame in a digging manner. Embedded type water absorbing bars are fixedly connected into the water guide holes. Multiple side air drying holes are formed in the left inner side end and the right inner side end of the aluminum alloy door and window in a digging manner correspondingly. Upper air drying holes distributed uniformly are formed in the upper inner side end of the aluminum alloy door and window outer frame in a digging manner. Accordingto the aluminum alloy door and window, the multiple embedded type water absorbing bars are utilized for absorbing trace water spots on the surface of a sliding rail of the aluminum alloy door and window, the absorbed water is transferred and dried through the water absorbing frame, the surface of the sliding rail is effectively prevented from rusting, and flexibility of the door and window opening and closing is ensured.

Owner:江苏海鹰德拉图节能科技有限公司

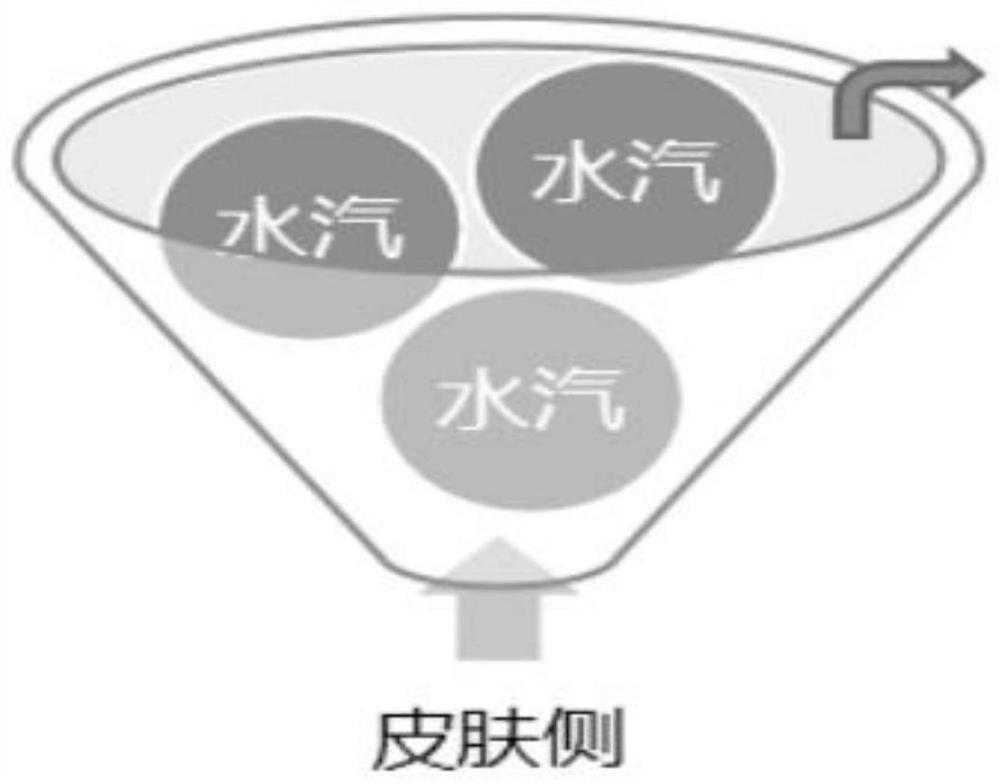

Moisture-conducting knitted fabric with special structure

The invention provides a moisture-conducting knitted fabric with a special structure. The moisture-conducting knitted fabric is characterized by comprising an inner layer, an outer layer and a moisture-conducting functional layer; the moisture conducting functional layer is clamped between the inner layer and the outer layer; the moisture guiding functional layer is in a horn shape; and the opening direction of the horn shape is opposite to the outer layer. The moisture-conducting knitted fabric has good wear resistance and antistatic performance, and further has excellent moisture-conducting and heat-discharging capability.

Owner:SHANGHAI JIALE

Swimming pool all-round cleaning filter robot

ActiveCN104790696BFreedom of movementControl the direction of movementGymnasiumSwimming poolsWater volumeSolenoid valve

Owner:苏州市振渭城镇建设发展有限公司

Novel tree permeating trickle irrigation system

InactiveCN102696452BIncrease profitPrevent evaporationWatering devicesCultivating equipmentsEngineeringMoisture

The invention discloses a novel tree permeating trickle irrigation system, which comprises a water main. The novel tree permeating trickle irrigation system is characterized in that at least one sponge cushion is arranged on the water main. Since the novel tree permeating trickle irrigation system adopts the sponge cushions to replace conventional trickle irrigation nozzles, the moisture utilization rate is high, blockage can be prevented, moreover, the water-absorbing area is large, and soil cannot be easily hardened.

Owner:苏州市绿韵园林工程有限公司

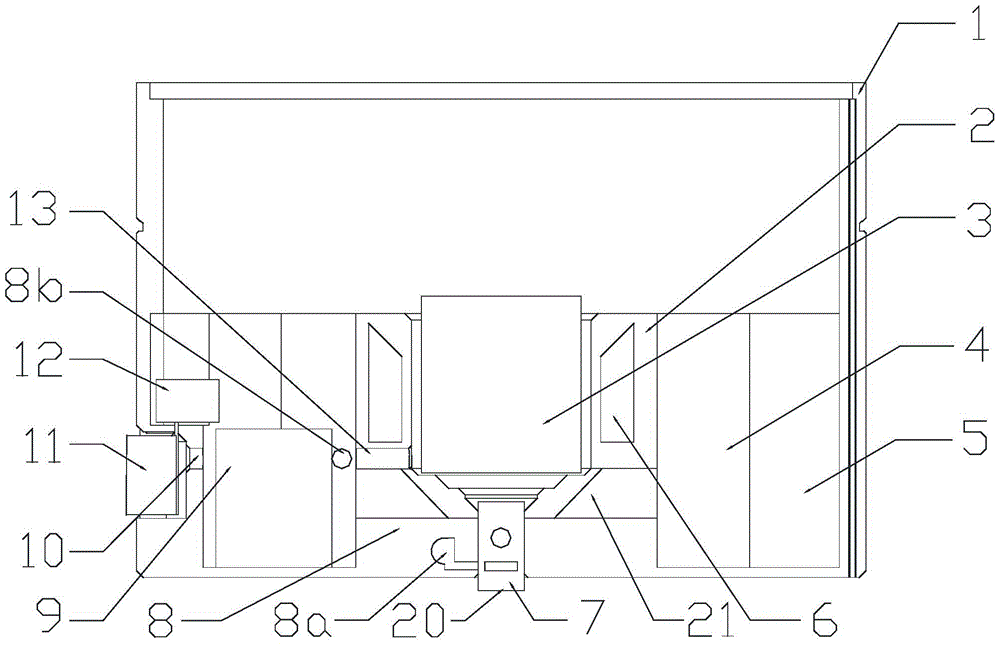

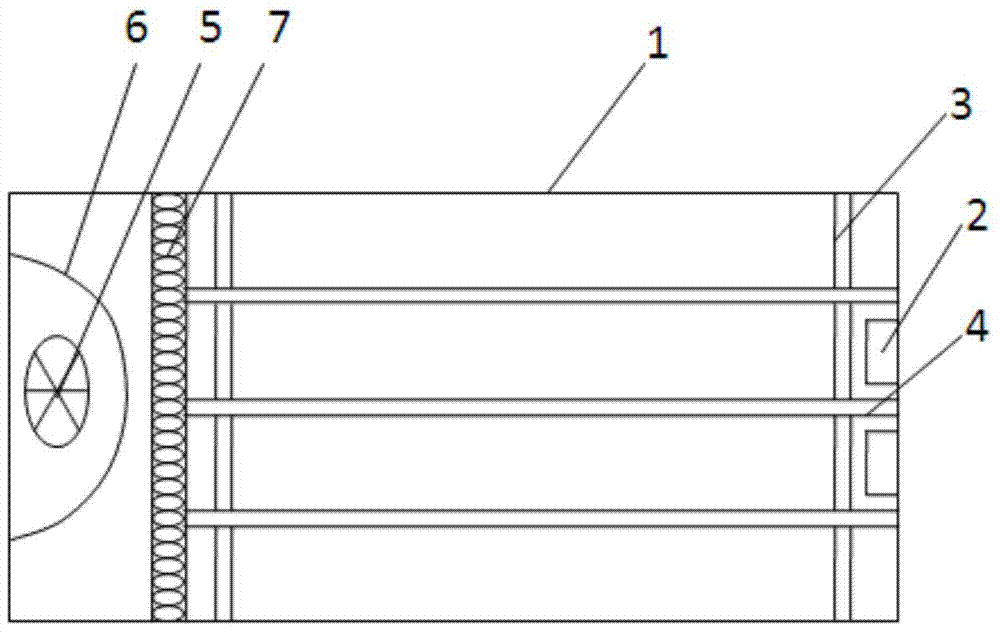

Normal-temperature air based drying device

InactiveCN104762796APrevent aliasing and deformationAvoid damageOther drying apparatusTextiles and paperRoom temperatureHeat sensitive

The invention provides a normal-temperature air based drying device. The device comprises a box body, an air blower, an air spreading plate, a dehumidifying plate, a drying frame and an air outlet, wherein the air blower is arranged at one end of the box body, and while the air outlet is formed in the other end of the box body; the air spreading plate is positioned between the air blower and the dehumidifying plate. According to the device, clothes can be dried through normal temperature air; the device is particularly suitable for the clothes manufactured from heat sensitive fabrics, easily-oxidized fabrics and fabrics the like.

