Patents

Literature

819 results about "Entrapment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In criminal law, entrapment is a practice whereby a law enforcement agent or agent of the state induces a person to commit a criminal offense that the person would have otherwise been unlikely or unwilling to commit. It "is the conception and planning of an offense by an officer or agent, and the procurement of its commission by one who would not have perpetrated it except for the trickery, persuasion or fraud of the officer or state agent."

Method of producing sustained-release preparation

InactiveUS6267981B1Maintain good propertiesEnhancement of entrapmentPowder deliveryPeptide/protein ingredientsEntrapmentBiodegradable polymer

This invention provides a sustained-release preparation comprising a biodegradable polymer metal salt and broactive polypeptide, with enhanced entrapment of the bioactive polypeptides, a suppression of initial burst, and a constant long-term release of the bioactive polypeptides.

Owner:TAKEDA PHARMA CO LTD

Method of producing a sustained-release preparation

InactiveUS6197350B1Reduce the number of stepsSuitable for industrializationPowder deliveryPeptide/protein ingredientsBlood concentrationOrganic solvent

A method of producing sustained-release microcapsules which comprises dispersing a physiologically active polypeptide into a solution of a biodegradable polymer and zinc oxide in an organic solvent, followed by removing the organic solvent; which provides a sustained-release preparation showing a high entrapment ratio of the physiologically active polypeptide and its constant high blood concentration levels over a long period of time.

Owner:TAKEDA PHARMA CO LTD

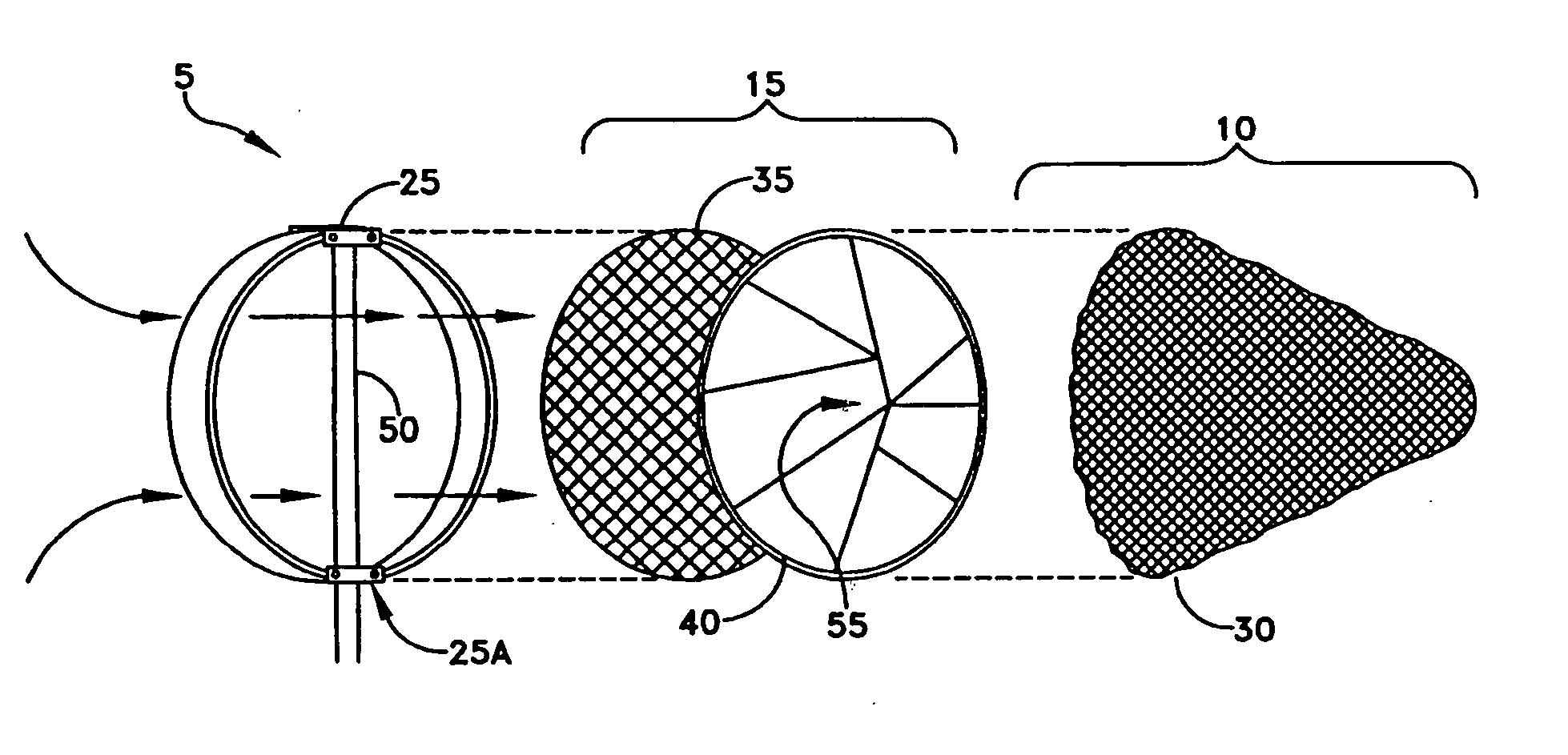

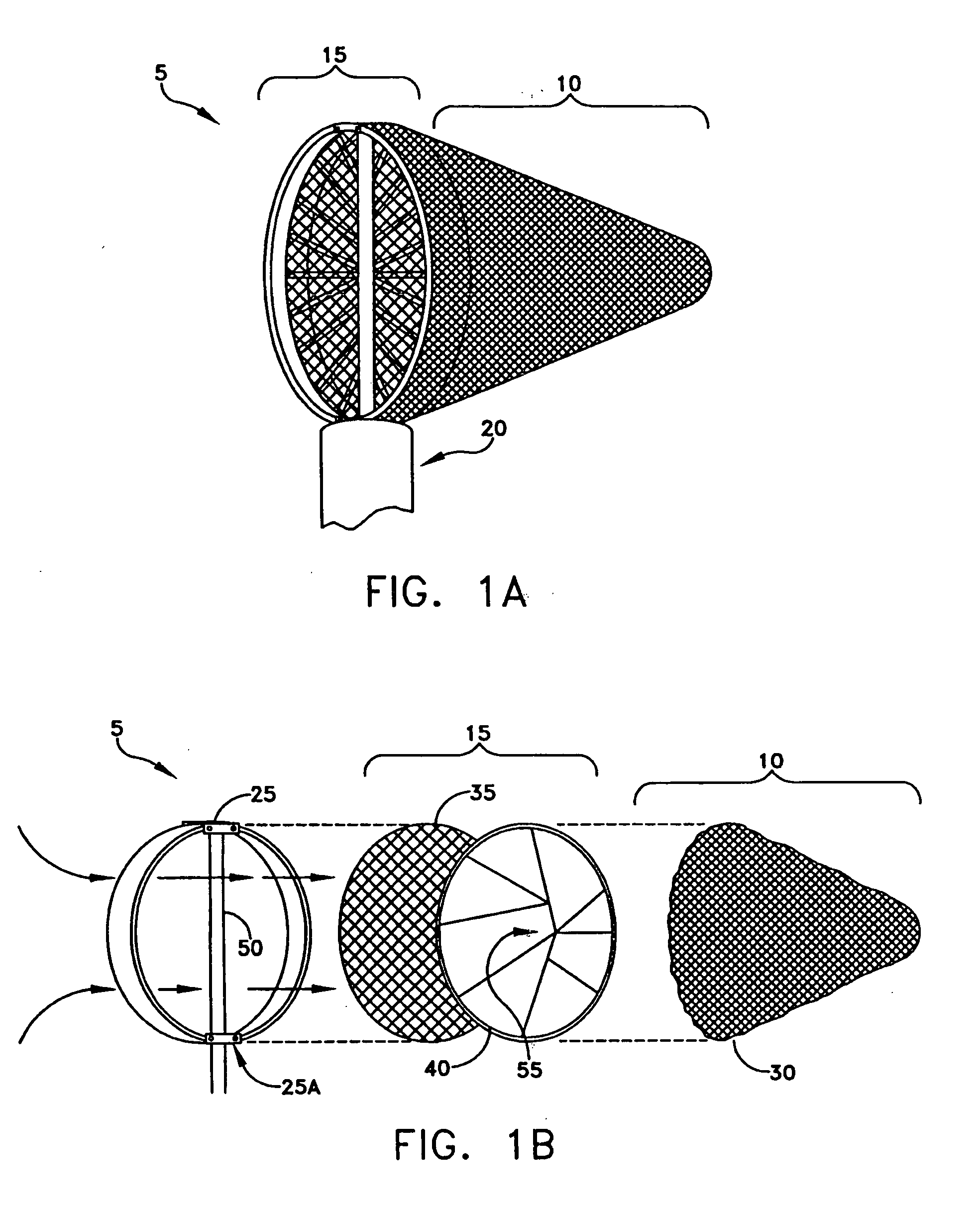

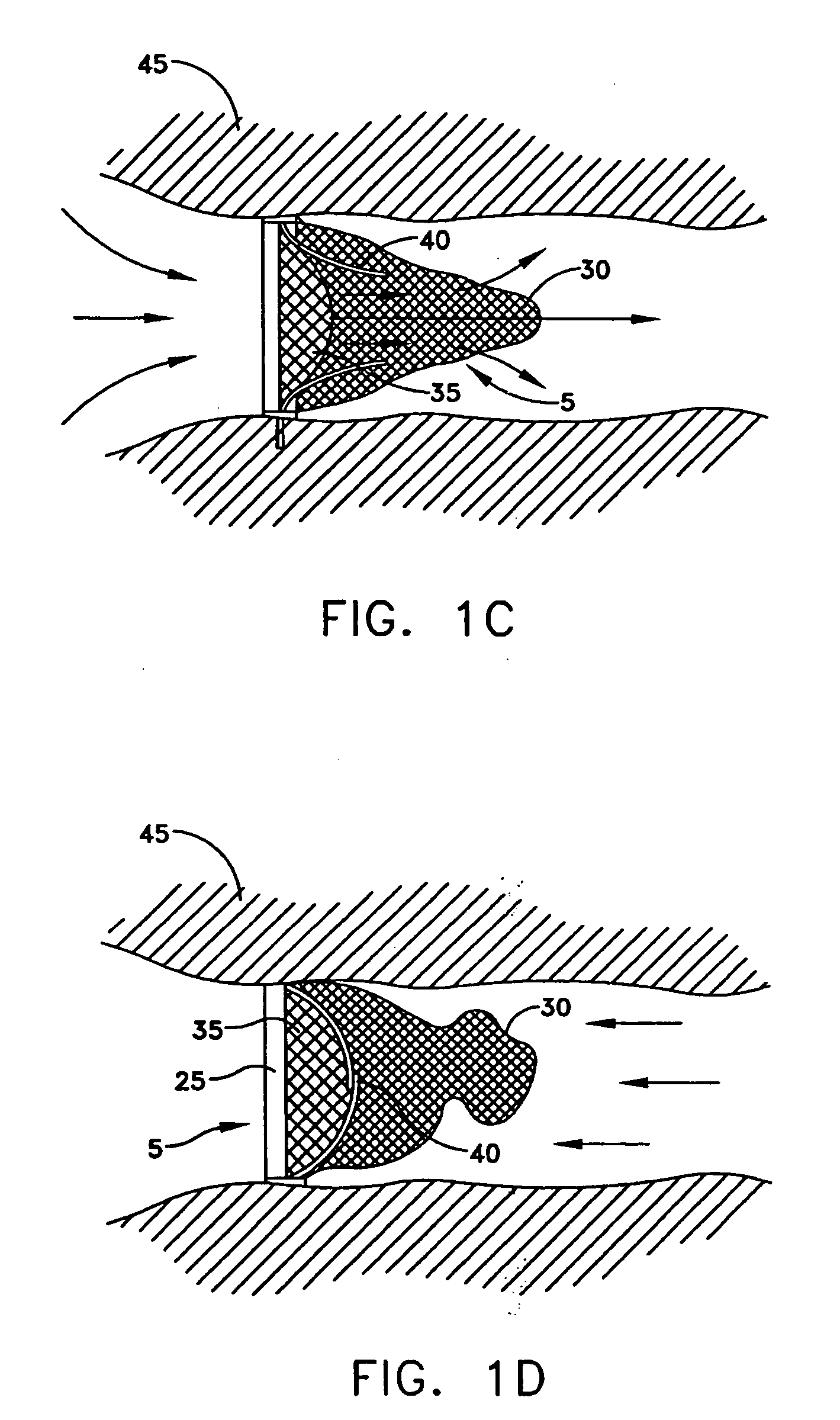

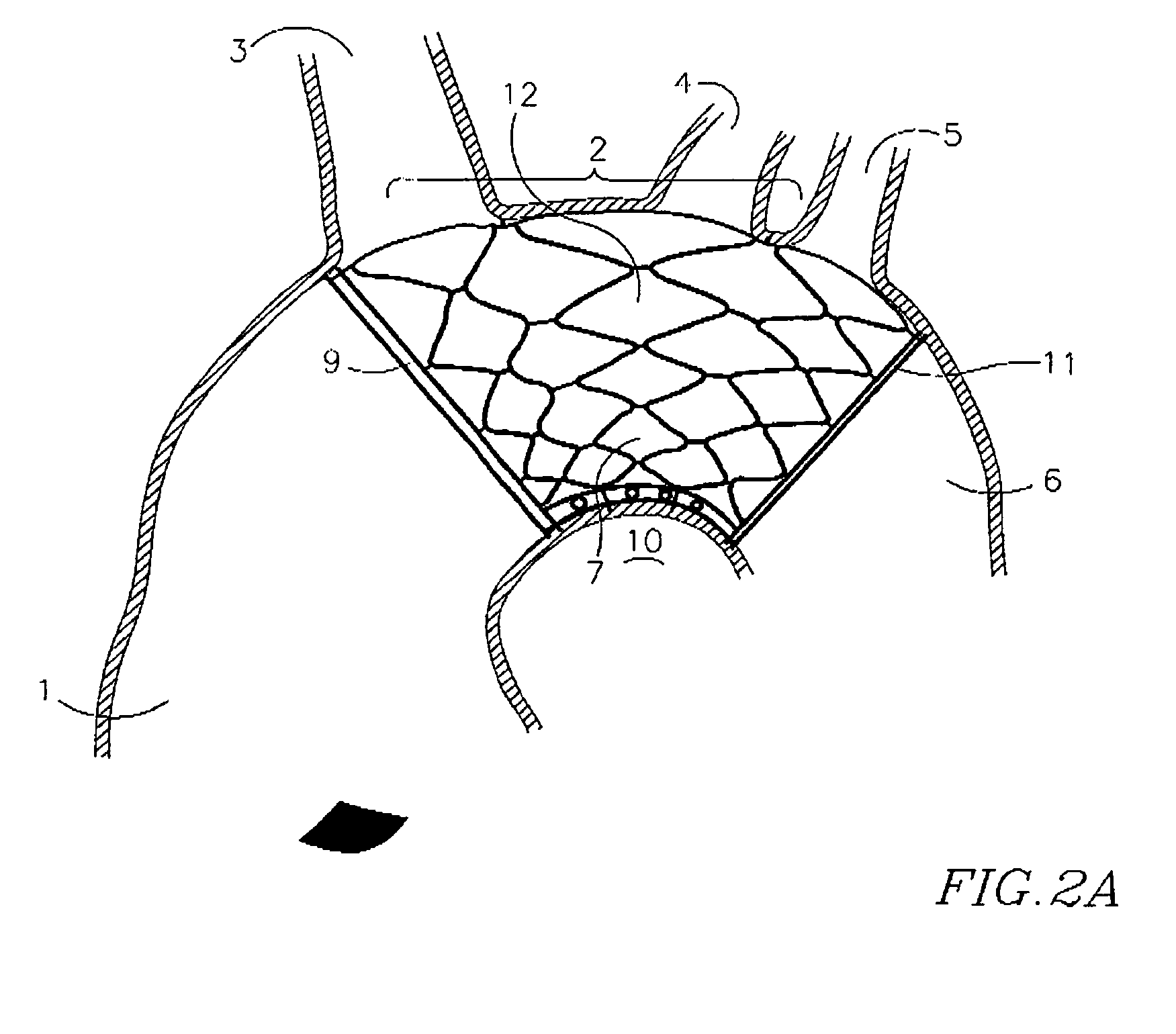

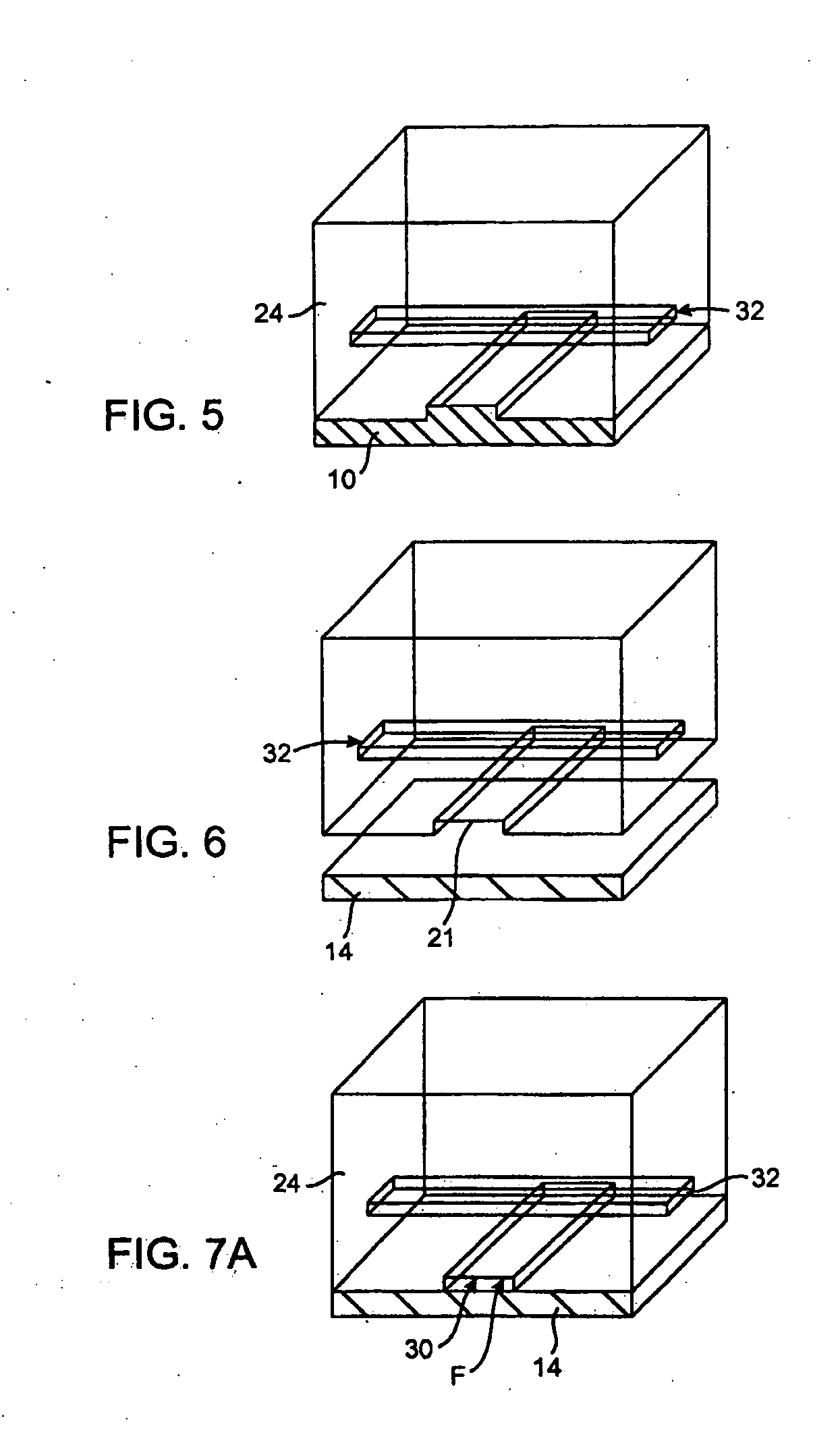

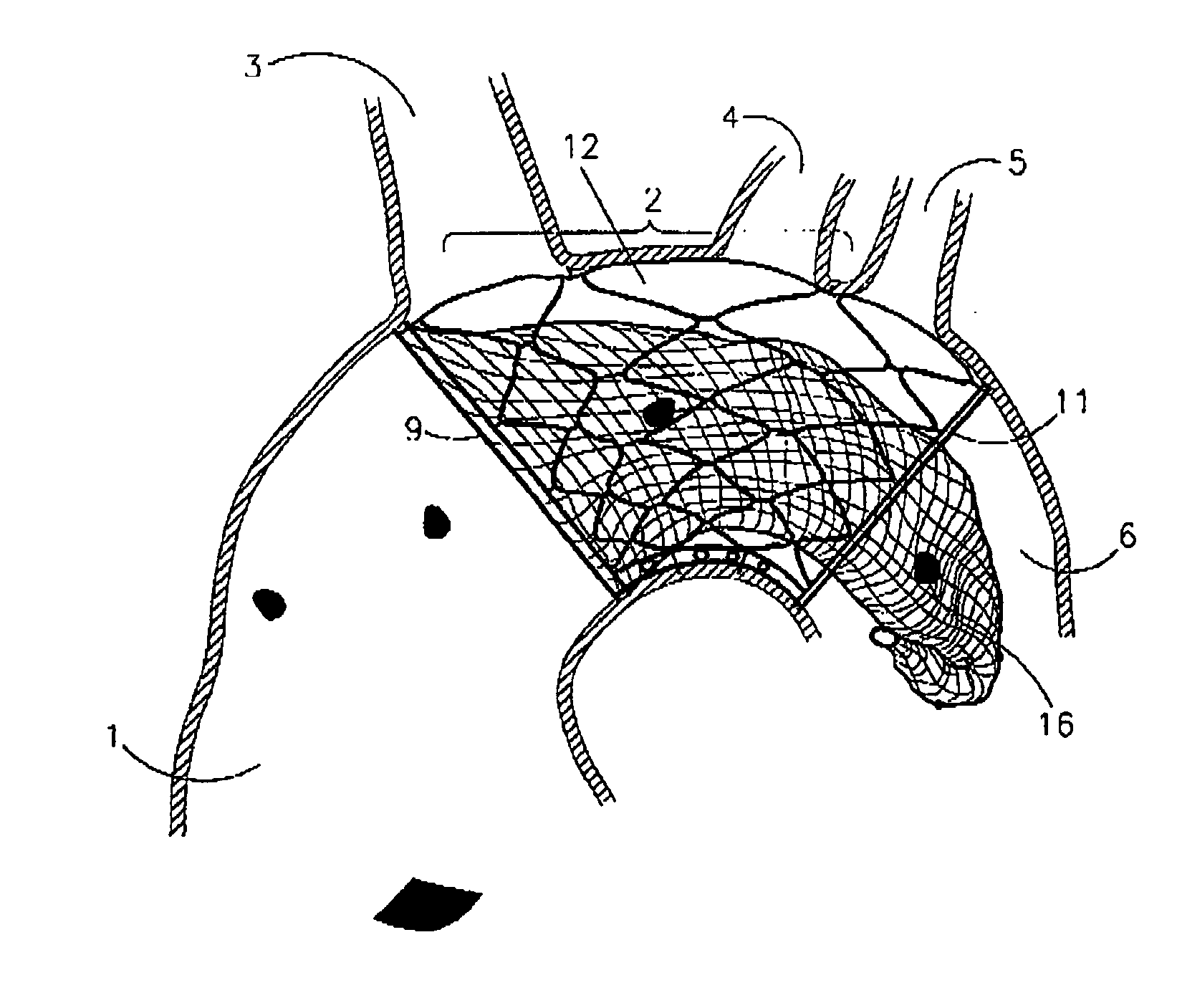

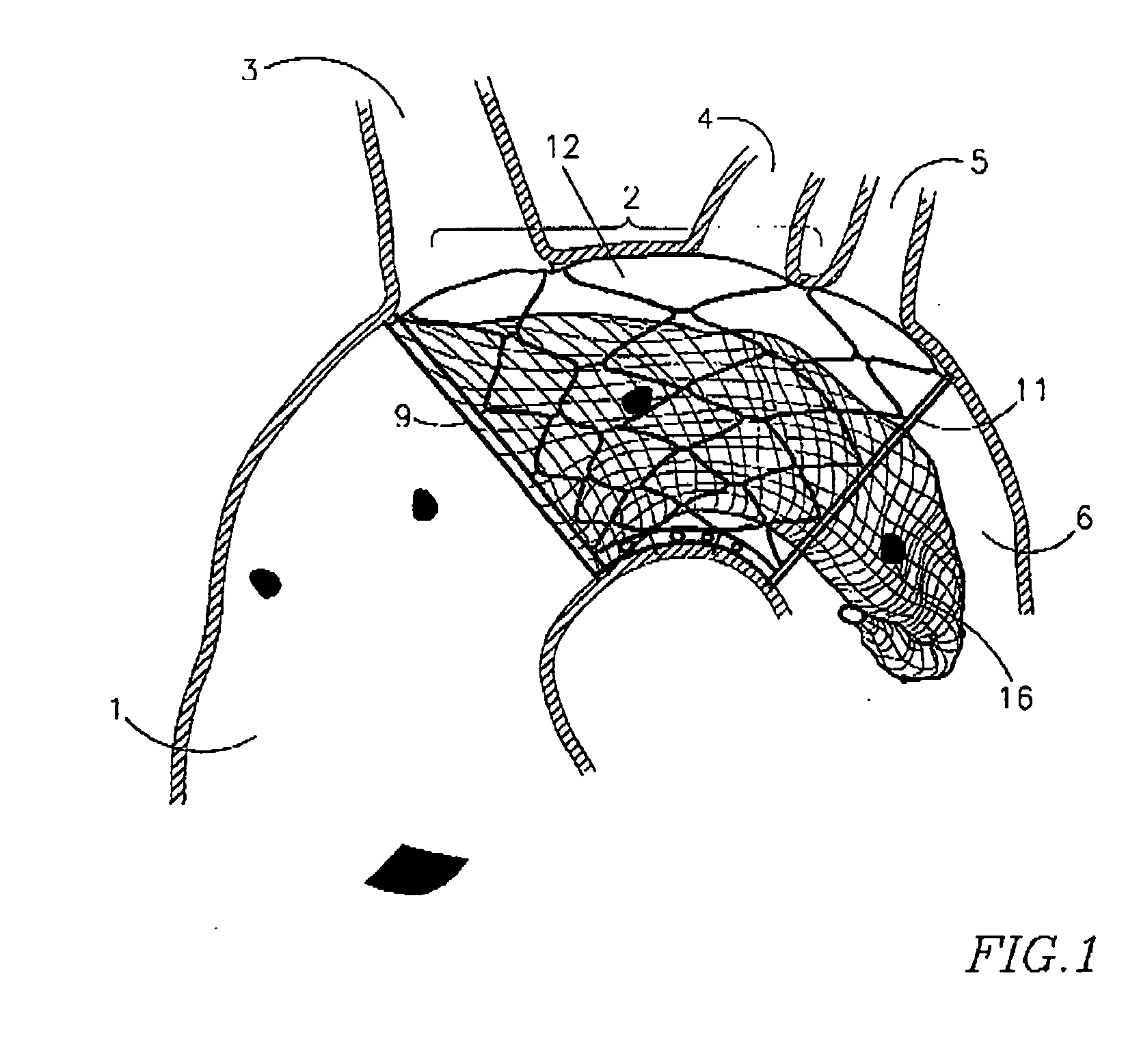

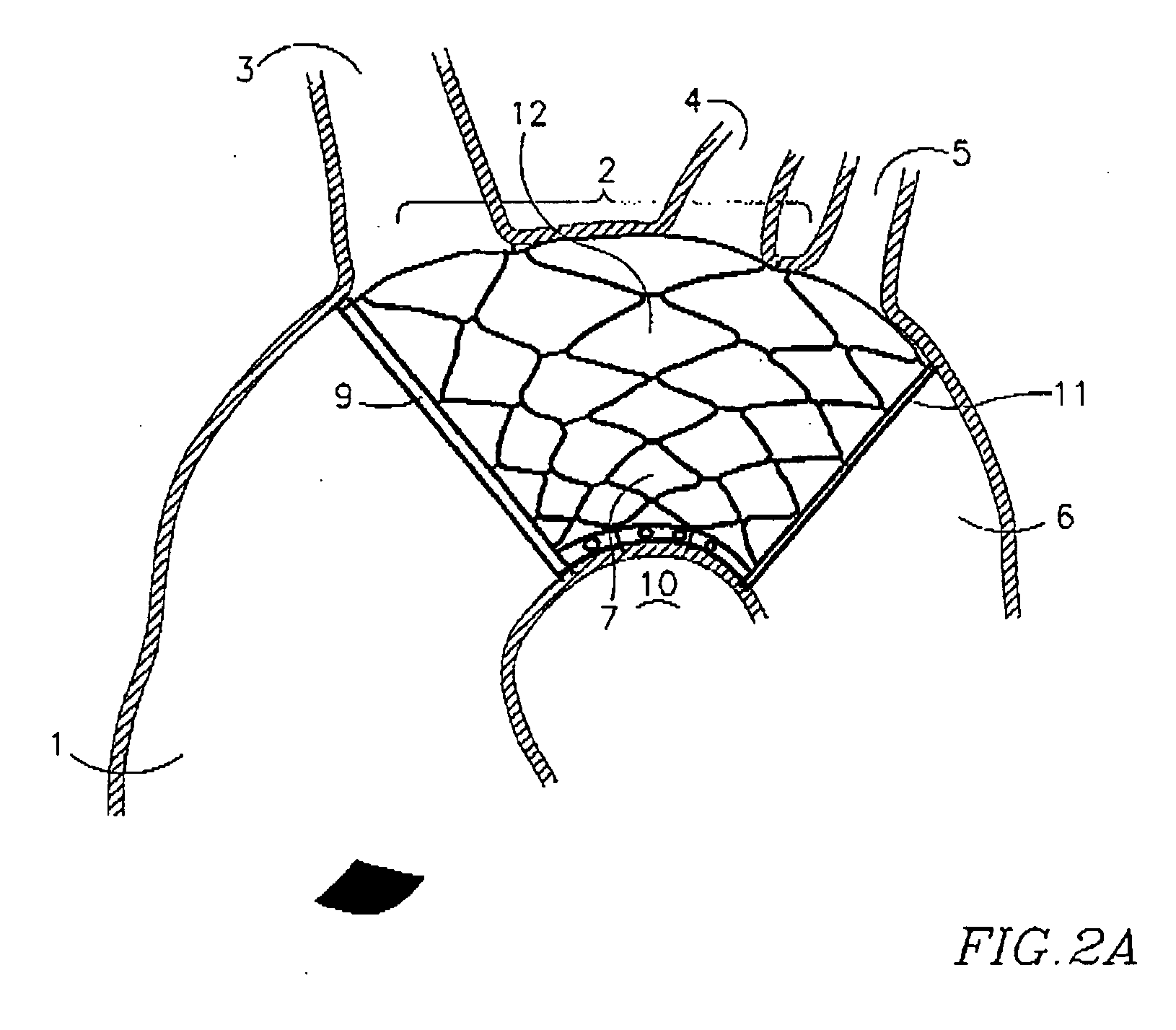

Intravascular filter with debris entrapment mechanism

Apparatus for filtering and entrapping debris in the vascular system of a patient, the apparatus including a filter to allow blood to flow therethrough and to restrict passage of debris, wherein the filter captures debris carried in a first direction of blood flow. The apparatus further includes an entrapment mechanism which allows passage of debris and blood therethrough, in the first direction of blood flow and prevents debris passage in a second direction. The entrapment mechanism and filter allow blood and debris therethrough in the first direction of blood flow. The entrapment mechanism prevents debris flow in the second direction of blood flow. A method for filtering and entrapping debris in the vascular system includes inserting the apparatus into the vascular system, allowing blood and debris carried therein to flow through the entrapment mechanism, and removing the apparatus and accumulated debris from the vascular system.

