Patents

Literature

187 results about "Embedding Agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Approach to provide self-protection function to web content at client side

ActiveUS7475152B2Increase flexibilityProvide securityComputer security arrangementsMultiple digital computer combinationsProtection mechanismApplication software

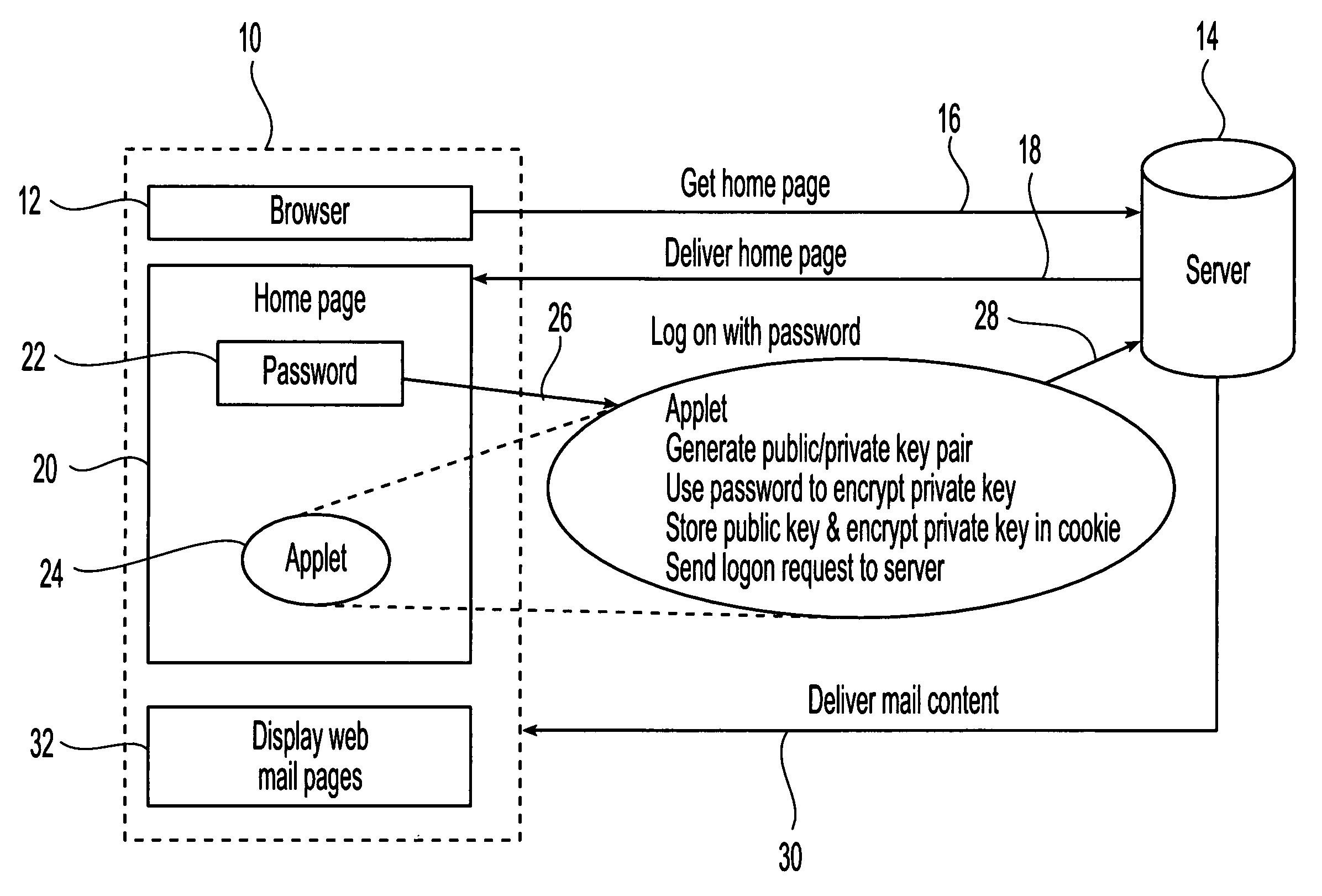

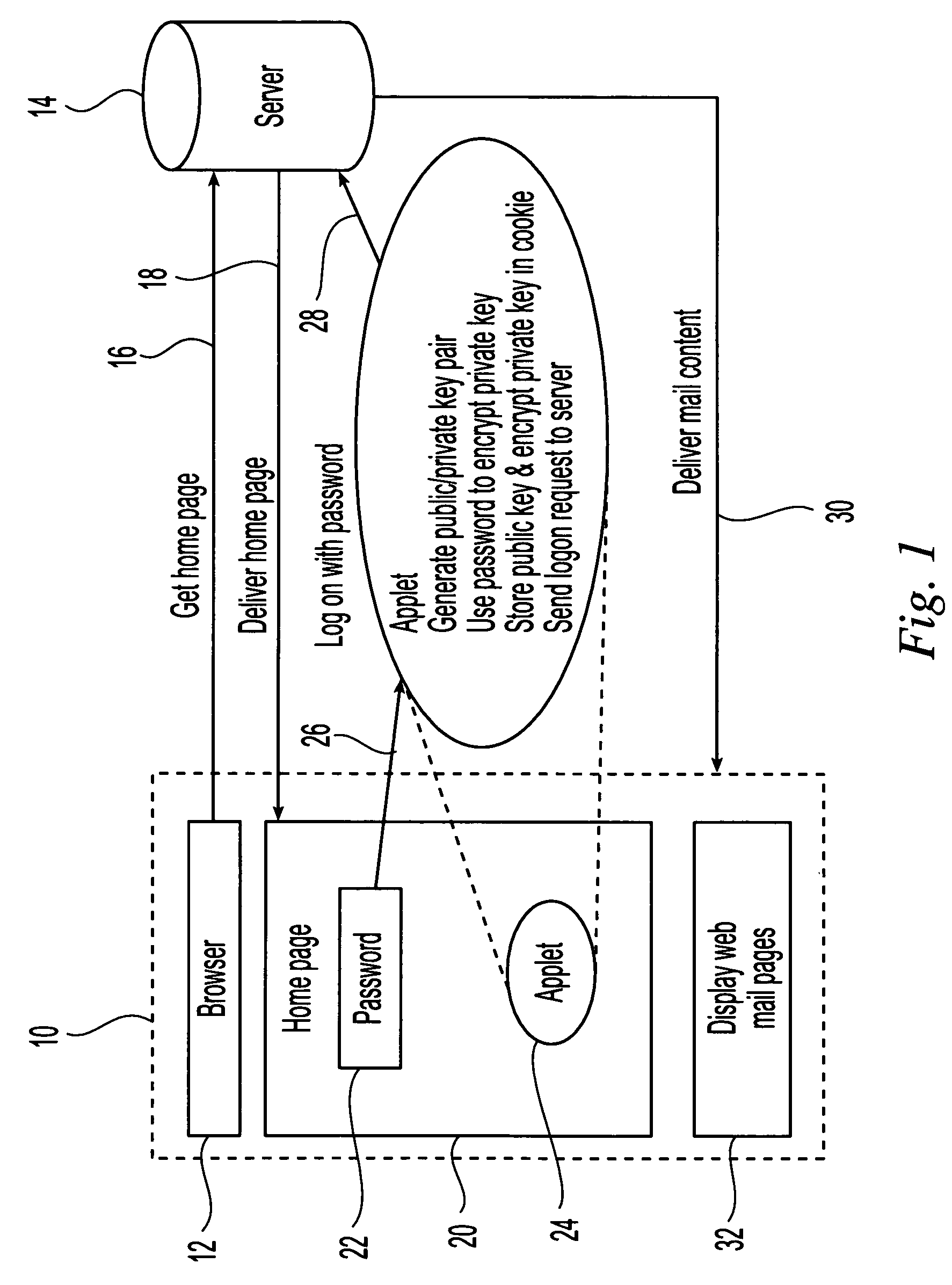

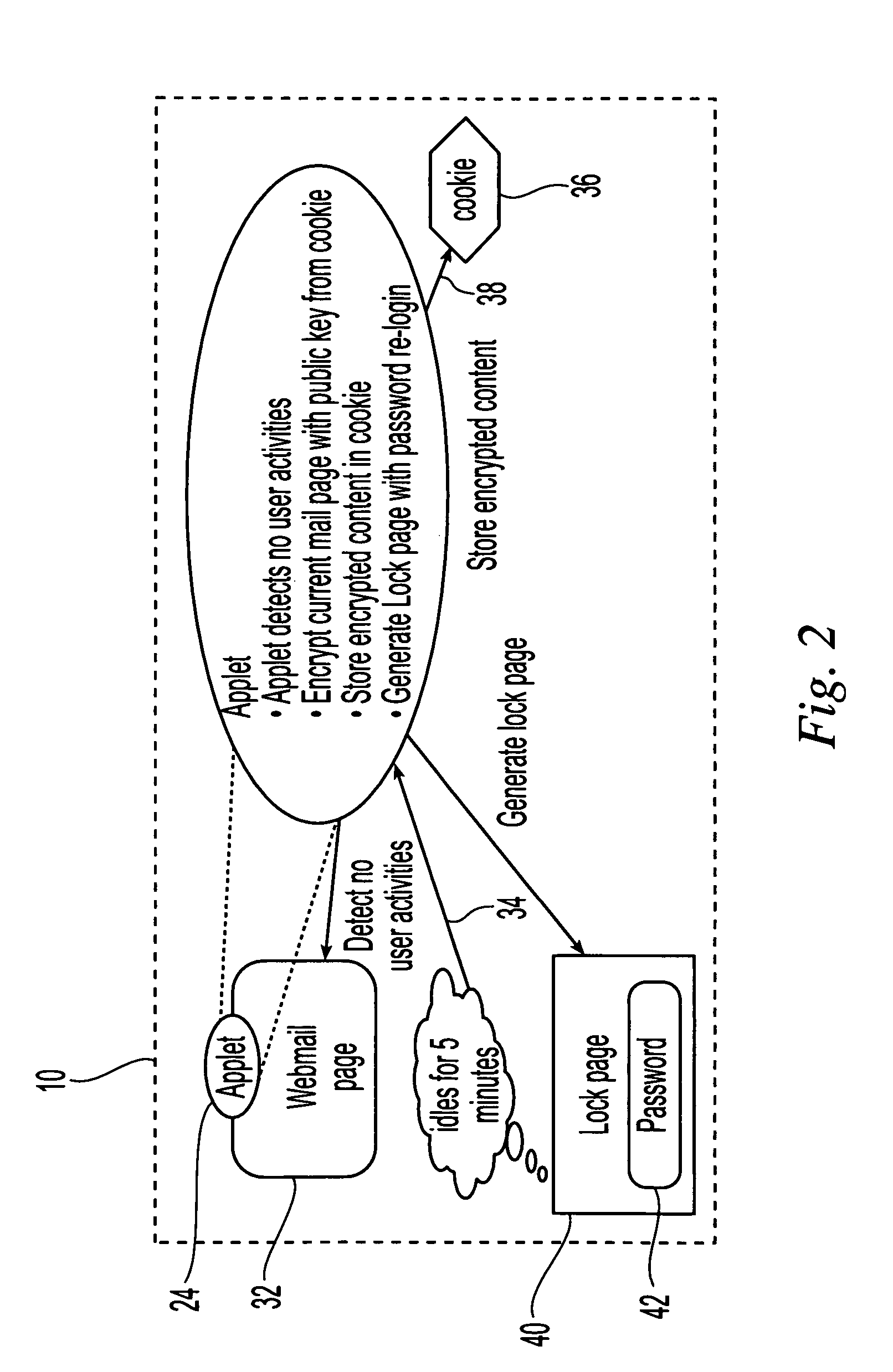

The present invention utilizes agents embedded in content delivered to clients across a network to provide client-side security for the data delivered to a client. These embedded agents provide application-specific protection for the delivered content in which they are embedded and eliminate the need for using plug-ins for security functions. Different agents, e.g. programs such as Java applets, are configured having a variety of different client or application specific protection mechanisms, and the agents are dynamically configured, e.g. selected, in accordance with the application, the client to be protected or other environment criteria. Once the agent has been appropriately configured, the agent is embedded in the content, and the content is delivered to the client. Once delivered, the embedded agent is uploaded to the client and executed, providing the configured security protection at the client side for the content in which it was embedded.

Owner:IBM CORP

Method and apparatus for universal device management

InactiveUS20040001095A1Cathode-ray tube indicatorsDigital data authenticationAutomotive systemsUser interface