Owner:SUZHOU HUANING MACHINERY MFG

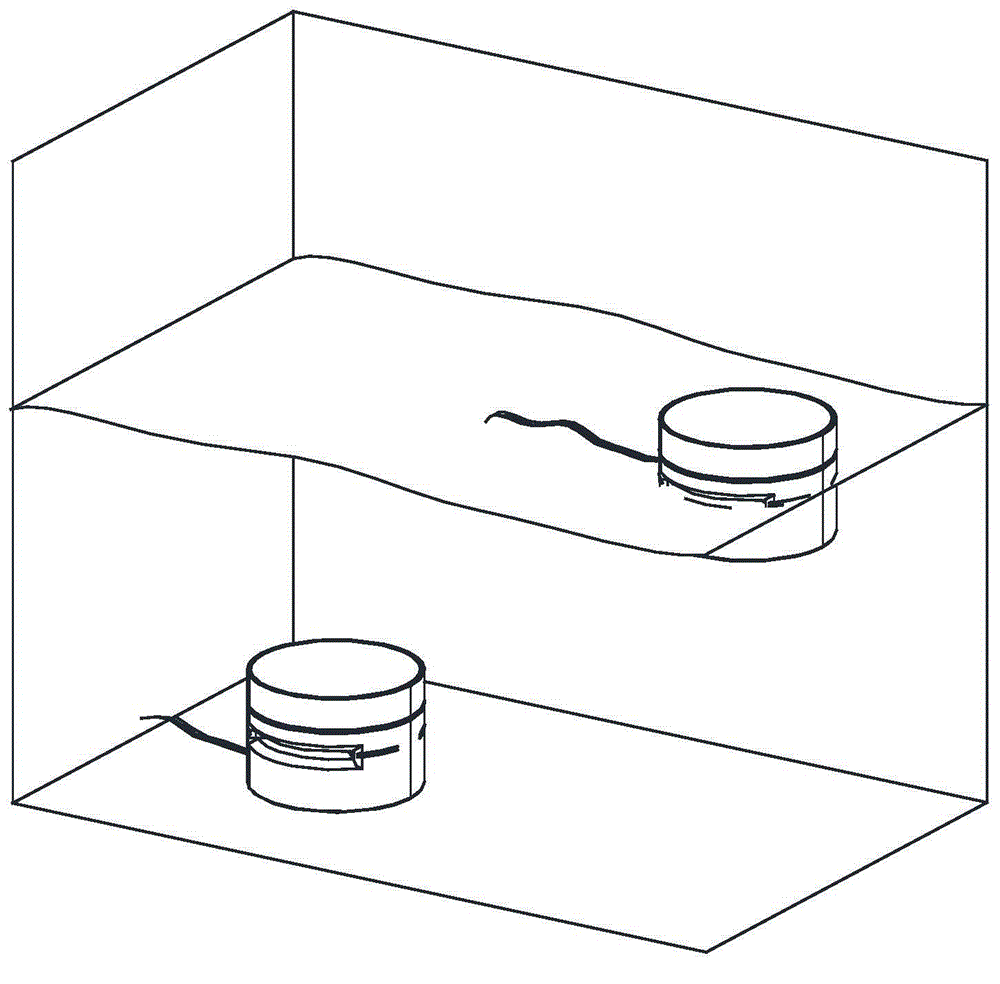

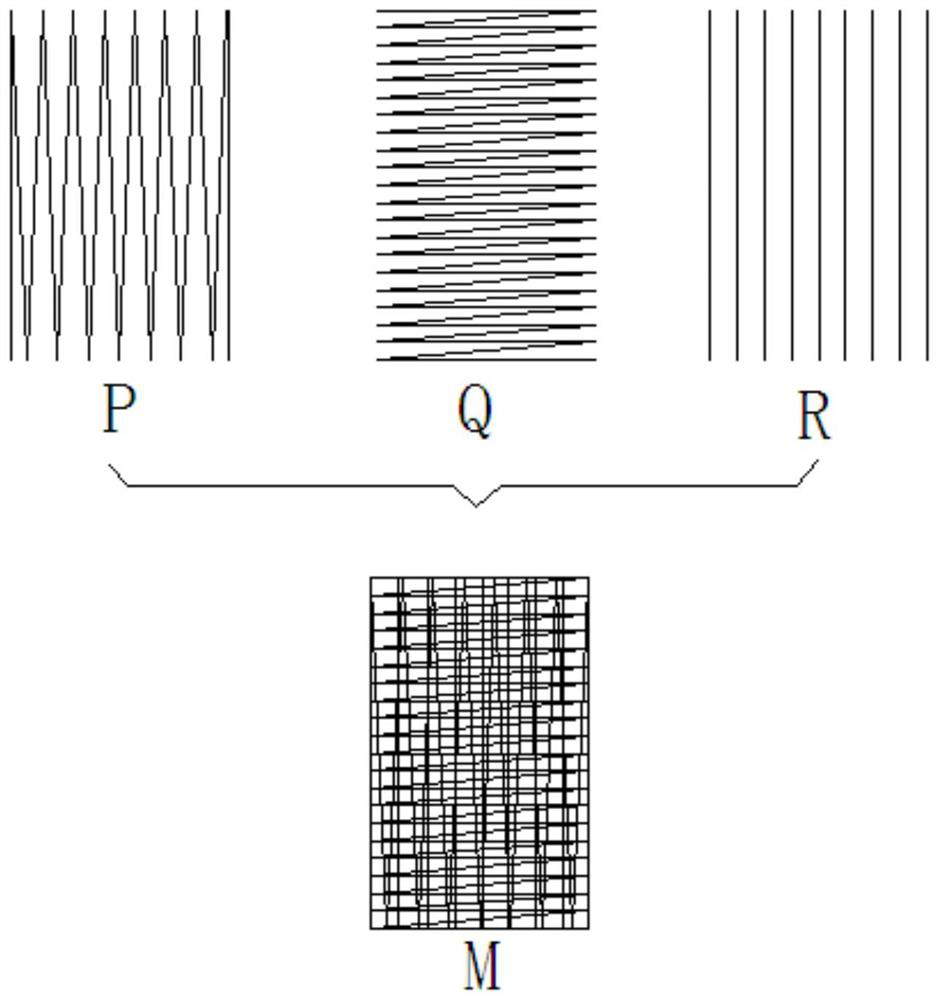

Intelligent flexible water drop detection device for flexible multiple application scenes