Owner:MEDTRONIC INC

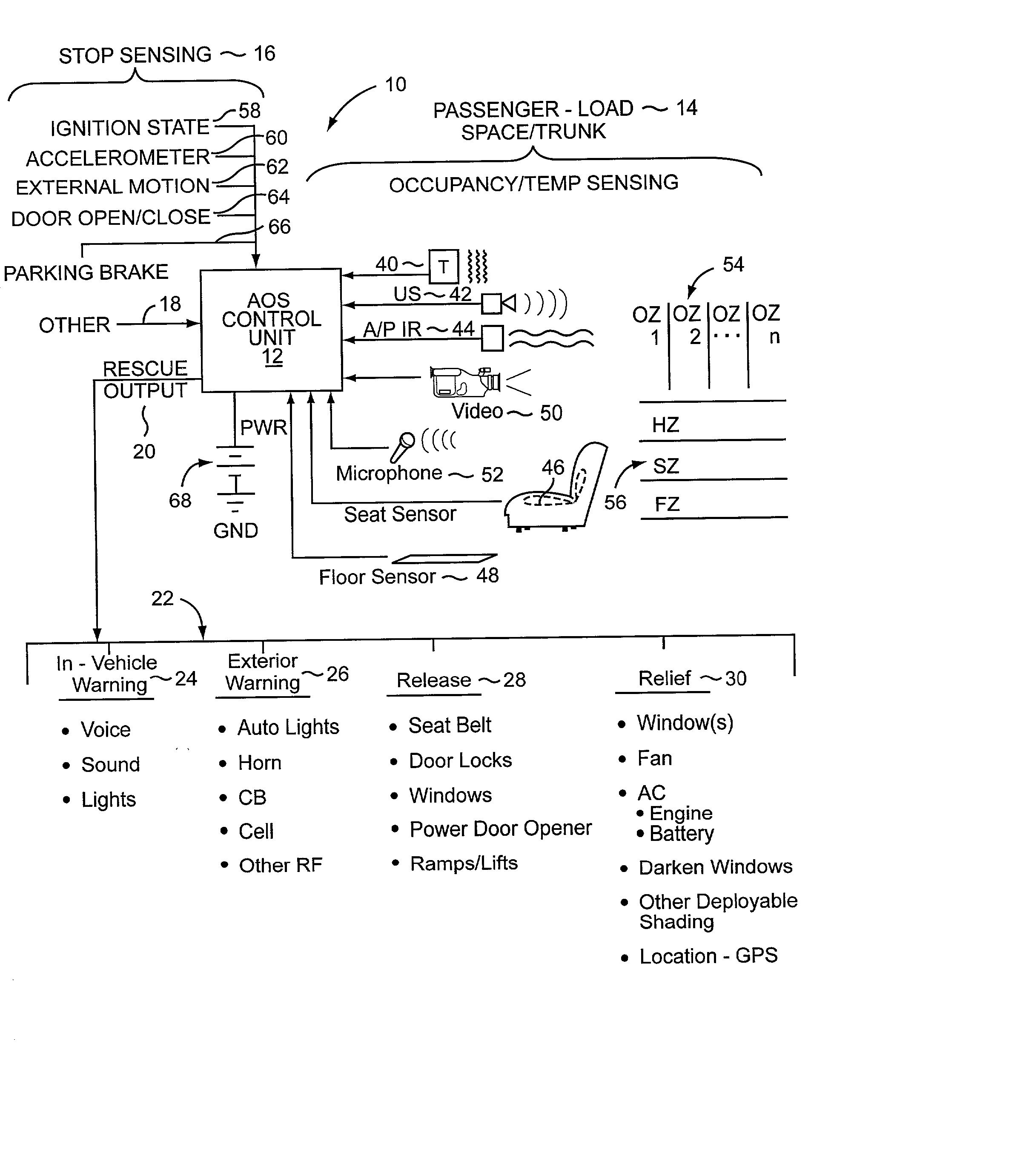

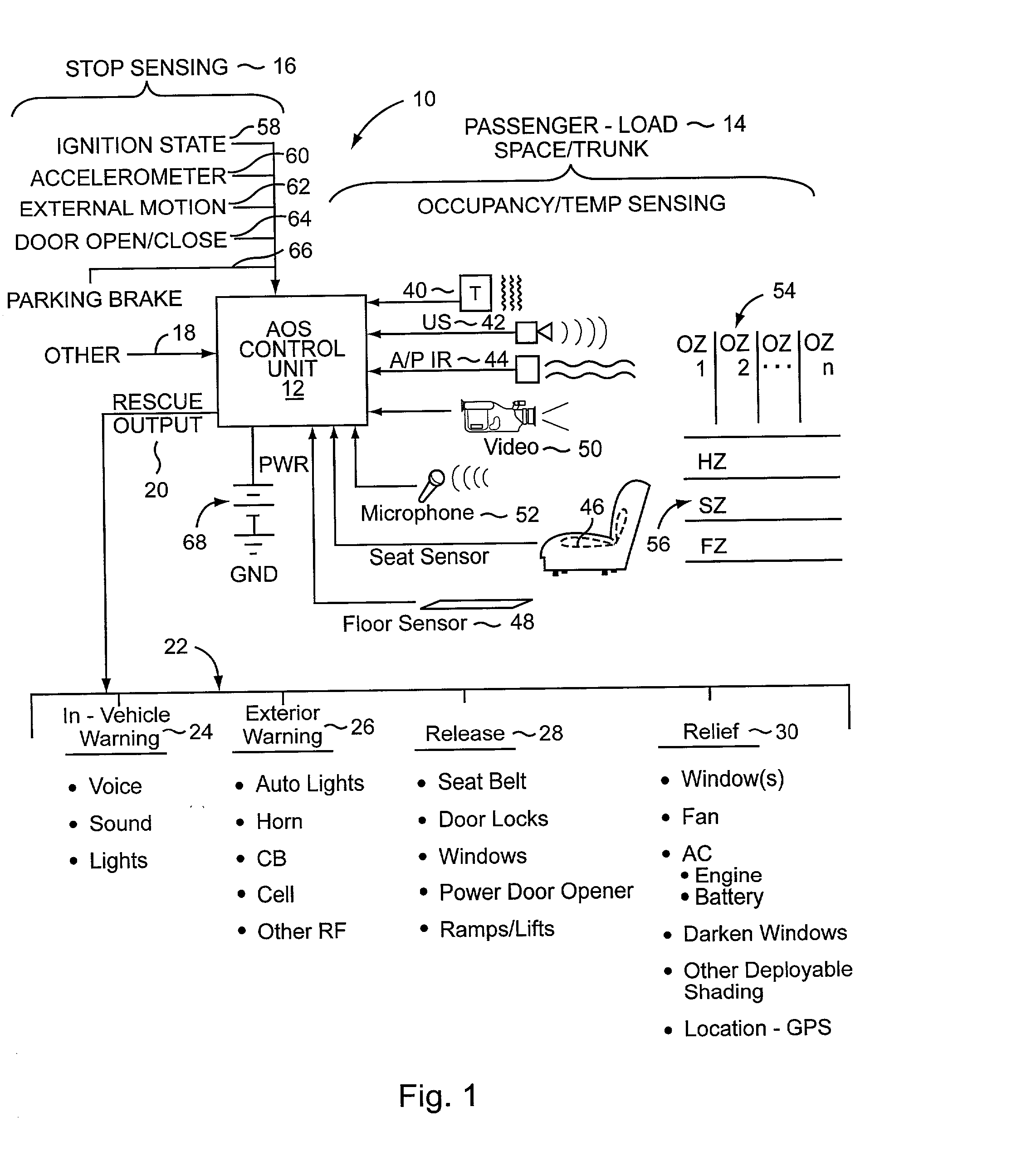

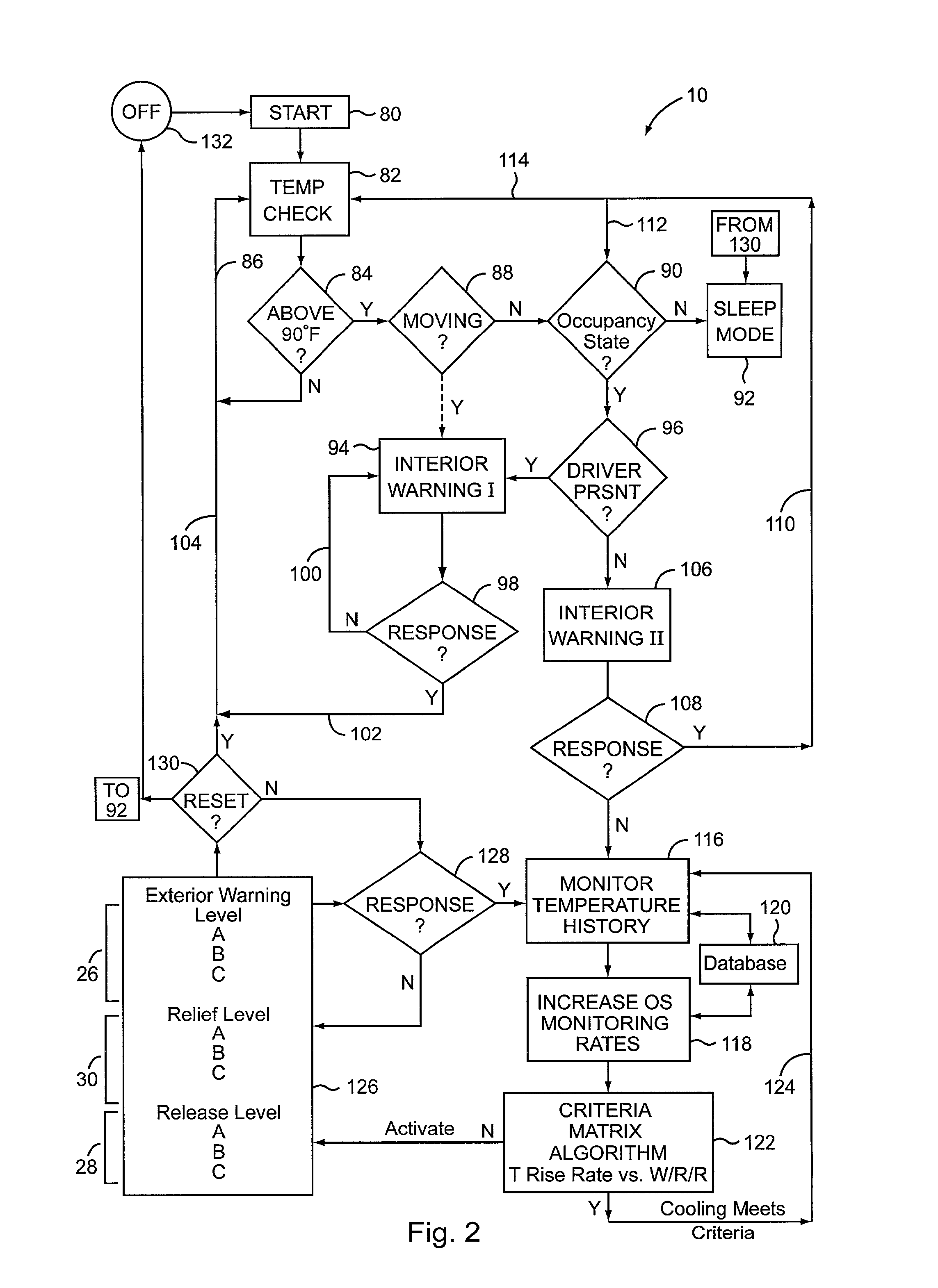

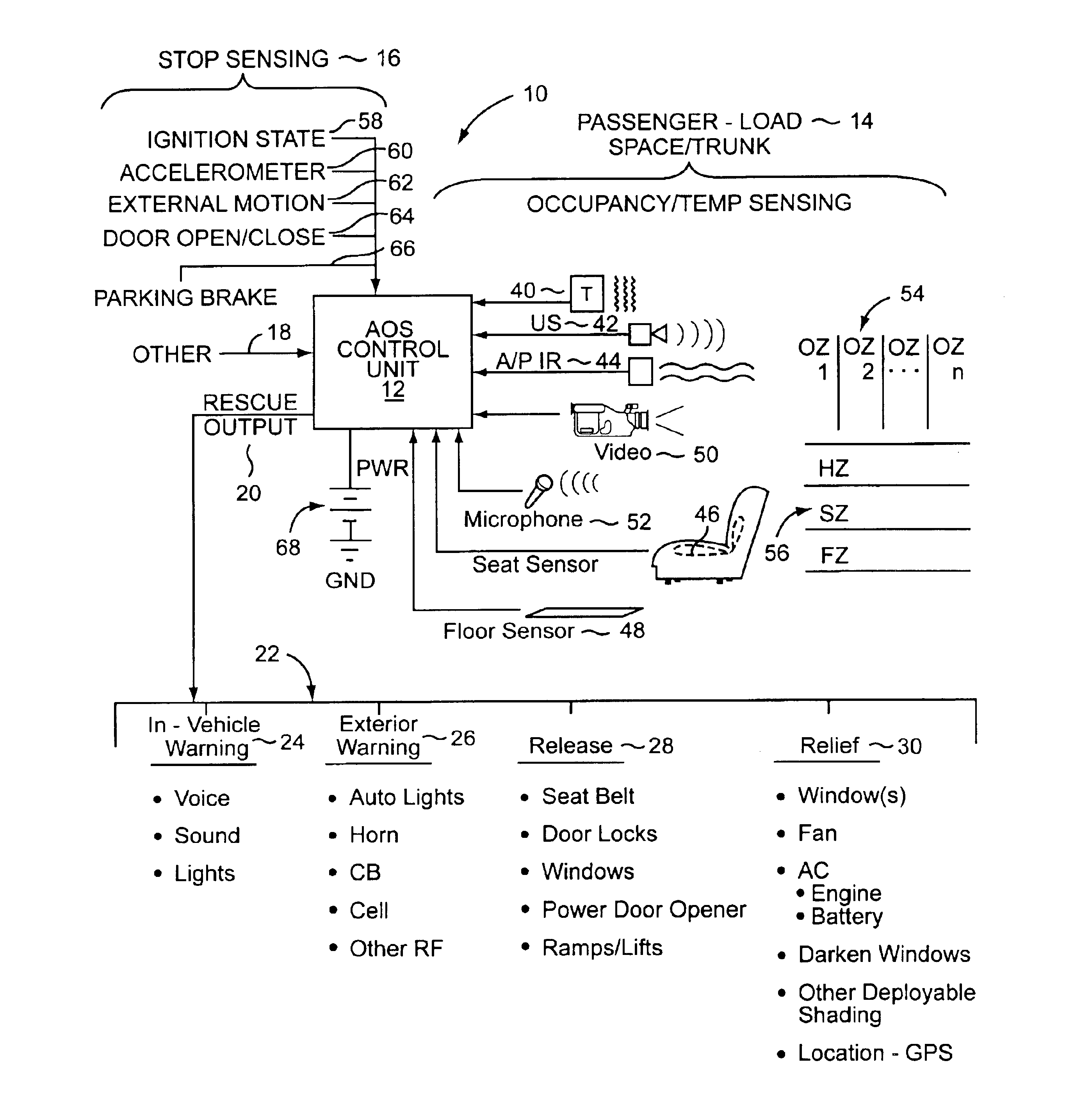

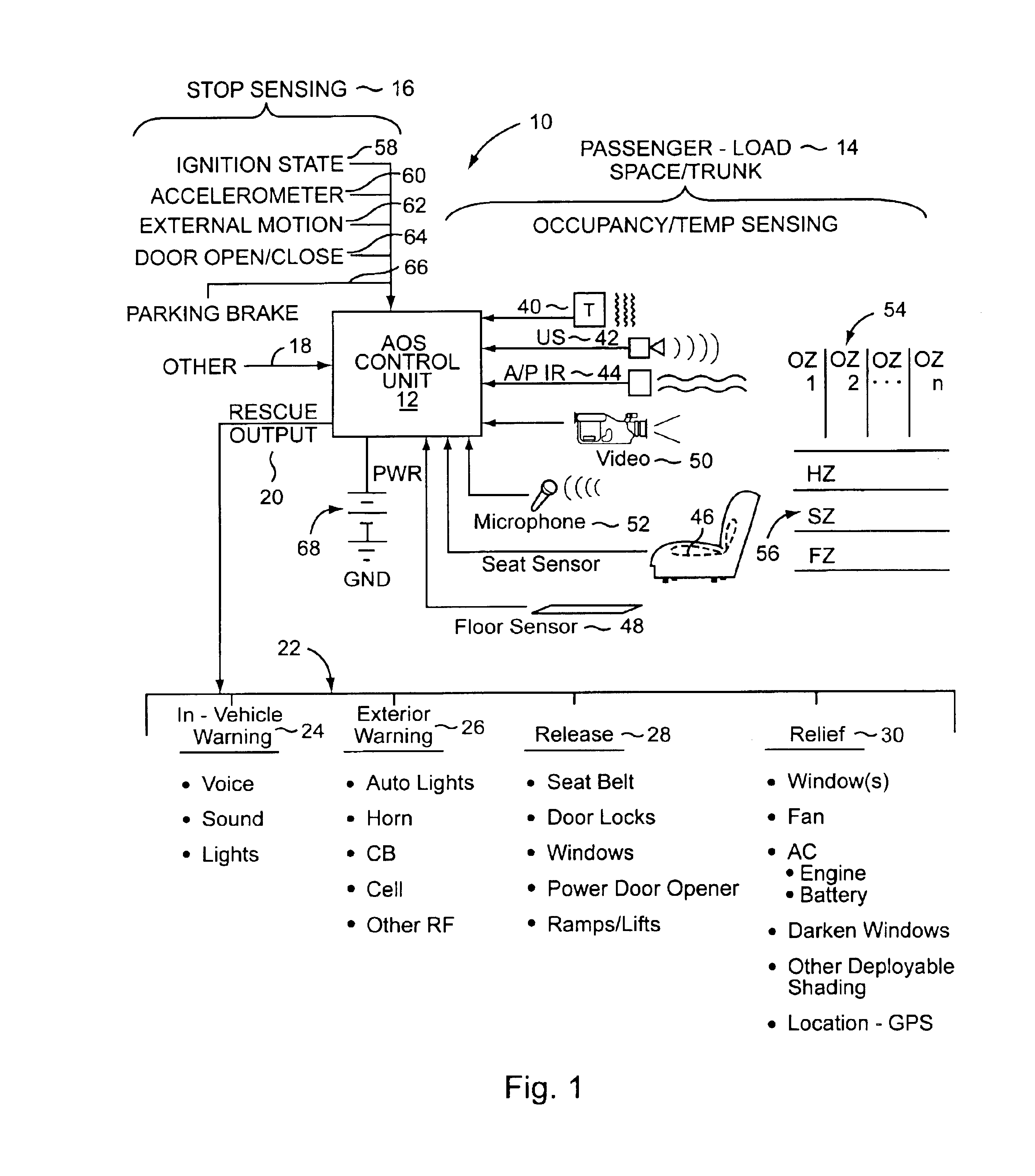

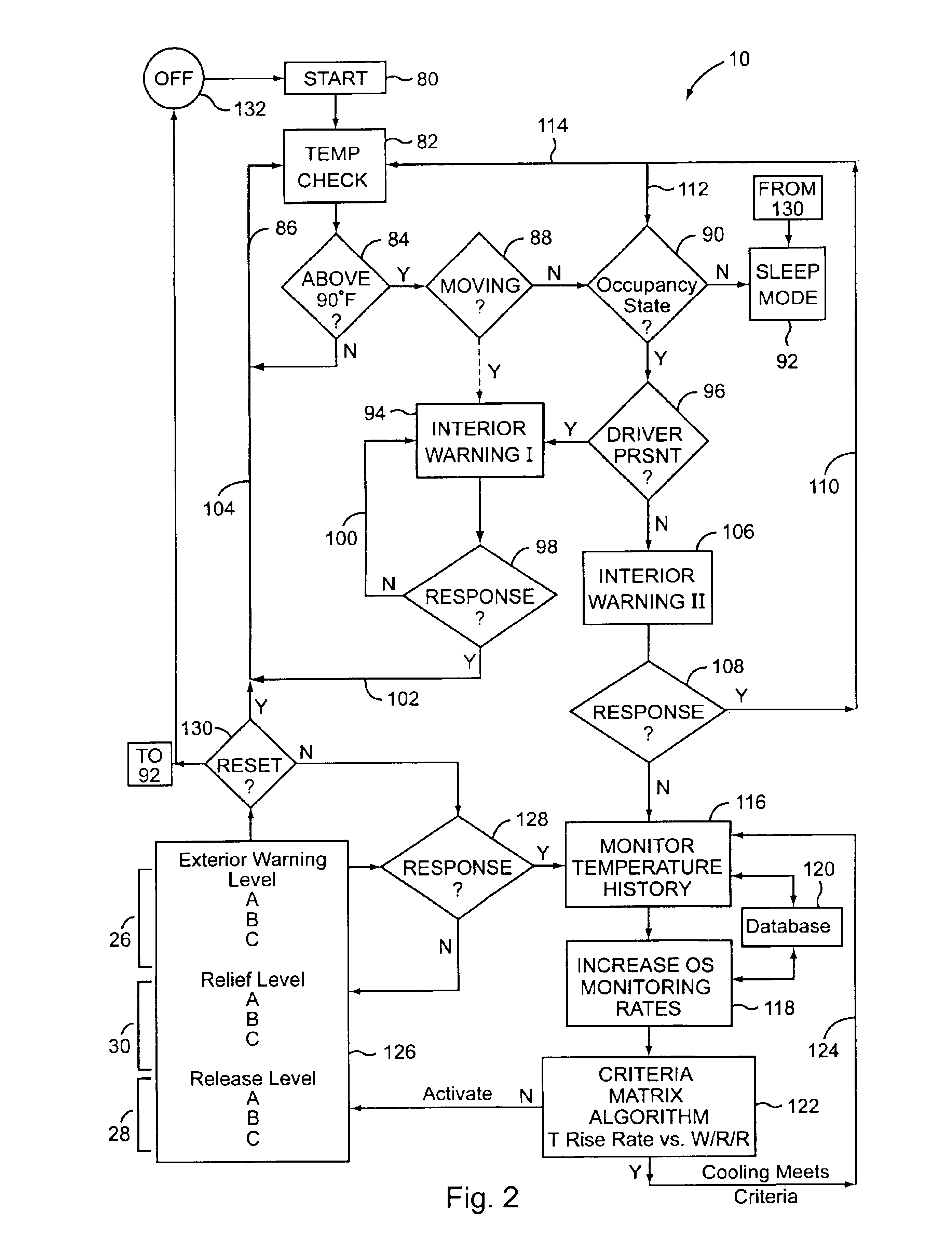

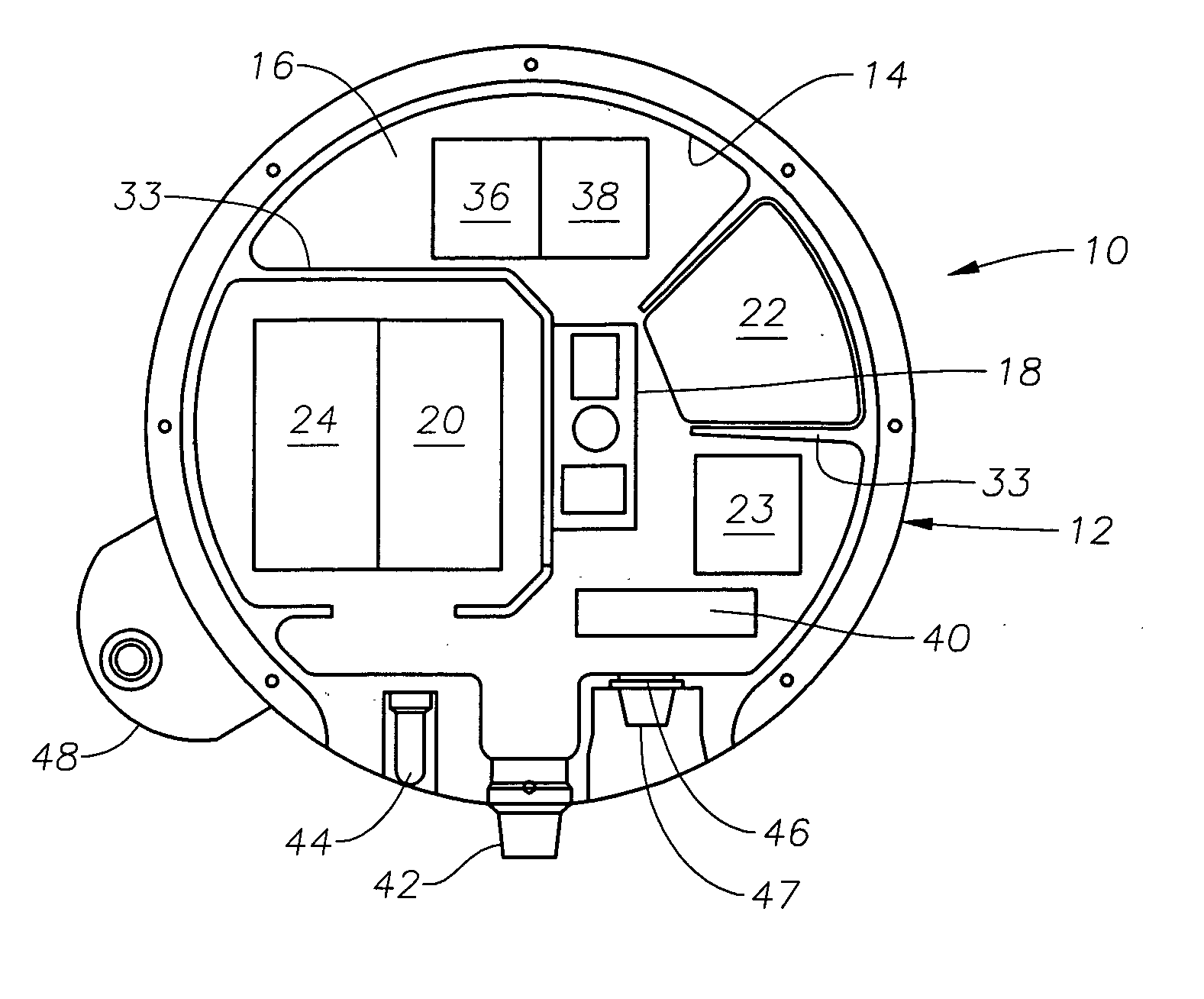

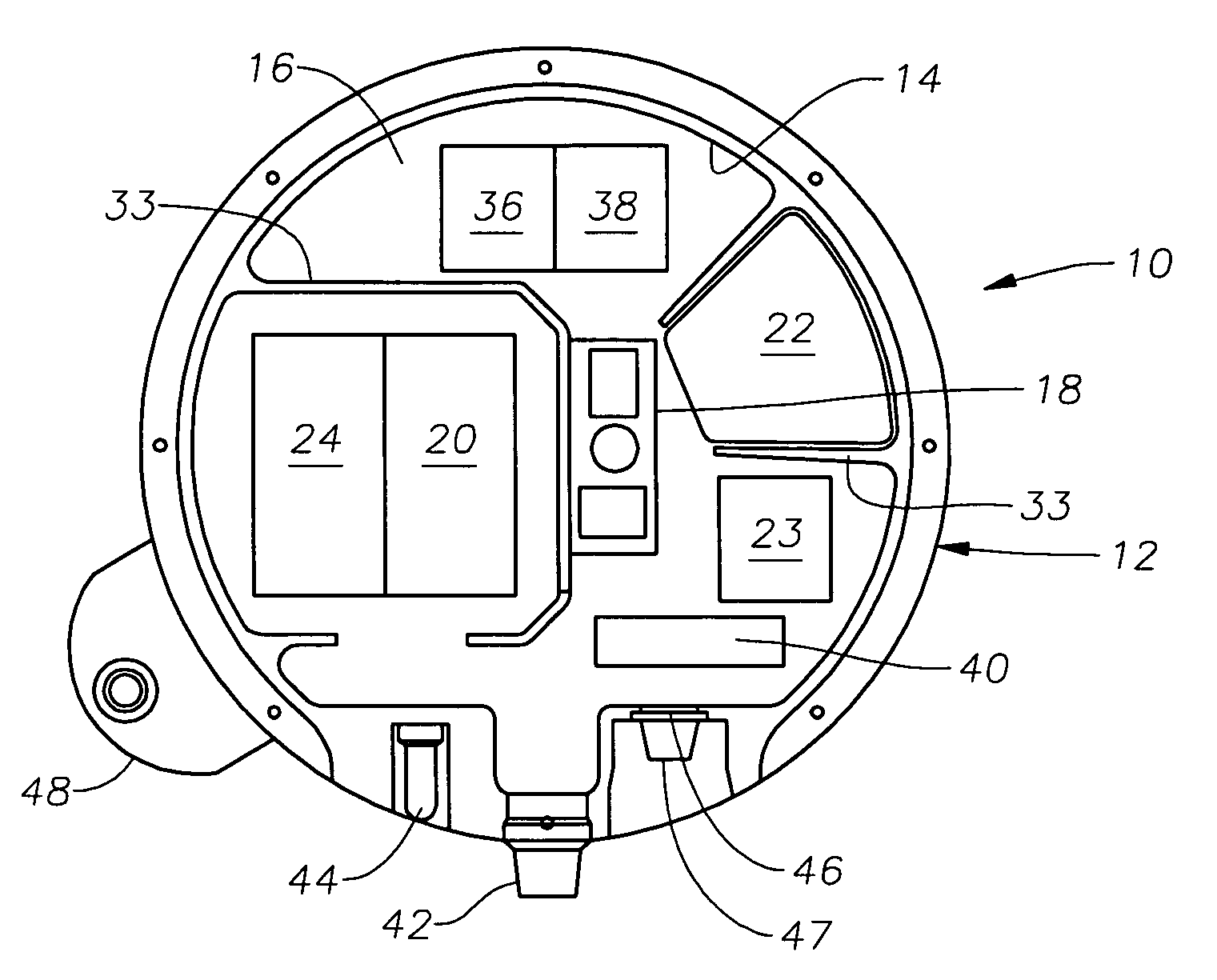

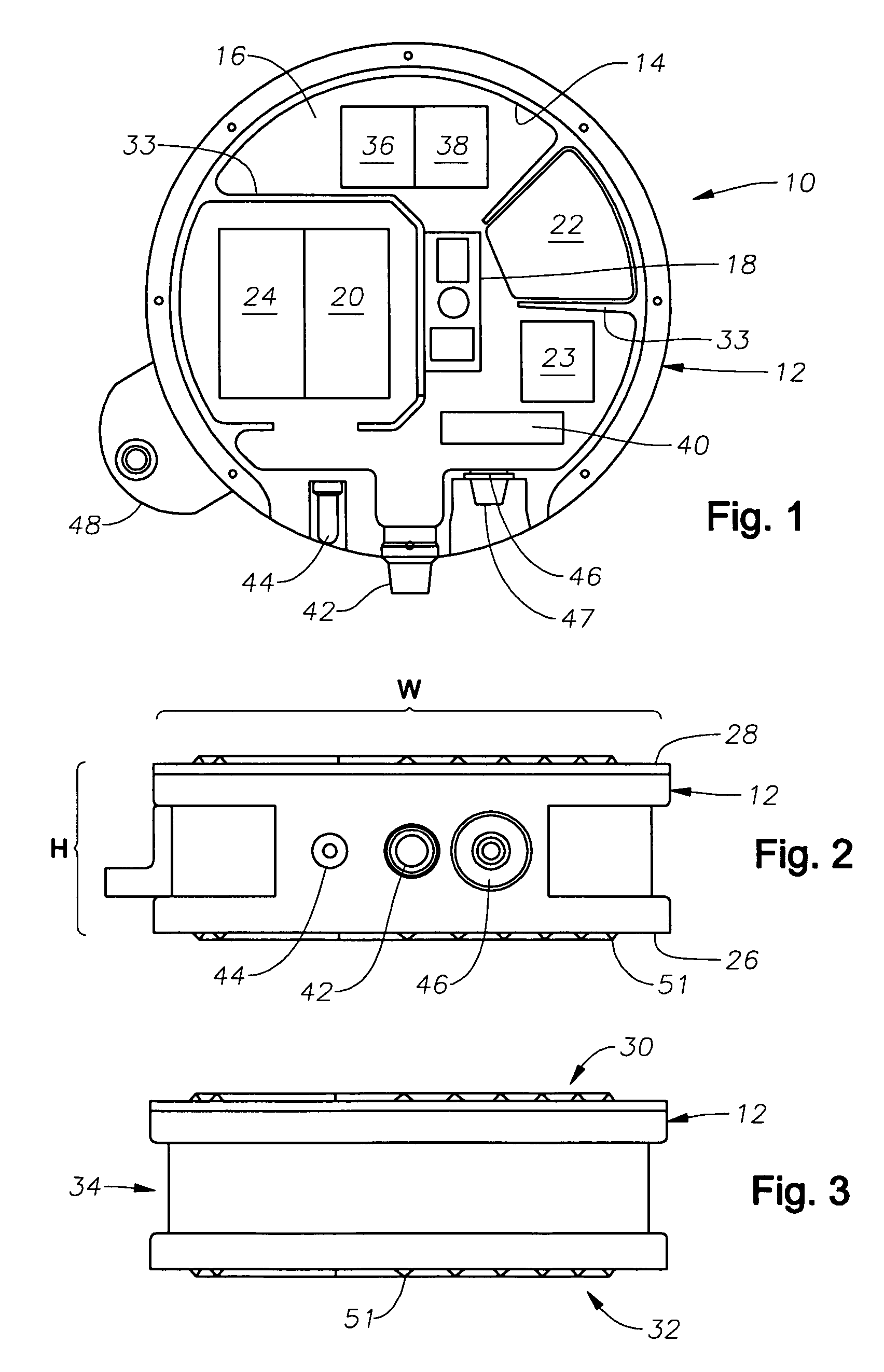

Hot vehicle safety system and methods of preventing passenger entrapment and heat suffocation

InactiveUS20020161501A1Low powerSave battery powerAnti-theft cycle devicesDigital data processing detailsSeat beltVehicle horn

Safety systems for vehicles, primarily passenger vehicles, comprising automated systems and methods for preventing entrapment of children, disabled, aged or infirm persons, or pets from being trapped in closed vehicles left in the sun, so that they will not suffocate from the heat. The invention is characterized by use of one or more systems to sense the occupancy state and temperature inside the vehicle passenger or load space, and provide one or more outputs which can selectively be employed to provide interior and exterior warning of a trapped passenger in a dangerously hot car to permit rescue, and / or to activate vehicle electro-mechanical systems to relieve the heat, such as rolling down windows, unlatching seat belts, unlocking doors, starting the car and / or fans or air conditioning systems and the like. The exterior warnings may be any suitable warning, such as sounding the car horn or alarm siren, flashing head, tail or special lights, placing an emergency call via a vehicle dedicated cell phone, CB radio, GPS system, or the like.

Owner:ROBERT BOSCH CORP

Crystal growth devices and systems, and methods for using same

Owner:FLUIDIGM CORP

Hot vehicle safety system and methods of preventing passenger entrapment and heat suffocation

Safety systems for vehicles, primarily passenger vehicles, comprising automated systems and methods for preventing entrapment of children, disabled, aged or infirm persons, or pets from being trapped in closed vehicles left in the sun, so that they will not suffocate from the heat. The invention is characterized by use of one or more systems to sense the occupancy state and temperature inside the vehicle passenger or load space, and provide one or more outputs which can selectively be employed to provide interior and exterior warning of a trapped passenger in a dangerously hot car to permit rescue, and / or to activate vehicle electro-mechanical systems to relieve the heat, such as rolling down windows, unlatching seat belts, unlocking doors, starting the car and / or fans or air conditioning systems and the like. The exterior warnings may be any suitable warning, such as sounding the car horn or alarm siren, flashing head, tail or special lights, placing an emergency call via a vehicle dedicated cell phone, CB radio, GPS system, or the like.

Owner:ROBERT BOSCH CORP

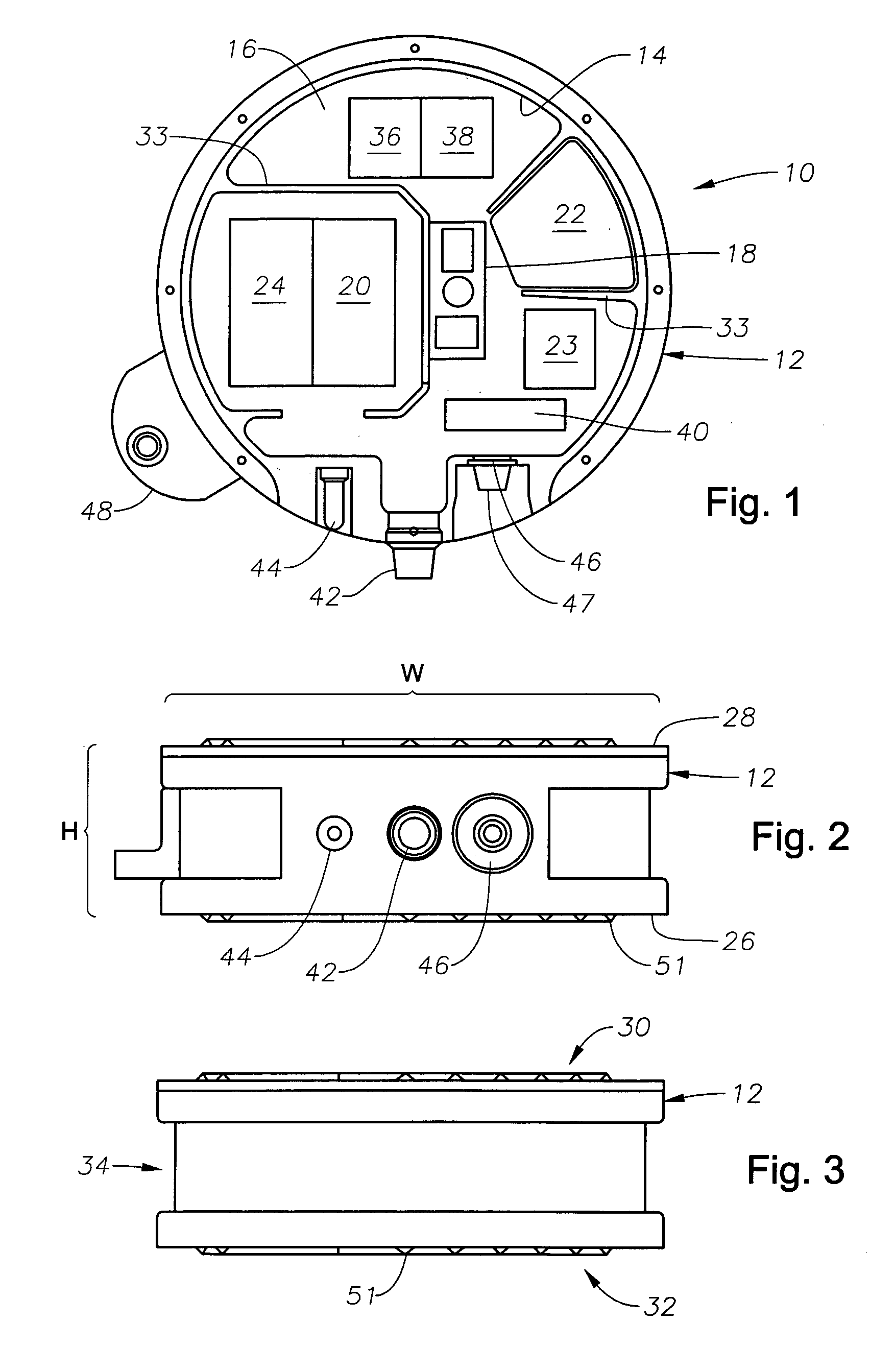

Method and apparatus for seismic data acquisition

InactiveUS20050052951A1Avoid entrapmentMinimize the possibilityTransducer detailsSeismic signal receiversOcean bottomRubidium

A marine seismic exploration method and system comprised of continuous recording, self-contained ocean bottom pods characterized by low profile casings. An external bumper is provided to promote ocean bottom coupling and prevent fishing net entrapment. Pods are tethered together with flexible, non-rigid, non-conducting cable used to control pod deployment. Pods are deployed and retrieved from a boat deck configured to have a storage system and a handling system to attach pods to cable on-the-fly. The storage system is a juke box configuration of slots wherein individual pods are randomly stored in the slots to permit data extraction, charging, testing and synchronizing without opening the pods. A pod may include an inertial navigation system to determine ocean floor location and a rubidium clock for timing. The system includes mathematical gimballing. The cable may include shear couplings designed to automatically shear apart if a certain level of cable tension is reached.

