Patents

Literature

644results about How to "Clear outline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

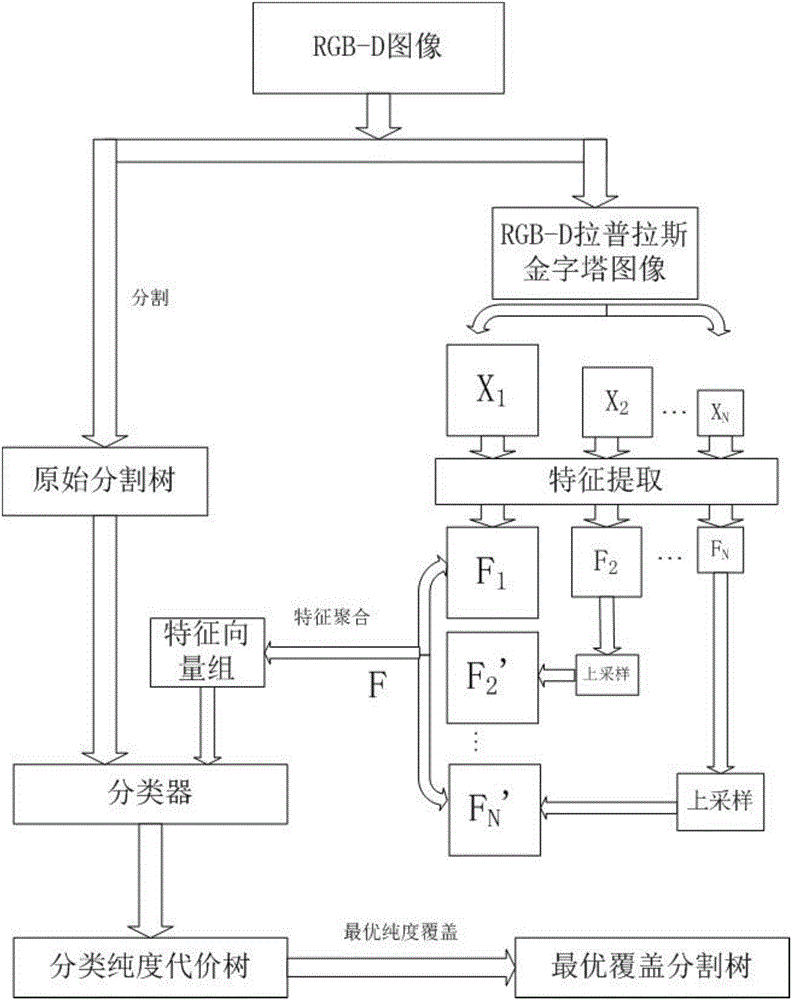

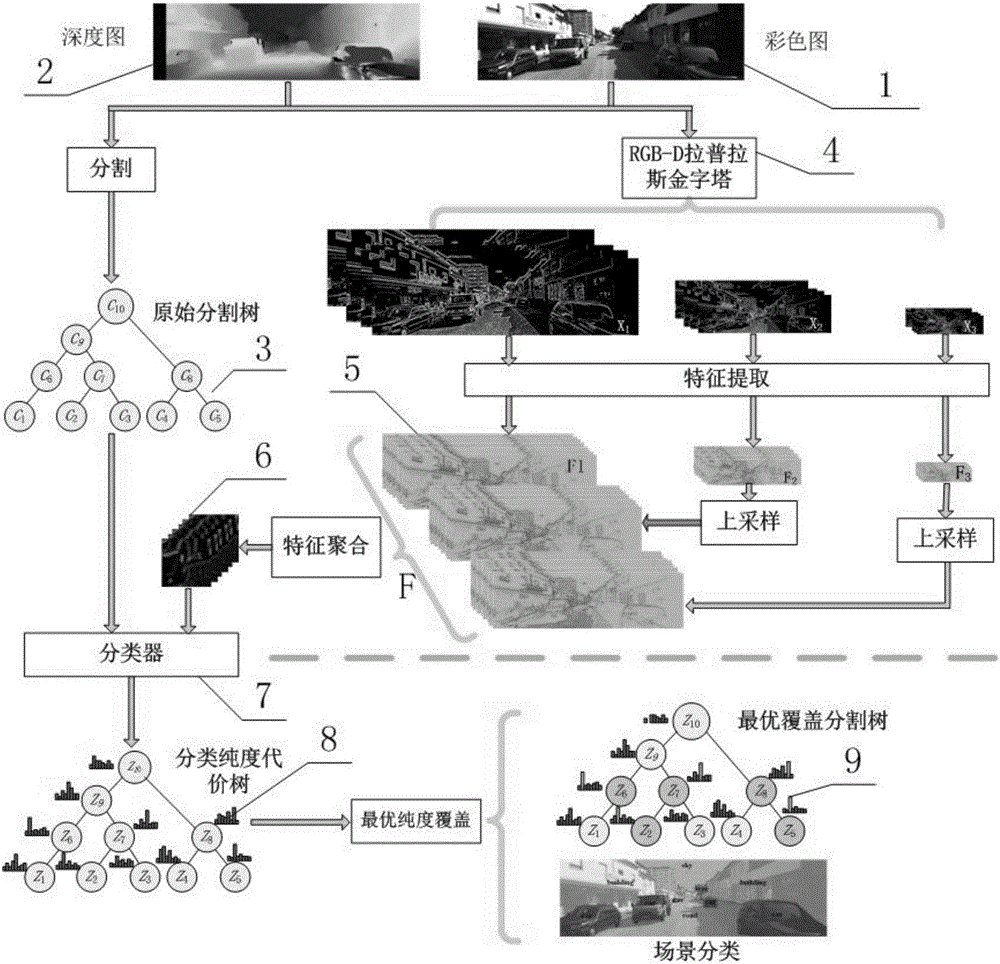

Traffic scene classification method based on multi-scale convolution neural network

InactiveCN105956532AClear outlineRich and effective accessCharacter and pattern recognitionNeural learning methodsClassification methodsMulti targeting

The invention discloses a traffic scene multi-target classification method, to be specific, discloses a traffic scene classification method based on a multi-scale convolution neural network. The traffic scene classification method is characterized in that recessive characteristics based on the multi-scale convolution neural network are extracted; and an optimal covering segmentation tree is acquired. During the realizing of the traffic scene classification, the multi-scale convolution neural network is adopted, and the excellent recessive characteristics having the invariance property are effectively extracted from an original image in different scales, and by comparing with the single-scale convolution neural network, the acquisition of the abundant and effective characteristic information of the image is realized. The effective information extracted by the convolution neural network is combined with the original segmentation tree of the image to form an optimal purity price tree, and the covering having the optimal purity is carried out, and therefore a clearer target contour is acquired, and the classification accuracy is increased. The RGB-D is used as the convolution neural network input, and by comparing with the conventional RGB convolution neural network input, the training characteristic is additionally provided with the depth information, and the classification of the input image is more accurate.

Owner:DALIAN UNIV OF TECH

Improved image edge detection method

InactiveCN107067382AClear outlineImprove continuityImage enhancementImage analysisPerpendicular directionDouble threshold

The invention discloses an improved image edge detection method. The improved image edge detection method comprise steps of S1, performing smoothing processing on an image and using an improved media filter to suppress noise, S2, obtaining a difference between a horizontal direction and a perpendicular direction through first-order-partial derivatives of directions of x,y,45 degrees and 135 degrees and thus obtaining a gradient amplitude and a gradient direction, S3, performing non-maximum value inhibition on the gradient amplitude, S4, using a gradient histogram to solve a high threshold and a low threshold and then using a double-threshold algorithm to perform edge detection on the image, and S5, performing sharpening processing and connecting the edges to obtain a final edge image. The improved image edge detection method use weighted media filtering to replace gauss filtering, uses the partial derivatives of four directions, uses the gradient histogram to determine the high threshold and the low threshold, reduces detection errors, improves detection accuracy, and makes the counter of the edge image more clear and continuity better.

Owner:南宁市正祥科技有限公司

Method for preparing Al-Ti-B grain refiner

The Al-Ti-B crystal grain fining agent for metal material has the components including Ti 2-10 wt%, B 2 wt% and Al the rest. The preparation process includes the steps of: mixing industrial pure potassium fluorotitanate and potassium fluoroborate homogeneously, heating to melt industrial pure aluminum, adding the mixed salt into aluminum melt and covering the surface of the melt with KCl, introducing ultrasonic wave to over the melt, skimming slag, cooling the melt naturally while continuous ultrasonic treatment until the intermediate alloy solidifies completely to obtain the Al-Ti-B crystal grain fining agent. The present invention has short preparation period and less oxidation loss of aluminum melt, and the obtained casting structure has fine TiAl3 grains of homogeneous size below 20 microns and TiB2 grains with clear contour. The Al-Ti-B crystal grain fining agent is used in preparing industrial pure aluminum with crystal grains smaller than 120 microns.

Owner:SHANGHAI JIAO TONG UNIV

Method for displaying and quantitatively determining retained austenite or island martensite- austenite in TRIP steel

InactiveCN101382494AEasy extractionImprove accuracyMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationObject structureTRIP steel

The invention relates to a display and quantitative detection method of residual austenite or island martensite-austenite (MA island for short) in TRIP steel. The method comprises the steps: (1) a TRIP tapping sample is prepared into a metallographic specimen; (2) after grinding and polishing, the metallographic specimen is light etched for 5 to 8 seconds in Nital of 1 to 3 percent by weight, and water is sprinkled on a flannel polishing disk for 1 to 2 seconds; sodium pyrosulfite water solution of 1 to 3 percent by weight and picral of 2 to 6 percent by weight are mixed by volume ratio of 1:1 to prepare corrosive liquid, then the metallographic specimen is put into the corrosive liquid for etching of 55 to 65 seconds; (3) the structure of the TRIP steel is observed under a metallurgical microscopy: the delta ferrite is minus blue, the residual austenite or MA island is white, and bainite is brownish-black; and (4) each phase in the structure is carried out quantitative analysis. The method presents different colors, each phase of structure has distinct layers which are easy to distinguish; and a quantitative image analysis method is utilized to fix amount of the feature object structure, which is objective and accurate and has good repeatability.

Owner:WUHAN IRON & STEEL (GROUP) CORP

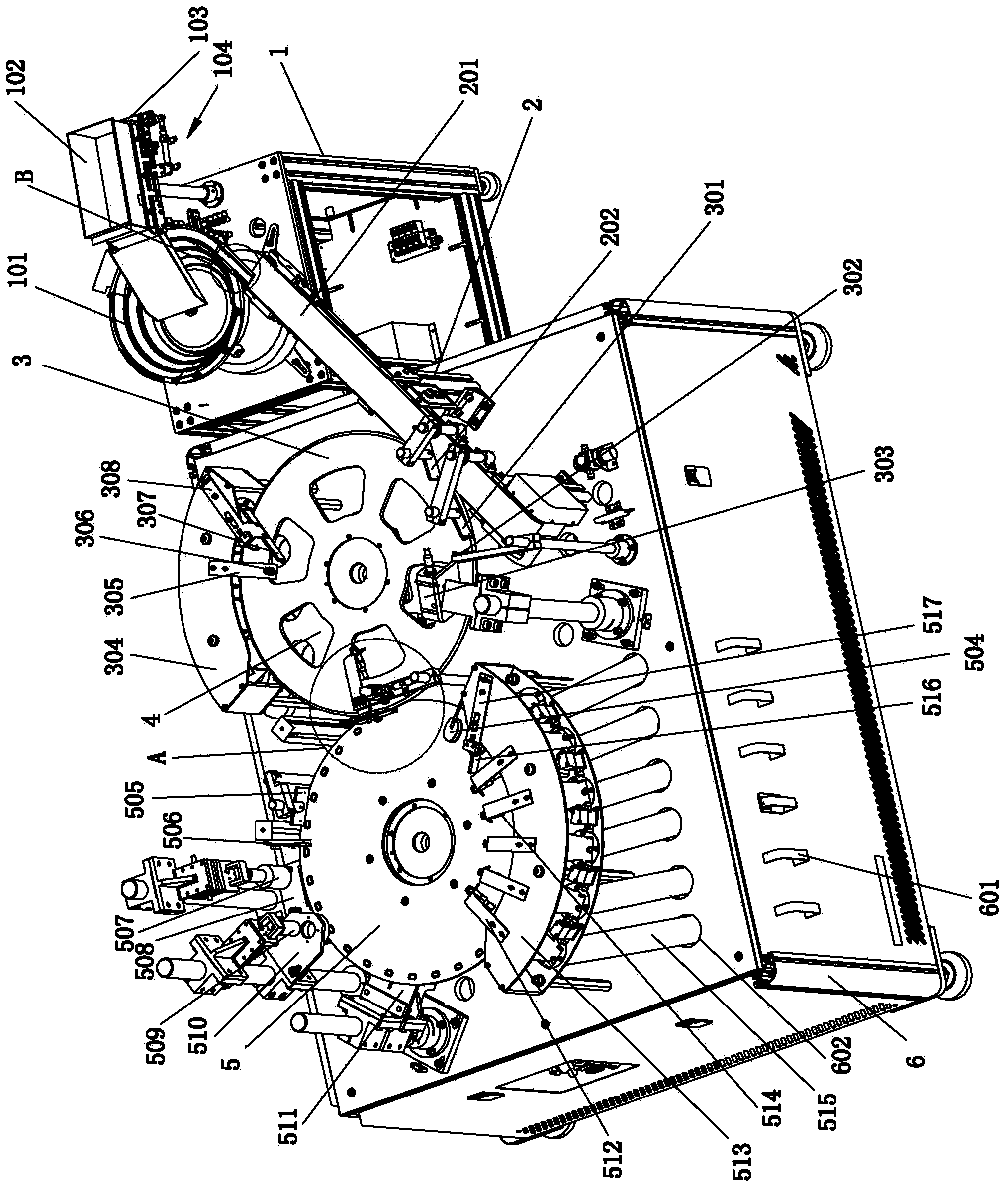

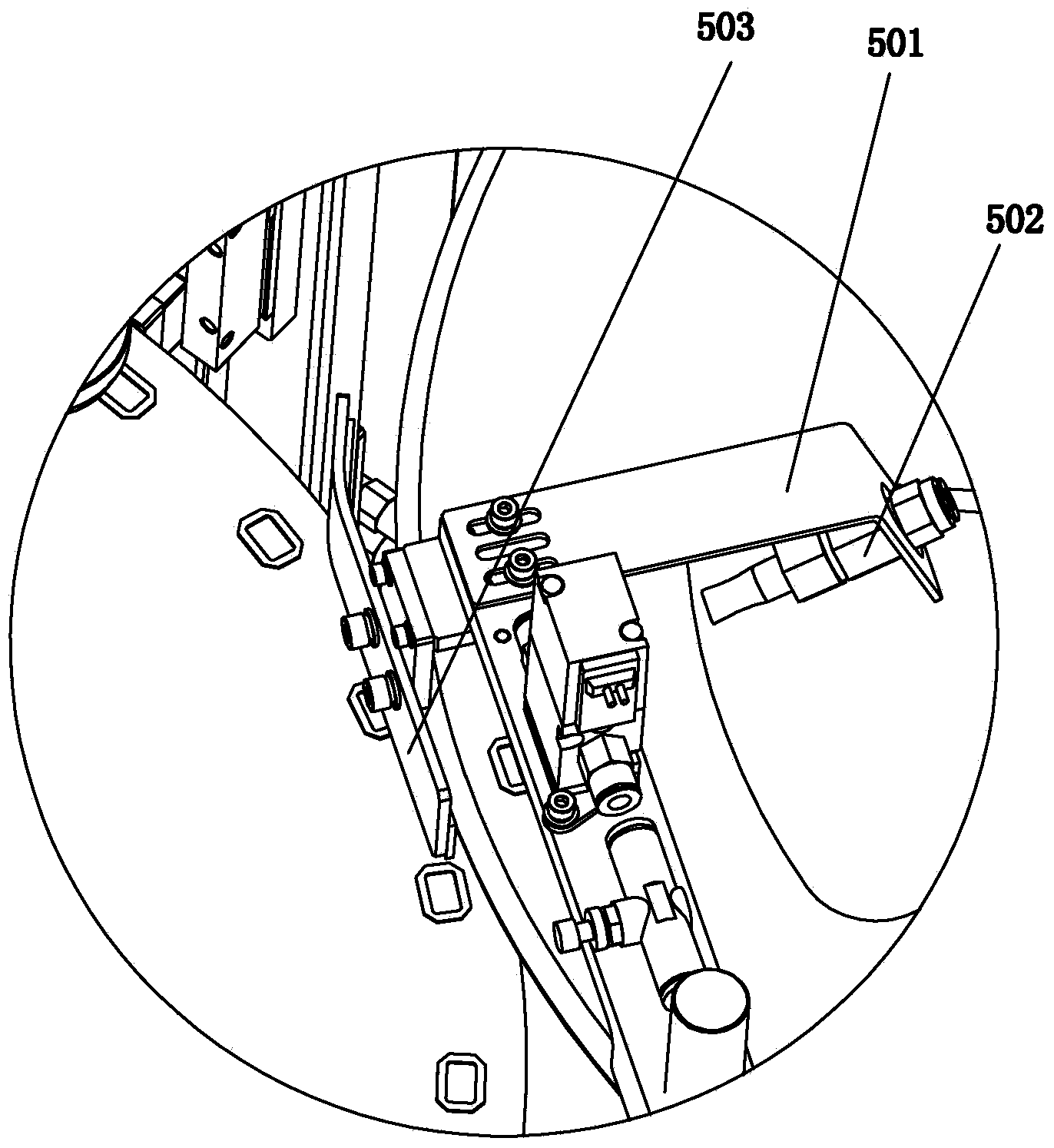

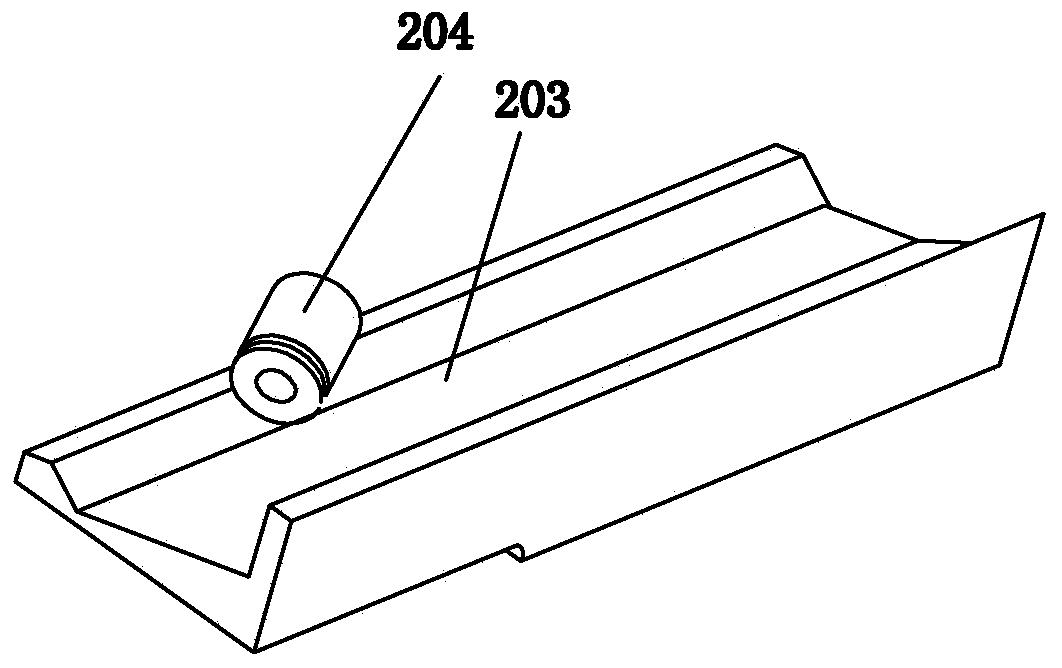

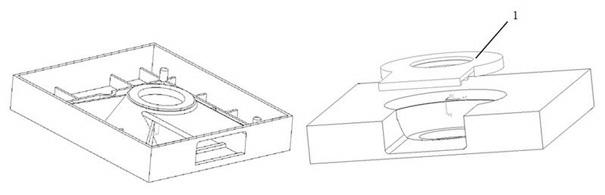

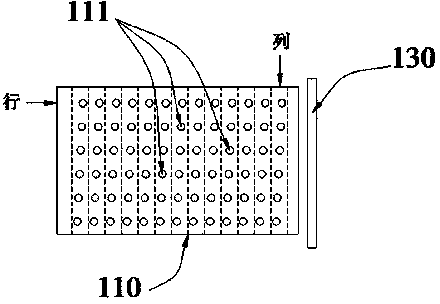

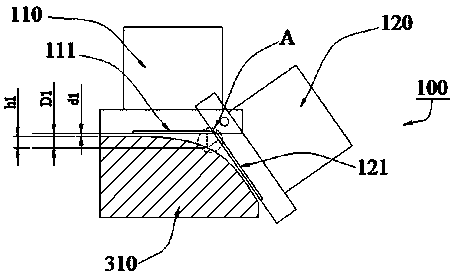

High-precision precise workpiece detecting-sorting machine

The invention discloses a high-precision precise workpiece detecting-sorting machine. The machine comprises a first stander and a second stander, wherein a loading mechanism is arranged on the first stander; a first metal rotating disc, a second transparent rotating disc, a first conveying mechanism and an electric control unit are arranged on the second stander, the first metal rotating disc and the second transparent rotating disc are respectively driven by power devices, and the first conveying mechanism is used for conveying a workpiece from the loading mechanism to the first rotating disc; a first sensor, a longitudinal surface size detection mechanism, a second conveying mechanism and a first receiving mechanism are circumferentially arranged on the first rotating disc, and the second conveying mechanism is used for conveying the workpiece on the first rotating disc to the second rotating disc; a second sensor, a transverse surface size detection mechanism, an appearance detection mechanism and a second receiving mechanism are circumferentially arranged on the second rotating disc; the electric control unit is used for coordinating and controlling the action of each component. According to the high-precision precise workpiece detecting-sorting machine, the mechanical production line automatic detection is realized, and the first rotating disc can be subjected to surface polishing in a later machining period, so that the longitudinal surface size detection precision is improved, and the detection and sorting efficiencies are further increased; meanwhile, as workpieces with different shapes can be detected, the universality is enhanced.