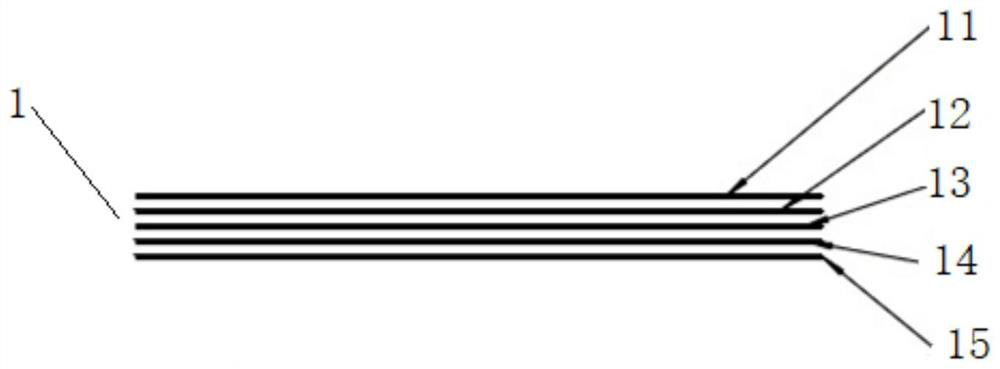

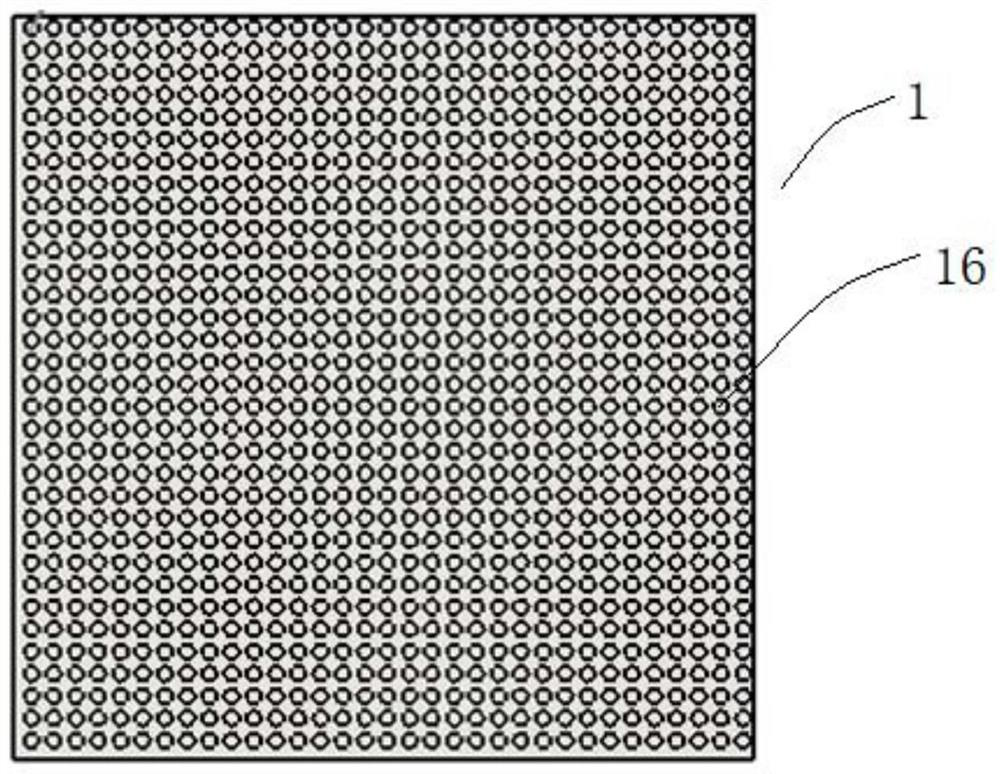

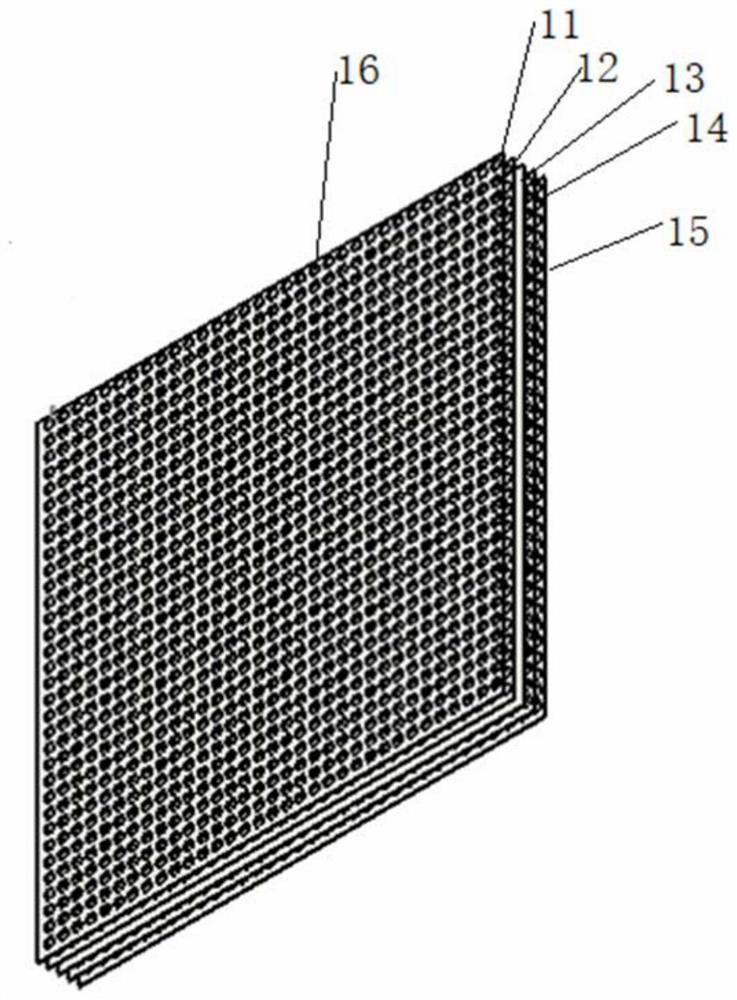

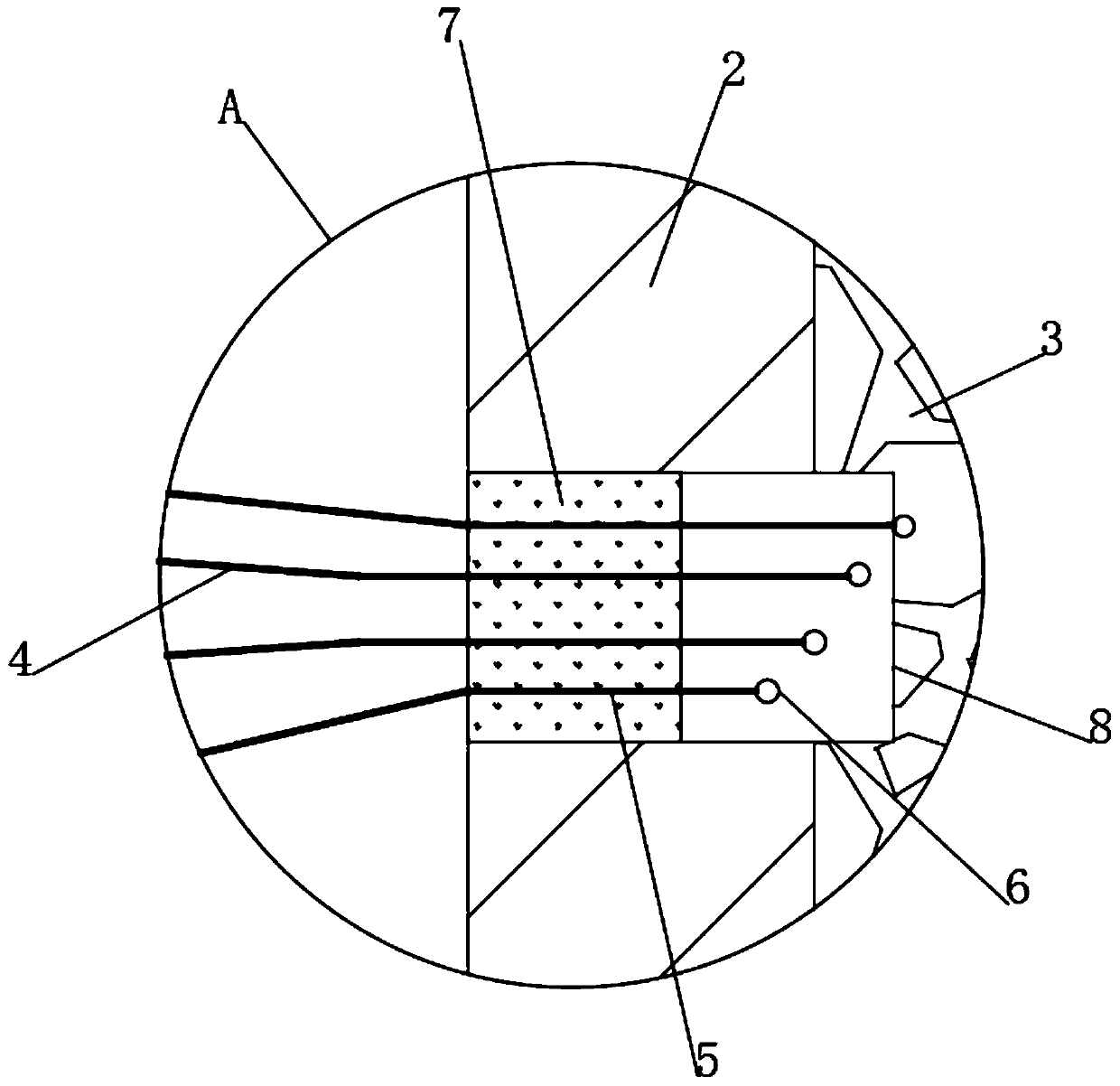

PendingCN113432800AReduce volumeReduce the chance of errorsDetection of fluid at leakage pointMaterial resistanceElectrically conductiveMultiple applications

The invention discloses a flexible multi-application scene intelligent flexible water drop detection device. The device comprises a flexible water drop detection device and a main control module, and is characterized in that the flexible water drop detection device comprises five layers of composite materials which are a first insulating layer, a second conductive layer, a third water absorption layer, a fourth conductive layer and a fifth insulating layer in sequence from top to bottom; the first insulating layer, the second conducting layer, the fourth conducting layer and the fifth insulating layer are all provided with uniformly distributed small holes, the second conducting layer and the fourth conducting layer are both provided with wires, the second conducting layer and the fourth conducting layer are matched to form a water drop detection device R1, and two electrodes of the water drop detection device R1 are respectively connected with a power supply Ui and a divider resistor R2; the other end of the divider resistor R2 is grounded; the divider resistor R2 is connected with an input port of the master control module through a cable; and the main control module judges whether water leaks or not according to the acquired sampling voltage value A. The flexible water drop detection device is connected with the main control module, a large amount of labor cost does not need to be spent, and the probability of errors in the detection process is reduced.