Owner:MAGSEIS FF LLC

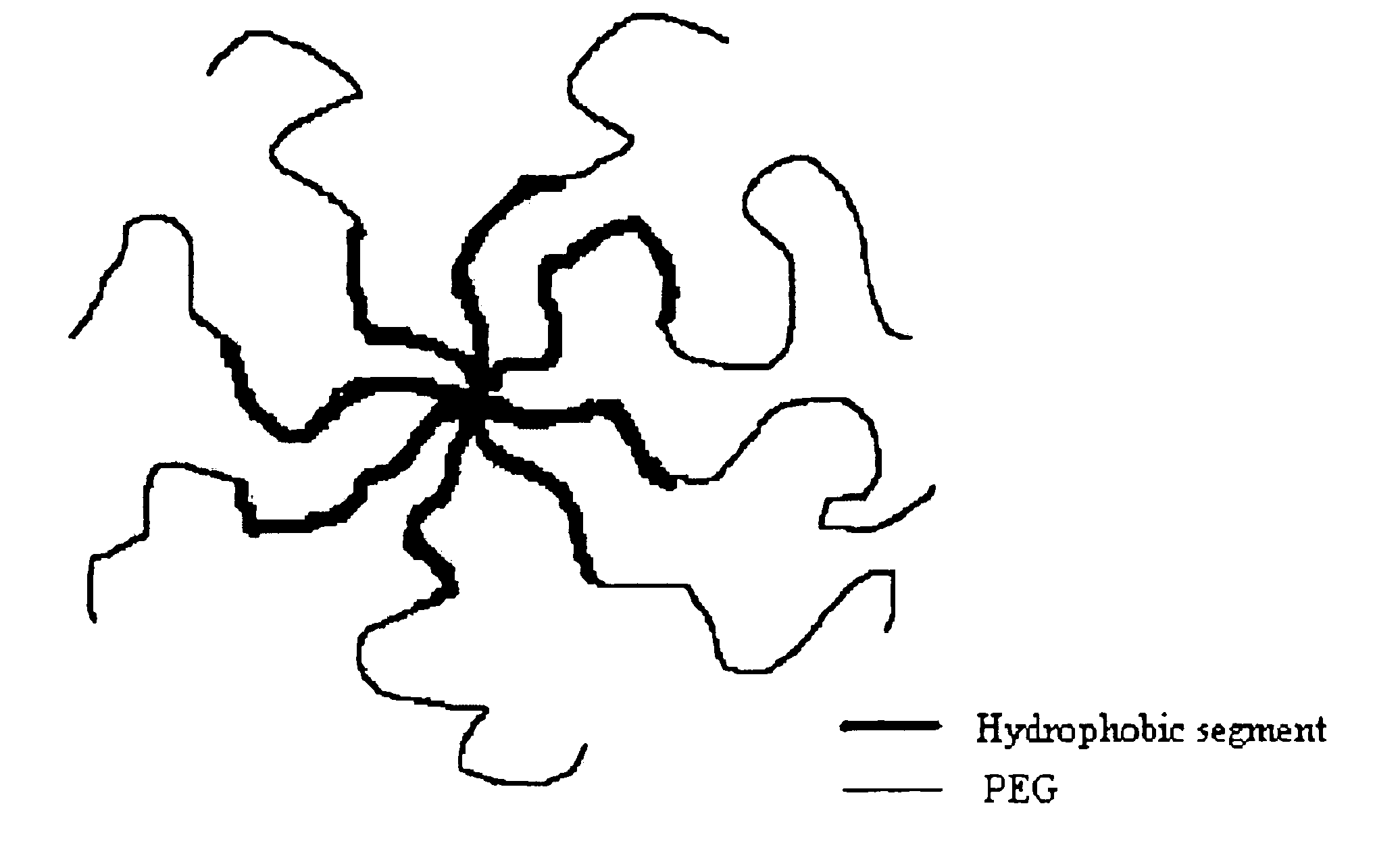

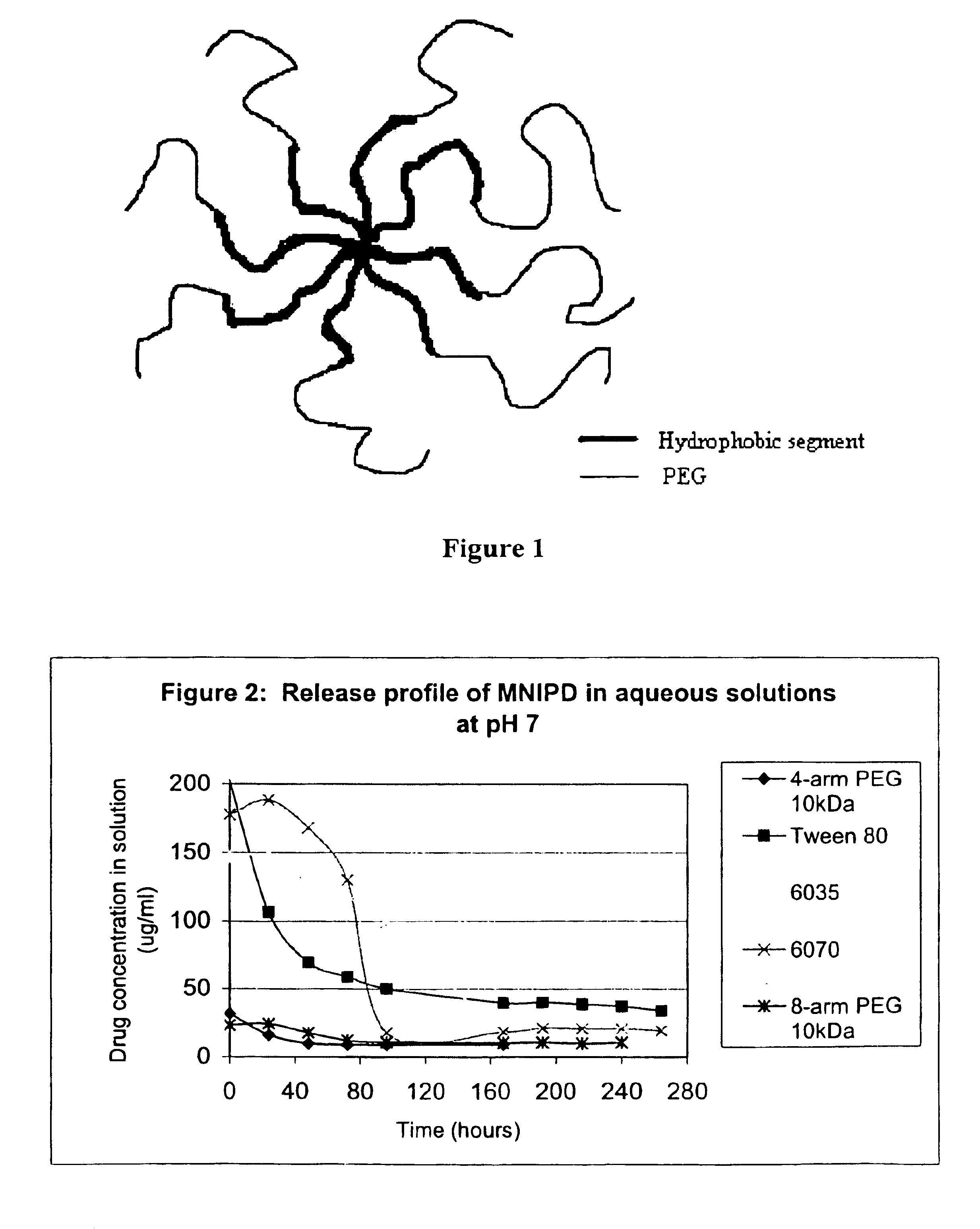

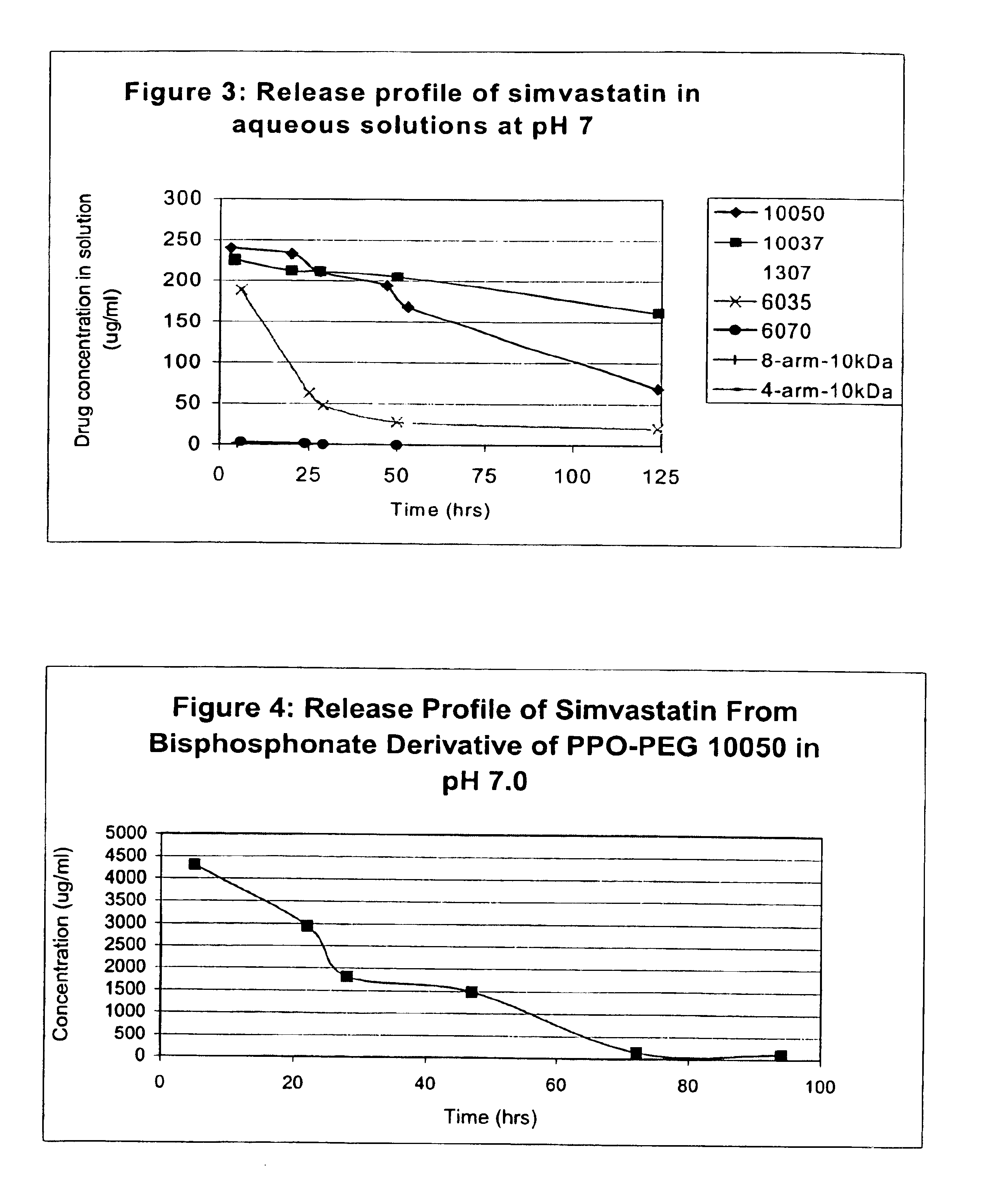

Multi-arm block copolymers as drug delivery vehicles

InactiveUS6838528B2Improve solubilityReduce deliveryPeptide/protein ingredientsNanomedicineSolubilityHydrophilic polymers

The invention provides multi-arm block copolymers useful as drug delivery vehicles comprising a central core molecule, such as a residue of a polyol, and at least three copolymer arms covalently attached to the central core molecule, each copolymer arm comprising an inner hydrophobic polymer segment covalently attached to the central core molecule and an outer hydrophilic polymer segment covalently attached to the hydrophobic polymer segment, wherein the central core molecule and the hydrophobic polymer segment define a hydrophobic core region. The solubility of hydrophobic biologically active agents can be improved by entrapment within the hydrophobic core region of the block copolymer. The invention further includes pharmaceutical compositions including such block copolymers, methods of making such copolymers and pharmaceutical compositions, and methods of using the block copolymers as drug delivery vehicles.

Owner:NEKTAR THERAPEUTICS INC

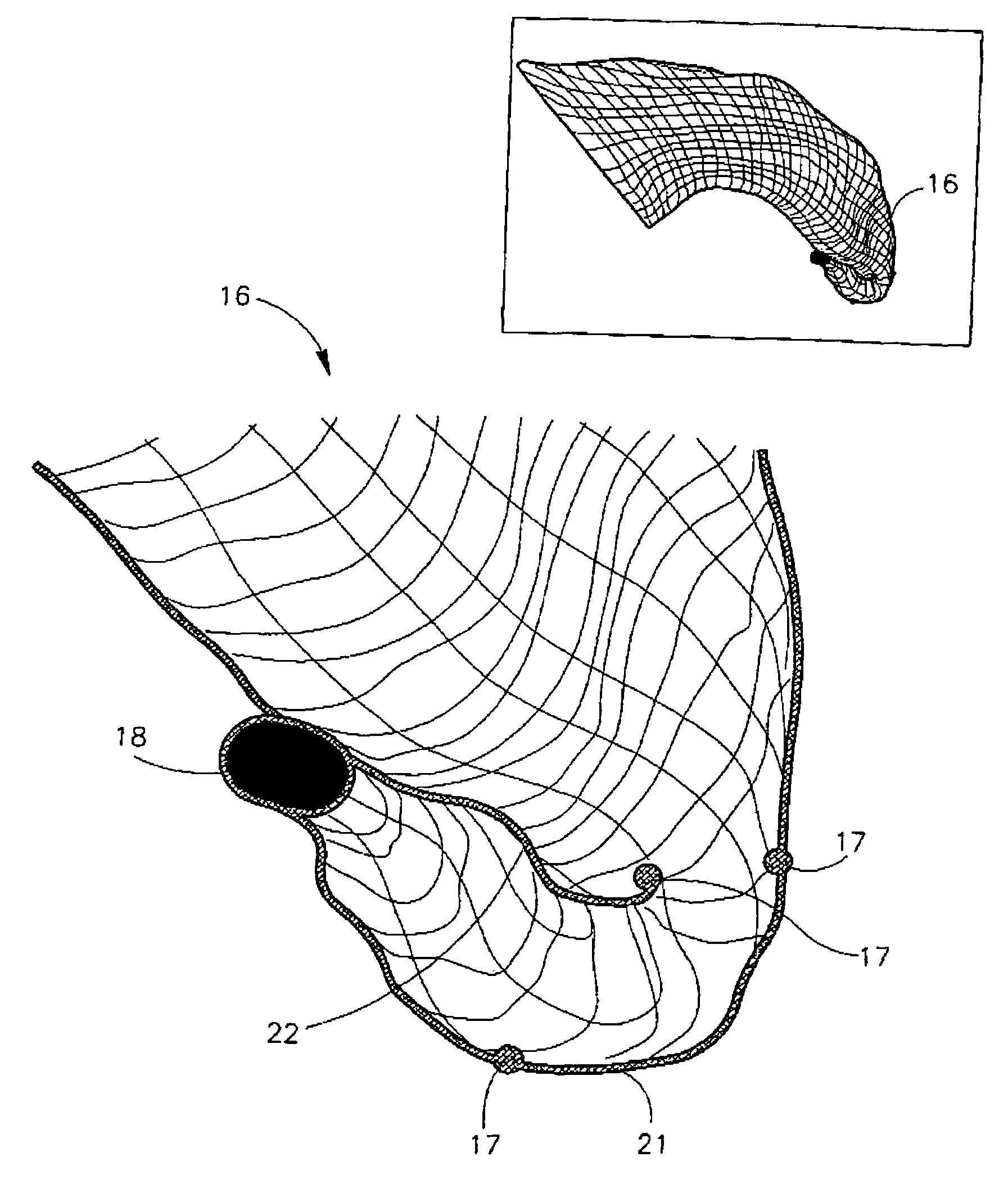

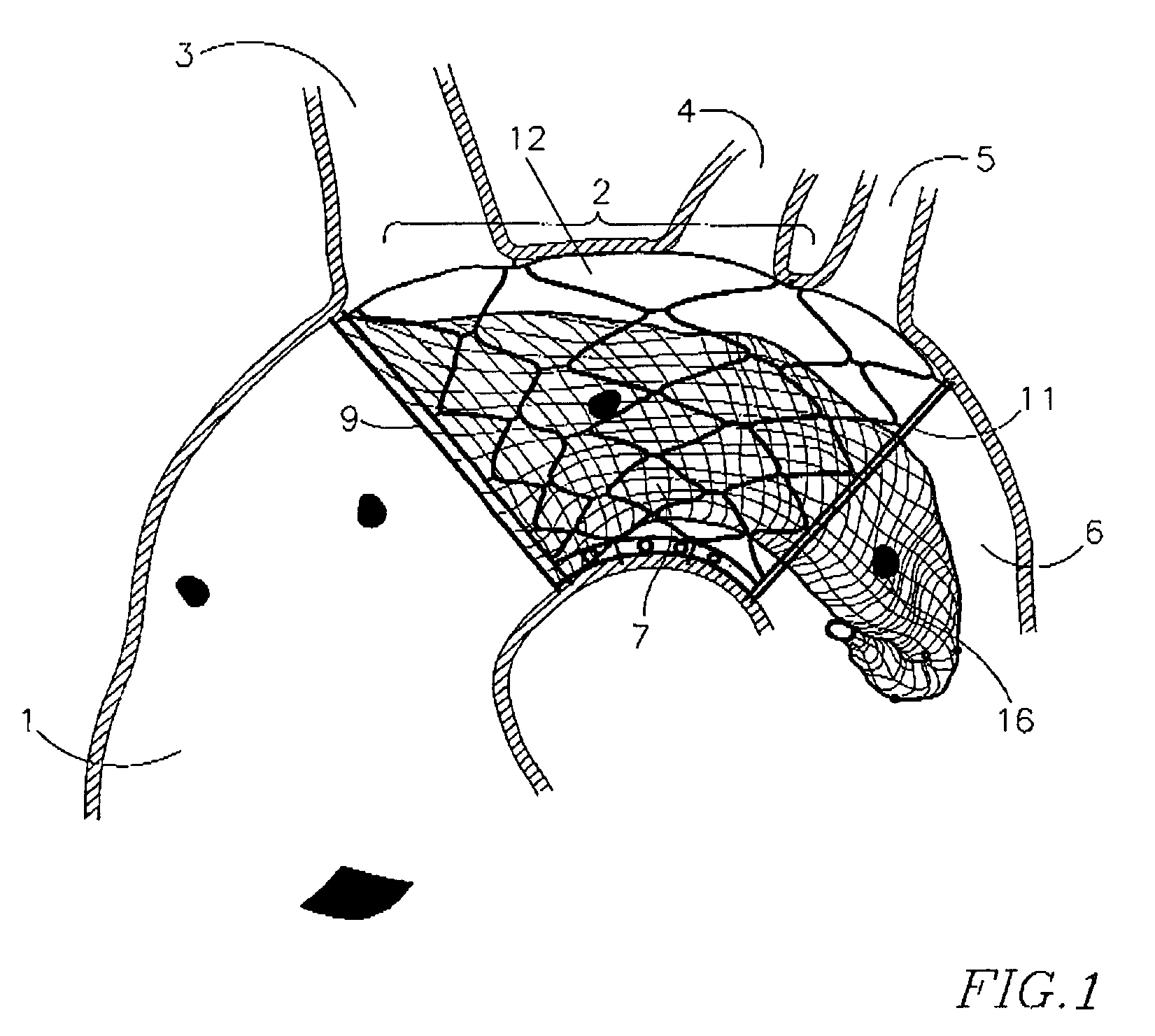

Endovascular device for entrapment of particulate matter and method for use

A device and method for protecting a blood vessel, and hence bodily tissues, against damage caused by particulate such as an embolus. The device may be a stent, for insertion in a large artery such as the ascending aorta, and may be combined with a filter. In one embodiment, the device includes an outer wire frame rather than a stent. The stent may be made of at least one layer of mesh, which is typically attached or mounted to the arterial wall. Typically only part of the stent is attached (for example at a reinforcing ring structure). Typically the size of the apertures of the mesh at the top portion of the stent is smaller than the bottom portion of the stent. The device and method are particularly useful in preventing blockages of flow to the brain, but have other uses as well. An electric charge may be placed on the device, for example, to prevent blood components from collecting.

Owner:KEYSTONE HEART

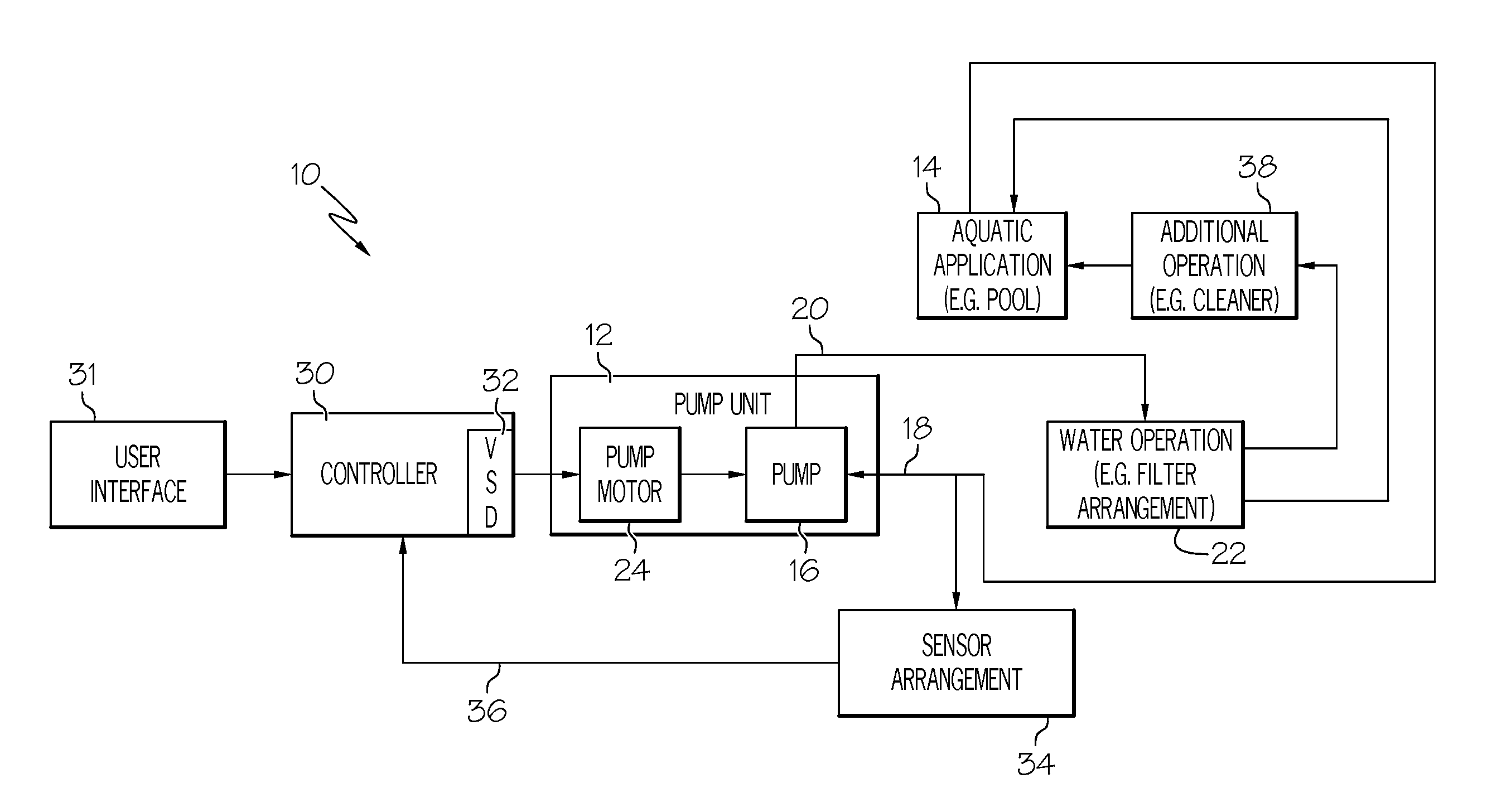

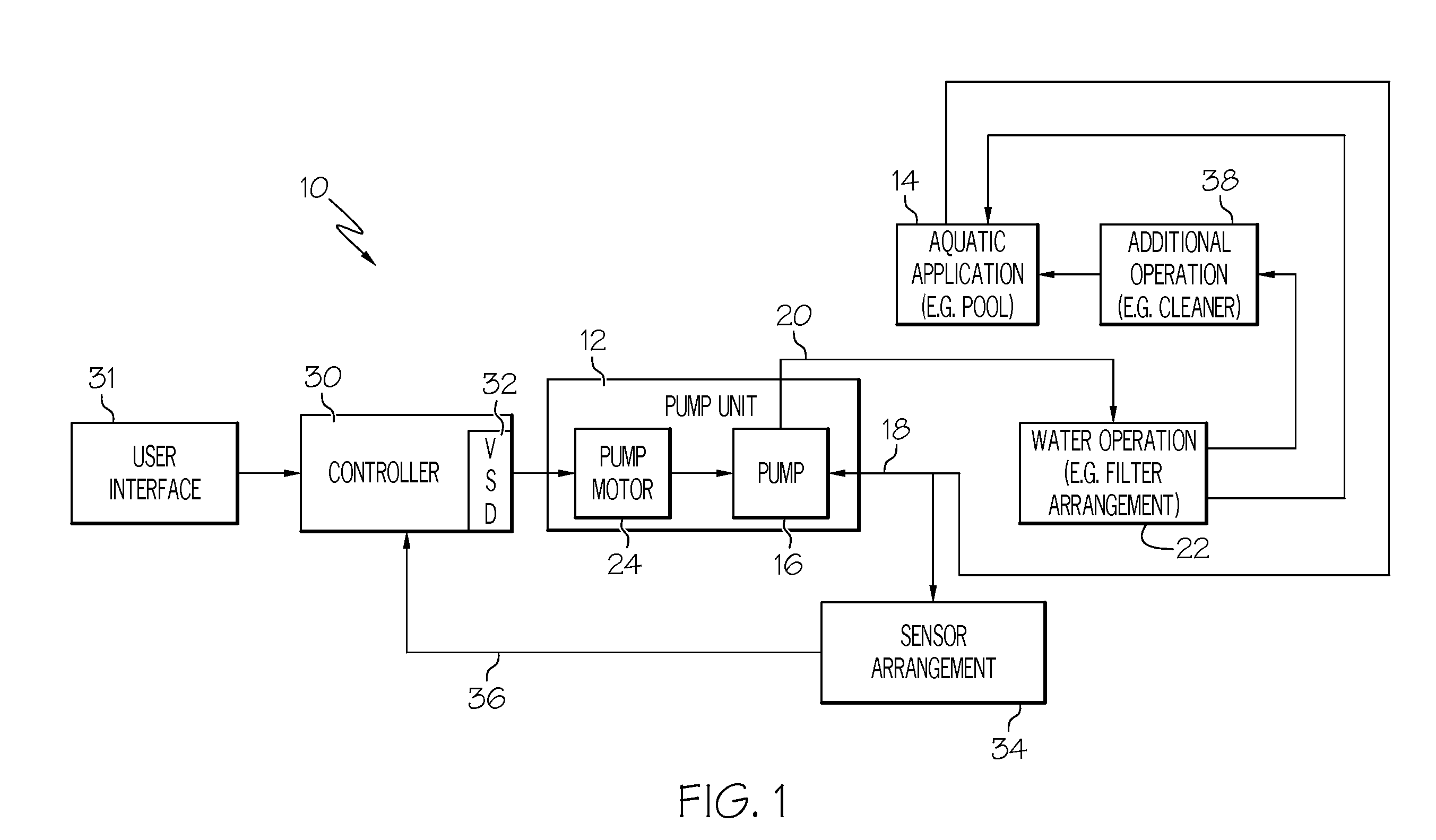

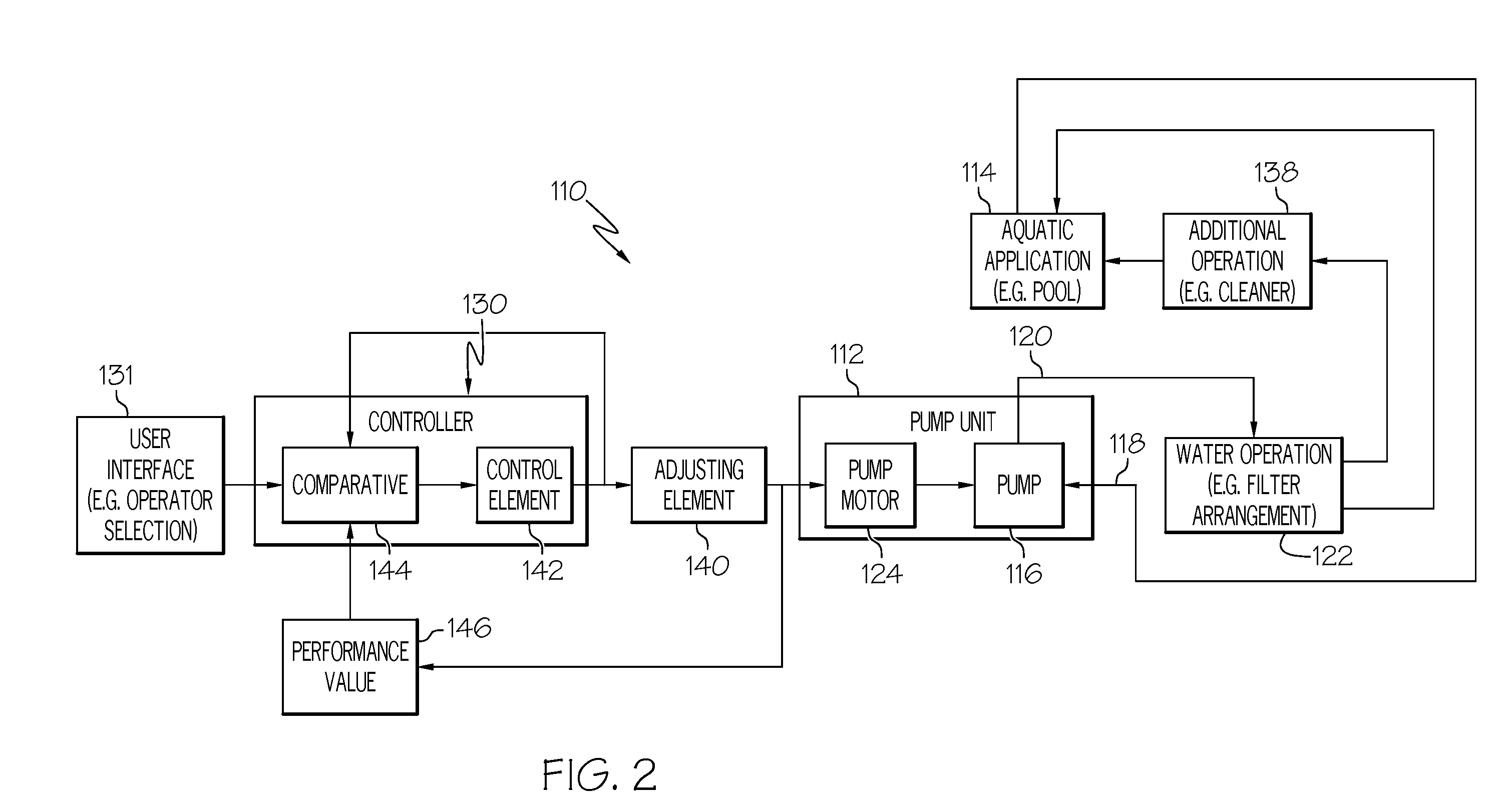

Anti-entrapment and Anti-dead head function

ActiveUS20070183902A1Adapted to consume powerEngine controlPump controlEntrapmentIndustrial engineering

A pumping system includes a water pump for moving water. The pumping system includes means for determining a value indicative of a blockage that inhibits the movement of water through the pumping system, and means for determining a performance value of the pumping system. In one example, the pumping system includes means for comparing the performance value to the value indicative of a blockage and means for controlling the pump in response to the comparison. In another example, the system includes means for determining a change in power consumption of the water pump. In another example, the system includes means for determining a threshold value and means for controlling the pump when the performance value exceeds the threshold value. In another example, the system includes means for determining a difference value based upon a plurality of performance valves during a first time period and a second time period. A method of controlling the pumping system is also included.

Owner:DANFOSS POWER ELECTRONICS AS +1

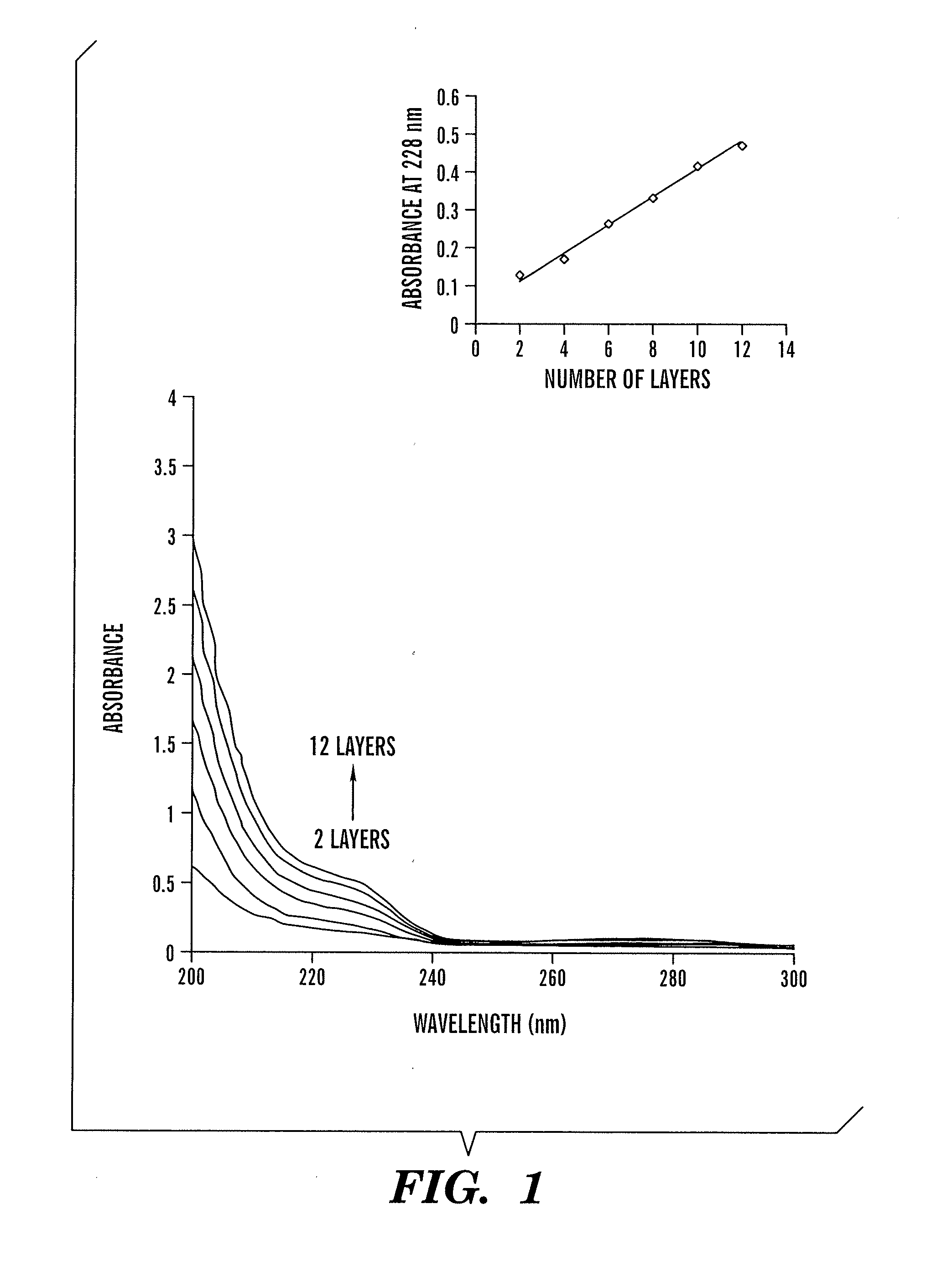

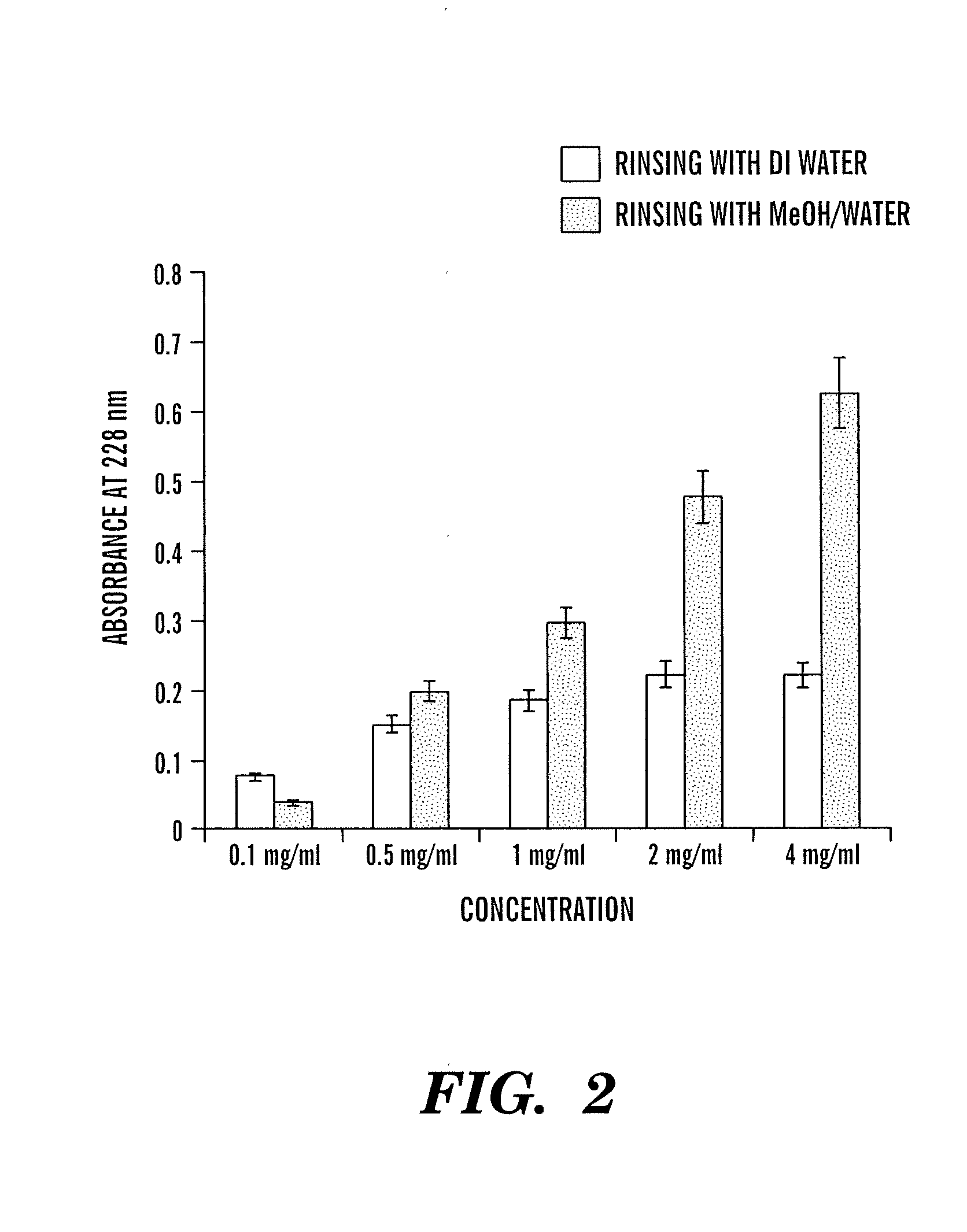

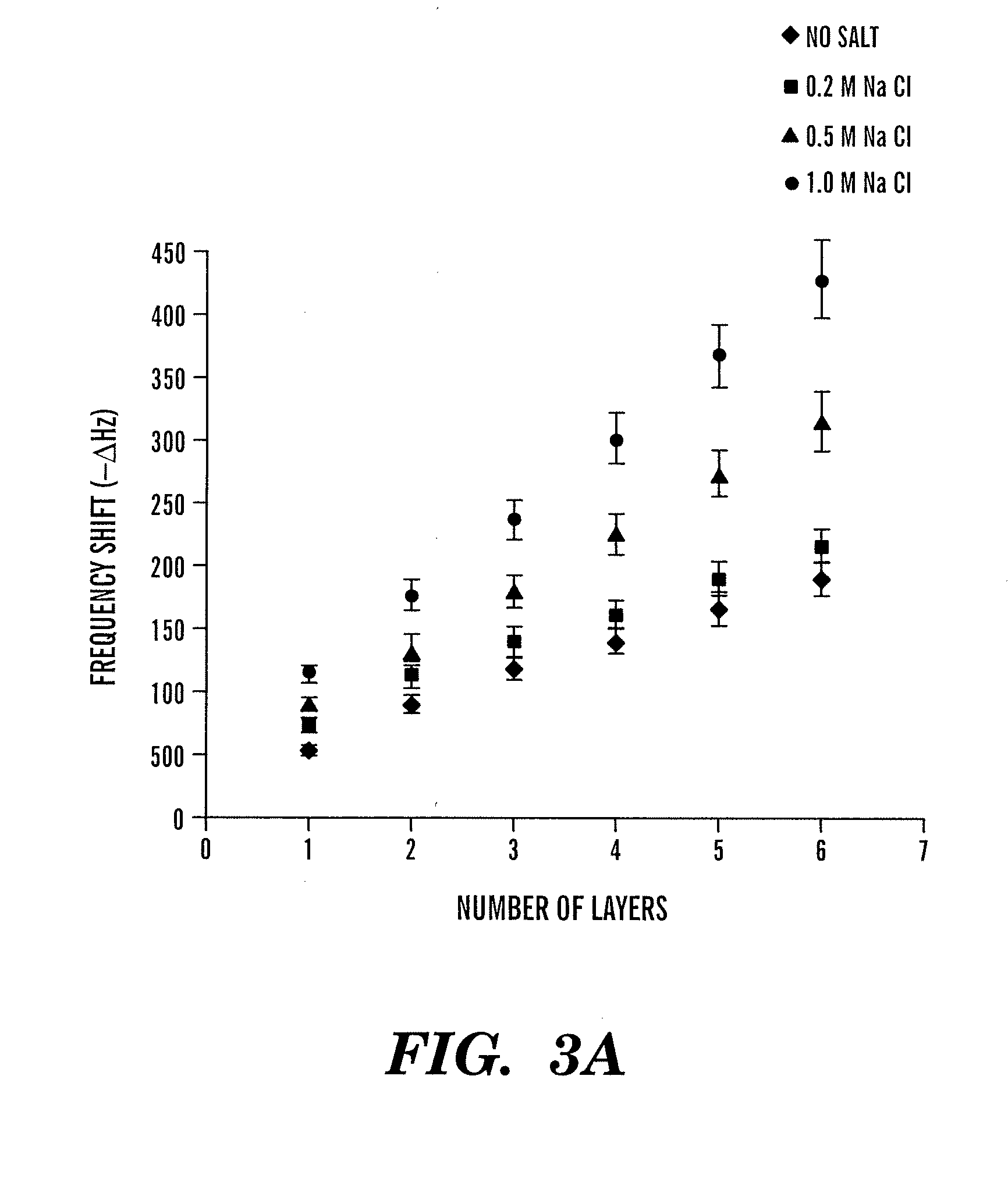

Methods for stepwise deposition of silk fibroin coatings

ActiveUS20090202614A1Suppression of initial burstFacilitated releasePeptide/protein ingredientsLayered productsChemical treatmentEntrapment