Owner:WEIFANG LOKOMO PRECISION IND

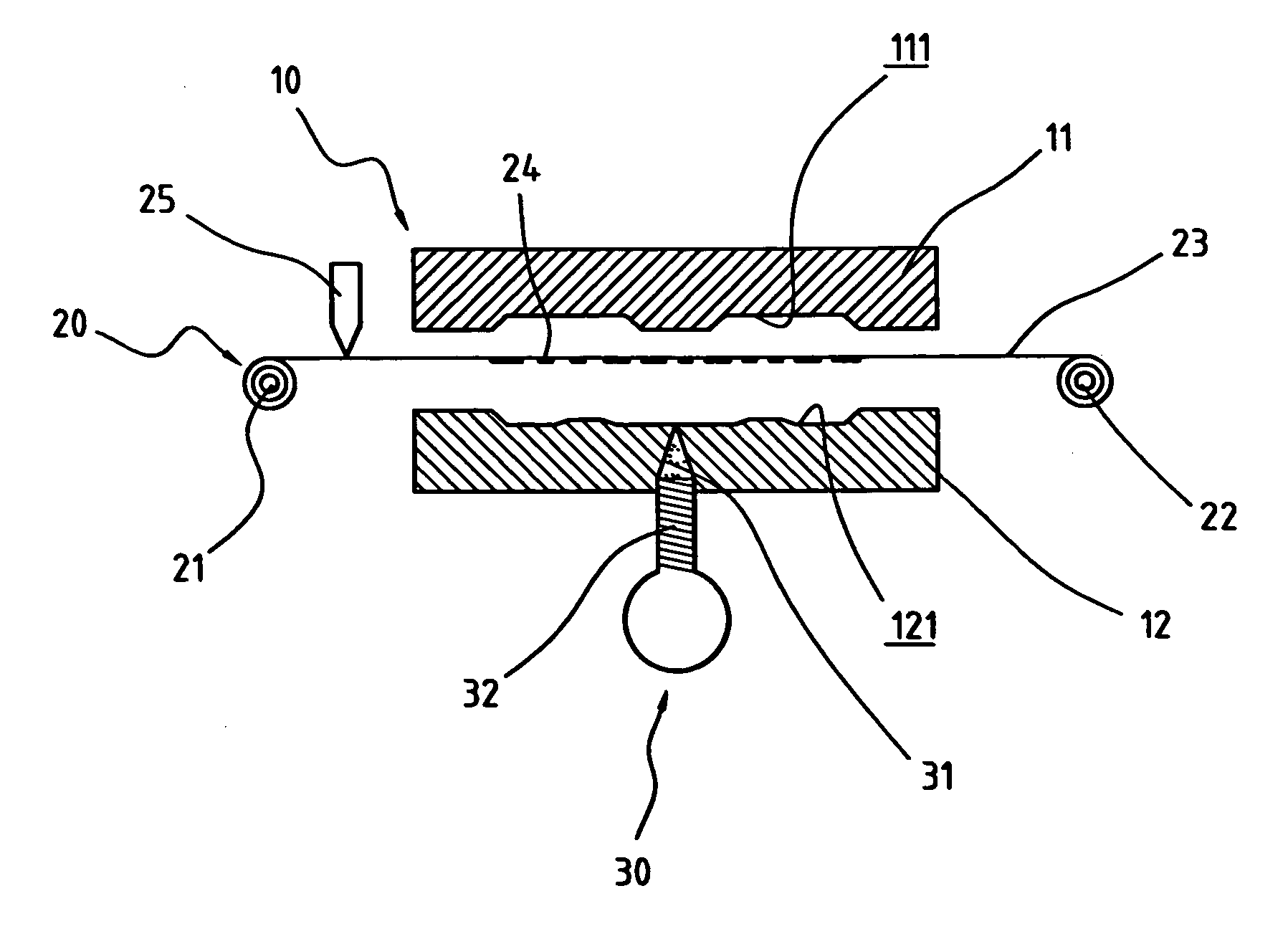

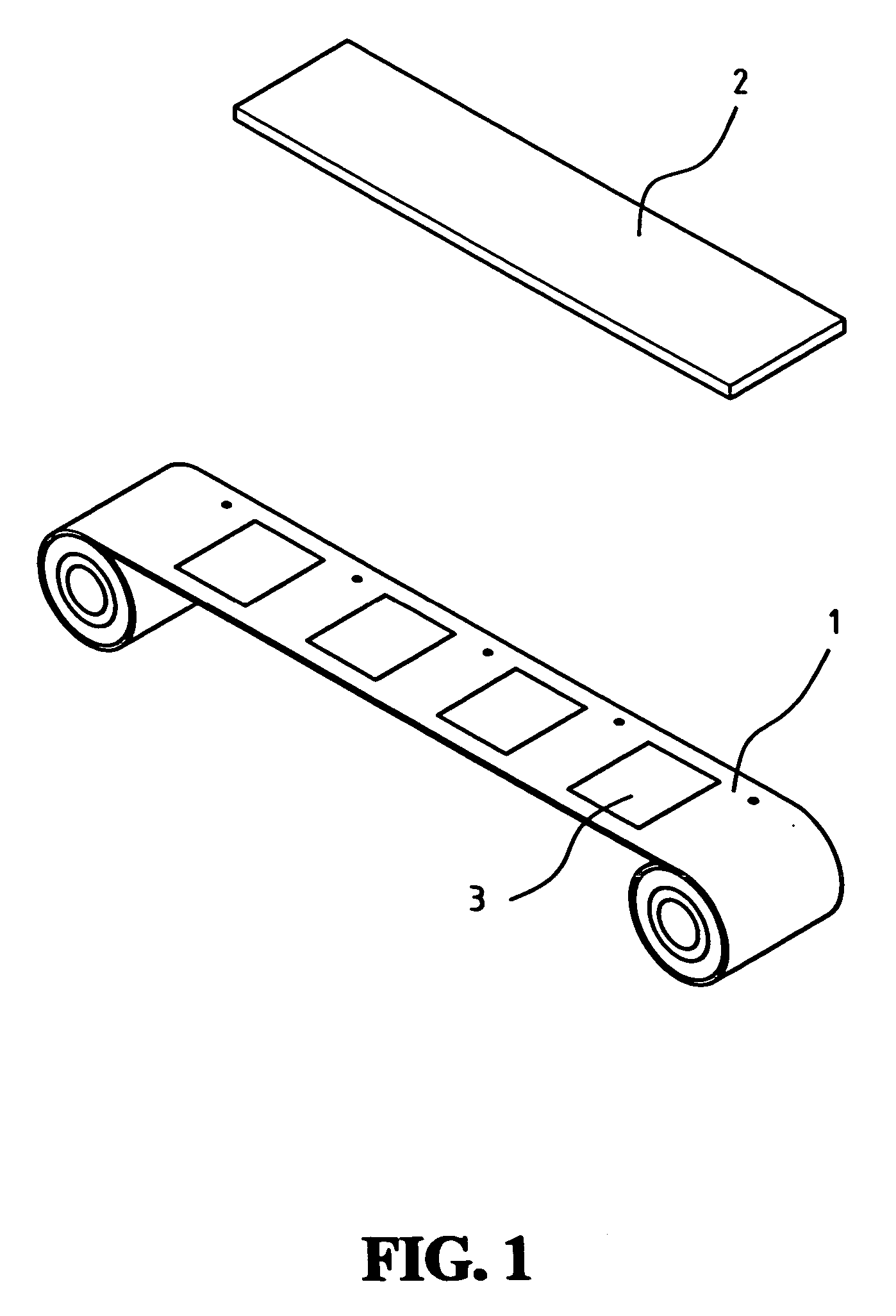

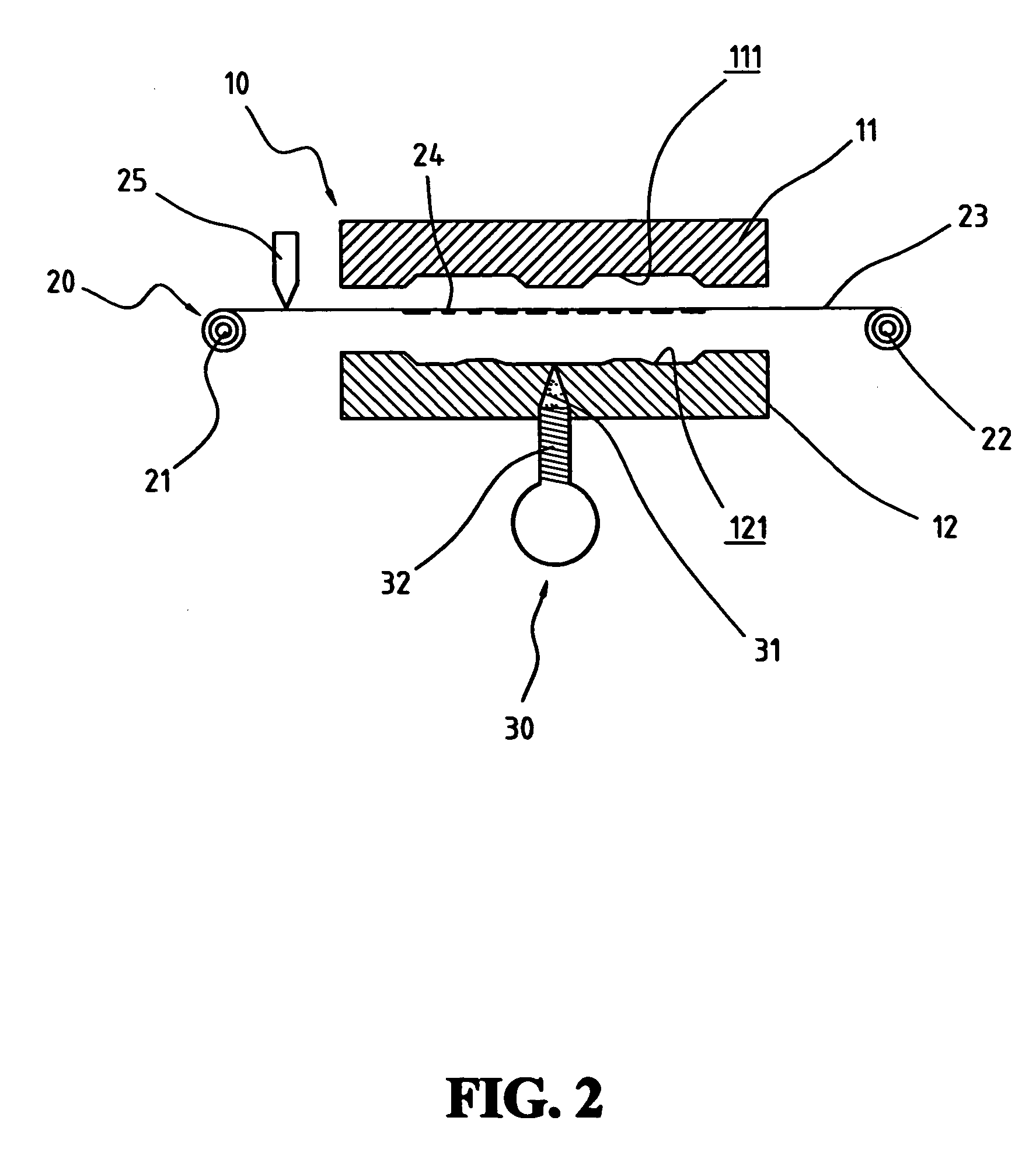

Stereo in mold transfer printing method of silicone

Disclosed is a stereo transfer printing method of in mold transfer printing concurs with injection molding of silicone. The stereo in mold transfer printing method of silicone includes the following steps: (a) providing ink mixed with silicone; (b) using the silicone containing ink to print text or graphic needed on the substrate film; (c) positioning the text or graphic on the substrate film between the mold dies; (d) closing and locking the mold; (e) injecting the silicone; and (f) opening the mold and getting the silicone product.

Owner:WANG CHING SHING

Transmission electron microscope processing method for insect antenna samples

ActiveCN103115809AEffective immobilizationEffective preservationPreparing sample for investigationElectron microscopeBiology

The invention belongs to the field of experimental sample processing technologies, relates to insect antenna sample processing methods and particularly relates to a transmission electron microscope processing method for insect antenna samples. The method sequentially comprises the following steps of: (A) preparing fixing liquid; (B) preparing various embedding agents; (C) dissecting, fixing and rinsing; (D) dewatering and soaking; and (E) gathering, so as to obtain the samples. The method has the advantages that the problems of difficulty in fixing liquid soaking and insufficiency in embedding agent soaking during the process of insect antenna transmission processing are solved, finally-obtained sample slices can be relatively flat, the phenomena of sample wrinkling, damaging and losing are greatly reduced, internal structures of the sample slices are all effectively fixed, and subcellular structures are clearly visible.

Owner:ZHEJIANG UNIV

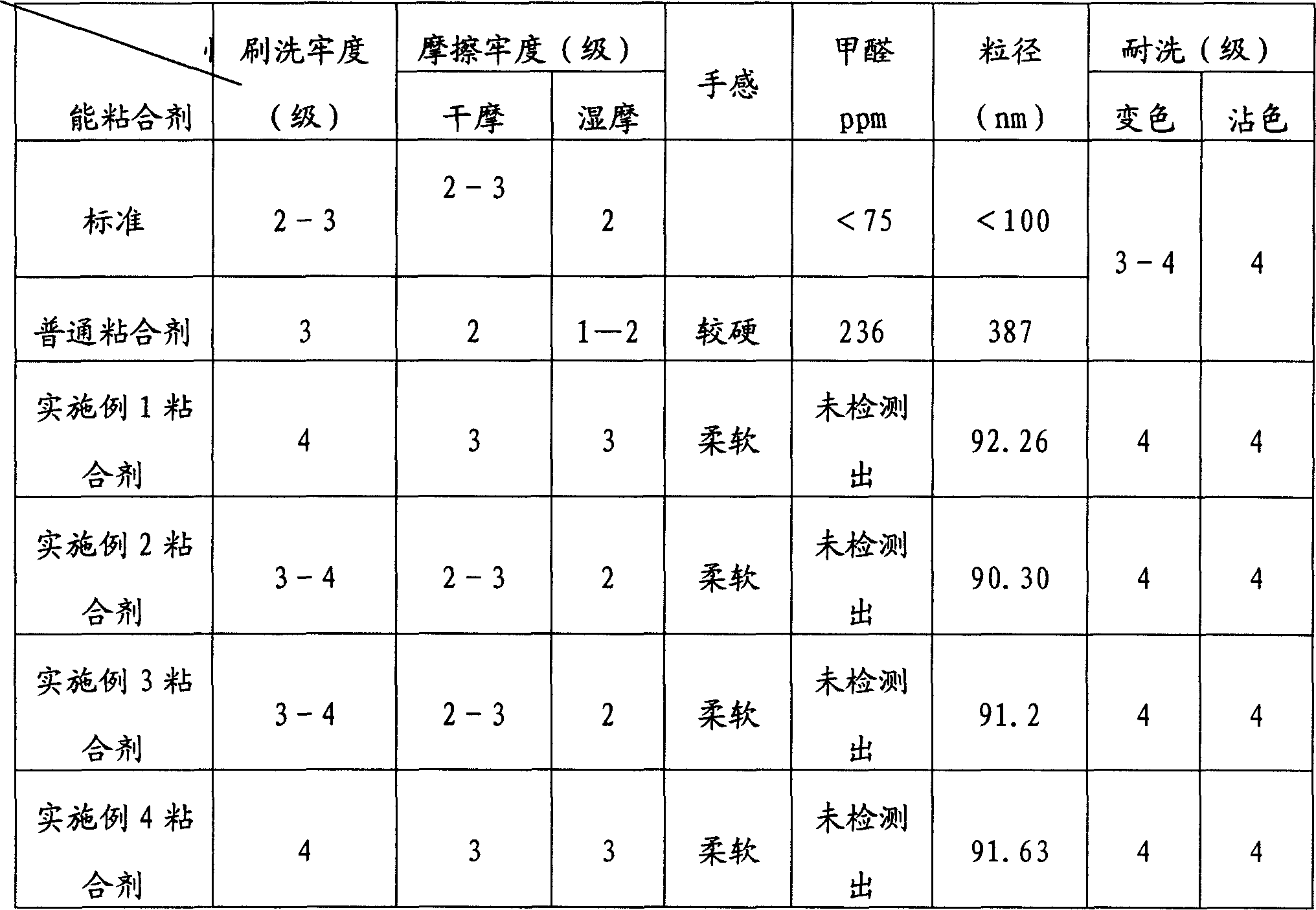

Nano-level formaldehyde-free coating printing-dyeing adhesvie, and its preparing method and use

The invention discloses a nano-level formaldehyde-free paint dye printing adhesive and the preparing method and application thereof. And it comprises N-epoxy propyl acrylamide cross-linking monomer, butyl acrylate, isooctyl acrylate, ethyl acrylate, methyl methacrylate, styrene, vinyl acetic acid, crylic acid, methacrylic acid, reactive surface active agent, unsaturated strongly hydrophilic monomer, vinyl- containing organosilicon monomer, etc. and its grain size can reach nano level and it does not comprise formaldehyde. And it can be used for paint printing and for paint dyeing, as well as for other fields, such as building field.

Owner:SICHUAN TEXTILE SCI RES INST +1

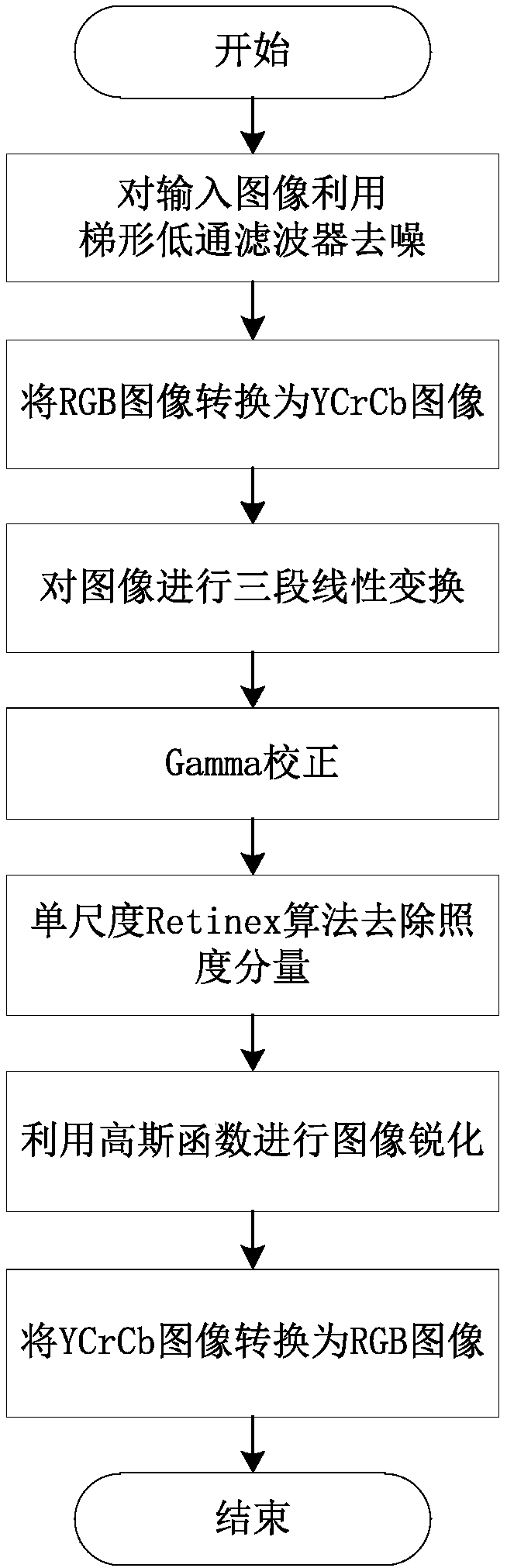

Low-contrast image enhancement method based on YCrCb

ActiveCN108122213AImprove darkLarge dynamic rangeImage enhancementImage analysisLow-pass filterRetinex algorithm

The invention relates to a low-contrast image enhancement method based on YCrCb. The low-contrast image enhancement method comprises the following steps: (1) performing image de-noising on an obtainedoriginal image by utilizing a trapezoidal low-pass filter; (2) performing conversion between a RGB color space and a YCrCb color space on the de-noised image to obtain an image brightness component;(3) performing piecewise linear transformation on a brightness component image by adopting a traditional spatial domain linear transformation method; (4) performing Gamma correction on the transformedimage; (5) performing Gaussian filtering on the corrected image by utilizing a single-scale Retinex algorithm and estimating illumination component and reflection component images; (6) performing image sharpening by utilizing a Gaussian sharpening algorithm aiming at the reflection component image; and (7) performing conversion between the YCrCb color space and the RGB color space on the sharpened image.