Owner:温尚熙

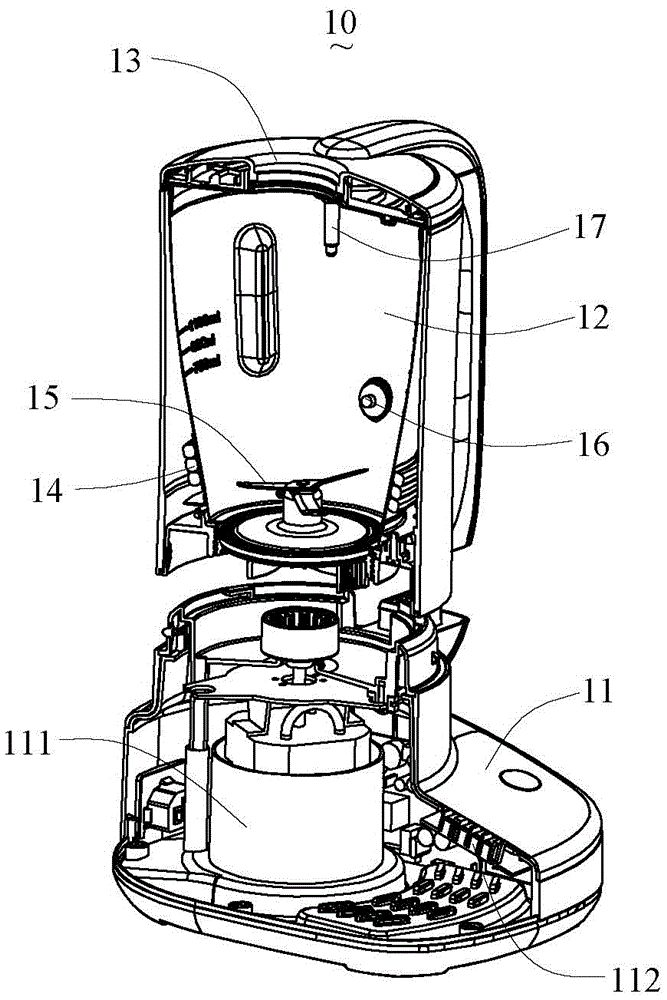

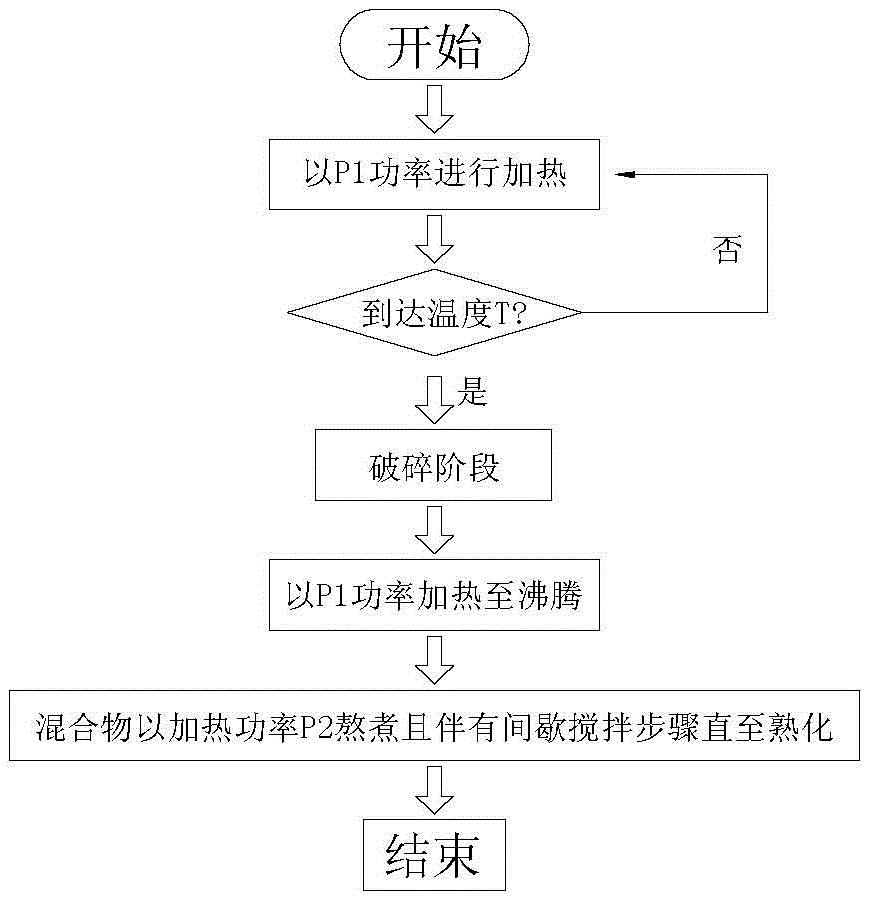

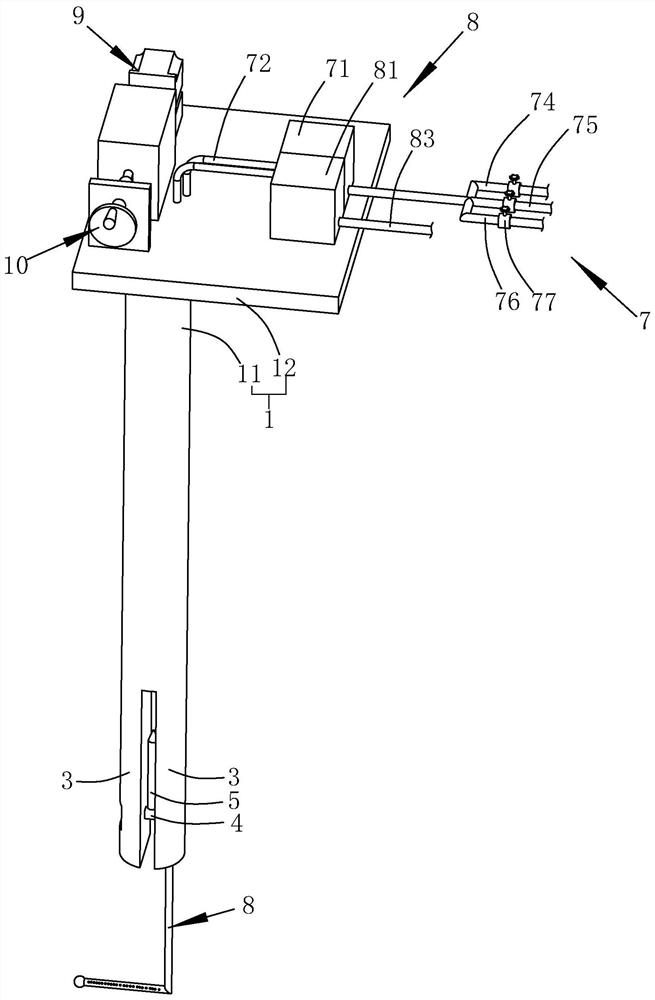

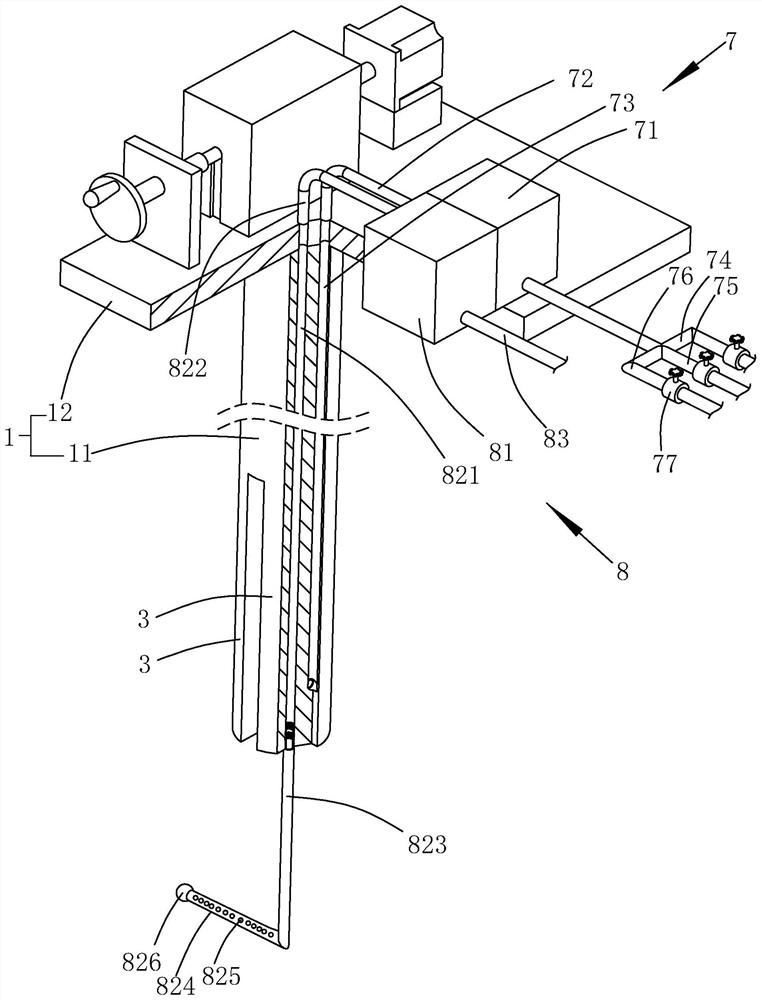

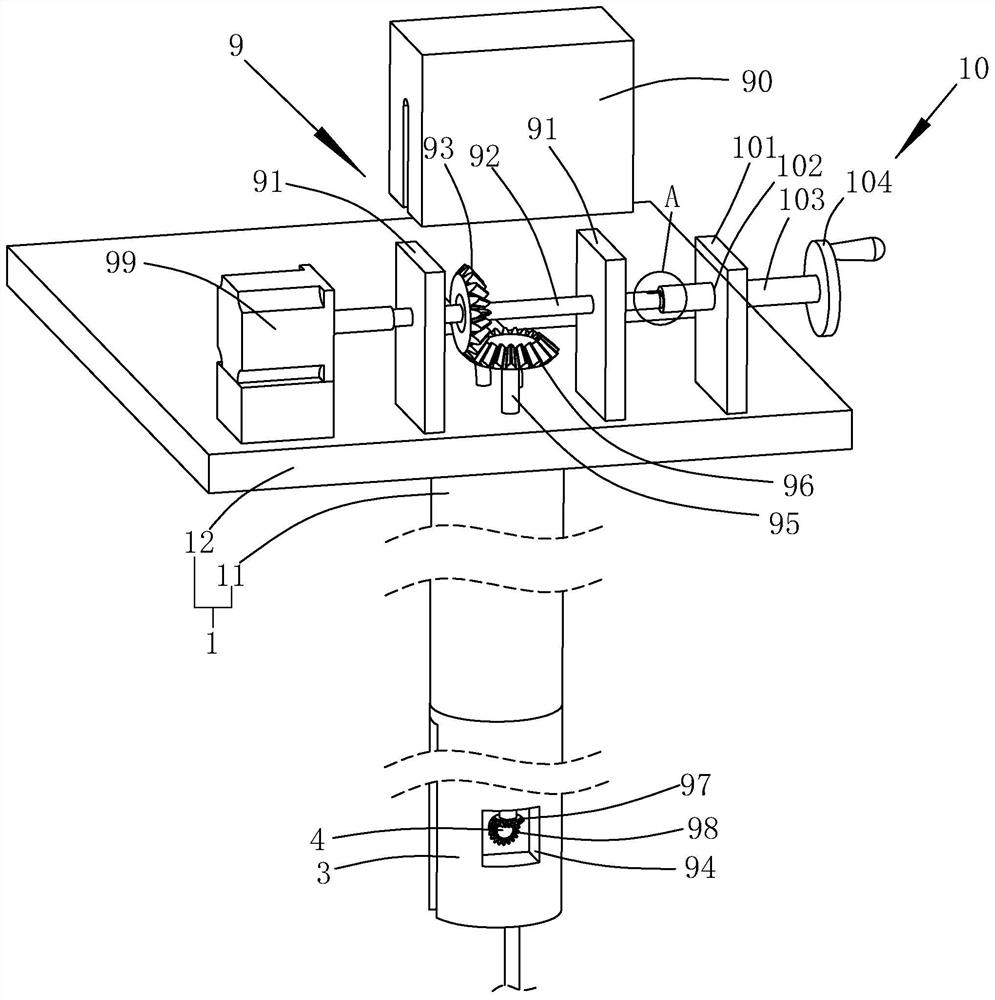

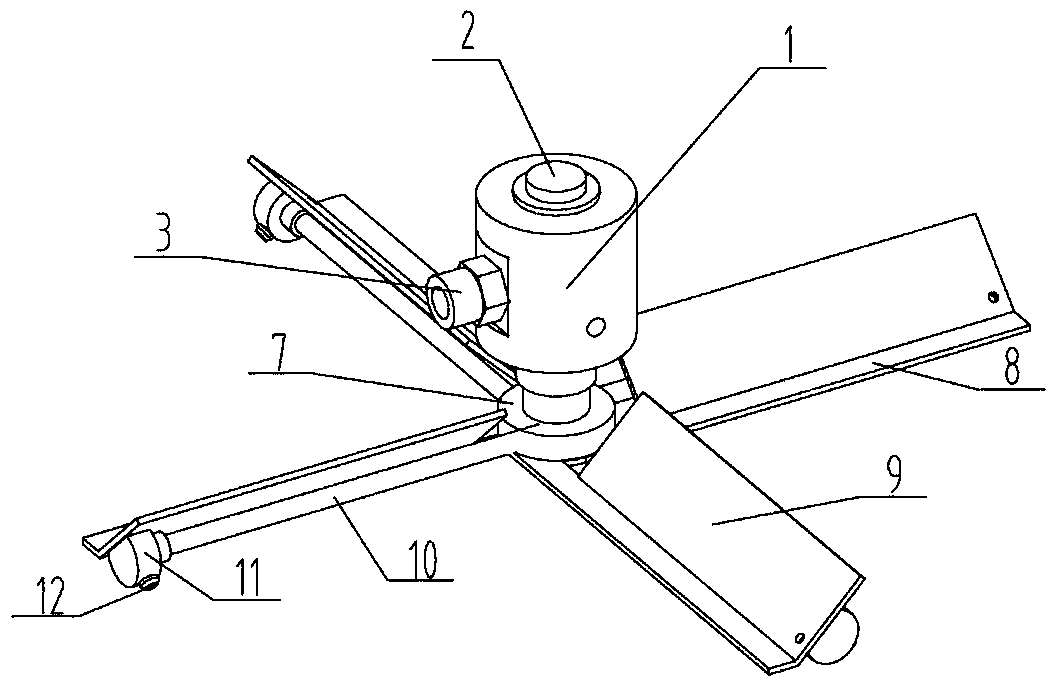

Method for quickly making rice porridge and its household food processor

ActiveCN103431745BIncrease water absorption areaImprove water absorption speedCooking vesselsProcess engineeringHeating power

The invention relates to a rapid rice porridge production method. The method at least comprises the following stages: (a) a preheating stage: heating water and materials by a heating assembly in the heating power of P1, and entering a next stage when the water and the materials are heated to the set temperature T, wherein the P1 is the rated power of the heating assembly, and the temperature T is lower than the gelatinization temperature of the materials; (b) a crushing stage: driving a cutter to rotate by a motor, crushing the materials, and entering a next stage; (c) a ripening stage: rapidly boiling a mixture of water and the crushed materials in the heating power of P1, and decocting the mixture in the heating power of P2 while intermittently stirring, wherein the P1 is higher than the P2. Compared with the prior art, the rapid rice porridge production method has the advantages that the rice porridge production cycle is shortened greatly, and fast-paced lives of people are met.

