Preparation method of flavone sustained-release algal inhibition preparation

A flavonoid, slow-release technology, applied in botany equipment and methods, herbicides and algicides, chemicals for biological control, etc., can solve the problem of affecting the growth of non-algae organisms, short duration of drug efficacy, ecological environment Side effects and other issues, to achieve the effect of long-lasting action, good ecological safety, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

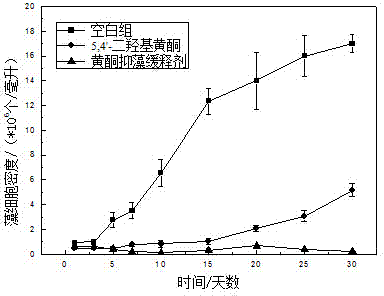

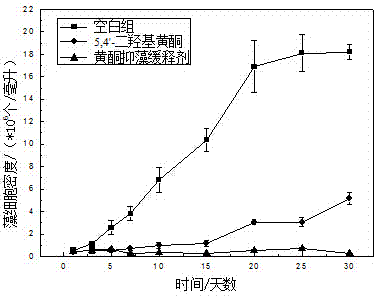

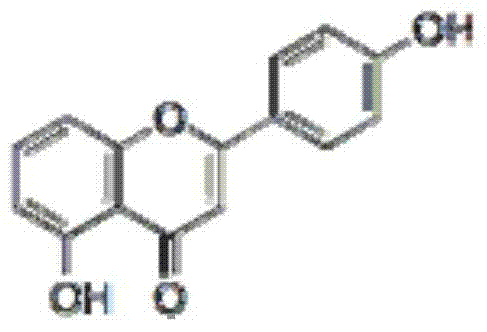

[0022] A flavonoid slow-release anti-algae preparation, which contains 5,4'-dihydroxyflavone with a mass fraction of 30-50%, embedding agents such as sodium alginate with a mass fraction of 50-70%, and an encapsulation efficiency of 50- 70%.

[0023] Weigh 5,4'-dihydroxyflavone and dissolve it in dimethyl sulfoxide to prepare a 5,4'-dihydroxyflavone dimethyl sulfoxide solution with a concentration of 10 mg / mL; weigh sodium alginate and It is dissolved in distilled water to prepare a sodium alginate solution with a mass fraction of 5%. Mix 5,4'-dihydroxyflavone dimethyl sulfoxide solution with a concentration of 10 mg / mL and 5% sodium alginate solution with a mass fraction of 1:10 by volume, shake well and prepare a flavone-sodium alginate solution. Take chitosan and anhydrous calcium chloride, and dissolve it in the distilled aqueous solution of 1% acetic acid by volume fraction, be formulated with chitosan-calcium chloride mixed solution, wherein the amount of chitosan in th...

Embodiment 2

[0024] Weigh 5,4'-dihydroxyflavone and dissolve it in dimethyl sulfoxide to prepare a 5,4'-dihydroxyflavone dimethyl sulfoxide solution with a concentration of 5 mg / mL; weigh sodium alginate and It was dissolved in distilled water and prepared as a 5% sodium alginate solution by mass fraction; 5,4'-dihydroxyflavone dimethyl sulfoxide solution with a mass fraction of 5 mg / mL and a 5% sodium alginate solution by volume Mix at a ratio of 1:10, shake well and prepare a flavonoid-sodium alginate solution. Weigh chitosan and anhydrous calcium chloride and dissolve it in the distilled aqueous solution of 1% acetic acid by volume fraction to prepare chitosan-calcium chloride mixed solution, wherein the mass of chitosan in the mixed solution The fraction is 1%, and the mass fraction of calcium chloride in the mixed solution is 0.5%; and the pH value of the polysaccharide-calcium chloride mixed solution is adjusted to 7.0 with a NaOH solution having a concentration of 0.2 g / mL. Take th...

Embodiment 3

[0026] Weigh 5,4'-dihydroxyflavone and dissolve it in dimethyl sulfoxide to prepare a 5,4'-dihydroxyflavone dimethyl sulfoxide solution with a concentration of 10 mg / mL; weigh sodium alginate and It was dissolved in distilled water and prepared as a 3% sodium alginate solution; the 5,4'-dihydroxyflavone dimethyl sulfoxide solution with a concentration of 10 mg / mL was mixed with a 5% sodium alginate solution Mix according to volume ratio 1:10, shake well to make flavone-sodium alginate solution. Take chitosan and anhydrous calcium chloride, and dissolve it in the distilled aqueous solution of 1% acetic acid by volume fraction, be formulated with chitosan-calcium chloride mixed solution, wherein the amount of chitosan in the mixed solution The mass fraction is 2%, and the mass fraction of calcium chloride in the mixed solution is 0.5%; and the pH value of the chitosan solution is adjusted to 7.0 with 0.2 g / mL NaOH solution. Take the chitosan-calcium chloride solution and place ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com