Patents

Literature

594results about How to "Tightly bonded" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low dielectric constant materials and method

InactiveUS6051321AImprove rotational flexibilityTightly boundSemiconductor/solid-state device detailsSynthetic resin layered productsElectrical conductorCopper

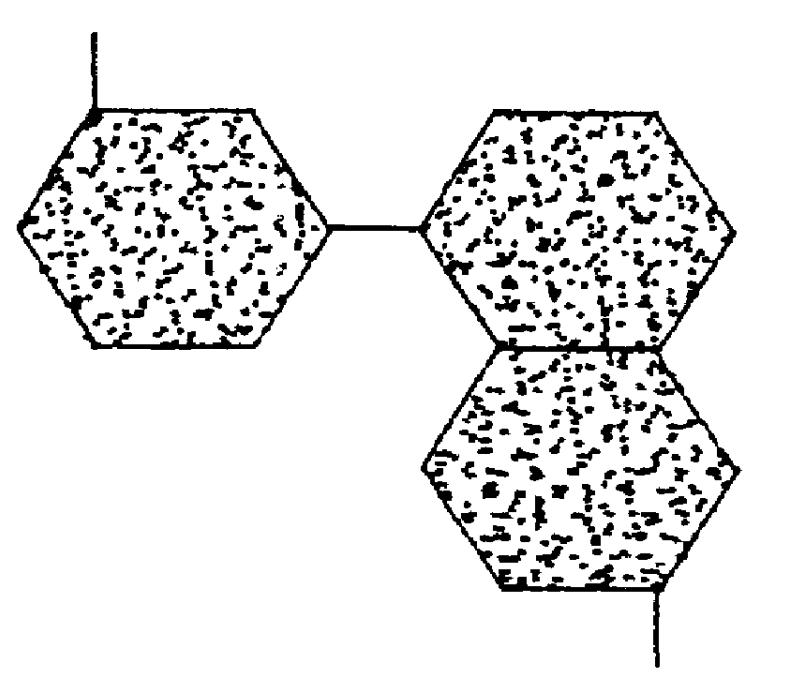

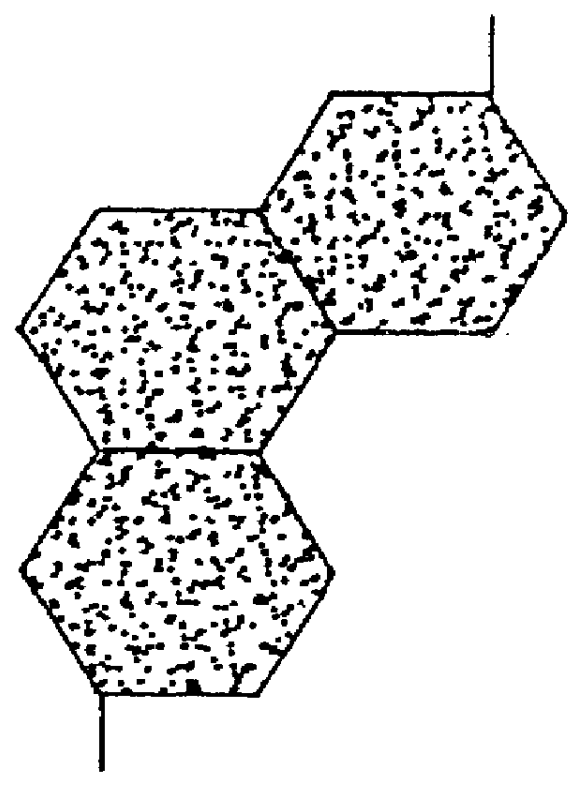

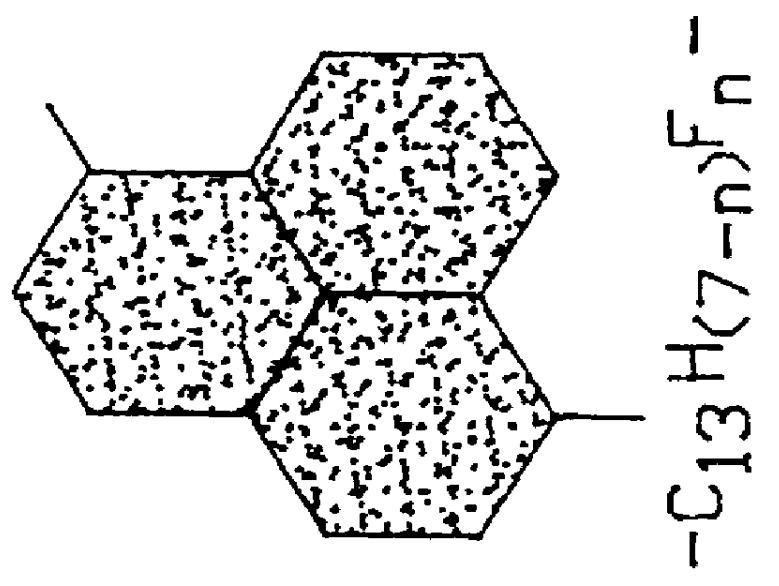

Intermetal dielectric (IMD) and interlevel dielectric (ILD) that have dielectric constants (K) ranging from 2.0 to 2.6 are prepared from plasma or photon assisted CVD (PACVD) or transport polymerization (TP). The low K dielectric (LKD) materials are prepared from PACVD or TP of some selected siloxanes and F-containing aromatic compounds. The thin films combine barrier and adhesion layer functions with low dielectric constant functions, thus eliminating the necessity for separate adhesion and barrier layers, and layers of low dielectric constant. The LKD materials disclosed in this invention are particularly useful for <0.18 .mu.m ICs, or when copper is used as conductor in future ICs.

Owner:CANON USA

Construction material produced by utilizing industrial residue

The invention discloses a construction material produced from industrial residue, aims to provide a construction material having the advantages of light weight, sound insulation, heat insulation, low cost, fire resistance, dense products, high rigidity and the like, and solves the problems with land occupation and pollute environment of phosphate slag and phosphogypsum at the same time. the invention is realized through the following technical scheme: phosphate slag and phosphogypsum are used as raw materials for producing the construction material, which comprises the following components by the weight part: 35 to 65 parts of phosphate slag, 10 to 40 parts of phosphogypsum, 5 to 15 parts of lime, 15 to 28 parts of cement, 0.1 to 0.4 part of light aggregate, 0.02 to 0.05 part of soluble glass, 0.02 to 0.05 part of water-reducing agent, 0 to 0.004 part of retarding agent, 0 to 0.005 part of early-strength admixture, and 0 to 0.008 part of foam killer; the components are weighed by the formula weight part and added to a blender; water is added to the blender with the water-to-material proportion being 4 to 10 and mixed evenly with the materials; and the solution is cast into a die and natural air dried after molding. Dies with different structures can be used according to purposes to conduct cast molding. The construction materials such as wall plates, guardrail decoration pillars, door and window sleeves, vase sleeves and the like can be produced.

Owner:张勇飞

Ecological shell powder inorganic nanometer composite coating material and preparation method thereof

The present invention relates to an ecological shell powder inorganic nanometer composite coating material and a preparation method thereof. The ecological shell powder inorganic nanometer composite coating material comprises, by mass, 70-90% of shell powder and 10-30% of a composite glue adhesive, wherein the shell powder contains 1-3% by mass of titanium dioxide nanoparticles and 1-3% by mass of tourmaline powder, and the composite glue adhesive contains 80-90% by mass of water, 3-10% by mass of polyvinyl alcohol, and 0.5-3% by mass of cellulose. According to the present invention, natural shell powder is adopted as a main material, any toxic and hazardous substances are not added, and the ecological shell powder inorganic nanometer composite coating material has functions of indoor toxic gas absorption and decomposition, and has the following characteristics that: construction is simple, shedding due to scrubbing can not be generated, negative oxygen ions can be released for a long time so as to carry out a purification and sterilization treatment on indoor air.

Owner:山东贝壳屋新材料科技有限公司

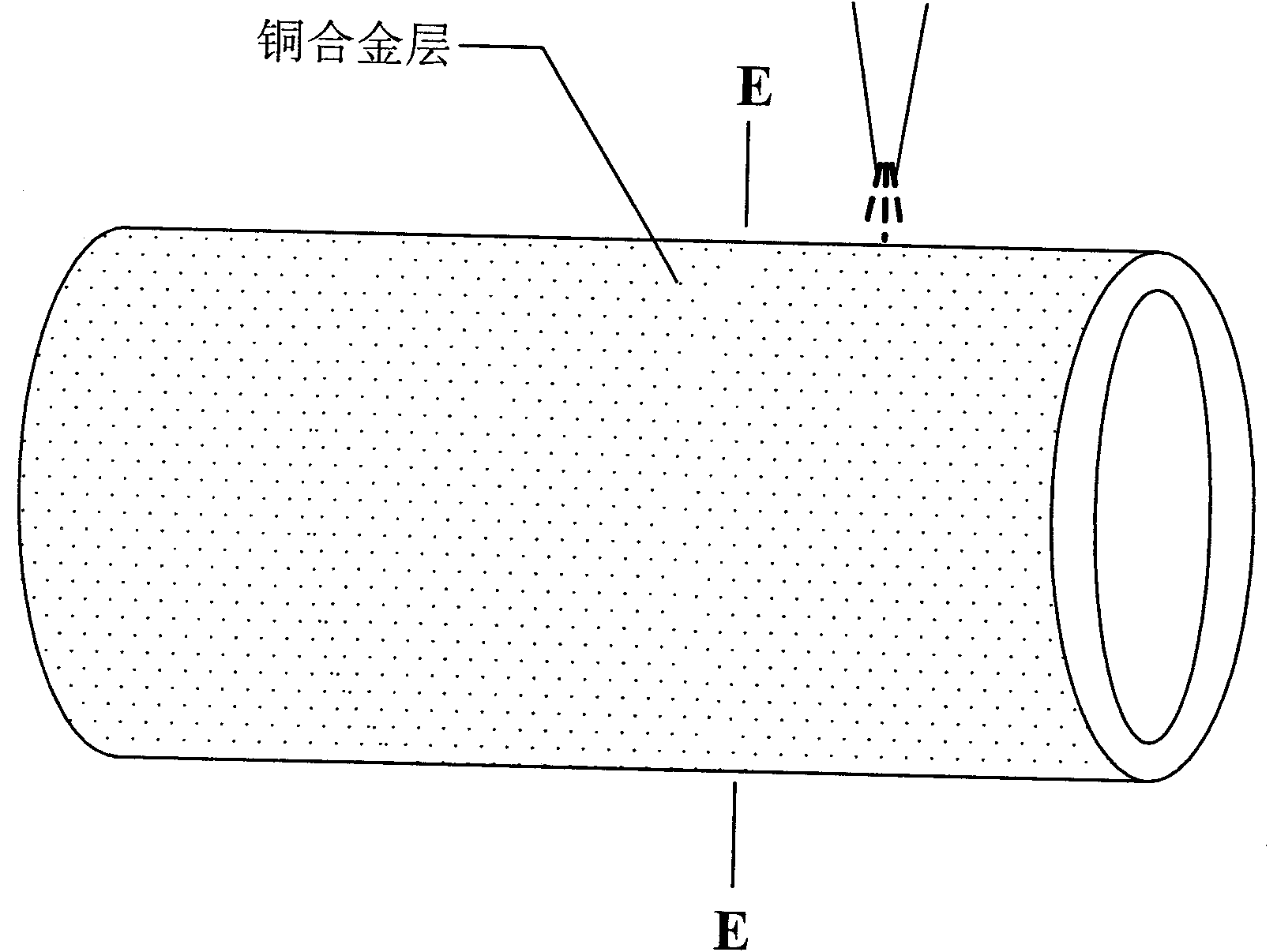

Method for cladding copper alloy layer on surface of steel substrate by laser brazing

InactiveCN101805903ATightly bondedImprove bindingMetallic material coating processesWear resistanceHeat treated

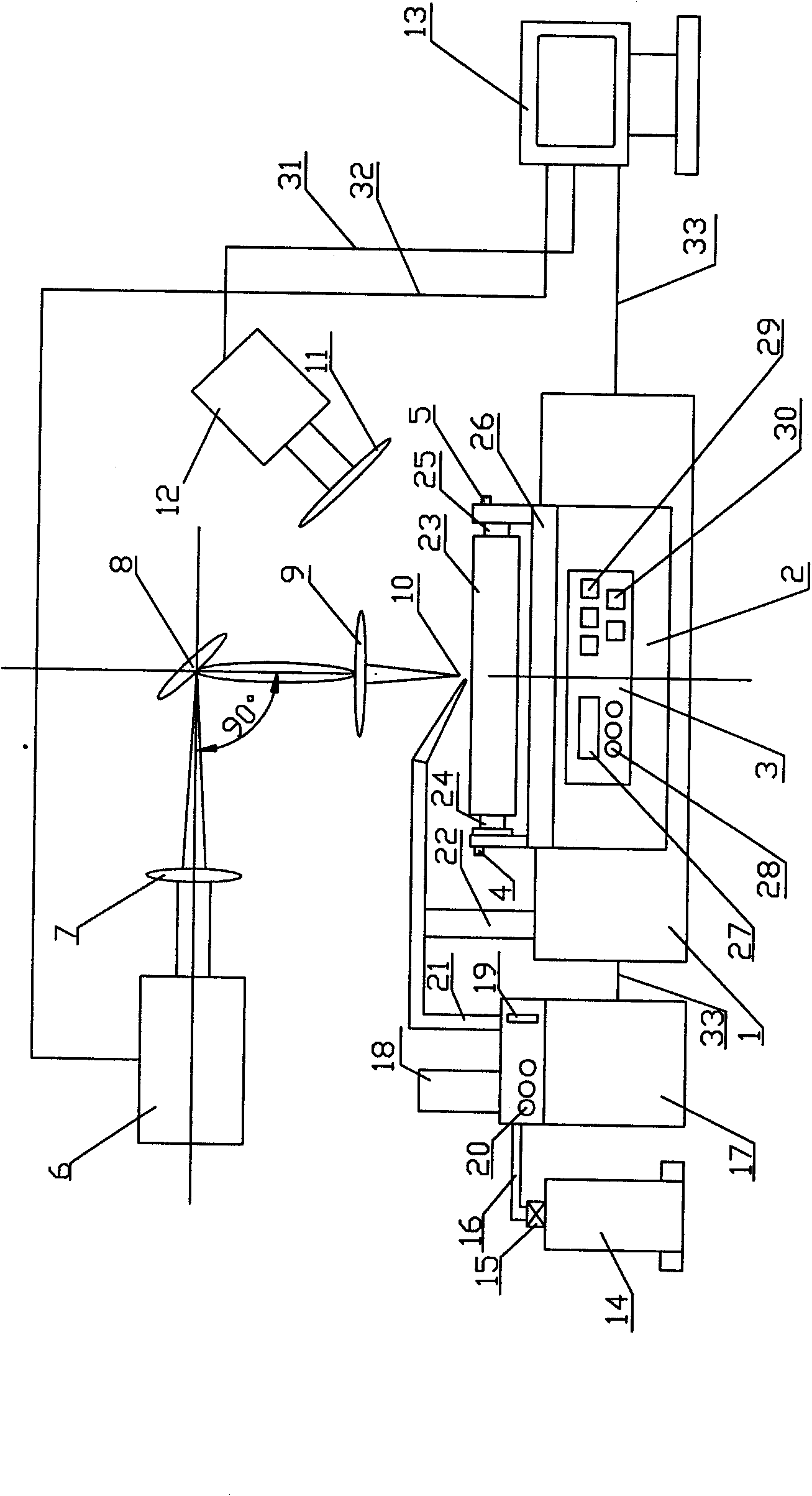

The invention relates to a method for cladding a copper alloy layer on the surface of a steel substrate by laser brazing. A method of feeding powder by argon gas, cladding by laser brazing and vacuum heat treatment is used on a laser machine for cladding a copper alloy layer on the surface of the steel substrate by laser brazing; the laser machine is used for remelting and curing the surface of the steel substrate firstly; and laser beams irradiate in all directions according to the geometric locus of ring steel set by computer programs to enable copper alloy powder and borax powder to be melted and cured on the surface of the steel substrate to form the copper alloy layer. The thickness of the copper alloy layer is 0.5mm; the average microhardness of the copper alloy layer is 375HV0.2 which is 2 times of the average microhardness of the steel substrate; and compared with the steel substrate, the wear resistance of the copper alloy layer is improved by 52.8%, and the corrosion resistance of the copper alloy layer is improved by 45.3%. The method has advanced processes and reasonable parameters; the metallographic structure of the cured and melted layer is compact and firm and can not fall off easily; and the method can be used for cladding alloy layers on the surfaces of steel substrates of various molded surfaces by brazing and can be used for cladding alloy layers on various molded surfaces and special-shaped non-standard molded surfaces, thereby greatly improving the performance of the surfaces of the steel substrates.

Owner:TAIYUAN UNIV OF TECH

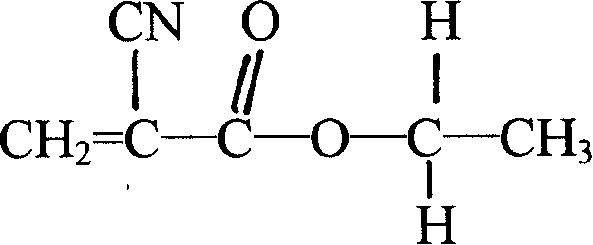

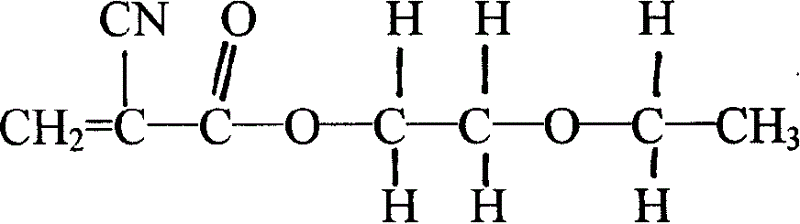

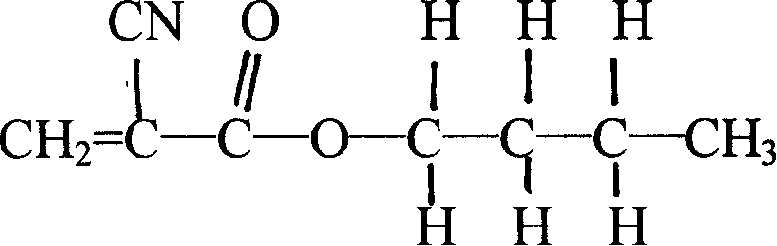

Medical adhesive used for adhering skin and viscus hemostasis, and its prepn. method

A medical adhesive for adhering skin and hemostasis of viscera is prepared from at least two organic compounds chosen from alpha-ethyl cyanoacrylate, alpha-ethoxyethyl cyanoacrylate, alpha-butyl cyanoacrylate and alpha-octyl cyanoacrylate through proportional mixing.