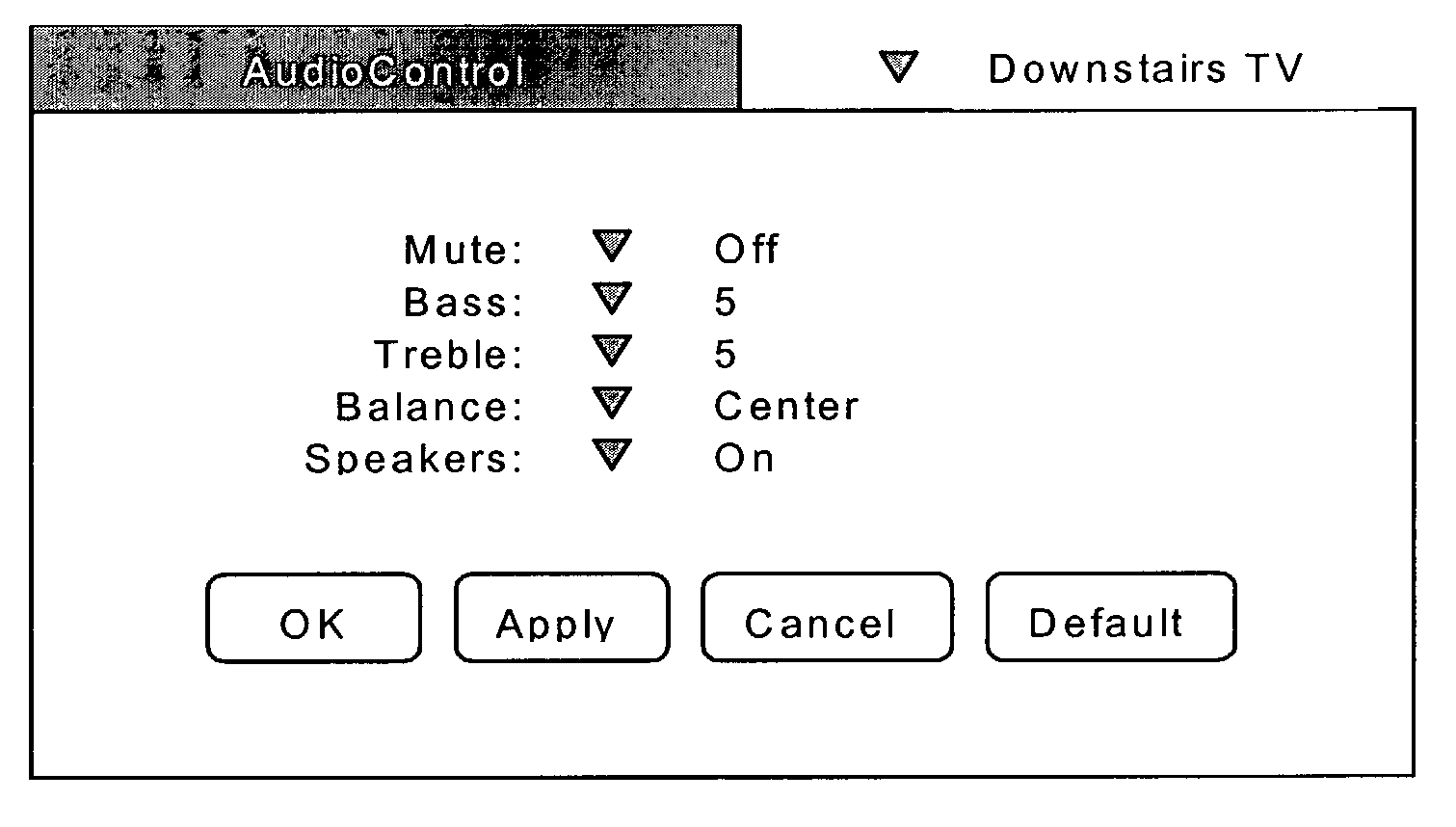

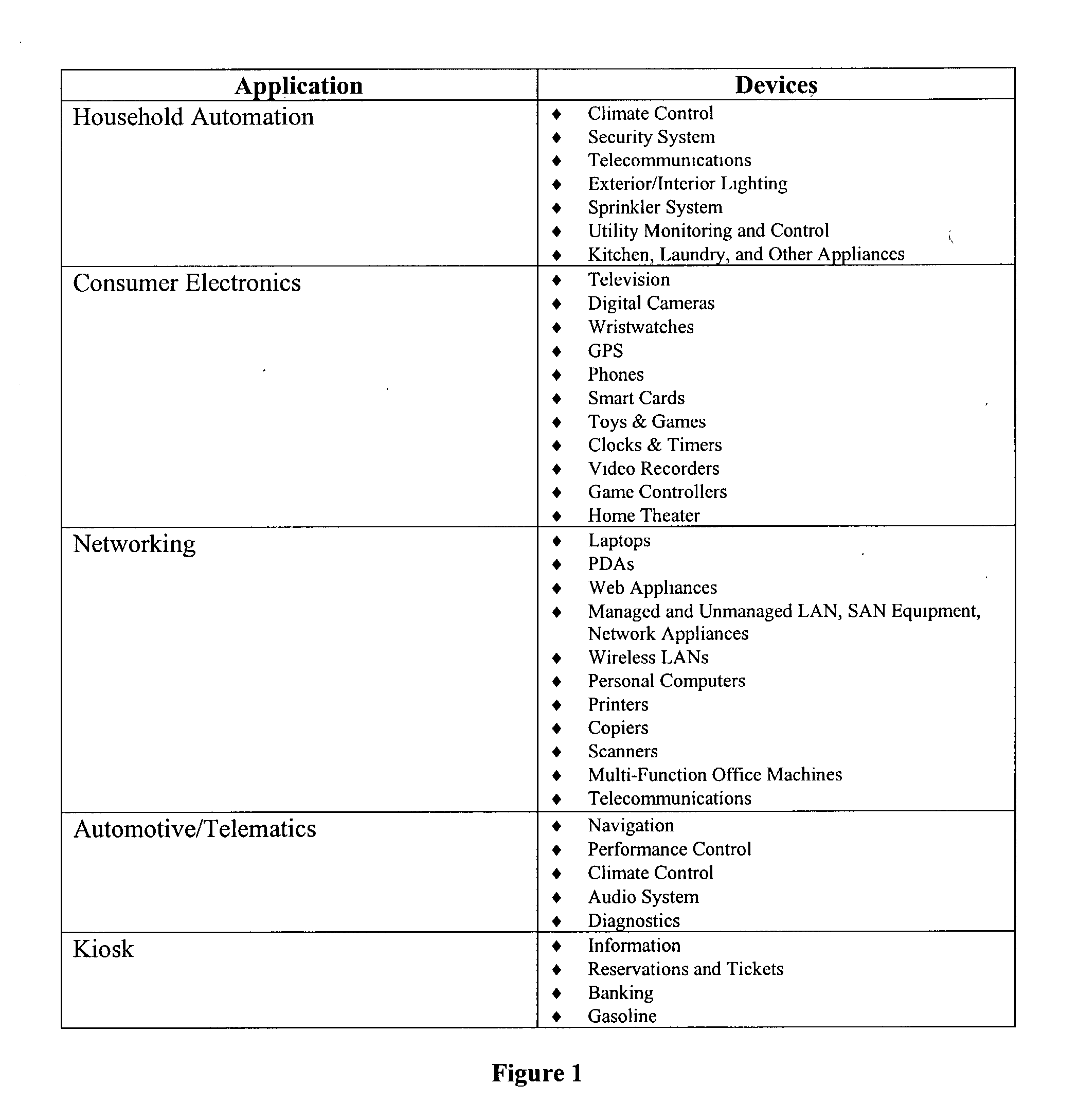

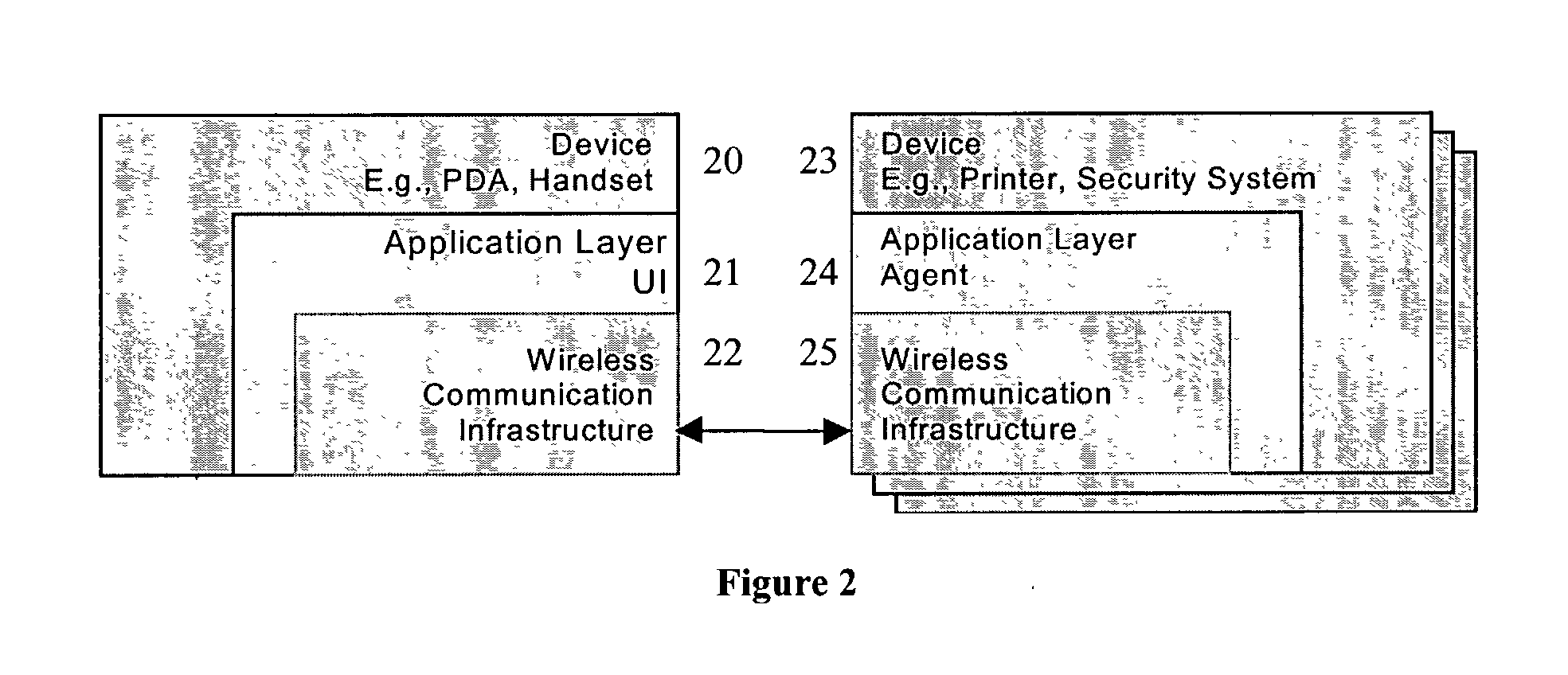

A method and apparatus for universal device management using in its preferred embodiment, a software-based process that enables devices such as PDA's and mobile phones to discover, monitor, and control electronic devices in diverse applications such home entertainment, mobile computing, automotive systems, data networking, and household and office automation. The system comprises a user interface residing typically on a handheld device, a lightweight embedded agent that runs on all managed devices, and a wireless communication infrastructure that allows wireless communication between the interface and all devices, regardless of device type or manufacturer. The user interface provides users with a common look-and-feel for managing all devices.

Owner:ZURADO

Multifunctional essence slow-release carrier and preparation method thereof

InactiveCN105112162AImprove protectionLong lasting fragranceEssential-oils/perfumesControl releaseAdhesive

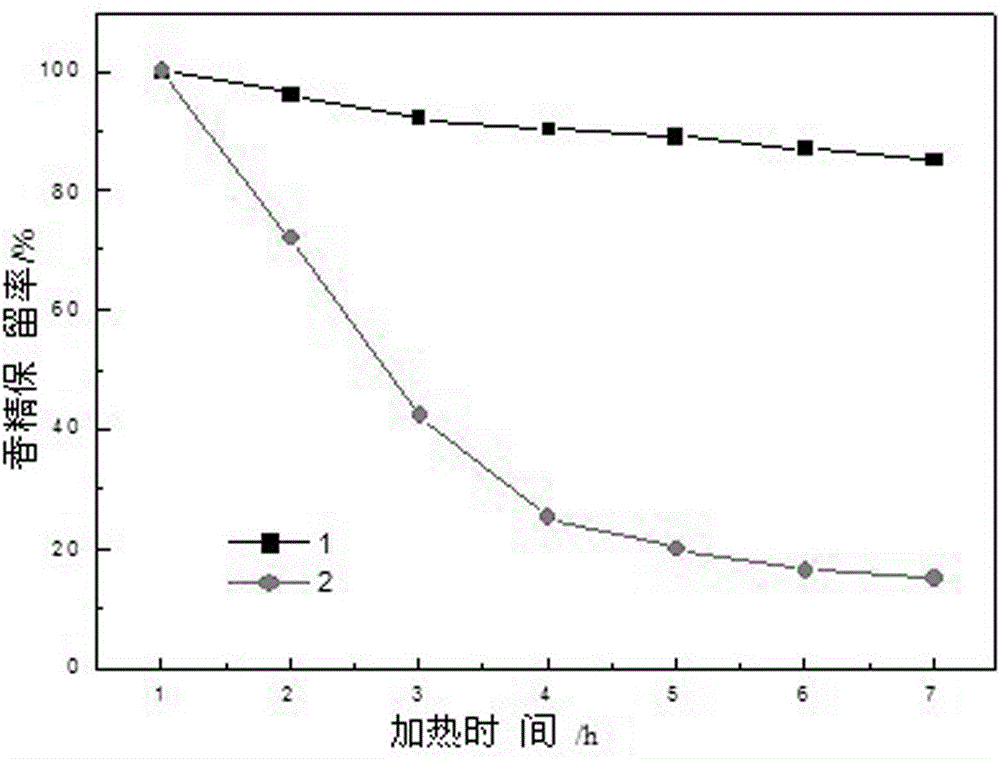

The invention relates to the field of essences, particularly a multifunctional essence slow-release carrier and a preparation method thereof. The multifunctional essence slow-release carrier comprises the following raw materials in percentage by weight: 0.1-25% of essence, 1-35% of high-efficiency embedding material, 30-80% of excipient, 0-1% of adhesive and 0.1-10% of coating agent. The multifunctional essence slow-release carrier is spherical or subsphaeroidal granules. The three embedding techniques of nano emulsification, high-efficiency adsorption and granulation forming-coating are utilized to obtain the essence slow-release carrier granules with adjustable aroma type, adjustable color, adjustable functions, favorable flowability and beautiful appearance. The multifunctional essence slow-release carrier can effectively solve the problems of aroma volatilization and sensitive essence deterioration, prolong the aroma retention time and implement slow and controlled release, and is applicable to the industries of food, daily chemicals, cigarettes, medical health care and the like, thereby prolonging the aroma retention time of the product and prolonging the shelf life.

Owner:DONGGUAN BOTON FLAVORS & FRAGRANCES

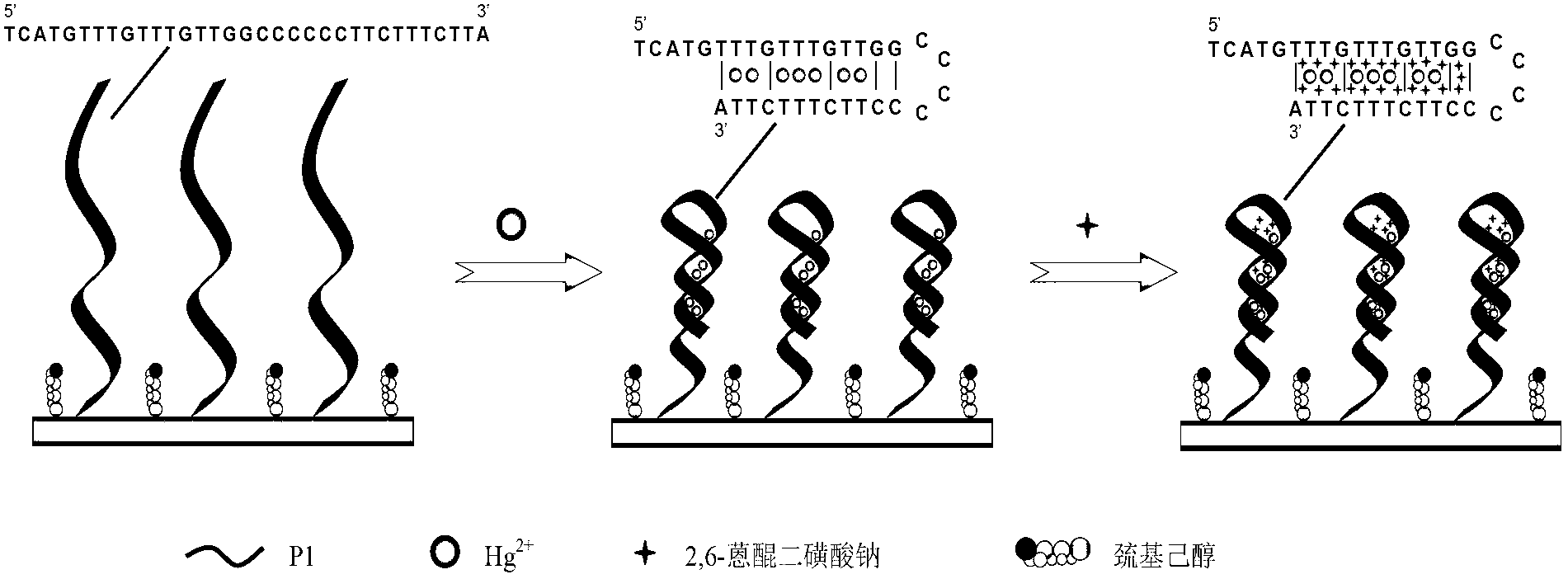

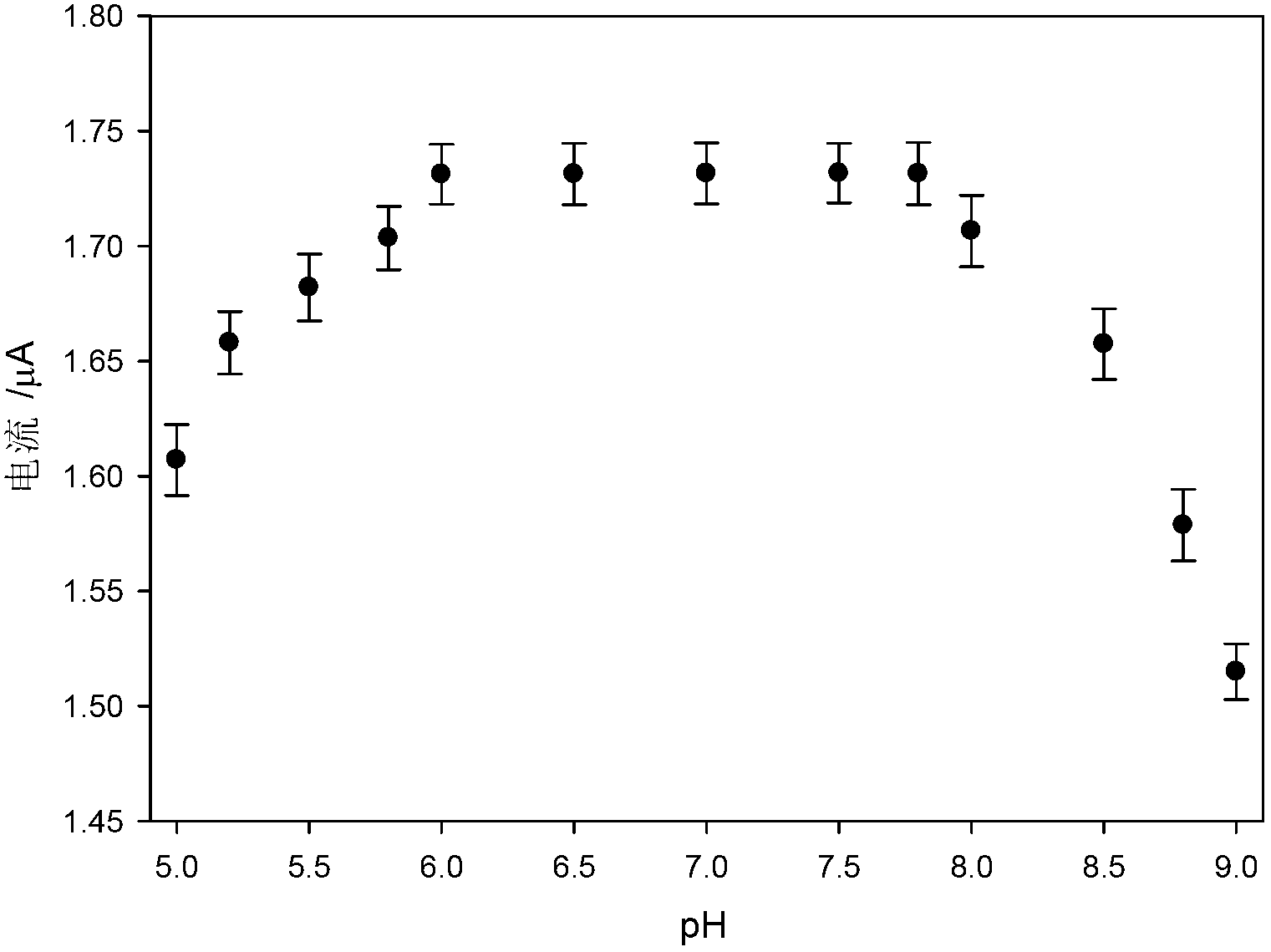

Electrochemical sensor capable of detecting trace mercury in water body, and preparation method and application thereof

InactiveCN102706940ASimple structureEasy to manufactureMaterial electrochemical variablesPeak currentSquare wave voltammetry

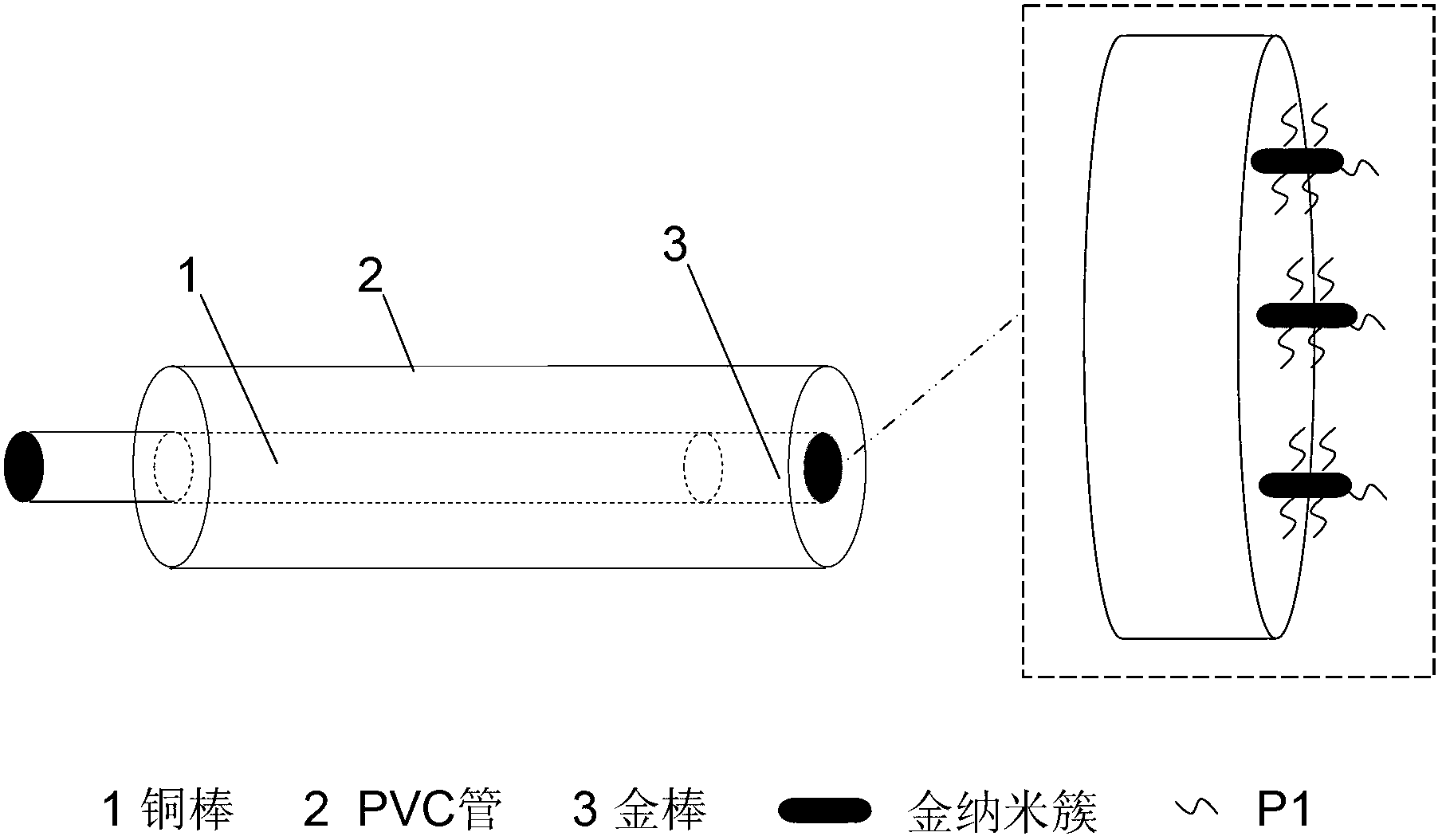

The invention discloses an electrochemical sensor capable of detecting trace mercury in a water body. The electrochemical sensor comprises a gold electrode, wherein gold nanoclusters are deposited on the surface of the reaction end of the gold electrode; and sulfhydryl-modified mercury-specific oligonucleotide probes are self-assembled on the gold nanoclusters. The preparation method for the electrochemical sensor comprises the following steps of: first, preparing the gold electrode; then, electrodepositing the gold nanoclusters on the surface of the reaction end of the gold electrode; and finally, self-assembling the sulfhydryl-modified mercury-specific oligonucleotide probes on the end surfaces of the gold nanoclusters so as to finish the manufacturing of the sensor. By using the sensor provided by the invention, the trace mercury in the water body can be detected; and the specific operation comprises the following steps of: first, placing the reaction end of the sensor in a water sample for reacting; then, immersing the reaction end into an anion double-stranded deoxyribonucleic acid (DNA) signal embedded agent for complete treatment; later on, connecting the sensor into an electrolytic cell of a three-electrode system and measuring the change of a response peak current by using square wave voltammetry; and finally, judging whether the water sample contains mercury ions on the basis of the change. The electrochemical sensor has the advantages of simple and practical structure, convenience in manufacturing, high sensitivity, high selection specificity and the like.