Owner:BEIHANG UNIV

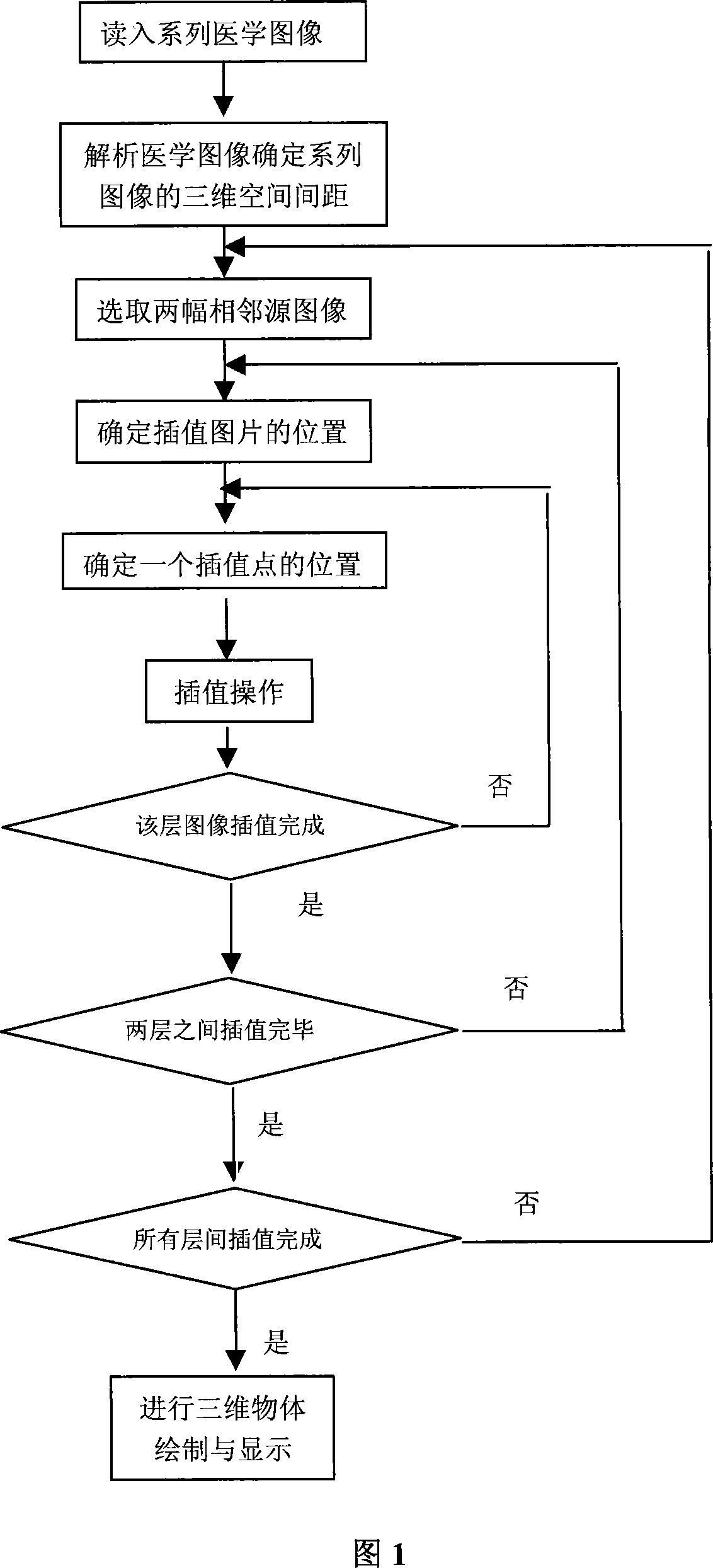

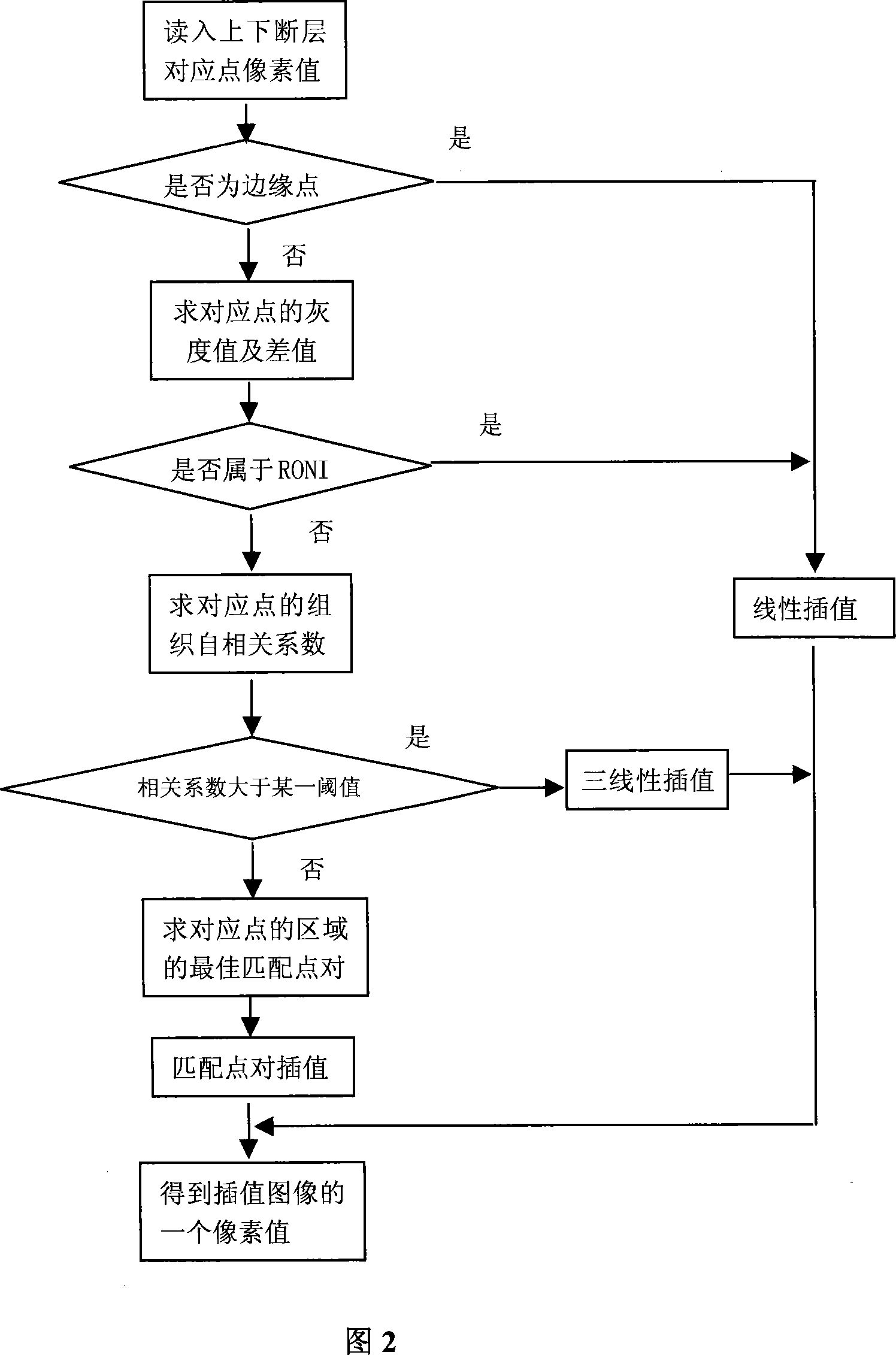

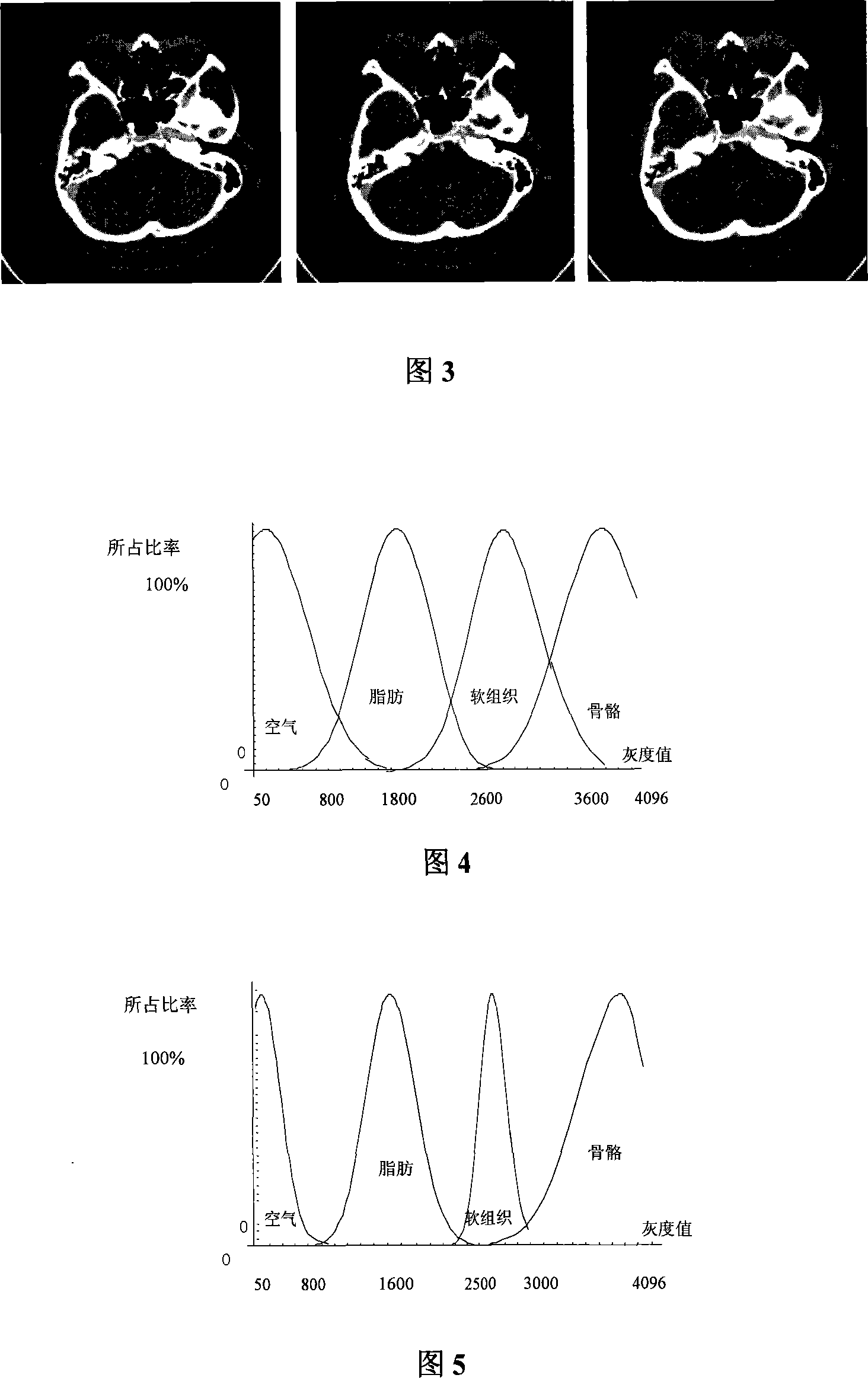

Self-adapting medicine sequence image values inserting method based on interested region

InactiveCN101082983AHigh precisionImprove work efficiencyGeometric image transformation2D-image generationImaging qualityVisual perception

The invention discloses an interpolating method of self-adapting medical sequence image among fault space based on interesting area, which utilizes tissue relativity and body relativity to judge whether the interpolated point belongs to the interesting area to select fitful interpolating method. The invention considers the change of grey and structural outline, which solves the insufficiency of traditional interpolating method to make new interpolated image approach actual condition. The interpolating method modifies the visual effect and image quality greatly, which reduces the noise and shortens the calculating time to be applied in three-dimensional reconstruction and display system.

Owner:SUZHOU SOUKE INFORMATION TECH

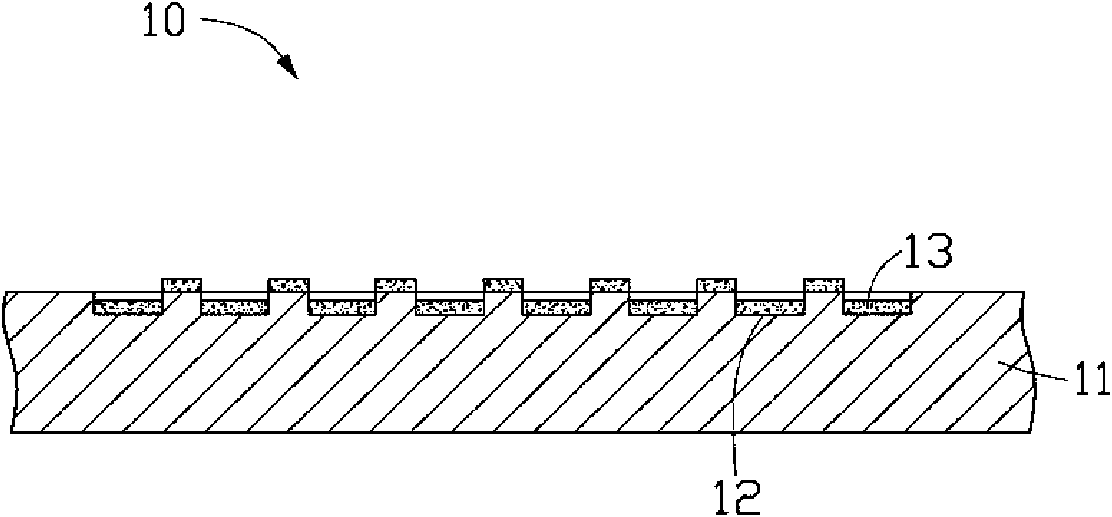

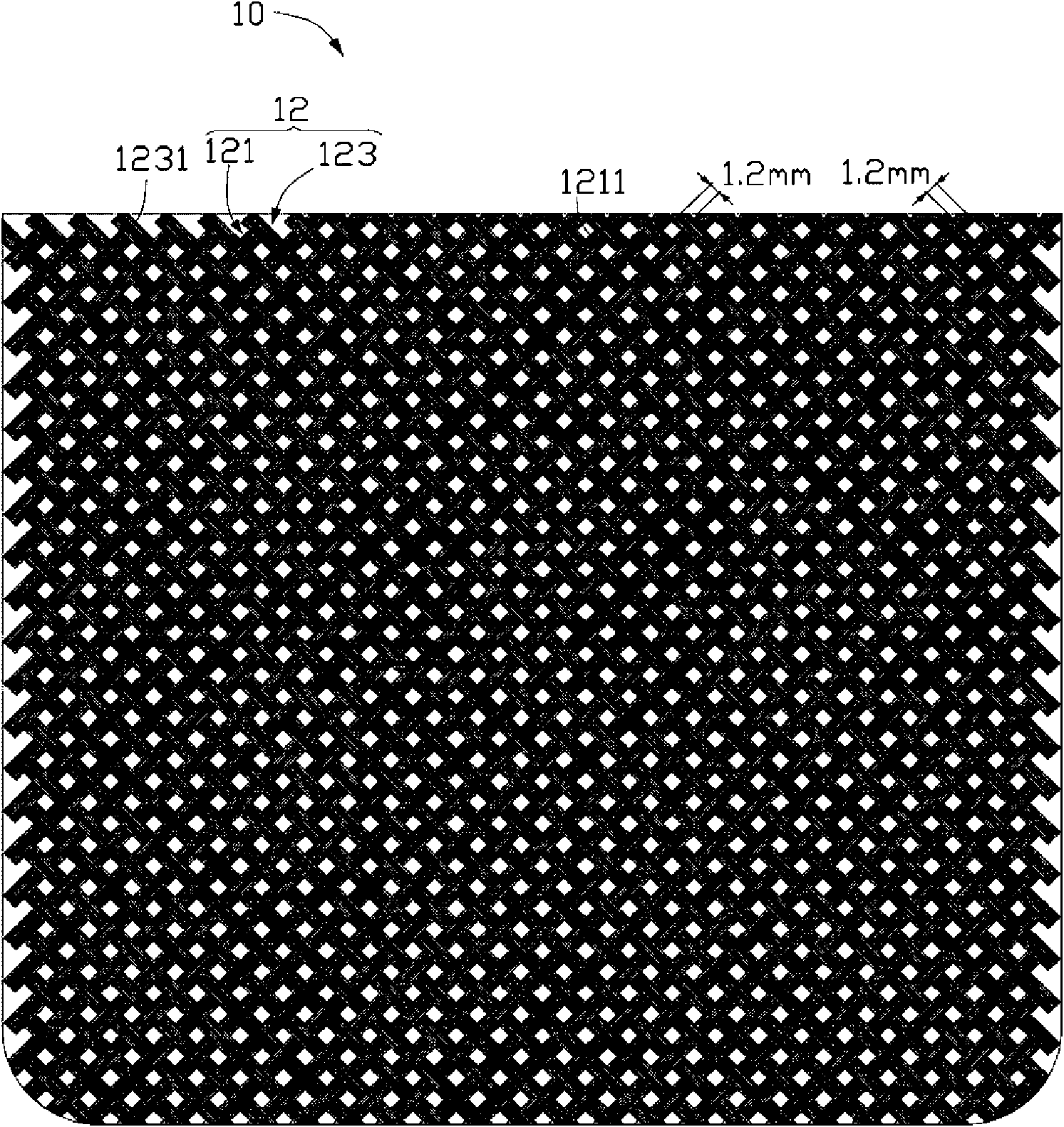

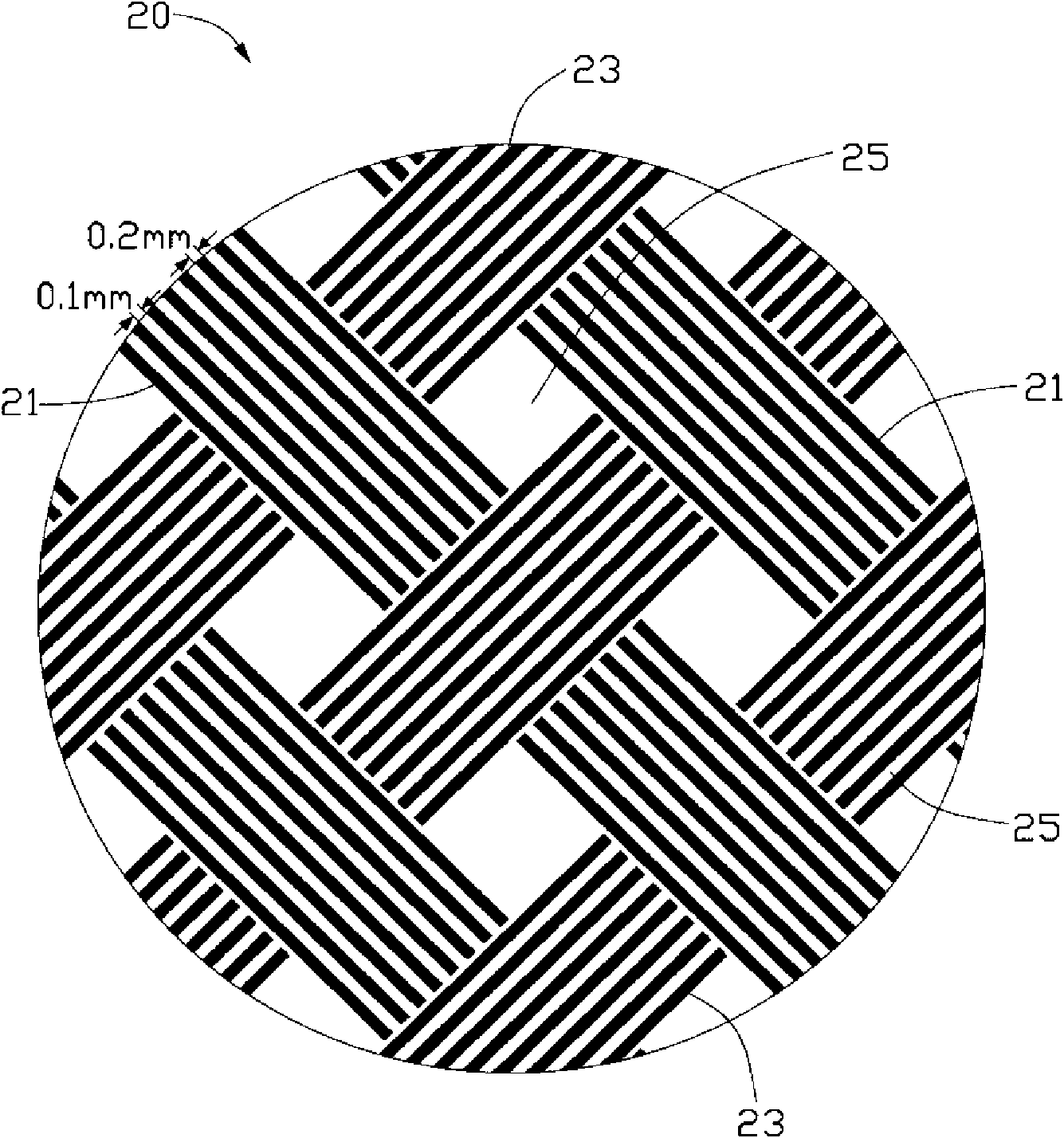

Shell having knitted patterns and manufacturing method thereof

InactiveCN101873775ANeat textureStrong three-dimensional senseDecorative surface effectsThin material handlingEngineeringMetal

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

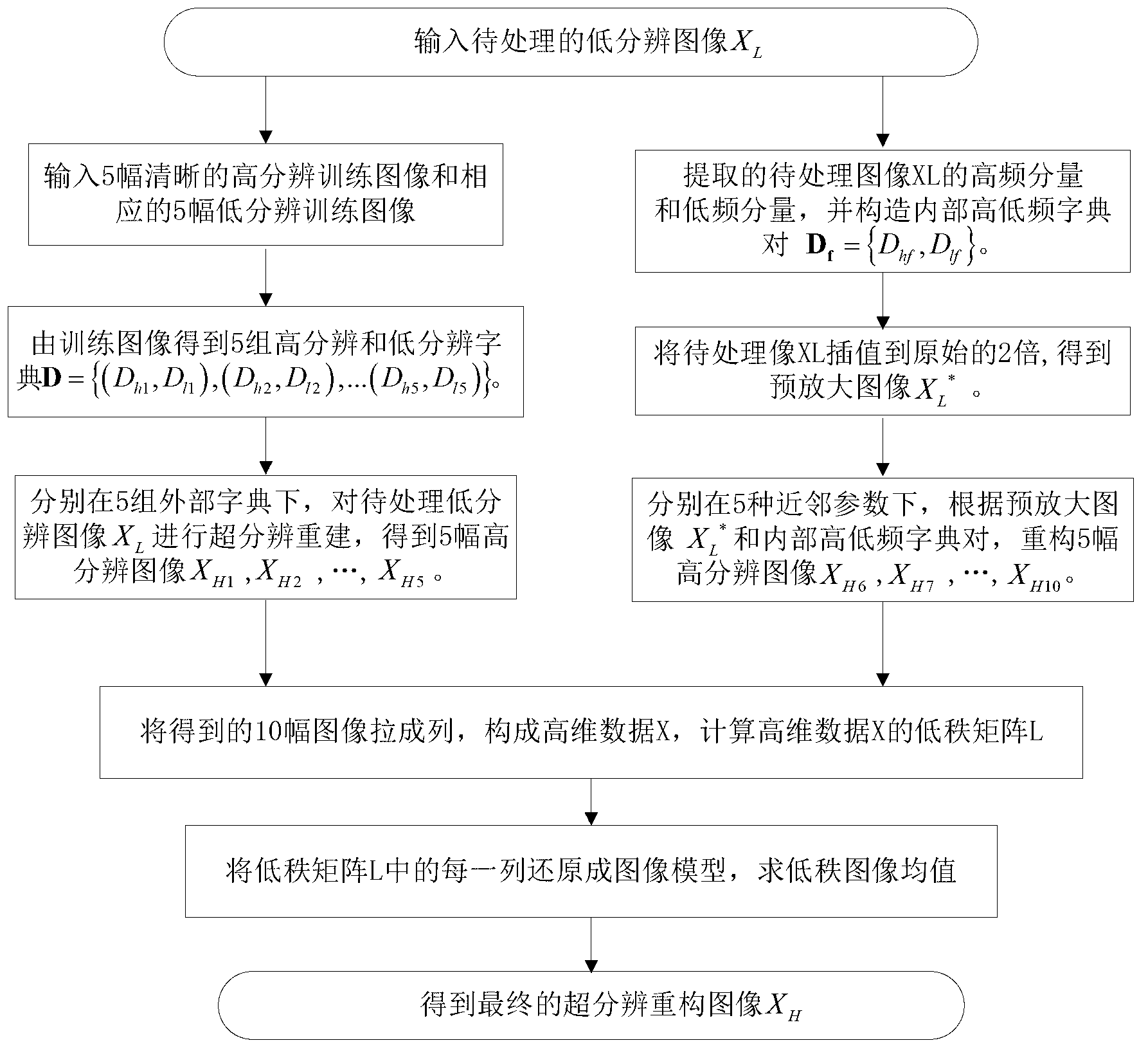

Image super-resolution reconstruction method based on double-dictionary learning

The invention discloses an image super-resolution reconstruction method based on double-dictionary learning, which mainly solves the problem that detailed information cannot be effectively supplemented in the prior art when super-resolution reconstruction is performed on a low-resolution image. A realization process comprises the following steps of: firstly, inputting a low-resolution image XL to be processed, constructing five pairs of high-resolution dictionaries and low-resolution dictionaries (Dh1, Dl1), (Dh2, Dl2),..., (Dh5, Dl5), and reconstructing five high-resolution estimation images under the five pairs of dictionaries; constructing one pair of high-frequency dictionary and low-resolution dictionary Df={Dhf, Dlf} by virtue of the high-frequency information and low-frequency information of the input low-resolution image, and reconstructing five pairs of high-resolution estimation images with different neighbor parameters; and finally, performing low-rank decomposition on the ten pairs of reconstructed high-resolution estimation images, and solving a mean value of a low-rank matrix obtained from the decomposition to obtain a final reconstructed high-resolution image XH. The method provided by the invention can be used for obtaining the high-resolution image with clear edges and rich details when being used for performing the super-resolution reconstruction on the low-resolution image and is suitable for super-resolution reconstruction on various natural images.