Owner:JOYOUNG CO LTD

Branch-cuttage planting method for Xinhui Citrus reticulata cv. Chachiensis

InactiveCN111264199AImprove survival rateGrow fastCultivating equipmentsVegetative propogationSeedlingCitrus reticulata (plant)

The invention discloses a branch-cuttage planting method for Xinhui Citrus reticulata cv. Chachiensis. The branch-cuttage planting method comprises the following steps: step 1) selection of branch-cuttage seedlings: a step of selecting the Xinhui Citrus reticulata cv. Chachiensis variety of branch-cuttage seedlings with top ends containing complete branches and leaves, wherein the number of leaveson each branch-cuttage seedling is no less than two; step 2) treatment of the branch-cuttage seedlings: a step of cutting the branch-cuttage seedlings selected in the step 1) by using a cutter, wherein an oblique incision is cut at one side of the root part of each branch-cuttage seedling; step 3) planting of the branch-cuttage seedlings: a step of inserting the root parts of the branch-cuttage seedlings treated in the step 2) into soil with an inserting depth of 3-5 cm, wherein the distance between every two adjacent branch-cuttage seedlings is 30-50 cm; and step 4) cultivation of the branch-cuttage seedlings: a step of irrigating the branch-cuttage seedlings planted in the step 3) with distilled water in first three months, placing a planting shed above the branch-cuttage seedlings in three months at the same time, and removing the planting shed located above the branch-cuttage seedlings after three months. The fruiting quality of adult Citrus reticulata cv. Chachiensis is more uniform compared with the fruiting quality of conventional planted trees, so standardized management of products is facilitated.

Owner:江门市润之林生态农业科技有限公司

A hand-held quick bottle washer

The invention relates to a hand-held fast bottle washer, which includes an insertion rod, and two fixed blocks integrally formed on one end surface of the insertion rod, a conduction pipe rotatably connected between the two fixation blocks, and a guide tube threadedly connected to the The spray head on the through pipe and communicated with the lead pipe, the water supply device installed on the plunger for supplying cleaning liquid to the spray head, the electric drive device installed on the plunger for driving the lead pipe to rotate, and the electric drive device installed on the plunger A manual drive for turning the catheter. Its advantages are: the round-bottom flask is cleaned without dead ends by high-pressure water flushing, thereby washing away the dirt attached to the inner wall of the round-bottom flask.

Owner:深圳市华保科技有限公司

A novel antibacterial and fragrant quilt fabric and its preparation method

ActiveCN104213306BIncrease water absorption areaStrengthen antibacterial and deodorizing effectSucessive textile treatmentsWoven fabricsPolyesterYarn

The invention discloses a novel antibacterial and aromatic quilt and a manufacturing method thereof. In the preparation process, the blended yarn of polyester high-fiber, bamboo fiber and cupro ammonia fiber is used to weave the fabric, so that the fabric has good deodorizing and antibacterial, antibacterial and antibacterial properties. Thermal insulation performance, antistatic performance; microcapsule fragrance finishing agent is used to evenly distribute fragrance microcapsules on the surface of fabric fibers, and the fragrance coated in polymer capsules will be released slowly, thus greatly prolonging the fragrance retention time of fibers.

Owner:浙江新千禧纺织股份有限公司

Method for sowing corn by pressing with water

The invention discloses a method for sowing corn by pressing with water. The method particularly includes during field sowing of the corn, sufficiently watering a sowing trench (hole), pressing seeds into wet soil, and earthing. Compared with a method without pressing with water, the method has the advantages of being high in emergency rate and uniform in seedling.

Owner:ANHUI SCI & TECH UNIV

An underwater washing net dish

ActiveCN105123564BEasy to replaceEasy maintenanceClimate change adaptationPisciculture and aquariaHigh pressureGuide tube