Owner:石平安

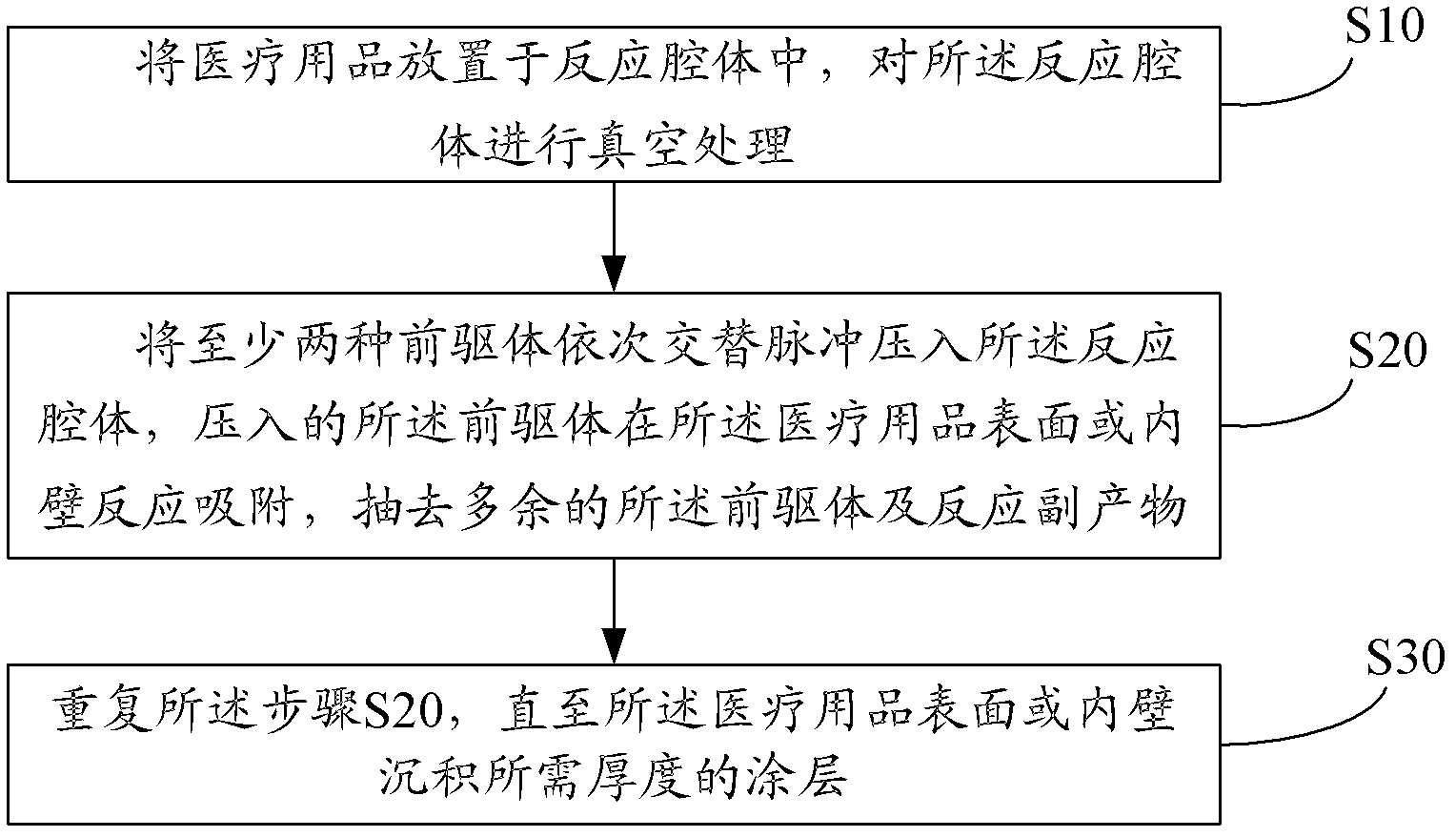

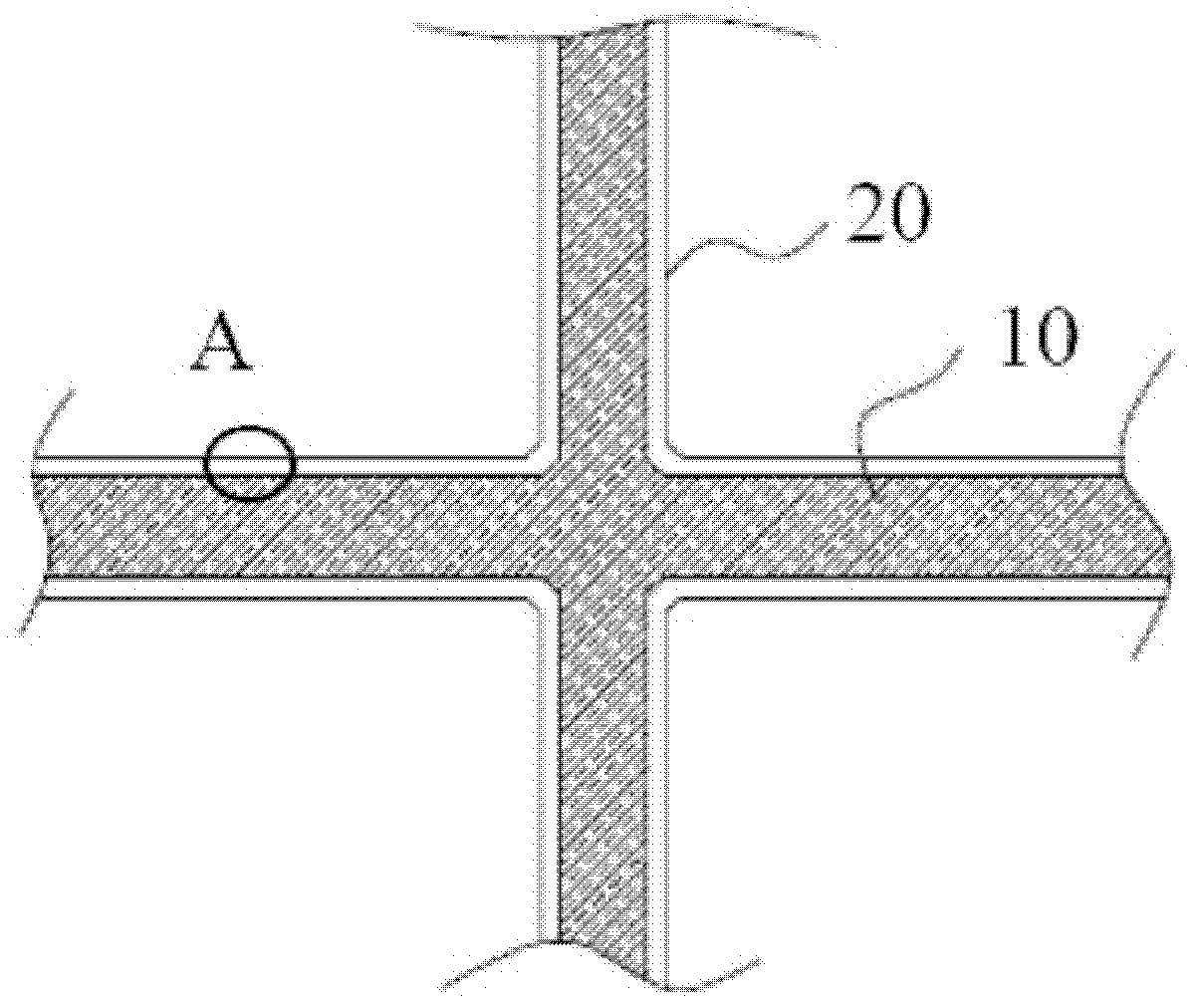

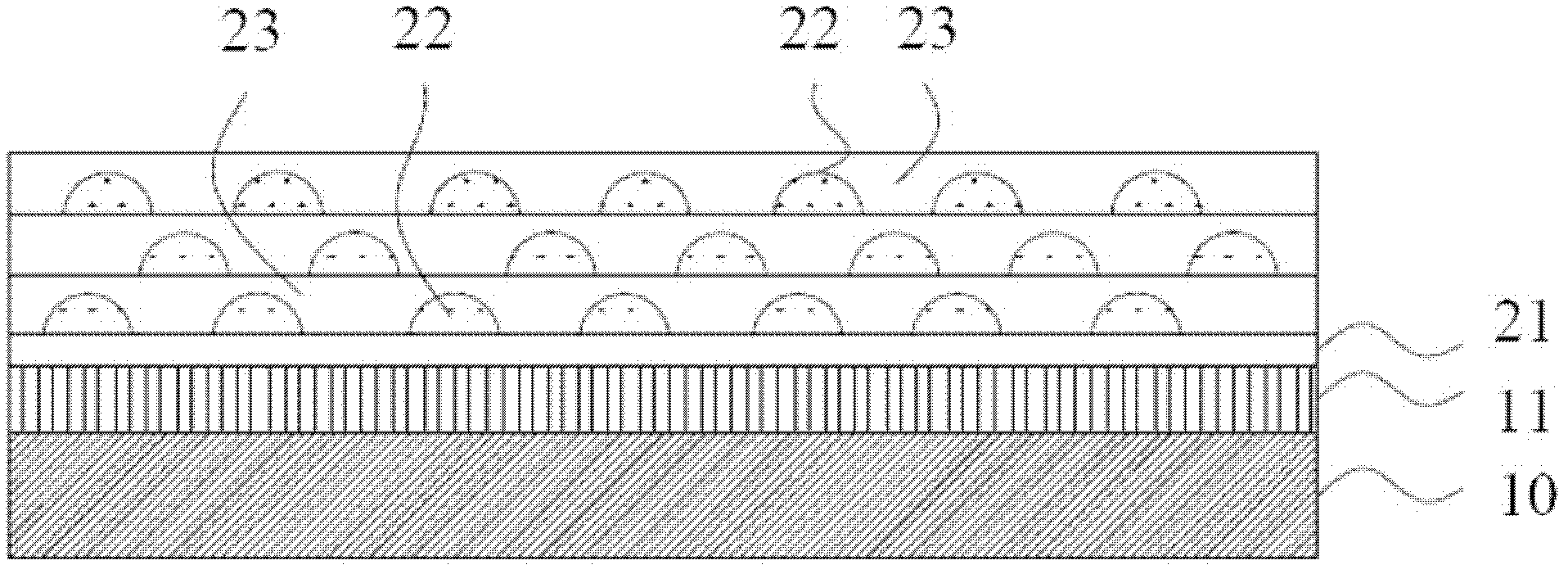

Preparation method for coatings of medical supplies and products thereof

InactiveCN103132045AUniform thicknessGood coating effectChemical vapor deposition coatingBiocompatibility TestingMedical treatment

The invention discloses a preparation method for coatings of medical supplies. The preparation method includes a first step of placing the medical supplies into a reaction cavity, and carrying out vacuum treatment on the reaction cavity, a second step of pressing at least two types of precursors into the reaction cavity in sequence in a pulse alternating mode, enabling the pressed precursors to carry out reaction and absorption on the surfaces or the inner walls of the medical supplies, sucking out the redundant precursors and reaction accessory substances, and a third step of repeating the second step until that coatings with needed thickness are deposited on the surfaces or the inner walls of the medical supplies. The invention further discloses the novel medical supplies manufactured through the preparation method. The preparation method can be used for preparing the coatings which are even in thickness, good in biocompatibility, antimicrobial, antiallergic, corrosion resisting, non-toxic, insulated or conductive, fully coated or partially coated, and smooth on the surfaces or the inner walls of any kinds of medical supplies.

Owner:英作纳米科技(北京)有限公司

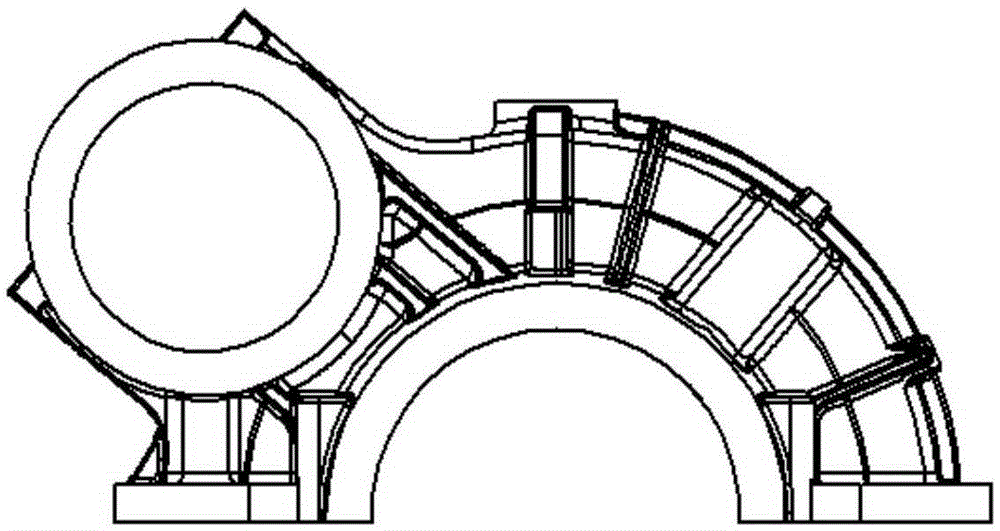

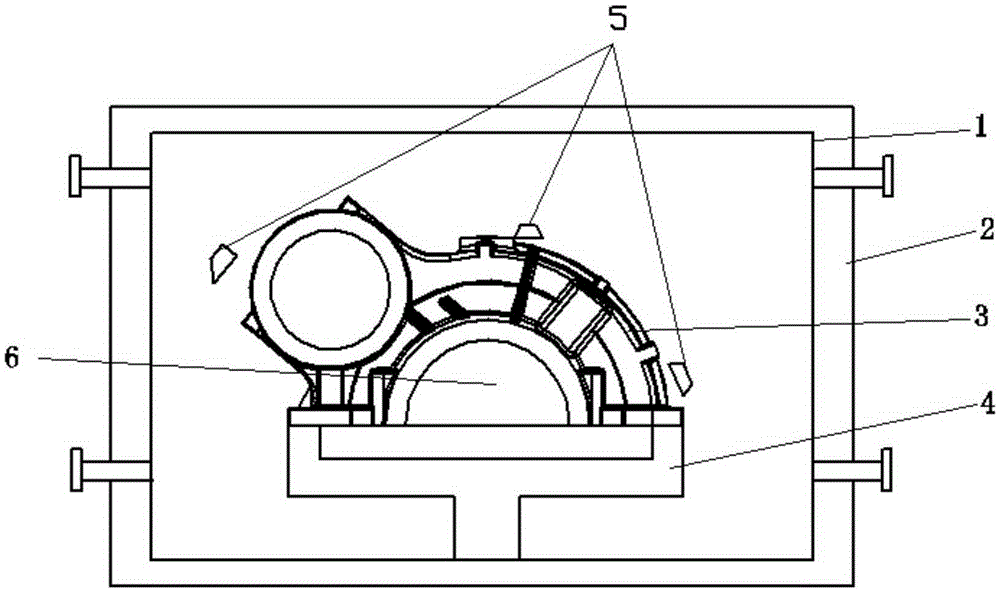

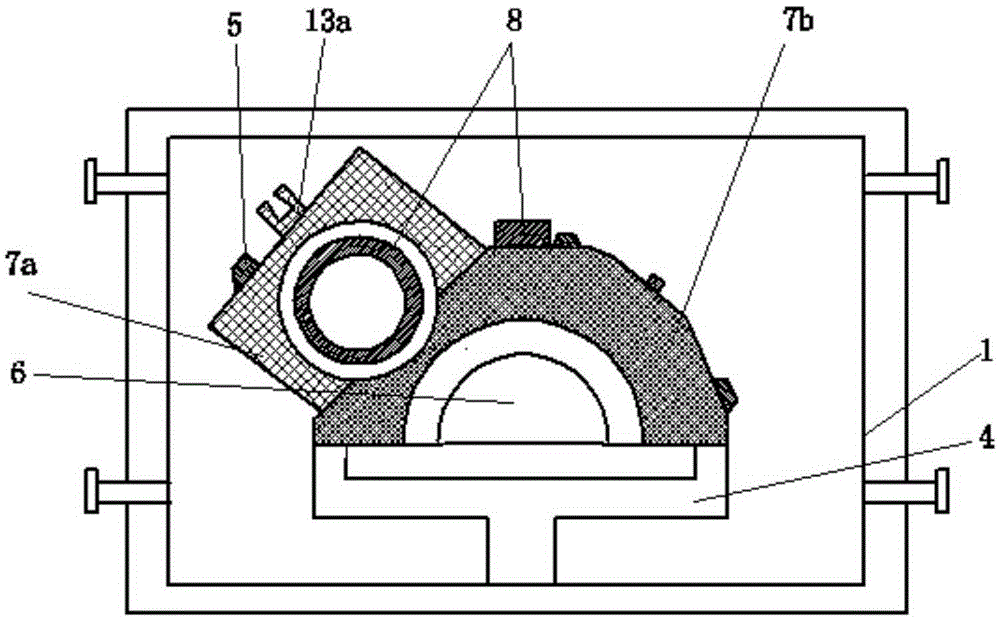

Casting mold and forming method for box body of gearbox

ActiveCN105382206AClear outlineFilled tightlyFoundry mouldsFoundry coresCasting moldMaterials science

The invention provides a casting mold and forming method for a box body of a gearbox and belongs to the technical field of liquid formation of metal. The forming method comprises the following steps that precoated sand is used for core shooting, so that precoated sand blocks are manufactured, then an outer precoated sand mold layer is formed by splicing the precoated sand blocks, and the outer precoated sand mold layer and a sand core are used for forming a casting cavity of the box body of the gearbox; and finally the box body of the gearbox is manufactured through the casting mold in a low-pressure casting way. According to the specific structure of the casting mold, the sand core is located in the center of the casting mold; the casting cavity is formed in the outer layer of the sand core and mainly formed by the sand core and the outer precoated sand mold layer; an outer resin sand mold layer is arranged on the outer layer of the outer precoated sand mold layer, and the outer precoated sand mold layer and a sand box are connected through the outer resin sand mold layer, so that the casting mold is formed. According to the casting mold and forming method for the box body of the gearbox, the cavity which is formed by the precoated sand and used for large complicated castings is used for low-pressure casting for the first time, the precoated sand blocks are subjected to core shooting under pressure, high-temperature sintering formation is conducted, filling is compact, and the situations that sand filling is incompact and sand adhesion defects are caused due to human factors during resin sand molding are avoided.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

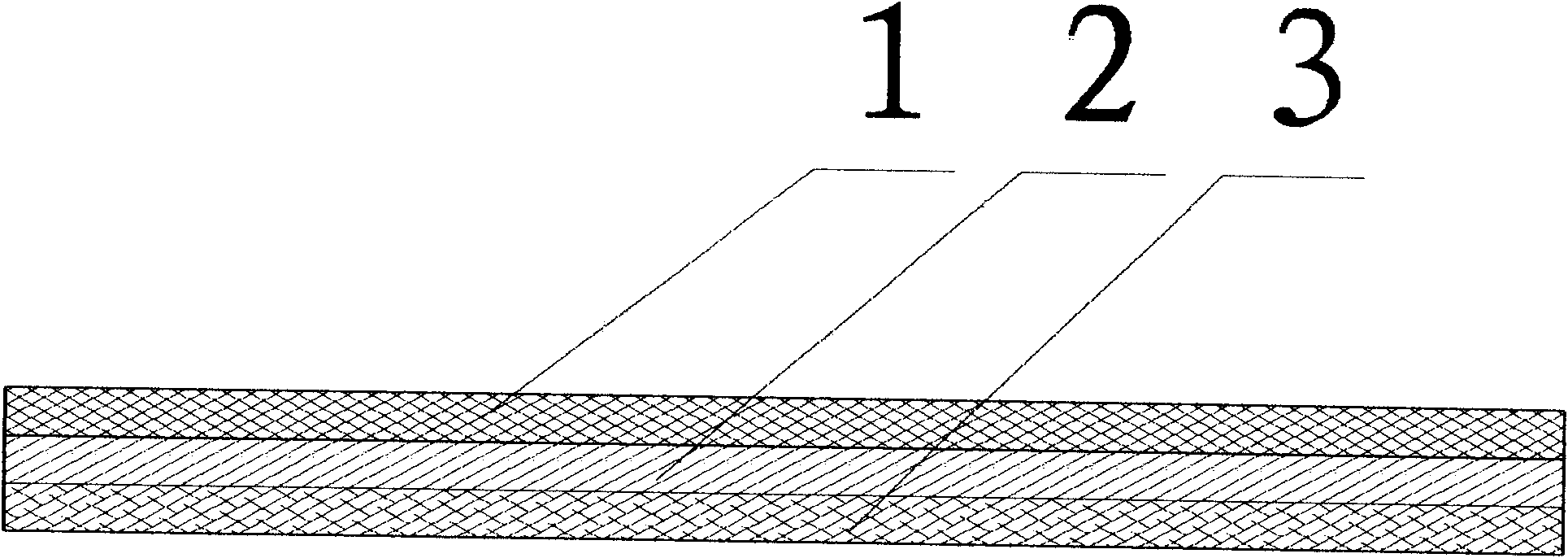

Production technology of composite nonwoven fabric-film dust-free paper

InactiveCN102337702ATightly bondedFast absorptionNon-fibrous pulp additionSpecial paperPapermakingHot melt

The invention, belonging to the technical field of papermaking, relates to a production technology of a composite nonwoven fabric-film dust-free paper, comprising the following steps: using heat bonding non-woven fabrics as bedding, mixing fluffy pulp wood fibers, melt composite fibers and superabsorbent fibers (SAF) in a moulding case and carrying out suction to form a dust-free paper structure, carrying out hot melting on non-woven fabrics, and then carrying out hot bonding on the hot melt non-woven fabrics with the dust-free paper to form a composite structure, coating a polyethylene film through a calender to obtain a composite product, and rewinding to obtain the finished product. The invention has the advantages of high tensile strength of the product, tight bonding of materials, difficult layering of the product after absorbing liquid, product performance assurance, and rapid absorption of a large amount of liquid.

Owner:NANNING QIAOHONG NEW MATERIALS

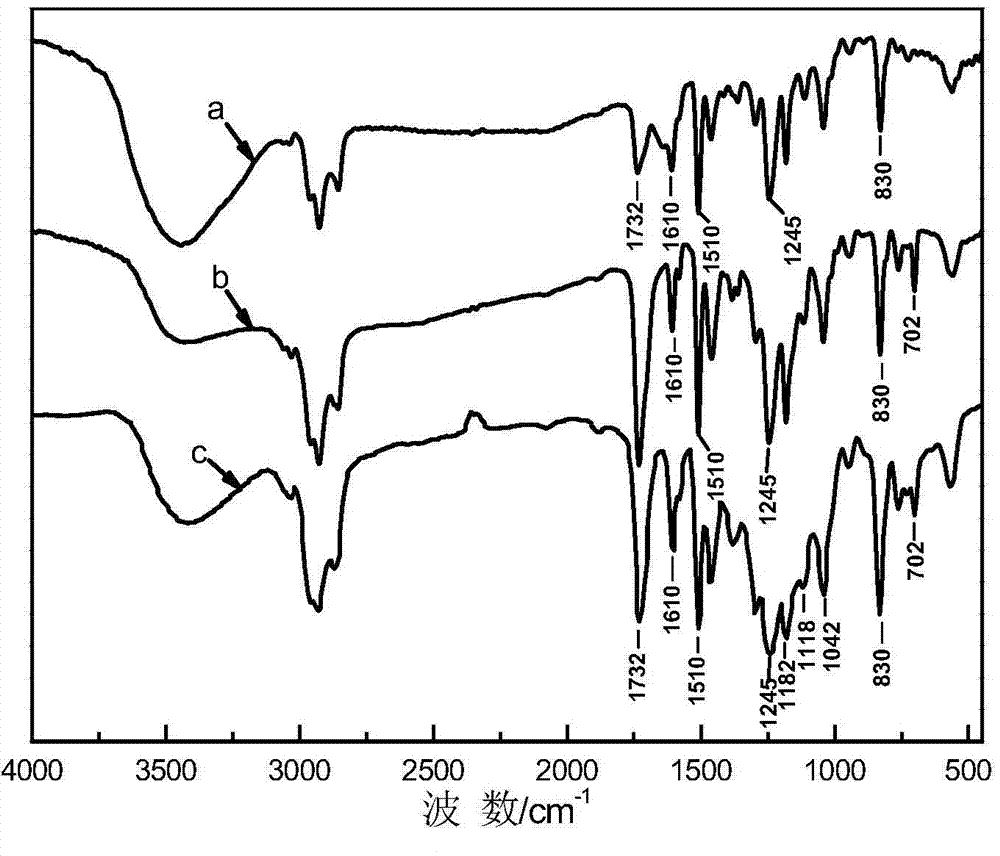

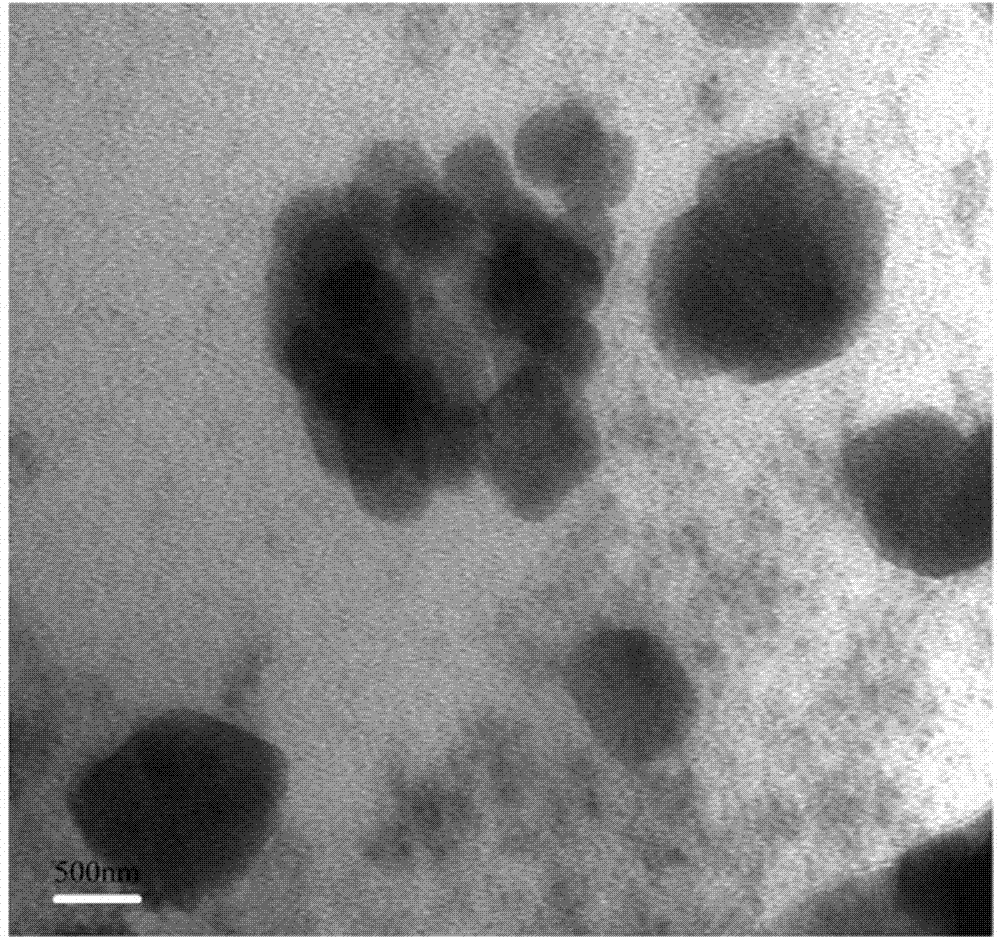

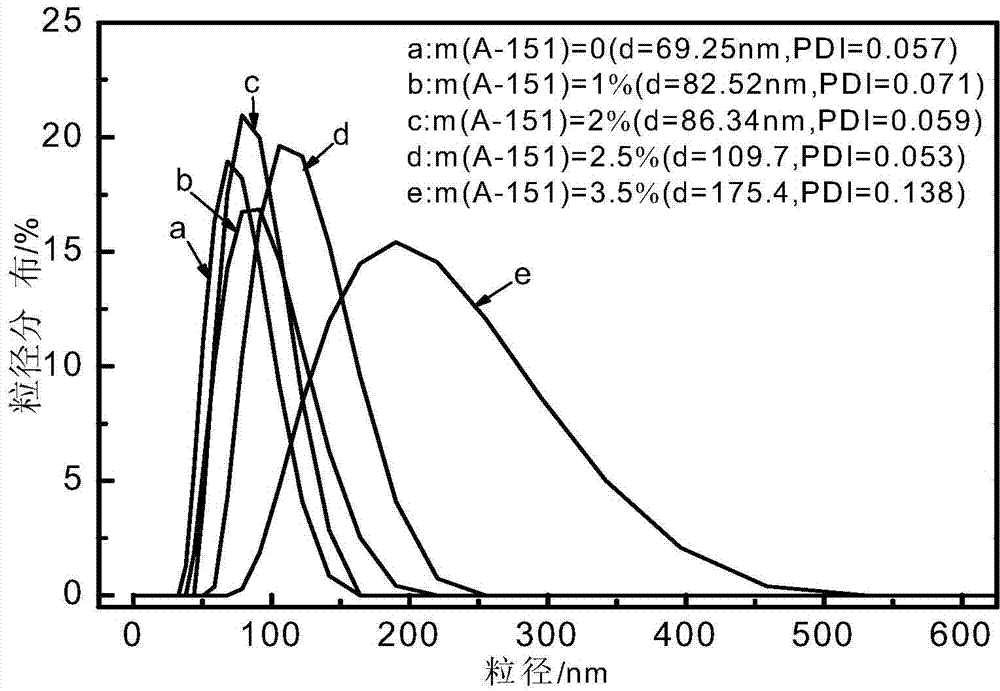

Preparation method of organic silicon modified normal-temperature multiple self-crosslinked epoxy resin emulsion

The invention discloses a preparation method of organic silicon modified normal-temperature multiple self-crosslinked epoxy resin emulsion. The preparation method comprises the following steps: opening a ring of epoxy resin by using lauric acid; consuming away epoxy groups; performing grafting polymerization by using double-bond organo-siloxane, diacetone-acrylamide and an acrylic acid type monomer; and neutralizing the emulsion and adding hexane diacid dihydrazide to obtain the organic silicon modified normal-temperature multiple self-crosslinked epoxy resin emulsion. After the emulsion is formed into a film, ketone carbonyl and hydrazine have dehydration reaction under an acidic condition to generate a hydrazine compound; silanol and an active group of a polymer are condensed to form a three-dimensional network structure in order to realize normal-temperature multiple self-crosslinking. The solid content of the emulsion prepared by the method disclosed by the invention is 45% to 55%; the adhesive force reaches 0-1 grade after the film is formed by room temperature curing; the impact resistance is 50kg.cm to 65kg.cm; the flexibility is 2mm to 3mm; the water resistance is 120h to 150h; and the resistance to a 3% NaCl solution is 100h to 180h. The emulsion disclosed by the invention can be widely applied to various water-based paints as base resin.

