Waste thermosetting plastic modified asphalt and preparation method thereof

A modified asphalt and thermosetting technology, which is applied to building insulation materials, building components, buildings, etc., can solve the problems of huge amount of thermosetting plastics, increased demand and consumption, and recovery rate of less than 10%, achieving a three-dimensional structure and increasing Viscosity and tightness, homogeneous and dense effect of internal connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

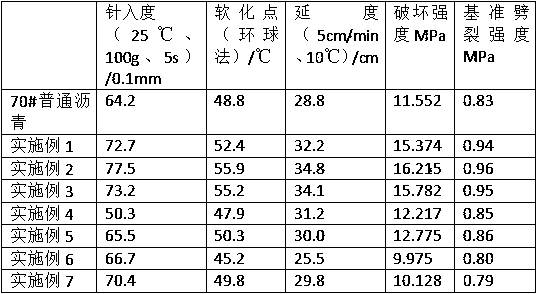

Examples

Embodiment 1

[0022] A waste thermosetting plastic modified asphalt, which is composed of the following components in parts by weight: 100 parts of base asphalt, 20 parts of waste thermosetting plastic, 2 parts of modifier, 0.1 part of foaming agent, and 0.2 parts of foam stabilizer , 0.1 part of defoamer, 0.05 part of stabilizer, 10 parts of vinyltriethoxysilane, 30 parts of water.

[0023] The modifier is block copolymer (SBS) modified asphalt.

[0024] Foaming agent is fatty alcohol polyoxyethylene ether sodium sulfate.

[0025] Foam stabilizer is silicone resin polyether emulsion (MPS).

[0026] The defoamer is simethicone.

[0027] The stabilizer is calcium chloride.

[0028] Waste thermosetting plastics are phenolic plastics, aminoplasts, epoxy resins, furan resins, unsaturated polyester resins and silicone resins.

Embodiment 2

[0030] A waste thermosetting plastic modified asphalt, which is composed of the following components in parts by weight: 100 parts of base asphalt, 30 parts of waste thermosetting plastic, 3 parts of modifier, 0.2 part of foaming agent, and 0.3 part of foam stabilizer , 0.15 parts of defoamer, 0.1 part of stabilizer, 15 parts of vinyltriethoxysilane, and 40 parts of water.

[0031] The modifier is block copolymer (SBS) modified asphalt.

[0032] Foaming agent is fatty alcohol polyoxyethylene ether sodium sulfate.

[0033] Foam stabilizer is silicone resin polyether emulsion (MPS).

[0034] The defoamer is simethicone.

[0035] The stabilizer is calcium chloride.

[0036] Waste thermosetting plastics are phenolic plastics, aminoplasts, epoxy resins, furan resins, unsaturated polyester resins and silicone resins.

Embodiment 3

[0038] A waste thermosetting plastic modified asphalt, which is composed of the following components in parts by weight: 100 parts of base asphalt, 40 parts of waste thermosetting plastic, 5 parts of modifier, 0.2 part of foaming agent, and 0.5 part of foam stabilizer , 0.2 parts of defoamer, 0.1 part of stabilizer, 20 parts of vinyltriethoxysilane, and 50 parts of water.

[0039] The modifier is block copolymer (SBS) modified asphalt.

[0040] Foaming agent is fatty alcohol polyoxyethylene ether sodium sulfate.

[0041] Foam stabilizer is silicone resin polyether emulsion (MPS).

[0042] The defoamer is simethicone.

[0043] The stabilizer is calcium chloride.

[0044] Waste thermosetting plastics are phenolic plastics, aminoplasts, epoxy resins, furan resins, unsaturated polyester resins and silicone resins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com