Slab continuous-casting bleedout forecast control method

A slab continuous casting and control method technology, which is applied in the field of slab continuous casting breakout forecast control, can solve the problems that slag rolling cannot be predicted in time, and the interference factors are not fully considered, so as to achieve the effect of avoiding bonding breakout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

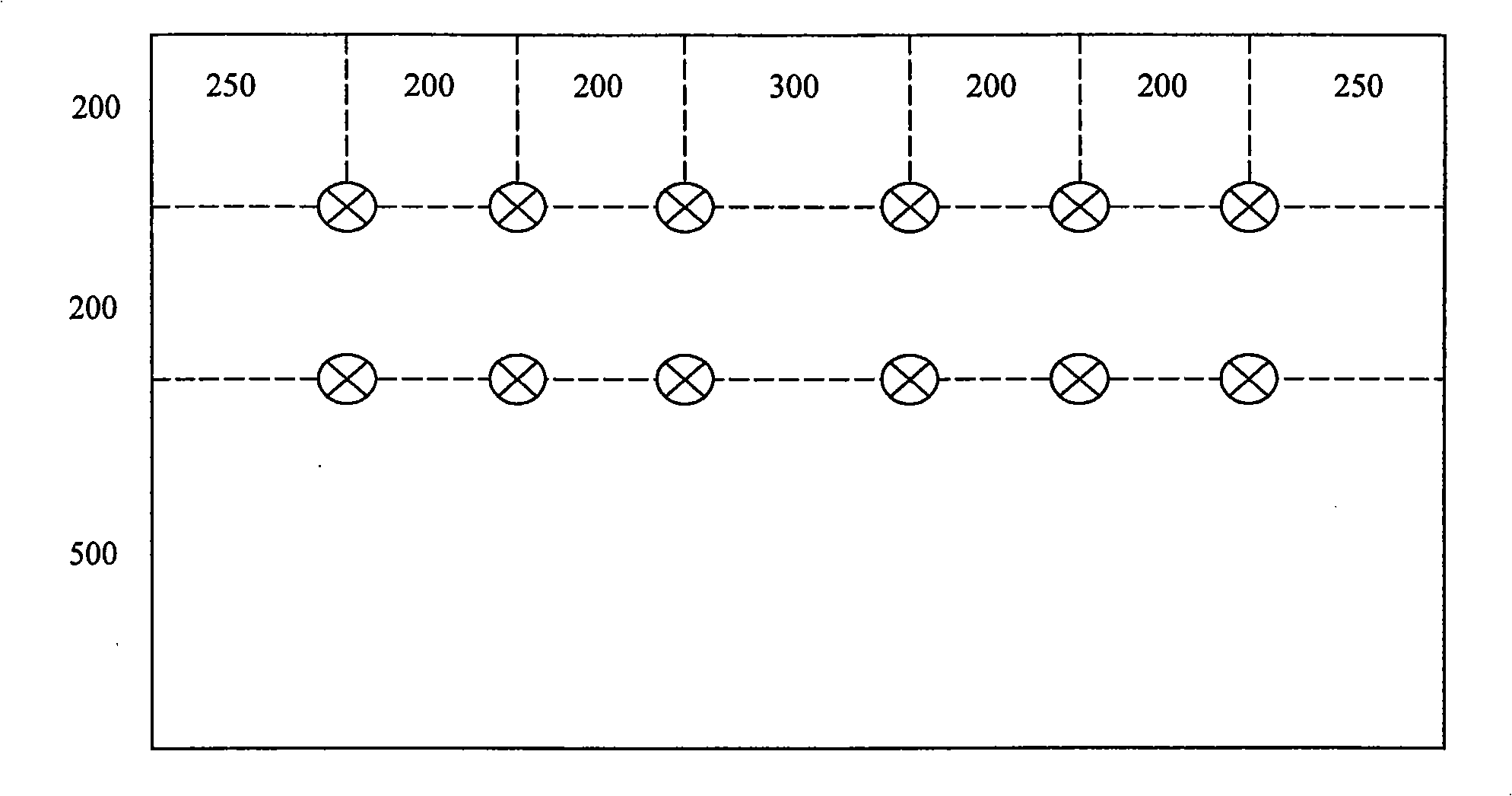

[0035] Combined with the specific conditions of the slab continuous casting machine, the outlet of the mold is 220mm×1340mm, and the thermocouple installation position of the mold is 6 in each row on the wide side, and one in each row on the narrow side, a total of two rows. The layout of the thermocouples on the wide side is as follows image 3 , the first row of thermocouples is 200 mm away from the top of the crystallizer, the distance between the two rows of thermocouples is 200 mm, and the maximum casting speed of the casting machine is 2.4 meters.