Owner:SOUTH CHINA UNIV OF TECH

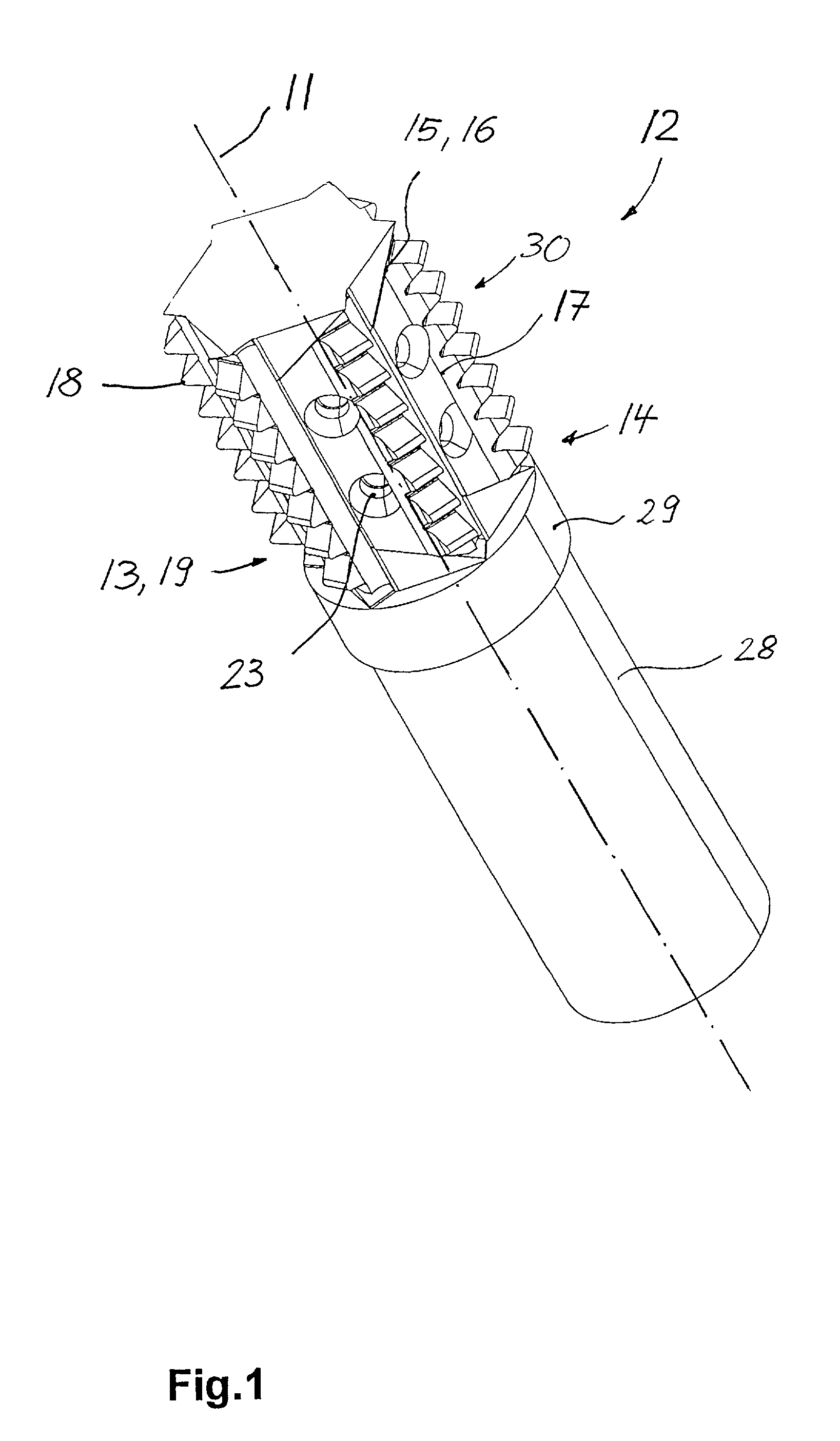

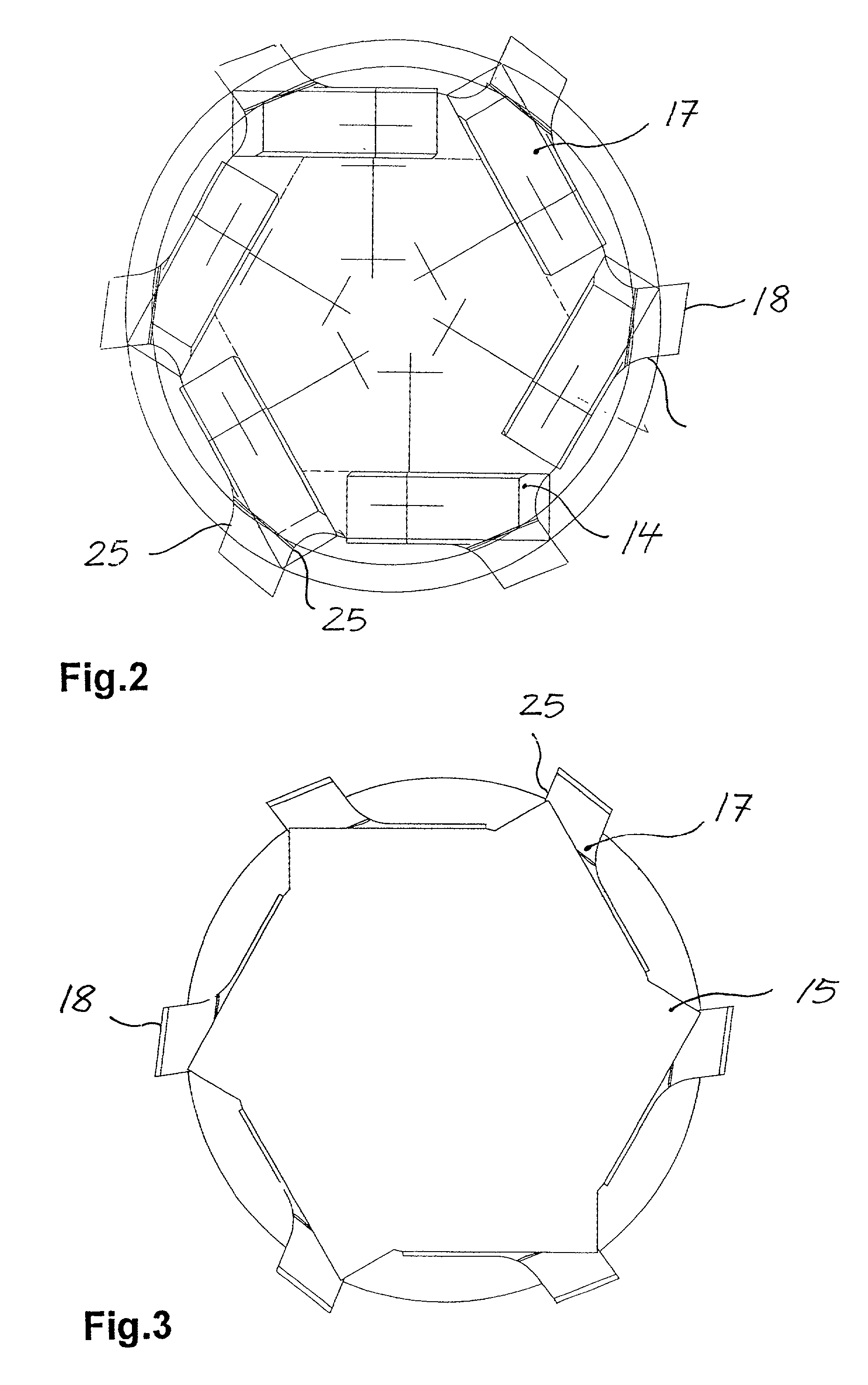

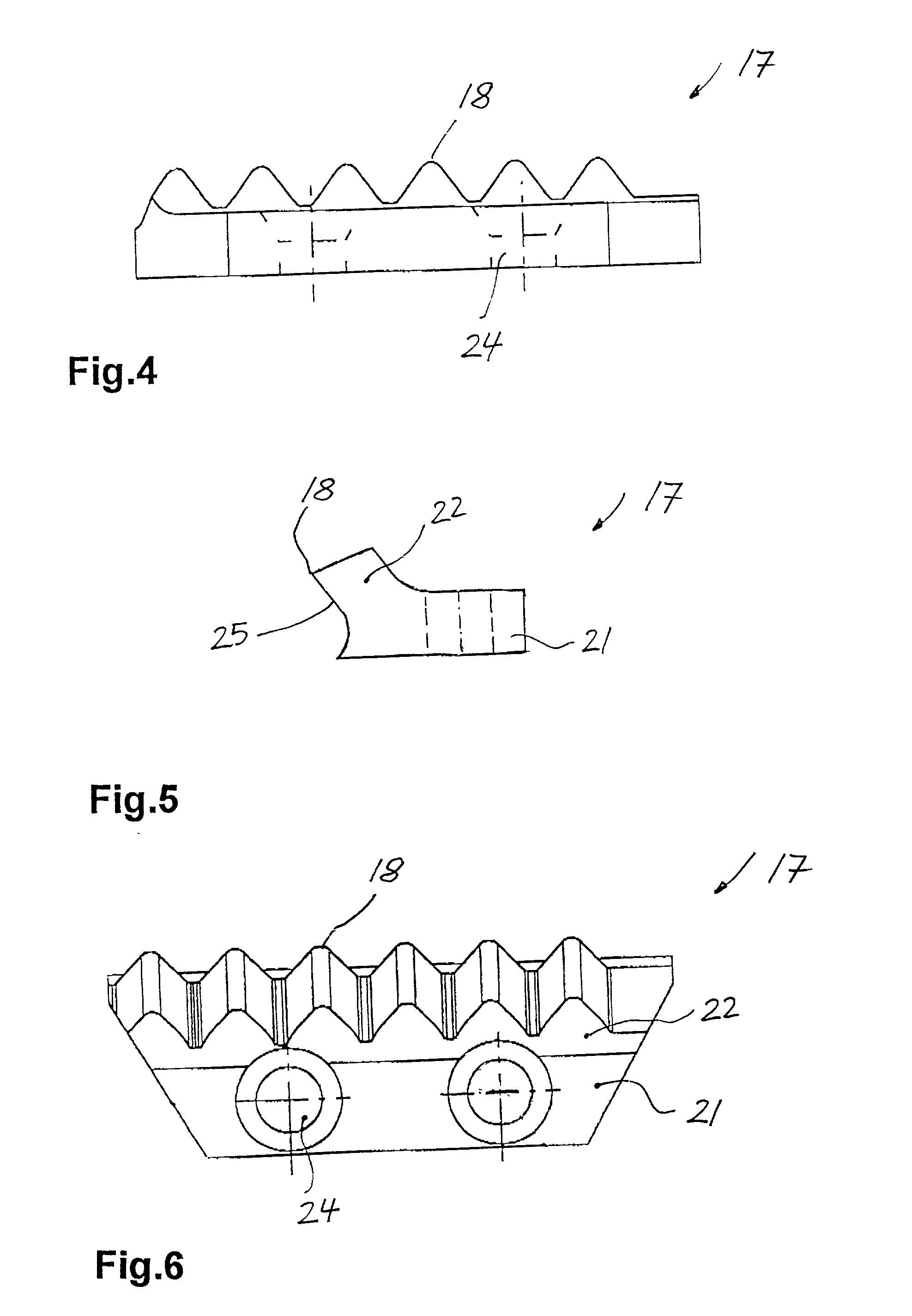

Milling tool and insert, particularly thread milling cutter

InactiveUS20010018010A1Reduced stabilityTightly bondedThread cutting toolsMilling cuttersMilling cutterEngineering

Owner:VARGUS TOOL MFG

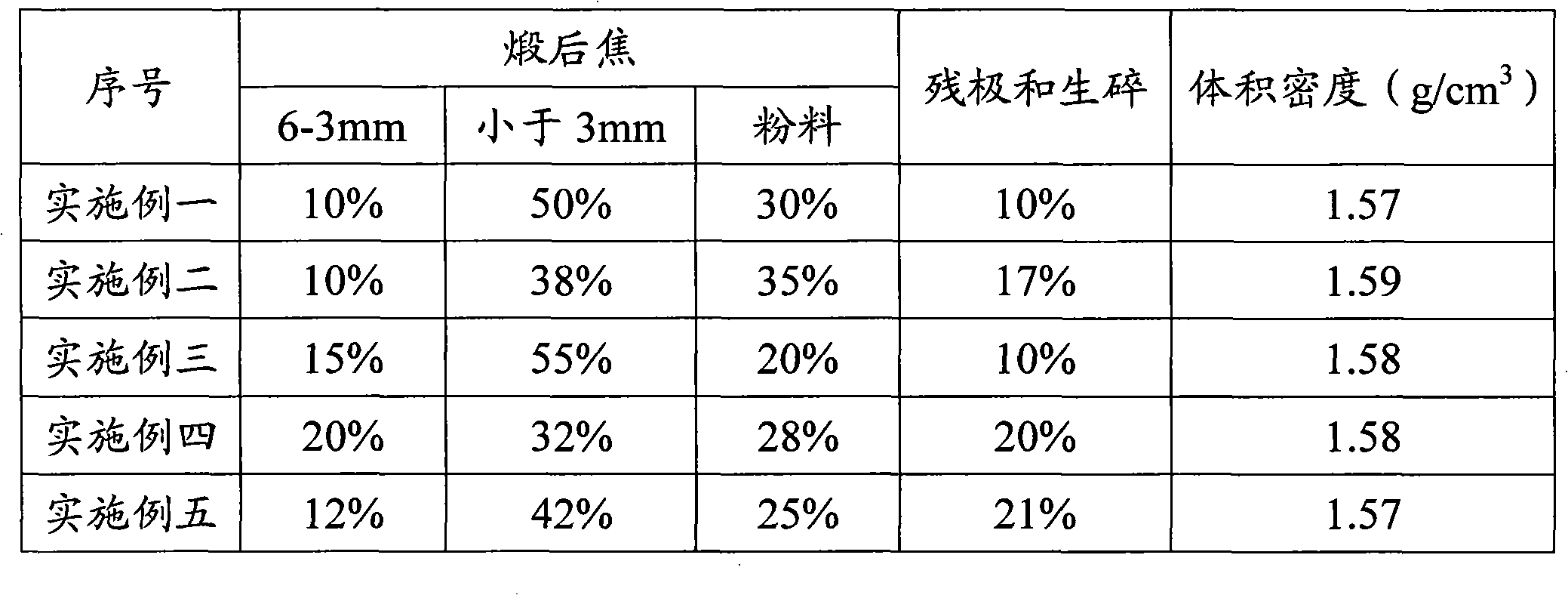

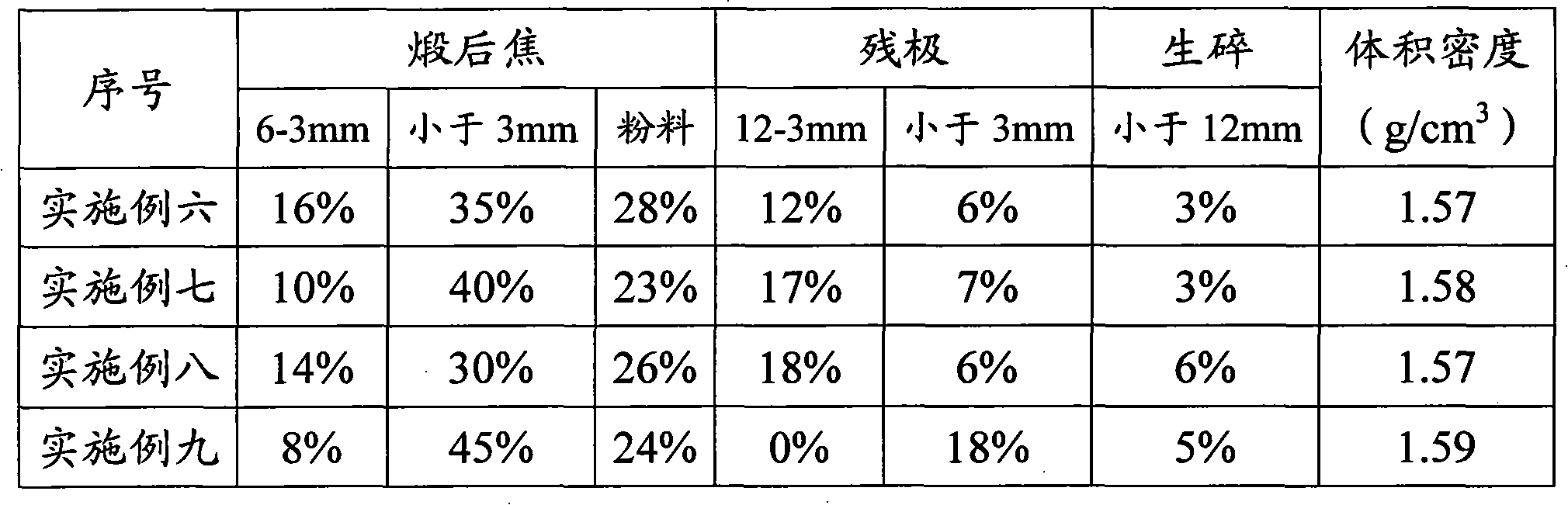

Carbon prebaked anode

The invention discloses a carbon prebaked anode in aluminum electrolysis industry. The aggregate of the carbon prebaked anode comprises calcined coke, residual anode and raw crushed straw, wherein the calcined coke with a particle size ranging from 3 to 6 millimeters accounts for 10 to 20 percent of the total weight of the aggregate, the calcined coke with a particle size ranging from 0 to 3 millimeters accounts for 30 to 55 percent of the total weight of the aggregate and the 200-mesh calcined coke powder accounts for 20 to 35 percent of the total weight of the aggregate. The formula of the anode does not adopt coarse calcined coke like the formula of the conventional carbon prebaked anode and increases the content of the fine calcined coke and 200-mesh calcined coke powder compared with the formula of the conventional carbon prebaked anode, thereby improving the volume density and compression strength of the anode and reduces the resistivity of the anode.

Owner:SNTO TECH GRP

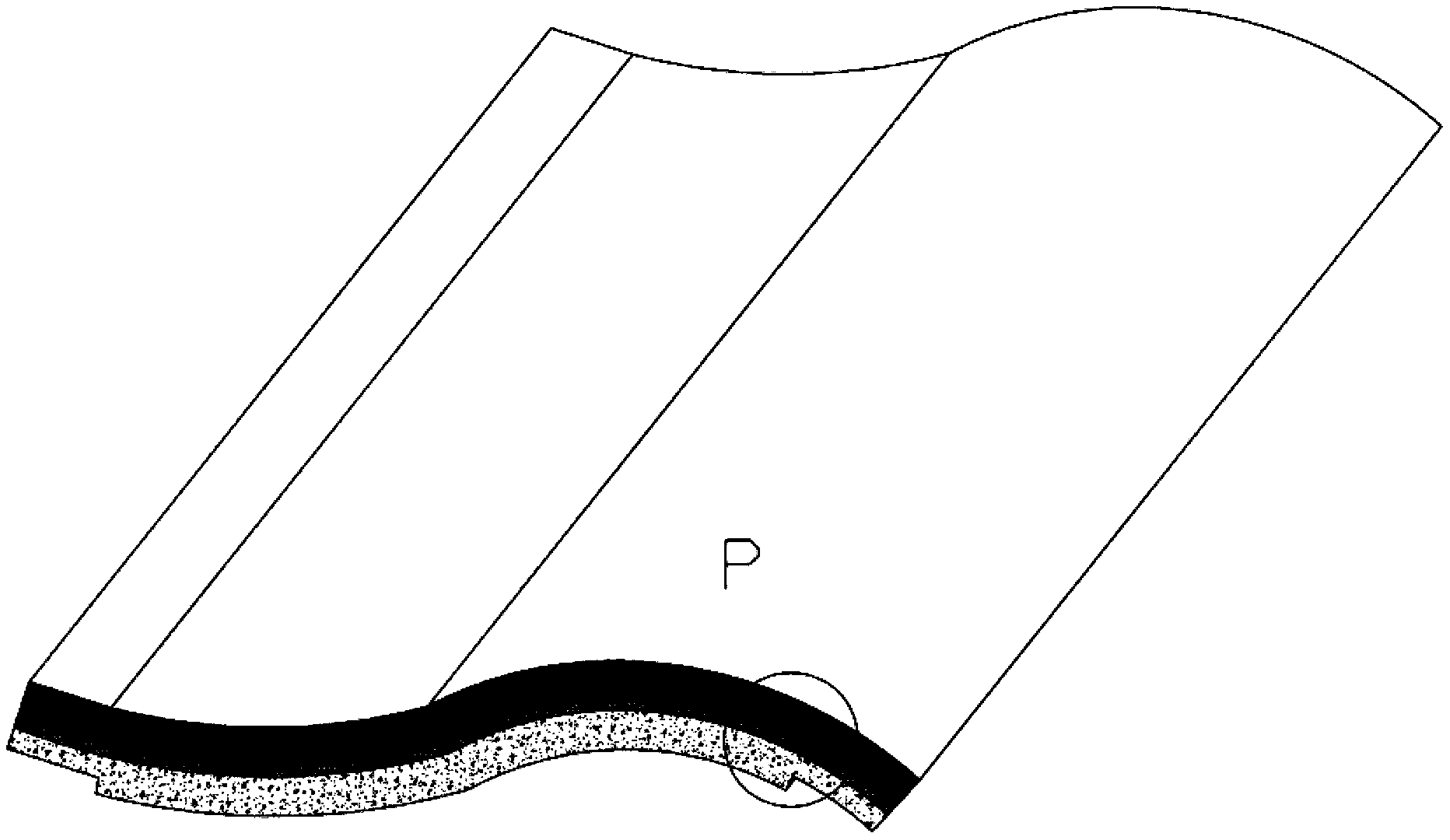

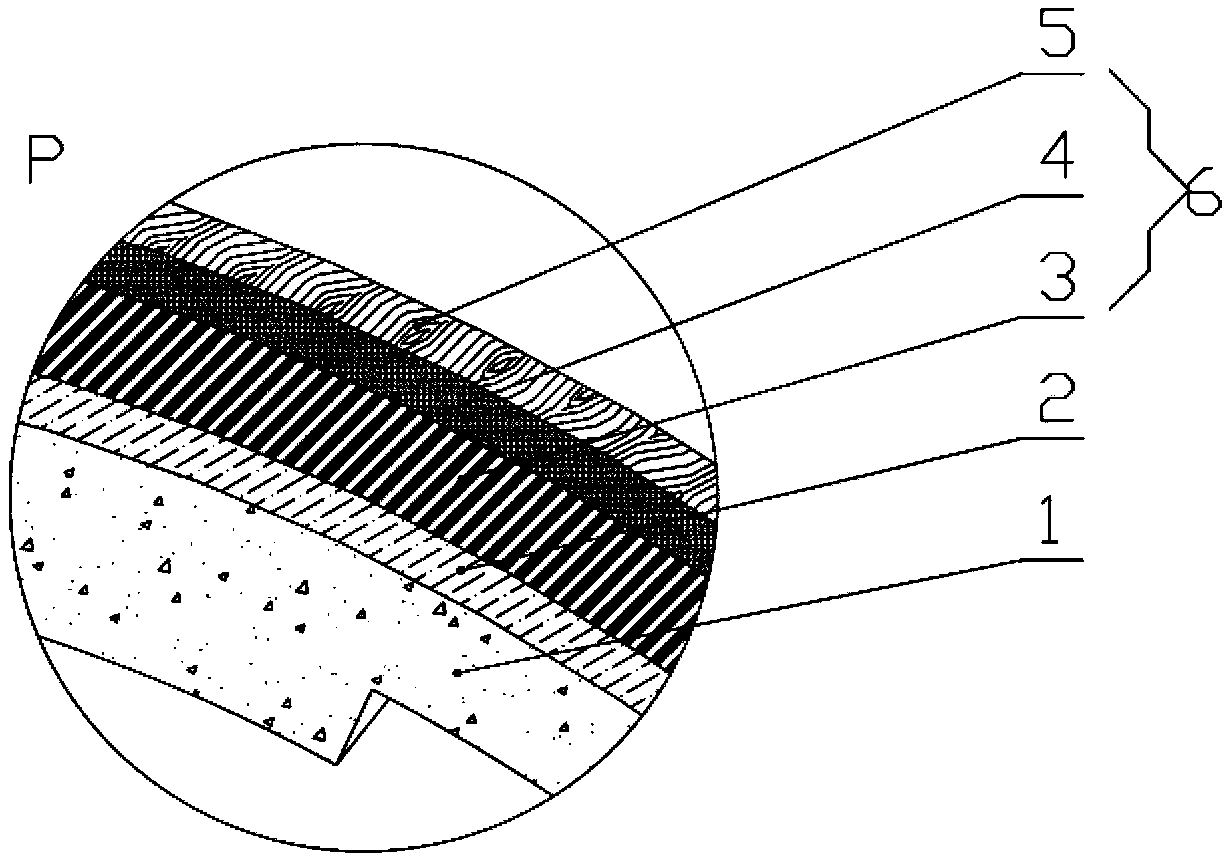

Photovoltaic tile on roof and manufacturing method thereof

ActiveCN103413847AThe function of photovoltaic power generation is soft and beautifulDoes not affect the decorative effectPhotovoltaic energy generationSemiconductor devicesRoof tileEngineering