The invention provides a method for the controlled assembly of layered silk fibroin coatings using aqueous silk fibroin material. The methods described herein can be used to coat substrates of any material, shape, or size. Importantly, the described methods enable control of the biomaterial surface chemistry, thickness, morphology and structure using layered thin film coatings, or bulk coatings. Furthermore, the methods can be performed in all water and do not require intensive chemical processing enabling controlled entrapment of labile molecules such as, drugs, cytokines, and even cells or viruses to generate functional coatings that can be used in a variety of applications.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

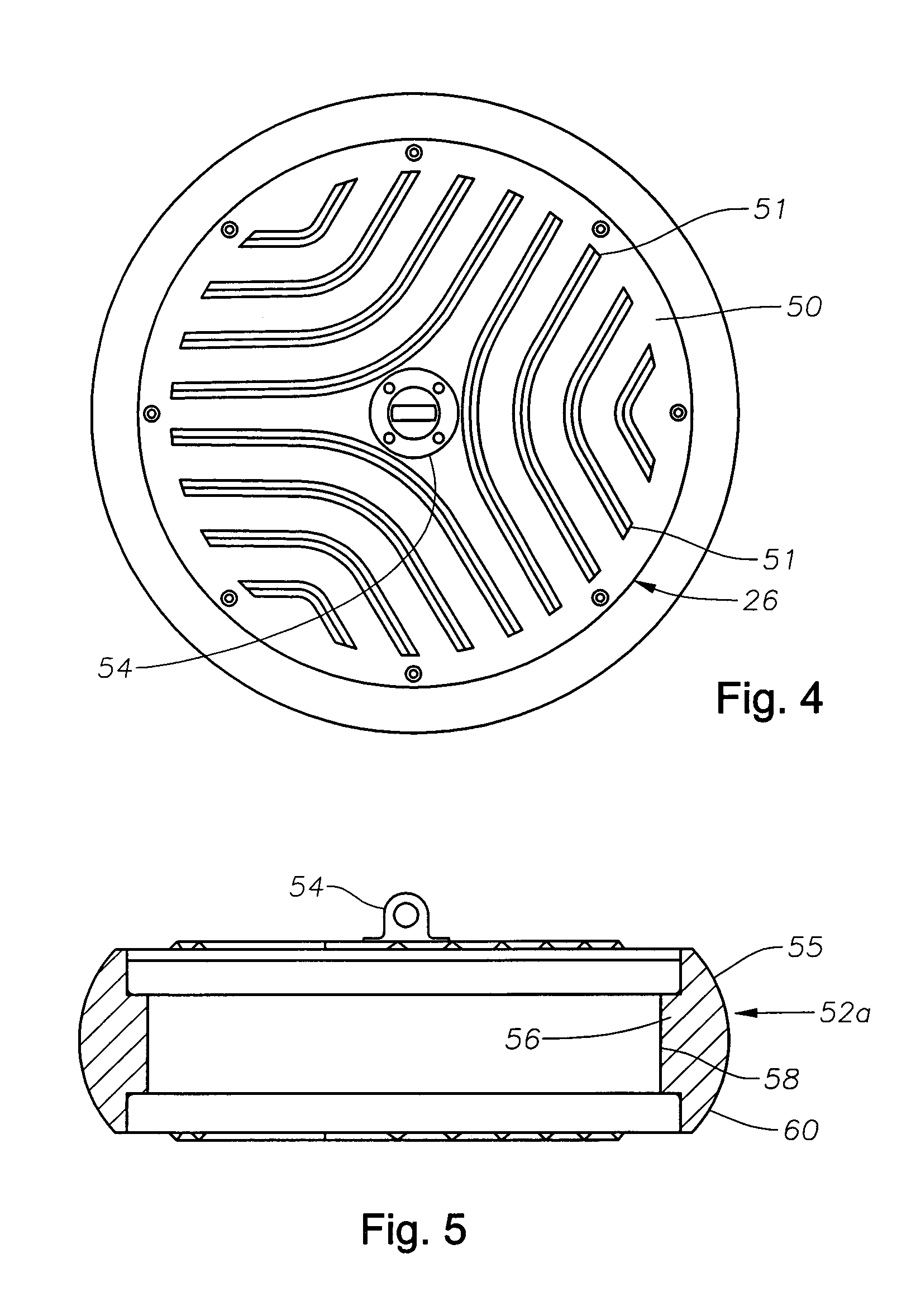

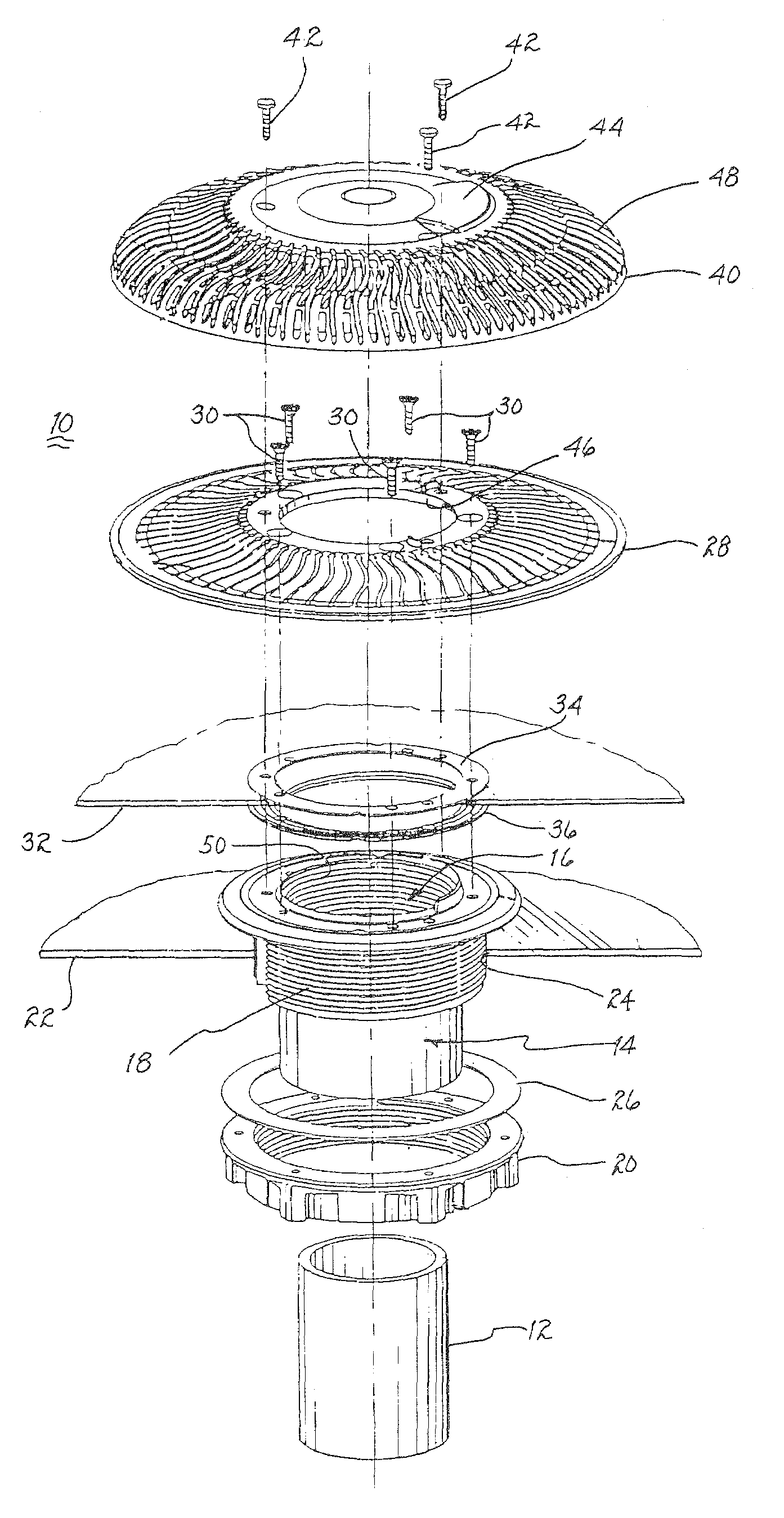

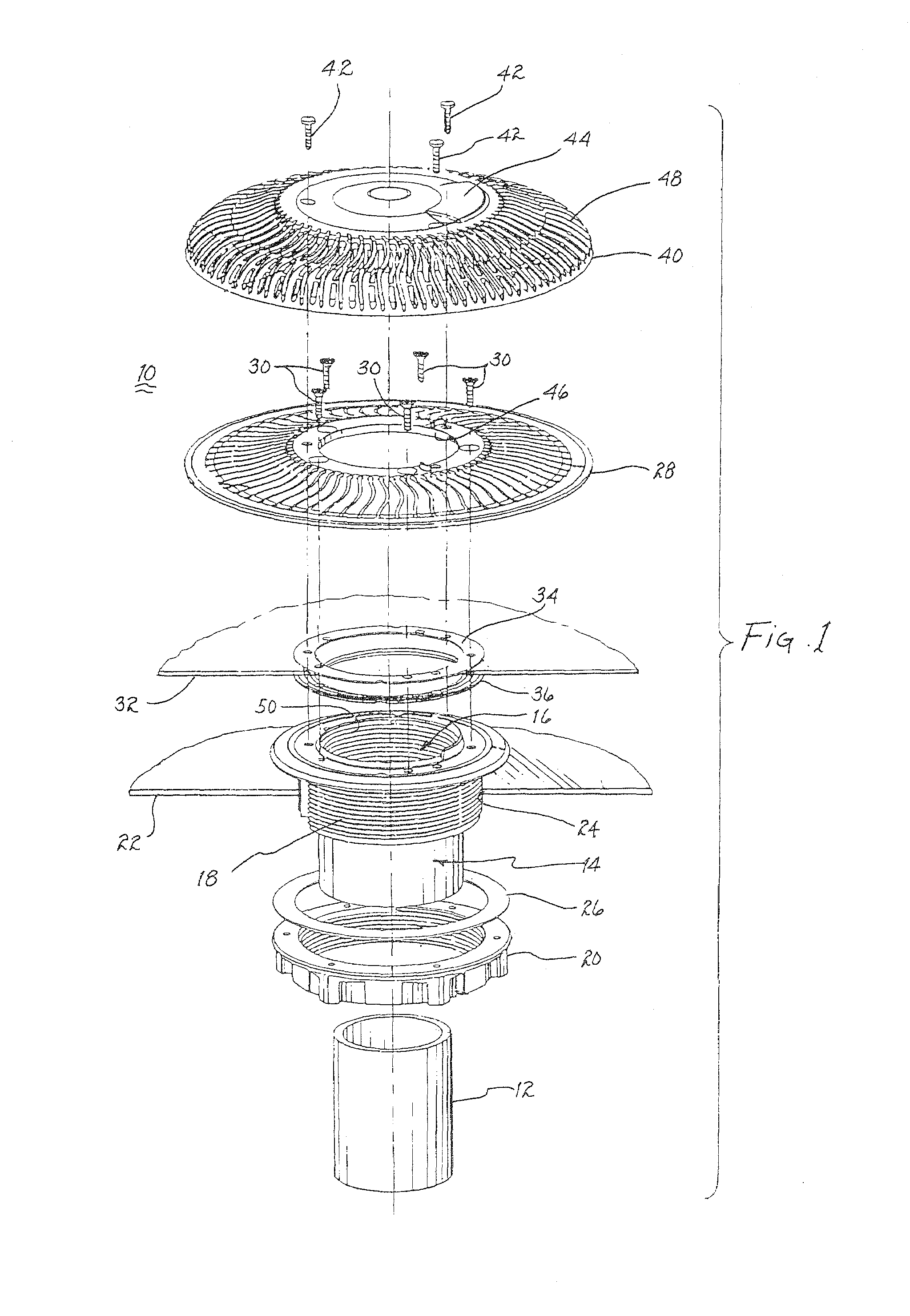

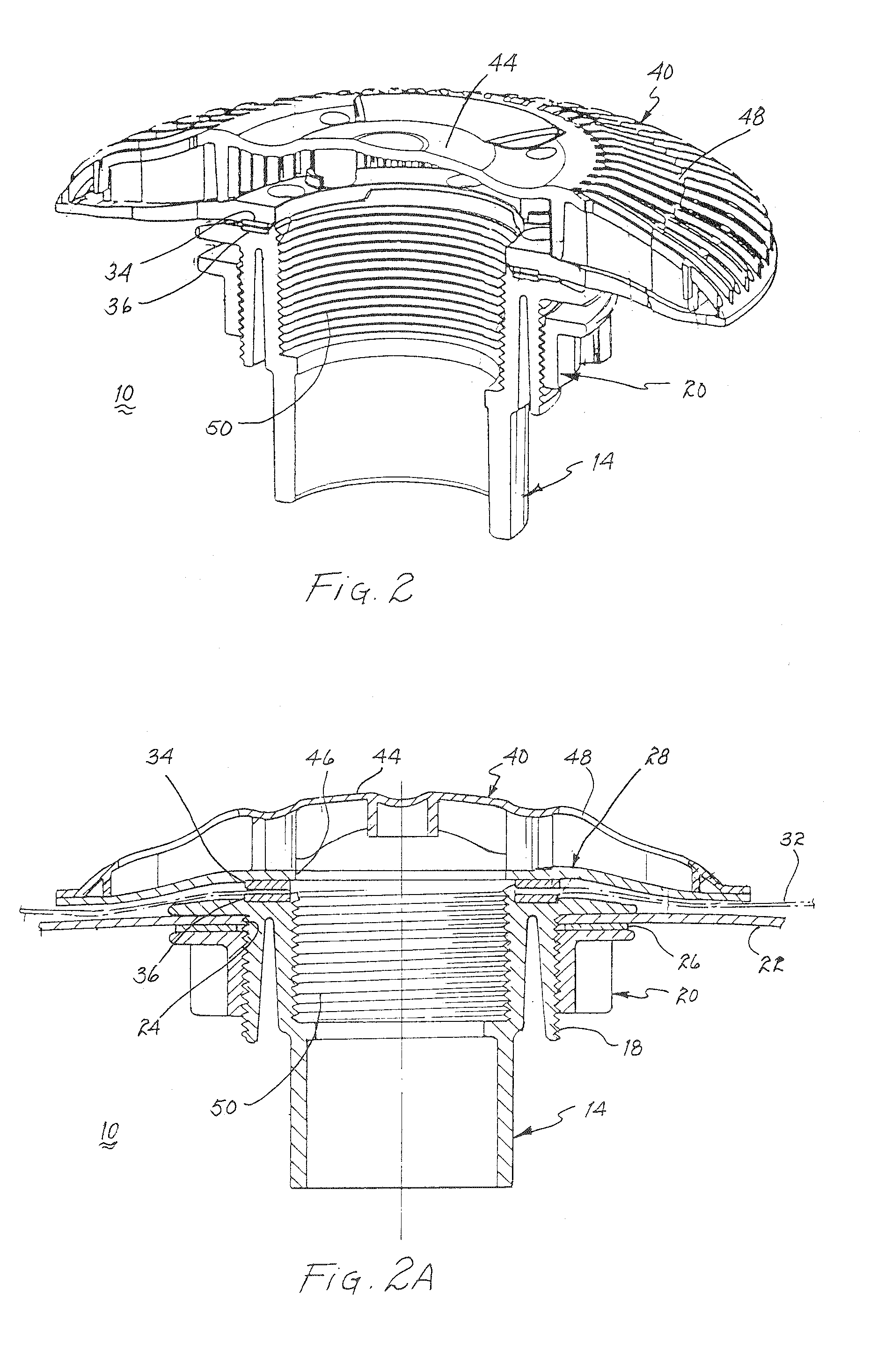

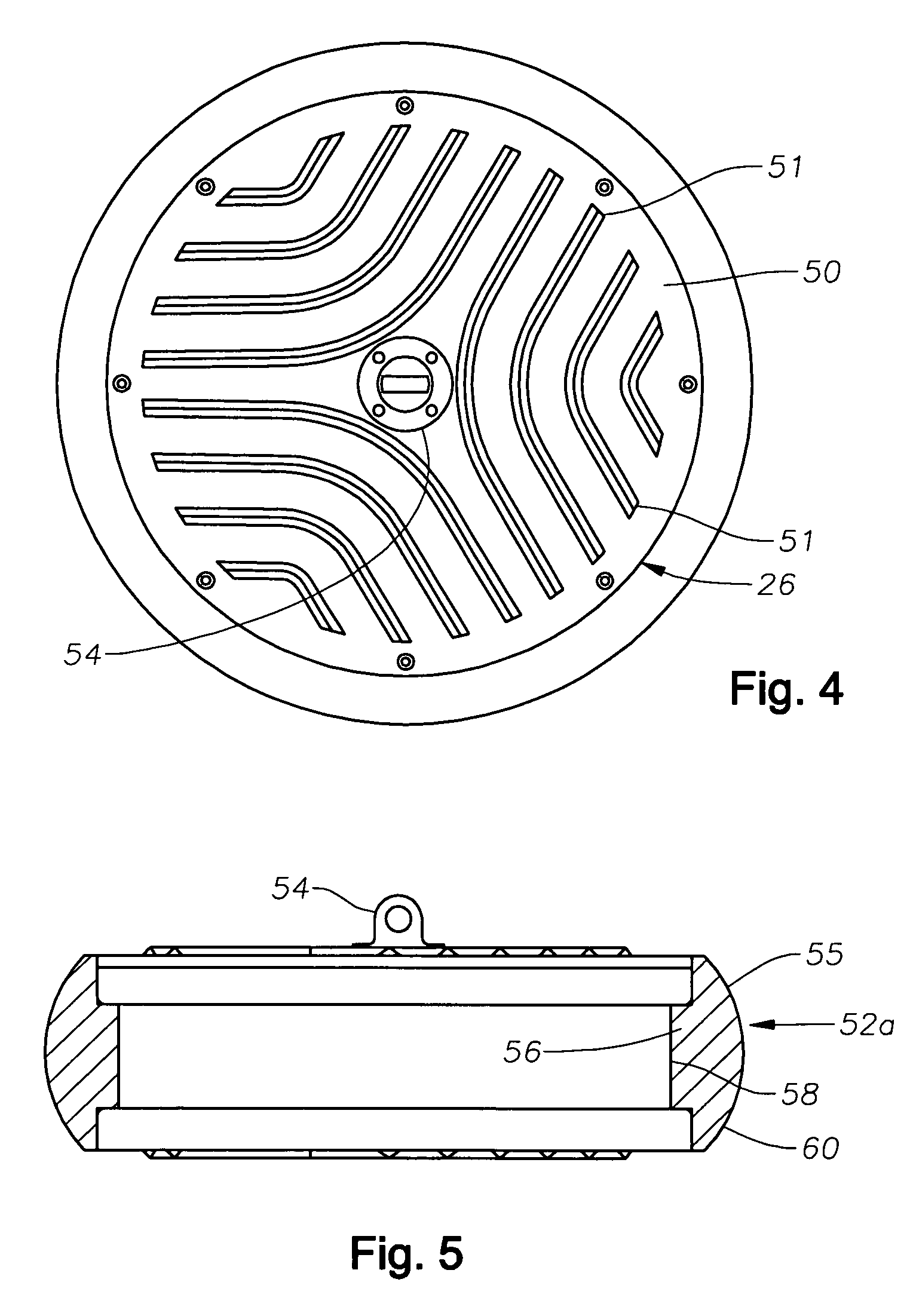

Anti-entrapment drain

A drain for swimming pools, spas, whirlpool baths, etc., includes a plurality of first orifices in communication with corresponding serpentine passageways to minimize hair or a body part from covering and entering the first orifices to a degree sufficient to entrap a bather. A plurality of second orifices independent of the first orifices and in fluid communication with one another through a peripheral passageway provide a flow of water from the peripheral passageway into the serpentine passageways to create an alternate water inflow path and reduce the pressure differential and possible entrapment that might occur should a body part or hair come in contact with or enter the first orifices. Moreover, a plurality of ridges are attendant the first orifices to reduce the likelihood of direct contact with the first orifices by a body part or hair.

Owner:HAYWARD IND INC

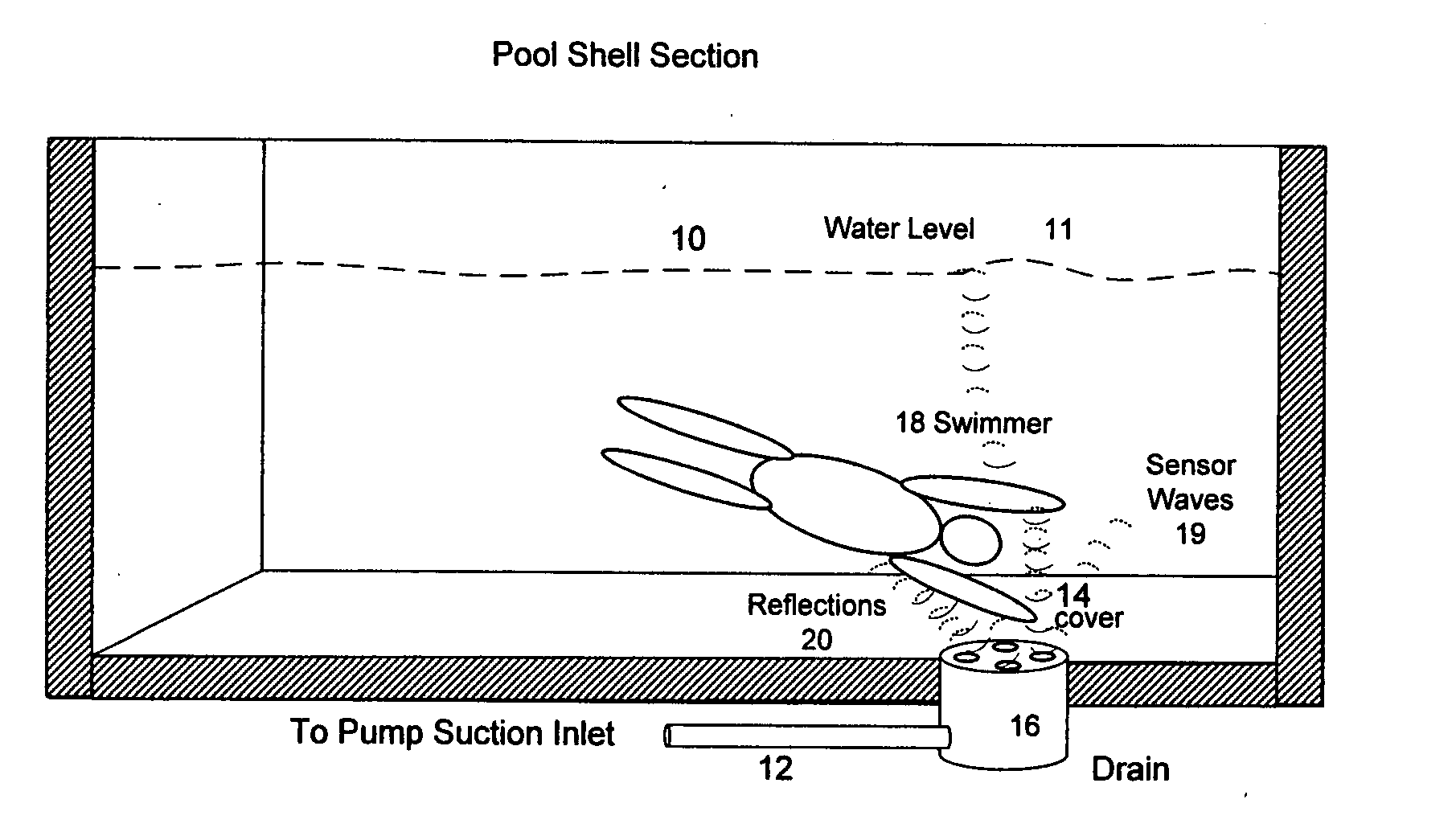

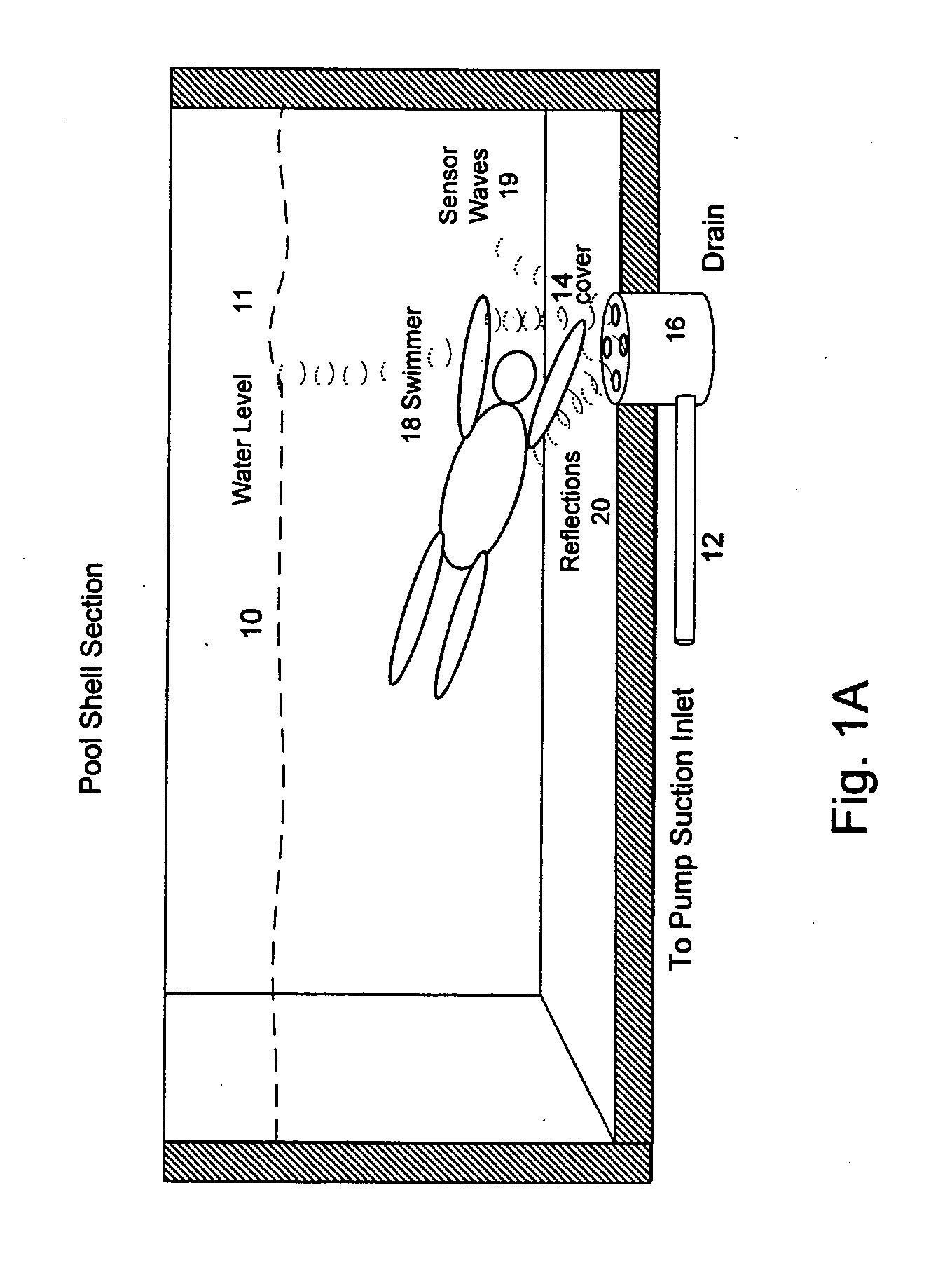

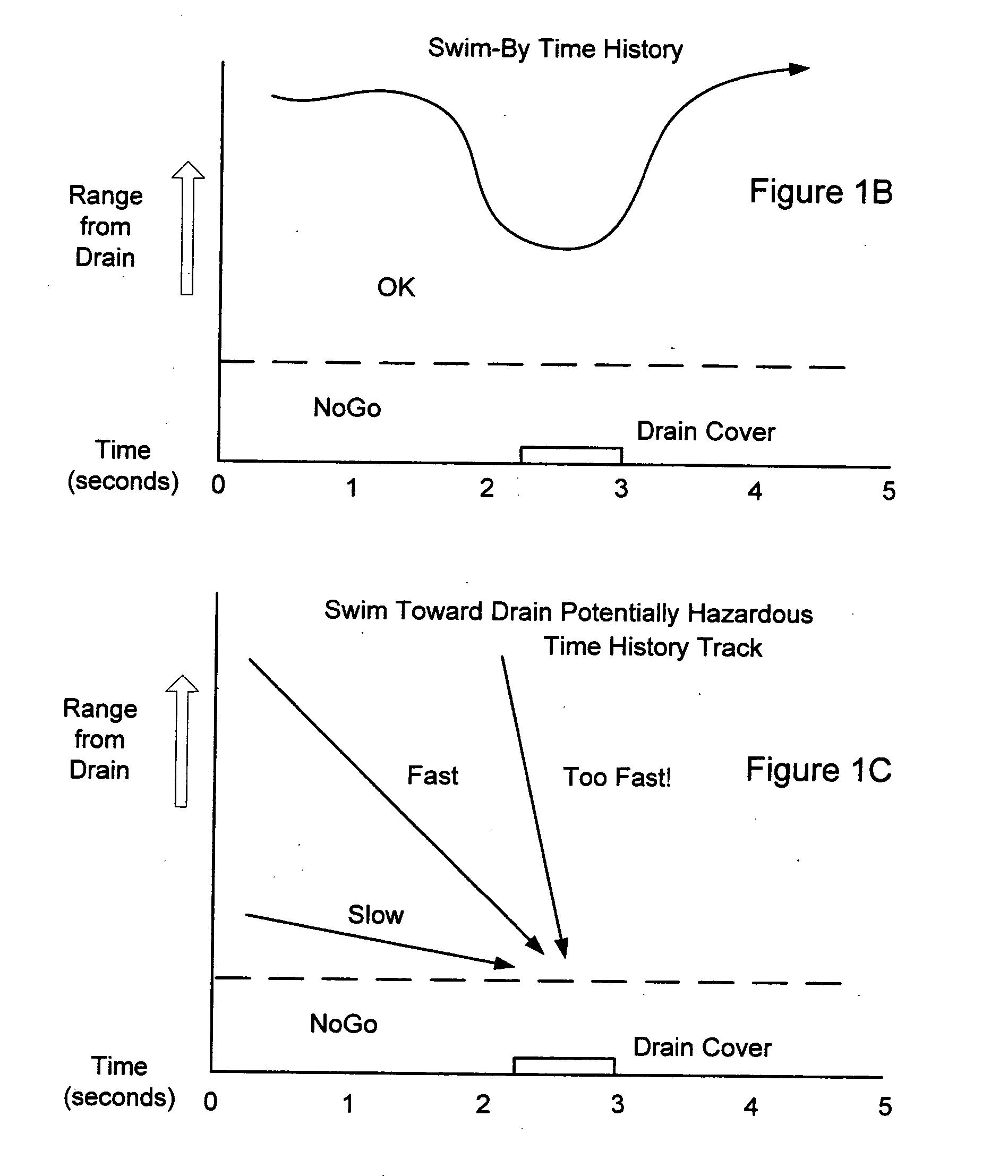

Machine for anticipatory sensing and intervention to avoid swimmer entrapment

A machine for anticipatory sensing and intervention to avoid swimmer entrapment, with an active pre-entrapment sensor (e.g. ultrasonic) that assesses the relative hazard based on swimmer proximity to the drain cover. An Ultrasonic Transducer launches waves into the suction piping and / or drain system, and to receive echoes from the drain cover, swimmer limbs, hair or body, and the water surface parellel to the drain cover. A Transmitter / Pulser electrically energizes the ultrasonic transducer to launch waves into the suction piping and / or drain system, A Receiver / Processor detects the echoes electrical signals from the the ultrasonic transducer and to receive echoes from objects of interest beyond the pool drain. A Logic and Control element converts the detected signals into reliable information regarding a swimmer safety / hazard status. An Output provides a pump shutdown command when required. Solutions for both new construction and retrofit are described.

