Mining crushing head structure of mining tunneling equipment

A technology of crushing head and equipment, used in mining equipment, earth-moving drilling, tunnels, etc., can solve the problems of poor adaptability of irregular plane inside the tunnel, easy water seepage in the soil layer, etc., to avoid water accumulation inside the tunnel, large water absorption area, etc. High adsorption and cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] as attached figure 1 to attach Figure 5 Shown:

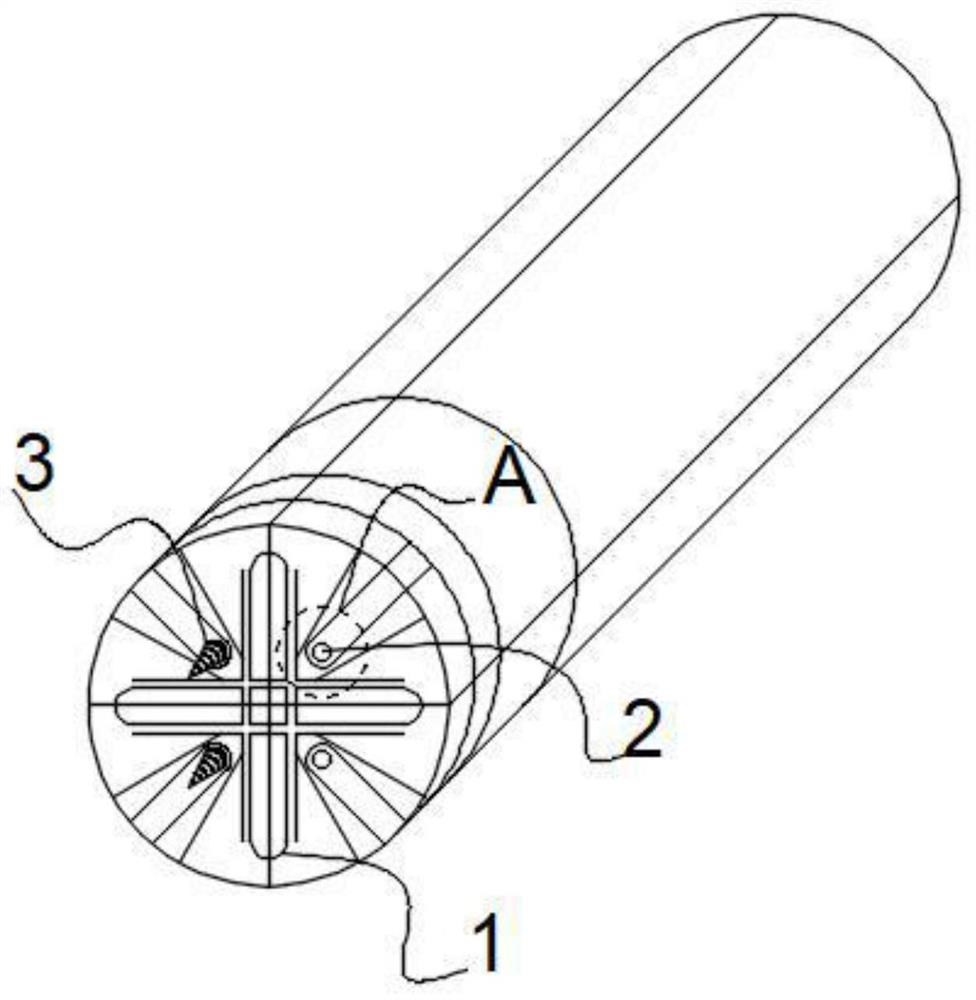

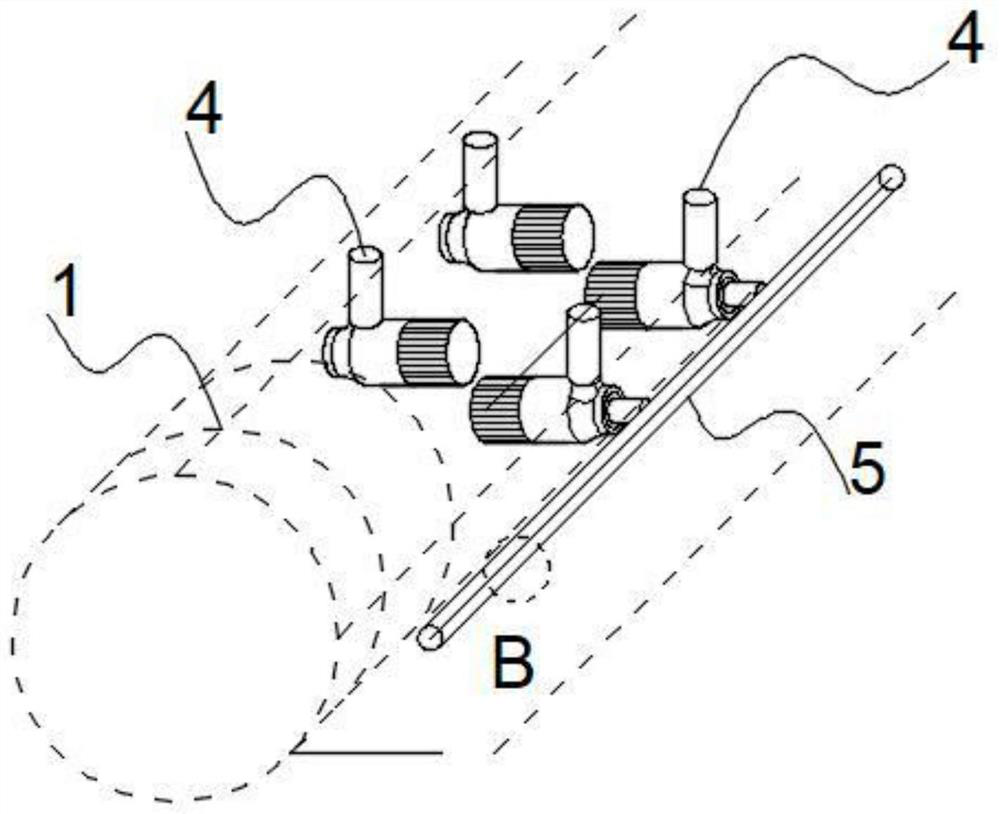

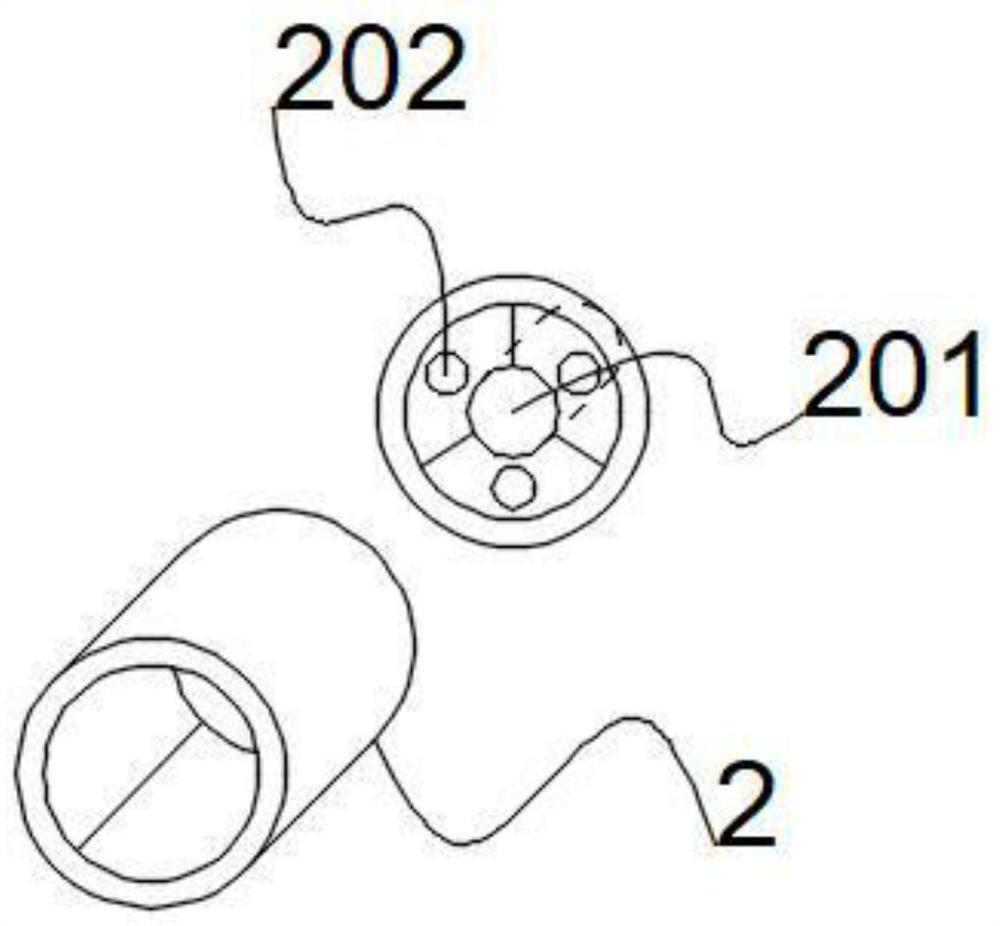

[0029] The invention provides a mining crushing head structure for mining tunneling equipment, which includes a small shield machine base 1; the redundant space on the top cutting cutter head surface of the small shield machine base 1 is provided with an expanded hole 2, and the small shield machine base 1 The surface of the top cutting cutter head is connected and fixedly installed with an independent drill bit 3 through the expanded hole 2; the inside of the small shield machine base 1 body is connected and fixedly installed with an embedded water pump 4 through structures such as screws; A pipe 5 is connected to the outside of the water pump 4 .

[0030] Wherein, the base 1 of the small-sized shield machine includes a filling disc 101; the filling disc 101 is a mutual replacement structure of the independent drill bit 3, and the filling disc 101 is installed in the expanded hole 2 to fill the expanded hole 2 surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com