The invention discloses a photovoltaic tile on a roof and a manufacturing method of the photovoltaic tile on the roof, wherein the photovoltaic tile on the roof integrates the functions of fire prevention, water prevention, decoration and photovoltaic power generation. The photovoltaic tile on the roof comprises a roof tile base material and a photovoltaic decorative layer, wherein the photovoltaic decorative layer and the curved surface of the roof tile base material are bonded into a whole through adhesion agents; the roof tile base material is a clay tile or a ceramic tile or a metal tile or a glass tile or a cement tile; the roof tile base material is coated with high molecular adhesion agents; the photovoltaic decorative layer sequentially comprises a flexible thin film batter assembly, a film layer and a coating layer from interior to exterior. As non-crystalline silicon and other flexible solar photovoltaic thin film batteries are bonded to the surfaces, with the waving feeling, of the ceramic tile, the clay tile, the glass tile and the like through high molecular polymer glue, photovoltaic tiles on roofs which have various complex models, can achieve the function of the photovoltaic power generation and can also keep the shape and color of the tiles on the building roofs can be produced in a factory.

Owner:嘉兴如运建筑科技有限公司

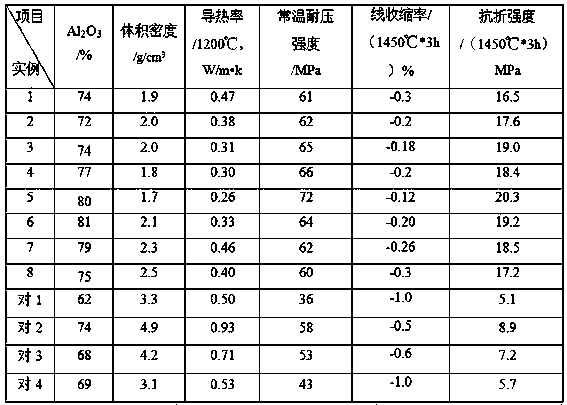

High-alumina refractory castable and preparation method thereof

The invention belongs to the technical field of refractory materials, in particular to a high-alumina refractory castable and a preparation method thereof. The high-alumina refractory castable is prepared from the following raw materials in parts by weight: 50-70 parts of high bauxite, 8-13 parts of andalusite, 11-23 parts of floating bead, 15-20 parts of silicon carbide, 10-15 parts of silicon nitride, 7-12 parts of alpha-Al2O3 micro powder, 3-9 parts of silica-alumina colloid powder, 1-5 parts of attapulgite clay, 10-25 parts of calcium aluminate cement, water reducer and aluminium silicatefiber, wherein the water reducer occupies 0.1-0.3% of total mass of the above raw materials, and the aluminium silicate fiber occupies 0.05-0.12% of total mass of the above raw materials. The high-alumina refractory castable has the advantages of high Al2O3 content, light weight, low heat conductivity and high castable strength.

Owner:黎文泰

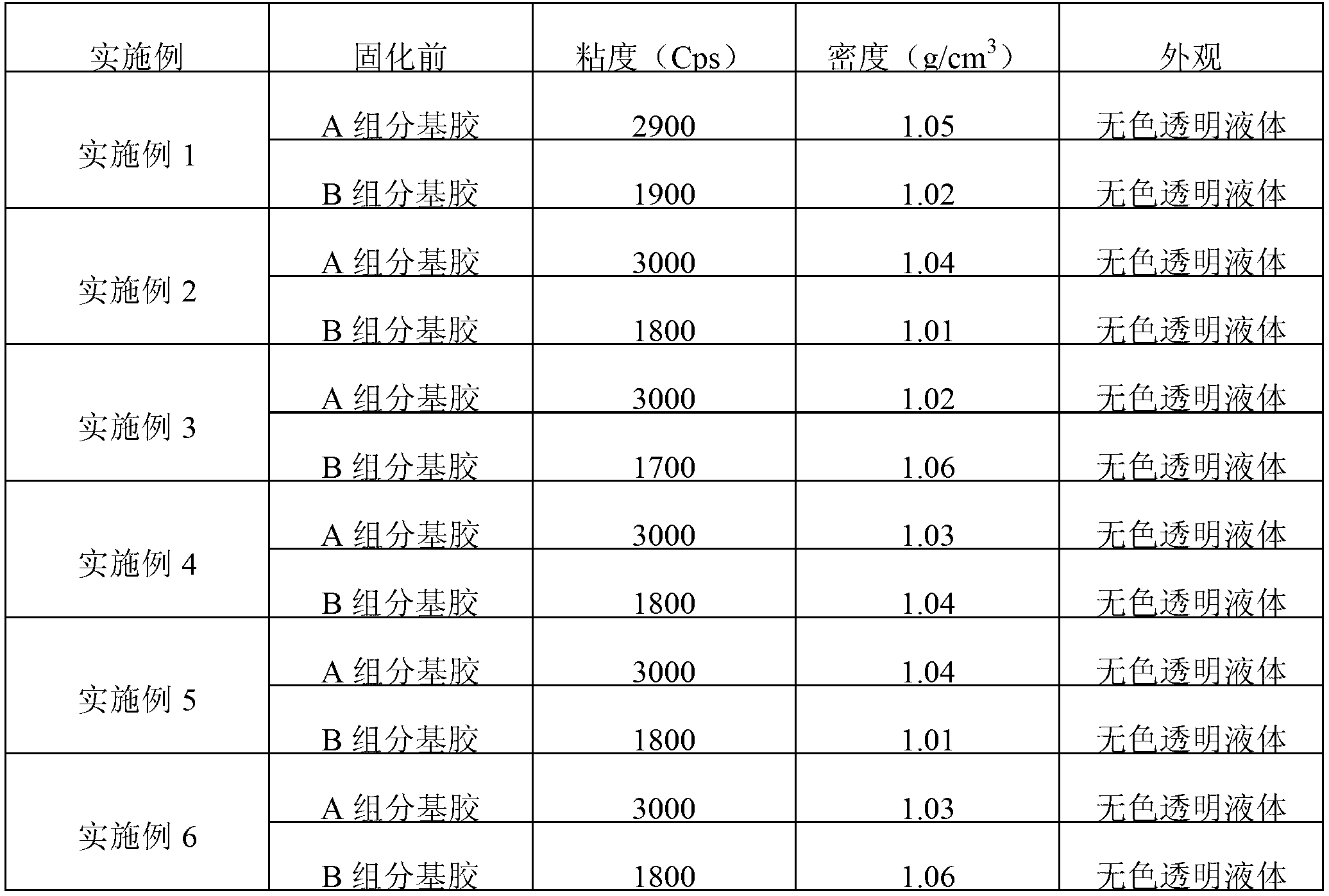

LED packaging glue and preparation method thereof

The invention relates to LED packaging glue and a preparation method thereof, and belongs to the field of glues. The preparation method comprises the following steps: firstly, adding first vinyl silicone oil and first vinyl MQ silicon resin in a reaction vessel and stirring , and adding platinum catalyzer to the reaction vessel under the condition of normal temperature and vacuum to obtain separation base glue of group A; secondly, adding methyl hydrogen silicone oil, second vinyl silicone oil and second vinyl MQ silicon resin in sequence to the reaction vessel and stirring, and adding 1-Ethynyl-1-cyclohexanol and tackifier in sequence under the condition of normal temperature and vacuum to obtain separation base glue of group B; and finally, mixing the separation base glue of group A obtained in step a and the separation base glue of group B obtained in step b at mass radio of 0.5:1 to 2:1, and solidifying to obtain the LED packaging glue. The LED packaging glue provided by the invention has the advantages of good liquidity, high transparence, good flexibility, good weathering resistance, non-yellowing, adaptability to high-and-low temperature and the like.

Owner:SHENZHEN JINLIAN TECH

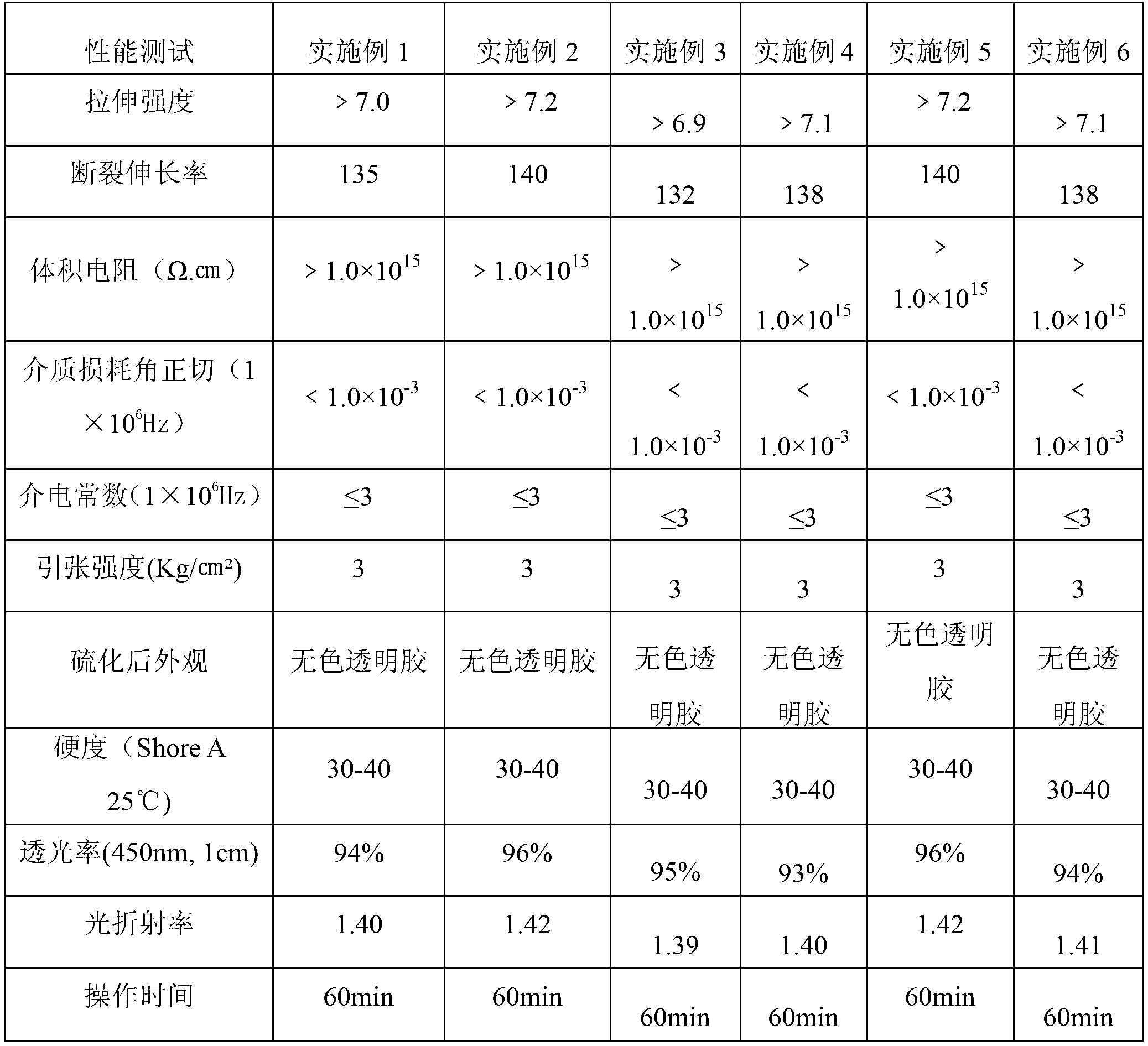

Test paper for rapidly testing nitrite and standard colourimetric card and application of test paper

InactiveCN104535712AUniform infiltrationExcellent gas barrier propertiesAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorPolyvinyl alcoholN-(1-Naphthyl)ethylenediamine

The invention belongs to the field of chemical detection and particularly relates to test paper for rapidly detecting nitrite and a preparation method and application of the test paper. According preparation method, the test paper for rapidly detecting the nitrite is prepared by taking a filter paper body as a carrier, a p-aminobenzene sulfonic acid solution and an N-1-naphthyl ethylenediamine hydrochloride as color developing agents, as well as an ethanol water solution of polyvinyl alcohol as a surface protectant and can be used for detecting the content of the nitrite. The test paper is low in cost, convenient and rapid to use and has long-term stability.