Owner:QINGDAO LUOBOFEI OCEAN TECH

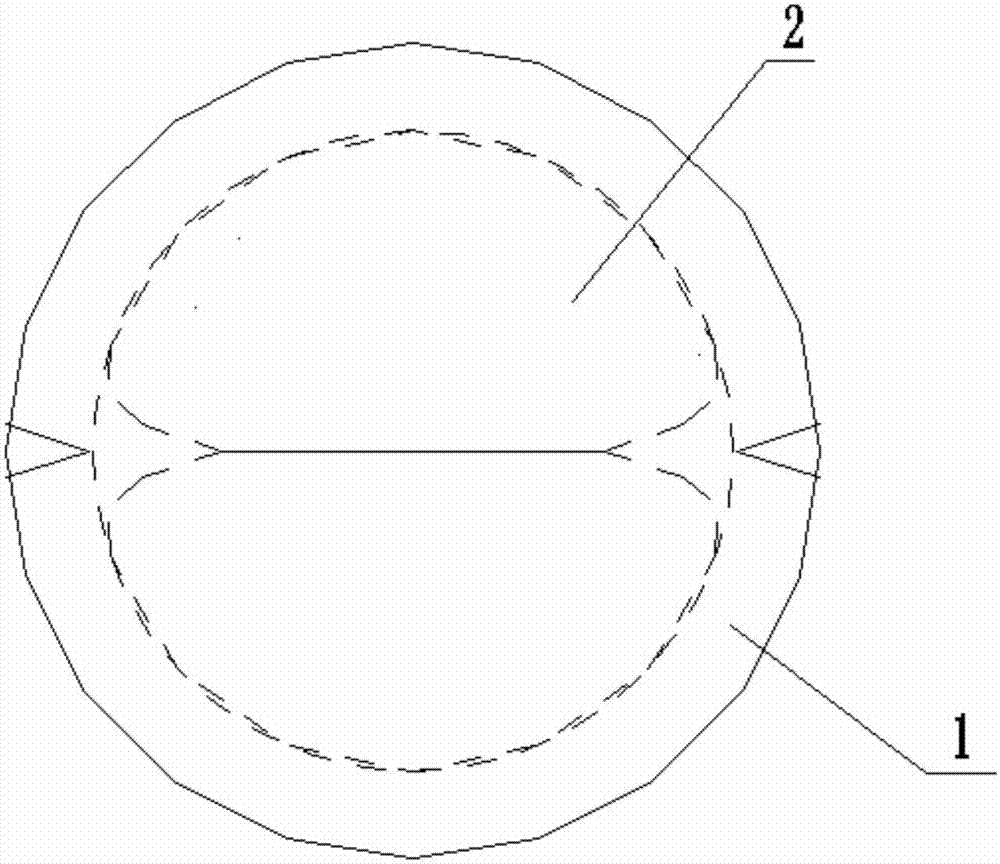

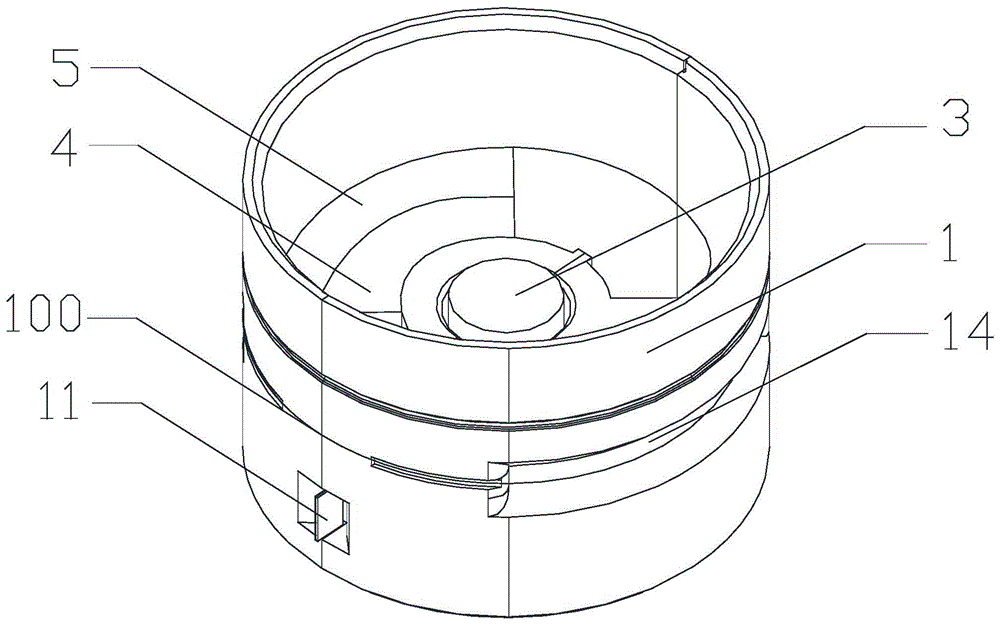

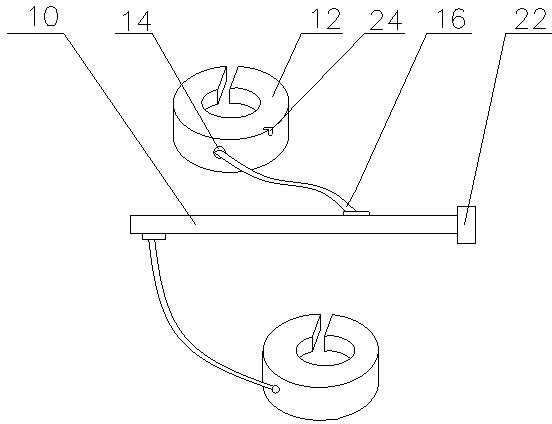

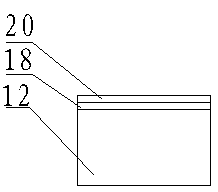

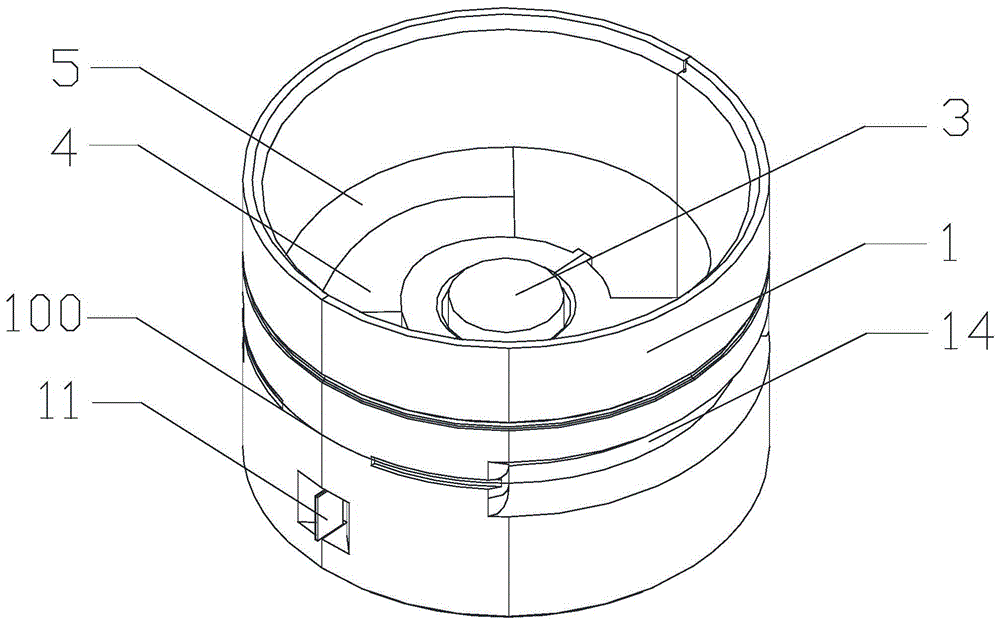

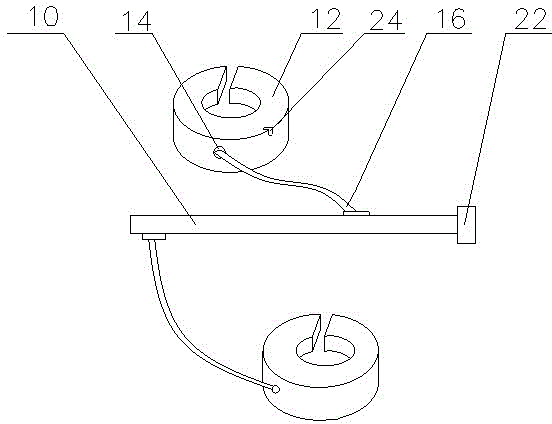

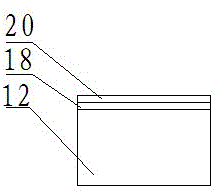

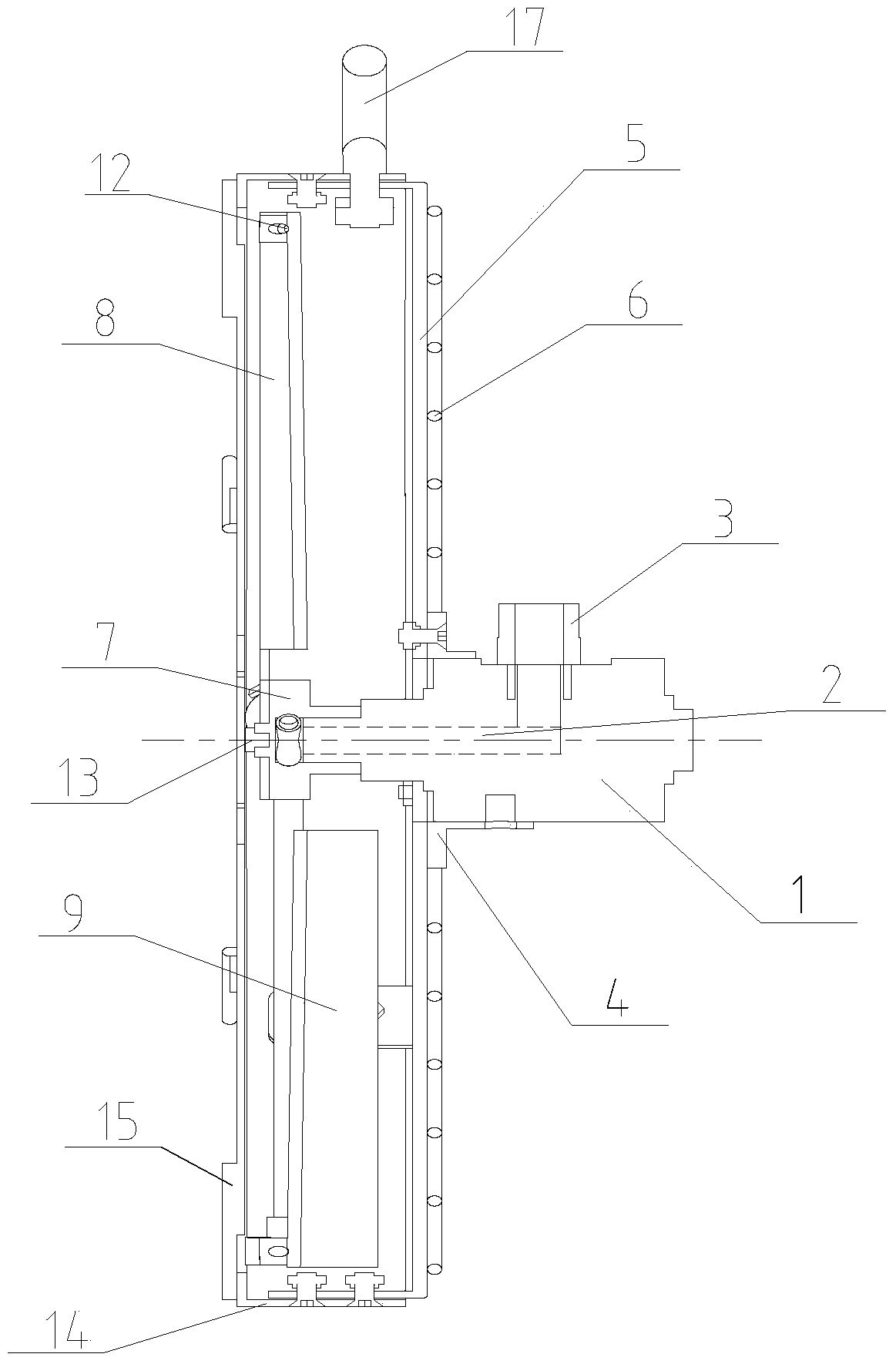

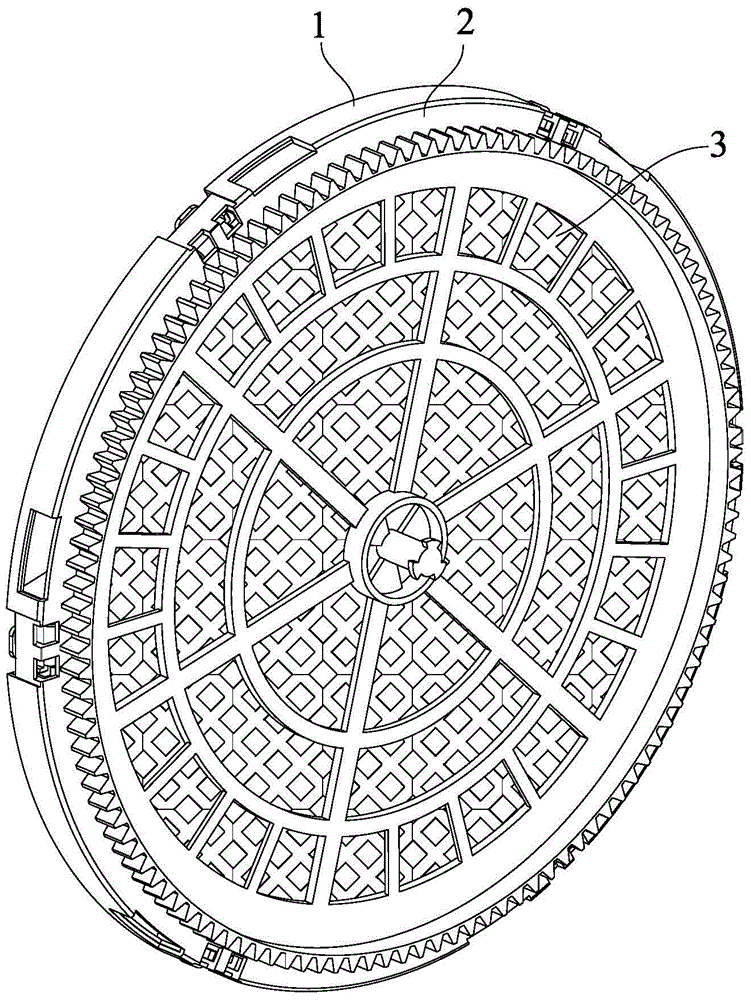

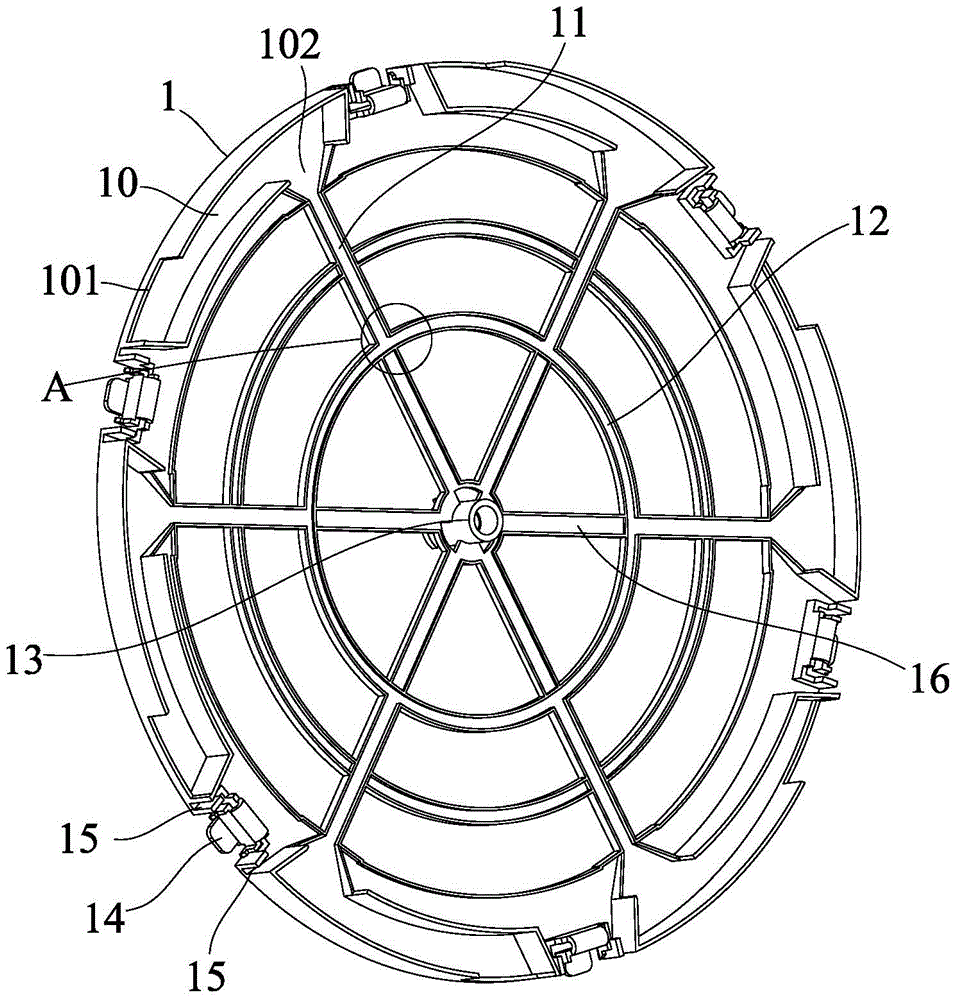

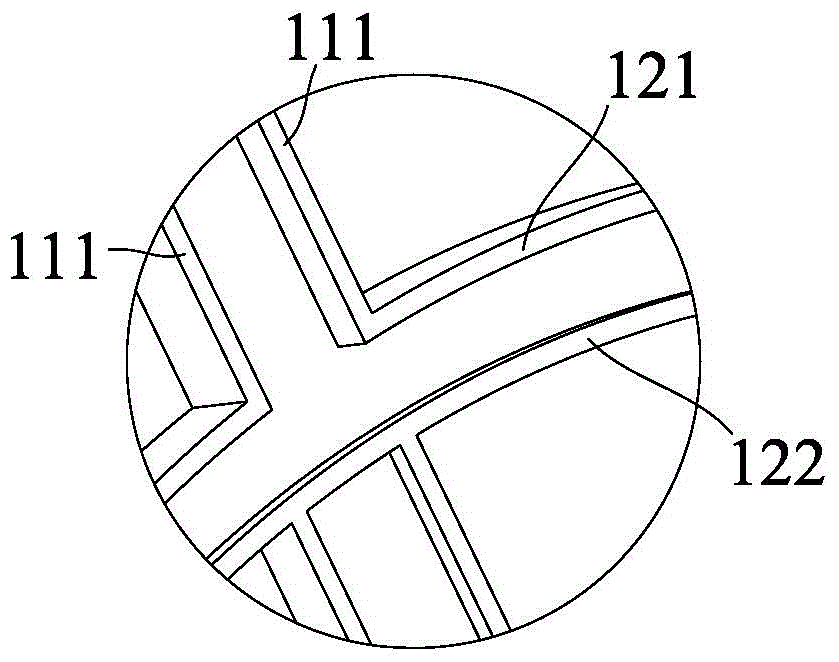

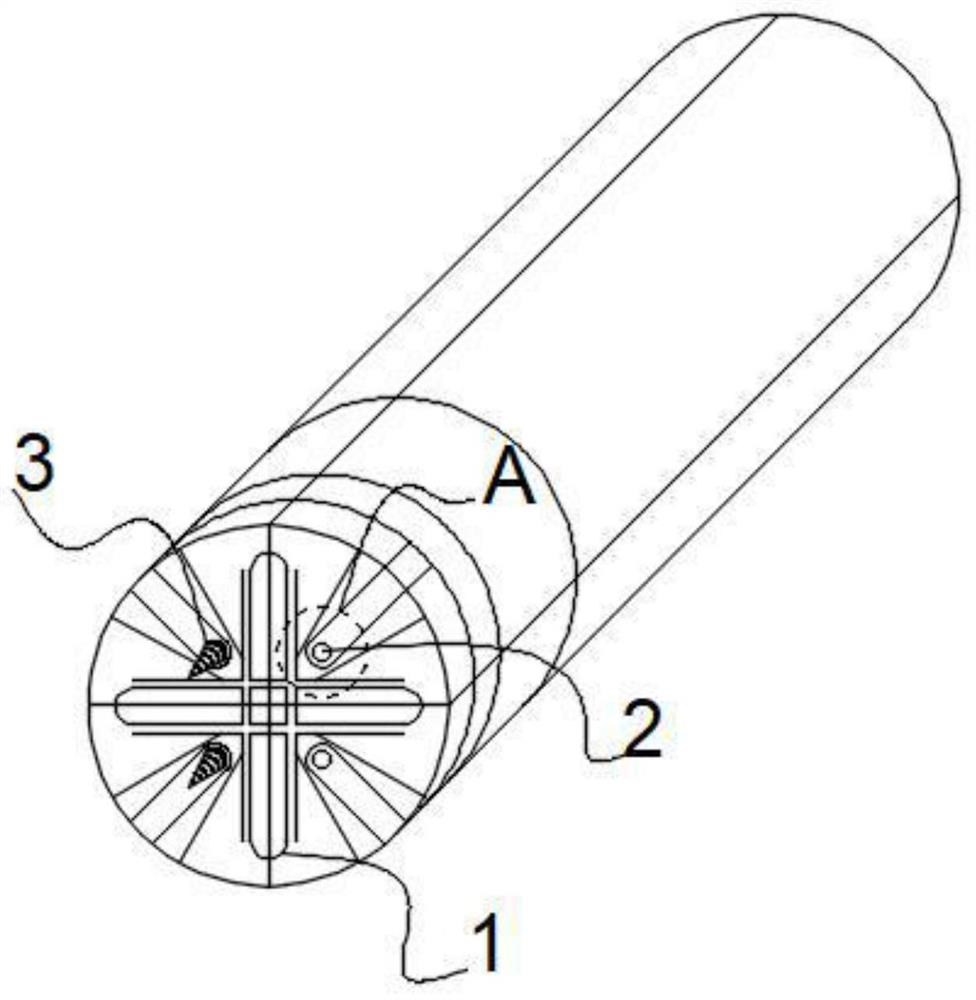

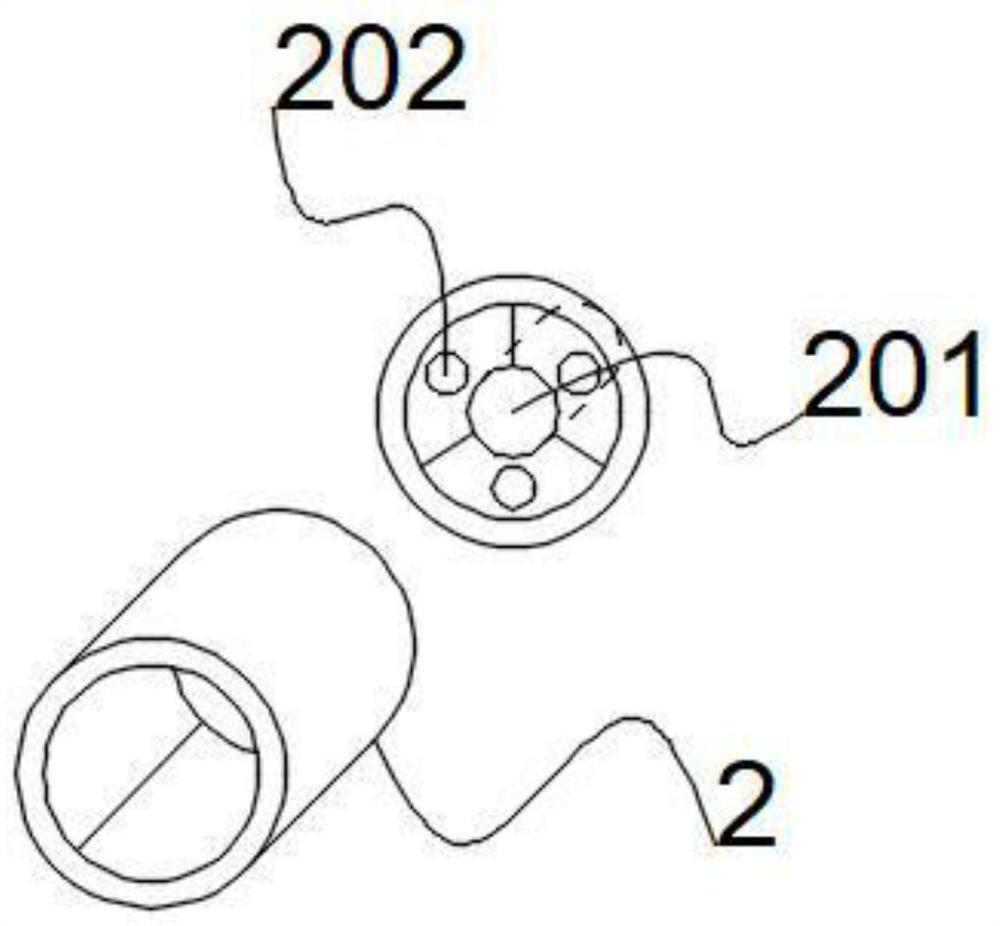

Water wheel device of air purification equipment and air purification equipment thereof

InactiveCN103912951BIncrease water absorption areaUniform water absorptionLighting and heating apparatusUsing liquid separation agentWater storageWater wheel

The invention discloses a water wheel device for air purification equipment and air purification equipment. The water wheel device comprises a water wheel which comprises a water wheel upper cover, a water wheel lower cover and humidification cloth arranged between the water wheel upper cover and the water wheel lower cover. A plurality of water storage grooves are formed at intervals in the edge of the water wheel circumferentially, water inlets are formed in the outer side walls of the water storage grooves, water outlets are formed in the inner side walls of the water storage grooves, and first radial flow channels distributed radially are arranged on the water wheel upper cover and / or the water wheel lower cover and are communicated with the water outlets of the water storage grooves. The water wheel device is used for air purification equipment, such as productions of air humidifiers and air humidification purifiers.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