Owner:XIDIAN UNIV

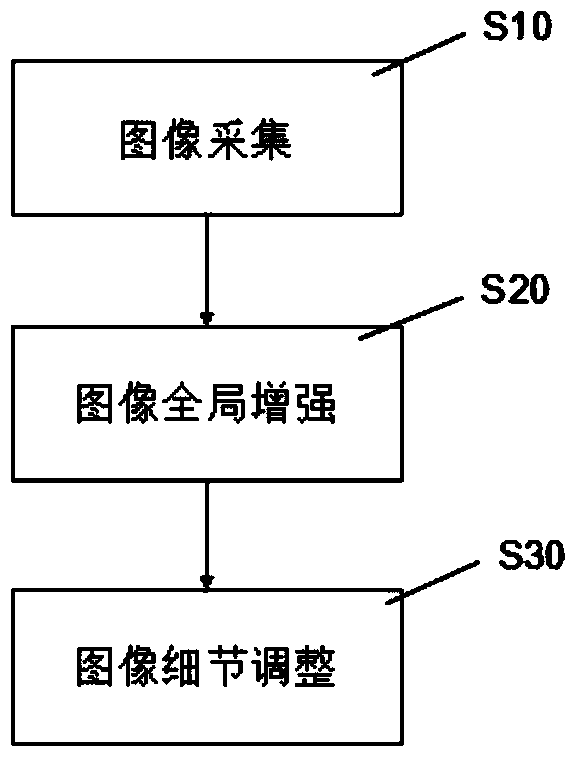

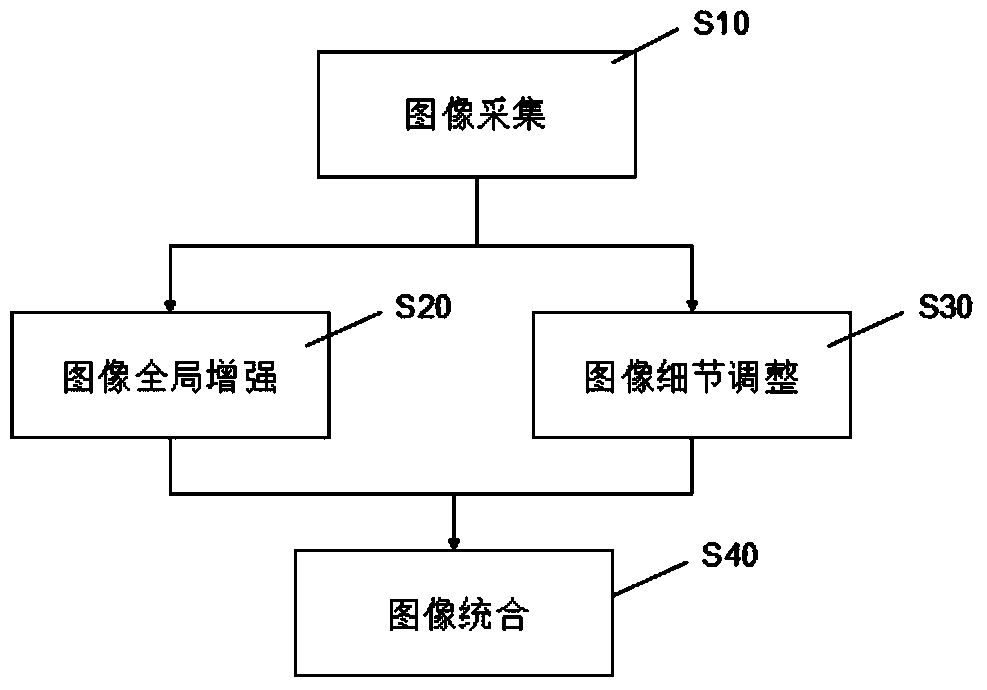

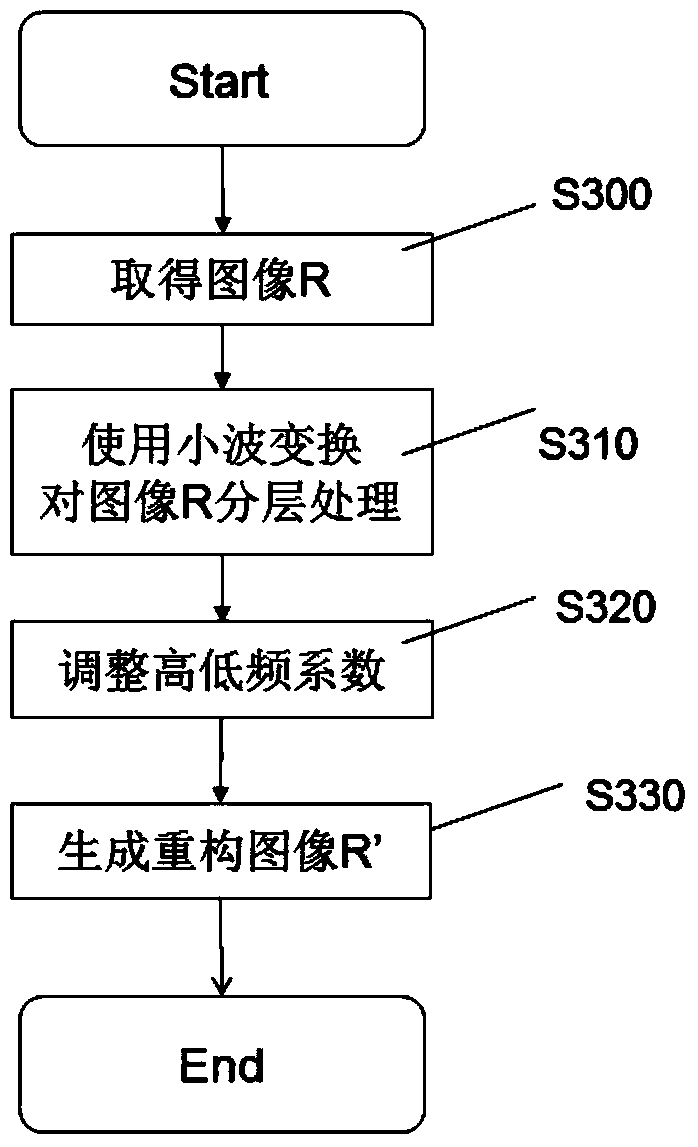

Image defogging method

ActiveCN104200437AImprove contourEnhanced contour informationImage enhancementRetinex algorithmWavelet transform

The invention relates to an image defogging method. To solve the problems that city streetscape / traffic monitoring images shot in foggy days are not clear, target objects such as vehicles and pedestrians in the images are not easy to recognize and the like, foggy-day images are integrally enhanced, and then high-frequency information of the images is extracted to strengthen details to finally acquire clear defogged images. The method includes collecting the foggy-day images, performing overall image enhancement on the foggy-day images by the Retinex algorithm, adjusting the details of the images and integrating the images. Tests prove that defogging effect of the Retinex<+> wavelet transform method is better than that of the Retinex algorithm and the Dark Channel algorithm. According to the image defogging method, auxiliary information such as depth information is not needed, and complex methods such as 3D (three-dimensional) modeling are not needed, so that defogging can be realized simply and quickly, and good real-time performance is realized.

Owner:BEIJING UNIV OF TECH

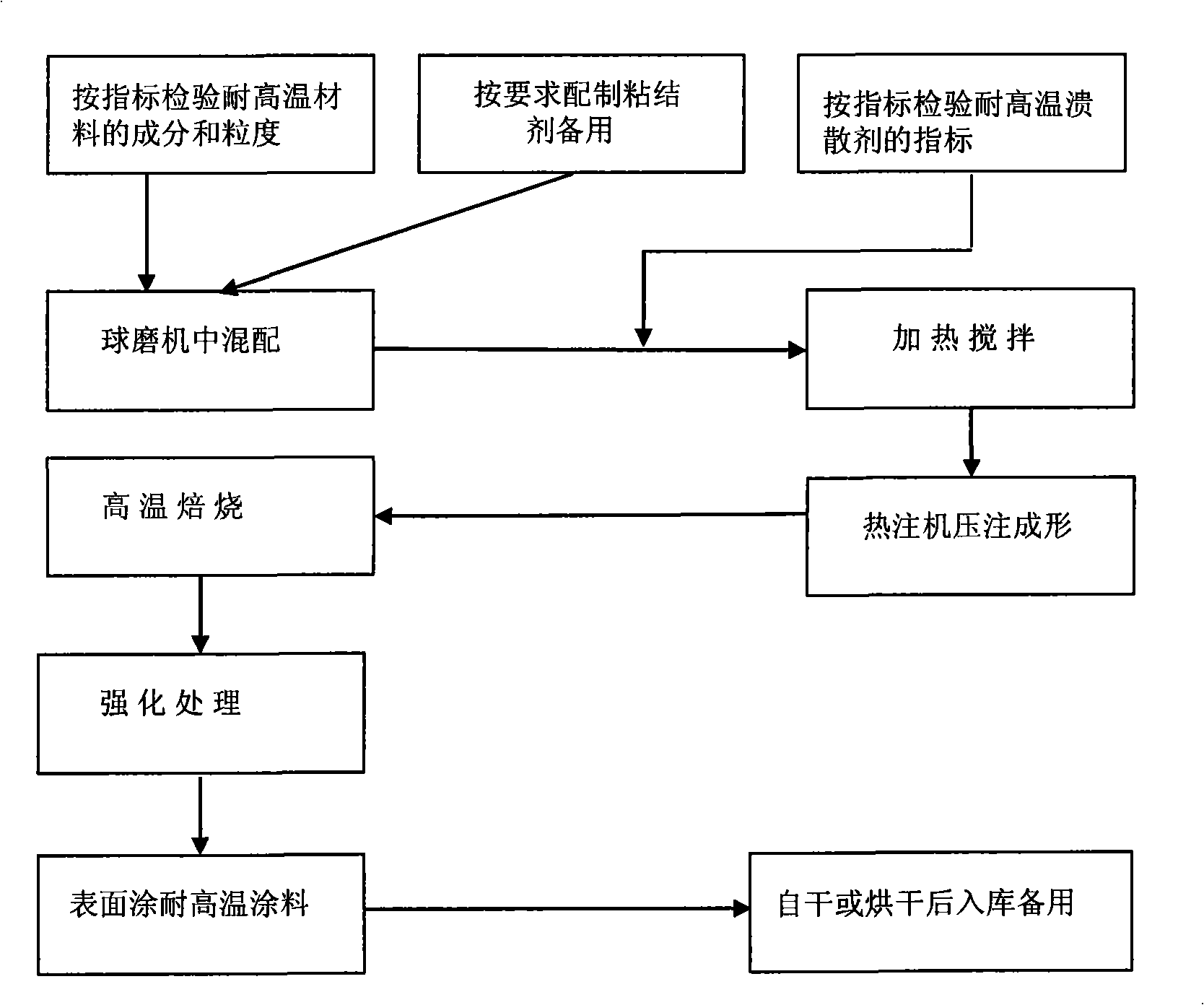

Ceramic core for silica sol precision casting and manufacturing process thereof

InactiveCN101537473AShorten roasting timeLow firing temperatureFoundry mouldsMould handling/dressing devicesTemperature resistanceChoice making

The invention discloses a ceramic core for silica sol precision casting and a manufacturing process thereof. Main body components of the ceramic core comprise refined quartz powder and a proper amount of collapsing agent, and the surface of the ceramic core is coated with high-temperature resistant paint with a thickness of 0.1 to 0.2 millimeter; and at the same reasonable manufacturing processes such as mixing, core making and roasting are adopted. In the ceramic core for casting, the unique material mixing and manufacturing processes are adopted, and the reasonable use of the refined quartz powder and the collapsing agent improves the collapsibility of the ceramic core after casting considerably, the high-quality high-temperature resistant material in ingredients enables the core to resist the erosion of high-temperature molten metals, and the high-temperature resistant paint on the surface of the ceramic core not only improves the high temperature resistance during casting, but also increases the cooling speed of the molten metal.

Owner:上海市机械制造工艺研究所有限公司

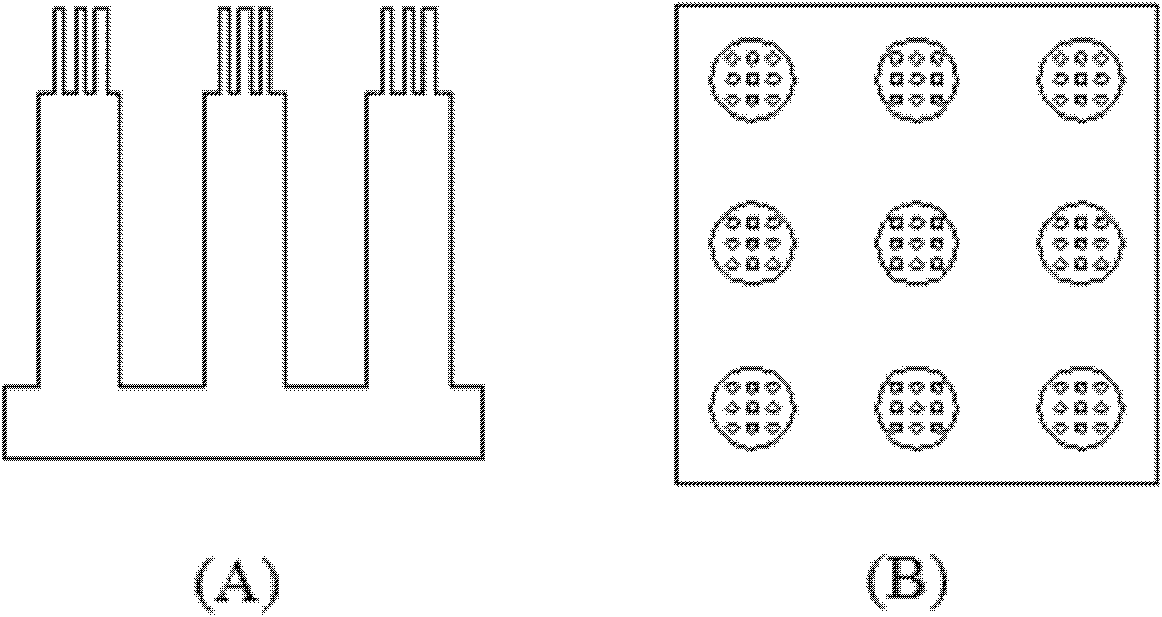

Method for preparing dry adhesive

ActiveCN101837946AHigh Young's modulusModerate flexibilityNanostructure manufactureDecorative surface effectsFiberLevel structure

The invention provides a method for preparing a dry adhesive in order that the existing wet adhesive has the disadvantages that the wet adhesive is prone to deterioration, pollution, self-adhesion and non-reusability after being torn open. Based on the research into the structural characteristics of micron-level and nano-level foot hair of a gecko in the nature, micron-level and nano-level fiber arrays can be molded and drawn in a way that the fiber arrays are molded successively for twice, thus obtaining the micron-level and nano-level structure of the bio-mimetic gecko hair, which is characterized by powerful adhesion. The method of the invention comprises the following steps: preparing a micron-level silicon mother stamp; preparing a micron-level mold; preparing micron-level fiber arrays; preparing a nano-level silicon mother stamp; preparing a nano-level mold; and preparing nano-level fiber arrays. The method of the invention is capable of preparing the micron-level and nano-level structure with the parameters thereof being close to those of the foot hair of the gecko in the nature; and the prepared powerful dry adhesive is capable of being fitted with various surfaces and easily detached in an active manner.

Owner:HUAZHONG UNIV OF SCI & TECH

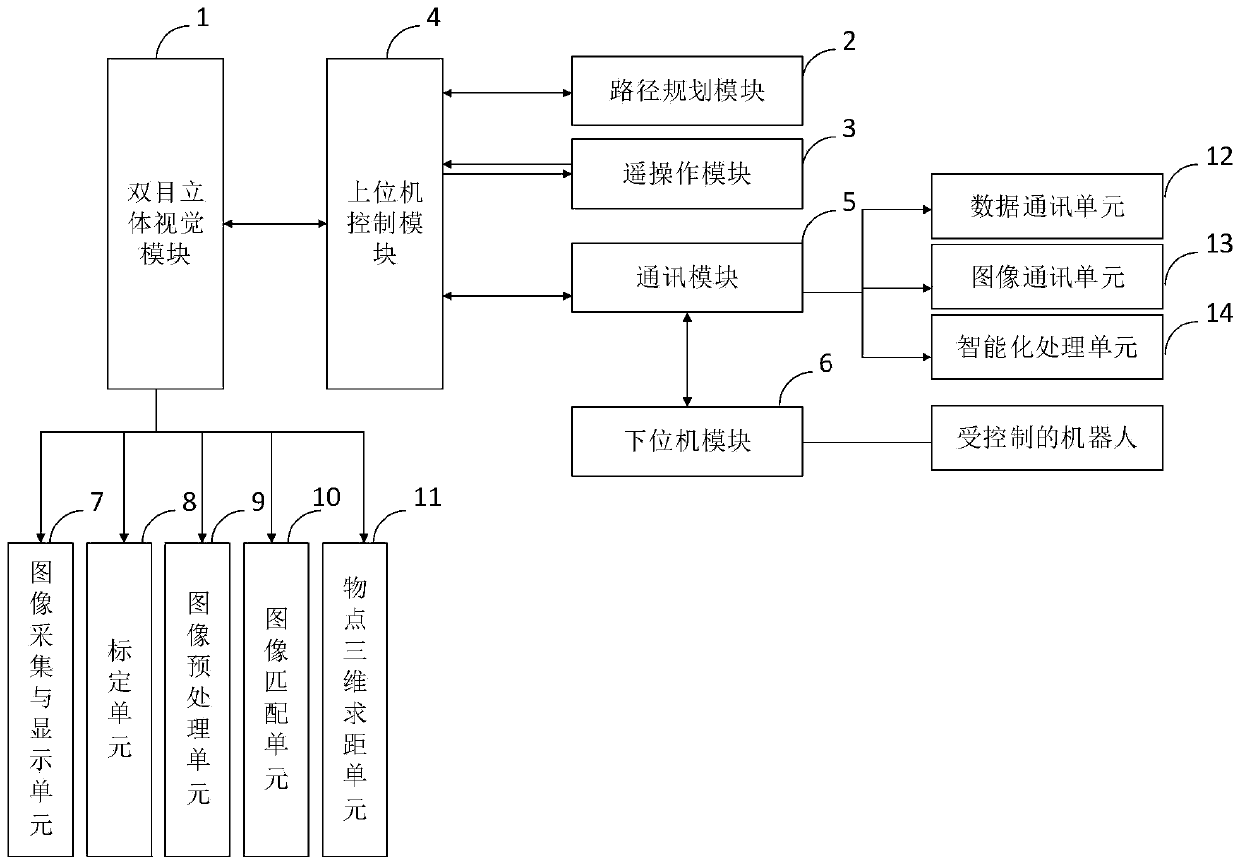

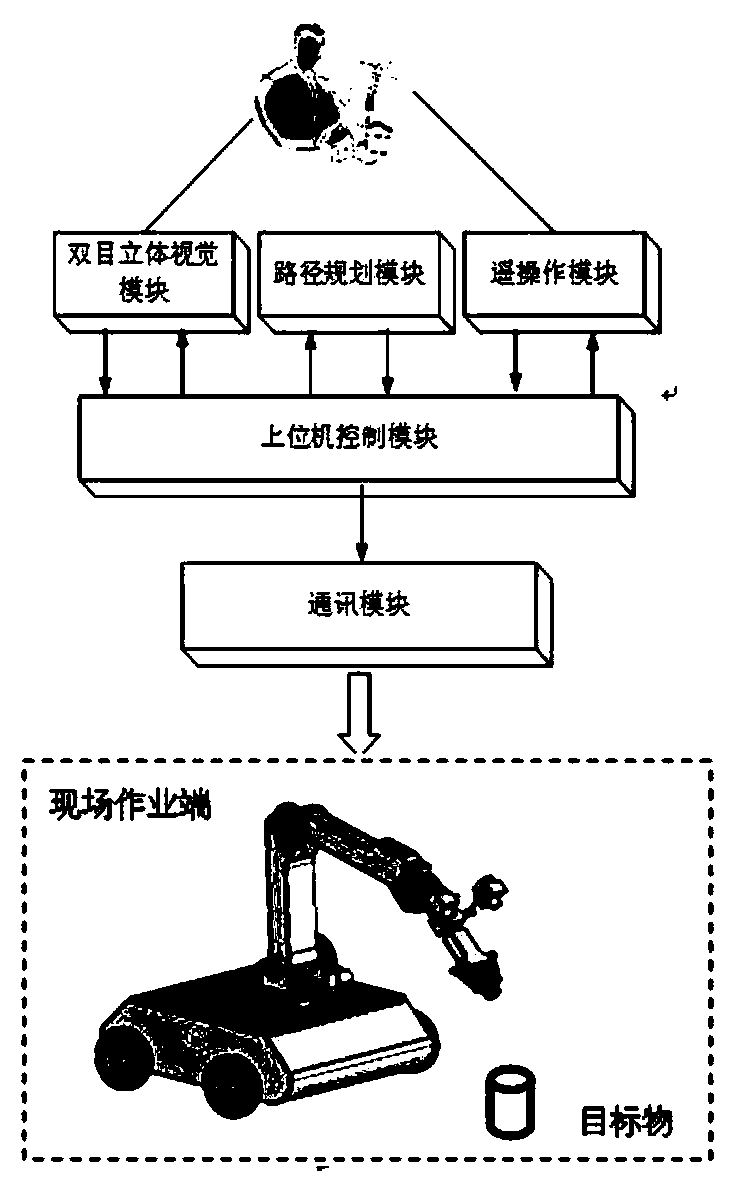

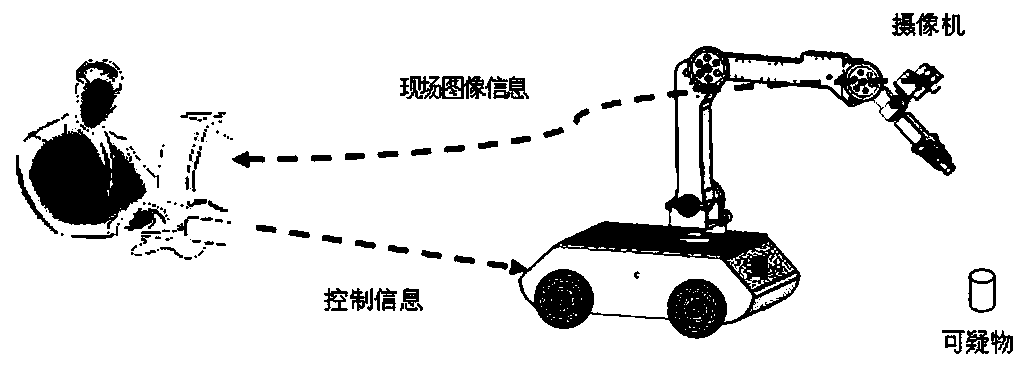

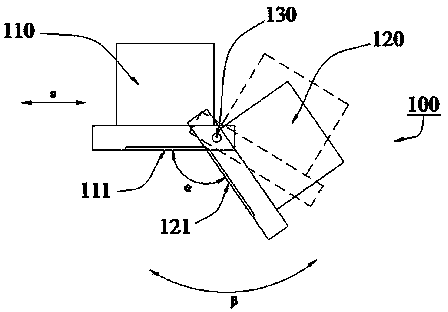

System and method for efficiently controlling robot

InactiveCN109910010AEasy to operateImprove work efficiencyProgramme-controlled manipulatorObject pointSimulation