Owner:SOUTH CHINA NORMAL UNIVERSITY

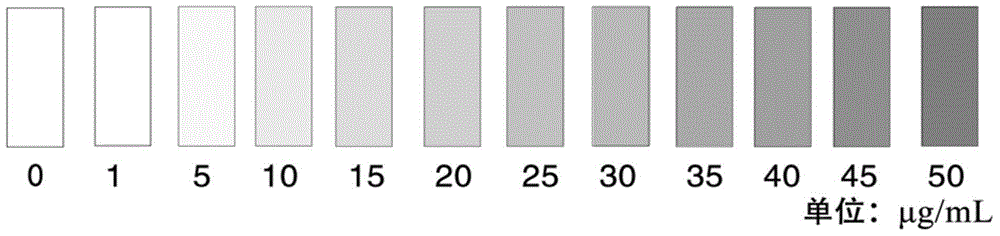

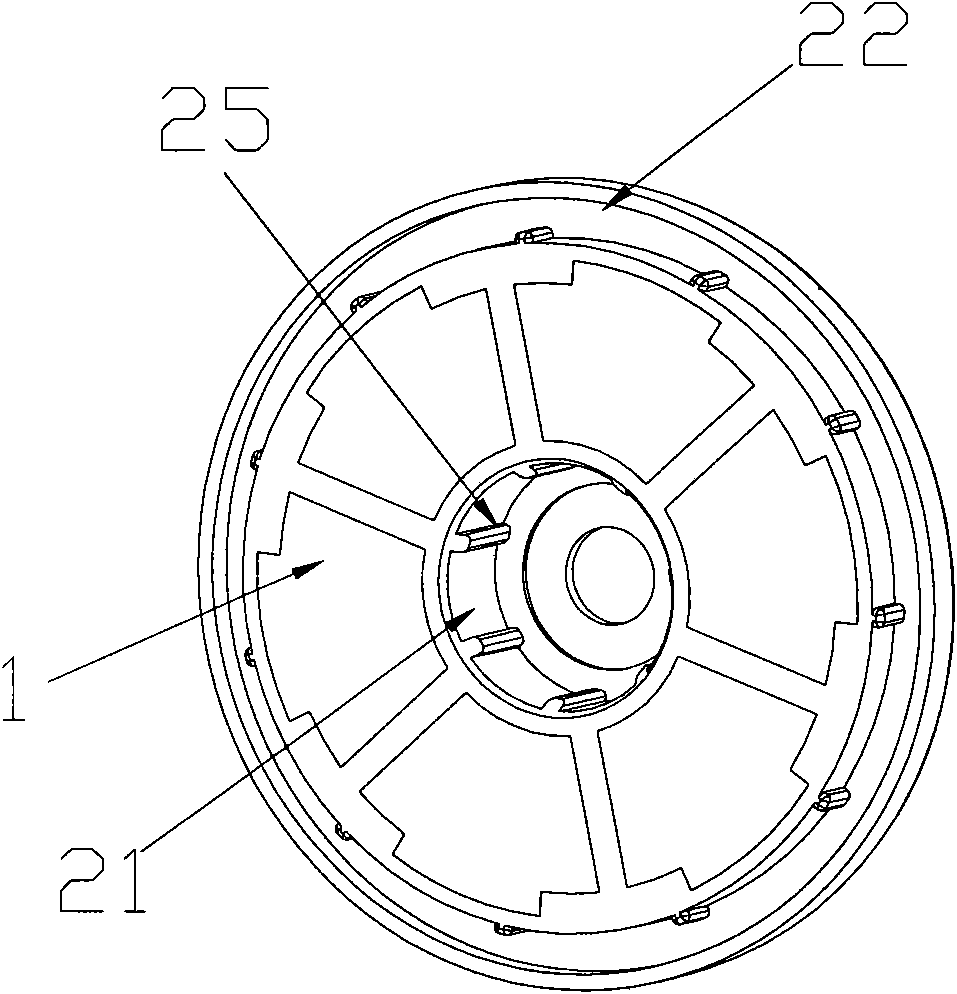

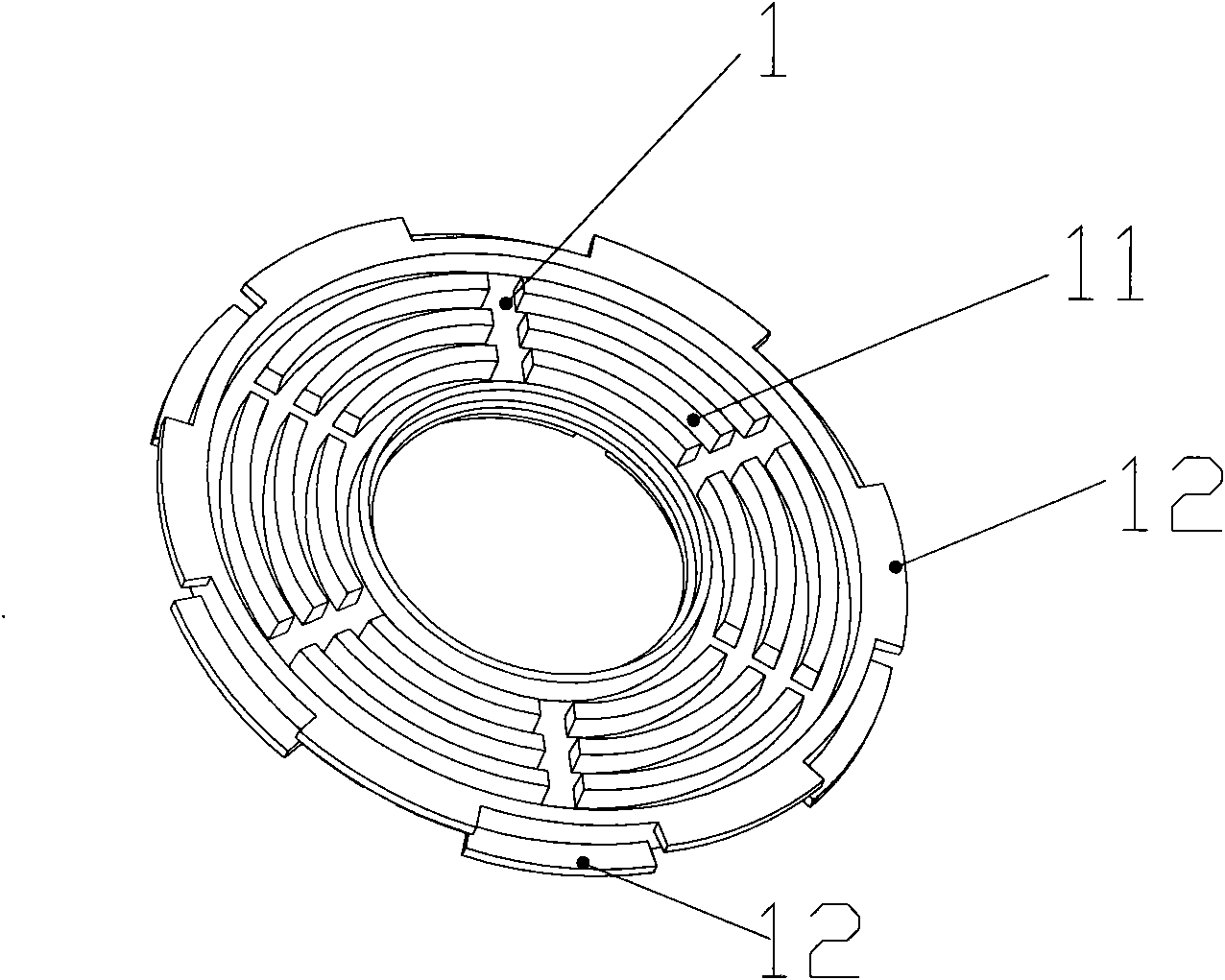

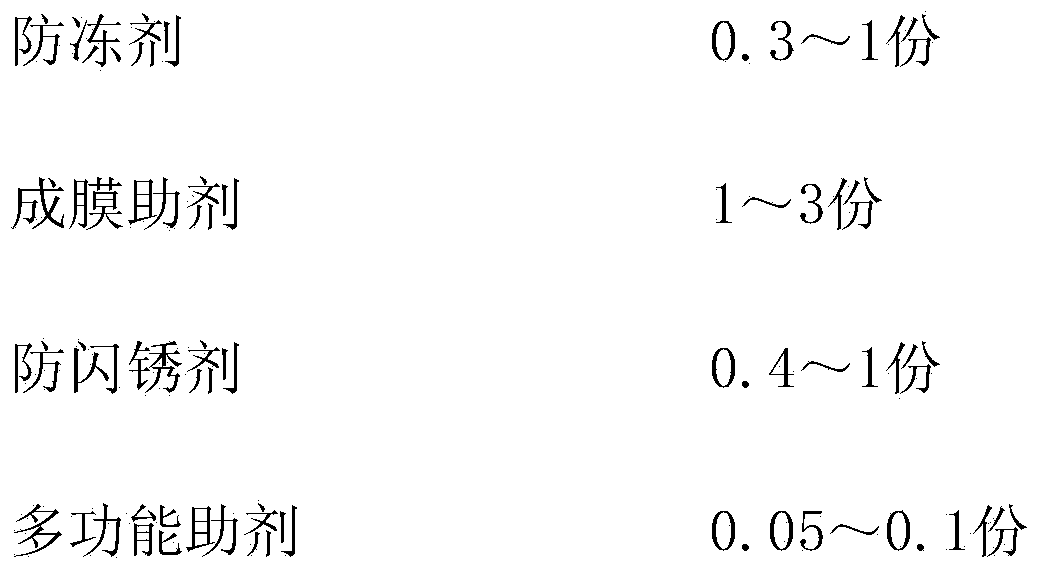

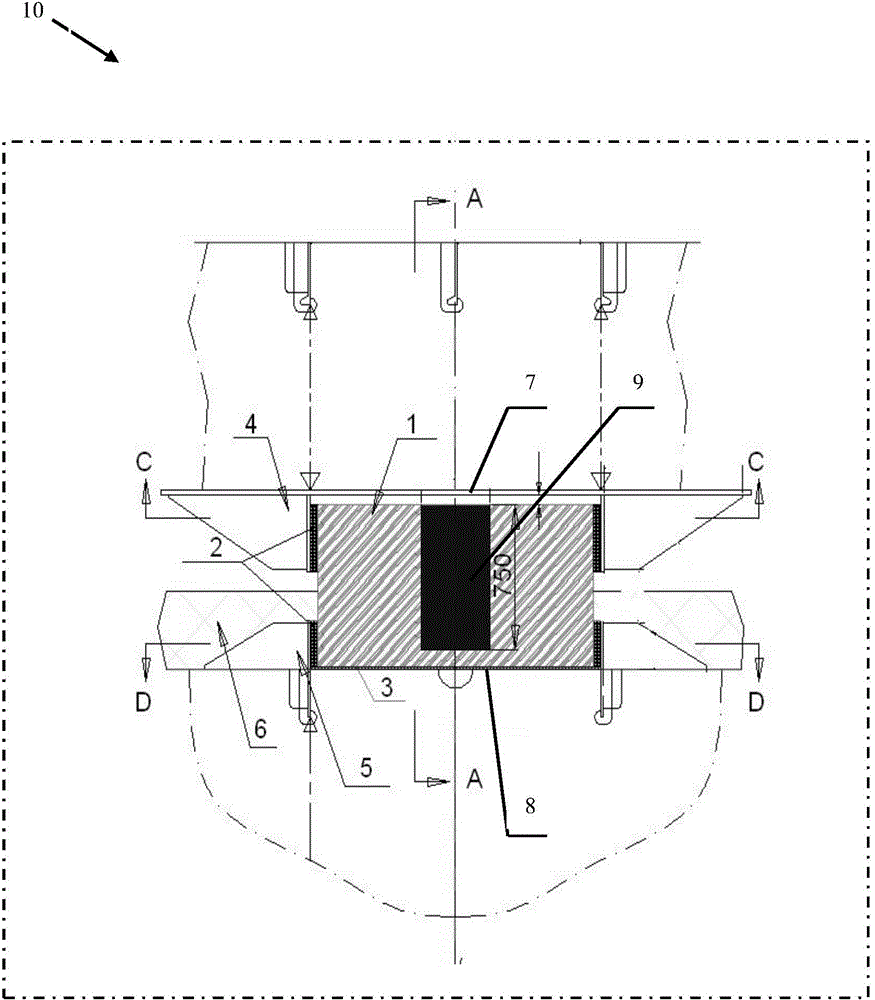

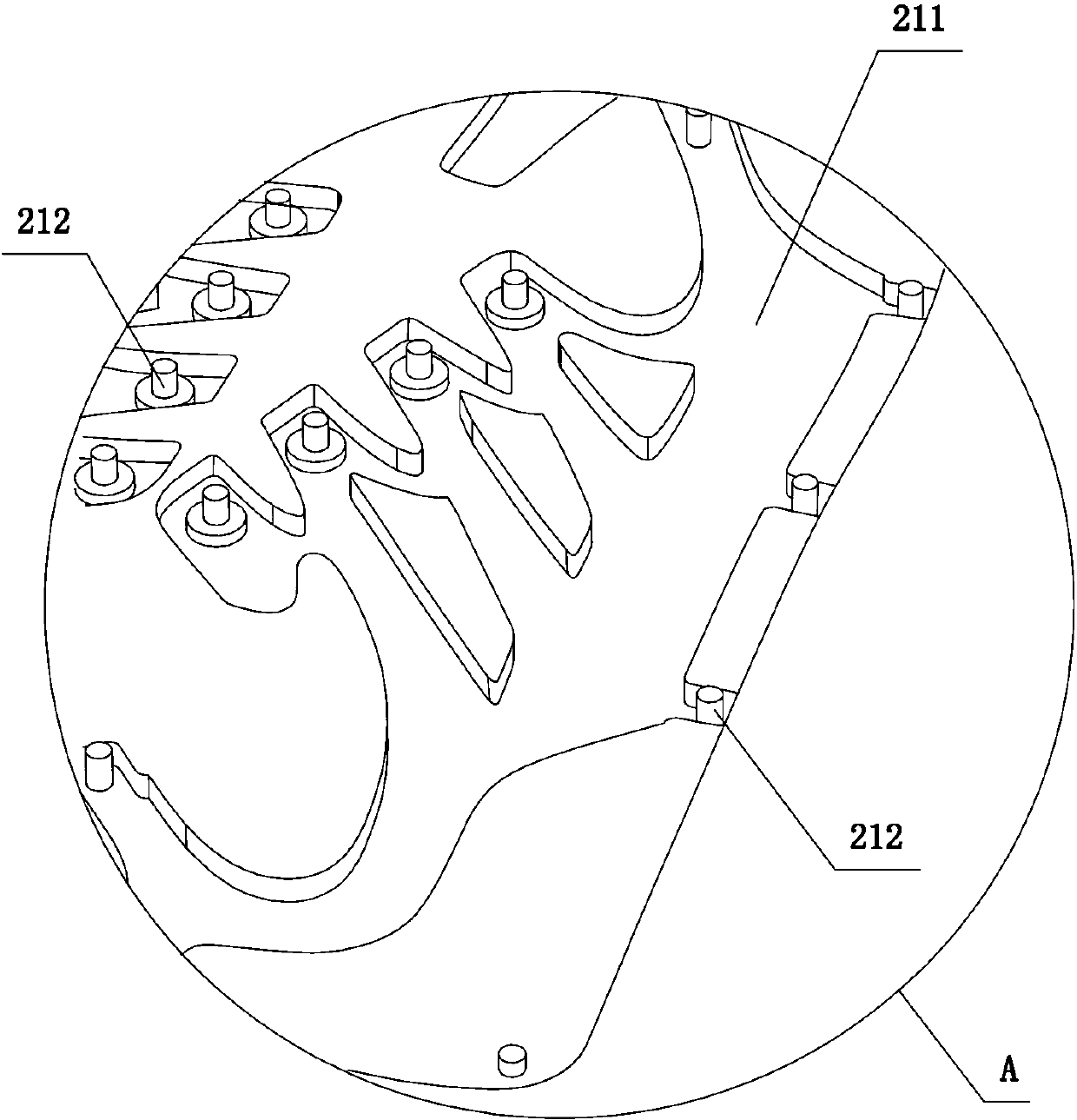

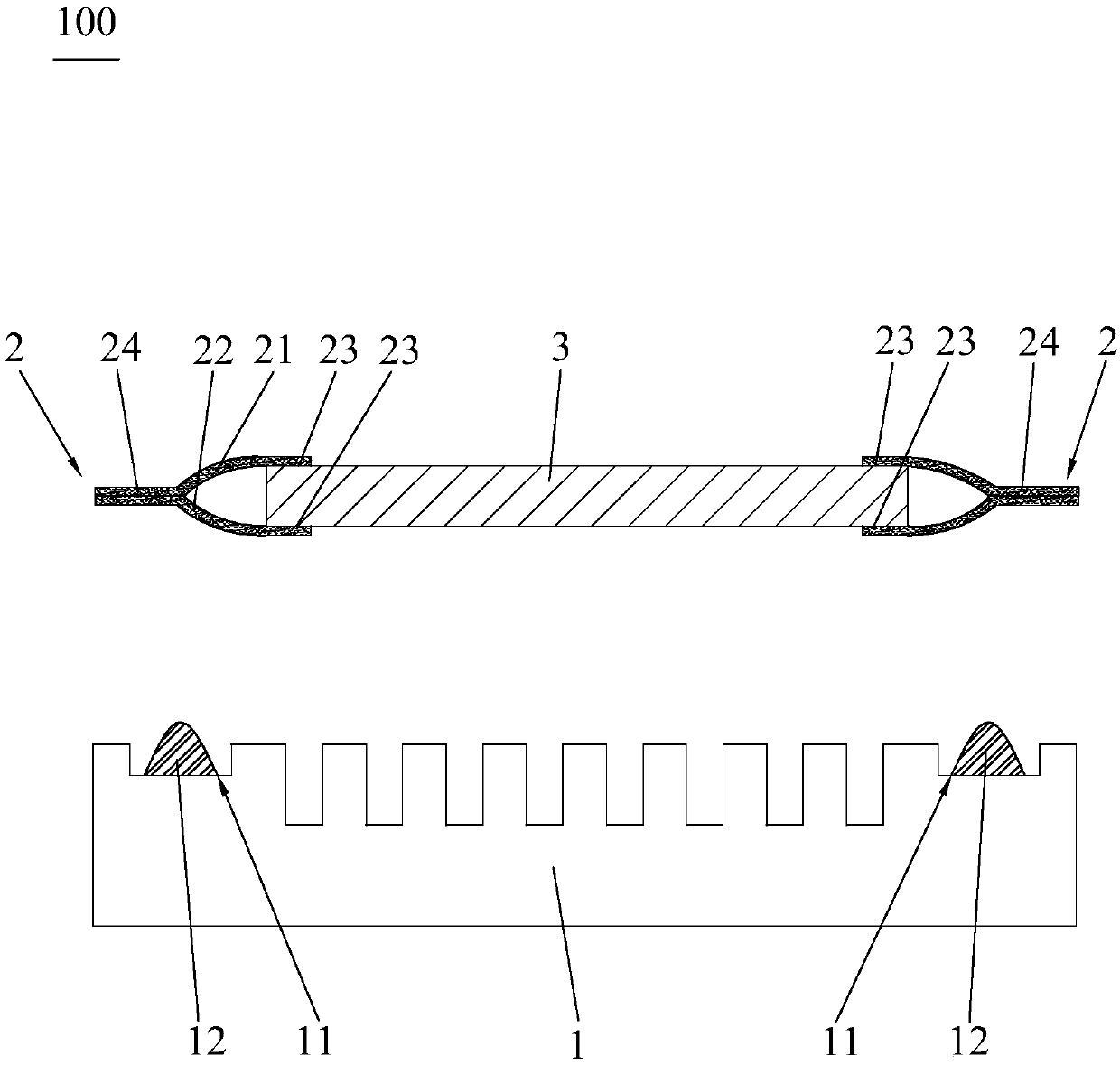

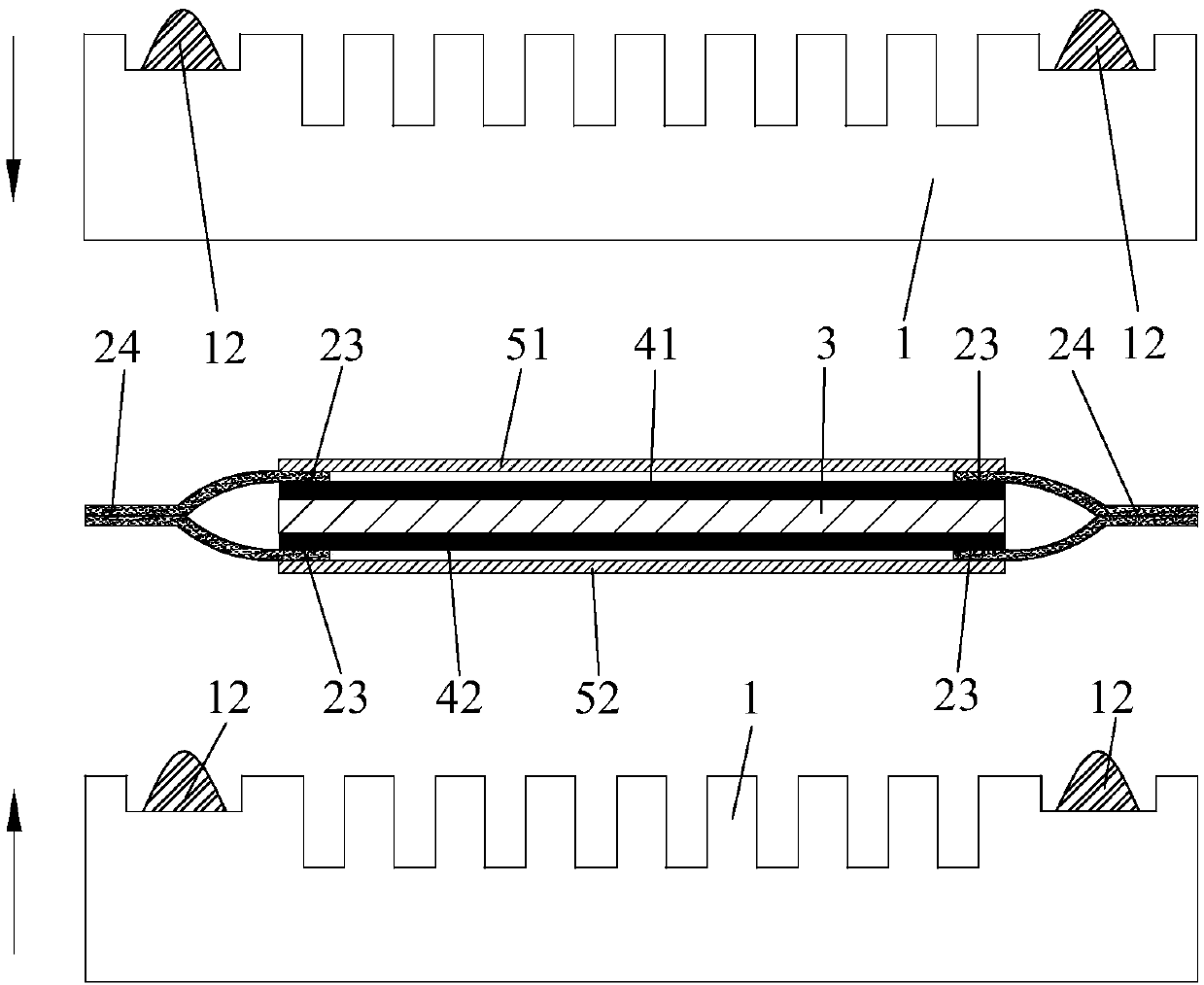

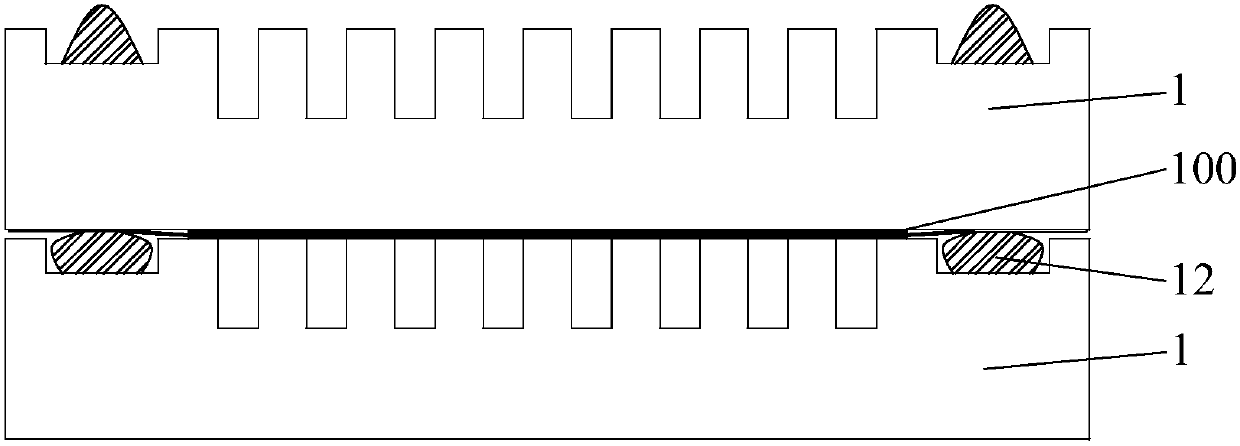

Motor end cover as well as manufacture method and applied motor thereof

ActiveCN101604878AAvoid heat differenceReduced precision requirementsManufacturing dynamo-electric machinesSupports/enclosures/casingsEngineeringInjection moulding

The invention relates to a motor end cover which comprises a metal heat dissipation piece (1) and an injection moulding piece (2), wherein the injection moulding piece comprises a bearing chamber (21) positioned at the center and a positioning clamp opening (22) positioned at the periphery; and the metal heat dissipation piece (1) is embedded between the bearing chamber (21) and the positioning clamp opening (22). The invention has the advantages of simple manufacture, lower cost, higher precision, light weight, high stability and easy heat dissipation.

Owner:ZHONGSHAN BROAD OCEAN

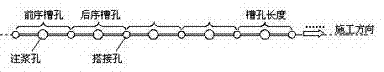

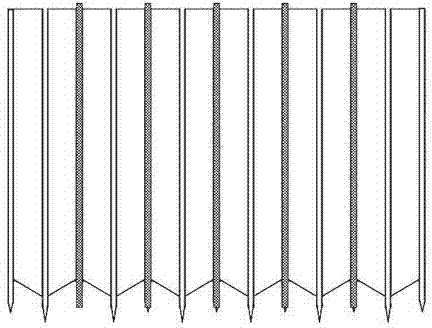

Grouting method for ultrathin high polymer cutoff wall

ActiveCN102444128AReduce disturbanceFast constructionProtective foundationMarine site engineeringEngineeringHigh polymer

The invention discloses a grouting method for an ultrathin high polymer cutoff wall, wherein continuous groove holes are constructed and formed in a dam and a foundation required to be turned into anti-seepage and consolidated according to the anti-seepage design requirement of the dam; two-component dilatant high polymer grouting materials are grouted into the groove holes through a grouting pipe; the high polymer grouting materials are quickly dilated after chemical reaction, then fill the groove holes to the brim and are solidified to form high polymer thin slice bodies, and the thin slice bodies in the neighboring groove holes are closely bonded, so as to form the continuous, uniform and regular ultrathin high polymer cutoff wall. The invention is highly distinct from the existing technology of the cutoff wall in aspects as material, mechanism, construction method and the like, has advantages of being quick, ultrathin, mini-wound, light, highly tenacious, economic, durable and the like, is successfully applied to multiple risk-removing consolidating projects of reservoir dams and embankment, and has huge economic and social benefits as well as wide development and application prospects.

Owner:SAFEKEY ENG TECHZHENGZHOU

Technology for fabricating big vessel shaped Ru porcelain bottle

The invention relates to a technology for fabricating big vessel shaped Ru porcelain bottle, which comprises the following steps of: taking the following constituents in percentage by weight as blank materials: 15-20% of kaolin, 4-10% of camwood knot, 25-40% of hargil, 15-25% of chinastone, 4-10% of quartz and 15-20% of potassium feldspar; grinding the blank materials, adding water for wet grinding, and regulating water content of the slurry to 35-45%; making the slurry into blank bodies of bottle opening part, middle part and bottom part respectively, bonding by mud, wiping the blanks and burning into bisques; grinding glaze material, and adding water for wetly grinding into the slurry; wiping the bisques, and placing in the glaze material slurry for glaze immersion; and placing the bisques in a kiln, burning in oxidation atmosphere, increasing temperature of the kiln to 1050 degrees centigrade, burning in reducing atmosphere, insulating for 1h at 1050 degrees centigrade, increasing temperature to 1250 degrees centigrade, insulating for half an hour, stopping burning and cooling to finish fabrication of the big vessel shaped Ru porcelain bottle. In the technical scheme, the constituents are firmly combined, the fabrication method can improve strength of the Ru porcelain to prevent cracks, and the fabricated Ru porcelain has thin body, big vessel shape and high strength.