Owner:HUNAN UNIV

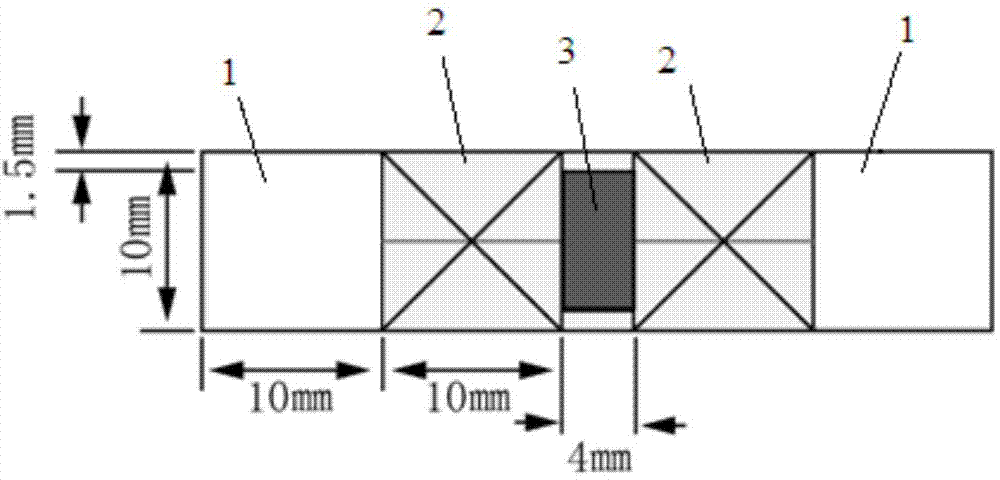

Cassette for Fixing, Embedding and Slicing Biological Tissues and Method of Using the Cassette

ActiveUS20100167338A1Prevent movementAvoid misplacingAnalysis using chemical indicatorsPreparing sample for investigationPlastic filmUltimate tensile strength

A cassette for fixing, embedding and slicing biological tissues includes a base sheet and a lid sheet formed of an elongated plastic sheet which is sliceable and has not less than predetermined strength. The base sheet has grooves as biological tissue receiving portions. The base plate and the lid sheet are formed by folding the plastic sheet along a fold line so that the lid sheet can be selectively opened and closed. Biological tissues are pressed against the bottoms of the grooves with pressing / retaining sponge members secured to the lid sheet at its portions corresponding to the respective grooves. In this state, the biological tissues are fixed by a fixing agent, and the cassette is dehydrated, infiltrated with paraffin as an embedding agent to embed the cassette, thereby forming a block including an embedding frame. The block is then sliced with a microtome to provide good biological tissue specimens.

Owner:KYOTO UNIV

Transmission electron microscope processing method for insect antenna samples

ActiveCN103115809AEffective immobilizationEffective preservationPreparing sample for investigationElectron microscopeBiology

The invention belongs to the field of experimental sample processing technologies, relates to insect antenna sample processing methods and particularly relates to a transmission electron microscope processing method for insect antenna samples. The method sequentially comprises the following steps of: (A) preparing fixing liquid; (B) preparing various embedding agents; (C) dissecting, fixing and rinsing; (D) dewatering and soaking; and (E) gathering, so as to obtain the samples. The method has the advantages that the problems of difficulty in fixing liquid soaking and insufficiency in embedding agent soaking during the process of insect antenna transmission processing are solved, finally-obtained sample slices can be relatively flat, the phenomena of sample wrinkling, damaging and losing are greatly reduced, internal structures of the sample slices are all effectively fixed, and subcellular structures are clearly visible.

Owner:ZHEJIANG UNIV

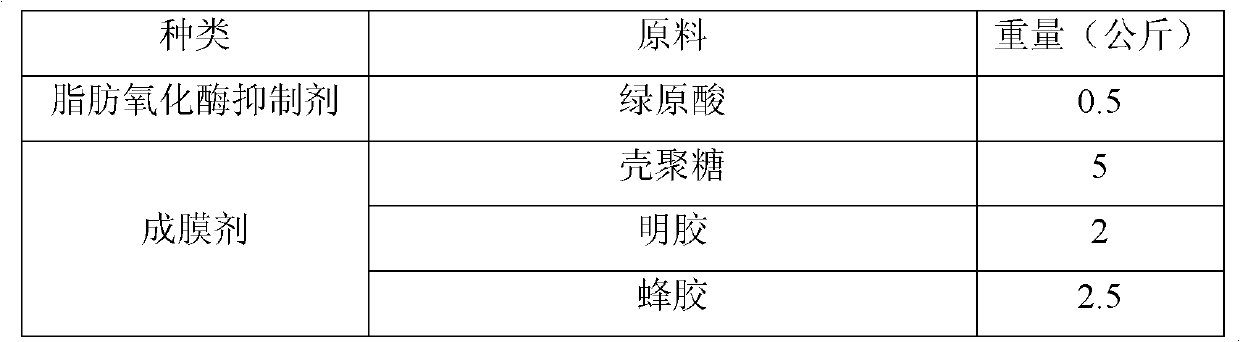

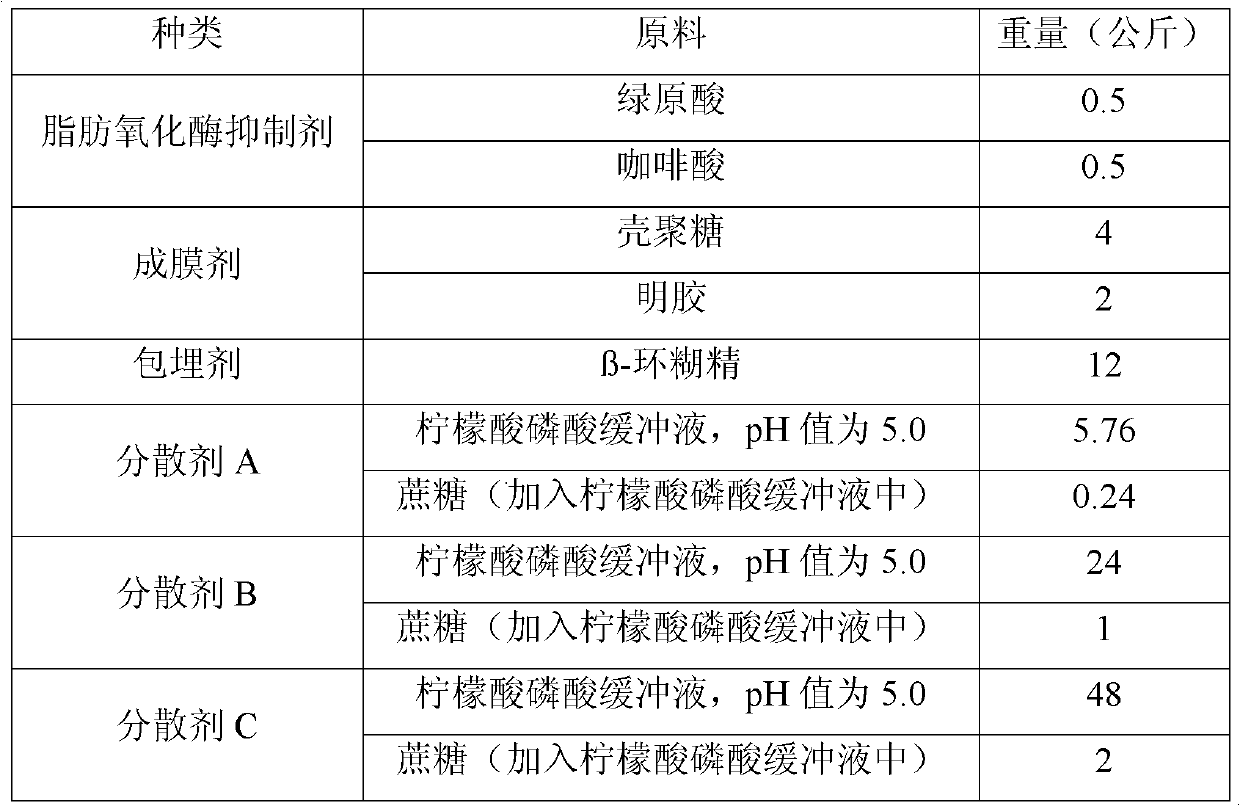

Rice antistaling agent as well as preparation method and application thereof

The invention provides a rice antistaling agent as well as a preparation method and an application thereof. The rice antistaling agent comprises the following raw materials in percentage by weight: 0.5-2% of lipoxidase inhibiting agent, 5-10% of film forming agent, 10-15% of embedding agent and 75-84% of dispersing agent. The rice antistaling agent inhibits the lipodieresis of rice during storage by regulating the activity of lipase so as to prevent rice rancidity.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Mustard essential oil biofungicide

InactiveCN101700009AExtended storage timeImprove disease resistanceBiocideFruit and vegetables preservationDiseaseFungicide

The invention relates to a mustard essential oil biofungicide, comprising the following components by parts by weight: 2-20 parts of mustard essential oil, 10-30 parts of embedding agent, 5-30 parts of carrier, 5-20 parts of binder, 5-15 parts of dispersing agent and 1-20 parts of filler. The biofungicide has the characteristics that: application method is simple and less influenced by external environment; the biofungicide is pollution-free, nuisanceless and non-toxic without side effect; platy or powdery fungicide is added into a packing container before storing, the biofungicide is applicable to storing and refreshing of multiple fruits and vegetables, forms a protective gas layer in the packing environment, effectively inhibits or kills off main postharvest pathogenic bacteria, improves disease resistance of fruits and vegetables, reduces rotting caused by common pathogenic bacteria in storing process and prolongs storing and refreshing time of fruits and vegetables.

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN

Instant spice powder preparation method

InactiveCN108030053APreserve the active flavor componentsWith standardized productionFood scienceWater solubleEmbedding Agent

The invention relates to a seasoning preparation method, and especially relates to an instant spice powder preparation method. The method comprises the following steps: raw material preparation, dispersion, pre-emulsification, embedding, blending, and packaging; an oil dispersant, an emulsifier, an embedding agent, a carrier are added, resin essential oil of whole spice can be fully dispersed, andis processed to water-soluble oil powder. The preparation method has the advantages of simple technology and low cost, realizes instant dissolution of the spice in water, and cannot influence original taste of the spice.

Owner:洛阳味之泉调味技术有限公司

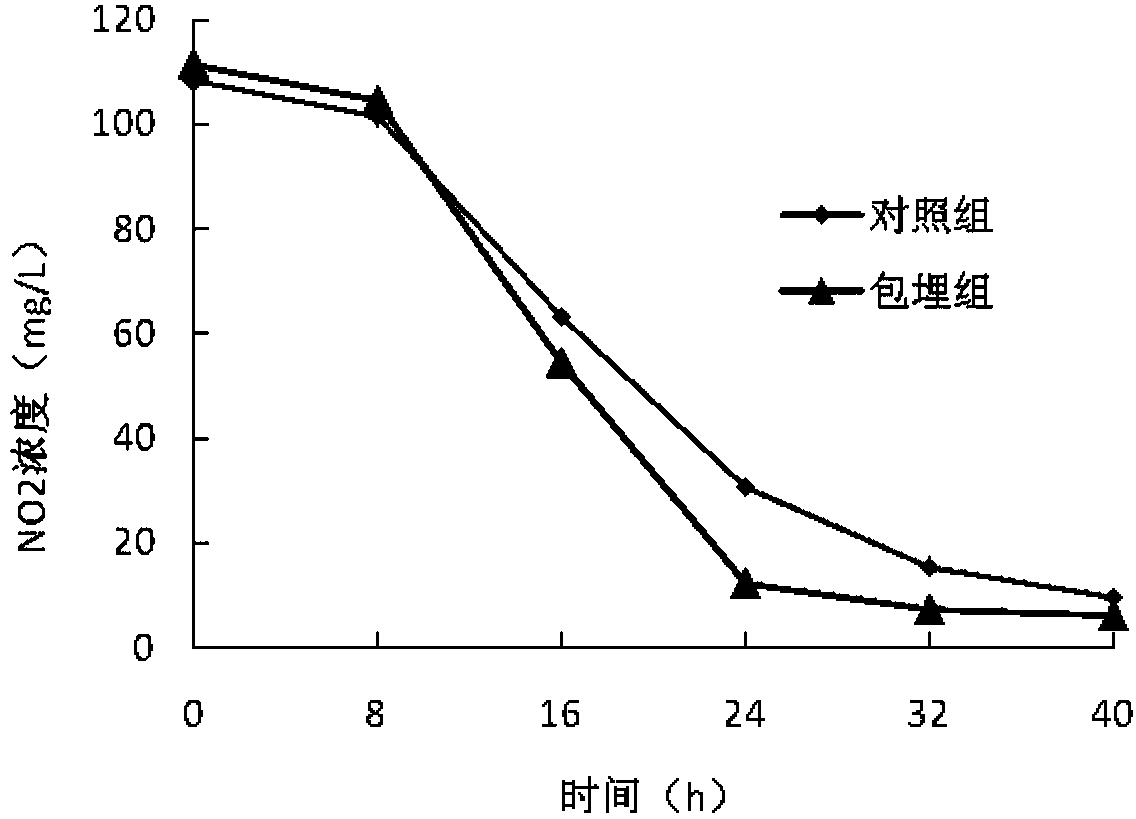

Method for realizing synchronous nitrification and denitrification nitrogen removal by utilizing immobilized microorganism technology

InactiveCN110482715ASolve problemsReduce consumptionWater contaminantsTreatment with aerobic and anaerobic processesNitrogen removalMicroorganism

The invention relates to the technical field of sewage treatment. The invention particularly provides a method for realizing synchronous nitrification and denitrification nitrogen removal by utilizingan immobilized microorganism technology. The adopted immobilized microorganism technology comprises the following steps: mixing a nitrifying bacterium agent and a denitrifying bacterium agent according to a certain ratio and adsorbing the mixture by using an adsorbent; embedding the adsorbed microbial inoculum by adopting an embedding agent; after embedding, adding dropwise a gel solution into across-linking agent to form gel beads with biological activity. The prepared gel beads sequentially form aerobic, anoxic and anaerobic environments from the surface to the inside which perform nitrification reaction, denitrification reaction and hydrolytic acidification respectively, nitrification liquid backflow is not needed, and synchronous nitrification and denitrification nitrogen removal canbe realized. Compared with a traditional biological denitrification process, the method has higher denitrification efficiency, and is simple in operation process, convenient to maintain and manage and easy to popularize.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

Preparation method of heterogeneous bacteria embedding particles

The invention provides a preparation method of heterogeneous bacteria embedding particles. The carrier particles can be used for embedding anaerobic bacteria in a load proportion of (1 to 2)-(1 to 3) (the weight of the bacteria to the weight of the embedding agent) and then embedding aerobic bacteria in a load proportion of (1 to 1.5)-(1 to 3) (the weight of the bacteria to the weight of the embedding agent). At 0-4 DEG C, the small particles are extruded into the solutions, such as CaCl2, acetic acid and glutaraldehyde, to be crosslinked, thus obtaining immobilized particles. Anaerobic environments are obtained inside the particles through microbial action to smoothly carry out microbial anaerobic reaction, and microbial aerobic reaction can be smoothly carried out as the particles have larger external hole and channel structures and are used for embedding aerobic microbes; therefore the composite particles can be used for carrying out anaerobic / aerobic reactions simultaneously and have better nitrogen and phosphorus removal effects. By utilizing the composite embedding particles, the wastewater treatment efficiency can be improved, the equipment volume can be reduced, the wastewater treatment process can be optimized and the microbial immobilization technology is expanded.