The invention belongs to the technical field of program control, and discloses a system and a method for efficiently controlling a robot. The system for efficiently controlling the robot specificallycomprises a binocular stereoscopic vision module, a path planning module, a remote operation module, an upper computer control module and a communication module, wherein the binocular stereoscopic vision module is used for acquiring an image by using a camera, and a three-dimensional coordinate of an object point is calculated; the path planning module is used for finding an optimal path which isfree from collision and arrives at the target object position for the robot in a specific environment; the remote operation module is used for improving the operation efficiency and operability of therobot by using a Teleoperation and Remote Control operation mode; the upper computer control module is used for packaging each module in a program through MFC programming; and the communication module is used for completing the two-way information exchange between an upper computer and a rear lower computer. According to the system for efficiently controlling the robot, the robustness and the fault-tolerant processing of the system are effectively improved, and the operability, the operation efficiency and the operation precision degree of the robot can be improved.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

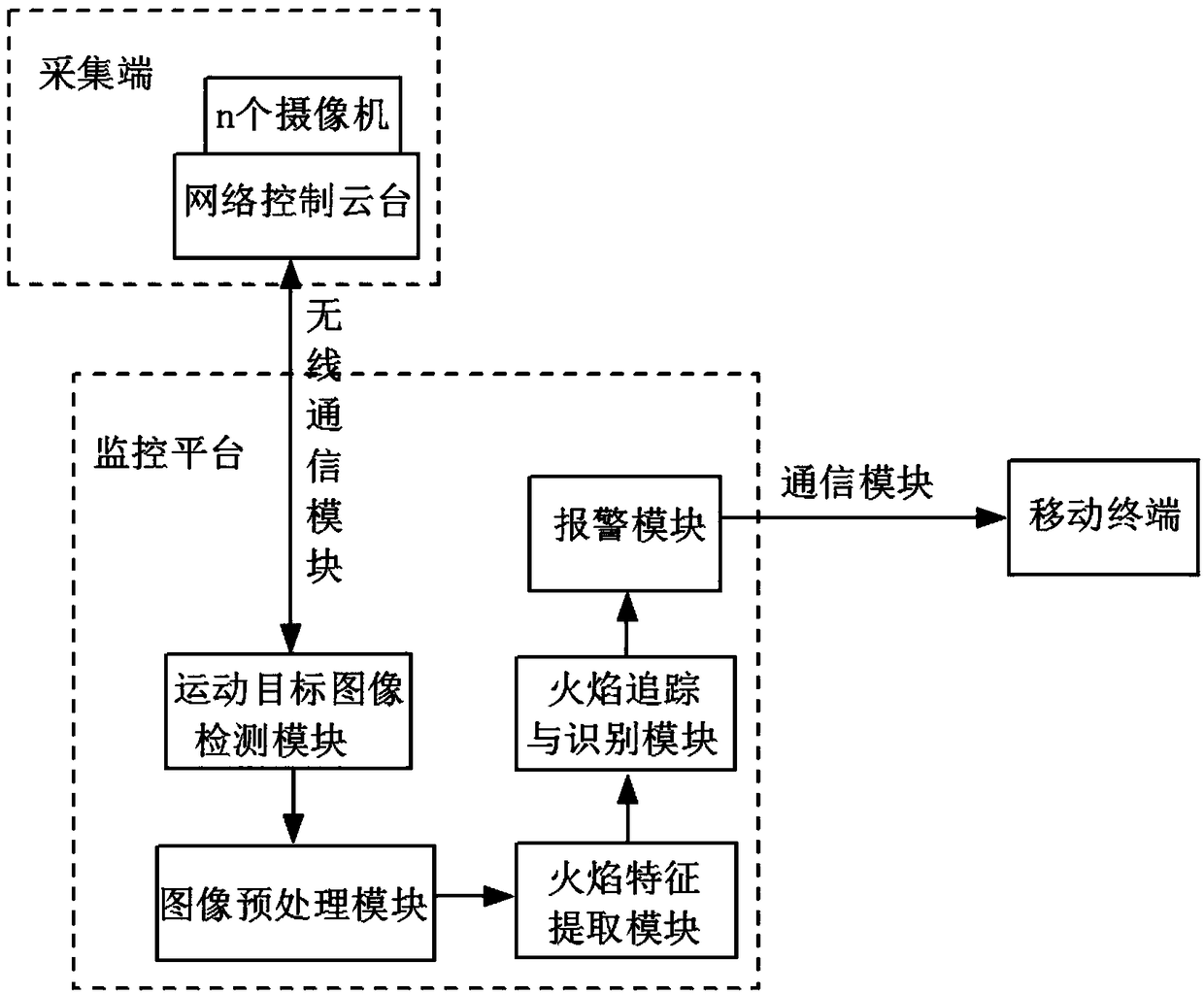

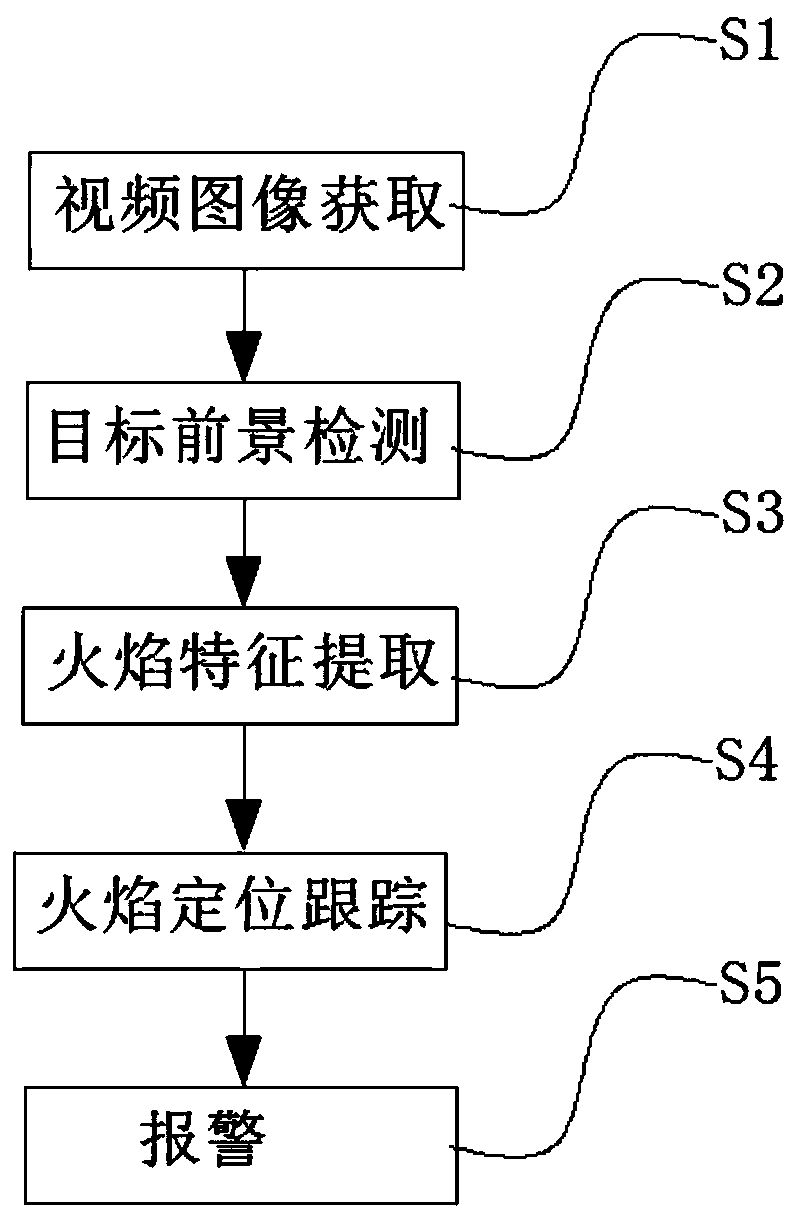

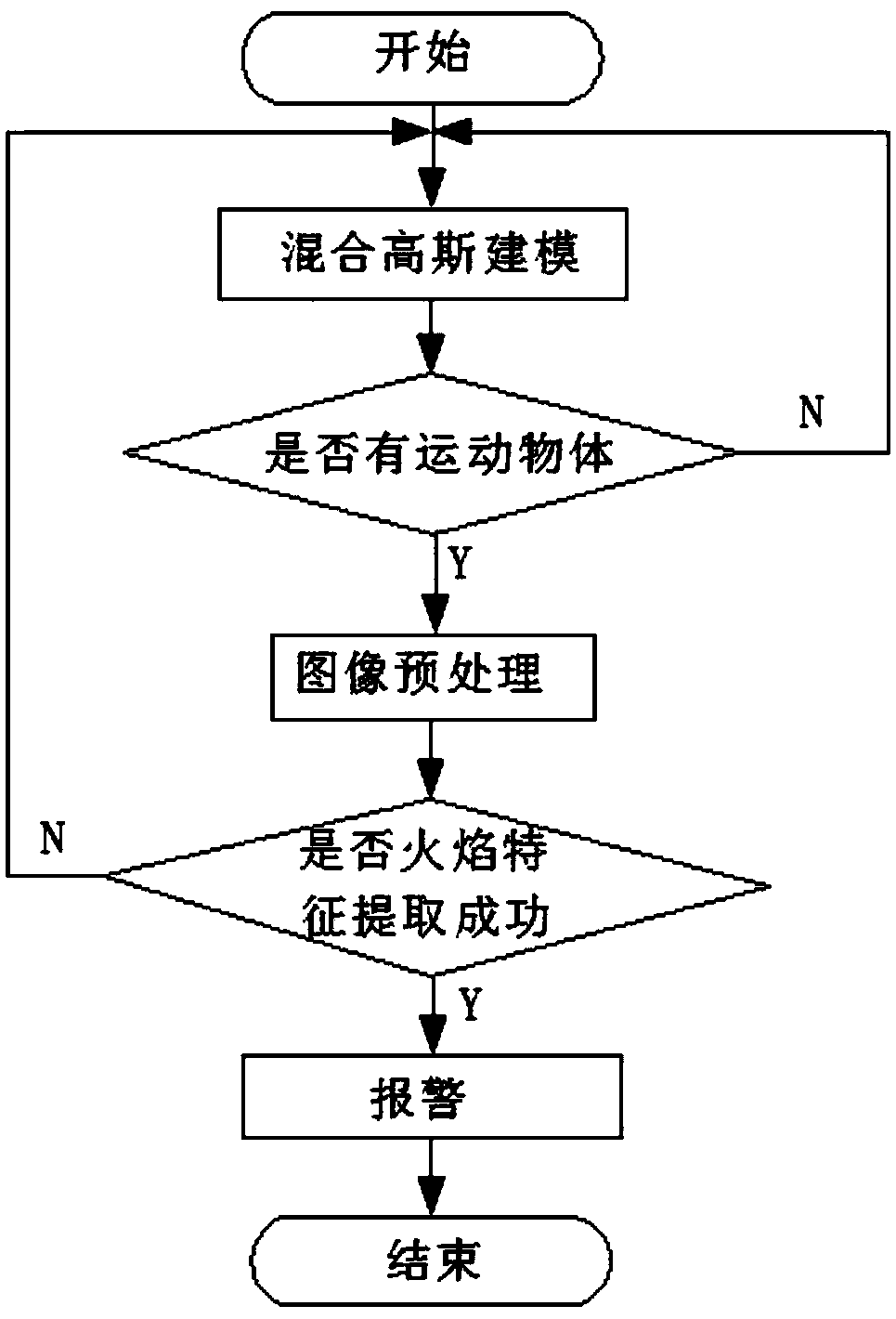

Machine vision based forest fire preventive early warning system and method thereof

InactiveCN109377703AAccurate Disaster Relief MeasuresAccurate trackingImage enhancementImage analysisEarly warning systemMachine vision

The invention discloses a machine vision based forest fire preventive early warning system and a method thereof. The system comprises a collection end and a monitoring platform composed of a movementtarget foreground detection module, a flame feature extraction module, a flame tracking and identification module and an alarm module, can monitor a fire hazard uninterruptedly in 24 hours, can identify occurrence of the fire hazard and track flame accurately, and emits a fire hazard early warning signal by the monitoring platform so that relates work staff can take measures accurately, and the system is high in practicality. A Gaussian mixture background model is sued when video images are detected to identify whether there are moving objects in the video images, a modeling algorithm is complete, targets can be extracted from videos effectively, the fire hazard identification rate can reach more than 92%, and the fire hazard identification accuracy can be improved substantially.

Owner:HECHI UNIV

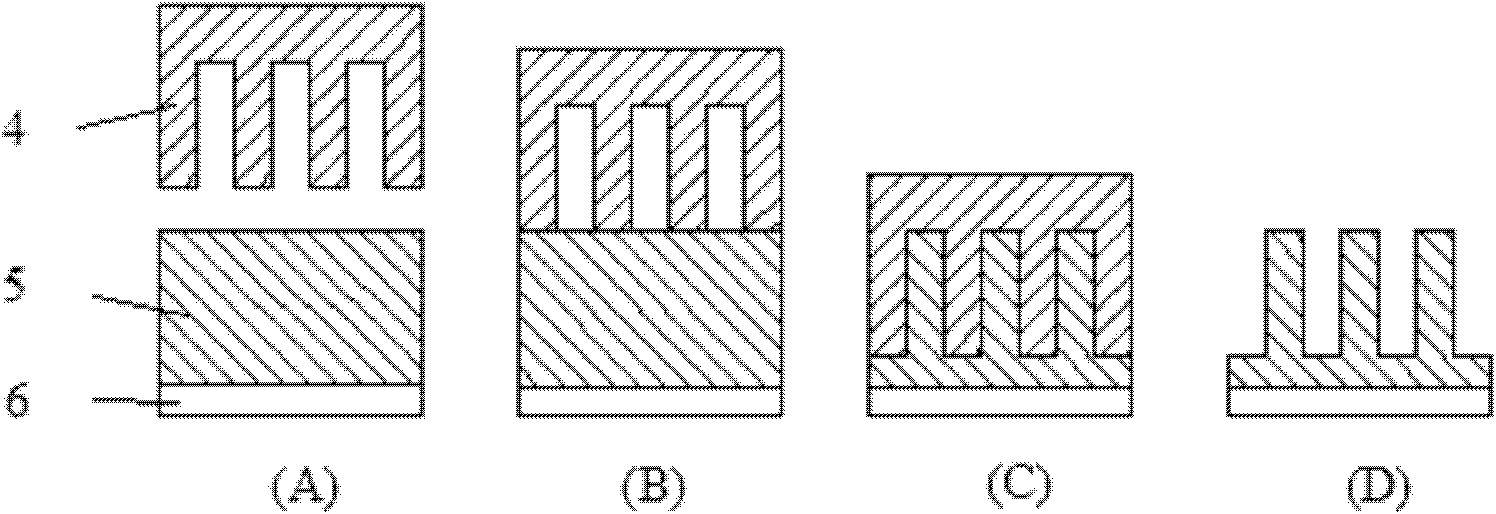

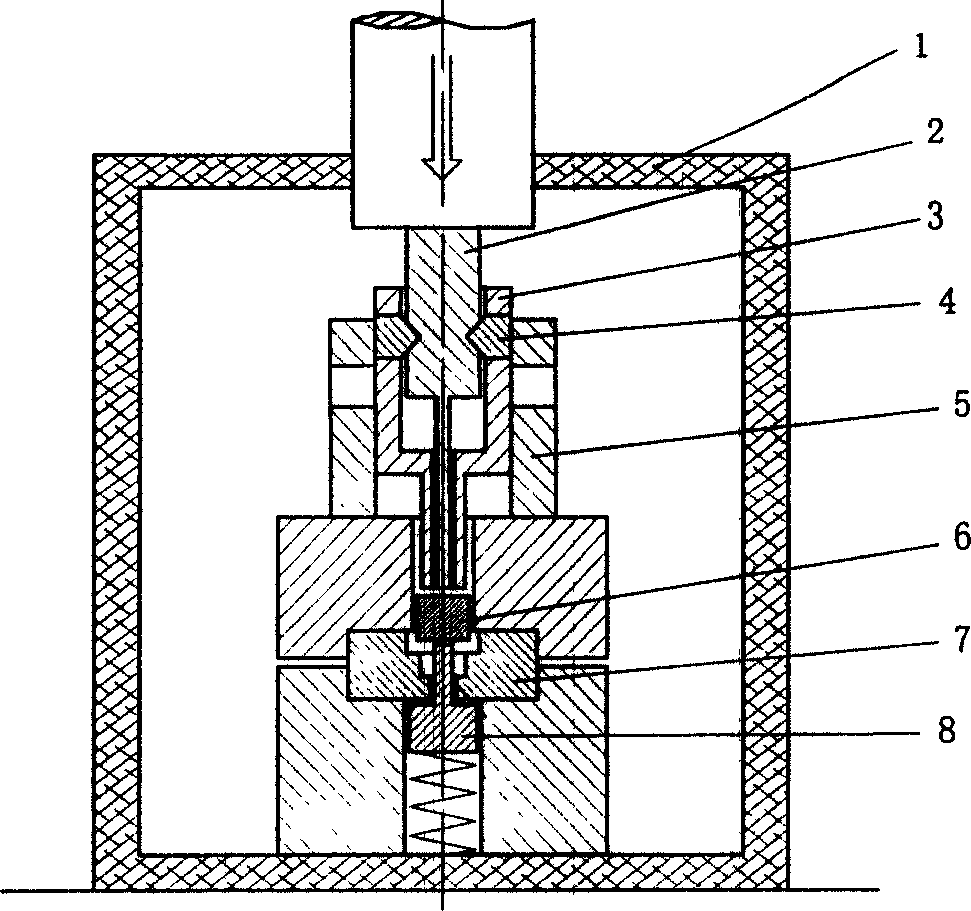

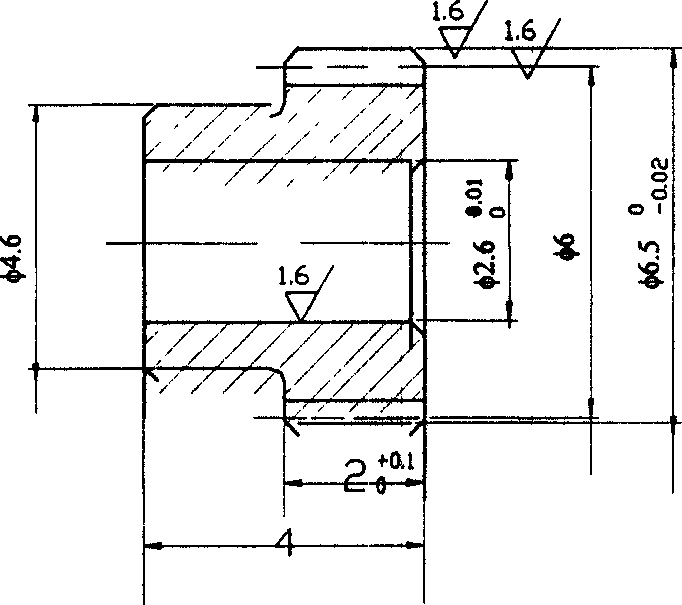

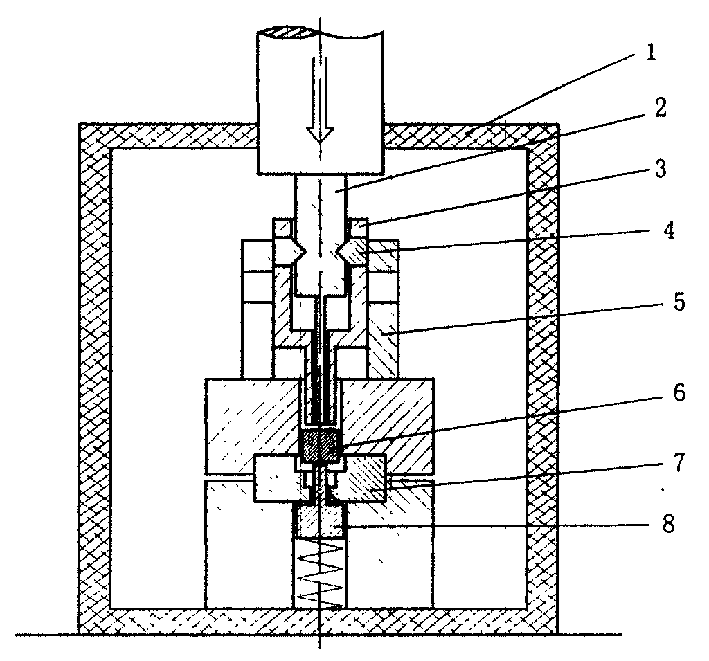

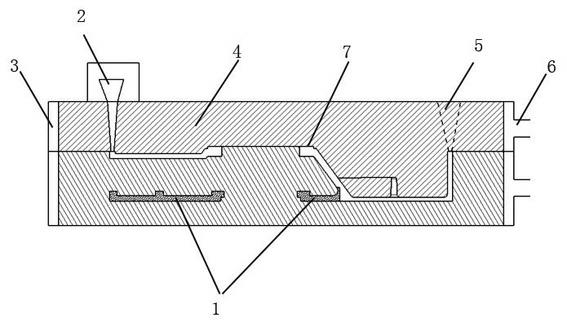

Amorphous alloy precision parts superplastic drop-forging shaper and method thereof

InactiveCN1199747CImprove mechanical propertiesGuaranteed surface qualityMetal-working apparatusSurface roughnessSuperplasticity

The invention provides a superplastic die forging forming device and method for amorphous alloy precision parts. The device is composed of a vacuum furnace (1), a replaceable pressure head and a mold. The replaceable indenter is made up of inner indenter (2), outer indenter (3), slide block (4), connecting seat (5), and mold is made up of mold (7), ejection mechanism (8). The process is to place the blank and the mold in a vacuum furnace, and when the vacuum degree reaches 8×10 -3 Pa, start heating, heating rate 0.5 ~ 3.0 ℃ / s; heating temperature should be between Tg ~ Tx; forming strain rate range of 1 × 10 -2 ~5×10 -4 the s -1 . The advantage is that it is suitable for the forming of bulk amorphous alloy materials with large supercooled regions such as Zr-based, La-based, and Pd-based. The dimensional accuracy of the prepared parts is between ±0.1% and ±0.3%, and the surface is rough. The degree Ra is less than 0.8μm, and it can even reach the nanoscale mirror surface.