Owner:韩琴

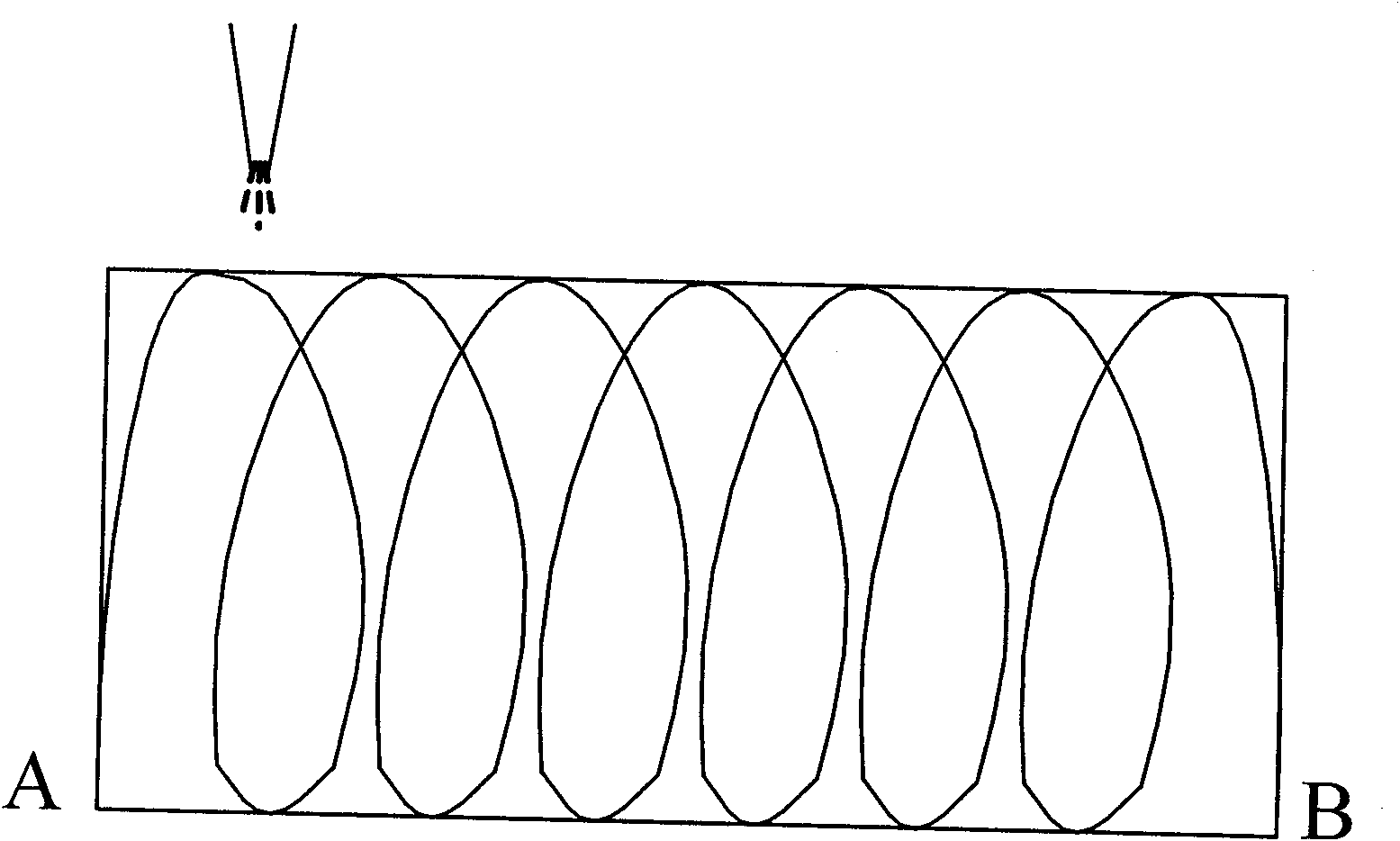

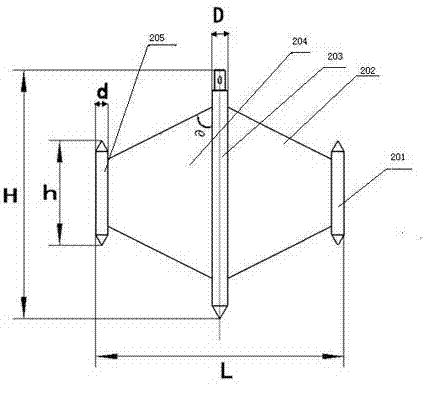

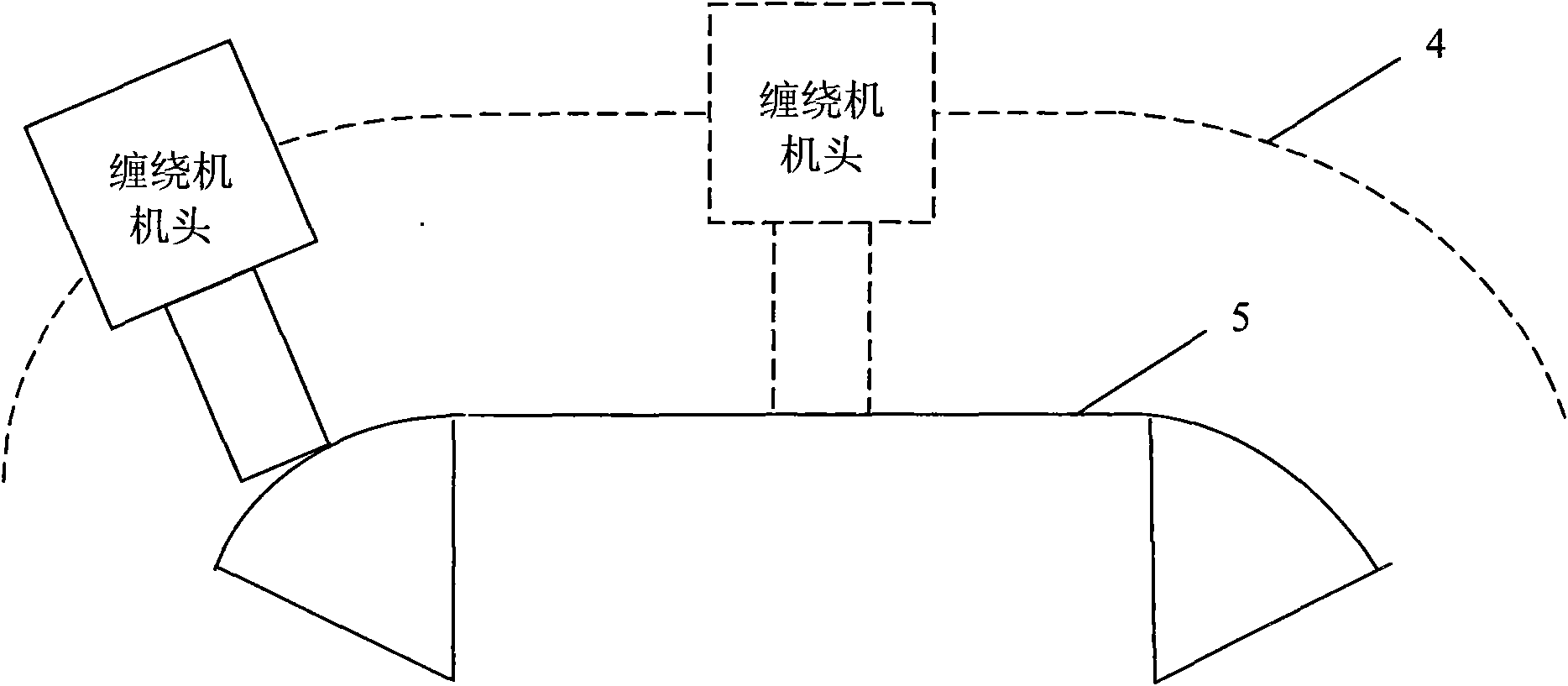

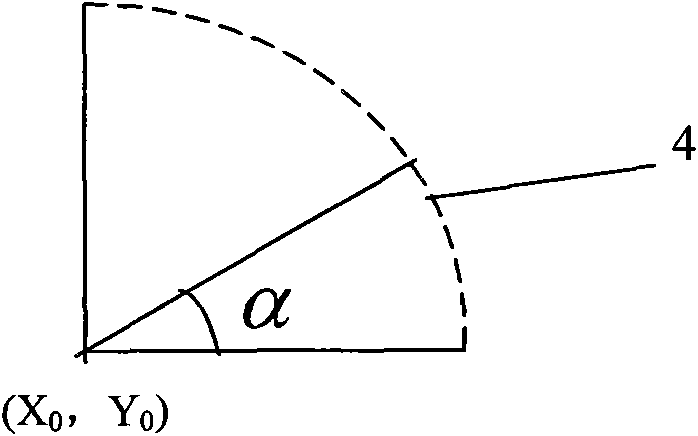

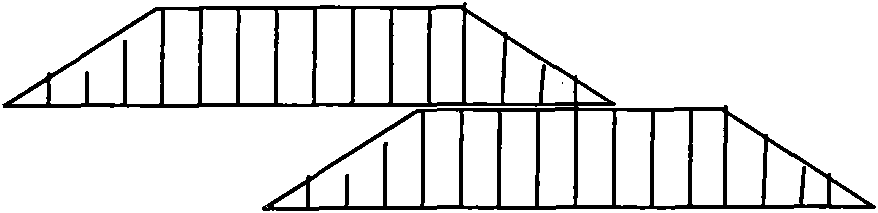

Controlling method for wrapping surface of tire

InactiveCN101625557AGood smoothnessImprove vulcanization effectProgramme control in sequence/logic controllersLine segmentEngineering

The invention provides a controlling method for wrapping the surface of a tire, comprising the following steps: an industrial personal computer (IPC) analog simulates the deformation of rubber pieces in the process of spire piling and the arrangement distribution situation of the each rubber piece in the surface of the tire to obtain spire pitches among each rubber piece; the IPC computes the virtual circle central coordinate and the radius of a wrapper at each loop of the arc of the surface of the tire, and sends a date to a PLC; the IPC respectively computes the arc of the each loop of the arc section of the surface of the tire, the horizontal coordinate of the each loop of the linear section of the surface of the tire and a corresponding theoretical velocity, to form a data table to be sent to the PLC; the PLC computes the real velocity of the wrapper according to the received data table; and the PLC computes to obtain a track coordinate data of the wrapper corresponding at the each loop and finally controls the wrapper to wrap the surface of the tire. The method realizes analog simulation in the process of wrapping the surface of the tire, adjusts the walk track and the walk velocity of the head of the wrapper immediately, and greatly improves the wrapping quality of the surface of the tire.

Owner:柳州市华工百川橡塑科技有限公司

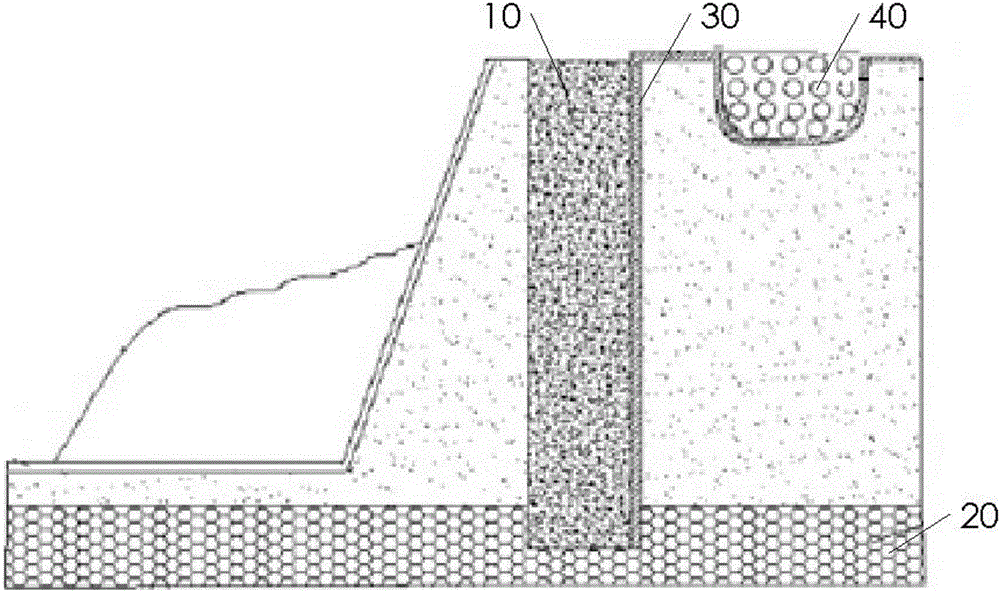

Vertical anti-seepage barrier and construction method thereof

InactiveCN106320385ATightly bondedLow permeability coefficientProtective foundationGeomembraneStructural engineering

The invention relates to a vertical anti-seepage barrier and a construction method thereof, relates to the technical field of vertical anti-seepage walls. The vertical anti-seepage barrier and the construction method mainly aim at improving the chemical corrosion prevention capacity of the vertical anti-seepage walls and improving the anti-seepage effect. According to the main adopted technical scheme, the construction method of the vertical anti-seepage barrier includes the steps that a groove is dug, wherein the bottom of the groove extends into an underground impermeable layer; a composite geo-membrane is laid on the side wall of at least one side of the groove, split bodies of the composite geo-membranes are connected in a lap joint manner through a sealant, and nonwoven fabric is arranged on the sides, facing the inner side of the groove, on the composite geo-membranes; and materials are backfilled in the groove, a vertical anti-seepage wall combined with the nonwoven fabric, facing the inner side of the groove, on the composite geo-membranes is formed in the groove, and the vertical anti-seepage barrier is composed of the composite geo-membranes, combined with one another, and the vertical anti-seepage wall. Compared with a vertical anti-seepage wall in the prior art, the permeability coefficient of the vertical anti-seepage barrier is small and smaller than or equal to 1*10<-7> cm / s, and the environment protection requirement can be met.

Owner:TIANJIN ZHONGLIANGELIN SCI & TECH DEV CO LTD

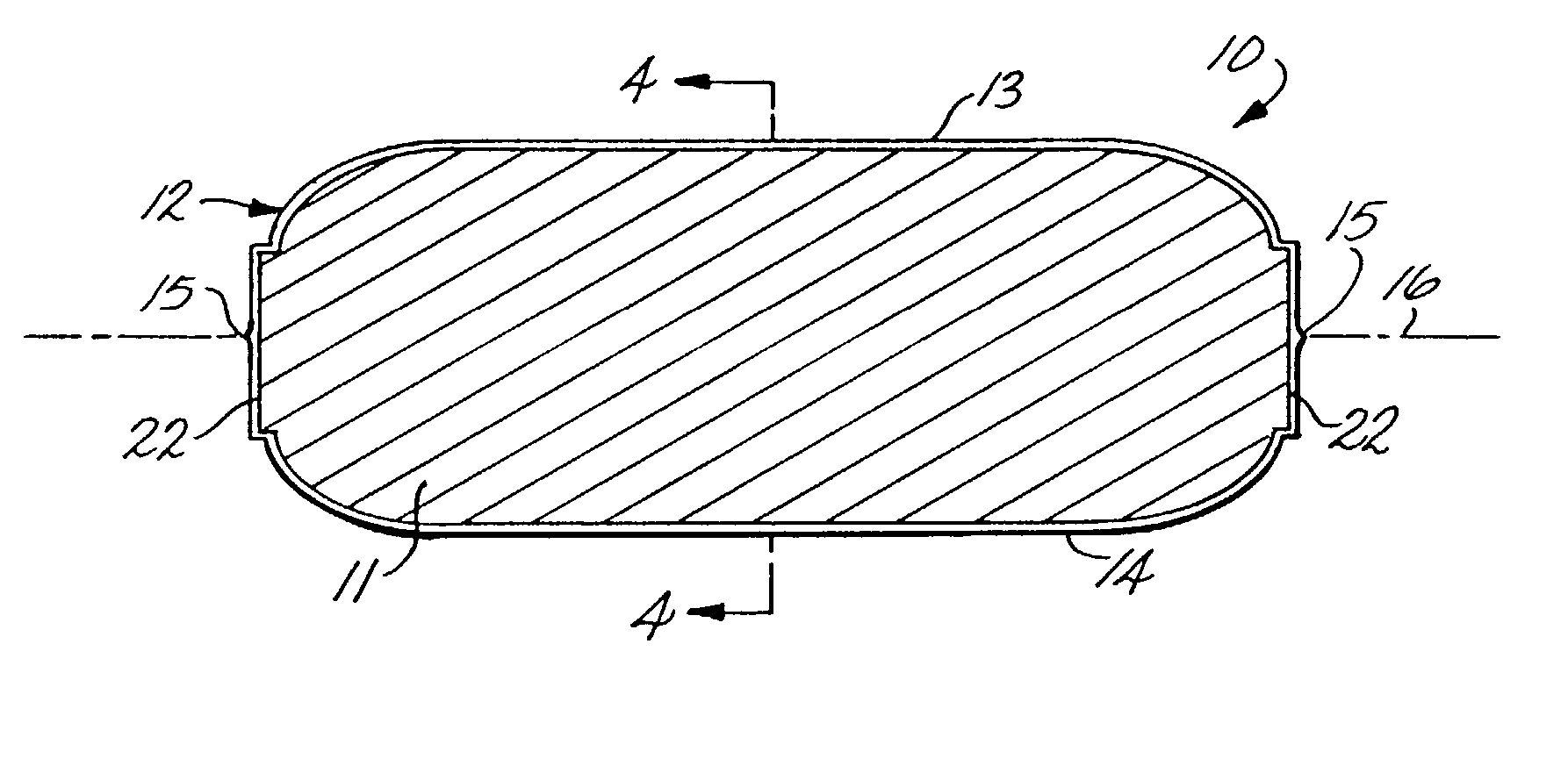

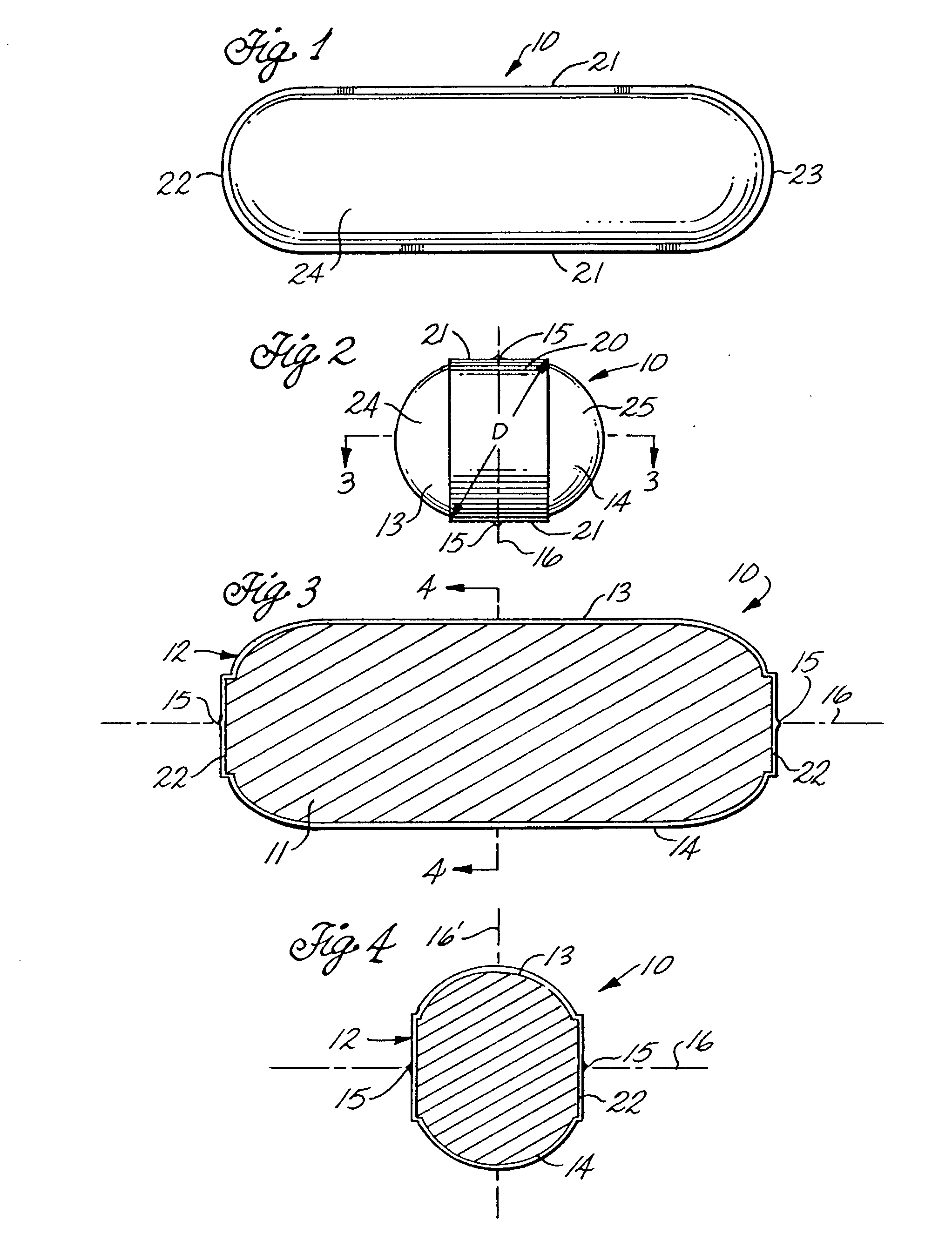

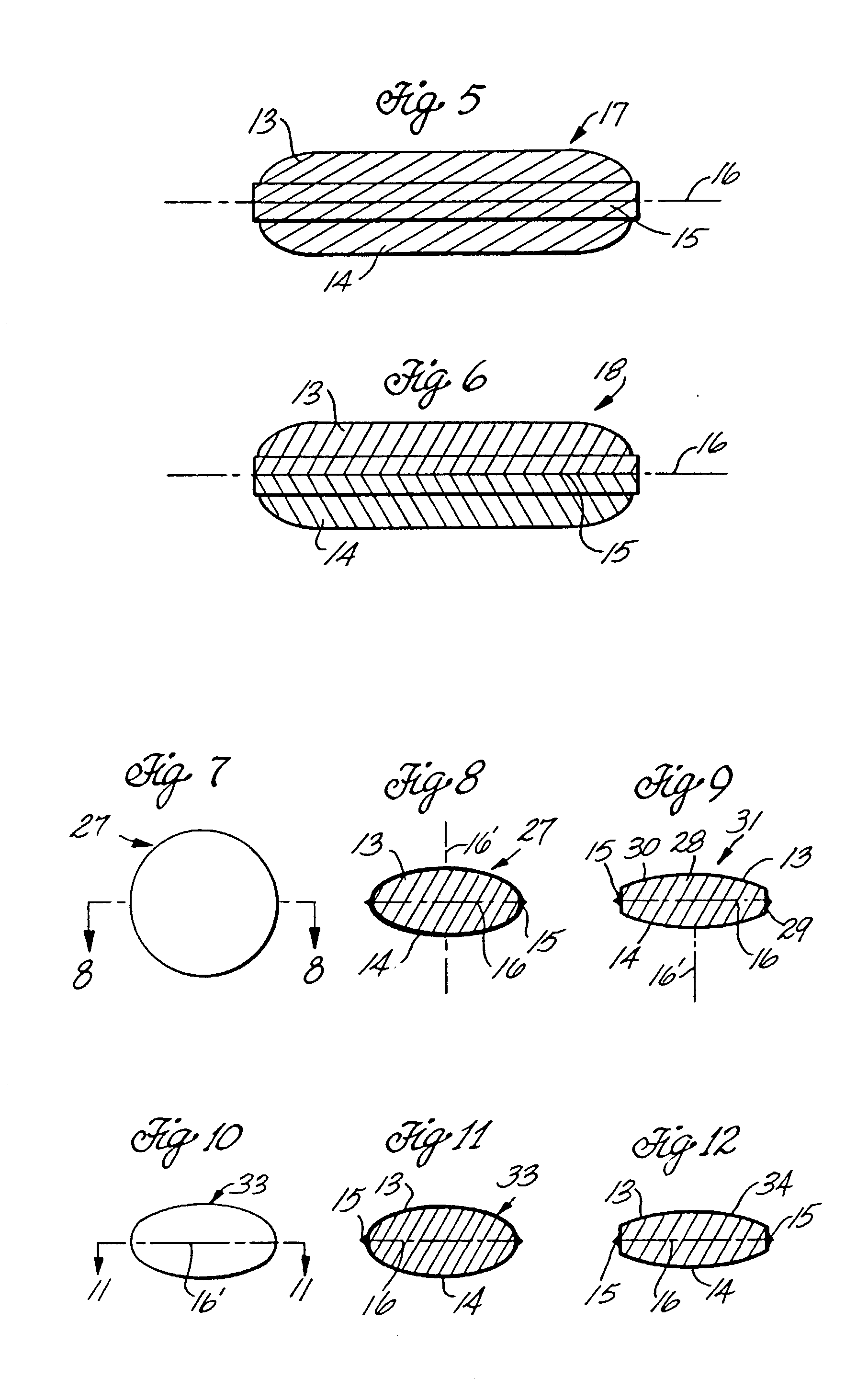

Enrobed core medicament

InactiveUS20030059614A1More resistance to breakageMore strengthGlass/slag layered productsWood layered productsGelatin filmPlasticizer

A medicine tablet is described as a new article of manufacture. The tablet is enrobed in a gelatin coating formed by application of respective layers of elastic gelatin film to opposite sides of the tablet. The applied gelatin layers conform tightly to the tablet surface, bond securely to the tablet, and are sealed together in essentially edge-to-edge manner at a seal line which extends around the tablet at a desired place on the tablet. The gelatin layers can be colored differently from the tablet and differently from each other. A range of formulations are described for film which can be peelable from a tablet or other product core, and for films which bond to the core. A presently preferred formulation for producing tablets having a bonded tamper-evident coating comprises a water-based gelatin preparation having about 45% gelatin and about 9% plasticizer (glycerin and / or sorbitol) by weight Method and apparatus for producing such new products are also described. Product cores can be dispensed on a self-timed basis into essentially simultaneous contact with two enrobing films which are supported on locally recessed coacting rotary dies. The cores contact the films adjacent a nip between the dies at places on the films which overlie die recesses which are oversize relative to the cores.. The films deform around each core and are sealed by the dies to each other before the dies coact to cut the enrobed cores from the films. A core feeding mechanism can include an alignment device which causes the cores to have a desired orientation as they are handled by the dies.