Owner:ZHEJIANG UNIV OF TECH

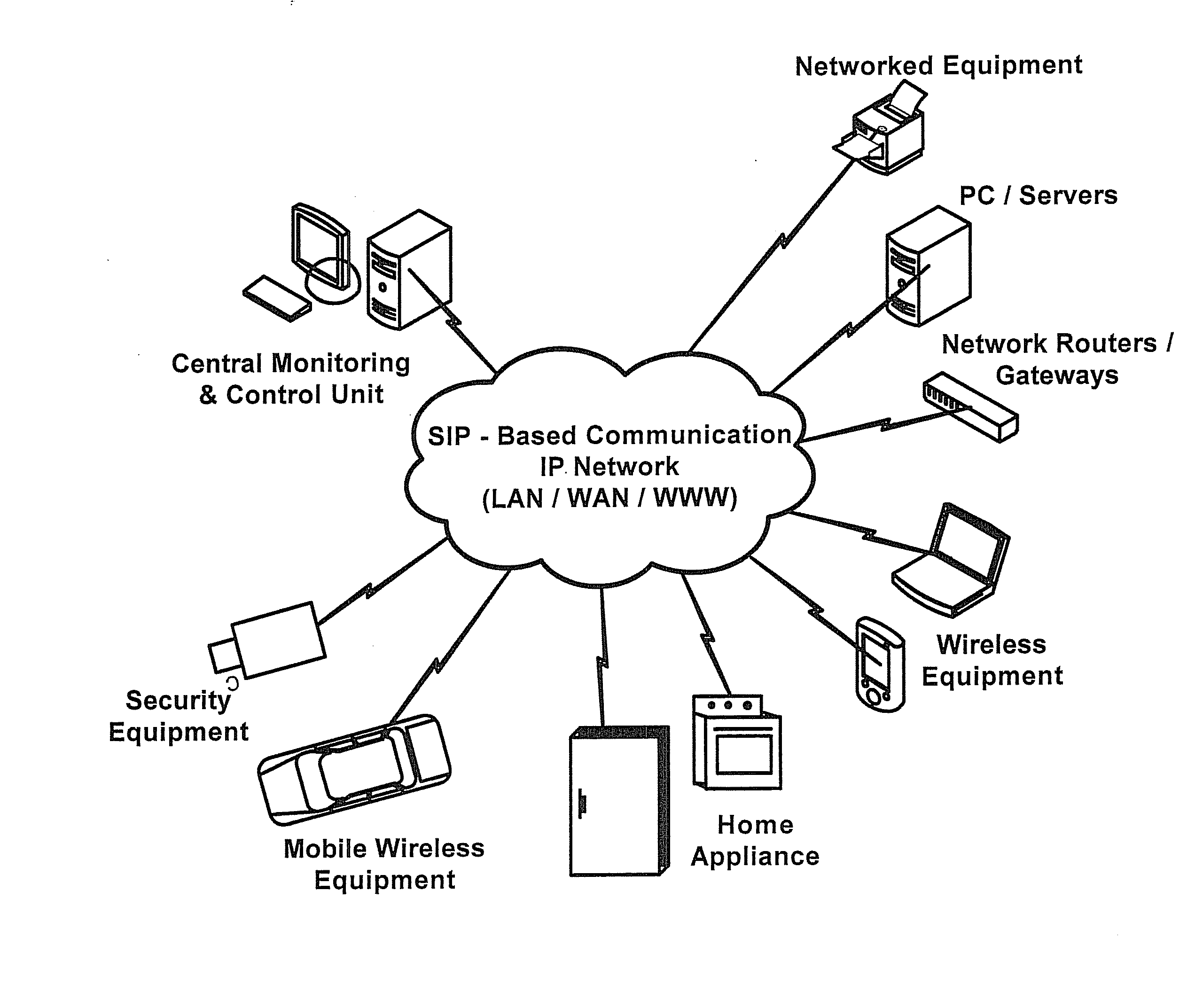

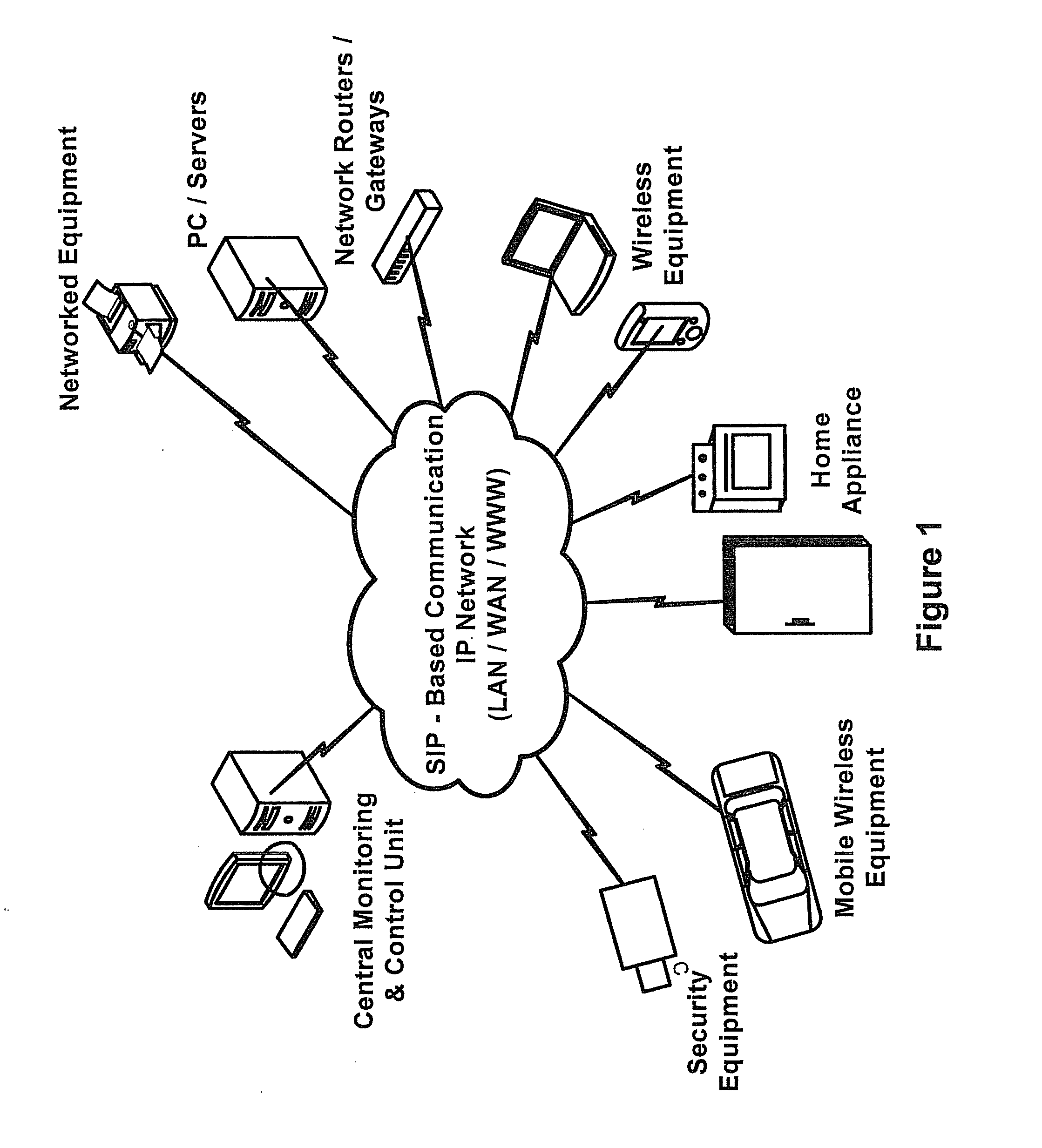

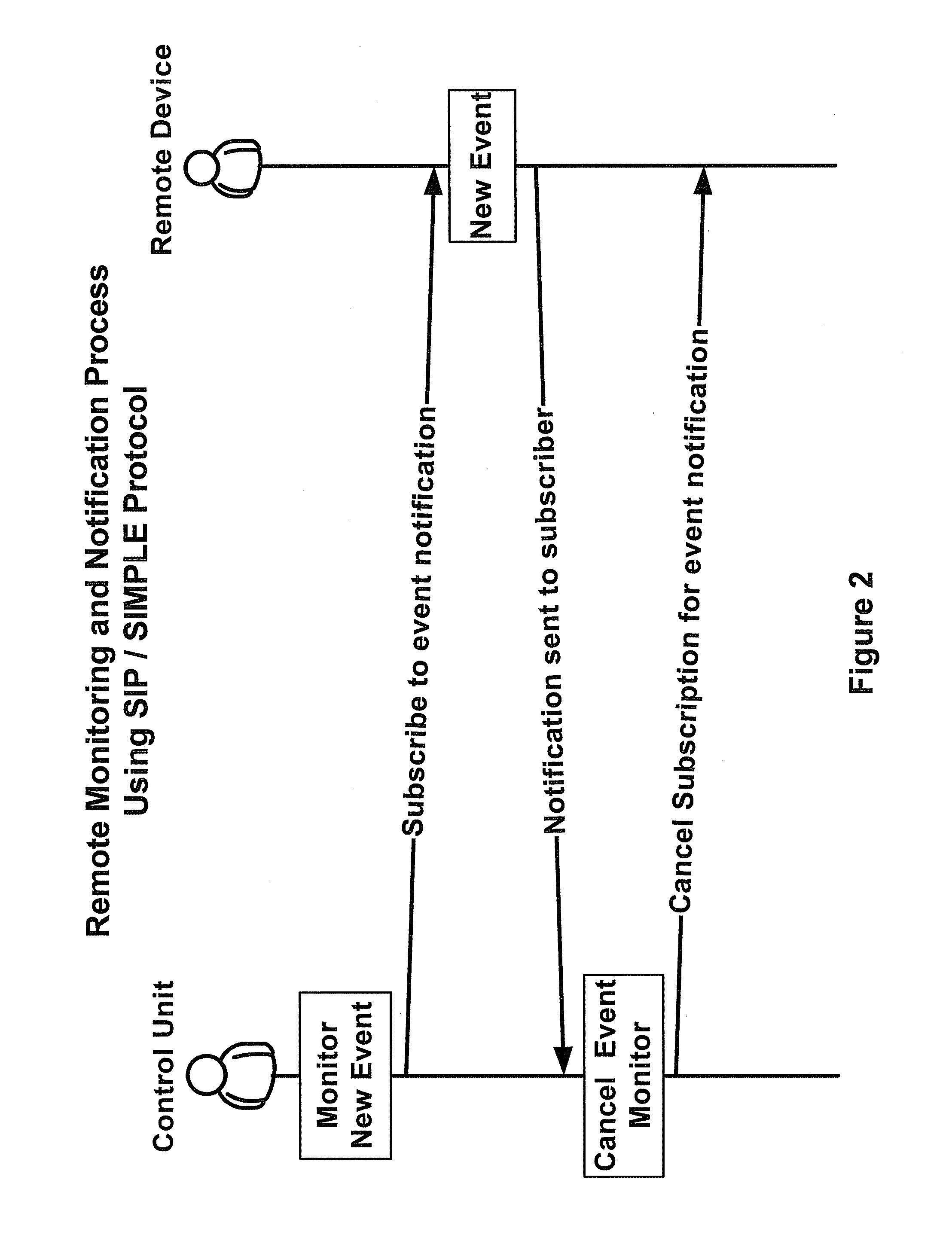

Method and system for controlling and monitoring an apparatus from a remote computer using session initiation protocol (SIP)

InactiveUS20080016157A1Multiple digital computer combinationsTransmissionSession Initiation ProtocolOperational system

A system for using Session Initiation Protocol for network element monitoring can issue network monitoring commands to embedded agents over a number of different network topologies. The embedded agents are SIP aware and can be designed for a number of different platforms allowing thin client systems to perform the required actions to respond to the SIP monitoring request and to create a SIP response. This system can be used to monitor any of a number of networked elements, and their associated peripherals, operating systems, applications, file systems, or hardware components.

Owner:CENTTOUCH TECH

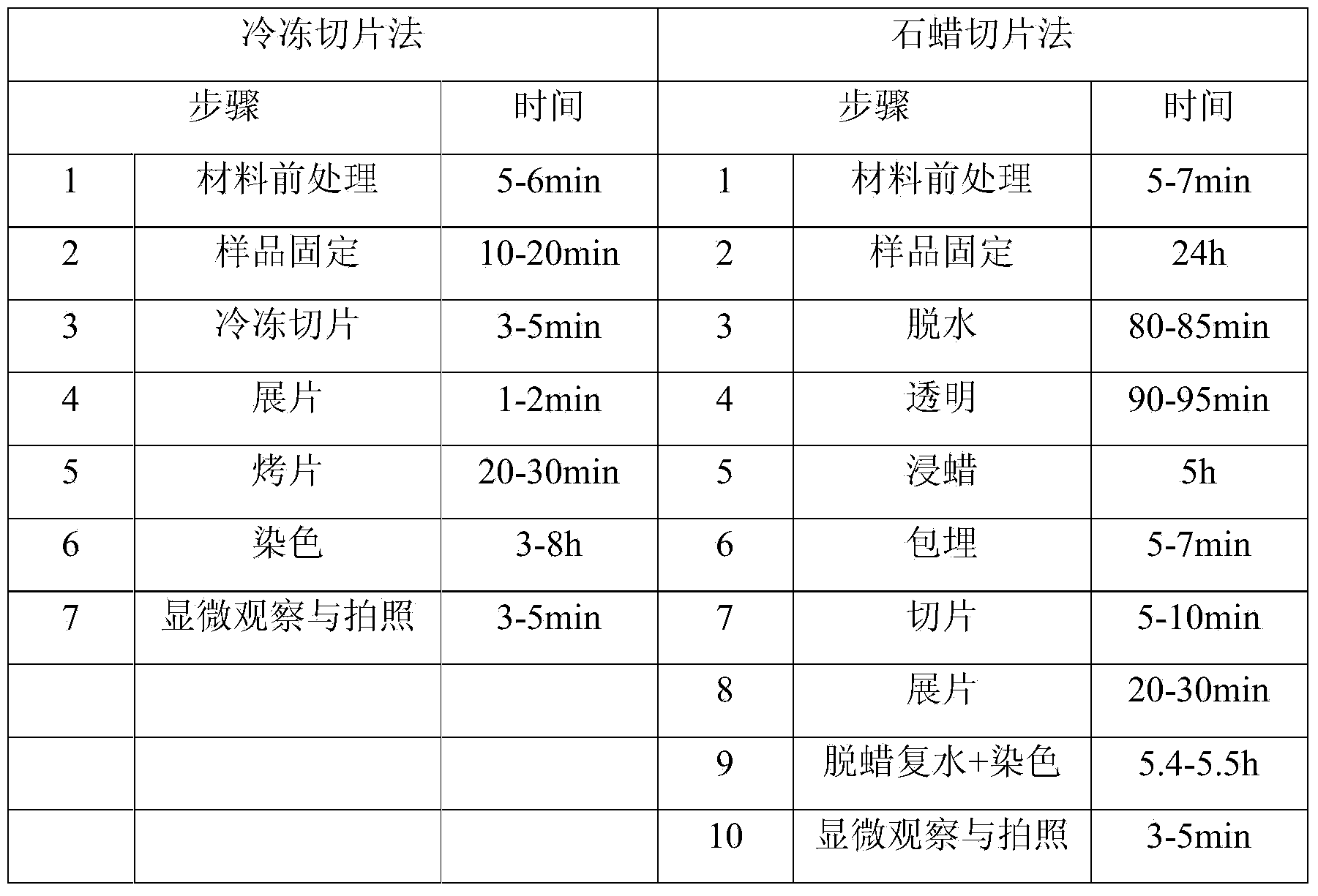

Manufacturing method of coconut blade freezing slice

ActiveCN103776657AComplete structureAvoid deformationWithdrawing sample devicesPreparing sample for investigationMicroscopic observationGermplasm

The invention relates to a manufacturing method of a coconut blade freezing slice. The manufacturing method comprises the following steps of cutting a coconut blade into a sample section, pasting a paper cuboid on a base, vertically placing the blade tissue sample on a sample support, fully wrapping the sample by using a freezing embedding agent, and placing on a sample platform for freezing slicing; and pasting the slices on a glass slide, adding a cover glass through roasting and dyeing, and observing and photographing the slices which are dry under a microscope. The manufacturing method provided by the invention has the advantages that a freezing slicing manner is adopted to rapidly obtain the freezing slice with an integrated structure, the period for manufacturing slices is effectively shortened, the material is not easy to deform, a microscopic observation effect of slices is good, the identification, evaluation and research on a coconut germplasm resource are rapidly developed, the structural observation and classification and identification of the coconut germplasm resource have the important meaning, and the foundation is laid for massively cultivating new coconut varieties in China.

Owner:COCONUT RES INST OF CHINESE ACAD OF TROPICAL AGRI SCI

Sewage treatment composite gel material for microbe embedding, and preparation method thereof

ActiveCN105523643AImprove water swellabilityGuaranteed normal growthWater contaminantsWater/sewage treatment by sorptionCross-linkCarrageenan

The invention relates to a sewage treatment composite gel material for microbe embedding, and a preparation method thereof. The sewage treatment composite gel material for microbe embedding comprises, by weight, 60-80 parts of carrageenan, 5-15 parts of polyacrylamide, 5-8 parts of porous starch, 4-8 parts of microbes, 0.1-0.3 parts of a growth factor, 1-4 parts of inorganic powder, 1-3 parts of a cross-linking agent and 0.5-0.8 parts of a potassium salt. The composite gel material is prepared by adopting carrageenan and the polyacrylamide composite gel as an embedding agent, the porous starch as an adsorbent and a carrier and the inorganic powder as an additive, is used for embedding microbes, is applied to sewage treatment, can effectively adsorb and remove heavy metal ions and degrade organic matters, and has the advantages of simple preparation process, low cost and market application prospect.

Owner:河南格恩阳光环境科技有限公司

Anaerobic ammoxidation sludge embedding immobilization method

ActiveCN103408133AHigh mechanical strengthPromote swellingSludge treatmentTreatment with anaerobic digestion processesActivated carbonSludge

The invention relates to an anaerobic ammoxidation sludge embedding immobilization method belonging to the field of sewage treatment, and particularly provides a method for performing embedding immobilization on anaerobic ammoxidation sludge by adding magnetic powder and powdered activated carbon. The method comprises the following steps: preparing an embedding agent, mixing anaerobic ammoxidation sludge with the embedding agent, preparing immobilized anaerobic ammoxidation balls, activating the immobilized anaerobic ammoxidation balls and the like. The preparation of the embedding agent comprises the following steps: weighing polyvinyl alcohol (PVA), sodium alginate (SA), powdered activated carbon and magnetic powder, and preparing into a solution, wherein on the basis of percentage in mass, the concentration of the PVA is 6-10wt%, the concentration of the SA is 2-3wt%, the concentration of the powdered activated carbon is 1-2wt%, and the concentration of the magnetic powder is 2-4wt%; and uniformly stirring, thus preparing the mixed embedding agent. The method is simple in preparation process, easy to operate and low in preparation cost; and the prepared embedding immobilization anaerobic ammoxidation balls are high in activity, favorable in stability and suitable for industrial production, and can achieve favorable economic and environmental benefits.

Owner:BEIJING UNIV OF TECH

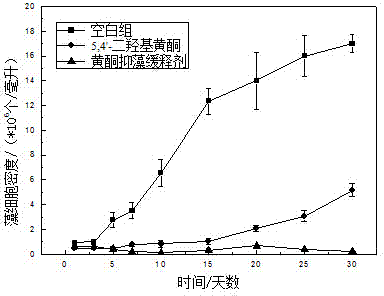

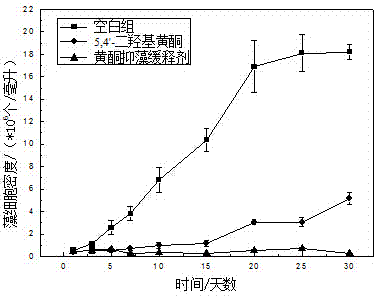

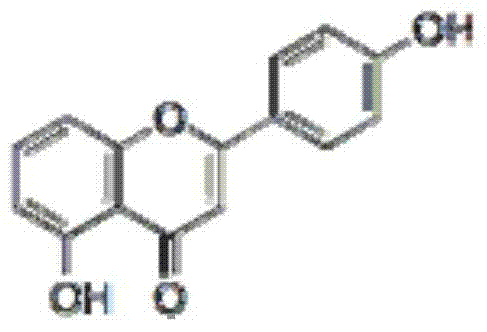

Preparation method of flavone sustained-release algal inhibition preparation

ActiveCN104839158AAvoid side effectsProlong the action timeBiocideAnimal repellantsEcological safetyEntrapment

The invention belongs to the field of water body pollution control, and provides a preparation method of a flavone sustained-release algal inhibition preparation. The flavone sustained-release algal inhibition preparation comprises 30% to 50% of 5,4'-dihydroxylflavone and 50% to 70% of embedding agent such as sodium alginate in percentage by weight, and has an entrapment rate of 50% to 70%. The preparation method of the flavone sustained-release algal inhibition preparation comprises the steps of: mixing a 5,4'-dihydroxylflavone dimethyl sulfoxide solution and a sodium alginate solution and mixing the obtained mixed solution and the mixed solution of chitosan and anhydrous calcium chloride; and then after performing the reaction for a certain time, filtering to obtain a precipitated flavone sustained-release algal inhibition preparation. According to the preparation method, the used materials are high in ecological safety; the prepared flavone sustained-release algal inhibition preparation can obviously inhibit the growth activity of bloom algae, particularly inhibits the growth activity of microcystis aeruginosa, and can control or manage outbreak of algal bloom in lakes. Compared with the prior art, the flavone sustained-release algal inhibition preparation has durable action time, and is particularly suitable for preventing and managing the algal bloom which frequently breaks out.

Owner:ZHEJIANG UNIV

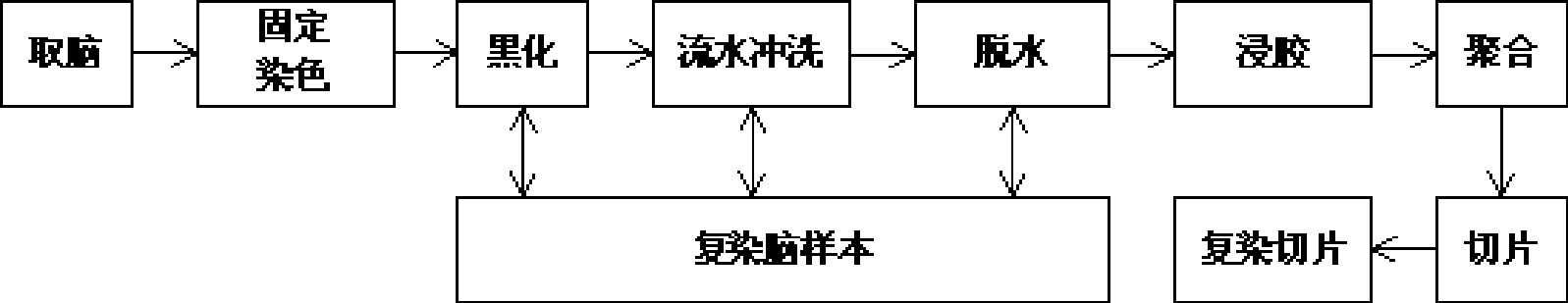

Method for preparing brain tissue frozen section

The invention discloses a method for preparing a brain tissue frozen section, belonging to the fields of biology and medical experiments. The method comprises (1) a step of tissue extraction, immobilization and dehydration, namely a step of subjecting an animal brain tissue to immobilization and gradient dehydration; (2) a step of freezing pretreatment, namely a step of washing the brain tissue with a PBS solution, wiping the brain tissue, leveling the brain tissue, wrapping the brain tissue with tin foil paper, freezing the brain tissue in a rapid freezing zone of a freezing microtome, and then taking the tissue out for subsequent treatment; (3) a step of semi-embedding treatment, namely a step of subjecting the brain tissue to semi-embedded treatment, and allowing the tissue to stand for1 minute; (4) a step of frozen sectioning, namely a step of fixing a sample holder to a probe of the microtome, and performing continuous coronal frozen sectioning; and (5) a step of section collection, namely a step of collecting sections of desired positions into a six-pore plate containing a frozen preserving fluid, and storing the sections at -20 DEG C for long time. Semi-embedding treatmentis adopted to treat the brain tissue, and therefore, influences of an embedding agent on the brain tissue are avoided, and sections are complete and free of ice crystals, and have good immunofluorescent staining properties.

Owner:SHANDONG UNIV OF TRADITIONAL CHINESE MEDICINE

An additive cigarette production technology

InactiveCN1543884AImprove stabilityNo effect on tasteTobacco treatmentCigar manufactureNitrosoNitroso Compounds

The invention relates to an addition agent for lowering the content of N-nitroso compound in cigarette and the cigarette production process, wherein the addition agent is a plant polyphenol microcapsule with plant polyphenol as the core, and alpha-cyclodextrin or beta-cyclodextrin or hydroxypropyl beta-cyclodextrin is used as molecular embedding agent for charging plant polyphenol microcapsule into the molecular embedding agent, forming stabilized colloid, by dissolving the colloidal solution and adding into the shredded tobacco, the content of N-nitroso compound in cigarette can be substantially reduced.