Owner:UNIV OF SCI & TECH BEIJING

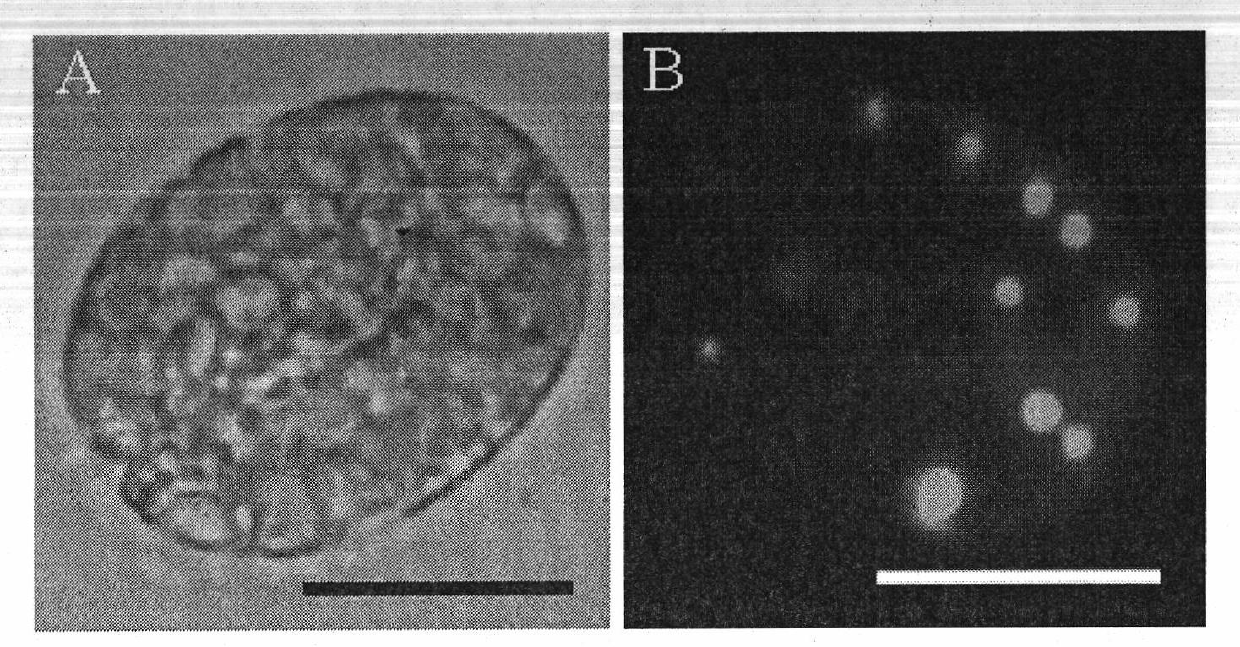

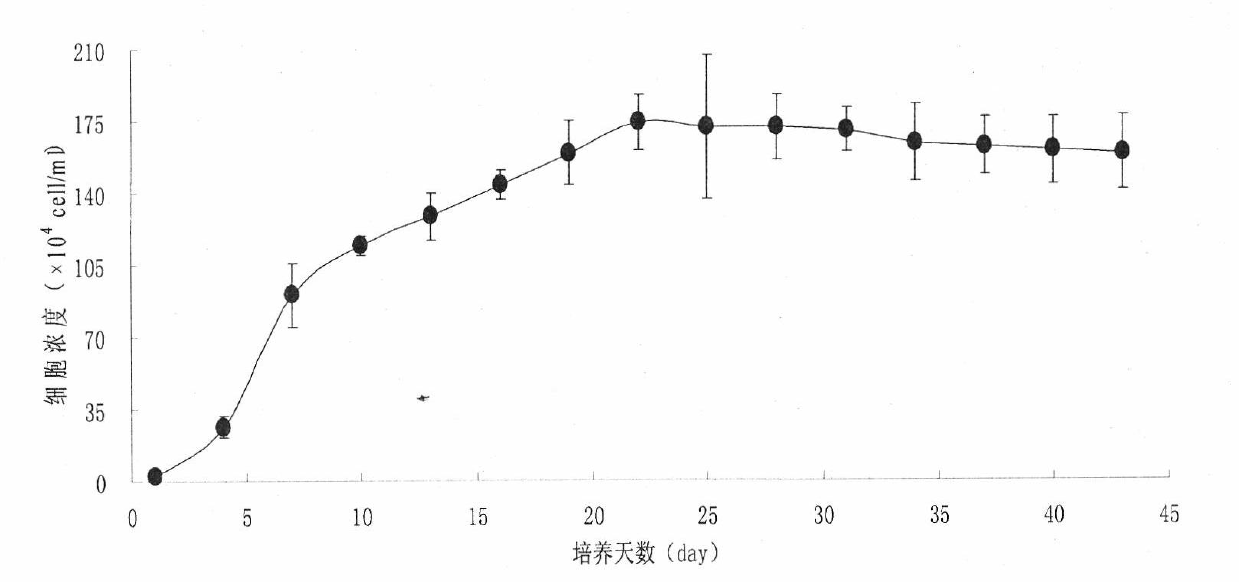

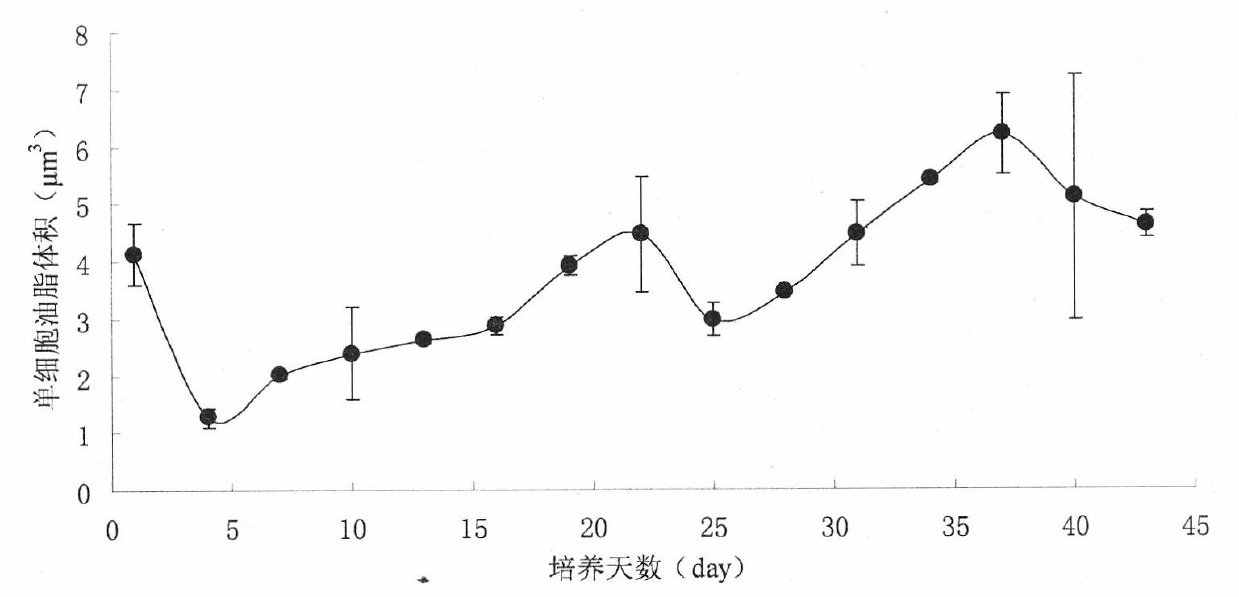

Method for detecting oil content of microalgae

InactiveCN102565012AEasy to detectThe process is simple and convenientUsing optical meansIndividual particle analysisLipid formationMicrobial oil

The invention relates to lipid producing microalgae, in particular relates to a method for detecting the oil content of microalgae, comprising the following steps of: 1) taking microalgae-cultivated algae liquid, and computing the quantity concentration C of microalgae cells; 2) observing the lipid of the microalgae: adopting a BODIPY (boron-dipyrromethene) 505 / 515 staining fluorescent recording method; staining for 1-2min by adopting dye use liquid with concentration of 1-2mM, and observing and recording accumulation change conditions of single-celled lipid in a photographing way by using excitation light with wave length of 488nm under a fluorescence microscope; recording the number (n) of single-celled oil drop grains according to a photograph, detecting the diameter (d) of each oil drop, and computing the volume of each oil drop according to a ball volume formula, wherein the content of each cell lipid is the sum of the volume of all the oil drops; and computing the lipid content of the algae liquid in unit volume according to the quantity concentration C of the microalgae and the lipid content of a single cell: Vt=CV, wherein C is the concentration of tetraselmis cells, V is the lipid volume of the single cell, and Vt is the lipid content in the unit volume.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

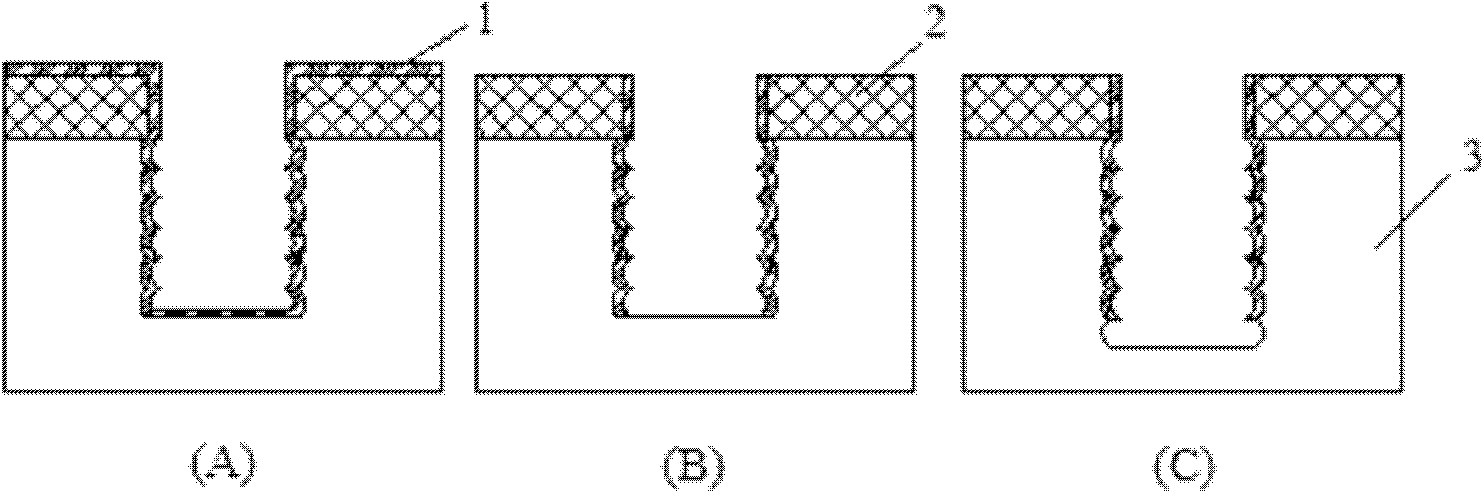

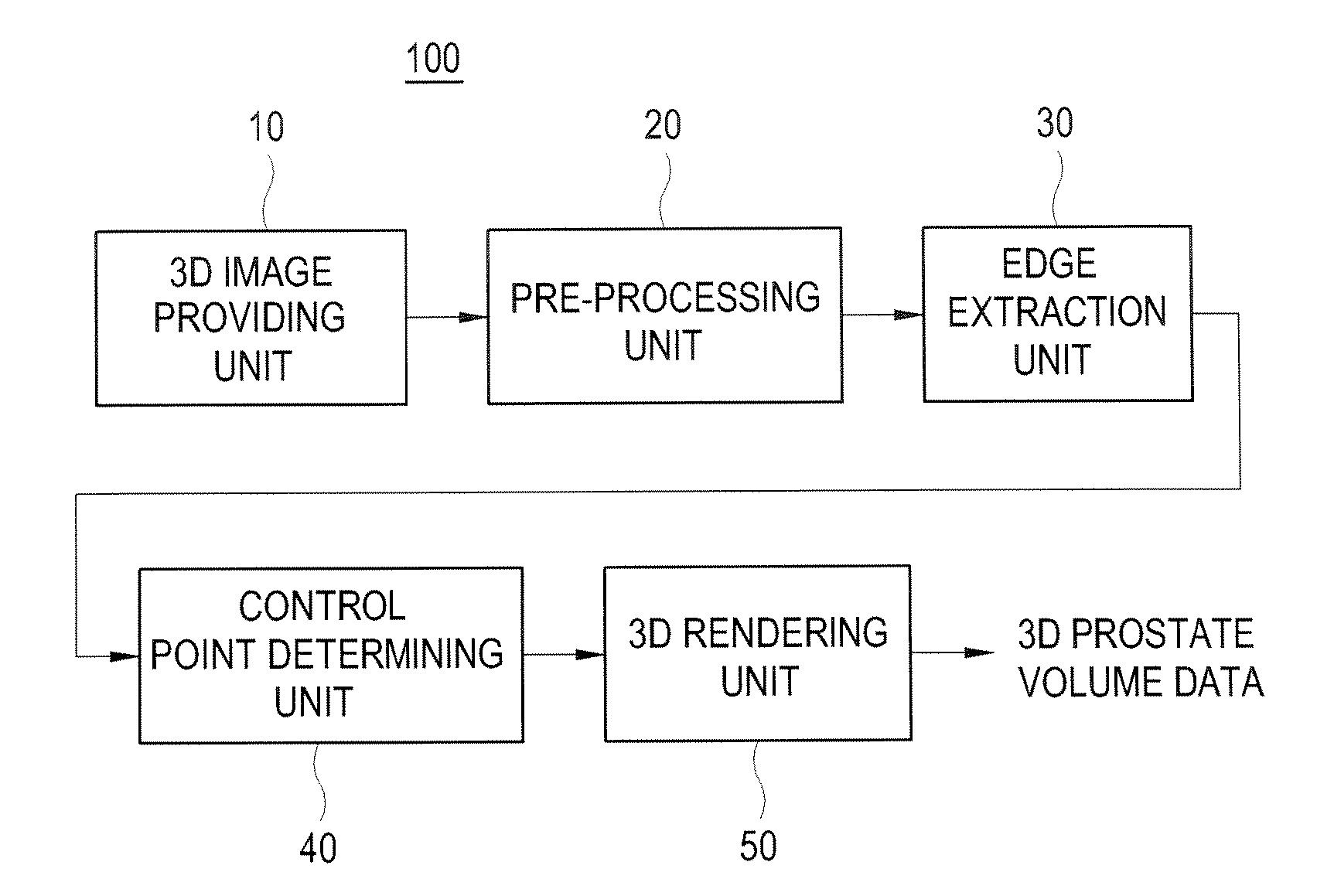

Ultrasound imaging system for extracting volume of an object from an ultrasound image and method for the same

InactiveUS20070167779A1Clear outlineReduce noiseImage enhancementImage analysisUltrasound imagingSupport vector machine

The present invention provides an ultrasound imaging system for forming 3D volume data of a target object, including a three-dimensional (3D) image providing unit for providing a 3D ultrasound image; a pre-processing unit for forming a number of two-dimensional (2D) images from the 3D ultrasound image and normalizing the 2D images to form normalized 2D images; an edge extraction unit for forming wavelet-transformed images of the normalized 2D images at a number of scales, the edge extraction unit further being configured to form edge images by averaging the wavelet-transformed images at a number of scales and threshold the edge images; a control point determining unit for determining control points by using a support vector machine (SVM) based on the normalized 2D images, the wavelet-transformed images and the thresholded edge images; and a rendering unit for forming 3D volume data of the target object by 3D rendering based on the control points.

Owner:MEDISON CO LTD

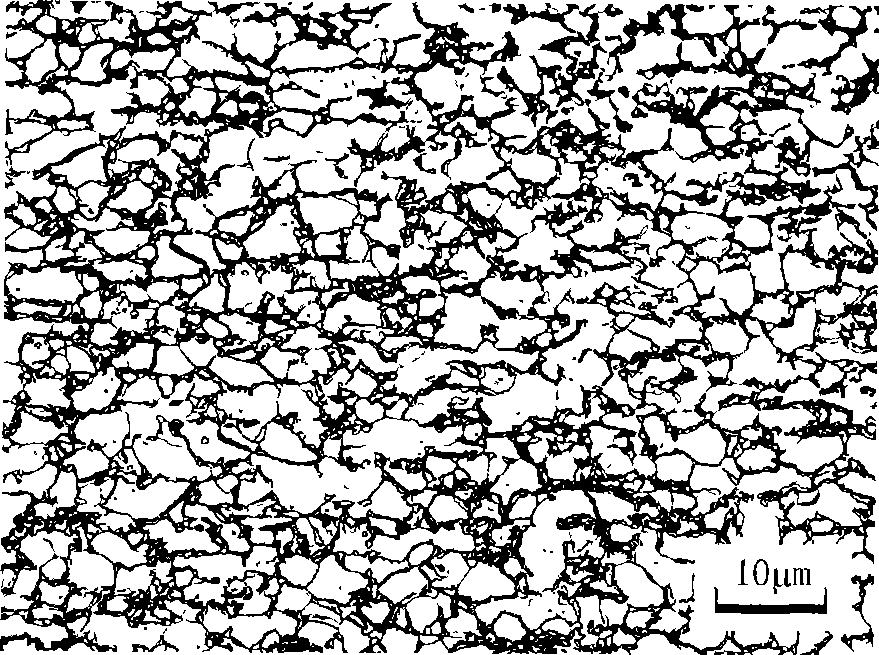

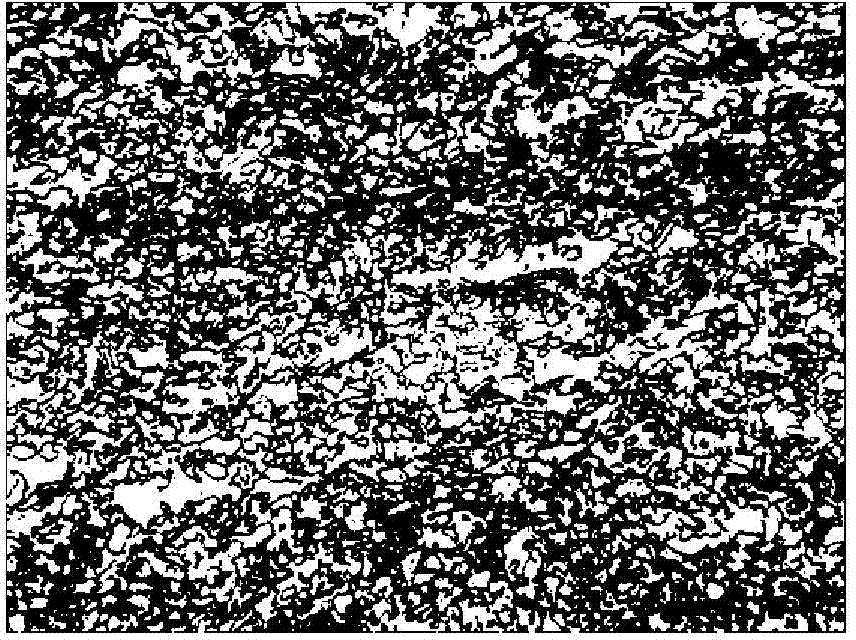

Metallographic corrosion method for clearly displaying 9-12% Cr heat-resistant steel original austenite grain boundary

InactiveCN103983502AIncrease the strength of the electrochemical reactionAvoid corrosionPreparing sample for investigationCorrosion reactionElectrochemical response

The invention provides a metallographic corrosion method for clearly displaying a 9-12% Cr heat-resistant steel original austenite grain boundary, solving the difficult problems that 9-12% Cr heat-resistant steel original austenite crystal grains subjected to quenching and tempering treatment are hardly displayed can be solved by adopting the metallographic corrosion method. By adopting corrosive liquid, on one hand, full acidification effects can be realized, and the electrochemical reaction intensity of a dissolved solution can be improved, and on the other hand, the corrosive liquid can be in chemical reaction with a matrix to generate Fe<3+>, wherein Fe<3+> can be used for inhibiting an intragranular corrosion reaction to a certain extent when heating so as to ensure that the corrosion degree of an intragranular structure is significantly slower than that of a grain boundary. Meanwhile, a certain amount of precipitates exist on the grain boundary to ensure that the corrosion of the grain boundary is relatively strong and can generate a relatively large difference from the intragranular corrosion degree in a certain time, thus obtaining an original austenite grain boundary with a clear outline.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

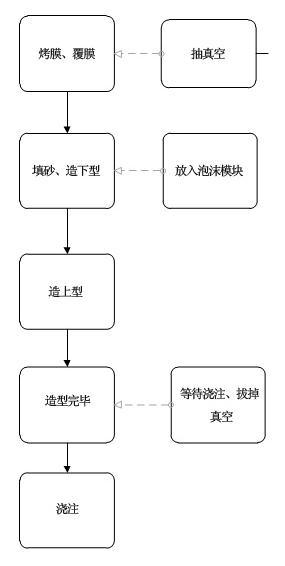

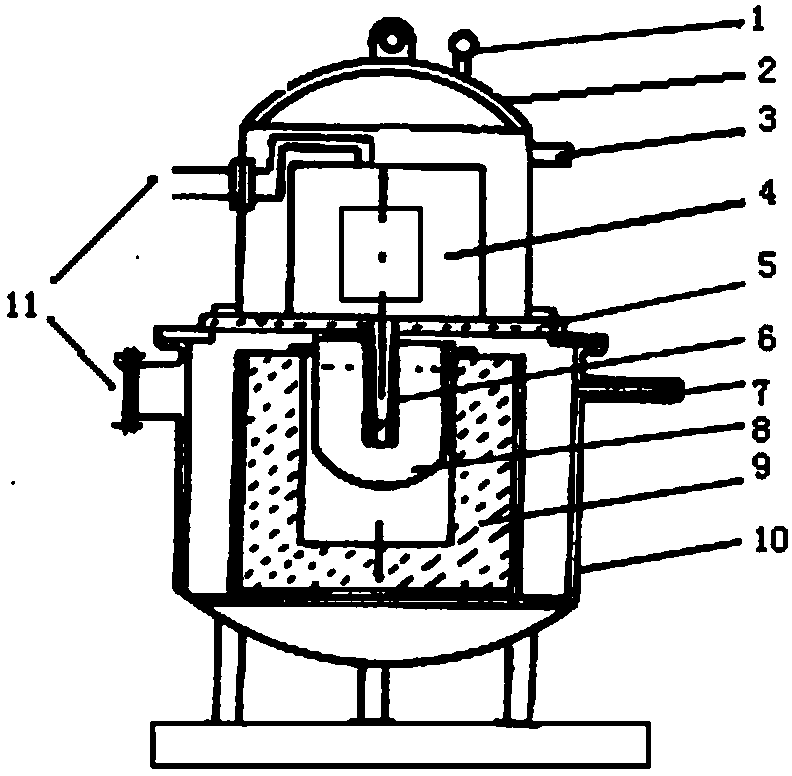

Precise casting technology for green sand vacuum sealing model

InactiveCN102218505ALow costReduce energy consumptionFoundry mouldsFoundry coresSmooth surfaceVacuum pumping

The present invention provides a precise casting technology for a green sand vacuum sealing model, which belongs the vacuum casting technical field. The invention is characterized in that the green sand is taken as a molding material, quantity of the sand core can be minimized through an effective usage of foamed materials, which is suitable for producing medium and small sized comparative precision castings. The problems of serious dust pollution, long vacuum-pumping time and production efficiency affected by using paint in a present V method can be solved. When a complex cavity is casted, the foamed material is provided at the position unsuitable for drafting to form a portion of the cavity, the foamed material is melted when casting, therefore the purposes of minimizing sand core quantity and weight can be reached, so that the production technology can be simplified as well as cost can be saved. The produced casting has the advantages of high dimensional precision, clear contour and smooth surface.