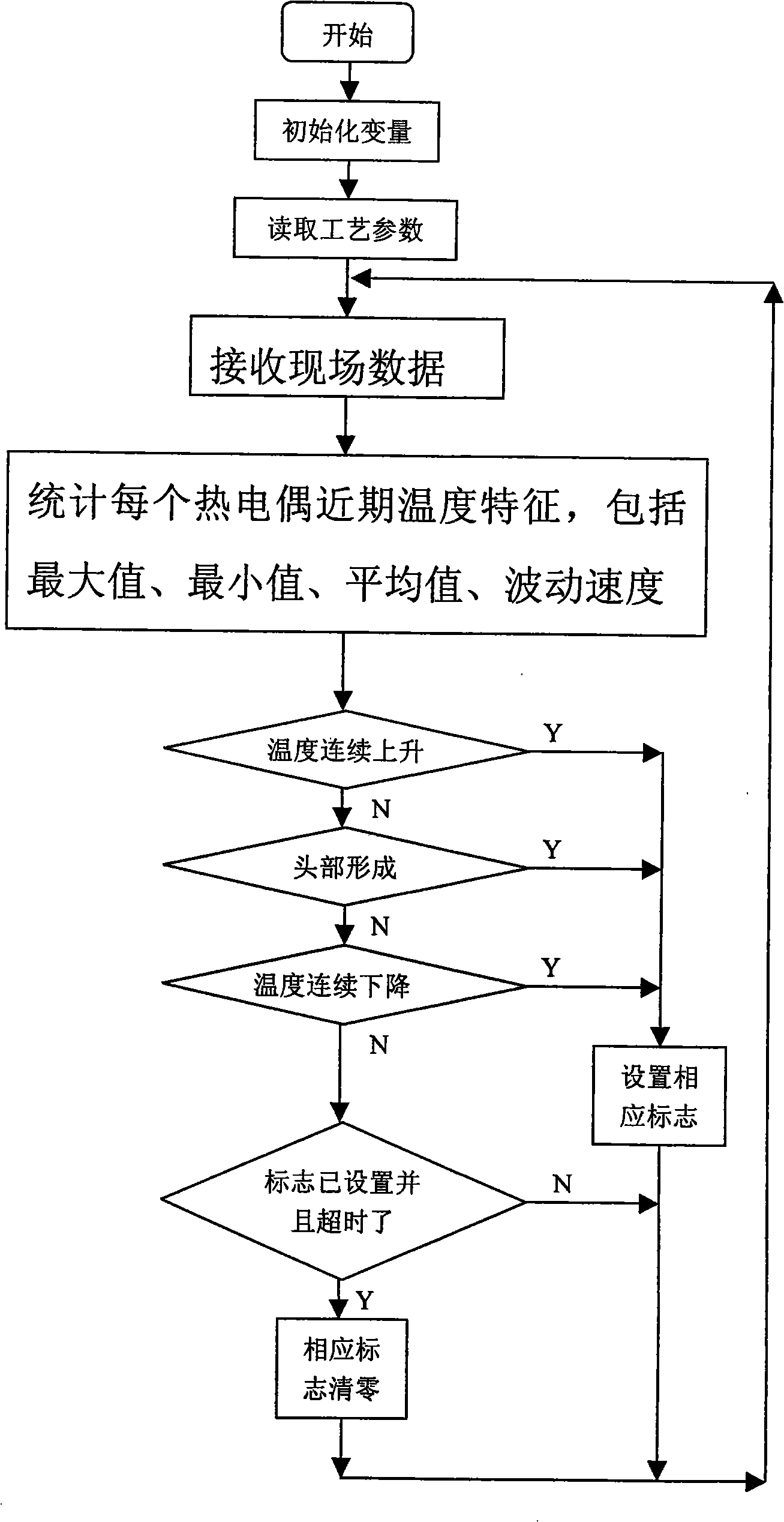

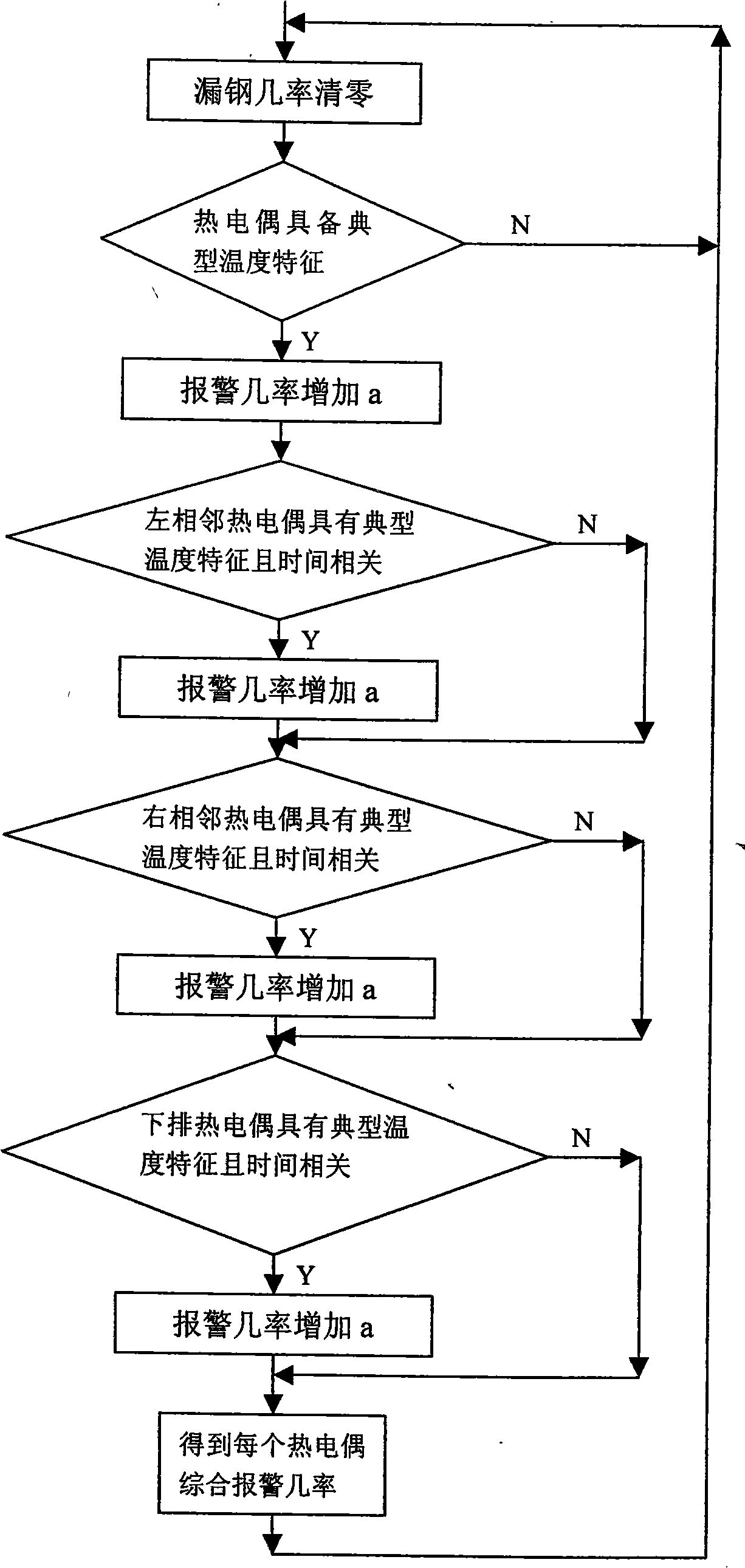

[0036] refer to figure 1 , the capture of typical temperature features includes the following steps:

[0037] 1. Initialize internal variables;

[0038] 2. Read the process parameters, including the steel type and its temperature fluctuation limit range;

[0039] 3. Receive on-site data, including steel code, mold liquid level, casting speed, and temperature of each thermocouple;

[0040] 4. Calculate the recent temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com