Owner:李波

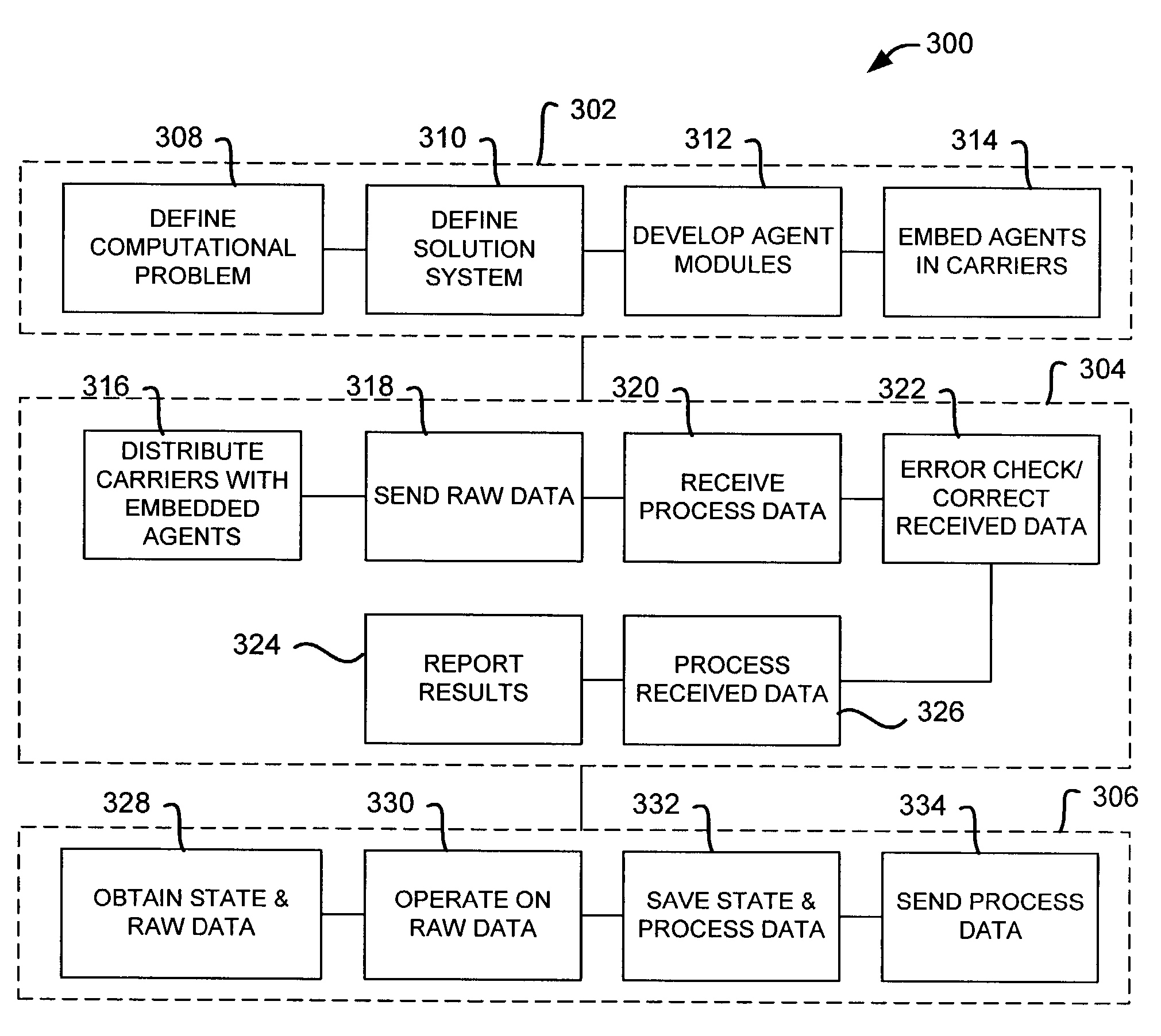

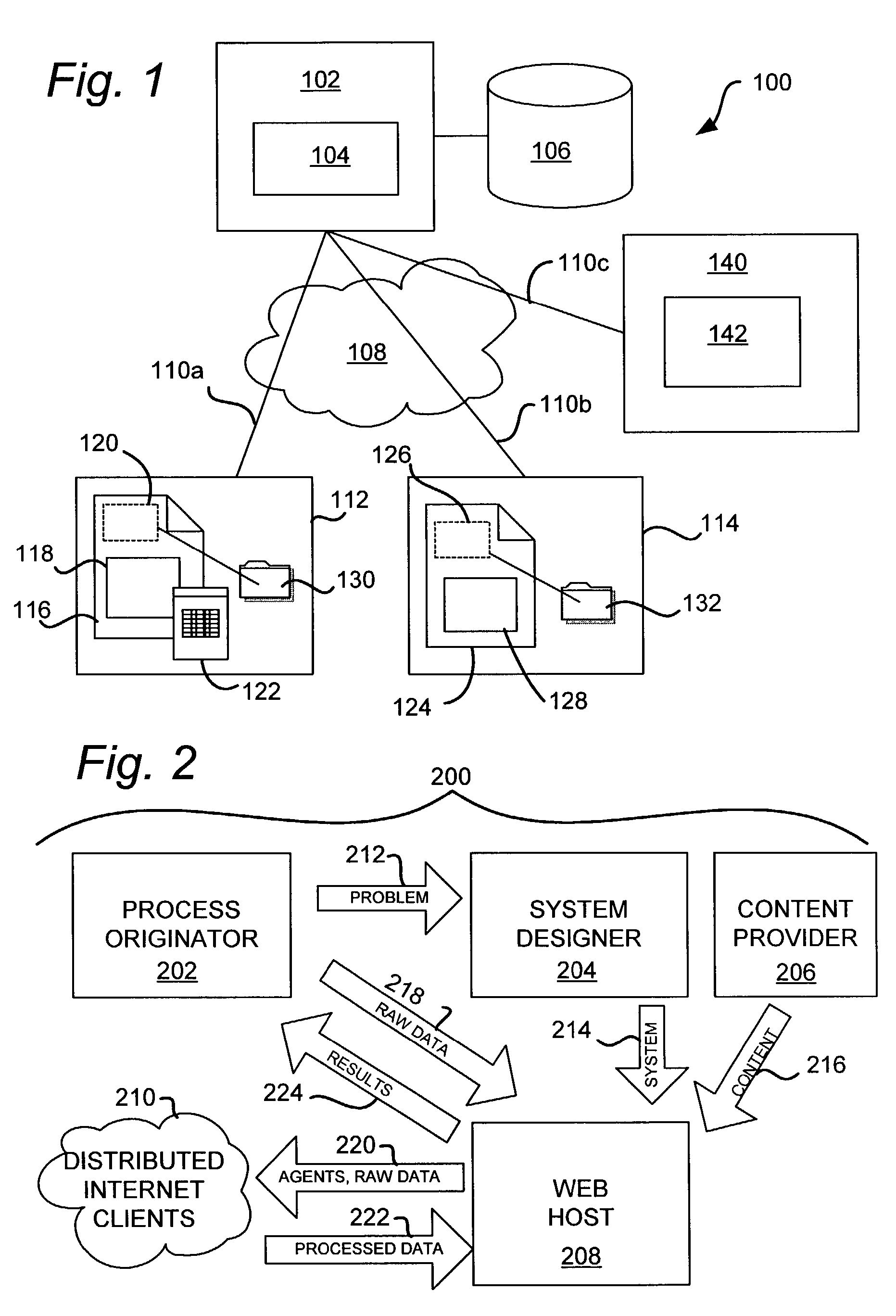

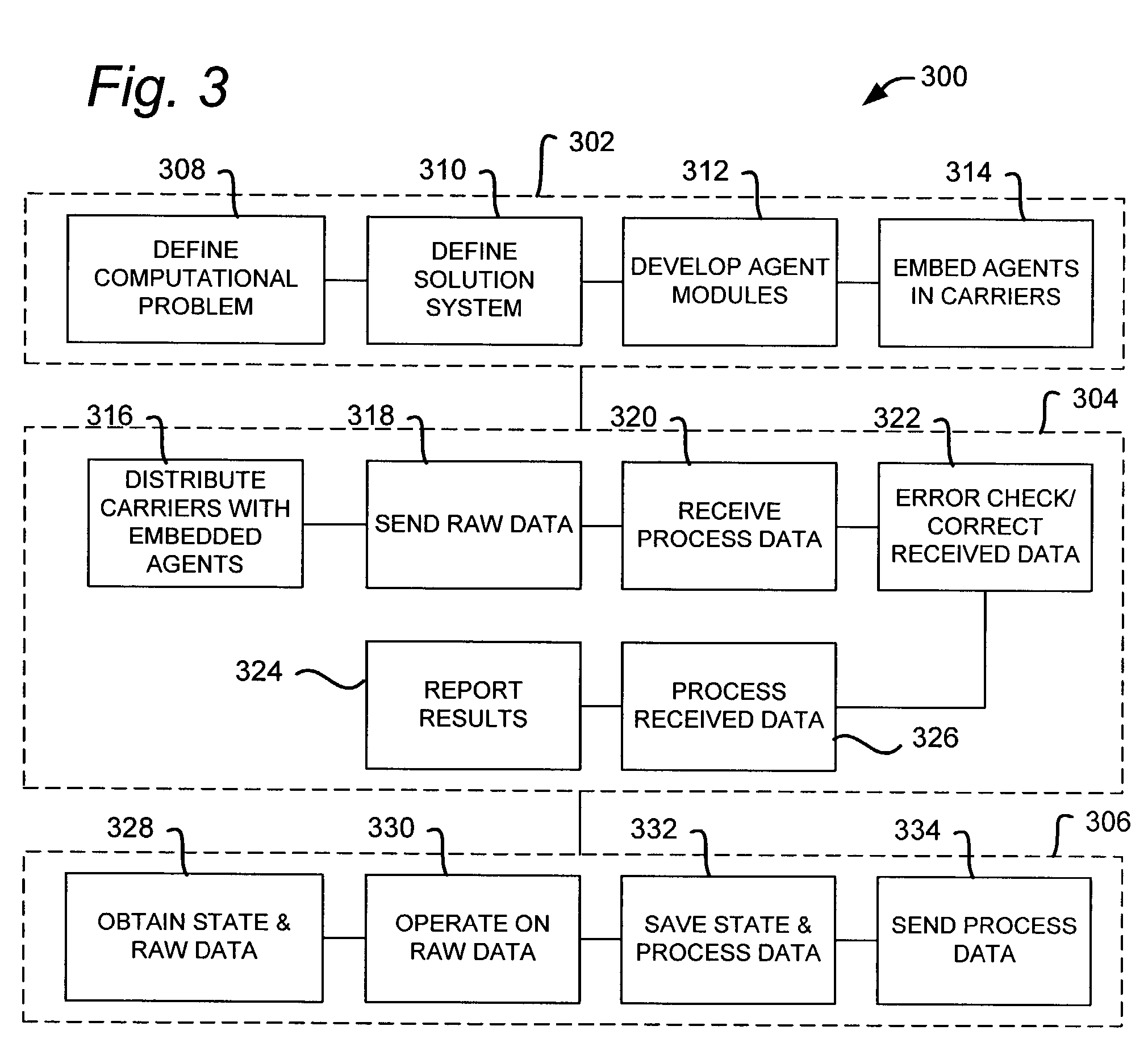

Distributed computing using agent embedded in content unrelated to agent's processing function

ActiveUS7801944B2Resource allocationMultiple digital computer combinationsOriginal dataApplication software

A method for operating a host layer of a distributed computing system on a wide area network includes attaching an autonomous agent to a client-requested carrier, such as web content. The method includes the steps of receiving a request for specified content from a client node via the wide area network, and sending the content and an embedded agent to the client via the wide area network. The agent has program instructions configured to execute autonomously on the client node to perform a processing function. The processing function is configured to operate on raw data to produce process data, according to instructions determined by a solution algorithm of the distributed computing system. The method further includes sending the raw data to the client node and receiving the process data from the client node as it is processed by the agent. The host layer may comprise a web server hosting a web site containing consumer-oriented web pages, and the carrier may comprise an HTML page containing user content. The agent may comprise a web page-enabled application embedded in the HTML page, such as a Java™ applet.

Owner:INTELLECTUAL VENTURES I LLC

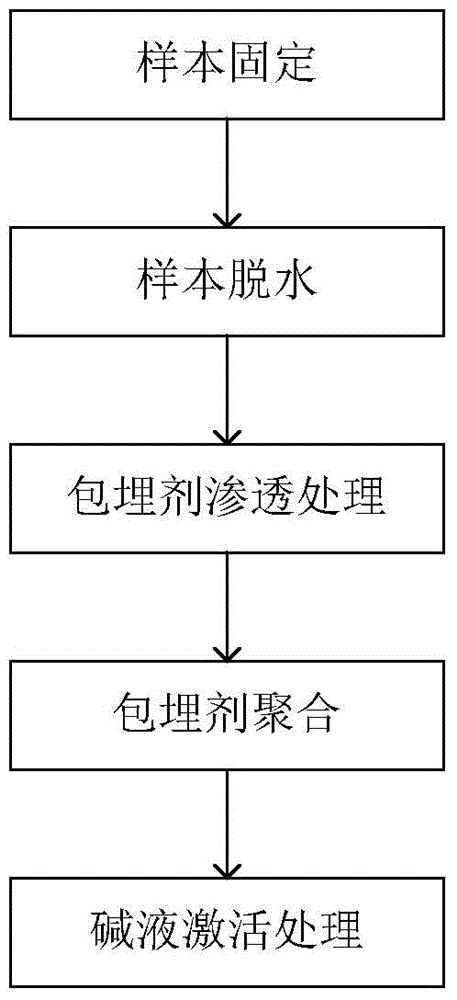

Resin embedding method for biological tissues marked by fluorescent protein and application of alkaline solution

InactiveCN105021431AHigh fluorescence intensityQuality improvementPreparing sample for investigationPermeationFluorescent protein

The invention discloses a resin embedding method for biological tissues marked by fluorescent protein. The resin embedding method comprises the following steps: (1), fixing the biological tissues marked by the fluorescent protein in a chemical fixing manner to obtain the fixed biological tissues marked by the fluorescent protein; (2), replacing the fixed biological tissues marked by the fluorescent protein with an organic solvent, so that the biologic tissues are dewatered to obtain dewatered biological tissues marked by the fluorescent protein; (3), performing embedding agent permeation treatment on the dewatered biological tissues marked by the fluorescent protein to obtain embedding-agent monomer-filled biological tissues marked by the fluorescent protein; (4), enabling the embedding agent to generate a polymerization reaction to obtain a resin-embedding sample of the biological tissues marked by the fluorescent protein; (5), soaking the resin-embedding sample in an alkaline solution, and adjusting the pH value to be 8-12. The resin embedding method for the biological tissues marked by the fluorescent protein can be suitable for biologic tissue samples of various sizes, the fluorescence intensity is high, the imaging effect is good, and the samples have excellent cutting performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Embedding medium suitable for plant tissue frozen section and frozen section method

InactiveCN102816401AOvercome the problem that it is easily soluble in fixative and cannot be fixed first and then slicedSlice flatDead plant preservationPreparing sample for investigationBiotechnologyCellulose

Owner:HUNAN UNIV OF SCI & TECH

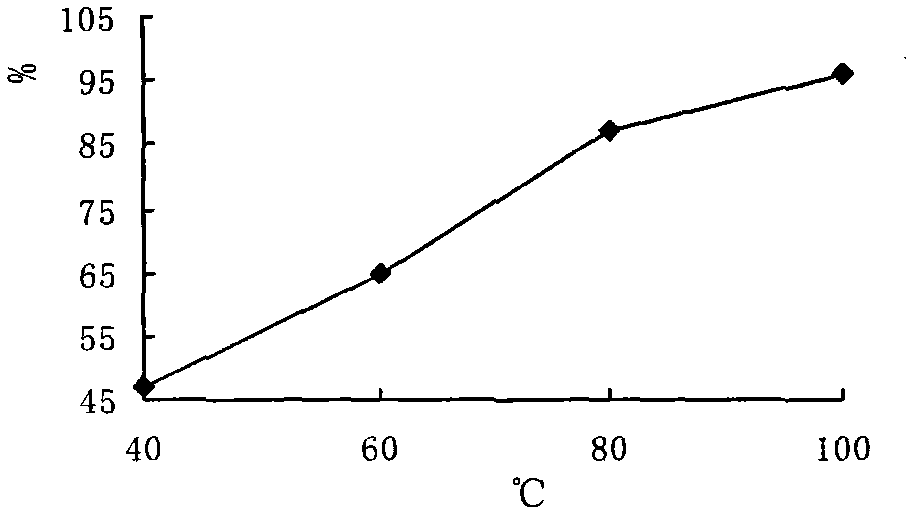

Embedding method of buckwheat flavonoids

The invention discloses an embedding method of buckwheat flavonoids. The embedding method comprises the following steps of: crushing tartary buckwheat seeds; digesting and purifying to obtain buckwheat flavonoids; preparing a mixed solution through buckwheat flavonoids, an emulsifying agent and an embedding agent; performing oscillating, mixing and embedding reaction; uniformly mixing; leaching through filter paper; and drying the filter paper after leaching to obtain a buckwheat flavonoids inclusion, wherein the embedding agent comprises one of or both beta-cyclodextrin and maltodextrin. According to the embedding method of the buckwheat flavonoids, the buckwheat flavonoids in the prepared embedding compound are high in embedding rate, reaching 53.41 to 91.42%. According to the evaluation on indicator quality of a buckwheat flavonoids microcapsule product prepared by the embedding method, the dissolvability is more than 90%, the product is greyish white and contains a little yellow powder, and the microcapsule has the size of about 5 to 25mu g.

Owner:NORTHWEST UNIV(CN)

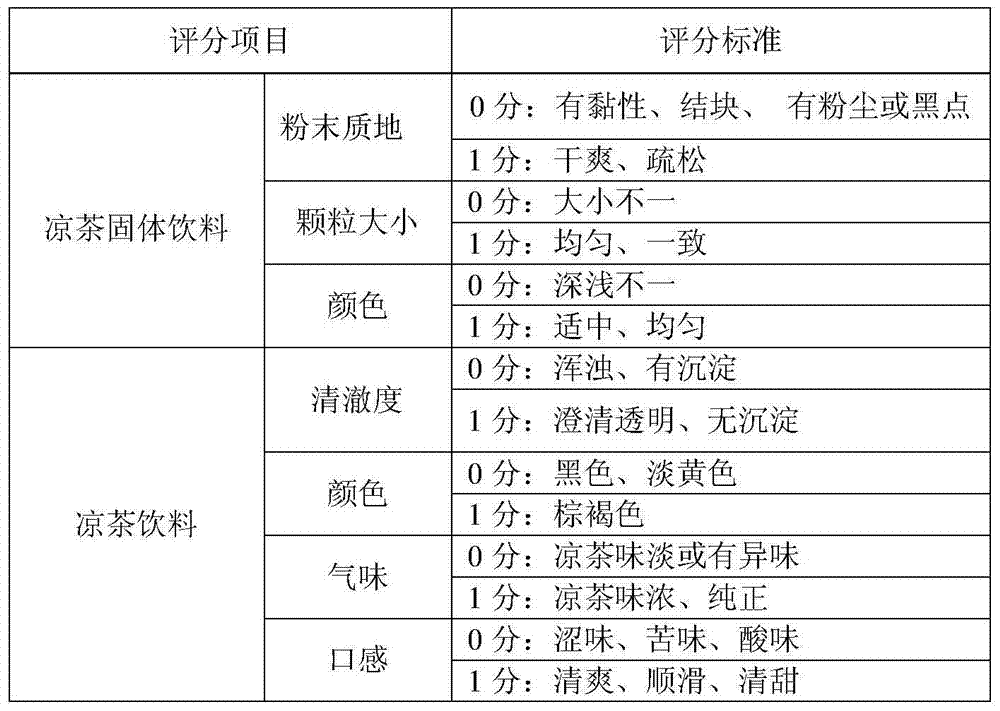

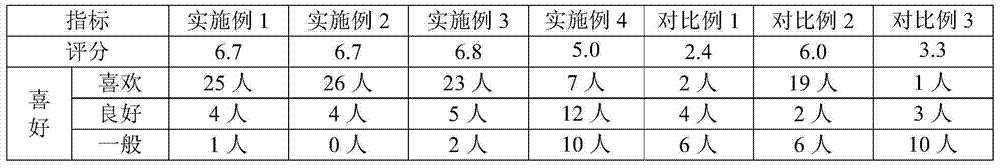

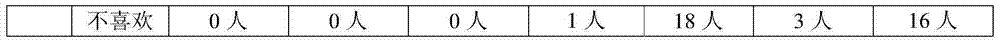

Herbal tea solid beverage and preparation method thereof

The invention discloses a herbal tea solid beverage. The herbal tea solid beverage is mainly prepared from the following raw auxiliaries: mesona chinensis, plumeria rubra, microcos paniculata, chrysanthemum, honeysuckle flower, selfheal, licorice roots, a polysaccharide embedding agent and a sweetening agent. The herbal tea solid beverage is reasonable in formula, has a good taste, and has the effects of clearing away heat and detoxifying, and preventing heat. The invention also discloses a preparation method of the herbal tea solid beverage; the method is simple and reasonable in procedure, and effective components and flavor substances of the herbal tea are maintained to the maximum limit.