Owner:JIAHE ZHONGHE CASTING +1

Plaster casting method for large-sized complex thin-walled magnesium alloy part

ActiveCN104209497ASolve Oxidation ProblemsImprove filling abilityFoundry mouldsFoundry coresVacuum castingMold filling

The invention relates to a plaster casting method for a large-sized complex thin-walled magnesium alloy part. The method comprises the following steps of coating the surface of an assembled form with a coating in situ, and arranging shapeless cold iron on a hot spot part, wherein a mixture for manufacturing the shapeless cold iron comprises the following components in percentage by mass: 1.25 percent of phenolic resin, 0.4 percent of toluenesulfonic acid, 1 to 1.5 percent of boric acid, 2 percent of bentonite and the balance of 70 to 140-mesh chromite sand; pouring a casting in an adjustable pressure casting device, arranging a plaster mold poured by the form at the casting position of the adjustable pressure casting device, filling a tank with dry air or a CO2 atmosphere with SF6 content of 0.1 to 1.0 percent, and performing vacuum casting and pressurized solidification, wherein the casting temperature is 710 to 750 DEG C, vacuum degree for primary mold filling is minus 0.6Mpa to minus 0.8Mpa, and the solidification pressure is 0.020 to 0.025Mpa. According to the method, oxidization can be prevented, the mold filling capability can be improved, shrinkage cavities and shrinkage porosities in the casting are reduced, and the obtained magnesium alloy casting is higher in density.

Owner:山西银光华盛镁业股份有限公司

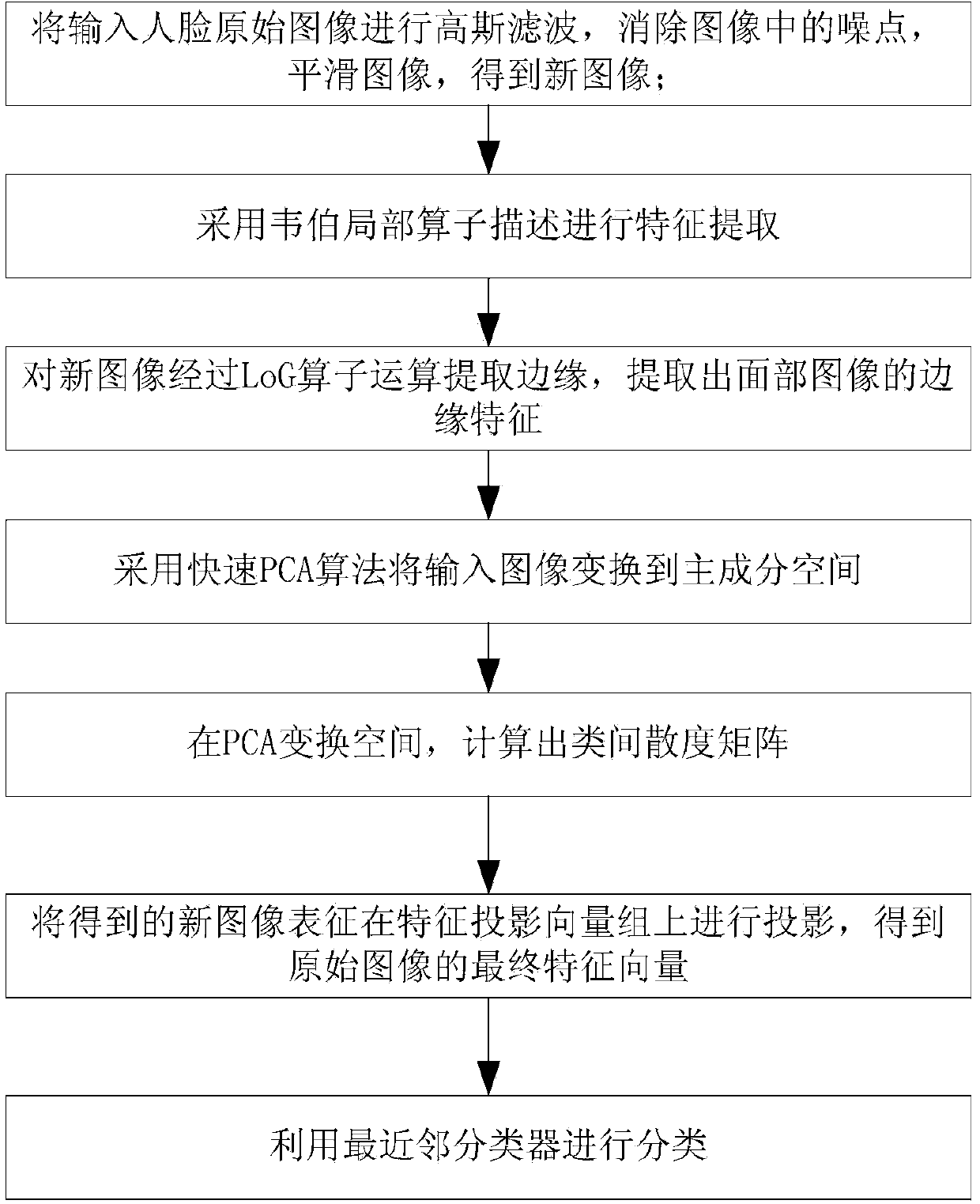

Face identification algorithm under different illumination conditions

InactiveCN103745237AClear outlineObvious structureCharacter and pattern recognitionImaging FeatureNearest neighbor classifier

The invention discloses a face identification algorithm under different illumination conditions, comprises the steps that: (1) the inputted face original image F(x, y) is subjected to Gaussian filter so as to eliminate noise point in the image and smooth the image, thereby obtaining a new image F'(x, y); (2) the F' (x, y) is subjected to feature extraction by using a Weber local operator description; (3) an edge is extracted from a new image WF(x, y) by LoG operator operation; (4) the inputted image is converted to a principal component space by using fast PCA algorithm; (5) in the PCA transform space, a inter-class scatter matrix is calculated (img file='DDA0000447013750000011.TIF' wi ='45' he='65' / ); (6) the obtained new image feature WF'(x, y) is projected on a feature projection vector group Phi; (7) finally, a nearest neighbor classifier carries out classification. The invention carries out feature extraction of the image operated by the LoG operator, more complete identification information of the original imagely can be extracted, the data from the above experiment shows that the new algorithm can obtain the prominent face identification rate from all three face databases, and also completely meet the real-time requirements in the speed.

Owner:JINAN UNIVERSITY

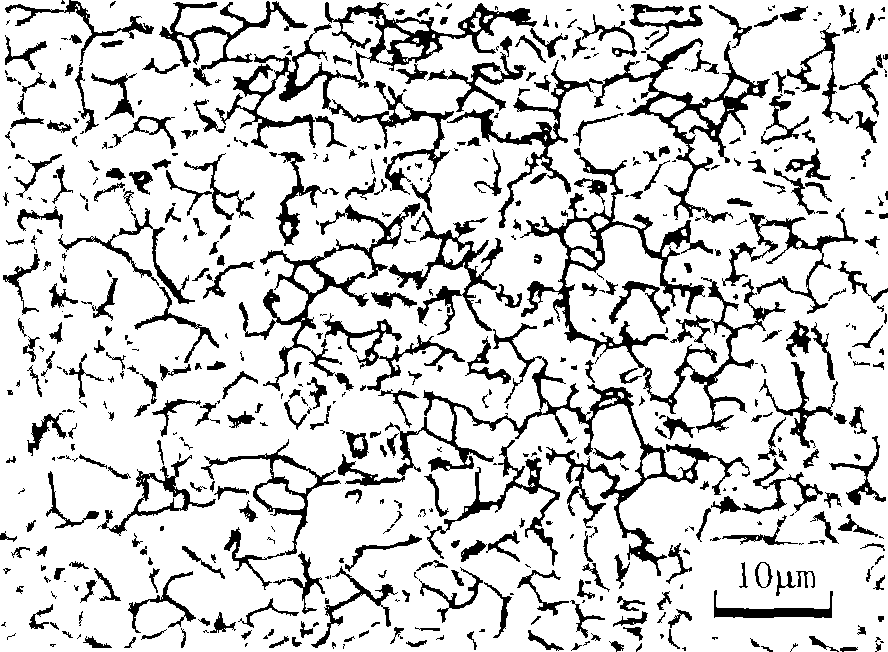

Retained austenite contained dual phase steel color metallography coloring agent and coloring display method

InactiveCN104236980AClear outlineStructuredPreparing sample for investigationColor/spectral properties measurementsPicric acidDyeing

The invention discloses a retained austenite contained dual phase steel color metallography coloring agent and a coloring display method and belongs to the technical field of steel and iron material microscopic structure metallographic dyeing. The coloring display method comprises the following steps of configuring sodium metabisulfite and water into an aqueous solution A with the concentration, by mass percent, being from 1 to 10% and configuring picric acid and ethyl alcohol into a solution B with the concentration, by mass percent, being from 2 to 4%; mixing the above aqueous solution A and B according to a volume ratio of 1:1, meanwhile adding 0.2 to 1ml concentrated hydrochloric acid with the concentration being from 37 to 38% and uniformly stirring after being fully mixed; arranging a dual phase steel sample into the above configured etching liquid, wherein the etching temperature is from 20 to 30 DEG C and the etching time is form 3 to 10s; washing through a large amount of fresh water, sprinkling through the ethyl alcohol and drying after moisture removal; observing under a metallographic microscope; measuring phase volume fractions. The coloring display method has the advantages of enabling ferrite, martensite, retained austenite and bainite tissues to be displayed in different colors, being clear in outline, distinct in gradation and easy to identify; being simple, reliable and rapid in process and easy to operate.

Owner:CENT IRON & STEEL RES INST

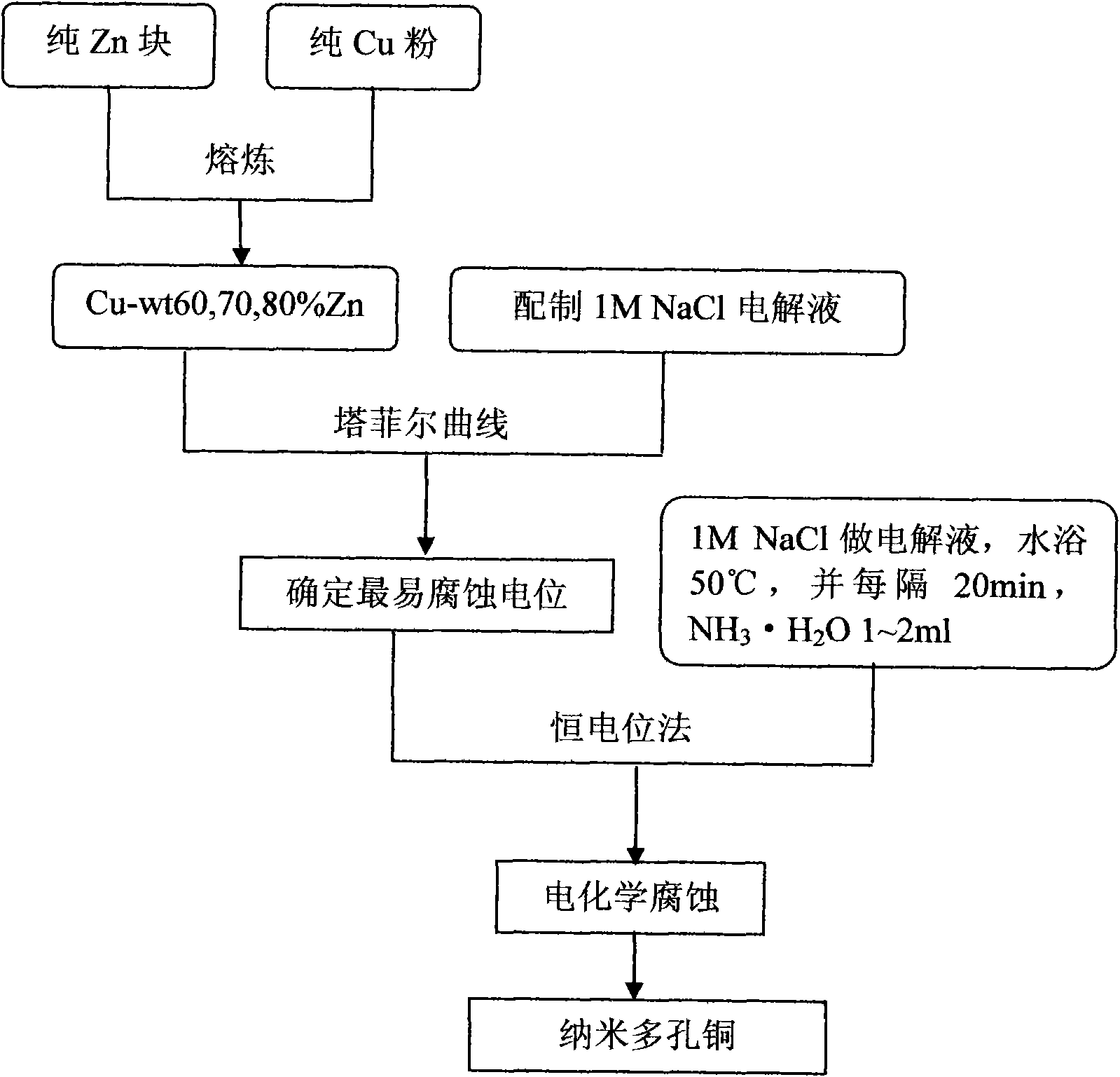

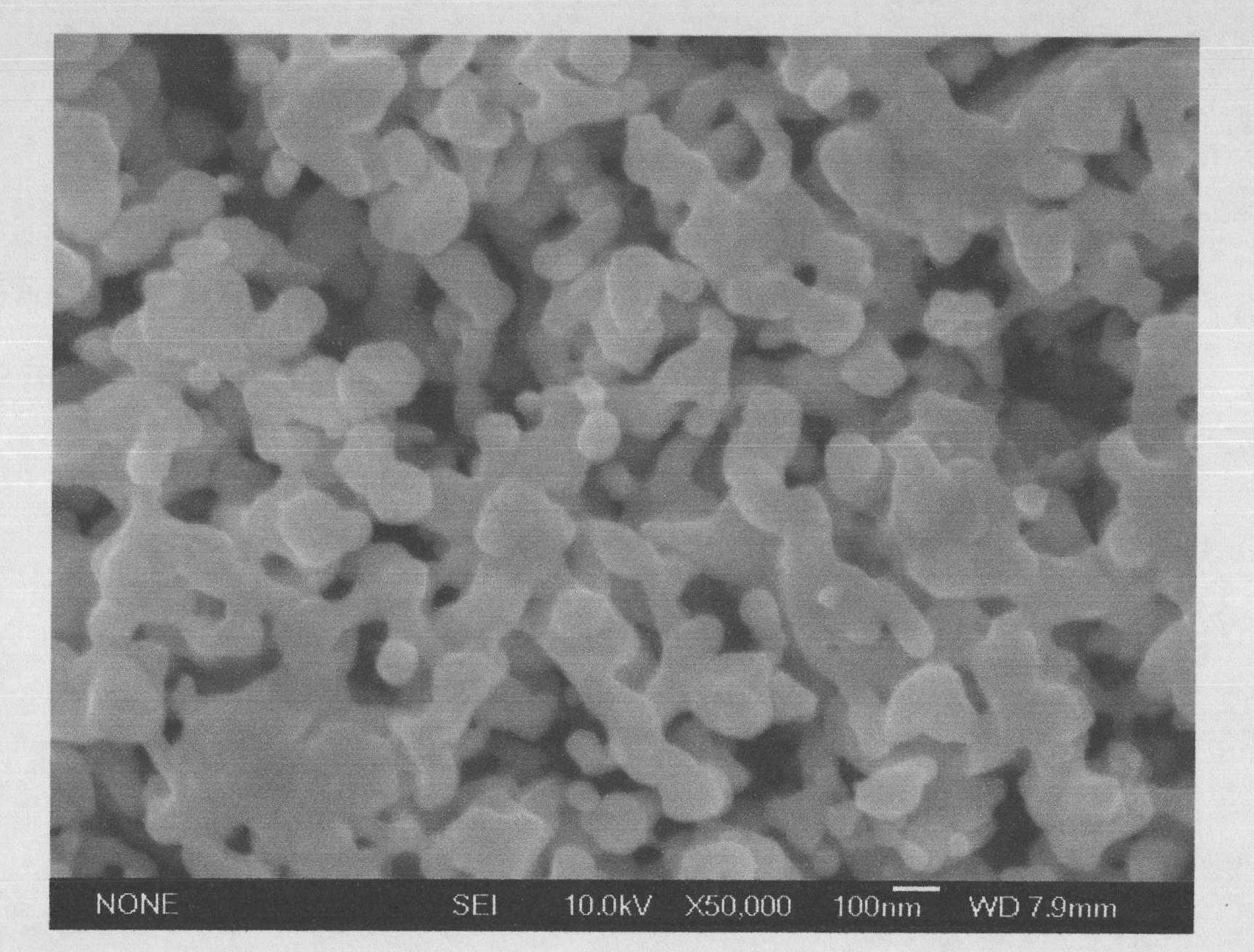

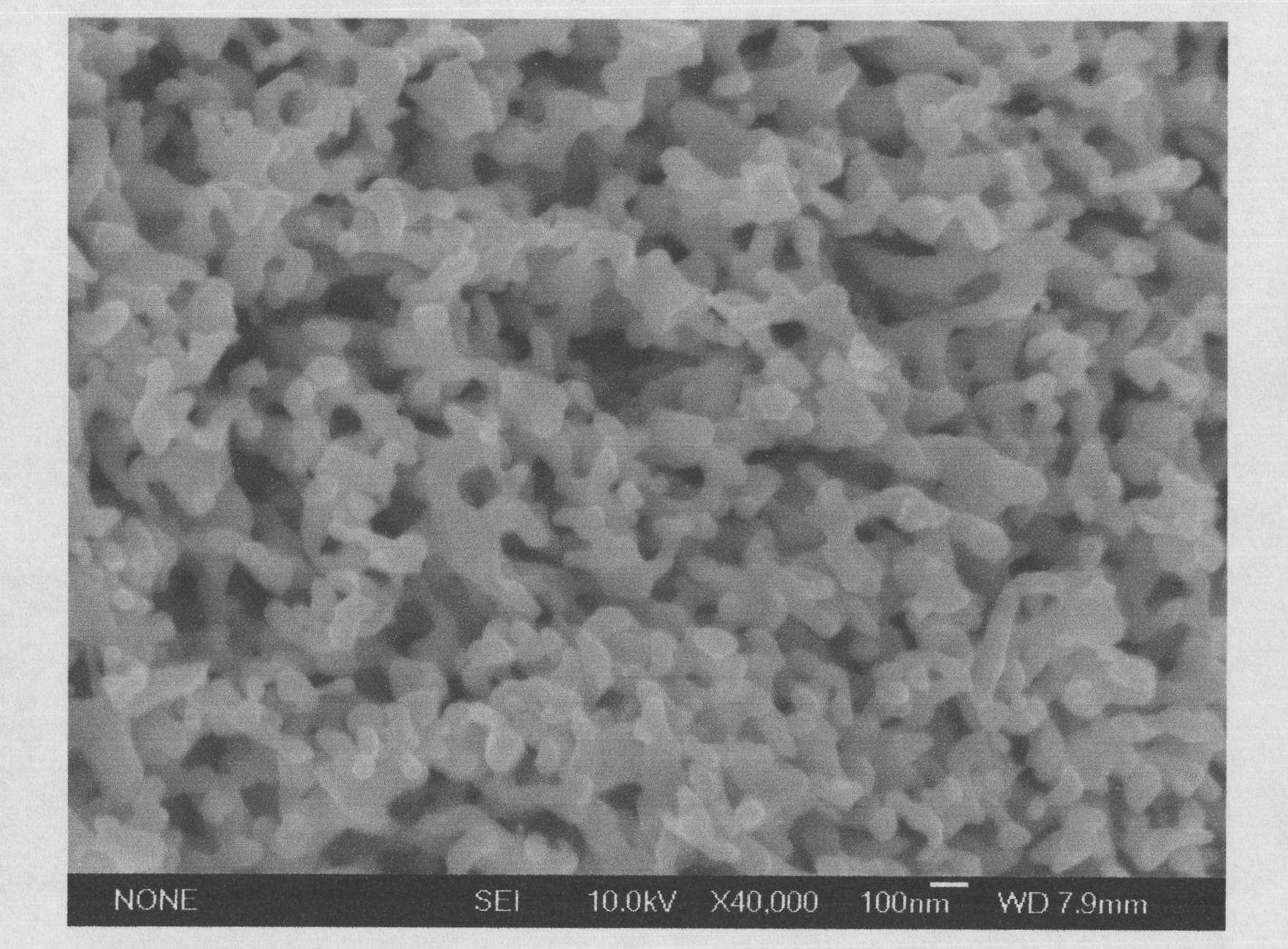

Method for preparing nano porous copper by adopting Cu-Zn alloy

The invention discloses a method for preparing nano porous copper by adopting Cu-Zn alloy. The method comprises the following steps of: preparing copper and zinc in a proportion that the copper is 60 weight percent or 70 weight percent or 80 weight percent of the zinc under the protection of nitrogen to obtain alloys by adopting a smelt technology; carrying out Tafel curve testing by taking a 1M NaCl solution as an electrolyte and utilizing a three-electrode method to obtain easies corrosion voltages of different alloys; carrying out water bath at 50-70 DEG C in the 1M NaCl solution under the condition that the volume ratio of corrosive liquid to the alloy volume is (1,000-1,500):1; carrying out electrochemical corrosion on the alloys under the easies corrosion voltages; dropwise adding 1-2ml of concentrated NH3.H2O solution every other 20 minutes to ensure that the electrolyte contains certain complex compounds to promote the reaction; and stopping the reaction until the cathode does not discharge obvious bubbles any more to obtain the nano porous copper. The nano porous copper prepared through the method has the advantages that the aperture is fine and small, the ligament outline is clear, the aperture is 50-200nm, and the ligament width is 70-100nm.