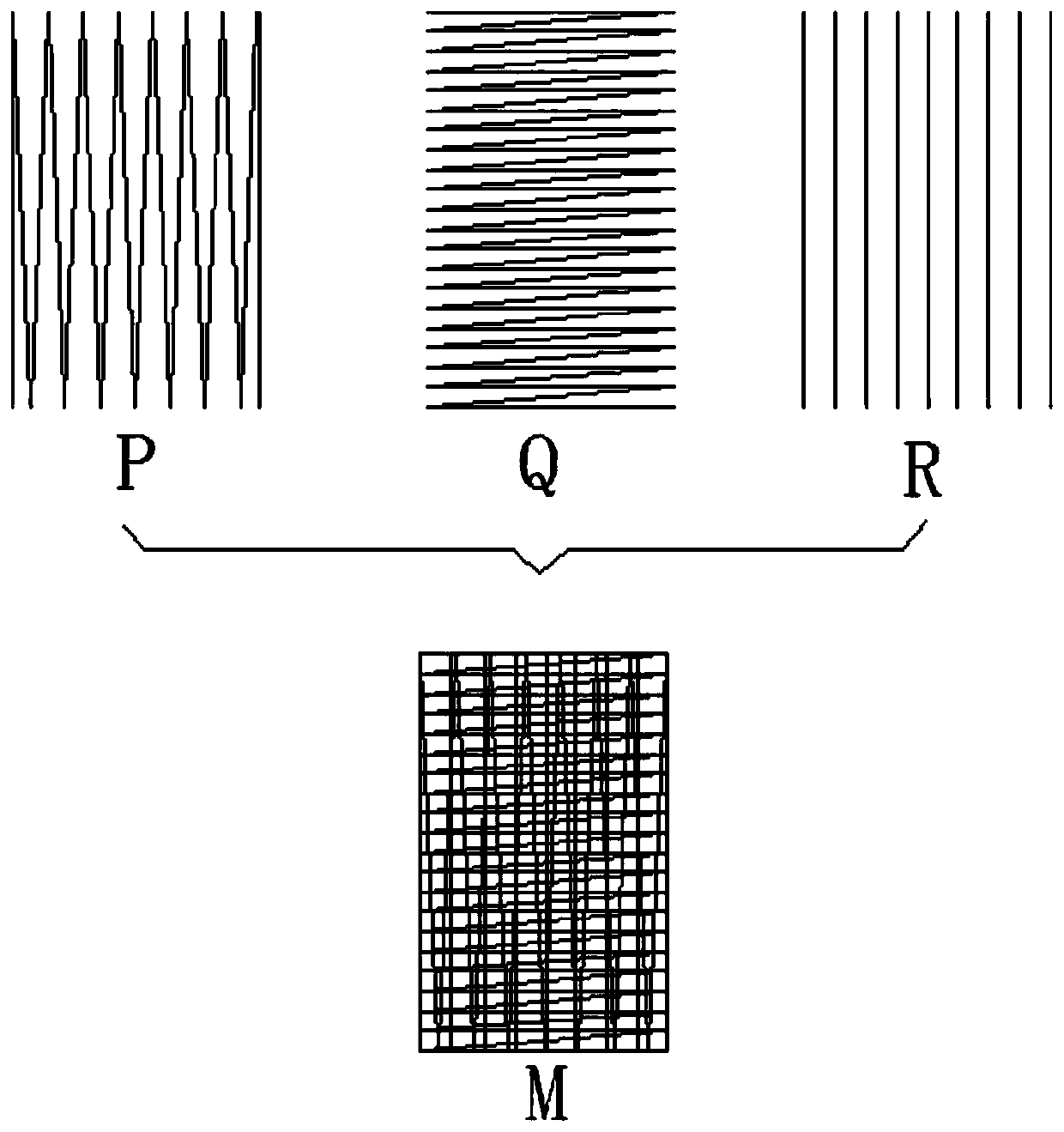

A kind of preparation technology of high physical property ultra-flat bovine fiber skin base cloth

ActiveCN110306288BHigh peel strengthHigh mechanical strengthNon-woven fabricsPolyesterPolymer science

The invention relates to the technical field of leather manufacturing, and discloses a preparation process of a high-physical-property extra-flat cowhide fiber leather base fabric. The preparation process comprises a blending process, a chemical fiber net forming process, a cowhide fiber net forming process and a chemical fiber net and cowhide fiber net laminating and net-forming process; according to the blending process, chemical fibers and cowhide fibers are blended according to the weight ratio of 1:0.8-1:1.2; the chemical fiber net forming process sequentially comprises the steps of opening, carding, lapping, pre-wetting and pre-needling: in the cowhide fiber net forming process, a cowhide fiber raw material is prepared into a cowhide fiber net through air-laying or water-laying; thechemical fibers are mixed fibers of polyester fibers and chinlon fibers, and the chinlon fibers account for 80% or above of the total weight of the mixed fibers; the laminating and net-forming processsequentially comprises the steps of net laminating, spunlace, vacuum drying, drying, trimming, calendering and buffing. According to the preparation process, the physical property of the cowhide fiber leather base fabric is improved, and the production cost is reduced.

Owner:JIANGYIN JUNHUA TEXTILE TECH

A kind of preparation technology of high physical property full water-based bovine fiber skin

ActiveCN110331517BFeel goodGood physical propertiesLamination ancillary operationsSynthetic resin layered productsFiber

The invention relates to the technical field of leather manufacturing, which discloses a preparation process of high-physical all-water-based bovine leather, which sequentially includes a base cloth preparation process, a base cloth post-treatment process, and a film coating process; the base cloth preparation process includes the following steps: Chemical fibers and kraft fibers are used as raw materials, and the chemical fibers are pre-stabbed into chemical fiber webs by hydroentanglement after laying, and the kraft fibers are made into kraft fiber webs by air-laid or water-laid methods, and then the chemical fiber webs, kraft fibers After the mesh is stacked, the process steps of spunlace solidification, vacuum drying, and drying are made into a bovine fiber leather base cloth; the post-treatment process of the base cloth includes water-based PU The process steps of permeating and drying one side of the material; wherein, the depth of permeating one side of the water-based PU material in the post-treatment process of the base fabric is 1 / 3 to 2 / 3 of the thickness of the cow fiber leather base cloth. The invention improves the physical properties of the all-water-based bovine fiber leather and reduces the production cost.

Owner:JIANGYIN JUNHUA TEXTILE TECH

Mining crushing head structure of mining tunneling equipment

ActiveCN110374620BThree-dimensional structureEasy to installDrainageTunnelsArchitectural engineeringStructural engineering

The invention provides a mining crushing head structure of mining tunneling equipment, which includes a small shield machine base body; the redundant space part on the surface of the cutting cutter head on the top of the small shield machine base body is provided with expanded holes, and the top cutting blade of the small shield machine base body The surface of the disc is connected by expanding holes and fixedly installed with an independent drill bit; the inner sides of the base body of the small shield machine are connected by screws and other structures and fixedly installed with an embedded water pump; the outside of the embedded water pump is connected with a pipe. The setting of the embedded water pump and the expansion hole solves the problem that the front end of the mining crushing head structure of the existing mining excavation equipment cannot be easily fine-tuned according to the subtle differences in the actual tunneling conditions to achieve a more experimental soil structure. At the same time, after the tunnel is excavated, the soil layer is prone to water seepage, and the existing water pump pipe structure has poor adaptability to the slight water seepage of the tunnel and the irregular plane inside the tunnel.

Owner:GUIZHOU UNIV

A kind of preparation technology of high physical properties cow fiber leather base cloth

ActiveCN110258022BHigh mechanical strengthHigh peel strengthDrying solid materials without heatNon-woven fabricsPolyesterPolymer science

The invention relates to the technical field of leather, which discloses a preparation process of a high-physical cowhide leather base cloth, including a batching process, a chemical fiber netting process, a kraft fiber netting process, a chemical fiber net and a kraft fiber net. Web process; in the batching process, chemical fiber and kraft fiber are batched according to the weight ratio of 1:0.8 to 1:1.2; the chemical fiber web forming process includes opening, carding, web laying, pre-wetting, pre-wetting The process of thorning: in the kraft fiber net forming process, the kraft fiber raw material is made into a kraft fiber net by air-laid or water-flow-laid net; The process of spunlace, vacuum drying, and drying; wherein, the chemical fiber is a mixed fiber of polyester fiber and nylon fiber, and the nylon fiber in the mixed fiber accounts for more than 80% of the total weight of the mixed fiber. The invention improves the physical performance of the cow fiber leather base cloth and reduces the production cost.

Owner:JIANGYIN JUNHUA TEXTILE TECH

Garden drainage system

ActiveCN111576588AReduce gapAvoid accessFatty/oily/floating substances removal devicesSewerage structuresPlant rootsEnvironmental engineering

The invention discloses a garden drainage system and belongs to the field of garden drainage. The garden drainage system can guide water abnormally increased in soil into drainage channels from the interior of the soil through extension water guide mechanisms arranged in the inner walls of the drainage channels at the high precipitation amount so as to drain the water in the soil. Meanwhile, whenthe exceptional water in the soil is guided into the drainage channels, water absorbed by the extension water guide mechanisms drips in variable force blocks to increase the gravity of the variable force blocks. When touching the inner wall of water guide pipes, the gravity of the variable force blocks is reduced, and elastic water guide rods can gradually recover deformation upwards. Accordingly,in the whole drainage process, the elastic water guide rods continuously vibrate so as to accelerate dripping of water guided by the elastic water guide rods into the water guide pipes and acceleratedraining of water in the soil. Therefore, the garden drainage system achieves the protection effect on plant root systems at the high precipitation amount.

Owner:广州市中景园林环保工程有限公司

A preparation process of fully pierced cow fiber leather base cloth

ActiveCN110258023BImprove physical performanceEasy alignmentDrying solid materials without heatNon-woven fabricsFiberEngineering

The invention relates to the technical field of leather manufacturing, and discloses a preparation process of fully-penetrated cow fiber leather base cloth. The preparation process includes a batching process, a chemical fiber net forming process, a cow leather fiber net forming process, and a process of laminating the chemical fiber net and the cow leather fiber net into a net, wherein the batching process includes taking chemical fibers and cow leather fibers as raw materials for preparing fully-penetrated cow fiber leather base cloth, and batching according to a proportion; the chemical fiber net forming process sequentially includes the working procedures of opening, carding, net laying, pre-wetting and pre-penetrating: in the cow leather fiber net forming process, making cow leather fiber raw materials into a cow leather fiber net by adopting airflow net forming or water flow net forming; and the process for laminating the chemical fiber net and the cow leather fiber net into a net sequentially includes the working procedures of laminating the net, spunlacing, vacuum suction and drying, and the net laying working procedure includes warp cross laying and weft cross laying. The preparation process improves the physical properties of the cow fiber leather base cloth and reduces the production cost.

Owner:JIANGYIN JUNHUA TEXTILE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com