Owner:GUANGZHOU WANGLAOJI MAJOR HEALTH IND

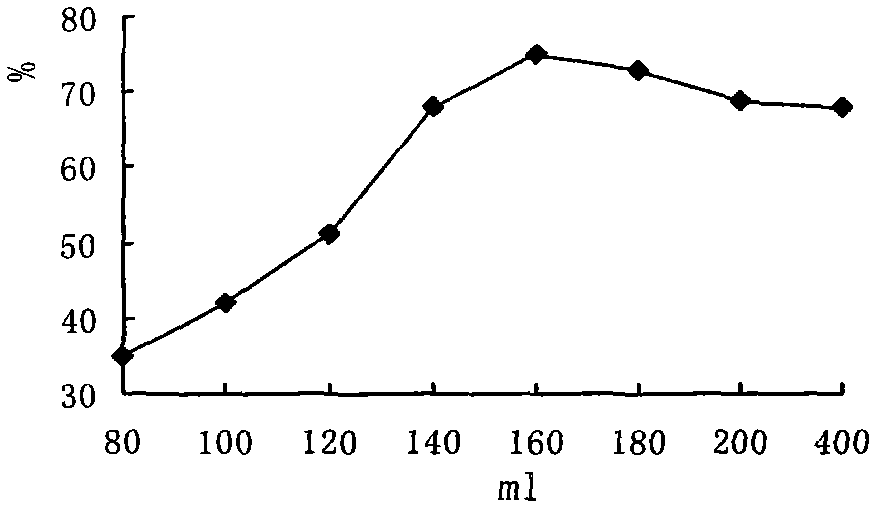

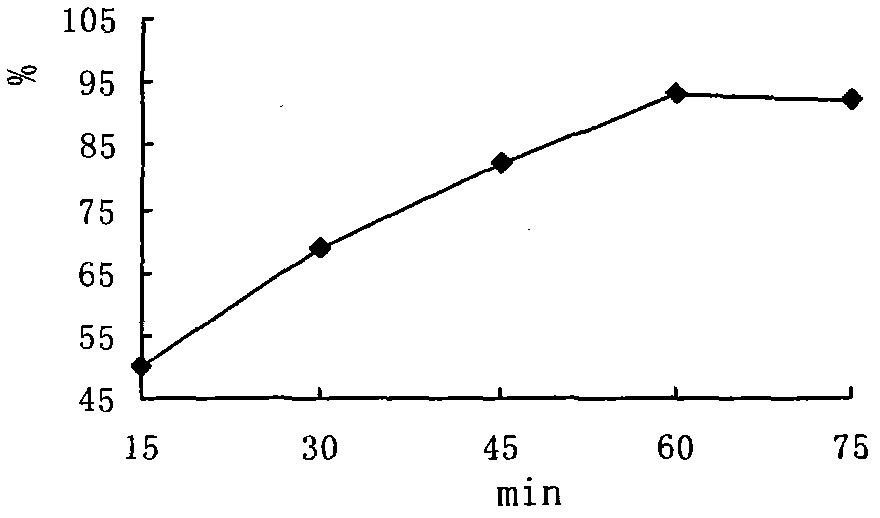

Method for producing brain sample of small animal

InactiveCN101458182AIncrease contrastNot easy to fadePreparing sample for investigationEducational modelsSmall animalStaining

The invention discloses a method for preparing a whole brain specimen of a baby animal. The steps are as follows: a. a baby animal brain sample is fixed and imbued; b. the fixed and imbued brain sample is blackened by using blackening liquor that is alkali liquor with the pH value being more than 10, and the blackening period is 1-24 hours; c. the obtained brain sample is dehydrated, and the dehydration is carried out by 100% dehydrating agent in weight; d. the blackened brain sample is gummed by using an embedding agent, and two continuous gumming are carried out by 100% embedding agent in weight; e. after being gummed by the embedding agent, the brain sample is put into an embedding box and then submerged by adding the 100% embedding agent in weight; f. the embedding box for submerging the brain sample is heated, so that the embedding agent is polymerized, the polymerization temperature is 35 to 80 DEG C, and the polymerization period is 6-96 hours. The method for preparing the baby animal brain specimen of the invention can dye more neurons as well as neuron cell bodies, dendrite and axon; the contrast is high; the color is not faded easily; and whole brain neuron three dimensional morphology structures can be observed in the sub-micro scale.

Owner:HUAZHONG UNIV OF SCI & TECH

Bitter free gingko leaf product and its preparation process

InactiveCN1593582AFull retention of functional ingredientsFully retain nutrientsPowder deliveryUnknown materialsOrganic solventAntioxidant

The invention discloses a bitter free gingko leaf product and its preparation process, wherein the product comprises ginkgo leaf extract 100 parts, macromolecular embedding agent 100-1000 parts, anti-oxidizing agent 10-50 parts, flavoring agent and other findings

Owner:夏建伟

Production technology of high-calcium tartary buckwheat flavone instant beverage

The invention discloses a production technology of a high-calcium tartary buckwheat flavone instant beverage. The production technology is a novel tartary buckwheat deep-processing method. The production technology comprises 1, extracting an optimal tartary buckwheat flavone water-extraction blended agent at a ratio of tartary buckwheat to water of 1: 8 at a temperature of 100 DEG C for 60min, 2, drying the extract at a temperature of 125 DEG C in an oven to obtain tartary buckwheat flavone powder having flavone content of 11.18%, wherein optimal spray drying conditions of the optimal tartary buckwheat flavone water-extraction blended agent comprise that the content of an embedding agent in a flavone extracting solution is 10%; a feeding concentration is 30%; an inlet temperature is 125 DEG C; and an outlet temperature is 80 DEG C, and 3, adding an appropriate amount of active biological calcium powder into the tartary buckwheat flavone powder to obtain high-calcium tartary buckwheat flavone powder, adding 0.35g of xanthan gum, 0.15g of beta-CD and 0.45g of CMCNa into each 6g of the high-calcium tartary buckwheat flavone powder to obtain the high-calcium tartary buckwheat flavone instant beverage in a solid state, wherein the optimal brewing state of the high-calcium tartary buckwheat flavone instant beverage is a suspension state. The brewing conditions comprise that 7g of the high-calcium tartary buckwheat flavone instant beverage is added into 250 to 300ml of water having a temperature of 80 to 90 DEG C so that an optimal taste is obtained. The high-calcium tartary buckwheat flavone instant beverage contains tartary buckwheat flavone having effects of reducing blood sugar, blood pressure and blood fat, and adopts high-calcium dried small shrimp powder rich in proteins so that calcium is reinforced.

Owner:HEBEI AGRICULTURAL UNIV. +1

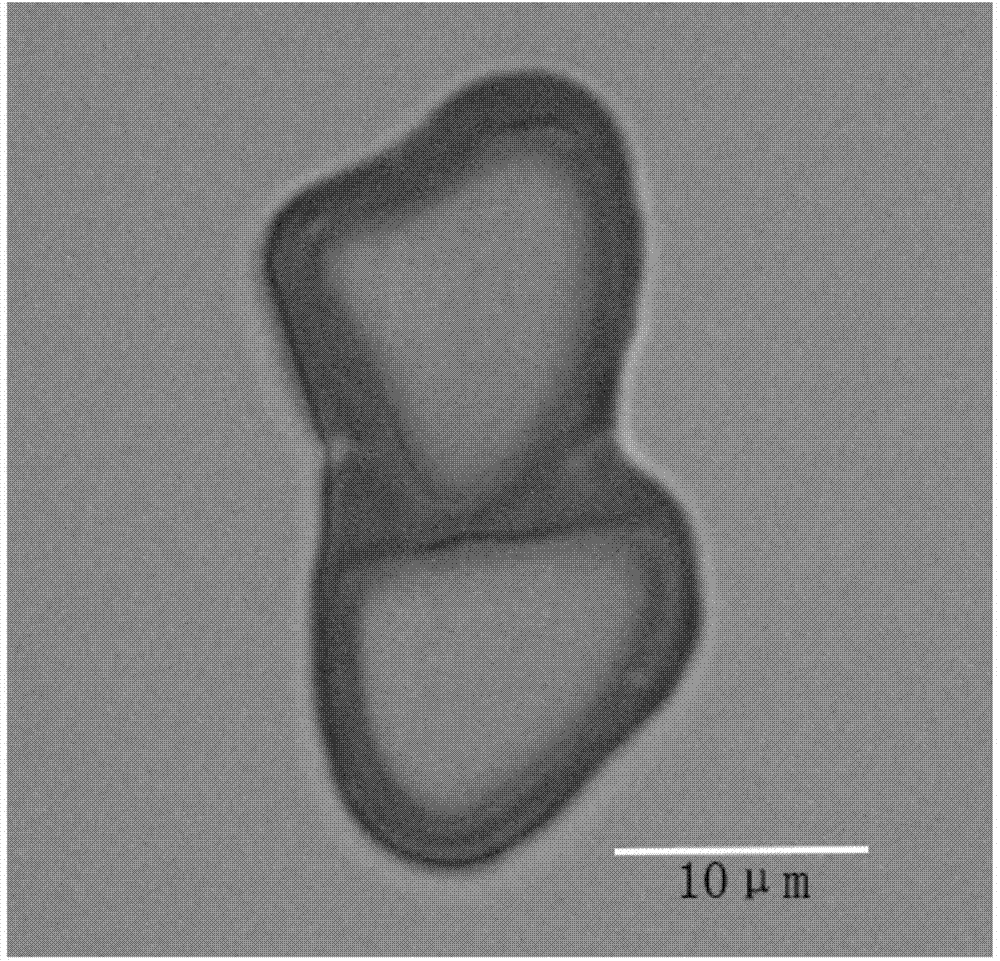

Method of accurately measuring cross section area of single silk and application thereof

InactiveCN104330056AAvoid errorsEasy to handlePreparing sample for investigationMaterial strength using tensile/compressive forcesImaging processingData acquisition

The invention discloses a method of accurately measuring the cross section area of single silk and an application of the method in mechanical property testing. The method specifically includes: preparing a die, fixing a dyed silk on the die, making the silk to be parallel to one side of the die, and vertically fixing the die through embedding agents; conducting sample slicing and producing; collecting the image of the cross section of the silk; conducting data collection through image processing software, and obtaining the cross section area of the silk through formula computing. By adopting the method, image collection can be conducted by aid of optical microscopes used in normal laboratories, measuring of the cross section area of the silk can be finished in the normal laboratories without electron microscopes or other high-quality precision equipment, and therefore experiment operations are facilitated and experiment cost is saved; image processing is conducted through normal image processing software, people not versed in image processing and relevant computer knowledge can process the experiment results conveniently, and the experiment result obtaining period can be shortened.