Owner:XIAN UNIV OF TECH

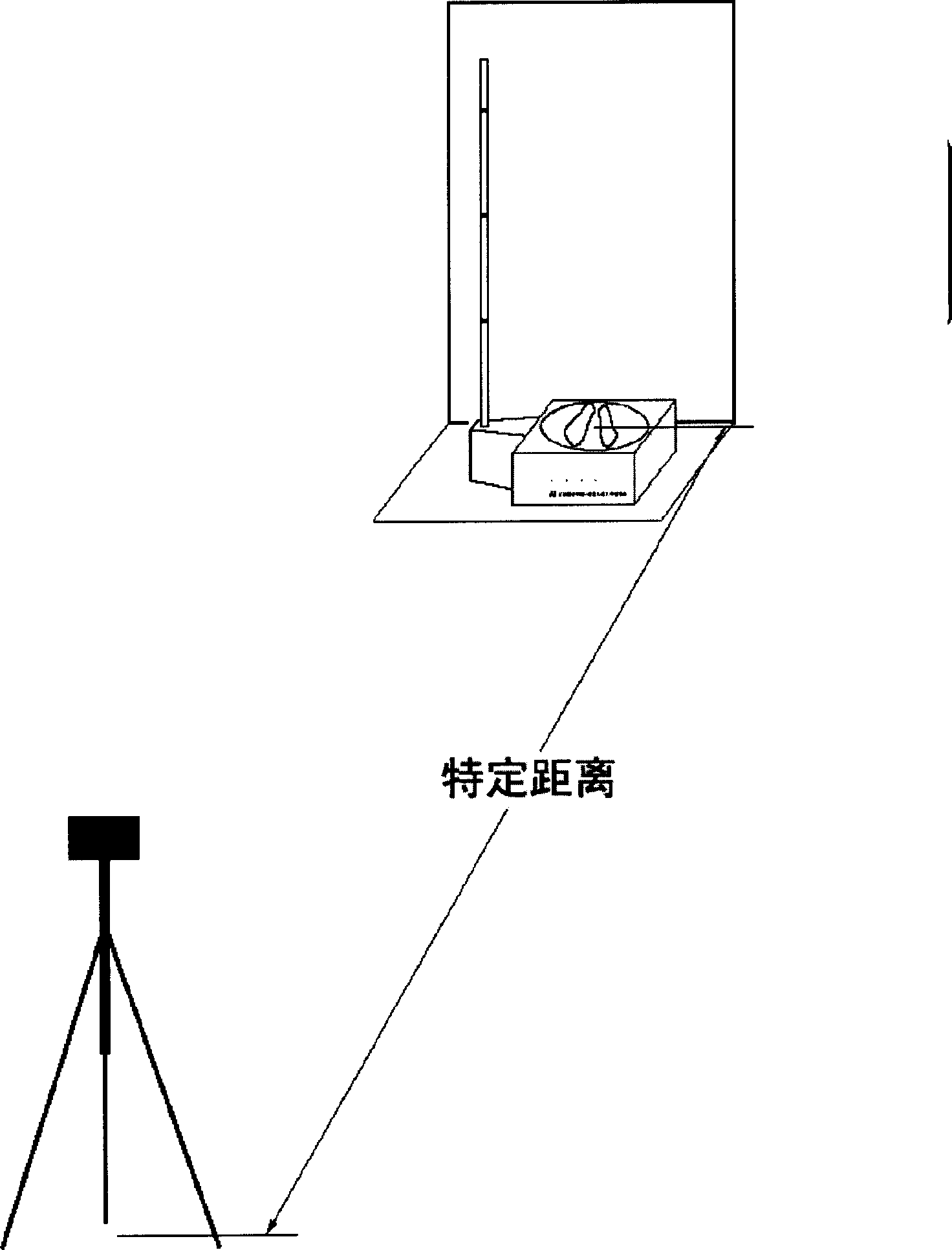

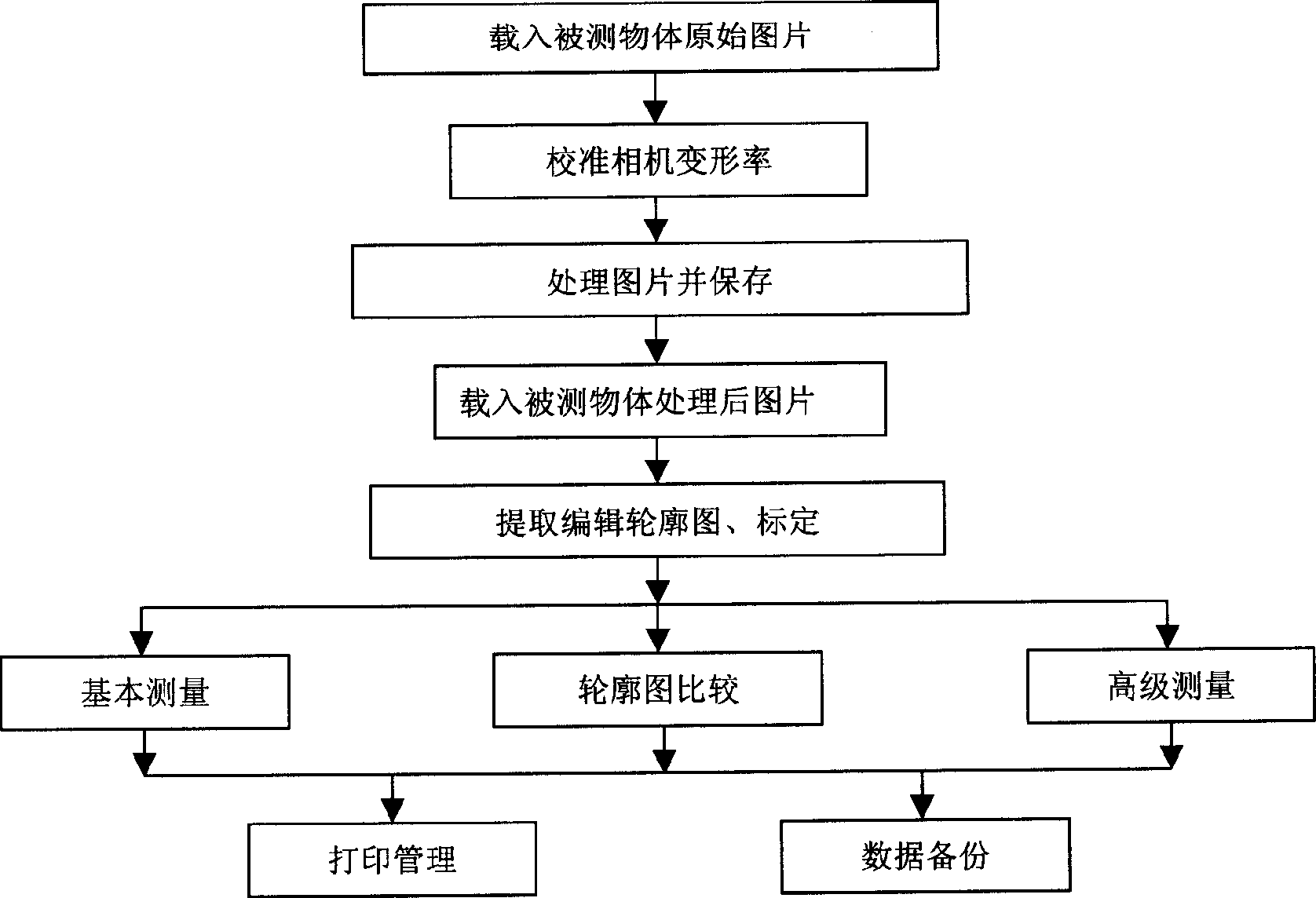

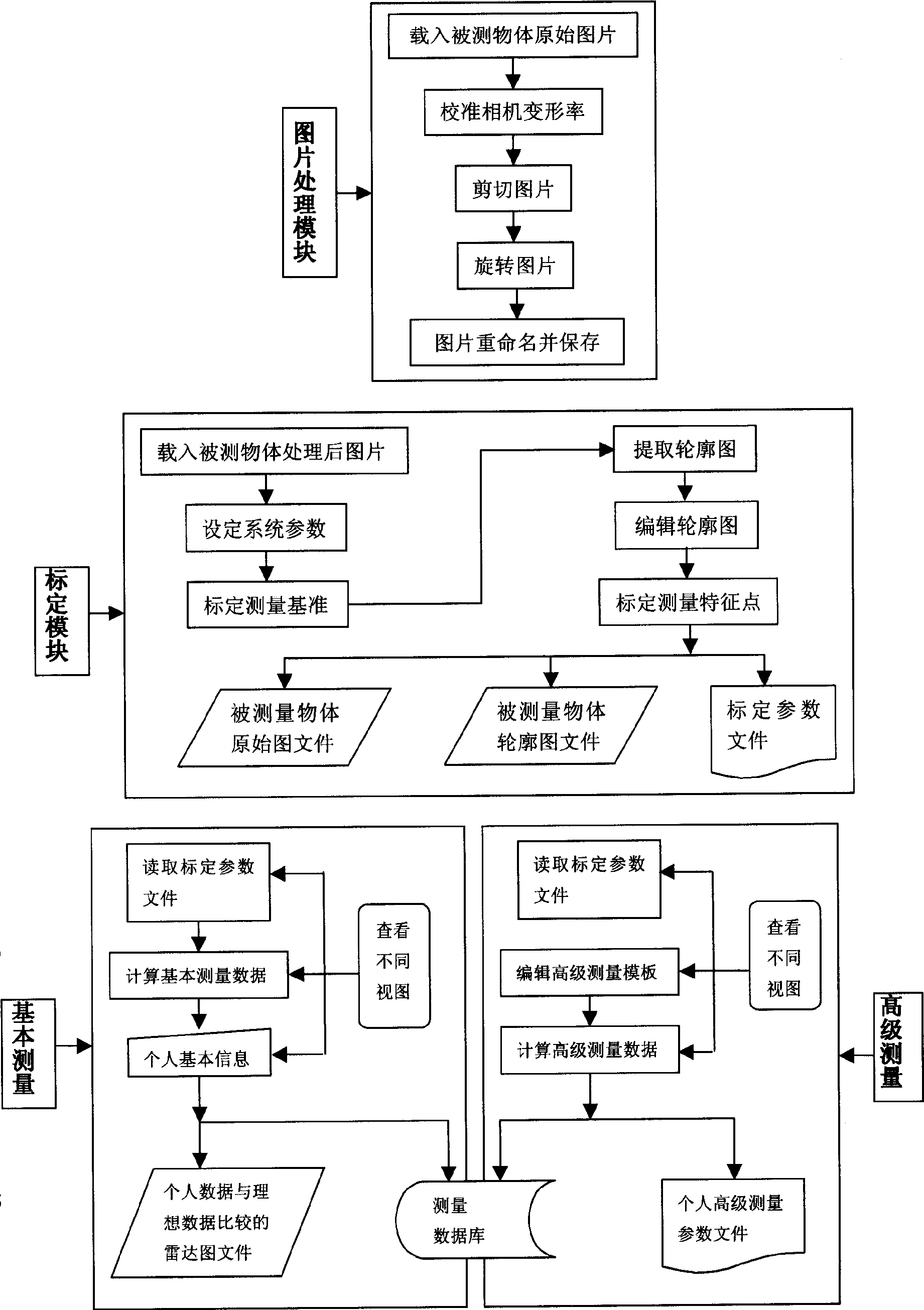

Human body measurement calculating and analysis method

InactiveCN1596827AEasy to operateImprove stabilityRadiation diagnosticsPhotographic processesDark colorEngineering

A method for measuring, calculating and analyzing the height, width, thickness, angles and the measurements of chest, waist and buttocks of a person and offering a suggestion on its clothing is disclosed. Its apparatus is composed of a measuring stand, dark-color background, digital camera, and computer.

Owner:BEIJING INST OF CLOTHING TECH

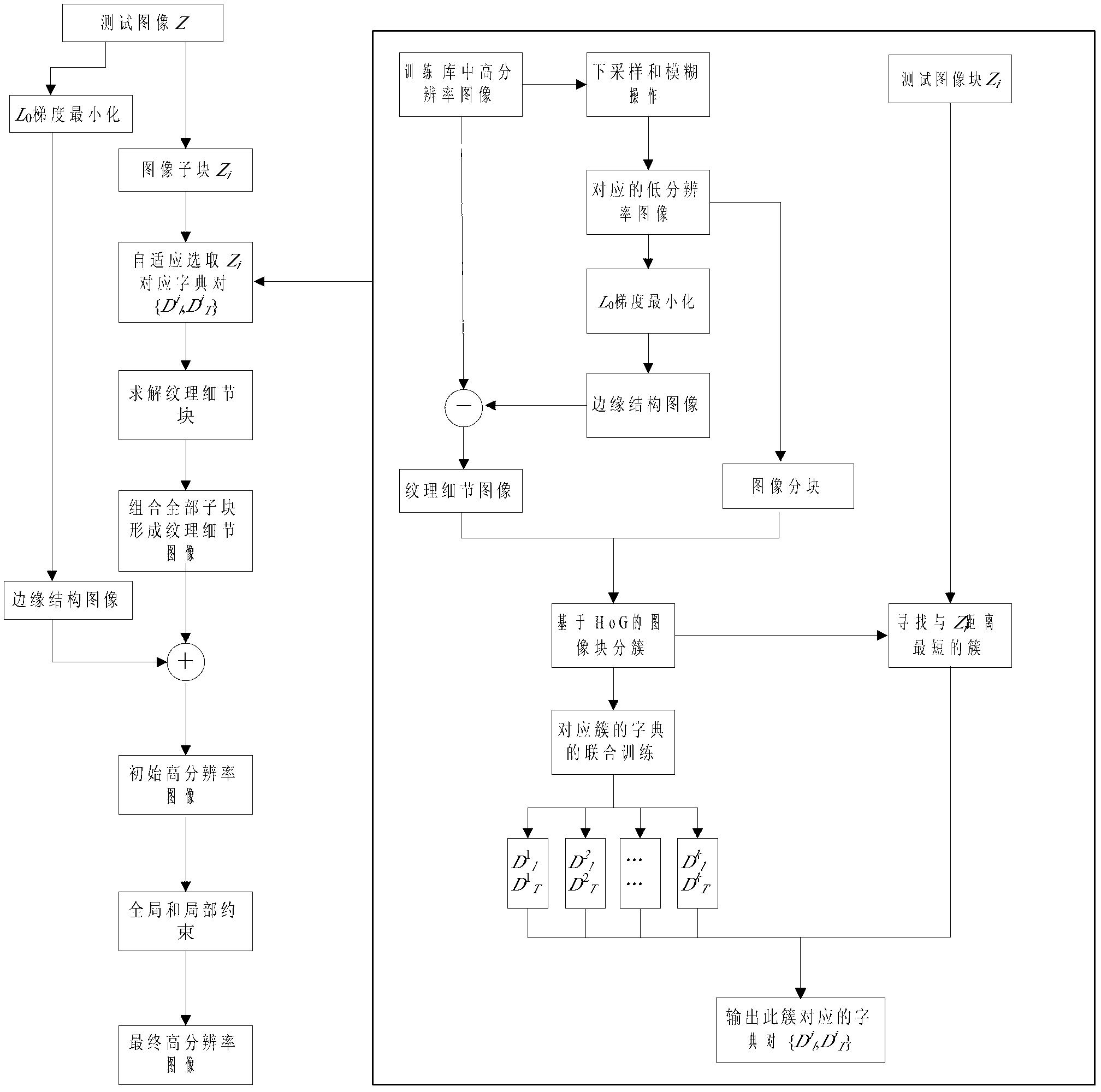

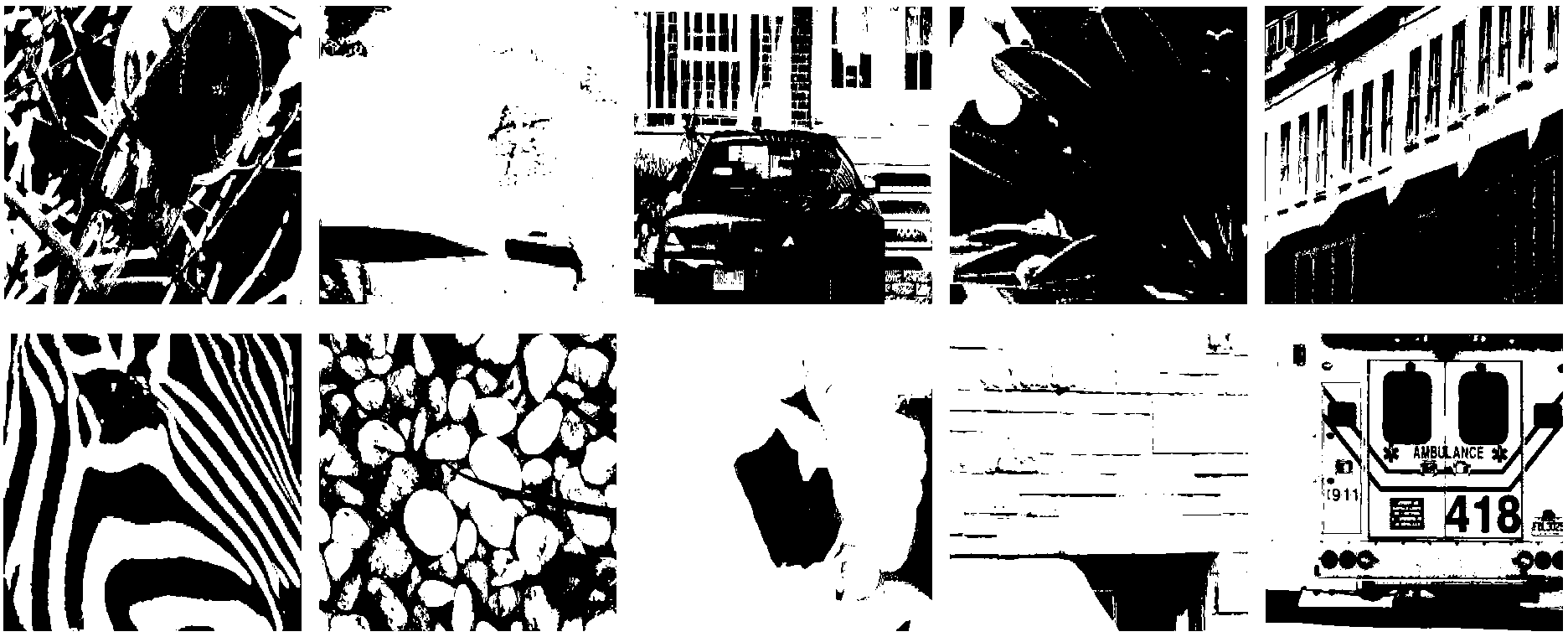

Method for reconstructing single-image super-resolution based on double-layer model

InactiveCN103279933AEasy maintenanceImage edges are sharpImage enhancementImage resolutionSingle image

The invention discloses a method for reconstructing a single-image super-resolution based on a double-layer model. The method comprises the following steps: (1) using the L0 gradient minimizing method and a HoG operator to generate K training clusters, then training corresponding dictionary pairs of the clusters, (2) selecting a geometrical dictionary pair corresponding to a low-resolution image block for testing in a self-adapting mode according to the HoG operator, solving a high-resolution line detail image corresponding to a low-resolution image, (3) using the L0 gradient minimizing method to solve a high-resolution edge structure image corresponding to the low-resolution image for testing, (4) adding the solved high-resolution line detail image to the high-resolution edge structure image to obtain an initial high-resolution image, and (5) carrying out global restriction and local restriction on the initial high-resolution image to obtain a final high-resolution image. According to the method for reconstructing the single-image super-resolution based on the double-layer model, a reconstructed image contour is clear, detail information is abundant, and quality of the reconstructed image is improved.

Owner:CHONGQING UNIV

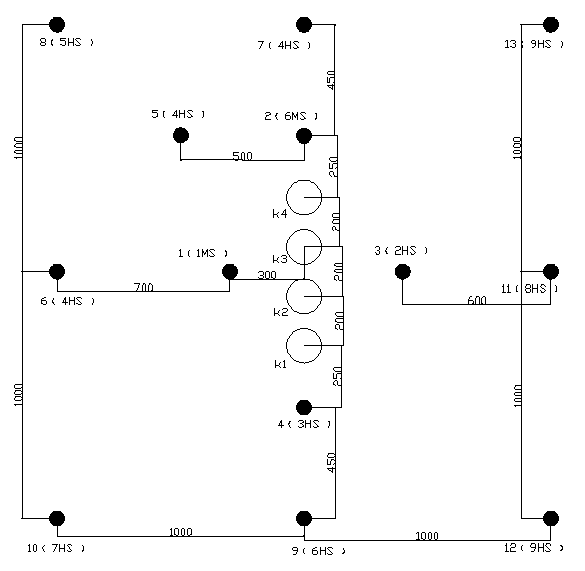

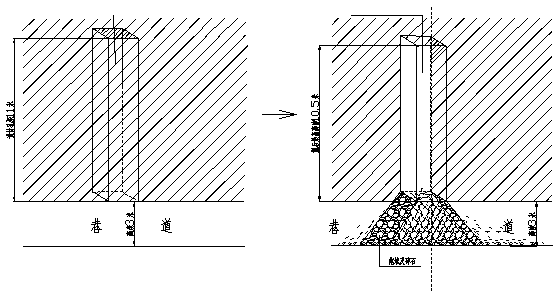

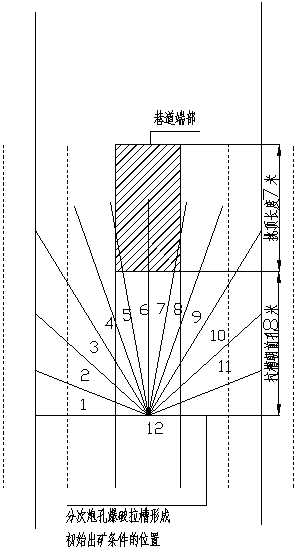

'|'-shaped free surface holing one-step well completion technology

ActiveCN103306679AImprove recovery rateReduce the number of constructionBlastingShaft raisingBuilding constructionEngineering

The invention discloses a '|'-shaped free surface holing one-step well completion technology, which comprises the following steps: (1) confirming the holing way and arranging blasting holes, wherein holing holes and peripheral holes and assistant holes are formed in the position needed to complete the well at the end part of a mining roadway, the number of the holing holes is 8, and the total number of the peripheral holes and the assistant holes is 9; and the specific way is that four hollow holes are longitudinally formed in the center line at the end part in a '|'-shaped manner to be taken as a blasting initial free surface and compensation space, four explosive filling holes are formed in the periphery of the four hollow holes under a principle to the benefit of the forming of the groove cavity and not to mutually blast, and the nine peripheral holes and assistant holes are formed in the periphery of the groove cavity; (2) drilling; (3) filling explosive; and (4) blasting. The technology can reduce the lose of the ore, improves the ore recovery rate, can also guarantee the blasting quality, reduces the construction number of the blasting holes, reduces the groove-pulling blasting times, reduces the explosive consumption, relieves the labor intensity of the blaster, improves the safety performance, reduces the manufacturing cost, and meanwhile can also be directly used for constructing vertical wells.

Owner:安徽马钢矿业资源集团姑山矿业有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com