Owner:WOLFE MICHAEL LAWRENCE

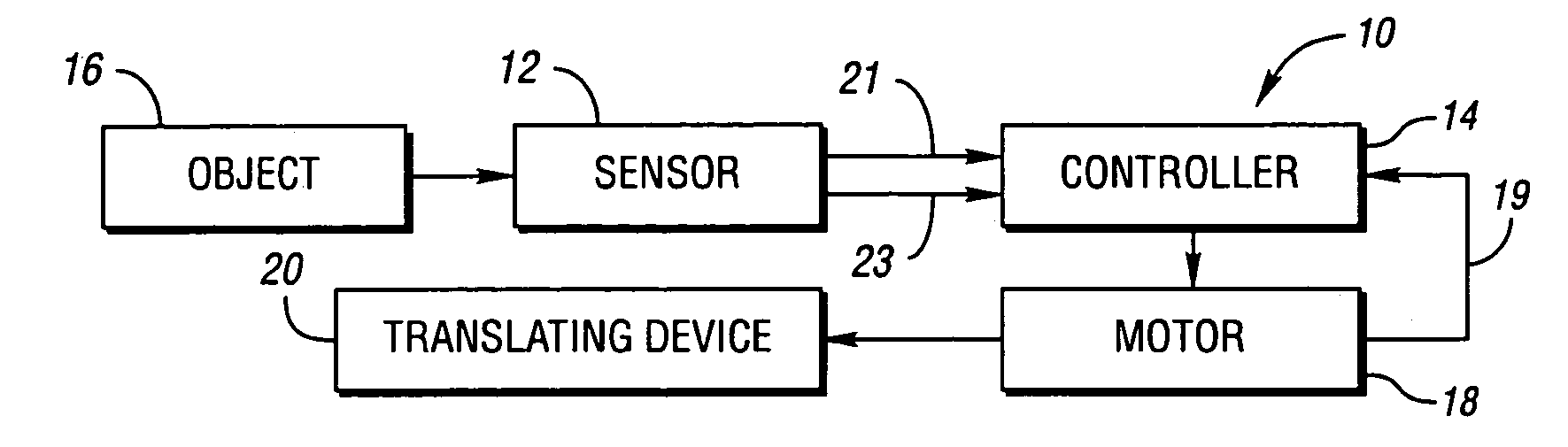

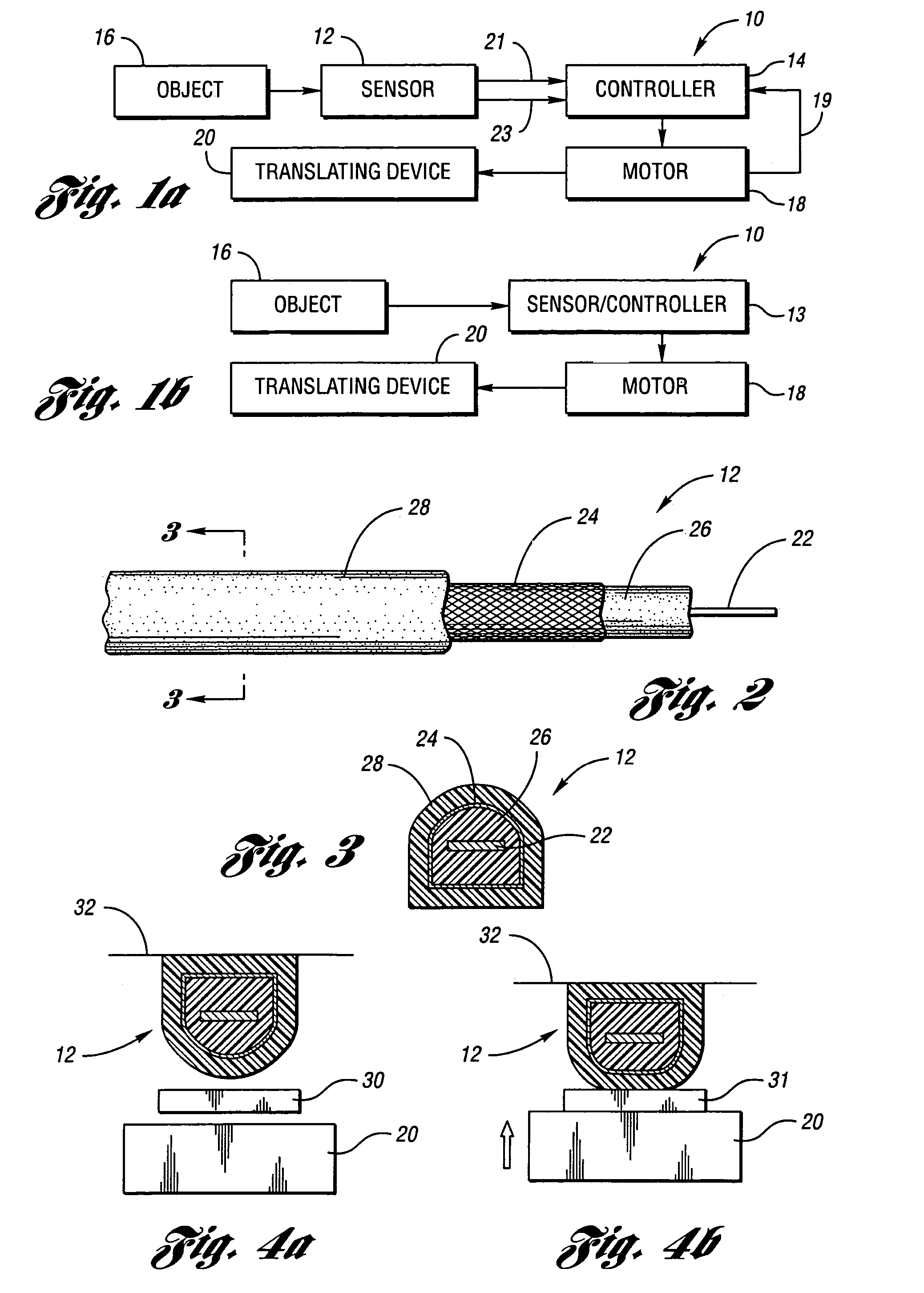

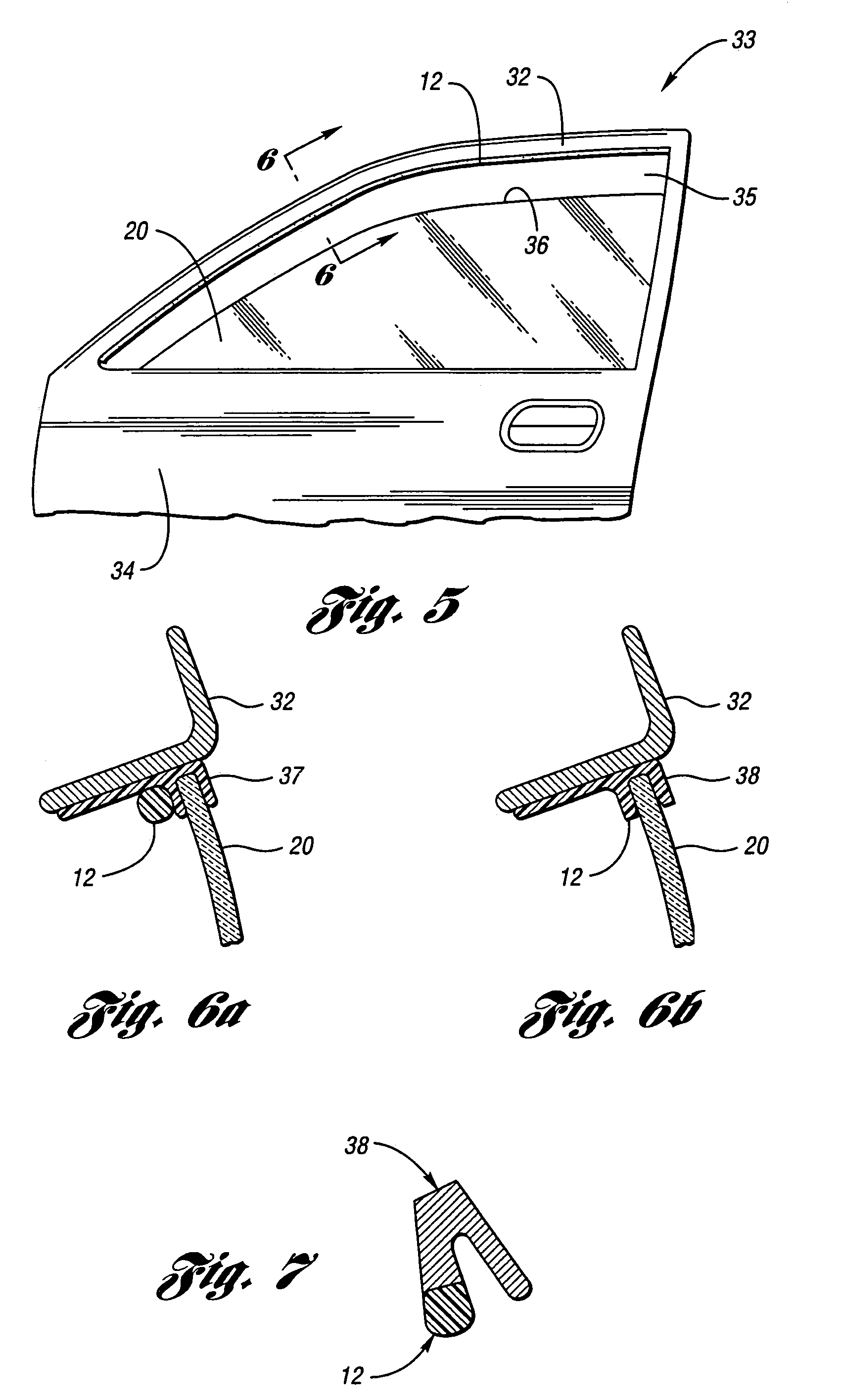

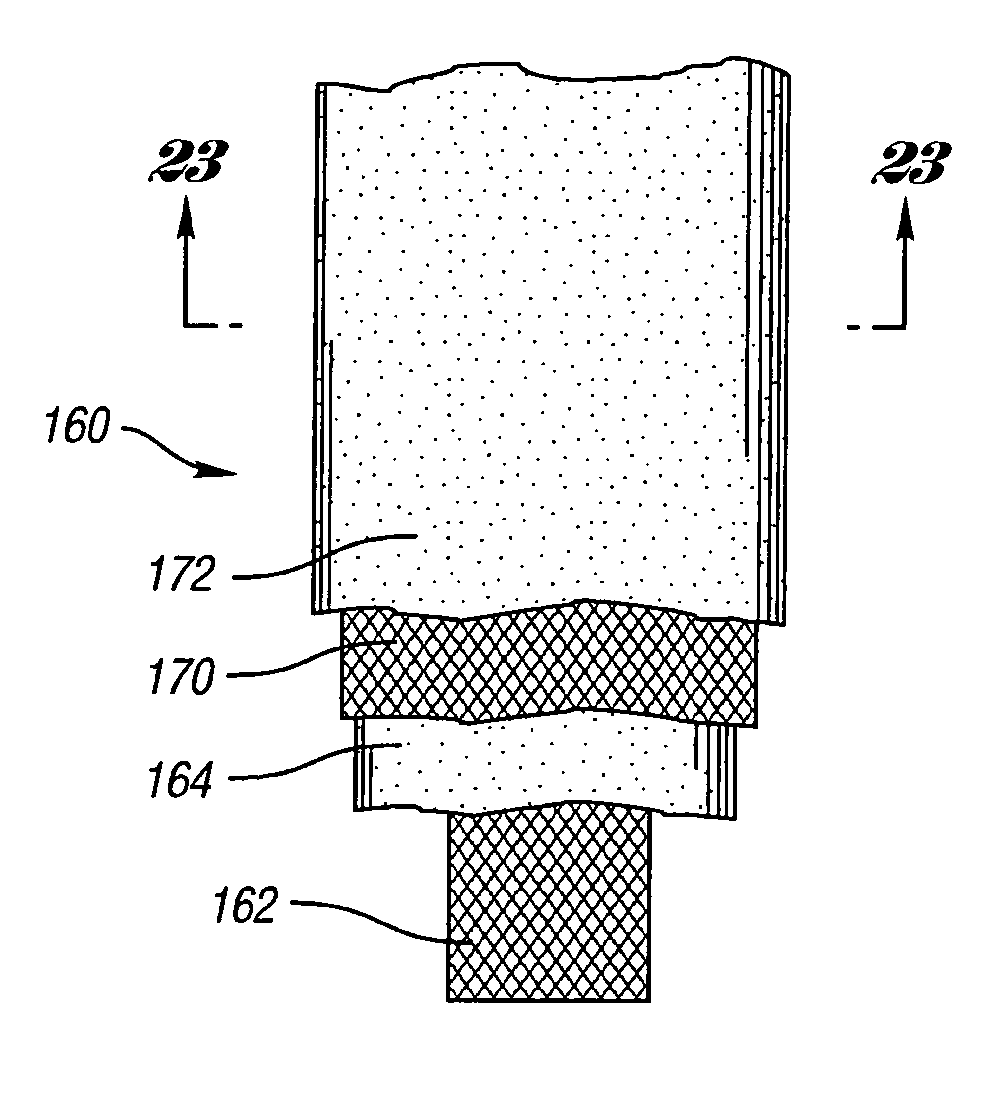

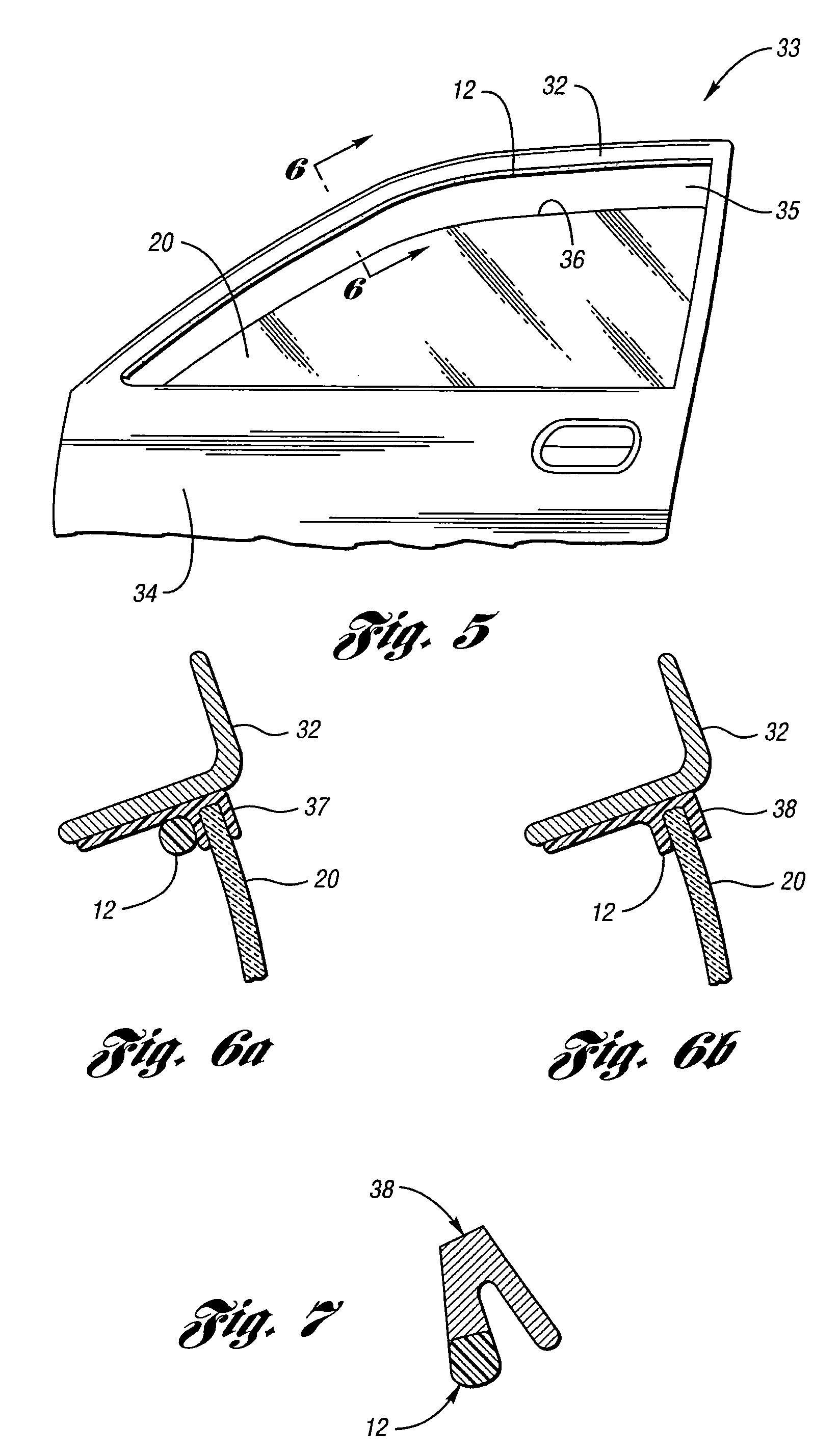

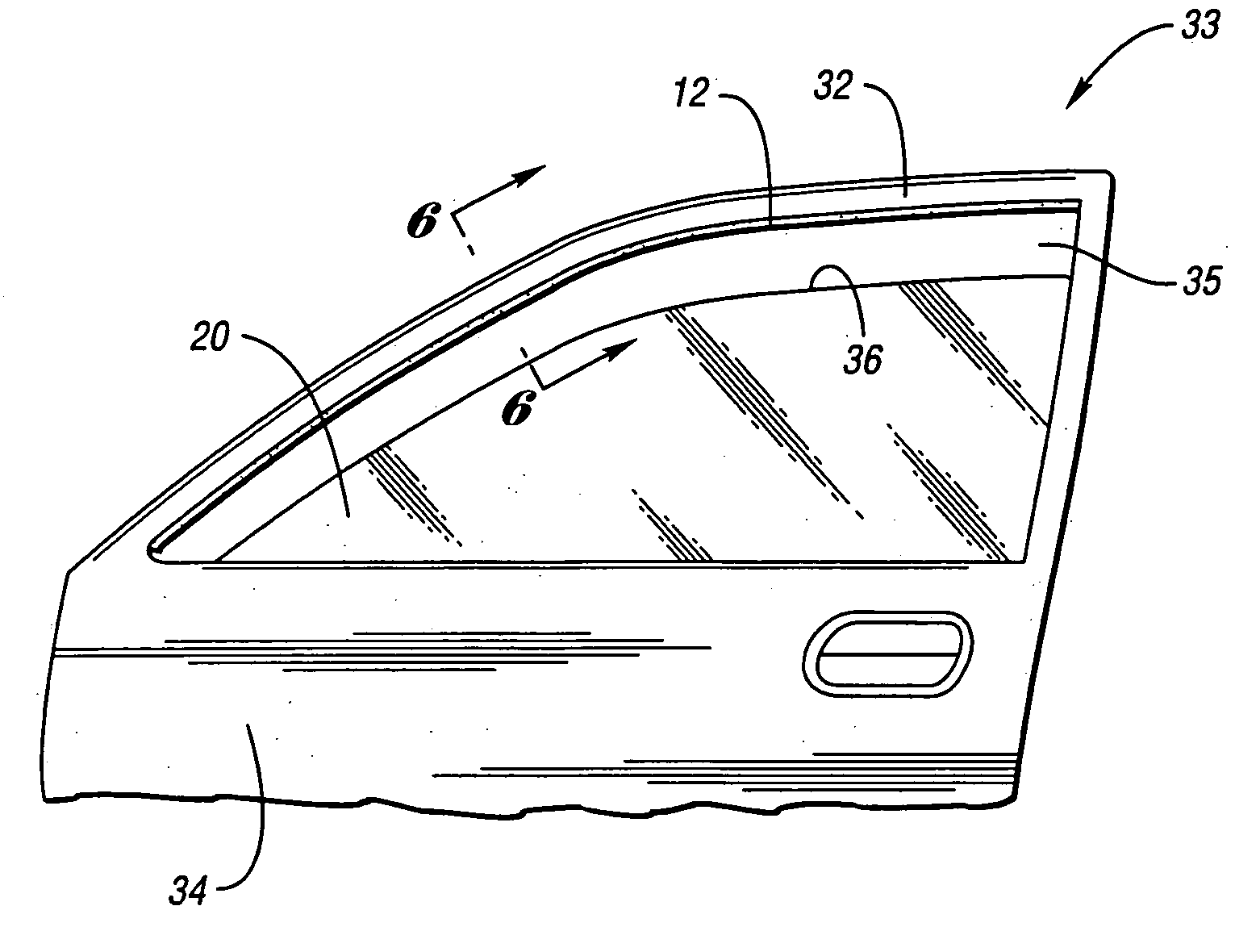

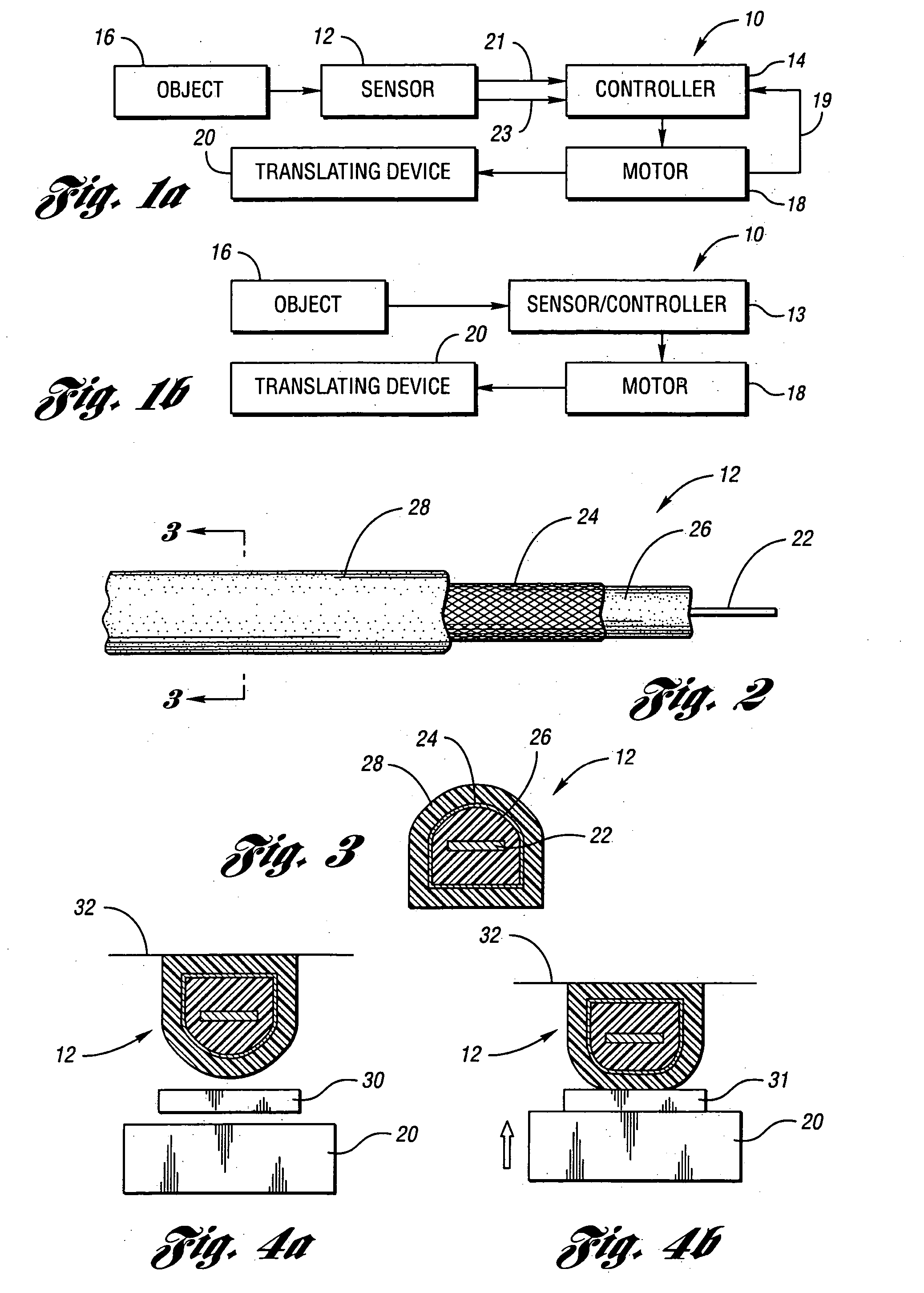

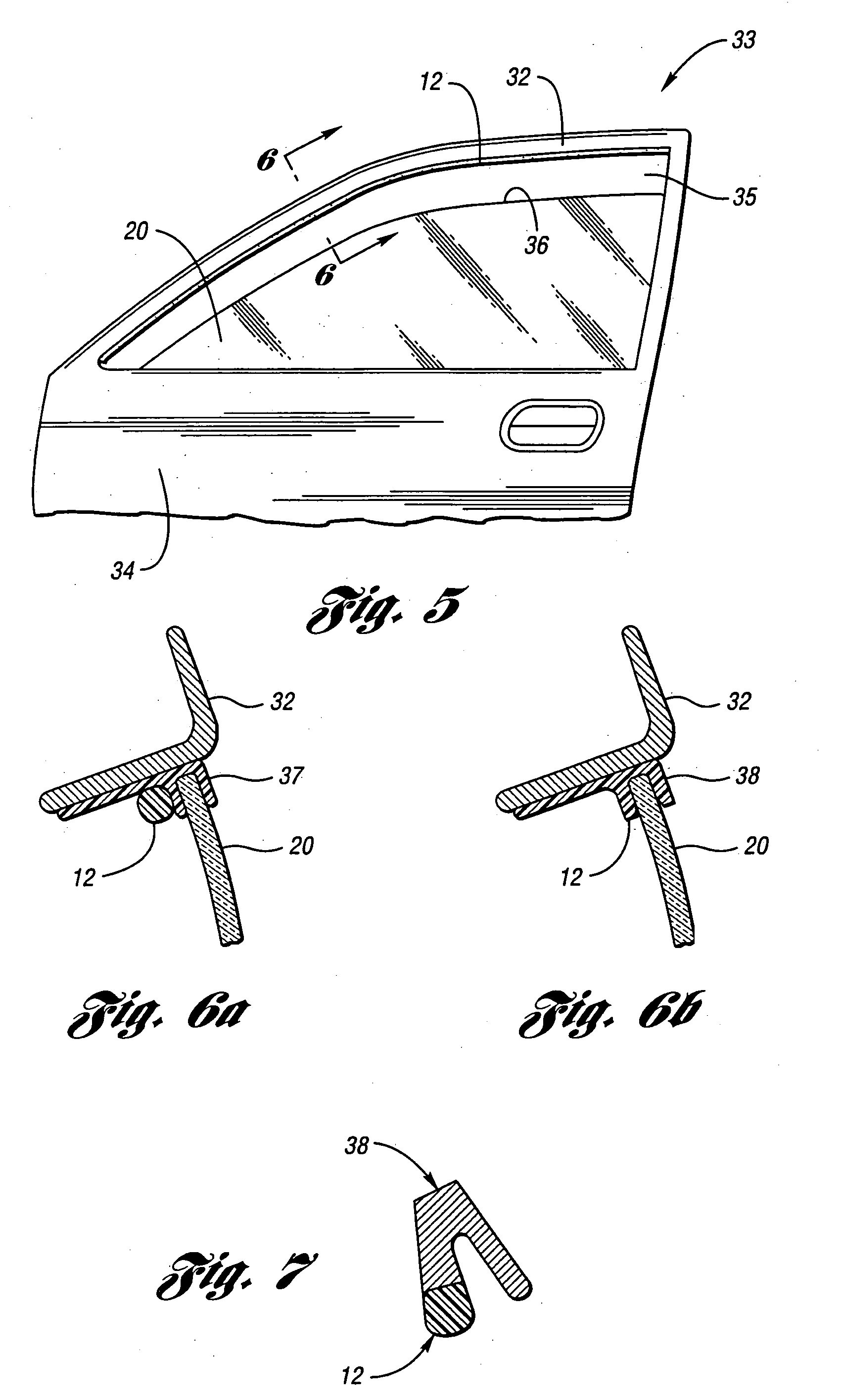

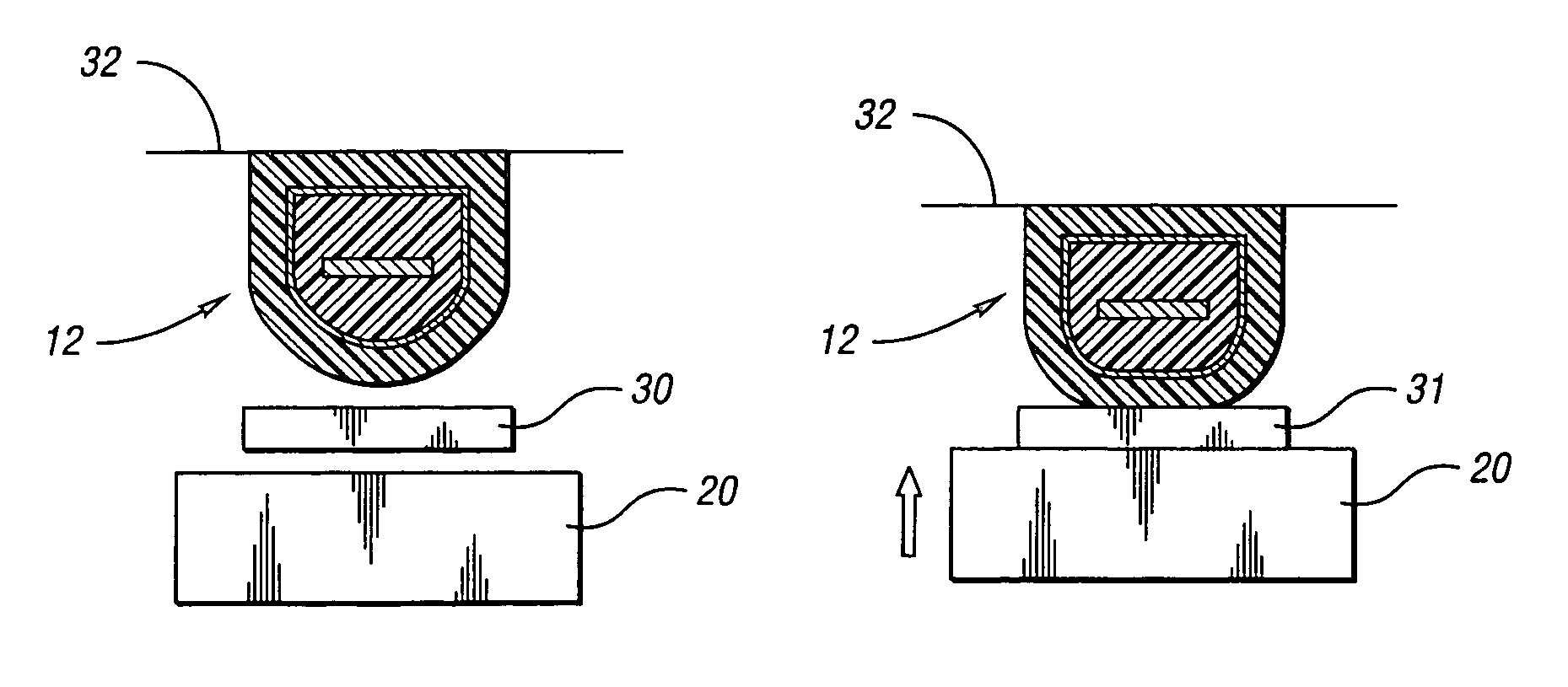

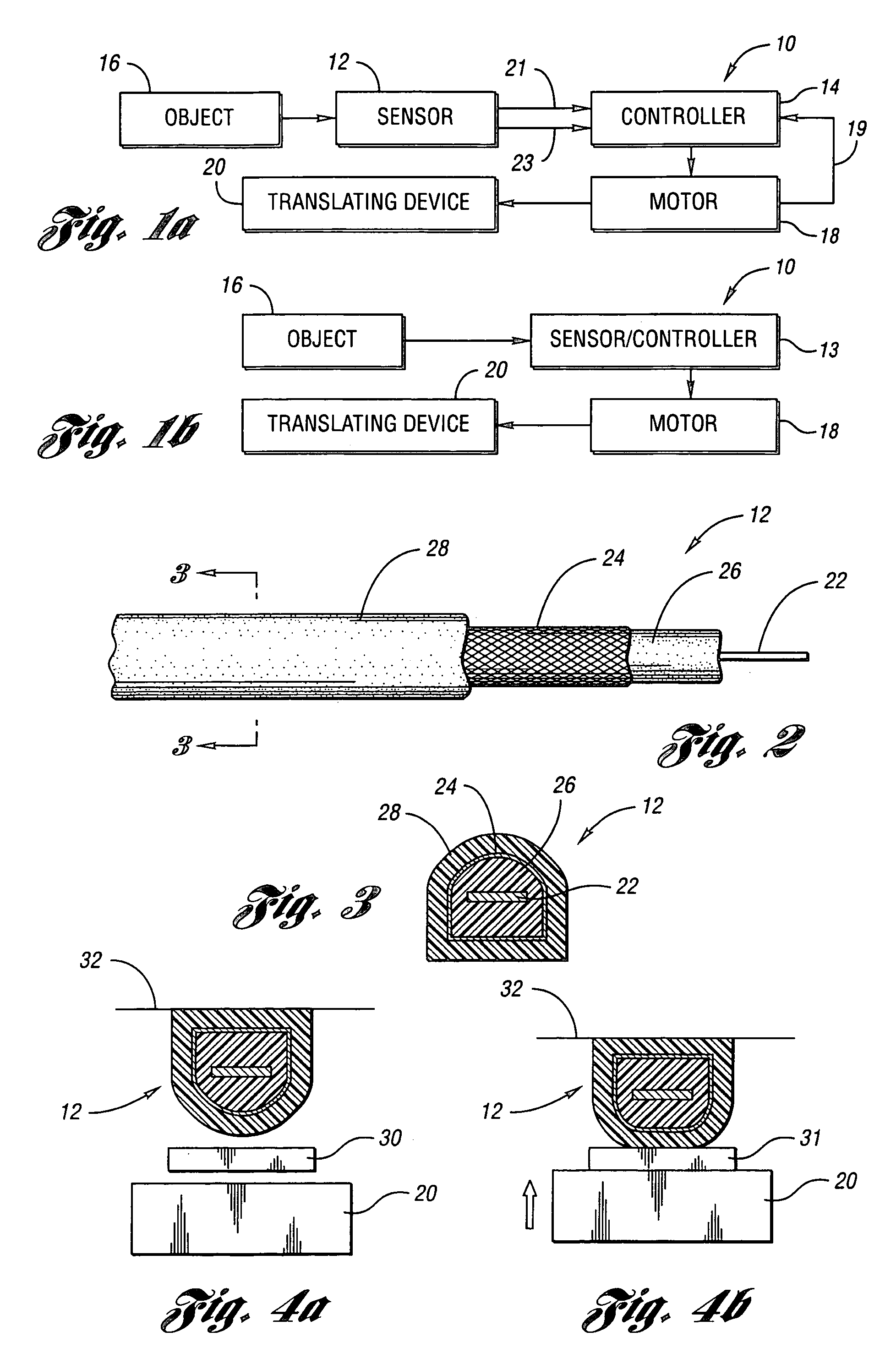

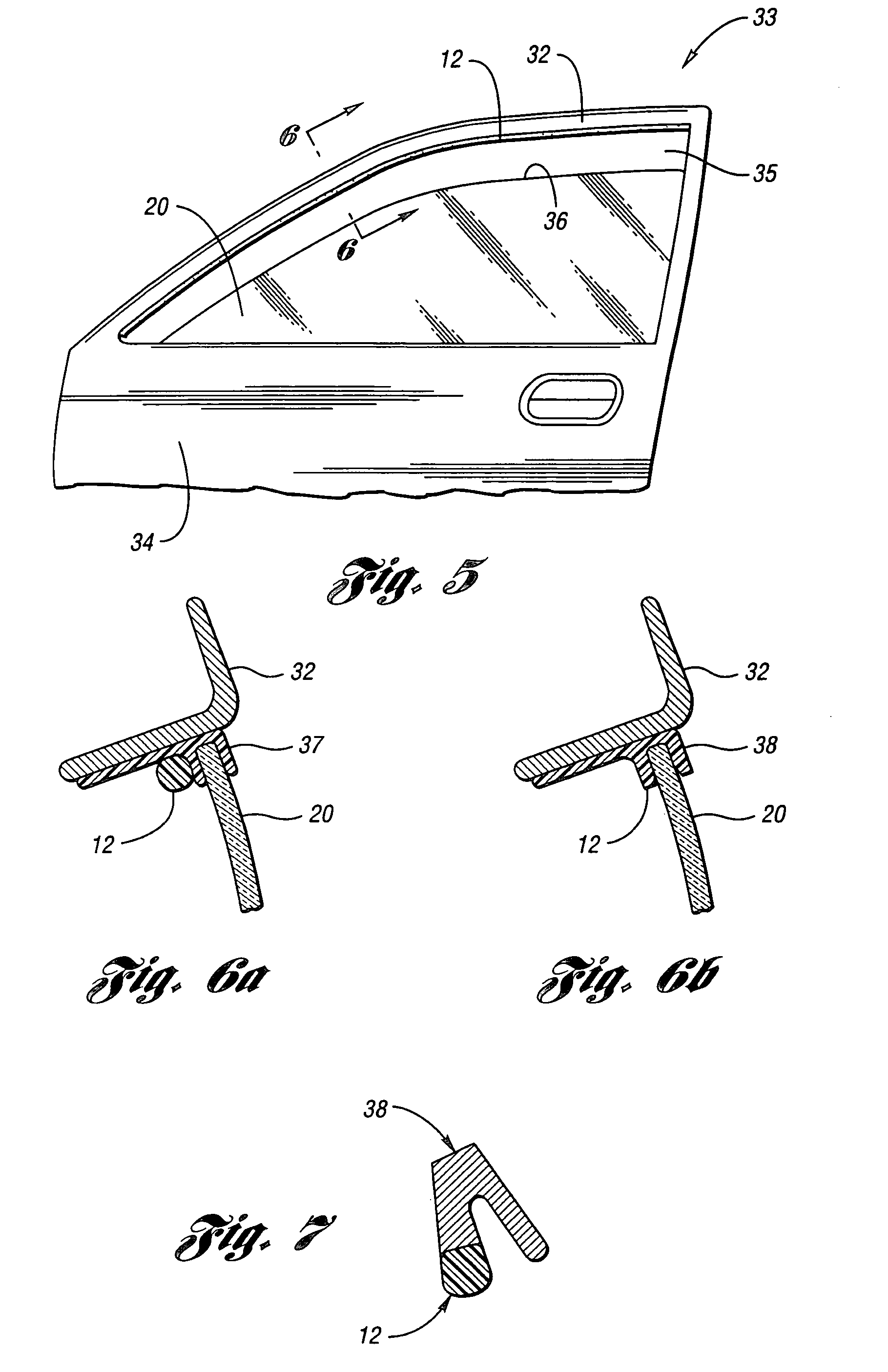

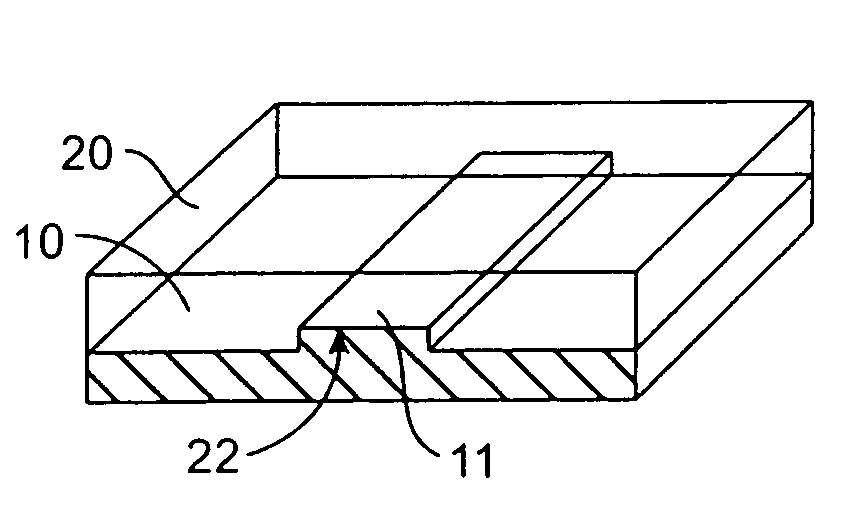

Anti-entrapment systems for preventing objects from being entrapped by translating devices

InactiveUS7132642B2Prevent any pinching of the objectHigher compressive forceVehicle seatsForce measurementDielectricElastomer

An anti-entrapment system for preventing an object from being entrapped by a translating device includes a capacitance sensor positioned adjacent to the translating device. The sensor has first and second conductors separated by a separation distance, a compressible dielectric element interposed between the conductors, and a non-conductive elastomer outer jacket encasing the conductors and the dielectric element. The sensor having a capacitance dependent upon the separation distance between the conductors. The capacitance changes in response to the separation distance changing as a result of the dielectric element compressing in response to a first object touching the outer jacket, and in response to a second conductive object coming into proximity with at least one of the conductors. A controller controls the translating device as a function of the capacitance in order to prevent the translating device from entrapping either object.