Owner:SOUTHWEST UNIV

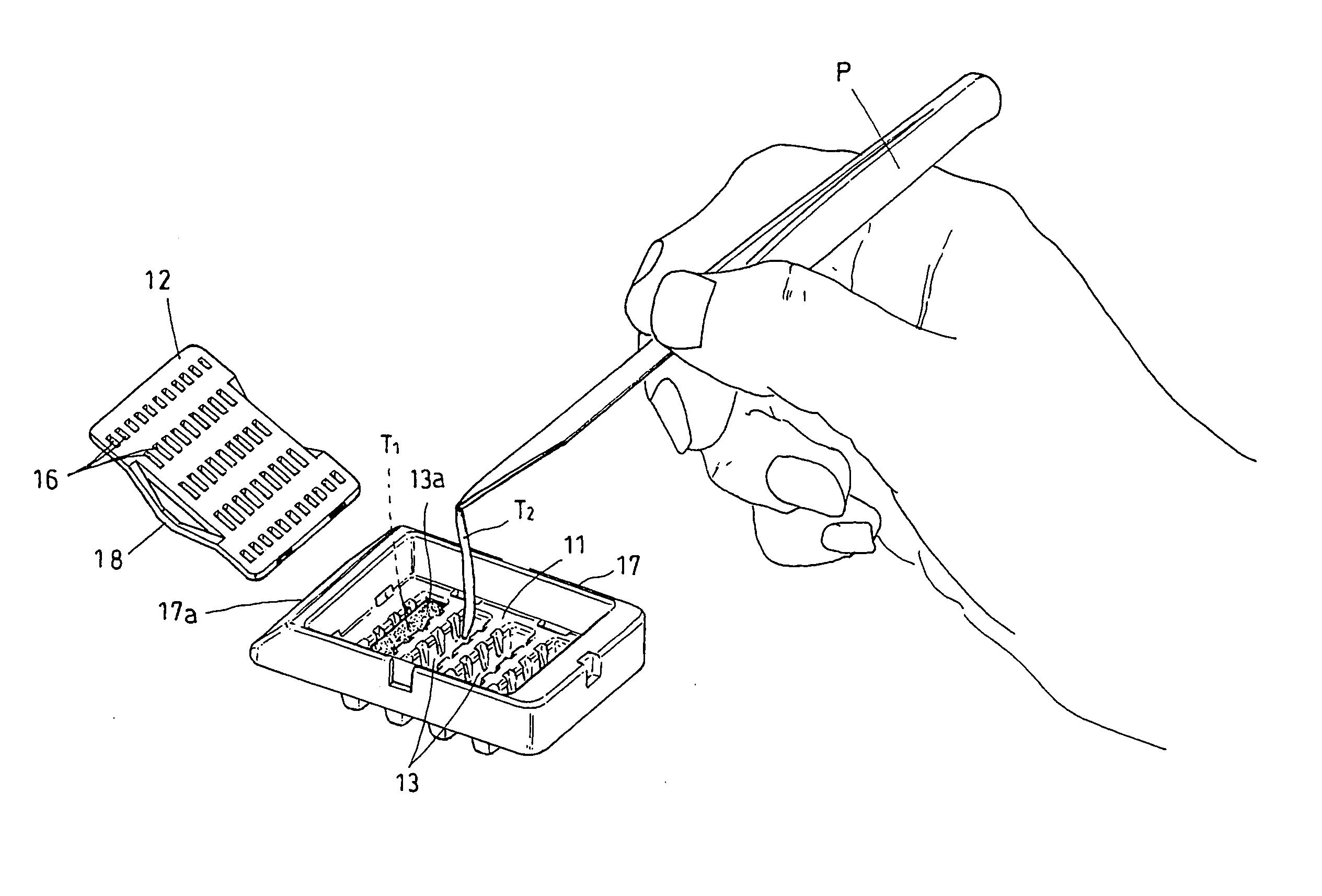

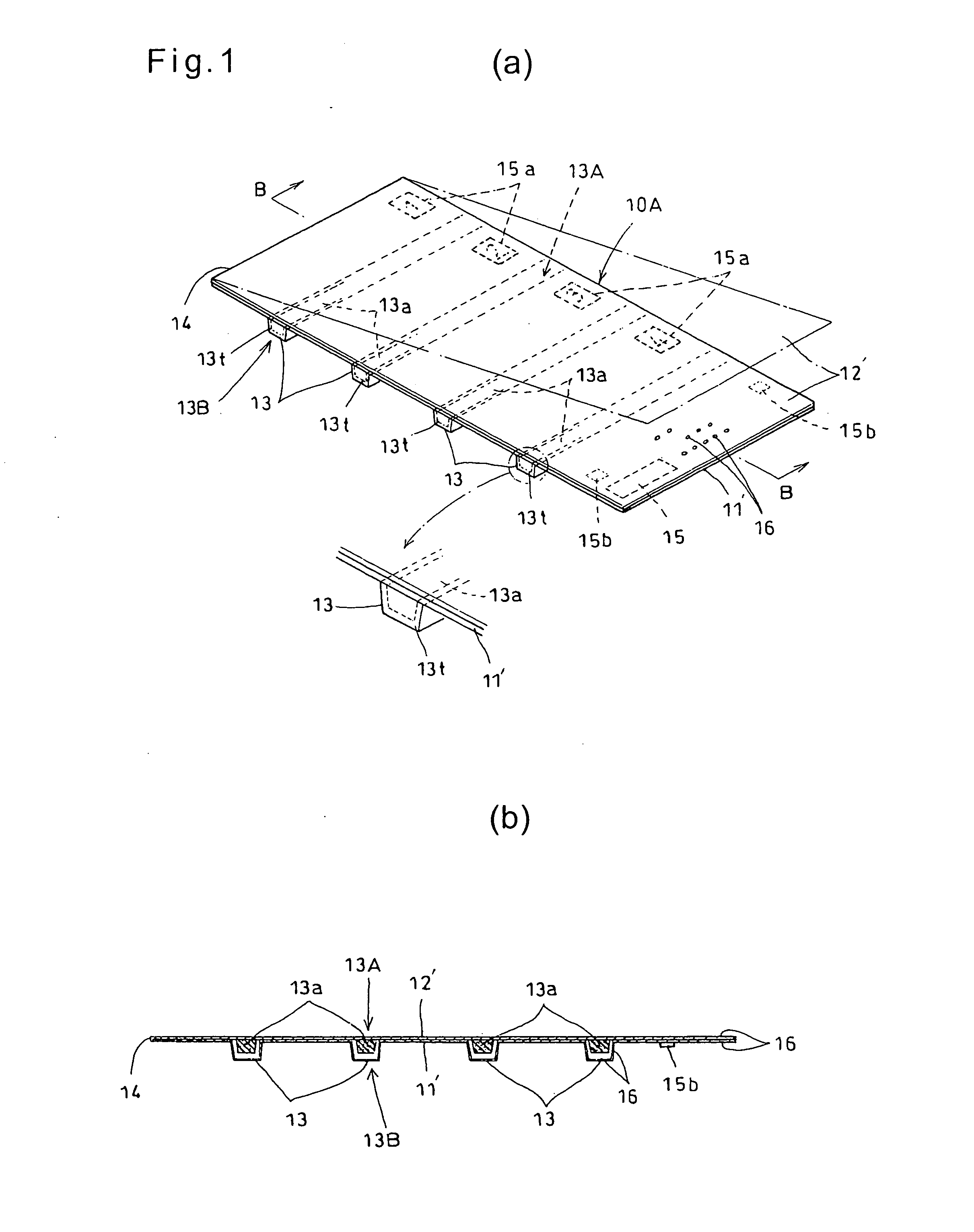

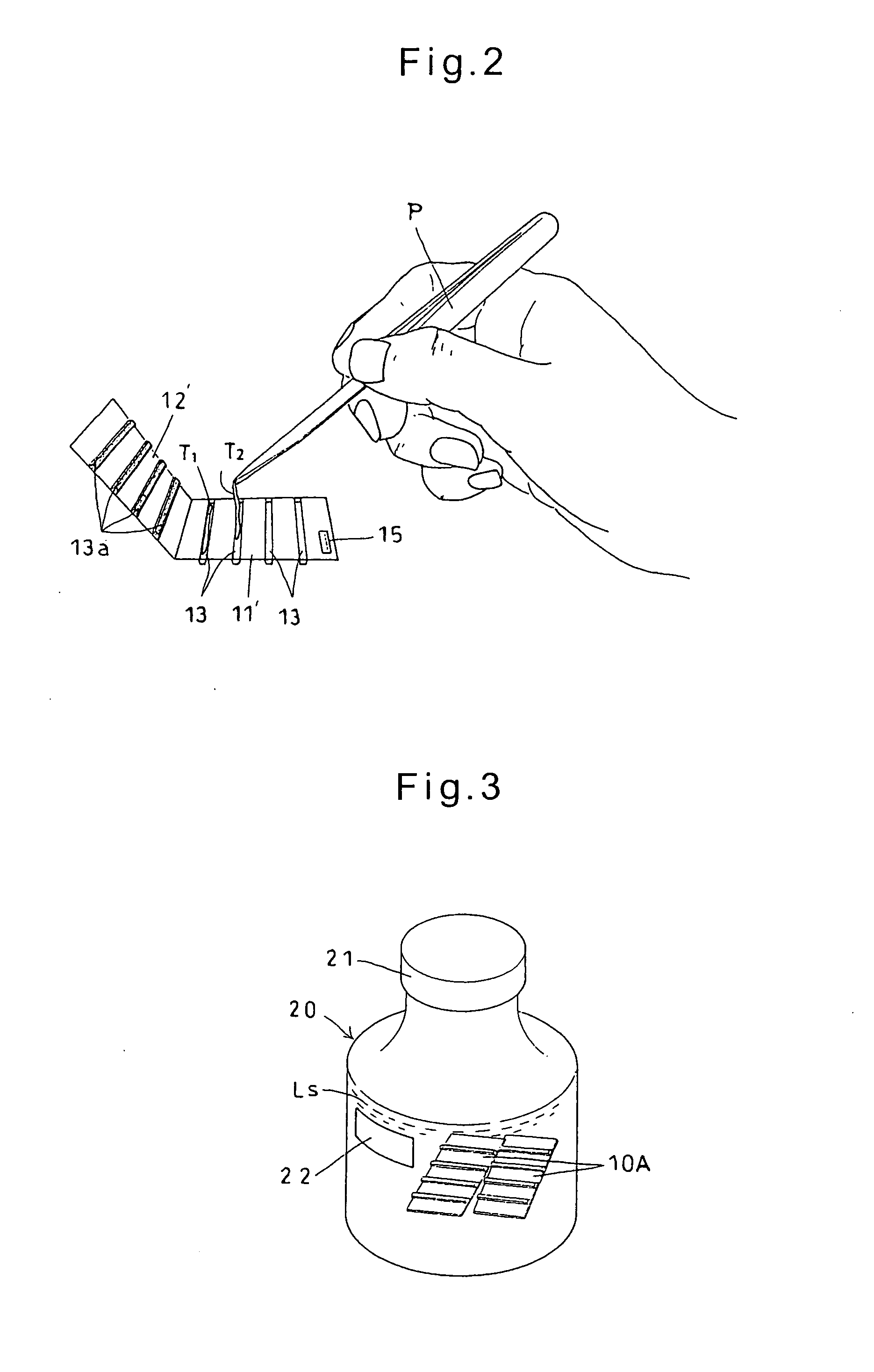

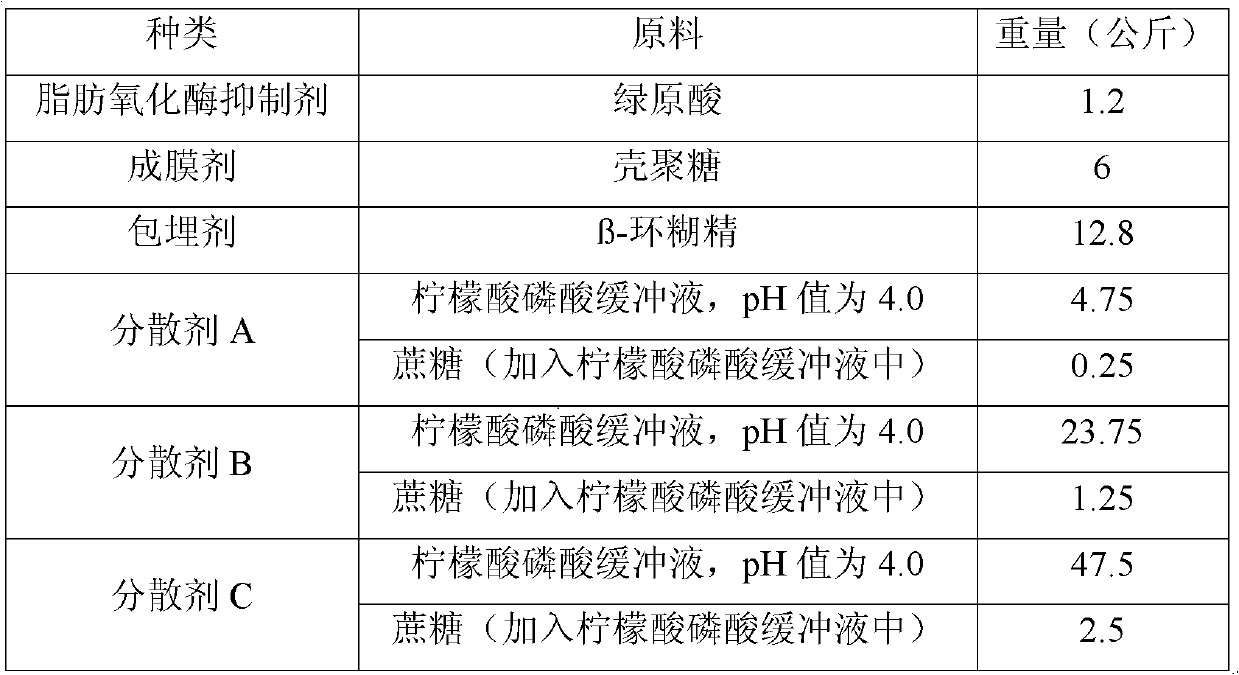

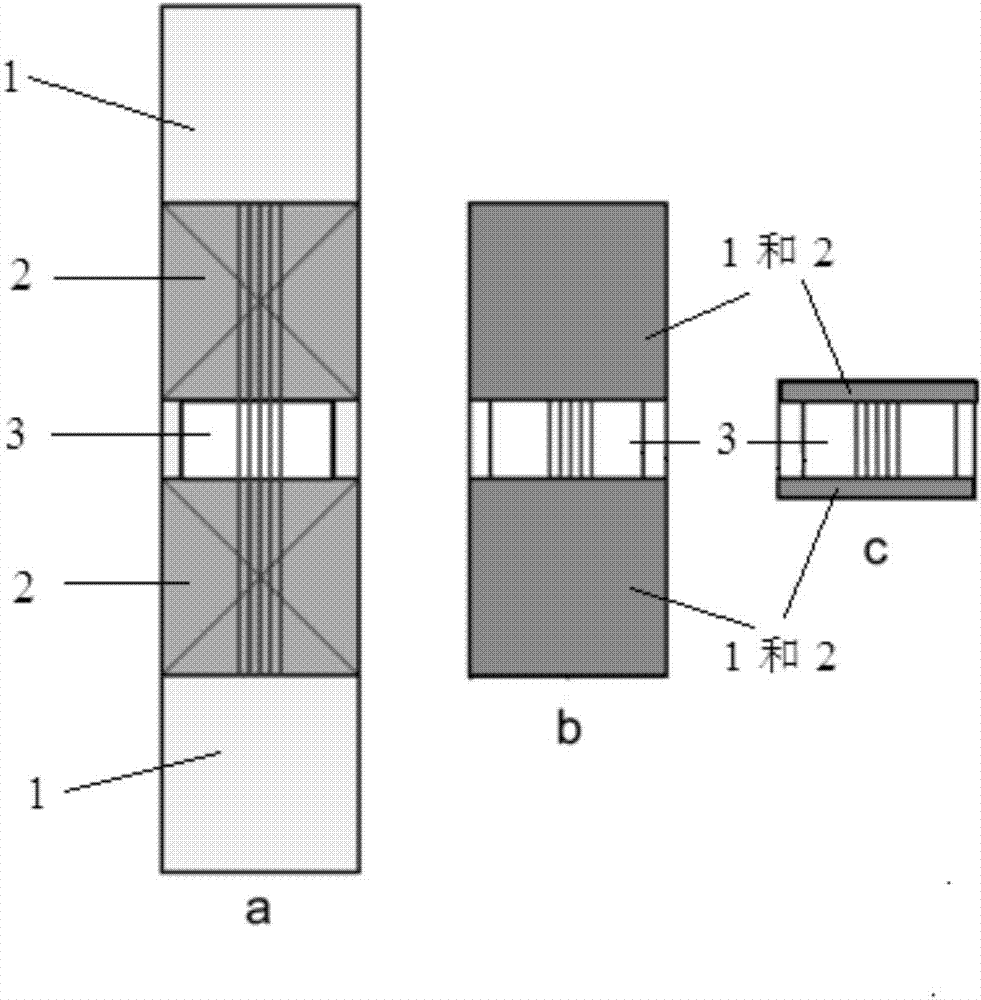

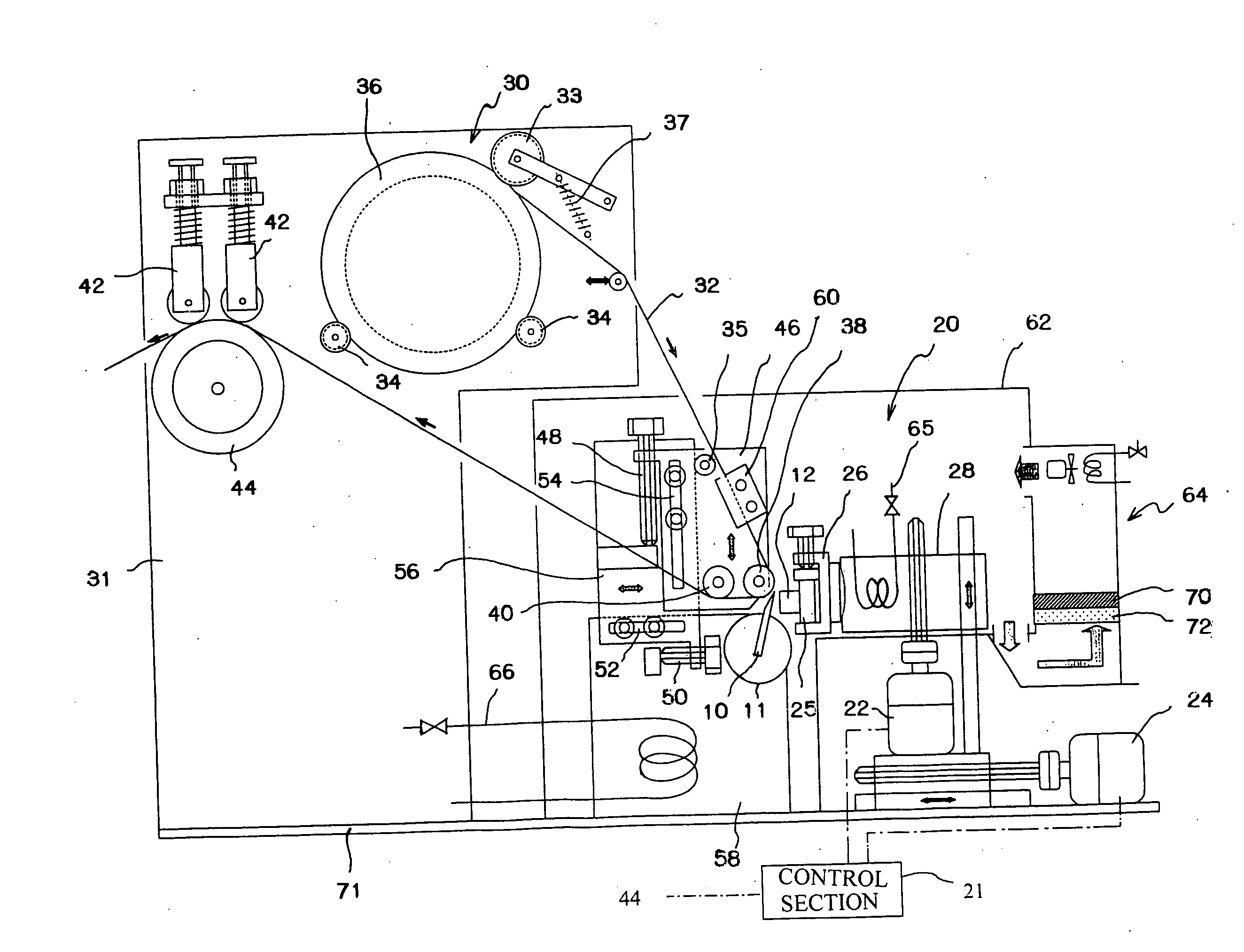

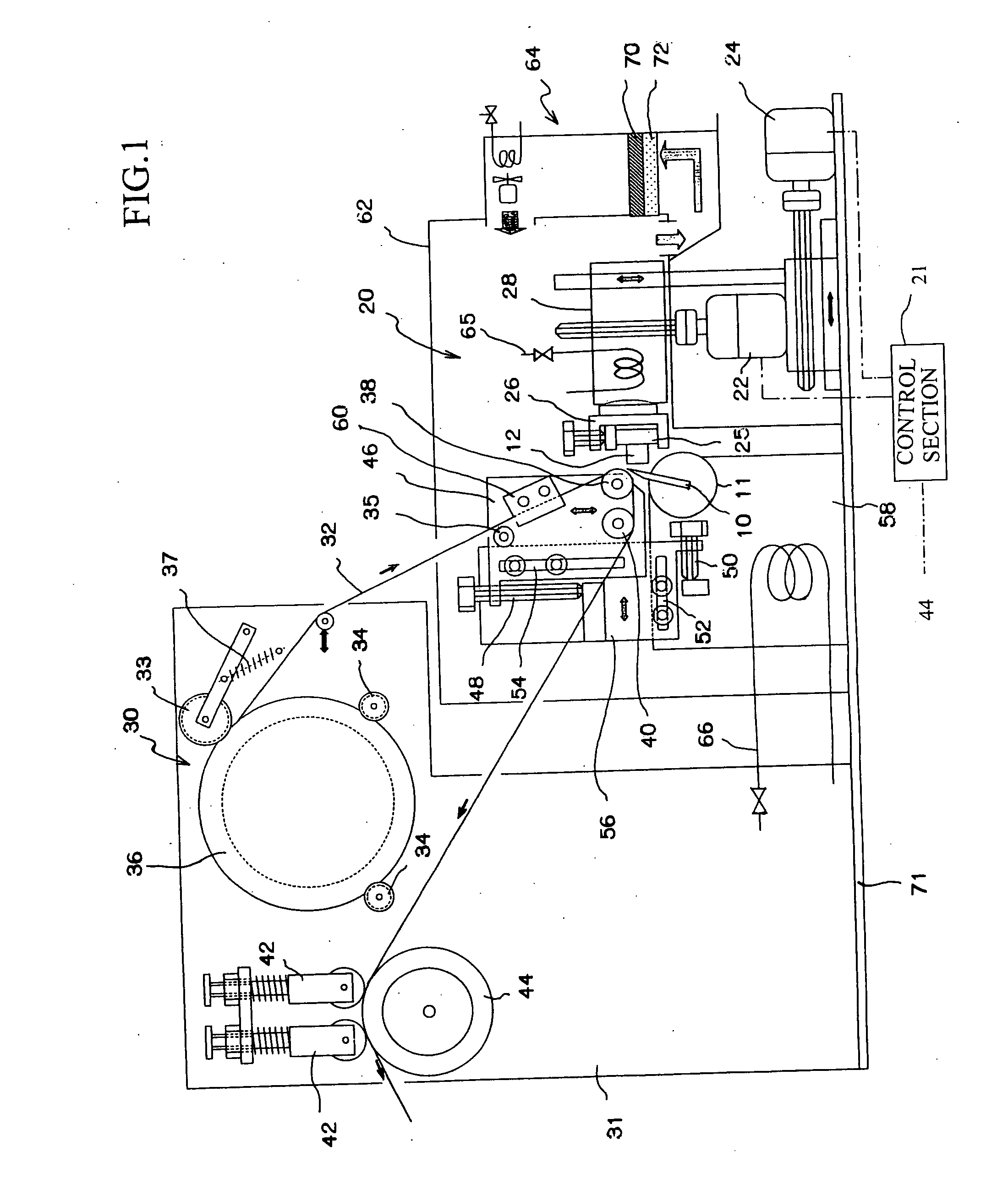

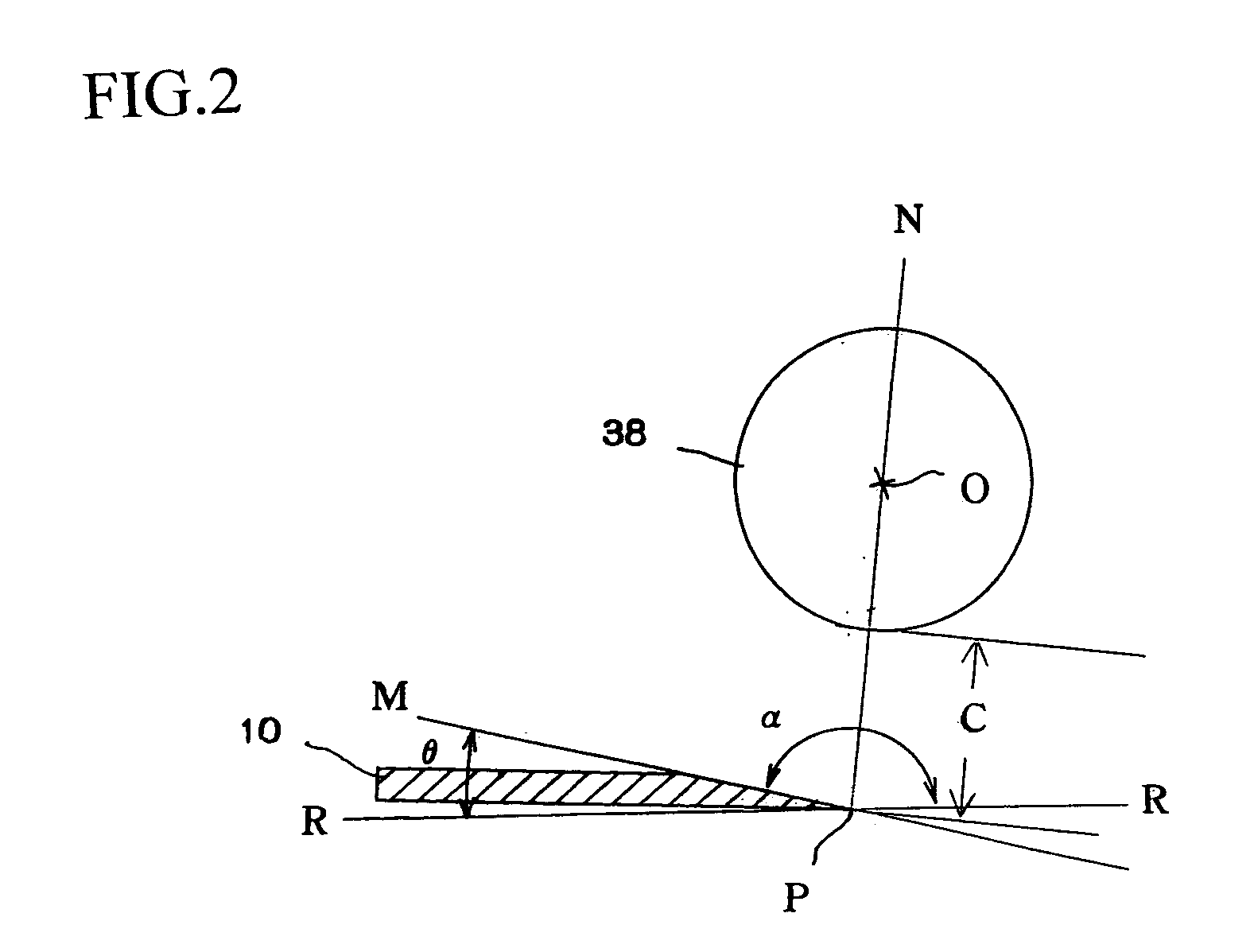

Method and device for manufacturing tissue section

ActiveUS20050126311A1Uniform thicknessStable productionWithdrawing sample devicesPreparing sample for investigationBiological bodyMicroscopic observation

The method for manufacturing a tissue section, which is used for a sample for observation by a microscope, comprises the steps of slicing an organism specimen (12), whose form has been fixed by freezing or by using an embedding agent, along a slicing surface, characterized by: adjusting a distance between the slicing surface of the organism specimen (12) and one side of a tape (32) and a temperature difference between the organism specimen (12) and the tape (32) when the slicing of the organism specimen (12) is started, thereby a tip part of the tissue section (16) curling to the outside of the slicing surface of the organism specimen (12) is allowed to adhesively abut on one side of the tape (32) running apart from the slicing surface of the organism specimen (12); and running the tape (32) at a speed in synchronism with a slicing speed of the tissue section (16) after the tip part of the tissue section (16) is allowed to adhesively abut on the one side of the tape (32), thereby the entire tissue section (16) cut off from the organism specimen (12) can be adhered onto the one side of the tape (32).