Owner:SADEK HANI +1

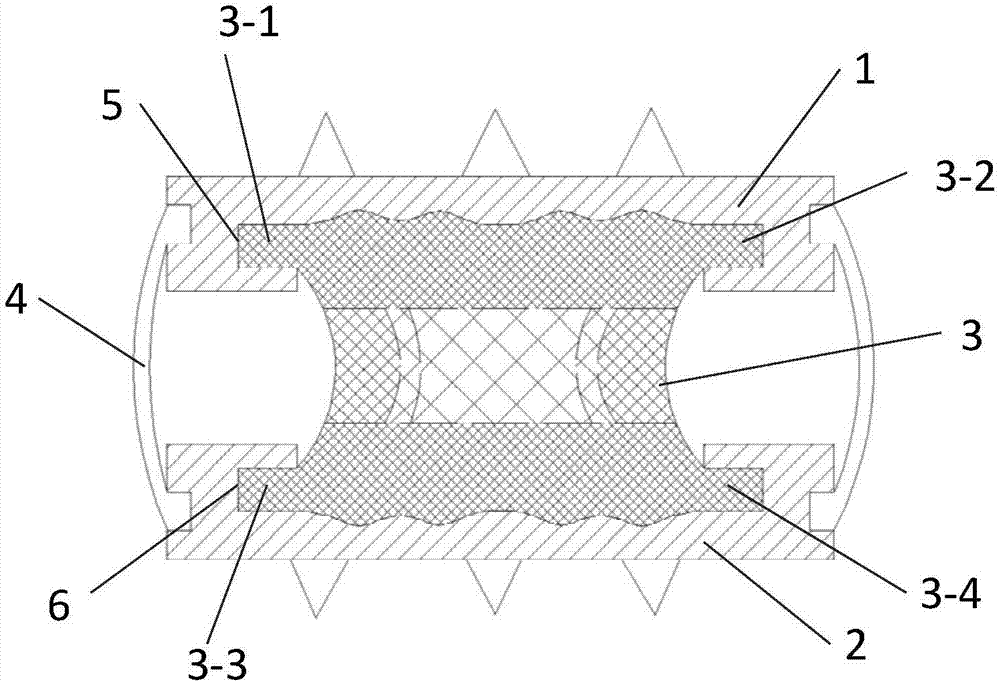

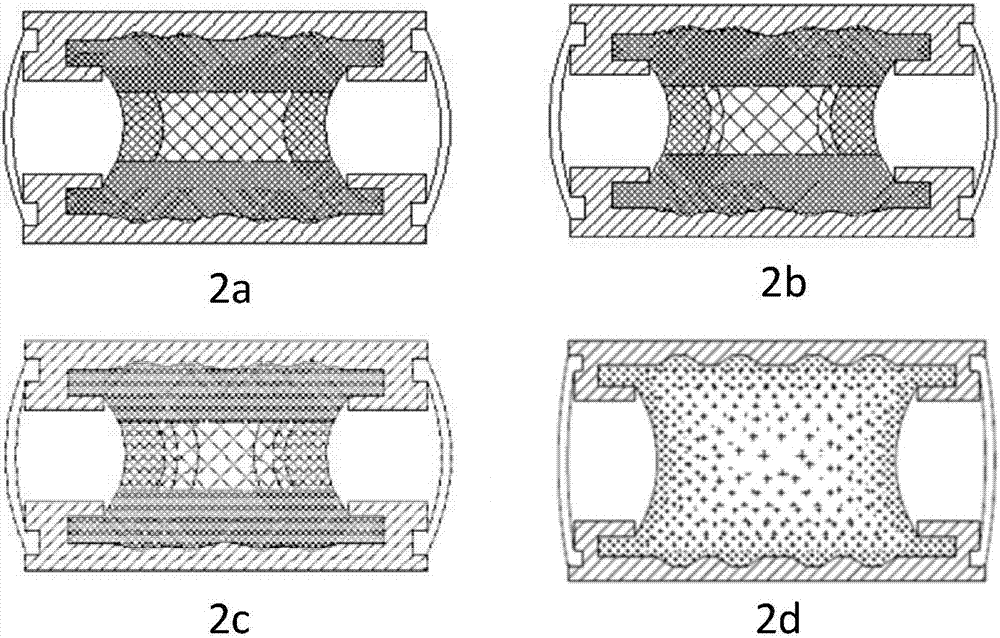

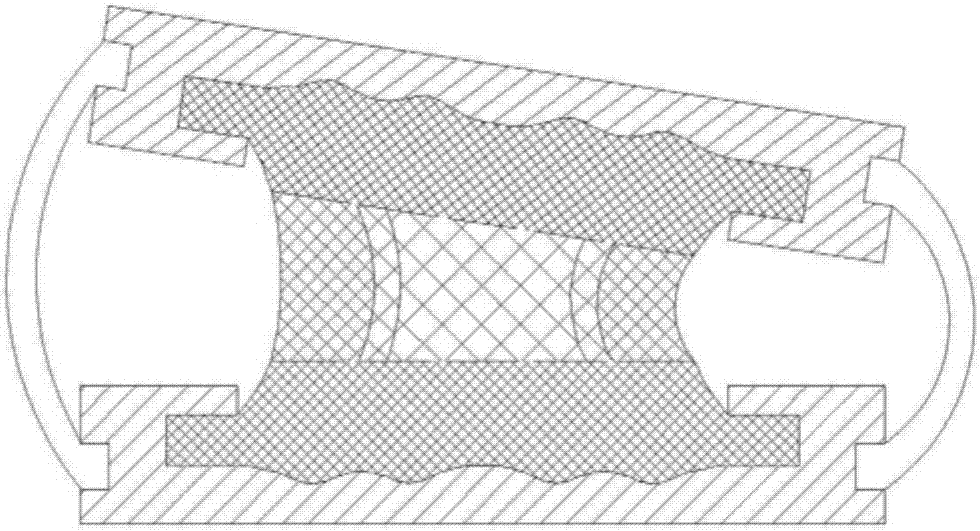

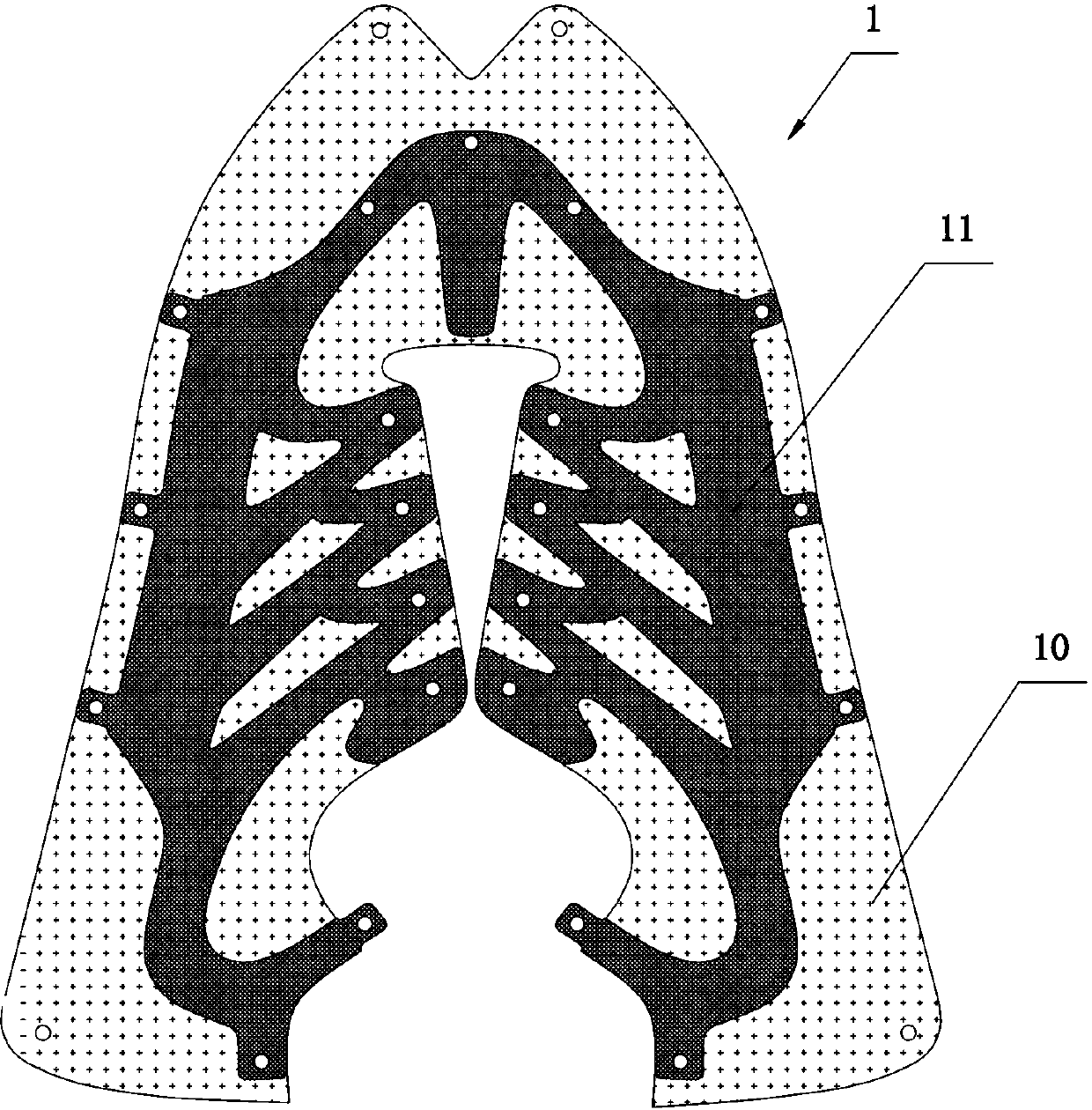

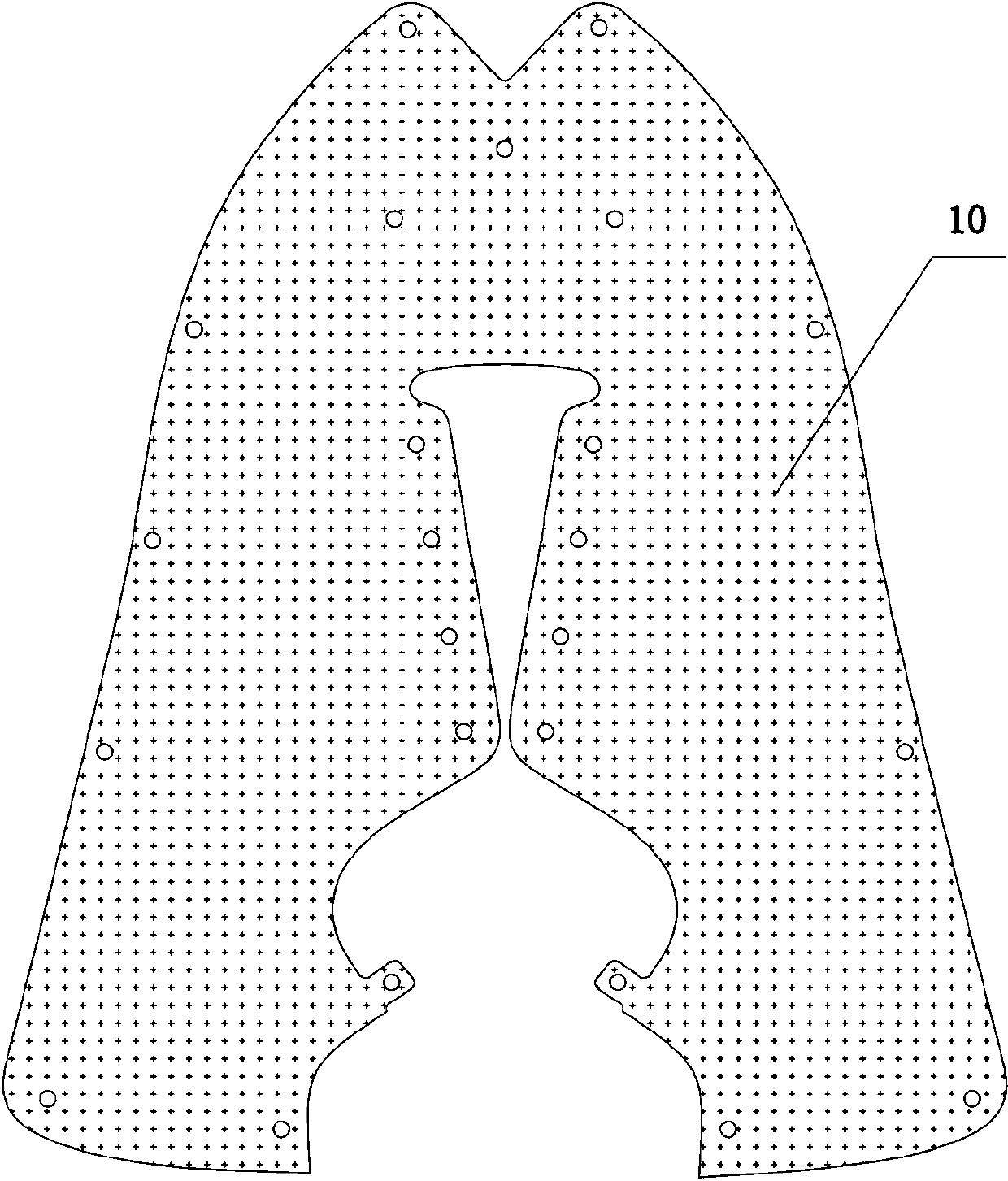

Bionic type artificial intervertebral disc and forming method thereof

ActiveCN106901876ATightly bondedAchieve immediate stabilitySpinal implantsCoatingsEngineeringIntervertebral disk

The invention relates to a bionic type artificial intervertebral disc and a forming method thereof. The bionic type artificial intervertebral disc is composed of an upper rigid end plate, a lower rigid end plate, an elastic nucleus pulposus arranged between the upper rigid end plate and the lower rigid end plate and a film body arranged at the outer side of the elastic nucleus pulposus; the elastic nucleus pulposus is constituted by adopting two or more polyurethane materials with different elasticity moduli, and the polyurethane materials with the different elasticity moduli are integrally connected. When the bionic type artificial intervertebral disc is molded, the center of the nucleus pulposus is firstly formed to connect the upper rigid end plate-polyurethane material workpiece and the lower rigid end plate-polyurethane material workpiece, and then the outer side is injected with the polyurethane materials. The bionic type artificial intervertebral disc is of an integral structure, and when the bionic type artificial intervertebral disc is loaded, through elastic deformation of the elastic nucleus pulposus, physiological activities of the artificial intervertebral disc in all directions are achieved.

Owner:BEIJING UNIV OF CHEM TECH

Lead-acid storage battery separator and preparation method thereof

InactiveCN104852002AReasonable structureTightly bondedFinal product manufactureCell component detailsGlass fiberPolyester

The invention discloses a lead-acid storage battery separator which comprises 85-95 percent by weight of superfine glass fibers, 4-10 percent by weight of polyester fibers and 1-5 percent of cellulose acetate fibers. A preparation method comprises the following steps: pulping the superfine glass fibers for 5-10min and then adding the polyester fibers and the cellulose acetate fibers, pulping for 8-12min, forming and beating to enter a drying system at a constant speed, drying at a temperature of 160-2500 DEG C, winding and cutting to obtain the lead-acid storage battery separator. The lead-acid storage battery separator prepared by adopting the preparation method is reasonable in structure; the polyester fibers and the cellulose acetate fibers are added, so that the advantages of insulation, isolation and storage of an acid liquor of an existing AGM separator can be kept, the relatively high mechanical strength, excellent puncture resistance and excellent compression rebound property are obtained, the performance of a storage battery is improved, the service life of the storage battery is prolonged, and the application is relatively wide.

Owner:QIDONG HENGRUI POWER SUPPLY TECH CO LTD

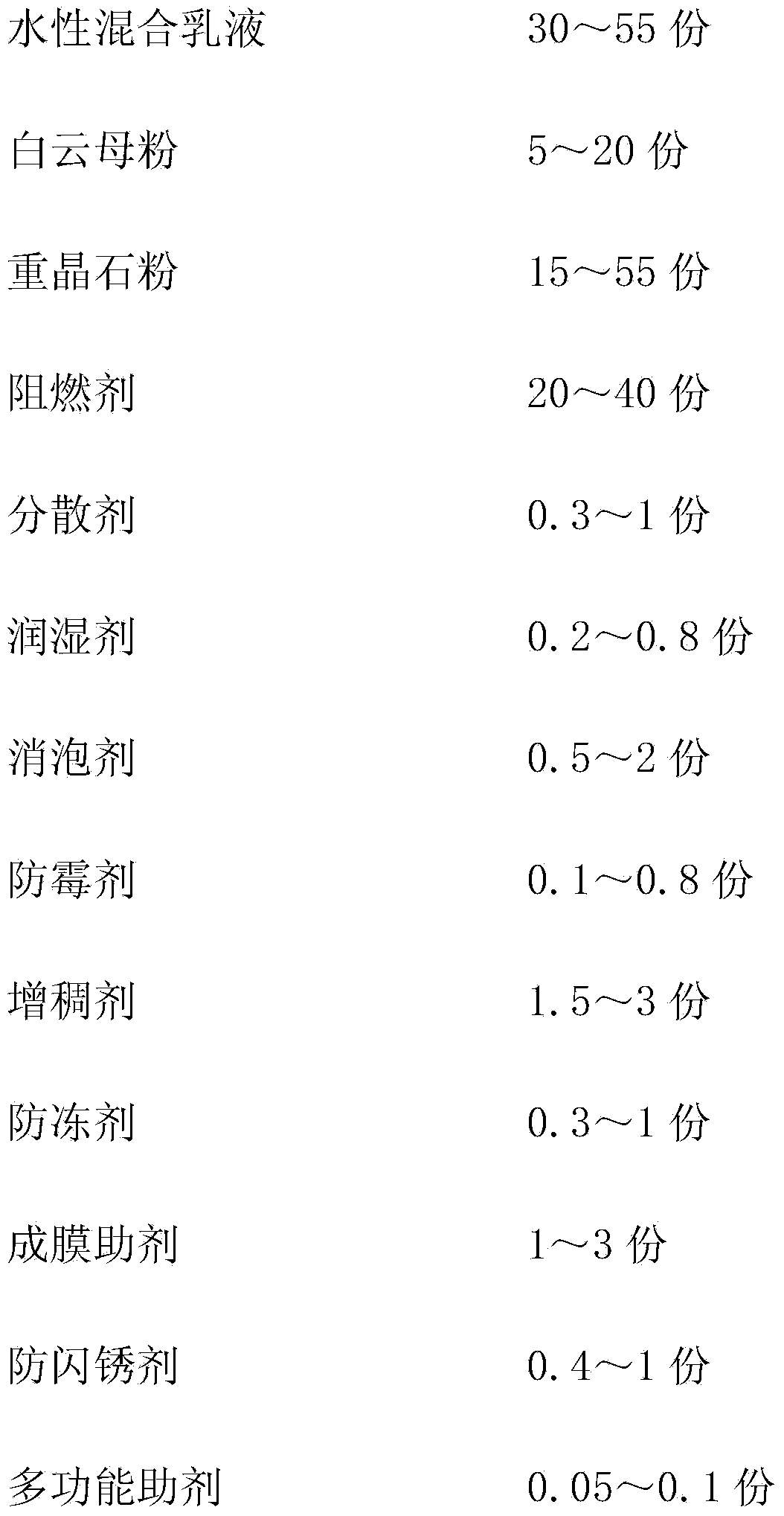

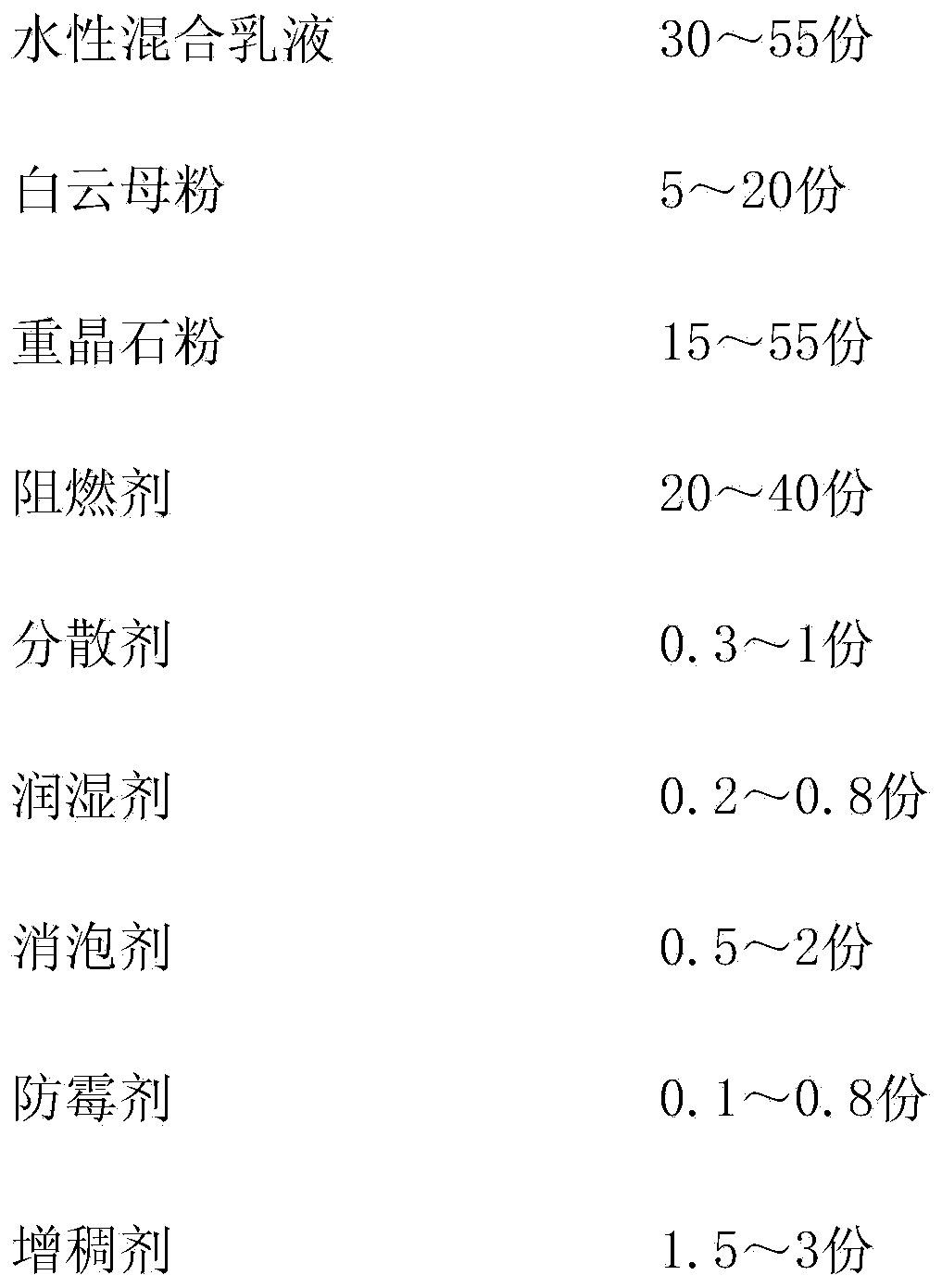

Water-borne sound-insulating damping coating for ship and preparation method thereof

InactiveCN104004418AImproved damping propertiesGood flame retardant performanceAnti-corrosive paintsSteel platesEmulsion

The invention provides a water-borne sound-insulating damping coating for a ship. According to the water-borne sound-insulating damping coating for the ship, water-borne mixed emulsion is used as film forming matter, inorganic filter is used as main filler, and coating aids are added. The water-borne sound-insulating damping coating for the ship mainly comprises, by weight, 30 parts to 55 parts of water-borne styrene-acrylic emulsion which is of an interpenetrated network structure, 30 parts to 60 parts of the inorganic filler and 20 parts to 40 parts of fire retardants. The water-borne sound-insulating damping coating for the ship is prepared by preparing the water-borne mixed emulsion, adding the filler and the aids, and conducting paint mixing, white mica powder is used as functional damping filler, and blanc fixe is used as functional sound-insulating filler. The water-borne sound-insulating damping coating for the ship has the advantages that the recombination loss factor is high, and the sound insulation coefficient is high; the performance of being rapidly dried at normal temperature can be achieved; the adhesive force to a steel plate is high; the fire retardant property is high, and the shipment use requirement is met; the steel plate is free of rust; the workability is high; no hazardous substances exist, and environmental friendliness is achieved.