Owner:UUSI

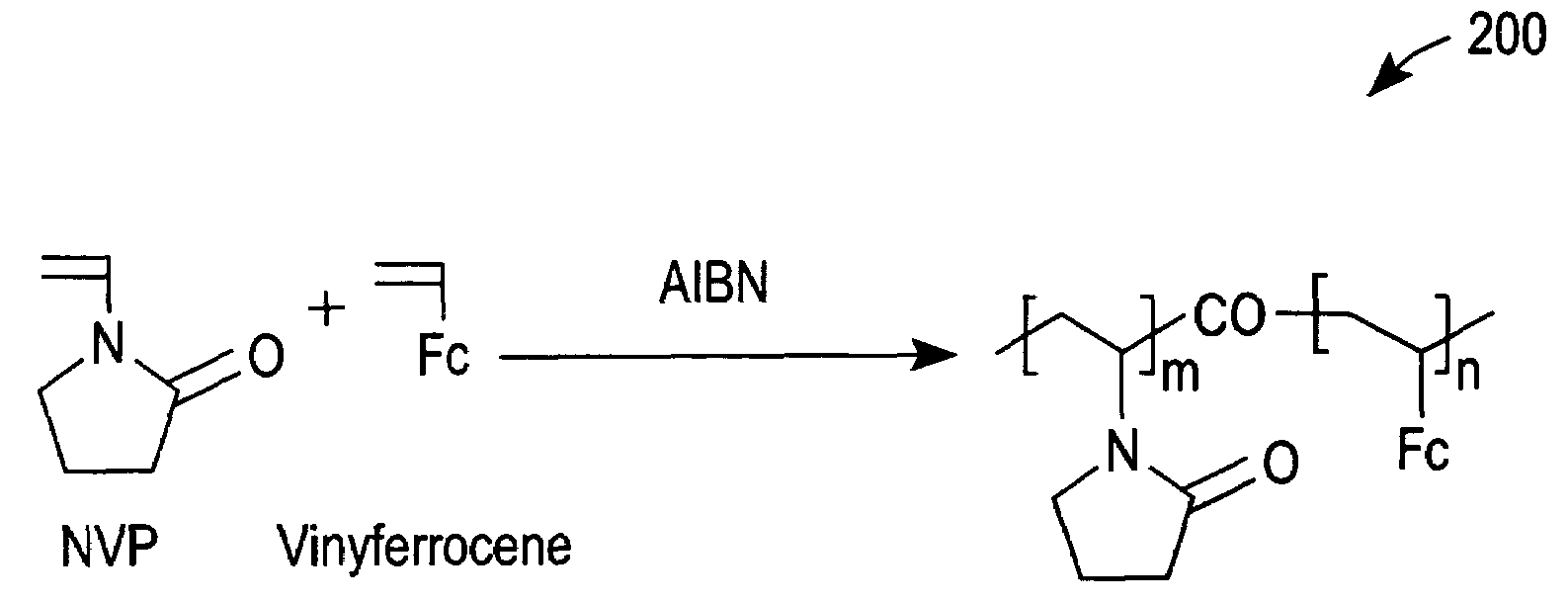

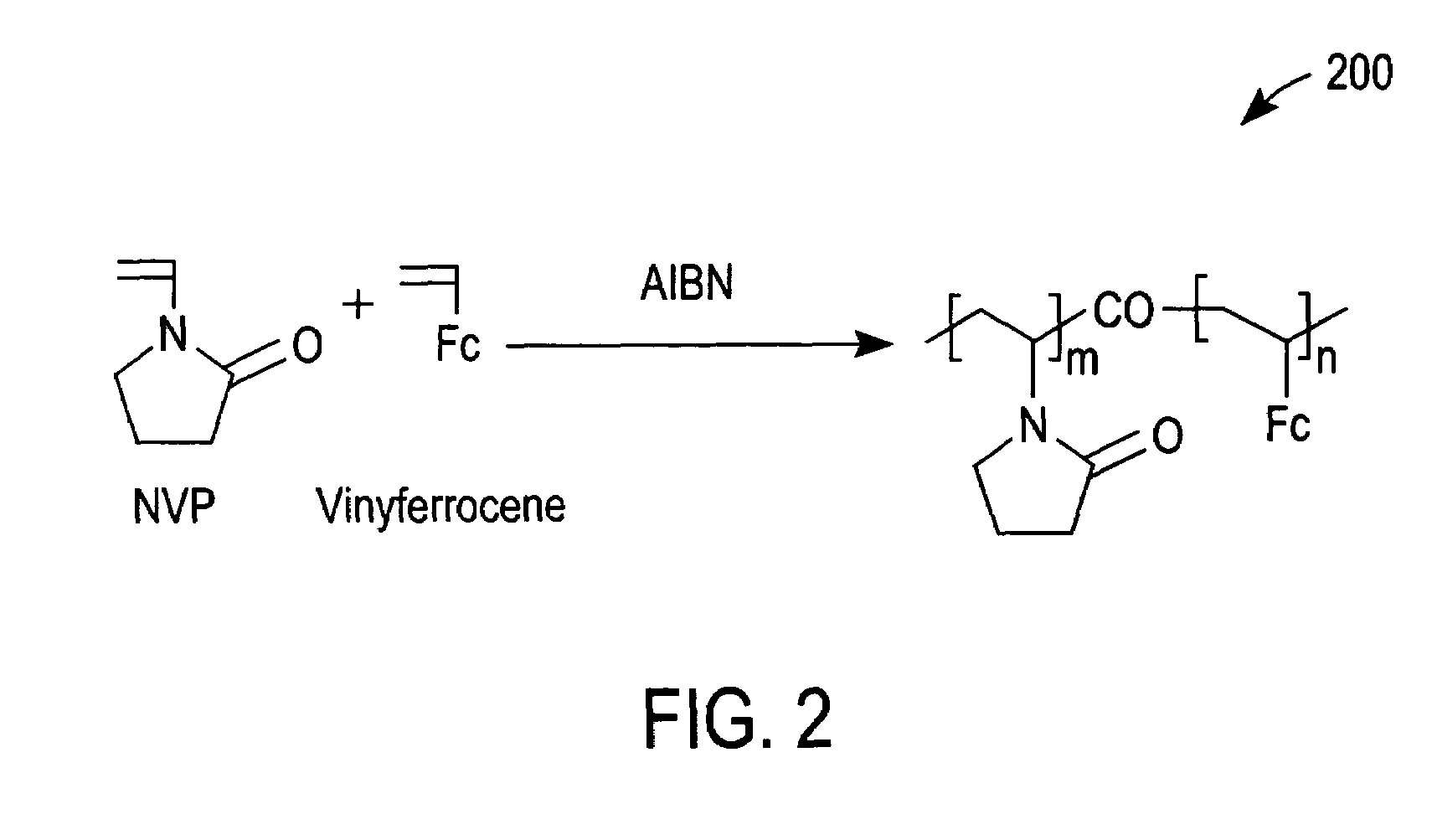

Electrochemical-based sensor with a redox polymer and redox enzyme entrapped by a dialysis membrane

ActiveUS7572356B2Rapid responseImmobilised enzymesBioreactor/fermenter combinationsRedox enzymesDialysis membranes

An electrochemical-based sensor includes an electrode with at least one electrode surface, a film disposed on the electrode surface, and a dialysis membrane disposed on the film. The film includes a redox enzyme and a hydrophilic redox polymer (i.e., a polymer with an attached redox mediator(s)). In addition, the dialysis membrane serves to entrap the redox polymer and redox enzyme in the vicinity of the electrode. Such entrapment is accomplished by employing a redox enzyme and a hydrophilic redox polymer of a sufficiently high molecular weight that they do not pass through the dialysis membrane.

Owner:CILAG GMBH INT +1

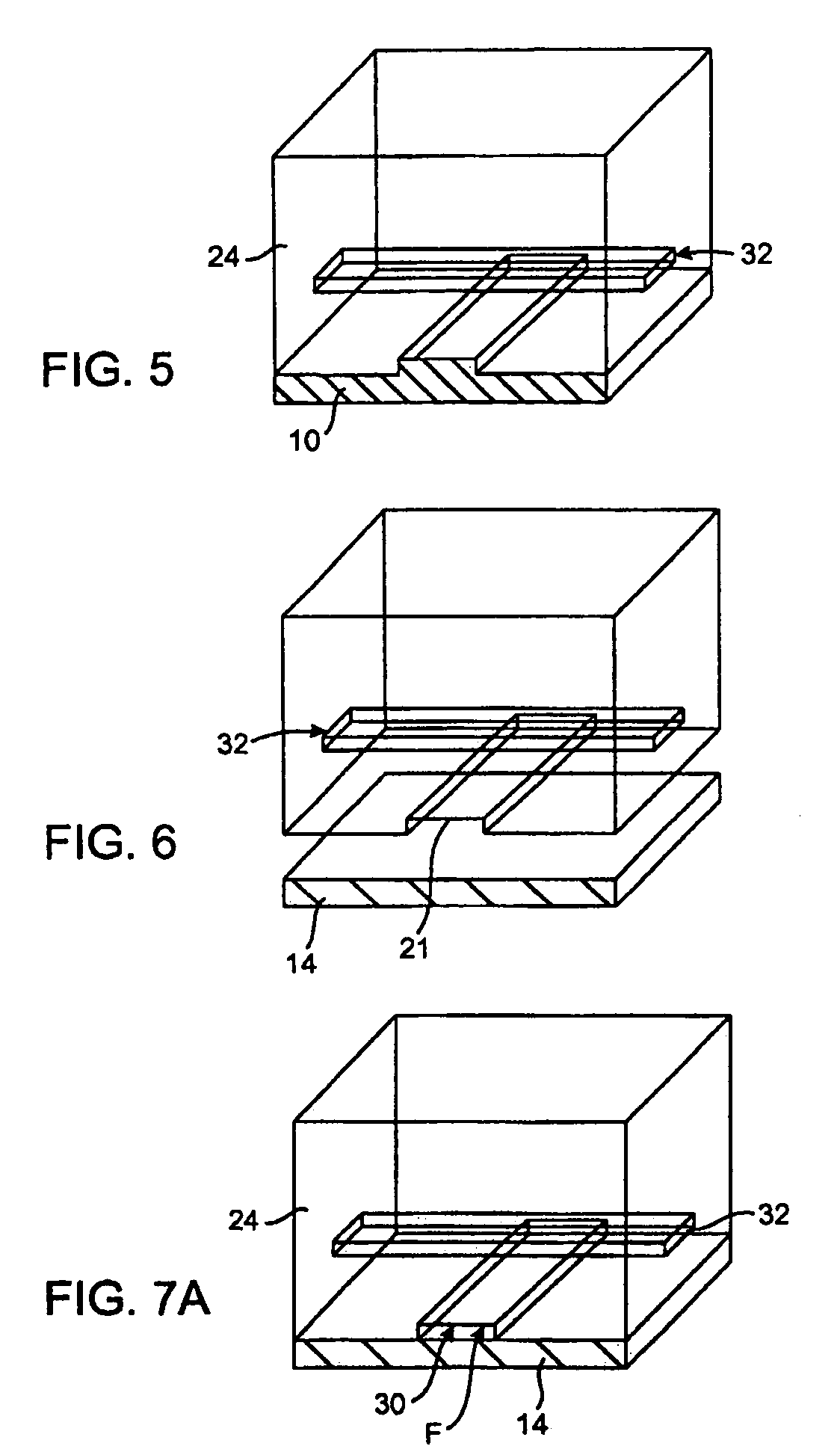

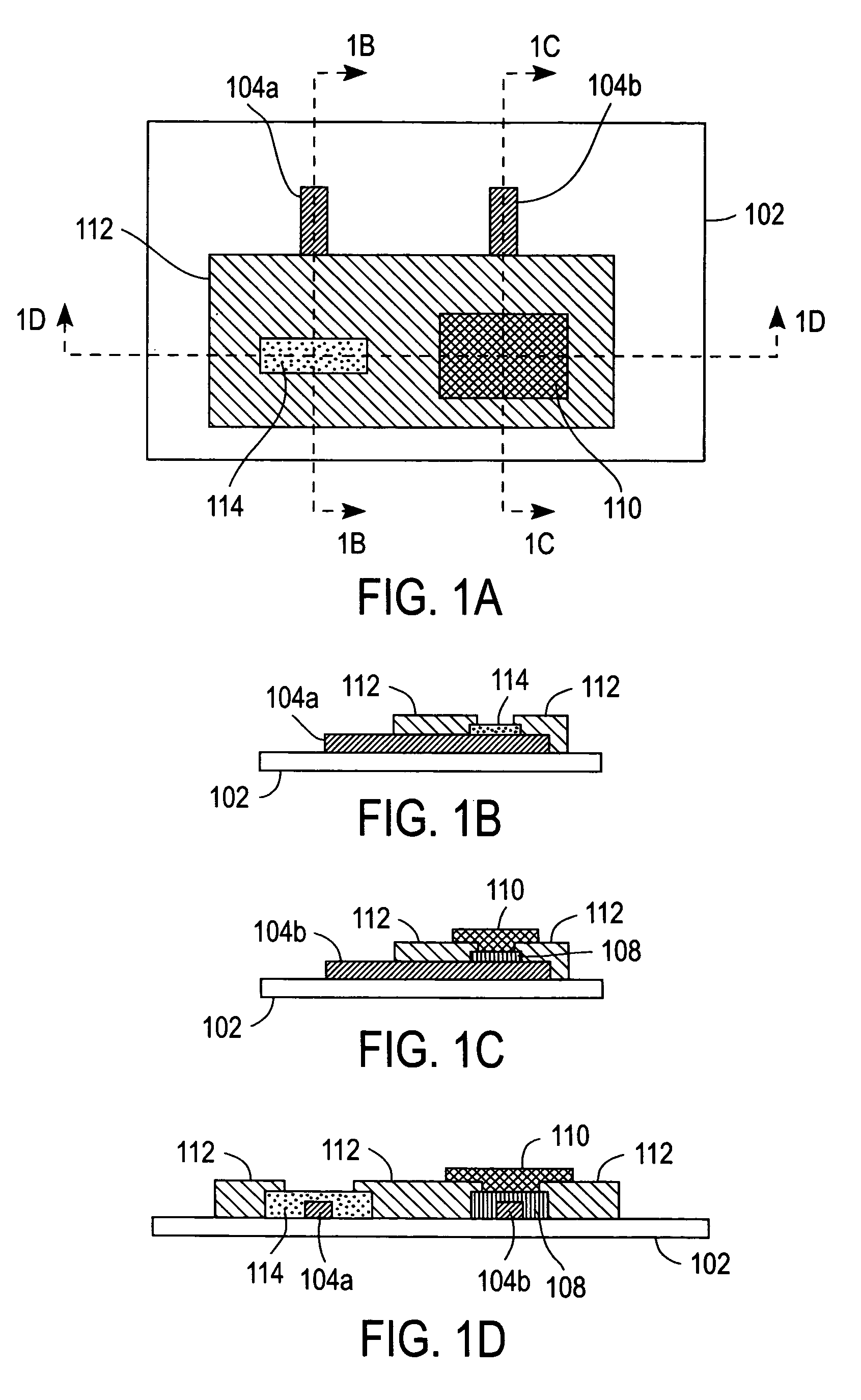

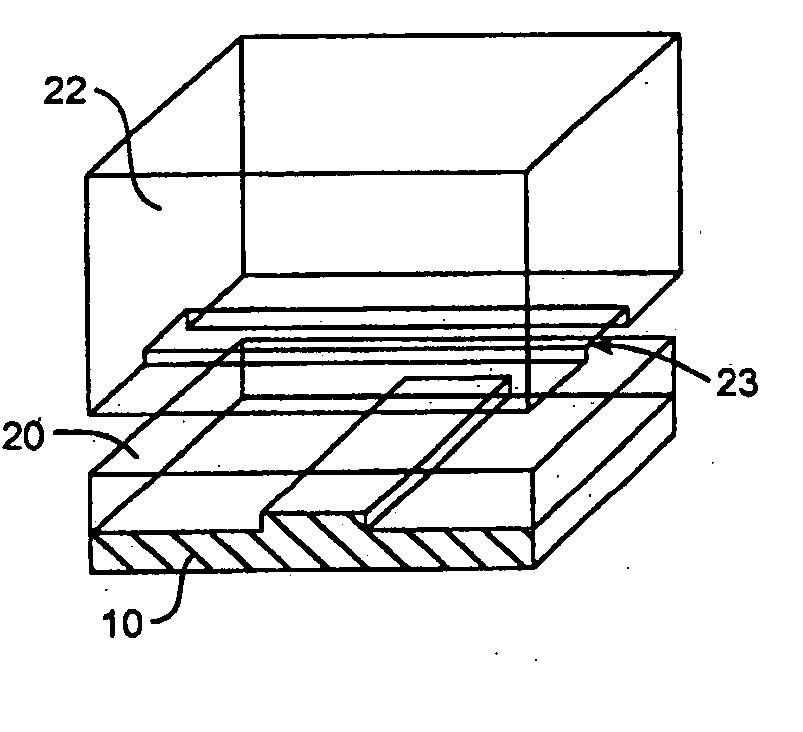

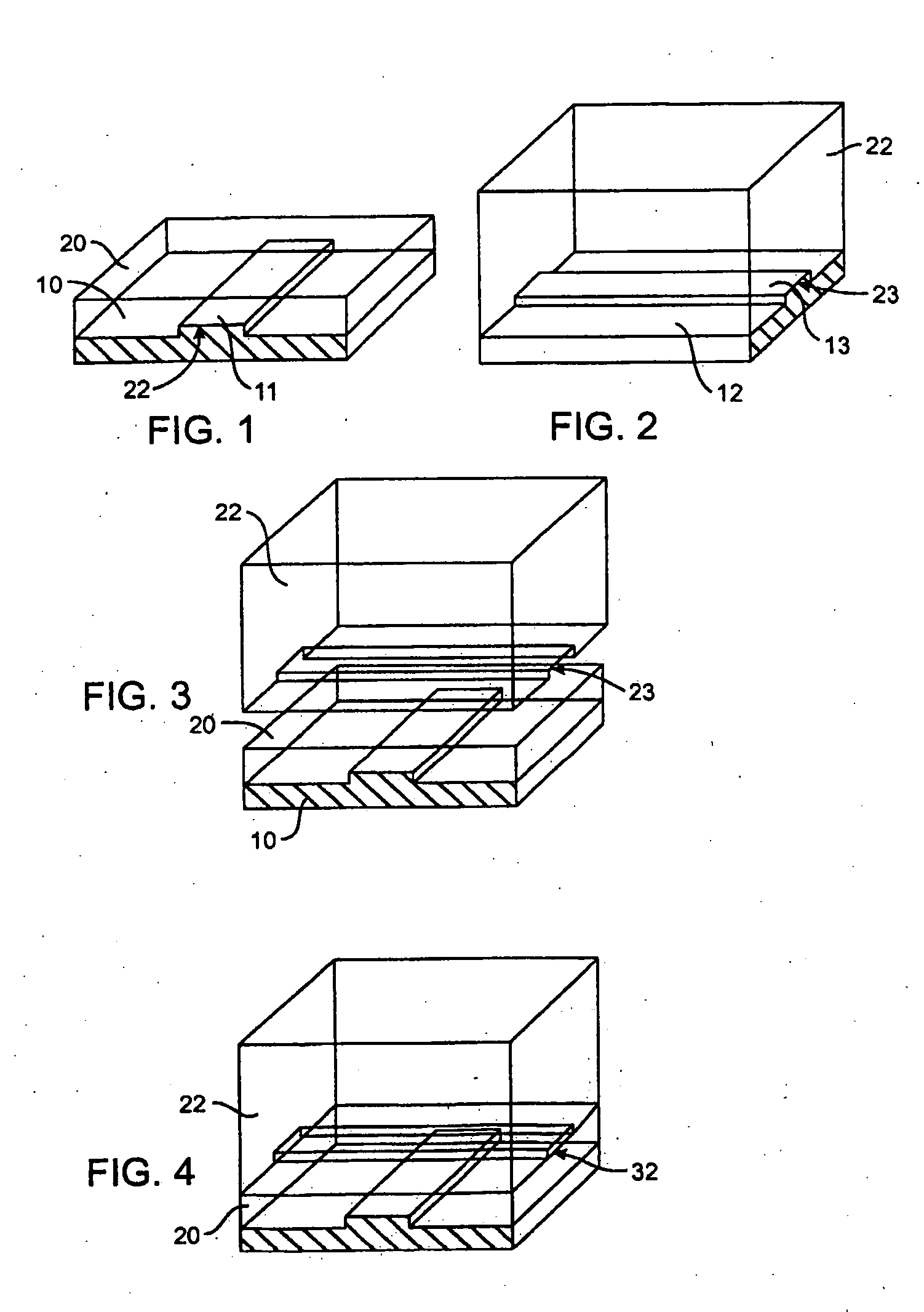

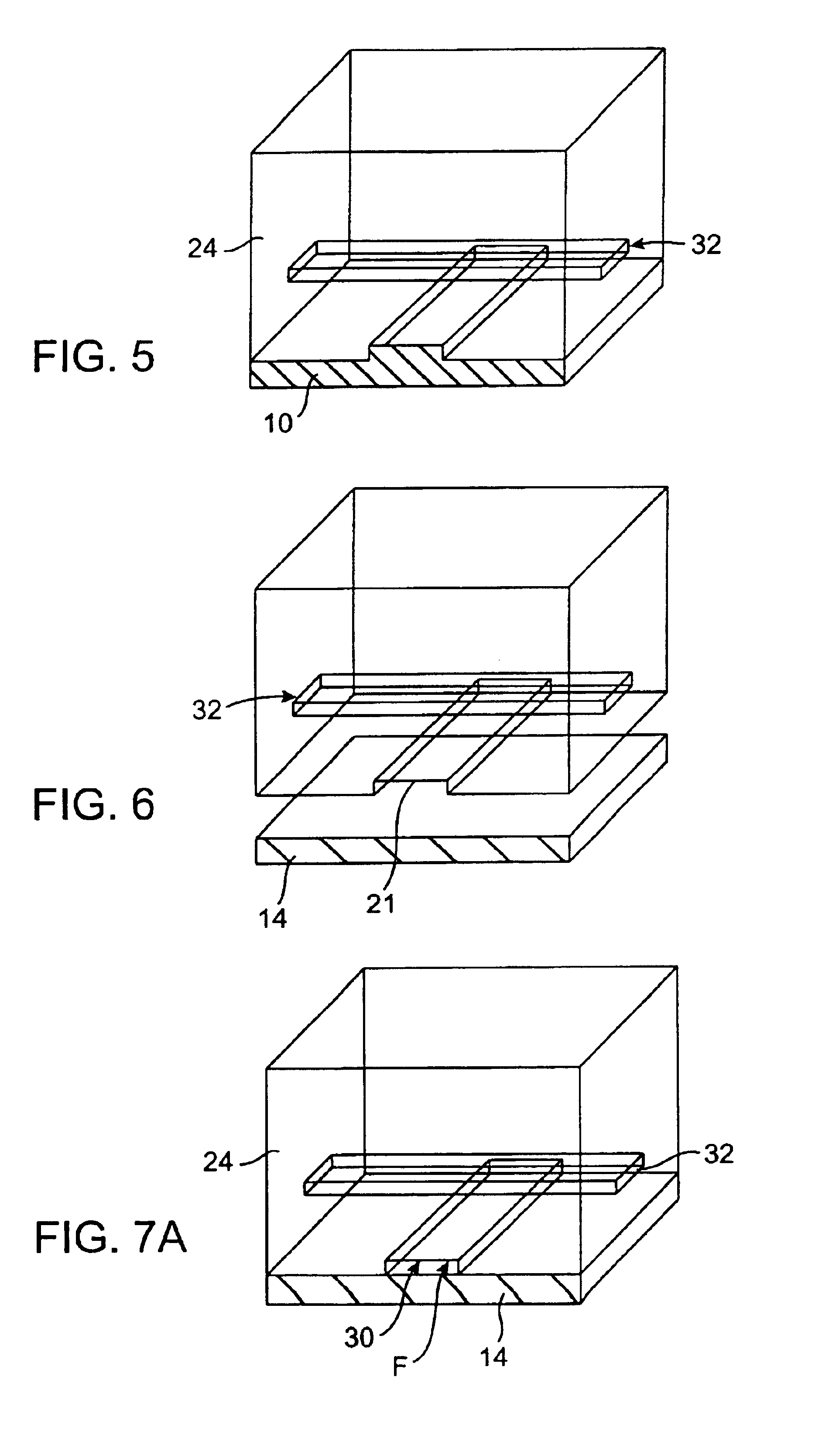

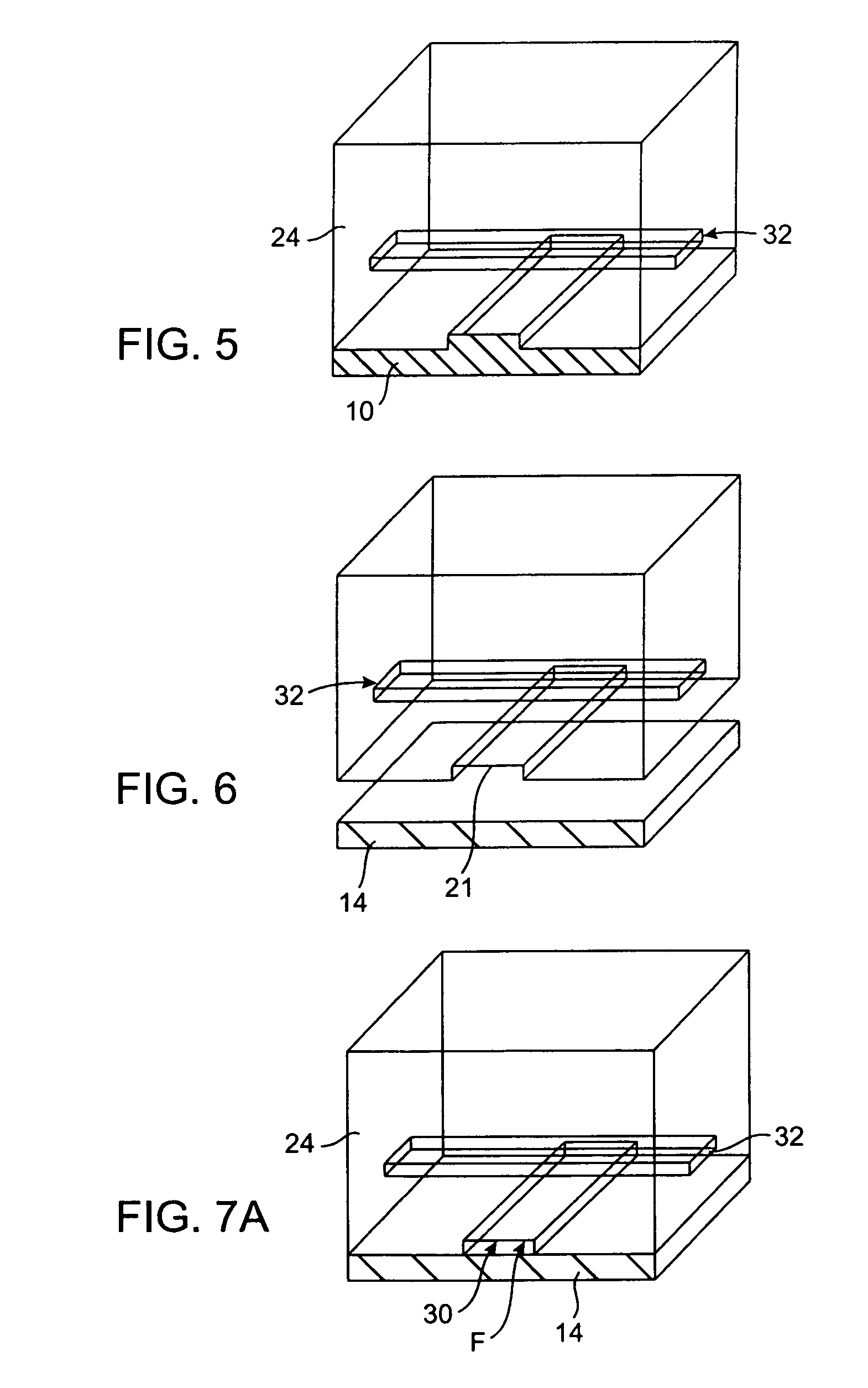

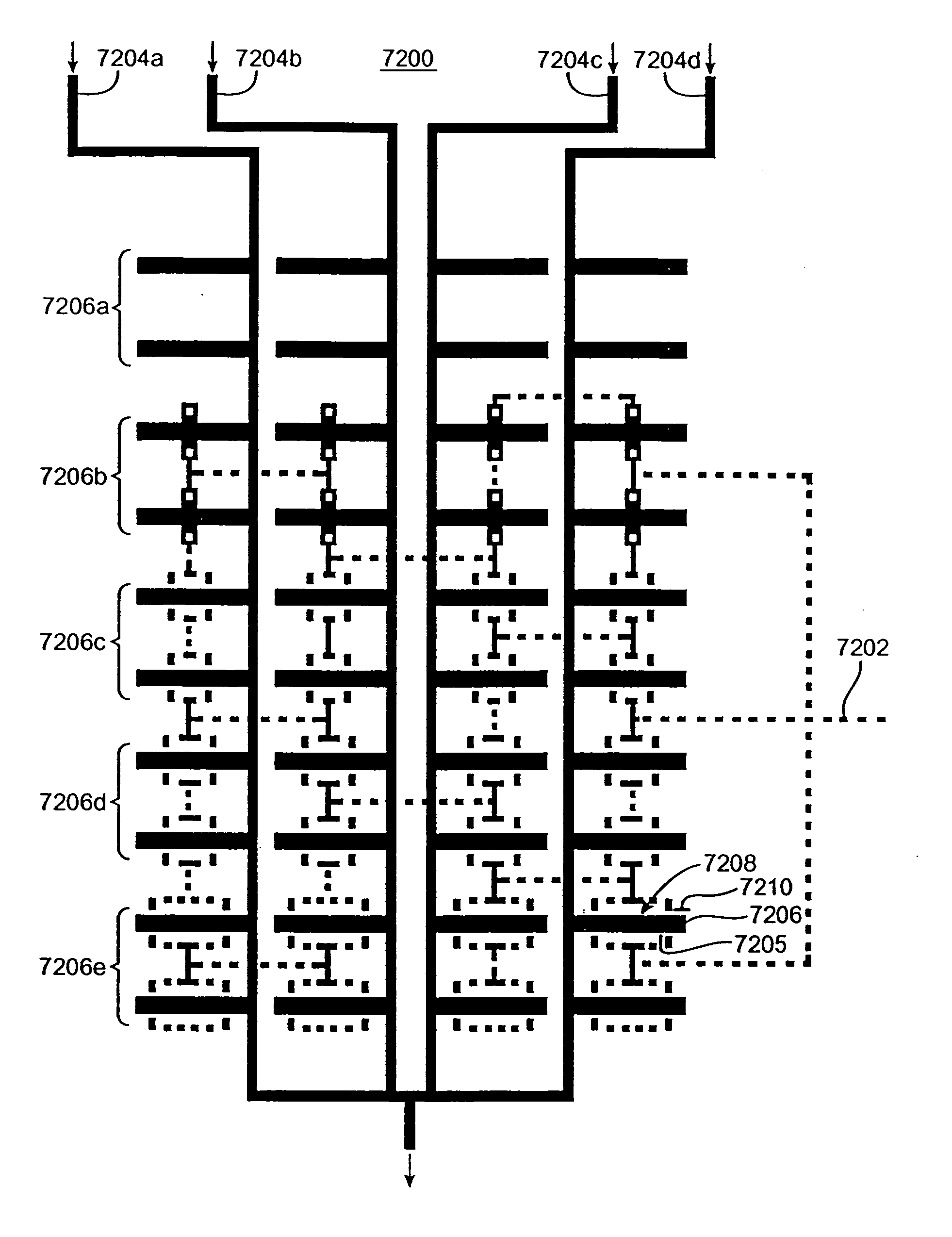

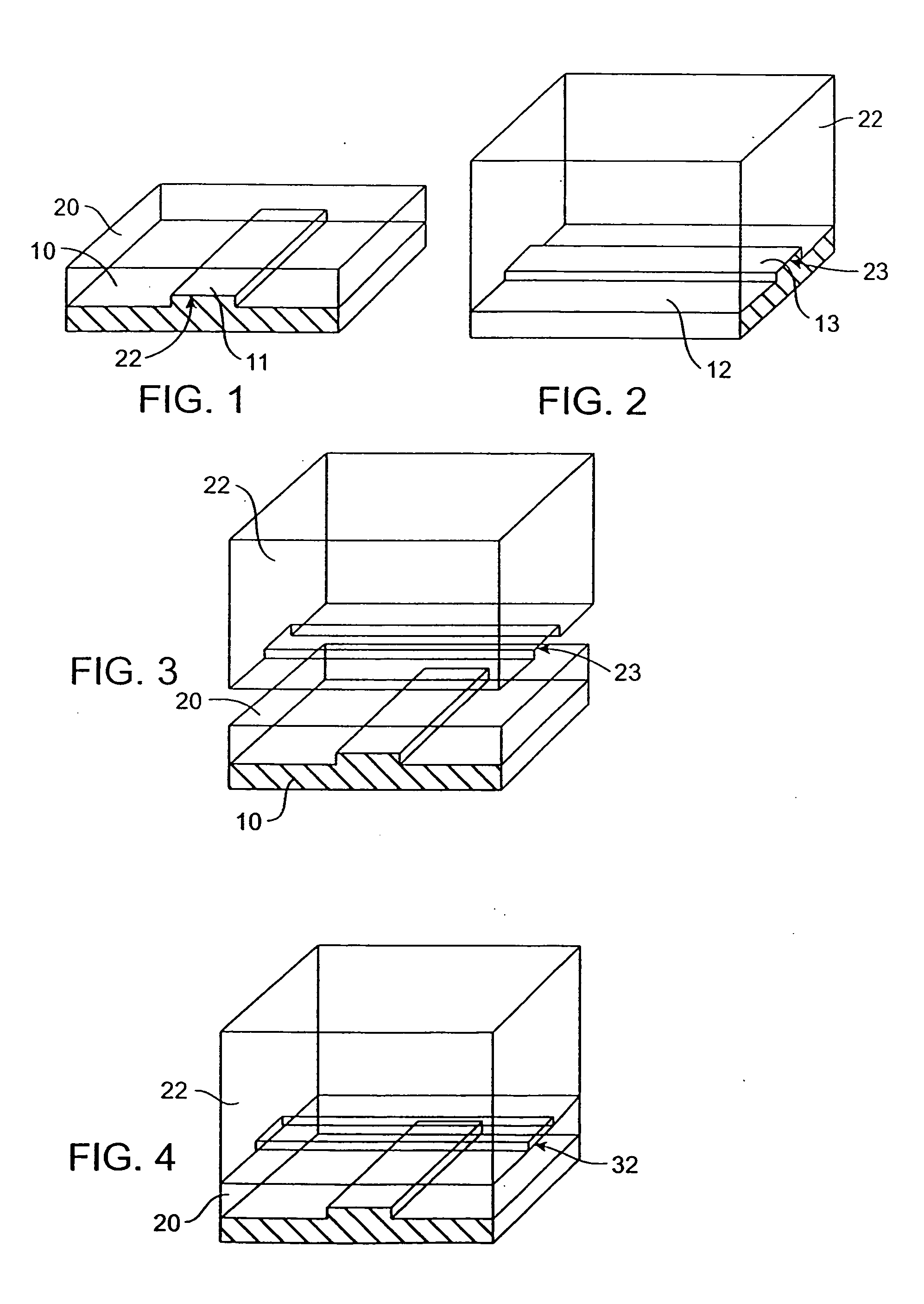

Crystal growth devices and systems, and methods for using same

High throughput screening of crystallization of a target material is accomplished by simultaneously introducing a solution of the target material into a plurality of chambers of a microfabricated fluidic device. The microfabricated fluidic device is then manipulated to vary the solution condition in the chambers, thereby simultaneously providing a large number of crystallization environments. Control over changed solution conditions may result from a variety of techniques, including but not limited to metering volumes of crystallizing agent into the chamber by volume exclusion, by entrapment of volumes of crystallizing agent determined by the dimensions of the microfabricated structure, or by cross-channel injection of sample and crystallizing agent into an array of junctions defined by intersecting orthogonal flow channels.

Owner:FLUIDIGM CORP

Anti-entrapment system

ActiveUS7162928B2Prevent any pinching of either objectVehicle seatsForce measurementElectrical conductorEngineering

An anti-entrapment system for preventing objects from being entrapped by a translating device includes a capacitance sensor positioned adjacent to the translating device and a controller. The sensor has first and second conductors separated by a separation distance and a compressible dielectric element interposed between the conductors. The conductors have a capacitance dependent upon the separation distance. The capacitance of the conductors changes in response to a geometry of the sensor changing as a result of either conductor or the dielectric element deforming in response to a first object touching the sensor. The capacitance of the conductors changes in response to a second conductive object coming into proximity with either conductor. The controller receives a signal from the sensor indicative of the capacitance of the conductors, and controls the translating device as a function of the capacitance of the conductors to prevent the translating device from entrapping either object.