Owner:SAKURA SEIKI

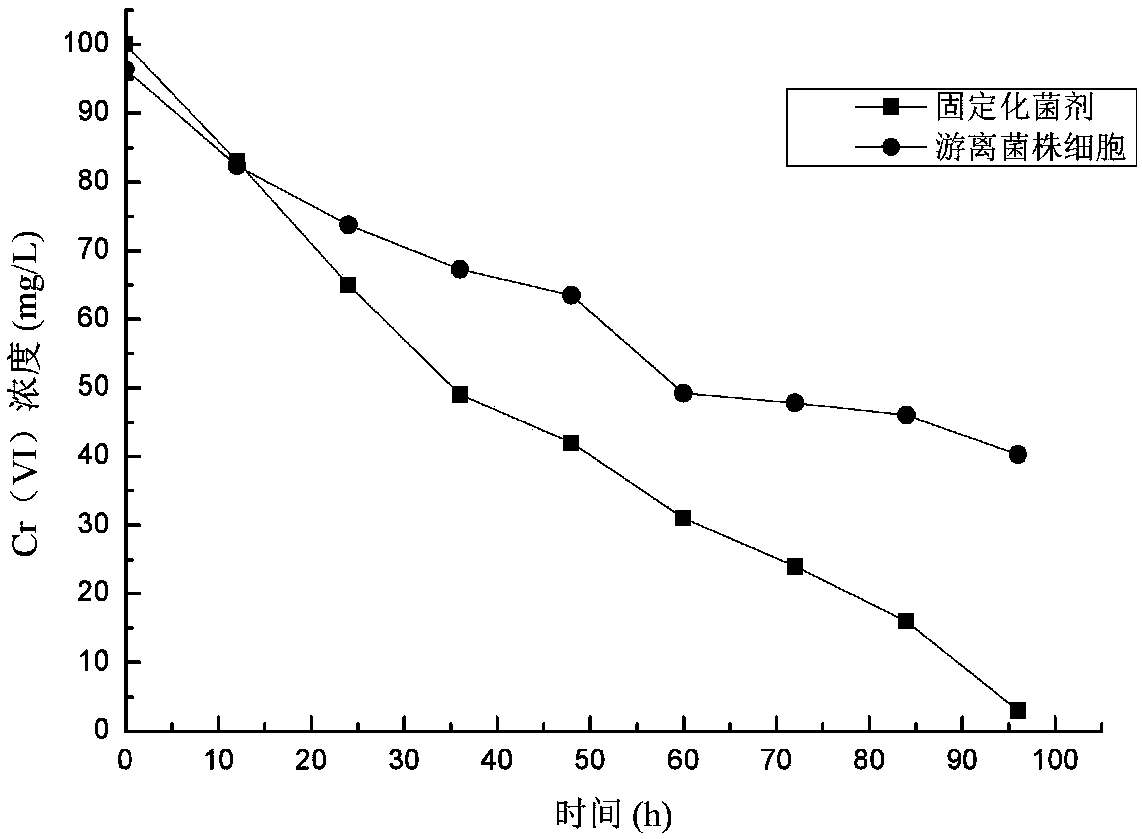

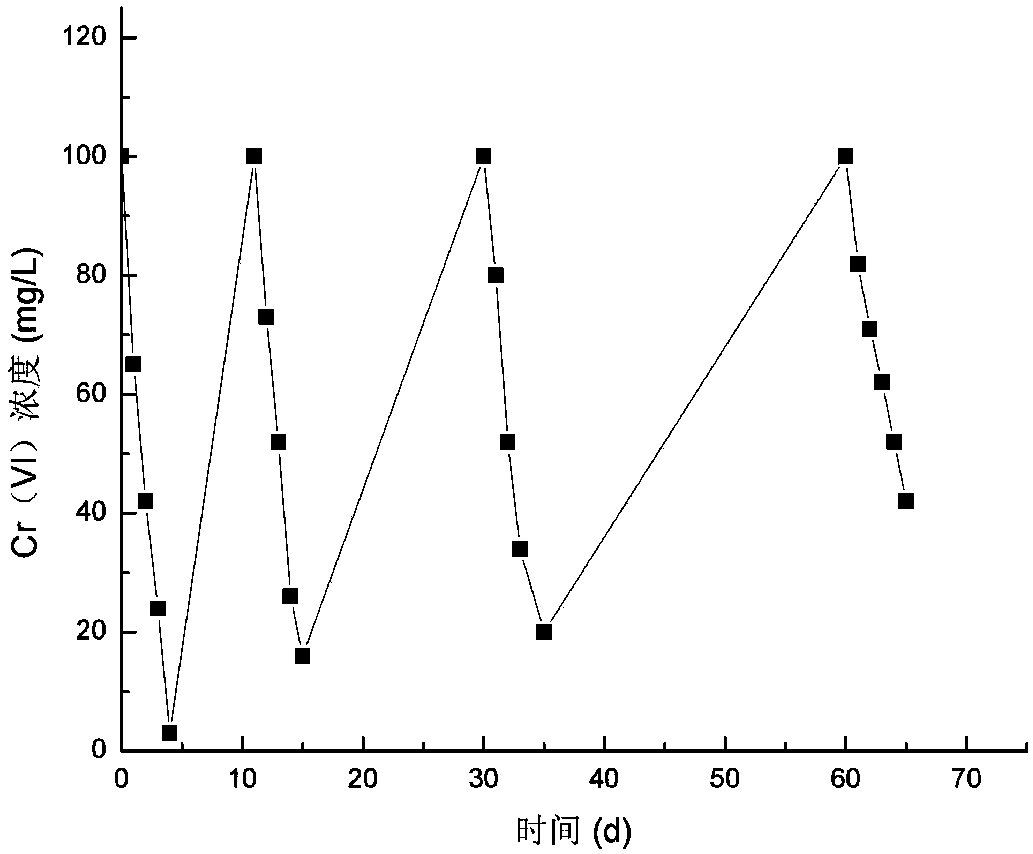

Hexavalent-chromium reduction immobilization bacterial agent and preparing method

InactiveCN108018229AWill not destroy the structure and biological characteristicsEasy to spreadBacteriaWater contaminantsCalcium alginateRepeatability

The invention discloses an immobilized microbial hexavalent-chromium removing bacterial agent and a preparing method, and belongs to the technical field of chromium pollution site microbial remediation. The bacterial agent is prepared in the mode that calcium alginate serves as a carrier and is embedded with independently-separated wild bacillus. The preparing method includes the steps that an embedding agent and microbial bacterial suspension are evenly mixed according to the proportion of 1:1, the obtained thick mixed liquid is dropped into a CaCl2 solution and is dispersed into balls, coupling is carried out for a certain time, and the gel-state immobilization hexavalent-chromium removing bacterial agent can be obtained. The hexavalent-chromium reduction immobilization bacterial agent is compared with a free chromium reducing bacterium, the removing efficiency of hexavalent chromium can be remarkably improved, and the removing rate can be 100% at 96 h. According to the hexavalent-chromium reduction immobilization bacterial agent prepared with the method, the preparing method is simple and easy to operate, the reaction condition is mild, and the activity and the concentration ofmicrobial bacterial suspension can be efficiently kept; the formed bacterial agent is good in repeatability and stability, the microbial bacterial suspension is not prone to leakage, solid-liquid separation after reacting is facilitated, and the hexavalent-chromium reduction immobilization bacterial agent and the preparing method are suitable for industrial application.

Owner:CENT SOUTH UNIV

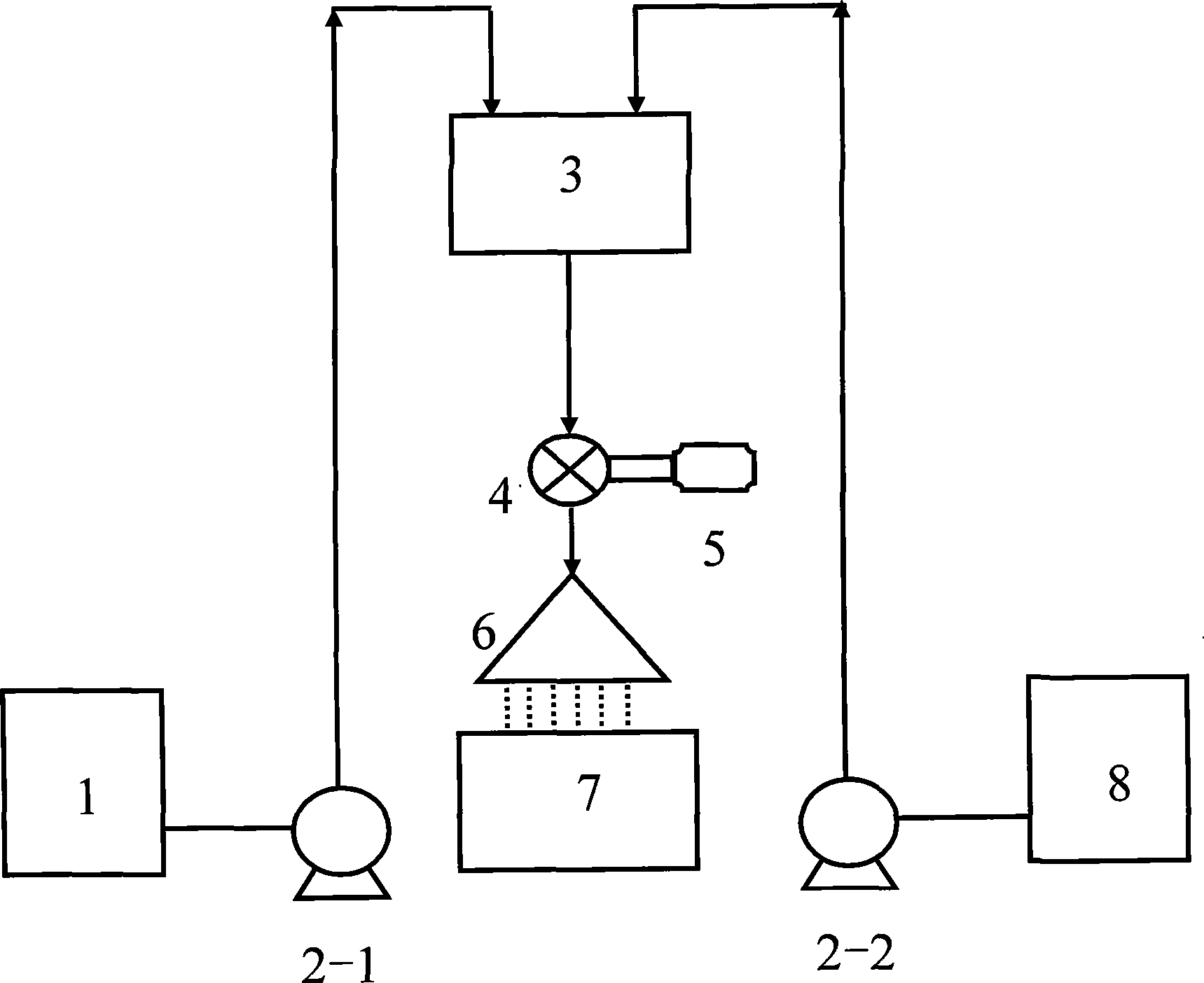

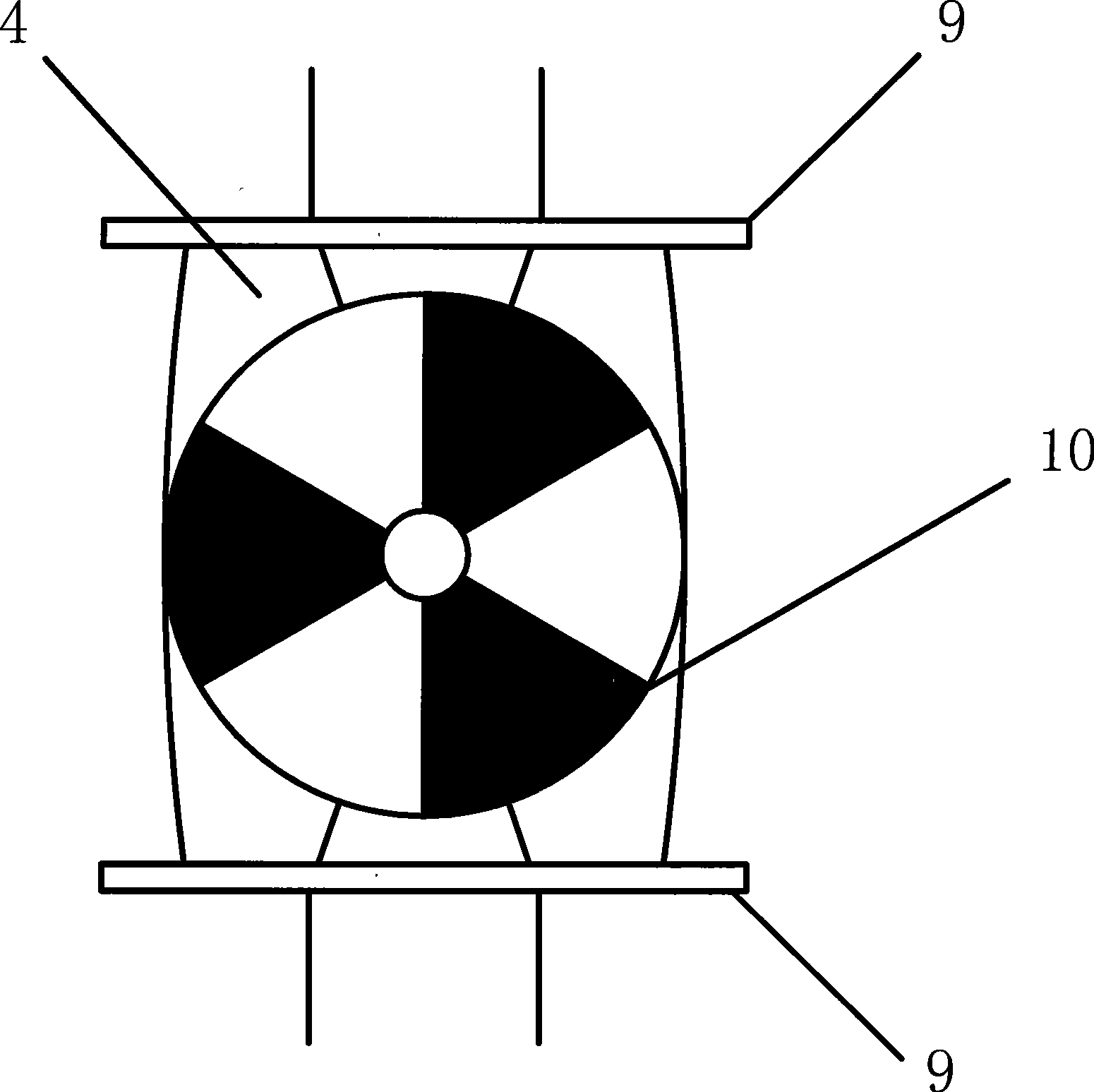

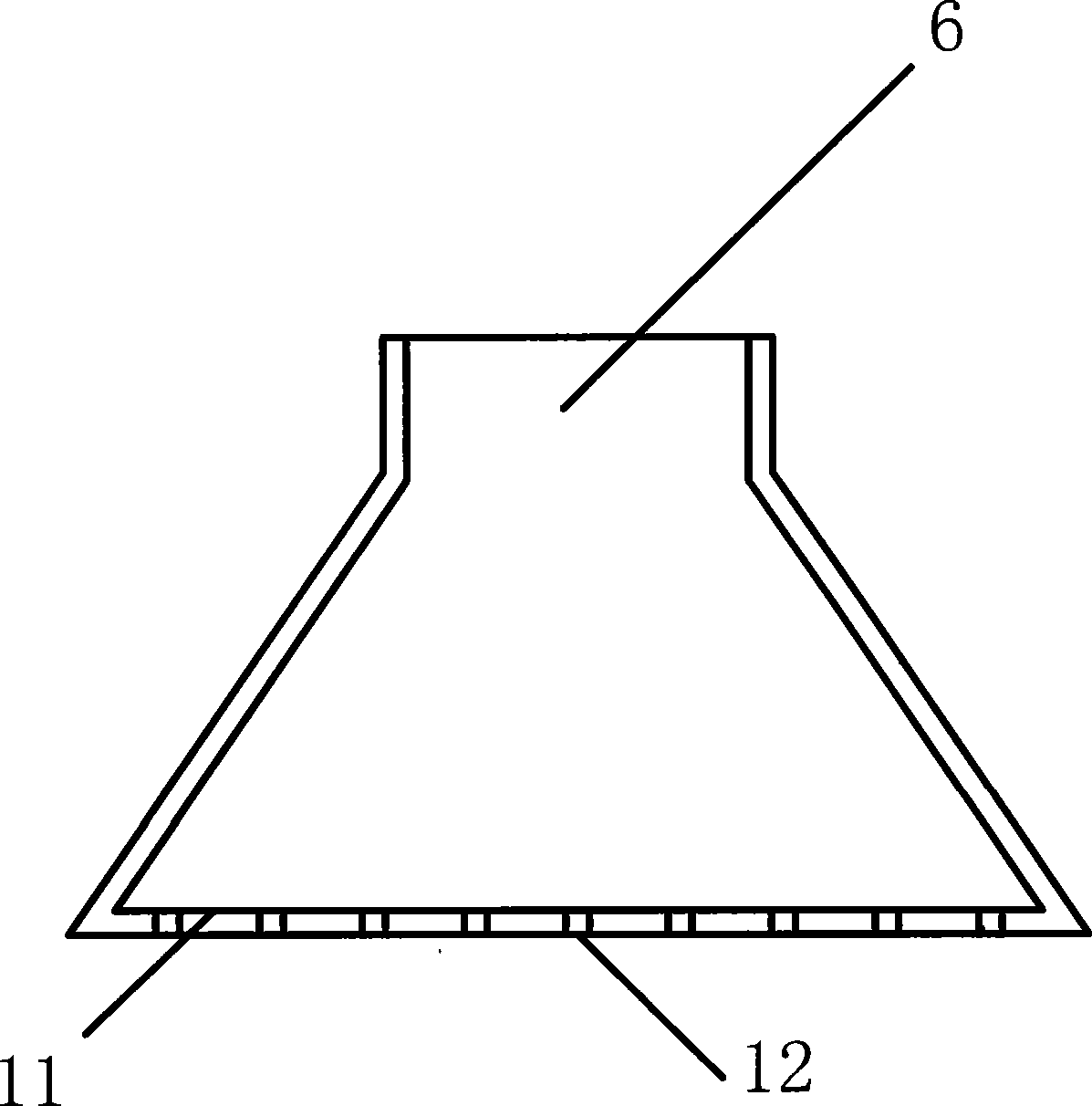

Device and technology for preparing engineering embedding fixing microorganism spheric bodies

InactiveCN101519632AImprove stabilityBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringCross linker

The invention relates to a device and a technology for preparing engineering embedding fixing microorganism spheric bodies. Embedding medium solution in an embedding medium kettle is added into a mixing kettle, and a sorption agent in a sorption agent organism kettle and microorganism solution are added into the mixing kettle. After fully mixed, the two solutions enter a shunting head by an isolating valve and then are sprayed into a cross linker kettle. After solidifying and cross linking, spheric grains which are the microorganism embedding spheric bodies are obtained. The invention overcomes the defect that large-scale mass production can not carried out by the prior embedding fixing microorganism technology, divides liquid which continuously flows in a pipeline connected in front of the valve by the isolating valve so as to discontinuously provide feed liquid for the shunting head, and further shunts the feed liquid provided by the isolating valve by the shunting action of the shunting head so as to ensure that miscible liquid from the mixing kettle enters cross linker solution in a spraying mode to form precipitation of solid spheric grains. The invention realizes the mass production of microorganism embedding solid globes having good stability by the embedding fixing technology.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com