Owner:太仓市兰燕新材料有限公司

Shaking stopping device for B-type enclosure system of large-scale LNG ship

ActiveCN104986287AGood insulation performanceGood mechanical propertiesHull interior subdivisionFor bulk goodsMetallic materialsEngineering

The invention relates to a shaking stopping device for a B-type enclosure system of a large-scale LNG ship. The shaking stopping device arranged above the enclosure system is characterized by comprising a lower retainer ring, a laminating flitch arranged in the lower retainer ring, and an upper baffle wedged in the upper part of the laminating flitch, wherein a metallic material is embedded in the laminating flitch; the upper baffle comprises an upper toggle plate and an upper panel; the lower retainer ring comprises a lower toggle plate and a lower panel; a first gap is formed between each of the two lateral sides of the upper part of the laminating flitch and the upper toggle plate; a second gap is formed between each of the left side and the right side of the bottom of the laminating flitch and the lower toggle plate; a third gap is formed between the bottom of the laminating flitch and the lower panel; a fourth gap is formed between each of the front side and rear sides of the laminating flitch and the lower toggle plate; stopping laminating wooden wedge blocks are respectively embedded in the first gap and the second gap, and low temperature resistant epoxy resins are poured in the third gap and the fourth gap. Through the adoption of the shaking stopping device for the B-type enclosure system of the large-scale LNG ship, disclosed by the invention, the structure is simple, the manufacturing is convenient, the situation that liquid cargoes on the ship are evaporated does not occur, the low temperature resistance is good, and the shaking stopping device has a high practical value.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Novel protective shoe upper and production technique thereof

InactiveCN103271511AImprove protection strengthReduce collision damageUpperBootlegsSkin treatmentsFoaming agent

A process for manufacturing a novel protective shoe upper comprises the following steps: adding a processing adjuvant, a bridging agent, a foaming agent, an active agent, and pigment in EVA raw materials, forming EVA foaming body after fully mixing, finally cutting into an EVA foaming body layer; covering a bonding layer on the EVA foaming body layer, then blanking into a preset pattern modeling; placing the blanked EVA foaming body layer in a bottom die; coating a cloth-skin treatment agent on the bonding surface of the bottom layer of a shoe upper and placing on the bottom die of the die, closing a die cover, firstly pressurizing and heating and then pressurizing and cooling and fetching an end product. The protective shoe upper manufactured by the invention can effectively improve protective strength of the shoe upper, reduce collision harm from external impact force to an instep, and play a protective role for a user in outdoor activities.

Owner:泉州泰亚鞋业有限公司

Fuel cell sealing assembly and sealing method

InactiveCN108054406AAchieve fitFit tightlyFinal product manufactureSealing/support meansFuel cellsMechanical engineering

The invention provides a fuel cell sealing assembly. The fuel cell sealing assembly comprises a sealing part and a supporting structure and is used for sealing a fuel cell monomer including a bipolarplate and a membrane electrode, the bipolar plate is provided with a sealing groove, the membrane electrode comprises a proton exchange membrane, the sealing part is arranged in the sealing groove, the supporting structure comprises an upper supporting structure body and a lower supporting structure body, one end of the upper supporting structure body and one end of the lower supporting structurebody form attaching areas for being attached to the upper top face and the lower bottom face of the proton exchange membrane respectively, and the other end of the upper supporting structure body is attached to the other end of the lower supporting structure body to form a sealing area for abutting against the sealing part. The fuel cell sealing assembly is simple in structure and low in production difficulty coefficient and has a good sealing effect, very high economy and practicability. The invention further provides a fuel cell and a sealing method of the fuel cell.

Owner:BEIJING UNIV OF AERONAUTICS & ASTRONAUTICS DONGGUAN

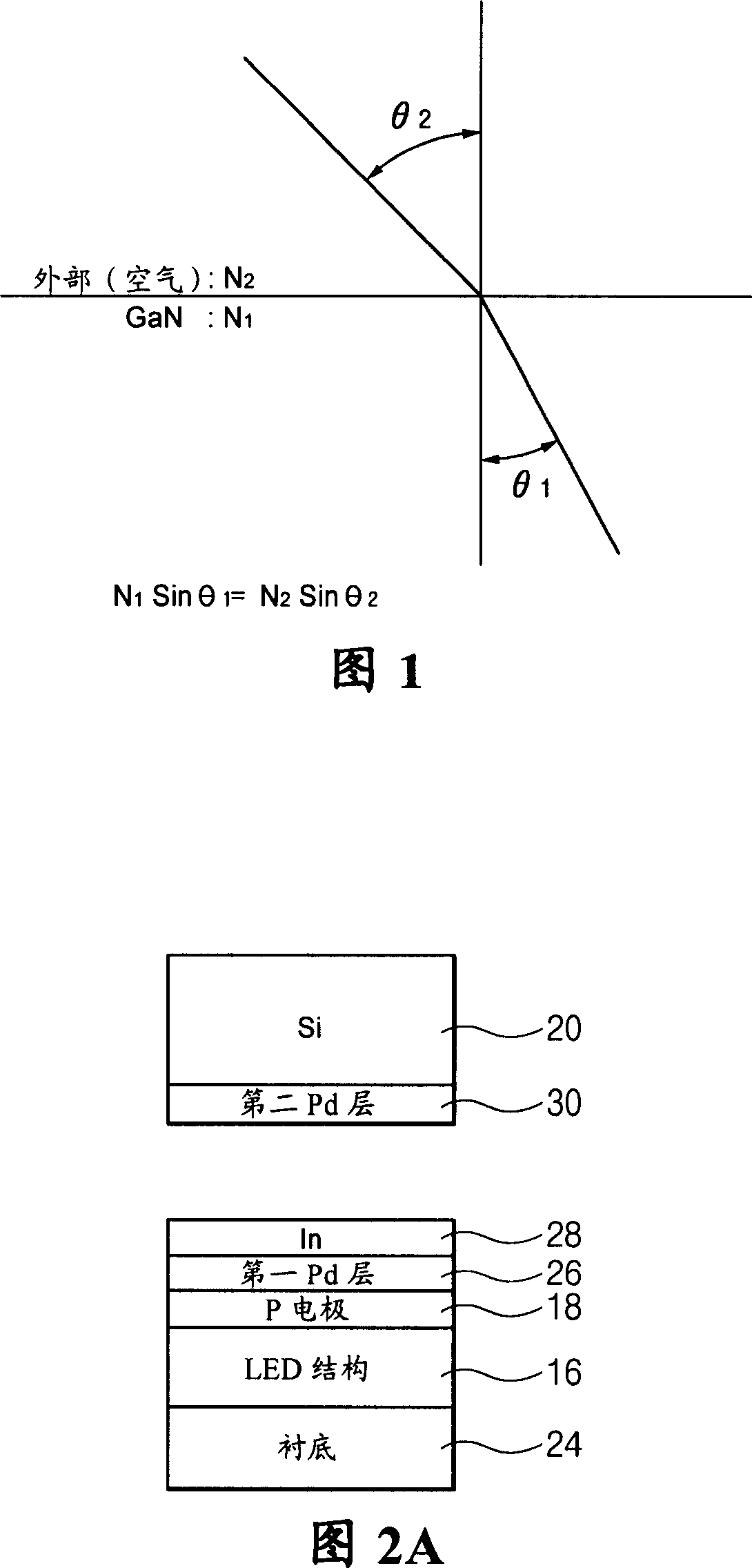

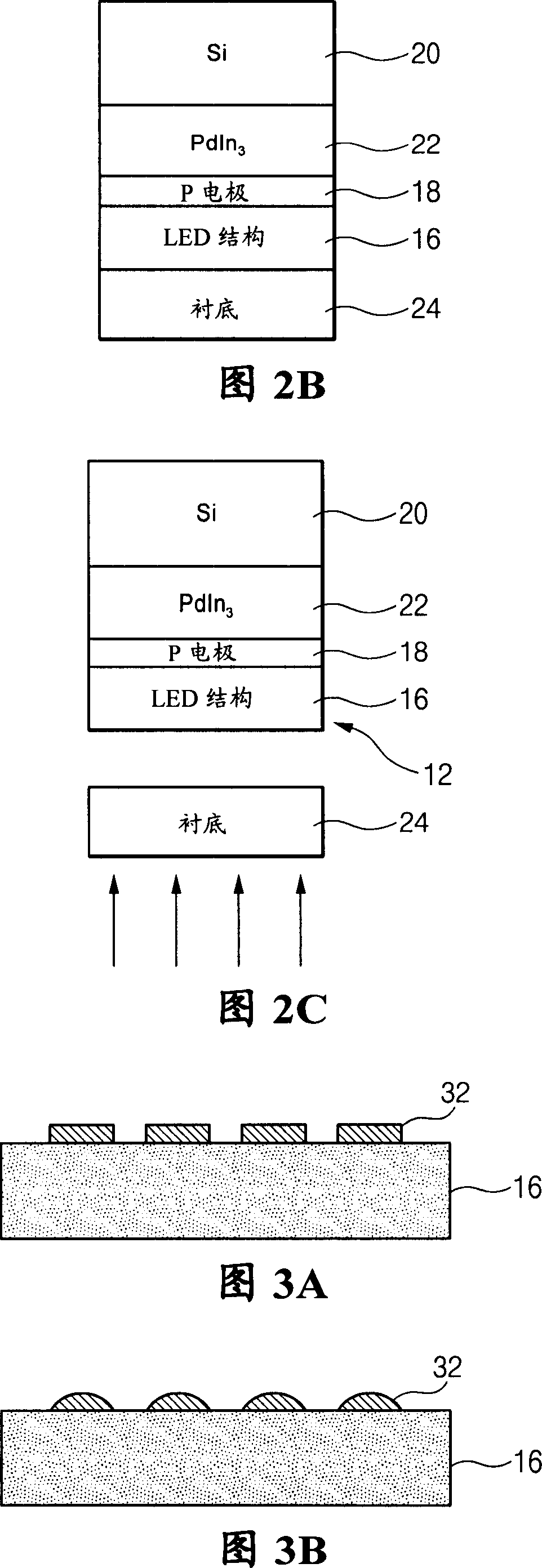

Vertically structured gan type led device

The invention provides an LED vertical to a GaN. The LED vertical to a GaN comprises: an n-electrode; an n-type GaN layer formed under the n-electrode; an active layer formed under the n-type GaN layer; a p-type GaN layer formed under the active layer, the p-type GaN layer having a first uneven structure formed on a surface that does not contact the active layer; a p-type reflective electrode formed under the p-type GaN layer having the first uneven structure; and a support layer formed under the p-type reflective electrode.

Owner:SAMSUNG LED CO LTD

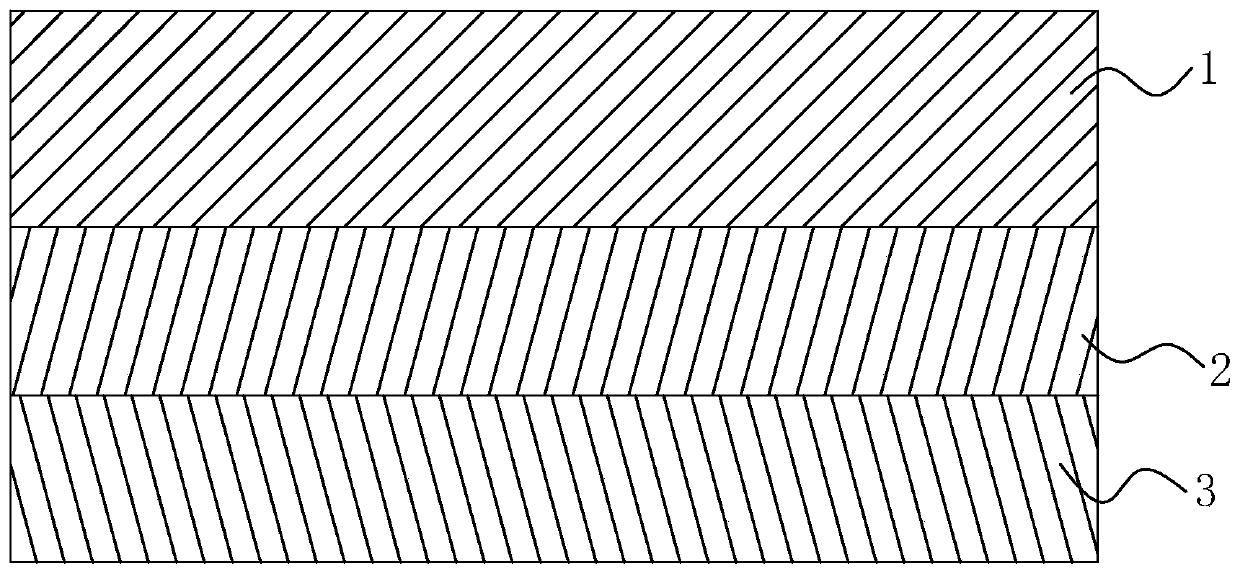

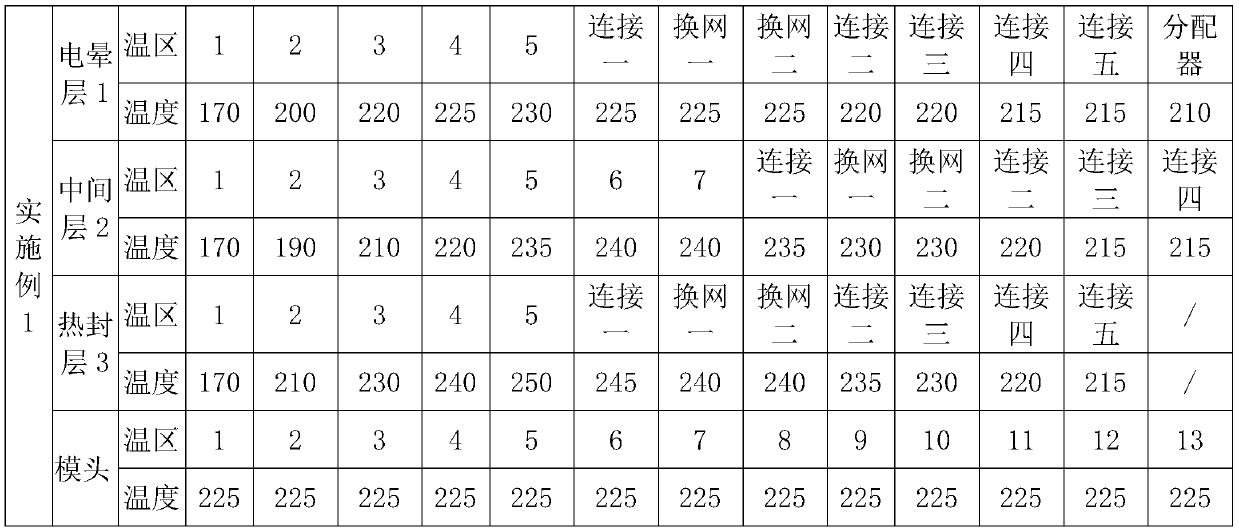

CPE heat-sealing composite film and preparation method thereof

ActiveCN110466225AHigh impact strengthHigh tensile strengthSynthetic resin layered productsComposite filmMaterials science

The invention discloses a CPE heat-sealing composite film and a preparation method thereof. The CPE heat-sealing composite film includes a corona layer, an intermediate layer and a heat-sealing layerconnected in sequence. The corona layer includes the following components by weight: 64-68 parts of LLDPE, 18-22 parts of LDPE, 4-6 parts of POE, 2-4 parts of MPE, 0.8-1.2 parts of an anti-block slipping agent and 0.8-1.2 parts of a modified heat-sealing material. The intermediate layer includes the following components by weight: 78-82 parts of LLDPE, 8-12 parts of LDPE and 8-10 parts of HDPE. The heat-sealing layer includes the following components by weight: 8-12 parts of mLLDPE, 5-7 parts of a modified heat-sealing material, 18-22 parts of LDPE, 42-46 parts of LLDPE and 1.8-2.2 parts of aprocessing aid. The CPE heat-sealing composite film of the invention has the advantages of good heat-sealing performance in overlapping sealing, good drop resistance, and low bag breaking rate.

Owner:福建立邦包装有限公司

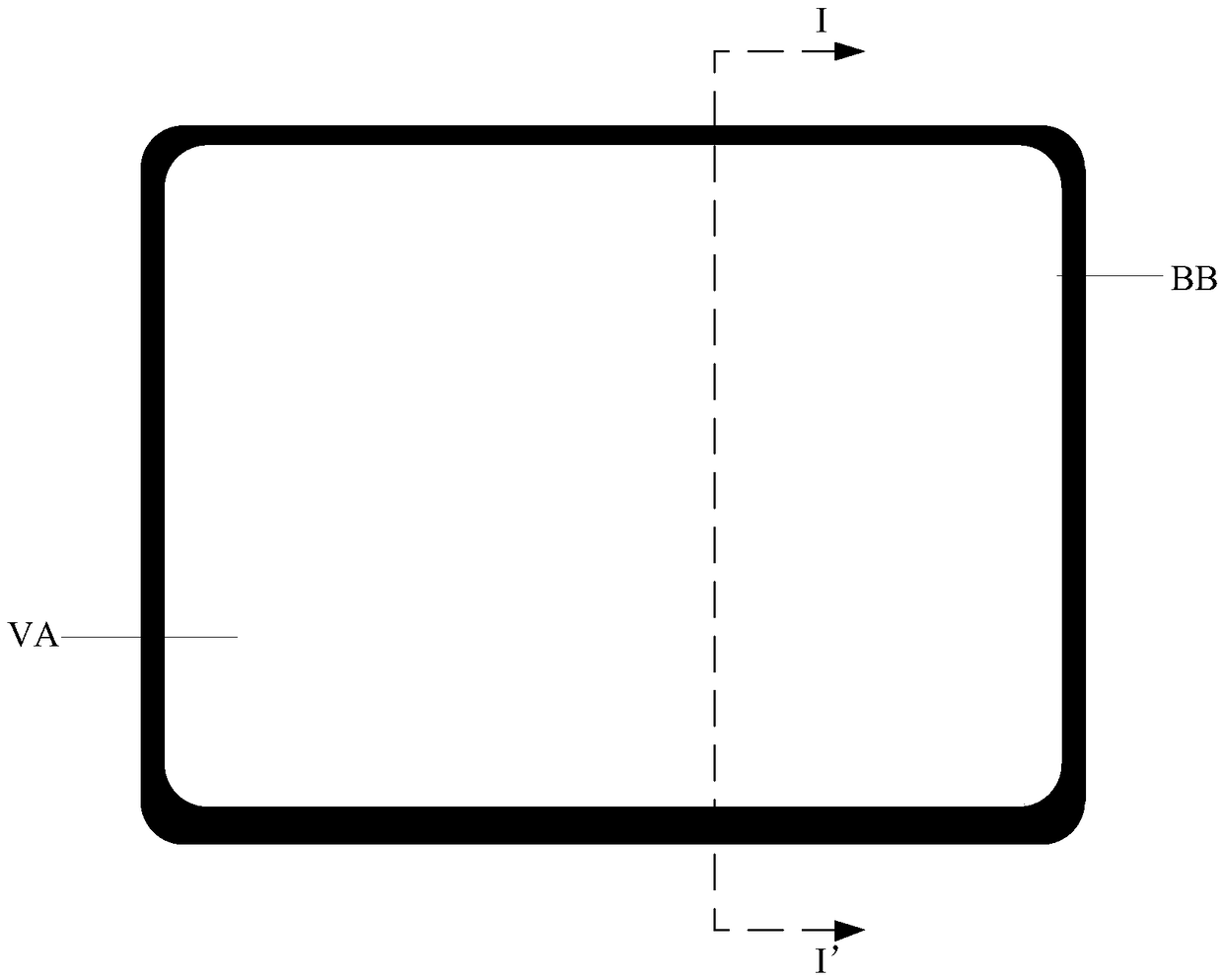

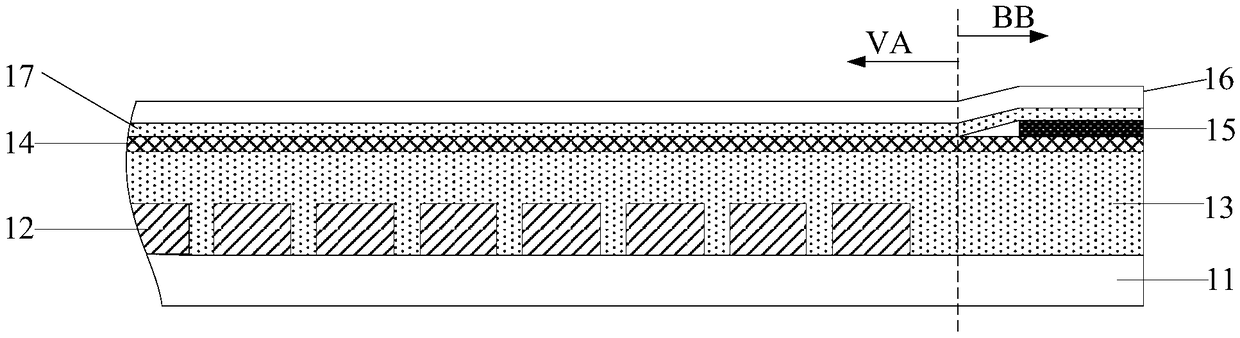

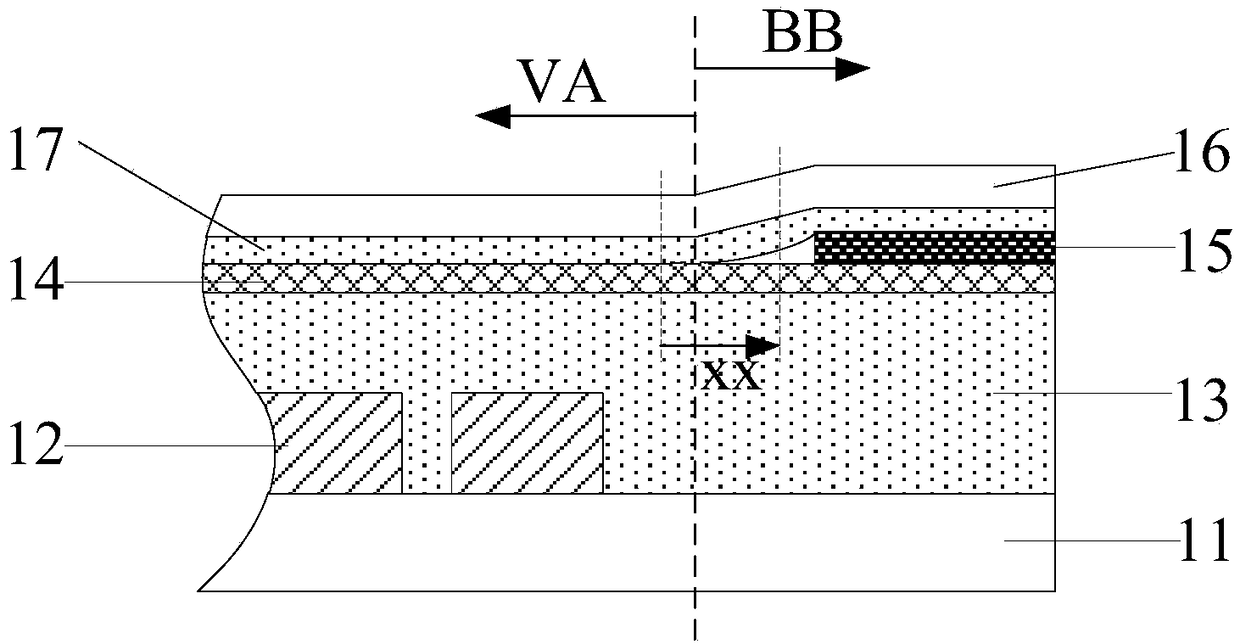

Organic light-emitting display panel, manufacturing method thereof and display device

ActiveCN109148722AAvoid light leakageTightly bondedSolid-state devicesSemiconductor/solid-state device manufacturingViscosity gradeDisplay device

The invention discloses an organic light emitting display panel, a manufacturing method thereof and a display device, the organic light-emitting display panel includes a substrate, a plurality of organic light emitting diode devices located on the substrate, an encapsulation layer located on one side of the organic light emitting diode devices deviating from the substrate, a touch electrode layeron one side of the encapsulation layer deviating from the organic light emitting diode devices, a peripheral circuit on the side of the touch electrode layer facing away from the encapsulation layer,a circular polarizer on the side of the touch electrode layer and the peripheral circuit facing away from the encapsulation layer, and an adhesive layer between the touch electrode layer and the circular polarizer; The touch electrode layer is tightly bonded to the circular polarizer through the adhesive layer in the visible region. The adhesive layer can be a glue material with high viscosity grade, so that the circular polarizer and the touch electrode layer can be tightly bonded in a large range, and there is no gap or bubble in the visible region and the edge position of the visible region, thereby avoiding the light leakage phenomenon of the display panel and improving the display quality.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com