Owner:UUSI

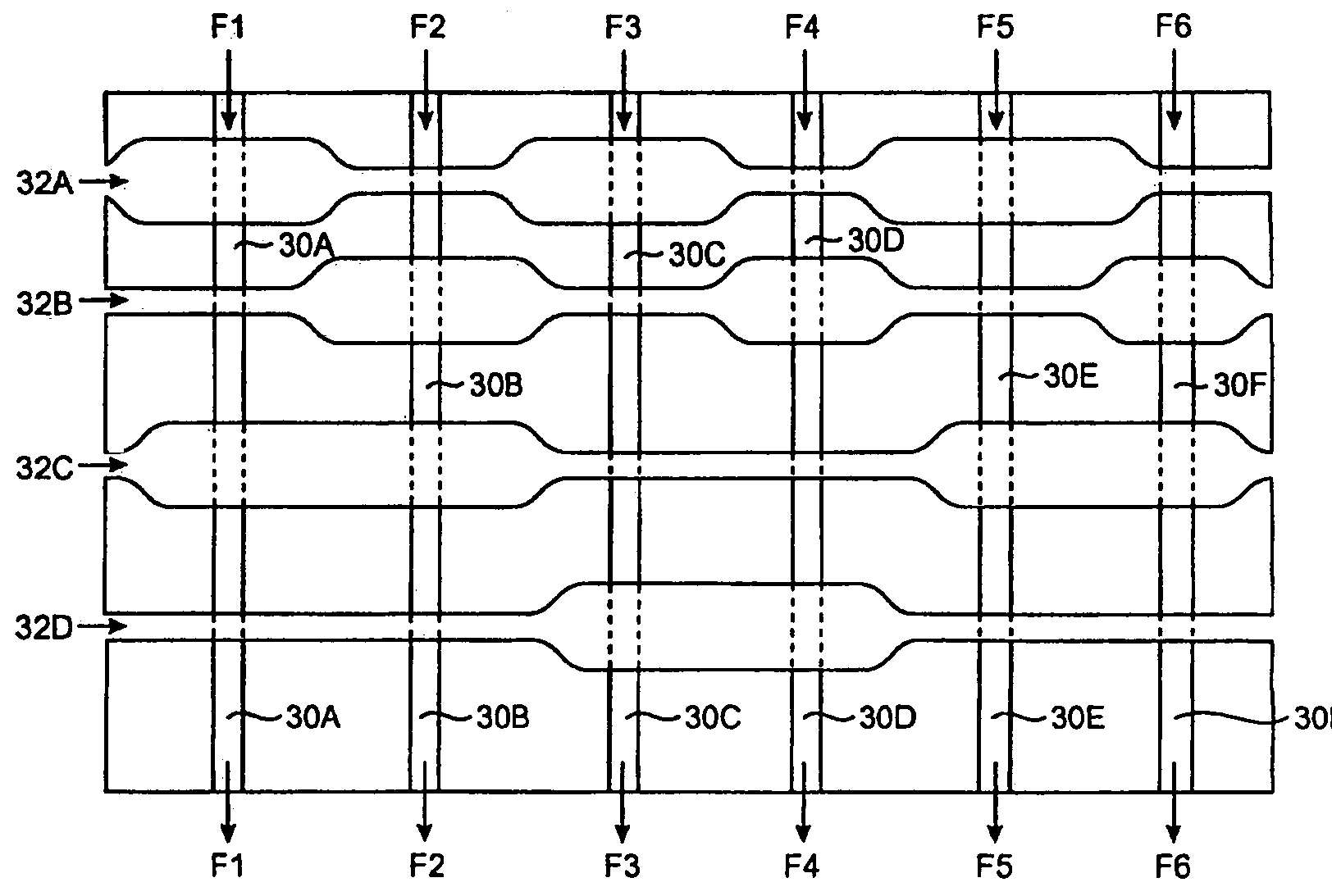

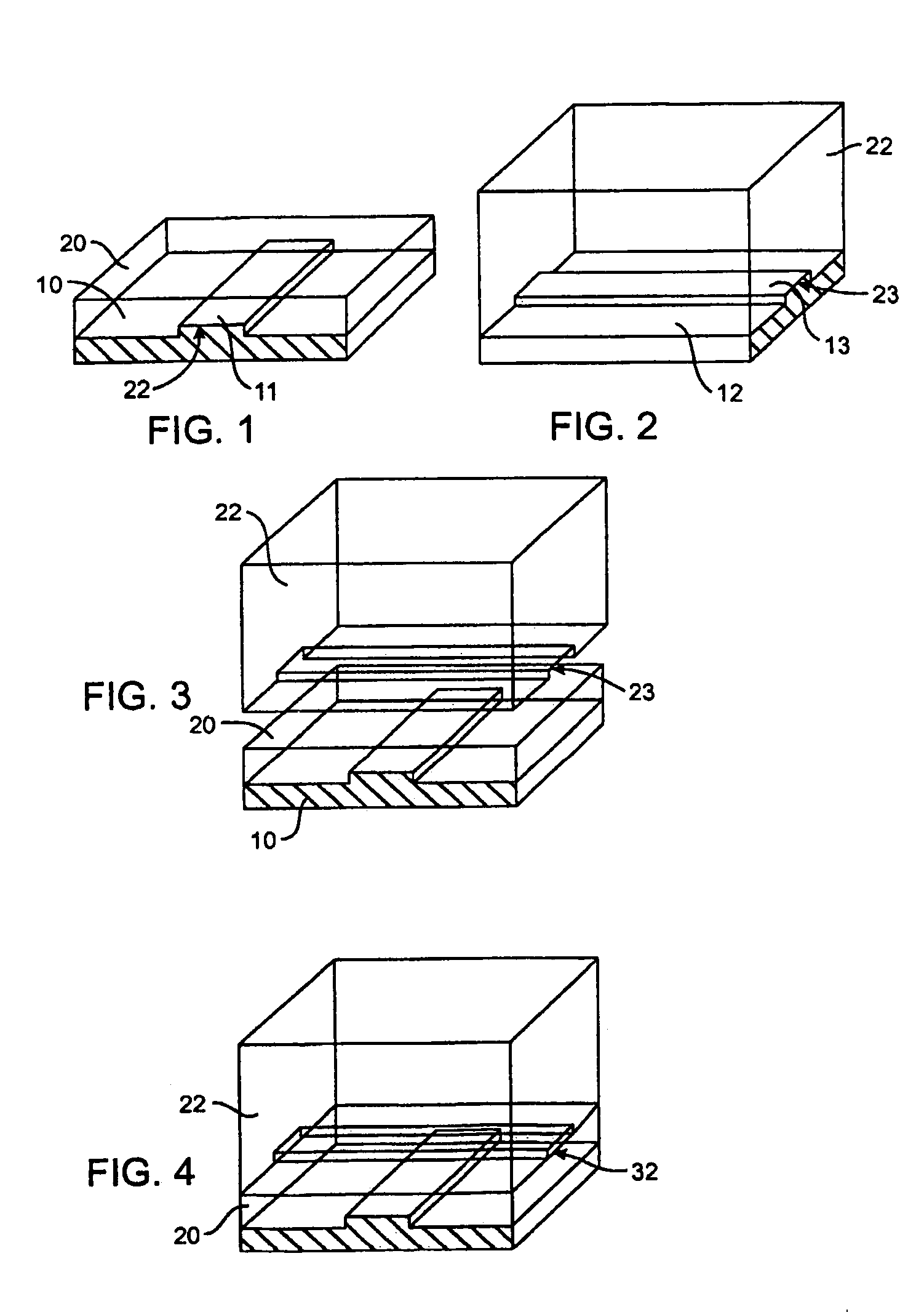

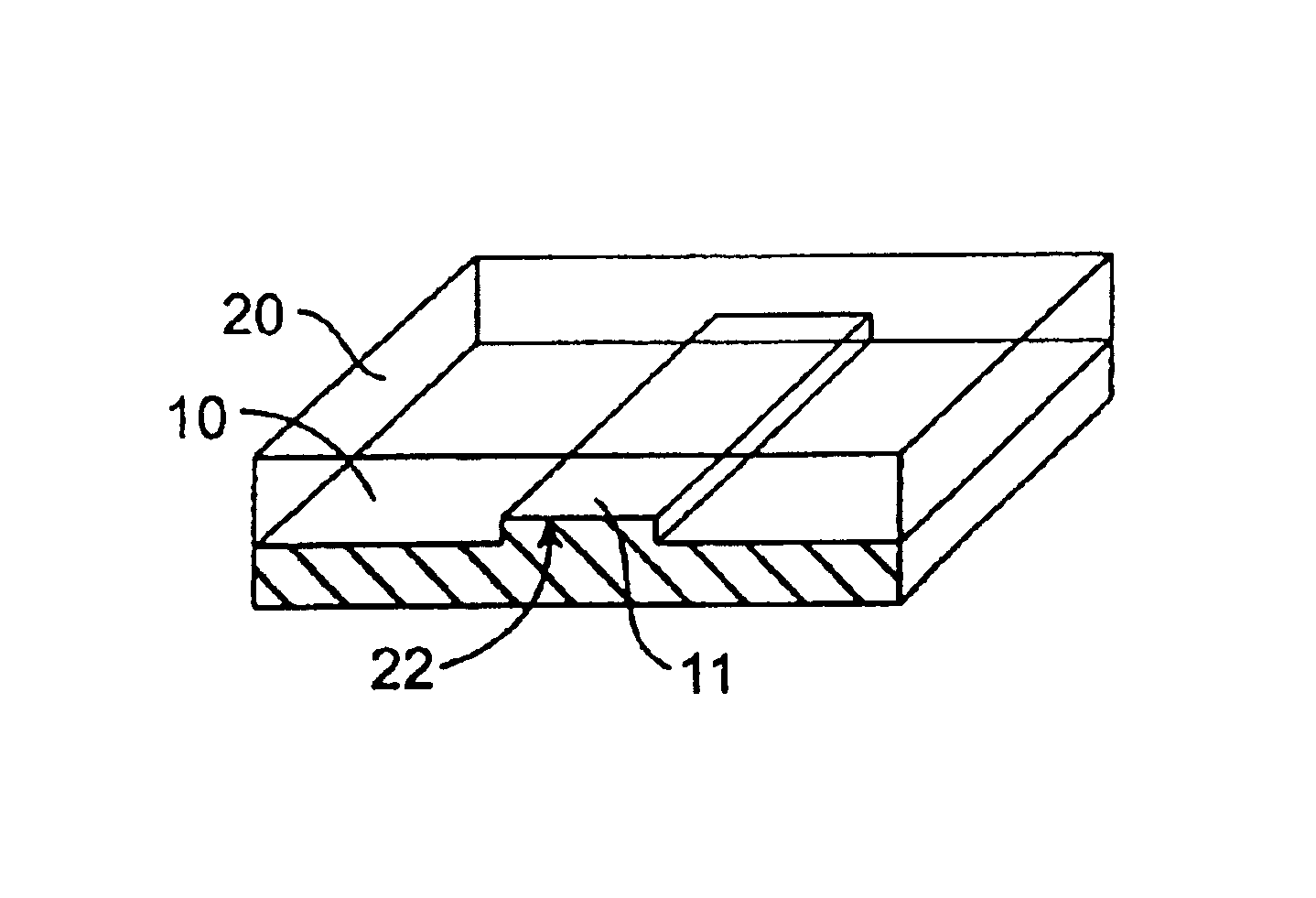

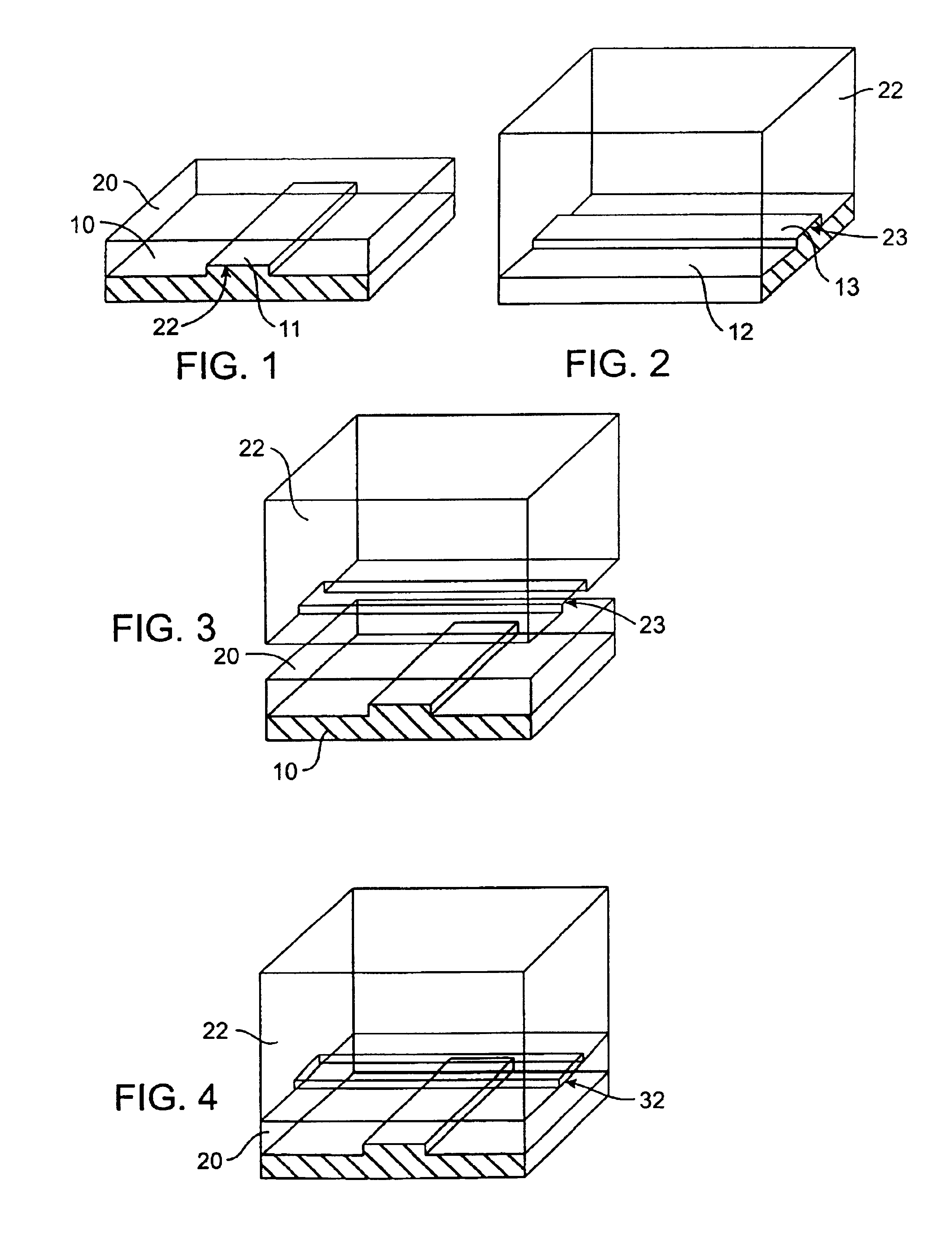

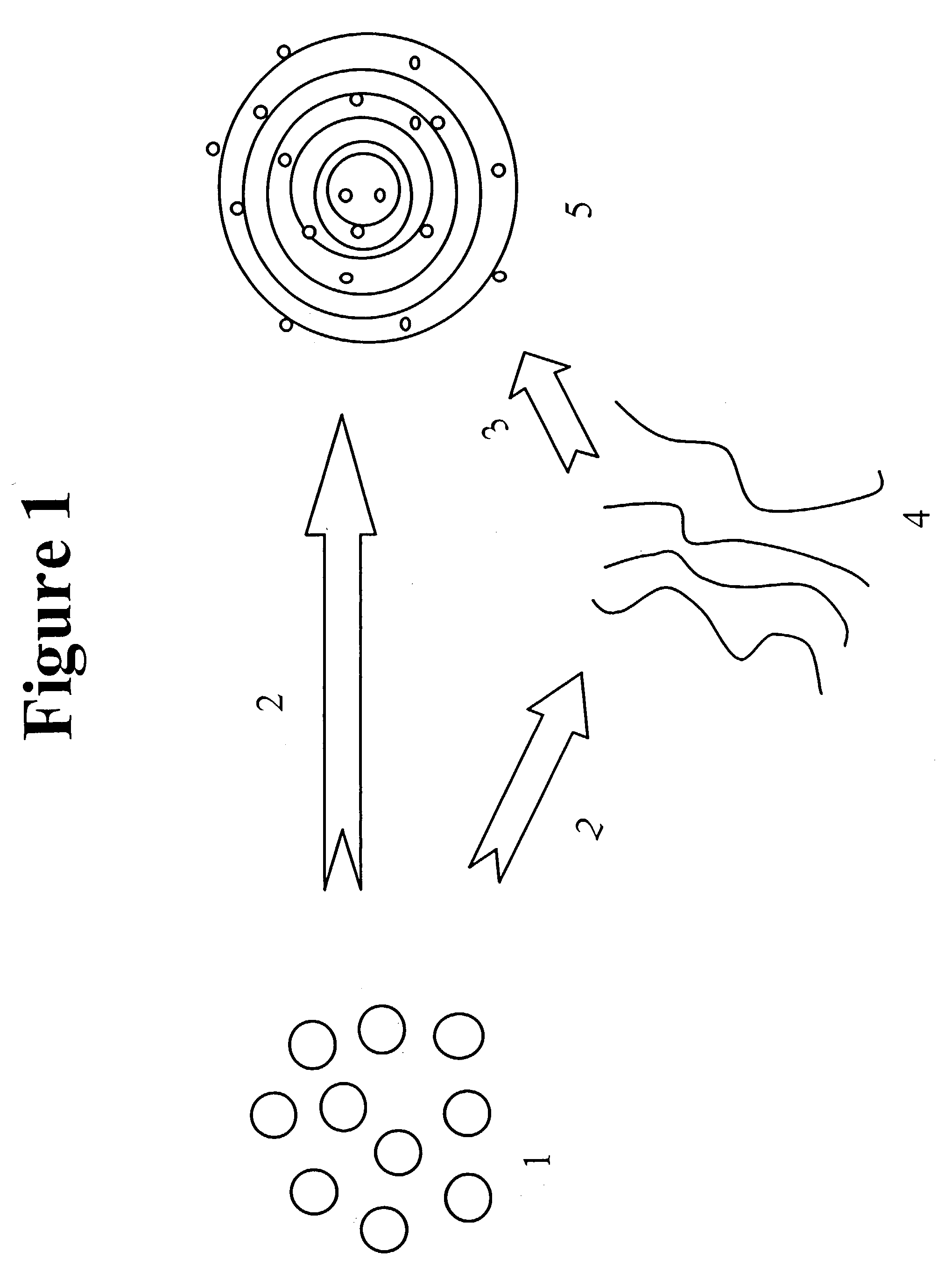

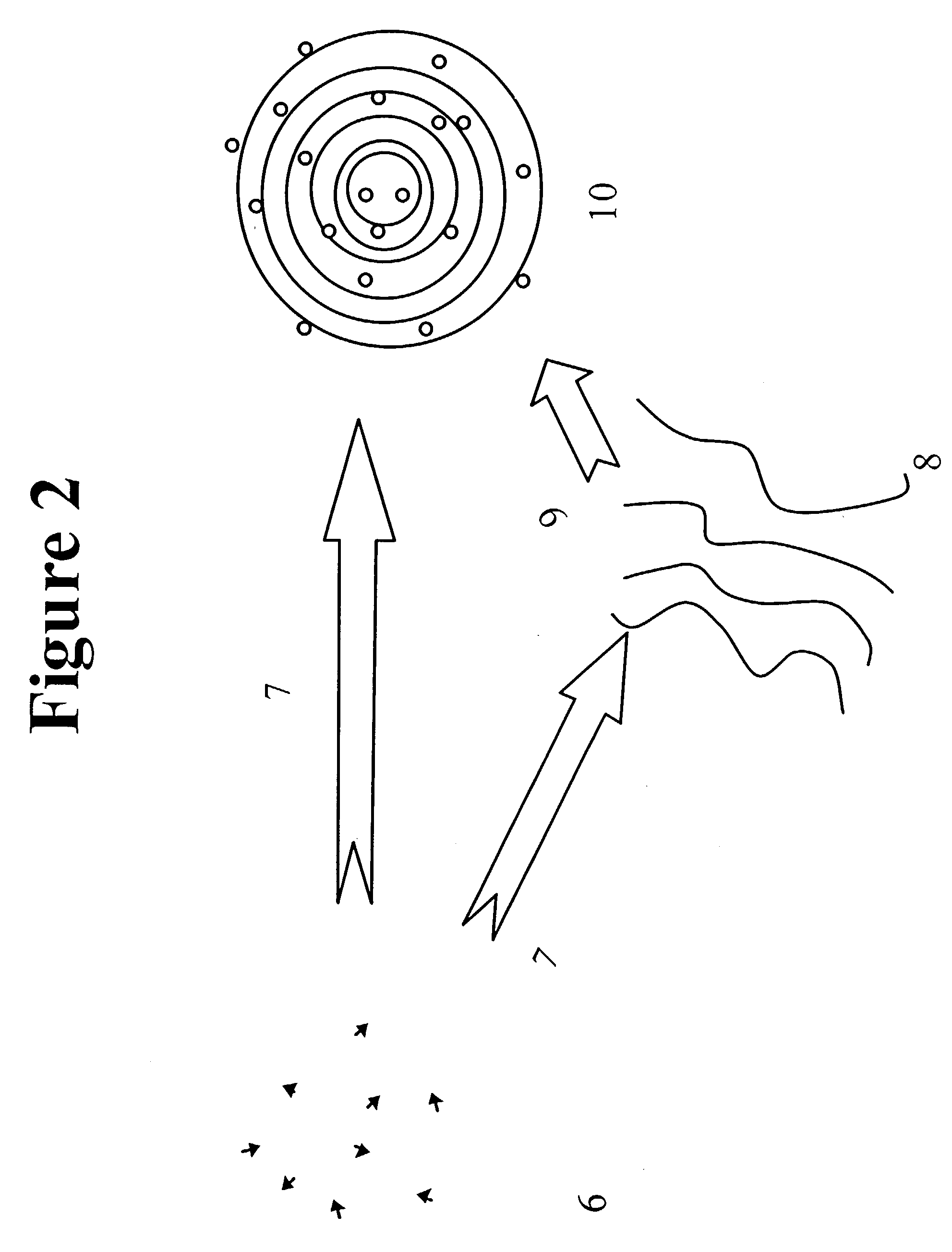

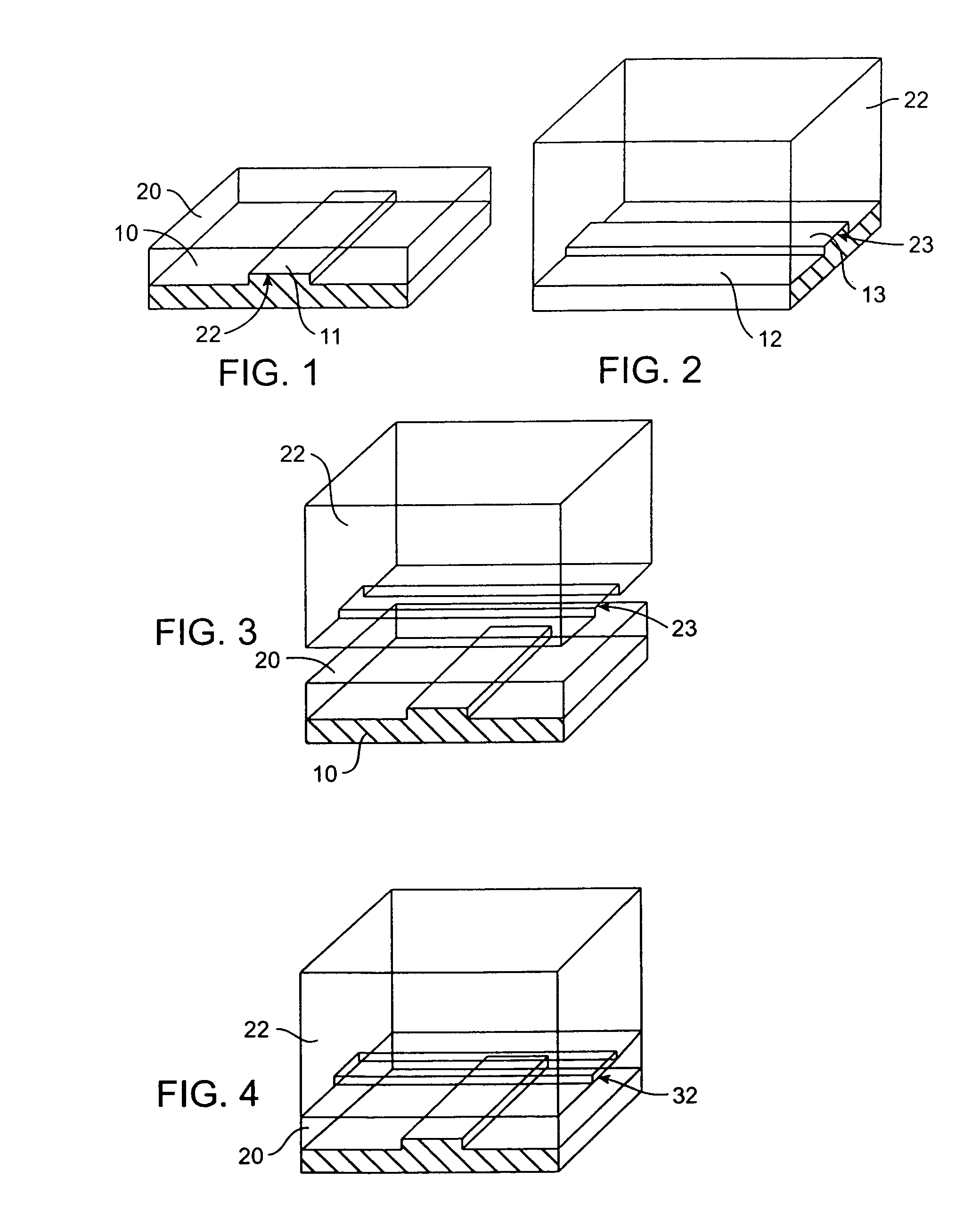

High throughput screening of crystallization of materials

InactiveUS7052545B2Sequential/parallel process reactionsFrom normal temperature solutionsHigh-Throughput Screening MethodsSize determination

High throughput screening of crystallization of a target material is accomplished by simultaneously introducing a solution of the target material into a plurality of chambers of a microfabricated fluidic device. The microfabricated fluidic device is then manipulated to vary the solution condition in the chambers, thereby simultaneously providing a large number of crystallization environments. Control over changed solution conditions may result from a variety of techniques, including but not limited to metering volumes of crystallizing agent into the chamber by volume exclusion, by entrapment of volumes of crystallizing agent determined by the dimensions of the microfabricated structure, or by cross-channel injection of sample and crystallizing agent into an array of junctions defined by intersecting orthogonal flow channels.

Owner:RGT UNIV OF CALIFORNIA +1

Endovascular device for entrapment of participate matter and method for use

Owner:KEYSTONE HEART

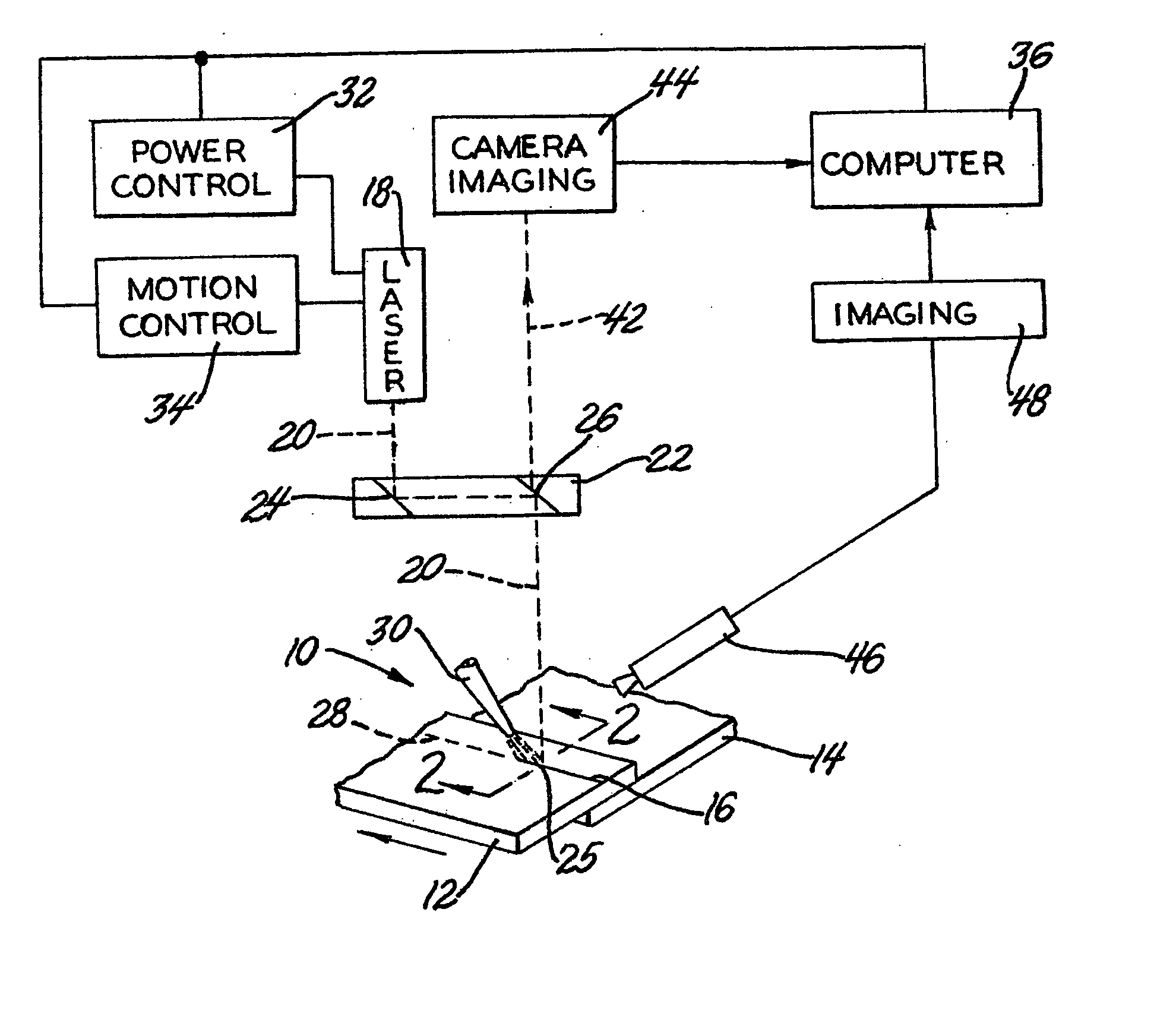

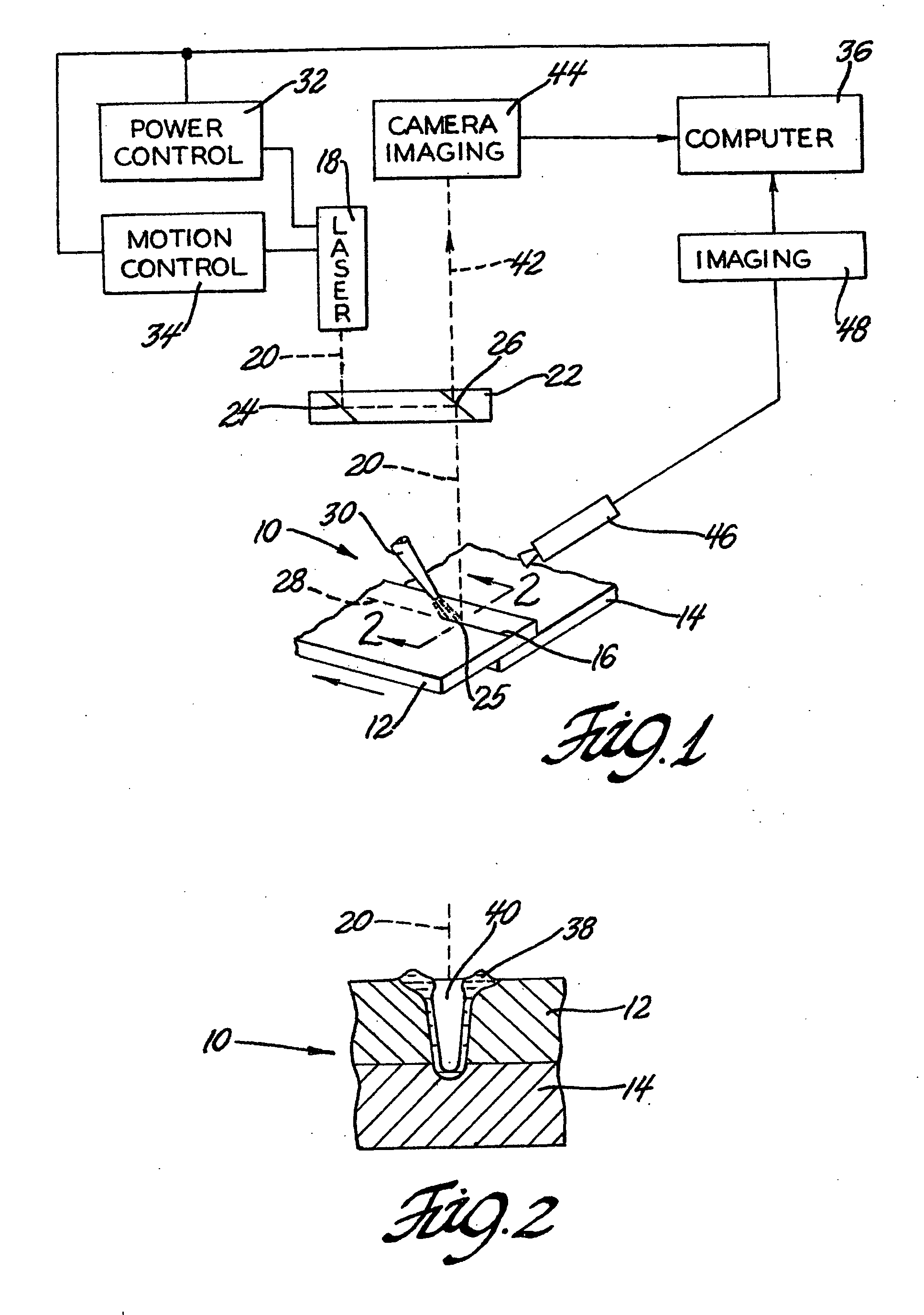

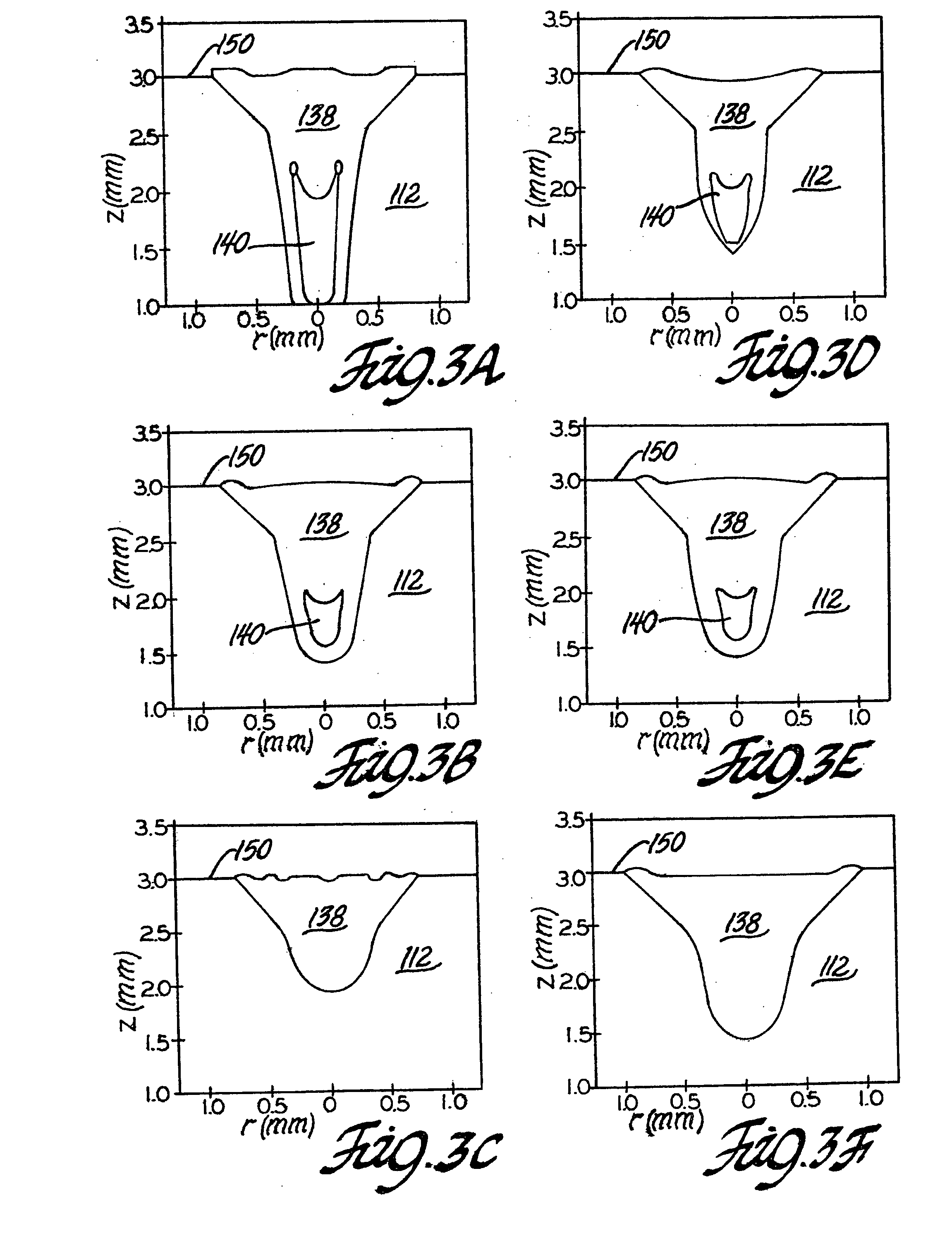

Laser welding control

In laser welding of metallic workpieces, the energetic beam is moved over the workpiece surface to form a pool of molten weld metal that quickly solidifies behind the advance of the laser into a weld nugget. The laser beam produces a keyhole of plasma-containing vapor within the molten pool. Weld nugget porosity, due to entrapment of the vapor, is minimized by continually sensing radiation from the molten metal pool to determine pool depth and width and then controlling laser power and speed to continually produce a weld metal pool wide enough for the liquid to fully expel the vapor and solidify into a pore free nugget.

Owner:GENERAL MOTORS COMPANY

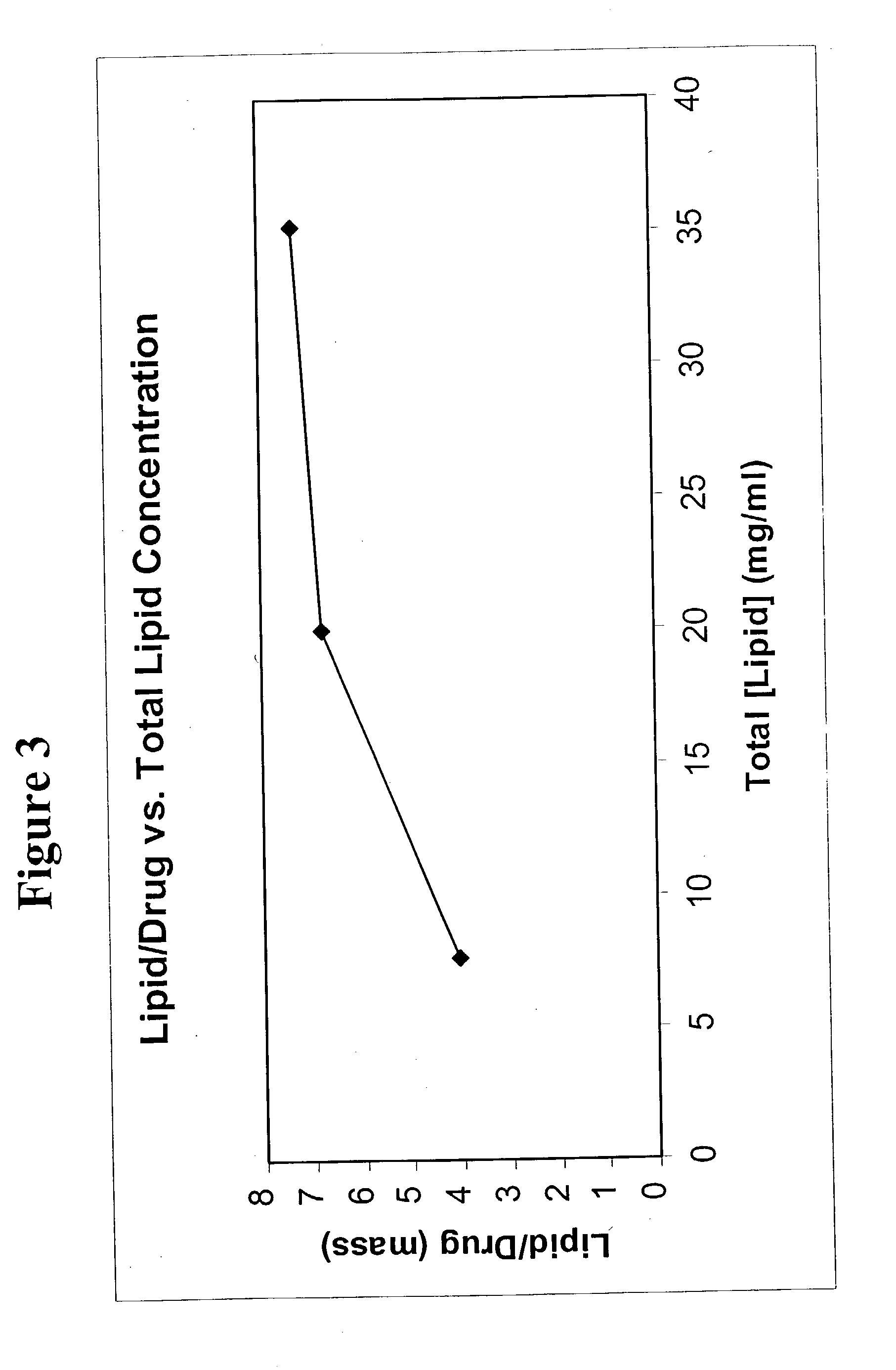

Methods for entrapment of bioactive agent in a liposome or lipid complex

A method of preparing a liposomal bioactive agent comprising infusing an lipid-ethanol mixture with an aqueous or ethanolic solution of the bioactive agent at a temperature below the phase transition of at least one of the lipid components of the lipid and compositions produced by the method of the invention.

Owner:TRANSAVE

Anti-entrapment system

InactiveUS20050092097A1Prevent any pinching of the objectHigher compressive forceVehicle seatsForce measurementDielectricElastomer

An anti-entrapment system for preventing an object from being entrapped by a translating device includes a capacitance sensor positioned adjacent to the translating device. The sensor has first and second conductors separated by a separation distance, a compressible dielectric element interposed between the conductors, and a non-conductive elastomer outer jacket encasing the conductors and the dielectric element. The sensor having a capacitance dependent upon the separation distance between the conductors. The capacitance changes in response to the separation distance changing as a result of the dielectric element compressing in response to a first object touching the outer jacket, and in response to a second conductive object coming into proximity with at least one of the conductors. A controller controls the translating device as a function of the capacitance in order to prevent the translating device from entrapping either object.

Owner:UUSI

Anti-entrapment system

InactiveUS6968746B2Prevent any pinching of the objectVehicle seatsForce measurementElectrical conductorEntrapment

An anti-entrapment system for preventing an object from being entrapped by a translating device includes a capacitance sensor positioned in a jamb portion of the translating device, on the translating device, or adjacent to the translating device. The sensor has first and second flexible conductors separated by a separation distance and a compressible dielectric element interposed between the conductors. The conductors have a capacitance dependent on the separation distance. The capacitance changes in response to the separation distance changing as a result of the dielectric element compressing in response to a first object touching the capacitance sensor, and changes in response to a second conductive object coming into proximity with at least one of the conductors. A controller controls the translating device as a function of the capacitance in order to prevent the translating device from entrapping either object.

Owner:UUSI

High throughput screening of crystallization of materials

InactiveUS7195670B2From normal temperature solutionsFixed microstructural devicesHigh-Throughput Screening MethodsSize determination

High throughput screening of crystallization of a target material is accomplished by simultaneously introducing a solution of the target material into a plurality of chambers of a microfabricated fluidic device. The microfabricated fluidic device is then manipulated to vary the solution condition in the chambers, thereby simultaneously providing a large number of crystallization environments. Control over changed solution conditions may result from a variety of techniques, including but not limited to metering volumes of crystallizing agent into the chamber by volume exclusion, by entrapment of volumes of crystallizing agent determined by the dimensions of the microfabricated structure, or by cross-channel injection of sample and crystallizing agent into an array of junctions defined by intersecting orthogonal flow channels.

Owner:CALIFORNIA INST OF TECH +1

Method and apparatus for seismic data acquisition

InactiveUS20060120216A1Avoid entrapmentMinimize the possibilitySeismic signal receiversSeismology for water-covered areasOcean bottomRubidium

A marine seismic exploration method and system comprised of continuous recording, self-contained ocean bottom pods characterized by low profile casings. An external bumper is provided to promote ocean bottom coupling and prevent fishing net entrapment. Pods are tethered together with flexible, non-rigid, non-conducting cable used to control pod deployment. Pods are deployed and retrieved from a boat deck configured to have a storage system and a handling system to attach pods to cable on-the-fly. The storage system is a juke box configuration of slots wherein individual pods are randomly stored in the slots to permit data extraction, charging, testing and synchronizing without opening the pods. A pod may include an inertial navigation system to determine ocean floor location and a rubidium clock for timing. The system includes mathematical gimballing. The cable may include shear couplings designed to automatically shear apart if a certain level of cable tension is reached.

Owner:MAGSEIS FF LLC

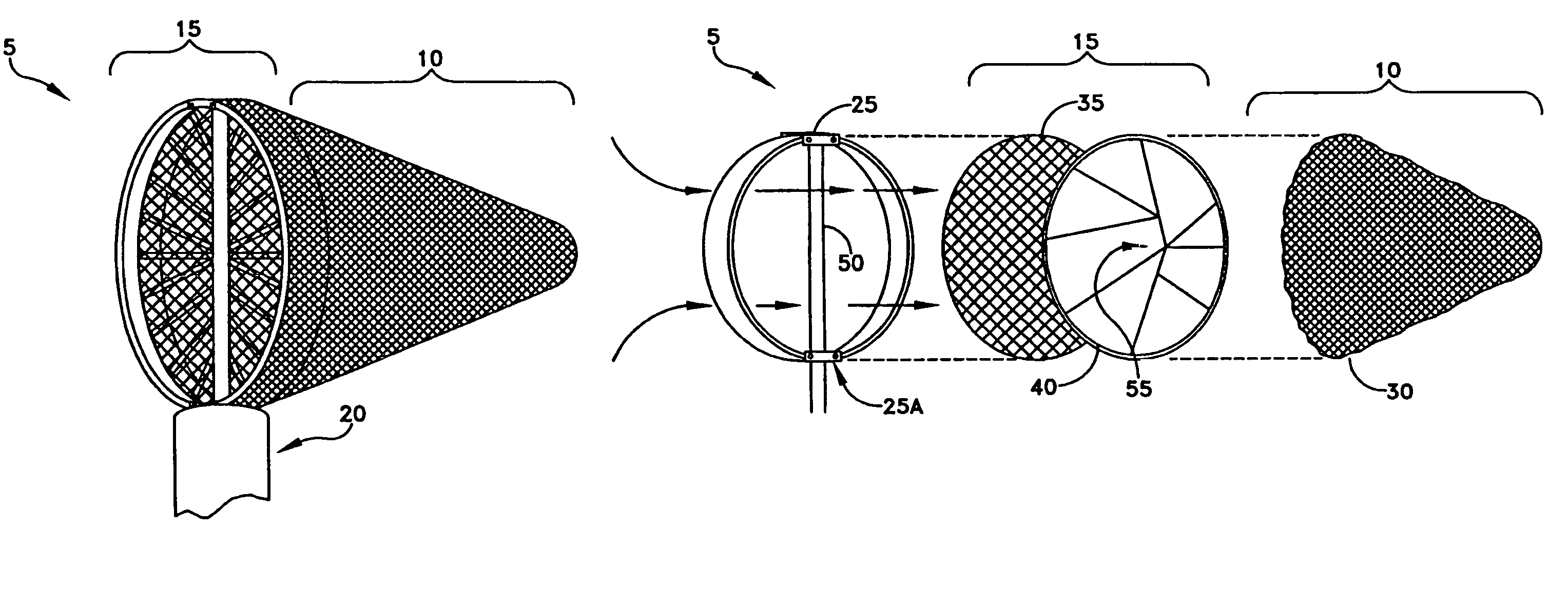

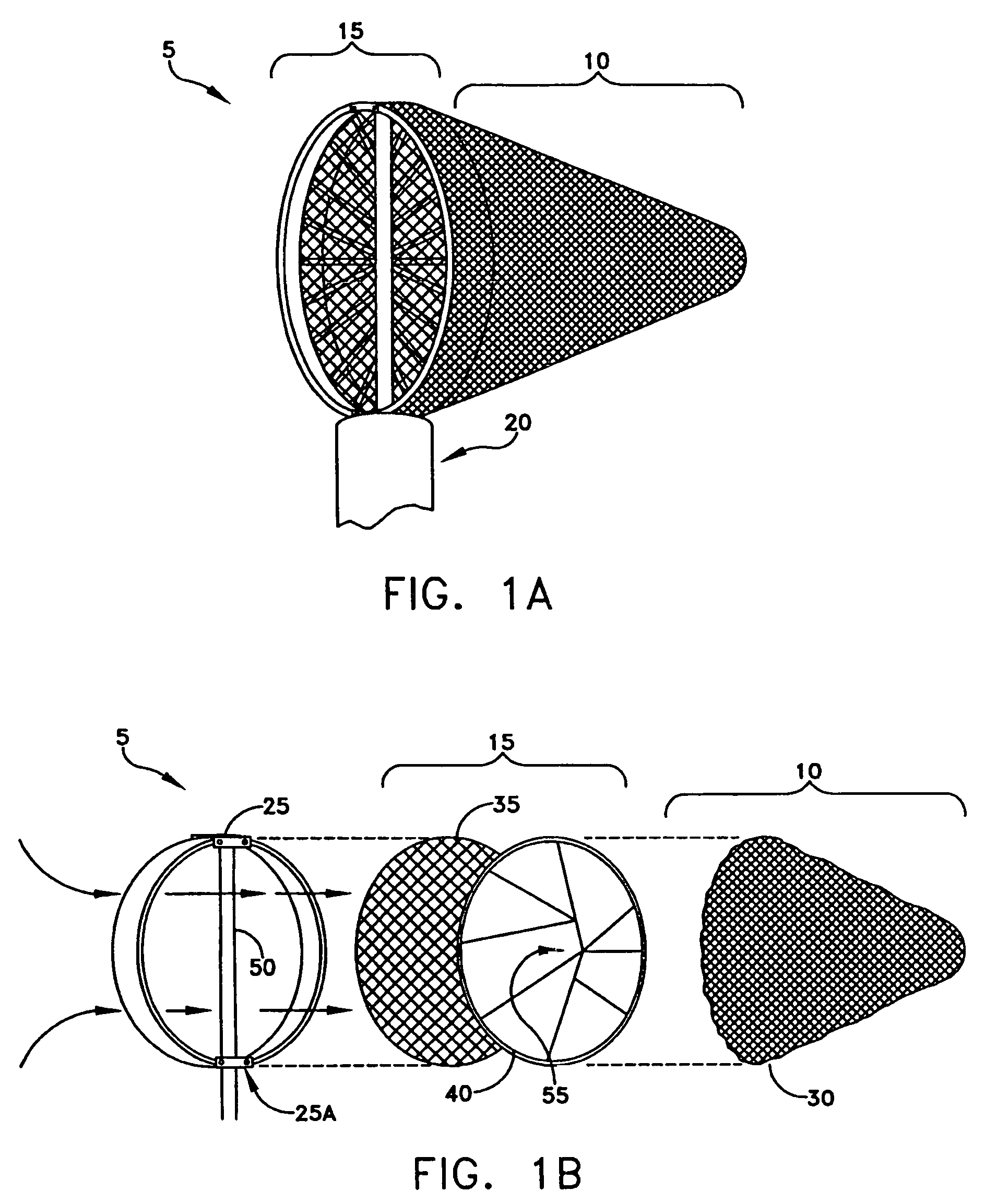

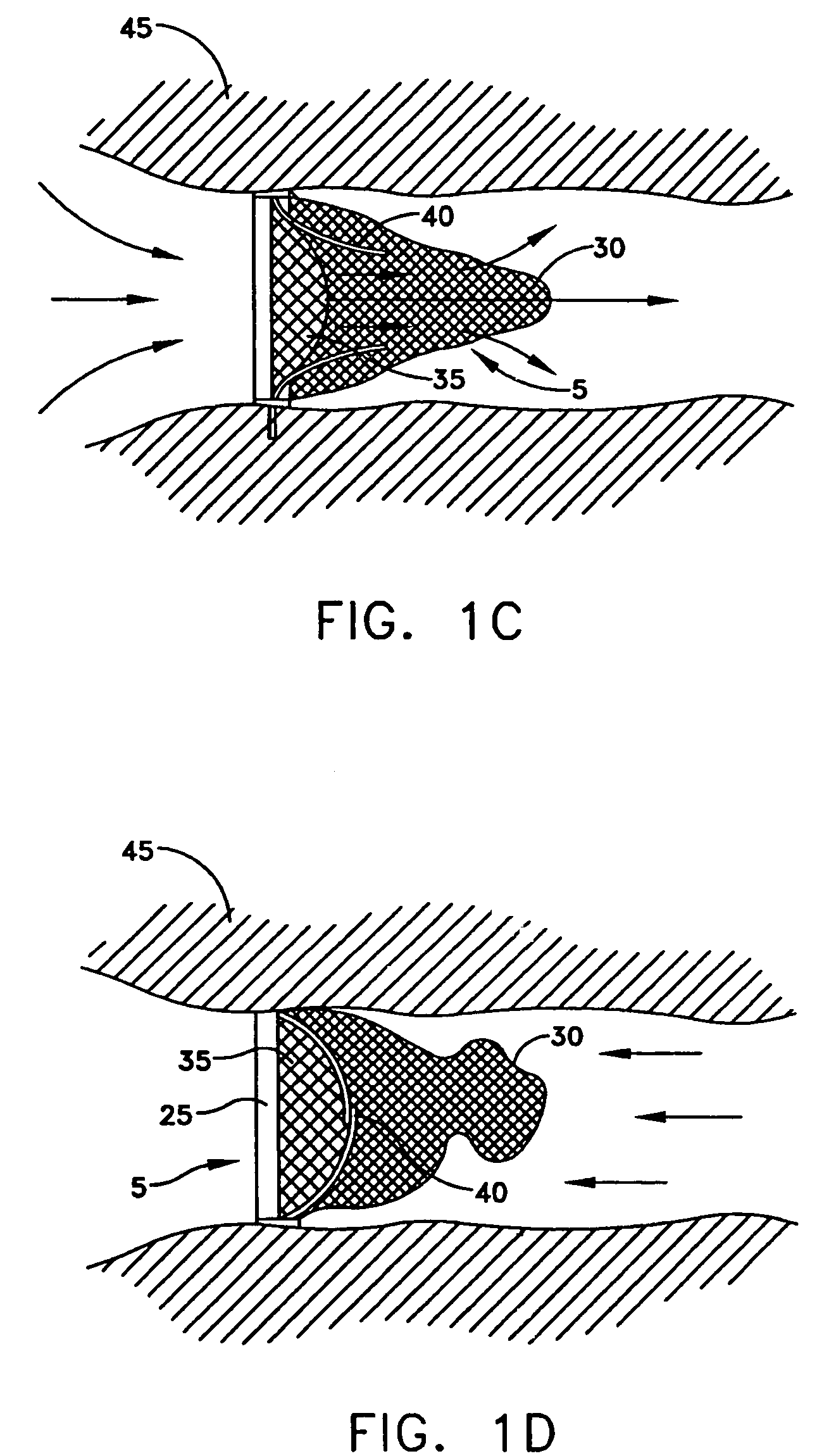

Intravascular filter with debris entrapment mechanism

InactiveUS7758606B2Great ability to collect debrisReduce in quantityHeart valvesSurgeryEntrapmentDebris flow

Apparatus for filtering and entrapping debris in the vascular system of a patient, the apparatus including a filter to allow blood to flow therethrough and to restrict passage of debris, wherein the filter captures debris carried in a first direction of blood flow. The apparatus further includes an entrapment mechanism which allows passage of debris and blood therethrough, in the first direction of blood flow and prevents debris passage in a second direction. The entrapment mechanism and filter allow blood and debris therethrough in the first direction of blood flow. The entrapment mechanism prevents debris flow in the second direction of blood flow. A method for filtering and entrapping debris in the vascular system includes inserting the apparatus into the vascular system, allowing blood and debris carried therein to flow through the entrapment mechanism, and removing the apparatus and accumulated debris from the vascular system.

Owner:MEDTRONIC INC

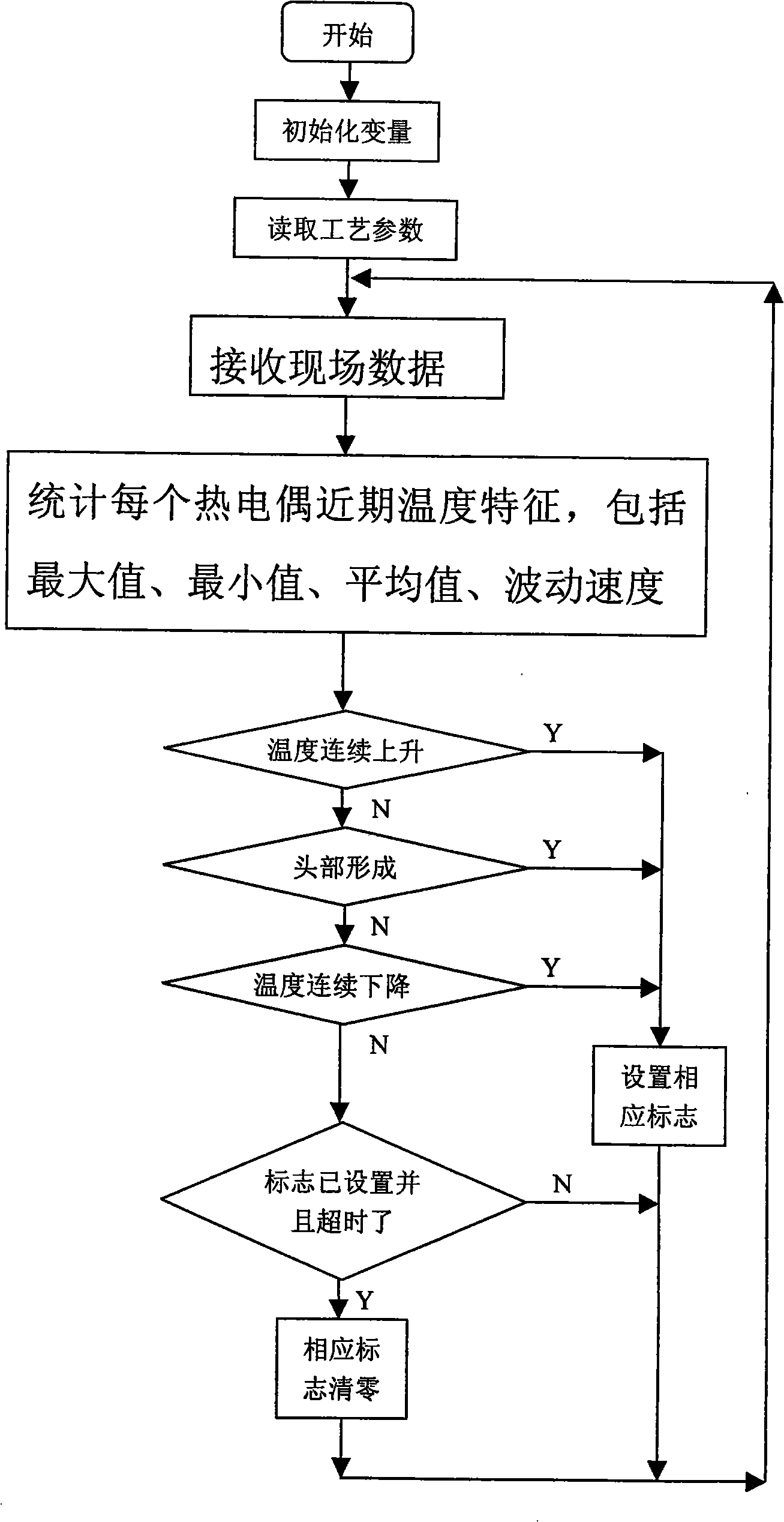

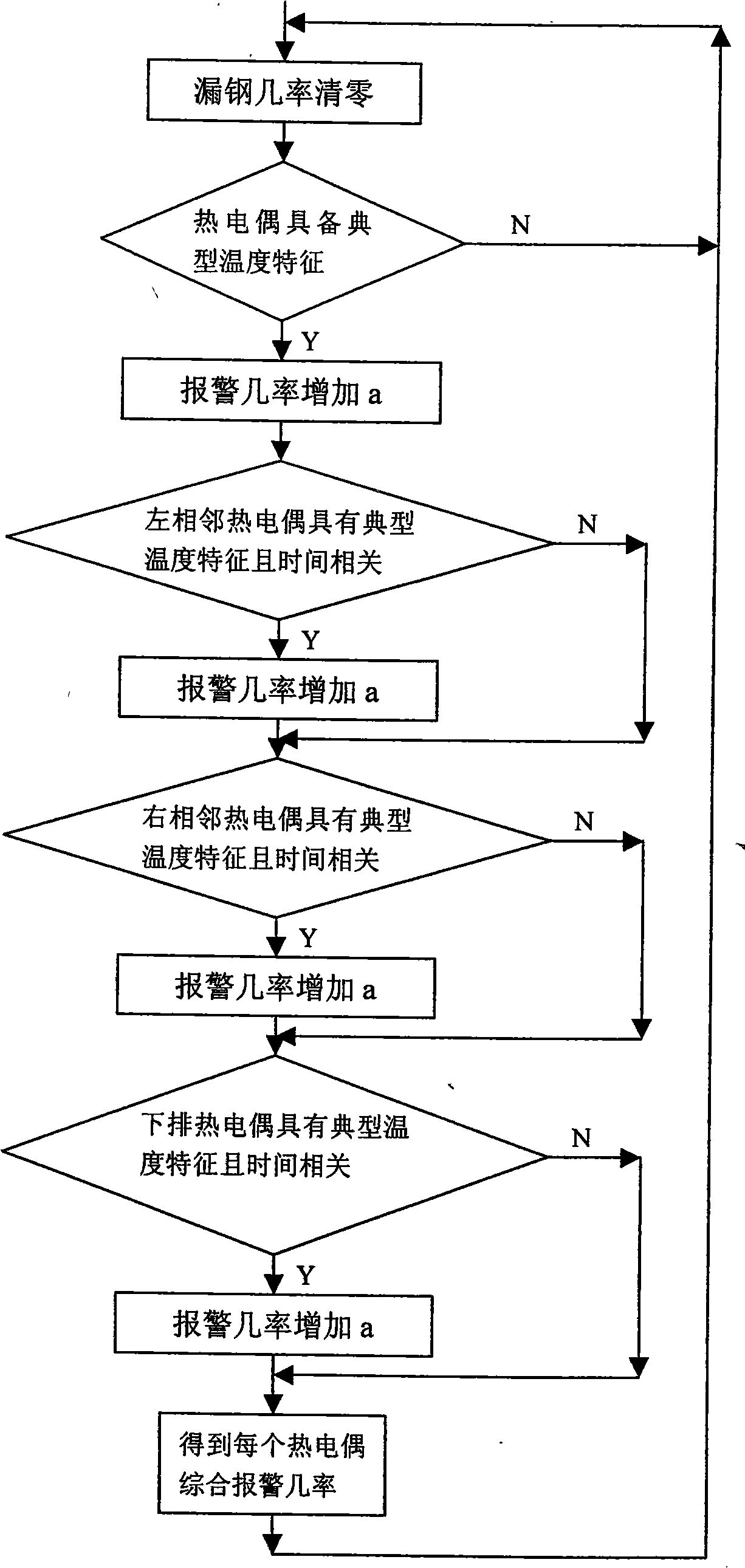

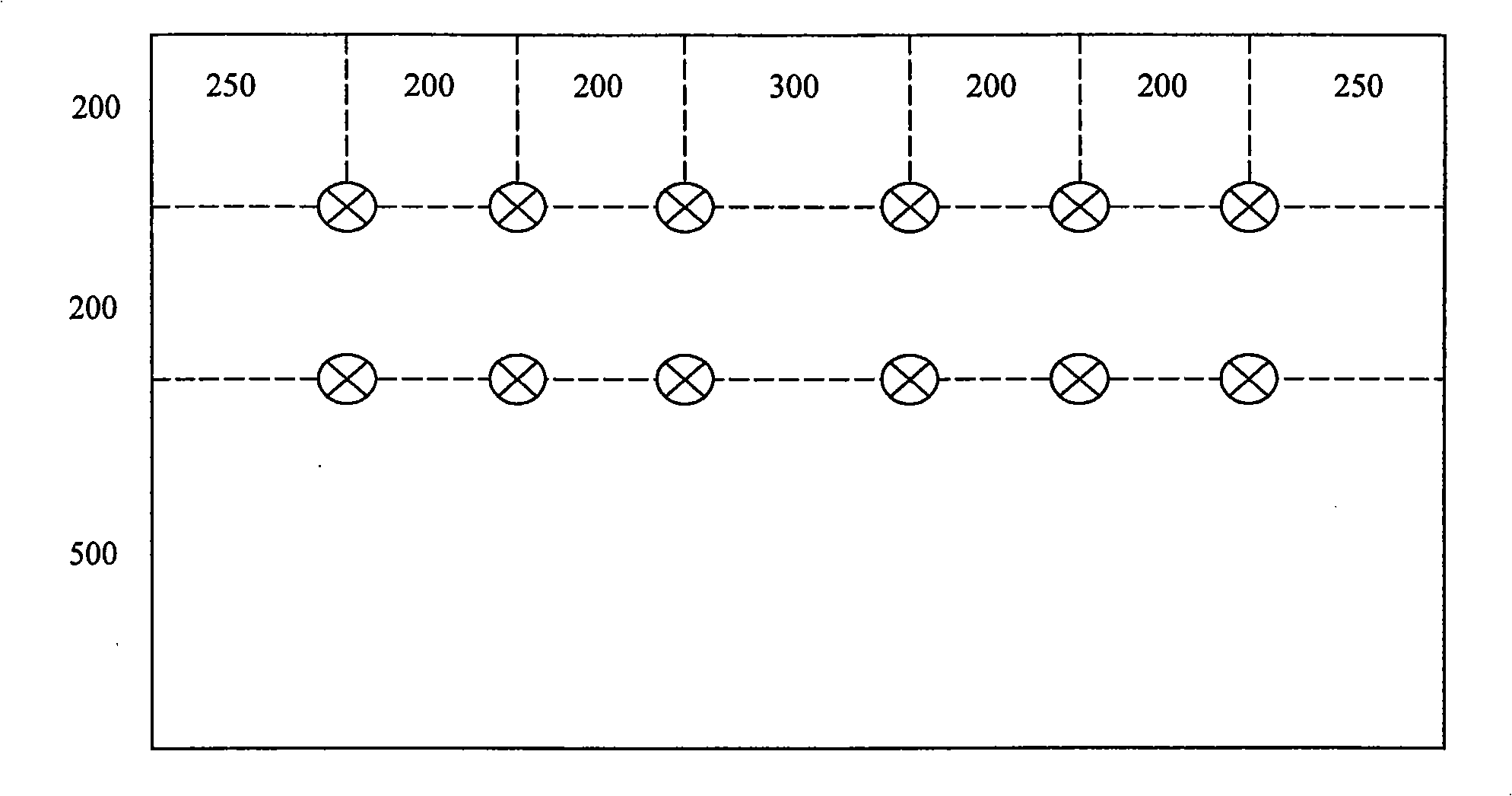

Slab continuous-casting bleedout forecast control method

The invention relates to a method for predicting and controlling slab continuous casting breakout, in particular to a method for preventing sticking breakout according to the temperature variation condition of a thermocouple in a crystallizer in the process of slab continuous casting. The method mainly aims at solving the technical problems that the existing various breakout prediction methods can not compressively consider interference factors and can not predict small-scale sticking and slag entrapment in time. The technical proposal of the invention is that the method for predicting and controlling the slab continuous casting breakout comprises the step that lines of thermocouples are arranged on the crystallizer, and the method is characterized by comprising the following steps: a. capture of typical temperature characteristics: the typical temperature characteristics of each thermocouple is determined according to the crystallizer parameters and the installment location of the crystallizer on the thermocouple; b. determination of breakout probability: the breakout probability of each thermocouple is determined according to the typical temperature characteristics of the adjacent thermocouples as well as the characteristics of the breakout thermal conductance and abnormal temperature distribution; c. control of casting speed: when the breakout probability of the thermocouples is up to 95%, the casting is stopped. The method is mainly used for warning continuous casting breakout.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

High throughput screening of crystallization of materials

InactiveUS20050229839A1Sequential/parallel process reactionsFrom normal temperature solutionsHigh-Throughput Screening MethodsSize determination

High throughput screening of crystallization of a target material is accomplished by simultaneously introducing a solution of the target material into a plurality of chambers of a microfabricated fluidic device. The microfabricated fluidic device is then manipulated to vary the solution condition in the chambers, thereby simultaneously providing a large number of crystallization environments. Control over changed solution conditions may result from a variety of techniques, including but not limited to metering volumes of crystallizing agent into the chamber by volume exclusion, by entrapment of volumes of crystallizing agent determined by the dimensions of the microfabricated structure, or by cross-channel injection of sample and crystallizing agent into an array of junctions defined by intersecting orthogonal flow channels.

Owner:CALIFORNIA INST OF TECH +1

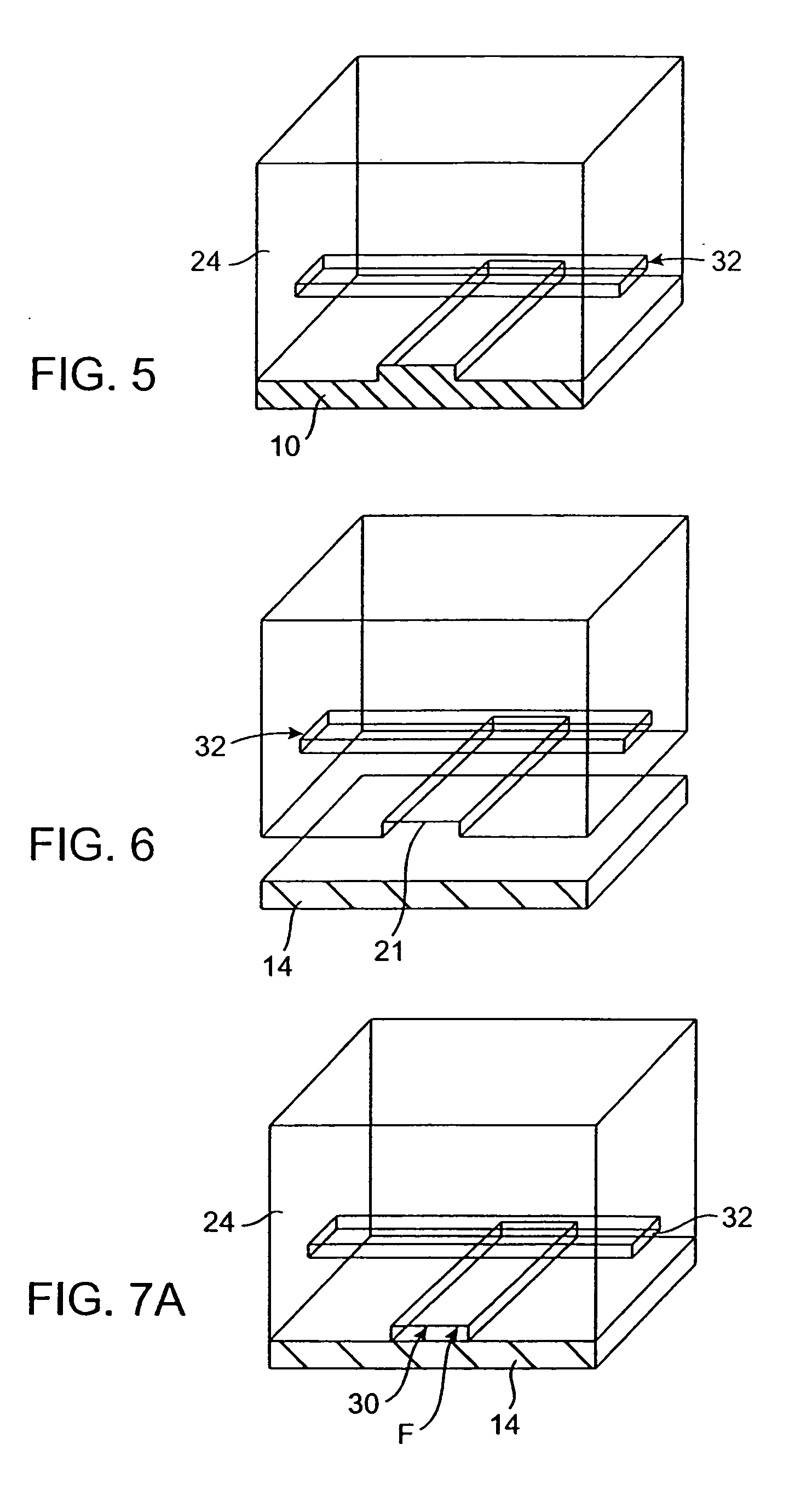

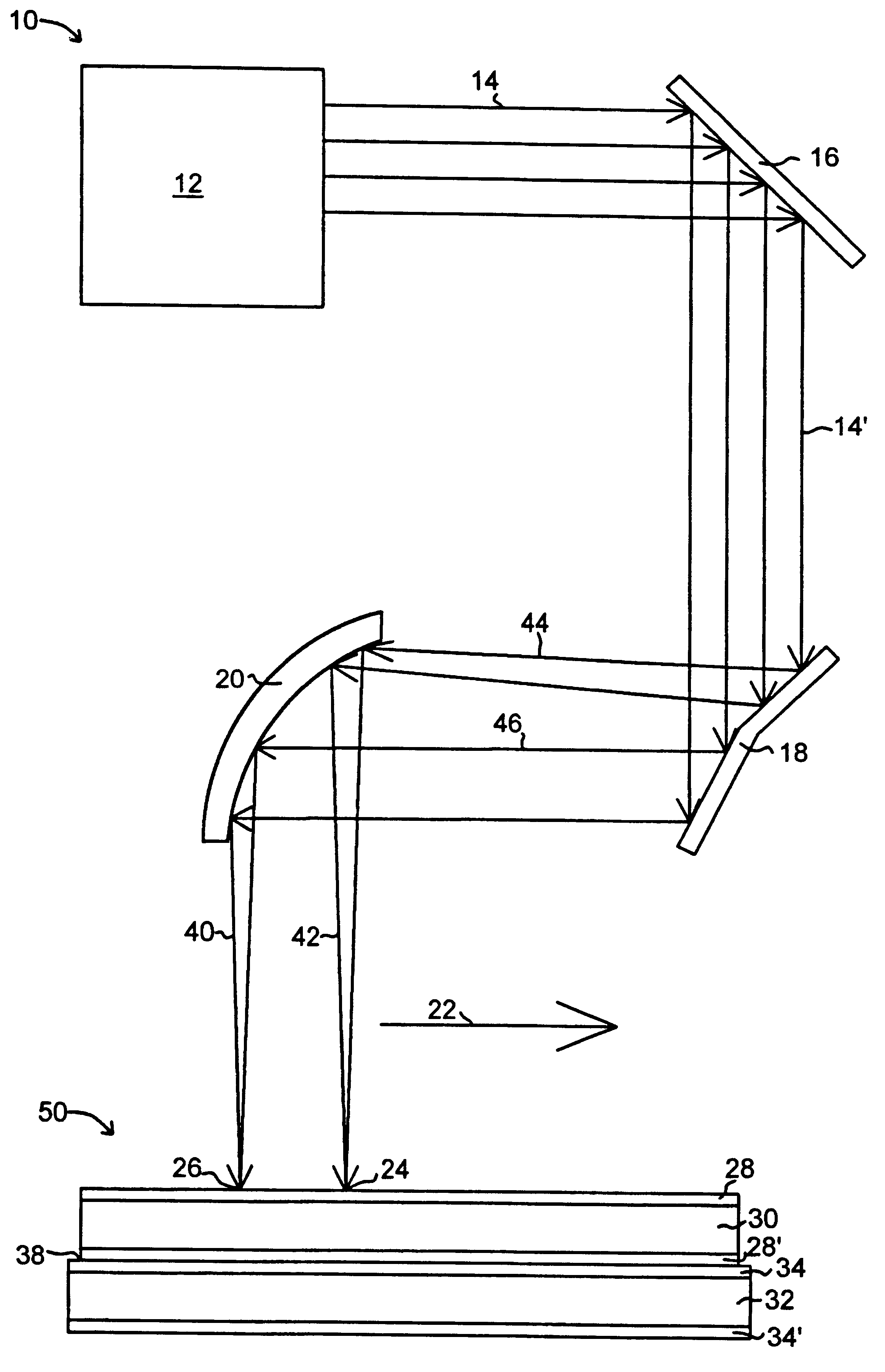

Coated material welding with multiple energy beams

InactiveUS6608278B1High level of porosityQuality improvementVehicle componentsWelding/soldering/cutting articlesPorosityBeam source

To overcome 1) the high levels of porosity due to coating material vaporization and entrapment into the weld, 2) spewing of molten base metal from the weld leaving holes and pits in the weld, and 3) humping effects when oblong beam configurations are used at higher weld speeds to weld coated materials, the present invention features an energy source (10) with multiple separated energy beams (24, 26) (formed by using multiple separate beam sources or manipulation of a single beam (14) into separated multiple energy beams (44, 46) using wedge mirror (18) and parabolic focusing mirror (20)) that produces high quality (porosity free) lap welds in a weld stack (50) of layered materials (30, 32) coated with coating material (28, 28', 34, 34') with zero gap at interface (38) during the welding process. An energy source (12) with multiple, separated energy beams (24, 26) extends the beam keyhole and increases the time and conditions available for vapor / gas to diffuse less violently through the molten weld pool.

Owner:EDISON WELDING INSTITUTE INC

Pain relief composition

InactiveUS7282224B1Long-termEffective and comfortable to applyBiocideOrganic active ingredientsGlucosamine SulfateMedicine

Disclosed is a pain relief composition comprising an effective amount of a nerve inhibiting component, including capsaicin, a capsaicinoid or a capsaicin analogue, which numbs or inhibits the nerve endings that signal pain, in combination with at least one of the following: an effective amount of an inflammation control component which is designed to reduce immediate pain and discourage future pain in the joints and muscles; an effective amount of a cooling component; an effective amount of a heat minimizing or blocking component; an effective amount of a circulation increasing component which effectuates better penetration of the actives to the skin and nerves; and an effective amount of a soothing and anti-inflammatory complex for the joints and / or muscles comprising Glucosamine sulfate or HCl, Zingiber officiniale (Ginger Root) extract, Methyl sulfonylmethane (MSM), Polygonum cuspidatum (Mexican Bamboo) extract, Aloe barbadensis leaf, and Salix alba (white willow) bark extract. Additionally, the composition includes an encapsulation or entrapment system for a timed release delivery.

Owner:GUTHY-RENKER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com